Patents

Literature

71results about How to "Maintain positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

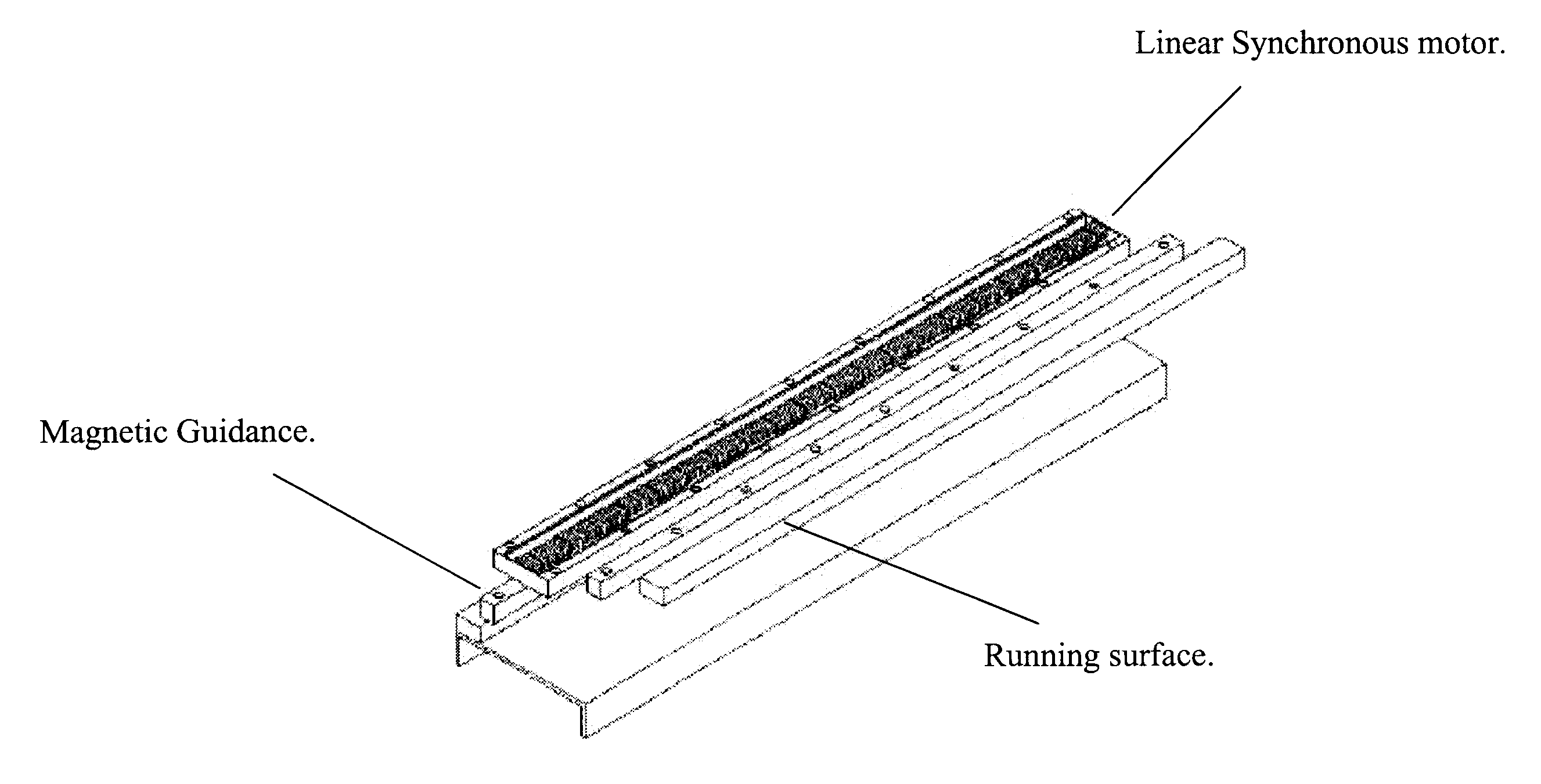

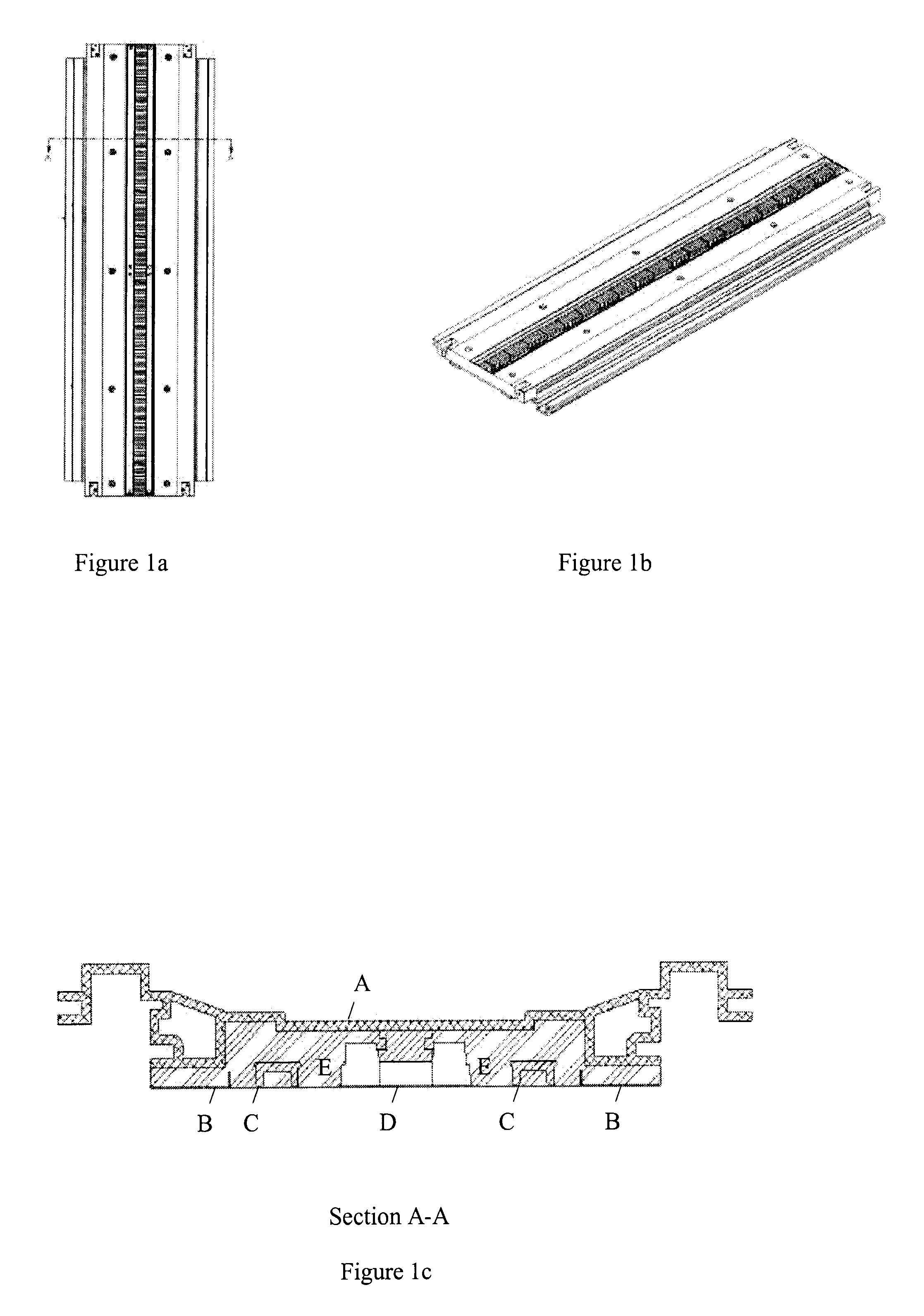

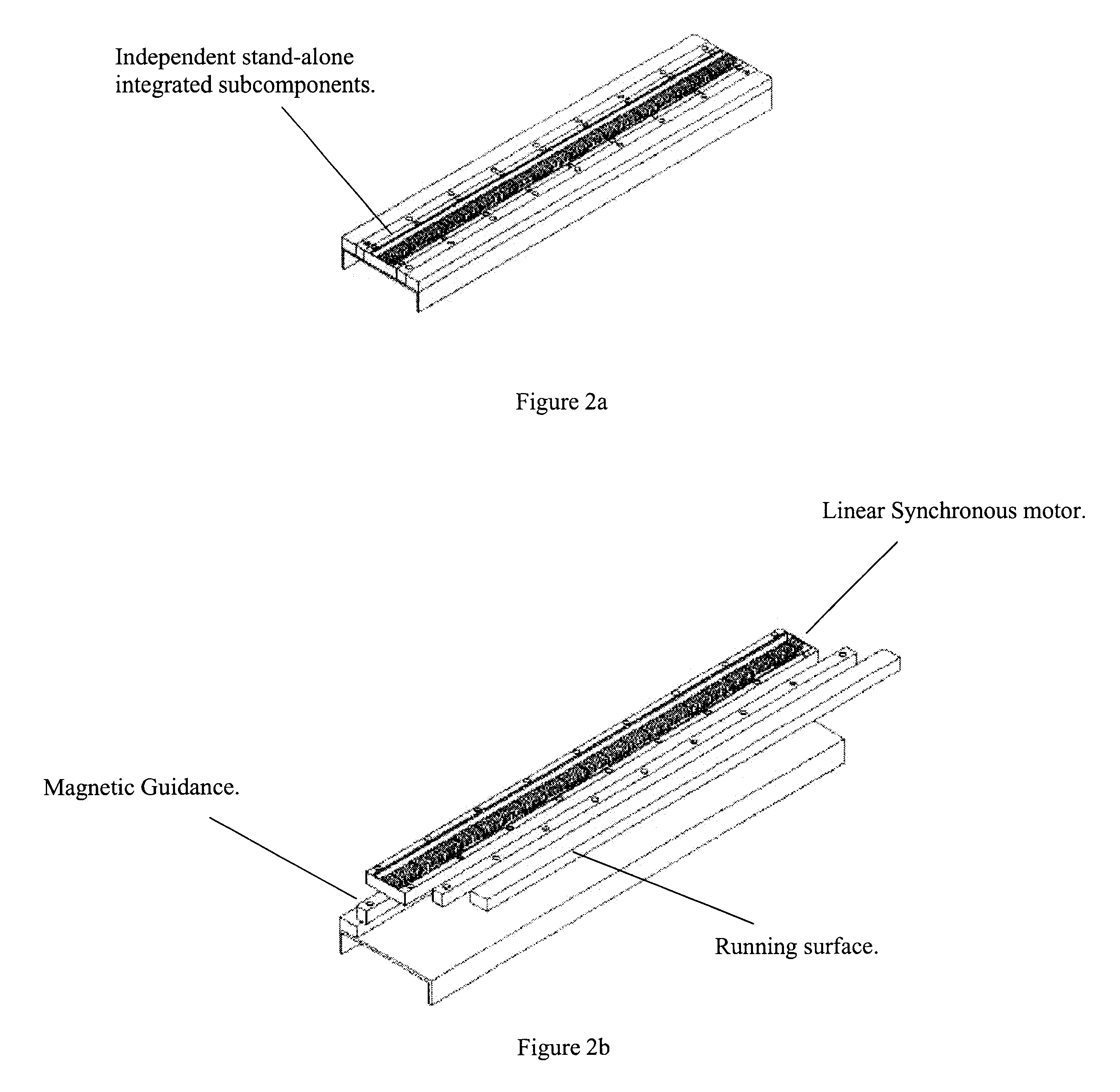

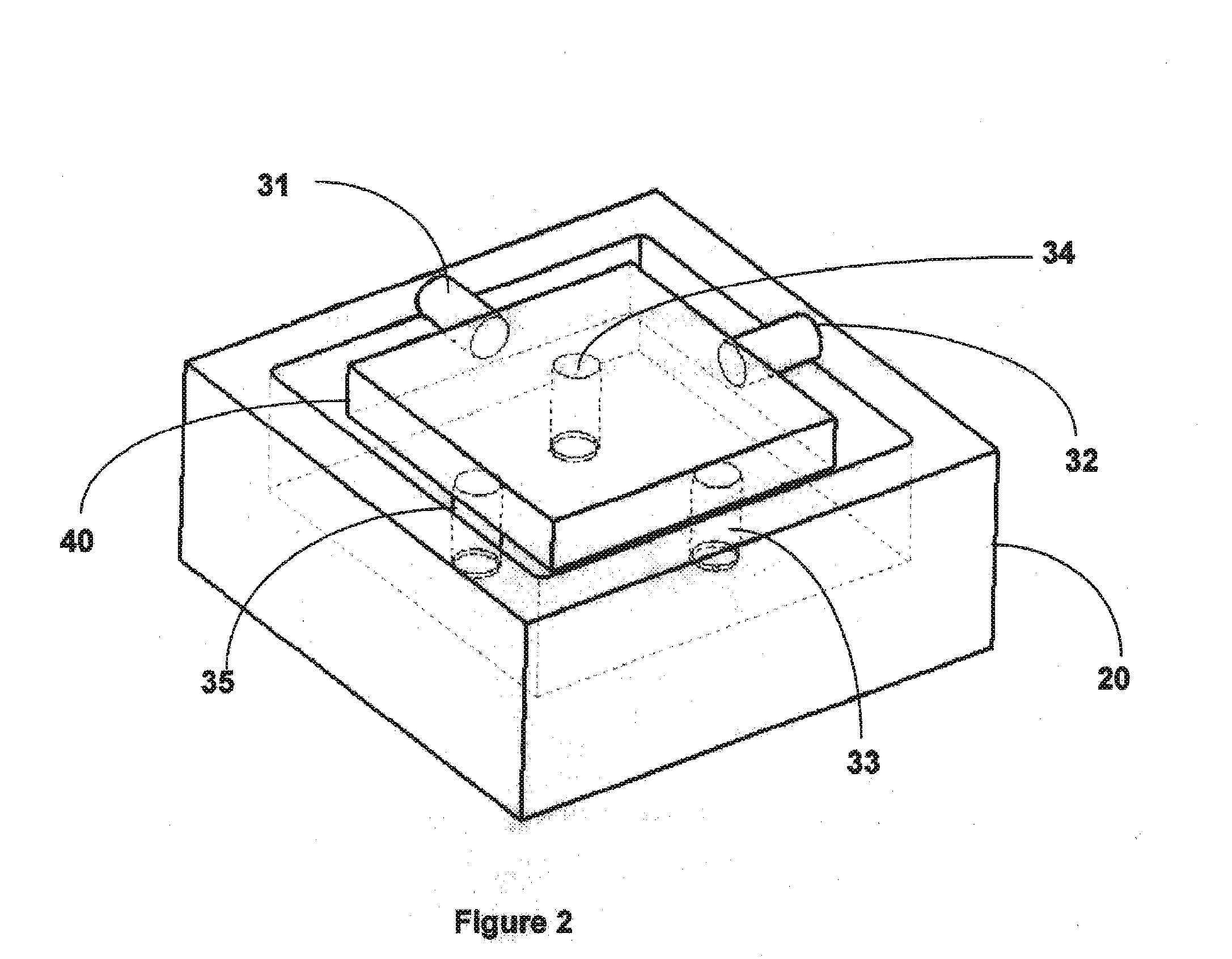

Modular linear motor tracks and methods of fabricating same

InactiveUS6578495B1Low costMaintain positioning accuracyRailway vehiclesElectric vehicle charging technologyModularityComputer module

A module for a linear motor propulsion guideway contains a combination of linear motor propulsion, vehicle guidance, position sensing, communication, and vehicle or pallet running surface subcomponents. These are integrated during the manufacturing into a single component or module for ease of shipping and precision of installation at a site where the guideway is to be installed. A single manufacturing operation is used to position, affix, and encapsulate the selected subcomponent(s) in a module or modules. For example, the component(s) can be designed to be located in a plastic injection mold, typically, a reaction injection mold (RIM), which allows the subcomponent(s) to be positioned, aligned, and encapsulated in a single manufacturing step that has only a several minute cycle time. In this manner positional accuracy among the relationship of the subcomponent(s) can be maintained within a small tolerance (on the order of 0.25 mm) while costs remain very low.

Owner:MAGNEMOTION INC

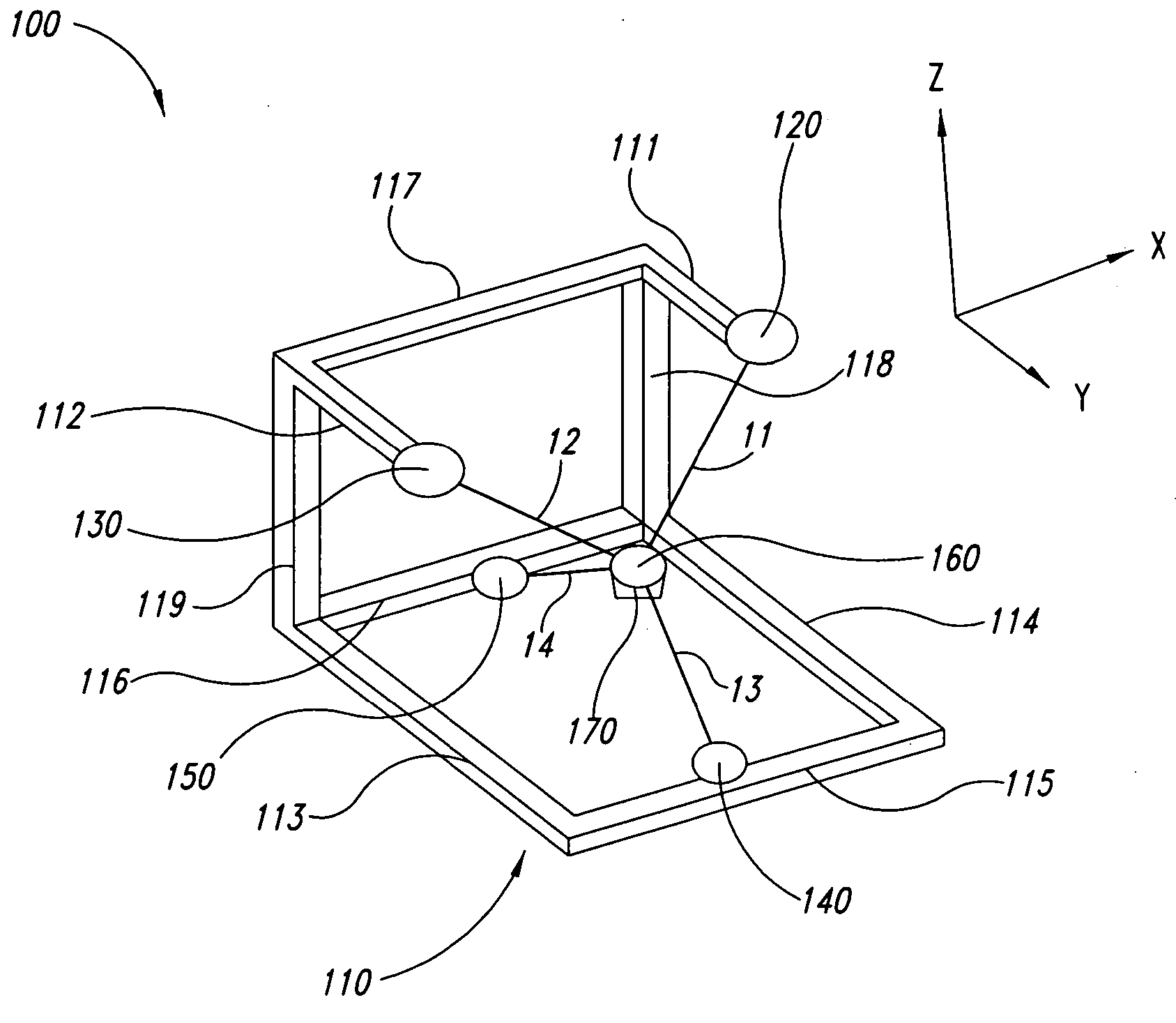

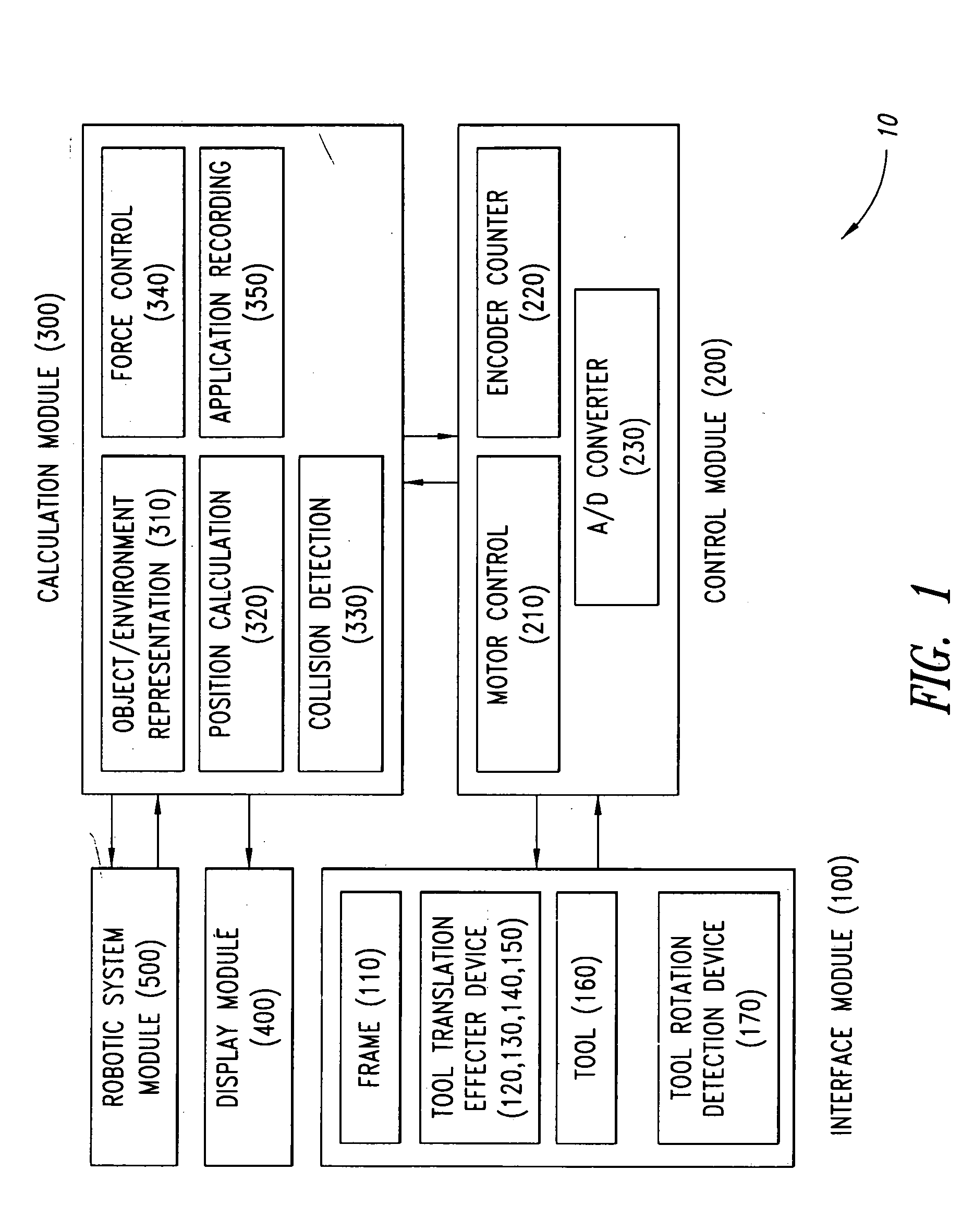

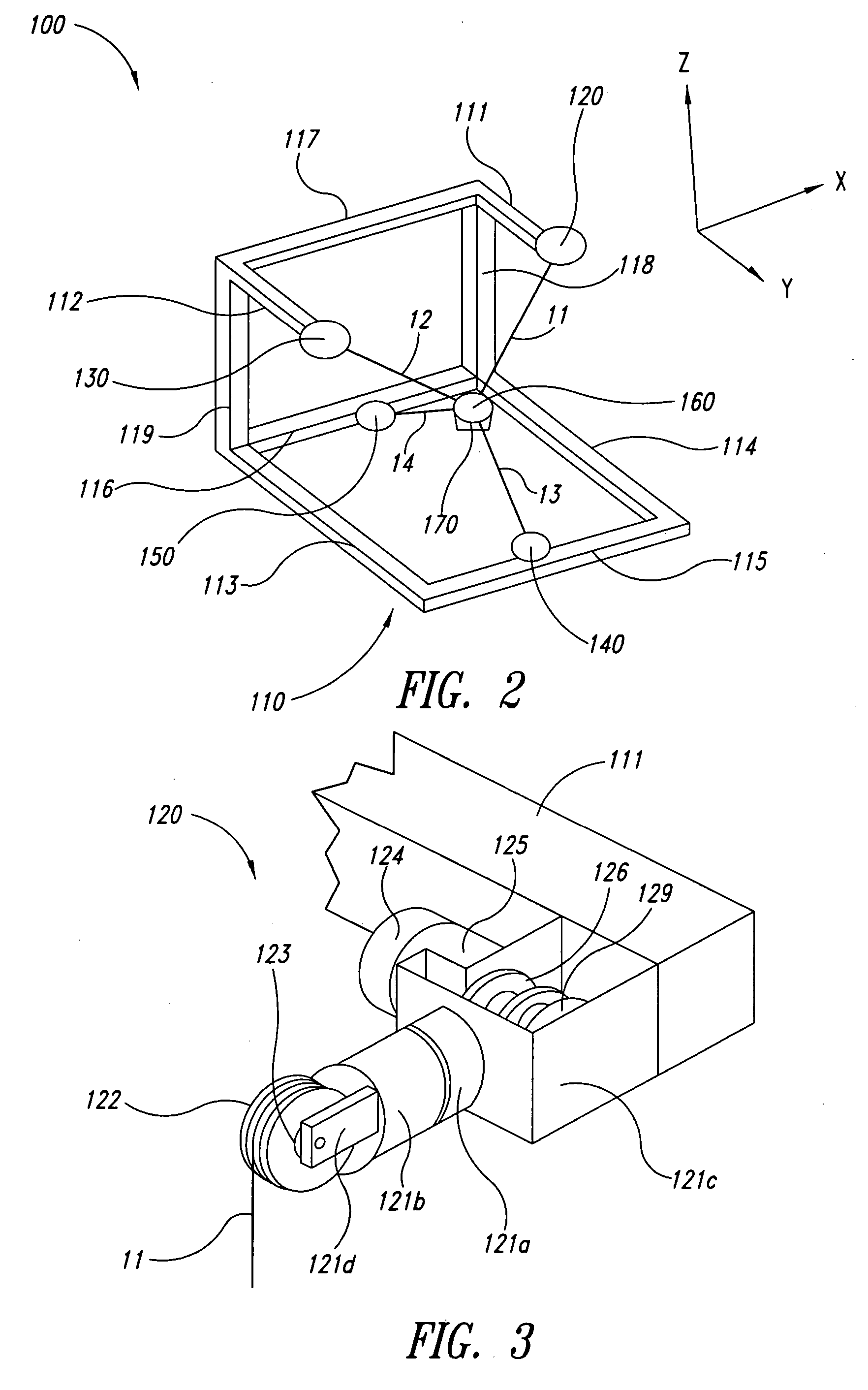

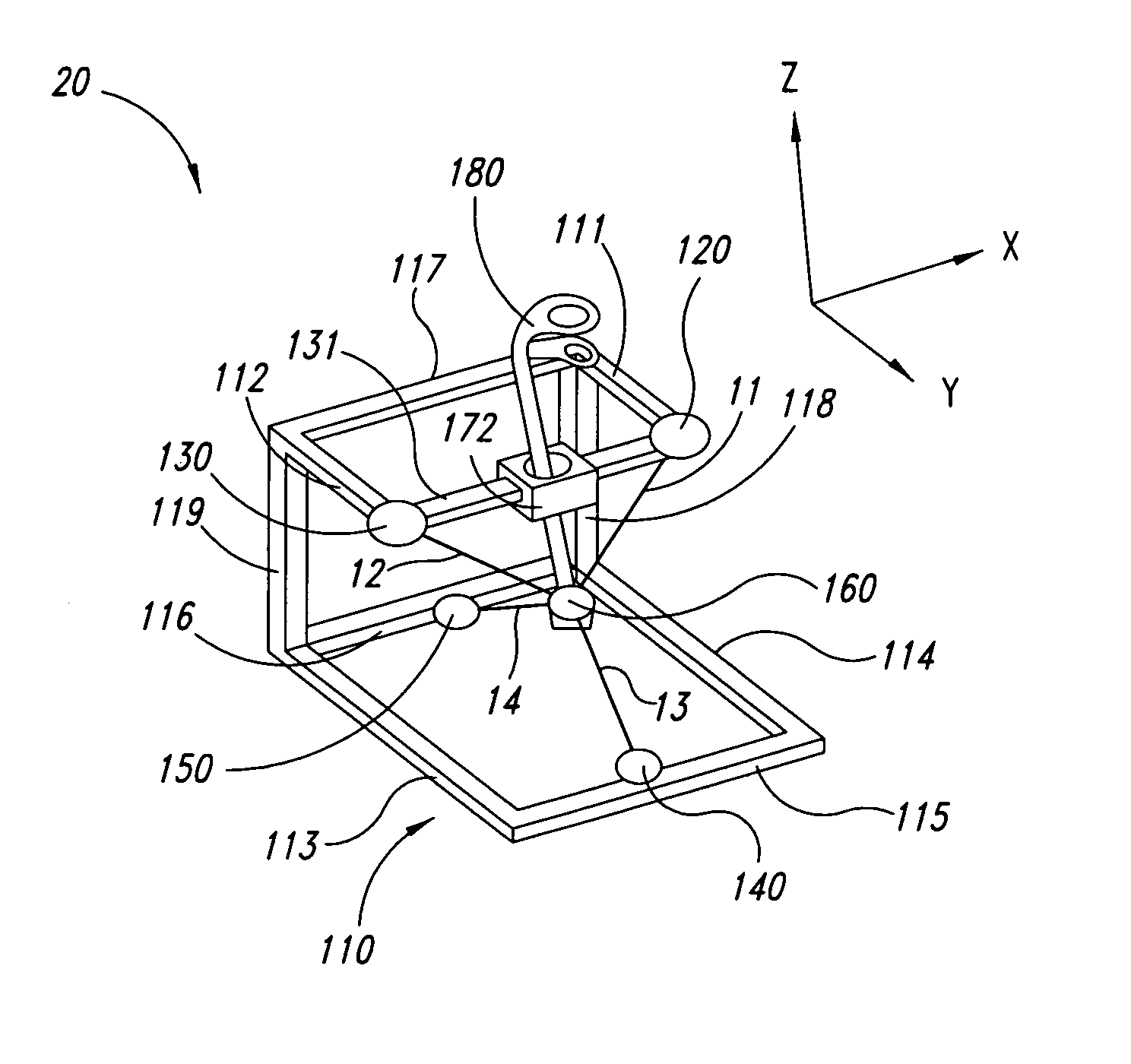

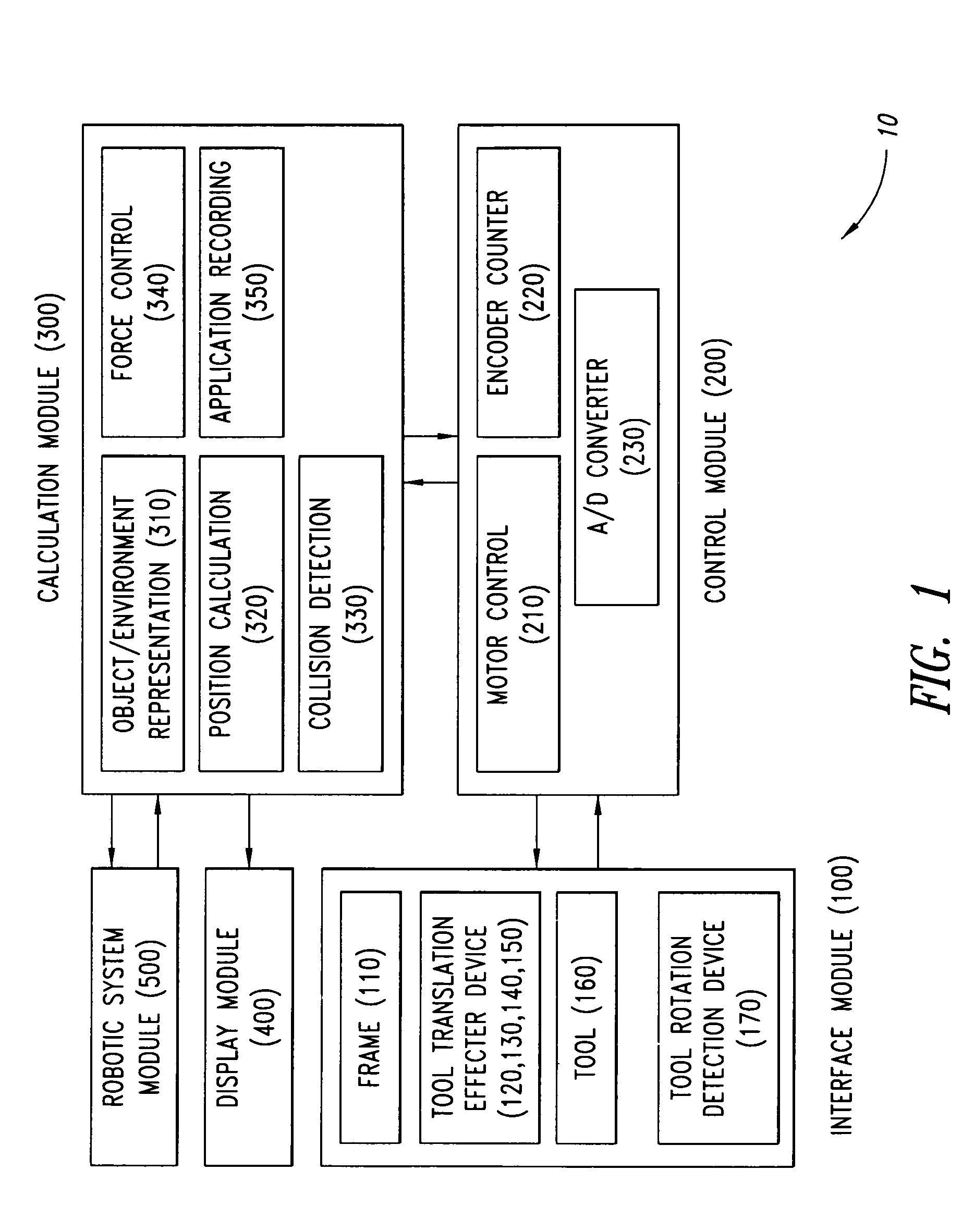

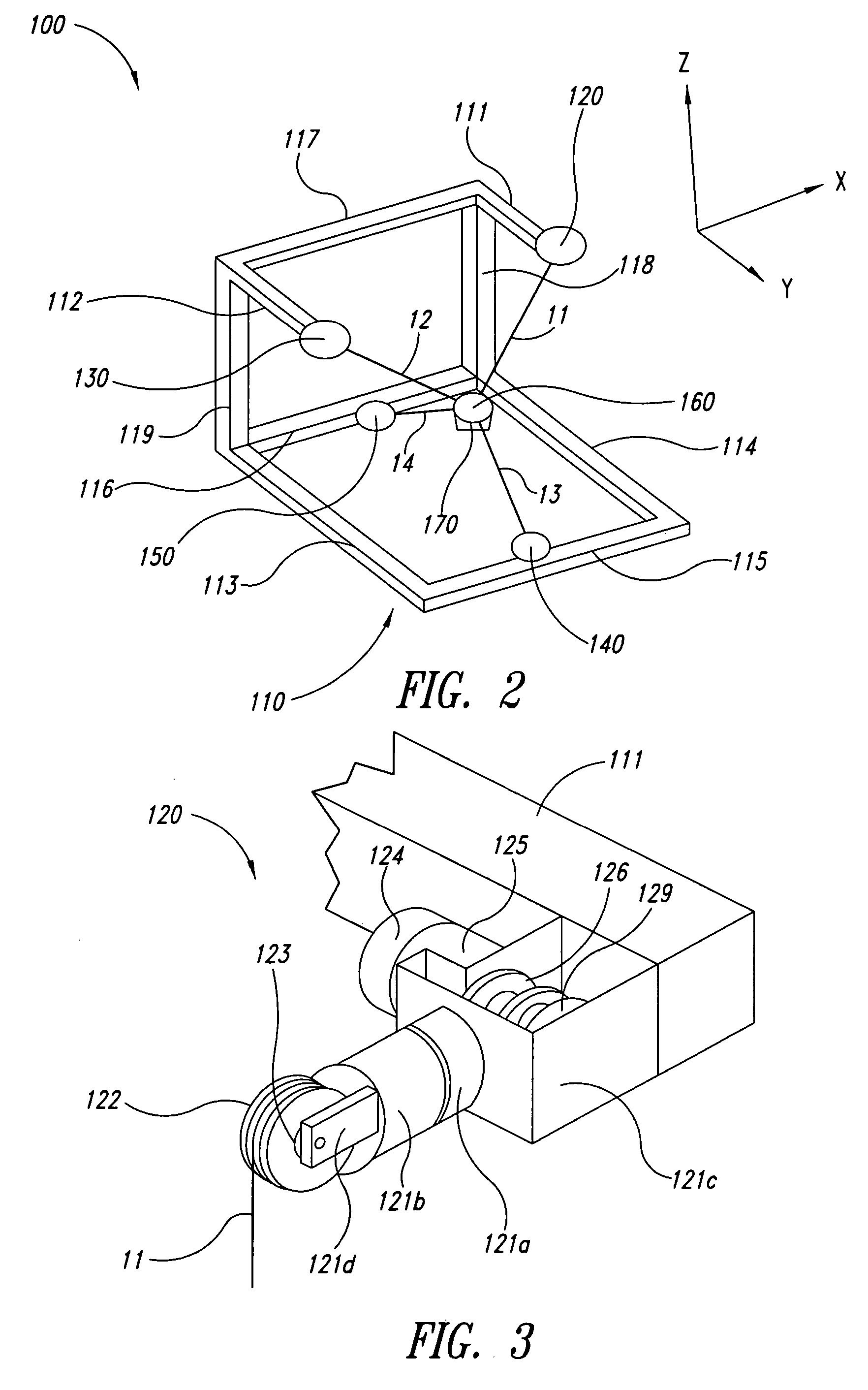

Method, apparatus, and article for force feedback based on tension control and tracking through cables

InactiveUS20050024331A1Maintain positioning accuracyMinimal interventionProgramme-controlled manipulatorGripping headsSensor arrayEngineering

A haptic device for human / computer interface includes a user interface tool coupled via cables to first, second, third, and fourth cable control units, each positioned at a vertex of a tetrahedron. Each of the cable control units includes a spool and an encoder configured to provide a signal corresponding to rotation of the respective spool. The cables are wound onto the spool of a respective one of the cable control units. The encoders provide signals corresponding to rotation of the respective spools to track the length of each cable. As the cables wind onto the spools, variations in spool diameter are compensated for. The absolute length of each cable is determined during initialization by retracting each cable In turn to a zero length position. A sensor array coupled to the tool detects rotation around one or more axes.

Owner:MIMIC TECH

Method, apparatus, and article for force feedback based on tension control and tracking through cables

InactiveUS7880717B2Maintain positioning accuracyMinimal interventionProgramme-controlled manipulatorGripping headsSensor arrayEngineering

A haptic device for human / computer interface includes a user interface tool coupled via cables to first, second, third, and fourth cable control units, each positioned at a vertex of a tetrahedron. Each of the cable control units includes a spool and an encoder configured to provide a signal corresponding to rotation of the respective spool. The cables are wound onto the spool of a respective one of the cable control units. The encoders provide signals corresponding to rotation of the respective spools to track the length of each cable. As the cables wind onto the spools, variations in spool diameter are compensated for. The absolute length of each cable is determined during initialization by retracting each cable In turn to a zero length position. A sensor array coupled to the tool detects rotation around one or more axes.

