Patents

Literature

651 results about "Rake angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rake angle is a parameter used in various cutting and machining processes, describing the angle of the cutting face relative to the work. There are three types of rake angles: positive, negative, and neutral.

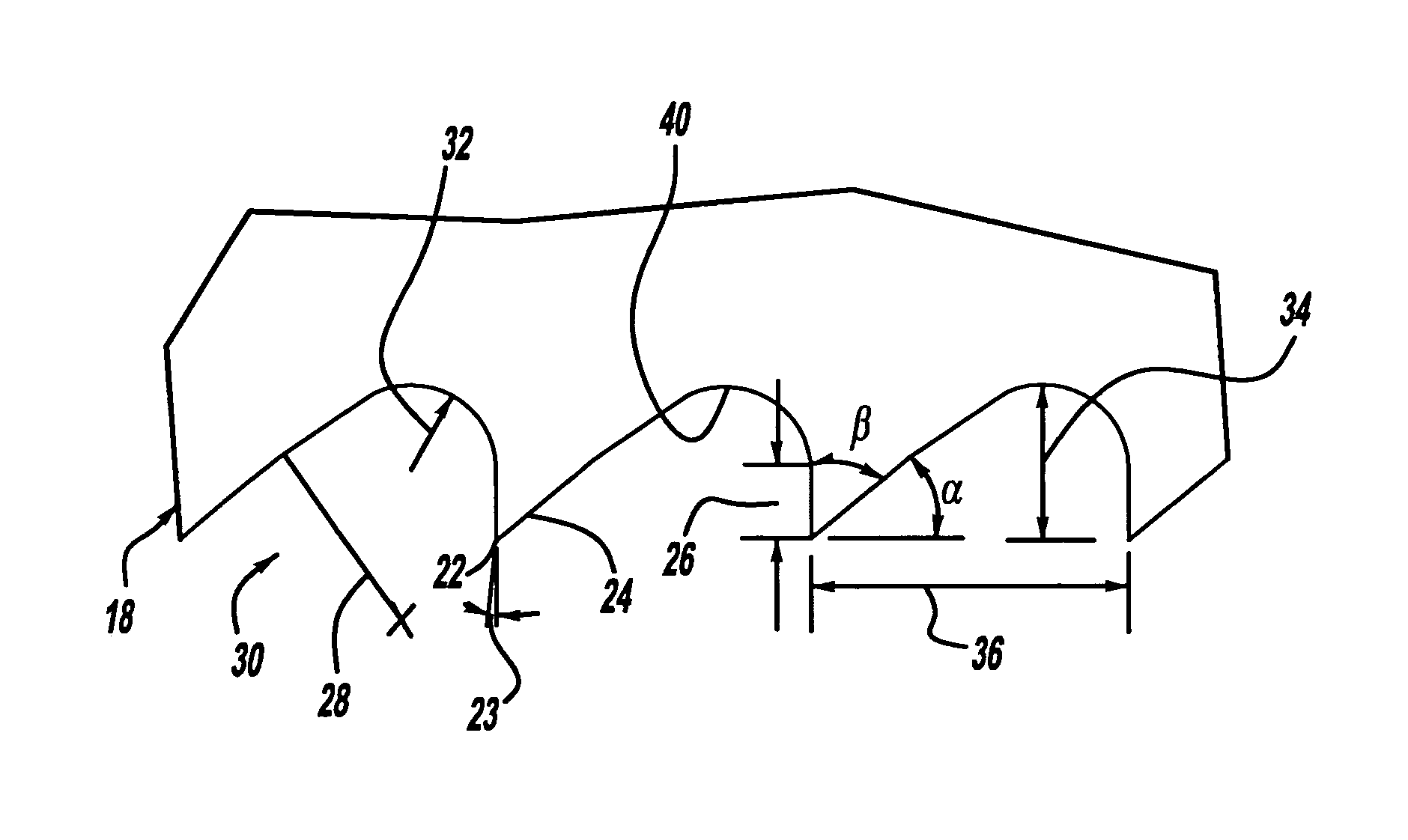

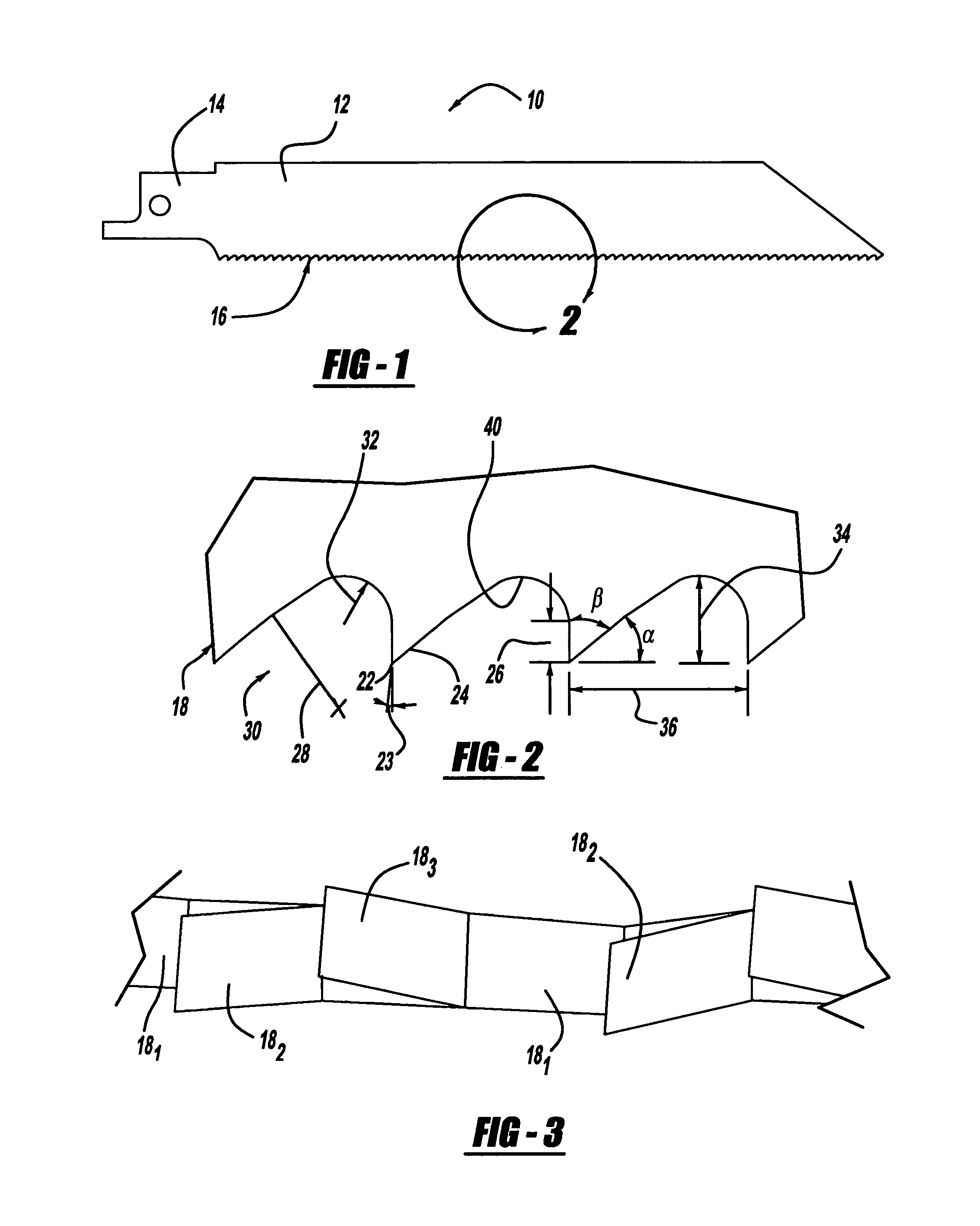

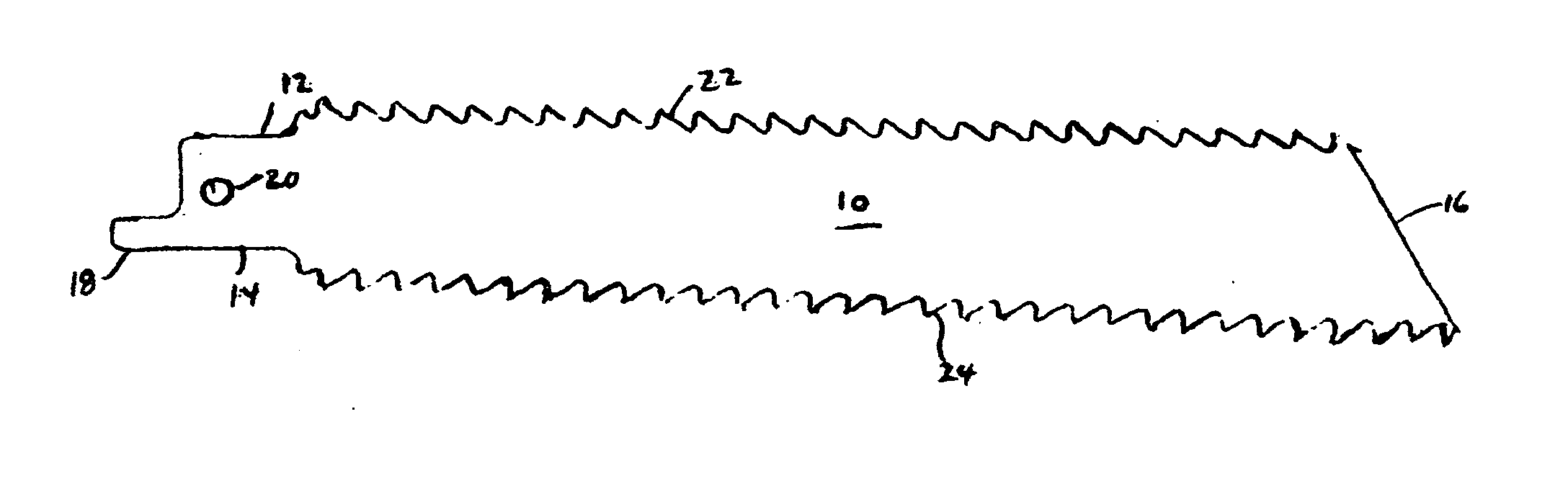

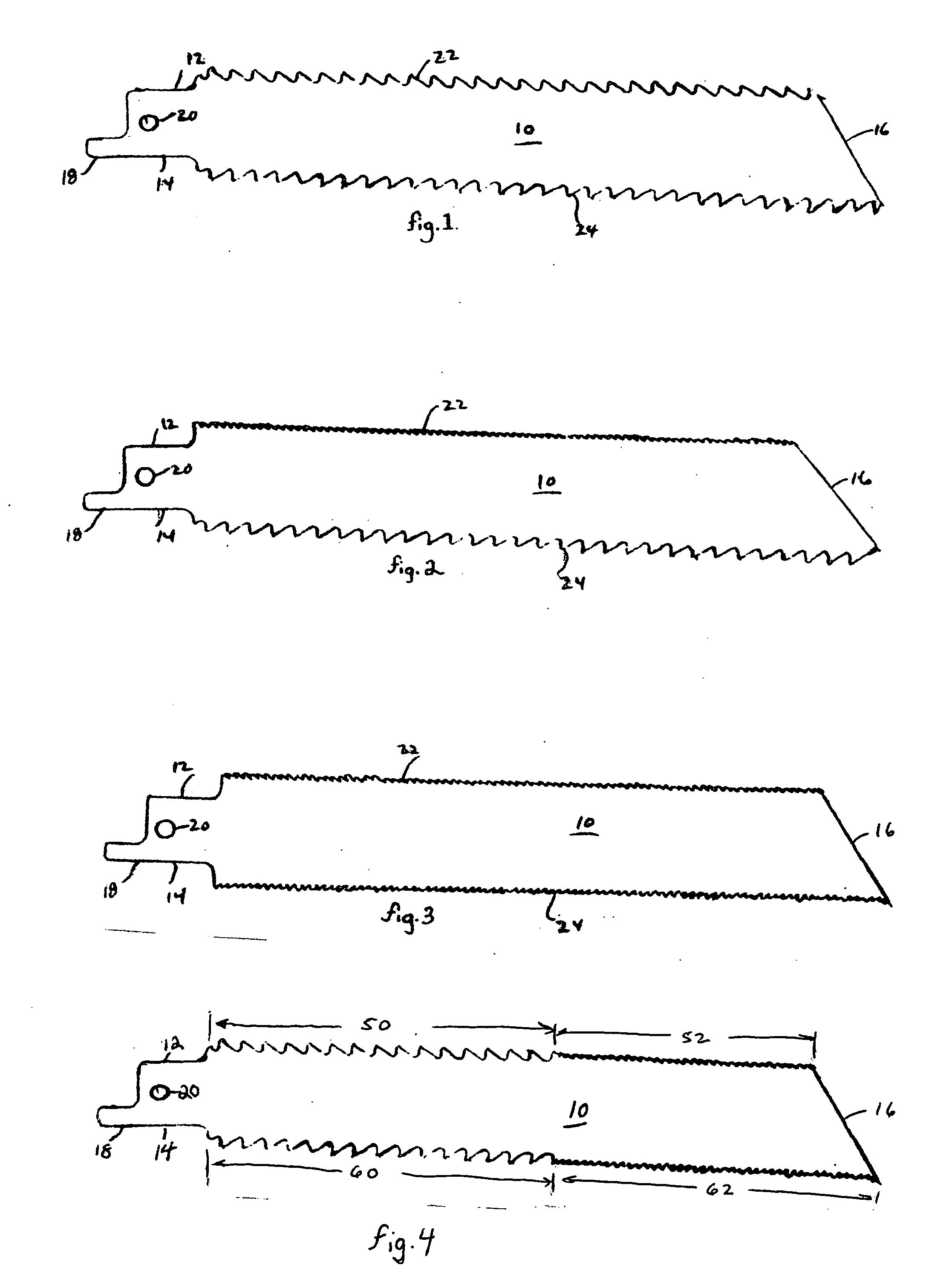

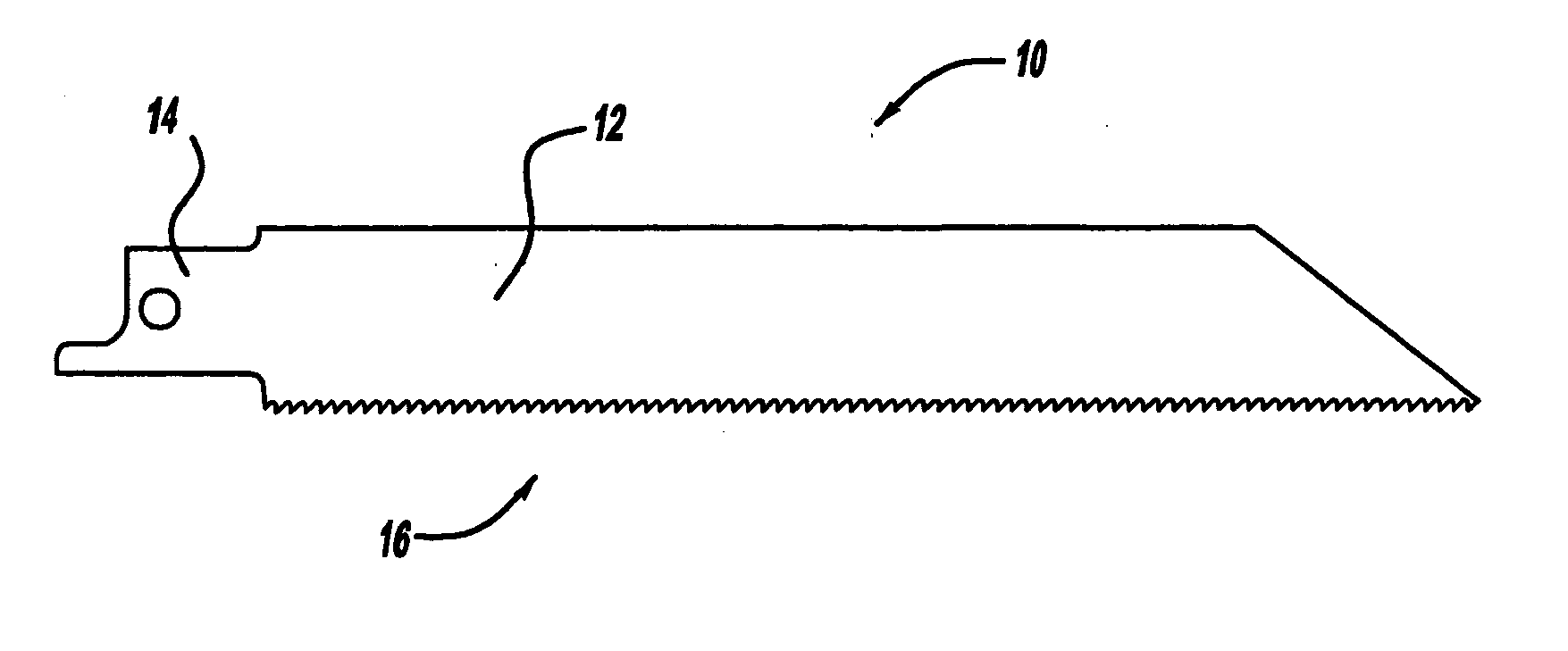

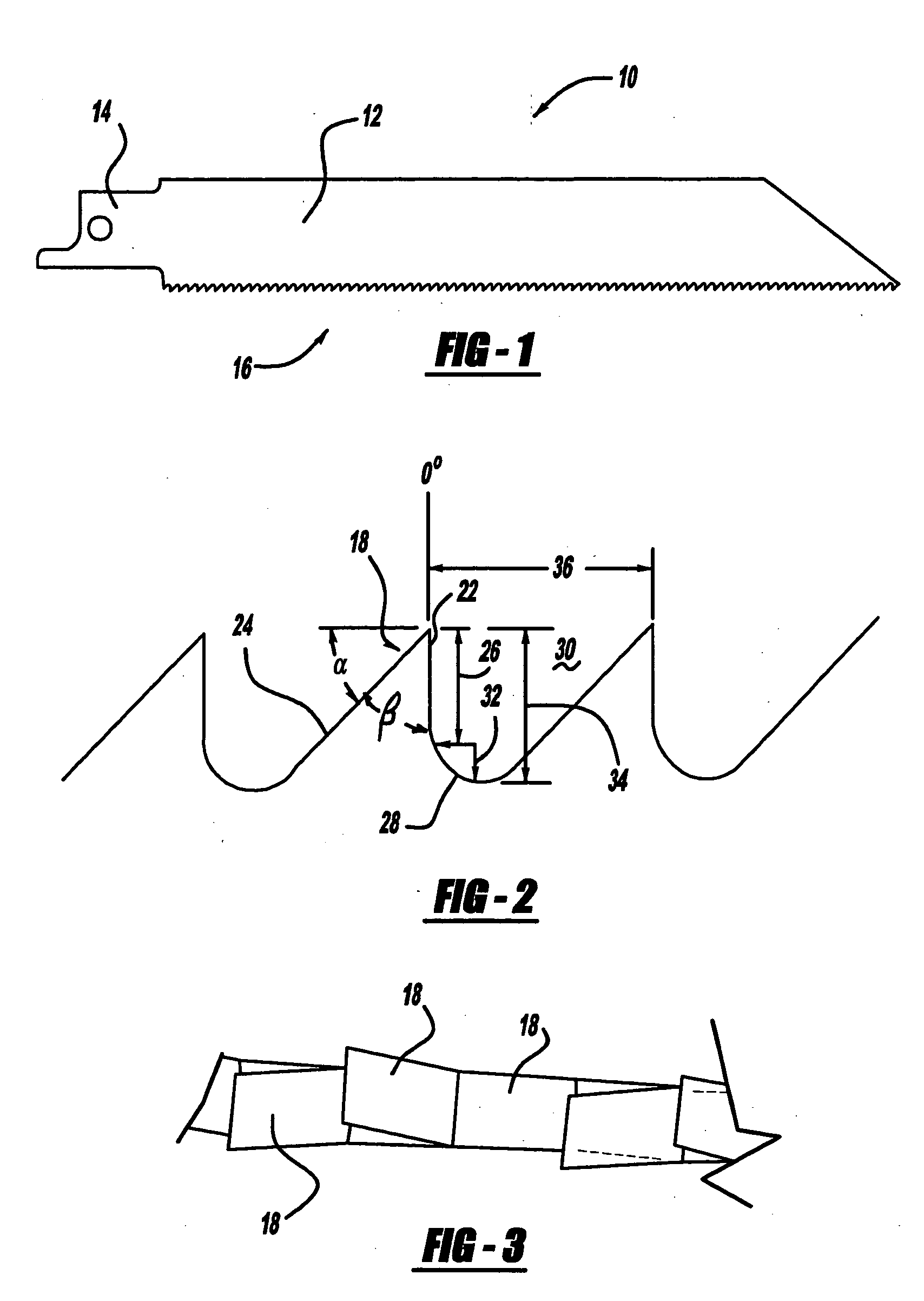

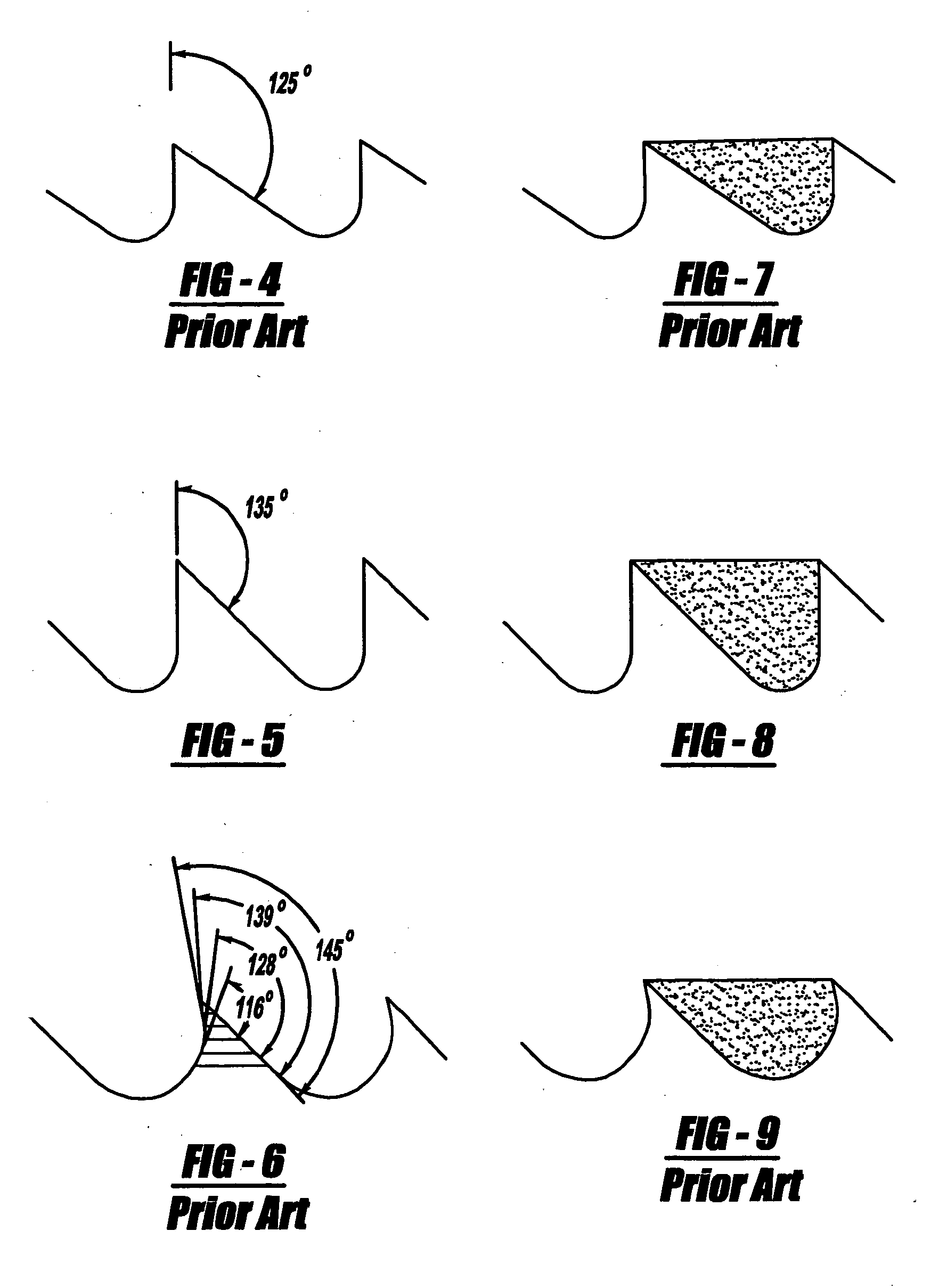

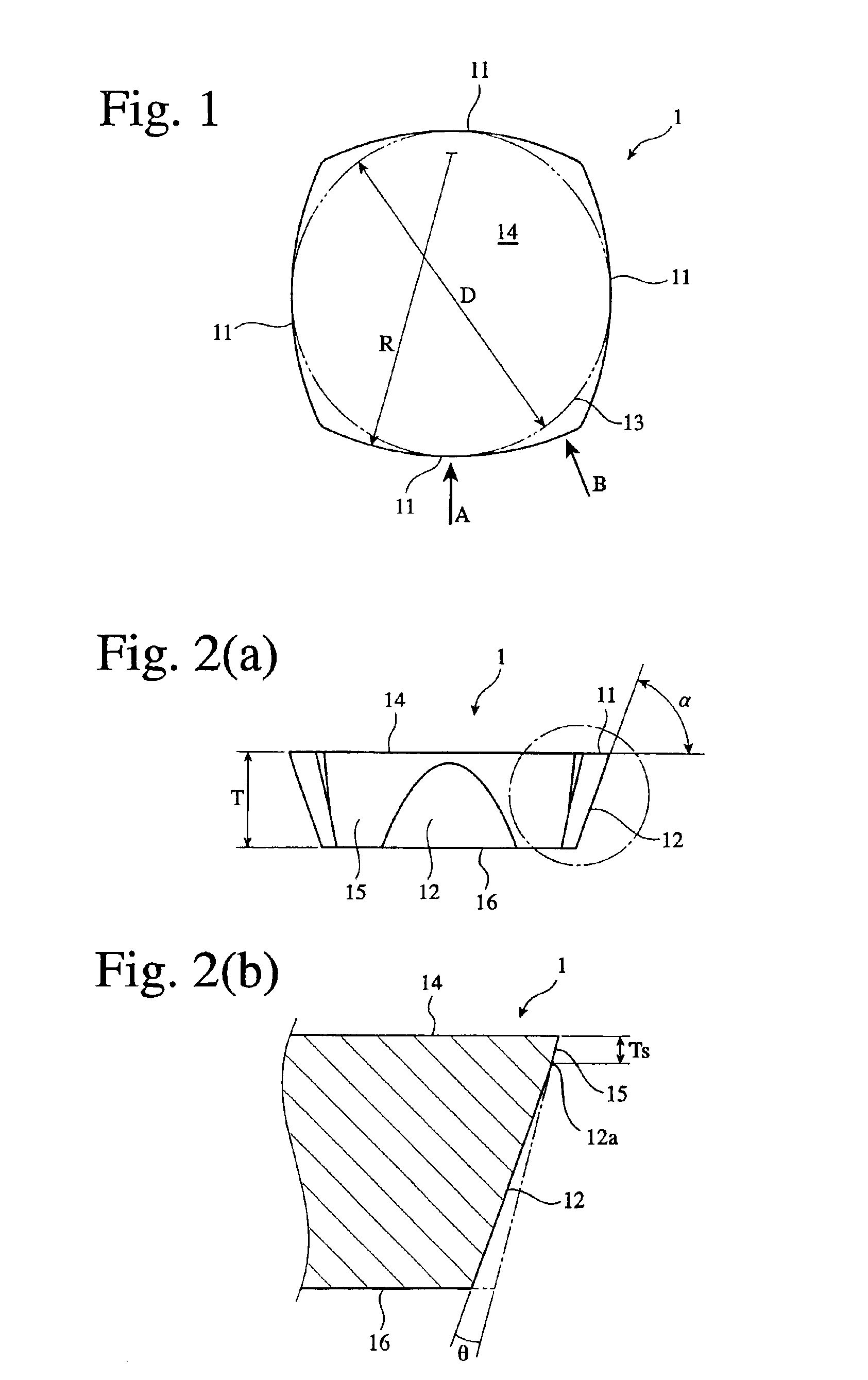

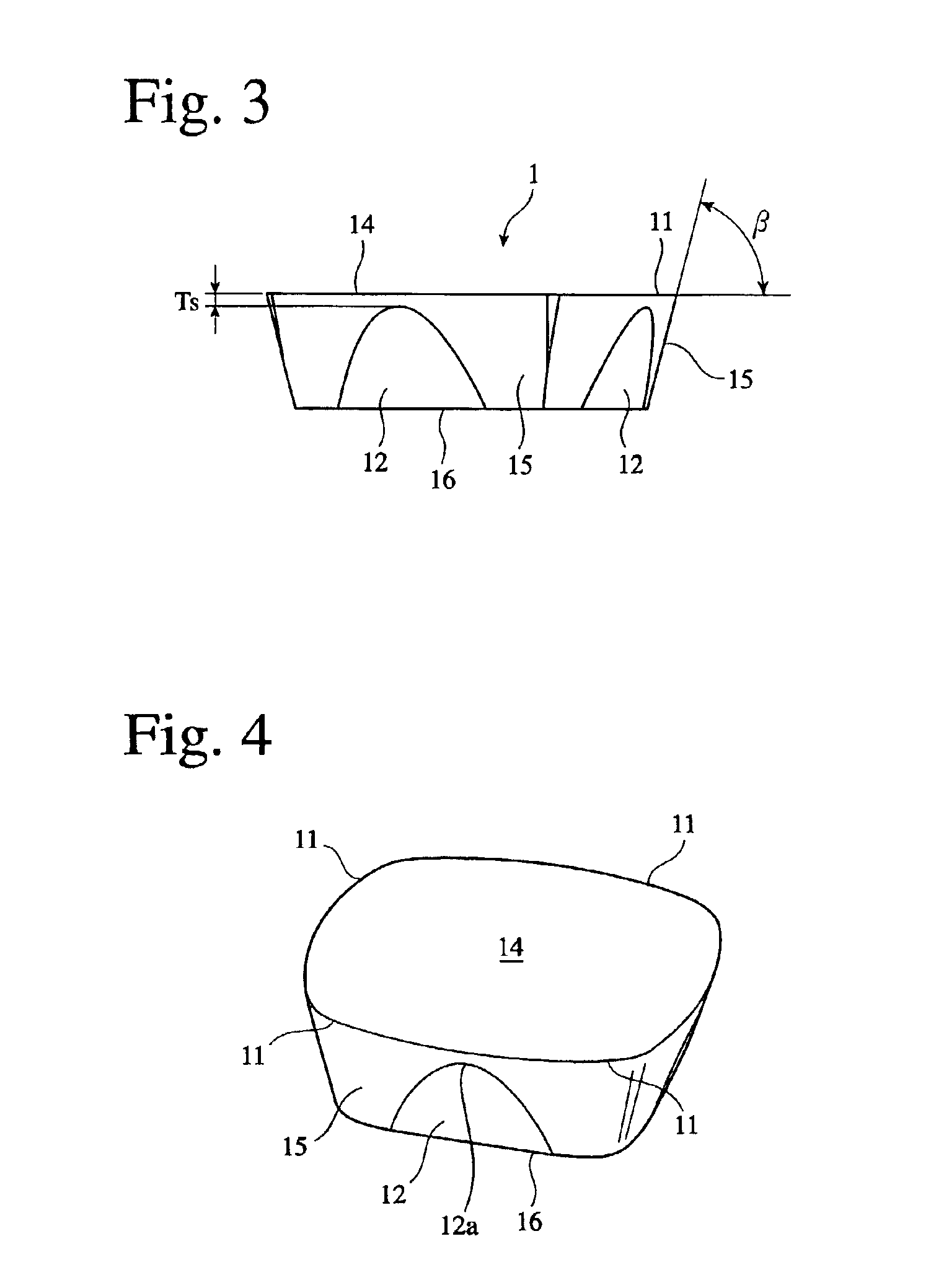

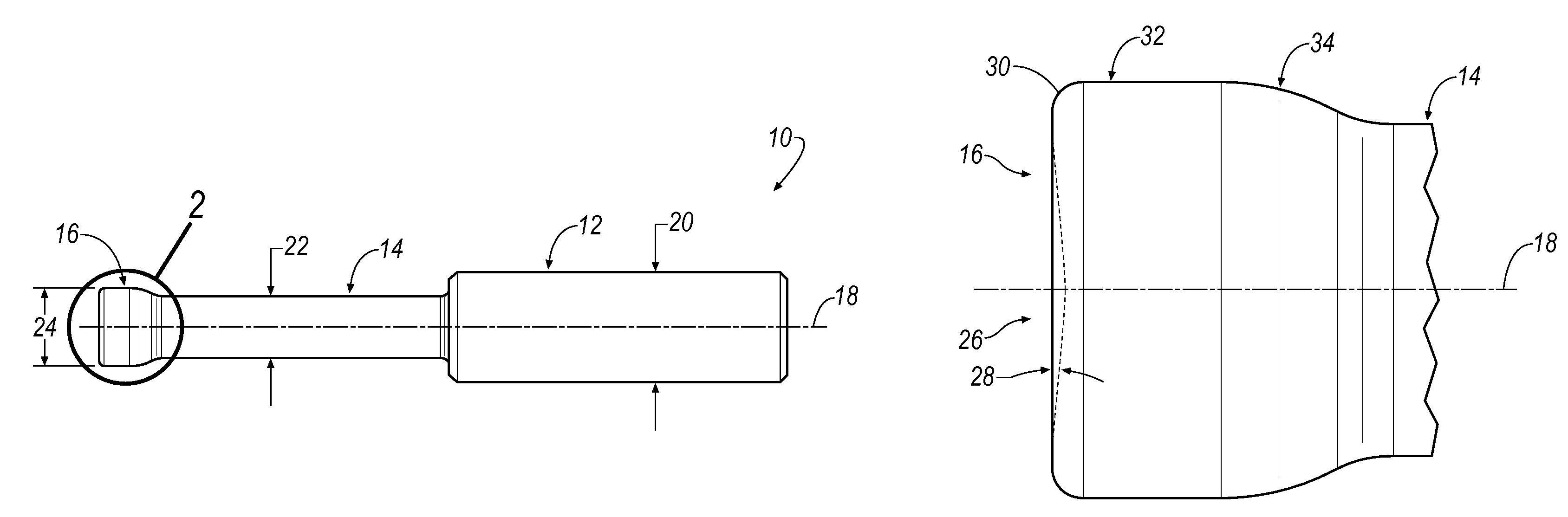

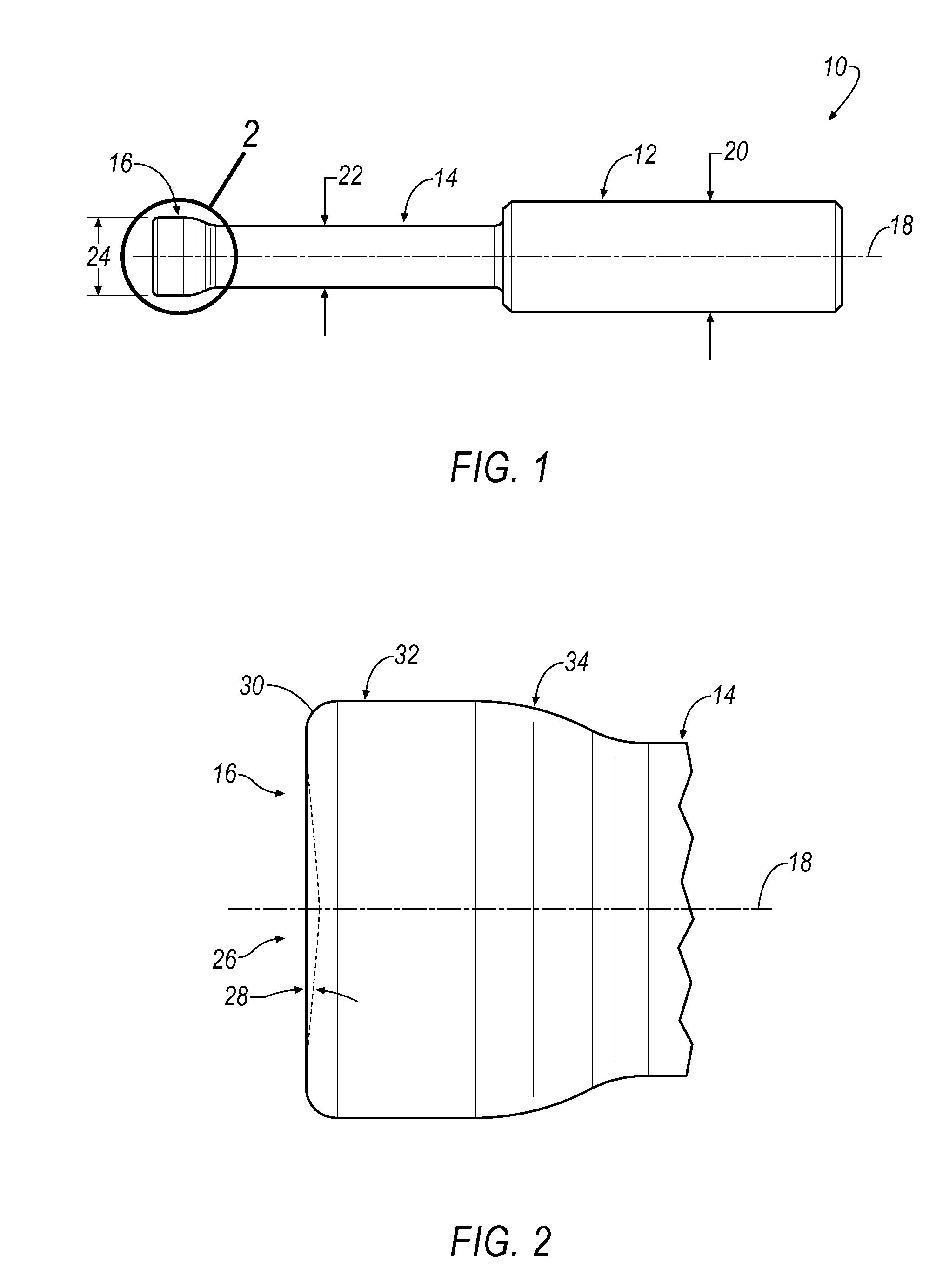

Tooth form design for reciprocating saw blade

A reciprocating saw has a tooth form that decreases the cutting time of the saw blade and extends the life of the saw blade. The tooth height is longer than conventional metal cutting reciprocating saws. Also, the tooth form has a larger gullet. The tooth rake angle remains substantially constant during the life of the saw blade.

