Patents

Literature

167results about "Till seeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

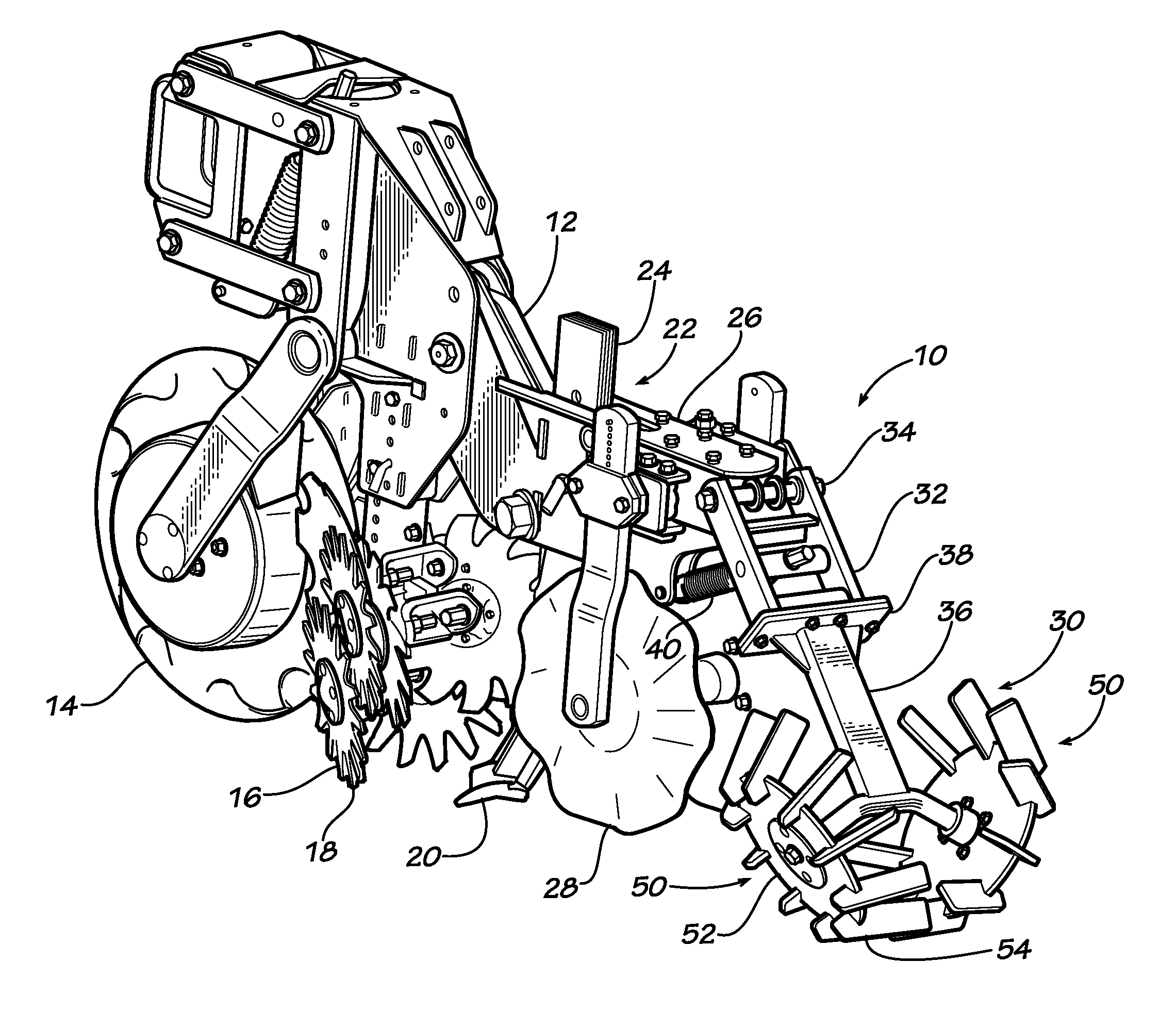

Fertilizer injector wing for disc openers

InactiveUS7004090B2High speed useReduce distractionsTill seedingDirect liquid fertiliser deliverySeederAgricultural engineering

