Split mounting type battery box module fixing frame and power battery box provided with same

A battery module and battery box technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of battery box bottom wall falling off, complex production process, unfavorable disassembly and assembly, etc., and achieve high assembly efficiency and structural strength High, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

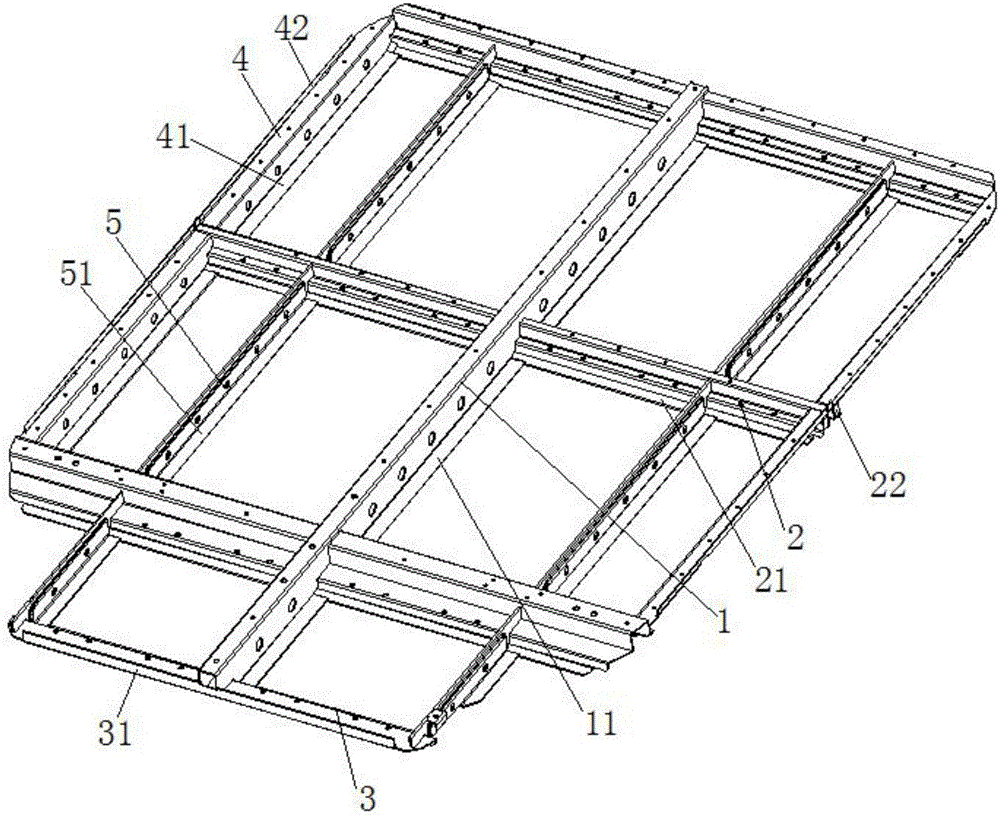

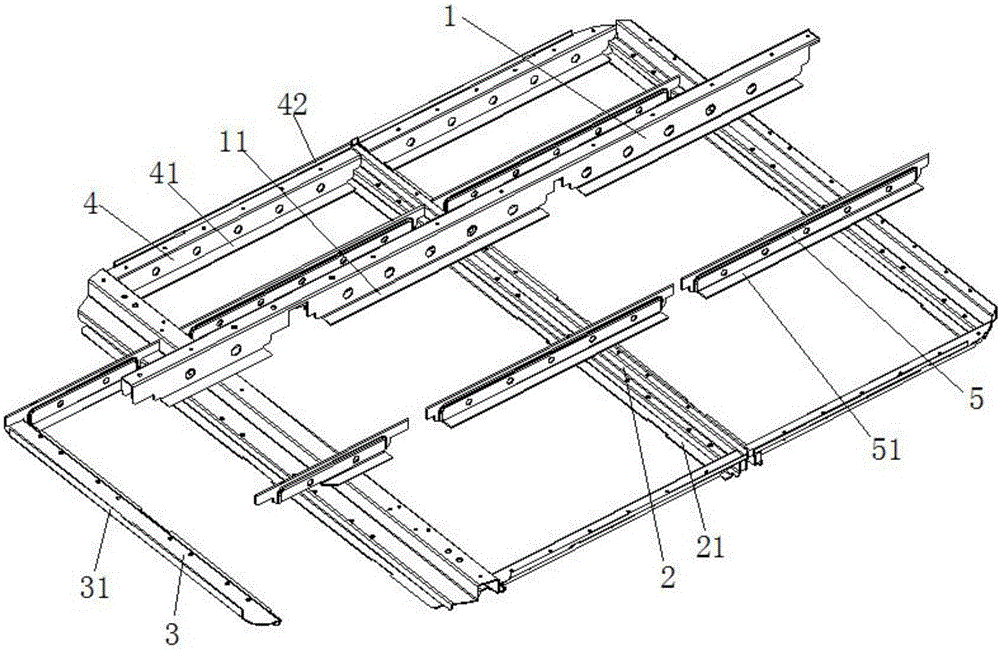

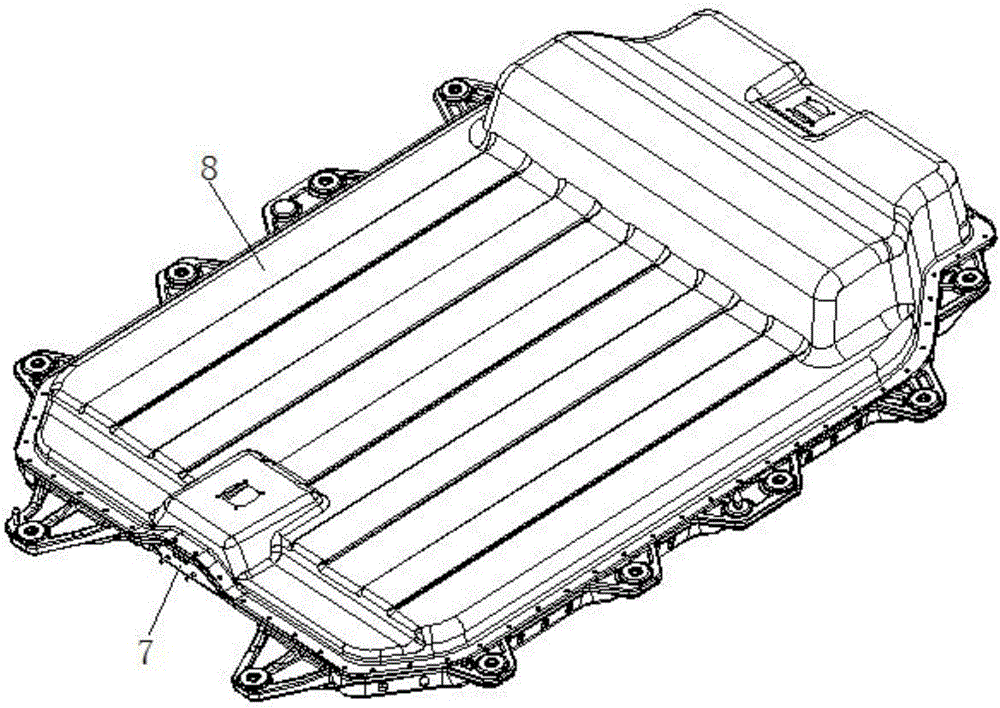

[0036] Example: such as figure 1 and 2 As shown, the assembled battery box module fixing frame of this embodiment includes a longitudinal beam keel 1, a plurality of cross beam keels 2 and a plurality of side beams 4;

[0037] A plurality of the above-mentioned beam keels 2 are arranged at intervals and parallel to each other, the above-mentioned longitudinal beam keels 1 are vertically arranged in the middle position of the plurality of the above-mentioned beam keels 2, and are respectively engaged on the multiple above-mentioned beam keels 2;

[0038] The ends of two adjacent beam keels 2 are connected by side beams 4;

[0039] Both sides of the bottom of the beam keel 2 are horizontally provided with a first side plate 21, the bottom of both sides of the above-mentioned longitudinal beam keel 1 is horizontally provided with a second side plate 11, and the bottom of the above-mentioned side beam 4 is horizontally provided with a third side plate 41. Limiting gaps are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com