Patents

Literature

232results about How to "Improve assembly strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

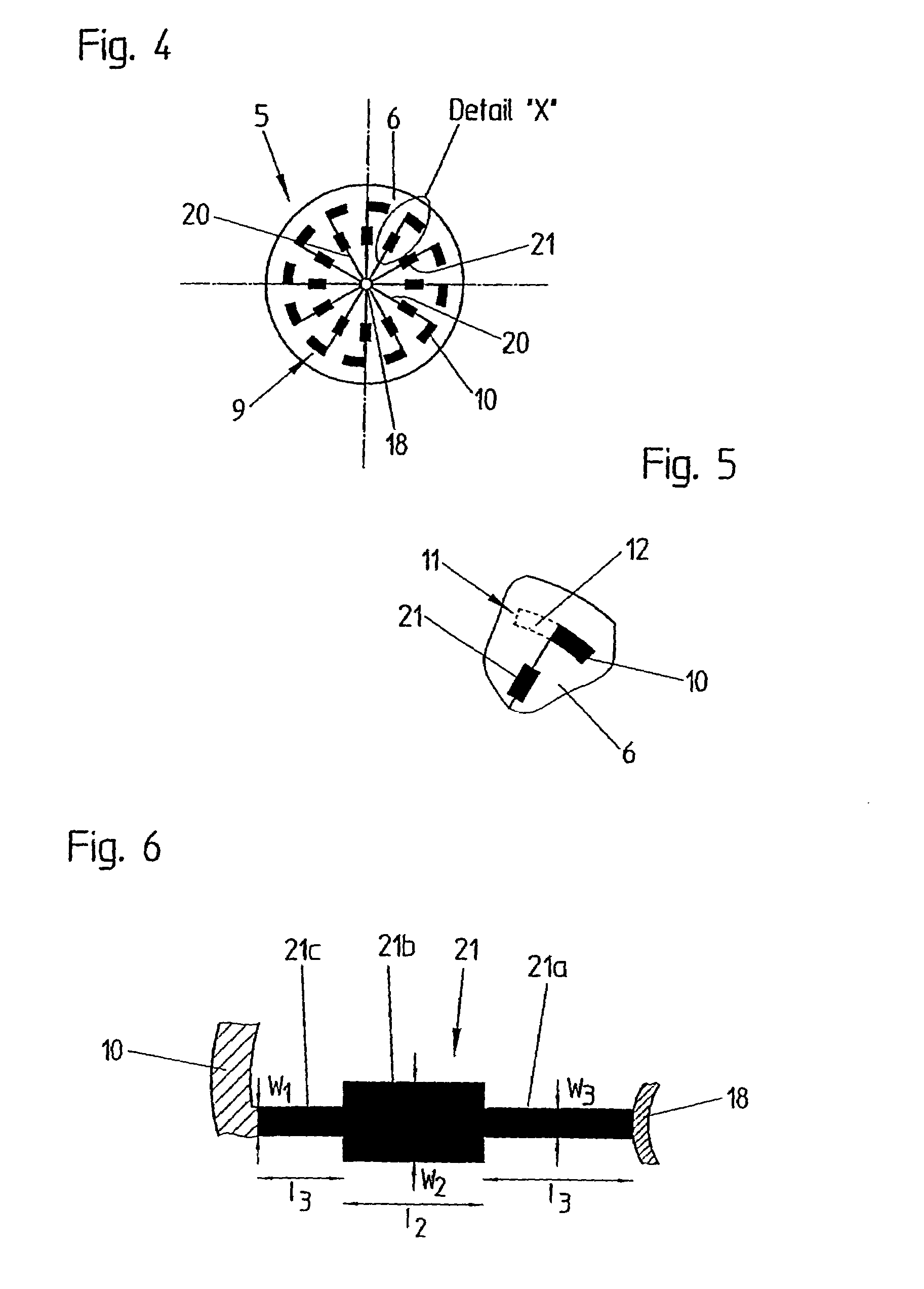

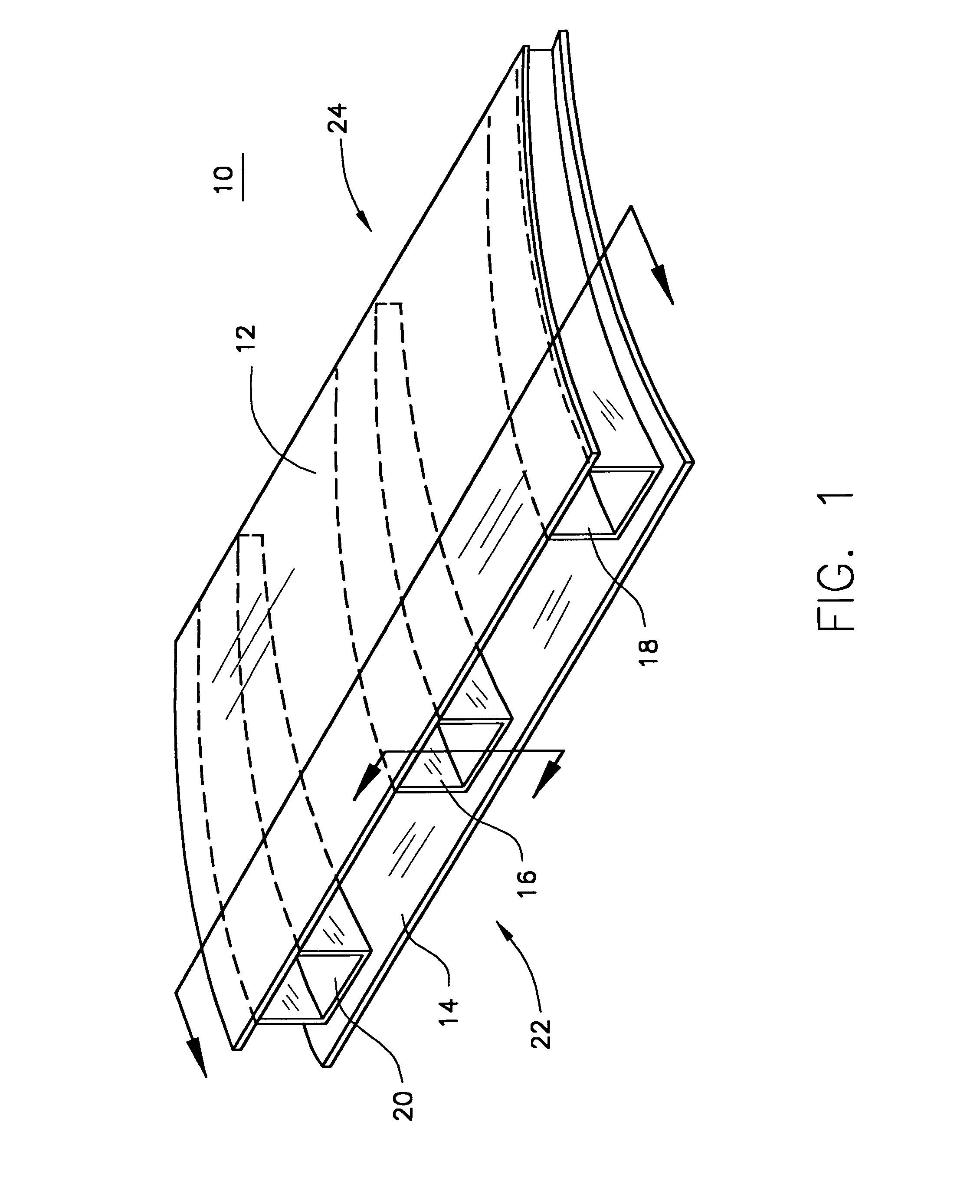

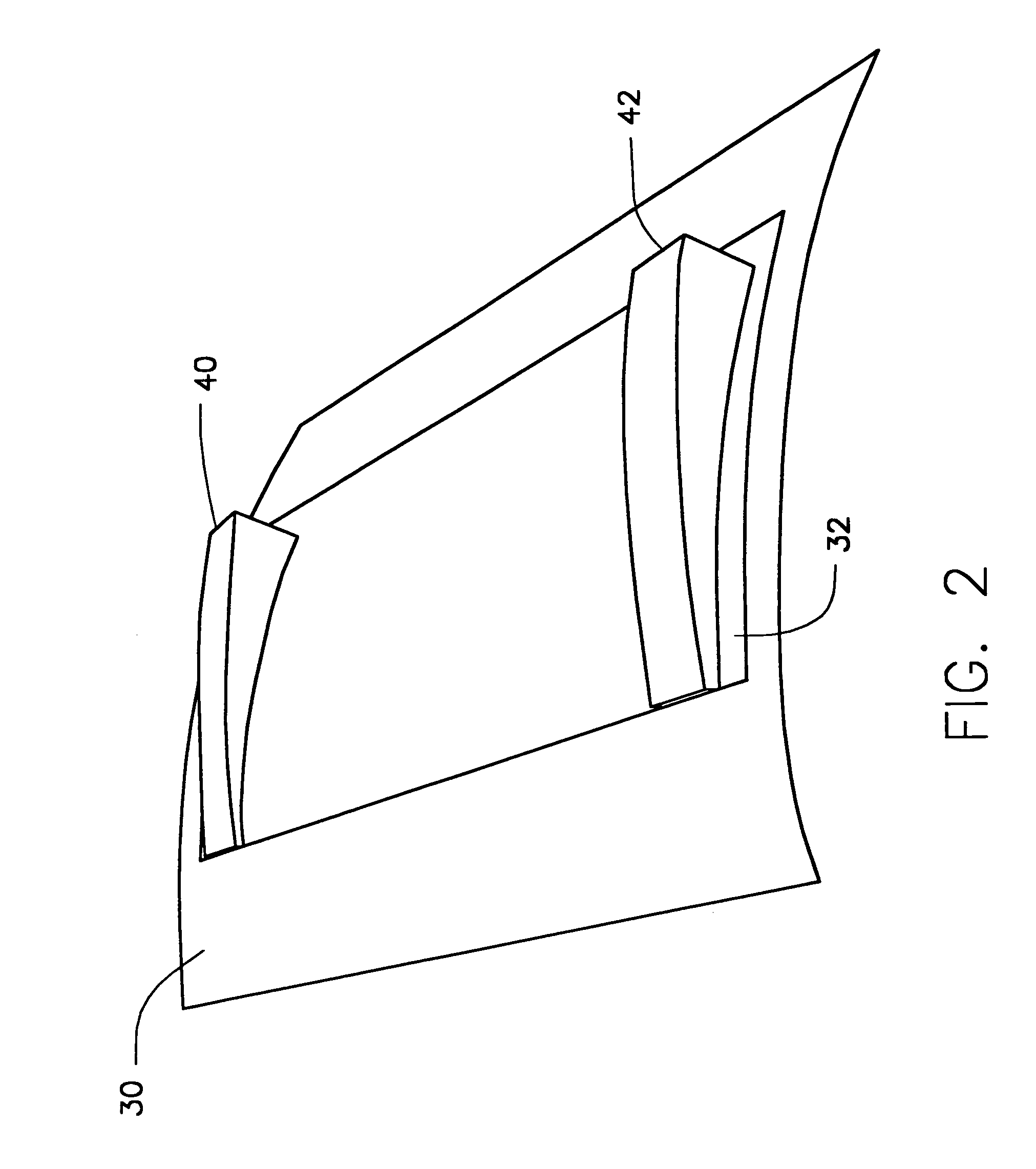

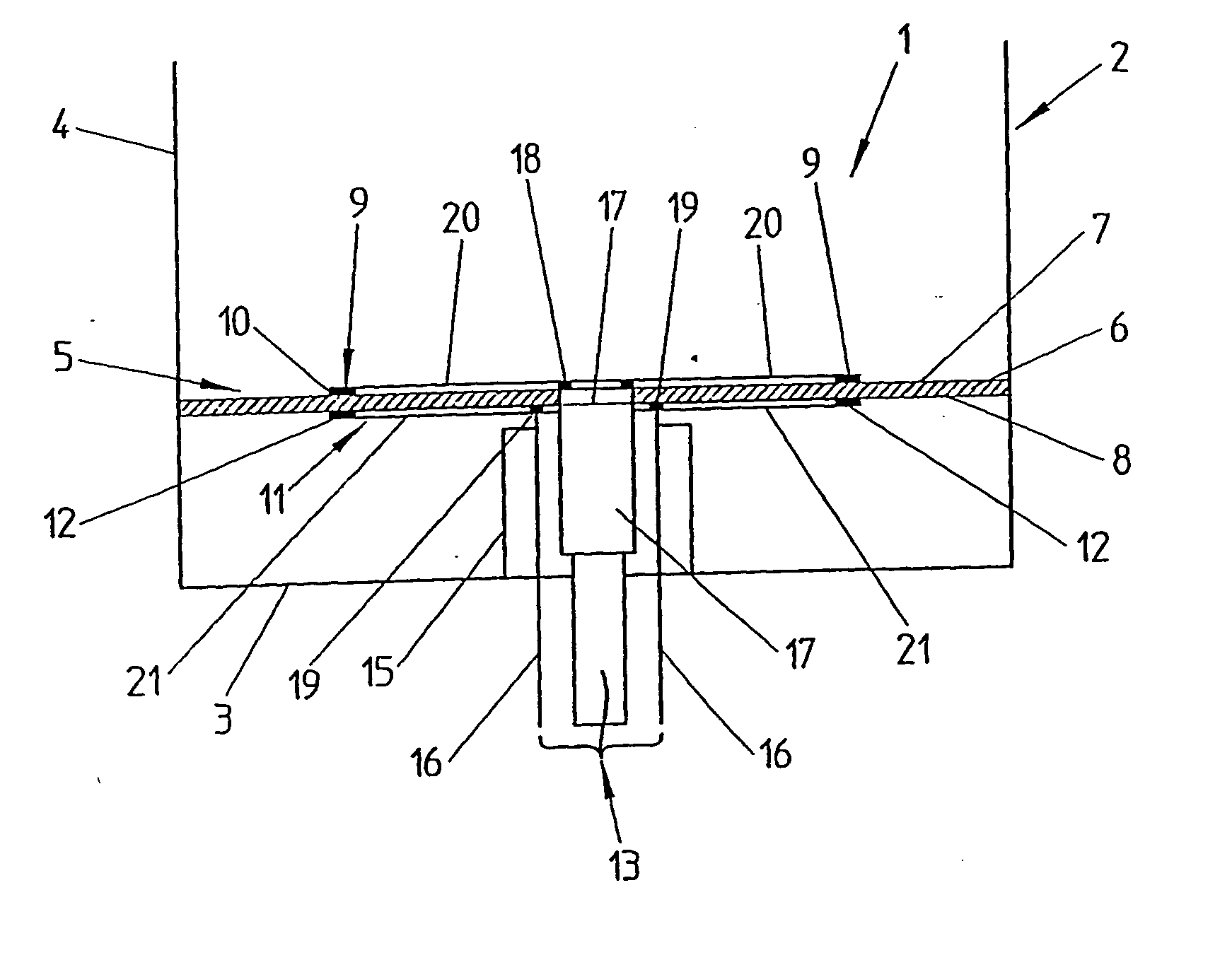

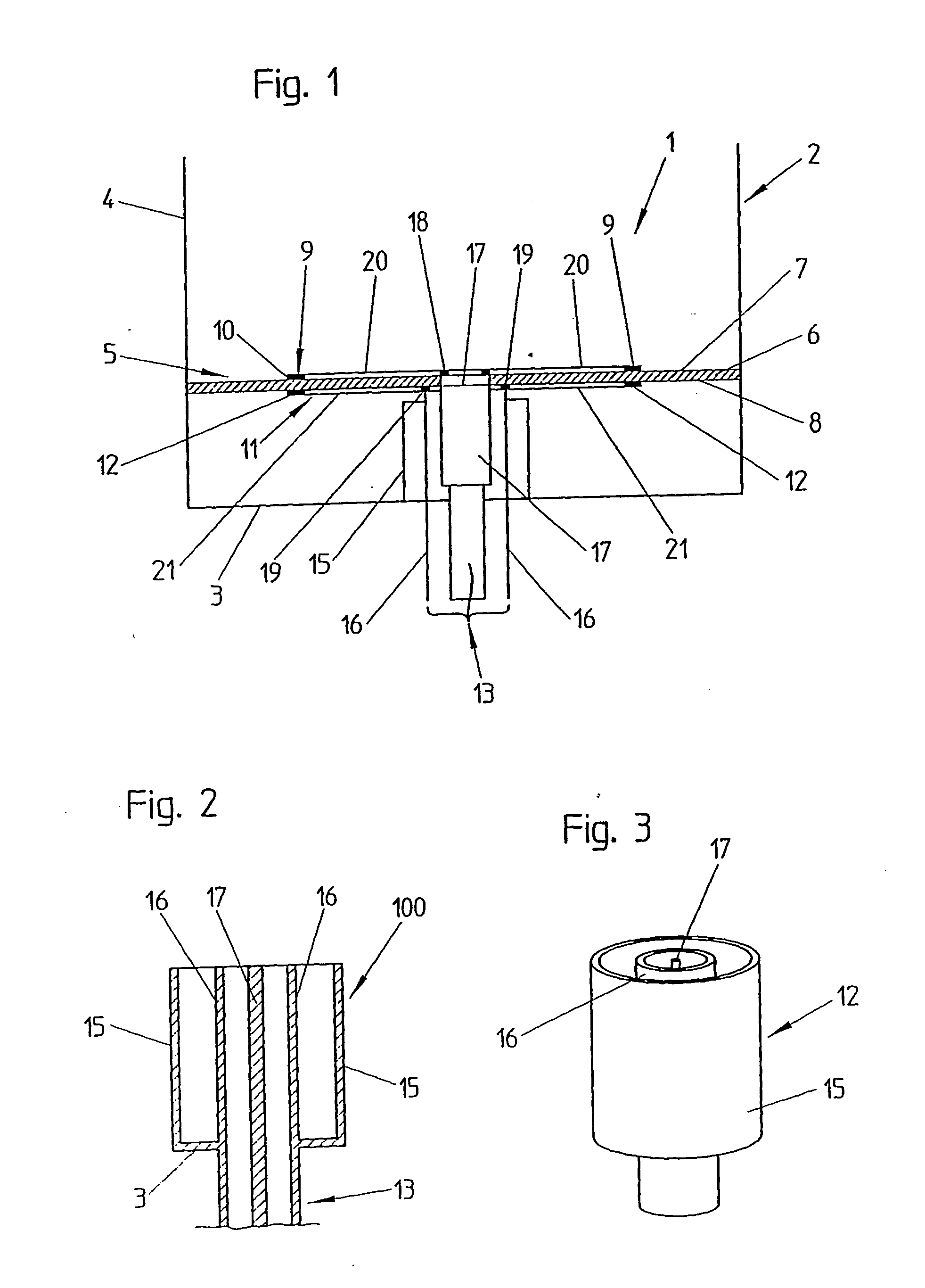

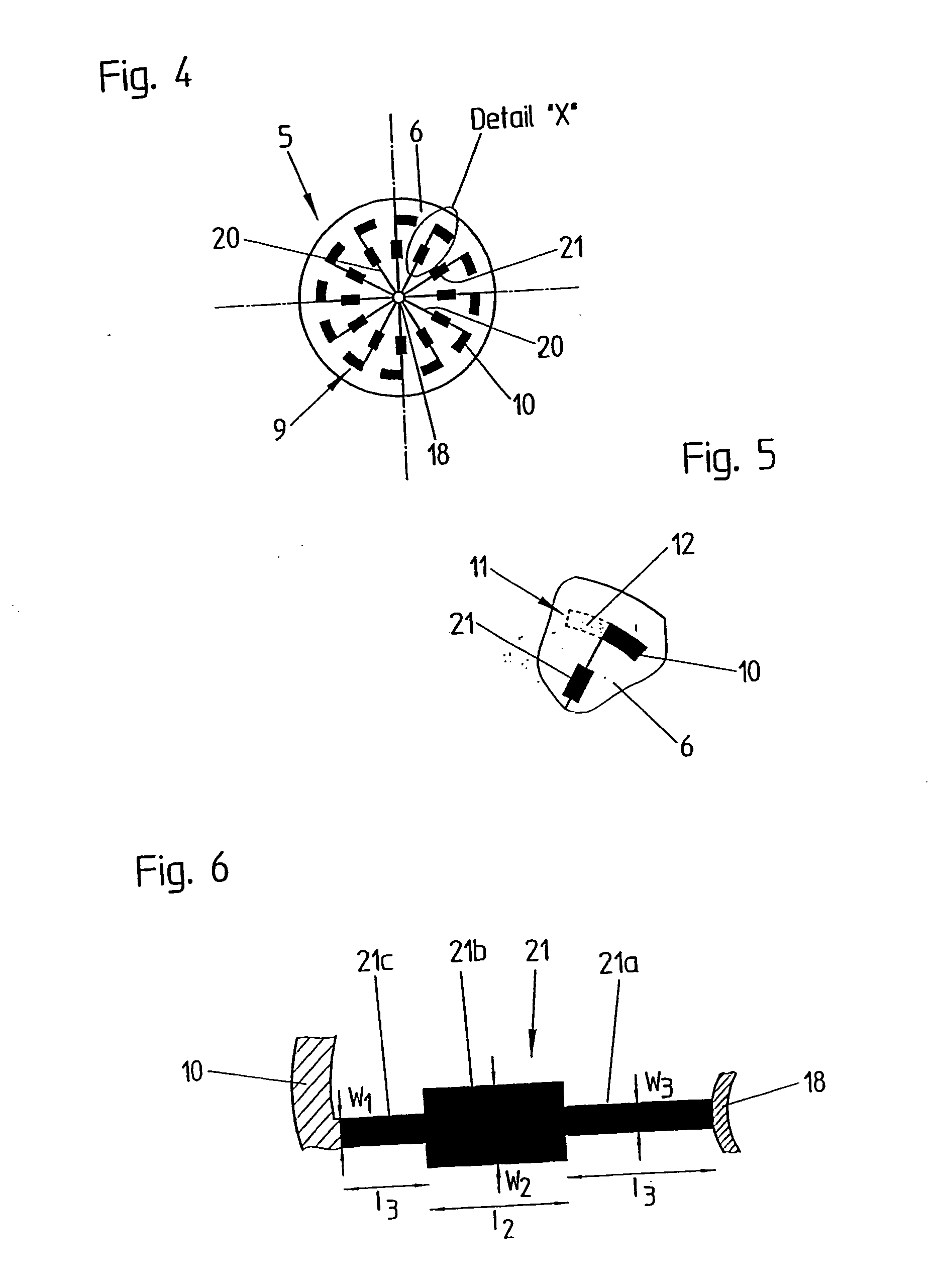

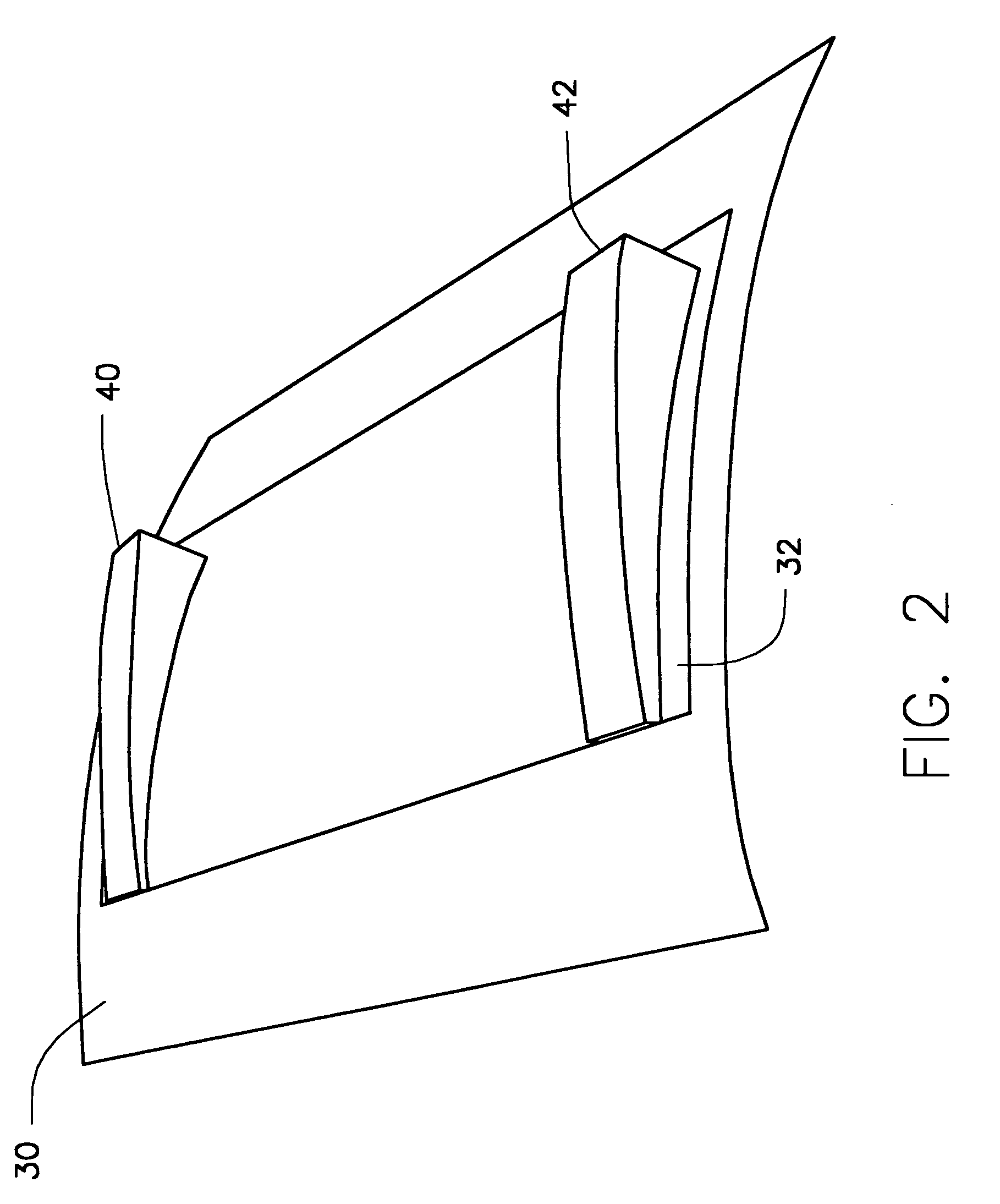

Planar antenna and antenna system

InactiveUS7030827B2Easy to manufactureImprove assembly strengthWaveguide mouthsAntenna supports/mountingsPhysicsCylindrical waveguide

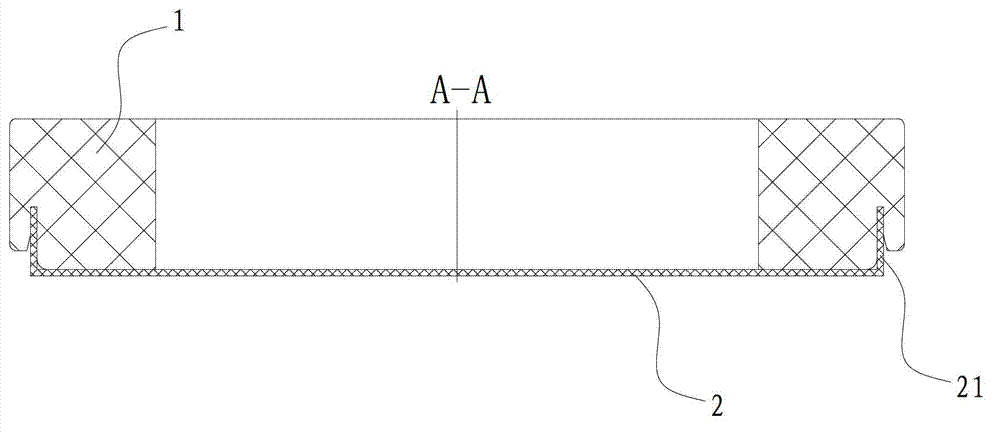

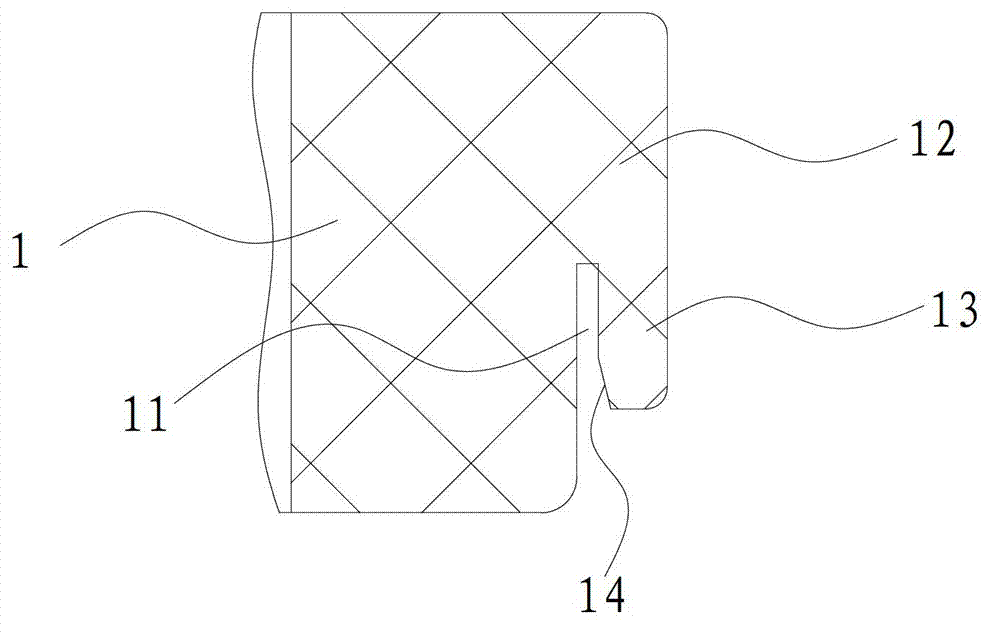

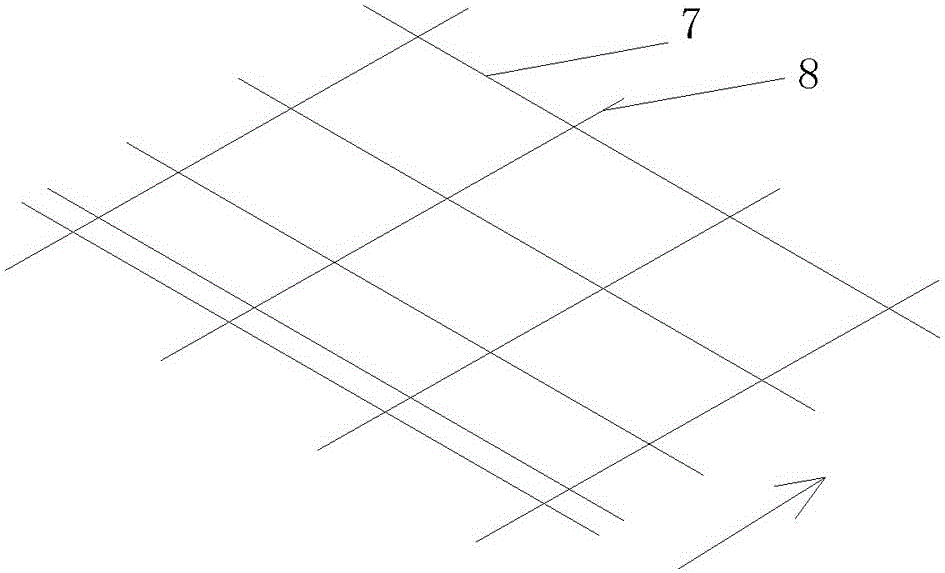

The present invention relates to a planar antenna (1) for excitation of the TE01-mode of an electromagnetic wave and adapted to be arranged in a waveguide tube (2). The planar antenna comprises a substrate (6) of dielectric material having a first surface (7) intended to face towards a filling good surface and a second surface (8) facing in an opposite direction. A first group (9) of a plurality of dipole arms (10) is arranged on the first surface (7) or the second surface (8) on a perimeter of a circle with a predetermined radius. A second group (11) of a plurality of dipole arms (12) is arranged on the first surface (7) or the second surface (8) on the perimeter of the circle with the predetermined radius. The dipole arms (10) of the first group (9) extend in a first direction and the dipole arms (12) of the second group (11) extend in a direction opposite the first direction. Furthermore, the present invention relates to an antenna system comprising a cylindrical waveguide tube (2) having a bottom plate (3) and a tube portion (4) and a planar antenna (1) as mentioned above.

