Patents

Literature

710 results about "Hole drilling method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

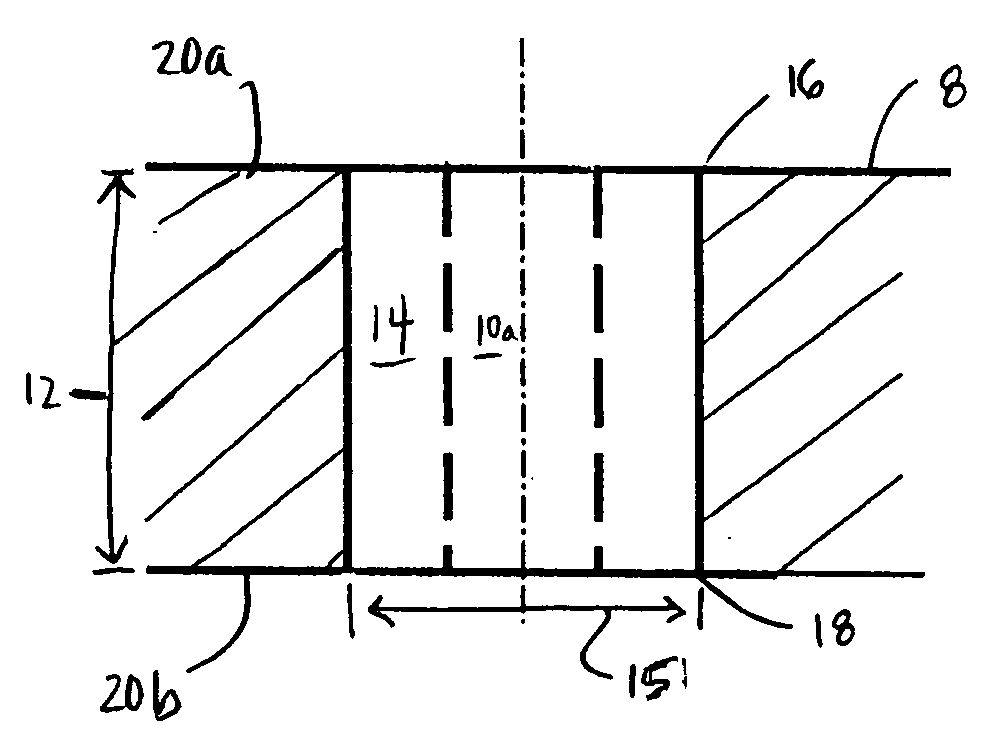

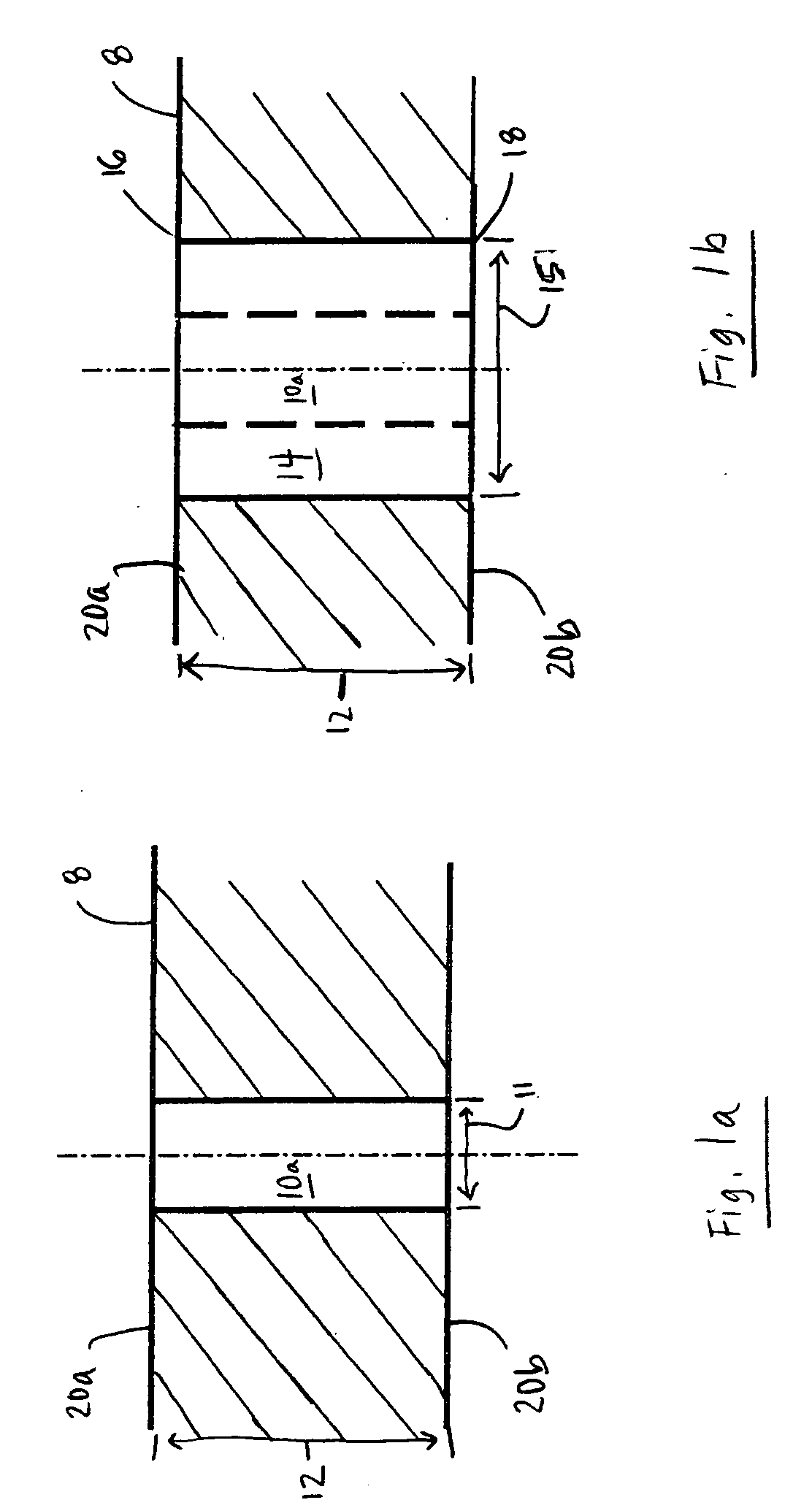

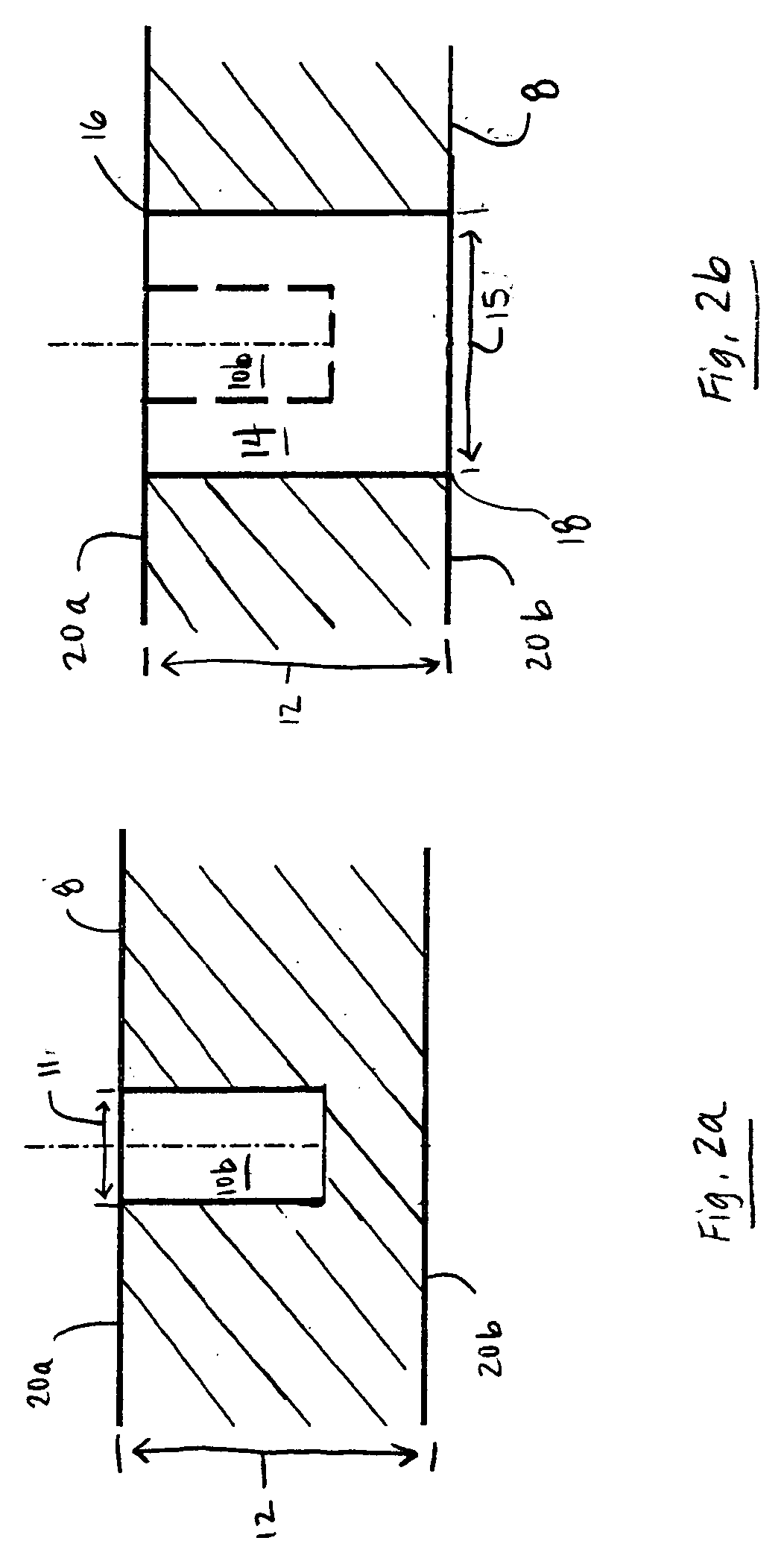

The hole drilling method is a method for measuring residual stresses, in a material. Residual stress occurs in a material in the absence of external loads. Residual stress interacts with the applied loading on the material to affect the overall strength, fatigue, and corrosion performance of the material. Residual stresses are measured through experiments. The hole drilling method is one of the most used methods for residual stress measurement.

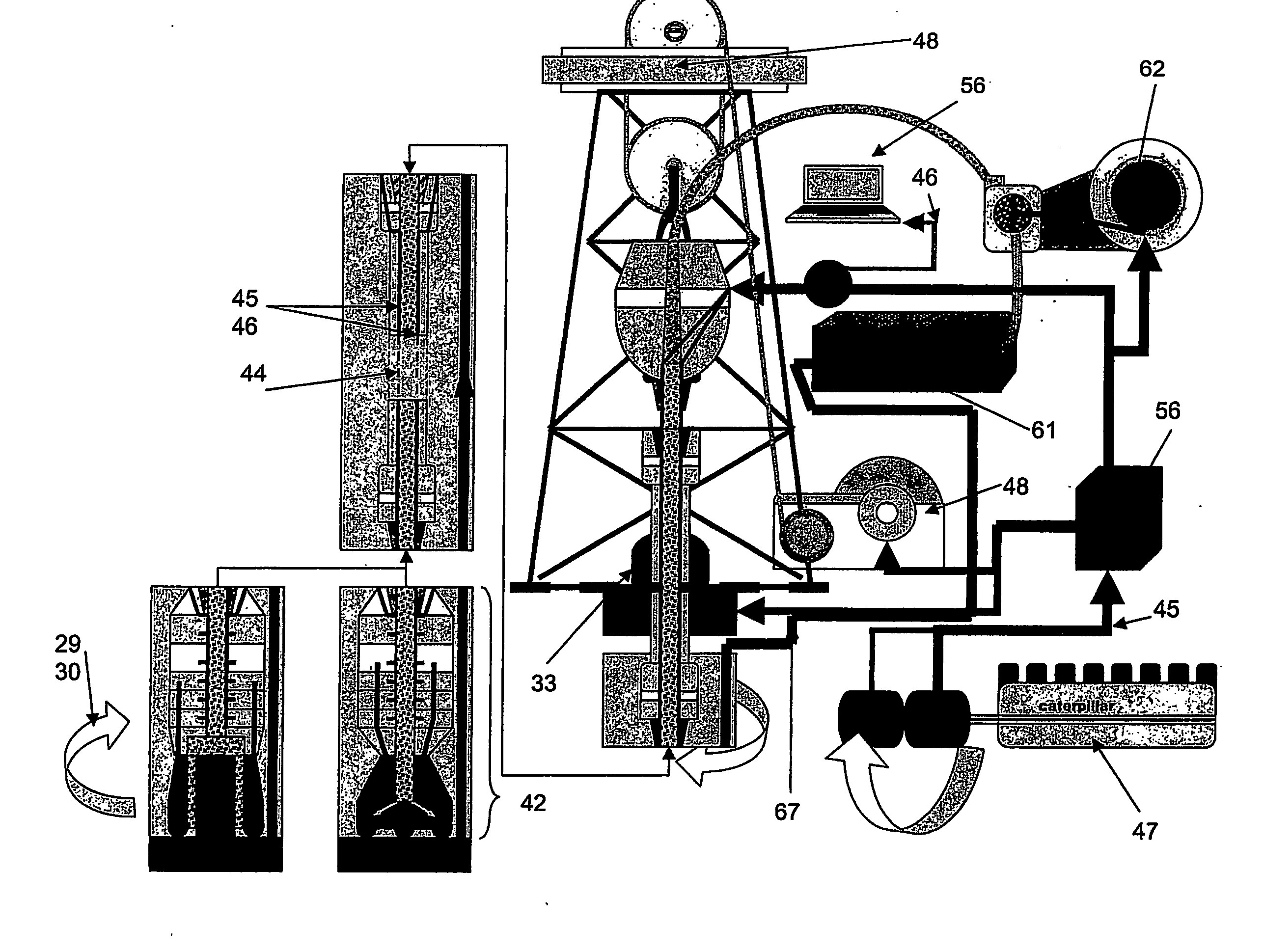

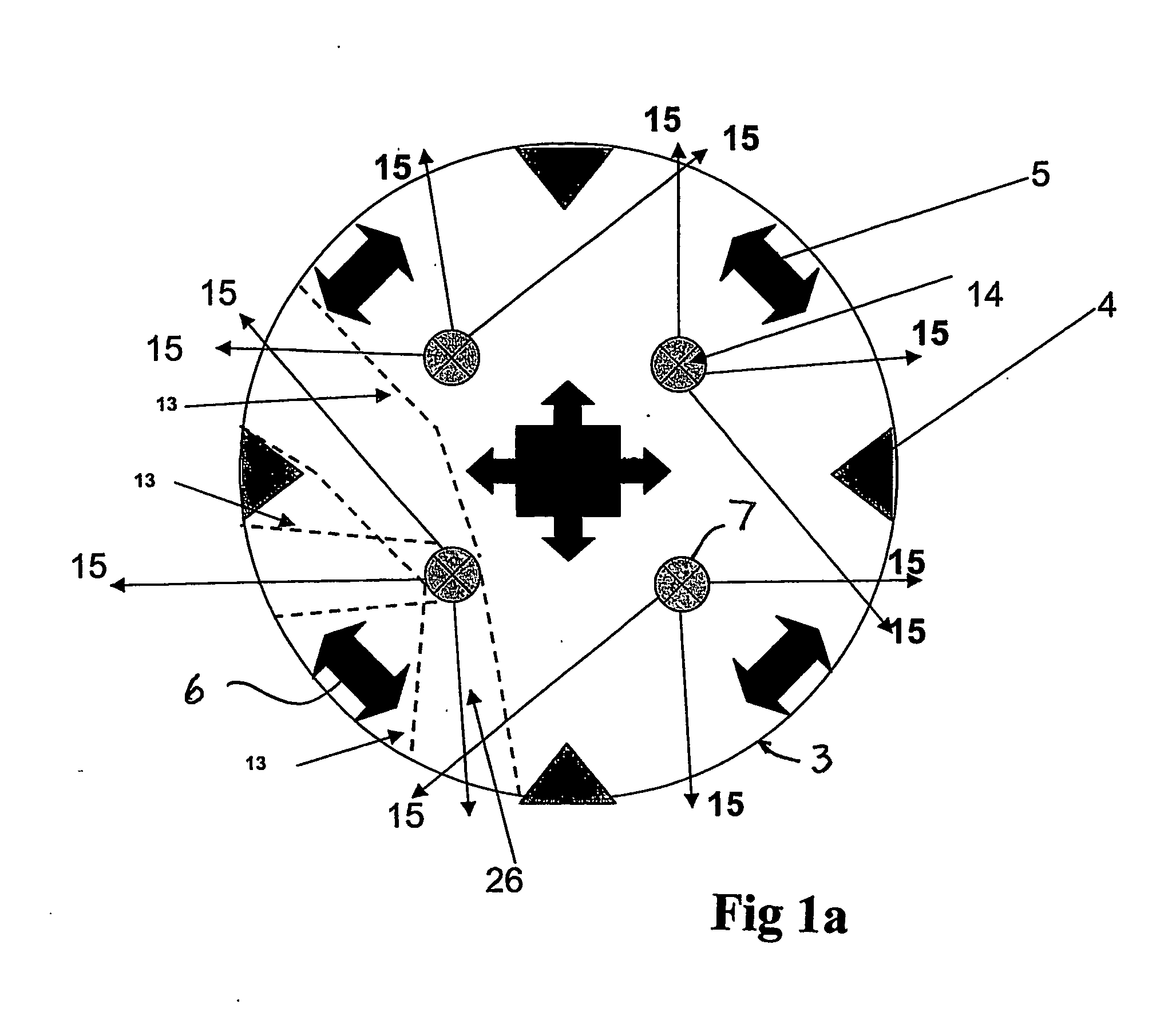

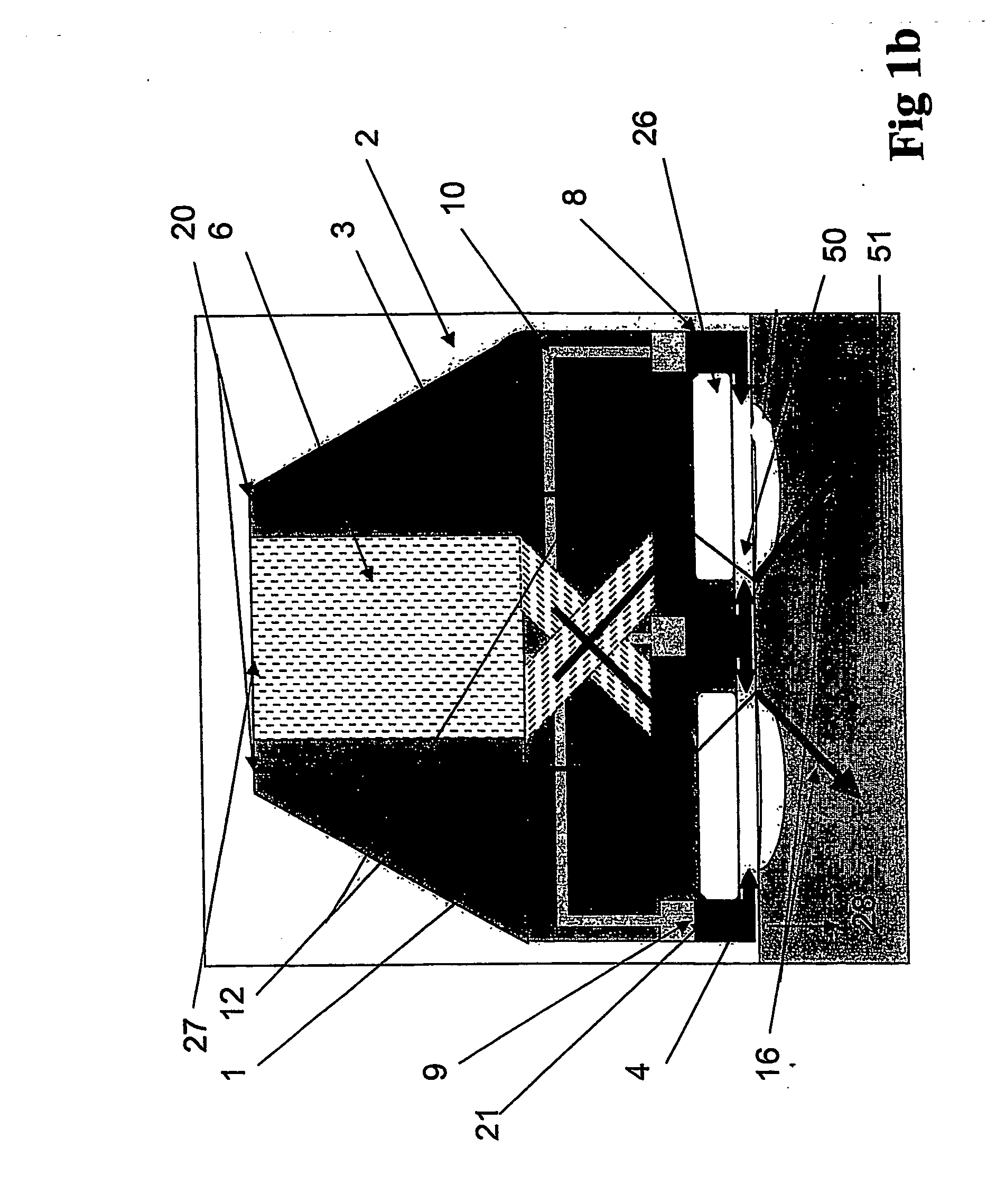

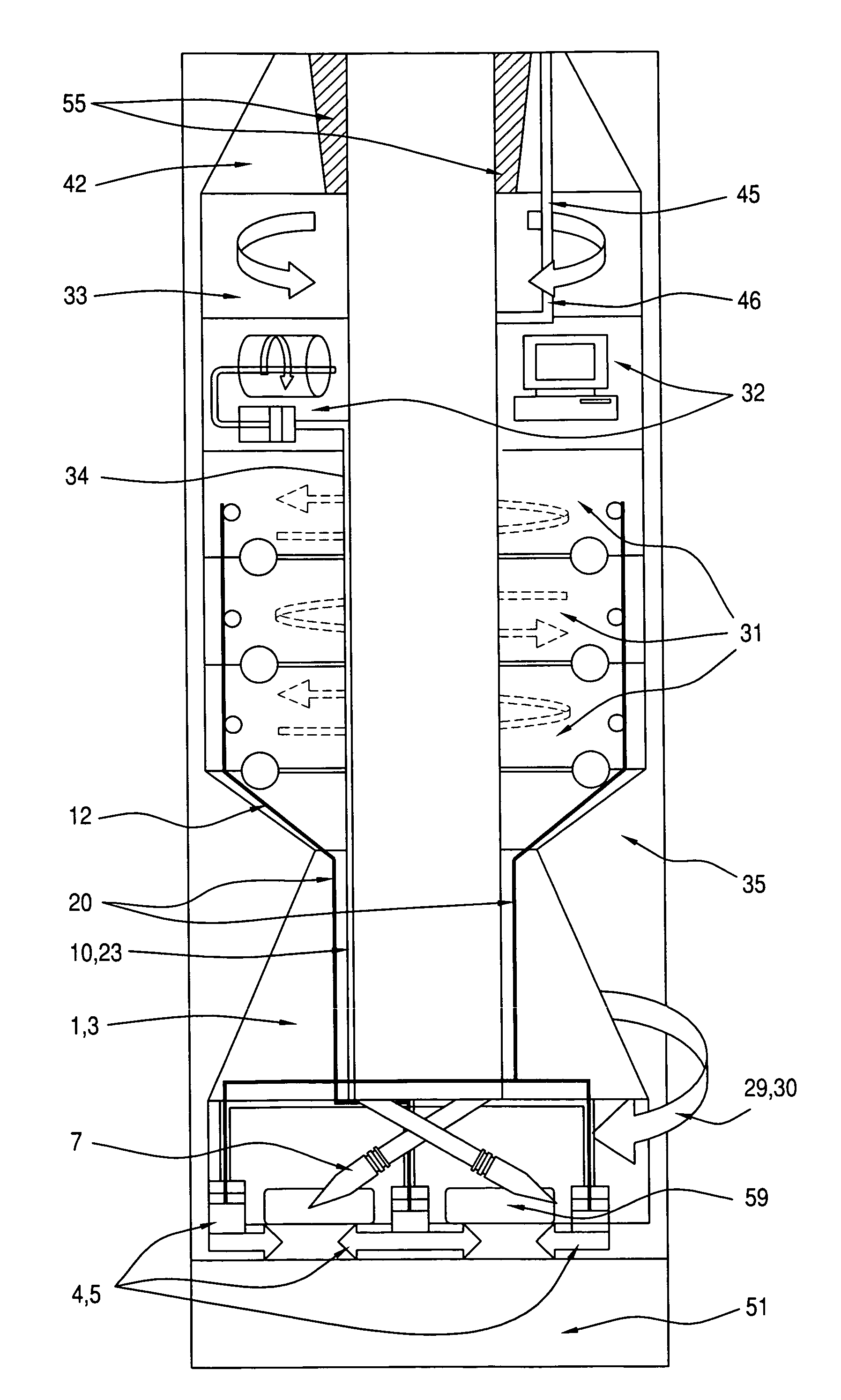

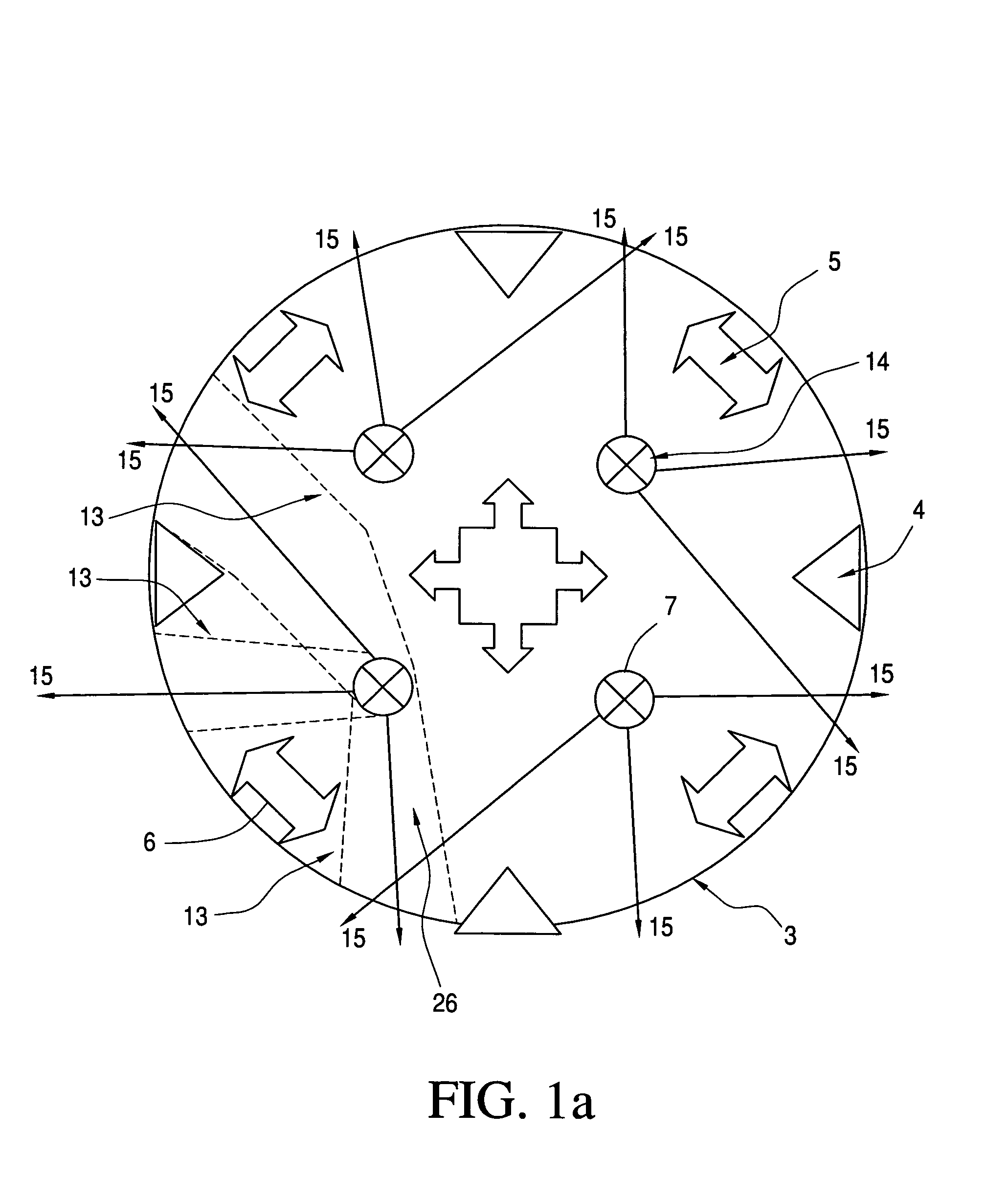

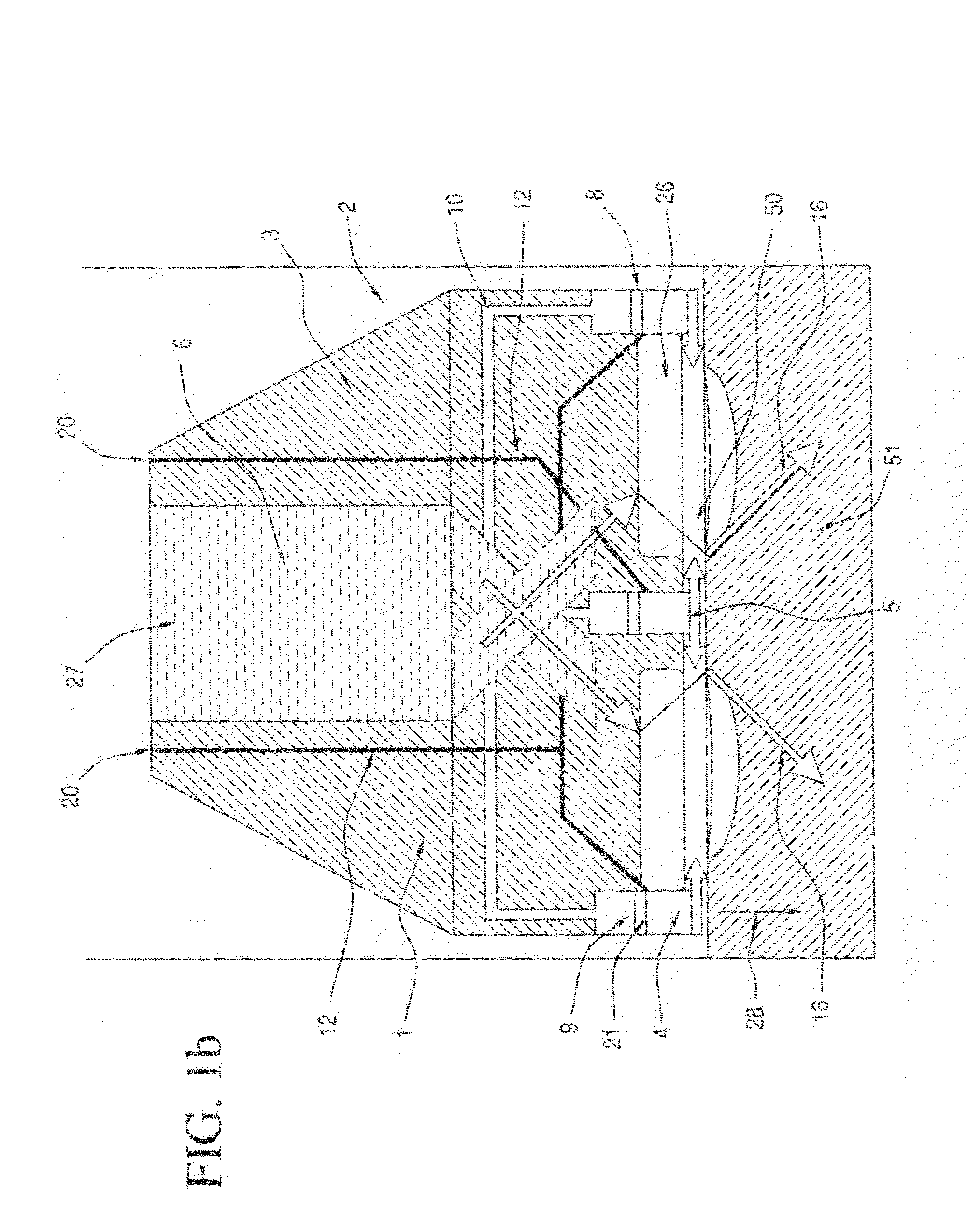

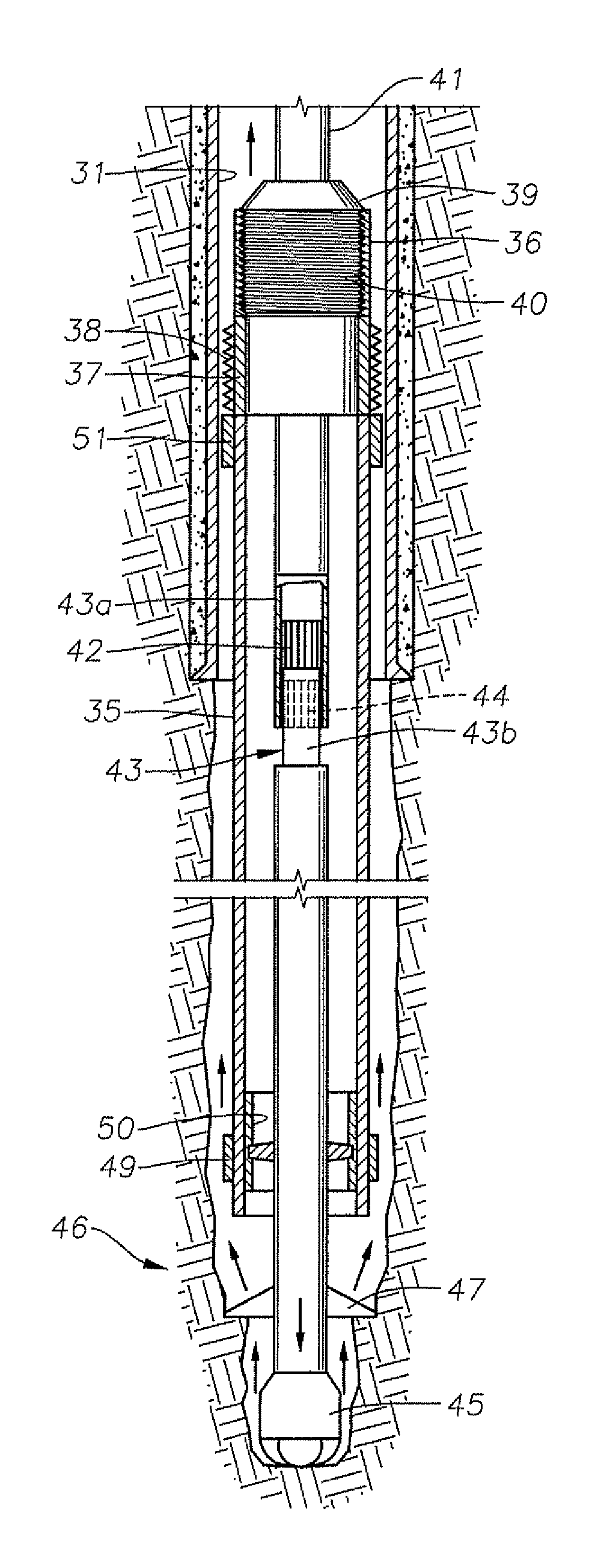

Method, Drilling Machine, Drill bit and Bottom Hole Assembly for Drilling by Electrical Discharge by Electrical Discharge Pulses