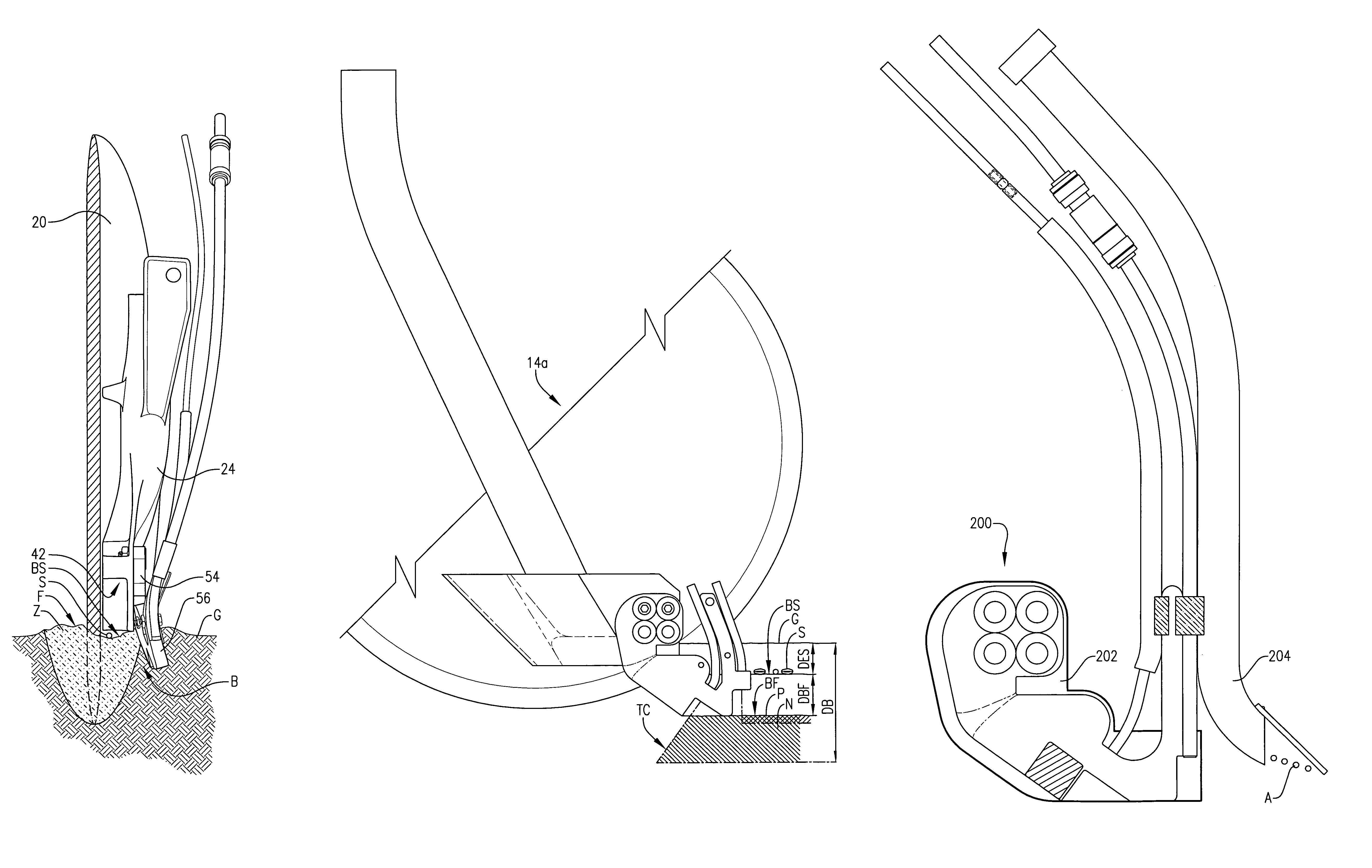

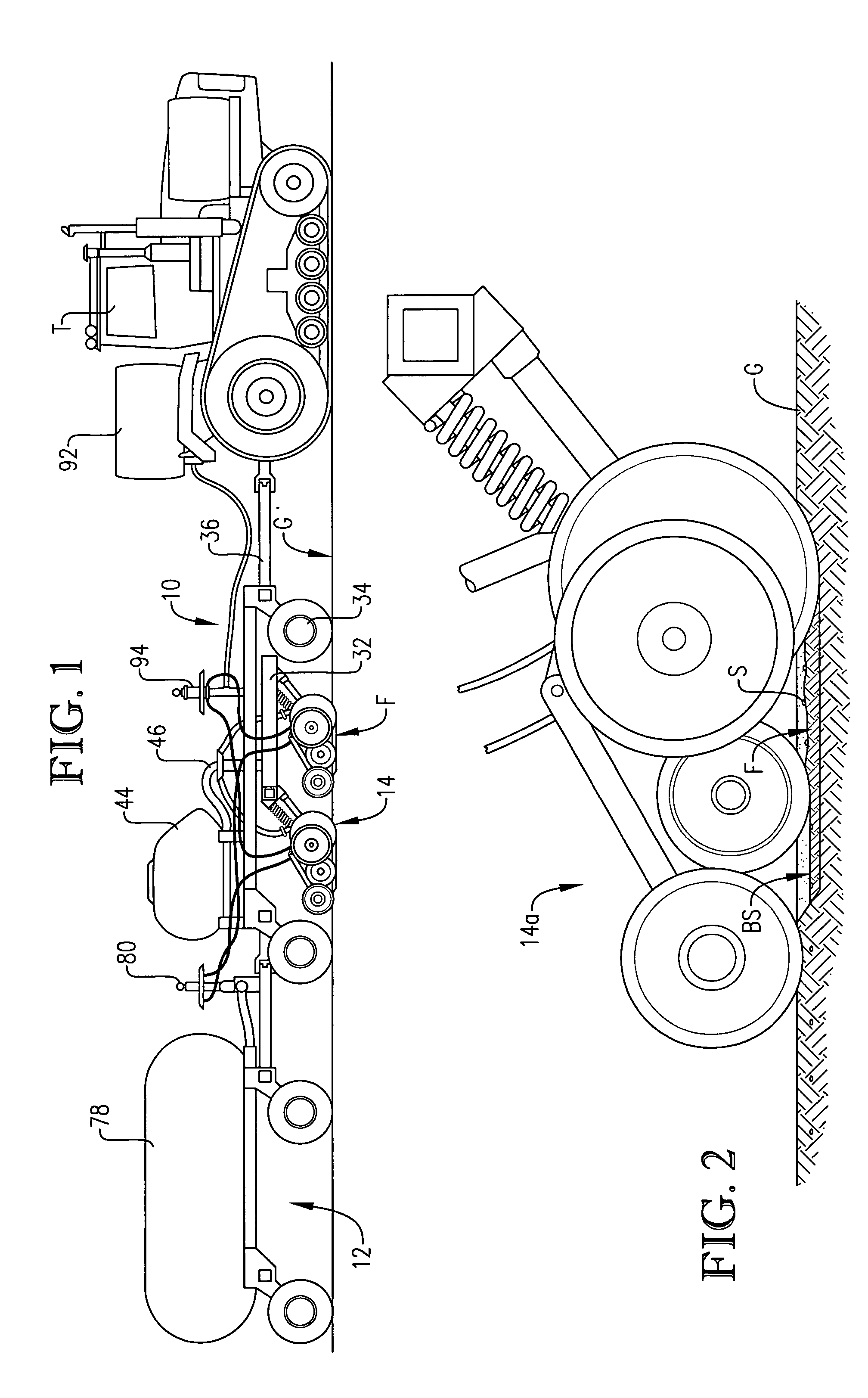

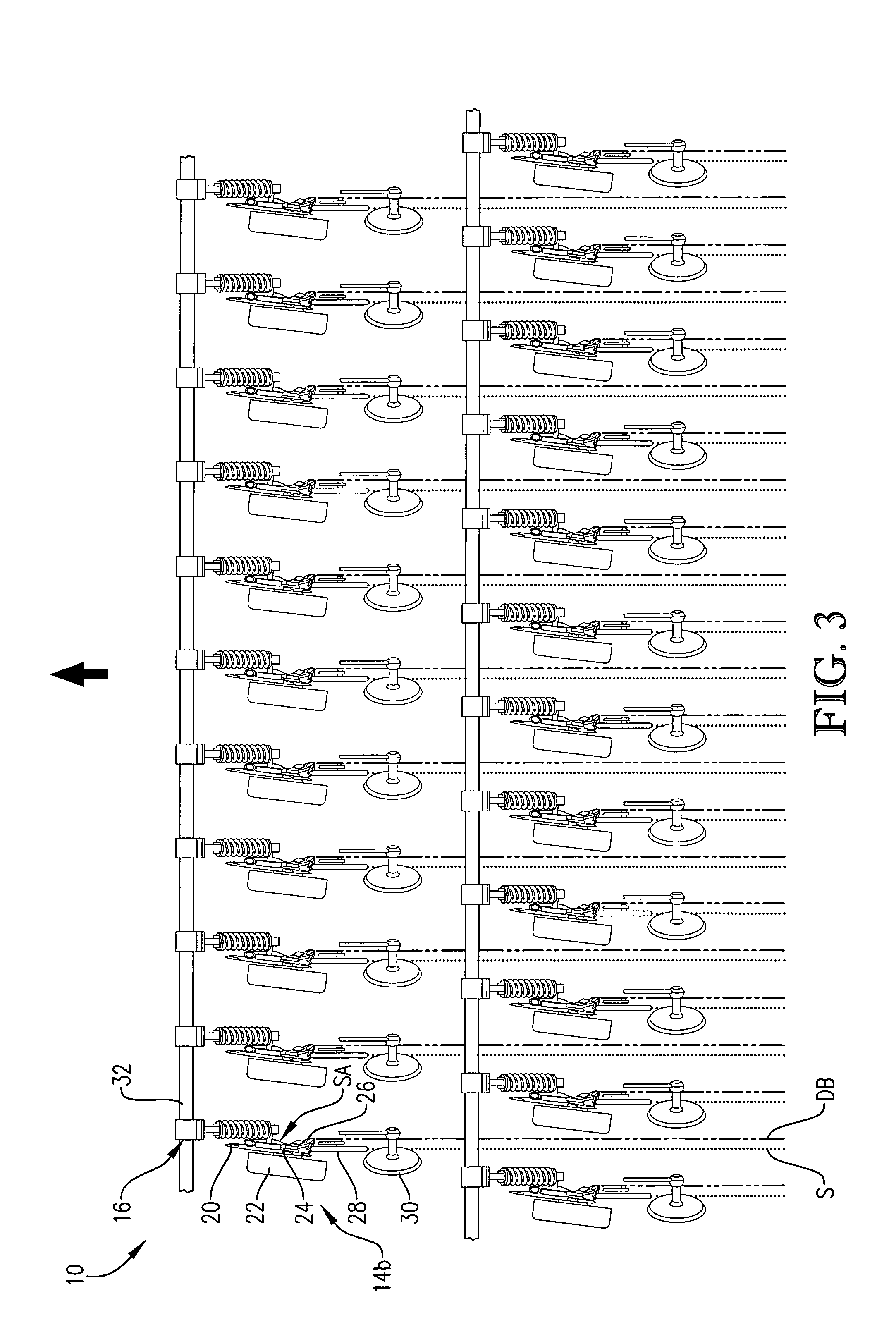

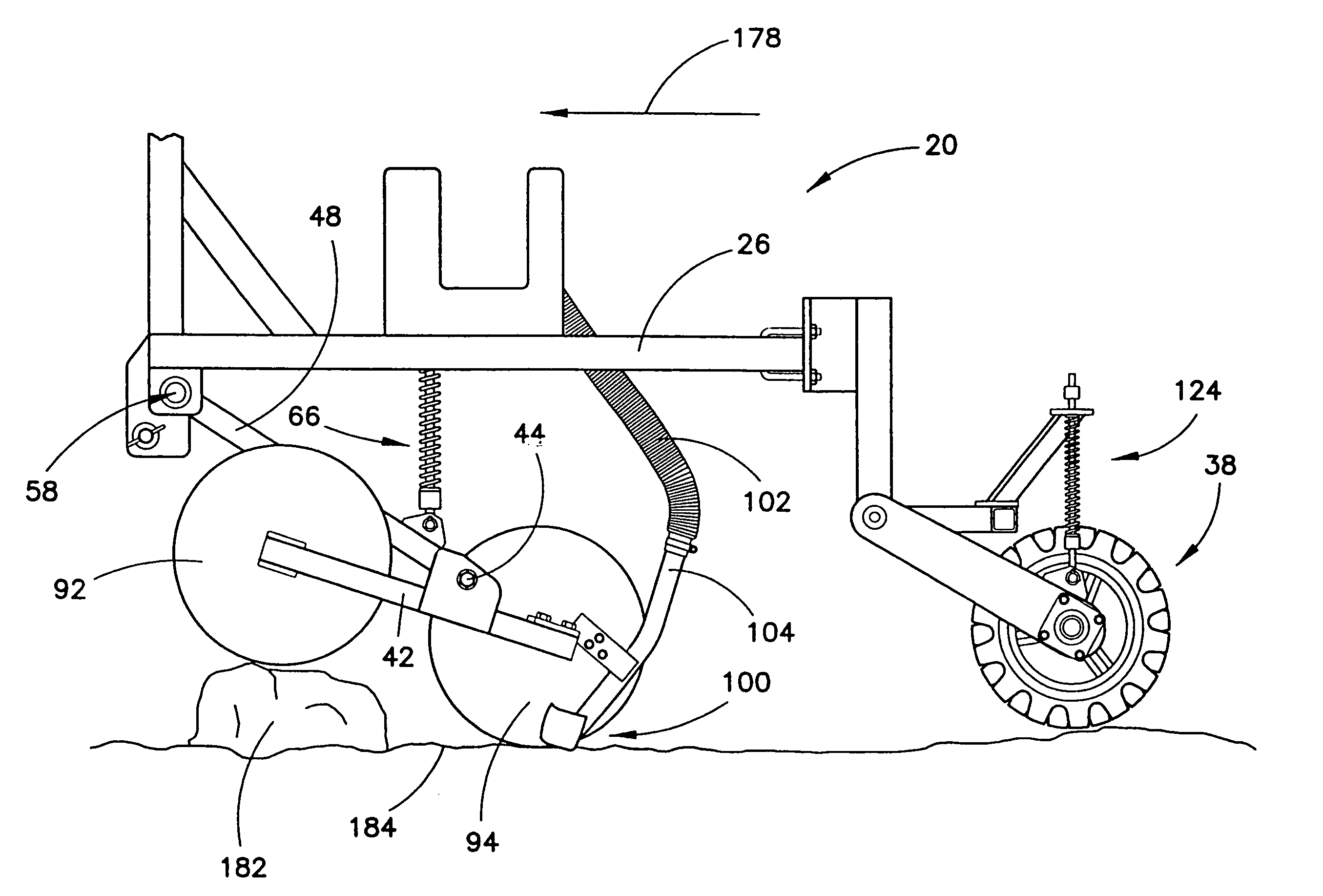

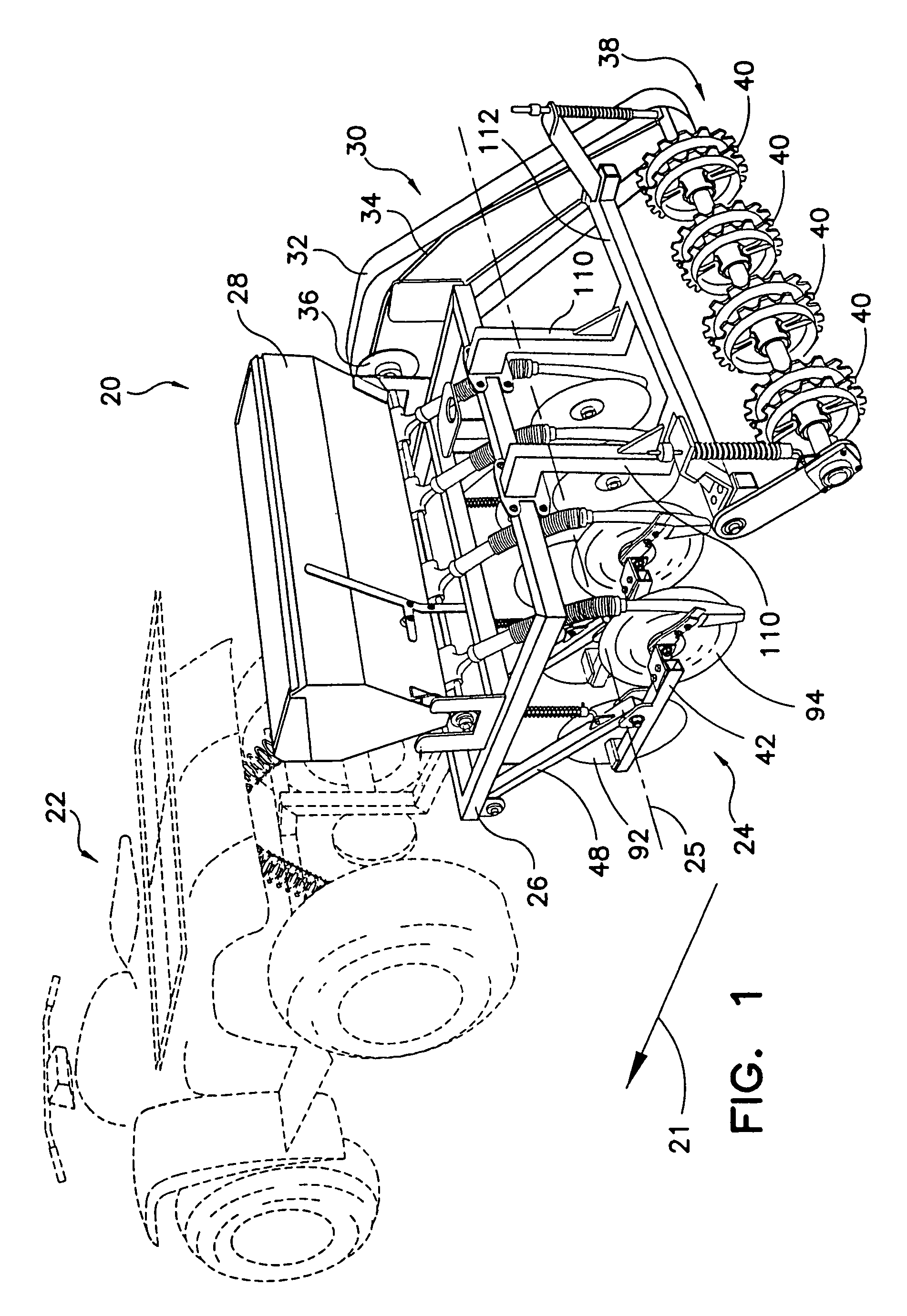

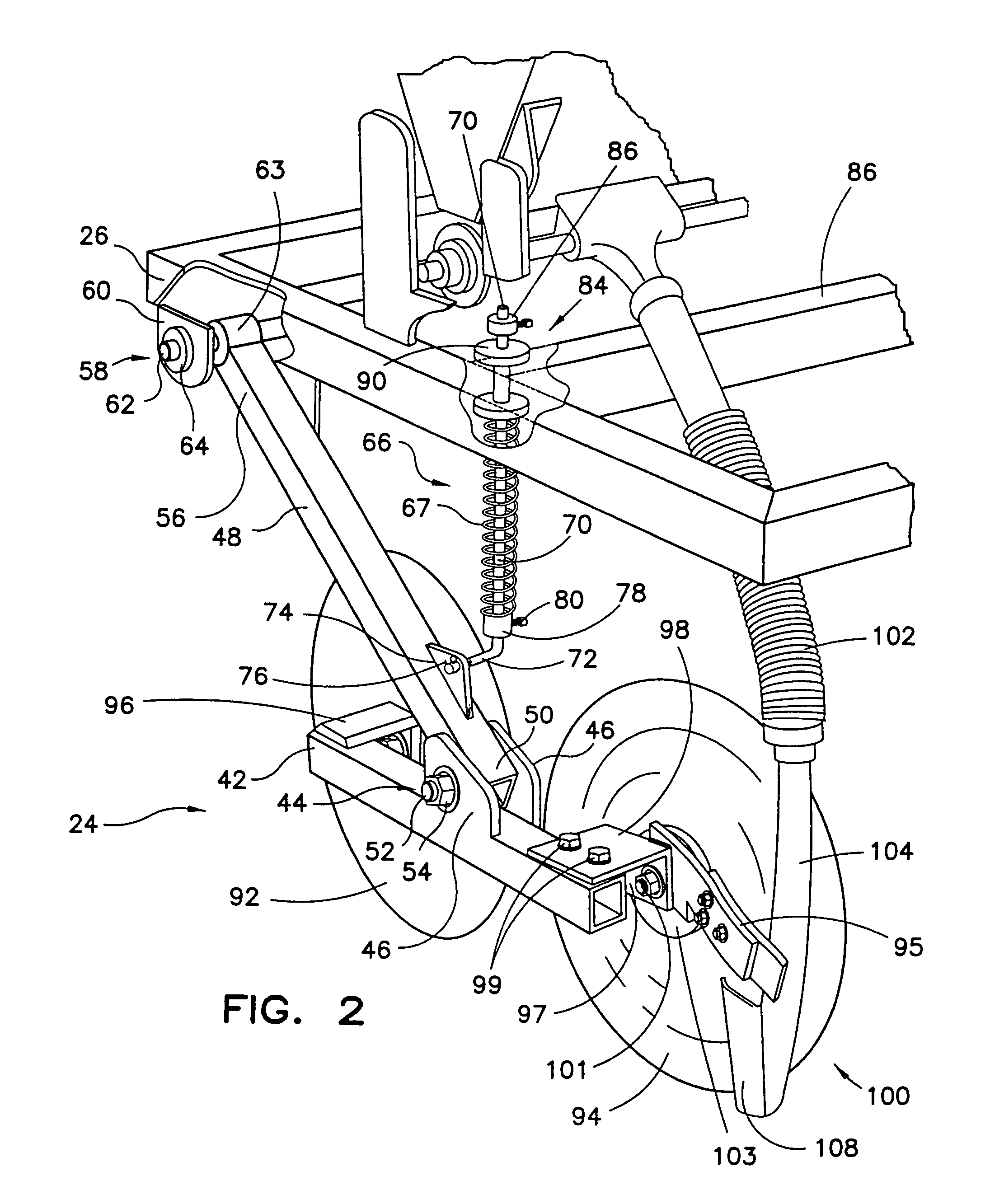

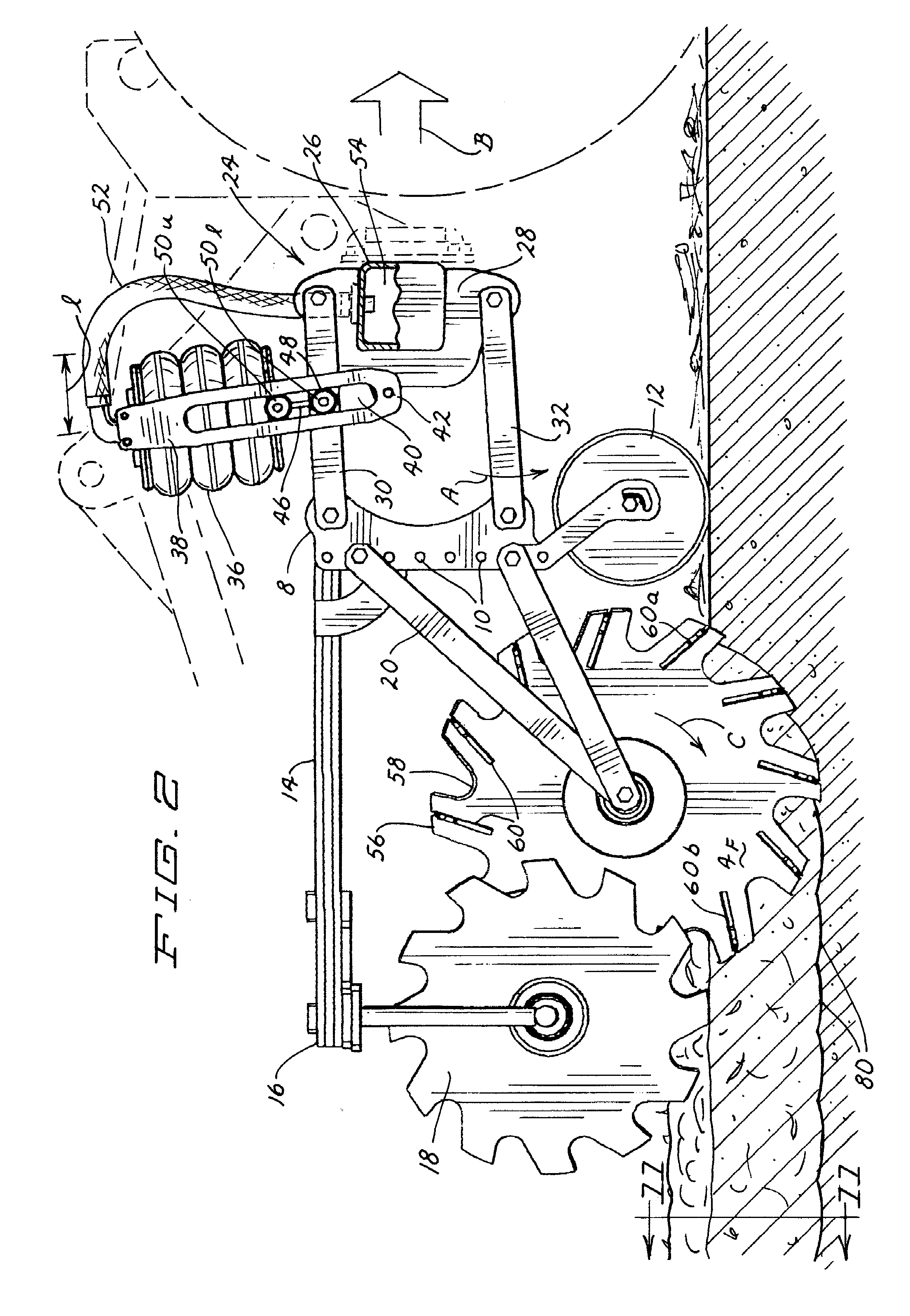

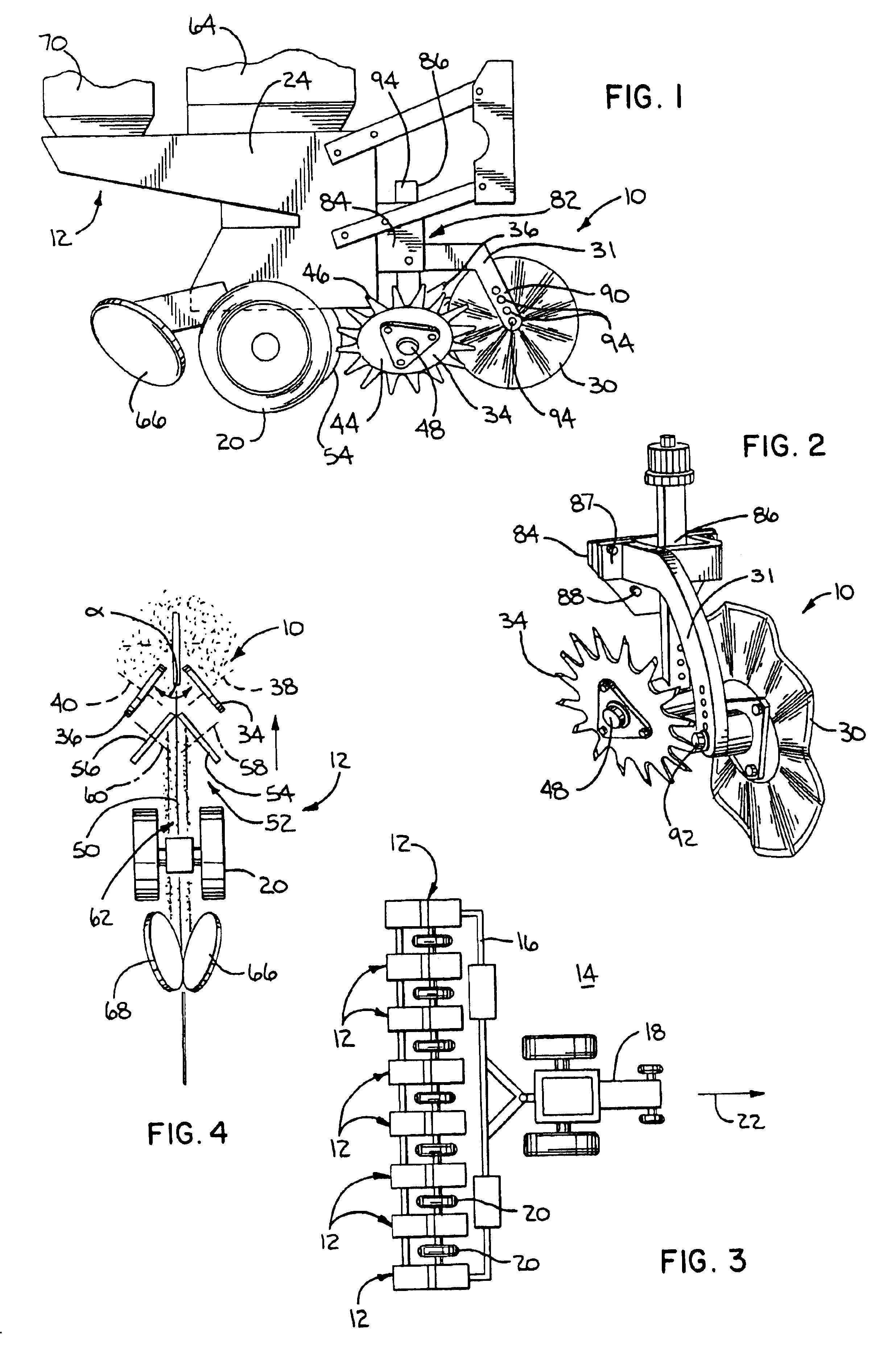

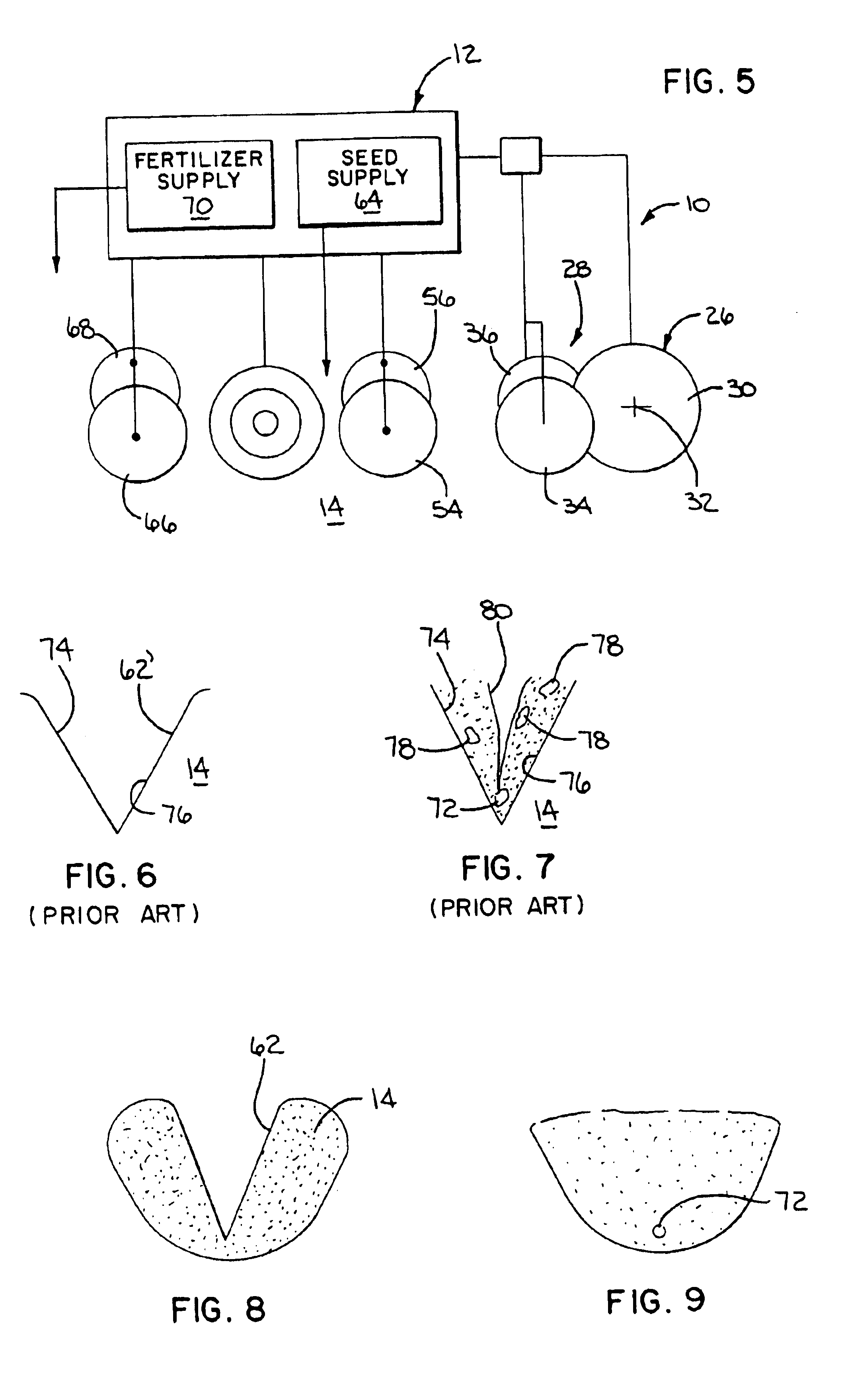

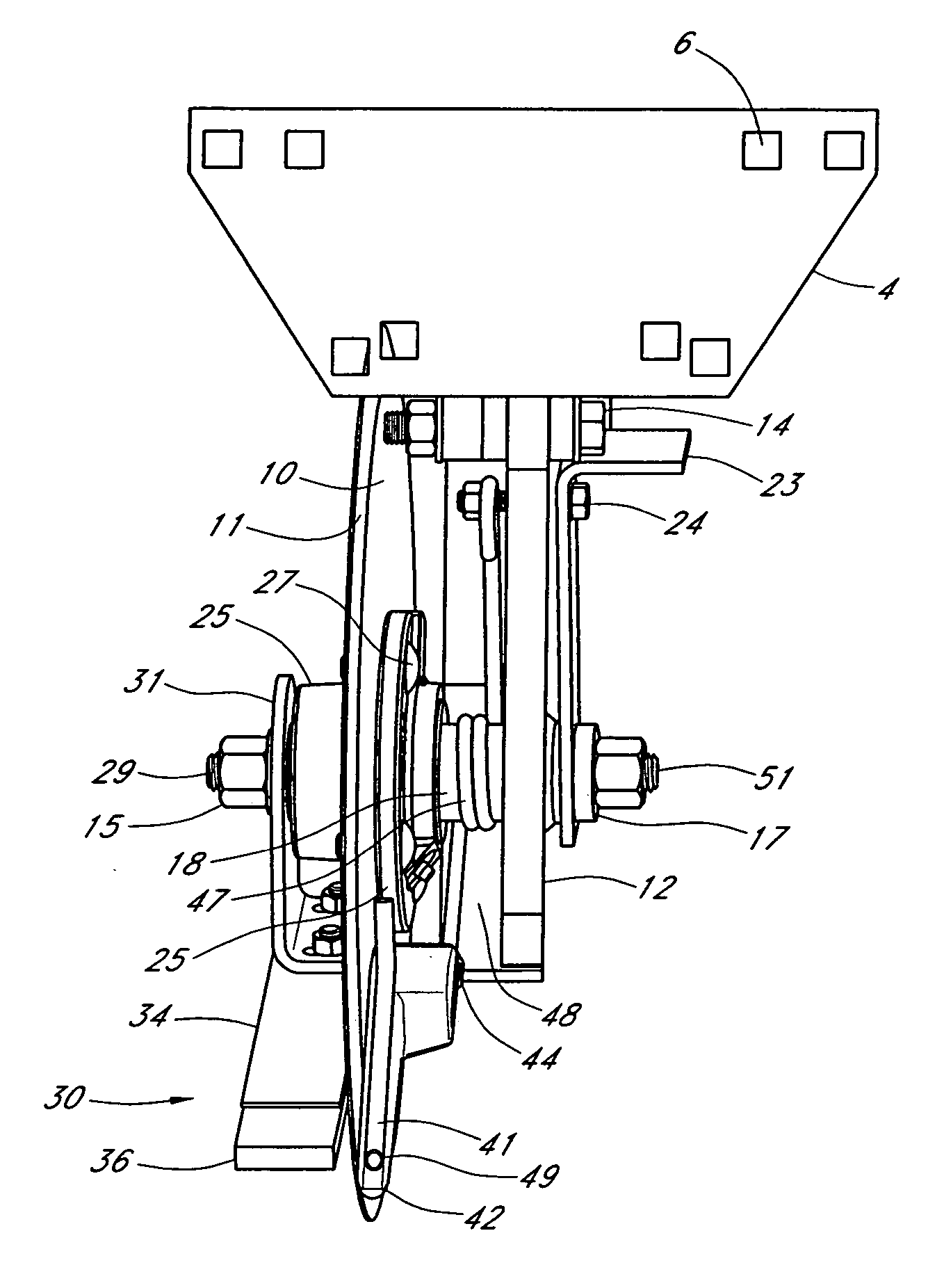

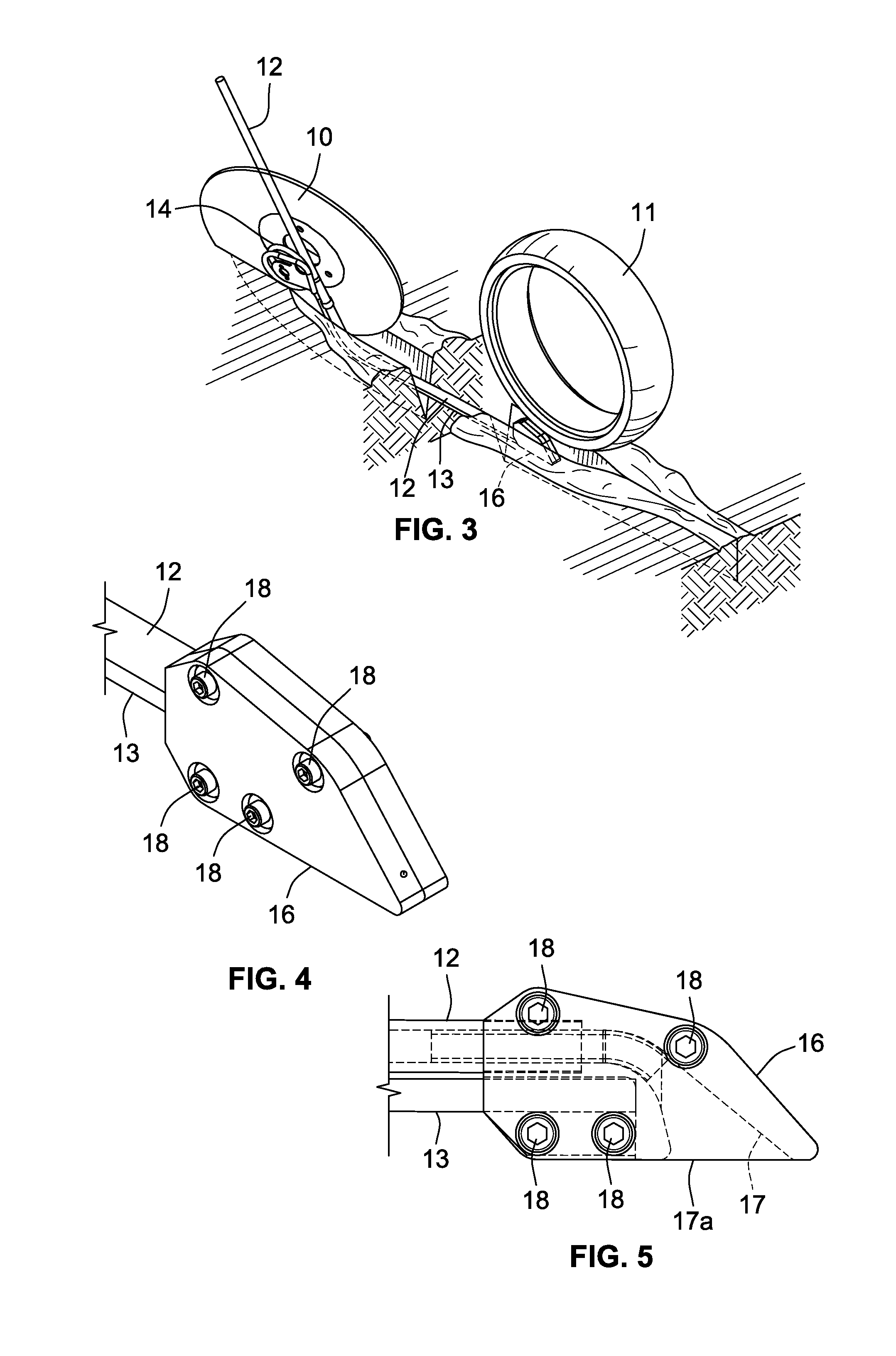

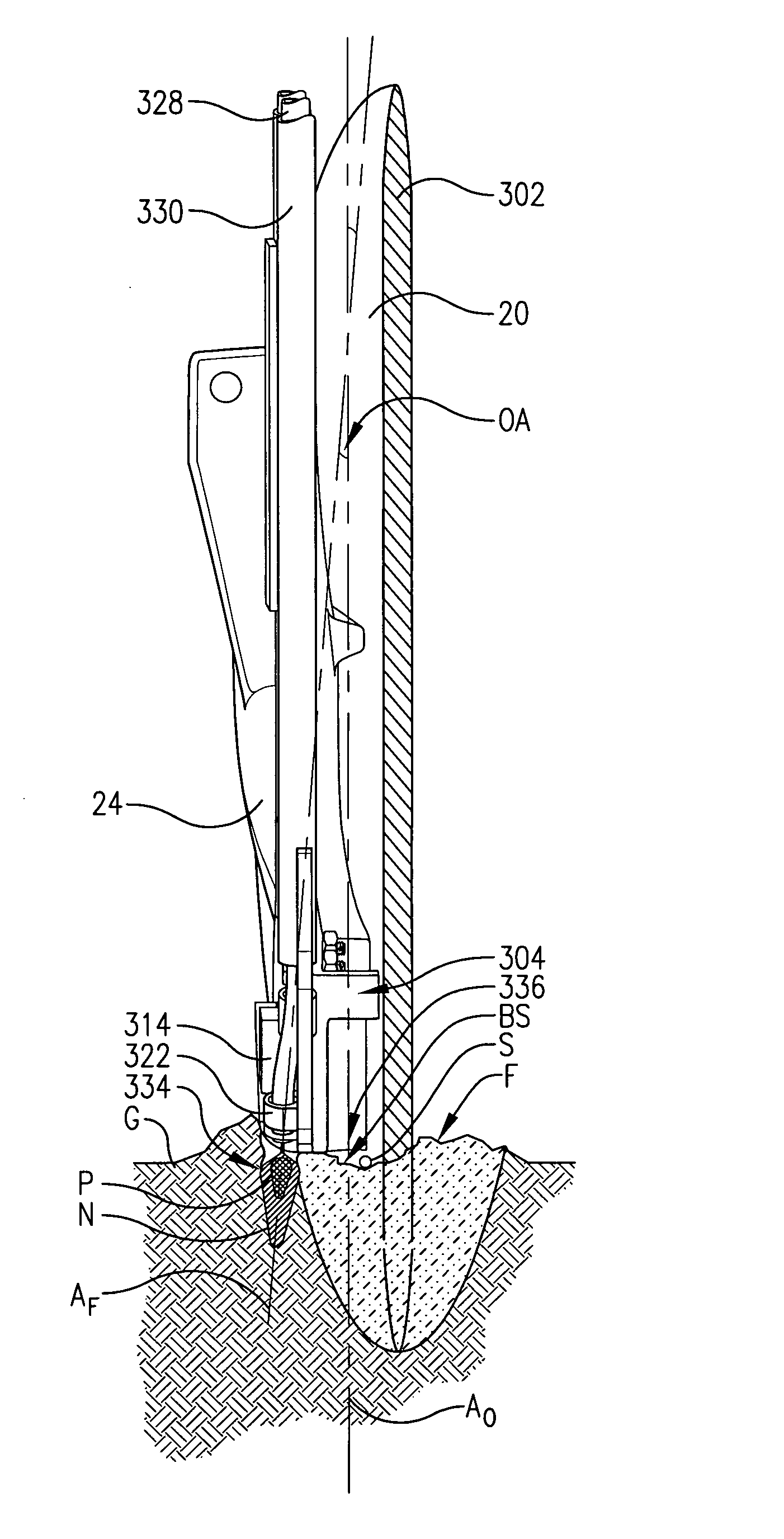

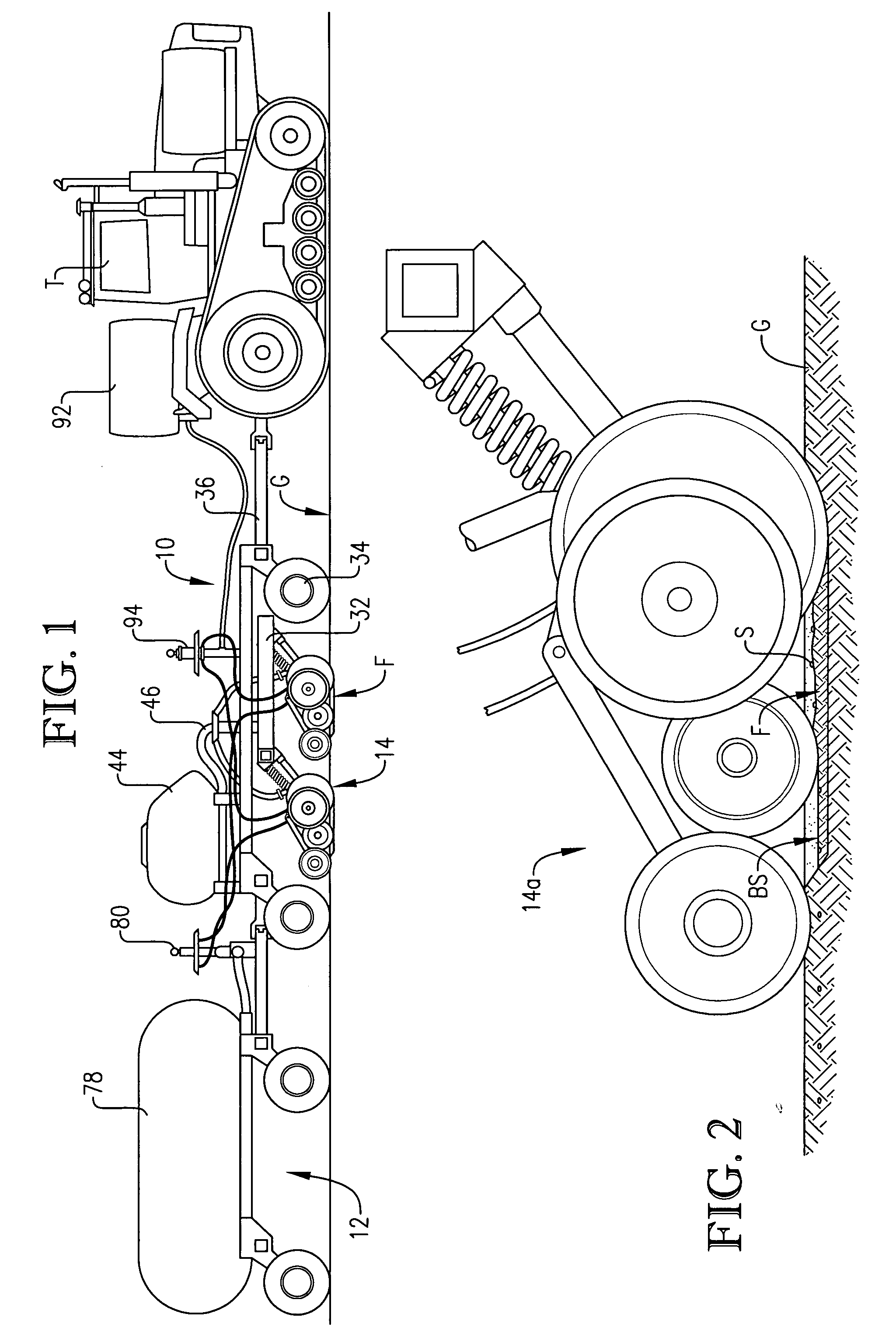

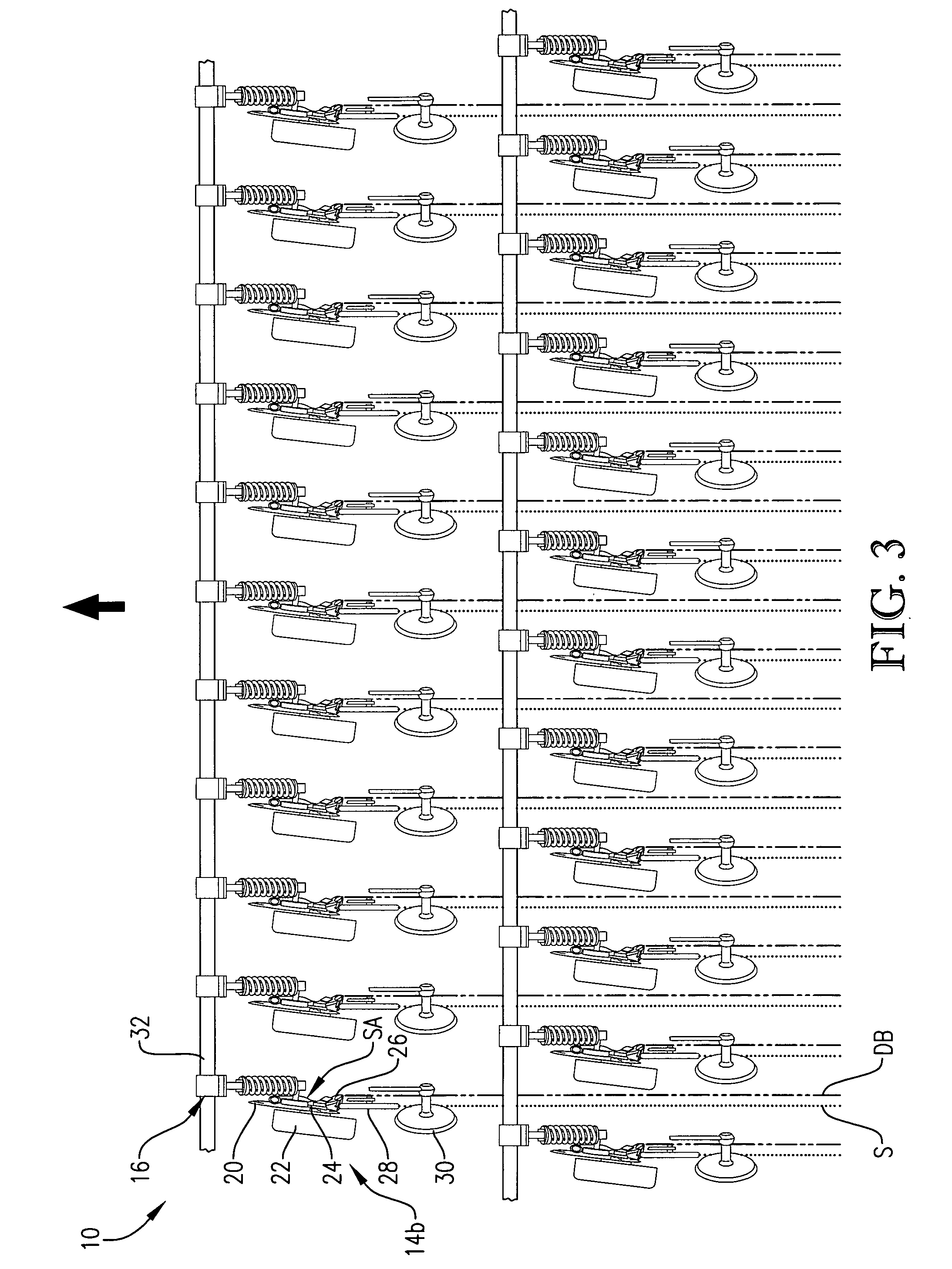

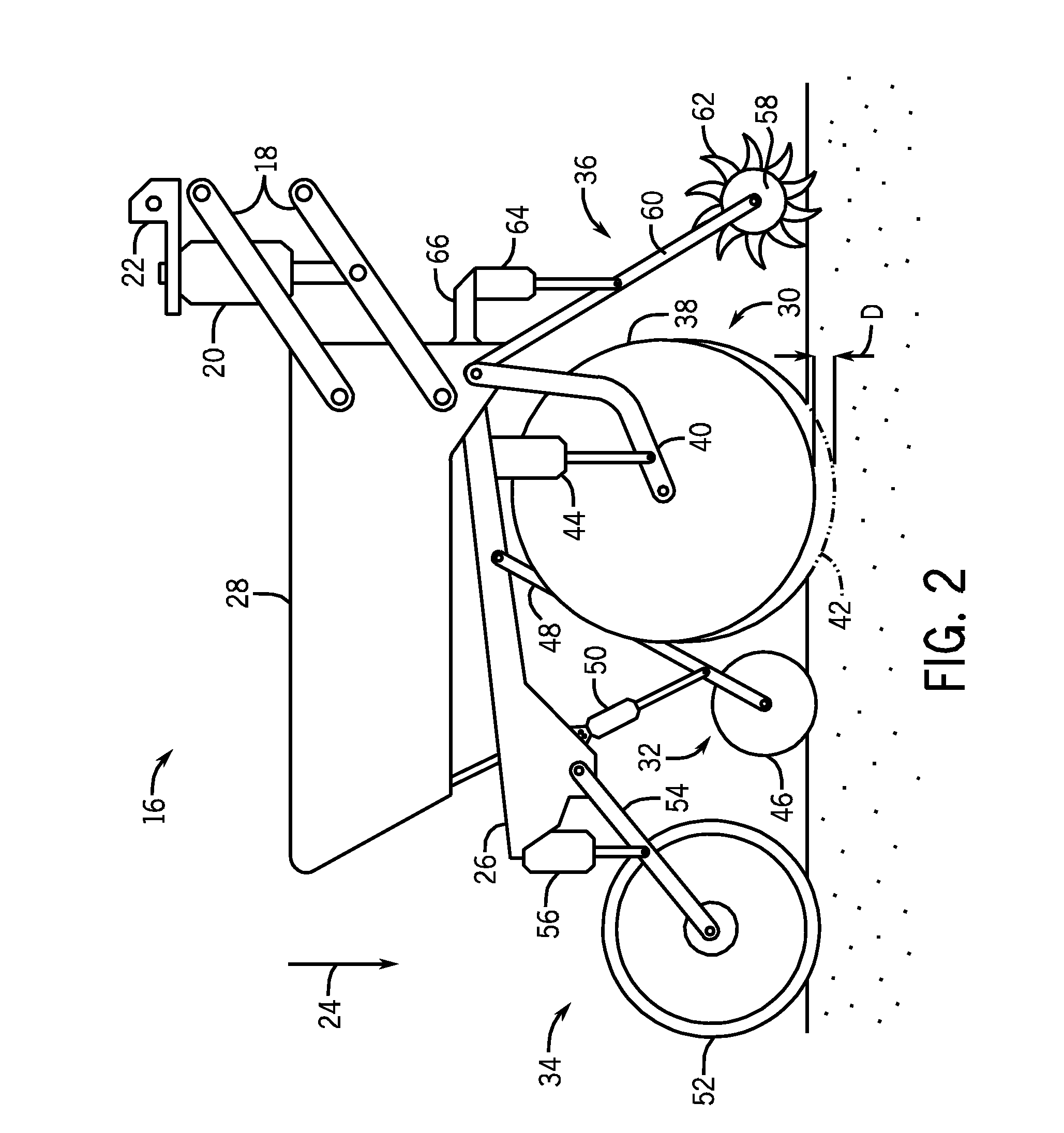

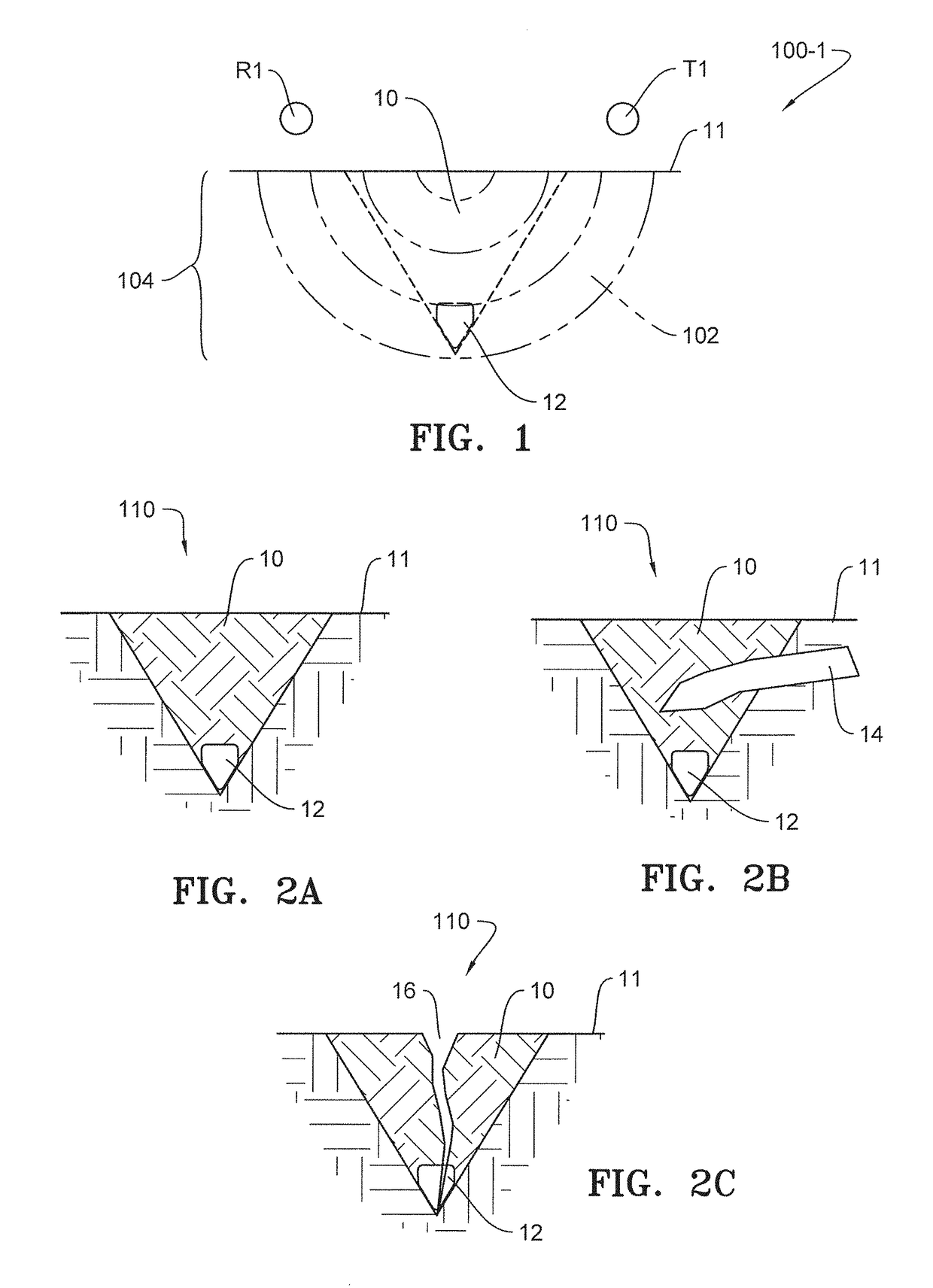

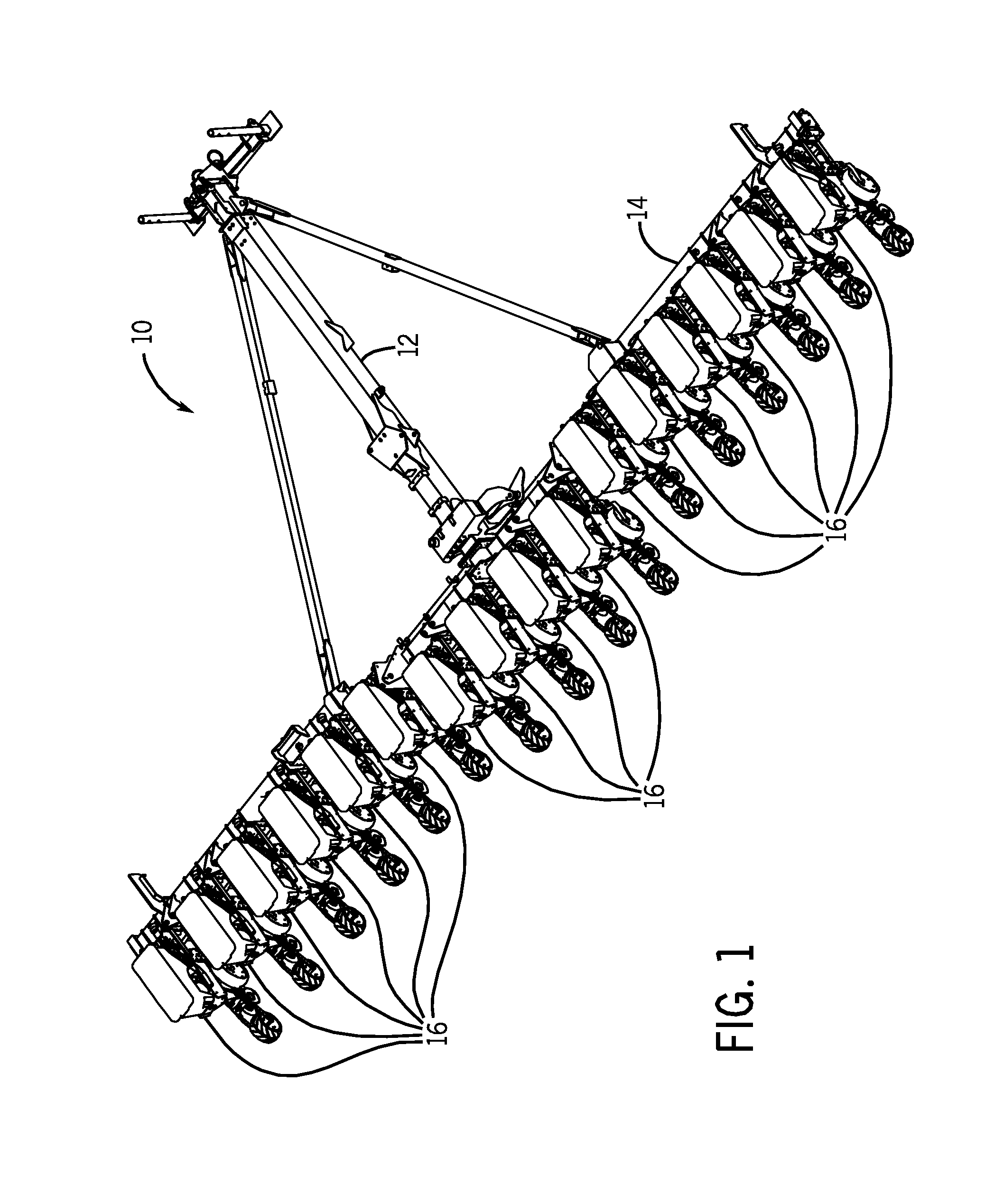

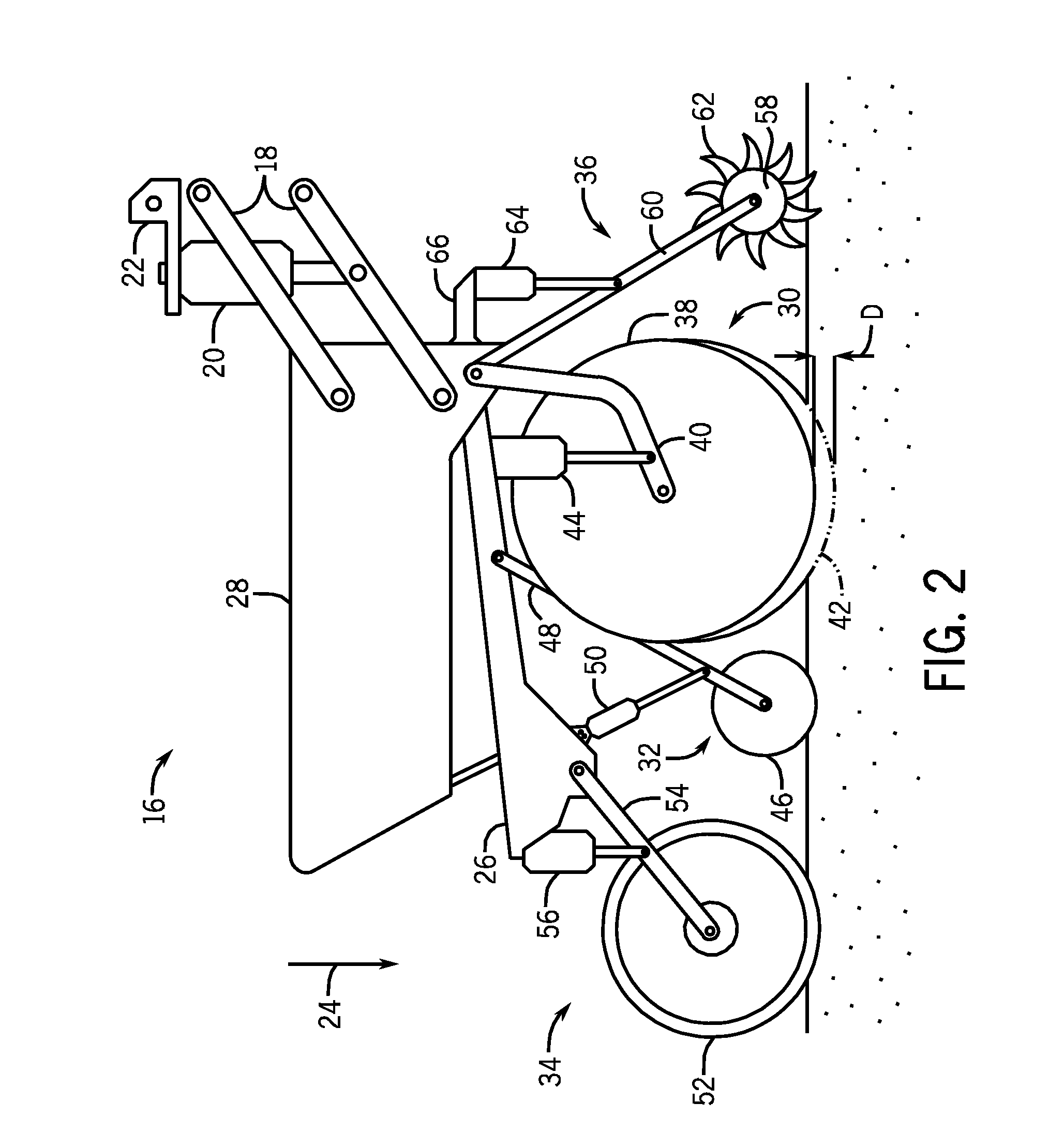

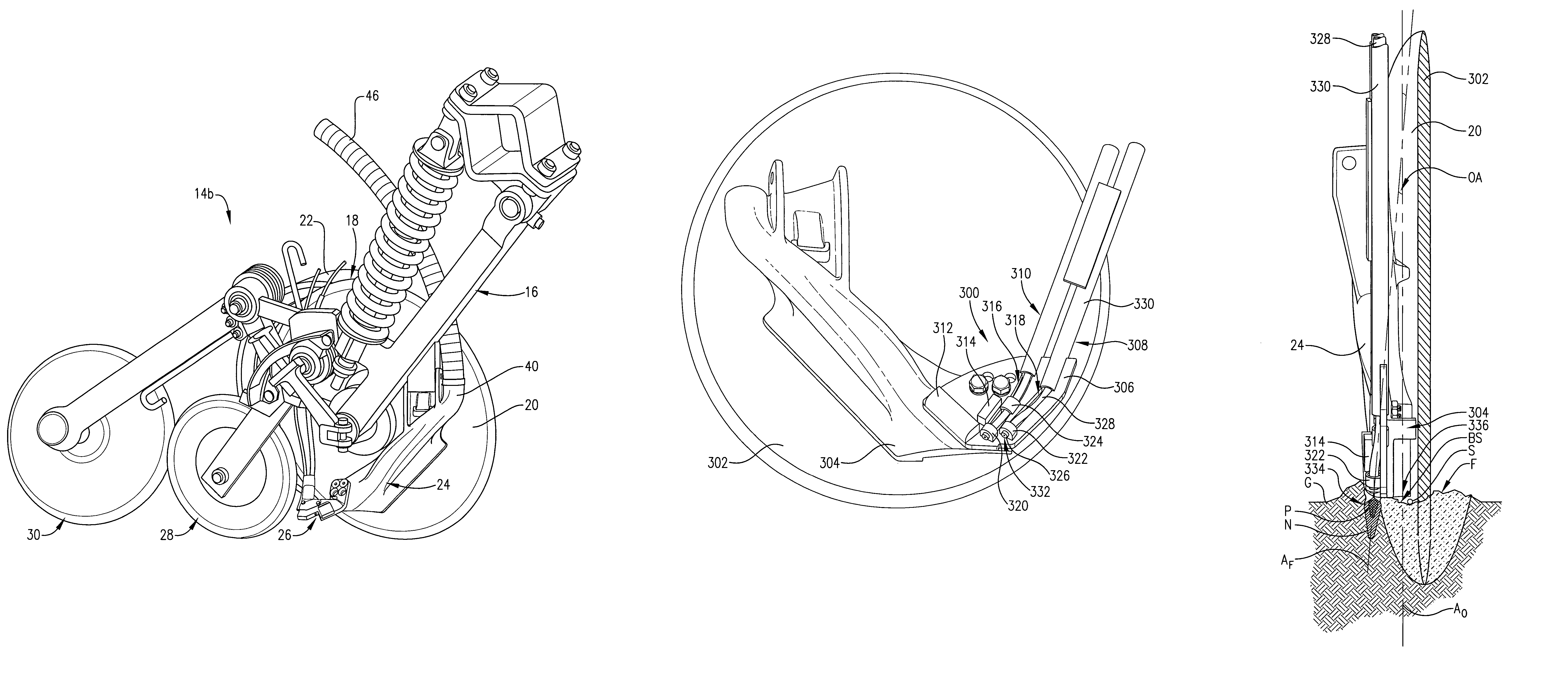

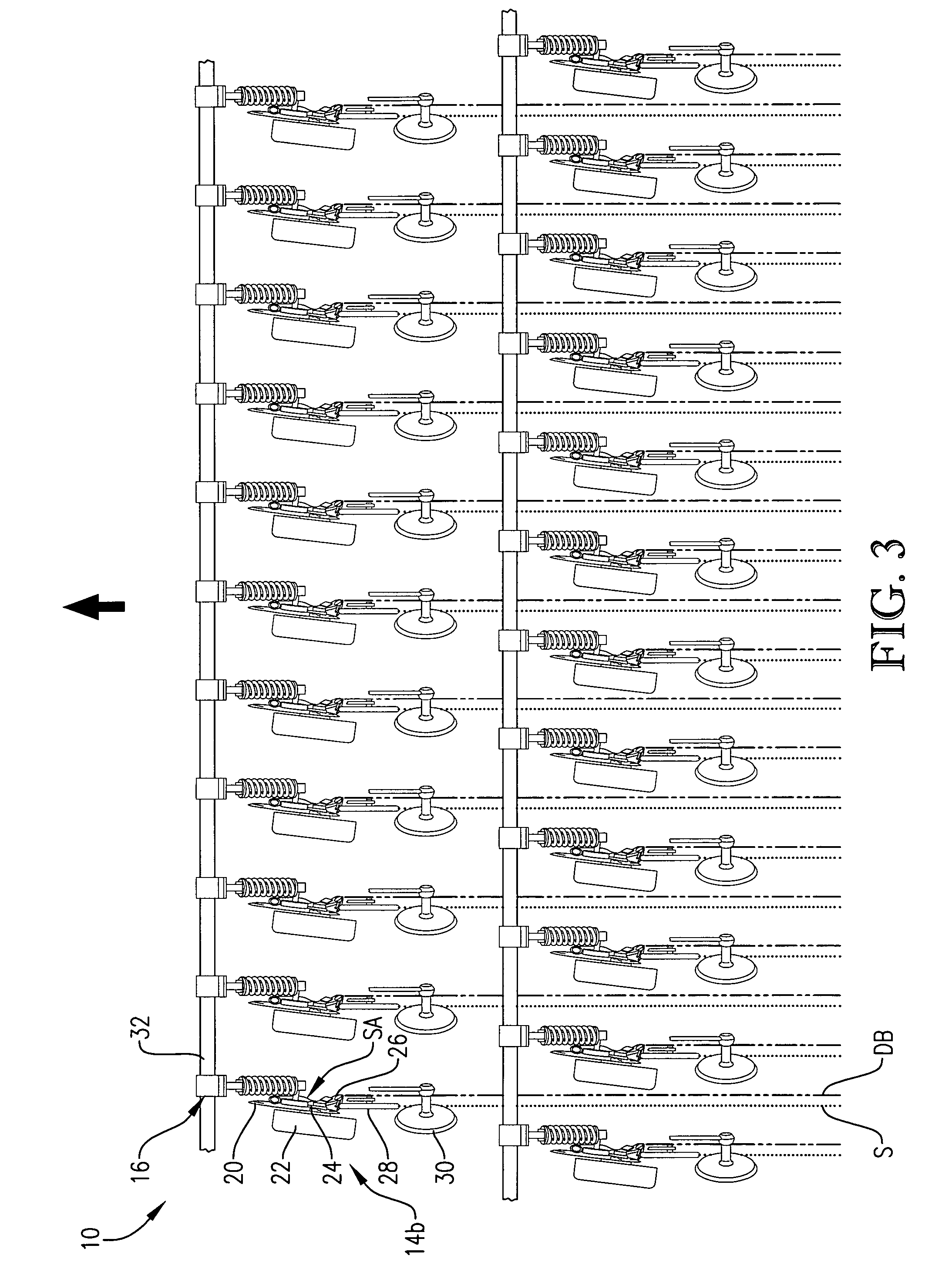

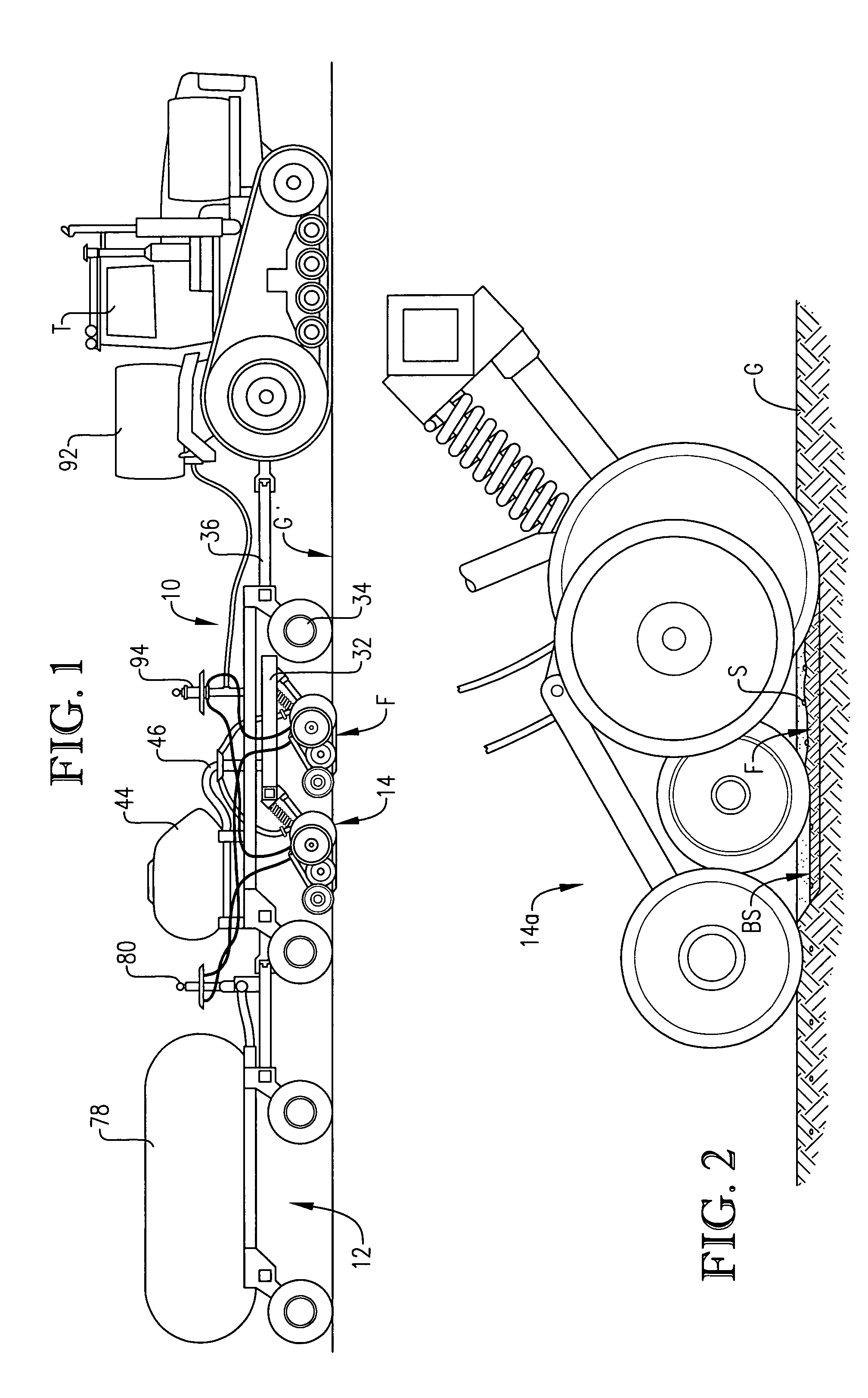

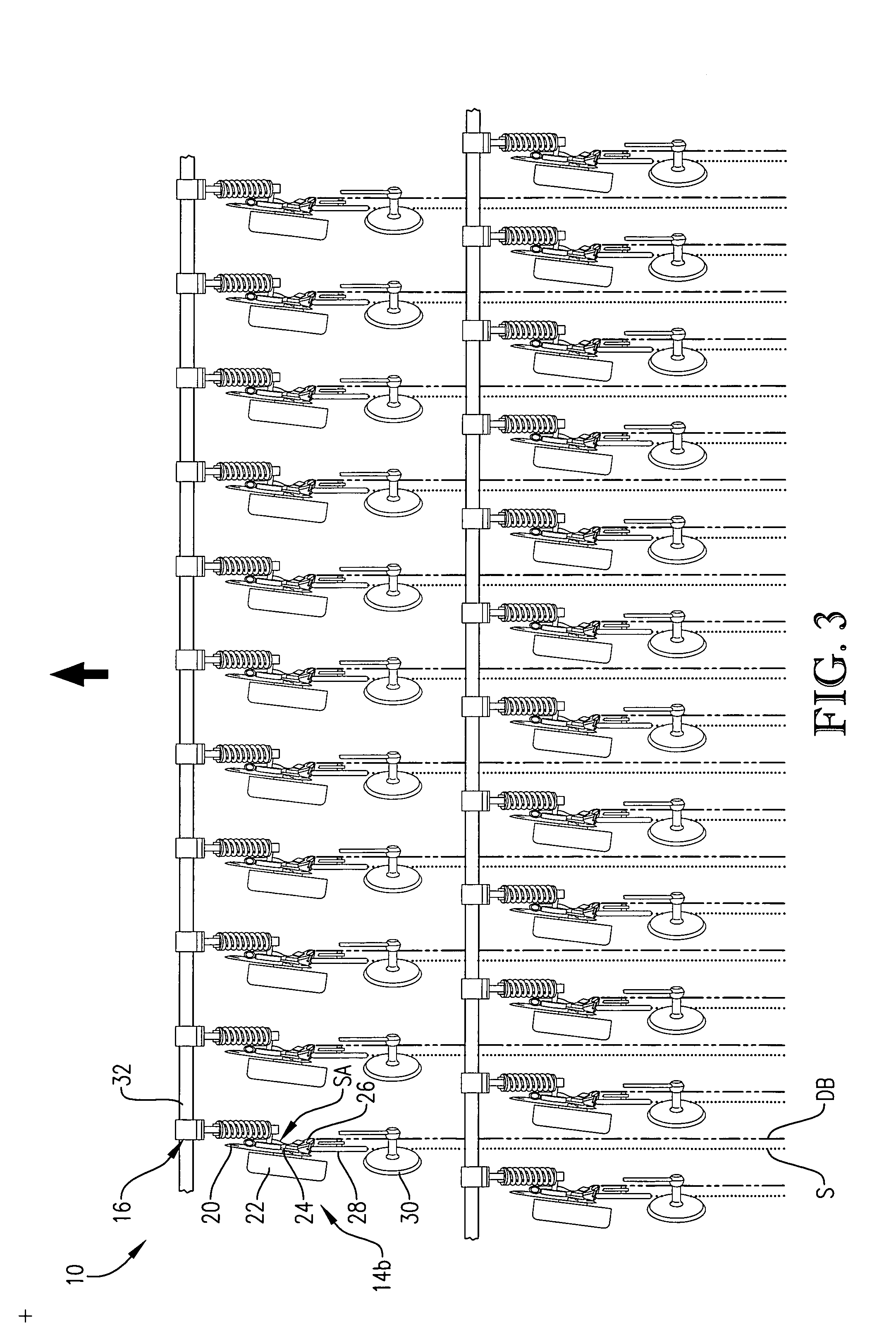

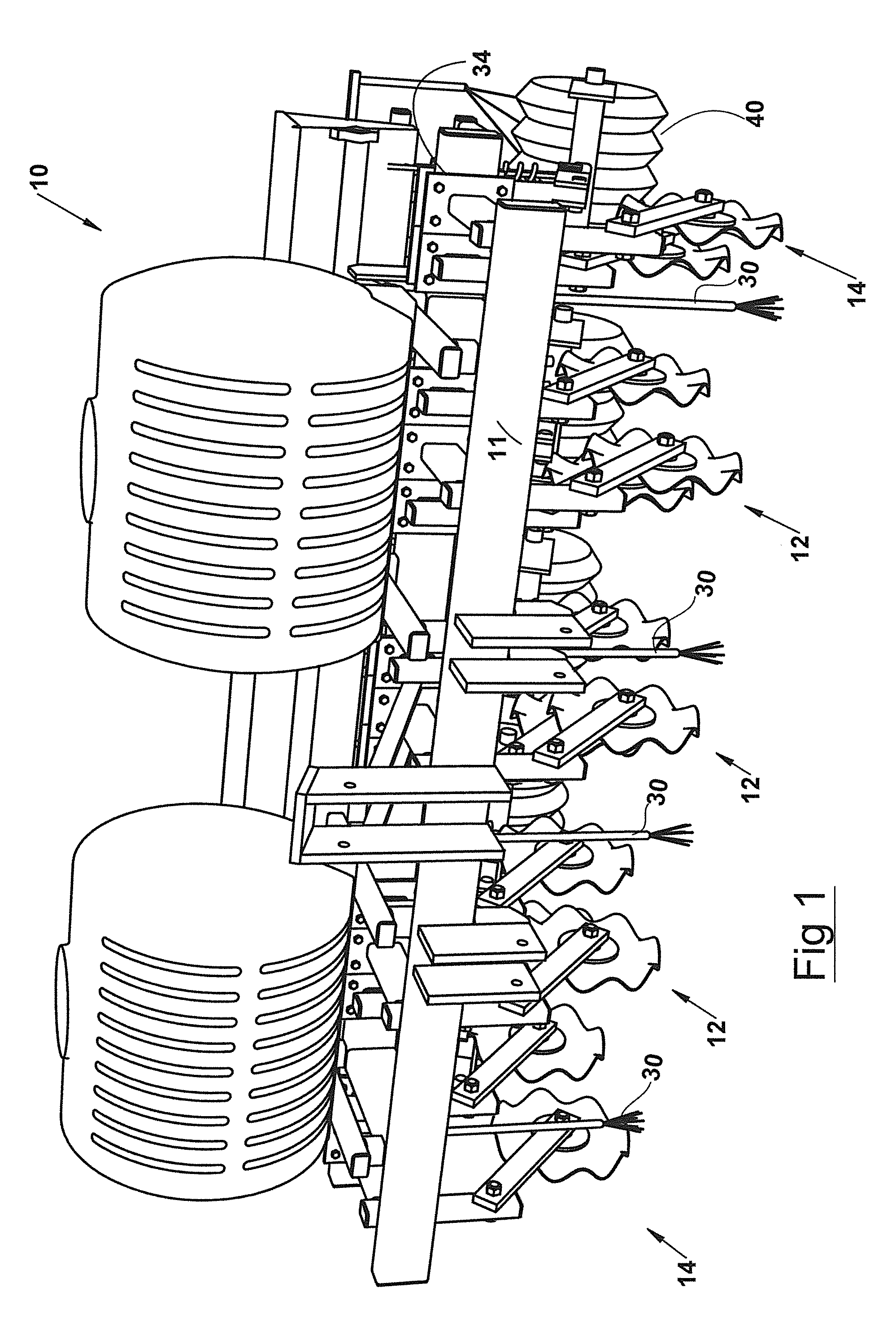

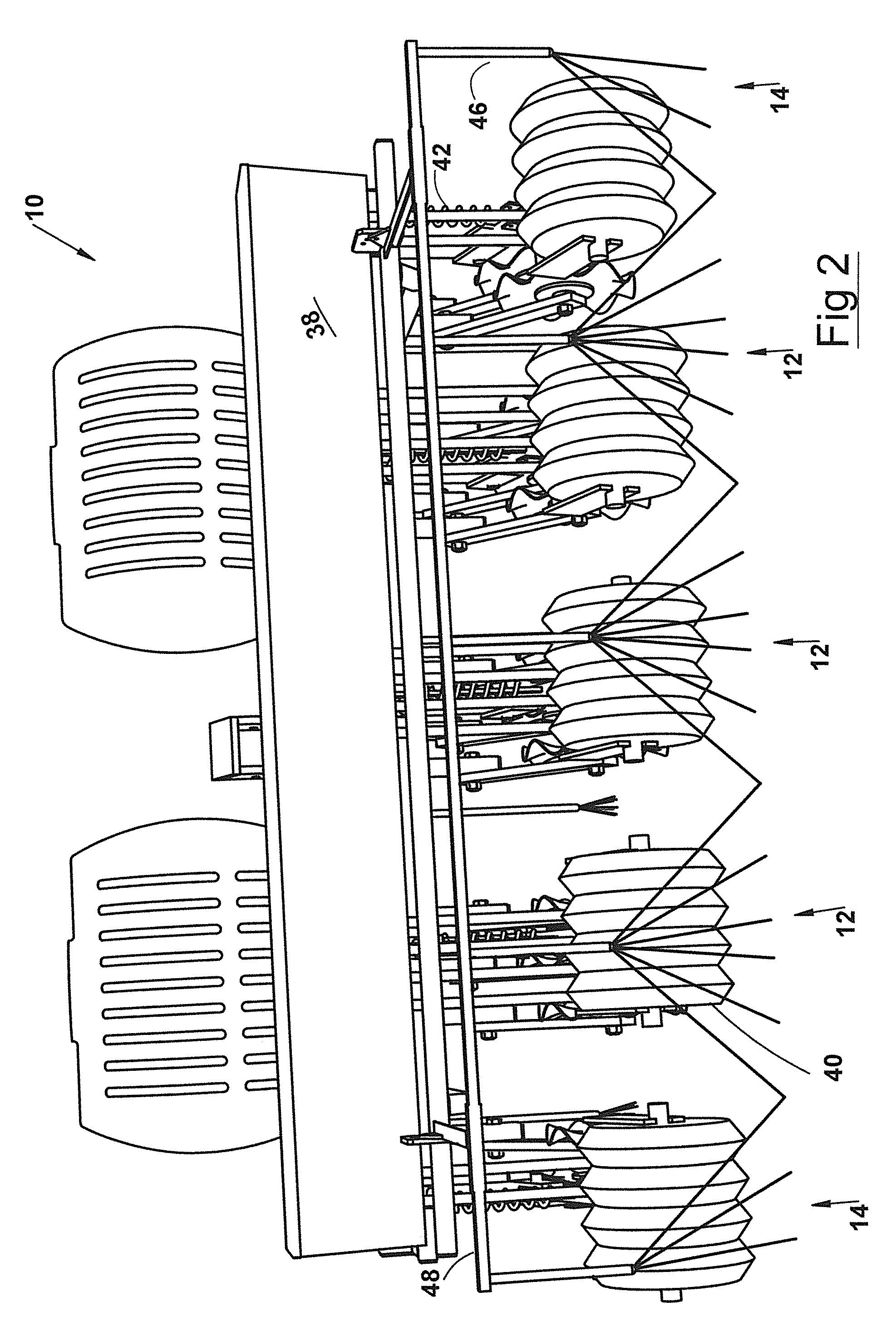

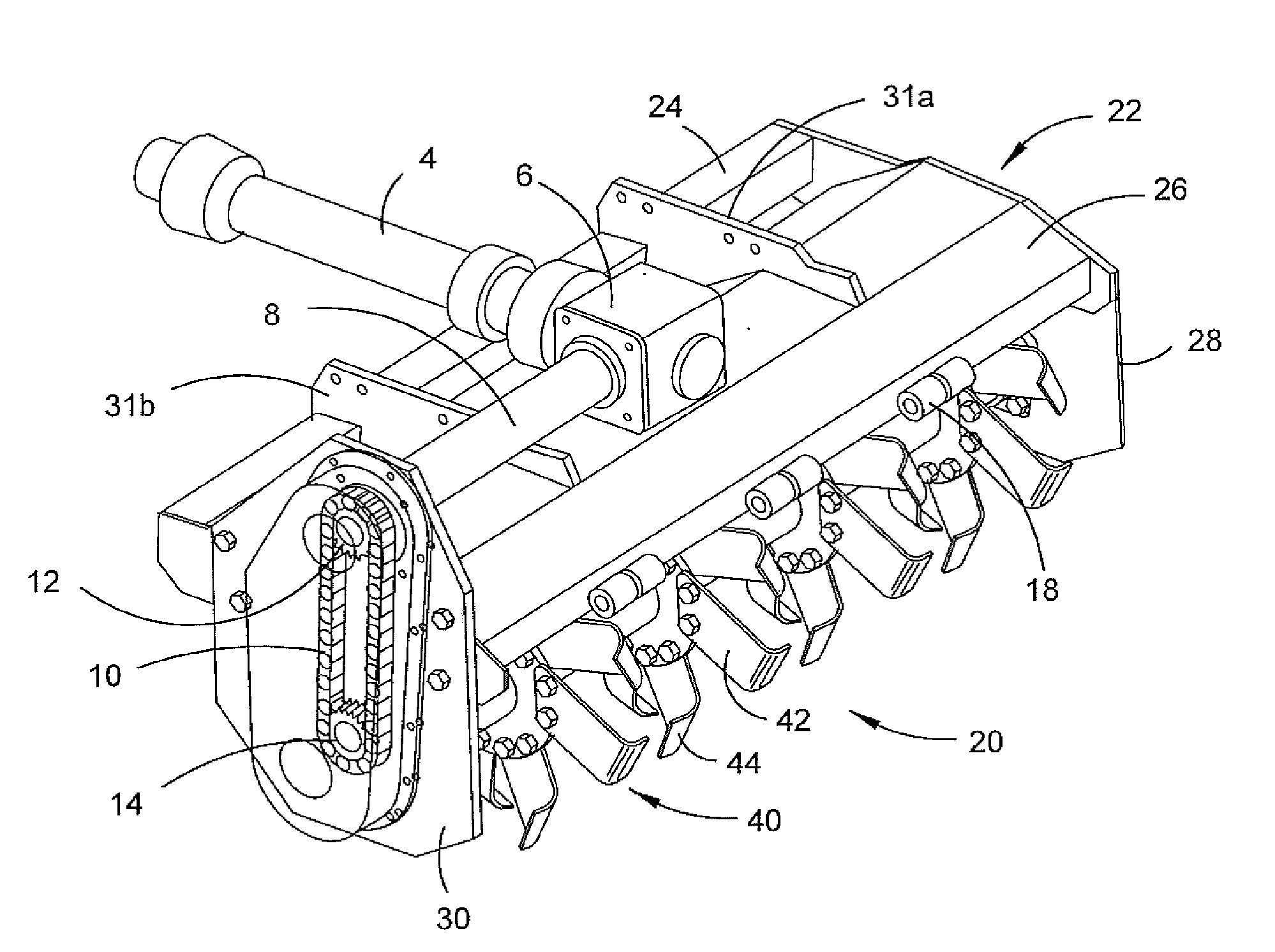

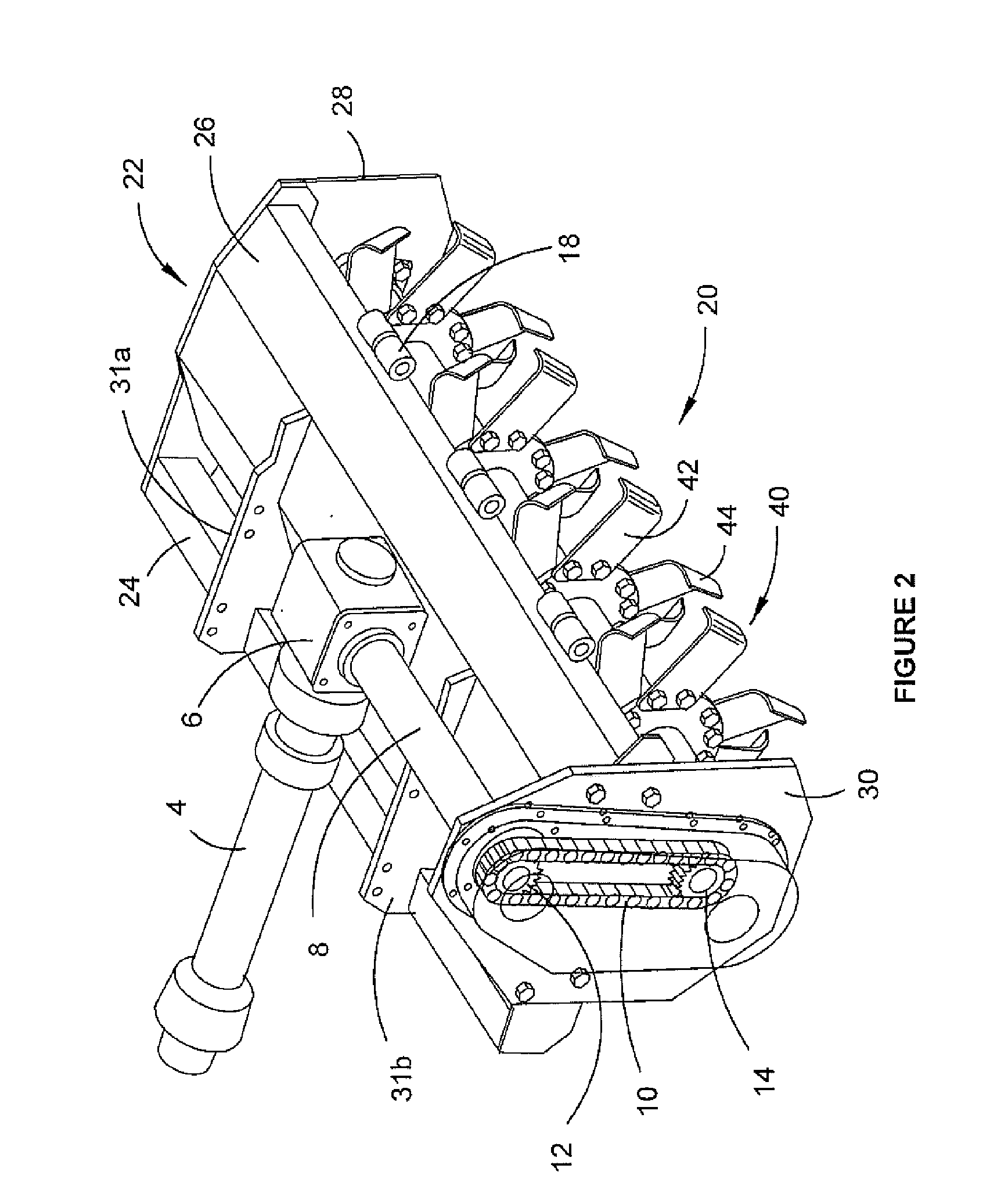

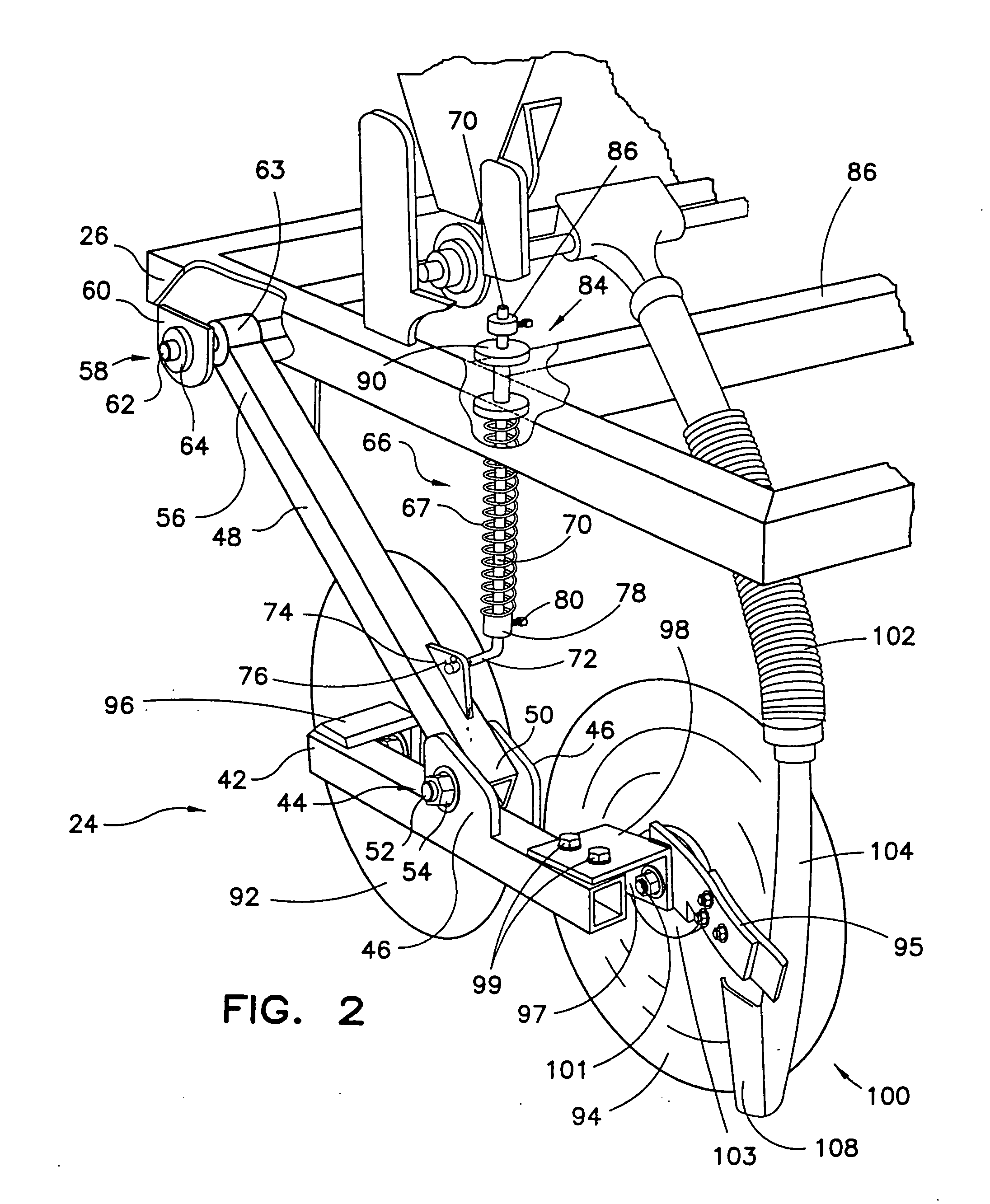

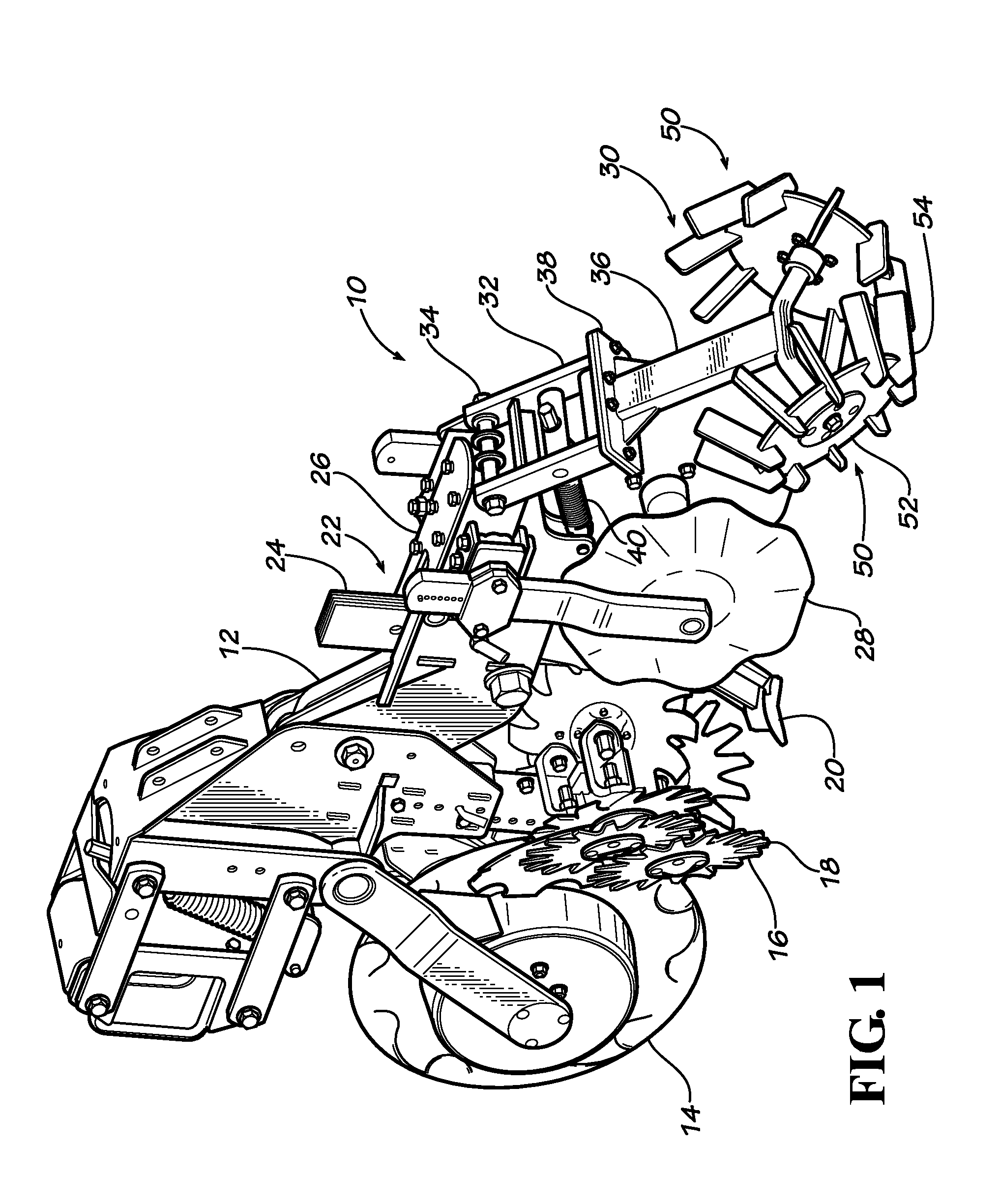

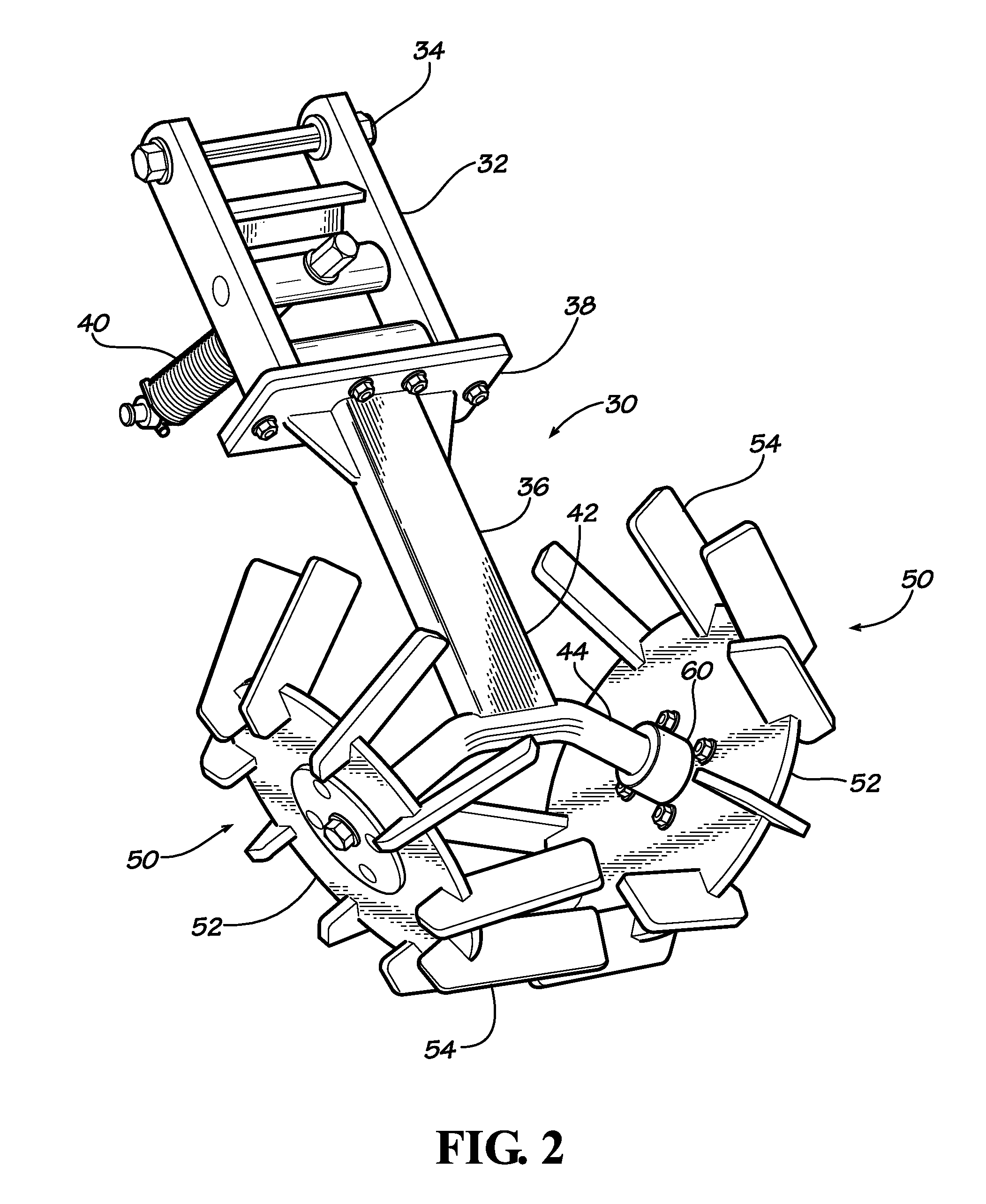