Owner:VEGA GRIESHABER GMBH & CO

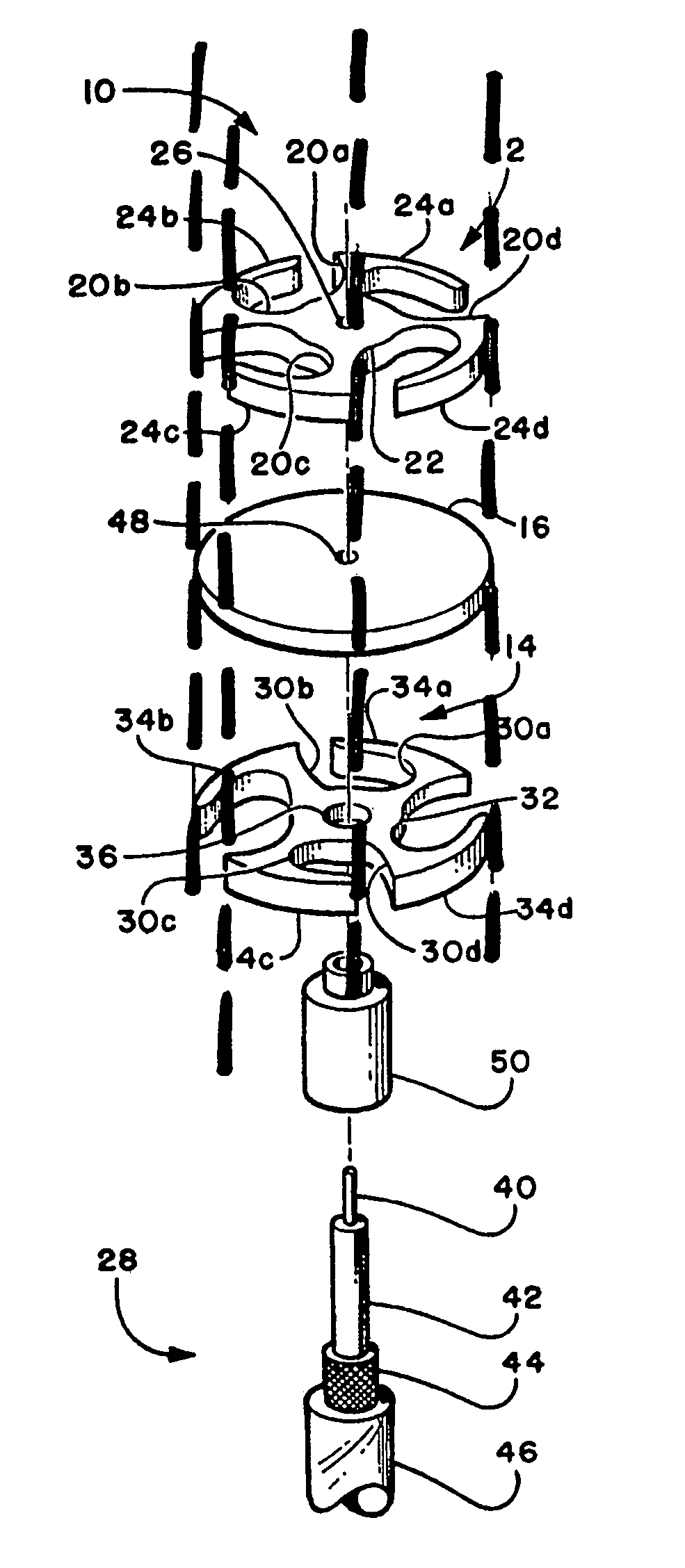

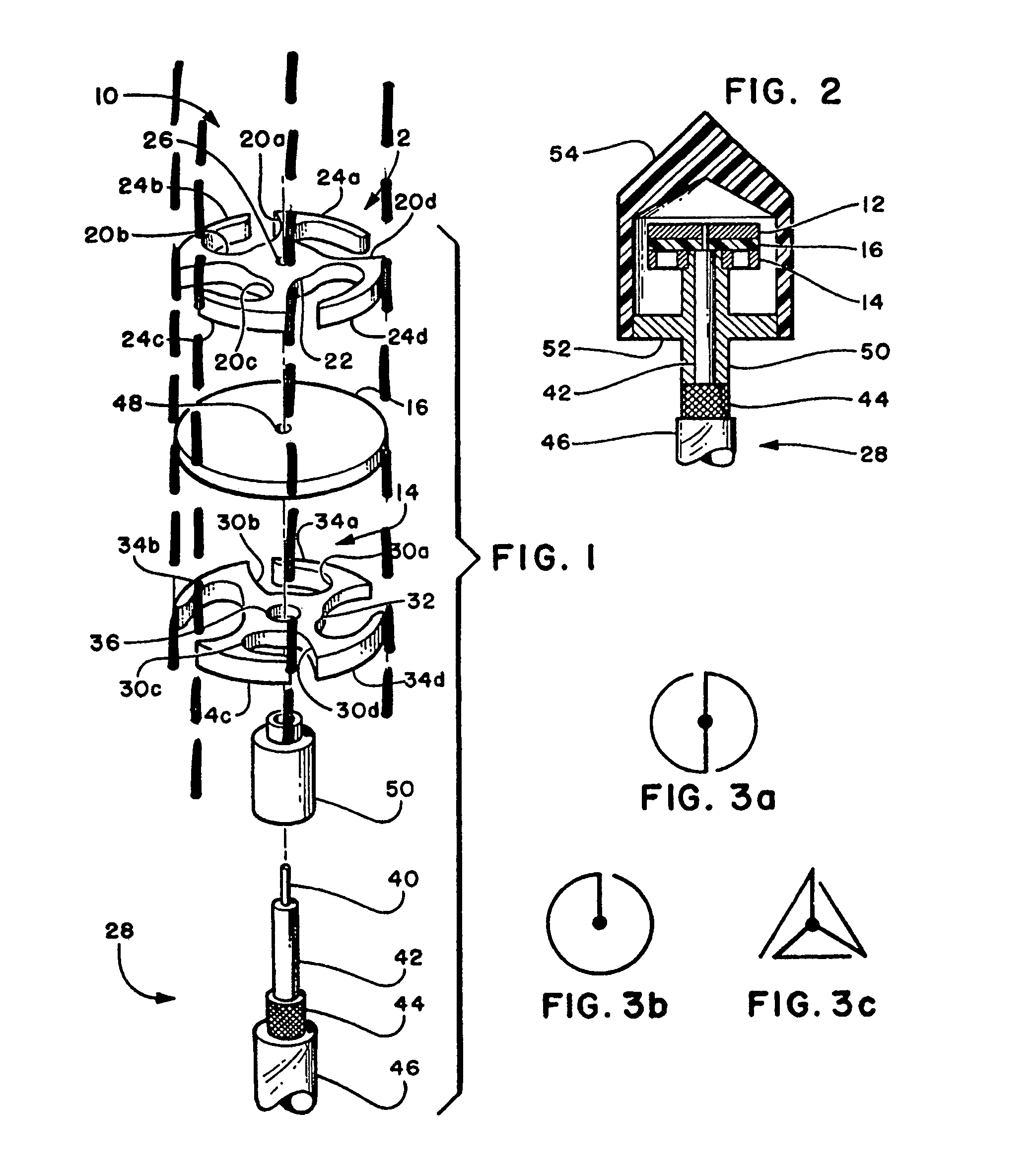

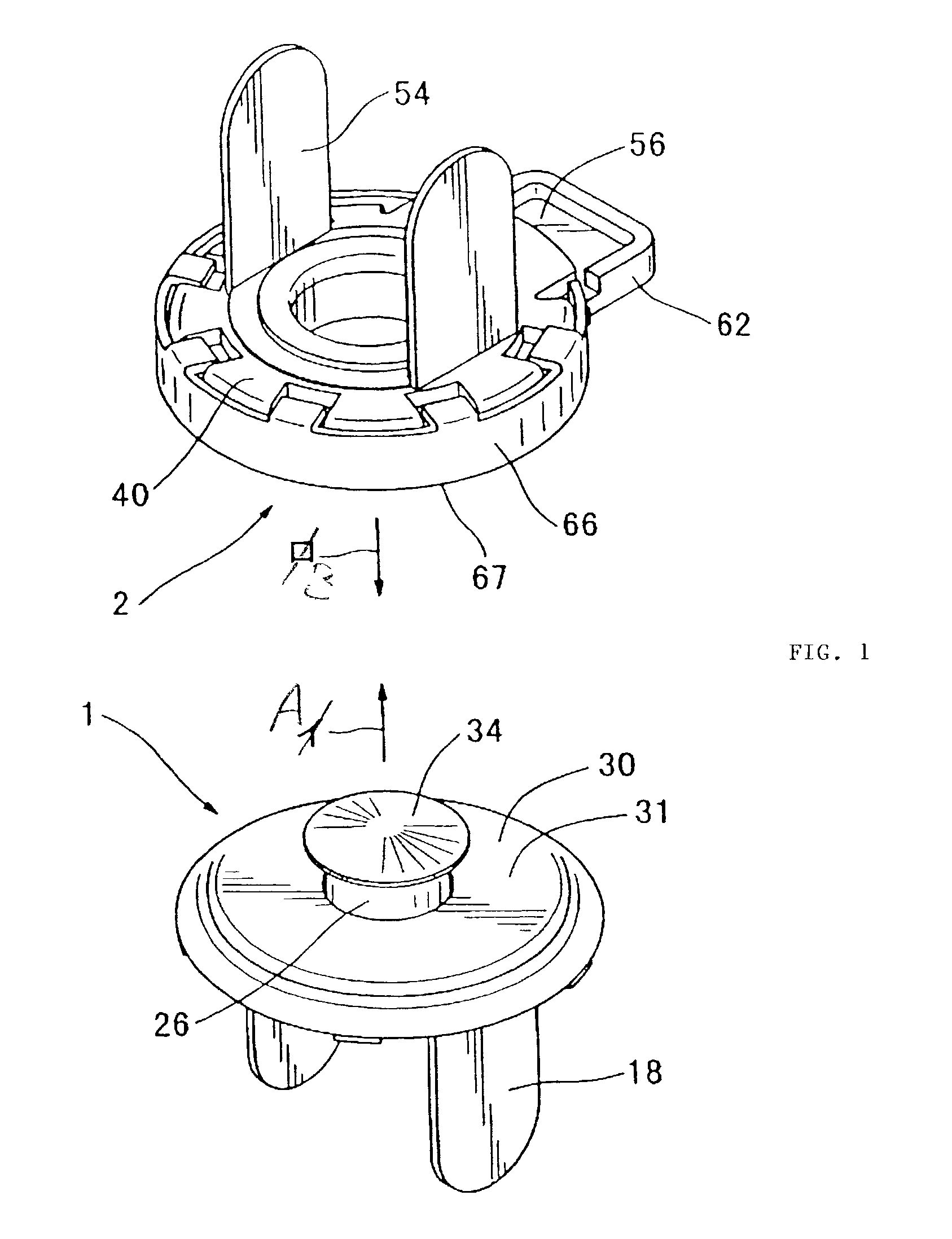

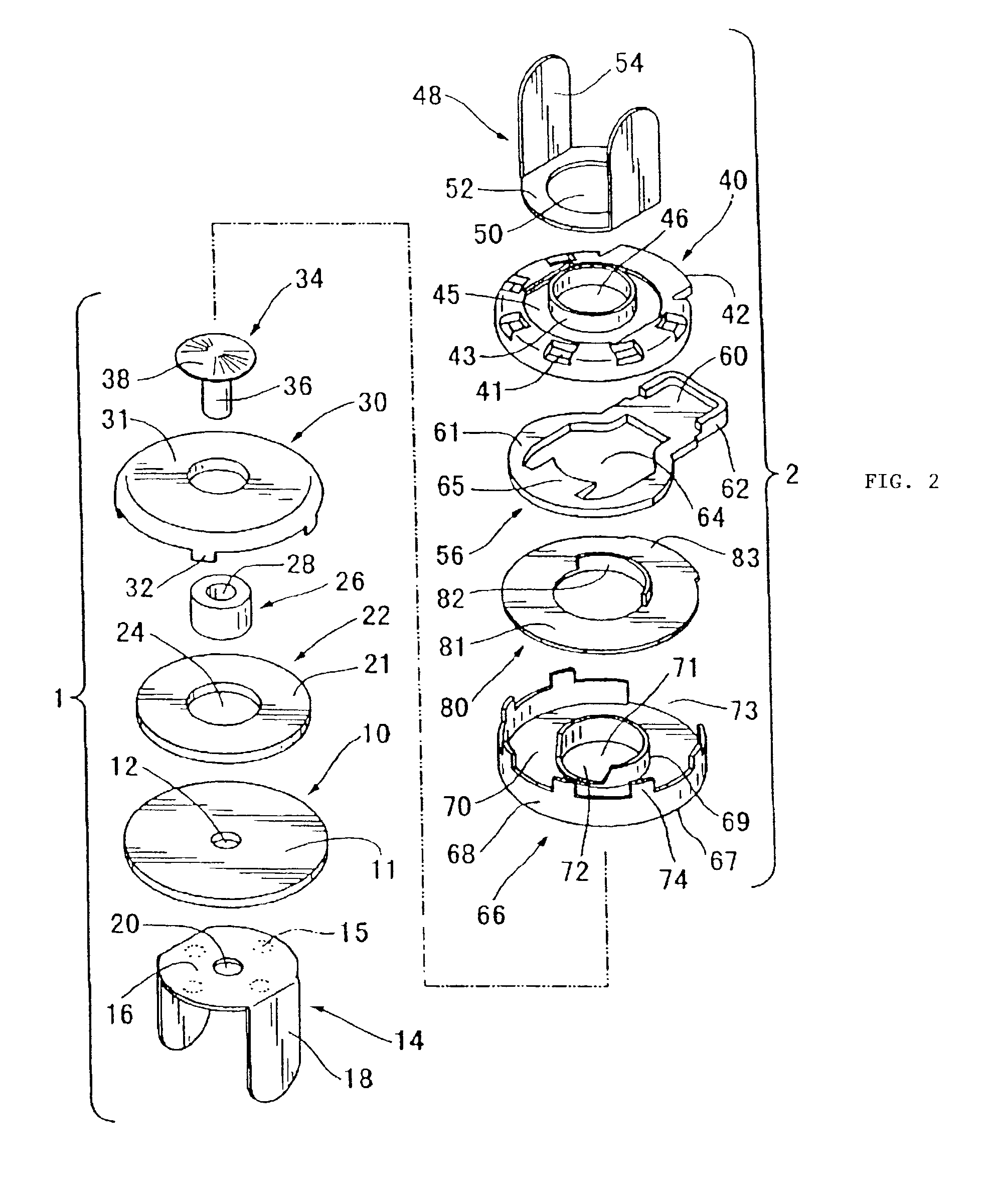

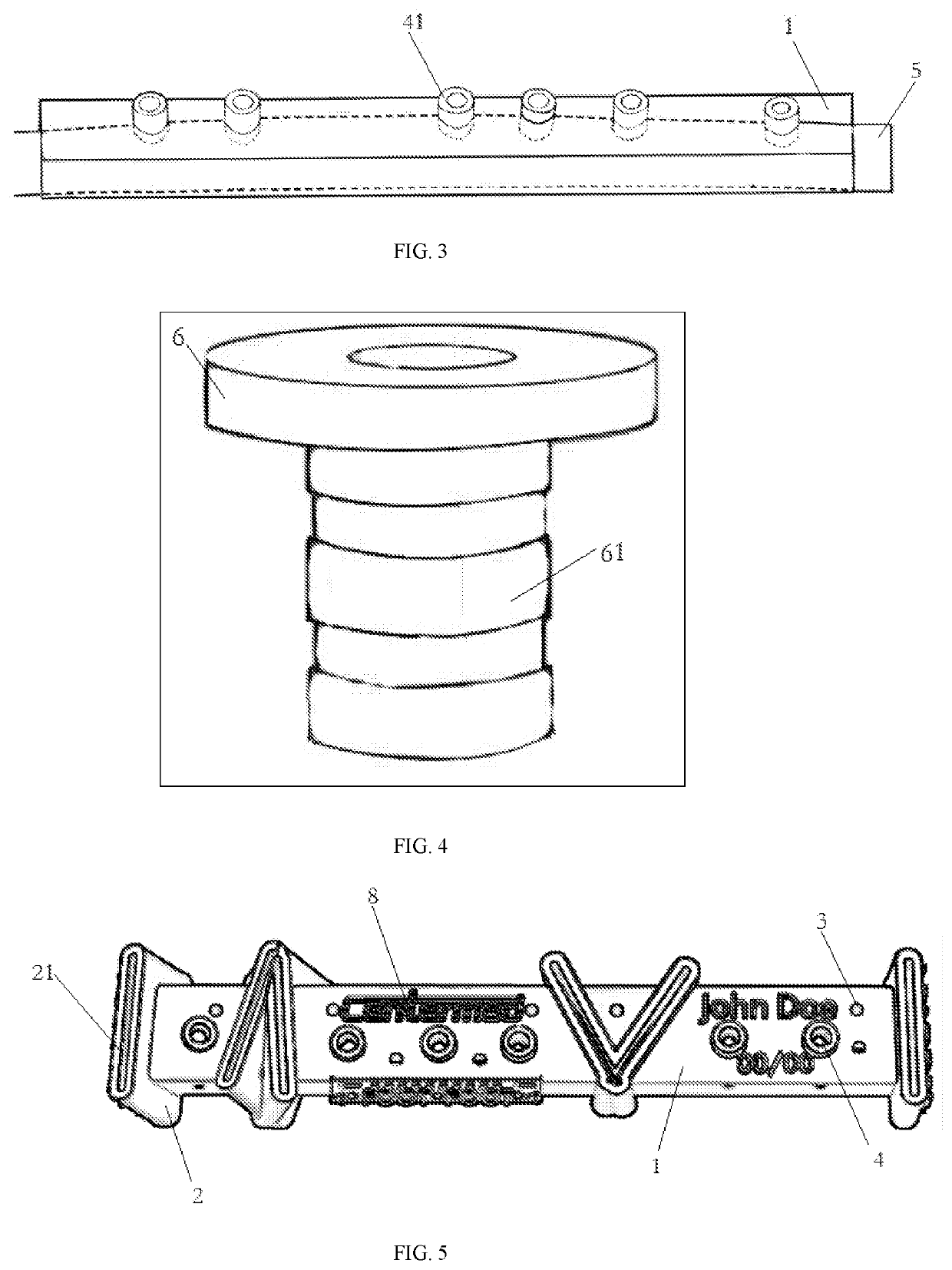

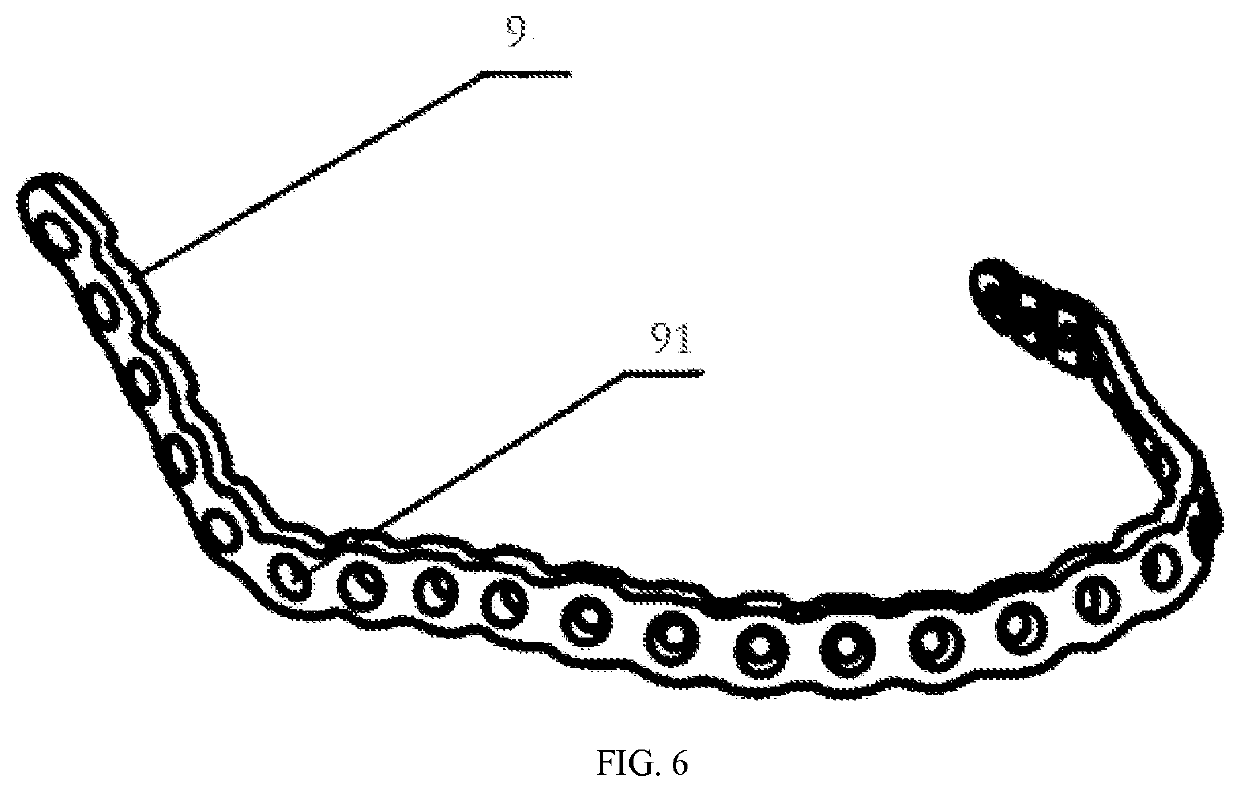

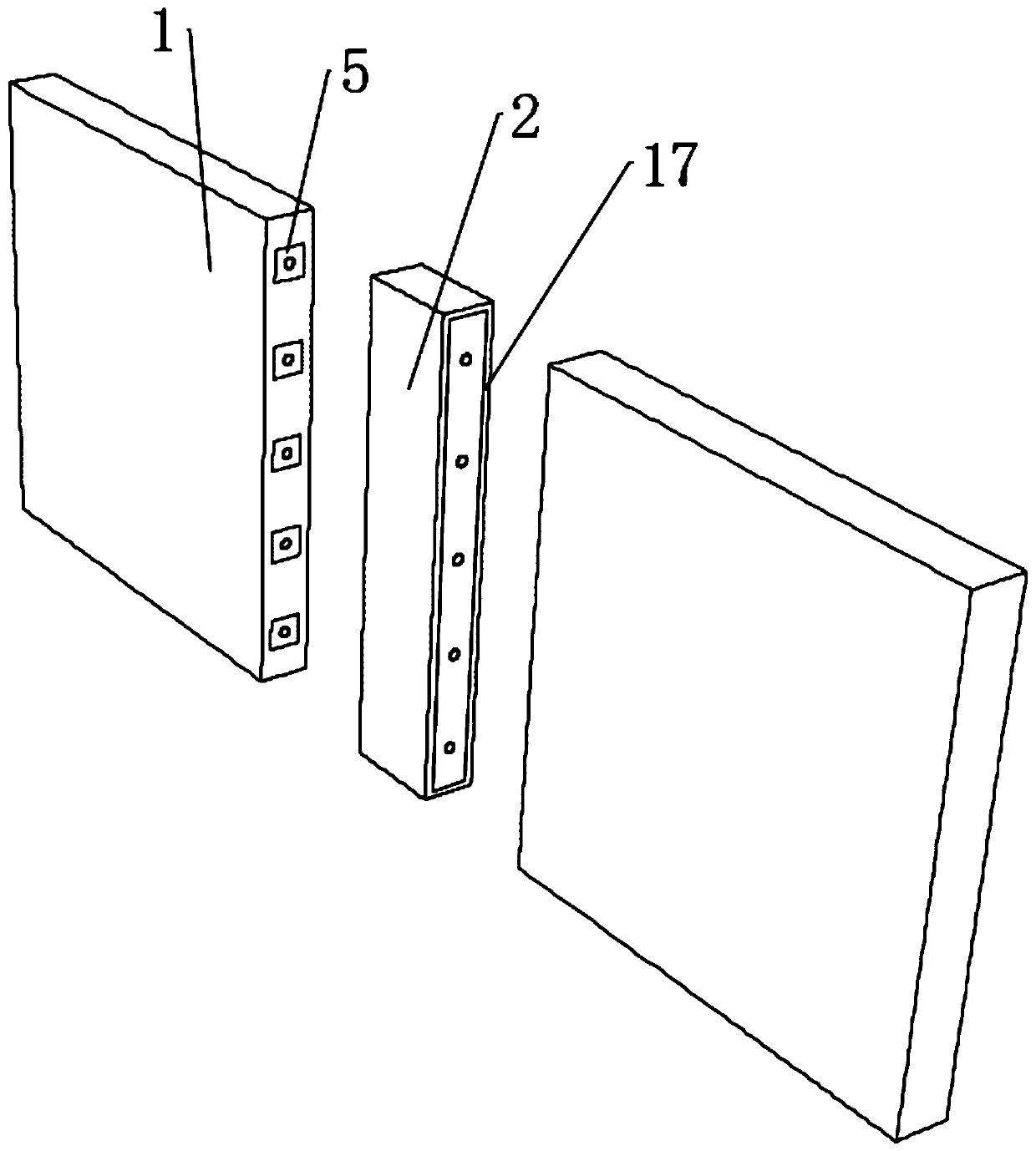

Magnetic fixing unit

InactiveUS6564434B1Easy to operateImprove assembly strengthSnap fastenersCollar-studsMagnetic tension forceEngineering

A magnetic fixing unit having a first and second sub-assembly with cooperative structure for increased strength of assembly and prevention of mutual shifting between the first and the second assemblies. The magnetic fixing unit further includes a guide structure on one of the first and second assemblies to effect cooperative locking engagement with an engaging member on the other of the assemblies.

Owner:MORITA TAMAO

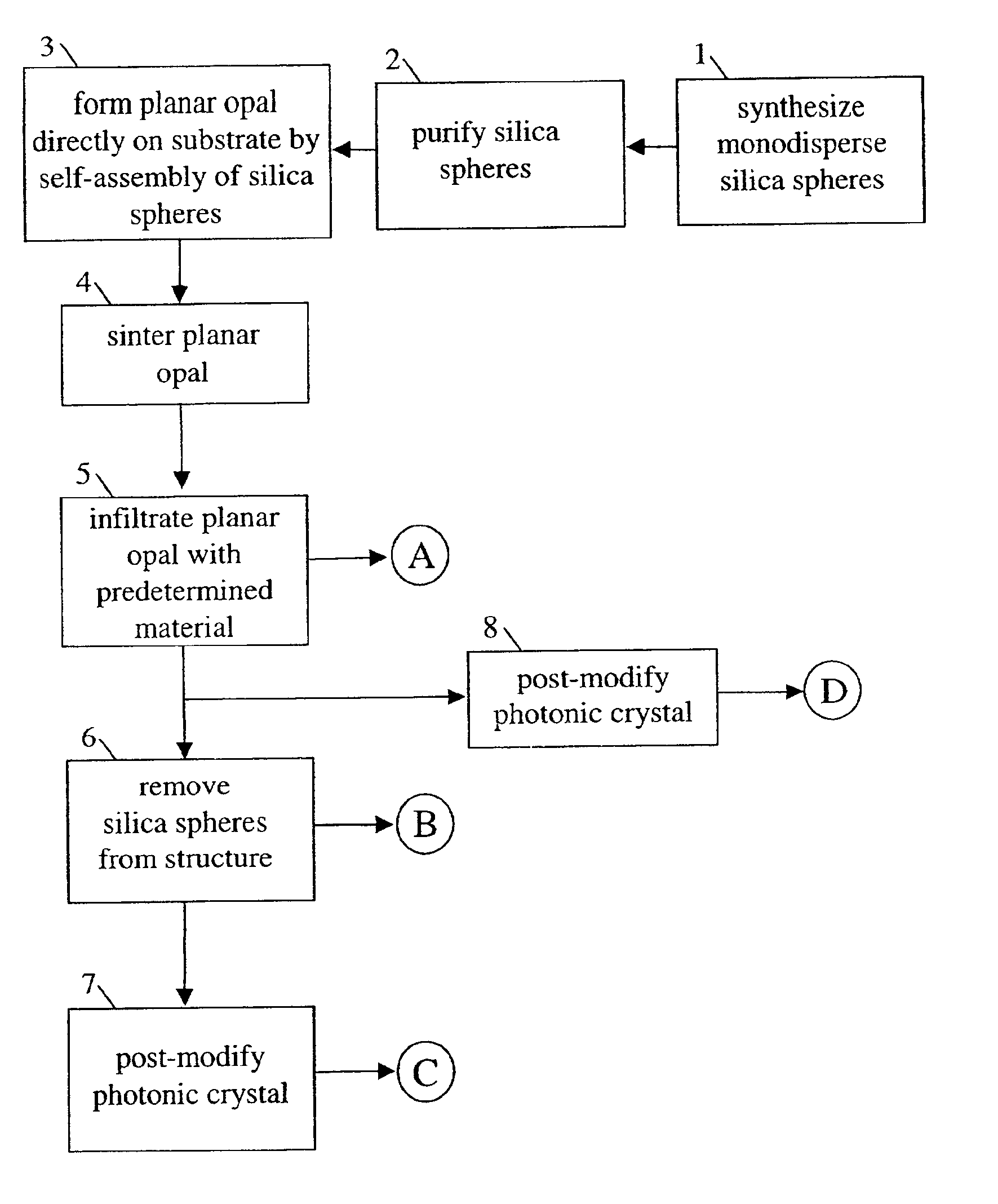

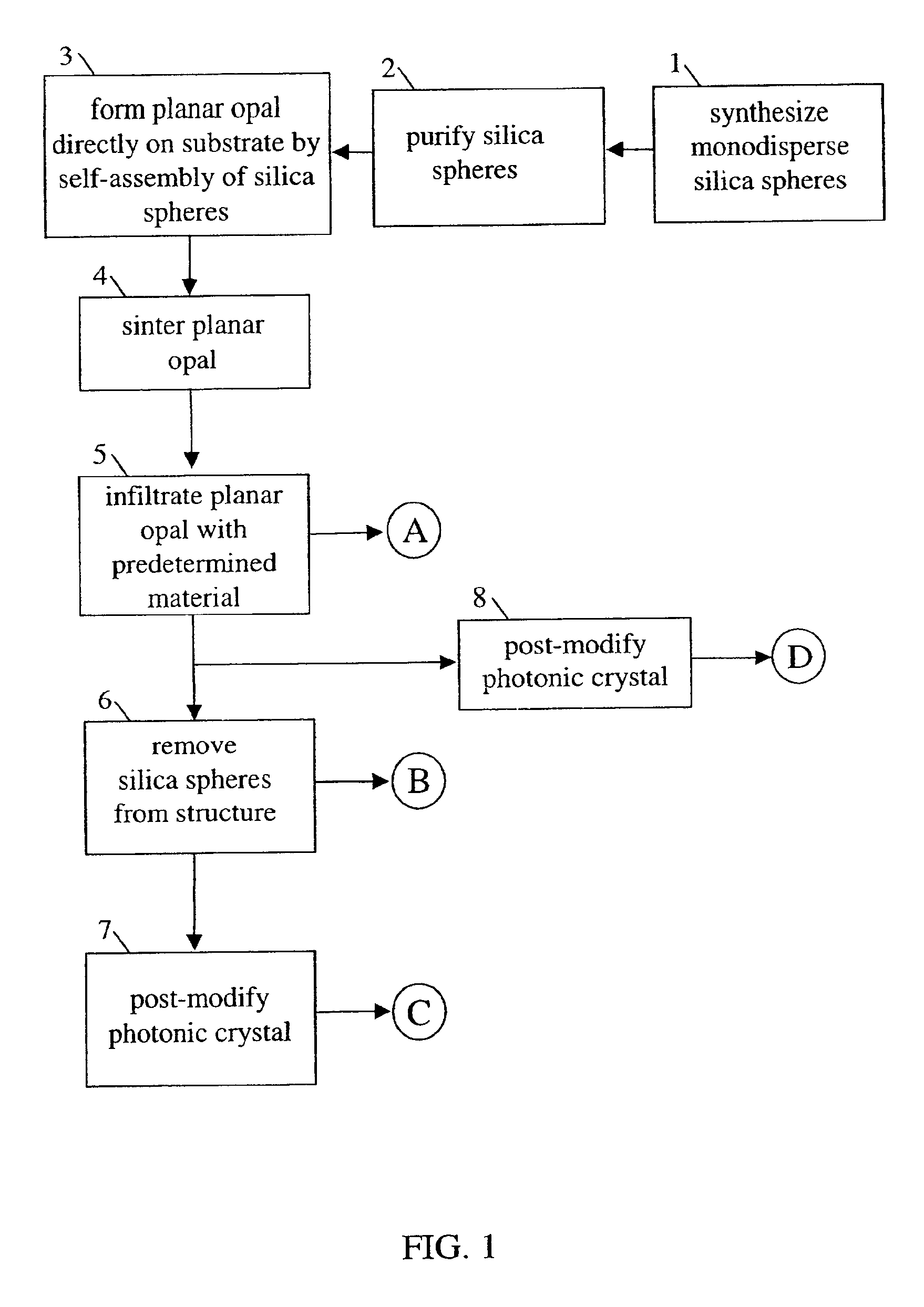

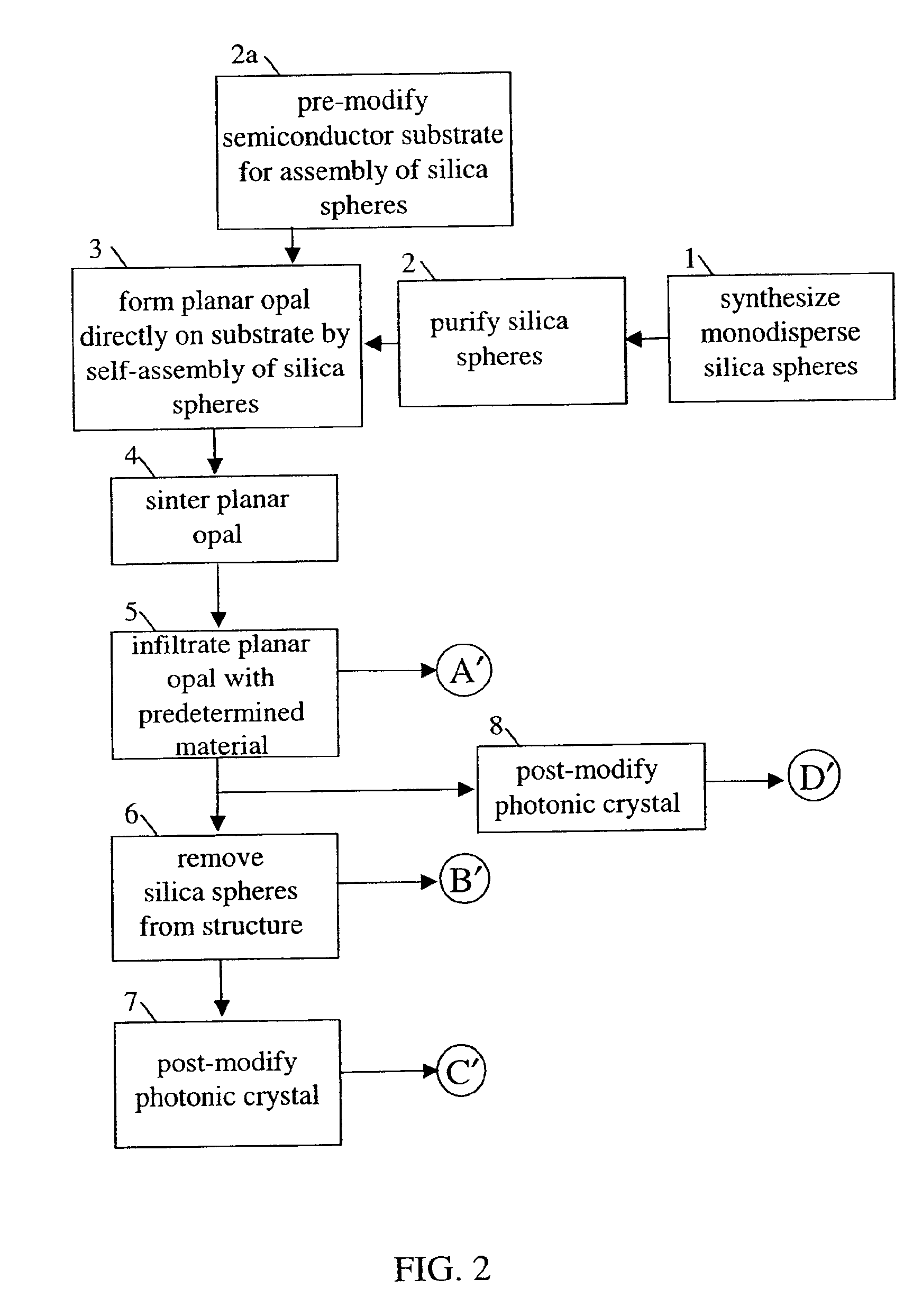

Self-assembled photonic crystals and methods for manufacturing same

InactiveUS6858079B2Well formedImprove assembly strengthFrom gel stateMaterial nanotechnologyPhotonic crystalGlobular shaped

Self-assembled photonic crystals, including large sphere planar opals, infiltrated planar opals and inverted planar opals, as well as methods for manufacturing same are provided. Large sphere planar opals are manufactured according to a method comprising the steps of: synthesizing monodisperse silica spheres, wherein each of the silica spheres has a diameter greater than or equal to about 400 nanometers; purifying the silica spheres; and self-assembling the silica spheres into a plurality of ordered, planar layers on a substrate. Infiltrated planar opals may also be manufactured by further processing the large sphere planar opal by sintering the planar opal and infiltrating the planar opal with a predetermined material. Inverted planar opals may further be manufactured by removing the silica spheres from the infiltrated planar opal. Various modifications to the substrate and planar opal are also provided to enhance the properties of these photonic crystals.

Owner:NEC CORP

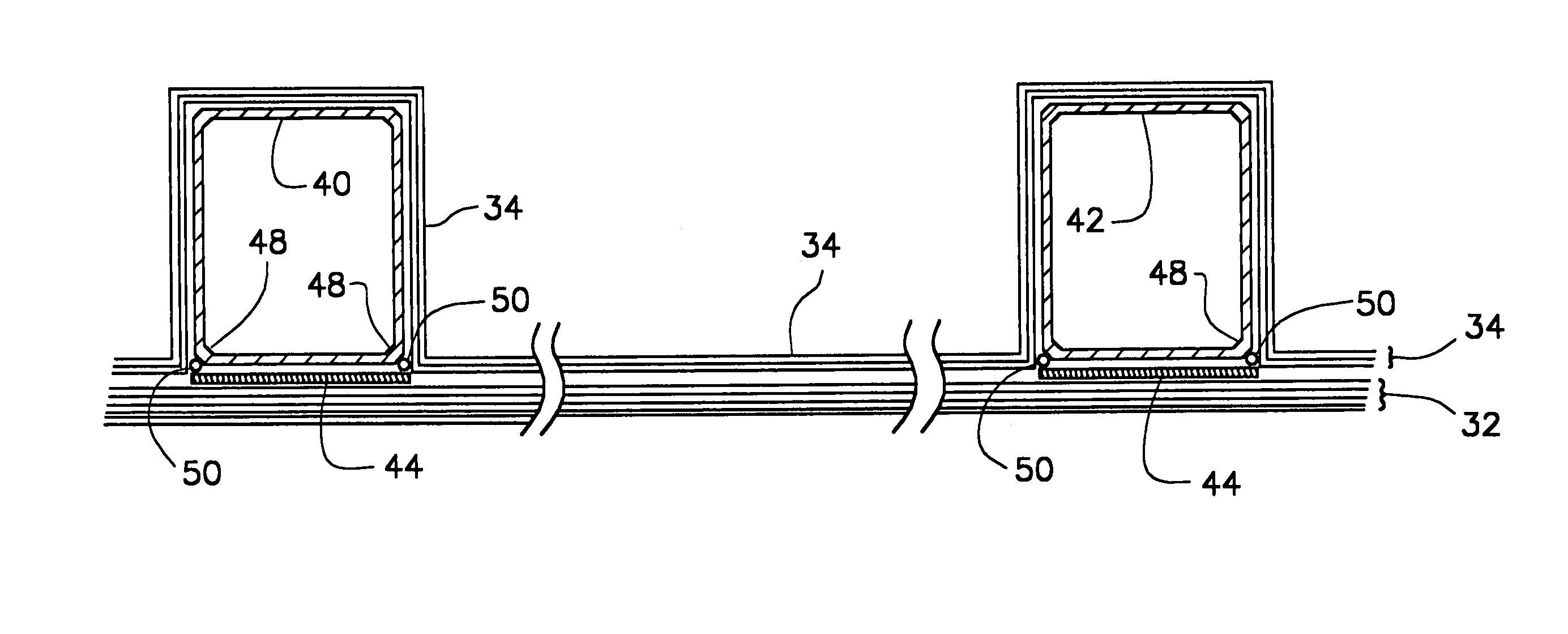

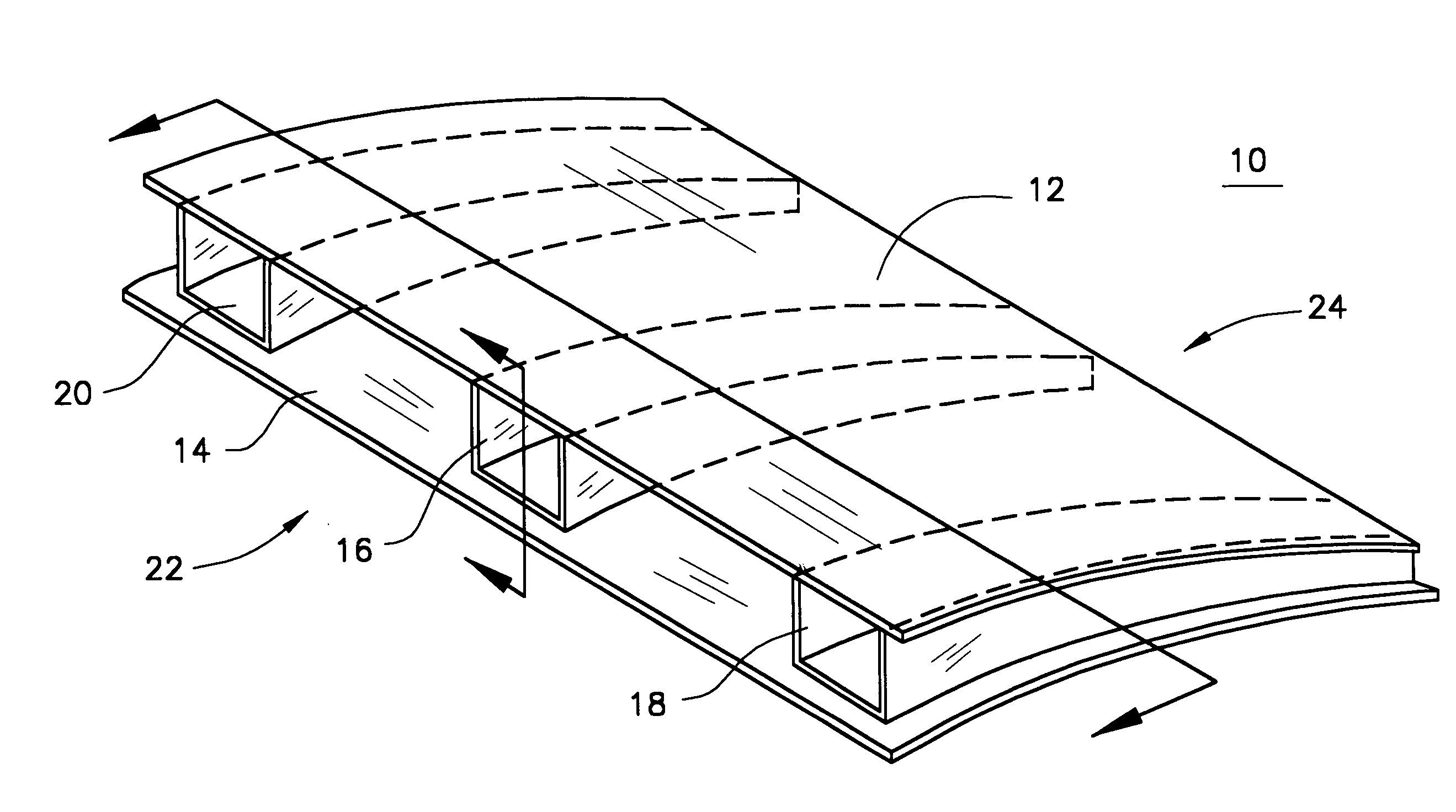

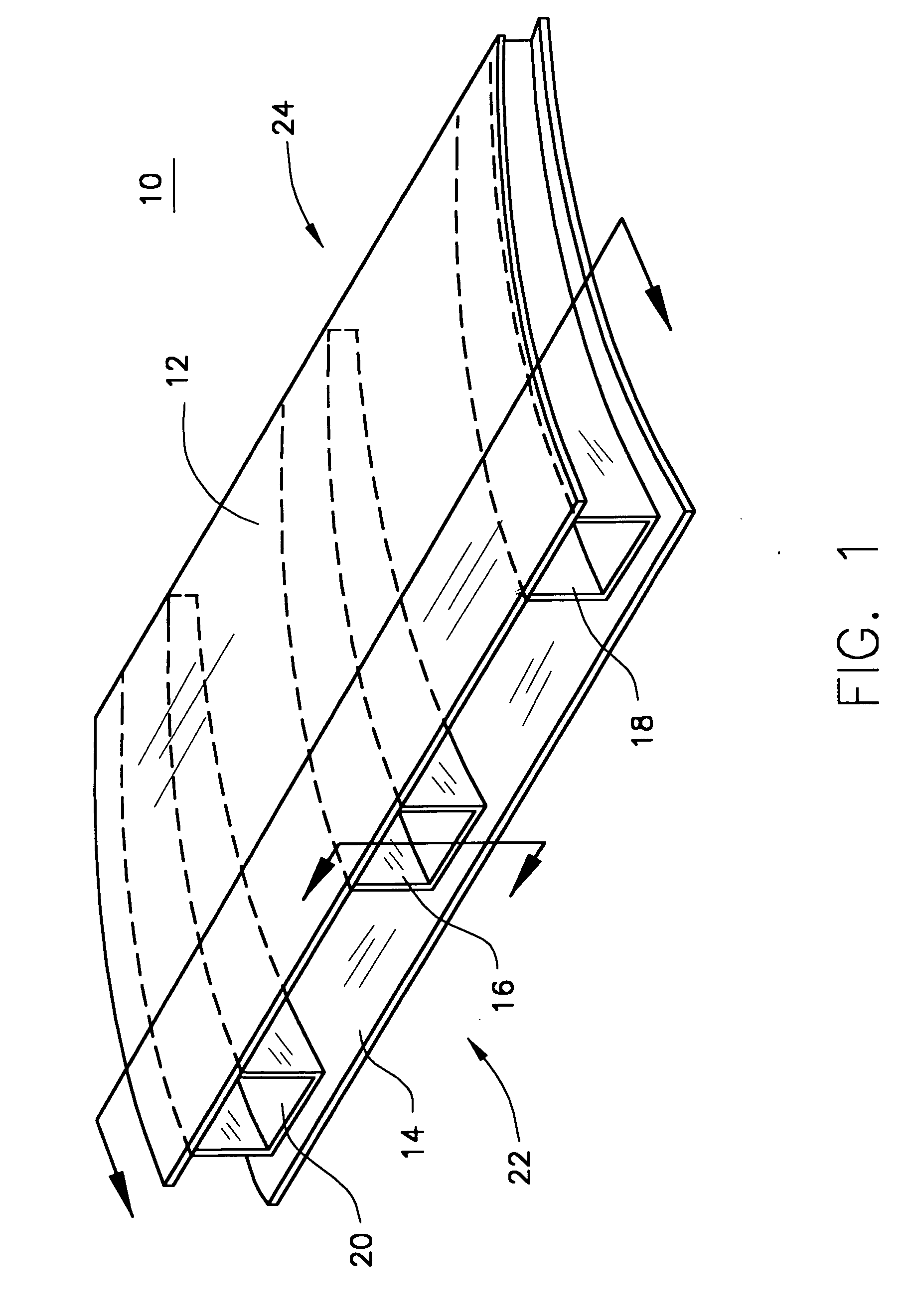

Advanced composite aerostructure article having a braided co-cured fly away hollow mandrel and method for fabrication

InactiveUS7625618B1Light weightEasy maintenanceSynthetic resin layered productsFlexible pipesFiber-reinforced compositeMaterials science

An article of fiber-reinforced composite material formed by co-curing a lay up under a cycle of heat and pressure. The lay up comprises a first uncured composite layer having at least one uncured resin-impregnated laminate layer. At least one hollow mandrel is provided comprised of a stiffened braided fabric and having an upper, a lower and side surfaces. The mandrel is secured on the upper surface of the first composite layer with the lower surface thereof in engagement with the upper surface of the first composite layer. A second uncured composite layer is positioned over the upper and side surfaces of the hollow mandrel and at least a portion of the upper surface the first uncured composite layer. The second uncured composite layer has at least one uncured resin-impregnated layer. After the cycle of heat and pressure in an autoclave, the hollow mandrel is retained in the co-cured article.

