Patents

Literature

363results about How to "Solve layering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

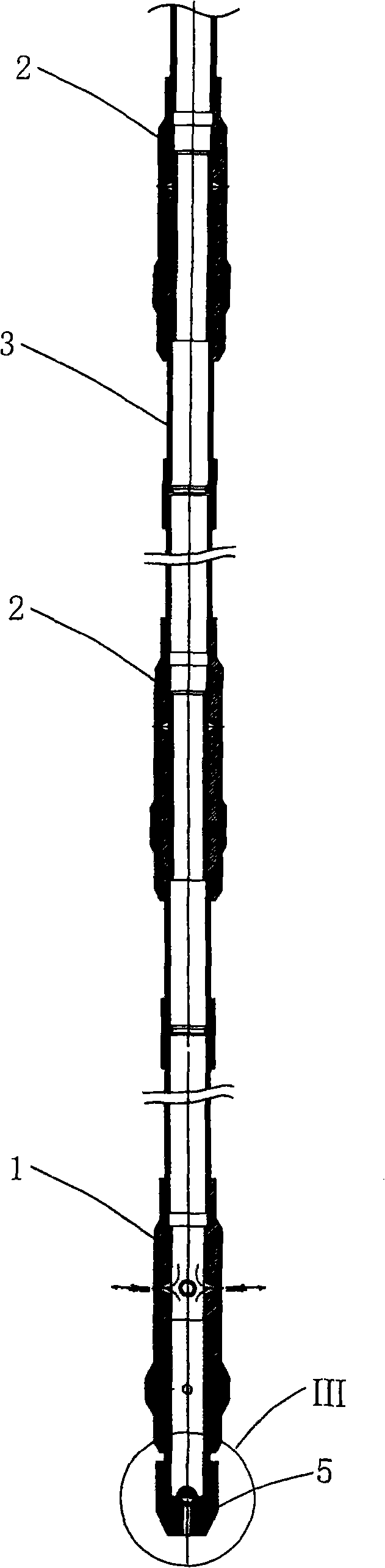

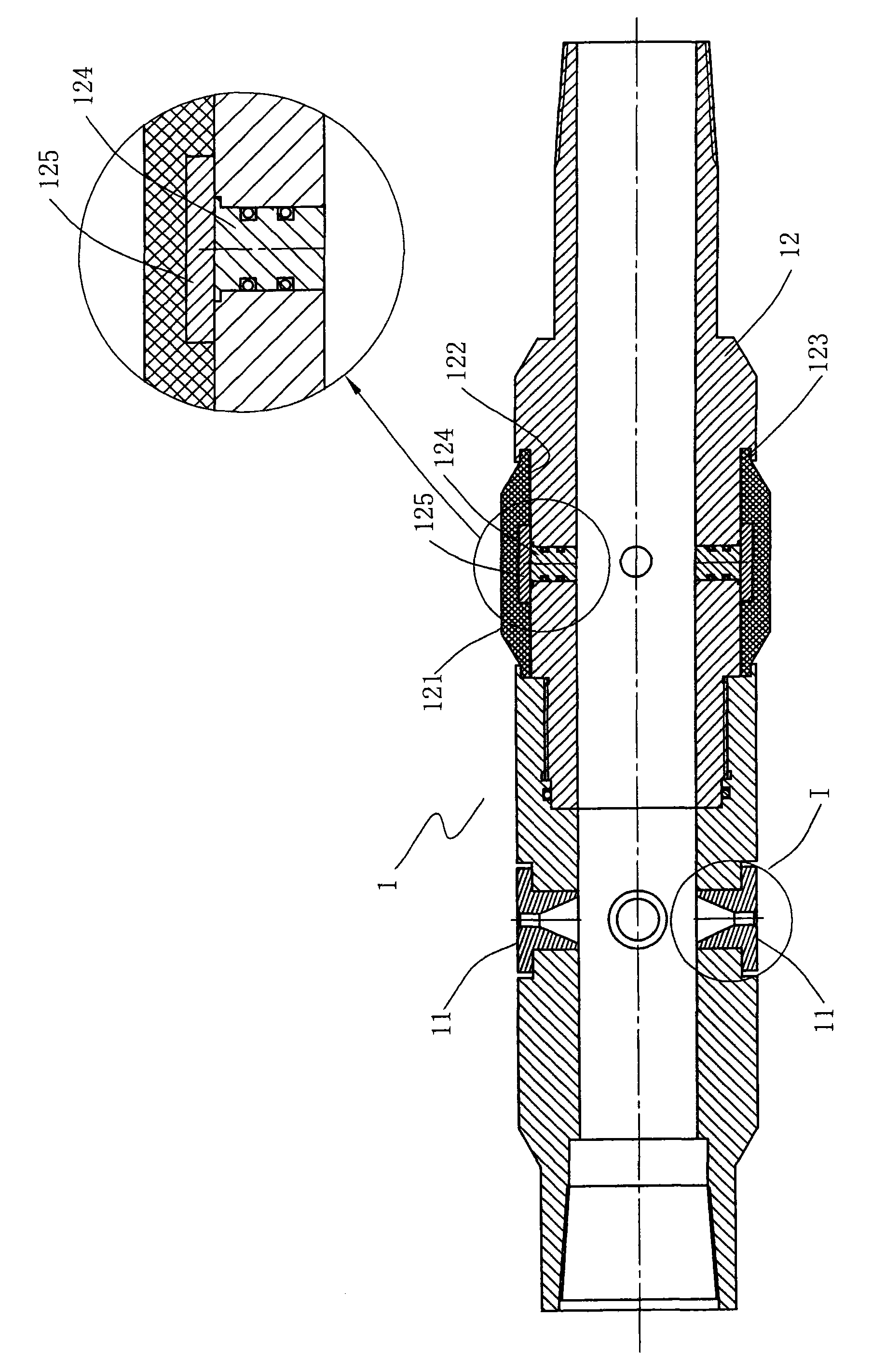

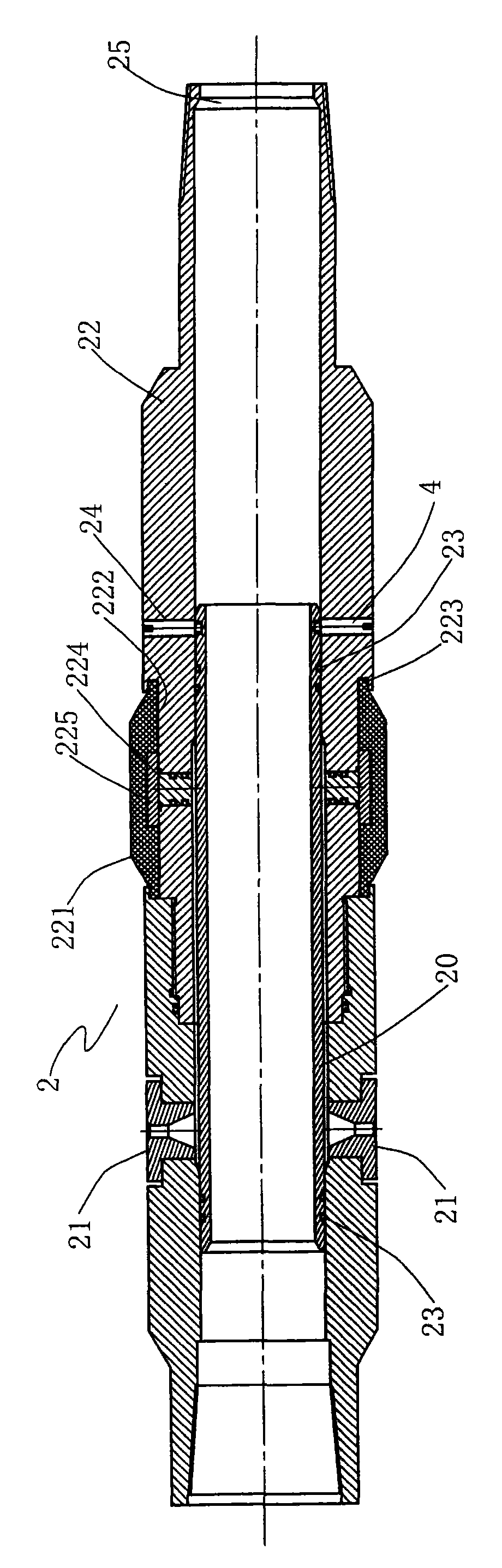

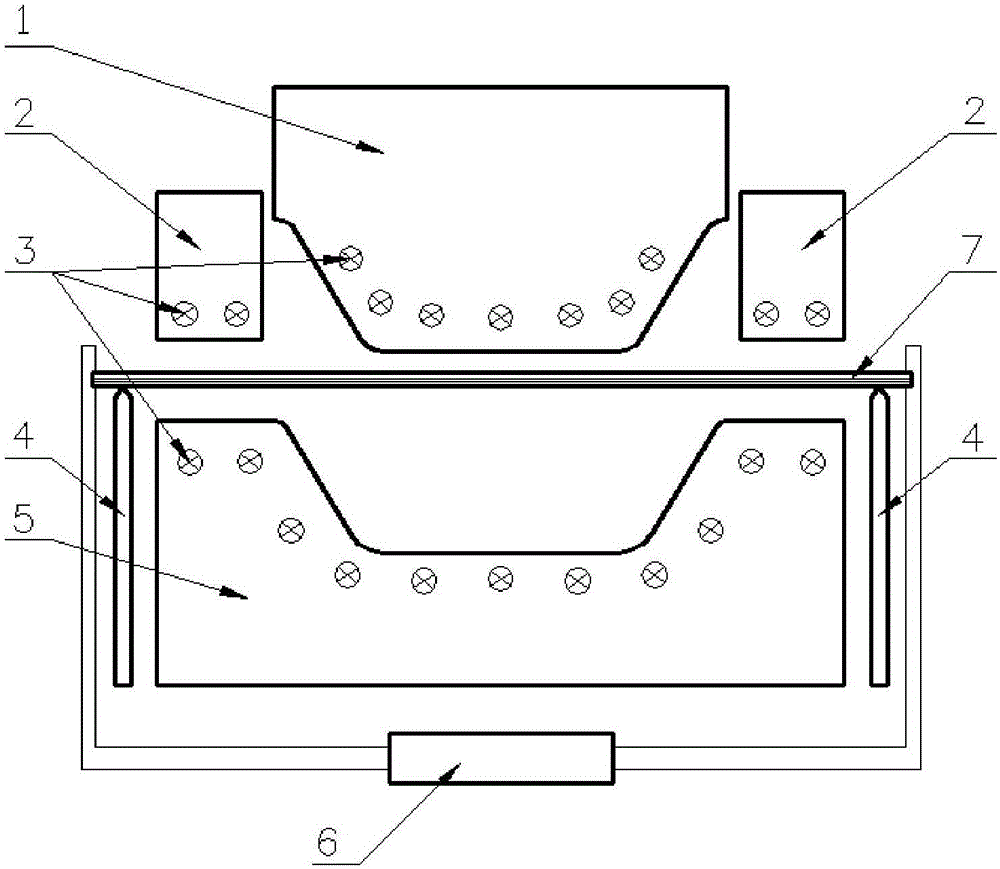

Abrasive jetting device and method for abrasive jetting flow and jetting perforation and multiple fracturing

InactiveCN101539007AAvoid defects that require moving the downhole stringGood sealingFluid removalLiquid spraying apparatusHorizontal wellsOil field