Owner:MIMIC TECH

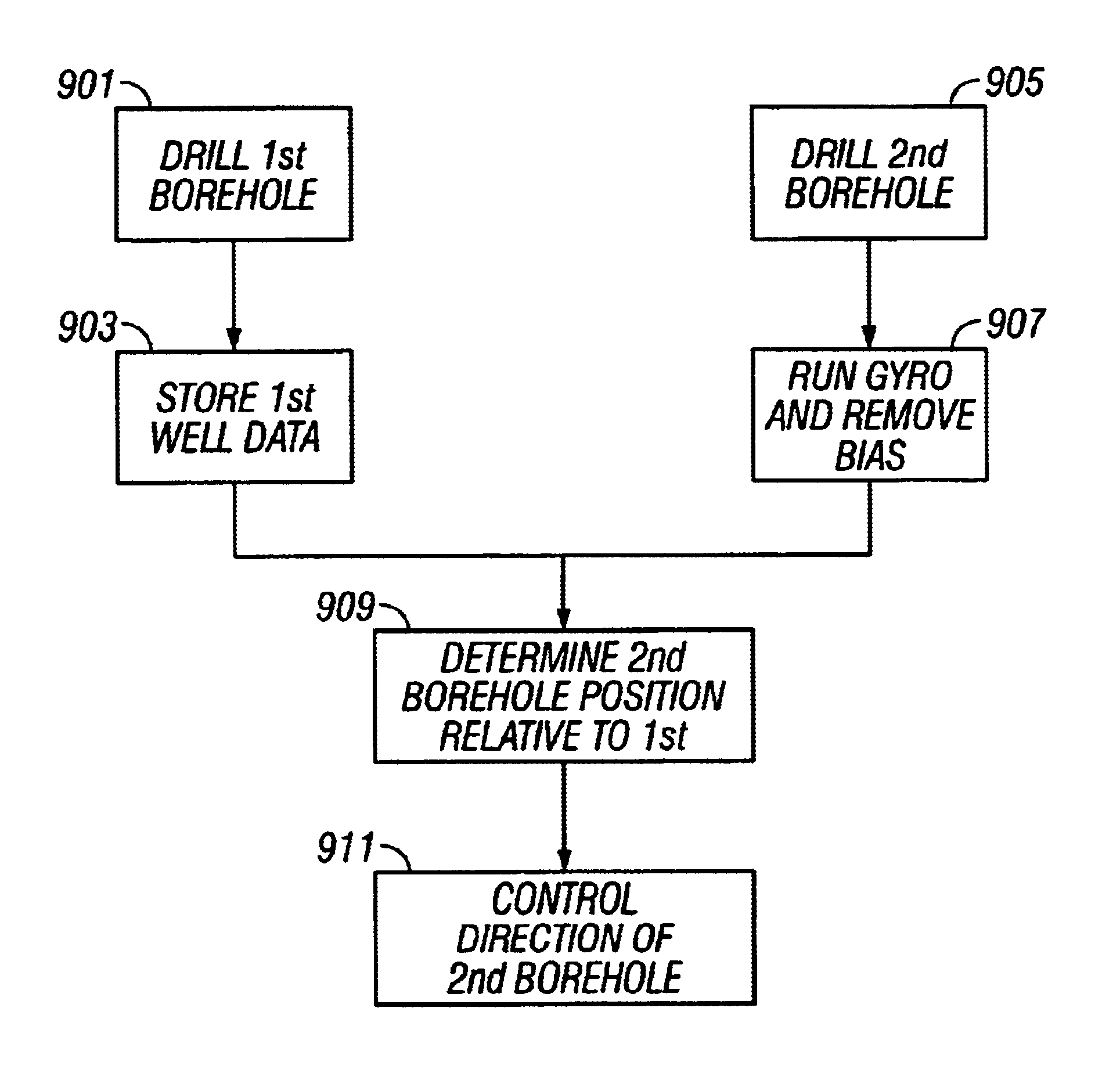

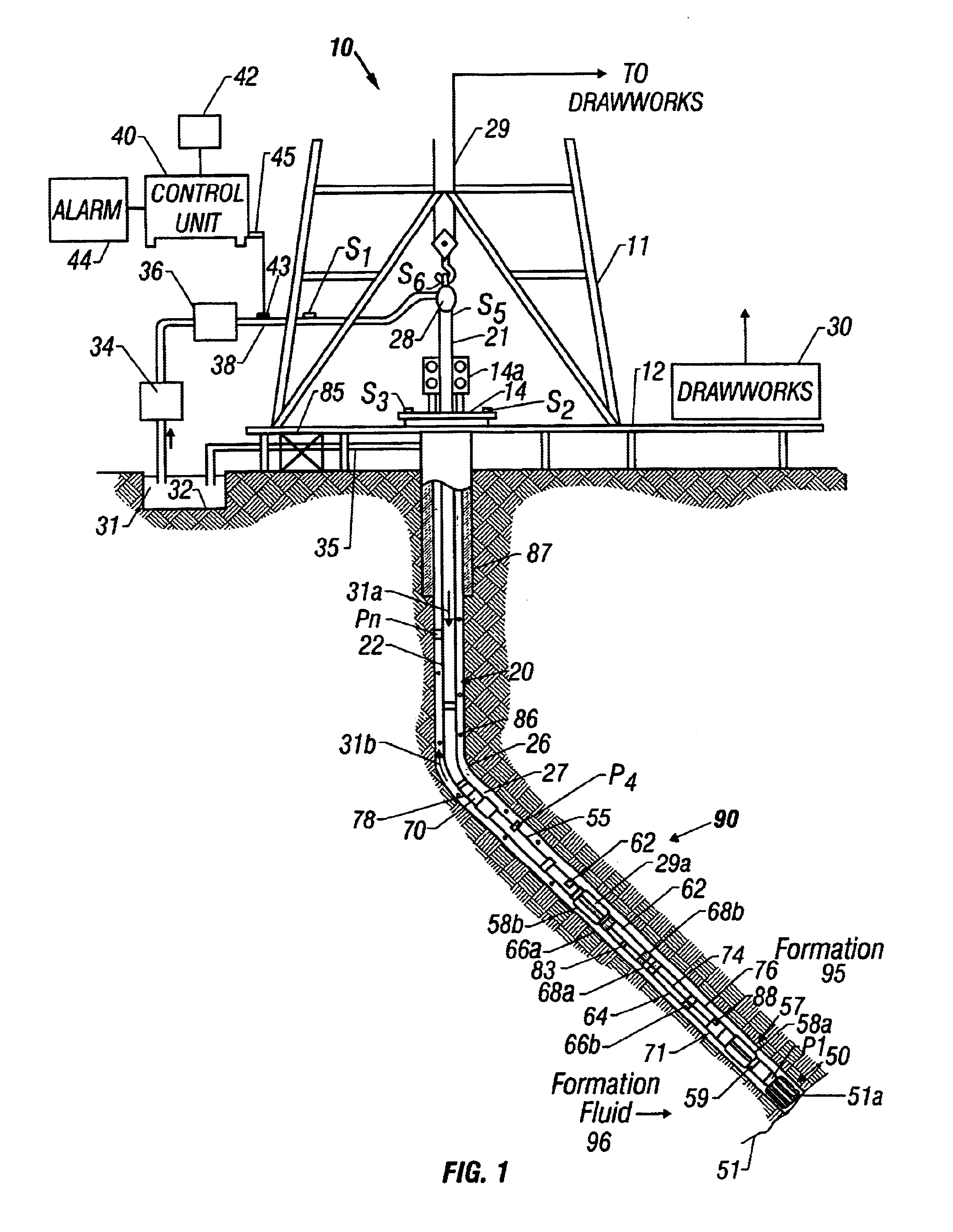

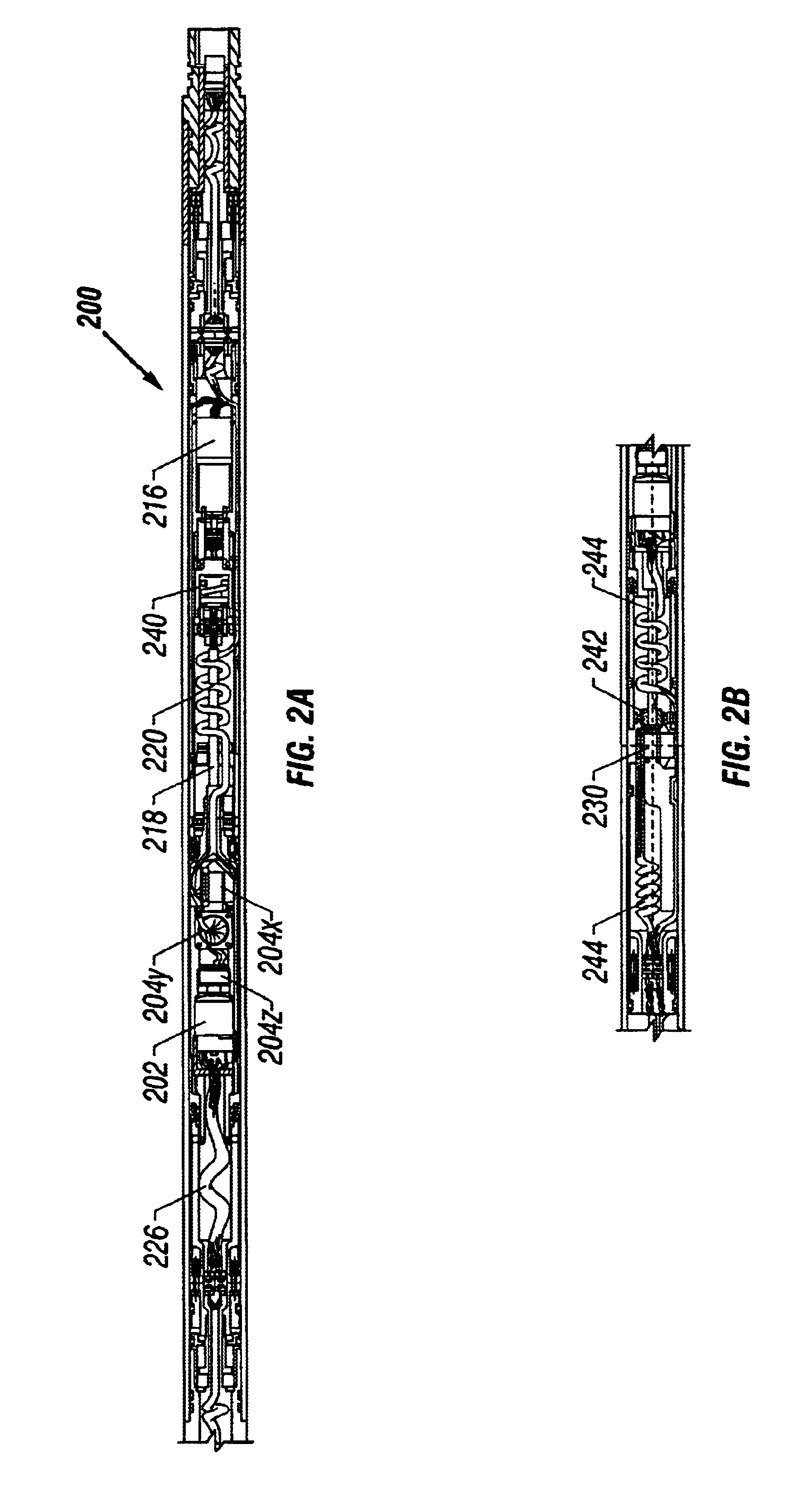

Use of MWD assembly for multiple-well drilling

InactiveUS6842699B2Maintain positioning accuracyElectric/magnetic detection for well-loggingSurveyGyroscopeAccelerometer

This invention provides a measurement-while-drilling (MWD) downhole assembly for use in drilling boreholes which utilizes gyroscopes, magnetometers and accelerometers for determining the borehole inclination and azimuth during the drilling of the borehole. With the present invention, a secondary borehole for secondary recovery operations may be drilled with accuracy in proximity to a cased producing borehole.

Owner:BAKER HUGHES INC

Indoor positioning method based on signal receiving strength indicator correlation

ActiveCN104302000AHigh precisionResolve differencesBeacon systems using radio wavesLocation information based servicePattern recognitionComputer vision

An indoor positioning method based on signal receiving strength indicator correlation includes the steps that correlation transformation of the signal receiving strength indicator is performed, and similarity calculation and positioning matching are performed on correlation fingerprint data. Through the technical scheme, the difference between terminals in a crowdsourcing mode can be overcome, and the stability and the positioning accuracy of an indoor positioning system are kept.

Owner:SHANGHAI JIAO TONG UNIV

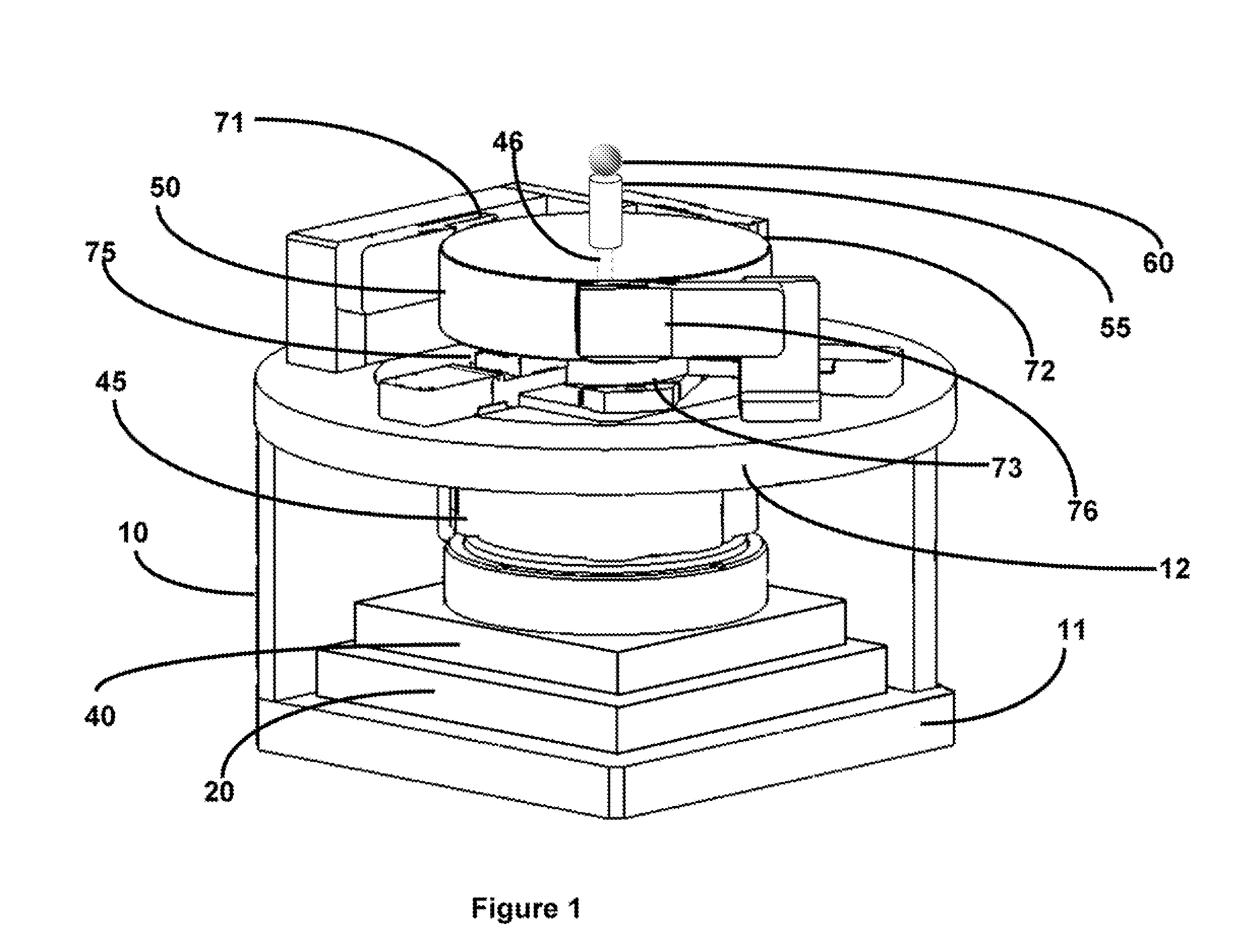

Five Axis Compensated Rotating Stage

ActiveUS20080309276A1Precise positioningMaintain positioning accuracyDC motor speed/torque controlPiezoelectric/electrostriction/magnetostriction machinesRotary stageActuator

A rotating stage assembly performs high precision rotational angle and position error correction by continuous sensing and correcting motor stage assembly errors. It performs these corrections, to adjust for motor environmental and operational errors by sensing and correcting using five sensors placed to measure the adjustments of five corresponding actuators, which adjust the entire motor rotating stage and rotary motor assembly relative to a reference frame.