Owner:ROHR INC

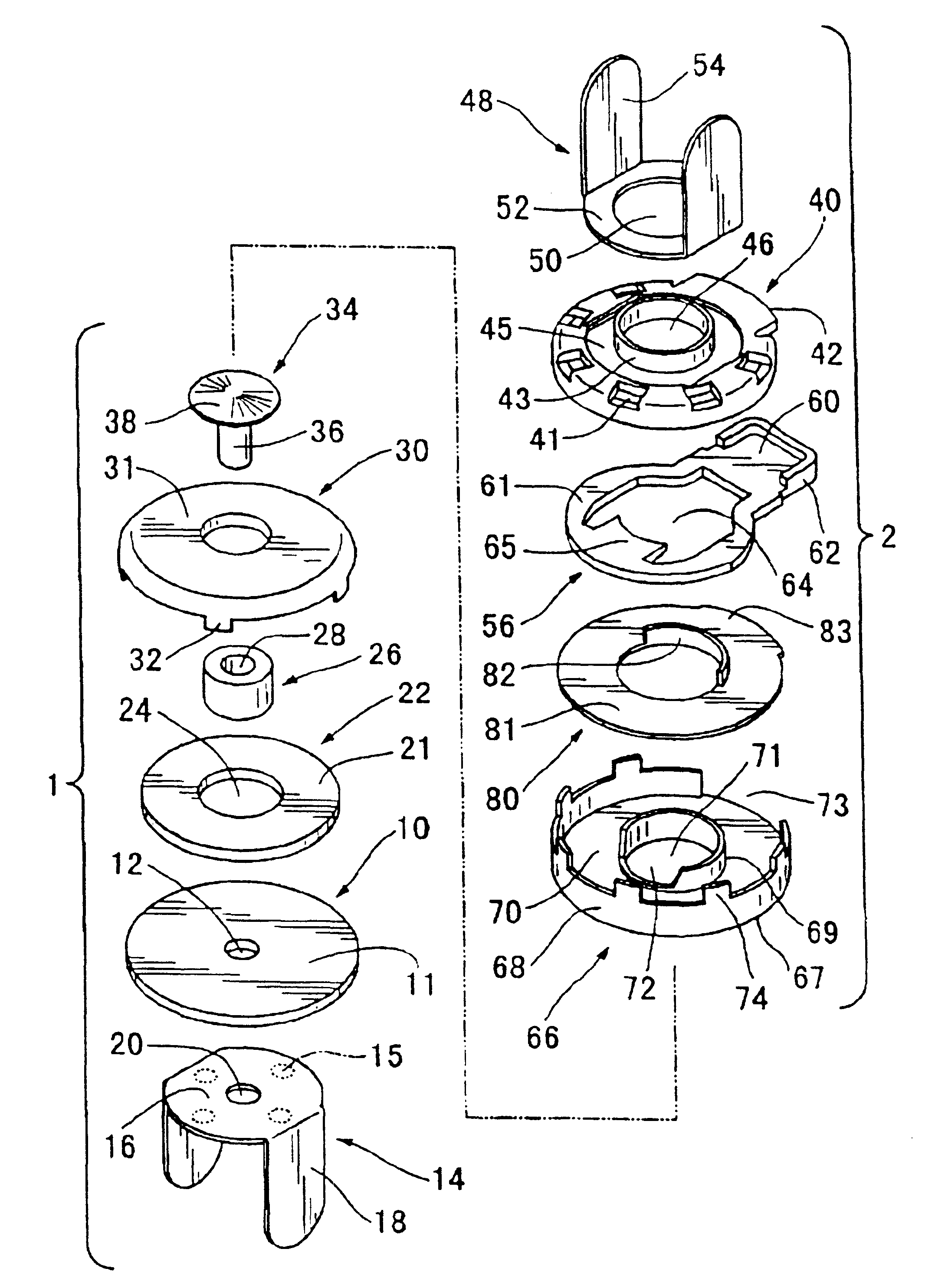

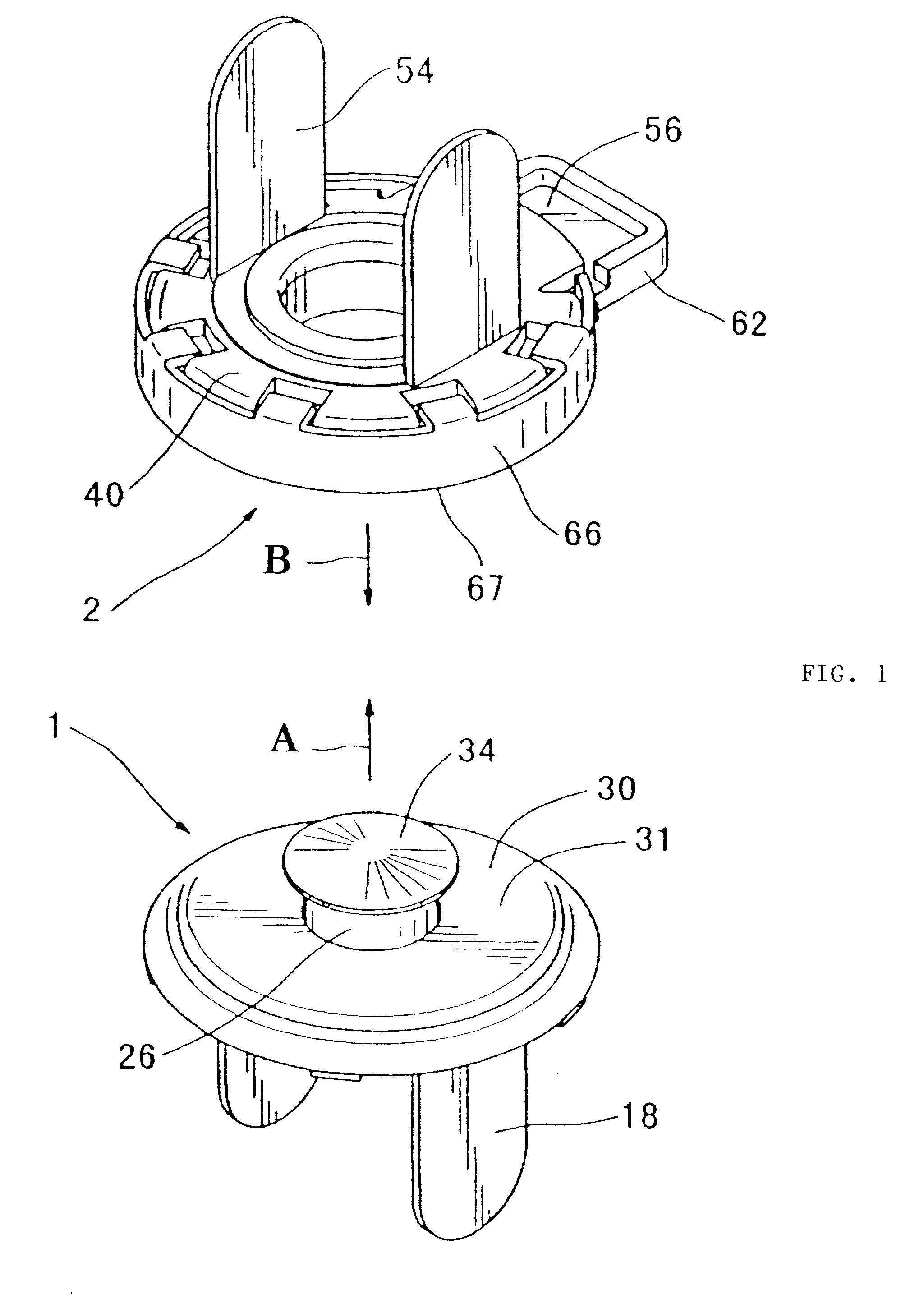

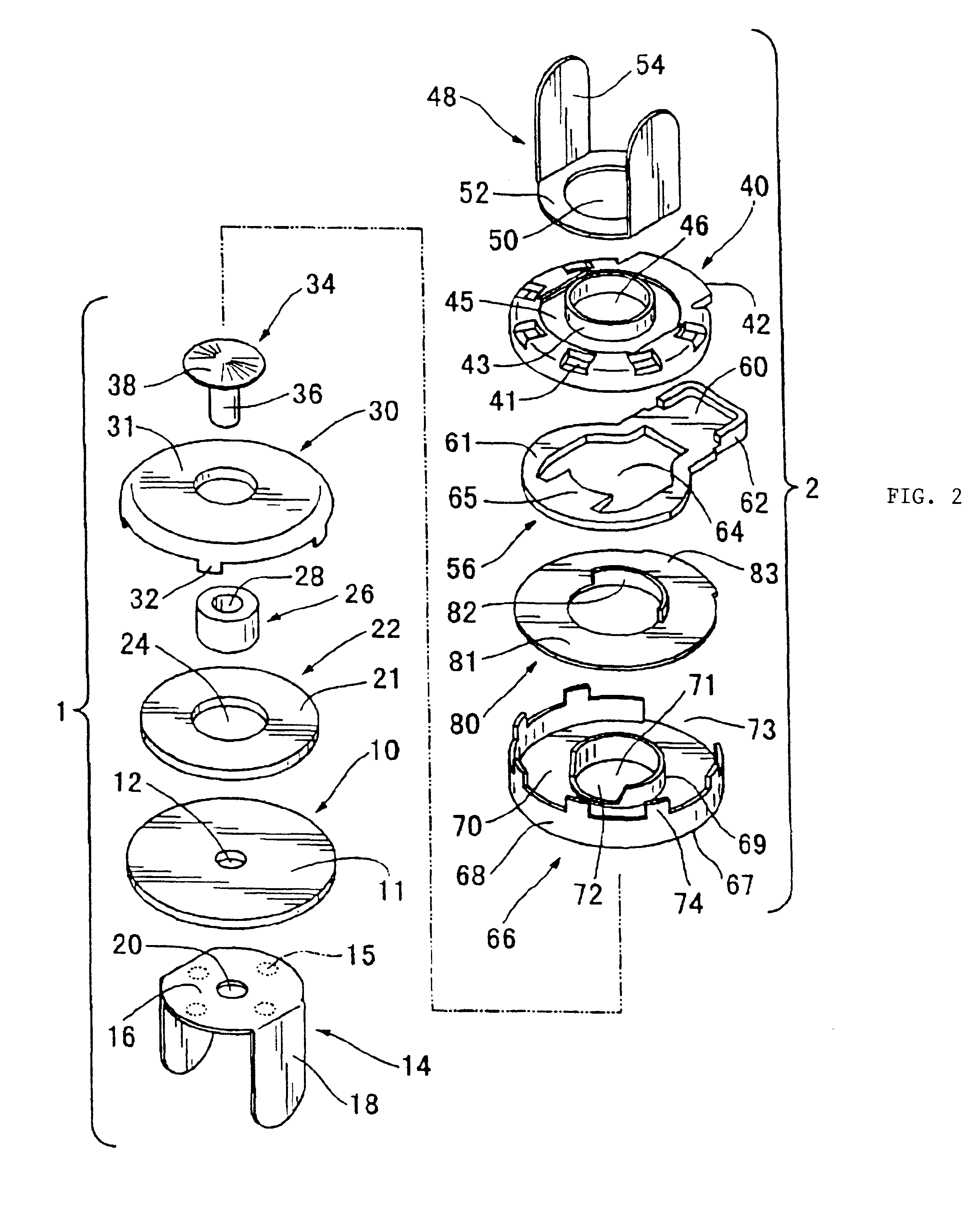

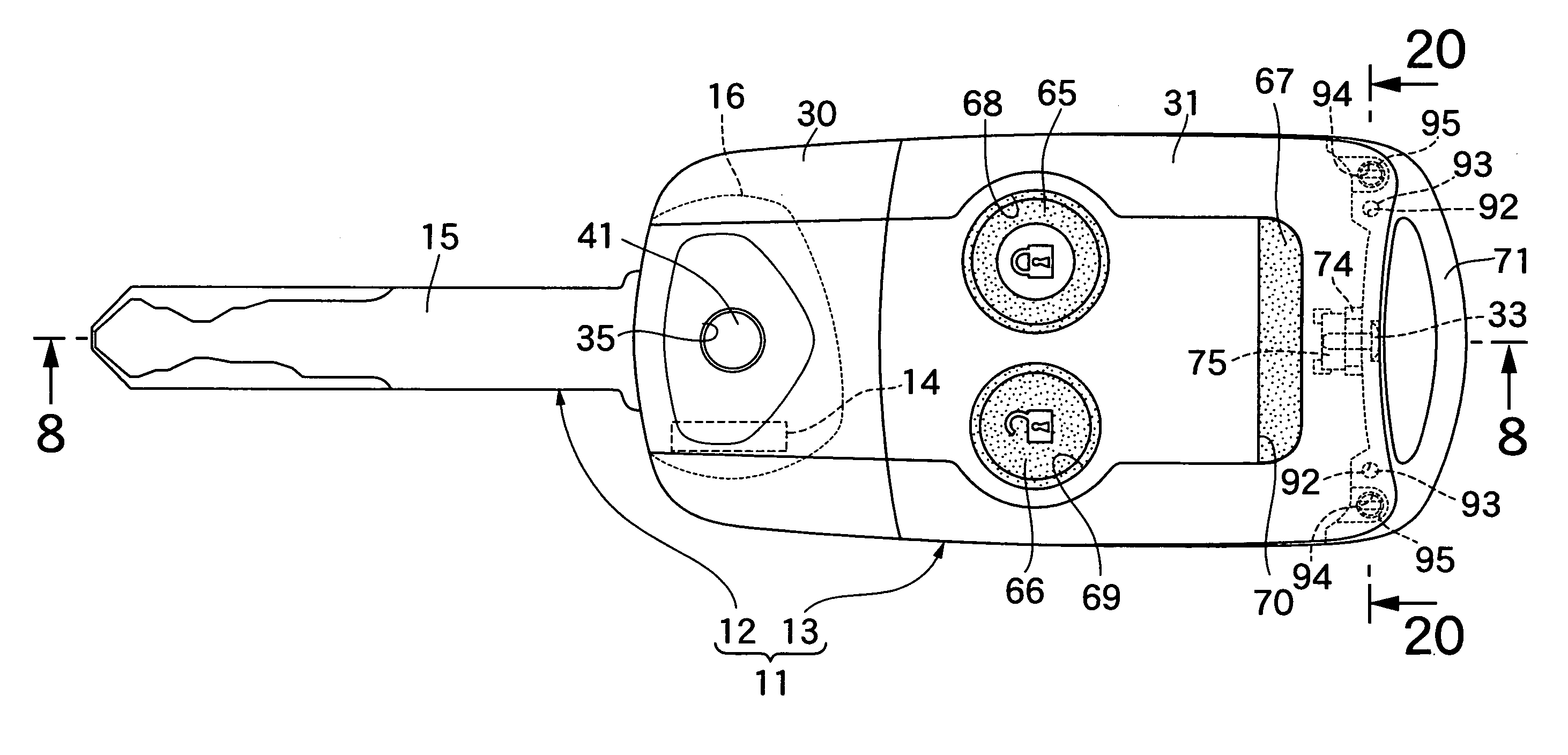

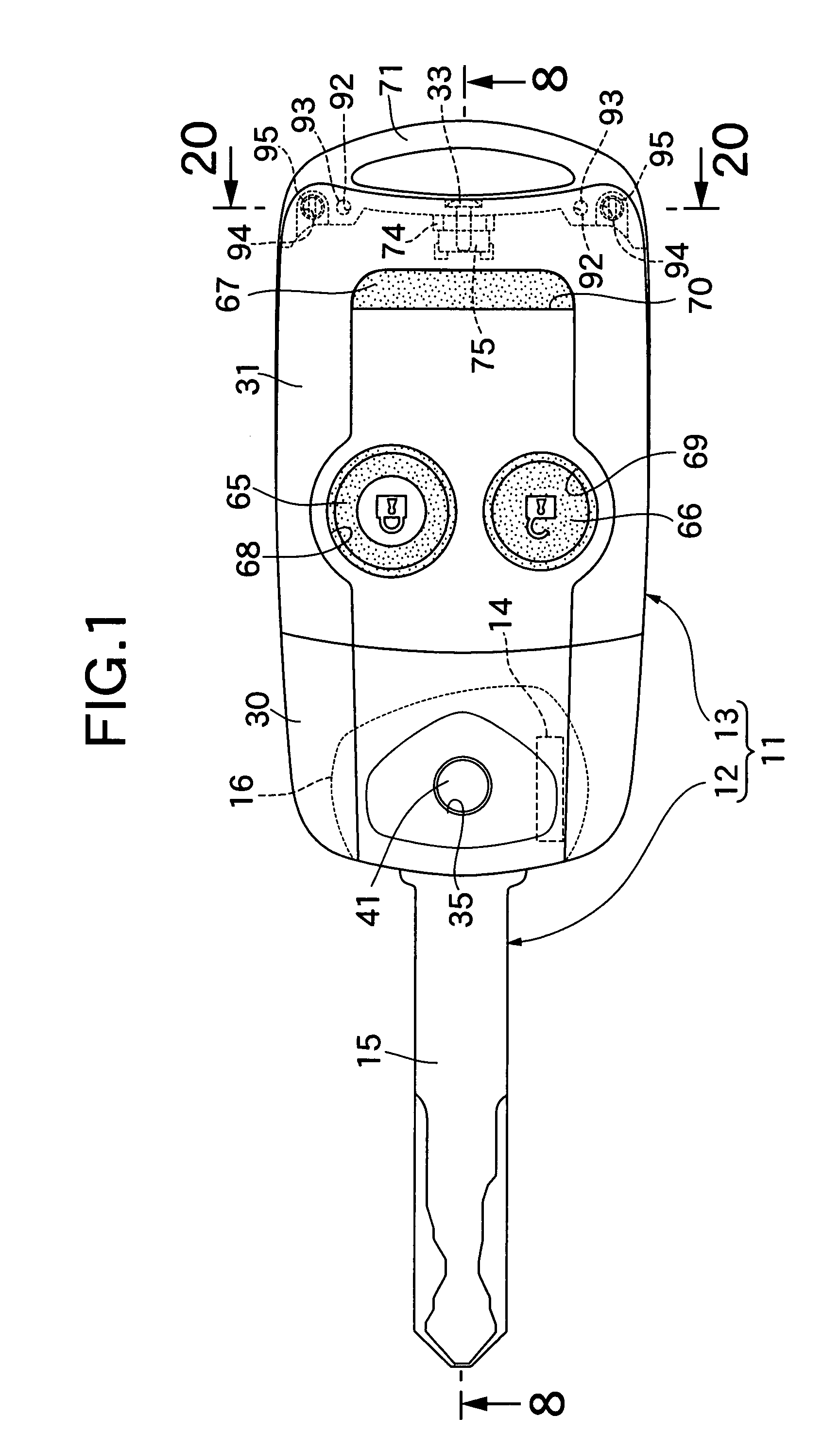

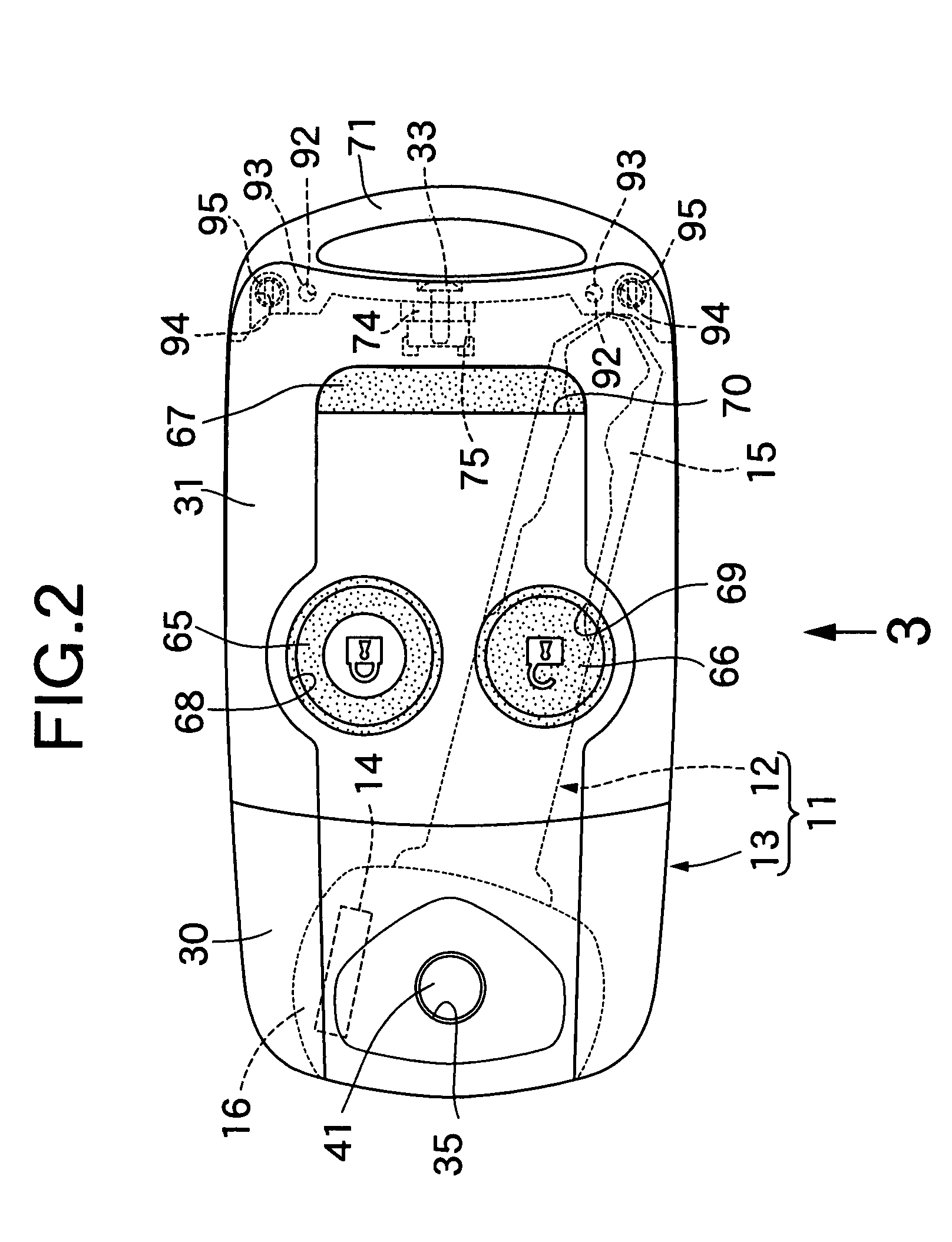

Key unit

ActiveUS7370501B2Easy to assembleImprove assembly strengthKeysIndividual entry/exit registersSynthetic resinMechanical engineering

A key unit includes a grip case which includes at least a pair of synthetic resin case members joined to each other, and a mechanical key supported in the grip case and having a pivotable key head. A plurality of fitting projections are projectingly provided integrally on a metal holder ring held between the case members. The fitting projections are respectively fitted into a plurality of fitting holes provided in at least one of the case members. An engagement hook resiliently engaging with an engagement hole provided in the holder ring is projectingly provided integrally on one of the case members. This facilitates assembling and enhances assembly strength in attaching the metal holder ring to the grip case.

