Patents

Literature

2160results about "Manufacture of electrical instruments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

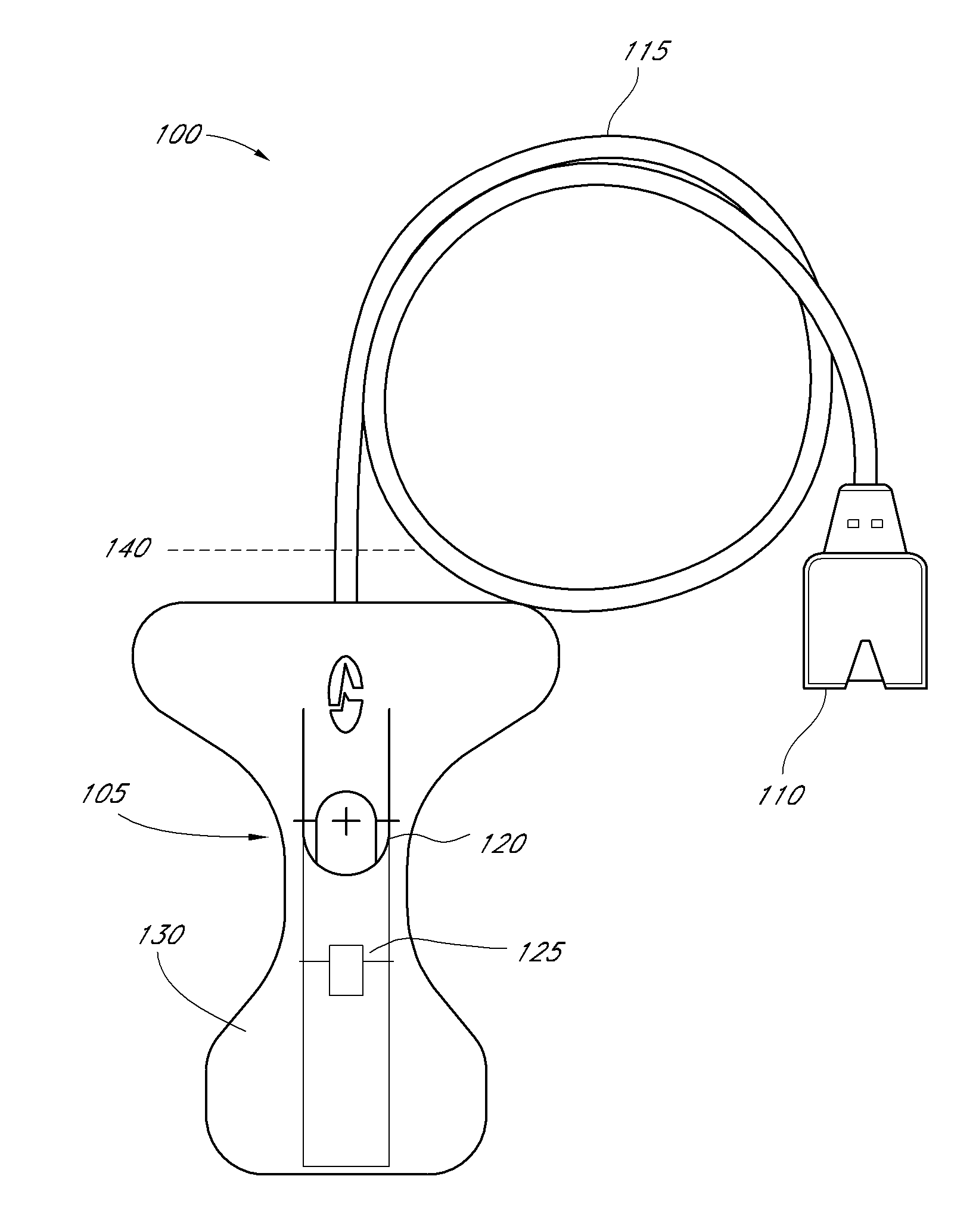

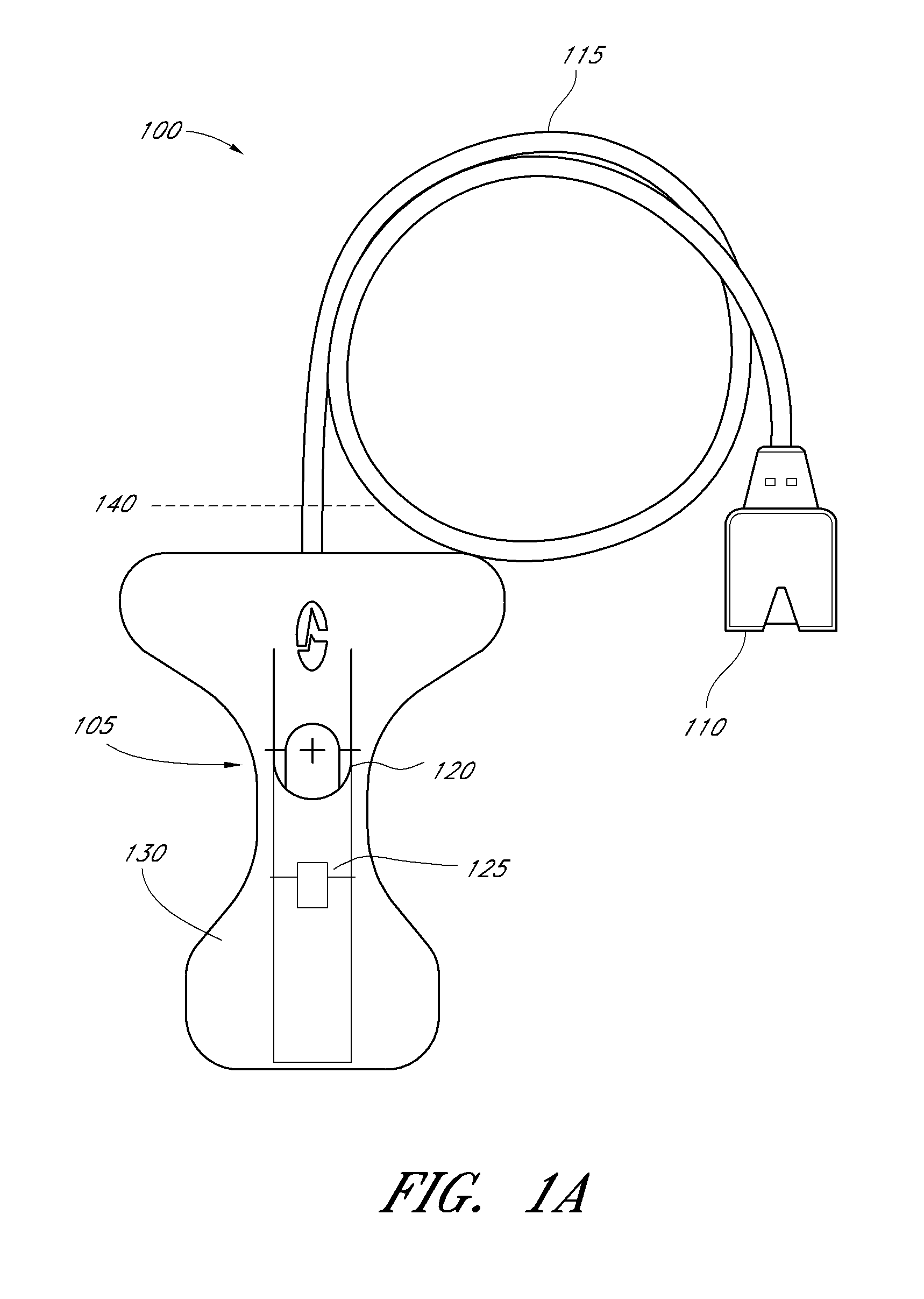

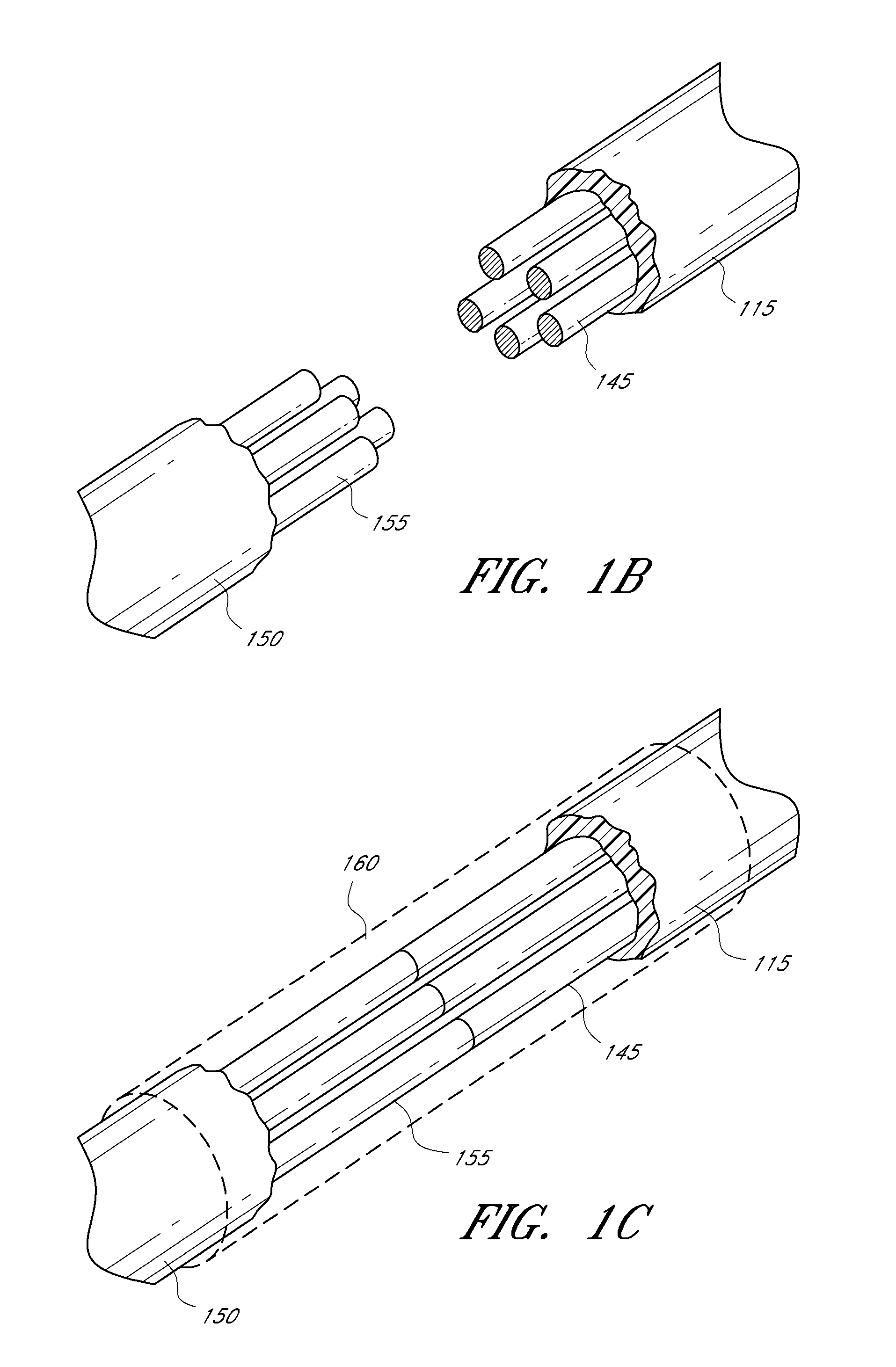

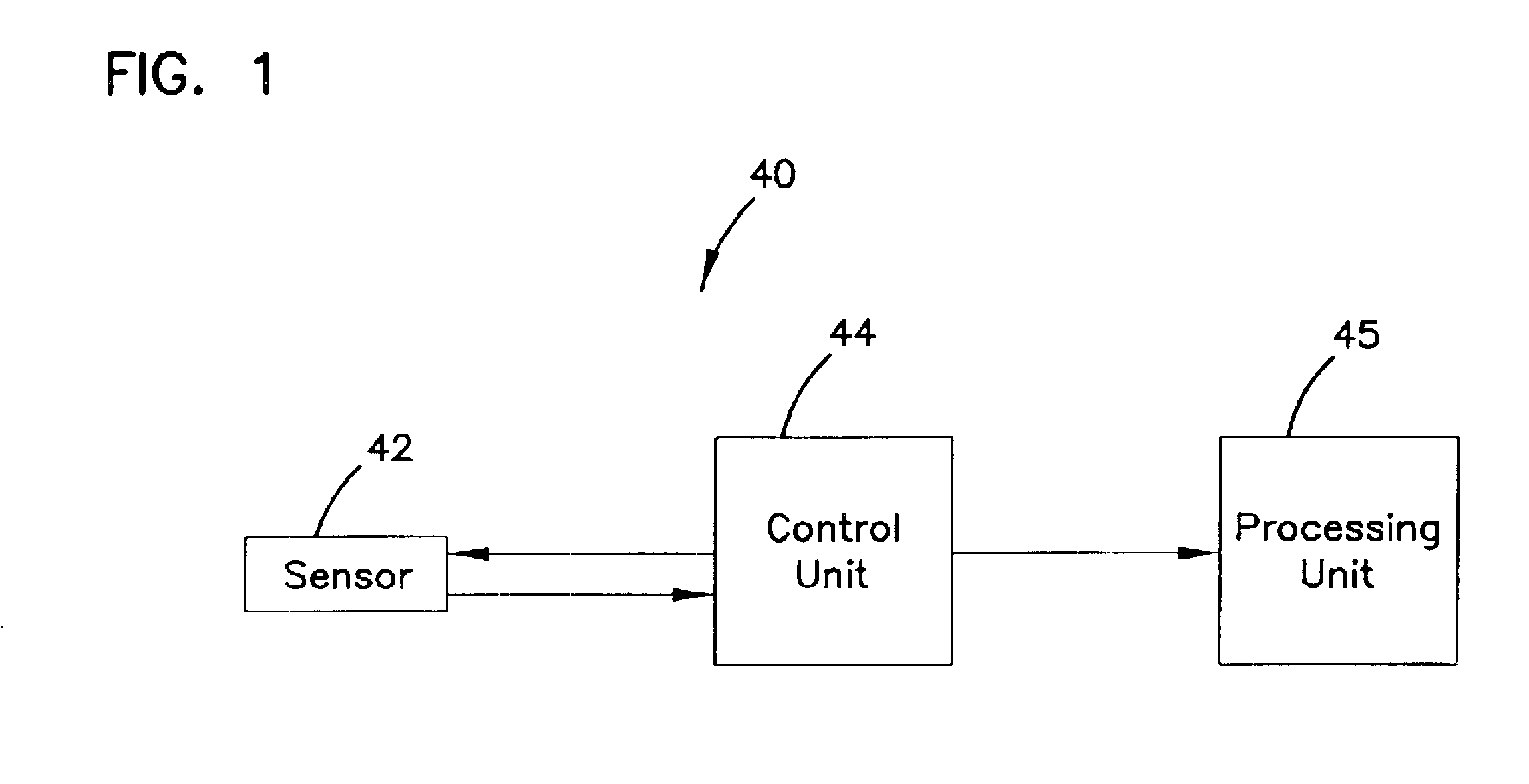

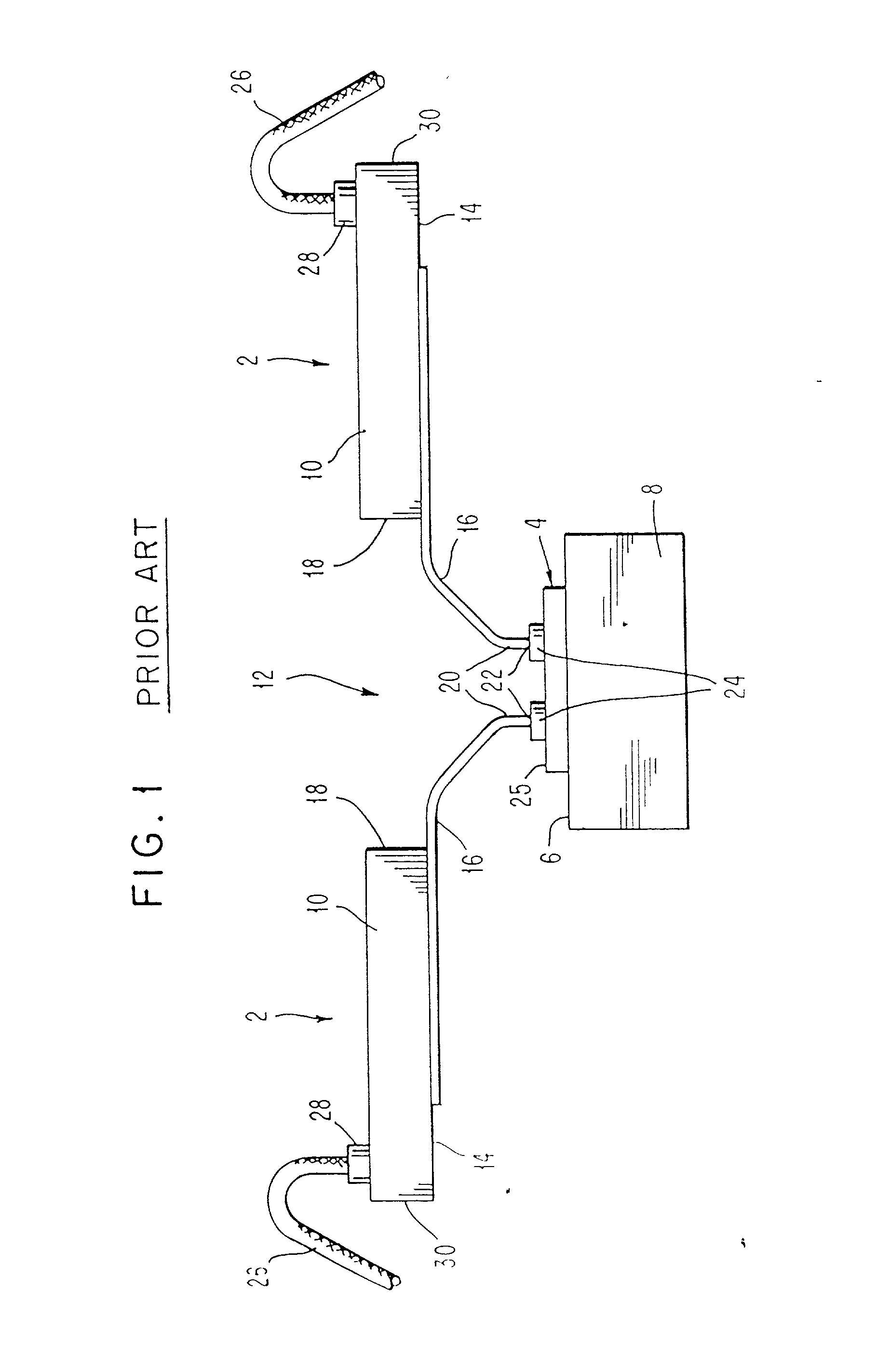

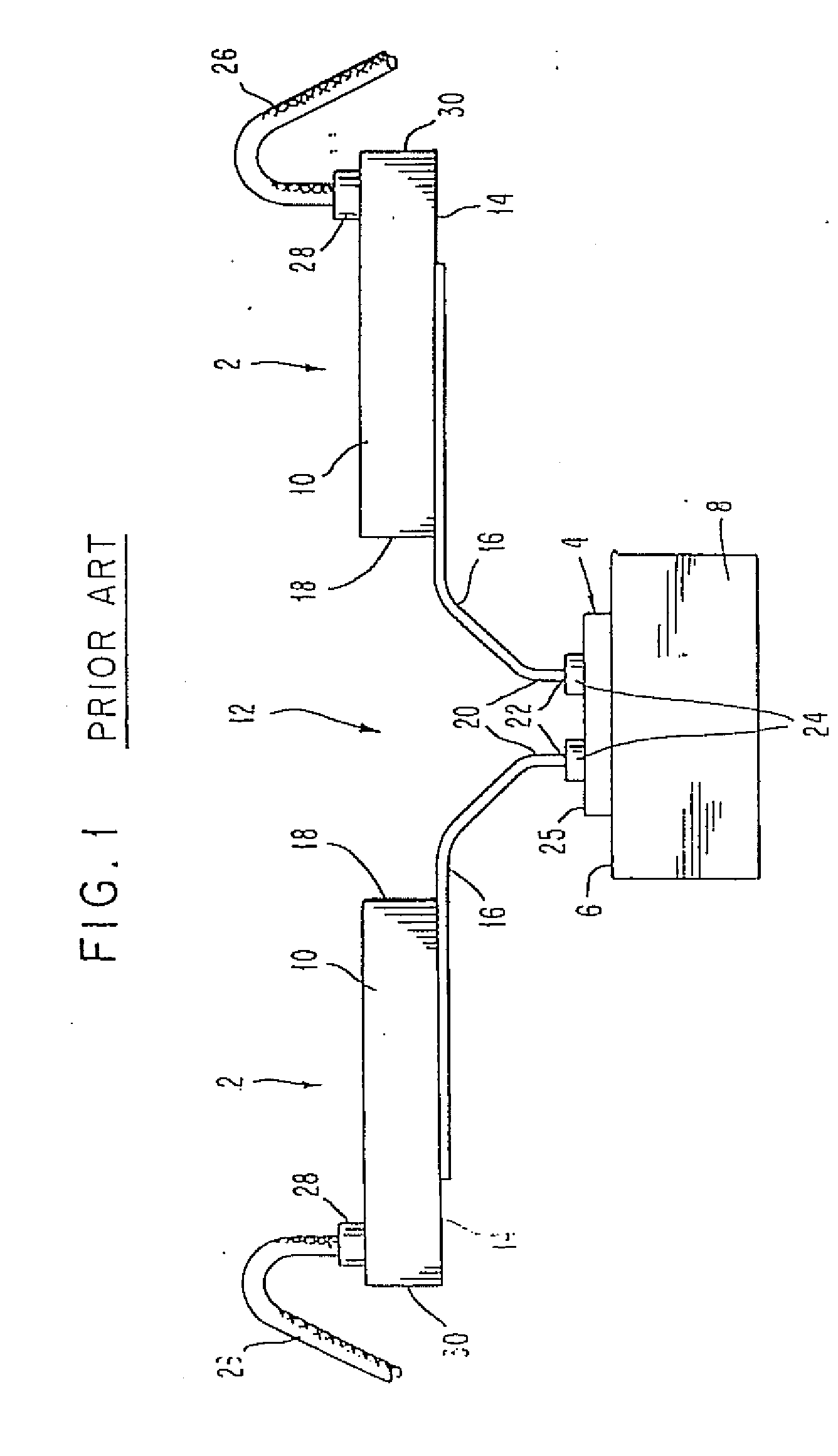

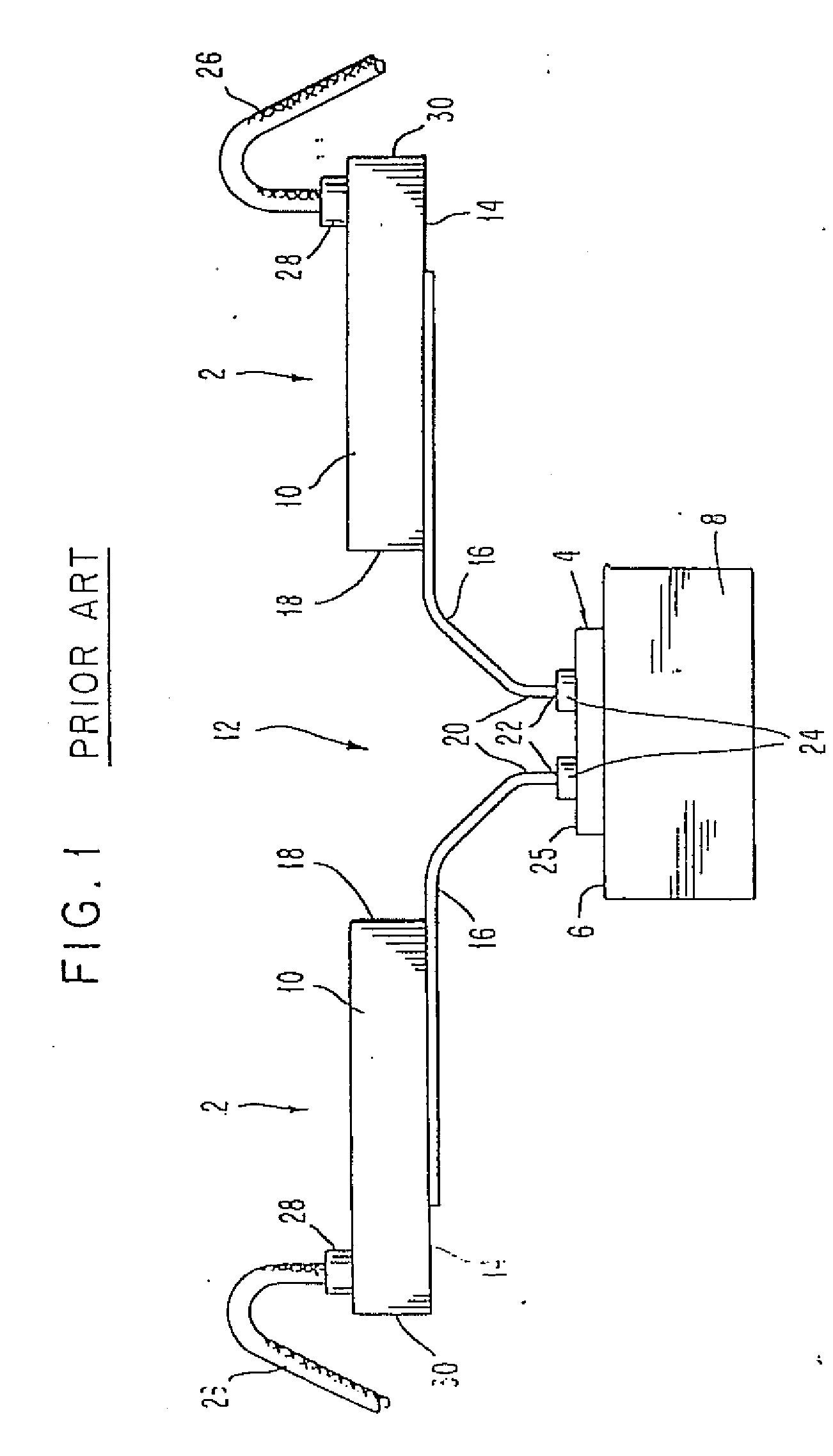

Reprocessing of a physiological sensor

ActiveUS8584345B2Low reliabilityReduce material costsWave amplification devicesManufacture of electrical instrumentsReprocessorEngineering

Because reprocessing or refurbishing of physiological sensors reuses large portions of an existing sensor, the material costs for refurbishing sensors is significantly lower than the material costs for making an entirely new sensor. Typically, existing reprocessors replace only the adhesive portion of an adhesive physiological sensor and reuse the sensing components. However, re-using the sensing components can reduce the reliability of the refurbished sensor and / or reduce the number of sensors eligible for refurbishing due to out-of-specification sensor components. It is therefore desirable to provide a process for refurbishing physiological sensors that replaces the sensing components of the sensor. While sensing components are replaced, generally, sensor cable and / or patient monitor attachments are retained, resulting in cost savings over producing new sensors.

Owner:JPMORGAN CHASE BANK NA

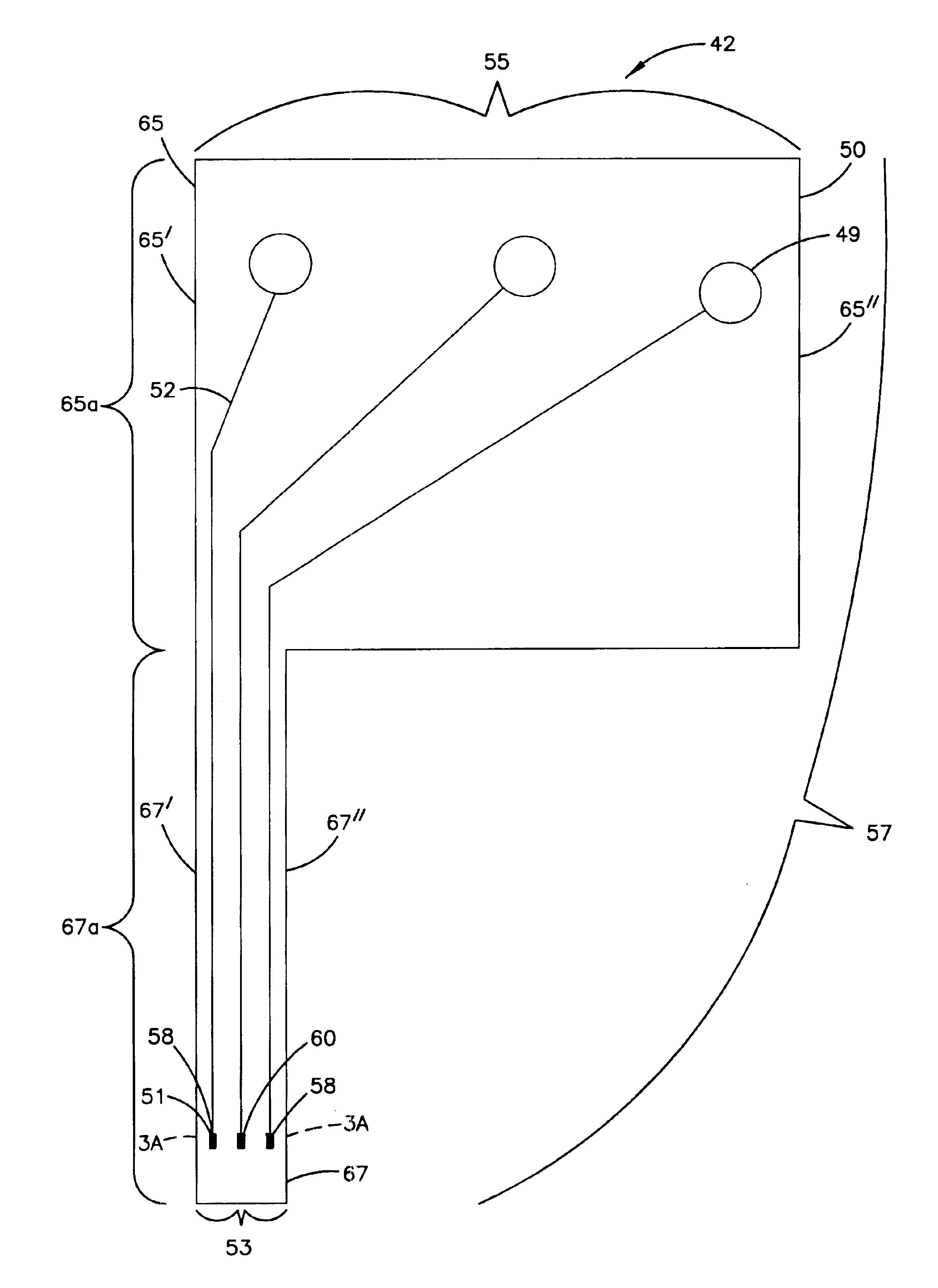

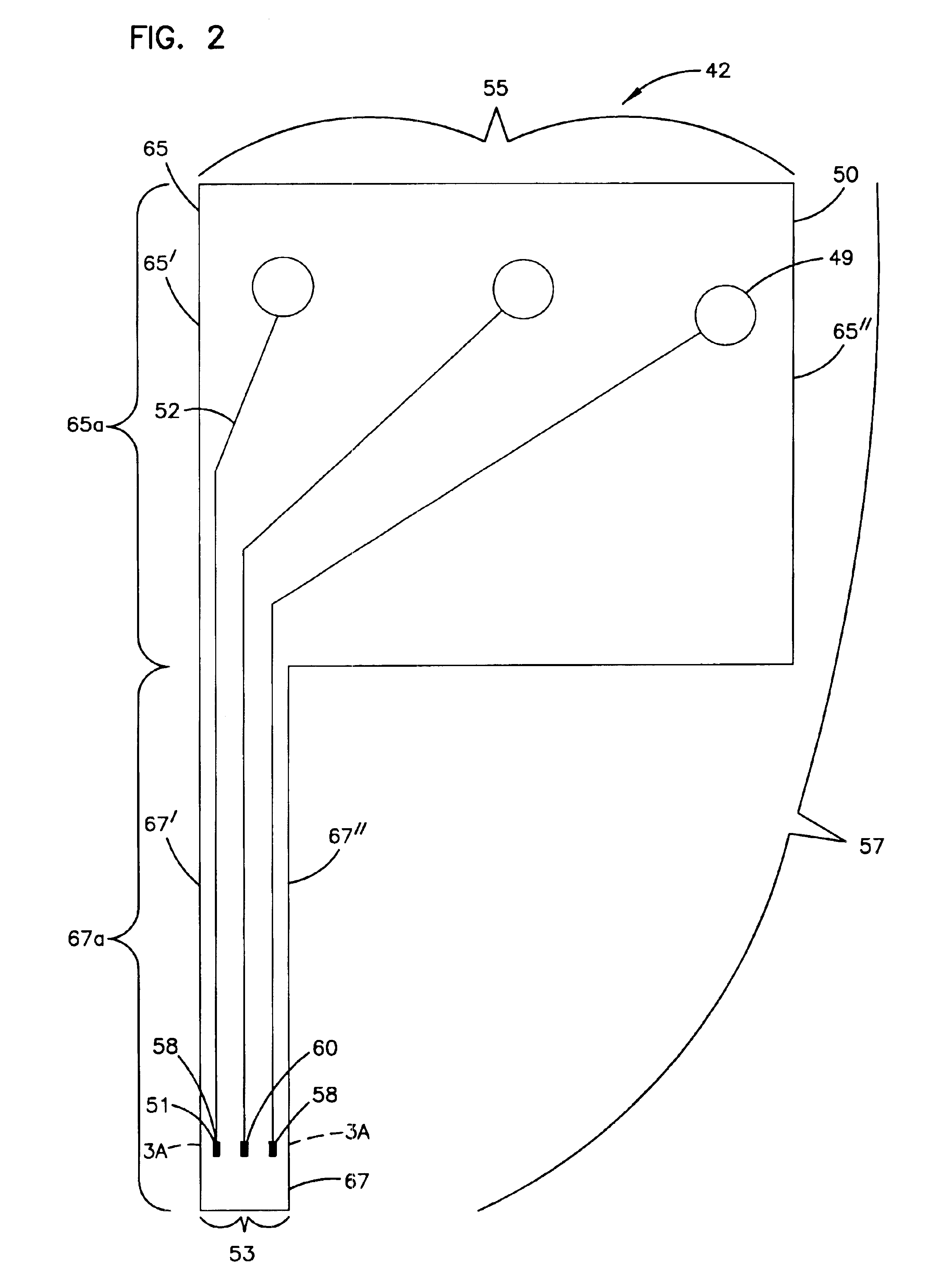

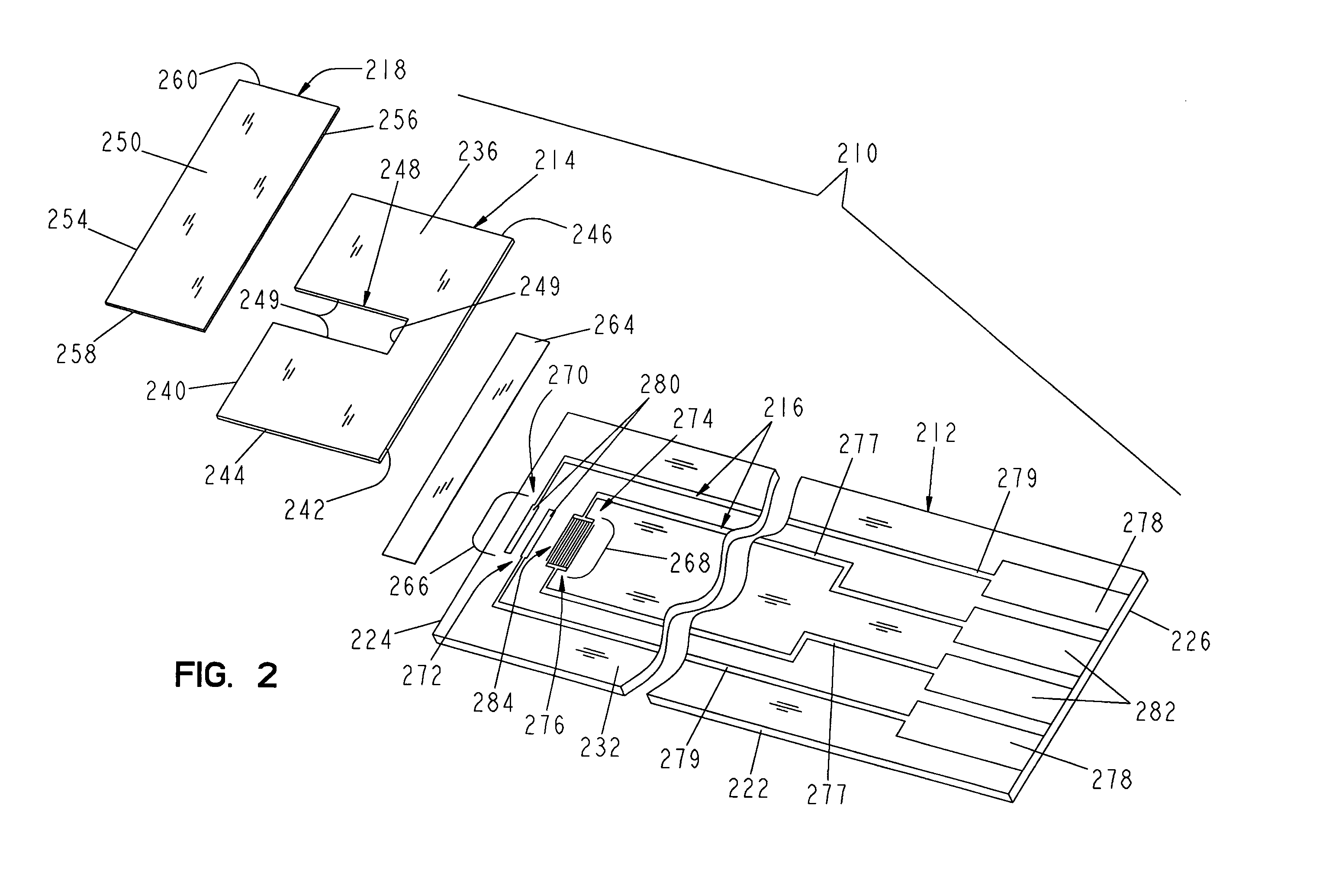

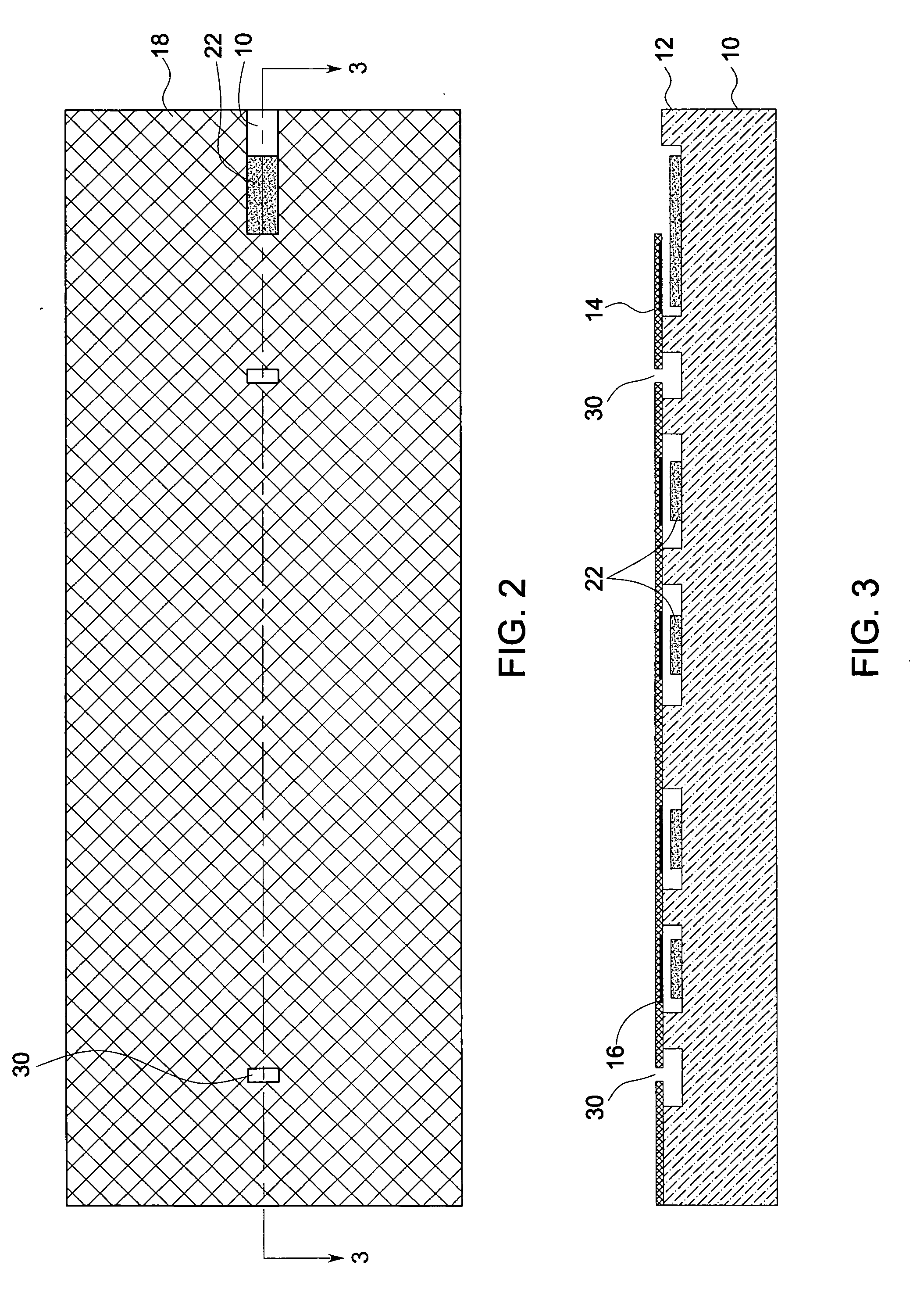

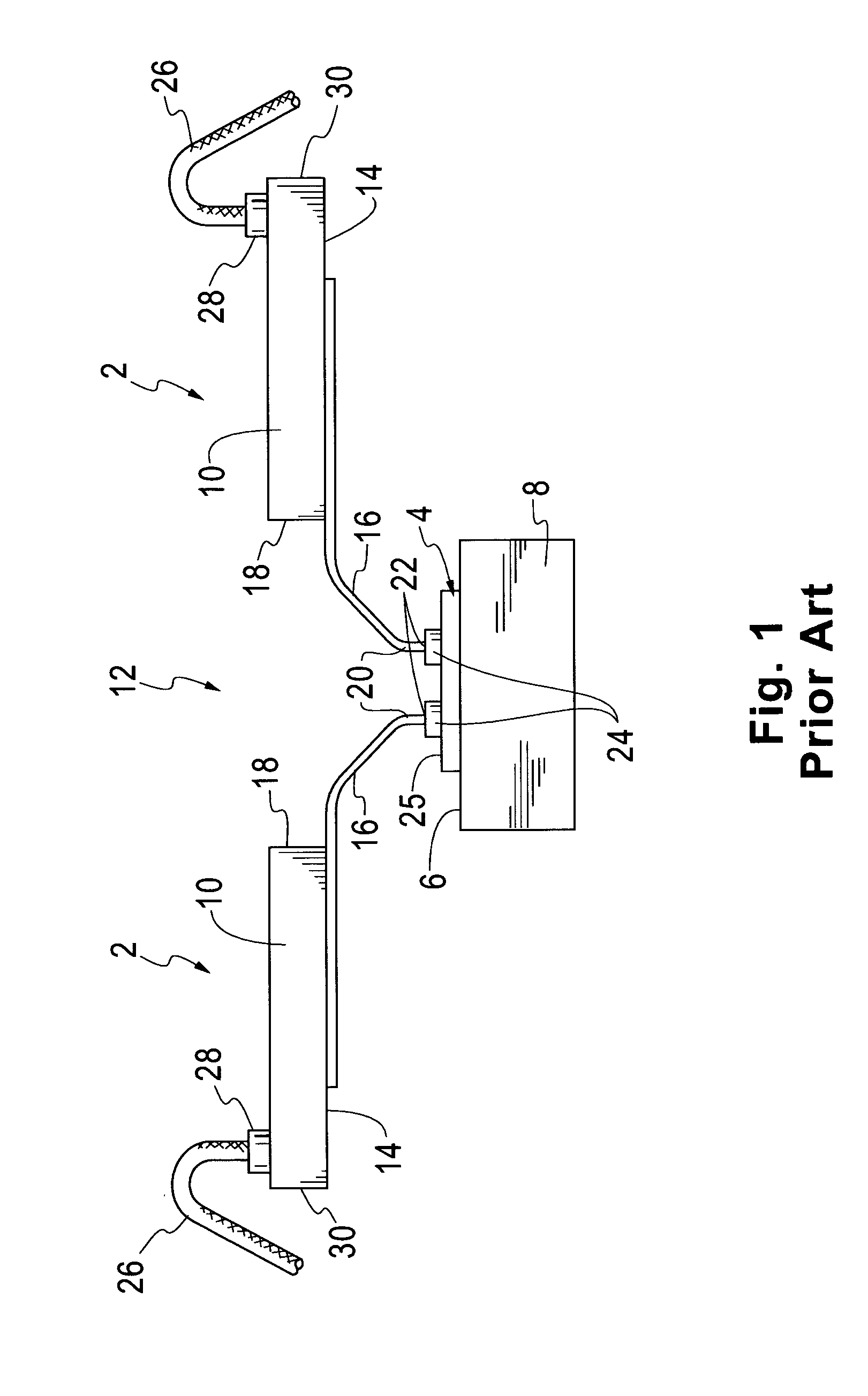

Method of making a transcutaneous electrochemical sensor

InactiveUS6973706B2Efficient productionWave amplification devicesDecorative surface effectsEngineeringConductive materials

A process for the manufacture of small sensors with reproducible surfaces, including electrochemical sensors. One process includes fanning channels in the surface of a substrate and disposing a conductive material in the channels to form an electrode. The conductive material can also be formed on the substrate by other impact and non-impact methods. In a preferred embodiment, the method includes cutting the substrate to form a sensor having a connector portion and a transcutaneous portion, the two portions having edges that define one continuous straight line.