Disc openers (14) for use with an air seeder (10), are configured for seeding and fertilizing a field (G). The opener (14b) broadly includes a drawbar assembly (16), a disc assembly (18) including a coulter disc (20) and a gauge wheel (22), a seed boot (24), a fertilizer injector wing (26), a firming wheel assembly (28), and a closing wheel assembly (30). The fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS).

Owner:EXACTRIX

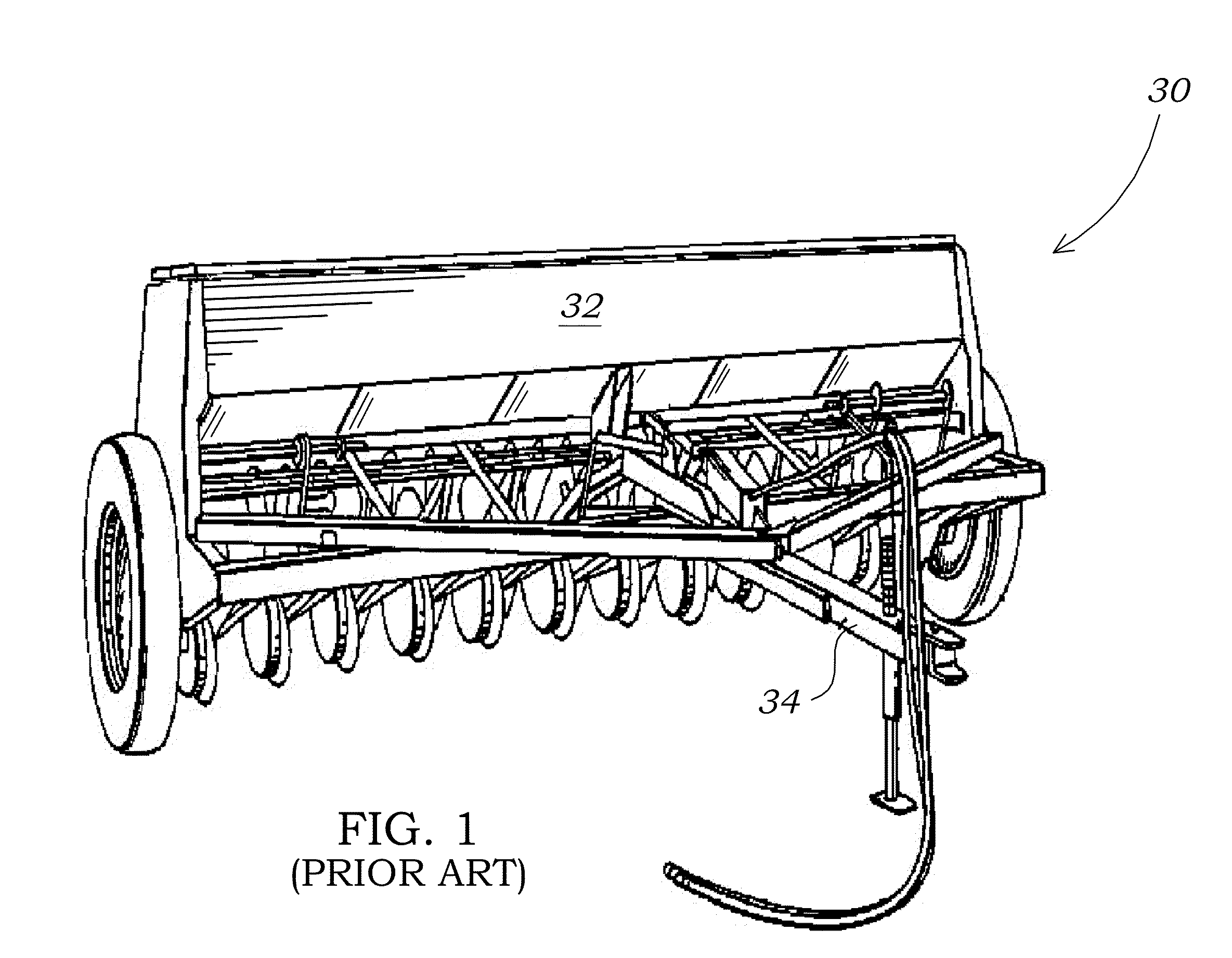

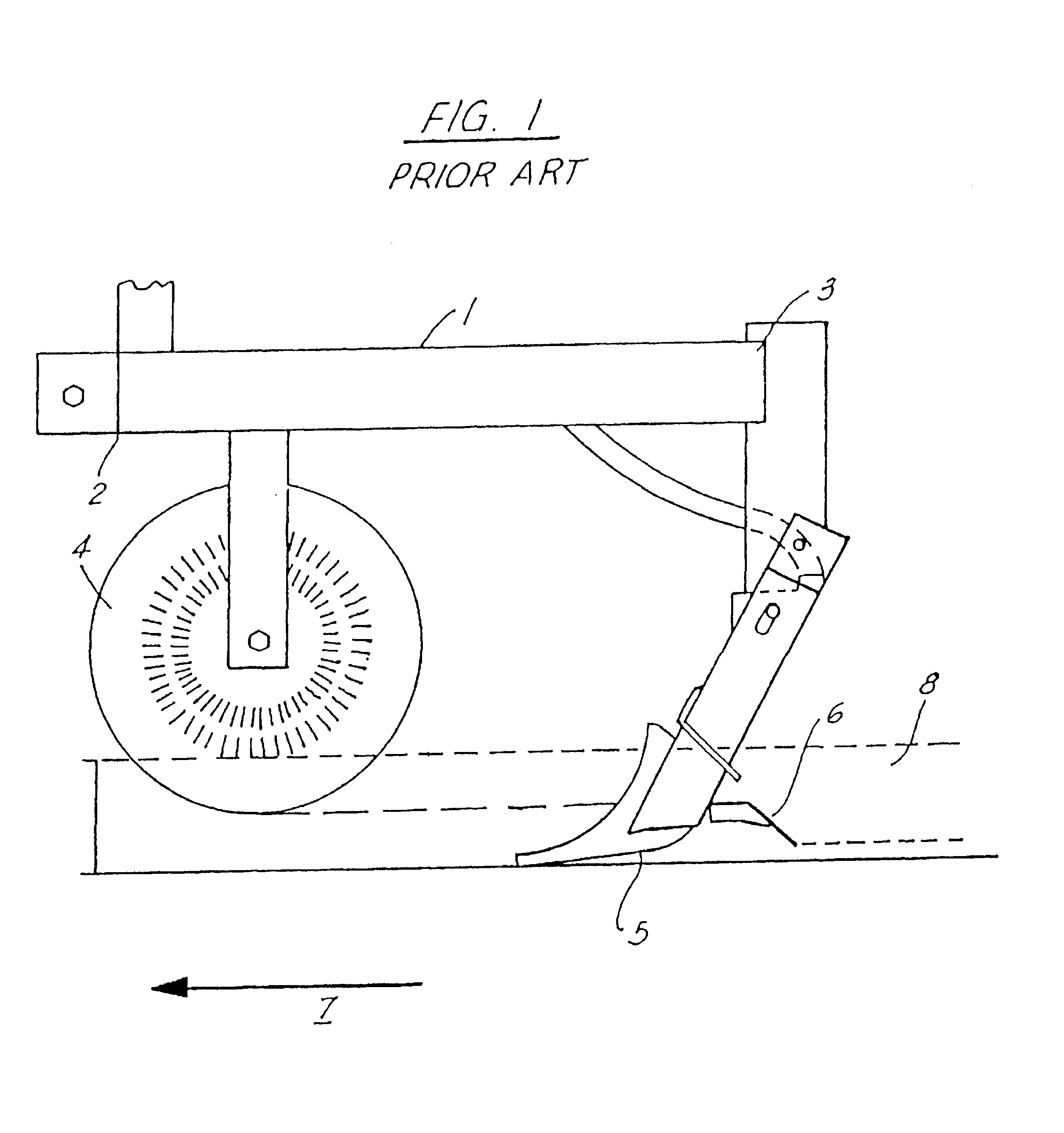

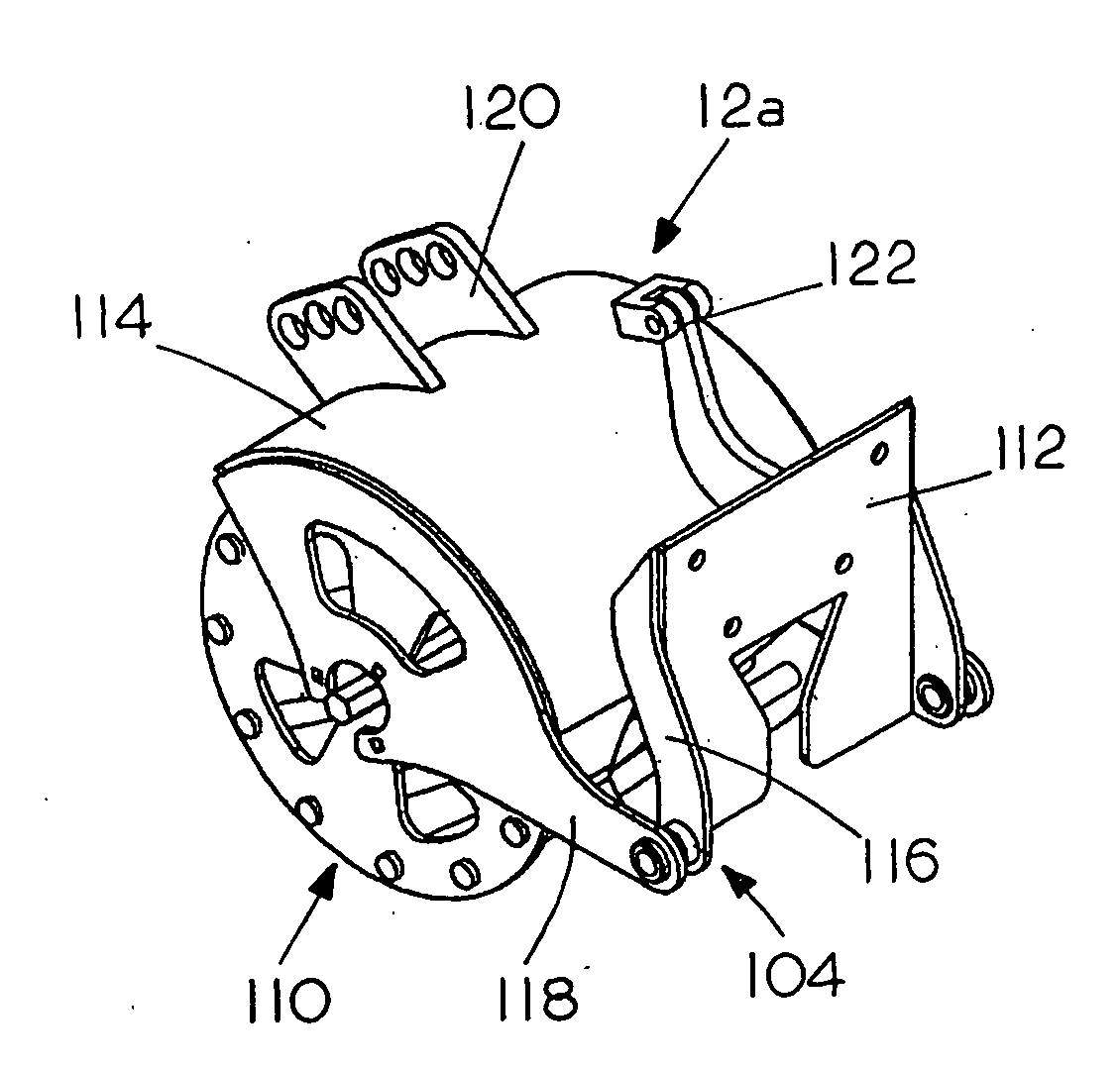

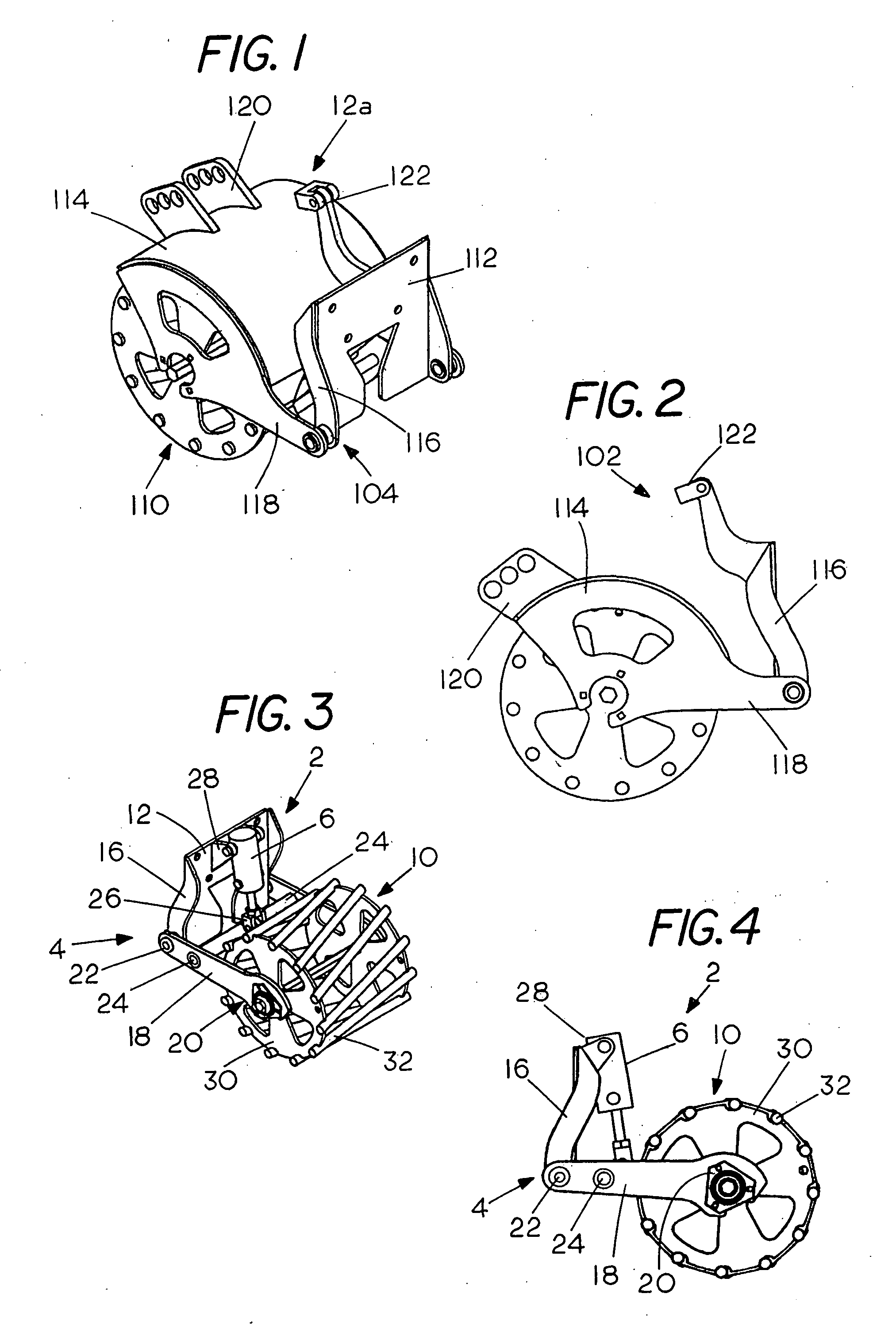

Seed drill with walking beam assembly

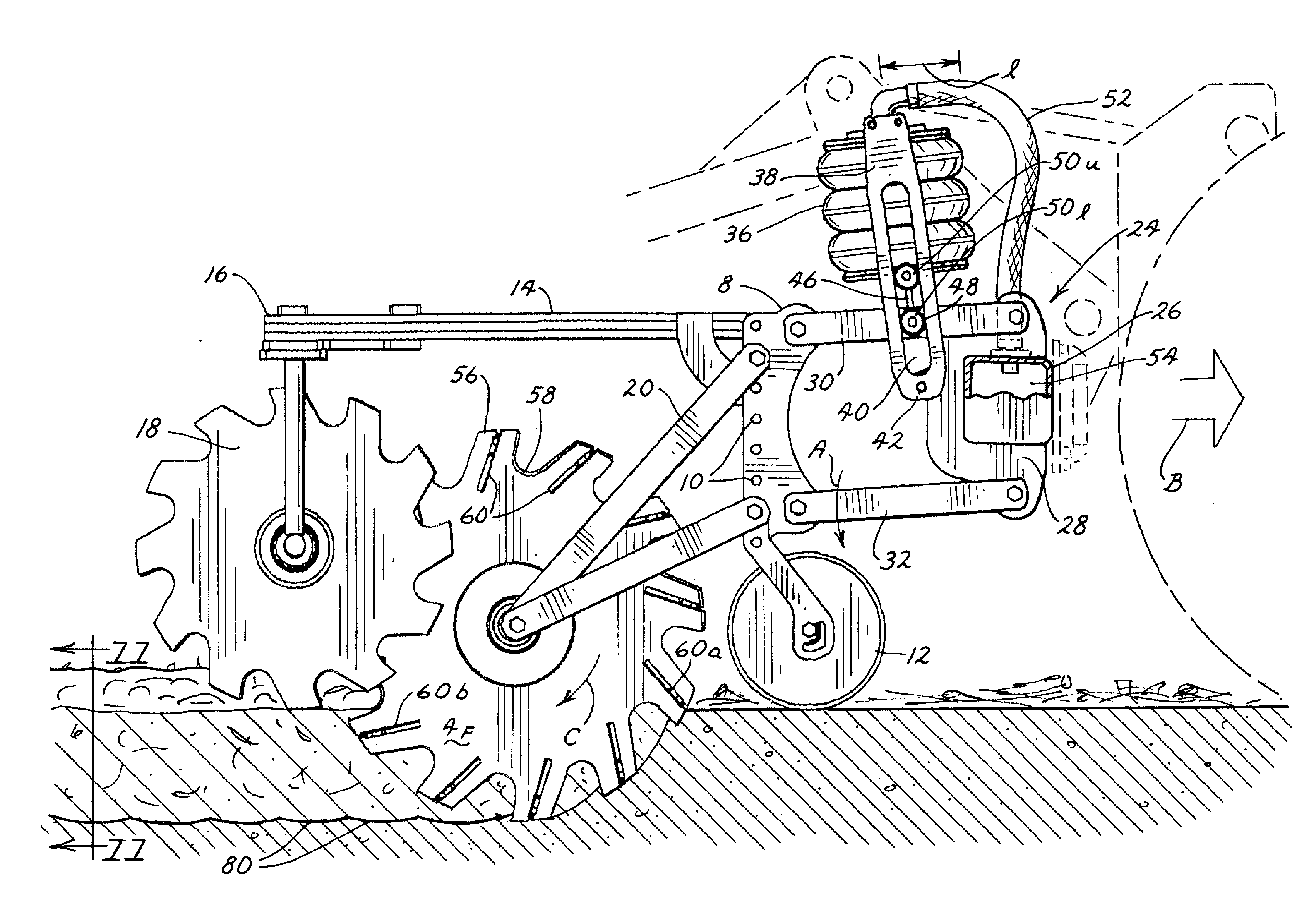

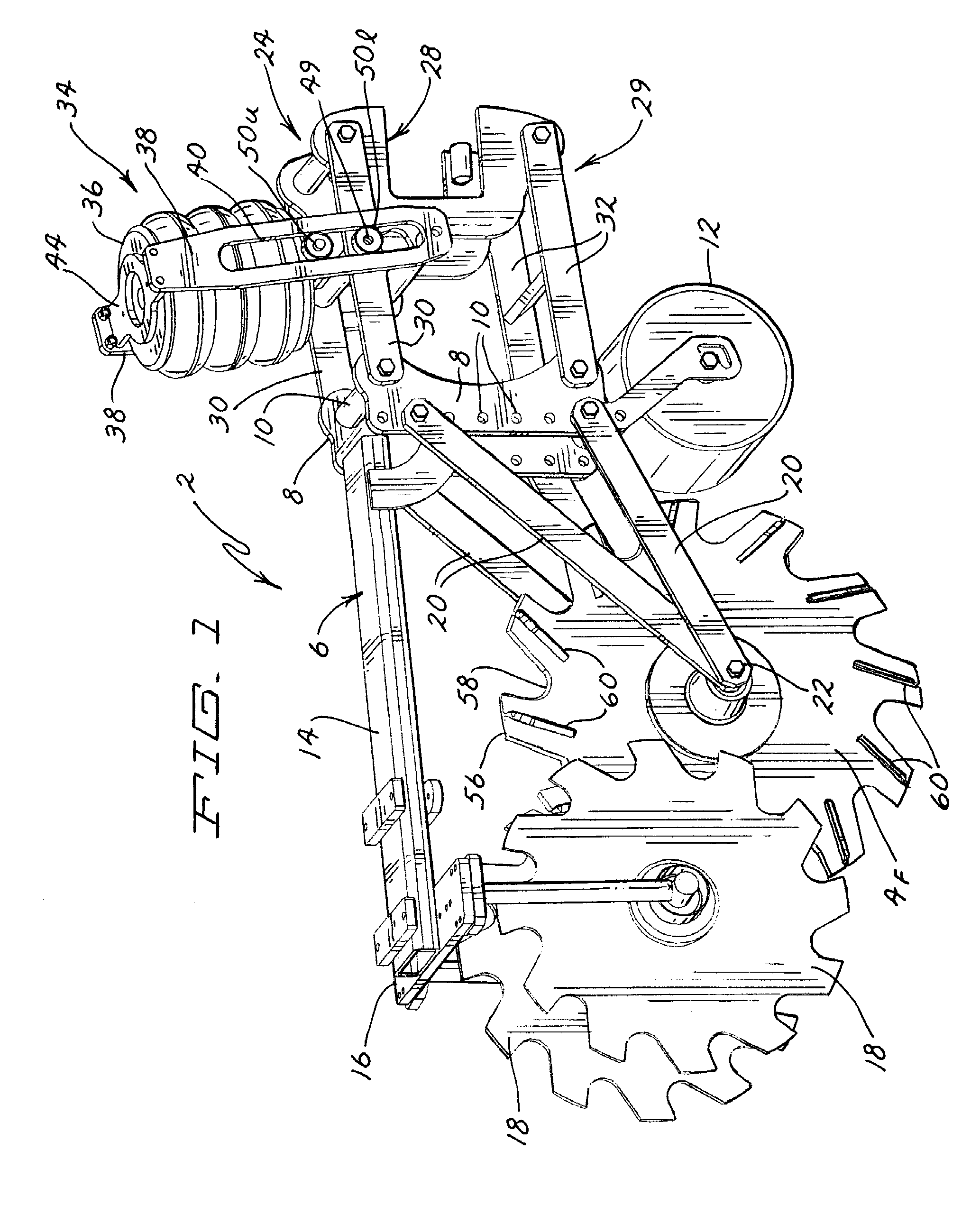

A no-till drill with a novel walking beam assembly that allows the drill to be pulled over severe terrain conditions that include large rocks, fallen limbs and other large obstructions. The inventive walking beam assembly includes two independent pivot points that allow the cutting and opening disks to maintain substantially constant or continuous contact with the ground, such that the length of the furrow formed and seed deposited therein are maximized. A closing disk assembly is suspended from the rear of the drill independently from the walking beam assembly. This independent suspension allows the walking beam assembly to function without interference from the closing disks.