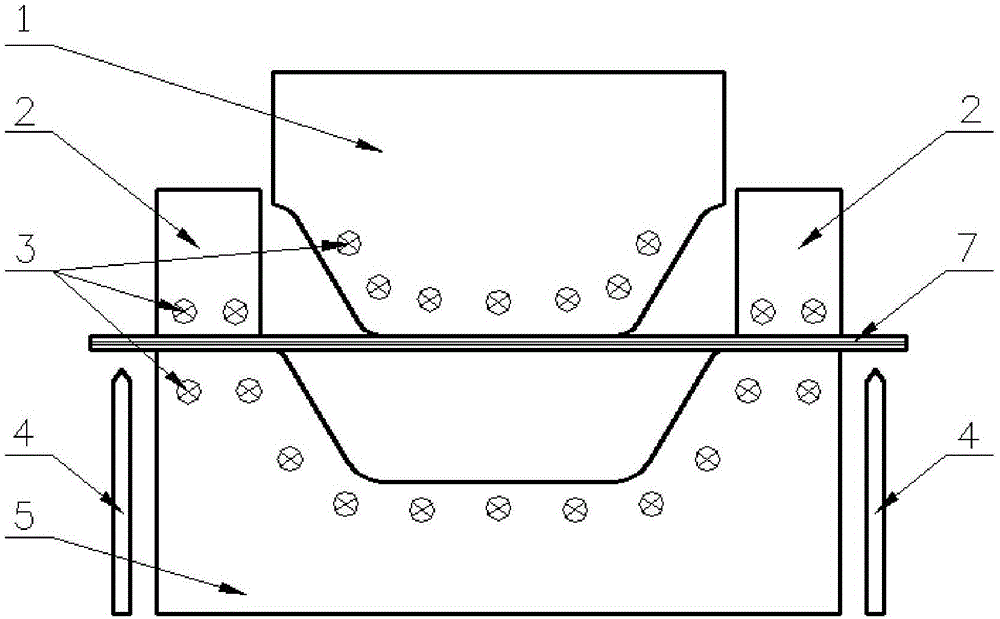

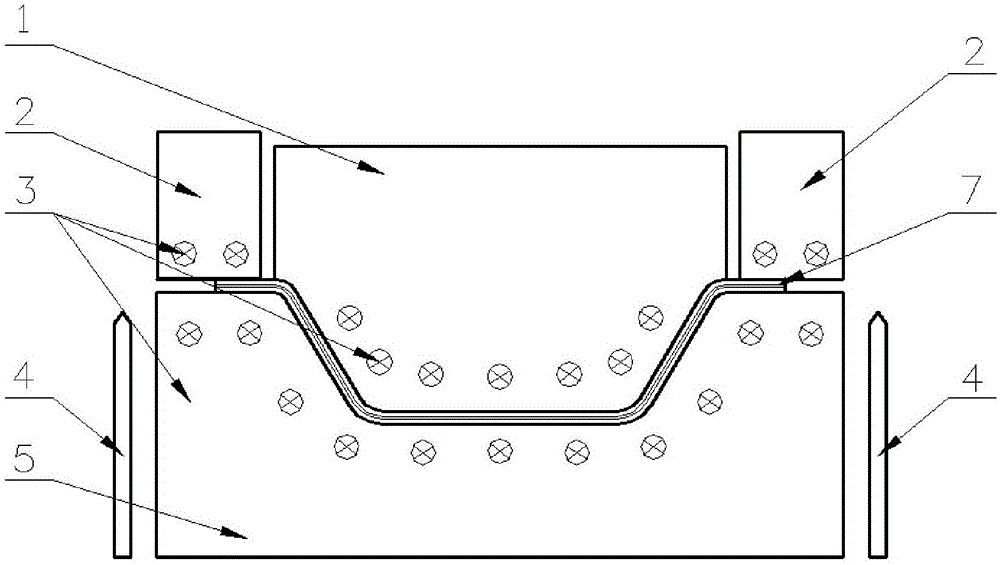

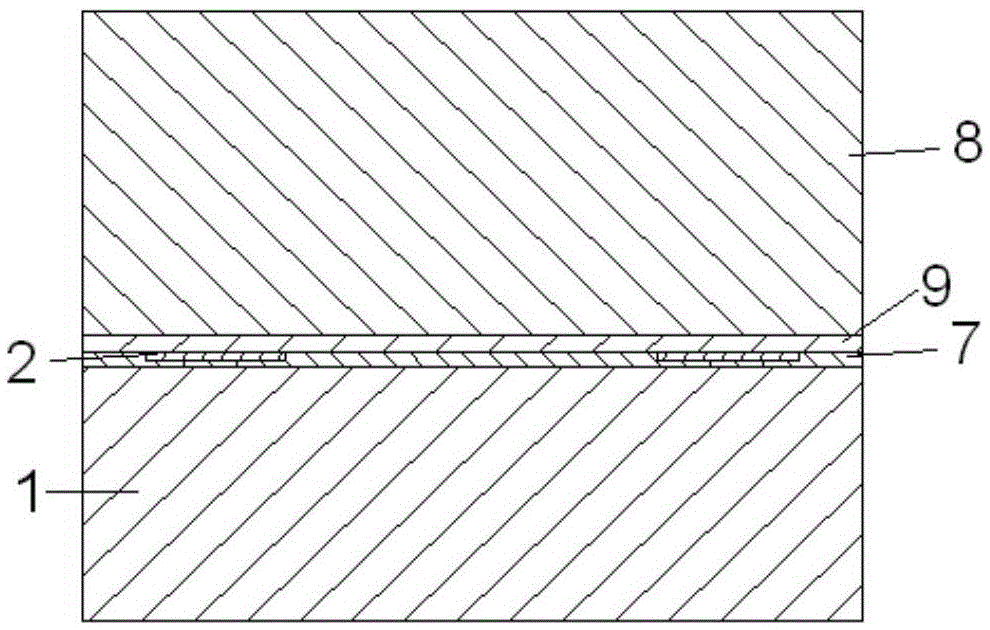

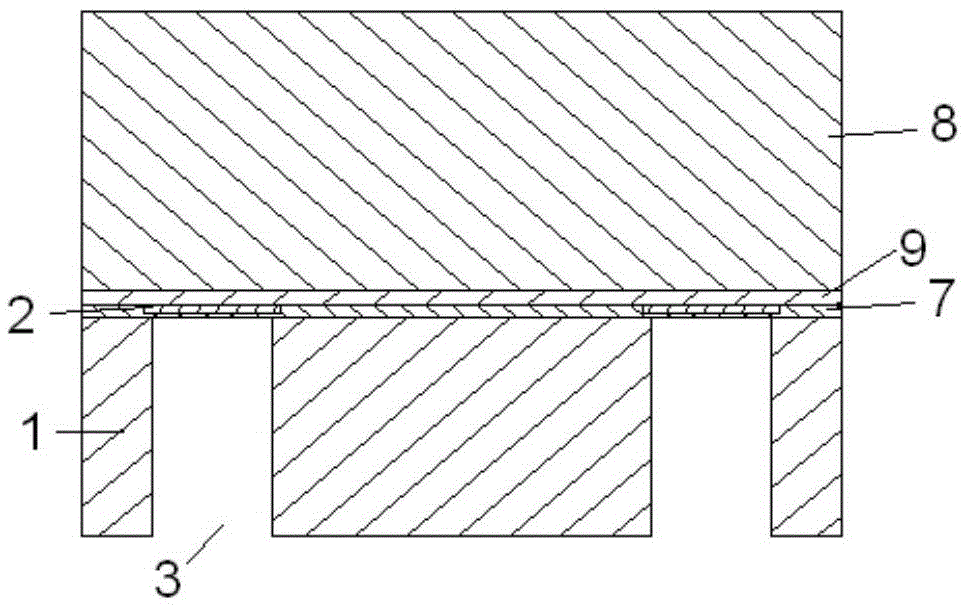

The invention relates to an abrasive jetting device and a method for abrasive water jet perforation and multiple fracturing; wherein the abrasive jetting device has multistage jet guns which are connected in series; the jet guns are all hollow columns; the side walls thereof are respectively provided with at least two nozzles; the lower part of each stage of jet gun is provided with a packer; the side wall of the packer is provided with a sealing sleeve which can expand outward under the action of high-pressure liquid; the jet guns comprise a first stage bottom jet gun arranged at the lower part of the abrasive jetting device and multistage upper jet guns arranged above the bottom jet gun; wherein all the upper jet guns are respectively provided with a sliding sleeve which can seal the nozzle of the stage of jet gun and sealing sleeve; and the sliding sleeve can slide to the lower part of the sealing sleeve under the action of external force so as to open the nozzle and the sealing sleeve. The invention can be used for casing straight wells or horizontal wells, solves the problem of layered or staged fracturing in the straight wells or the horizontal wells in oil fields, and achieves the purposes of saving fracturing cost, improving fracturing effect and reducing the construction risk.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

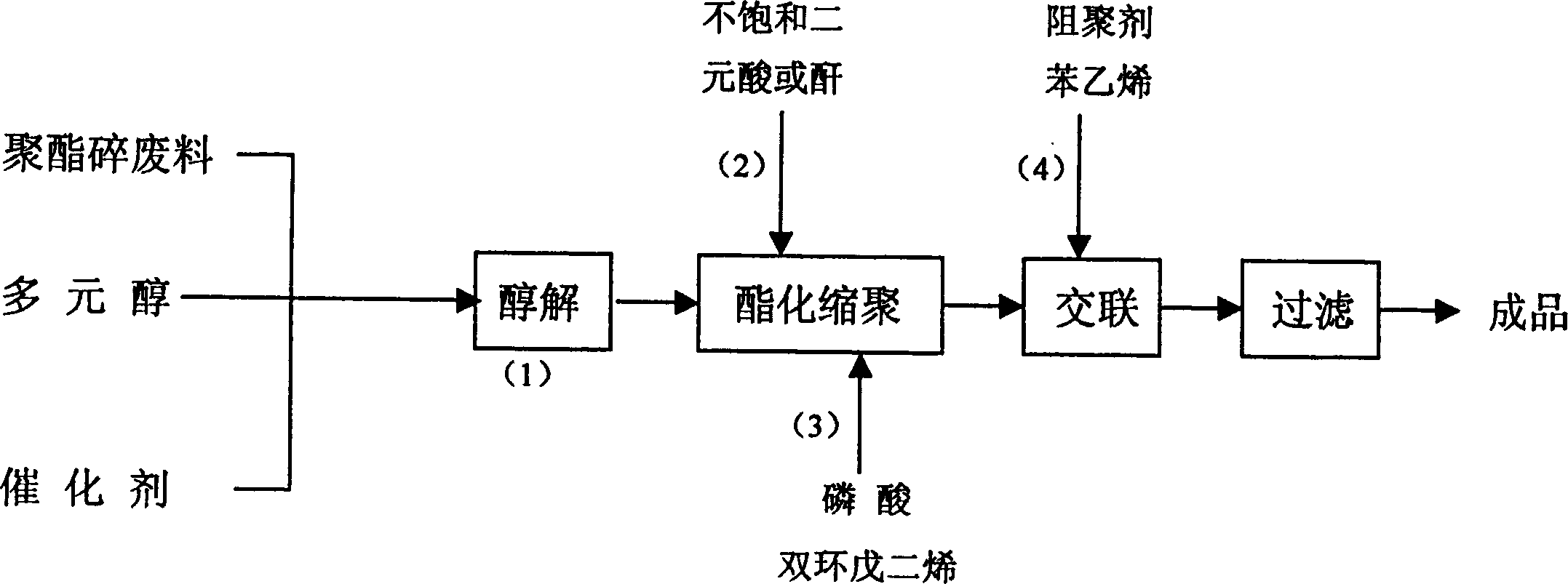

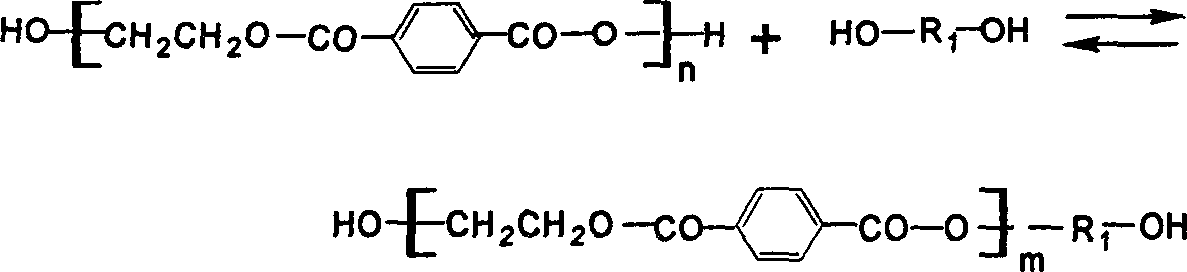

Synthesis of p-phenyl unsaturated polyester resin by using waste polyester material

The invention relates to a method for synthesizing unsaturated phenolic resin with various etherification waste, which includes the four steps: (1) etherification waste and polyhydric alcohol have alcohol sis and ester interchange with catalyst existing; (2)alcohol zed product and unsaturated binary acid or have etherification polycondensation; (3) use dicyclopentadiene (DCPD) to blocking modify in the later period of etherification polycondensation; (4) add into styrene solution for cross linking. The invention has plentiful sources of raw material, low price, decreased pollution and productive cost and energy saving, as well as eliminates the disadvantage of bad dissolubility in styrene .

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

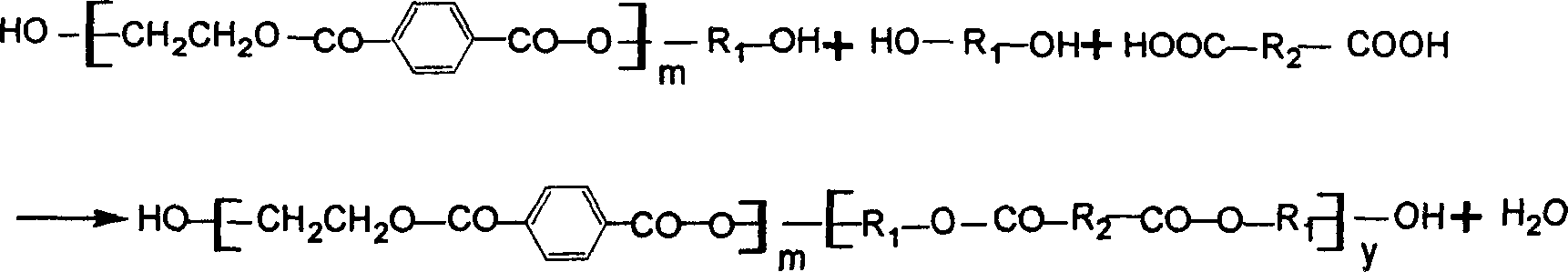

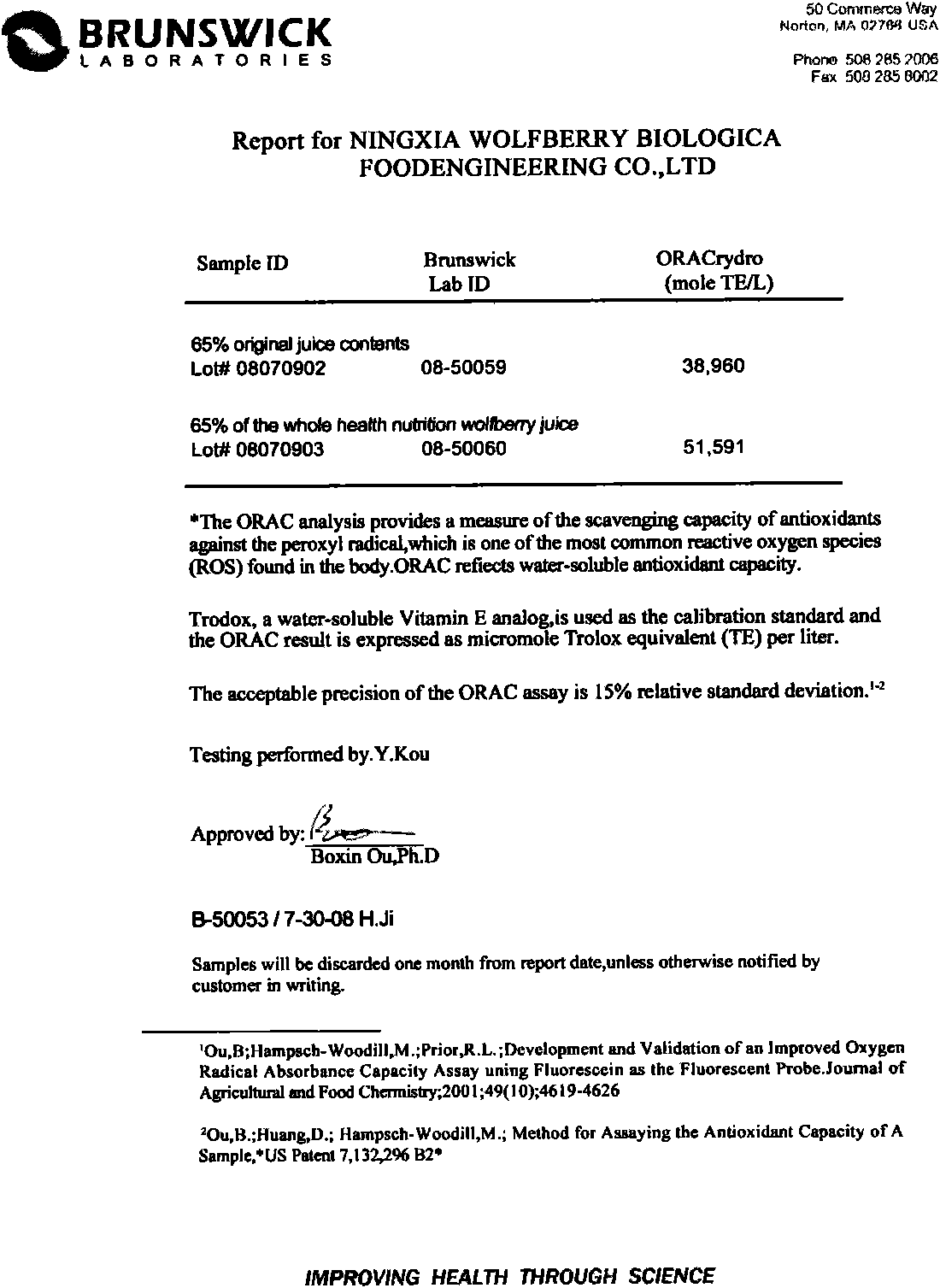

Full nutrient Chinese wolfberry health-care fruit juice and production method thereof

The invention relates to full nutrient Chinese wolfberry health-care fruit juice and a production method thereof. The formula of the full nutrient Chinese wolfberry health-care fruit juice comprises the following components: 20% to 85% of fresh Chinese wolfberry fruit juice, 3% to 20% of sour pomegranate juice, compatible medicinals comprising 0.5% to 10% of ophiopogon root, 0.5% to 10% of American ginseng, 0.5% to 10% of clove, 0.5% to 10% of raspberry, 0.5% to 10% of dipping juice or extract of radix adenophorae, 0.1% to 2.0% of lutein, 0.1% to 2.0% of zeaxanthin, 0.1% to 2.0% of tea polyphenol, 0.1% to 3.5% of citric acid and 0.1% to 1.0% of VC and the balance of purified water. The full nutrient Chinese wolfberry health-care fruit juice comprises the technological process that after the compatible medicinals are extracted or dipped and filtered, various components are mixed according to the formula, homogenized under high pressure, deaerated in vacuum, sterilized at ultrahigh pressure and filled aseptically so as to obtain a finished product.