Owner:THERASENSE

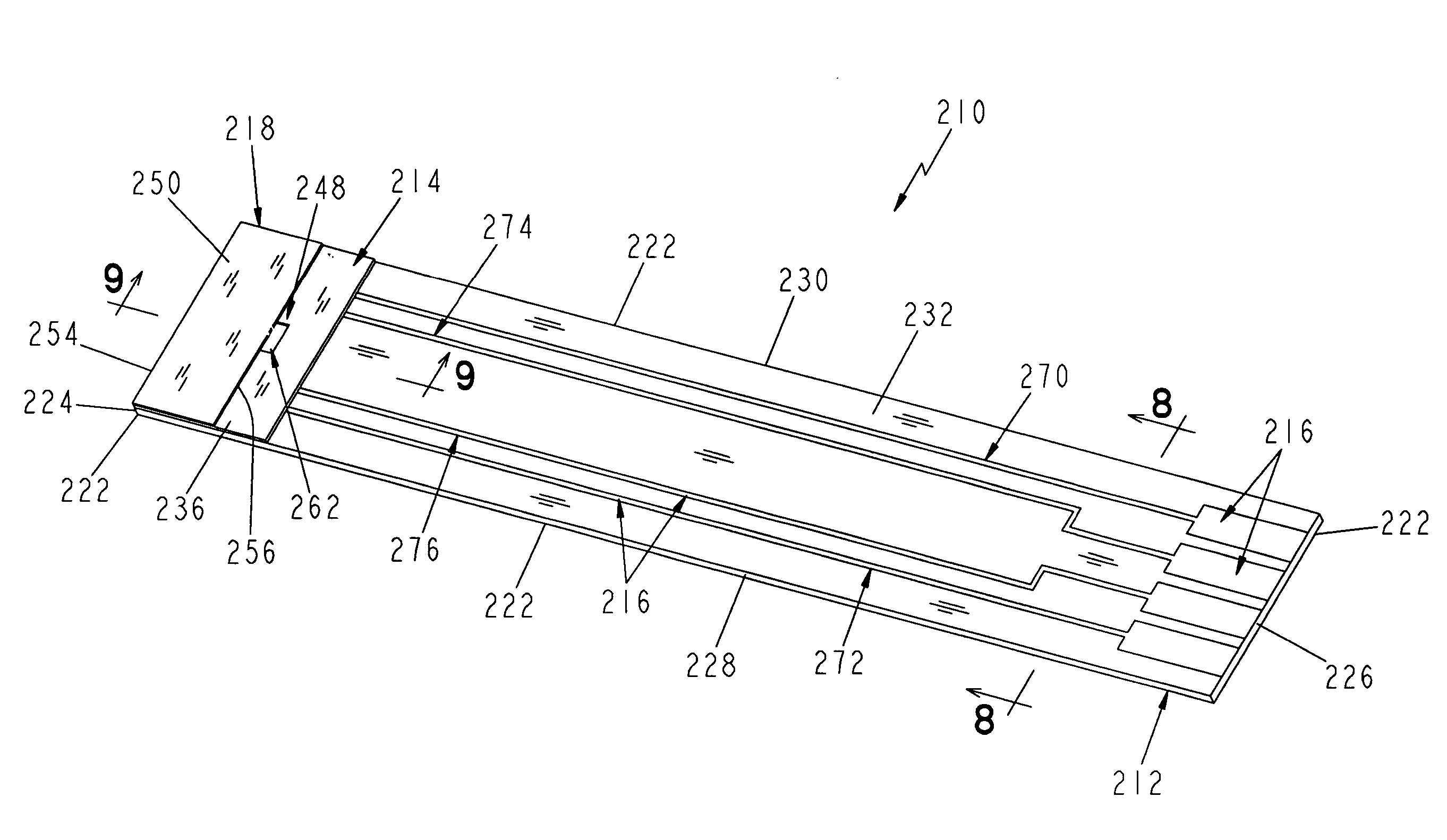

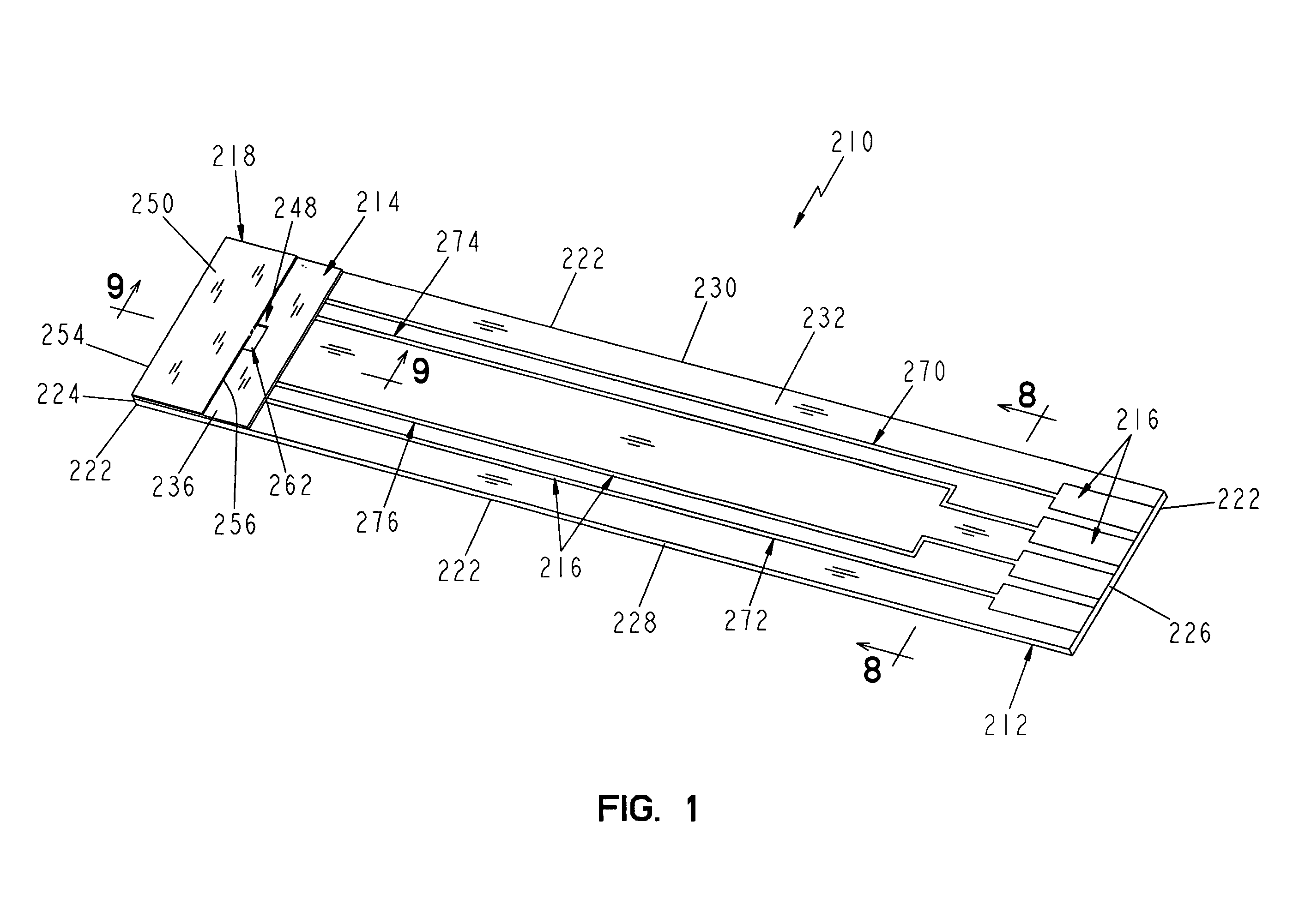

Method of making a biosensor

InactiveUS7073246B2Immobilised enzymesBioreactor/fermenter combinationsConductive materialsEngineering

A method of making a biosensor is provided. The biosensor includes an electrically conductive material on a base and electrode patterns formed on the base, the patterns having different feature sizes. The conductive material is partially removed from the base using broad field laser ablation so that less than 90% of the conductive material remains on the base and that the electrode pattern has an edge extending between two points. A standard deviation of the edge from a line extending between two points is less than about 6 μm.

Owner:ROCHE DIABETES CARE INC +1

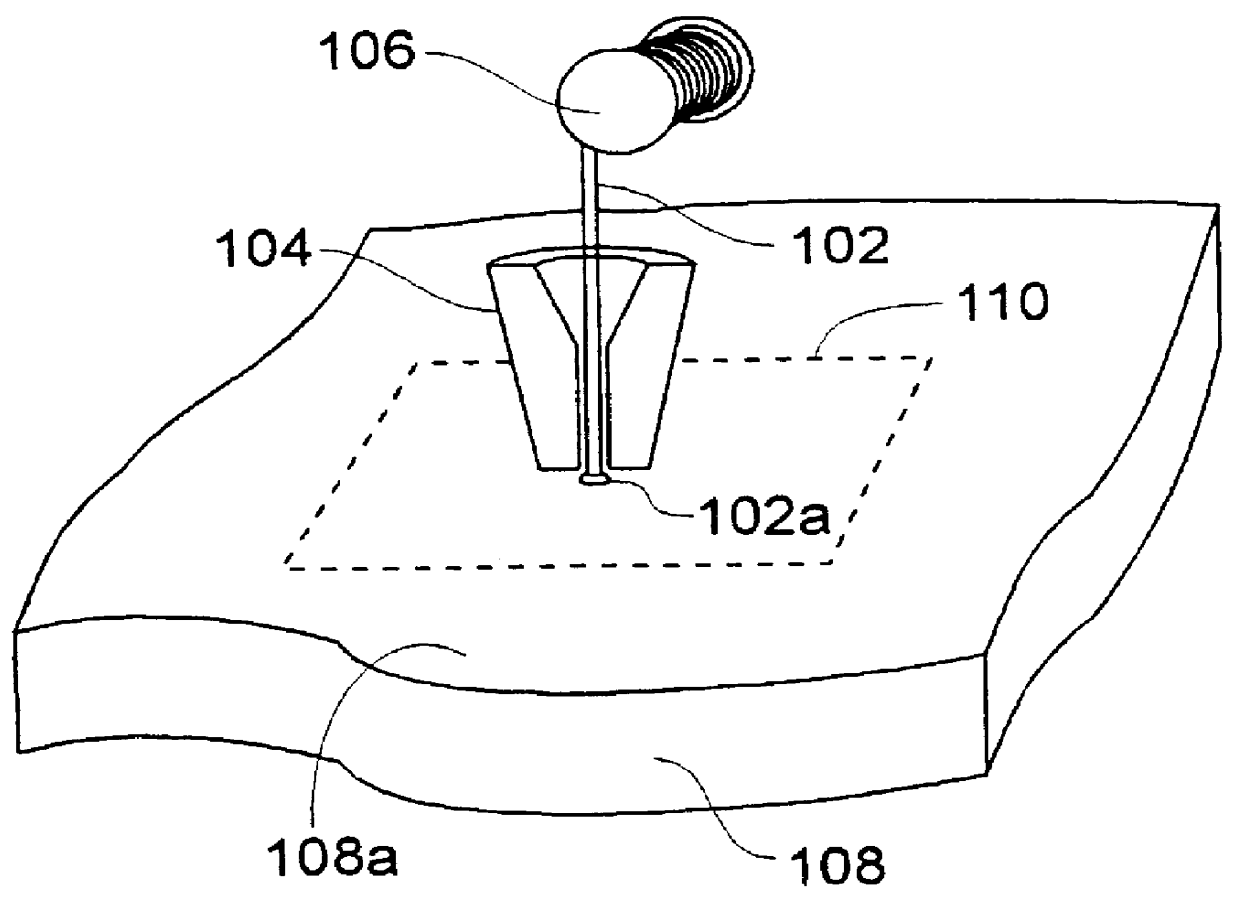

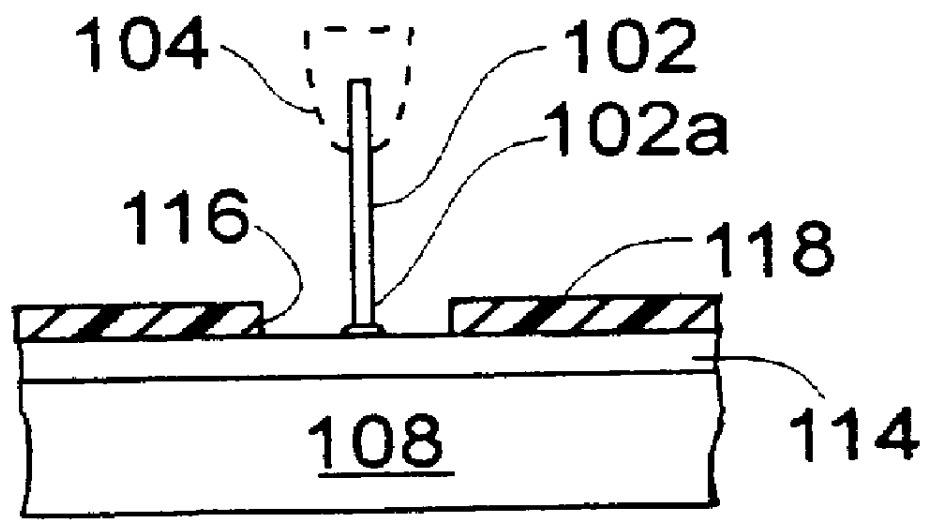

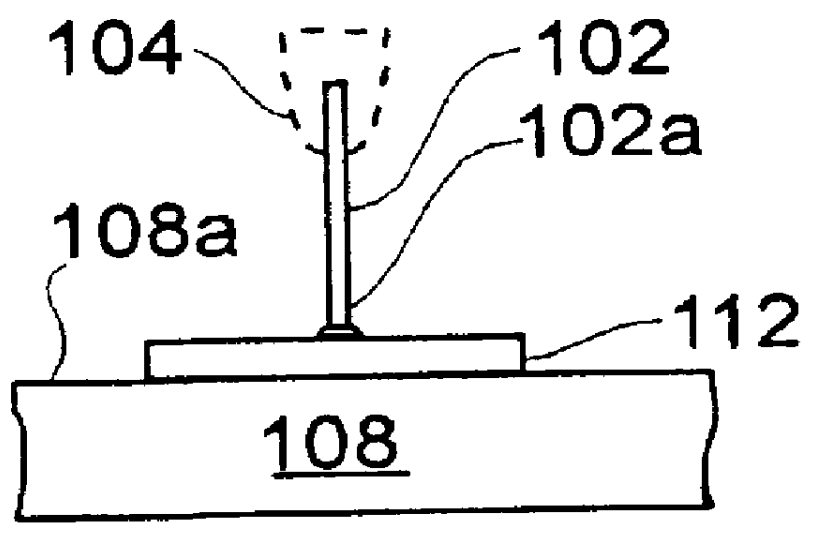

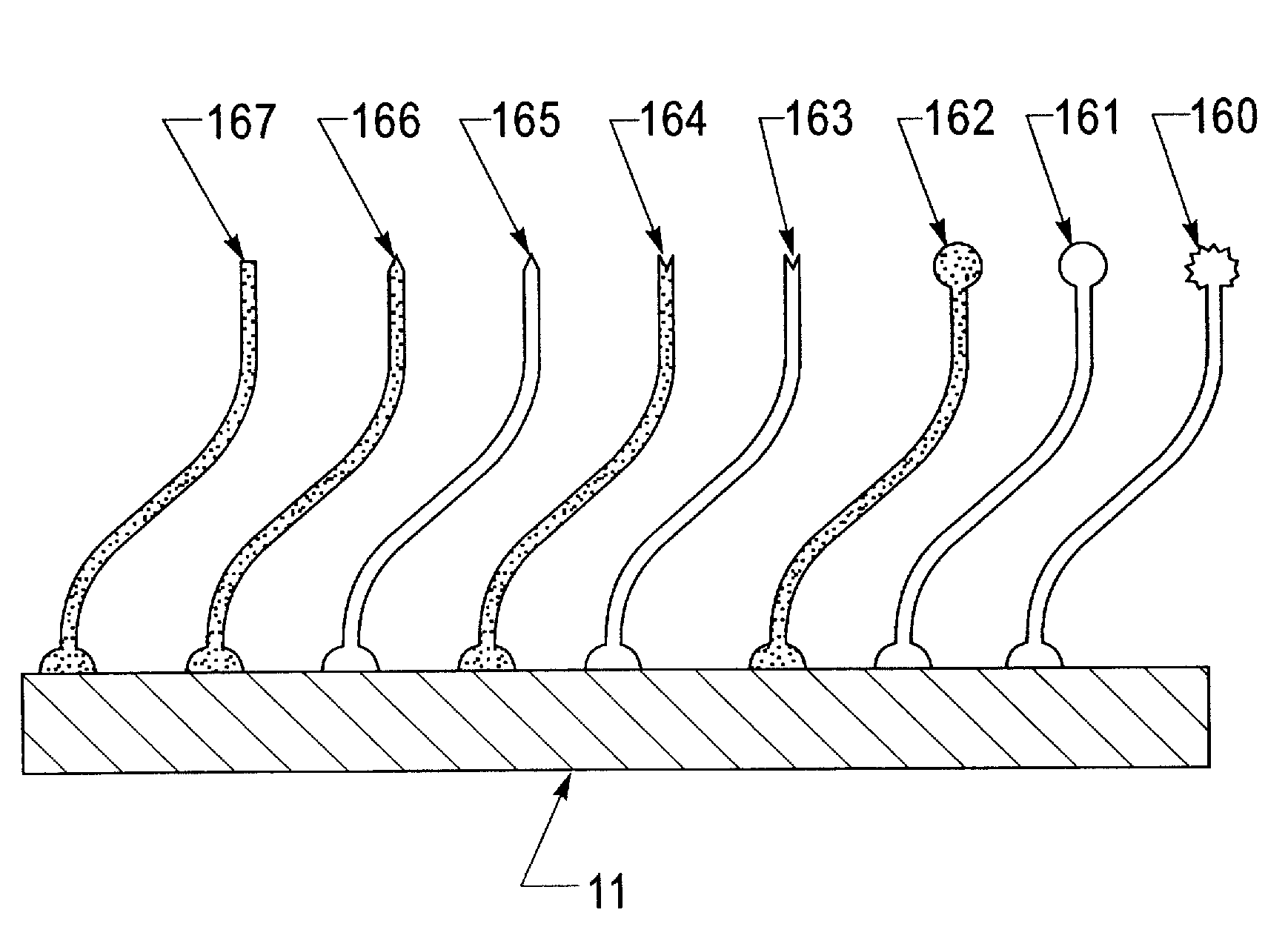

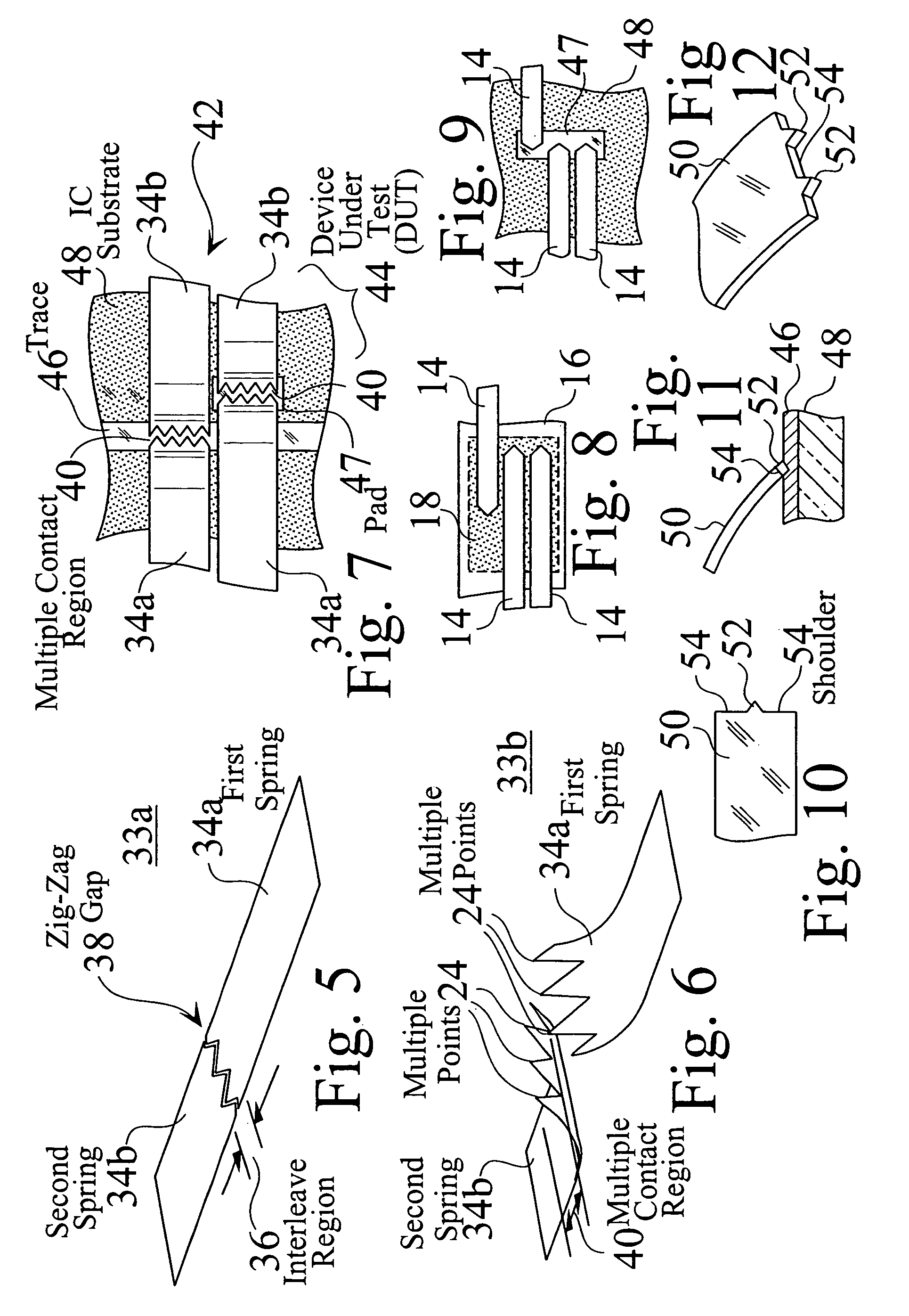

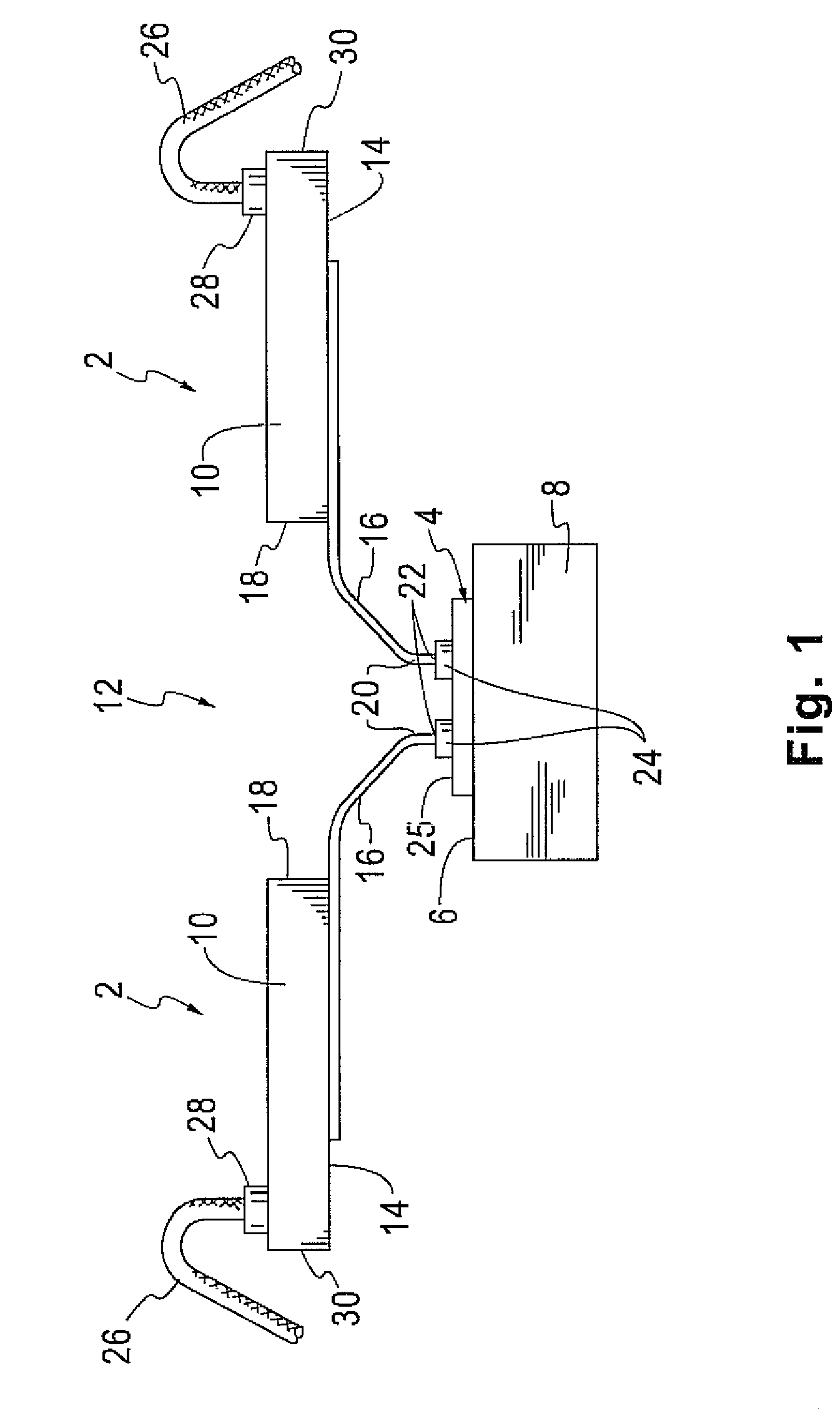

Method of modifying the thickness of a plating on a member by creating a temperature gradient on the member, applications for employing such a method, and structures resulting from such a method

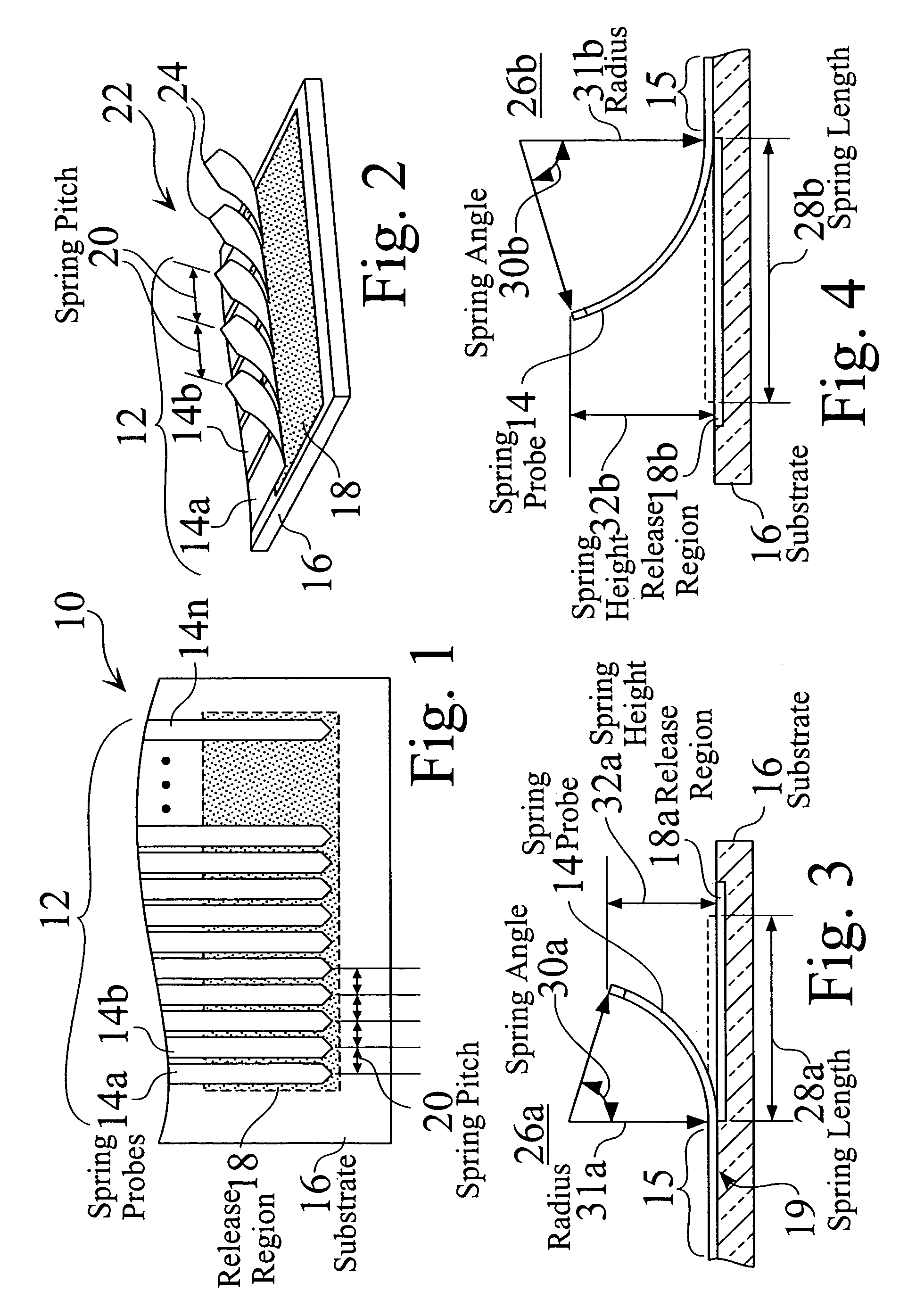

InactiveUS6110823ASimple technologyTrend downSemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringElectronic component

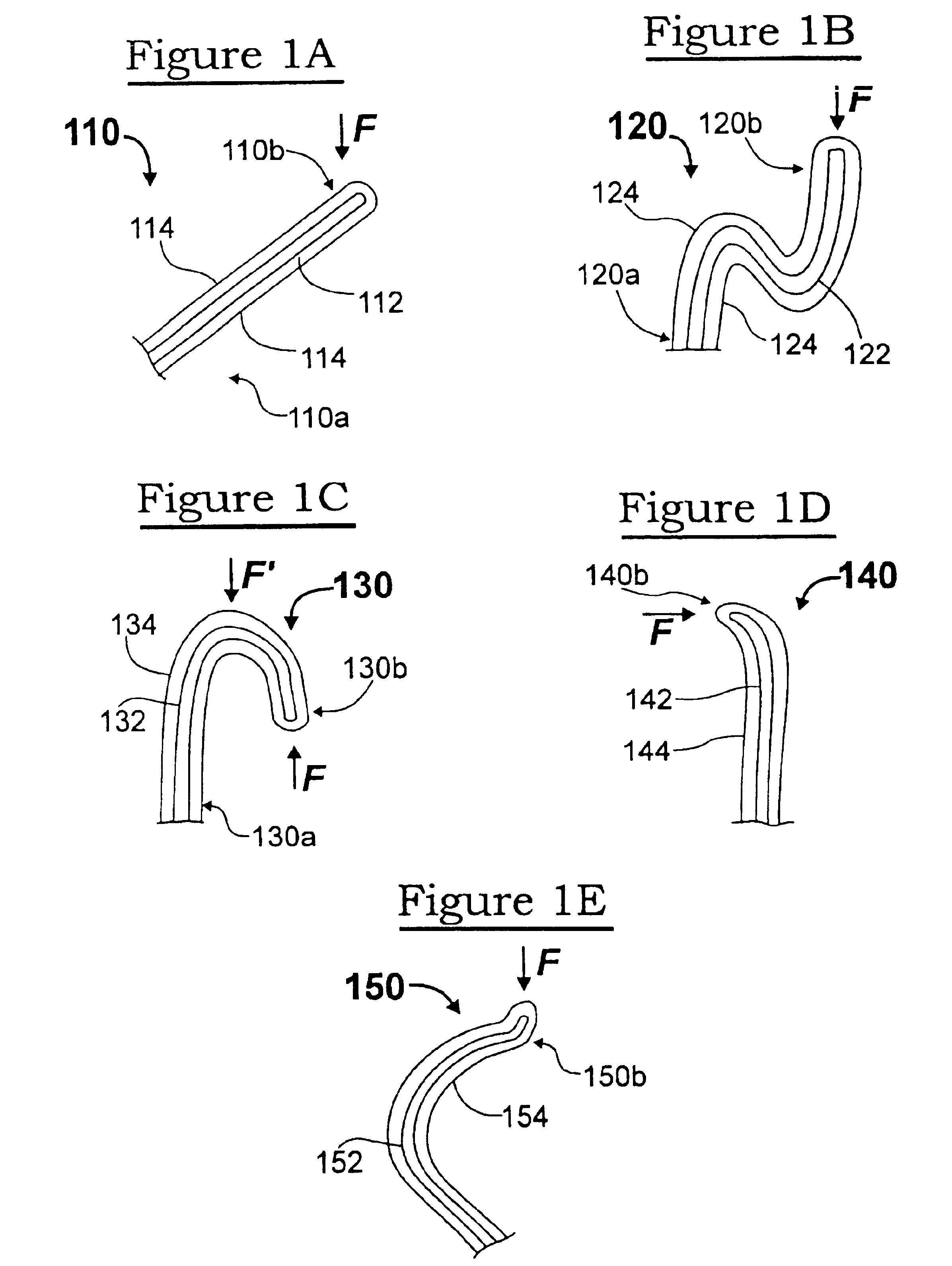

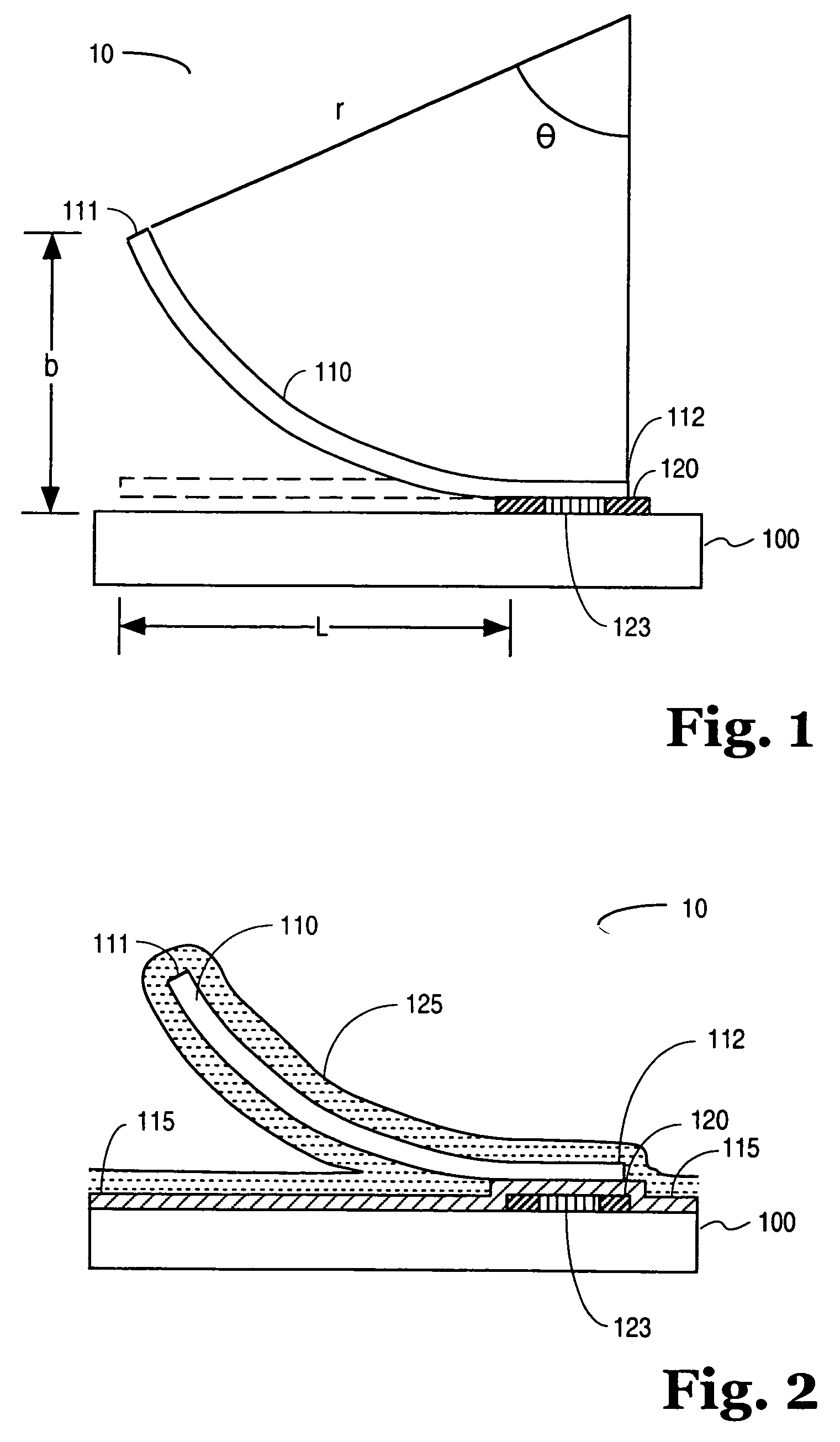

Contact structures exhibiting resilience or compliance for a variety of electronic components are formed by bonding a free end of a wire to a substrate, configuring thw wire into a wire stem having a springable shape, serving thw wire stem, and overcoating the wire stem with at least one layer of a material chosen primarily for its structural (resiliency, compliance) characteristics. A variety of techniques for configuring, serving, and overcoating the wire stem are disclosed. In an exemplary embodiment, a free end of a wire stem is bonded to a contact area on a substrate, the wire stem is configured to ahve a springable shape, the wire stem is served to be free-standing by an electrical discharge, and the free-standing wire stem is overcoating by plating.

