Drilling method of motherboard of circuit board

A drilling method and circuit board technology, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of large drilling diameter, broken drill, and affecting the quality of circuit boards, so as to improve quality, reduce broken drill bits, The effect of reducing chip removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

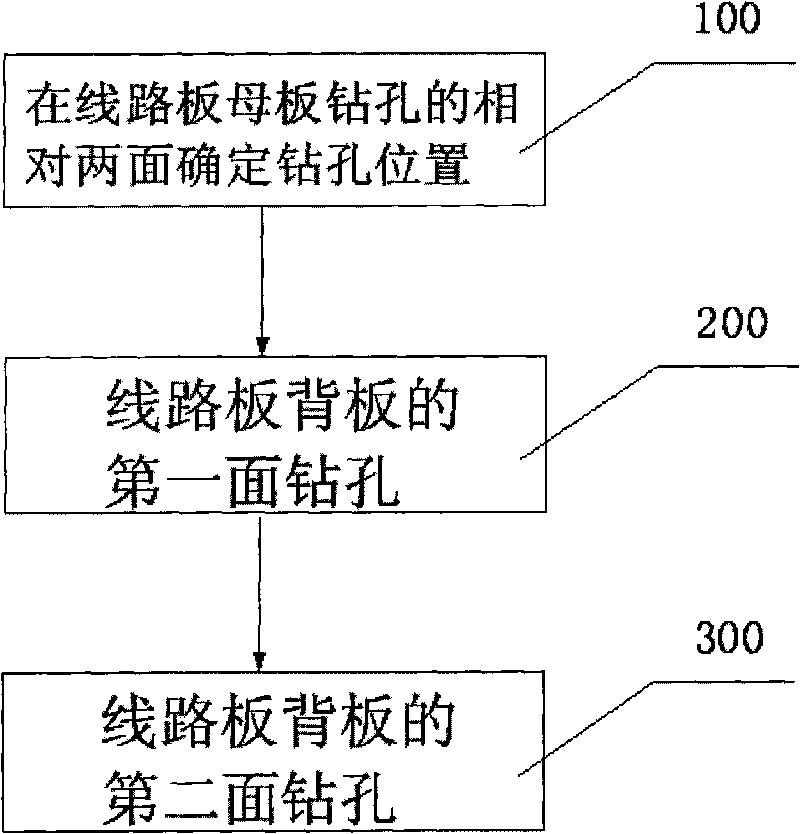

[0019] Such as figure 1 As shown, the specific embodiment of the present invention is: provide a kind of drilling method of circuit board mother board, comprise the steps:

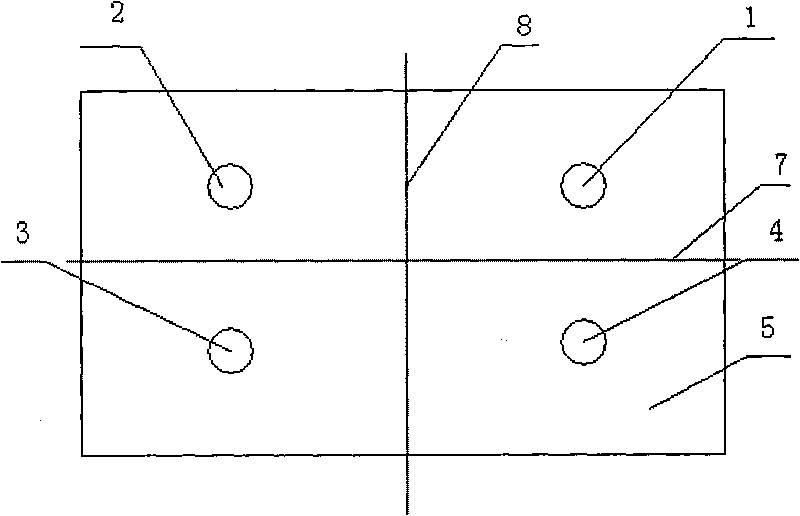

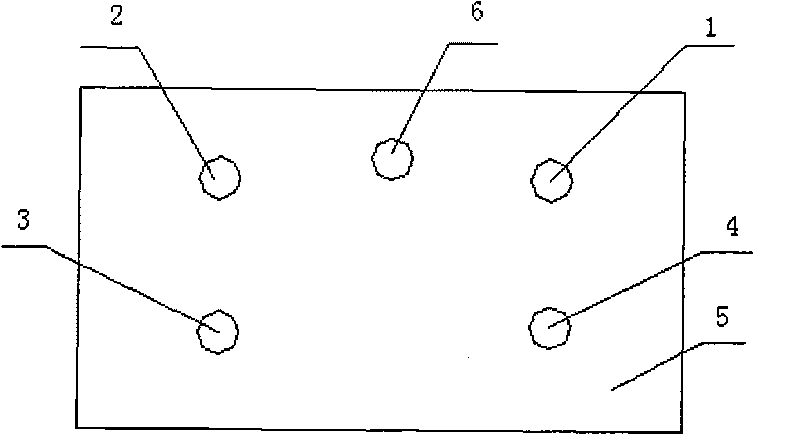

[0020] Step 100: Determine the drilling positions on the two opposite sides of the drilling holes on the motherboard of the circuit board. The drilling method of the motherboard of the circuit board of the present invention adopts the method of drilling the circuit board from both sides respectively. In order to ensure the accuracy of the drilling position and prevent the deviation of the drilling, the position of the drilling is determined from the two sides in a coordinate manner. First determine the drilling centers on both sides with the coordinates, and then use the center as a circle to determine the diameter of the drilling holes according to the drilling requirements....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com