Patents

Literature

87results about How to "Reduced fracturing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

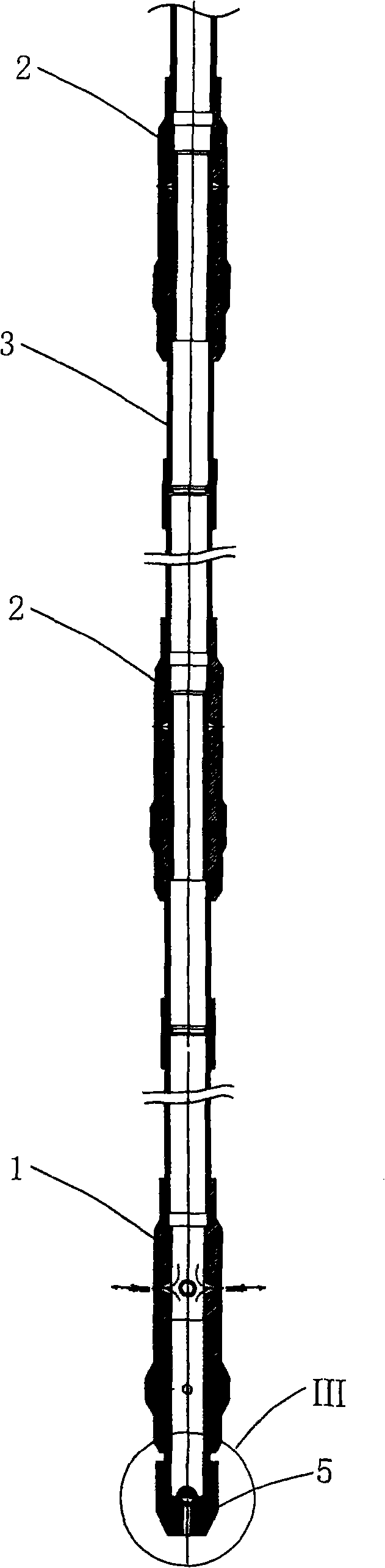

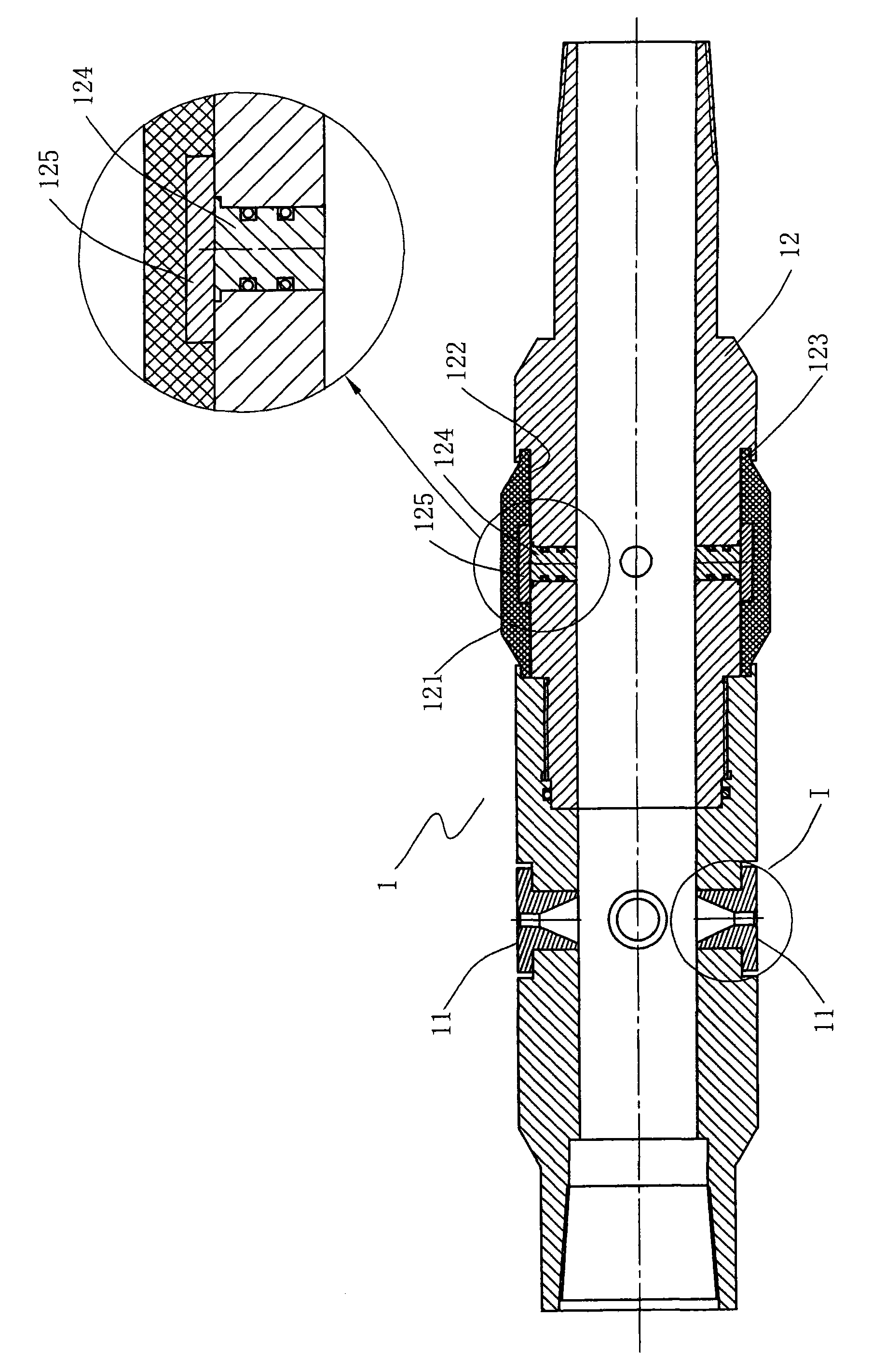

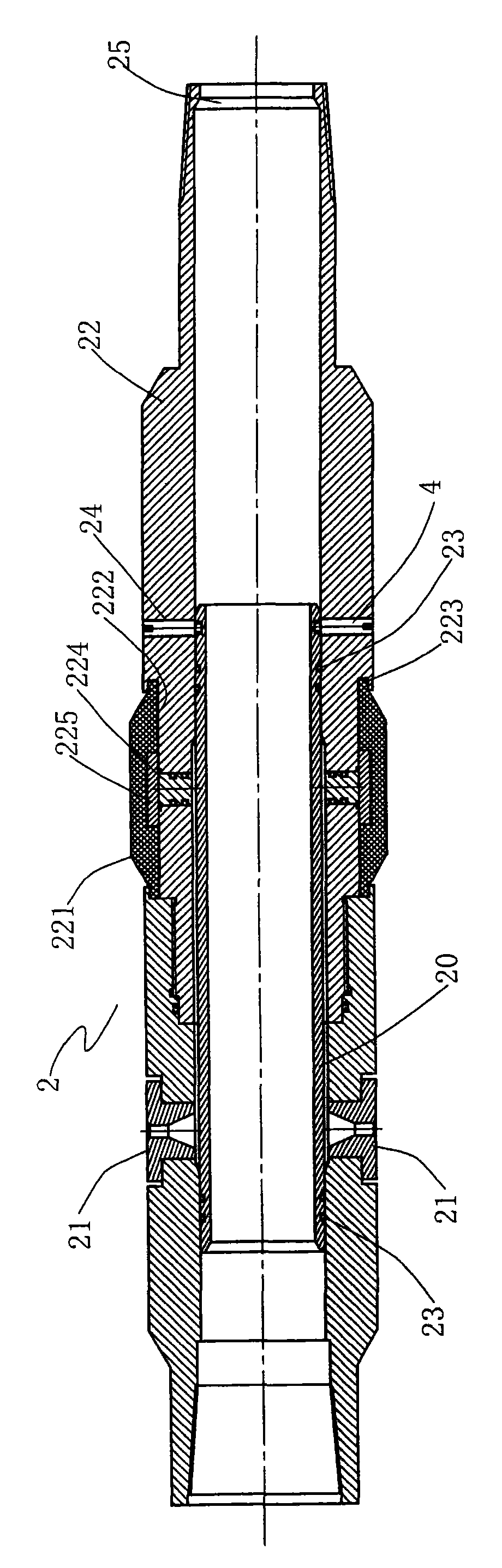

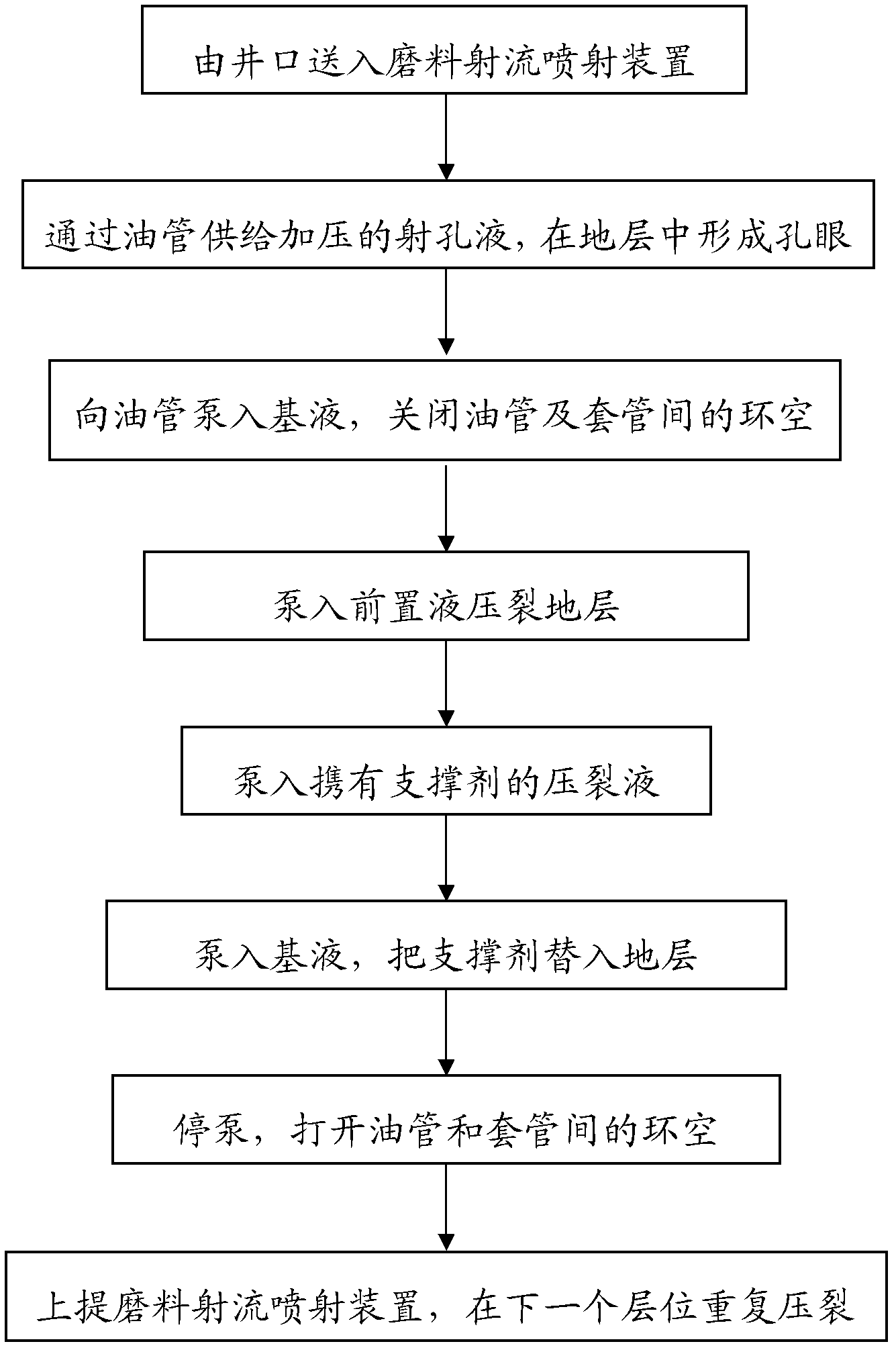

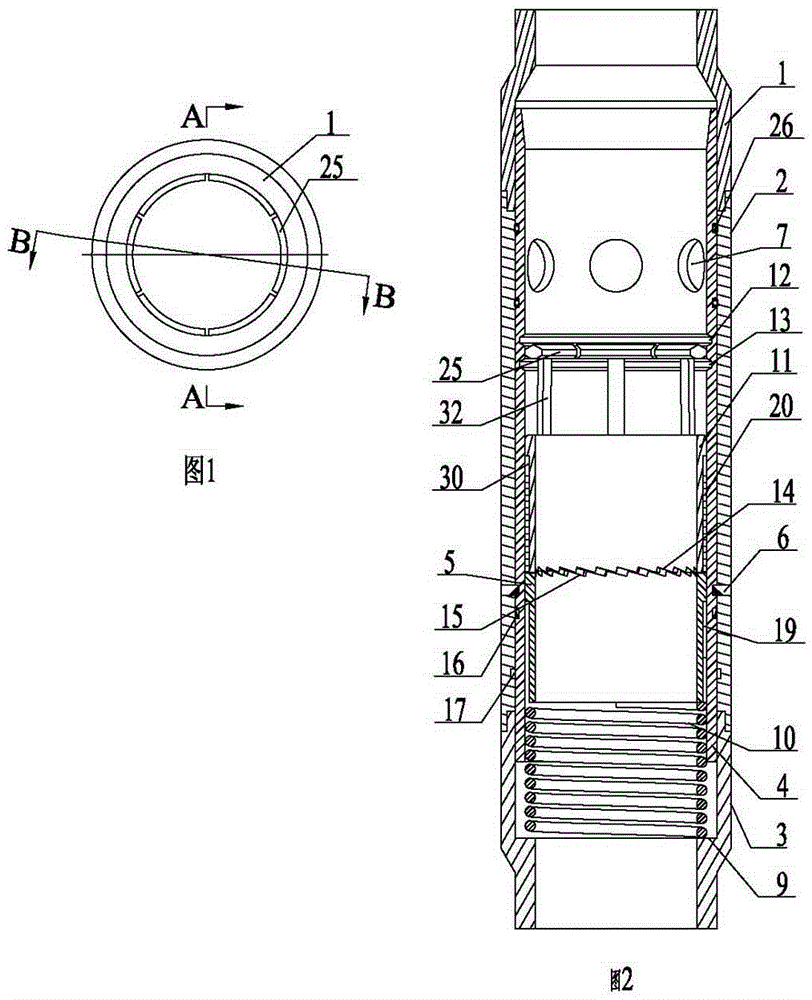

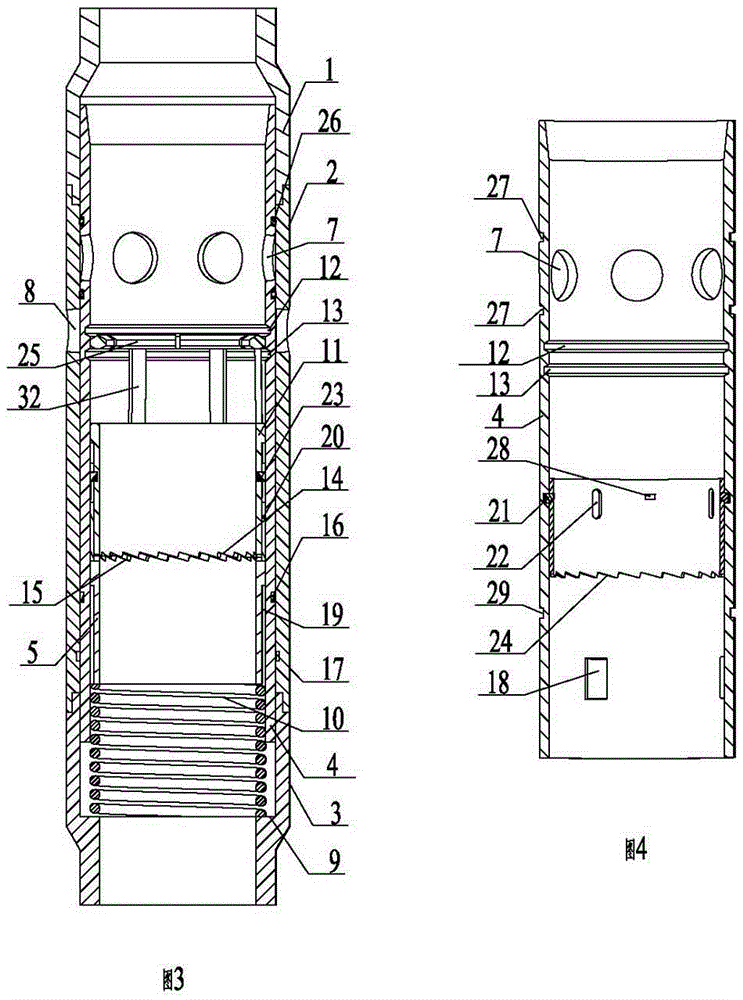

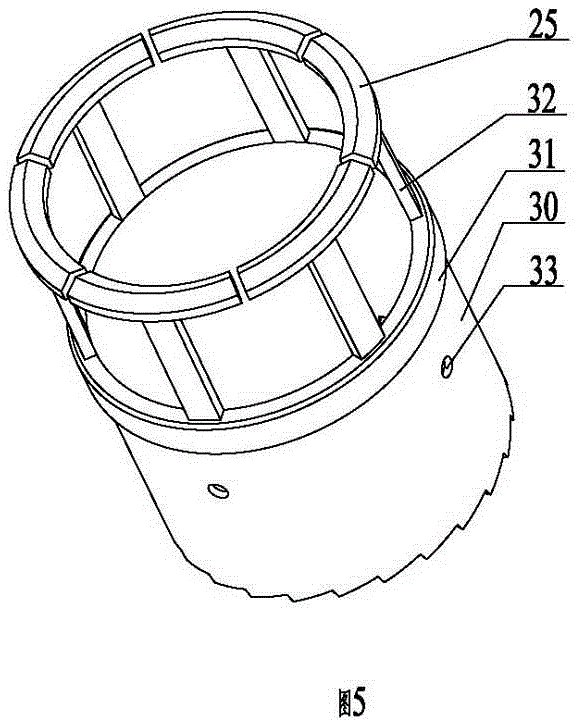

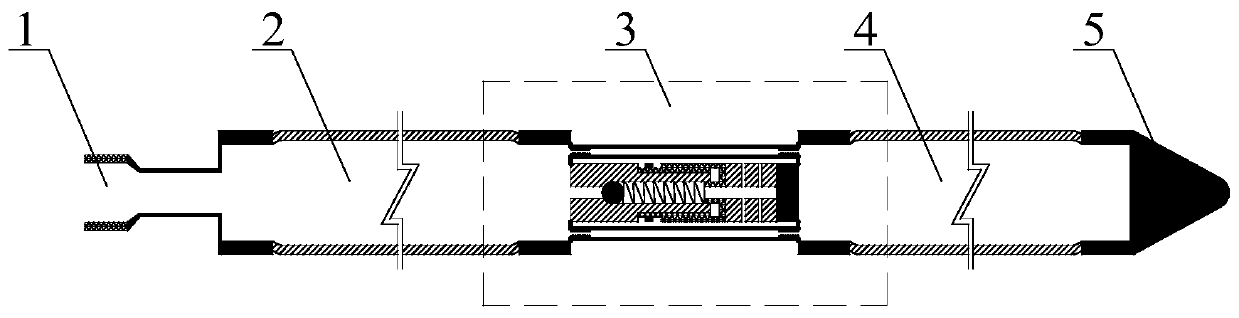

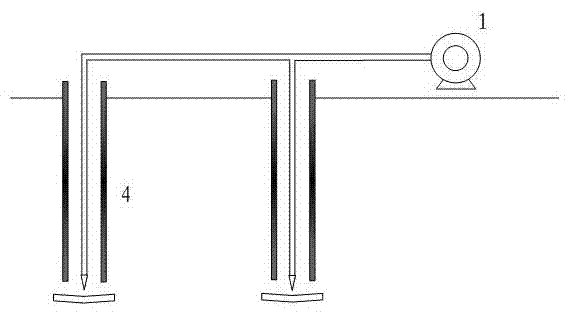

Abrasive jetting device and method for abrasive jetting flow and jetting perforation and multiple fracturing

InactiveCN101539007AAvoid defects that require moving the downhole stringGood sealingFluid removalLiquid spraying apparatusHorizontal wellsOil field

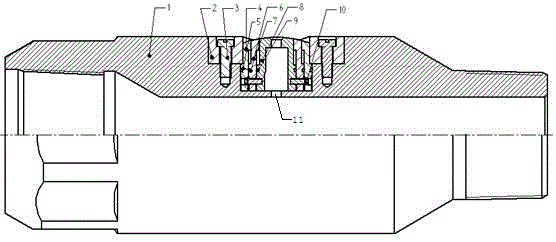

The invention relates to an abrasive jetting device and a method for abrasive water jet perforation and multiple fracturing; wherein the abrasive jetting device has multistage jet guns which are connected in series; the jet guns are all hollow columns; the side walls thereof are respectively provided with at least two nozzles; the lower part of each stage of jet gun is provided with a packer; the side wall of the packer is provided with a sealing sleeve which can expand outward under the action of high-pressure liquid; the jet guns comprise a first stage bottom jet gun arranged at the lower part of the abrasive jetting device and multistage upper jet guns arranged above the bottom jet gun; wherein all the upper jet guns are respectively provided with a sliding sleeve which can seal the nozzle of