Owner:宁夏沃福百瑞枸杞产业股份有限公司

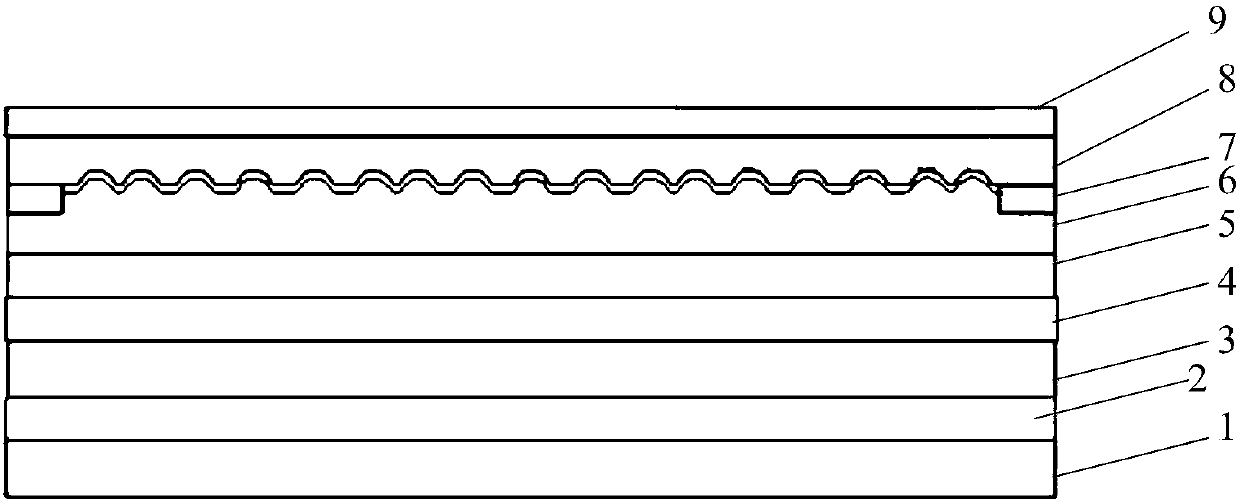

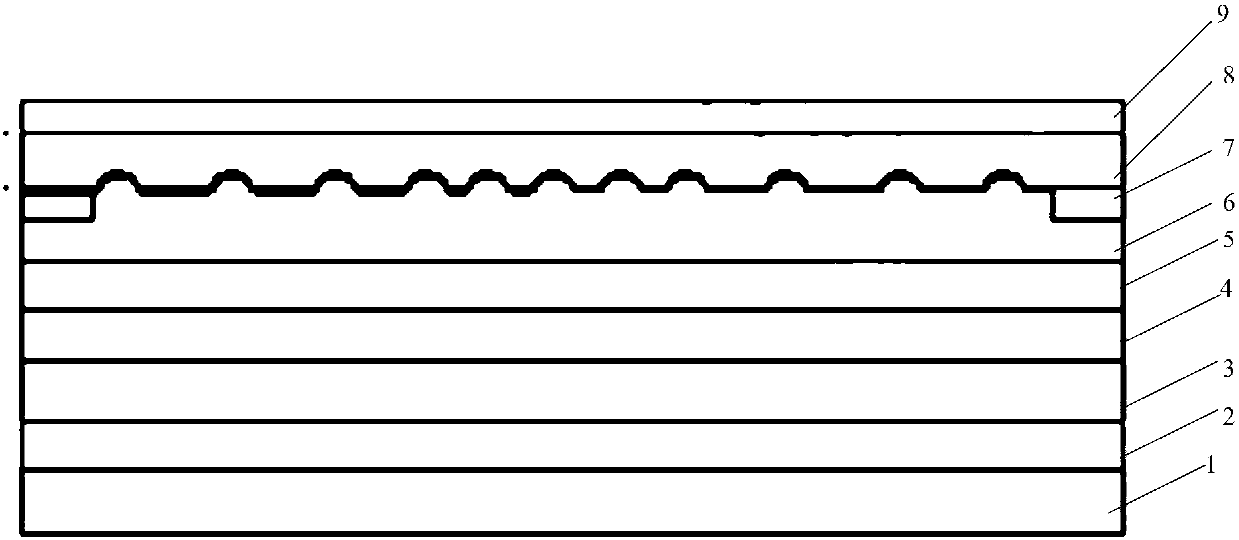

Flexible display device and manufacturing method thereof

ActiveCN107799574AReduce internal stressSolve crackingSemiconductor/solid-state device detailsSolid-state devicesEngineeringFlexible display

The invention discloses a flexible display device and a manufacturing method thereof, and belongs to the filed of display technology. The flexible display device comprises a flexible display module and a flexible covering layer, wherein the flexible display module is covered with the flexible covering layer; the flexible covering layer and the flexible display module are adhered together through an optical transparent adhesive tape; and the surface, in contact with the optical transparent adhesive tape, of the flexible covering layer is rugged. Through the technical scheme, the bending resistance of the flexible display device can be improved.

Owner:BOE TECH GRP CO LTD

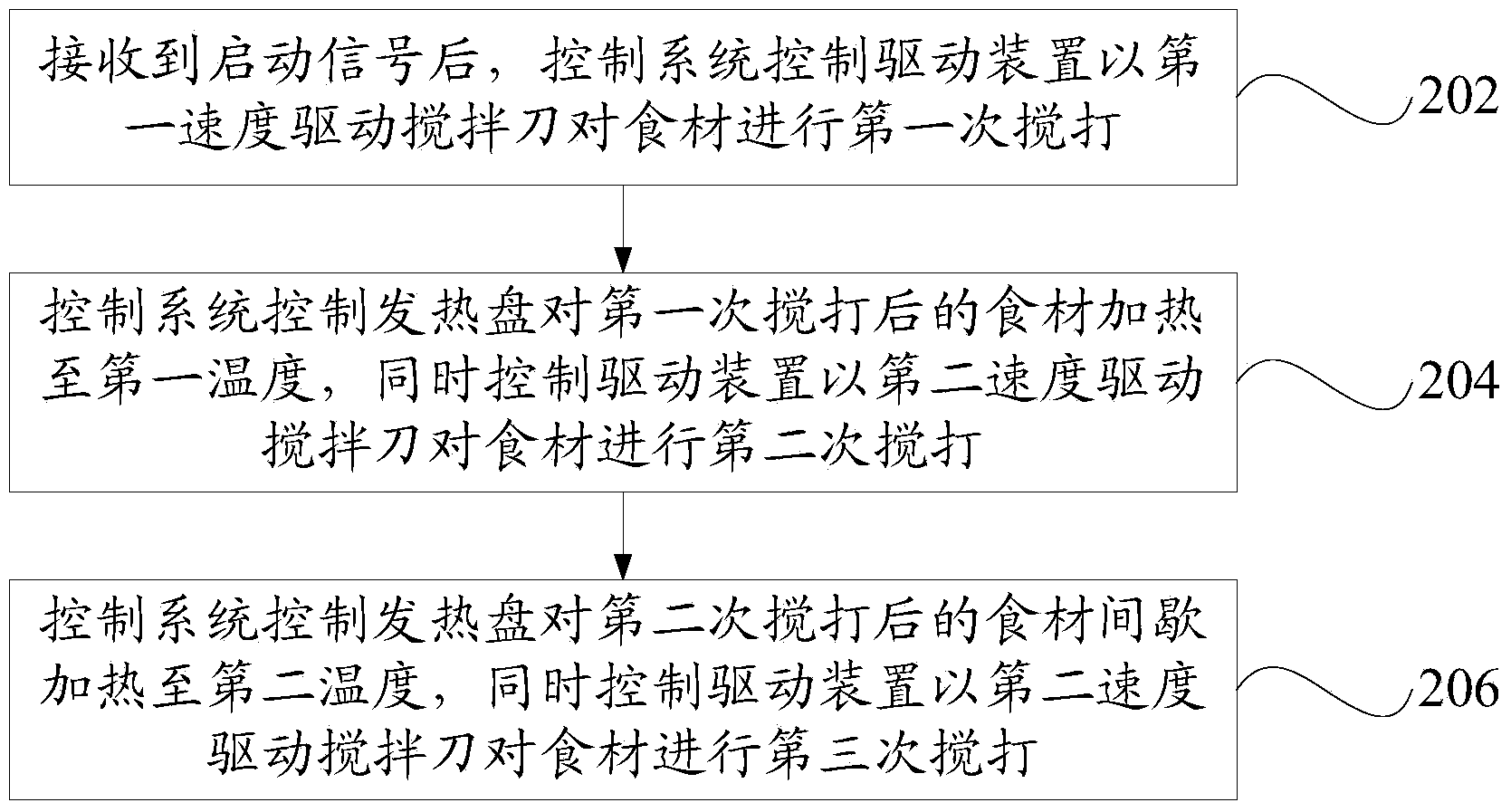

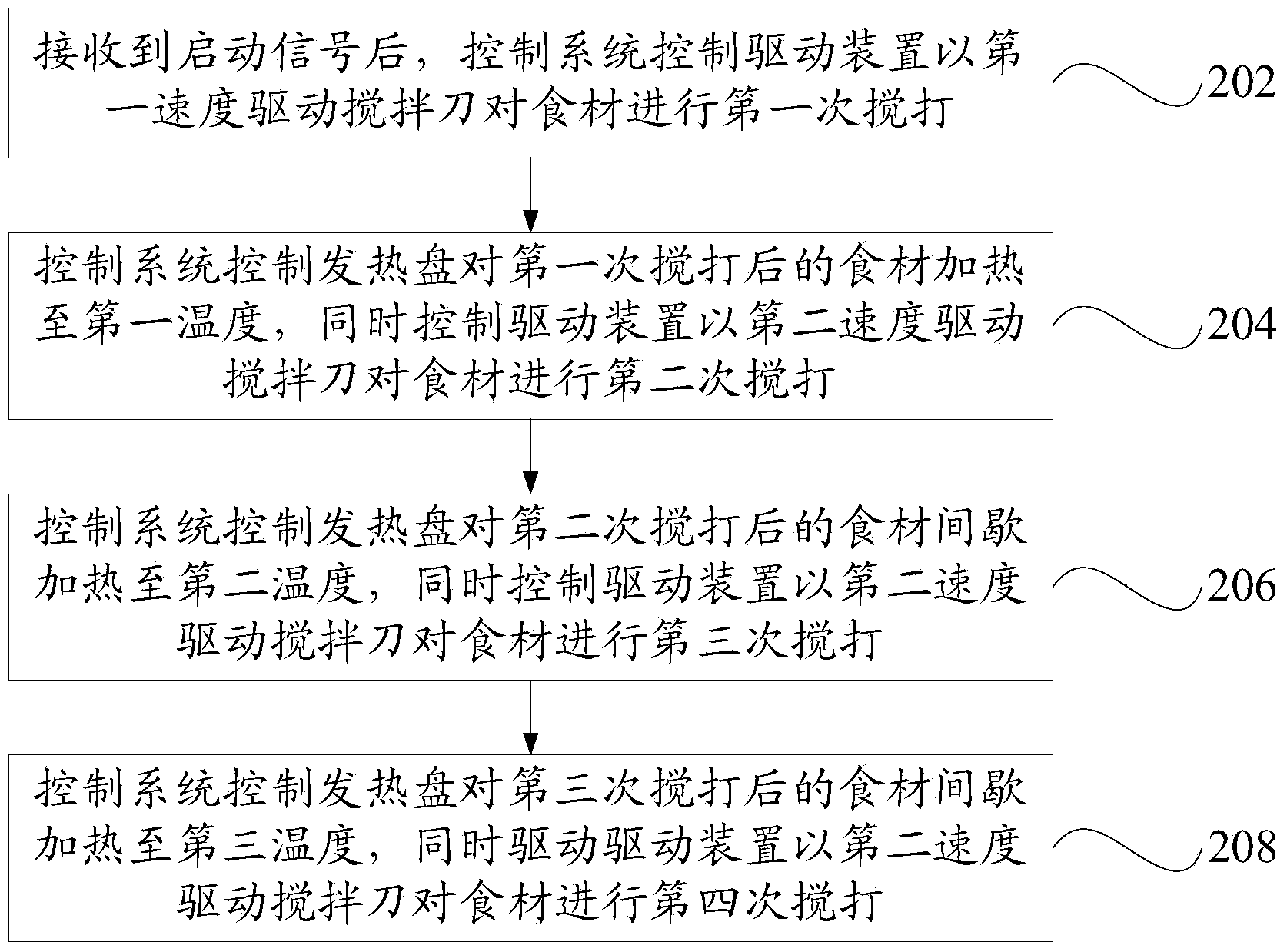

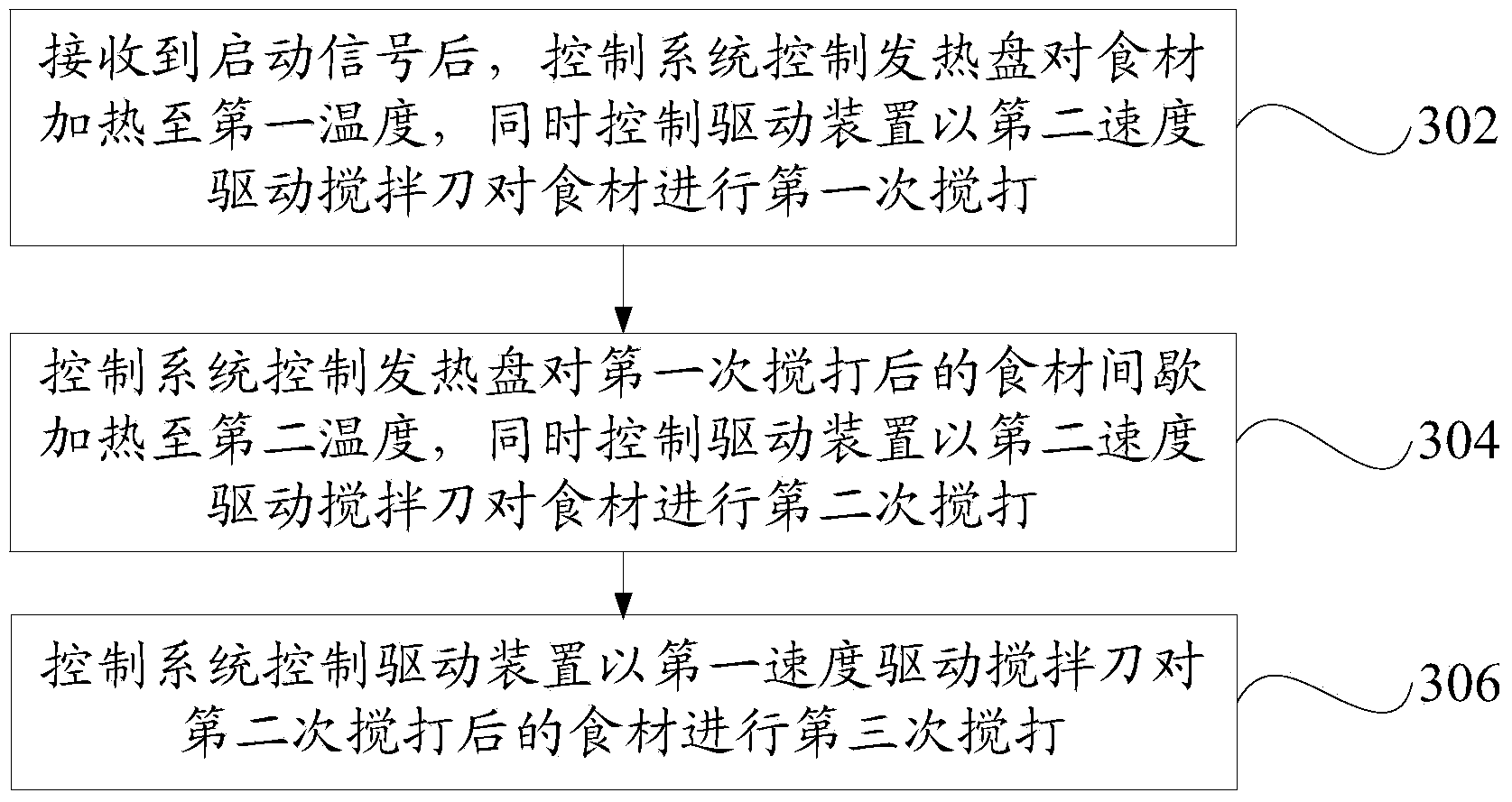

Milk making method of soybean milk maker

The invention provides a milk making method of a soybean milk maker. The milk making method includes the steps of smashing, heating and boiling. In the smashing step, a control system controls a driving device to drive a stirring cutter at a first speed to stir food materials for the first time after receiving a starting signal; in the heating step, the control system controls a heating plate to heat the food materials subjected to first stirring to a first temperature, and simultaneously controls the driving device to drive the stirring cutter at a second speed to stir the food materials for the second time; in the boiling step, the control system controls the heating plate to intermittently heat the food materials subjected to second stirring to a second temperature, and simultaneously controls the driving device to drive the stirring cutter at a second speed to stir the food materials for the third time. According to the milk making method, the stirring cutter continuously stirs the food materials in the steps of smashing, heating and boiling, so that the problems of smashing failure, layering and sticking during milk making in the prior art are effectively solved, milk made by the soybean milk maker tastes delicate, the soybean milk maker is simple and convenient to wash, and product quality is further improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

Ceramic mobile phone shell and preparation method thereof

InactiveCN106986631AHigh strengthImprove toughnessCeramic shaping apparatusTelephone set constructionsOrganic solventPlasticizer

The invention discloses a ceramic mobile phone shell preparation method which includes the steps: (1) dissolving submicron ceramic powder, dispersing agents, binding agents and plasticizers into organic solvents, and performing ball-mill mixing on mixture to form uniform slurry; (2) performing vacuum defoaming and tape-casting treatment on the slurry to obtain casting film wafers; (3) designing molds according to the shapes and the sizes of products, performing differentiation on the casting film wafers to form differential film wafers with corresponding shapes and sizes, stacking the differential film wafers on the molds, and performing vacuum packaging sealing and isostatic pressing treatment on the differential film wafers stacked on the molds to obtain green bodies; (4) performing glue coating and sintering on the green bodies to obtain ceramic wafers with preset shapes and sizes; (5) grinding and polishing the ceramic wafers to obtain ceramic mobile phone shells. The invention further discloses a ceramic mobile phone shell prepared by the method. According to the preparation method, subsequent machining amount is less, production efficiency is greatly improved, and product cost is reduced.