Owner:BLACK & DECKER INC

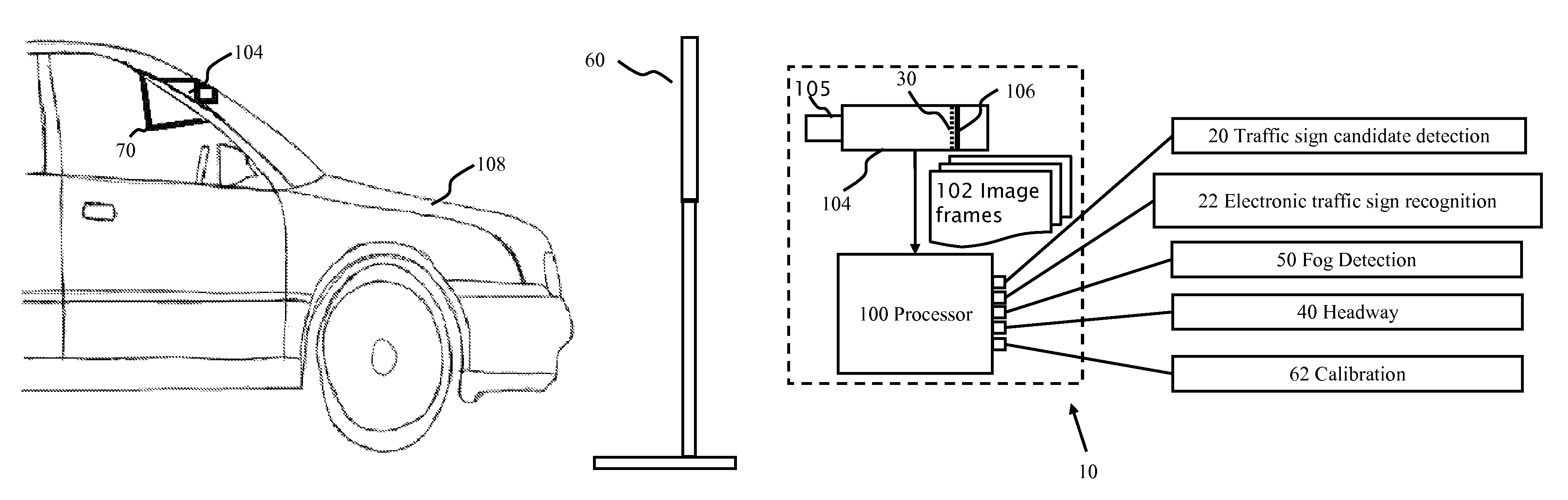

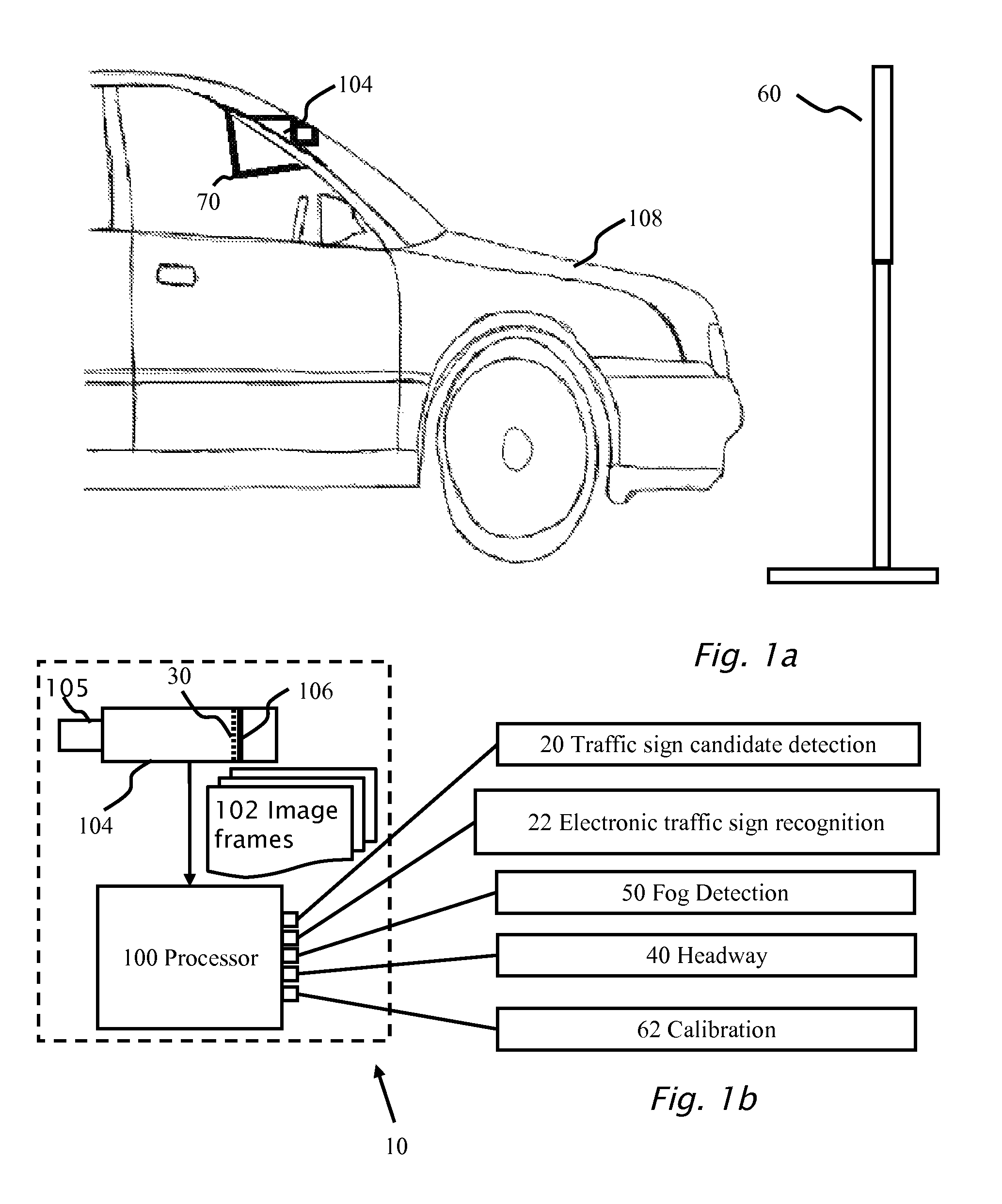

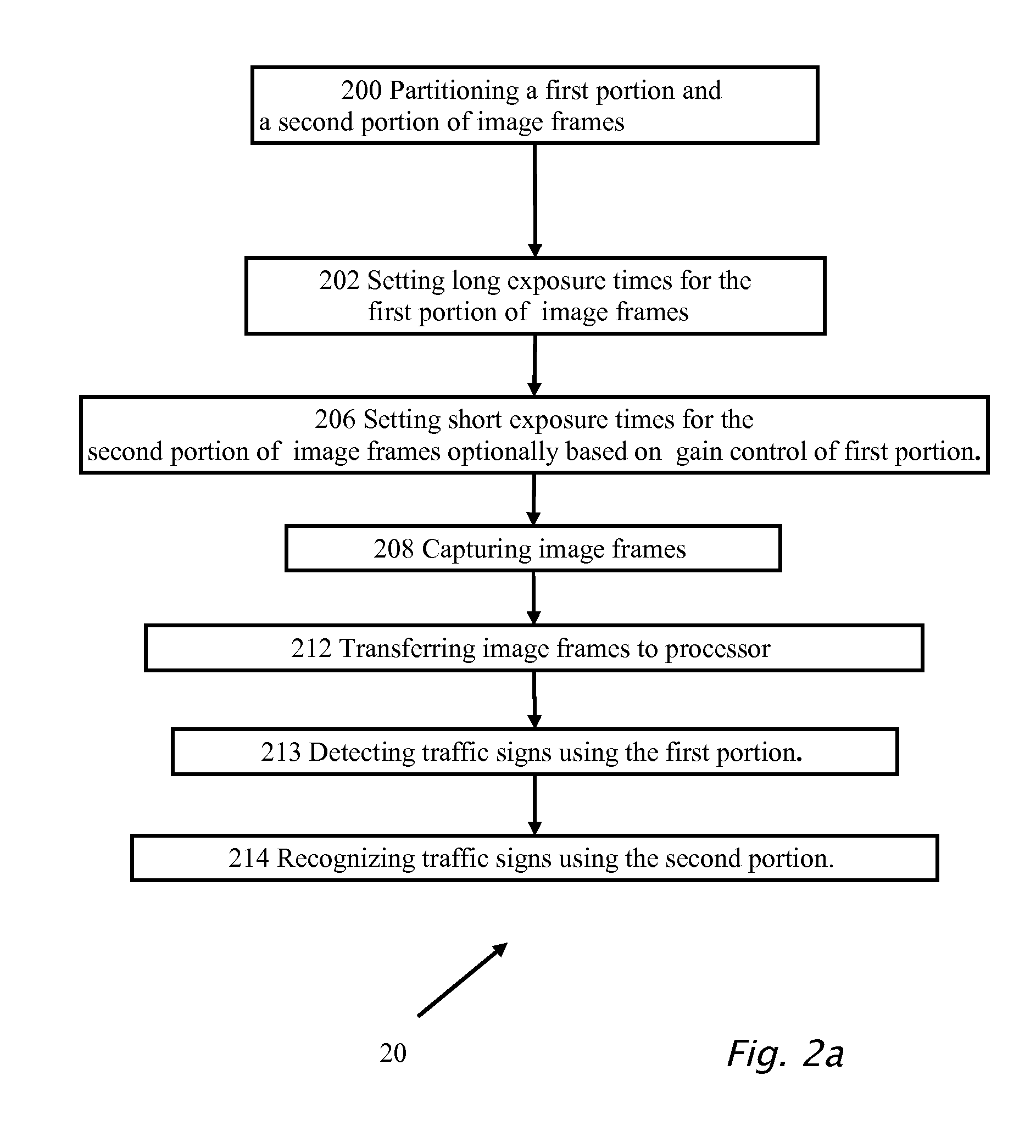

Adjustable camera mount for a vehicle windshield

A camera mount for mounting a camera inside a windshield of a vehicle. The camera includes a lens mount and a camera housing. The front tip of the lens mount is constrained to be in close proximity to or constrained to contact the inside of the windshield for different rake angles of the windshield.

Owner:MOBILEYE VISION TECH LTD

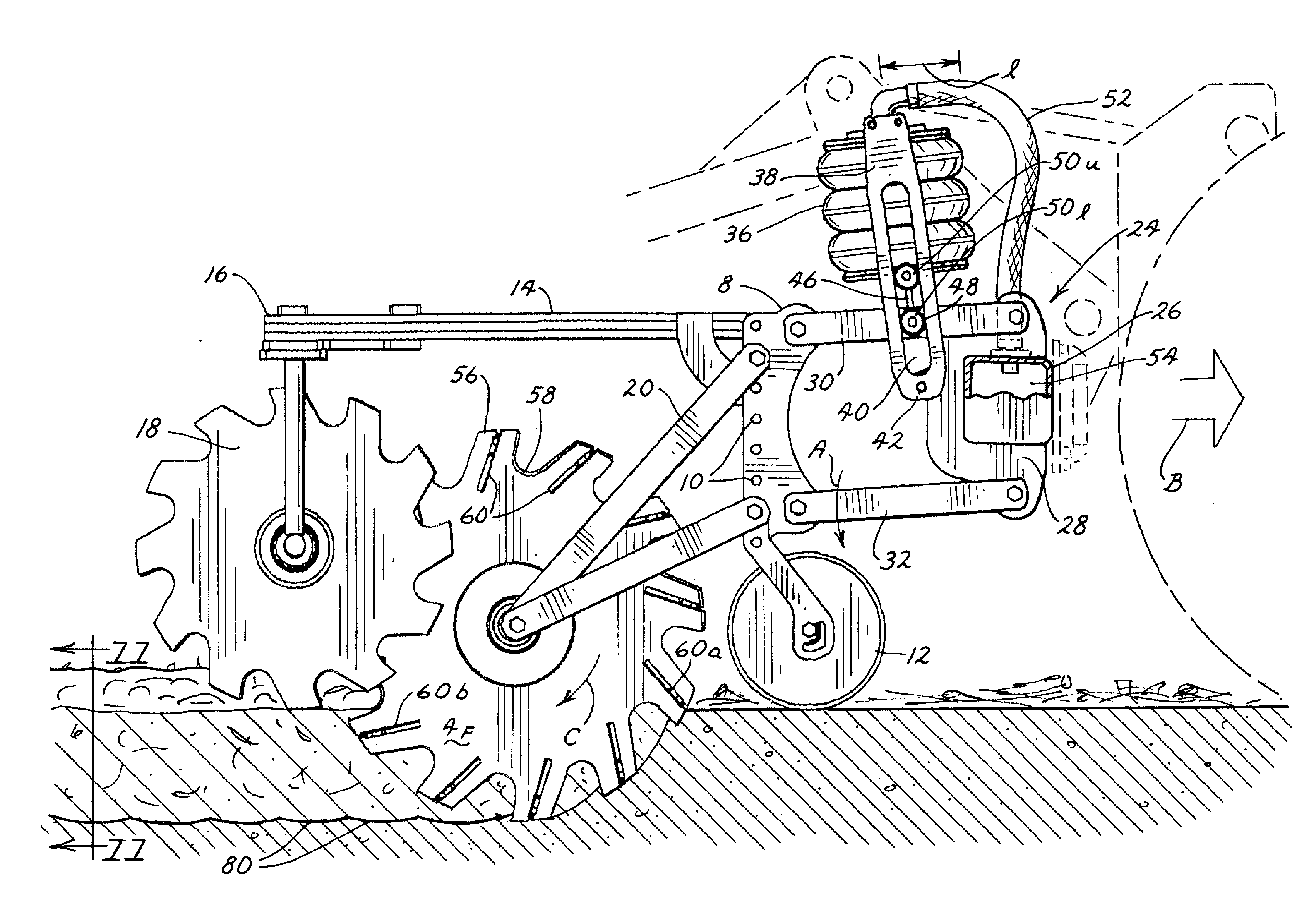

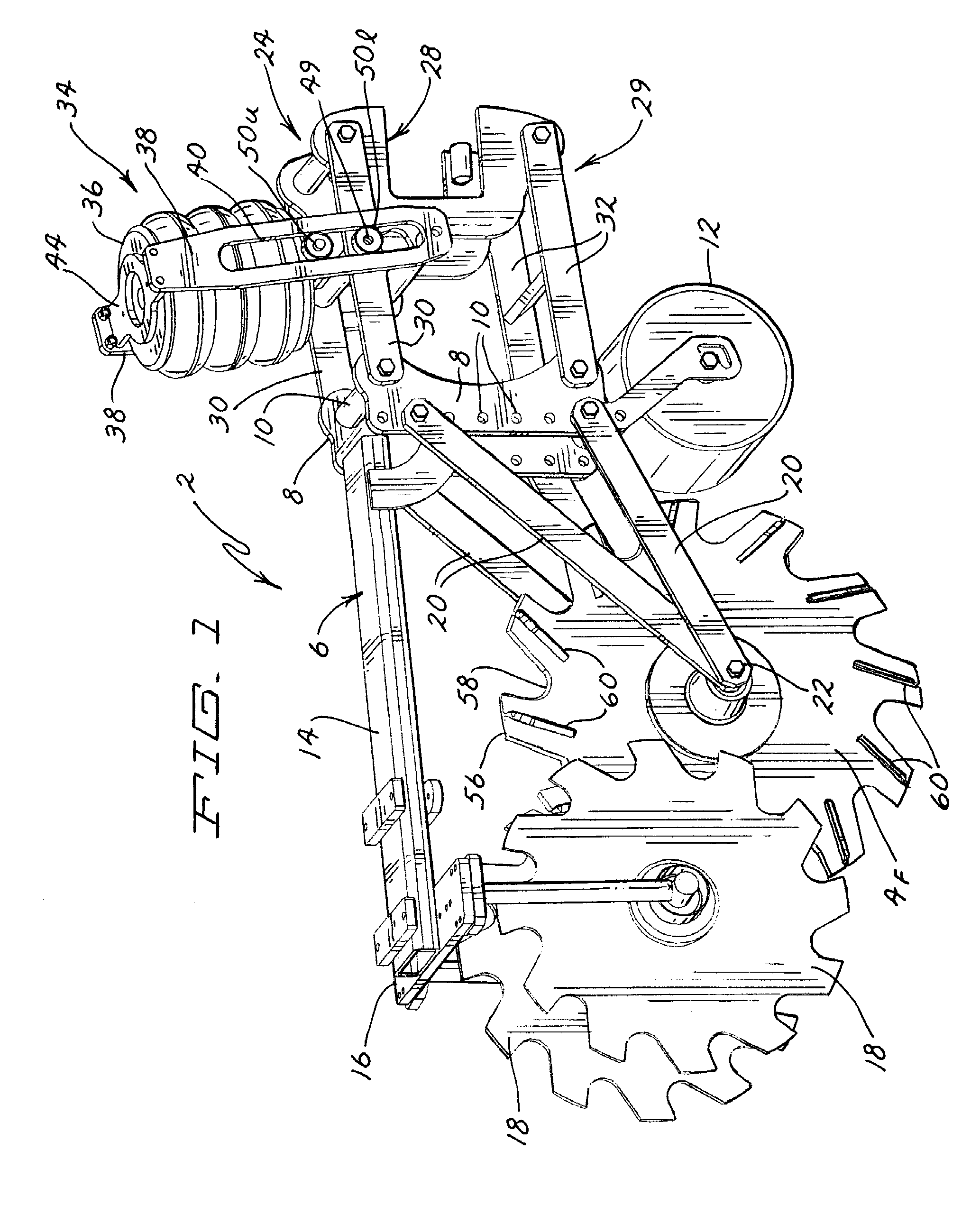

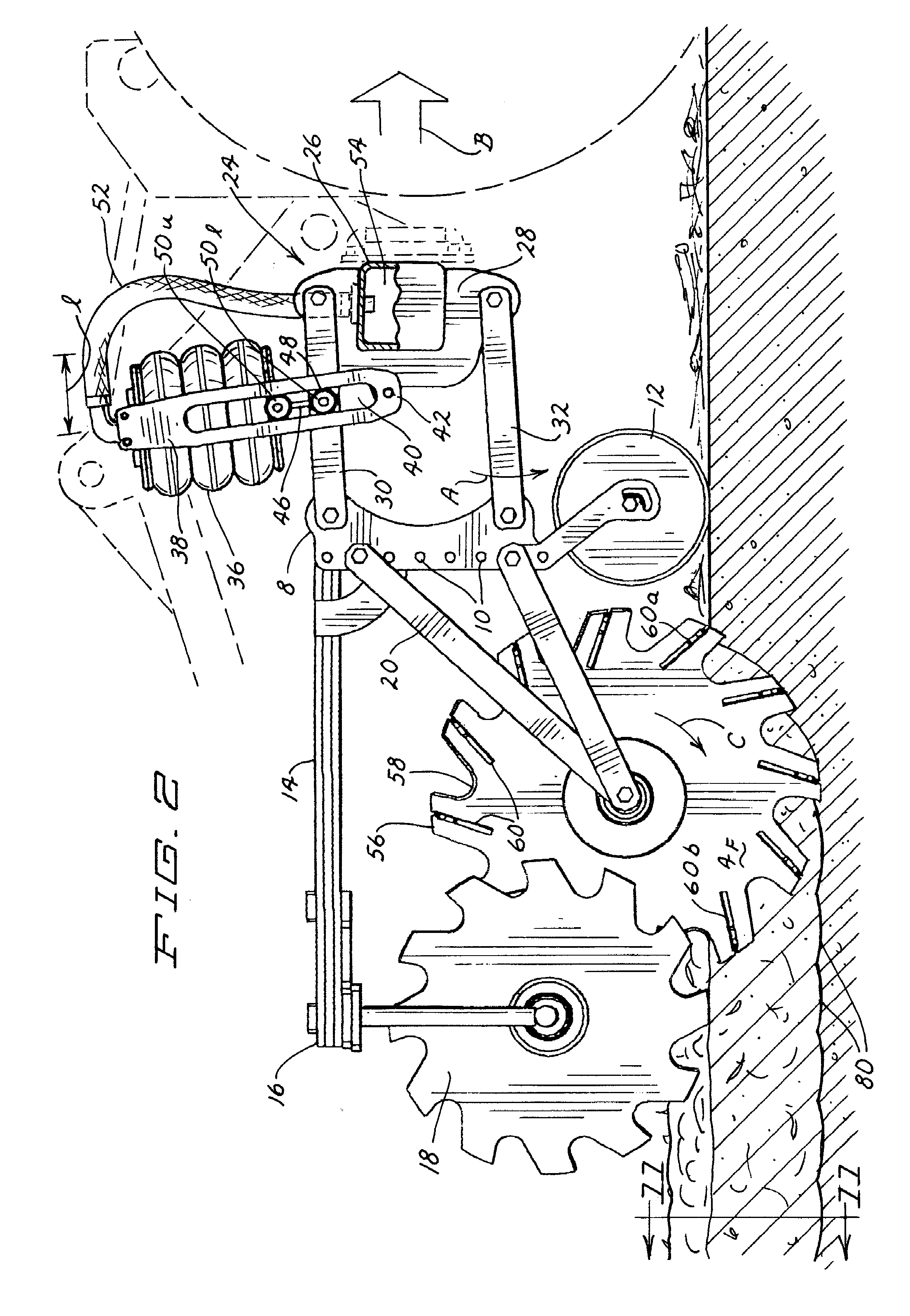

Zone tillage tool and method

A zone tillage tool comprises a tool frame connected by a parallel lift linkage to a tool bar. A fall tillage coulter or dual spring tillage coulters can be carried on the tool frame in advance of a pair of containment coulters. The fall tillage coulter tills soil in a zone that is approximately 7 to 9 inches deep while the spring tillage coulters till 2 to 3 inches deep. The fall tillage coulter includes a plurality of shovel bits located around the circumference thereof at a forward rake angle. The tip of each shovel bit has a generally vertical entry position into the ground due to the forward rake angle. As the fall tillage coulter rotates, the shovel bits rotate around and exit the soil in a generally horizontal position, thereby lifting and loosening the soil without compacting the soil through a series of rearwardly and upwardly directed soil scooping actions.

Owner:ENVIRONMENTAL TILLAGE SYST

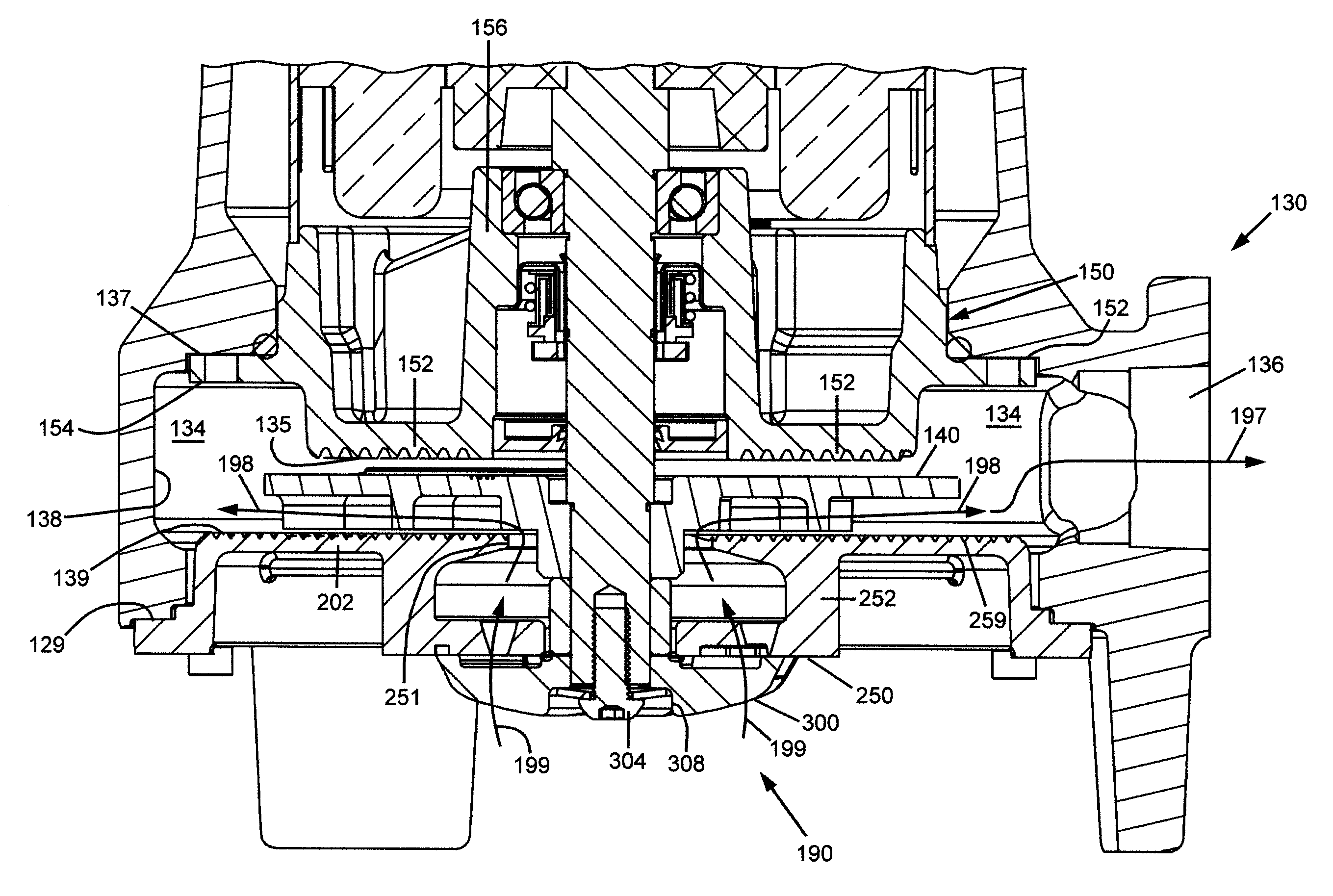

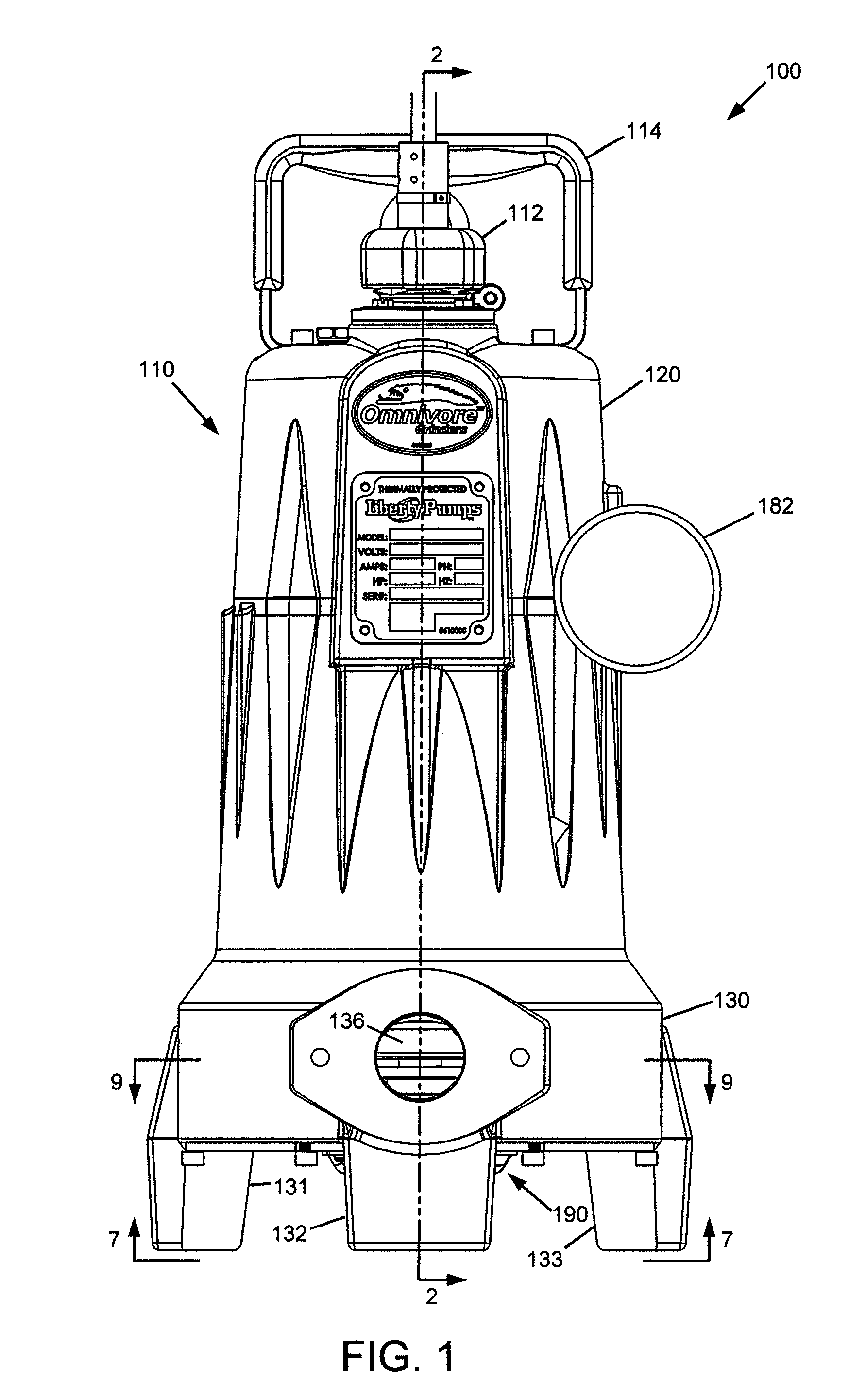

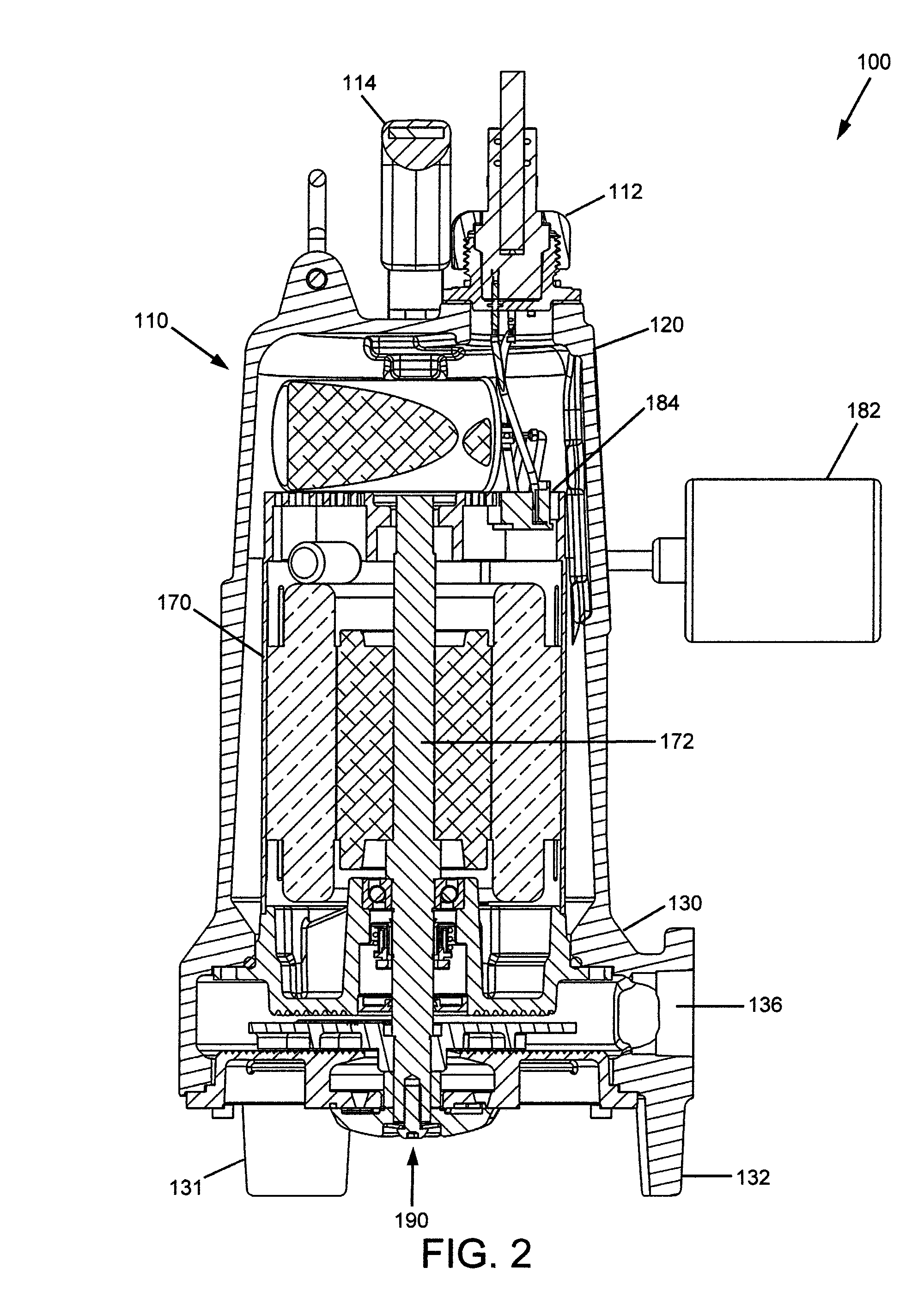

Cutter assembly for a grinder pump

A cutting assembly for a grinder pump comprised of a rotary cutter rotatable against an opposing plate cutter. The cutting edges of the plate cutter include a plurality of V-slice cutting teeth, which create bridging spaces to pinch material which is being sucked in to ports and begin cutting along the V-slice and then for cut material to pass through and onward into the volute of the pump. The rotary cutter has a ground edge with a rake angle which shears the gathered material in cooperation with the cutting edges of the plate cutter. A grinder pump including the cutter assembly is also disclosed.