ActiveUS20090133929A1Efficiently provideIncrease drilling speedDrill bitsDisloding machinesElectric dischargeClosed loop

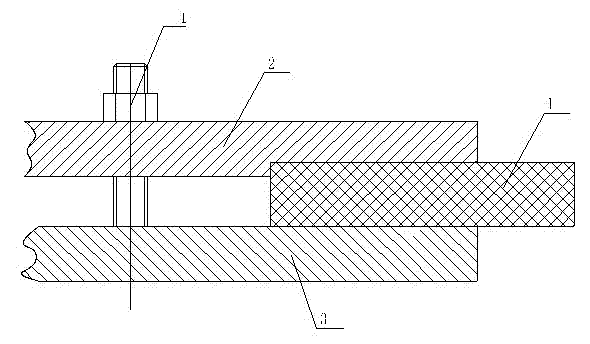

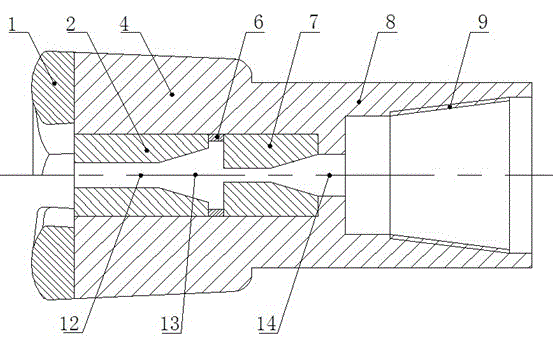

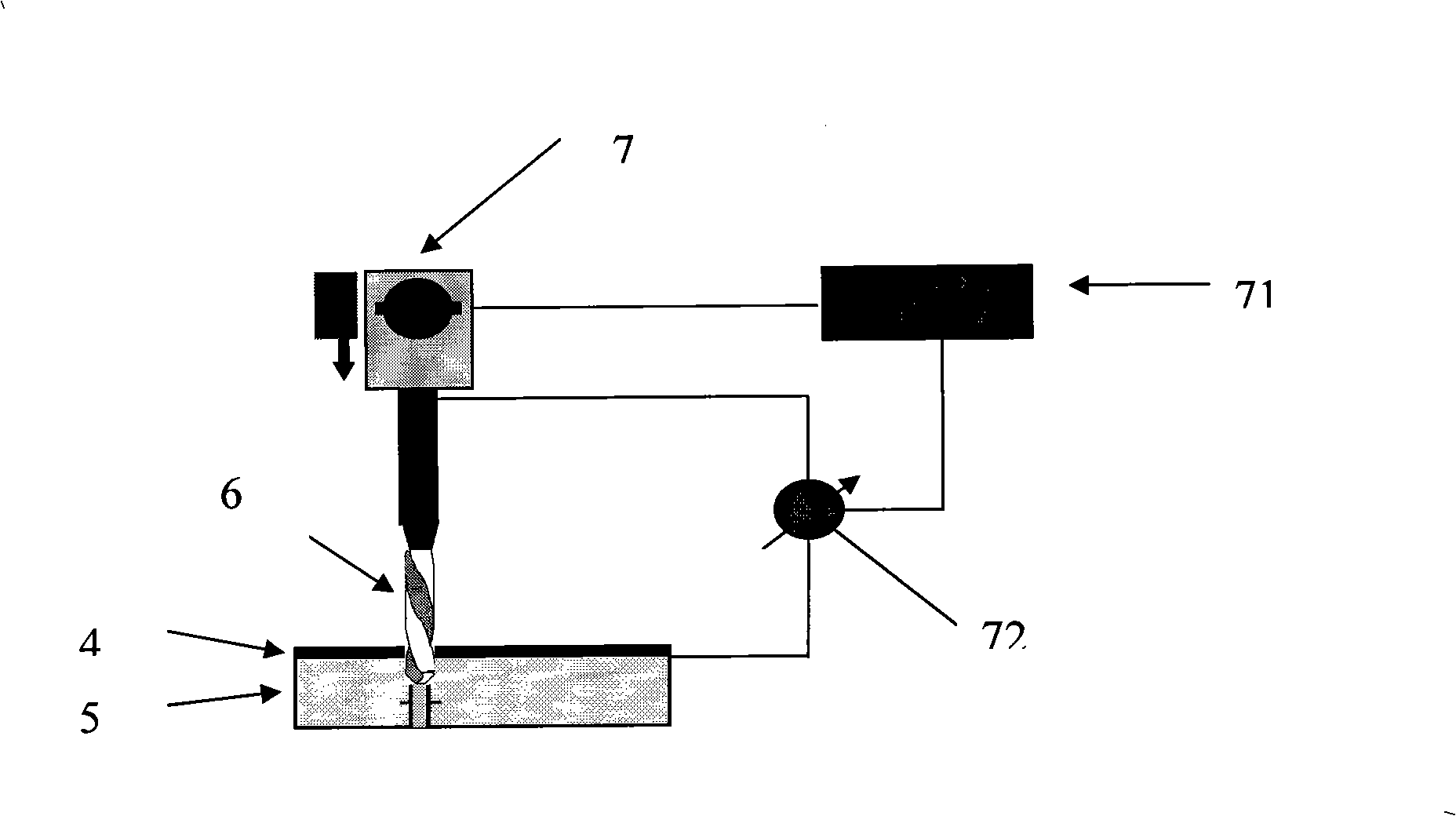

Machine for ground drilling, with a circulating fluid, by the utilization of electric discharge generated by high-voltage pulses between electrodes. It may comprise: —A drill-bit 1 with electrodes movable relative to each other, so that bottom-hole physical contact be secured for all the electrodes 4 on all bottom-hole topographies. —Pointed hydraulic nozzles for jetting the fluid, to remove primary cuttings and with pressure expansion across the nozzles 7 at no less than 4 MPa. —A high-voltage pulse generator deployed down-hole at a minimum distance from the drill-bit 1. —A rotating or oscillating bit causing the borehole cross-sectional excavation to occur, and electric discharge between a plurality of electrodes situated on the bit face along one or a few radii and tangents. —A bottom hole assembly for annular hole-making with core storage, transportation, down-hole closed loop discharge fluid circulation. A discharge fluid storage may be incorporated. A drilling method is also described.

Owner:UNODRILL

Telescopic drilling method

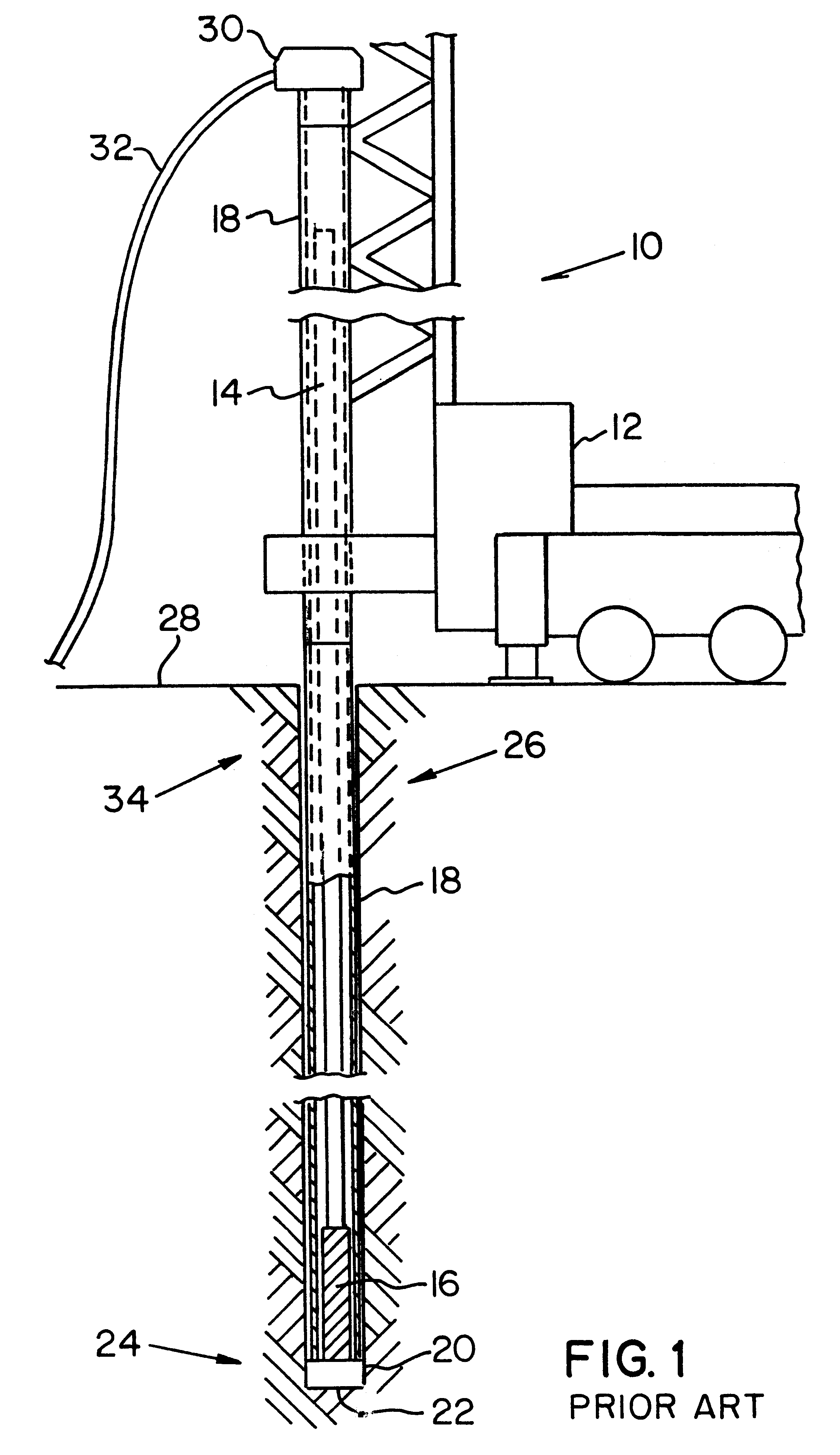

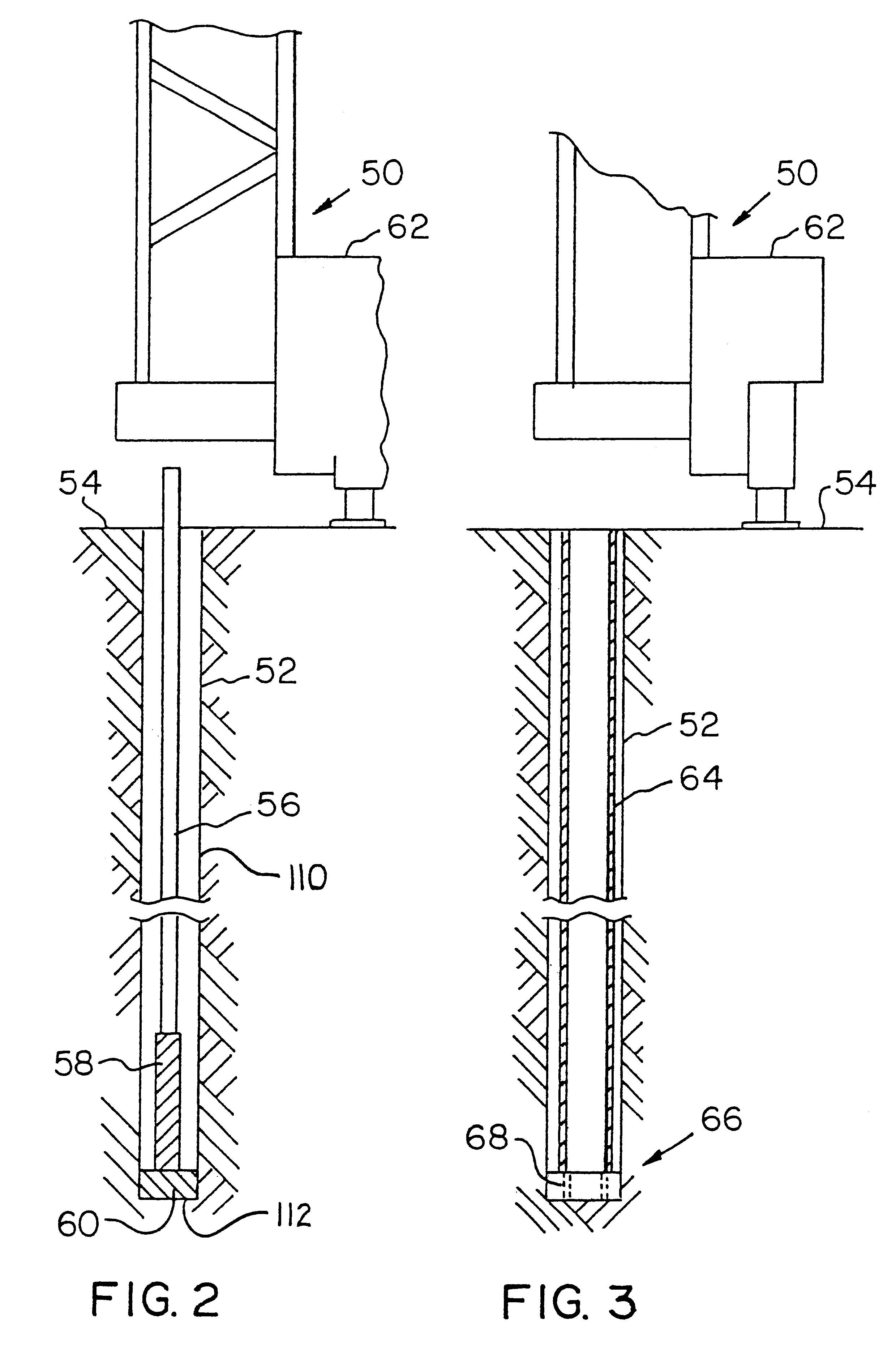

A telescopic drilling method includes the steps of drilling an outer bore through a surface, inserting a hollow outer conduit into the outer bore, and at least partially inserting a first hollow inner conduit through the outer conduit. Next, the method includes the steps of preventing the first inner conduit from moving longitudinal with respect to the outer conduit engaging a rotatable inner drill bit with a ring drill bit and further drilling the outer bore using a unitary drill bit head to a successive depth. The inner drill bit is disengaged from the ring drill bit and a second end of a successive hollow inner conduit is attached to a first end of a preceding one, and the preceding inner conduit is unclamped.

Owner:SENSENIG FLOYD R

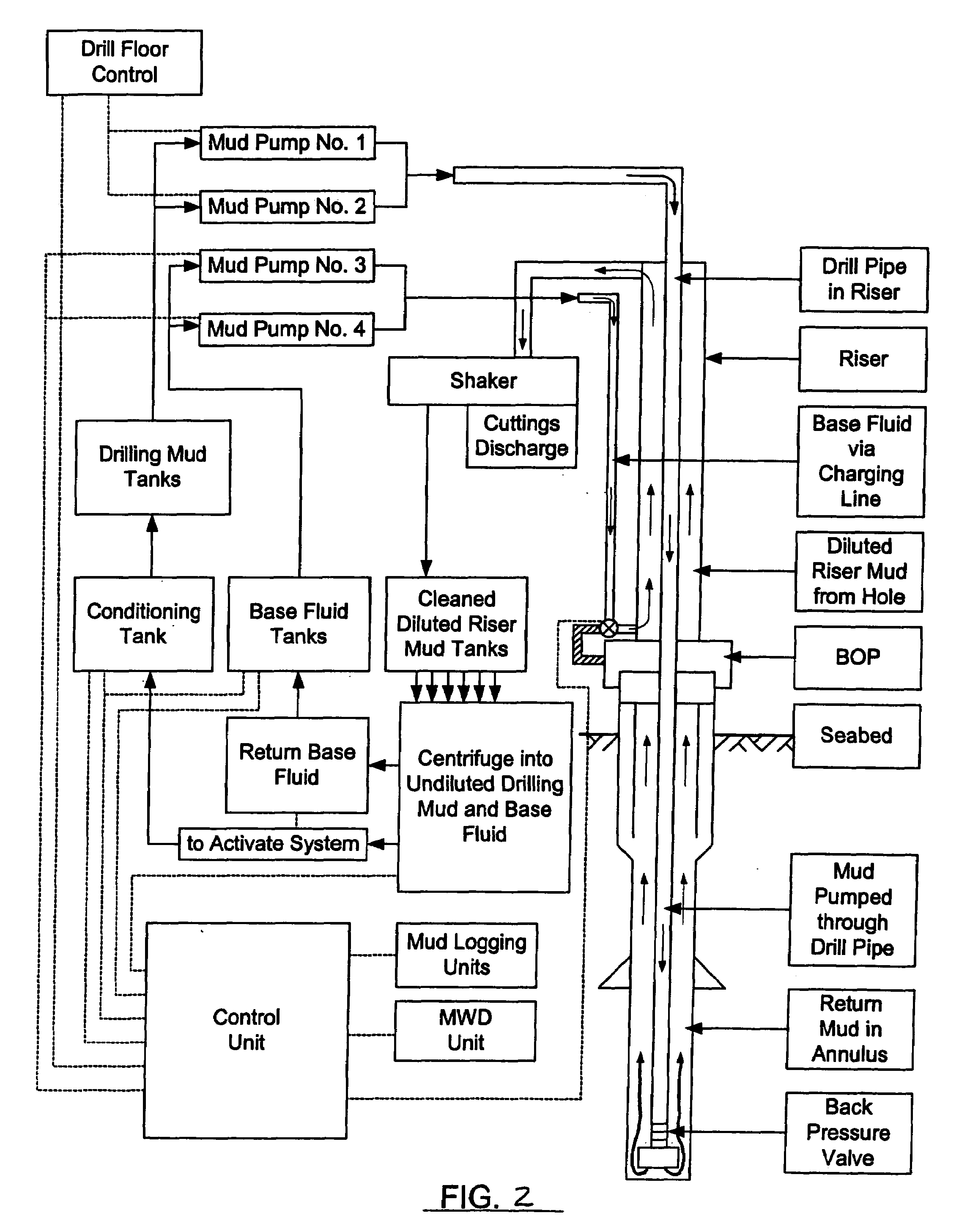

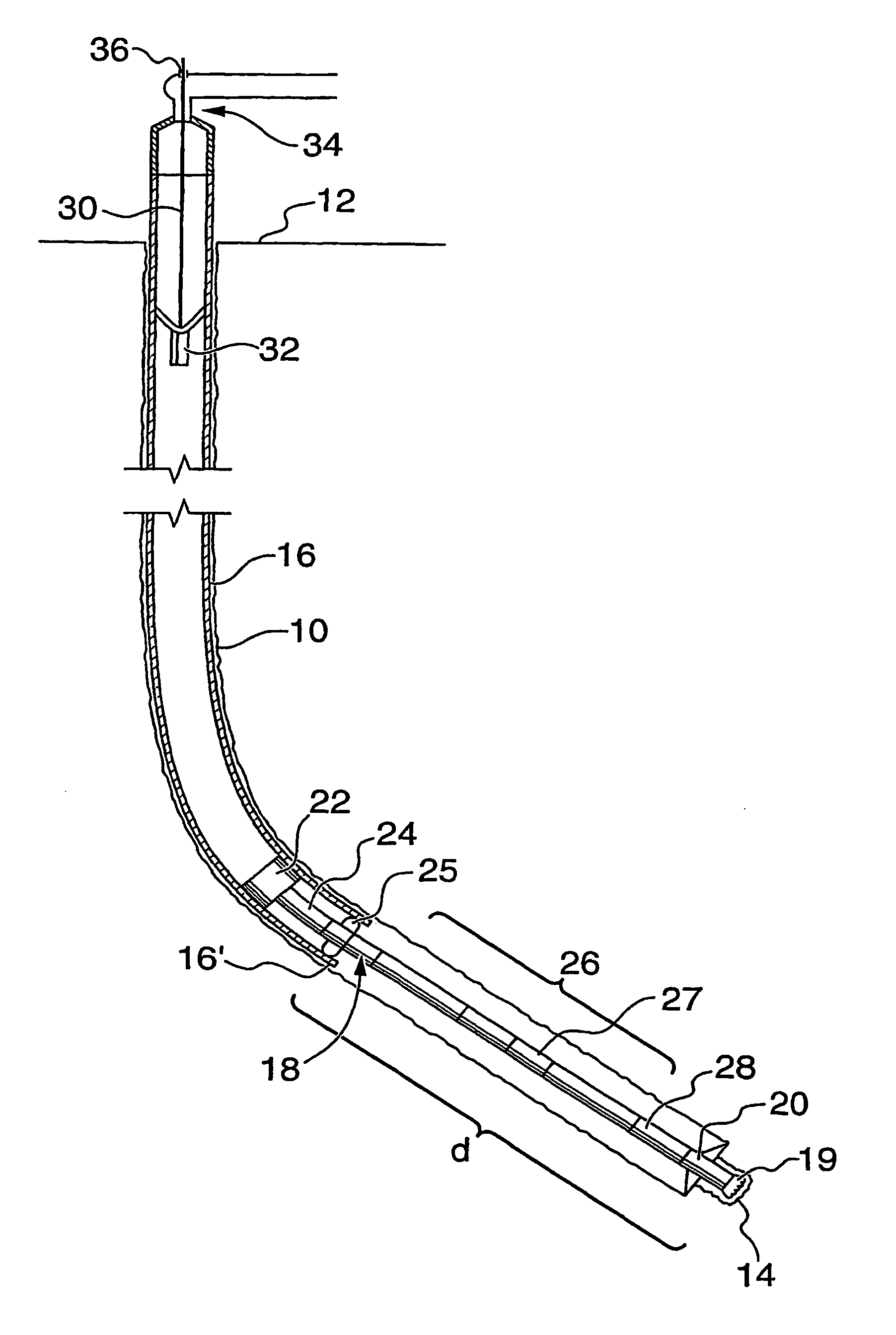

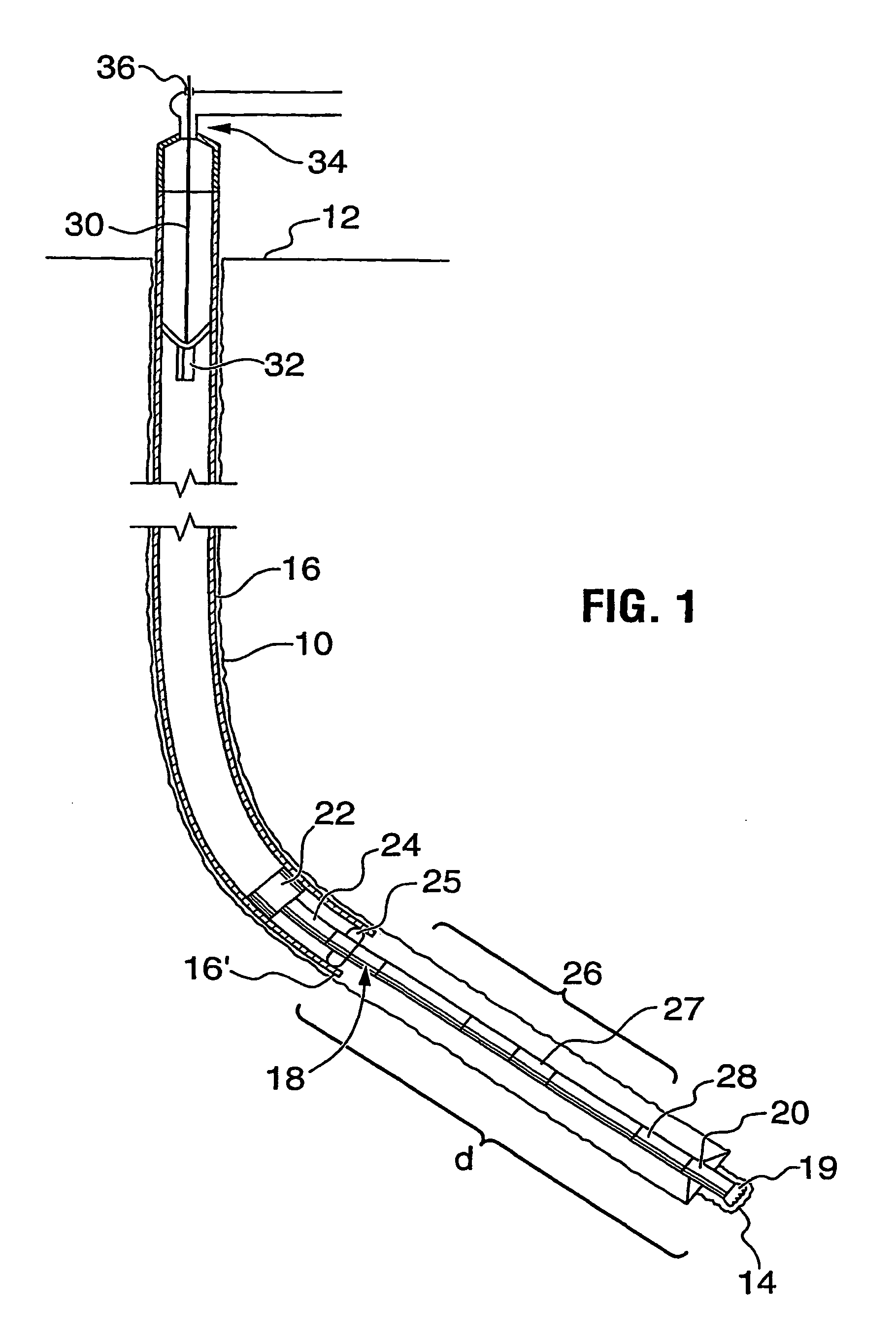

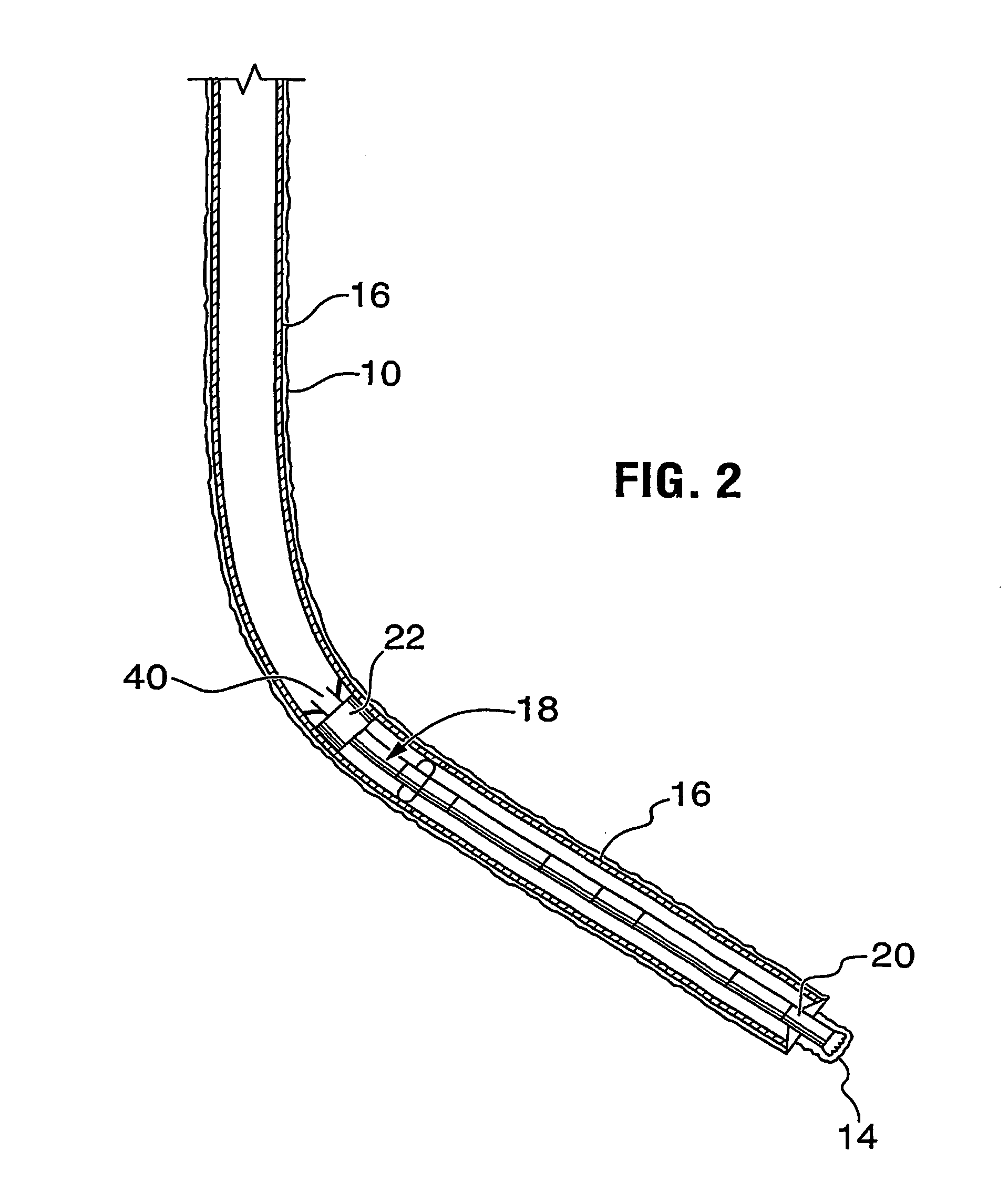

Dual Gradient Drilling Method And Apparatus With An Adjustable Centrifuge

A method and system for controlling drilling mud density in drilling operations. The mud required at the wellhead is combined with a base fluid of a different density to produce diluted mud in the riser. By combining the appropriate quantities of drilling mud with base fluid, riser mud density at or near the density of seawater may be achieved, thereby permitting greater control over the pressure in the wellbore and various risers. Blowout preventers may also be used in combination with the process to control these pressures. Concentric risers are disclosed, wherein an annulus defined within one riser is utilized to carry the different density base fluid to the injection point for injection into the drilling mud, while an annulus defined within another riser is utilized to carry the combination fluid and cuttings back to the drilling rig. Cuttings are separated in the usual manner at the surface. The diluted mud is passed through a centrifuge system to separate drilling mud from the different density base fluid. The centrifuge system may also be utilized to separate the recovered drilling fluid into a substantially barite portion and a substantially drilling fluid portion, wherein the two portions are stored locally at the rig and recirculated during drilling operations.

