Patents

Literature

1077 results about "Independent suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Independent suspension is any automobile suspension system that allows each wheel on the same axle to move vertically (i.e. reacting to a bump on the road) independently of the others. This is contrasted with a beam axle or deDion axle system in which the wheels are linked – movement on one side does not affect the wheel on the other side. "Independent" refers to the motion or path of movement of the wheels or suspension. It is common for the left and right sides of the suspension to be connected with anti-roll bars or other such mechanisms. The anti-roll bar ties the left and right suspension spring rates together but does not tie their motion together.

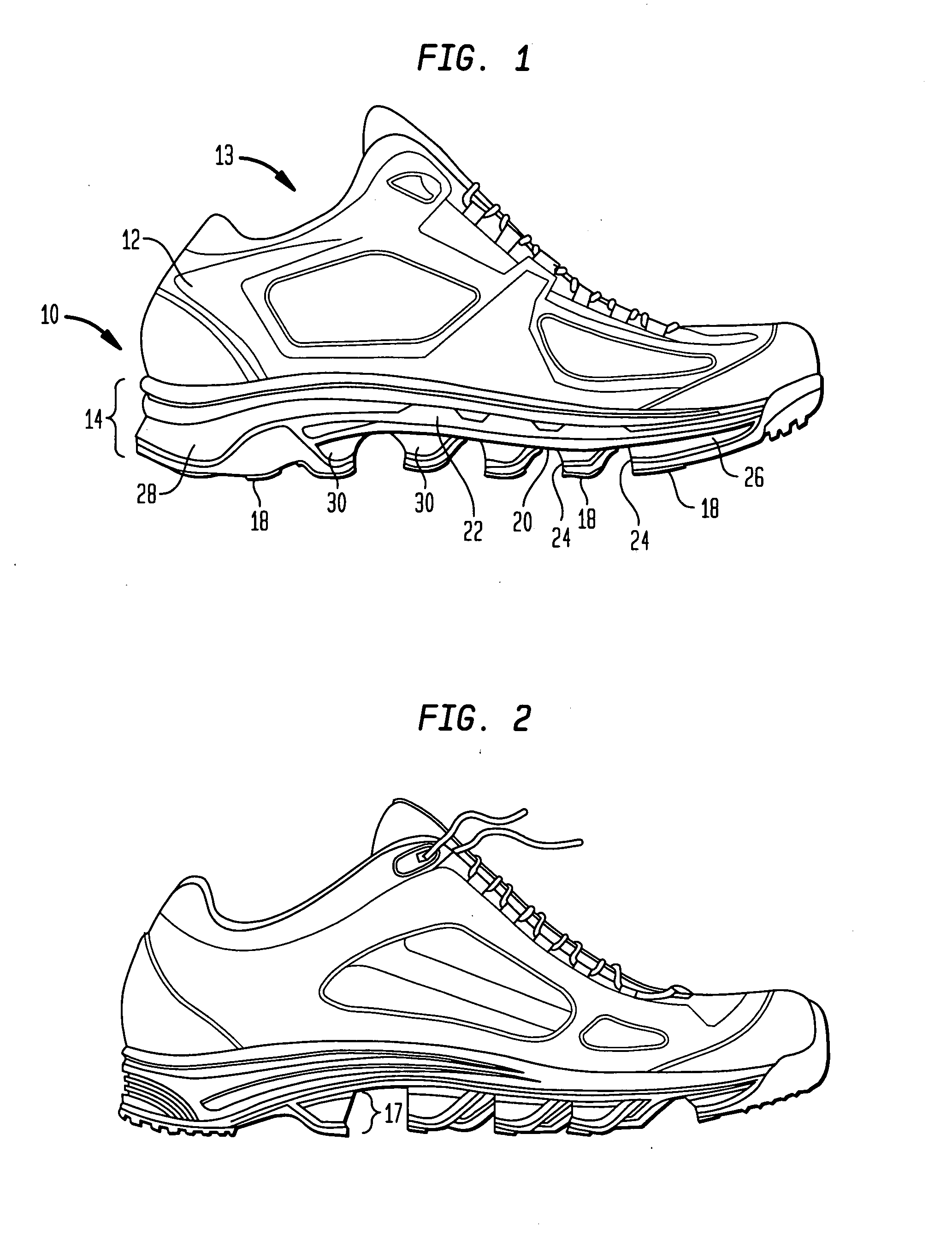

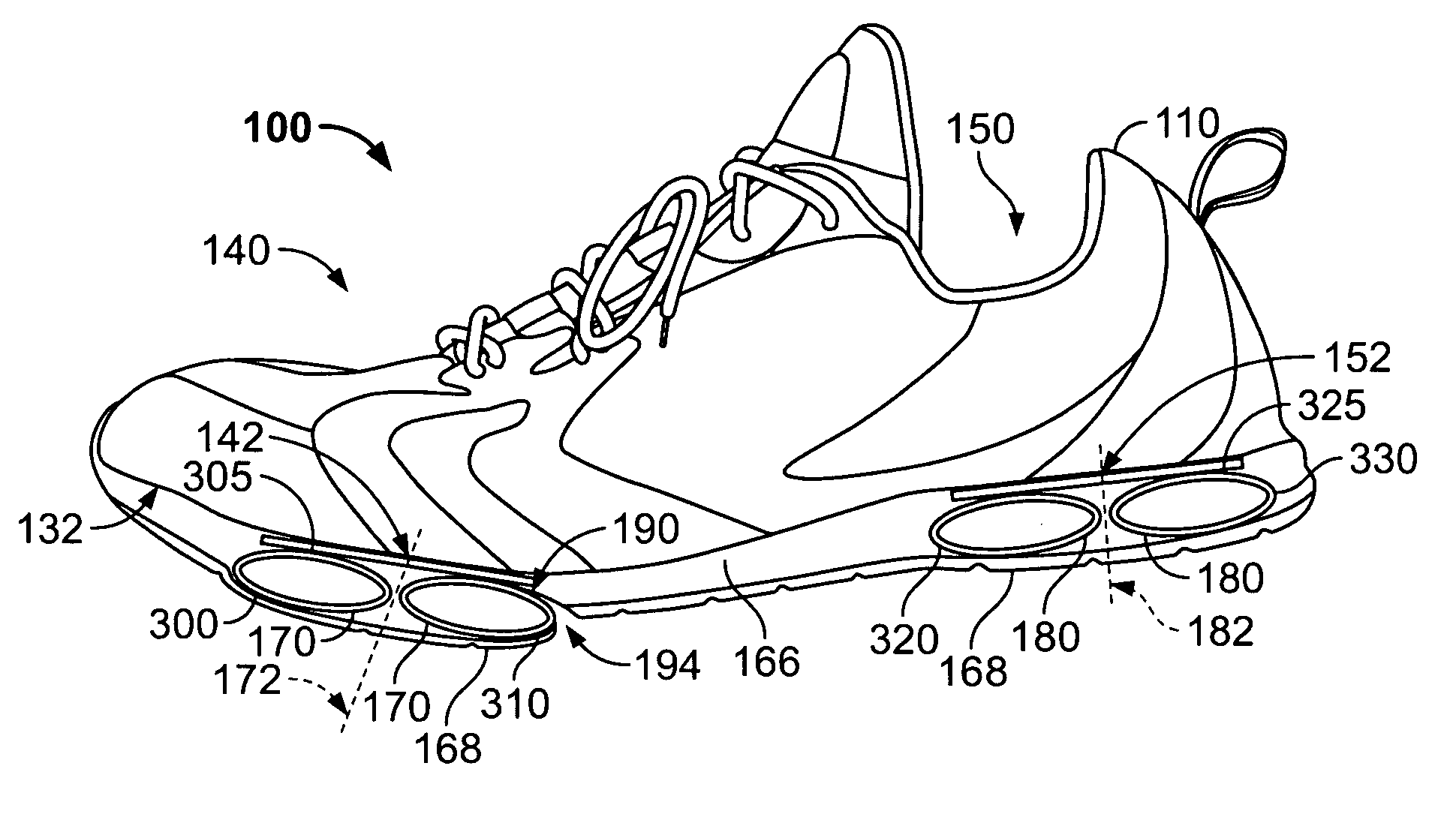

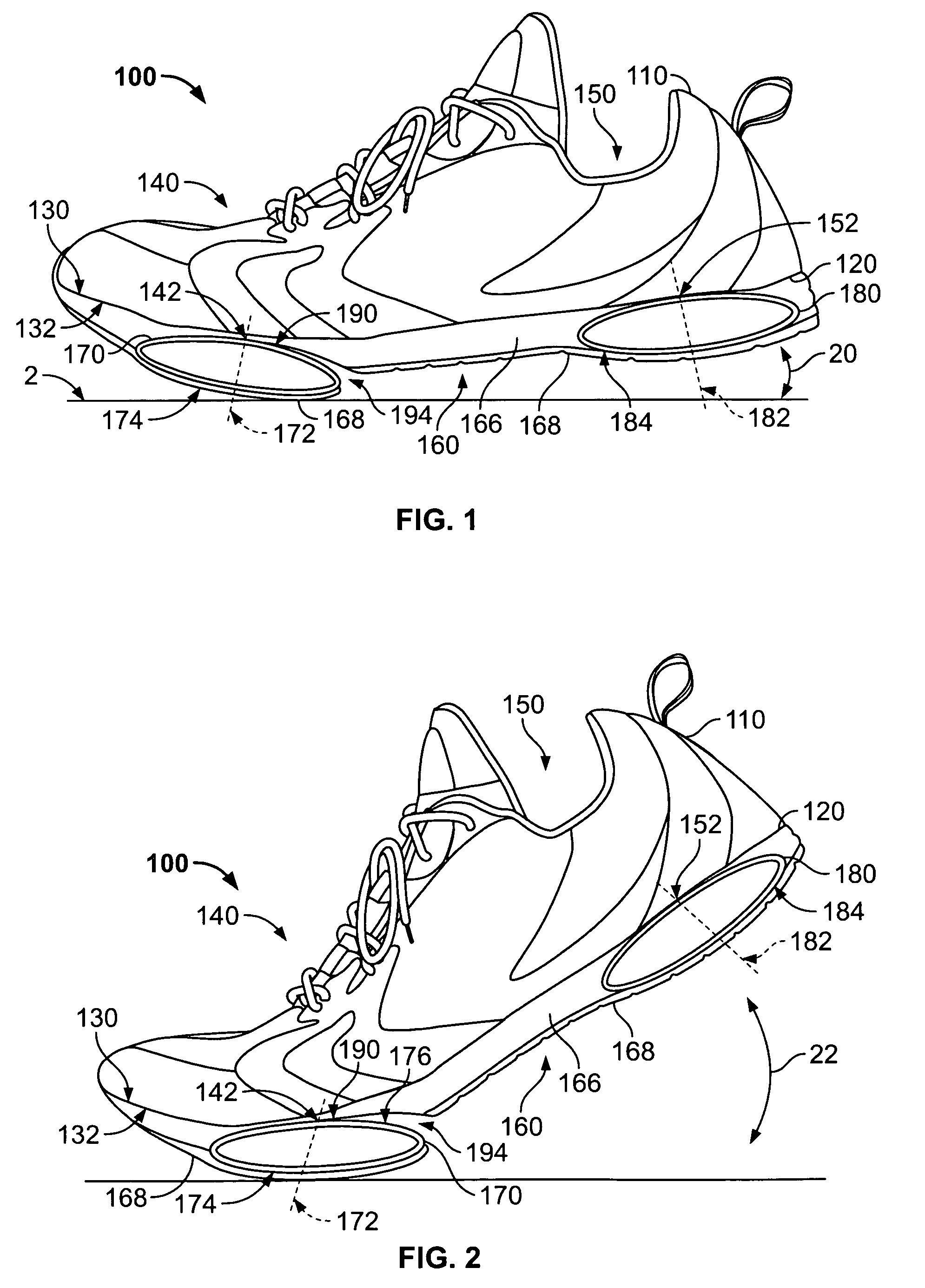

Footwear with independent suspension and protection

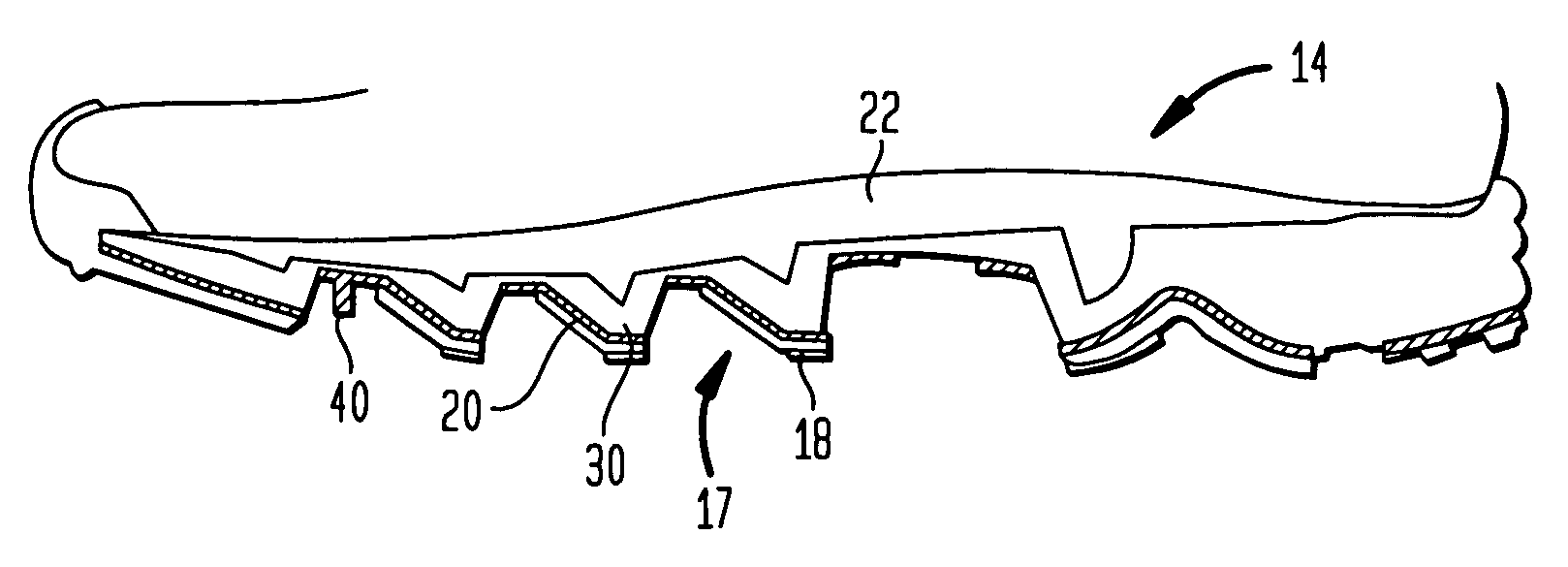

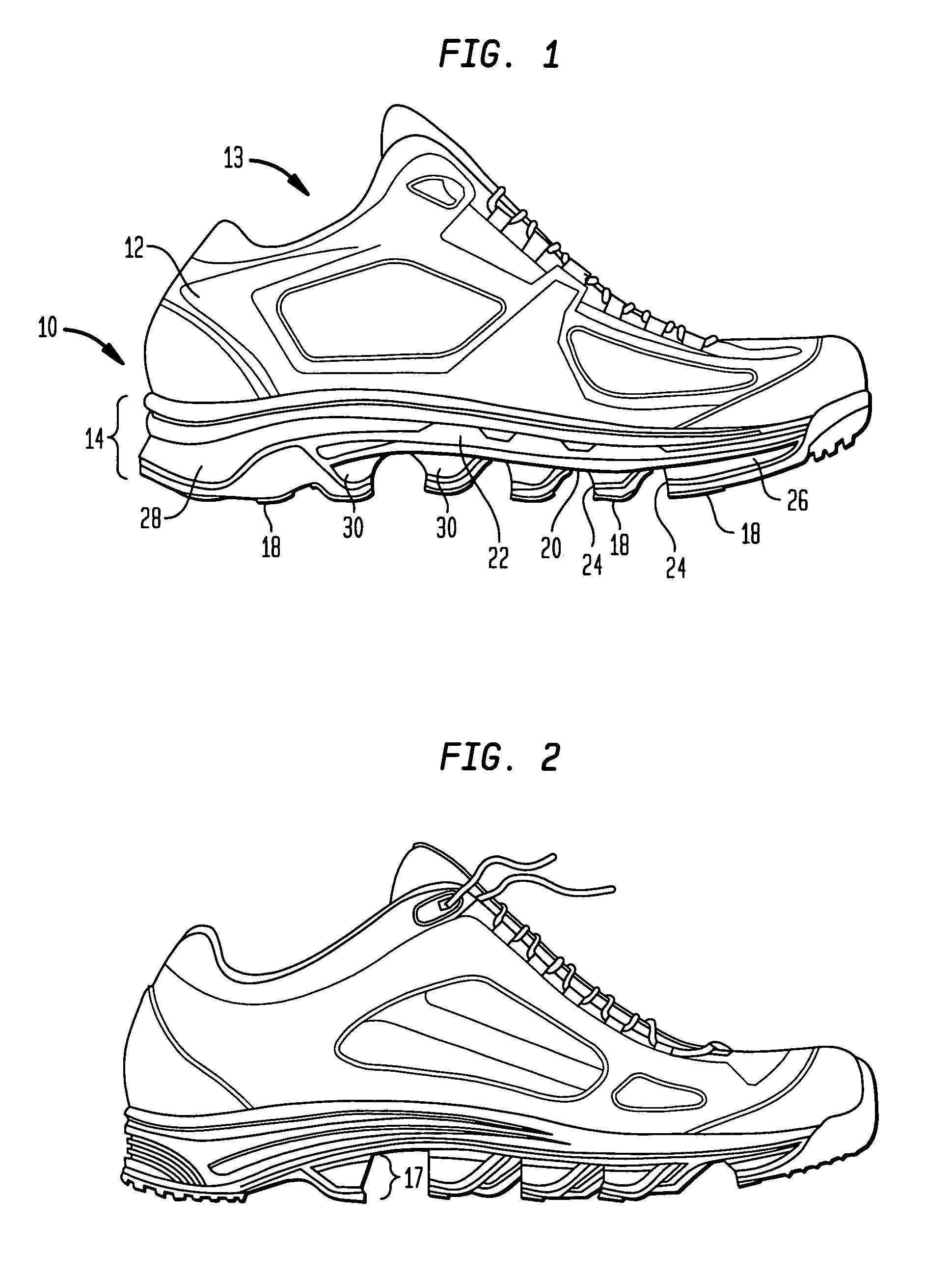

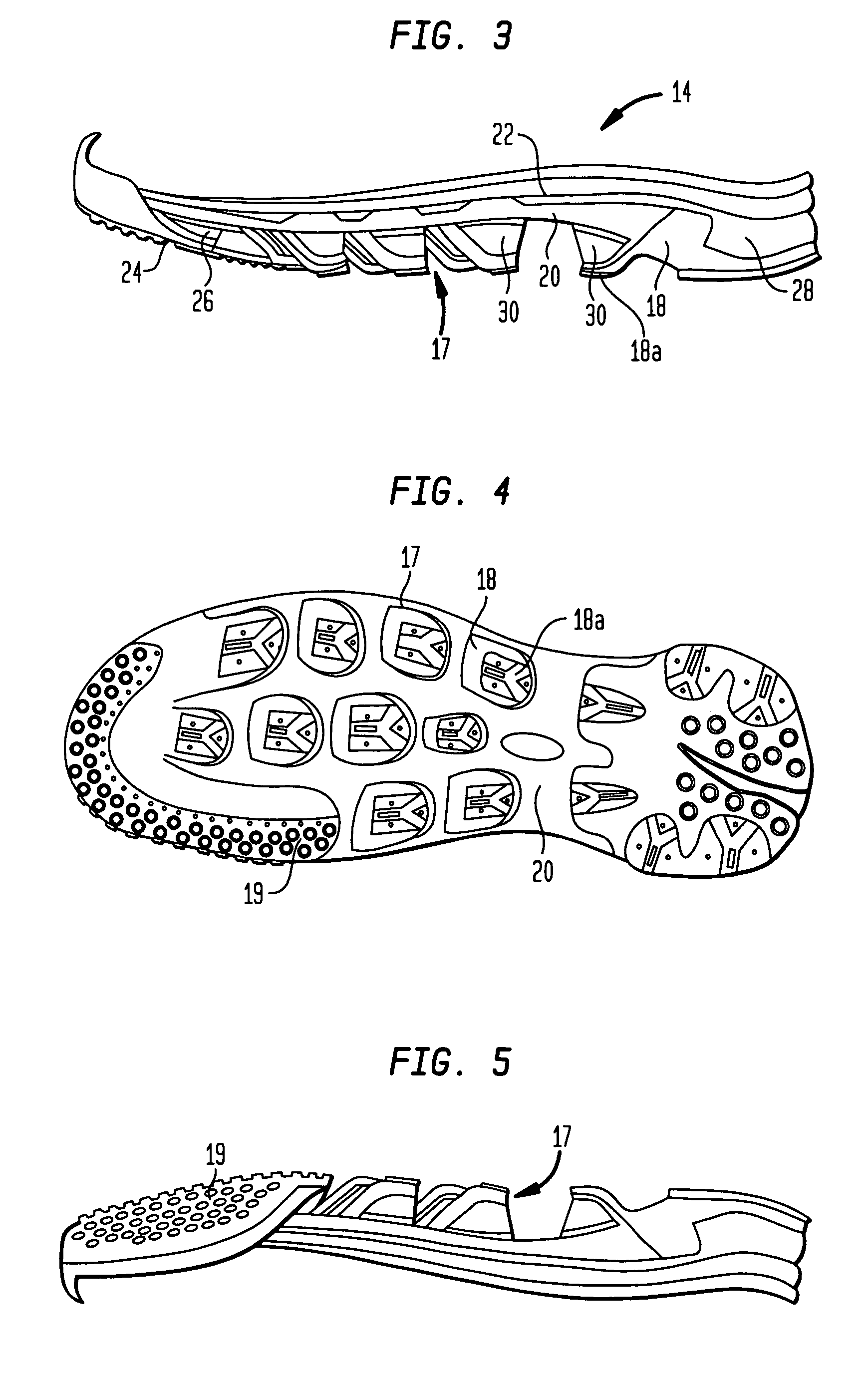

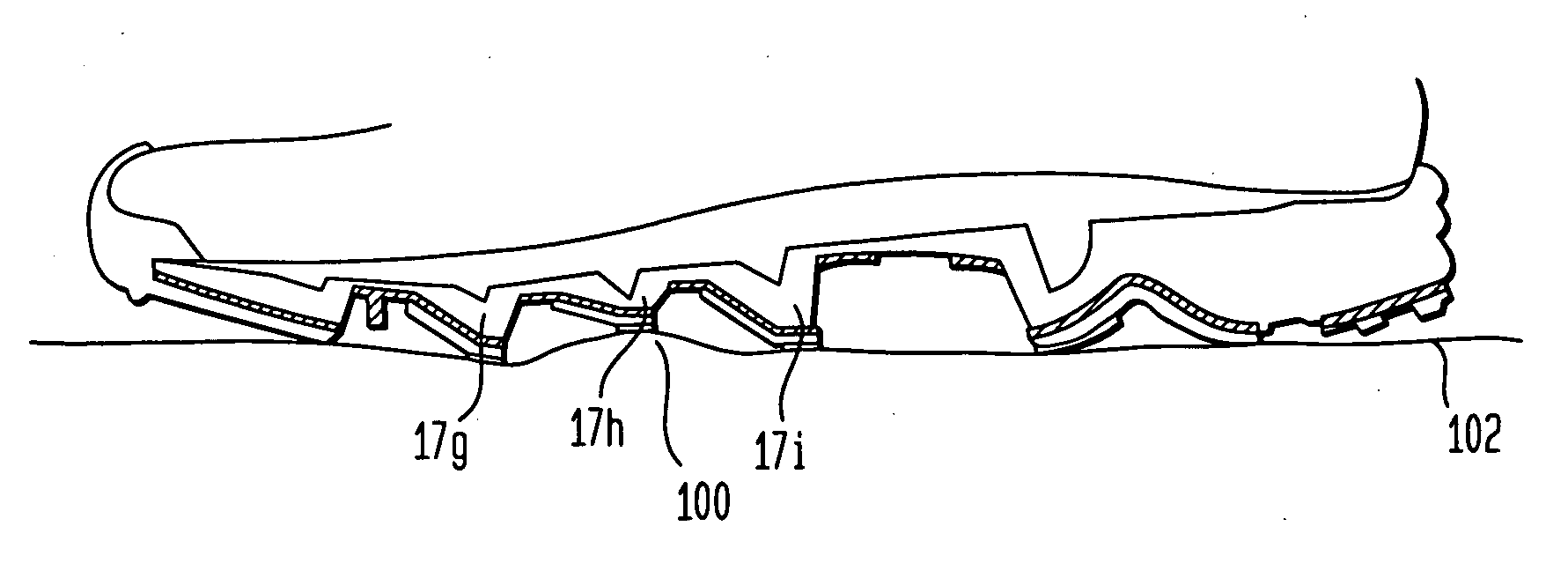

An article of footwear having an upper and a sole is disclosed. The sole of the article of footwear includes a midsole having a support portion and a plurality of projections extending from the support portion. The sole of the article of footwear also includes a plate contacting the support portion having a body positioned in an area between the plurality of projections. The plate further includes a plurality of openings which correspond to the plurality of projections and allow the projections to extend below the body of the plate. The plate further includes a plurality of cantilever elements extending on at least one side and on the bottom of each of the plurality of projections. The projections and the corresponding cantilever elements interact with one another to form a plurality of lugs located on the sole of the article of footwear.

Owner:JABIL CIRCUIT INC

Footwear with independent suspension and protection

An article of footwear having an upper and a sole is disclosed. The sole of the article of footwear includes a midsole having a support portion and a plurality of projections extending from the support portion. The sole of the article of footwear also includes a plate contacting the support portion having a body positioned in an area between the plurality of projections. The plate further includes a plurality of openings which correspond to the plurality of projections and allow the projections to extend below the body of the plate. The plate further includes a plurality of cantilever elements extending on at least one side and on the bottom of each of the plurality of projections. The projections and the corresponding cantilever elements interact with one another to form a plurality of lugs located on the sole of the article of footwear.