Owner:FORMFACTOR INC

Method of making a product with improved material properties by moderate heat-treatment of a metal incorporating a dilute additive

InactiveUS6150186AStable mechanical propertiesImprove conductivitySemiconductor/solid-state device testing/measurementFinal product manufactureUltimate tensile strengthMechanical property

Deposition of metal in a preferred shape, including coatings on parts, or stand-alone materials, and subsequent heat treatment to provide improved mechanical properties. In particular, the method gives products with relatively high yield strength. The products often have relatively high elastic modulus, and are thermally stable, maintaining the high yield strength at temperatures considerably above 25 DEG C. This technique involves depositing a material in the presence of a selected additive, and then subjecting the deposited material to a moderate heat treatment. This moderate heat treatment differs from other commonly employed "stress relief" heat treatments in using lower temperatures and / or shorter times, preferably just enough to reorganize the material to the new, desired form. Coating a shape and heat treating provides a shaped deposit with improved material properties. Coating a shape with a portion connected to a base and a portion detached therefrom can provide a resilient, conductive contact useful for electronic applications.

Owner:FORMFACTOR INC

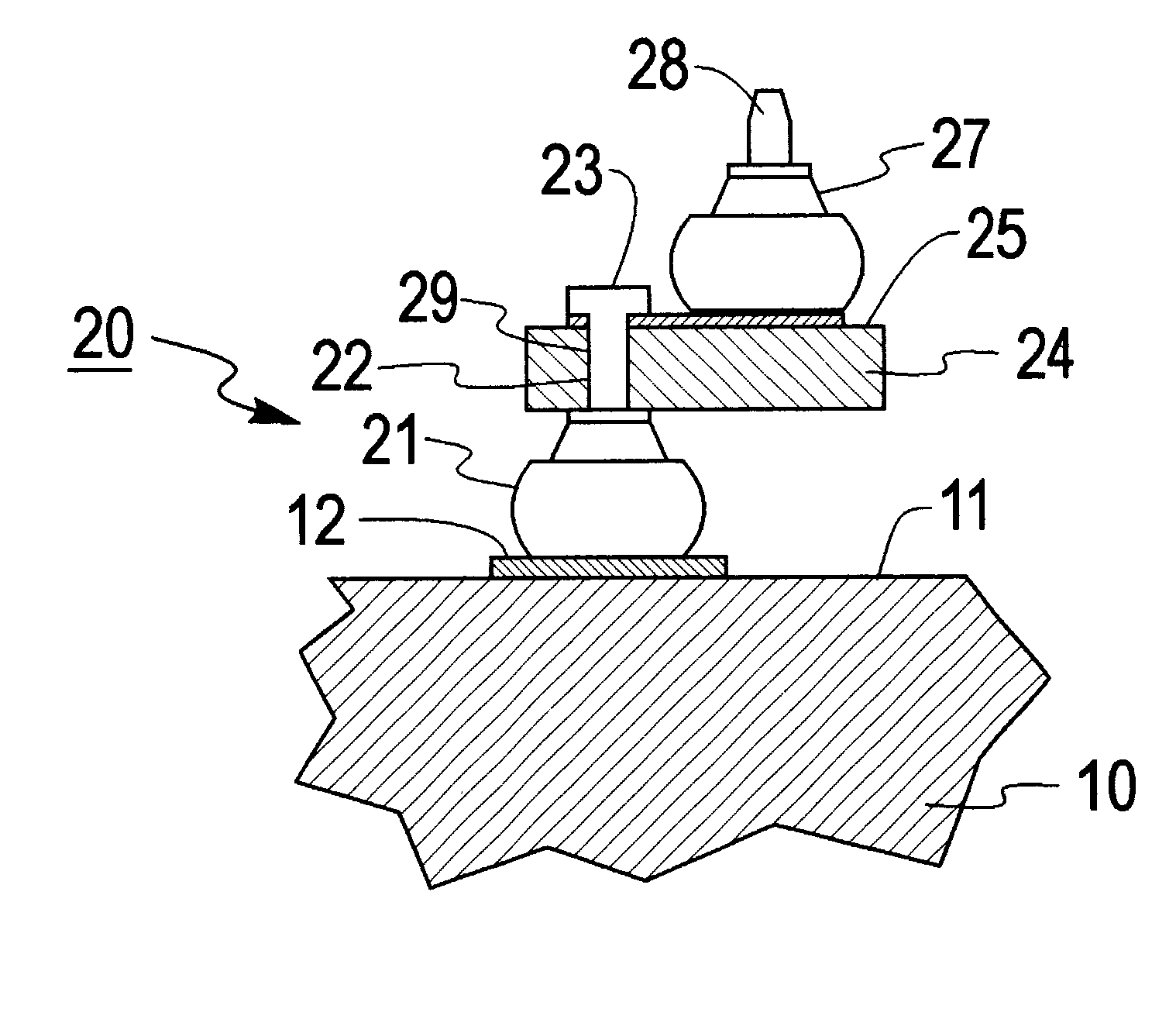

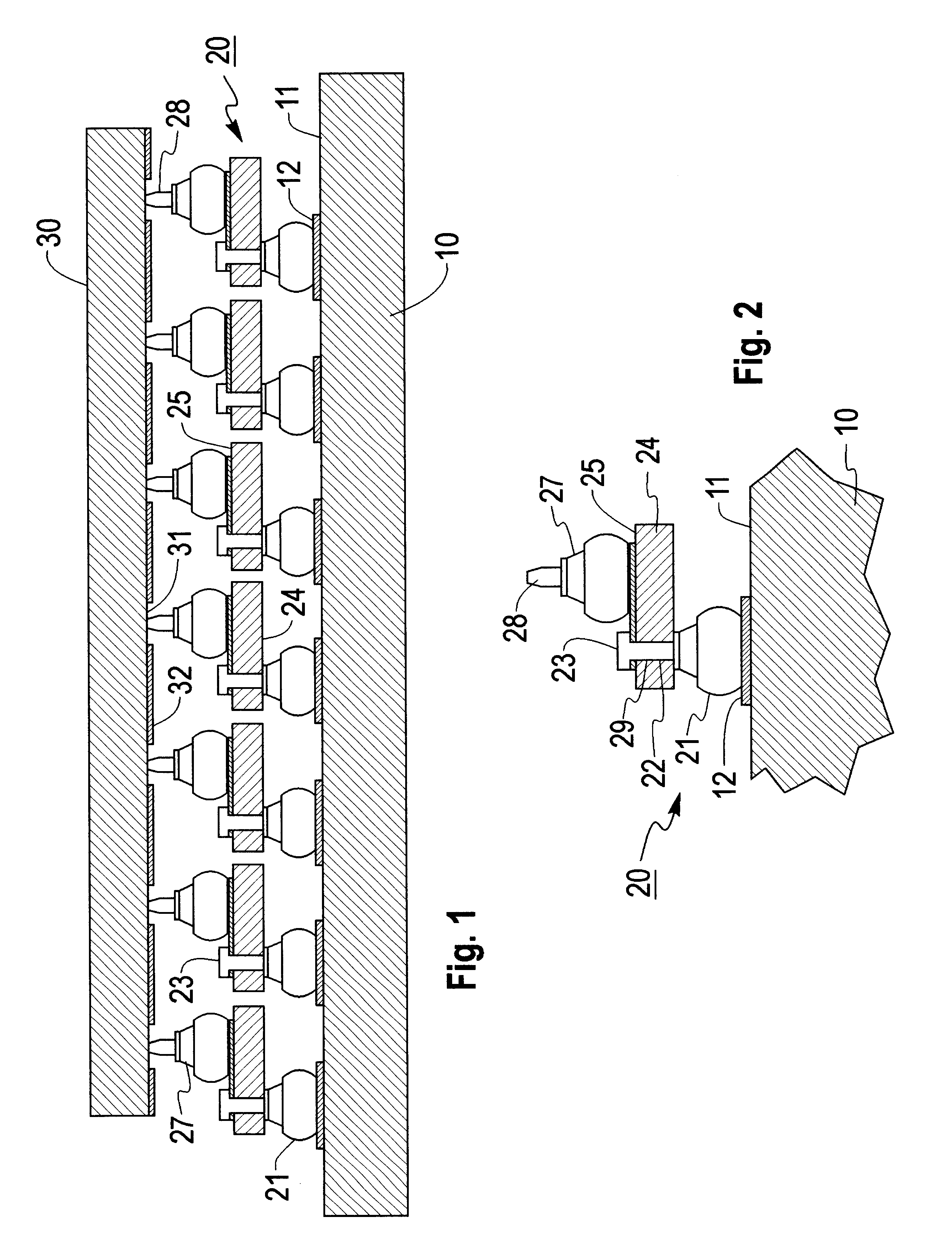

Methods of removably mounting electronic components to a circuit board, and sockets formed by the methods

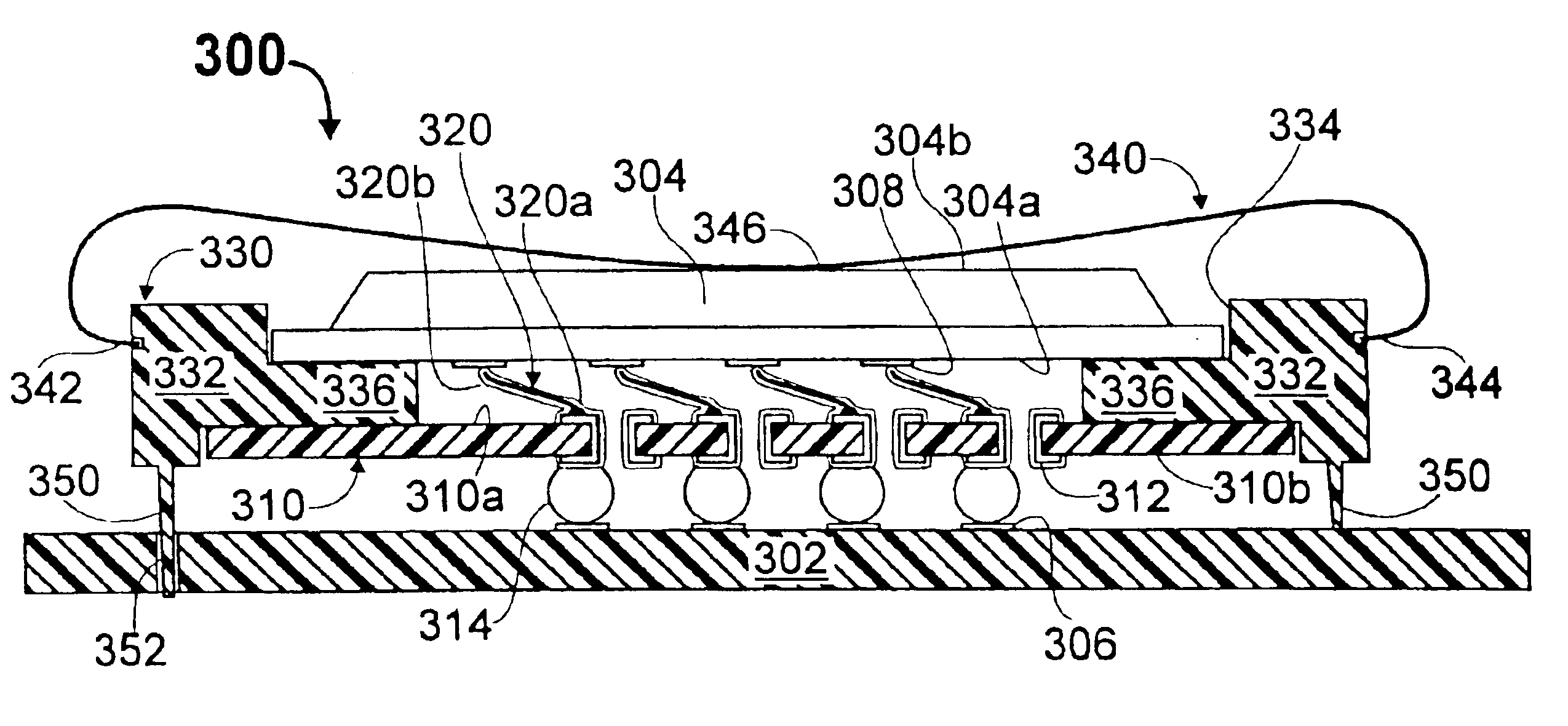

InactiveUS6913468B2Easy to disassembleEffective shieldingSemiconductor/solid-state device testing/measurementFinal product manufactureSurface mountingSolder ball

Surface-mount, solder-down sockets are described which permit electronic components such as semiconductor packages to be releasably mounted to a circuit board. Generally, the socket includes resilient contact structures extending from a top surface of a support substrate, and solder-ball (or other suitable) contact structures disposed on a bottom surface of the support substrate. Composite interconnection elements are described for use as the resilient contact structures disposed atop the support substrate. In use, the support substrate is soldered down onto the circuit board, the contact structures on the bottom surface of the support substrate contacting corresponding contact areas on the circuit board. In any suitable manner, selected ones of the resilient contact structures atop the support substrate are connected, via the support substrate, to corresponding ones of the contact structures on the bottom surface of the support substrate.

Owner:FORMFACTOR INC

High conducting thin-film nanoprobe card and its fabrication method

InactiveUS7012441B2Compensating for such errorLine/current collector detailsElectrically conductive connectionsPolymer resinNanotube

A conducting thin-film nanoprobe card fabrication method includes the steps of: (a) arranging nanotubes on a substrate in vertical; (b) covering the nanotubes with a liquid polymeric resin and then hardening the polymeric resin to form a conducting nanomembrane; (c) removing a part of the polymeric resin from the conducting nanomembrane to expose one end of each nanotube to outside; (d) removing the substrate and preparing a ceramic substrate having contacts at one side and metal bumps at the other side and plated through holes electrically respectively connected with the contacts and the metal bumps; (e) mounting the nanomembrane on the ceramic substrate to hold the nanotubes in contact with the contacts of the ceramic substrate, and (f) forming recessed holes in the nanomembrane by etching and inserting a metal rod in each recessed hole to form a respective probe.

Owner:IND TECH RES INST

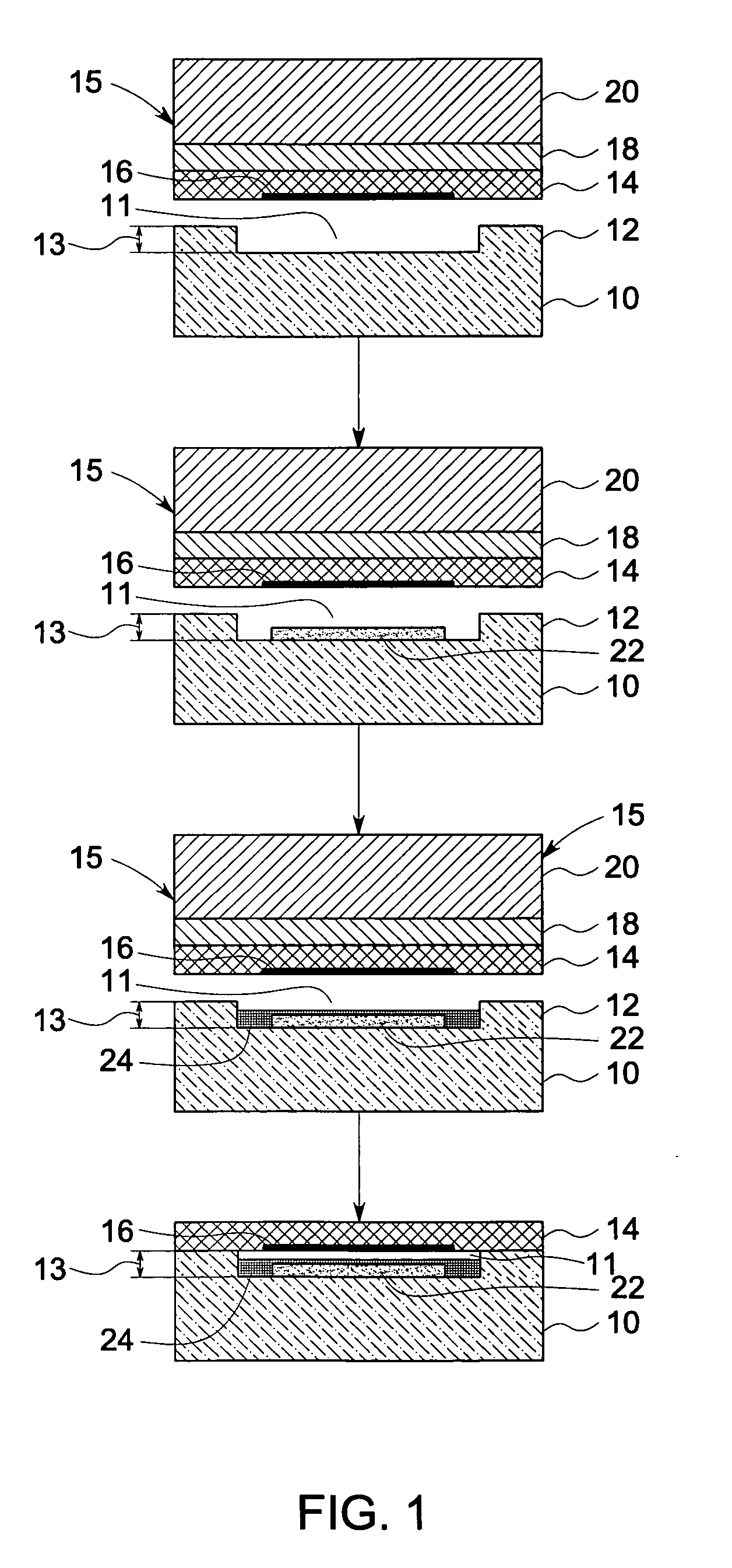

Capacitive micromachined ultrasound transducer and methods of making the same

InactiveUS20070180916A1Electrical transducersMaterial analysis using sonic/ultrasonic/infrasonic wavesCapacitanceUltrasonic sensor

A method of making a capacitive micromachined ultrasound transducer cell is provided. The method includes providing a carrier substrate, where the carrier substrate comprises glass. The step of providing the glass substrate may include forming vias in the glass substrate. Further, the method includes providing a membrane such that at least one of the carrier substrate, or the membrane comprises support posts, where the support posts are configured to define a cavity depth. The method further includes bonding the membrane to the carrier substrate by using the support posts, where the carrier substrate, the membrane and the support posts define an acoustic cavity.

Owner:GENERAL ELECTRIC CO

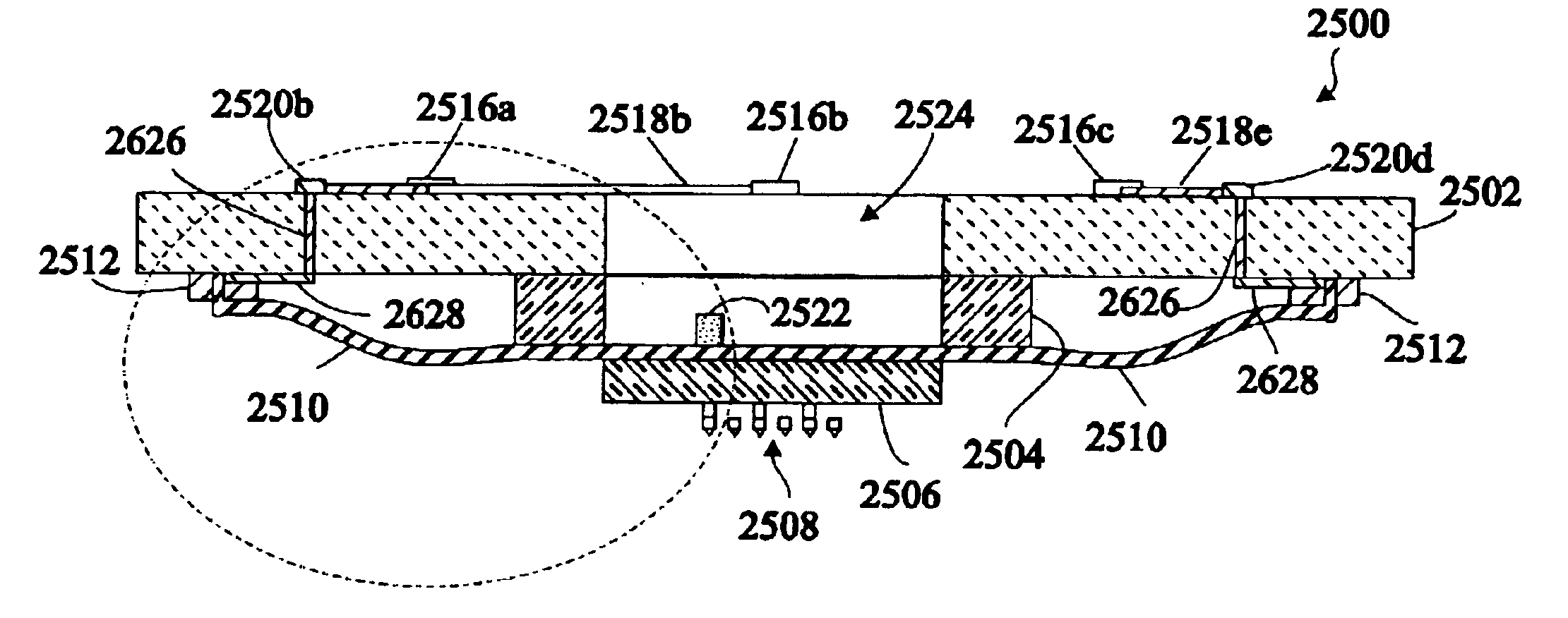

High performance probe system

InactiveUS6911835B2Semiconductor/solid-state device testing/measurementElectrical measurement instrument detailsHigh bandwidthΠ pad

A probe system for providing signal paths between an integrated circuit (IC) tester and input / output, power and ground pads on the surfaces of ICs to be tested includes a probe board assembly, a flex cable and a set of probes arranged to contact the IC's I / O pads. The probe board assembly includes one or more rigid substrate layers with traces and vias formed on or within the substrate layers providing relatively low bandwidth signal paths linking the tester to probes accessing some of the IC's pads. The flex cable provides relatively high bandwidth signal paths linking the tester to probes accessing others of the IC's pads. A flex strip may alternatively be disposed behind a substrate with probes.

Owner:FORMFACTOR INC

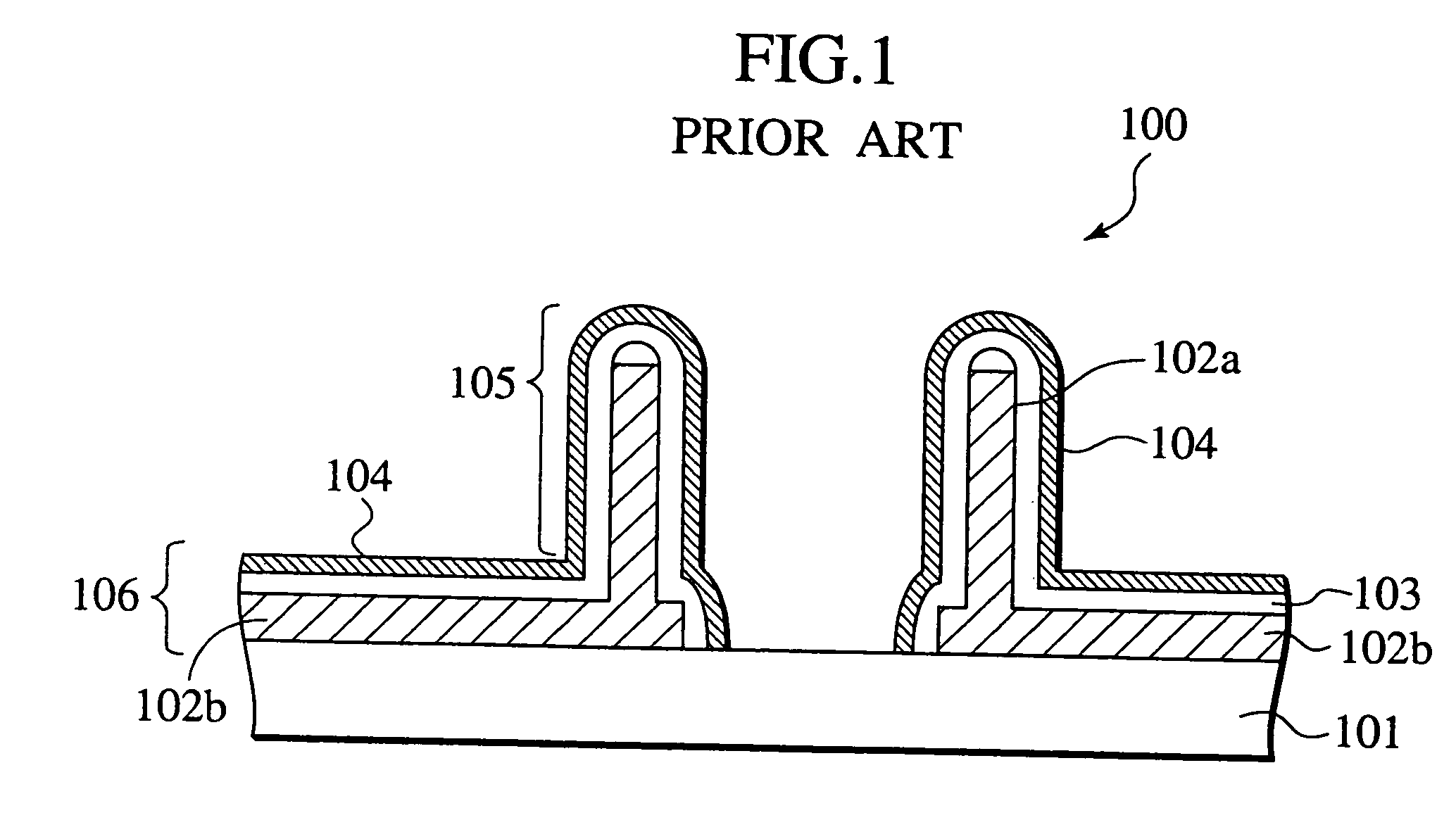

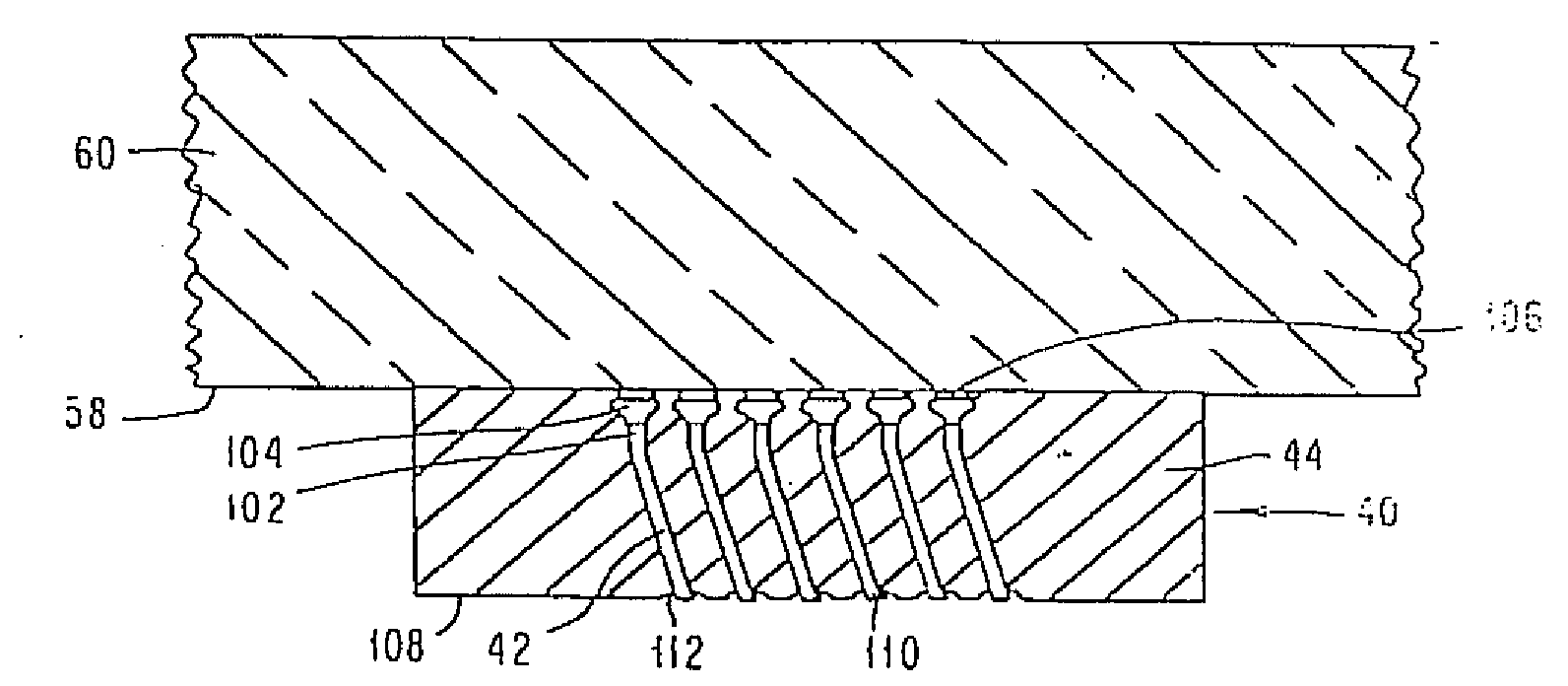

Needle fixture of a probe card in semiconductor inspection equipment and needle fixing method thereof

InactiveUS6900653B2Improve adhesion performanceAvoid crackingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardAdhesive

A needle fixture of a probe card and a needle fixing method in semiconductor inspection equipment include a needle fixture of a probe card in semiconductor inspection equipment including a printed circuit board; a needle fixture installed in the printed circuit board; a resin unit affixing a probe needle to the needle fixture using an adhesive; and a separation preventer for preventing separation of the resin unit from the needle fixture, wherein the separation preventer includes: a plurality of notches formed along a bottom surface of the needle fixture; and the adhesive filling the plurality of notches.

Owner:SAMSUNG ELECTRONICS CO LTD

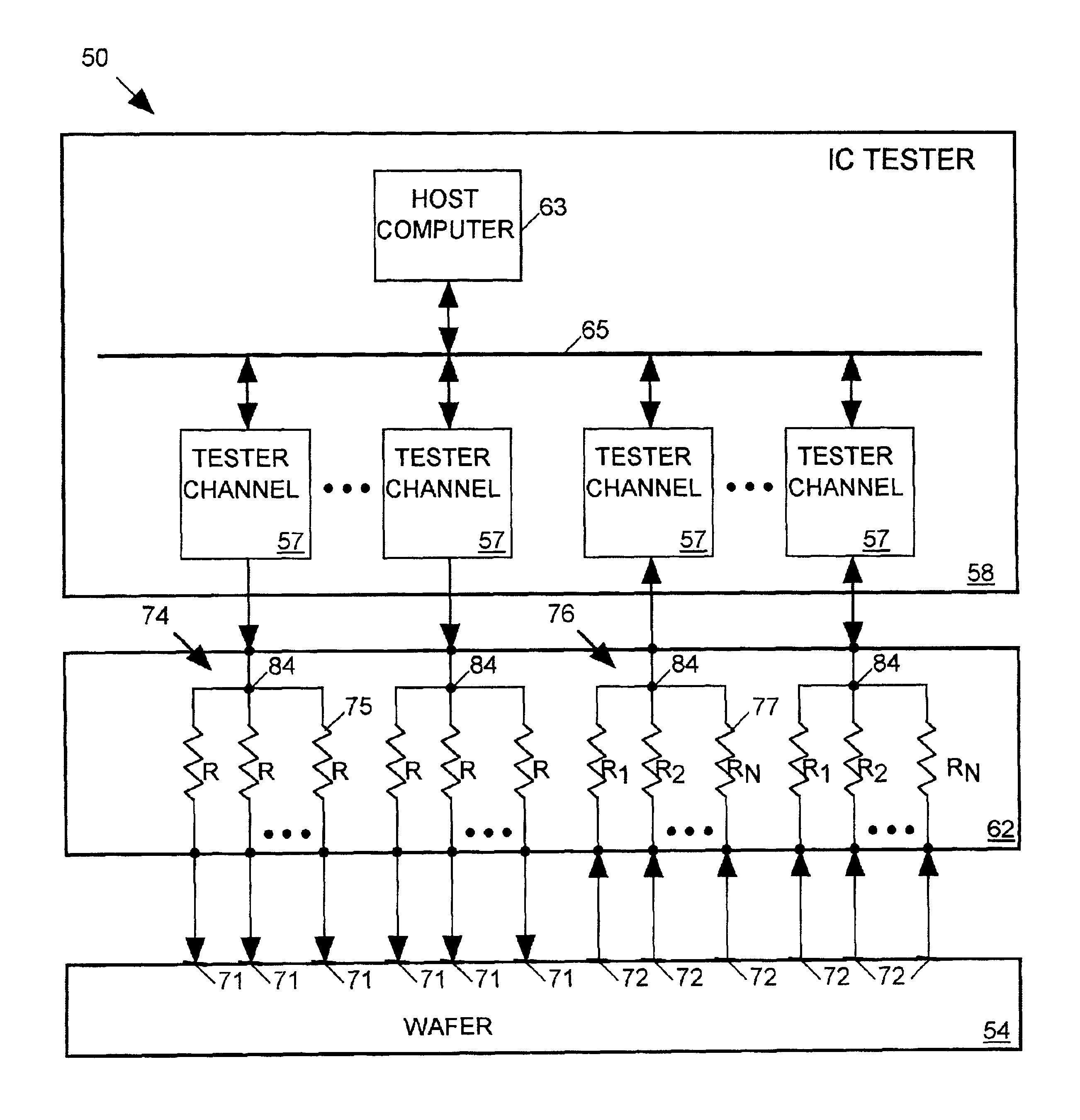

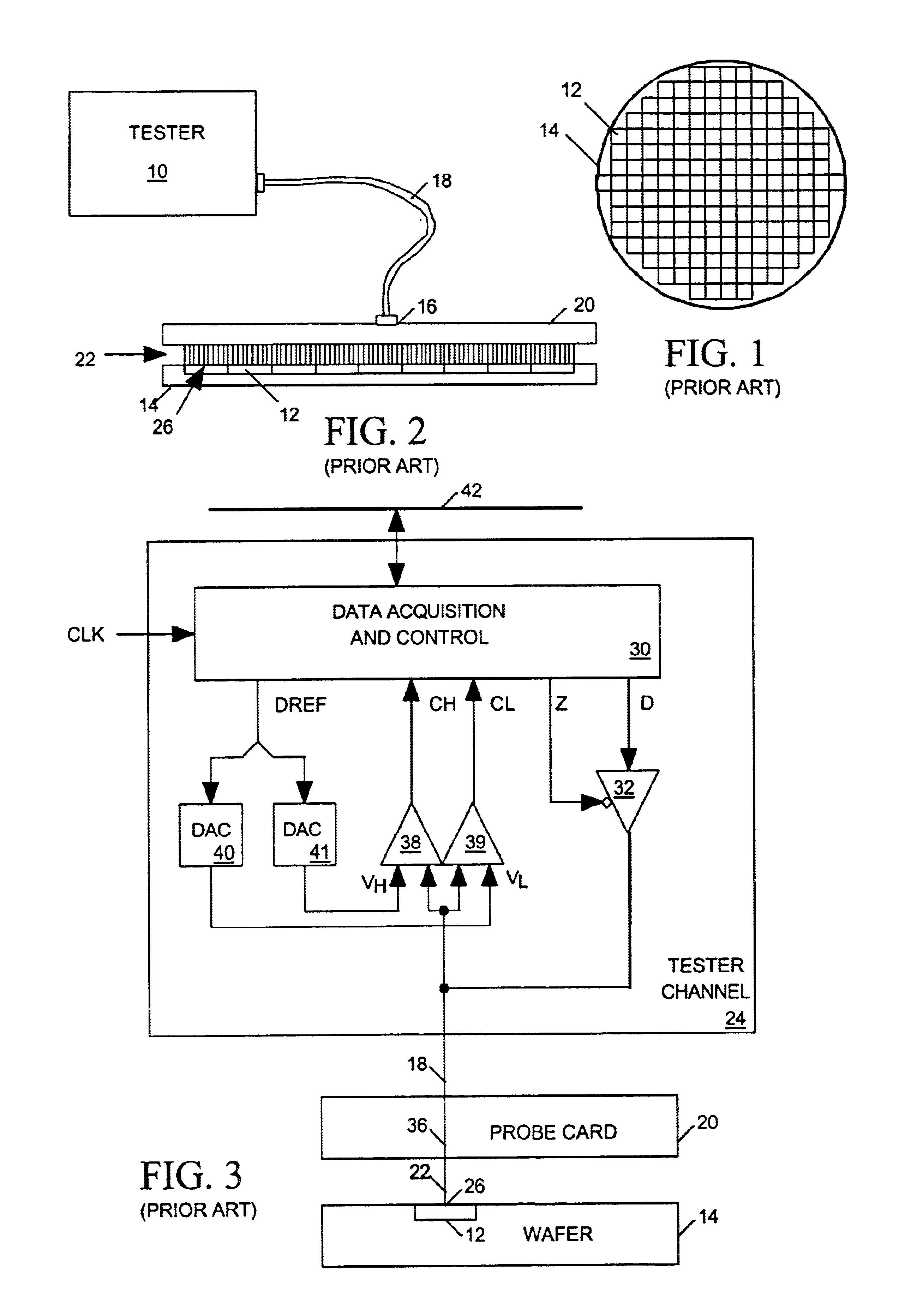

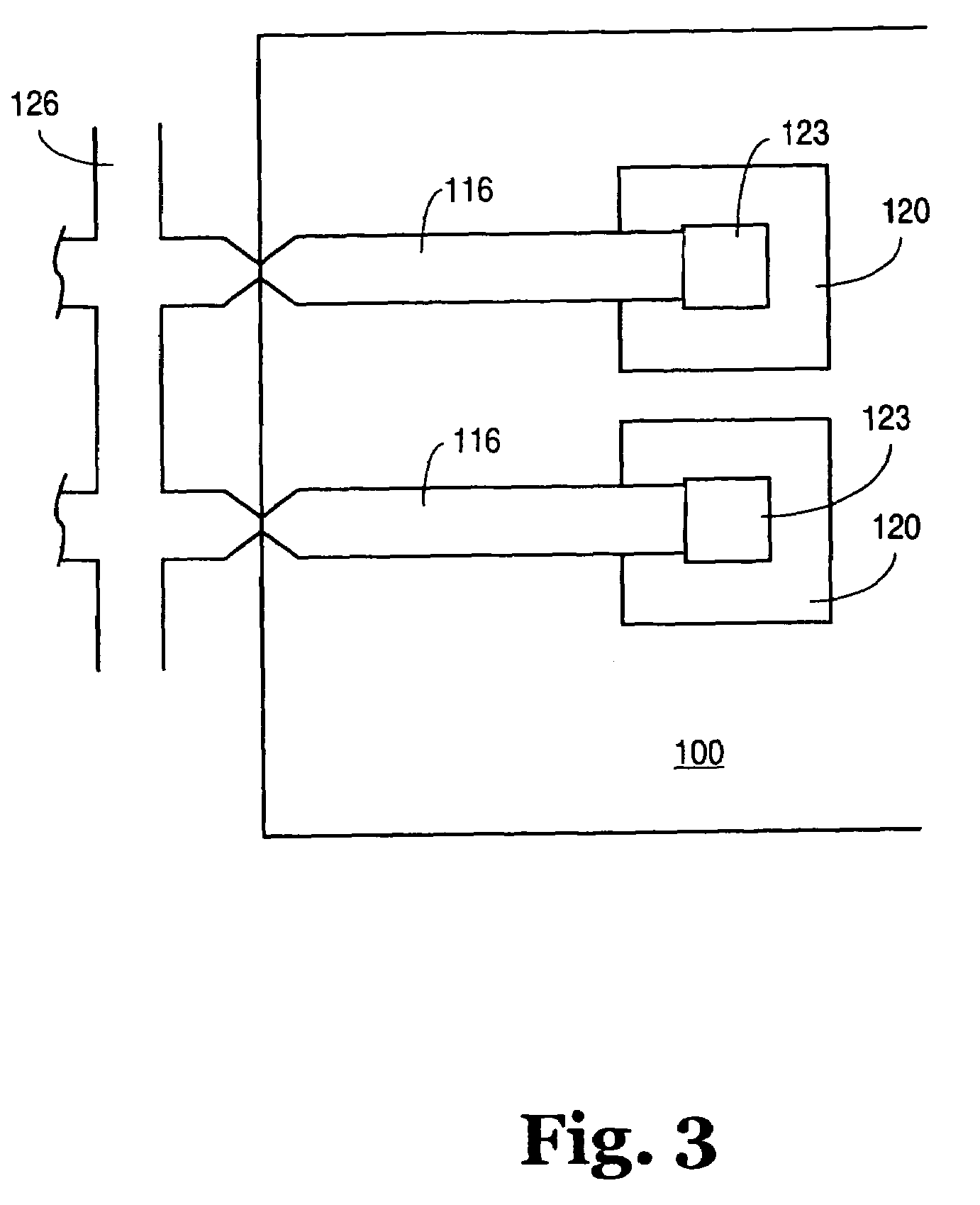

Tester channel to multiple IC terminals

InactiveUS6798225B2Digital circuit testingElectrical measurement instrument detailsElectrical resistance and conductanceProbe card

A probe card provides signal paths between integrated circuit (IC) tester channels and probes accessing input and output pads of ICs to be tested. When a single tester channel is to access multiple (N) IC pads, the probe card provides a branching path linking the channel to each of the N IC input pads. Each branch of the test signal distribution path includes a resistor for isolating the IC input pad accessed via that branch from all other branches of the path so that a fault on that IC pad does not substantially affect the voltage of signals appearing on any other IC pad. When a single tester channel is to monitor output signals produced at N IC pads, the resistance in each branch of the signal path linking the pads of the tester channel is uniquely sized to that the voltage of the input signal supplied to the tester channel is a function of the combination of logic states of the signals produced at the N IC pads. The tester channel measures the voltage of its input signal so that the logic state of the signals produced at each of the N IC output pads can be determined from the measured voltage.