Owner:HONDA LOCK MFG CO LTD

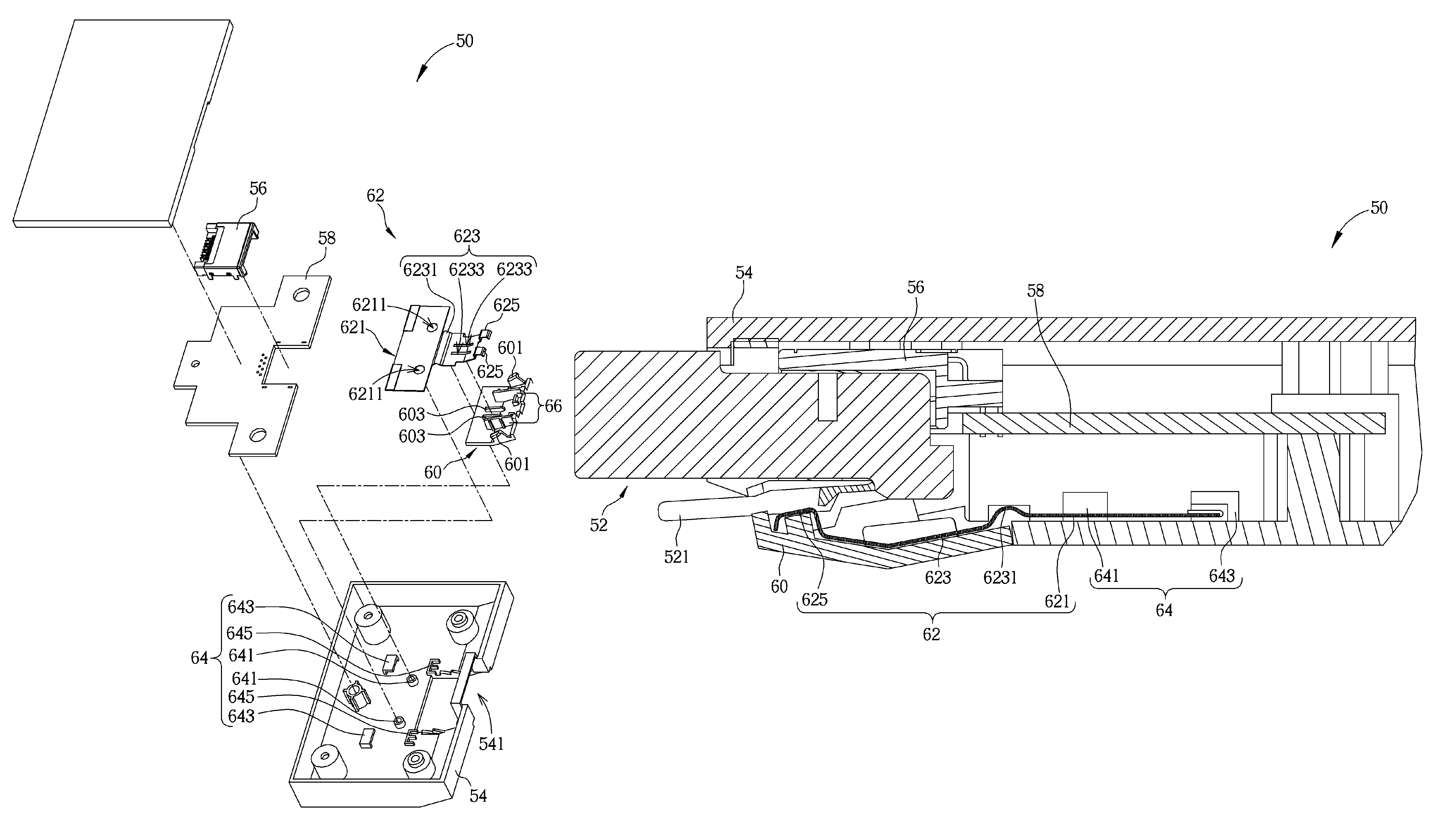

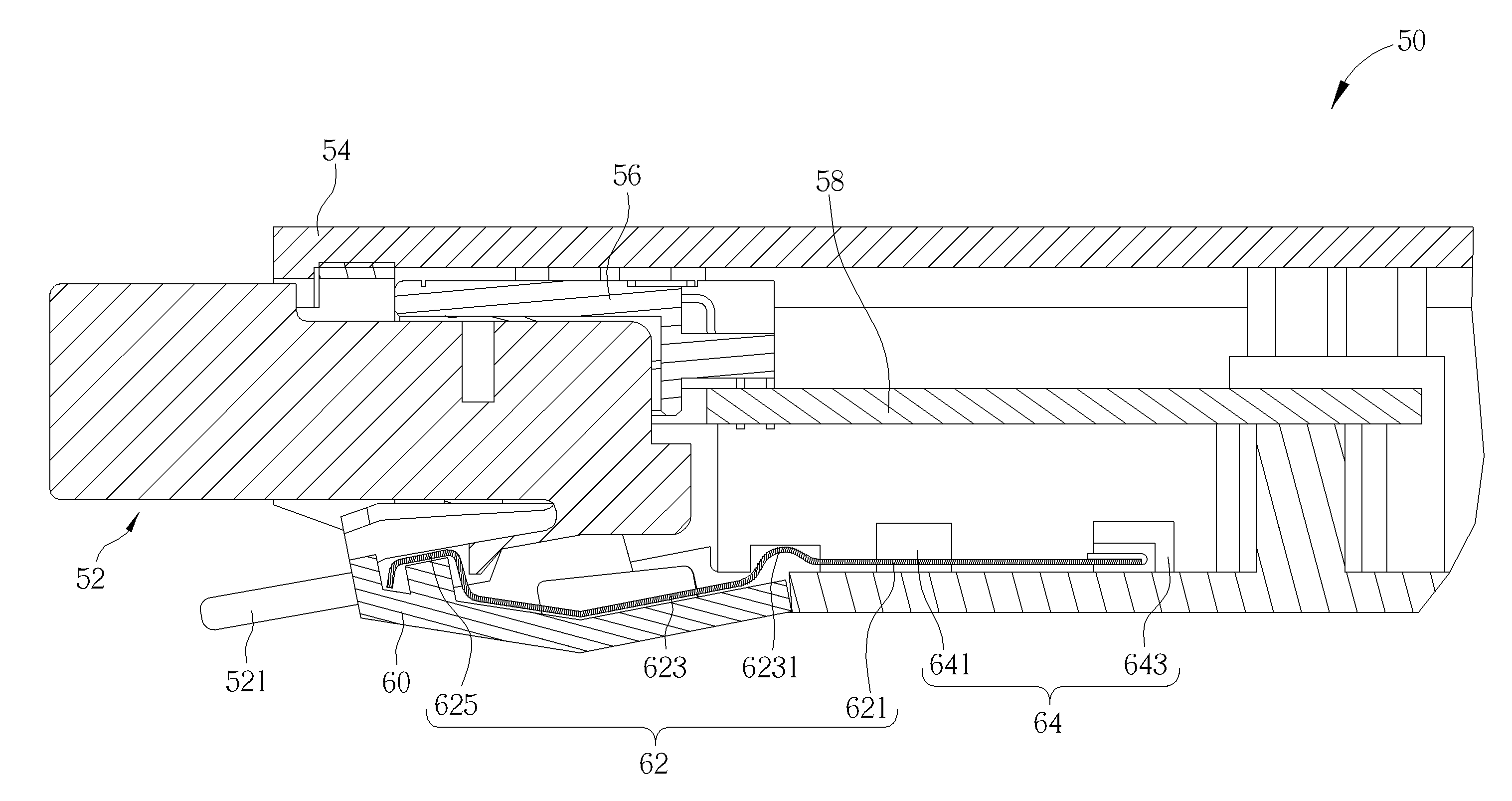

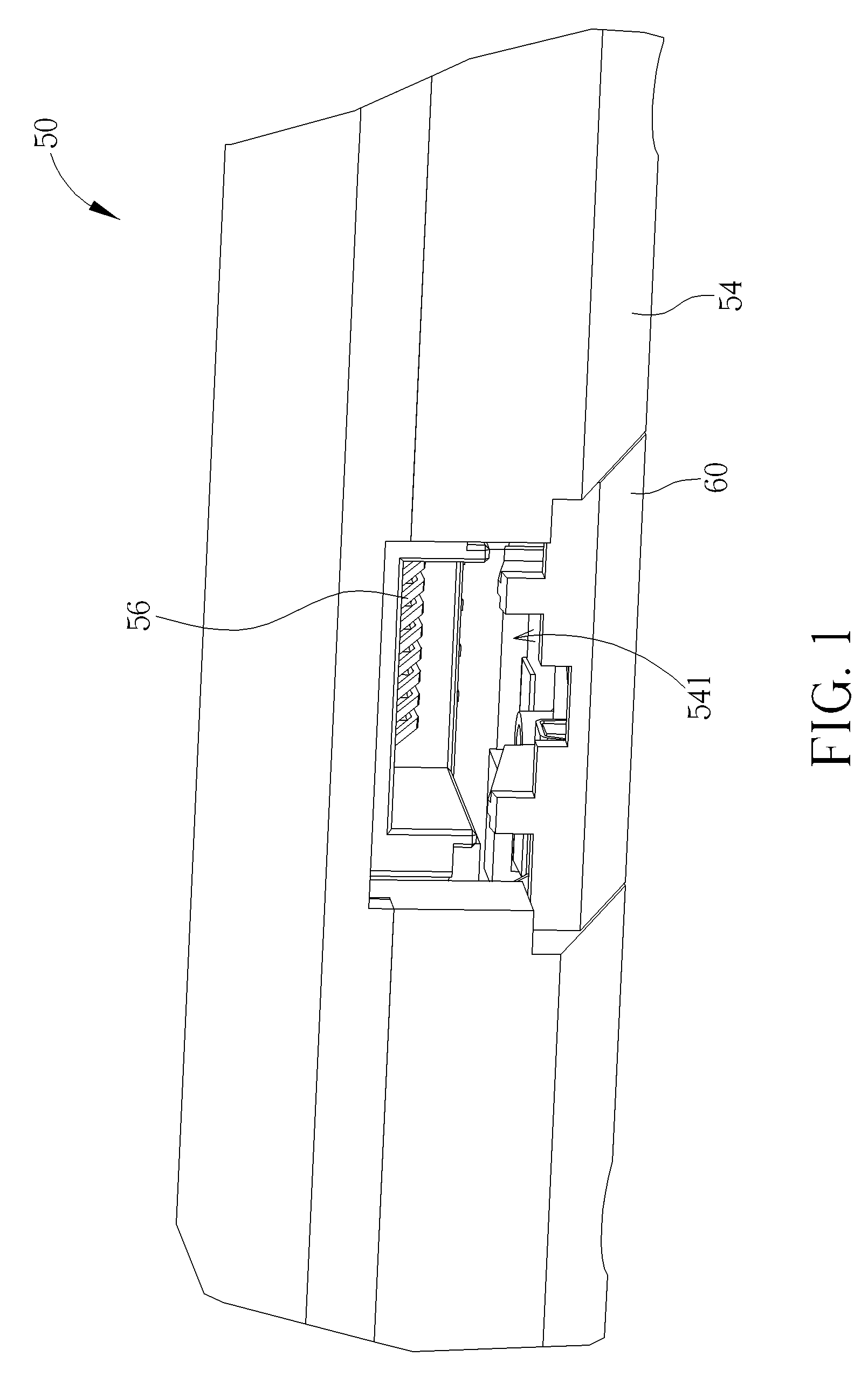

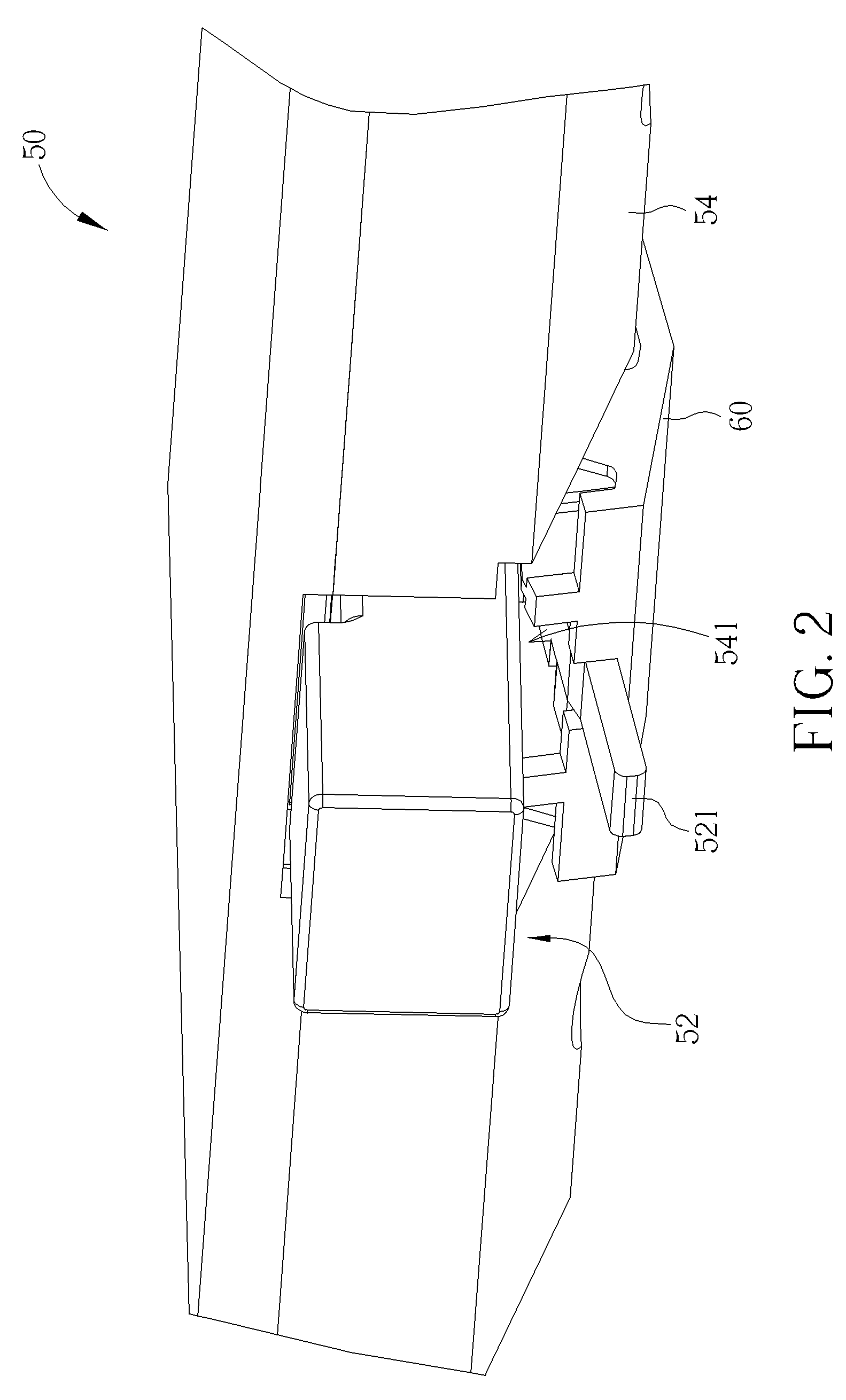

Connector mechanism for securing a plug to a casing

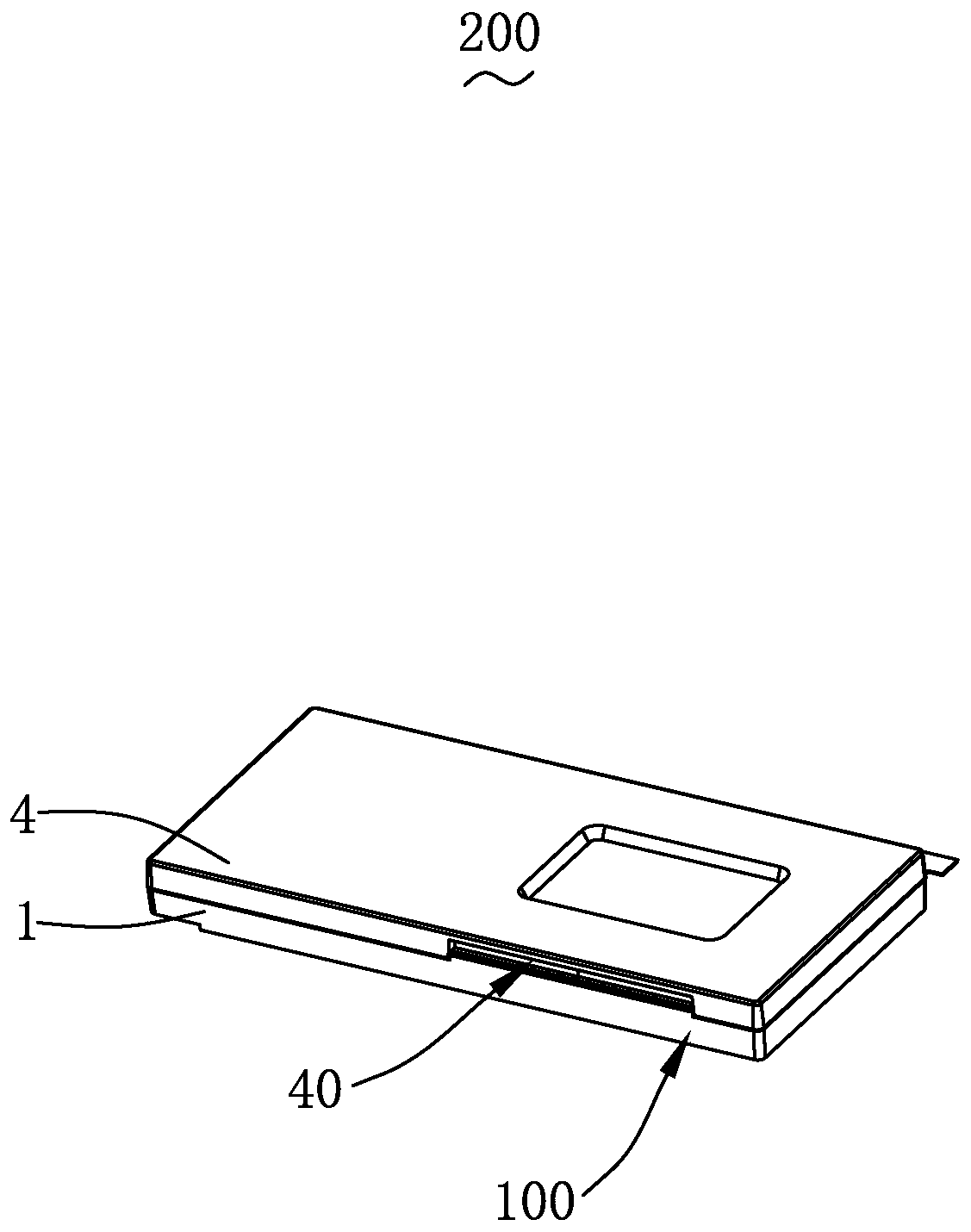

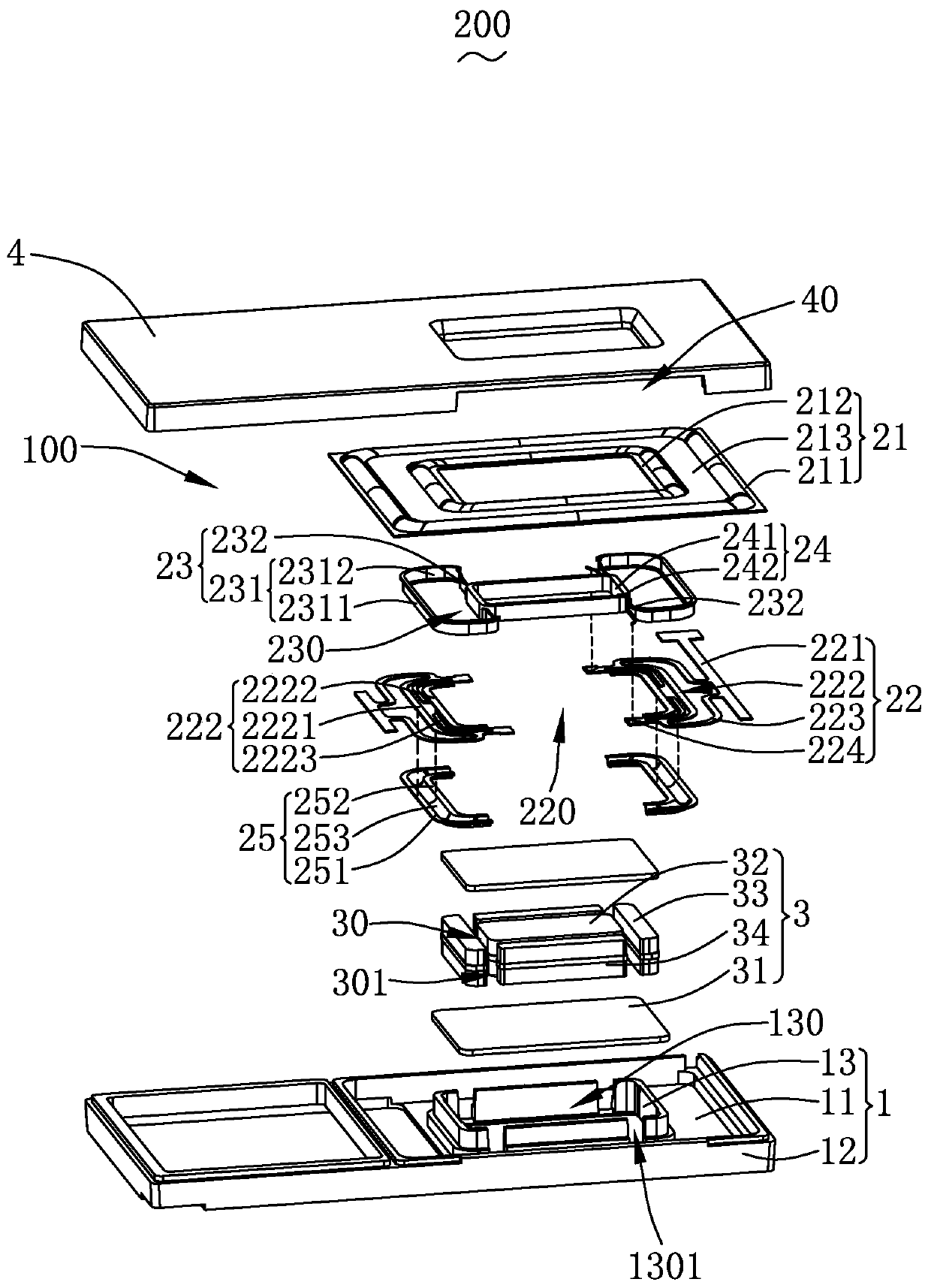

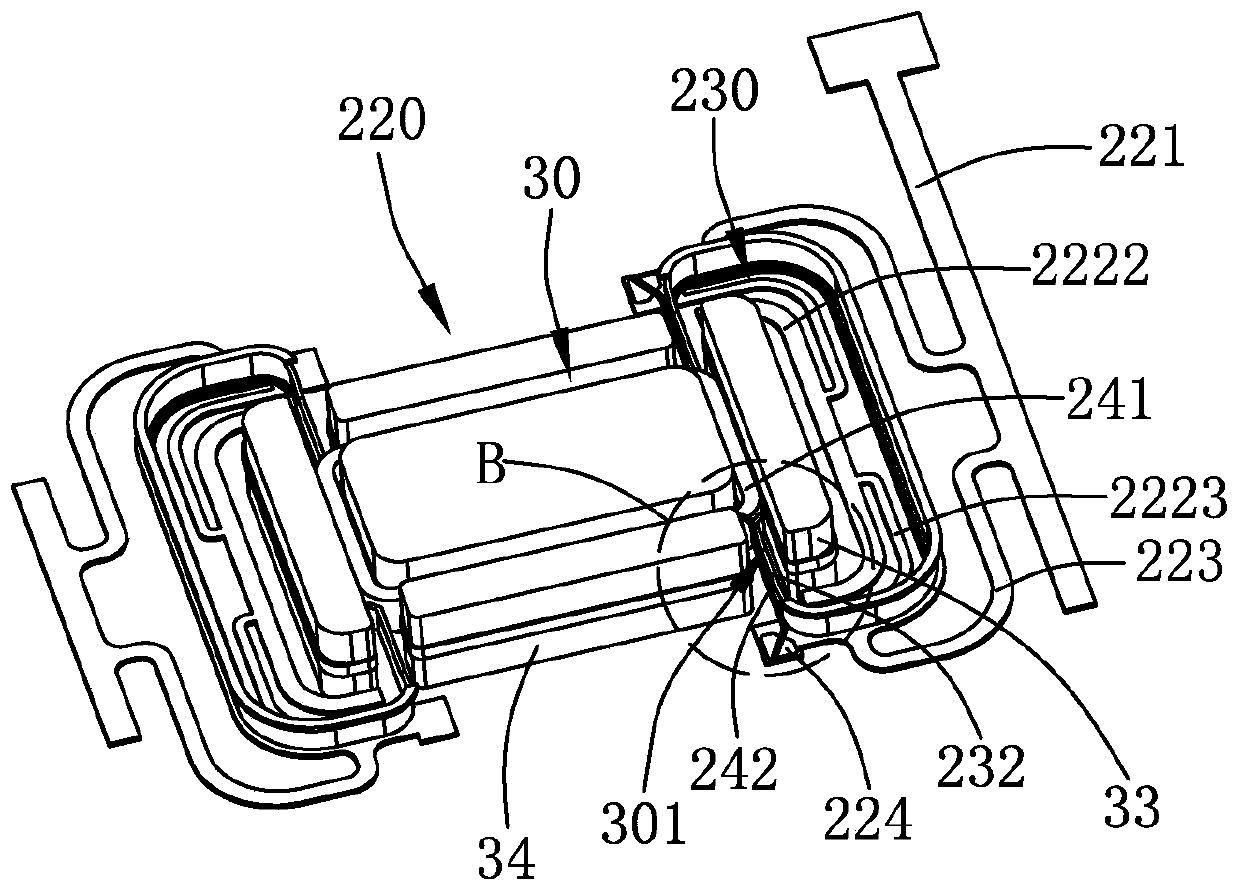

ActiveUS8777656B2Improve assembly strengthMaintain aestheticsEngagement/disengagement of coupling partsIncorrect coupling preventionEngineeringMechanical engineering

Owner:WISTRON CORP

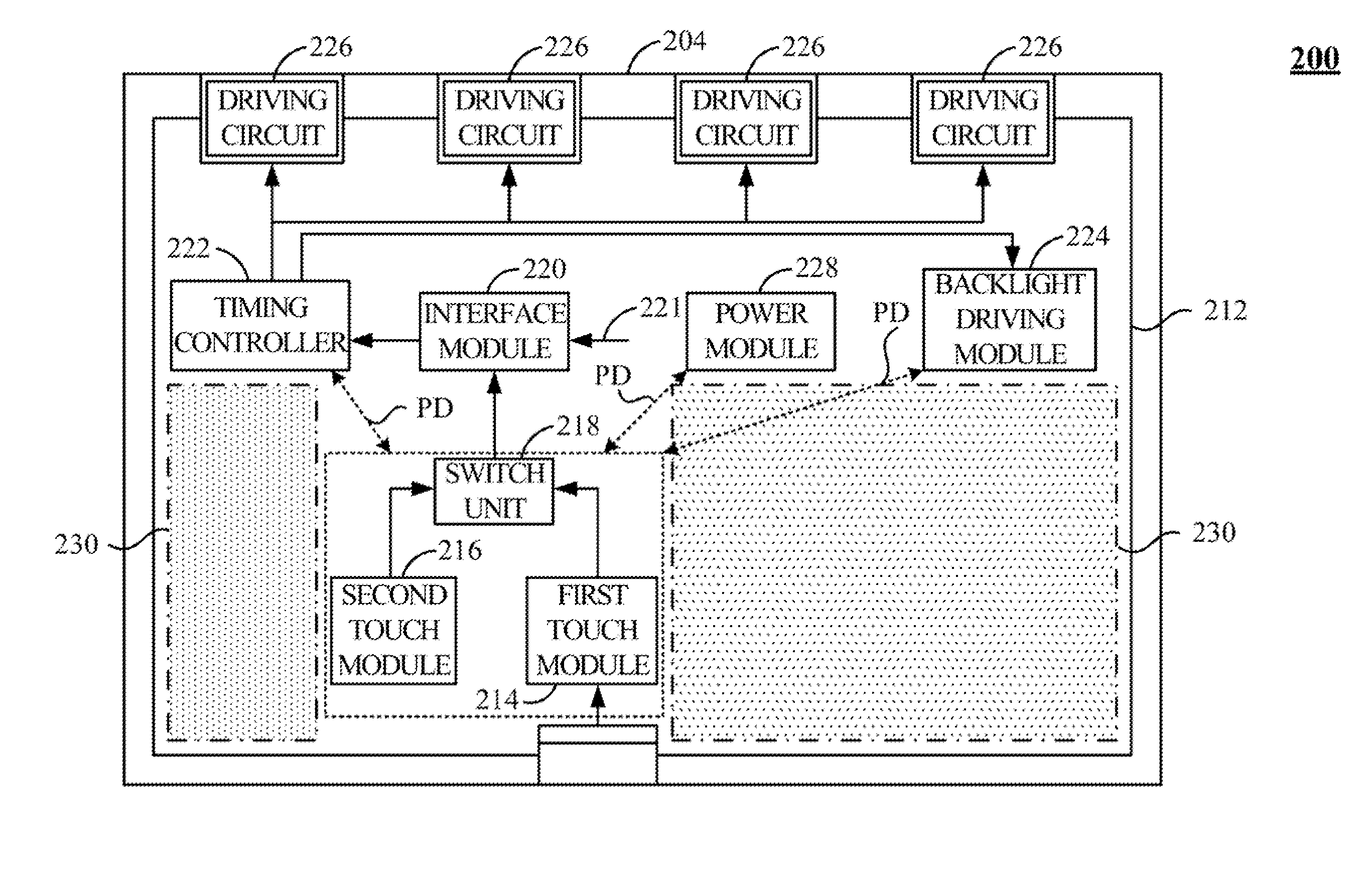

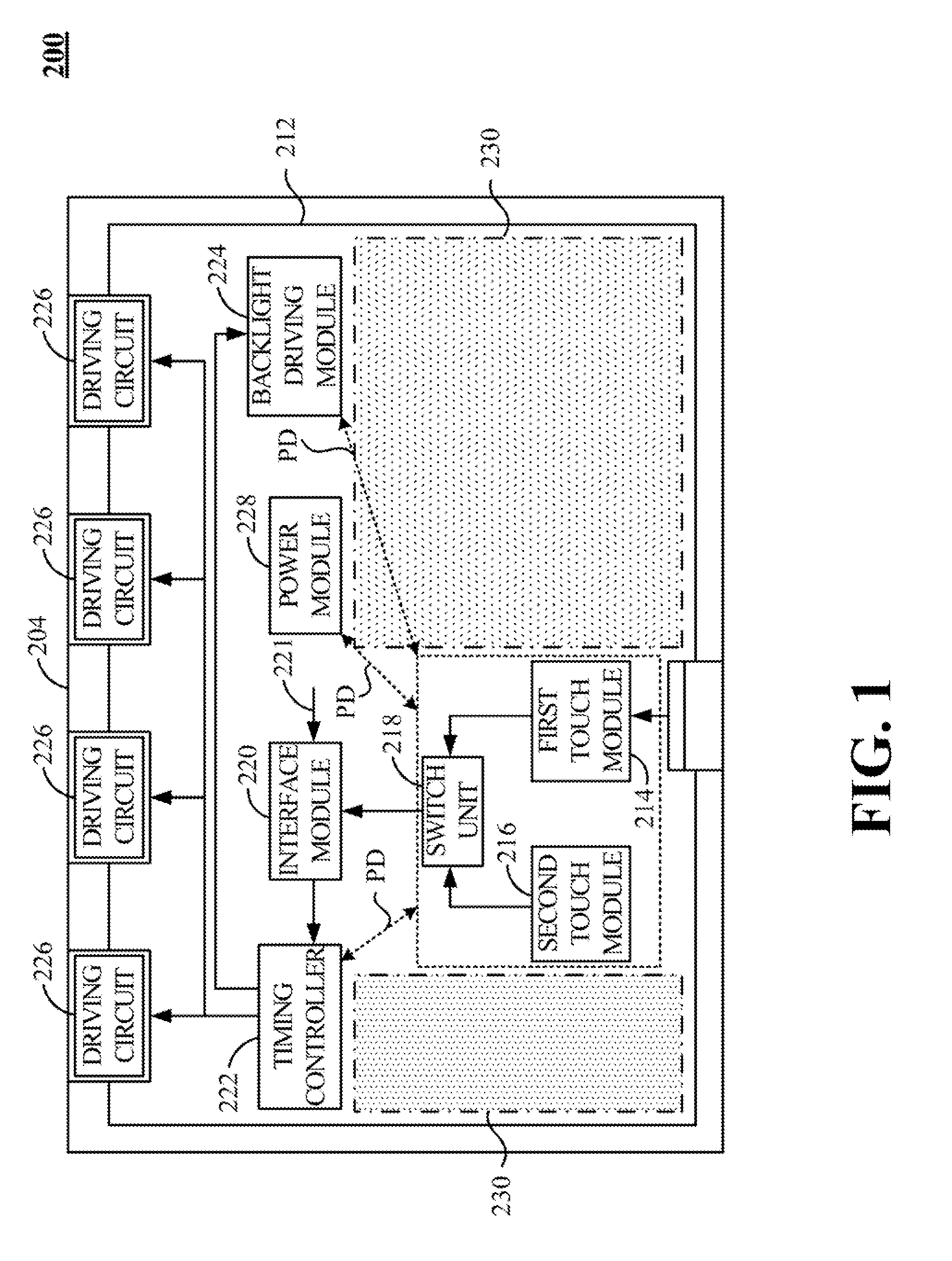

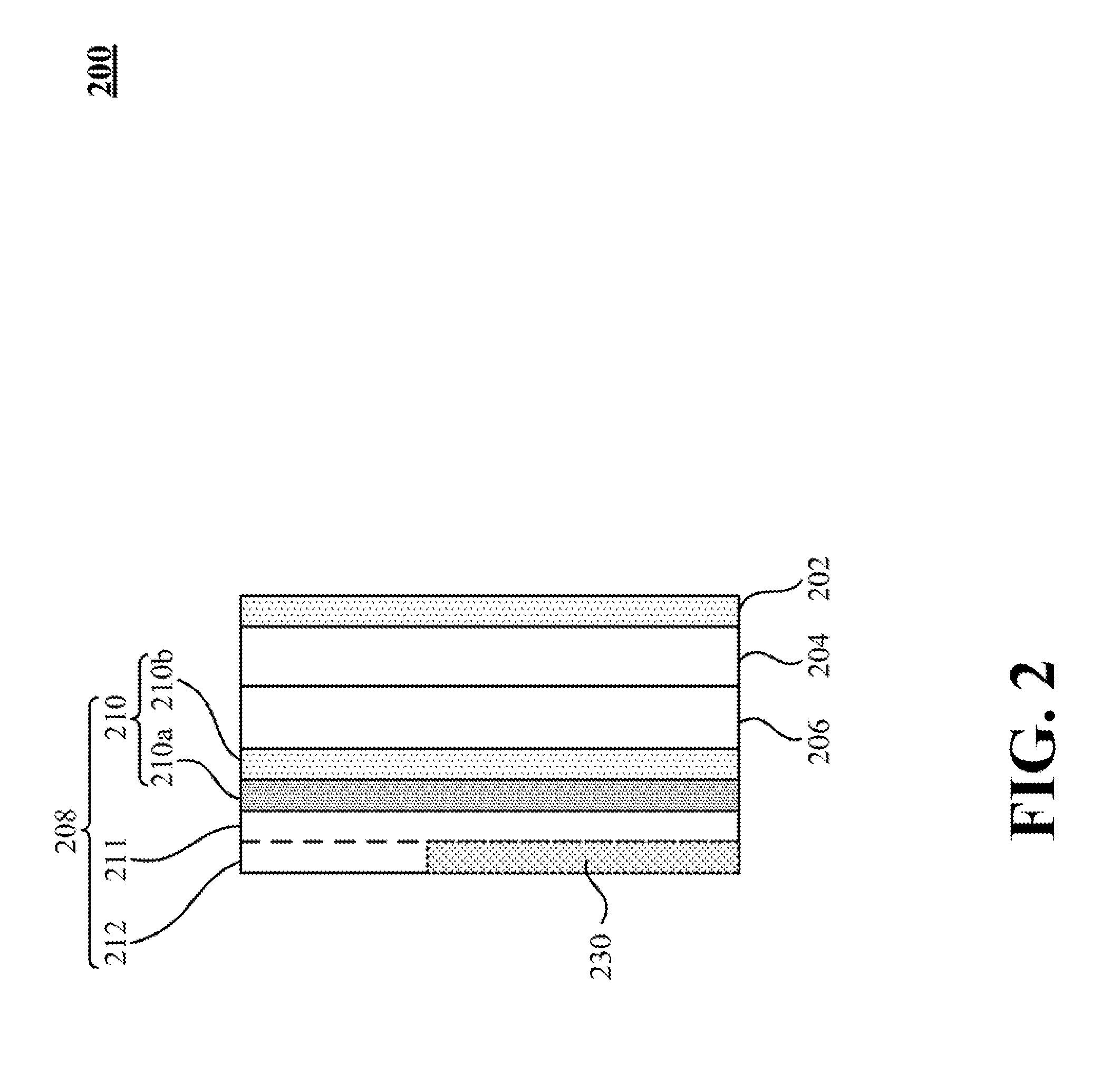

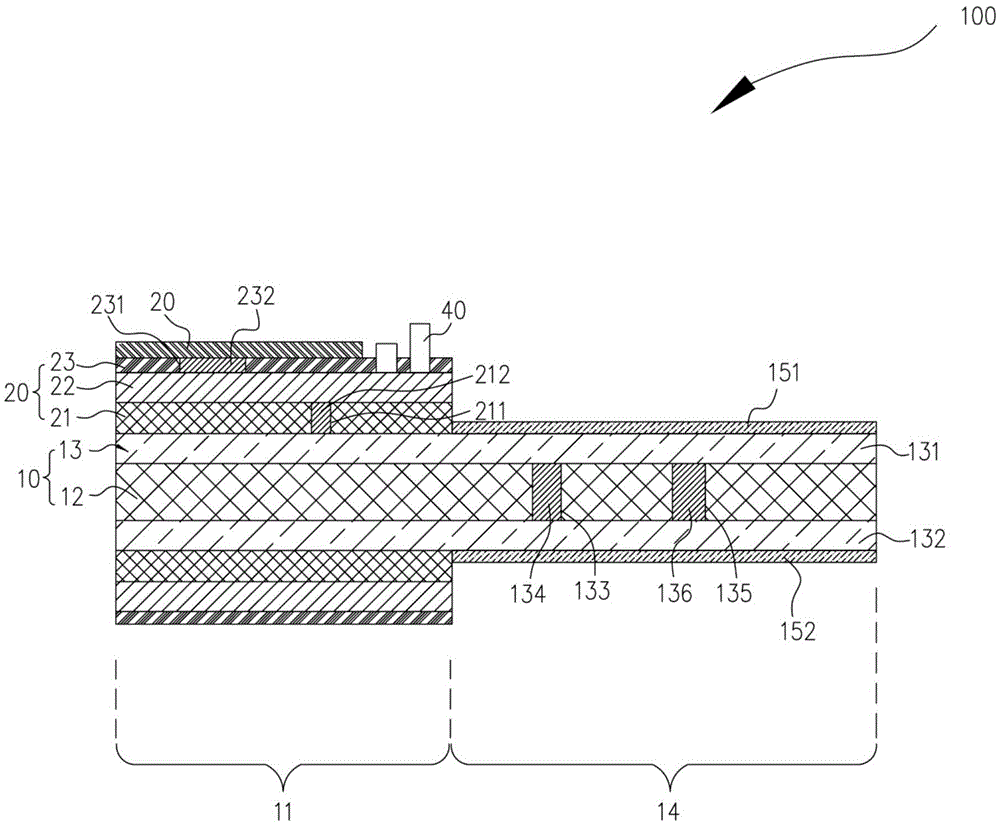

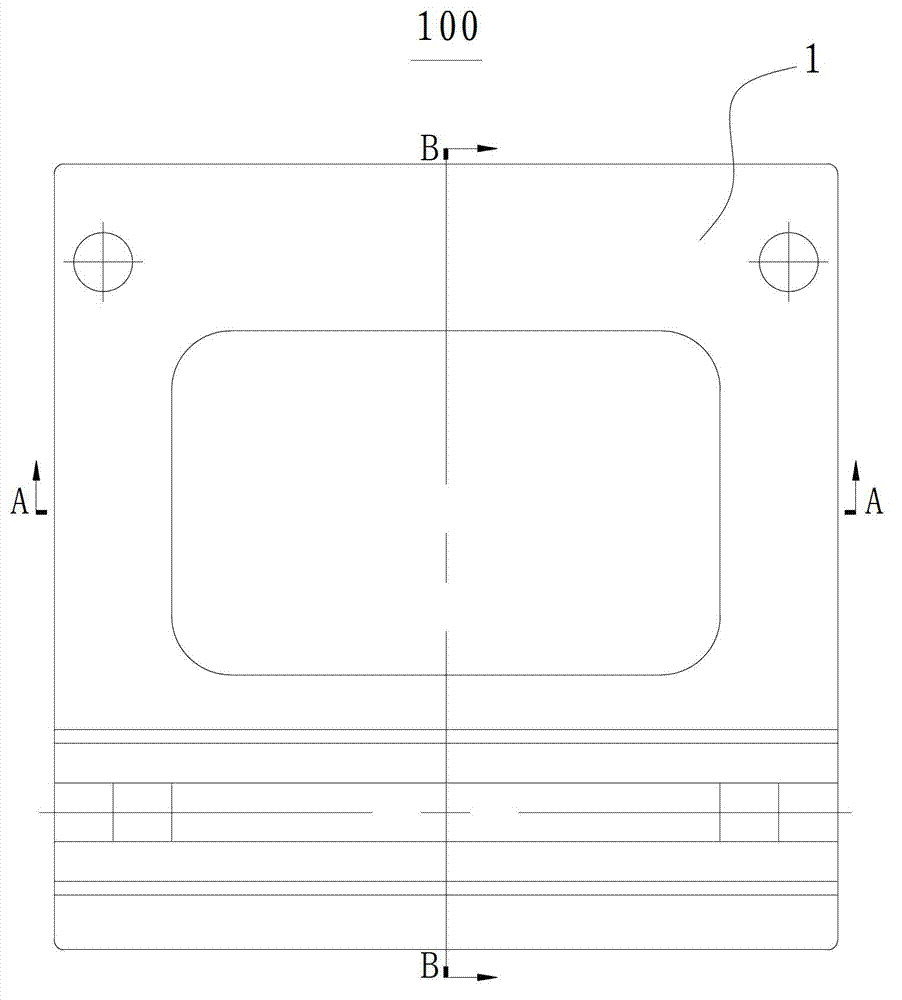

Integrated touch panel structure and manufacturing method thereof

InactiveUS20120313863A1Efficient separationReduce electromagnetic interferenceWave amplification devicesElectrical componentsElectromagnetic interferenceTouch panel

An integrated touch panel structure and manufacturing method thereof are described. The integrated touch panel structure is integrated by a first sensing layer, a displaying layer, a backlight plate and a composite component layer. The composite component layer includes a second sensing layer and a processing circuit layer. The processing circuit layer further includes a metal area for preventing a touch signal from electromagnetic interference to increase the precision of the touch signal.

Owner:HANNSTAR DISPLAY CORPORATION

Connector mechanism for connecting a plug

ActiveUS20130260581A1Reduce manufacturing costImprove assembly strengthNetwork connectorsComputer periphery connectorsEngineeringMechanical engineering

Owner:WISTRON CORP

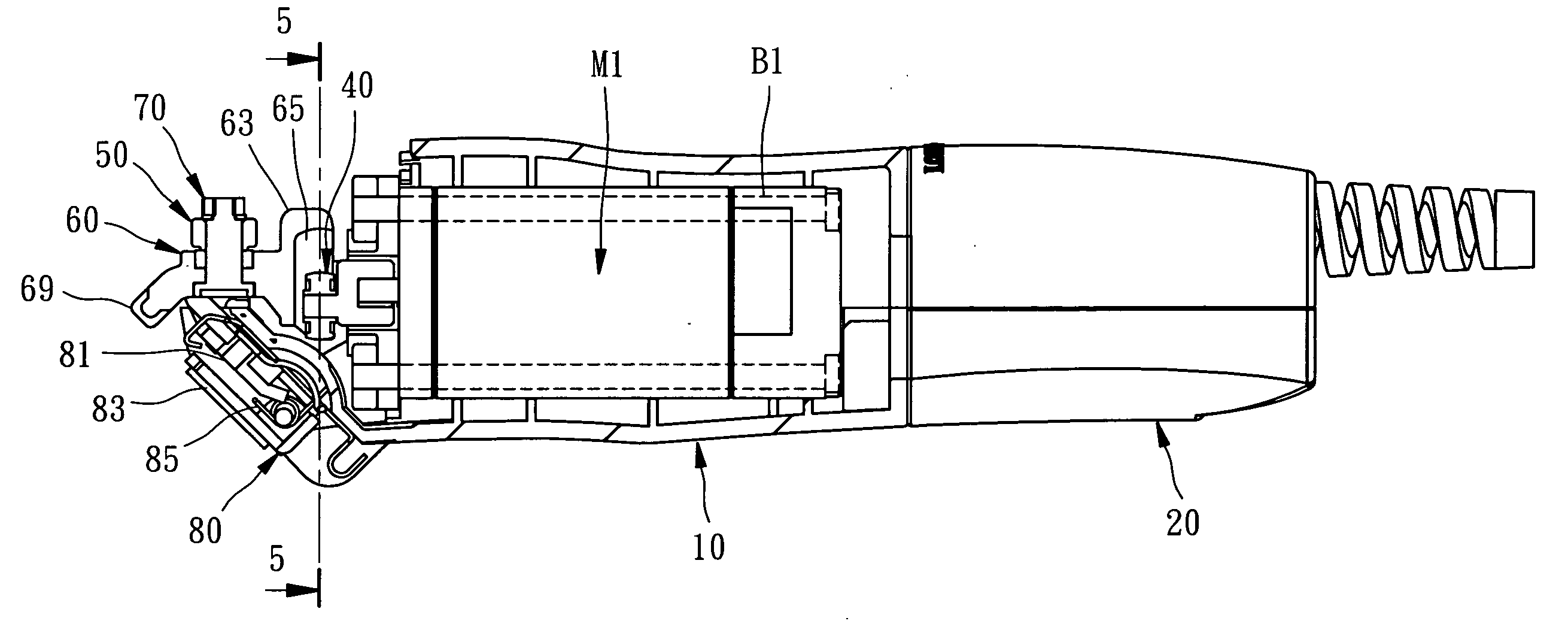

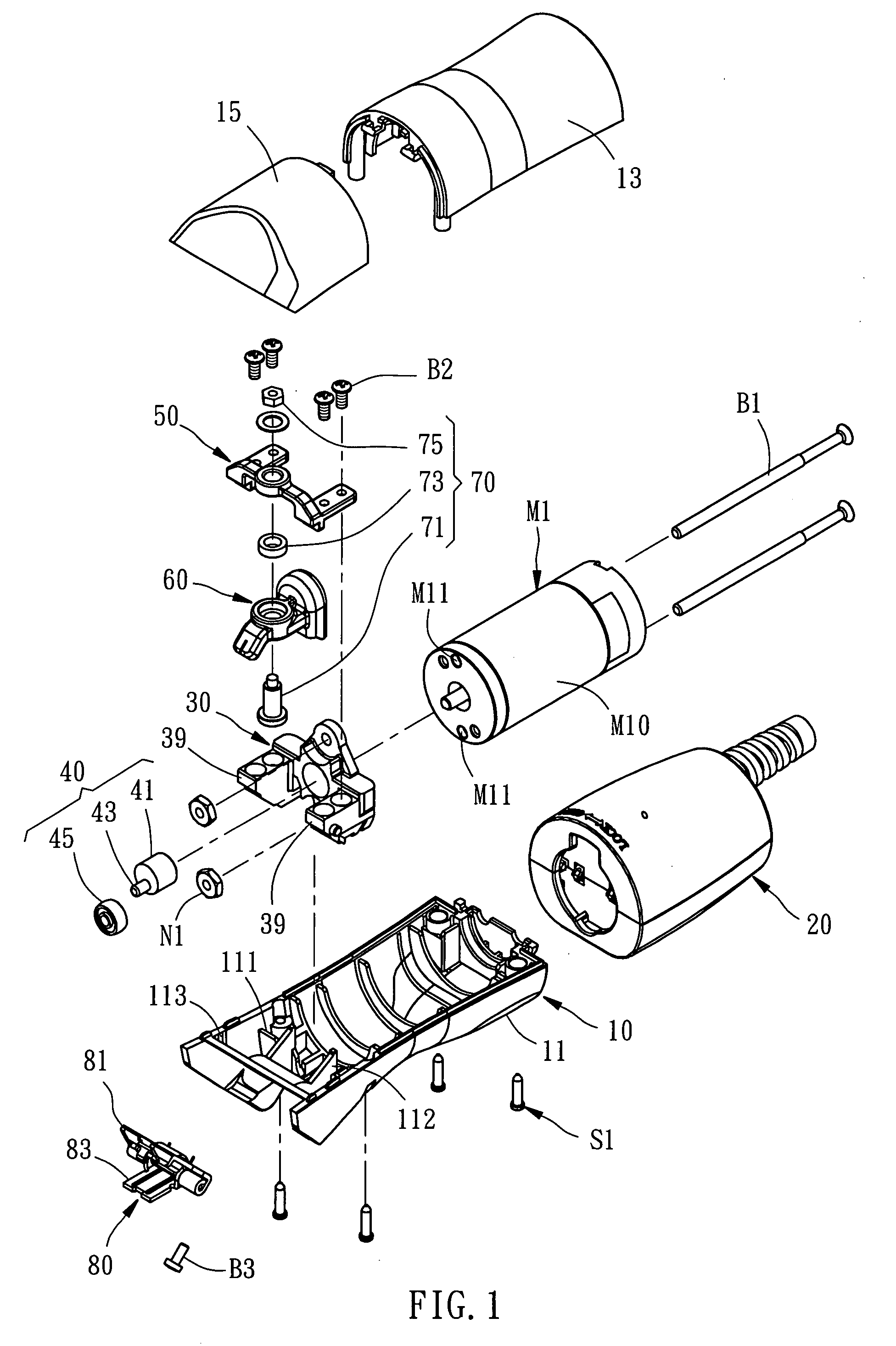

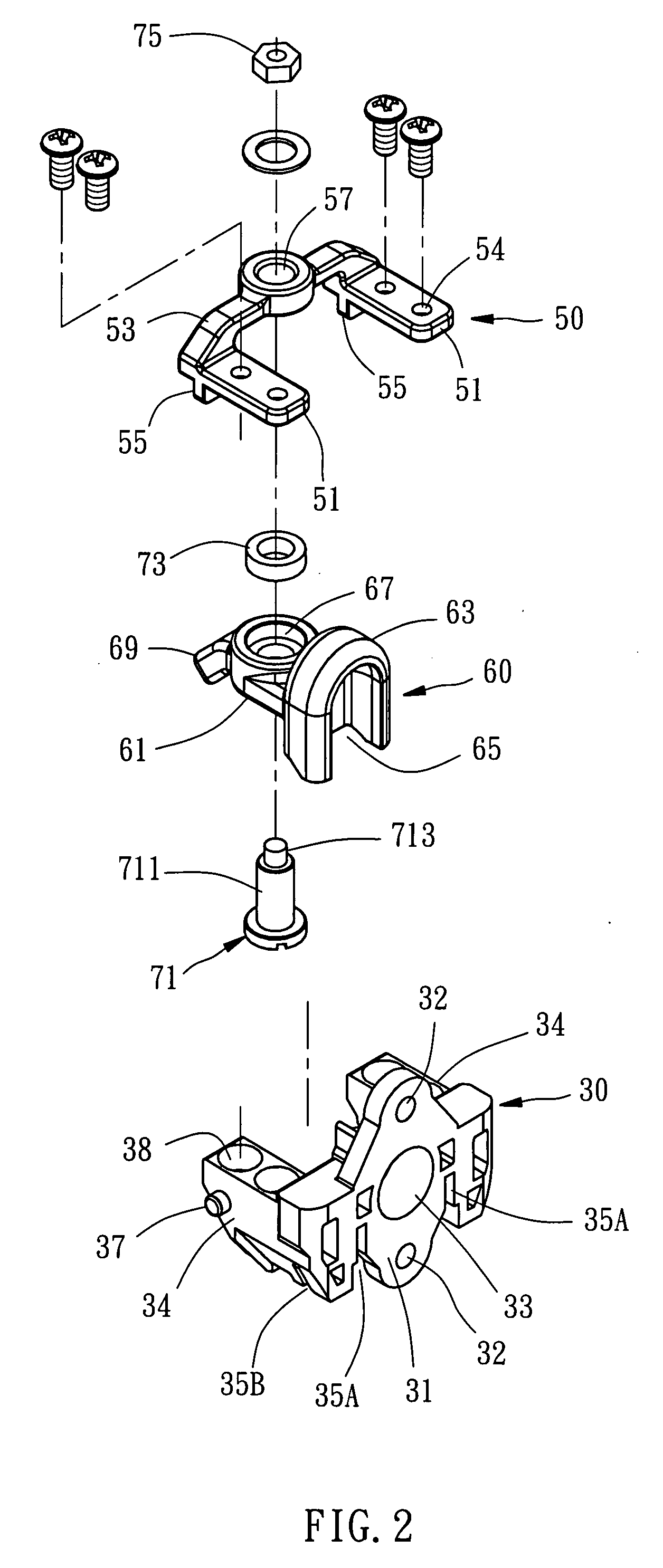

Hair clipper with improved mounting structures

InactiveUS20080263871A1Optimize the installation structureAssembly strength is strongMetal working apparatusHair clipperElectric motor

An electric hair clipper for adjusting a cutter kit includes a combination housing having a first locating rib and a second locating rib. A motor is received inside the combination housing, the motor has a fixing means, a spindle is provided to rotate. A fixation mounter has a mounting seat fixed by the fixing means, a first locating slot and a second locating slot engaged with the first locating rib and second locating rib of the combination housing respectively. A driving roller set has an impelling roller eccentrically and rotatably connected to the spindle of the motor. A linking frame has two mounter fixing portions, a bridge connects the two mounter fixing portions. A swiveling leverage has a lever body, a driven portion and a blade driving portion connected to each end of the lever body. And a pivot set pivoted to the linking frame and the swiveling leverage.

Owner:JENG SHYUAN PRECISION

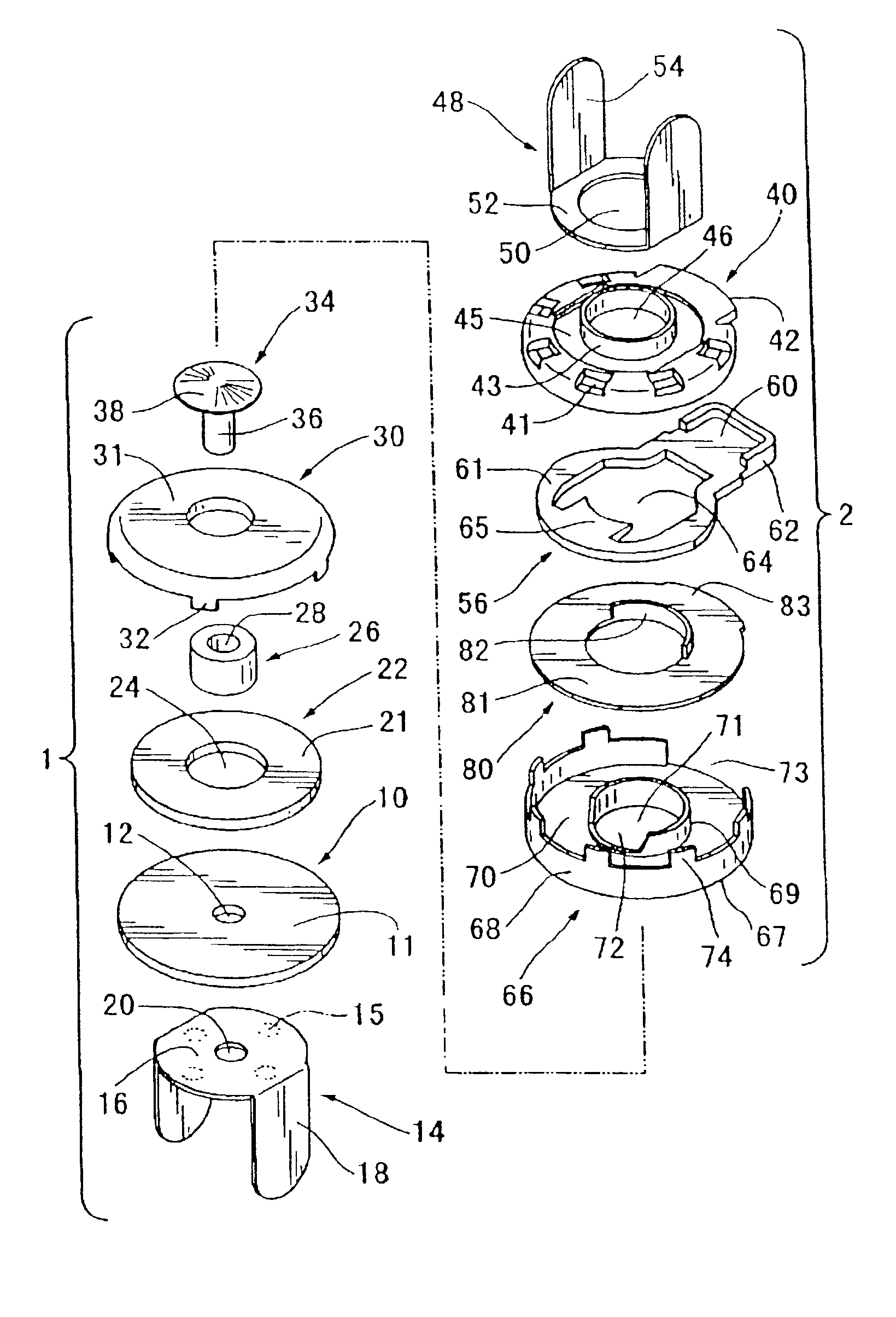

Magnetic fixing unit

InactiveUS20030024079A1Easy to operateImprove assembly strengthSnap fastenersWing fastenersMagnetic tension forceEngineering

A magnetic fixing unit having a first and second sub-assembly with cooperative structure for increased strength of assembly and prevention of mutual shifting between the first and the second assemblies. The magnetic fixing unit further includes a guide structure on one of the first and second assemblies to effect cooperative locking engagement with an engaging member on the other of the assemblies.

