Commercial vehicle single front axle structure with independent suspensions

A technology of independent suspension and commercial vehicle, applied in the direction of suspension, elastic suspension, vehicle spring, etc., can solve problems such as poor reliability of suspension, and achieve the effect of strong bearing capacity, strong bearing capacity and good ride comfort of suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

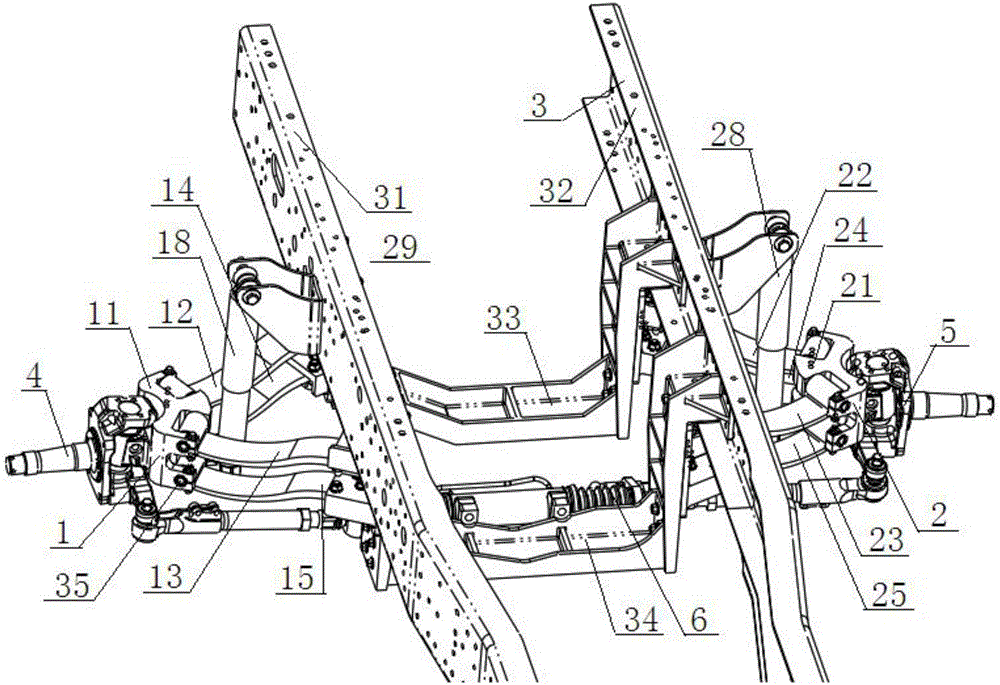

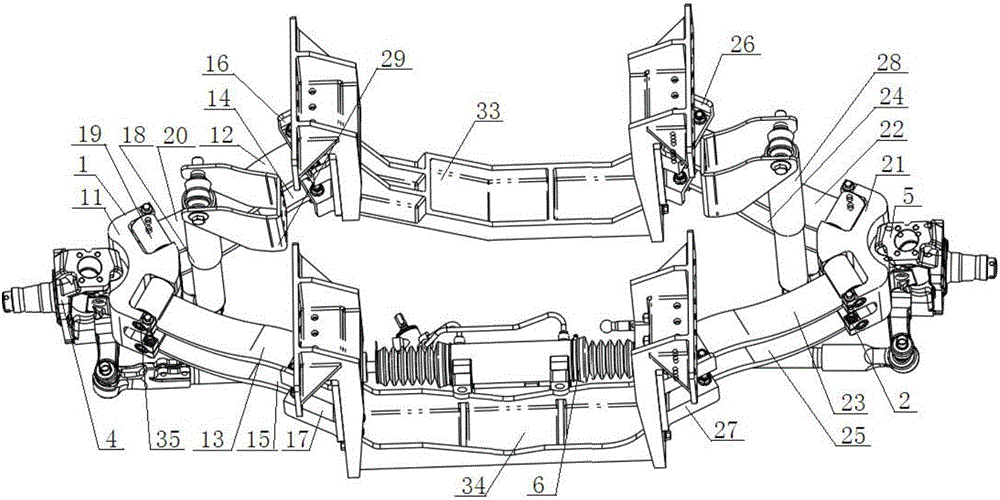

[0068] see Figure 1 to Figure 6, a commercial vehicle single front axle structure with independent suspension, including symmetrically arranged left independent suspension 1 and right independent suspension 2, said left independent suspension 1 is connected with right independent suspension 2 through vehicle frame 3 connection; the vehicle frame 3 includes symmetrically arranged left longitudinal beams 31 and right longitudinal beams 32, and the left longitudinal beams 31 are fixedly connected to the right longitudinal beams 32 through the front pocket beams 33 and the rear pocket beams 34 respectively; the left independent The suspension 1 includes a left connecting bracket 11, a first left leaf spring 12, a second left leaf spring 13, a third left leaf spring 14 and a fourth left leaf spring 15; one side of the left connecting bracket 11 is connected to the left steering knuckle 4, the other side of the left connecting bracket 11 is respectively connected with the first lef...

Embodiment 2