Owner:FORMFACTOR INC

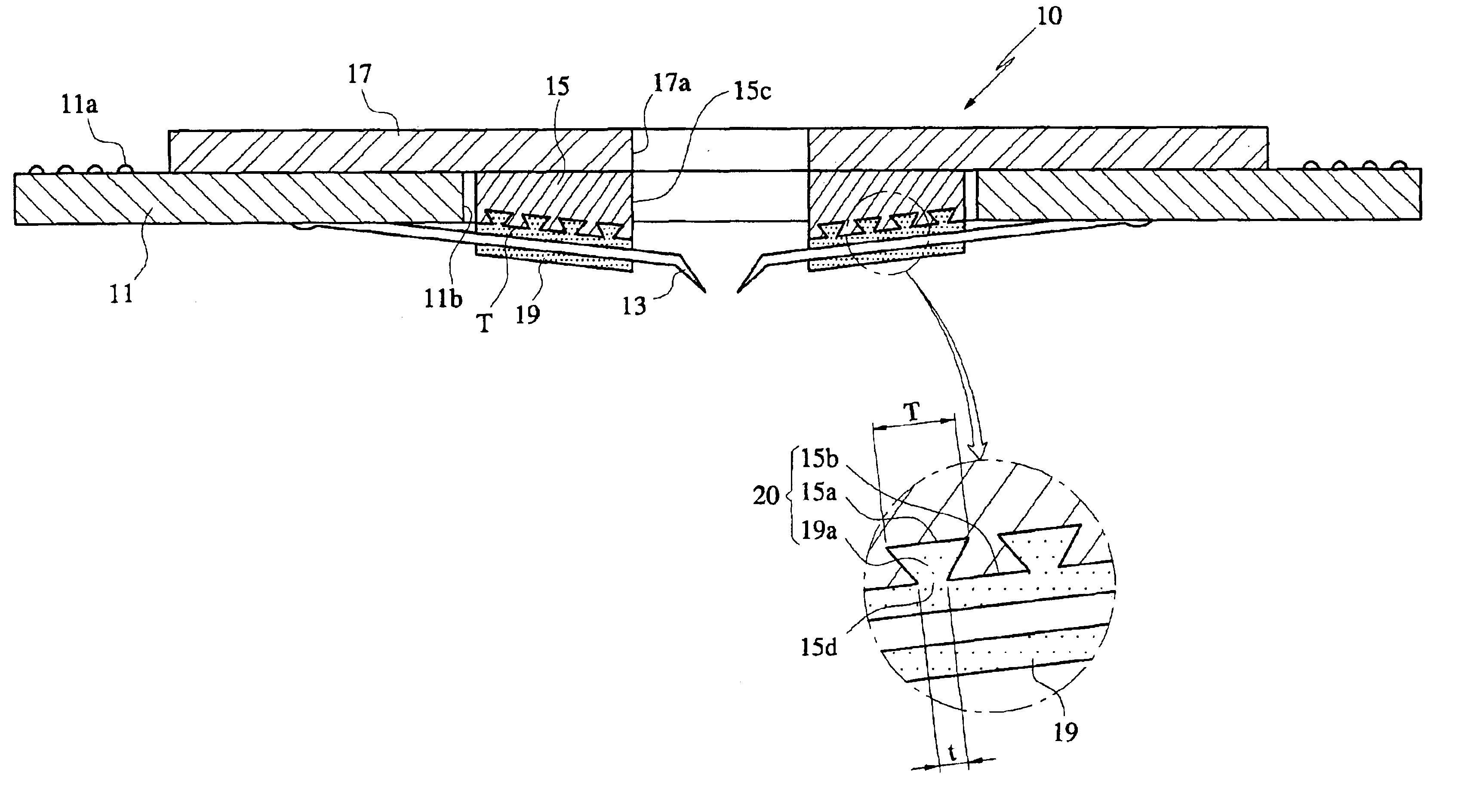

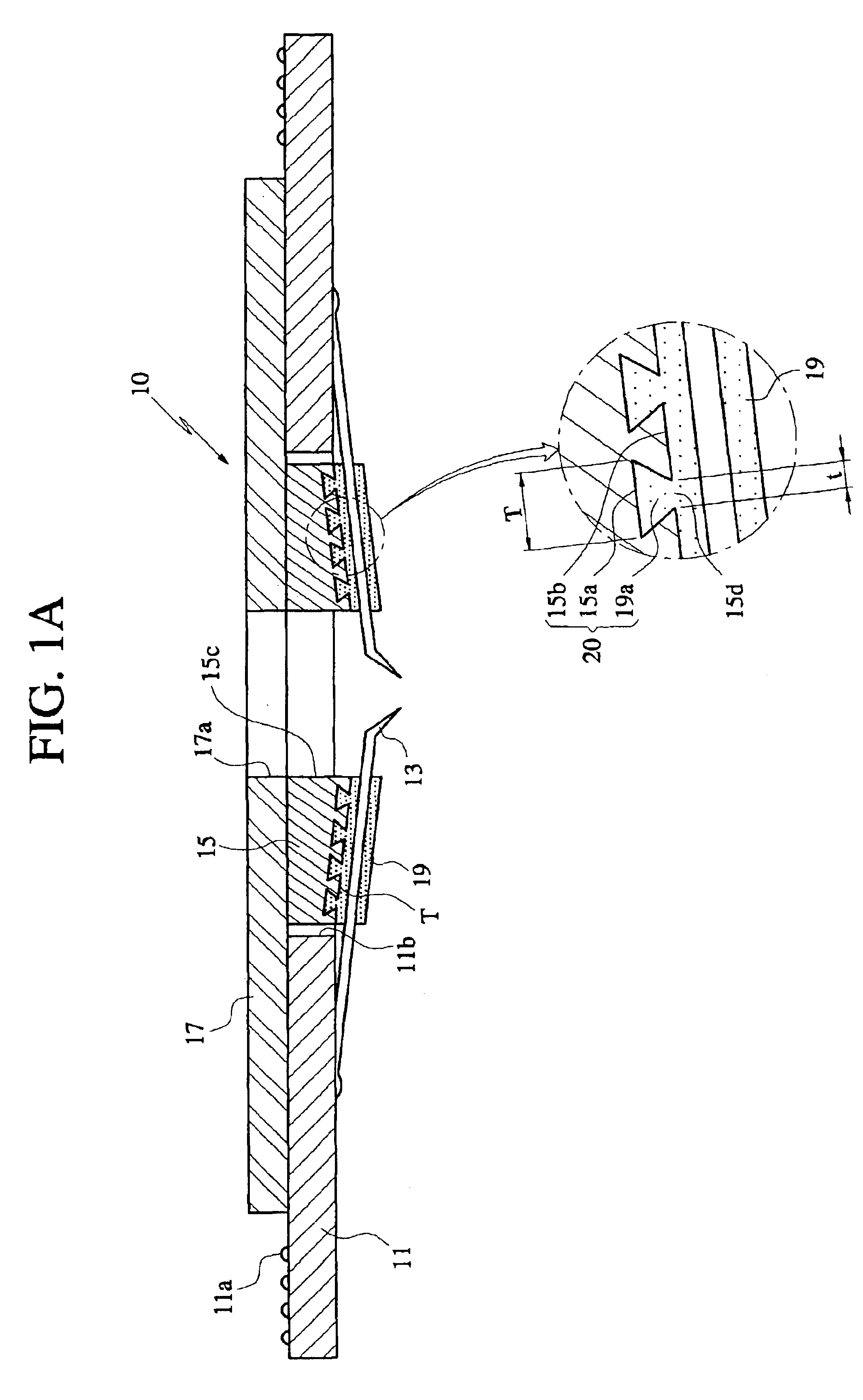

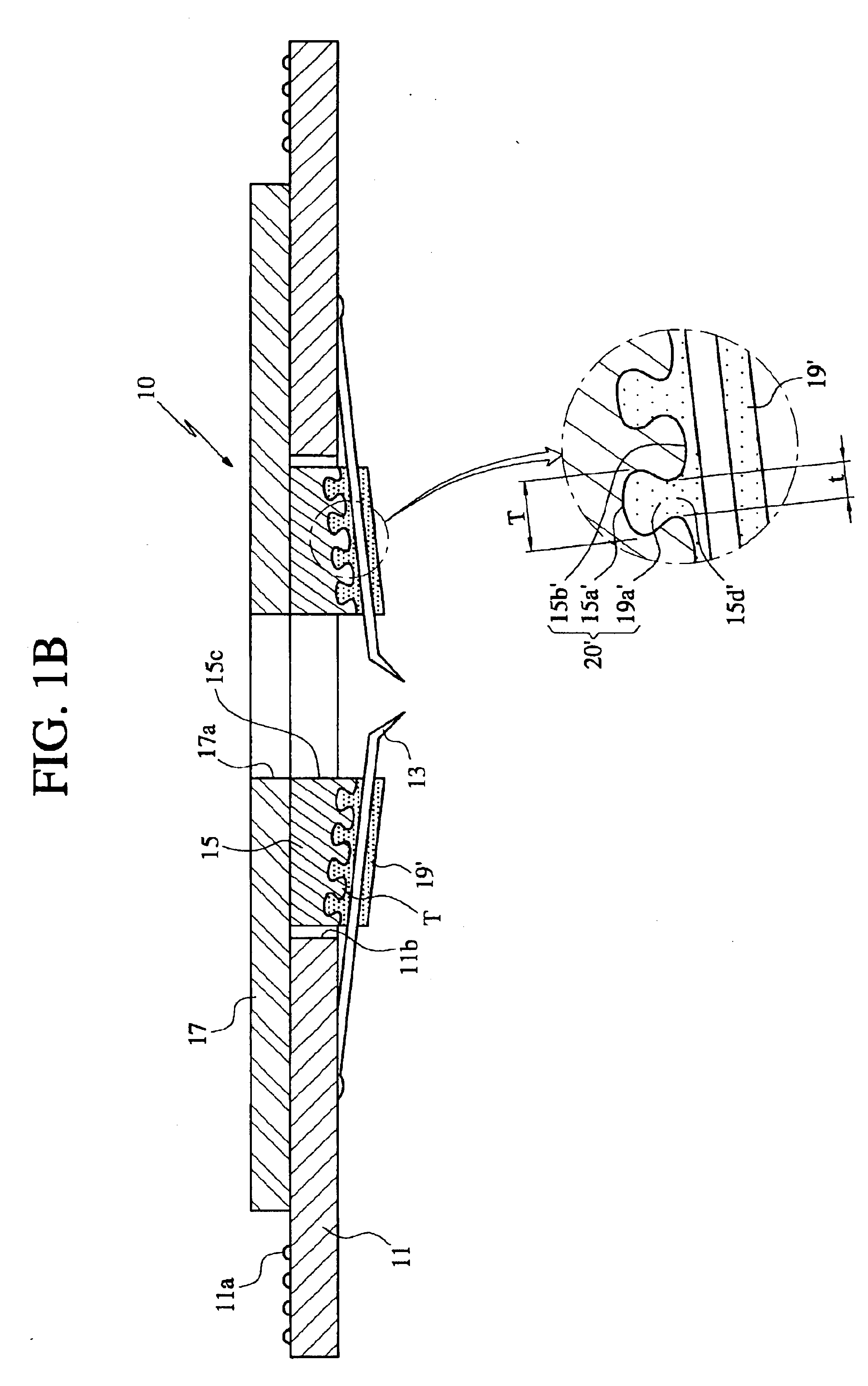

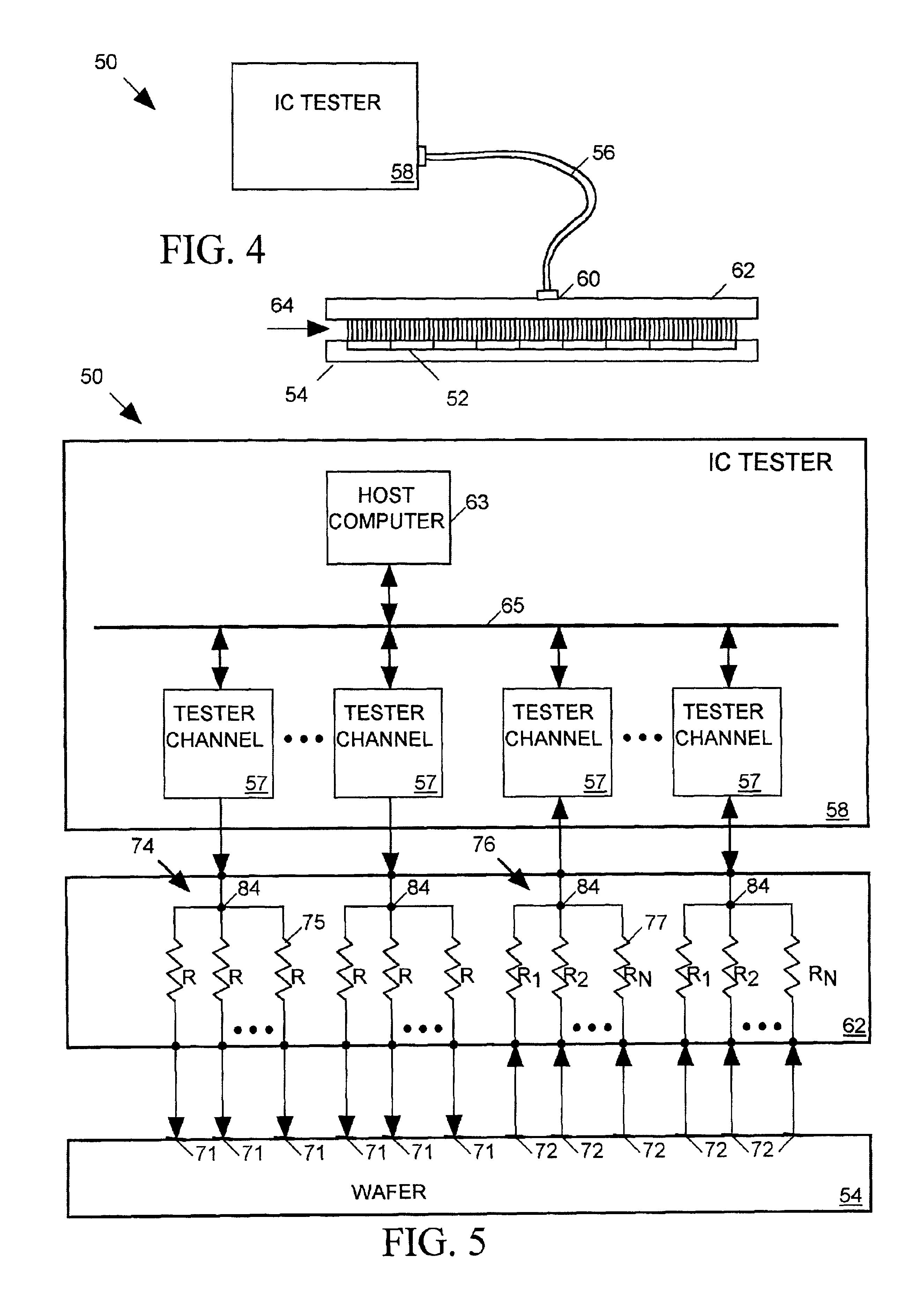

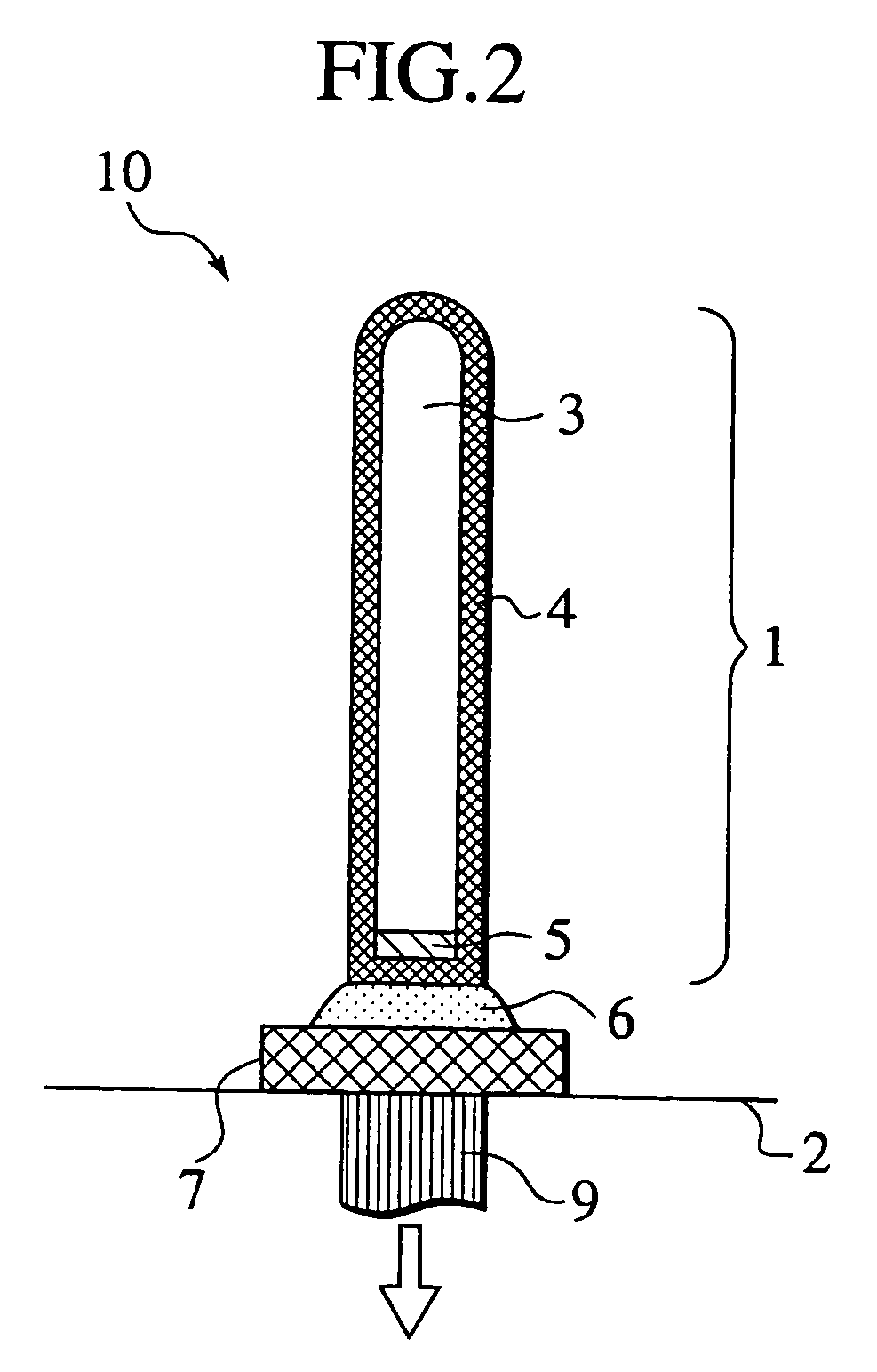

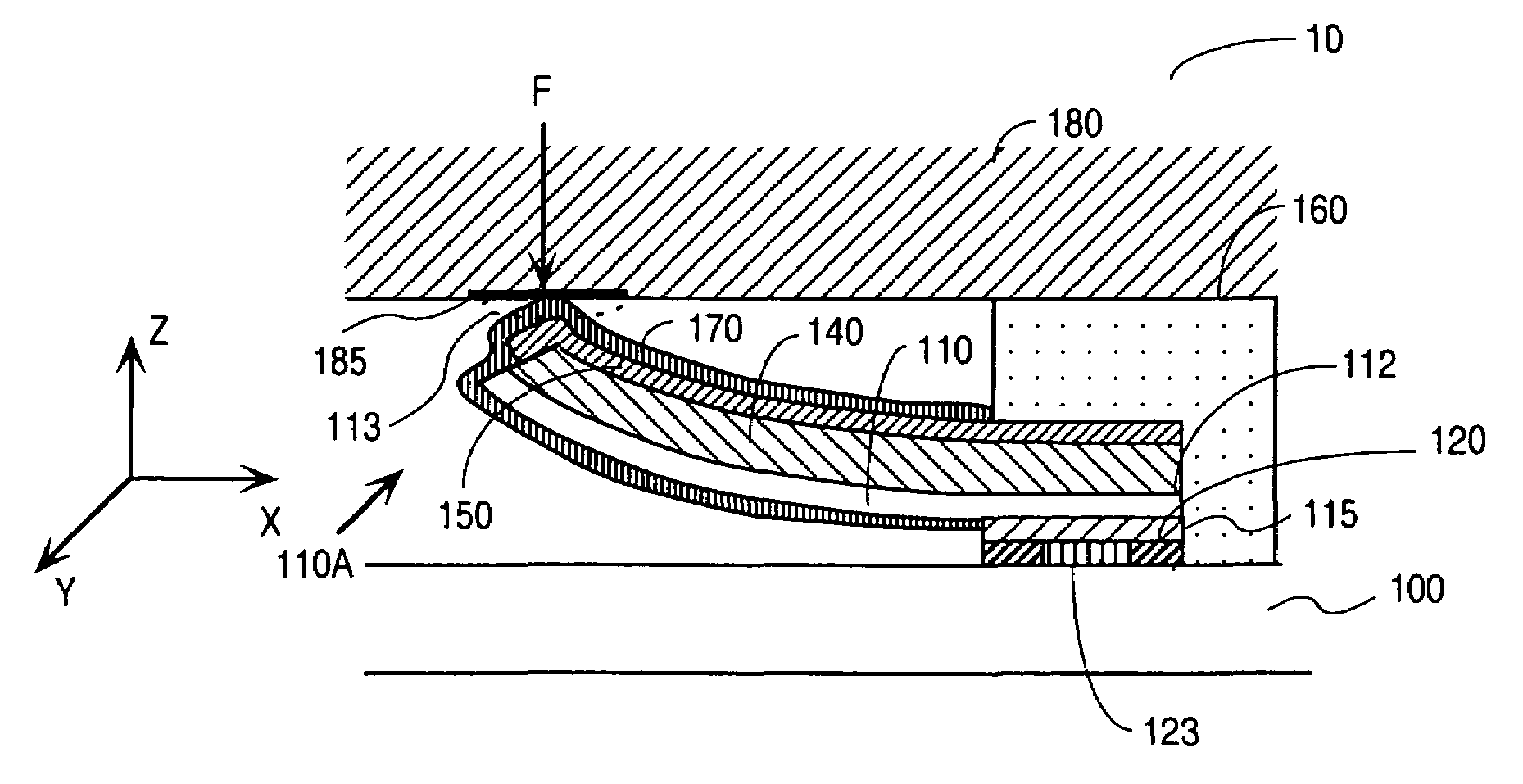

Probing device and manufacturing method thereof, as well as testing apparatus and manufacturing method of semiconductor with use thereof

InactiveUS6900646B2High densityImprove accuracySemiconductor/solid-state device testing/measurementElectronic circuit testingContact formationElectricity

A probing device for electrically contacting with a plurality of electrodes 3, 6 aligned on an object 1 to be tested so as to transfer electrical signal therewith, comprising: a wiring sheet being formed by aligning a plurality of contact electrodes 21, 110b, corresponding to each of said electrodes, each being planted with projecting probes 20, 110a covered with hard metal films on basis of a conductor thin film 41 formed on one surface of an insulator sheet 22 of a polyimide film by etching thereof, while extension wiring 23, 110c for electrically connecting to said each of said contact electrodes being formed on basis of a conductor thin film formed on either said one surface or the other surface opposing thereto of said insulator sheet of the polyimide film; and means for giving contacting pressure for obtaining electrical conduction between said extension wiring and said object to be tested by contacting tips of said projecting contact probe formed onto said each contact electrode through giving pressuring force between said wiring sheet and said object to be tested.

Owner:RENESAS ELECTRONICS CORP

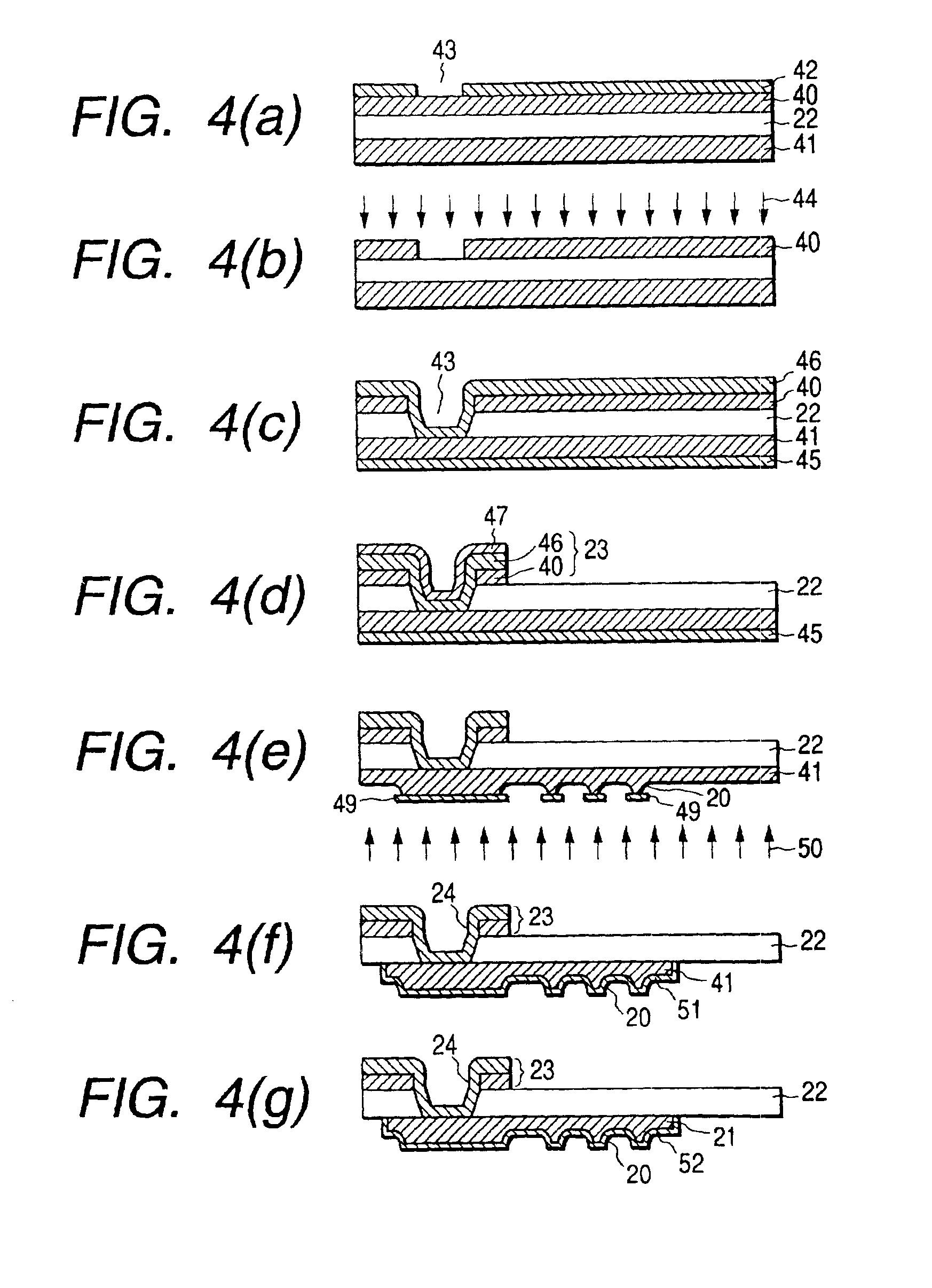

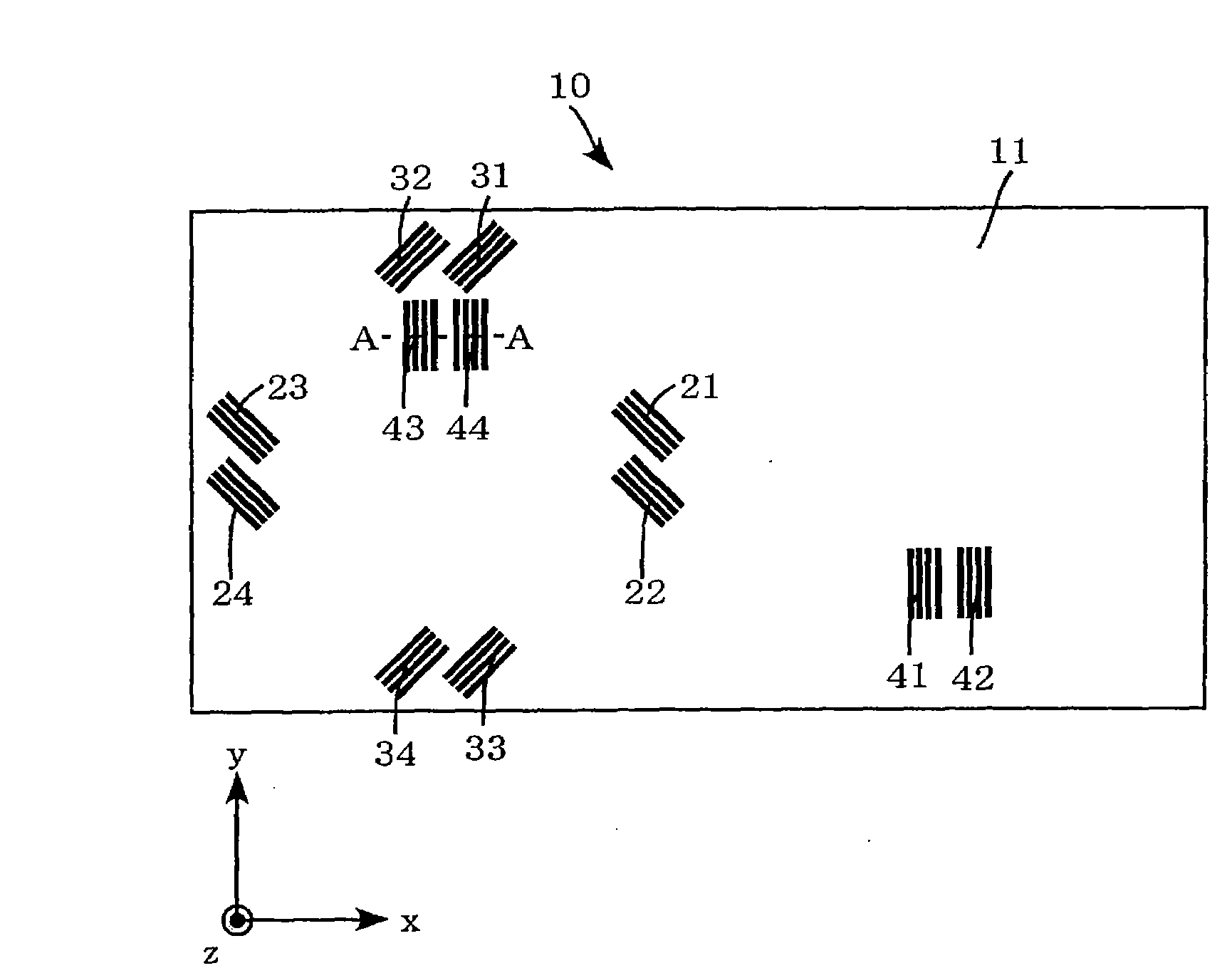

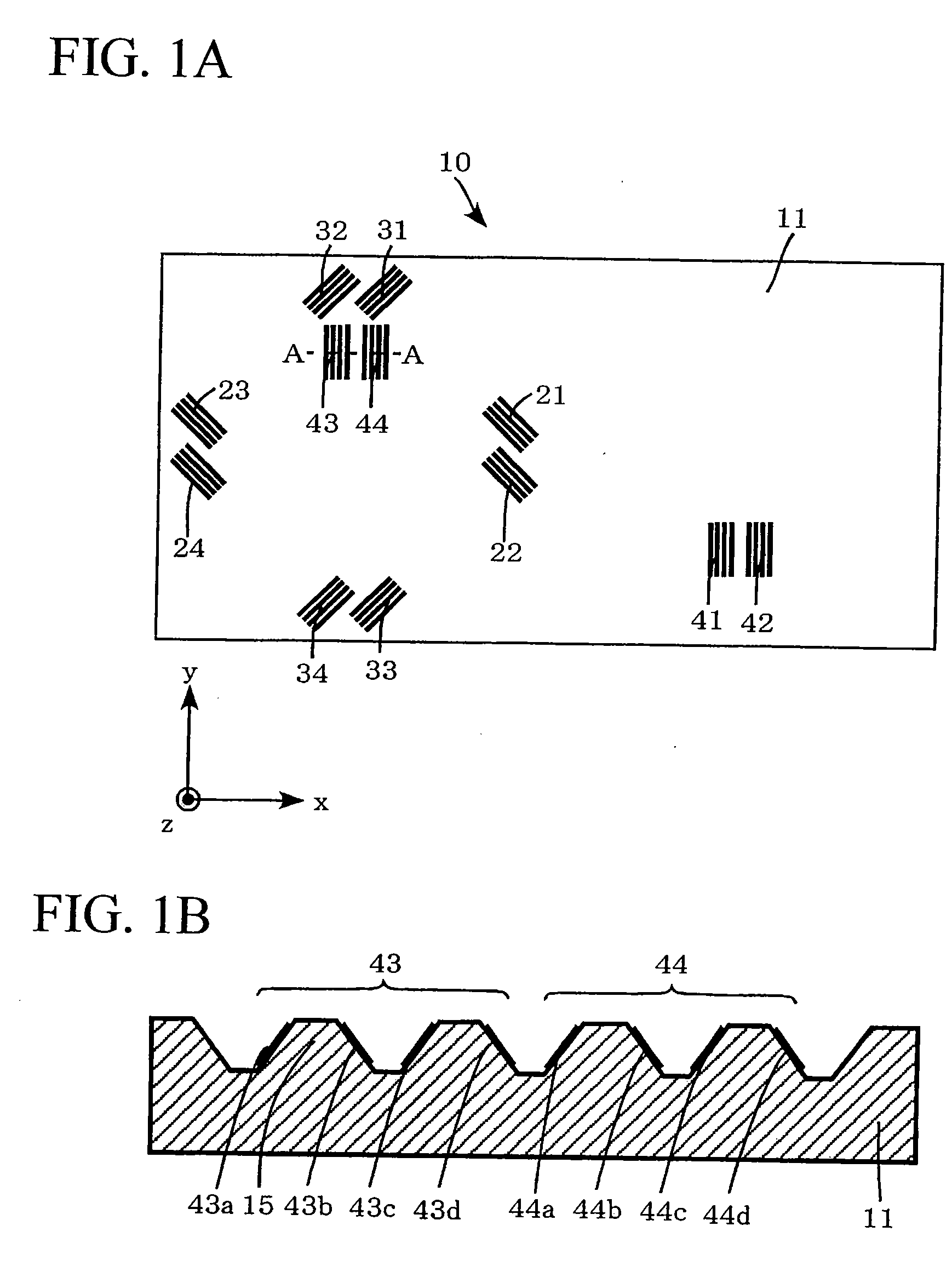

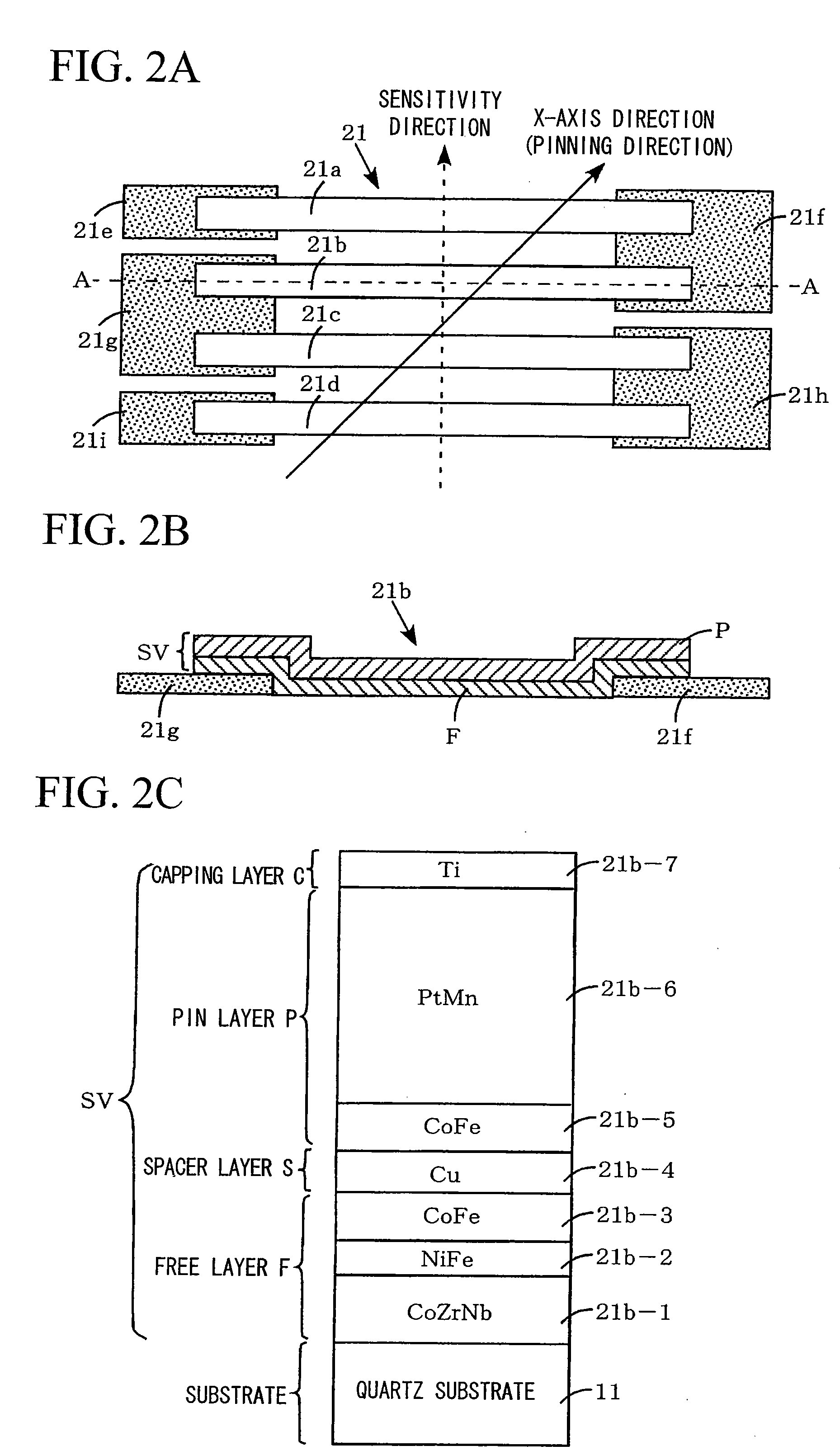

Three-Axis Magnetic Sensor and Method for Manufacturing the Same

InactiveUS20090027048A1Easy to makeEasy and inexpensiveNanomagnetismSolid-state devicesMagnetizationMagnet

In the three-axis magnetic sensor of the present invention, a plurality of magnetoresistive effect element bars are connected in series by means of bias magnets to constitute magnetoresistive effect elements, and magnetoresistive effect elements of the X-axis sensor and those of the Y-axis sensor are formed on a flat surface parallel to the flat surface of the substrate. The sensitivity direction of magnetization is a direction vertical to the longitudinal direction of each of the magnetoresistive effect element bars, and magnetoresistive effect elements of the X-axis sensor and those of the Y-axis sensor are formed in such a way that the magnetization directions are orthogonal to each other. Further, magnetoresistive effect elements of the Z-axis sensor are formed on a tilted surface of the projection projected from the flat surface of the substrate in such a way that the magnetization direction is inside the tilted surface. The Z-axis sensor is provided in such a way that the sensitivity direction is vertical to the longitudinal direction of the magnetoresistive effect element bar.