Owner:LIBERTY PUMPS

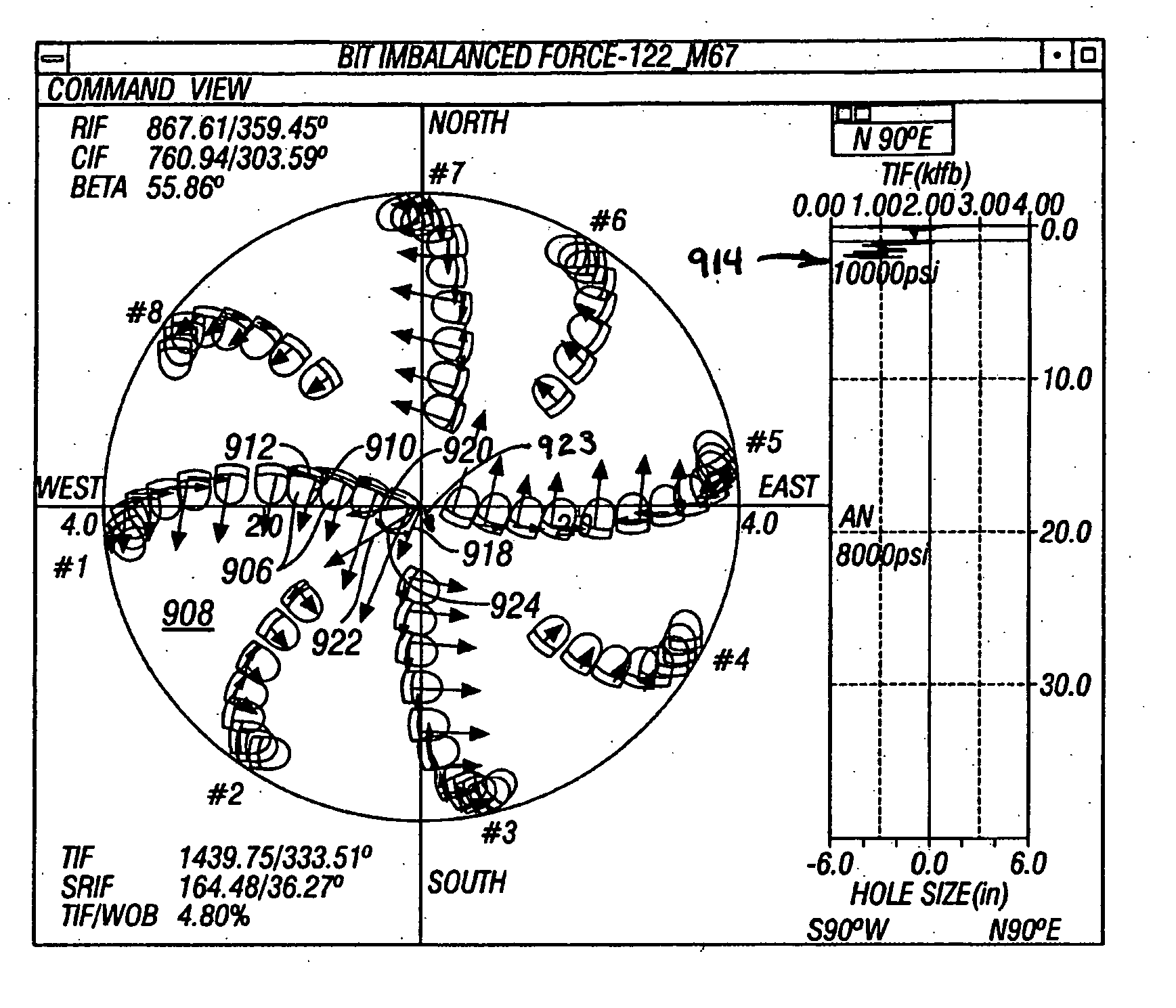

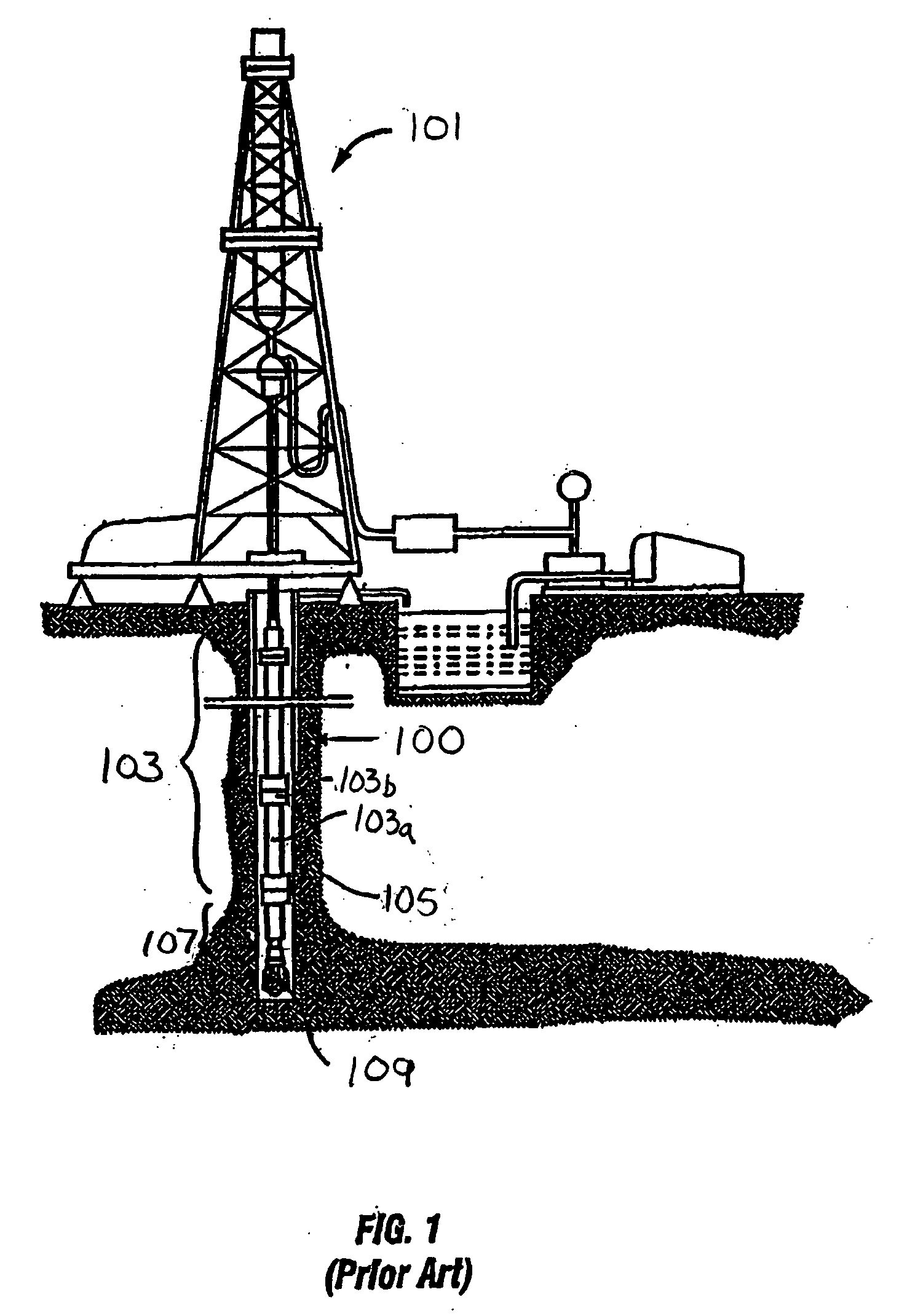

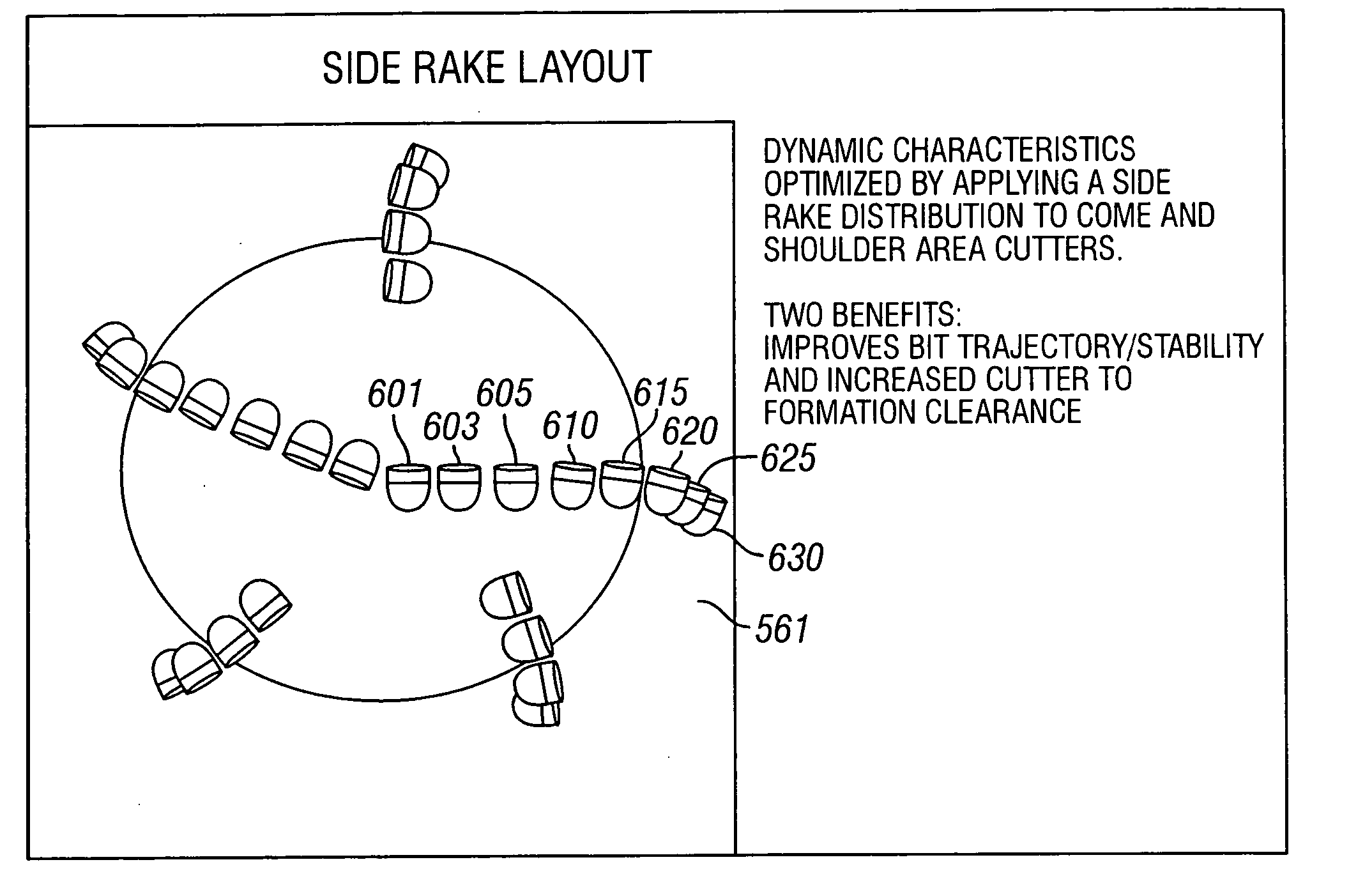

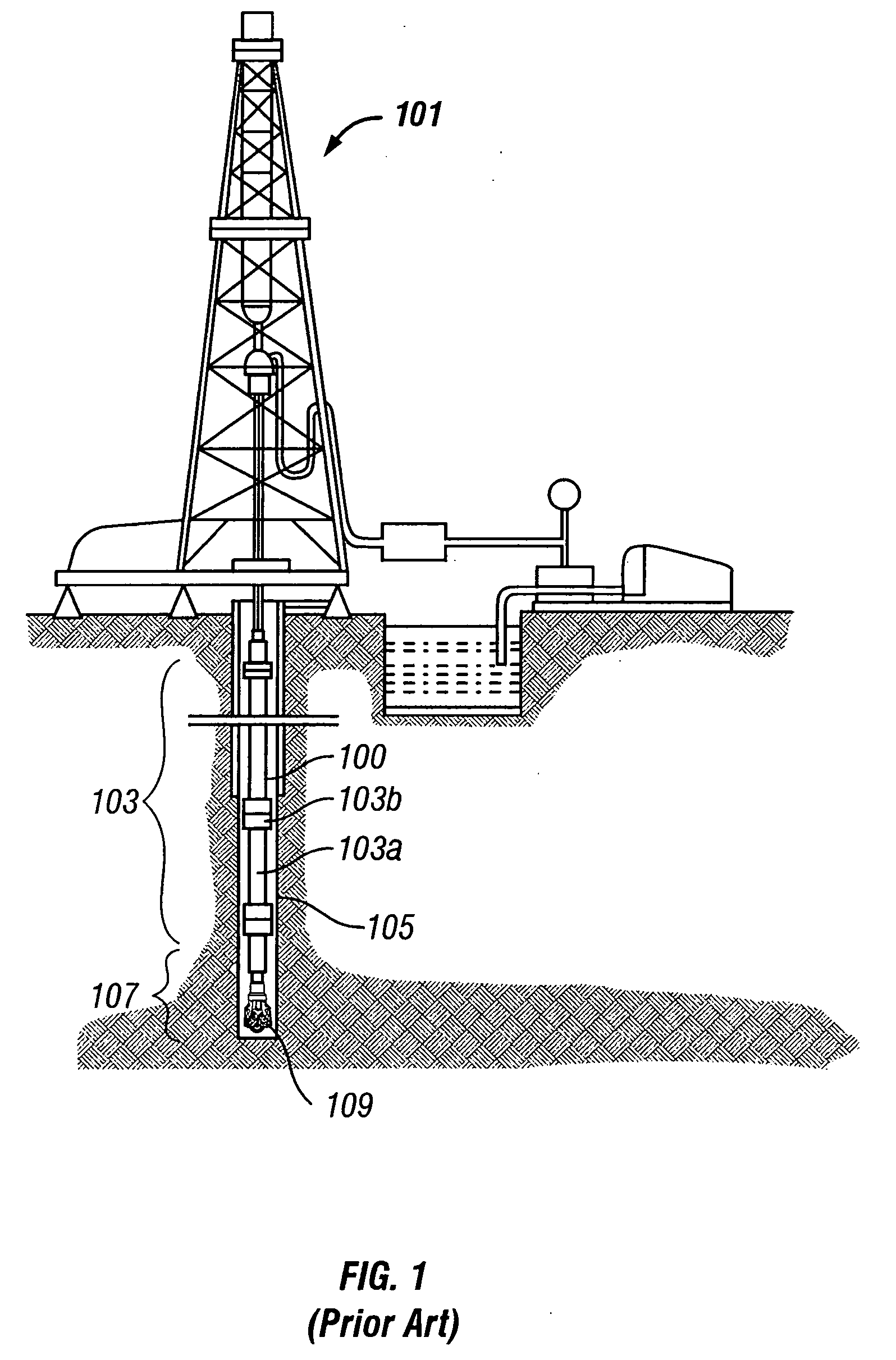

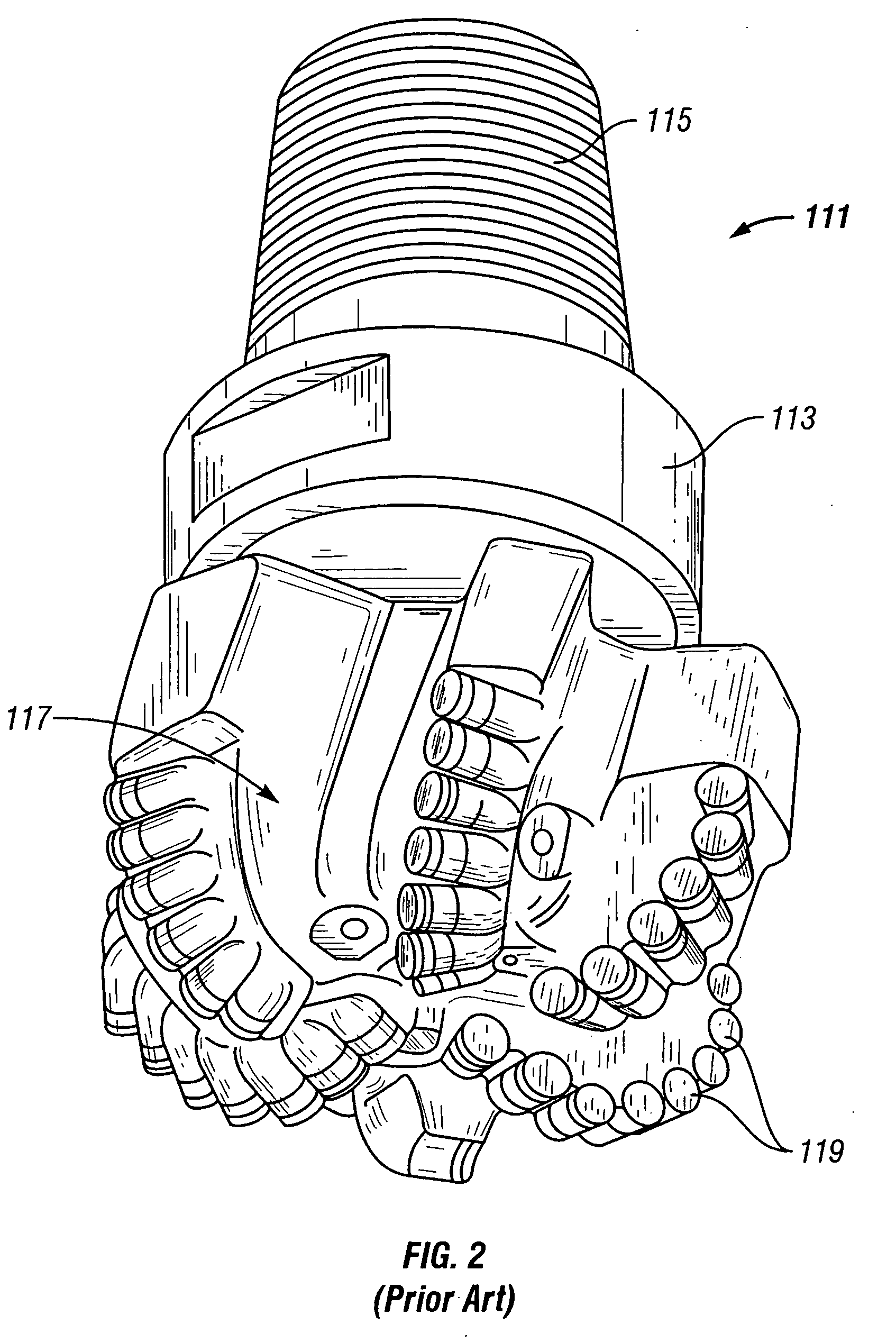

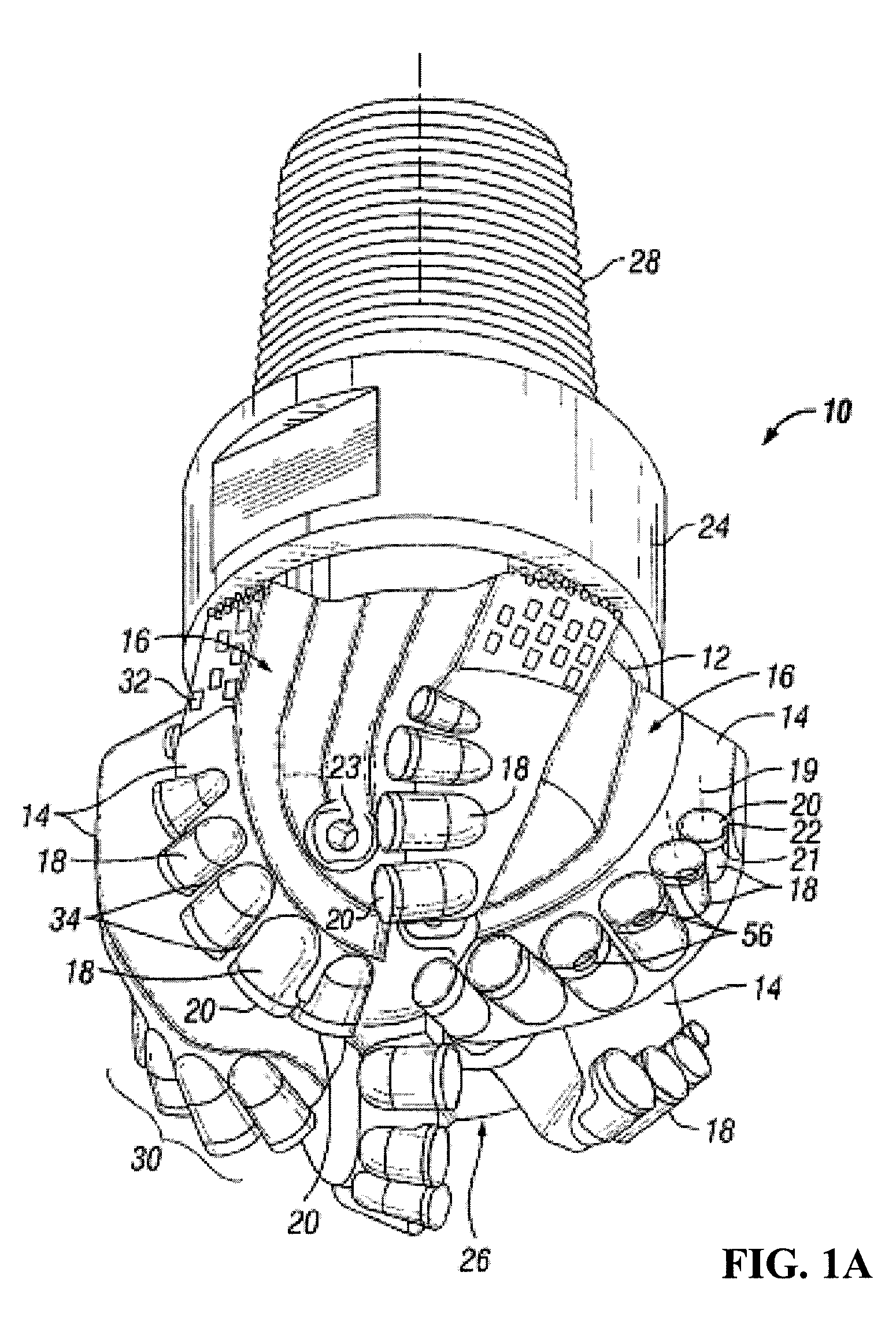

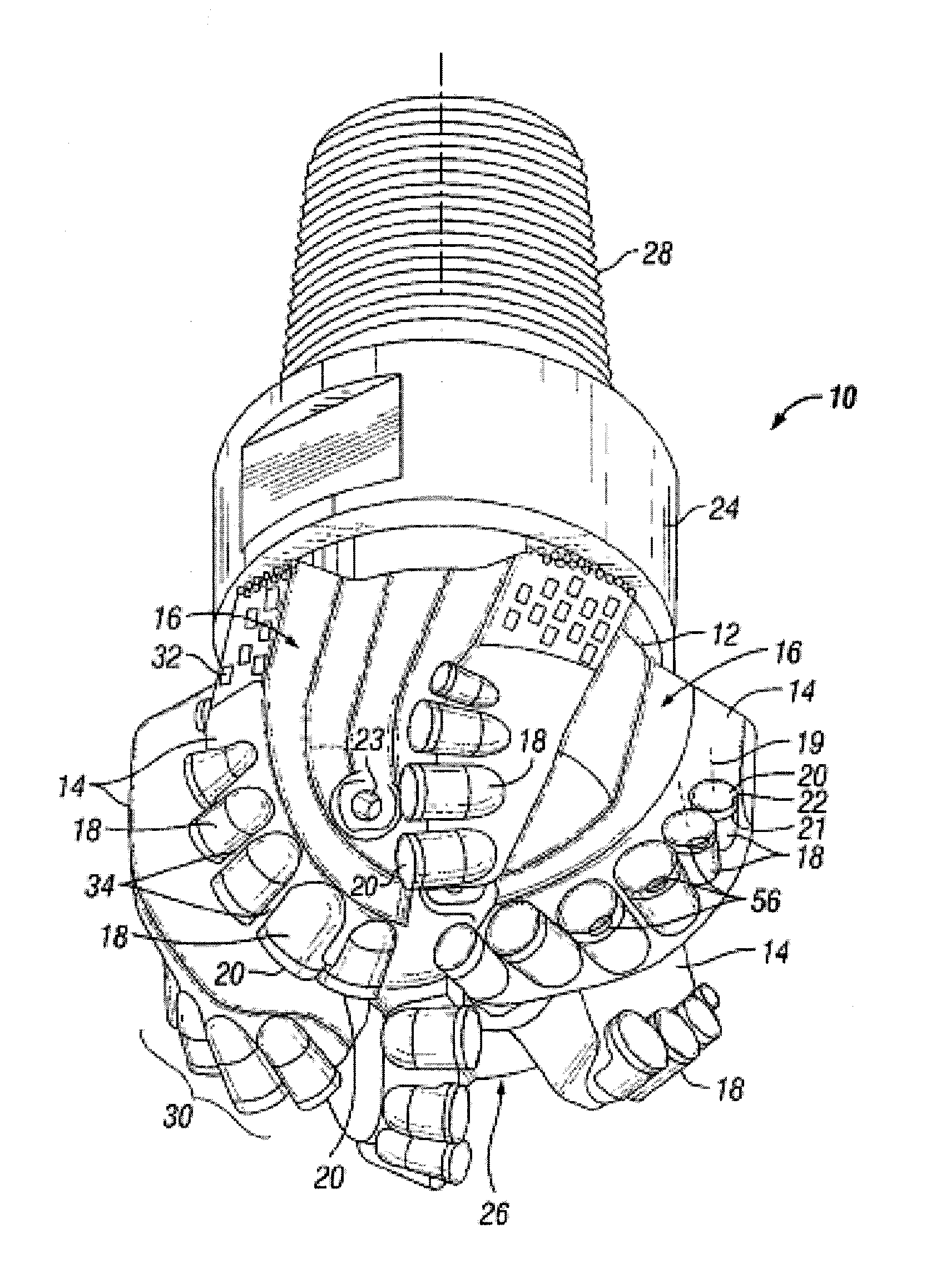

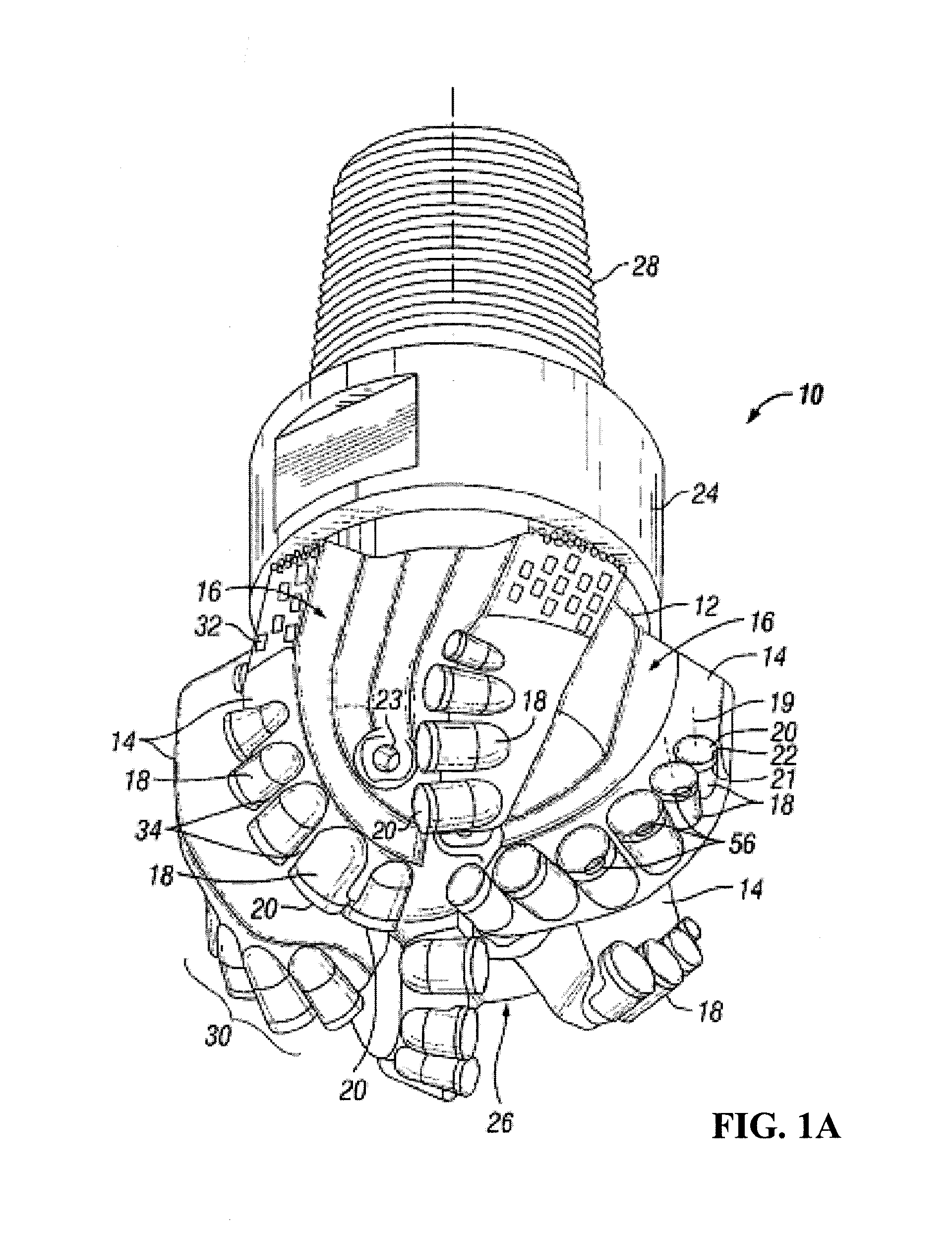

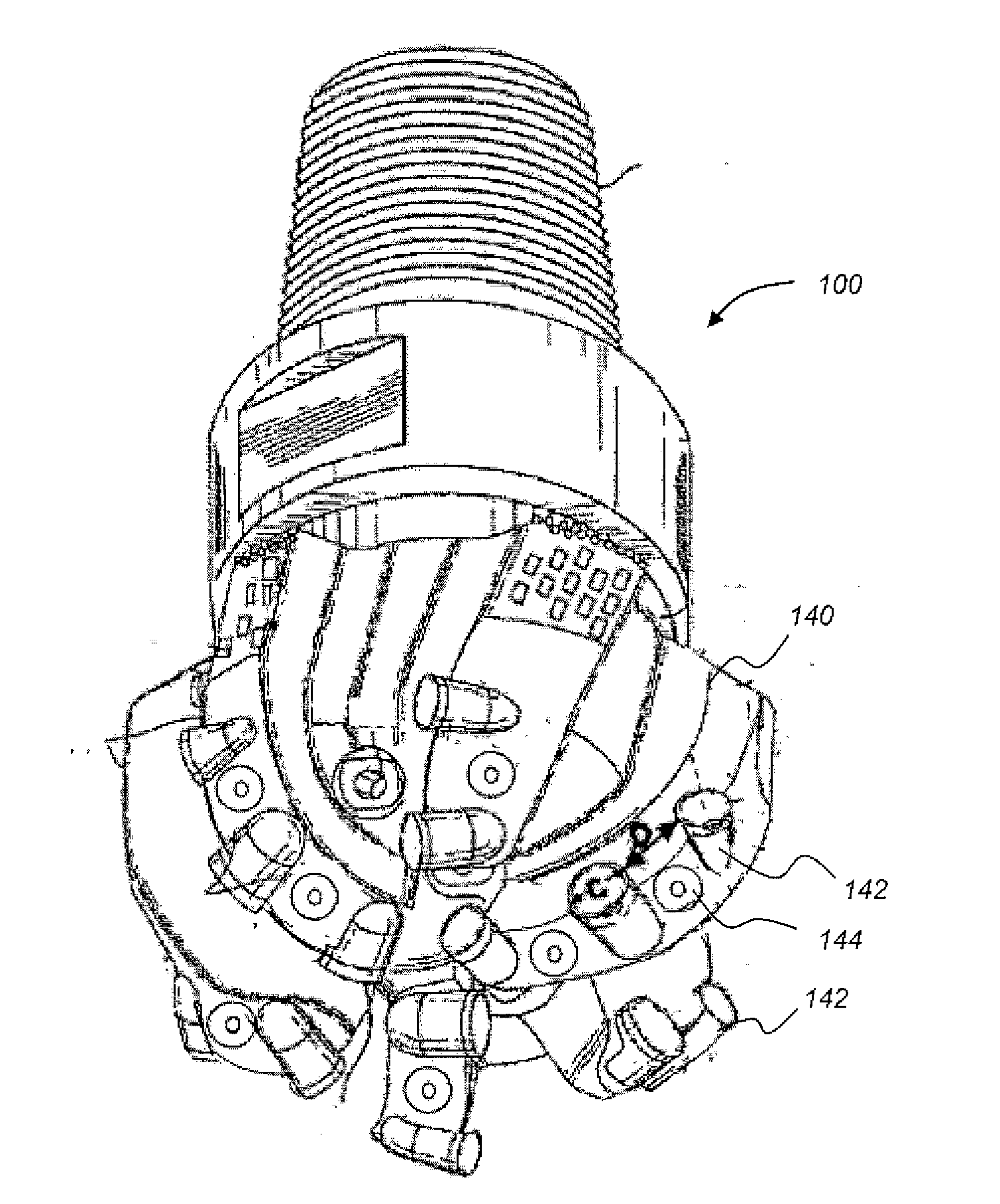

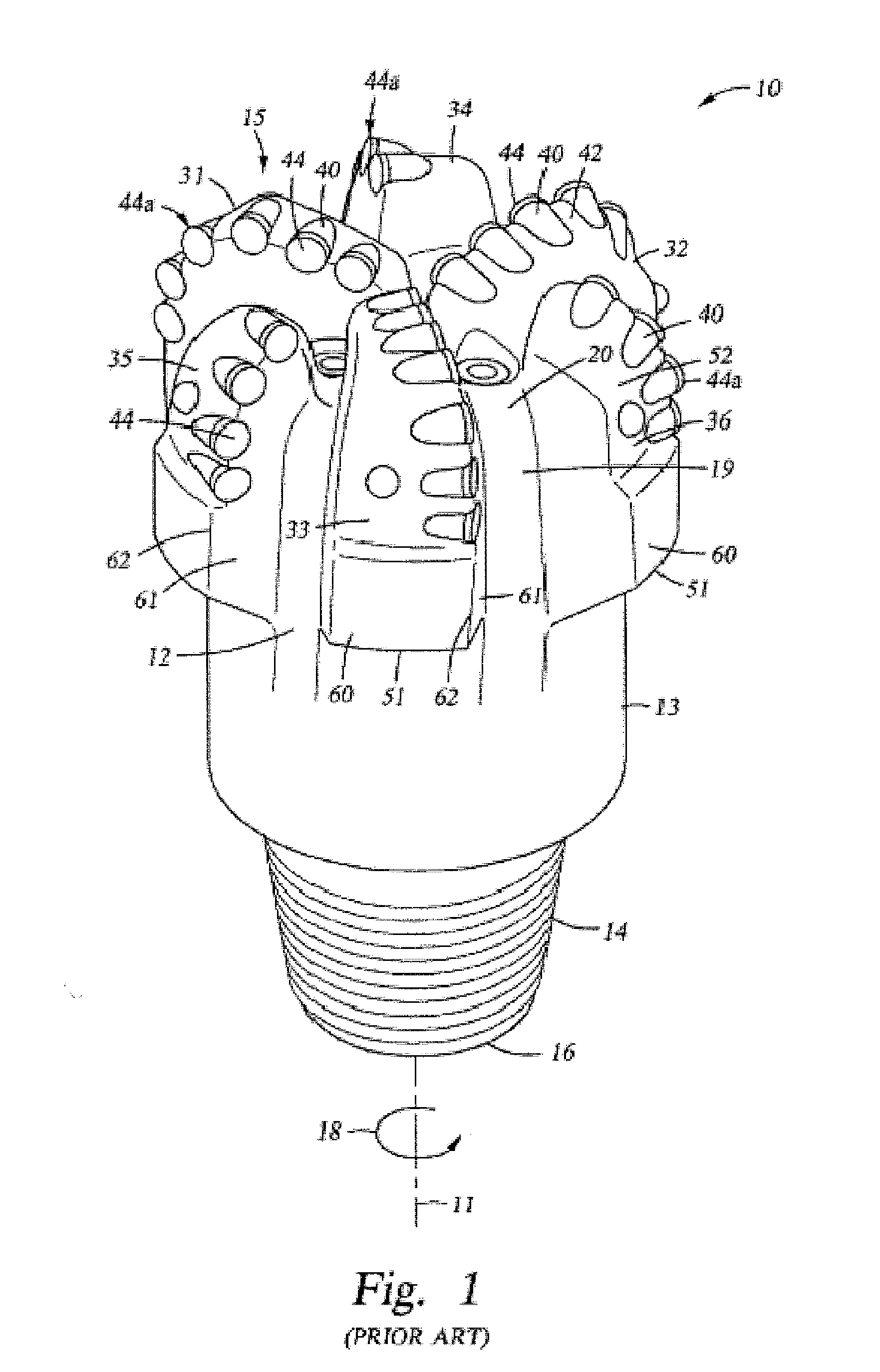

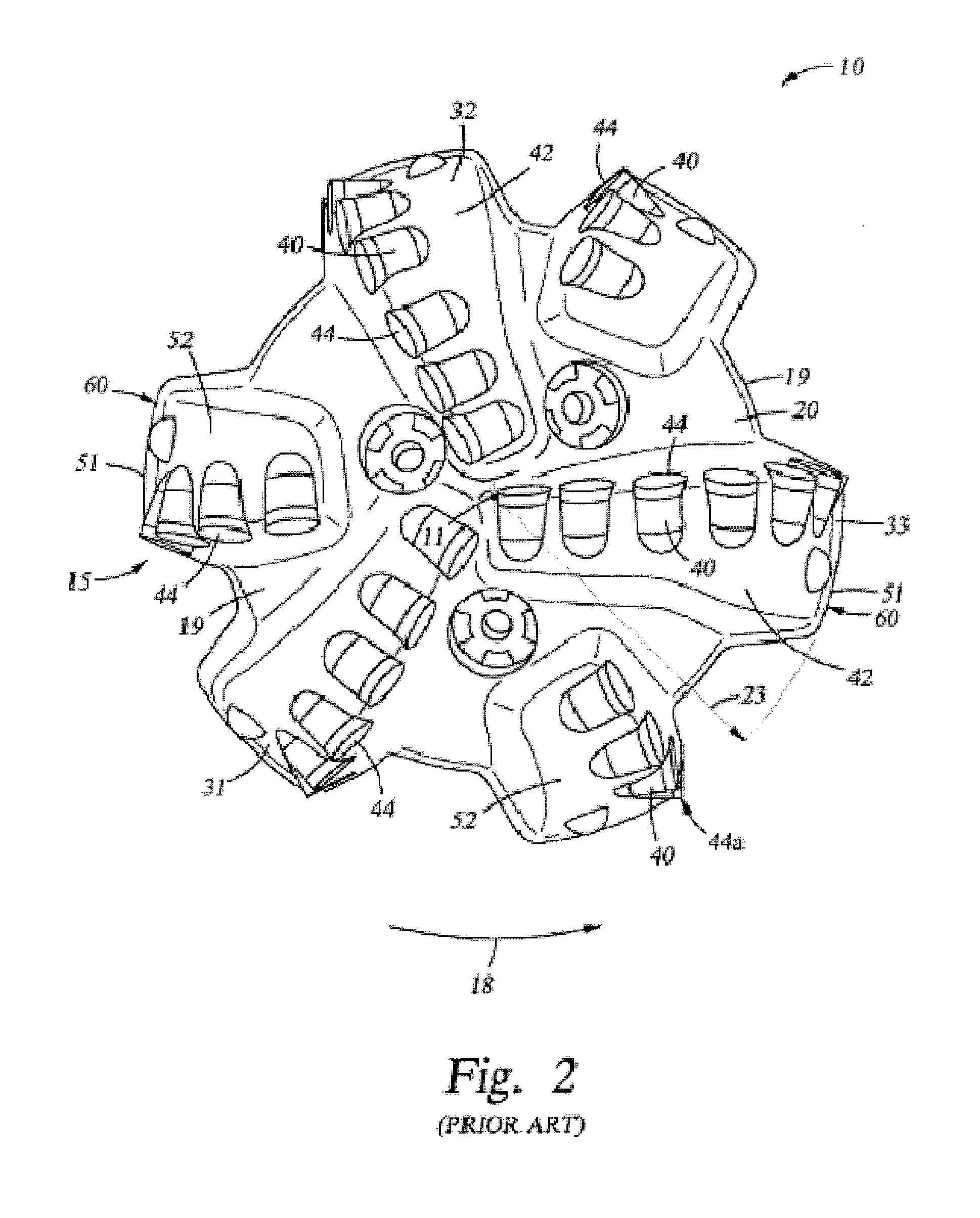

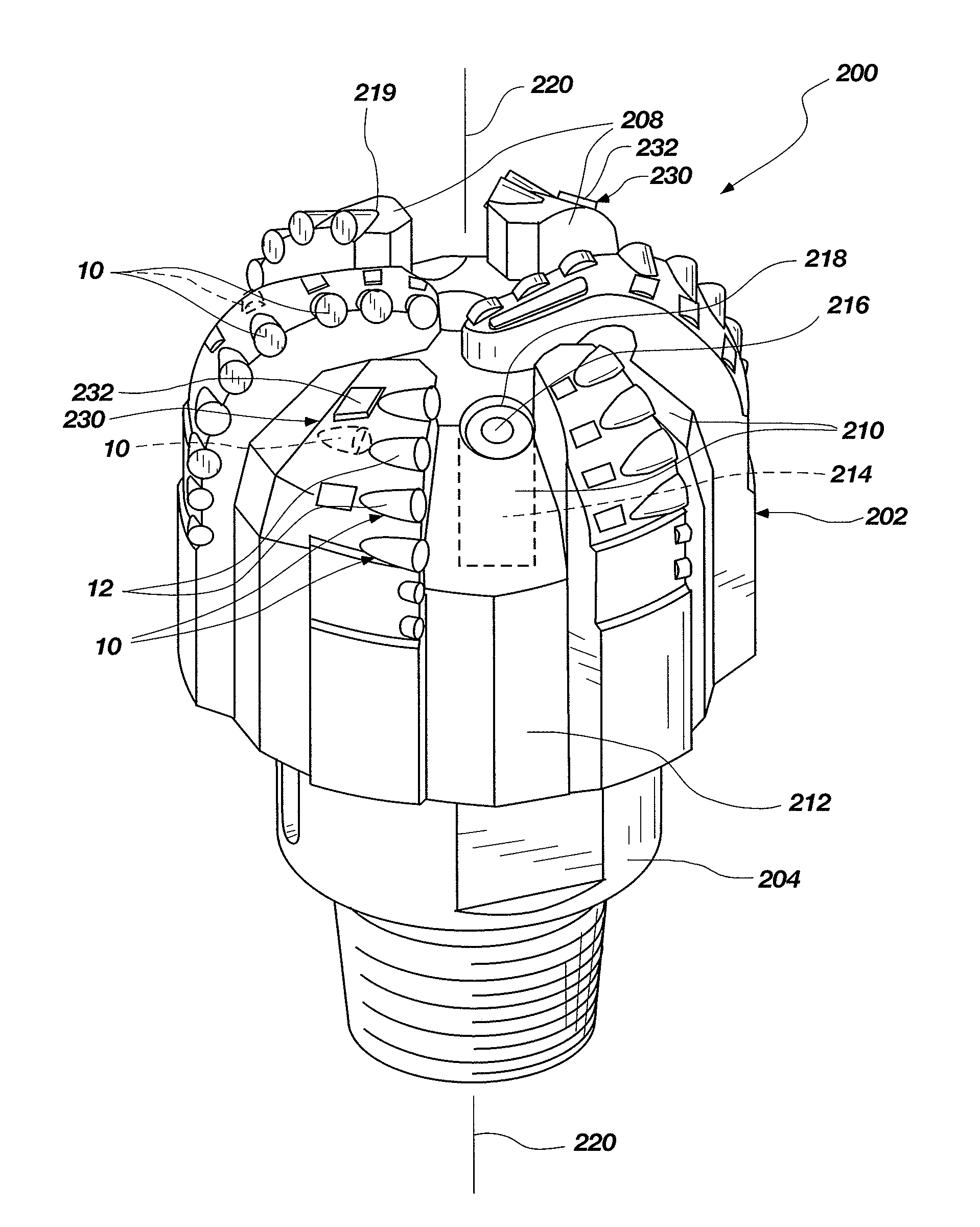

PDC drill bit using optimized side rake distribution that minimized vibration and deviation

InactiveUS20060162968A1Improve performancePerformance can be improved and optimizedDrill bitsConstructionsKnife bladesRake angle

A fixed cutter drill bit and a method for designing a fixed cutter drill bit includes simulating the fixed cutter drill bit drilling in an earth formation. A performance characteristic of the simulated fixed cutter drill bit is determined. A side rake angle distribution of the cutters is adjusted at least along a cone region of a blade of the fixed cutter drill bit to change the performance characteristic of the fixed cutter drill bit.

Owner:SMITH INT INC

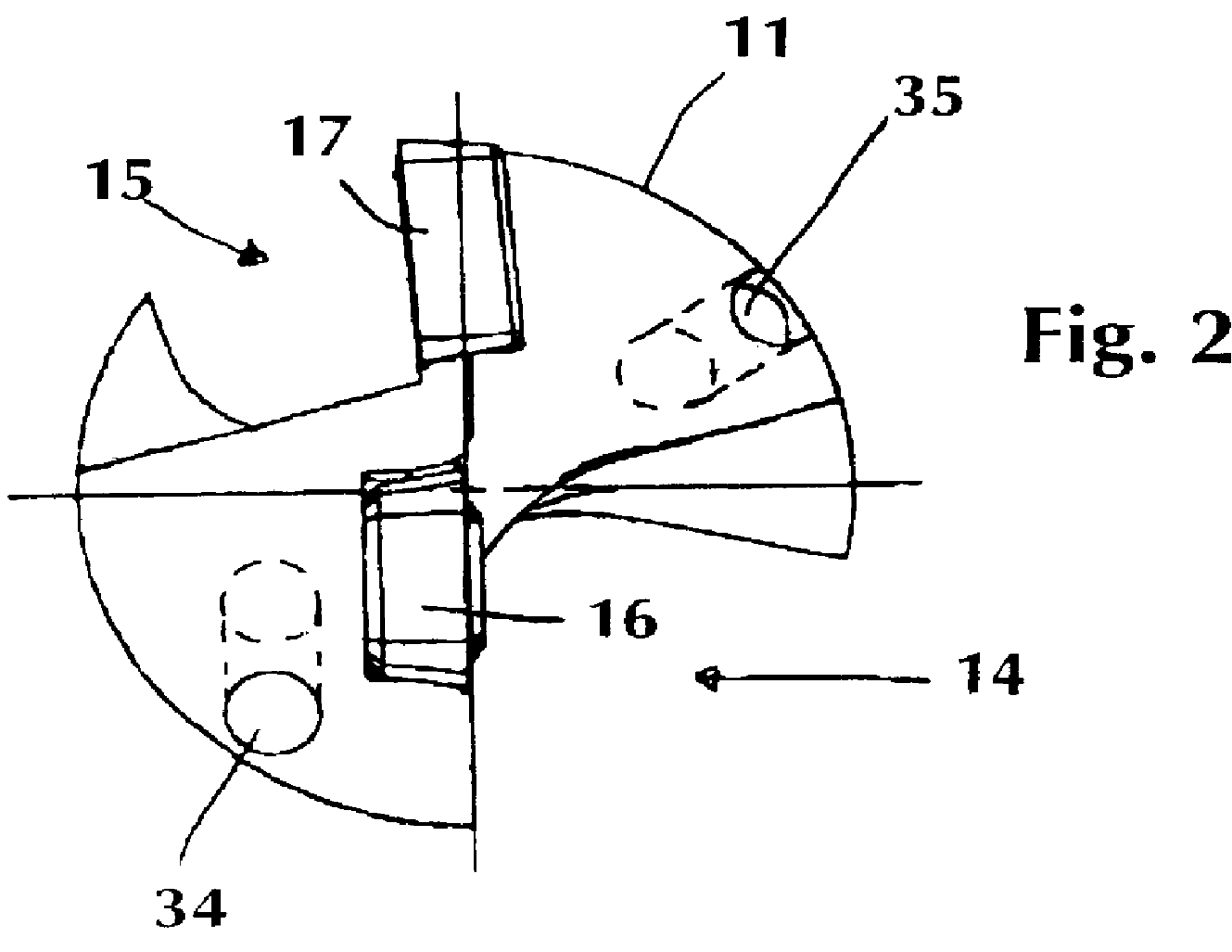

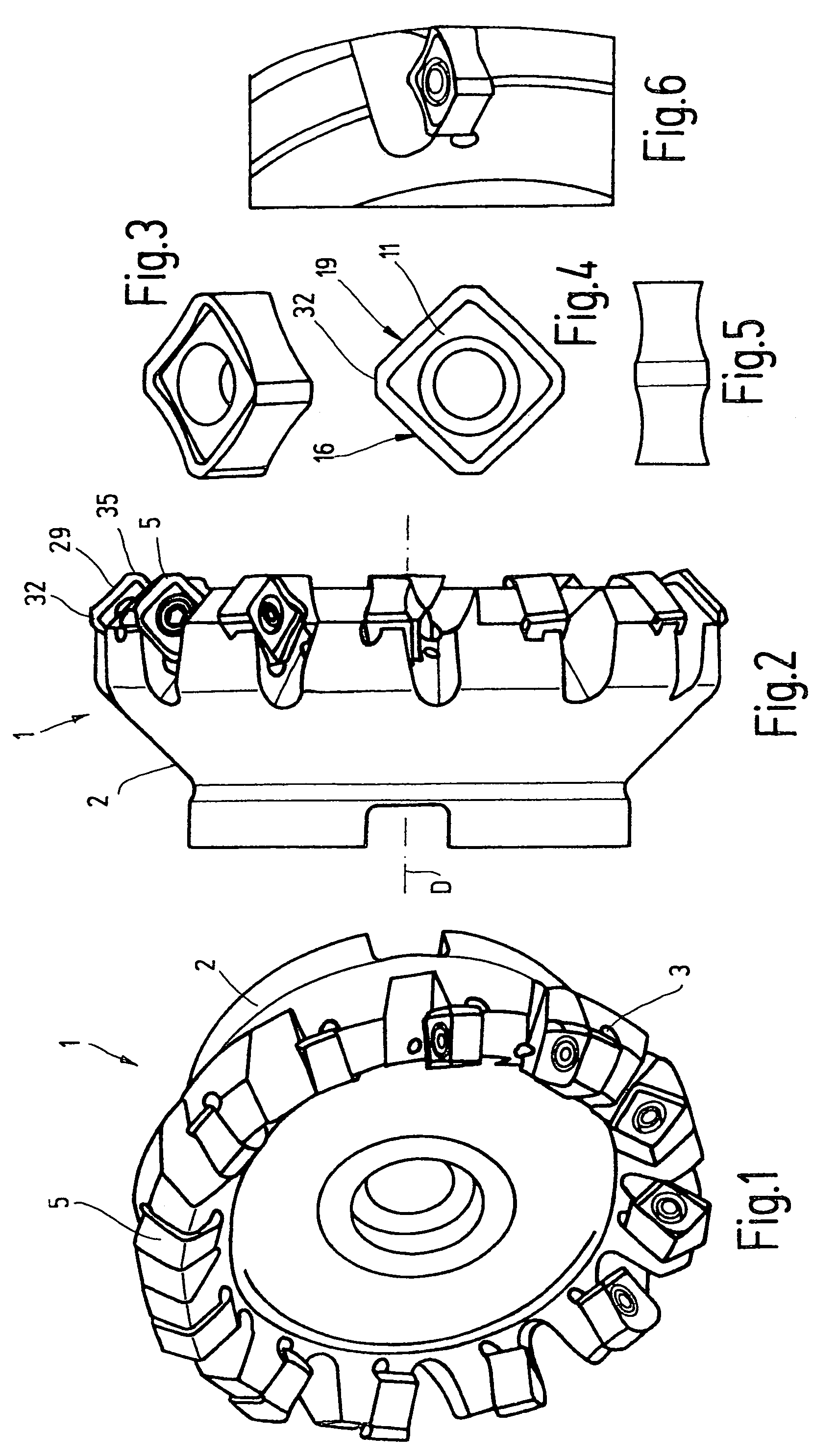

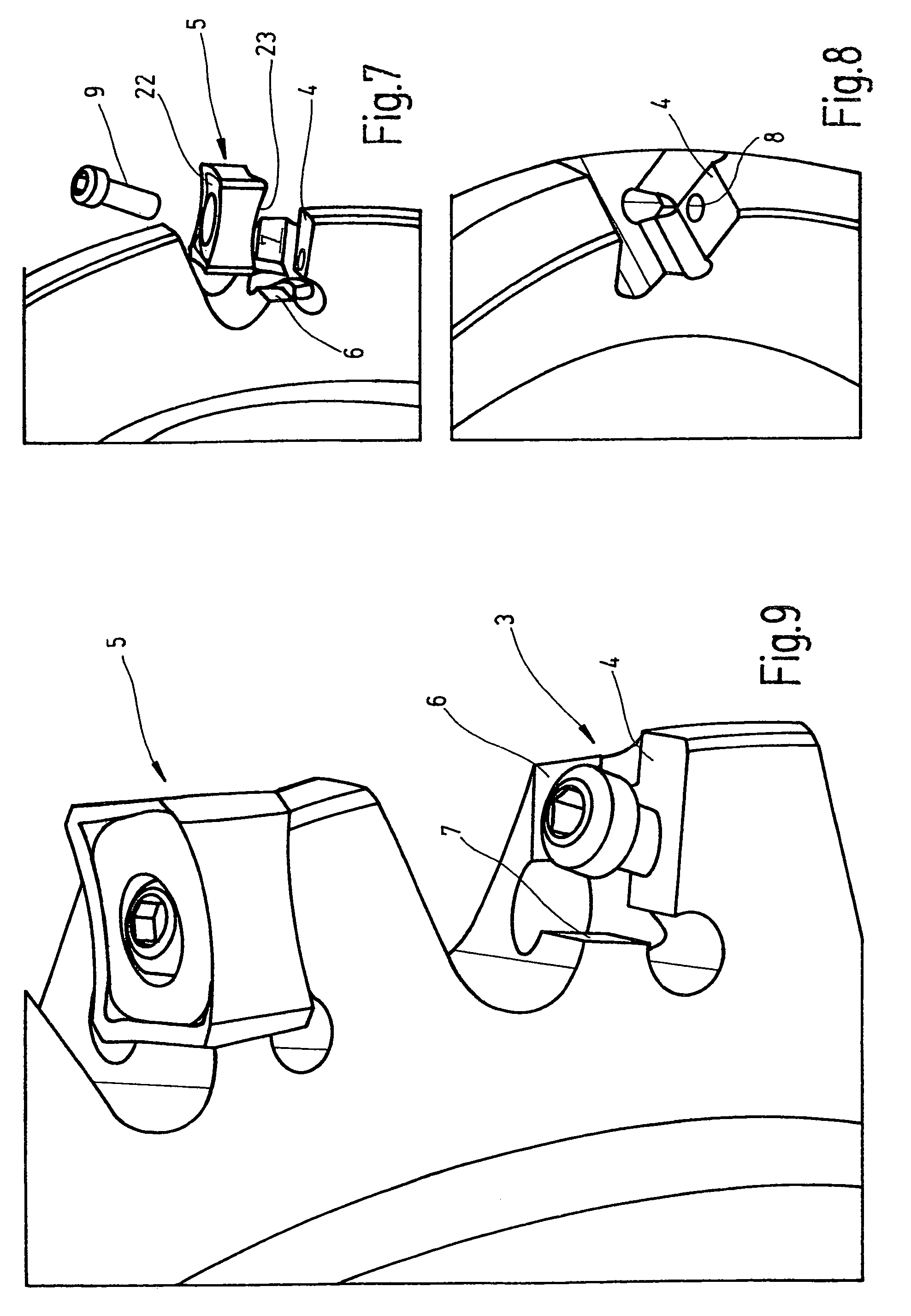

Drill having radially overlapping indexable cutting inserts

A drill includes a shank, a central insert and a peripheral insert. The shank defines a central axis of rotation and has pockets which carry the peripheral and central inserts. Chip flutes are formed in an outer periphery of the shank for conducting chips cut by the respective inserts. The peripheral insert includes a first operative cutting edge, and the central insert includes a second operative cutting edge which overlaps the first cutting edge at an overlap region. The central insert forms a rake surface adjacent to the second cutting edge. The rake surface includes a first portion disposed at the overlap region, and a second portion disposed at the axis of rotation of the shank. The first portion has a larger rake angle than the second portion.