Owner:广东百工新材料科技有限公司

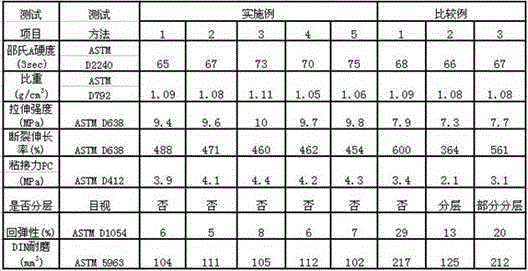

High-shock-absorbance wear-resistant thermoplastic elastomer and preparation method thereof

The invention relates to the technical field of thermoplastic elastomer materials and particularly relates to a high-shock-absorbance wear-resistant thermoplastic elastomer and a preparation method thereof. The high-shock-absorbance wear-resistant thermoplastic elastomer comprises the following components in parts by weight: 40-60 parts of SIS resin, 10-20 parts of thermoplastic polyurethane, 5-10 parts of a compatilizer, 5-15 parts of extending oil, 5-10 parts of mineral filler, 1-3 parts of a processing aid and 0.2-0.5 part of an antioxidant. The preparation method comprises the following steps of firstly, placing the SIS resin, carbonate calcium, the antioxidant, the processing aid and extending oil into a high-speed mixer, mixing, adding other raw materials and mixing to obtain a premix; and secondly, placing the premix into a twin-screw extruder, extruding and granulating. The thermoplastic elastomer has the characteristics of capability of secondary injection molding, good adhesion with PC and ABS materials and high shock absorbance and wear resistance.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

Children coating and preparation method thereof

The invention provides a children coating and a preparation method of the children coating. The children coating provided by the invention comprises the following raw materials: wood fibers, a purified emulsion, kieselguhr, an anion additive, titanium dioxide, triple superphosphate powder, a dispersing agent, a wetting agent, a defoaming agent, a thickening agent, a preservative, a mildew preventive and tap water and the like. The wood fibers are added into the environmentally-friendly children coating by the invention so as to change the structure and the texture of a surface of a paint film, thereby feeling soft and smooth; and in addition, the porosity of the paint film is improved by the wood fibers in the paint film, the breathable performance is good, the quantity of heat and the transmission capacity of voice are reduced, and a good humidifying function can be created by the gaps of the paint film.

Owner:ZHEJIANG ZHIQIANG PAINT

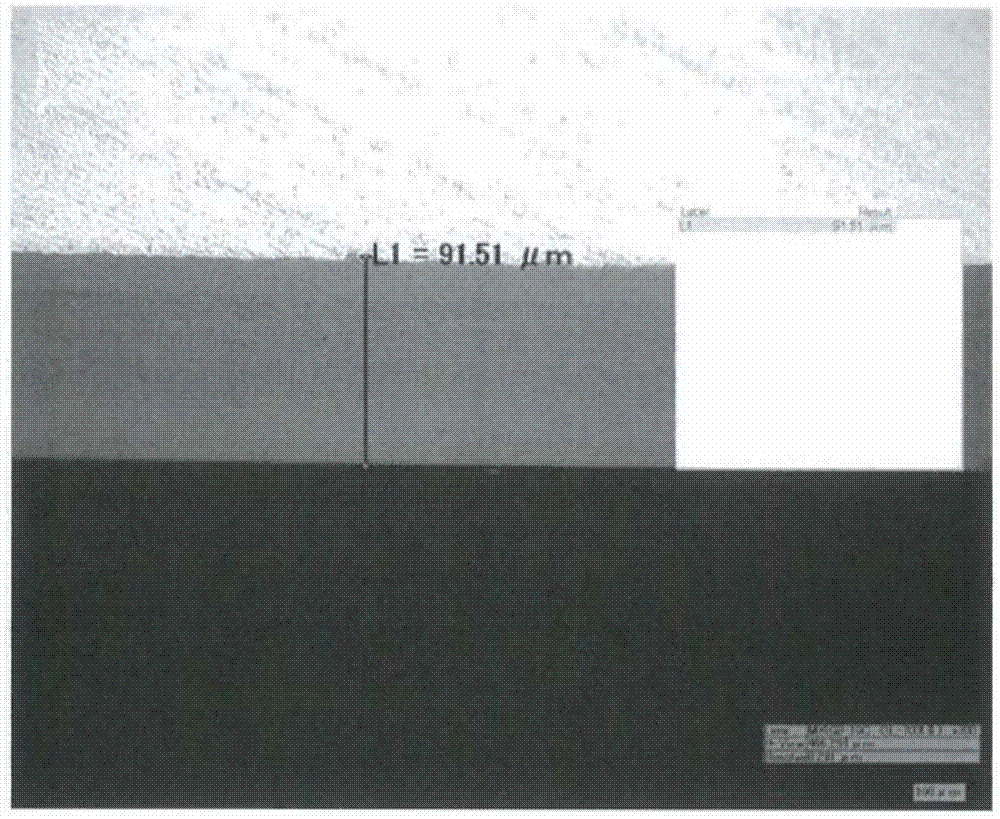

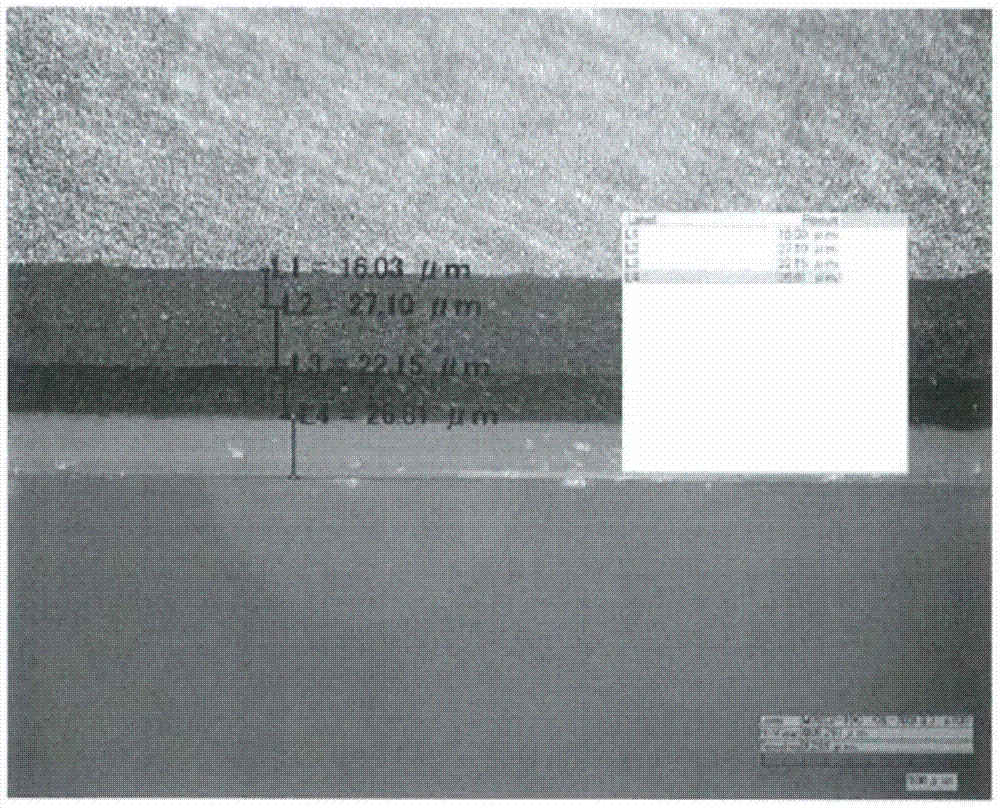

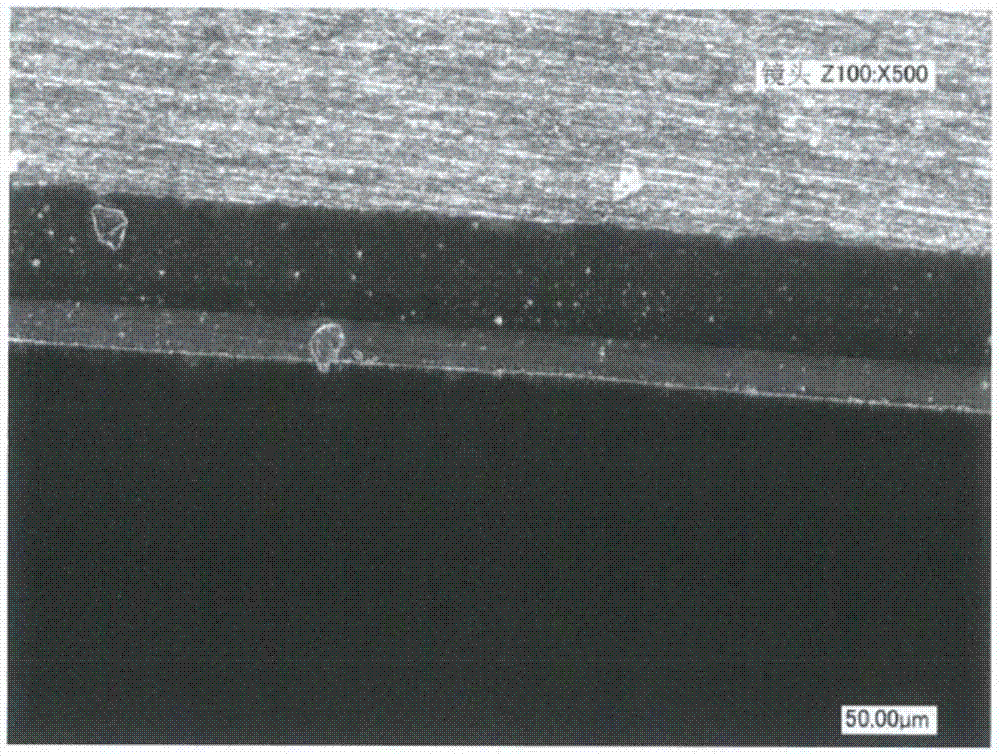

Detection method for measuring thicknesses of multiple coating layers

InactiveCN103575733AAvoid red tapeAccurate detectionPreparing sample for investigationMaterial analysis by optical meansPhysicsAmplification factor

The invention belongs to the technical field of detection on automobile parts, and provides a detection method for measuring thicknesses of multiple coating layers. The detection method comprises the following steps: cutting a sample part to be detected, burnishing vertically to the cross section of a sample, properly polishing the sample, putting the sample on a measuring table of a microscope, regulating the amplification factor of the microscope, observing under the 100-1000-fold microscope, observing by adding a cold light source on the side surface of the sample to be detected, and measuring the thicknesses of the coating layers at the same time. The detection method has the advantages as follows: by varying the light line and the light intensity of the microscope, a layering problem of the coating layers with similar colors, such as an ED layer and a primer layer, white paint and varnish as well as black finishing paint and varnish, can be effectively solved, thus avoiding a special sampling cumbersome procedure in the production process; the detection method is accurate in detection and high in reliability; a reliable basis is provided for routine detection and defect analysis of metal and plastic coating products.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

High-fluidity pumping ceramsite concrete and preparation method thereof

The invention provides high-fluidity pumping ceramsite concrete and a preparation method thereof. A formula of the concrete comprises cement, coal ash, water, fine aggregate, limestone flour, pumping aid, ceramsites, ceramic sand, redispersable emulsion and hydroxypropyl methyl cellulose. The method comprises the following steps: reasonably selecting respective raw materials and usage thereof according to a unit weight of concrete to be prepared, soaking the ceramsites to a saturated water absorption state in advance, then mixing with other raw materials, and stirring to prepare the ceramsite concrete. By controlling the grain size of the ceramsites and a fineness modulus of the fine aggregate, the redispersable emulsion and hydroxypropyl methyl cellulose are cooperatively added to promote the cementation of the cementing materials such as the cement, the coal ash and the limestone flour with the ceramsites, and the cohesiveness and water retaining property of the concrete are increased, and the problems of easy floating, layering and separation of the ceramsites in the ceramsite concrete are effectively solved, moreover, separation and layering of the ceramsites can be effectively avoided by using the ceramsite concrete produced according to the invention, and slump loss in a material transporting and waiting process is obviously reduced.

Owner:重庆富普新材料有限公司

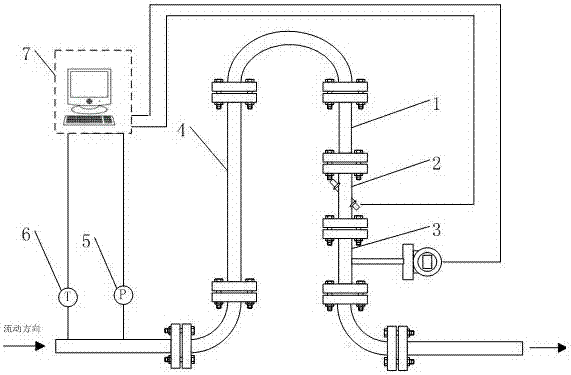

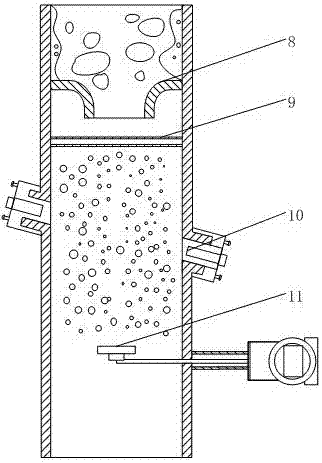

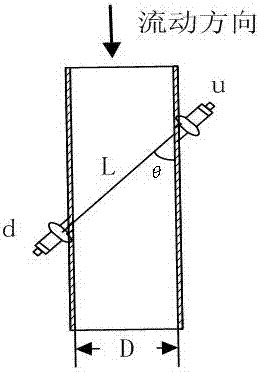

Method for measuring wet natural gas flow rate by combining ultrasound with target flowmeter

ActiveCN106979808ARealize online non-separation measurementSimple structureVolume flow measuring devicesSonificationGas phase

The invention discloses a rectification-technology-based method for measuring a wet natural gas flow rate by combining ultrasound with a target flowmeter. A measuring system includes an inverted U-shaped measuring pipeline, a nozzle rectification machine, an ultrasound flowmeter, the target flowmeter, a pressure sensor, a temperature sensor and the like. The nozzle rectification machine, the ultrasound flowmeter and the target flowmeter are mounted at the descending side of a U-shaped measuring pipe. Wet gas flows through the nozzle rectification machine and is adjusted into approximate homogeneous phase flow; when ultrasonic is propagated, the ultrasonic flowmeter which works in a transit time mode measures the apparent volume flow rate of the wet gas; in combination with the apparent volume flow rate measured by the ultrasonic flowmeter, the target flowmeter measures the apparent density of the wet gas; under the conditions that gas-phase components of the wet gas are known, the liquid phase is incompressible and the liquid-phase density is known, according to pressure and temperature parameters, the gas-phase density can be calculated; finally, according to the apparent volume flow rate and apparent density of the wet gas, the liquid-phase density and the gas-phase density, a liquid-phase volume fraction, a liquid-phase volume fraction, a liquid-phase volume flow rate, a liquid-phase mass flow rate, a gas-phase volume flow rate and a gas-phase mass flow rate are calculated, and therefore the online non-separation measurement of the wet natural gas flow rate is achieved.