Owner:JABIL CIRCUIT INC

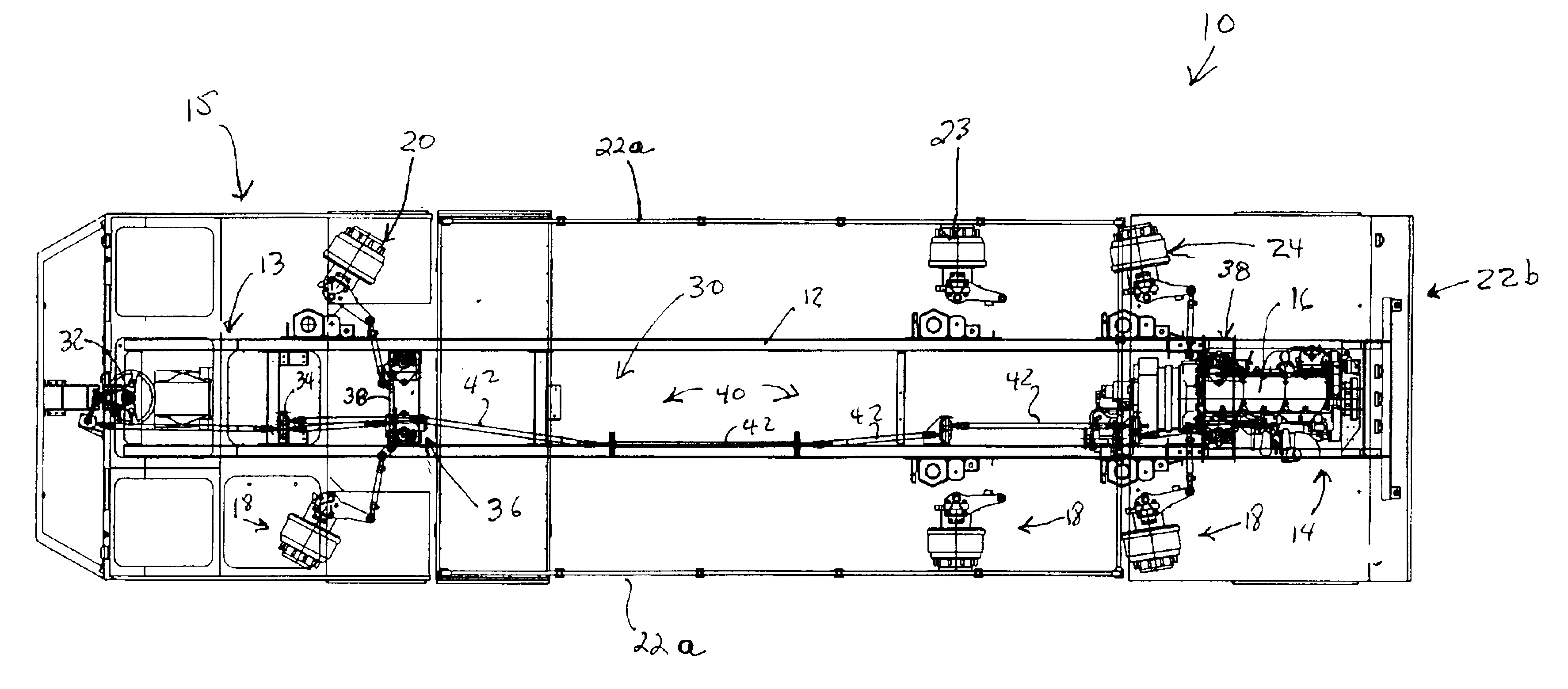

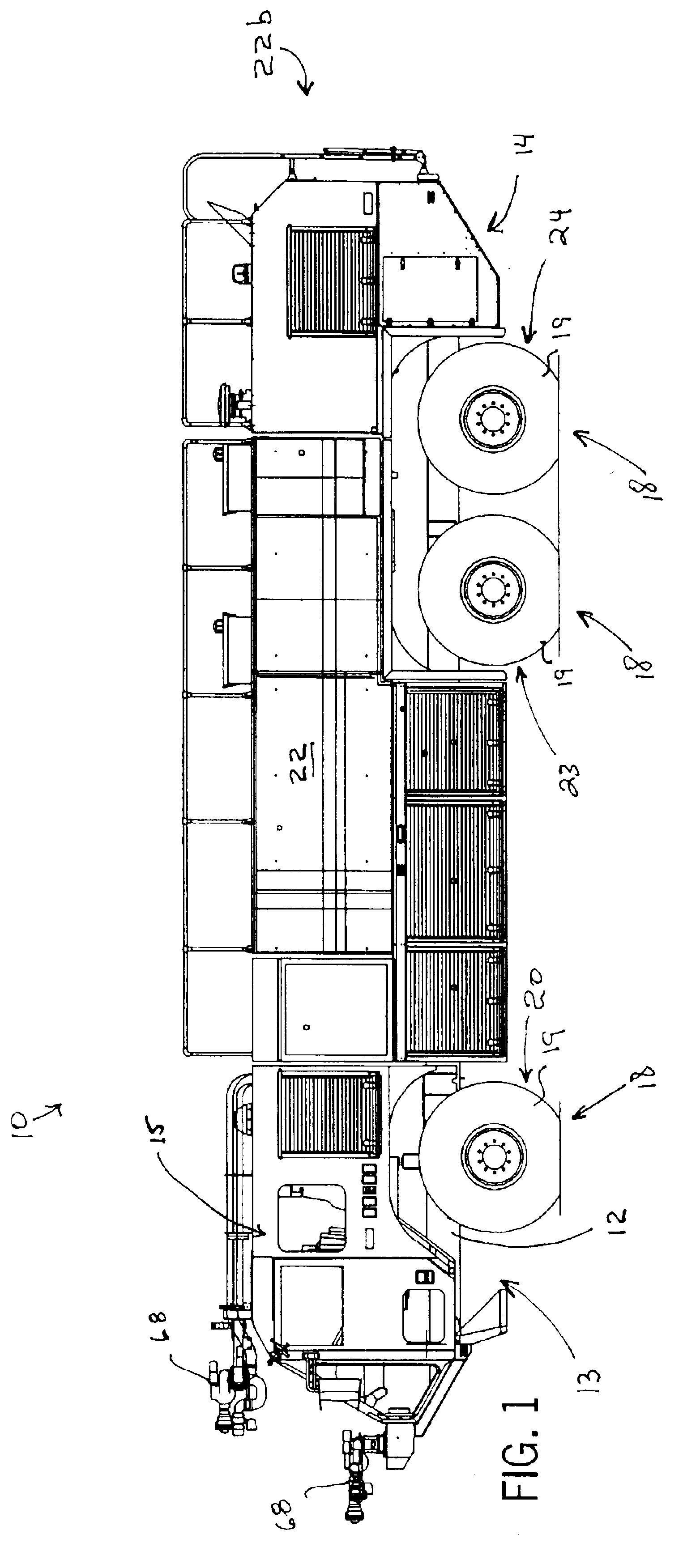

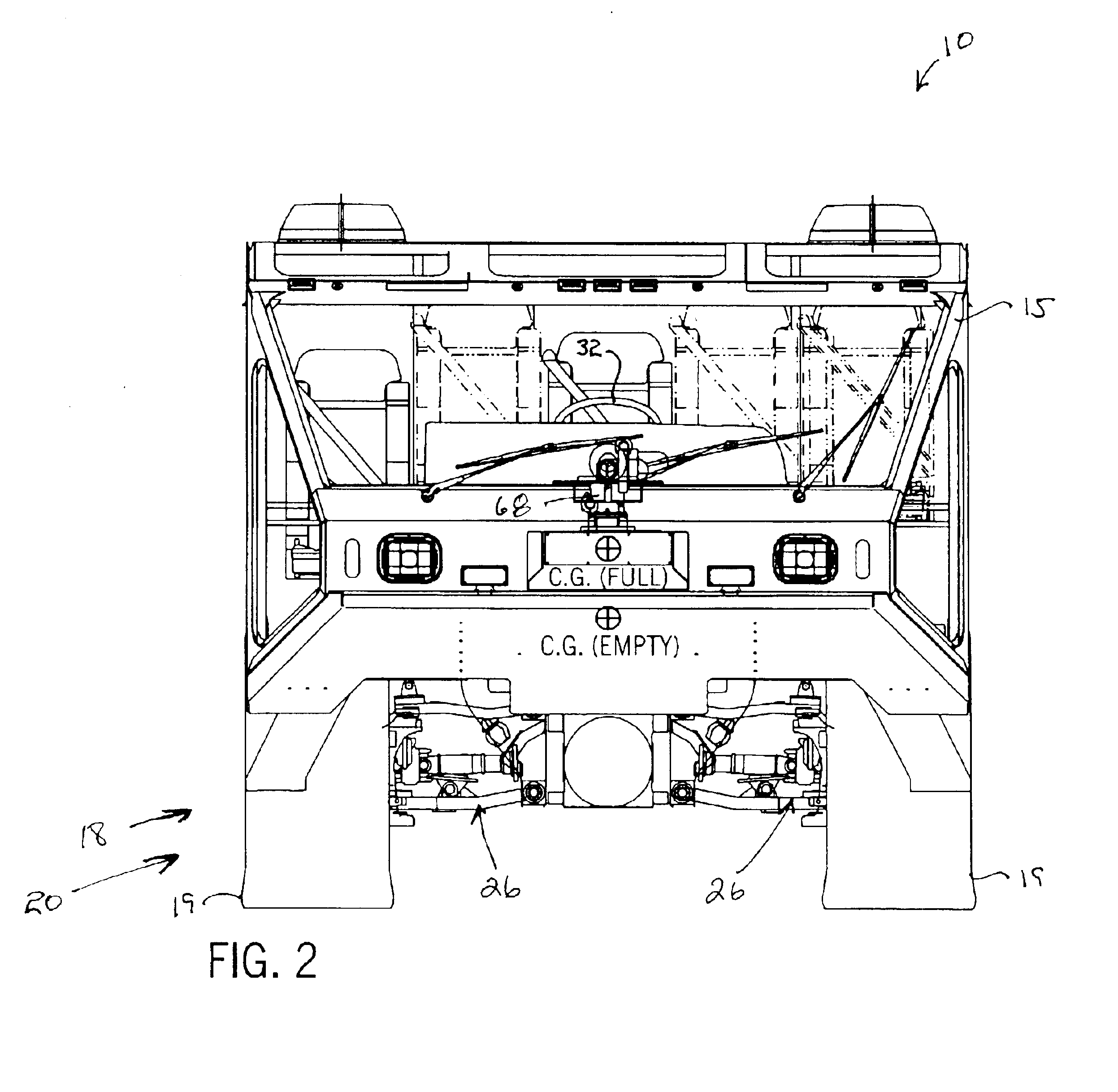

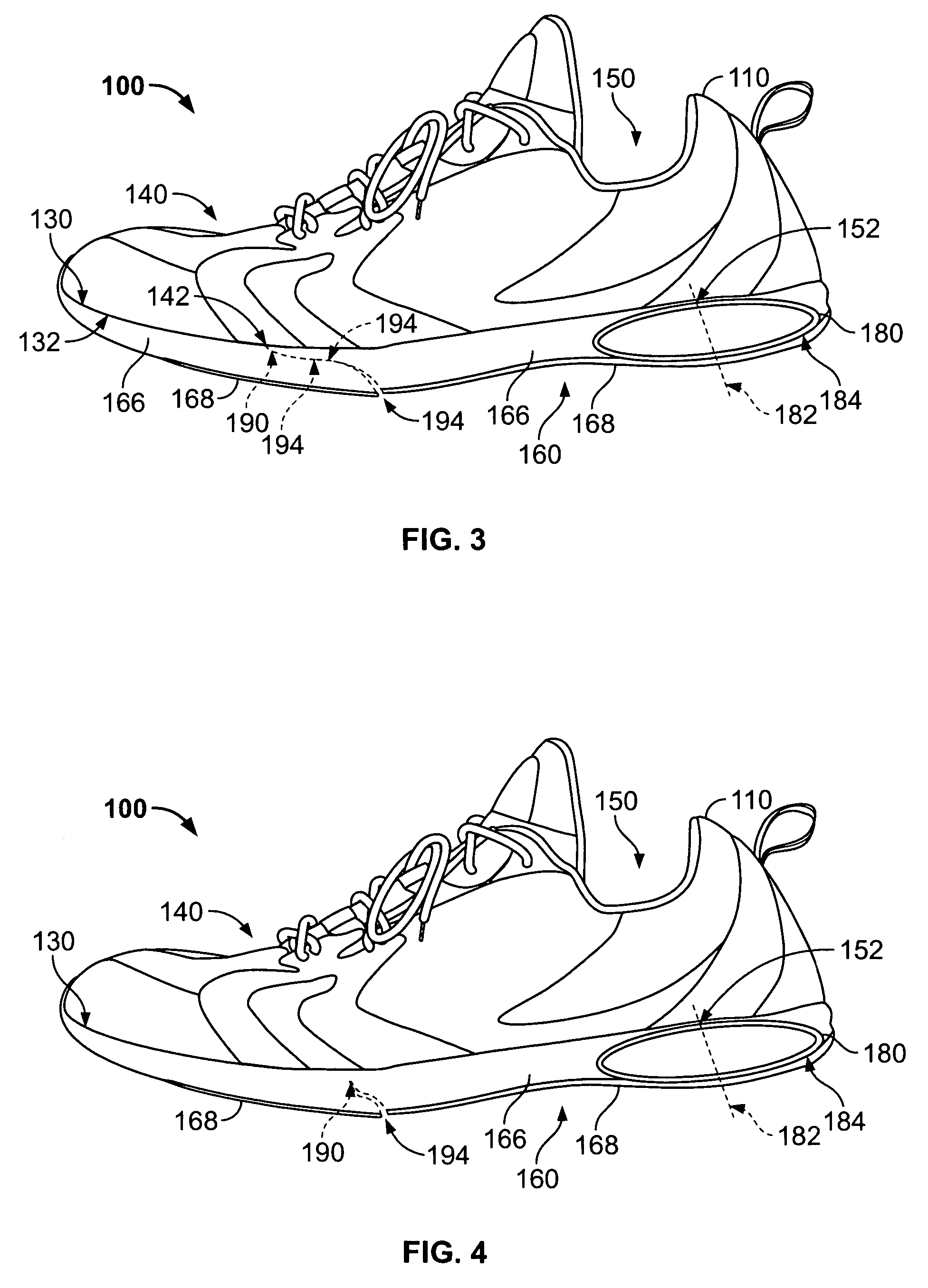

Fire-fighting vehicle

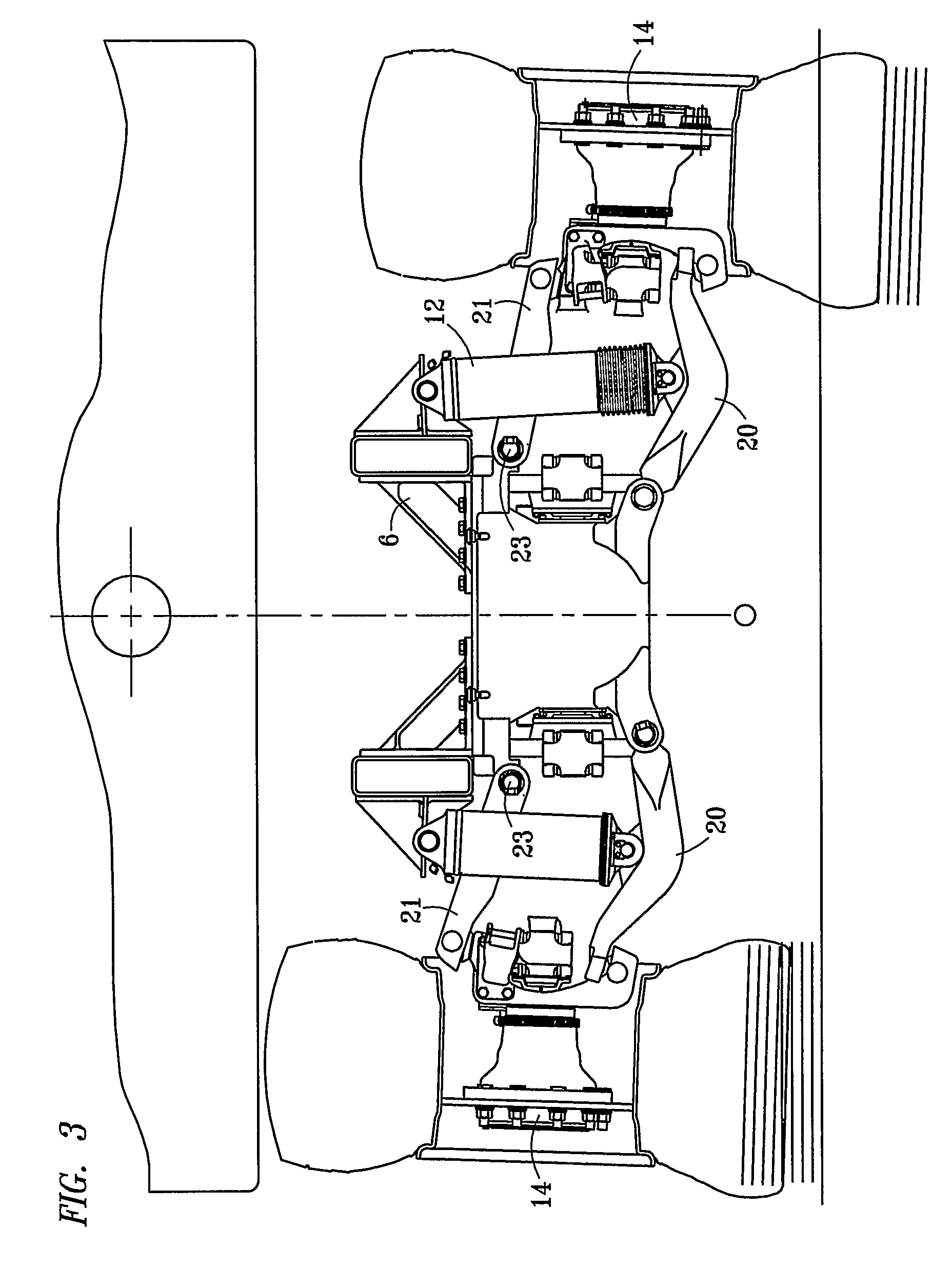

An airport rescue fire-fighting vehicle comprising a support structure coupled to at least two wheel sets. The support structure has a front end and a back end with one wheel set coupled to the front end of the support structure and one wheel set coupled to the back end of the support structure. A power source is mounted on the support structure and coupled to at least one wheel set. Each wheel of the vehicle is coupled to a modular independent suspension. A mechanical steering apparatus is coupled to the front wheel set and at least one rear wheel set.

Owner:OSHKOSH CORPORATION

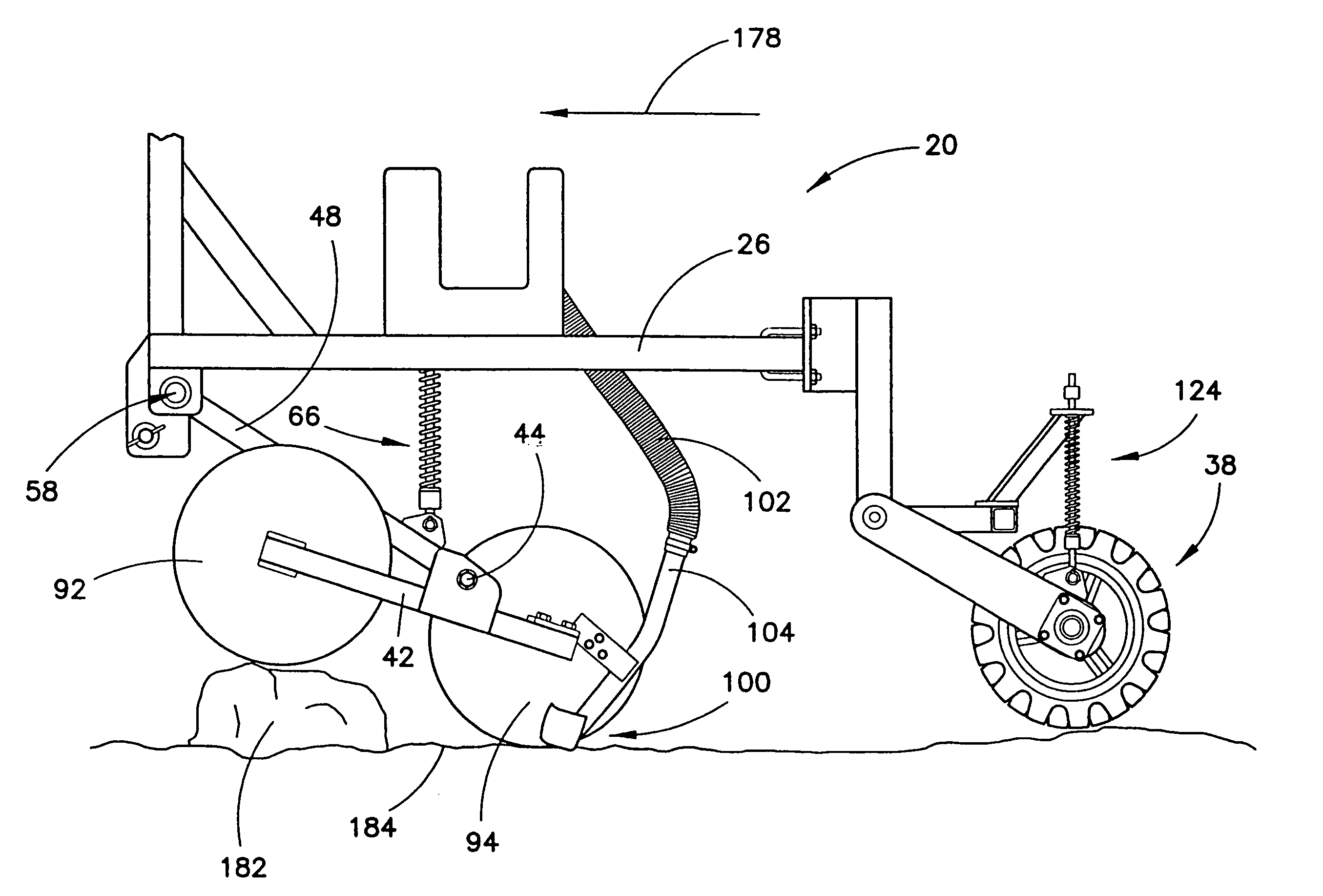

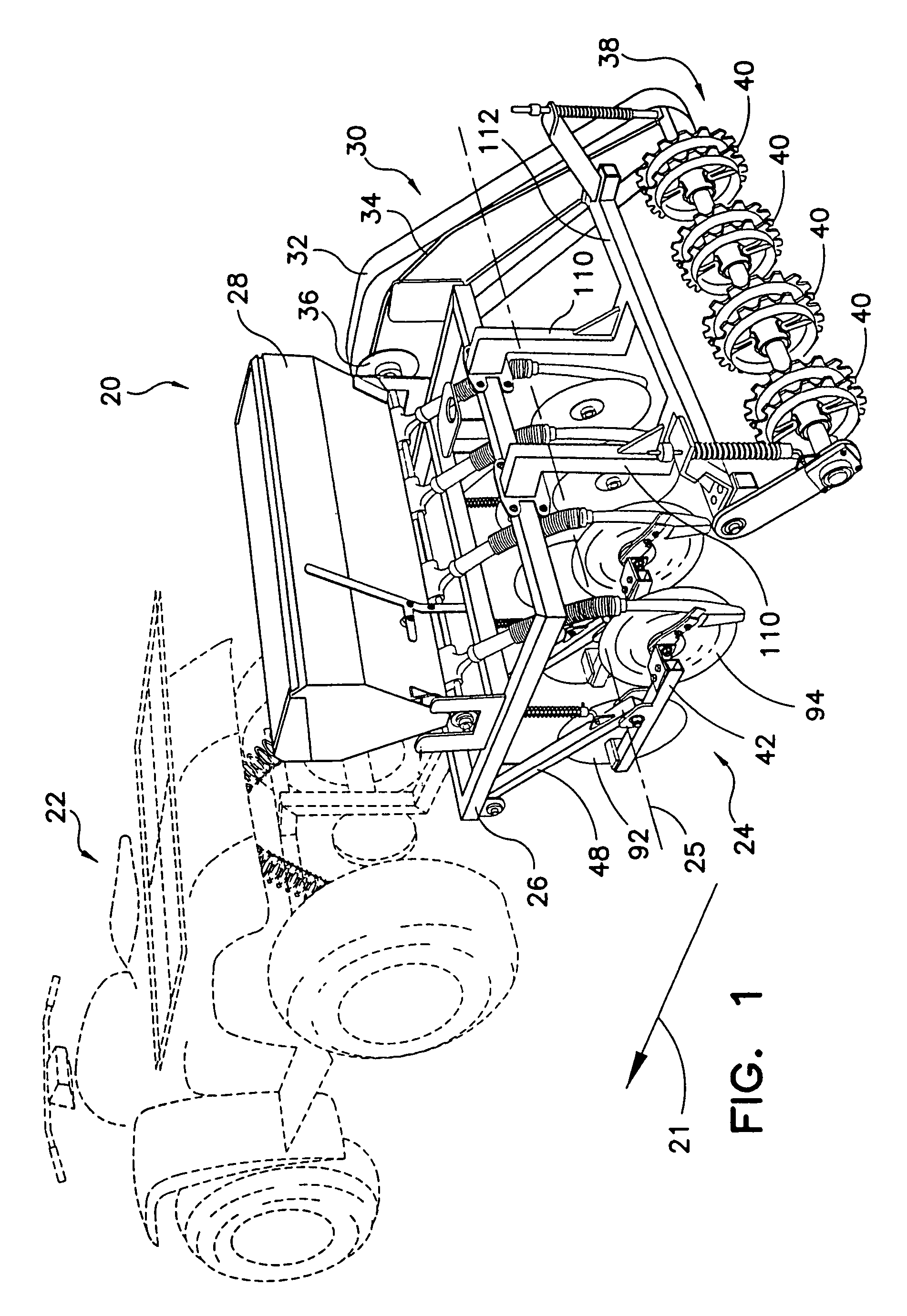

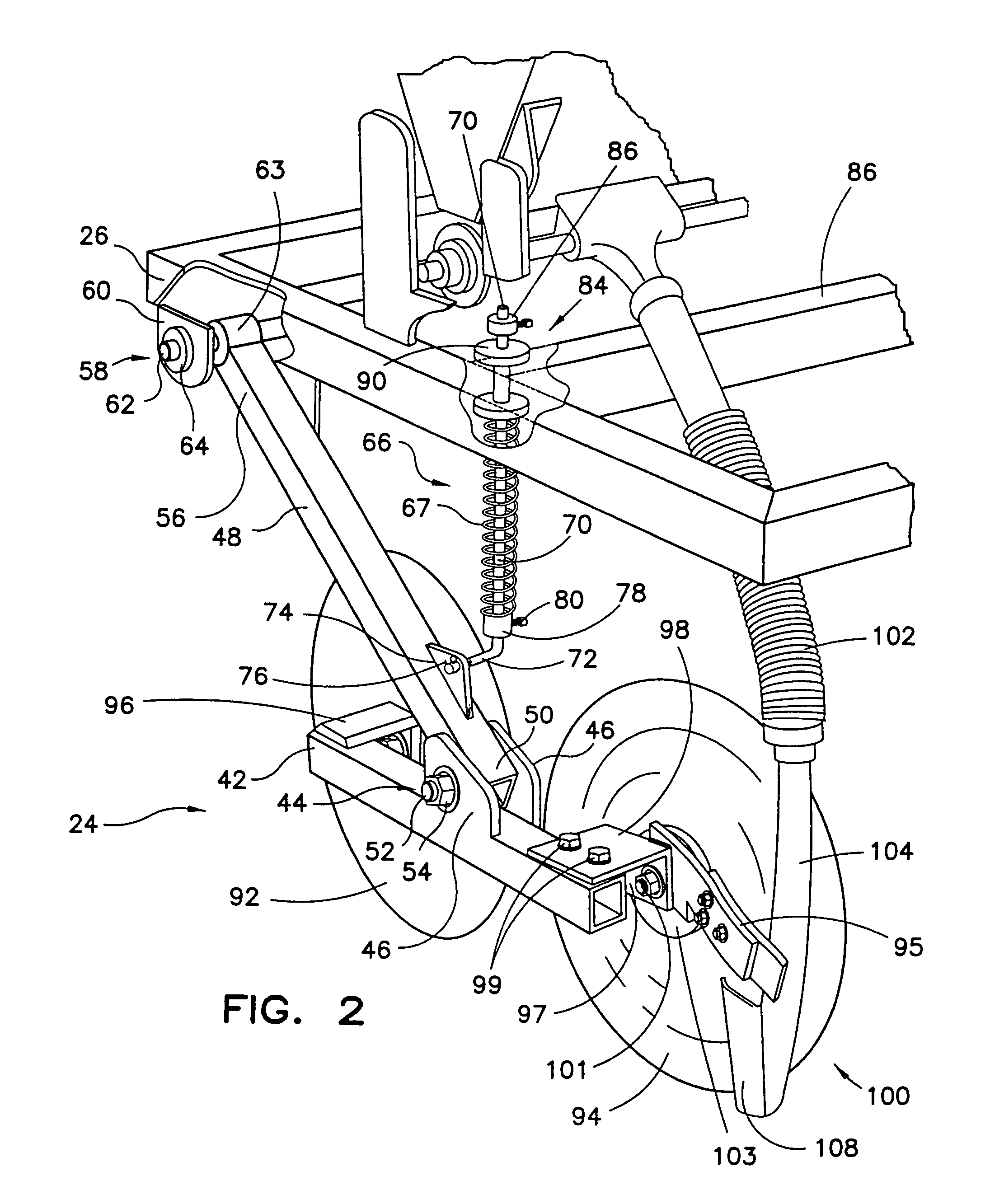

Seed drill with walking beam assembly

A no-till drill with a novel walking beam assembly that allows the drill to be pulled over severe terrain conditions that include large rocks, fallen limbs and other large obstructions. The inventive walking beam assembly includes two independent pivot points that allow the cutting and opening disks to maintain substantially constant or continuous contact with the ground, such that the length of the furrow formed and seed deposited therein are maximized. A closing disk assembly is suspended from the rear of the drill independently from the walking beam assembly. This independent suspension allows the walking beam assembly to function without interference from the closing disks.

Owner:KASCO MFG

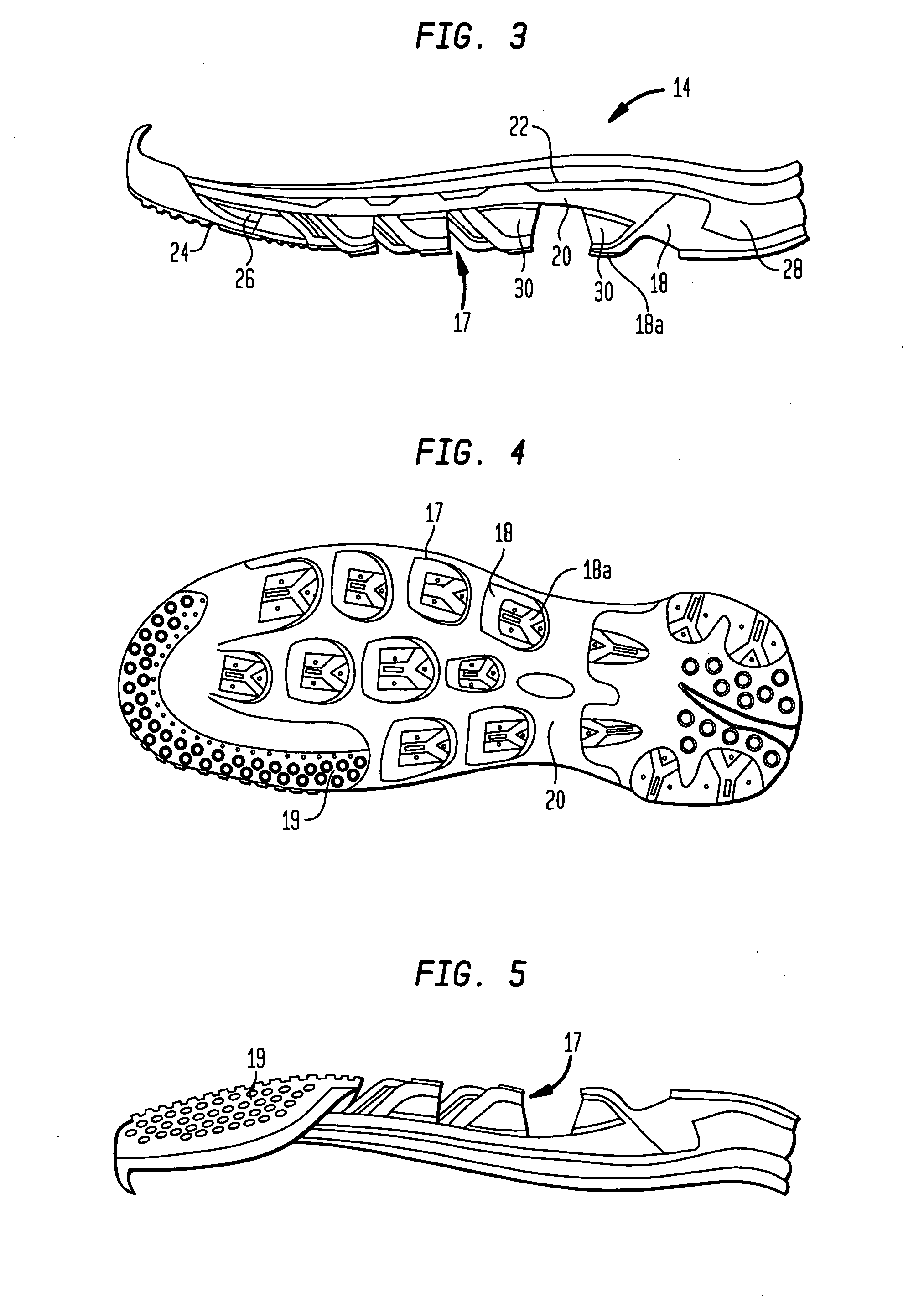

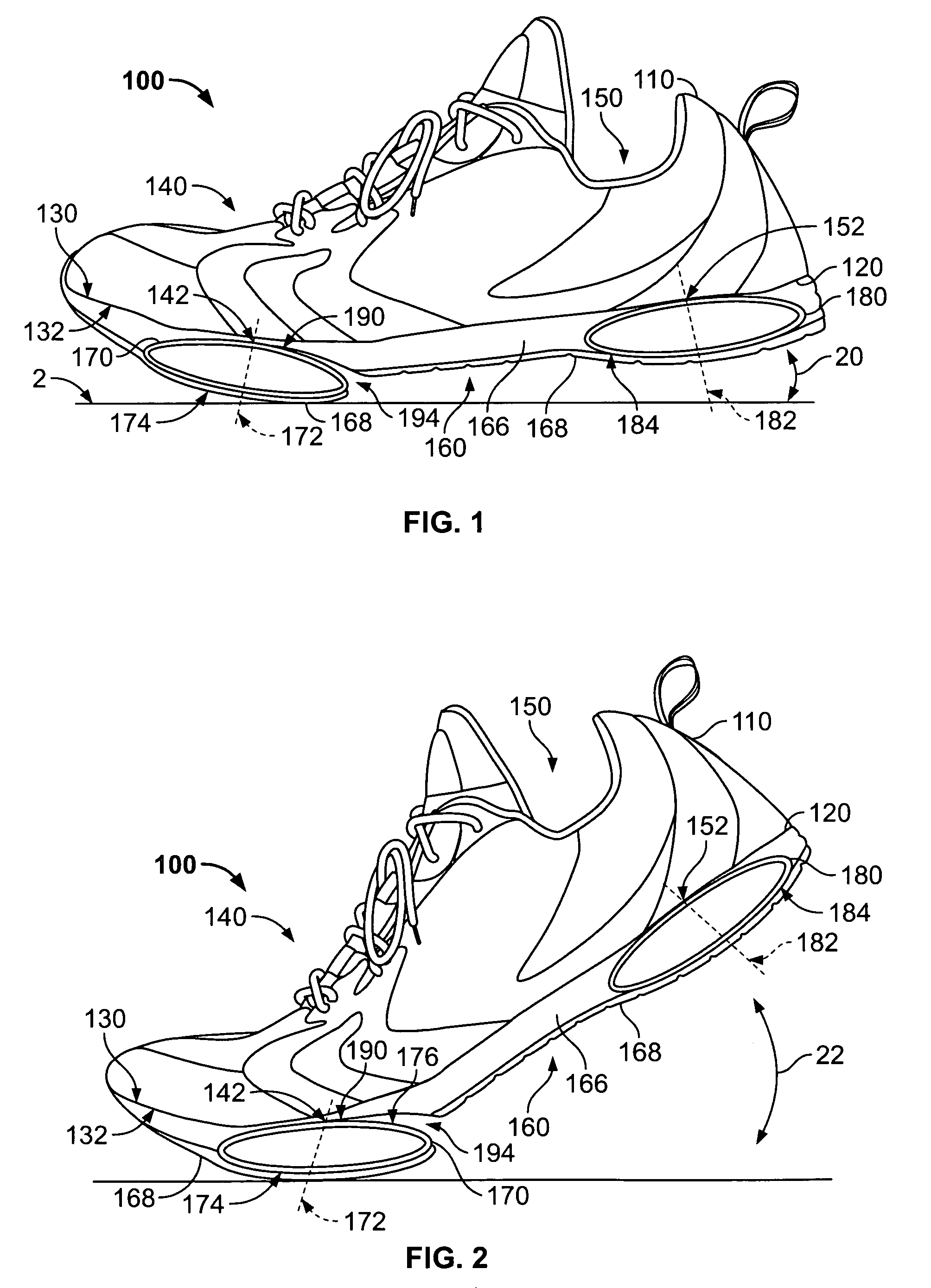

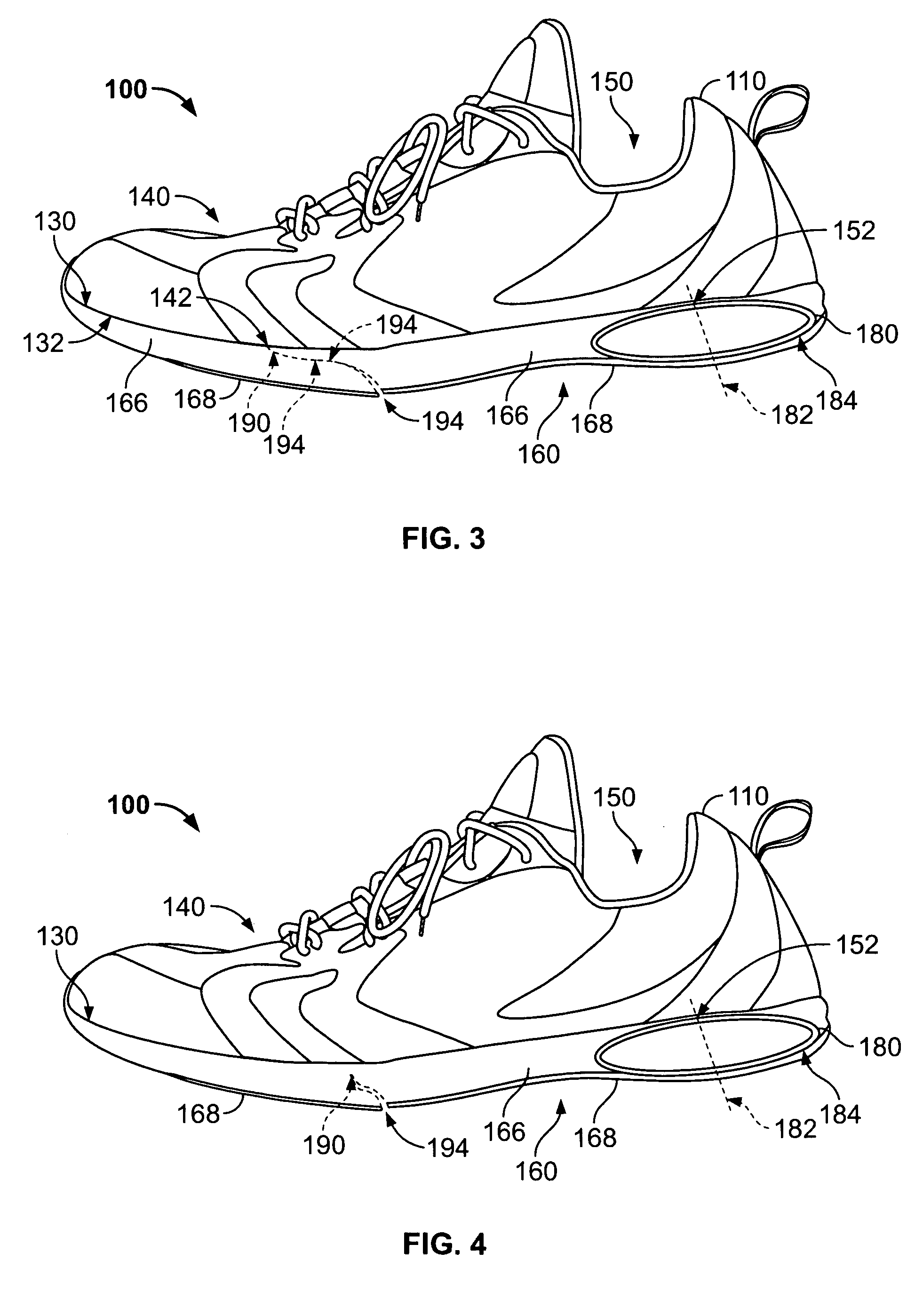

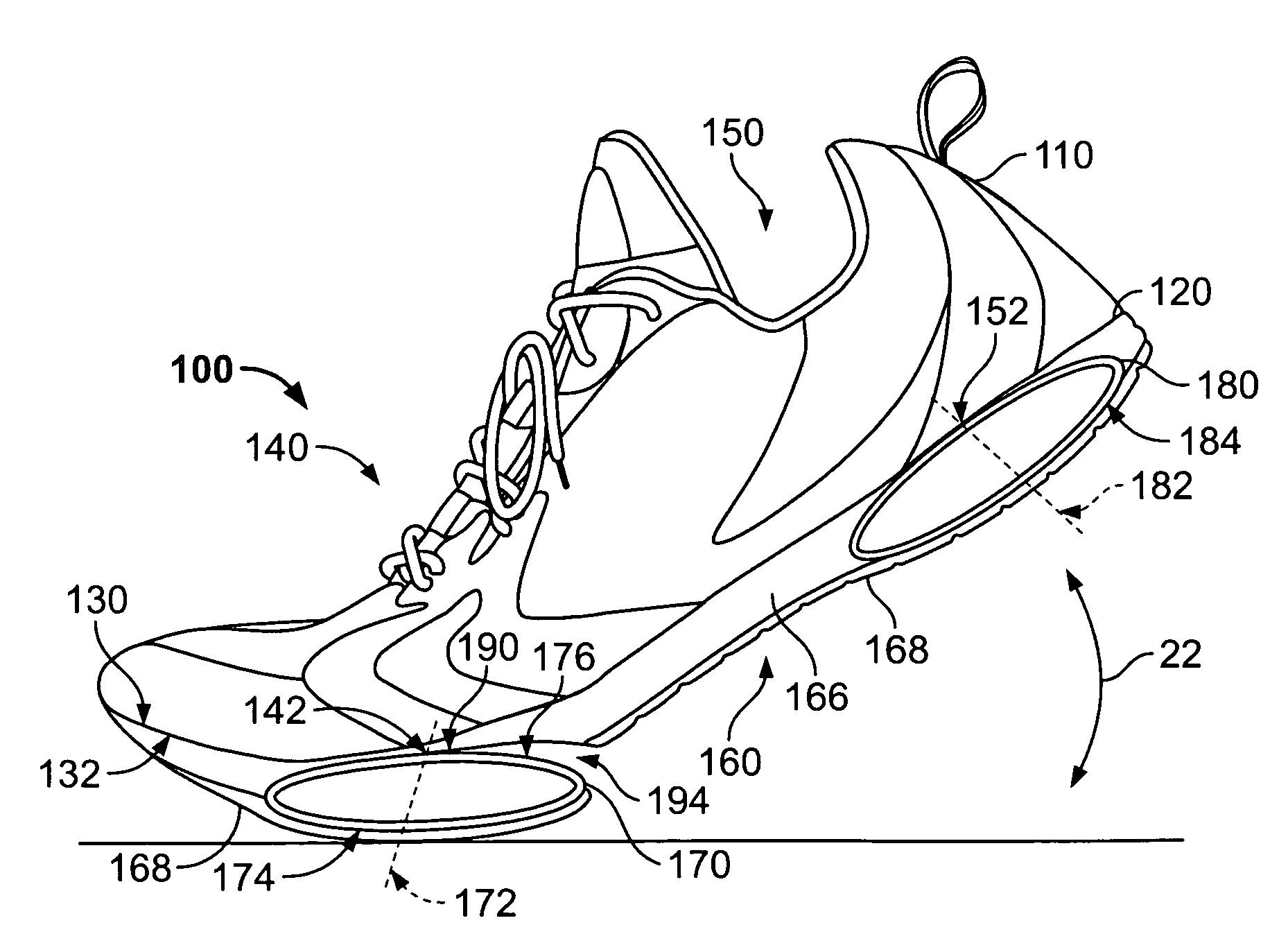

Shoe apparatus with improved efficiency

A shoe is provided for improving use efficiency through reduction of neuromuscular fatigue. The shoe includes an upper having a generally horizontal bottom wall. The bottom wall includes an upper surface and a lower surface. The upper comprises a forward region having a forward center of loading and a rear region having a rear center of loading. The shoe further includes a sole comprising a midsole and an outsole. The midsole comprises a suspension element, which can have a generally elongated shape. The suspension element further has a center of compression, which is generally aligned with at least one of the first and second centers of loading of the upper. The shoe can have a hinge located within the sole for providing enhanced efficiency to the user. The hinge and suspension element(s) can take various forms. The position and structure of the hinge and suspension element(s) in relation to the midsole can take various forms as well. The biomechanical action of the heel element, forefoot element and hinge can be dynamically coupled to create a highly resilient suspension system with a low rate of loading throughout the stride, thus allowing a natural, “barefoot” gait for the wearer. As a result, the wearer experiences a significant reduction in jarring impacts for any phase of the stride, a corresponding reduction in cumulative fatigue and a lower rate of chronic or traumatic injury. A method of manufacturing a suspension element for a shoe is also provided, and includes the steps of providing a die having a length, a width and a thickness, the length accommodating a plurality of suspension elements; wrapping a plurality of coated or wetted fibers around the width of the die to form the suspension elements; drying or curing the fibers to a substantially integrated form; and separating the plurality of suspension elements into independent suspension elements.