the stage of jet gun and sealing sleeve; and the sliding sleeve can slide to the lower part of the sealing sleeve under the action of external force so as to open the nozzle and the sealing sleeve. The invention can be used for casing straight wells or horizontal wells, solves the problem of layered or staged fracturing in the straight wells or the horizontal wells in oil fields, and achieves the purposes of saving fracturing cost, improving fracturing effect and reducing the construction risk.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

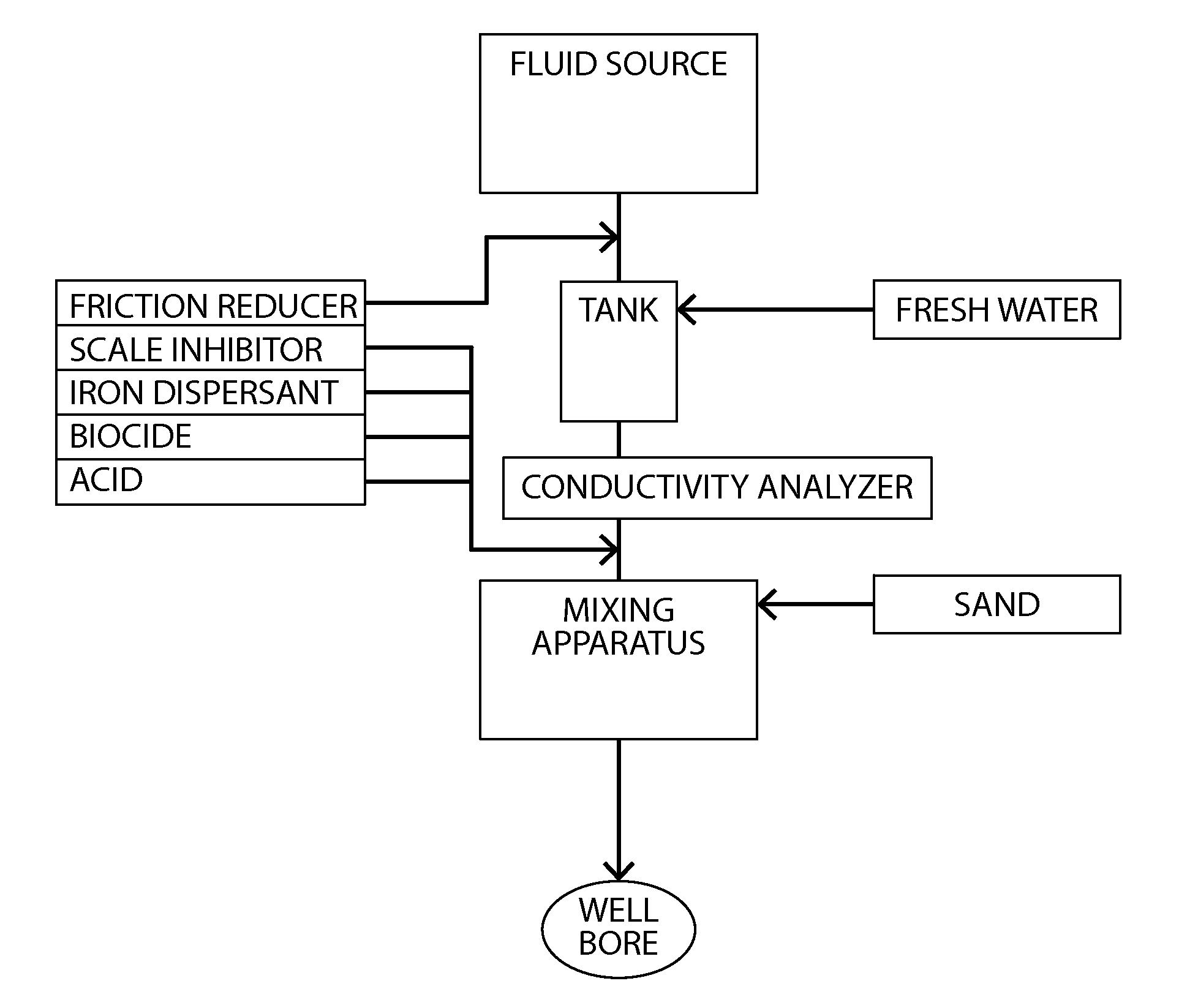

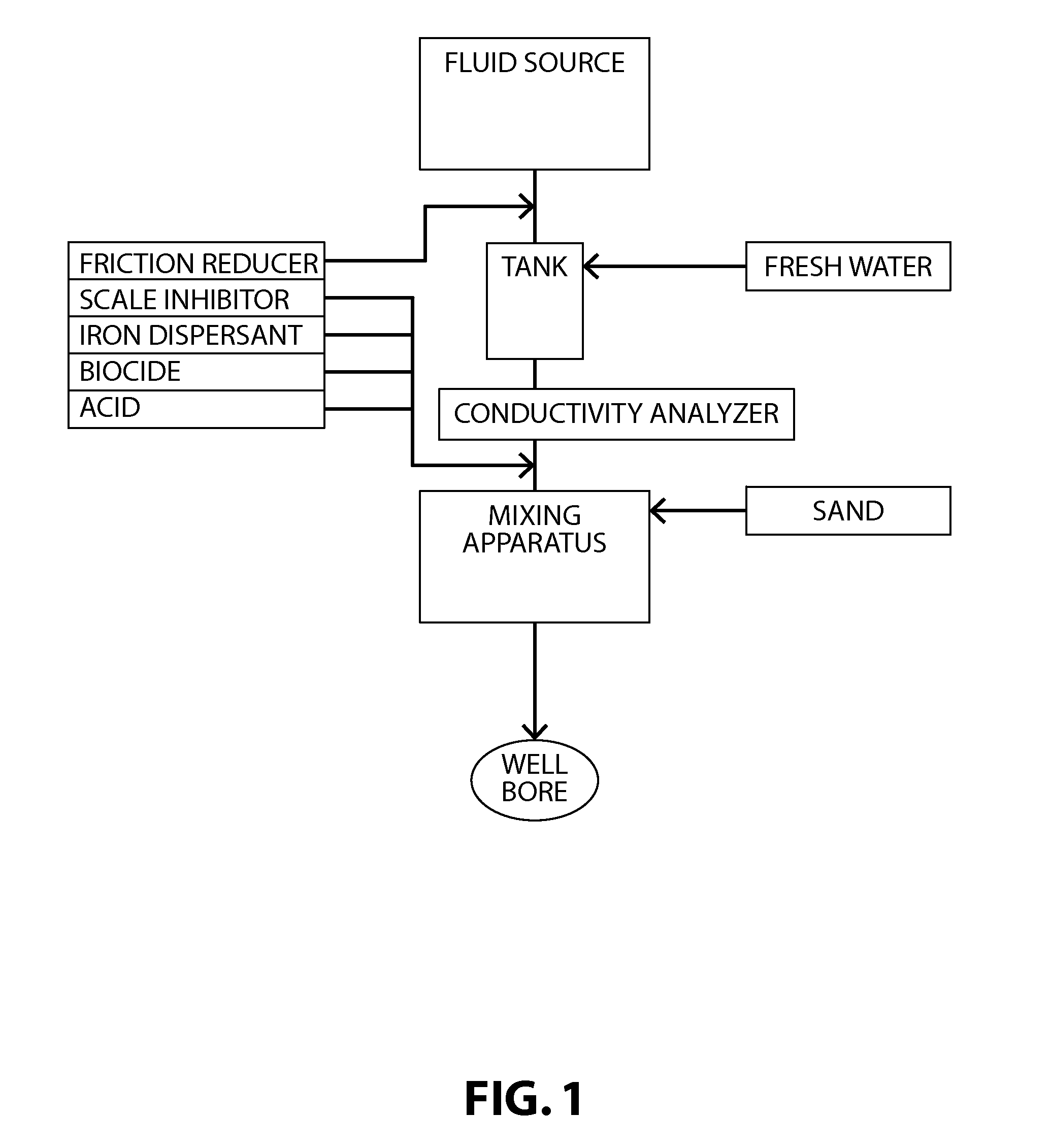

Fracturing fluid water reuse system and method

ActiveUS20120024525A1Low costIncreasing well productionFluid removalMixer accessoriesFracturing fluidHydraulic fracturing

Methods of processing a fluid recovered from an oil or gas extraction operation for reuse in a hydraulic fracturing fluid are described. The methods include providing an amount of a produced fluid composition containing iron and suspended solids and controlling at least one of the conductivity, iron content, oxidative strength, and pH of the composition, such that Fenton's reagent is formed in situ. Also described are hydraulic fracturing fluids produced using fluid recovered from an oil or gas production process and treated in accordance with the methods described herein as well as systems for preparing a hydraulic fracturing fluid having, as a fluid source, fluid recovered from an oil or gas production process that has been treated in accordance with the methods described herein.