Owner:大庆嘉鸿达石油钻采设备有限公司

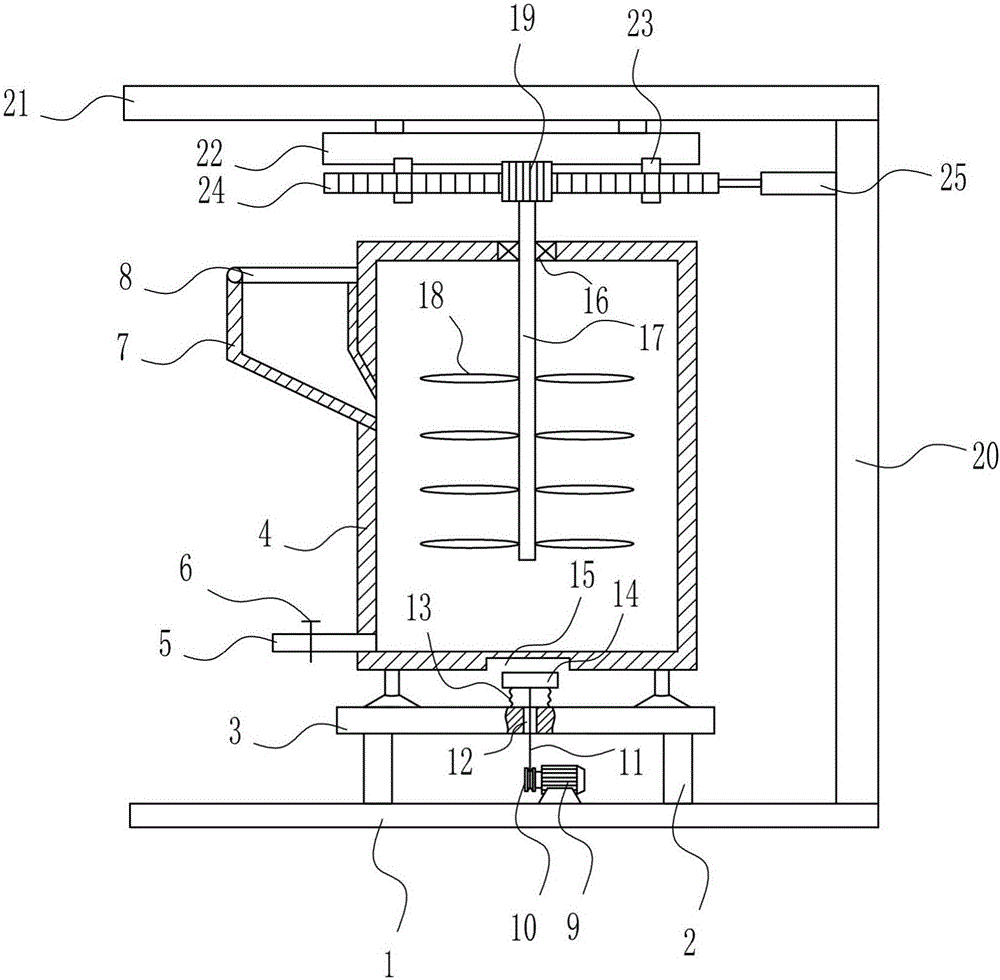

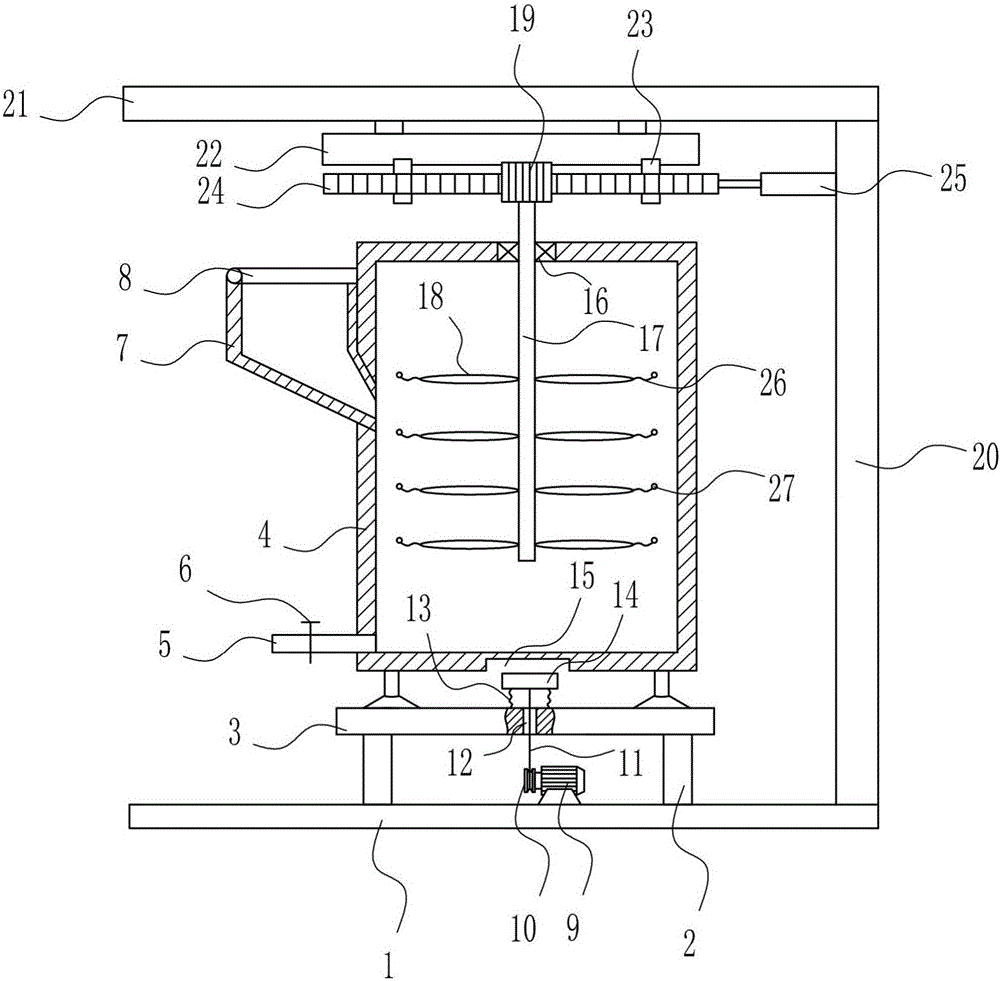

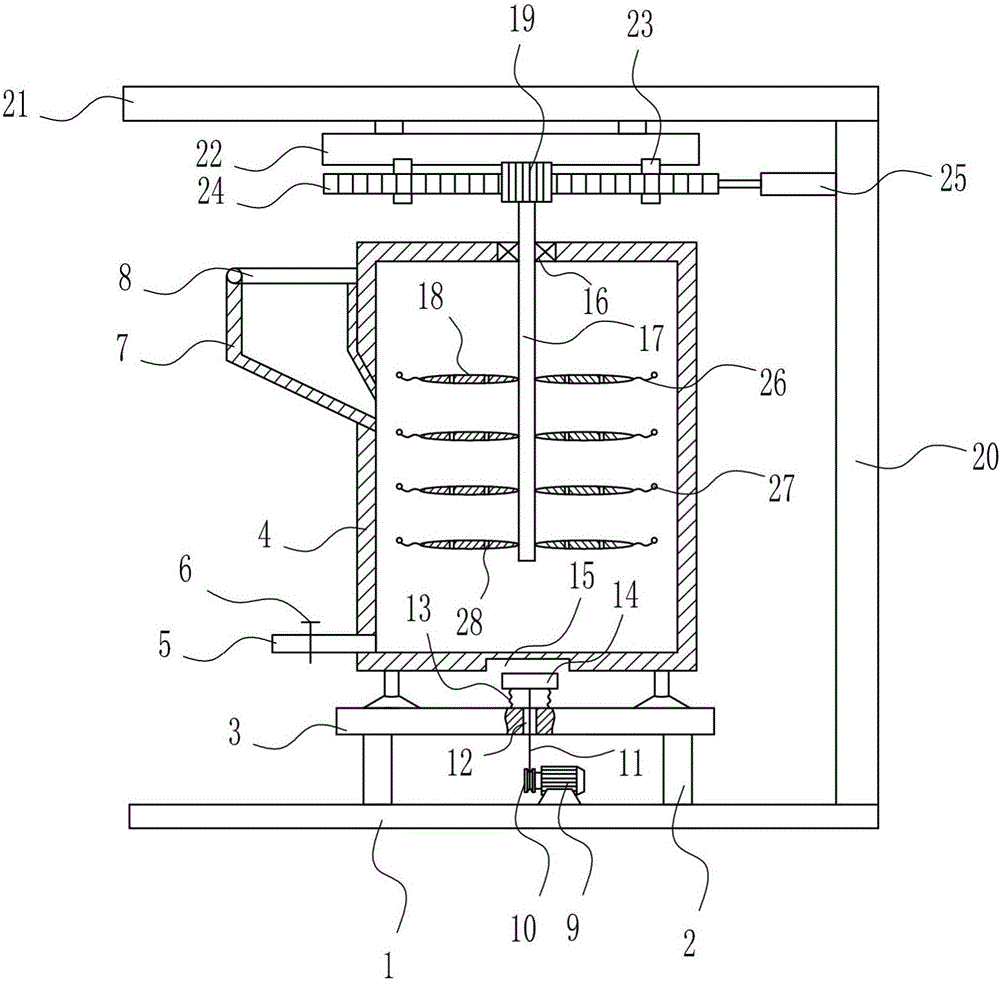

Raw material high-efficiency stirring device for lithium battery manufacturing technology

ActiveCN106732090AEvenly dispersedSettle settlementElectrode manufacturing processesShaking/oscillating/vibrating mixersManufacturing technologyEngineering

The invention belongs to the technical field of lithium battery manufacturing, and particularly relates to a raw material high-efficiency stirring device for lithium battery manufacture technology. The invention aims to provide a raw material high-efficiency stirring device for lithium battery manufacturing technology, which is uniform in stirring, simple in structure and convenient to operate. In order to solve the technical problems, the invention provides a raw material high-efficiency stirring device for lithium battery manufacture technology, which comprises a bottom plate, a bracket, a mounting plate, a mixing barrel, a discharge pipe, an electric control valve, a feed hopper, a cover, a rotating machine, a winding wheel, a pull wire, a first spring, a link stopper and the like, wherein the left and right of the top of the bottom plate are welded with the bracket; the top of the bracket is welded with the mounting plate; and the mixing barrel is welded to the mounting plate. The stirring device achieves the effects of uniform stirring, simple structure and operation convenience, has the advantages of novel structure and high practicality, can uniformly disperse the slurry, and can solve the problems of settling and stratification of the slurry.