Owner:DUAL GRADIENT SYST

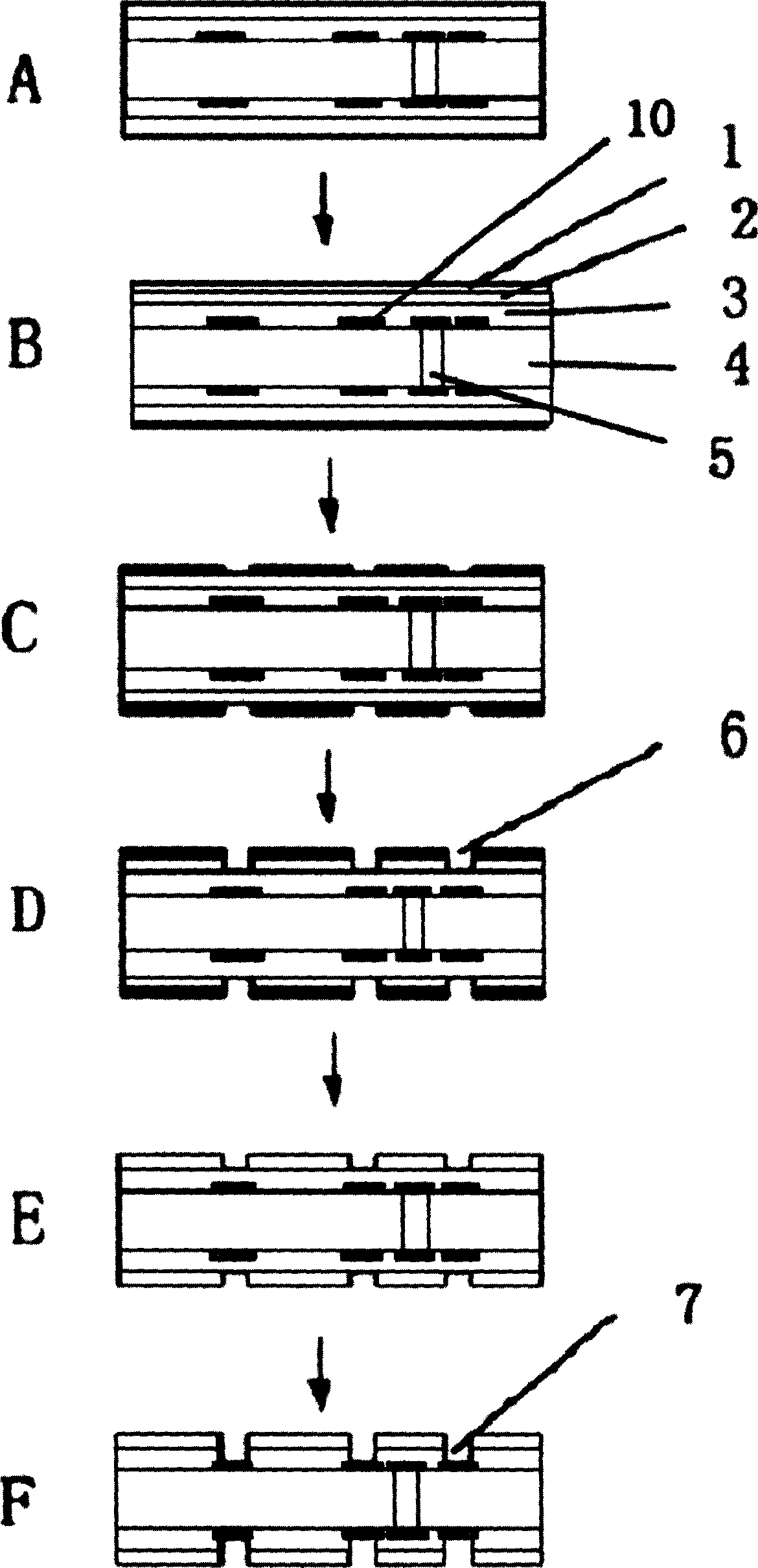

Method of drilling a hole through Co2 laser directly

InactiveCN1761378AHigh precisionGuaranteed alignmentConductive material chemical/electrolytical removalLaser beam welding apparatusEtchingCopper foil

Drilling method of carbon dioxide laser includes steps: preparing locating point on layer next to the outer layer; before pressfitting added layer, browning oxidizing surface of target bonding pad; after pressfitting added layer, milling location hole / polishing edge, washing surface under high pressure; browning front surface of copper, thinning and coursing the surface before drilling hole by layer; first time to drill hole by laser; positioning film perforation by using plate location hole in original etching method for making window of copper, burning through copper foil and resin above the locating point on layer next to the outer layer so as to expose the locating point; second time to drill hole by laser; using the exposed locating point as position fixing to make micro hole inplate; washing surface under high pressure to remove browning layer after drill hole. The invention saves dry film and etching liquid, and raises process precision.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

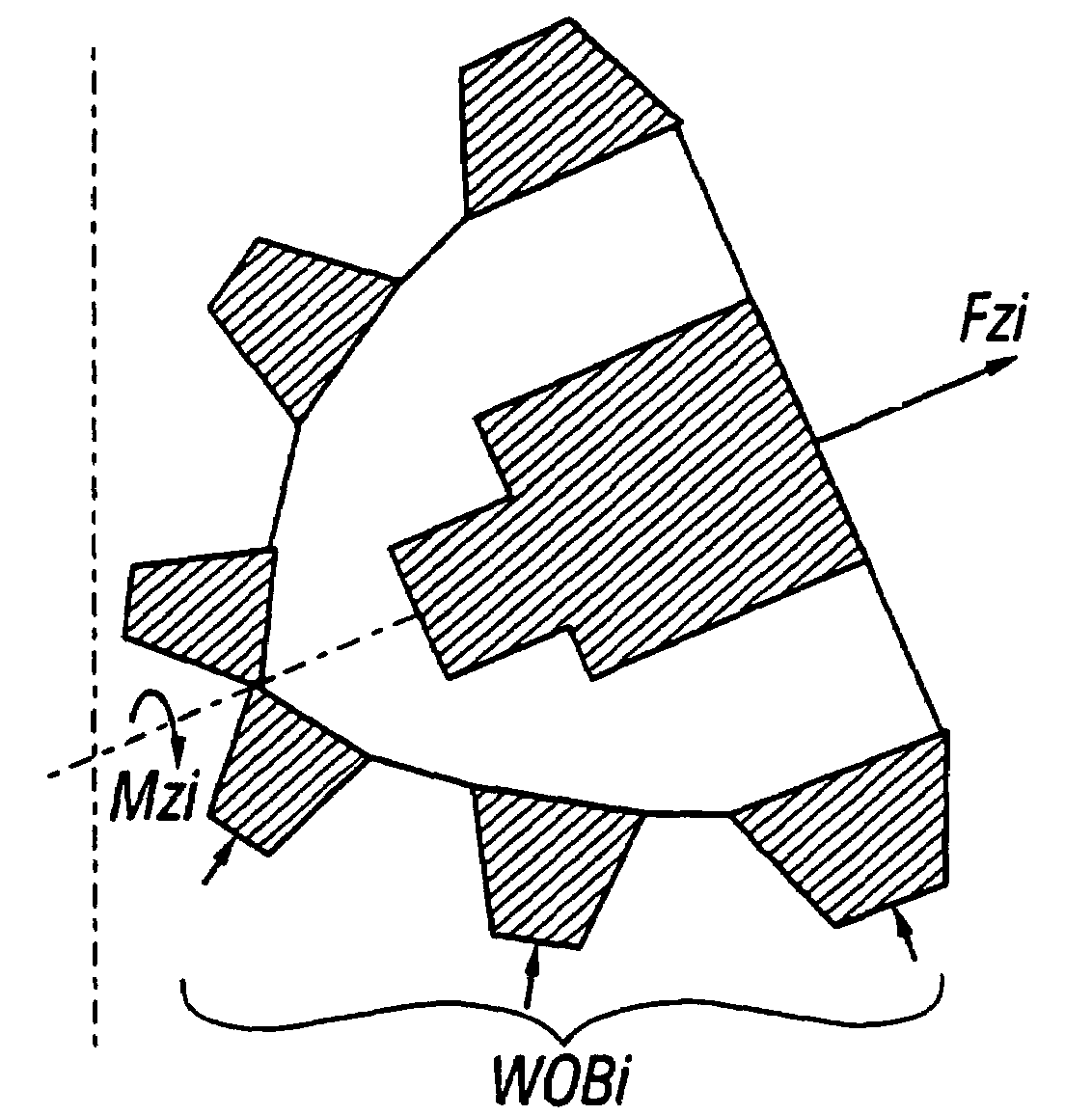

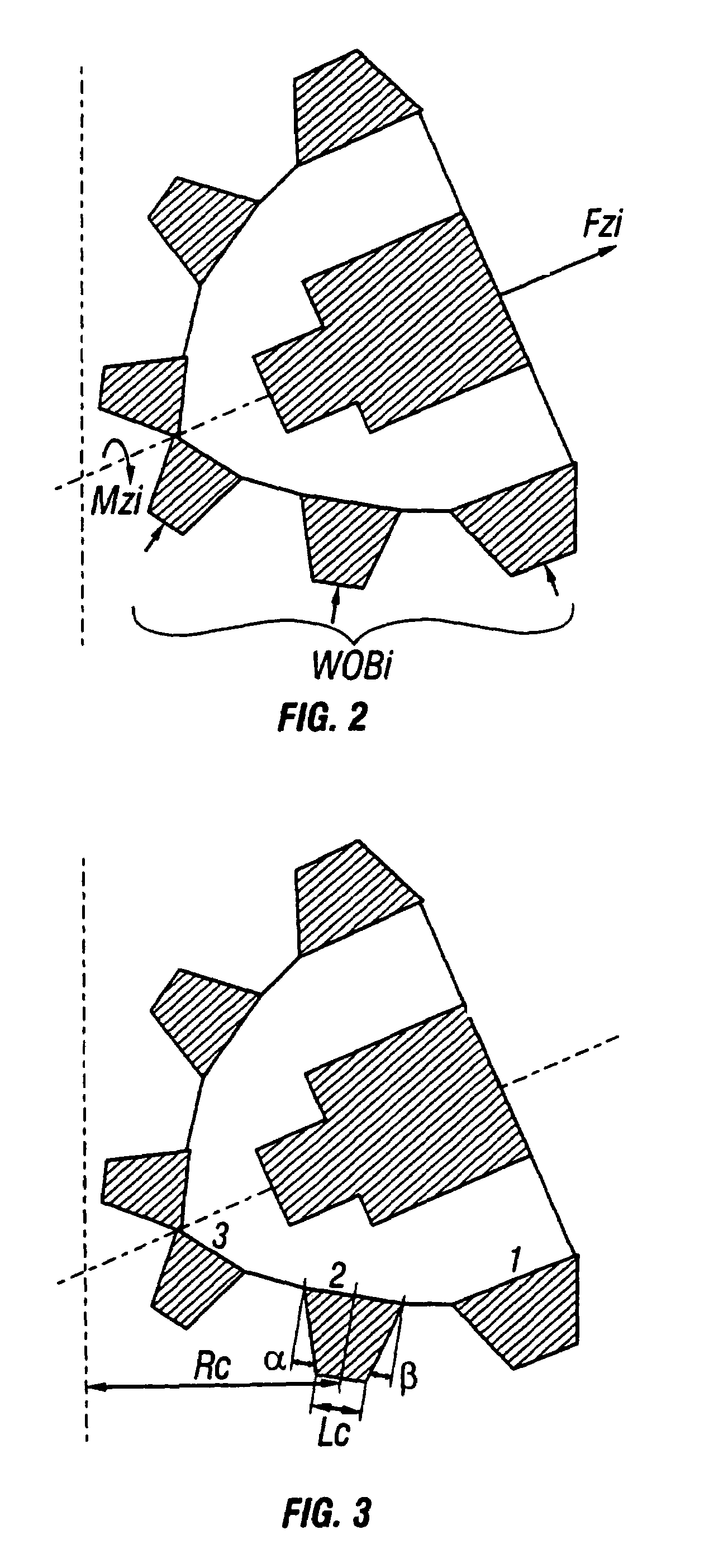

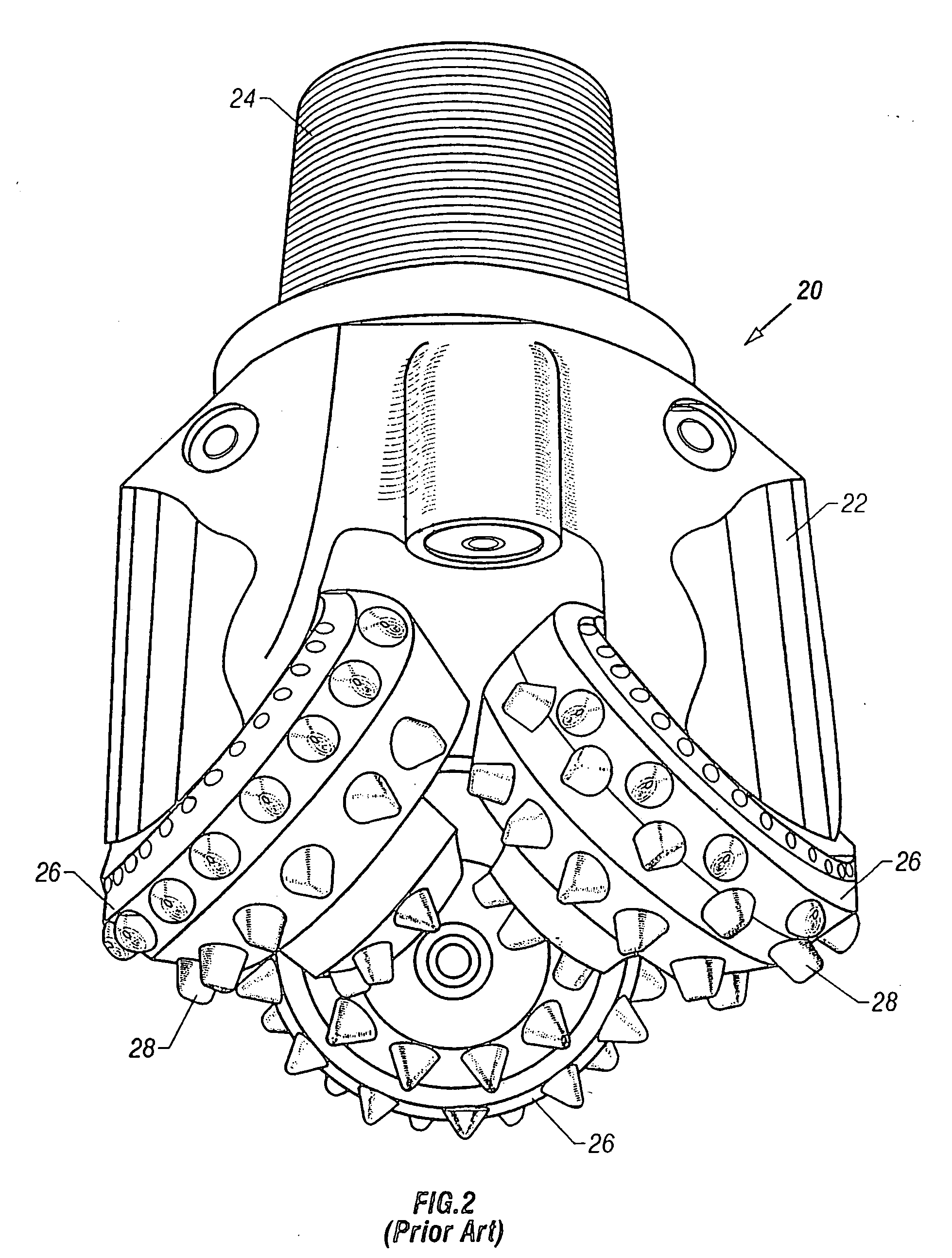

Force-balanced roller-cone bits, systems, drilling methods, and design methods

InactiveUS6986395B2Reduce rotationImprove drilling efficiencyEarth drilling toolsDrill bitsAxial forceEngineering

Roller cone drilling wherein the bit optimization process equalizes the downforce (axial force) for the cones (as nearly as possible, subject to other design constraints).

Owner:HALLIBURTON ENERGY SERVICES INC

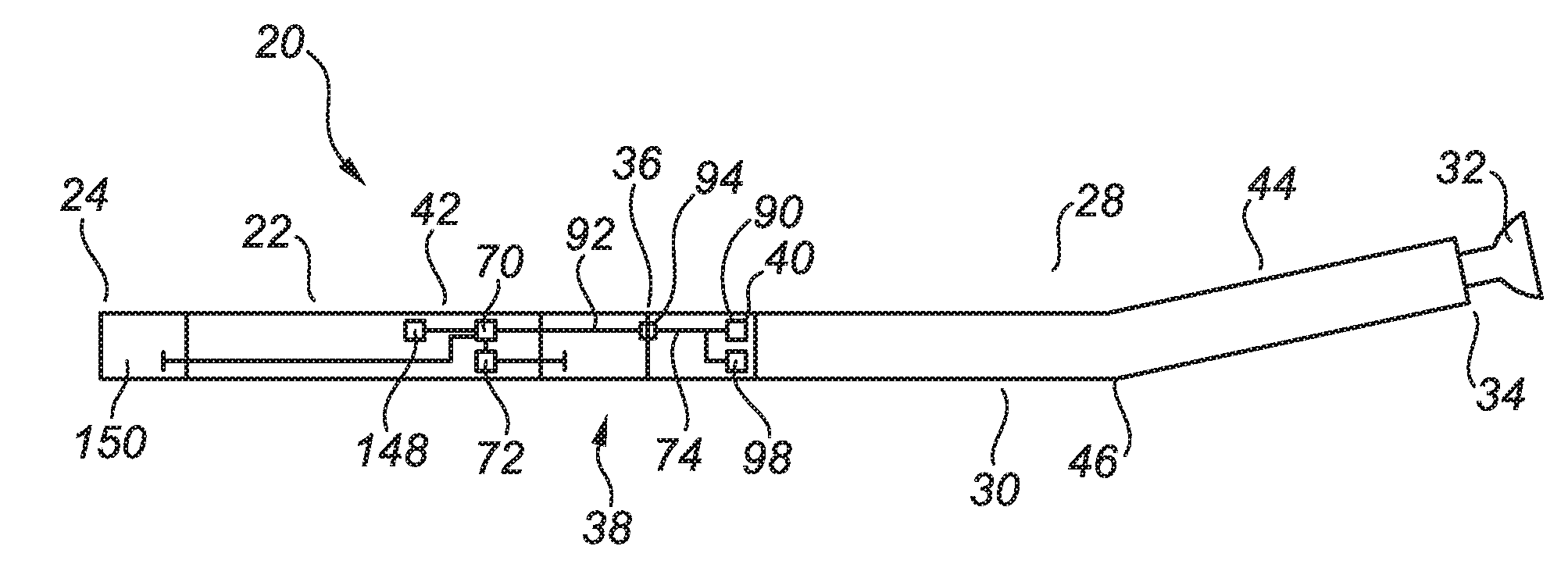

Drilling Apparatus and Method

A drilling apparatus includes an upper drill string, a lower drill string including a rotary drilling motor, an orientable rotatable connection between the drill strings, a reactive torque control device associated with the orientable rotatable connection, an orientation sensing device for providing a sensed actual orientation of the lower drill string, and a feedback control system configured to actuate the control device in response to the sensed actual orientation to achieve a target orientation of the lower drill string. A drilling method includes actuating the control device to prevent relative rotation of the drill strings, providing a sensed actual orientation of the lower drill string, comparing the sensed actual orientation with a target orientation of the lower drill string, actuating the control device to allow the lower drill string to rotate to provide the target orientation, and actuating the control device to prevent relative rotation of the drill strings.

Owner:HALLIBURTON ENERGY SERVICES INC

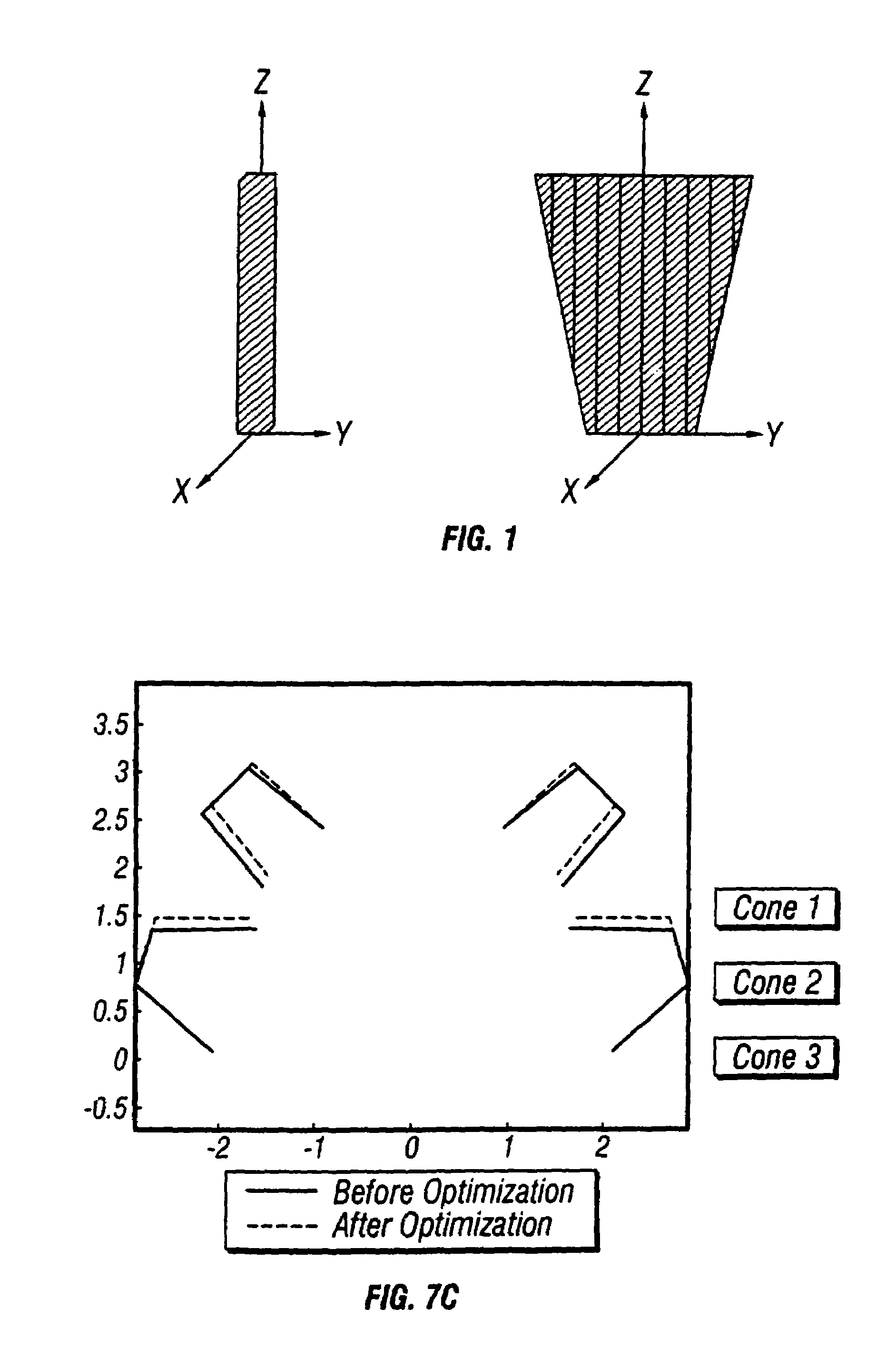

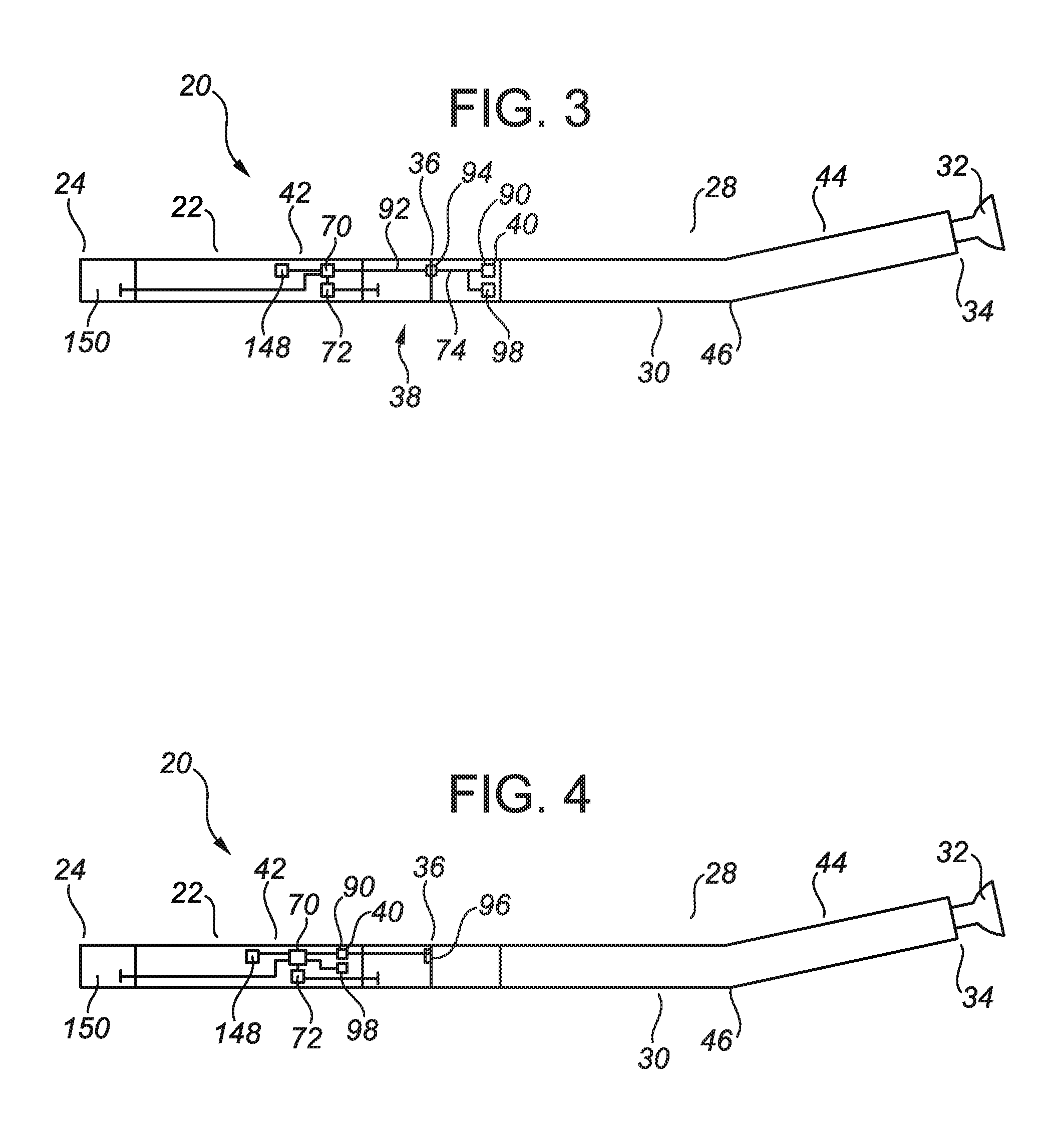

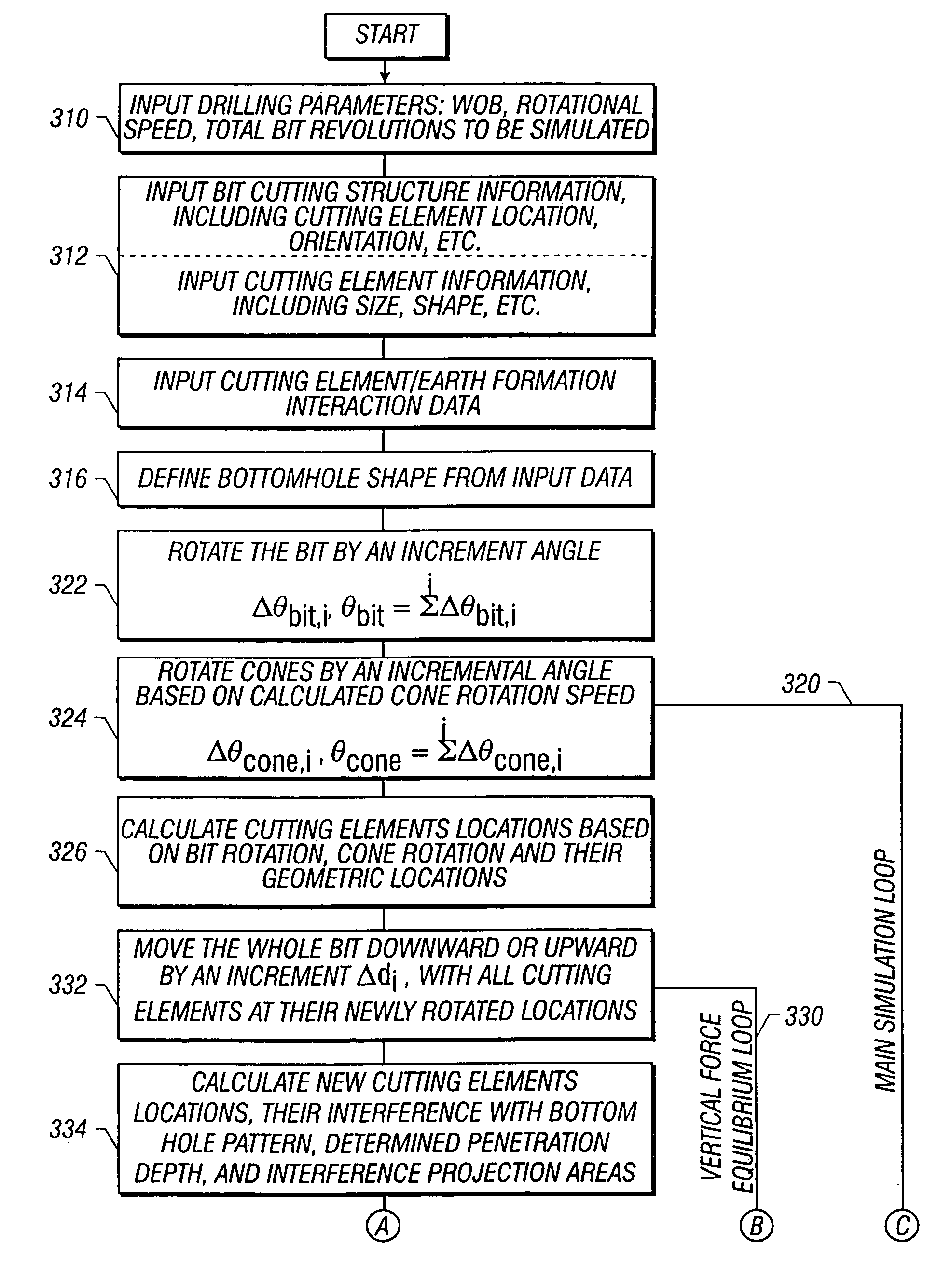

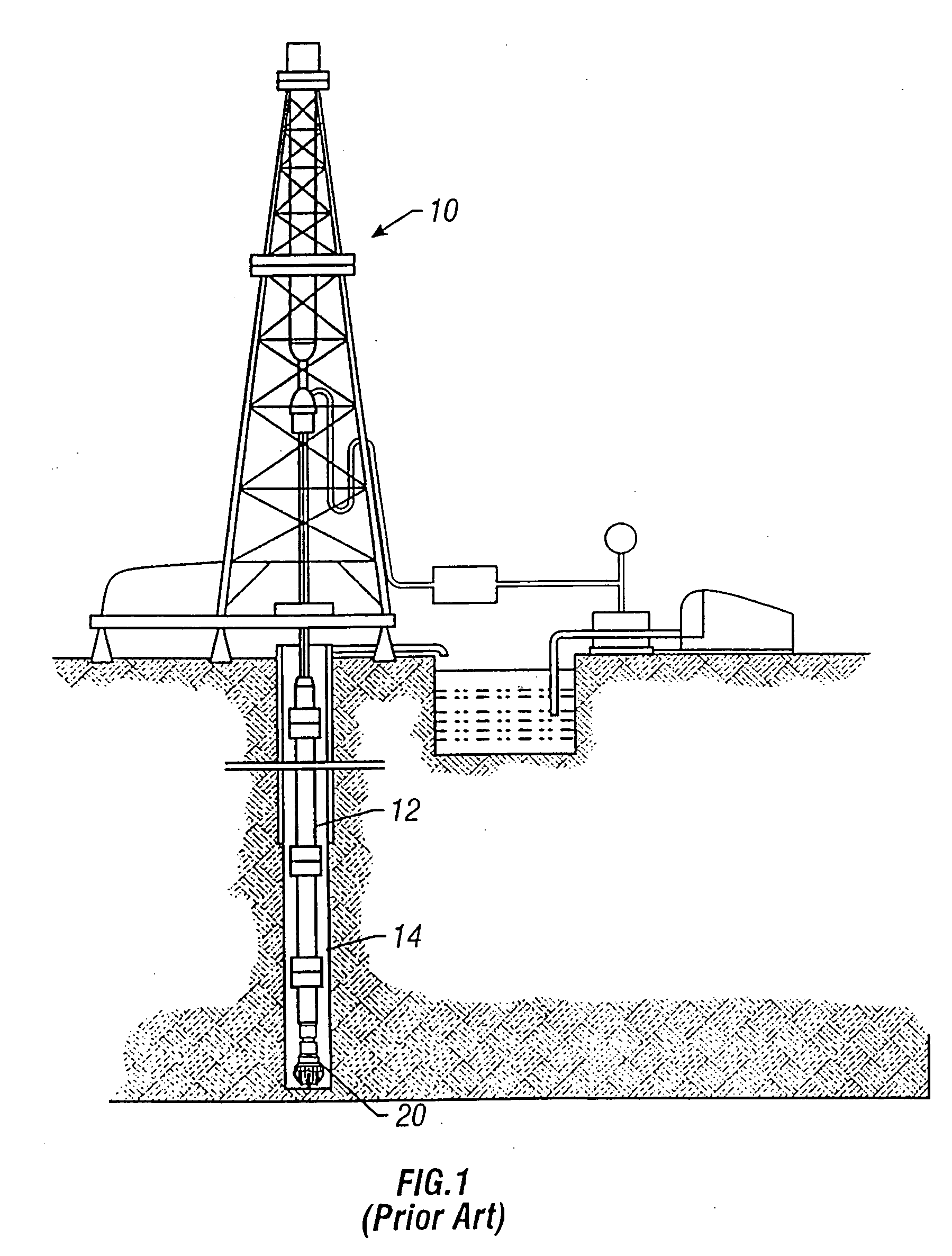

Method for simulating drilling of roller cone bits and its application to roller cone bit design and performance

InactiveUS20040143427A1Drill bitsAnalogue processes for specific applicationsEngineeringVisual perception

A method for simulating the drilling performance of a roller cone bit drilling an earth formation may be used to generate a visual representation of drilling, to design roller cone drill bits, and to optimize the drilling performance of a roller cone bit. The method for generating a visual representation of a roller cone bit drilling earth formations includes selecting bit design parameters, selecting drilling parameters, and selecting an earth formation to be drilled. The method further includes calculating, from the bit design parameters, drilling parameters and earth formation, parameters of a crater formed when one of a plurality of cutting elements contacts the earth formation. The method further includes calculating a bottomhole geometry, wherein the crater is removed from a bottomhole surface. The method also includes incrementally rotating the bit and repeating the calculating of crater parameters and bottomhole geometry based on calculated roller cone rotation speed and geometrical location with respect to rotation of said roller cone drill bit about its axis. The method also includes converting the crater and bottomhole geometry parameters into a visual representation.