Owner:MORITA TAMAO

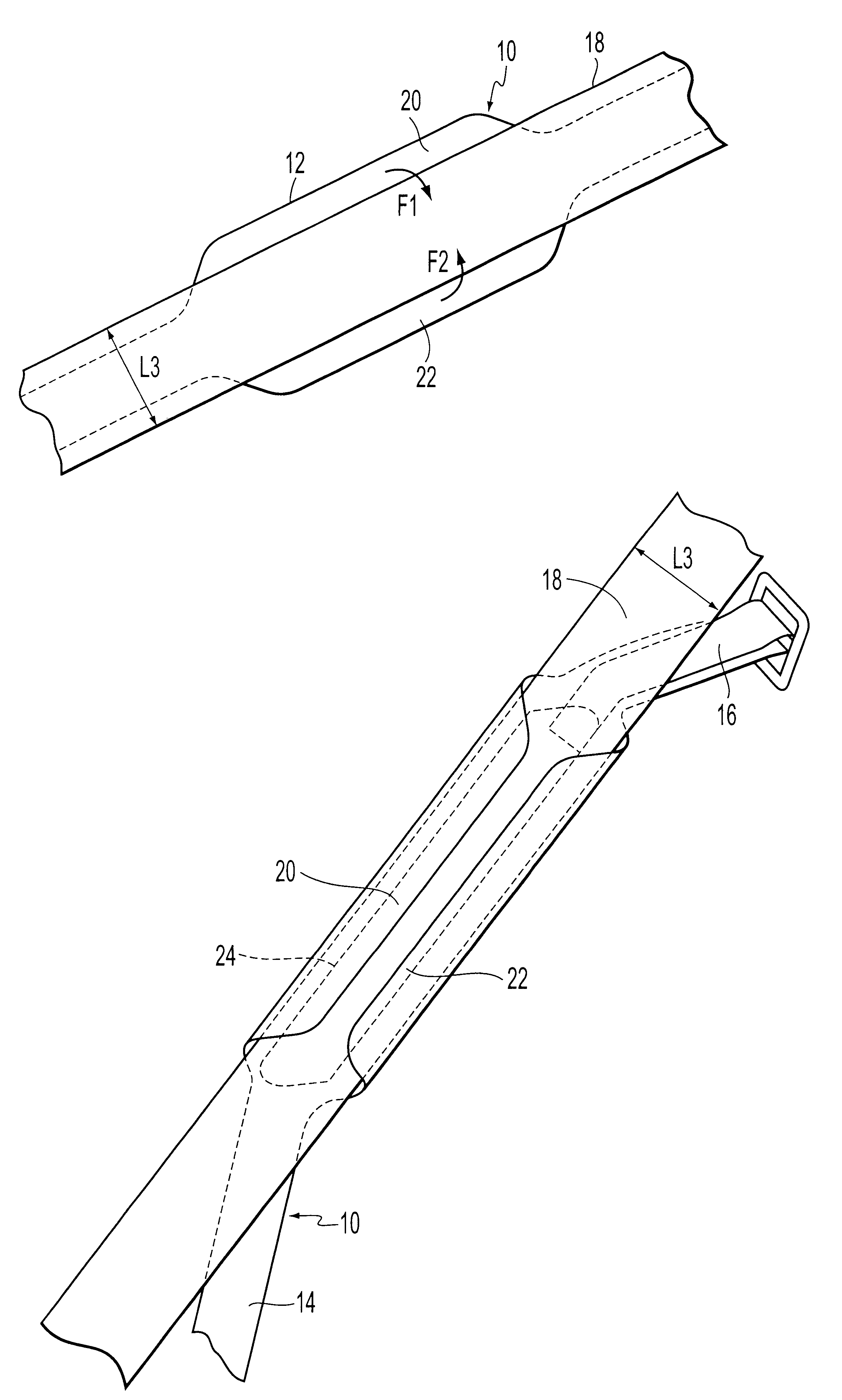

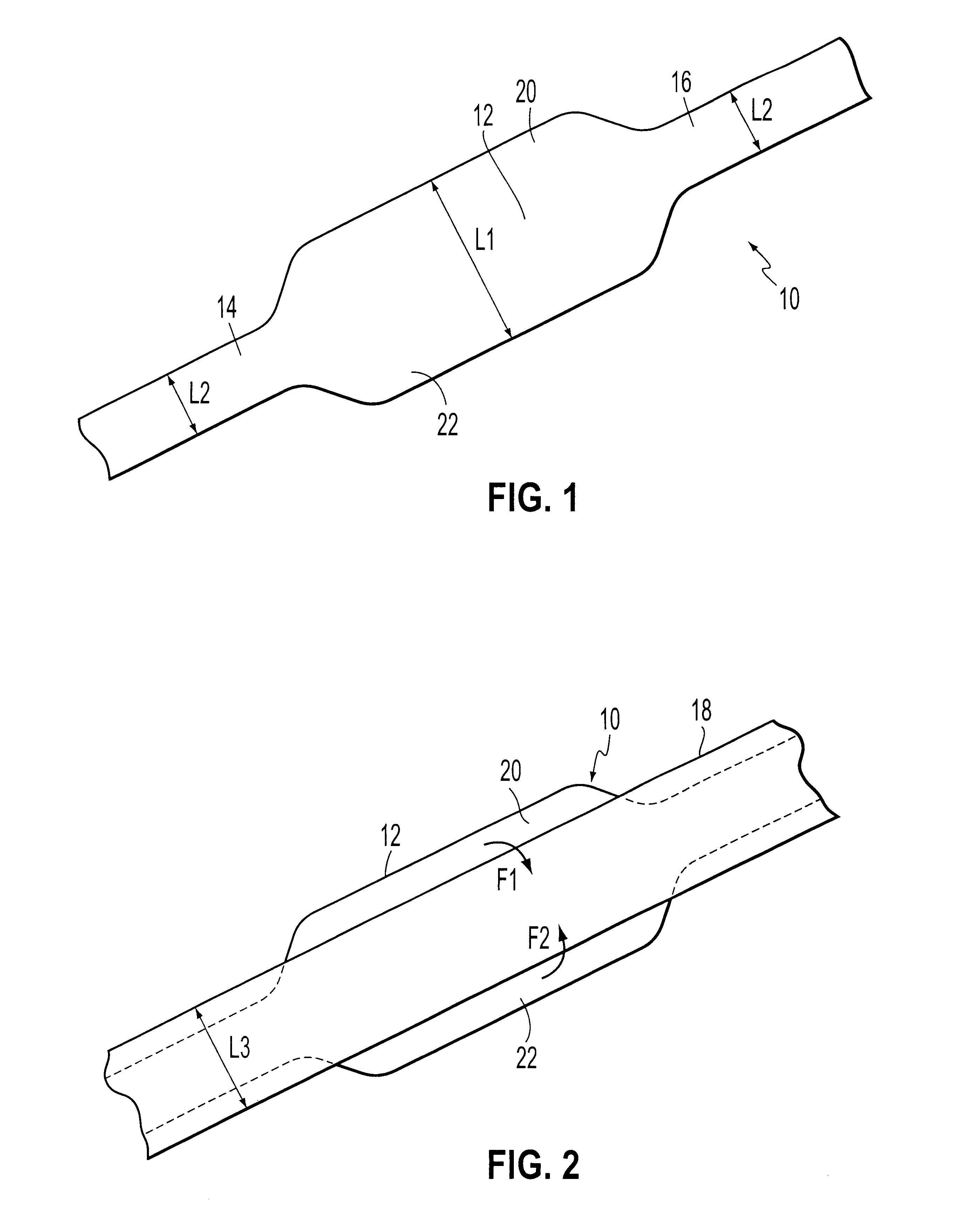

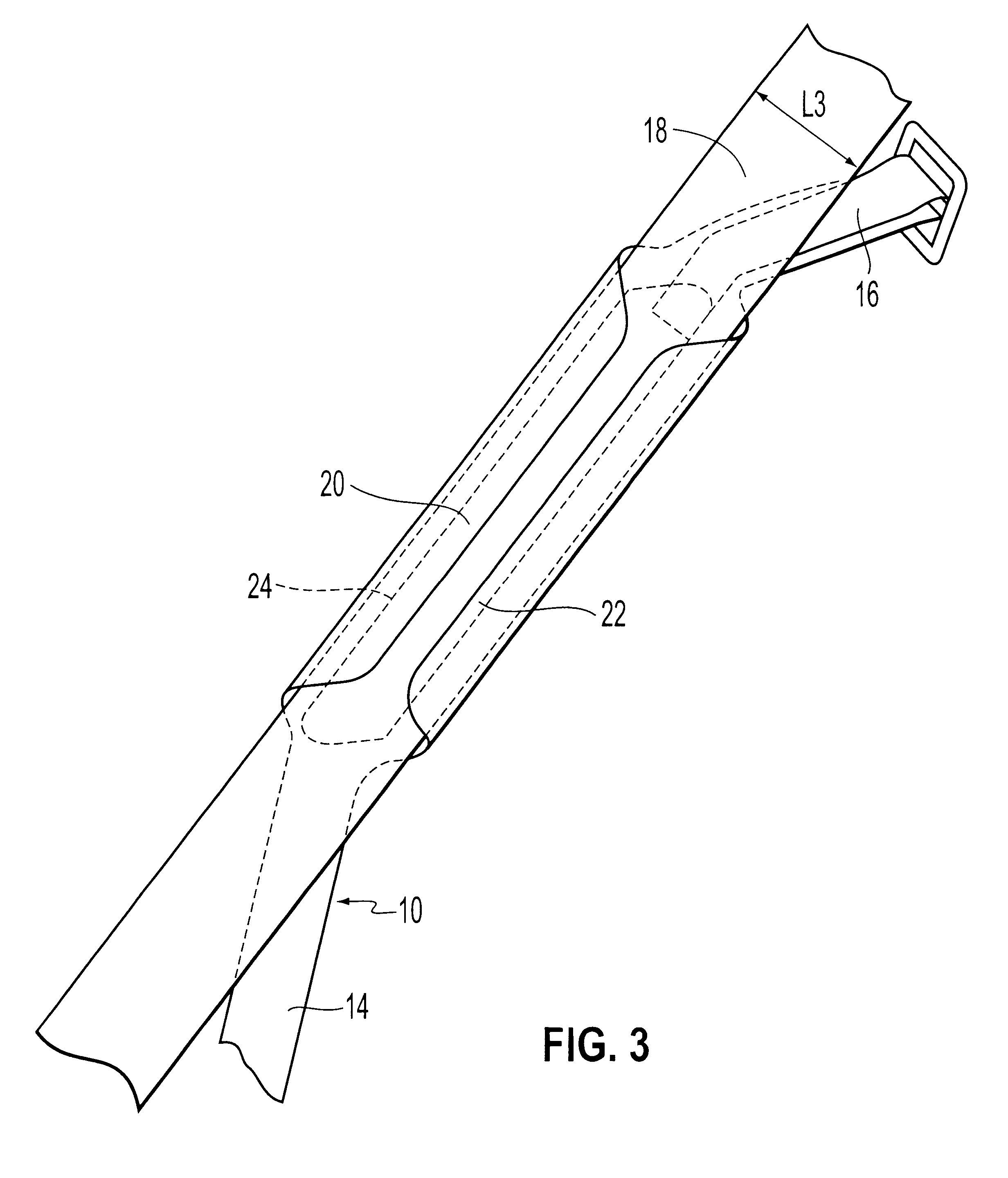

Manufacturing process of a wear resistant attachment device for a sit harness or roping harness, and attachement device with a strap obtained according to the process

InactiveUS6581726B1Mechanical assembly strength be improveSimplify implementationSafety beltsParachutesWear resistantEngineering

A wear resistant attachment for a sit harness or roping harness including a first strap having an enlarged part provided with joining edges which are folded onto the opposite face of a second strap to form wear resistant overlap parts.

Owner:ZEDEL CORP

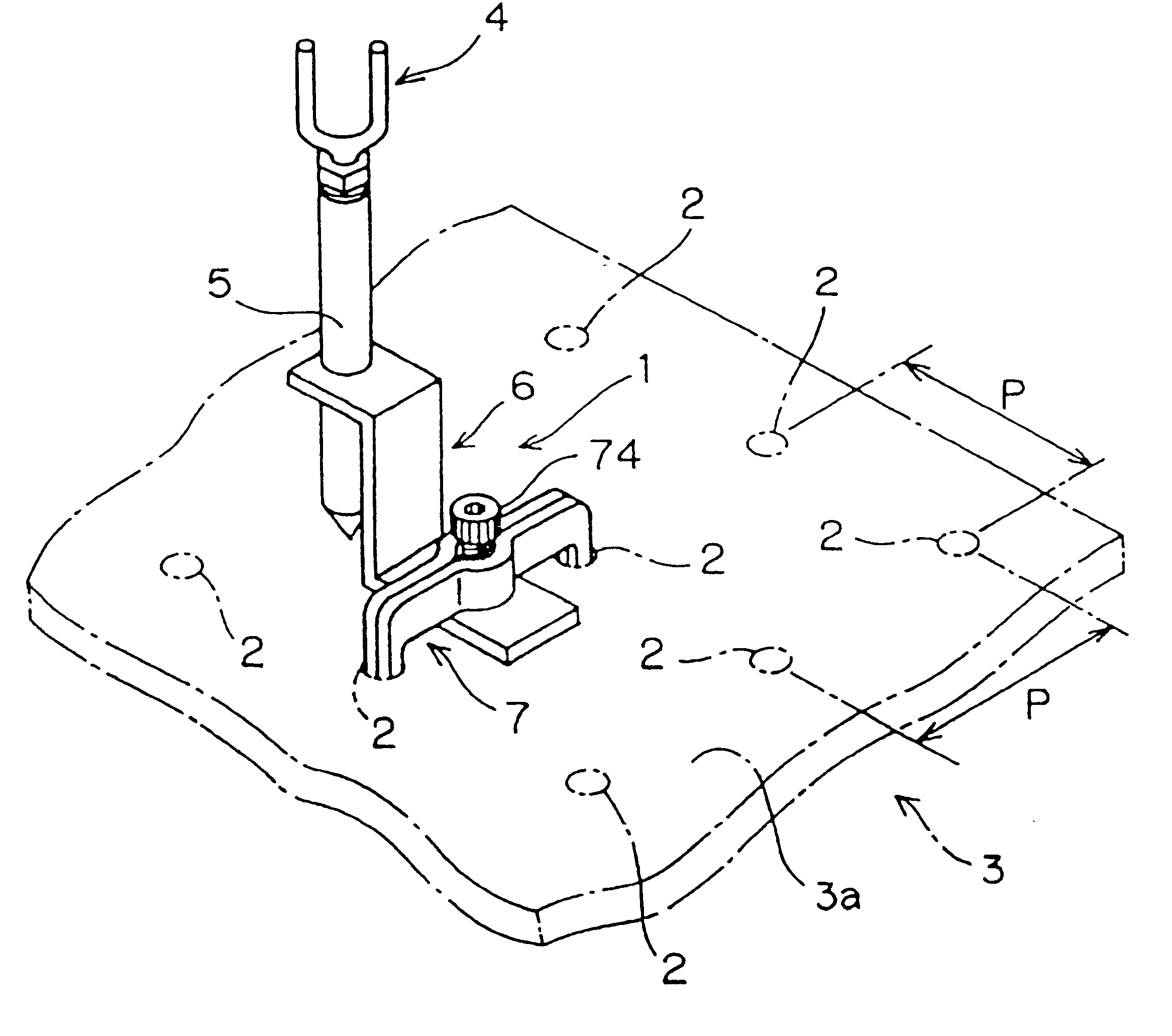

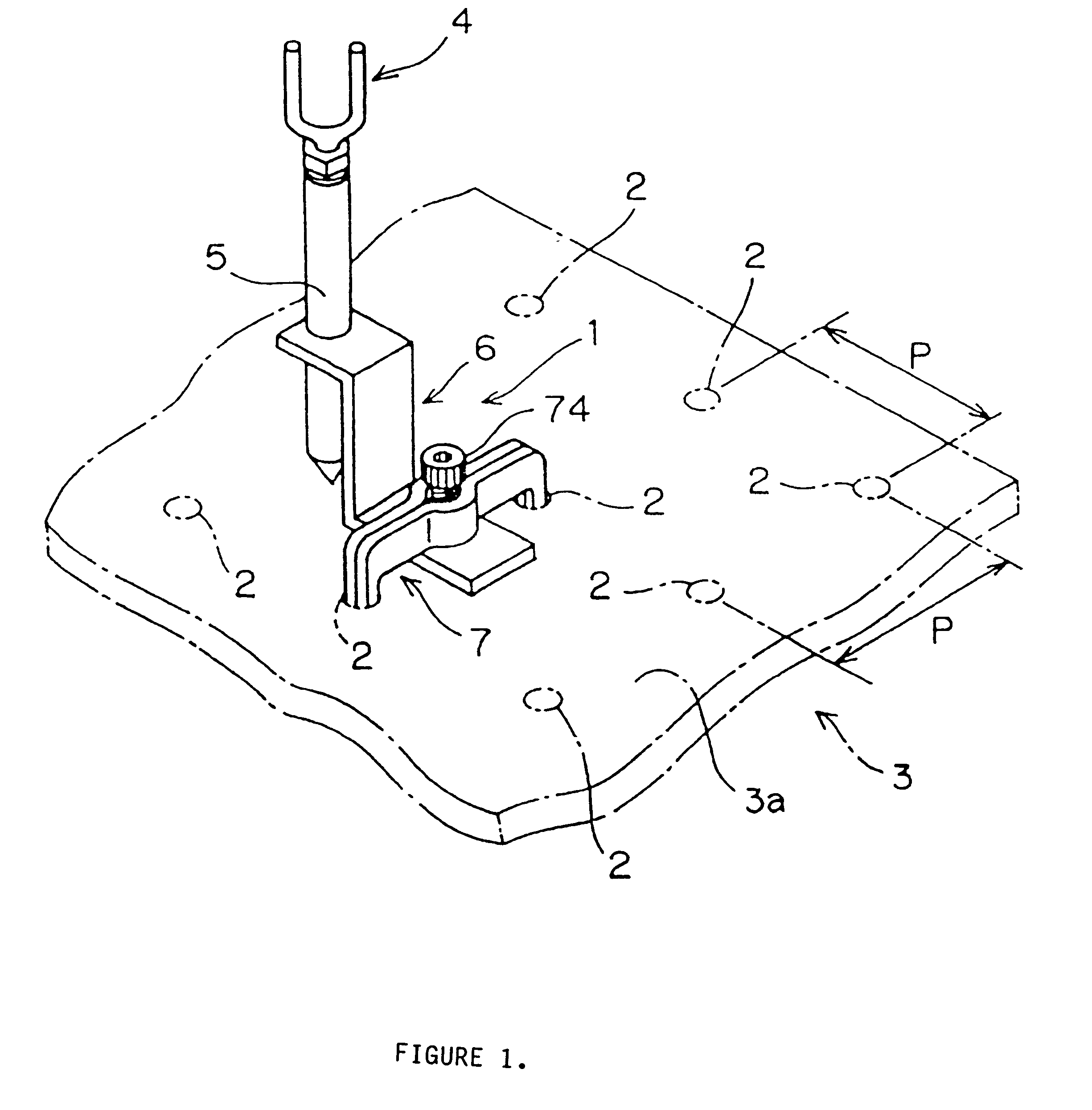

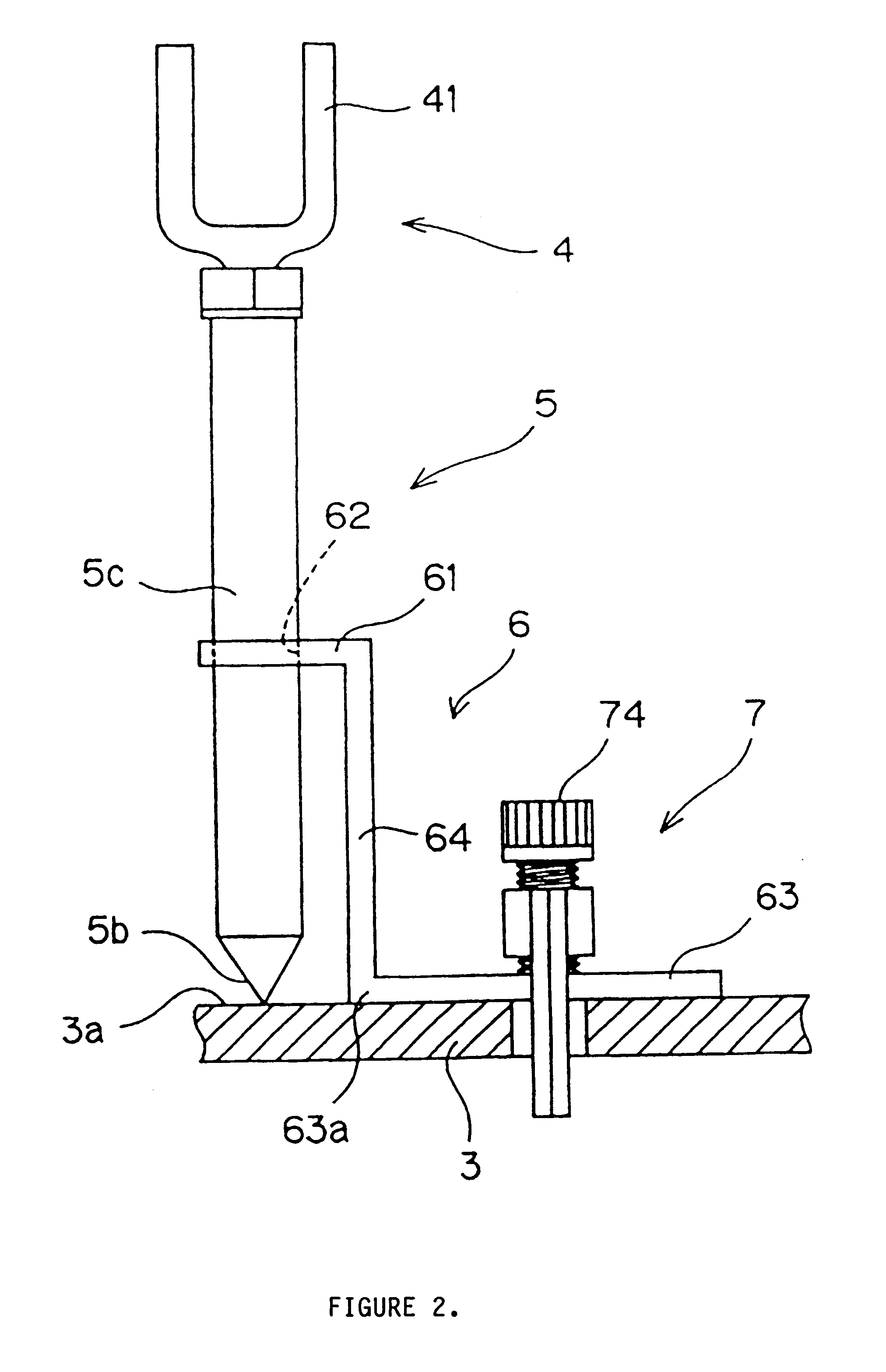

Assembly jig including a fixture for a perforated panel

InactiveUS6308944B1Improve assembly strengthHigh strengthWorkpiece holdersManufacturing wire harnessesEngineeringMechanical engineering

A wiring jig is provided with a cable receiving area which receives cables. A crank-shaped supporting member supports a pillar which supports the cable receiving area. A pressing member having a pair of locating feet is provided with a pressing screw. Tightening the pressing screw of the pressing member fastens the supporting member to a perforated panel. Loosening the pressing screw allows the supporting member to rotate and / or slide so that the pillar can be installed at any desired position without being limited by the position of mounting holes pre-formed with a predetermined spacing in a perforated panel which receive the pair of locating feet of the pressing member.

Owner:SUMITOMO WIRING SYST LTD

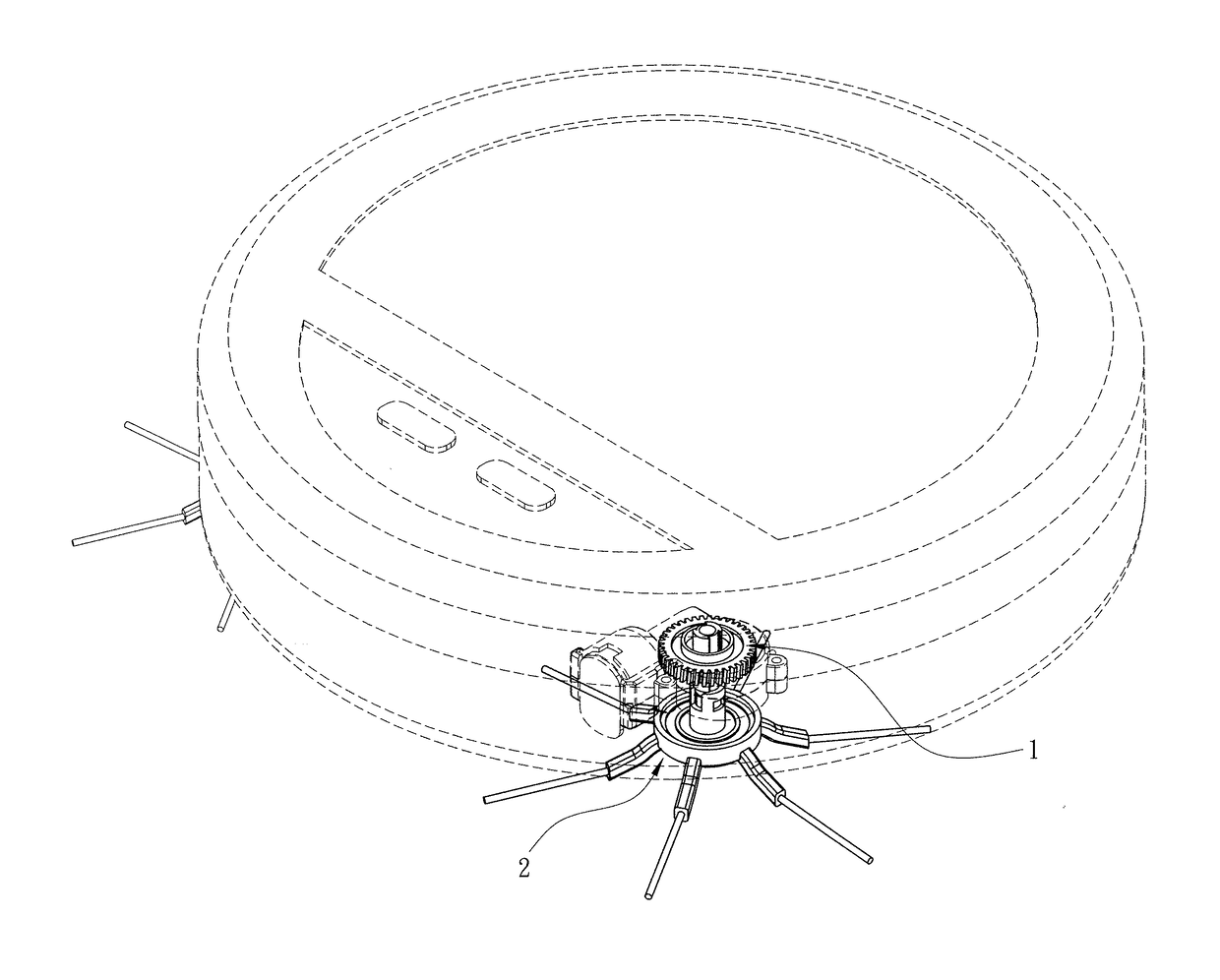

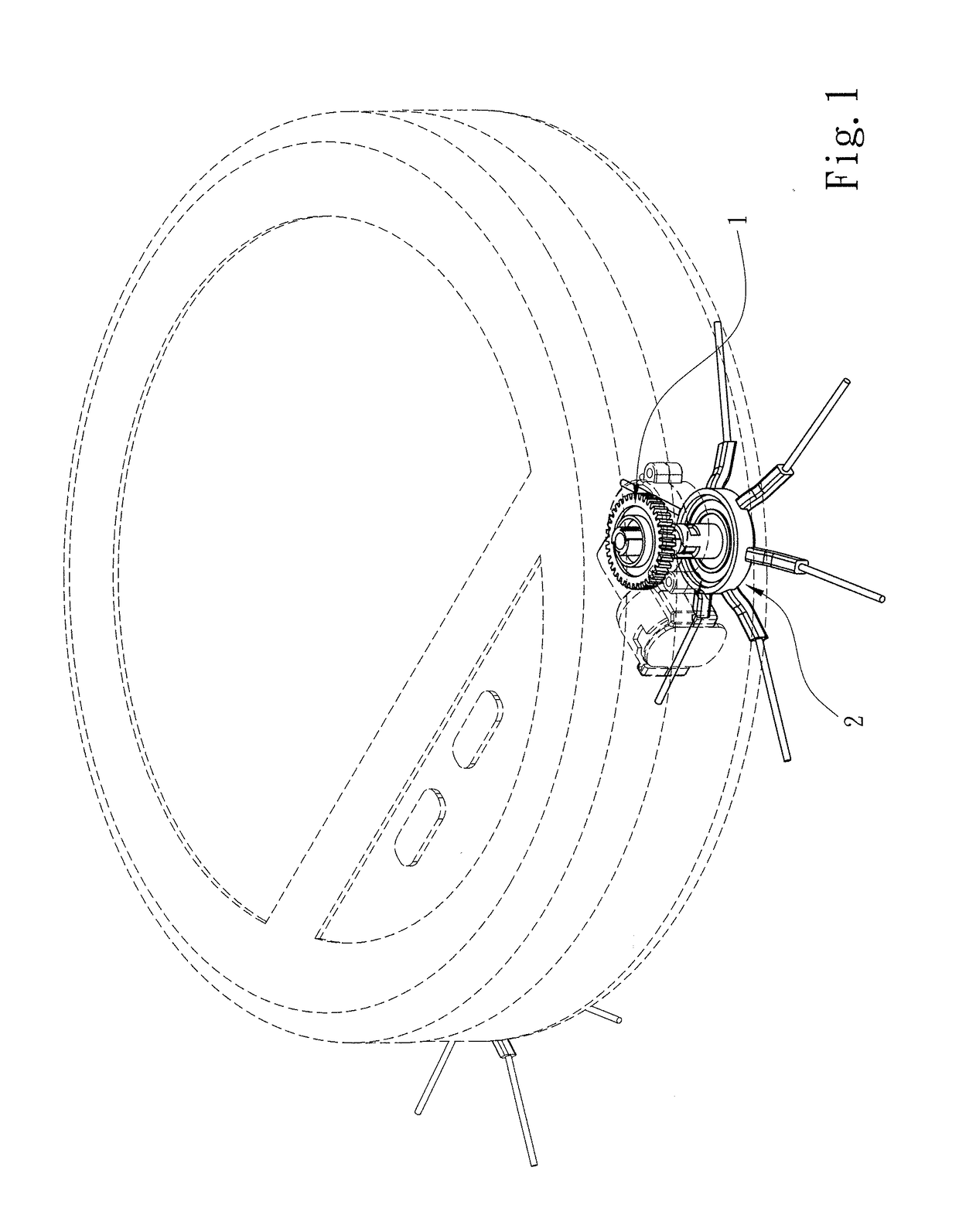

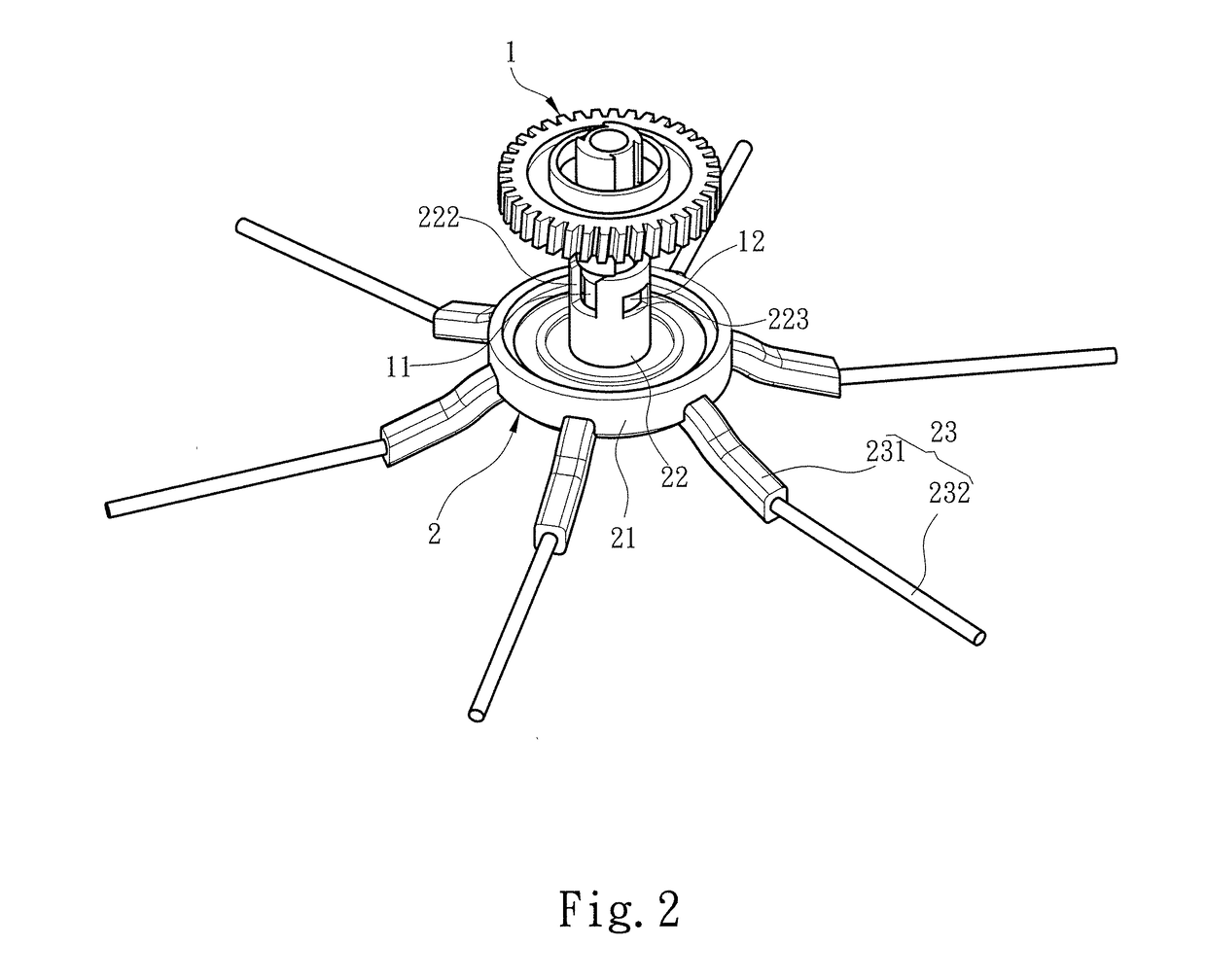

Fast detachable automatic cleaning device

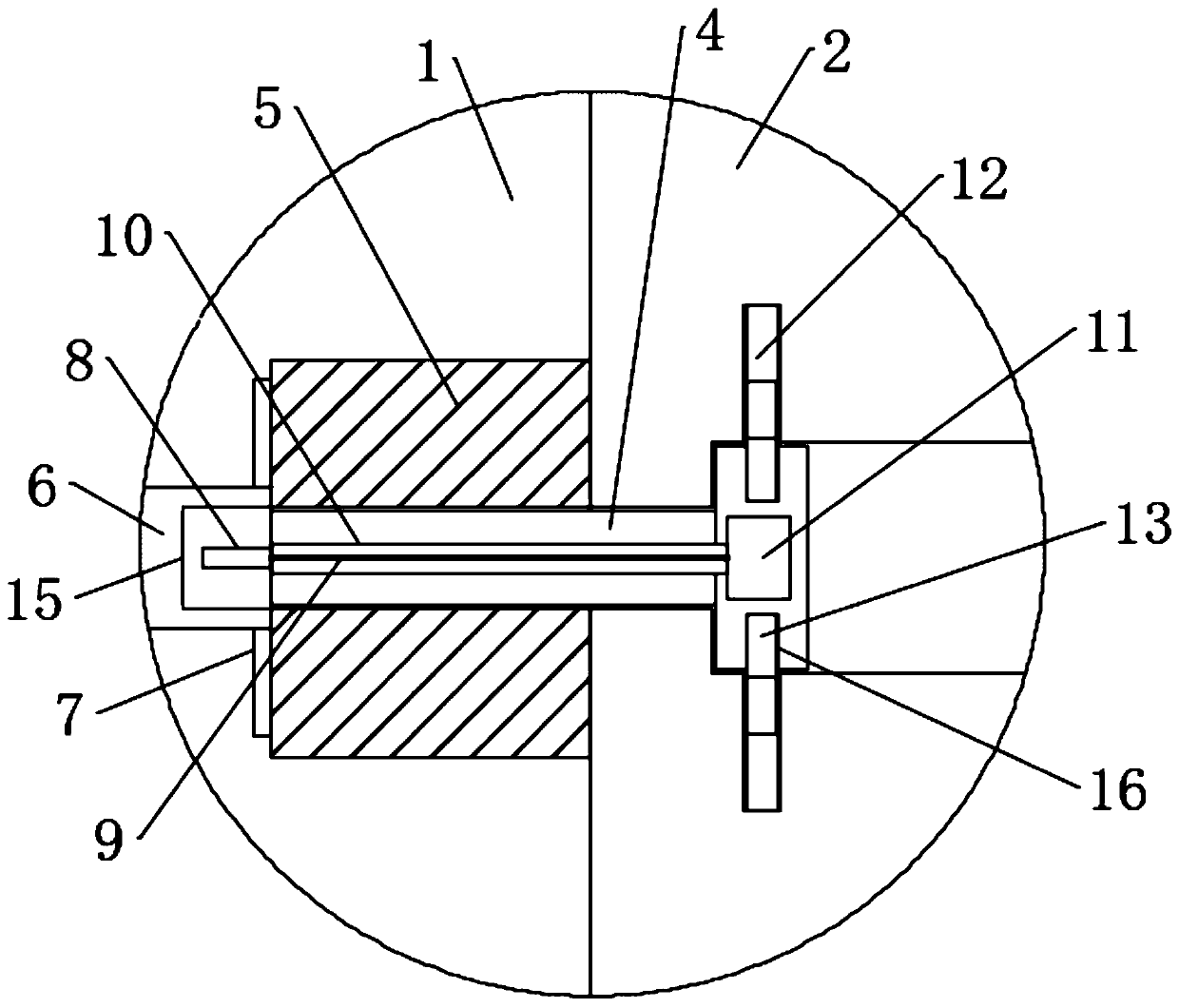

InactiveUS20170325648A1Enhance assembling strengthSimplify structureCarpet cleanersFloor cleanersEngineeringDrive shaft

A fast detachable automatic cleaning device includes a driving assembly and a cleaning assembly. The driving assembly includes a transmission shaft and at least one protrusion block that is a formed integral with the transmission shaft. The cleaning assembly includes a seat, a bearing sleeve connected to the seat, and a cleaning portion surrounding the seat. The bearing sleeve includes an assembly space, at least one track and at least one fixing hole. The driving assembly may be in a simplified structure through the formed integral of the transmission shaft and the protrusion block. Further, the protrusion block may be securely fastened in the fixing hole to enhance the assembly strength of the transmission shaft and the bearing sleeve to solve issues of a complicated structure and insufficient strength of convention solutions.