Owner:YAMAHA CORP

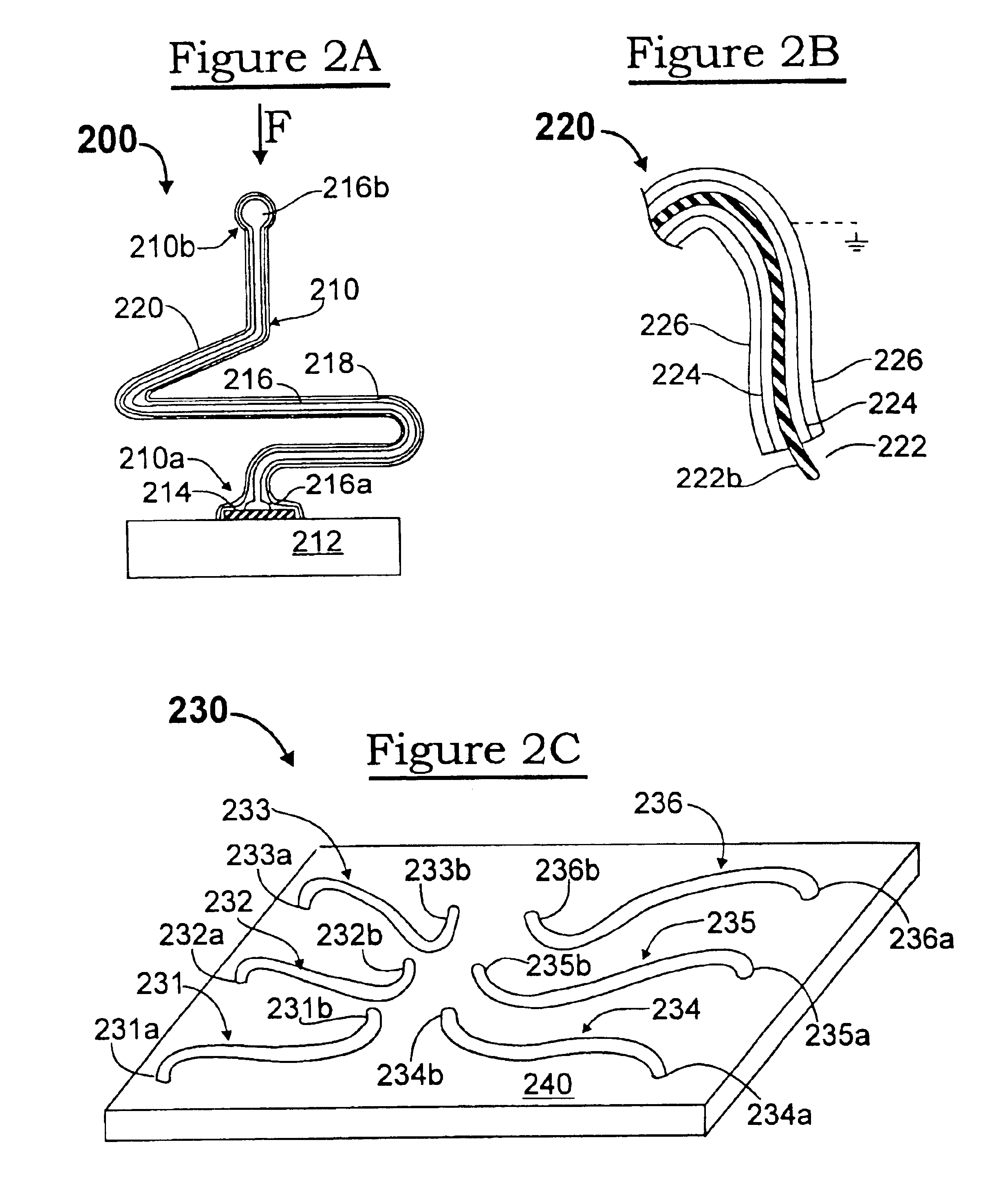

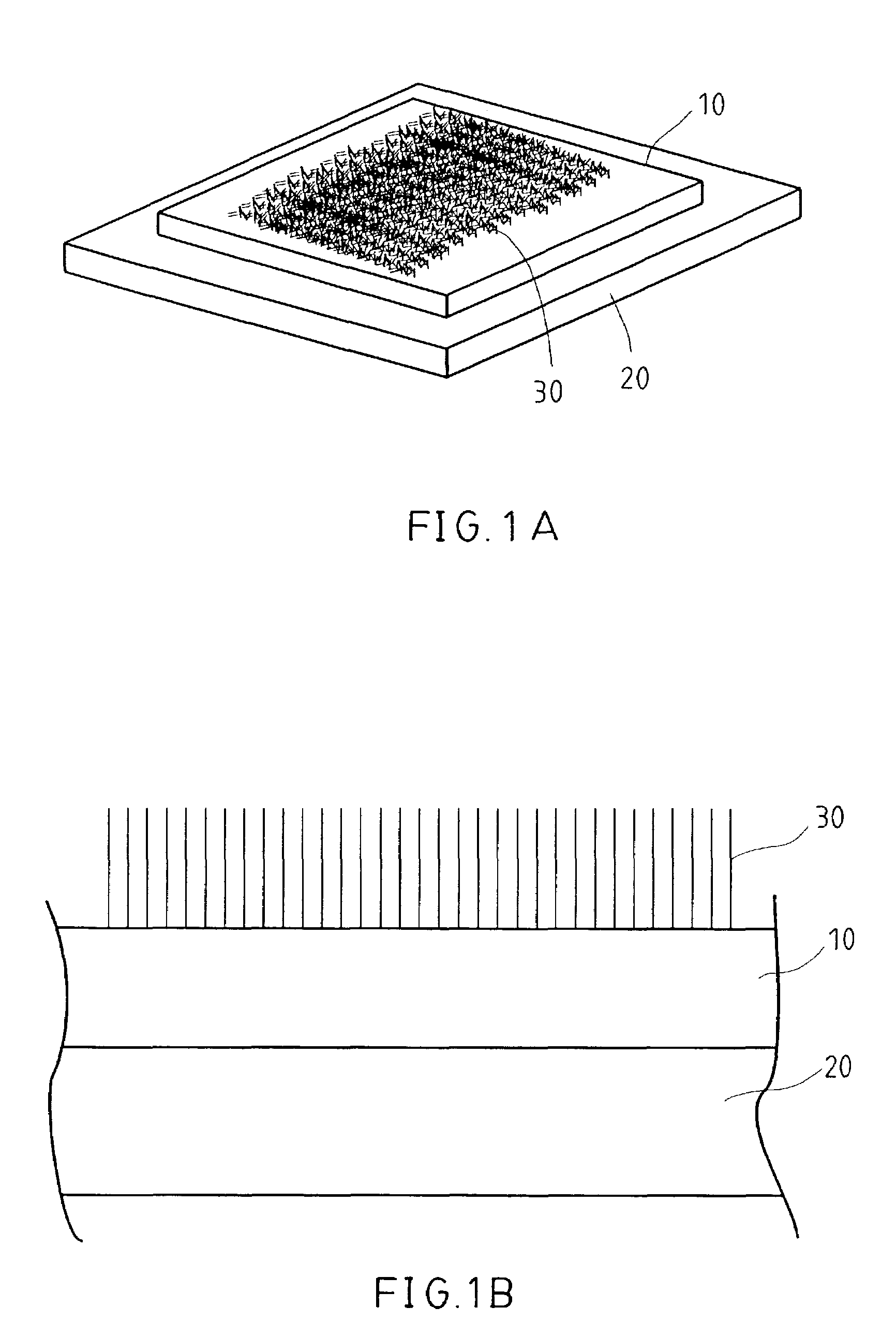

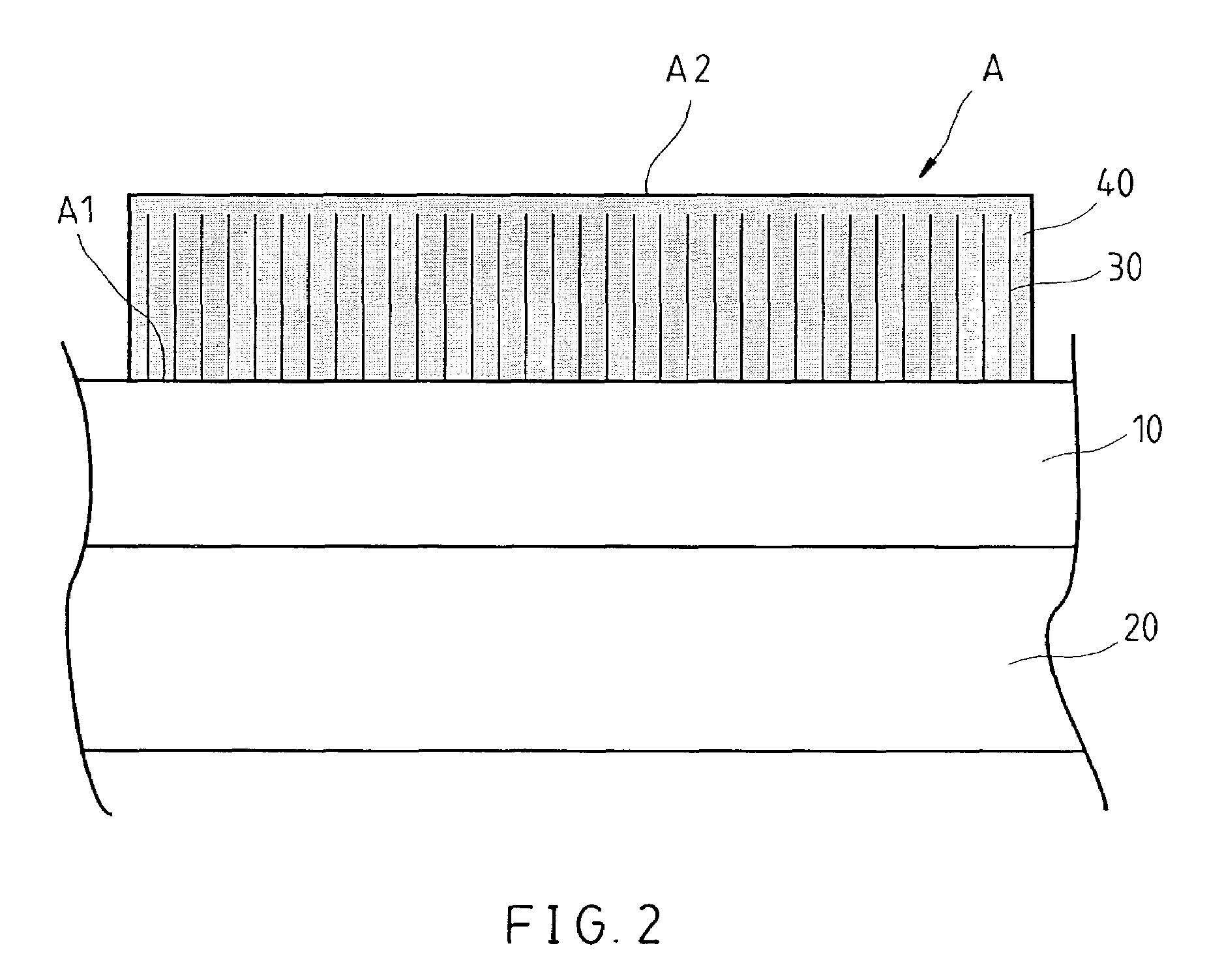

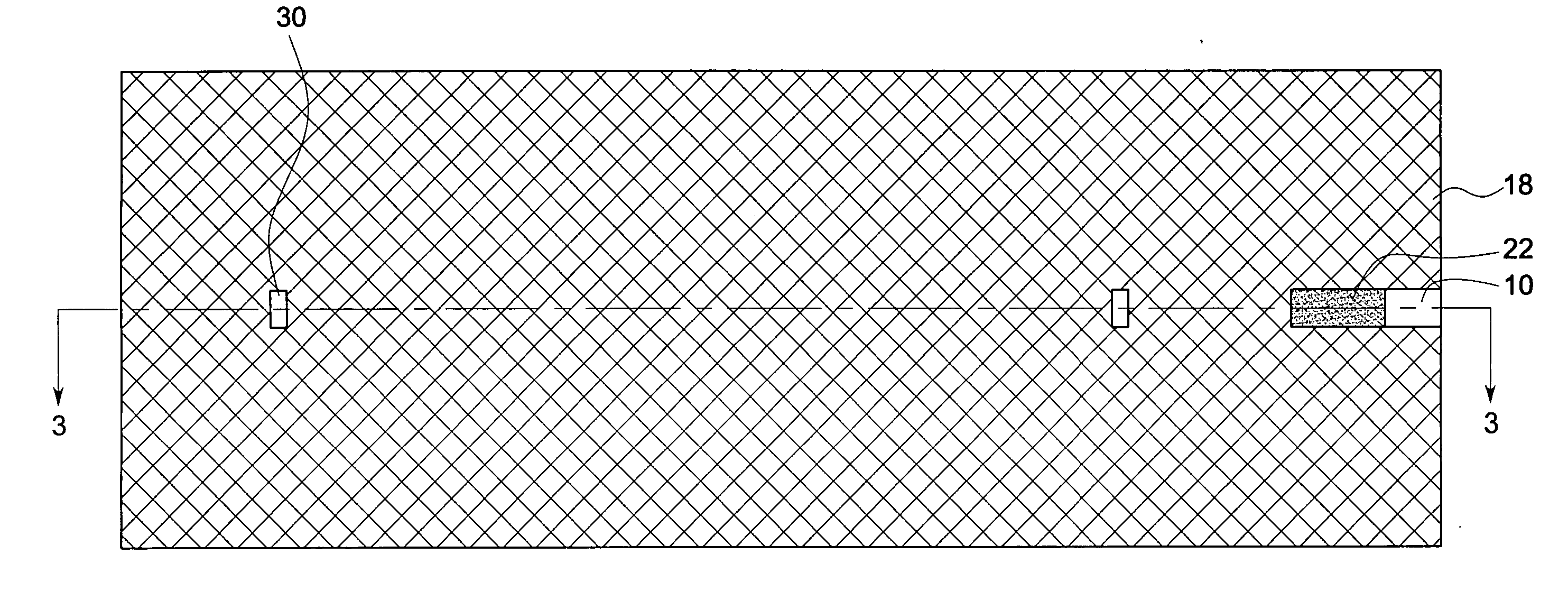

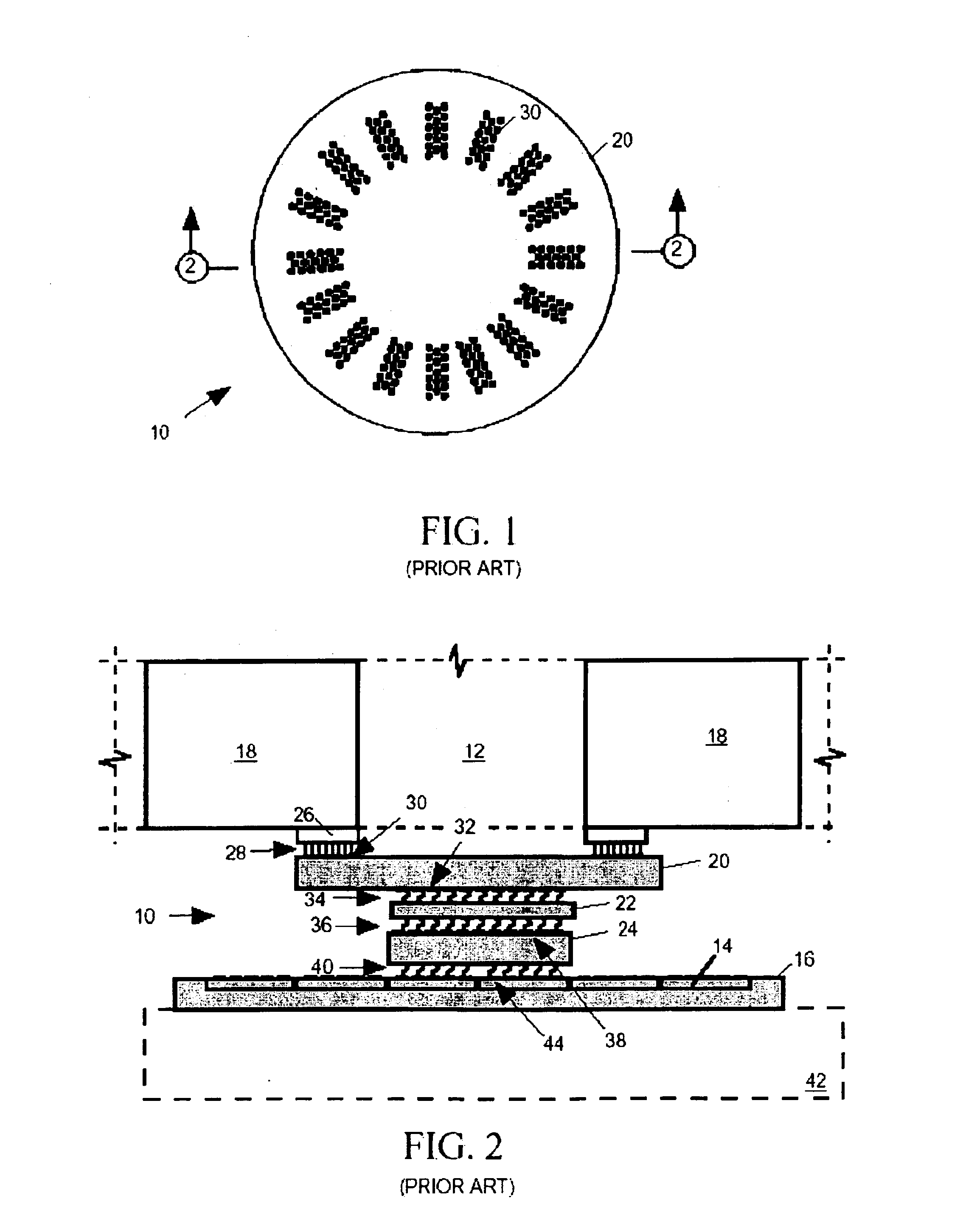

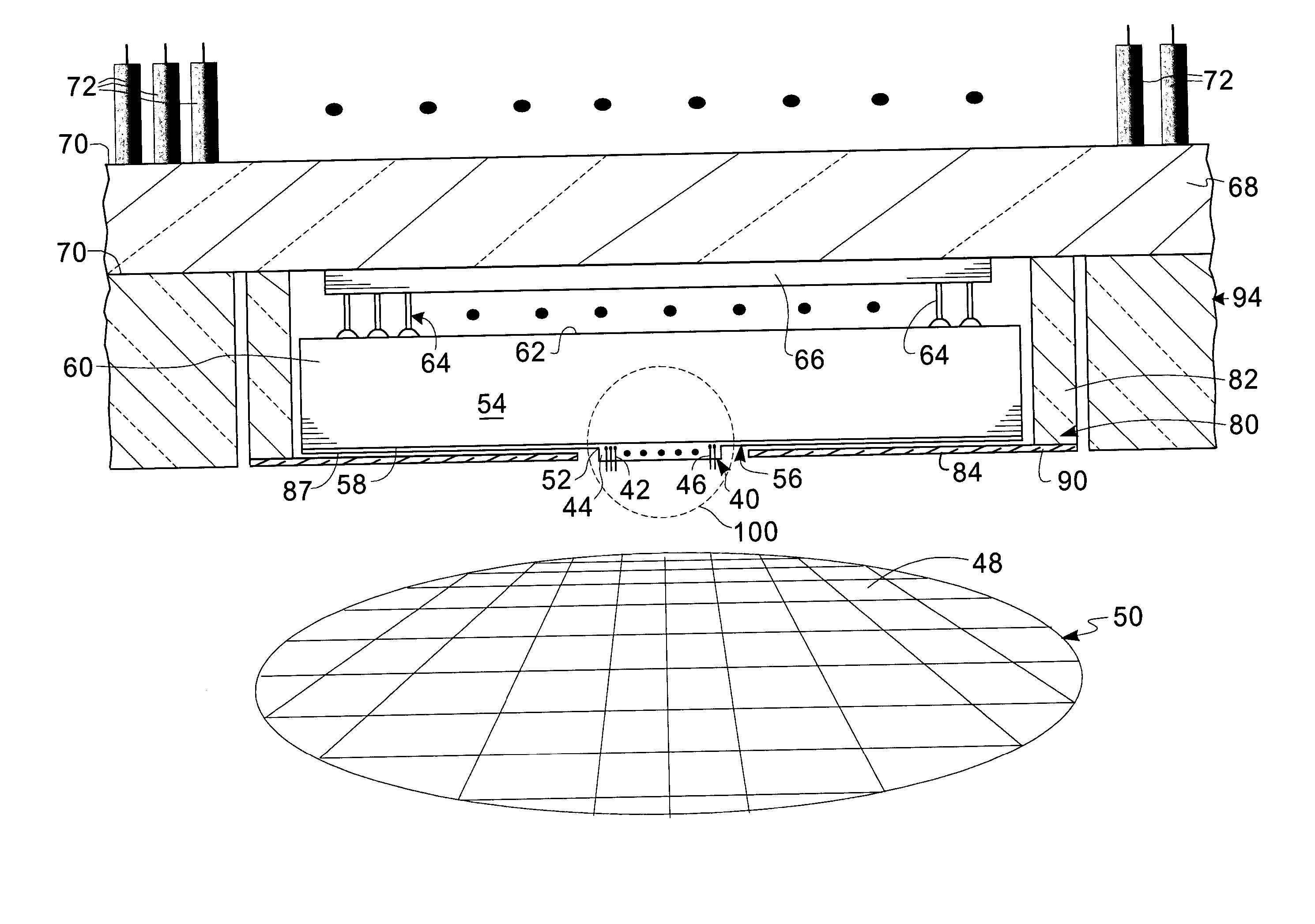

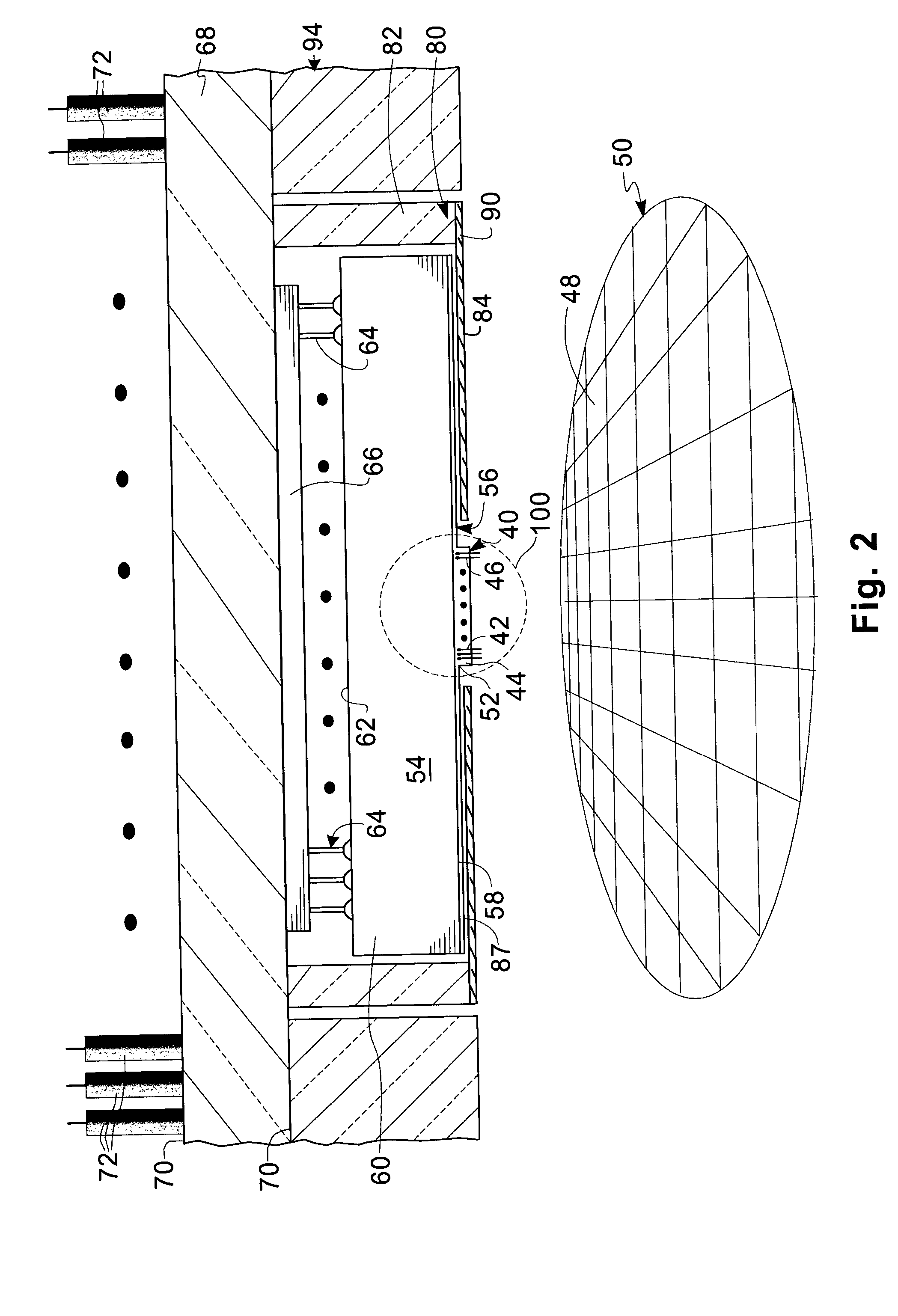

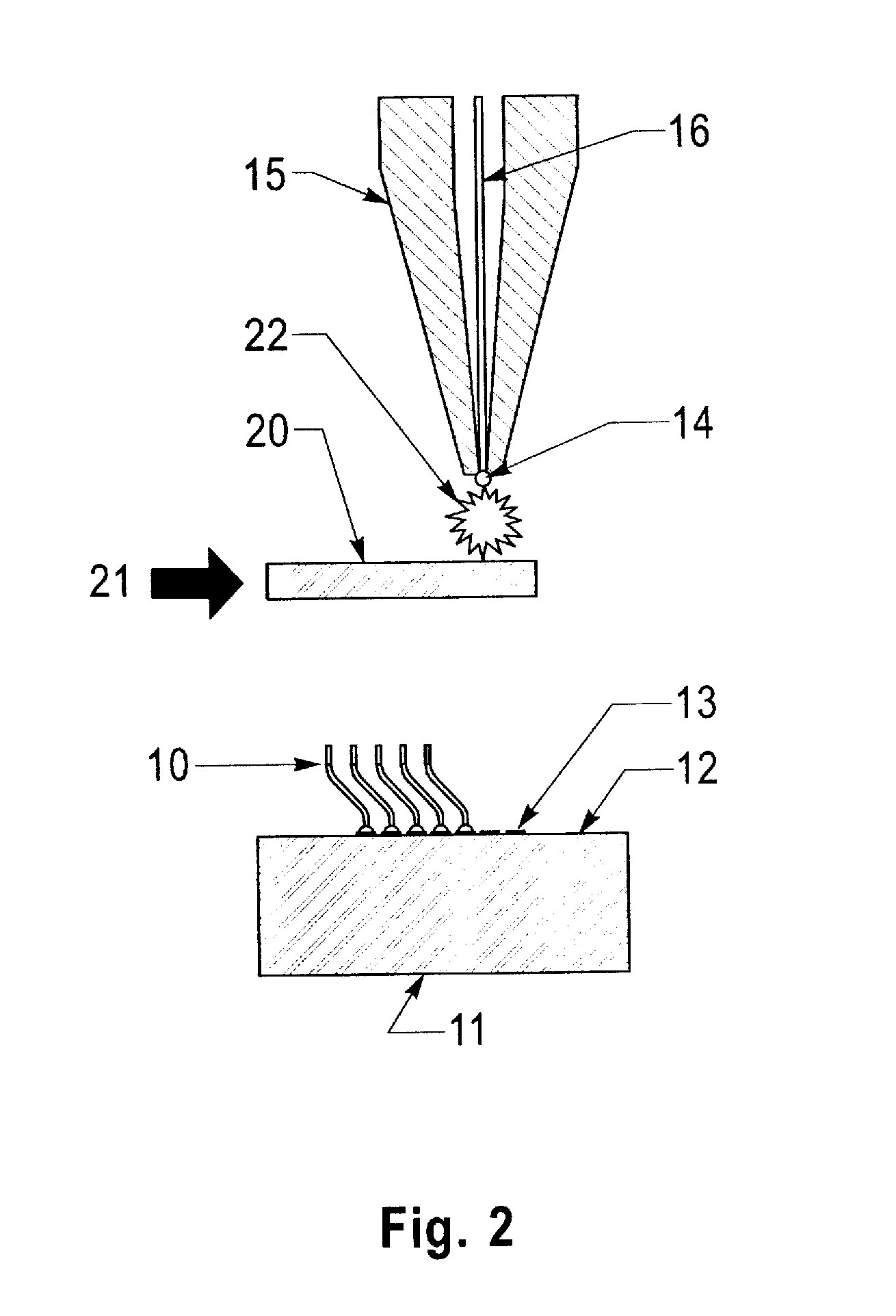

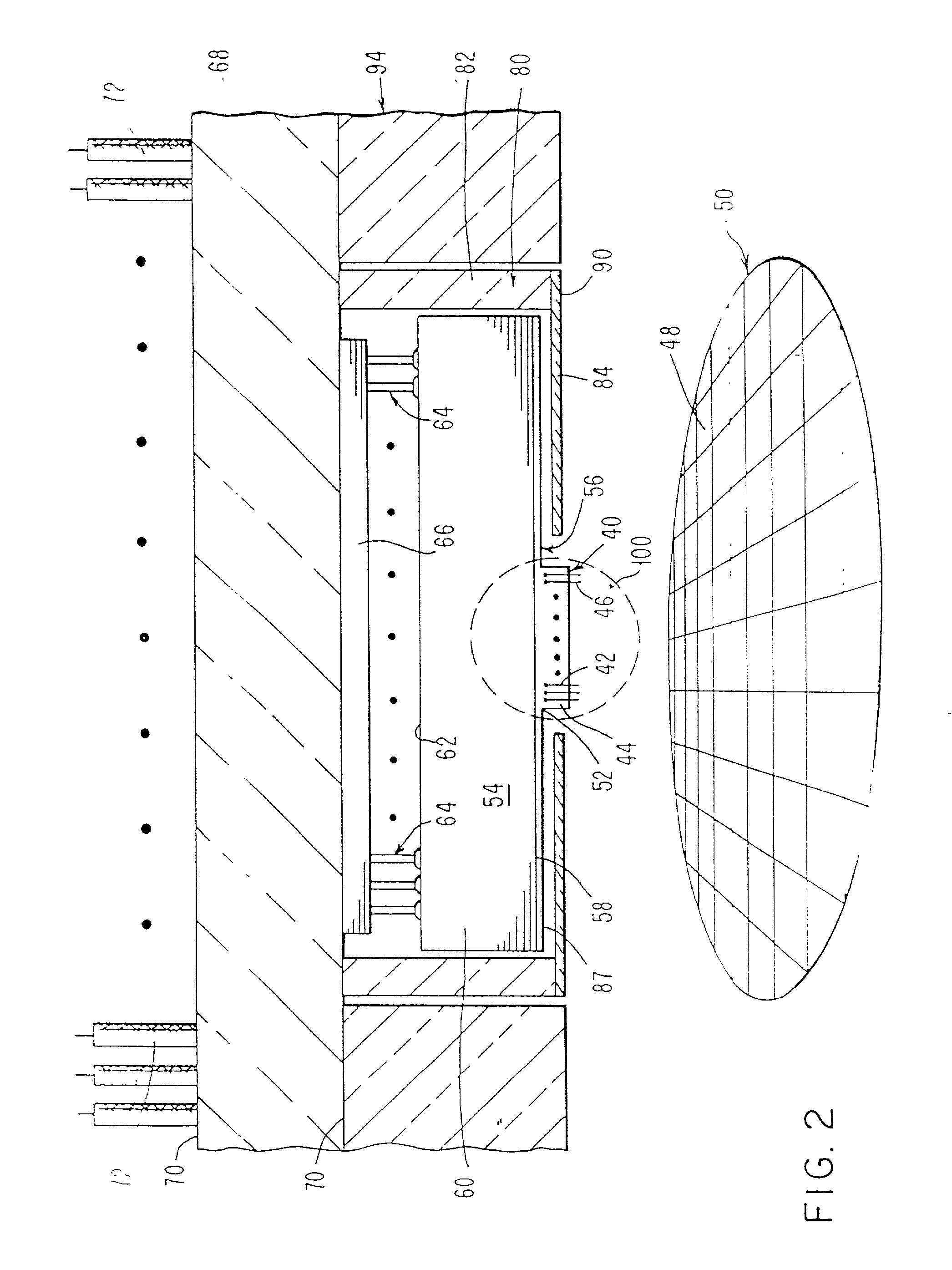

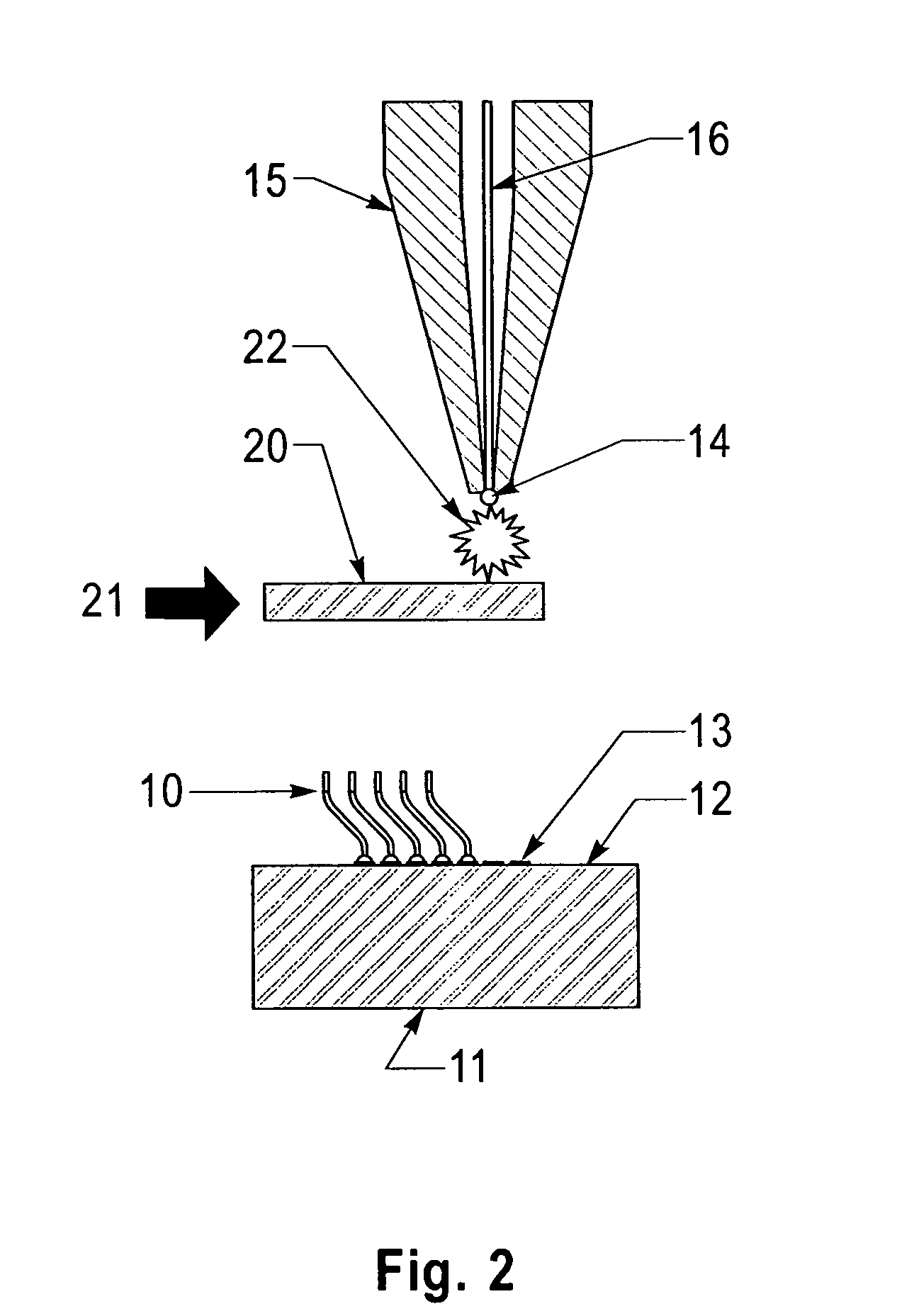

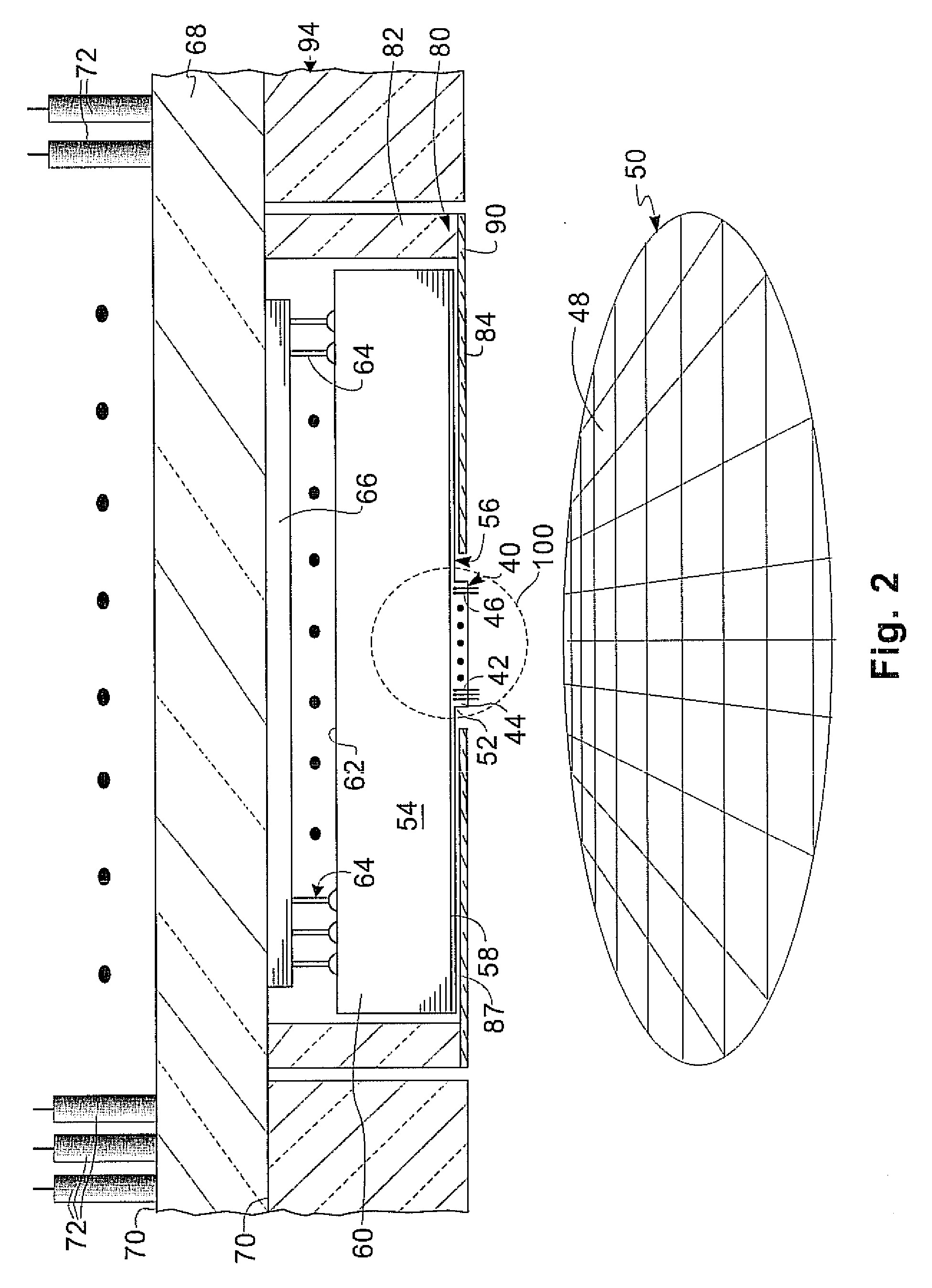

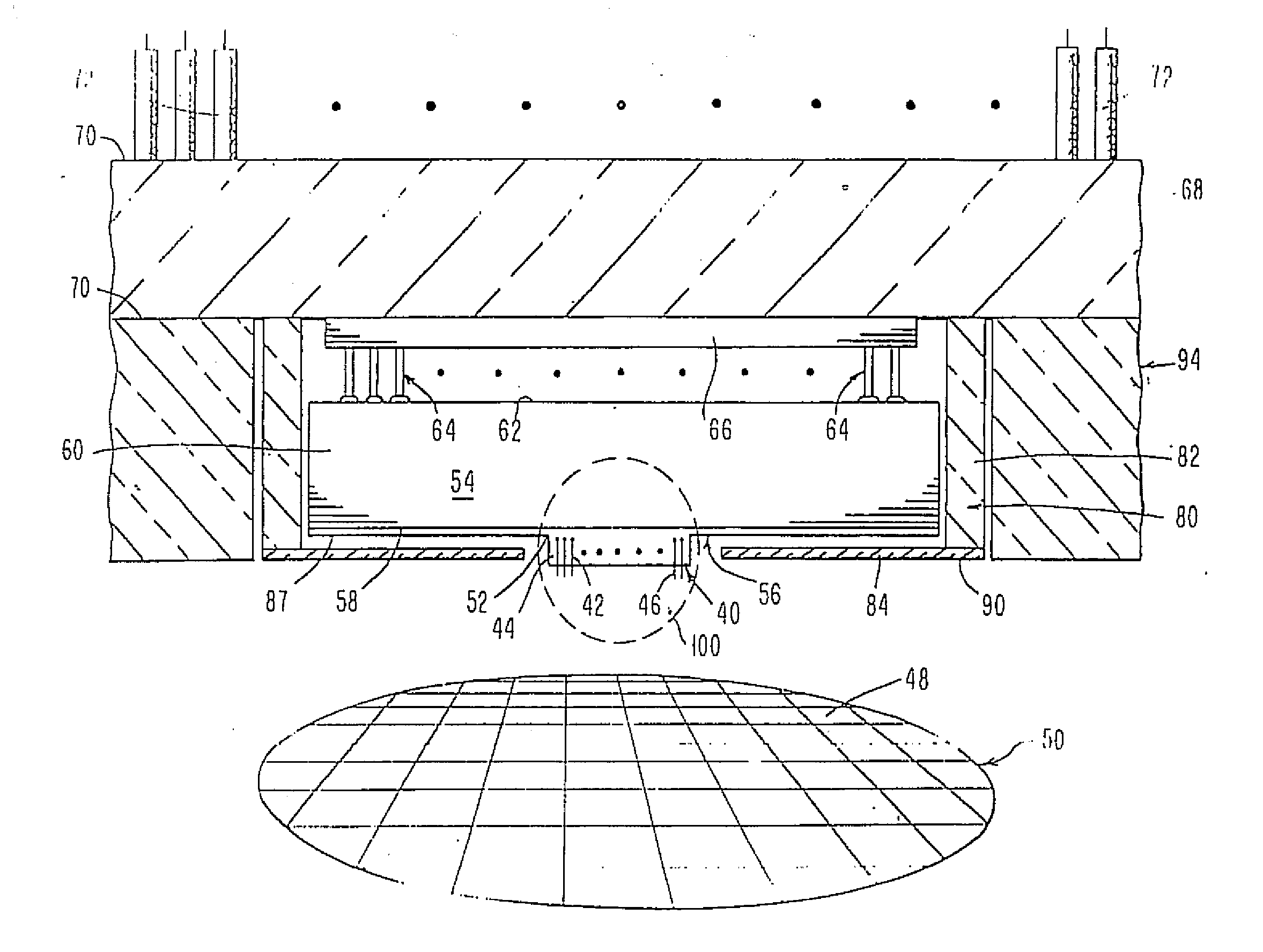

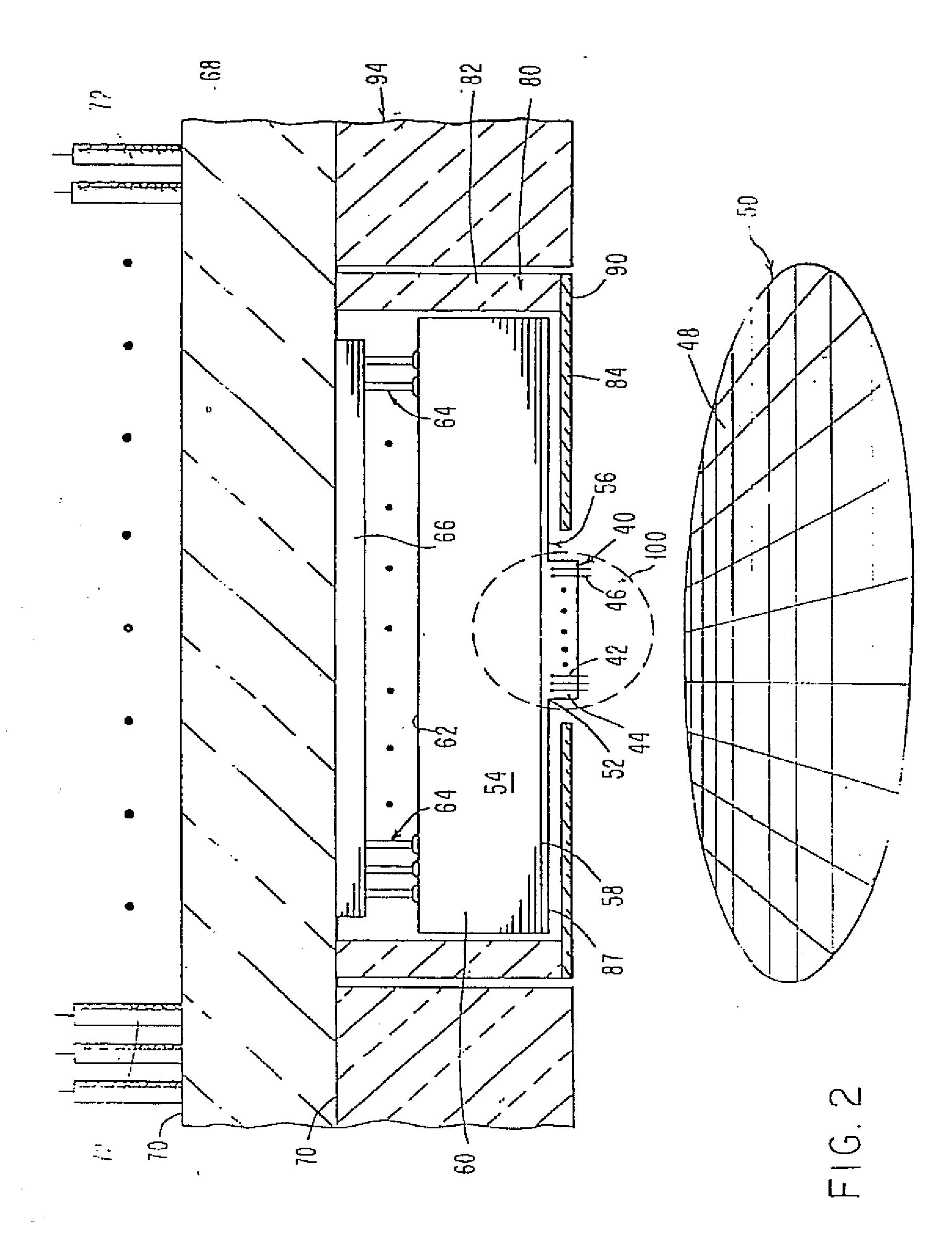