Owner:HUANG SUJIAN +1

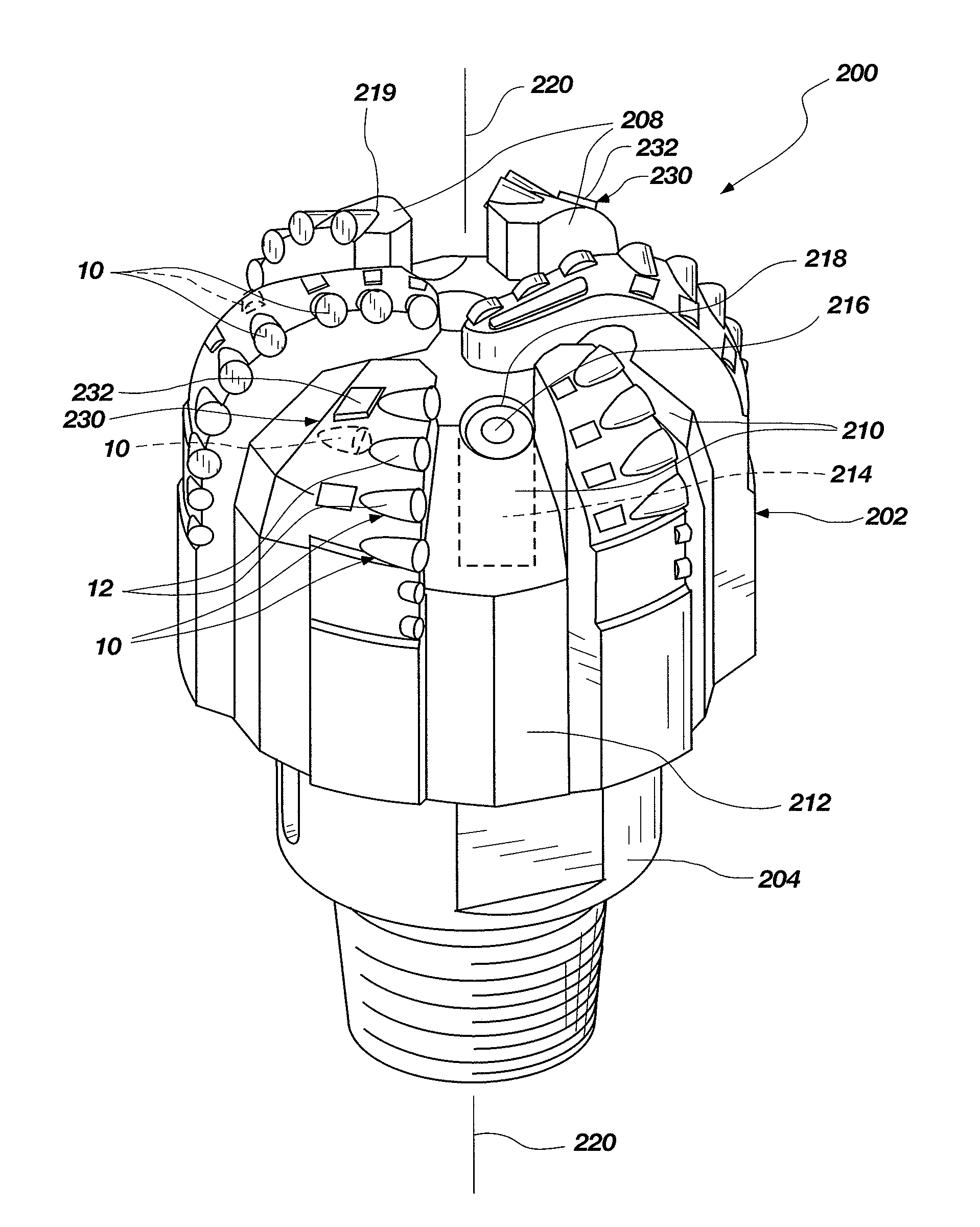

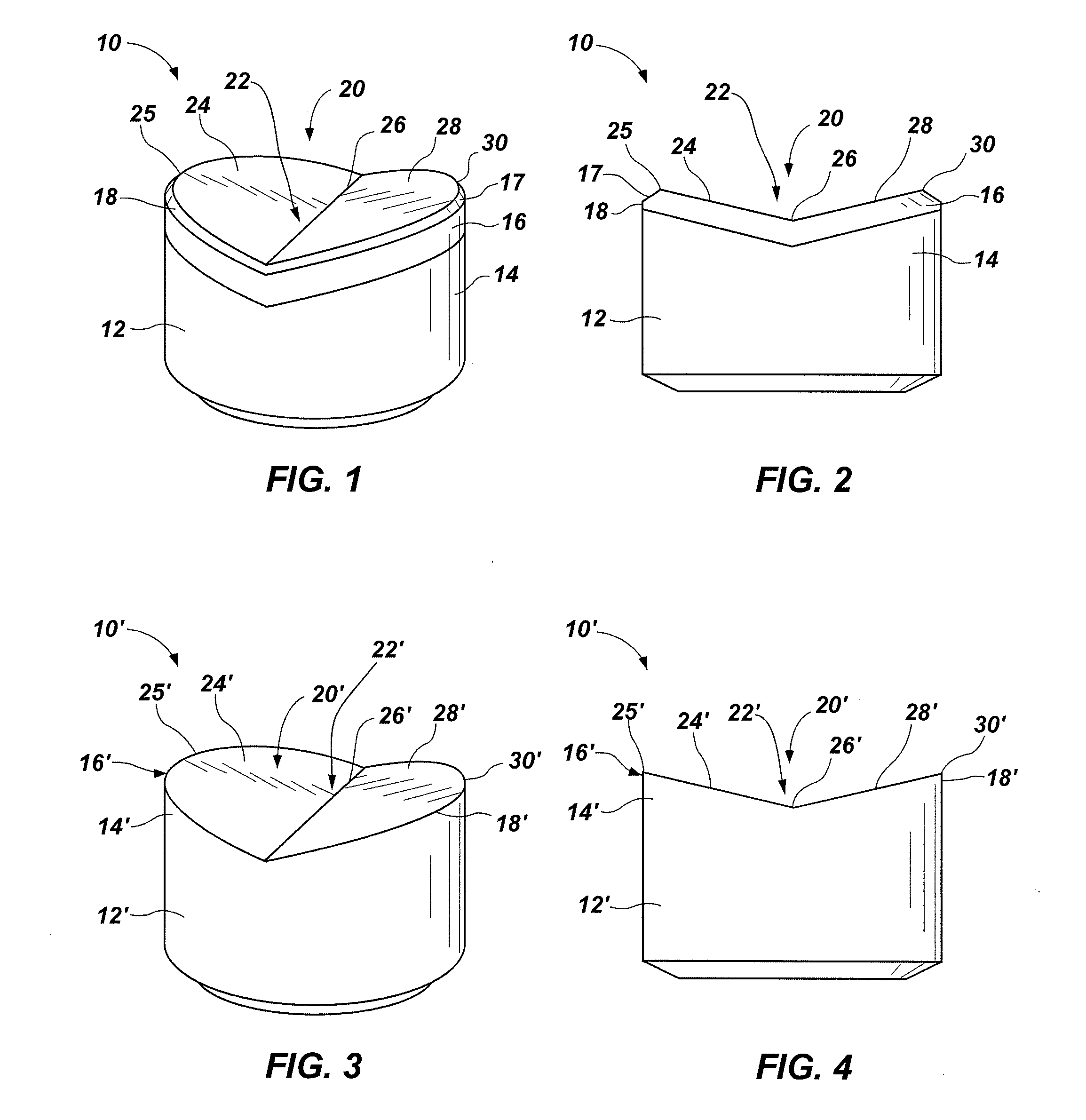

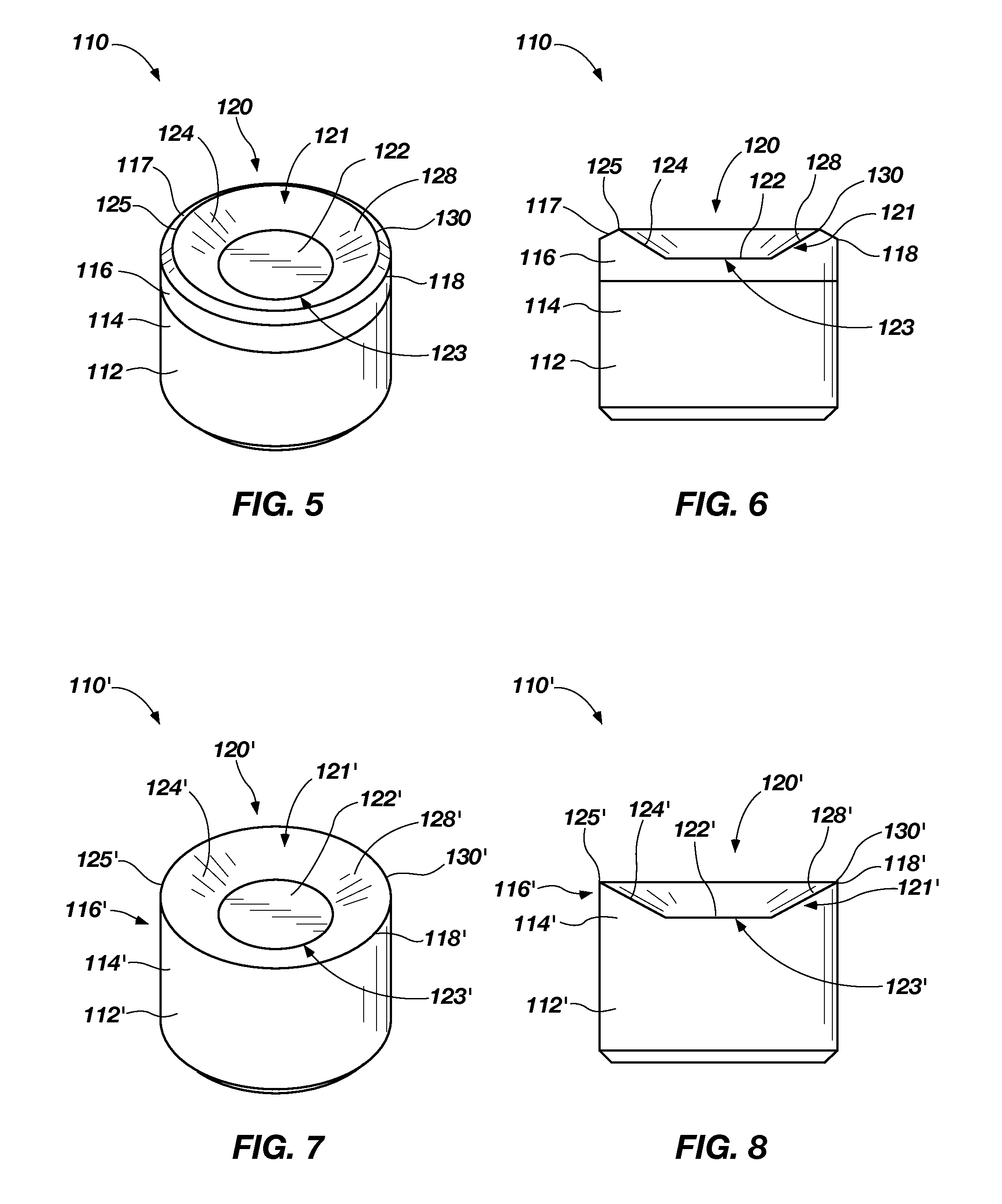

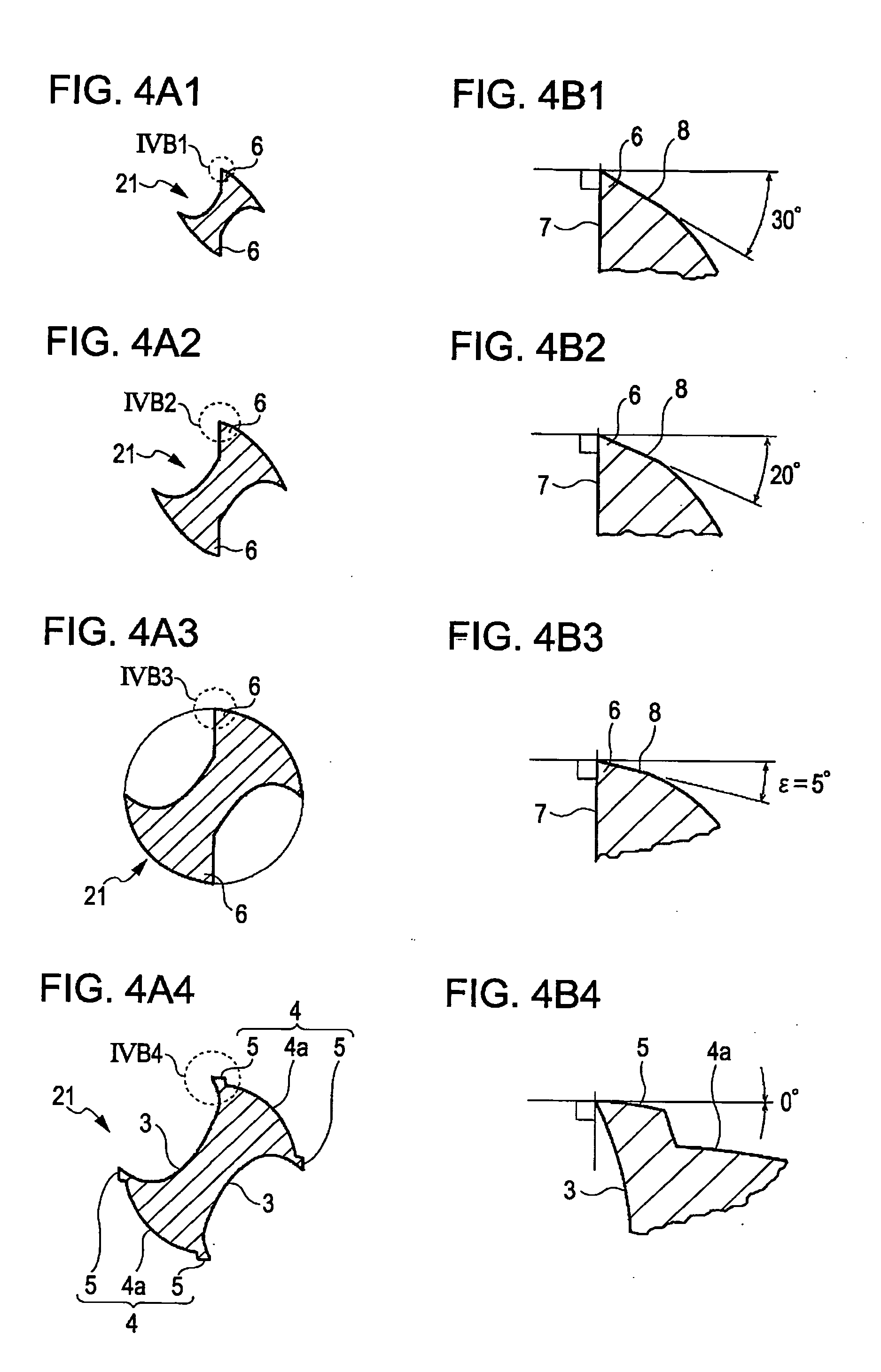

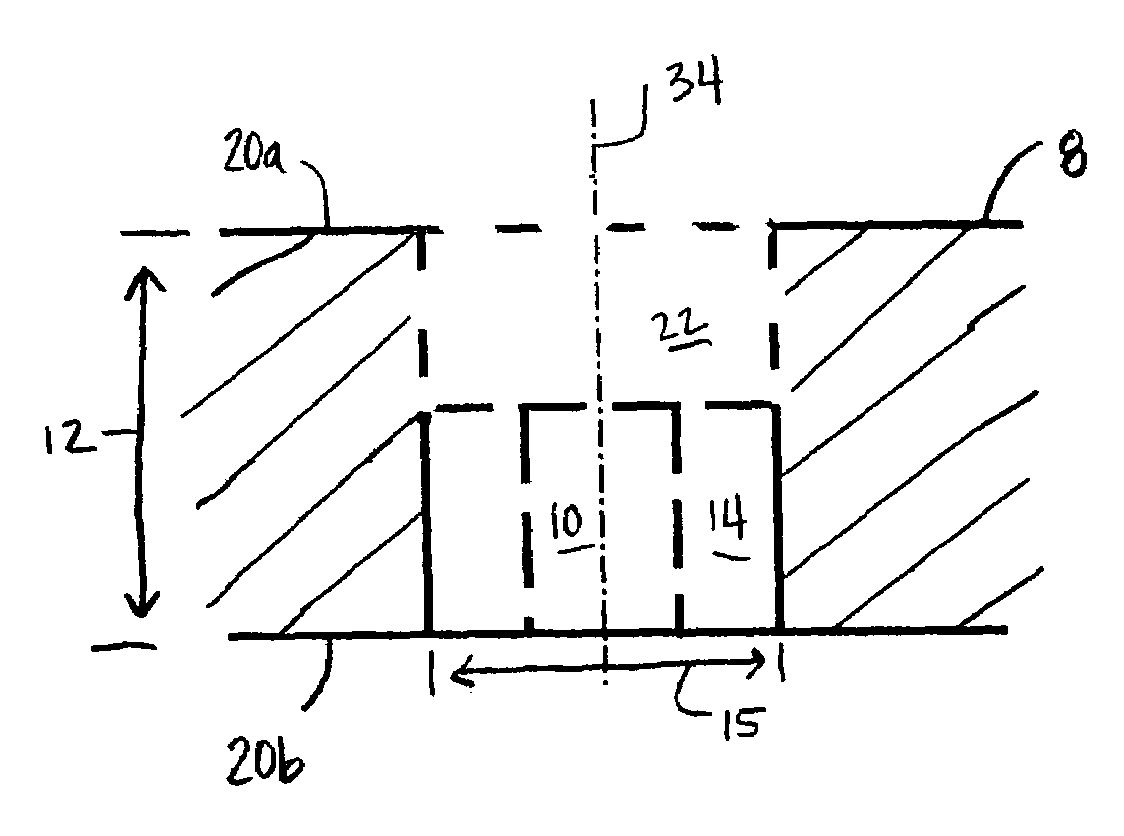

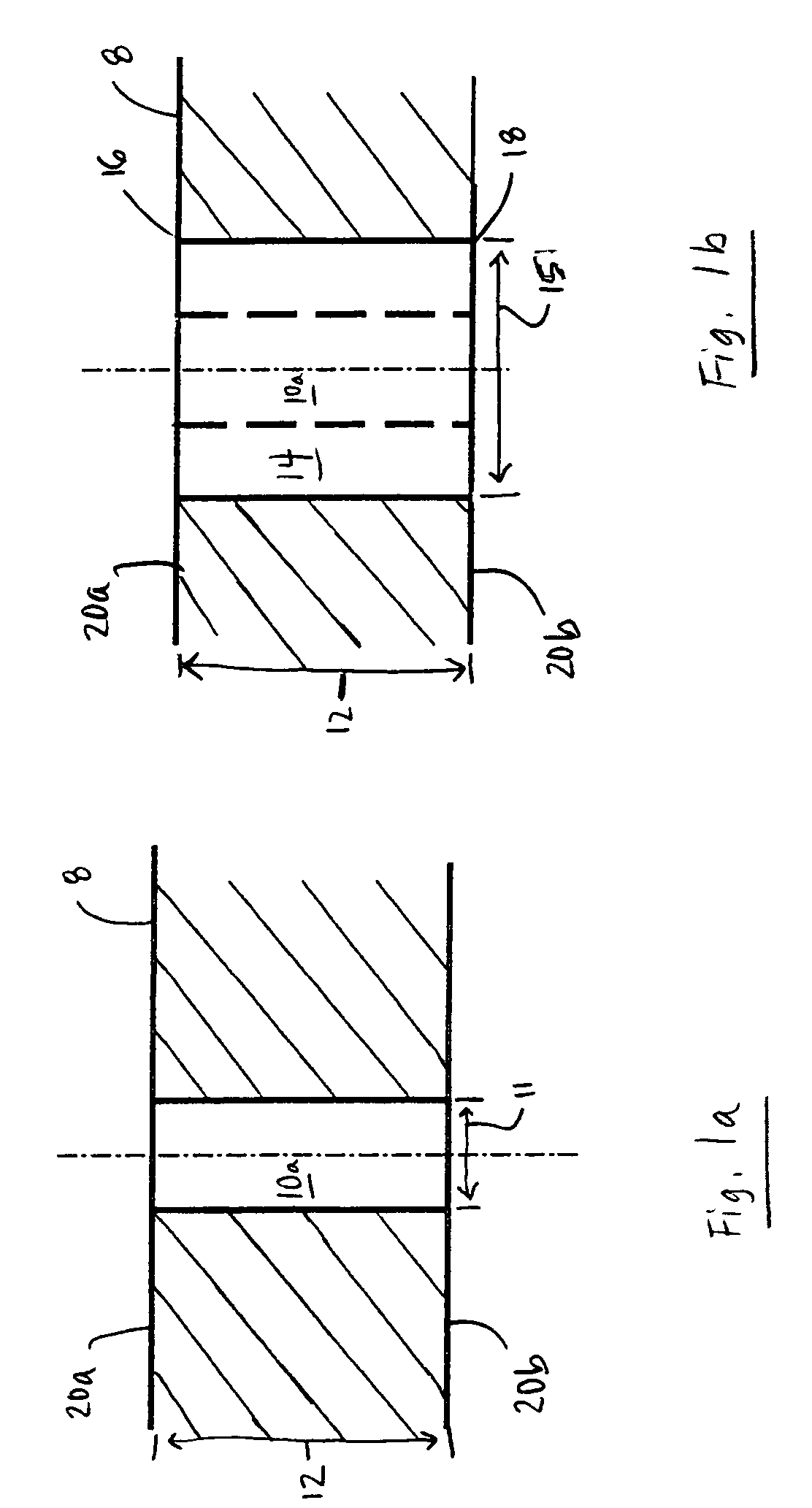

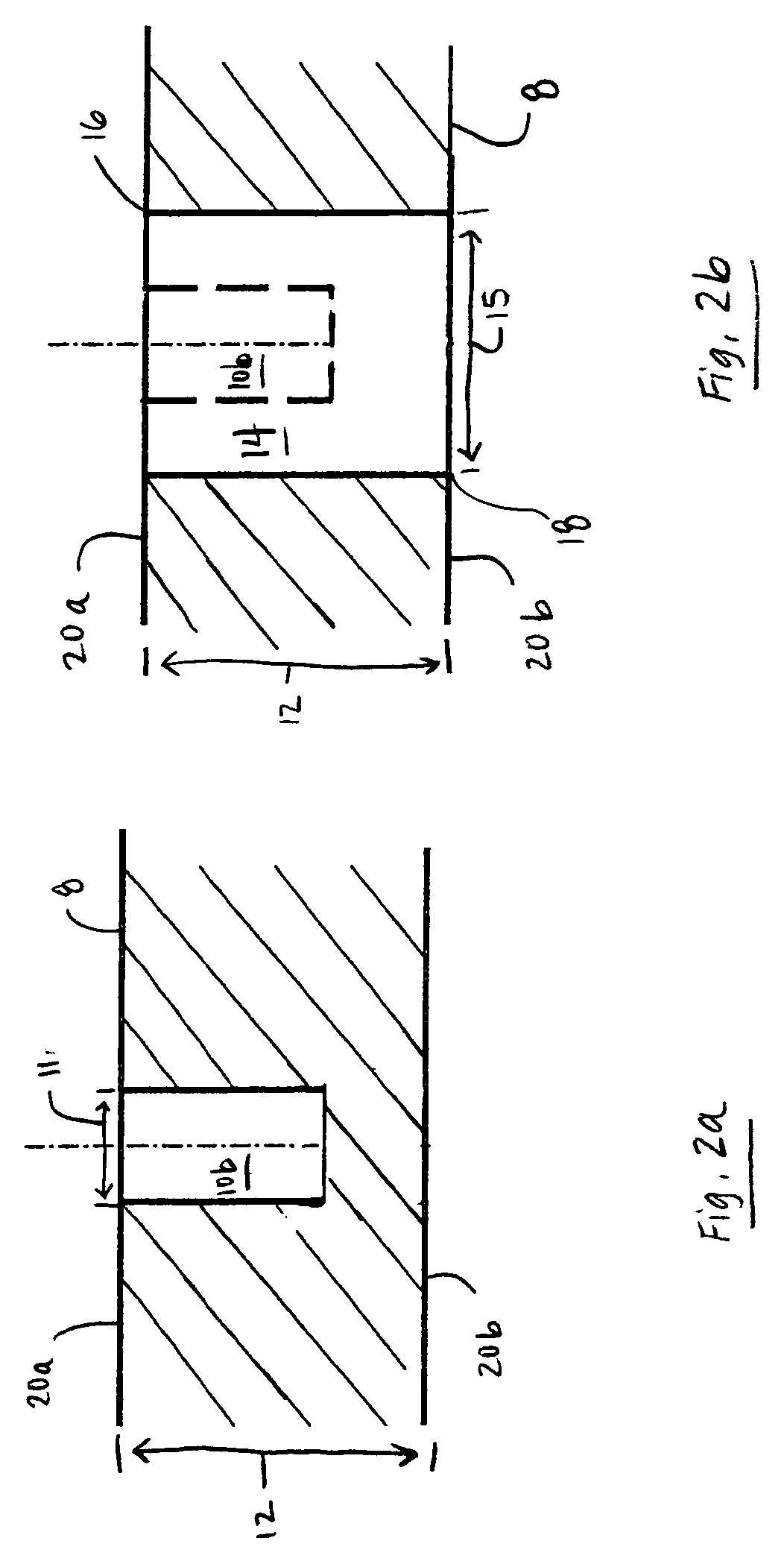

Cutting elements including cutting tables with shaped faces configured to provide continuous effective positive back rake angles, drill bits so equipped and methods of drilling

ActiveUS20100307829A1Reducing eliminating damageAvoid collectingDrill bitsConstructionsMechanical engineeringHole drilling method

A cutting element for a drag-type earth-boring drill bit includes a cutting table with a face including a region that is configured cut into a formation at an effective positive back rake angle and to direct formation cuttings, or chips, that have been cut from the earth formation toward the hydraulics of the drill bit. Drill bits that include one or more cutting elements that have been configured in this manner are also disclosed. Such a drill bit may also include a wear pad for limiting the depth to which a cutting element penetrates a surface of a bore hole in an earth formation. Such a wear pad may have a substantially constant thickness. Methods for removing material from earth formations are also disclosed.