Owner:KASCO MFG

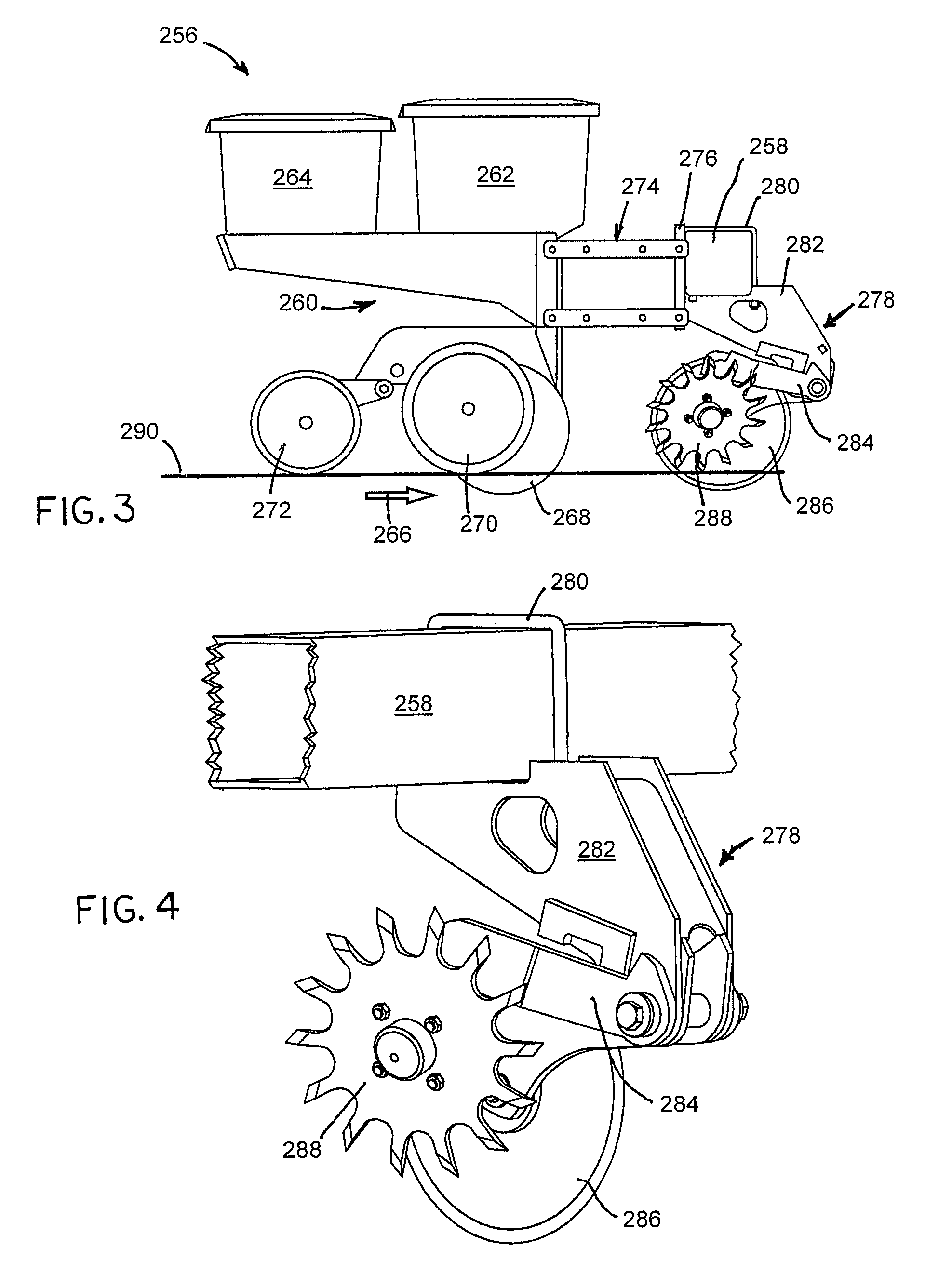

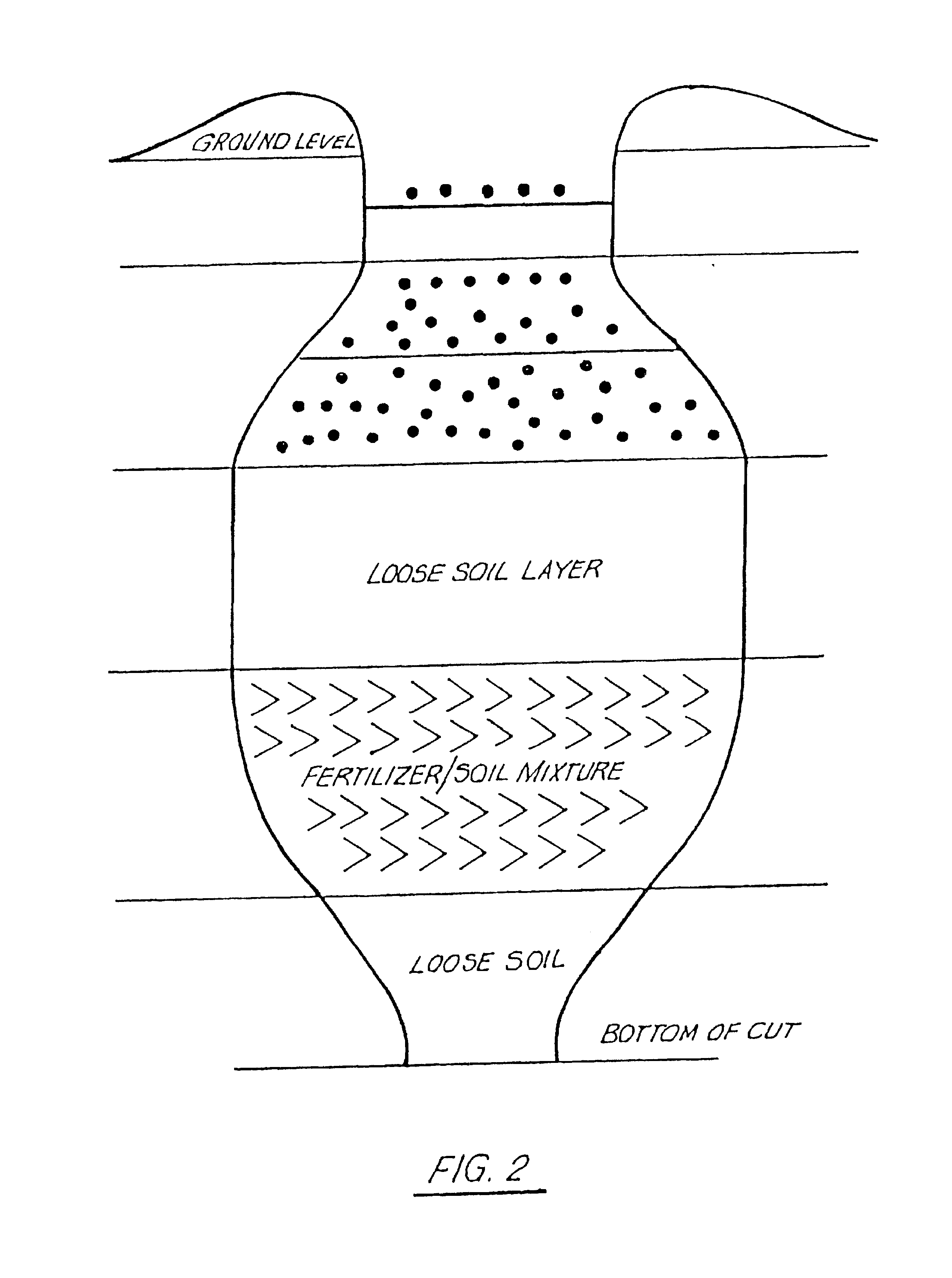

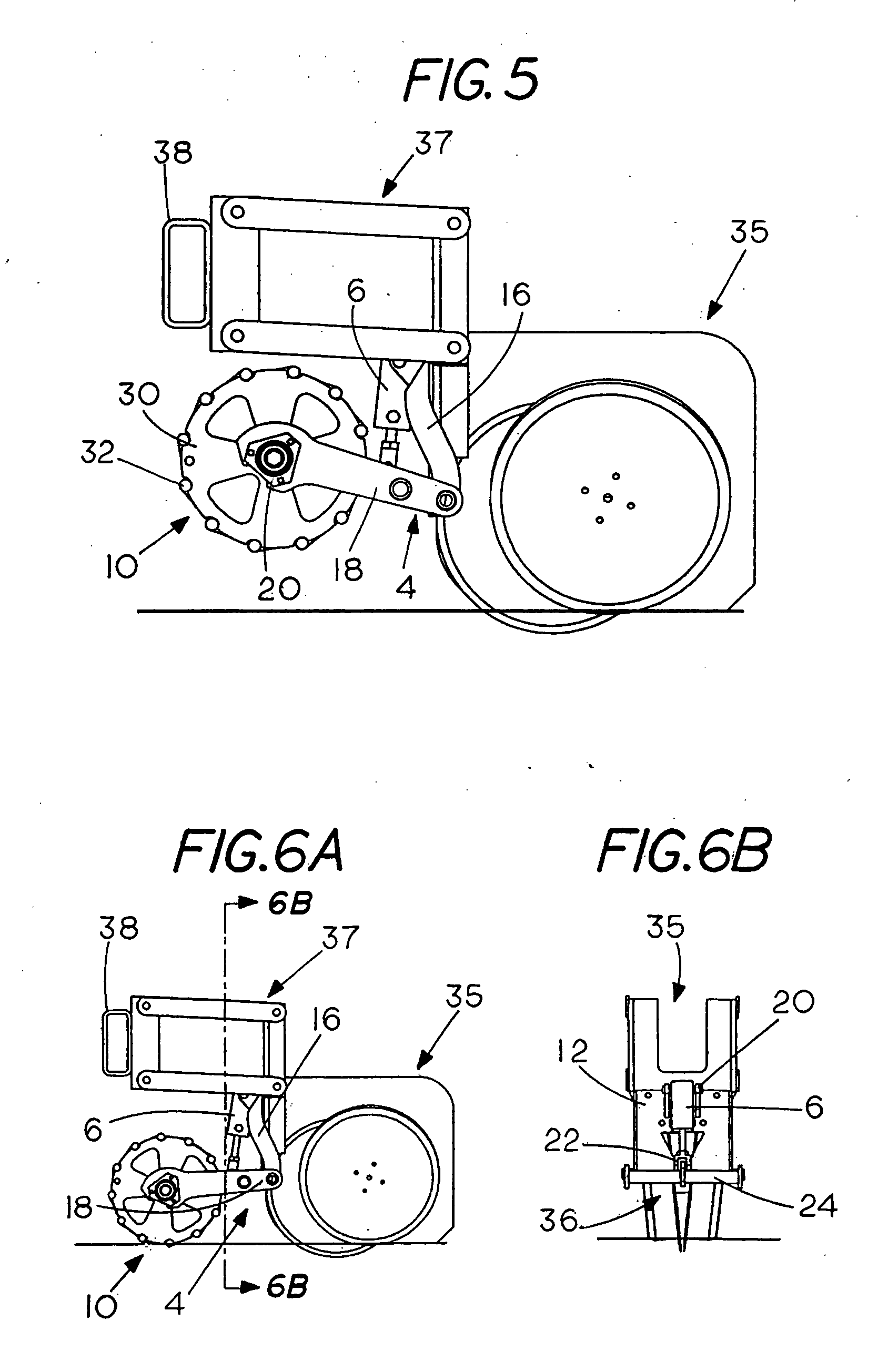

Zone tillage tool and method

A zone tillage tool comprises a tool frame connected by a parallel lift linkage to a tool bar. A fall tillage coulter or dual spring tillage coulters can be carried on the tool frame in advance of a pair of containment coulters. The fall tillage coulter tills soil in a zone that is approximately 7 to 9 inches deep while the spring tillage coulters till 2 to 3 inches deep. The fall tillage coulter includes a plurality of shovel bits located around the circumference thereof at a forward rake angle. The tip of each shovel bit has a generally vertical entry position into the ground due to the forward rake angle. As the fall tillage coulter rotates, the shovel bits rotate around and exit the soil in a generally horizontal position, thereby lifting and loosening the soil without compacting the soil through a series of rearwardly and upwardly directed soil scooping actions.

Owner:ENVIRONMENTAL TILLAGE SYST

Apparatus for preparing soil for the placement of seed and additive

An apparatus for preparing soil for the placement therein of at least one of seed and fertilizer. A frame is provided with there being first structure on the frame for penetrating the soil to create an opening for at least one of seed and fertilizer as the frame is advanced in a travel direction. A second structure is provided on the frame at least partially downstream of the first structure for at least one of a) stripping soil clods from the first structure and b) loosening soil downstream of the first structure.

Owner:BASSETT JAMES H

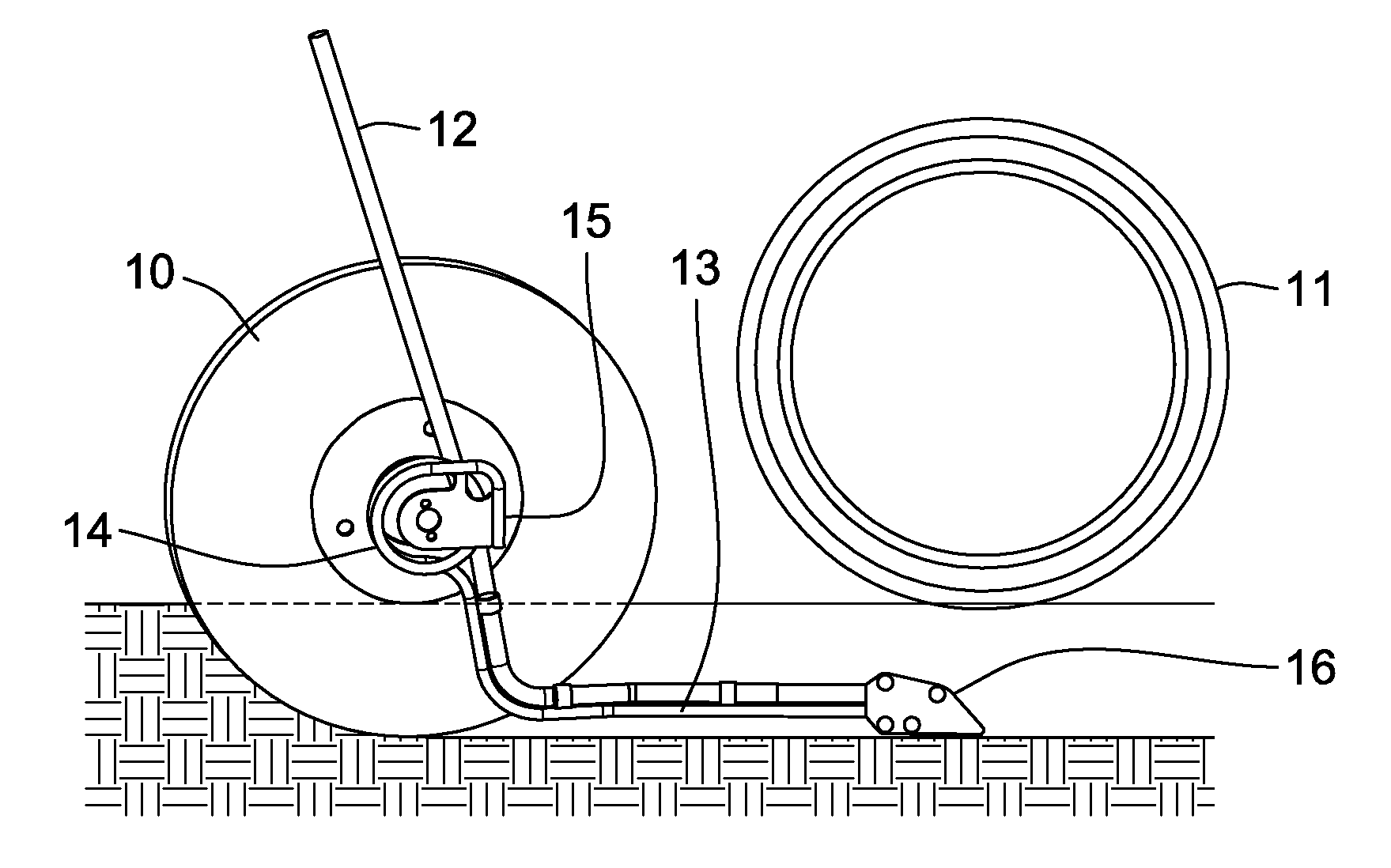

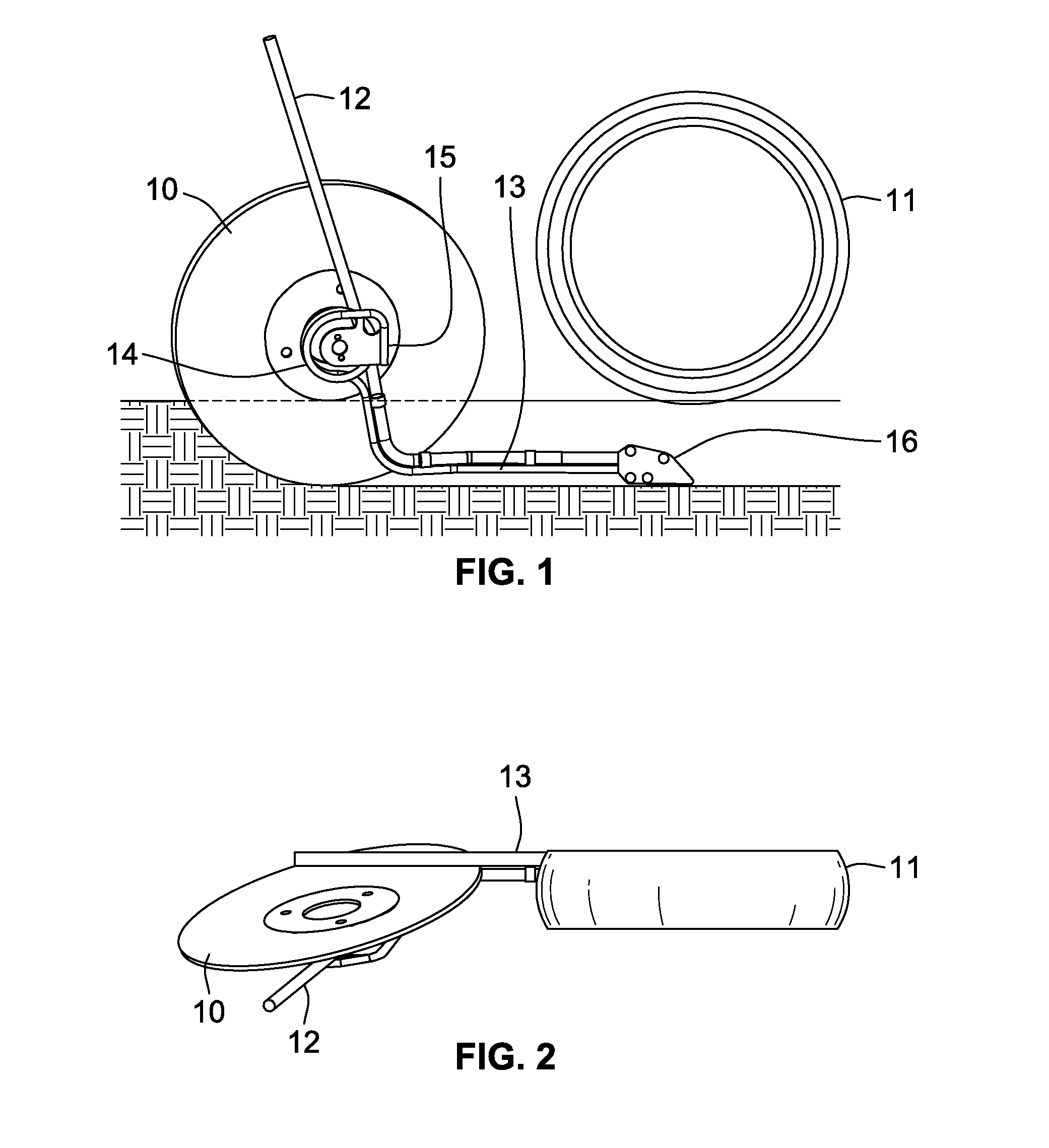

Single disc liquid fertilizer opener

ActiveUS20070044694A1Minimize opportunityEliminate premature mechanical failureTill seedingPlantingForce structureCircular disc

A method and apparatus to be mounted upon a planter row unit for delivering liquid fertilizer to the bottom of a trench without contacting the seed to be planted is disclosed and claimed. The system as claimed and described is adapted for mounting to substantially all modern row units employing floating row units. The method and apparatus as described does not interfere with existing down pressure or seed placement systems as found on modern row crop planters. As described and implemented, the method and apparatus is more compact and lighter in weight than the prior art. The attached assembly for a seed planting unit works in combination with a seed trench opener to form a trench for the deposit of liquid fertilizer offset from and parallel to the later formed seed trench. The apparatus allows directed liquid fertilizer delivery in close proximity to the seed trench with minimal disruption of said seed trench. The attachment includes a single disk blade disposed forward of the seed trench forming unit. The single disk blade is disposed at an angle of four degrees or less from the line defining the direction of travel of the seed planting implement in combination with a furrow strap. The attachment includes a selectively adjustable down force structure and a selectively adjustable depth control mechanism.

Owner:MARTIN HOWARD D

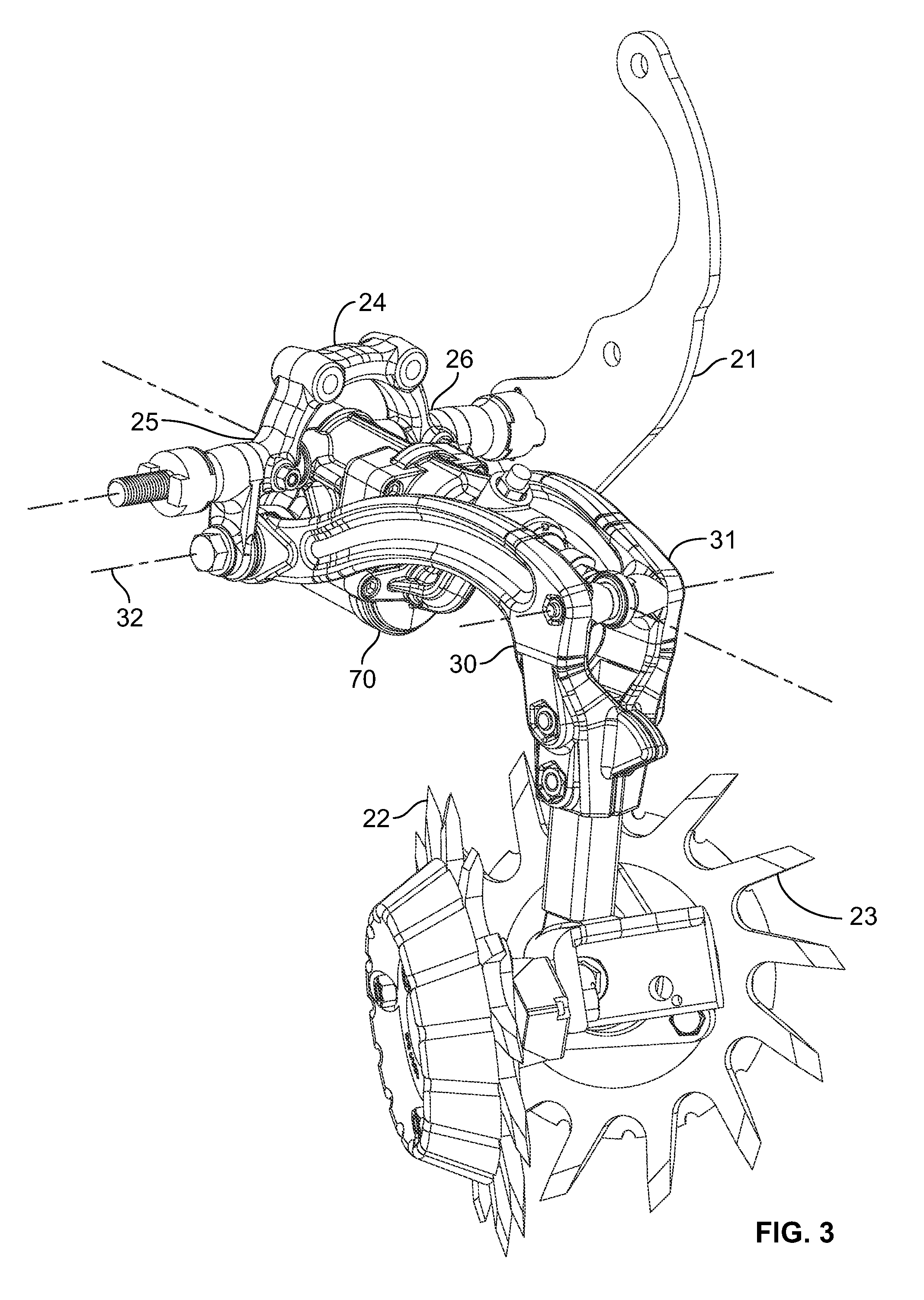

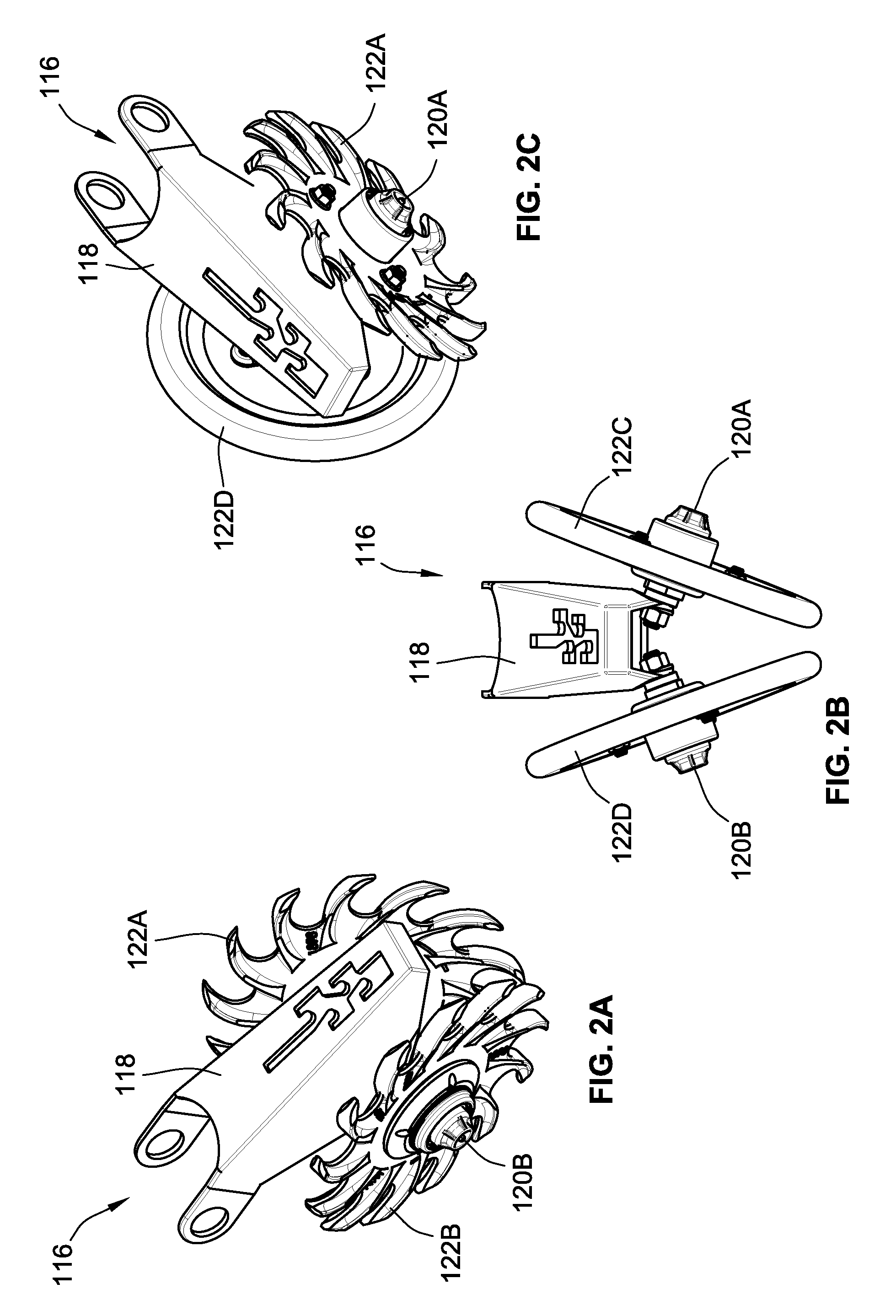

Crop residue clearing device

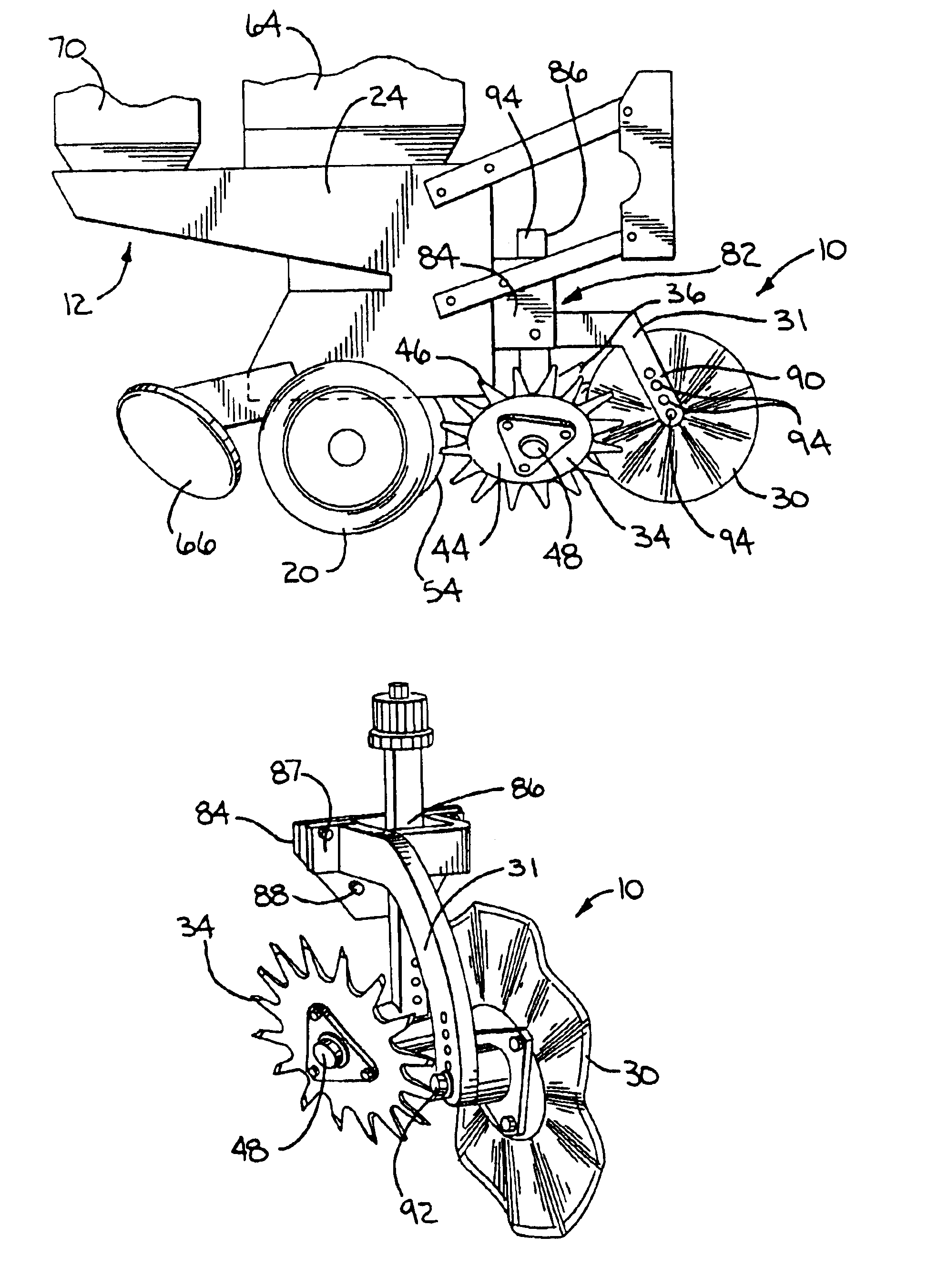

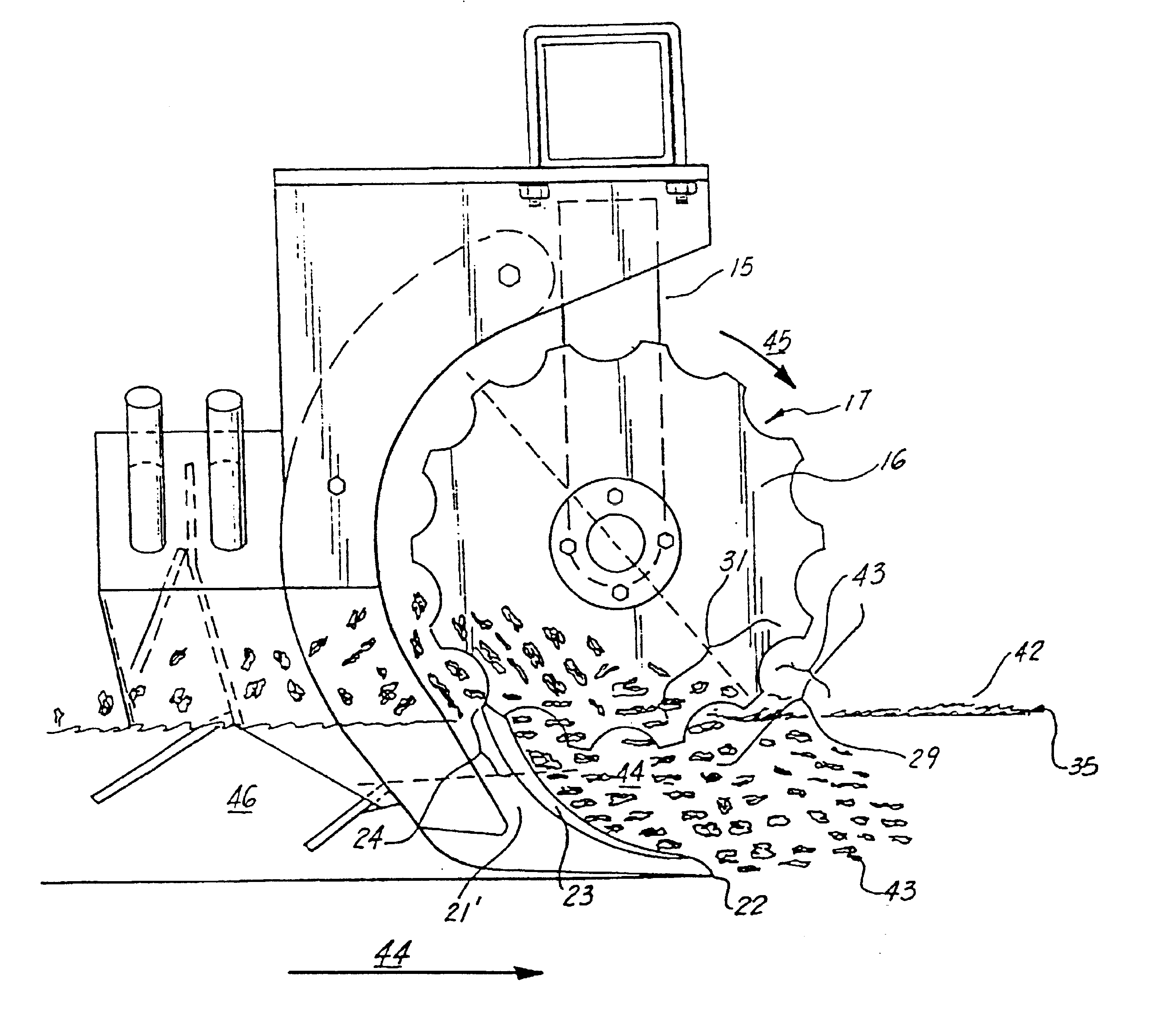

ActiveUS8393407B2Less susceptible to damage and destructionReduce penetrationSpadesTill seedingGear wheelCrop residue

Apparatus for clearing crop residue from a field is adapted for attachment to a tool bar of an agricultural implement or to a planter unit such that the apparatus is pulled through a field by the implement. The apparatus includes a support structure extending forward of the tool bar and at least one and preferably a pair of floating arms pivotally attached to a forward portion of the support structure and extending rearwardly, with a toothed wheel rotationally attached to an aft end of the arm(s). A coulter attached to the support structure is disposed between and extends forward of the soil-engaging toothed wheel(s) and in combination with the wheel(s) severs and removes residue in the seeding pathway. An adjustable biasing arrangement urges the toothed wheels, either in unison or independently, downwardly into engagement with the soil. Upper and lower stop limits are provided to limit vertical positioning of the toothed wheel(s).

Owner:AG FOCUS LLC

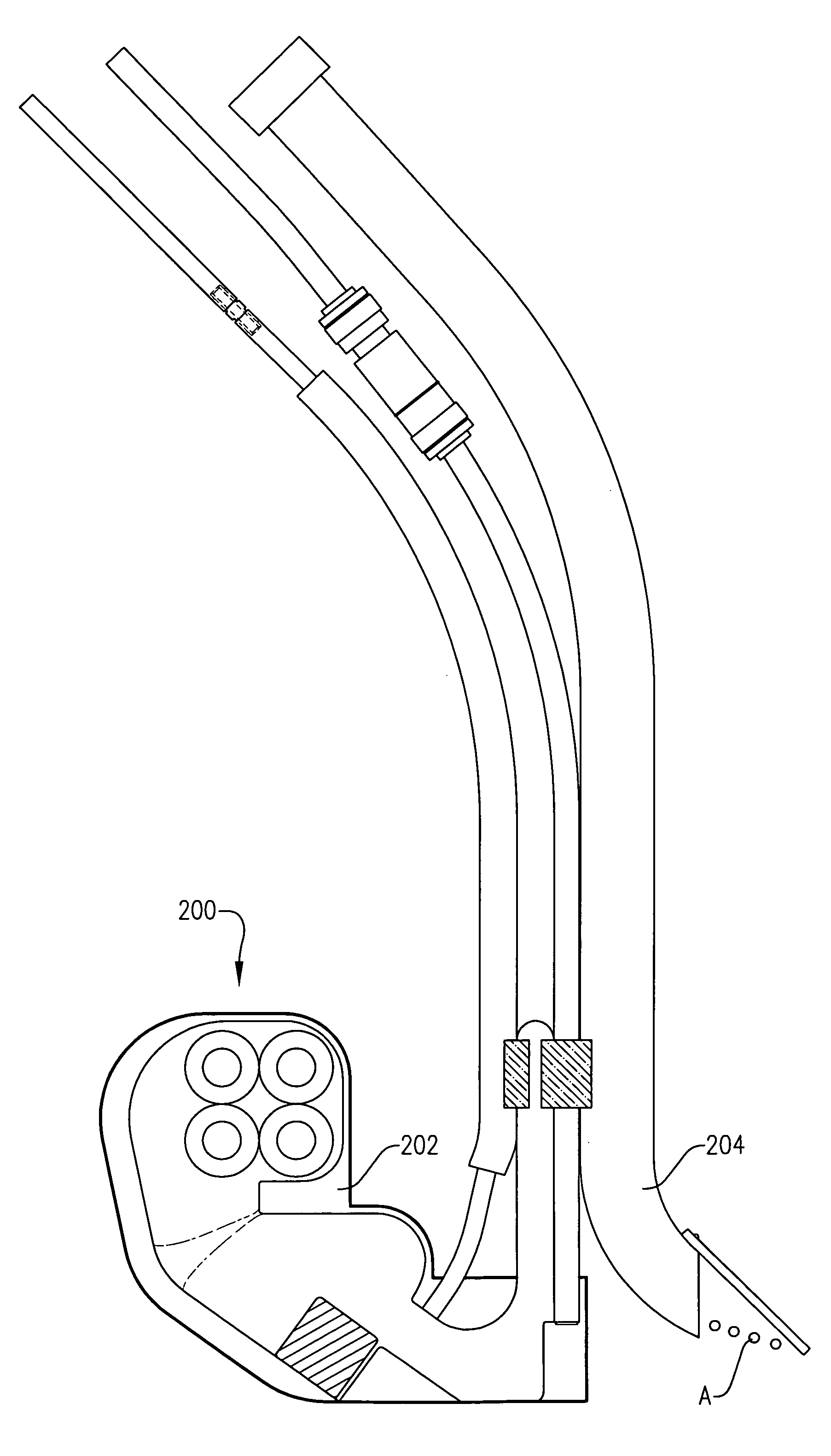

Agricultural implement having fluid delivery features

An agricultural implement for delivering fluid fertilizer into a furrow in the soil of an agricultural field includes a main frame, an opener device attached to the main frame for forming a furrow in the soil, a closing device having an axis of rotation and trailing the opener device for closing the furrow, and a dispensing device for delivering a fluid into the furrow. The injection device has a bottom end extending downwardly into the furrow between the opener device and the axis of rotation of the closing device, an inlet port for receiving the fluid, at least two outlet ports for discharging the fluid into different regions of the furrow, and a bifurcated passageway for conducting the fluid from the inlet port to the outlet ports. The outlet ports may be located to discharge the fluid onto or adjacent to both of the side walls of the furrow.

