Detection method for measuring thicknesses of multiple coating layers

A detection method, multi-layer coating technology, applied in the field of auto parts product detection, can solve the problems of tedious, difficult to layer, unable to effectively determine the thickness of paint and varnish, ED and primer, etc., to avoid cumbersome Program, strong reliability, accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

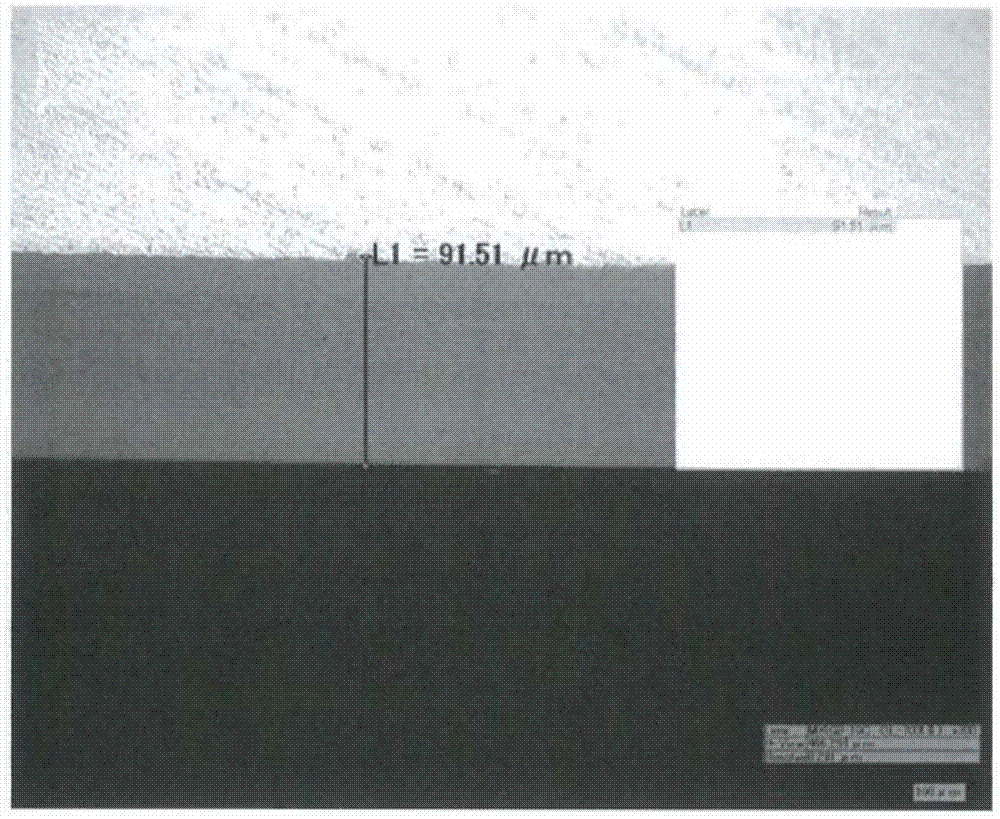

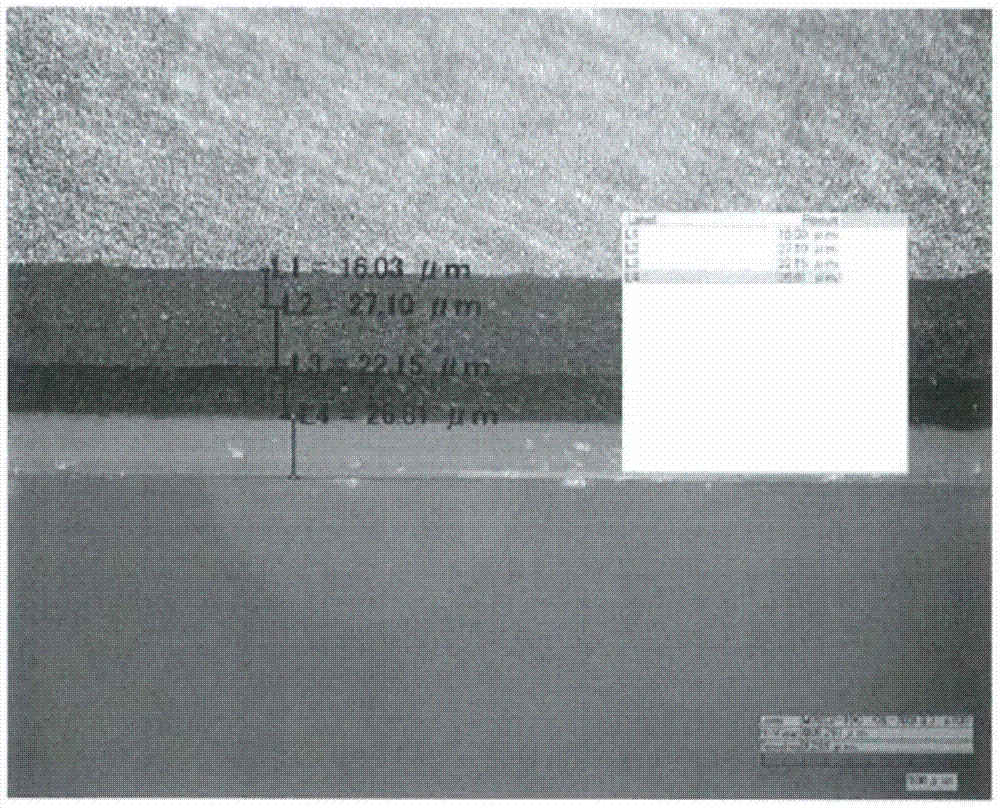

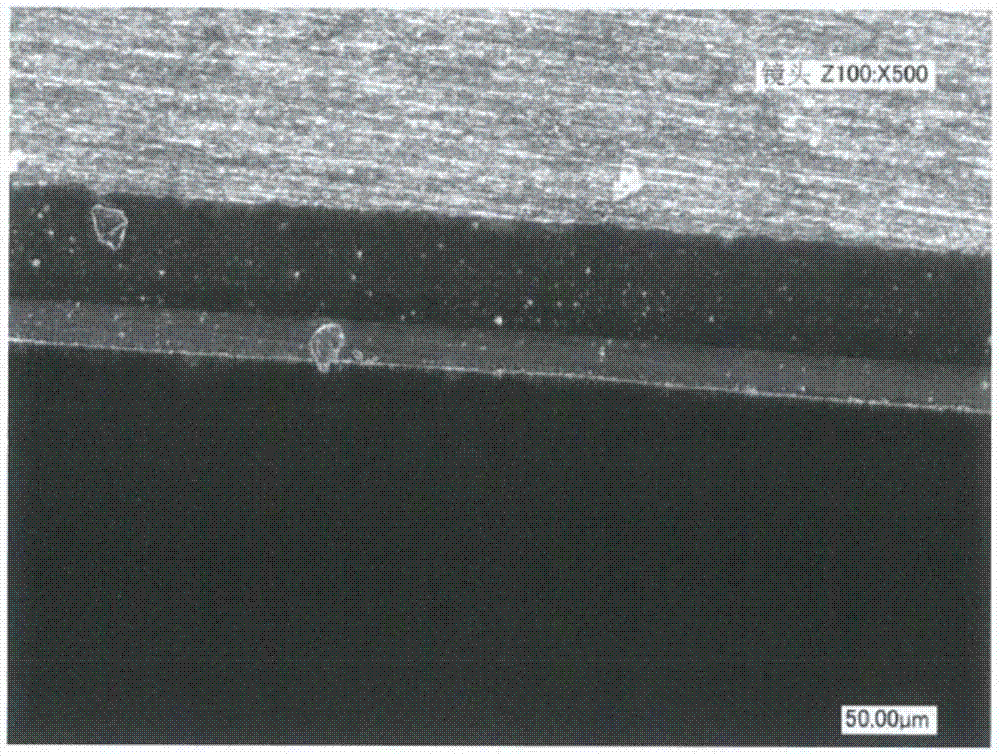

[0017] Such as image 3 As shown in the layered photo of the coating, this is a photo of the coating interface resolved by the microscope of Keyence, a well-known microscope manufacturer on the market. It can be seen that the multi-layer coating interface cannot be resolved by this microscope, and at most one layer can be resolved. However, this detection method for measuring the thickness of multi-layer coatings can directly measure the film thickness delamination of multi-layer coating products, and can make the film thickness of multi-layer coatings clear and delaminated, especially the delamination of black paint and varnish. The detection method comprises the following steps:

[0018] Step a: cutting the sample part to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com