Owner:CARL ZEISS X RAY MICROSCOPY

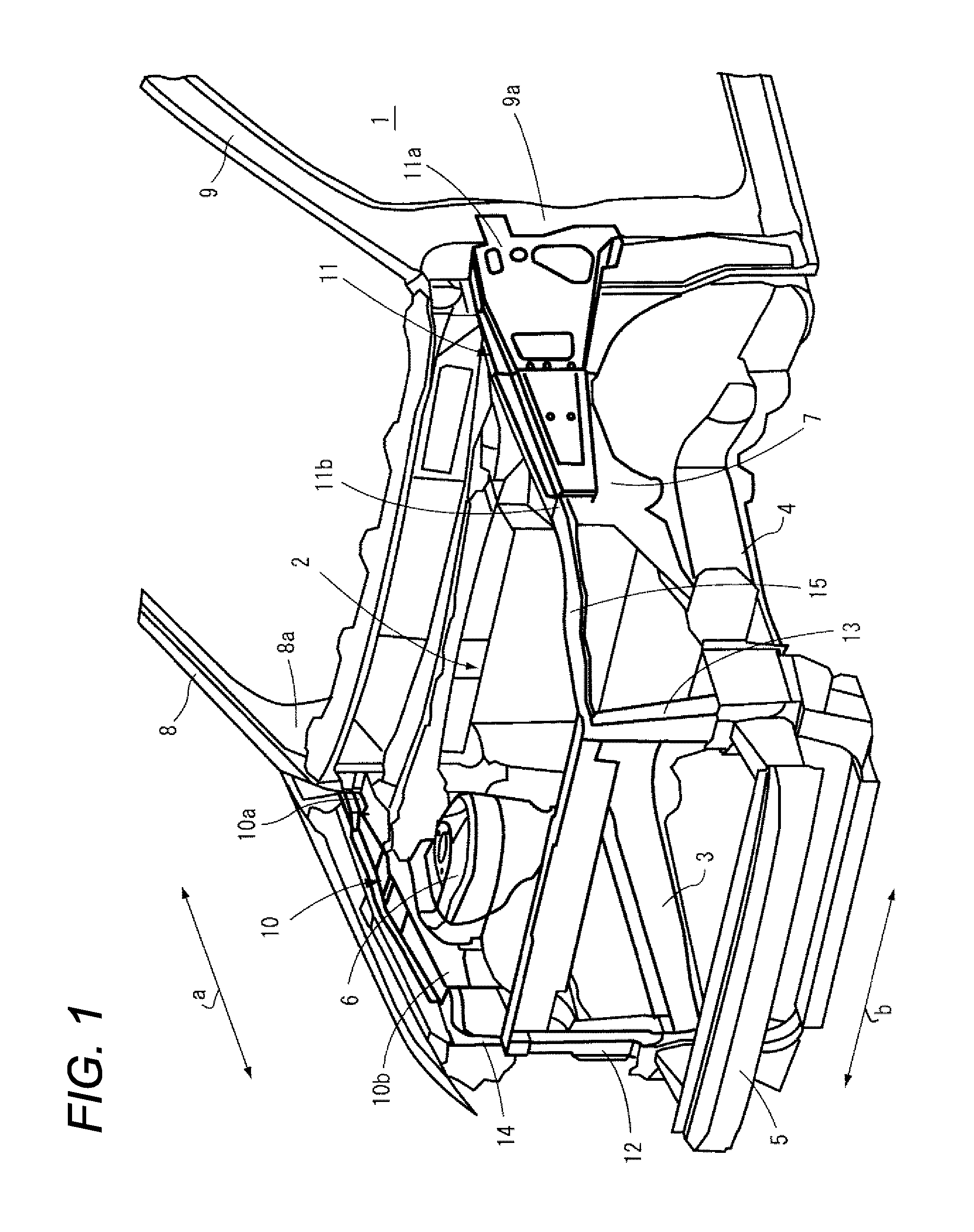

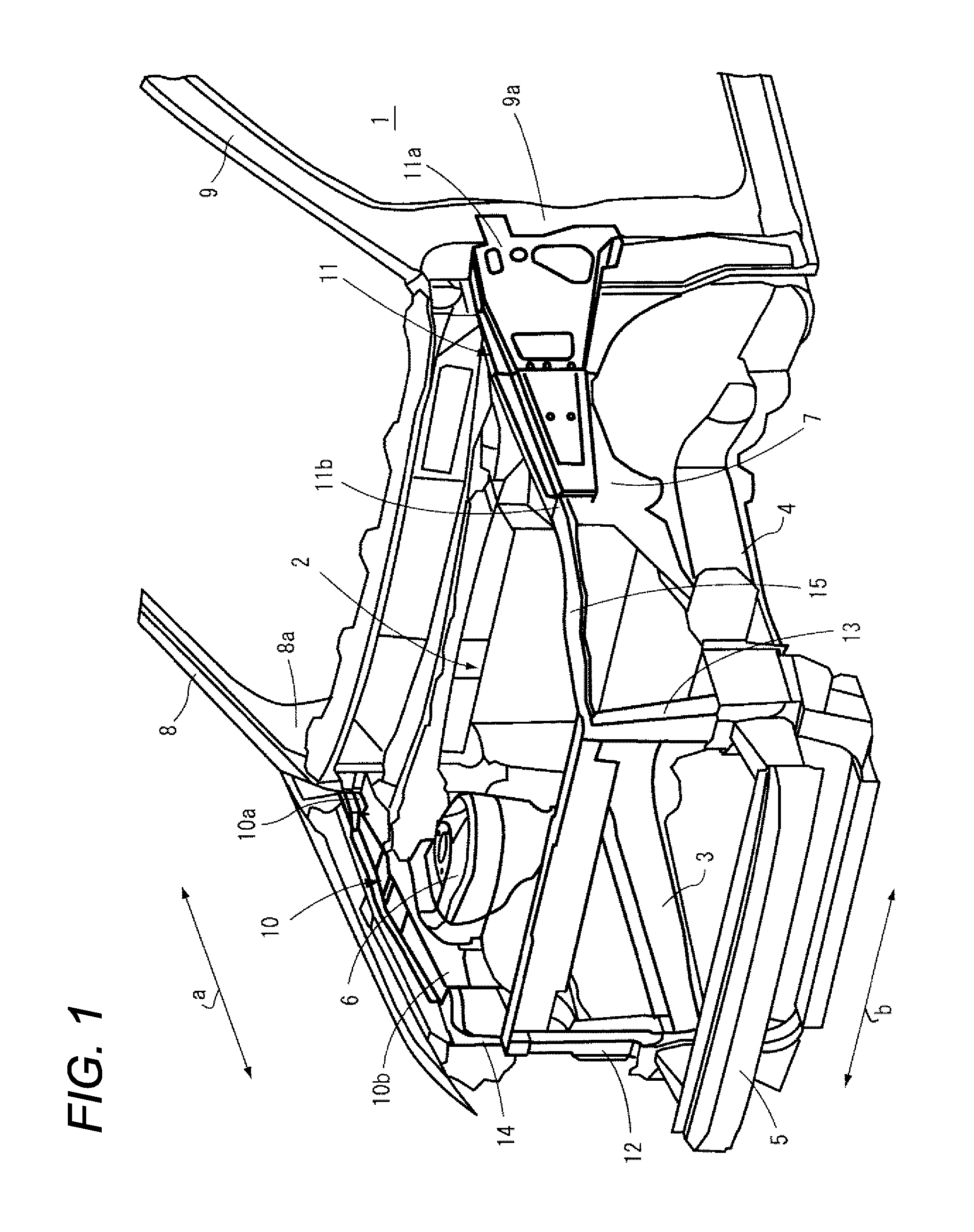

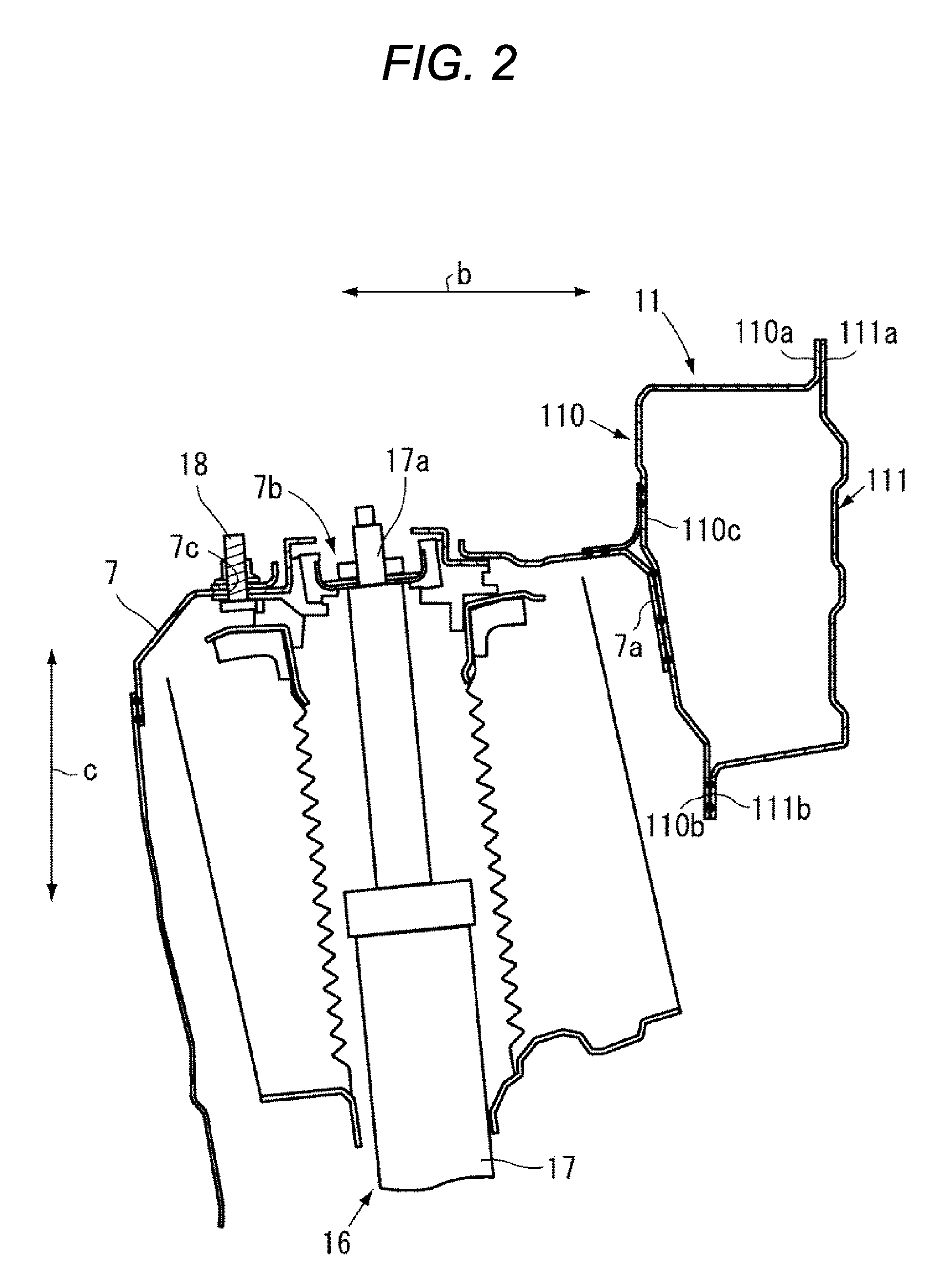

Front part body structure of vehicle

Owner:MITSUBISHI MOTORS CORP

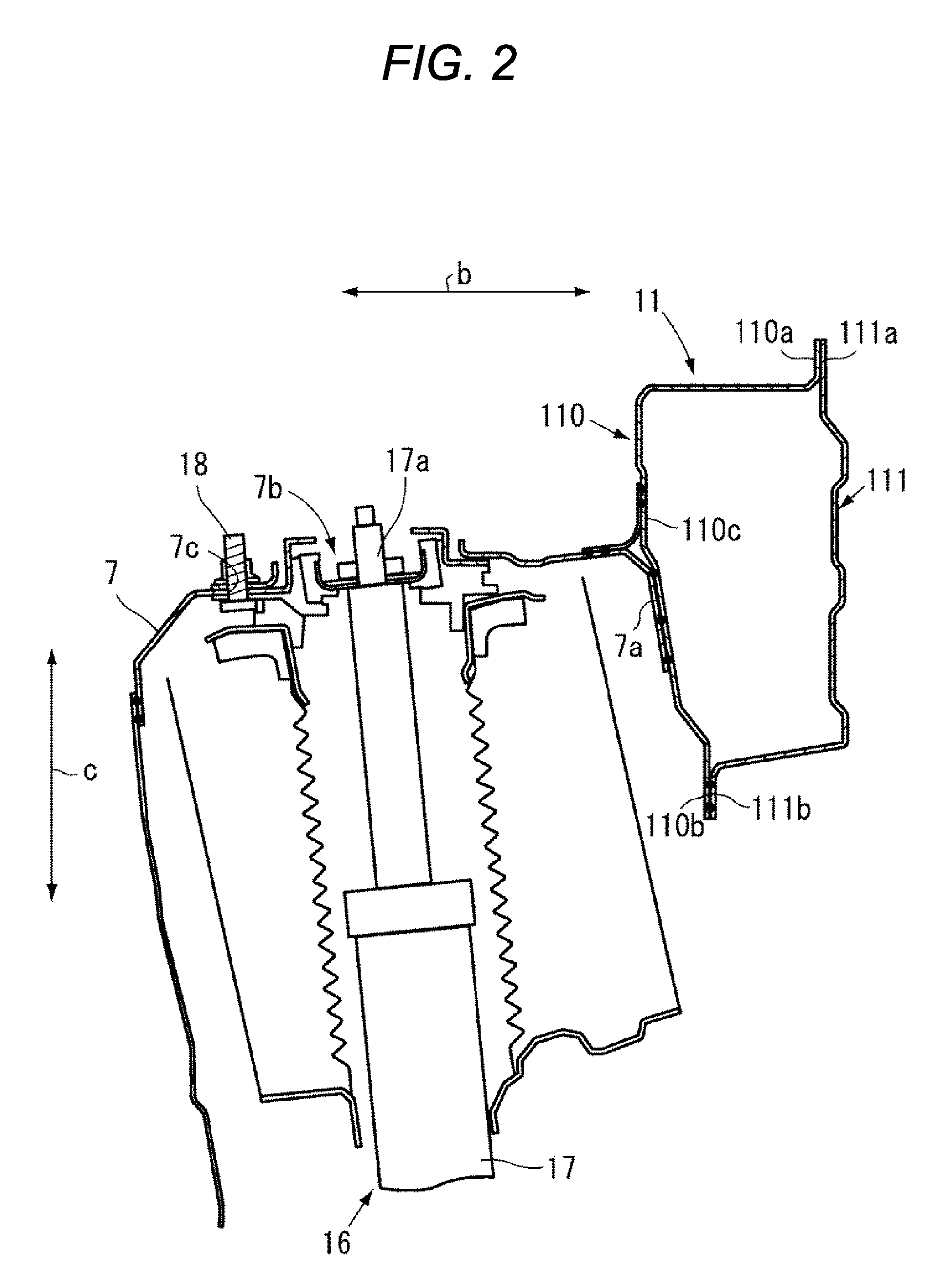

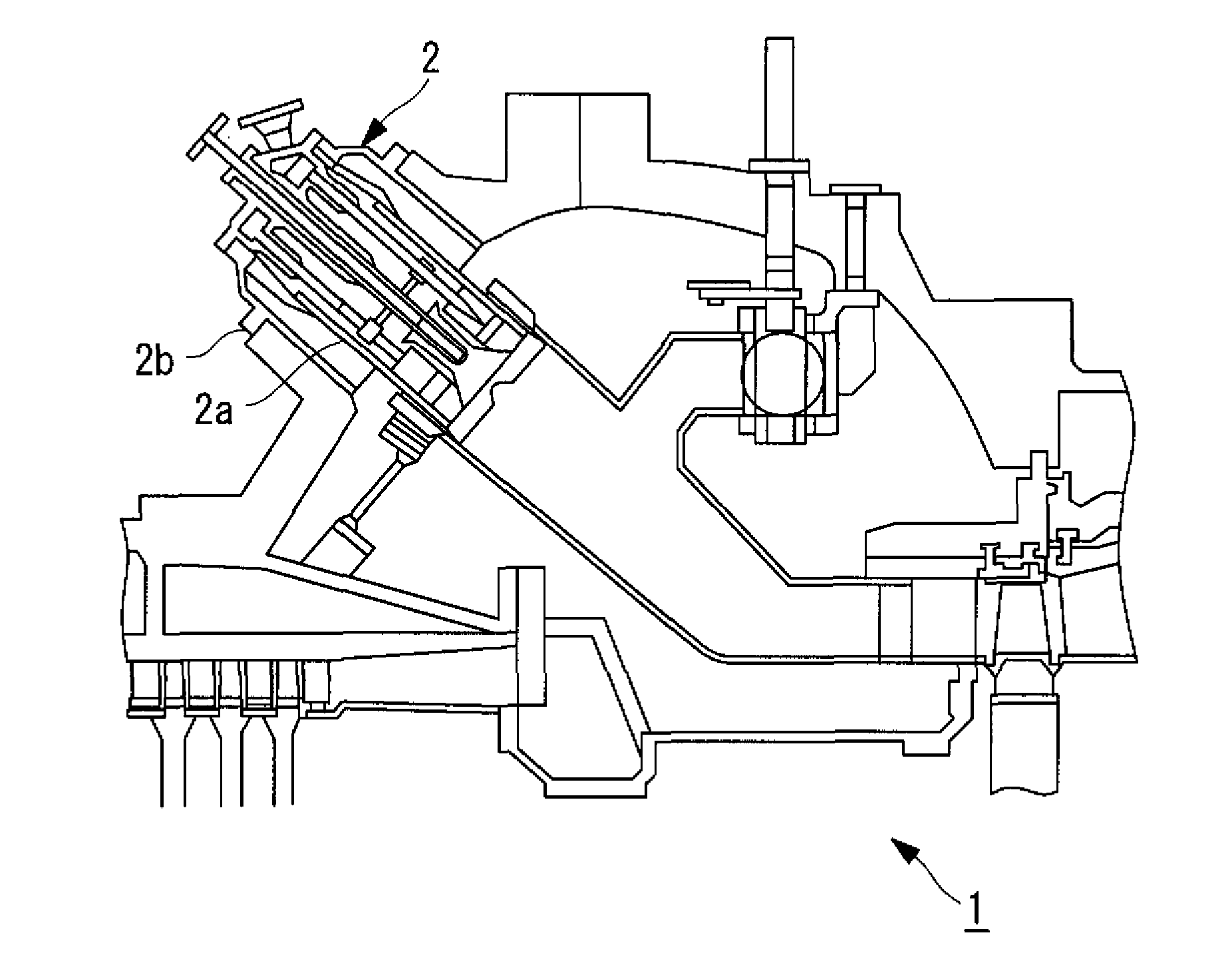

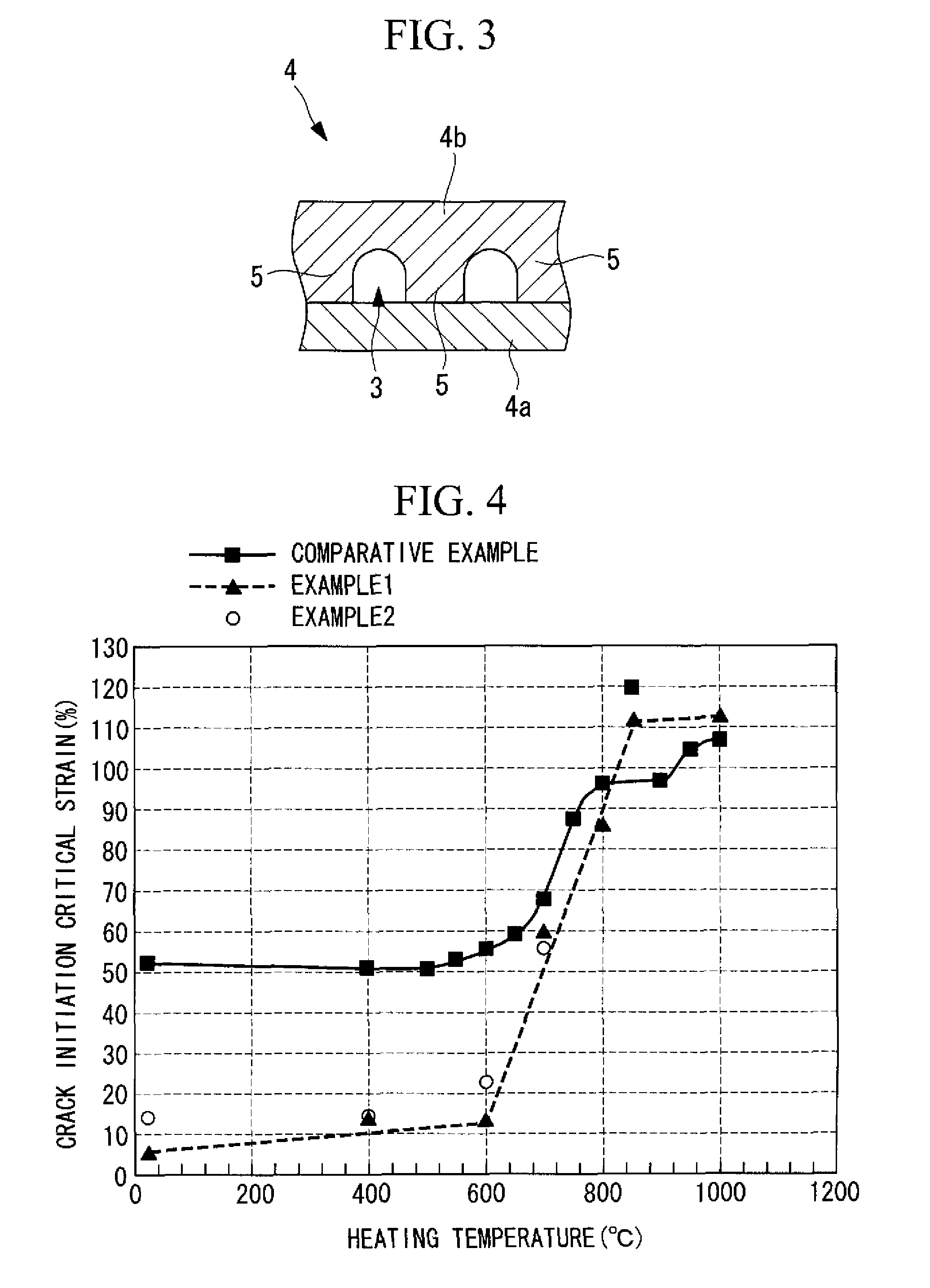

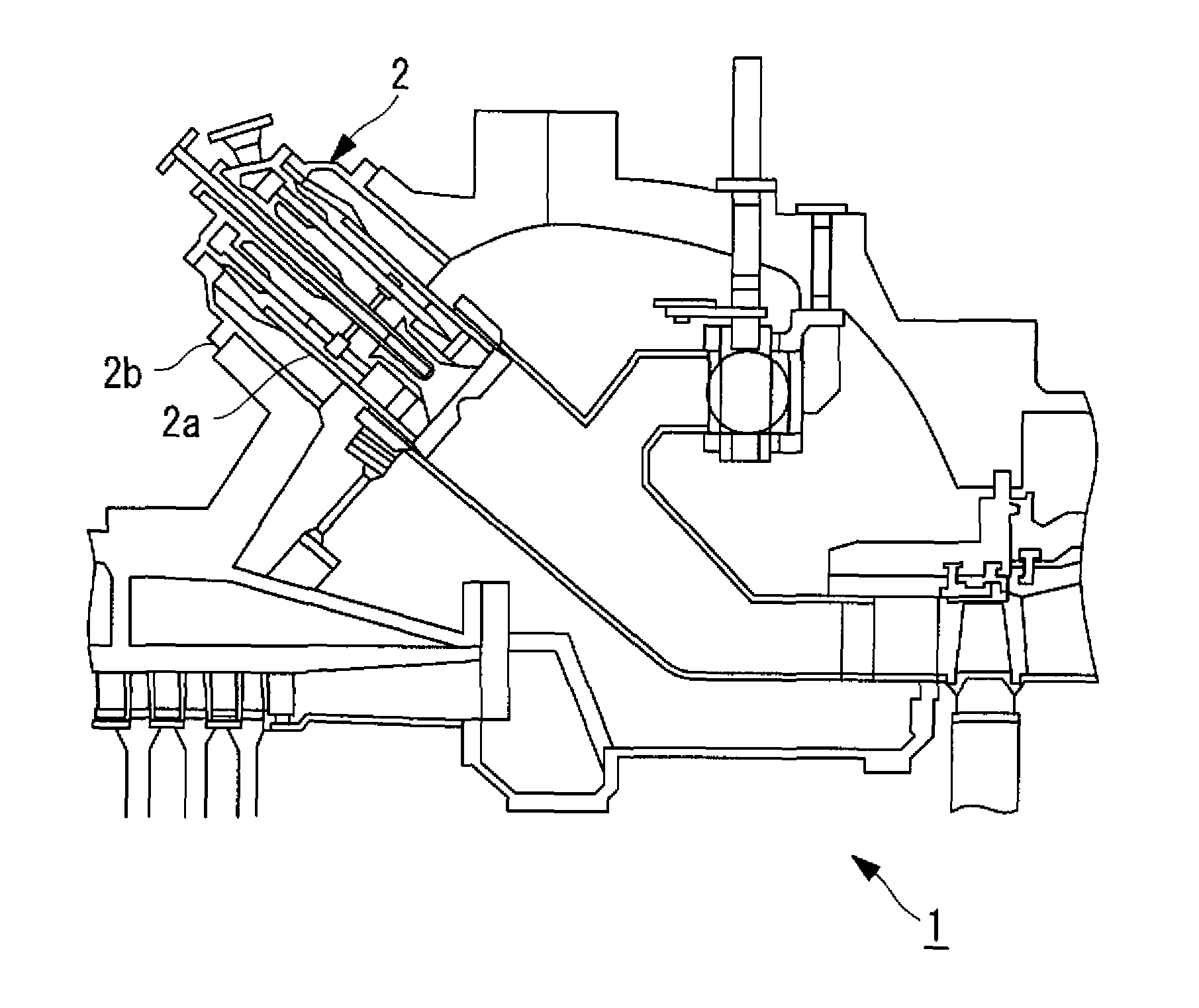

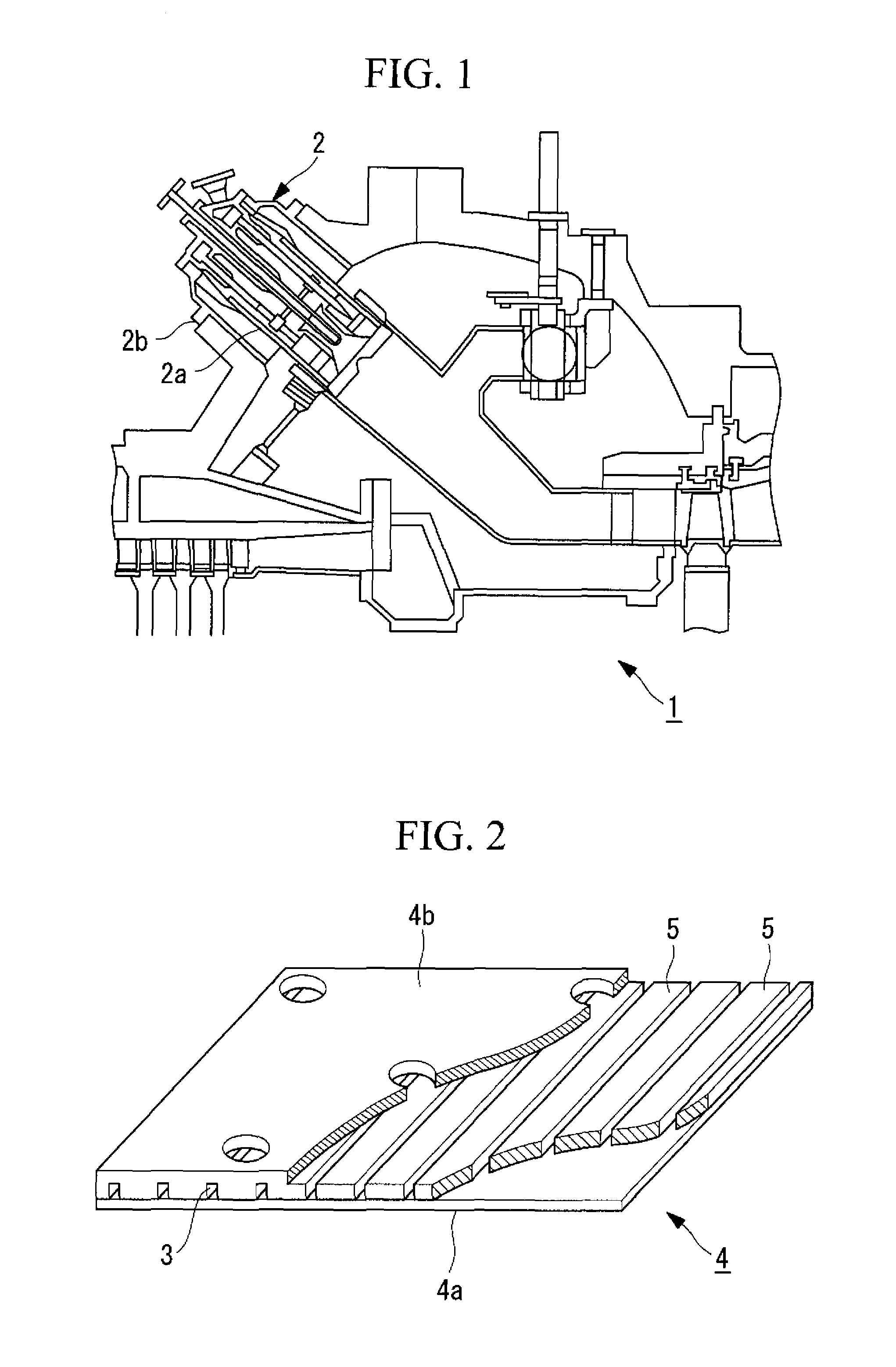

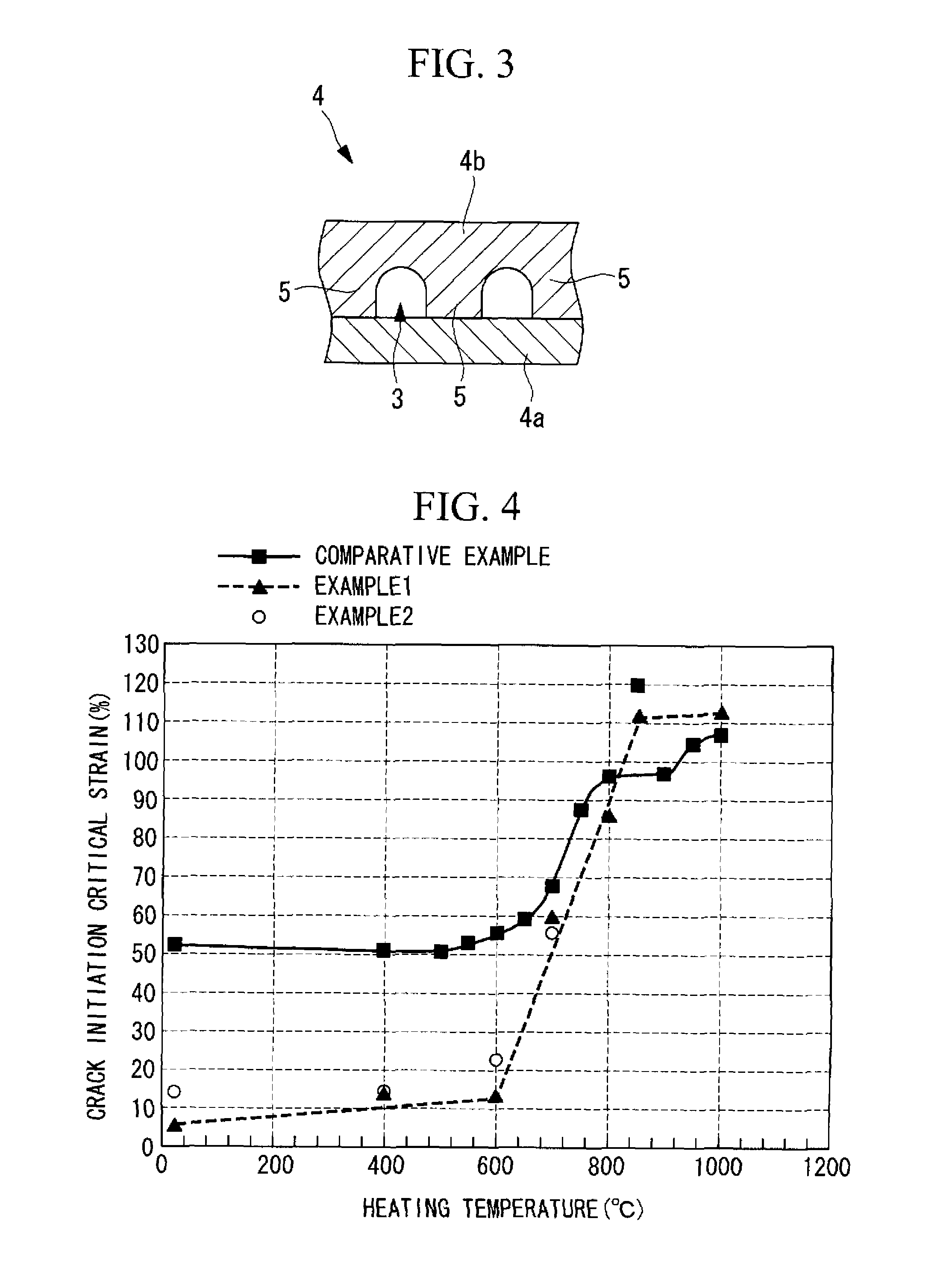

Process for producing combustor structural member, and combustor structural member, combustor for gas turbine and gas turbine

ActiveUS20100300115A1Maintain positioning accuracyNo crackContinuous combustion chamberMetal-working apparatusGas turbinesEngineering

A process for producing a combustor structural member, the process comprising a plate-like assembly formation step of brazing a first plate-like member formed from a heat-resistant alloy, and a second plate-like member formed from a heat-resistant alloy and having a plurality of fins on the surface, with the second plate-like member positioned with the fins facing the first plate-like member, by interposing a brazing filler metal comprising a melting point lowering element between the two plate-like members, thereby forming a plate-like assembly, a press molding step of press molding the plate-like assembly to form a combustor structural member of the desired shape, a strain location identification step of identifying, in accordance with the shape of the combustor structural member, strain locations where the strain generated during the press molding step exceeds a predetermined value, a localized heating step of performing localized heating of the locations within the plate-like assembly corresponding with the strain locations identified in the strain location identification step, and a cold press molding step, which is performed as the above press molding step and comprises subjecting the plate-like assembly to cold press molding with the temperature of the heated locations corresponding with the strain locations maintained at a desired temperature.