Owner:SECO TOOLS AB

Construction saw blade

A construction saw blade having pluralities of cutting teeth along upper and lower edge surfaces thereof, an aperture transversely extending through the blade adjacent its rearwardly facing back end of a configuration and dimension to receive a fastener to removably secure the blade to a reciprocating saw for use, and wherein each plurality of cutting teeth include rake angles for cutting substantially only on a pull stroke of the reciprocating saw.

Owner:HAWTHORN JOHN E

PDC drill bit using optimized side rake angle

ActiveUS20060180356A1Performance can be improved and optimizedImprove performanceDrill bitsMetal-working drilling toolsRake anglePetroleum engineering

A fixed cutter drill bit and a method for designing a fixed cutter drill bit includes simulating the fixed cutter drill bit drilling in an earth formation. A performance characteristic of the simulated fixed cutter drill bit is determined. A side rake angle distribution of the cutters is adjusted at least along a cone region of a blade of the fixed cutter drill bit to change the performance characteristic of the fixed cutter drill bit.

Owner:SMITH INT INC

Tooth form design for reciprocating saw blade

A reciprocating saw has a tooth form that decreases the cutting time of the saw blade and extends the life of the saw blade. The tooth height is longer than conventional metal cutting reciprocating saws. Also, the tooth form has a larger gullet. The tooth rake angle remains substantially constant during the life of the saw blade.

Owner:BLACK & DECKER INC

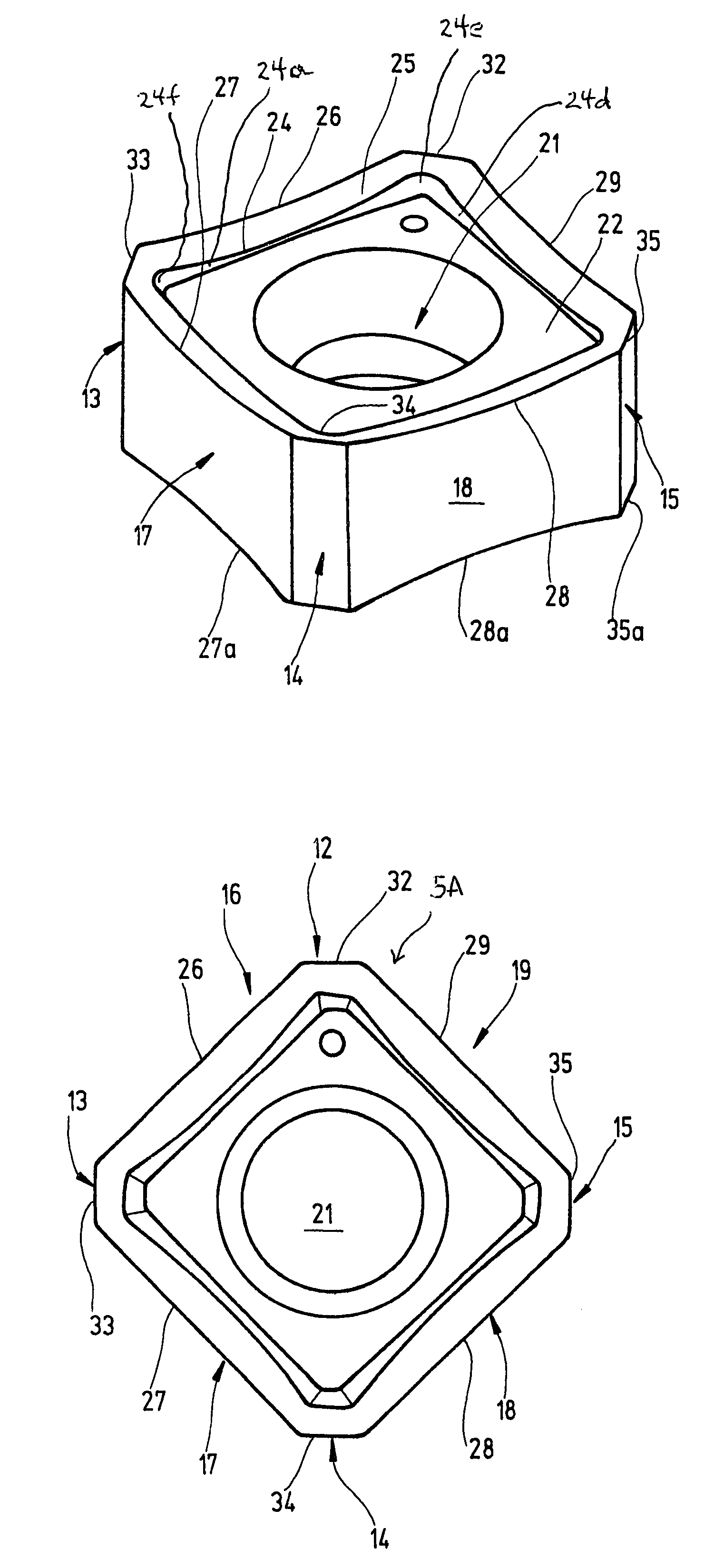

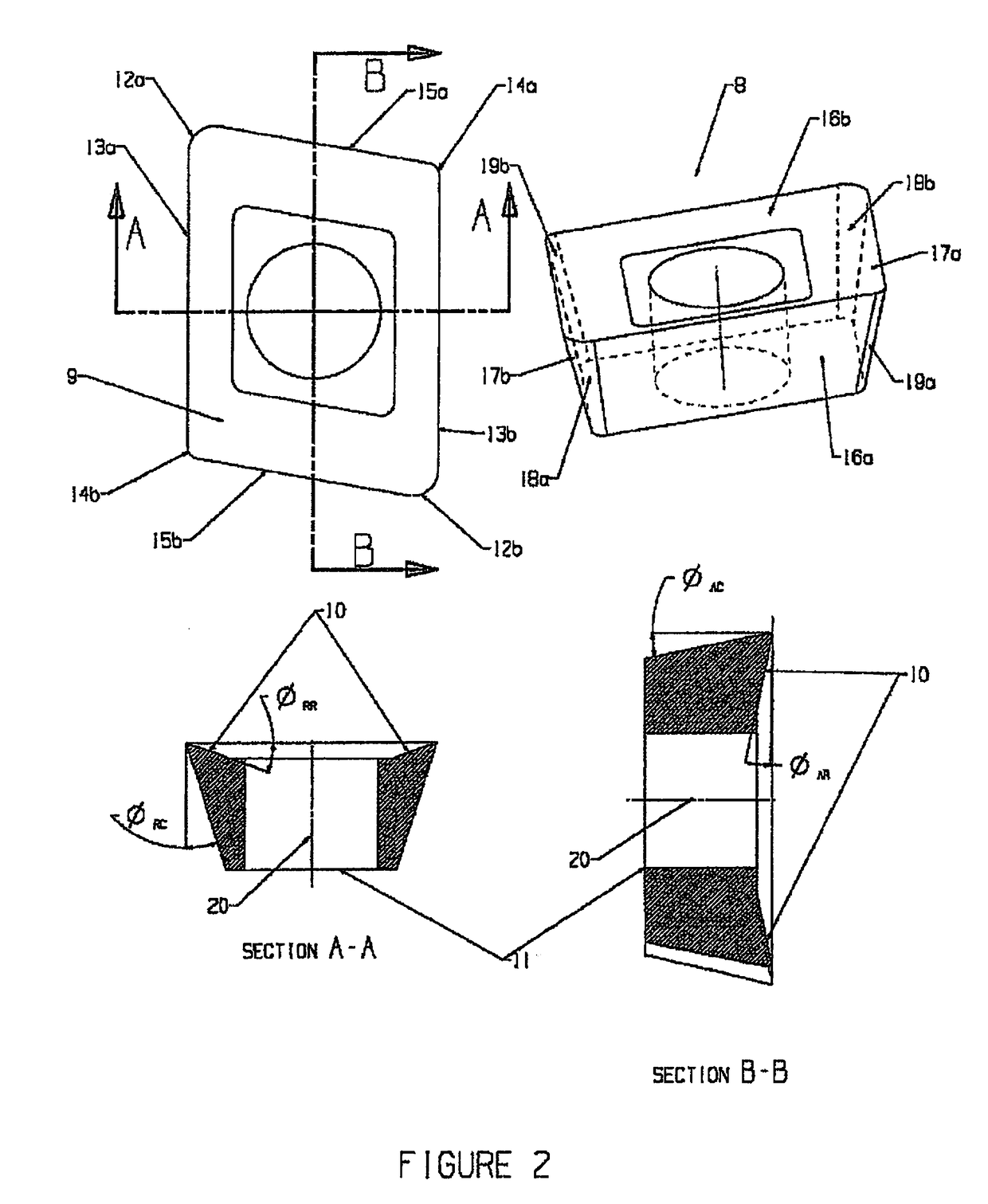

Cutting insert having a rake surface and a plateau surface separated by a step

ActiveUS7306409B2Convenient heightImprove protectionTransportation and packagingMilling cuttersMilling cutterPlateau

A cutting insert intended exemplarily for use in a face-milling cutter, has an all-around extending rake surface which changes into a plateau surface by an uninterrupted step. The step reaches its greatest height in the corner regions of the cutting insert. The rake surface defines a positive rake angle. The step prevents the produced chips from running onto the plateau surface. As a result of such a measure, a smear-on of material onto the plateau surface from a chip is prevented.

Owner:WALTER AG

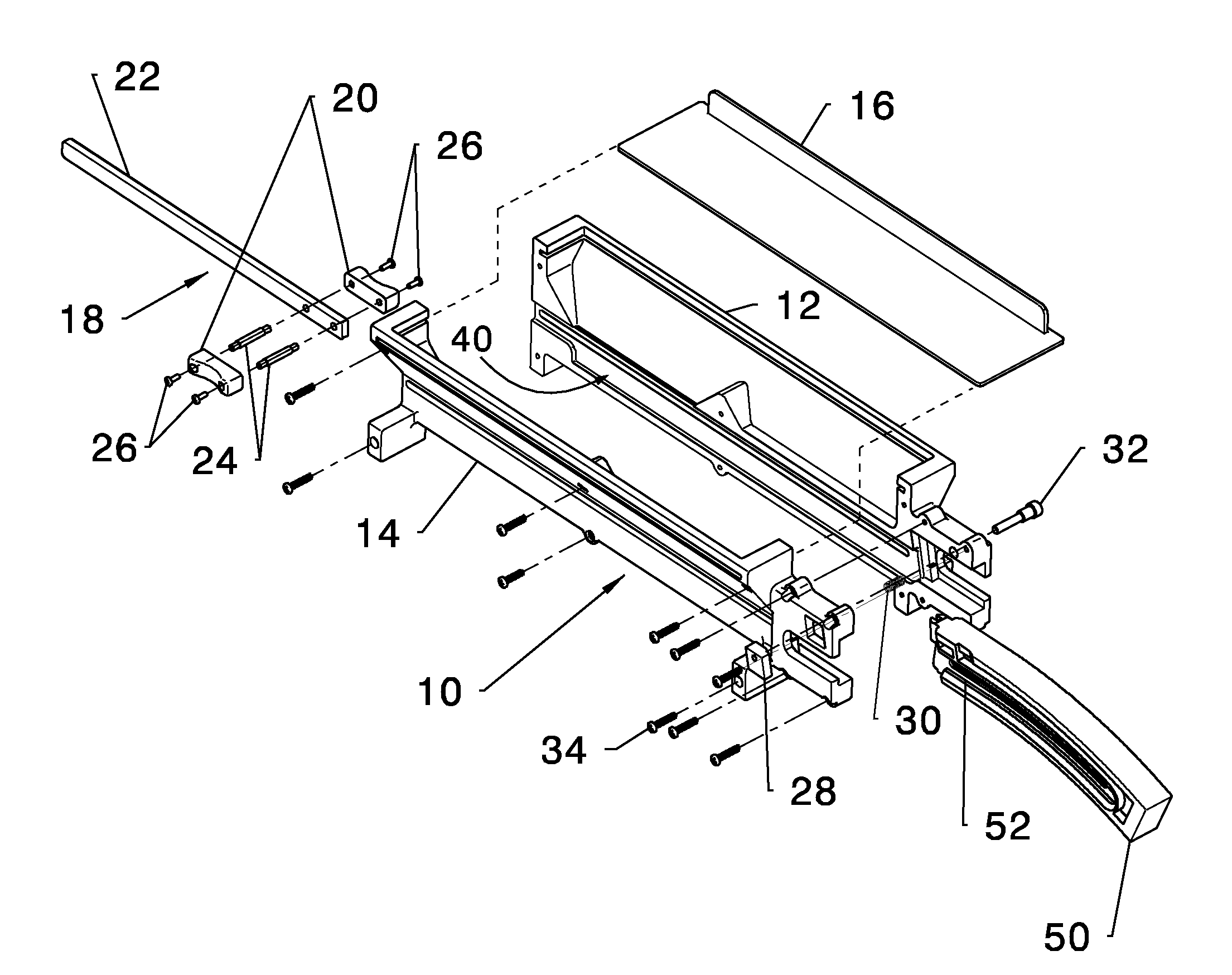

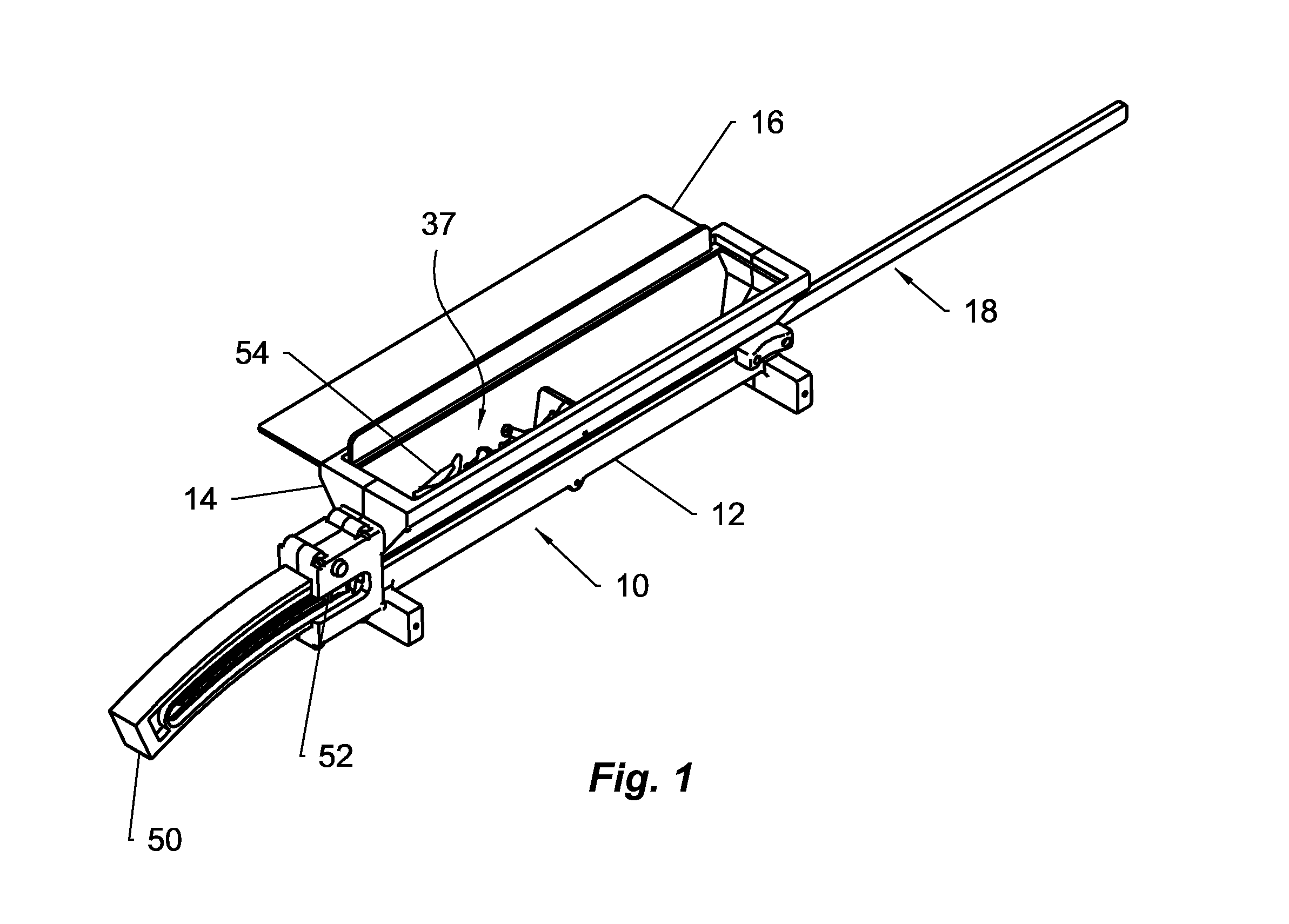

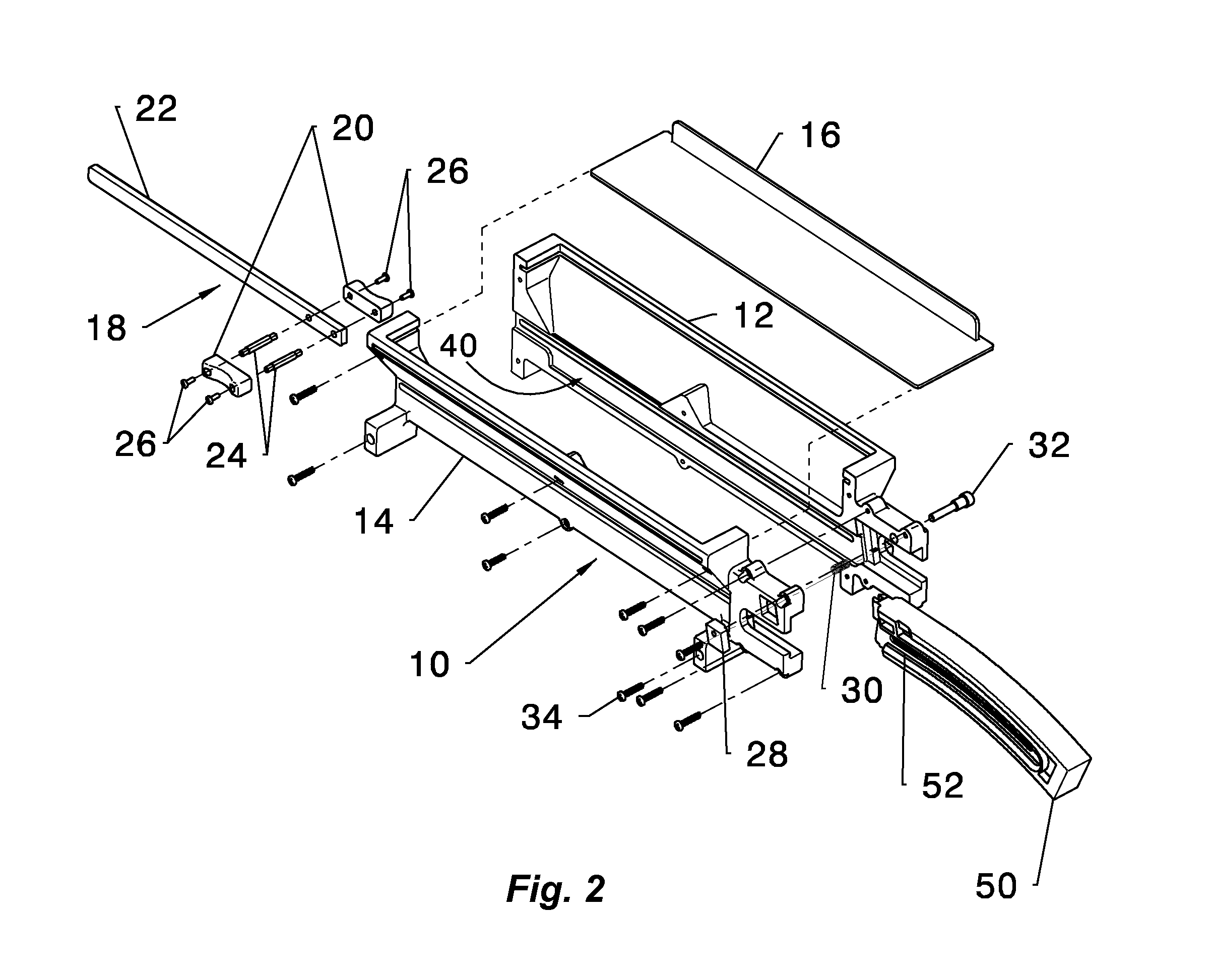

Gun magazine speed loader and methods

InactiveUS20140033592A1Avoid disorientationFast loadingAmmunition loadingDental ArticulatorsEngineering

A gun magazine speed loader that can load an entire magazine simply by pulling the magazines external follower in a downward motion. Rimmed cartridges are aligned nose down and side-by-side in a loading channel and the magazine and speed loader are then tipped up toward a vertical position with the magazine below the loader. By passing the stream of cartridges through an “articulator” that articulates the nose of the cartridge and feeds cartridges ‘rim-first’ and up through feed lips and into the magazine, the cartridges fill the magazine in a continuous stream, essentially at the speed of gravity-falling cartridges under control of the external follower. The articulator has no moving parts and operates with rimmed cartridges and with curved or low-rake angle magazines having an external follower.

Owner:FIORUCCI DANA JOSEPH

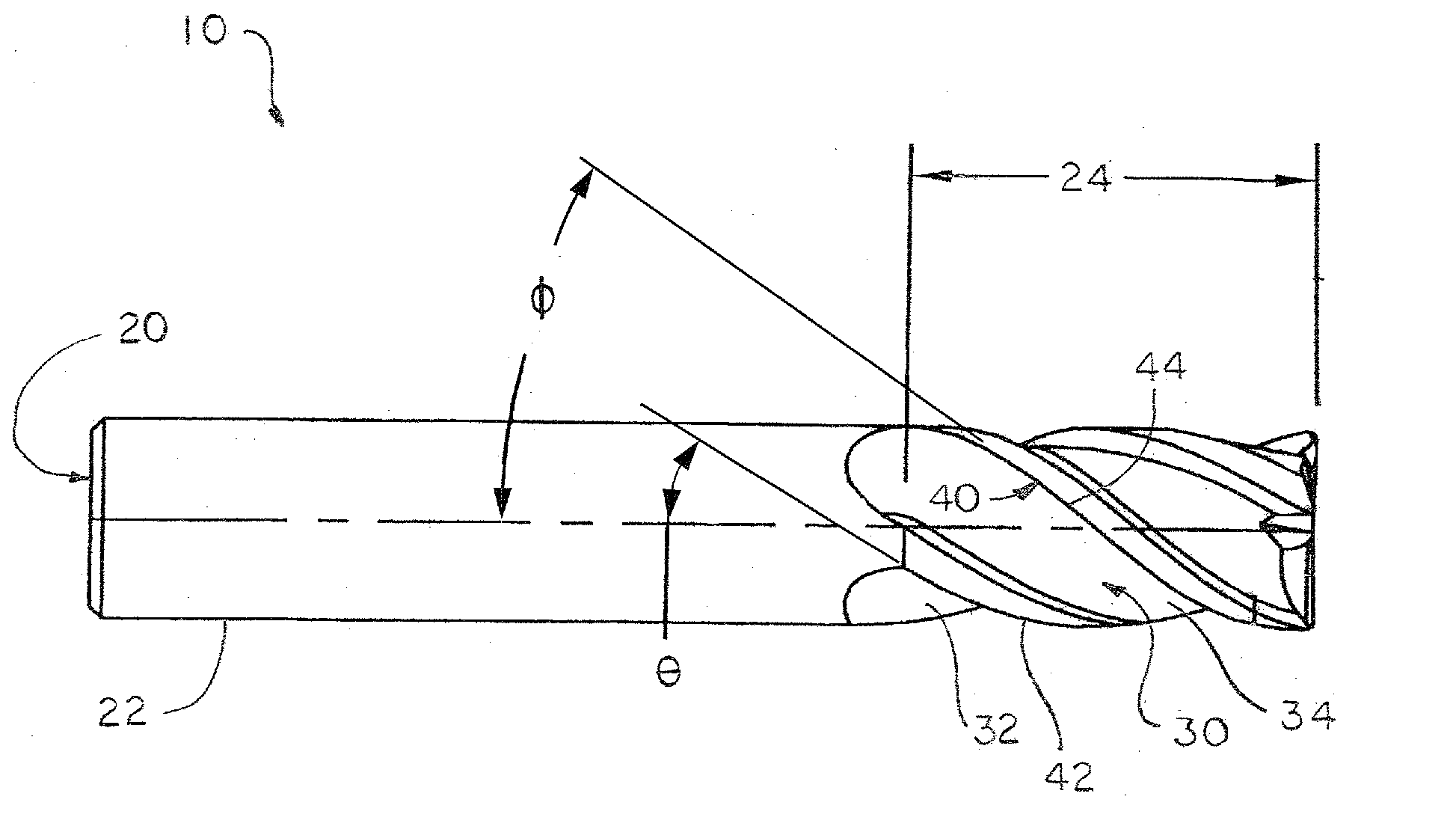

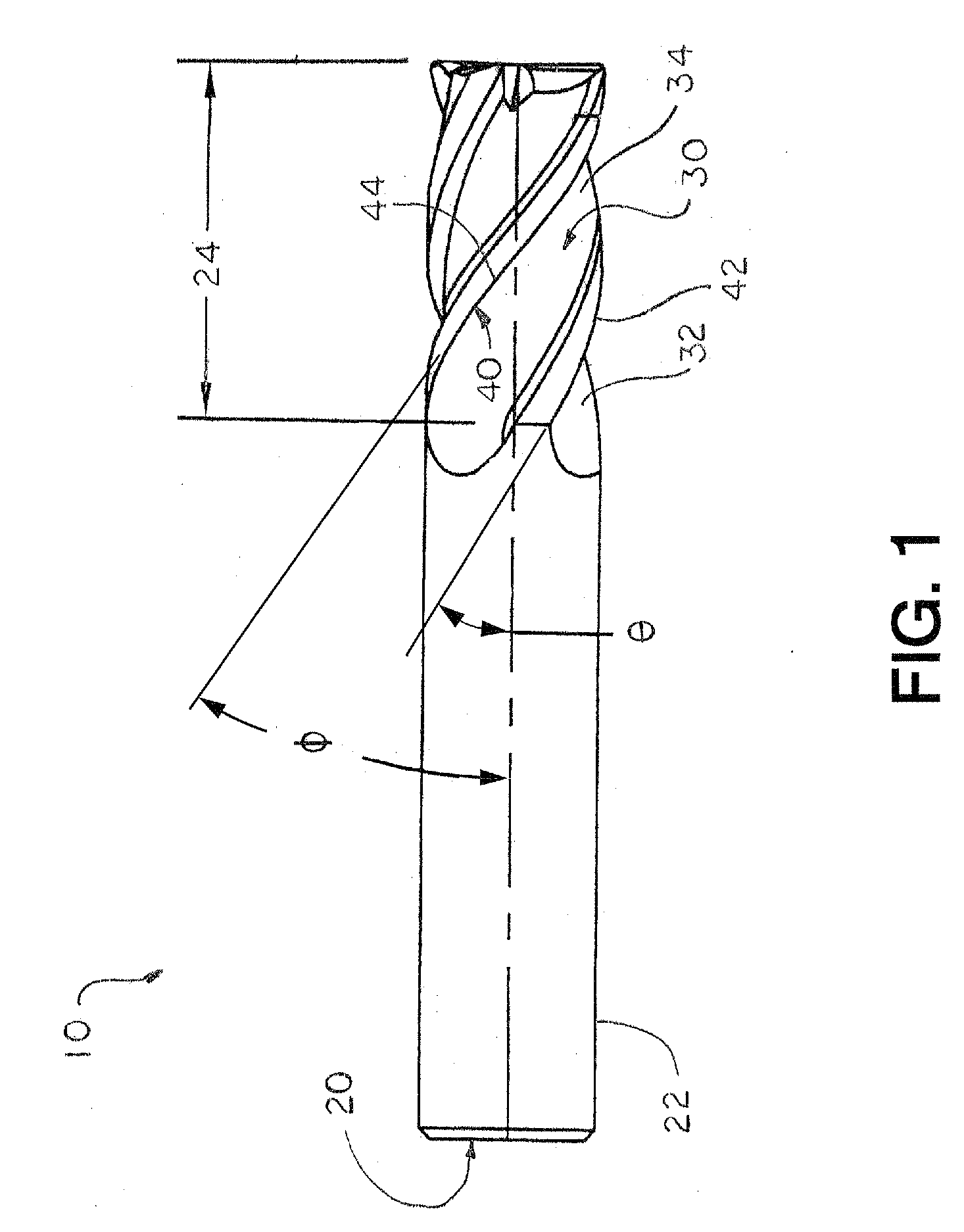

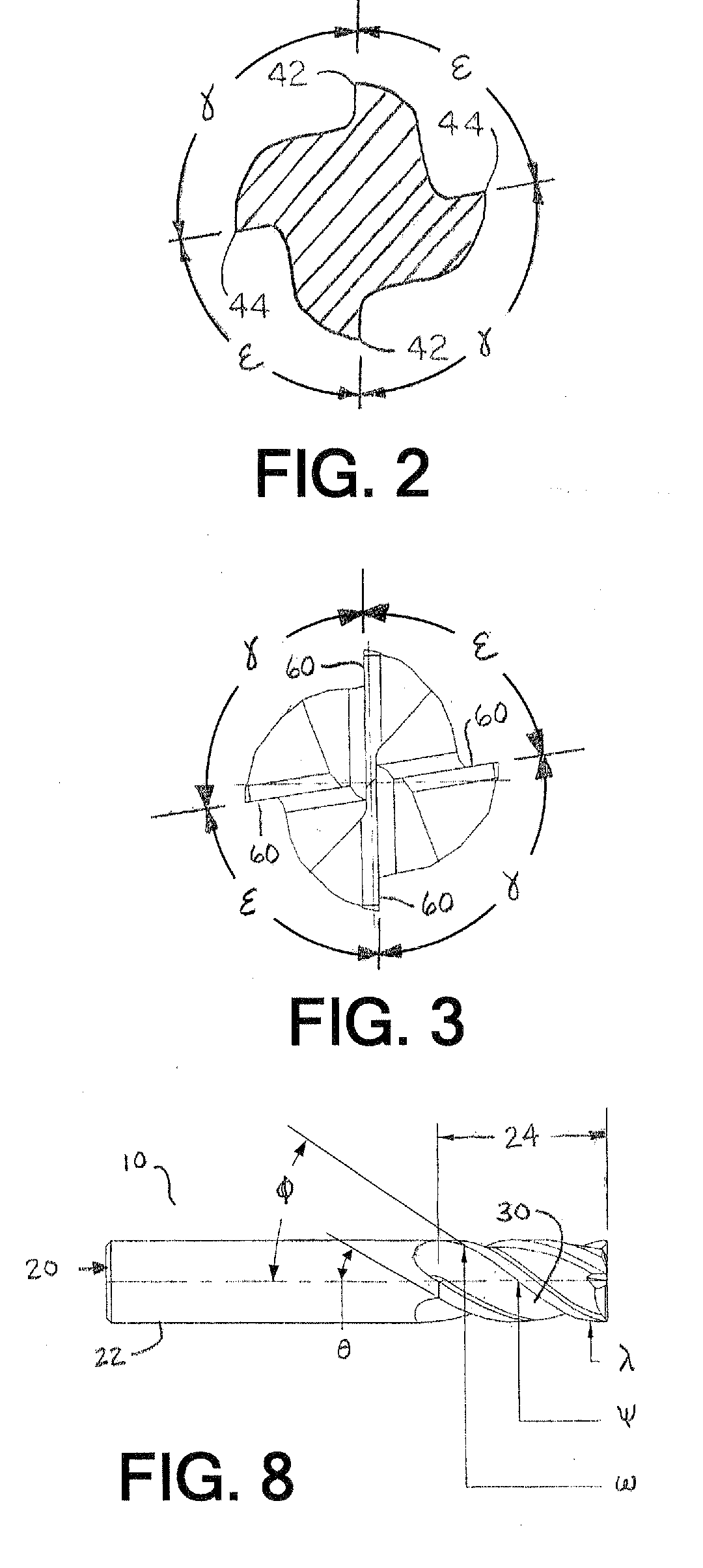

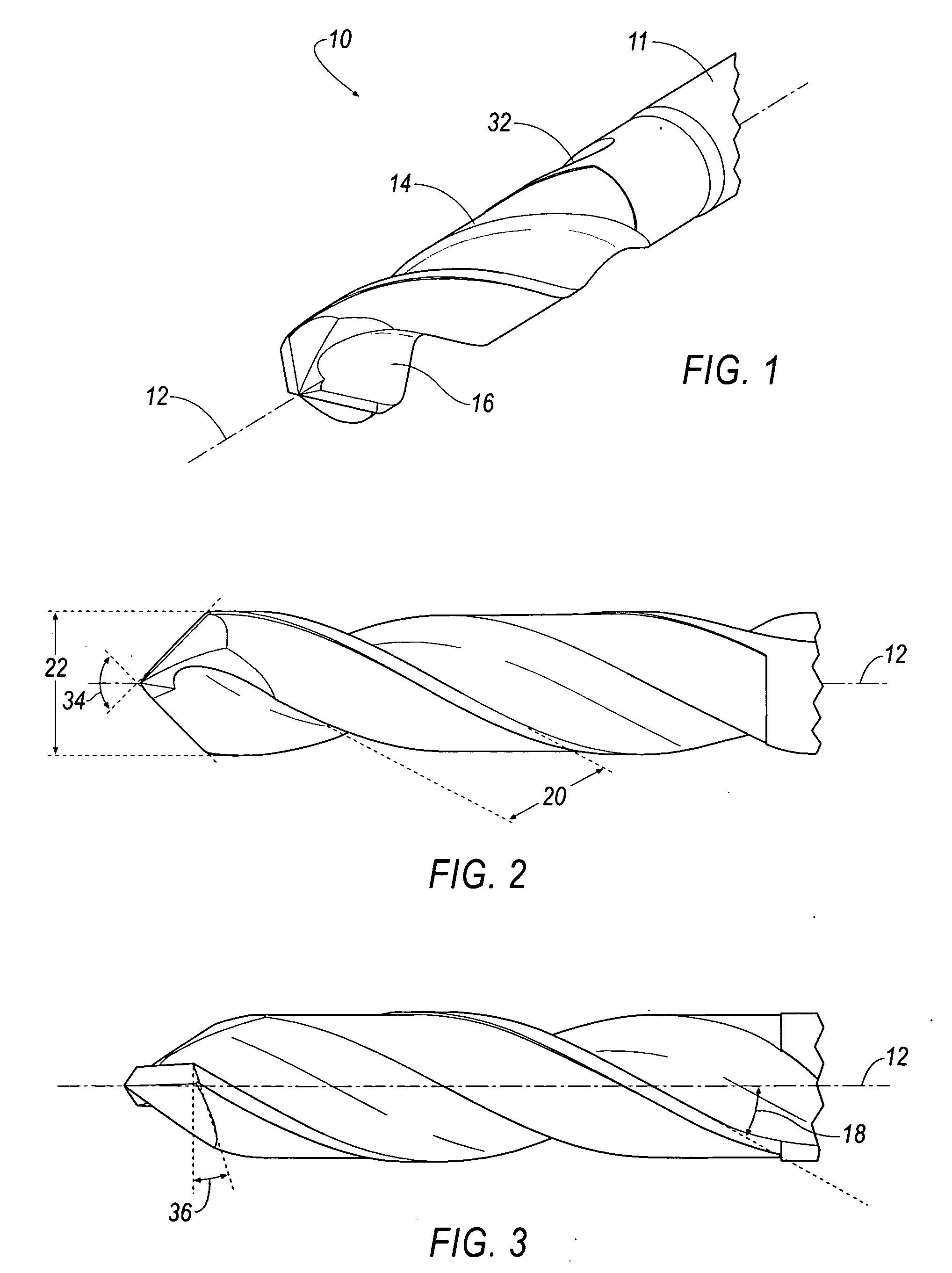

Rotary cutting tool

ActiveUS20070154272A1Overcome disadvantagesMilling cuttersAdverse effect compensationFluteRadial plane

A rotary cutting tool or end mill is provided, the tool comprising a plurality of pairs of diametrically-opposed, symmetrical, helical flutes formed in a cutting portion of the tool body, wherein the pitch between at least one pair of adjacent helical flutes is less than or greater than the pitch of at least one other pair of adjacent helical flutes in at least one radial plane along the axial length of the flutes, a plurality of peripheral cutting edges, wherein at least one of the peripheral cutting edges has a radial rake angle different from radial rake angle of a peripheral cutting edge of a different helical flute.