Owner:HANN ATHLETIC LLC

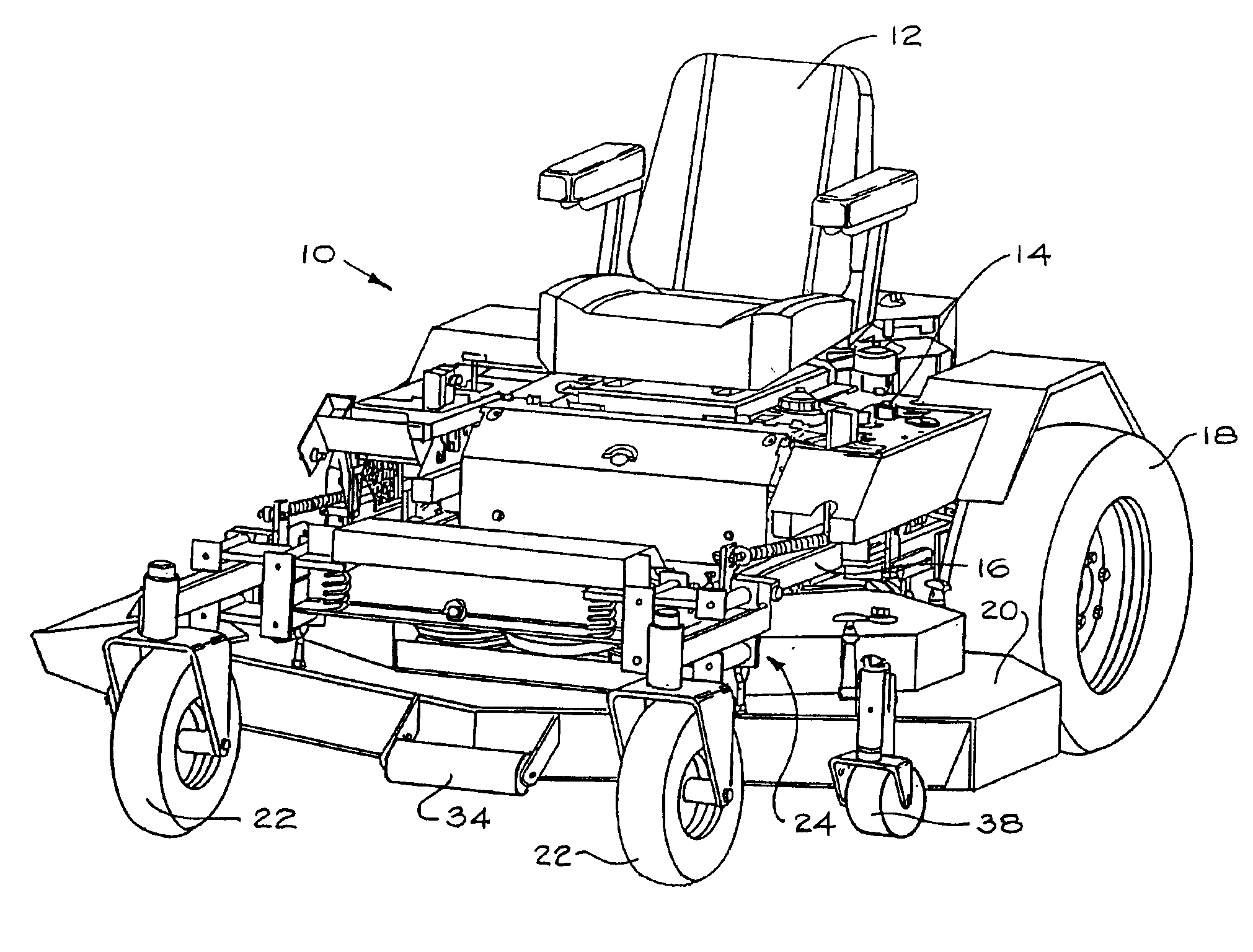

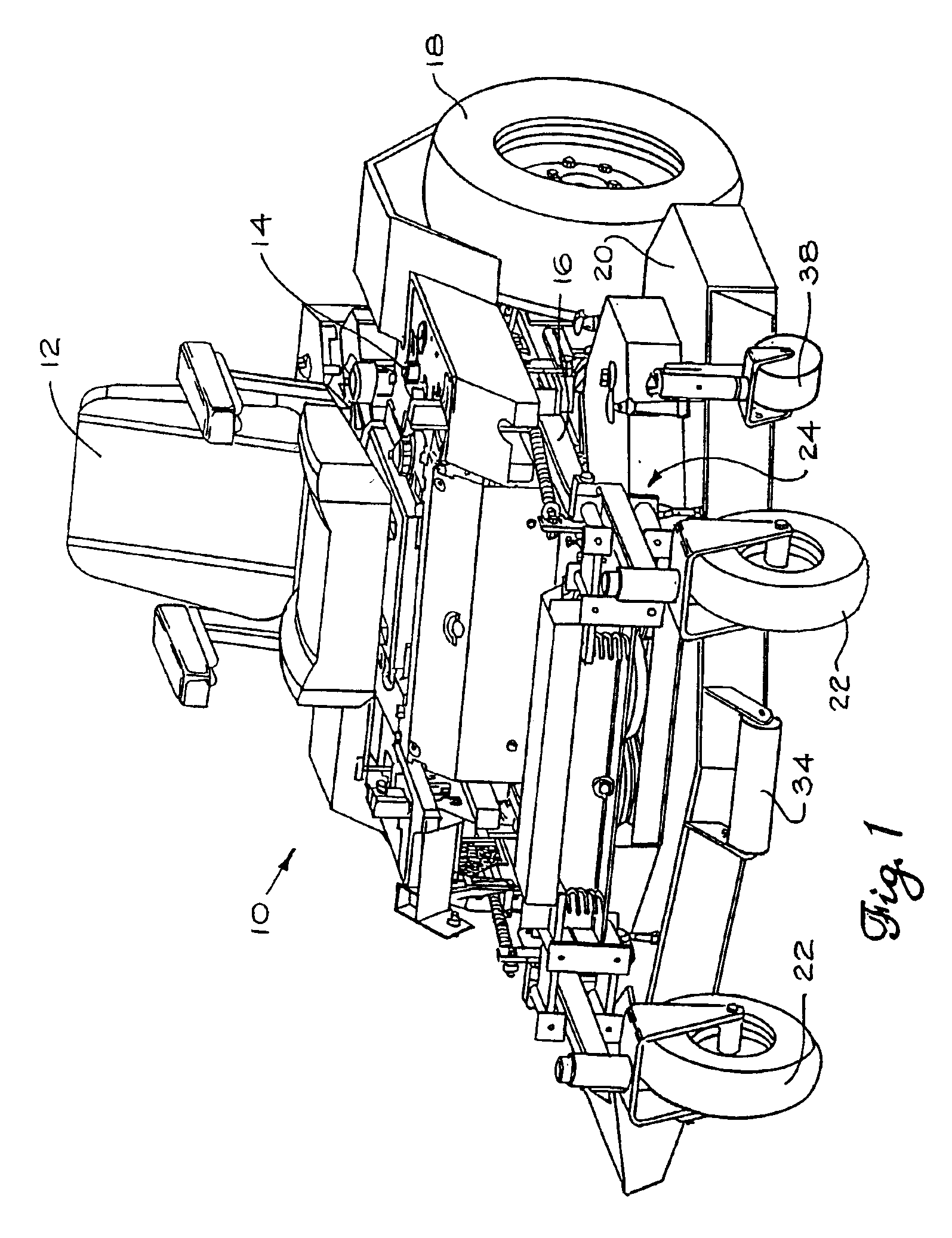

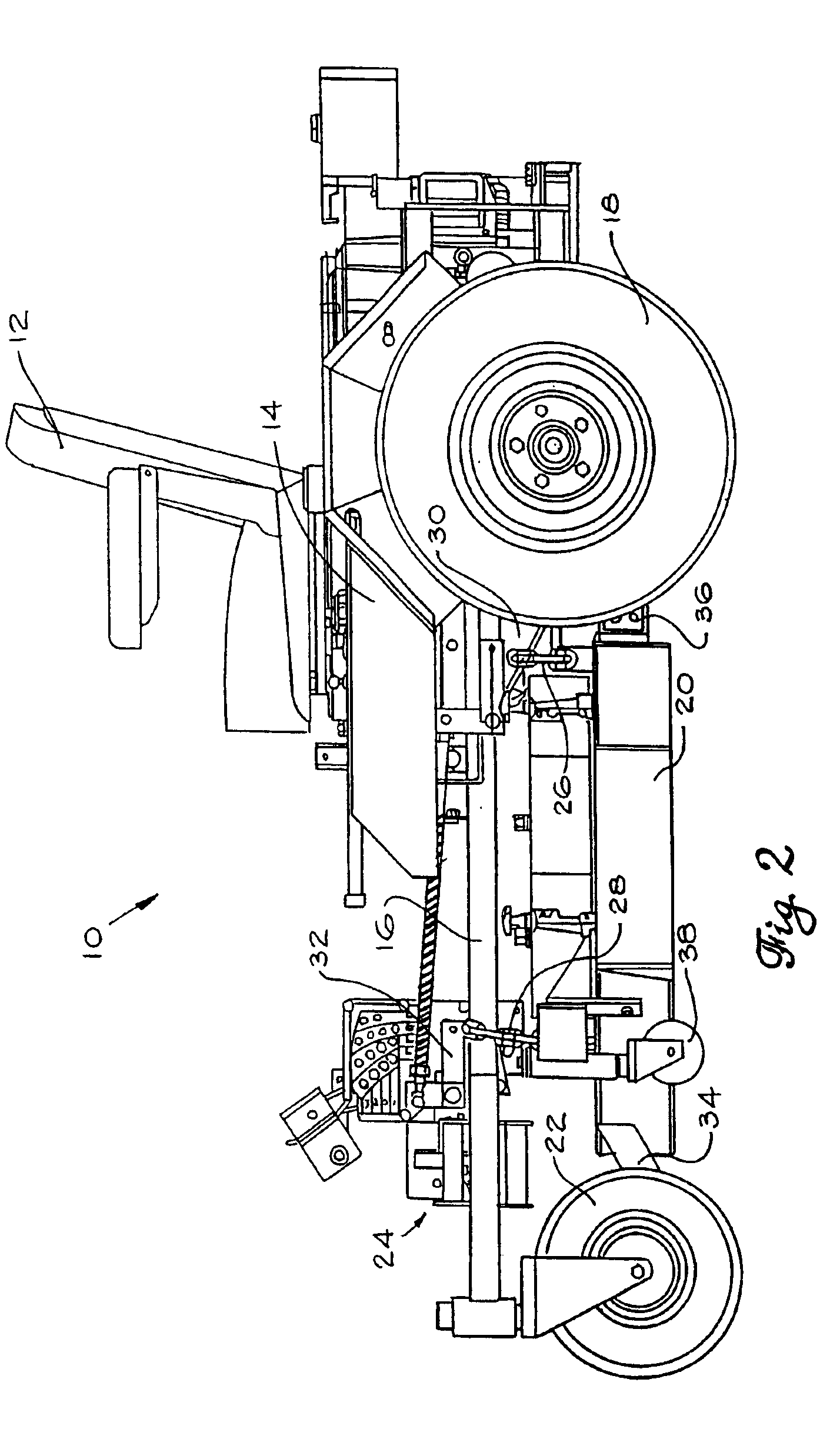

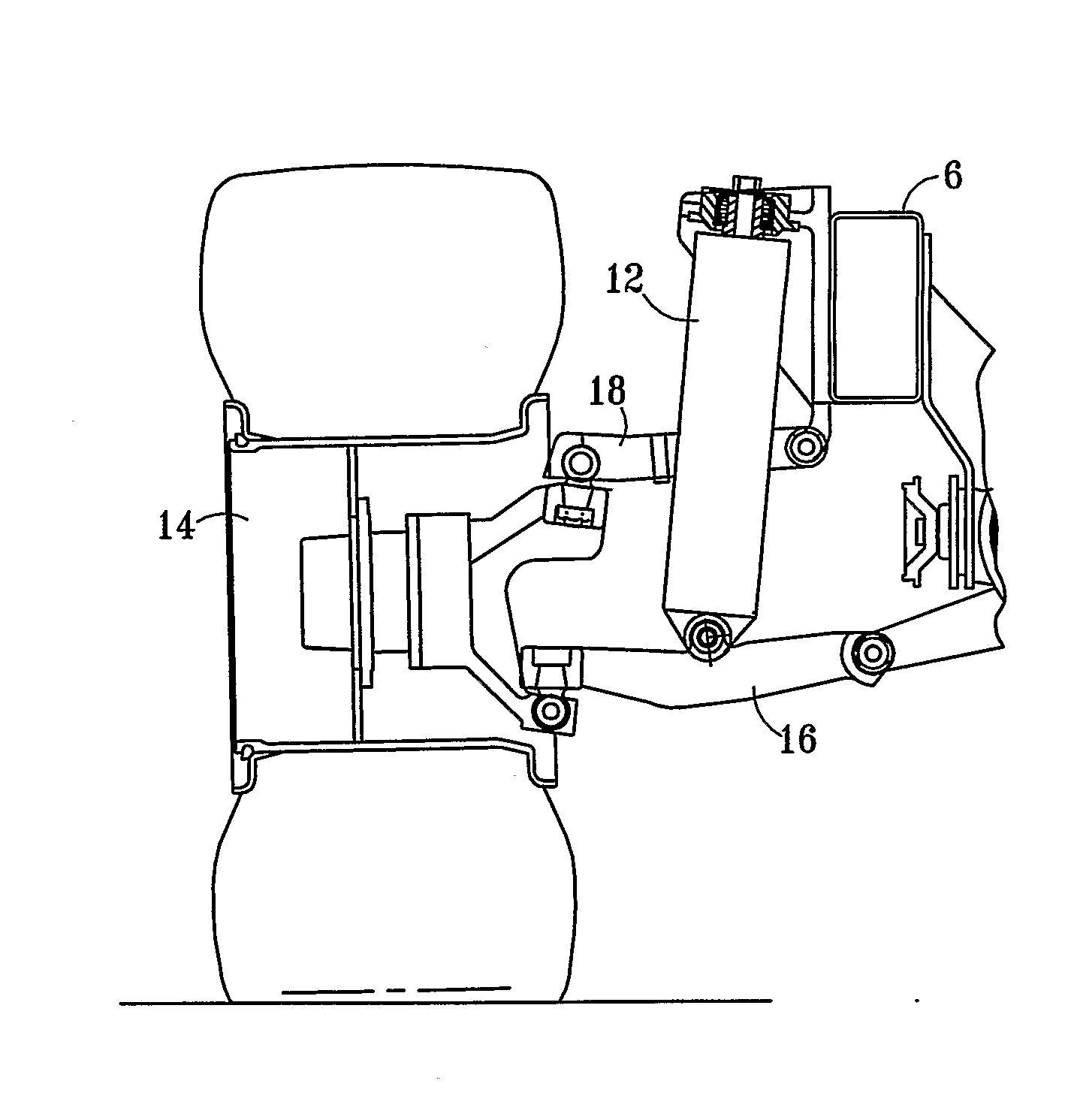

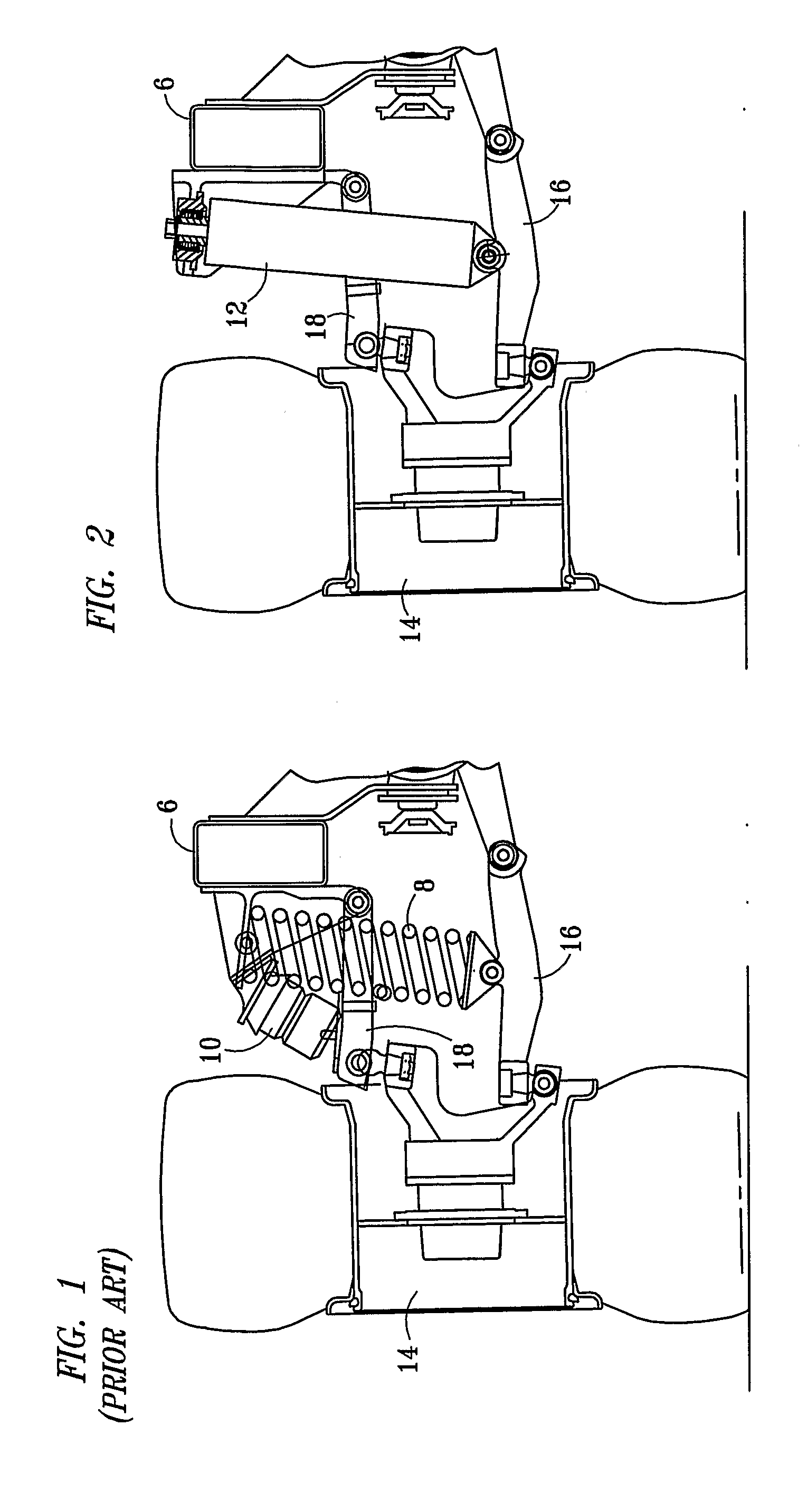

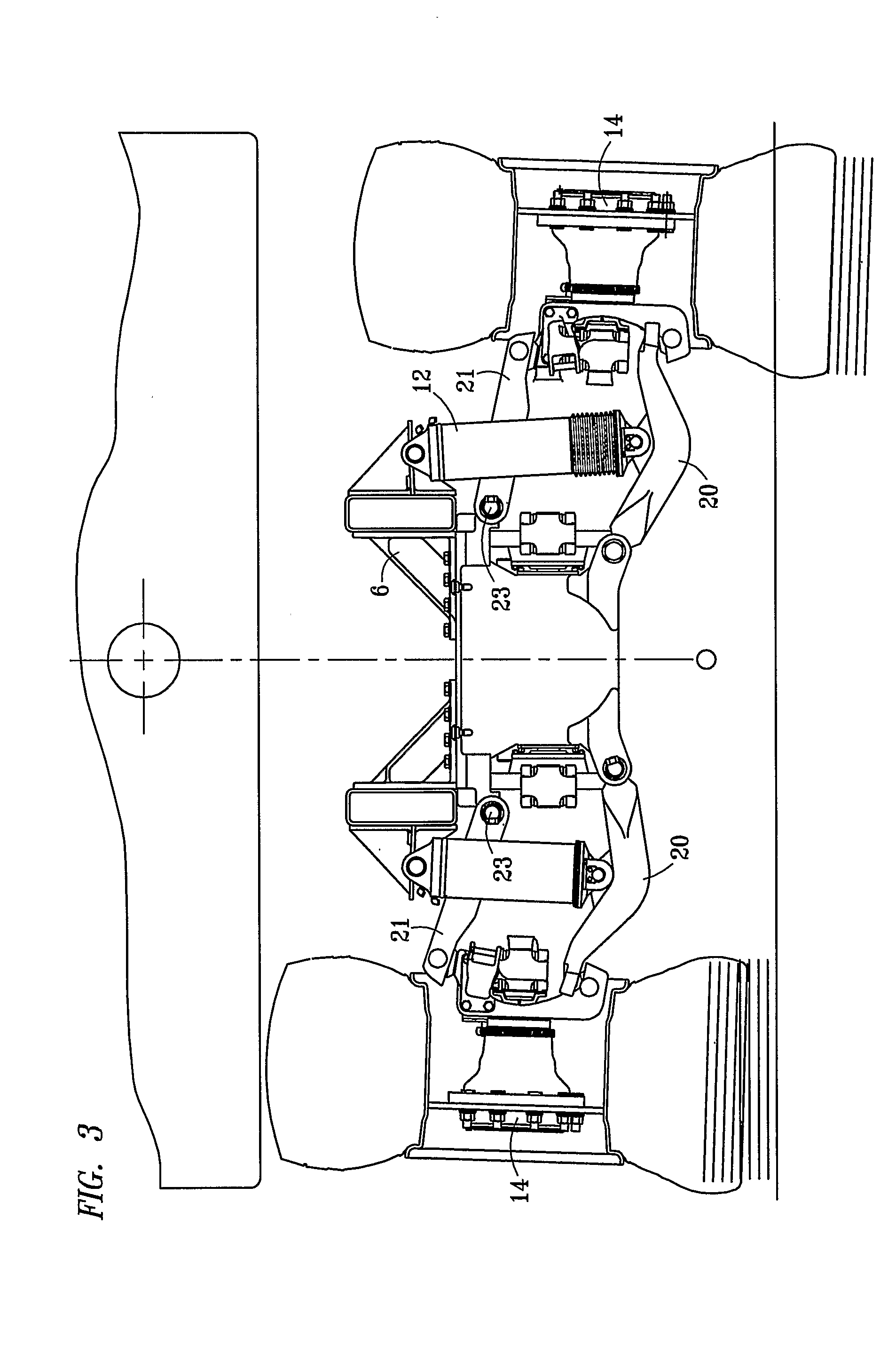

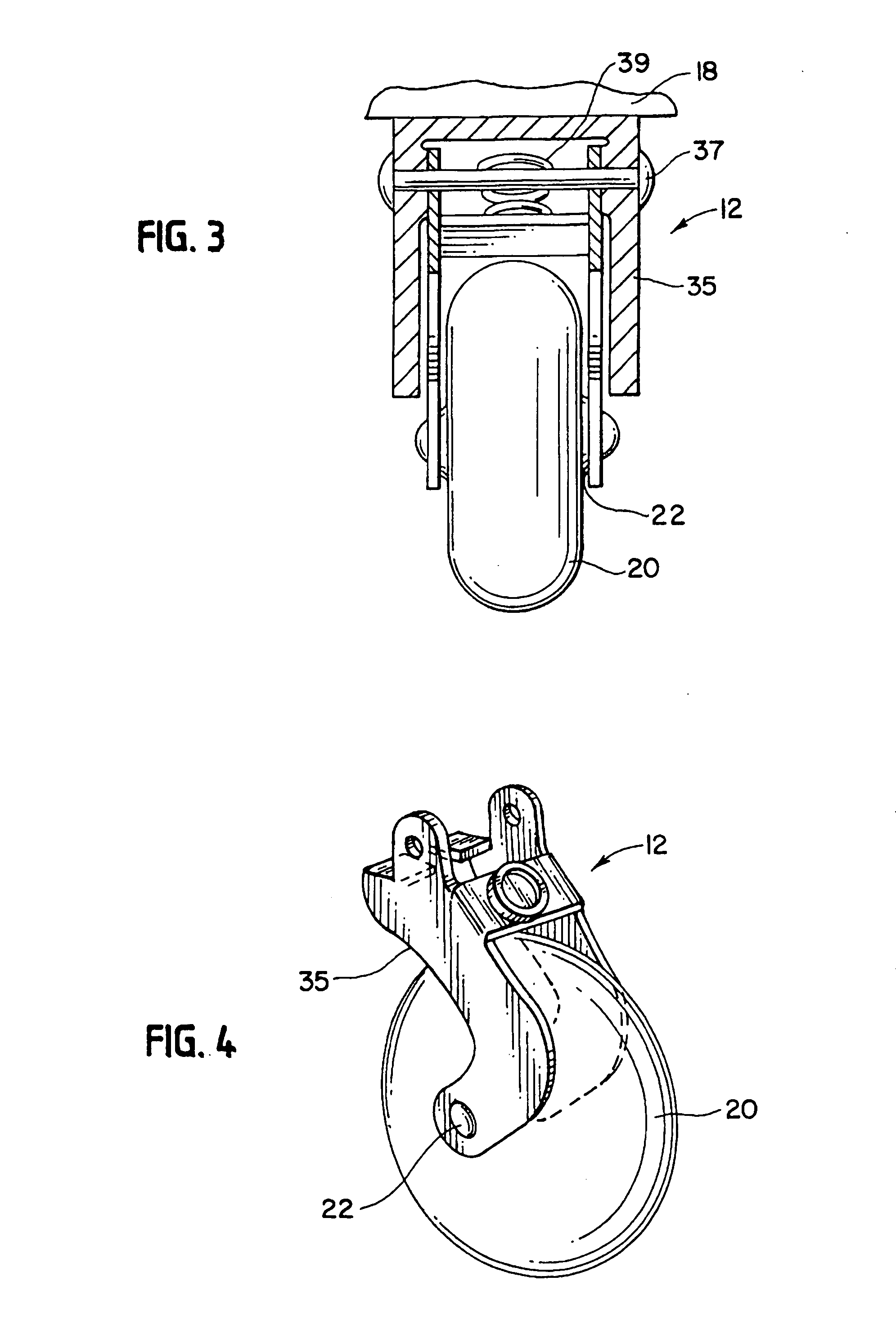

Mower suspension system and method

InactiveUS6857254B2Good suspensionImproved cutter deck movementHigh internal friction springsCastorsEngineeringCantilever

The mower front independent suspension assembly in some embodiments of the present invention includes a first suspension arm connected to the front of the lawn mower frame and a second suspension arm connected to the side of the lawn mower frame. In some embodiments, the first suspension arm is connected to the front of the frame at or near the longitudinal center of the frame, while the second suspension arm is connected to the side of the frame a distance from the front of the frame. Also, in some embodiments the cutter deck of the lawn mower is connected to the front independent suspension assemblies for movement therewith.

Owner:FERRIS IND

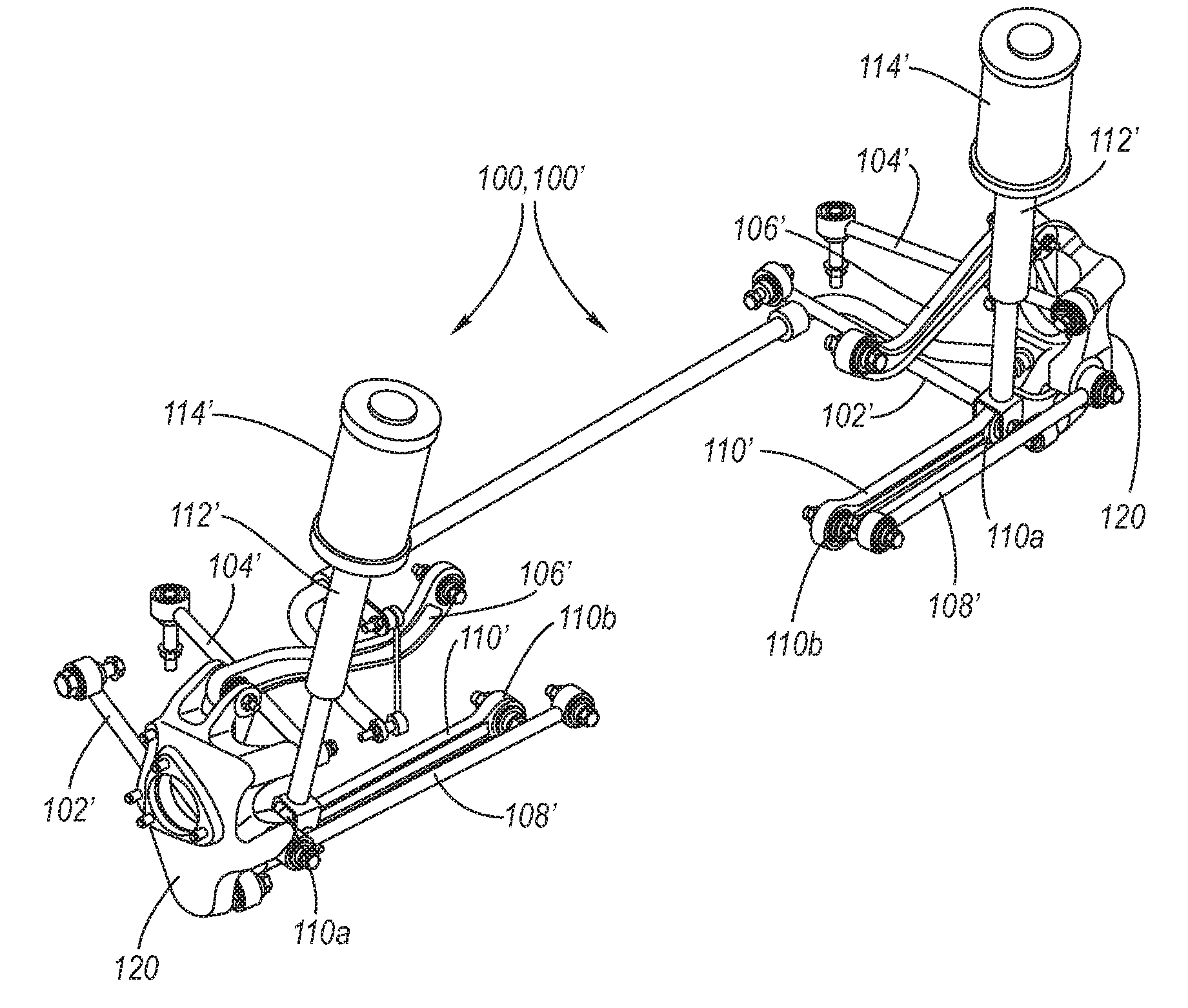

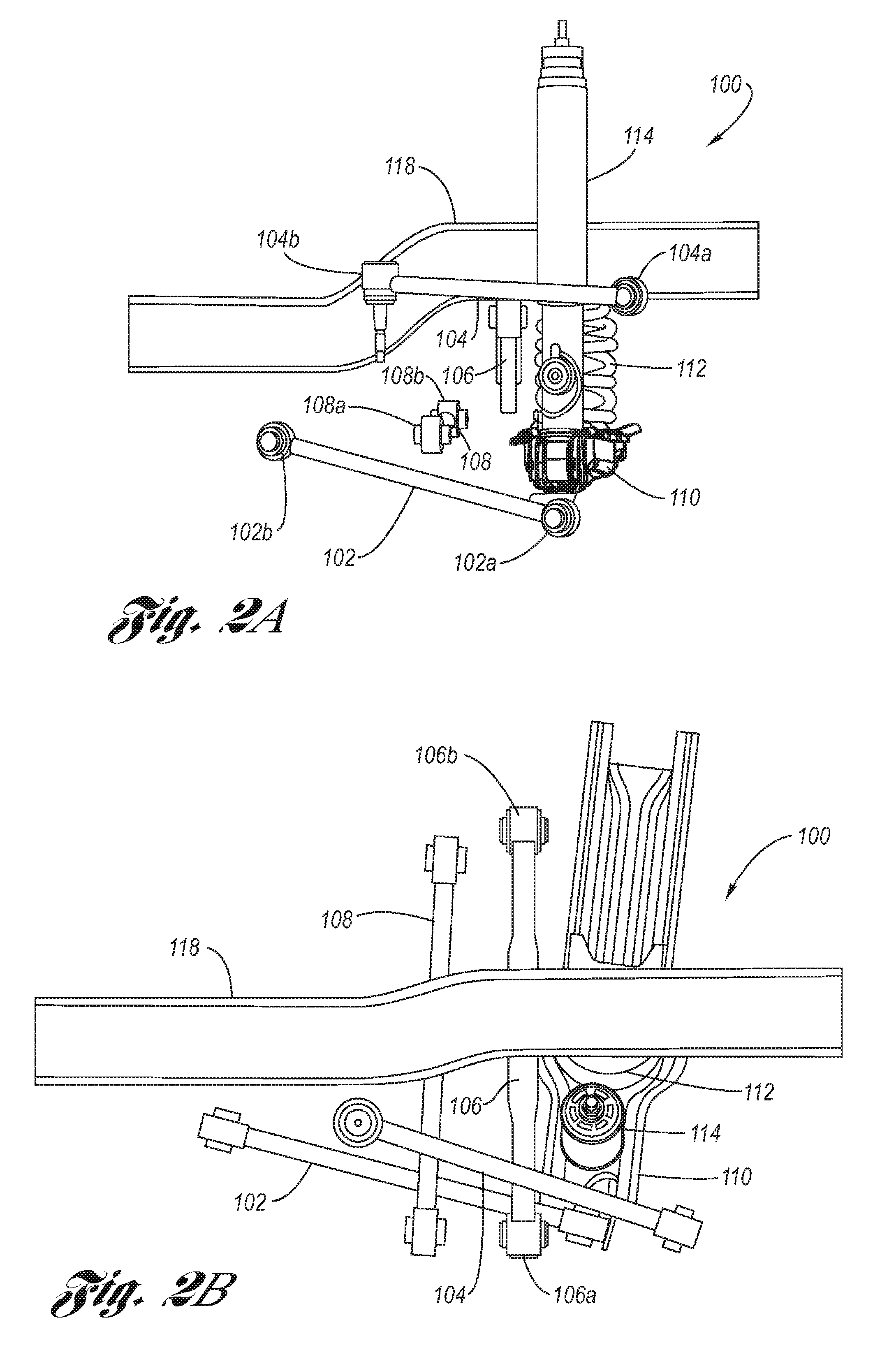

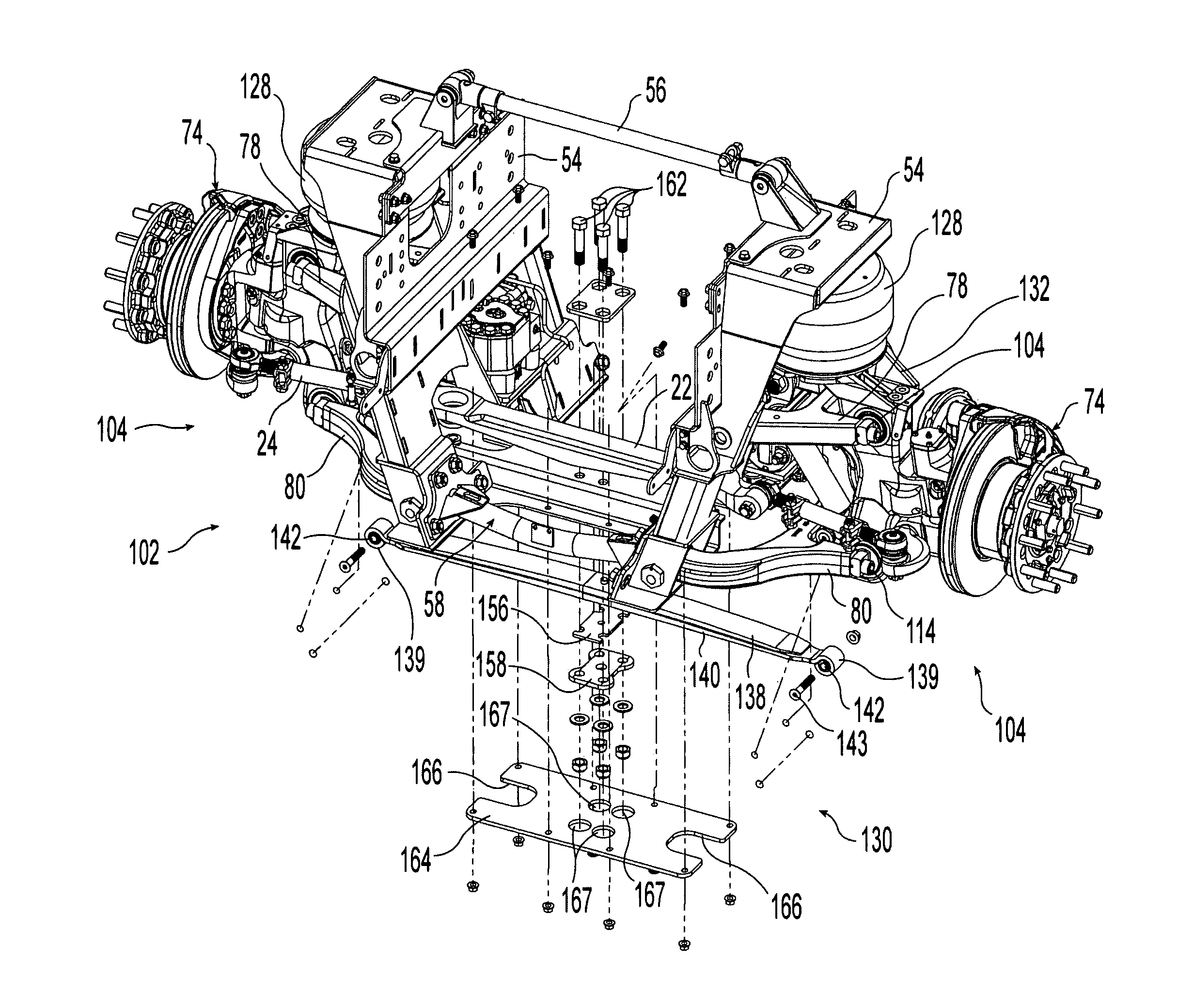

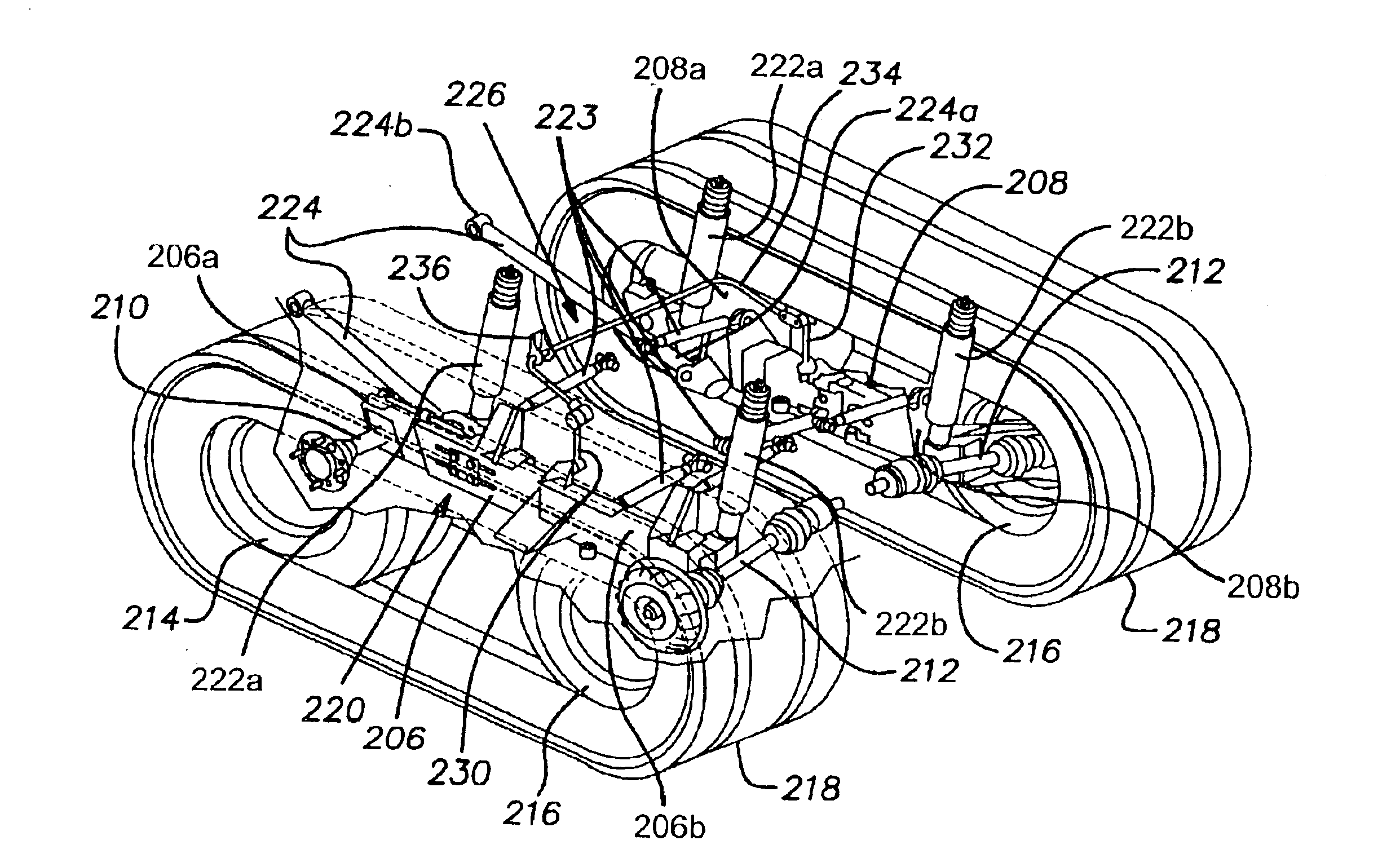

Decoupled 5-link independent rear suspension

InactiveUS7891684B1Easy to manageIncrease spacingInterconnection systemsResilient suspensionsBrake torqueMobile vehicle

A decoupled 5-link independent rear suspension system (IRS) for motor vehicles. Three lateral linkages, the toe, camber and spring links, establish the wheel plane orientation and react to vertical and lateral loads, and two longitudinal links, the upper and lower trailing links, react to tractive loads and brake torques. The upper and lower trailing links are longitudinally orientated and disposed outboard of the body rail, thus allowing for improved load reactions of the suspension system, as well as optimization of the body rail configuration and space accommodation for other vehicle components, such as for example fuel, batteries and exhaust.