Owner:DAWN EQUIPMENT COMPANY

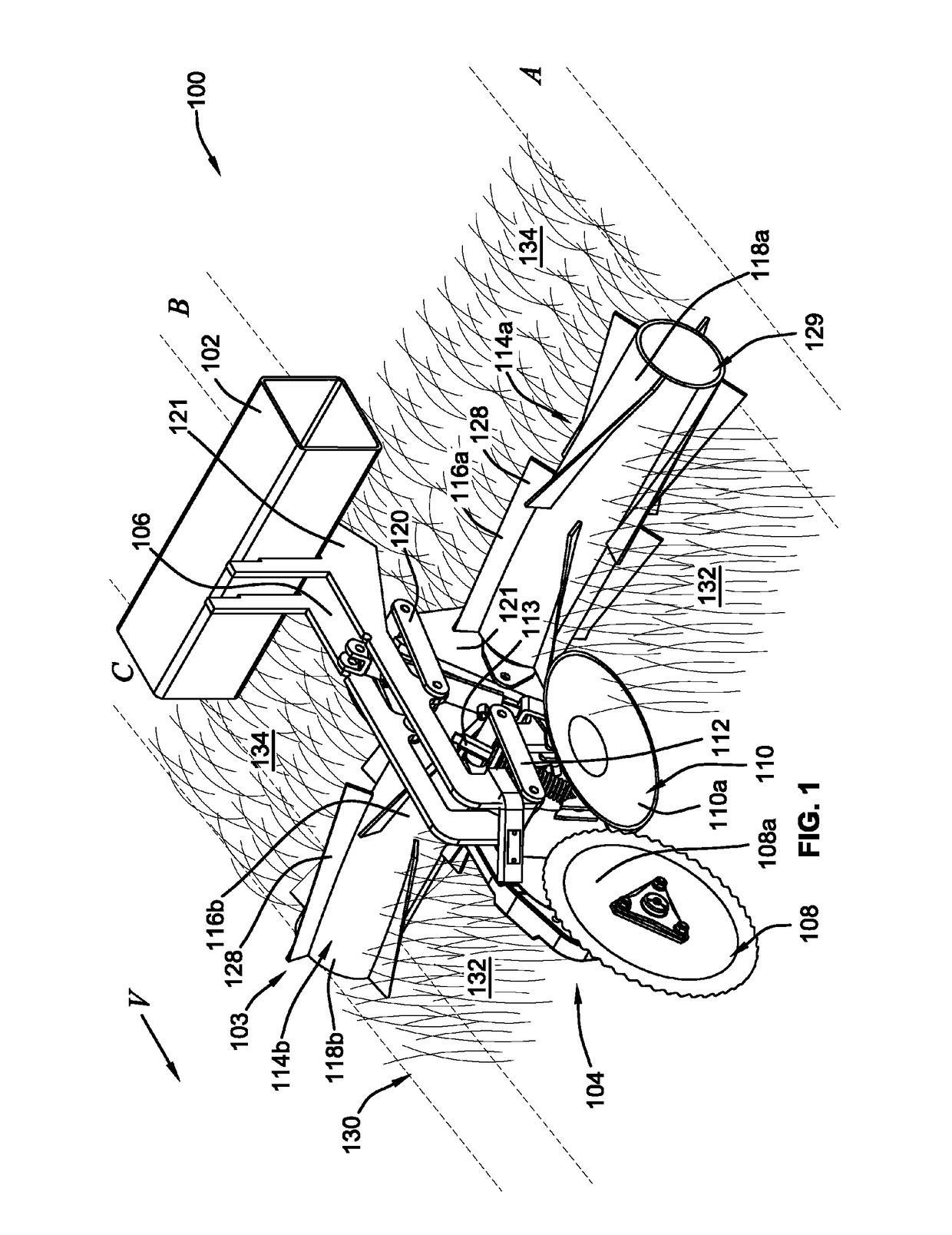

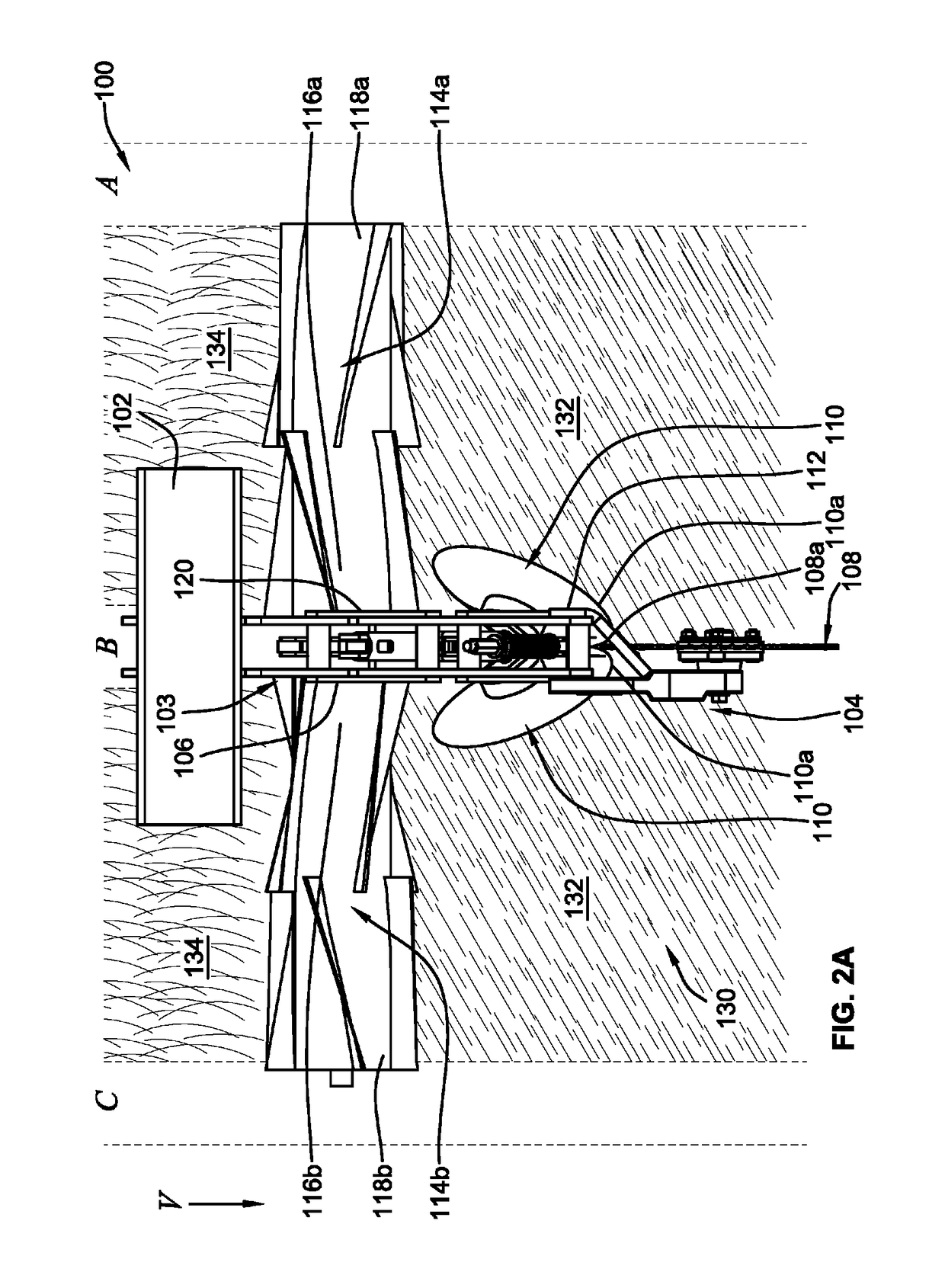

Fertilizer injector wing for disc openers

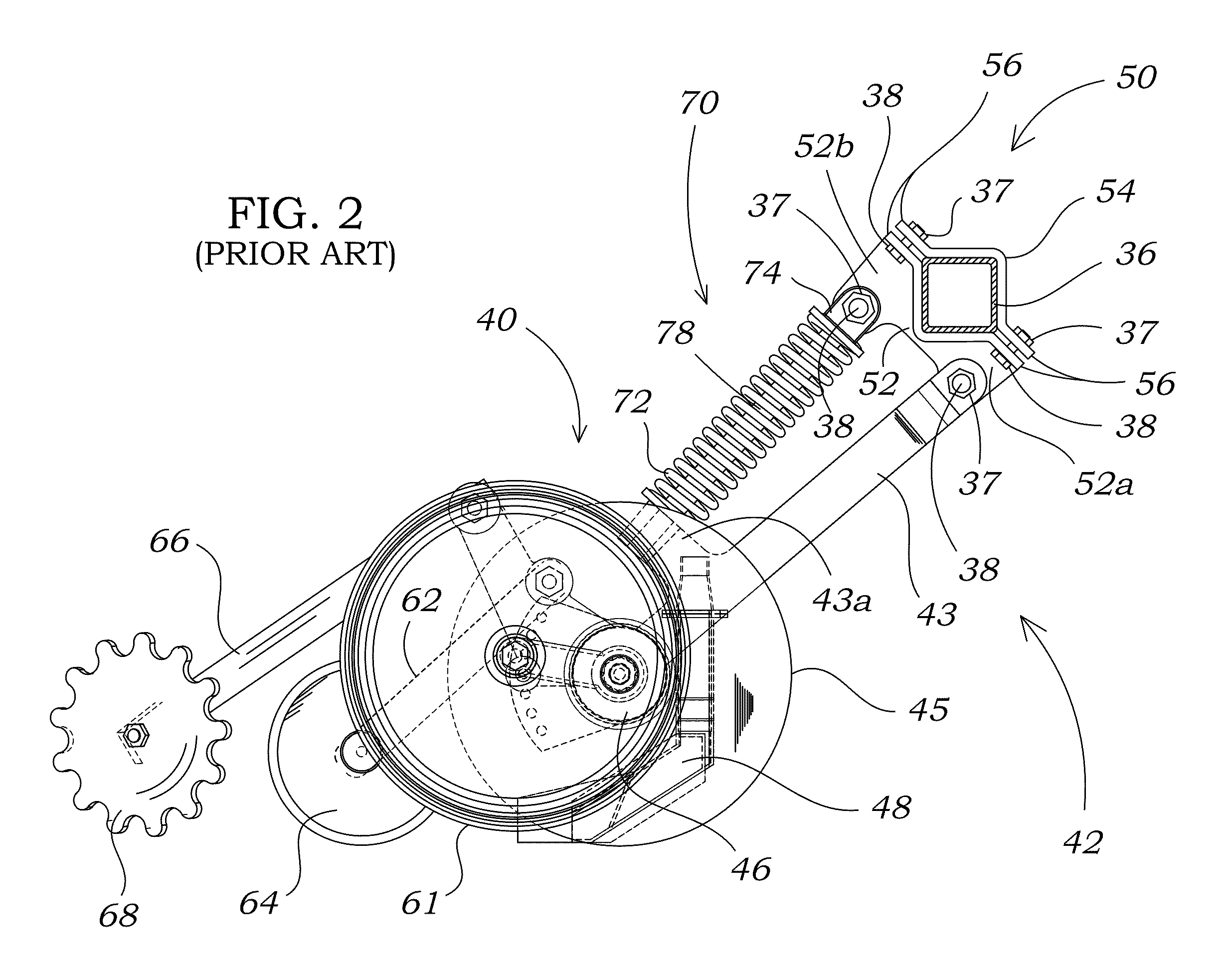

InactiveUS20060102058A1High speed useReduce weed growthTill seedingDirect liquid fertiliser deliverySeederEngineering

Disc openers (14) for use with an air seeder (10) are configured for seeding and fertilizing a field (G). The opener (14b) broadly includes a coulter disc (20), a seed boot (24), and a fertilizer injector wing (26). The fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS). In alternative wings (300 and 400), the sufficiently safe geometric positioning is accomplished by the force of delivery of the fertilizers (N and P) coupled with an offset angle (OA) defined between a fertilizer injection axis (AF) and a seed outlet axis (AO).

Owner:EXACTRIX

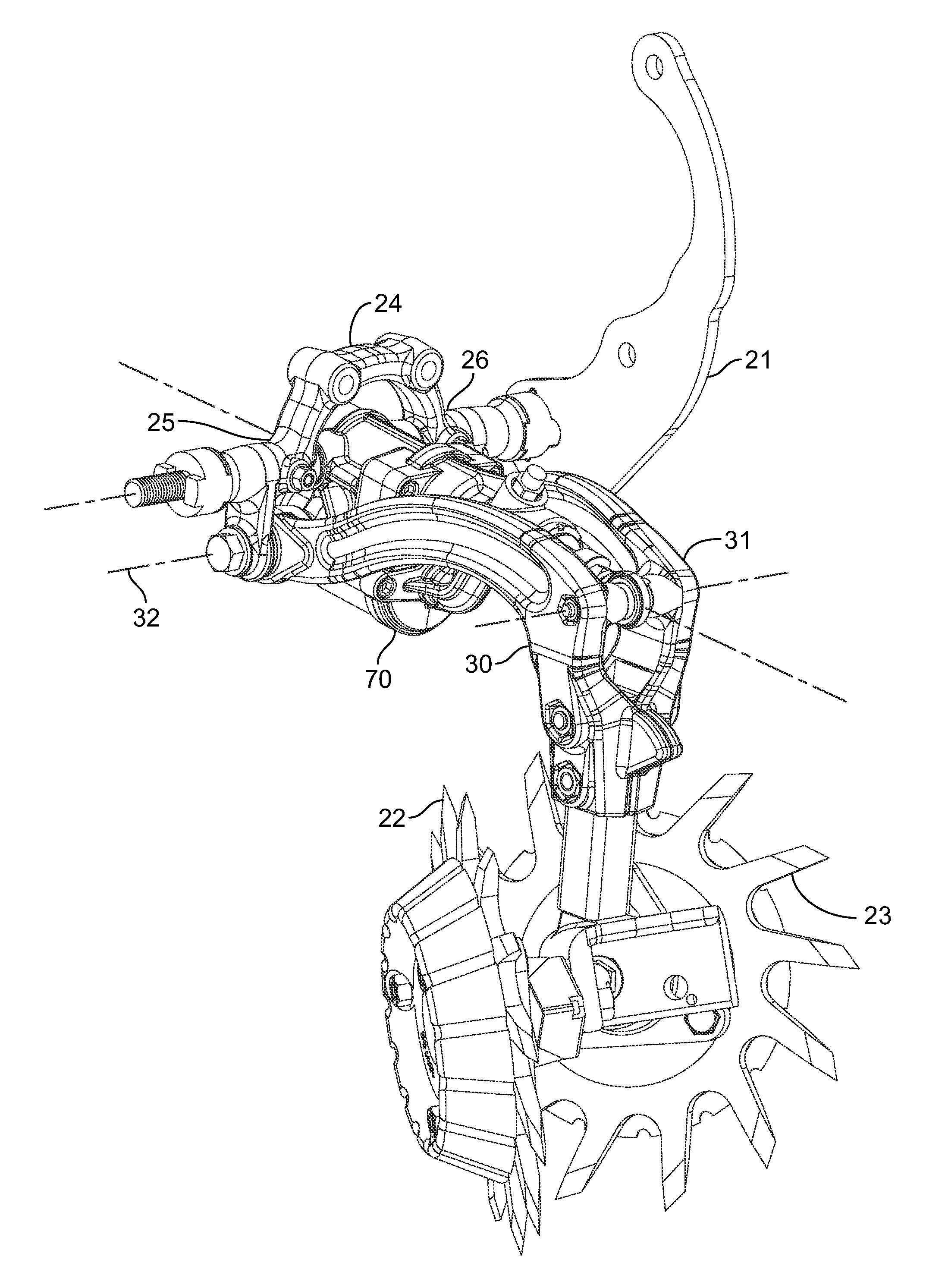

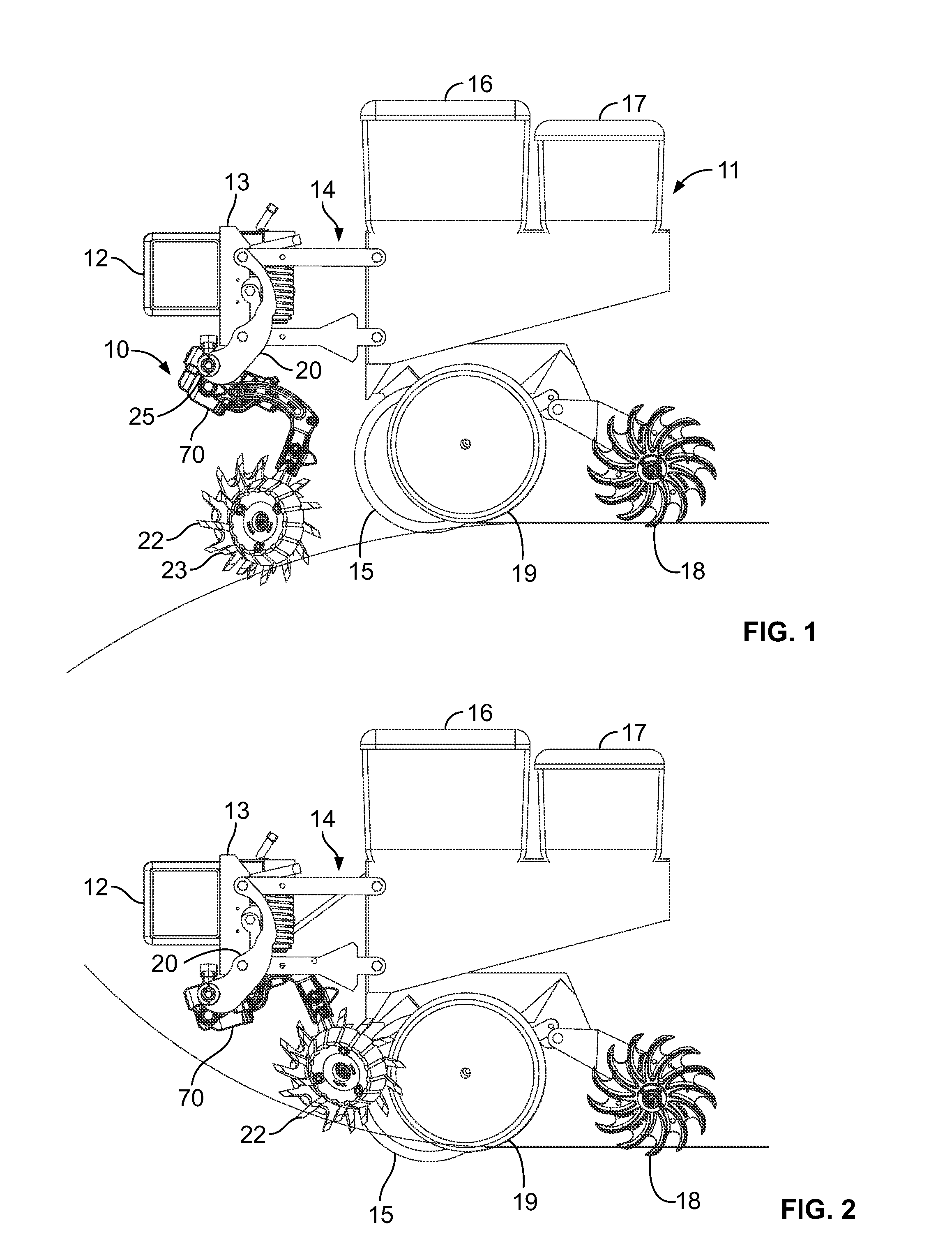

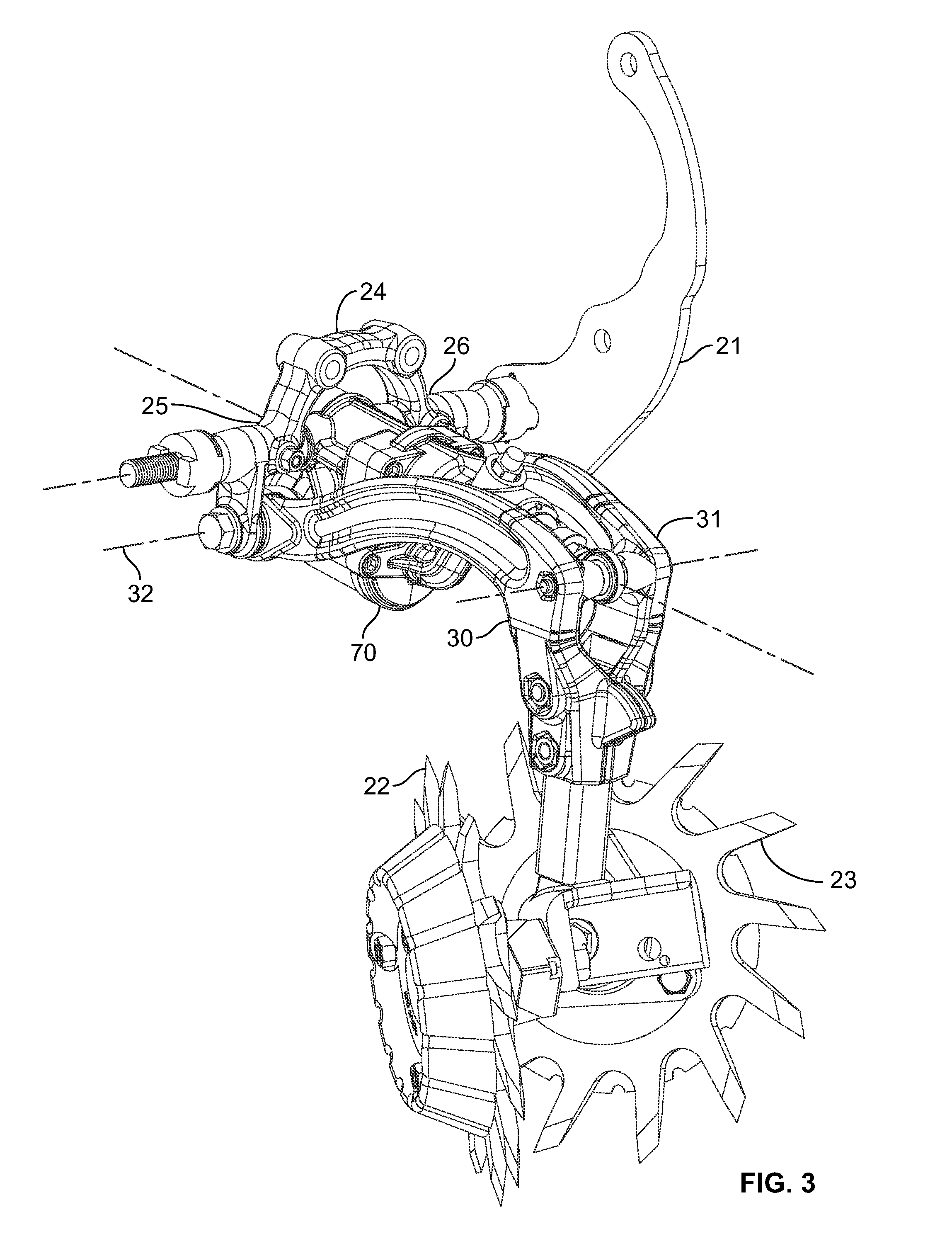

Single arm row cleaner

A single arm row cleaner unit mountable to a grain drill opener arm includes a row cleaner arm and a mounting saddle. The mounting saddle is generally configured for attachment to a main arm of a furrow forming assembly. A row cleaner arm may be pivotally attached to the mounting saddle about a mandrel, and a row cleaner wheel may be pivotally mounted to the row cleaner arm. A biasing member may be positioned adjacent the mandrel to engage the row cleaner arm and a biasing member retainer, which may be affixed to the mounting saddle. A deflector may be positioned adjacent the row cleaner wheel and biased there against. A connector and lever arm may be used to communicate forces from a closing wheel arm to the row cleaner wheel for adequate clearance of the row cleaner wheel during transport of the grain drill.

Owner:MARTIN HOWARD D +1

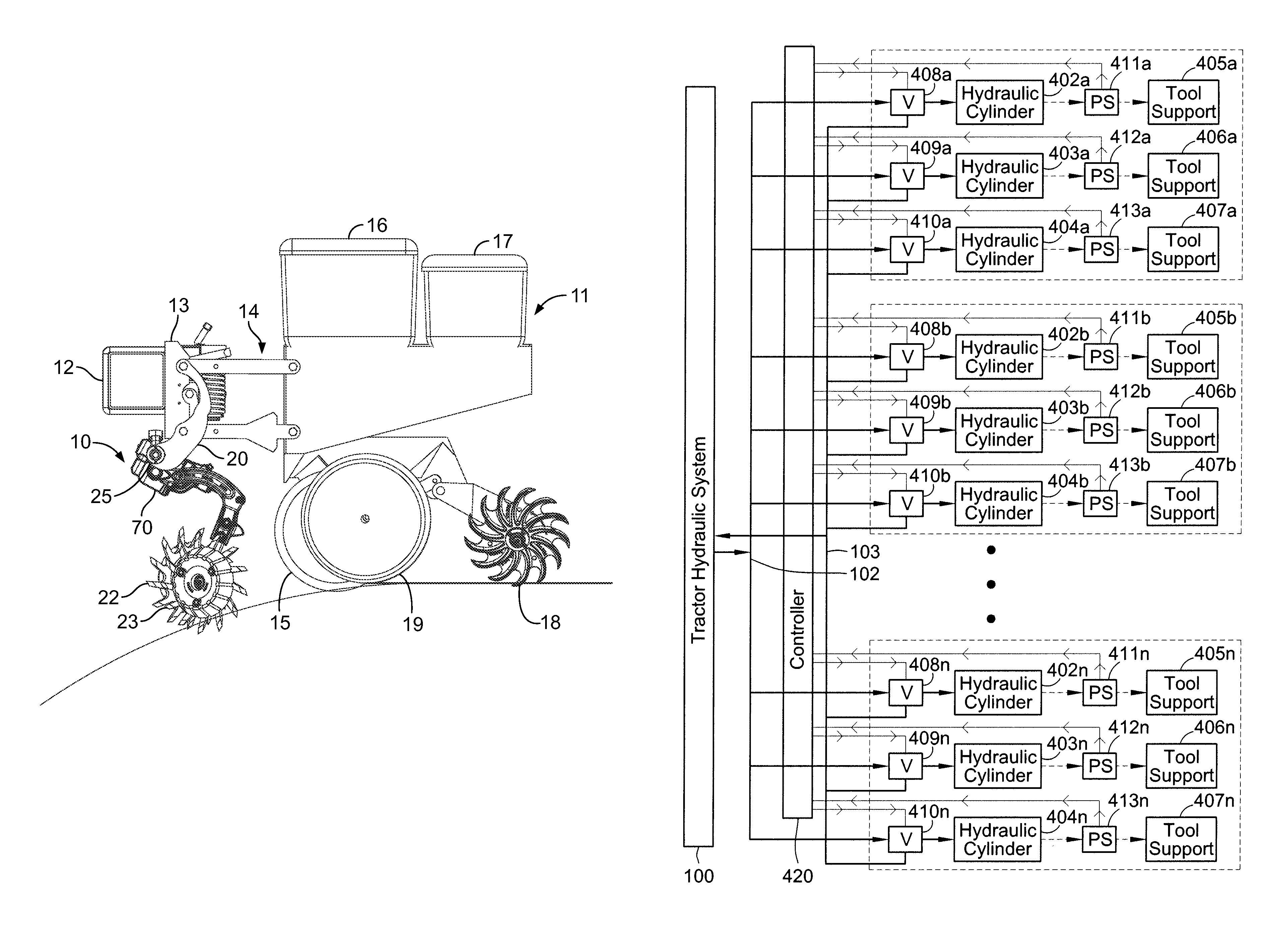

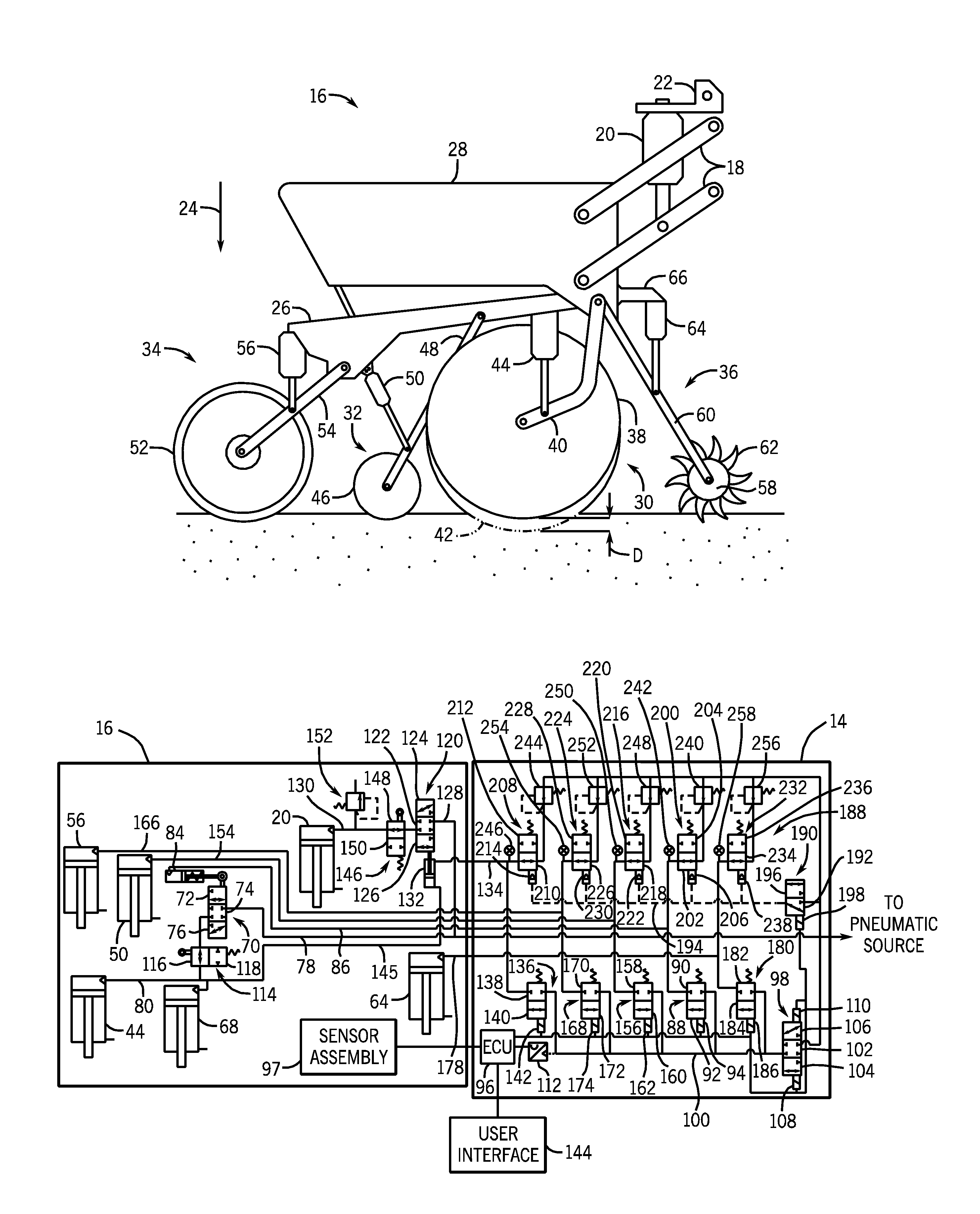

Manual backup system for controlling fluid flow to cylinders within an agricultural implement

An agricultural implement system is provided that includes a down force cylinder configured to apply a downward force to a row unit, a depth control cylinder configured to vary a penetration depth of a ground engaging tool of the row unit, a press wheel cylinder configured to vary contact force between a press wheel and a soil surface, a closing disk cylinder configured to vary contact force between a closing disk and the soil surface, a residue manager cylinder configured to vary contact force between a residue manager and the soil surface, or a combination thereof. The agricultural implement system also includes an electronic control unit configured to automatically regulate a pressure within the cylinders, and a manual backup system configured to facilitate manual pressure adjustment of the cylinders.

Owner:CNH IND AMERICA LLC

Agricultural implement with automatic down pressure control

Owner:DAWN EQUIPMENT COMPANY

Agricultural apparatus for sensing and providing feedback of soil property changes in real time

Owner:DAWN EQUIPMENT COMPANY

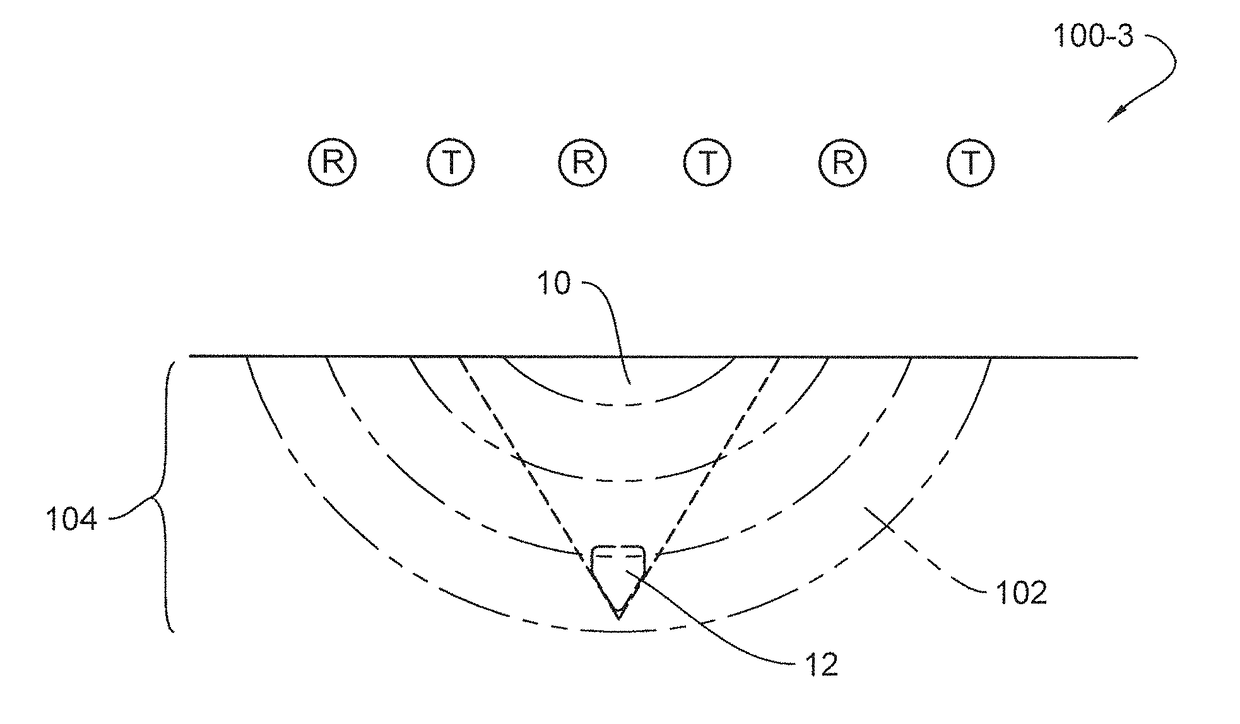

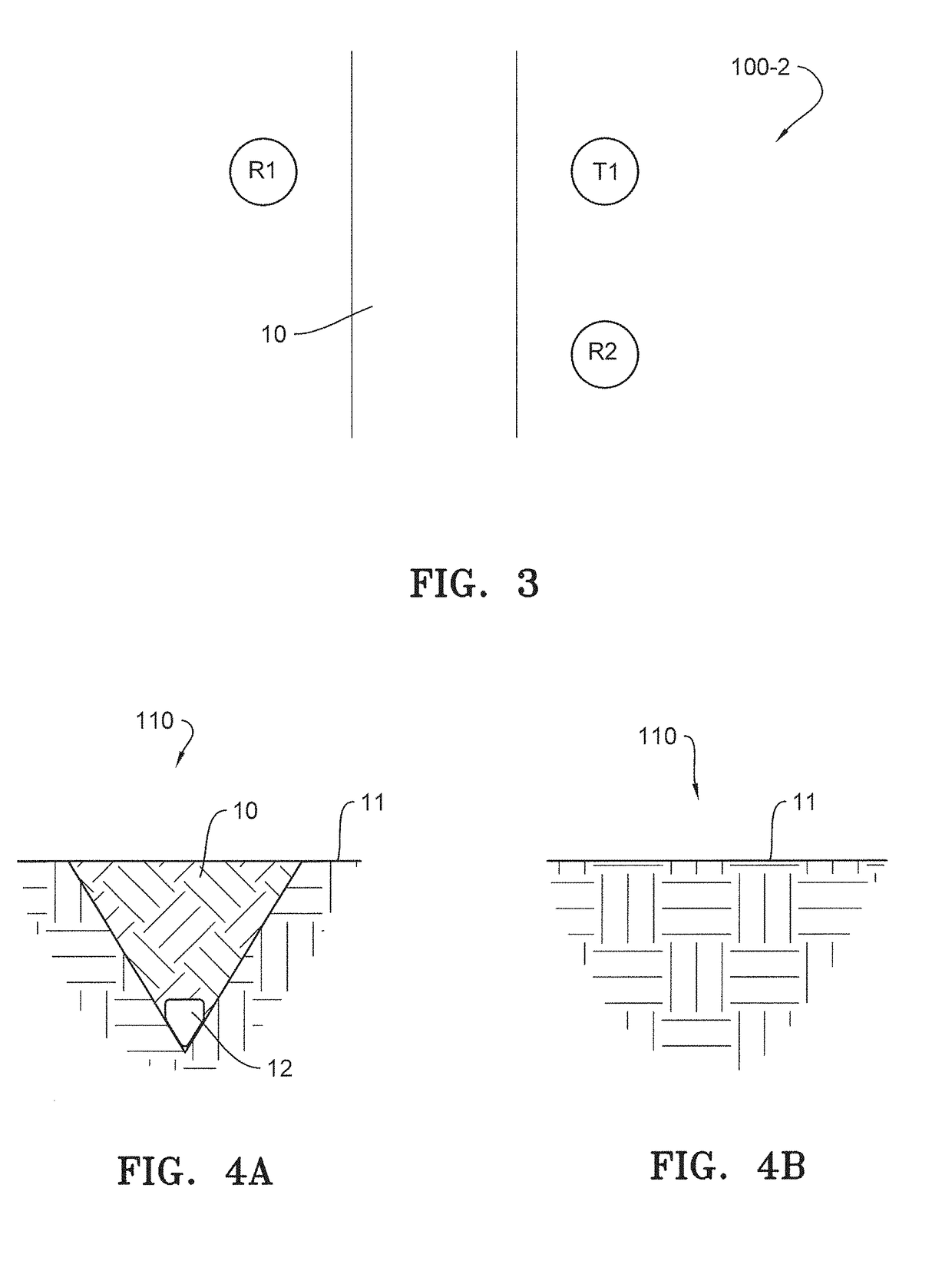

Work layer imaging and analysis for implement monitoring, control and operator feedback

A soil imaging system having a work layer sensor disposed on an agricultural implement to generate an electromagnetic field through a soil area of interest as the agricultural implement traverses a field. A monitor in communication with the work layer sensor is adapted to generate a work layer image of the soil layer of interest based on the generated electromagnetic field. The work layer sensor may also generate a reference image by generating an electromagnetic field through undisturbed soil. The monitor may compare at least one characteristic of the reference image with at least one characteristic of the work layer image to generate a characterized image of the work layer of interest. The monitor may display operator feedback and may affect operational control of the agricultural implement based on the characterized image.

Owner:CLIMATE LLC

Manual backup system for controlling fluid flow to cylinders within an agricultural implement

An agricultural implement system is provided that includes a down force cylinder configured to apply a downward force to a row unit, a depth control cylinder configured to vary a penetration depth of a ground engaging tool of the row unit, a press wheel cylinder configured to vary contact force between a press wheel and a soil surface, a closing disk cylinder configured to vary contact force between a closing disk and the soil surface, a residue manager cylinder configured to vary contact force between a residue manager and the soil surface, or a combination thereof. The agricultural implement system also includes an electronic control unit configured to automatically regulate a pressure within the cylinders, and a manual backup system configured to facilitate manual pressure adjustment of the cylinders.

Owner:CNH IND AMERICA LLC

Fertilizer injector wing for disc openers

InactiveUS7152539B2High speed useReduce distractionsTill seedingDirect liquid fertiliser deliverySeederEngineering

Disc openers (14) for use with an air seeder (10) are configured for seeding and fertilizing a field (G). The opener (14b) broadly includes a coulter disc (20), a seed boot (24), and a fertilizer injector wing (26). The fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS). In alternative wings (300 and 400), the sufficiently safe geometric positioning is accomplished by the force of delivery of the fertilizers (N and P) coupled with an offset angle (OA) defined between a fertilizer injection axis (AF) and a seed outlet axis (AO).