Owner:IBOT CO LTD

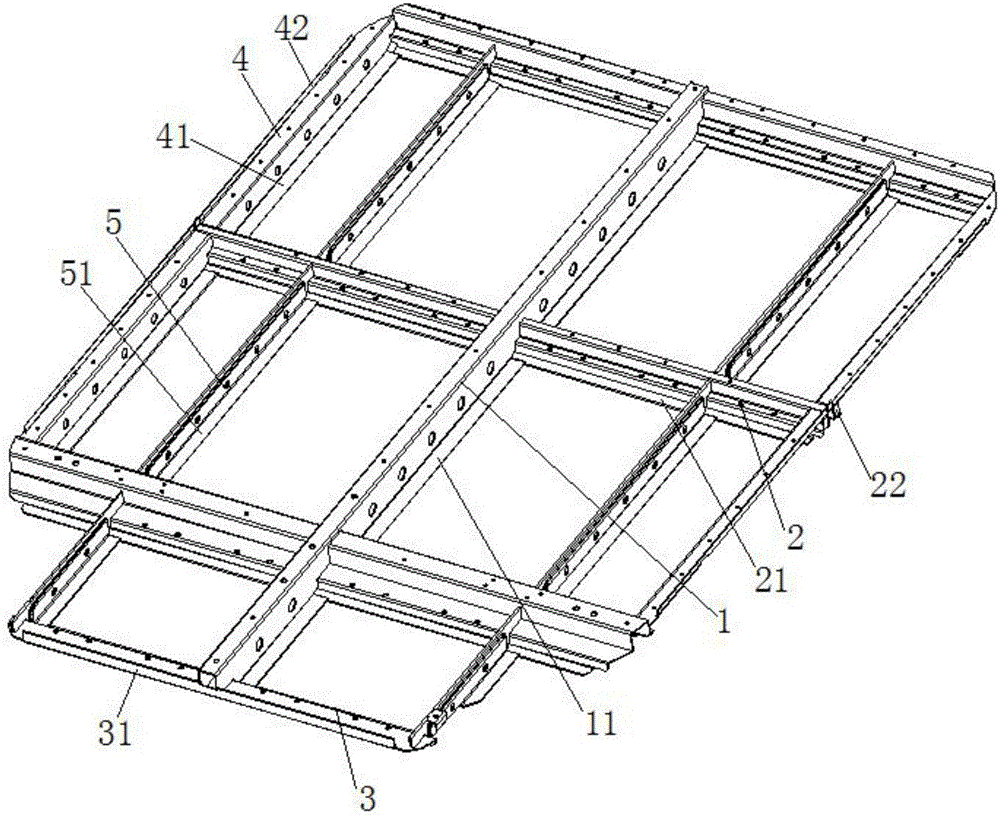

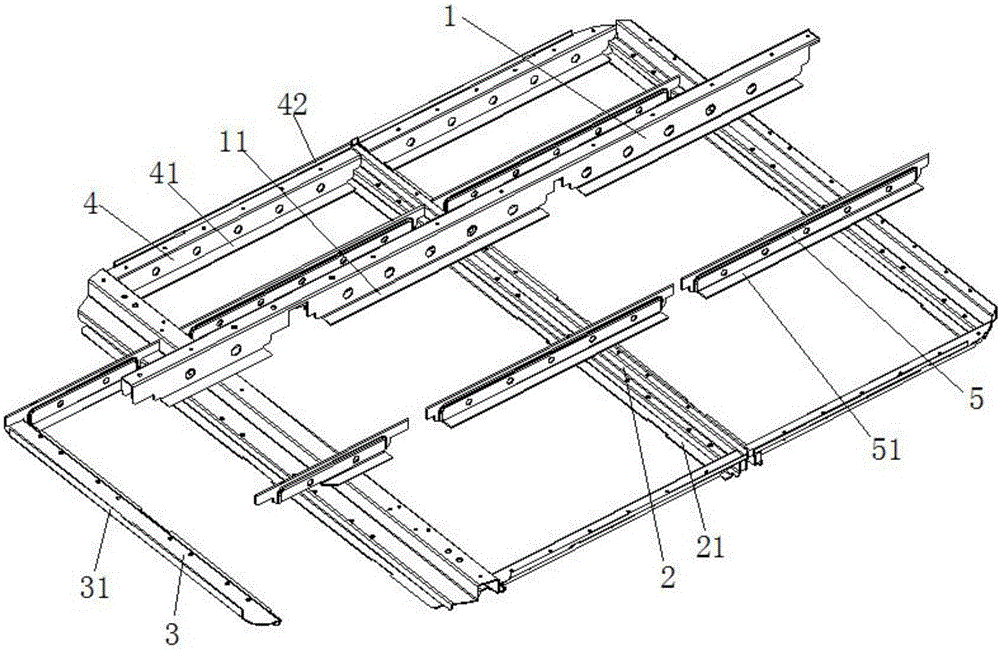

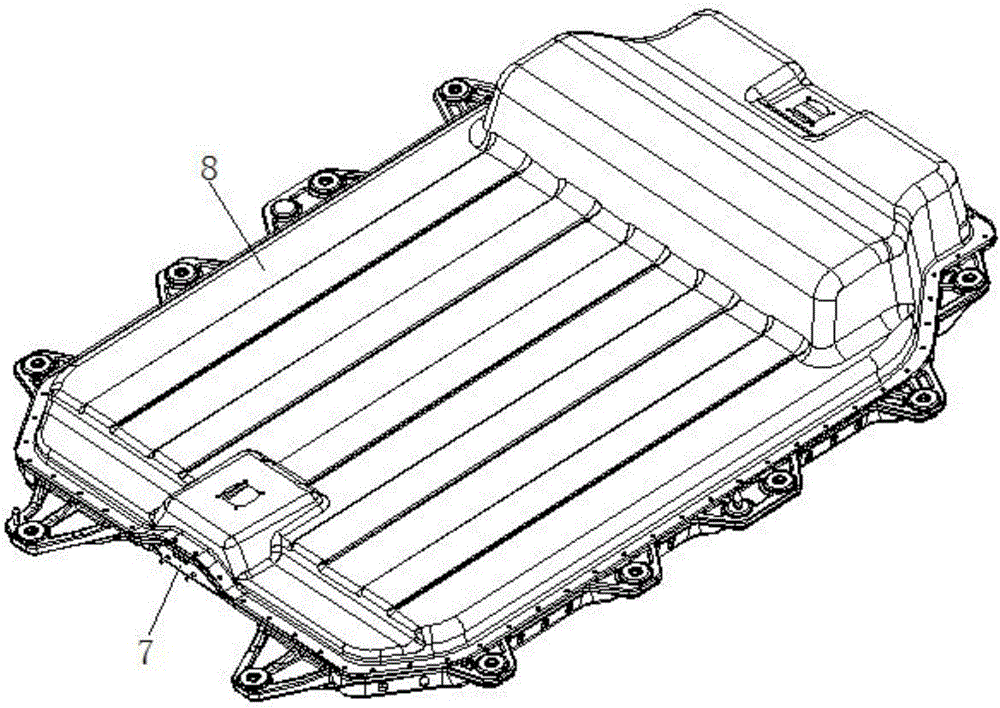

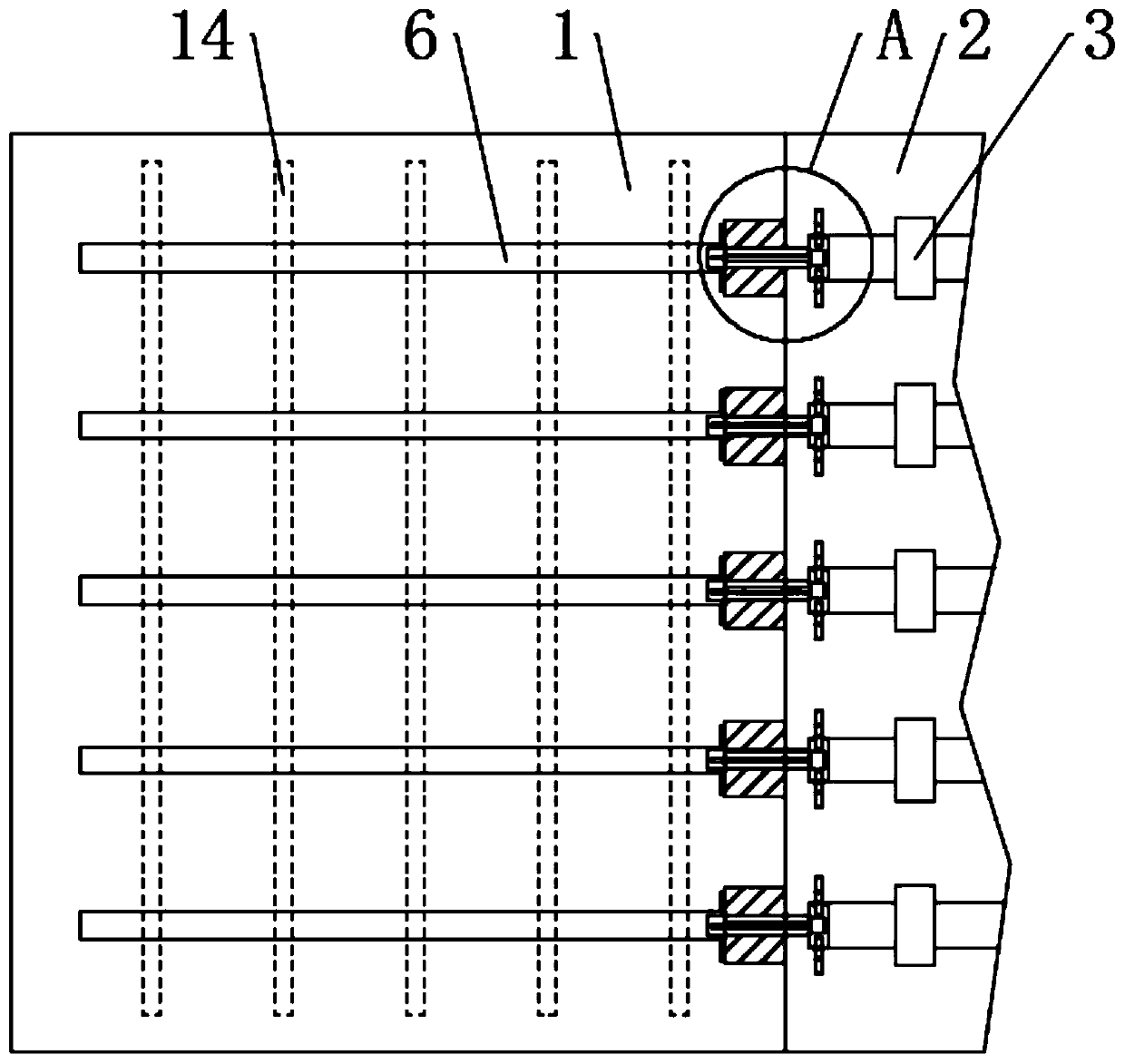

Split mounting type battery box module fixing frame and power battery box provided with same

PendingCN106299192AImprove the fixing strengthImprove installation strengthCell component detailsPower batteryKeel

The invention relates to a split mounting type battery box module fixing frame. The split mounting type battery box module fixing frame comprises a longitudinal beam keel, multiple cross beam keels and multiple boundary beams, wherein the multiple cross beam keels are arranged at intervals in parallel, and the longitudinal beam keel is perpendicularly arranged in the middle of the multiple cross beam keels and clamped on the multiple cross beam keels; the ends of every two adjacent cross beam keels are connected through the boundary beams, first side plates are horizontally arranged on the two sides of the bottom of each cross beam keel respectively, second side plates are horizontally arranged on the two sides of the bottom of the longitudinal beam keel respectively, and a third side plate is horizontally arranged on the bottom of each boundary beam; limiting notches are formed in the first side plates corresponding to the second side plates and the third side plates, and the two ends of each second side plate and the two ends of each third side plate stretch into the corresponding limiting notches respectively and abut against the corresponding first side plates; the first side plates, the second side plates and the third side plates are all fixed to the bottom wall of an electric box, and fold fins used for being connected with the side wall of the electric box are arranged at the two ends of each cross beam keel respectively. The split mounting type battery box module fixing frame has the advantages that the whole module fixing frame is convenient to assemble and disassemble, high in structural strength and high in stability.

Owner:江苏和中普方新能源科技有限公司

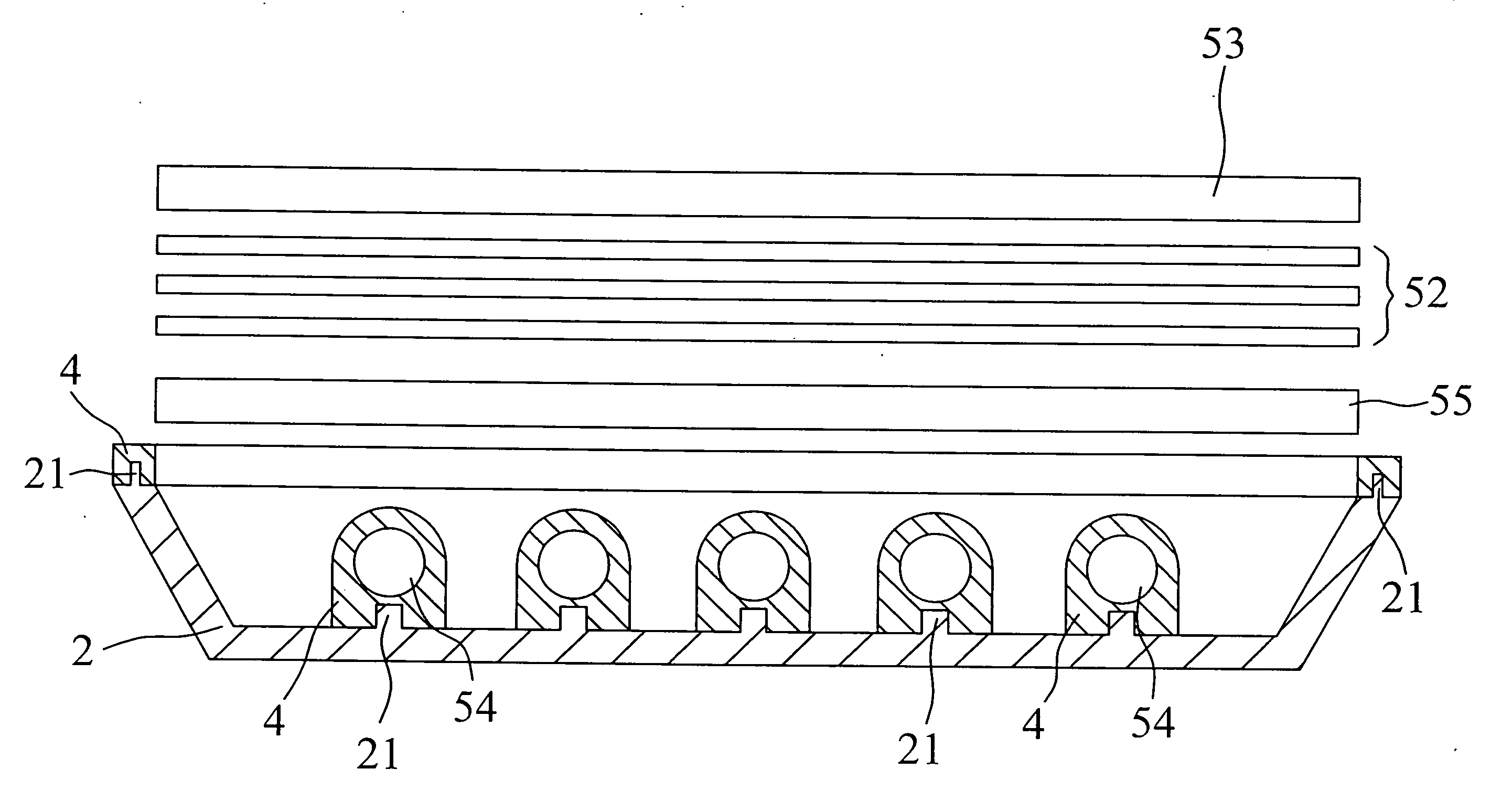

Planar antenna and antenna system

InactiveUS20050184920A1Improved strengthEasy to manufactureWaveguide mouthsAntenna supports/mountingsPhysicsCylindrical waveguide

The present invention relates to a planar antenna (1) for excitation of the TE01-mode of an electromagnetic wave and adapted to be arranged in a waveguide tube (2). The planar antenna comprises a substrate (6) of dielectric material having a first surface (7) intended to face towards a filling good surface and a second surface (8) facing in an opposite direction. A first group (9) of a plurality of dipole arms (10) is arranged on the first surface (7) or the second surface (8) on a perimeter of a circle with a predetermined radius. A second group (11) of a plurality of dipole arms (12) is arranged on the first surface (7) or the second surface (8) on the perimeter of the circle with the predetermined radius. The dipole arms (10) of the first group (9) extend in a first direction and the dipole arms (12) of the second group (11) extend in a direction opposite the first direction. Furthermore, the present invention relates to an antenna system comprising a cylindrical waveguide tube (2) having a bottom plate (3) and a tube portion (4) and a planar antenna (1) as mentioned above.

Owner:VEGA GRIESHABER GMBH & CO

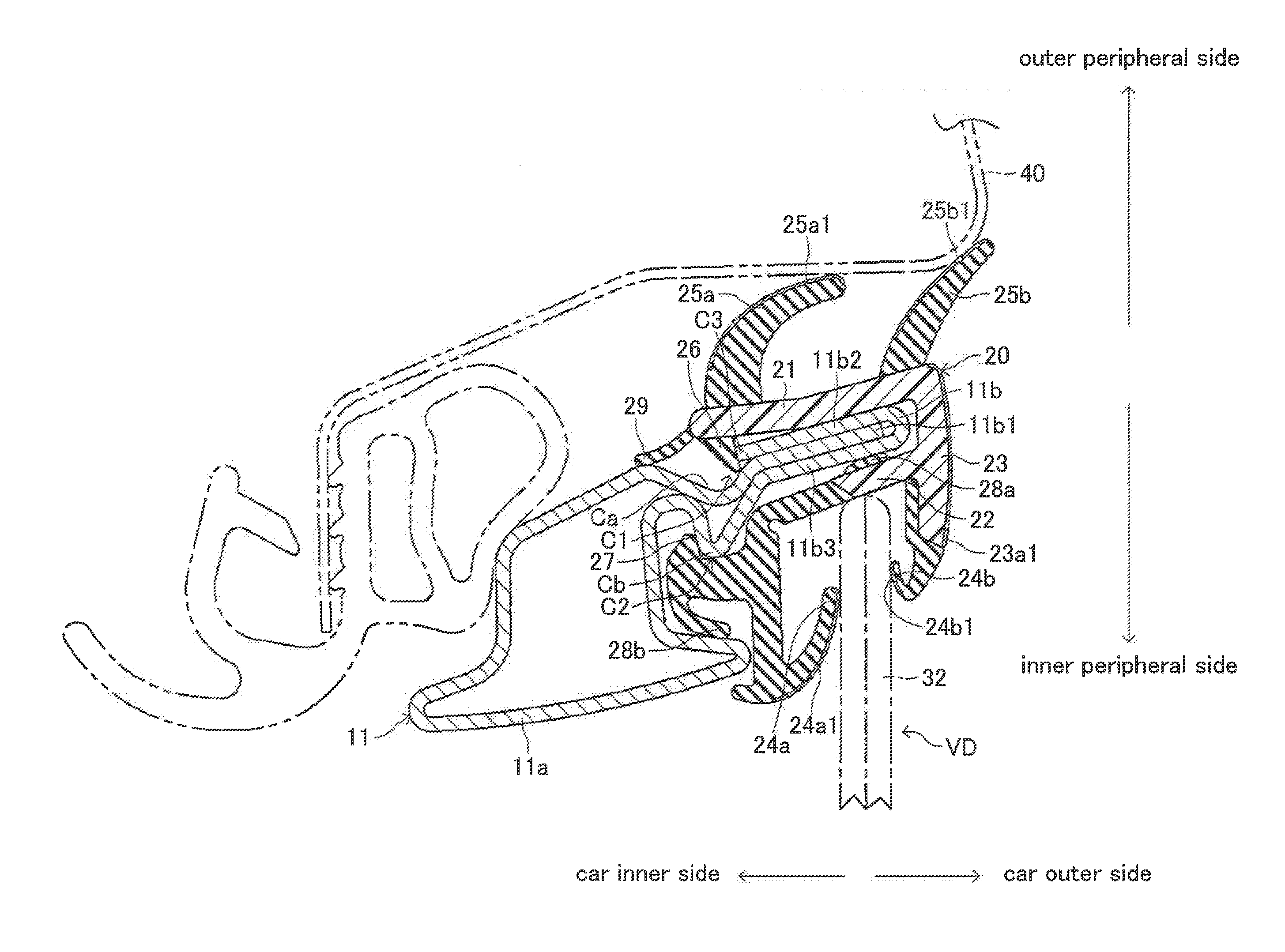

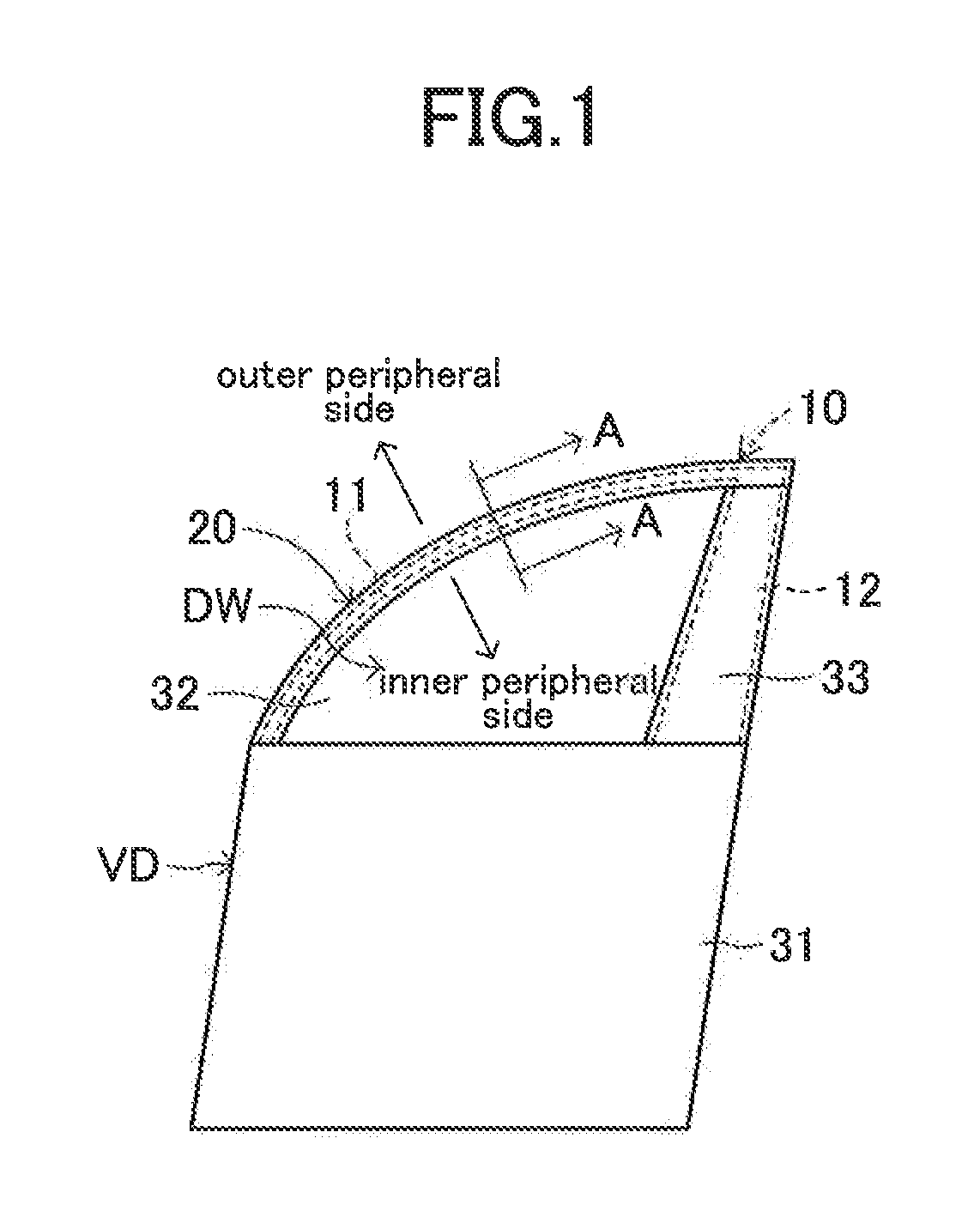

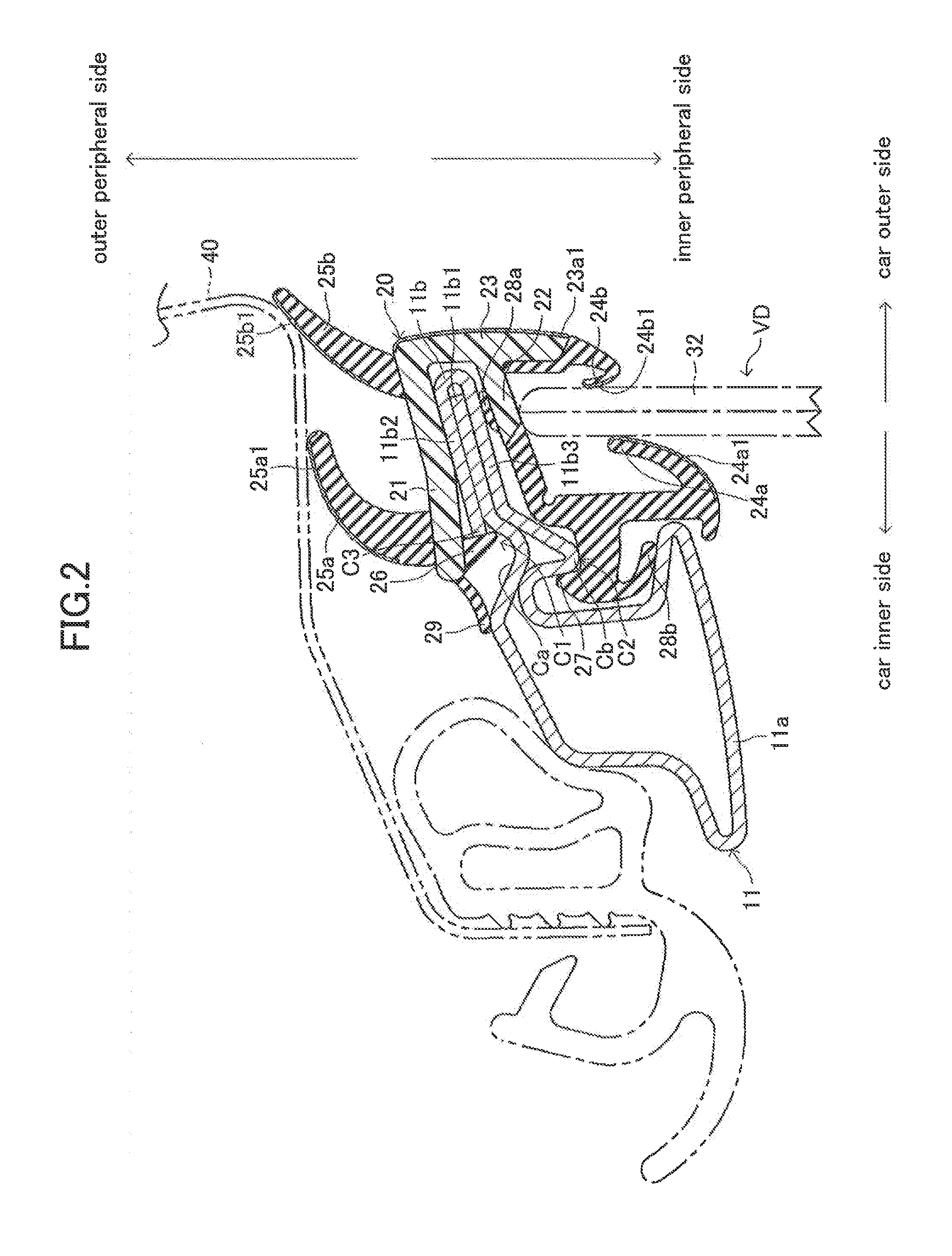

Glass run integral molding and door frame structure

InactiveUS20130219799A1Reduce weightDesired sealabilityEngine sealsWindow/door framesWindow openingEngineering

Owner:AISIN SEIKI KK

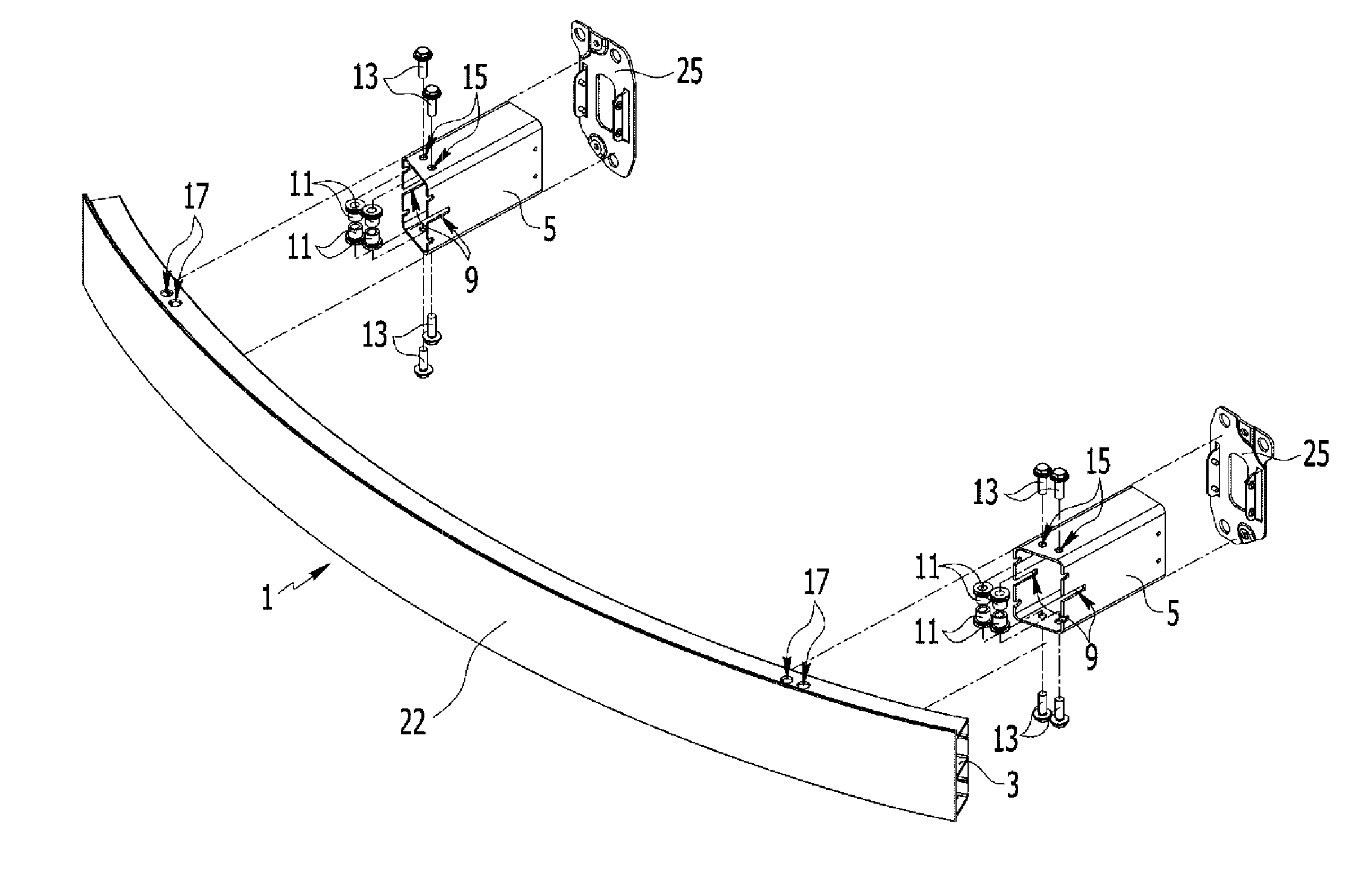

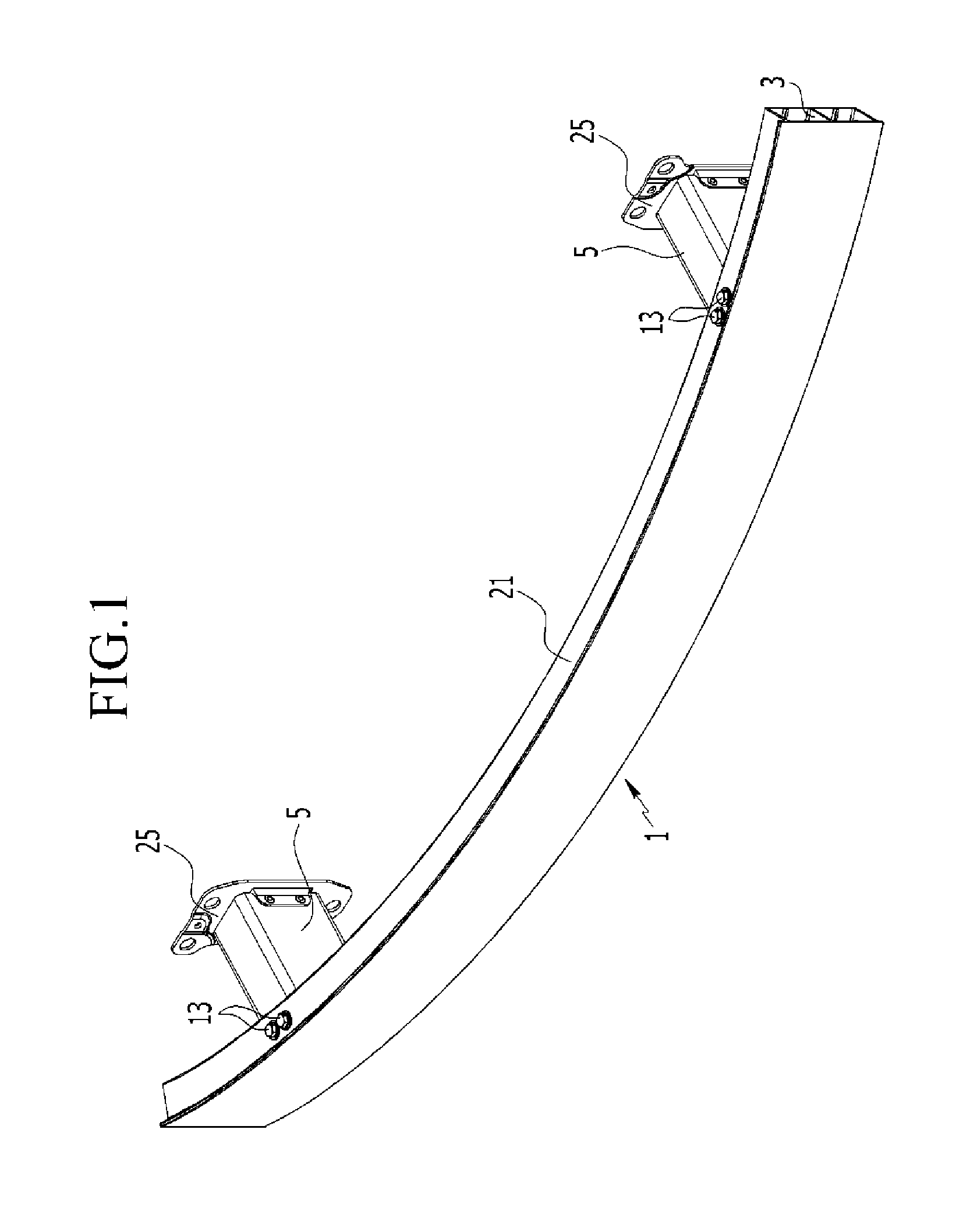

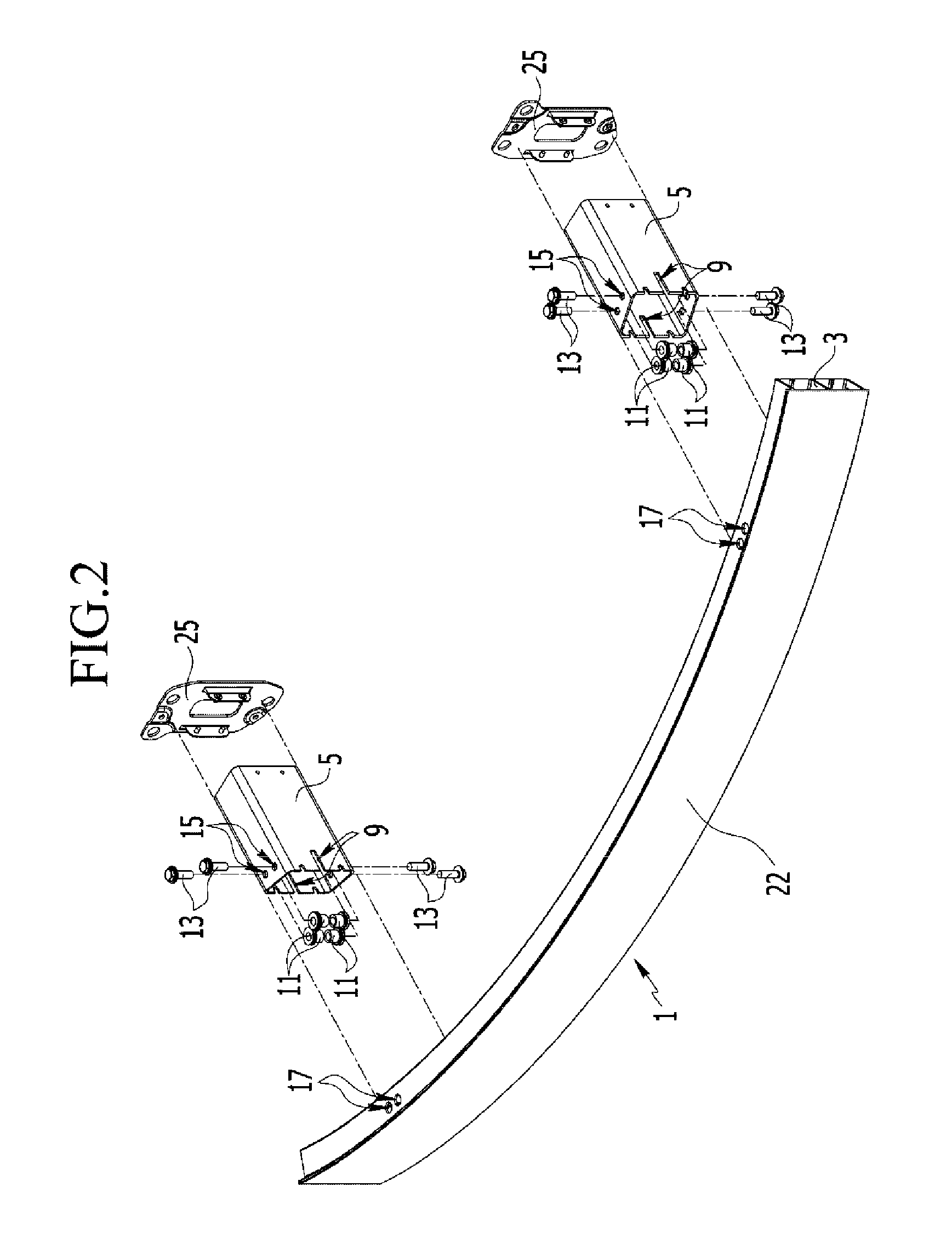

Bumper beam assembly for vehicle

ActiveUS20110285152A1Easy to assembleImprove assembly strengthBumpersEngineeringMechanical engineering

A bumper beam assembly for a vehicle may include a bumper beam having a horizontal support plate, front and rear vertical support plates attached to the horizontal support plate, wherein the rear vertical support plate includes an insertion hole, a partition formed along the horizontal support plate between the front and rear vertical support plates, and a stay, an end portion of which may be inserted into the insertion hole.