Owner:GM GLOBAL TECH OPERATIONS LLC

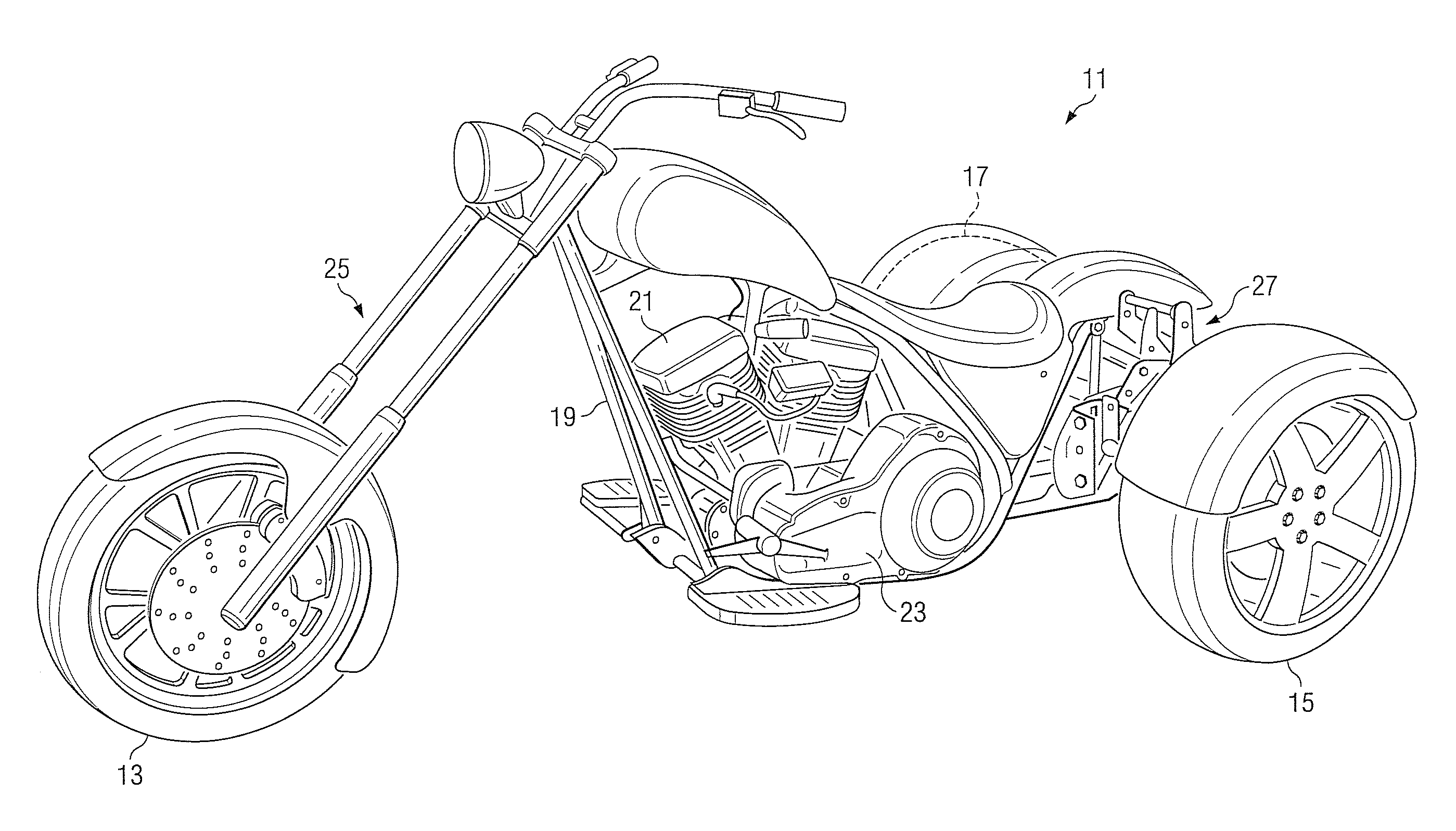

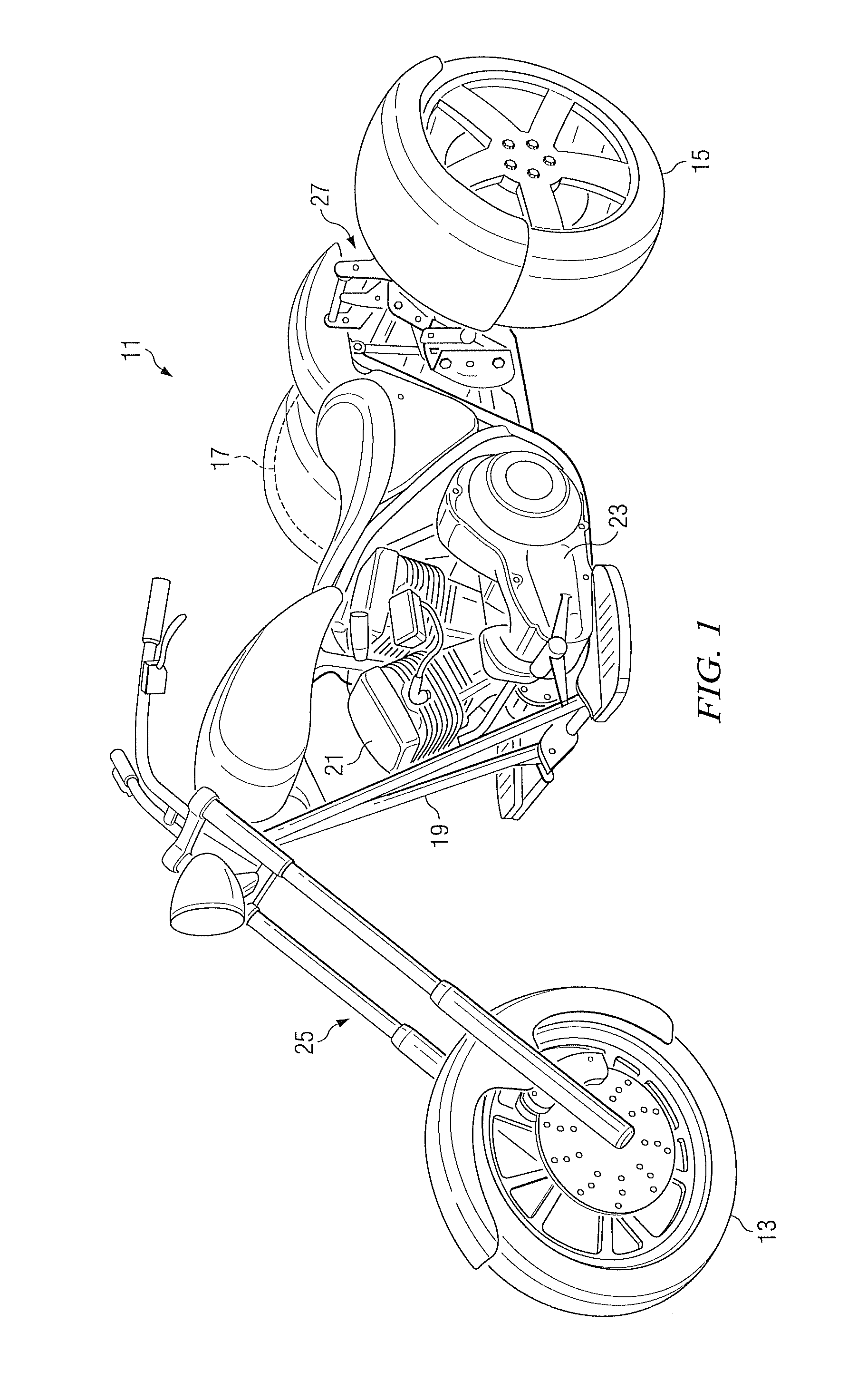

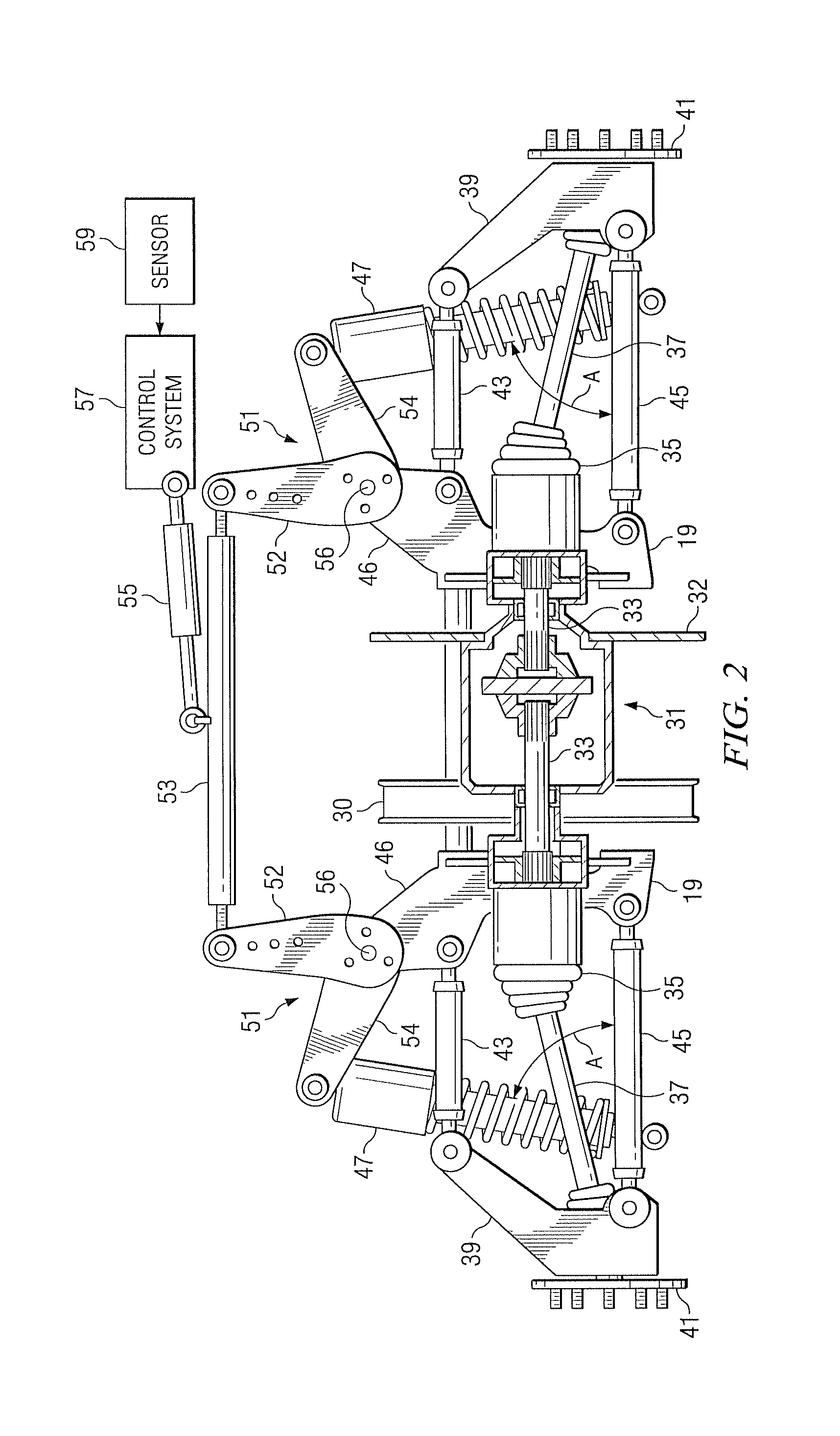

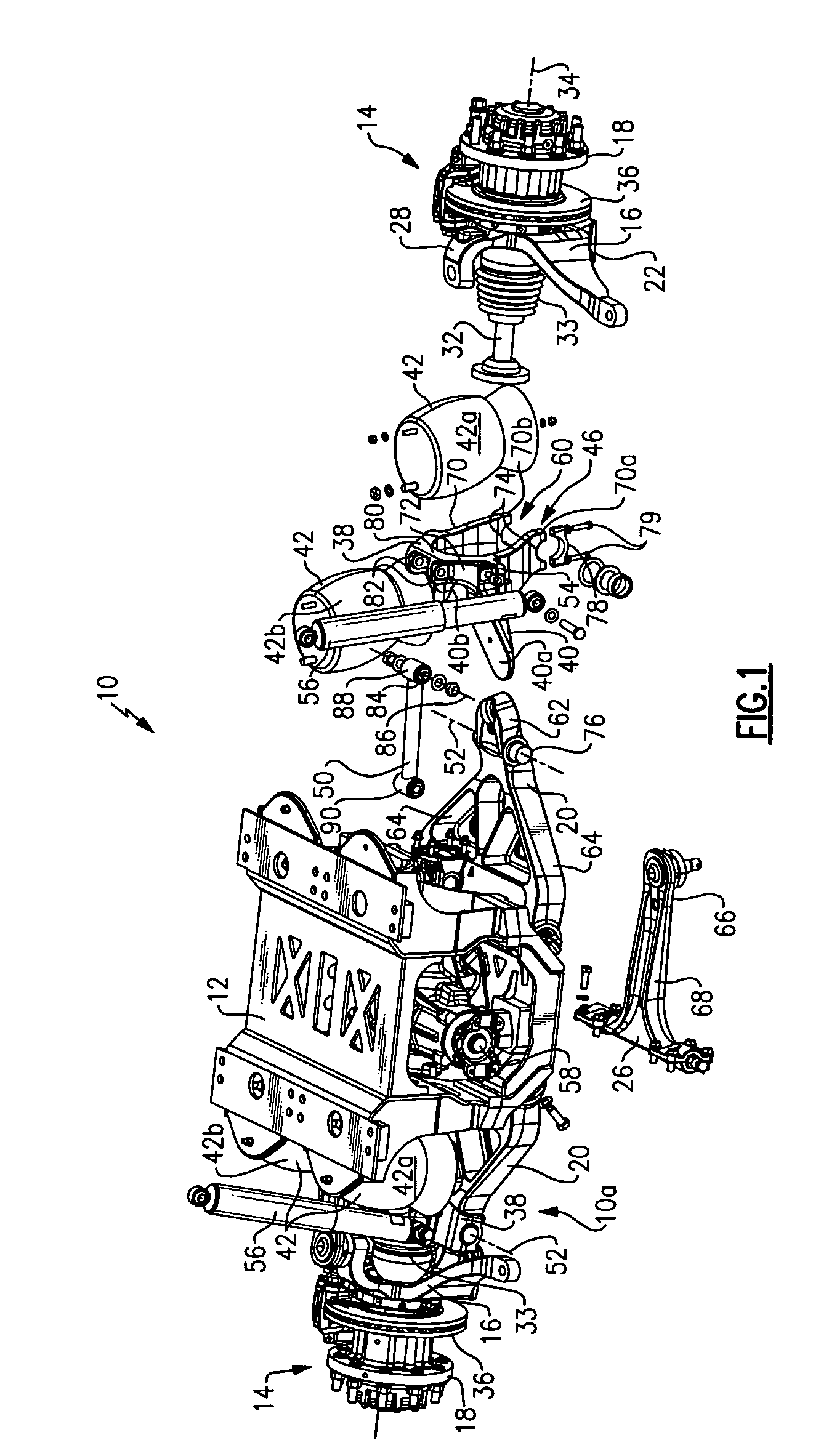

Tilting independent suspension system for motorcycle trike

A tilting suspension system is adapted for use with a vehicle having three wheels and a frame. The system has two sets of control arms, each set of control arms being pivotally connected to one side of the frame. An upright is pivotally connected to each set of control arms, each upright having a rotatable hub for allowing one of the wheels to be mounted thereto. Two rocker arms are pivotally connected to the frame, and a control link is pivotally connected to each of the rocker arms, such that pivoting of one rocker arm causes corresponding pivoting of the other rocker arm. A link member operably connects each rocker arm to a corresponding upright, such that pivoting of each rocker arm causes corresponding movement of the uprights. An actuator is configured to selectively pivot the rocker arms, such that actuation of the actuator pivots the rocker arms, thereby causing the frame to rotate about a generally longitudinal roll center and causing each upright to rotate about a generally longitudinal axis.

Owner:MATTHIES LAWAYNE

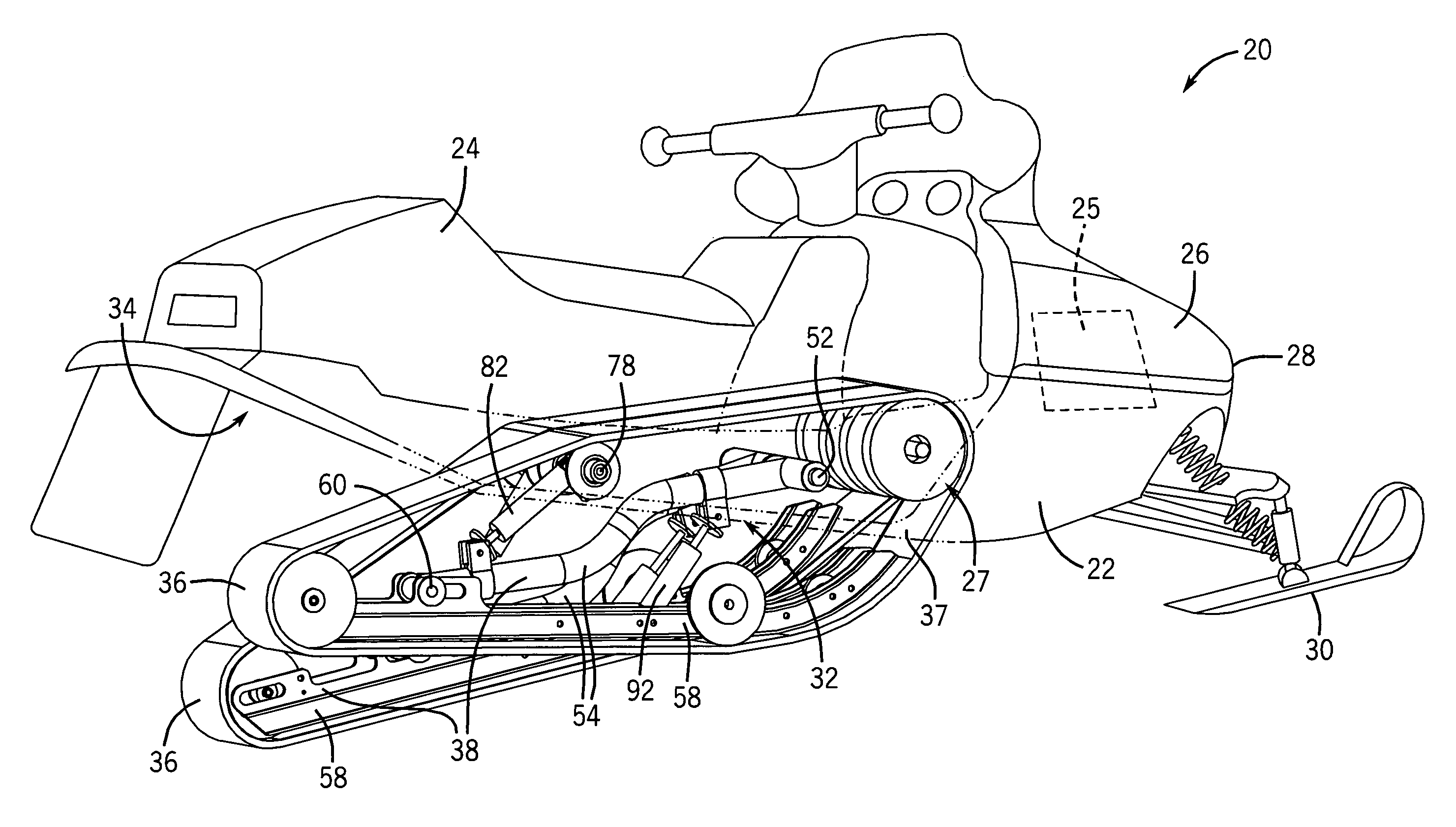

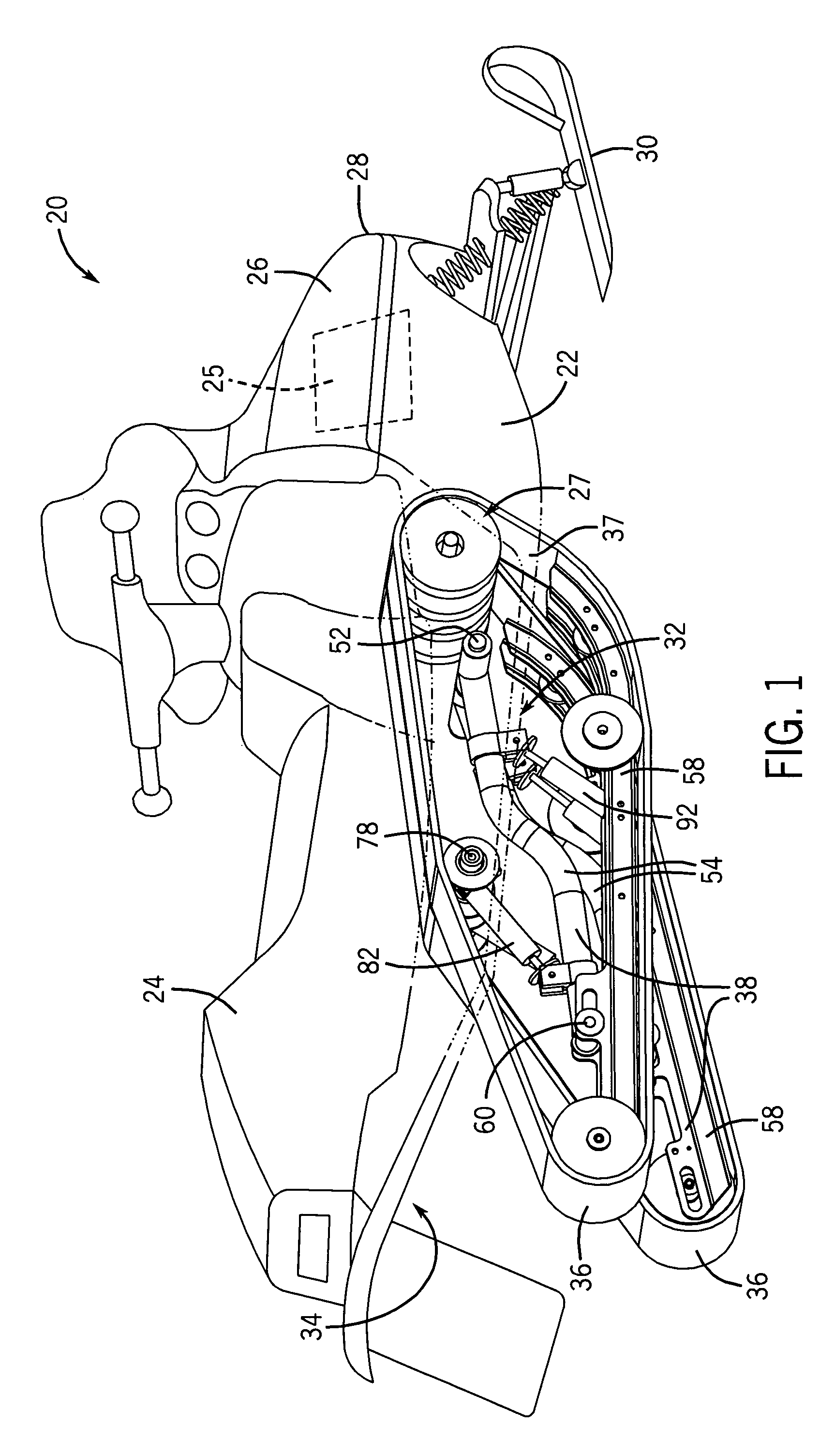

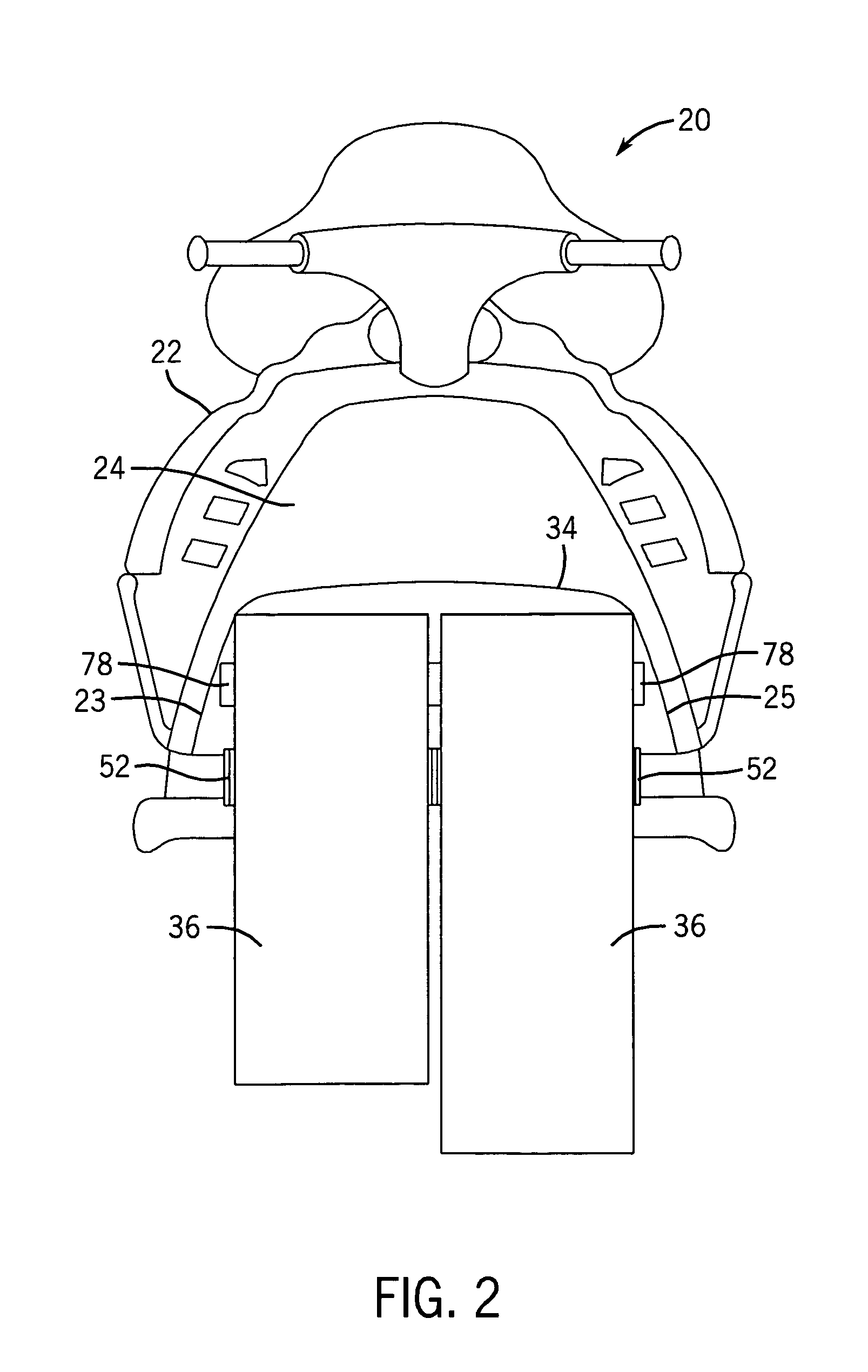

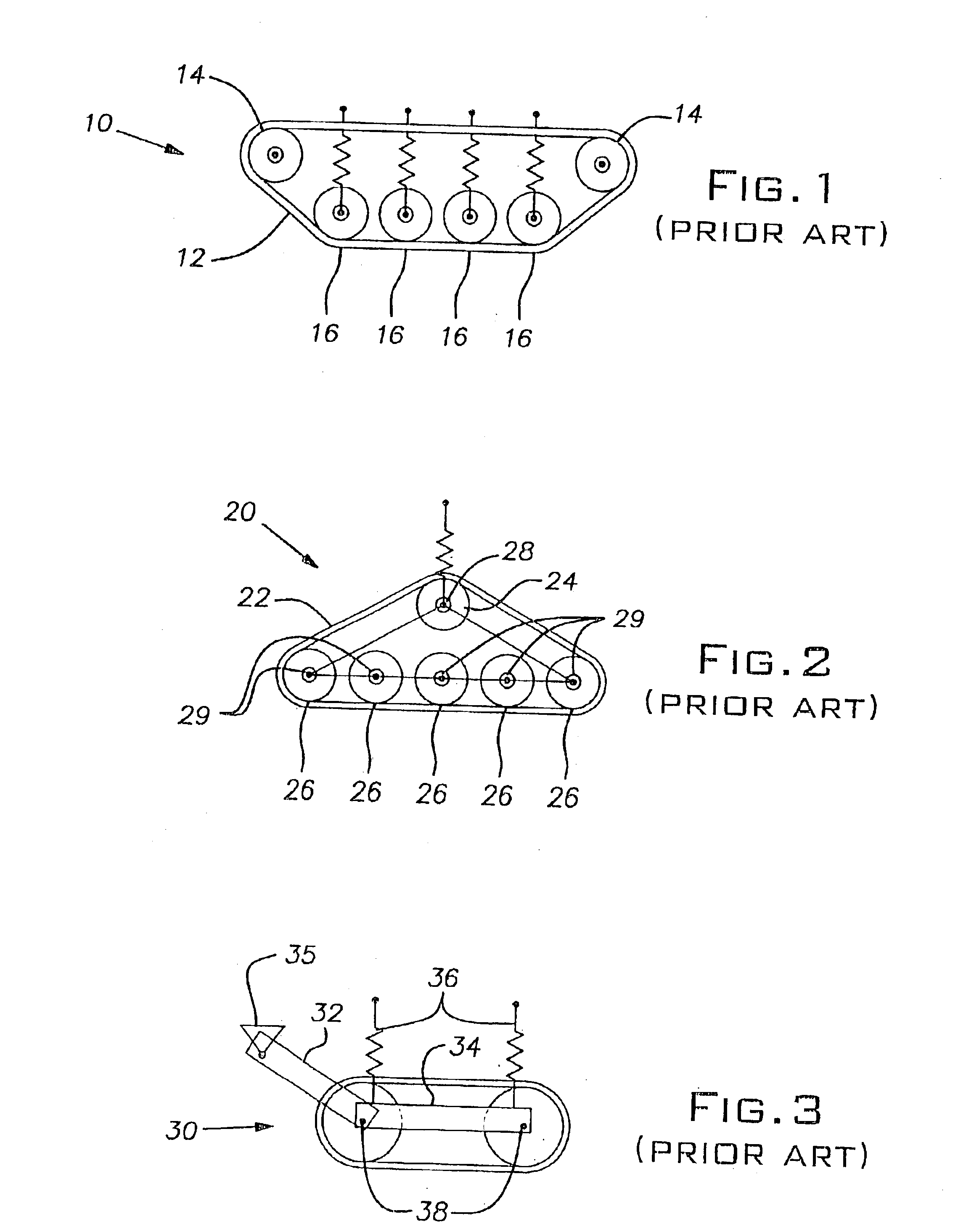

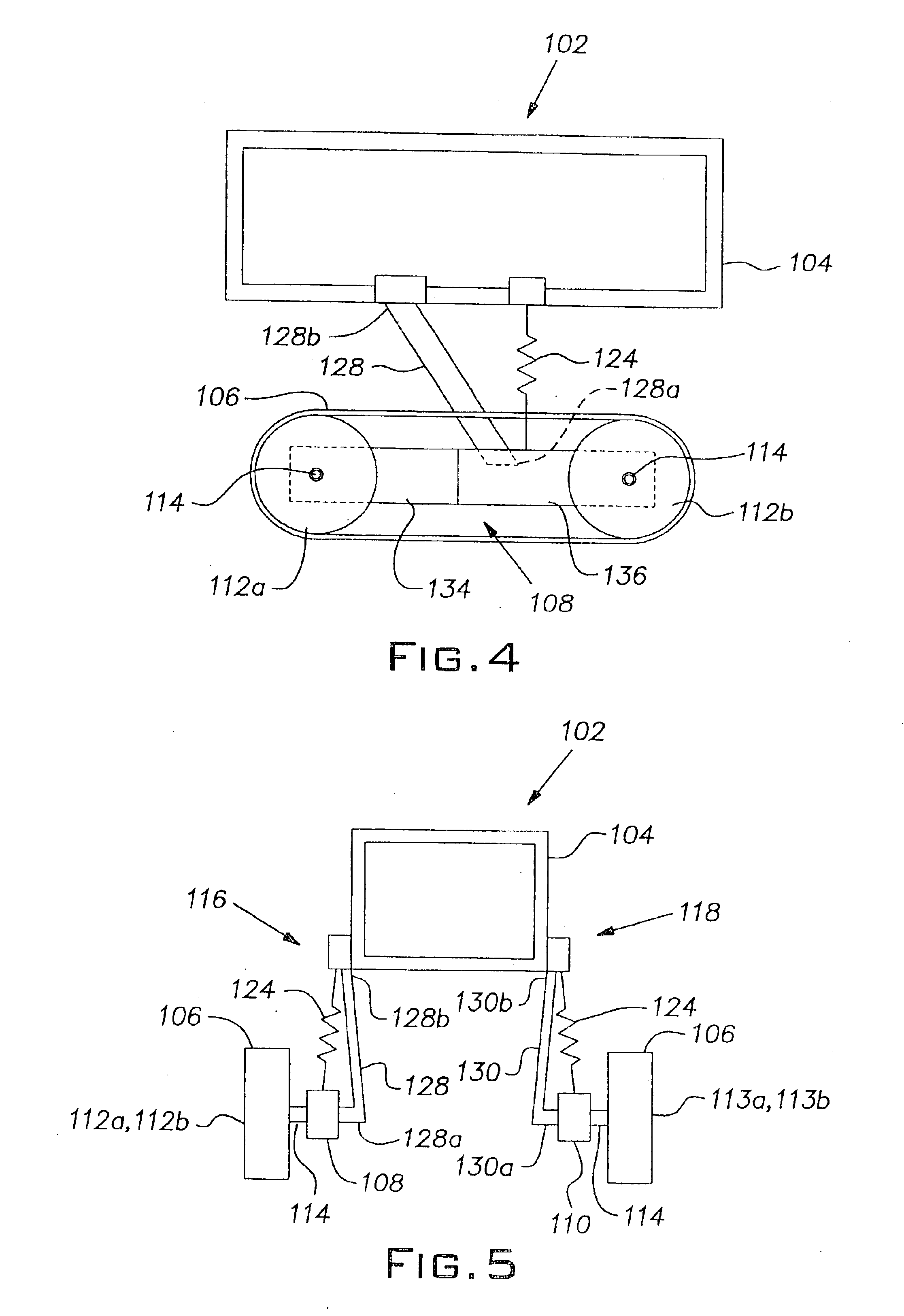

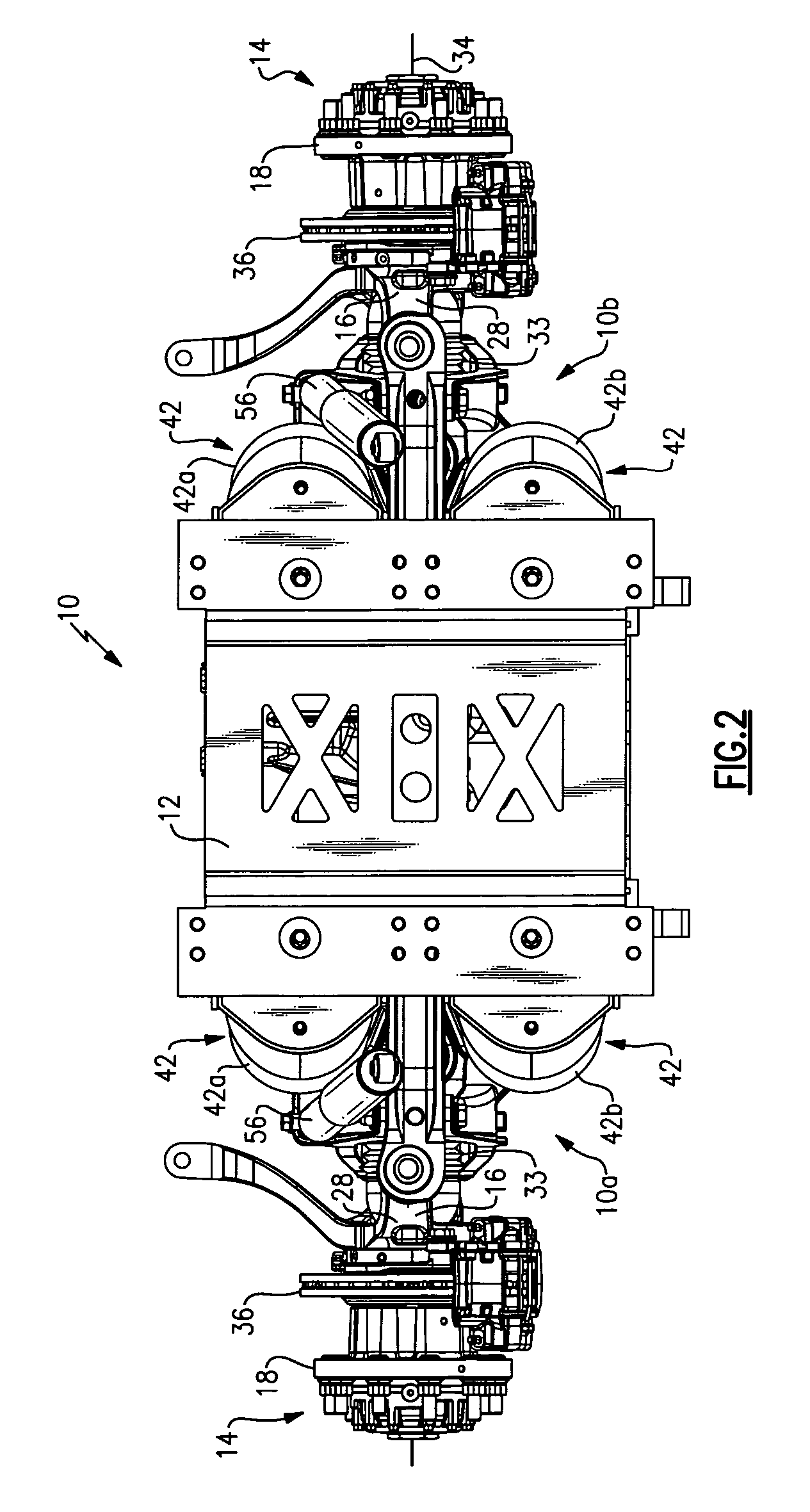

Snowmobile rear suspension system

A rear suspension system for a snowmobile includes a plurality of adjacent closed-loop tracks disposed in a rear tunnel of the snowmobile. Each of the plurality of adjacent closed-loop tracks are rotatably driven by a drive system. One of a plurality of independent suspension assemblies is disposed in each closed-loop track and the plurality of independent suspension assemblies articulate independently of each other during travel of the rear suspension system.