Owner:BAKER HUGHES INC

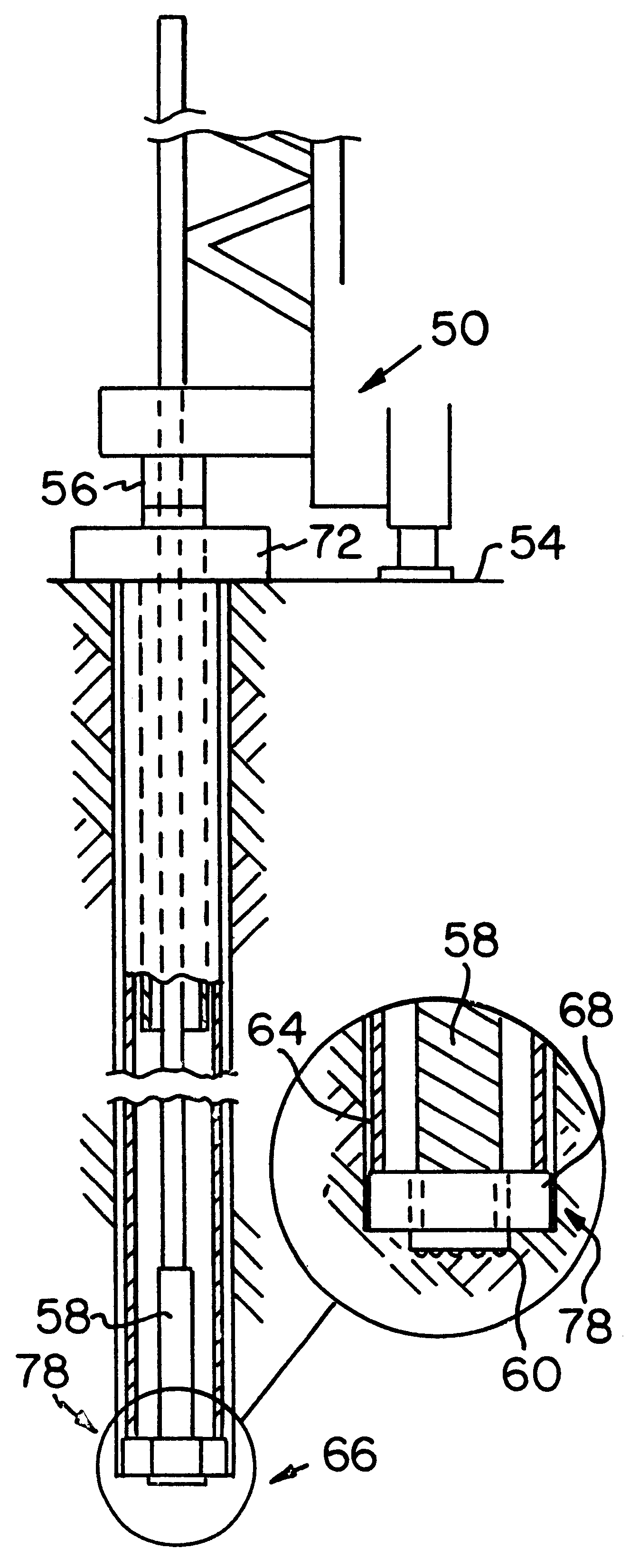

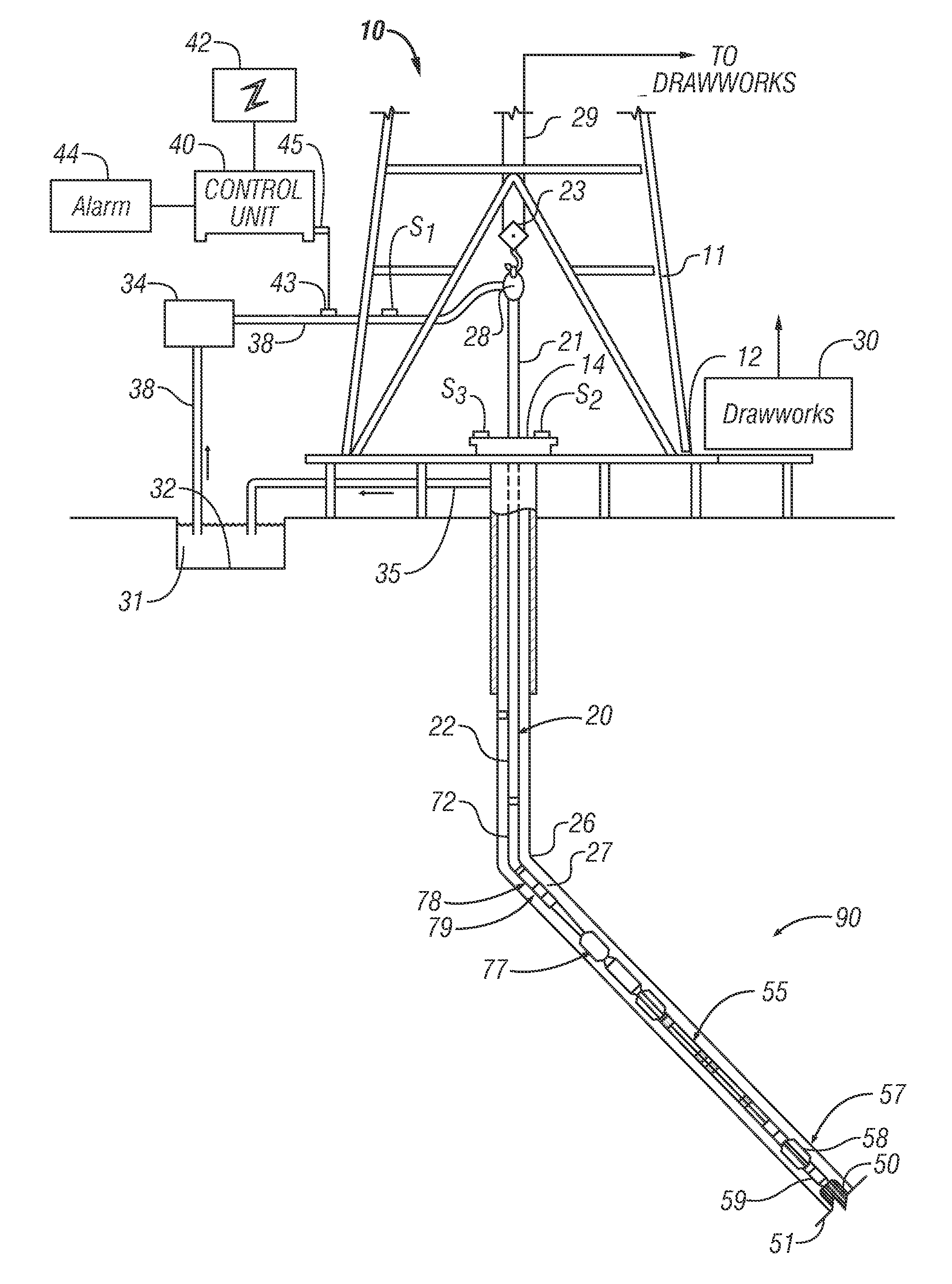

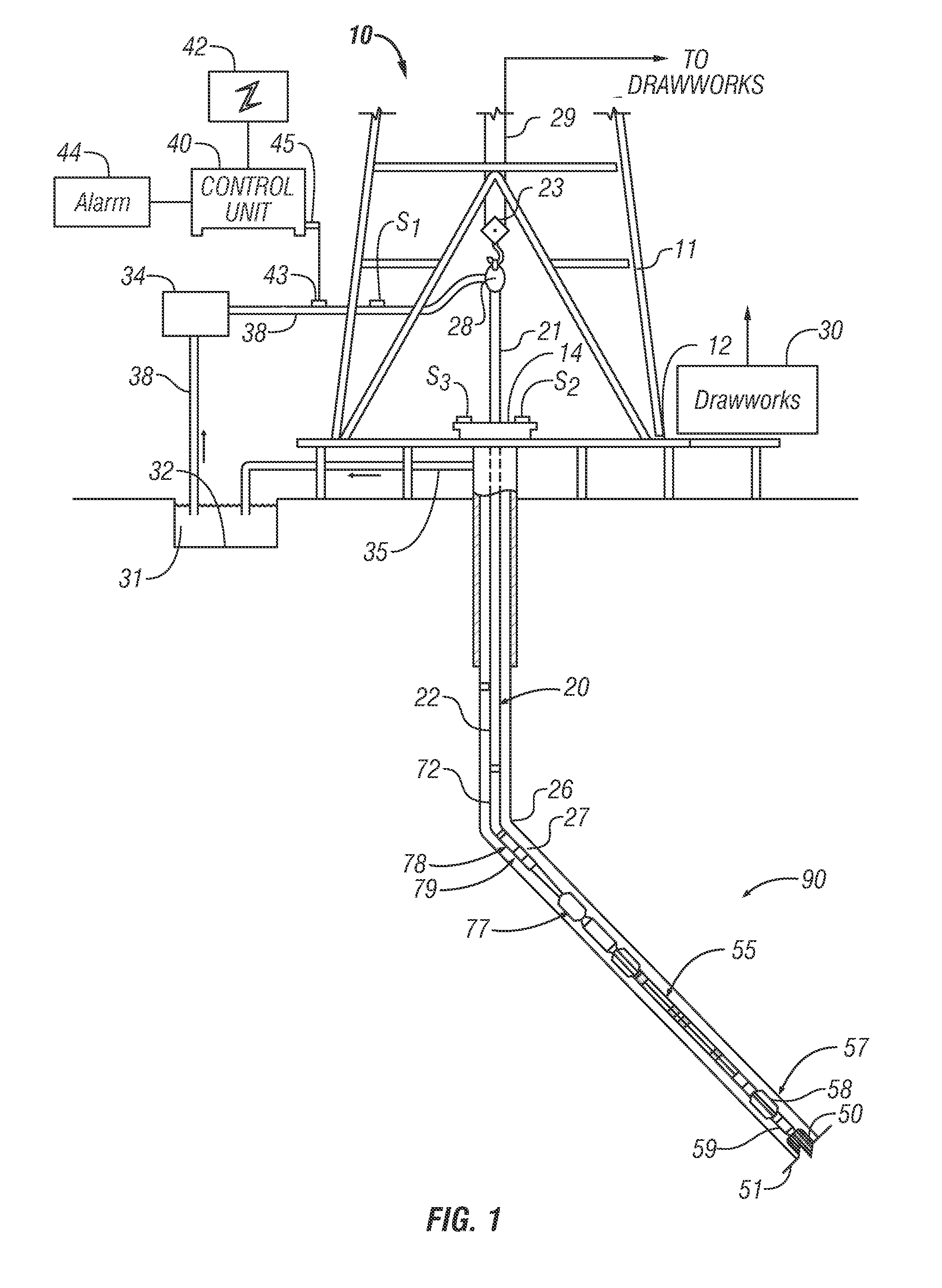

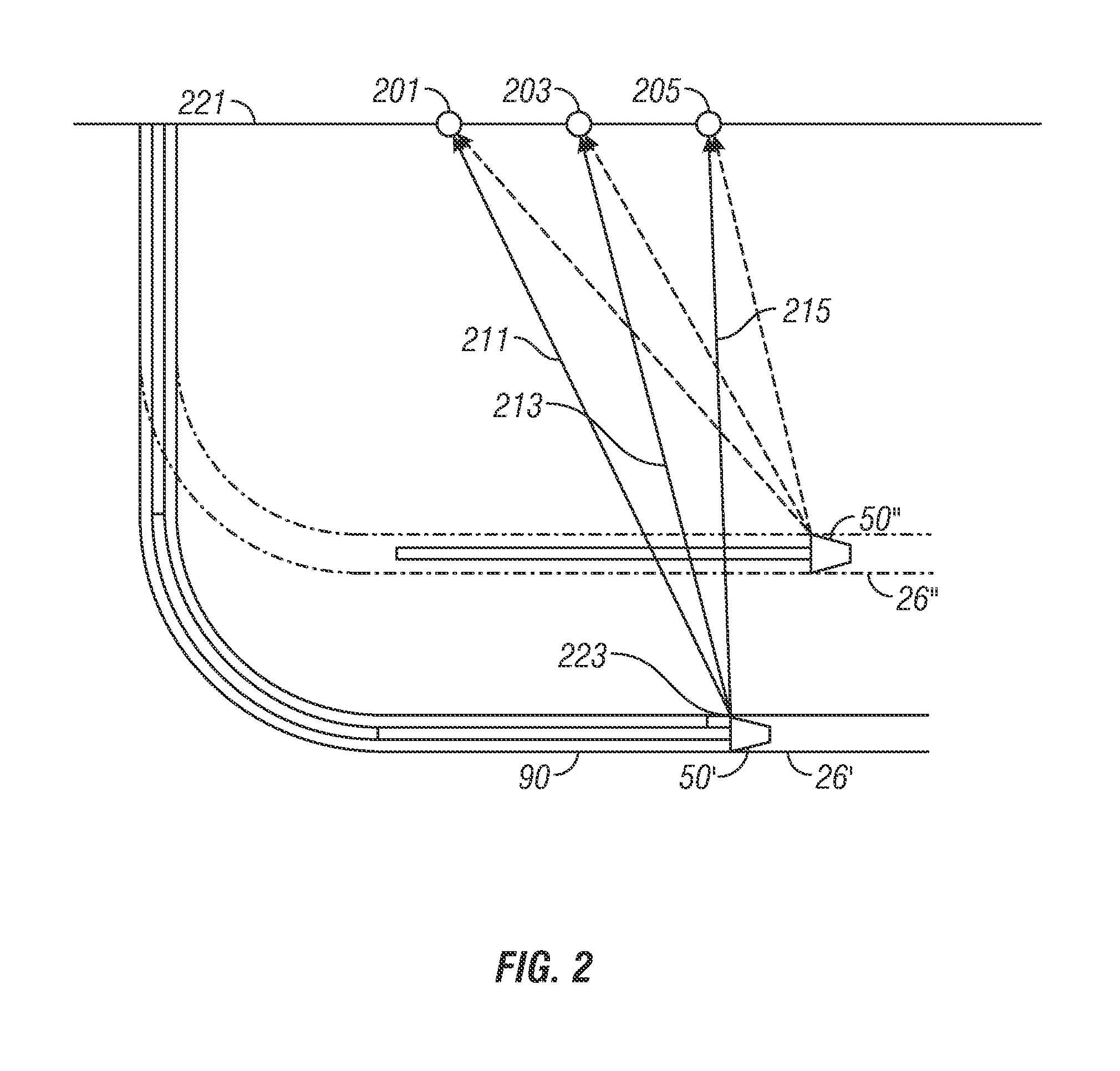

Method and Apparatus for Borehole Positioning

A method of drilling boreholes is provided. The method, according to one embodiment, may include drilling a borehole, transmitting a signal into the earth formation, receiving signals at least three spaced sensors responsive to the transmitted signals and estimating a path of the borehole using the signals received by the at least three sensors. In another aspect, the method may include drilling a borehole, transmitting signals into the earth formation from at least three spaced transmitters, receiving signals at least one sensor responsive to the transmitted signals and estimating a path of the borehole using the signals received by the at least one sensor.

Owner:BAKER HUGHES INC

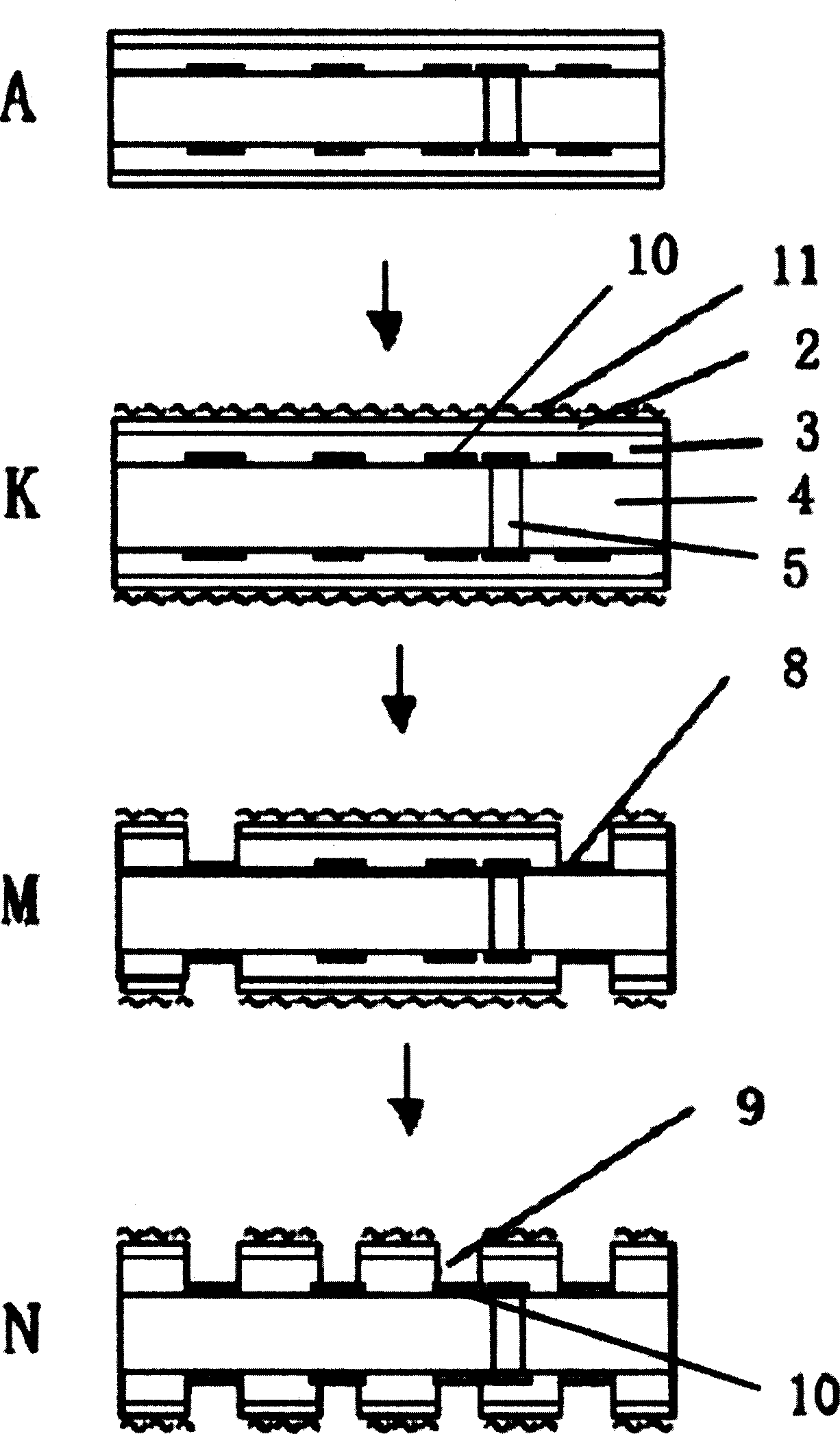

Methods of drilling through-holes in homogenous and non-homogeneous substrates

InactiveUS20050230365A1Minimum thermal damageImprove performanceSemiconductor/solid-state device detailsSolid-state devicesThermal energyPilot hole

A differential diameter hole drilling method by which through-holes having improved major surface quality are formed in a target material involves drilling a pilot hole having a diameter that is less than the desired diameter of the through-hole and then drilling a through-hole having the desired diameter. The pilot hole forms a channel from which thermal energy produced during laser drilling can diffuse into the environment, thereby reducing the amount of thermal energy diffusing into the surrounding target material matrix and the degree of thermal damage to the heat affected zone of the target material matrix. The pilot hole also forms a channel through which ablated target material may be removed, thereby increasing overall through-hole throughput. Pilot hole formation reduces the thermal energy required to form the remaining portion of the through-hole and thereby results in less thermal damage to the surrounding target material matrix.

Owner:ELECTRO SCI IND INC

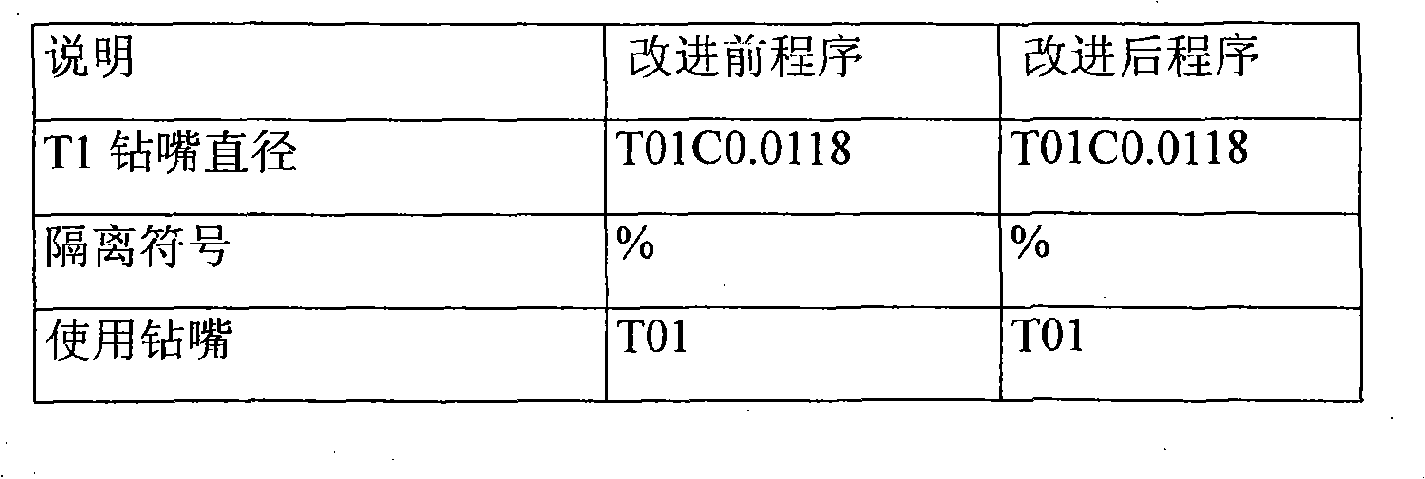

Small-aperture high-density drilling method of printed circuit board

InactiveCN101537505AIncrease working edge lengthReduce the spindle dynamic yaw valuePrinted circuit manufactureHigh densityEngineering

The invention aims at the technical state of the prior printed circuit board drilling method to provide a mechanically drilling method of a high-density and small-aperture multilayer printed circuit board, which improves the drilling machine yield and has good drilling quality by improving drilling parameters. The method mainly comprises the following steps of adjusting zero-position, setting drilling parameters, drilling positioning holes, installing bearing plate, substrate and aluminum sheet, drilling, grinding raw edges, blowing holes and inspecting, wherein the drilling order is set by a leap-frog method with coordinate hole space not smaller than 4 mm; the hole position requirements are converted into a PCB drilling program by CAM, the original hole positions are arranged in sequence, and the drilling sequence is deigned according to the standard of the coordinate hole space not smaller than 4 mm; the pressure foot gasket of a main shaft of a drilling machine is a soft plastic pressure foot gasket; and the bit is a UC-type bit with good chip removal effect, and the total thickness of the drilled substrate is up to 4.5 to 4.8 mm.

Owner:NANJING ELEC & ELTEK ELECTRON

Method, drilling machine, drill bit and bottom hole assembly for drilling by electrical discharge by electrical discharge pulses

ActiveUS7784563B2Easy to cleanReduce consumptionDrill bitsDisloding machinesElectric dischargeClosed loop

Owner:UNODRILL

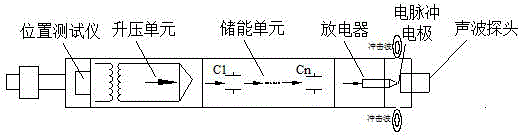

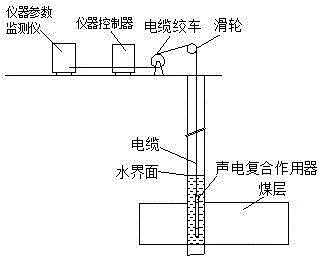

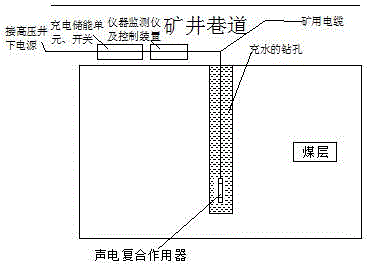

Method for improving coal seam gas permeability through high energy acoustoelectric composite technology

ActiveCN104481574APlay a blocking roleUnblocking effectFluid removalVibration devicesCavitationFiltration

The invention discloses a method for improving coal seam gas permeability through a high energy acoustoelectric composite technology to mainly solve the problems that the prior art pollutes a coal seam, cannot thoroughly improve the coal seam gas permeability, cannot improve the coal seam gas desorption and seepage and the like. According to the method for improving the coal seam gas permeability through the high energy acoustoelectric composite technology, high electric field pulses and sound waves are combined, the coal seam generates new cracks due to functions of impact wave generation, mechanical vibration and the like, original cracks are expanded, and accordingly coal seam gas transport channels are increased; meanwhile the coal seam gas deabsorption is improved through generated high-temperature effect, cavitation effect and the like and the gas filtration capacity is improved. The method for improving the coal seam gas permeability through the high energy acoustoelectric composite technology comprises a ground drainage well drilling method and a drainage drill hole method parallel to the coal seam. An implementation process comprises the following steps of (1) pulling out devices inside a drill hole; (2) injecting water to the drill hole and drill well through drift tools such as a well gauge, arranging an acoustoelectric composite action device at an appointed position and dividing the coal seam into different sections, wherein the thickness of every section is 30cm; (3) enabling the action device to repeatedly act in the sections; (4) pulling out the devices such as the acoustoelectric composite action device; (5) exhausting and mining the drill hole of the coal seam.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