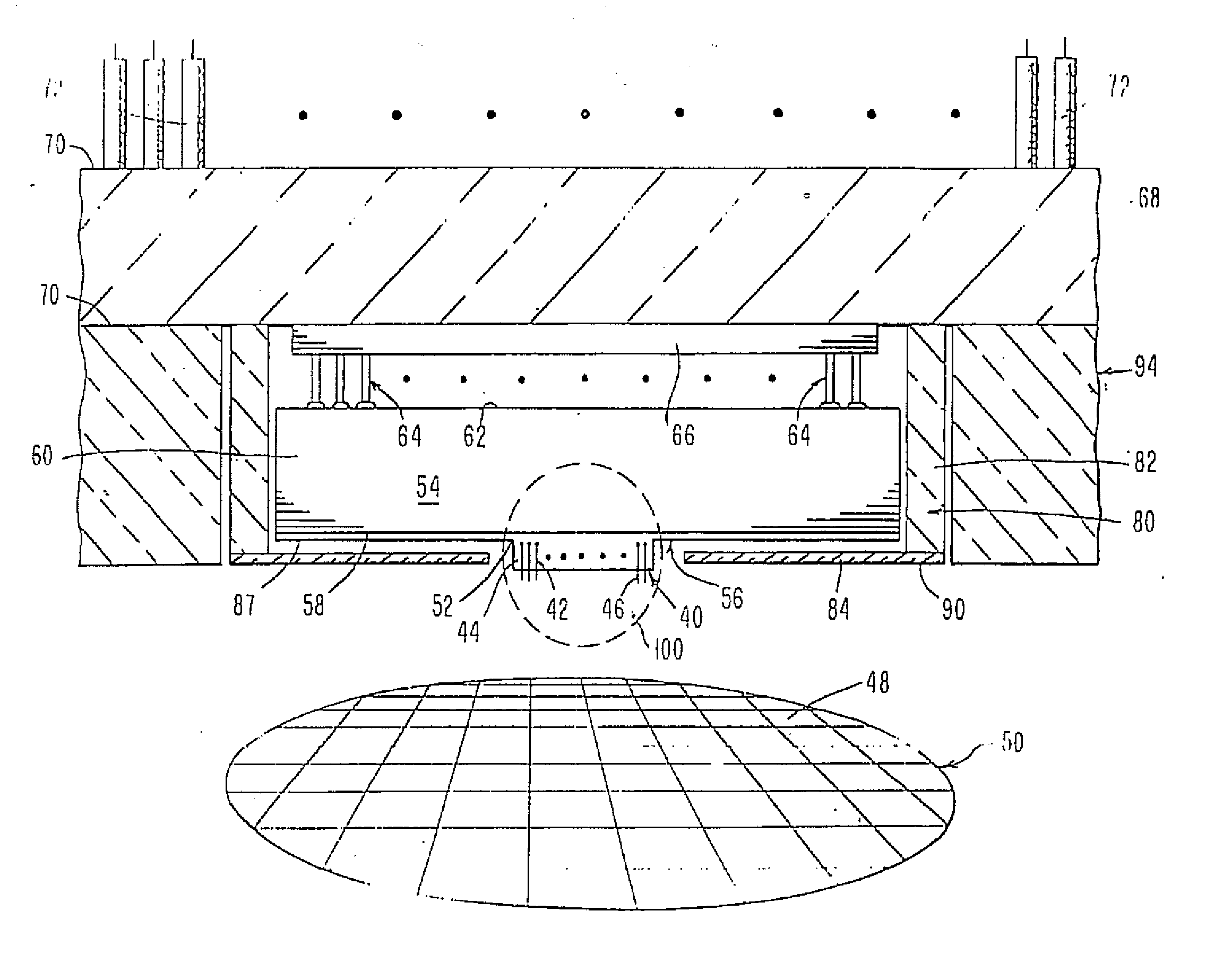

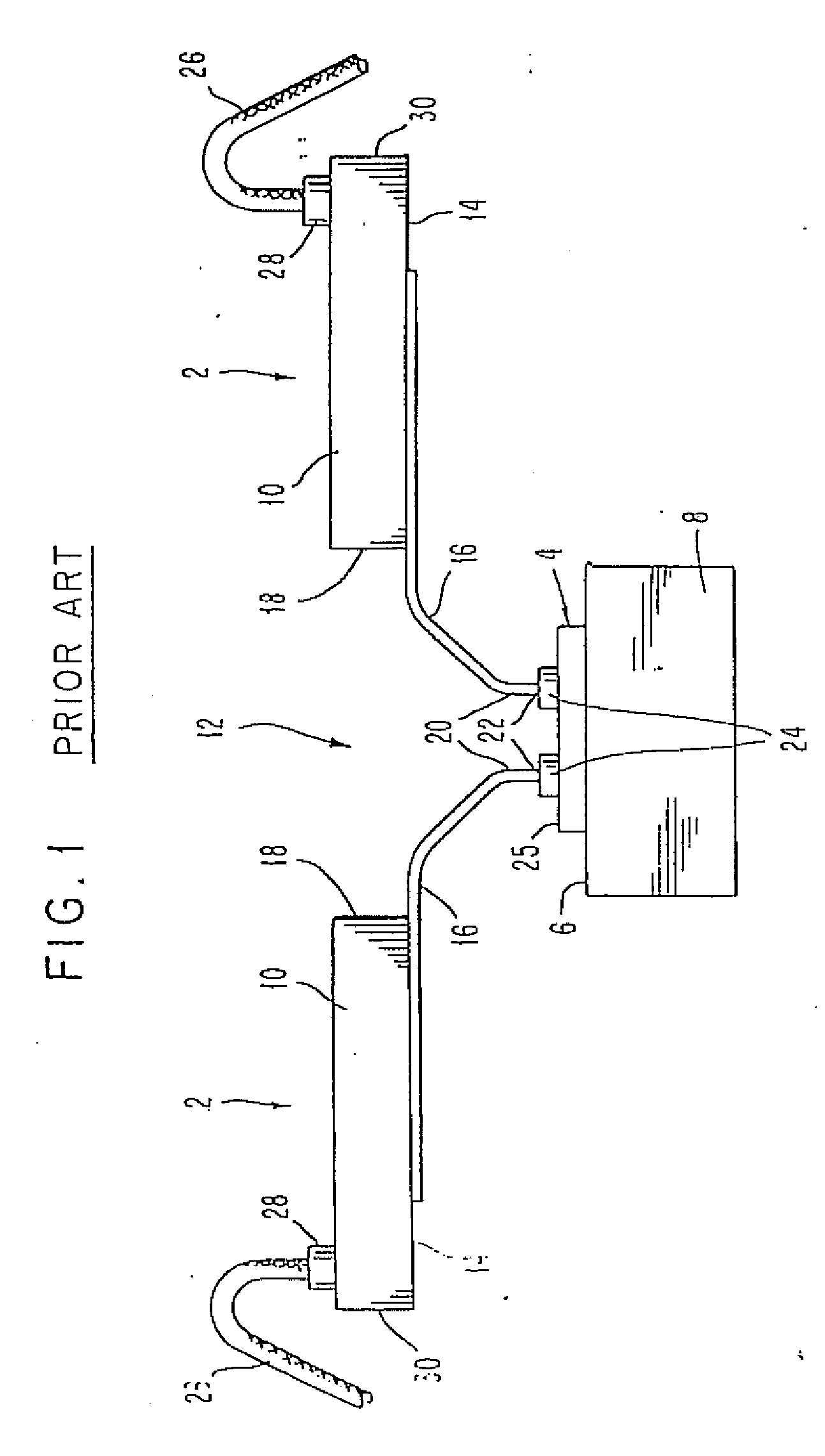

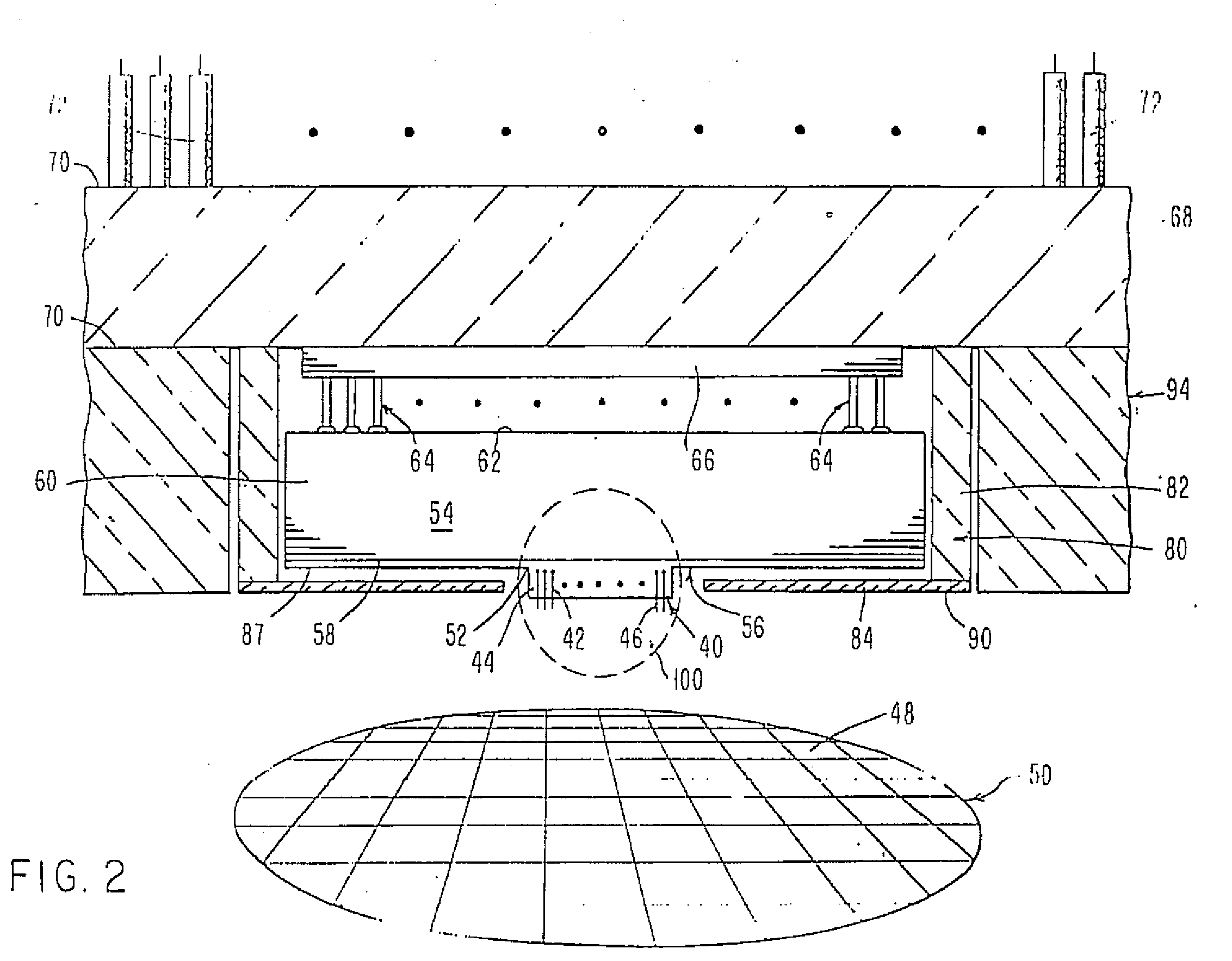

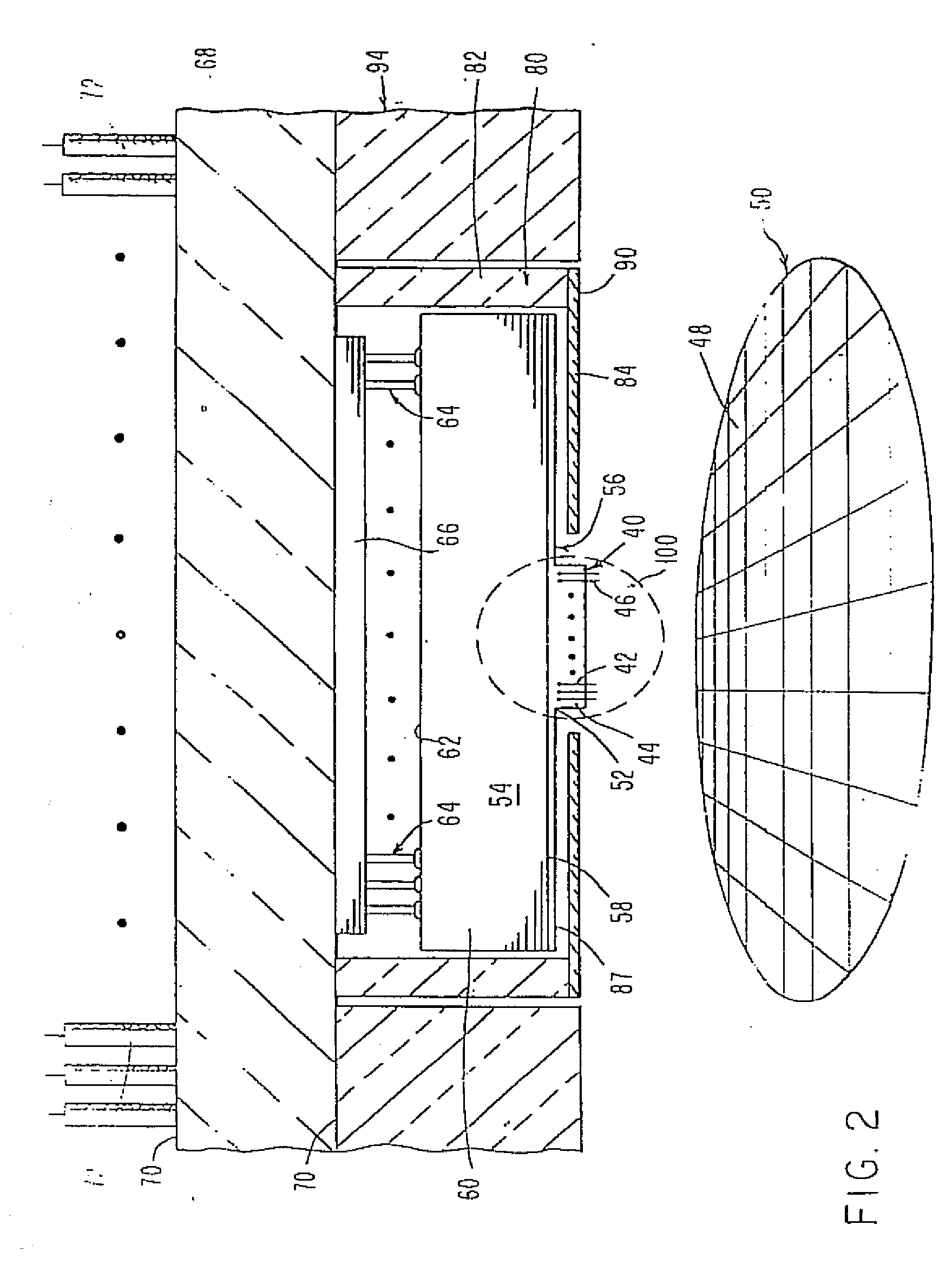

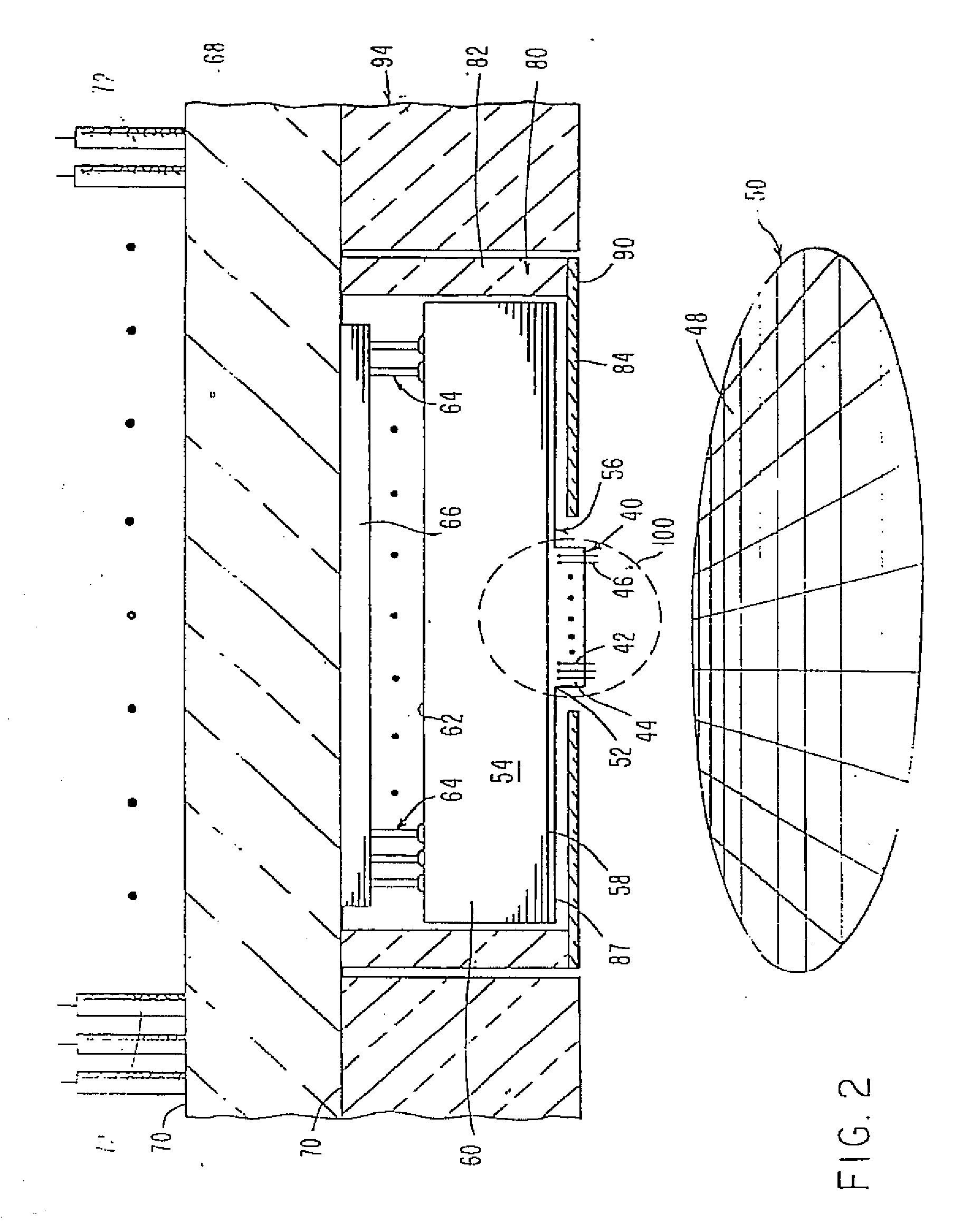

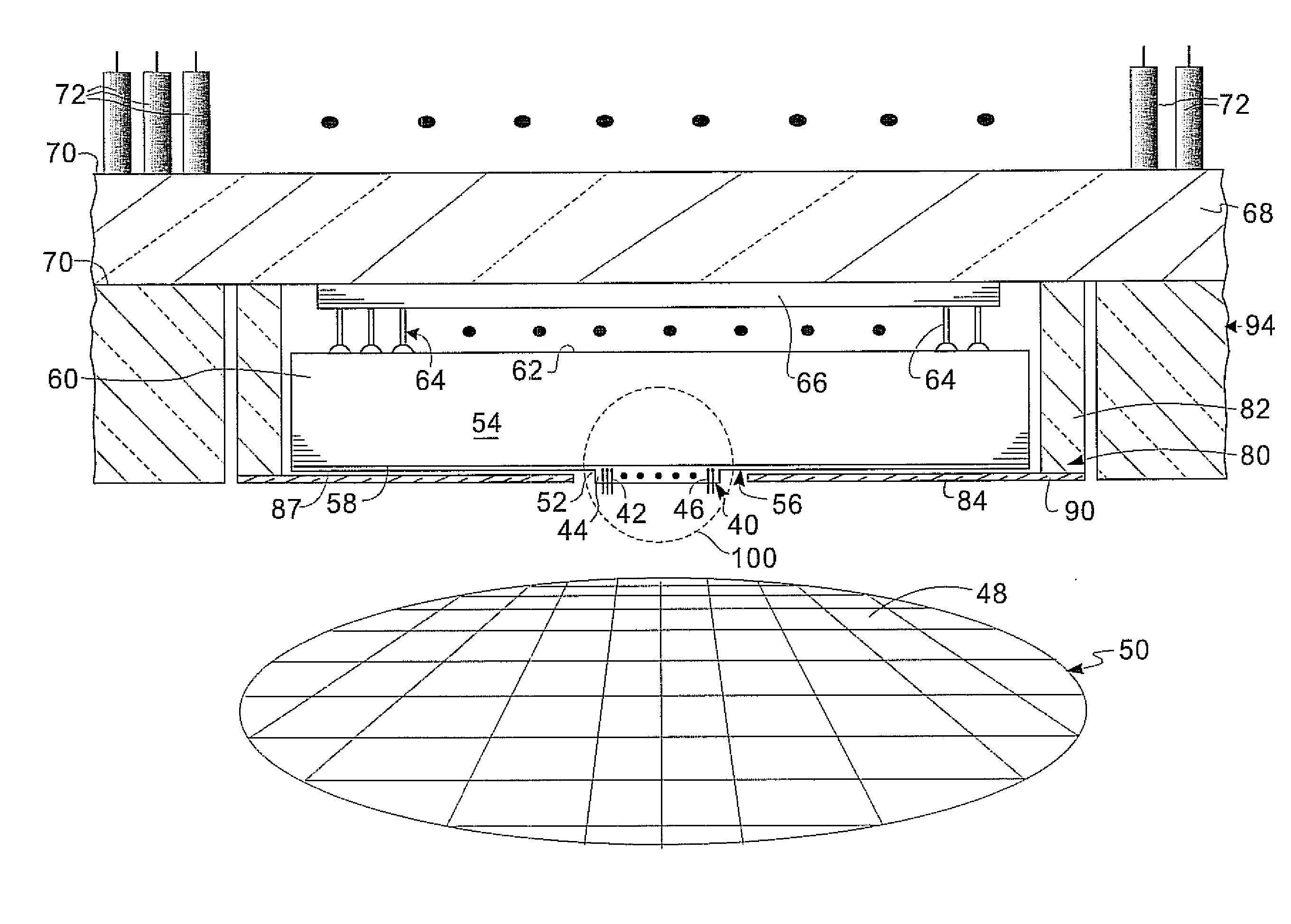

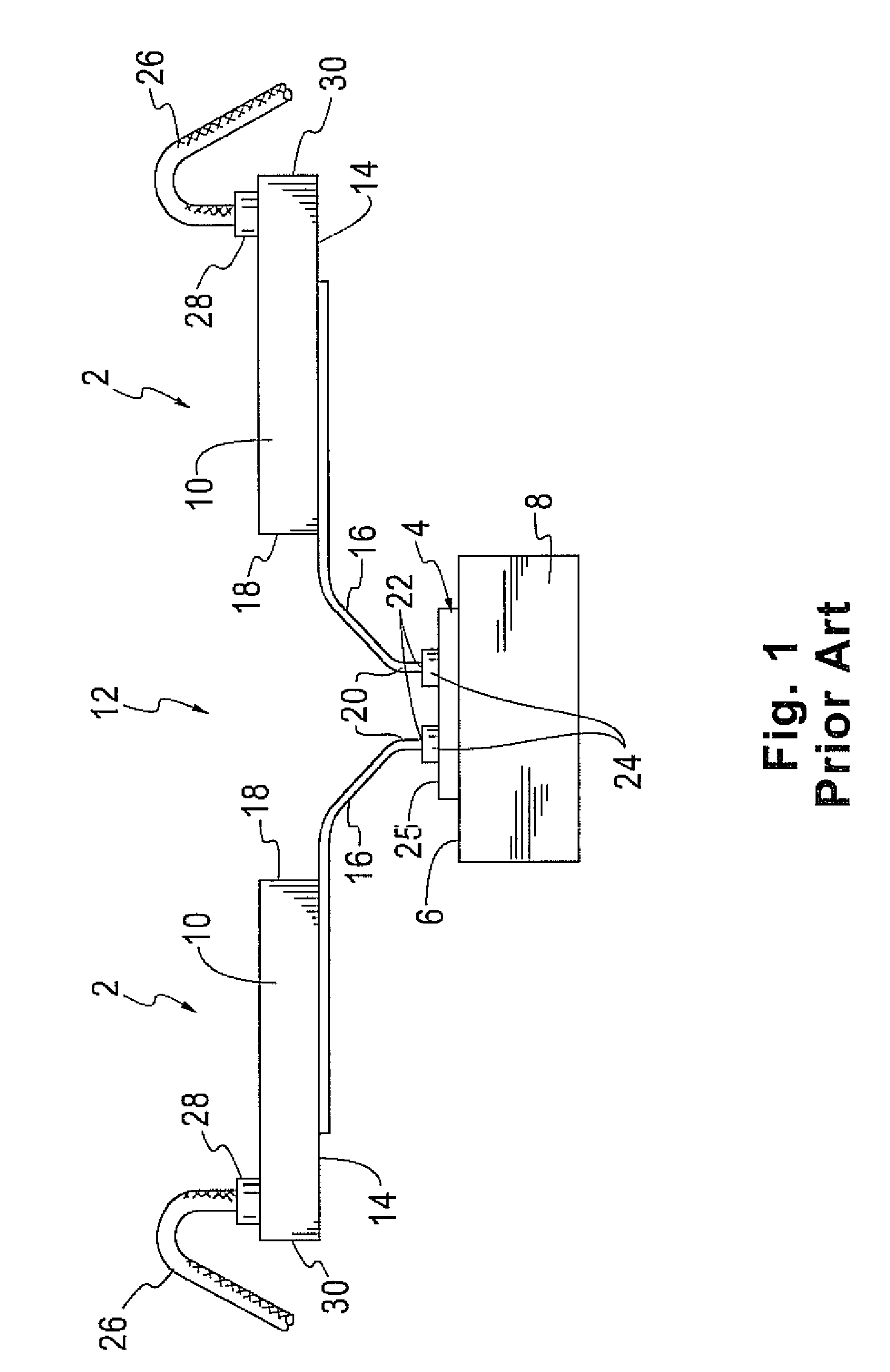

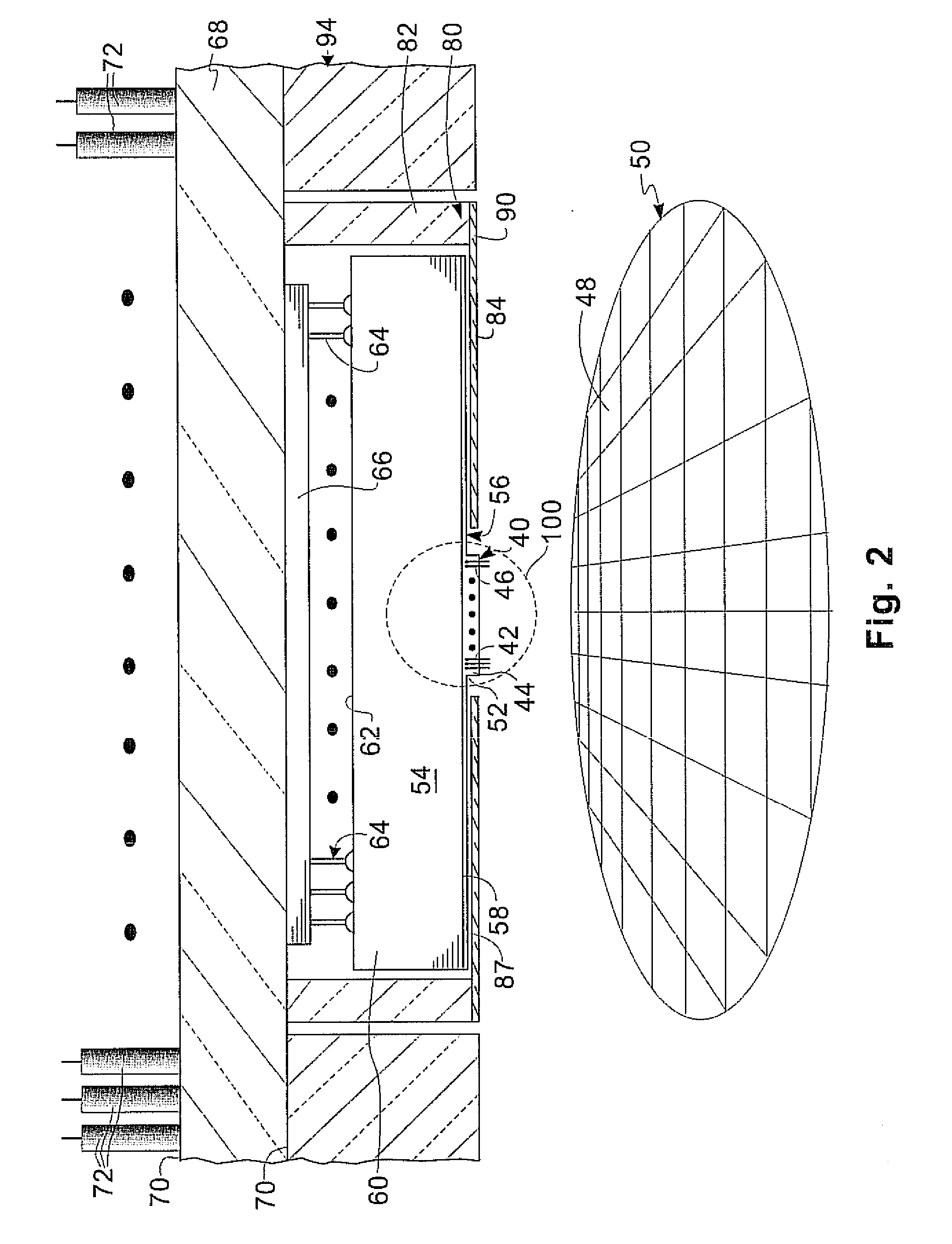

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20050062492A1High performance functional testingHigh-temperature burnElectrical measurement instrument detailsManufacture of electrical instrumentsConvertersContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