Owner:KYOCERA SGS PRECISION TOOLS INC

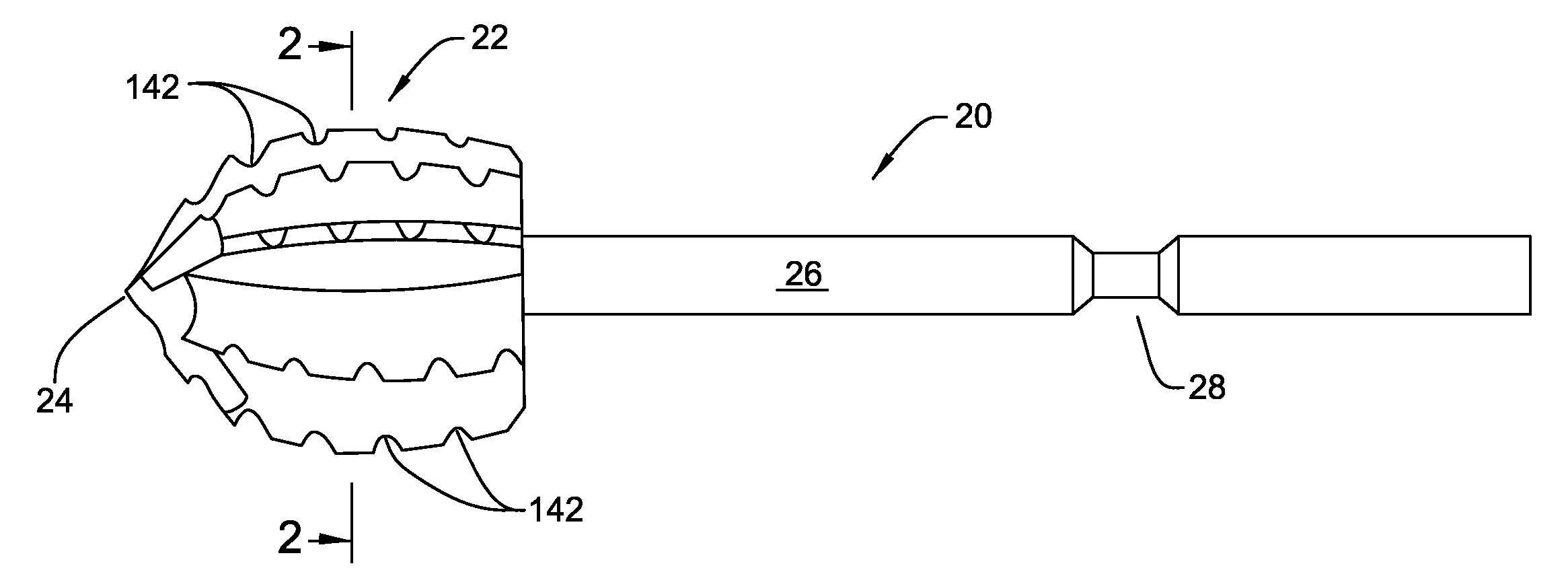

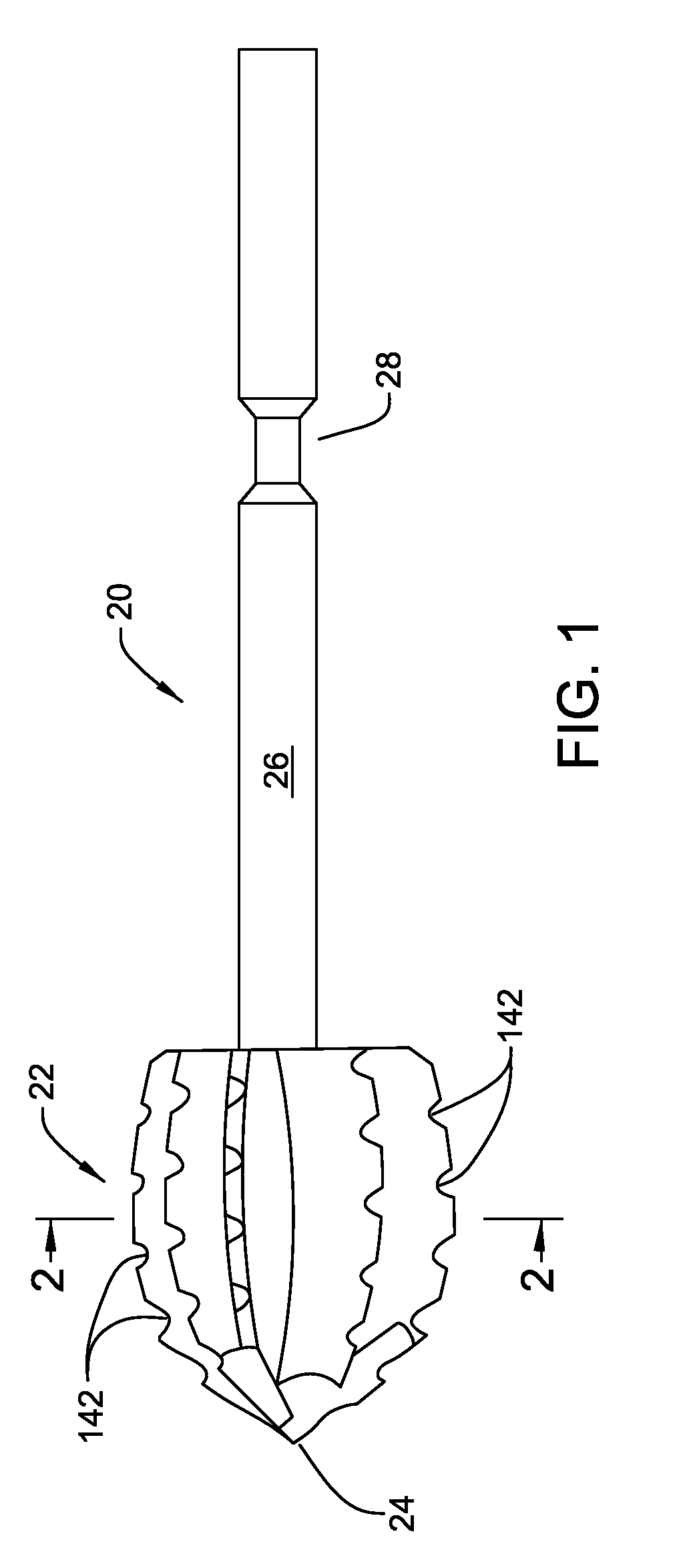

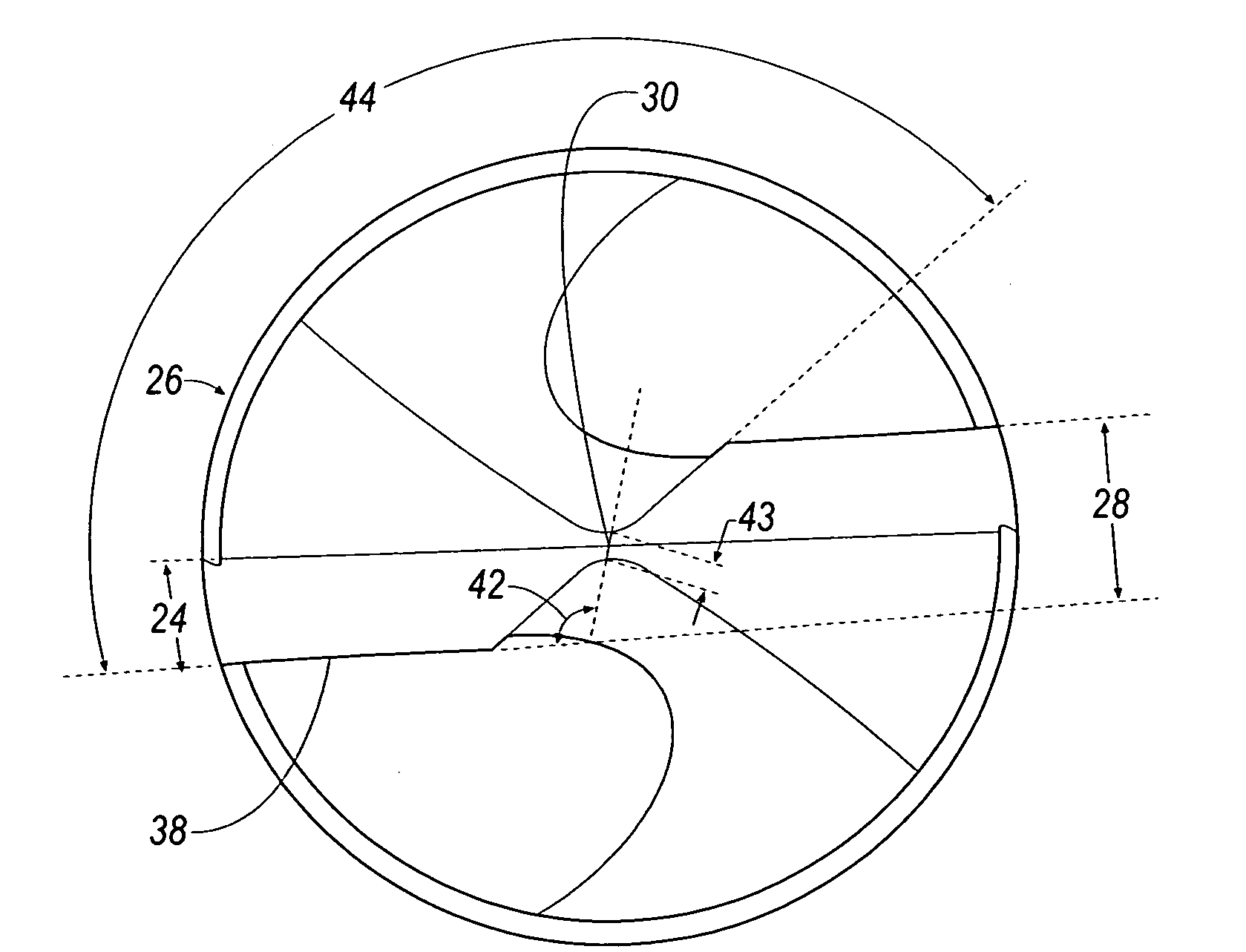

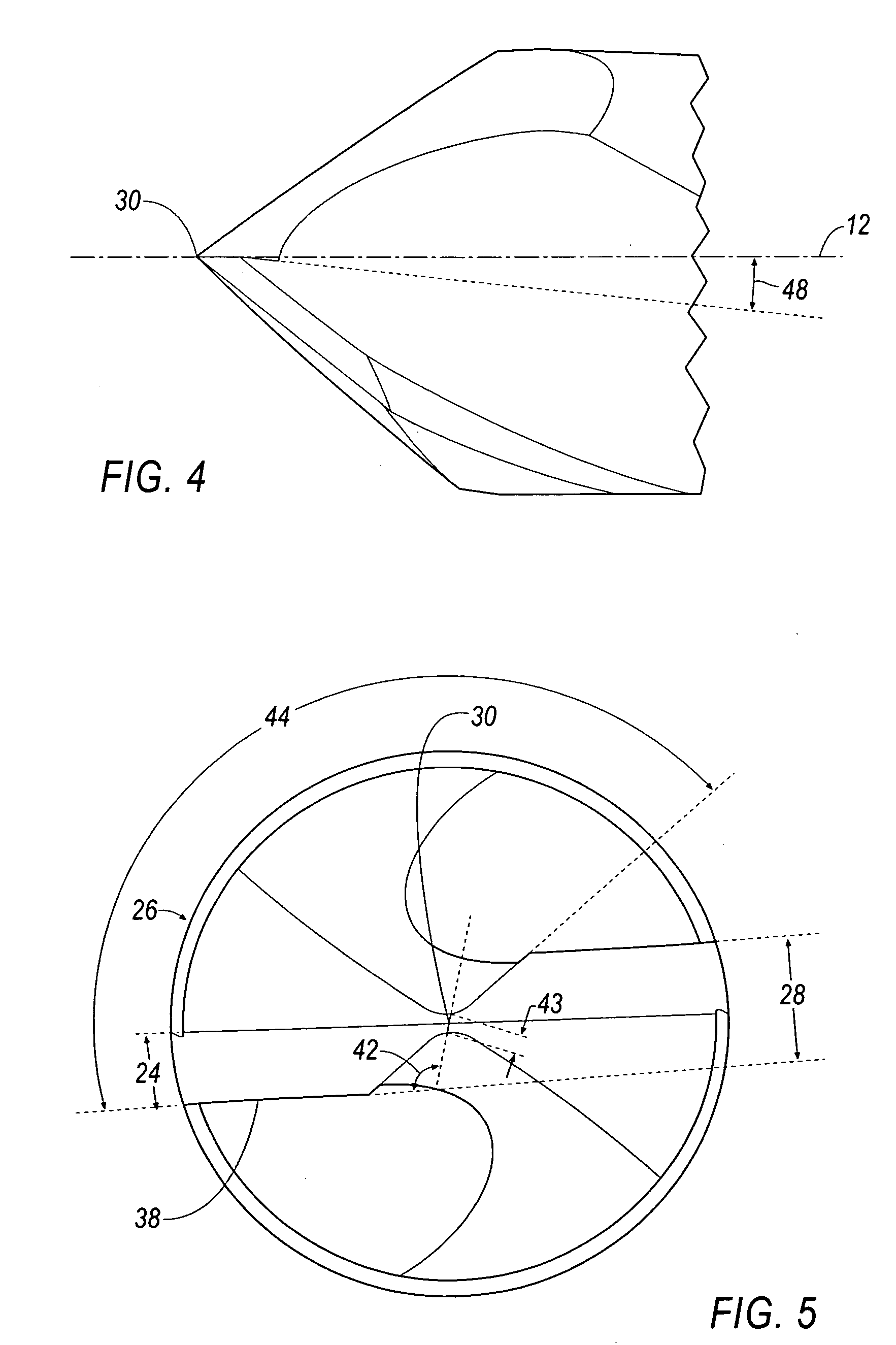

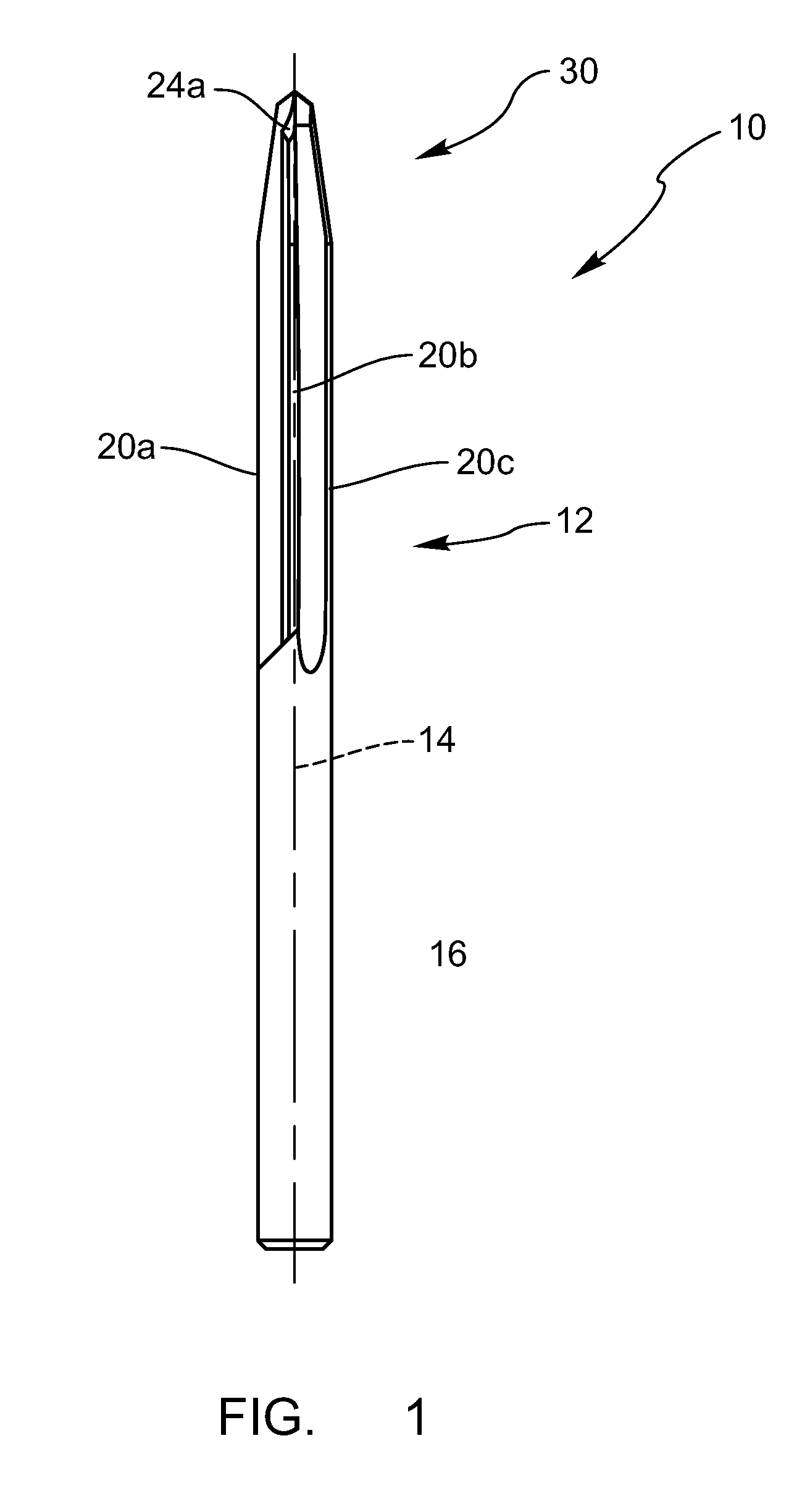

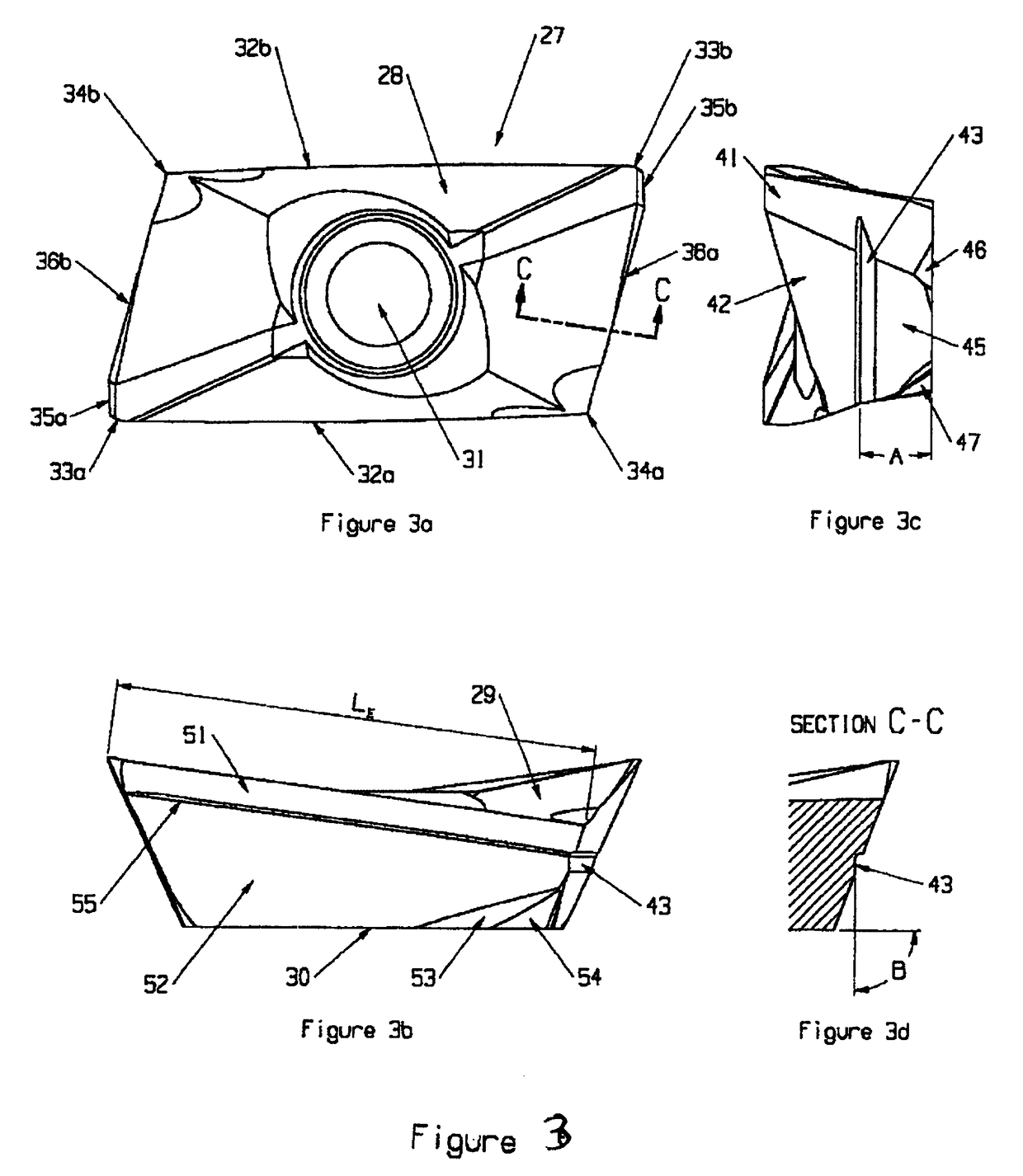

Surgical bur with unequally spaced flutes, flutes with different rake angles and flutes with alternating reliefs

A surgical bur including a shaft with a head on the distal end of the shaft. A number of flutes extend outwardly from the head, each flute having a rake surface and a clearance surface. On some flutes the rake and clearance surfaces meet to form the flute cutting edges. Other flutes have relief surfaces between the rake and cutting surfaces. On these flutes, the cutting edges are the edges where the rake and relief surfaces meet. The flutes are further designed to have rake angles that are less negative, than the flutes without the relief surfaces. The flutes are radially spaced apart around the head such that between any three adjacent flutes, the first and second flutes are spaced apart a first angle; the second and third flutes are spaced apart a second angle different from the first angle.

Owner:STRYKER EURO OPERATIONS HLDG LLC

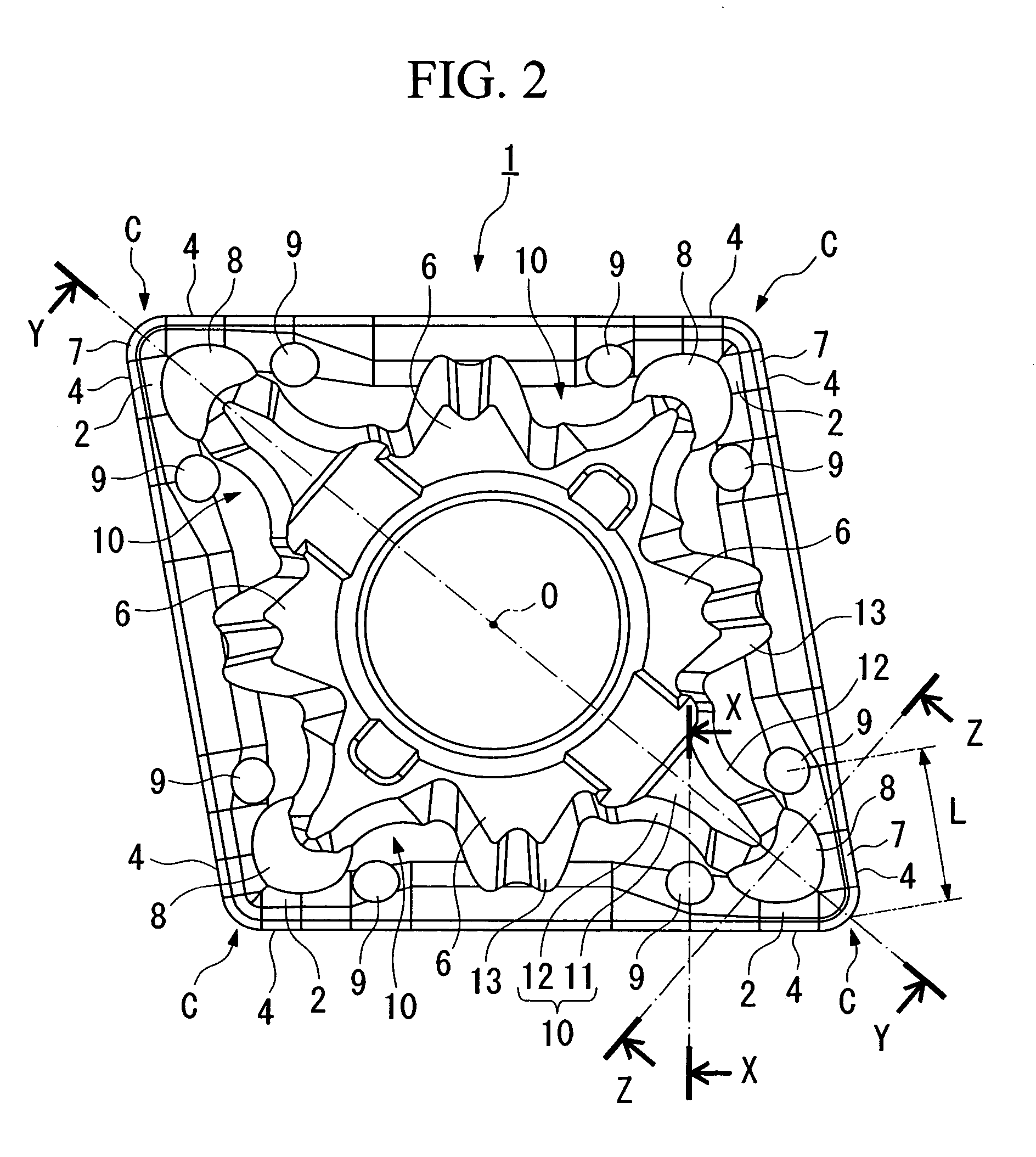

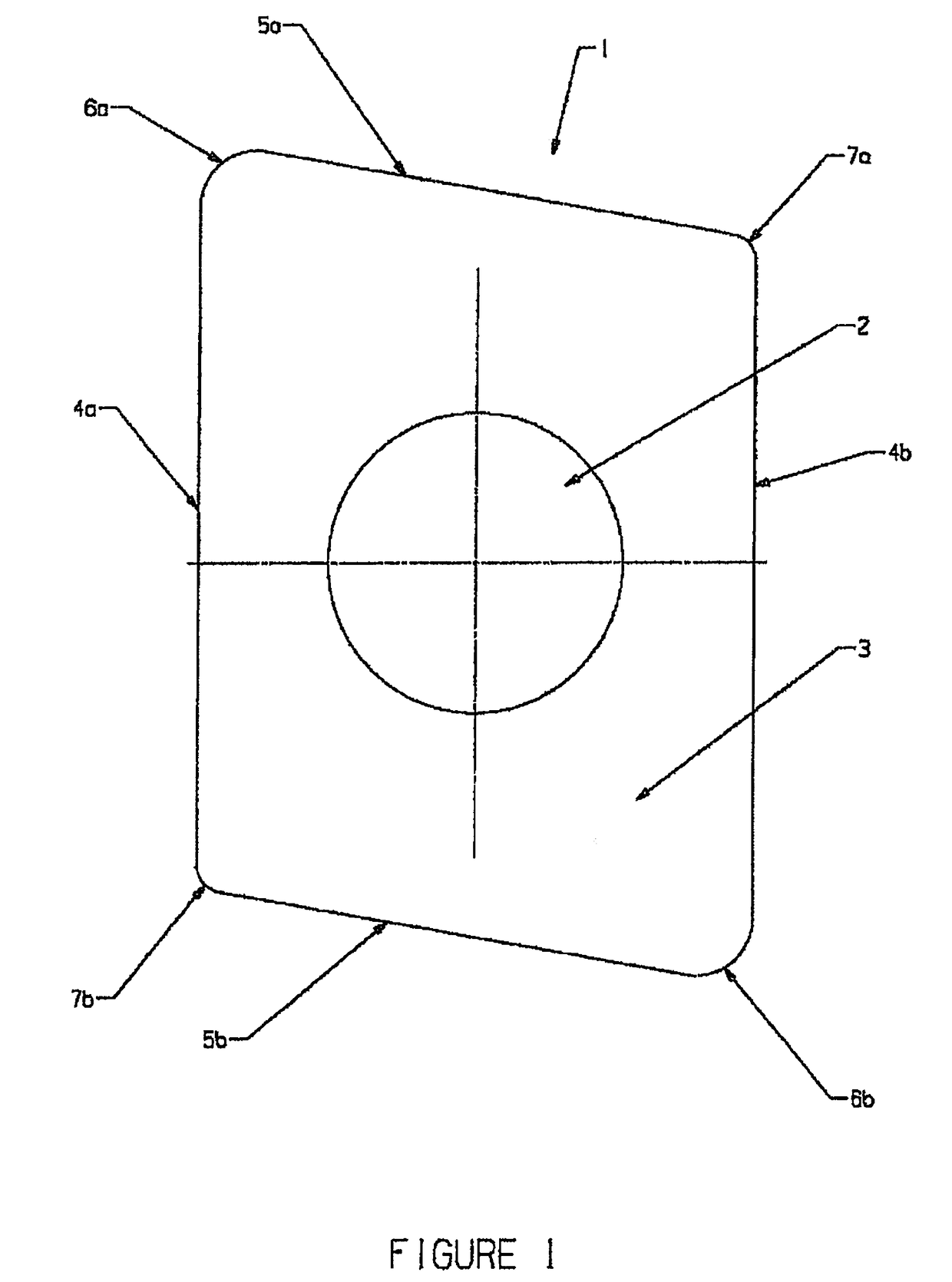

Indexable cutting insert with positive axial rake angle and multiple cutting edges

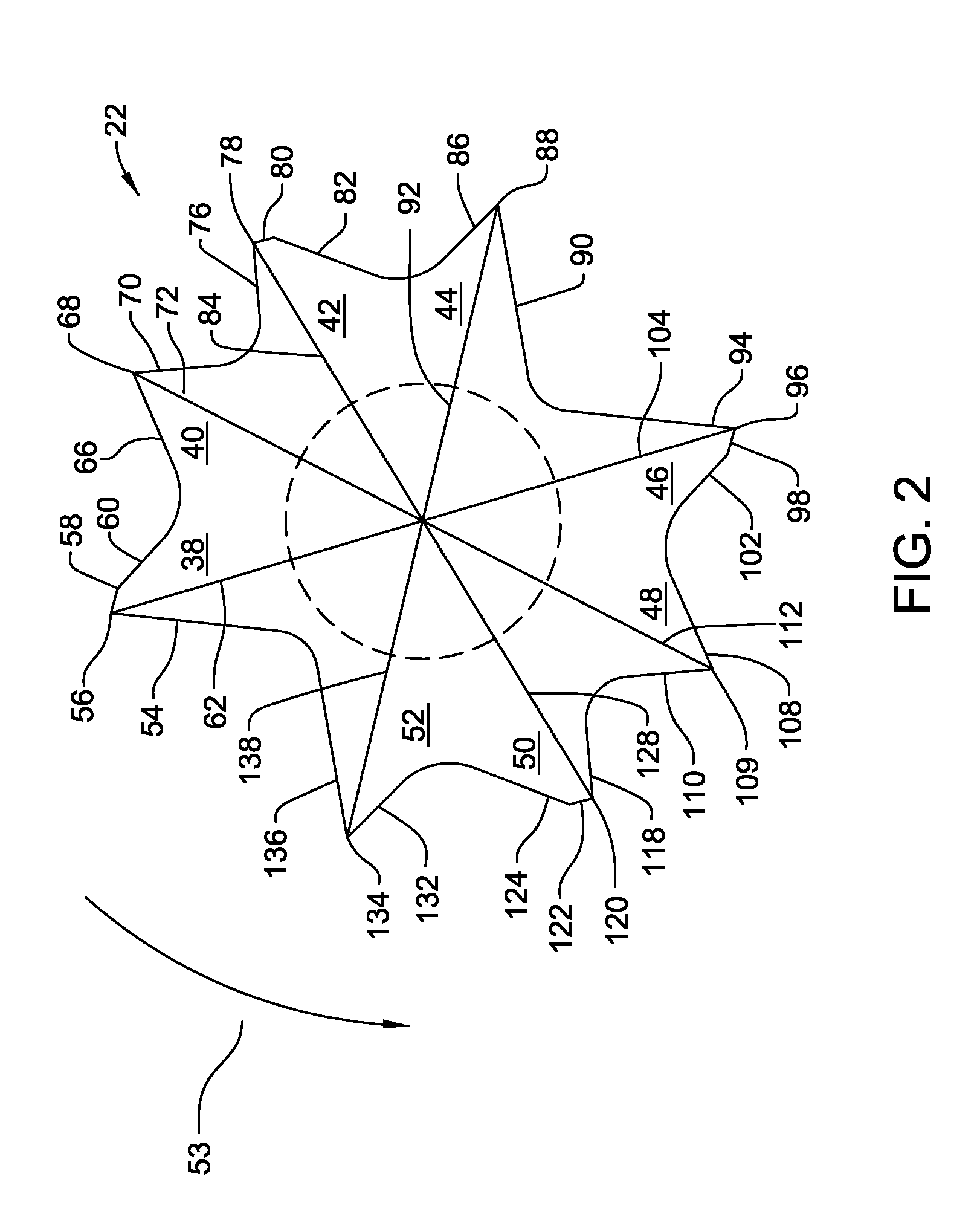

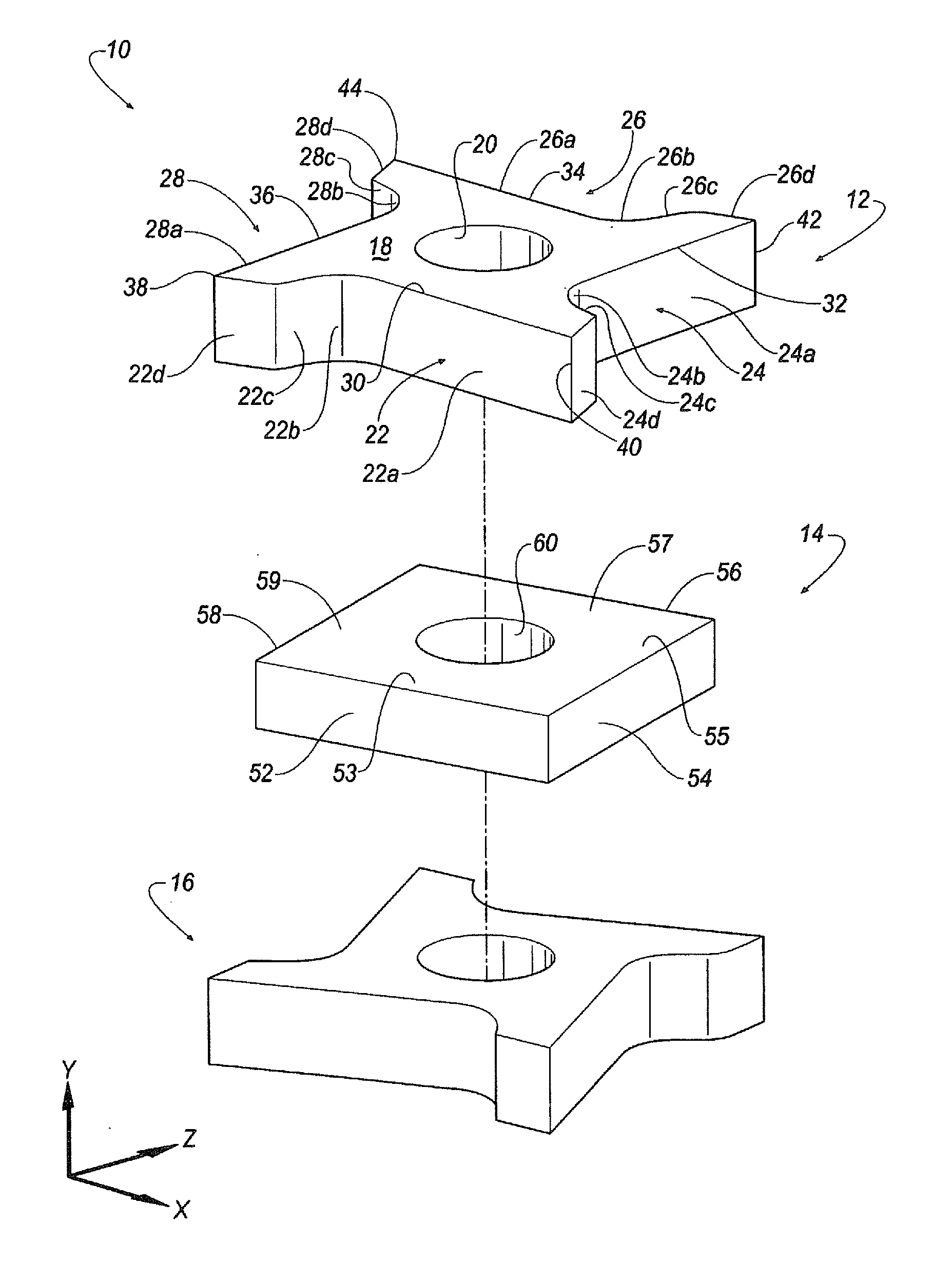

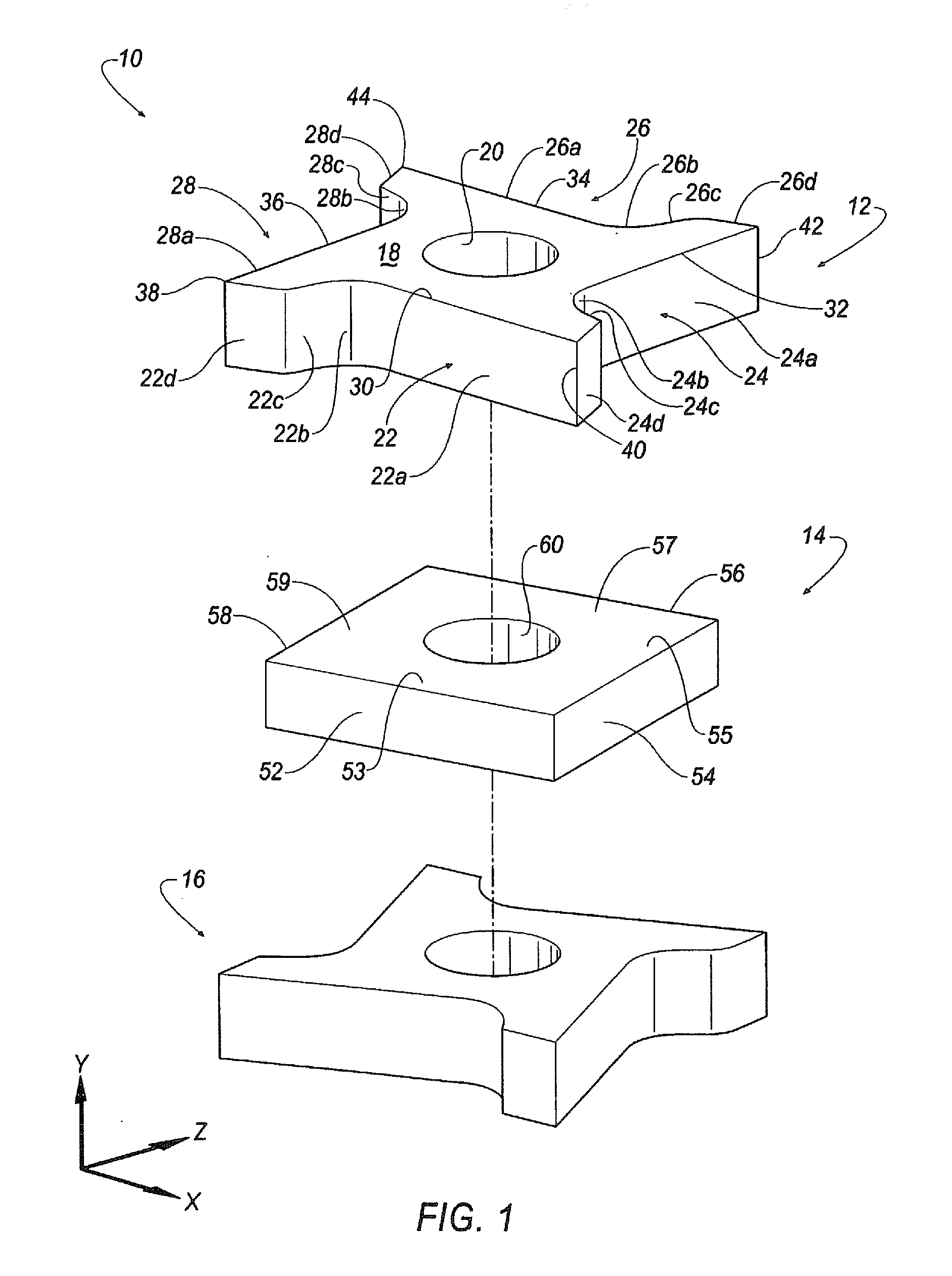

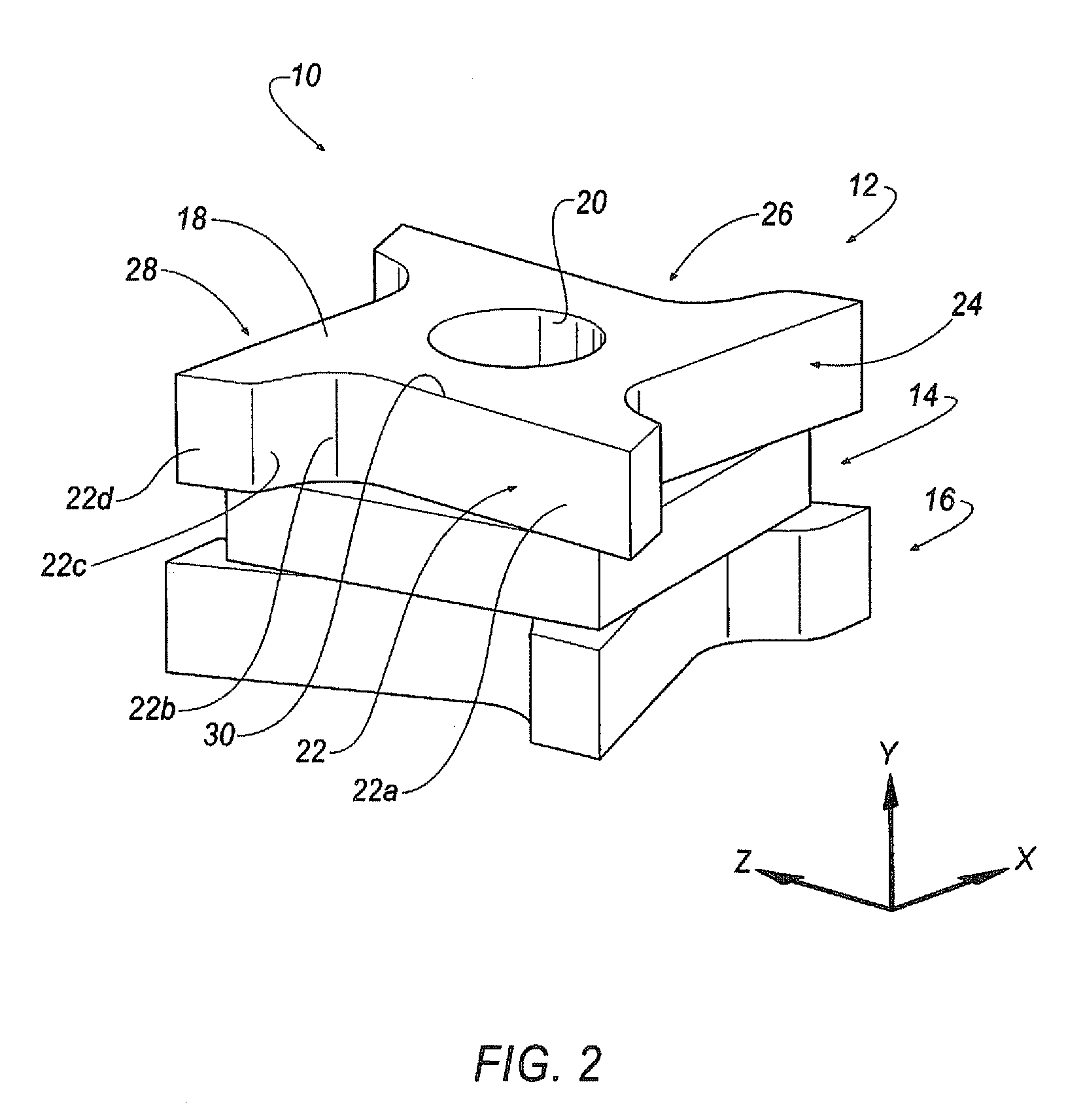

An indexable cutting insert includes a first component with an outer or top surface and side surfaces. A third component is mirror symmetric with respect to the first component about a vertical or y-axis of the cutting insert. A second component is disposed between the first and third components. Multiple cutting edges are defined at an intersection between the side surfaces and the top surface, wherein the cutting edges define a positive axial rake angle. In one embodiment, the first and third components are in the shape of a polygonal with a star appearance, and the second component is in the shape of a square. The first and third components are offset from one another by a first offset angle, while the second component is offset from the first and third components by a second offset angle to allow the cutting insert to be indexable.