Owner:MITSUBISHI POWER LTD

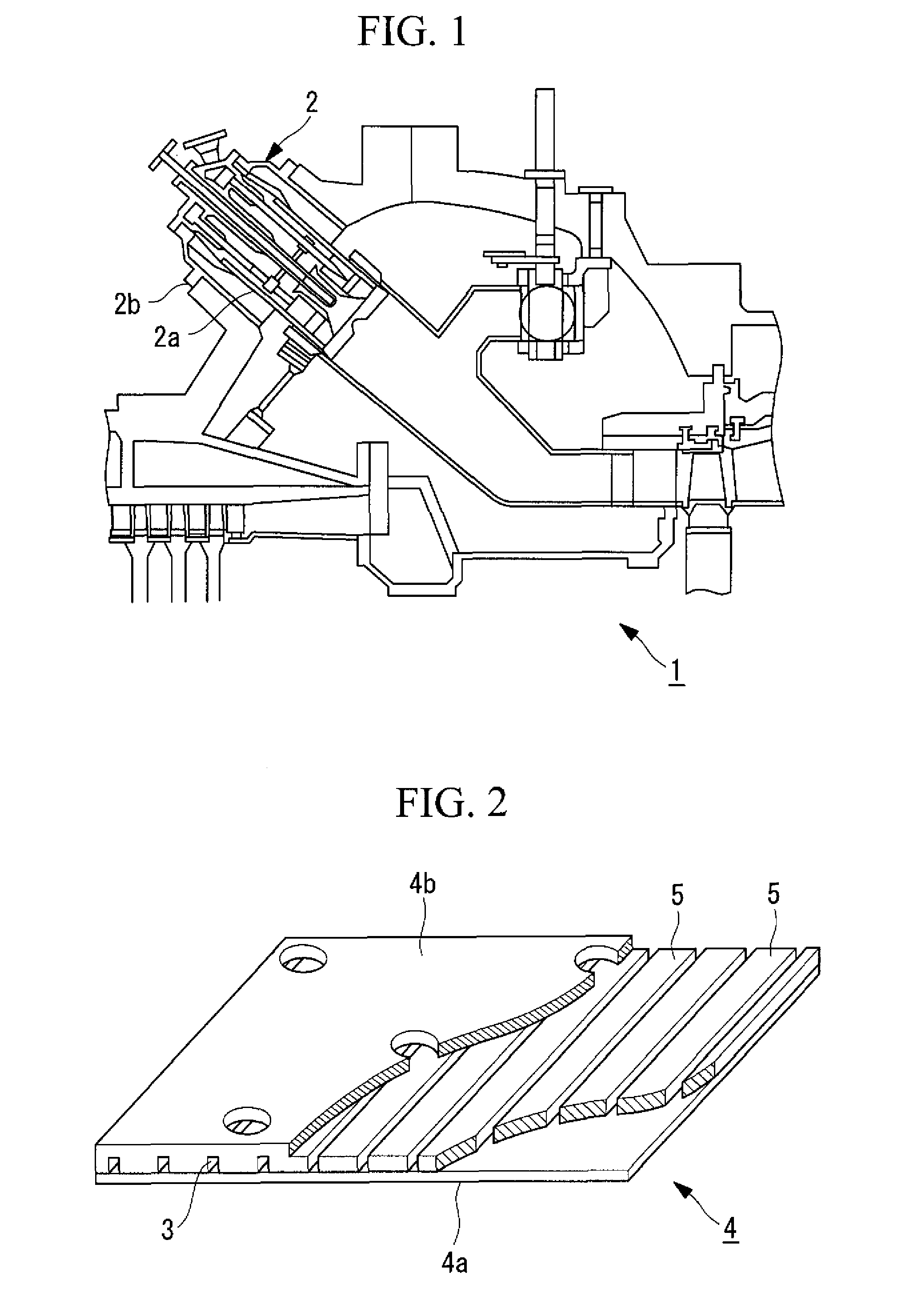

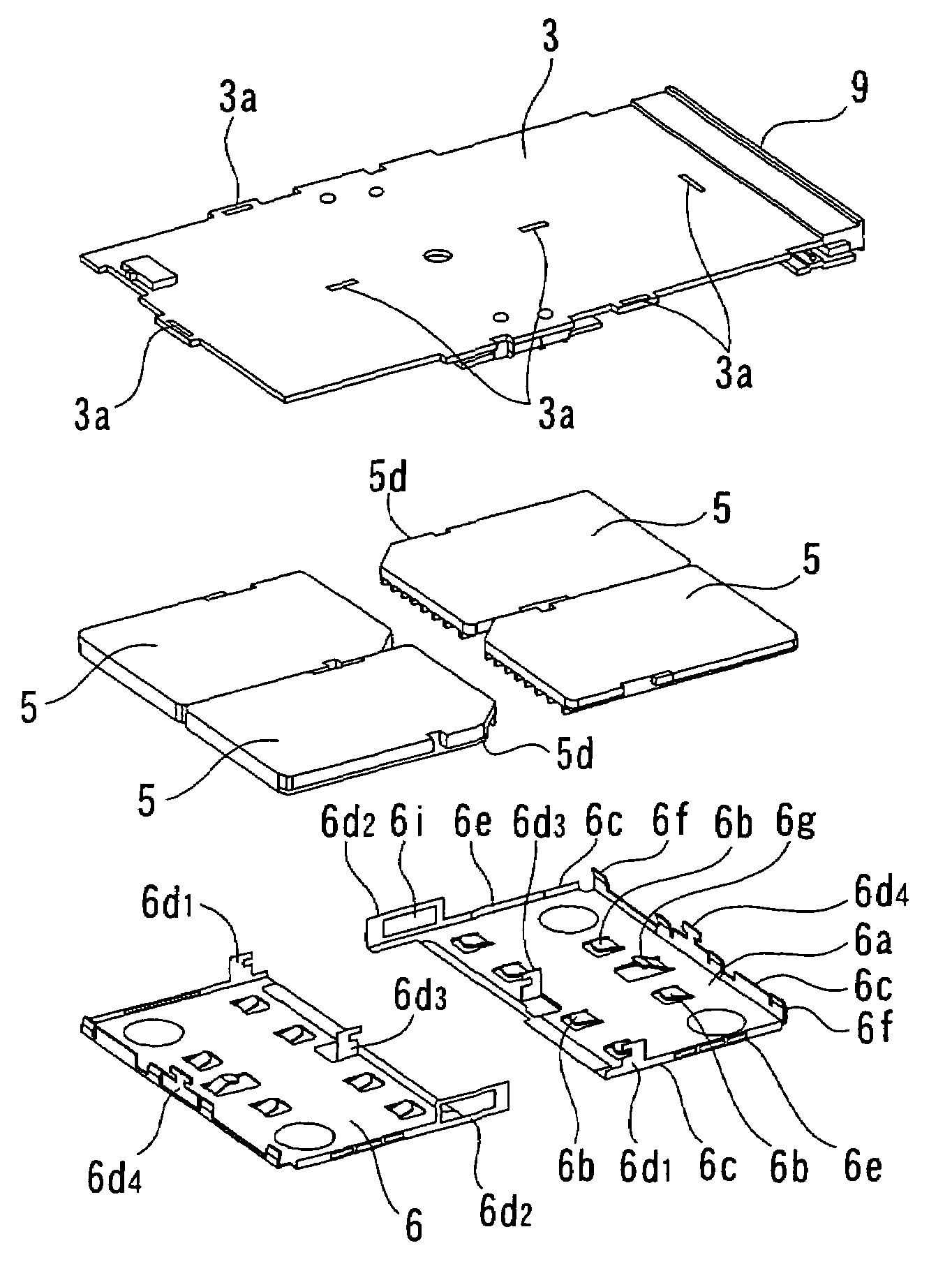

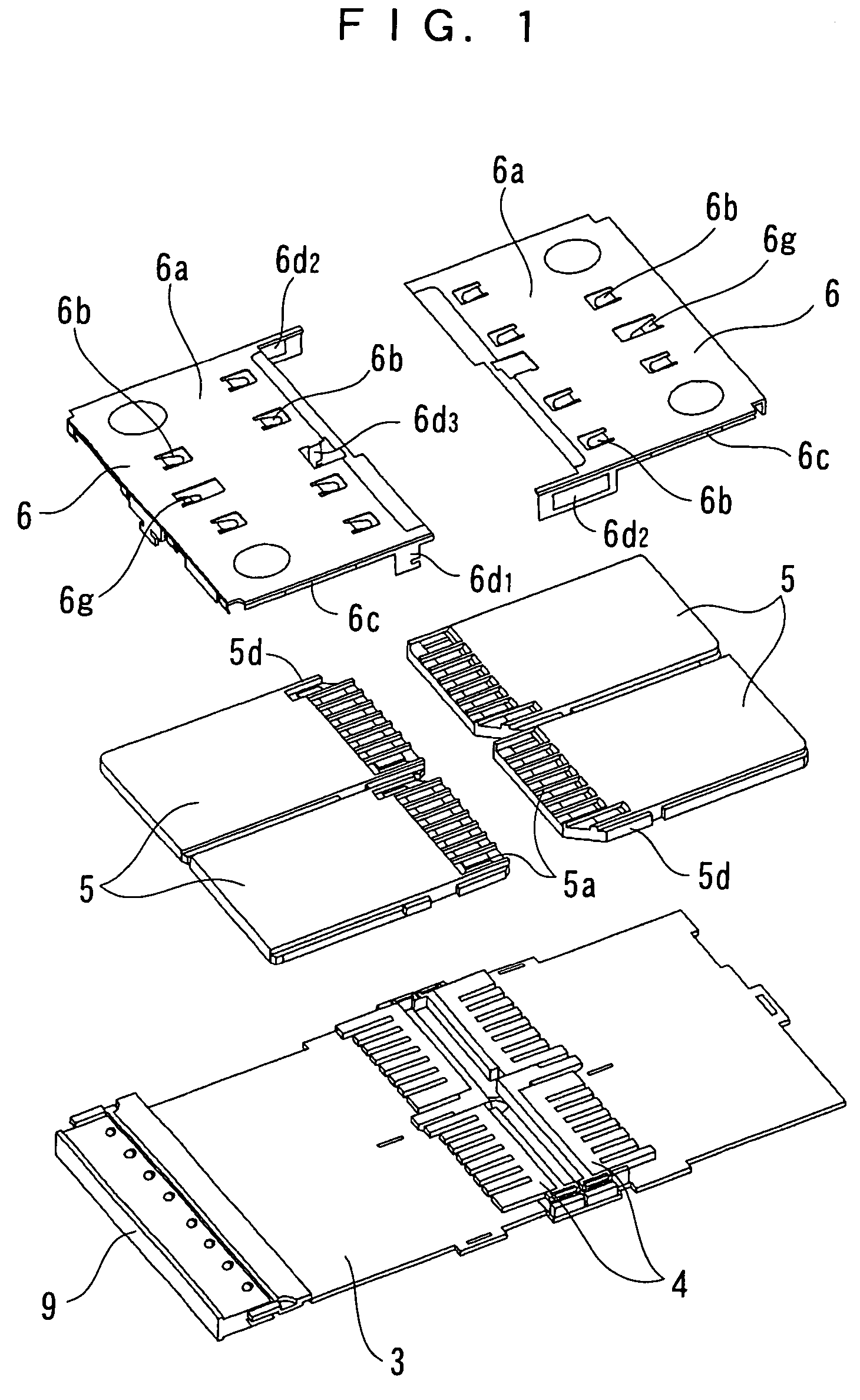

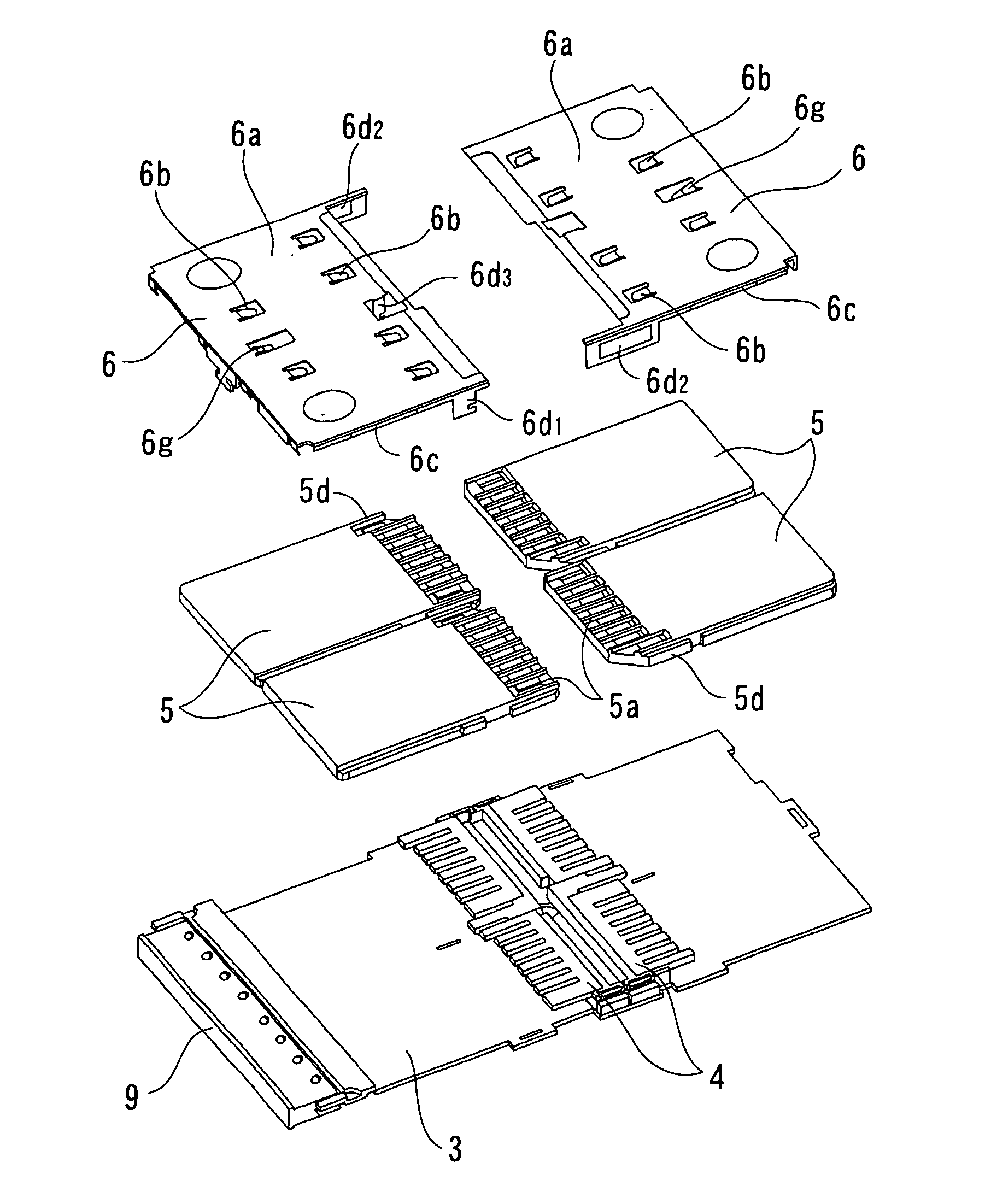

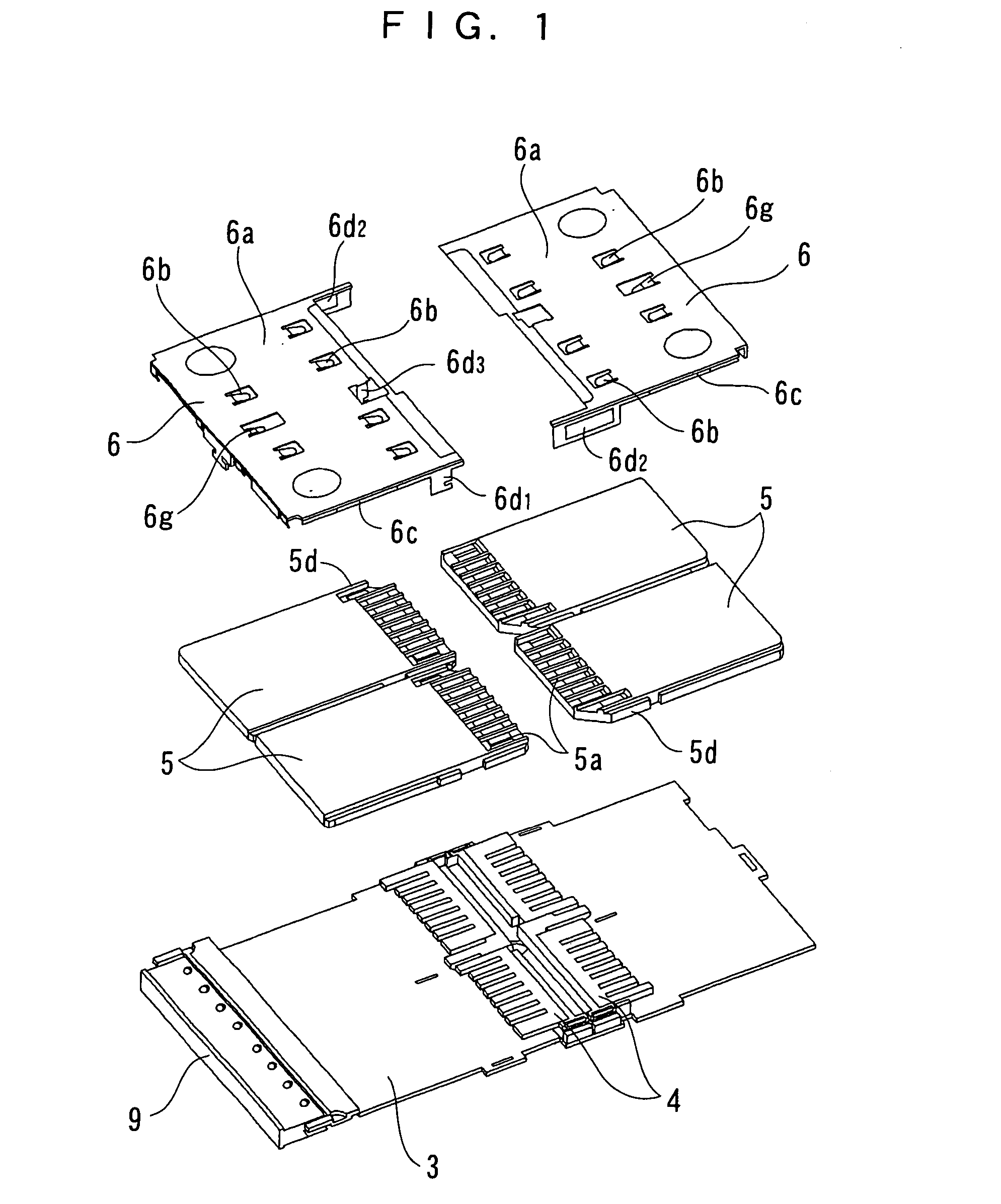

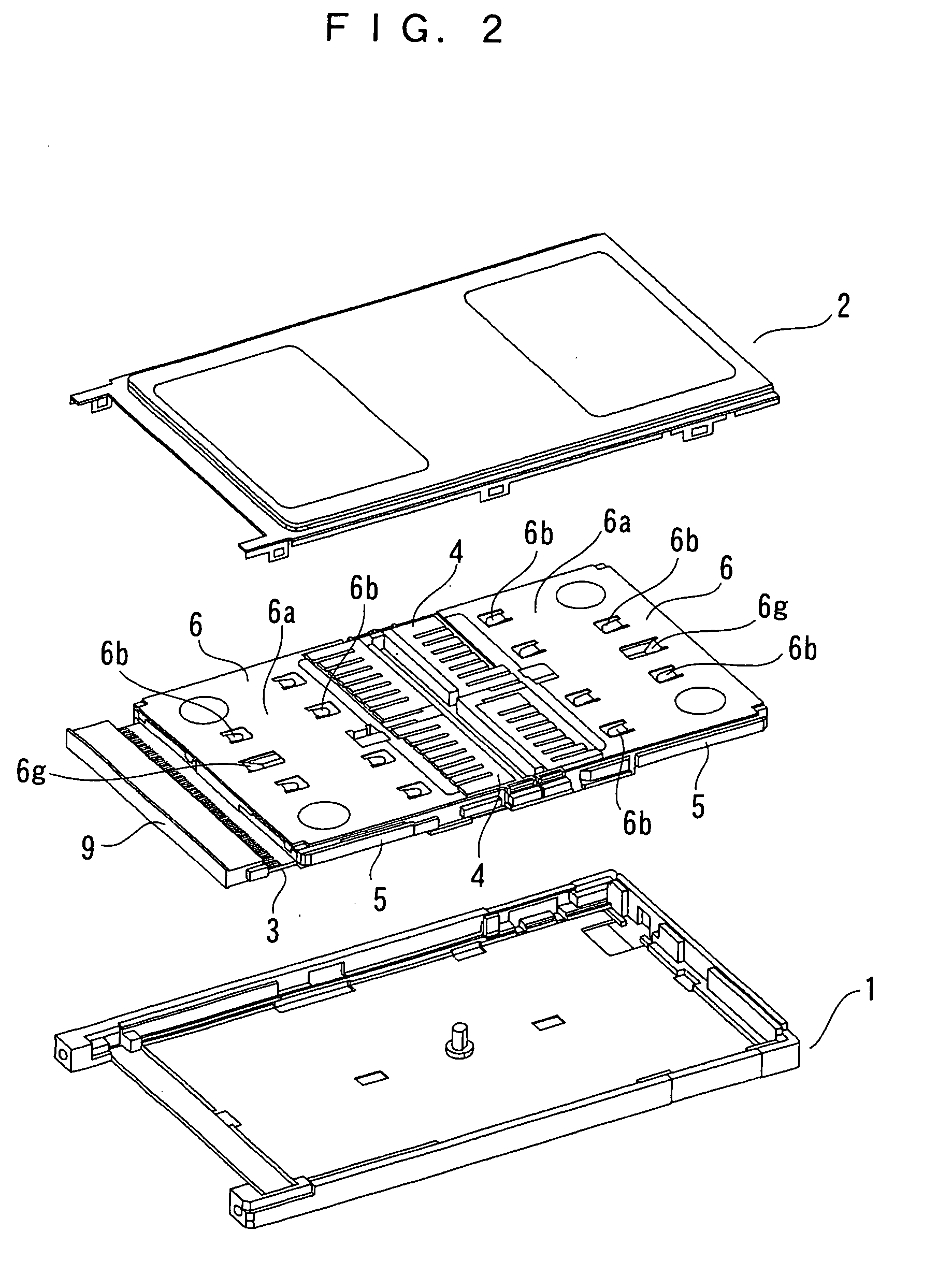

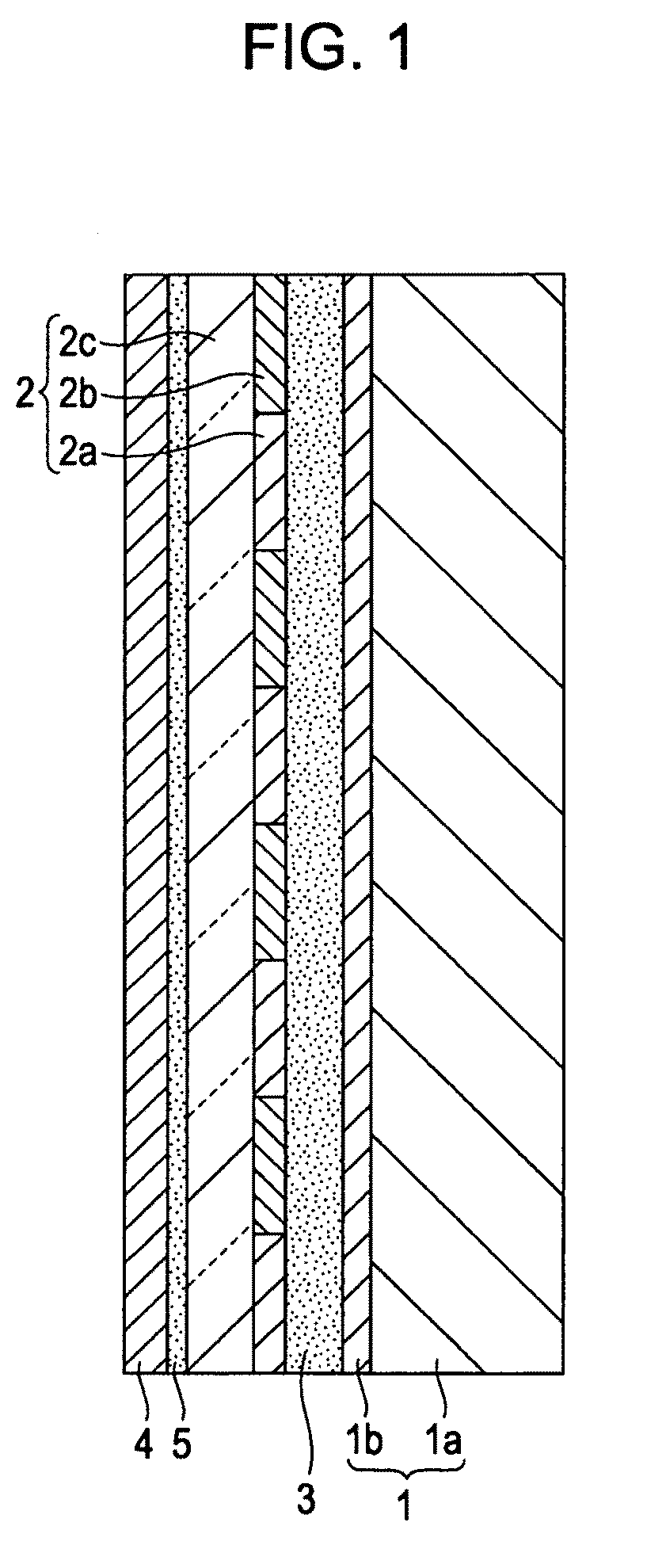

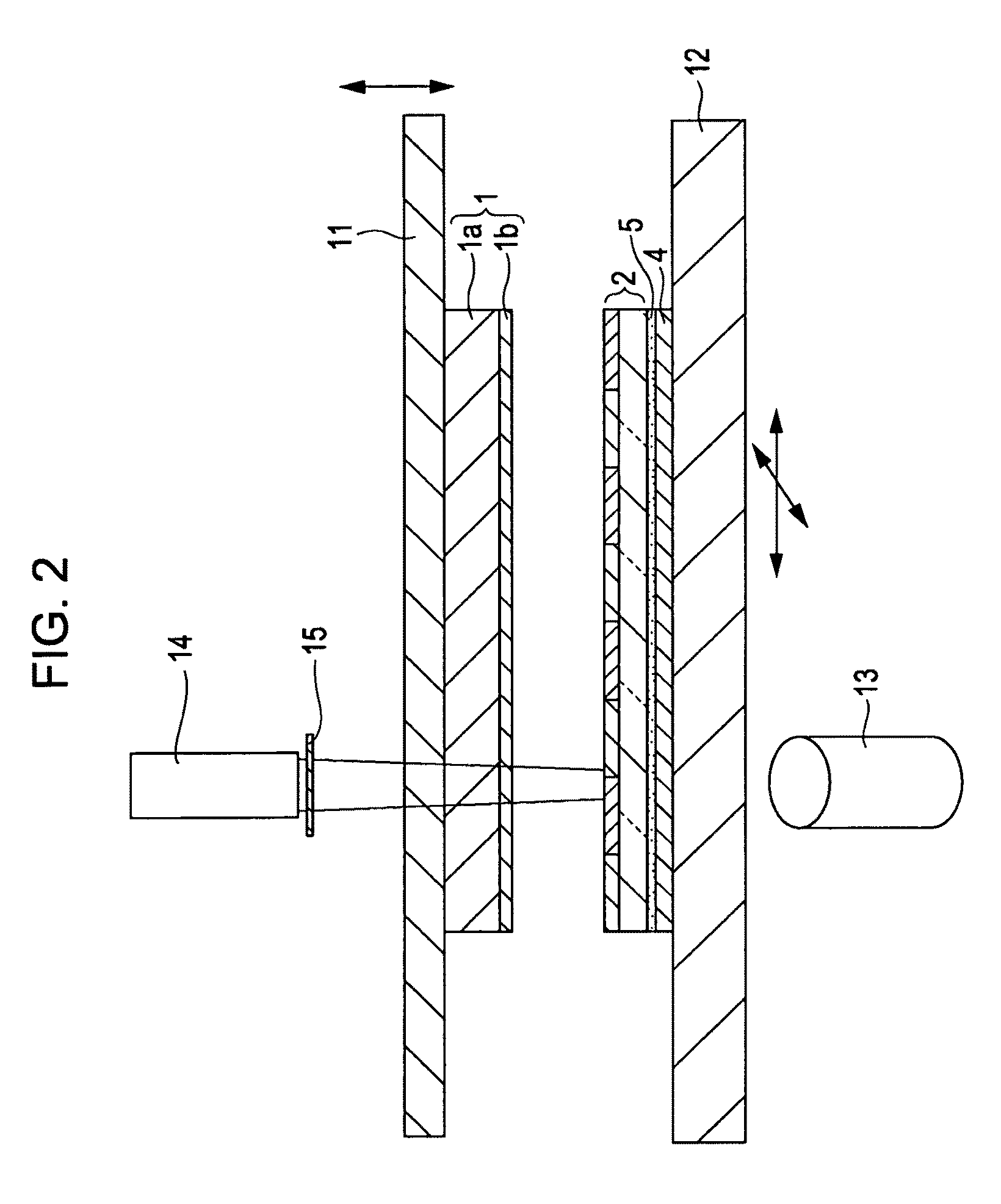

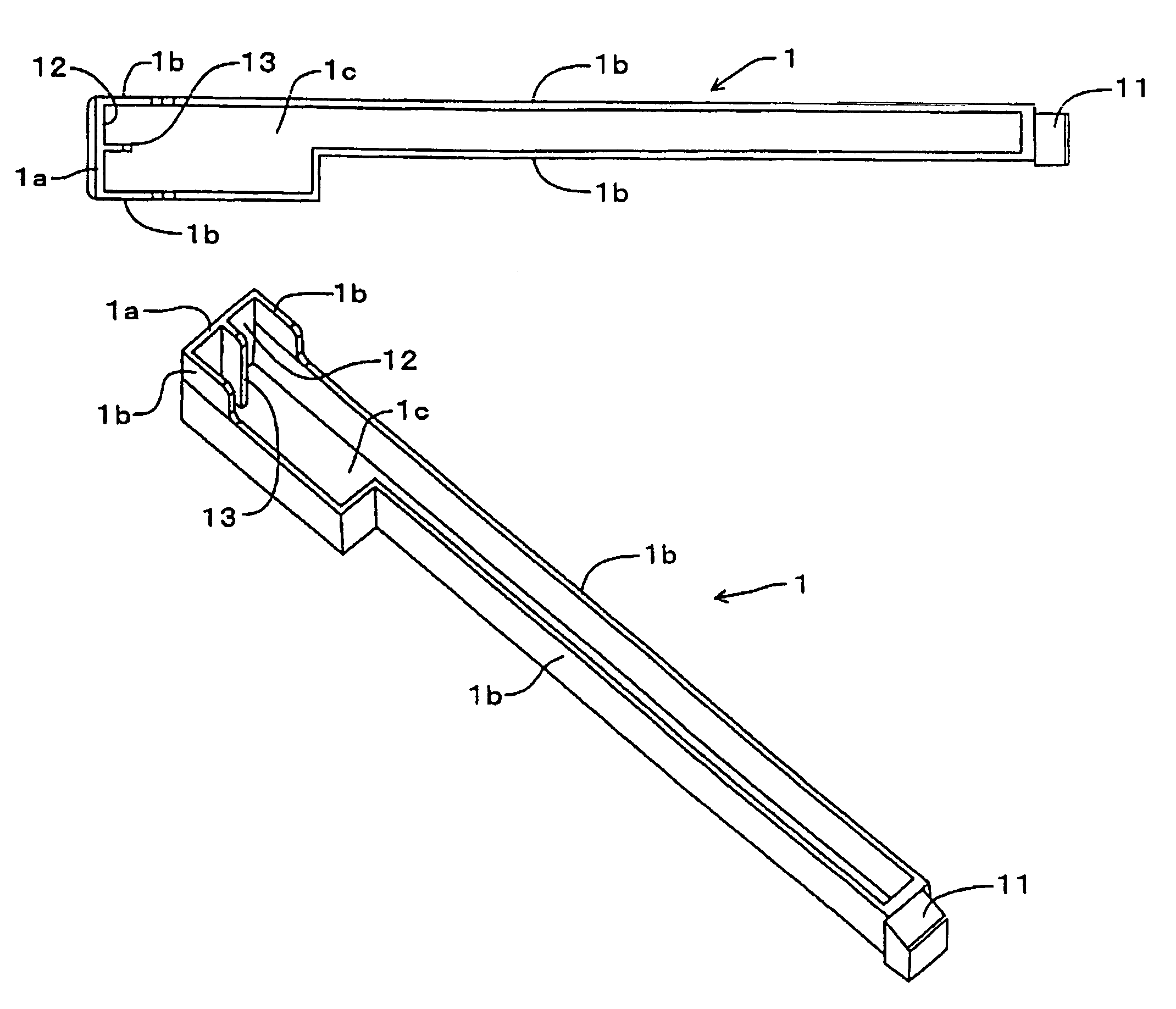

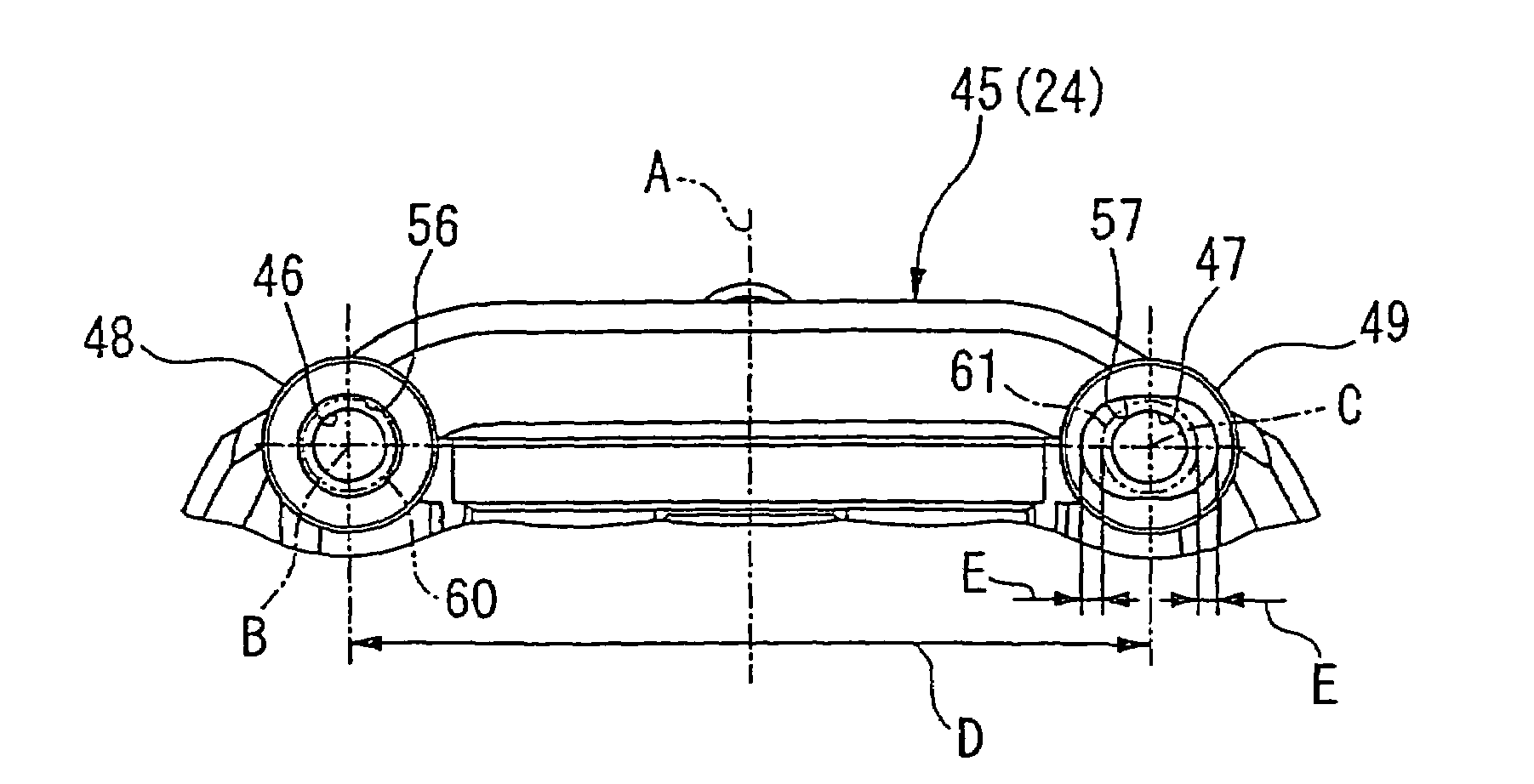

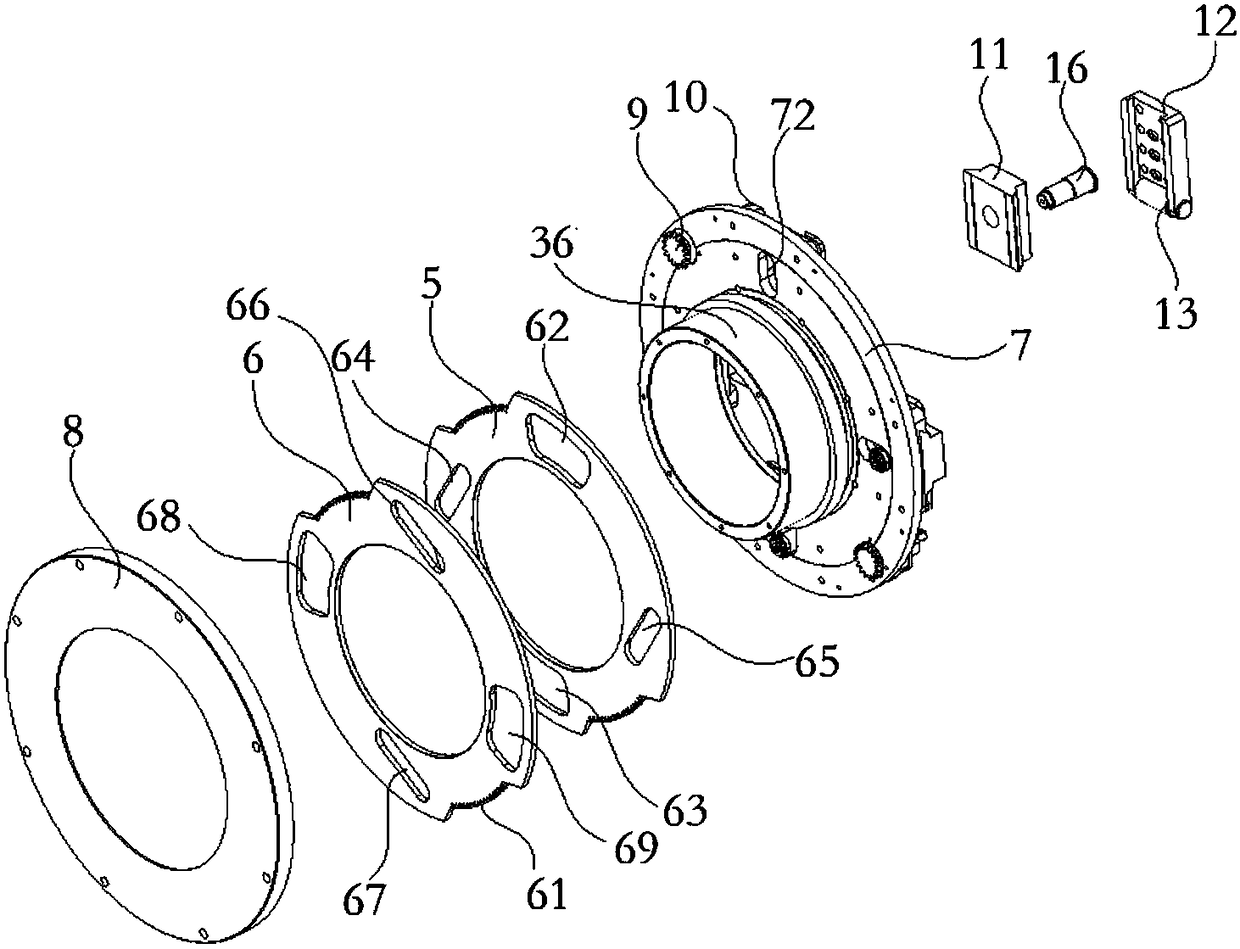

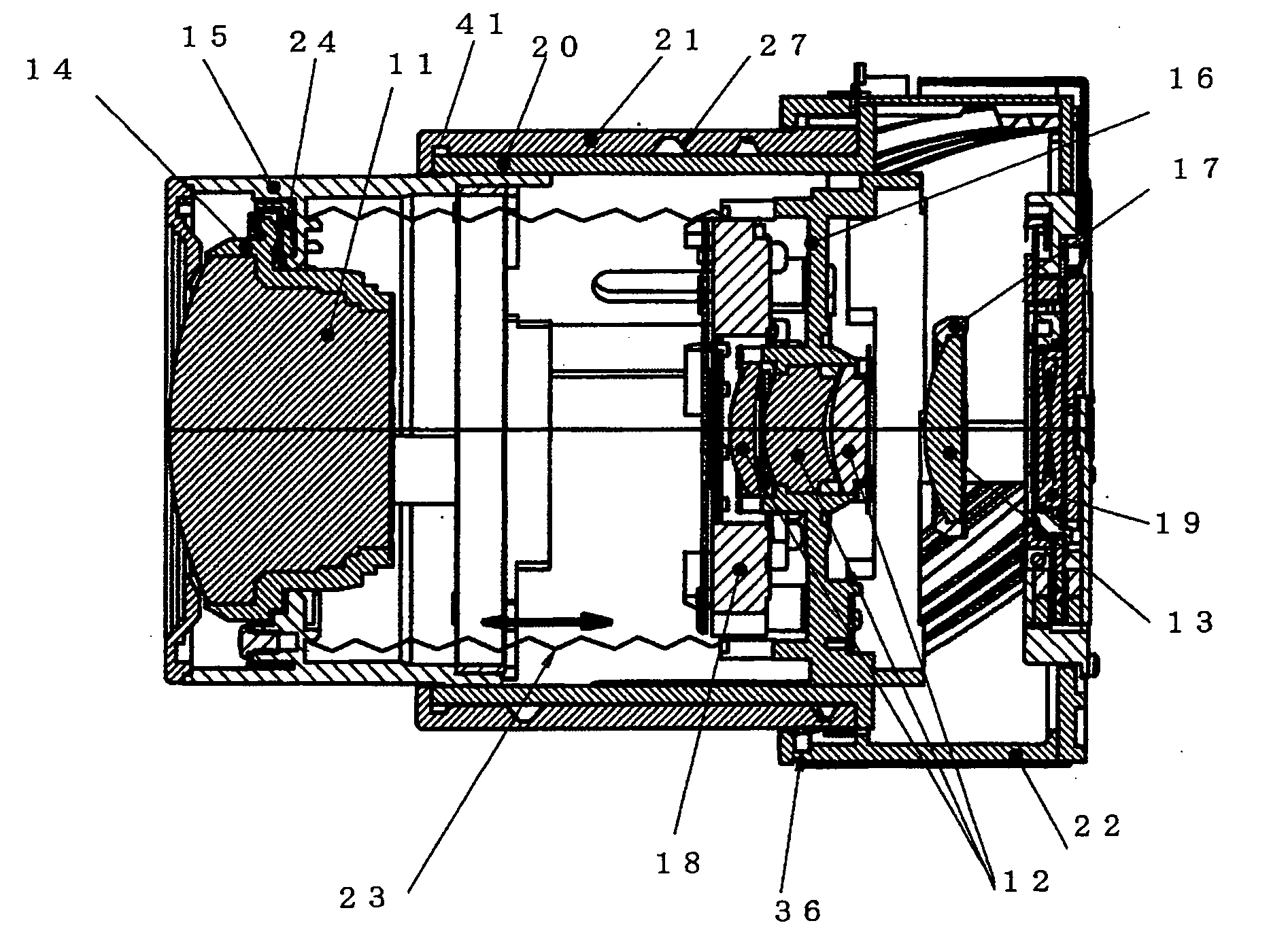

PC card

ActiveUS7238051B2Improve reliabilityNot easily affectedCasings/cabinets/drawers detailsTwo-part coupling devicesEngineeringPrinted circuit board

An object of the present invention is to provide a PC card having four SD memory cards therein, which maintains the positional accuracy of the SD memory cards and connectors, and has high contact stability. The PC card includes in its case a printed circuit board (3), connectors (4) secured to the printed circuit board (3), and pressing members (6) secured to the printed circuit board (3). The pressing members (6) hold two SD memory cards respectively, while pressing them to the printed circuit board (3) and the connector (4).

Owner:PANASONIC CORP

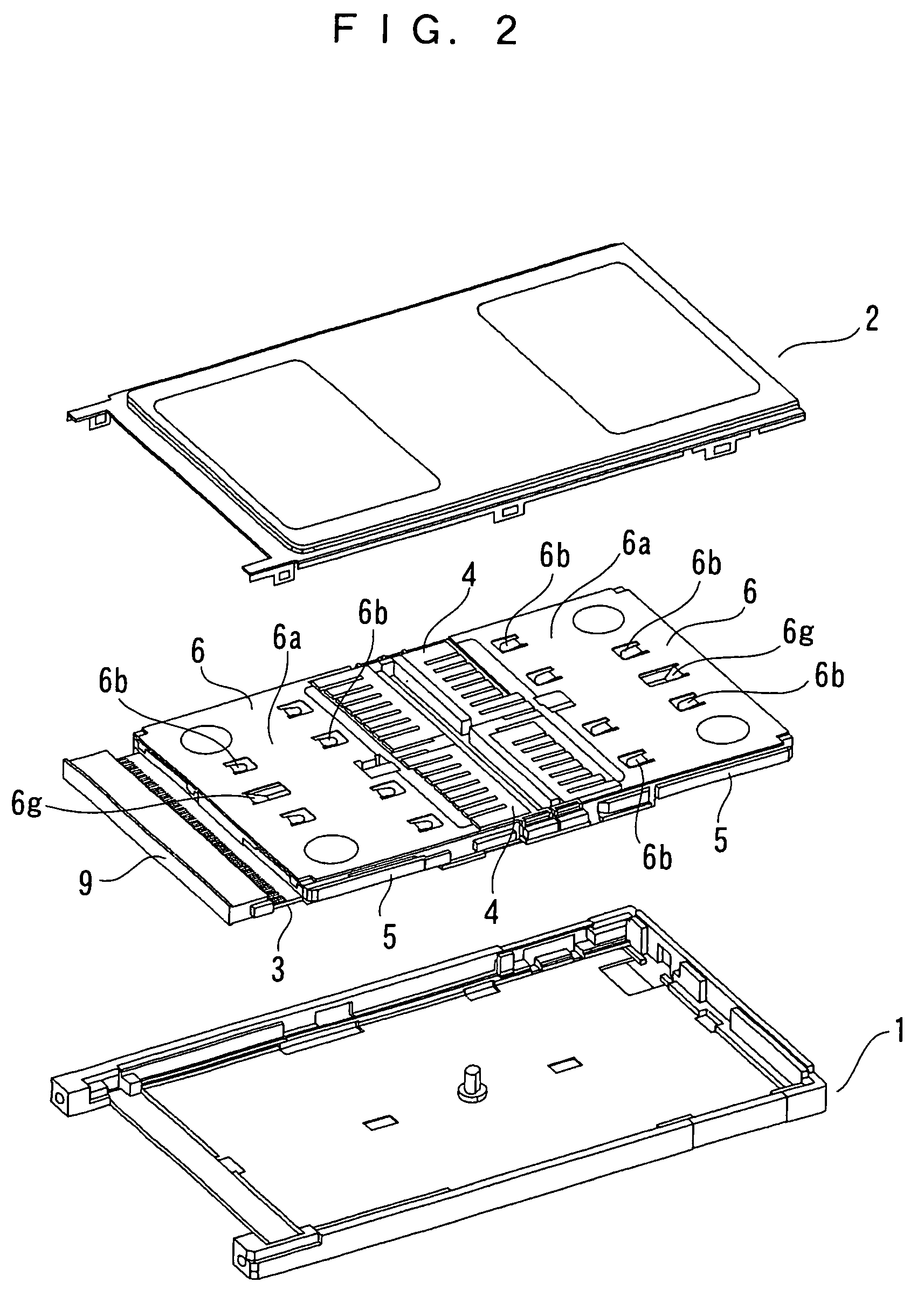

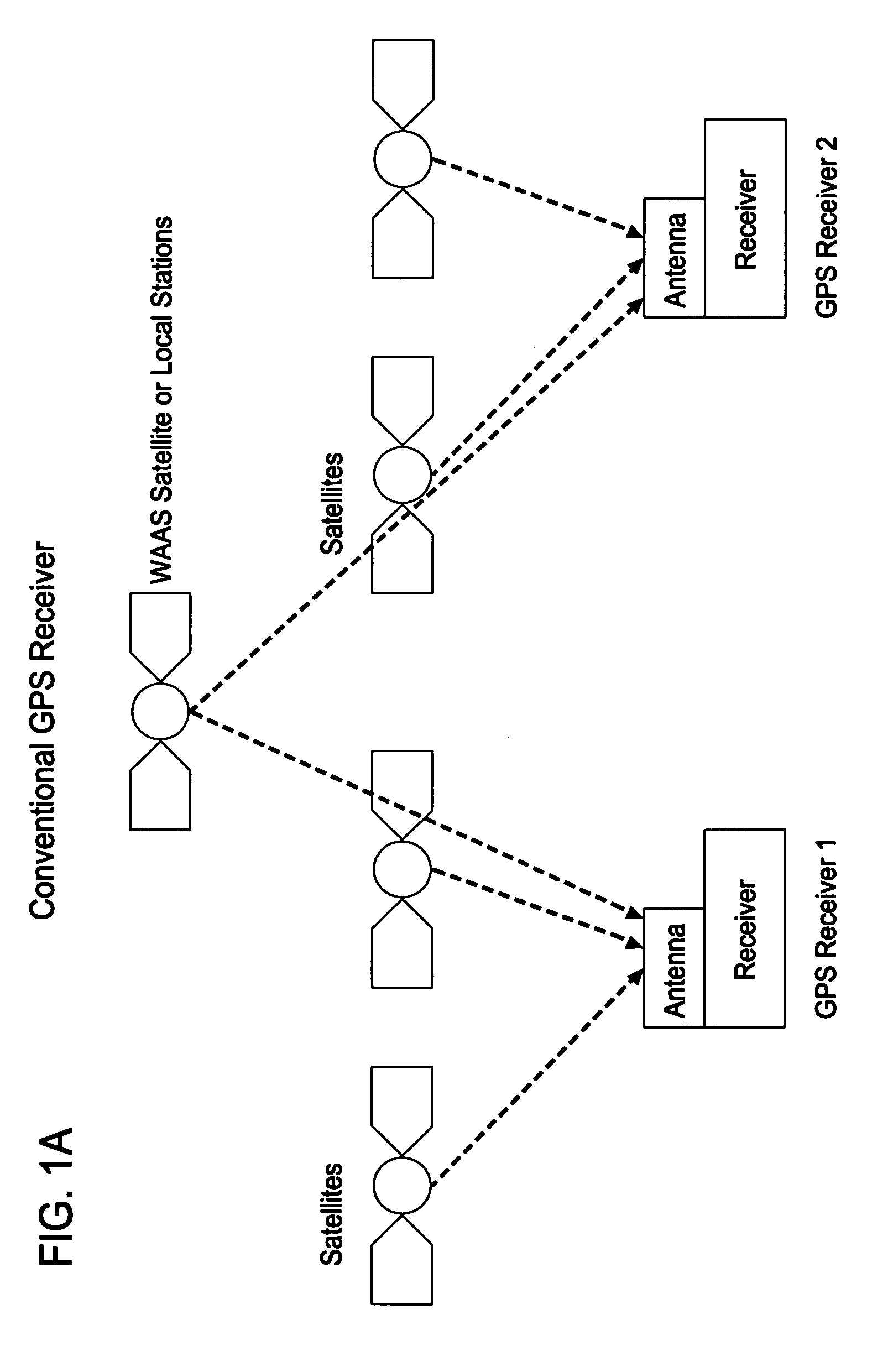

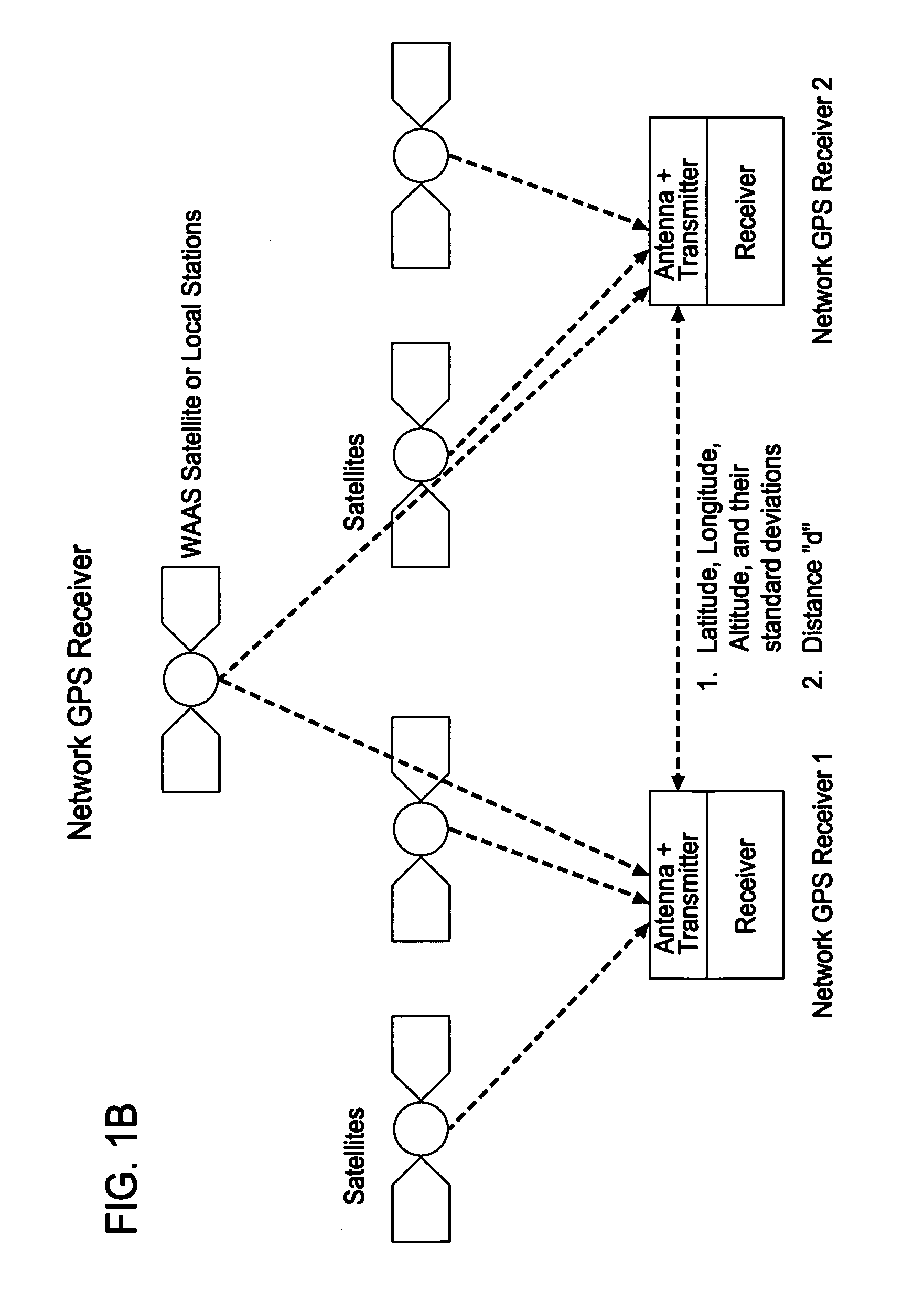

User based positioning aiding network by mobile GPS station/receiver

InactiveUS20100090893A1Good chanceHigh positioning accuracyPosition fixationSatellite radio beaconingPositioning aidsGps receiver

A navigation system with a capability of receiving positioning aiding signals from other users is disclosed. The first aspect is to serve both roles of mobile GPS receiver and mobile GPS station by receiving signals from positioning reference sources and transmitting out the estimated position. The second aspect is to receive other users' position estimates information and to measure distances from other users in the positioning aiding purpose. According to the aspects noted above: (1) the users will have much better chances in finding positioning aiding signals than conventional differential GPS receivers; (2) the more users exist, the better positioning accuracy is obtained; (3) without building local stations, ubiquitous positioning aiding signals are available.

Owner:ALPINE ELECTRONICS INC

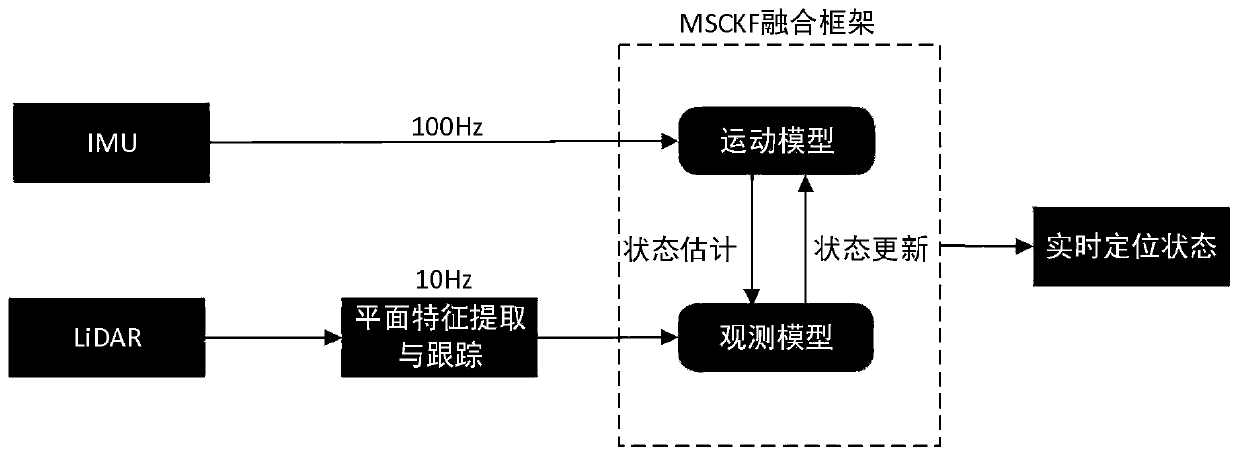

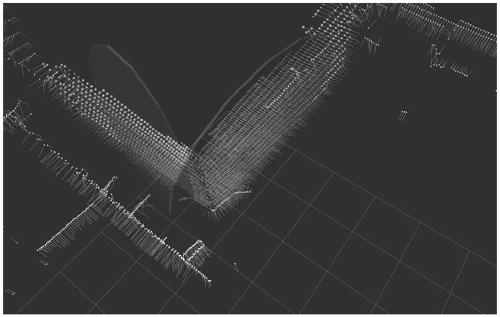

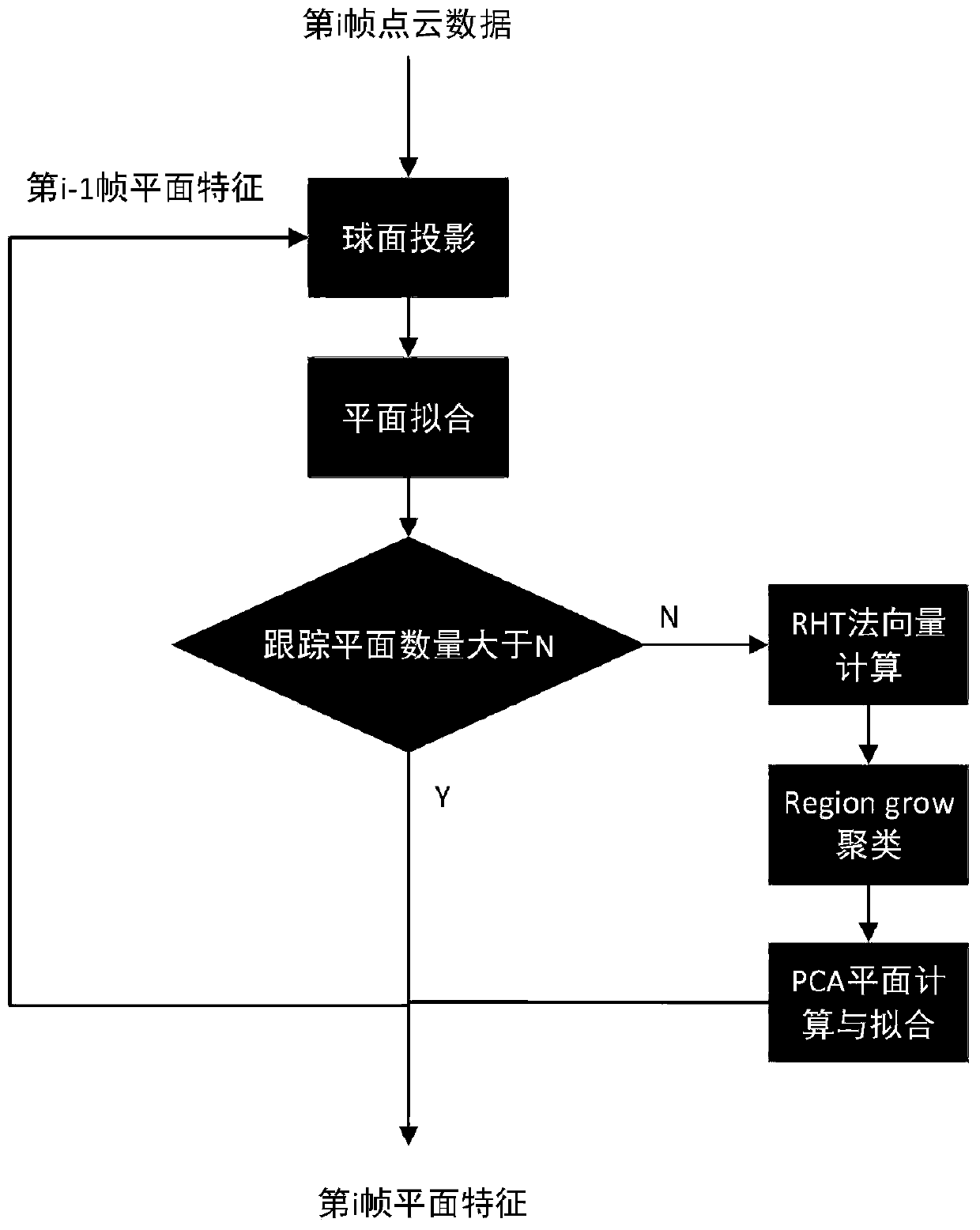

Positioning method based on laser radar and IMU tight coupling

ActiveCN111366153AFast and Robust DetectionAchieving Tightly Coupled PositioningNavigation by speed/acceleration measurementsElectromagnetic wave reradiationComputation complexityPoint cloud

The invention discloses a robot positioning method based on laser radar and IMU tight coupling, and the method comprises the steps: estimating the real-time motion state of a system through an IMU, extracting plane features for tracking through the point cloud data of the laser radar, and correcting the motion state estimated by the IMU through an observation model of the plane features. Accordingto the method of the invention, the MSCKF framework is utilized to realize advantage complementation of the laser radar sensor and the IMU sensor. On one hand, IMU high-frequency motion estimation can estimate the real-time state of the system, and on the other hand, the plane features extracted by the laser radar point cloud can be tracked in the environment in a robust manner, so that the system state can be corrected regularly, and the robustness and accuracy of positioning are maintained while the calculation complexity is reduced.

Owner:ZHEJIANG UNIV

Pc card

ActiveUS20060232950A1Improve reliabilityNot easily affectedCasings/cabinets/drawers detailsTwo-part coupling devicesPC CardPrinted circuit board

An object of the present invention is to provide a PC card having four SD memory cards therein, which maintains the positional accuracy of the SD memory cards and connectors, and has high contact stability. The PC card includes in its case a printed circuit board (3), connectors (4) secured to the printed circuit board (3), and pressing members (6) secured to the printed circuit board (3). The pressing members (6) hold two SD memory cards respectively, while pressing them to the printed circuit board (3) and the connector (4).

Owner:PANASONIC CORP

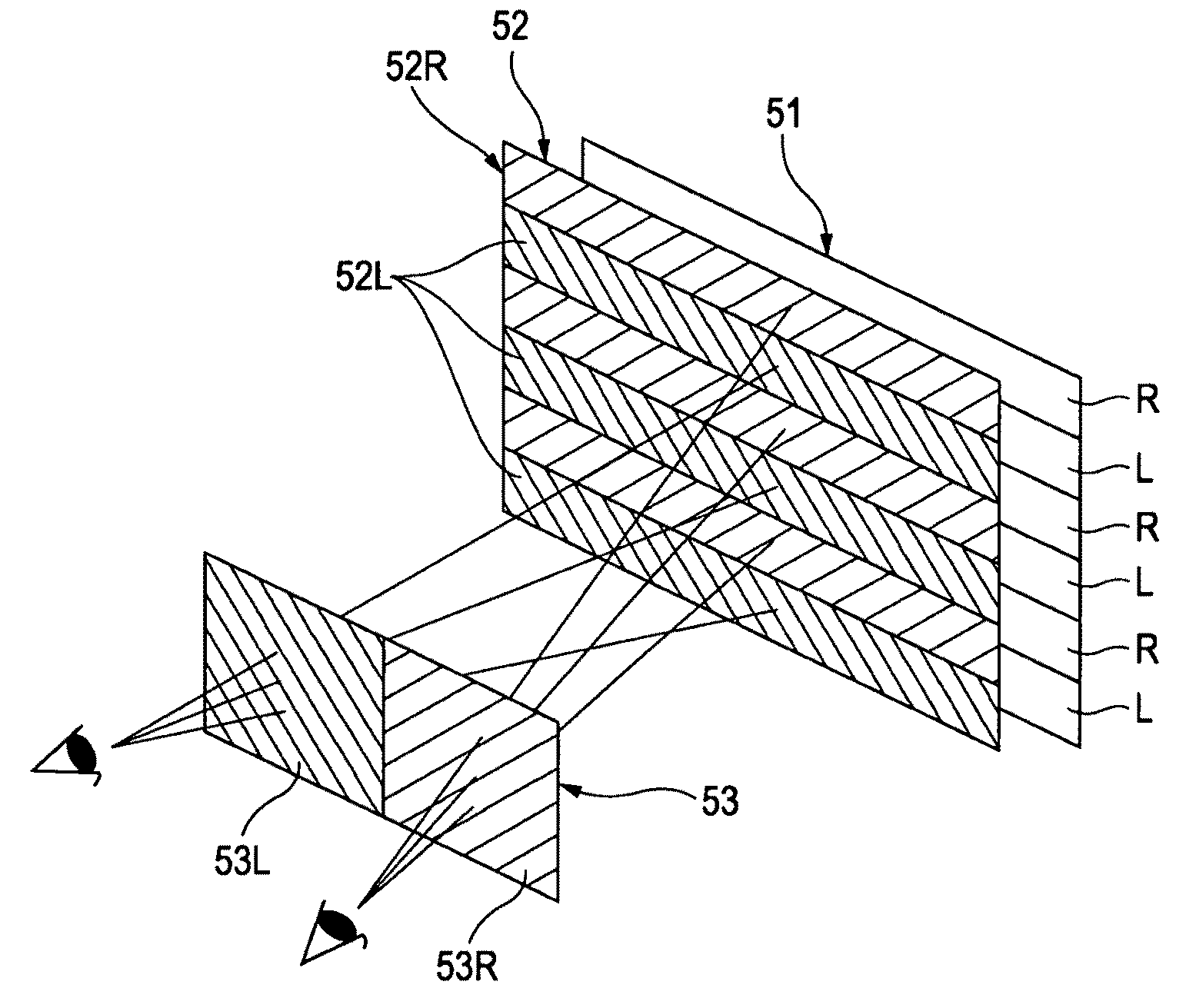

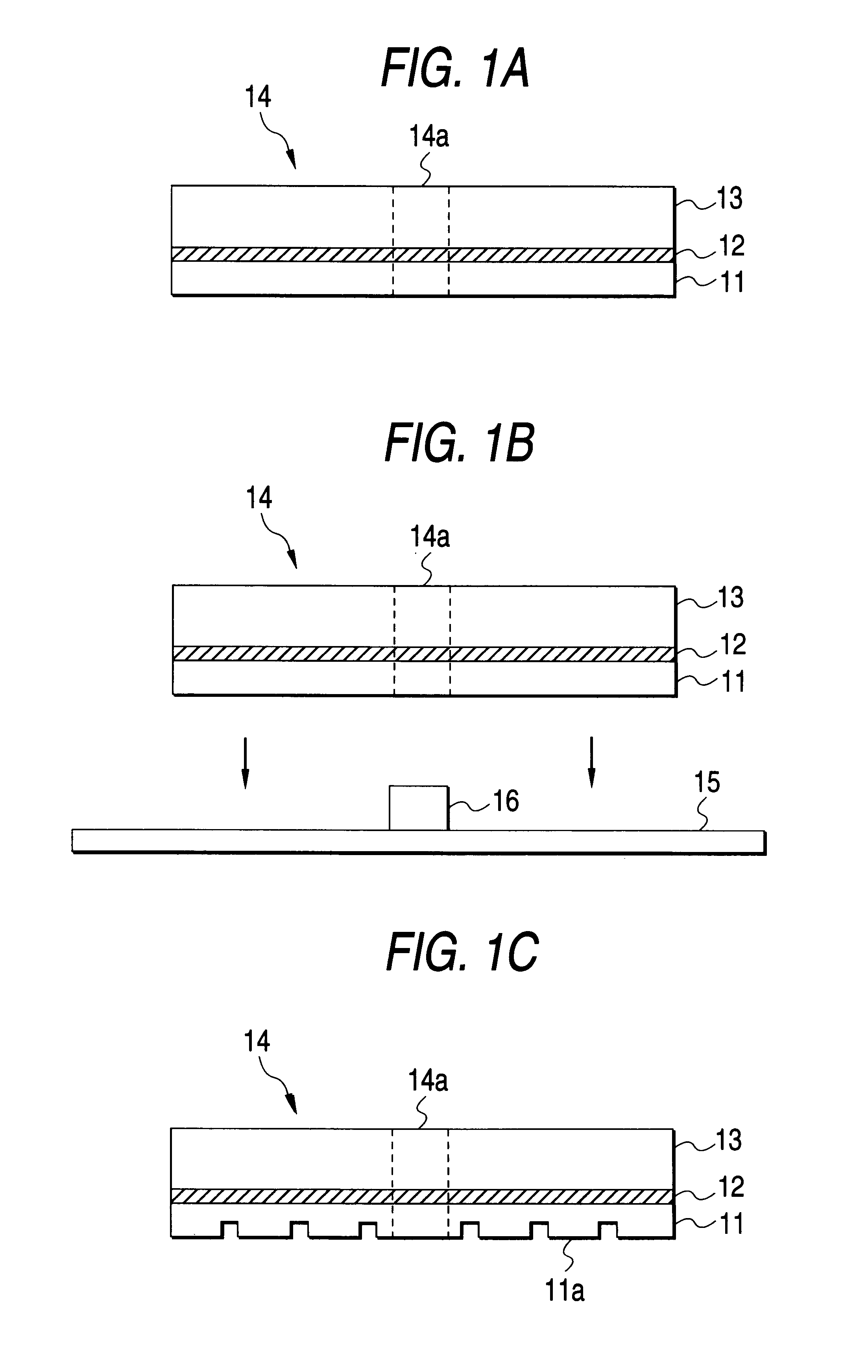

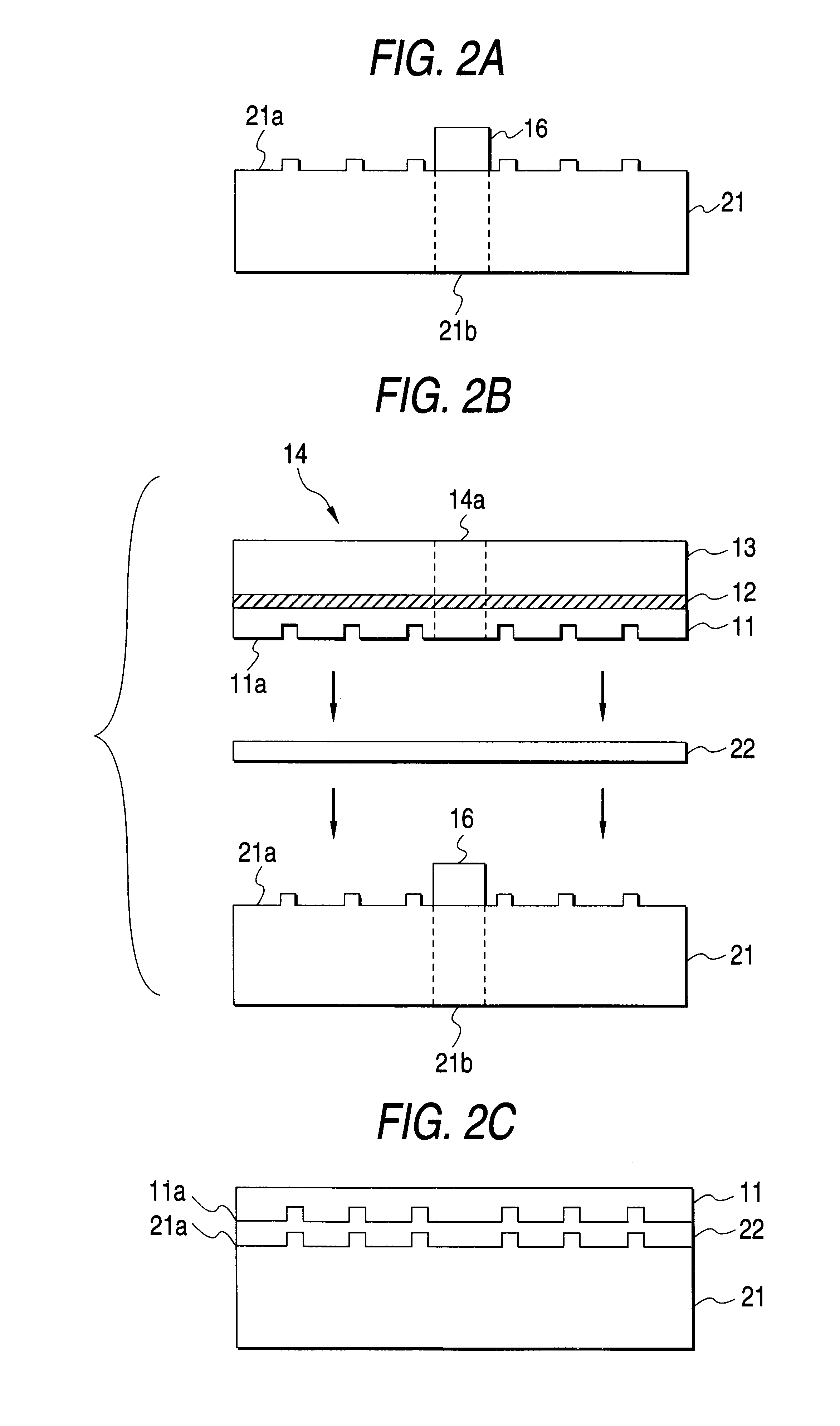

Method for manufacturing stereoscopic image display apparatus and stereoscopic image display apparatus

InactiveUS20100026792A1Easy to uniformlyAvoid mixingSemiconductor/solid-state device manufacturingColor television detailsRegular patternPhase difference

A method for manufacturing a stereoscopic image display apparatus includes a bonding step of bonding an image display panel and a phase difference element by disposing an adhesive layer between the entire surfaces thereof, the image display panel displaying a right-eye image and a left-eye image by regularly mixing them in a plane, the phase difference element including a right-eye image display section corresponding to the right-eye image and a left-eye image display section corresponding to the left-eye image, the phase difference element achieving different polarizations between the right-eye image display section and the left-eye image display section, the adhesive layer being composed of a transparent gel acrylic adhesive with a thickness of 25 to 100 μm, hardness of the adhesive being more than 0 and 350000 μN or less, holding strength of the adhesive at 40° C. after bonding being 8 to 20 N / 20 mm.