Owner:CHEVROU USA INC

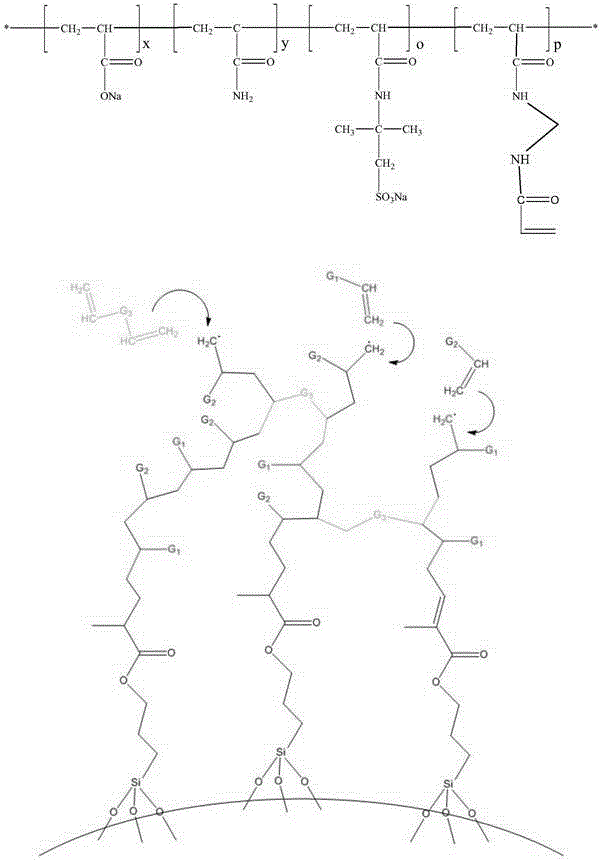

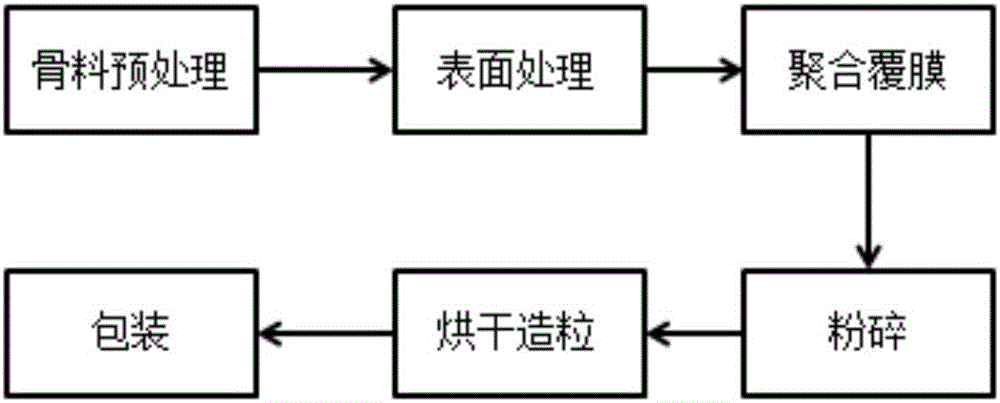

Preparation method for self-suspension propping agent in laboratory

InactiveCN106634939AReduced fracturing costsShear stableFluid removalDrilling compositionFunctional monomerExpanded clay aggregate

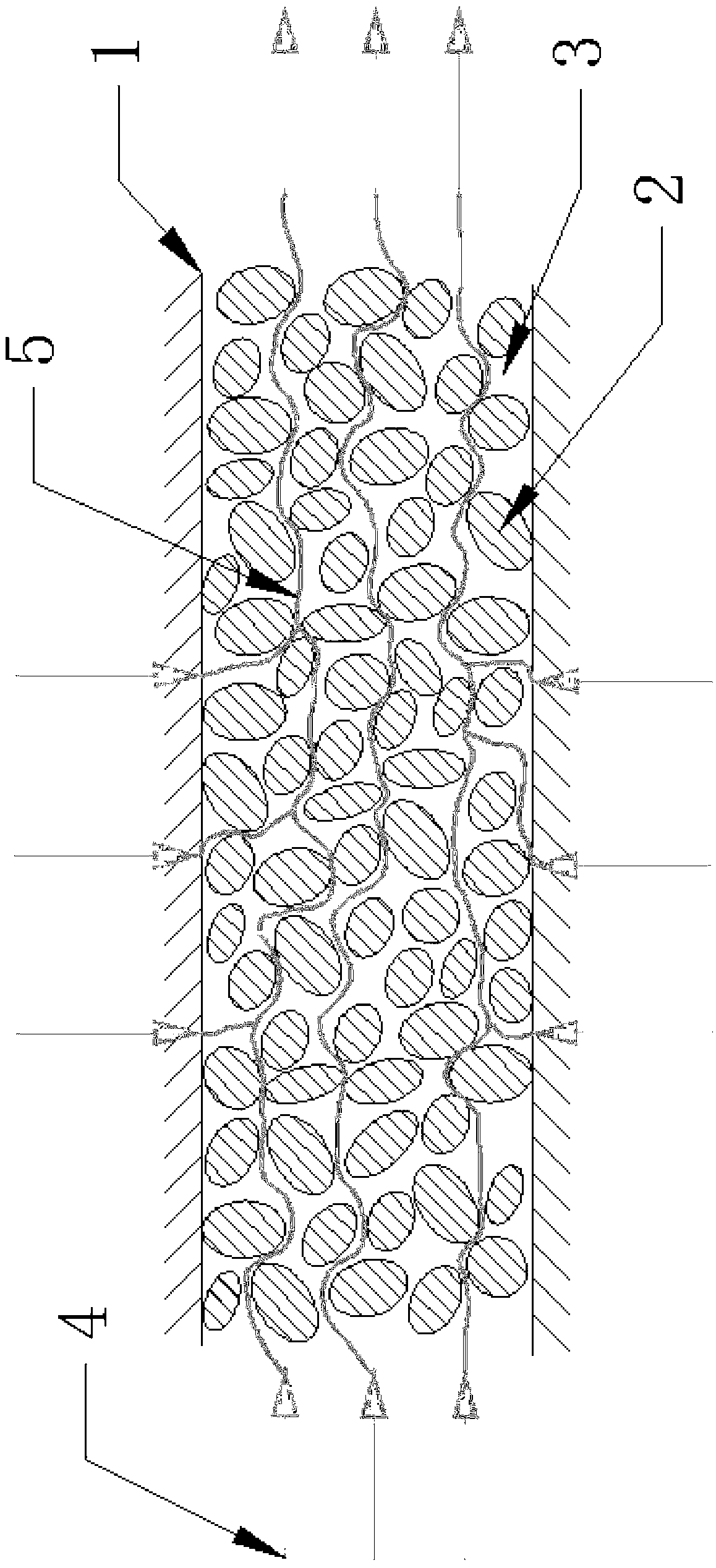

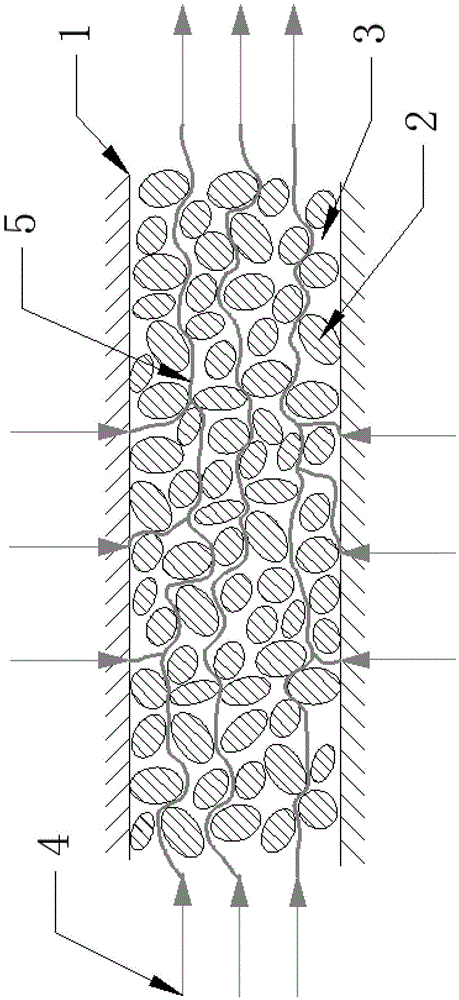

The invention belongs to the technical field of yield increasing and fracturing of petroleum engineering and provides a method for preparing a self-suspension propping agent in a laboratory. The method comprises the following steps: taking quartz sand / ceramsite / propping agent as aggregates; pre-treating with an organic solvent and treating the surface with a coupling reagent; polymerizing and coating; and crushing, drying, pelletizing and then packaging. A coating polymerizing product (as shown in the figure) is acquired through the polybasic polymerization of the reactant and acrylamide / sodium acrylate / functional monomer / cross-linking agent. The expansion times of the prepared self-suspension propping agent is 3-12 times; the self-suspension propping agent can be completely hydrated within 1min-2min; the hydrated layer is stably expanded at 2 DEG C to 193 DEG C; the self-suspension propping agent swells once encountering with water, the volume density is reduced from 2.4g / cm3 to 1.3g / cm3 and the excellent self-suspension characteristic after the clean water system swelling is presented. The self-suspension propping agent prepared in the laboratory can realize the onsite mixing for hydraulic fracturing construction, the water for fracturing is greatly reduced, the labor cost is lowered and the application prospect is wide.