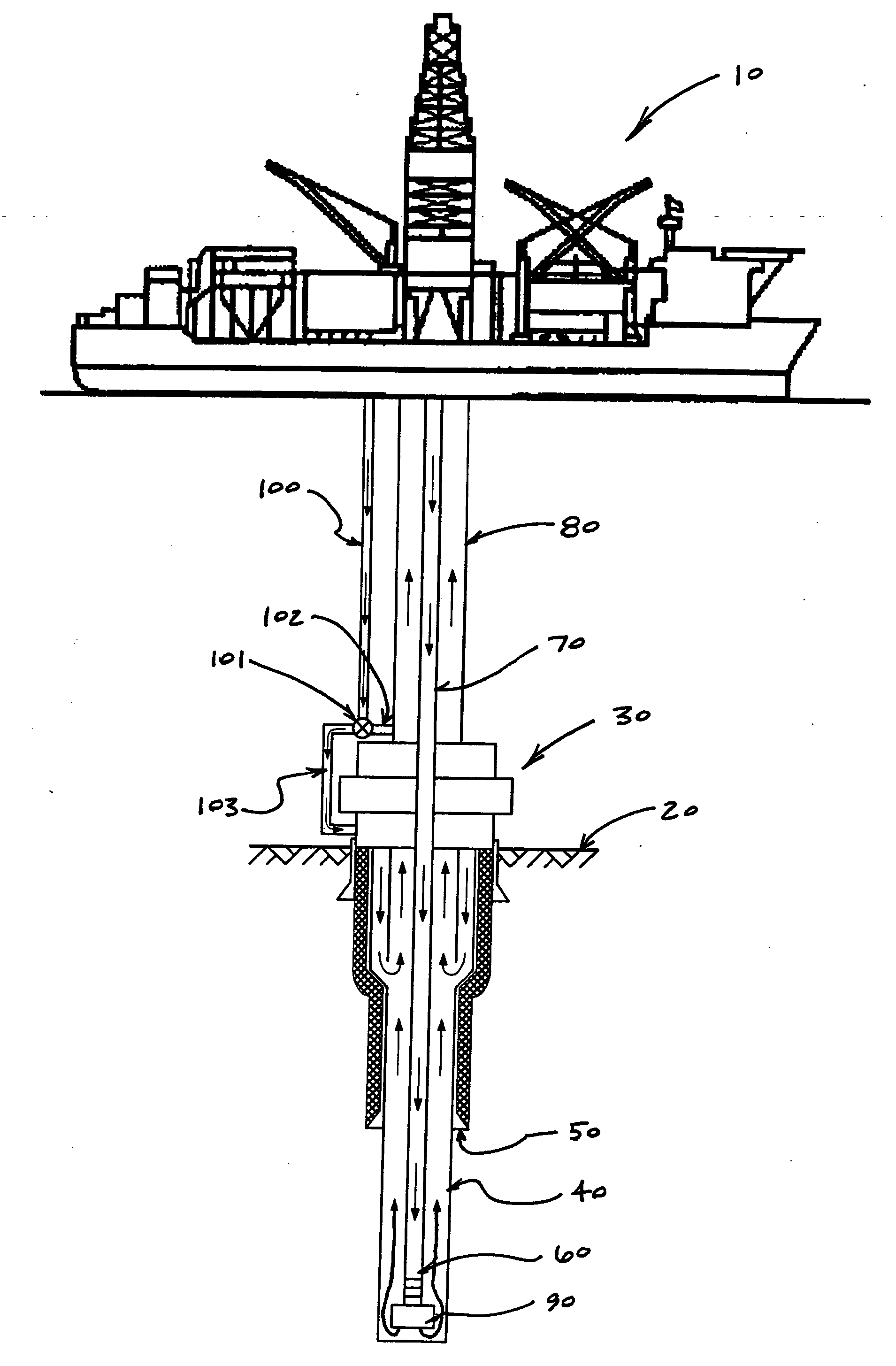

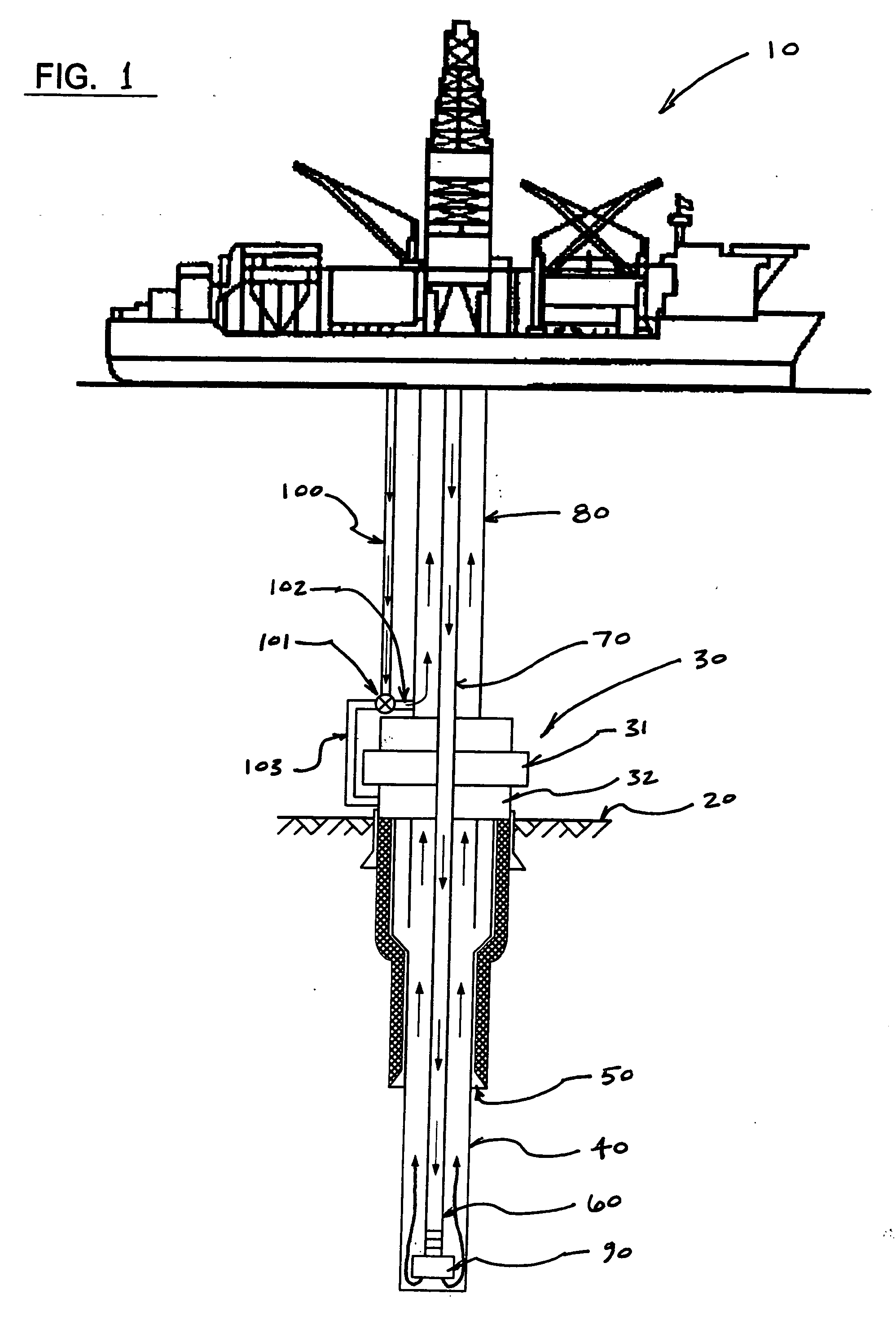

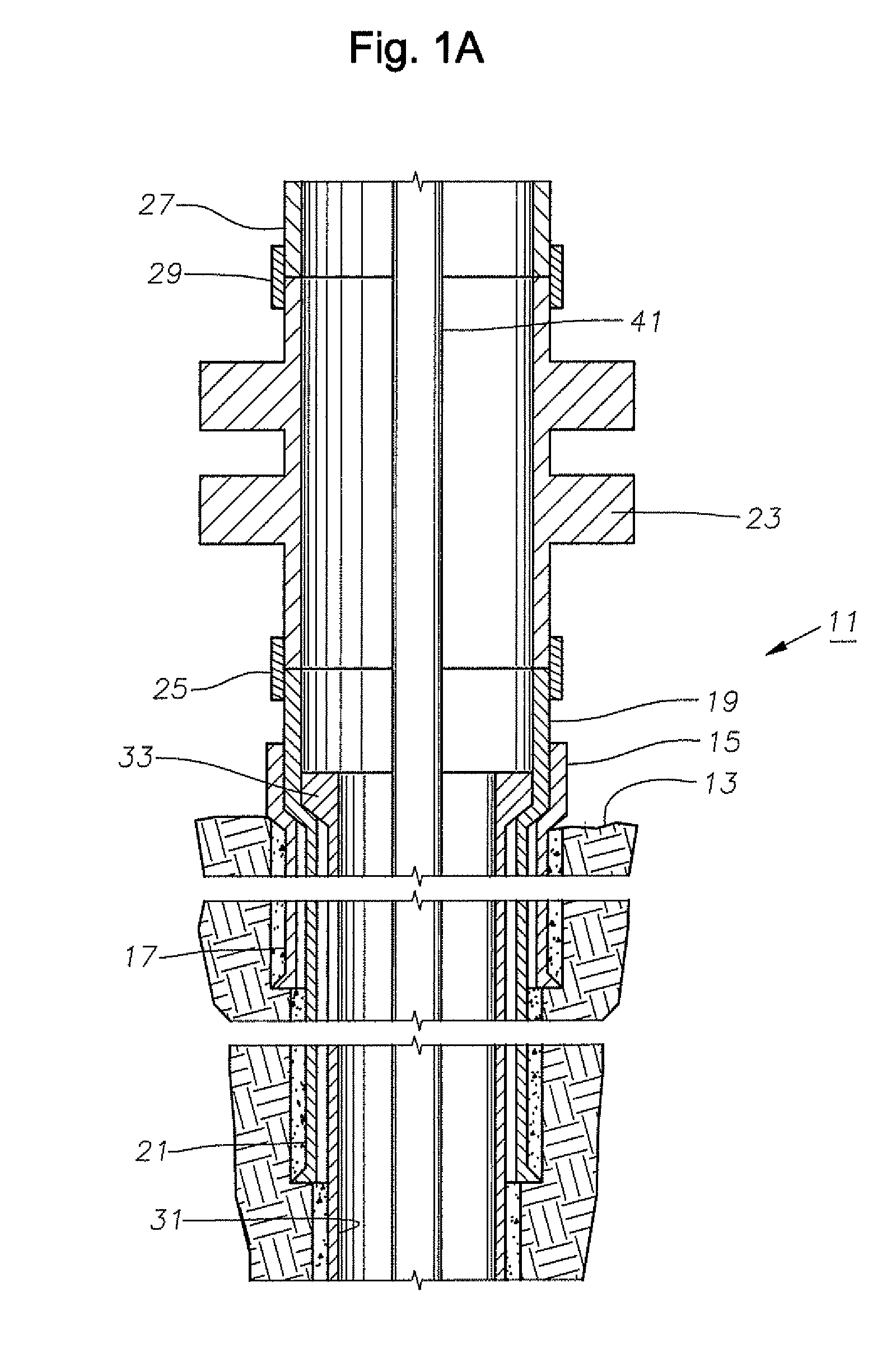

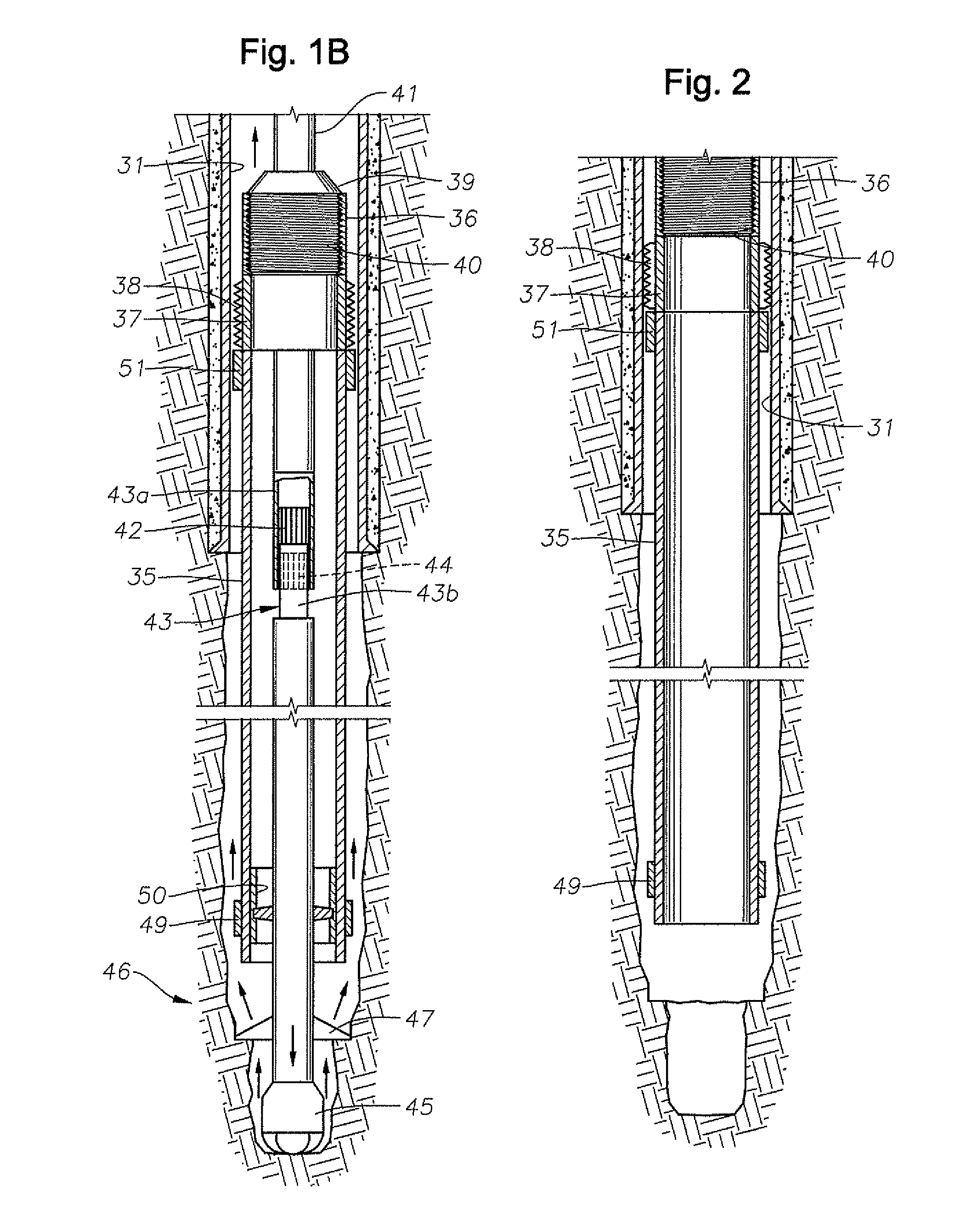

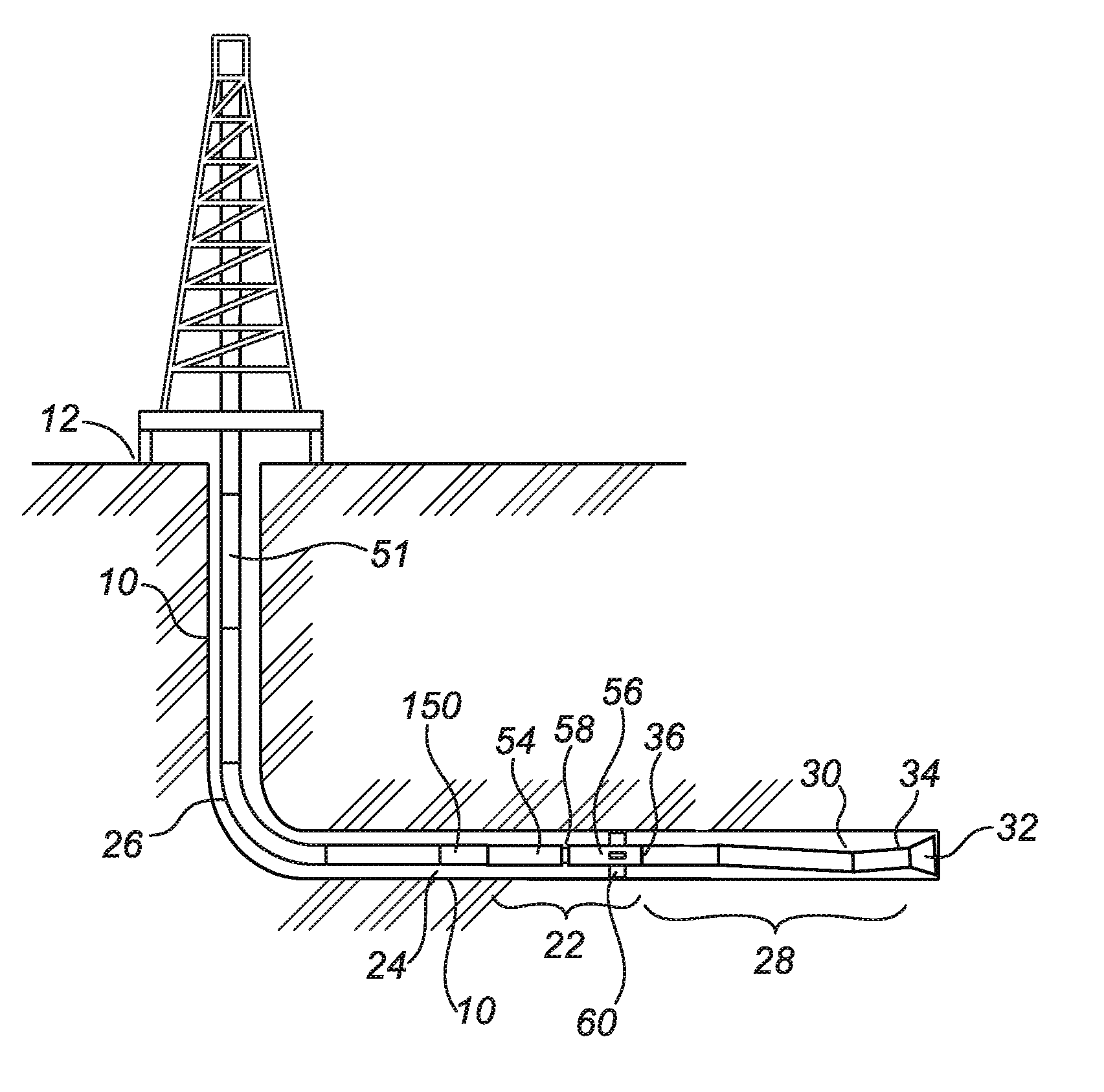

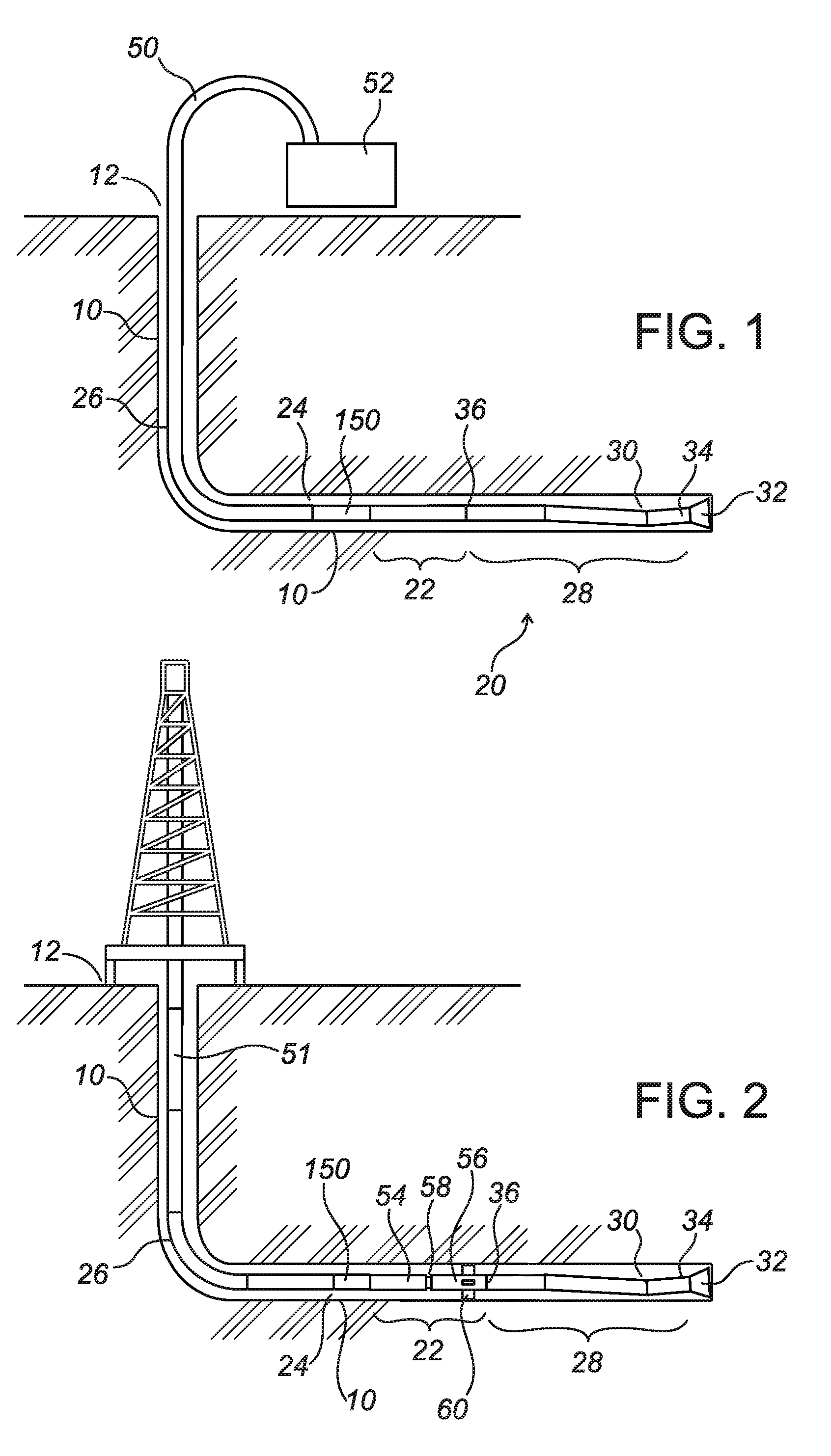

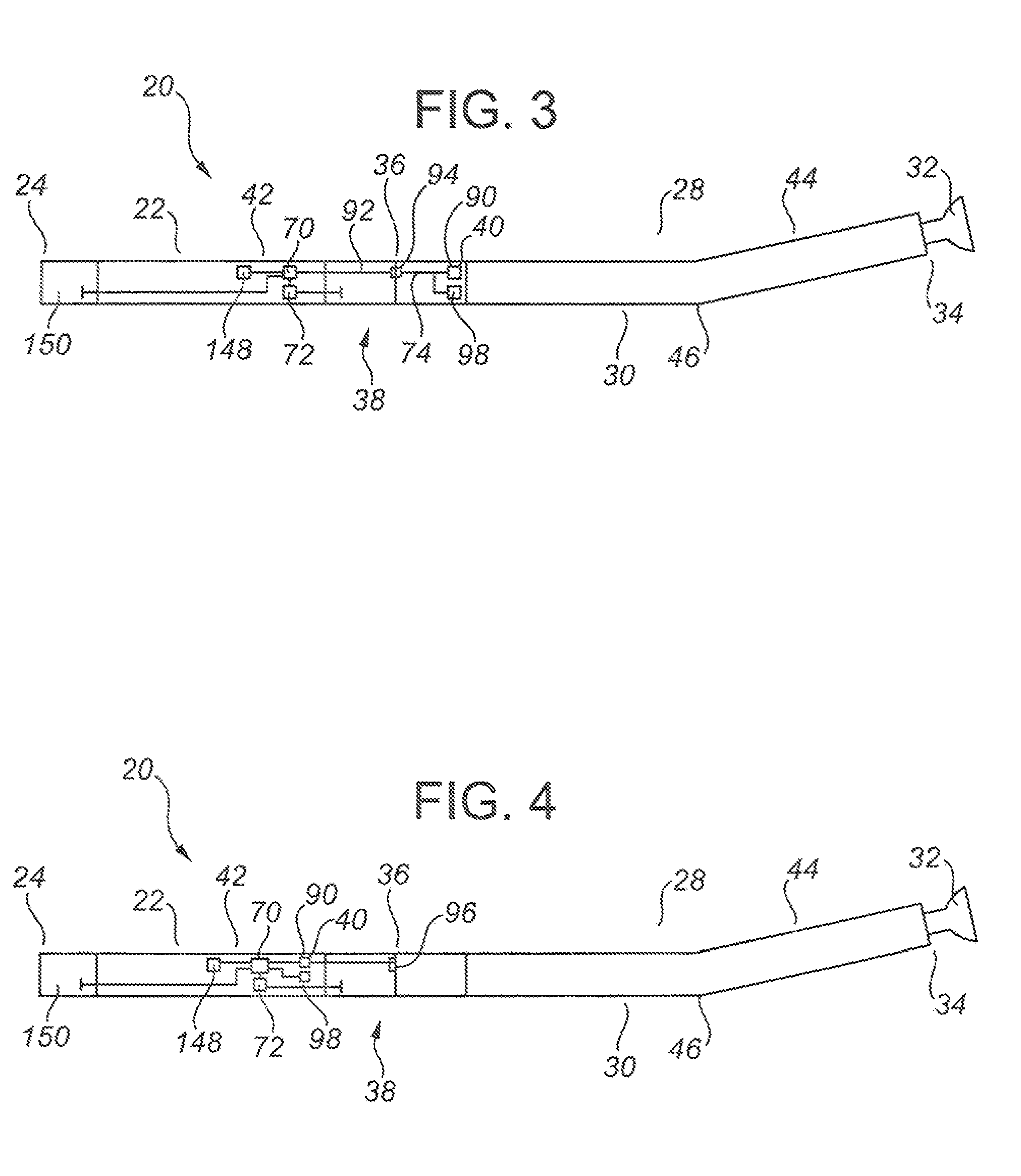

Liner drilling method

An installation system for installing a liner in a well includes drilling while simultaneously running the liner. A string of drill pipe with a bottom hole assembly including a drill bit on a lower end is lowered into the liner while the liner is suspended at the rig floor. The bottom hole assembly engages a lower sub of the liner for torque transmission. A running tool secured to the drill pipe engages the upper sub such that the running tool supports the weight of the liner and transmits torque. The drill pipe and liner are rotated to drill deeper into the wellbore. The liner hanger can be set to engage the casing, then released and reset at a different point.

Owner:SCHLUMBERGER TECH CORP

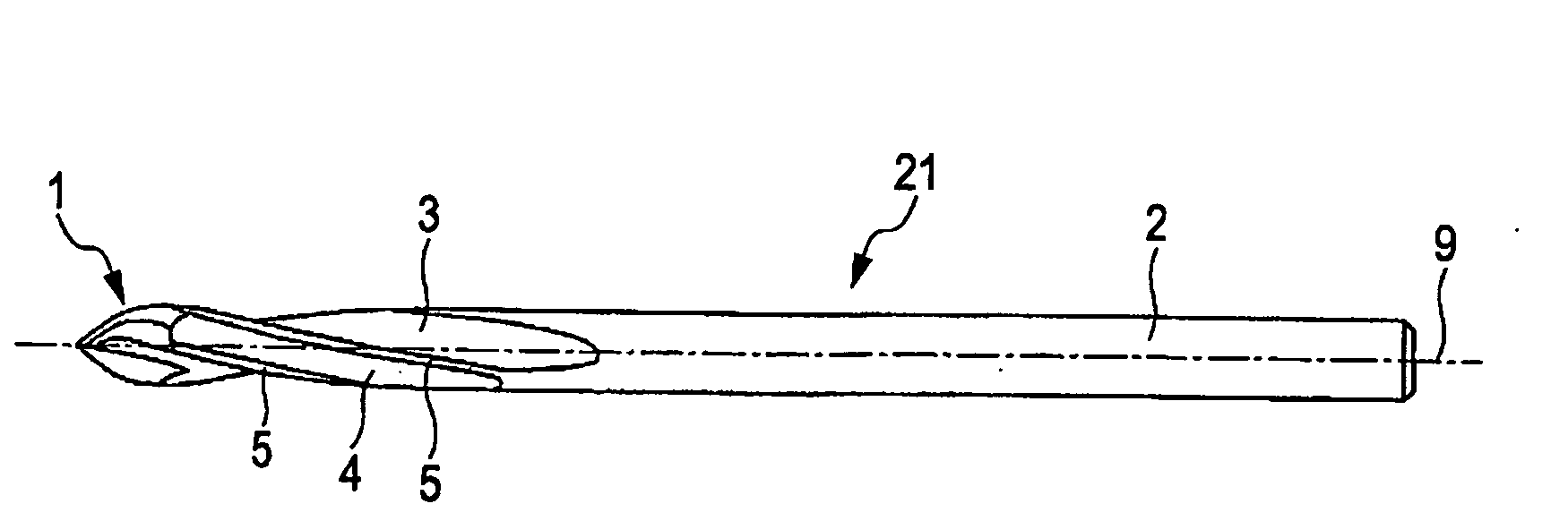

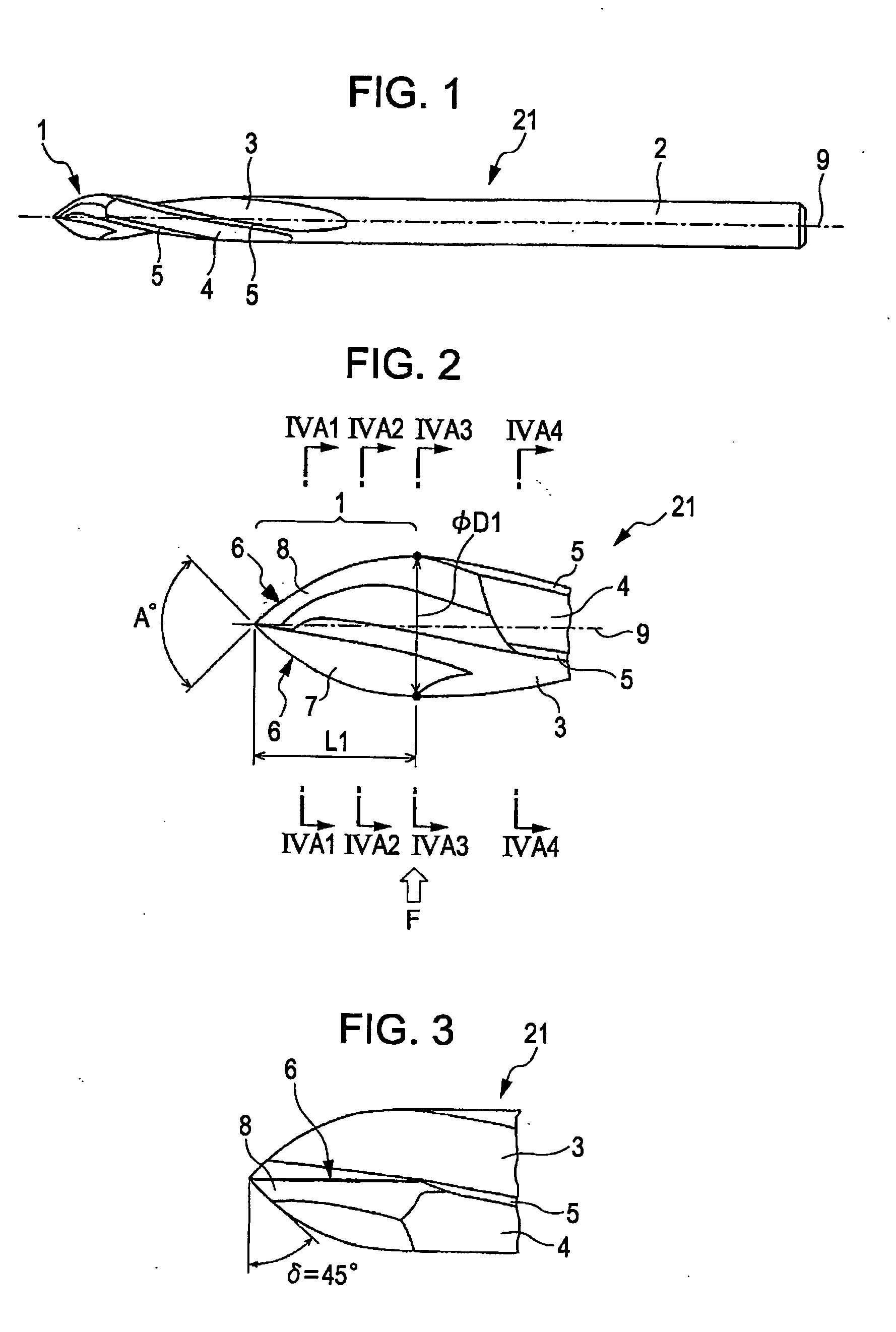

Drill and drilling method for workpiece

ActiveUS20100158626A1Improve wear resistanceImprove accuracyWood turning toolsTransportation and packagingMaximum diameterEngineering

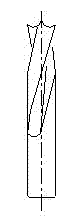

A drill includes a cutting edge. The cutting edge has a point angle which is continuously decreased from a center-position point angle A (herein, 0°<A<180°) at a center position to a maximum-diameter-position point angle of 0° at a maximum diameter position. The cutting edge has a relief angle which is continuously decreased from the center position to the maximum diameter position. The cutting edge of the drill has a relief angle at the maximum diameter position. Hence, the cutting edge also serves as a cutting edge for reaming. The ridgeline and relief face of the cutting edge have no corner, thereby providing good wear resistance.

Owner:SUBARU CORP

Methods of drilling through-holes in homogenous and non-homogenous substrates

InactiveUS7057133B2Efficient and economicalMinimal damageSemiconductor/solid-state device detailsSolid-state devicesThermal energyHeat-affected zone

A differential diameter hole drilling method by which through-holes having improved major surface quality are formed in a target material involves drilling a pilot hole having a diameter that is less than the desired diameter of the through-hole and then drilling a through-hole having the desired diameter. The pilot hole forms a channel from which thermal energy produced during laser drilling can diffuse into the environment, thereby reducing the amount of thermal energy diffusing into the surrounding target material matrix and the degree of thermal damage to the heat affected zone of the target material matrix. The pilot hole also forms a channel through which ablated target material may be removed, thereby increasing overall through-hole throughput. Pilot hole formation reduces the thermal energy required to form the remaining portion of the through-hole and thereby results in less thermal damage to the surrounding target material matrix.

Owner:ELECTRO SCI IND INC

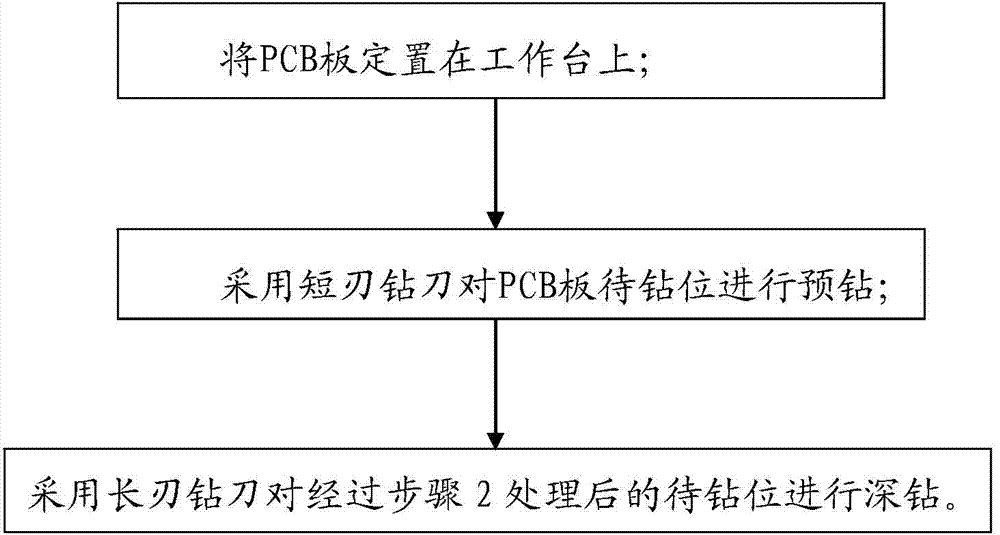

Drilling method for achieving PCB high hole-site precision

ActiveCN103786189AImprove rigidityAvoid the influence of hole position accuracyPrinted circuit manufactureMetal working apparatusHole drilling methodDeep drilling

The invention discloses a drilling method for achieving PCB high hole-site precision. The method comprises the following steps that firstly, a PCB is fixed on a workbench, secondly, the position to be drilled on the PCB is pre-drilled through a short-blade drilling tool, and thirdly, the position, to be drilled, processed in the second step is deep drilled through a long-blade drilling tool. The operation is easy and convenient and cost is low. The PCB is fixed in the first step, so that the PCB does not move during the drilling process, and the drilling precision cannot be affected. The position to be drilled on the PCB is pre-drilled through the short-blade drilling tool in the second step, and the rigidity of the short-blade drilling tool is better relative to the long-blade drilling tool, so that in the moment that the short-blade drilling tool makes contact with a PCB surface, the short-blade drilling tool is not prone to sliding. The position, to be drilled, processed in the second step is deep drilled through the long-blade drilling tool, the lateral sliding of the long-blade drilling tool during the drilling process is reduced, and therefore the drilling alignment of the long-blade drilling tool during the deep drilling process is guaranteed, and the drilled hole site can meet the requirement for the PCB high hole-site precision.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

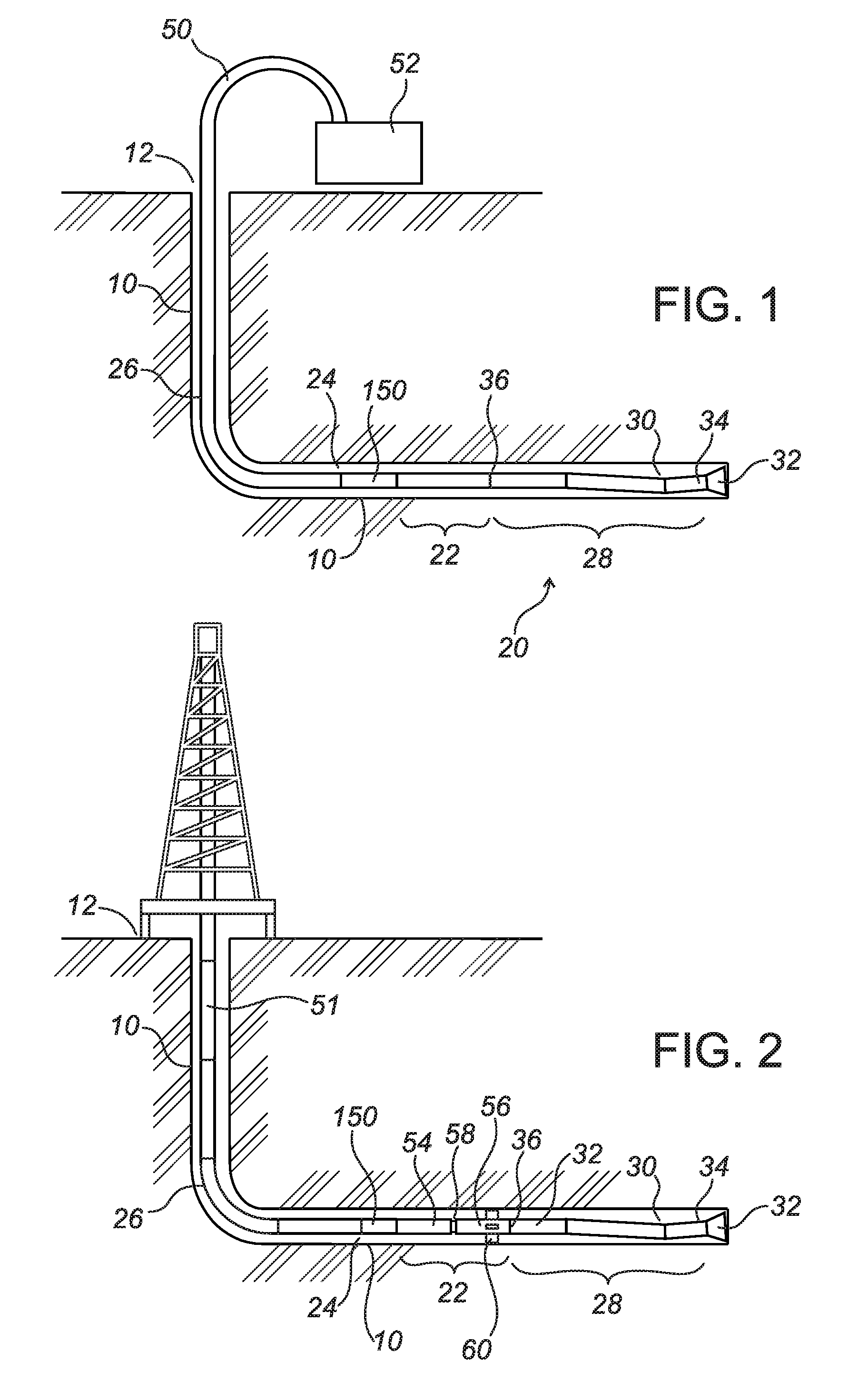

Drilling apparatus and method

A drilling apparatus includes an upper drill string, a lower drill string including a rotary drilling motor, an orientable rotatable connection between the drill strings, a reactive torque control device associated with the orientable rotatable connection, an orientation sensing device for providing a sensed actual orientation of the lower drill string, and a feedback control system configured to actuate the control device in response to the sensed actual orientation to achieve a target orientation of the lower drill string. A drilling method includes actuating the control device to prevent relative rotation of the drill strings, providing a sensed actual orientation of the lower drill string, comparing the sensed actual orientation with a target orientation of the lower drill string, actuating the control device to allow the lower drill string to rotate to provide the target orientation, and actuating the control device to prevent relative rotation of the drill strings.

Owner:HALLIBURTON ENERGY SERVICES INC

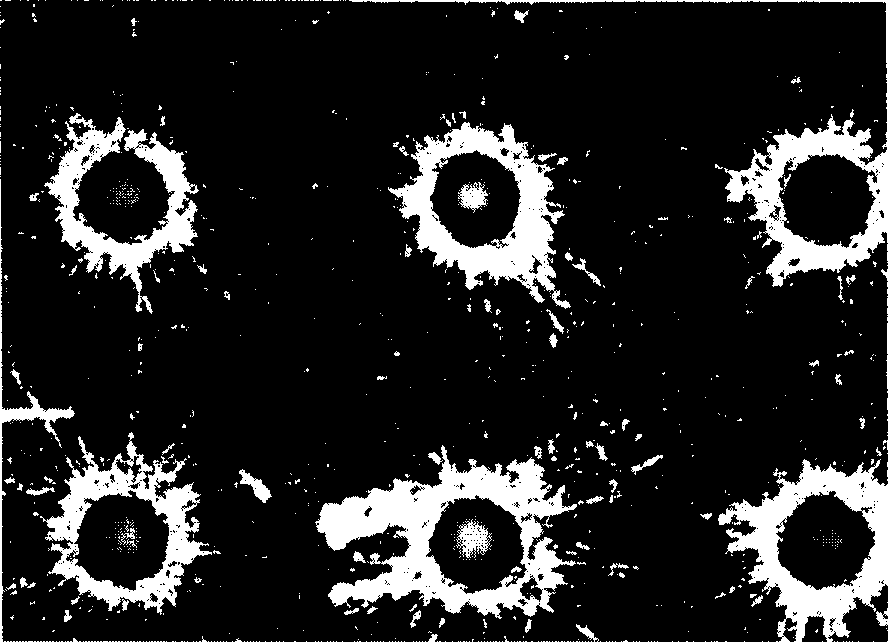

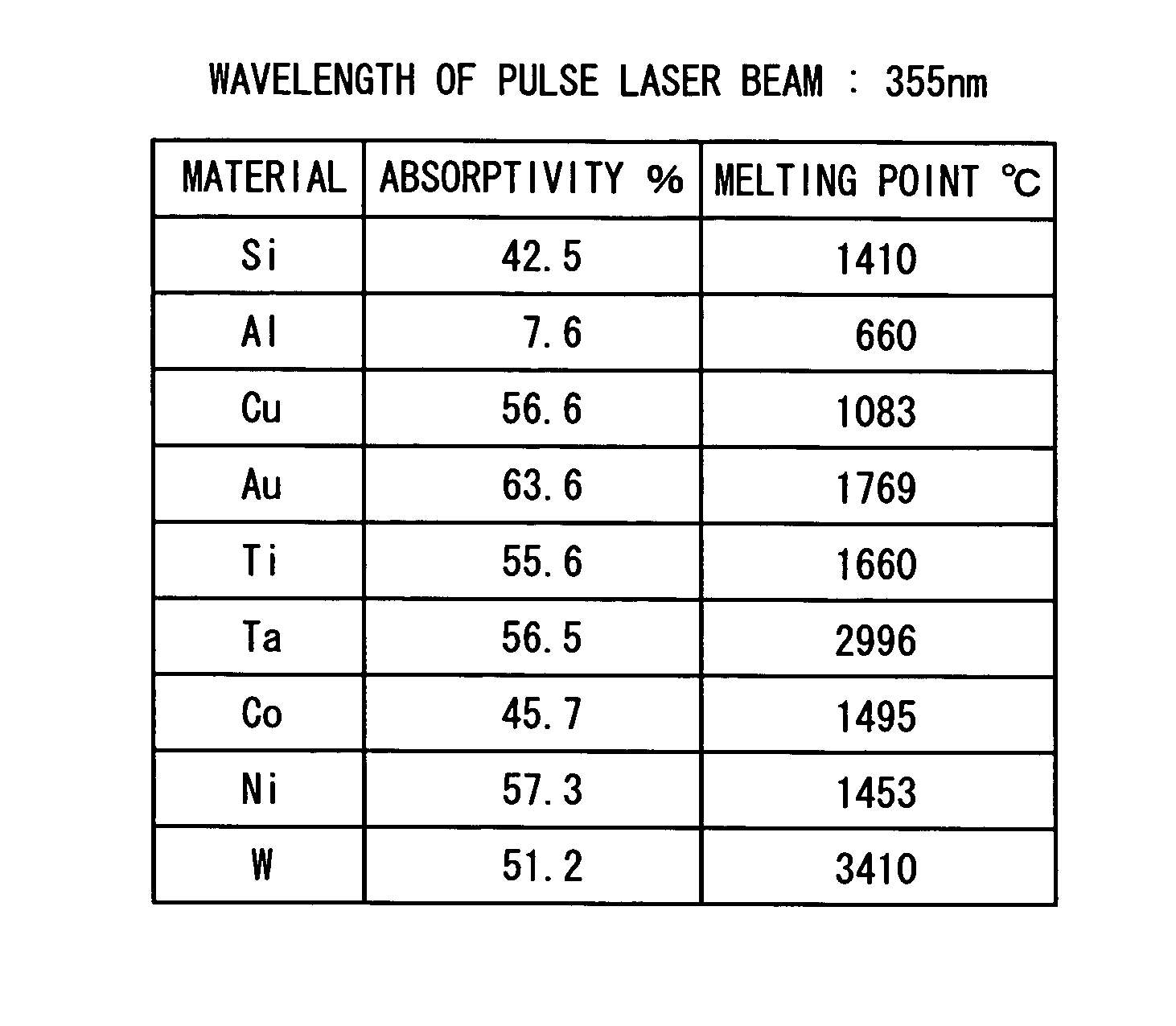

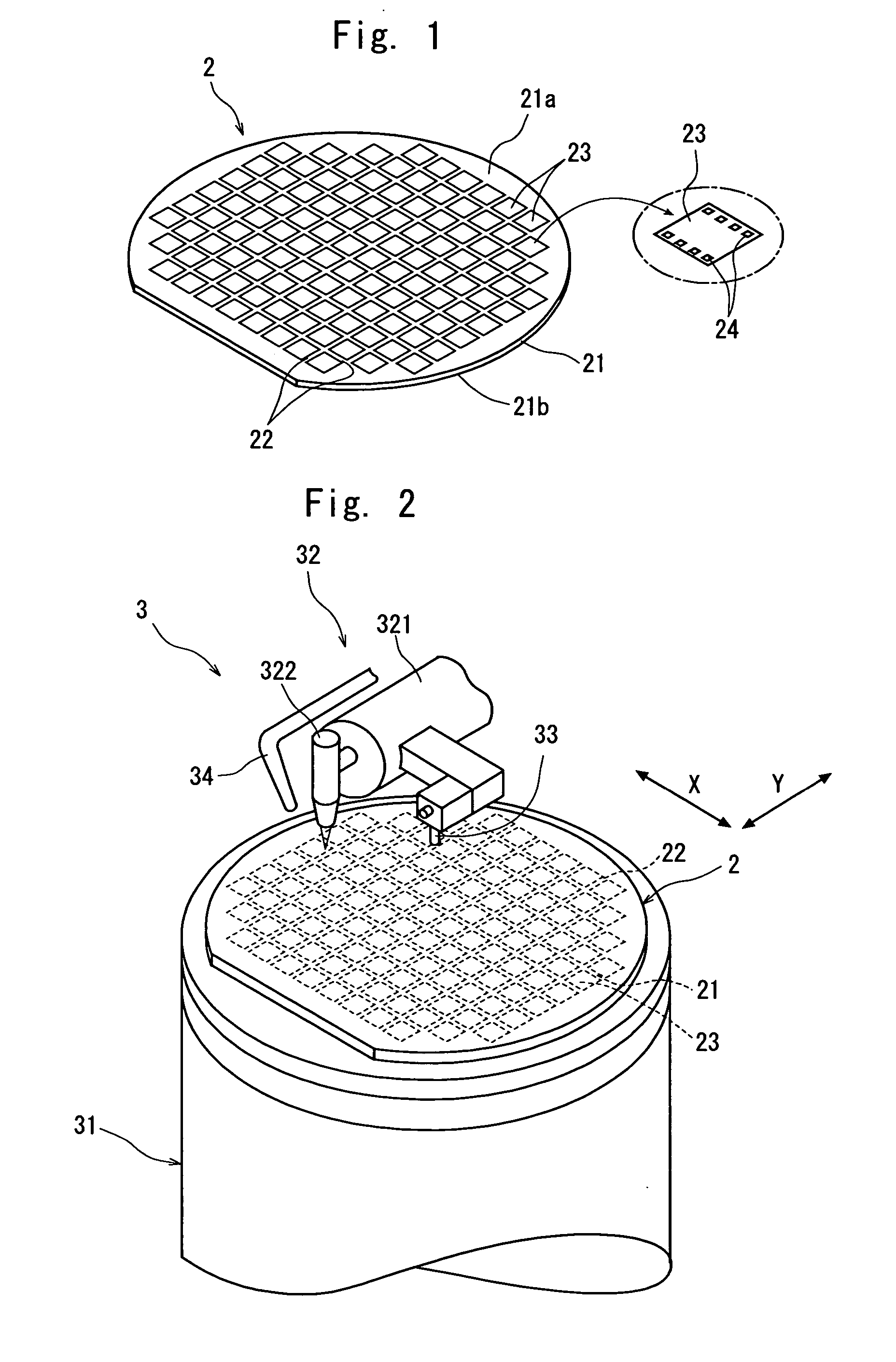

Wafer drilling method

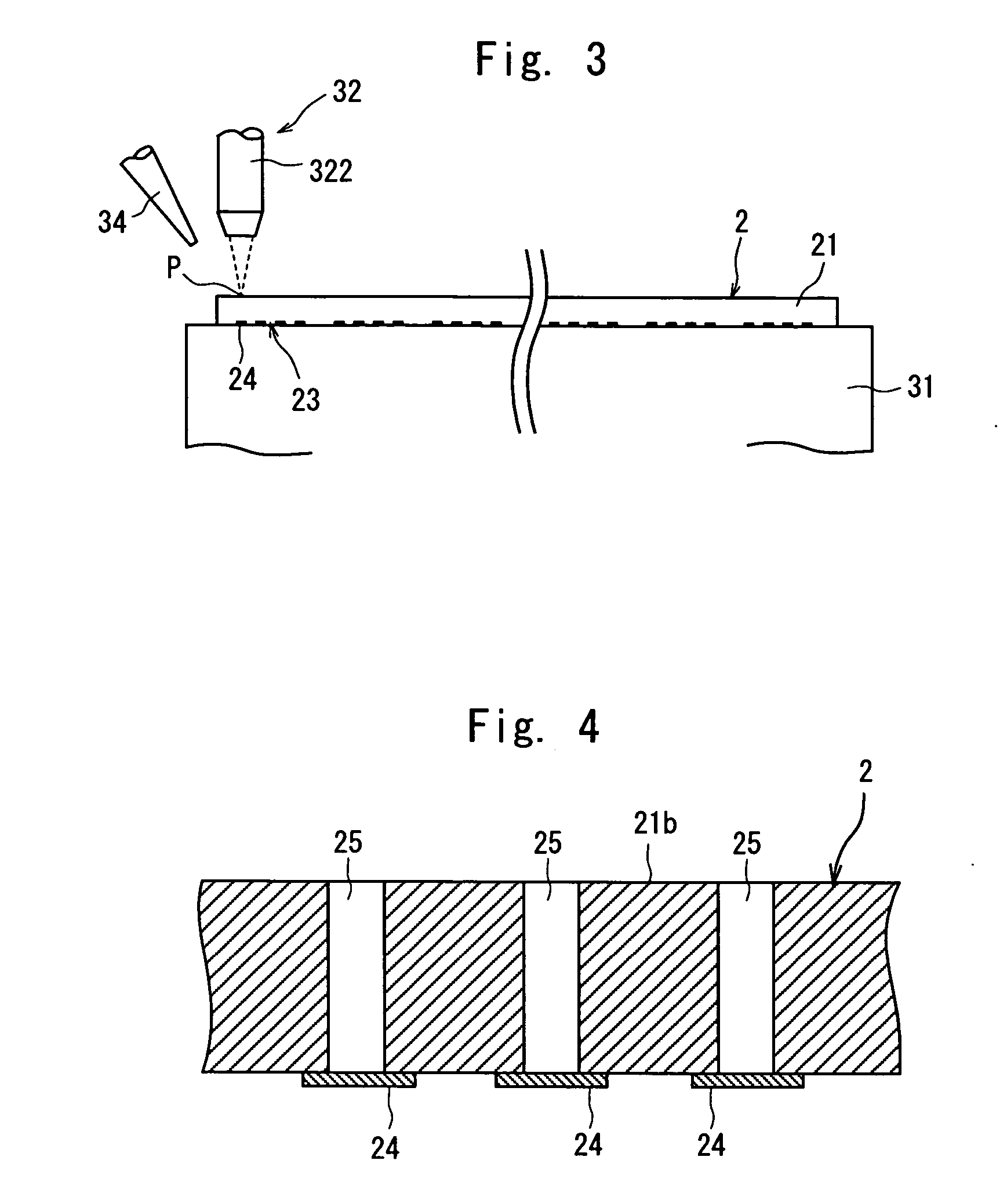

InactiveUS20070045254A1Efficiently formedEfficient damageSemiconductor/solid-state device detailsSolid-state devicesDevice formLight beam

A wafer drilling method for forming via holes reaching electrodes in a wafer having a plurality of devices formed on the front surface of a substrate and electrodes formed on the devices by applying a pulse laser beam from the rear surface side of the substrate, wherein a material forming the substrate, a material forming the electrodes and a wavelength of the pulse laser beam are selected based on absorptivity for the wavelength of the pulse laser beam, and the material forming the substrate, the material forming the electrodes and the wavelength of the pulse laser beam are set to ensure that the absorptivity of the electrodes for the wavelength of the pulse laser beam becomes lower than the absorptivity of the substrate for the wavelength of the pulse laser beam.