Owner:奥特贝(天津)机器人有限公司

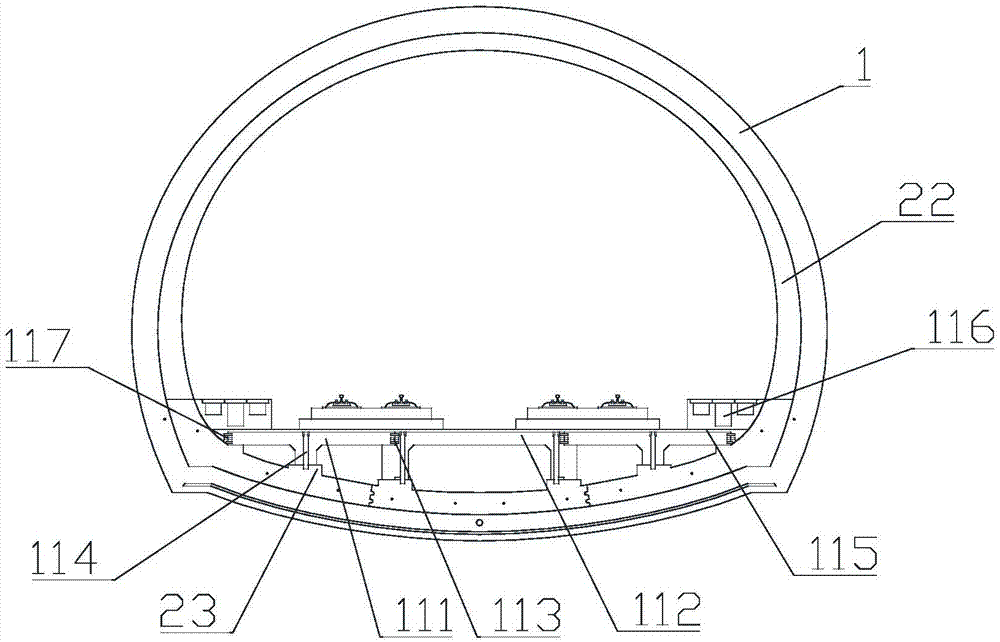

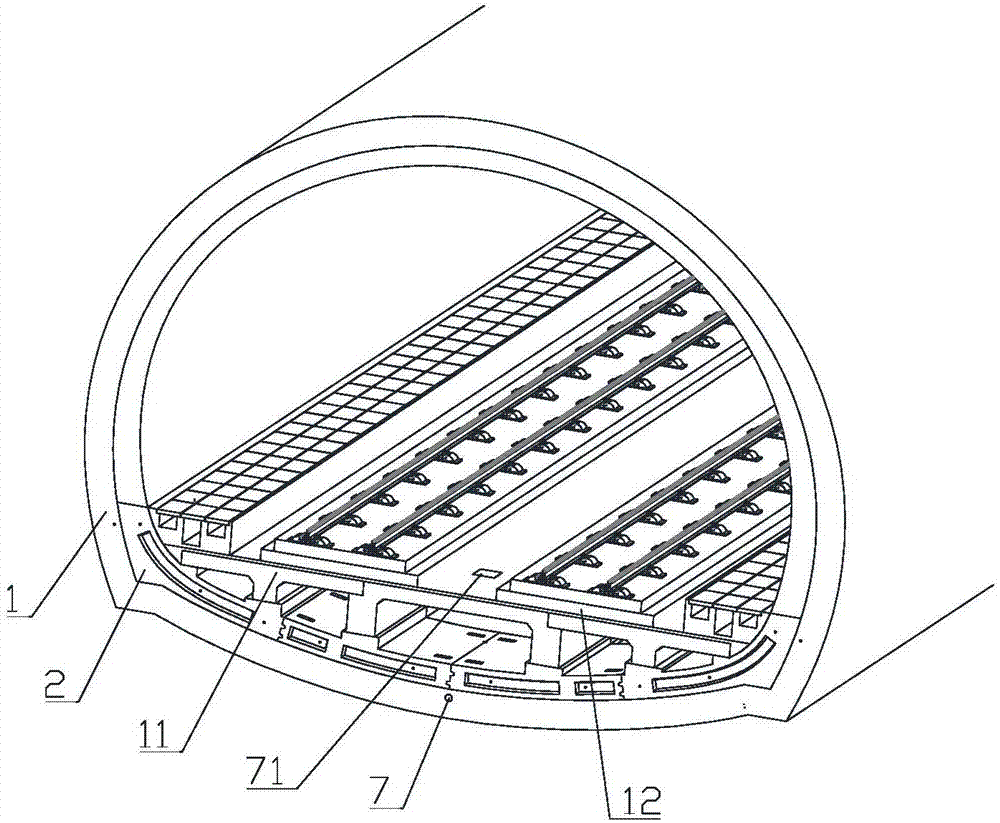

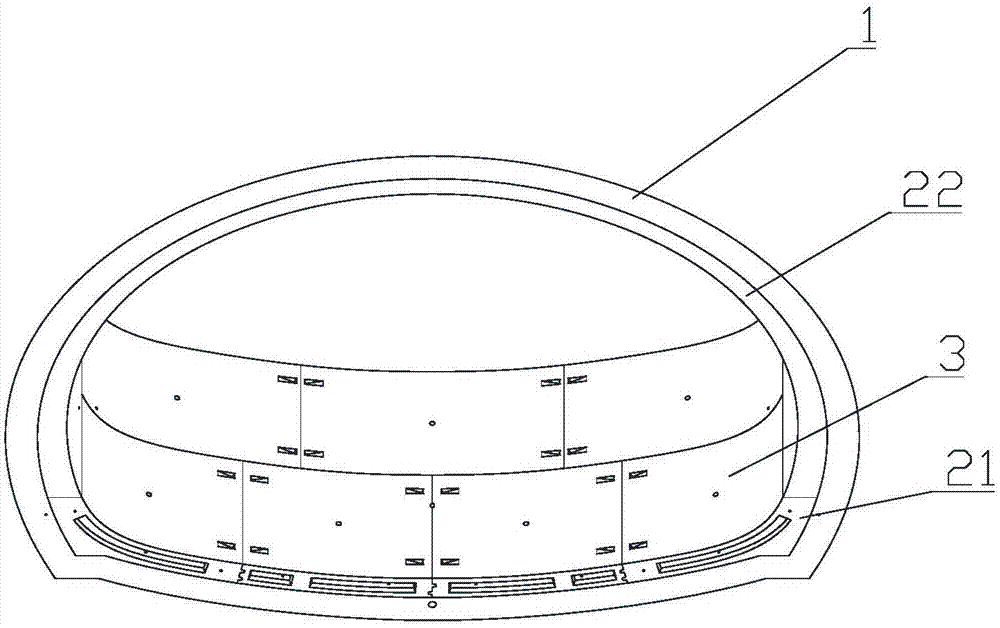

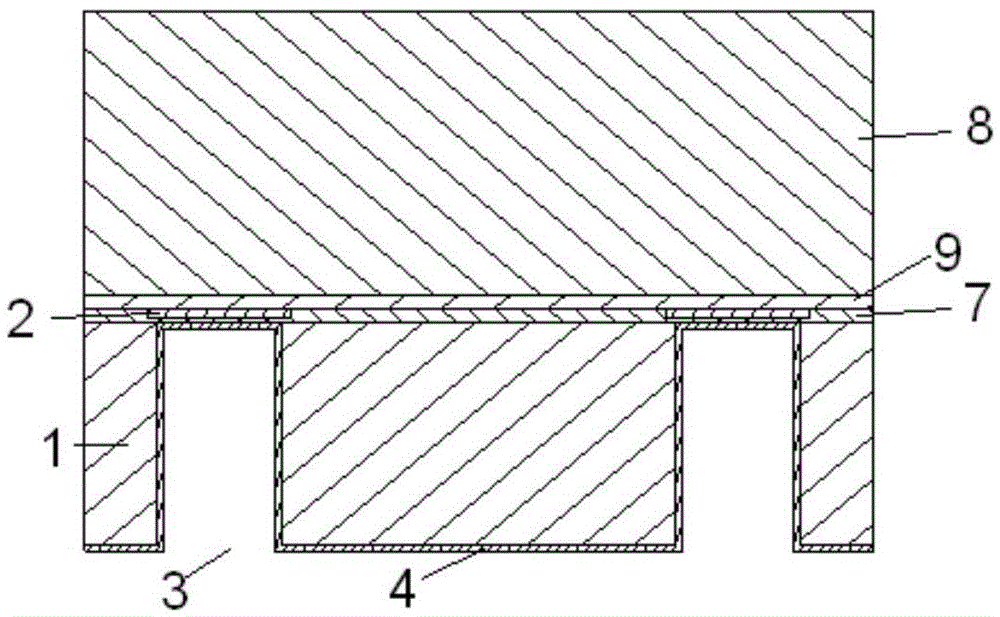

Tunnel bottom prefabricated assembly type tunnel structure and construction method thereof

PendingCN107387117ASimple structureReduce construction costsUnderground chambersTunnel liningDisease injuryBuilding construction

The invention relates to the technical field of tunnel engineering and discloses a tunnel bottom prefabricated assembly type tunnel structure. The tunnel bottom prefabricated assembly type tunnel structure comprises a primary support, a secondary lining, a drainage system and a filling layer. Six protrusions are arranged on the secondary lining, and the six protrusions are arranged at intervals in the transverse direction of a tunnel. Each protrusion extends in the extending direction of the tunnel. A box type plate prefabricated block and two T type plate prefabricated blocks located on the two sides of the box type plate prefabricated plate and connected with the box type plate prefabricated block are adopted for the filling layer. The box type plate prefabricated block comprises a top plate, a left vertical plate and a right vertical plate, wherein the left vertical plate and the right vertical plate are arranged on the two sides of the lower portion of the top plate. The left vertical plate, the right vertical plate, vertical plates of the two T type plate prefabricated blocks and the ends, away from the box type plate prefabricated block, of the two T type plate prefabricated blocks are correspondingly and fixedly connected with the six protrusions. By the adoption of the tunnel structure, the diseases of the delamination, cracking, bottom bulging, sinking, mud pumping and the like of the tunnel foundation can be solved effectively, the construction pollution is reduced, and the labor production efficiency is improved. The invention further discloses a construction method of the tunnel structure.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

Common yam rhizome dew beverage and production method thereof

The invention relates to a common yam rhizome dew beverage, which is prepared from fresh common yam rhizome serving as a main raw material. The beverage consists of the following components in part by weight: 8 to 20 parts of common yam rhizome, 0.001 to 0.005 part of thermo-stable amylase, 5 to 8 parts of sweetener, 0.10 to 0.15 part of vitamin C, 0.10 to 0.38 part of stabilizer, 0.06 to 0.16 part of acidity regulator and 71.3 to 86.7 parts of purified water. A production method comprises the following steps of: protecting color, coarsely grinding, cooking, pulping, raising the temperature for gelatinization, performing enzymolysis, inactivating at a high temperature, blending, homogenizing, degassing and the like. Common yam rhizome dew furthest keeps the specific active ingredients and flavor of the common yam rhizome, makes the common yam rhizome more easily absorbed and utilized by human bodies, and increases the nutritional value of the common yam rhizome; and the beverage has fragrant and mellow mouthfeel, is tasty and refreshing and has the effects of quenching thirst, moistening the lung, invigorating the spleen, protecting the liver, disintoxicating, tonifying middle-jiao and qi, nourishing the heart, soothing the nerves, preventing atherosclerosis, building the bodies, beautifying and delaying senility. The production method ensures that the common yam rhizome dew beverage is not browned, precipitated and demixed.

Owner:SHENZHEN VIGOR HEALTH CARE PROD CO LTD

Passivation solution for soft roll lithium battery and packaging material of soft roll lithium battery

InactiveCN108179407AHigh bonding strengthAvoid destructionMetallic material coating processesCell component detailsOrganic acidAluminum foil

The invention relates to a passivation solution for a soft roll lithium battery and a packaging material of the soft roll lithium battery. The passivation solution comprises, by weight part, 0.3 to 1part of a metallic compound, 0.5 to 2 parts of organic acid, 0.5 to 2 parts of film forming polymer, 0.1 to 1 part of bonding resin and 100 to 200 parts of water. The invention further relates to a packaging material for the soft roll lithium battery. The packaging material is composed of a heat resisting layer, a first adhesive layer, an aluminum foil surface passivation treatment layer, an aluminum foil layer, an aluminum foil surface passivation treatment layer, a second adhesive layer and a heat seal layer. The aluminum foil surface passivation treatment layer is formed by coating of the passivation solution on the surface of the aluminum foil. The problem that in the long-term electrolyte resistance operation, bonding performance between the aluminum foil layer and the heat seal layeris seriously reduced or layered is solved, and the service life of the soft roll lithium battery is prolonged.

Owner:乐凯胶片股份有限公司

Methanol diesel oil fuel and preparation method thereof

InactiveCN101235325ASolve layeringImprove performanceLiquid carbonaceous fuelsAcetic acidIsobutyl alcohol

The invention relates to novel vehicular energy-saving environment-friendly methanol diesel oil and a manufacturing method, the proportion of each component of methanol diesel oil fuel according to weight by parts is that diesel oil 23-50, methanol 35-70 and combined addition agent 5-13, wherein the components and contents of the combined addition agent are that ethyl nitrate 0-3, cyclopean ferrocene 0-0.008, carbon dodecanol 0-2.5, isobutyl alcohol 0-3, diethyl carbonate 0-4, acetic ether 0-2.5, benzyl alcohol 0-0.5 and butanol 0-3. The process for preparation comprises getting dissel oil, methanol and combined addition agent according formula ratio under the condition of normal temperature and normal pressure, firstly, adding combined addition agent in methanol, preparing denatured methanol after completely dissolving, secondly, adding the above denatured methanol in diesel oil, finally completely evenly stirring for 10-20 minutes to get products. The products have excellent property and environmental protection.