Owner:王展旭

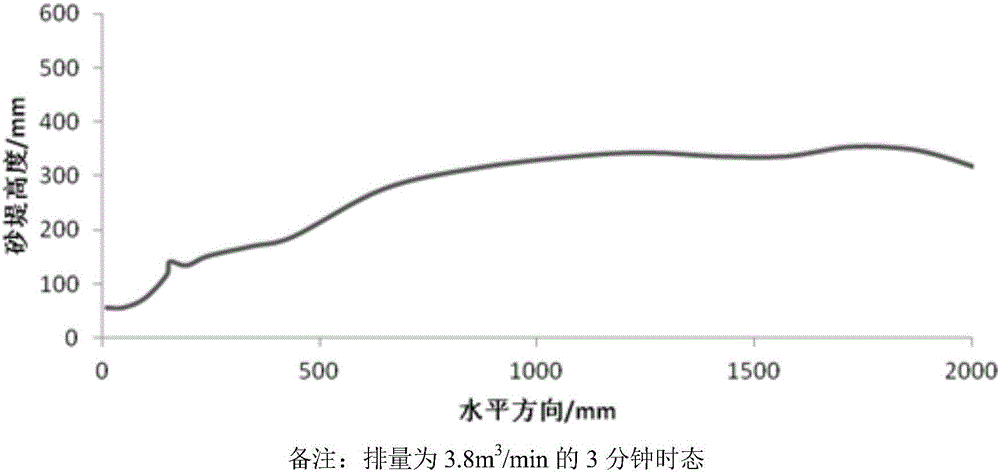

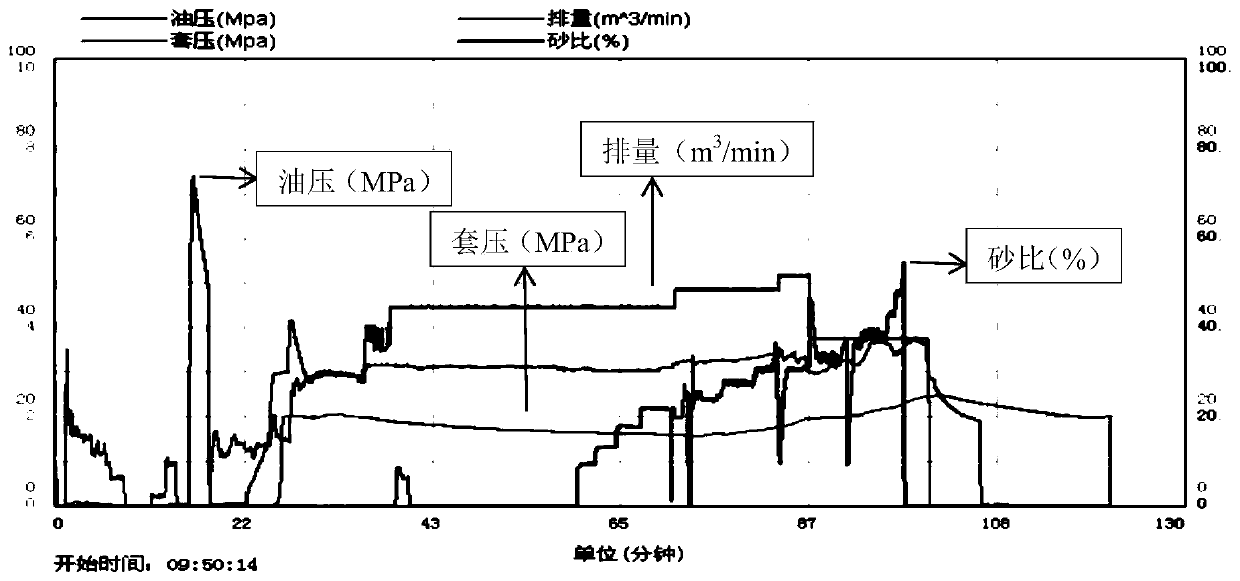

Fracturing technology for implementing ultrahigh flow conductivity

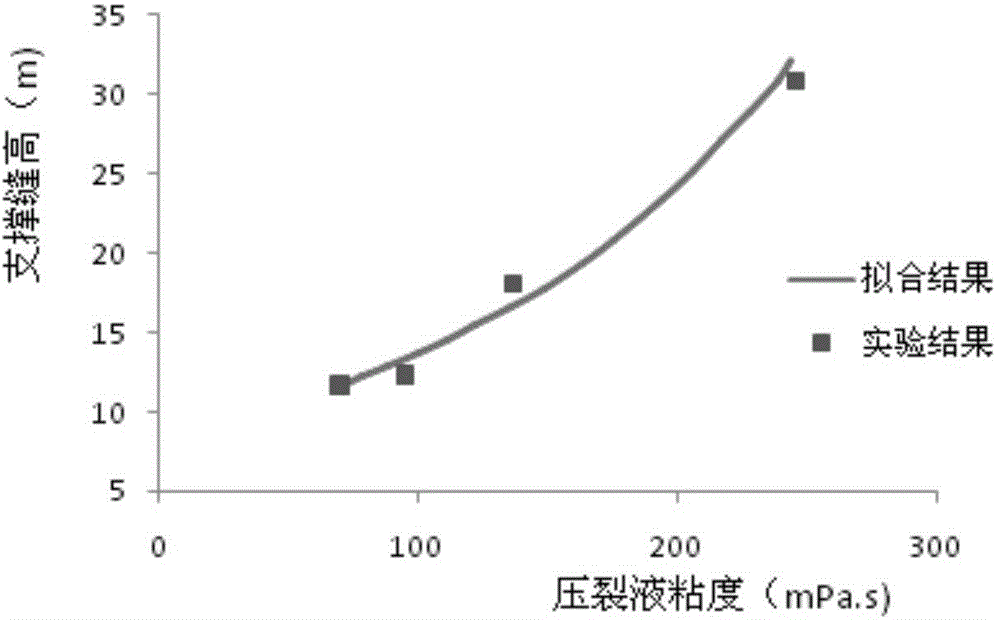

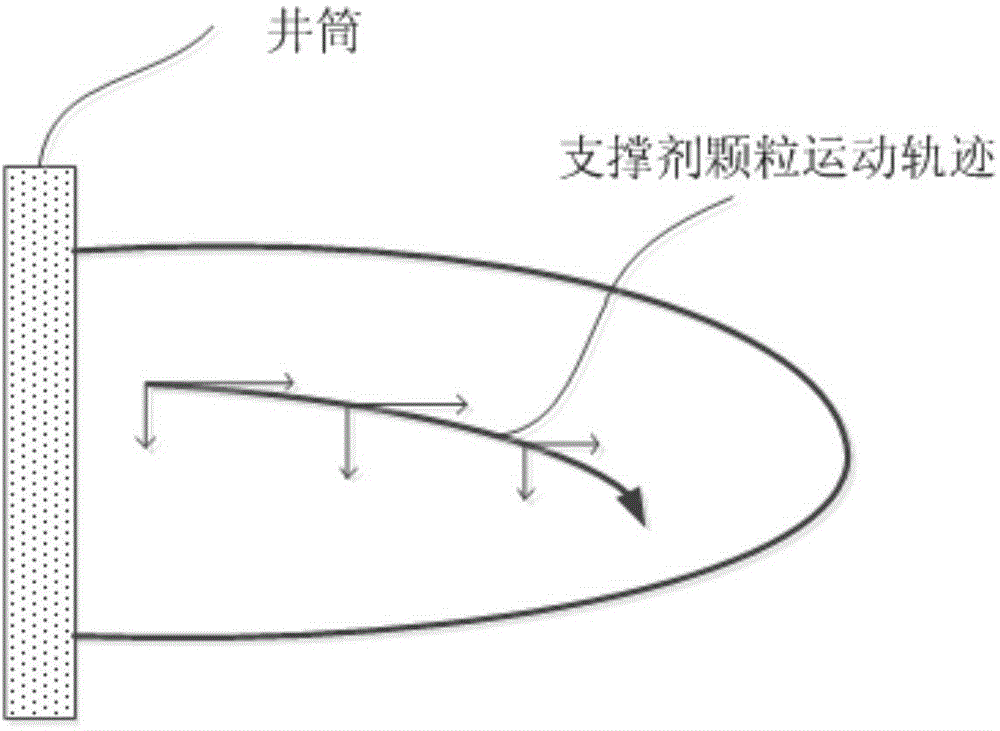

ActiveCN103306659ALow effective concentrationReduce the overall heightFluid removalMaterial PerforationOrder of magnitude

The invention relates to a fracturing technology for implementing the ultrahigh flow conductivity, which comprises the following steps: 1, judging whether geomechanics parameters of a target reservoir is suitable for the fracturing technology disclosed by the invention or not; 2, judging whether completion perforation of a target well is suitable for the fracturing technology disclosed by the invention or not, and if no, changing a perforating scheme of a well bottom; 3, before fracturing, selecting related fracturing materials; 4, carrying out fracturing on the target well by using a unique pumping program of the fracturing technology disclosed by the invention. According to the fracturing technology, proppant struts are formed in a stratum; flow conductivity of a stratum fracture is not improved by a filling layer of a proppant, but oil gas passes through by passages between the proppant struts; the flow conductivity is obviously improved by the open flowing passages; the flow conductivity of an existing conventional fracturing technology is not more than 200mum<2>*cm generally, but the flow conductivity of the fracturing technology for implementing the ultrahigh flow conductivity, which is disclosed by the invention, is higher than that of the conventional fracturing technology by 1 to 3 orders of magnitude; the fracturing technology reduces a pressure drop in the fracture, is helpful for improving drainage capacity and increases the effective fracture half-length and the production increase volume of the reservoir so as to improve yield.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Coal bed methane hydrofracture method

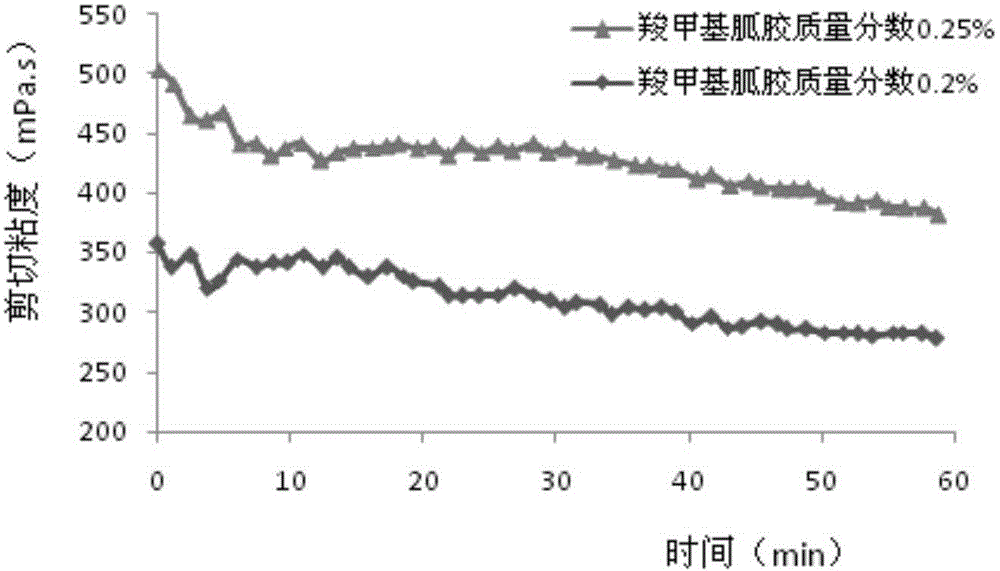

ActiveCN104088616ALow viscosityLow priceFluid removalDrilling compositionFracturing fluidMethane production

The invention relates to a coal bed methane hydrofracture method. Active water fracturing fluid is used as prepad fluid and displacing fluid, carboxymethyl guanidine gum fracturing fluid is used as sand-carrying fluid, four kinds of quartz sand different in particle size range are used as propping agents, the 100-mesh-to-70-mesh mealy sand and the 70-mesh-to-40-mesh fine sand serve as the propping agents in the prepad fluid, the 40-mesh-to-20-mesh medium sand and the 20-mesh-to-14-mesh coarse sand serve as the propping agents in the sand-carrying fluid, and the proportions of the added sand which is different in particle size and serves as the propping agents are different. The concentrations of clay stabilizers KCL in the active water fracturing fluid and the carboxymethyl guanidine gum fracturing fluid are determined according to the GR average value, represented with the API unit, of fractured objective layer section logging data. By means of the coal bed methane hydrofracture method, the coal bed methane production increasing effect is improved to a great extent, and the preparing cost of the fracturing fluid is reduced to the maximum degree while swelling is effectively prevented.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

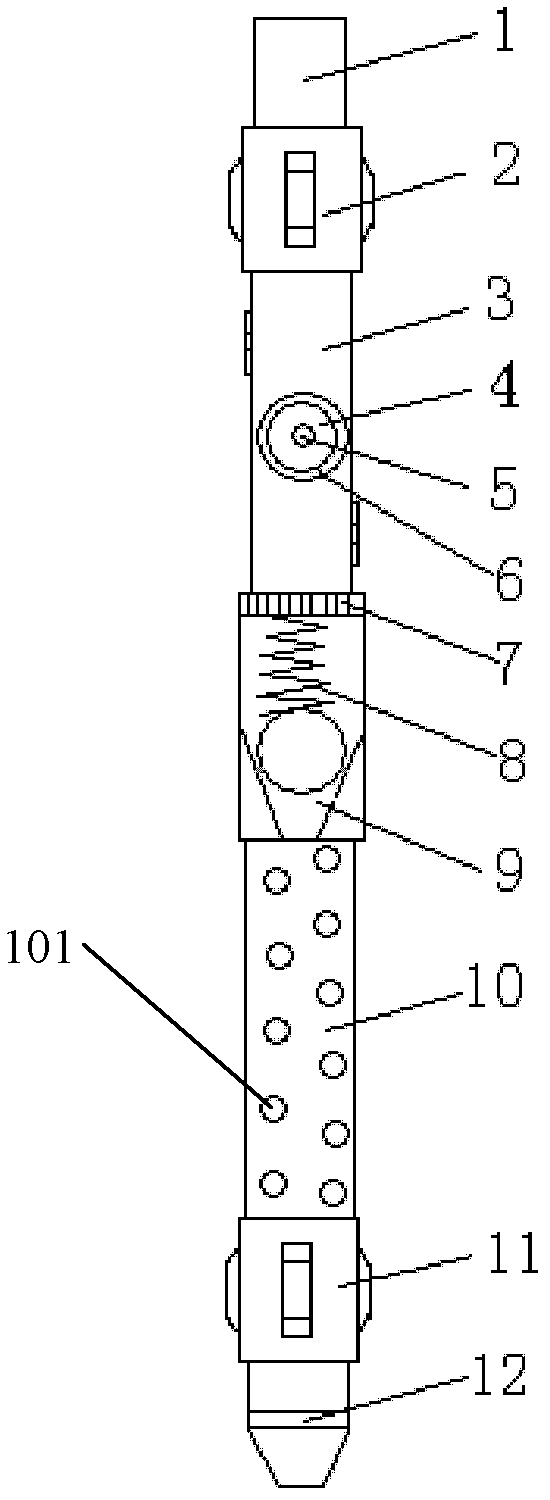

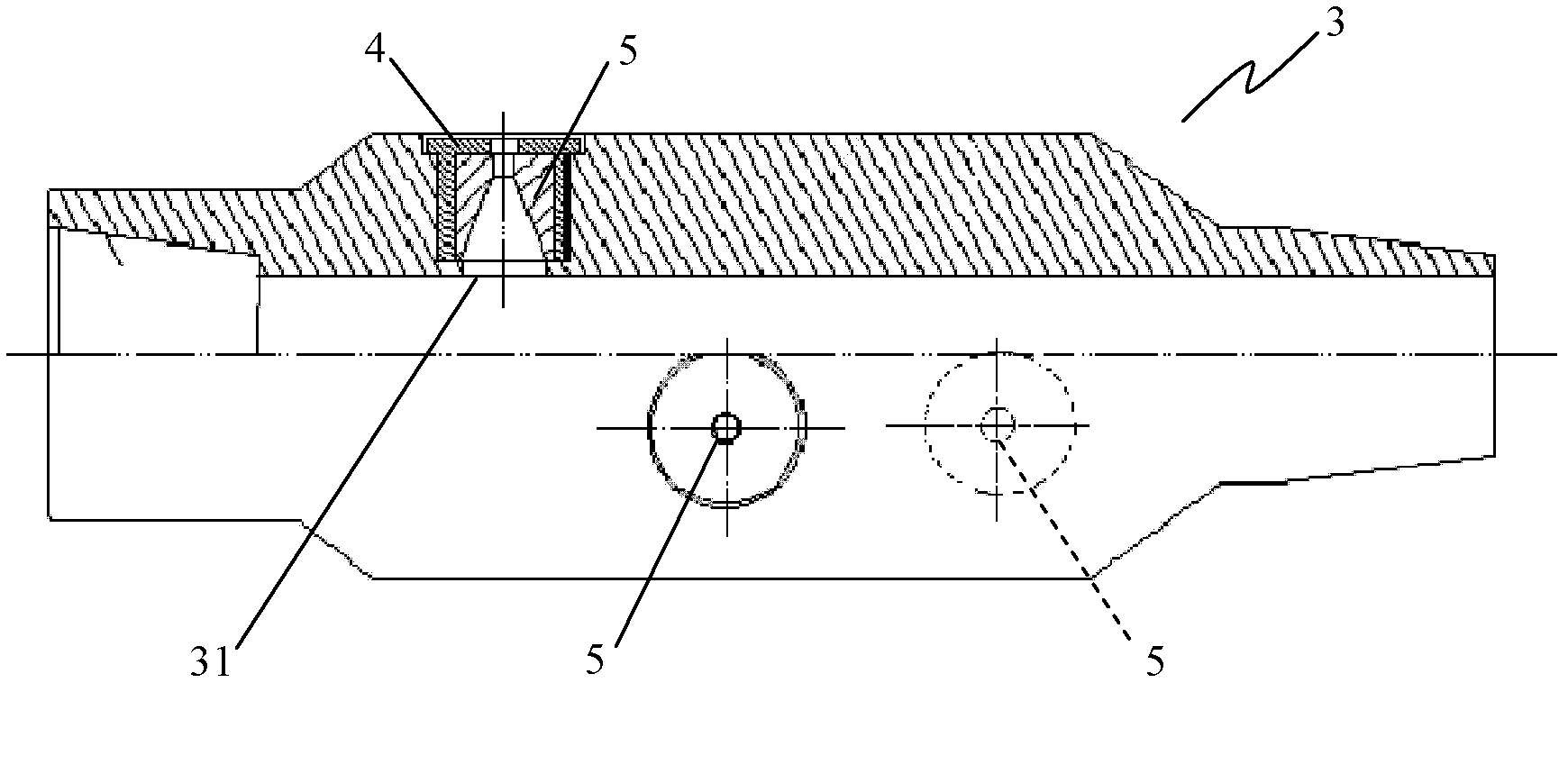

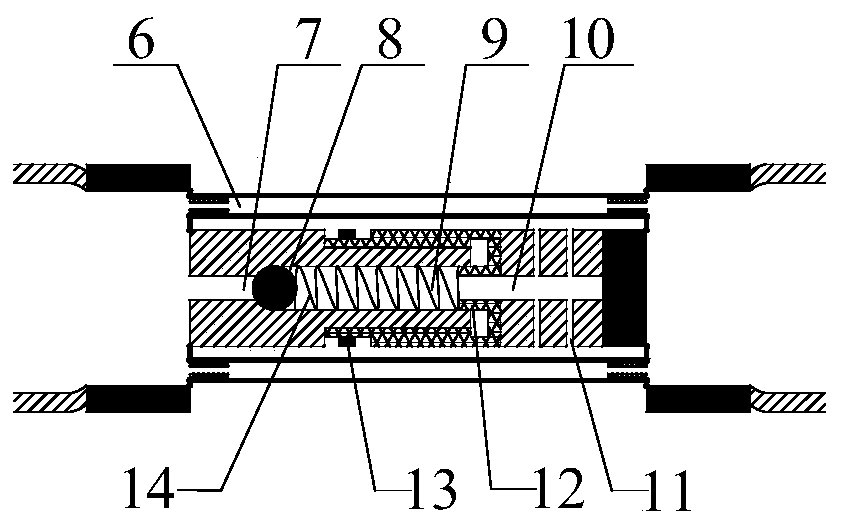

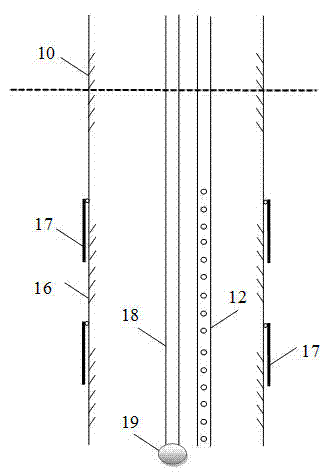

Abrasive material jet injection device

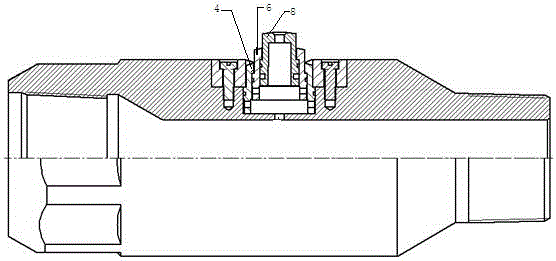

InactiveCN102493791APrecisely targeted layered fracturingAvoid blindnessFluid removalJet injectionSpray nozzle