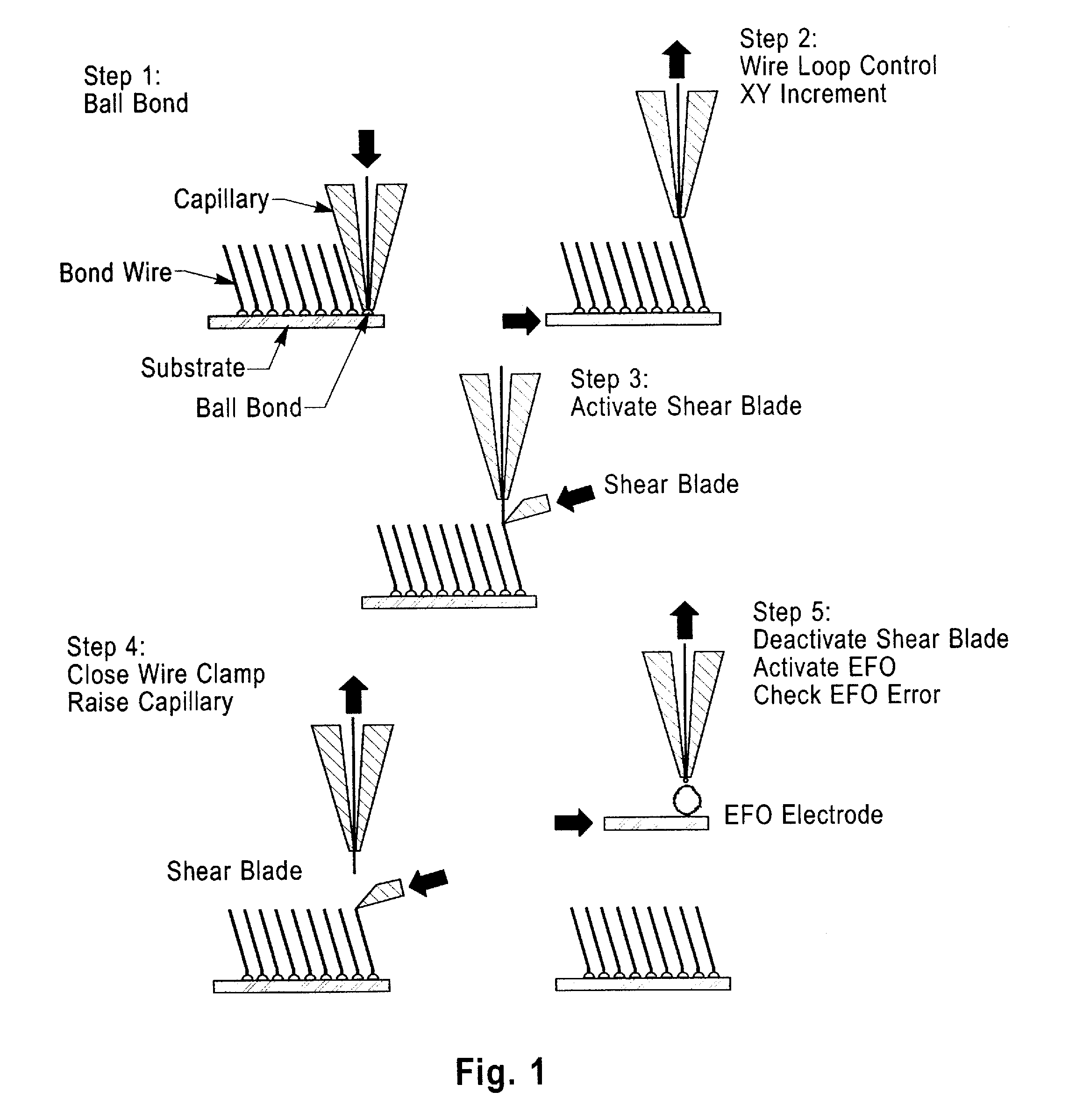

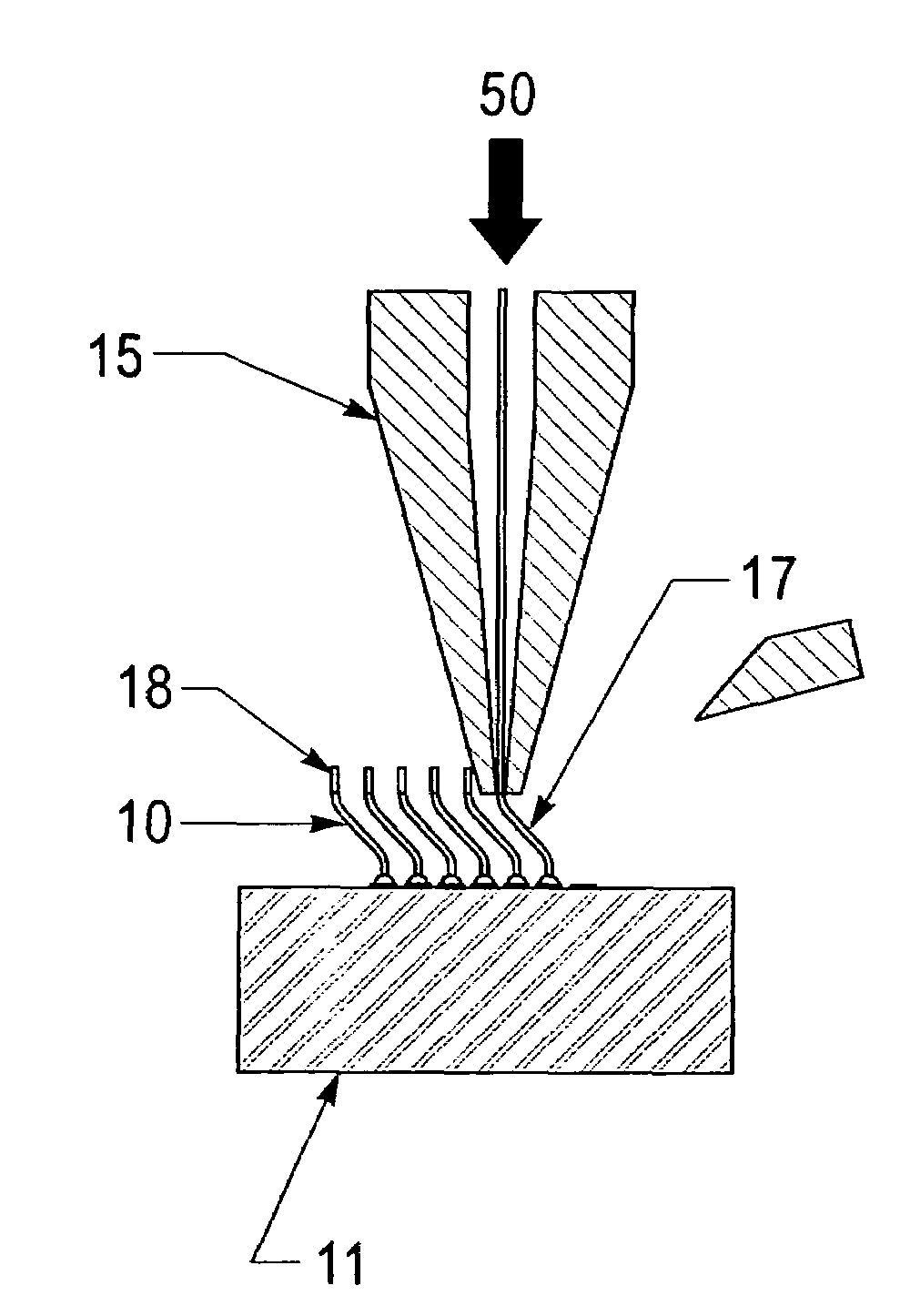

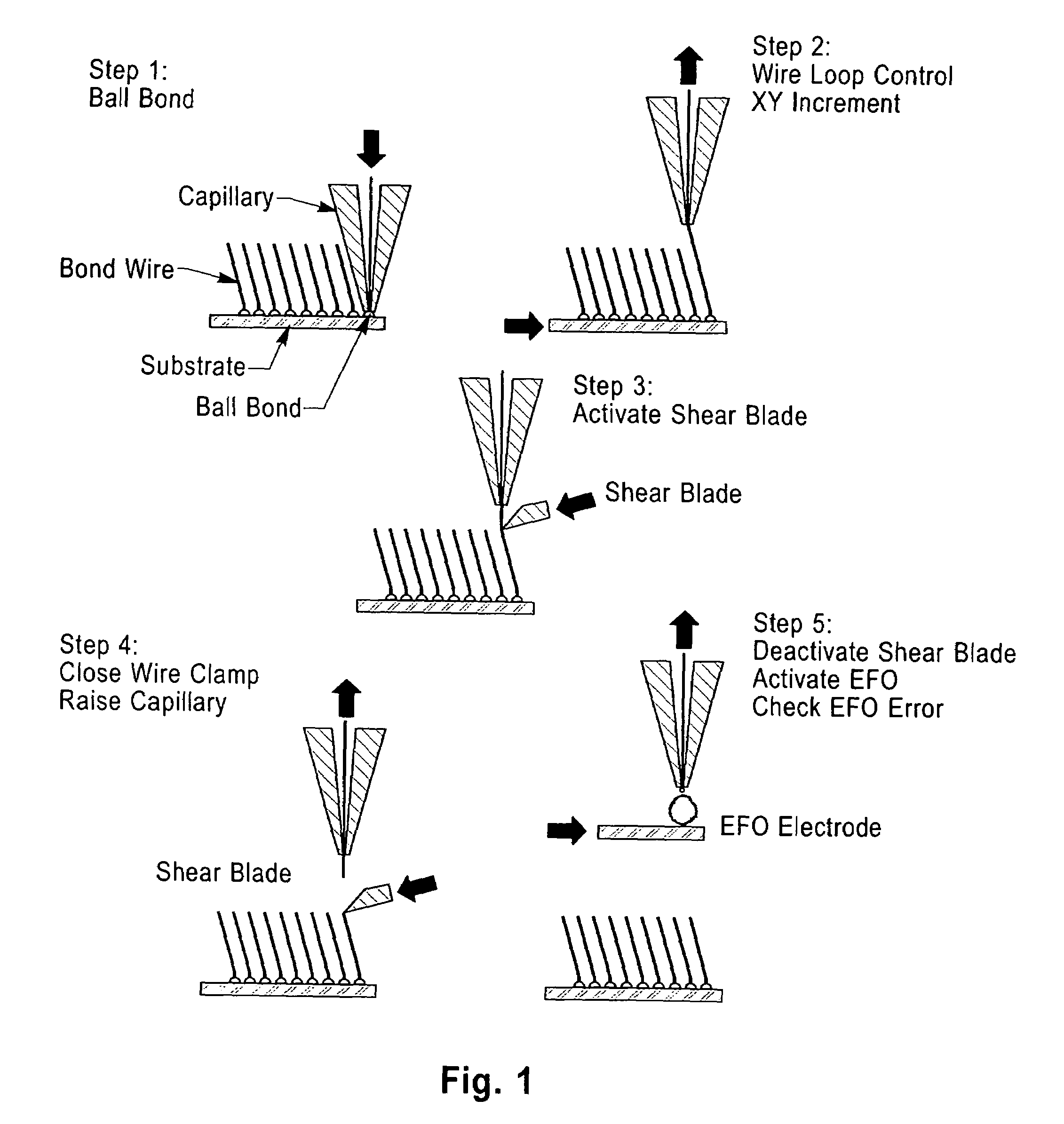

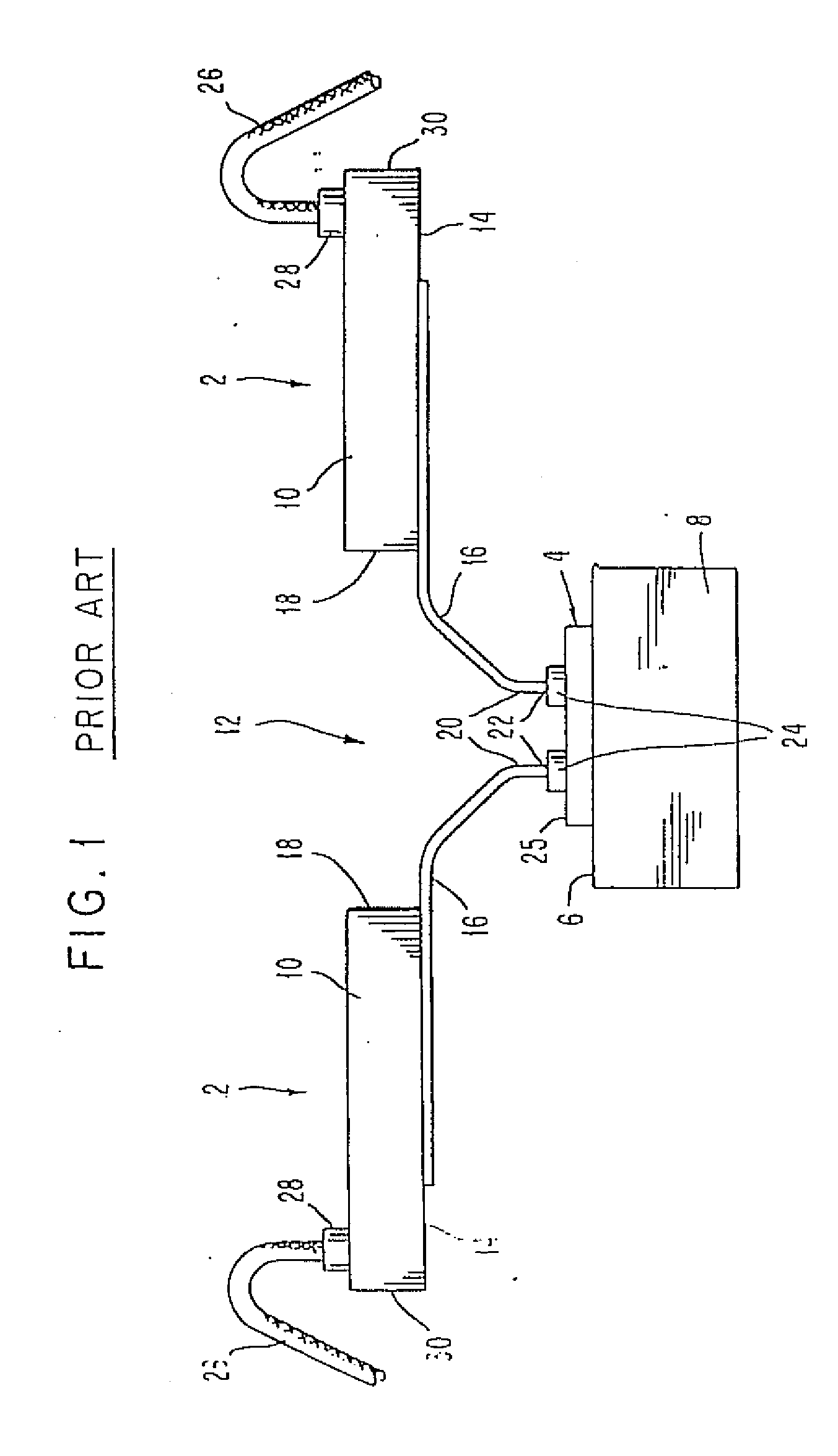

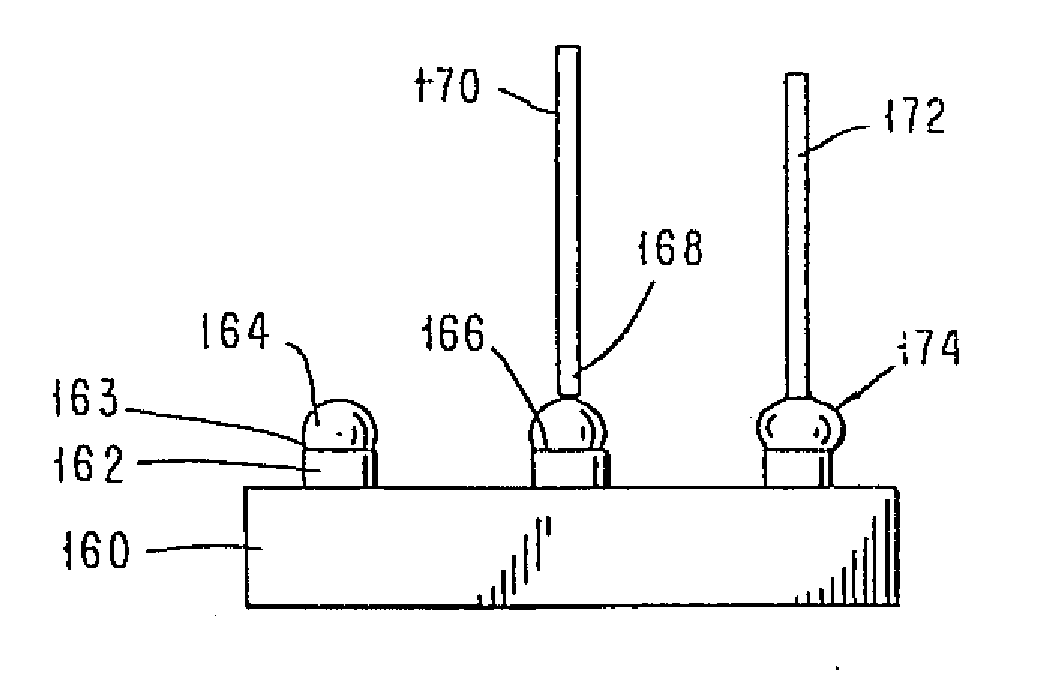

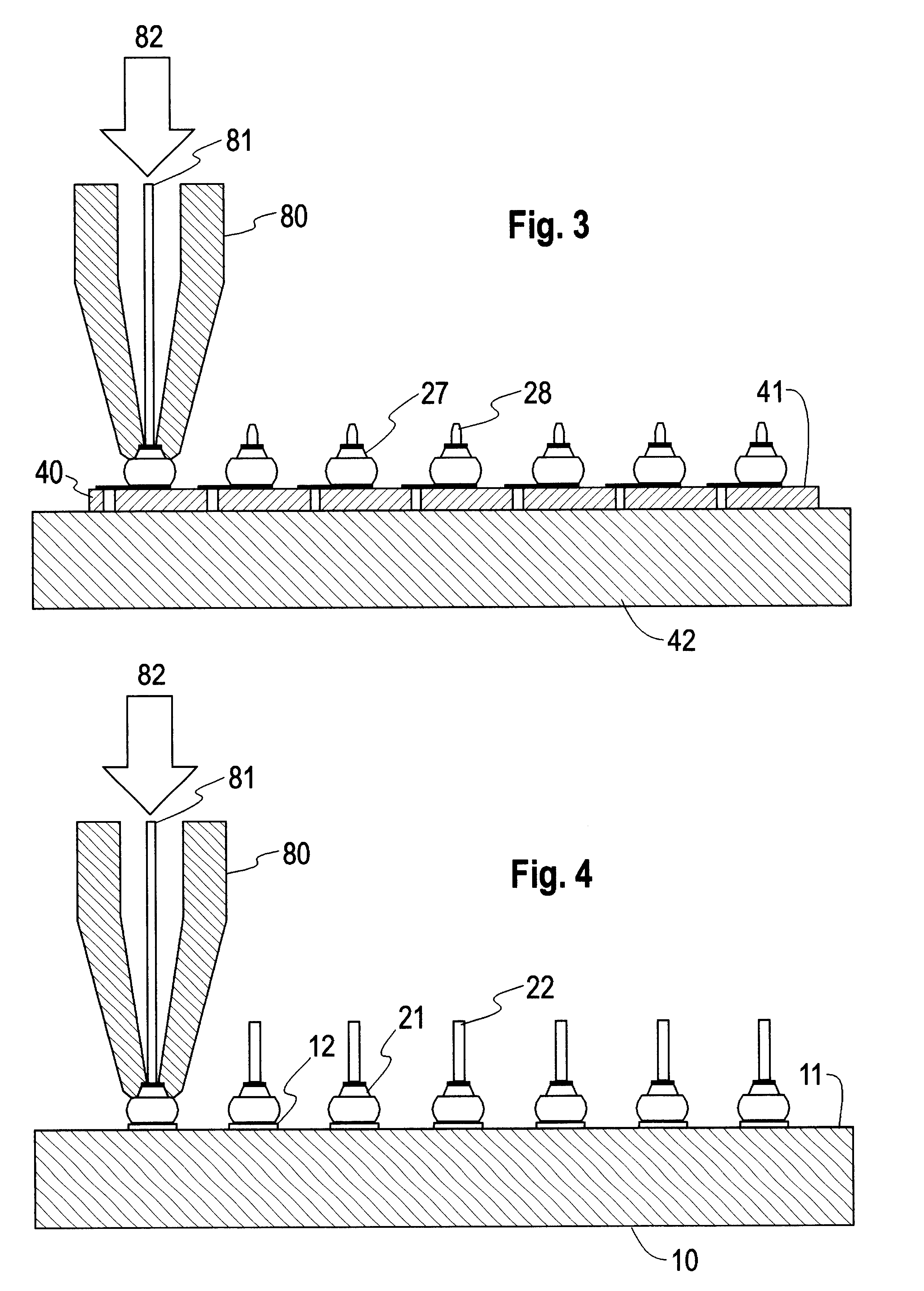

Angled flying lead wire bonding process

InactiveUS20090189288A1Line/current collector detailsElectrical measurement instrument detailsLead bondingEngineering

A method is described having the steps of providing a surface having a plurality of wire bondable locations; wire bonding a wire to each of the wire bondable locations using a wire capillary tool; controlling the position of the capillary tool with respect to the substrate; after forming a wire bond of the wire to the wire bondable location moving the capillary tool relative to the surface as the capillary tool is moved away from the surface to form a wire having a predetermined shape.

Owner:GLOBALFOUNDRIES INC

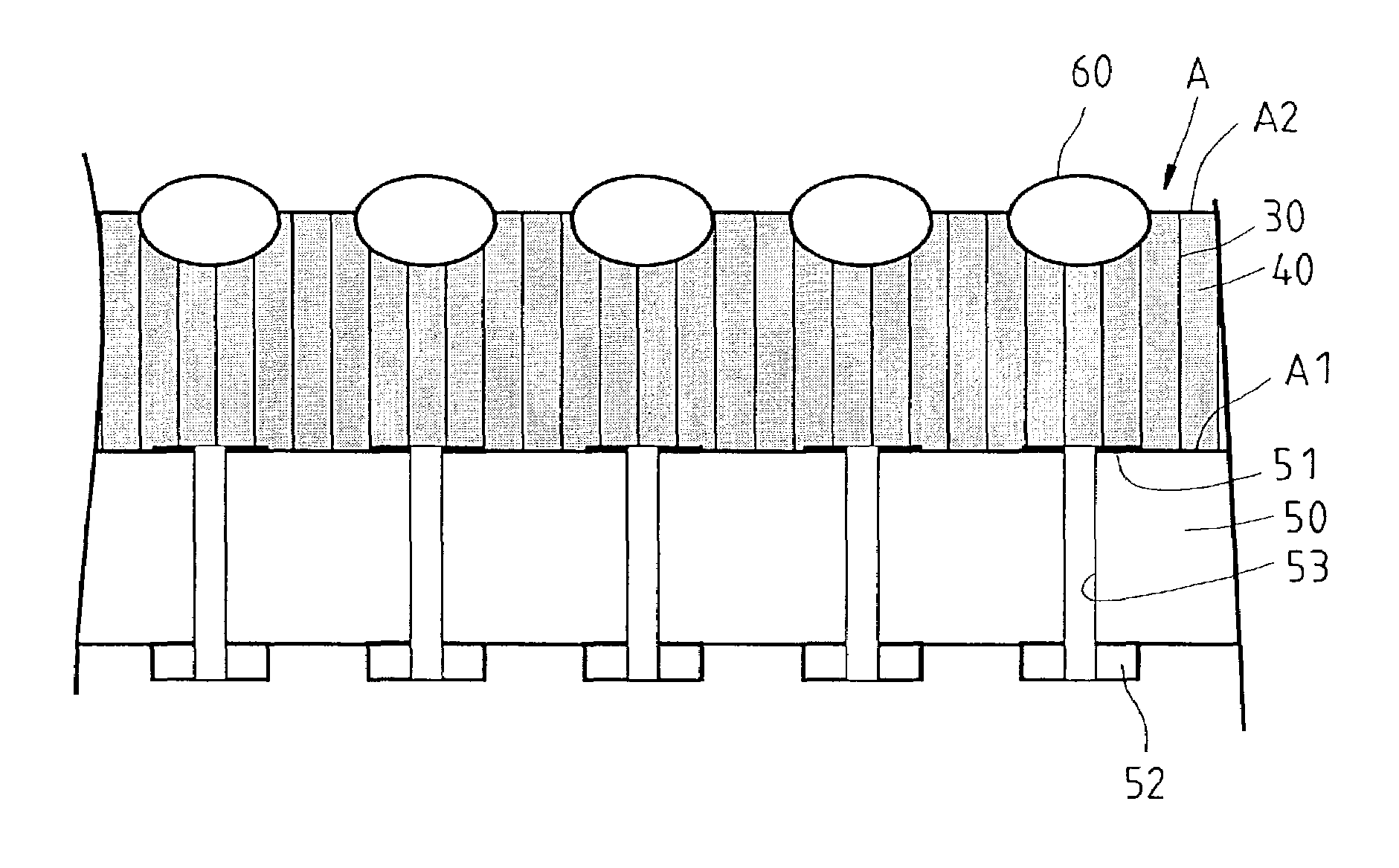

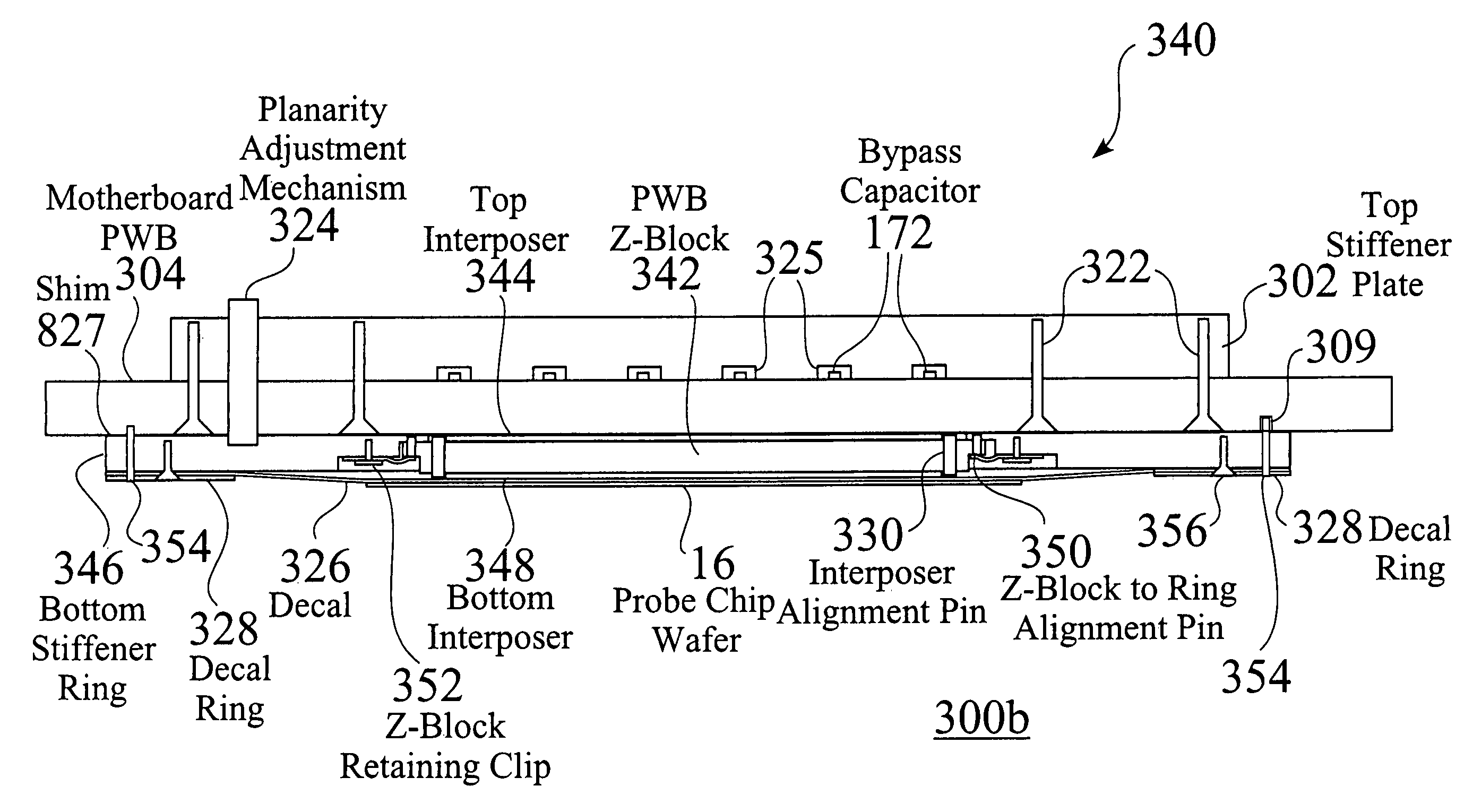

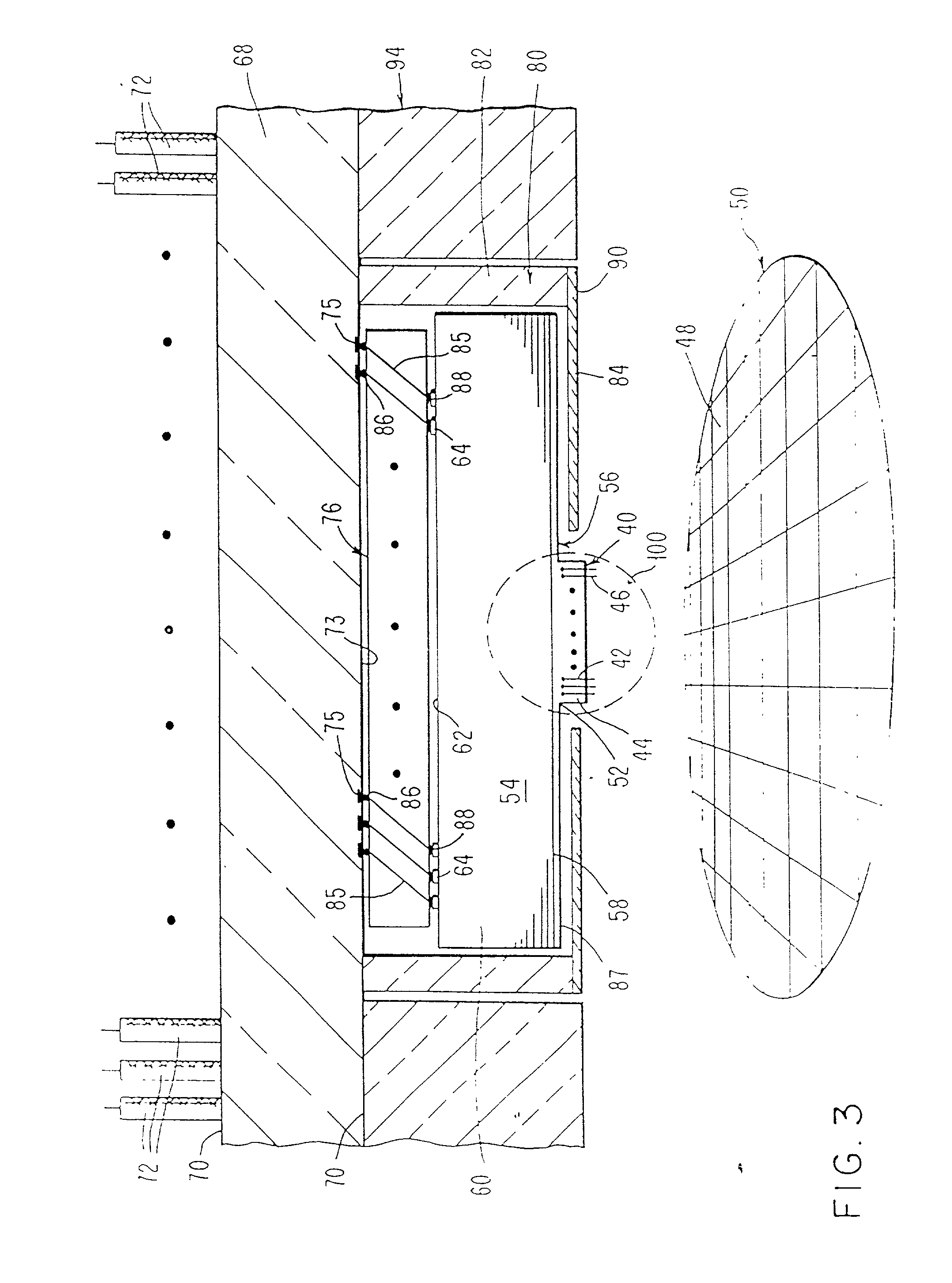

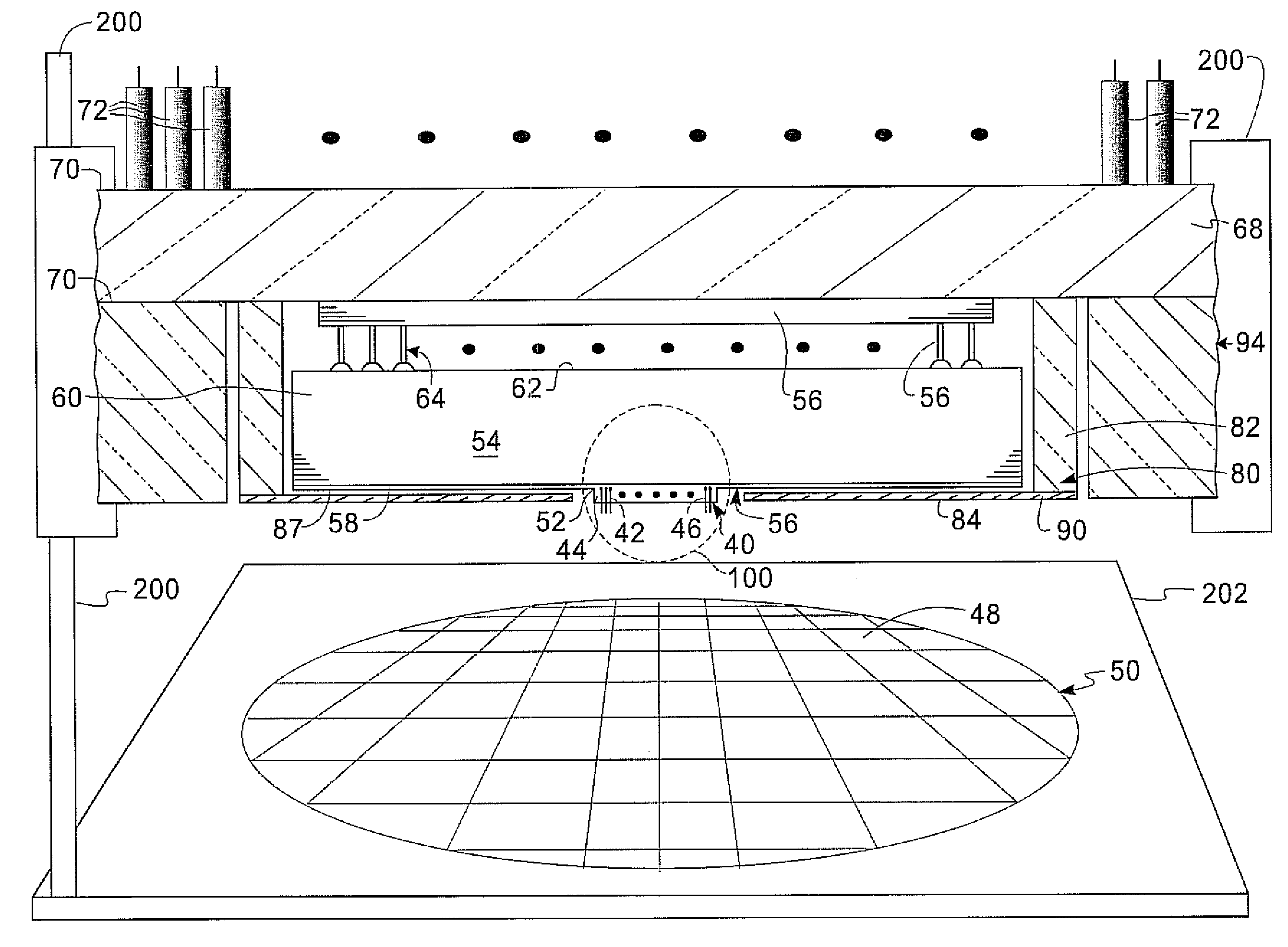

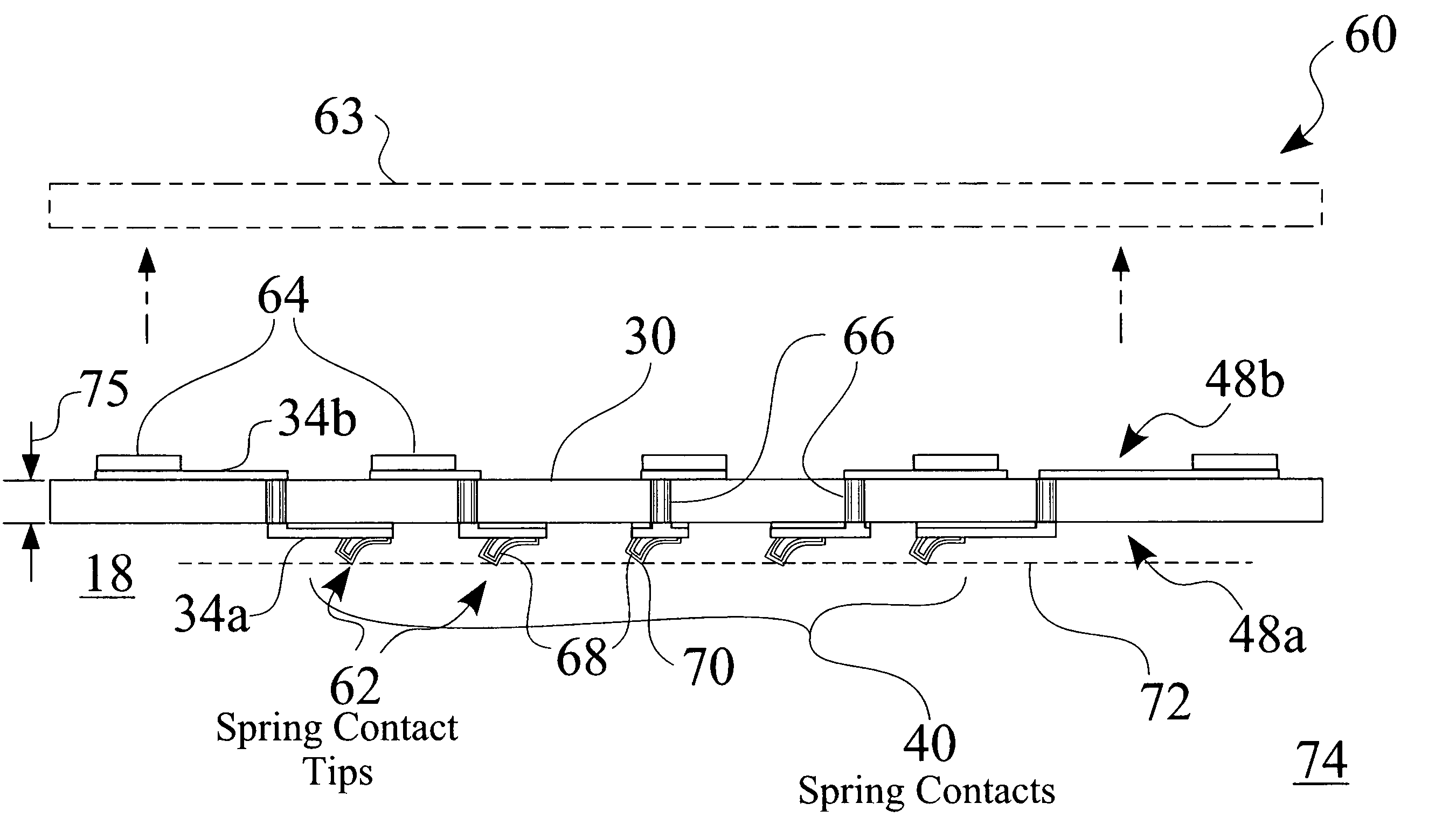

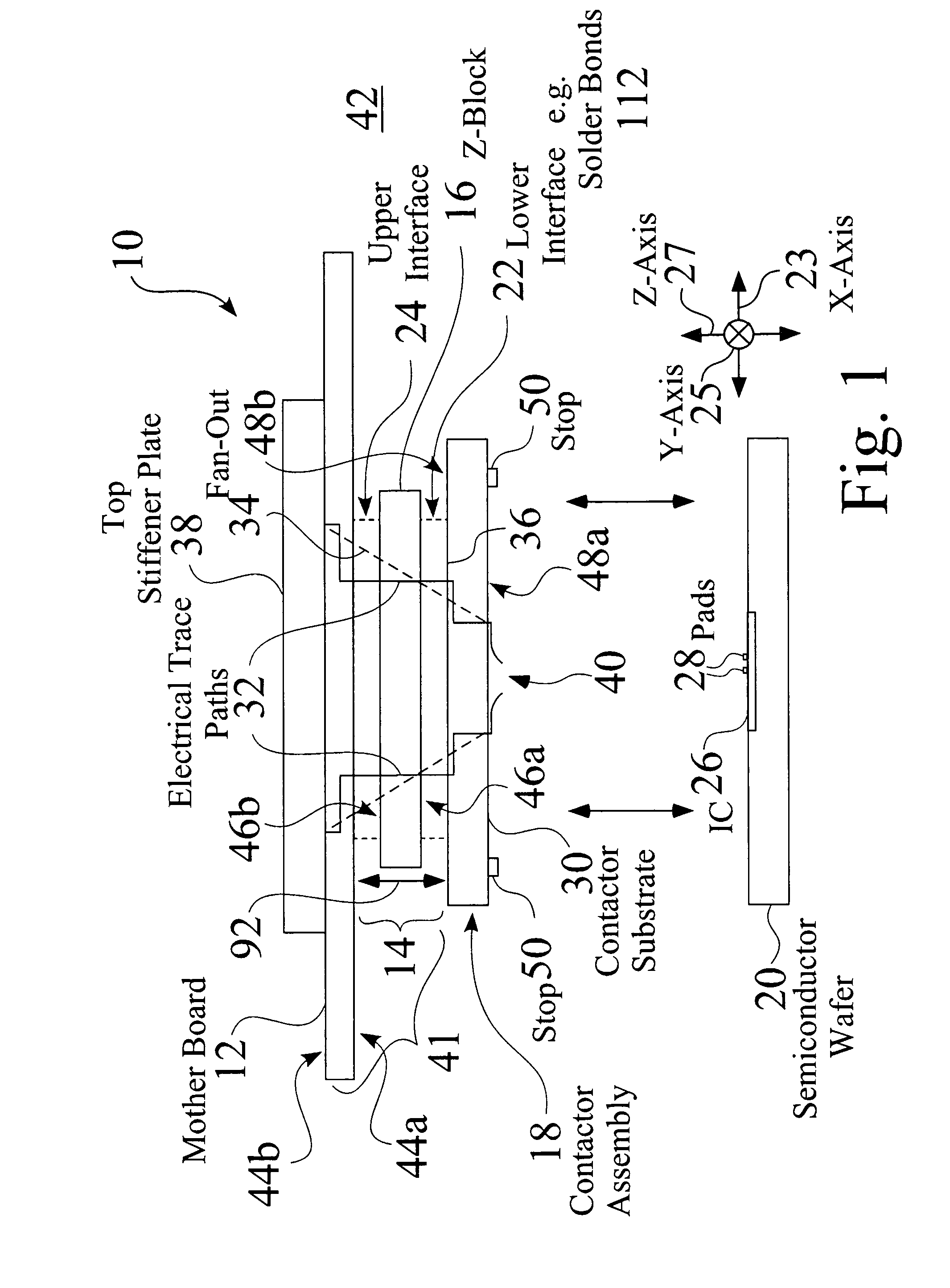

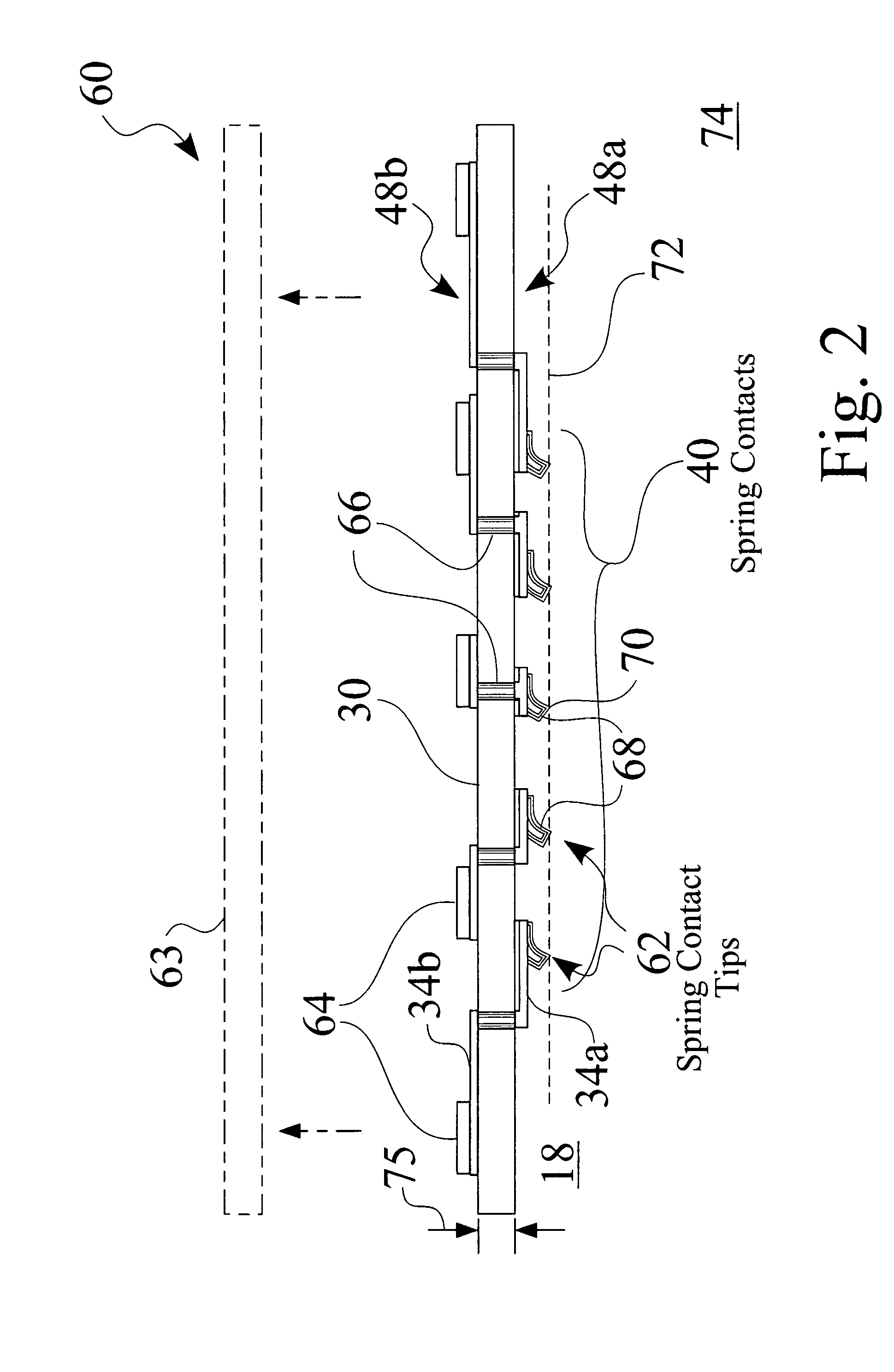

Enhanced compliant probe card systems having improved planarity

InactiveUS7349223B2Improve complianceImprove the level ofCoupling device connectionsSubstation/switching arrangement detailsProbe cardAssembly structure

Several embodiments of enhanced integrated circuit probe card and package assemblies are disclosed, which extend the mechanical compliance of both MEMS and thin-film fabricated probes, such that these types of spring probe structures can be used to test one or more integrated circuits on a semiconductor wafer. Several embodiments of probe card assemblies, which provide tight signal pad pitch compliance and / or enable high levels of parallel testing in commercial wafer probing equipment, are disclosed. In some preferred embodiments, the probe card assembly structures include separable standard components, which reduce assembly manufacturing cost and manufacturing time. These structures and assemblies enable high speed testing in wafer form. The probes also have built in mechanical protection for both the integrated circuits and the MEMS or thin film fabricated spring tips and probe layout structures on substrates. Alternate card assembly structures comprise a stiffening structure and a compliant carrier structure, such as a decal or screen, which is fixedly attached to the probe chip substrate.