Owner:SONY CORP

Process for producing combustor structural member, and combustor structural member, combustor for gas turbine and gas turbine

ActiveUS9370846B2Maintain positioning accuracyNo crackContinuous combustion chamberMetal-working apparatusCombustorAlloy

A process including brazing a first plate-like member formed from a heat-resistant alloy, and a second plate-like member formed from a heat-resistant alloy and having fins on the surface, with the fins facing the first plate-like member, by interposing a brazing filler metal comprising a melting point lowering element between the two plate-like members, molding the plate-like assembly to form a combustor structural member, identifying, in accordance with the shape of the combustor structural member, strain locations where the strain generated during the press molding step exceeds a predetermined value, performing localized heating of the locations within the plate-like assembly corresponding with the strain locations identified, and as the above press molding step subjecting the plate-like assembly to cold press molding with the temperature of the heated locations corresponding with the strain locations maintained at a desired temperature.

Owner:MITSUBISHI POWER LTD

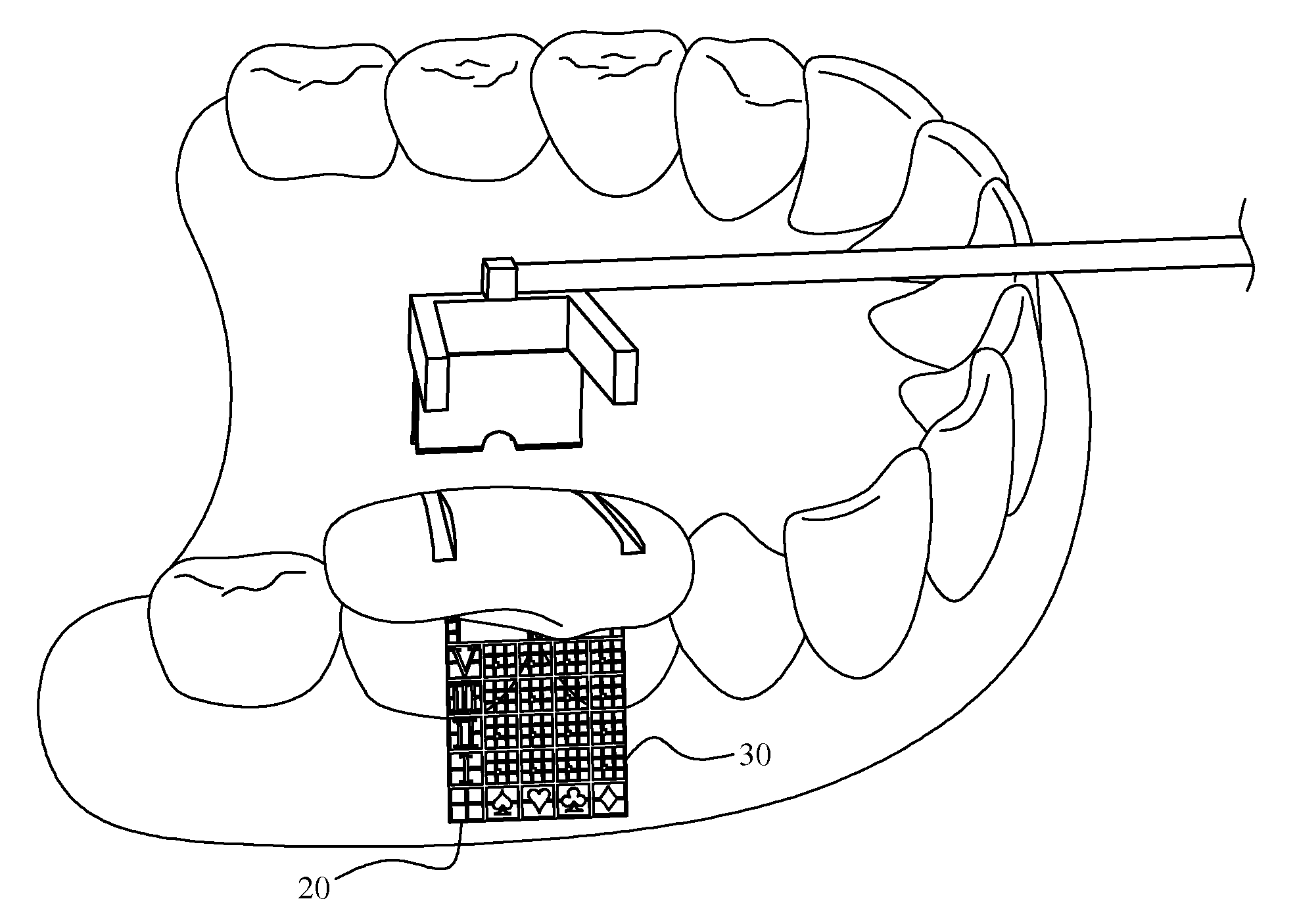

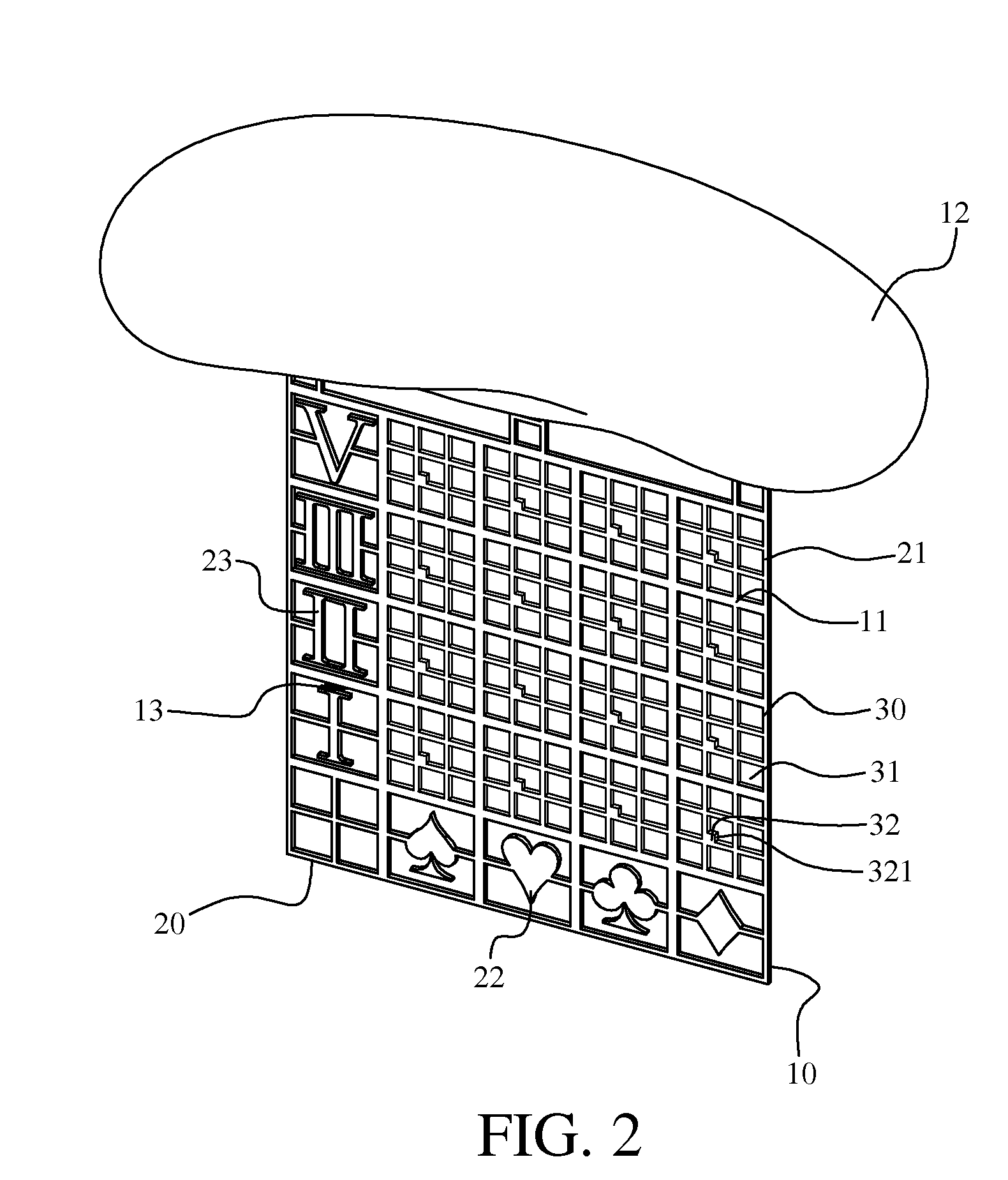

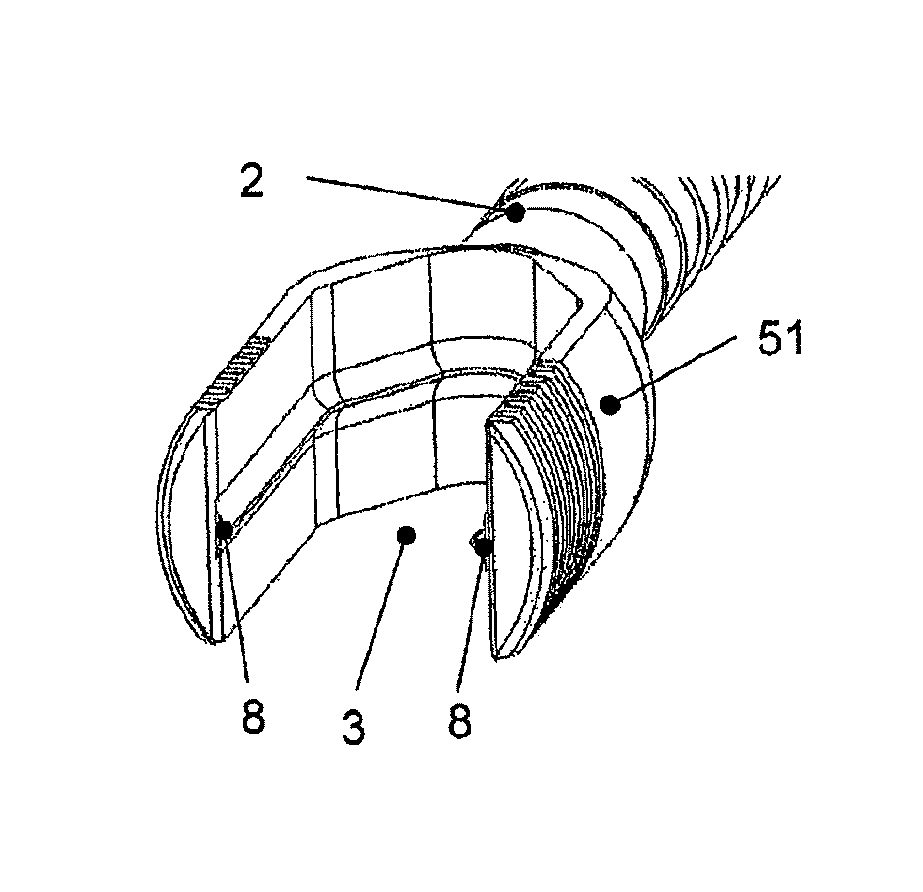

Multi-coordinate orthodontic implant positioning device

InactiveUS20120129123A1Precise positioningMaintain positioning accuracyDental implantsOthrodonticsEngineeringImplant surgery

A multi-coordinate orthodontic implant positioning device includes a measuring reference member having a predetermined thickness and being provided thereon with measuring scales formed of a radiopaque material. The measuring reference member is connected at an edge to a fixing member for fixedly attaching to the patient's teeth. The measuring scales define a coordinate-type positioning structure, which includes at least a main coordinate system and a sub-coordinate system. The main coordinate system divides the positioning structure into a plurality of coordinate blocks, each of which has a main coordinate code readable from the main coordinate system; and the sub-coordinate system is provided in some specified ones of the coordinate blocks. Since the main coordinate system and the sub-coordinate system are two different and independent coordinate systems, the use of them enables primary and more accurate positioning of an implant point to effectively upgrade the efficiency in the orthodontic implant surgery.

Owner:YAO YIN CHAO

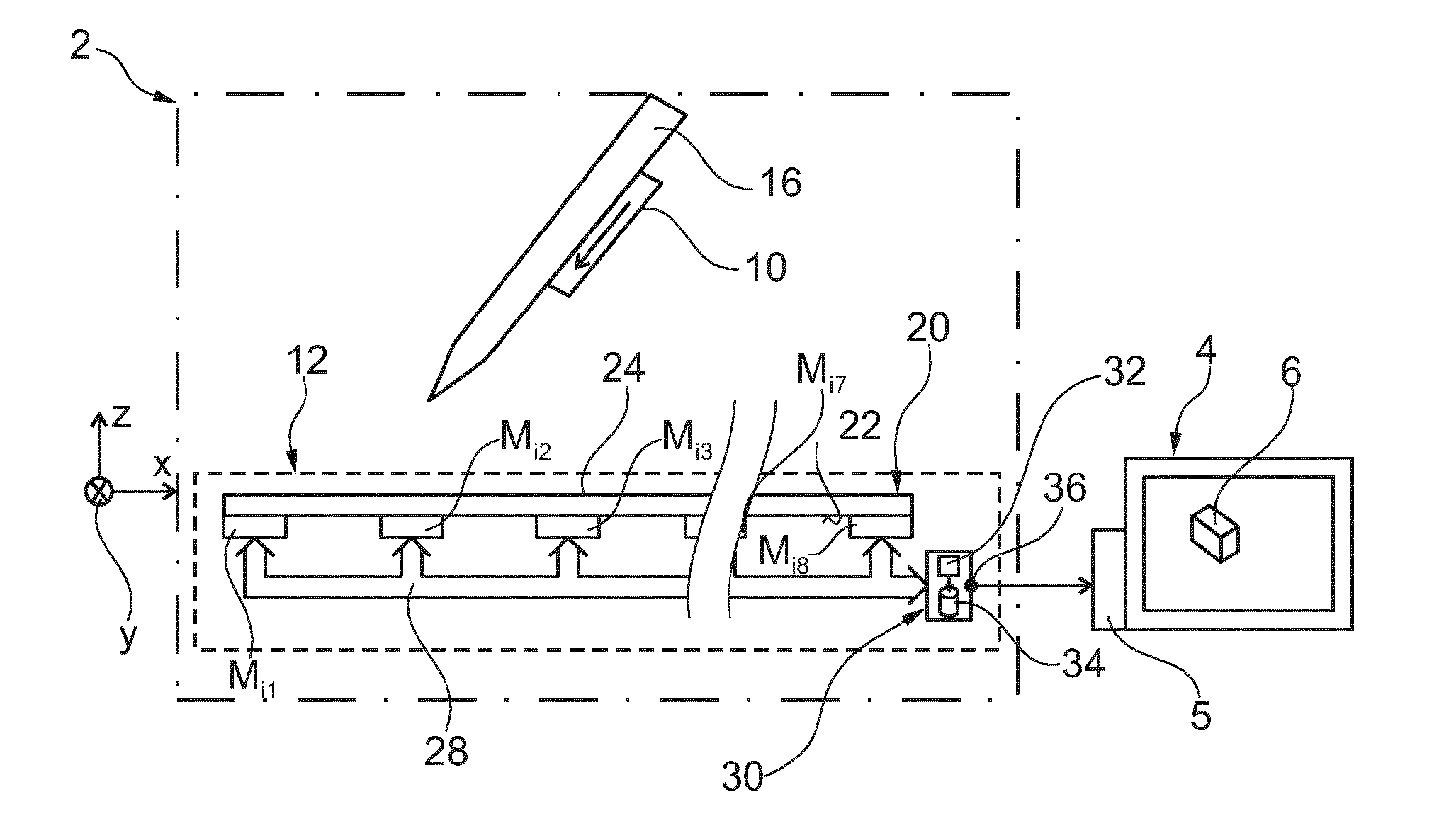

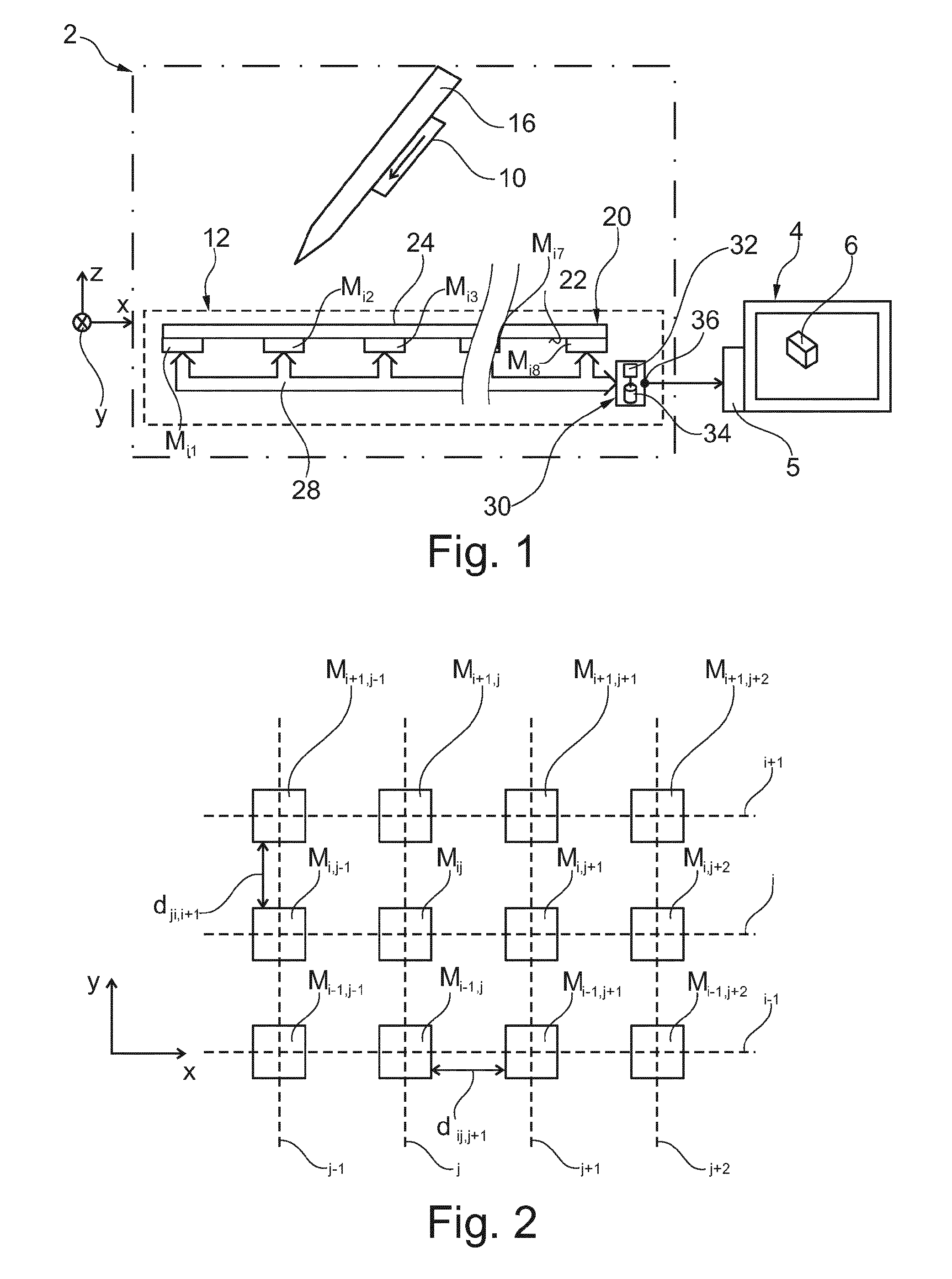

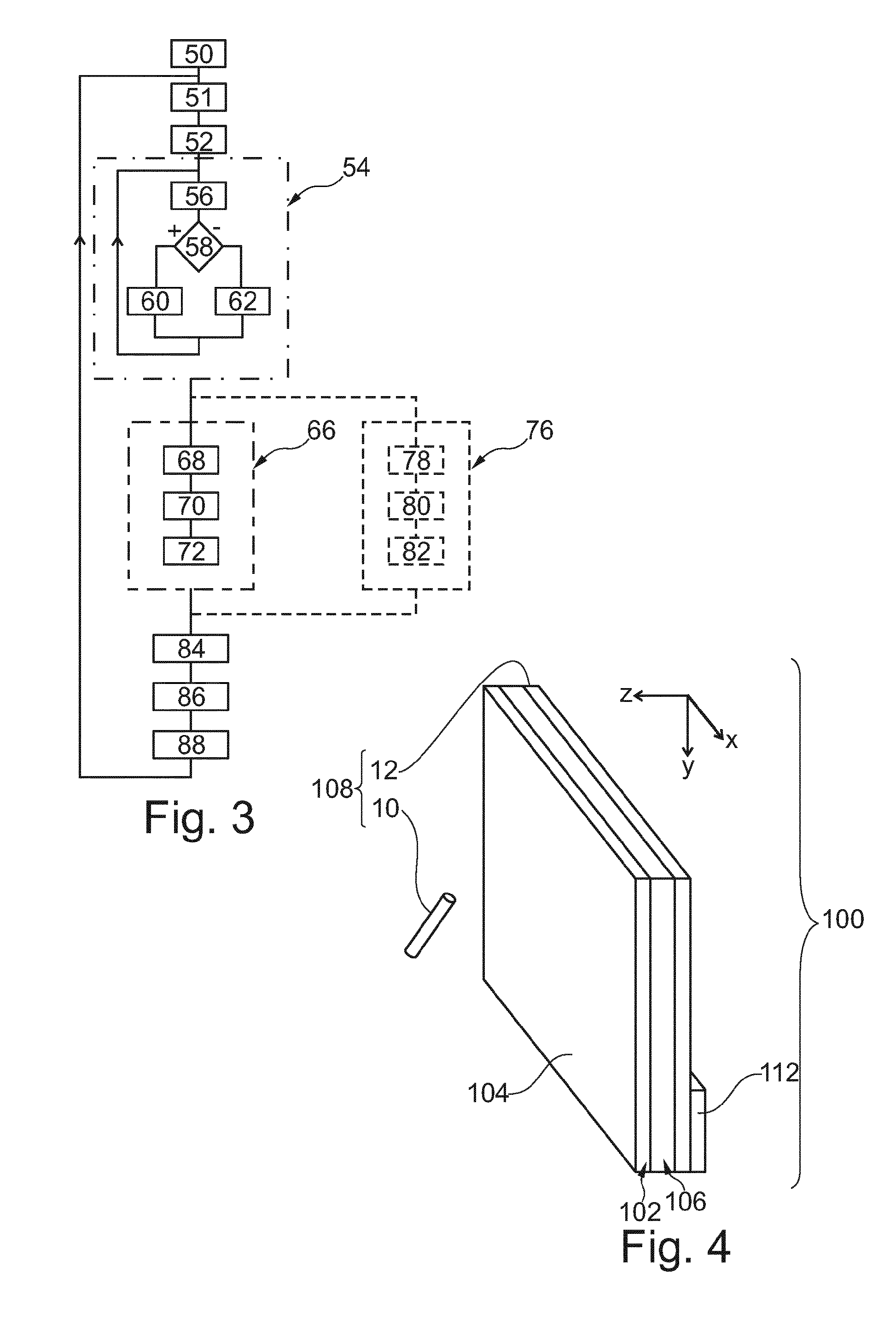

Method and device for locating a magnetic object

ActiveUS20150057969A1Reduce electricity consumptionReduce in quantityDigital computer detailsSpeed measurement using gyroscopic effectsMagnetic tension forceClassical mechanics

A method for locating a moving magnetic object, comprising: determining the position or the orientation of the magnetic object from measurements of an array of N (an integer greater than 5) tri-axial magnetometers mechanically linked to one another with no degree, the method also comprises the reiteration of the following steps. Estimating the position of the magnetic object relative to the array of magnetometers from measurements of the magnetometers made in a preceding iteration or from a measurement of a sensor distinct from the magnetometers of the array of magnetometers so that this estimation is obtained before making a new measurement using the magnetometers of the array; computing the distance between each magnetometer and the estimated position of the magnetic object; eliminating the Ni magnetometers closest to this estimated position, where Ni is a positive integer number strictly less than N; making a new measurement, by each non-eliminated magnetometer, of the magnetic field generated or modified by the magnetic object; and determining a new position or a new orientation of the magnetic object from the new measurements of the magnetometers which have not been eliminated and without taking into account new measurements made by the eliminated magnetometers, so as to obtain a new location of the magnetic object.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Key guide structure in keyboard apparatus

ActiveUS7488885B2Minimize changesMaintain positioning accuracyStringed musical instrumentsIndication apparatusEngineeringLateral movement

Keyboard apparatus has a frame and a key pivotably mounted on the frame. Key guide structure includes a key-side guide member provided inside the key, and a frame-side guide member provided on the frame. The key-side guide member has at least one convexly-formed portion projecting from the inner surface of a distal end portion of the key, remote from a pivot point of the key, toward the pivot point. The frame-side guide member permits movement of the key-side guide member along a pivoting direction of the key, but limits lateral movement of the key-side guide member.

Owner:YAMAHA CORP

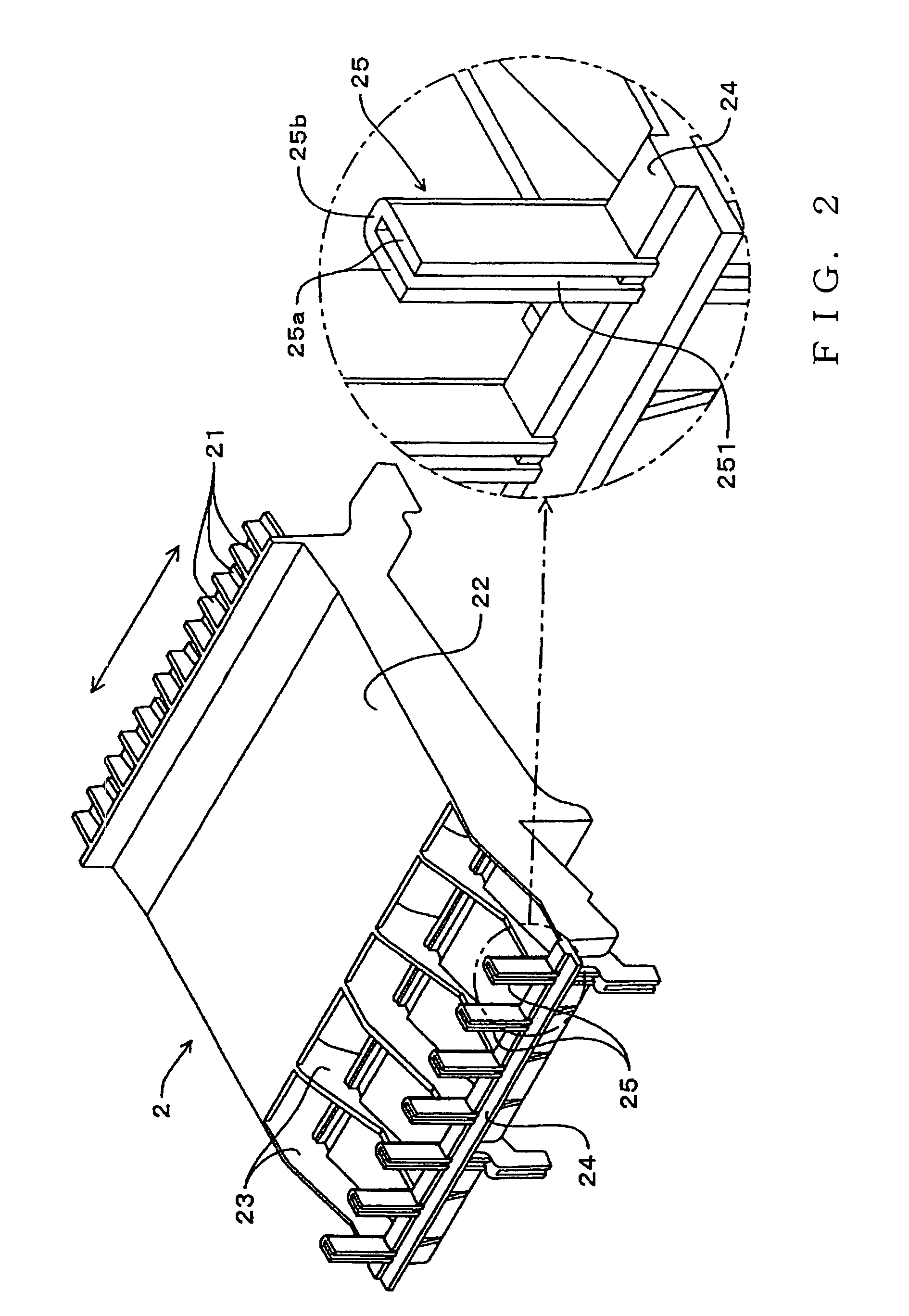

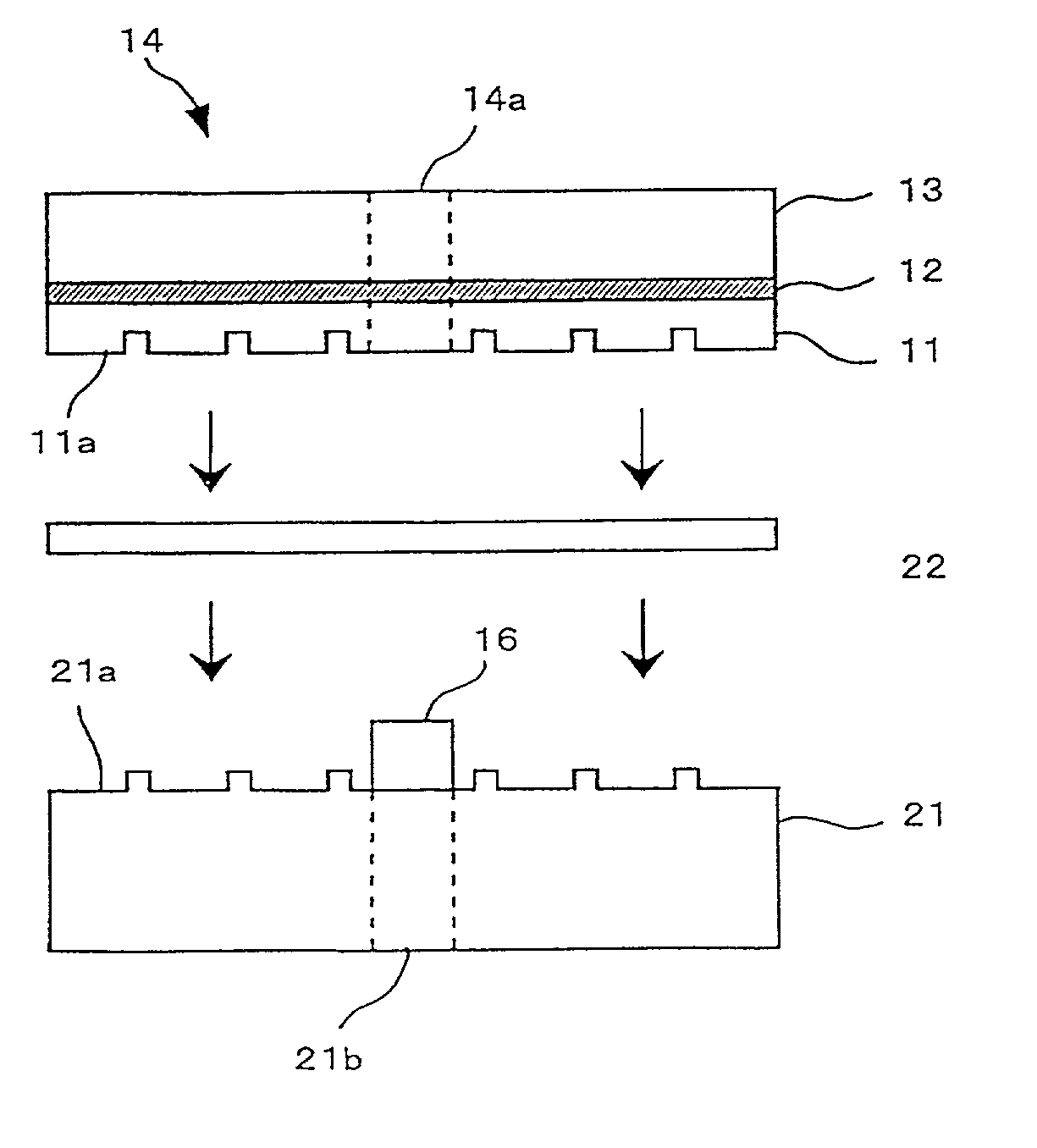

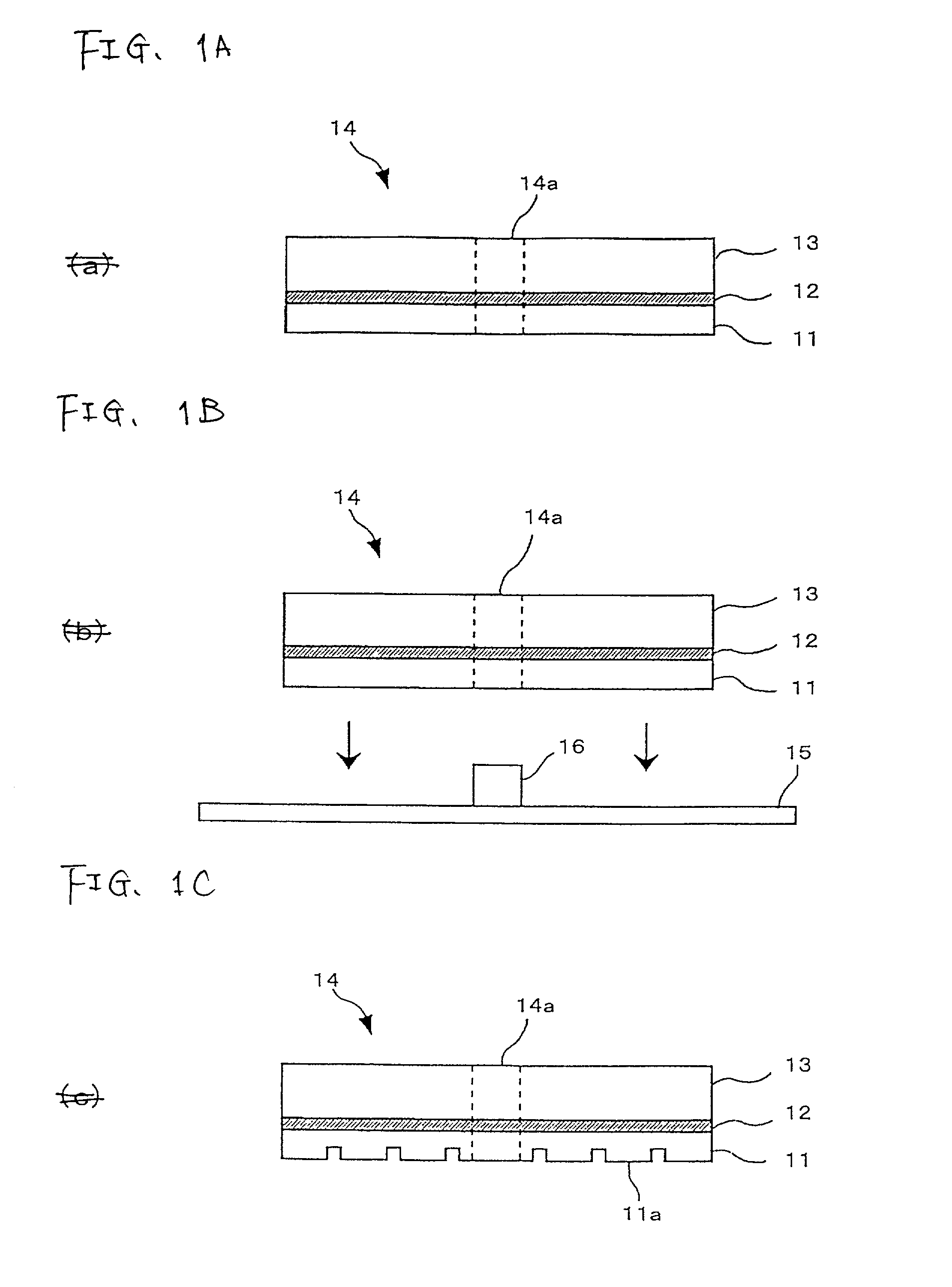

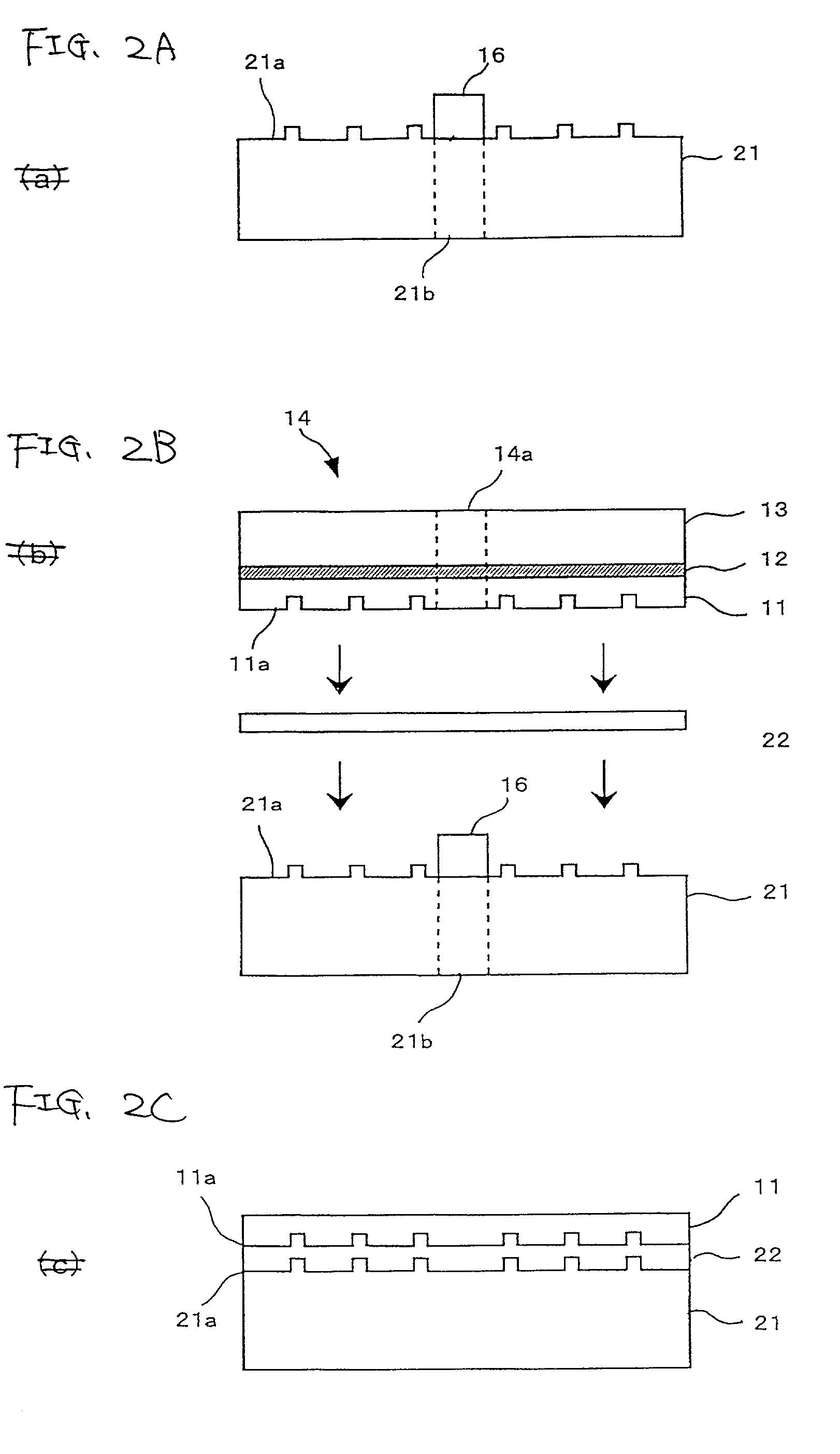

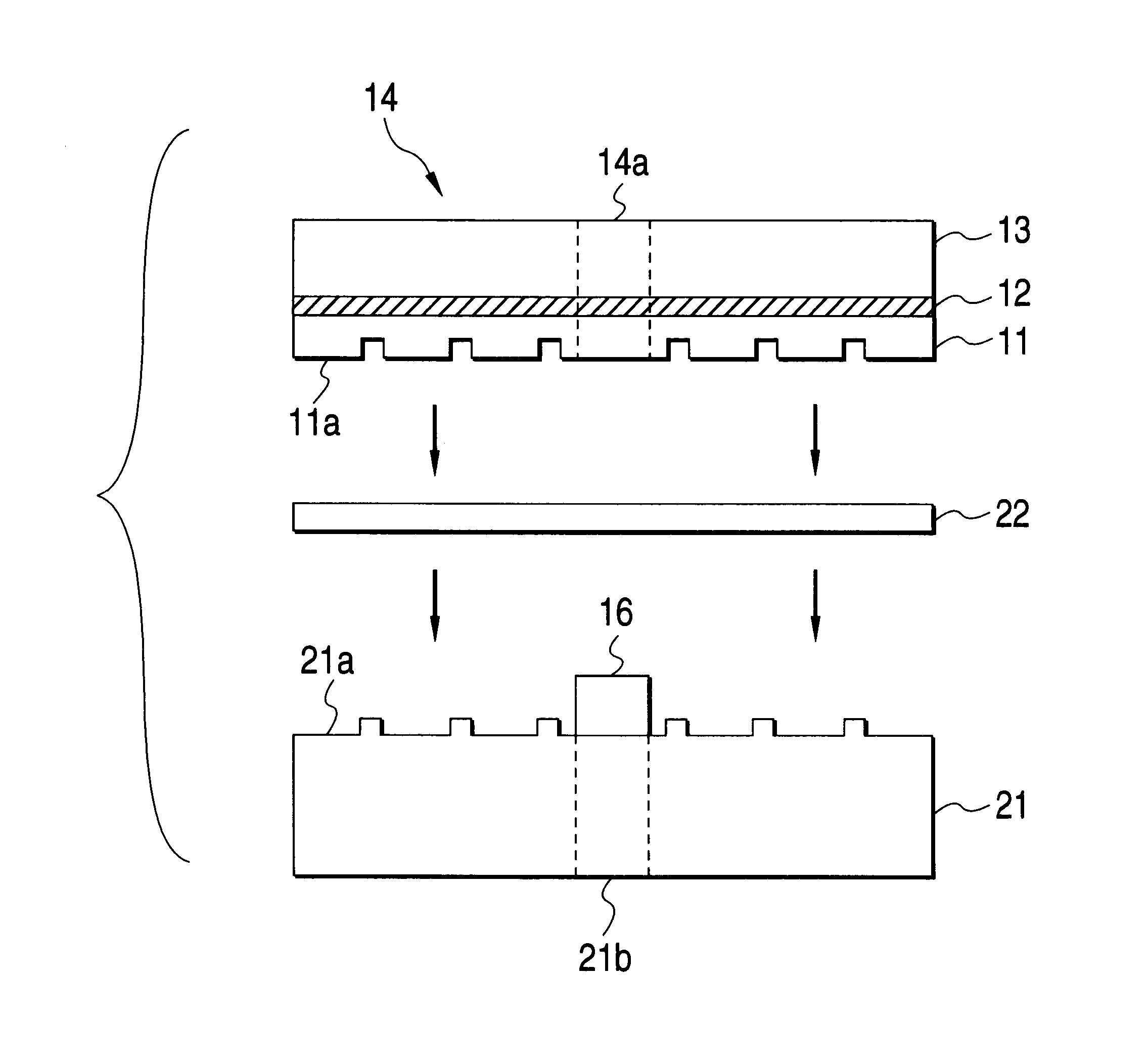

Method of manufacturing a disk and transfer method for the disk

InactiveUS20020036056A1Avoid it happening againAvoid displacementRecording apparatusRecord carriersEngineering

In case of manufacturing a disk having a two-layer structure, a glass substrate 13 is bonded to a cover layer 11 through an adhesive layer 12, and a mount hole 14a is formed in a center thereof to form a bonded substrate 14 having a three-layer structure (a). In a state where a stamper 15 formed a predetermined pit pattern is set to a center boss 16, the bonded substrate 14 is pressed downward in a vertical direction while the mount hole 14a of the bonded substrate 14 is aligned with the center boss 16(b). Whereby an information recording surface 11a is transferred onto the cover layer 11(c). Subsequently, after the bonded substrate 14 has been bonded to another layer substrate of the disk, the adhesive layer 12 is removed to separate the glass substrate 13. Finally, there is manufactured the disk having the two-layer structure.

