Hole drilling method with single-side brass plate as back drill cover plate

A drilling method and copper clad plate technology are applied in the direction of boring/drilling, drilling/drilling equipment, electrical components, etc., which can solve the problems of large tolerance and reduced precision, and achieve small copper thickness tolerance, reduce influence, The effect of improving the accuracy of back drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

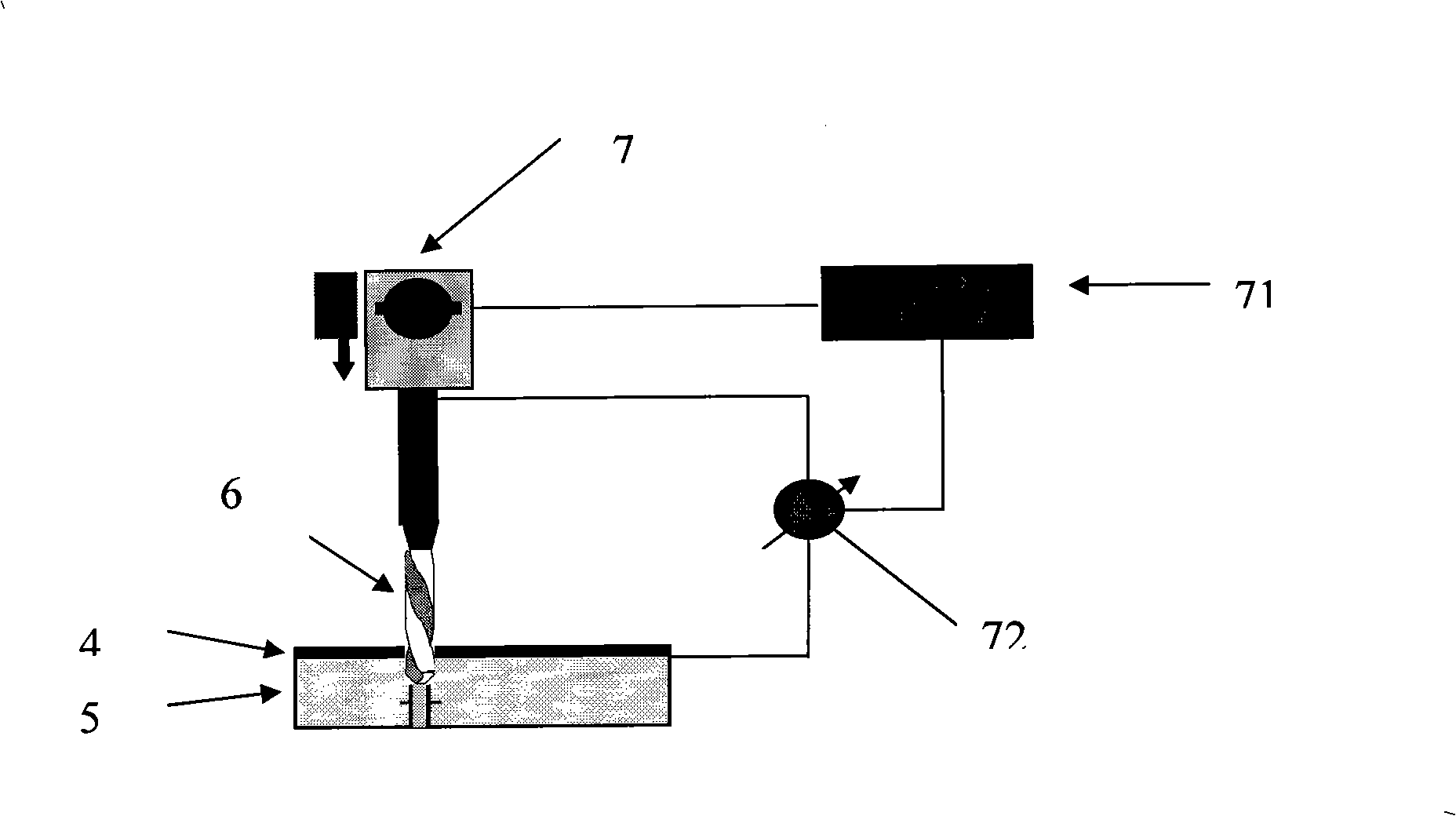

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

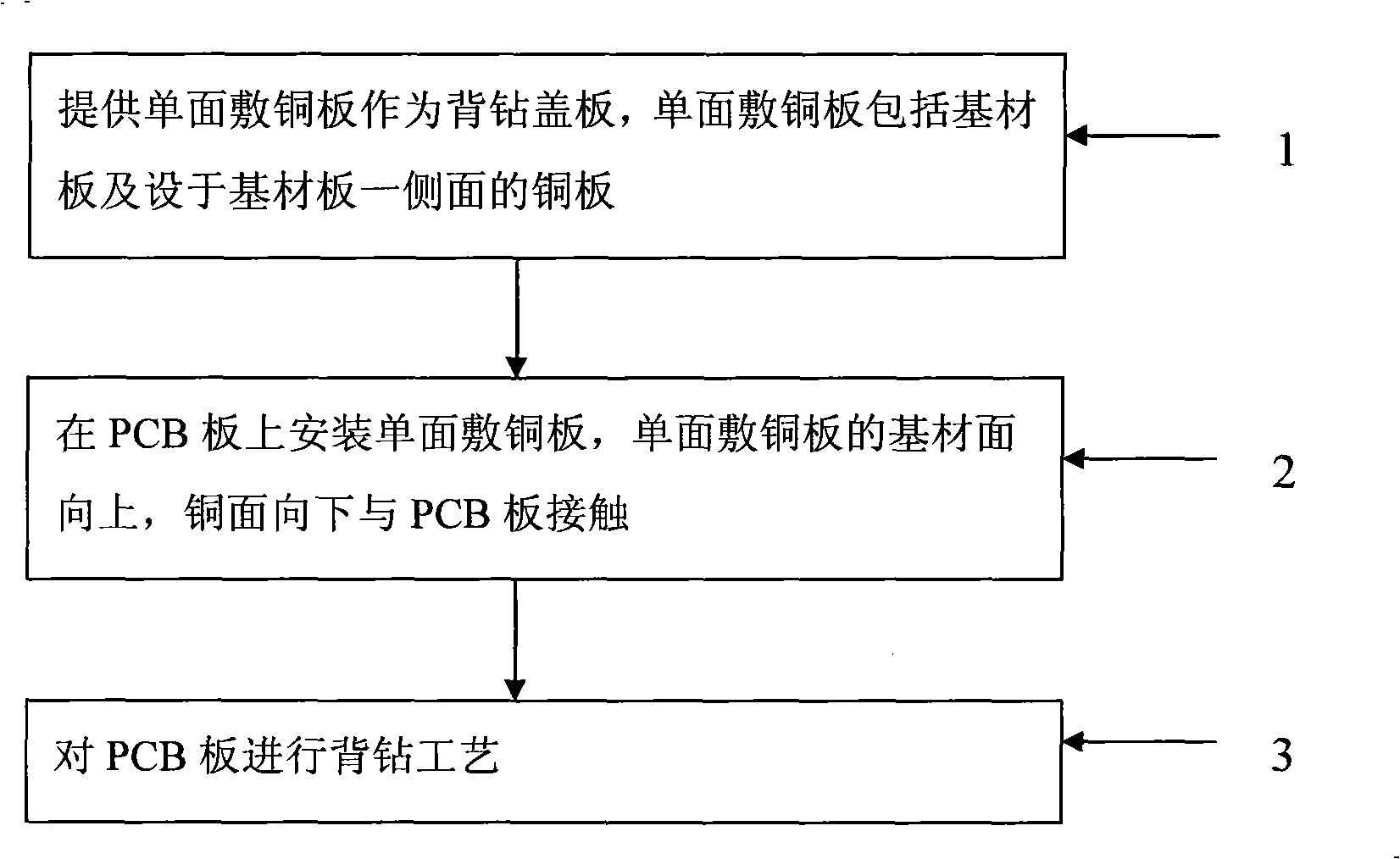

[0017] Such as figure 1 As shown, the present invention uses a single-sided copper-clad plate as a drilling method for back-drilling cover plate, comprising the following steps:

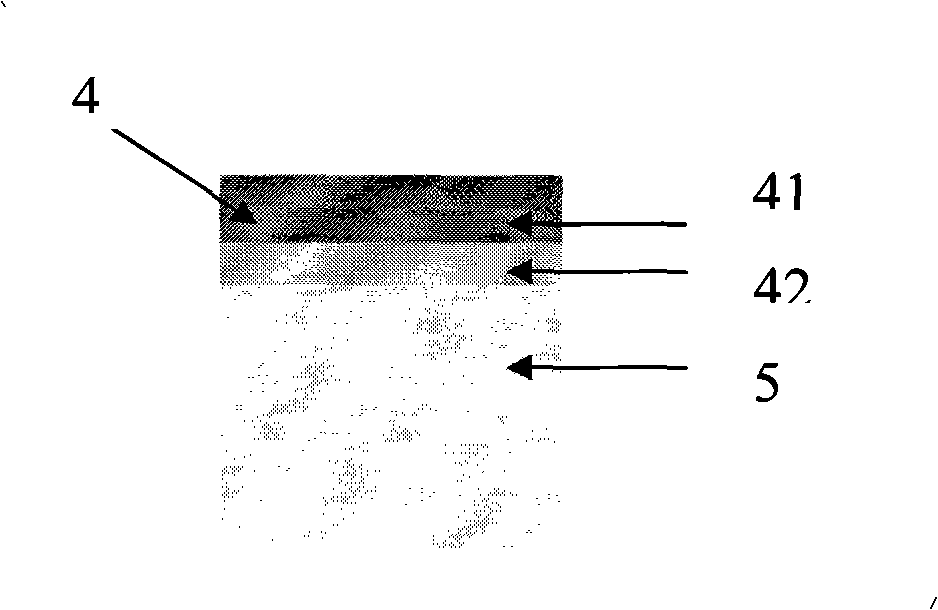

[0018] Step 1: Provide a single-sided copper-clad board 4 as a back drill cover; the single-sided copper-clad board 4 includes a base plate 41 and a copper plate 42 disposed on one side of the base plate 41, which is made by etching a double-sided copper-clad plate, The double-sided copper-clad board includes a base plate and copper plates arranged on both sides of the base plate. After etching the copper plate on one side, the copper plate 42 on the other side is used as a dielectric material for high-frequency electronic conduction. In this embodiment Among them, the thickness of the double-sided copper clad plate is 1.0mm, and its copper thickness specification is 0.018±0.003mm.

[001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com