Owner:ADVANTEST SINGAPORE PTE LTD

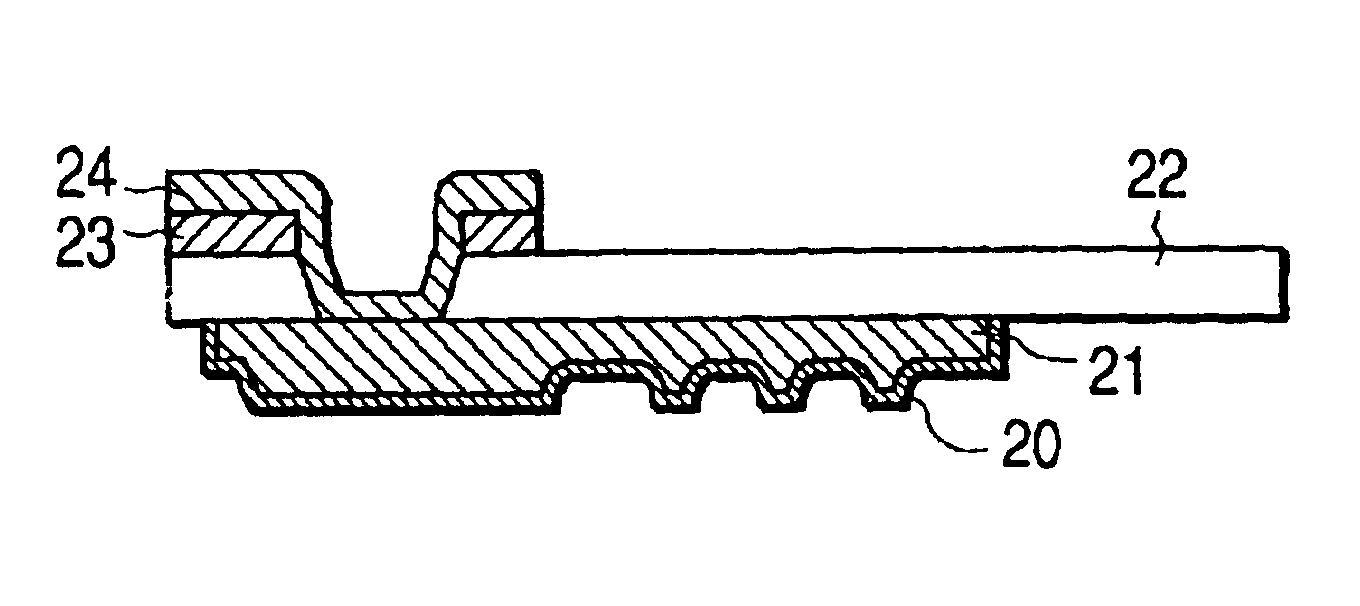

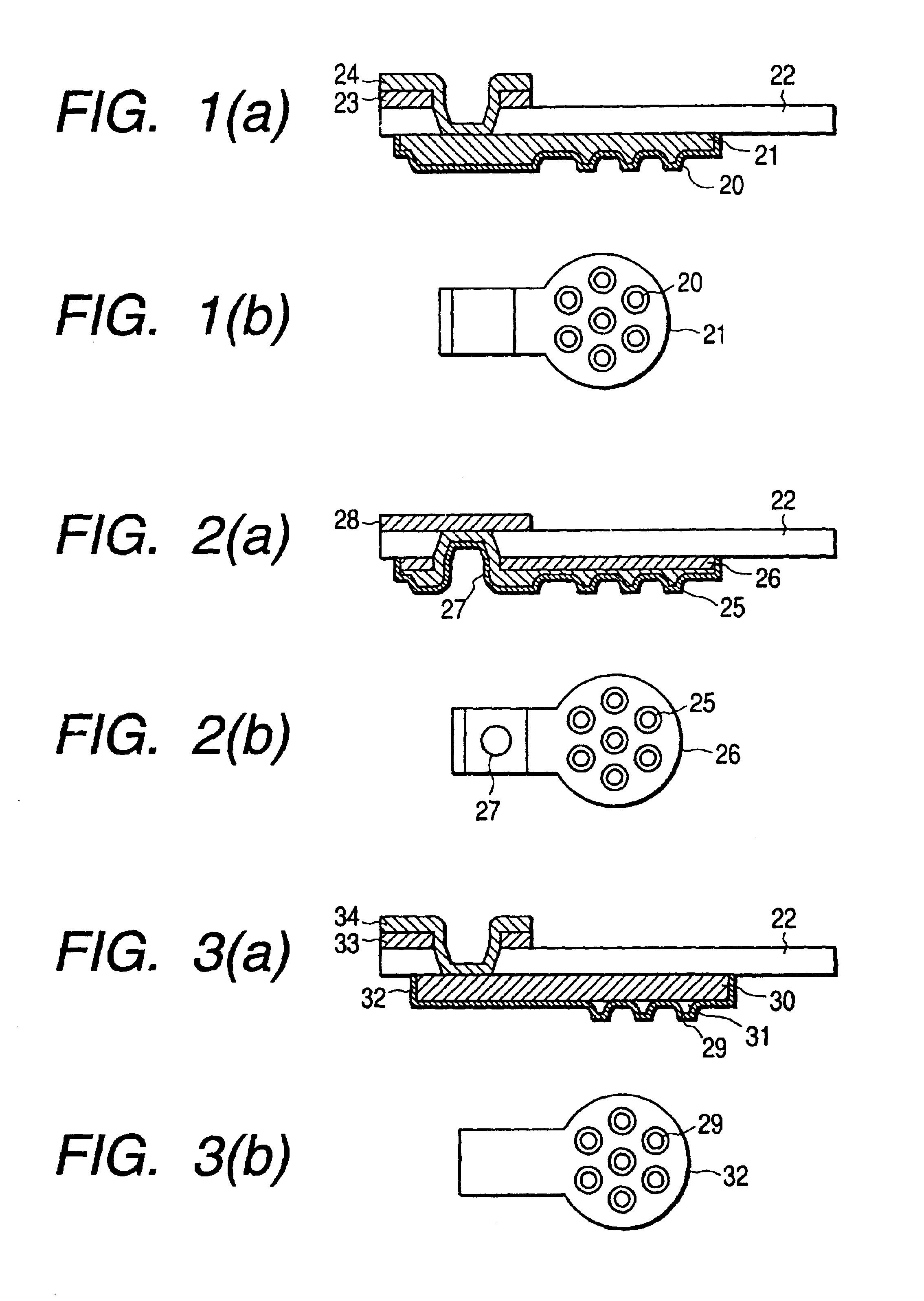

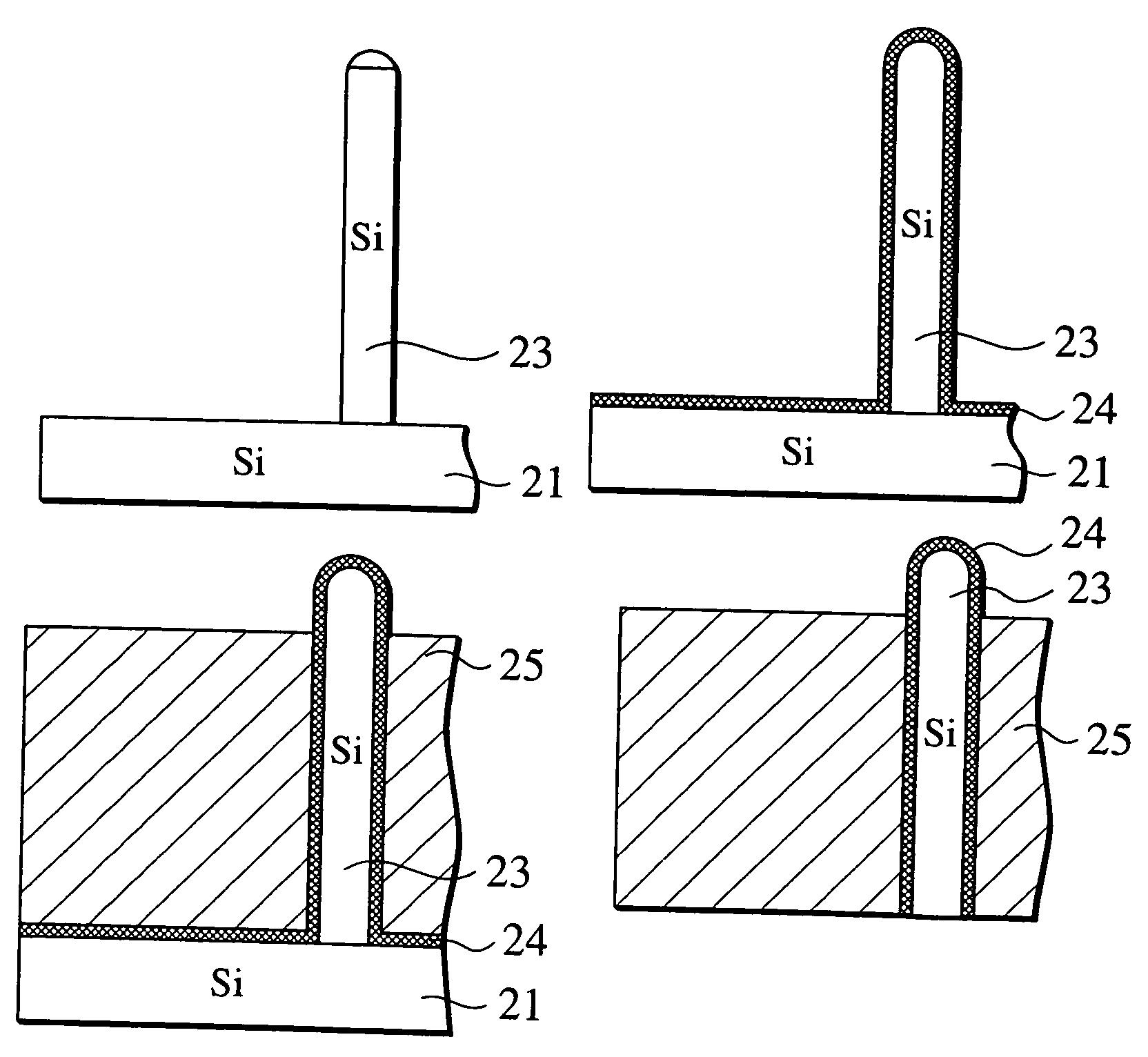

Method for fabricating a probe pin for testing electrical characteristics of an apparatus

InactiveUS7032307B2Reduce contact resistancePitch of probe pins to be reducedLine/current collector detailsSemiconductor/solid-state device testing/measurementProbe cardHigh density

A probe pin for testing electric characteristics of a semiconductor device comprises a silicon pin core (3, 23, 33), and a conductive film (4, 24, 34) covering the entire surface, including the bottom face, of the pin core. The bottom face of the probe pin is connected directly to an electrode (7, 37) positioned in or on a print wiring board. A number of probe pins can be connected to the associated electrodes at a high density, thereby forming a fine-pitch probe card having a superior high-frequency signal characteristic.

Owner:KK TOSHIBA

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20070271781A9High performance functional testingHigh-temperature burnElectrically conductive connectionsElectronic circuit testingElastomerElectricity

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed ion the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

Angled flying lead wire bonding process

InactiveUS7495342B2Line/current collector detailsElectrical measurement instrument detailsWire rodLead bonding

A method is described having the steps of providing a surface having a plurality of wire bondable locations, wire bonding a wire to each of the wire bondable locations using a wire capillary tool; controlling the position of the capillary tool with respect to the substrate; after forming a wire bond of the wire to the wire bondable location moving the capillary tool relative to the surface as the capillary tool is moved away from the surface to form a wire having a predetermined shape.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080106291A1High performance functional testingHigh temperature burn in applicationsElectronic circuit testingElectrical measurement instrument detailsElastomerElectricity

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer forms or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer. The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080048697A1High performance functional testingHigh temperature burn in applicationsElectrical measurement instrument detailsManufacture of electrical instrumentsElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080047741A1High performance functional testingHigh temperature burn in applicationsElectrical measurement instrument detailsElectrical testingElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer. Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080048690A1High performance functional testingHigh temperature burn in applicationsElectrical measurement instrument detailsManufacture of electrical instrumentsElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080048691A1High performance functional testingHigh temperature burn in applicationsElectrical measurement instrument detailsElectrical testingElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density integrated circuit apparatus, test probe and methods of use thereof

InactiveUS20080100316A1High performance functional testingHigh temperature burn in applicationsManufacture of electrical instrumentsMeasurement leads/probesElastomerContact pad

The present invention is directed to a high density test probe which provides a means for testing a high density and high performance integrated circuits in wafer form or as discrete chips. The test probe is formed from a dense array of elongated electrical conductors which are embedded in an compliant or high modulus elastomeric material. A standard packaging substrate, such as a ceramic integrated circuit chip packaging substrate is used to provide a space transformer Wires are bonded to an array of contact pads on the surface of the space transformer. The space transformer formed from a multilayer integrated circuit chip packaging substrate. The wires are as dense as the contact location array. A mold is disposed surrounding the array of outwardly projecting wires. A liquid elastomer is disposed in the mold to fill the spaces between the wires. The elastomer is cured and the mold is removed, leaving an array of wires disposed in the elastomer and in electrical contact with the space transformer The space transformer can have an array of pins which are on the opposite surface of the space transformer opposite to that on which the elongated conductors are bonded. The pins are inserted into a socket on a second space transformer, such as a printed circuit board to form a probe assembly. Alternatively, an interposer electrical connector can be disposed between the first and second space transformer.

Owner:GLOBALFOUNDRIES INC

High density cantilevered probe for electronic devices

InactiveUS6329827B1Minimizes potential for damagingHigh densityPrinted circuit assemblingElectrical measurement instrument detailsContact padHigh density

Connectors for electronic devices are described. The connector is formed by ball bonding a plurality of wires to contact locations on a fan out substrate surface. The wires are cut off leaving stubs. A patterned polymer sheet having electrical conductor patterns therein is disposed over the stubs which extend through holes in the sheet. The ends of the wires are flattened to remit the polymer sheet in place. The wire is connected to an electrical conductor on the polymer sheet which is converted to a contact pad on the polymer sheet. A second wire is ball bonded to the pad on the polymer sheet and cut to leave a second stub. The polymer sheet is laser cut so that each second stub is free to move independently of the other second studs. The ends of the second stubs are disposed against contact locations of an electronic device, such as an FC chip, to test the electronic device.

Owner:TOKYO ELECTRON LTD

Interconnect for microelectronic structures with enhanced spring characteristics

InactiveUS7048548B2Measurable amount of resiliencyIncrease elasticityElectrical measurement instrument detailsSemiconductor/solid-state device detailsElectronic structureEngineering

An interconnection element and a method of forming an interconnection element. In one embodiment, the interconnection element includes a first structure and a second structure coupled to the first structure. The second structure coupled with the first material has a spring constant greater than the spring constant of the first structure alone. In one embodiment, the interconnection element is adapted to be coupled to an electronic component tracked as a conductive path from the electronic component. In one embodiment, the method includes forming a first (interconnection) structure coupled to a substrate to define a shape suitable as an interconnection in an integrated circuit environment and then coupling, such as by coating, a second (interconnection) structure to the first (interconnection) structure to form an interconnection element. Collectively, the first (interconnection) structure and the second (interconnection) structure have a spring constant greater than a spring constant of the first (interconnection) structure.

Owner:FORMFACTOR INC

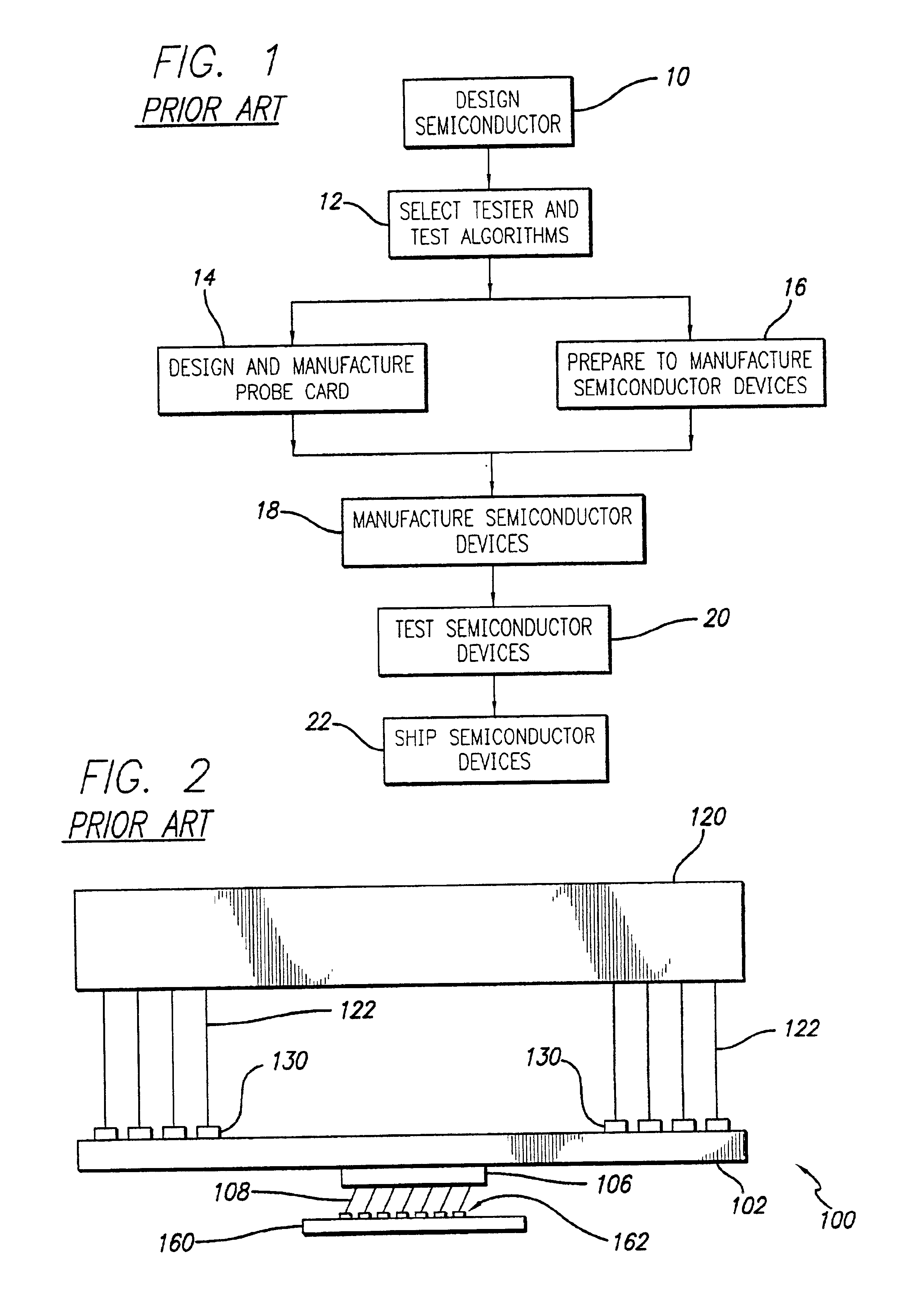

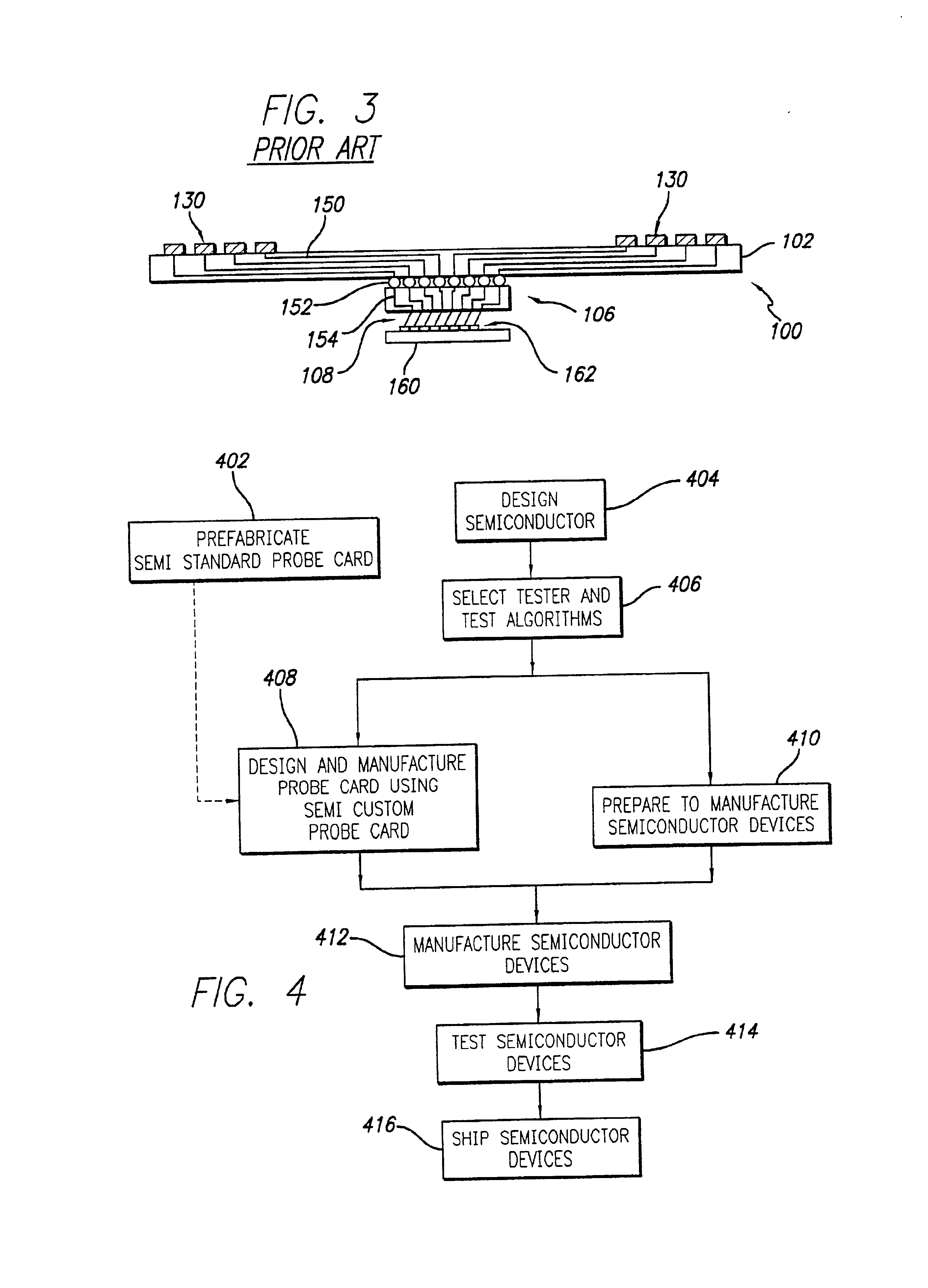

Method of manufacturing a probe card

InactiveUS6864105B2Reduce designSemiconductor/solid-state device testing/measurementElectronic circuit testingProbe cardEngineering

Owner:FORMFACTOR INC

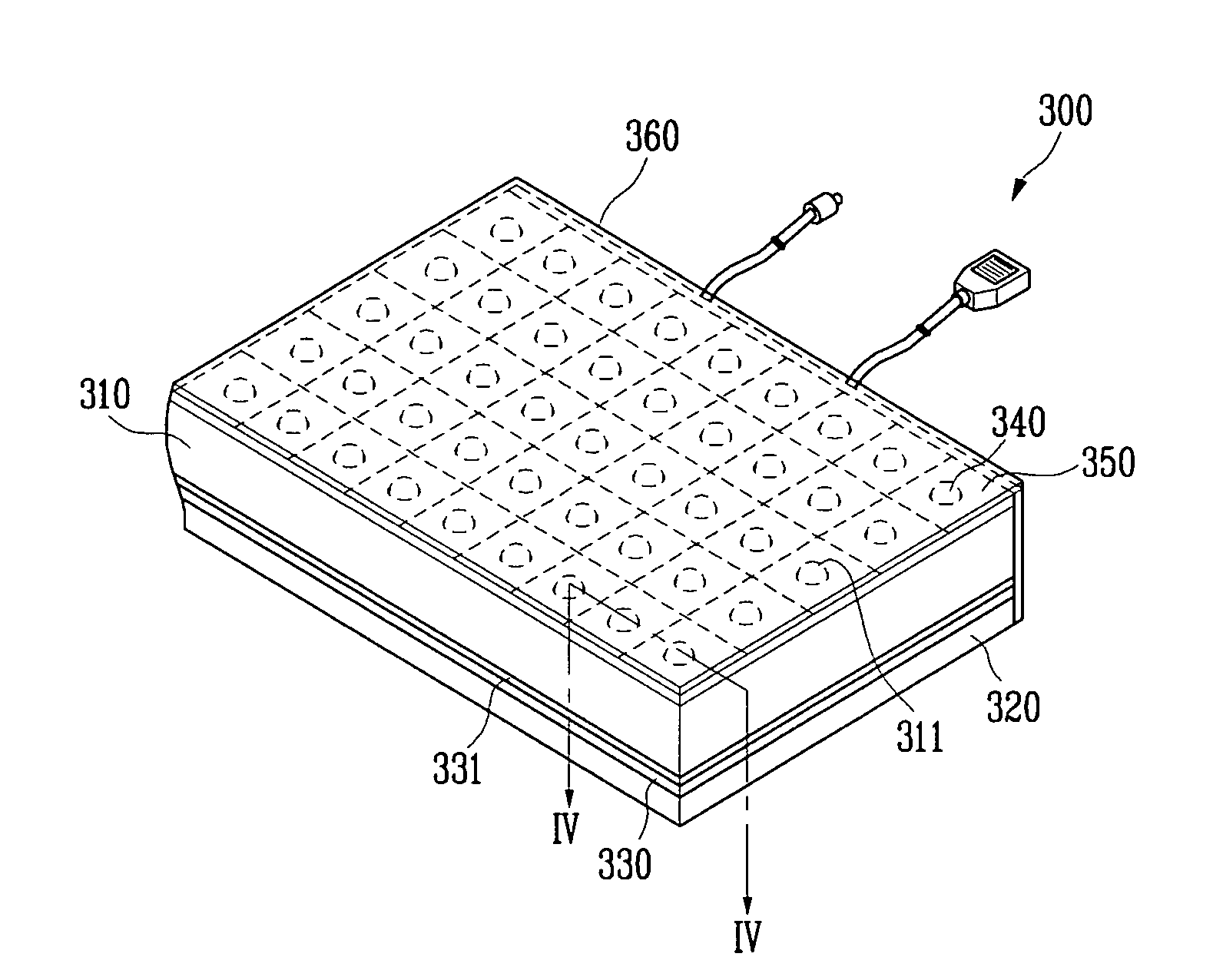

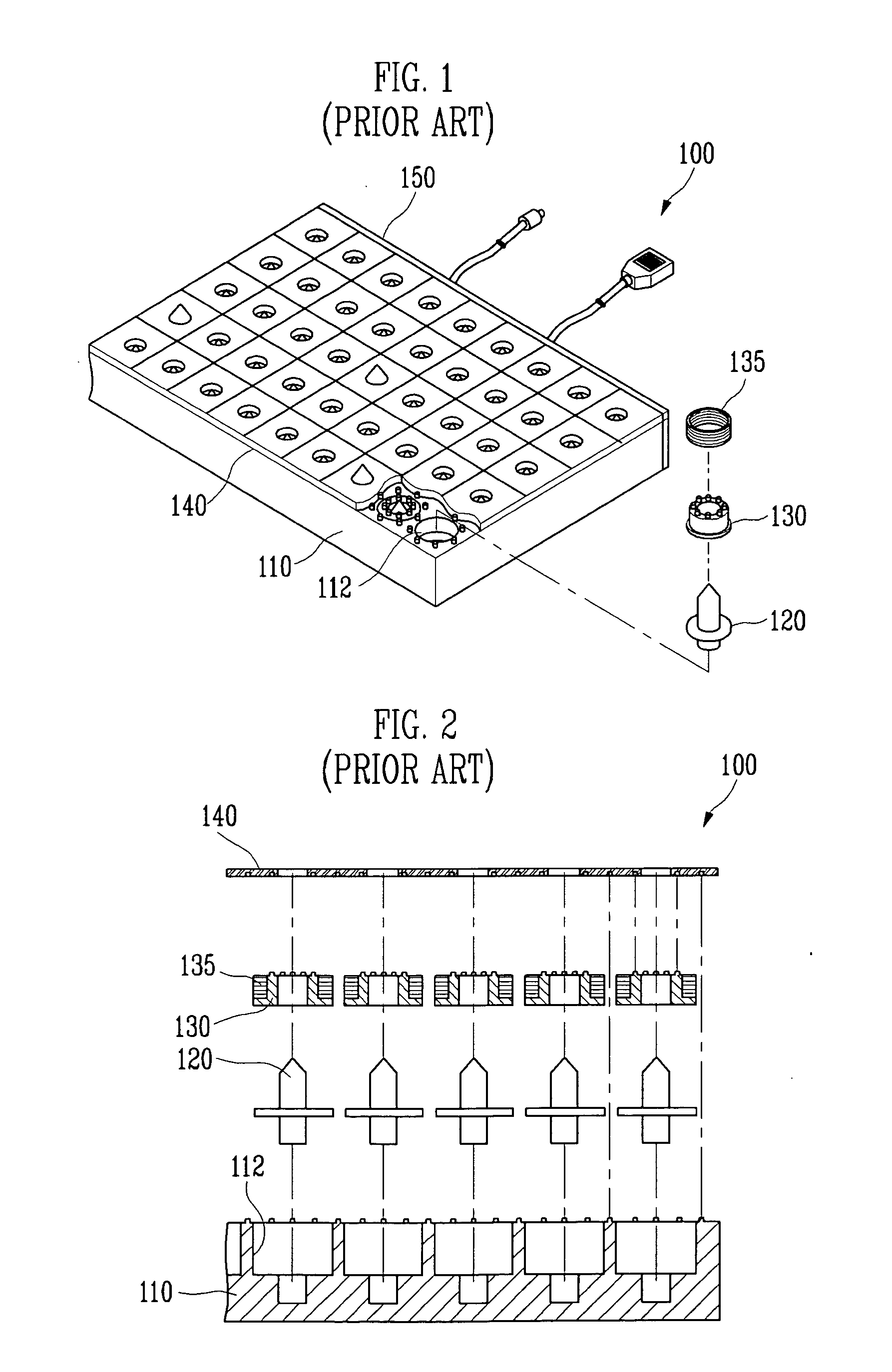

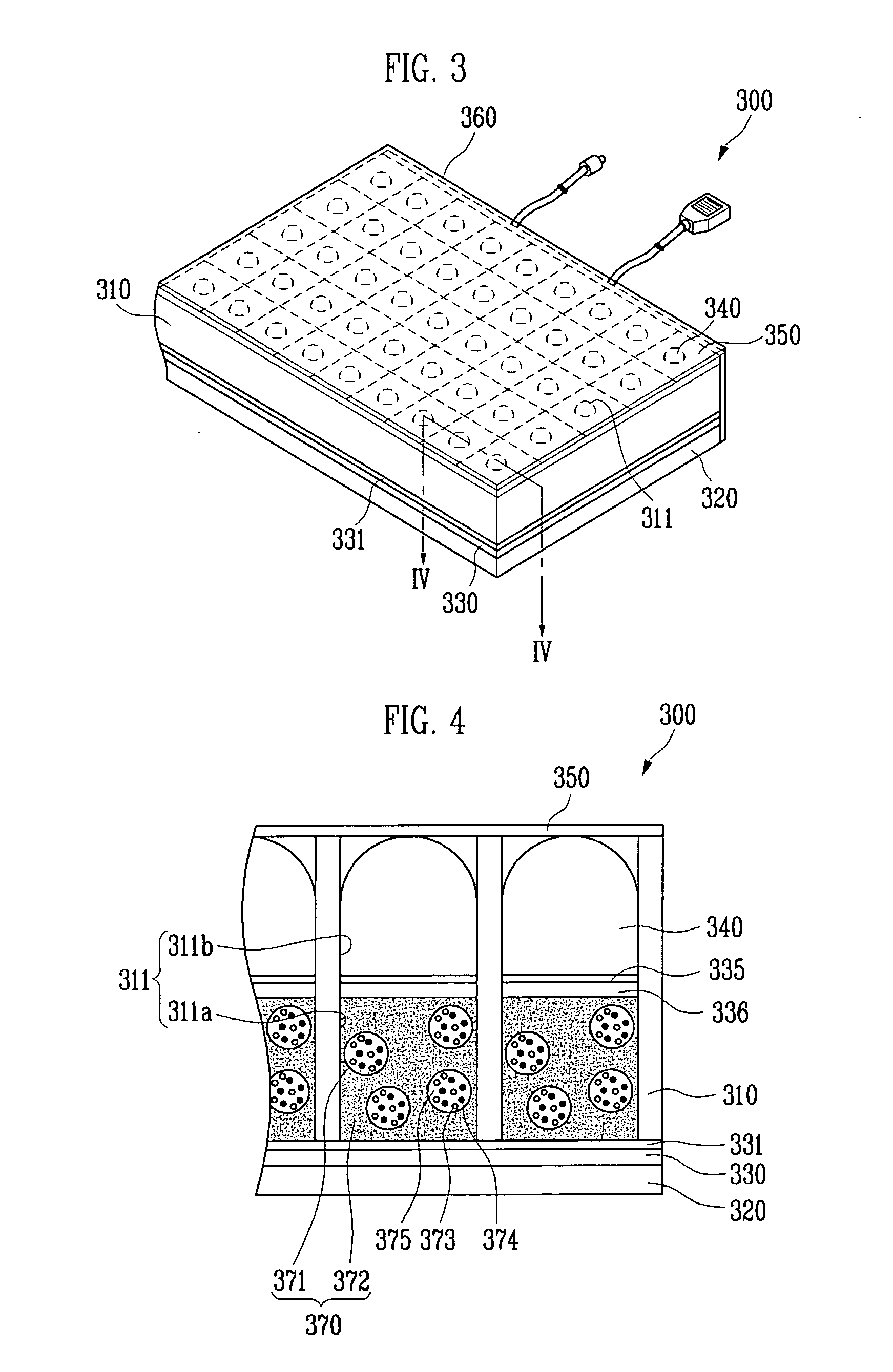

Braille display device using electrorheological fluid and manufacturing method thereof

ActiveUS20080138774A1Wave amplification devicesManufacture of electrical instrumentsElectrophoresisDisplay device

Provided are a braille display device using an electrorheological fluid and a method for manufacturing the same. The braille display device includes: a base body in which a plurality of insulating reception grooves are formed; a first electrode arranged below the base body; an electrorheological fluid received in the reception groove; a microcapsule having an electrophoresis particle which is dispersed in the electrorheological fluid; a second electrode arranged above the microcapsule; a braille pin installed above the second electrode; and a braille pin protection film arranged above the braille pin.

Owner:ELECTRONICS & TELECOMM RES INST

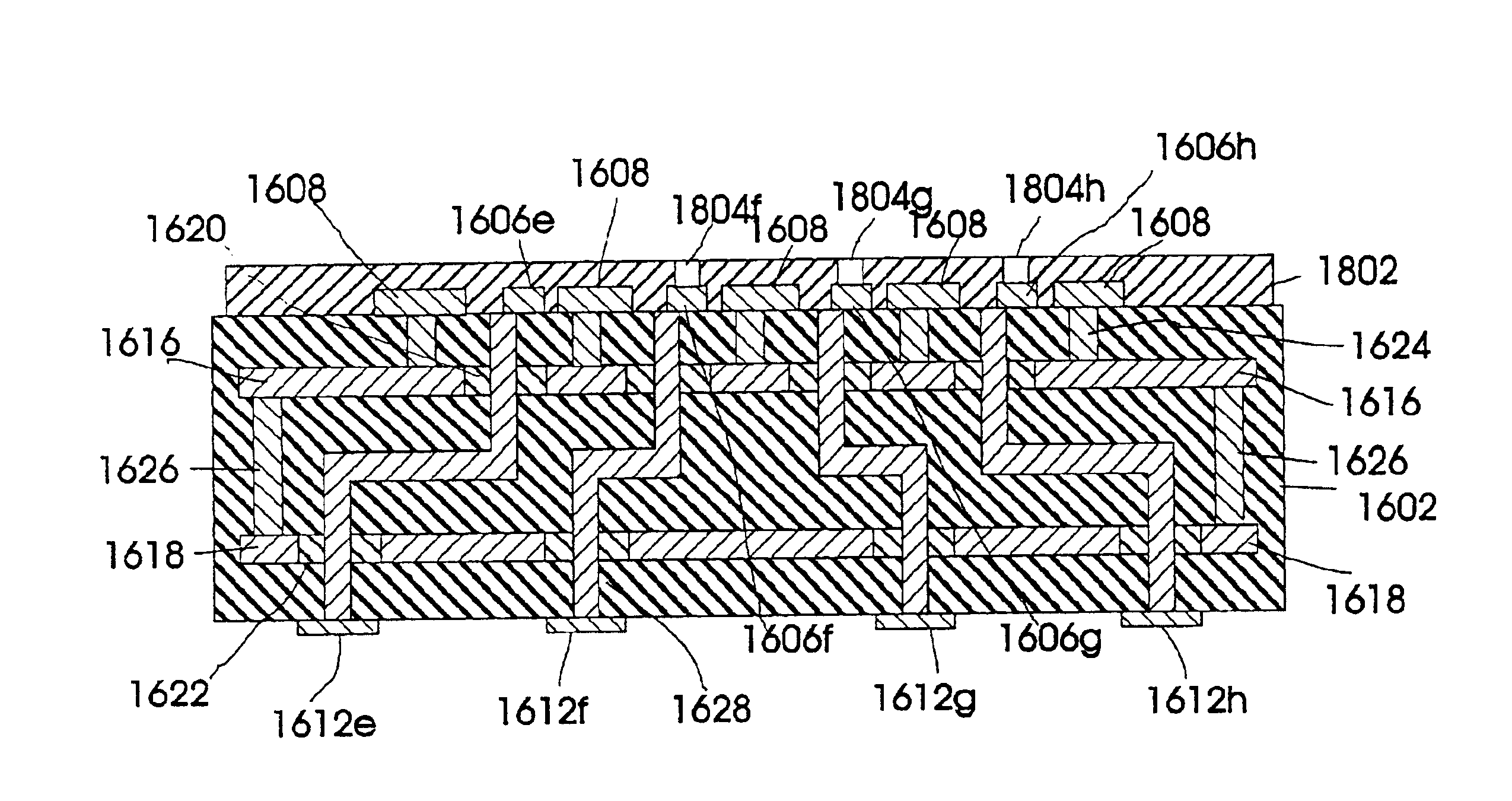

High density interconnect system for IC packages and interconnect assemblies

InactiveUS20060186906A1Electrical measurement instrument detailsManufacture of electrical instrumentsProbe cardHigh density

An improved interconnection system is described, such as for electrical contactors and connectors, electronic device or module package assemblies, socket assemblies, and / or probe card assembly systems. An exemplary connector comprises a first connector structure comprising a contactor substrate having a contact surface and a bonding surface, and one or more electrically conductive micro-fabricated spring contacts extending from the probe surface, a second connector structure comprising at least one substrate and having a set of at least one electrically conductive contact pad located on a connector surface and corresponding to the set of spring contacts, and means for movably positioning and aligning the first connector structure and the second connector structure between at least a first position and a second position, such that in at least one position, at least one electrically conductive micro-fabricated spring contact is electrically connected to at least one electrically conductive contact pad.

Owner:ADVANTEST SINGAPORE PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com