Owner:HYUNDAI MOTOR CO LTD +1

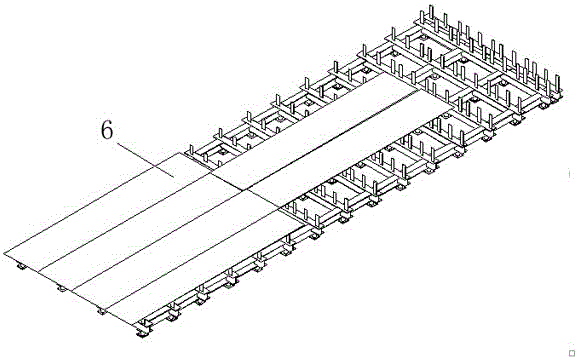

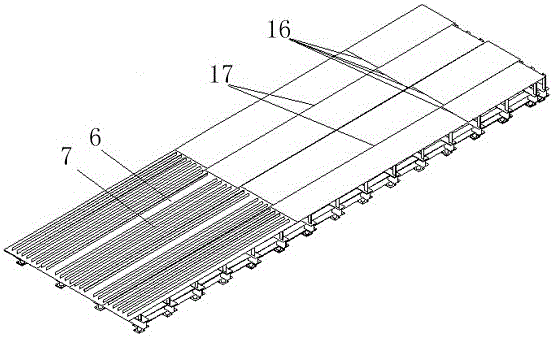

Interchange steel bridge and manufacture method thereof

ActiveCN105040567ACompact structureImprove assembly accuracyBridge erection/assemblyBridge materialsCantileverUltimate tensile strength

The invention relates to an interchange steel bridge, and particularly to the interchange steel bridge and a manufacture method thereof. The interchange steel bridge belongs to the field of steel structures. The interchange steel bridge comprises a base plate unit, baffle plate units, longitudinal web units, a top plate unit and a cantilever unit. The longitudinal web plates are arranged above the base plate unit. Each longitudinal web plate is internally provided with a baffle plate unit. The top plate unit is arranged above the baffle plate units and the longitudinal web units. One side of the top plate unit is provided with the cantilever unit. The manufacture method comprises the following steps of laying a supporting moulding bed, testing the moulding bed, forming the interchange steel bridge, splicing the baffle plate unit at a middle position, performing one-time splicing on the longitudinal web plate at the middle position, splicing the baffle plate units at sides, performing secondary splicing on the longitudinal web units at the sides, splicing the top plate unit, splicing the cantilever unit, and performing quality detection on a steel bridge box girder. The interchange steel bridge and the manufacture method thereof have advantages of compact structure, high splicing precision, effective splicing strength improvement, and effective line type improvement of the manufactured bridge.

Owner:浙江东南网架股份有限公司

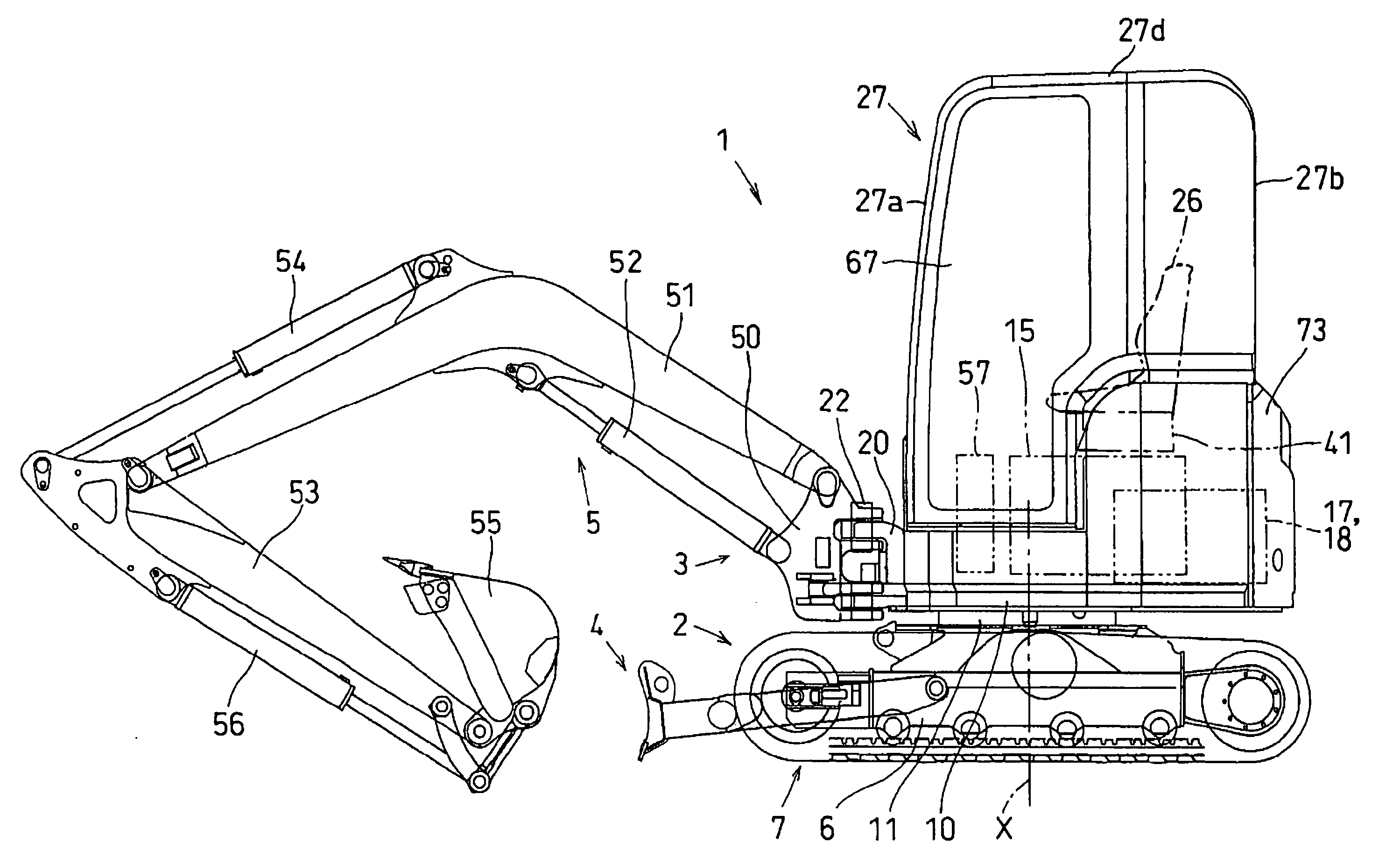

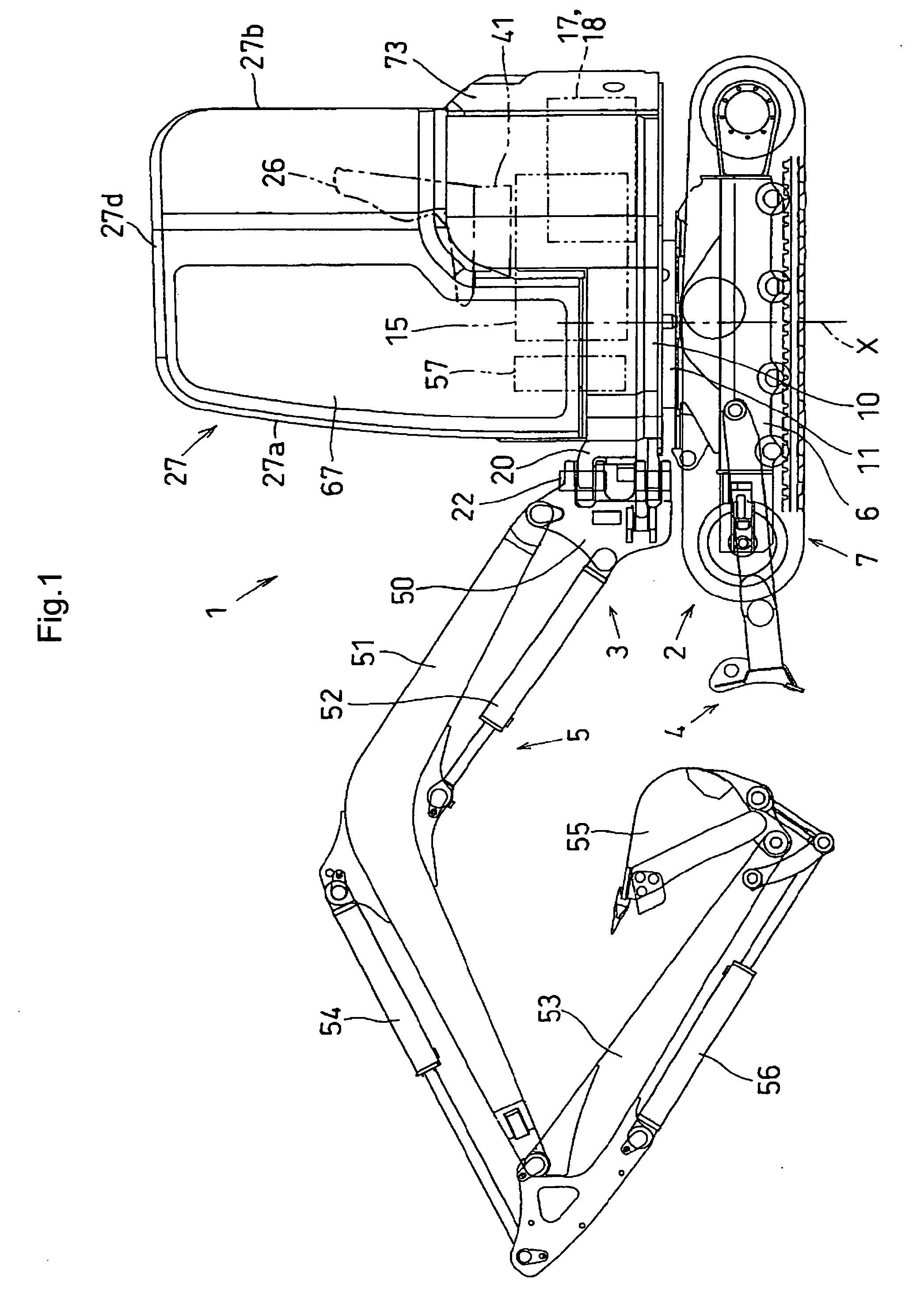

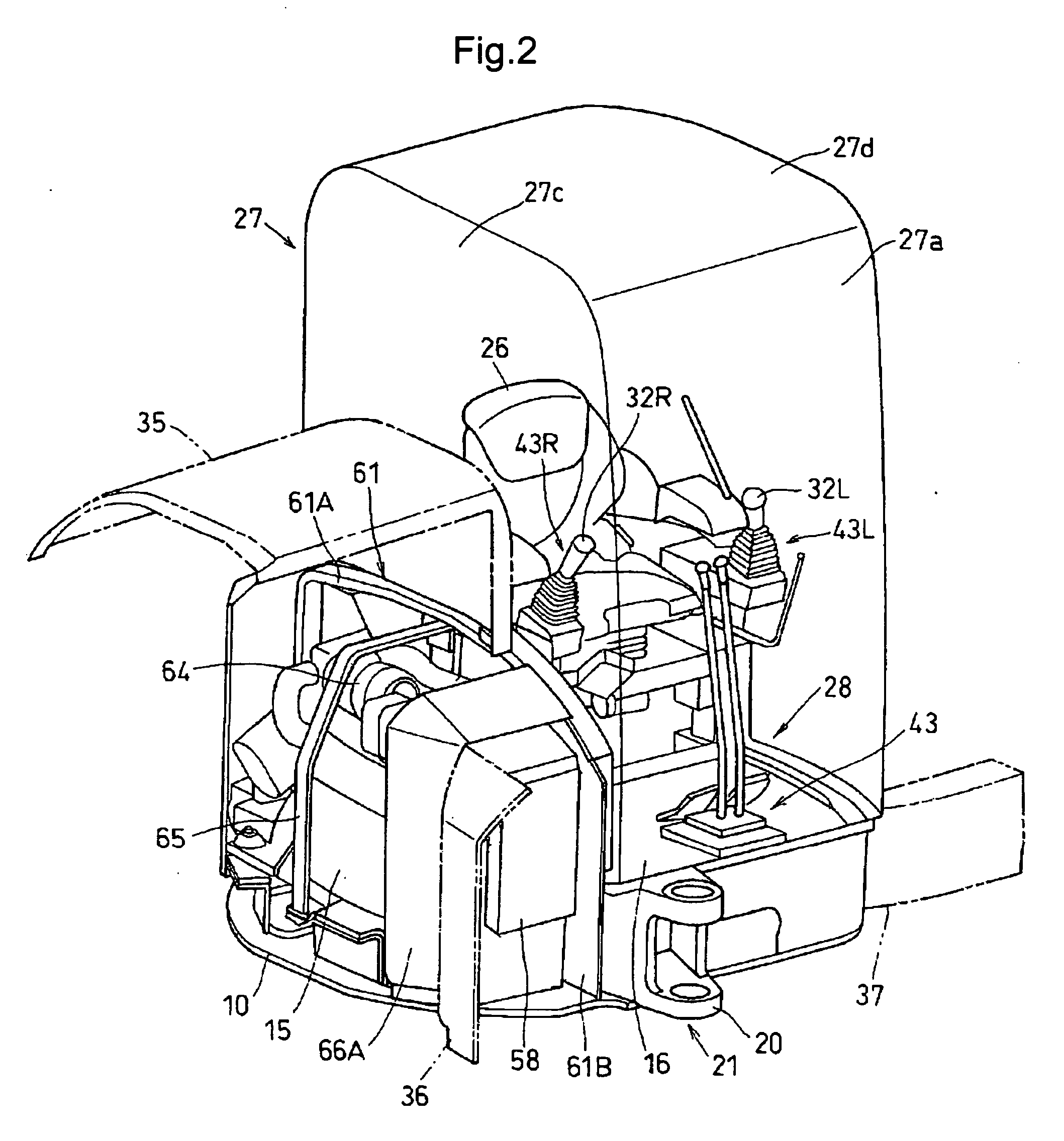

Backhoe

InactiveUS20070068722A1Stress be distributeReduce stress concentrationSoil-shifting machines/dredgersVehicle mounted steering controlsEngineeringLateral extension

An improvement is realized in mutual assembly strength between a swing bearing member and right and left longitudinal ribs, and welds are subjected to a reduced stress concentration. A backhoe comprises a swivel deck (10); a first longitudinal rib (19L) disposed on the swivel deck, the first longitudinal rib extending in a fore and aft direction, and having a front portion (19La) extending in a transverse direction; a second longitudinal rib (19R) disposed on said swivel deck, the second longitudinal rib extending in the fore and aft direction, and having a front end thereof connected to the front portion of the first longitudinal rib; and a swing bearing member (20) attached to a front surface of the front portion of the first longitudinal rib for supporting a ground working implement through a swing shaft.

Owner:KUBOTA LTD

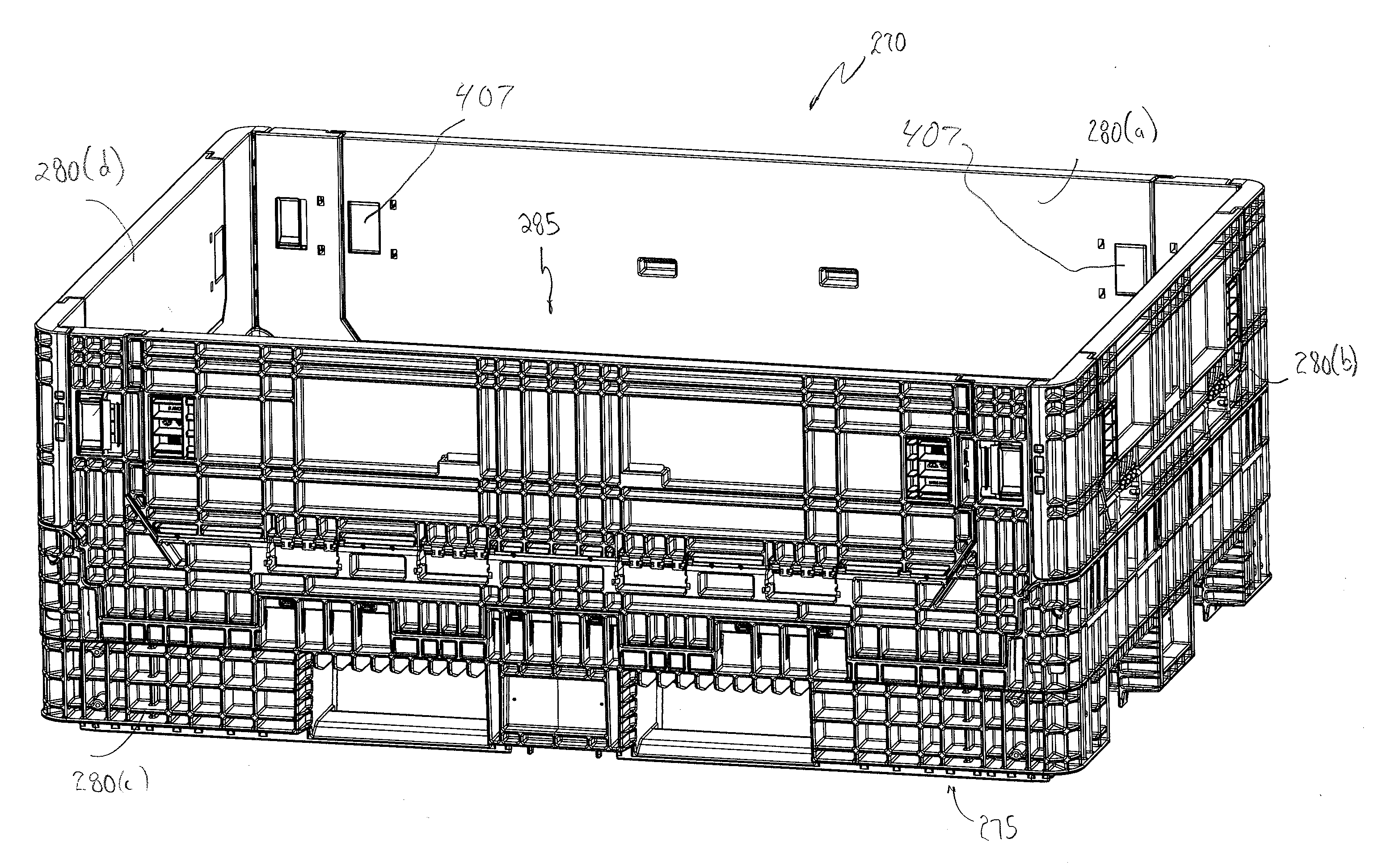

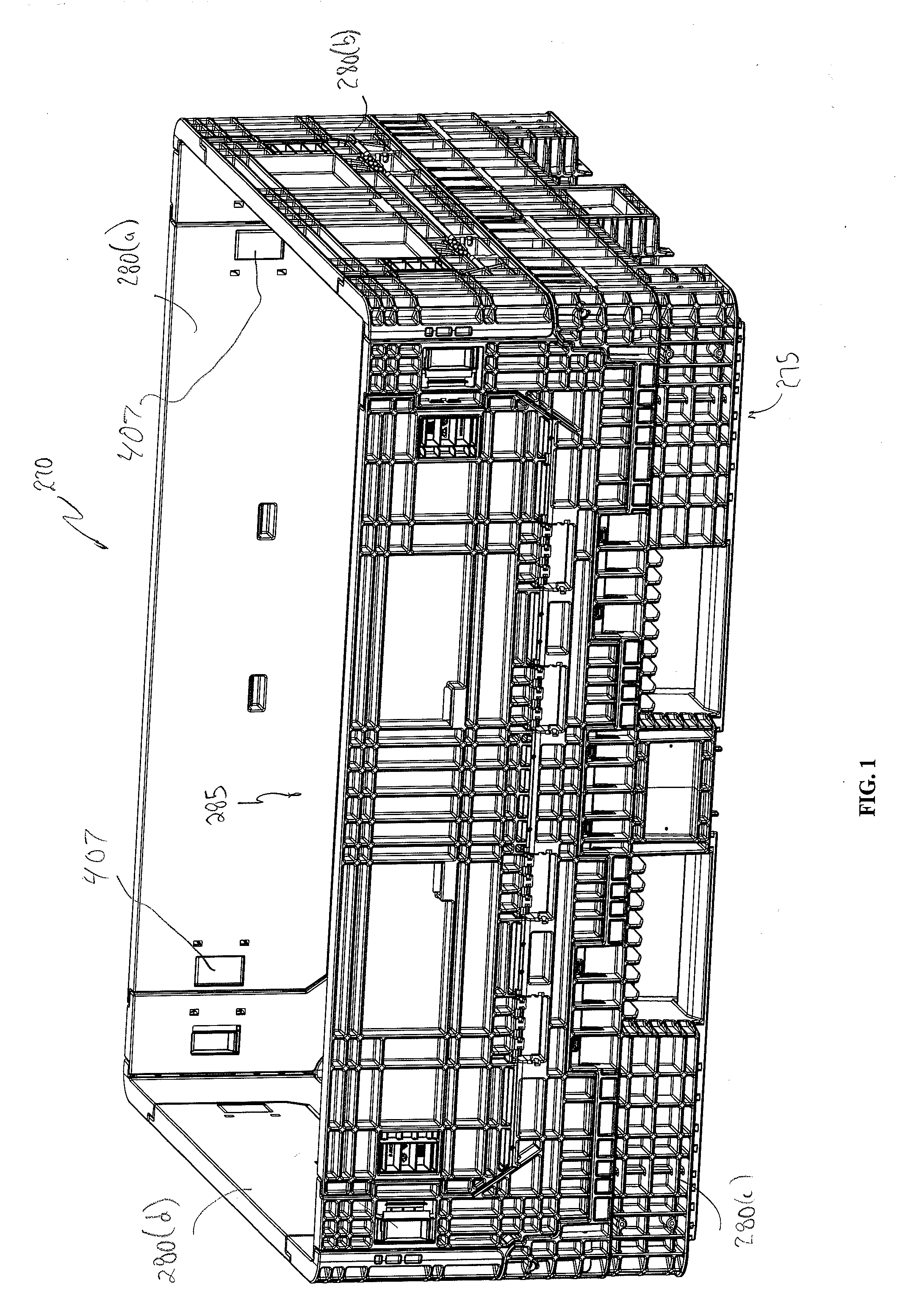

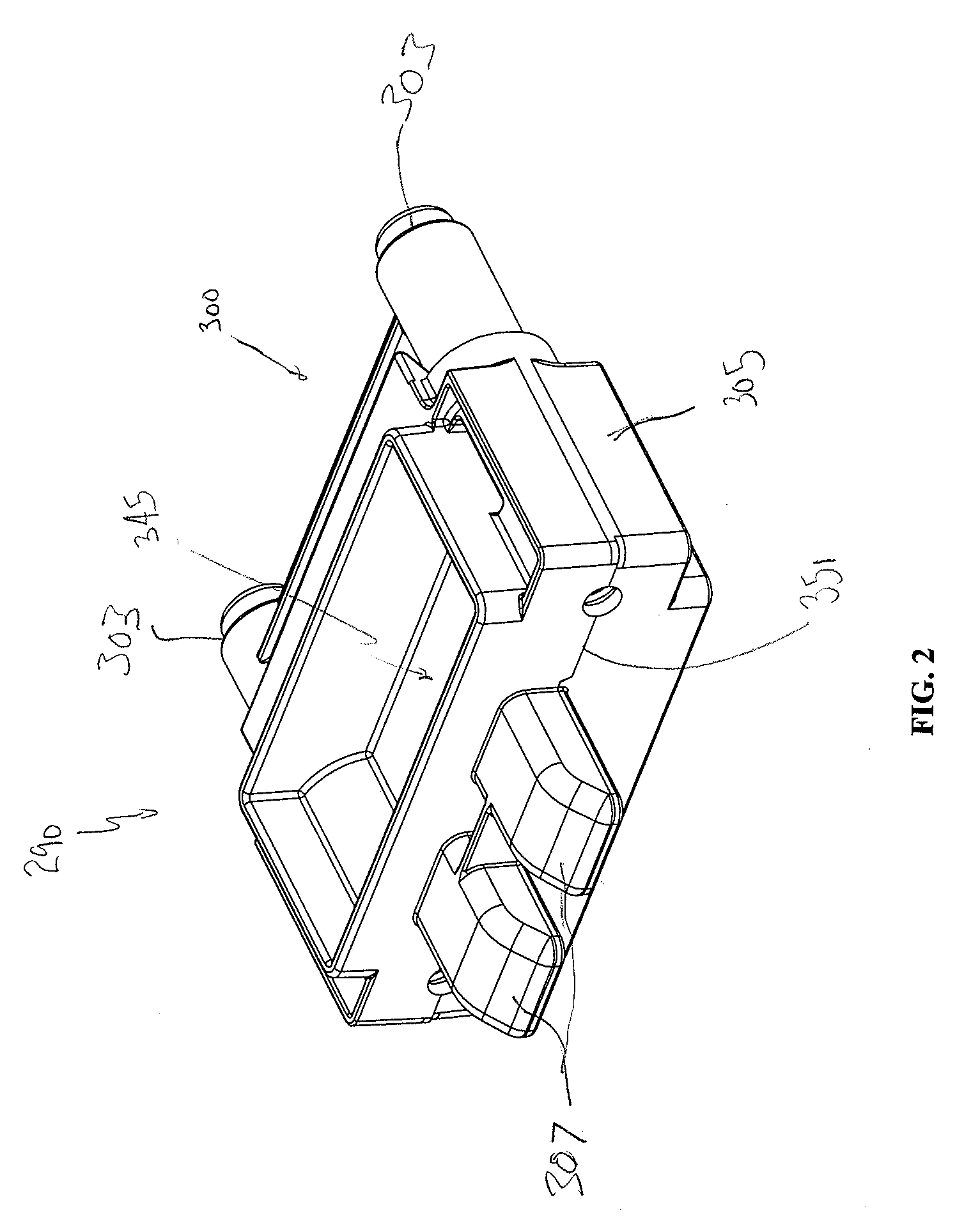

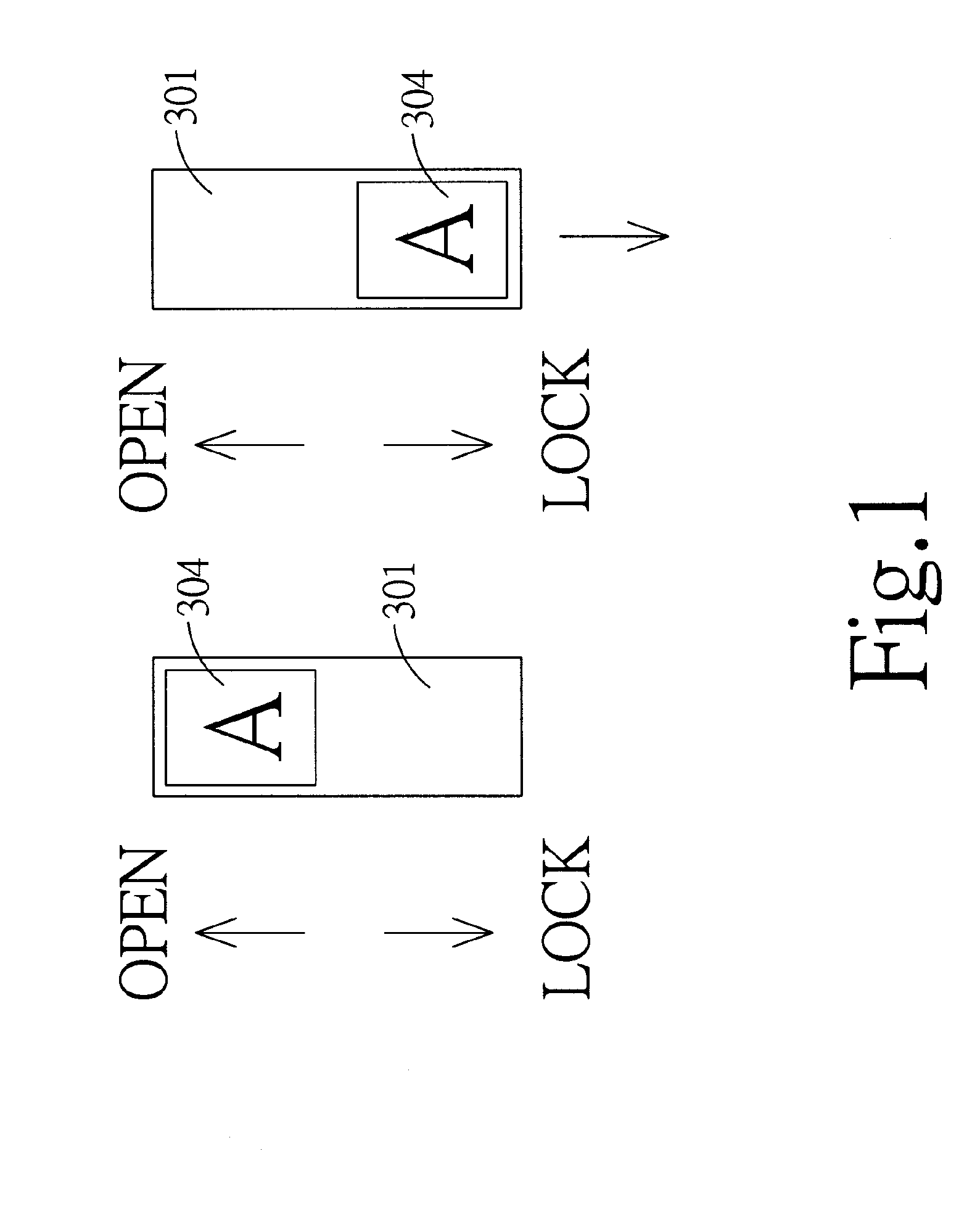

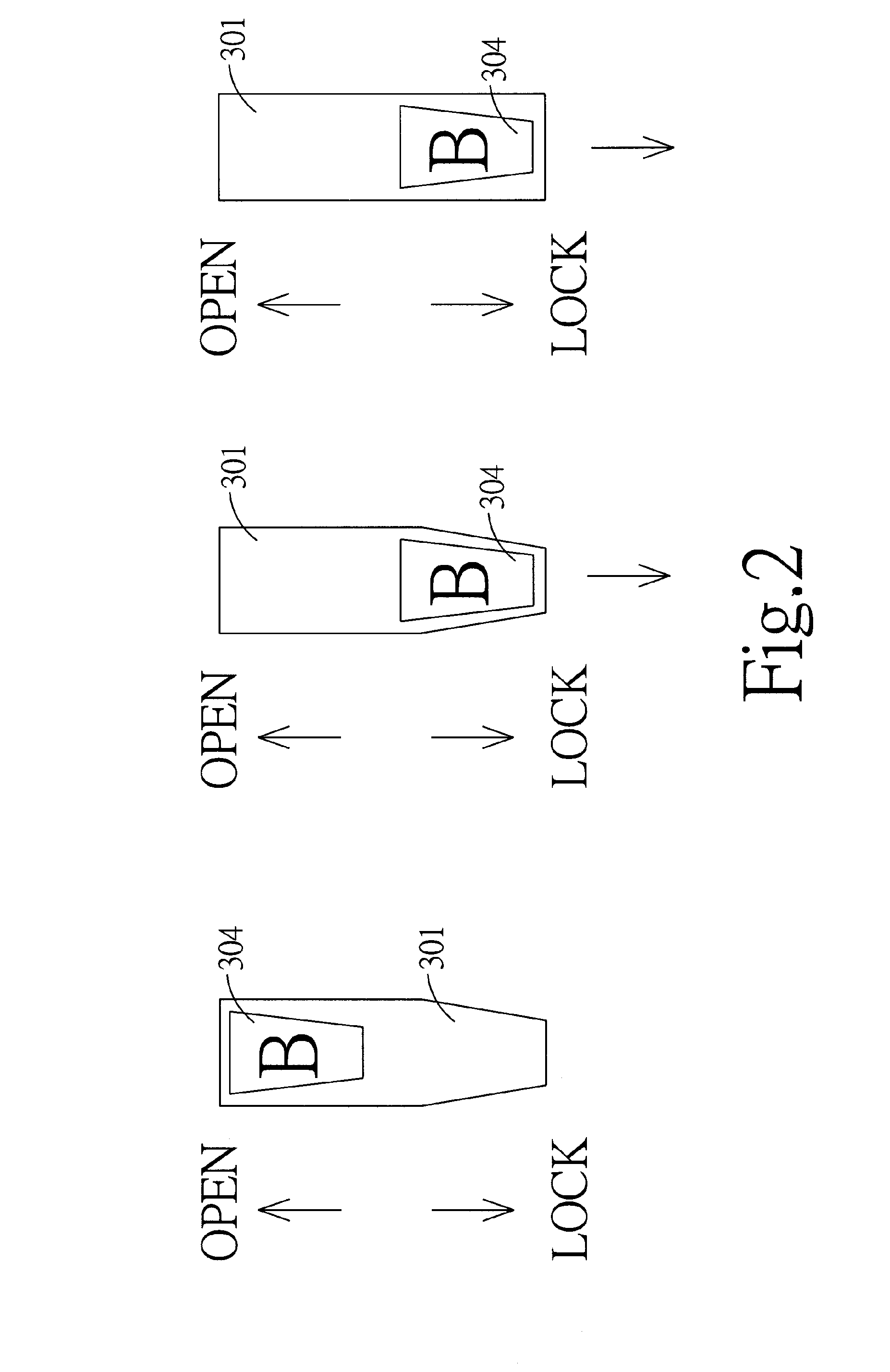

Container assembly and latch apparatus, and related methods

ActiveUS20090205169A1Easy to insertReadily manipulatedConstruction fastening devicesHingesSoftware engineeringMechanical engineering

Apparatus and methods for engaging and disengaging various members (280) to each other are described herein. The preferred apparatus and methods reduce the number of components and / or sub-assemblies in hinged apparatus (270) and methods and other applications, and simplify and improve the quality and efficiency of installation and removal of latches (290) associated with the hinged elements or members (280). The latching / locking system and methods of the invention also enable selective relatively permanent engagement of the hinged elements or members (280) to each other, and can permit selective transition between the foregoing hinged and locked relationships. Improved latches (290) are disclosed, with interchangeability, keying to assist assembly, and other features. Methods of fabrication and assembly are disclosed.

Owner:ORBIS CORP

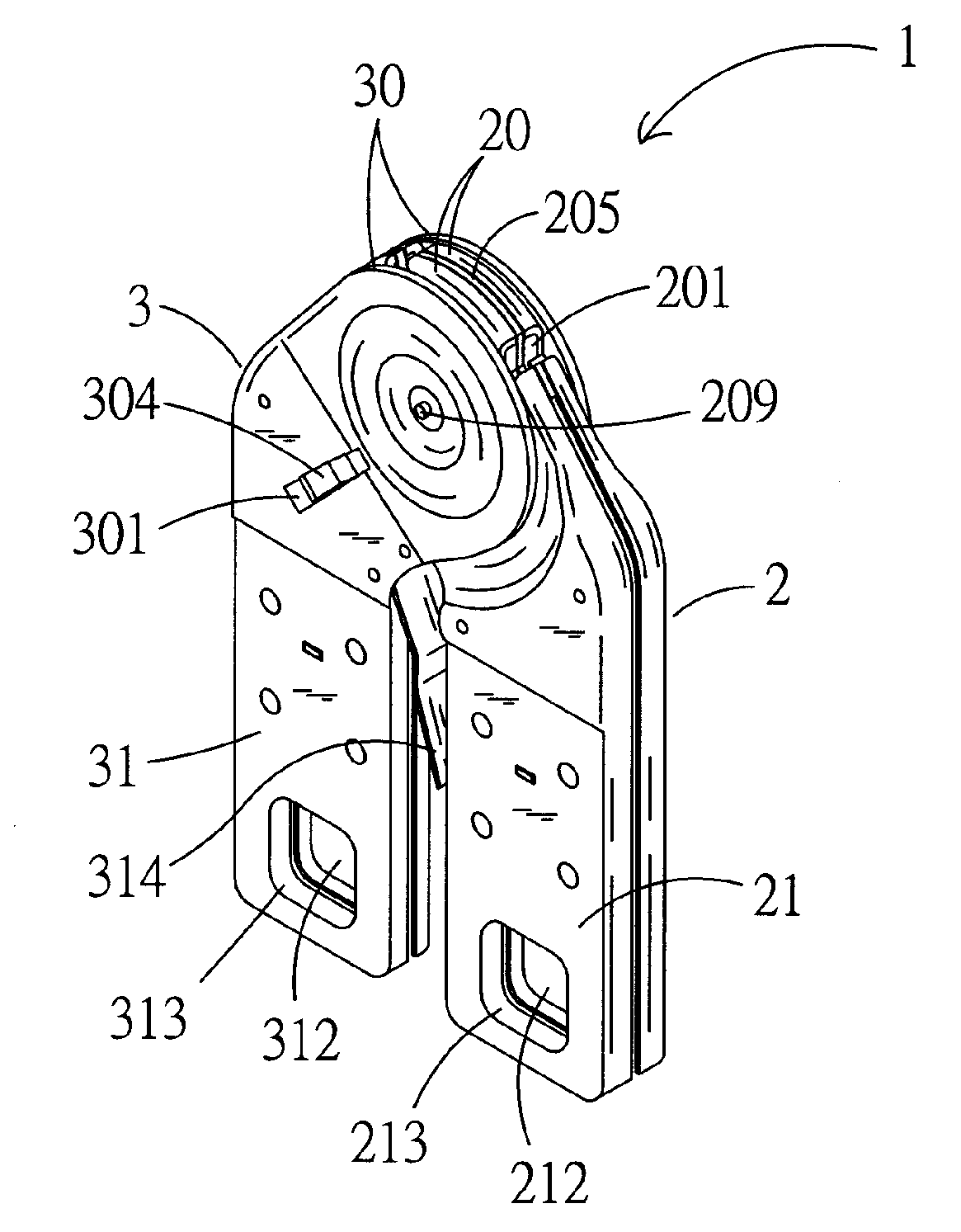

Sound production device and loudspeaker box thereof

InactiveCN111405431AImprove reliabilityImprove assembly strengthElectrical transducersSound productionLoudspeaker

The invention provides a sound production device, which comprises a basin stand, a vibration system supported on the basin stand and a magnetic circuit system for driving the vibration system to vibrate and produce sound. The magnetic circuit system has a magnetic gap. The vibration system comprises a diaphragm, an elastic conductive member, a skeleton and a voice coil. The elastic conductive member comprises a first fixing arm connected to the basin stand, a second fixing arm spaced from the first fixing arm, a first elastic arm connecting the first fixing arm and the second fixing arm, and abonding pad extending from the second fixing arm. The framework comprises a framework body supported on the second fixing arm and connected to the vibrating diaphragm and an extension wall formed bybending and extending the framework body, and part of the extension wall extends into the magnetic gap. The voice coil comprises a voice coil body which is fixed on the extension wall and inserted into the magnetic gap and a voice coil lead which bends and extends from the voice coil body to the bonding pad and is electrically connected with the bonding pad. The voice coil lead is attached to theextension wall and extends to the bonding pad along the extension wall. Compared with the prior art, the sound production device and the loudspeaker box are high in reliability.

Owner:AAC TECH PTE LTD

Safety Reinforcing Structure for Aluminum Ladder Hinge

InactiveUS20080073150A1Improve structural safetySimple structural designLaddersFriction lossEngineering

The invention provides aluminum ladder hinge with enhanced safety structure. The hinge is made of flat inner case and outer case. Especially, the hinge has a locking block design to stabilize the angle of opening and closure. There is also a design of a joint reinforcing disk and a reinforcing tab to enhance the guiding groove and reduce friction loss. There is also design of prolonged caps and a rectangular hole, liner to strengthen the assembly of the hinge and the aluminum ladder. Based on the above designs, an advanced aluminum ladder hinge with enhanced safety structure is invented to improve the safety of aluminum ladder in use.

Owner:ALFA METAL CORP

Flexible-rigid combined board and terminal

ActiveCN105682343AImprove assembly strengthImprove electrostatic shielding performancePrinted circuit assemblingCircuit bendability/stretchabilityElectricitySolder mask

The invention provides a flexible-rigid combined board and a terminal. The flexible-rigid combined board comprises a flexible substrate, a rigid substrate and a steel sheet, wherein the flexible substrate comprises a first region; the rigid substrate comprises a rigid insulating layer, a line layer and a solder mask layer; the rigid insulating layer is fixed on the flexible substrate and is orthographically projected on the flexible substrate; the projection region overlaps with the first region; the line layer is superposed on the rigid insulating layer; the solder mask layer covers the line layer; at least one grounding through hole is formed in the solder mask layer; a grounding conductor which is electrically connected with the line layer is arranged in the grounding through hole; the steel sheet is fixed on the solder mask layer and is electrically connected with the grounding conductor; and the steel sheet is orthographically projected in the first region of the flexible substrate. The steel sheet can strengthen the assembly strength of the flexible-rigid combined board; and the grounding conductor makes the steel sheet grounded and prevents the steel sheet from receiving static electricity, so that the service lifetime of the flexible-rigid combined board is prolonged.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Base pad assembly

ActiveCN102897441AEasy to fixImprove assembly efficiencyPackaging vehiclesContainers for machinesEngineeringMechanical engineering

The invention discloses a base pad assembly which comprises a base pad and a base plate, wherein a limiting slot is arranged on the base pad; and the base plate is arranged at the bottom of the base pad and is used for supporting the base pad, and a limiting plate matched with the limiting slot is arranged on the base plate. The base pad assembly provided by the invention is suitable to be used when refrigerating equipment such as a refrigerator are packaged, the base is held at the bottom of the refrigerator to protect the refrigerator, and the base pad can be conveniently fixed on the base plate when the base pad assembly is assembled by arranging the limiting slot on the base pad and arranging the limiting plate matched with the limiting slot on the base plate. The base pad assembly has high assembly efficiency and fastness for assembly, the traditional adhesive tape is omitted at the same time, and the cost is greatly reduced.