The invention relates to an abrasive material jet injection device which is provided with a spray gun for injecting abrasive material jet, wherein the spray gun is provided with at least two nozzles, and the spray gun is connected with an oil tube. The abrasive material jet injection device has simple structure and is easy to assemble and maintain. The key part (nozzle) in the device has longer service life so as to satisfy the requirements of two operations of perforating and fracturing. Because a check valve and a sieve tube are arranged, the phenomenon that the nozzle of the injection device is subjected to sand jamming can be greatly lowered; meanwhile, when the device is subjected to sand jamming faults, base fluid is pumped into the annulus of an annular tube, the base fluid enters the injection device via the check valve by the sieve tube, which is convenient to flush the device, and therefore the well can be subjected to backflushing to ensure that the operation is successfully carried out. Because a packer is omitted, construction equipment is simplified. According to the abrasive material jet injection device, the defect of the known technology is overcome, abrasive material jet pore forming and fracturing are combined, and therefore layering can be precisely carried out in a vertical well or sectional fracturing can be precisely carried out in a horizontal well section.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

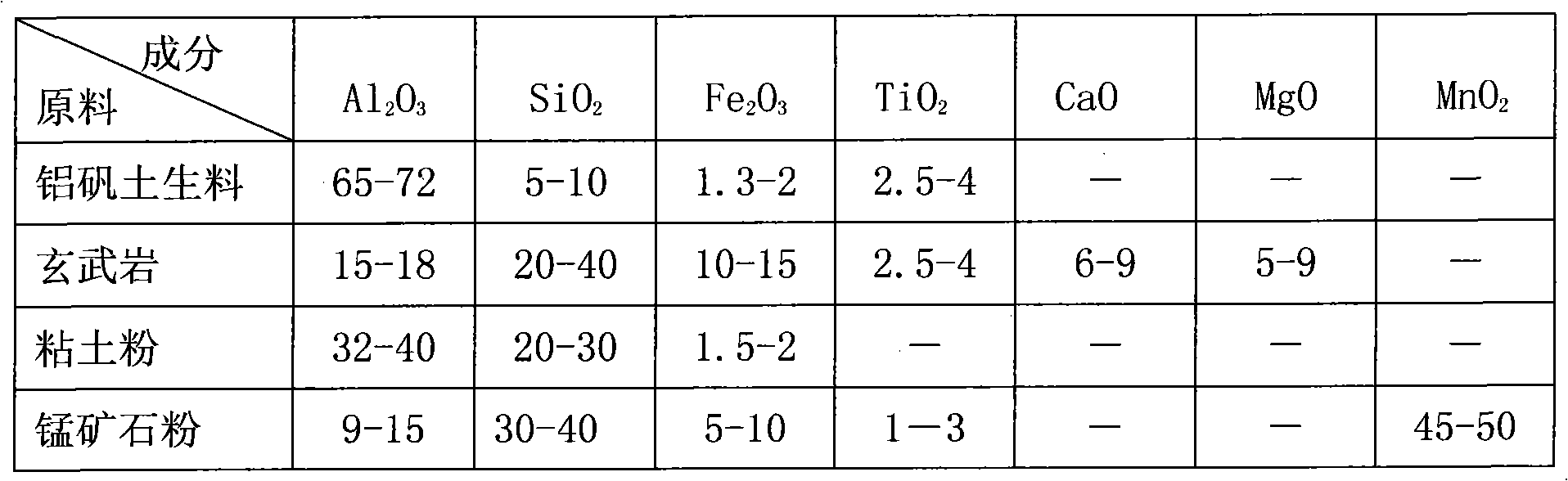

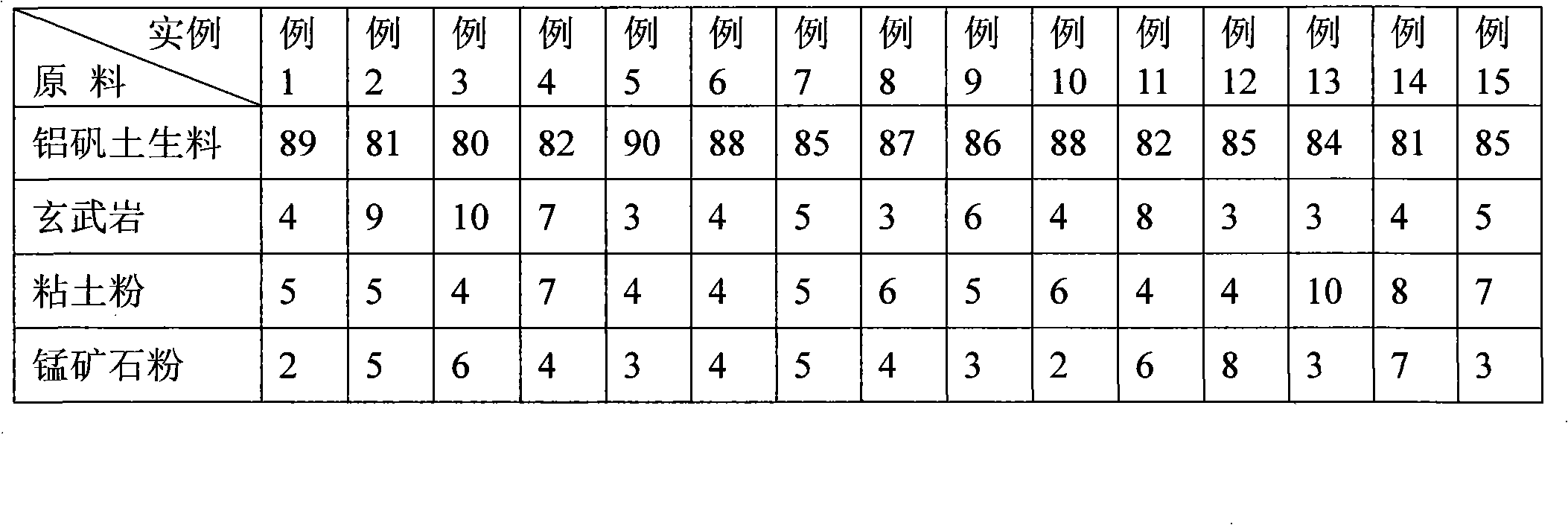

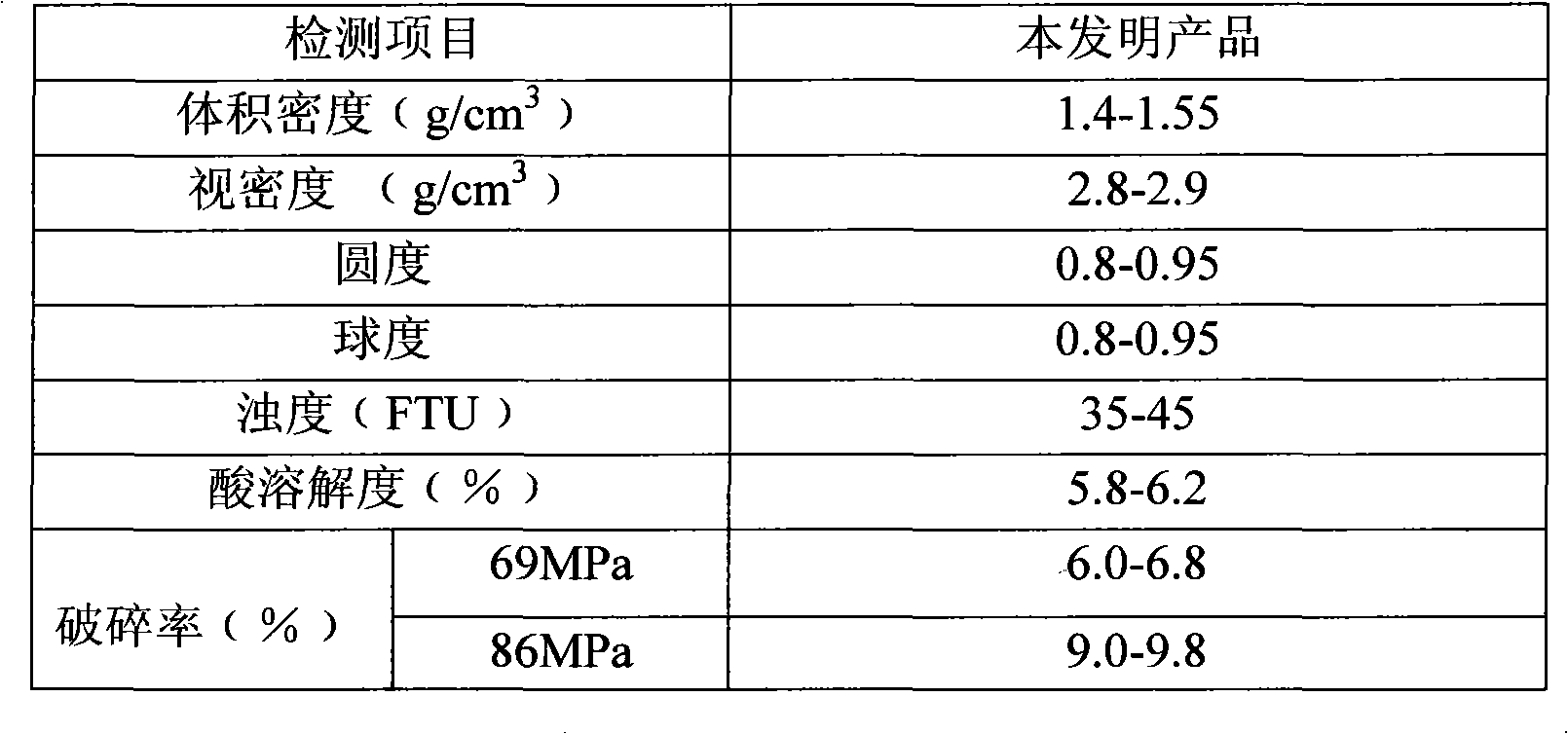

Low-density and high-strength ceramic proppant and production method thereof

InactiveCN101831286AHigh surface finishGuaranteed StrengthFluid removalClaywaresExpanded clay aggregateMixed materials

The invention relates to a low-density and high-strength ceramic proppant and a production method thereof. The raw material comprises 80 to 90% of raw bauxite, 3 to 10% of basalt, 4 to 10% of clay silt, 4 to 10% of clay powder and 2 to 8% of manganese ore powder. The production method comprises the following steps of: firstly, weighing the raw materials in production, grinding the raw materials into fine powder, filtering the fine powder by a sieve of 320 meshes, uniformly mixing and stirring the powder and pelletizing the mixed material, and adding the atomizing steam till the mixed materialform semi-finished pellets; secondly, baking the semi-finished pellets in a rotary kiln for 6-8h, to obtain the finished product, wherein the temperature of the kiln head is 1280 to 1310 DEG C and the temperature of the kiln tail is 290 to 320 DEG C. The damage rate of the product of the invention at the pressure of 69 MPa and 86 MPa are respectively lower than 6.8% and 9.8%; the volume densityis only 1.45 to 1.55 g / sq.cm and obviously lower than the like products; and the product has higher strength. The invention has the advantages of less and easily obtained needed raw materials in the formulation, simplification of the production process, little investment, low cost and easy popularization and application.

Owner:郑州德赛尔陶粒有限公司

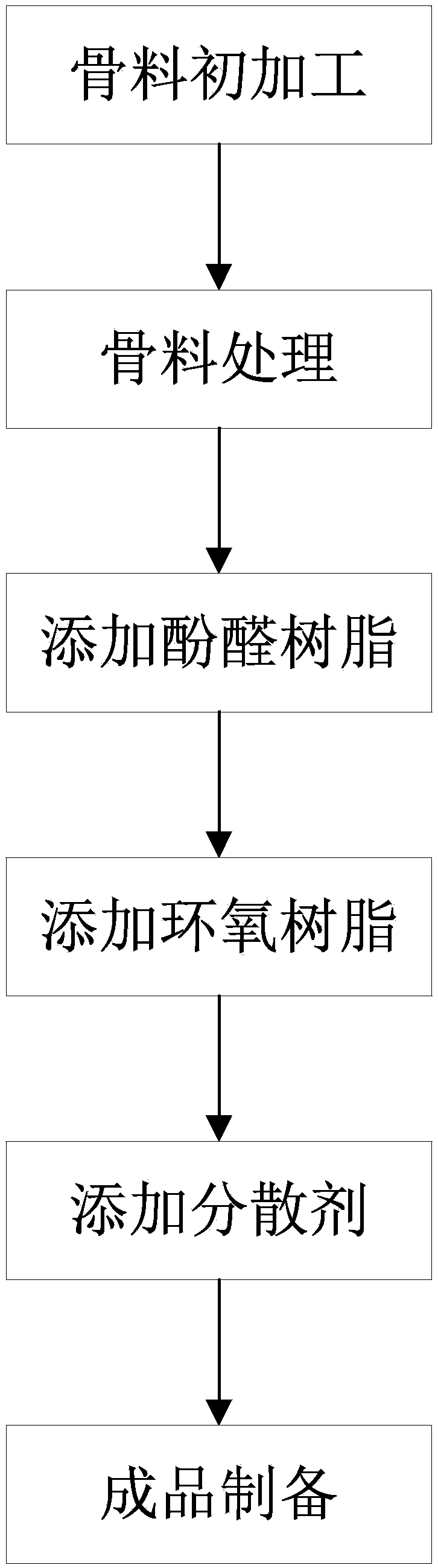

Low-density superhigh-strength corrosion-resistant propping agent and preparation method thereof

ActiveCN105368442AAchieving Proppant Requirements for MiningReduced fracturing costsFluid removalDrilling compositionEpoxyLow density

The invention discloses a low-density superhigh-strength corrosion-resistant propping agent and a preparation method thereof. The propping agent comprises aggregate, thermoplastic phenolic resin, a thermoplastic phenolic resin curing agent, epoxy resin, an epoxy resin curing agent and a dispersant. The aggregate comprises, by mass, 80-90% of bauxite, 9-15% of coal gangue and 1-5% of clay. A mass ratio of the thermoplastic phenolic resin to the aggregate is 2-4%. A mass ratio of the thermoplastic phenolic resin curing agent to the thermoplastic phenolic resin is in a range of 12-18%. A mass ratio of the epoxy resin to the aggregate is in a range of 1-3%. A mass ratio of the epoxy resin curing agent to the epoxy resin is in a range of 5-20%. A mass ratio of the dispersant to the aggregate is in a range of 0.1-0.5%. The propping agent has density greatly lower than that of the general high-strength propping agent so that an oil field pressing crack cost is greatly reduced.

