Method for machining slotted holes on carbon fiber laminated boards

A technology of carbon fiber layer and carbon fiber, which is applied in the field of processing slots on carbon fiber laminates, and can solve the problems of easy delamination, burns, and splitting of carbon fiber laminates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, for processing rectangular slots in flat carbon fiber laminates, including clamping steps, milling steps and post-processing steps;

[0034] (1) Clamping steps:

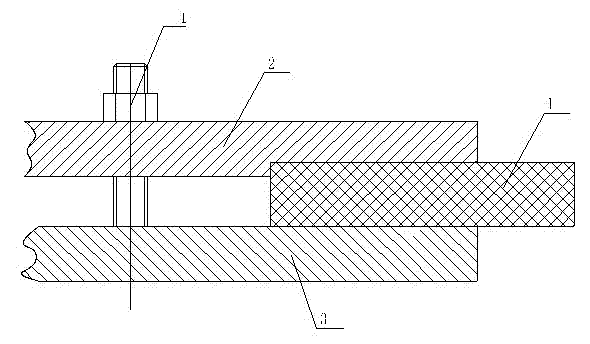

[0035] Such as figure 1 As shown, backing plates are arranged on the upper and lower sides of the carbon fiber laminate and clamped; in the figure, the carbon fiber laminate 1, the upper backing plate 2 and the lower backing plate 3 are all aluminum plates, which are fixed and tightened with bolts 4;

[0036] (2) Milling process steps:

[0037] Carbide cutters are used. When milling the opening, the spiral lower cutter is used, the spindle speed is 6000r / min, the feed speed is 3000mm / min, the cutting depth is 1mm, and the dry cutting conditions are used; milling and processing from one side of the carbon fiber laminate To the required size; the geometric parameters of the hard alloy tool: rake angle γ = 12°, rear angle α = 6°, the shape of the knife tip is an arc edge, the radius of the arc of ...

Embodiment 2

[0040] Embodiment 2 is used to process elliptical holes on irregularly curved carbon fiber laminates, including clamping steps, milling steps and post-processing steps;

[0041] (1) Clamping steps:

[0042] Paste scotch tape on the milling parts on the upper and lower sides of the carbon fiber laminate or around the drilling parts;

[0043] (2) Milling process steps:

[0044] Adopt artificial diamond cutter, when milling processing opening, adopt spiral lower cutter, spindle speed 8000r / min, feed speed 4000mm / min, cut depth 0.5mm, dry cutting condition; The geometry of described artificial diamond cutter Parameters: rake angle γ = 15°, relief angle α = 8°, the shape of the knife tip is a wiper edge, the radius of the knife tip arc r = 0.5mm, and the chamfer of the tool tip c = 0.5mm;

[0045] Process the groove or hole from one side of the carbon fiber laminate to one-third of the material thickness, leave a margin of about 0.5mm around the groove or hole, and then mill and ...

Embodiment 3

[0048] Embodiment 3, for processing 10mm round holes in flat carbon fiber laminates, including clamping steps, drilling processing steps and post-processing steps;

[0049] (1) Clamping steps:

[0050] Wooden boards are set on the upper and lower sides of the carbon fiber laminate and clamped;

[0051] (2) Drilling process steps:

[0052] For drilling, tungsten-cobalt carbide drills are used, the feed rate is 100mm / min, the tool speed is 2400r / min, and the drill bit is a twist drill with a cone angle of 118°;

[0053] (3) Post-processing steps:

[0054] After the processing is completed, remove the wooden boards set on the upper and lower sides of the carbon fiber laminate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com