Owner:PIONEER CORP

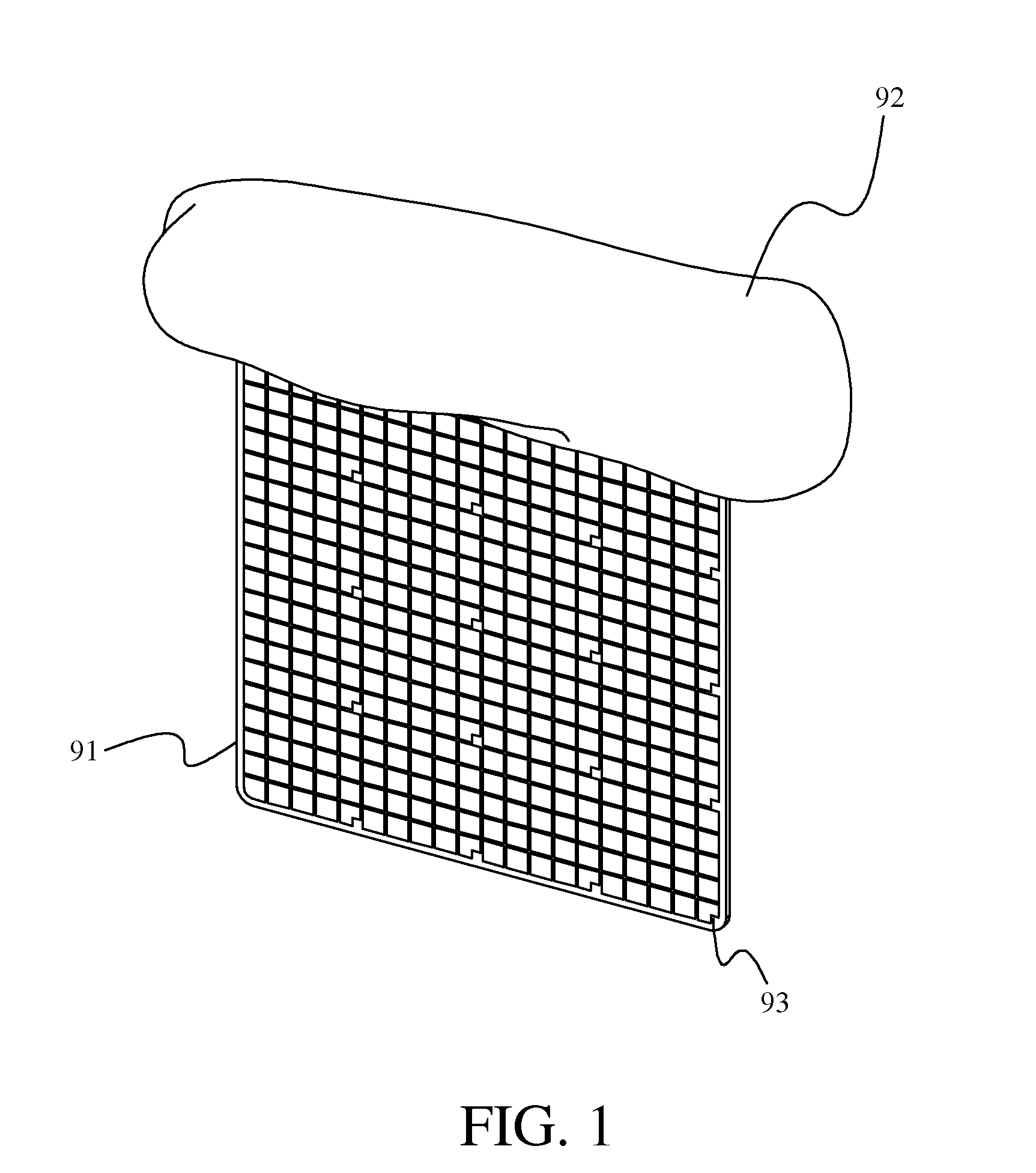

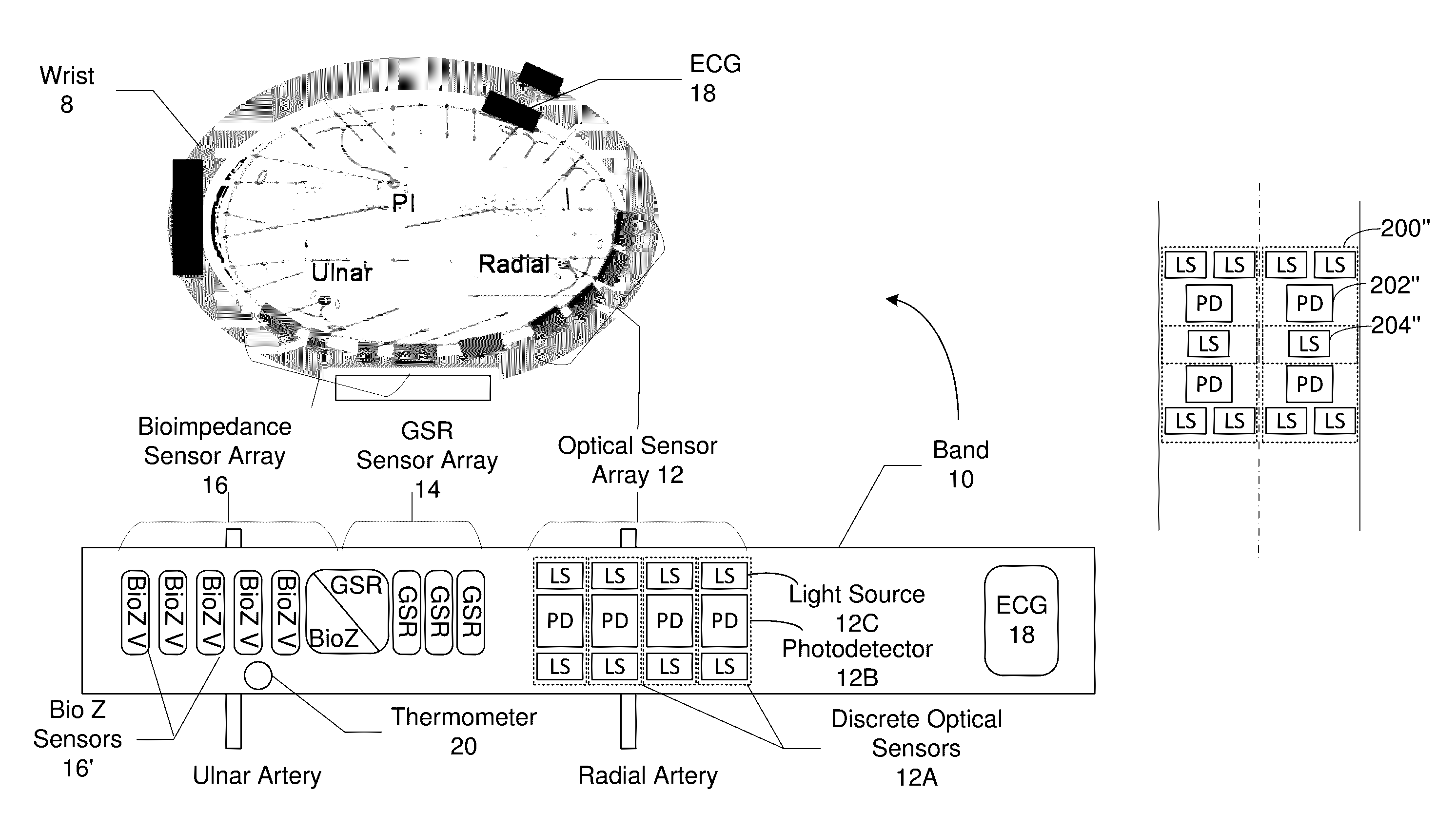

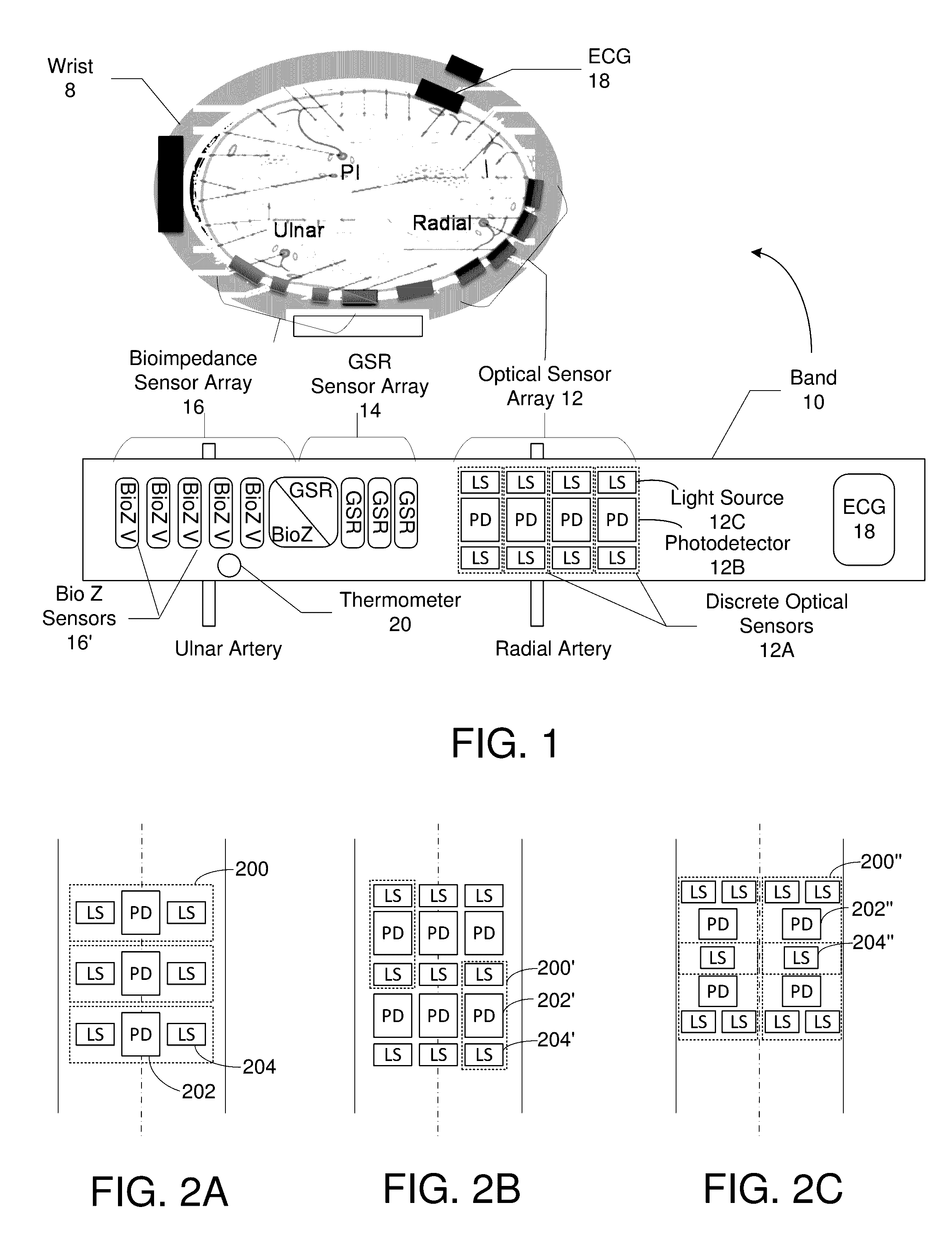

Self-aligning sensor array

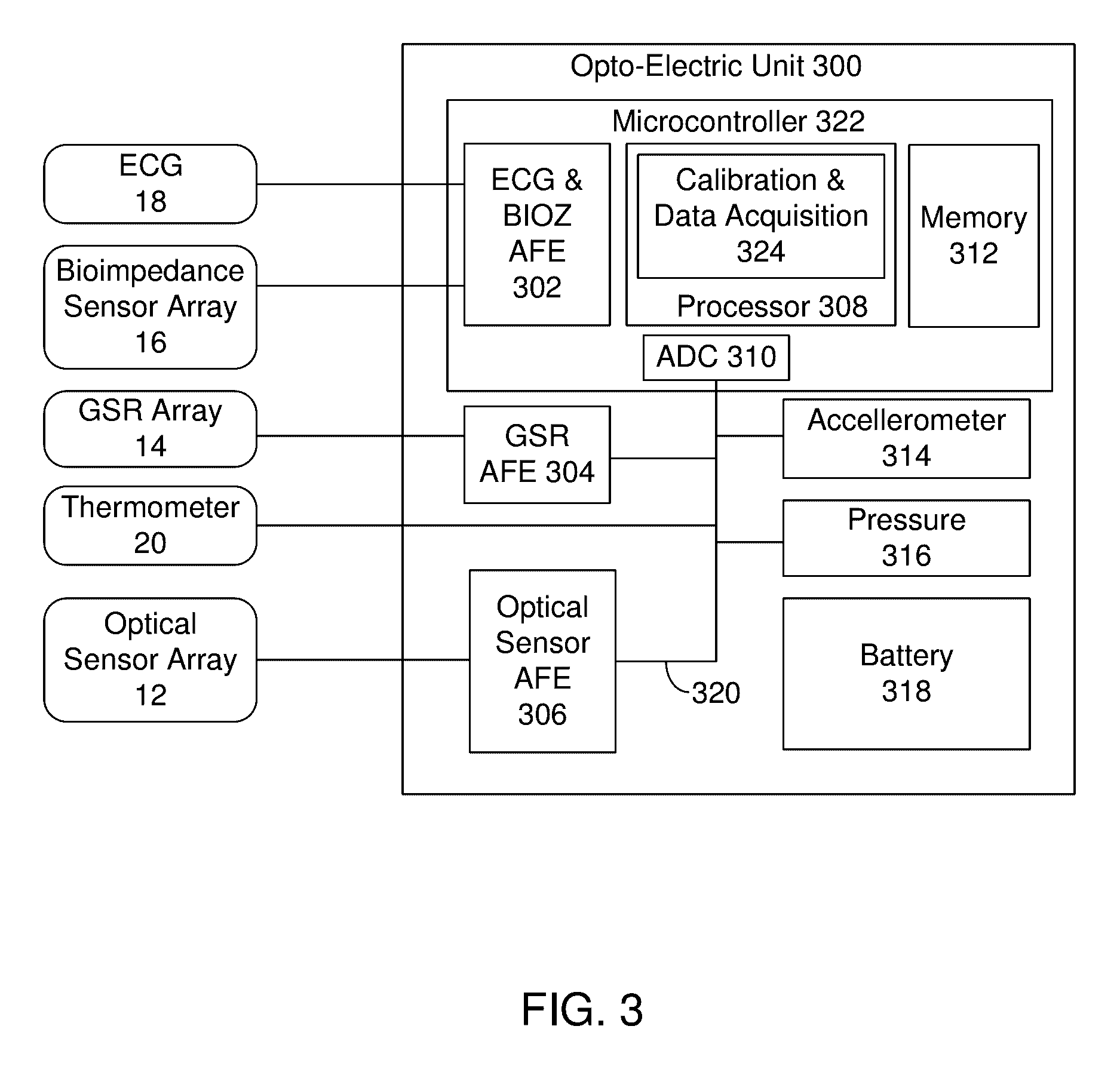

ActiveUS9554724B2Maintain positioning accuracySensorsMeasuring/recording heart/pulse rateSensor arraySignal-to-noise ratio (imaging)

Exemplary embodiments for self-aligning a sensor array with respect to blood vessel of a user comprise: determining an optimal sensor in a sensor array comprising an array of discrete sensors arranged on a band such that the sensor array straddles or otherwise addresses a blood vessel or other targeted area of a user by activating each of the discrete sensors to generate respective signals; designating as the optimal discrete sensor a particular discrete sensor producing a highest signal-to-noise ratio; and using the optimal sensor to collect physiological data of the user.

Owner:SAMSUNG ELECTRONICS CO LTD

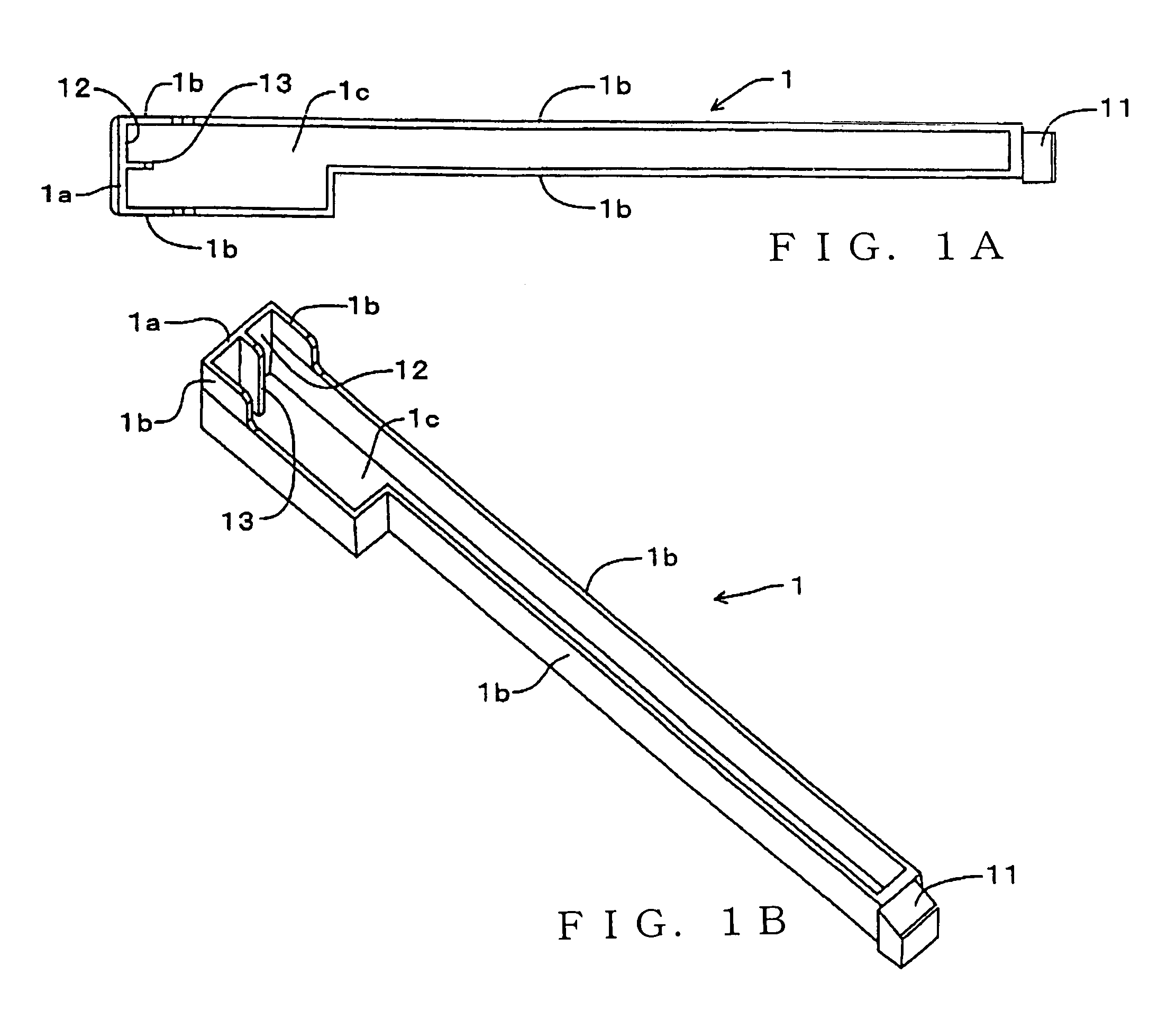

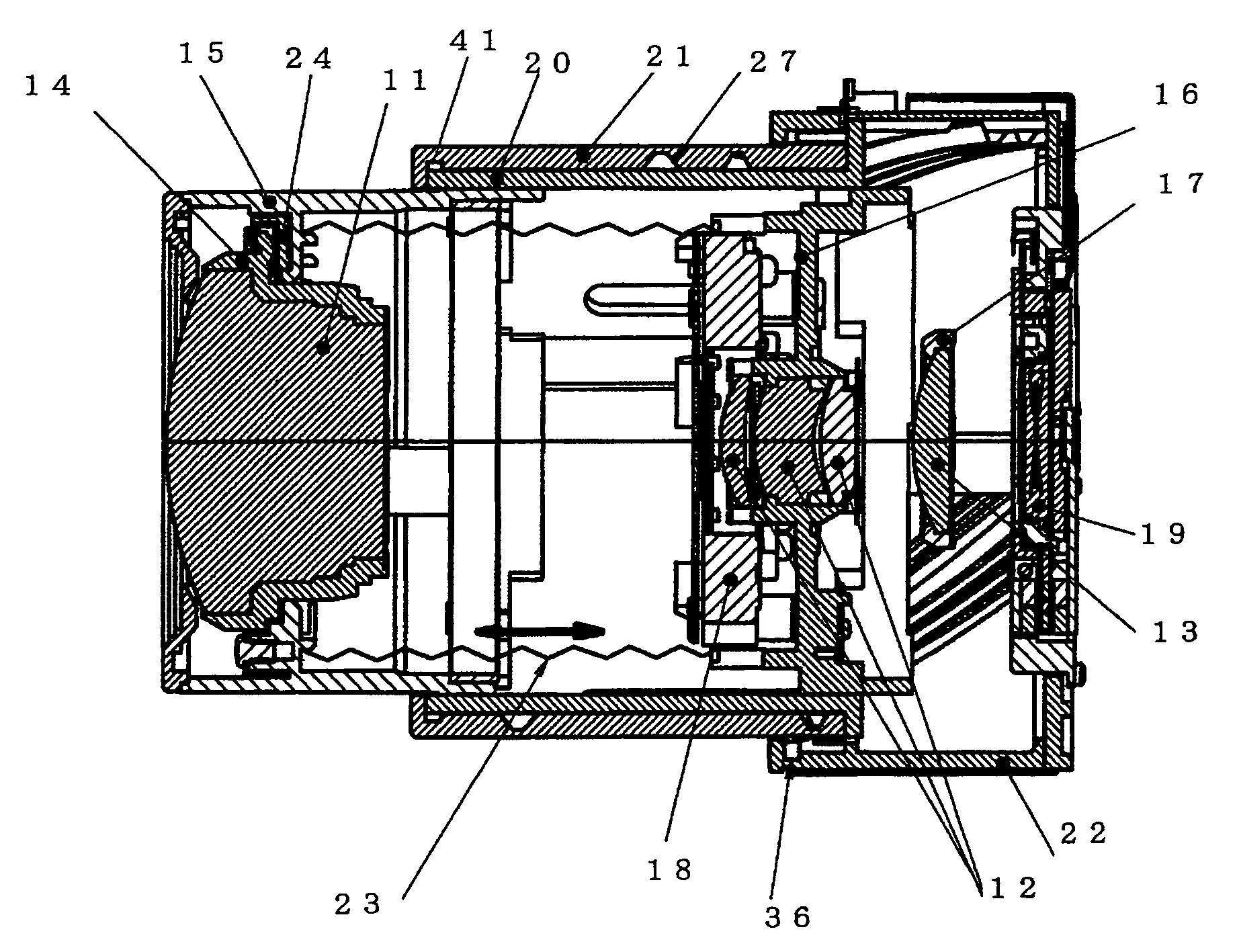

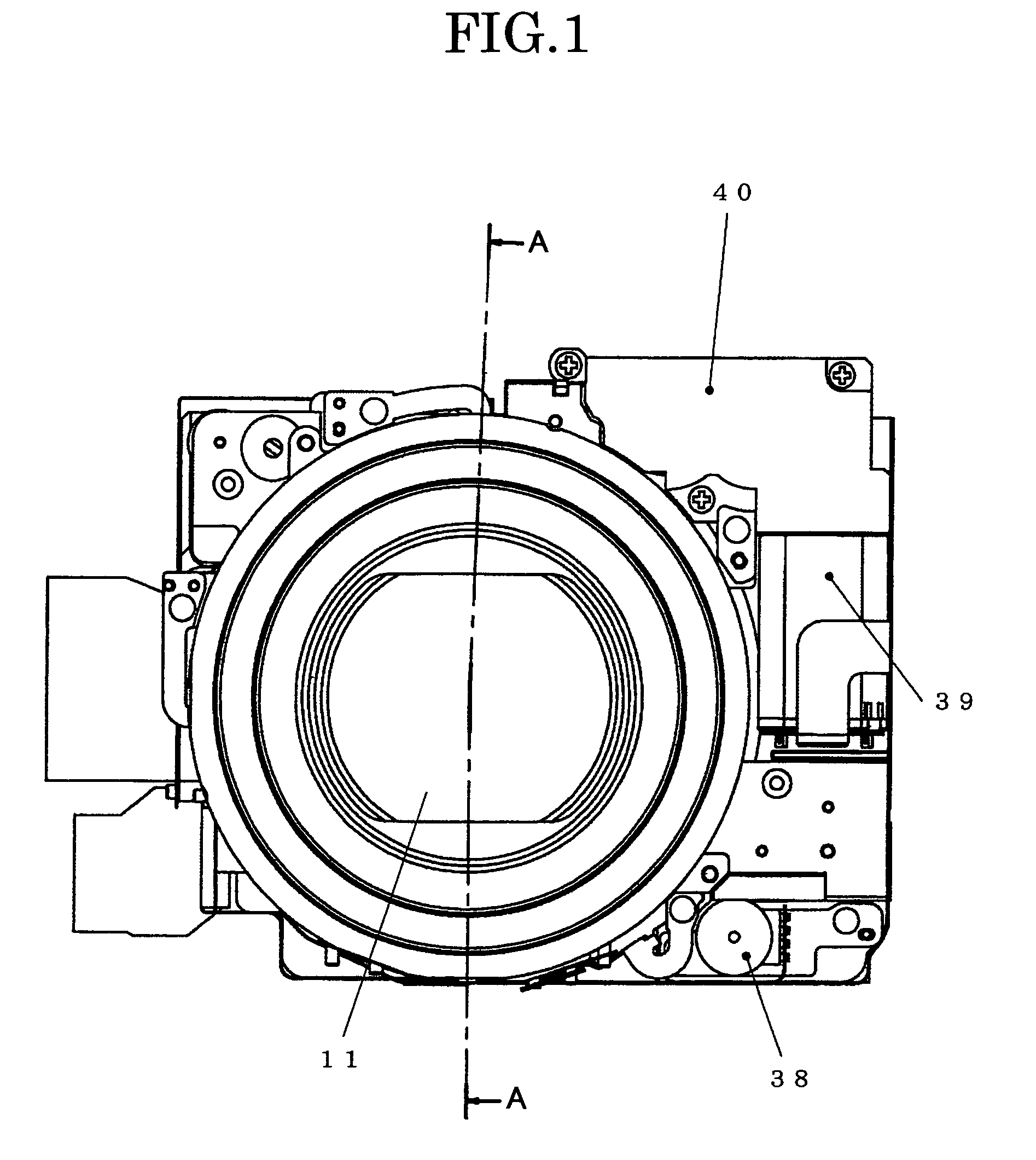

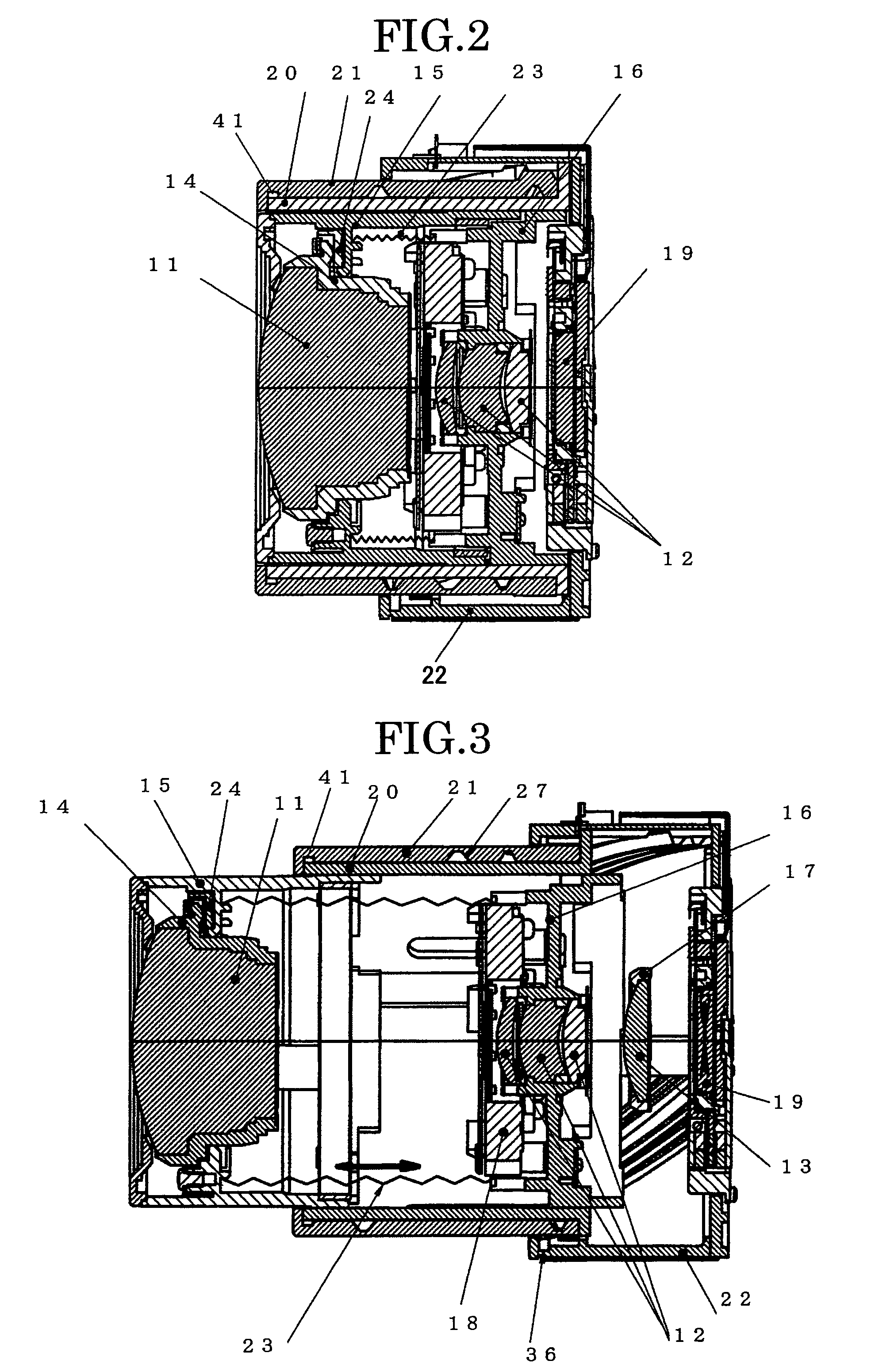

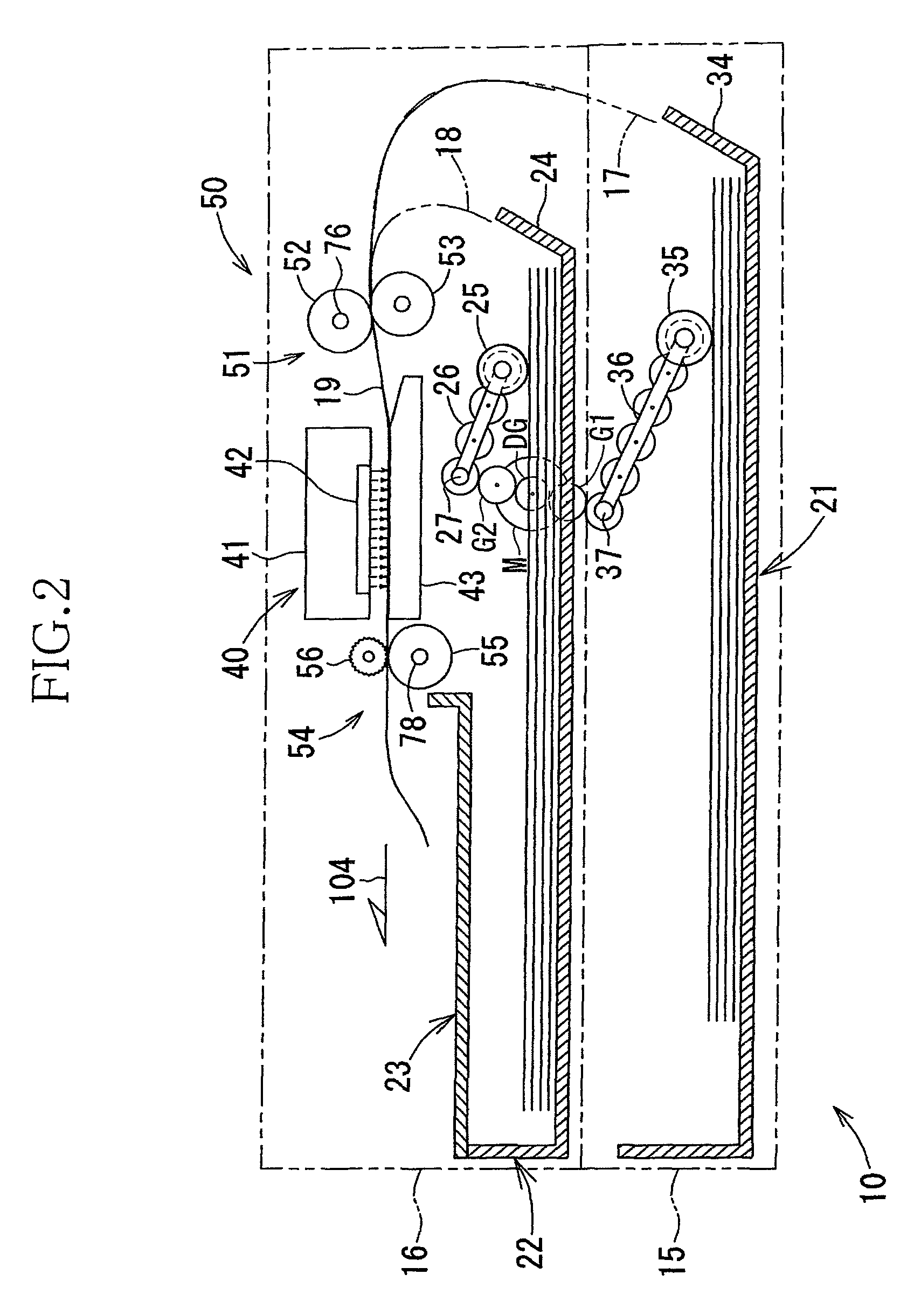

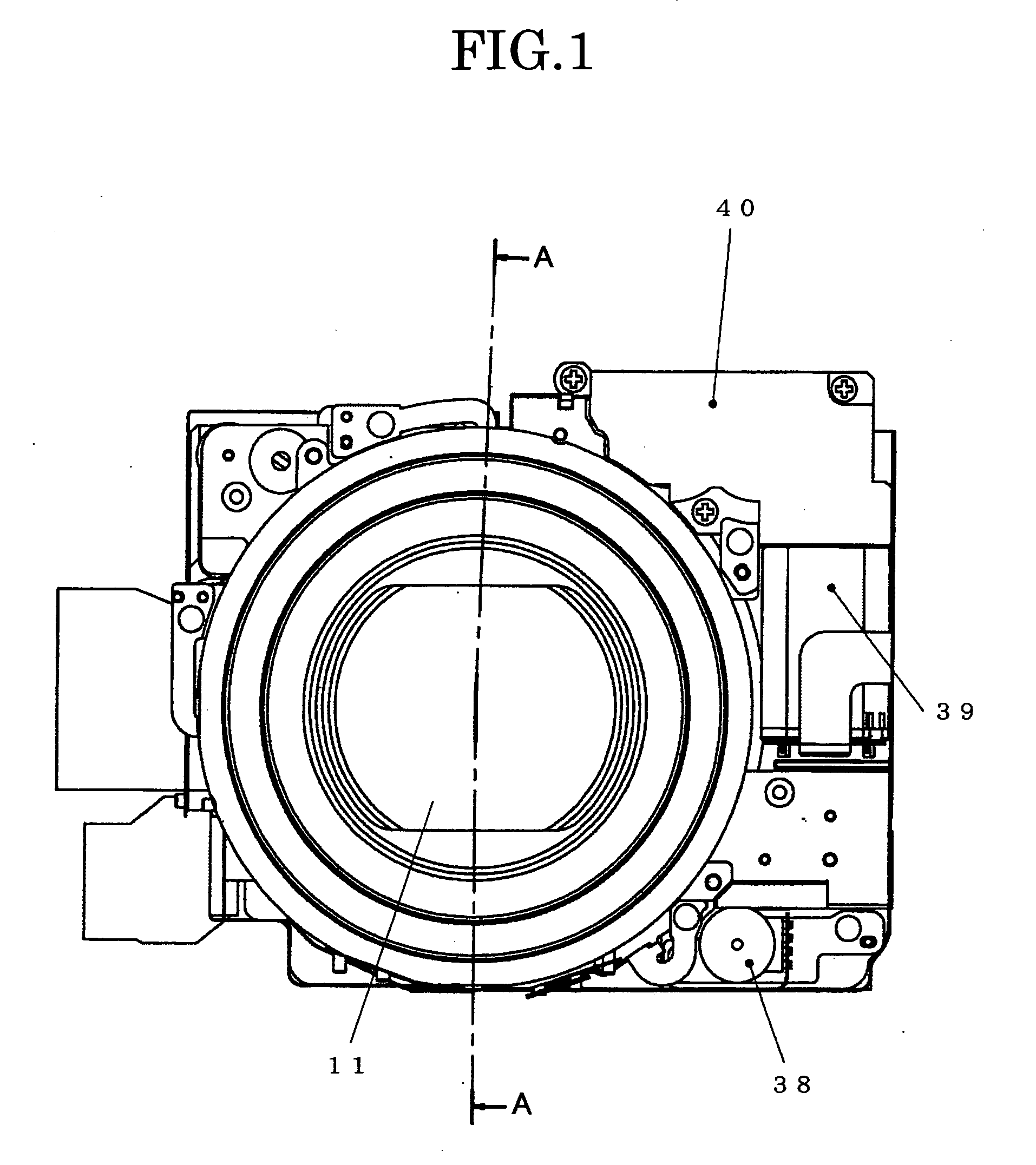

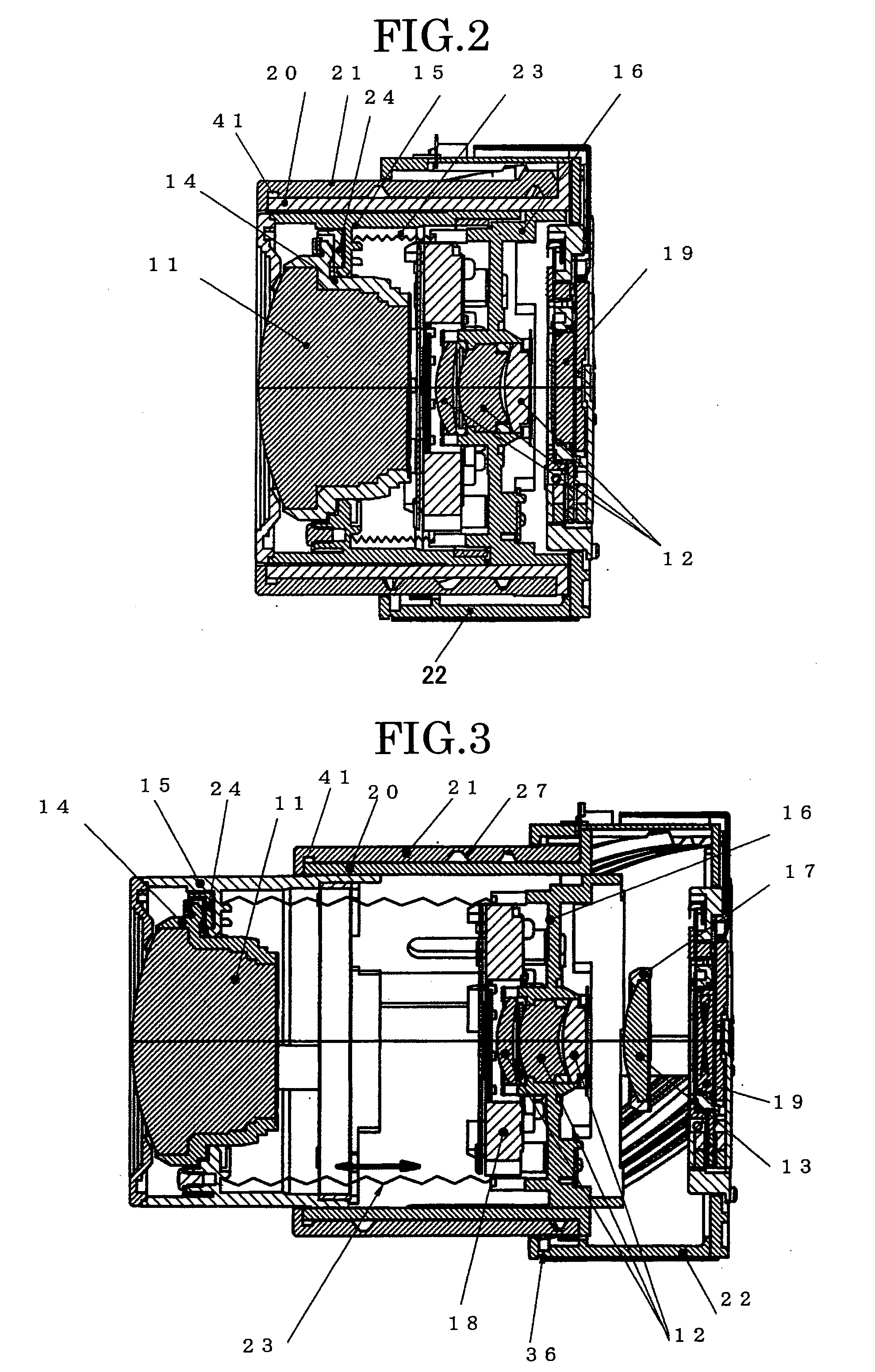

Lens barrel, camera and information device

InactiveUS7839579B2Avoid positioningEasy maintenanceMountingsCamera body detailsCamera lensOptical axis

A cam locus of the cam surface (G1) on the image plane side of the first group cam groove (27) of the rotating cylinder (21) has an angle to a flat surface where the optical axis crosses perpendicularly. In a case in which the cam follower (25) engages with (abuts on) the cam surface (G1) on the image plane side, an impact force is dispersed into the optical axis direction and into the rotating direction of the rotating cylinder (21), and a load which the cam follower (25) and the male helicoid (31) of the rotating cylinder (21) receive is reduced. Additionally, when the first group lens system (11) is pressed by a light load such as a hand operation by a user and the like, the cam follower (25) of the first group lens movement frame (15) engages with (or abuts on) the cam surface (G1) on the image plane side, and an angle of the cam surface (G1) is an angle that an occurring force in the rotating direction is so as to be a moving direction from the collapsed position (S1) to the wide angle end position (W1). Therefore, the rotating cylinder (21) does not rotate easily, and when the load is removed, returns to a position before the load is received.