Owner:浙江赛孚能源科技有限公司

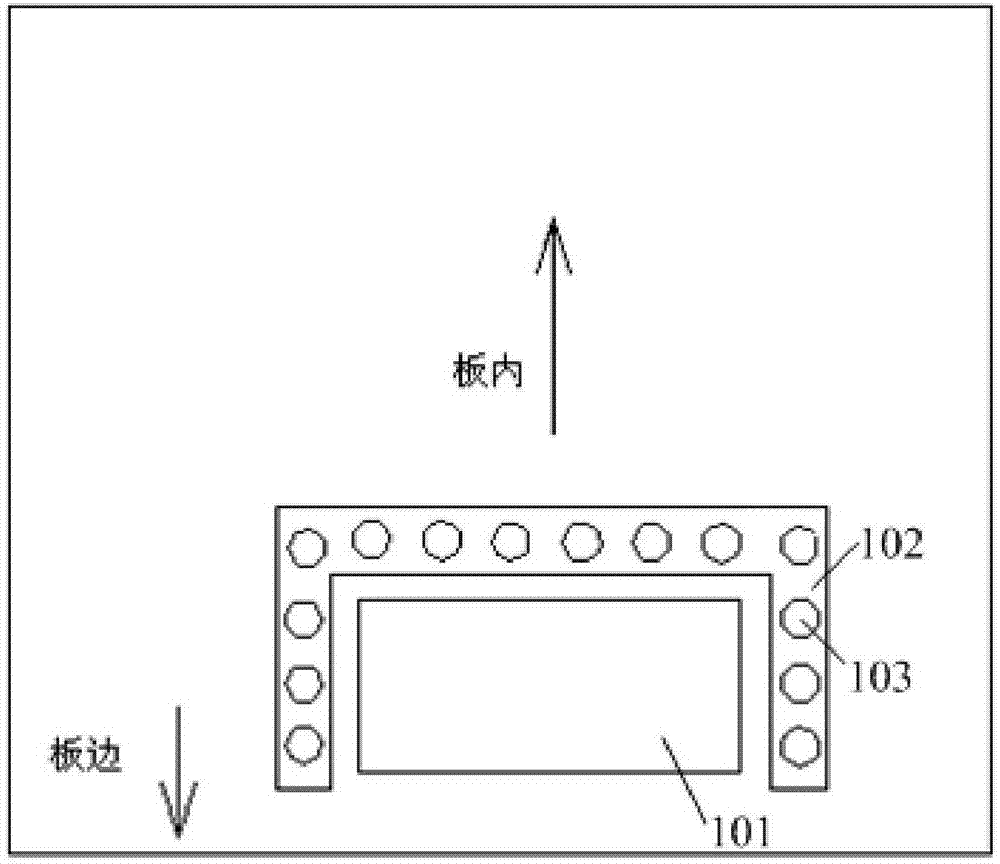

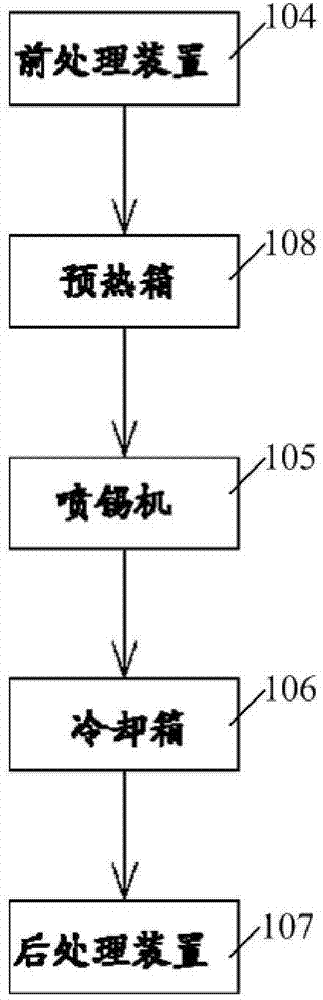

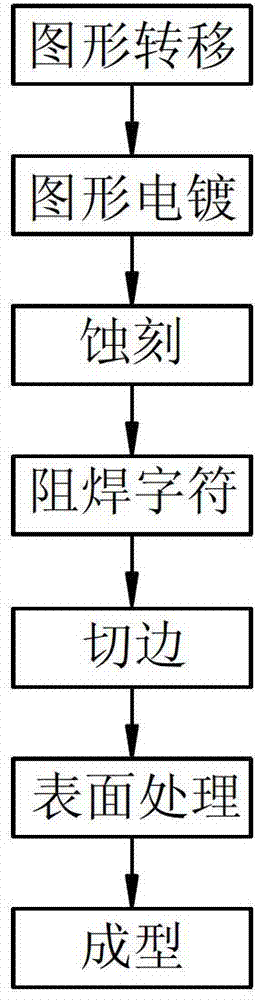

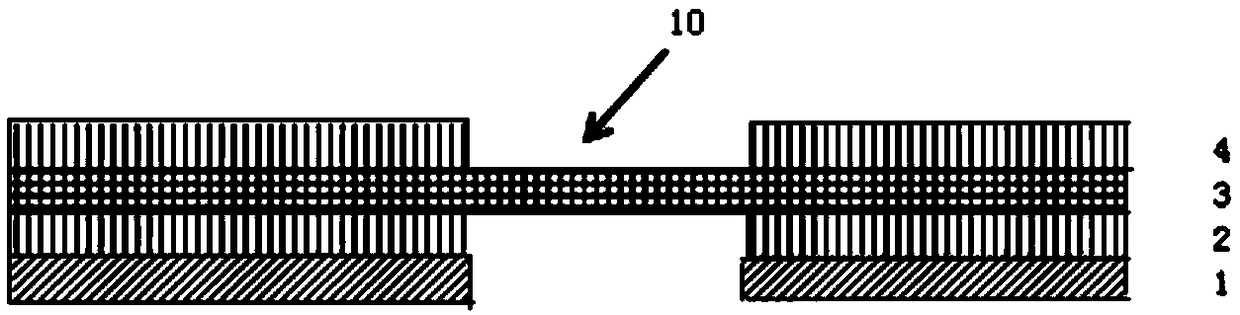

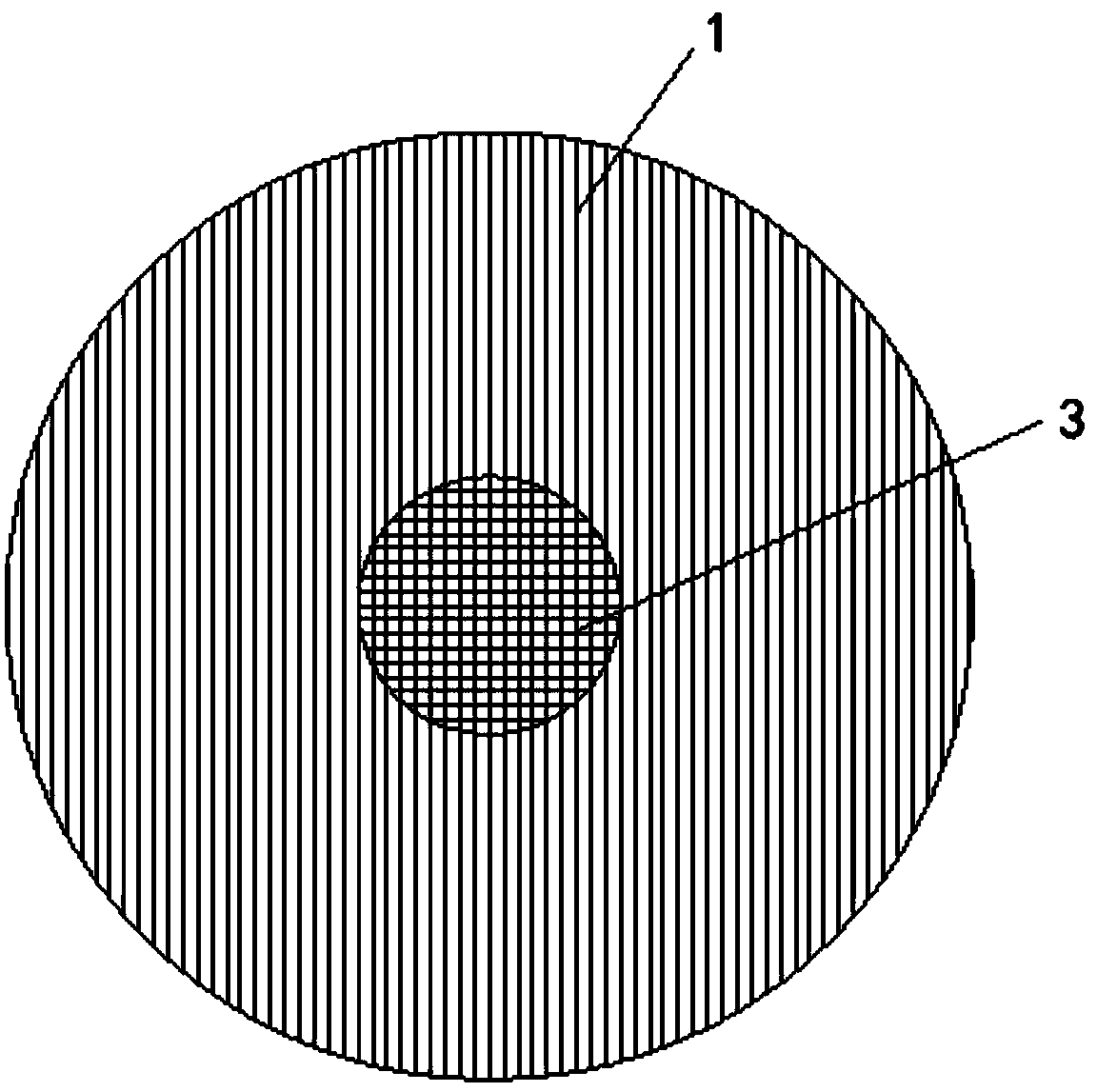

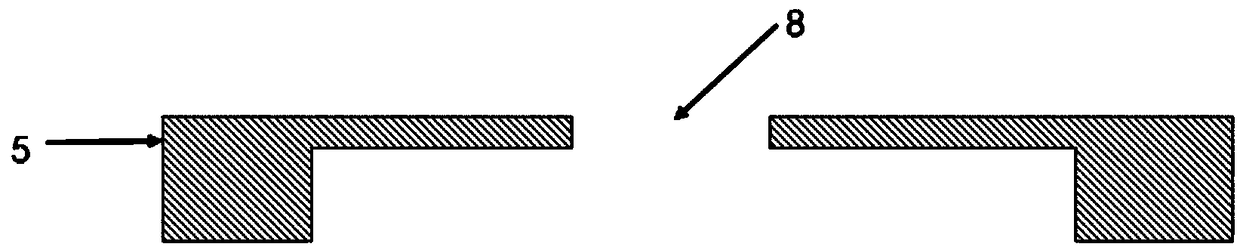

Processing method of printed circuit board (PCB) and PCB

ActiveCN103096631APromote stratificationSolve the problem of board edge delaminationPrinted circuit secondary treatmentEngineeringCopper

The invention discloses a processing method of a printed circuit board (PCB) and the PCB. The processing method includes a first step of eliminating a copper layer arranged at the edge of the PCB before a step of solder coating surface treatment and a second step of heating the PCB after eliminating the copper layer arranged at the edge of the PCB. Due to the facts that the copper layer wrapping the edge of the PCB is eliminated before solder coating, base materials of PCB board sides are exposed, and moisture can be directly eliminated by the PCB board sides when the solder coating is conducted successively, a problem of board side delamination is improved. Heating is conducted after the copper layer which wrapps the edge of the PCB is eliminated, residual moisture in the PCB can be actively eliminated, and therefore the problem of board side delamination in the process of the following solder coating is fundamentally solved. The processing method of the PCB can be finished by means of PCB convention processing equipment and therefore the processing method of the PCB is easy to achieve and low in cost.

Owner:GUANGDONG SHENGYI SCI TECH

Water quality modifier

InactiveCN103588274AQuality improvementReduce harmful effectsWater/sewage treatment by neutralisationWater/sewage treatment using germicide/oligodynamic-processSolubilityWater source

A disclosed water quality modified is composed of disodium ethylene diamine tetraacetate, citric acid, potassium monopersulfate triple salt, polyferric sulfate and phytic acid according to a weight ratio. The water quality modifier is good in water solubility, helps to purify water, improve water quality, reduce the mortality and elimination rate and increase breeding income, is widely applicable to modification on poultry and livestock drinking water and aquaculture animal water source.

Owner:TAIAN DAIYUE DISTRICT SHANNONG GAOKE VETERINARY MEDICINE RES INST

Air-permeable sound-permeable waterproof membrane

PendingCN109203623ASolve layeringPrevent impregnationSynthetic resin layered productsMetal layered productsEngineeringWater pressure

The invention provides an air-permeable sound-permeable waterproof membrane. The air-permeable sound-permeable waterproof membrane comprises a shell and further comprises a pressure plate and a waterproof air-permeable membrane assembly mounted in the shell, wherein the shell is provided with a first through hole; the pressure plate and the part, where the first through hole is arranged, of the shell form a closed area; the pressure plate is hermetically connected with the shell; the pressure plate is provided with a second through hole; the second through hole is arranged at a position corresponding to the position of the first through hole, and the two through holes communicate with each other; the waterproof air-permeable membrane assembly is installed in the closed area, and is closely attached to and fixedly connected with both the shell and the pressure plate; the waterproof air-permeable membrane assembly comprises a waterproof air-permeable membrane; and the waterproof air-permeable membrane is the only member that blocks the communication between the first through hole and the second through hole. The air-permeable sound-permeable waterproof membrane of the invention hasgood water resistance and can resist water pressure of 1 to 70 meters; and when the air-permeable sound-permeable waterproof membrane cooperates with an intelligent hardware shell structure, a part using the membrane has water resistance, air permeability and sound permeability.

Owner:崔福文

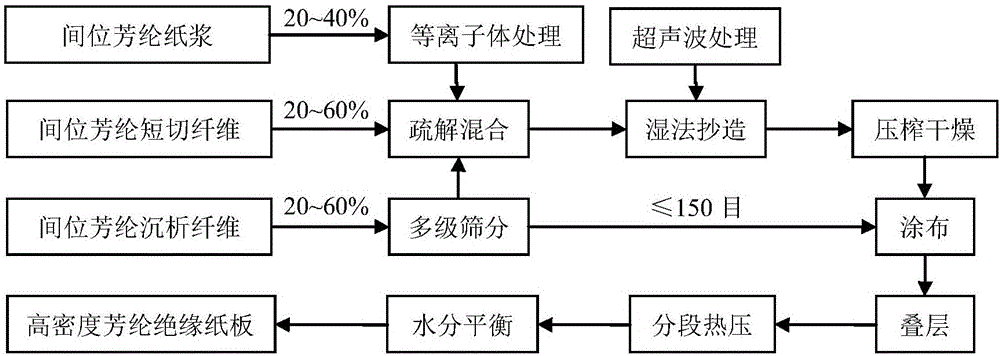

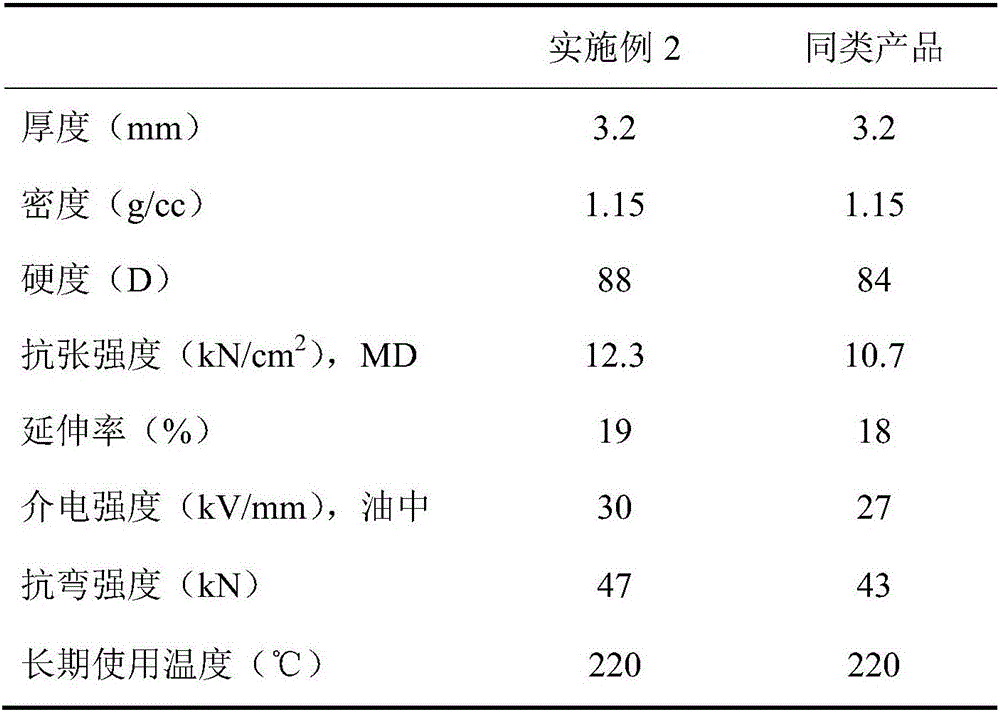

Preparation method of high-density aramid insulating hardboard

ActiveCN106283836AHigh densityDensity does not affectSynthetic cellulose/non-cellulose material pulp/paperPaper-making machinesCardboardHigh density

The invention discloses a preparation method of a high-density aramid insulating hardboard. The preparation method comprises the following steps: defibering meta-aramid chopped fibers, meta-aramid precipitation fibers and meta-aramid paper pulp in water respectively; after mixing, carrying out wet-process papermaking and forming by utilizing an inclined-wire forming device; carrying out ultrasonic treatment in the forming device; after squeezing and drying, carrying out surface coating treatment; reeling a wet paper web through a laminated layer; after chopping off, spreading on a conveyor to form a wet paper blank; conveying the wet paper blank into a plate type hot press through a feeding trolley and carrying out subsection hot pressing; after cooling, unloading a board, conveying the board into a semi-finished product chamber and carrying out balance treatment; trimming and finishing to finally obtain a high-density aramid insulating hardboard product. The high-density aramid insulating hardboard prepared by the invention is composed of pure meta-aramid fibers, the thickness is 1.0mm to 10mm and the density is 1.1g / cc to 1.2g / cc; the size precision is high; the product has excellent mechanical strength and dielectric property, has high temprature-resisting grade and has good compatibility on oil and paint; the product can be widely applied to power equipment including motors, transformers and the like.

Owner:YANTAI METASTAR SPECIAL PAPER

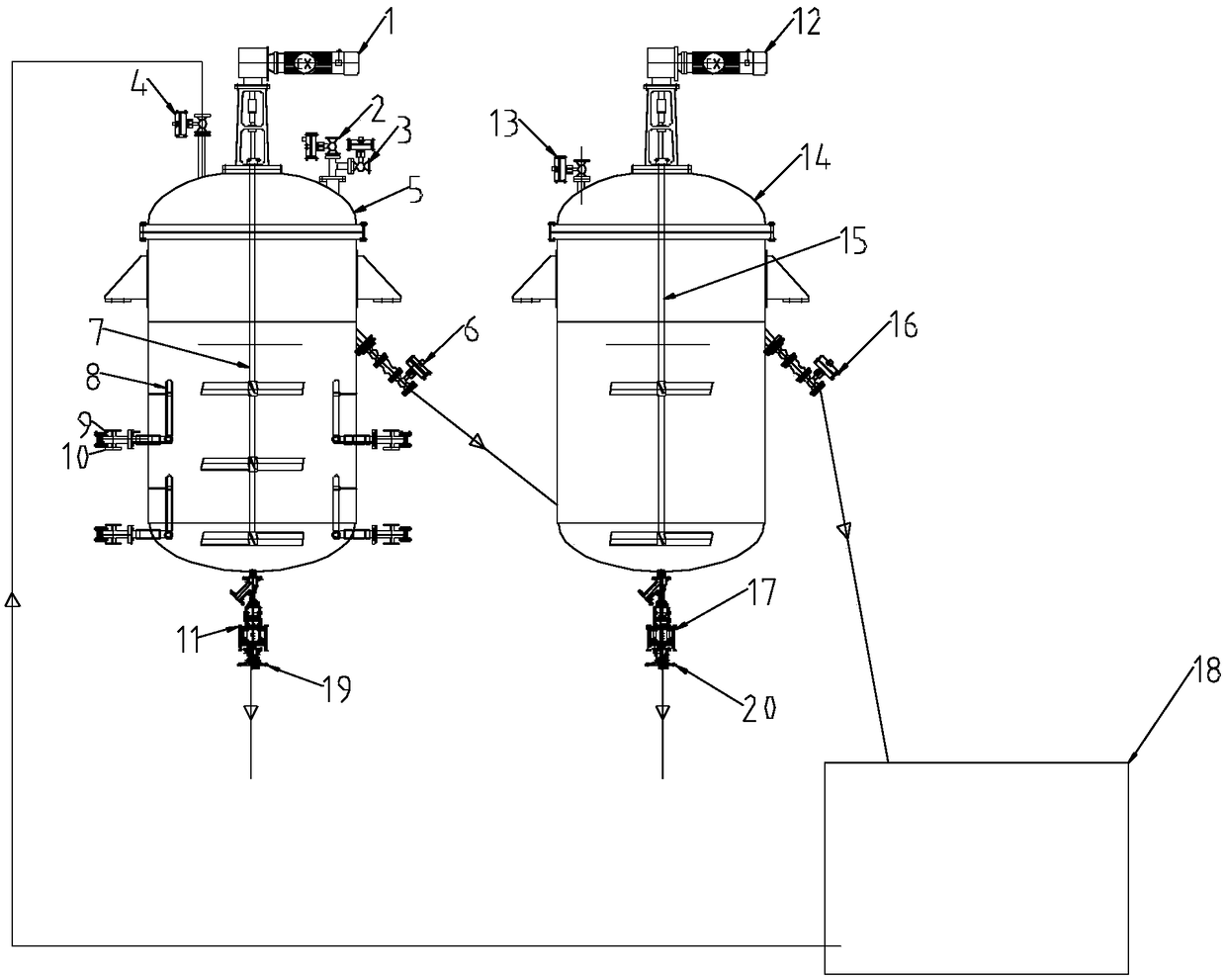

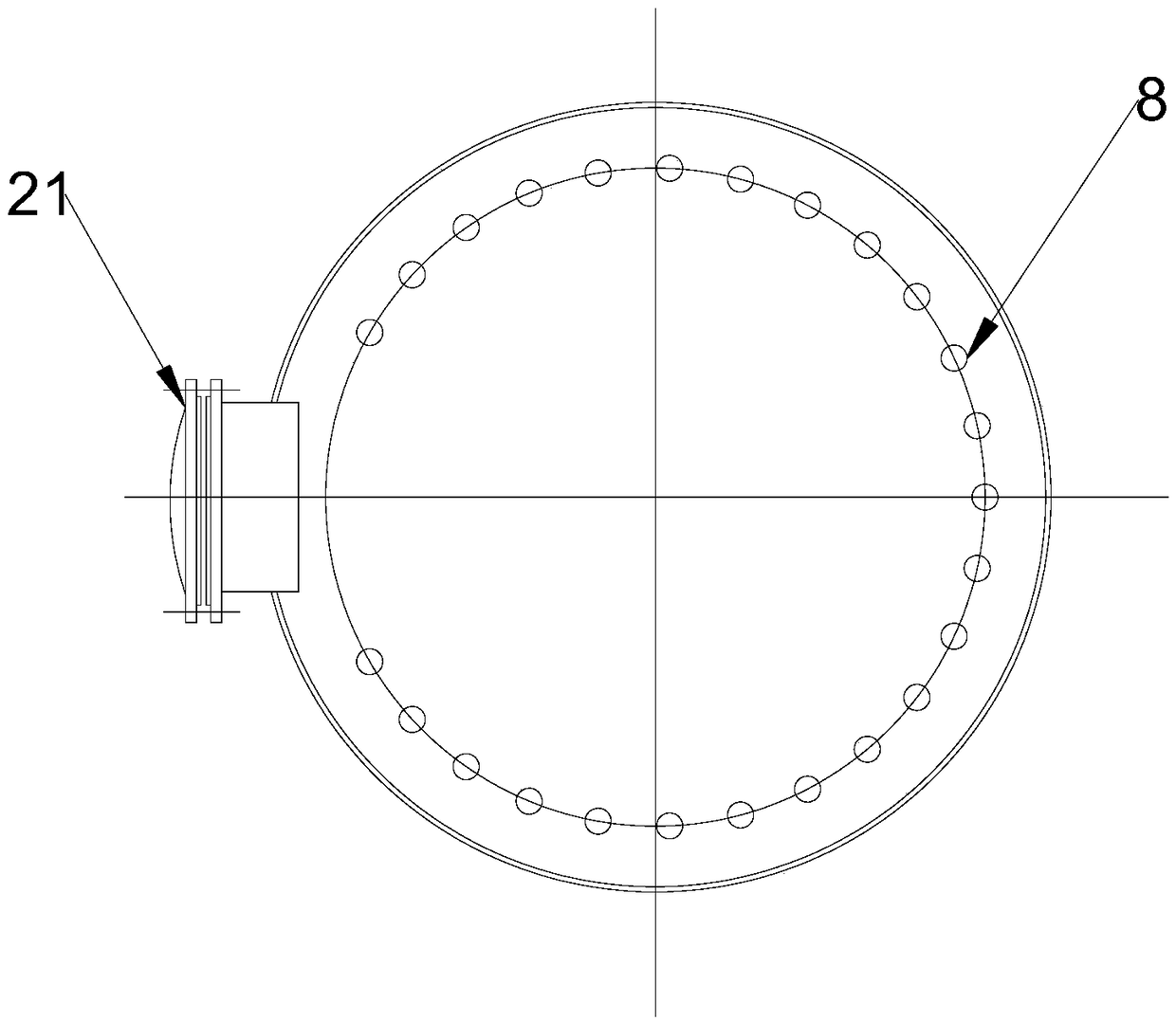

Novel filtering and concentrating device and main reaction kettle device

PendingCN109382058ASolve layeringAchieve reuseChemical/physical/physico-chemical stationary reactorsStationary filtering element filtersNitrogenPulp and paper industry