Owner:EXACTRIX

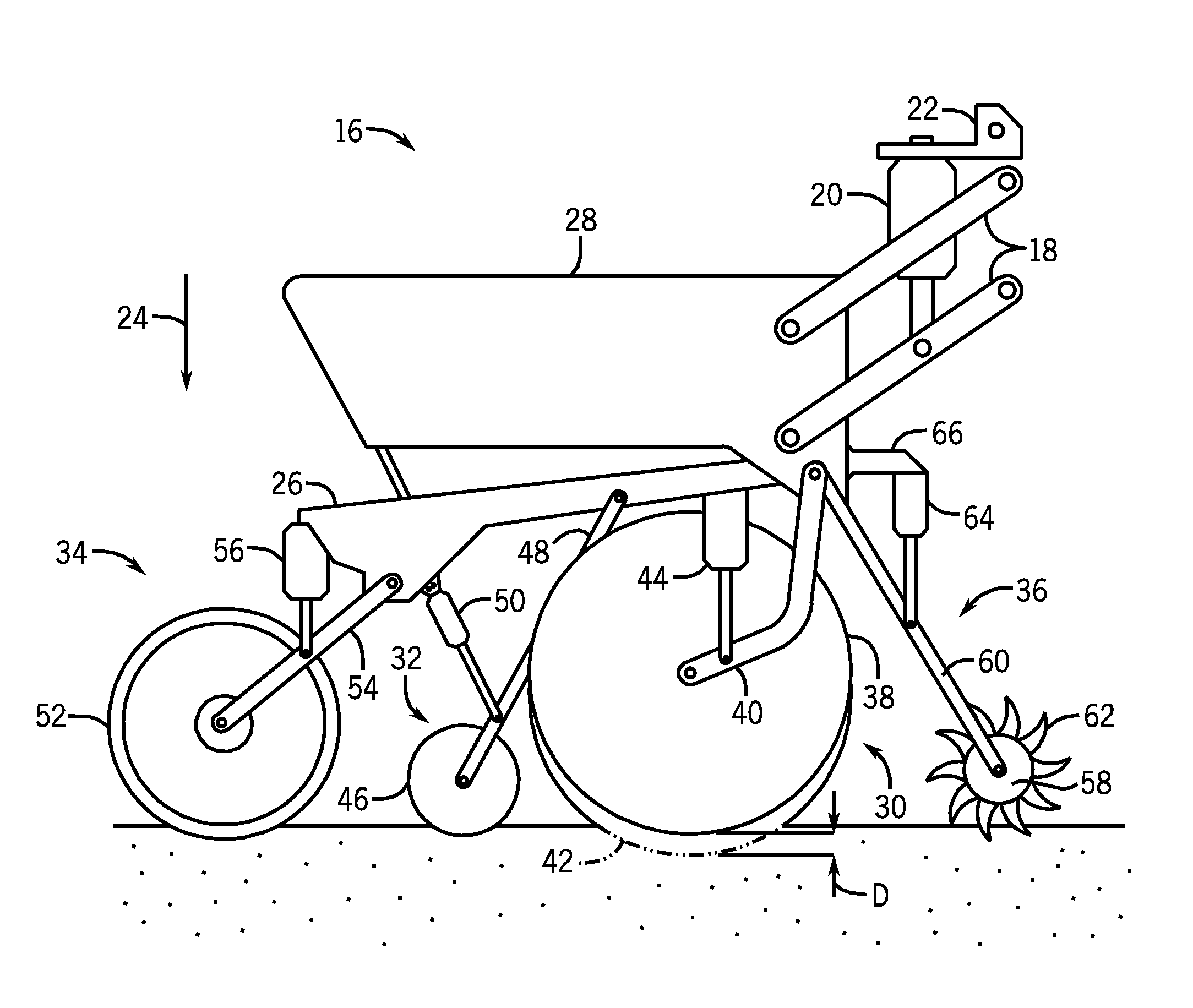

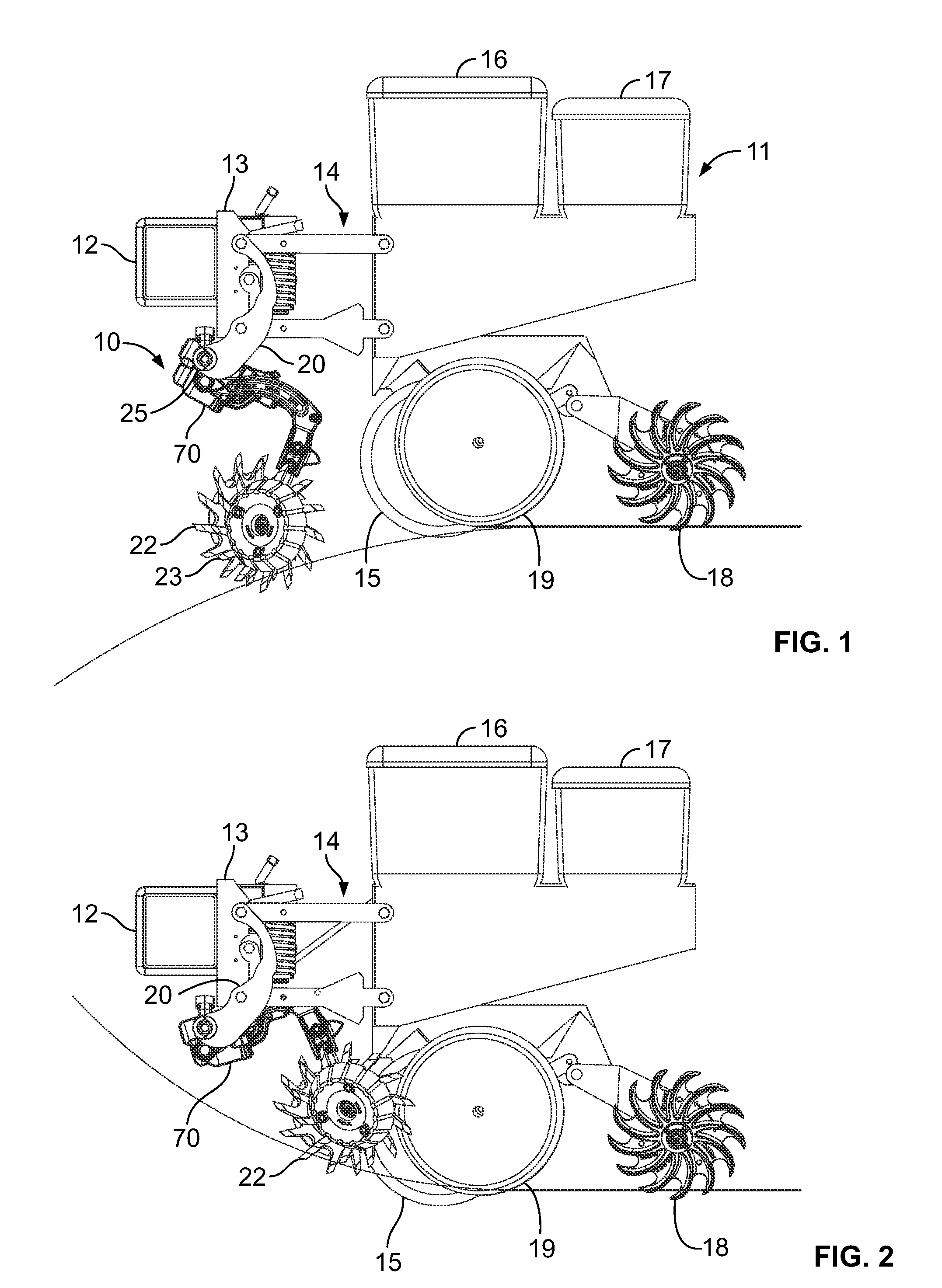

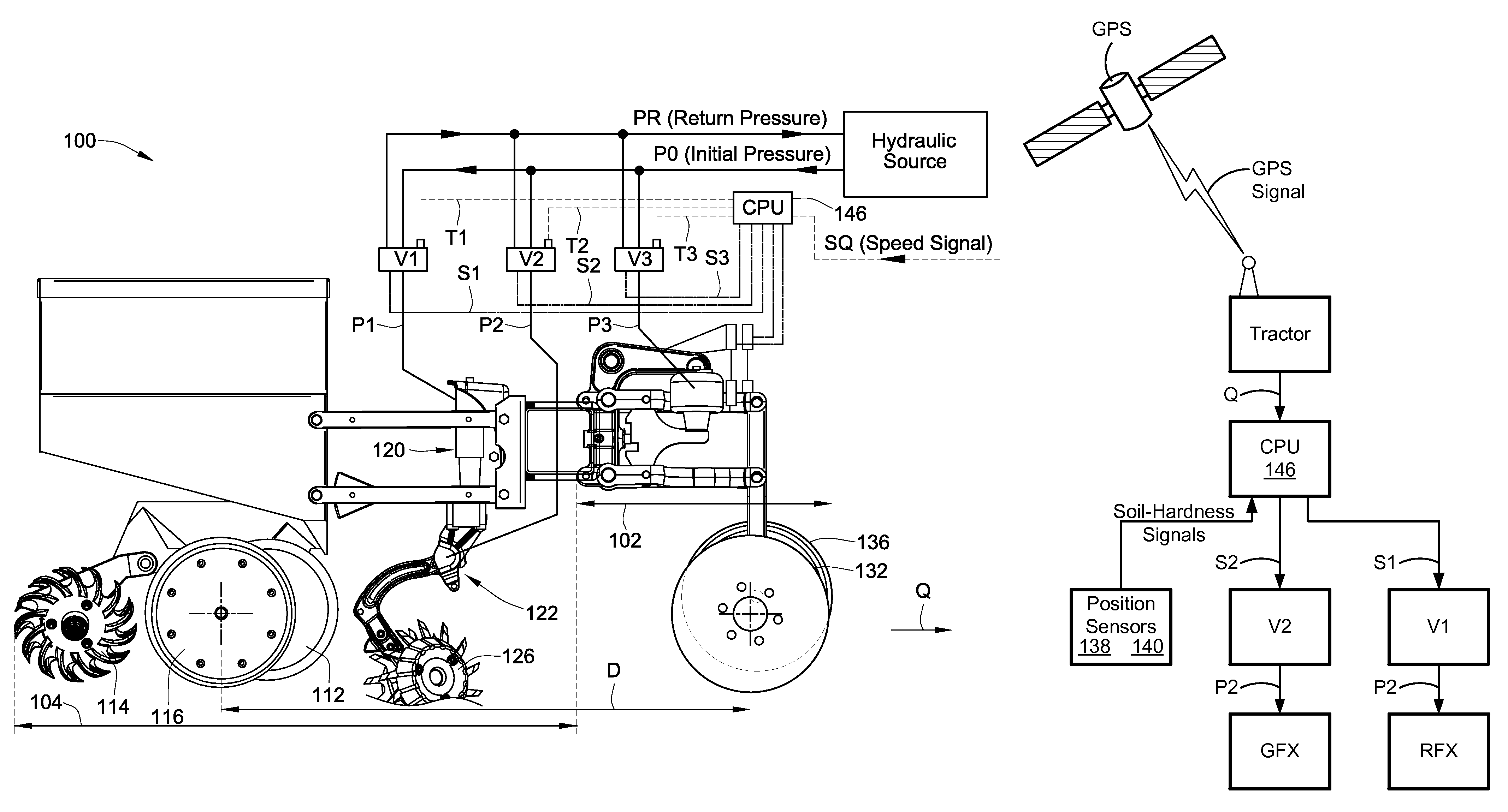

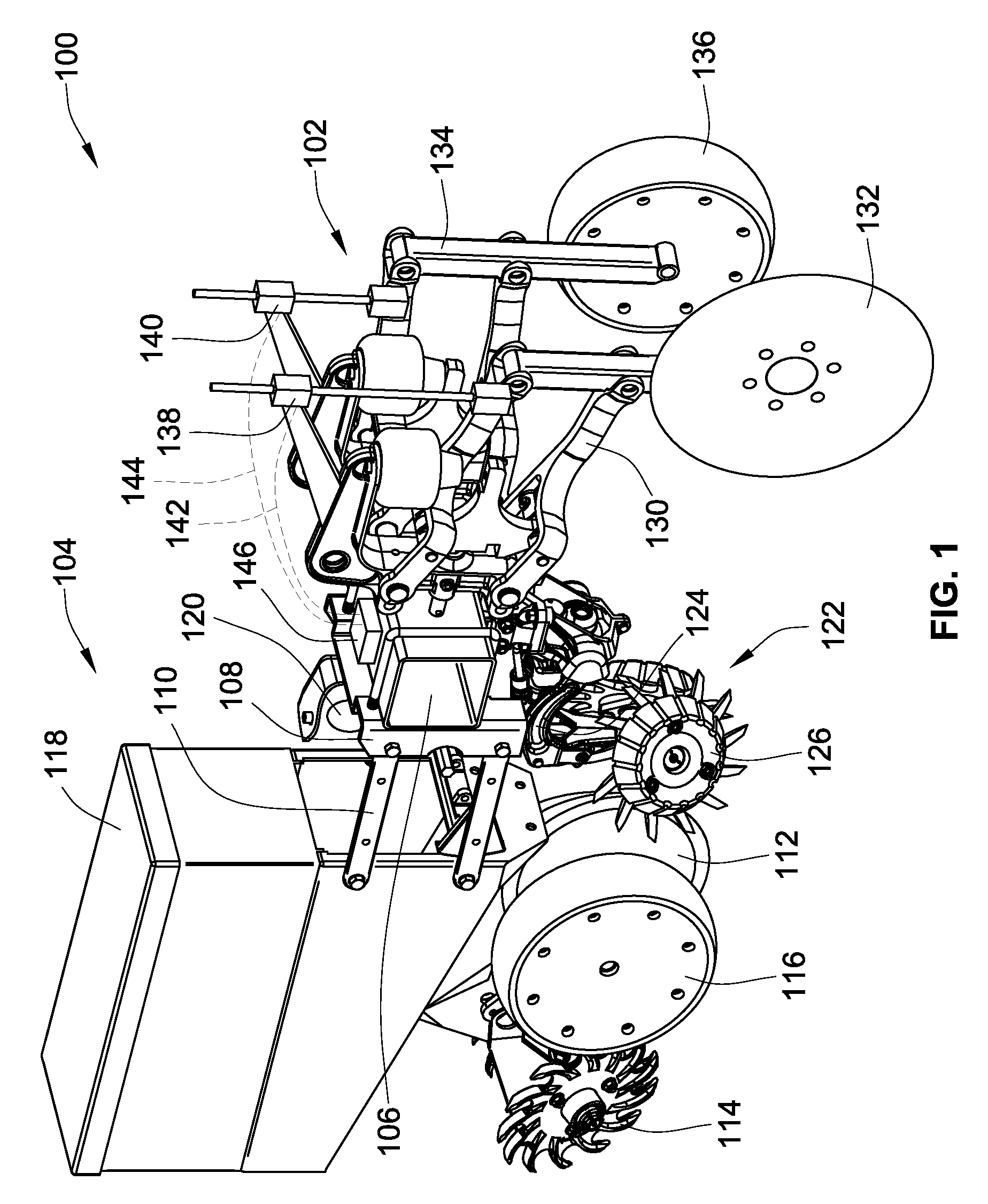

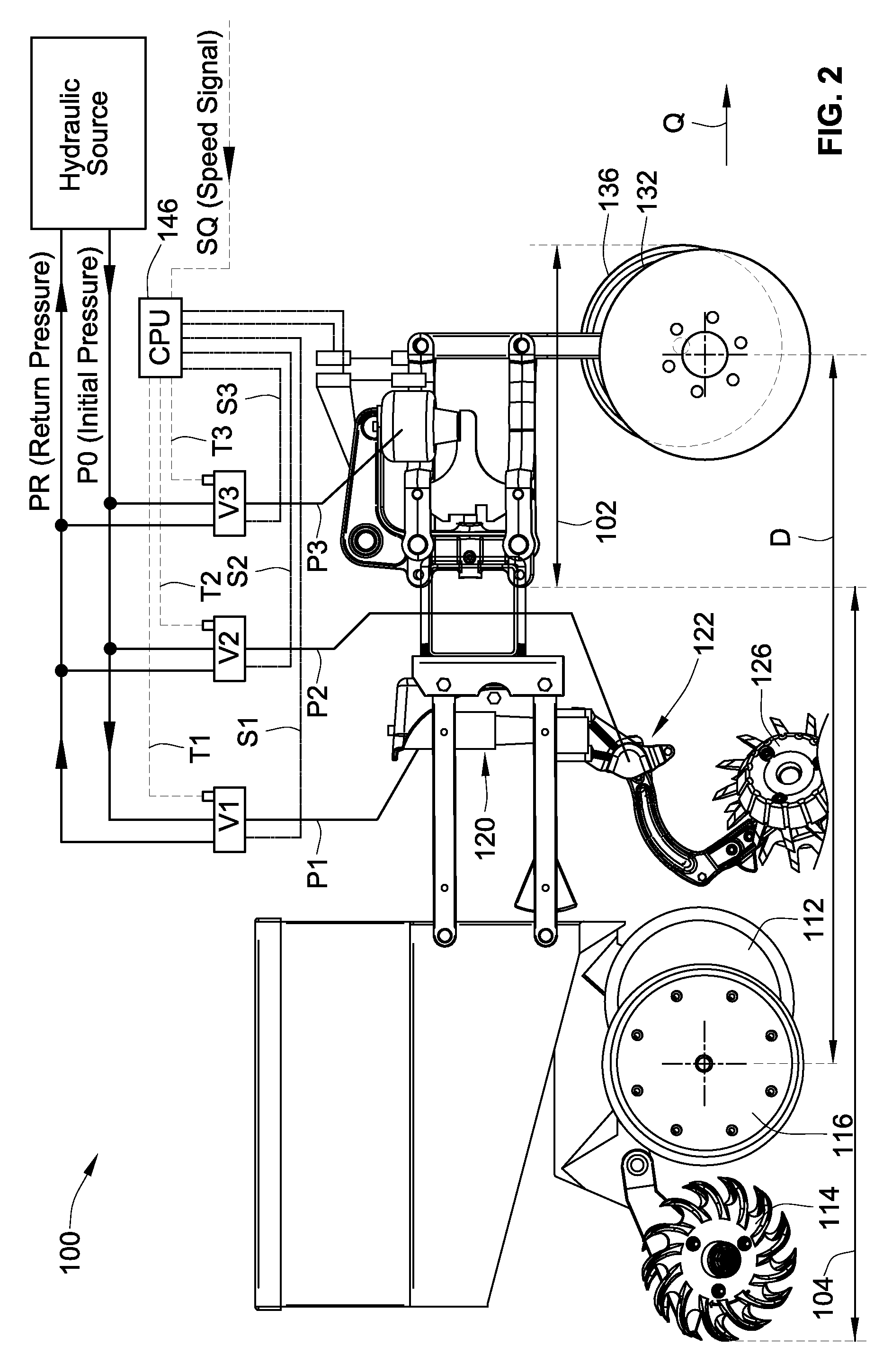

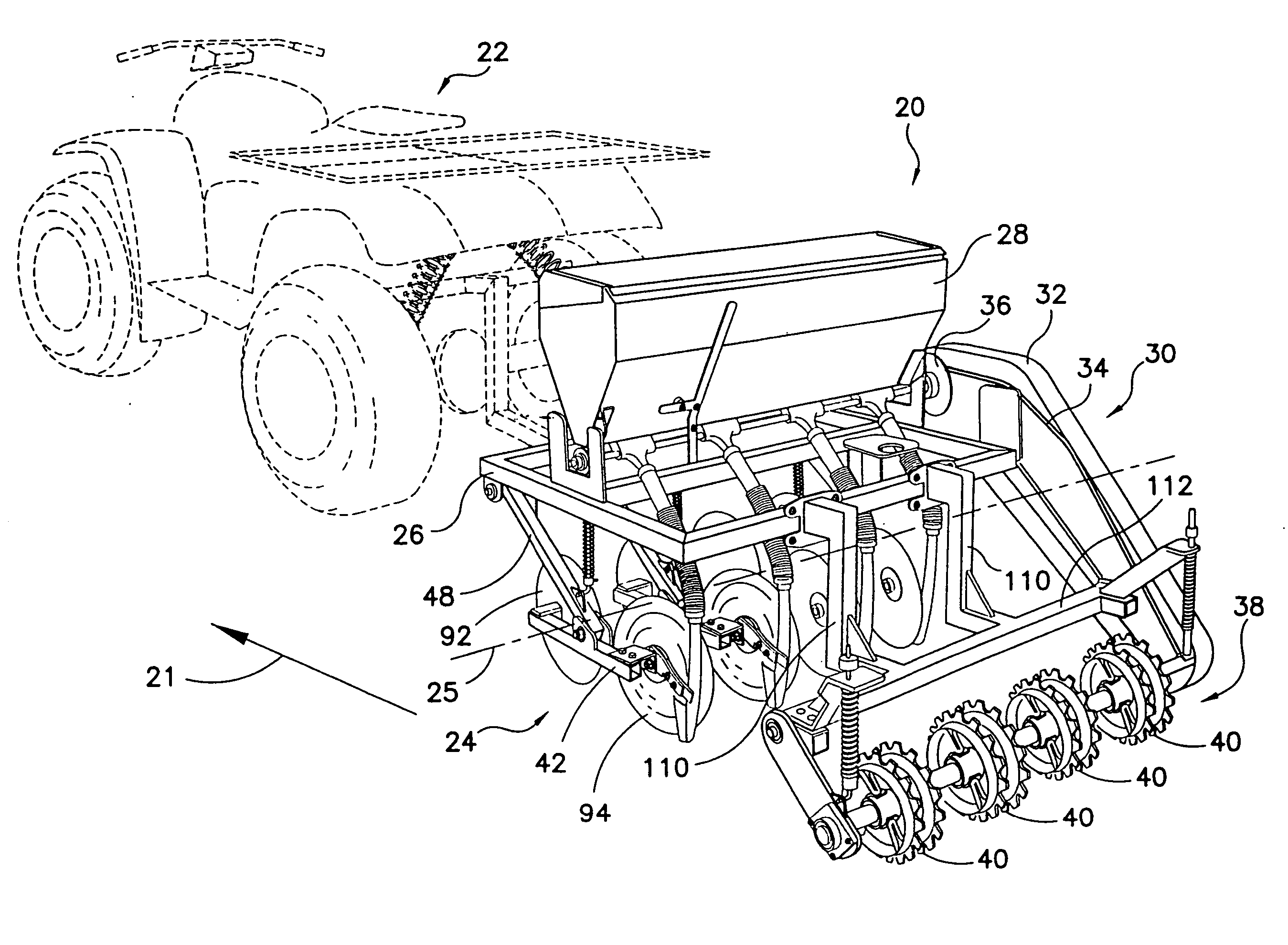

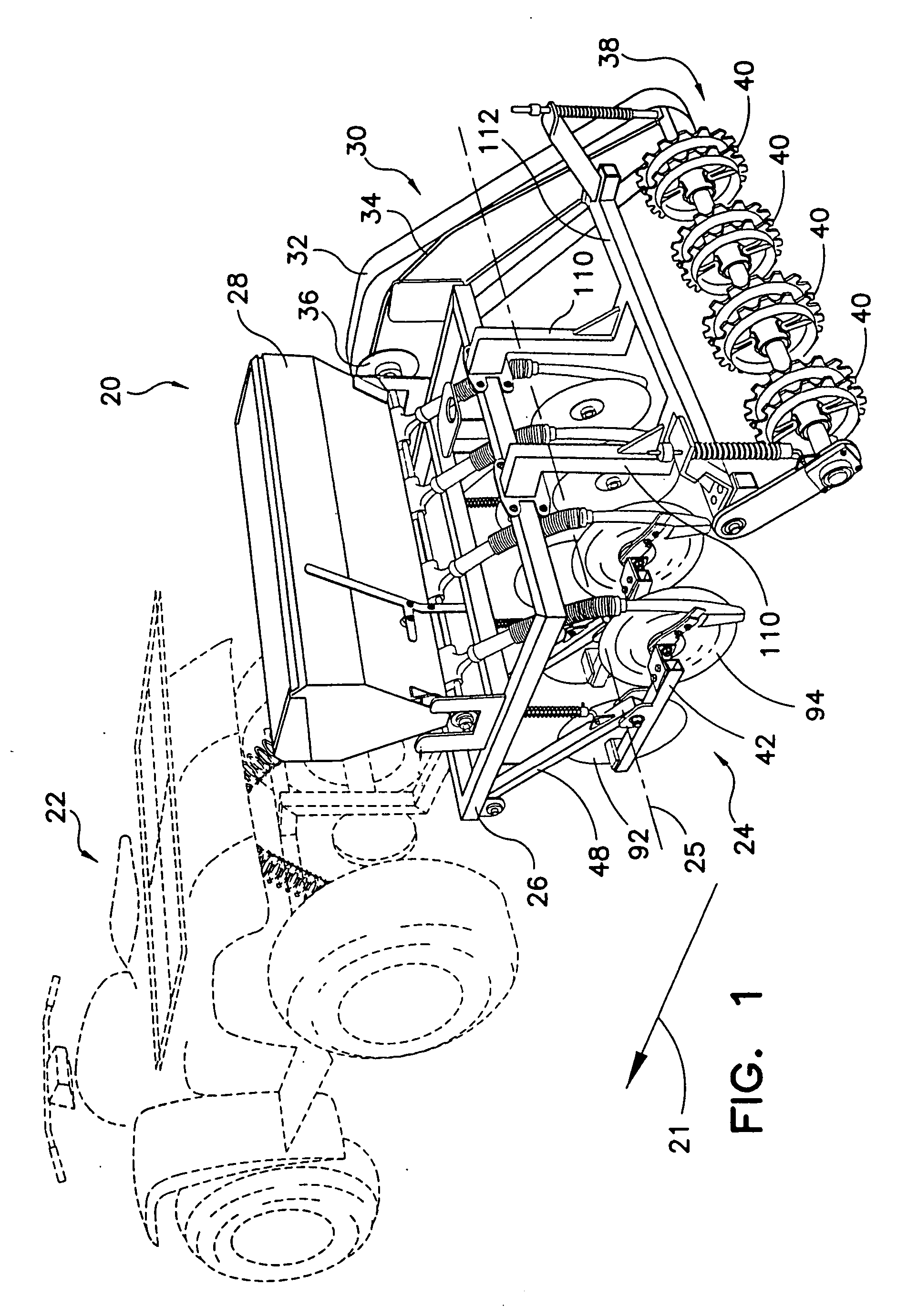

Agricultural Apparatus For Sensing And Providing Feedback Of Soil Property Changes In Real Time