Owner:DISCO CORP

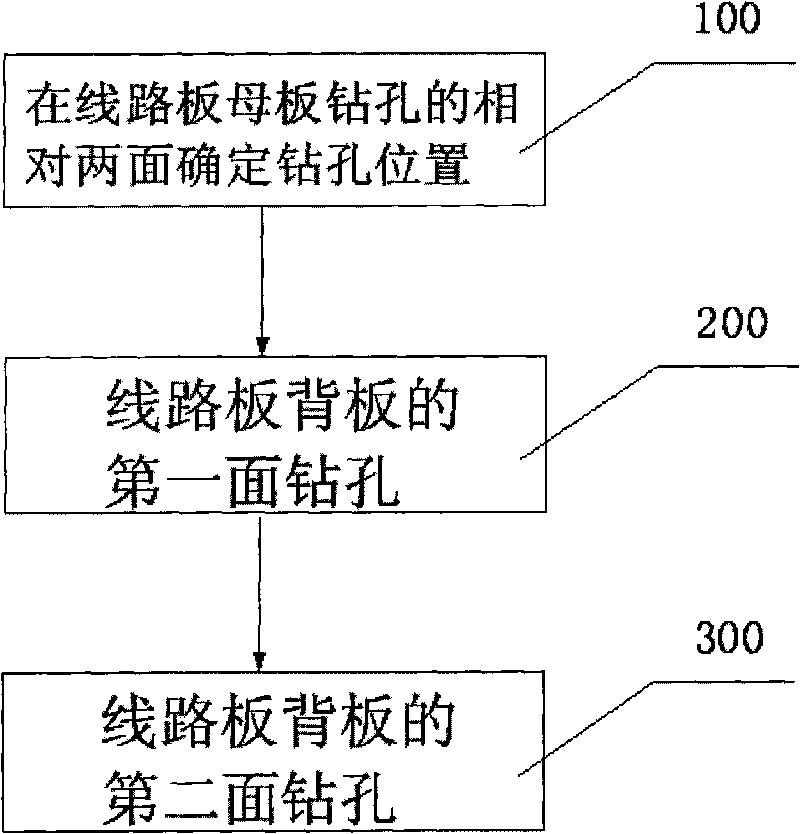

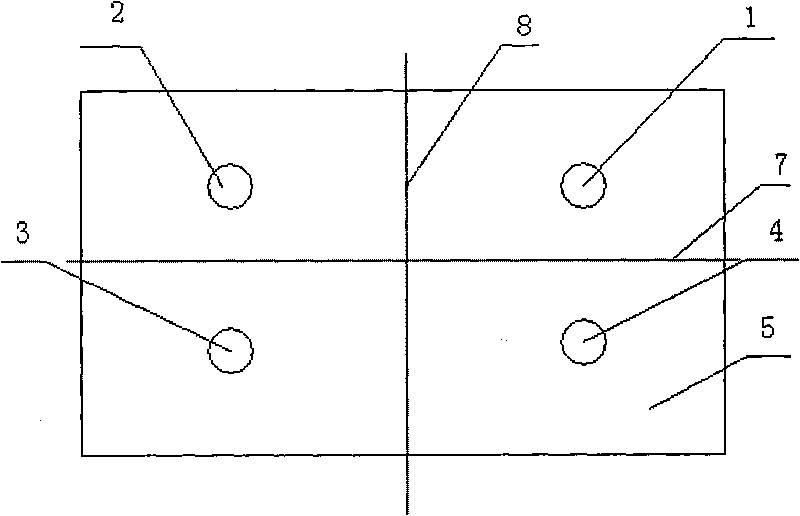

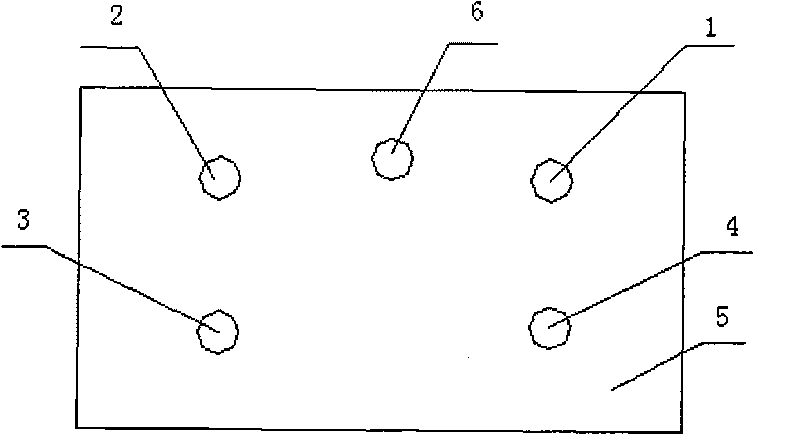

Drilling method of motherboard of circuit board

InactiveCN101765296AQuality improvementReduce chip removalPrinted circuit manufactureHole drilling methodMotherboard

The invention relates to a drilling method of a motherboard of a circuit board, which comprises the following steps of: determining drilling positions at the two opposite drilling faces of the motherboard of the circuit board; drilling at the first face of the motherboard of the circuit board: the determined position at the first face of the motherboard of the circuit board is drilled, and the drilling-in depth is 1 / 3 to 2 / 3 of the thickness of the motherboard of the circuit board; and drilling the second face of the motherboard of the circuit board: a position in the second face of the motherboard of the circuit board, which is superposed with a drill hole at the first face, is drilled with a through hole. The drilling method of the motherboard of the circuit board, which is provided by the invention, adopts the structure that the first face of the motherboard of the circuit board is firstly drilled, the drilling-in depth is 1 / 3 to 2 / 3 of the thickness of the motherboard of the circuit board, and then the second face of the motherboard of the circuit board is drilled with the through hole. For a mode of directly drilling the through hole at the thicker motherboard of the circuit board, the drilling method reduces the chip removal of drilling, solves the problem that a drill bit is broken in the drilling process, and enhances the drilling quality of the circuit board. Meanwhile, a method of drilling at both faces is adopted, and the problem of deviation in the drilling process is solved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Method for machining slotted holes on carbon fiber laminated boards

The invention discloses a method for machining slotted holes on carbon fiber laminated boards, which belongs to a machining method for nonmetallic materials, solves the problem that by the existing milling and drilling methods, carbon fiber laminated boards are easy to laminate, split and burn, and aims at improving the machining precision of carbon fiber composite products and reducing the surface roughness of carbon fiber composite products. The method disclosed by the invention comprises a clamping step, a machining step and a post-processing step, wherein the machining step is one or two of a milling machining step and a drilling machining step. According to the invention, in the machining process, a non-deformed clamping mode is used, and through selecting reasonable cutting tool materials, geometric parameters of cutting tools, and milling and drilling machining parameters, the appearance allowances in machining are reasonably arranged, thereby solving the quality problems of laminating, splitting and burning and the like existing in the process of opening or drilling carbon fiber thin-wall revolution bodies and carbon fiber laminated boards by using the traditional methods, so that the qualified rate of carbon fiber parts is increased from 50% to more than 99%.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

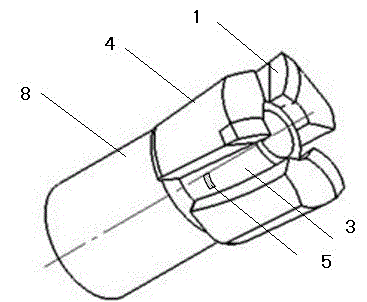

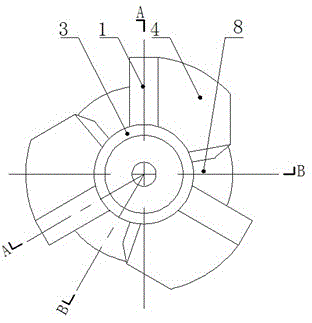

Coal mine underground self-suction abrasive jet flow drill bit and drilling method

ActiveCN103556947ARealize continuous additionSimple structureDrill bitsLiquid/gas jet drillingHole drilling methodCoal

The invention discloses a coal mine underground self-suction abrasive jet flow drill bit which can utilize the combination of abrasive jet flow guiding smash and mechanical smash to increase the drilling speed during the coal mine underground drilling operation. The self-suction abrasive jet flow drill bit comprises an abrasive jet flow nozzle, a self-suction device and a main smashing structure, wherein the self-suction device comprises a cavity, a filter screen, a support ring positioned inside the cavity and an inlet nozzle positioned at the rear end of the cavity. According to the invention, coal debris generated in the drilling process can be sifted by the filter screen, then enters the inside of the cavity of the self-suction device, and is fully mixed with a water jet flow to form an abrasive jet flow, the abrasive jet flow is jetted from the abrasive jet flow nozzle to perform guiding smash on coal and rock mass; the main smashing structure of the drill bit comprises three cutting pieces and three main smashing teeth, and a finished drill-hole can be formed under the mechanical smash action of the main smashing structure. The invention further relates to a method for utilizing the drill bit to drill in an underground coal mine. The drill bit has high drilling speed and little abrasion, and can be widely applied to coal mine underground drilling operation.

Owner:CHONGQING UNIV

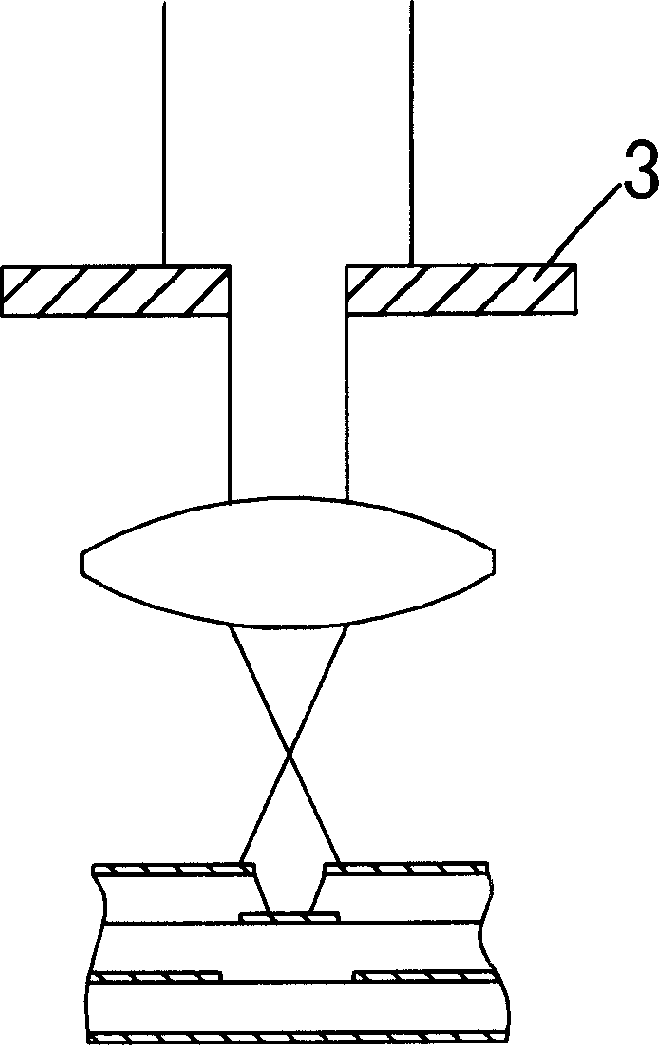

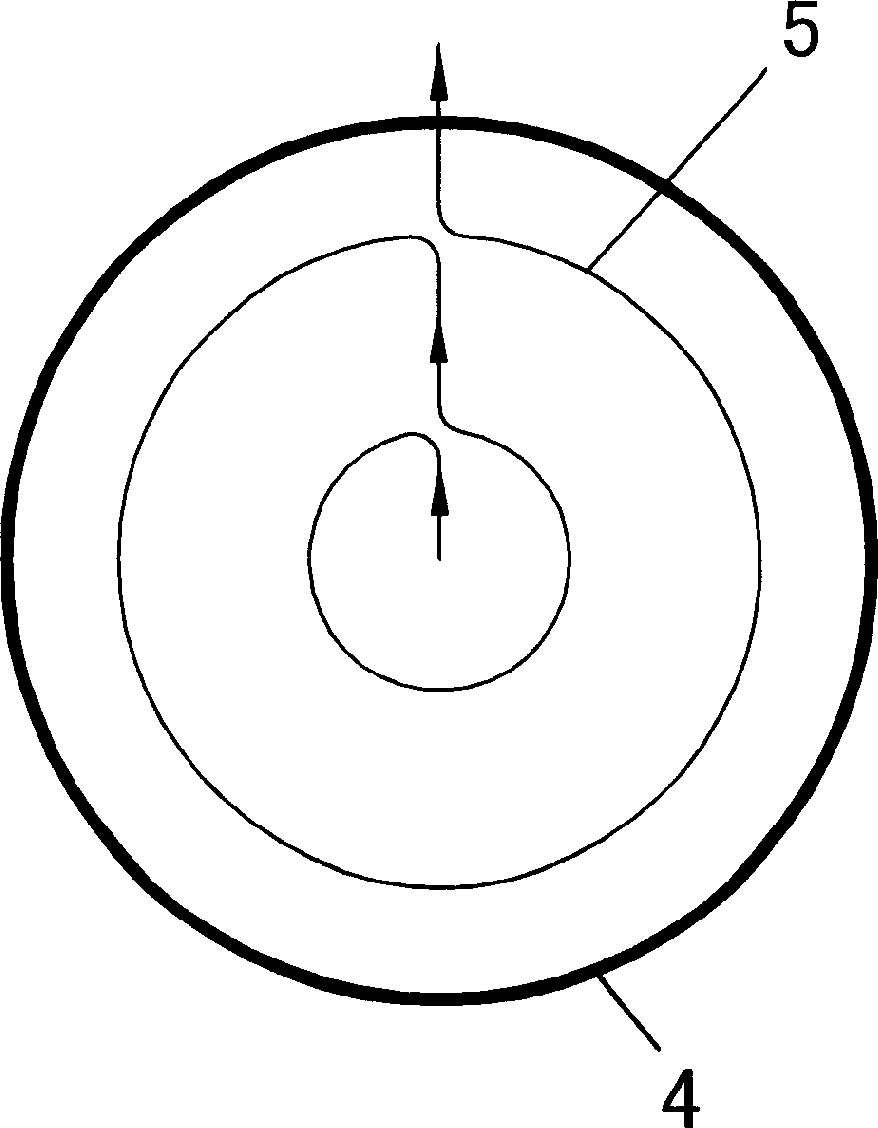

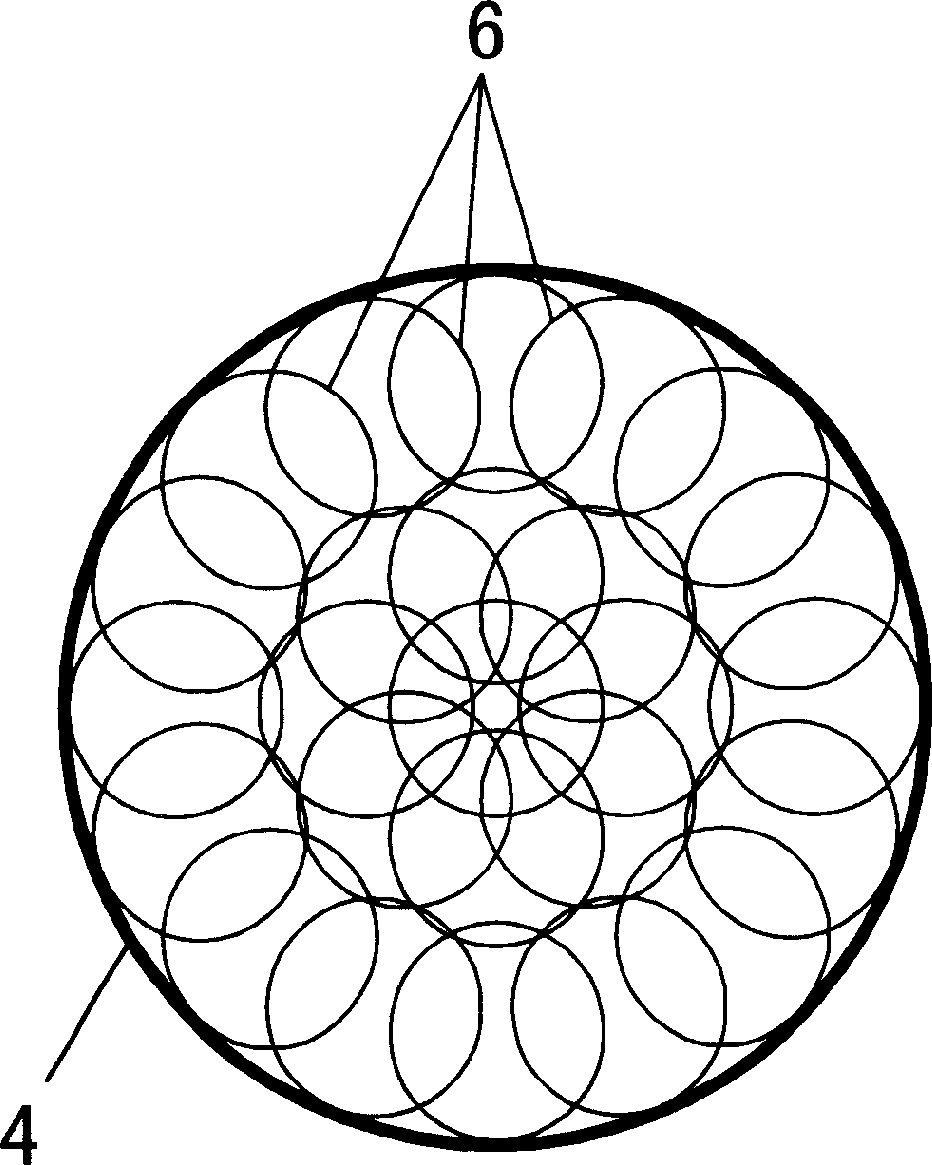

UV laser drilling hole method

InactiveCN1674765ASolution to too much laser energySolve the problemConductive material mechanical removalUv laserLight beam

The present invention relates to an UV laser drilling method for making microconductive through-hole one printed circuit base board. Said method includes the following steps: utilizing UV laser beam to scan the position having need of making microconductive through-hole along a certain pathway, then successively making several microholes until the area of whole surface around the microconductive through-hole in covered with the made microholes all over, and then carving the whole microconductive through-hole. Said invention adopts the ring sawing process, so that it can raise the making quality of the microconductive through-hole.

Owner:HANS LASER TECH IND GRP CO LTD +1

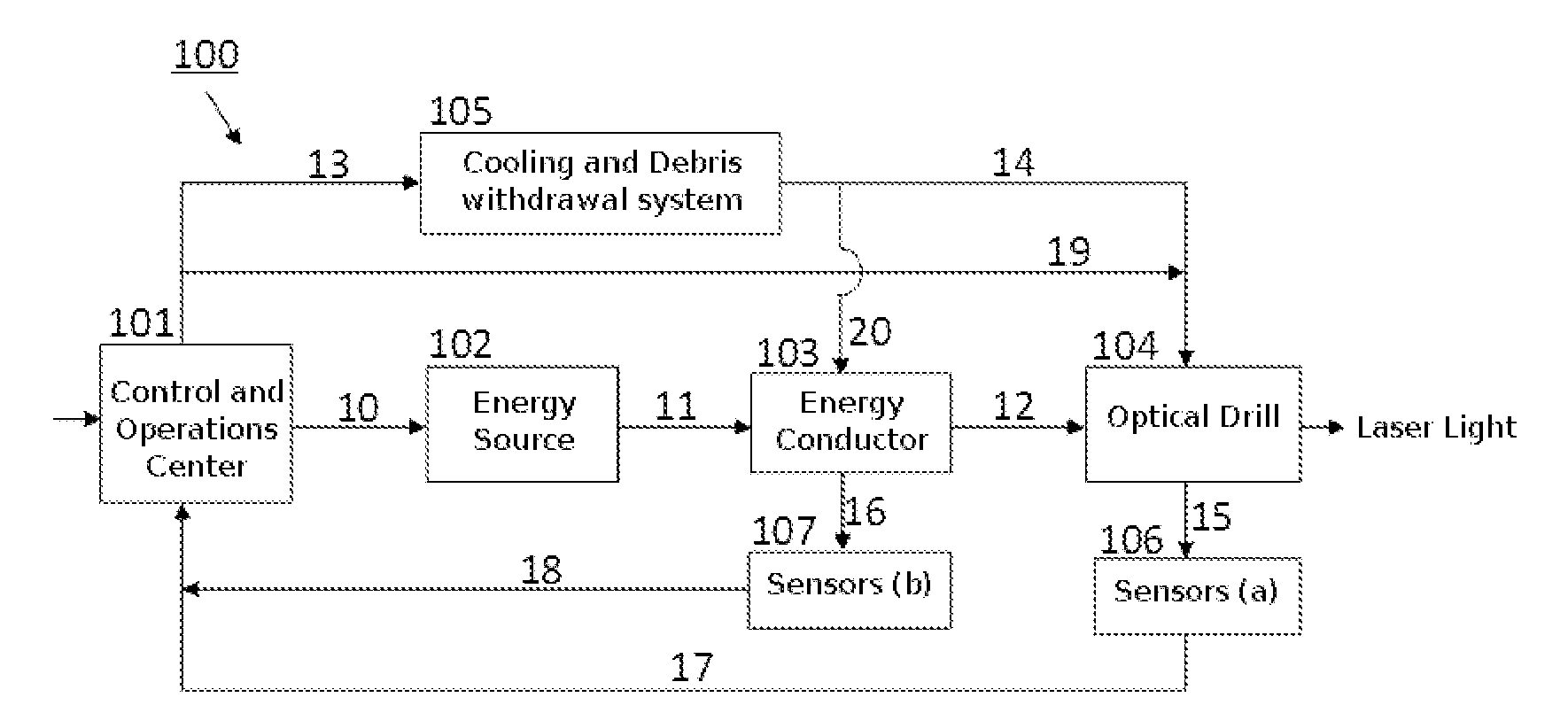

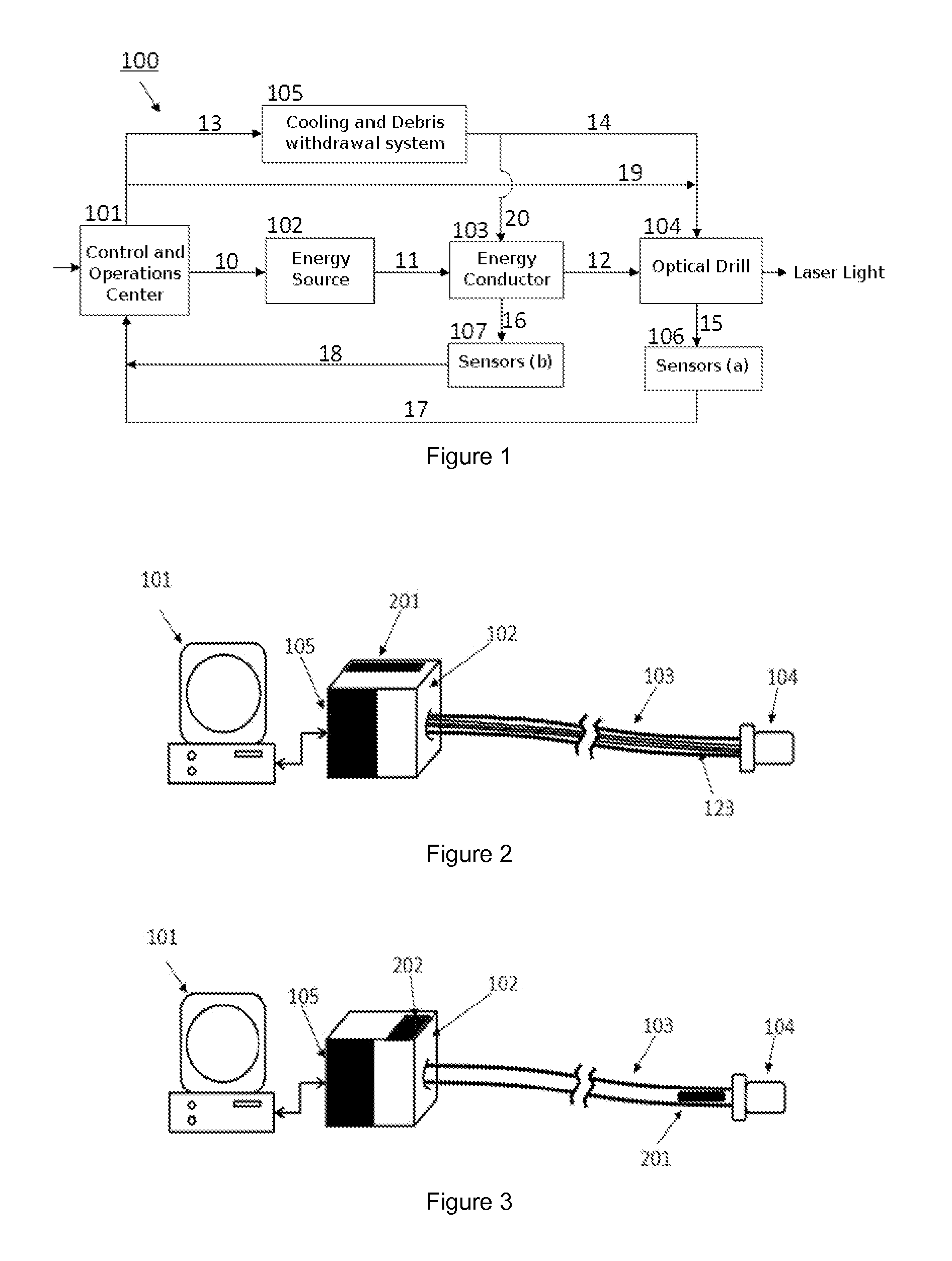

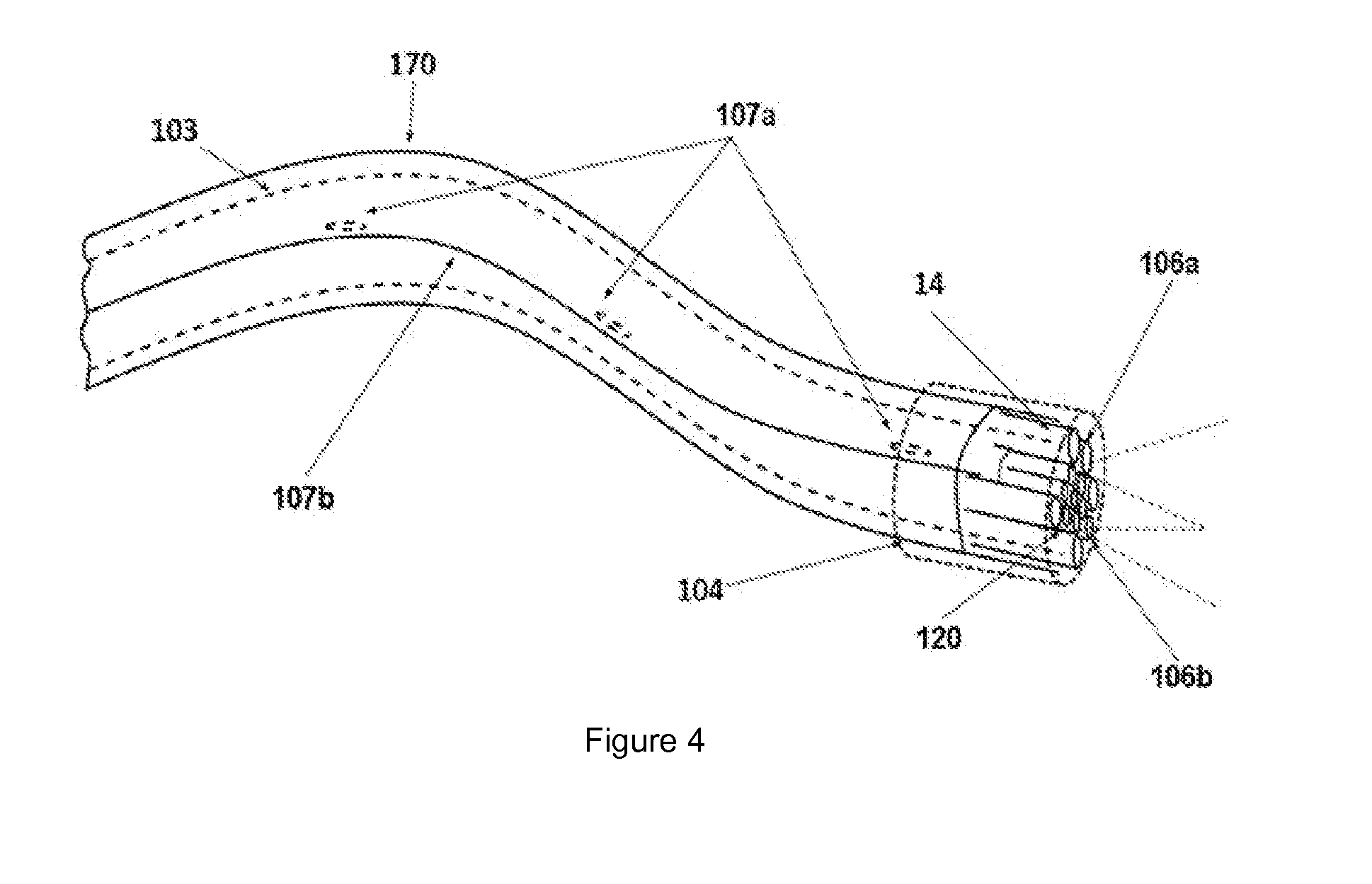

Laser drilling method and system

A laser drilling system (100) for drilling rocks, soil and engineering materials with the aid of high-intensity laser light is described, which comprises an optical drill (104) for supplying laser light for the drilling of said materials provided with sensors (106); a control and operations center (101) comprising computer and supervising software with integrated logic; a cooling and debris withdrawal system (105) an energy source (102); an energy conductor (103) provided with sensors (107) and laser systems (201) for emitting high-intensity laser light and optical fibers (123) for conducting the so-generated laser light, so that the information collected by sensors (106), (107) supply said control and operations center (101) and said control and operations center (101) determines improved operation conditions of the optical drill (104) for the drilling of said solid materials or mixtures of solid and liquid materials relative to state-of-the-art drilling systems. The drilling method employing the system of the invention is also described.