The invention discloses a novel filtering and concentrating device and a main reaction kettle device. The novel filtering and concentrating device comprises a cylinder body A, a cylinder body B, a gear motor A, a gear motor B, a stirring paddle A and a stirring paddle B, and further comprises a drain valve A, a drain valve B, a final concentrated product outlet A and a final concentrated product outlet B, wherein the gear motor A and the gear motor B are arranged at the top ends of the cylinder body A and the cylinder body B, the stirring paddle A and the stirring paddle B are arranged in theinner parts of the cylinder body A and the cylinder body B, the drain valve A and the drain valve B are arranged at the bottom ends of the cylinder body A and the cylinder body B; a nitrogen inlet, aregenerated liquid inlet and a spraying water inlet are arranged at the top end of the cylinder body A, an annular filter element is arranged on the inner wall of the cylinder body A, a back flushingport and a clear liquid outlet connected with the bottom part of the filter element and a filtered concentrated liquid outlet connected with a main reaction kettle are arranged on the side wall of thecylinder body A, a raw material feed port is arranged at the top end of the cylinder body B, an overflow port is arranged on the side wall of the cylinder body B and communicates with a middle tank,and the middle tank communicates with the top part of the filtering and concentrating device. The structure design of the novel filtering and concentrating device is more advanced and more reasonable,the mounting, dismounting and maintaining are simple and convenient, the problems of layering, shaking, sealing and the like of material liquid are effectively solved, and the filtering fineness is higher.

Owner:SICHUAN SIDANENG ENVIRONMENTAL PROTECTION TECH CO LTD

Metal tube taking plastic tube as liner and manufacturing method of metal tube

ActiveCN106907530AImprove water flow capacityImprove water delivery efficiencyCoatingsRigid pipesCooking & bakingHeating time

The invention provides a metal tube taking a plastic tube as a liner and a manufacturing method of the metal tube. The metal tube taking a plastic tube as a liner comprises a metal tube and a plastic composite tube stock; the plastic composite tube stock is formed by an outer layer hot melting adhesive layer and an inner layer plastic tube; plastic composite tube stock is manufactured online, the inner wall of the metal tube is subjected to sand blasting and shot blasting or grit blasting after being polished, the plastic composite tube stock is pulled into the well-processed metal tube, and the two ends of the plastic composite tube stock are sealed and inflated and are placed in a sealed steam room or baking room to be heated, such that the metal tube and the plastic composite tube stock are adhered fixedly, and trimming and spraying are performed. The invention further comprises a manufacturing method of the metal tube taking a plastic tube as a liner. The sealed steam room or baking room is adopted for heating, the product quality is stable, and percent of pass is high; a plurality of or even different models and types of tube stocks can be heated simultaneously, the total heating time is less, the production efficiency is high, the energy consumption cost for product heating can be saved, plants and production devices for production can be saved more, and investment cost is reduced.

Owner:肖和飞

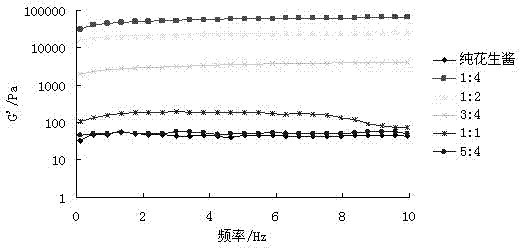

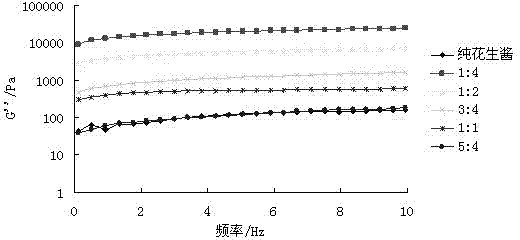

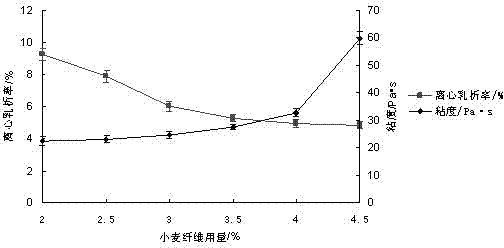

Method for improving peanut butter rheological characteristics by wheat fibers and composite emulsifier

InactiveCN103829292AEvenly distributedOptimize the best parametersFood ingredient as clouding agentFood preparationDeep processingOrganoleptic

The invention discloses a method for improving peanut butter rheological characteristics by wheat fibers and a composite emulsifier and belongs to the technical field of peanut product deep-processing. Water is added into raw peanut pulp as a raw materials so that the peanut butter is transformed into a stable oil-in-water structure and has rheological characteristic similar to that of pure peanut butter; and through combination of adsorption of free grease in the raw peanut pulp by wheat fibers and emulsification effects produced by the composite emulsifier, a peanut butter product which has long-term stability, is uniform, is not layered and has good rheological characteristics is produced. The peanut butter product has a centrifuged milk precipitation rate of 4.23% reduced by 57.5% than the centrifuged milk precipitation rate of the pure peanut butter and has good rheological characteristics, smearing characteristics and sensory quality. The peanut butter product satisfies current requirements on peanut butter stability and smearing characteristics and reduces damage caused by trans-fatty acids in the peanut butter on the health.

Owner:JIANGNAN UNIV

Cathode gold electrolytic refining process

InactiveCN102978658ASolving Corrosion ProblemsSolve layeringPhotography auxillary processesElectrodesSolubilityConcentration polarization

The invention provides a cathode gold electrolytic refining process. According to the invention, an electrolyte formula is changed, and electrolytic refining is carried out in a hydrochloric acid system with low gold ion solubility (Au<3+> 80-120g / L) and low acid (60-90g / L) with a titanium motherboard used for replacing a traditional gold starting sheet as a cathode. During the electrolysis process, with a quantitative dosing device, an inhibiting agent is automatically added online according to the variation of the components of the electrolyte, such that interferences of impurities such as lead and silver upon electric gold quality and an anode passivation problem are solved. Also, an automatic thermal insulation measure is provided for the electrolyte, such that a phenomenon of easy stratification and concentration polarization is eliminated. Higher than 99.995% electric gold products with qualified physical specifications and chemical qualities can be produced through one-step direct electrolysis. Aiming at a workplace environment ventilation problem, inner-ring and outer-ring skilful isolation is adopted, such that process exhaust problems of product pollution, environment pollution and equipment corrosion are solved. With the process provided by the invention, purposes of high efficiency, environment protection, and energy saving are realized. The process has a high popularization value in the field of precious metal refining.

Owner:JIANGXI COPPER

Aqueous high weather-proof matt exterior wall emulsion paint and preparation method thereof

InactiveCN103409023ALess detection finenessSmall smellEmulsion paintsPolymer scienceDefoaming Agents

The invention discloses an aqueous high weather-proof matt exterior wall emulsion paint and a preparation method thereof. The emulsion paint comprises the following components by weight: 30-40 parts of emulsion, 0.2-0.5 part of an organosilicone hydrophobic agent, 2-8 parts of diatomite, 4-7 parts of sericite powder, 20-25 parts of titanium dioxide, 6-14 parts of a calcium carbonate powder, 0.4-0.7 part of a dispersant, 0.1-0.3 part of a wetting agent, 0.3-0.6 part of a defoaming agent, 0.1-0.3 part of an antifreeze, 1.5-2 parts of a coalescing agent, 0.4-0.9 part of a thickening agent, 0.2-0.5 part of a leveling agent, 0.1-0.3 part of a preservative, 0.1-0.3 part of a mildew preventive and 20-30 parts of water. The preparation method provided by the present invention comprises steps of: pre-blending, grinding disperse, and addition of emulsion and auxiliary agent, etc. The aqueous high weather-proof matt exterior wall emulsion paint provided by the invention has advantages of soft texture, flattening and fine paint film surface, and soft matt effect.

Owner:ZHEJIANG ZHIQIANG PAINT

Forming method of fiber-reinforced thermoplastic resin aluminum alloy layer board part

ActiveCN105082723AImprove deformation abilityHigh dimensional accuracyLaminationMetal layered productsMelt temperatureMelting temperature

The invention discloses a forming method of a fiber-reinforced thermoplastic resin aluminum alloy layer board part. The forming method comprises the following steps: (1) placing a fiber-reinforced thermoplastic resin aluminum alloy layer board between a female die and a male die; (2) heating an aluminum alloy layer, and heating an aluminum alloy layer in the fiber-reinforced thermoplastic resin aluminum alloy layer board to a fiber-reinforced thermoplastic resin melting temperature and preserving heat for a certain time; (3) die assembling and pressure maintaining: maintaining a certain pressure after assembling the dies, and lasting for a certain time; and (4) die stripping and cooling. According to the forming method disclosed by the invention, the fiber-reinforced thermoplastic resin is heated and melted by aluminum alloy current with self-resistance, and the formed part is cured under maintained pressure, so that the problem of delamination between the aluminum alloy layer and the fiber thermoplastic resin layer in a forming process is solved; and by softening the fiber-reinforced thermoplastic resin before the fiber-reinforced thermoplastic resin is melted, the deformation capability of the fiber-reinforced thermoplastic resin layer is improved.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Interconnection structure of low-cost chip back through silicon via (TSV) and preparation method thereof

ActiveCN105655320AImprove reliabilityReduce processing costsSemiconductor/solid-state device detailsSolid-state devicesChemical platingConductive materials

The invention discloses an interconnection structure of a low-cost chip back through silicon via (TSV) and a preparation method thereof. The interconnection structure comprises at least one chip. The front surface of each chip is provided with a welding pad, and the back surface of the chip is provided with a through via corresponding to the welding pad. The bottom opening of the through via is exposed to the welding pad, and the size of the bottom opening of the through via is smaller than the size of the welding pad. The back surface of the chip and the sidewall of the through via are coated with an insulating layer. The surface of the welding pad, exposed out of the bottom opening of the through via, is formed with a metal layer of a certain thickness through the chemical plating process. The electrically conductive material is filled inside the through via through the non-metal plating process. According to the technical scheme of the invention, the electroless plating of the sidewall of the TSV is not required any more. Meanwhile, the deep hole physical vapor deposition and the deep hole plating are avoided, so that the interconnection structure is low in cost, simple in process and high in reliability.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

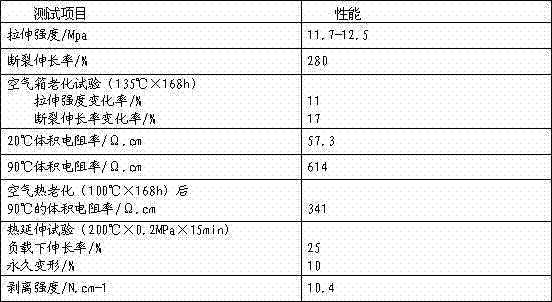

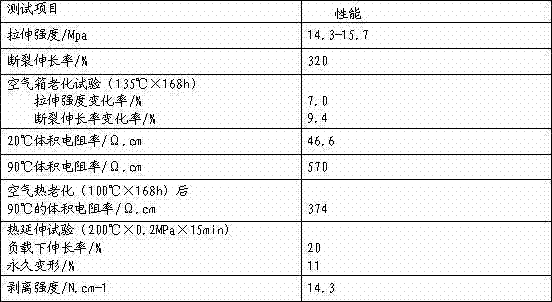

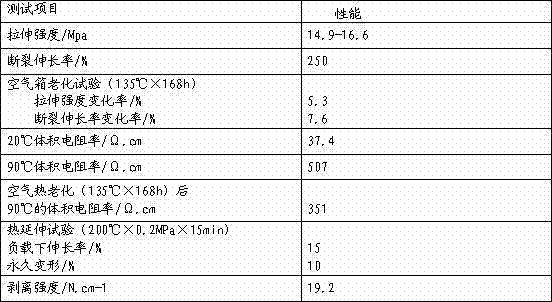

Strippable semi-conductive shielding material for ethylene propylene rubber cable

InactiveCN102558660AExcellent performance indexSemi-conductive and stableInsulated cablesInsulated conductorsVulcanizationPolymer science

The invention discloses a strippable semi-conductive shielding material for an ethylene propylene rubber cable. The shielding material is prepared by mixing the following raw materials in part by weight: 70 parts of ethylene vinyl acetate, 30 parts of chlorinated polyethylene, 50 to 70 parts of conductive carbon black, 5 to 15 parts of coarse-particle carbon black, 5 to 10 parts of metal oxide, 20 to 40 parts of mineral filler, 3 to 20 parts of dispersing agent, 2 to 6 parts of cross-linking agent, 4 to 6 parts of cross-linking aid, 2 to 5 parts of anti-ageing agent and 15 to 20 parts of plasticizer. The defects that the shielding material has overhigh volume resistivity, and insufficient adhesion with an ethylene propylene insulation layer, and is difficult to strip, the shielding material and the ethylene propylene insulation layer cannot be synchronously vulcanized, and the like in the prior art are overcome, and the strippable semi-conductive shielding material for the ethylene propylene rubber cable has high semi-conductivity, high extrusion processability, and moderate adhesion with the insulation layer, is easy to strip and has a vulcanization rate equivalent to that of ethylene propylene rubber.

Owner:重庆鸽牌电线电缆有限公司

Energy-saving discharge-reducing methanol diesel oil

InactiveCN101215483AEasy to prepareImprove cold start performanceLiquid carbonaceous fuelsVegetable oilHazardous substance

Energy-saving emission-reducing type carbinol diesel, the weight by parts proportion of auxiliary raw materials which are used is that carbinol is 1-35 parts, diesel is 61-80 parts, methyl tert-butyl ether is 2-5 parts, vegetable oil acid is 1-5 parts, thick tea water is 1-2 parts, hexane is 0.2-0.5 part, isopropanol is 0.3-0.5 part, tert-butanol is 0.25-0.6 part, and the above auxiliary raw materials should only be mixed evenly under normal temperature and nor pressure. The carbinol diesel does not separate layers in long-term storage and has good intersolubility, the tryout on diesel-engine road vehicles shows that compared with pure national standard diesel which uses the same mark number, the carbinol diesel saves fuel consumption by 5-10% for 100 kilometers, the discharging end gas does not have black smoke, the content of harmful substances as CO, NO X, HC and the like is greatly reduced, and the fuel does not exist corrosion and swelling problems to metal pieces and rubber pieces in oil ways. The invention has simple preparation, high heat quality of the product and low cost, and not only can save the fuel consumption and the emission of the harmful substances but also can overcome the drawbacks such as corrosiveness, swellability and poor motivation which occur when existing carbinol diesel is in use.

Owner:陈林 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com