Owner:KENNAMETAL INC

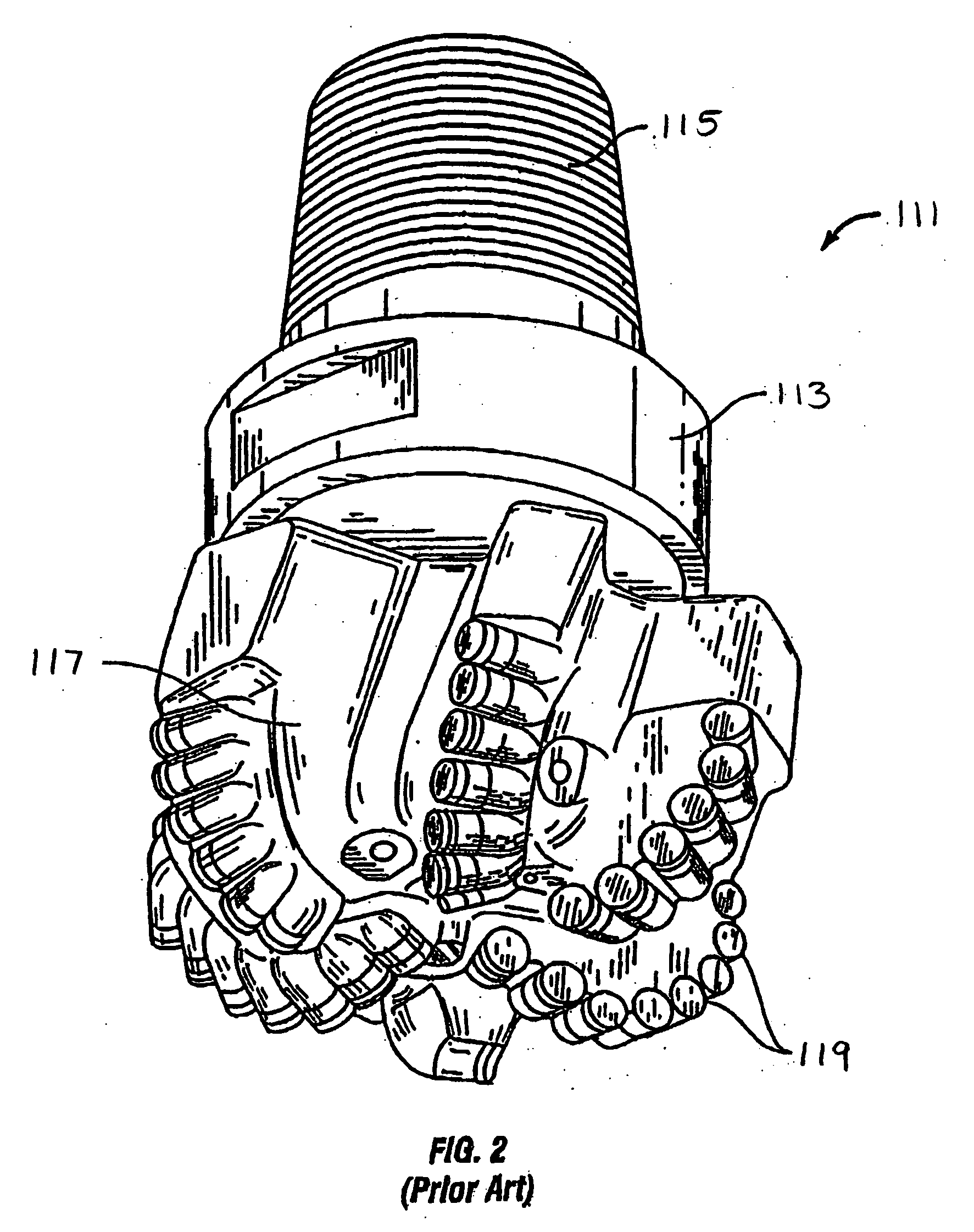

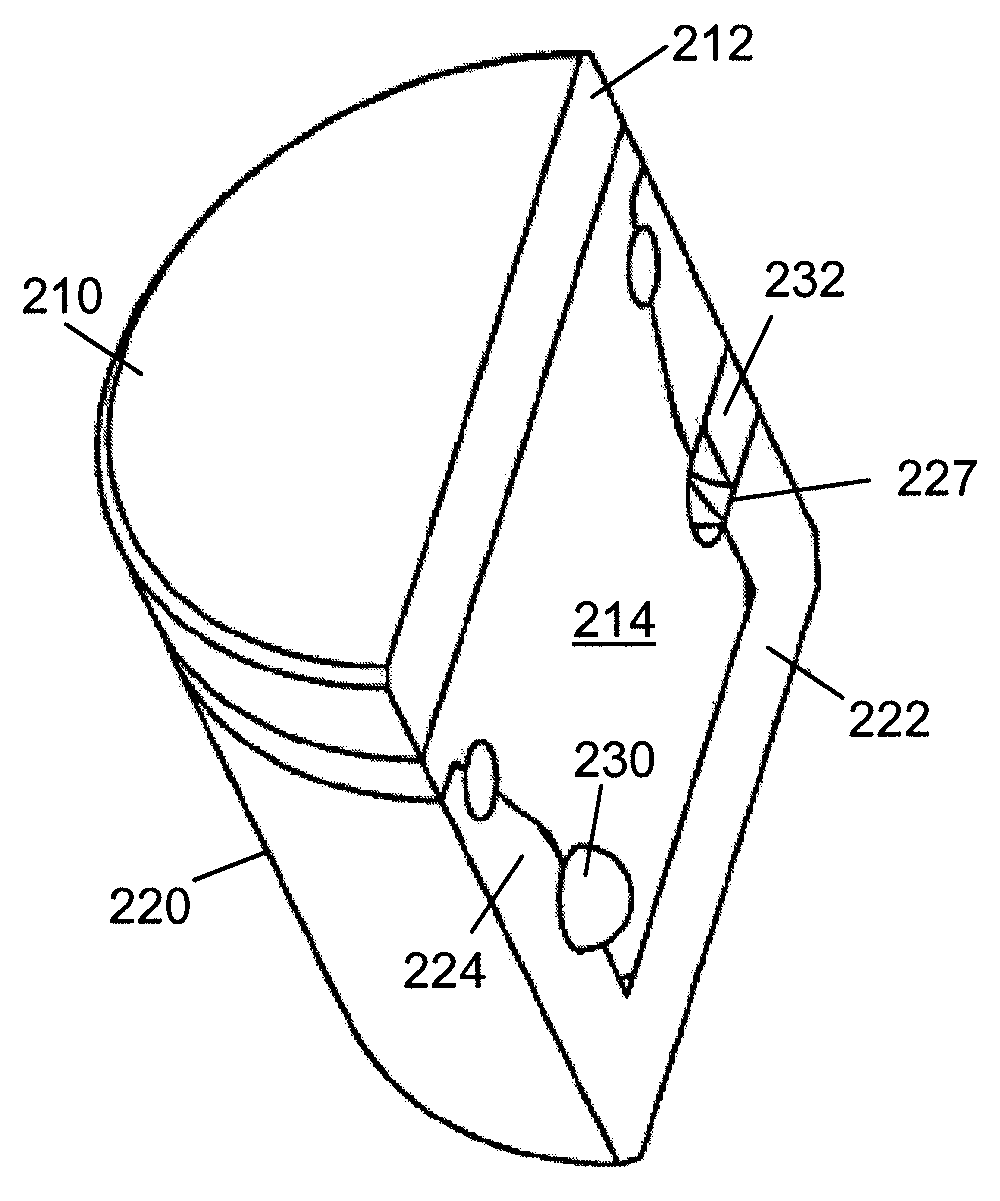

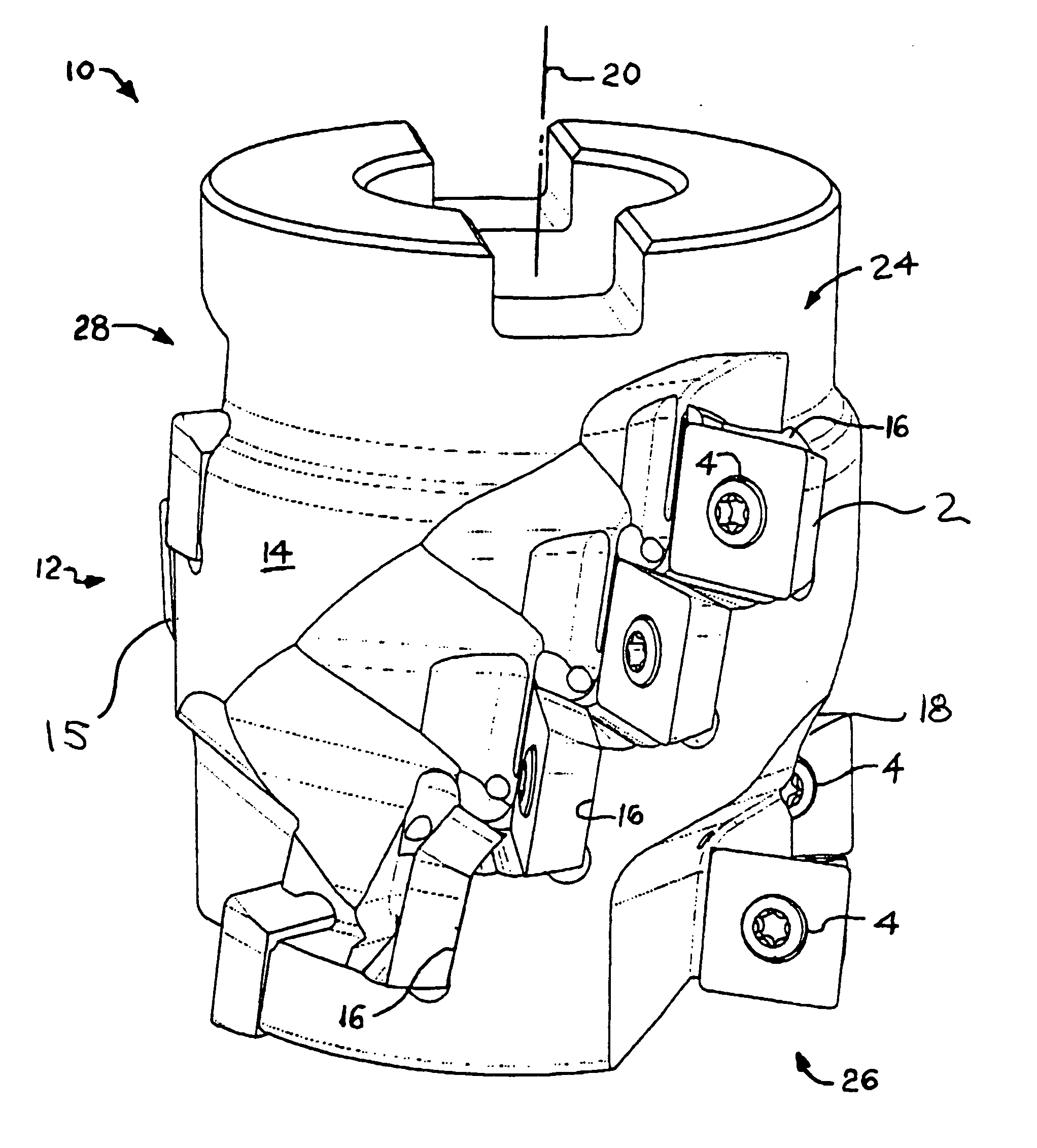

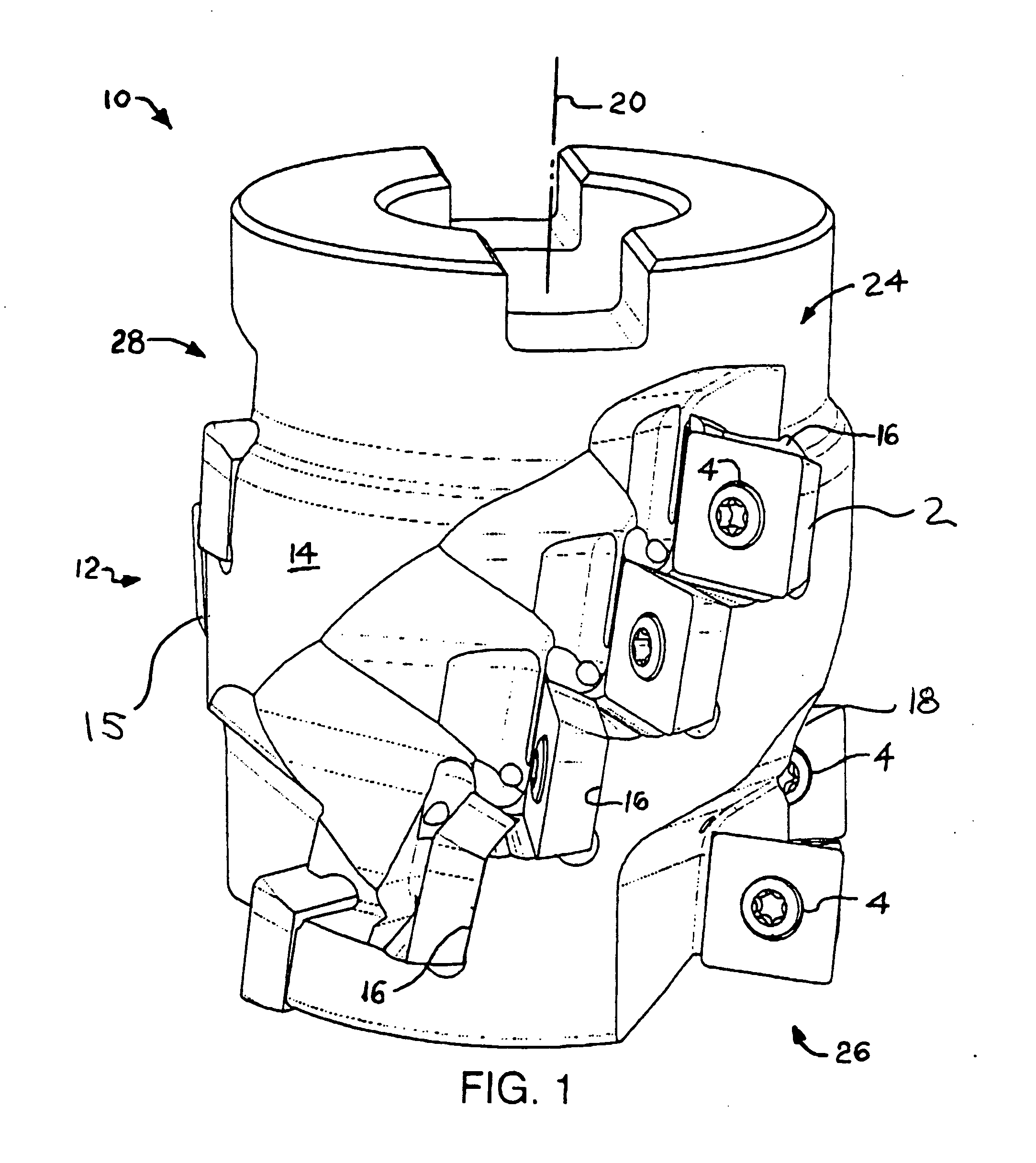

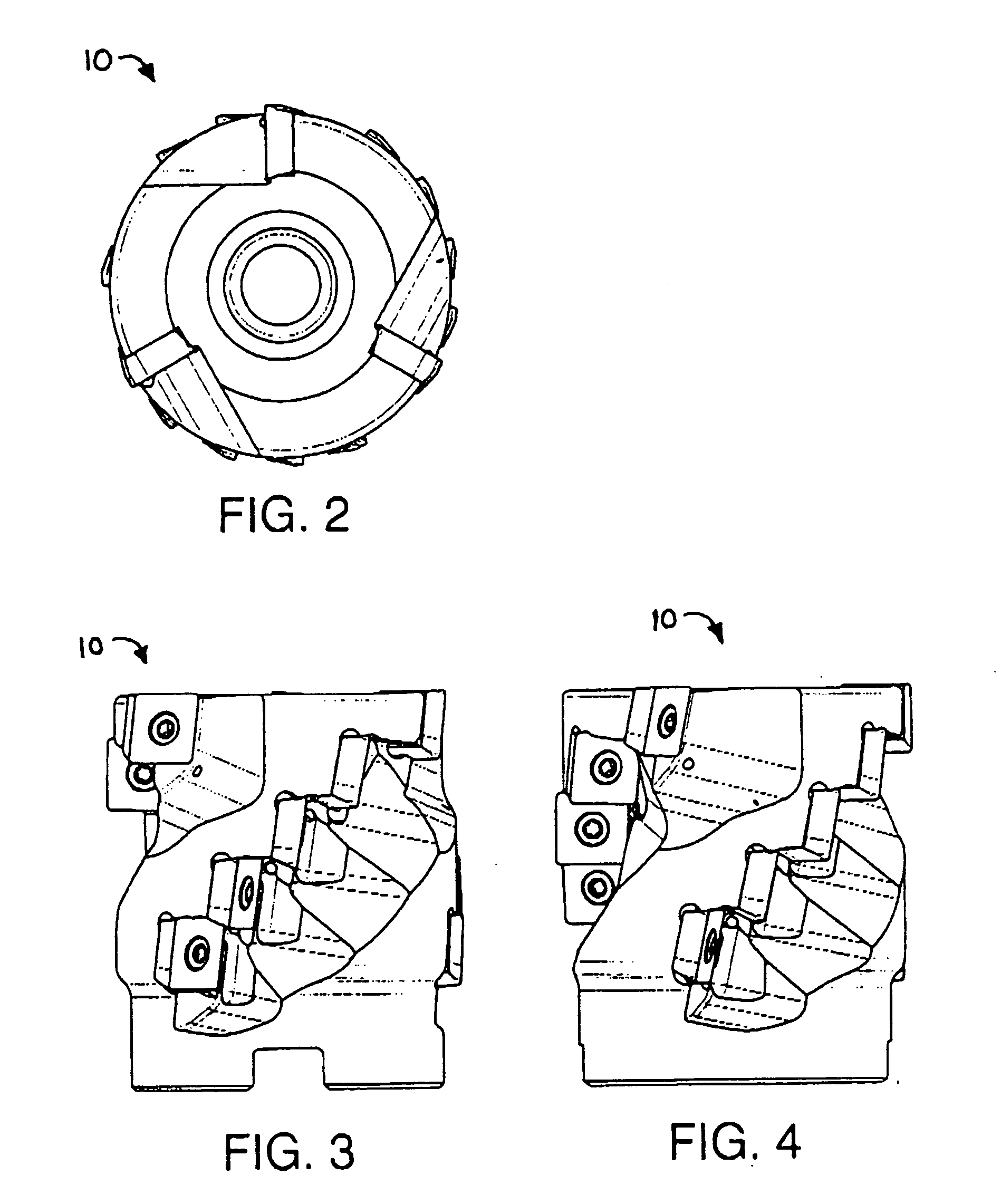

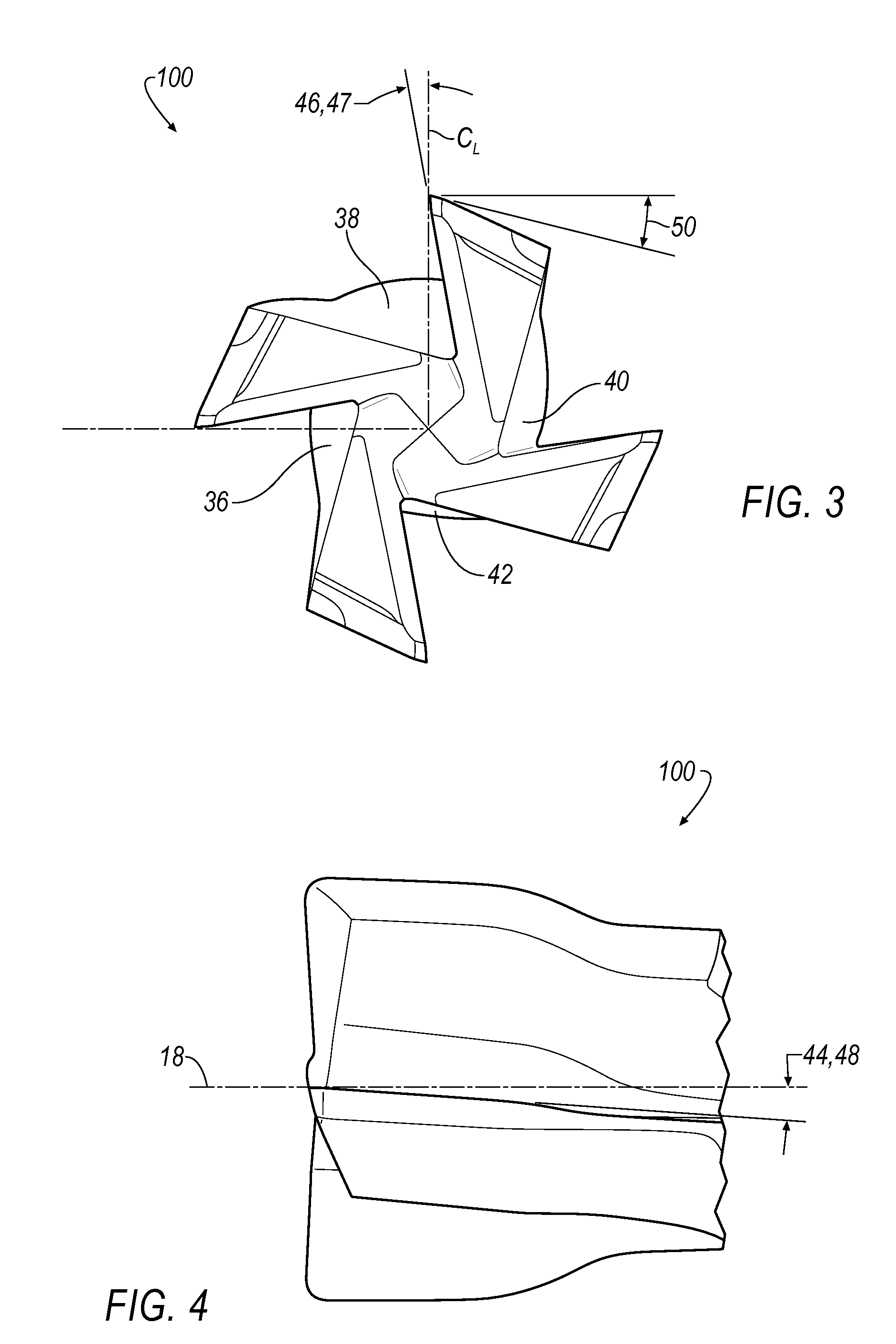

Rolling cutter bit design

A cutting tool having a tool body with a plurality of blades extending radially therefrom and a plurality of rotatable cutting elements mounted on at least one of the plurality of blades is disclosed, wherein the plurality of rotatable cutting elements are mounted on the at least one blade utilizing multiple side rake angles.

Owner:SMITH INT INC

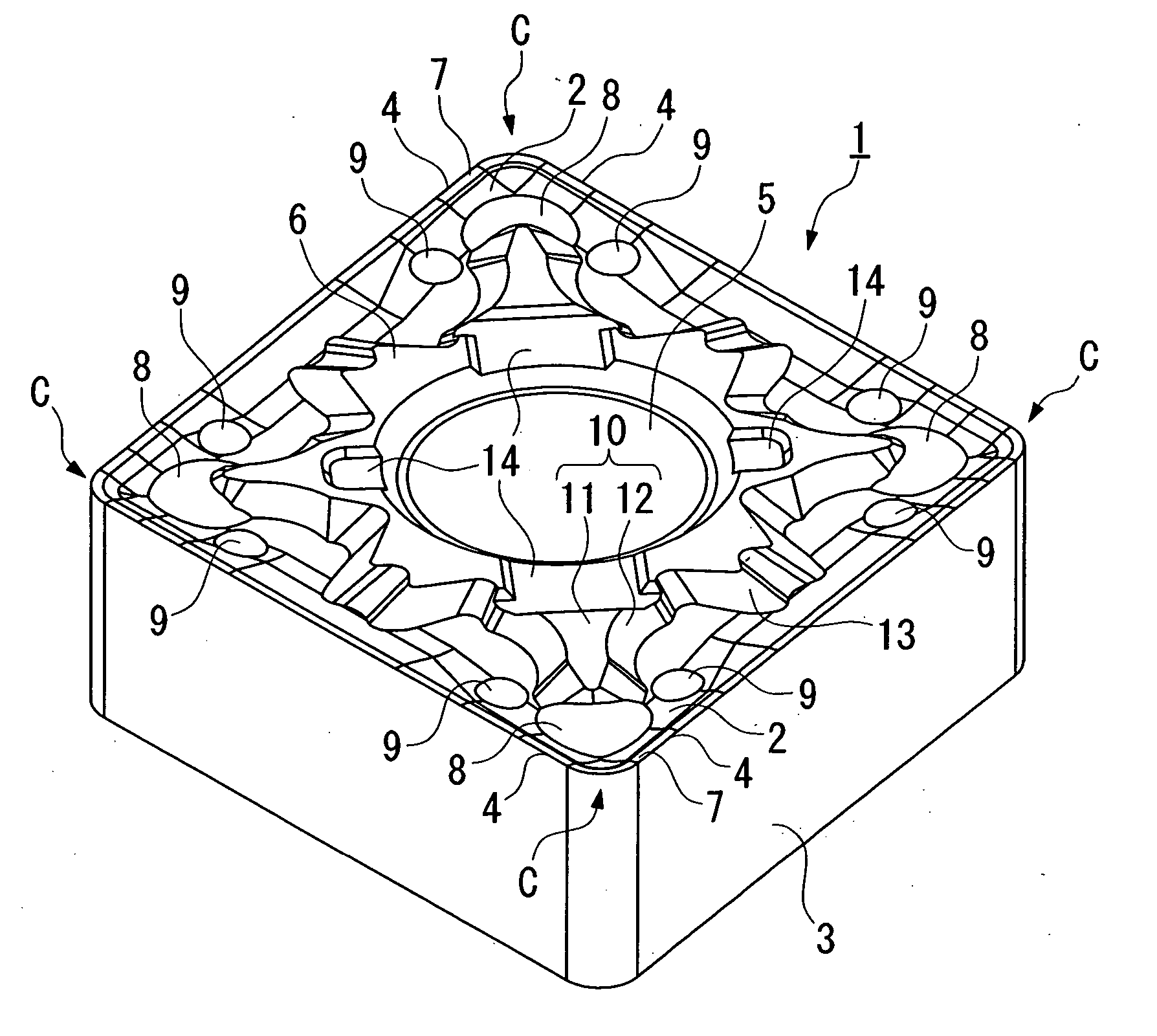

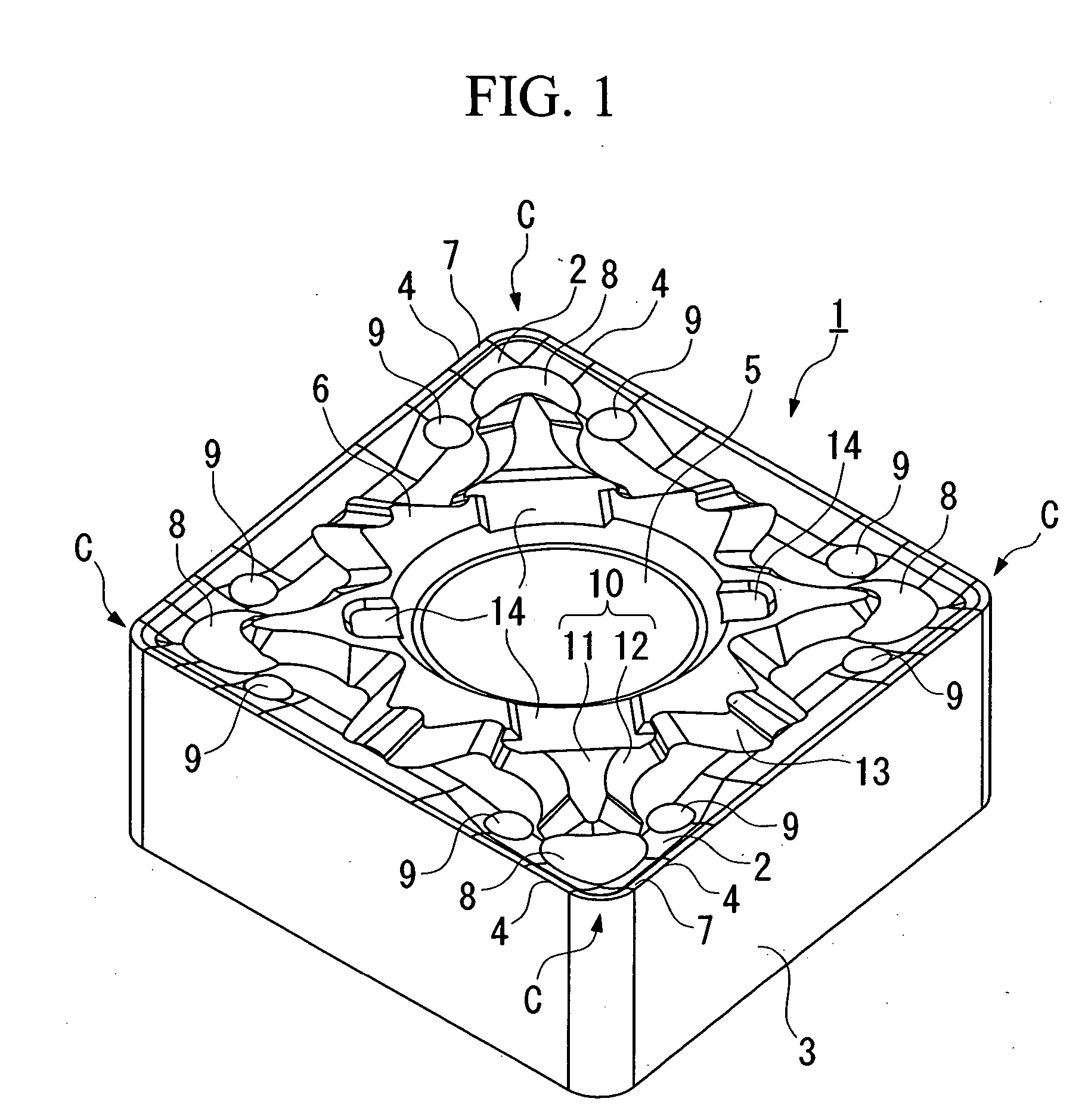

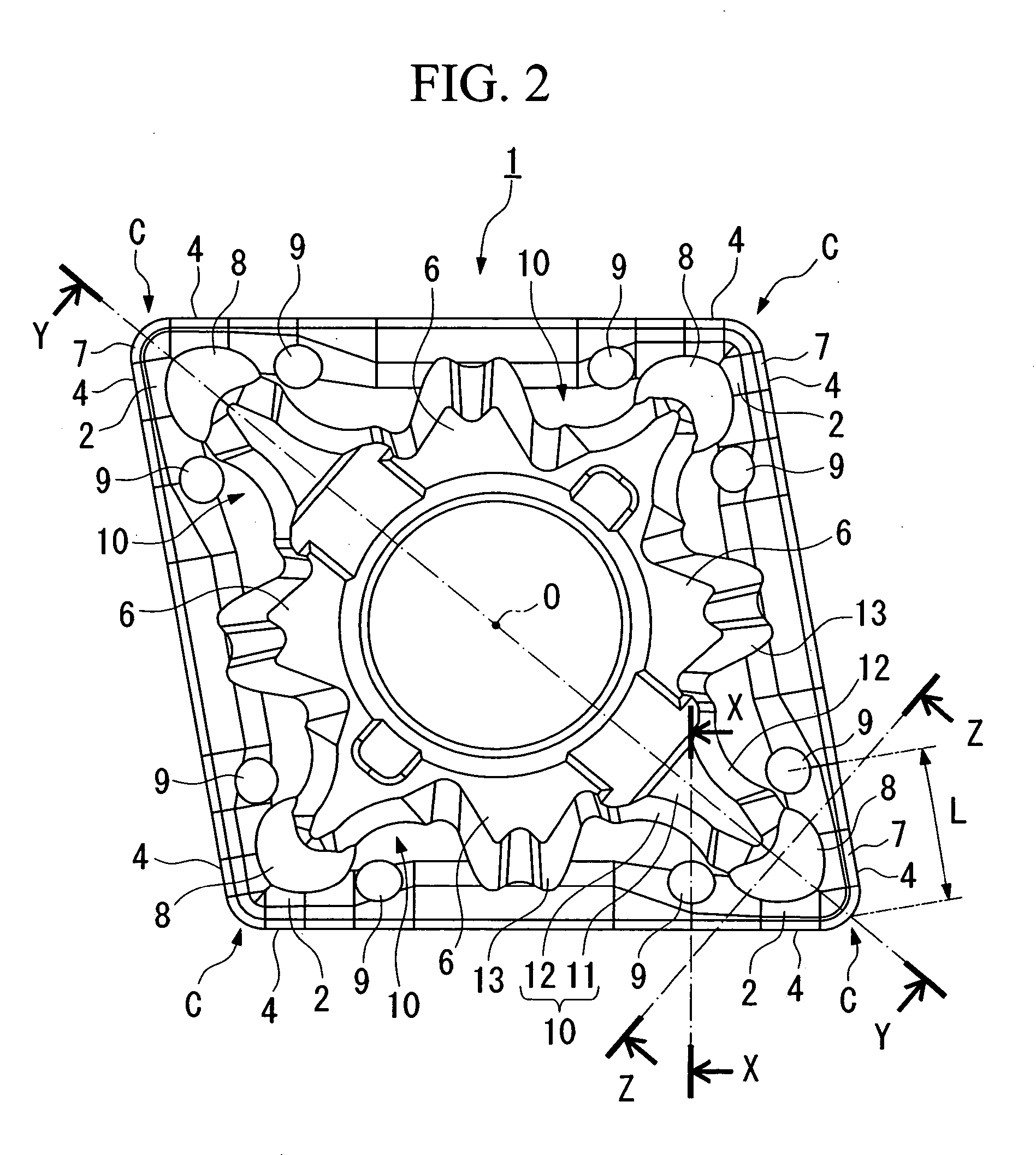

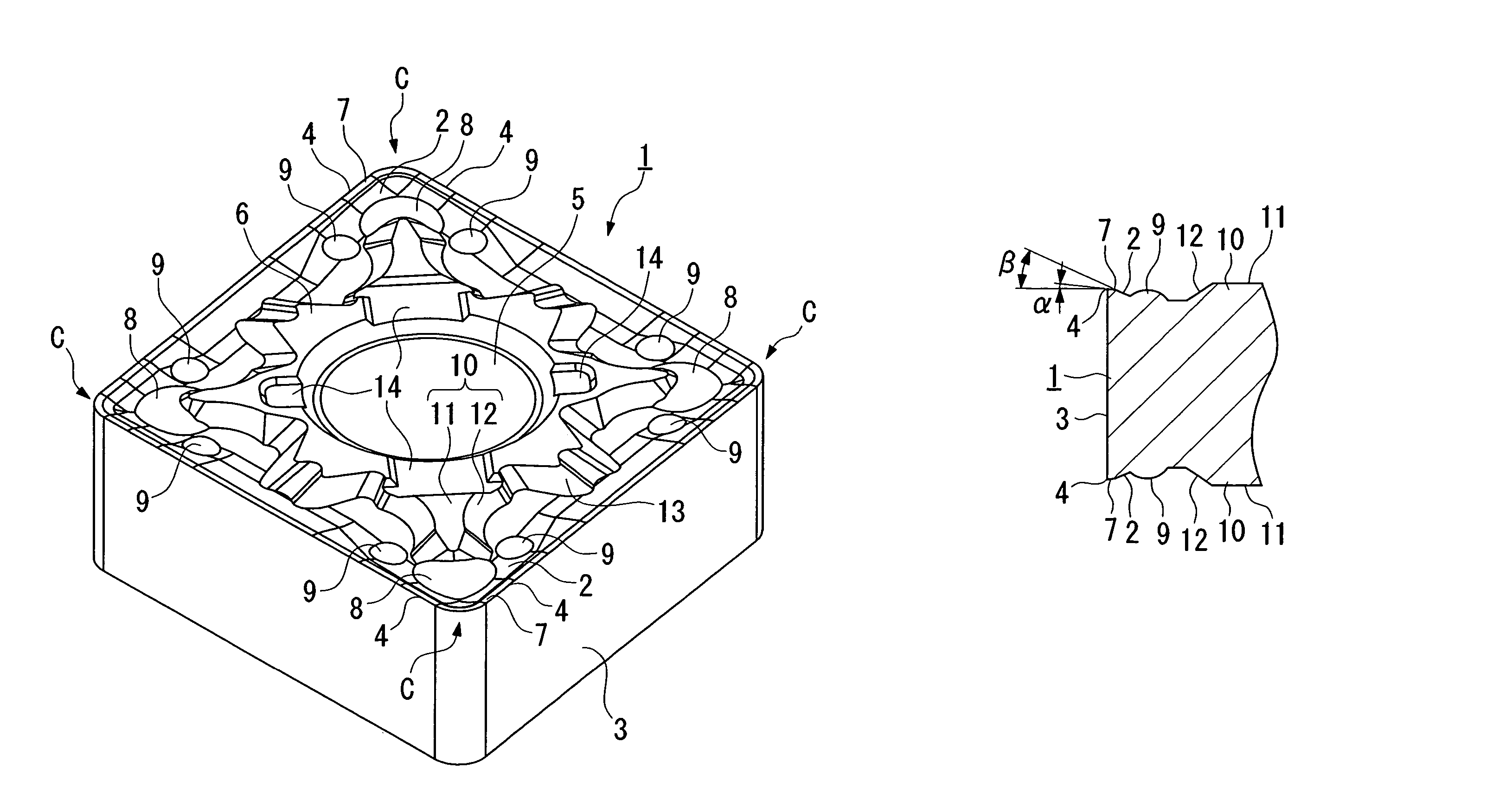

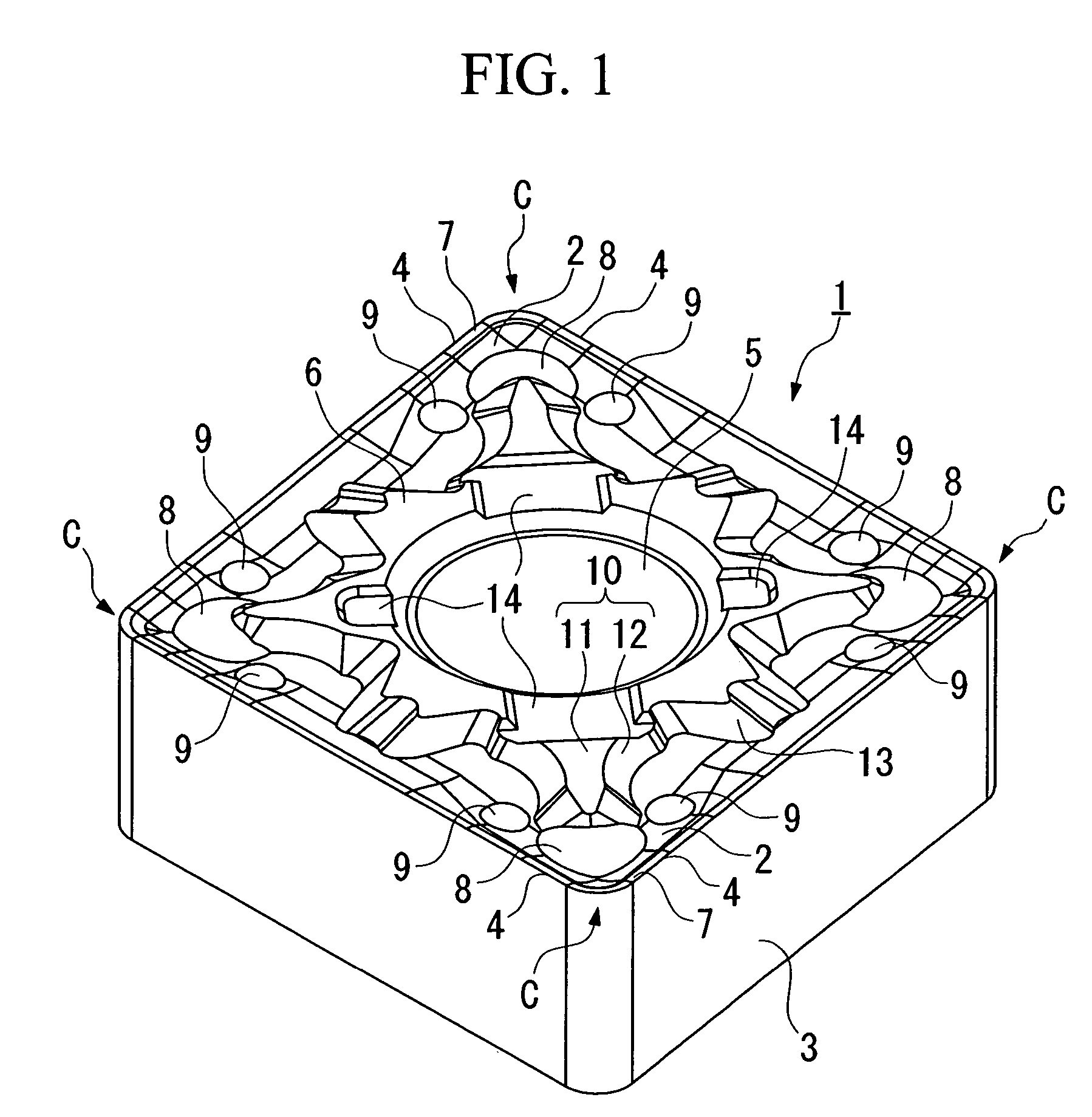

Throwaway tip

InactiveUS20050019111A1Reliable processing can be inhibitedSolve the broken effect is not goodCutting insertsTurning toolsConvex sideEngineering

An object of the invention is to reliably control chip, particularly that produced in profiling. To achieve this, rake faces are formed on polygon faces of an insert in the form of a polygonal plate shape, and a pair of cutting edges extending respectively from corner parts of the polygon faces are formed on a ridge part of the polygon faces, and each of the rake faces is gradually inclined as it becomes farther away from the cutting edge, and a land formed along the cutting edge, is inclined so that it gradually sinks as it become farther away from the cutting edge at an angle of inclination smaller than a rake angle, and angles of inclination of these rake face and land are made smaller in the direction to separate from a tip of the corner part along the cutting edge, and a main convex being a convex spherical face shape is formed at intervals between the cutting edges, on the corner part C, and at least one pair of sub convexes being a convex spherical face shape is also formed respectively at positions away from this main convex, along the pair of cutting edges.