Owner:FACULDADES CATOLICAS MANTENEDORA DA PONTIFICIA UNIV CATOLICA DO RIO DE JANEIRO - PUC RIO

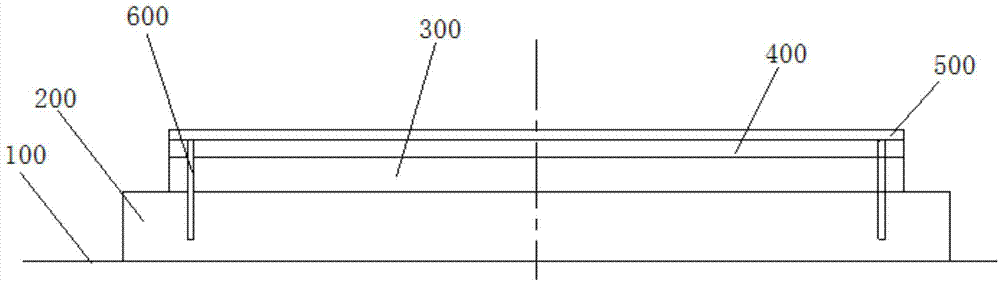

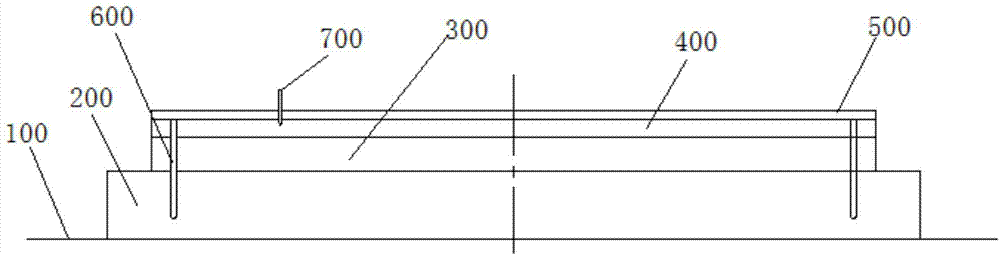

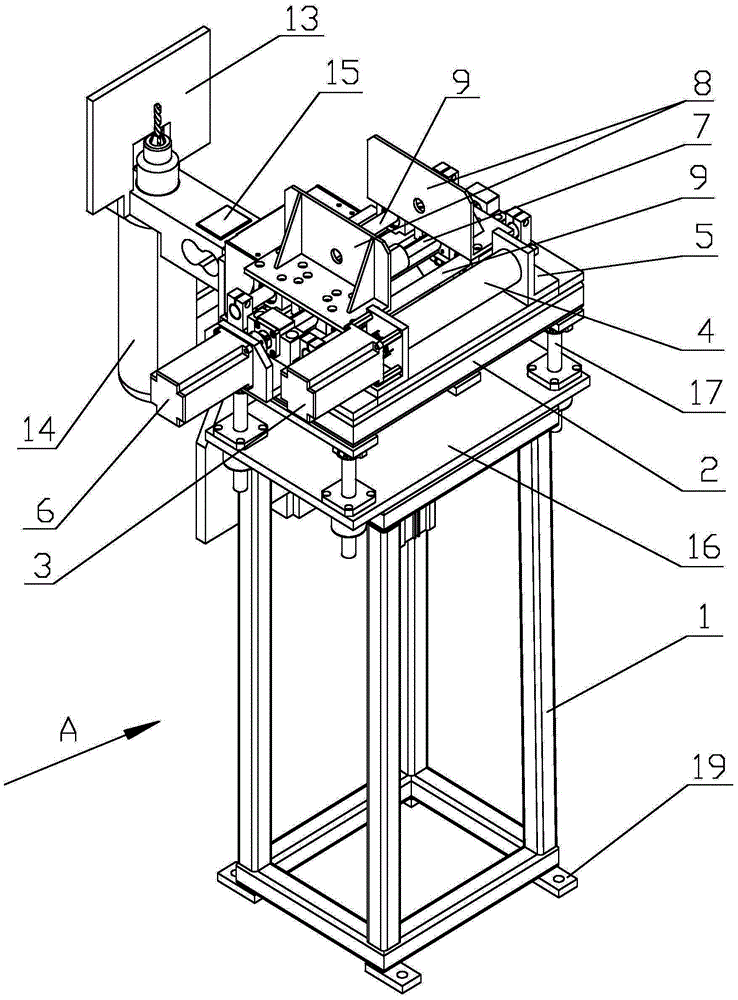

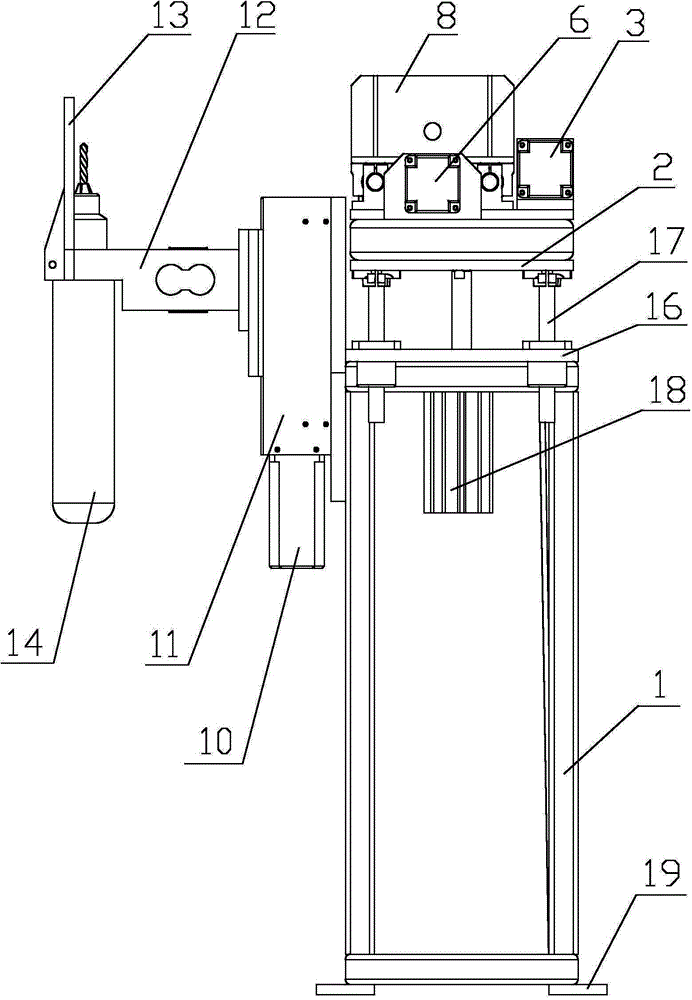

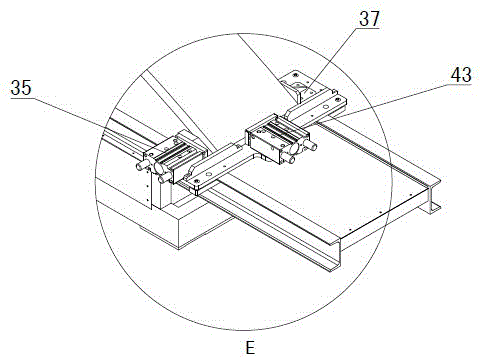

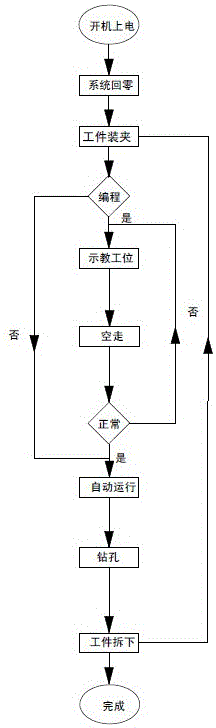

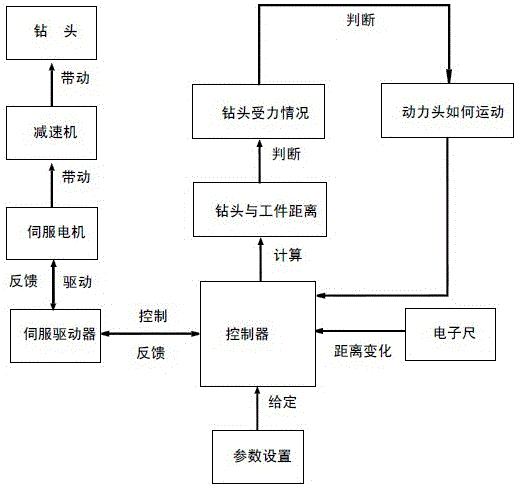

Automatic transmitting and positioning aluminum profile drilling machine and method

InactiveCN103600103ASimple structureEasy to useLarge fixed membersMetal working apparatusProduction lineHole drilling method

The invention discloses an automatic transmitting and positioning aluminum profile drilling machine and method. The drilling machine comprises a base, a lifting platform, a transporting mechanism, a clamping mechanism and a drilling mechanism, wherein the lifting platform is arranged on the top of the base, the transmitting mechanism and the clamping mechanism are arranged on the platform in parallel, the drilling mechanism is arranged on one side of the base, and the transmitting mechanism, the clamping mechanism and the drilling mechanism are sequentially connected in the transmitting direction of an aluminum profile. The drilling method includes the steps of firstly, adjusting the heights of all the mechanisms through the lifting platform; secondly, starting the transmitting mechanism, and sending the end, to undergo hole drilling, of the aluminum profile onto the drilling mechanism; thirdly, clamping the aluminum profile through the clamping mechanism; fourthly, conducting drilling on the end portion of the aluminum profile through the drilling mechanism. The aluminum profile drilling machine is simple in structure, convenient to use and capable of replacing traditional manual operation, enables automatic drilling to the achieved, and is high in work efficiency and safety coefficient. The drilling machine is high in integratability and high in compatibility, and can be flexibly embedded into other automated production lines or integrated into other function devices.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

Method for drilling with casing

A method for drilling boreholes using casing as the drill string and for removing a drilling assembly from the wellbore while leaving the casing in the well bore. In the method, the drilling assembly is prepared for removal from the wellbore by launching a release tool and manipulating the drilling assembly using the release tool.

Owner:SCHLUMBERGER TECH CORP

Truss type intelligent drilling device and arc plate drilling method

ActiveCN105108200AConstant distanceReduce work intensityLarge fixed membersPositioning apparatusEngineeringHole drilling method

The invention discloses a truss type intelligent drilling device and belongs to the field of special-shaped plate drilling devices. The upper portion of a gantry frame is provided with a Y-axis beam (2), a mechanical arm (9) is arranged on the Y-axis beam (2), the lower end of the mechanical arm (9) is provided with a drilling mechanism and a drilling positioning device, and a mechanical arm swinging mechanism used for driving the mechanical arm (9) to swing around the axis of the Y-axis beam (2) is arranged between the mechanical arm (9) and the Y-axis beam (2). The mechanical arm (9) is further connected with a drill bit lifting mechanism for driving the drilling mechanism to ascend and descend, a horizontal X-axis rail device perpendicular to the Y-axis beam (2) is arranged below the mechanical arm (9), a worktable is fixed to the X-axis rail device, a workpiece fixing mechanism is fixed to the worktable, and the Y-axis beam (2) and the worktable can move relatively in the length direction of the X-axis rail device. The invention further provides an arc plate drilling method with the device, and arc plates can be automatically drilled and machined.

Owner:淄博纽氏达特机器人系统技术有限公司

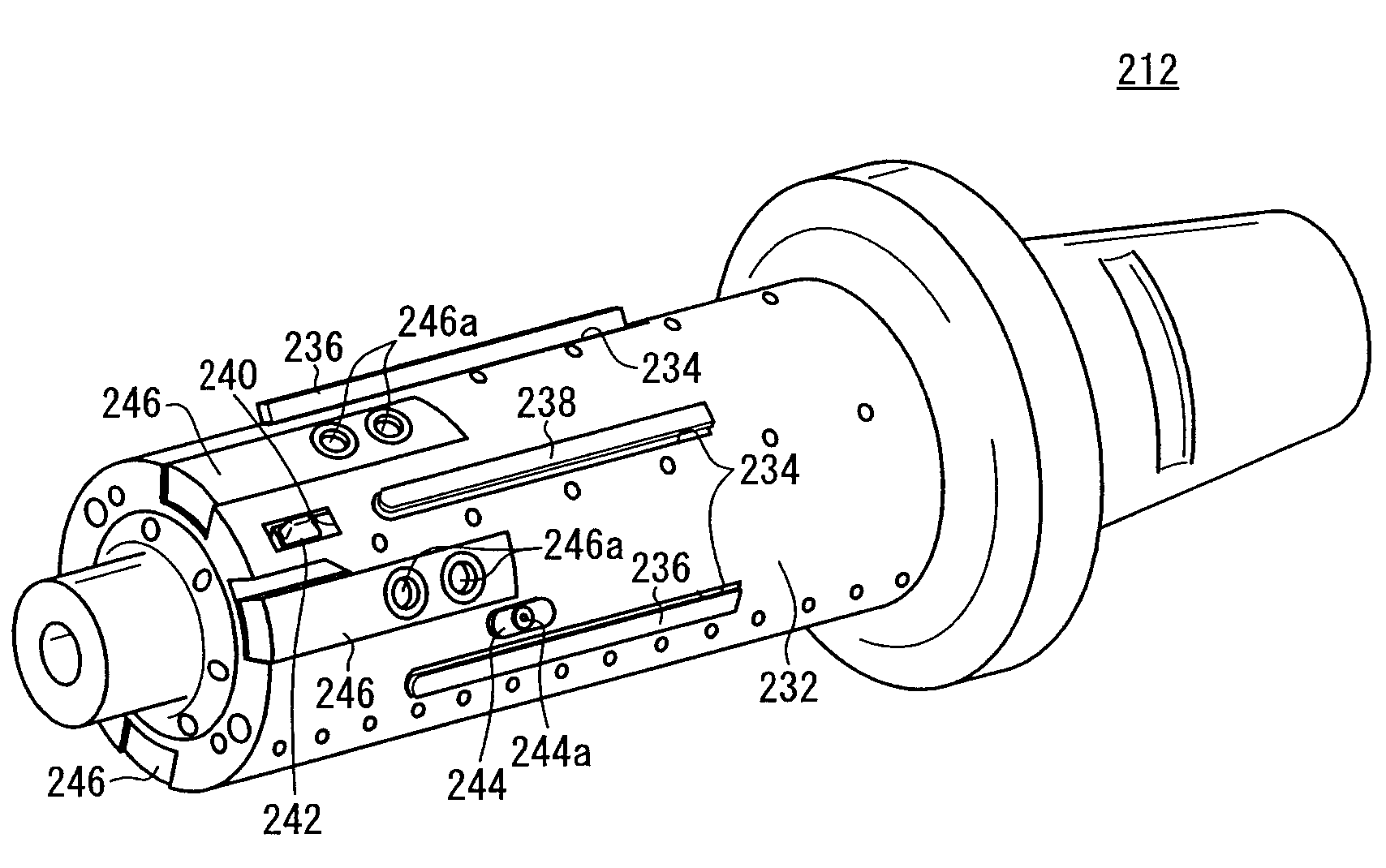

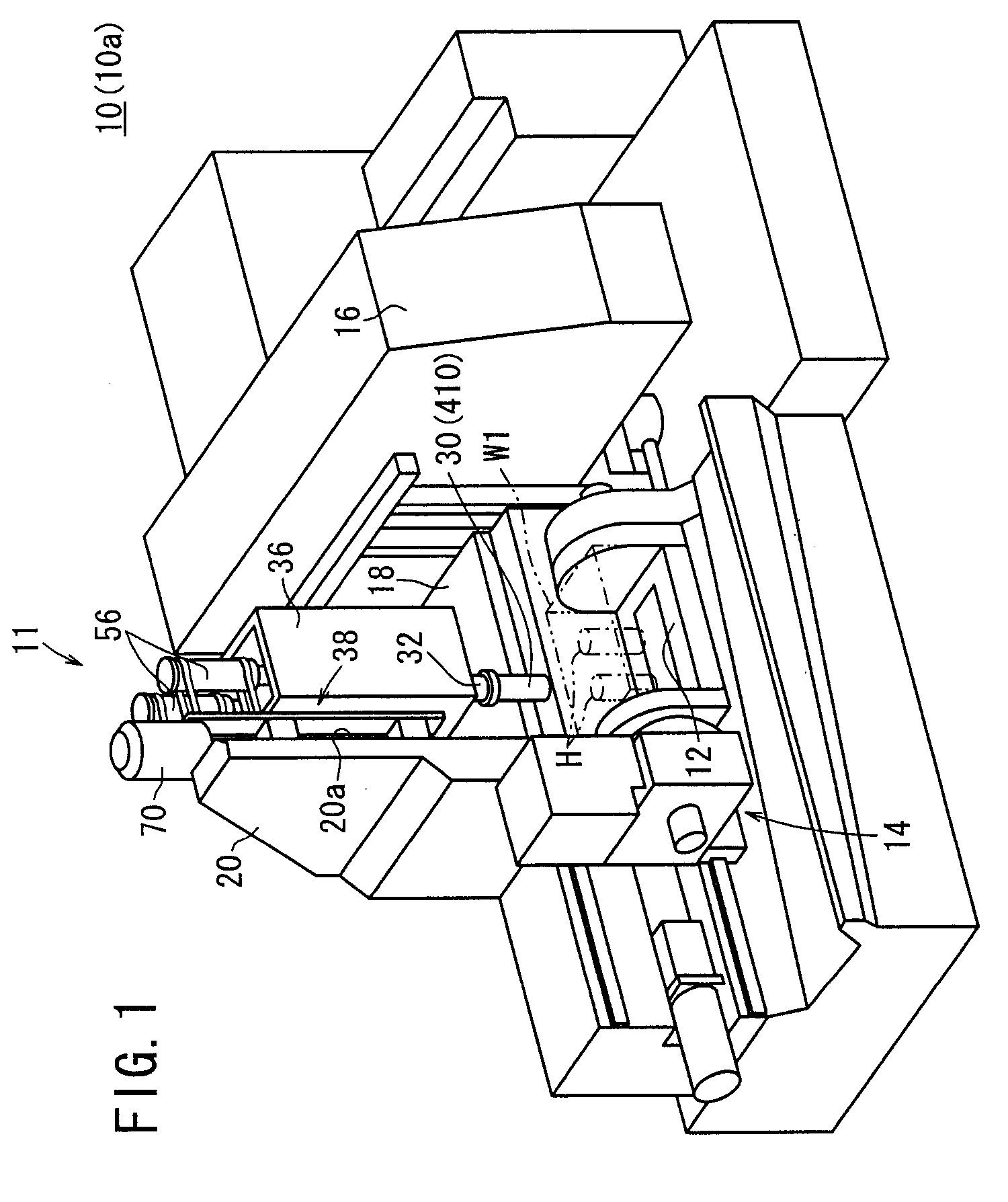

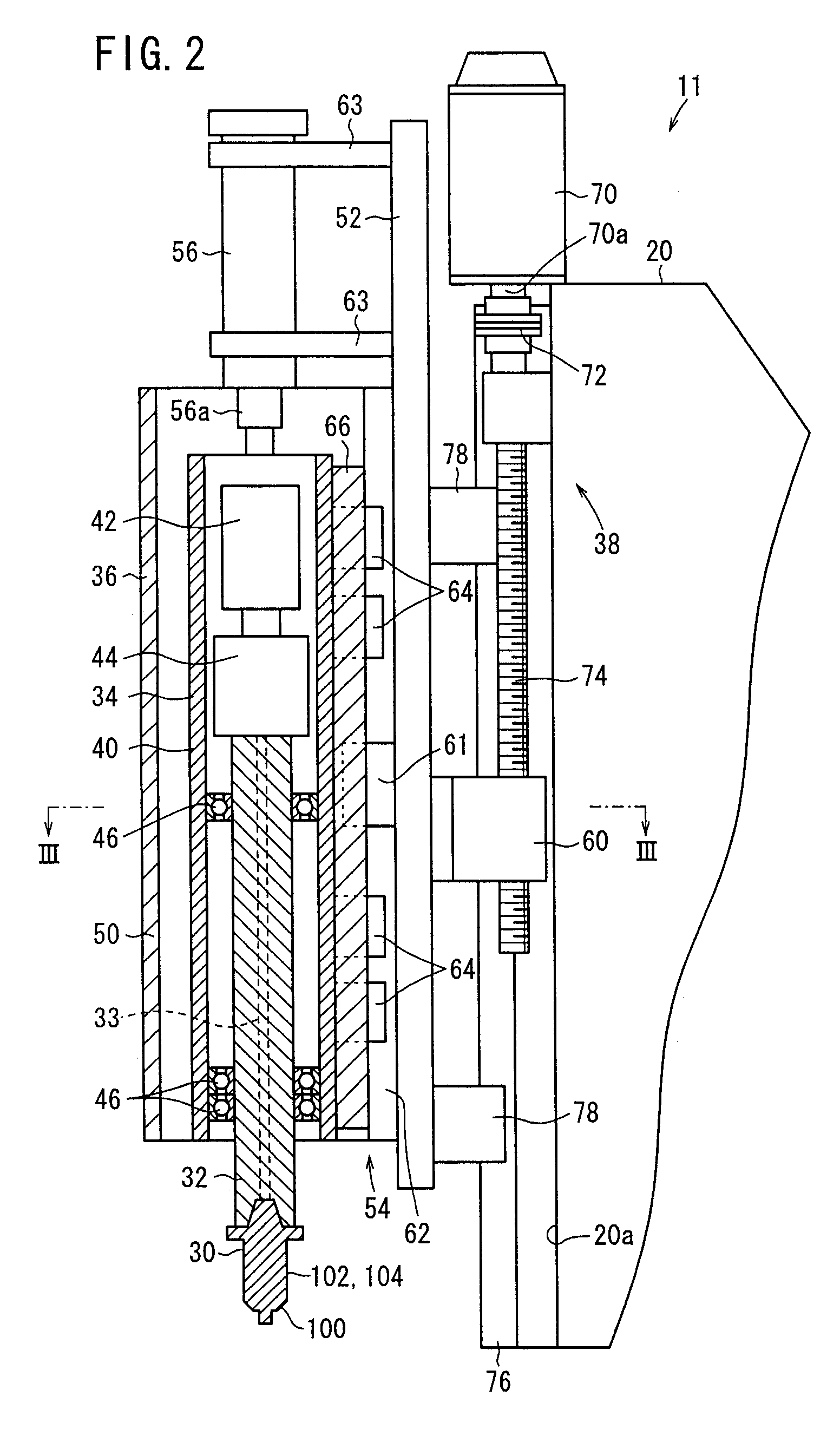

Tool head, machine tool and boring method of bore of cylinder block using the machine tool

ActiveUS20090129879A1Precise processingEasy to insertThread cutting toolsGrinding machine componentsEngineeringCylinder block

The spindle drive unit of a combined machine tool drives the spindle. The tip end of the spindle is provided with a boring tool and a tool head having a rough grinding stone and a finishing grinding stone. The spindle drive unit has a first support unit and a second support unit capable of receiving the spindle therethrough and supporting it rotatably, a linear motor and a column slide mechanism for moving the first and second support unit in the axis direction of the spindle, and a spindle motor for rotating the spindle.

Owner:HONDA MOTOR CO LTD

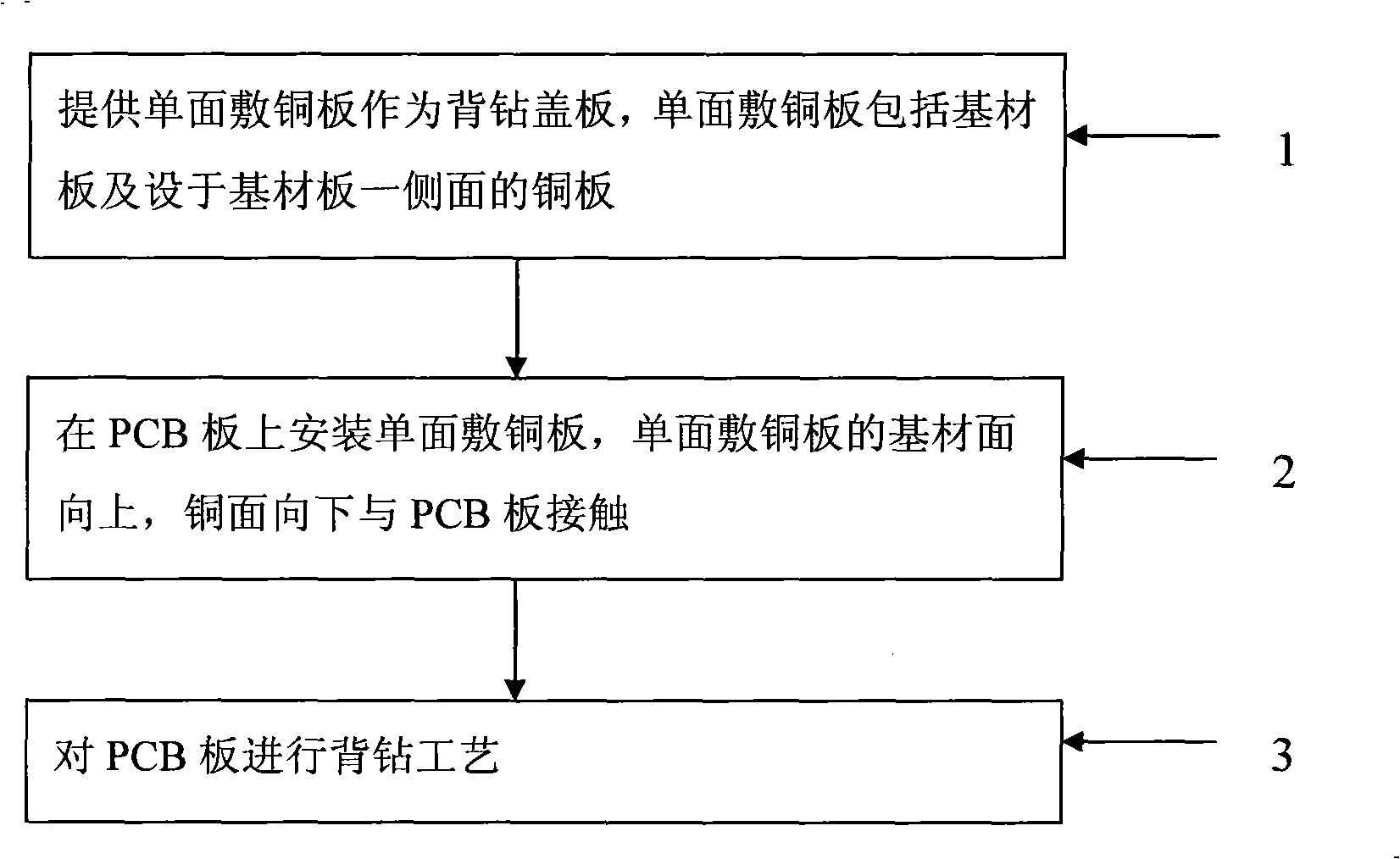

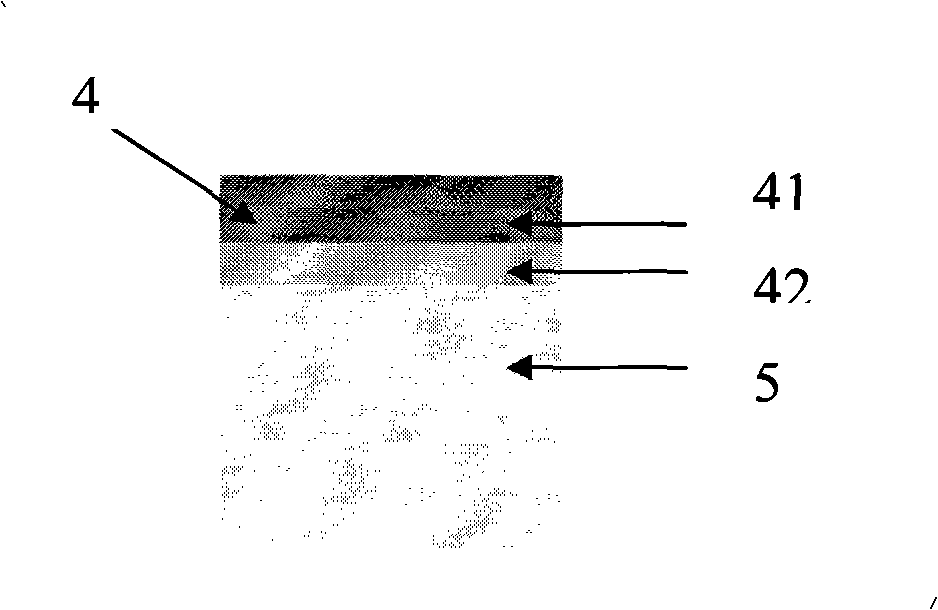

Hole drilling method with single-side brass plate as back drill cover plate

ActiveCN101342604AReduce the impactHigh hardnessPrinted circuit manufactureBoring/drilling machinesHardnessEngineering

The invention relates to a boring method of utilizing a single-side copper clad panel as a back-boring cover plate, which comprises the following procedures: providing the single-side copper clad panel as the back-boring cover plate, the single-side copper clad panel comprises a substrate plate and a copper plate which is positioned on one side of the substrate plate; installing the single-side copper clad panel on a PCB plate, the substrate side of the single-side copper clad panel is upward, the copper side is downward and contacts with the PCB plate; carrying out the back-boring process on the PCB plate. The invention utilizes the single-side copper clad panel as the back-boring cover plate, the thickness is larger and the hardness is larger and consequently the plate is not easily picked up, and the tolerance of the copper thickness of the single-side copper clad panel is less, thereby reducing the affect on the back-boring accuracy. Moreover, the substrate side of the single-side copper clad panel has the role of cleaning the drilling tool, can effectively avoid the depth error cauded by the advanced or delayed communication of high-frequency circuit caused by dust, copper scale and aluminum scale left on the drilling tool, thereby effectively promoting the back-boring accuracy.

Owner:DONGGUAN SHENGYI ELECTRONICS

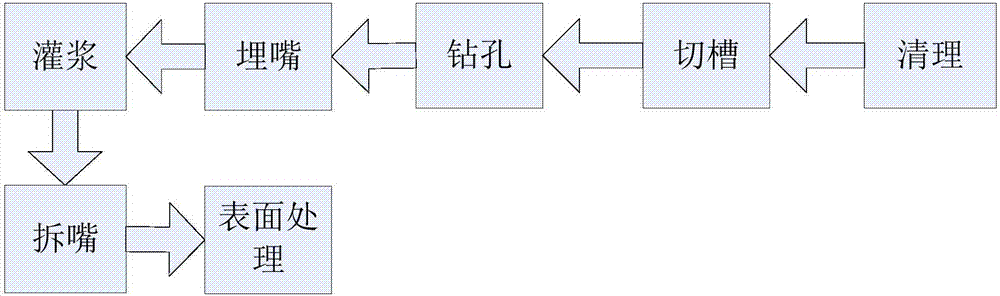

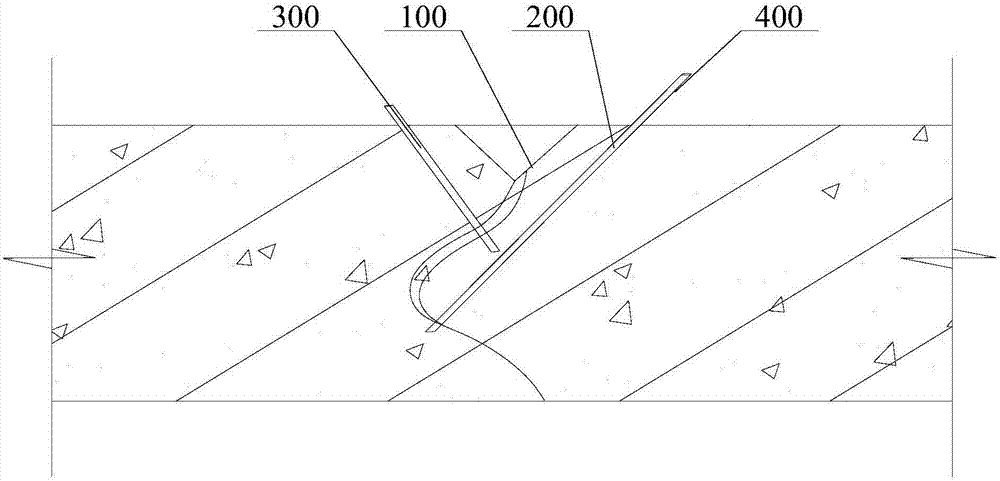

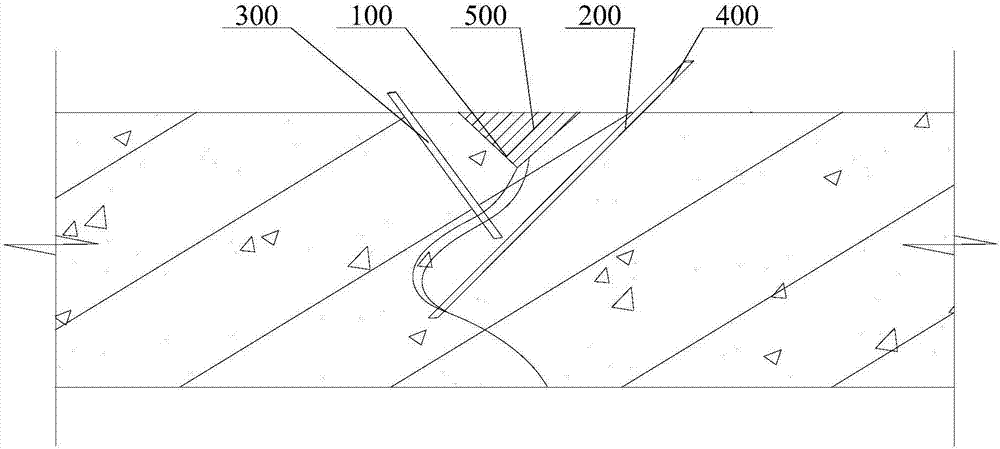

Leaking stoppage and reinforcement method for traffic tunnel cracks in vibration and disturbance environments

InactiveCN107201910ARecovery strengthPrevent leakageUnderground chambersTunnel liningWhole bodySlurry

The invention provides a traffic tunnel crack plugging and reinforcement method used in a vibration-disturbed environment, and relates to the technical field of crack repair in traffic tunnels. The grouting material is poured by using the method of minimal damage and adopting the pinhole oblique side drilling method. , Reinforcing while plugging. The specific method is to use a cutting machine to cut grooves along the seam first, clean them up and fill them with special cement for sealing, then make grouting holes along both sides of the seam to 1 / 3 to 1 / 2 of the seam. The grouting nozzle is installed in the hole, the grouting material is injected, and through the sealing effect of the cutting groove, and through the cross grouting, the grout is injected into the depth of the crack, so that the lining concrete at the crack is restored to form a whole, which solves the existing problems in the prior art. The technical problem that underground engineering cannot effectively plug leaks in the vibration-disturbed environment prevents leakage and cracking due to vibration-disturbed deformation and damage, and restores the compactness and structural integrity of the lining concrete.

Owner:南京康泰建筑灌浆科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com