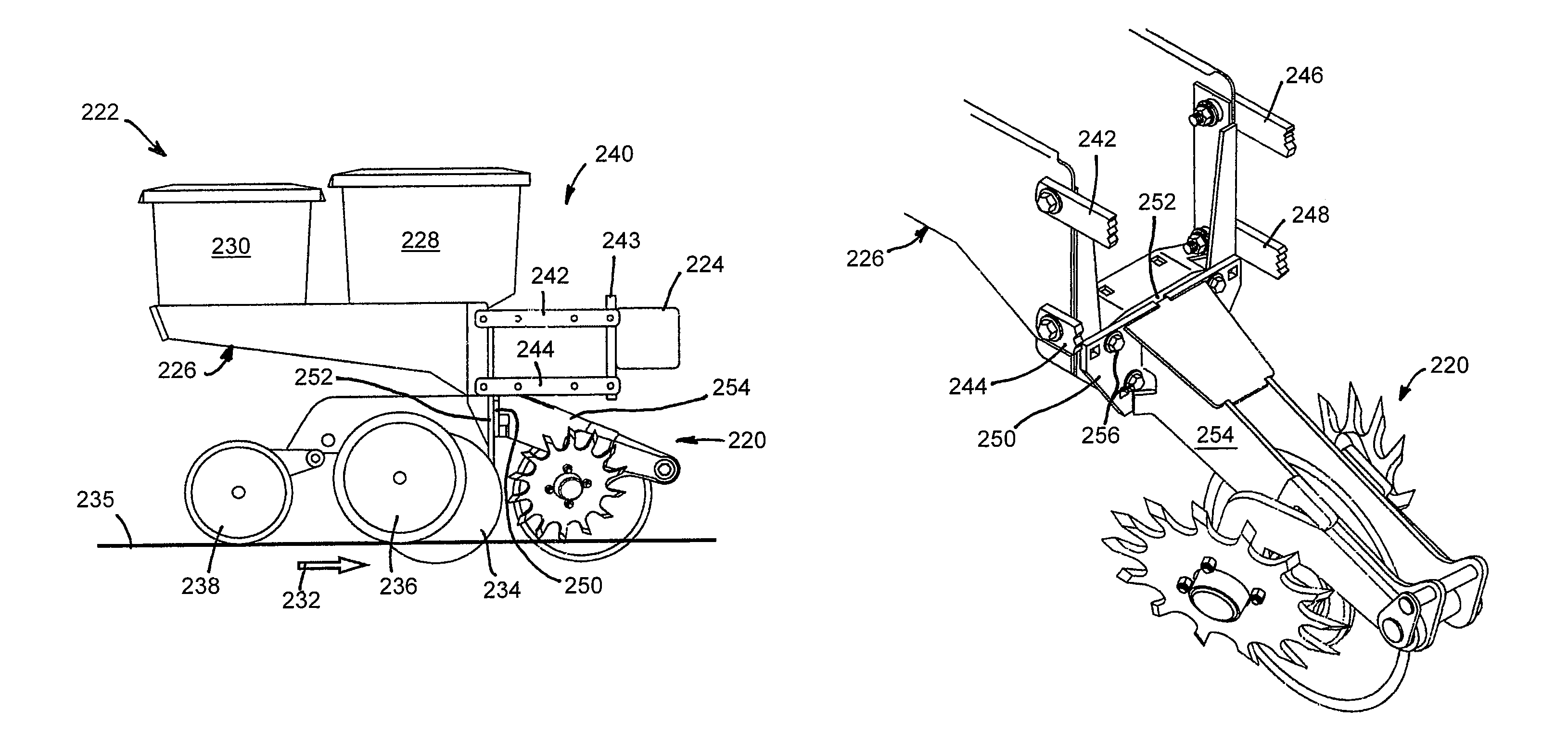

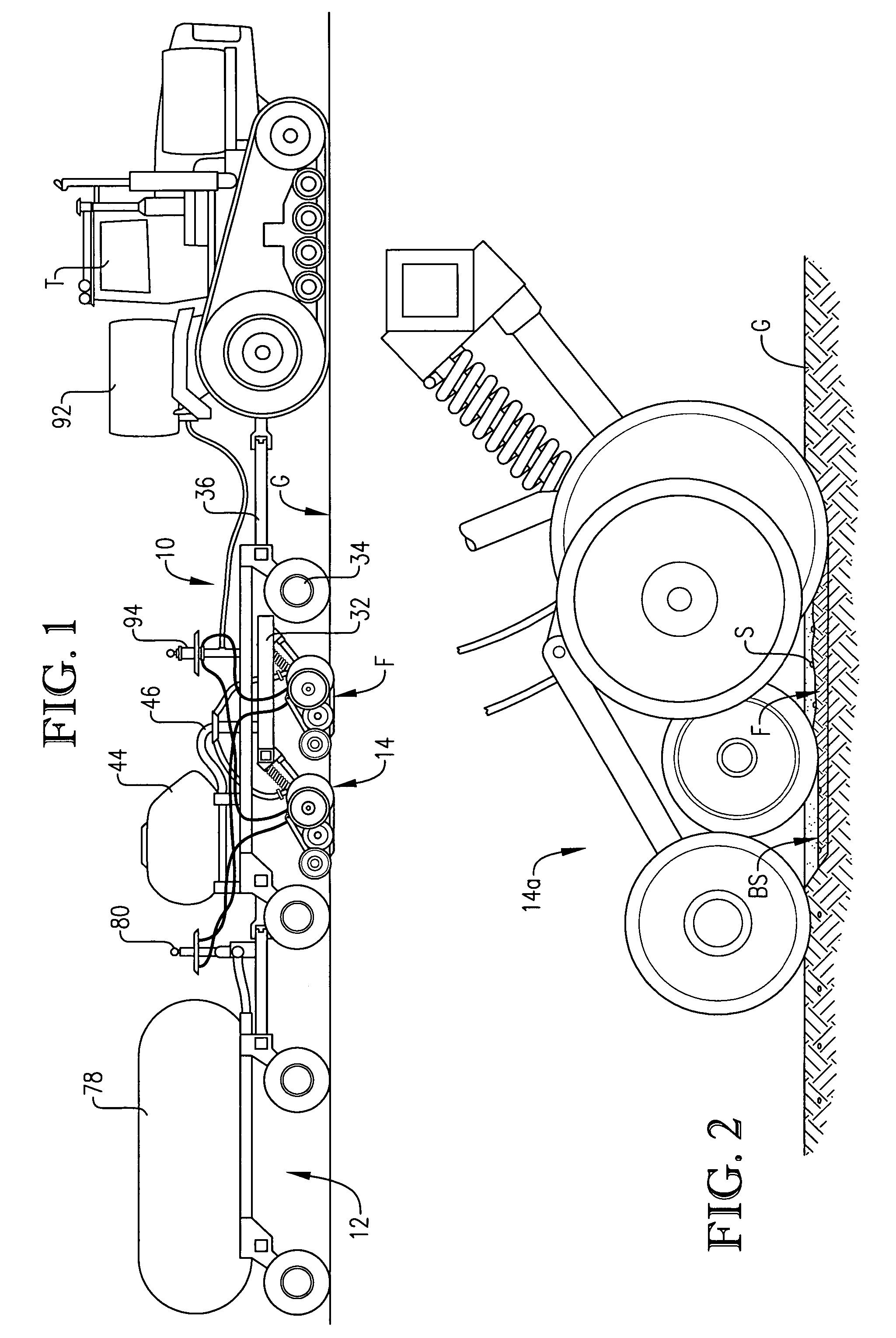

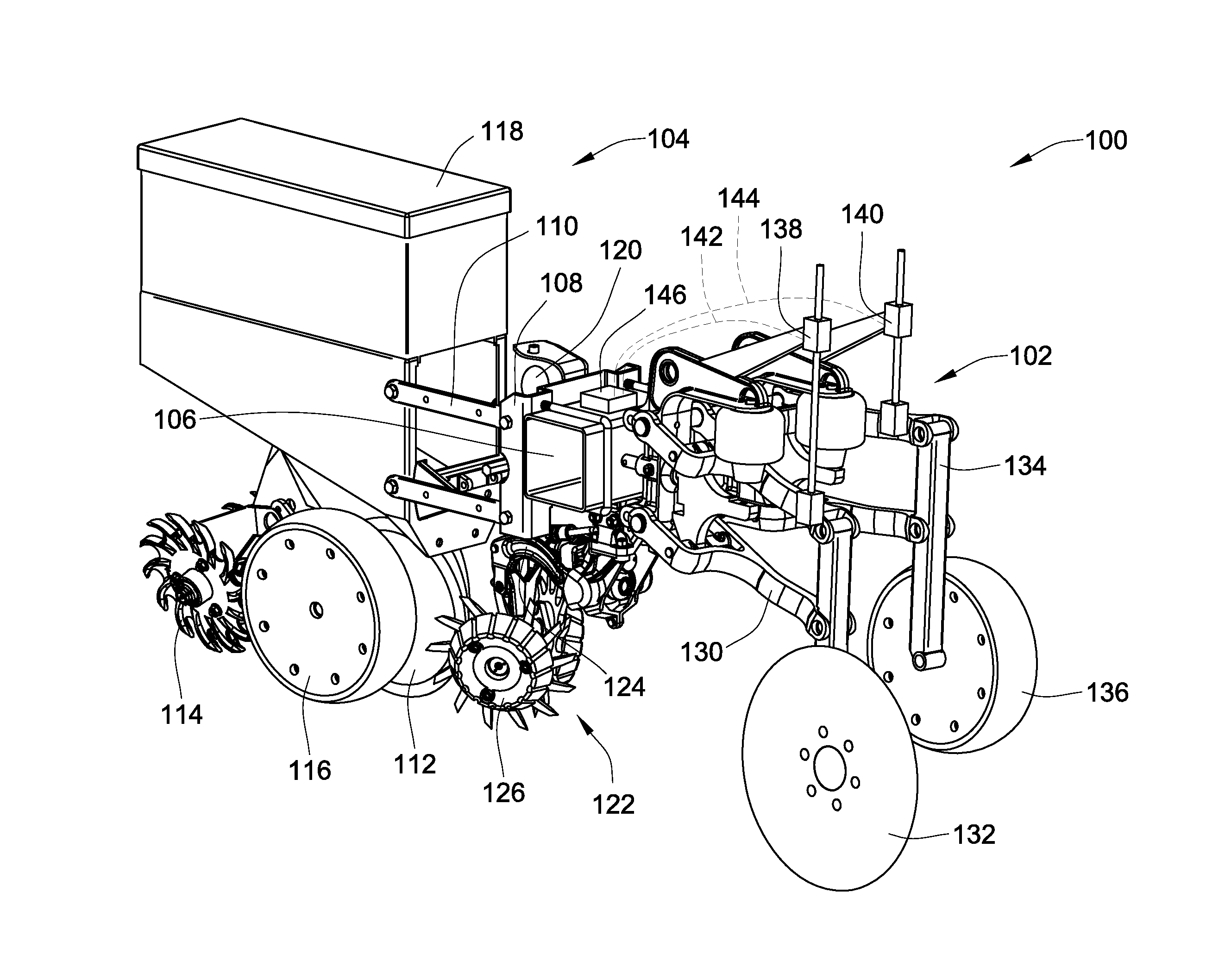

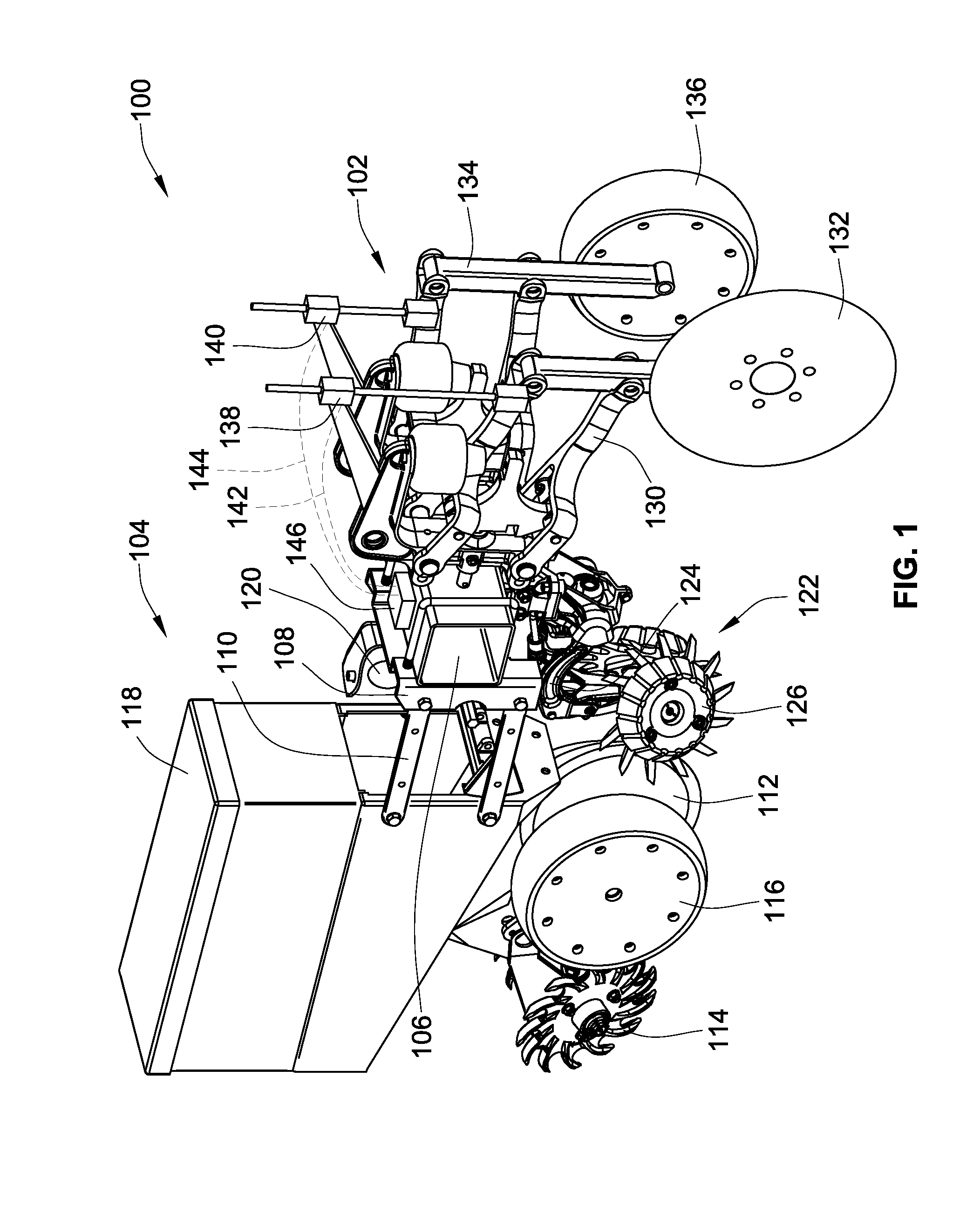

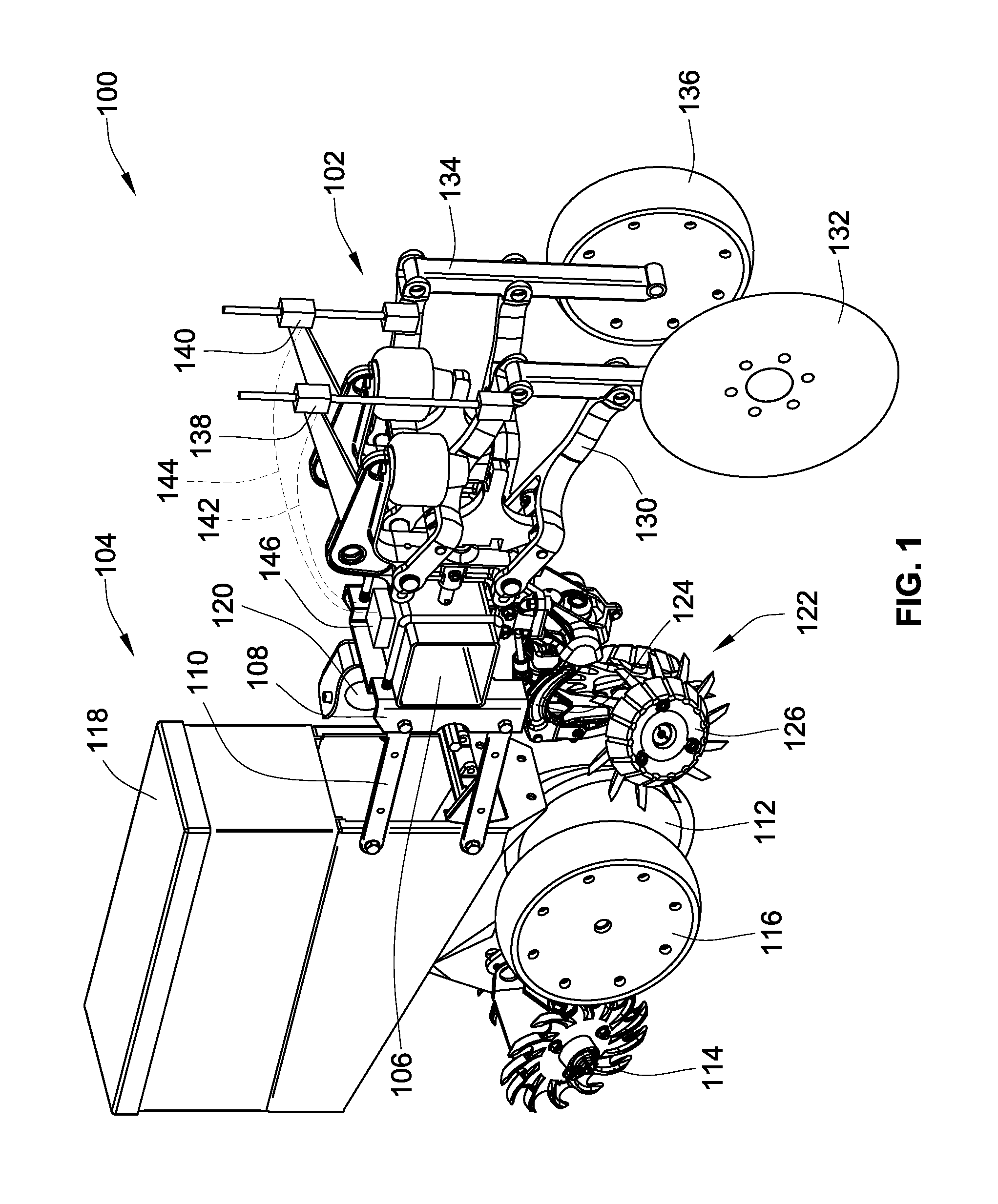

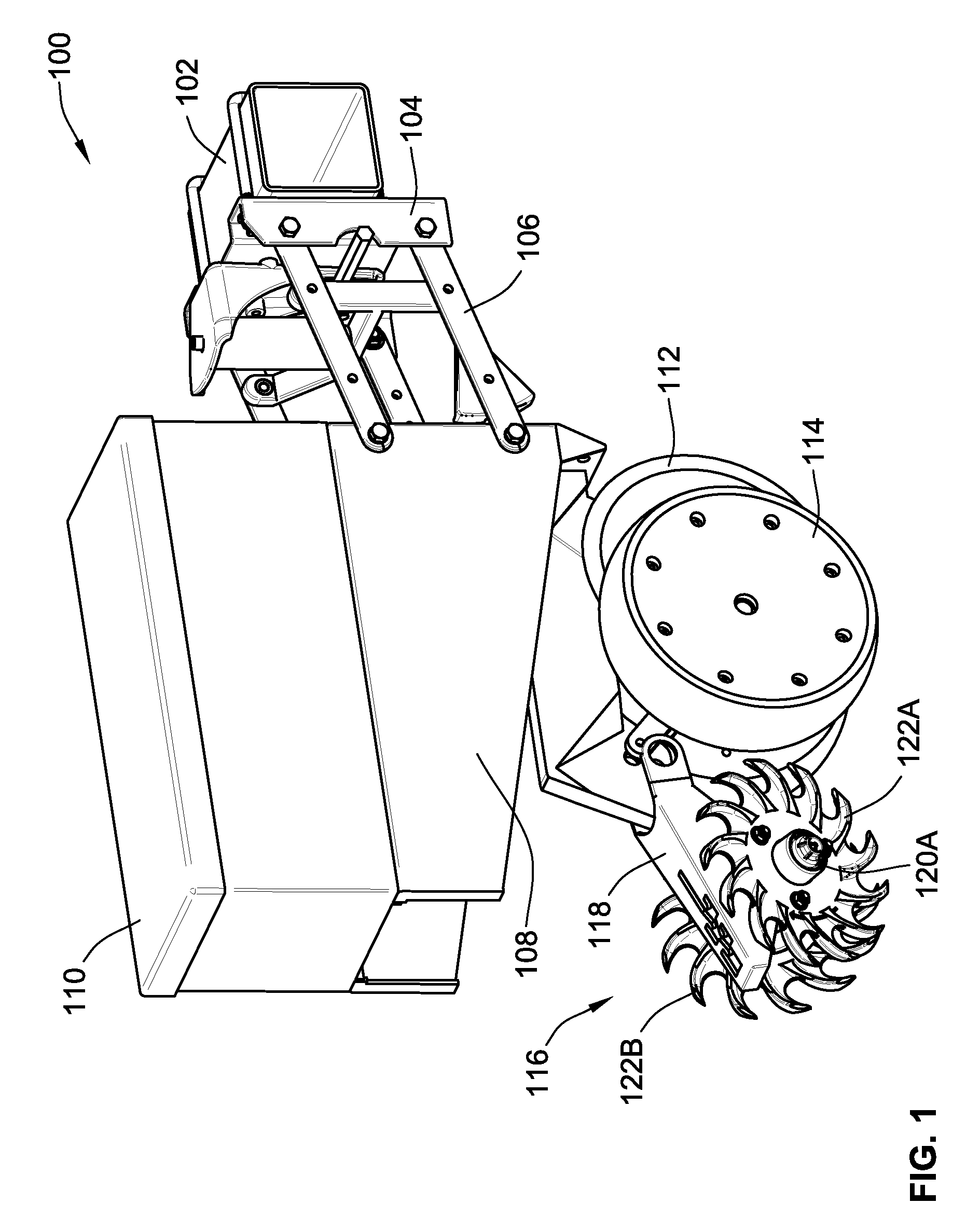

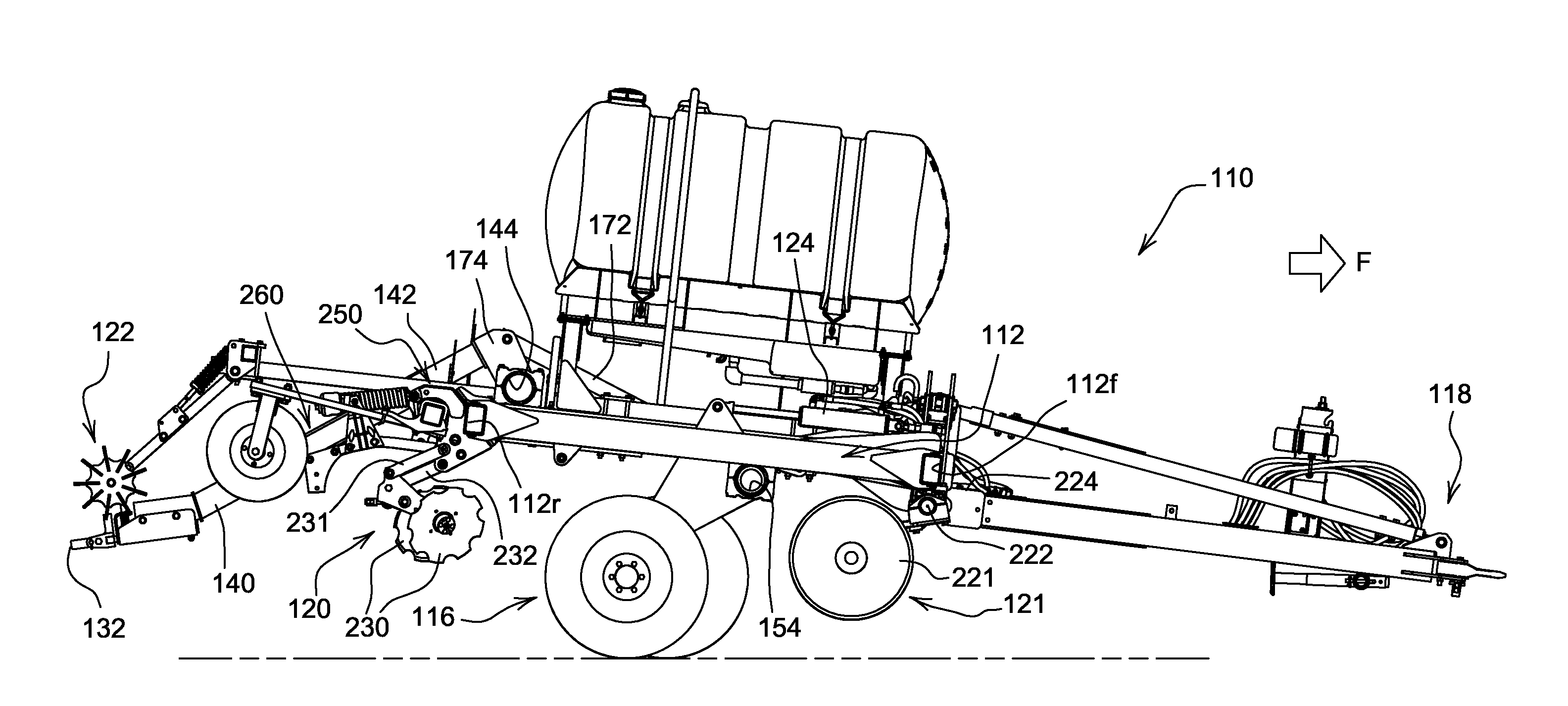

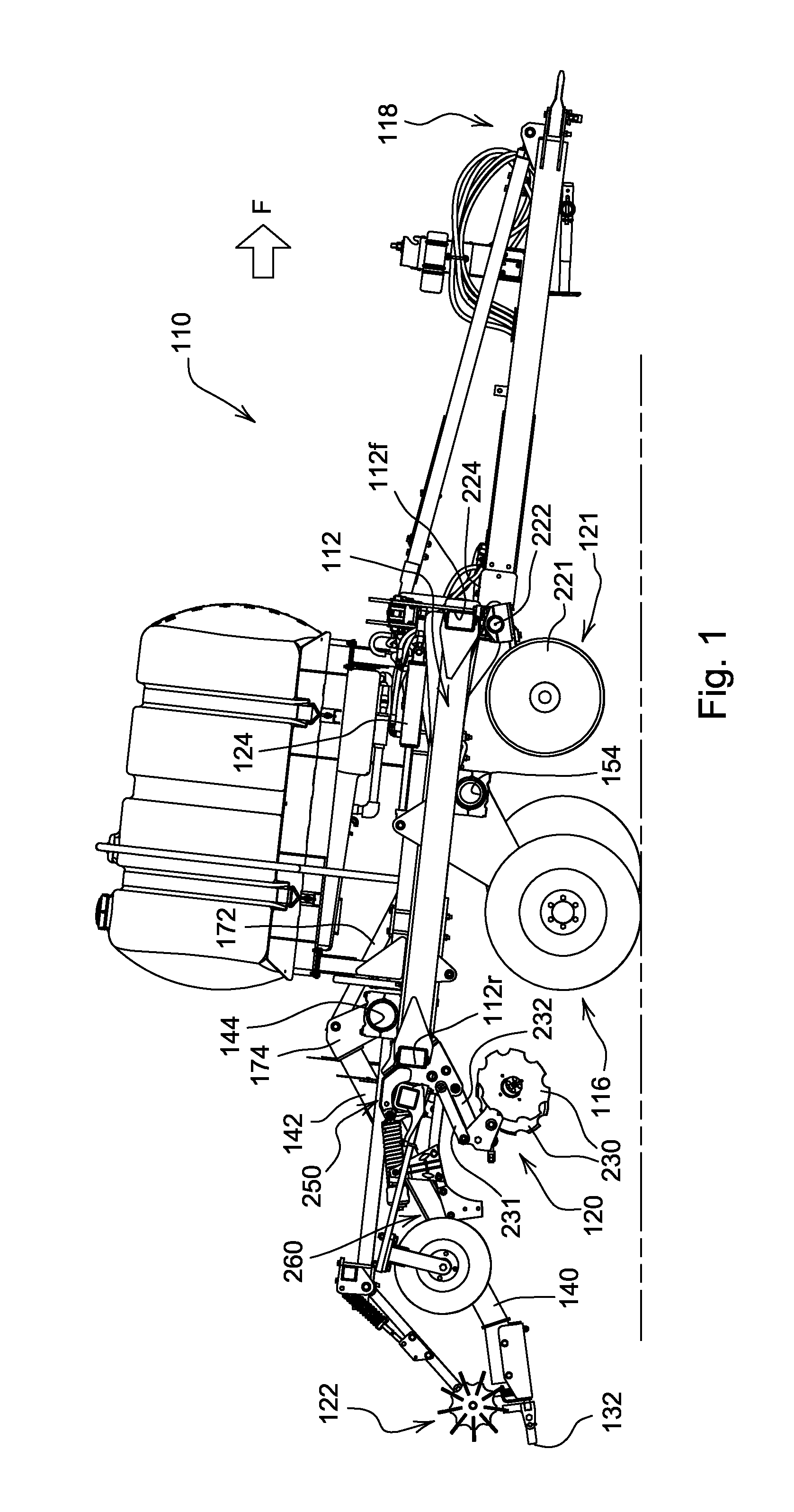

An agricultural system includes a towing frame to which a planting row unit is attached. The planting row unit is movable in a forward direction on a field having soil of varying hardness conditions, including a soft soil and a hard soil. The planting row unit includes a planting bin positioned rearwardly of the towing frame for carrying at least one of a fertilizer and seeds to be deposited into the soil. The planting row unit further includes a linkage assembly for coupling the planting bin to the towing frame, and an opener device forward of the towing frame. The opener device prepares the soil and includes an opener blade and a soil-hardness sensor. The opener blade maintains the same soil-penetration depth Z in the soft soil and the hard soil based on soil-hardness changes detected by the soil-hardness sensor.

Owner:DAWN EQUIPMENT COMPANY

Enhanced minimum tillage planter/renovator system

InactiveUS6425445B1Enhanced seed bedEnhanced clean furrowSpadesAgricultural machinesMinimum tillageEngineering

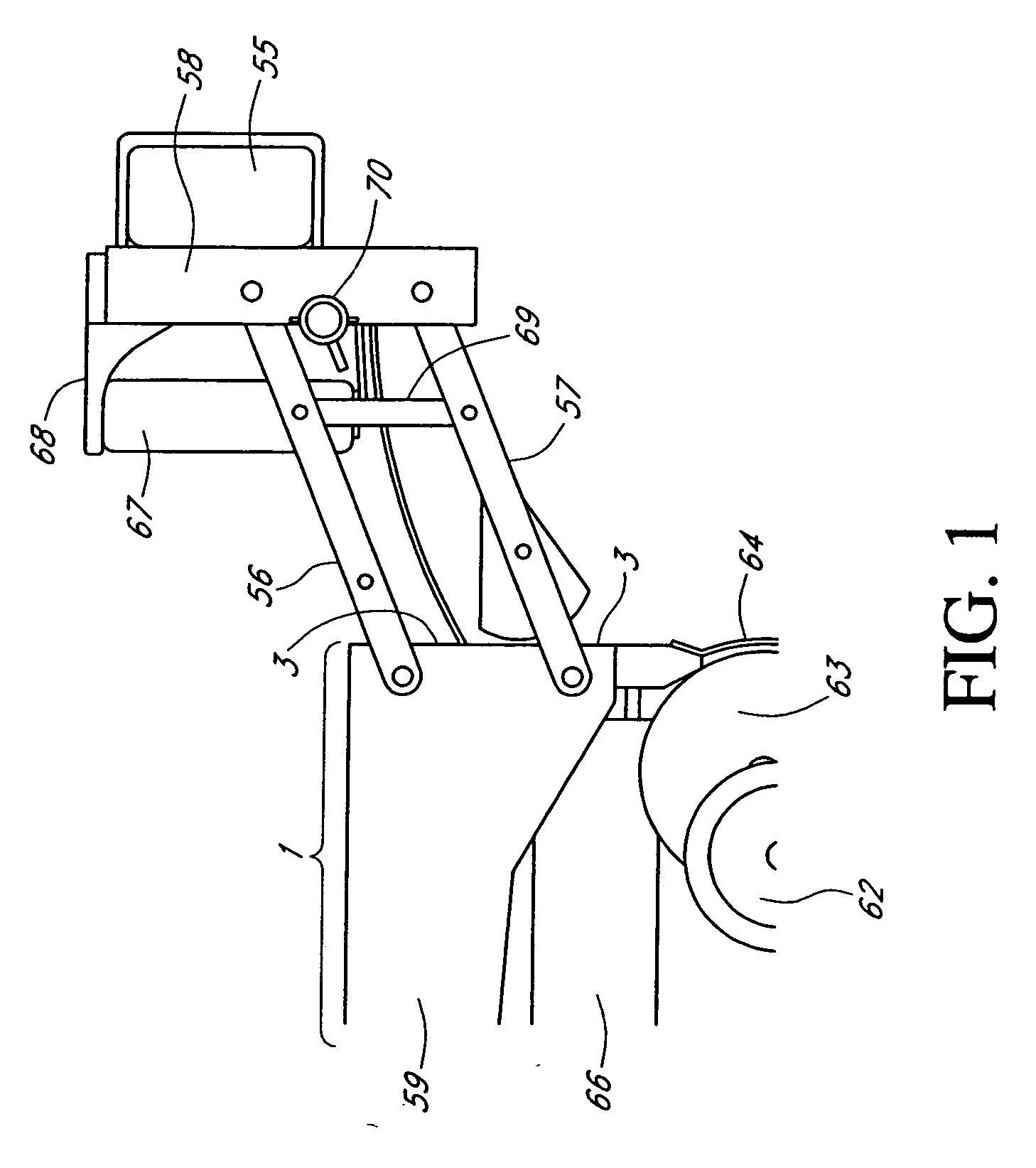

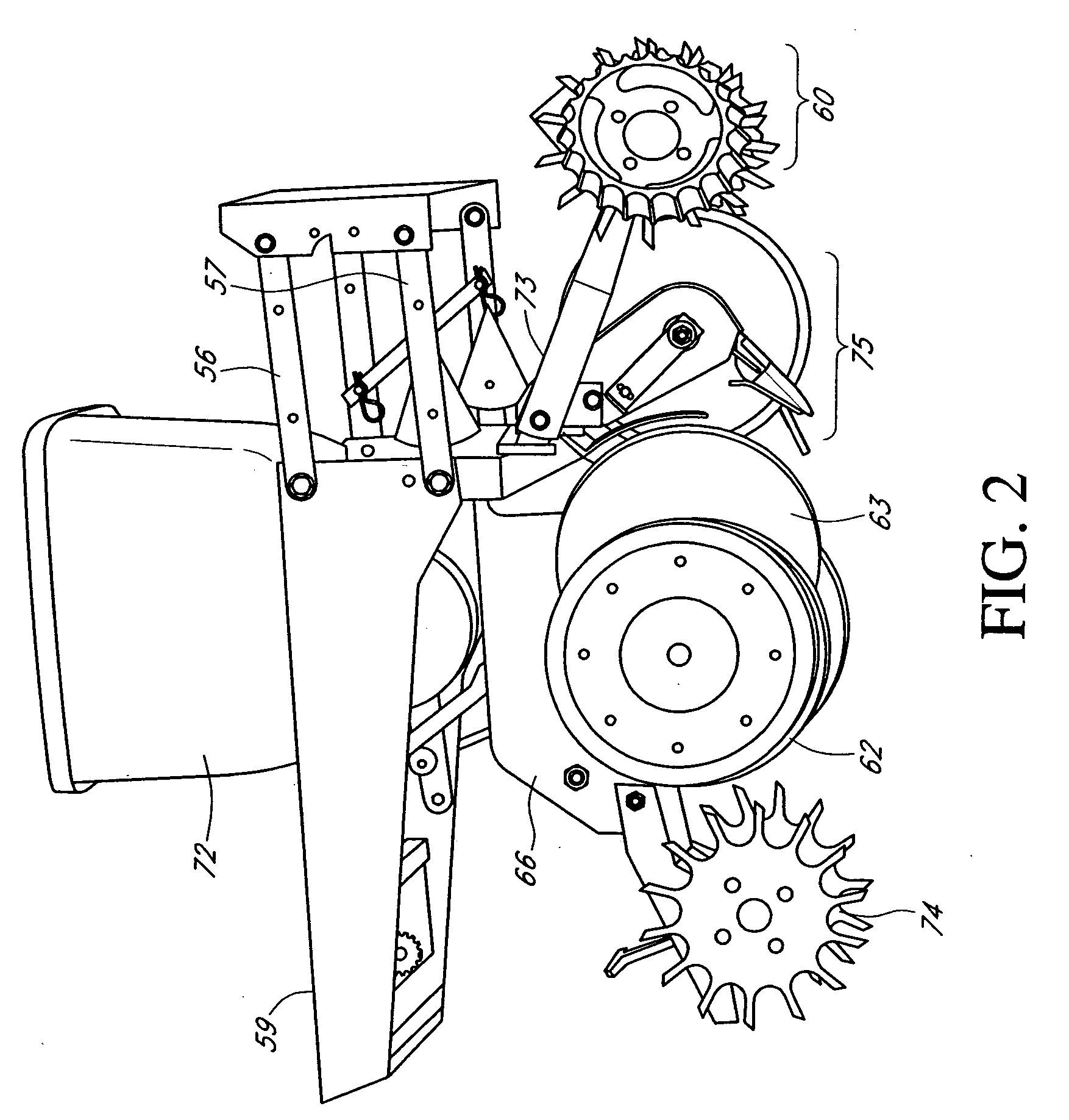

A planter / fertilizer wherein there is provided a ripping point configured to penetrate a predetermined depth into the soil or sod, the ripping point designed to facilitate a splitting and lifting of the soil, forming a seed bed void, while cutting any organic ground cover, which might comprise, for example, sod, widening the ground cover, and lifting same to a prominent head, wherein first and second coulters, situated above and about the ripping point, are configured to independently engage and cut first and second sides of the lifted ground cover, trash and the like, respectively, then cutting the lifted ground cover, etc., as the coulters rotate, the coulters cooperatively grinding at least a portion of the lifted ground cover, forming tilth, and redepositing the tilth into the seedbed void, providing an enhanced seedbed region with nominal surface disturbance, and a clean furrow. Situated behind the first and second mole plows and fertilizer and seed chutes are opposing first and second wheels, the first wheel a larger diameter furrow trimming wheel, having outwardly emanating therefrom a depth ring or drum for controlling the depth and covering of the seed for the first side of the furrow, the second wheel being smaller in diameter than the first and situated to trim the furrow and assist further in covering the seed for the second side of the furrow, the first and second wheels having different diameters so that they cooperatively rotate at different speeds to prevent clogging, and are situated at opposing angles on horizontal and vertical planes so as to be self cleaning in a variety of soil conditions. Following the first and second wheels is a pressure wheel about the width of the furrow, which is directed over the furrow so as to apply pressure to the furrow, flattening so as to complete the furrow forming process.

Owner:TARVER III SAM A

Fertilizer injector wing for disc openers

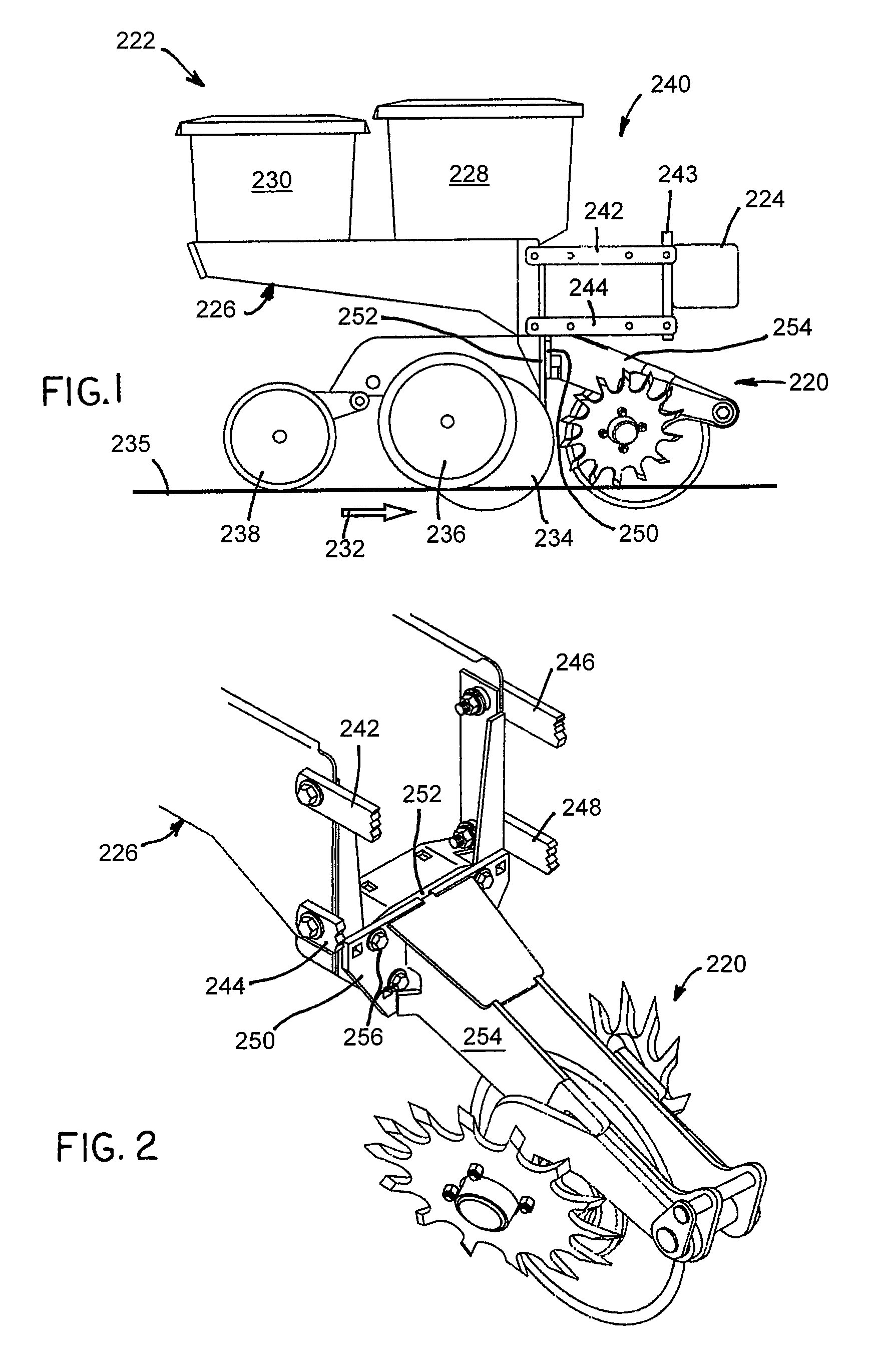

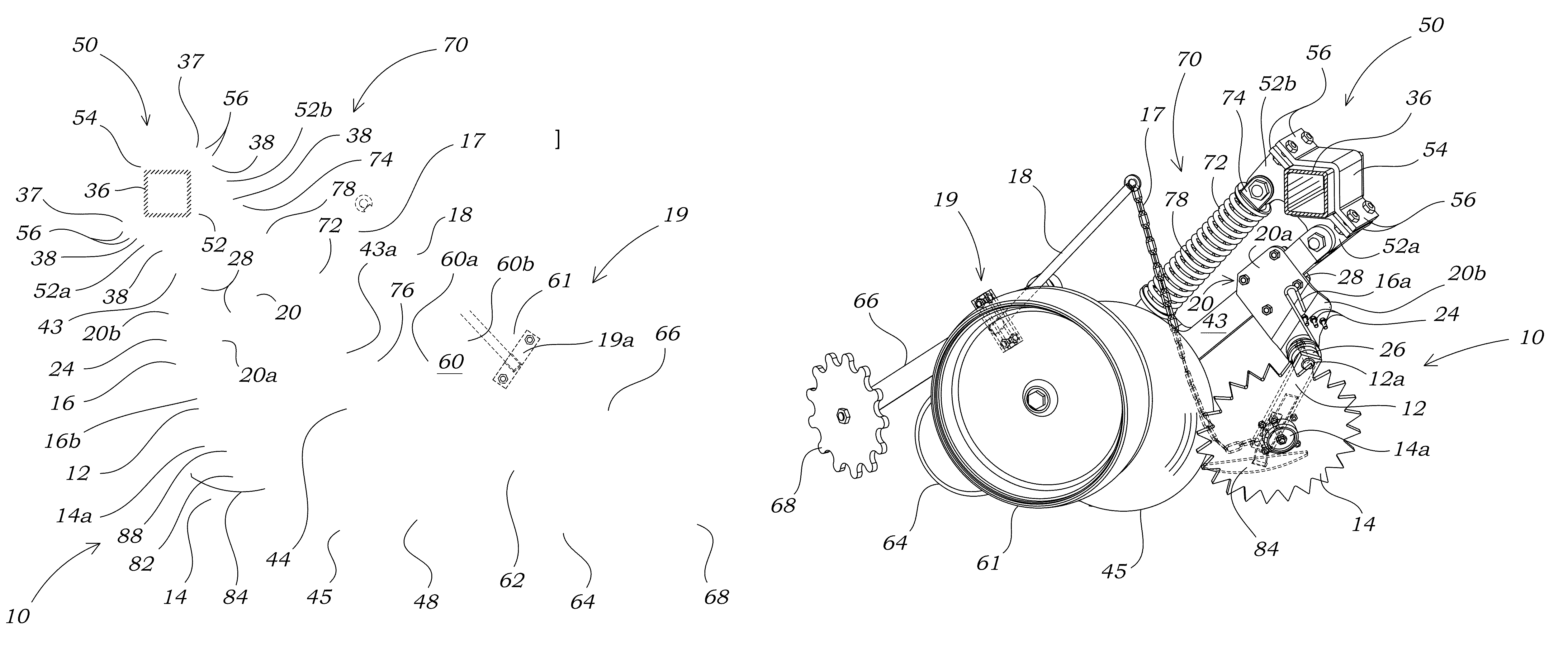

InactiveUS20050051068A1Eliminate needHigh speed useTill seedingDirect liquid fertiliser deliverySeederCircular disc

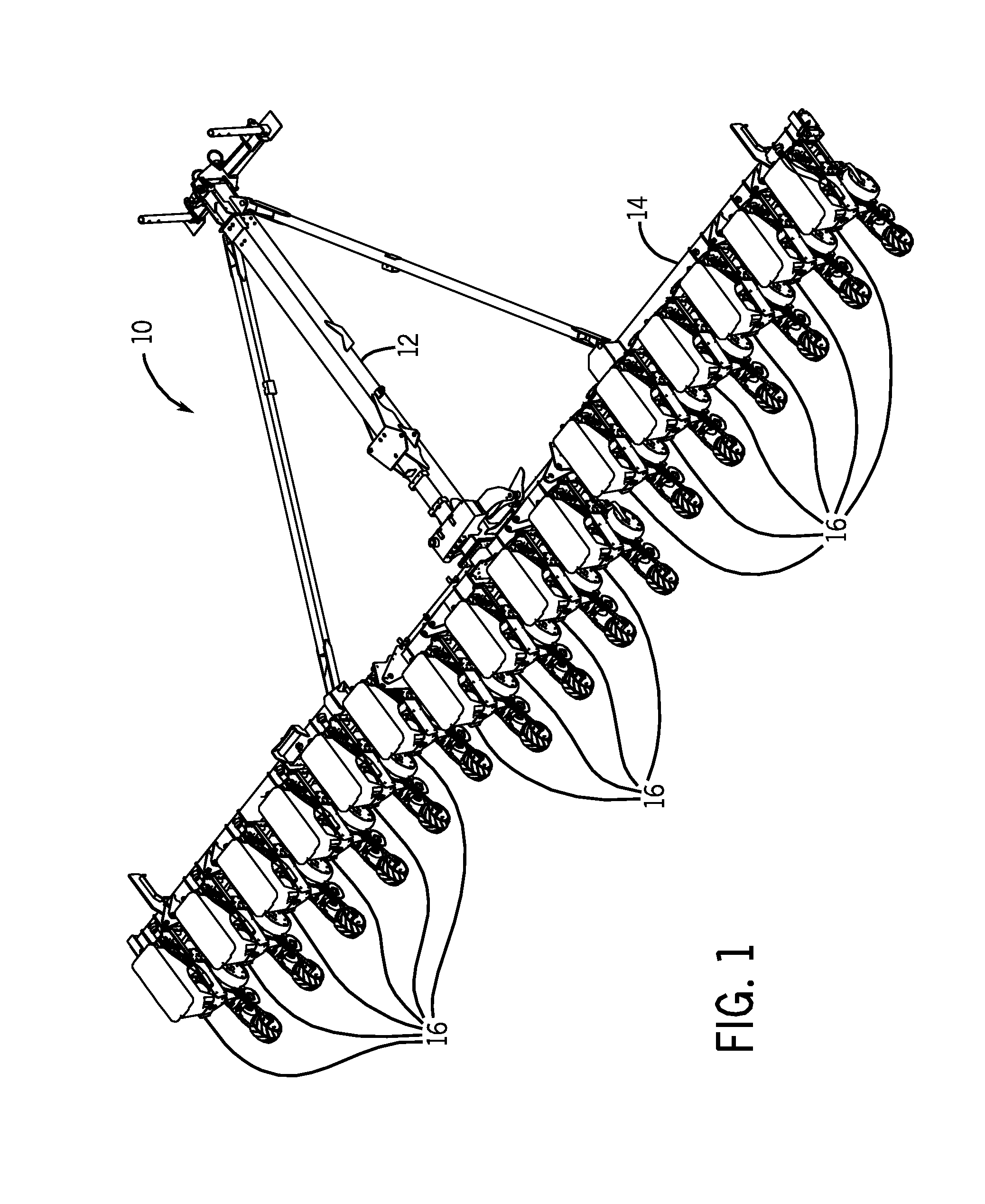

Disc openers (14) for use with an air seeder (10), or other no-till drill and the like, configured for seeding and fertilizing a field (G) for crop production are disclosed. The representative opener (14b) broadly includes a drawbar assembly (16), a disc assembly (18) including a coulter disc (20) and a gauge wheel (22), a seed boot (24), a fertilizer injector wing (26), a firming wheel assembly (28), and a closing wheel assembly (30). The inventive fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the unique fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS). The inventive wing (26) enables a toxic charge (TC) of the fertilizer (N,P)—a charge containing the optimum nutrient package to sustain season long growth of the crop—to be placed sufficiently close to the seed (S) while minimizing soil disturbance so that weed growth and moisture loss are minimized and crop yield is maximized.

Owner:EXACTRIX

Agricultural Apparatus For Sensing And Providing Feedback Of Soil Property Changes In Real Time

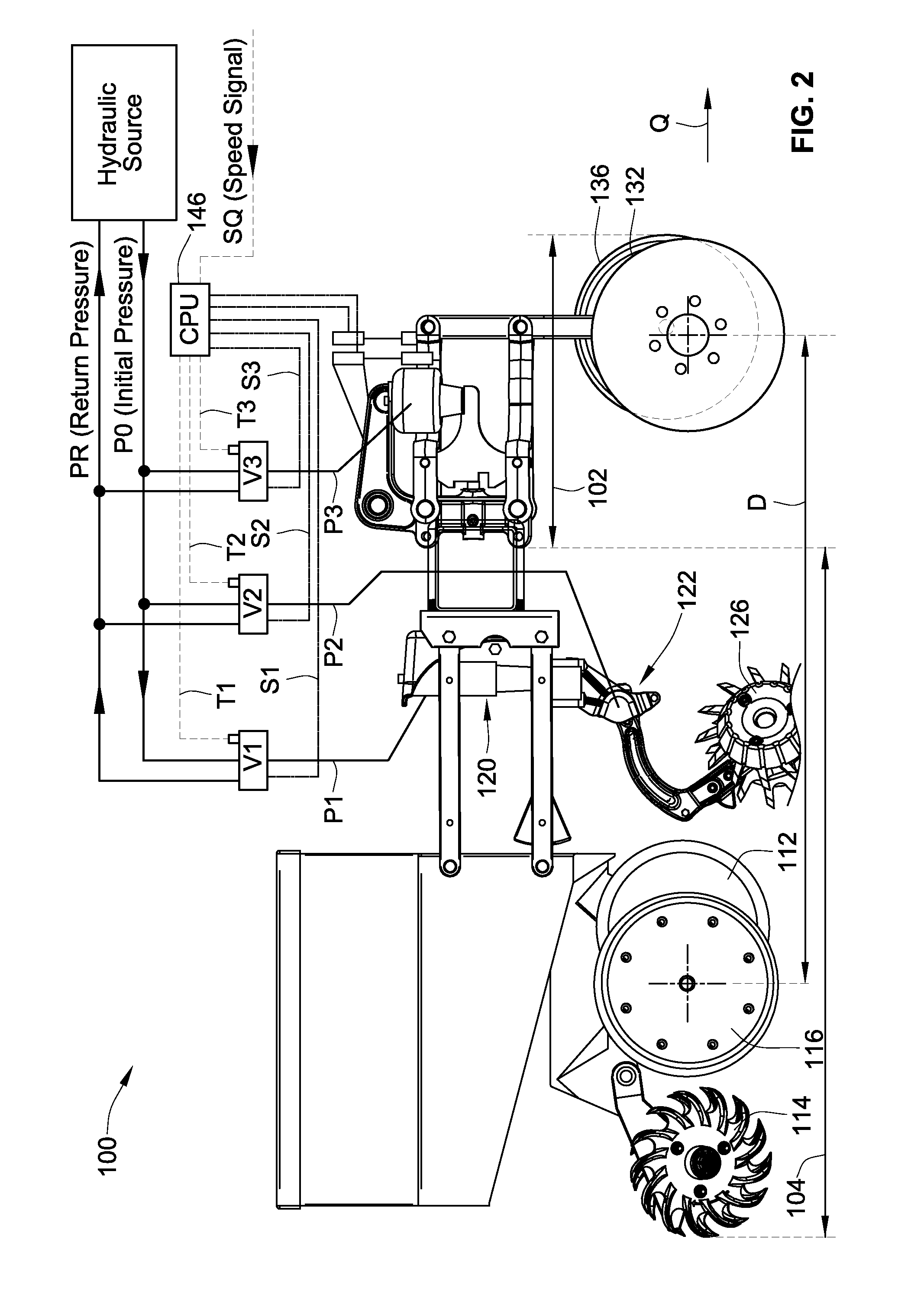

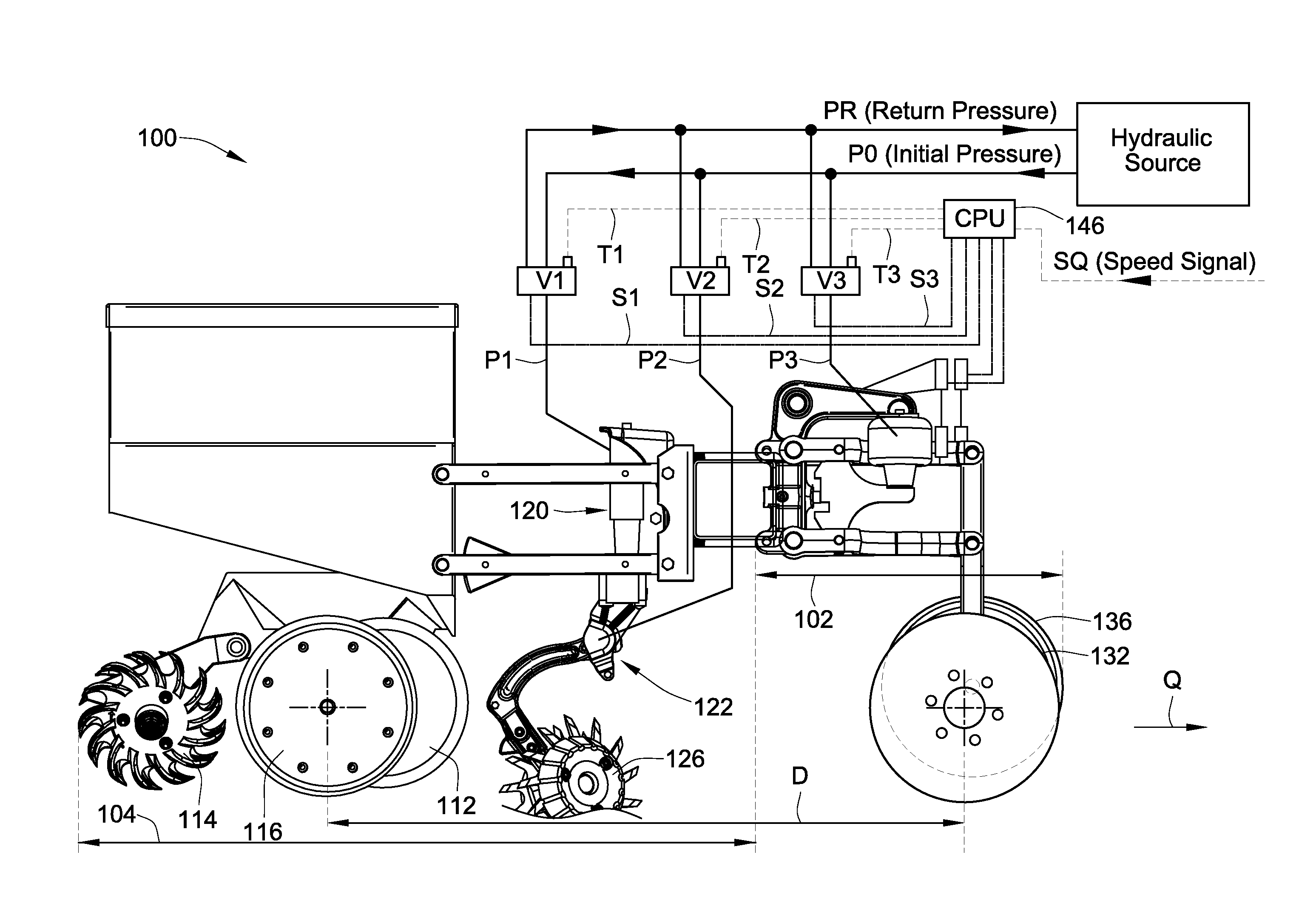

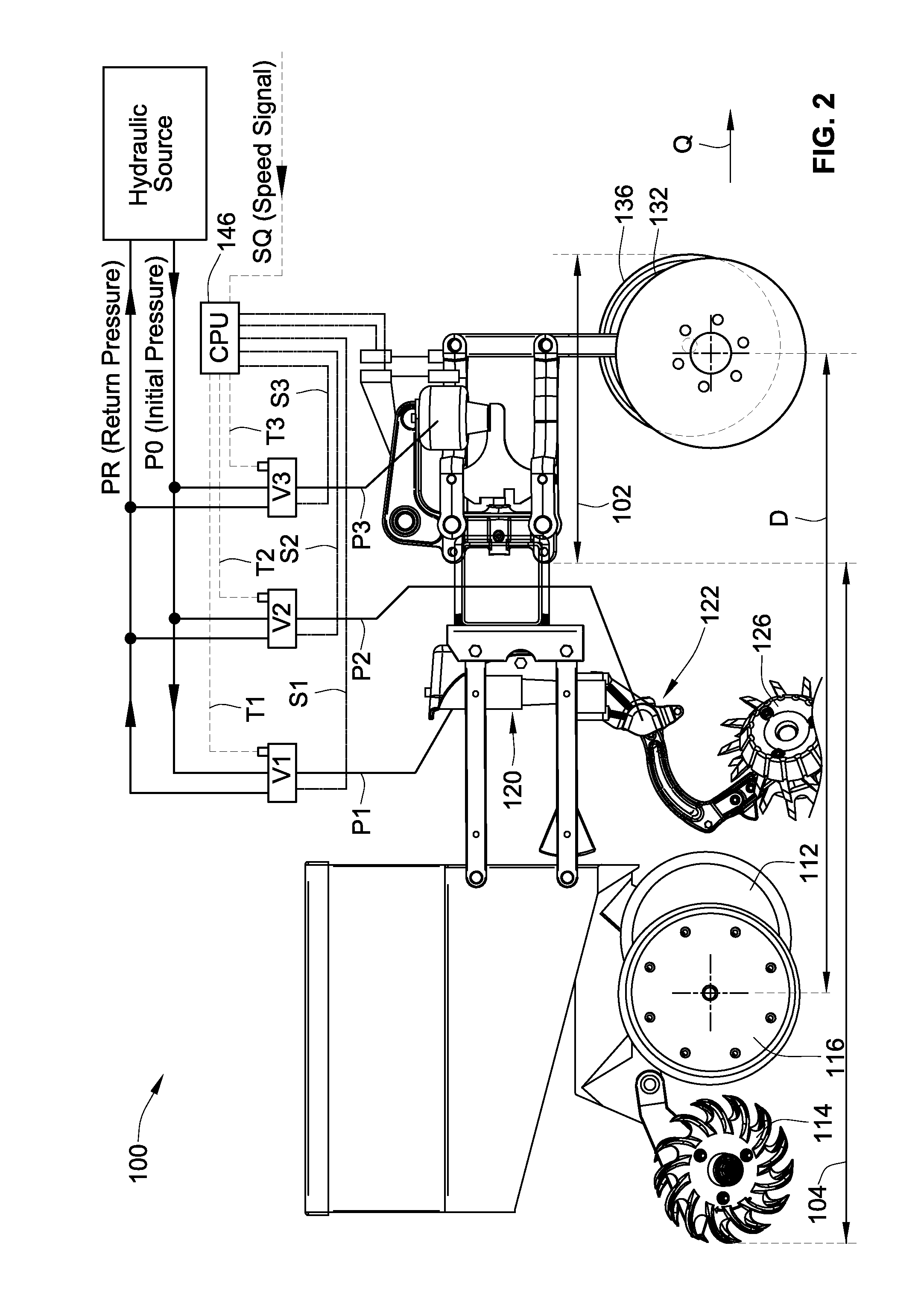

An agricultural system includes an agricultural row unit movable on a field between a first soil condition and a second soil condition, the first soil condition having a different soil hardness than the second soil condition. A down-pressure actuator applies an initial first pressure associated with the first soil condition. A soil-hardness sensing device is positioned at a distance D forward of the row unit and outputs a soil-hardness change signal when detecting a change from the first soil condition to the second soil condition. At least one memory device stores instructions that, when executed by at least one processor, cause the down-pressure actuator to change, in response to receiving the soil-hardness change signal, the initial first pressure to a different second pressure when the row unit encounters the second soil condition.