[0070] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0071] The first left leaf spring 12, the second left leaf spring 13, the third left leaf spring 14, the fourth left leaf spring 15, the first right leaf spring 22, the second right leaf spring 23, the third right leaf spring 24 It is equal to the included angle between the fourth right leaf spring 25 and the central axis of the vehicle frame 3 , and the included angle between the first left leaf spring 12 and the central axis of the vehicle frame 3 is 60 degrees.

Embodiment 3

[0073] Embodiment 3 is basically the same as Embodiment 2, the difference is:

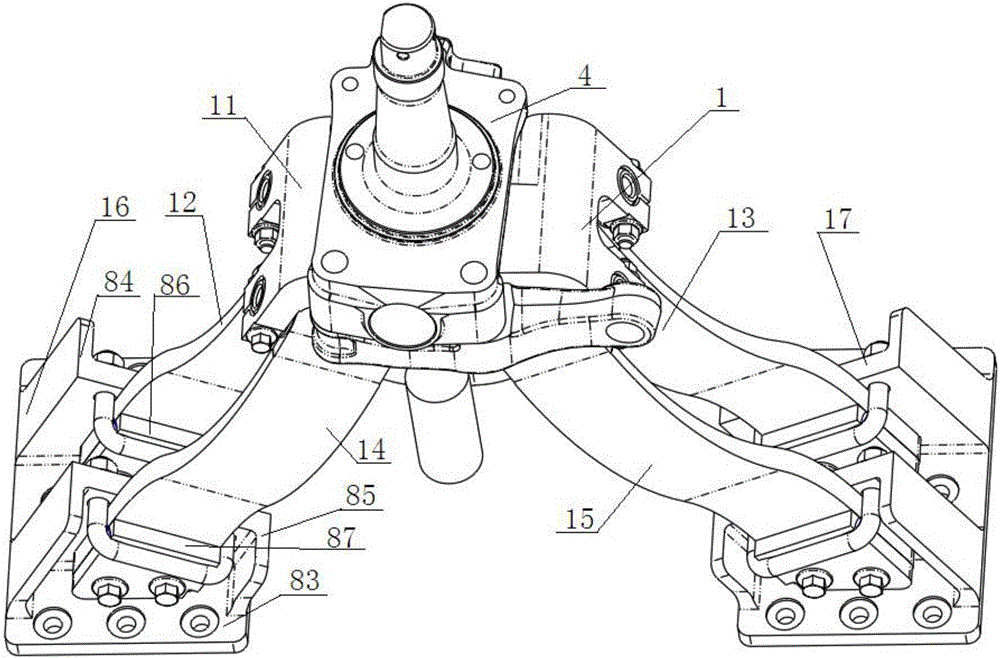

[0074] Described left front plate spring fixed frame 16 comprises fixed plate 83, upper fixed seat 84 and lower fixed seat 85, and described fixed plate 83 is fixedly connected with upper fixed seat 84 and lower fixed seat 85 respectively, and described first left leaf spring 12 The upper fixing seat 84 is fixedly connected by bolts and U-shaped bolts respectively, and the third left leaf spring 14 is fixedly connected with the lower fixing seat 85 by positioning bolts and U-shaped bolts respectively; the left rear leaf spring fixing frame 17 is the left front The mirror image structure of leaf spring holder 16; The structure of described left front leaf spring holder 16 is identical with the structure of right rear leaf spring holder 27, and the structure of described right front leaf spring holder 26 is identical with left rear leaf spring holder 17; The lower end of the upper fixing seat 84 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com