Owner:MITSUBISHI MATERIALS CORP

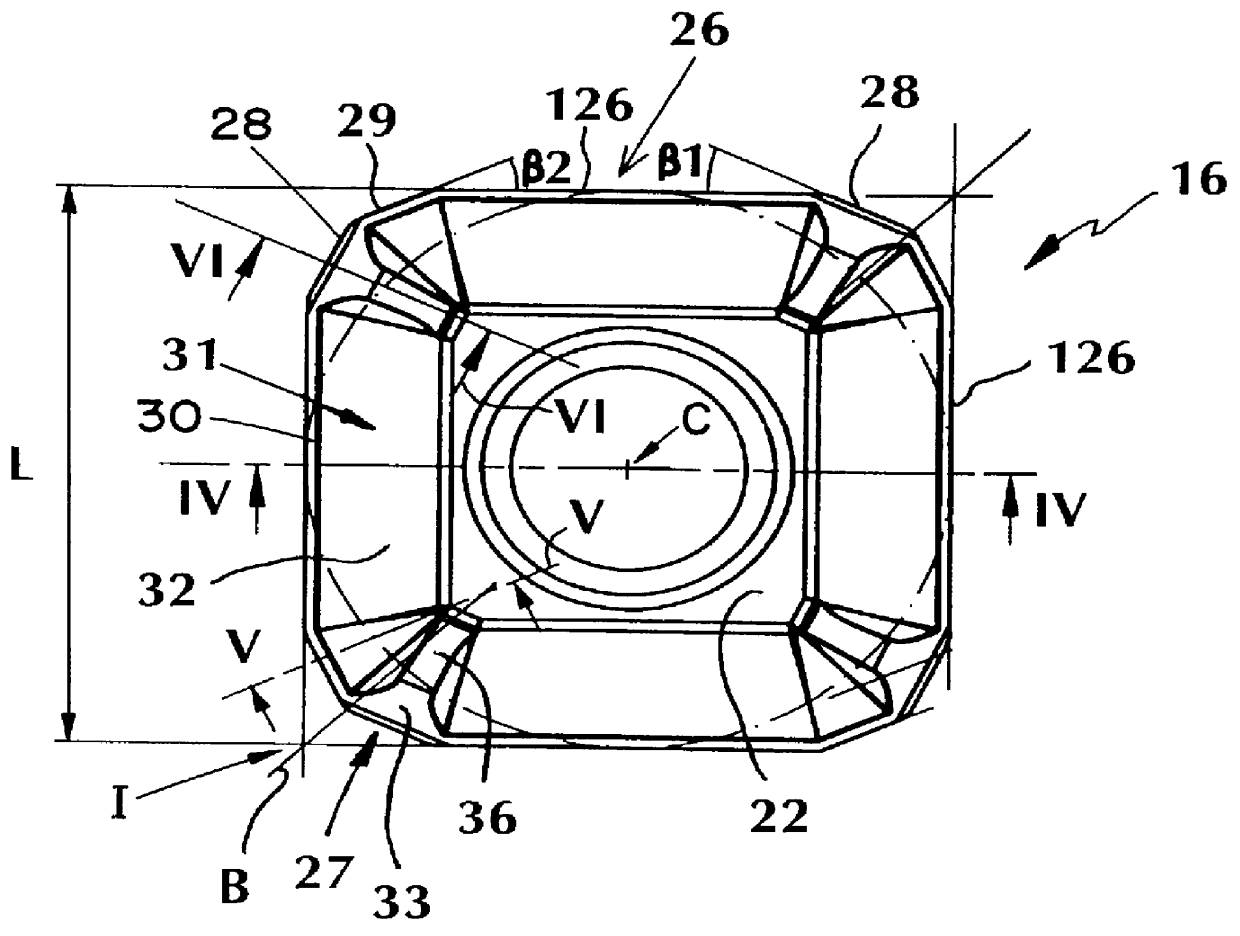

Indexable insert

InactiveUS7182555B2Easily brokenReadily broken and processedCutting insertsTurning toolsEngineeringKnife blades

An object of the invention is to reliably control chip, particularly that produced in profiling. To achieve this, rake faces are formed on polygon faces of an insert in the form of a polygonal plate shape, and a pair of cutting edges extending respectively from corner parts of the polygon faces are formed on a ridge part of the polygon faces, and each of the rake faces is gradually inclined as it becomes farther away from the cutting edge, and a land formed along the cutting edge, is inclined so that it gradually sinks as it become farther away from the cutting edge at an angle of inclination smaller than a rake angle, and angles of inclination of these rake face and land are made smaller in the direction to separate from a tip of the corner part along the cutting edge, and a main convex being a convex spherical face shape is formed at intervals between the cutting edges, on the corner part C, and at least one pair of sub convexes being a convex spherical face shape is also formed respectively at positions away from this main convex, along the pair of cutting edges.

Owner:MITSUBISHI MATERIALS CORP

Rolling cutter bit design

A cutting tool having a tool body with a plurality of blades extending radially therefrom and a plurality of rotatable cutting elements mounted on at least one of the plurality of blades is disclosed, wherein the plurality of rotatable cutting elements are mounted on the at least one blade utilizing multiple side rake angles.

Owner:SMITH INT INC

Drill for machining fiber reinforced composite material

InactiveUS20080019787A1Wood turning toolsTransportation and packagingFiber-reinforced compositeSplit point

A diamond coated drill capable of drilling holes in fiber reinforced composite materials. The drill is made from a tungsten carbide (WC) substrate with cemented cobalt (Co) in a range between about 3 to 10 wt. % and a diamond coating having a thickness in a range between 3 to 20 microns. The drill includes a shank, a longitudinal axis and includes two flutes at a helix angle that is in a range between 25 and 35 degrees with respect to the axis. A margin width is maintained between about 5 to 10 percent of the drill diameter. A body clearance diameter is maintained at between about 92 to 96 percent of the drill diameter. A web thickness before splitting is about 20 to 30 percent of the drill diameter. A clearance angle or lip relief angle is between about 10 and 20 degrees. A chisel edge angle is between about 105 and 120 degrees. A chisel edge length is up to about 0.035 mm. A splitting angle is between about 130 and 150 degrees. A notch angle is between about 30 and 40 degrees with respect to the drill axis. A notch rake angle lies between about −5 and 10 degrees. A split point angle is between about 70 and 100 degrees, and preferably about 90 degrees.

Owner:KENNAMETAL INC

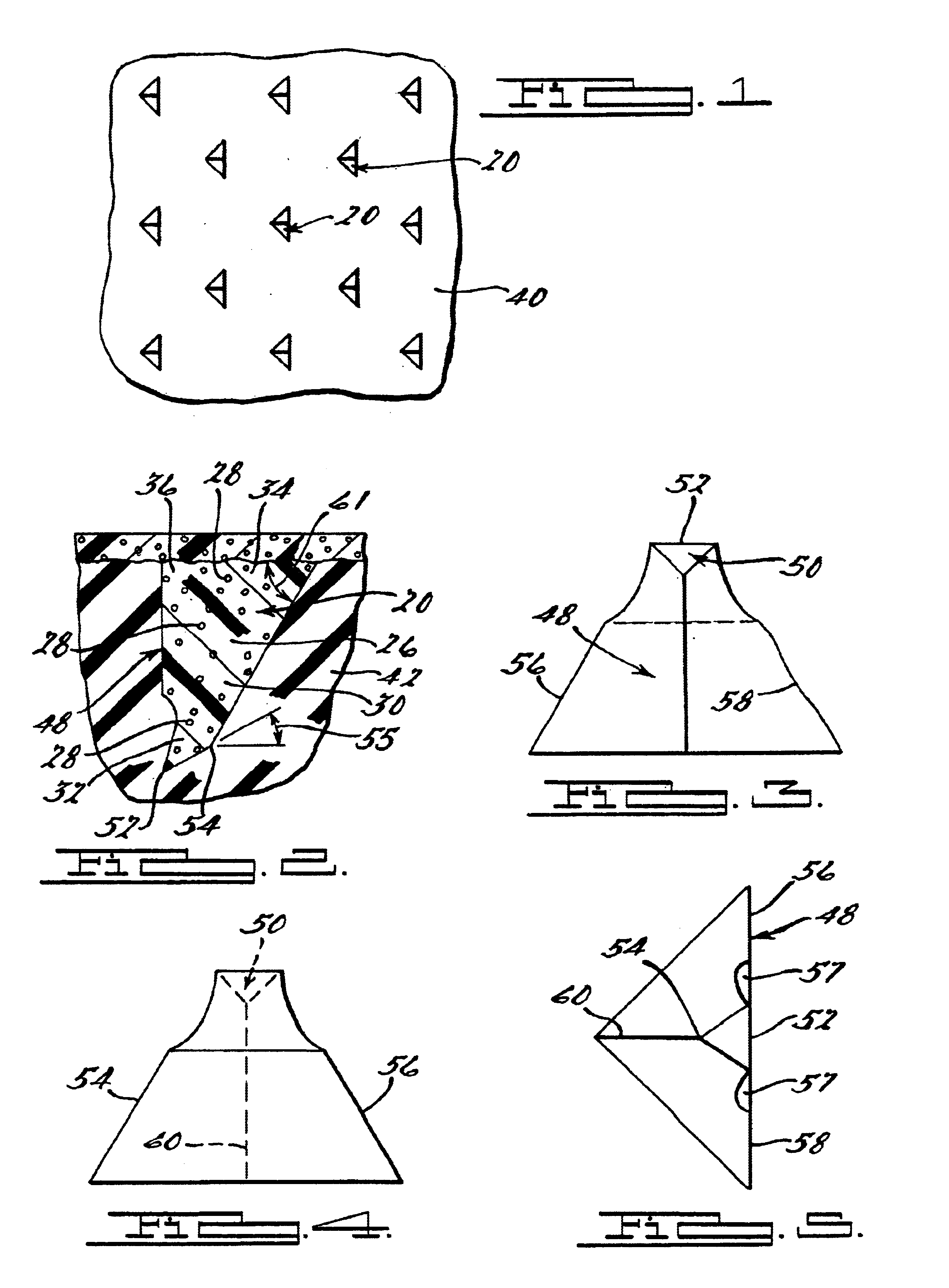

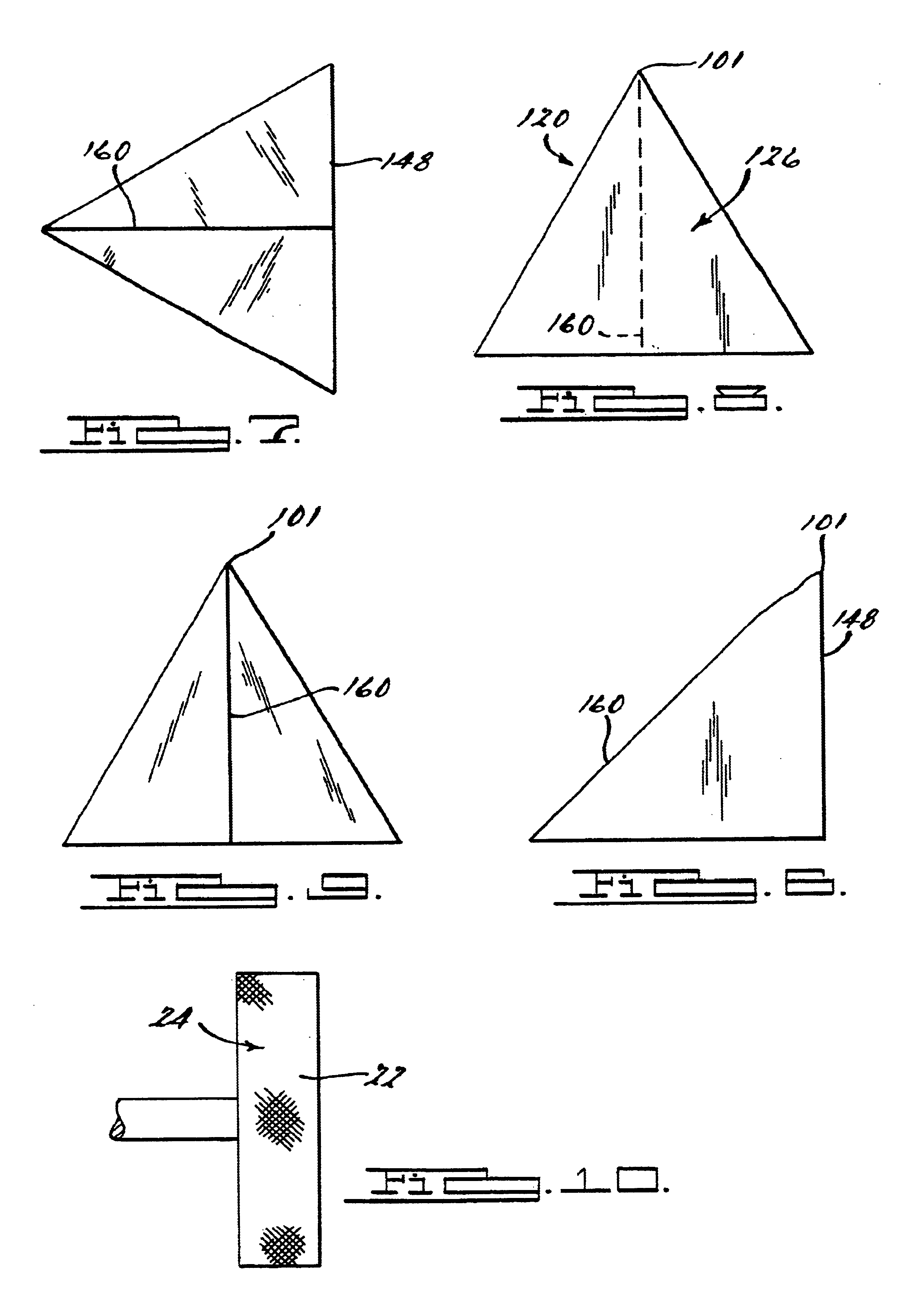

Pyramidal molded tooth structure

InactiveUS6821196B2Simple designLow costRevolution surface grinding machinesAbrasion apparatusMetallic materialsEngineering

A molded tooth design of generally pyramidal form made of various hard grit materials for use on a grinding wheel for grinding non-metal materials. The tooth structure generally includes a raked face having a neutral to positive rake angle that terminates to a sharp point. The tooth structure also includes on the raked face edge portions below the point extending from both sides thereof having a predetermined clearance angle to increase penetration and reduce friction of the tooth during the grinding process. The tooth structure may also include at a top end of the rake face a truncated clearance surface which will produce a wider cutting edge that is flat, for use in attacking the work surface of the work piece being ground. The rake face of the tooth generally may also be formed to have positive rake in the truncated surface.

Owner:L R OLIVER

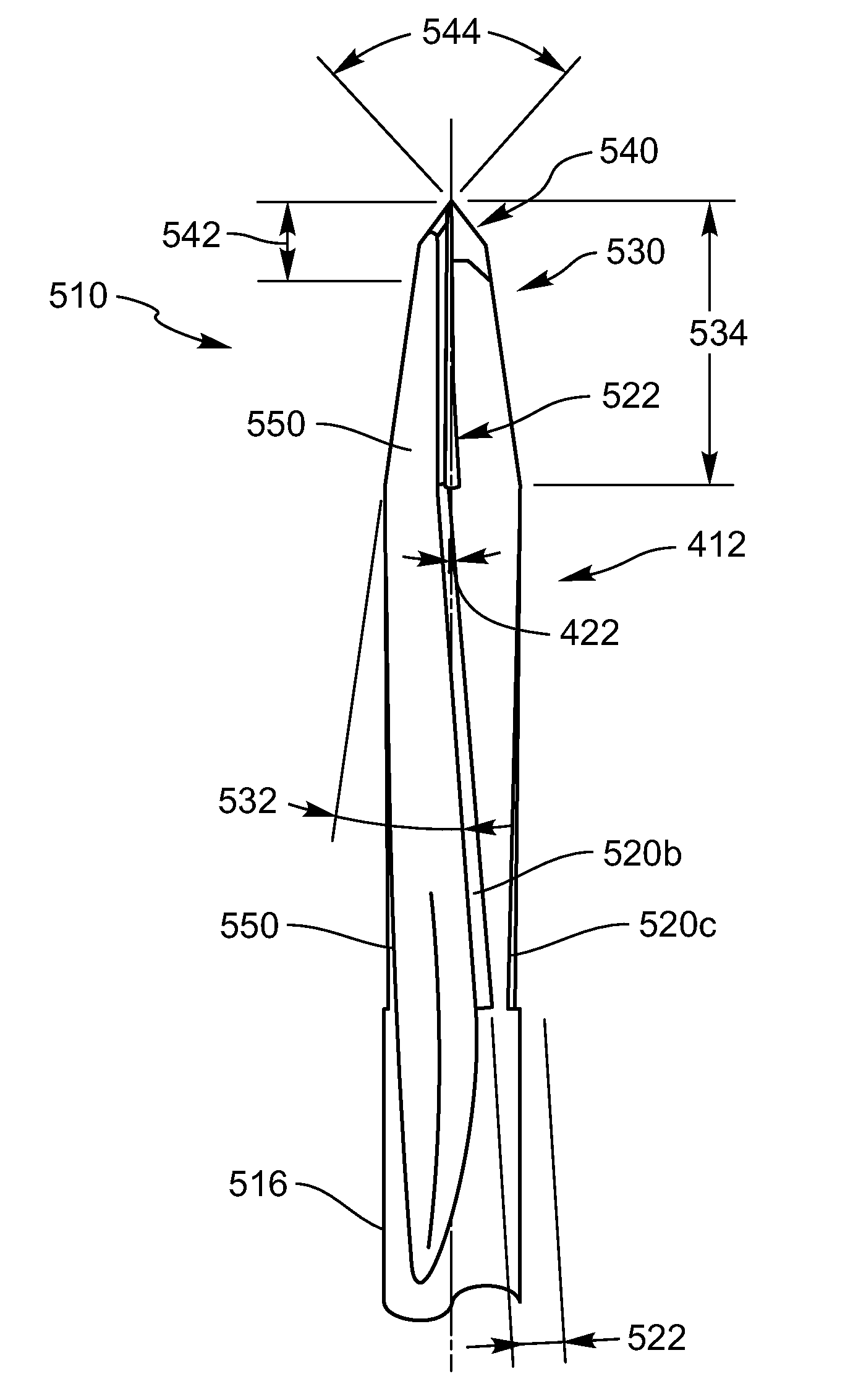

Carbide drill bit for composite materials

A drill bit for producing holes in composite materials is disclosed. The drill bit includes an elongate drill bit body having a drill bit diameter. The drill bit also includes at least two helical flutes. The helical flutes have a reverse helix angle and a primary cutting edge. The primary cutting edge may have a positive rake angle. The drill bit further includes a point having a point length. The drill bit may also include a cutting tip with a tip angle and a tip length. The tip length is at least twice the drill bit diameter.

Owner:PRECORP INC

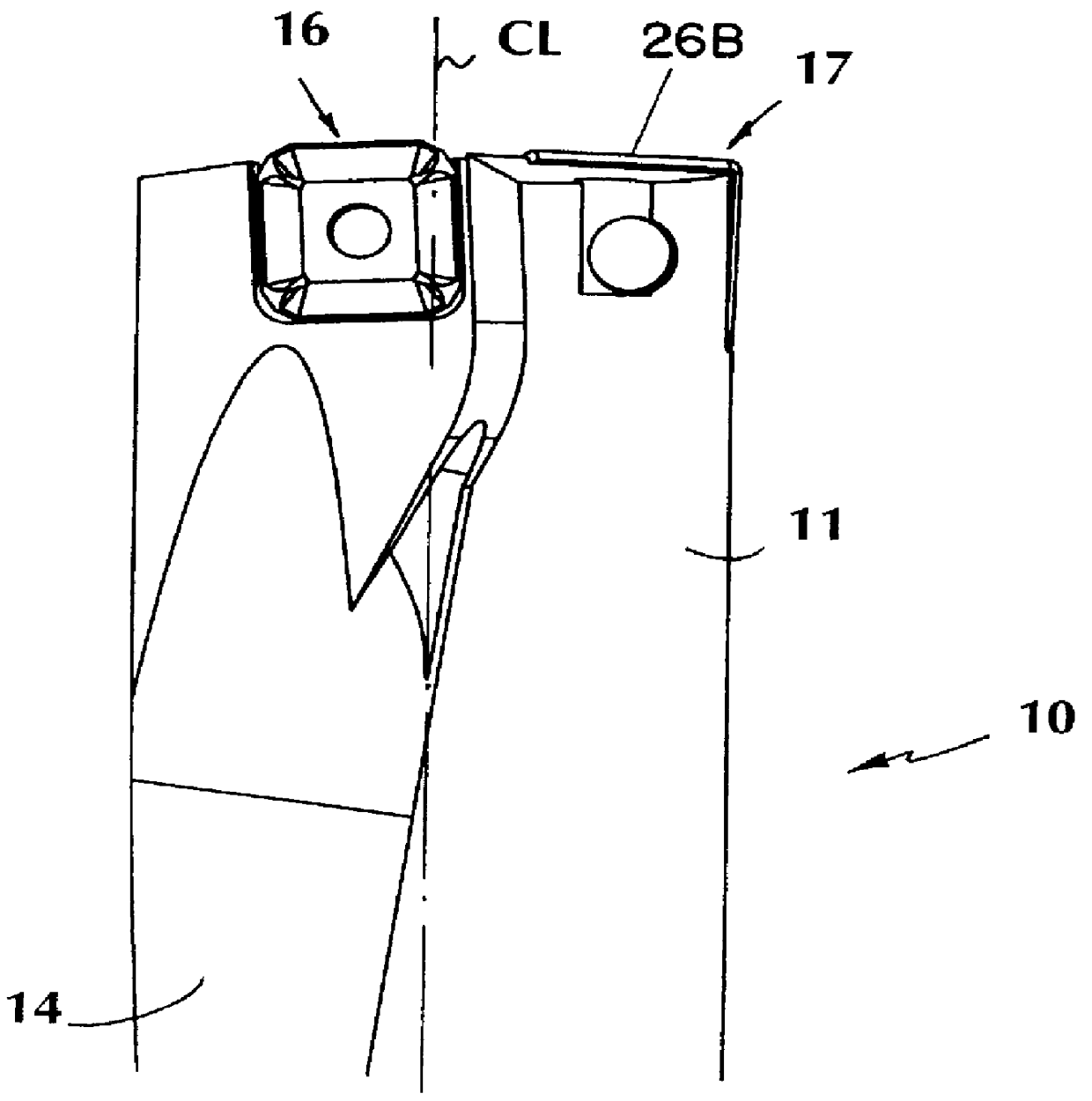

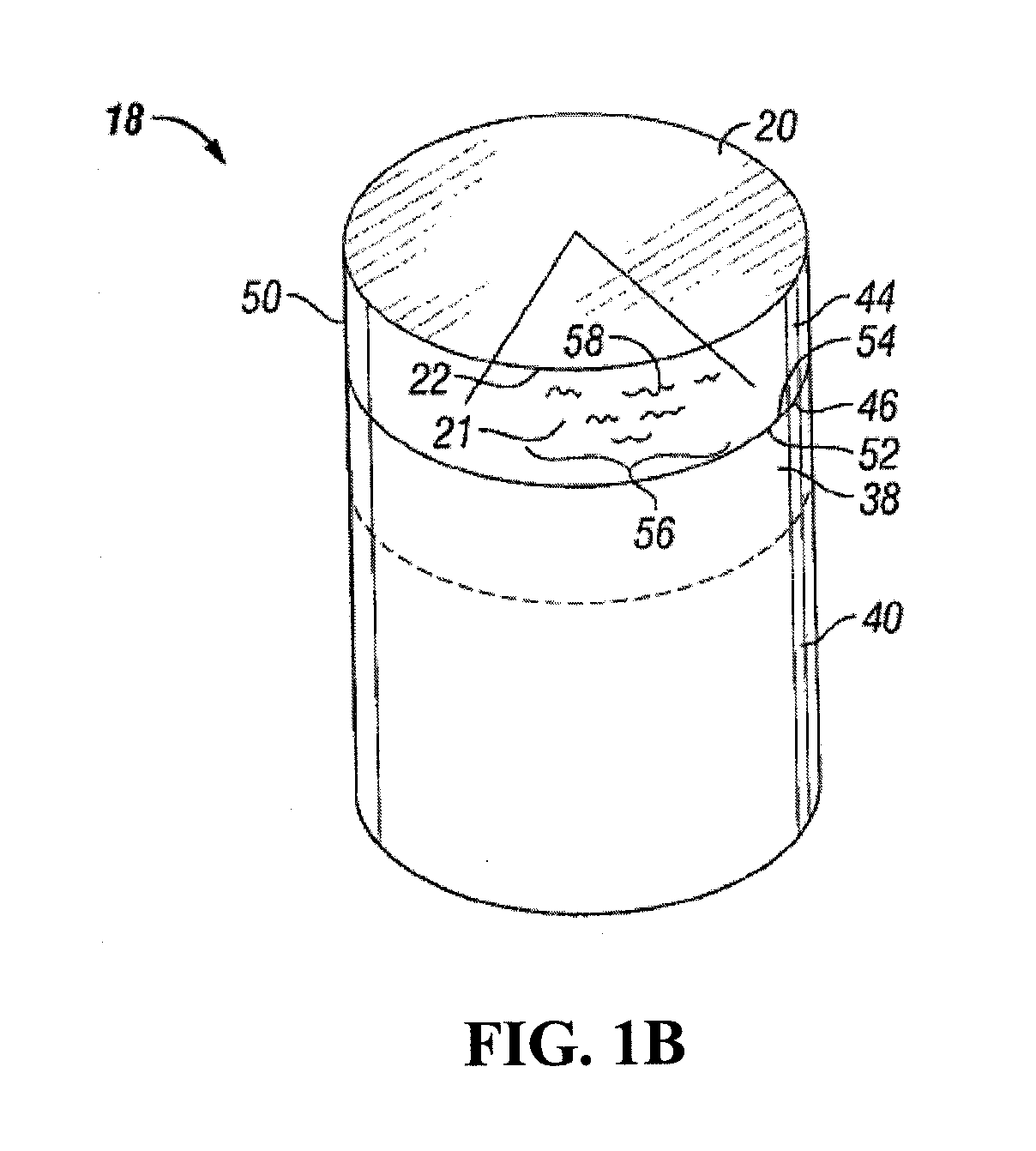

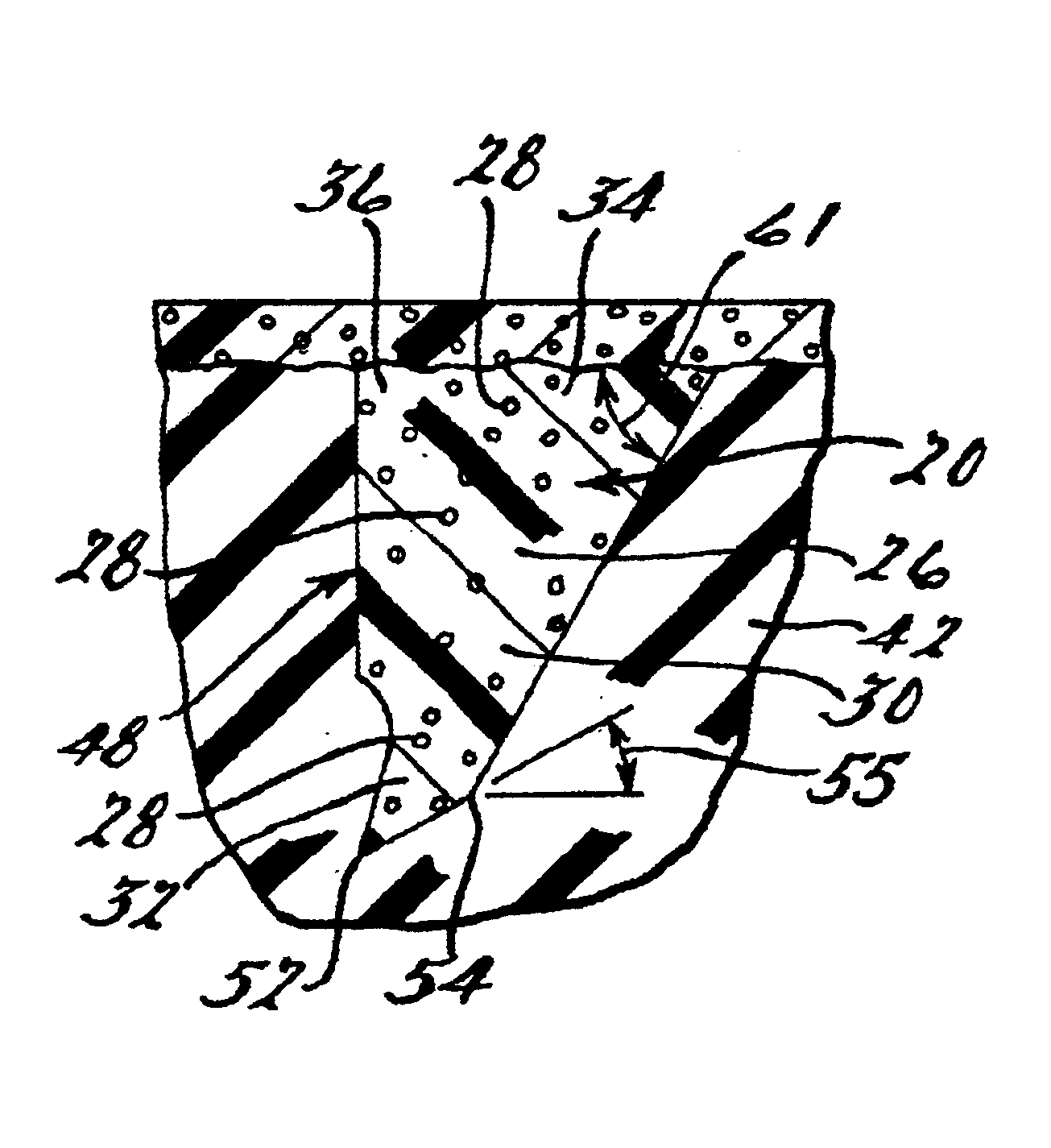

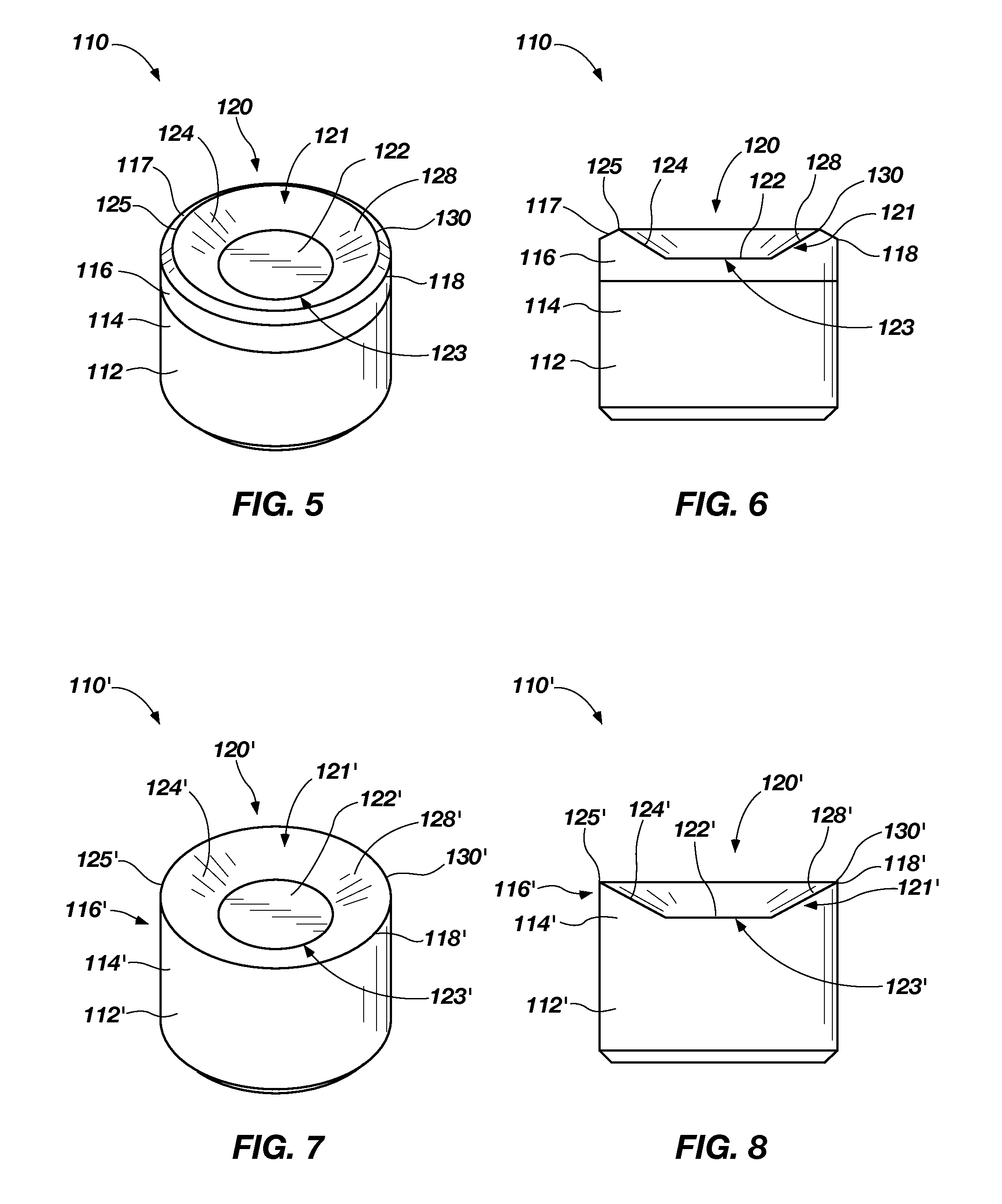

Cutting structures for fixed cutter drill bit and other downhole cutting tools

A downhole cutting tool may include a tool body; a plurality of blades extending azimuthally from the tool body; and a plurality of cutting elements disposed on the plurality of blades, the plurality of cutting elements comprising: at least two conical cutting elements comprising a substrate and a diamond layer having a conical cutting end, wherein at least one of the at least two conical cutting elements has a positive back rake angle, and at least one of the at least two conical cutting elements has a negative back rake angle.

Owner:SMITH INT INC

Cutting insert, cutting tool, and method of producing machined product using the same

ActiveUS20140298967A1Good chip removal effectCurl stableMilling cuttersShaping cuttersMechanical engineeringRake angle

A cutting insert comprises an upper surface sequentially including a first and second rake surface. The first rake surface is inclined toward the lower surface, going inward from the cutting edge at a first rake angle on a basis of a perpendicular plane perpendicular to a central axis extending between the upper surface and a lower surface. The second rake surface, located more inward than the first rake surface, is inclined toward the lower surface at a second rake angle different from the first rake angle on the basis of the perpendicular plane. An intersecting part of the first rake surface and the second rake surface includes a protruded part located at a highest position in a region of the intersecting part along the second side surface. A cutting tool with the cutting insert, and a method of producing a machined product using the cutting tool are provided.

Owner:KYOCERA CORP

Insert-exchangeable, rotary tool and throwaway insert

InactiveUS6884006B2High operating requirementsStable cuttingMilling cuttersShaping cuttersPositive typeEngineering

Owner:HITACHI TOOL ENG LTD

Rotary cutting tool having irregular insert orientation

A rotary cutting tool such as a helical end mill, having pockets arranged to overcome harmonic vibrations. The tool has at least two and in one embodiment all three of three spacing irregularities. In the first irregularity, columns of pockets, typically associated with flutes, are staggered circumferentially out of even spacing. In a preferred embodiment having three flutes, the flutes are mostly not centered on one hundred twenty degree intervals. In the second irregularity, at least some pockets are arranged at different radial rake angles. In the third irregularity, at least some pockets are arranged at different axial rake angles.

Owner:KENNAMETAL INC

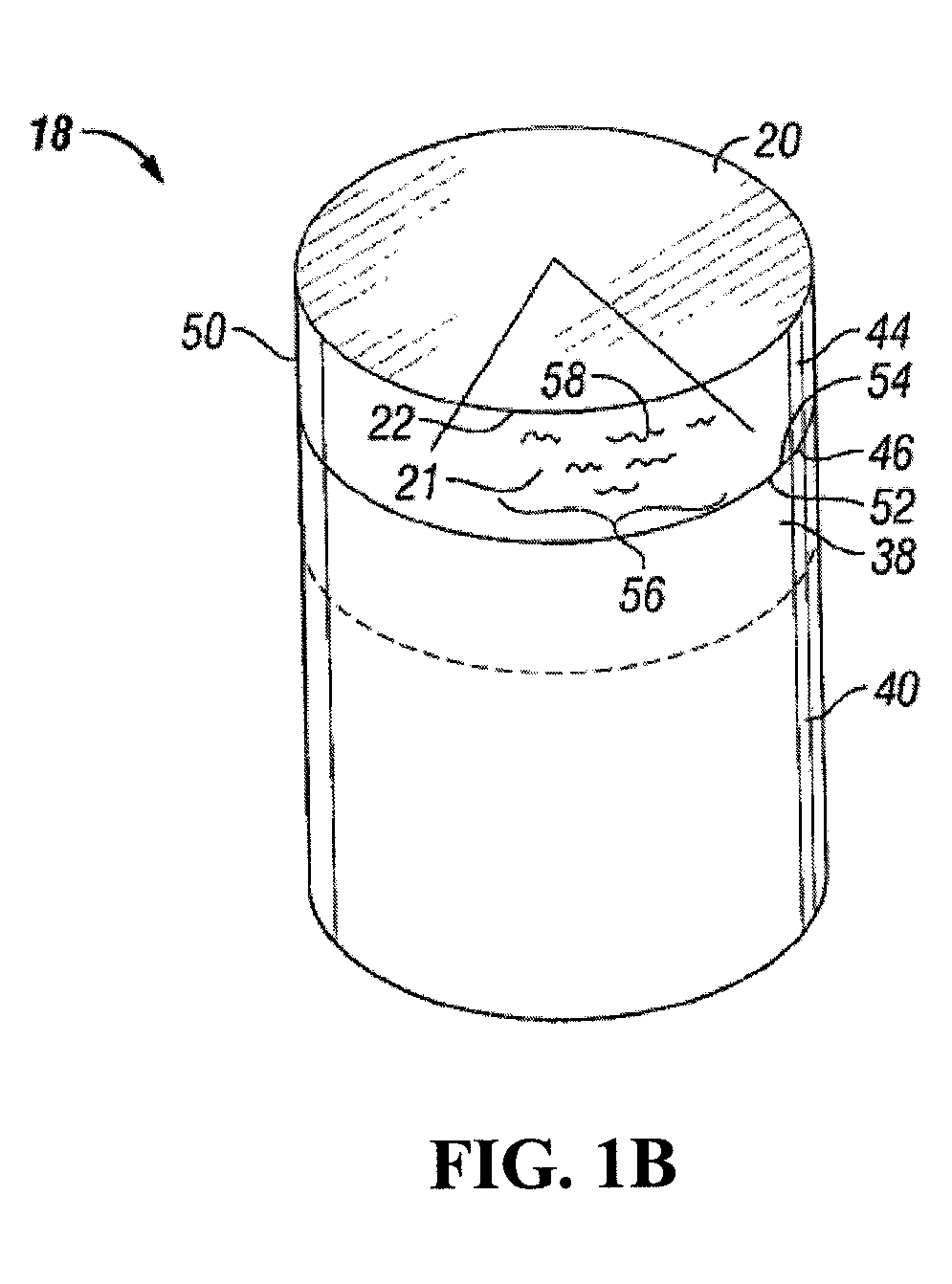

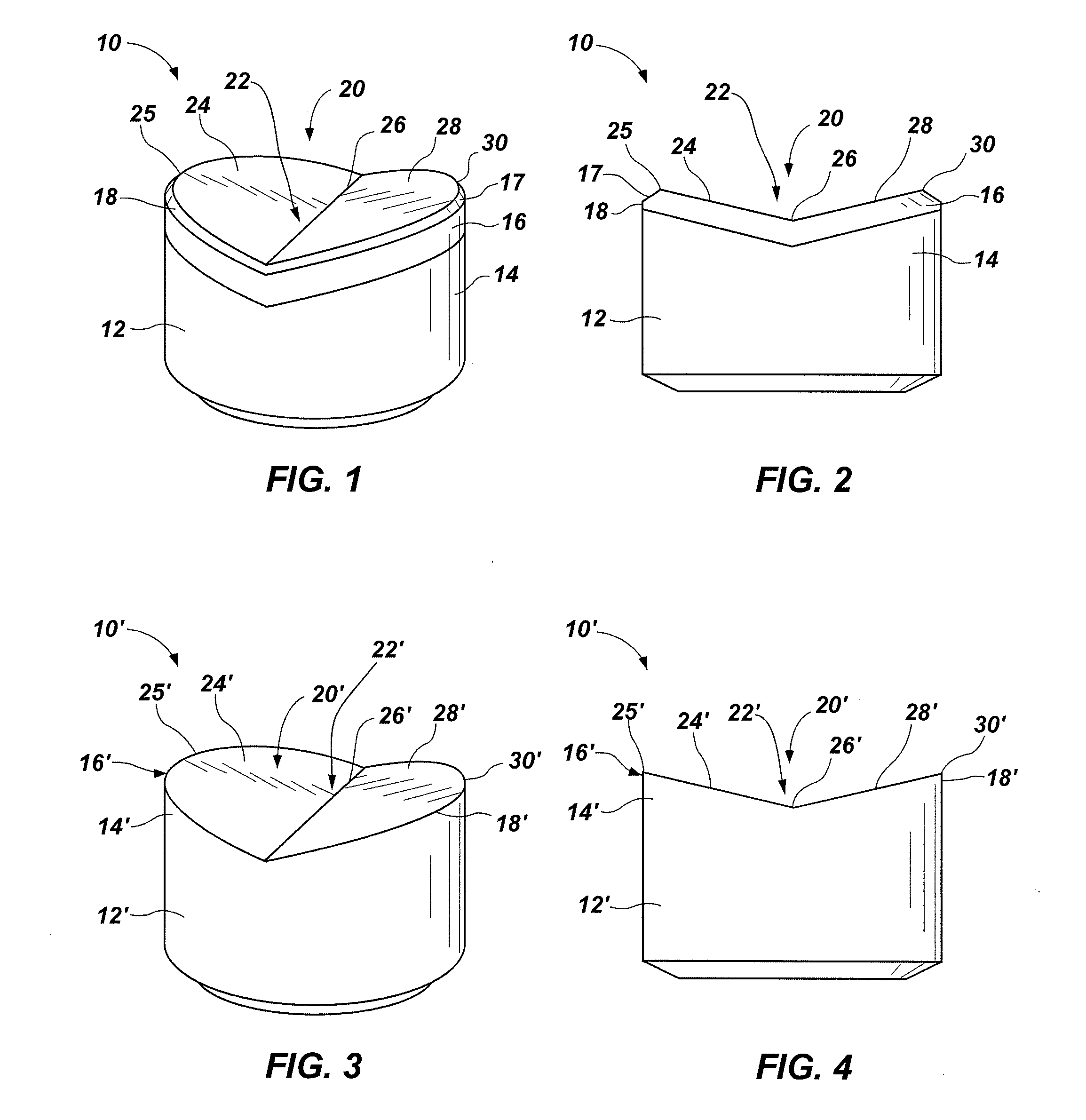

Cutting elements including cutting tables with shaped faces configured to provide continuous effective positive back rake angles, drill bits so equipped and methods of drilling

ActiveUS20100307829A1Reducing eliminating damageAvoid collectingDrill bitsConstructionsMechanical engineeringHole drilling method

A cutting element for a drag-type earth-boring drill bit includes a cutting table with a face including a region that is configured cut into a formation at an effective positive back rake angle and to direct formation cuttings, or chips, that have been cut from the earth formation toward the hydraulics of the drill bit. Drill bits that include one or more cutting elements that have been configured in this manner are also disclosed. Such a drill bit may also include a wear pad for limiting the depth to which a cutting element penetrates a surface of a bore hole in an earth formation. Such a wear pad may have a substantially constant thickness. Methods for removing material from earth formations are also disclosed.