Owner:DAWN EQUIPMENT COMPANY

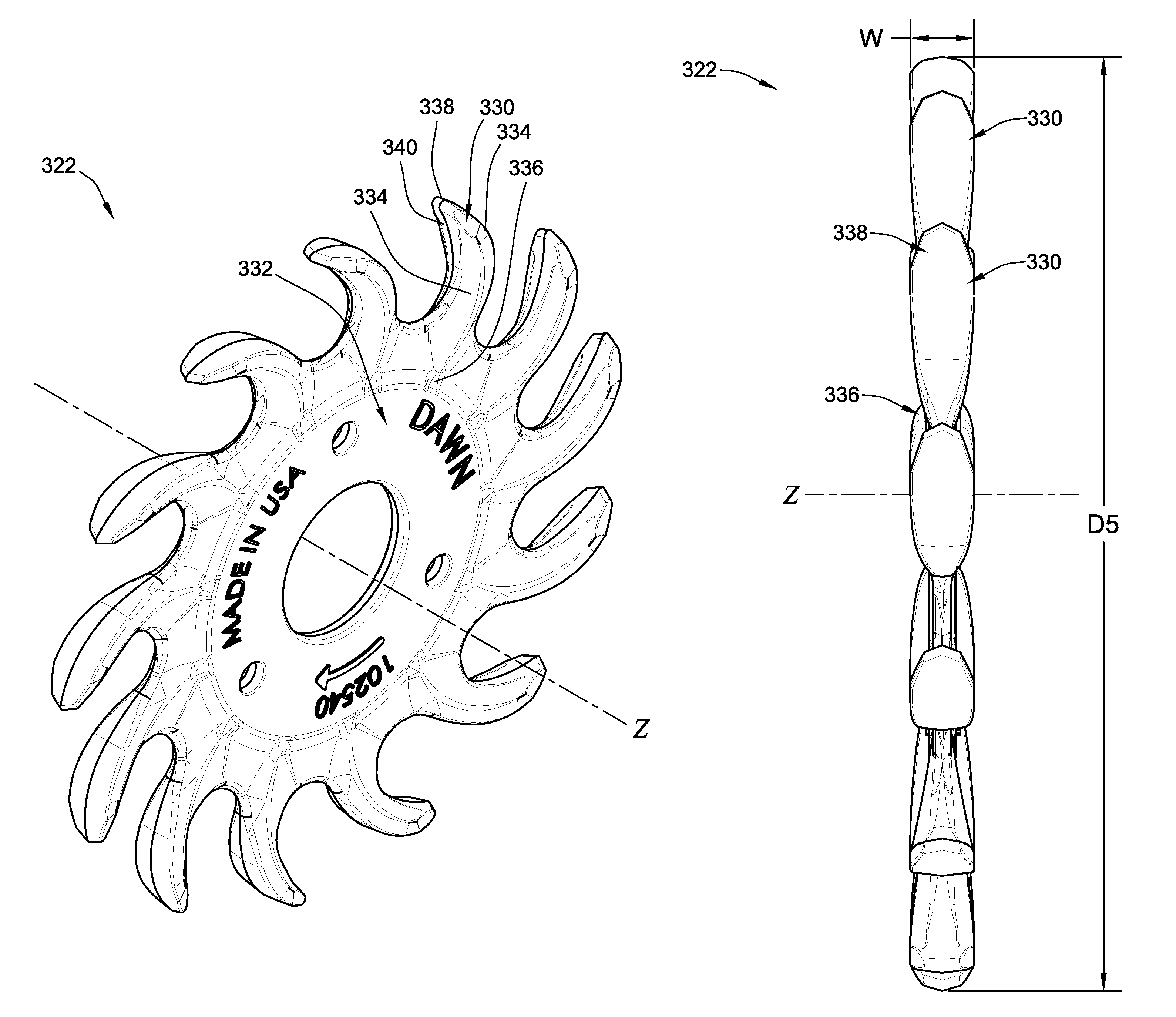

Forged toothed wheel for a row crop planter

A forged agricultural wheel with a radial grain pattern includes a plurality of teeth projecting radially outwardly from a hub, with each tooth having a tooth root adjacent to the internal periphery of the hub. Each tooth further has a leading soil-contacting surface extending from the tooth root in a curved counterclockwise manner and having a variable width with a maximum tooth width. A trailing surface opposite the leading soil-contacting surface extends from the tooth root in a curved counterclockwise manner. A tooth end is angled counterclockwise away from a radius passing from a central axis through a central point of the tooth root. The tooth end connects the two surfaces and converges to a point on a maximum outside diameter of the wheel. An adjoining root valley connects each pair of adjacent teeth and has a thickness that is substantially thinner than the maximum tooth width.

Owner:DAWN EQUIPMENT COMPANY

Agricultural implement with automatic down pressure control

An agricultural row unit includes a hydraulic cylinder coupled to a support member for urging a soil-engaging tool coupled to the support member downwardly toward the soil. A hydraulic line is coupled to the hydraulic cylinder for supplying pressurized hydraulic fluid to the cylinder, and a controllable valve is provided in the hydraulic line for controlling the supply of pressurized hydraulic fluid to the cylinder through the line. A pressure sensor, such as a load cell or strain gauge, is connected between the hydraulic cylinder and the support member for producing an electrical signal corresponding to the pressure on the tool, and a controller is coupled to the pressure sensor and the controllable valve, the controller being adapted to receive the electrical signal from the pressure sensor and produce a control signal for controlling the valve thus the supply of the hydraulic fluid to the cylinder.

Owner:DAWN EQUIPMENT COMPANY

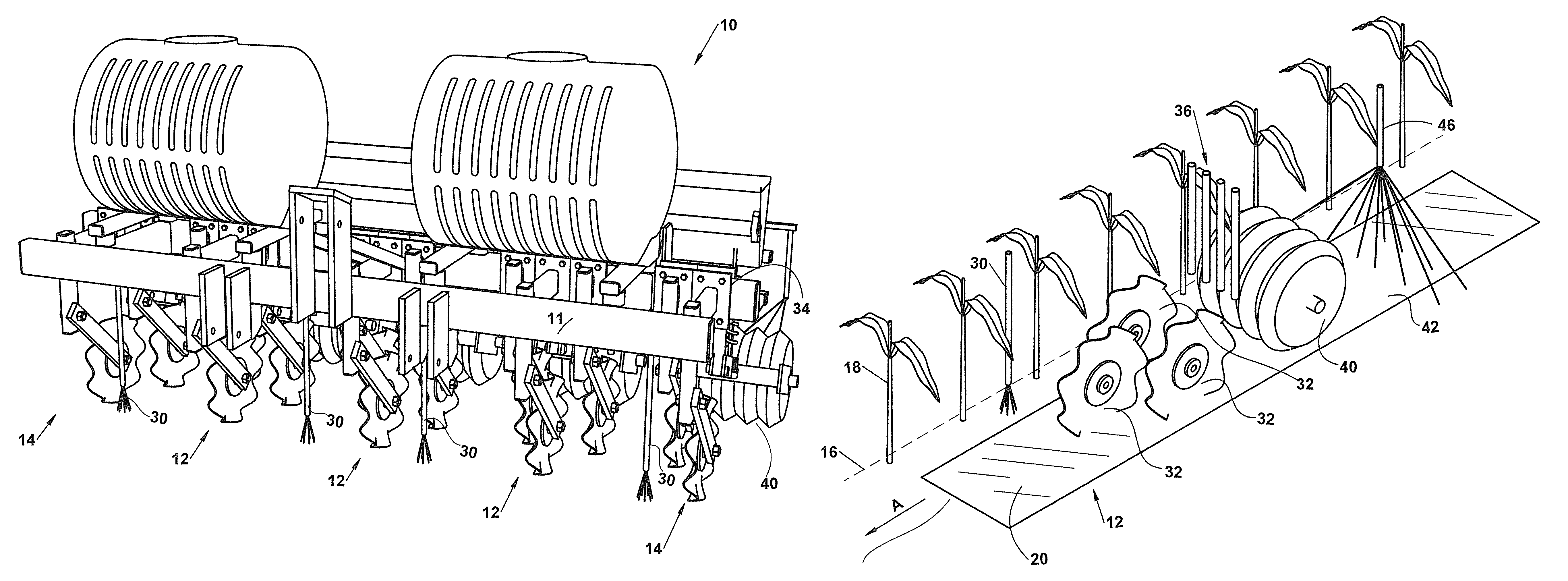

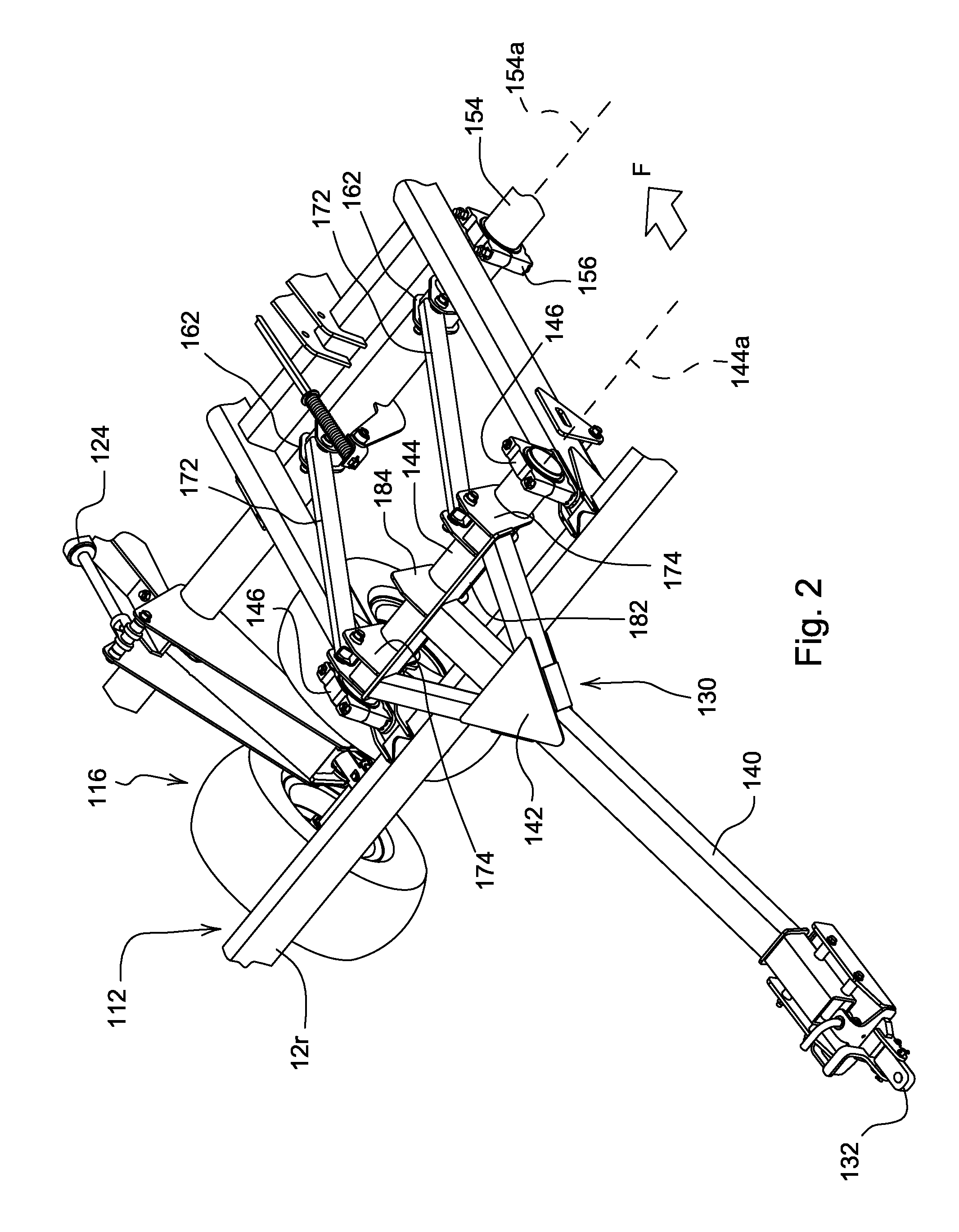

Apparatus and method for no-till inter-row simultaneous application of herbicide and fertilizer, soil preparation, and seeding of a cover crop in a standing crop

ActiveUS9003983B2Reduce impactTill seedingClimate change adaptationAgricultural scienceStanding crop

Owner:PENN STATE RES FOUND

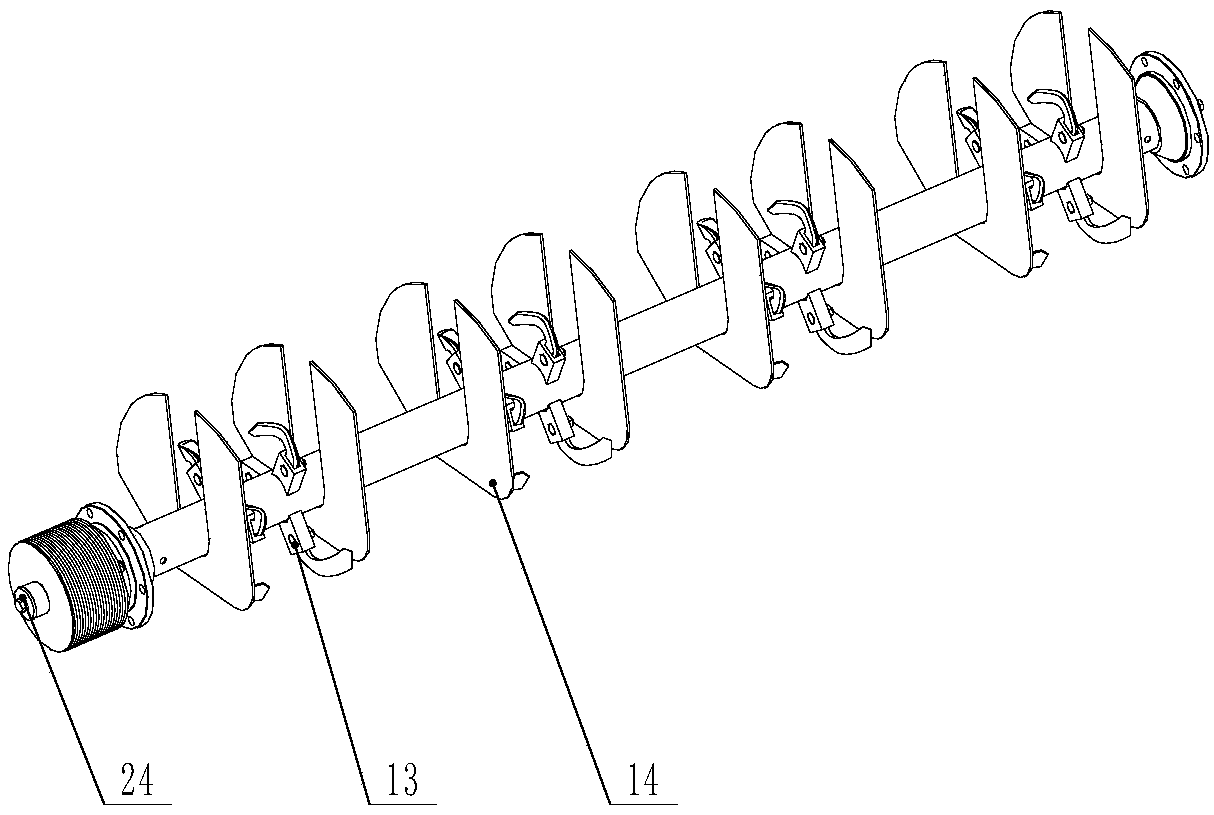

Tilling apparatus

A tilling apparatus and a method of tilling soils which includes the use of a rotational shaft having a number of cutter assemblies located at spaced apart locations on the shaft in which each cutter assembly has a multitude of blades which rotate as the rotary shaft rotates to form a plurality of spaced apart trenches having the same spacing as the spacing of the cutters, and a width caused by the width of the blades. As the blades dig the trench, the soil contacted by the blades is granulated and is tossed about by the spinning blades so that some soil falls back into the trench and some falls along the periphery of the trench to form rows of aerated granules which promote enhanced growth of plants or seeds in the trench and along the edge of the trench to improve the yield of pasture having the trenches. Various attachments can be provided on the tilling apparatus, either in front of or towards the rear of the spinning blades for different purposes, such as rippers, seeders, levellers, or similar. The advantage of the tilling apparatus is that the soil is formed into granules which are used to form an aerated array of soil granules having enhanced growing properties for plants.

Owner:SOILKEE

Strip tillage implement

ActiveUS20080190628A1Easy to adjustCompact designSpadesTill seedingGround contactMechanical engineering

A strip tillage implement includes a plurality of forward disk gang members for sizing plant residue. An upright tool support bracket extends rearwardly from the rear frame member and defines a downwardly opening accommodation space at a top portion of the bracket for a closing disk assembly rockshaft or support. The bracket includes a lower end supporting a parallel linkage that carries a clearing tool assembly in a generally constant horizontal attitude as the linkage pivots with movement of the clearing disks over obstacles. A tool support arm is pivotally connected to the bracket adjacent the parallel linkage and below the rear frame member. A closing disk arm supported from the rockshaft can be rotated to adjust down pressure or to lift the closing disk is completely out of ground contact. Closing disk spacing and disk angle are adjustable to provide the desired berm shape. Each closing disk arm is relatively long and independently supported to reduce torsional forces and improve plugging resistance of the units.

Owner:DEERE & CO

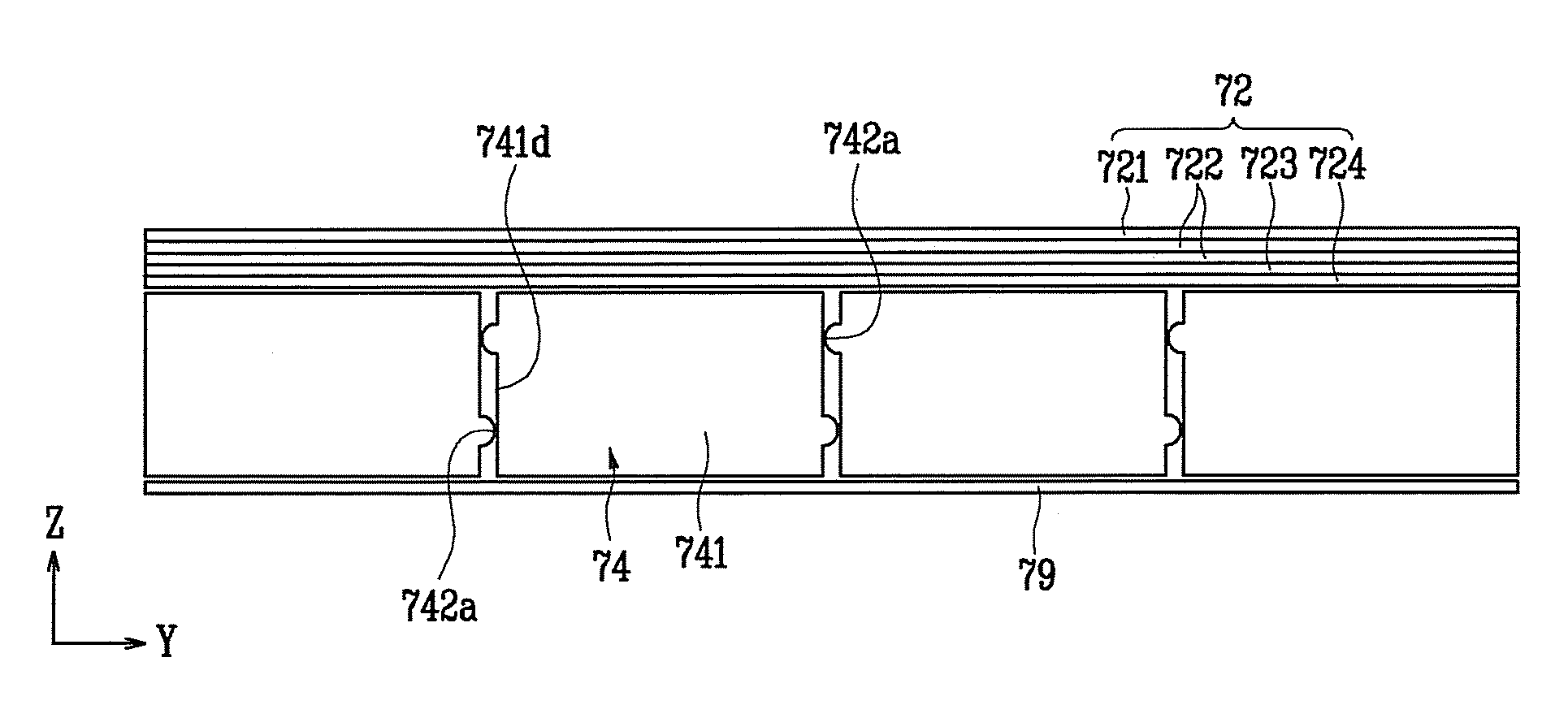

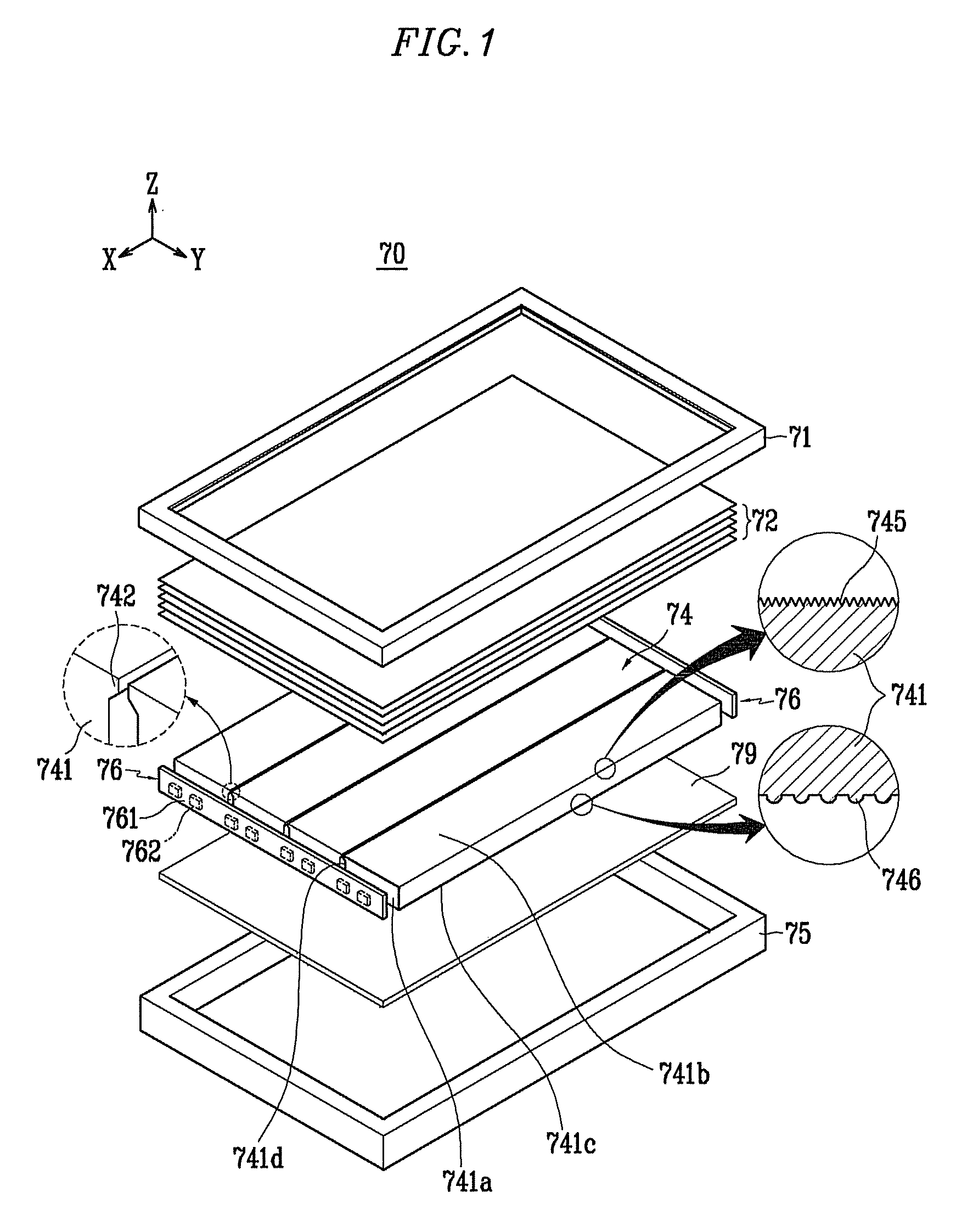

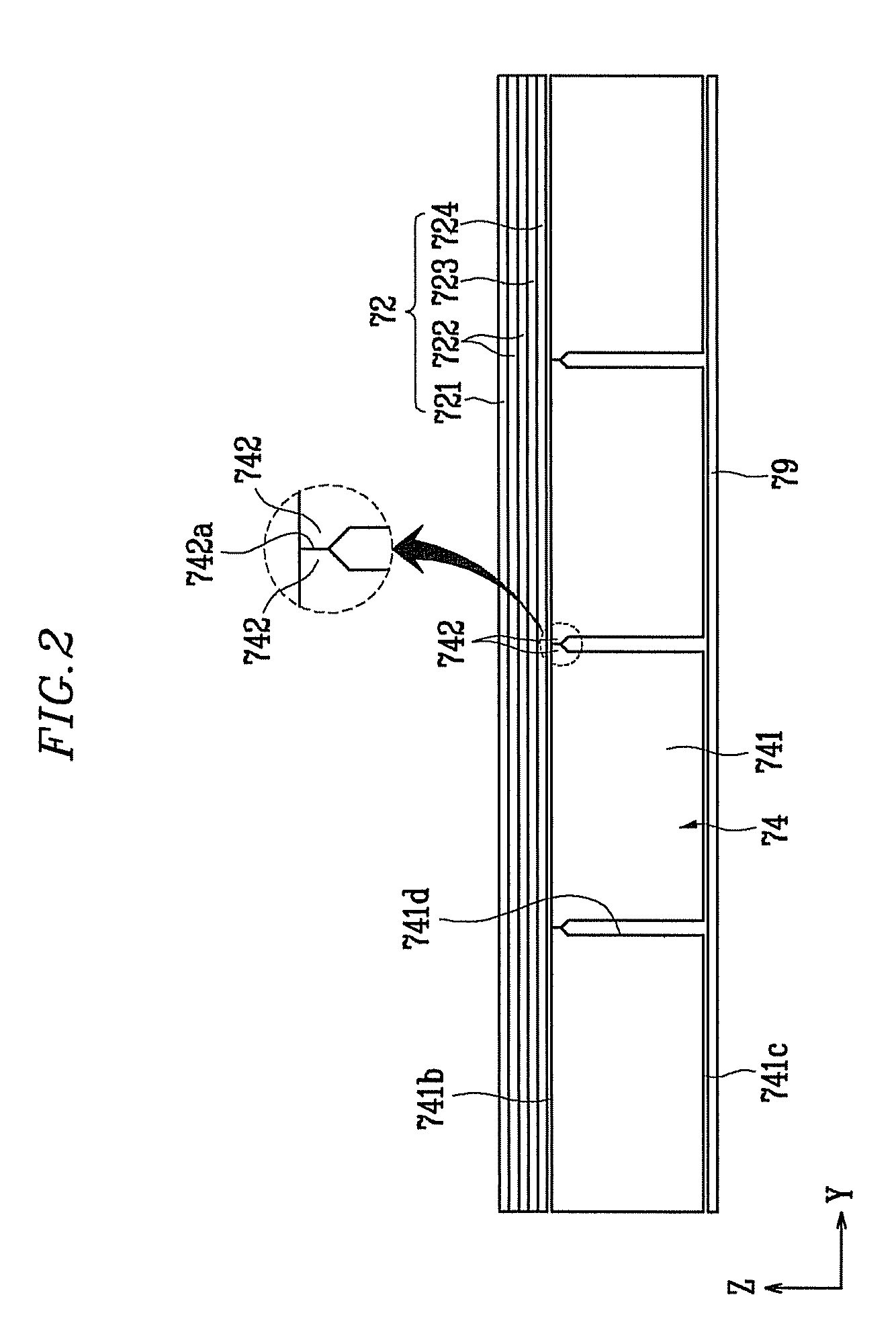

Backlight assembly with plural light guides separated by protrusions

InactiveUS7616271B2Improve brightness uniformityMinimizing dark portionsTill seedingSeed arrangmentsLight guideDisplay device

Owner:SAMSUNG DISPLAY CO LTD

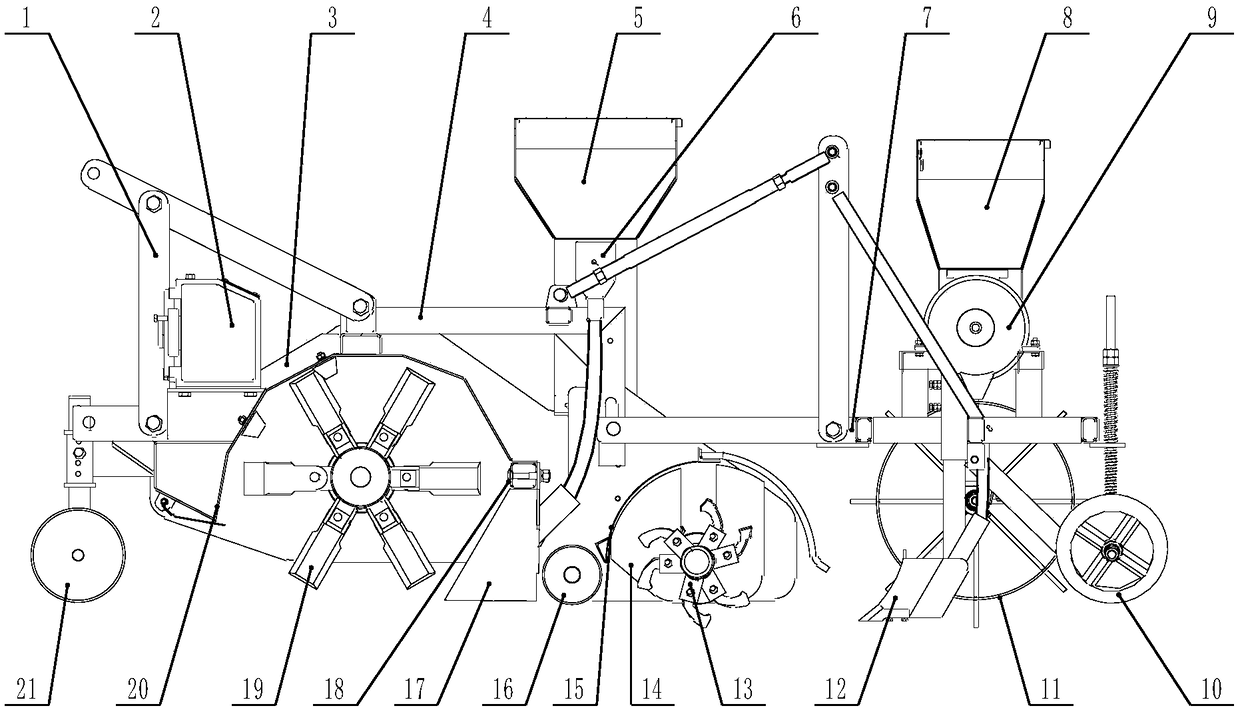

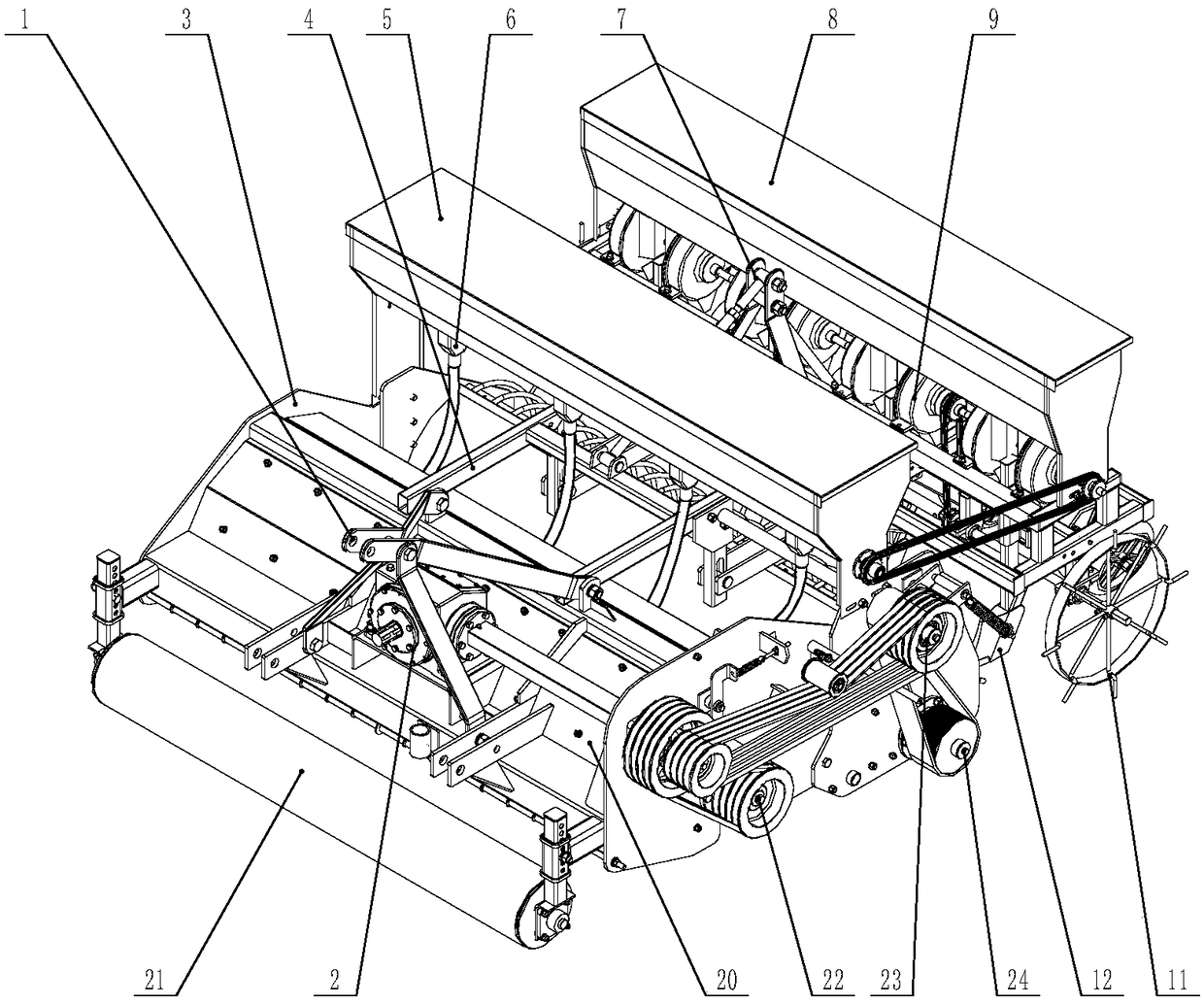

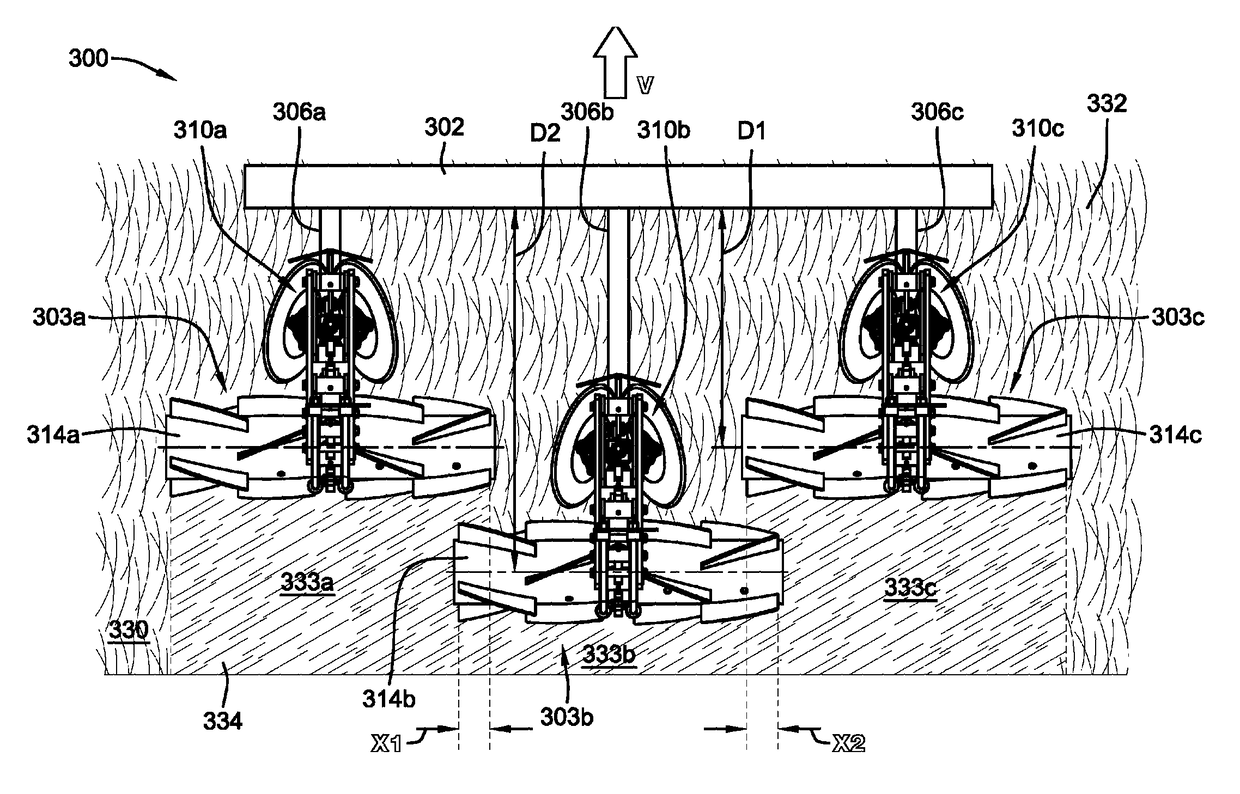

Straw smashing inter-row collecting and covering no-tillage planter

ActiveCN108718569AChange work modeHigh job integrationSpadesSoil-working equipmentsAgricultural engineeringOperation mode

The invention relates to agricultural seeding machinery, and provides a straw smashing inter-row collecting and covering no-tillage planter. A straw smashing device, a flow guiding device, a fertilizer discharging device and a furrowing and seeding device are successively arranged on a rack (3) from front to back; a plurality of straw smashing and flow guiding assemblies (17) of which the mountingpositions can be adjusted transversely are arranged on an adjusting cross beam (18) of the flow guiding device; each straw smashing and flow guiding assembly (17) is in the shape of the head of a naval ship, and is formed by combining a vertical back plate (17-3) positioned at the rear and two symmetric oblique flow guiding plates (17-1) in the front; and a fertilizer applying opening (17-5) is formed in the back plate (17-3). A straw smashing inter-row collecting and covering integrated technical operation mode is provided innovatively, and while straws in operation breadth are smashed integrally, the smashed straws are orderly and regularly laid on a straw covering belt between seeding belts to form a seeding belt free of straw barriers. The straw smashing inter-row collecting and covering no-tillage planter has the advantages of high operation integration level, simplicity in assembling, low energy consumption and the like, and straw smashing, straw cleaning on a seed belt, inter-row straw covering, fertilizer application and seeding, soil covering and pressing operations can be finished when farmers go to the field at a time.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

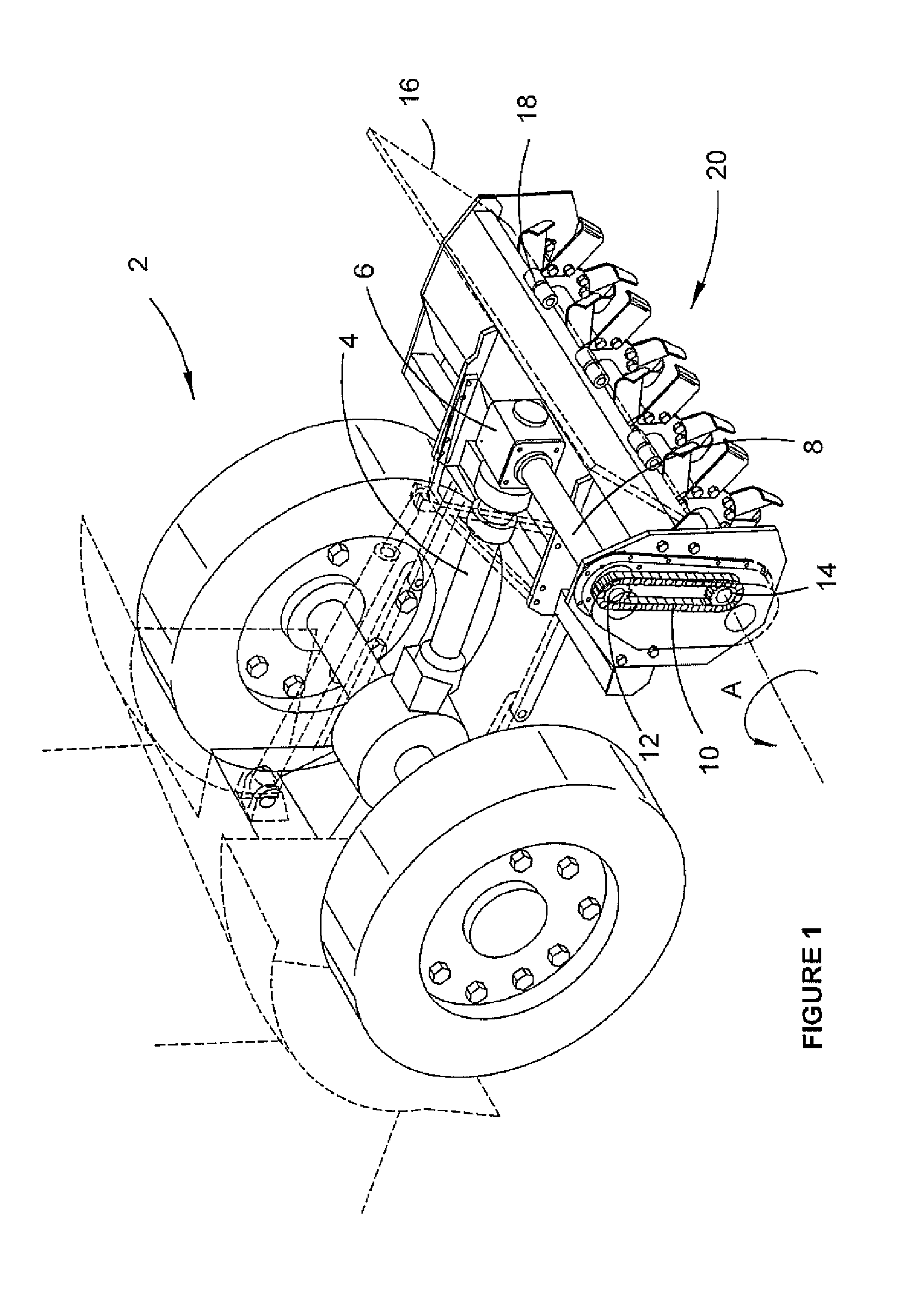

Seed drill with walking beam assembly

A no-till drill with a novel walking beam assembly that allows the drill to be pulled over severe terrain conditions that include large rocks, fallen limbs and other large obstructions. The inventive walking beam assembly includes two independent pivot points that allow the cutting and opening disks to maintain substantially constant or continuous contact with the ground, such that the length of the furrow formed and seed deposited therein are maximized. A closing disk assembly is suspended from the rear of the drill independently from the walking beam assembly. This independent suspension allows the walking beam assembly to function without interference from the closing disks.

Owner:KASCO MFG

Soil Tilling and Planting Implement

The combination of a rolling basket tillage implement and a seed distribution implement is disclosed. A height-adjustable mounting system for a rolling basket soil tillage implement is also disclosed for use with a planter that enables such an implement to be raised above the soil as needed to avoid wet conditions.

Owner:L & B MFG

Agricultural system for field preparation

An agricultural system includes a tow bar, a first row-cleaning device, and a second row-cleaning device. The first row-cleaning device is attached to the tow bar via a first frame and includes a first roller device in a trailing position relative to a first furrow-opener disk and configured to crush standing residual plant matter along a first path on a field. The second row-cleaning device is attached to the tow bar via a second frame and includes a second roller device in a trailing position relative to a second furrow-opener disk and configured to crush standing residual plant matter along a second path on the field. The second roller device is offset longitudinally from the first roller device.

Owner:DAWN EQUIPMENT COMPANY

Interlocking Basket for Strip Tillage Machine

A strip tillage implement for movement over a crop berm has a frame configured to carry a coulter, a row cleaner, a shank and closing discs. The implement includes a basket assembly located behind the closing discs having a downwardly and rearwardly directed basket drawbar that forks into left and right support arms. The basket assembly includes a left basket half section rotatably attached to the left support arm and a right basket half section rotatably attached to the right support arm of the basket drawbar in cantilever fashion. Each of the basket half sections includes a support plate and a plurality of clod-breaking tines spaced about the periphery of the plate. Each plate is substantially perpendicular to the axis of its respective support arms such that the two plates form an upwardly diverging angle with the drawbar acting between the basket half sections to clean residue collected between the half sections.

Owner:AGCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com