Owner:HEFEI HUALING CO LTD

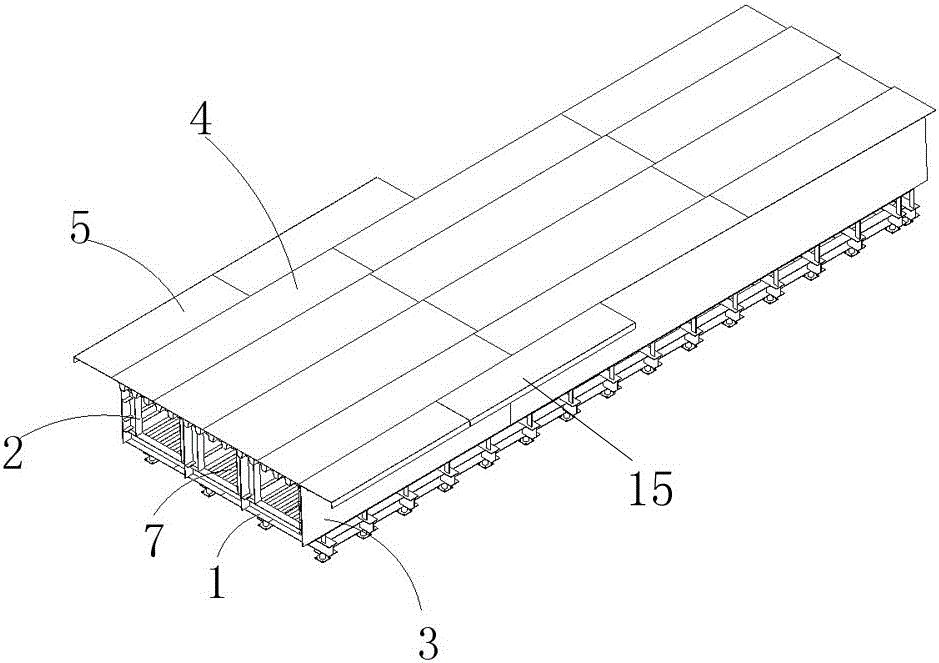

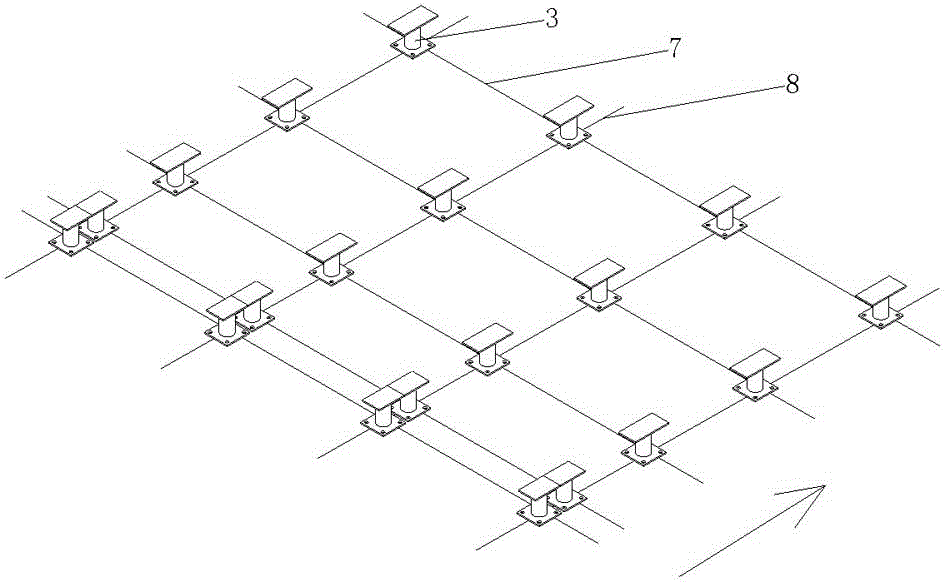

Support moulding bed and linear forming method for setting up road steel bridge using same

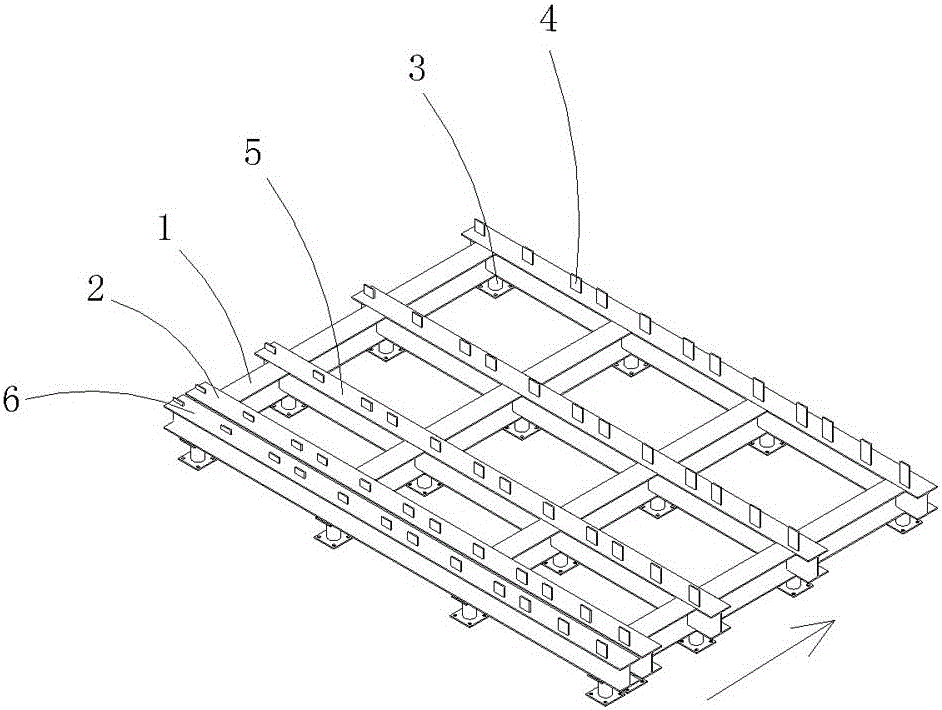

ActiveCN105113410ACompact structureImprove assembly accuracyBridge erection/assemblyUltimate tensile strengthTransverse beam

The invention relates to a support moulding bed, and particularly to a support moulding bed and a linear forming method for setting up a road steel bridge using the same, and belongs to the field of steel structures. The support moulding bed comprises more than two longitudinal beams and more than two transverse beams, the two transverse beams are fixed by the two longitudinal beams, bottoms of joints of the transverse beams and the longitudinal beams are provided with bases, and the upper portions of the transverse beams are provided with uniformly distributed moulding bed control boards. The linear forming method comprises the following steps of laying a support moulding bed, testing the moulding bed, and forming a road steel bridge. The support moulding bed is compact in structure, high in assembling precision, high in assembling intensity and good in line style of a formed bridge.

Owner:浙江东南网架股份有限公司

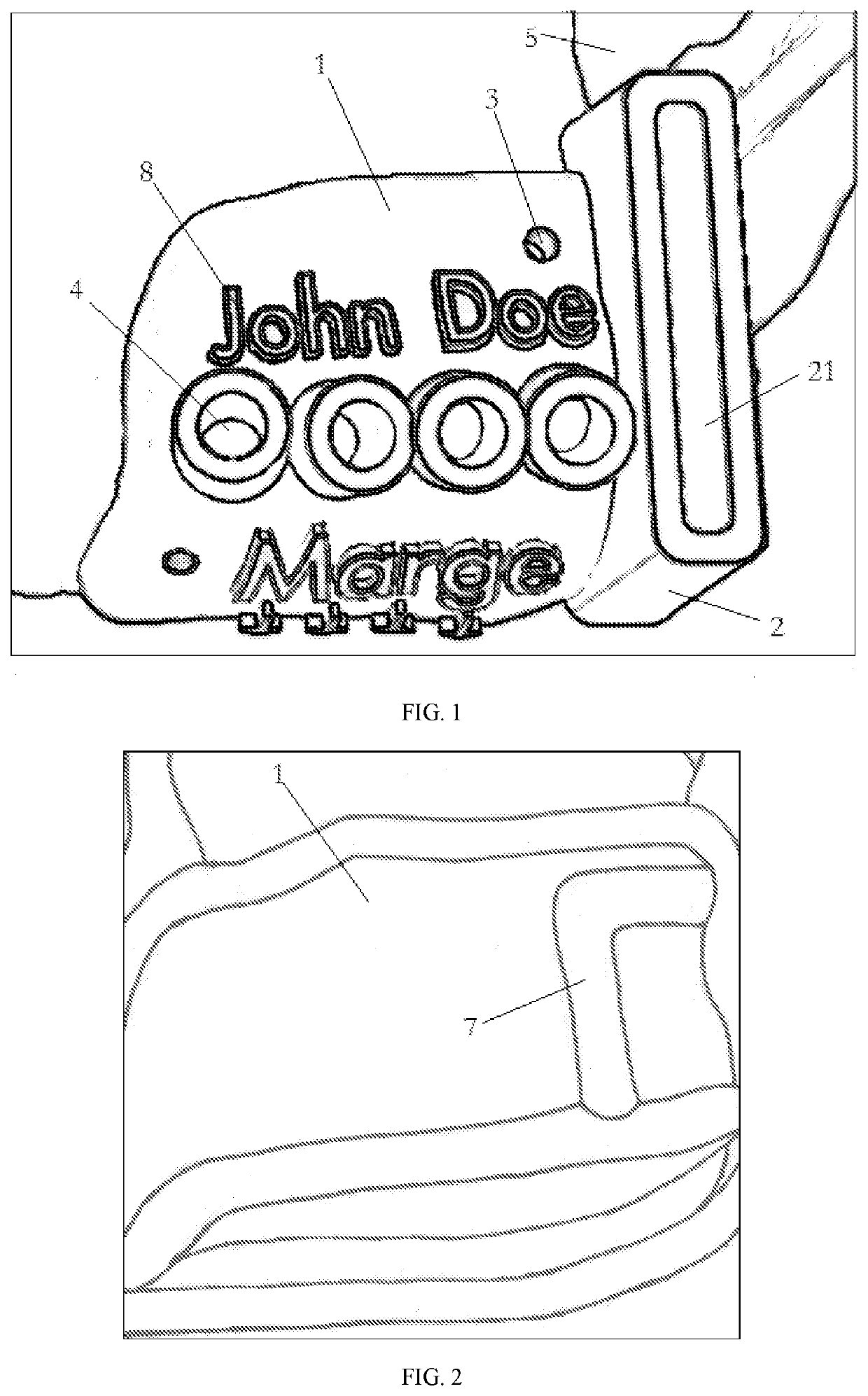

Osteotomy guide plate and preparation method thereof

ActiveUS20200281655A1Improve efficiencyKept from high risk of damageAdditive manufacturing apparatusComputer-aided planning/modellingEngineeringMechanical engineering

The invention discloses an osteotomy guide plate and a preparation method thereof. The osteotomy guide plate comprises a substrate, an osteotomy guide standardized part, a guide plate retention hole, a nail hole and a drainage channel; wherein the guide plate retention hole is distributed on the surface of the substrate; the outer end side of the nail hole is integrally formed with a standardized sleeve, and a detachably connected protective inner sleeve standardized part is provided within the standardized sleeve. The preparation method comprises parameter design and model printing, wherein an innovative nail hole positioning method is used in the parameter design. The invention is suitable for the osteotomy operation of different parts, with the advantages of convenient production, high precision and long service life; the preparation method improves the accuracy of opening a hole on the osteotomy guide plate.

Owner:CENTERMED INC

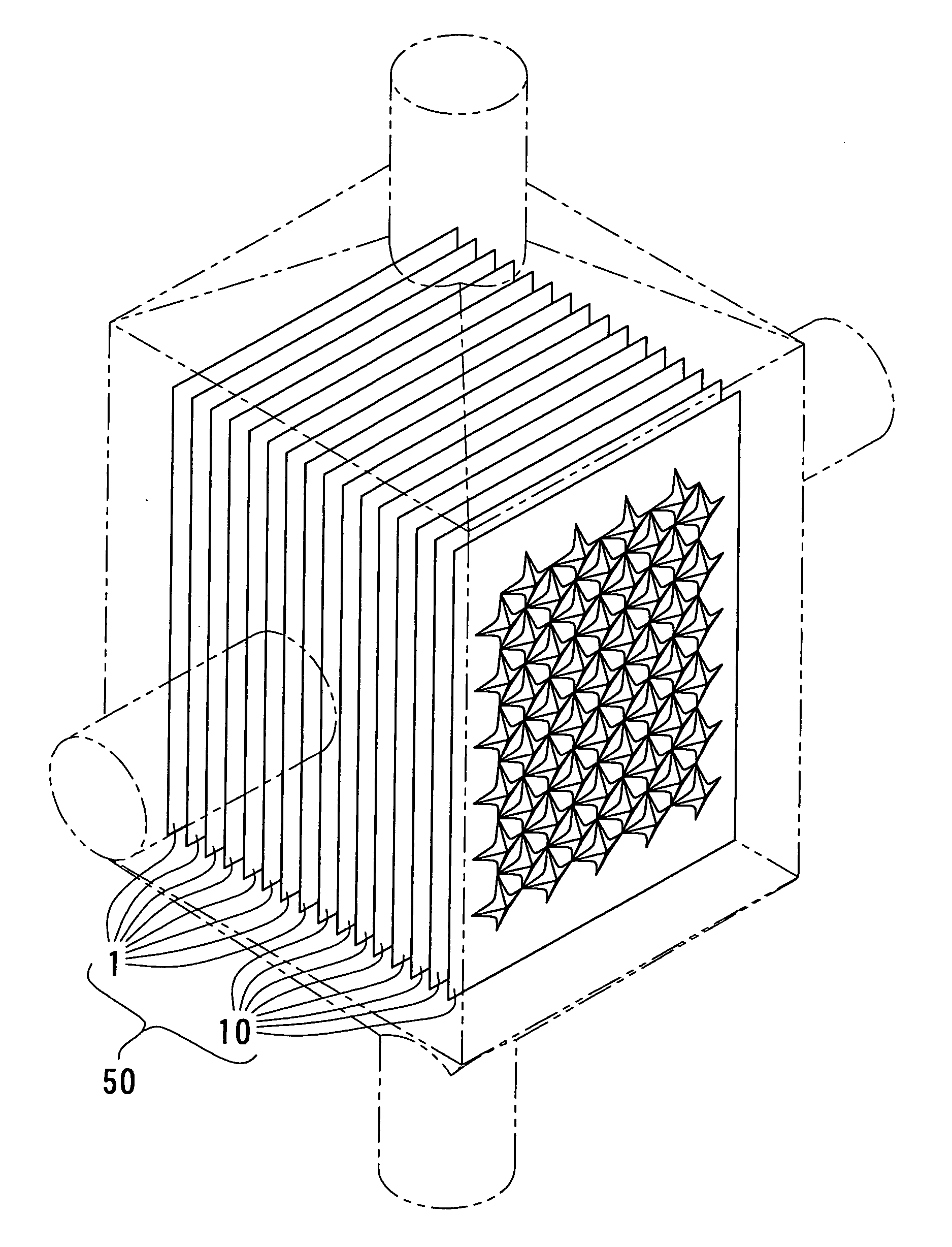

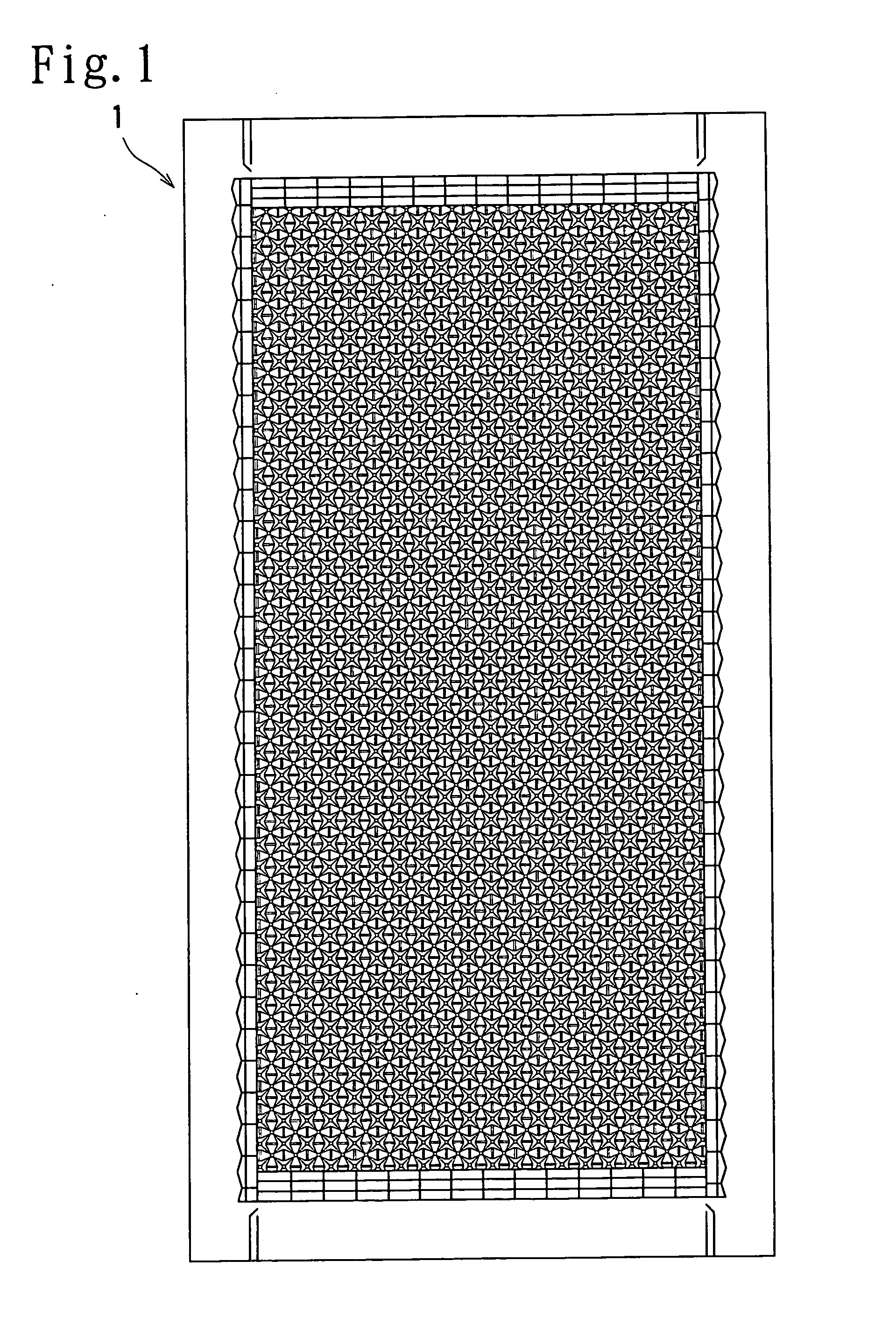

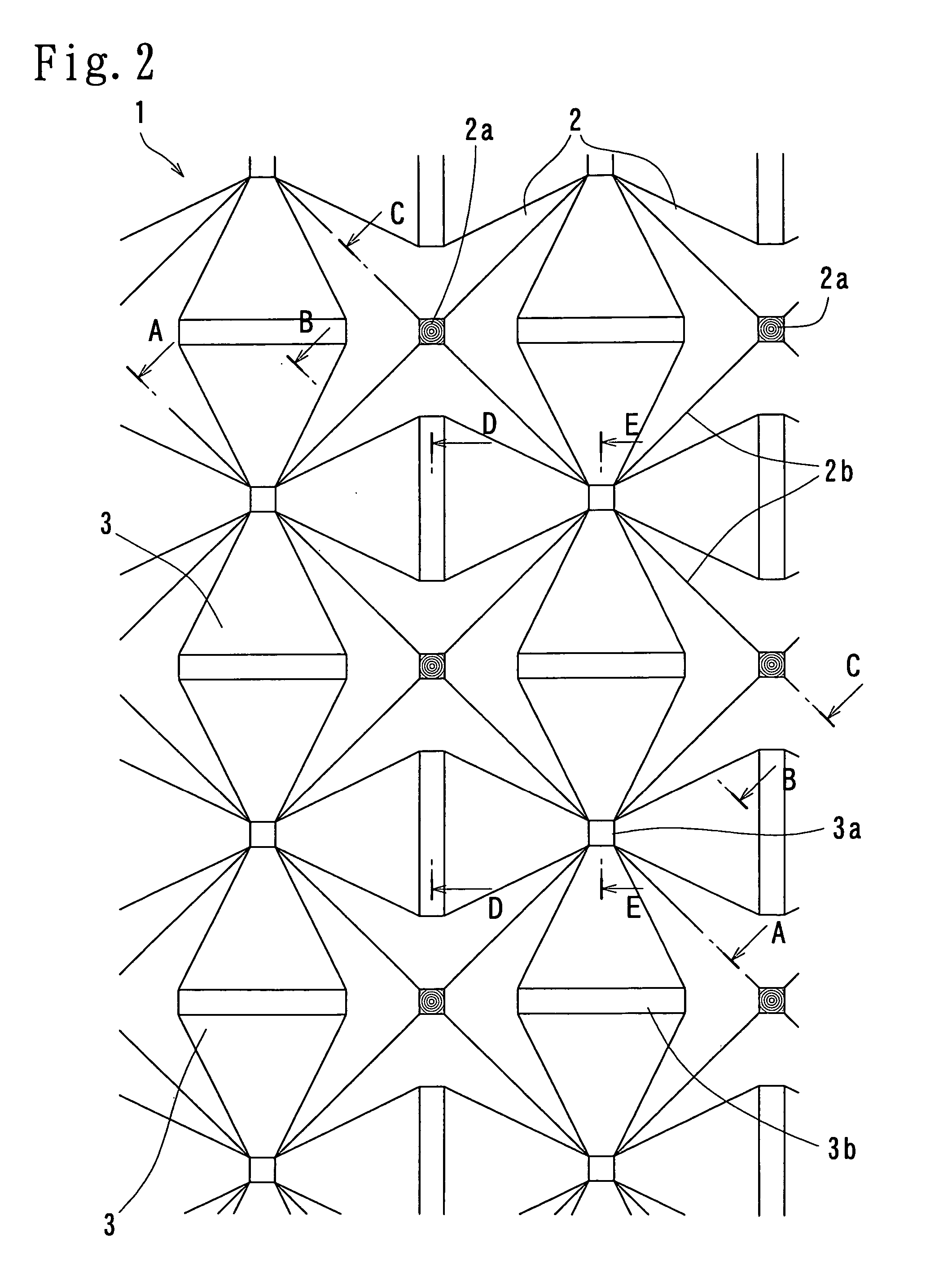

Plate for heat exchange and heat exchange unit

InactiveUS20050150645A1Improve heat transfer performanceIncrease freedomStationary conduit assembliesLaminated elementsBiomedical engineeringRidge

A heat exchange plate having a pattern of irregularity is combined with the other plates to constitute a heat exchanger. The plate has main and intermediate protrusions. The main protrusions have a quadrangular pyramid shape with a top, first and second pairs of side surfaces. The first and second pairs of side surfaces face each other in the first and second directions. The main protrusions are aligned in these directions so that these pairs of surfaces of the main protrusion face the corresponding surfaces of adjacent protrusions. The intermediate protrusion is placed between adjacent main protrusions and has opposite foot portions and a head ridge placed between them. The foot portion is placed in a lowermost position at which ridgelines of the adjacent two main protrusions intersect. The head ridge is placed in a level higher than the foot portions, but lower than the top of the main protrusion.

Owner:XENESYS

Advanced composite aerostructure article having a braided co-cured fly away hollow mandrel and method for fabrication

InactiveUS20100038030A1Light weightEasy maintenanceSynthetic resin layered productsLaminationFiber-reinforced compositePolyresin

Owner:ALLEN GREGORY A +1

Combined prefabricated floor slab for low-rise prefabricated steel structure dwellings

ActiveCN110485609ARealize seamless assemblyAchieve lossless recyclingFloorsFloor slabAgricultural engineering

The invention discloses a combined prefabricated floor slab for low-rise prefabricated steel structure dwellings, and belongs to the field of construction technology. The combined prefabricated floorslab for the low-rise prefabricated steel structure dwellings can quickly connect prefabricated slabs through connecting parts, and technicians initiates a rotating magnetic field in a wireless signalmode to drive the installation action of magnetic bolts to achieve seamless assembling between the prefabricated slabs, with pre-embedded prestressed steel bars in the prefabricated slabs, under thetwo-way memory effect of shape memory alloy, and the high-strength expansion connection is realized, so that the transmission and sharing of prestress are completed, the assembling strength between the prefabricated slabs is improved, the wireless signal is used for completing the disassembling during recycling, non-destructive recycling of the prefabricated slabs is basically achieved, direct secondary utilization can be achieved, and assembling efficiency is significantly improved while the construction cost is reduced, and the combined prefabricated floor slab for the low-rise prefabricatedsteel structure dwellings is in line with the green environmental protection concept of sustainable development in nowadays society.

Owner:宁夏神聚钢结构安装工程有限公司

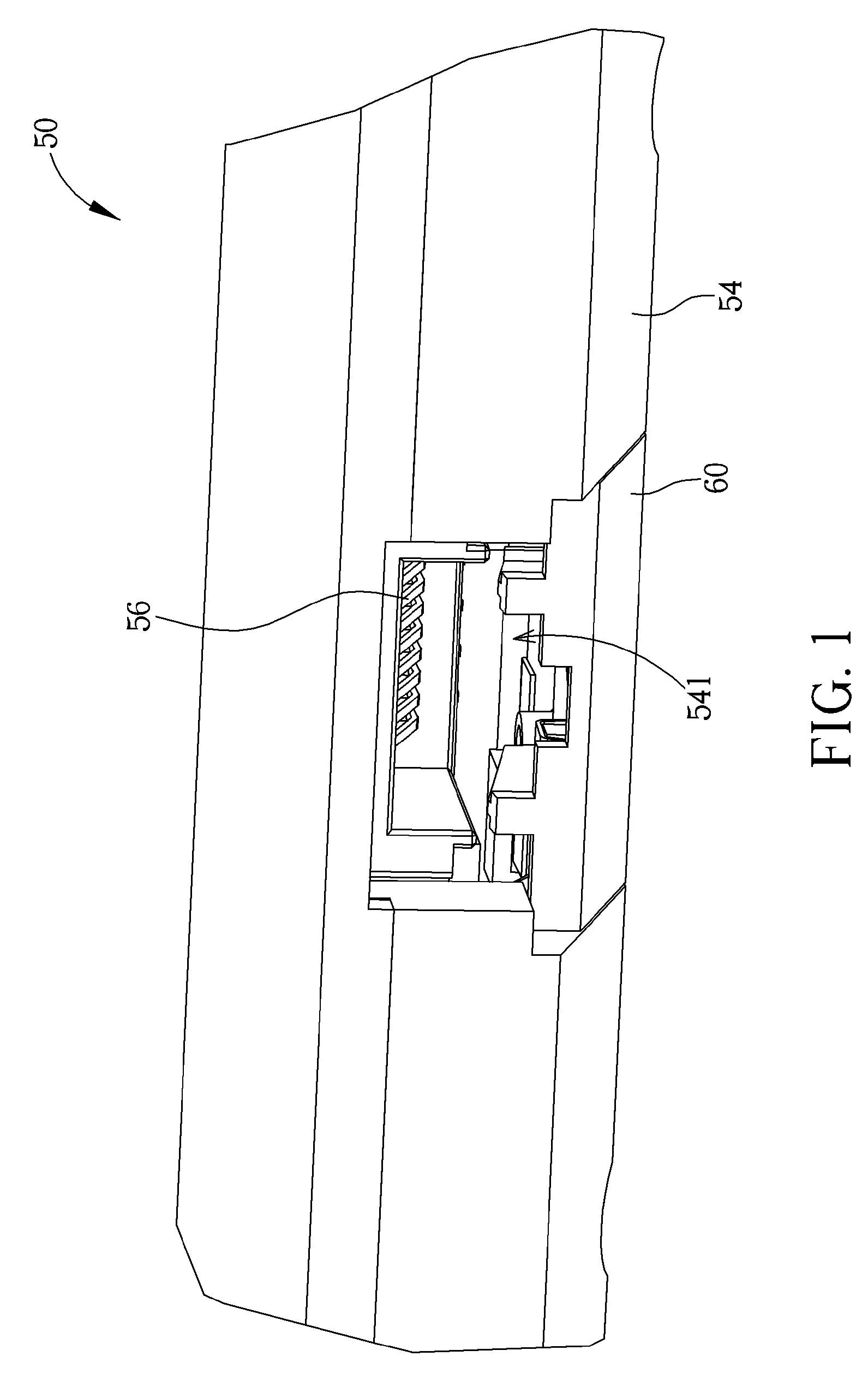

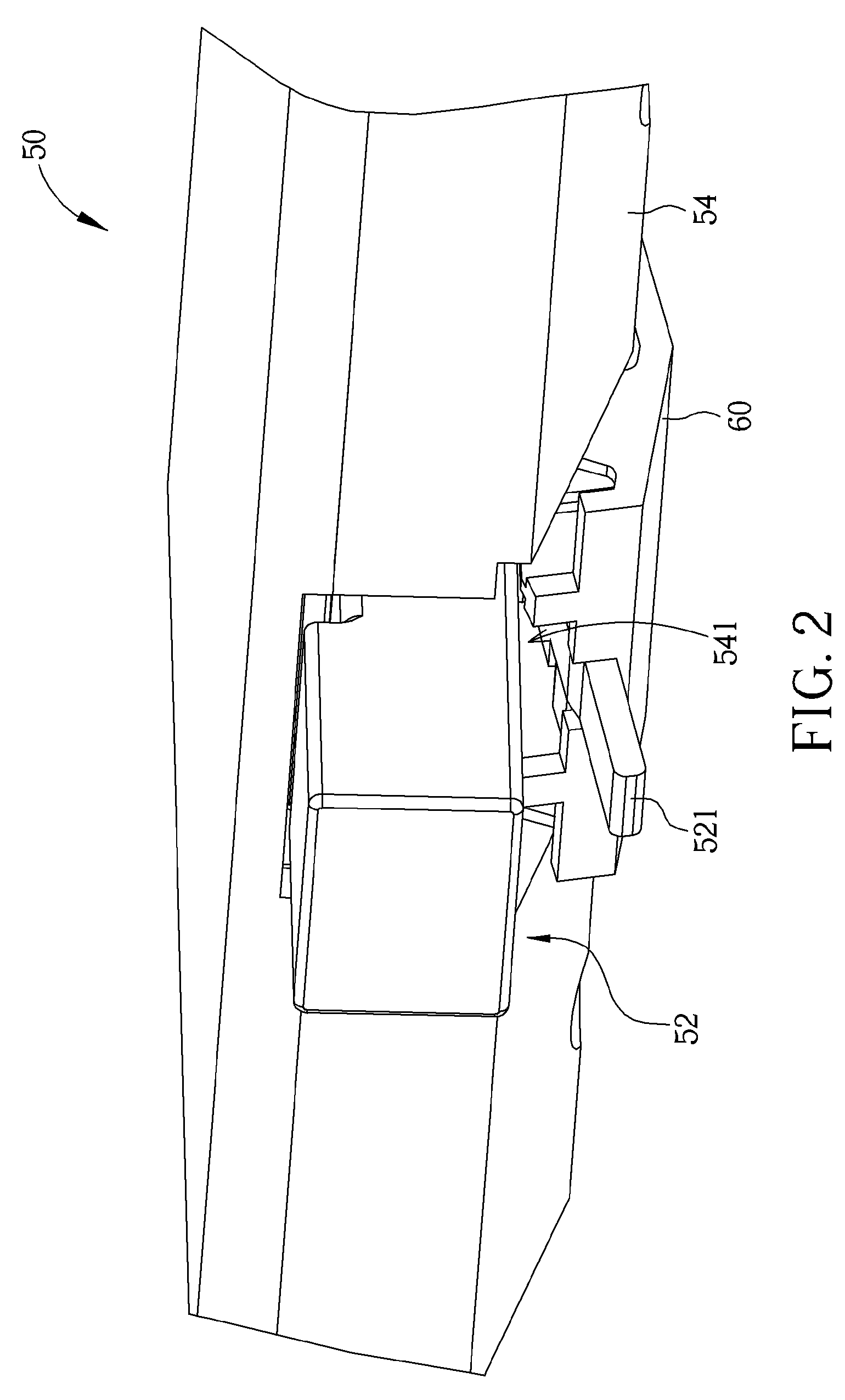

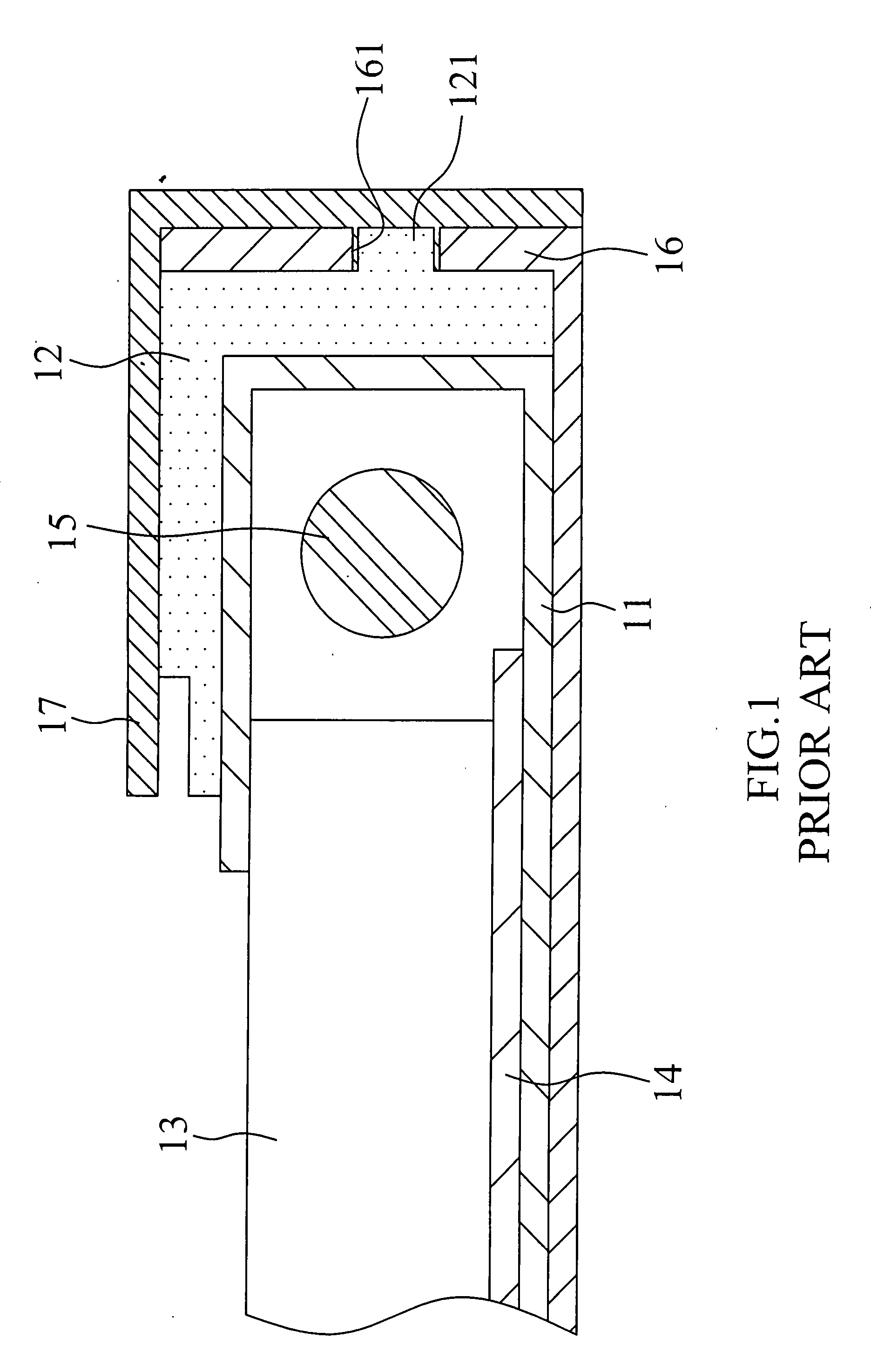

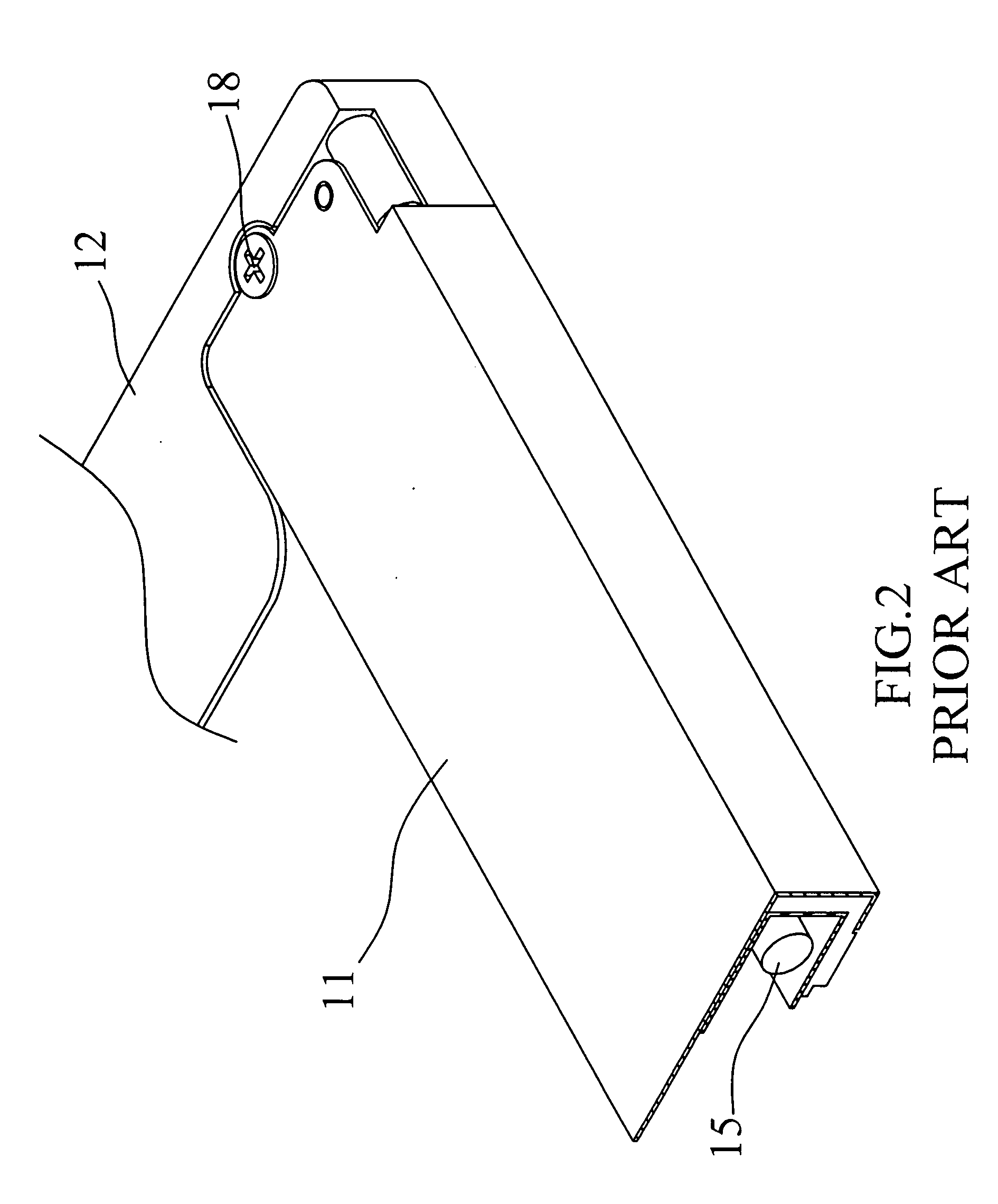

Backlight module locating device and method thereof

InactiveUS20080007959A1Improve assembly strengthReduce processNon-electric lightingLight fasteningsEngineeringAssembly structure

A locating device and method therefore for a first and a second parts of a backlight module by having, for example, a metal back plate or a metal reflection layer and a plastic frame secured to each other and made an integrated party without relying upon any other assembly part, e.g., a screw, or an assembly structure, e.g., an opening and a locking hook, thus to shorten assembly process and to improve assembly strength between the metal back plate or the metal reflection layer and the plastic frame.

Owner:K-BRIDGE ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com