Owner:RICOH KK

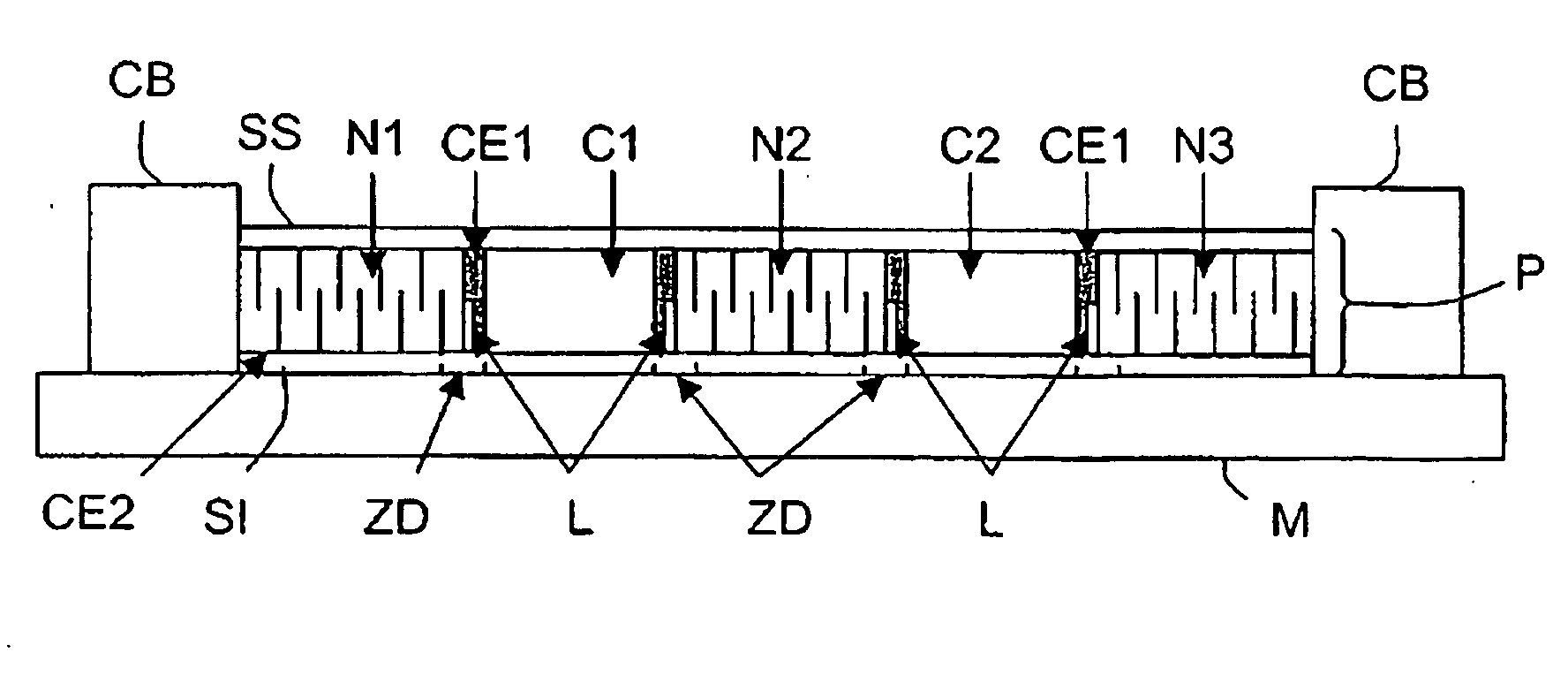

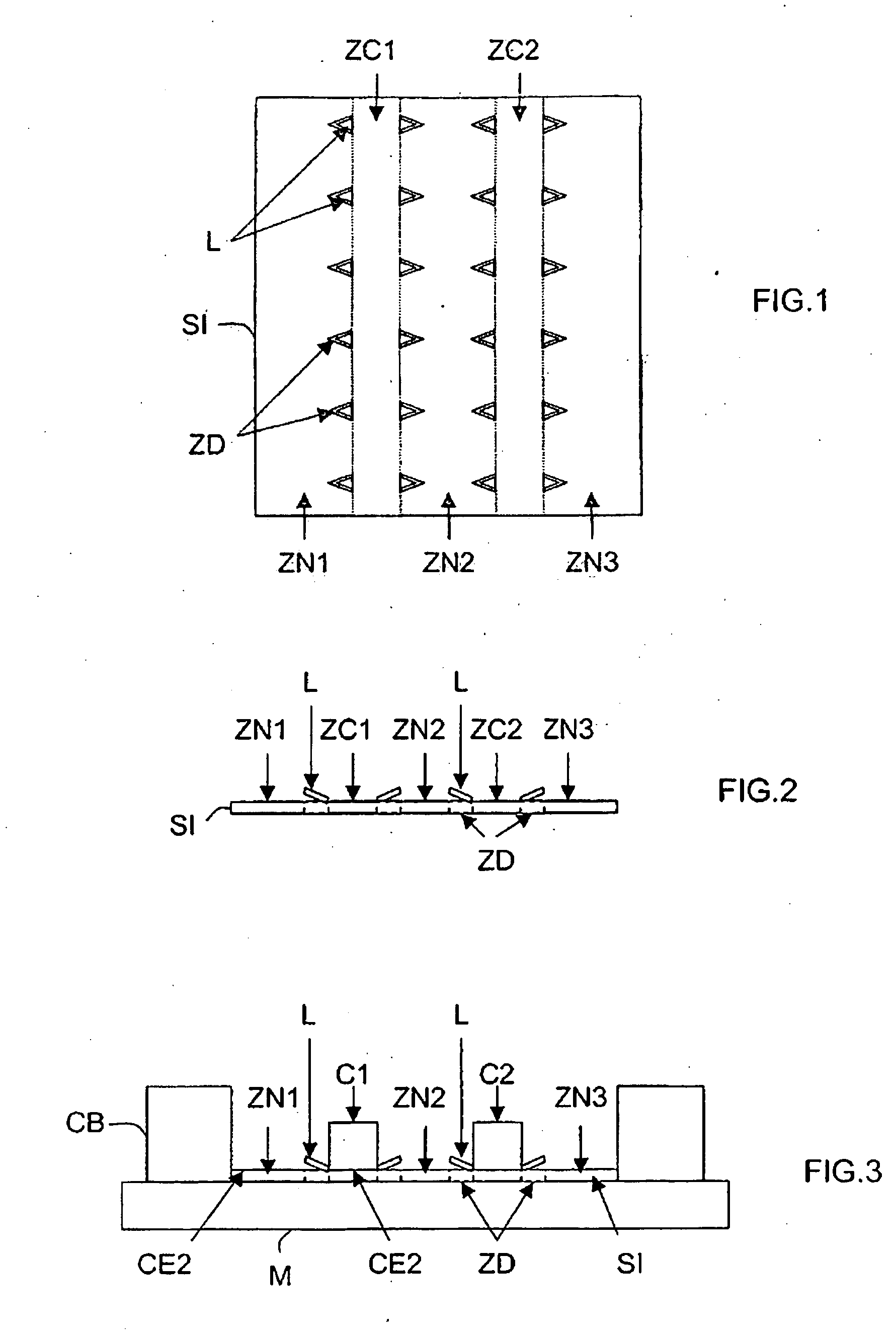

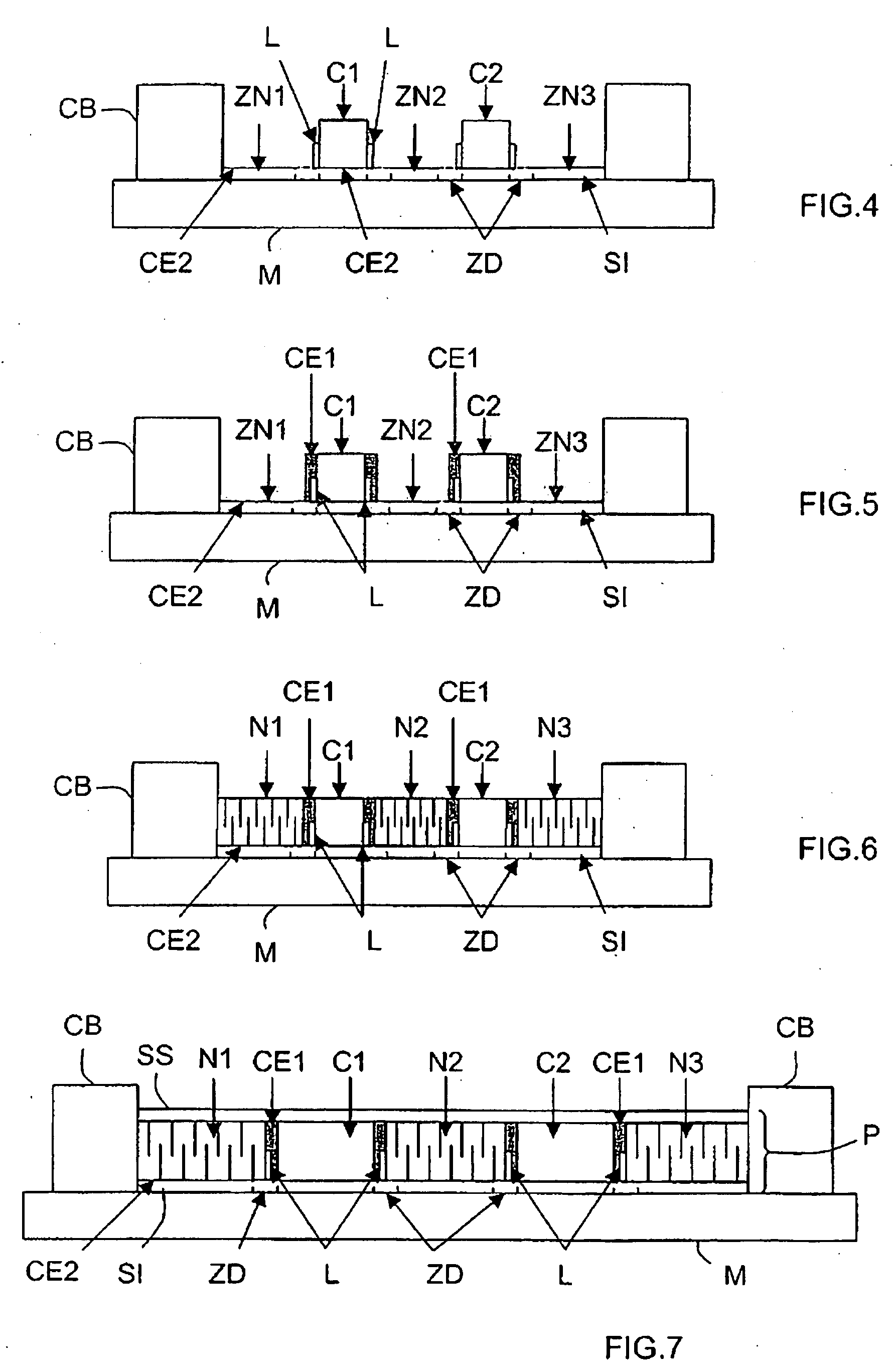

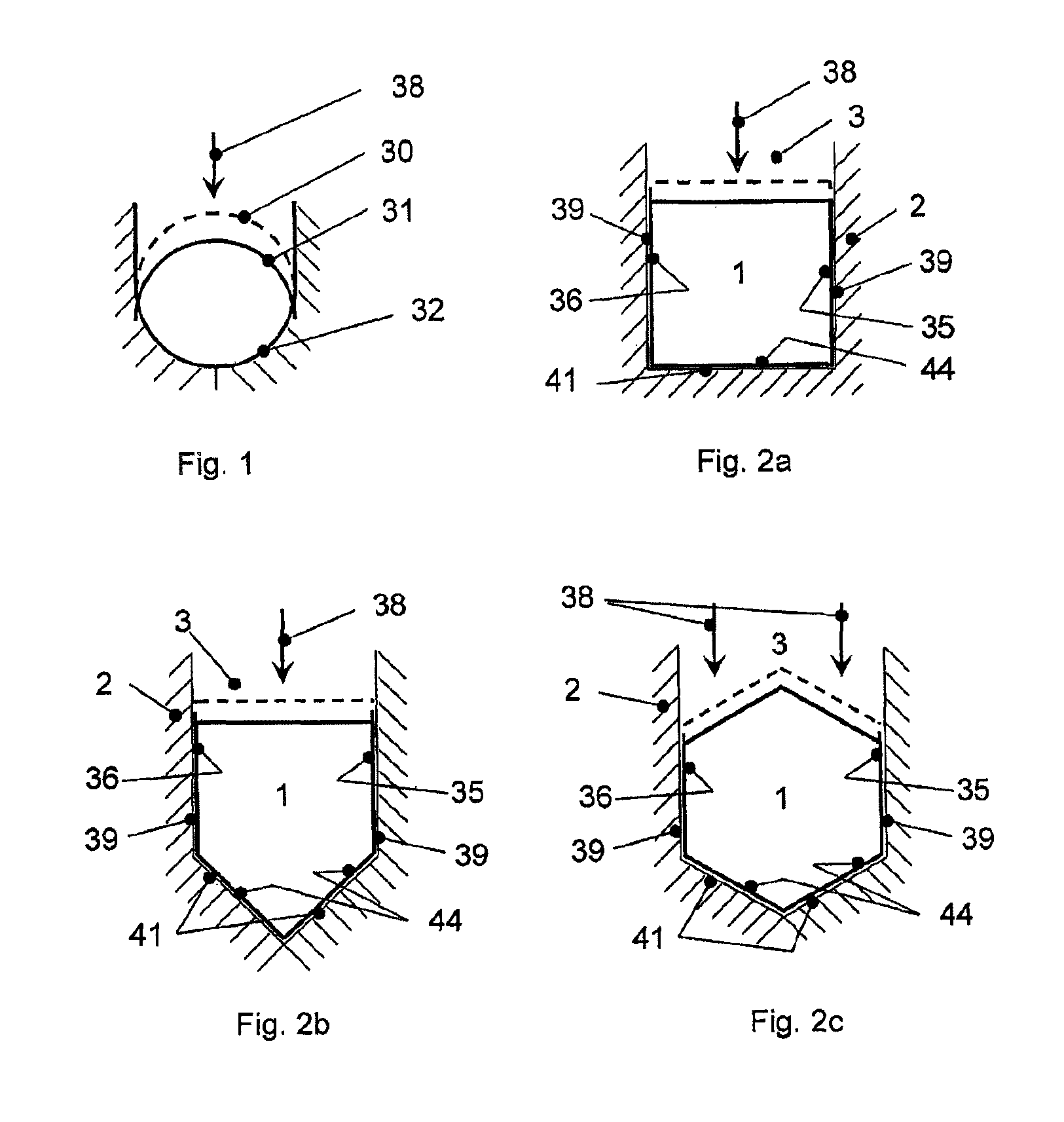

Method of manufacturing panels having integrated heat pipes and/or inserts maintained by tongues

InactiveUS20090218076A1Maintain positioning accuracyGood conditionIndirect heat exchangersHeat exchanger fasteningAdhesiveMechanical engineering

A method, dedicated to the fabrication of the panels having built-in heat pipe(s) and / or insert(s) (P), consists in a) providing a bottom plate (SI) comprising, in selected places on either side of the heat pipe or insert accommodation zones, tabs (L) which are substantially flat and suitable for being straightened above its upper face, b) partially straightening the tabs (L) toward the accommodation zones, c) positioning the heat pipes and / or the inserts (C1, C2) in each accommodation zone between the tabs (L) and in contact with the upper face of the bottom plate (SI), d) terminating the straightening of the tabs (L) so that they are pressed against the side faces of the heat pipes and / or inserts (Ci), e) depositing a selected thickness of a first adhesive against the side faces of the heat pipes and / or the inserts (Ci), f) positioning separating structures (N1-N3), substantially having the same height as that of the heat pipes and / or the inserts (C1, C2) on either side of the side faces of each heat pipe and / or insert and in contact with the upper face of the bottom plate (SI), and g) placing an upper plate (SS) above the heat pipes and / or inserts (C1, C2) and the separating structures (N1-N3) and in contact therewith.

Owner:THALES SA

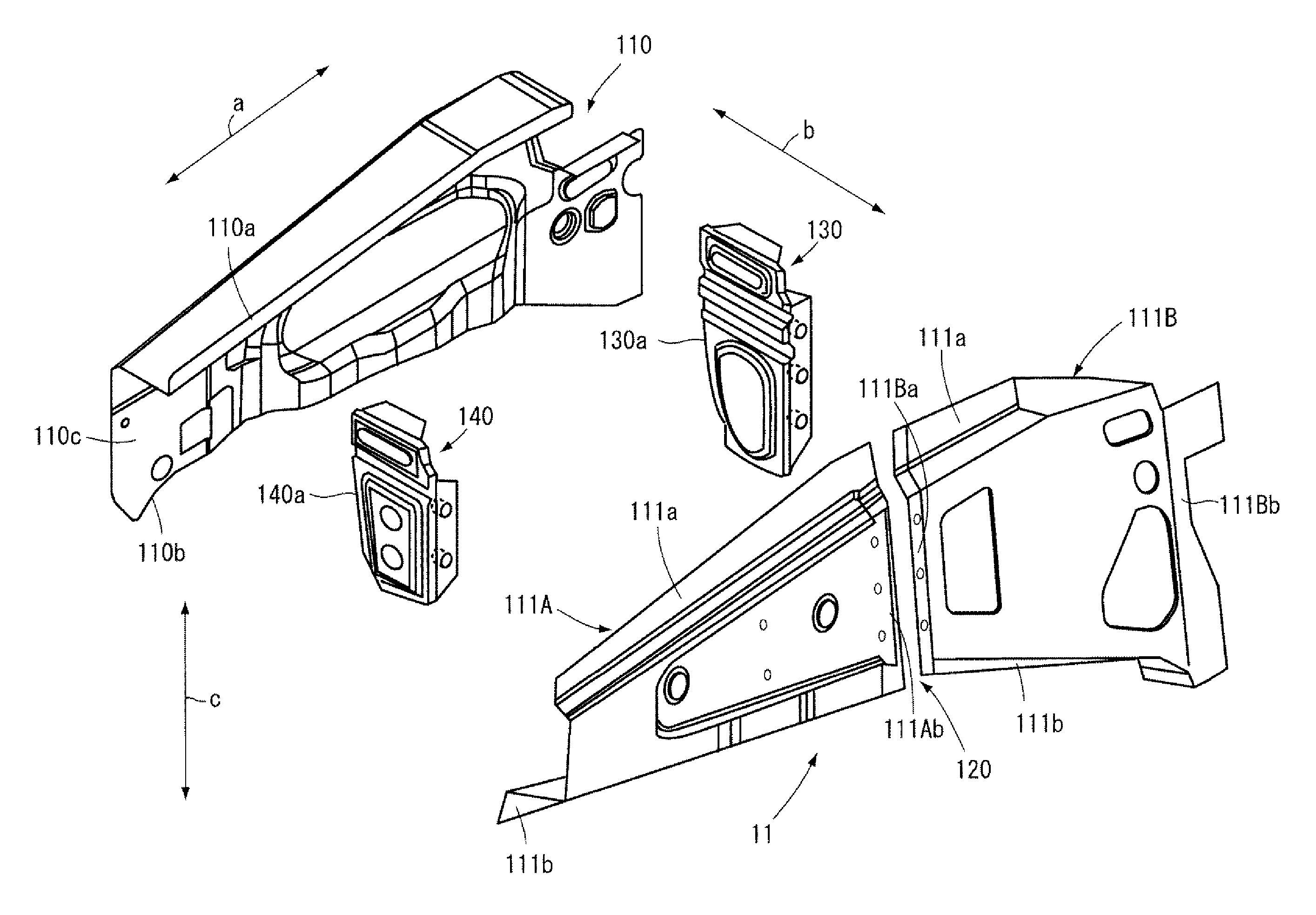

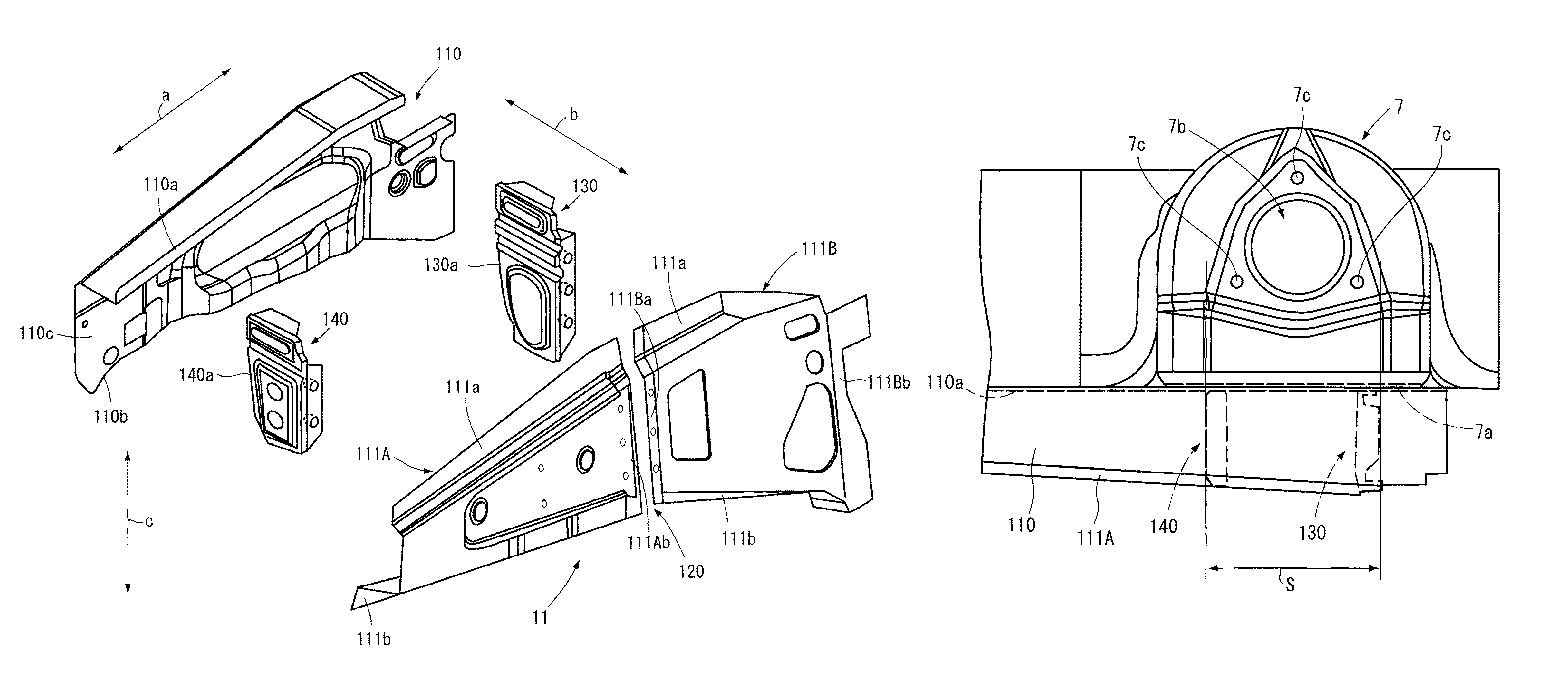

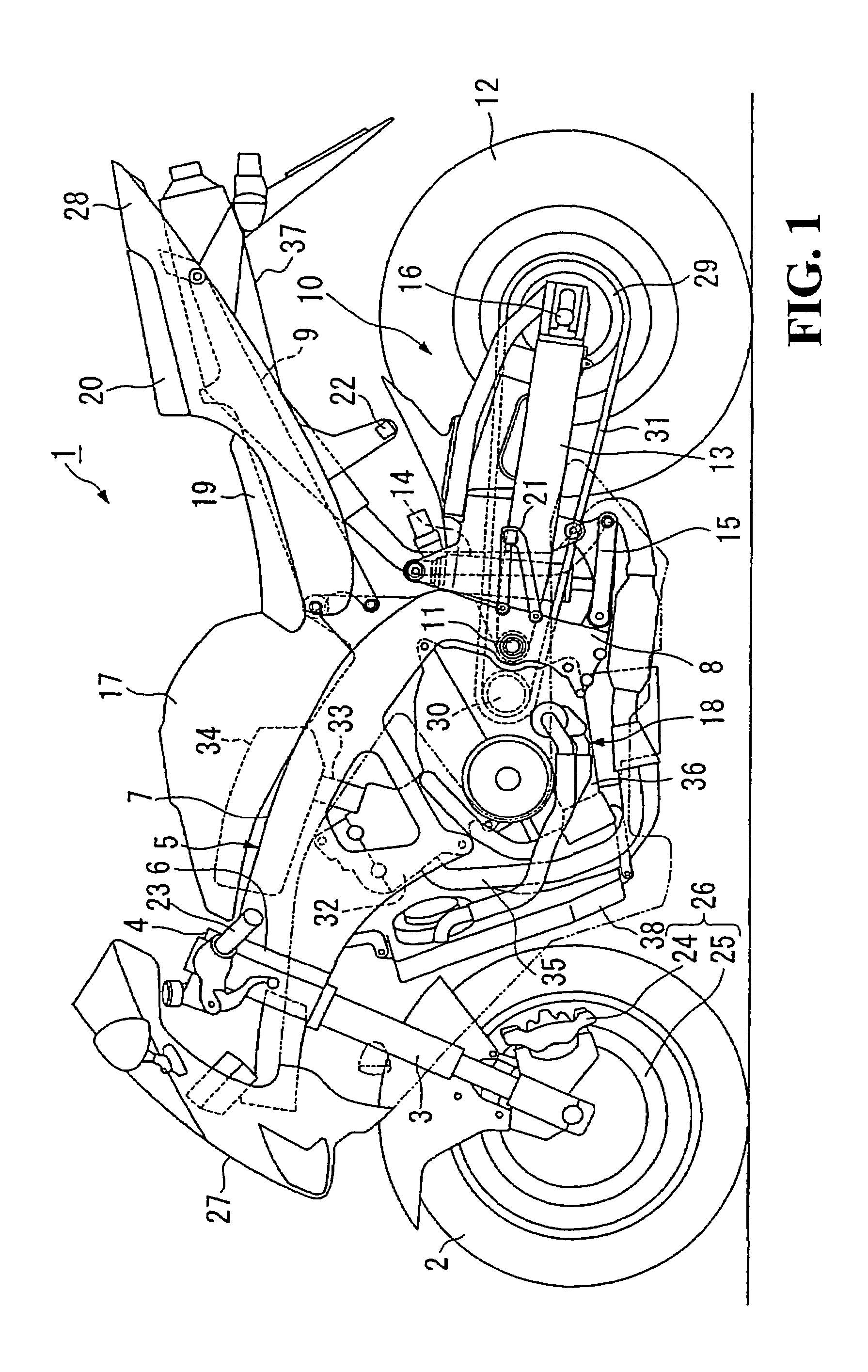

Front part body structure of vehicle

ActiveUS8727428B2Maintain positioning accuracyVehicle seatsSuperstructure subunitsEngineeringFastener

Owner:MITSUBISHI MOTORS CORP

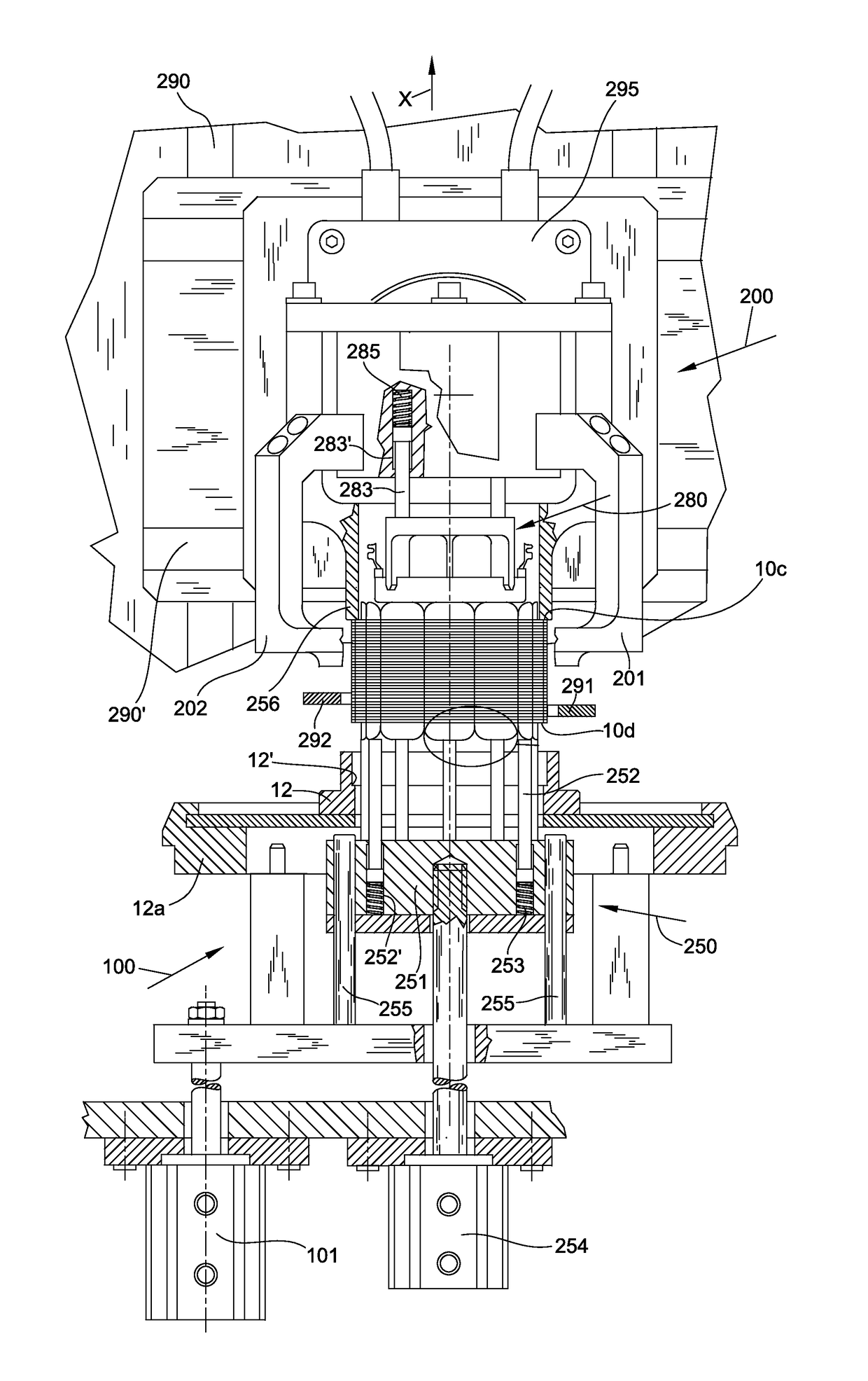

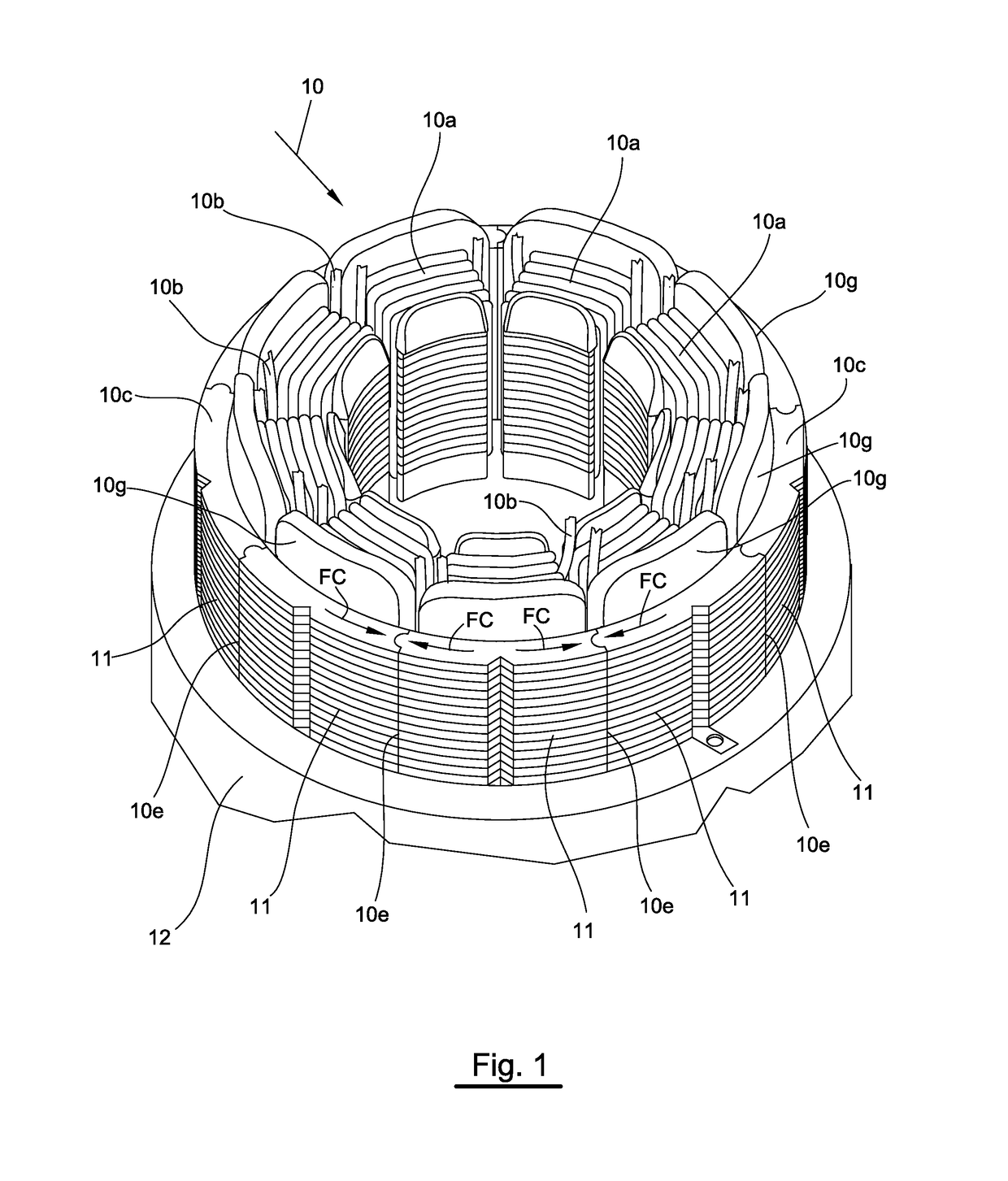

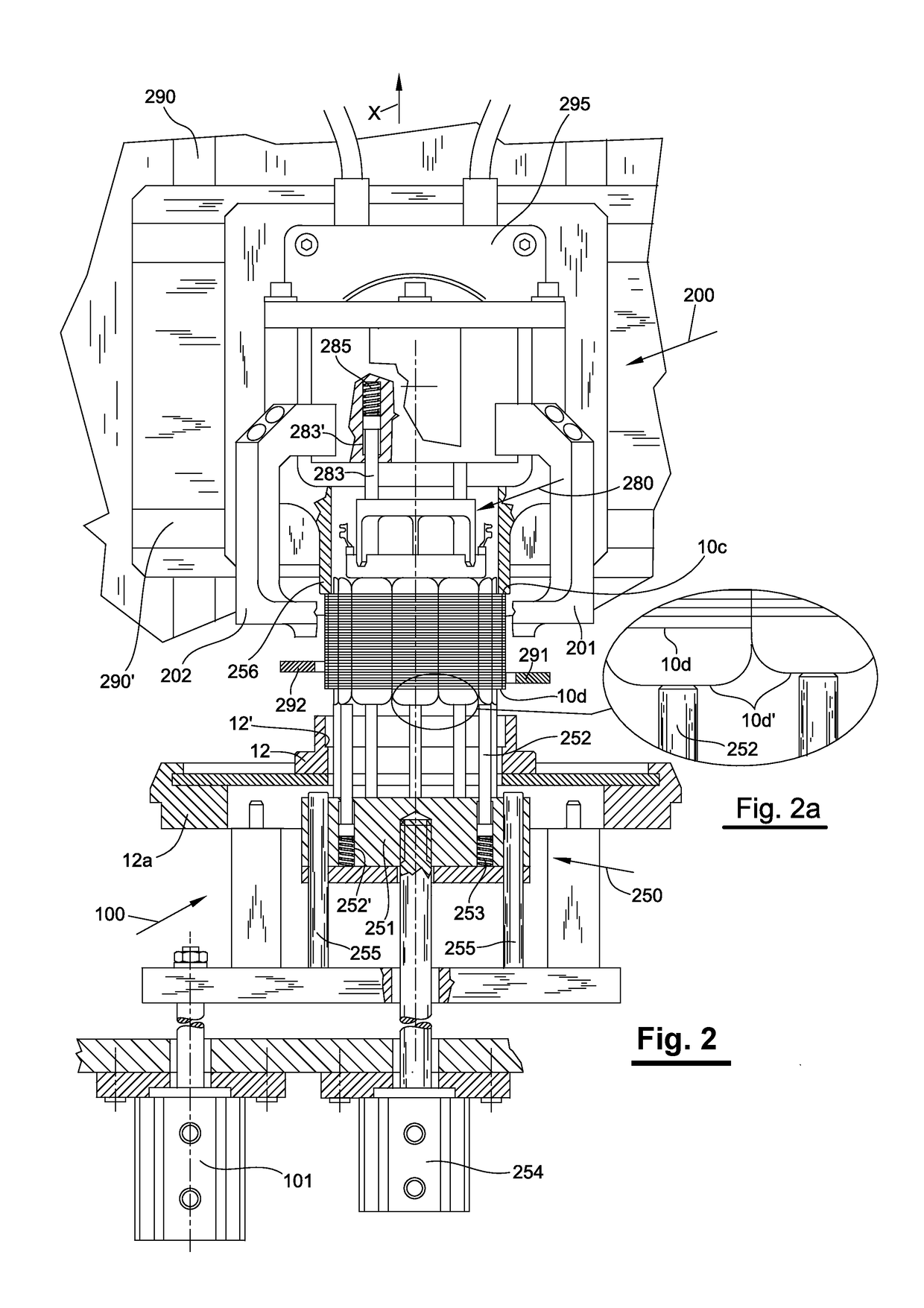

Apparatus for producing wound stators of dynamo electric machines formed from assembly of pole segments

ActiveUS10050498B2High degree of automationMaintain positioning accuracyMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringDynamo

An apparatus for manufacturing stators of dynamoelectric machines, the stators being formed as an assembly of pole segments; the apparatus comprising a seat where the assembly of pole segments are seated. An engagement assembly engages first ends of the pole segments for translation of the pole segments from the seat to a transfer device. A first holding assembly comprises a first plurality of holding members for clamping the pole segments to hold the pole segments as an assembly of pole segments. The first holding assembly being arranged on the transfer device moveable to transfer the assembly of pole segments from a first position to a second position. A containing assembly is located at the second position and provided with a second plurality of holding members for holding the assembly of pole segments. The second plurality of holding members are positioned on the containing assembly to surround the assembly of pole segments that are located at the containing assembly.