Owner:GREAT LAKES SOUND & VIBRATION

Shoe apparatus with improved efficiency

A shoe is provided for improving use efficiency through reduction of neuromuscular fatigue. The shoe includes an upper having a generally horizontal bottom wall. The bottom wall includes an upper surface and a lower surface. The upper comprises a forward region having a forward center of loading and a rear region having a rear center of loading. The shoe further includes a sole comprising a midsole and an outsole. The midsole comprises a suspension element, which can have a generally elongated shape. The suspension element further has a center of compression, which is generally aligned with at least one of the first and second centers of loading of the upper. The shoe can have a hinge located within the sole for providing enhanced efficiency to the user. The hinge and suspension element(s) can take various forms. The position and structure of the hinge and suspension element(s) in relation to the midsole can take various forms as well. The biomechanical action of the heel element, forefoot element and hinge can be dynamically coupled to create a highly resilient suspension system with a low rate of loading throughout the stride, thus allowing a natural, “barefoot” gait for the wearer. As a result, the wearer experiences a significant reduction in jarring impacts for any phase of the stride, a corresponding reduction in cumulative fatigue and a lower rate of chronic or traumatic injury. A method of manufacturing a suspension element for a shoe is also provided, and includes the steps of providing a die having a length, a width and a thickness, the length accommodating a plurality of suspension elements; wrapping a plurality of coated or wetted fibers around the width of the die to form the suspension elements; drying or curing the fibers to a substantially integrated form; and separating the plurality of suspension elements into independent suspension elements.

Owner:HANN ATHLETIC LLC

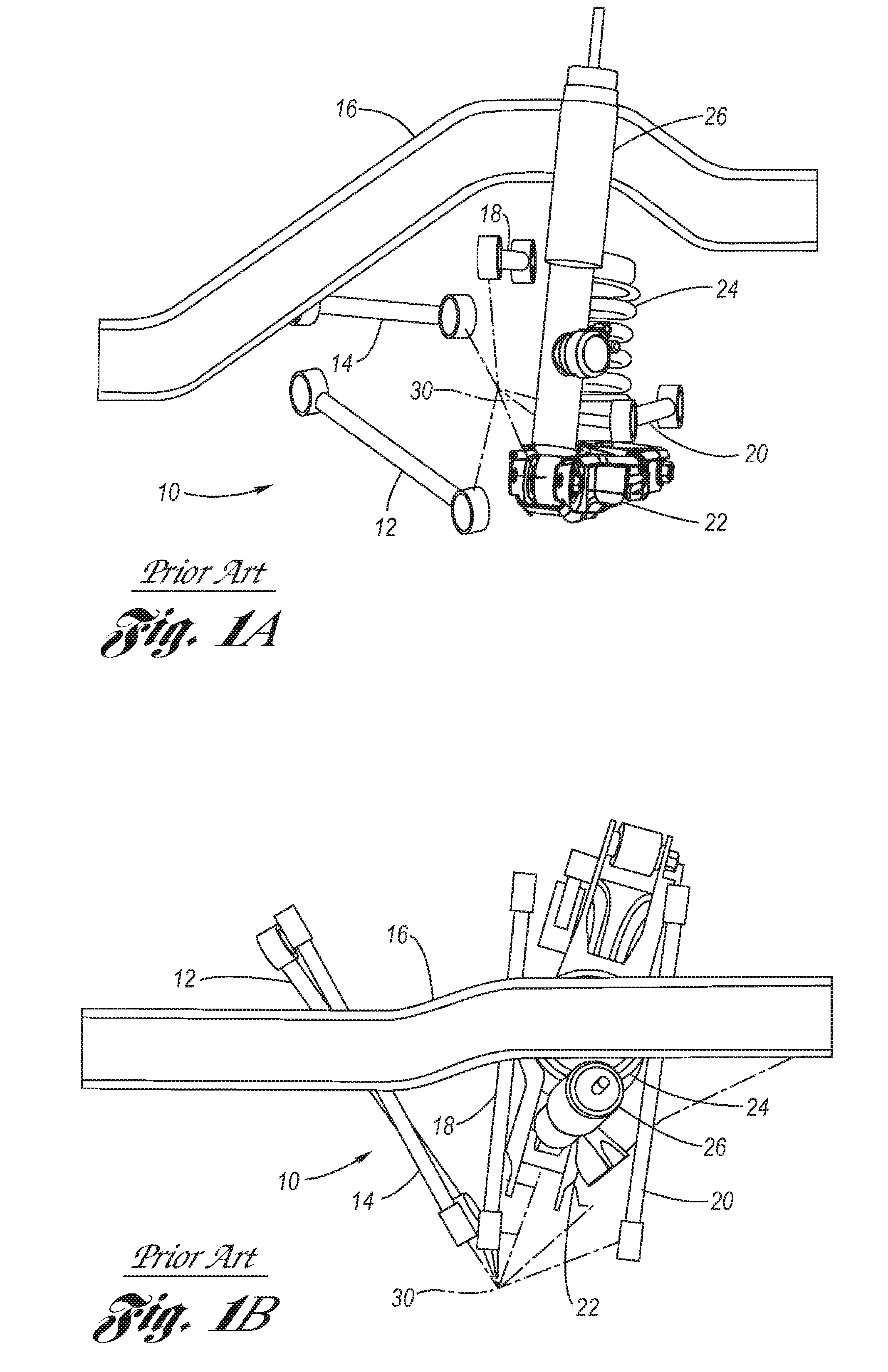

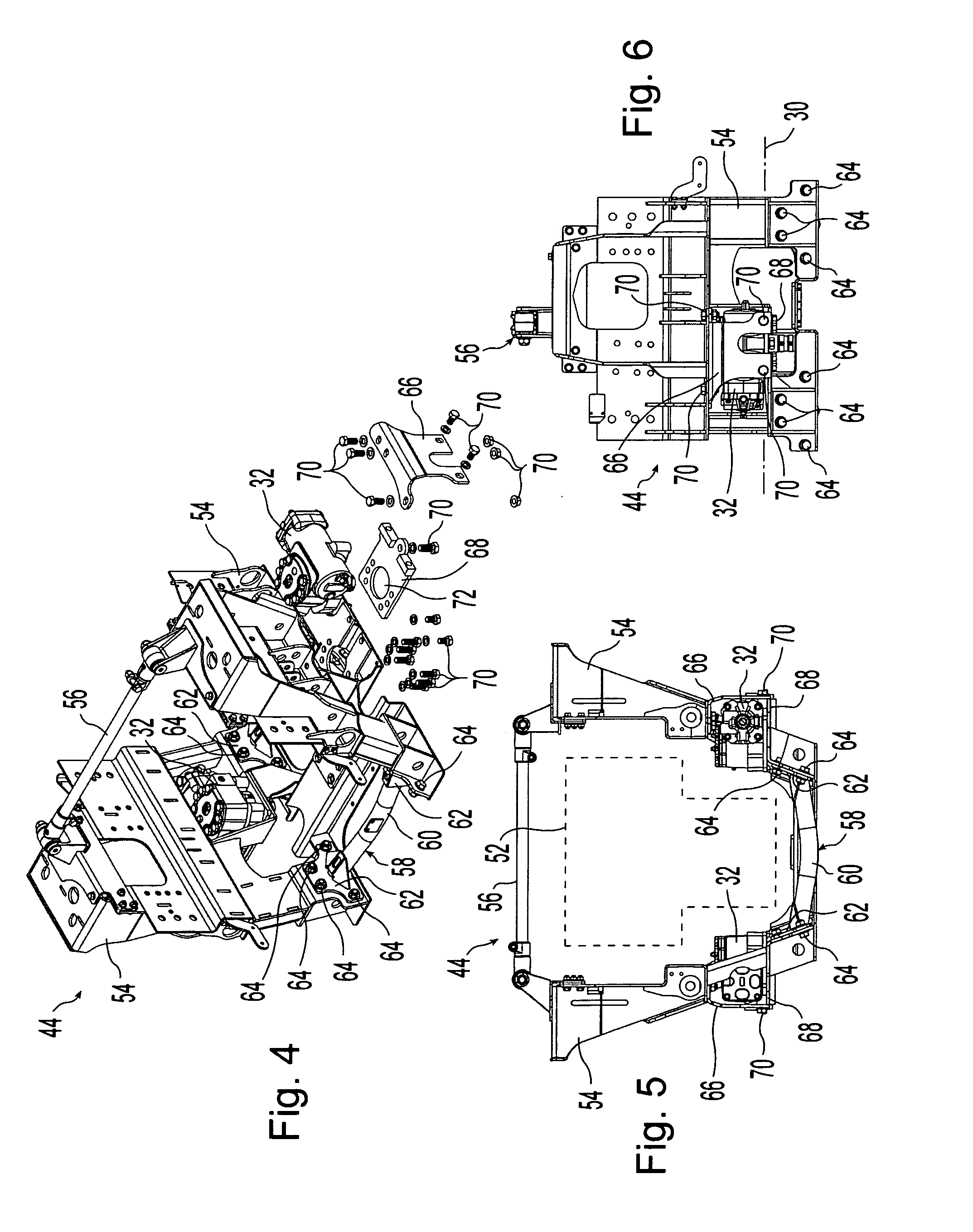

Independent suspension and steering assembly

An independent suspension and steering system that can be used with a large truck. The suspension system includes a transversely extending leaf spring assembly. The midpoint of the leaf spring assembly is secured at the centerline of the vehicle while the two opposing ends of the leaf spring assembly are shackled to vertically moveable carriers on which the steering knuckles are pivotally mounted. The steering unit includes a transversely extending relay rod which is attached to tie rods at its opposite ends. The tie rods are, in turn, attached to the steering knuckles. In some embodiments, at least one steering gear is coupled with the relay rod via a connecting rod that is secured at one end to the rotating output shaft of the steering gear and secured at its other end to the relay rod.

Owner:REYCO GRANNING

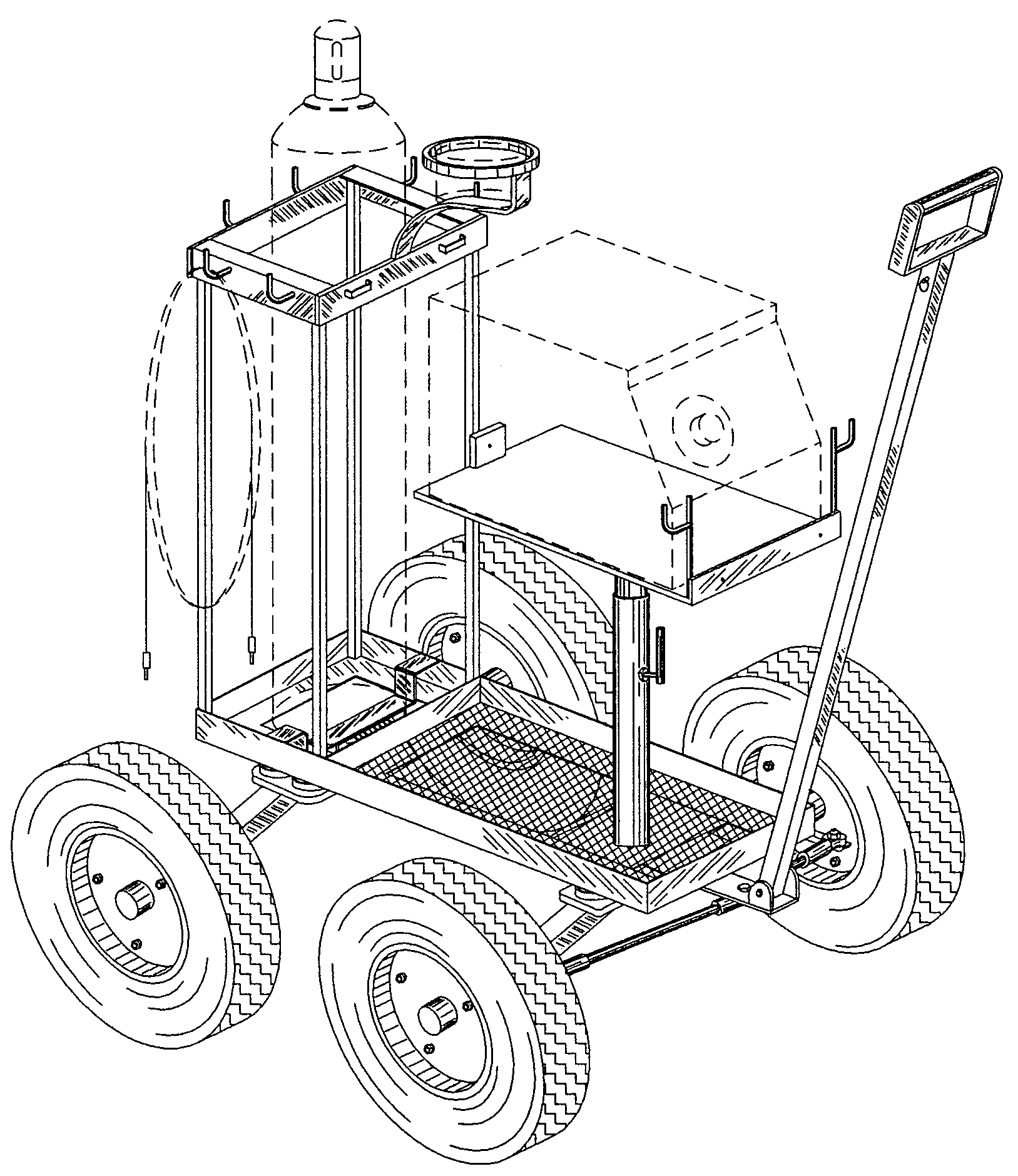

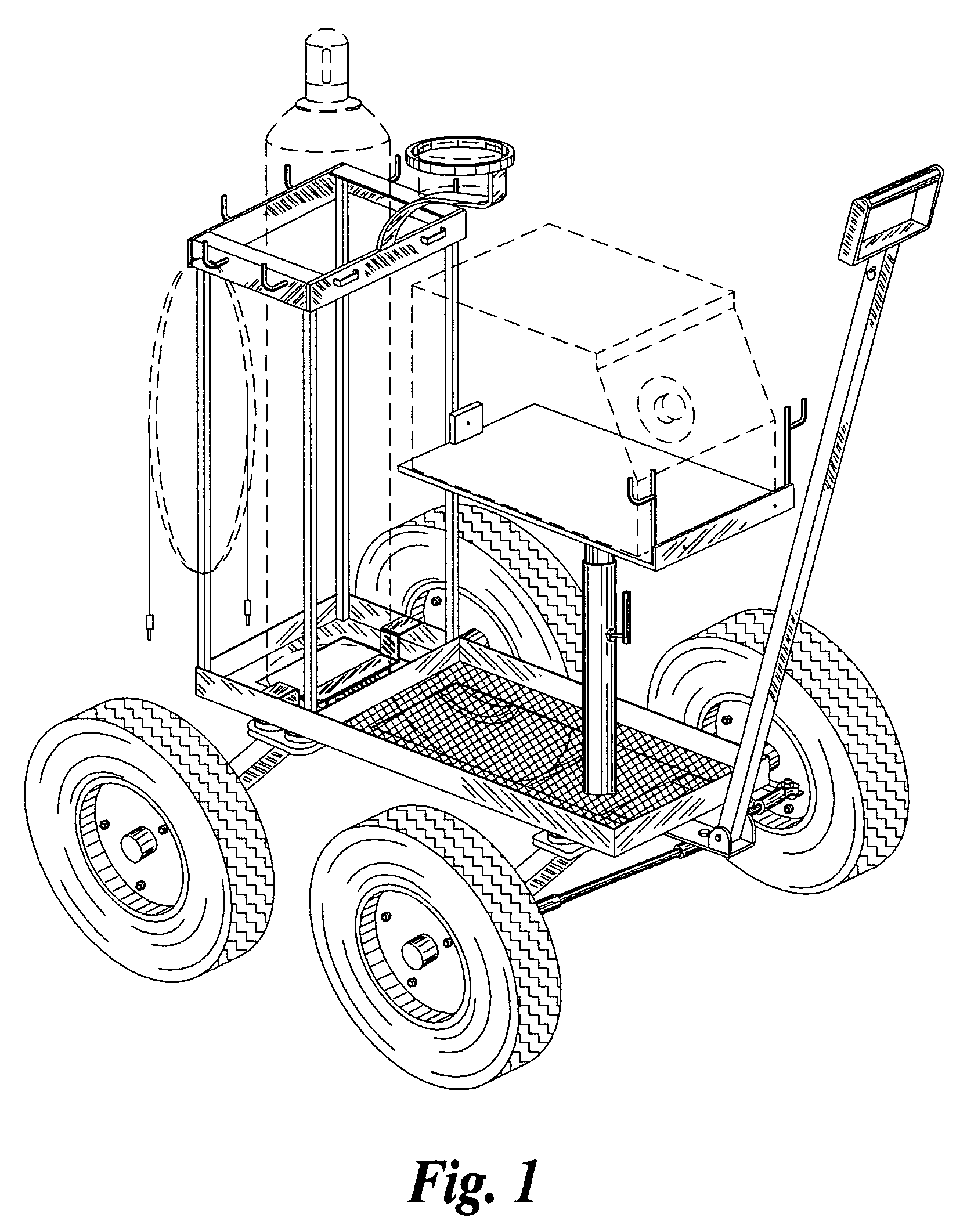

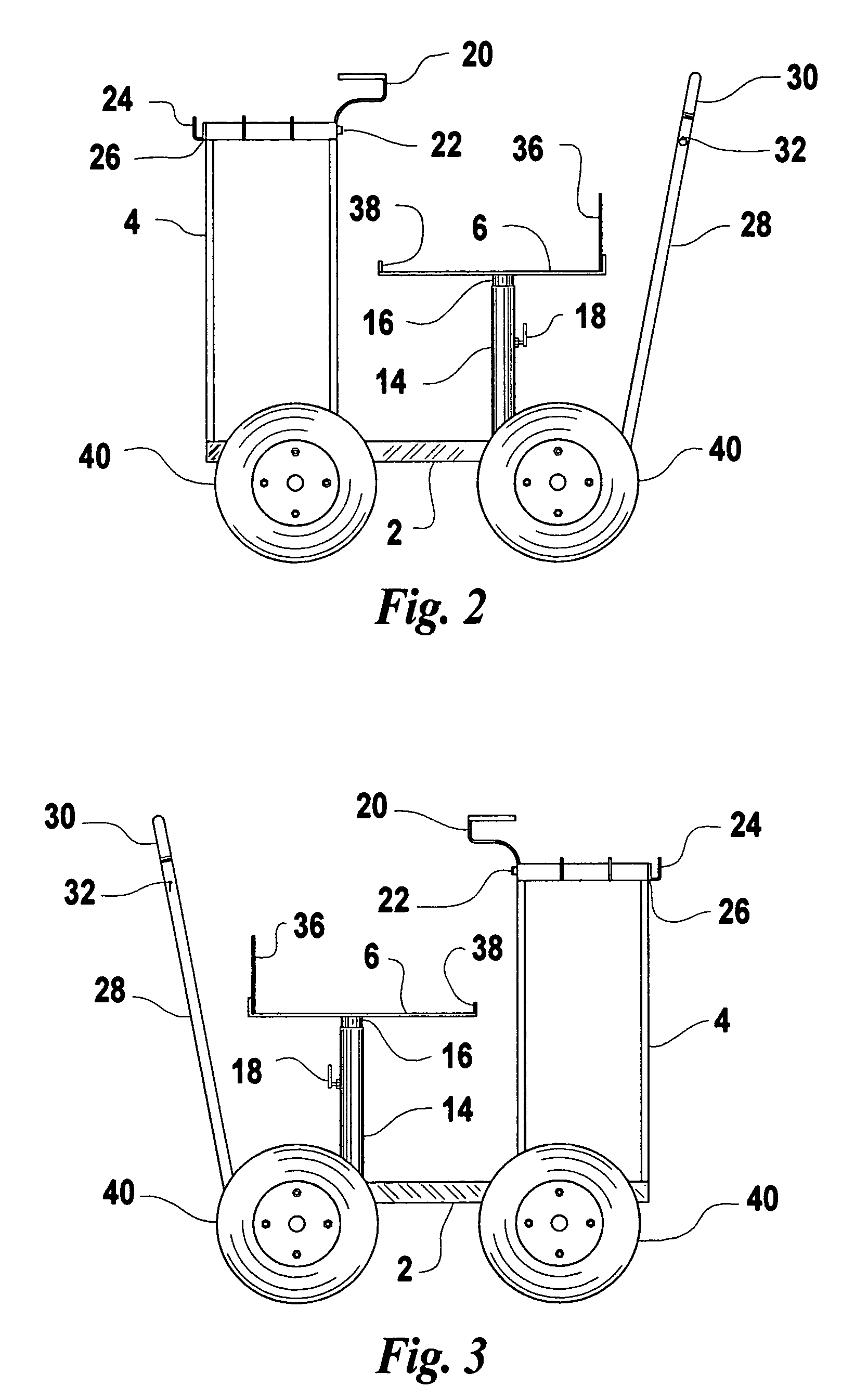

All-terrain welding cart

InactiveUS7114732B1Without sacrificing stabilityConquer rough terrain and ease of steeringCarriage/perambulator with single axisSledge wheelsTerrainEngineering

An all-terrain four wheel welding cart having an independent suspension system making the cart capable of traveling across a variety of terrains either by being manually pulled by a handle connected to the suspension system making it easy to control cart direction or by an interchangeable tow hitch which can replace the manual towing handle allowing the cart to be mounted onto a tow receiver and quickly driven away. Due to the cart's ground clearance, size of wheels and pneumatic tires, it can travel most terrains usually unavailable to standard welding carts.

Owner:ISMAIL JEFFERY A

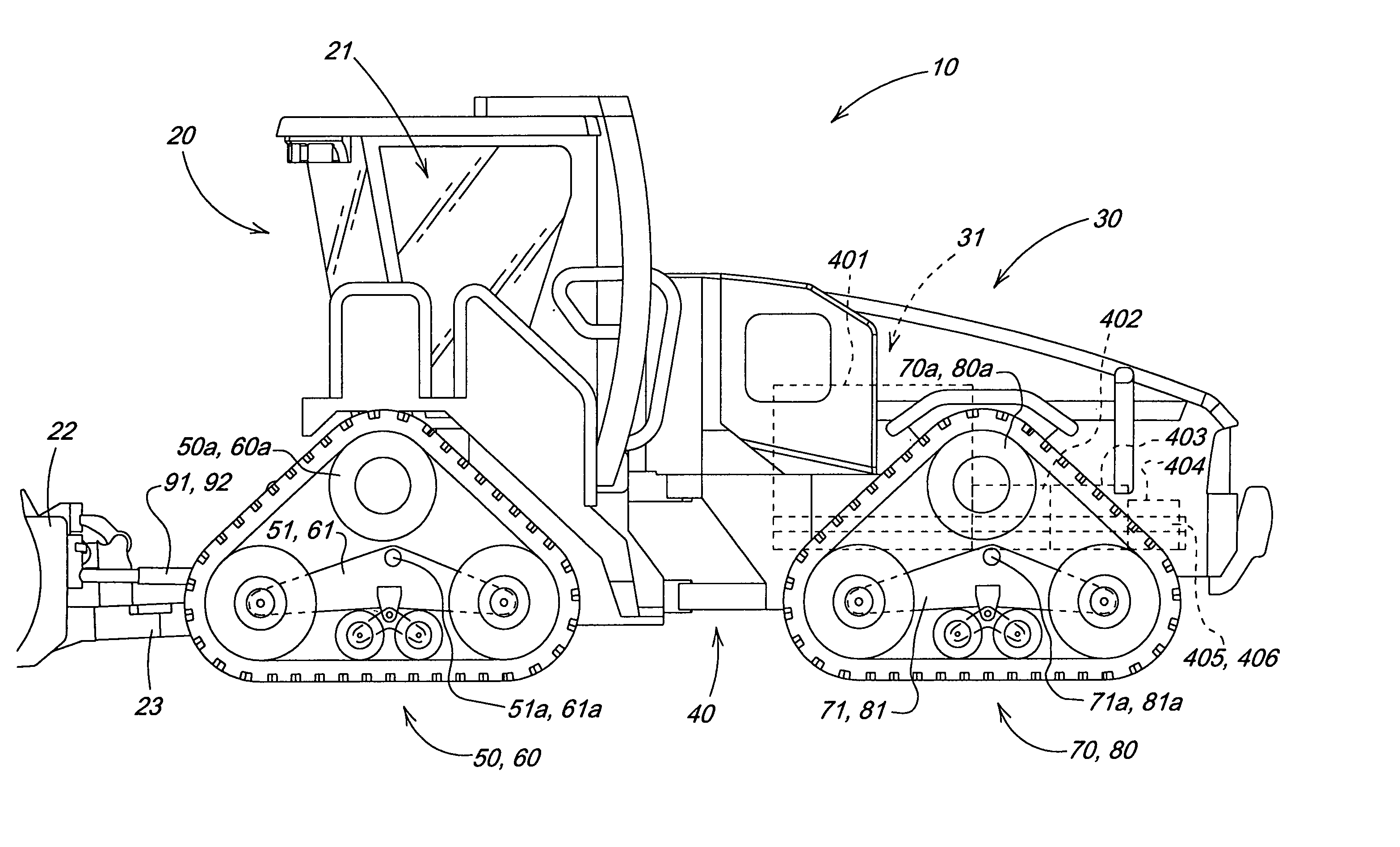

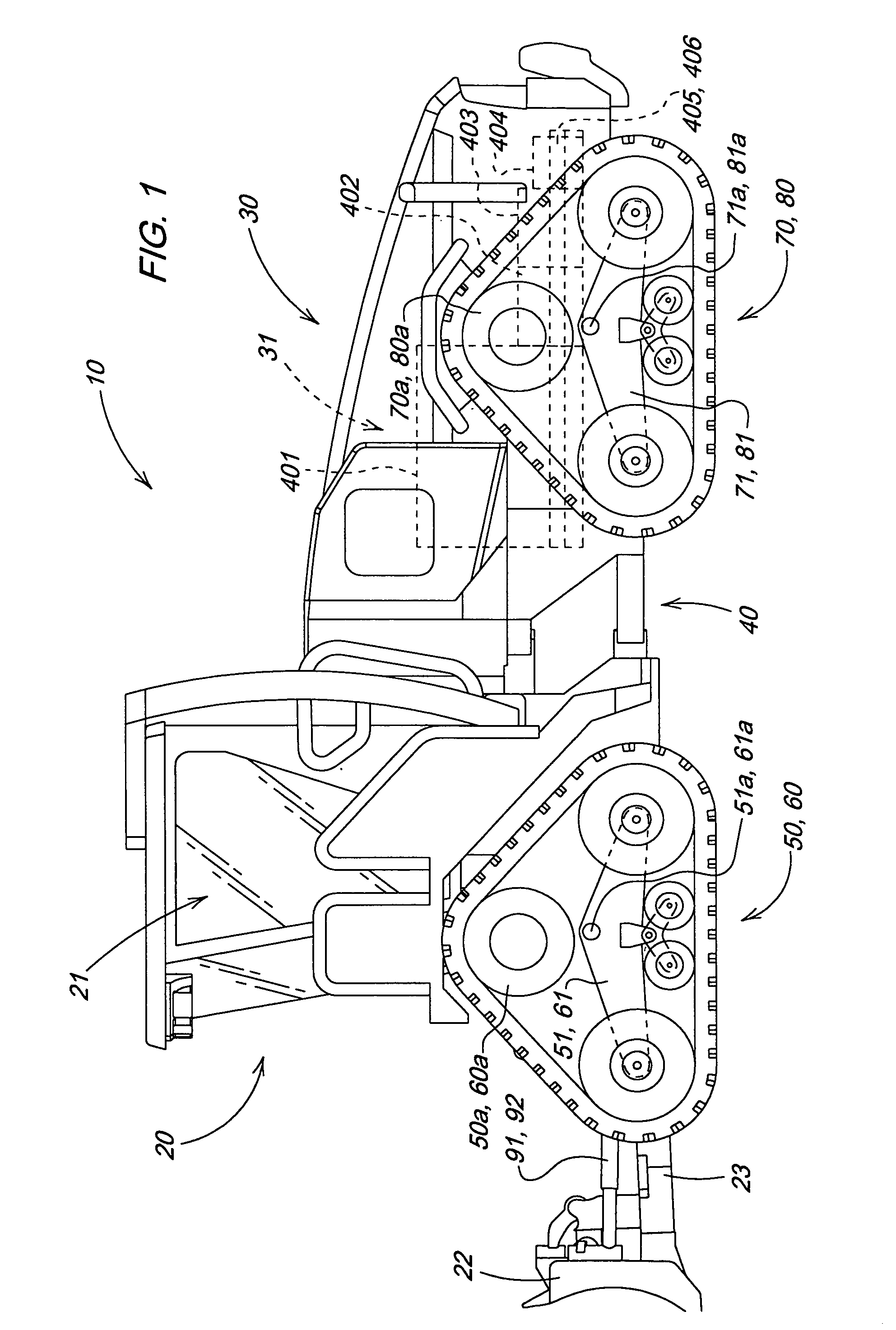

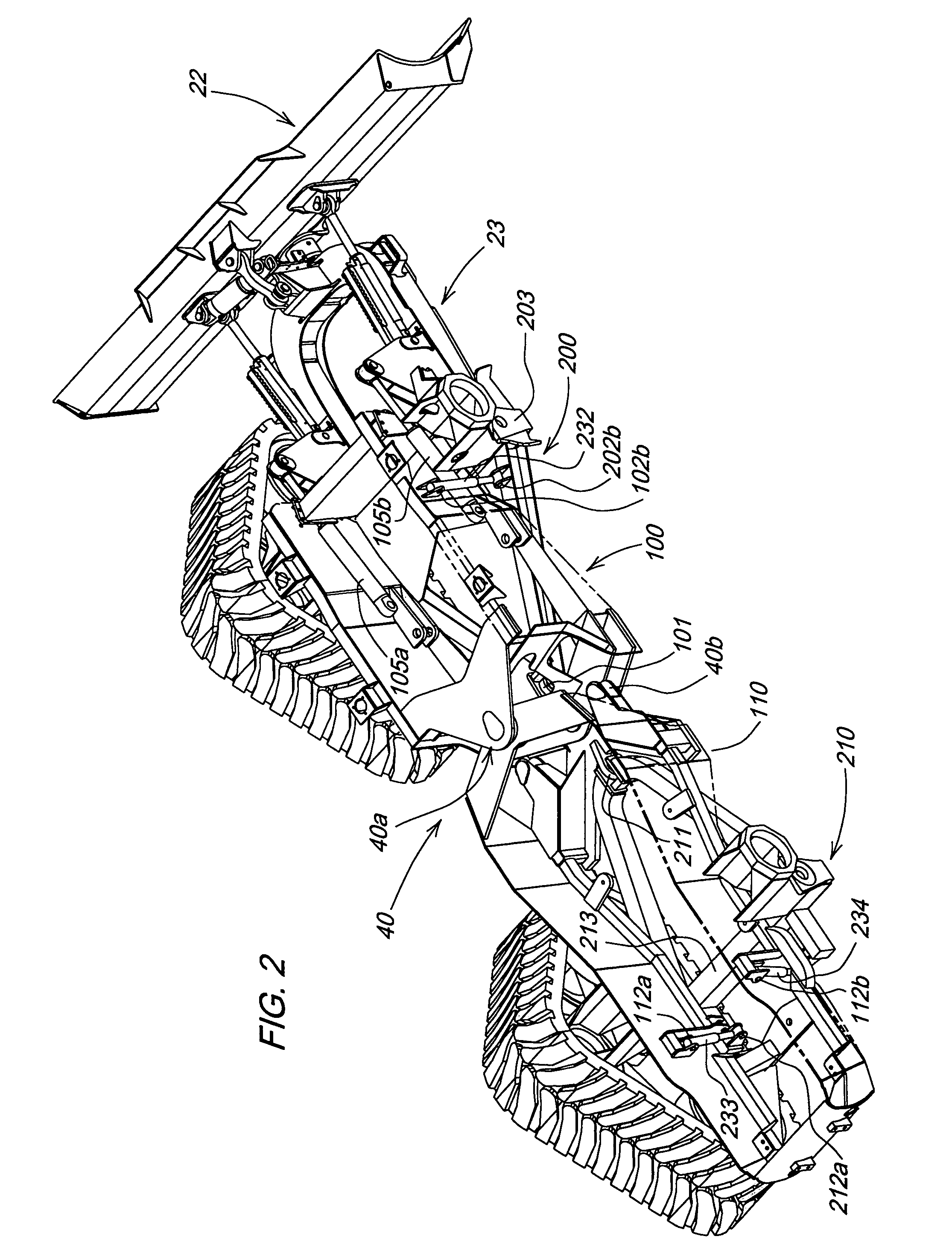

Articulated crawler tractor

InactiveUS20060113121A1Great tractionIncrease the number ofAgricultural machinesVehicle cleaning apparatusVisibilityBraced frame

An articulated dozer with a four point independent suspension system between a chassis and two support frames is described. The chassis includes a front chassis portion and a rear chassis portion connected by an articulation joint. The vehicle is compactly arrange so that the chassis and the two support frames fit between the track systems supporting and propelling the vehicle. Additionally, the engine is arranged near the articulation joint and lower than the top of the track systems for improved view and visibility. The cab is arranged over the track systems at the front of the vehicle for an optimal view of the blade.