Owner:BAKER HUGHES INC

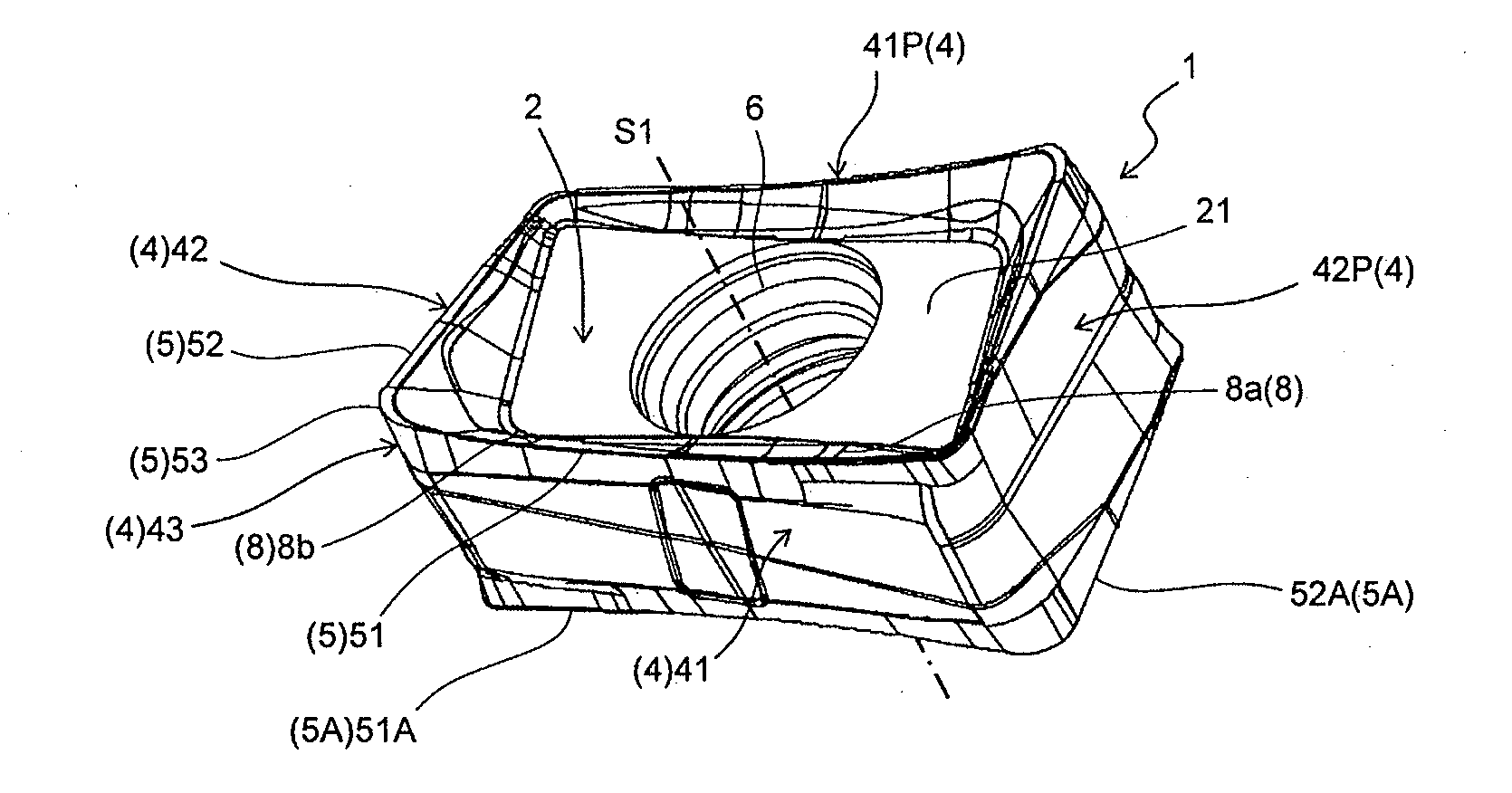

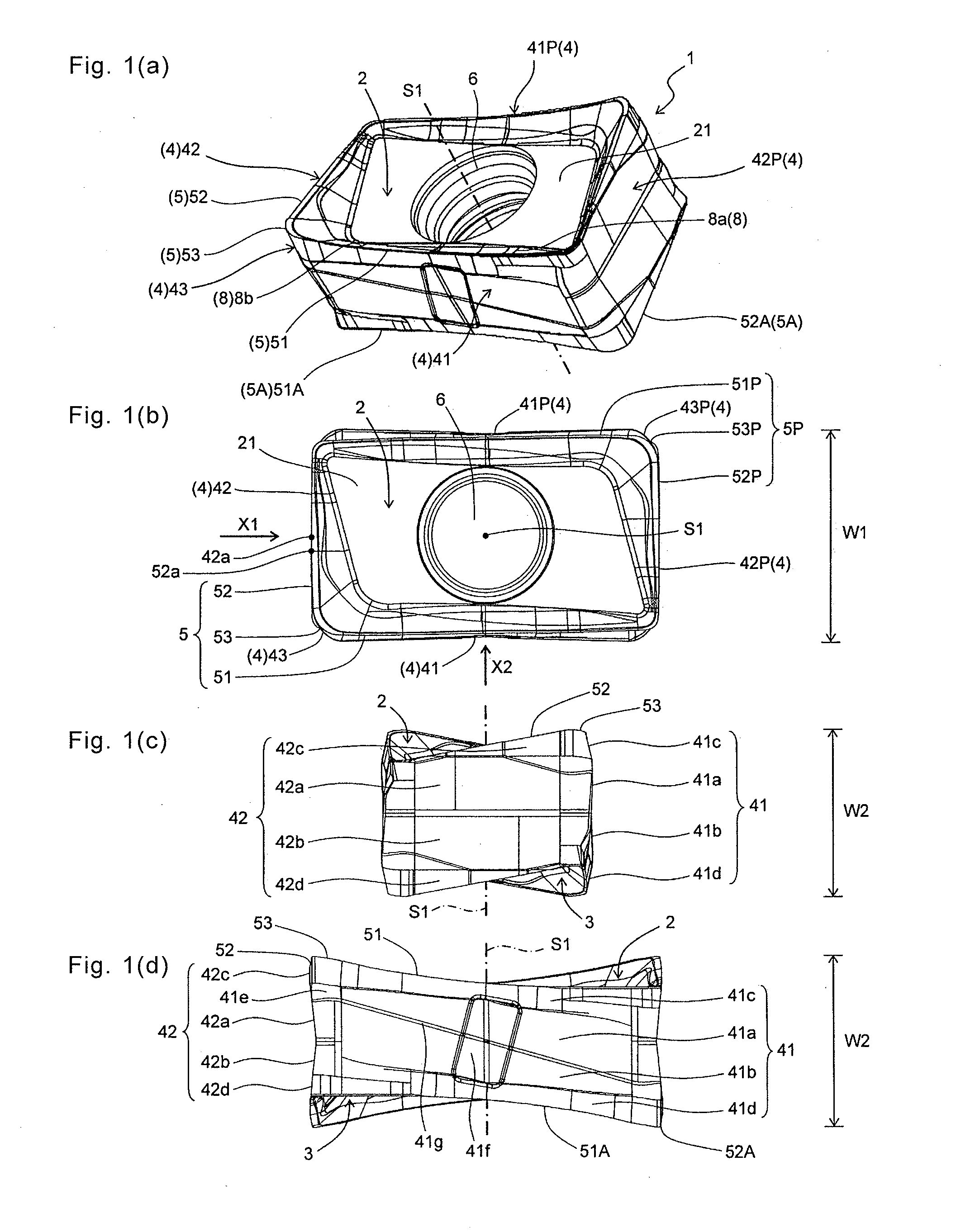

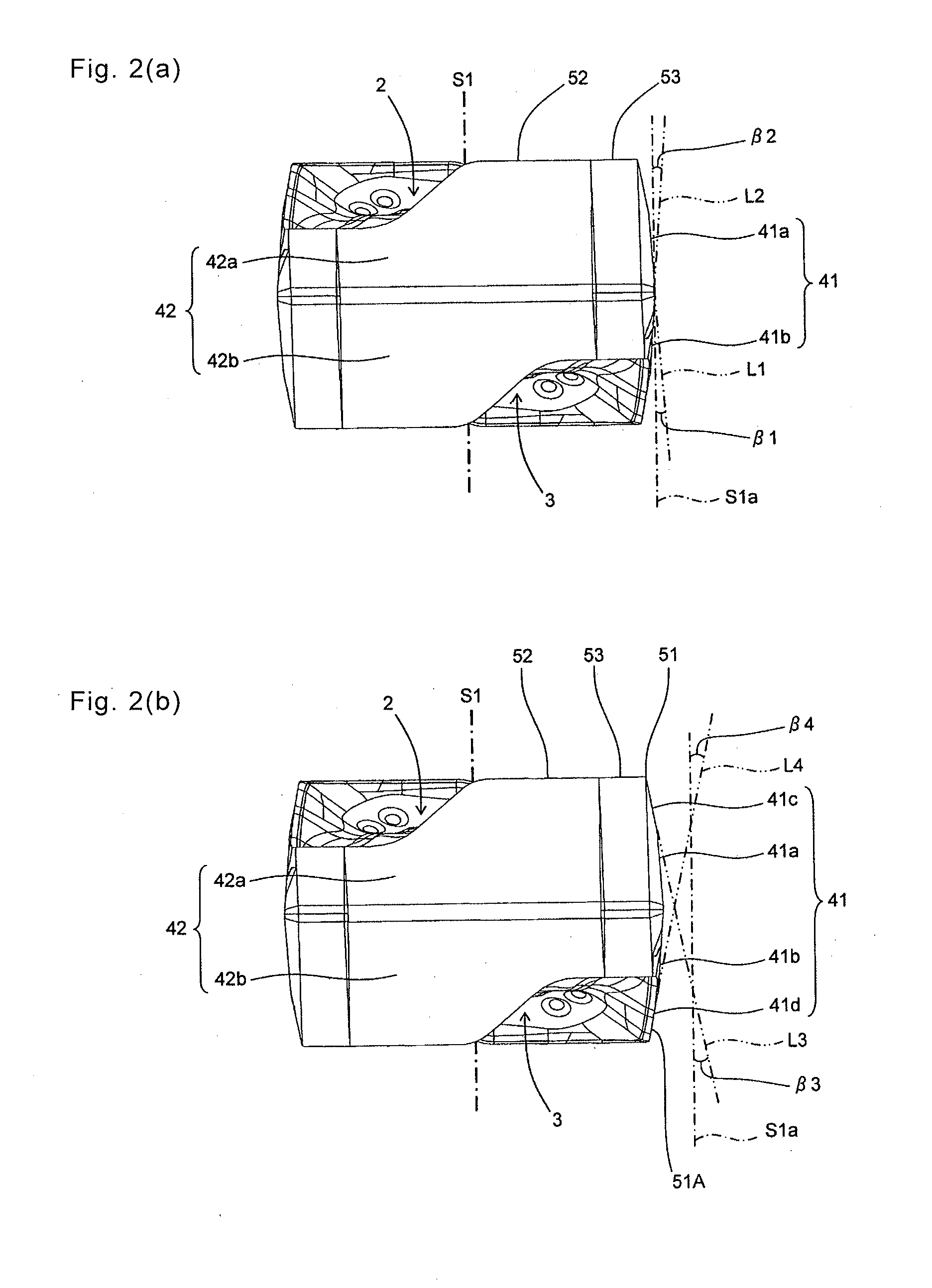

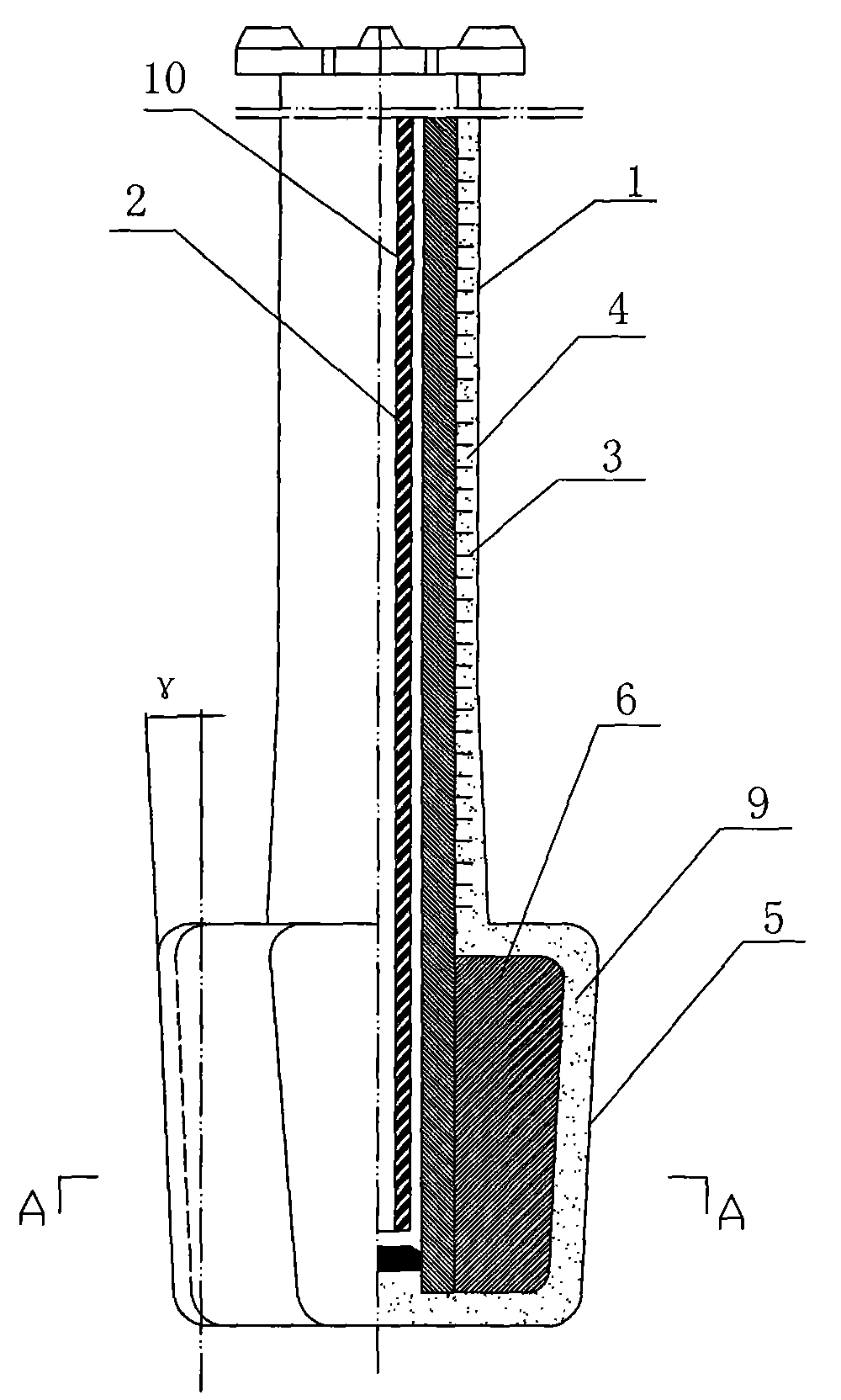

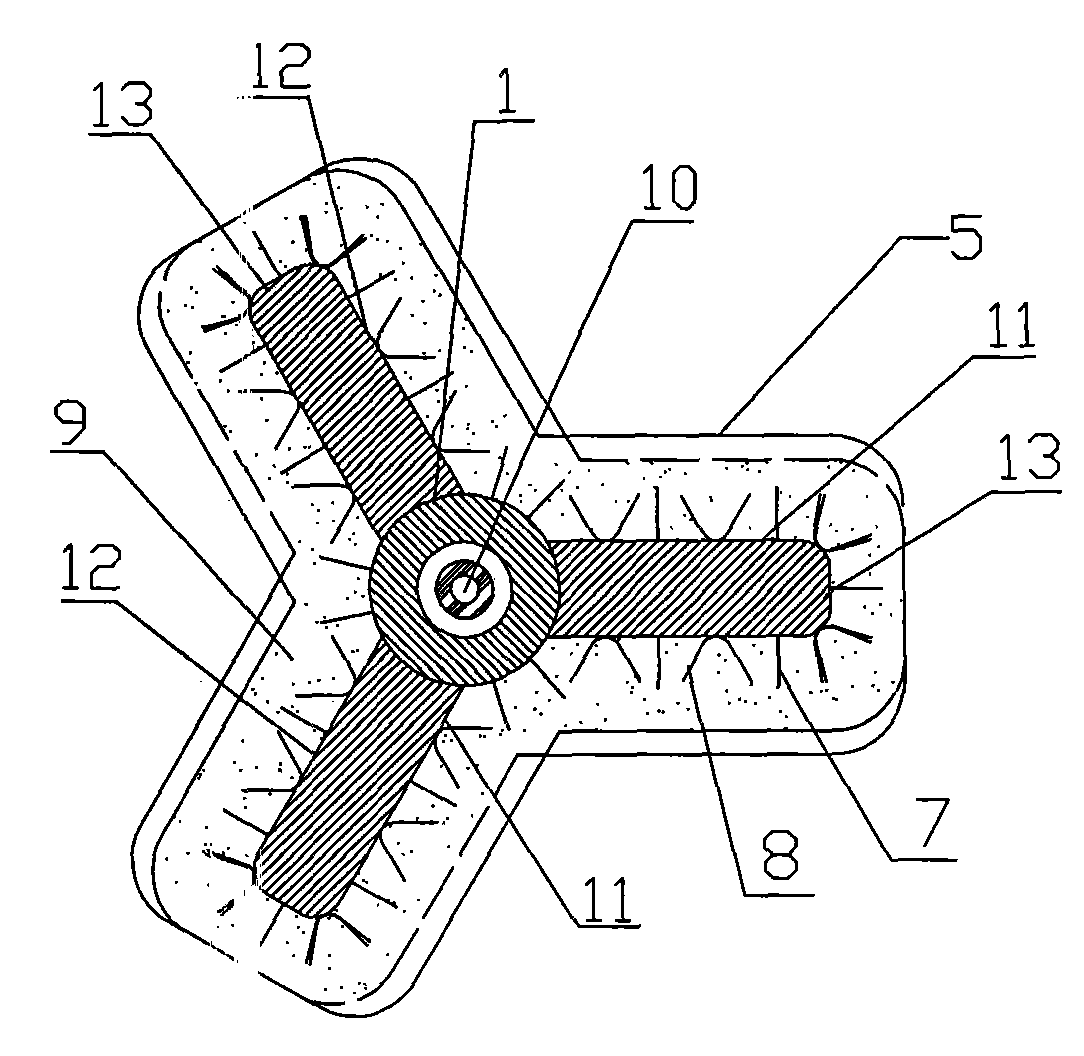

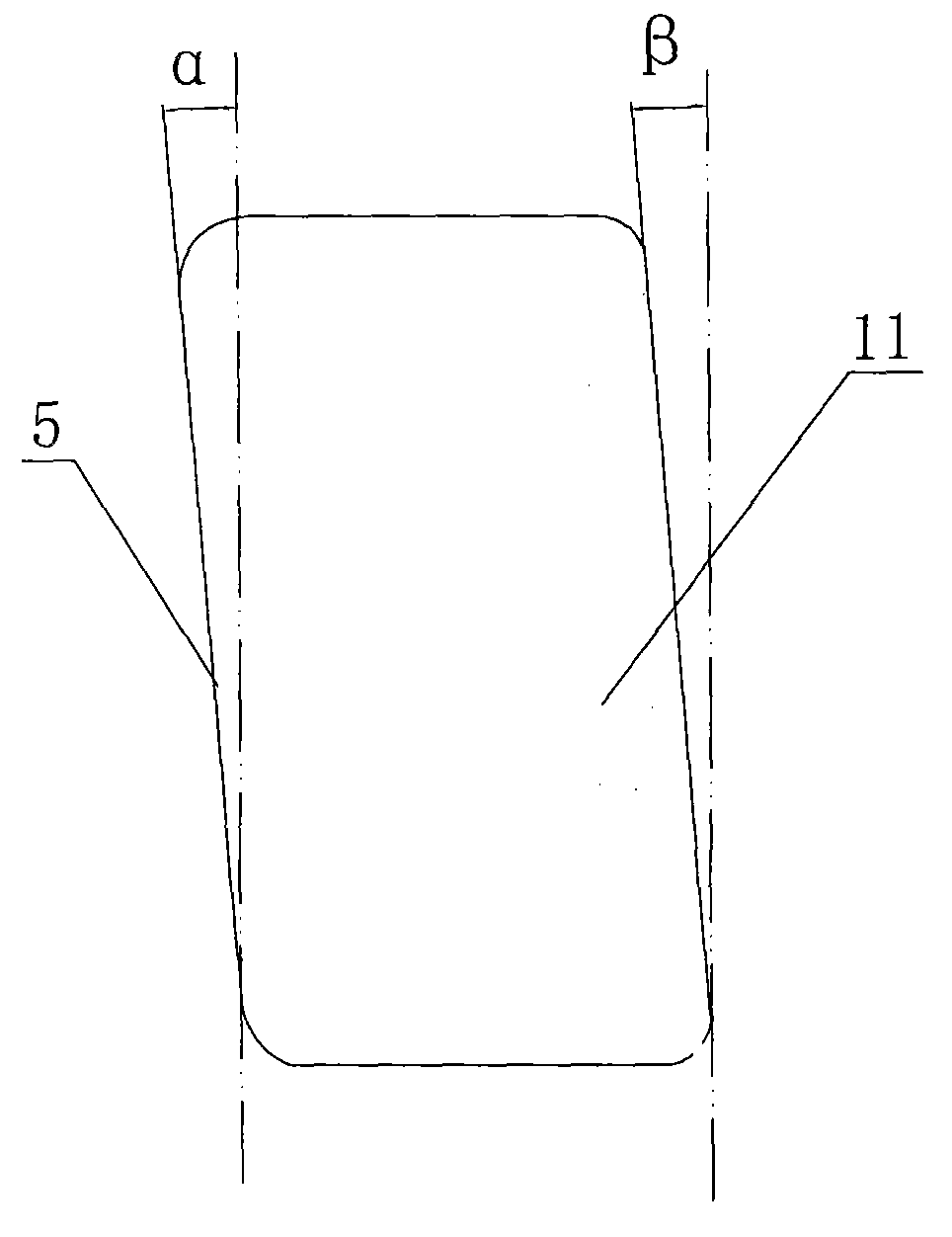

Stirrer for desulphurization of molten iron

The invention relates to a stirrer for external stirring desulphurization of molten iron before converter steelmaking, aiming at solving the existing deficiencies at present that slags among mixing blades are numerous, large intensity of vortex at the bottom of the metal opposing side of the mixing blades is disadvantageous to the discharging of the involved desulphurization slags. The invention comprises the following measures: the stirrer for desulphurization of molten iron is composed of a metal core 2, a V-shaped rivet firmware 3, a refractory liner 4, a metal chip 6, a V-shaped rivet firmware 7, a double V-shaped rivet firmware 8, a refractory liner 9 and an air cooling tube 10; the metal core 2, the V-shaped rivet firmware 3 and the refractory liner 4 constitute a rotation axis 1; the metal chip 6, the V-shaped rivet firmware 7, the double V-shaped rivet firmware 8, the refractory liner 9 and the air cooling tube 10 constitute mixing blades 5; three mixing blades 5 above the rotation axis 1 are evenly distributed; the front rake angle alpha of the inclined plane from bottom to top of the metal facing water surfaces 11 of the mixing blades 5 is 4.1-30 degrees, the front rake angle beta of the inclined plane from bottom to top of the metal opposing surfaces 12 is 0.1-30 degrees, the camber angle gamma of the inclined plane from bottom to top of the outside surface 13 is 4.1-15 degrees. In the invention, slags among the mixing blades are small, the dynamic condition for stirring desulphurization is excellent, the service life is long and the structure is simple.

Owner:武汉钢铁有限公司 +1

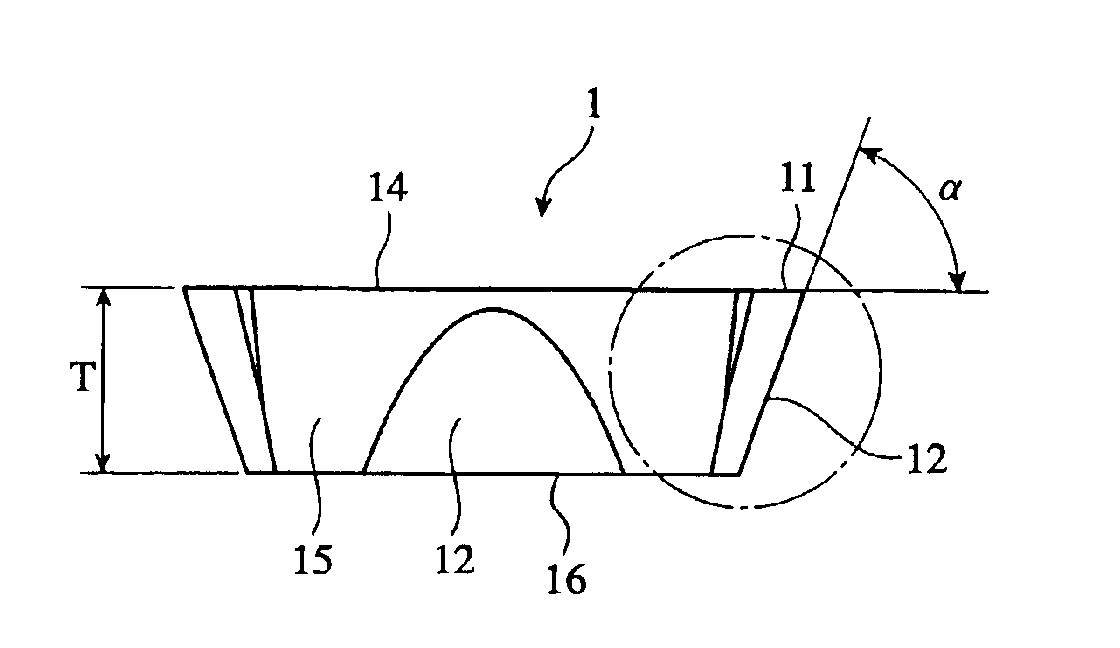

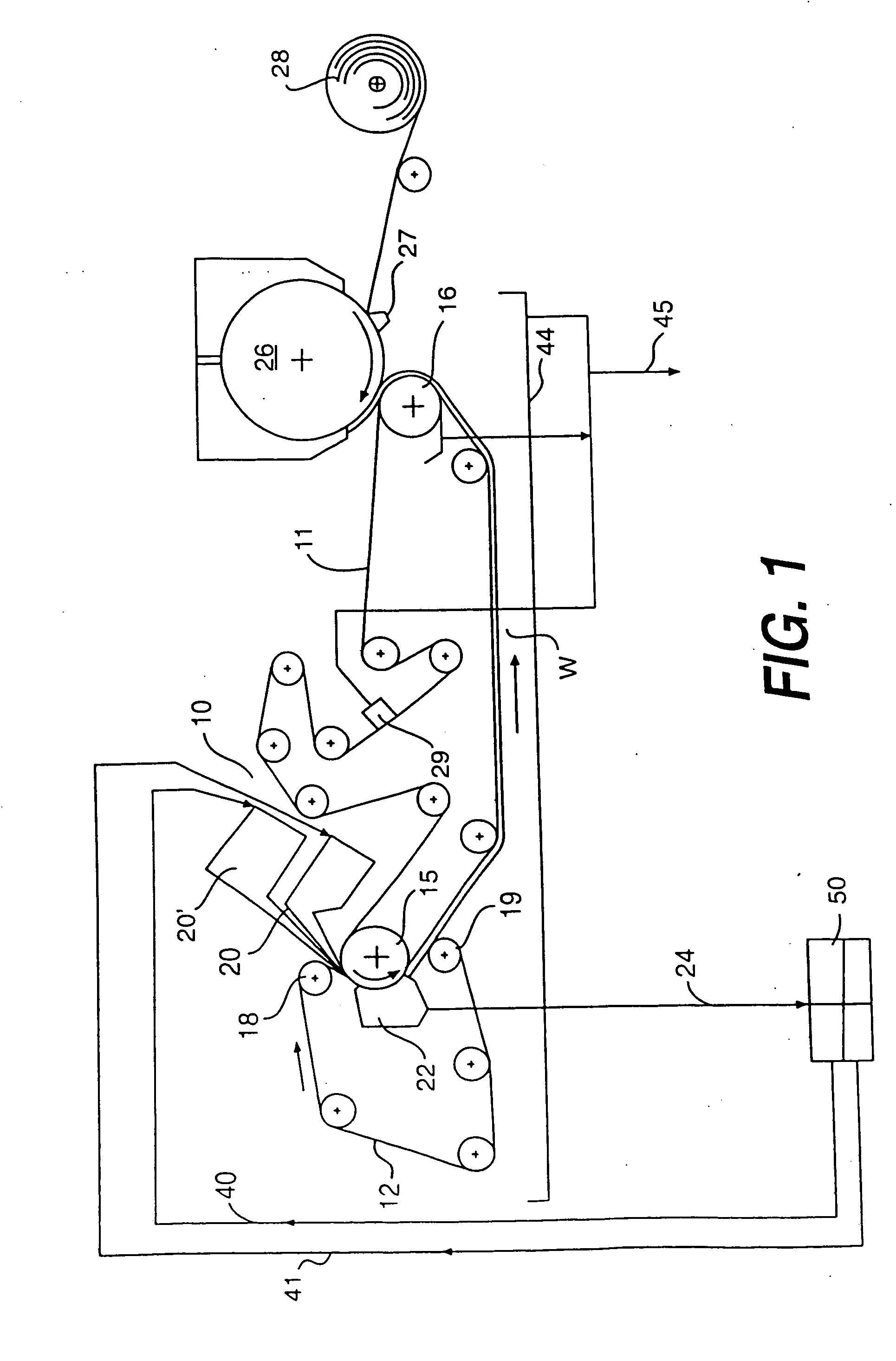

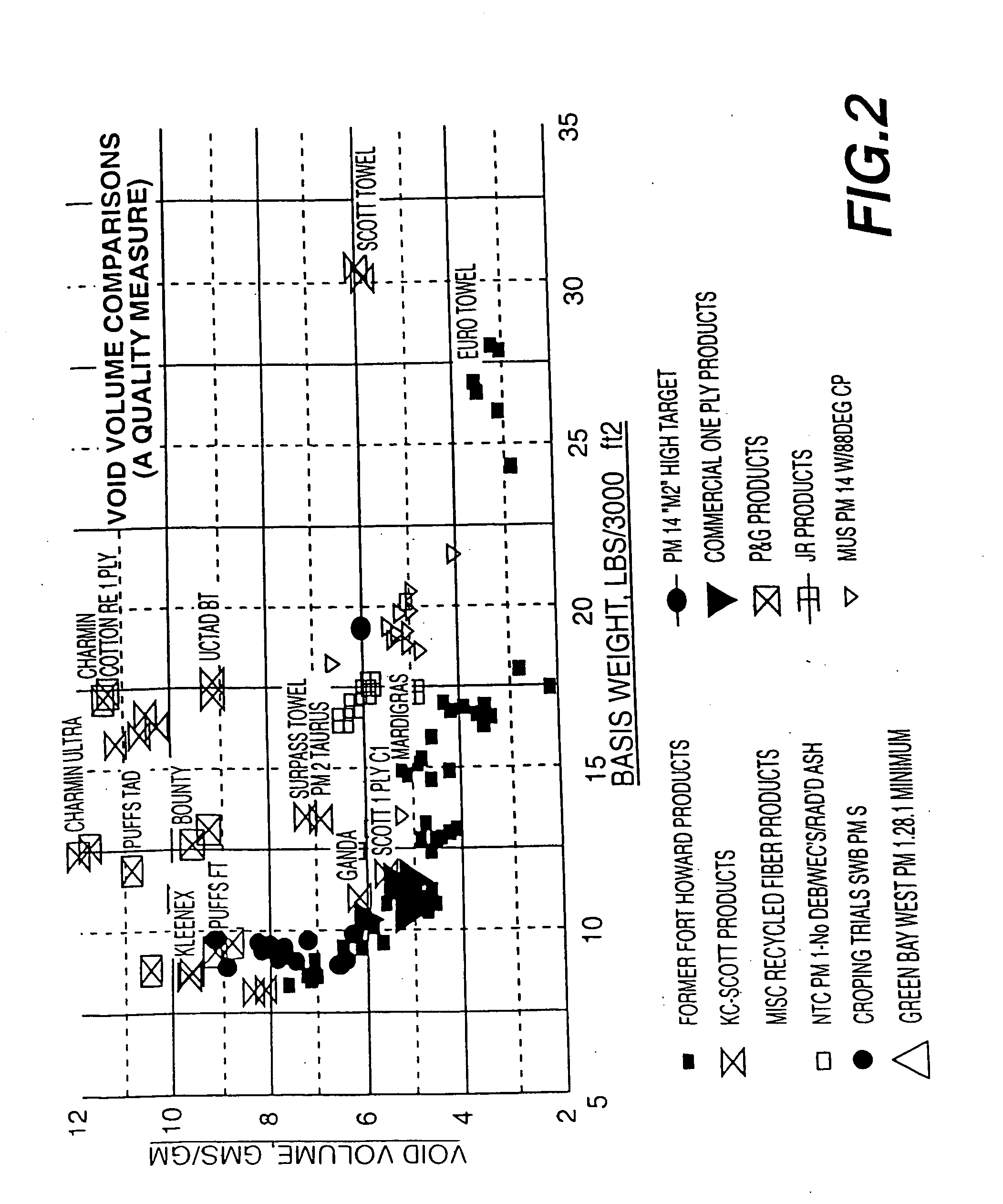

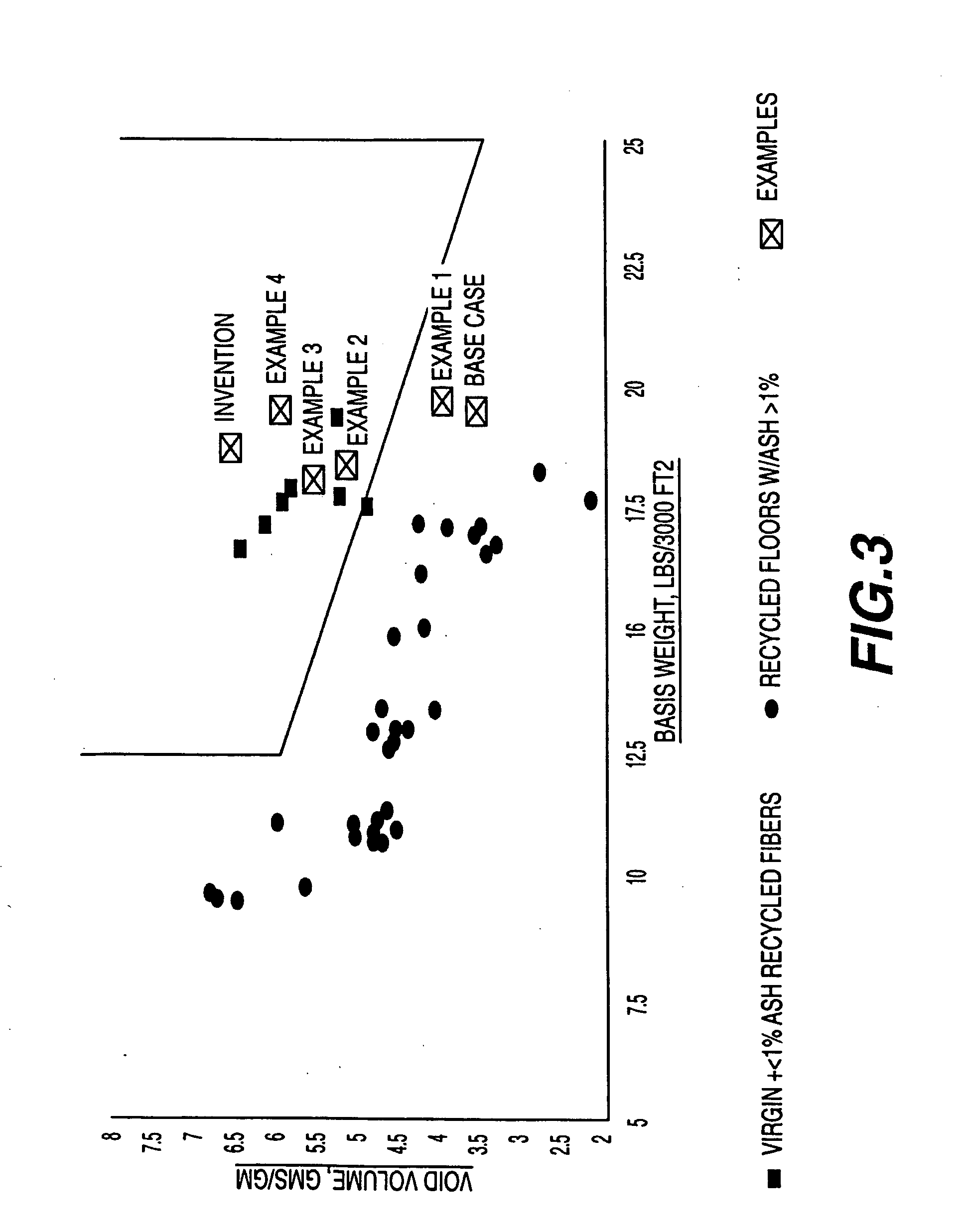

Method of making a paper web having a high internal void volume of secondary fibers

InactiveUS20050103455A1Improve efficiencyLow costNon-fibrous pulp additionNatural cellulose pulp/paperFiberPulp and paper industry

The present invention is a method of making a near-premium quality paper product having good strength and absorbency characteristics and a product made by that method. The invention is also a method for retaining a high ash content within a paper web formed by conventional wet pressing. The present invention is also a method for retaining a high percentage of softening agent within a paper web that includes such an agent. Further, the present invention is a soft absorbent paper product having a high void volume. Finally, the invention is also a method for producing a soft, absorbent, and near premium paper product having a high void volume using an undulatory crepe blade having a multiplicity of serrulations in its rake surface which presents differentiated creping angles and / or rake angles as to the paper being creped.

Owner:GPCP IP HLDG LLC

End mill for orbital drilling of fiber reinforced plastic materials

A center or non-center cutting end mill for orbital drilling of fiber reinforced plastic (FRP) materials includes a shank, a neck, a cutting head and two or more flutes. The end mill has a tool geometry with the following features: a dish angle between about 2 degrees to about 6 degrees; a helix angle between about 5 degrees to about 18 degrees; an end teeth radial rake angle between about 0 degrees and about 15 degrees; a peripheral teeth radial rake angle between about 8 degrees and about 16 degrees; a gashing axial rake angle between about 3 degrees to about 10 degrees; and a primary clearance angle between about 10 degrees to about 18 degrees. The end mill is made from a tungsten carbide substrate with cemented cobalt in a range between about 3 to 10 wt. % and a diamond coating having a thickness in a range between about 8 to 20 μm.

Owner:KENNAMETAL INC

Cutting insert, tool holder, and related method

A generally parallelogram-shaped cutting insert includes a top face; first and second main radial clearance faces, each intersecting the top face; first and second minor axial clearance faces each intersecting the top face and connecting the first and second main radial clearance faces; and a main cutting edge at the intersection of the top face and the first main radial clearance face. According to one non-limiting embodiment, the main cutting edge comprises a variable radial rake angle including a portion having a positive radial rake angle and a portion having a negative radial rake angle.

Owner:KENNAMETAL INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com