Owner:ATOP SPA

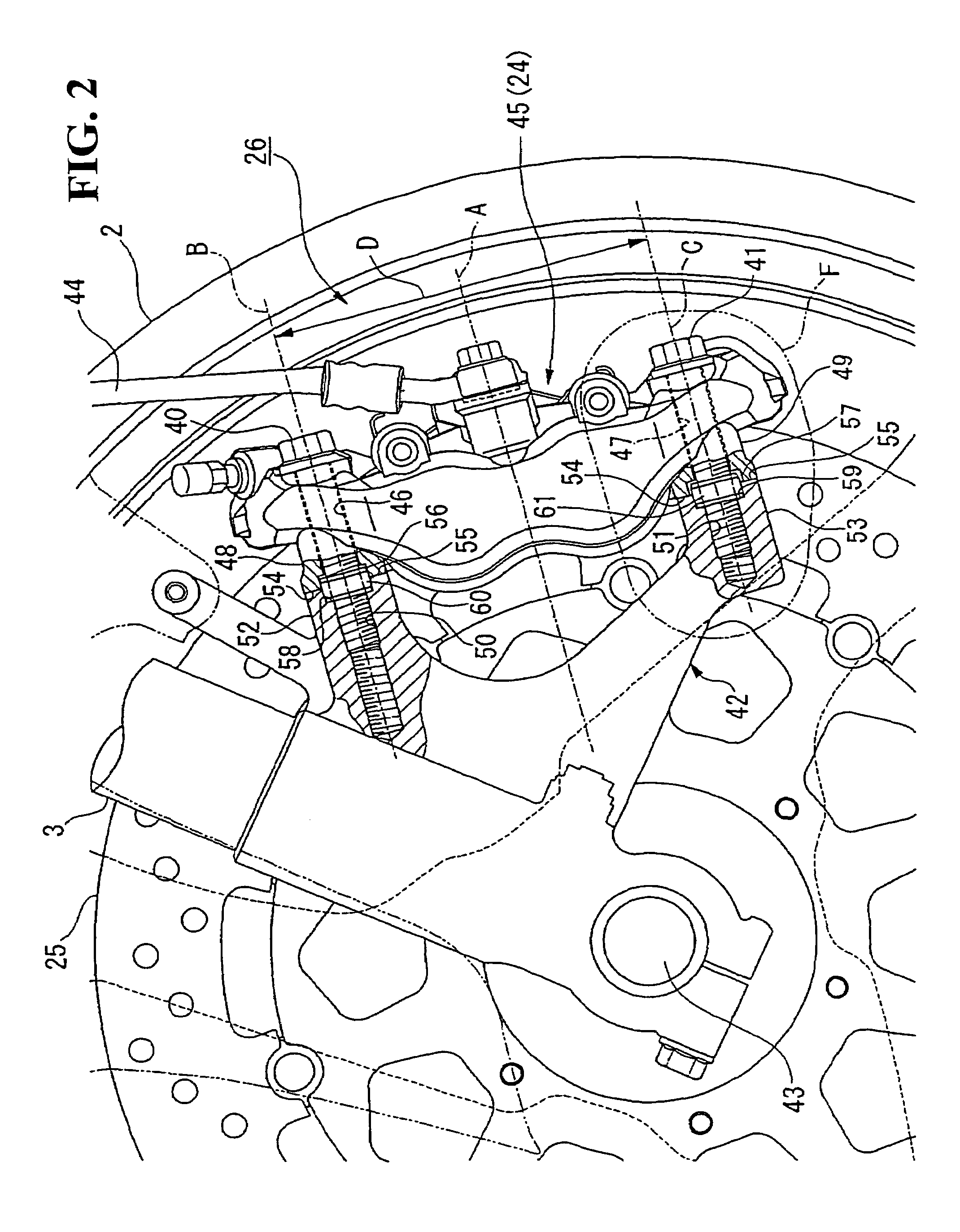

Disk brake

ActiveUS7407043B2Efficient preparationMaintain positioning accuracyBraking element arrangementsAxially engaging brakesEngineeringCounterbore

A front disk brake includes a brake caliper having a pair of caliper side mount portions, and a caliper bracket having a pair of bracket side mount portions. The brake caliper includes an oblong-shared lower-side counterbore and a circular-shaped upper-side counterbore, the lower-side counterbore being oblong sectional shaped in the arrangement direction of the lower-side counterbore and the upper-side counterbore paired therewith. The caliper bracket includes lower-side and upper side circular-shaped counterbores which are opposed, respectively, to the counterbores of the brake caliper. The brake caliper is fixed to the caliper bracket by mounting fastening bolts in bolt passing holes and screw holes formed respectively in the mount portions. The bolt passing holes and the screw holes are provided at their portions on the sides of opposed surfaces with counterbores in which collar members are to be fitted.

Owner:HONDA MOTOR CO LTD

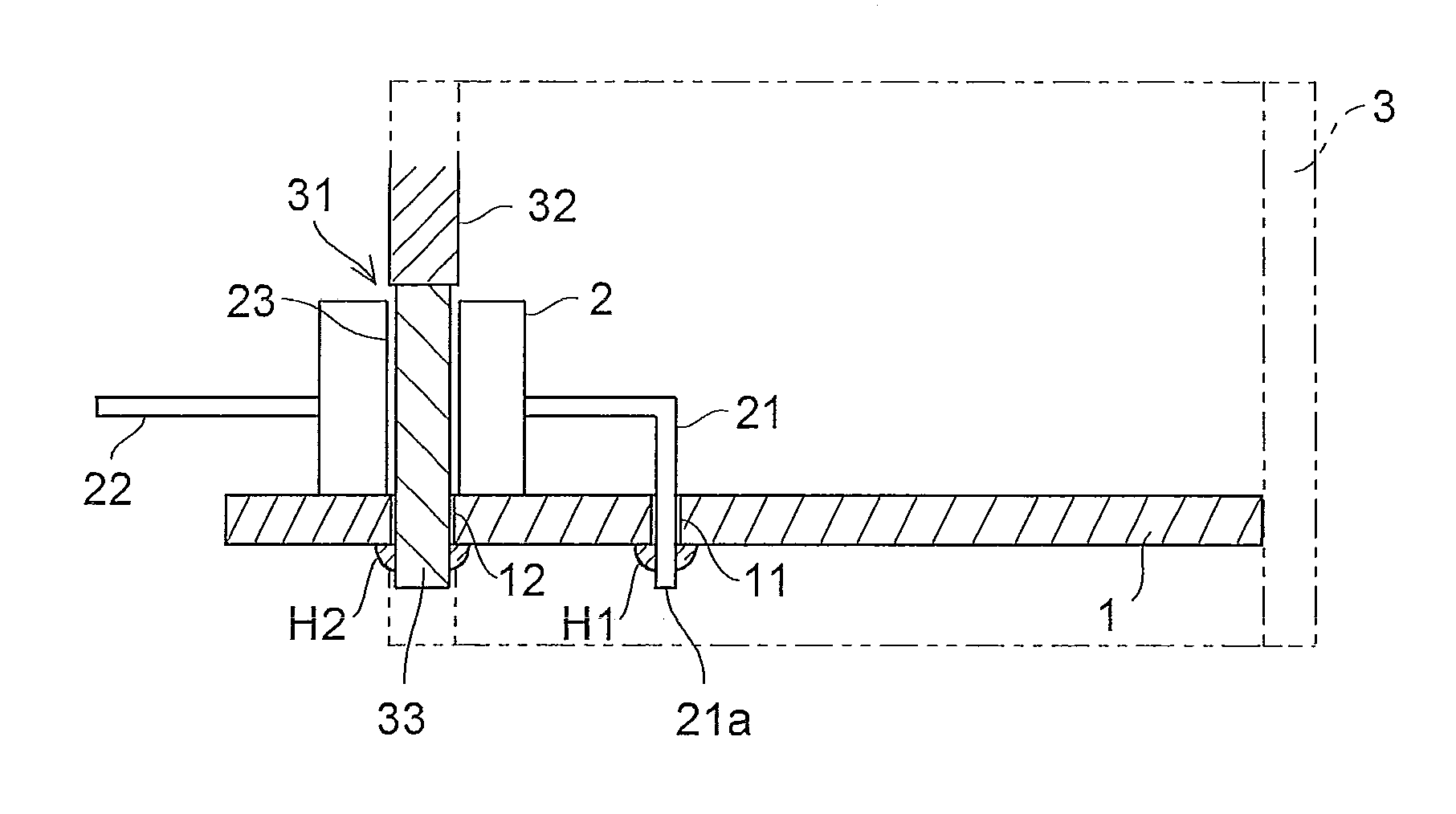

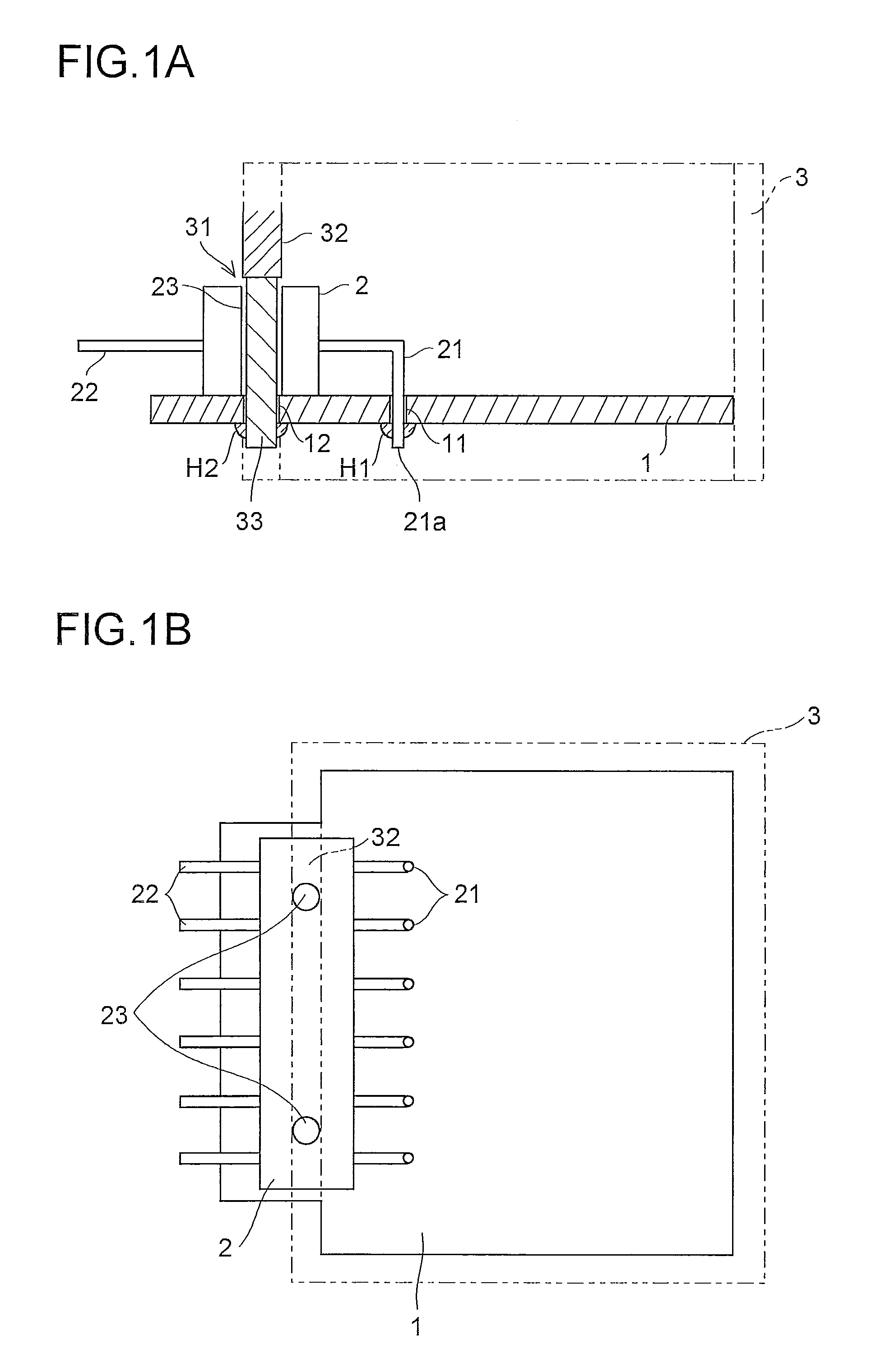

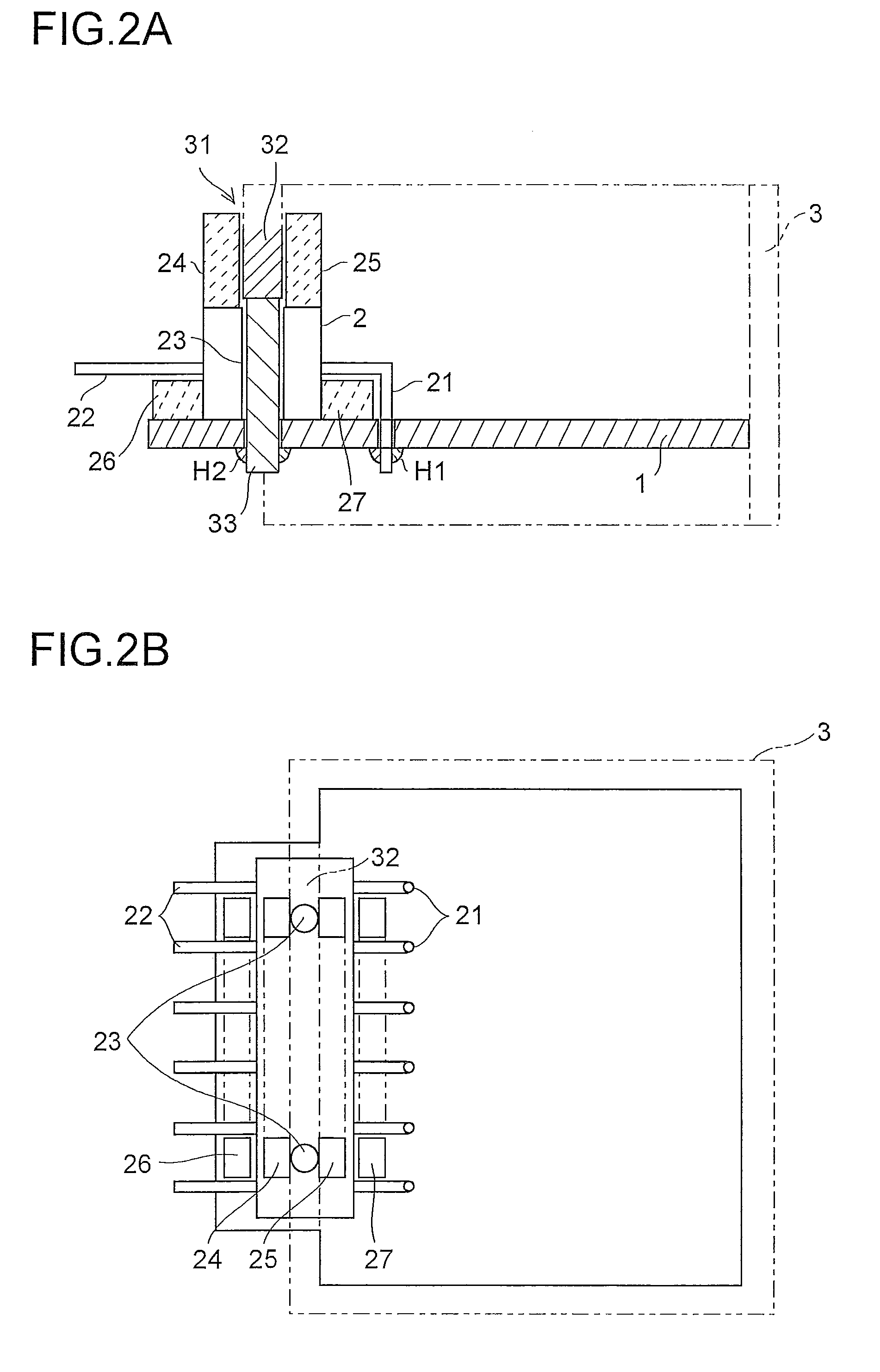

Terminal structure of an electronic component

InactiveUS20100124033A1Improve assembly strengthAvoid leaningMagnetic/electric field screeningPrinted circuit aspectsElectronic componentPrinted circuit board

The invention relates to a terminal structure of an electronic component, such as a tuner, in which a printed circuit board 1 on which electronic components including a pin header 2 having a plurality of pin terminals, and a case frame 3 housing the printed circuit board and having a notch opening exposing the pin terminals are provided. A guide hole 23 that penetrates from the upper surface of the pin header 2 to its lower surface in contact with the printed circuit board, and a guide axis 33—insertable into the guide hole 23—provided in a press portion 32 are provided, such that the pin header is held between the press portion 32 provided in the case frame 3 and the printed circuit board, enabling the pin header, even a slim, compact one, having a plurality of pin terminals to be fixed accurately to a predetermined position on the board with a predetermined posture.

Owner:SHARP KK

Method of manufacturing a disk and transfer method for the disk

InactiveUS6770162B2Avoid it happening againAvoid displacementRecording apparatusRecord carriersEngineeringVertical orientation

In case of manufacturing a disk having a two-layer structure, a glass substrate 13 is bonded to a cover layer 11 through an adhesive layer 12, and a mount hole 14a is formed in a center thereof to form a bonded substrate 14 having a three-layer structure (a). In a state where a stamper 15 formed a predetermined pit pattern is set to a center boss 16, the bonded substrate 14 is pressed downward in a vertical direction while the mount hole 14a of the bonded substrate 14 is aligned with the center boss 16(b). Whereby an information recording surface 11a is transferred onto the cover layer 11(c). Subsequently, after the bonded substrate 14 has been bonded to another layer substrate of the disk, the adhesive layer 12 is removed to separate the glass substrate 13. Finally, there is manufactured the disk having the two-layer structure.

Owner:PIONEER CORP

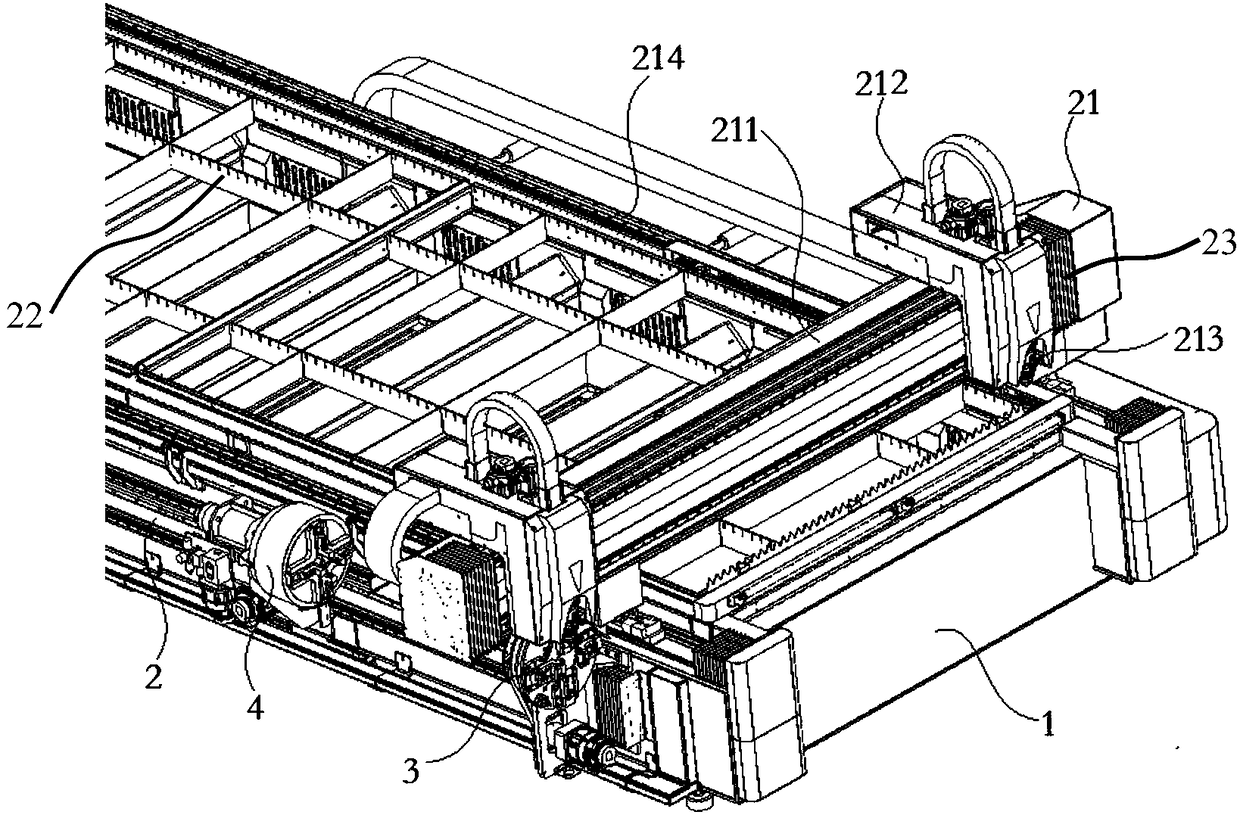

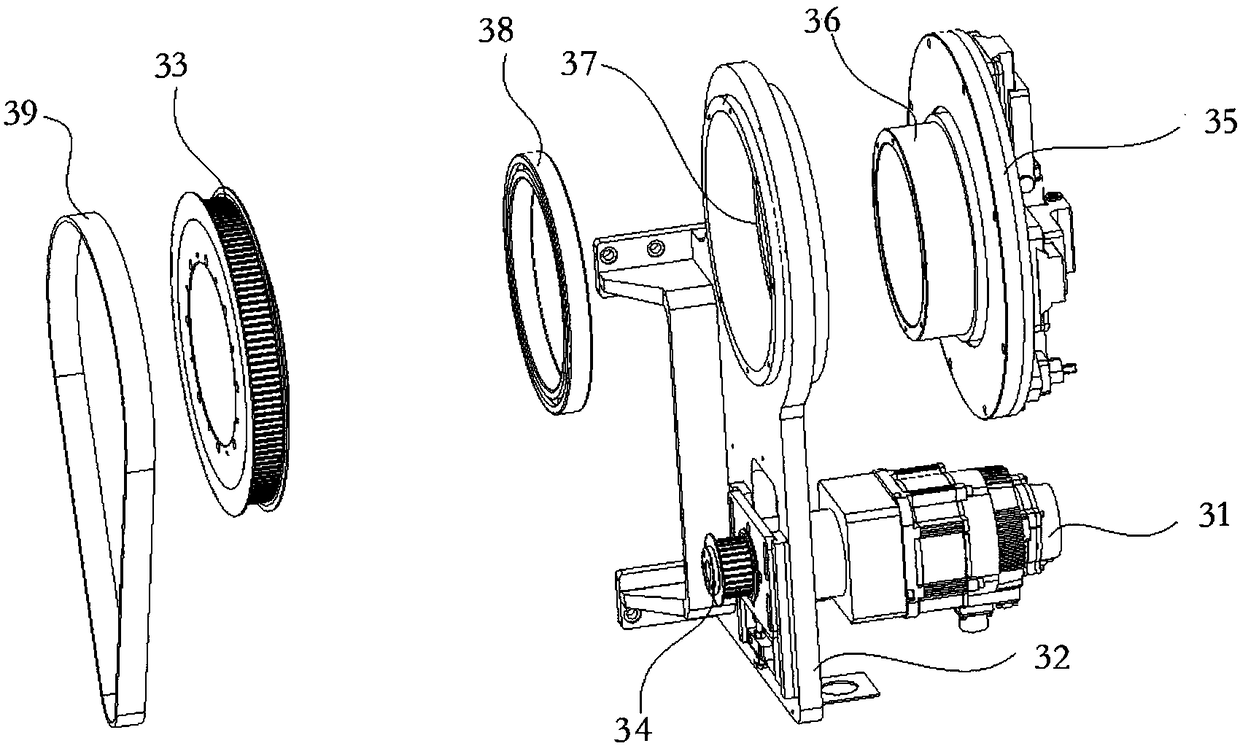

Laser cutting machine with focusing laser head

InactiveCN108655563ASolve the problem of not being able to cut thick platesAvoid Laser DamageLaser beam welding apparatusThick plateEngineering

The invention discloses a laser cutting machine with a focusing laser head. The laser cutting machine with the focusing laser head comprises a base, side guide rails, a front end supporting mechanism,a rear end rotating mechanism and a cutting mechanism, wherein the side guide rails are oppositely arranged on the surfaces of the two sides of the base; the cutting mechanism is movably installed onthe upper surface of the base, and the rear end rotating mechanism is installed on the surface of one side of the base through a guide rail and can move back and forth along the guide rail; the frontend supporting mechanism and the rear end rotating mechanism are arranged in parallel and are arranged at one end of the base, a main shaft is arranged on the rear end surface of the large disc, anda small gear shaft is connected to the inner wall of a through hole of a bearing seat through a bearing; and an outer locking nut is tightly connected to four clamping pieces of a locking bearing gland through threads, so that small gear shafts are clamped and positioned. According to the laser cutting machine with the focusing laser head, the laser cutting head of the laser cutting machine can set the focal point size, different focal point diameters are set according to different materials and plate thicknesses, and the problem that the thick plates cannot be cut by the optical fibers is solved; and the machine has the focusing function and can be used for cutting a workpiece with different material thicknesses, the position of the focal point can be adjusted only by parameter setting, and manual adjustment is not needed.

Owner:沧州领创激光科技有限公司

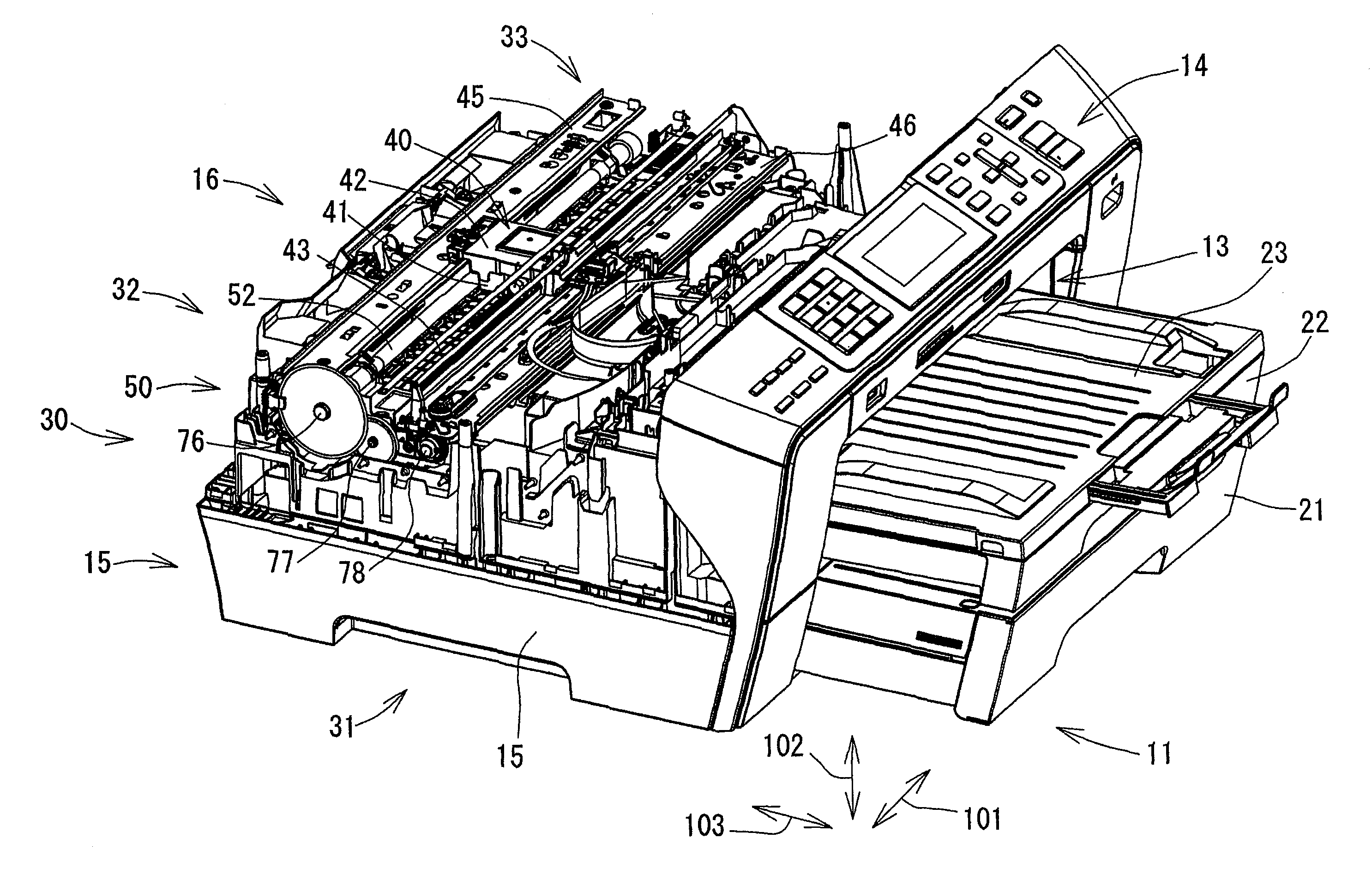

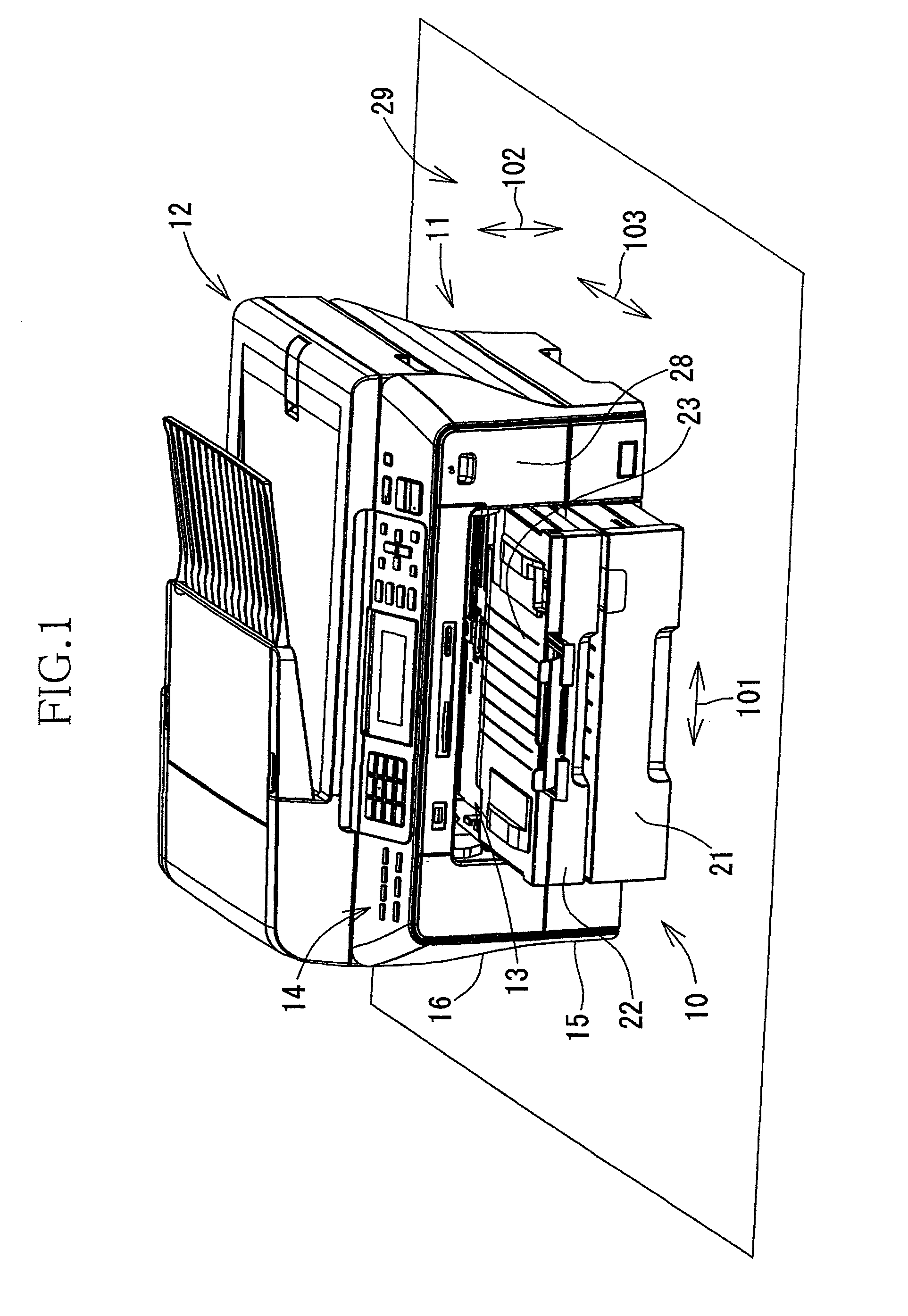

Image recording apparatus

ActiveUS8297611B2Maintain positioning accuracySuffer distortionArticle feedersArticle separationImage recordingEngineering

An image recording apparatus including first and second bodies that are removably connected to each other. The first body includes (i-a) a pair of first box portions (i-b) a connector interconnecting the first box portions, (i-c) at least one first foot portion provided on a bottom surface of each of the first box portions so as to be in contact with an installed surface, and (i-d) at least one first support portion extending upwardly from the at least one first foot portion. The second body includes (ii-a) a pair of second box portions, (ii-b) a connector interconnecting second box portions, and (ii-c) at least one second foot portion provided on a bottom surface of each of the second box portions. The second foot portion is located in a position aligned with the first support portion, so as to be in contact with a distal end of the first support portion. A sheet conveying device is held by a frame member which bridges between the second box portions.

Owner:SCOMI OILTOOLS CANADA +1

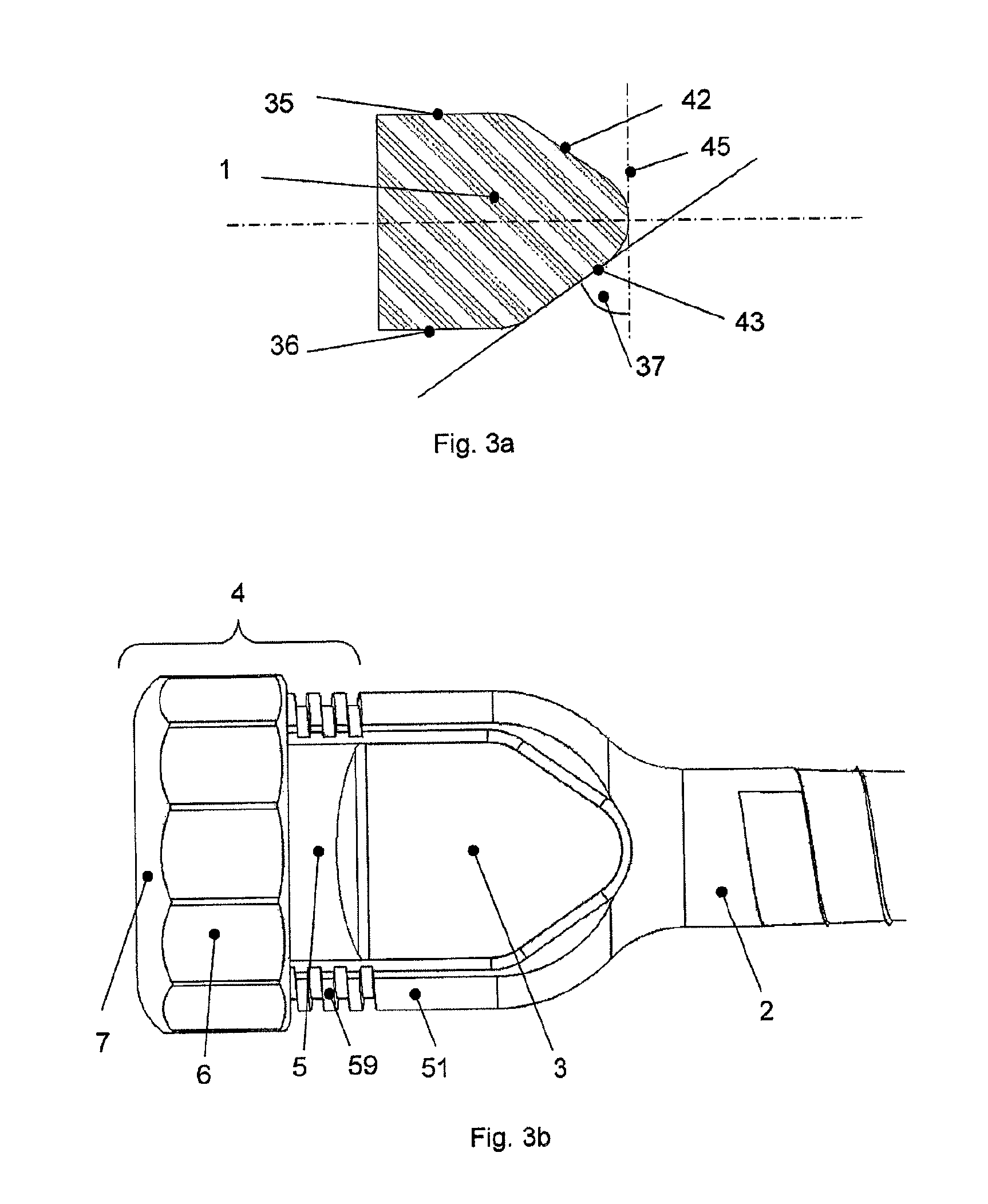

Anchorage arrangement for a connecting rod for the stabilization of the spine

ActiveUS9149298B2Less stressMaintain positioning accuracyInternal osteosythesisJoint implantsSurgical treatmentEngineering

Plastic rod anchorage for the surgical treatment of the spine where the plastic rod (1) has at least two plane-parallel surfaces (1a) in order to uniformly clamp the rod (1) on its entire circumference.

Owner:SPINESAVE

Lens barrel, camera and information device

InactiveUS20100046089A1Prevent lens positionReduce loadMountingsCamera body detailsCamera lensOptical axis

A cam locus of the cam surface (G1) on the image plane side of the first group cam groove (27) of the rotating cylinder (21) has an angle to a flat surface where the optical axis crosses perpendicularly. In a case in which the cam follower (25) engages with (abuts on) the cam surface (G1) on the image plane side, an impact force is dispersed into the optical axis direction and into the rotating direction of the rotating cylinder (21), and a load which the cam follower (25) and the male helicoid (31) of the rotating cylinder (21) receive is reduced. Additionally, when the first group lens system (11) is pressed by a light load such as a hand operation by a user and the like, the cam follower (25) of the first group lens movement frame (15) engages with (or abuts on) the cam surface (G1) on the image plane side, and an angle of the cam surface (G1) is an angle that an occurring force in the rotating direction is so as to be a moving direction from the collapsed position (S1) to the wide angle end position (W1). Therefore, the rotating cylinder (21) does not rotate easily, and when the load is removed, returns to a position before the load is received.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com