Owner:DEERE & CO

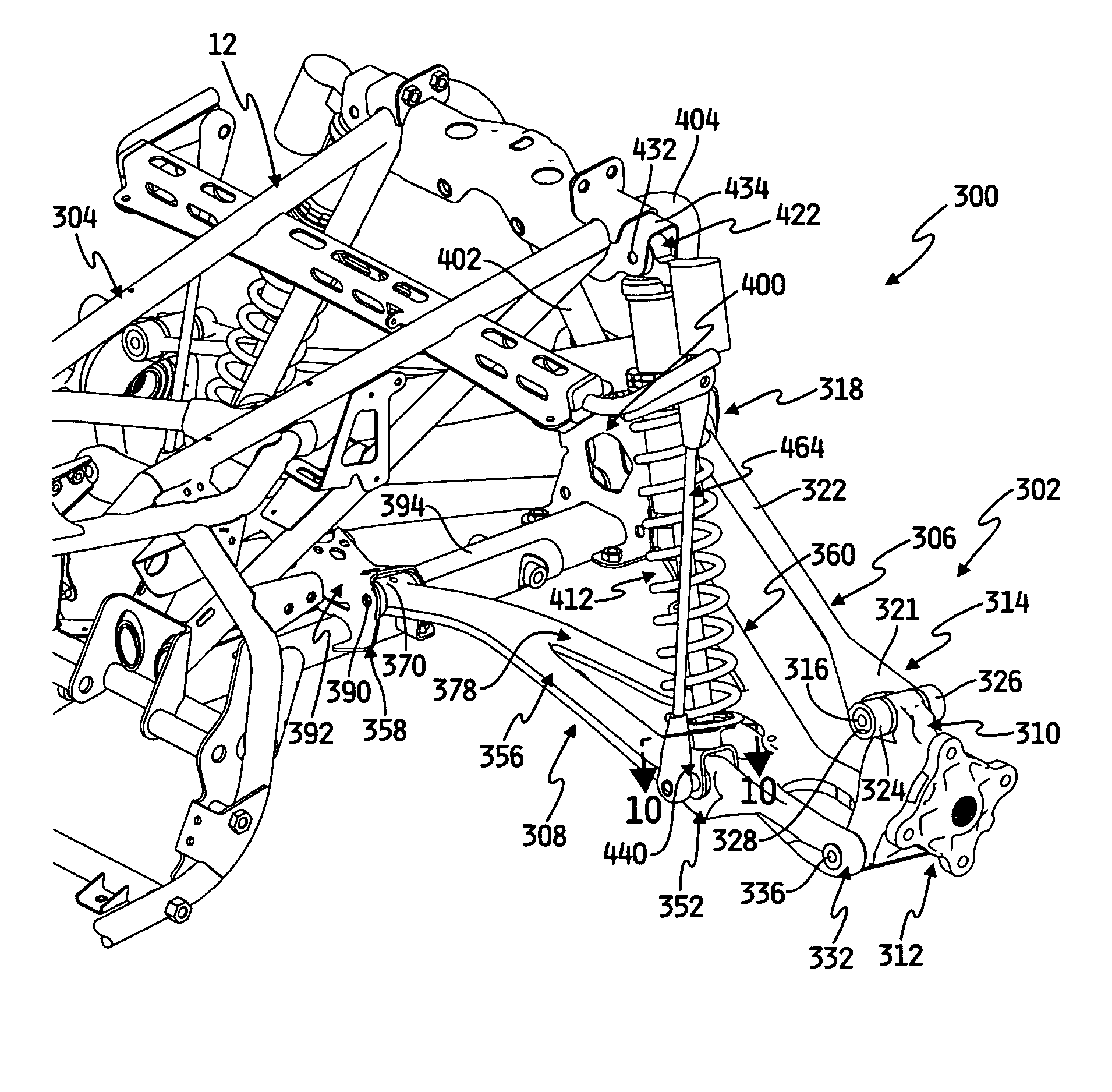

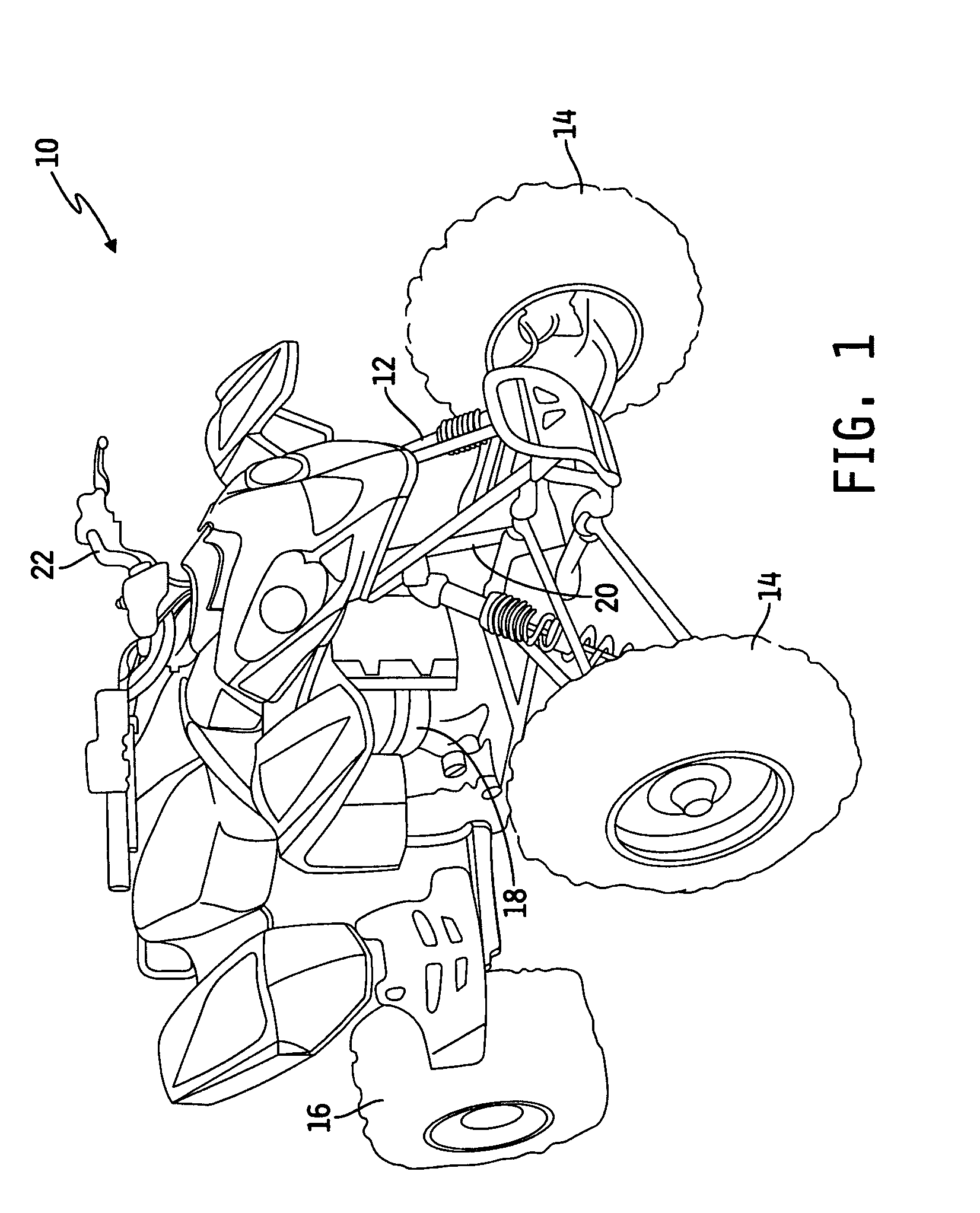

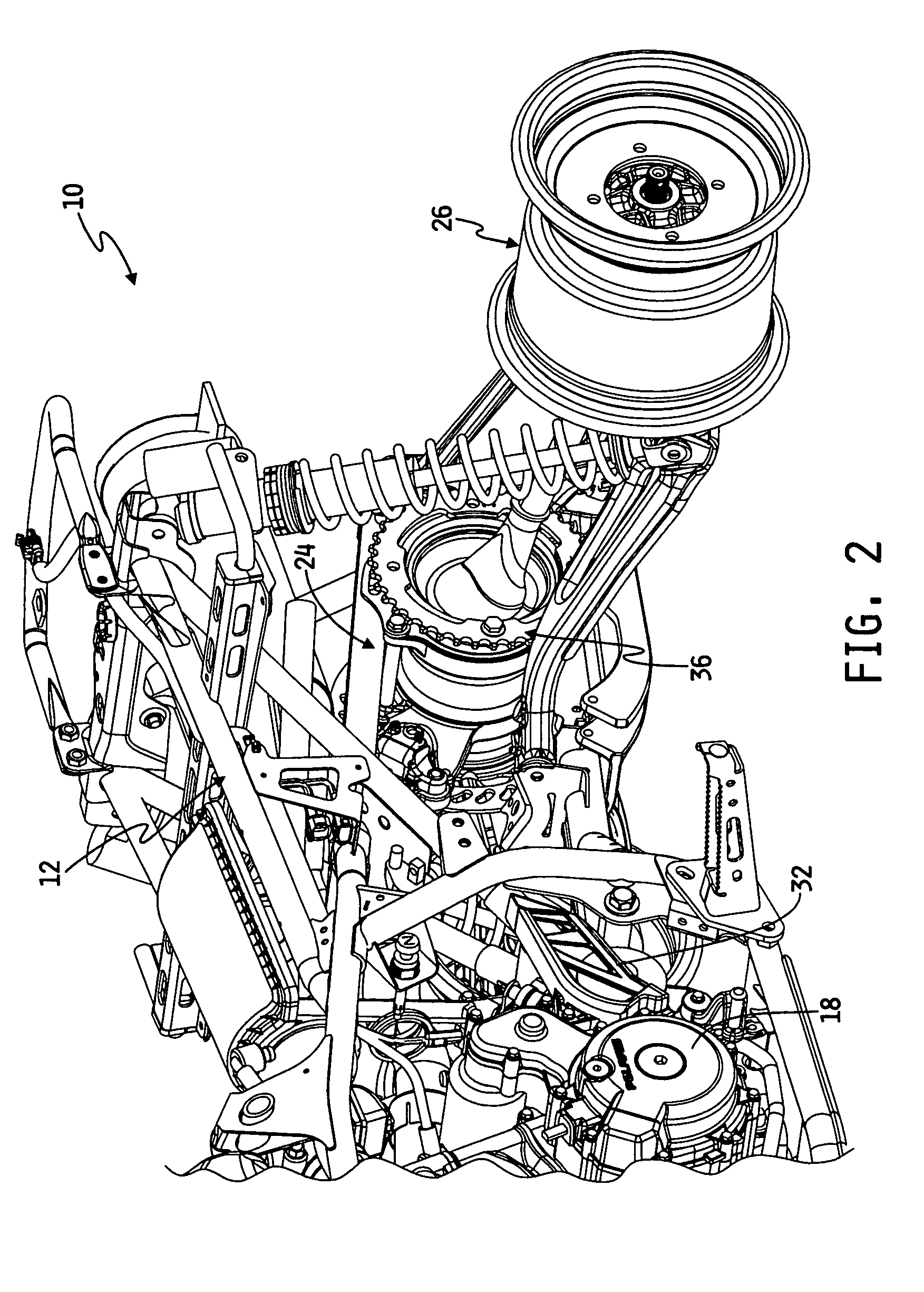

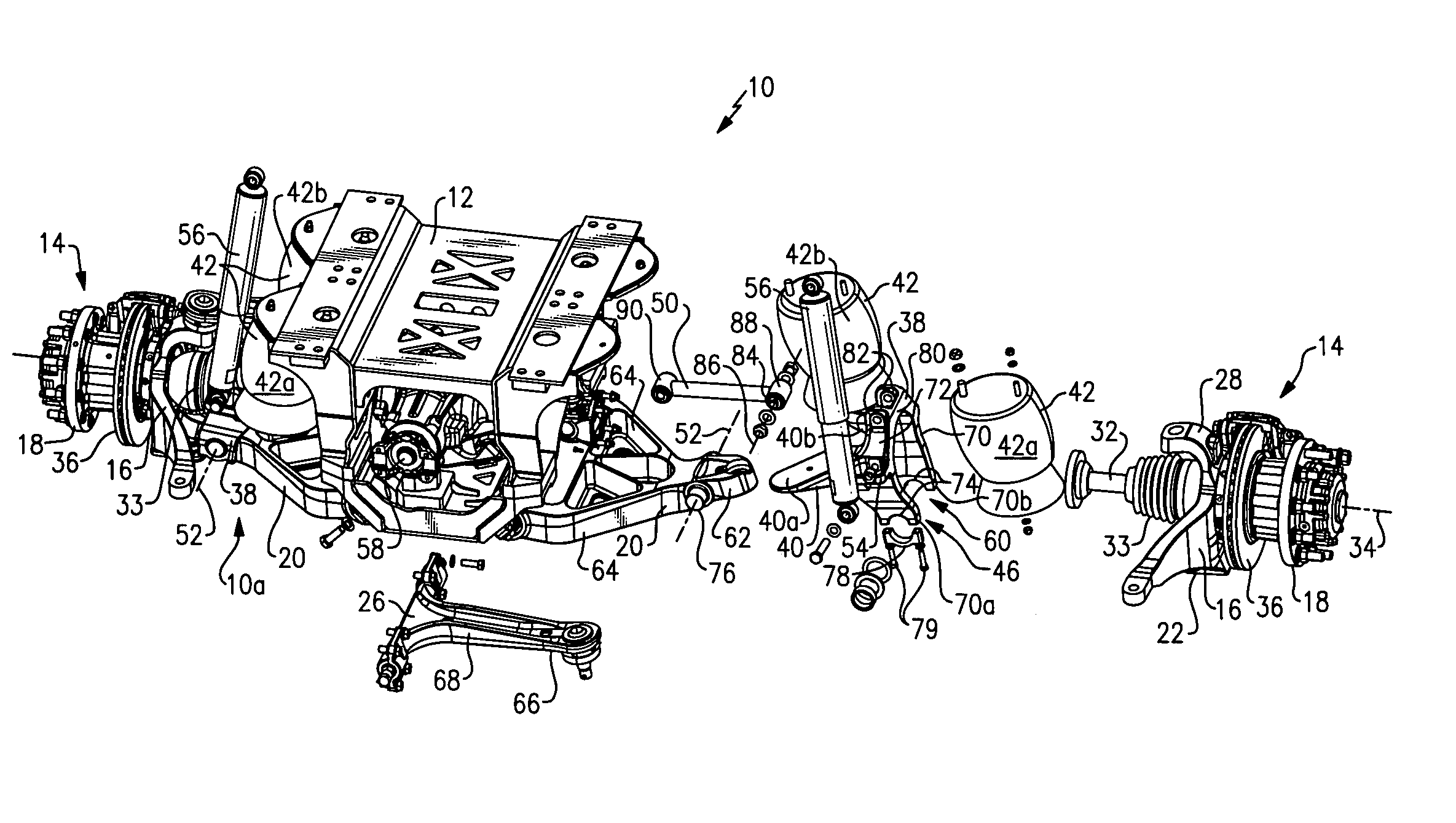

Independent rear suspension system for an all terrain vehicle

ActiveUS20070176386A1Reduce vehicle weightImprove performanceSteering partsInterconnection systemsControl armEngineering

An independent rear suspension for a vehicle having a chassis and a pair of rear wheels including a pair of IRS units. Each IRS unit includes an X-shaped lower control arm with a forward pivot connection to the chassis in front of the centerline of the driven sprocket and a rearward pivot connection behind the centerline, and a camber link connected to the chassis at a single pivot connection behind the centerline. Each IRS unit also includes a shock absorber coupled with an anti-sway bar to the lower control arm at a mount, and including a secondary spring in series with a main spring.

Owner:POLARIS IND INC

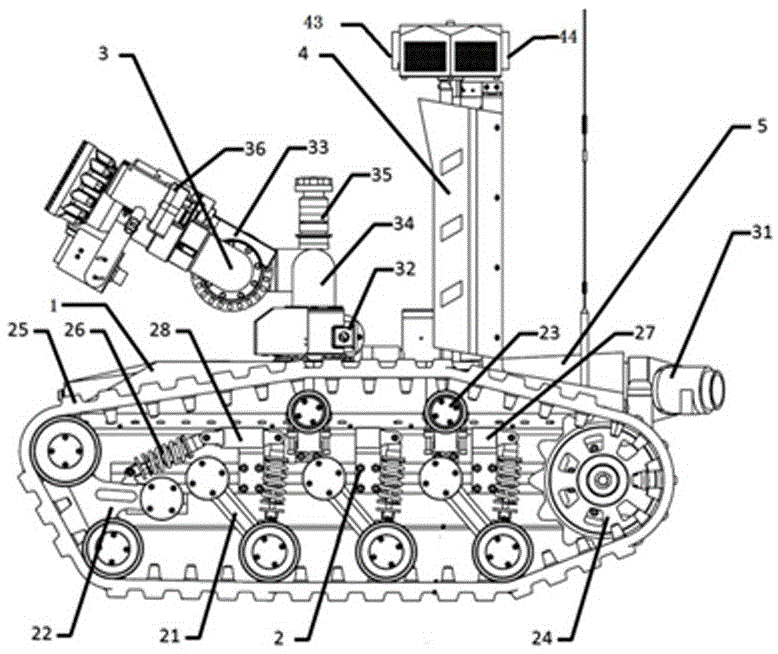

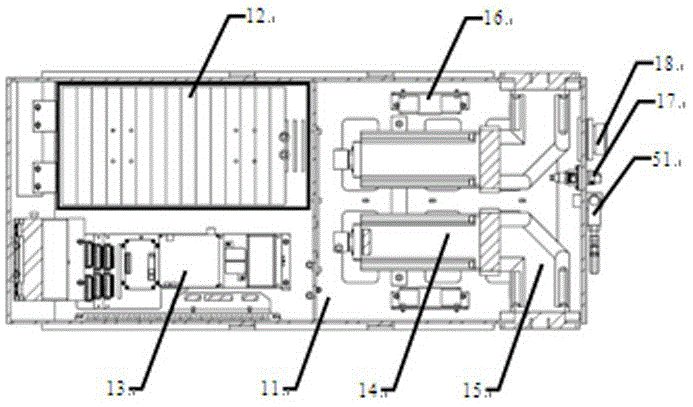

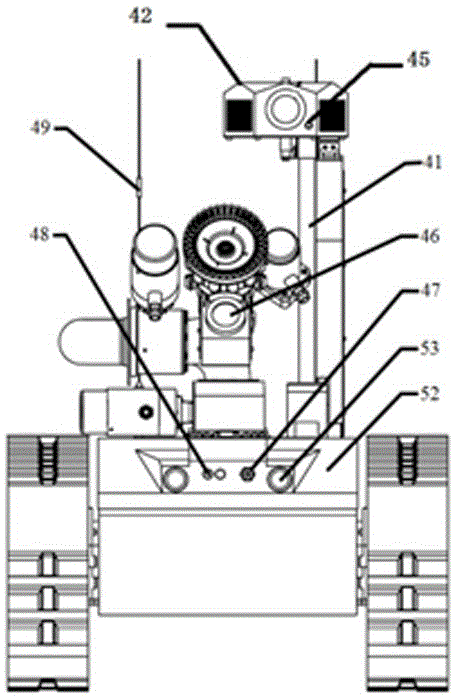

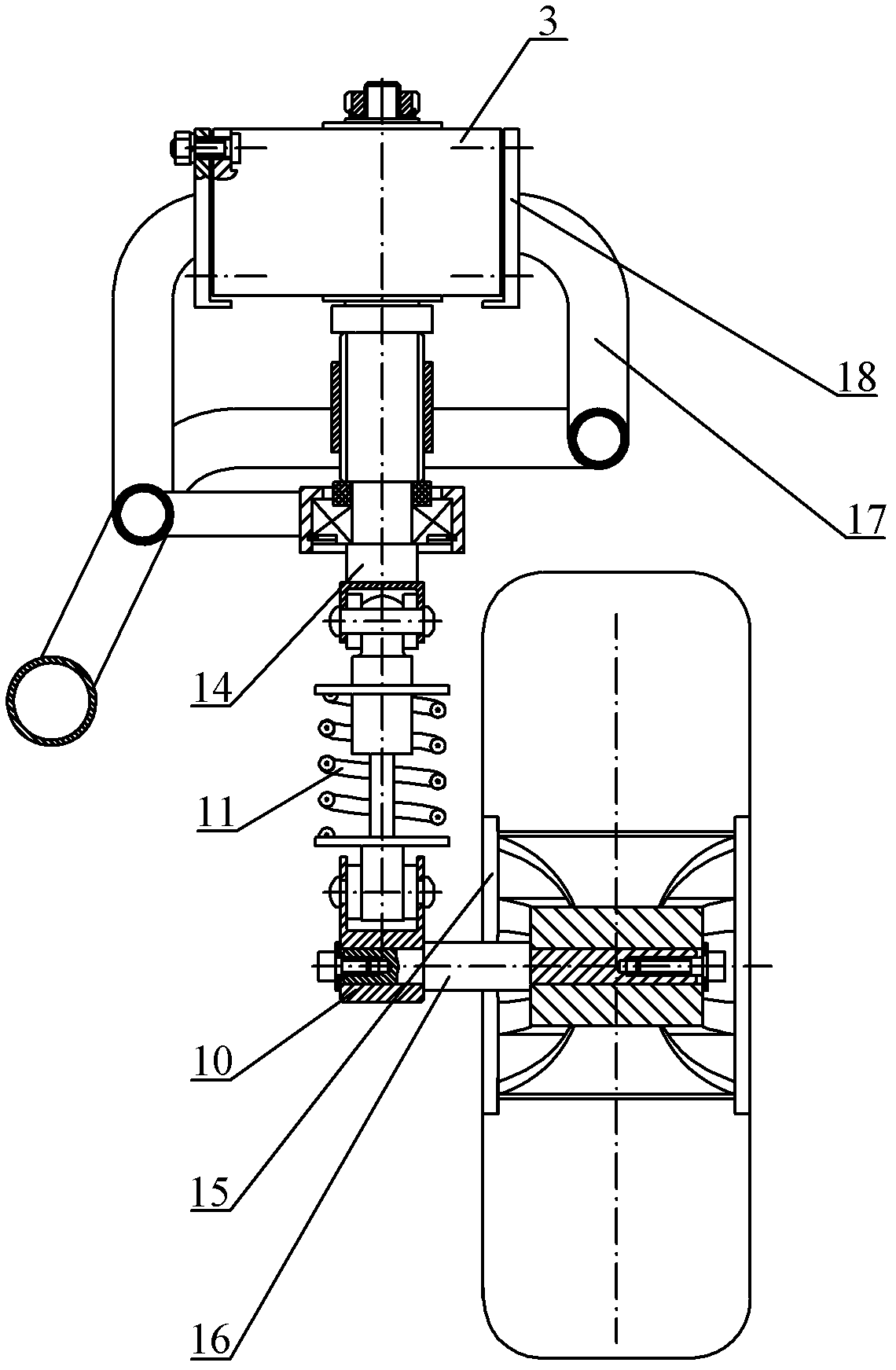

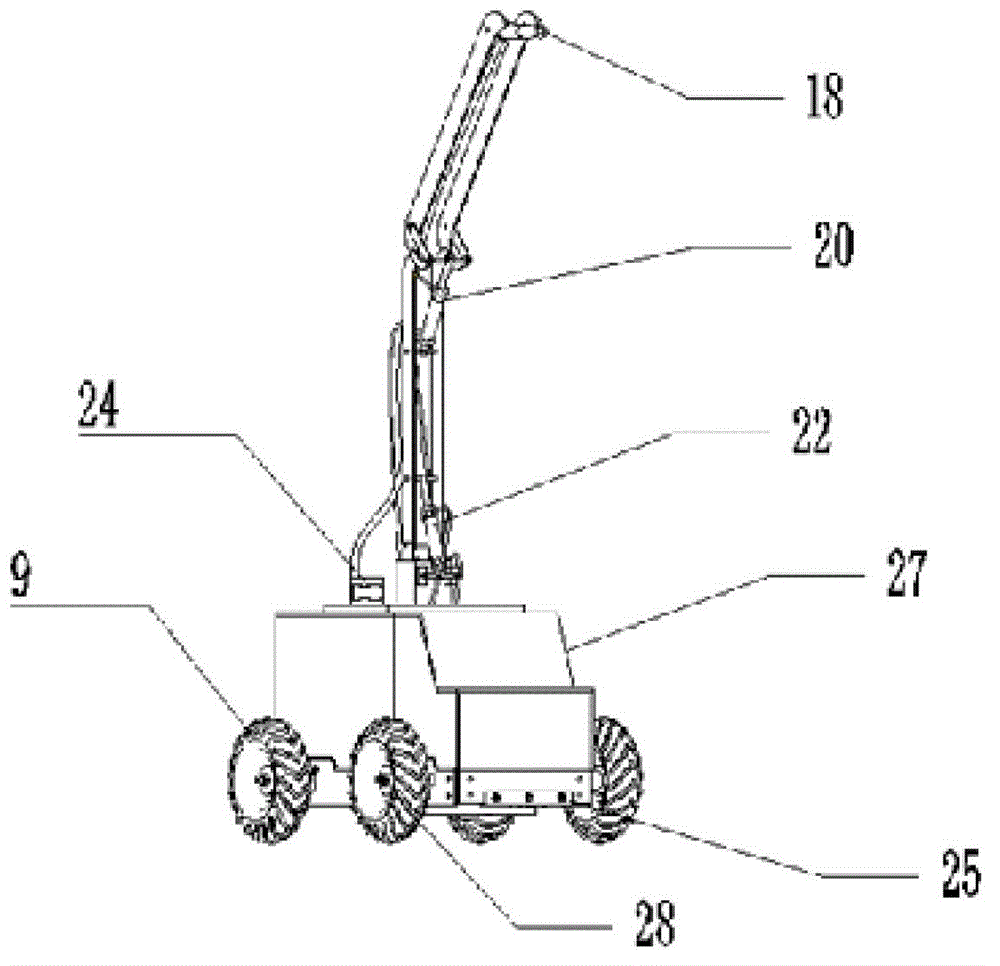

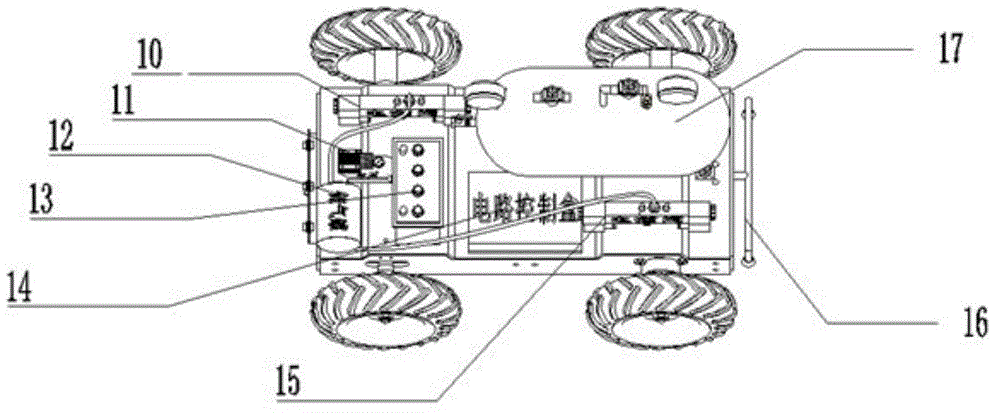

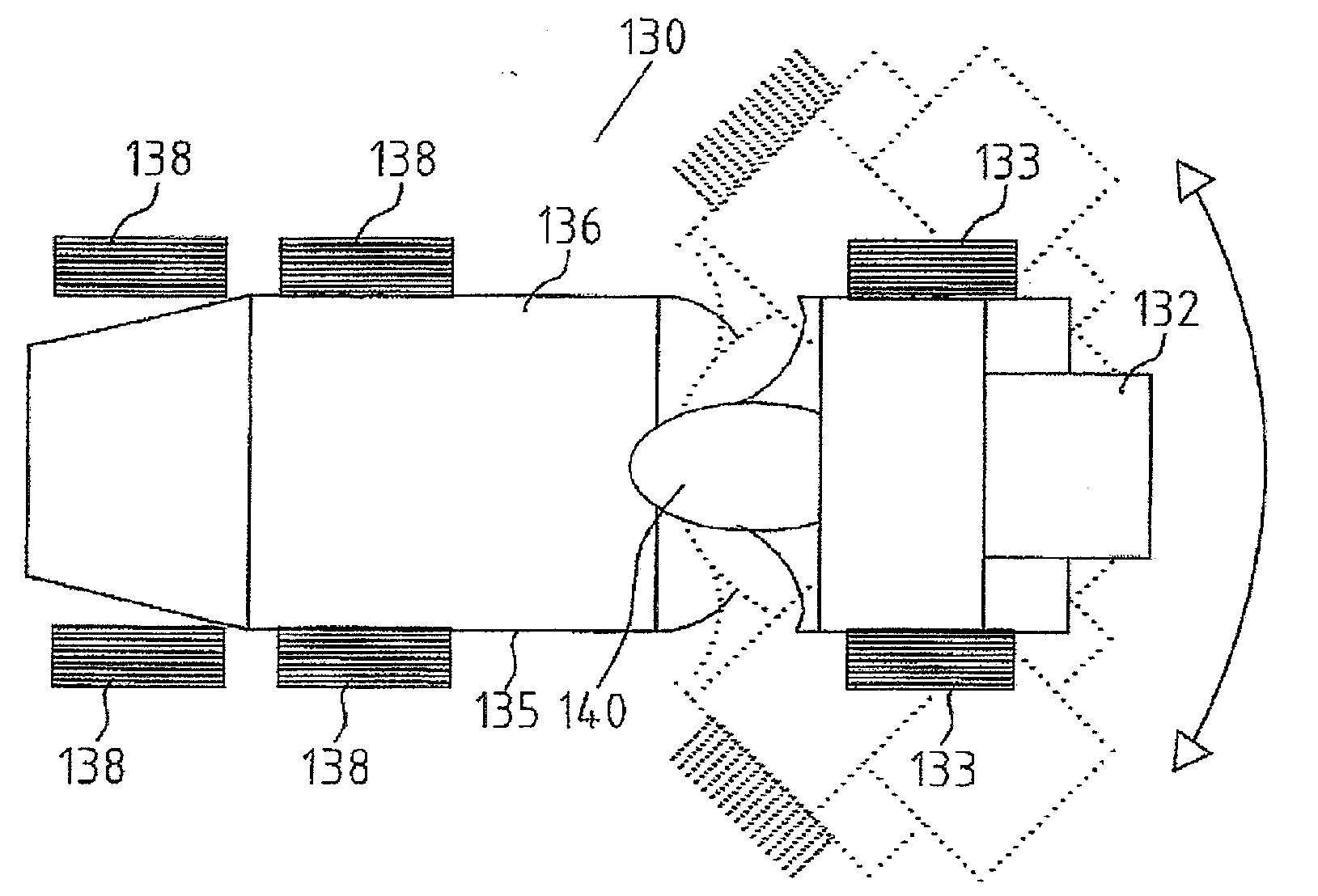

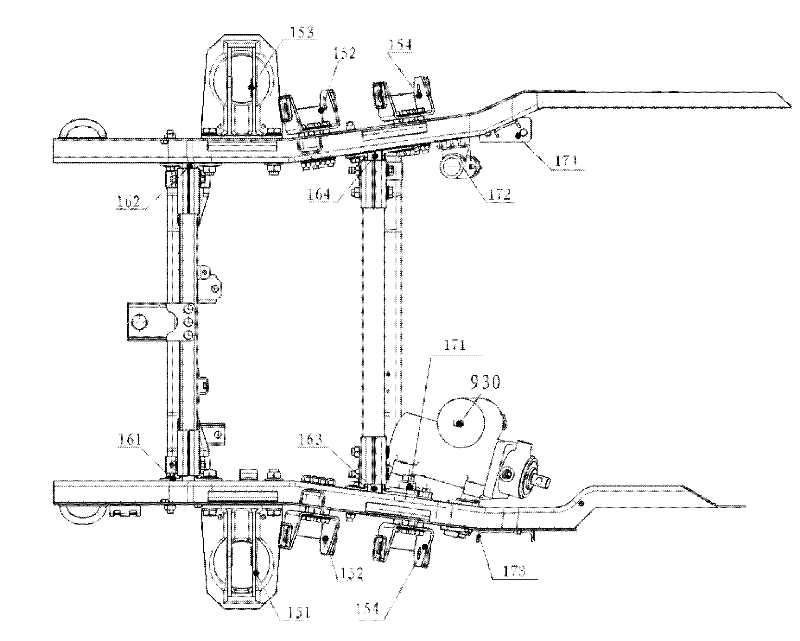

Explosion-proof and fire fighting reconnaissance robot

The invention discloses an explosion-proof and fire fighting reconnaissance robot. The robot comprises two parts including a fire fighting robot body and a remote control box, wherein the fire fighting robot body is composed of a box body assembly, an independent suspension shock absorption system, a fire fighting water cannon, a data acquisition multimedia assembly and an auxiliary part; the box body assembly adopts an explosion-proof design and is provided with a sensor, a camera and the fire fighting water cannon, so that the robot can replace fire fighters to enter inflammable and explosive environments and environments with toxic gas to detect and reconnoiter and can also enter accident scenes with rick smoke, fire disasters and the like to carry out fire fighting; the explosion-proof and fire fighting reconnaissance robot has the characteristics of small size, flexibility of walking, far communication distance, long working time and convenience for operation.

Owner:CITIC HIC KAICHENG INTELLIGENT EQUIP CO LTD

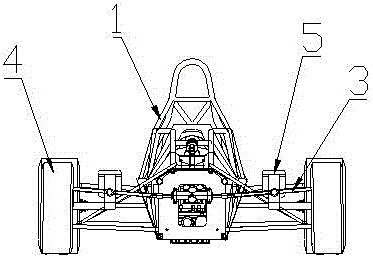

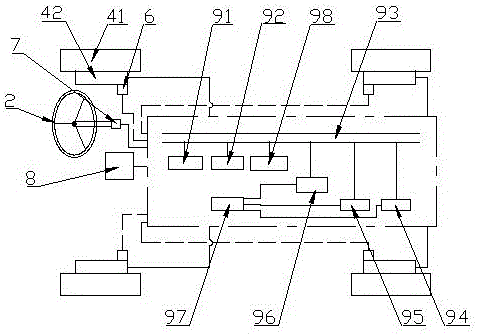

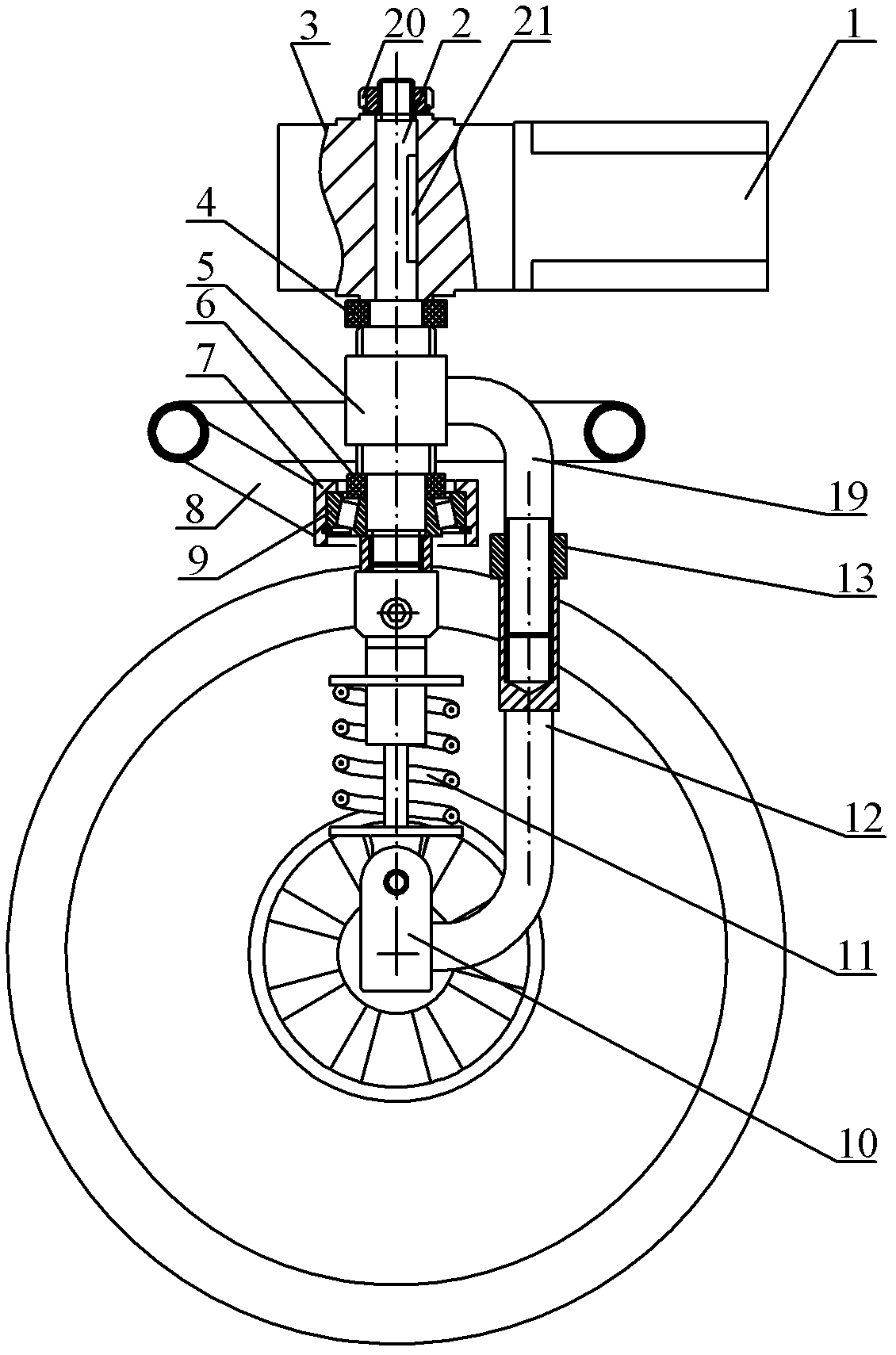

Test prototype automobile of electric wheel driving automobile and driving stability control method

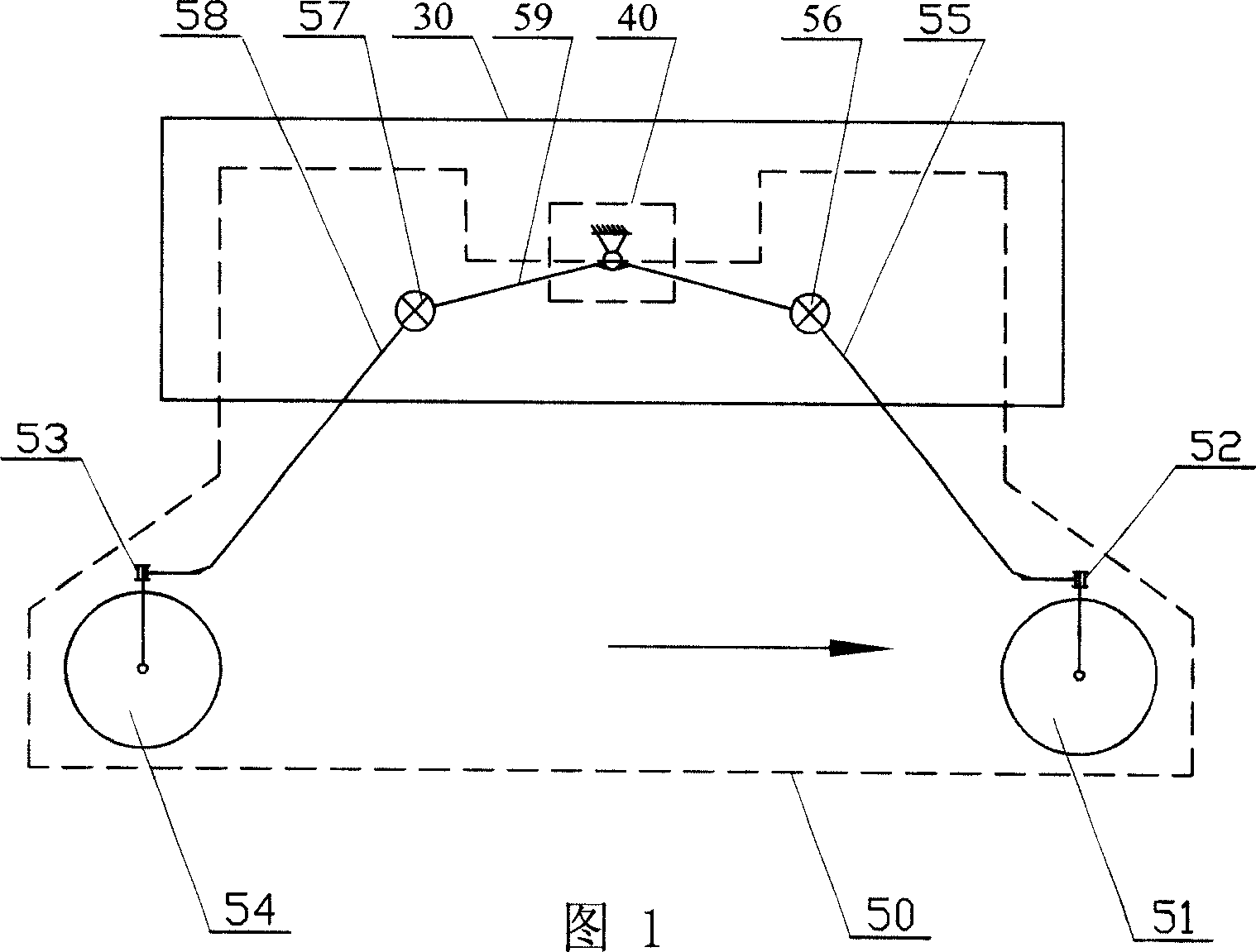

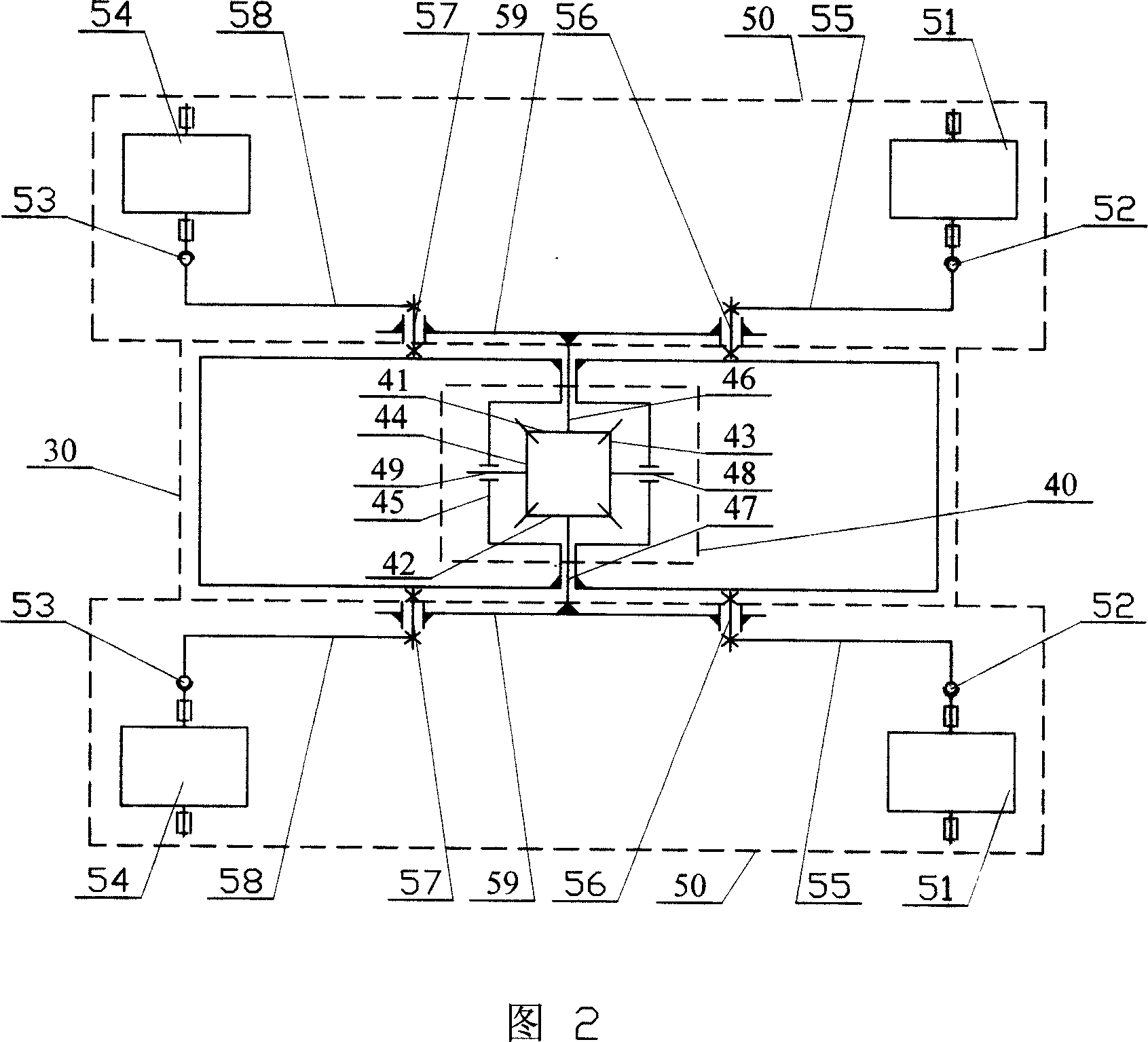

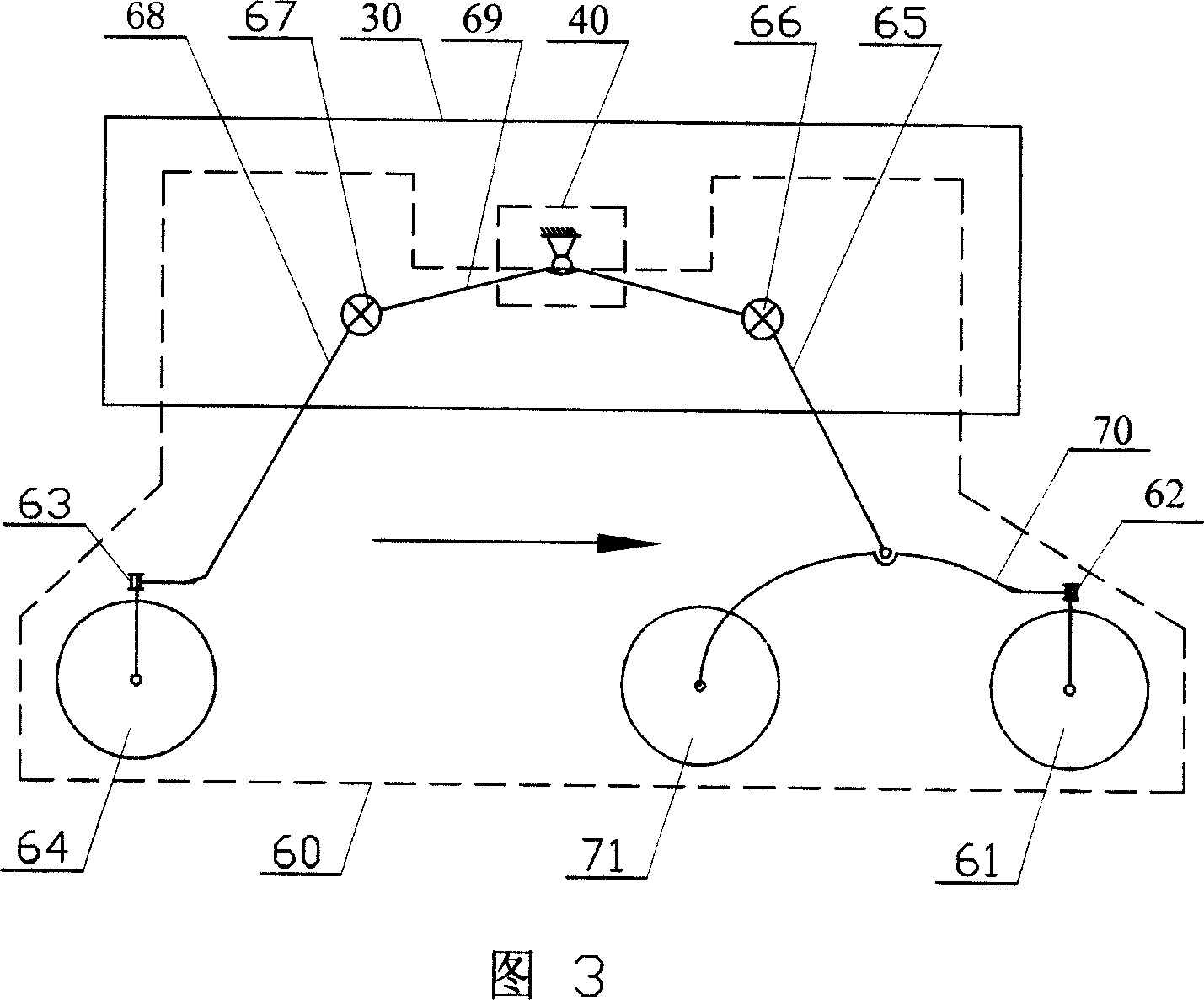

InactiveCN106183892ASimple structureImprove scalabilitySpeed controllerDriver input parametersGyroscopeCar driving