Owner:北京昆仑隆源石油开采技术有限公司

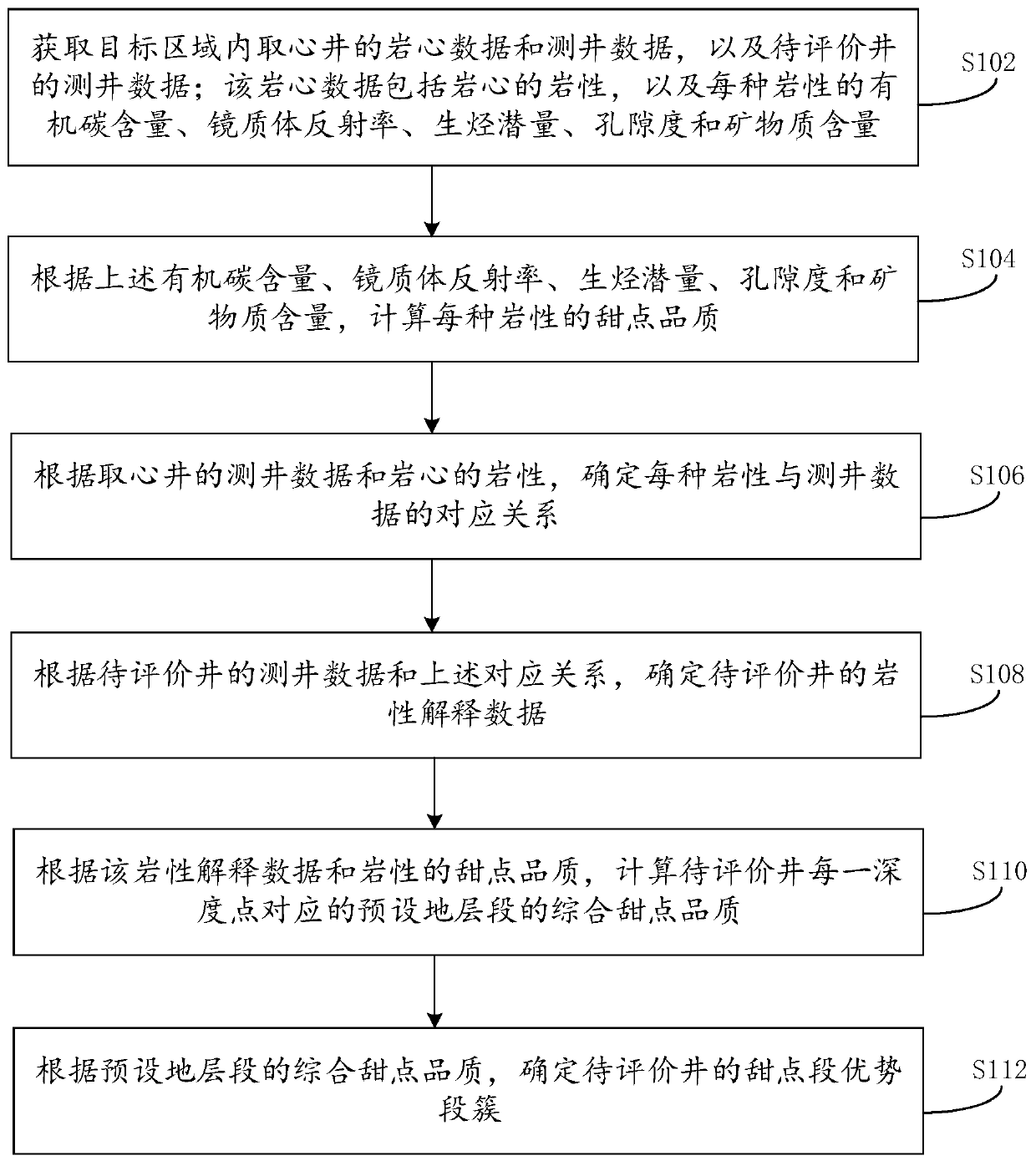

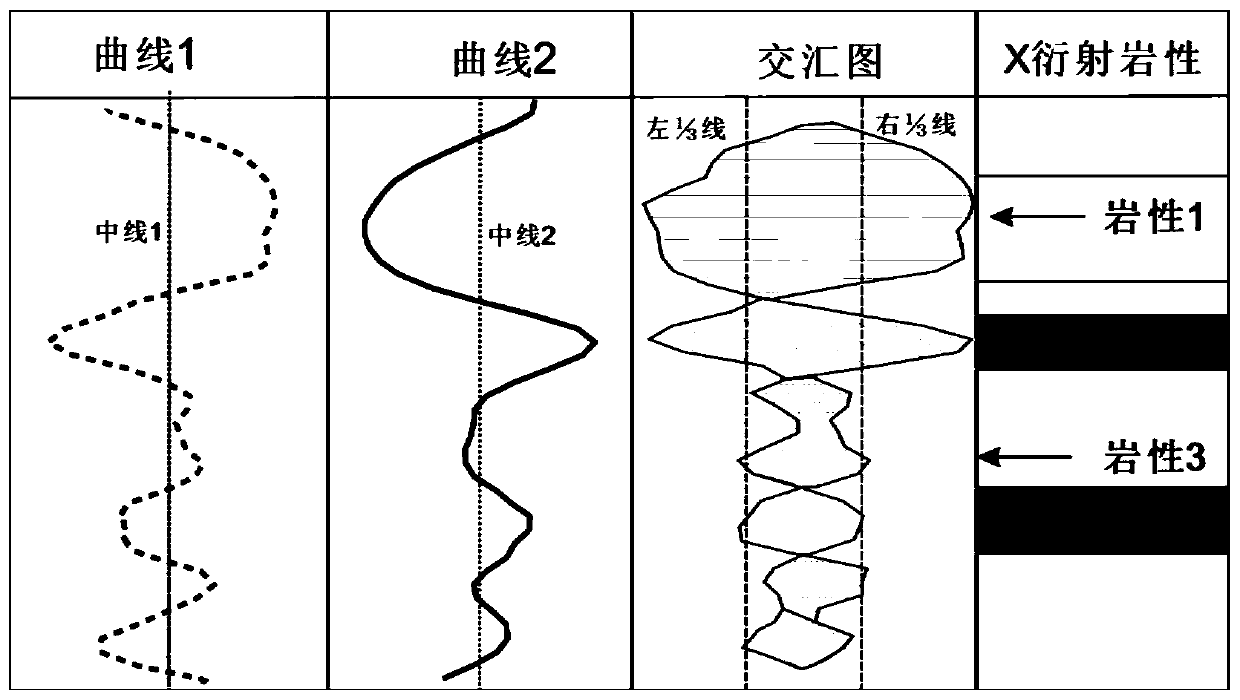

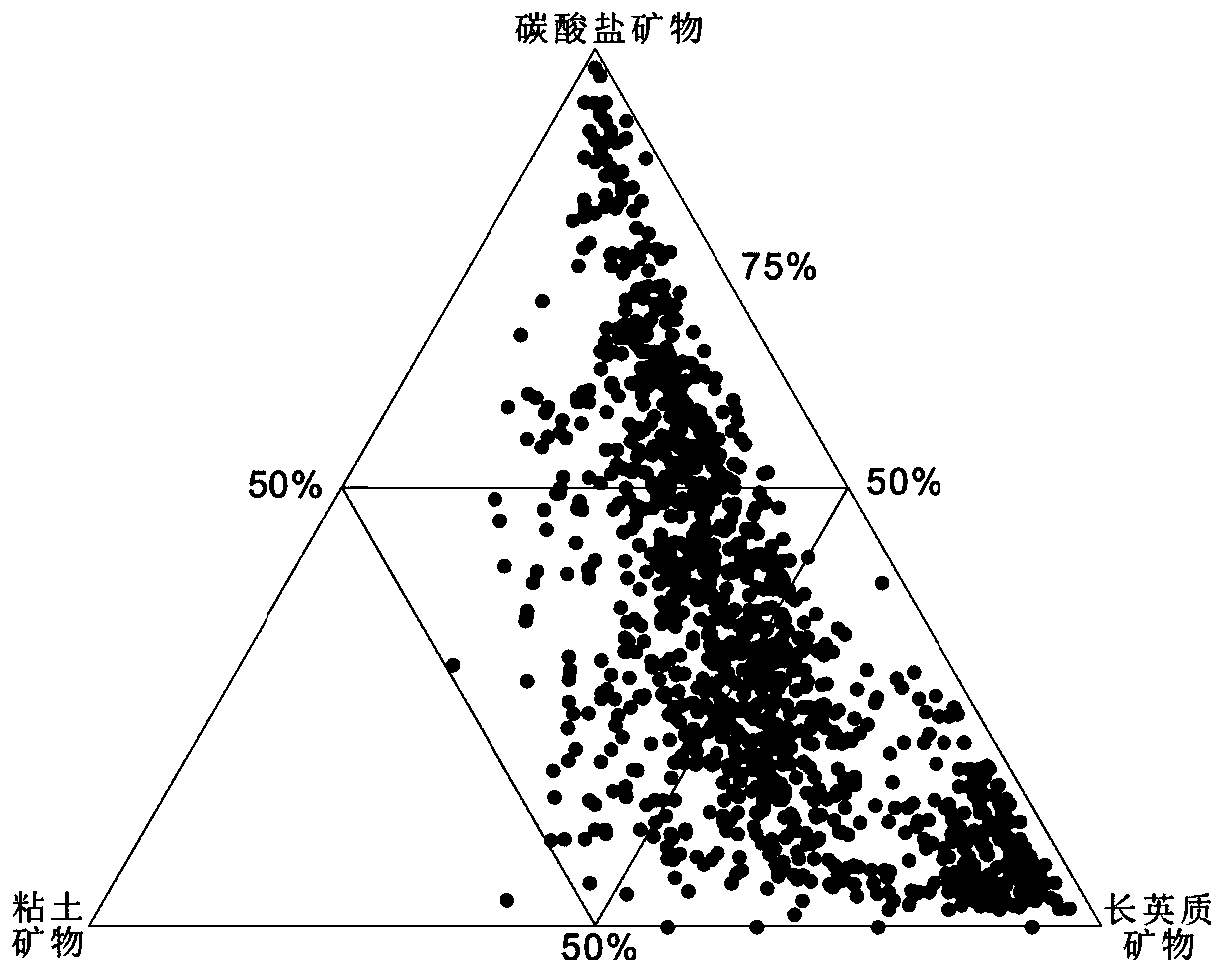

Evaluation method and device for dominant segment cluster of sweet heart segment of fine-grained rock oil and gas reservoir

ActiveCN110412661AConvenient spacingImprove crack initiation efficiencyEarth material testingProspecting/detection of underground/near-surface gasesLithologyRock core

The invention provides an evaluation method and device for a dominant segment cluster of a sweet heart segment of a fine-grained rock oil and gas reservoir. Firstly, core data and logging data of a cored well in a target area and logging data of a to-be-evaluated well are acquired; the sweet heart quality of each kind of lithology is calculated; then, according to the logging data of the cored well and the lithology of a core, a corresponding relationship between each kind of lithology and the logging data is determined; then, according to the logging data of the to-be-evaluated well and the corresponding relationship, lithology interpreting data of the to-be-evaluated well is determined; secondly, according to the lithology interpreting data and the sweet heart quality of the lithology, comprehensive sweet heart quality of a preset stratum segment corresponding to each depth point of the to-be-evaluated well is calculated; according to the comprehensive sweet heart quality of the preset stratum segment, the dominant segment cluster of the sweet heart segment of the to-be-evaluated well is accordingly determined. The method has the advantages that by screening the dominant segmentcluster of the sweet heart segment out from the to-be-evaluated well, the cracking efficiency of perforation clusters can be improved, the fracturing cost is reduced, and the yield of single well is increased.