The invention discloses a test prototype automobile of an electric wheel driving automobile and a driving stability control method. The test prototype automobile of the electric wheel driving automobile comprises an automobile body, a steering wheel, an independent suspension and an electric wheel assembly. A wheel speed sensor, a steering wheel rotation angle sensor, a gyroscope and a control system are arranged on the automobile body. The control system comprises a sensor signal processor, a road surface state evaluator, a CAN bus, an electronic differential controller, a yawing moment controller, a driving skid-resistance controller, a torque coordinating distributor and an automobile driving state evaluation system. The driving stability control method comprises the following steps that (A) the automobile driving state is calculated and judged; (B) driving skid-resistance control is conducted; (C) electronic differential control is conducted; and (D) yawing moment control is conducted. By the adoption of the test prototype automobile of the electric wheel driving automobile and the driving stability control method, four-wheel independent driving and independent steering can be achieved, and various control methods of the electric wheel driving automobile can be verified through the test prototype automobile.

Owner:CHONGQING UNIV OF TECH

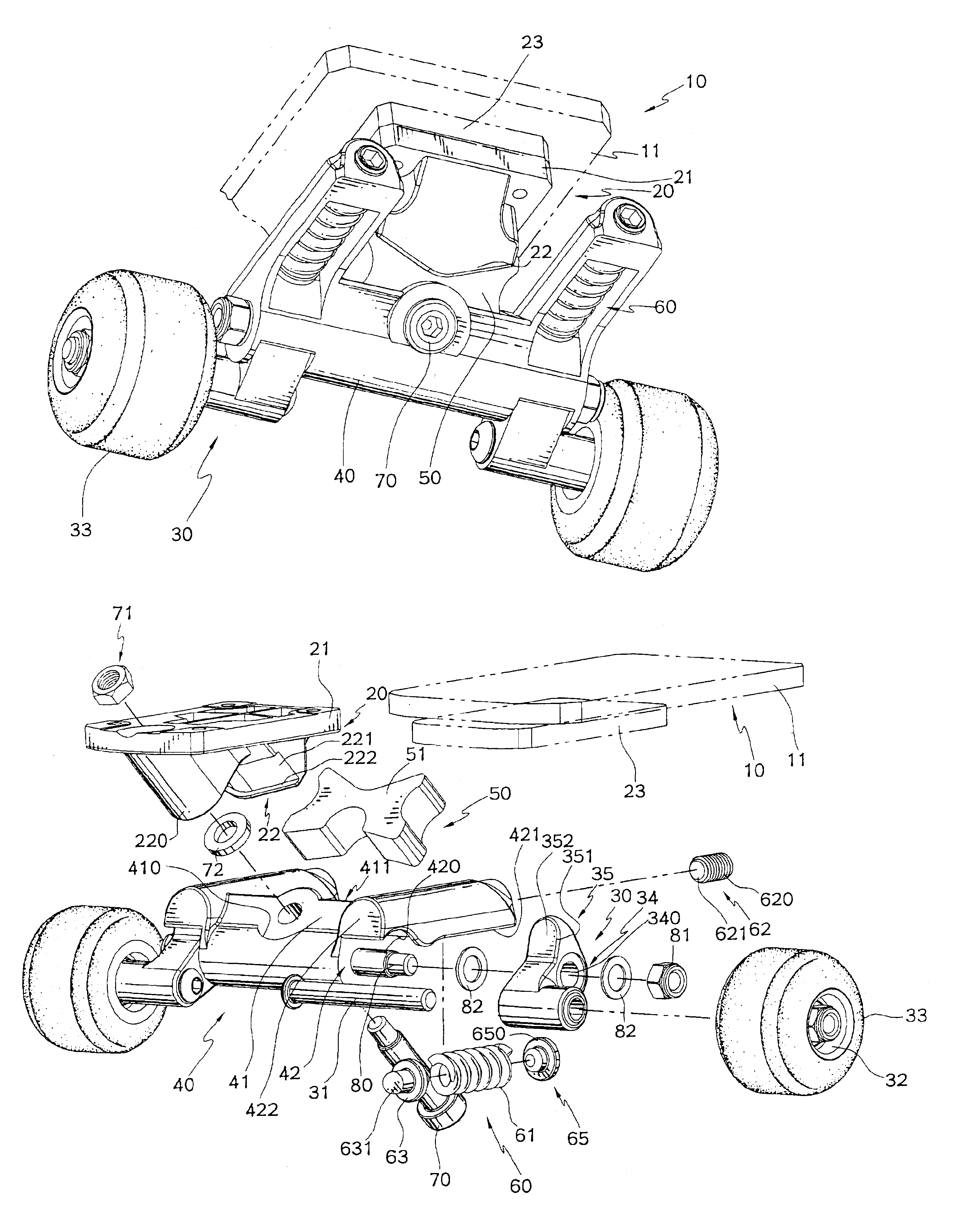

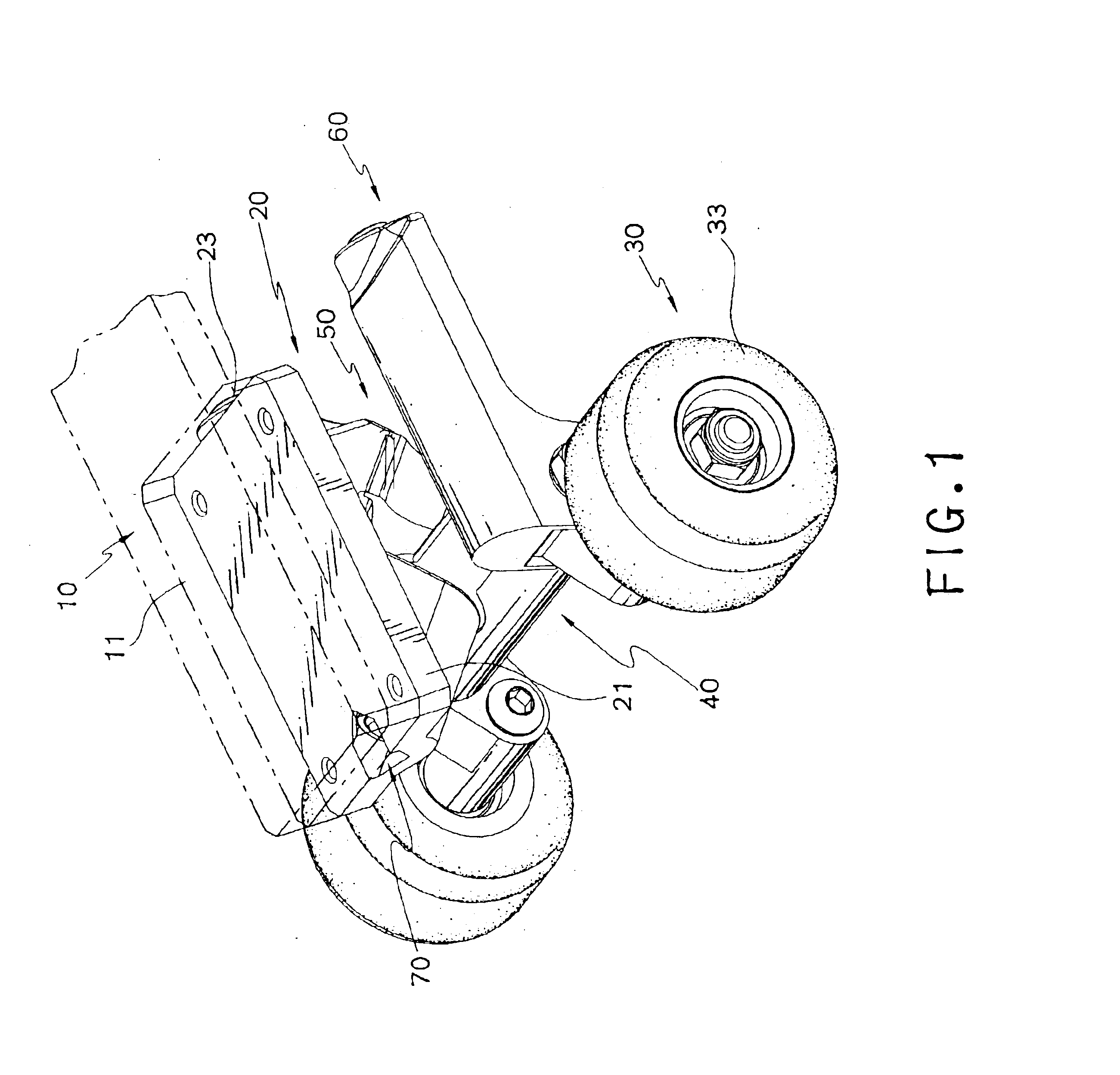

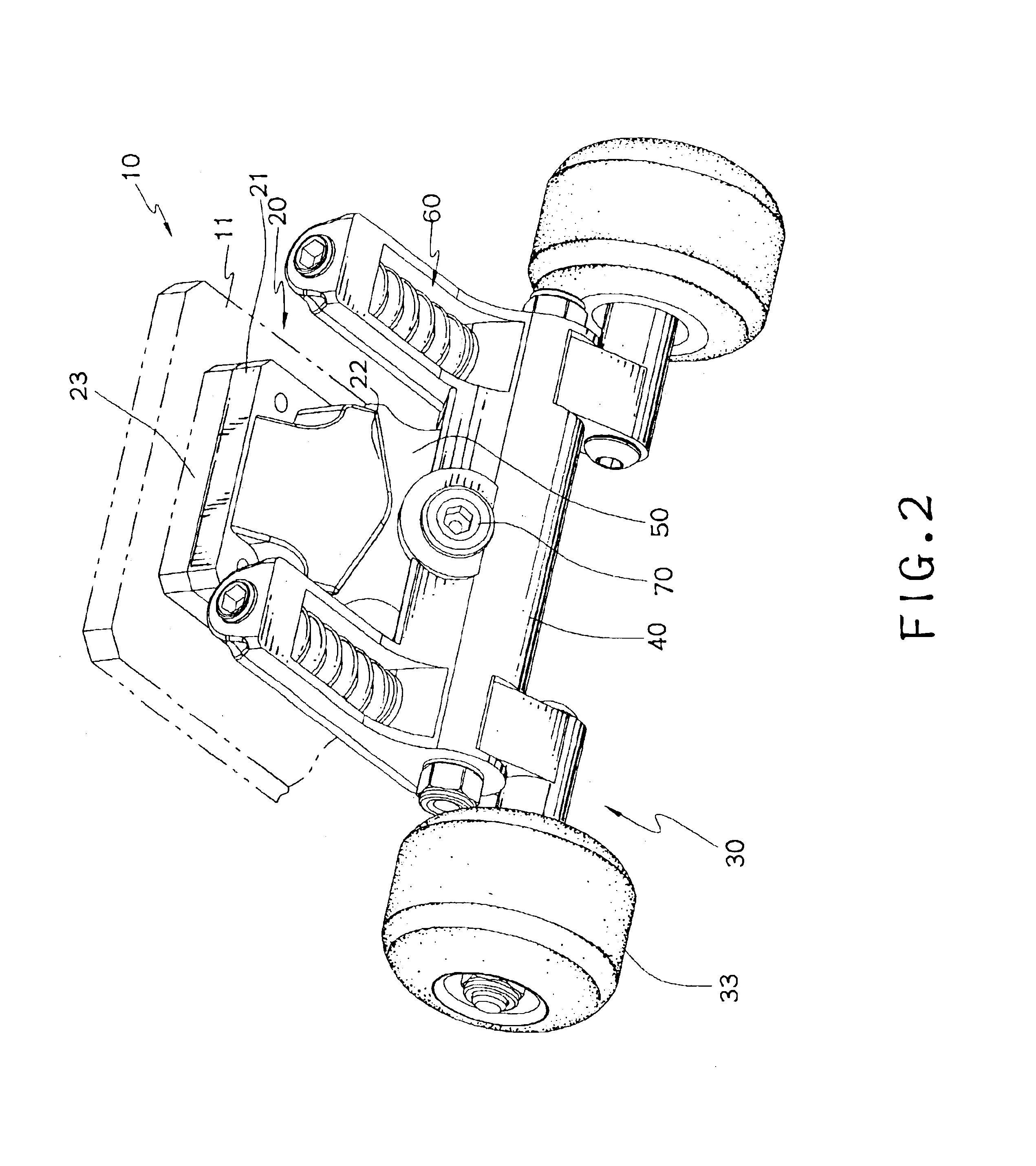

Skateboard having a three-dimensional independent suspension balance system

InactiveUS6913272B2Small turning diameterImprove mobilitySkatesRider propulsionEngineeringMechanical engineering

A skateboard includes a board body having a bottom provided with a base having a bottom provided with two opposite wheel seats. Each of the two wheel seats includes a wheel axle for mounting a roller. The wheel axle of each of the two wheel seats has a center located at a height different from that of a center of the respective wheel seat, thereby forming an eccentric state, so that each roller has independent horizontal and vertical displacement, thereby forming a balance effect, so that the skateboard can be moved in a stable manner.

Owner:CHANG CHUCK

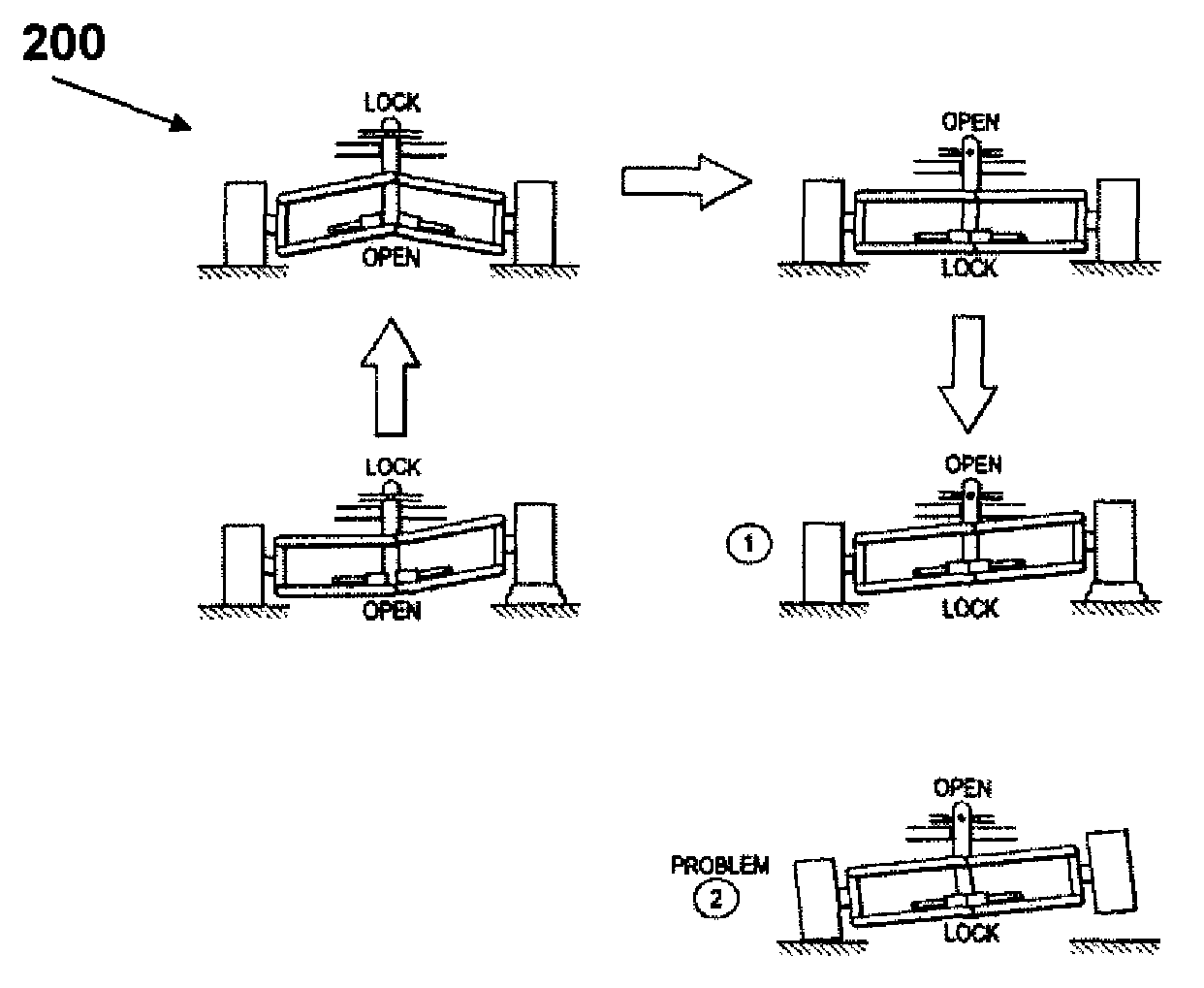

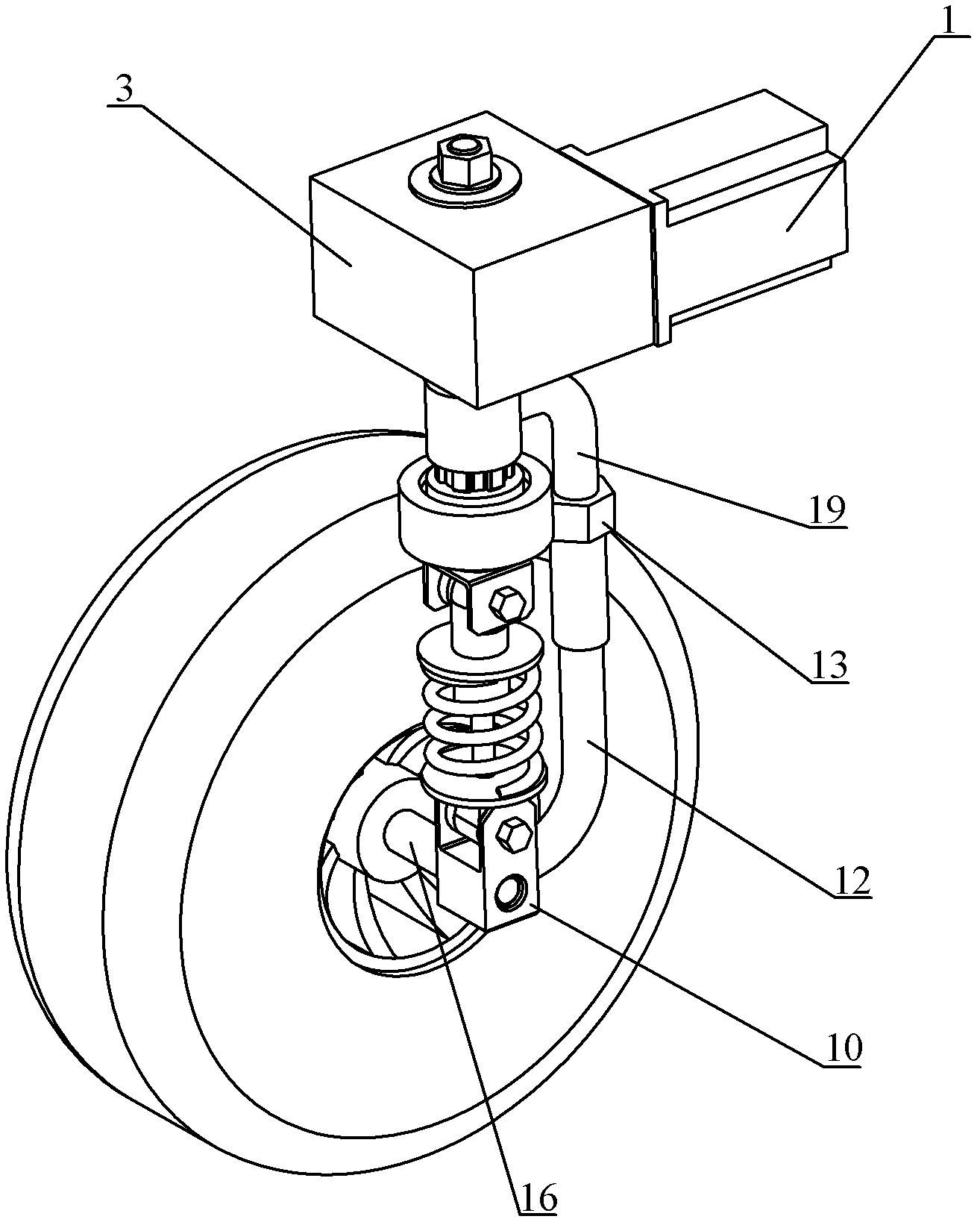

Dual suspension system

ActiveUS8480106B1Digital data processing detailsAnimal undercarriagesIndependent suspensionEmbedded system

A dual suspension system includes a chassis, a suspension arm rotatably connected to the chassis, a wheel connection connected coupled to the suspension arm, a first lock connected to the chassis and the suspension arm, and a second lock connected between a differential housing and the chassis. The first and second locks each have an unlocked state and a locked state. When the first lock is unlocked, and the second lock is locked, the vehicle substantially provides independent suspension. When the first lock is locked, and the second lock is unlocked, the vehicle substantially provides solid axle suspension.

Owner:GEORGE WASHINGTON UNIVERSITY

Integrated steering and suspension system

InactiveCN102431586ASteering Space ImprovementAddresses issues that make it difficult to make vehicles with small turning radiiSteering linkagesElectrical steeringReduction driveReducer

The invention provides an integrated steering and suspension system which comprises a steering motor. The steering motor is in transmission connection with one end of a main pin shaft through a speed reducer; a sleeve is sleeved outside the main pin shaft; the main pin shaft is not in rotation connection with the sleeve; the sleeve can slide axially relative to the main pin shaft; one end of a circular pipe is fixed on the outer surface of the sleeve and the other end is fixed on the side surface of a first connecting block; the first connecting block is fixedly connected with one end of a wheel axle; the other end of the wheel axle is fixedly connected with a wheel hub; the other end of the main pin shaft is fixed with one end of a second connecting block; the other end of the second connecting block is fixedly connected with one end of a damper spring; and the other end of the damper spring is fixedly connected with the first connecting block. The system does not need the independent suspension guide rod system and has a simple structure, the steering space of wheels is greatly improved, and the smaller steering radius can be realized.

Owner:TONGJI UNIV +1

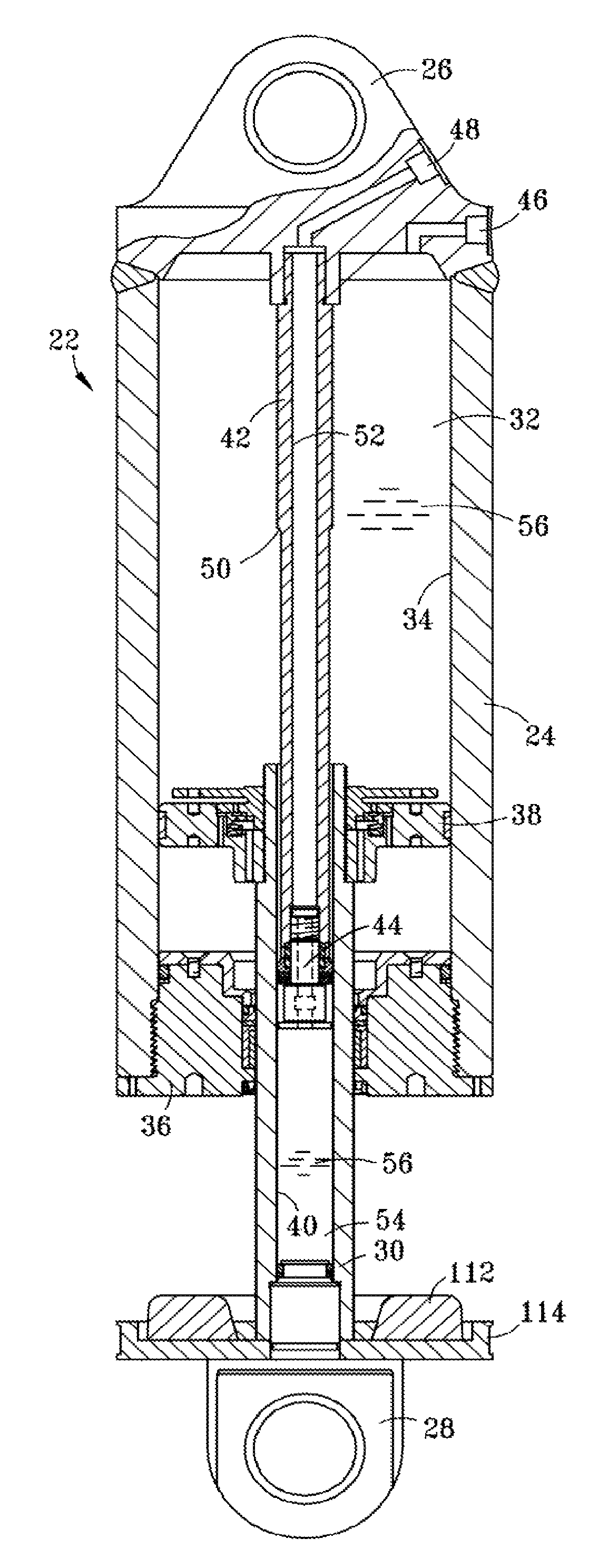

Compressible Fluid Independent Active Suspension

An active, independent suspension system has dual piston, compressible fluid struts (22). Each of the dual piston struts (22) has an outer cylinder (24) and an outer piston rod (30), which each respectively define exterior peripheries for an outer pressure chamber (32) and an inner pressure chamber (54). Pressures applied to a compressible fluid (56) in respective ones of the outer and inner pressure chambers (32, 54) urge the outer piston to extend from within the outer cylinder (24). A control system (240) is provided for actively controlling an amount of compressible fluid (56) disposed within each of the outer and inner chambers (32, 54).

Owner:HORSTMAN

Small-sized intelligent spraying vehicle

InactiveCN103147416ASimple structureLow costWatering devicesRoad cleaningSolenoid valveControl system

The invention provides a small-sized intelligent spraying vehicle. The spraying vehicle comprises a vehicle body (27), a power supply (13), a travel mechanism, a pressurizing spraying system and a control system, wherein the travel mechanism comprises front wheels (28) and rear wheels (9), which are arranged on a framework chassis; the front wheels (28) are driven by an independent suspension structure; the rear wheel (9) are respectively driven by a motor (8); the pressurizing spraying system consists of an air way and a waterway, and the on-off of the air way and the waterway are controlled by a solenoid valve; the control system comprises a master controller (14) and a pavement monitoring sensor for monitoring a pavement state and transmitting monitored information to the master controller; and the master controller receives signals from the pavement monitoring sensor, and analyzes and calculates the signals to control the corresponding actions of the front wheels, the rear wheels and the pressurizing spraying system to realize intelligent spraying without depending on manpower.

Owner:LUOYANG INST OF SCI & TECH

Articulation of suspension in an independently suspended beam structure

InactiveUS6840338B2Reduces and minimizes problemEasy to climbResilient suspensionsEndless track vehiclesEngineeringIndependent suspension

A half-track all-terrain vehicle having an independent suspension system that provides an improved vehicle ride and facilitates traversing obstacles. The vehicle includes a frame, a pair of beams that each holds front and rear wheels, and a suspension system extending between the each beam and the frame. The suspension system includes a plurality of cushions. The cushions are tuned such that forward cushions have a relatively greater suspension stroke than the rearward cushions and thereby permit the front wheels to engage the ground sequentially before the rear wheels when the vehicle goes over a step or drop off. The suspension system is further tuned to permit the vehicle to traverse an obstacle having a height that is slightly lower than the frame clearance by permitting the front wheels to lift vertically to a distance essentially equal to the frame clearance.

Owner:HONDA MOTOR CO LTD

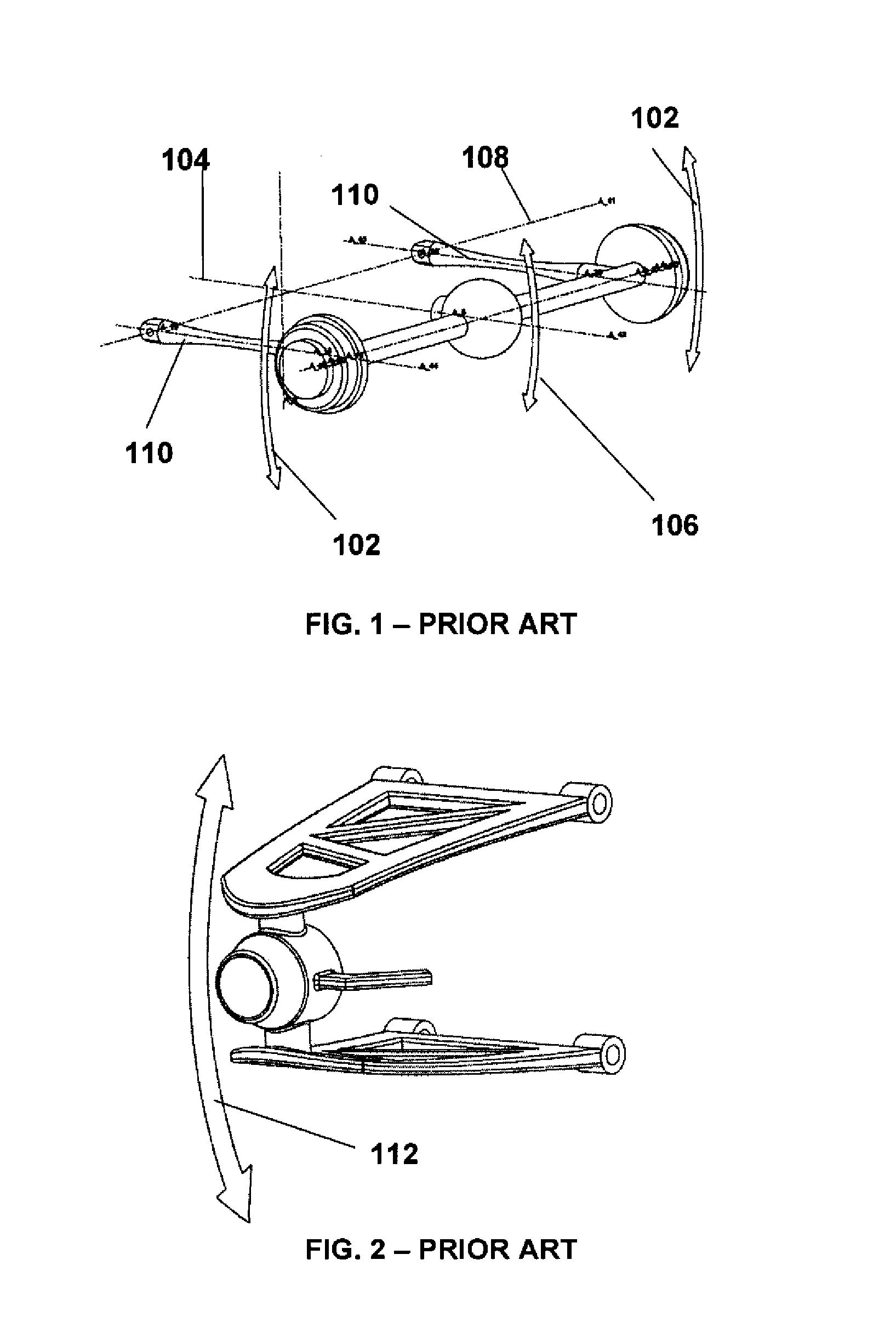

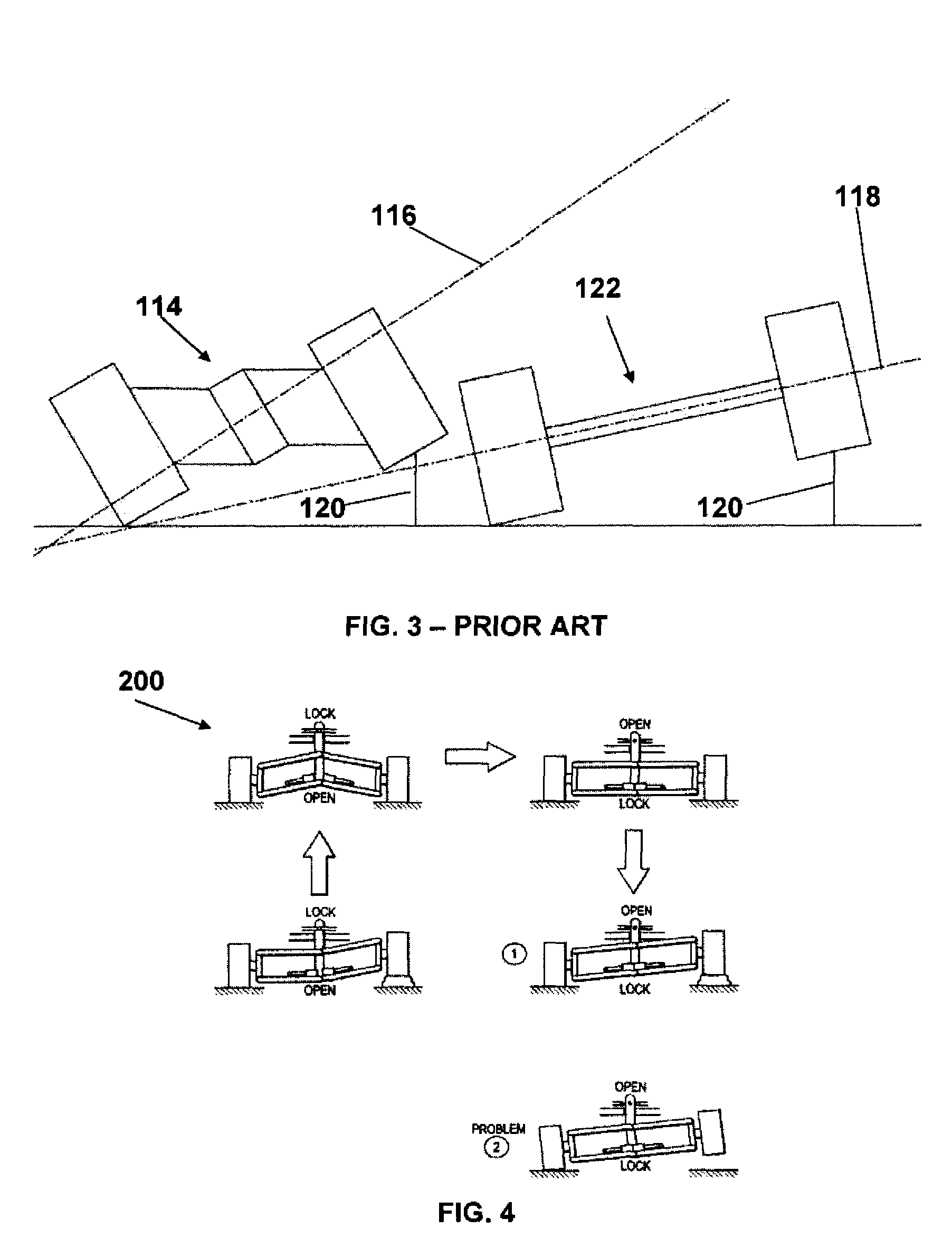

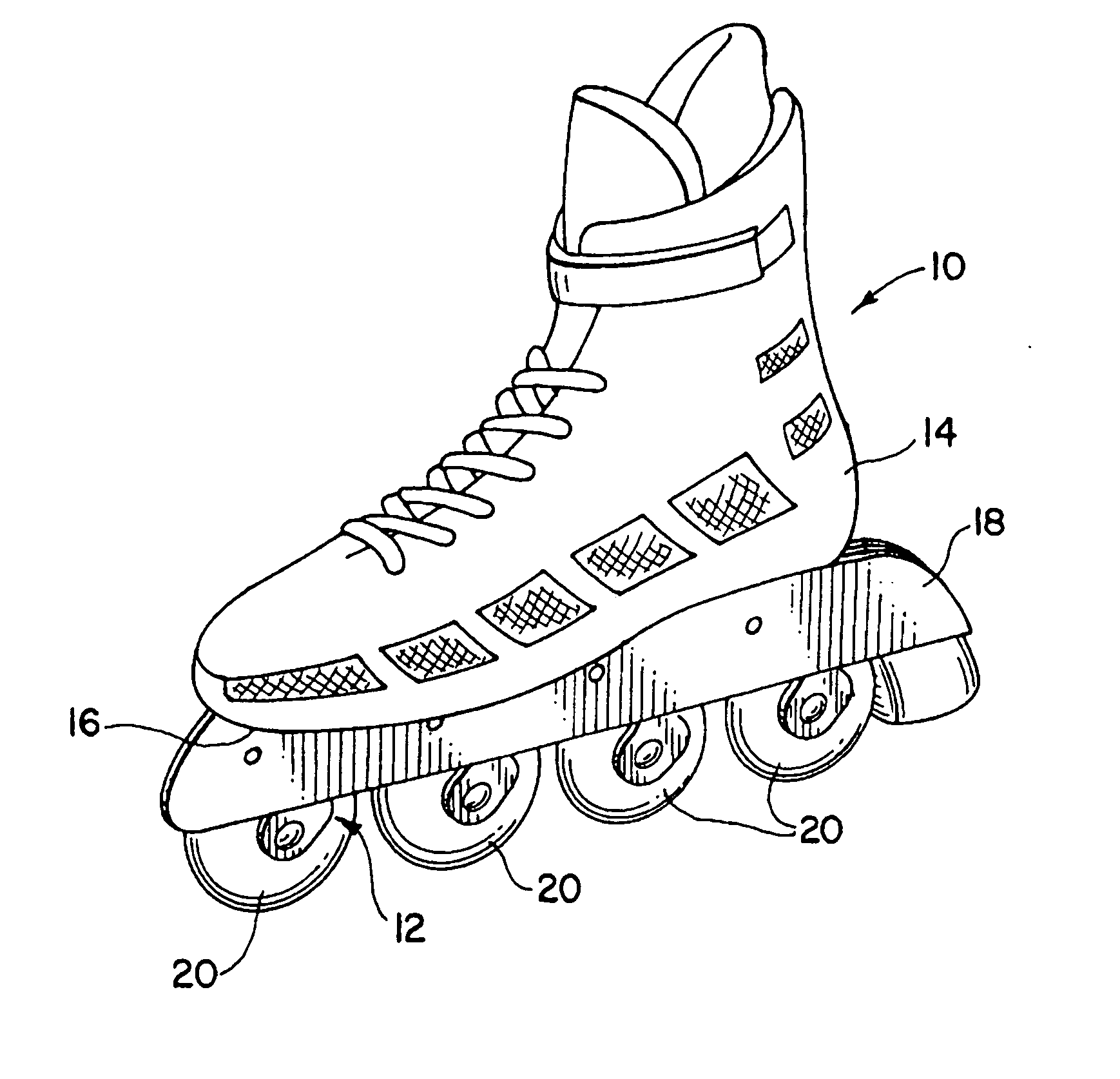

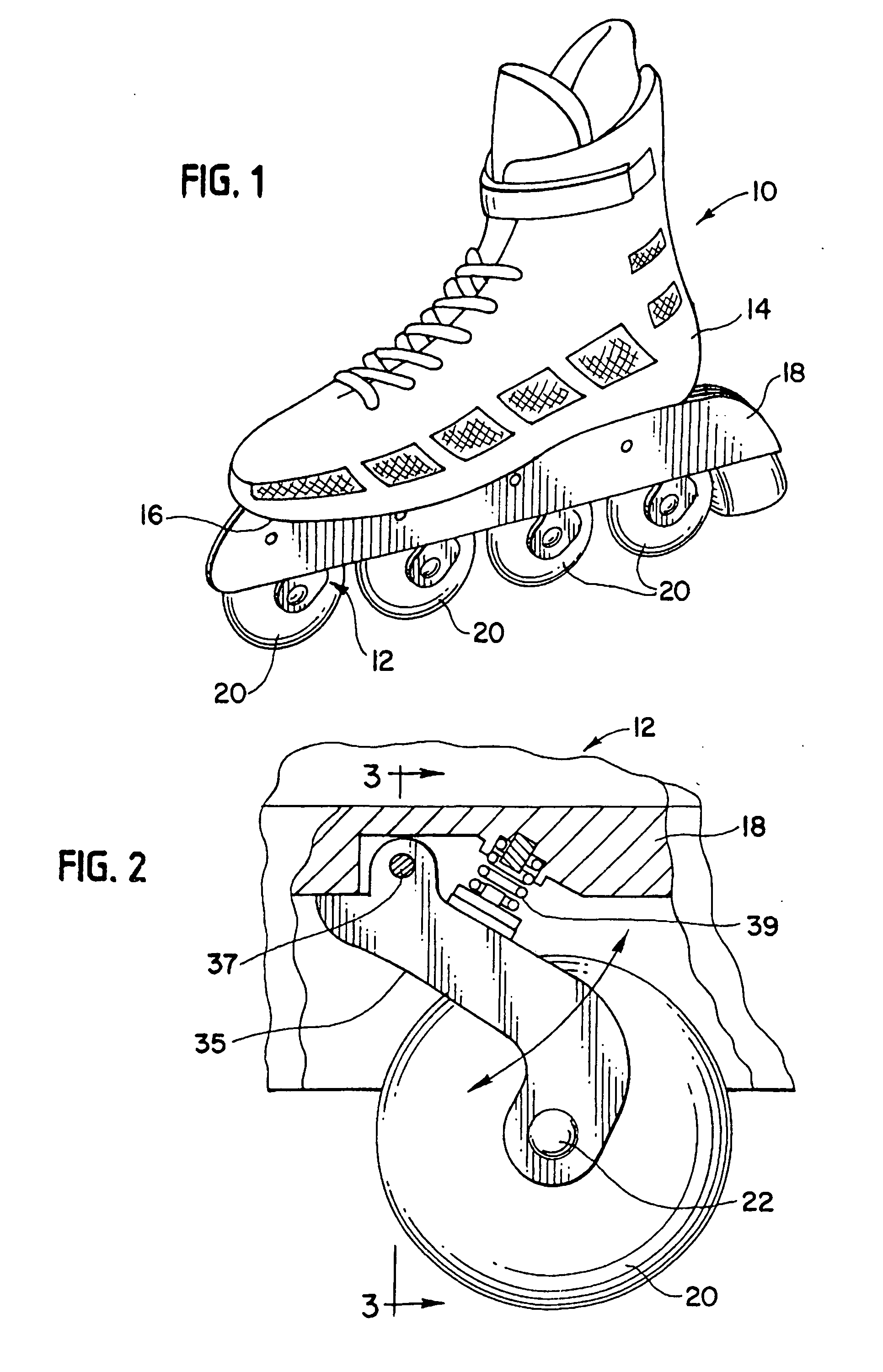

Independent suspension system for in-line skates having rocker arms and adjustable springs

InactiveUS20050225041A1Improve performanceEasy rideSkatesSkate-boardsEngineeringIndependent suspension

The present invention provides a suspension system for in-line skates. The in-line skate includes a boot and a tracking system attached to the sole of the boot. Opposing rocking arms that hold the wheels are connected to the tracking system using a truncated axle. In addition, an adjustable spring can be configured between the opposing rocker arms.

Owner:LONGINO ROBERT KEITH

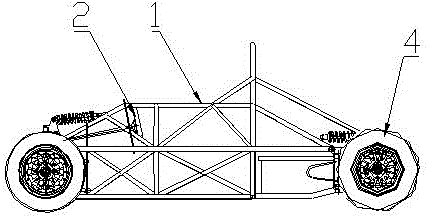

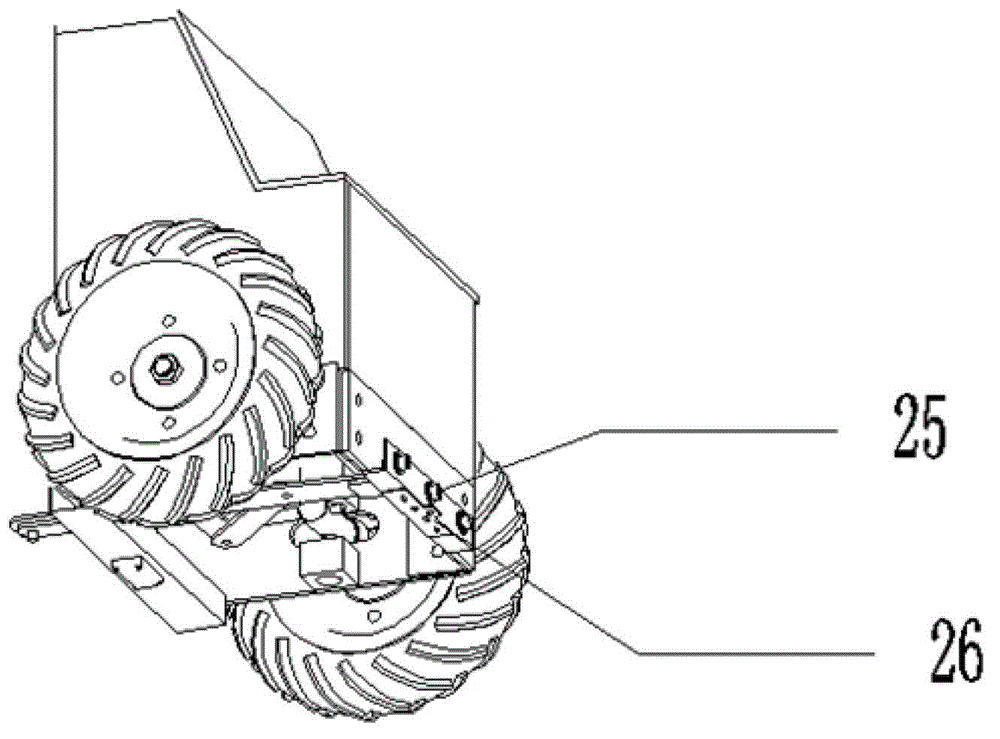

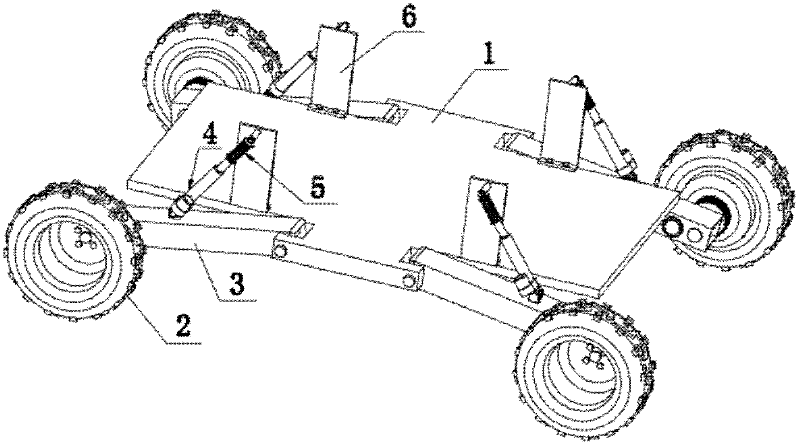

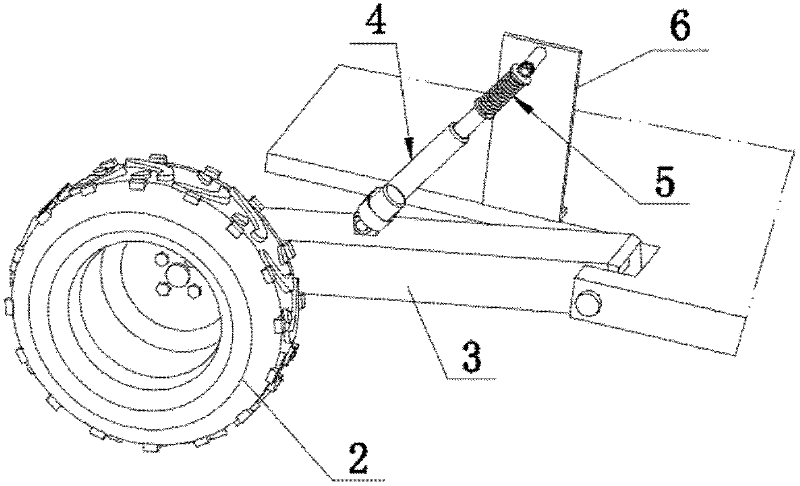

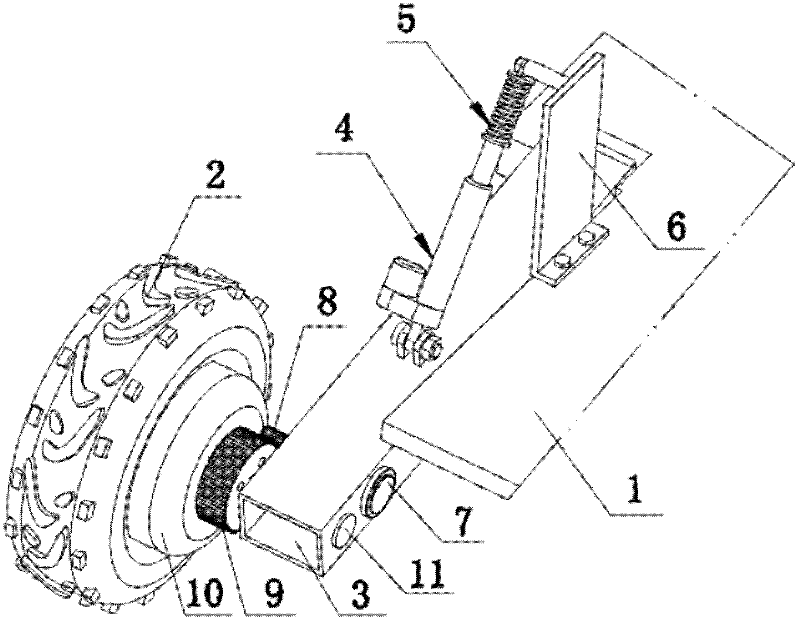

Robot traveling device with liftable frame

InactiveCN102390462AWalking smoothlyImprove obstacle performanceResilient suspensionsVehiclesVehicle frameMotor drive

The invention relates to a robot traveling device with a liftable frame. The traveling device is provided with a frame (1), four wheels (2), independent suspension brackets and a motor driving device, wherein each independent suspension bracket and the motor driving device are arranged between each wheel (2) and the frame (1); each independent suspension bracket consists of a cantilever (3) and adamper; the axis of the cantilever (3) is positioned in a longitudinal vertical plane of the frame (1), one end of the cantilever (3) is hinged with the frame (1), and the other end of the cantilever(3) is hinged with an axle (11) of the wheels (2); the lower end of the damper is hinged with the middle part of the cantilever (3), and the upper end of the damper is hinged with the frame (1); and the traveling device is characterized in that: the damper consists of an electric push rod (4) and a bidirectional telescopic damper (5) which is coaxially and serially arranged on the end part of a push rod (4-2) of the electric push rod (4). The traveling device has the advantages of high obstacle surmounting capacity and stable and safe traveling.

Owner:GUANGZHOU UNIVERSITY

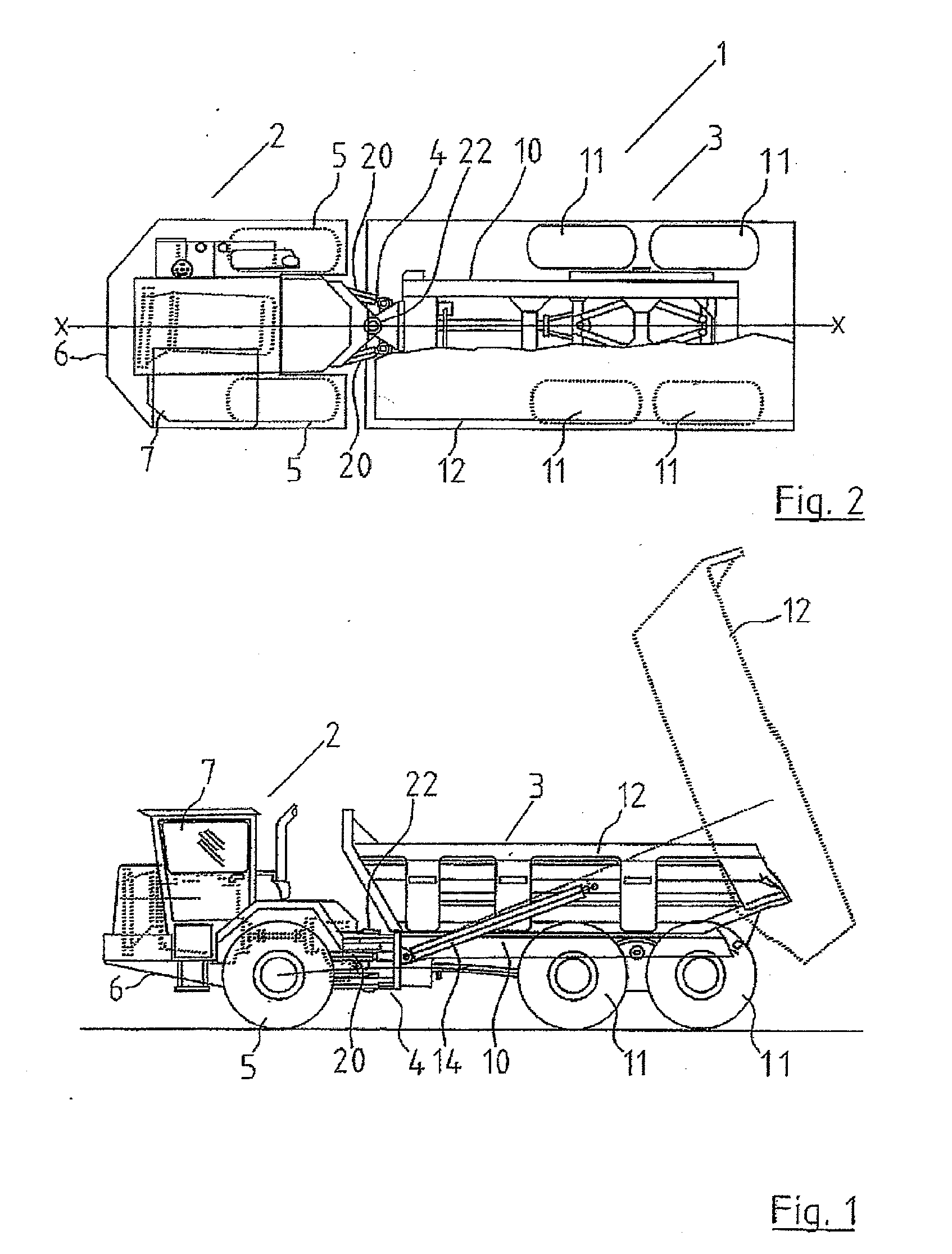

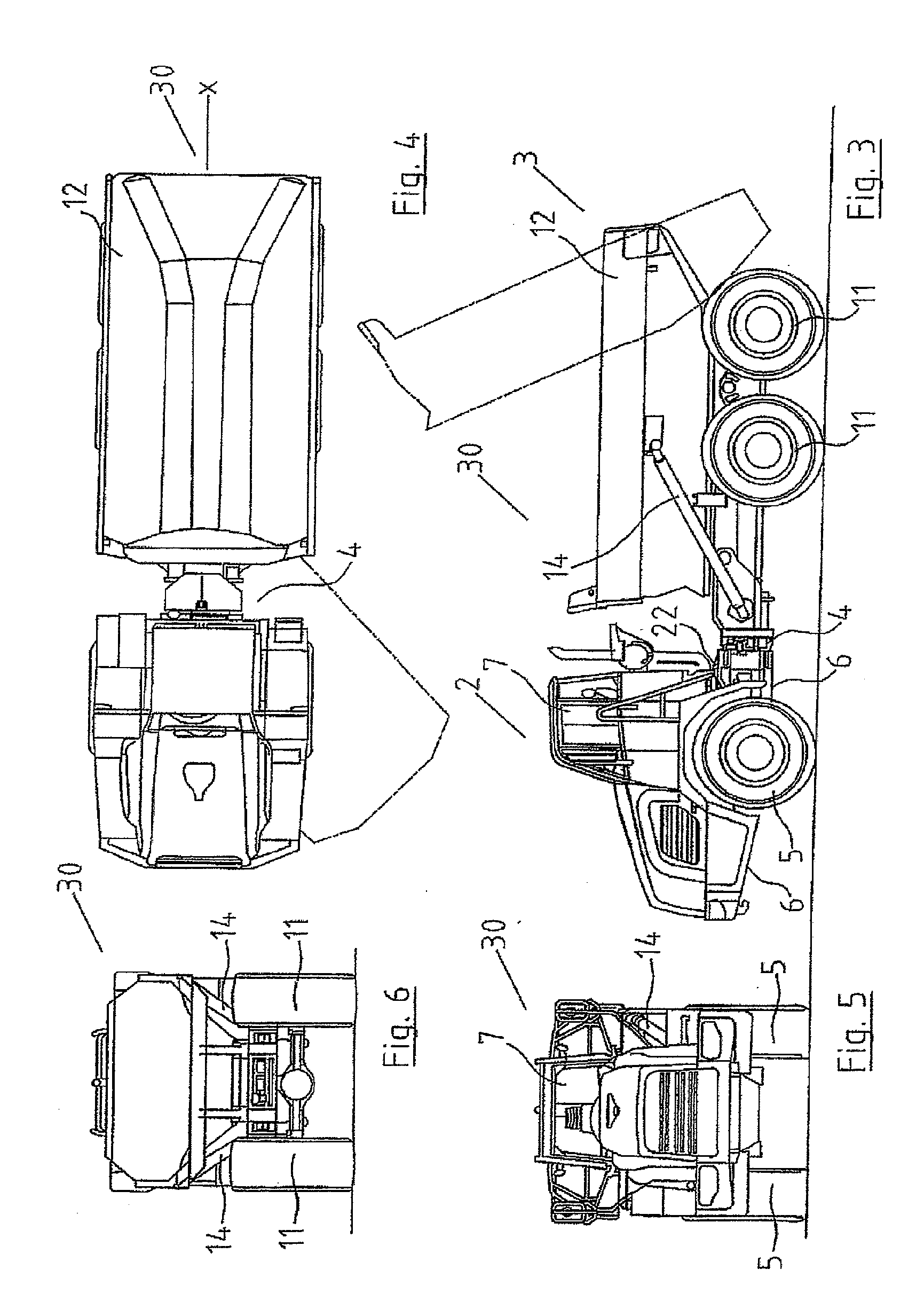

Articulated dump truck

InactiveUS20100102532A1Improve riding performanceVibration minimizationTractor-trailer combinationsInterconnection systemsCouplingTraction unit

Owner:TIMONEY EANNA PRONSIAS +1

Six link independent suspension for a drive axle

An independent suspension includes upper and lower control arms that are coupled to a knuckle that supports a wheel assembly. A spring bracket is pivotally connected to the lower control arm. A drive shaft extends through an opening in the spring bracket to drive the wheel assembly. The spring bracket includes first and second support plates that respectively support first and second springs on opposite sides of the drive shaft. A torque rod is pivotally connected to the spring bracket. The torque rod and the upper and lower control arms are also mounted to a vehicle frame member. The torque rod, knuckle, spring bracket, upper and lower control arms, and vehicle structure cooperate to provide a six link control that accommodates large wheel jounce travel.

Owner:ARVINMERITOR TECH

Compressible fluid independent active suspension

Owner:HORSTMAN

Four-wheel or six-wheel differential-torsion rod spring suspension type vehicle-carrying mechanism

ActiveCN101033008ALight in massReduce power consumptionExtraterrestrial carsControl devicesIndependent suspensionPower consumption

The present invention is one four wheel or six wheel differential torsion bar spring vehicle suspension mechanism, which consists of a vehicle body, a four wheel or six wheel independent suspension mechanism, a differential device inside the vehicle body. The independent suspension mechanism has two independent two or three wheel suspension mechanism units separately on two sides of the vehicle body, and the differential device is fixed to these two suspension mechanism units. The present invention has the advantages of less wheels, light weight, low power consumption and easy control, and may be used in lunar rover and planet rover as well as all terrain vehicle and toy vehicle.

Owner:湖南哈工机器人研究院有限公司

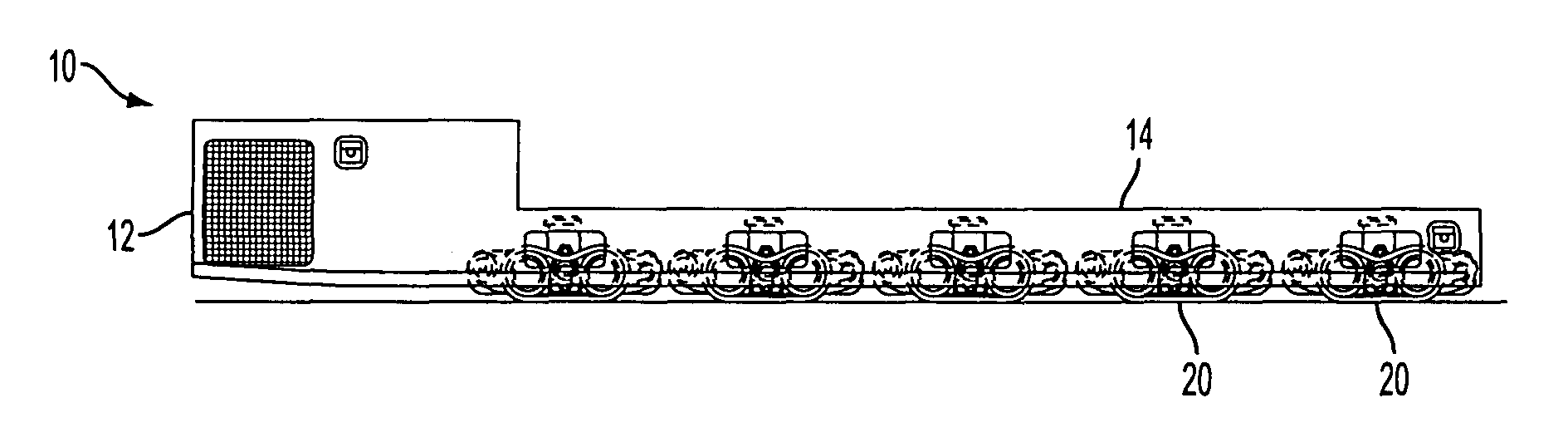

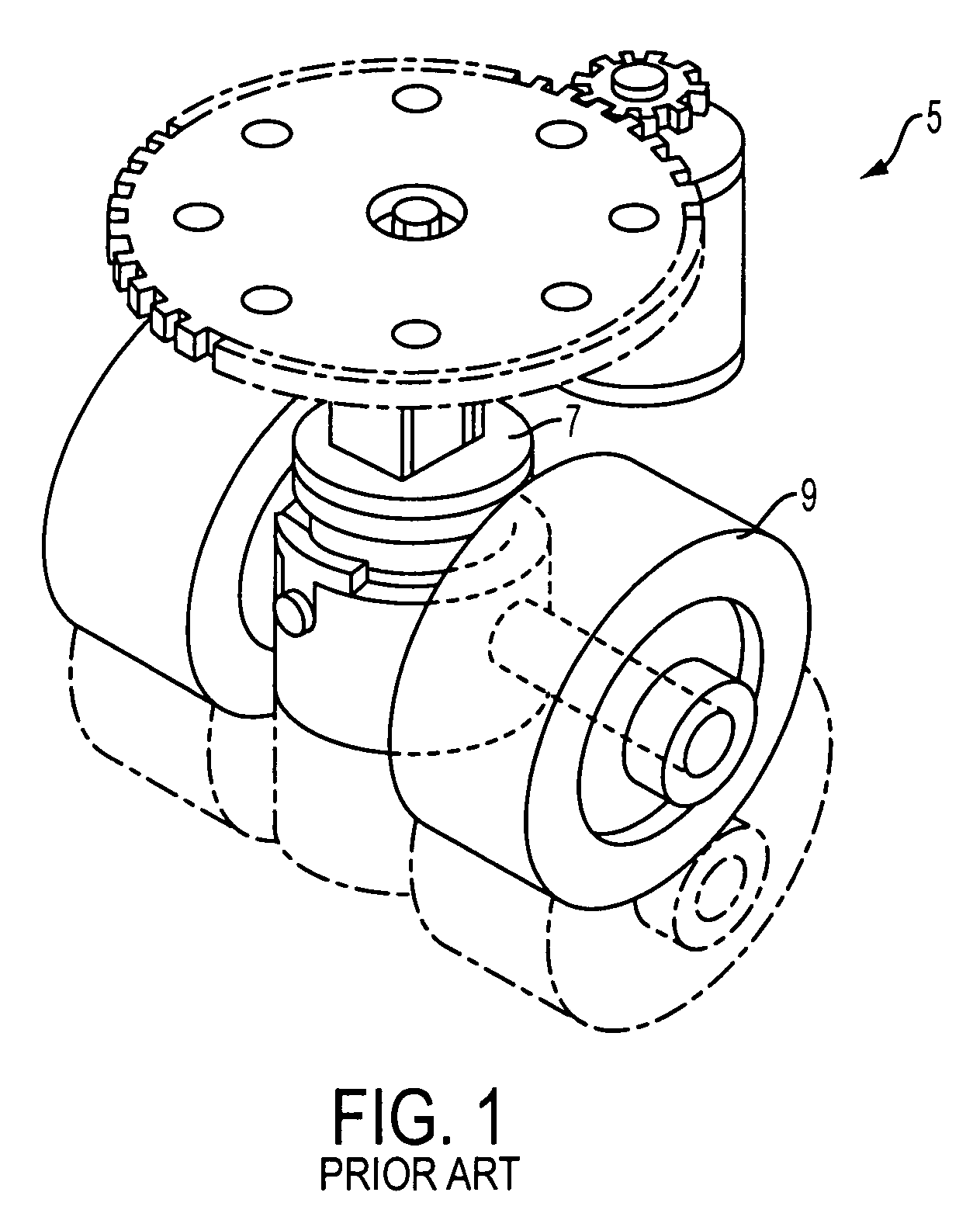

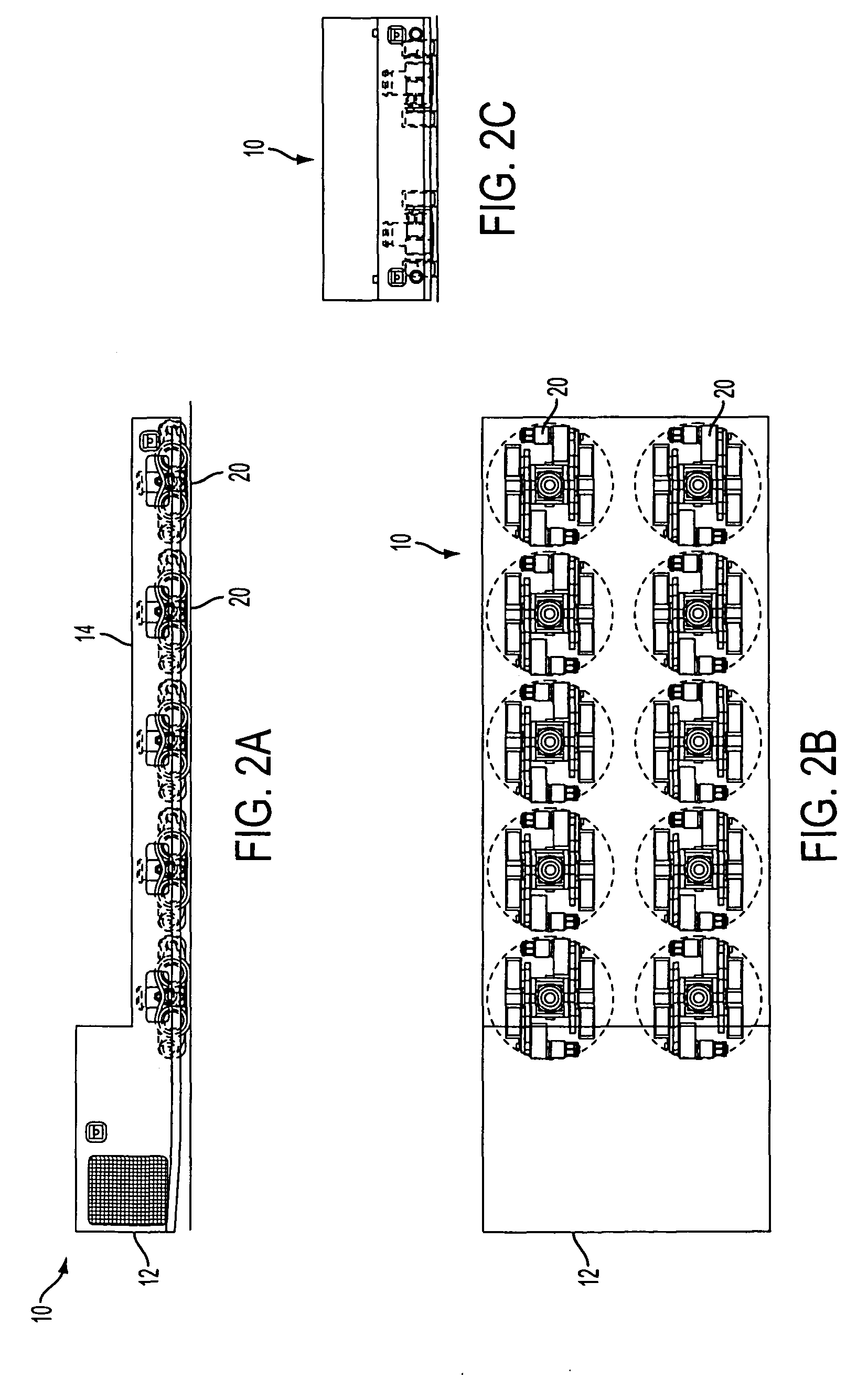

Heavy capacity transporter having multiple track-axles

InactiveUS7950478B2Reduce fluid pressureSteering linkagesLoading/unloading vehicle arrangmentEngineeringControl theory

A transporter having a plurality of track-axle assemblies. The track axle assemblies have independent suspension, self-loading, and on-center axle rotation capability. Each of the track axle assemblies include a cylinder housing and hydraulic piston and first and second track units connected on opposing sides of the axle frame.

Owner:INTELLIPORT CORP

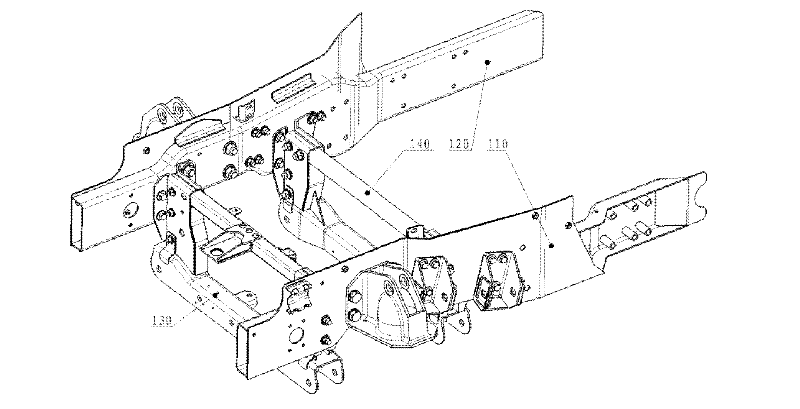

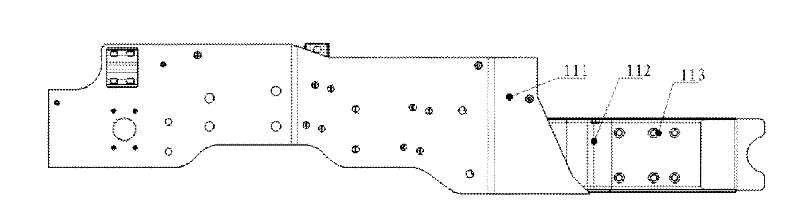

Independent suspension mounting bracket structure

InactiveCN102363407AHigh strengthStrong enoughUnderstructuresResilient suspensionsWhole bodyEngineering

The invention discloses an independent suspension mounting bracket structure. The independent suspension mounting bracket structure comprises a front independent suspension mounting structure and a rear independent suspension mounting structure. The independent suspension mounting structure comprises a left longitudinal body connecting beam, a right longitudinal body connecting beam, a first transverse mounting reinforcing beam, a second transverse mounting reinforcing beam, a bracket on a shock absorber and a triangular arm mounting bracket on a suspension. The independent suspension mounting structure also meets the mounting rigidity and strength requirements of steering, transmission, braking, cooling systems, air transport, air drop, mooring and securing and the like. The rigidity and the strength of the whole body are enhanced; and the requirements of the whole vehicle for the properties such as whole vehicle bearing, control stability, reliability and the like under the condition of a cross-country pavement with large torque or a severe pavement are met.

Owner:DONGFENG MOTOR CORP HUBEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com