Owner:PETROCHINA CO LTD

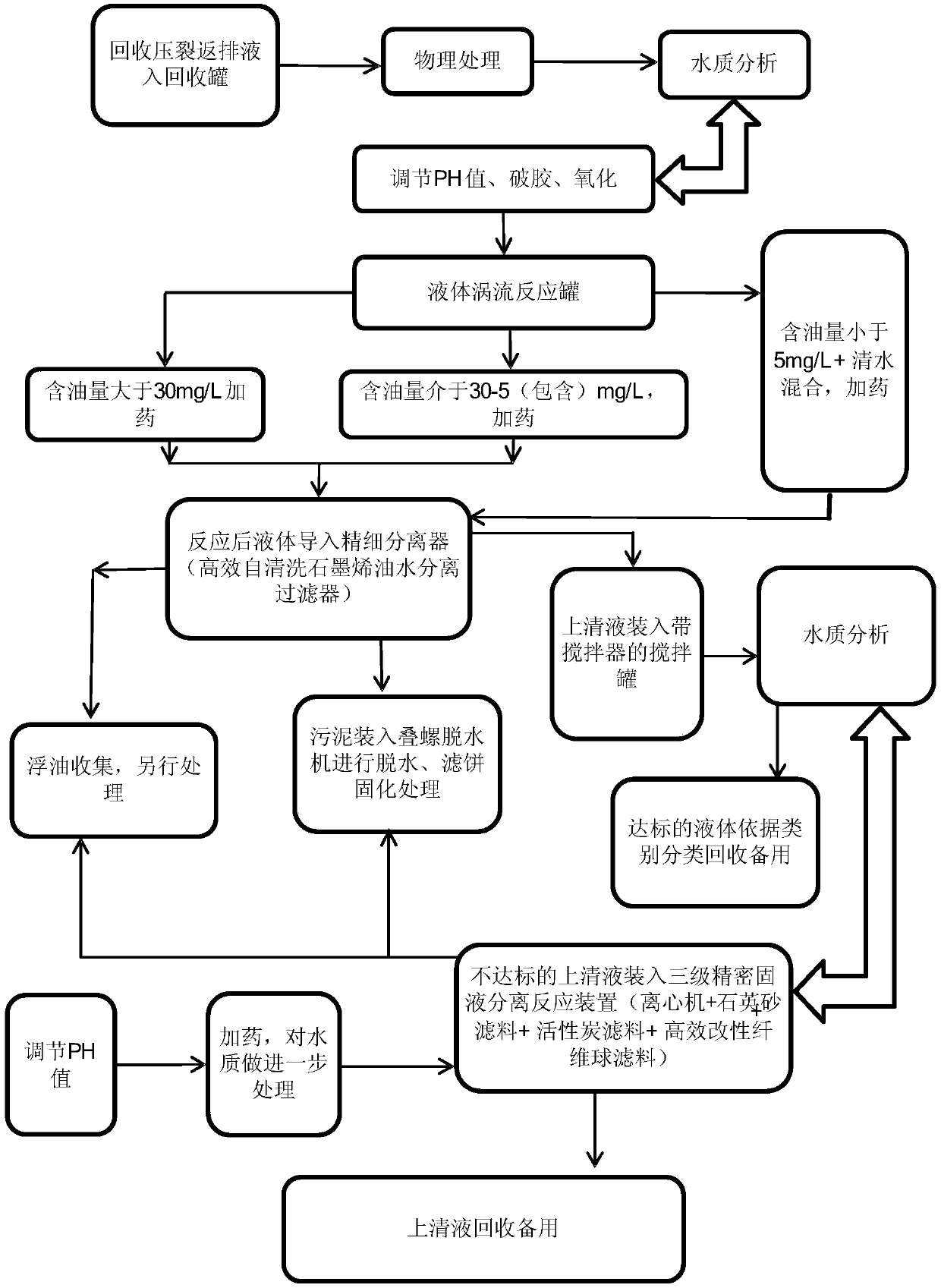

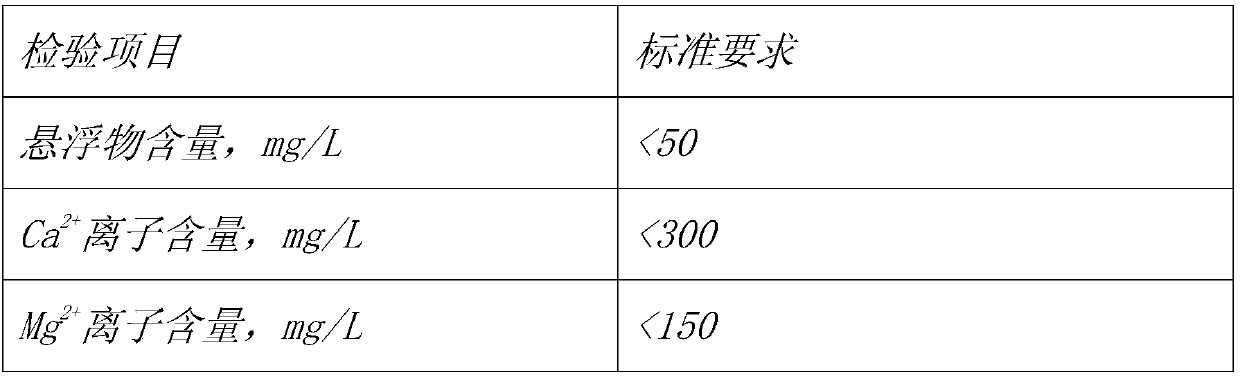

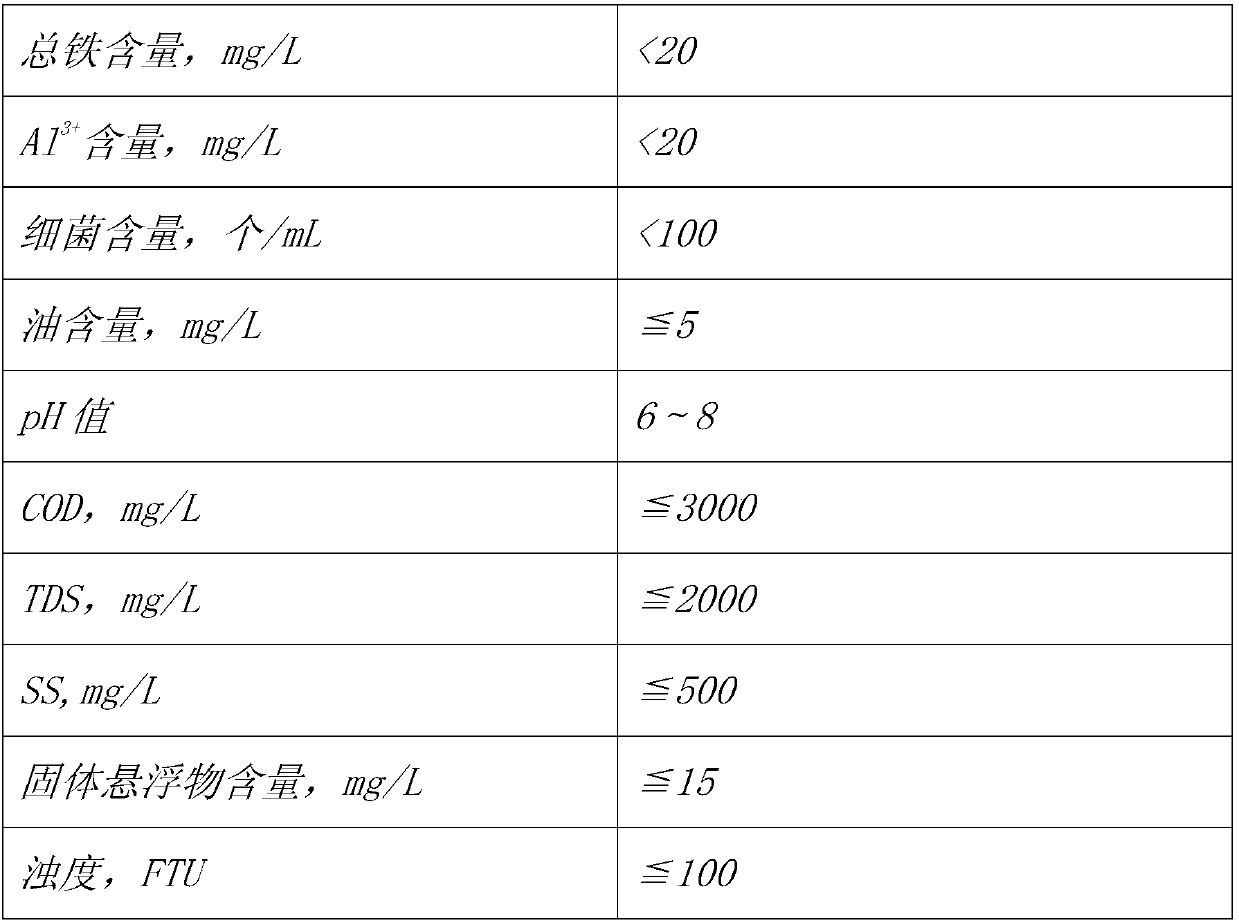

Treatment method of fracturing backflow fluid

ActiveCN109574394AReduce cloggingReduce harmWaste water treatment from quariesTreatment involving filtrationLiquid wasteWater quality

The invention discloses a treatment method of fracturing backflow fluid. The method comprises the following steps of 1), recovering the fracturing backflow fluid into a recovery tank, carrying out physical treatment on the fracturing backflow fluid recovered in the recovery tank, removing a mechanical impurity, a suspended solid impurity and an oil stain impurity in the fracturing backflow fluid,and preliminarily carrying out water quality detection analysis on the fracturing backflow fluid subjected to the physical treatment; and 2), according to a pH value obtained in the step 1), regulating by using a PH regulator, regulating the PH value to be between 6 and 9, then, carrying out gel breaking treatment on the fracturing backflow fluid finished in the regulation of the PH value by adopting a 0.002mg / L to 80mg / L of gel breaker, and carrying out oxidation treatment by adopting a 0.01mg / L to 200mg / L of oxidant after the gel breaking treatment is complete, so as to obtain the fracturingbackflow fluid which is complete in gel breaking and is further decreased in viscosity. By using the treatment method of the fracturing backflow fluid, which is provided by the invention, the backflow fluid is recovered and reutilized; not only can the problem that a water resource is short for the fracturing construction in a northwest region be relieved, but also the emission amount of waste fluid can be reduced at the same time; and the environment-friendly and energy-saving development of an unconventional oil-gas field is realized.

Owner:SHAANXI YANCHANG OIL FIELD FRACTURING MATERIAL CO LTD

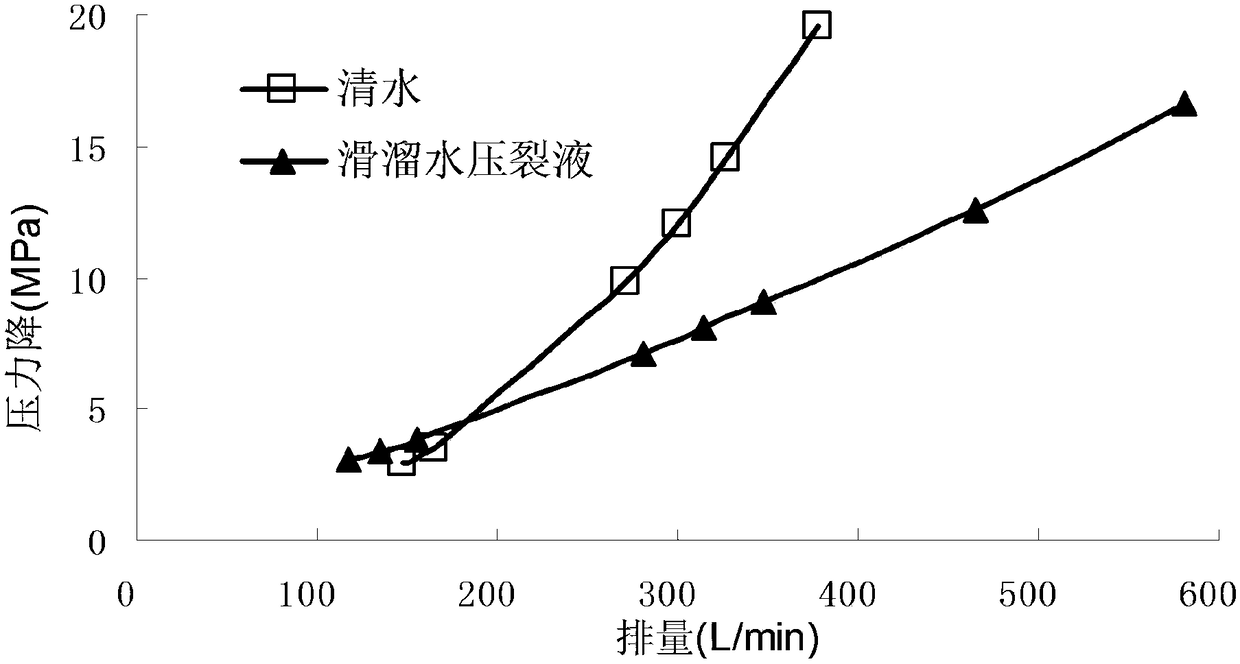

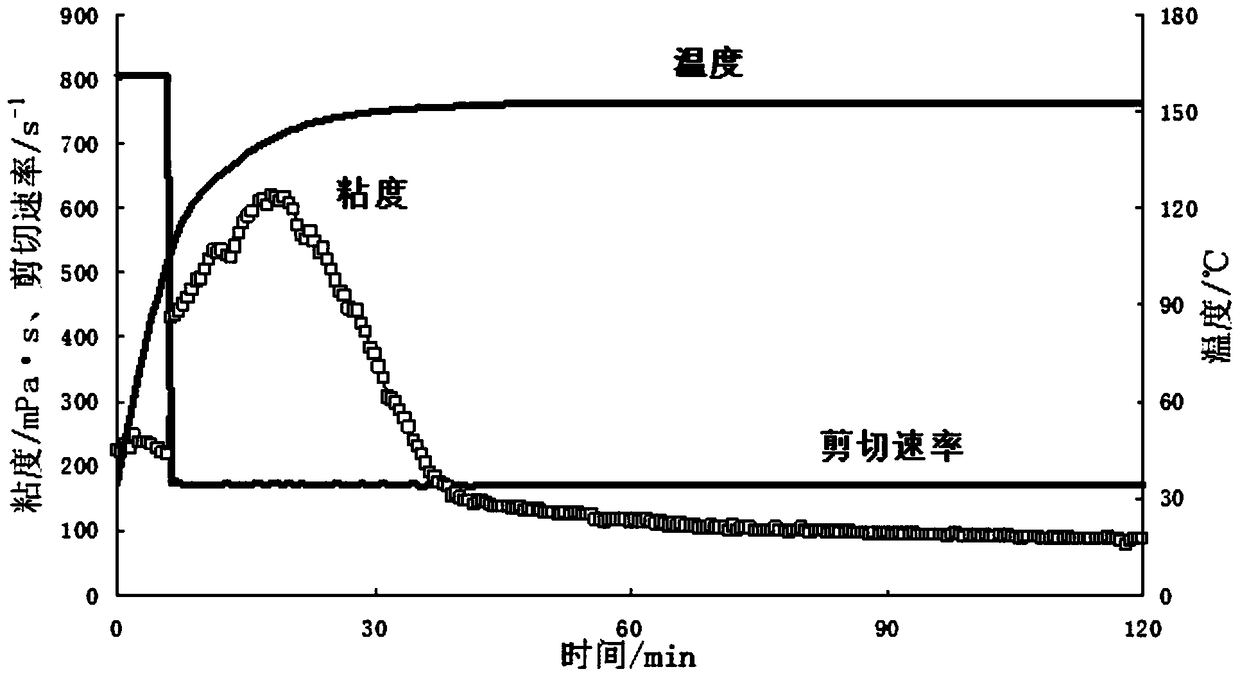

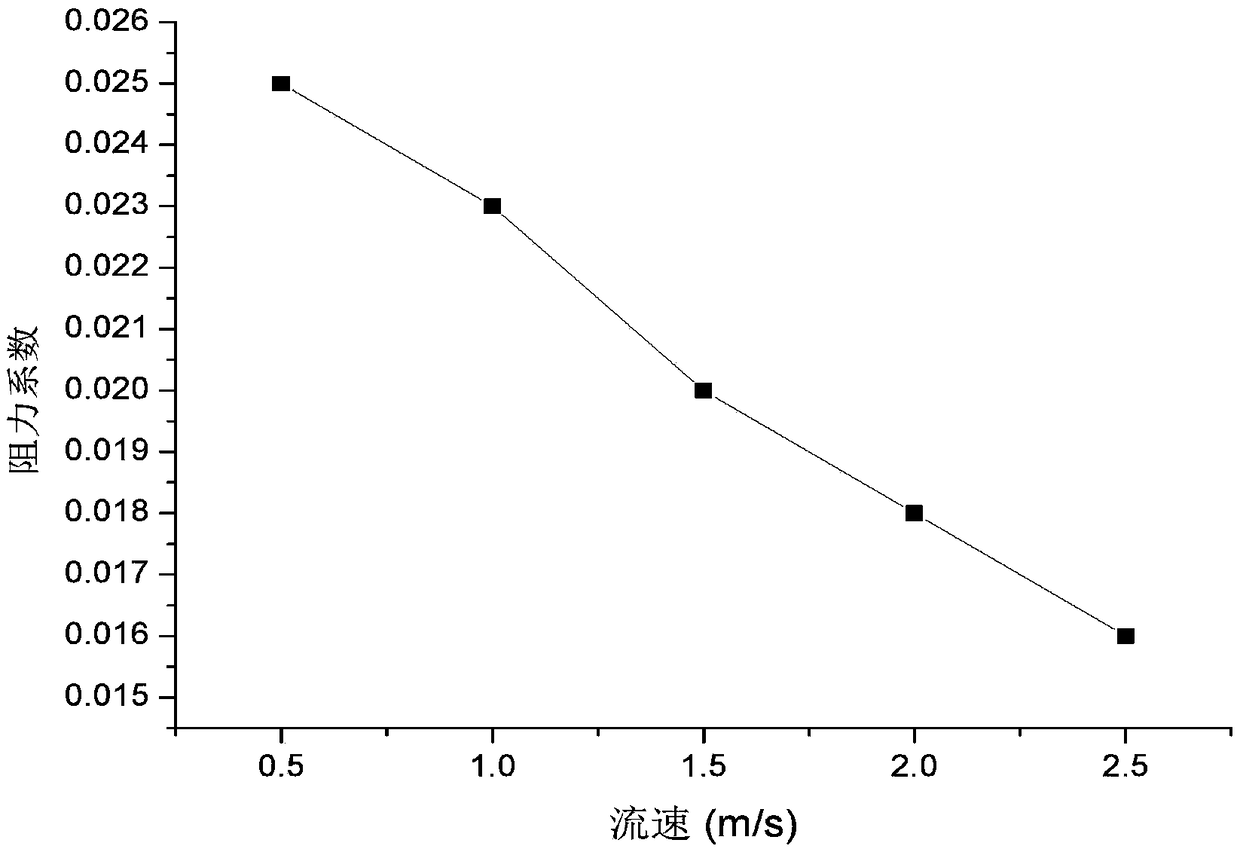

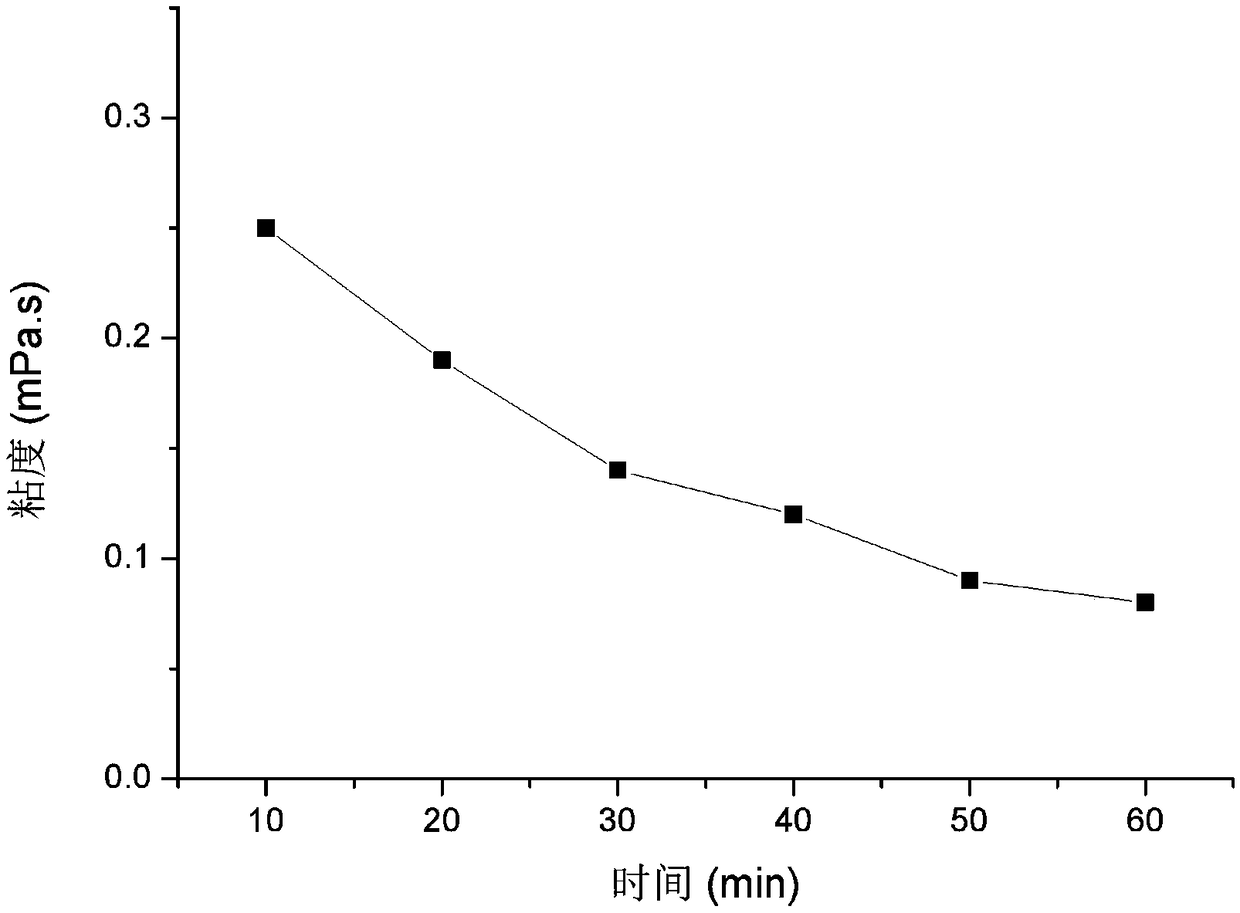

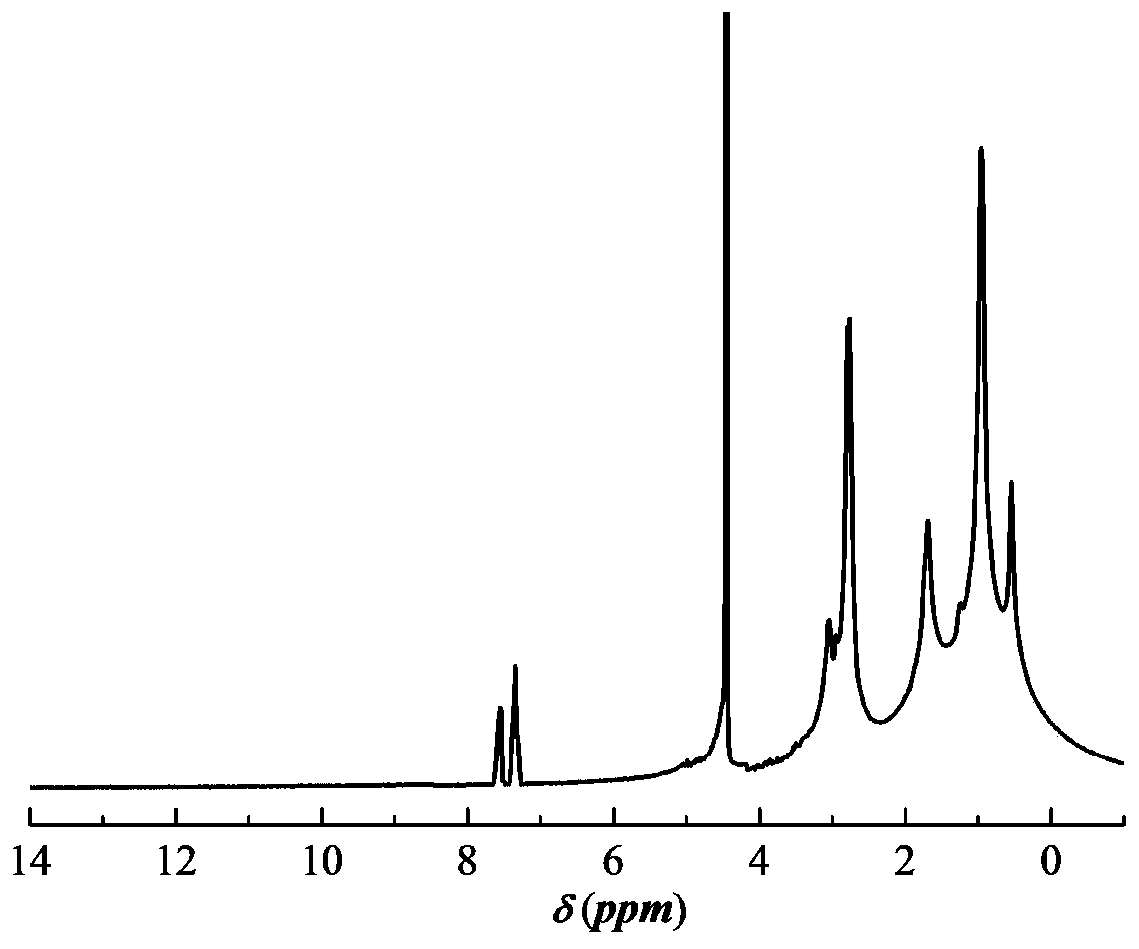

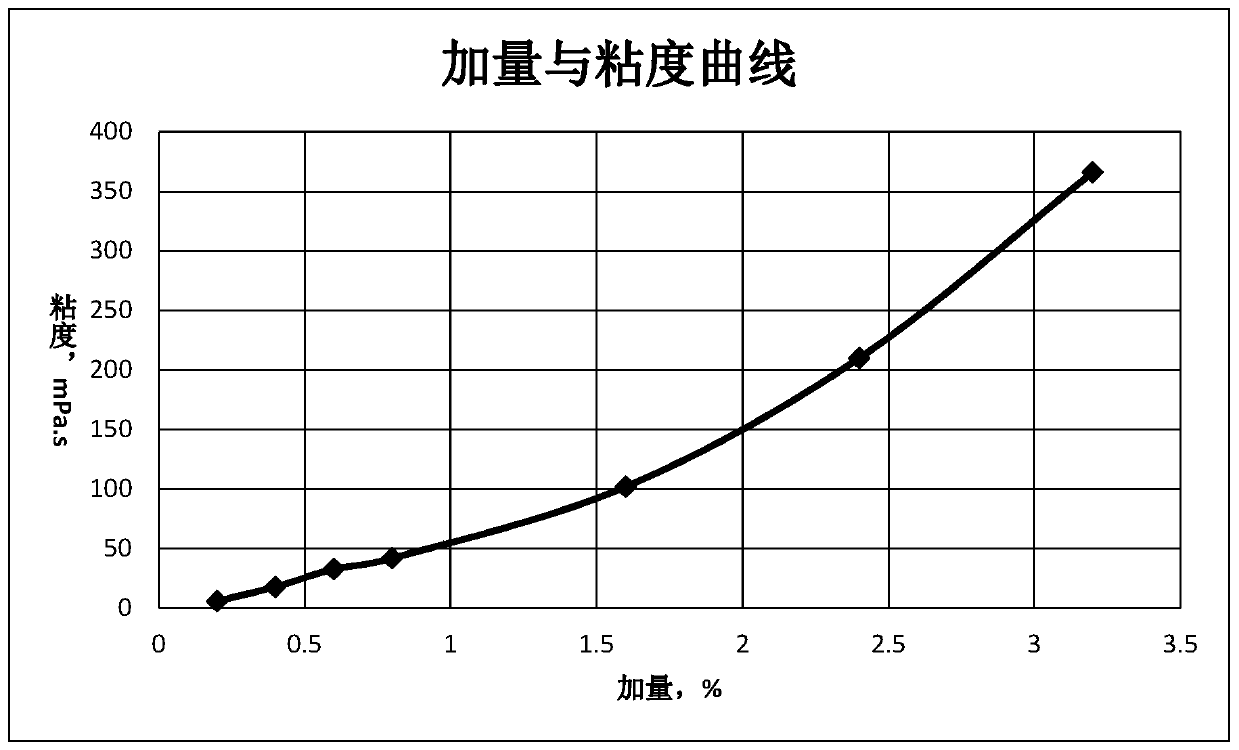

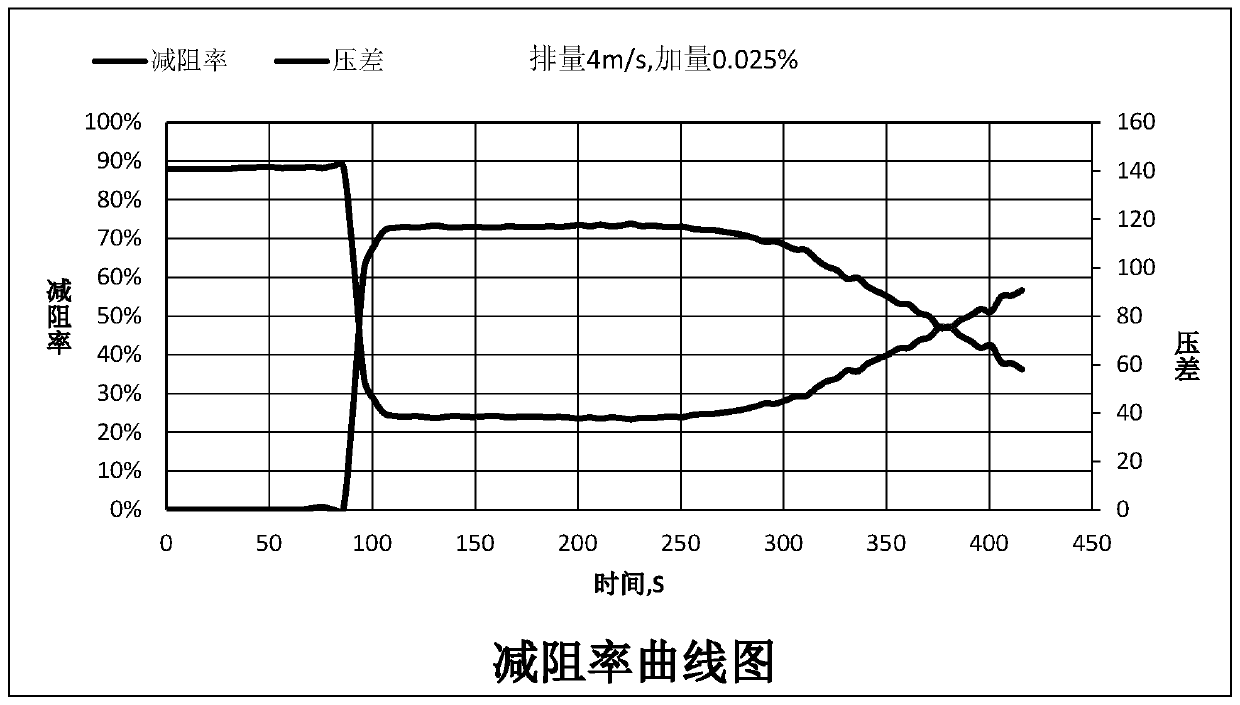

Inverse-phase micro-emulsion polymer fracturing fluid system with online construction function

ActiveCN108559479AGood resistance reduction effectEasy to reuseDrilling compositionMethacrylatePolymer science

The invention discloses an inverse-phase micro-emulsion polymer fracturing fluid system with an online construction function. The inverse-phase micro-emulsion polymer fracturing fluid system comprisesinstant dissolving emulsion thickening agents, functional auxiliaries, a clay stabilizer and fluid preparation water. The instant dissolving emulsion thickening agents are inverse-phase micro-emulsion polymers, and inverse-phase micro-emulsion polymerization is carried out on raw materials including acrylamide, acrylic acid, strong-hydrophilicity monomers, a functional monomer A, a functional monomer B, pH (potential of hydrogen) regulators, solubilizers, composite emulsifiers, oil solvents, initiators and deionized water to obtain the instant dissolving emulsion thickening agents; the functional monomer A is methyl methacrylate or ethyl methacrylate or a mixture of the methyl methacrylate and the ethyl methacrylate; the functional monomer B is vinylphosphonic acid or vinyl sulfonic acid;the functional auxiliaries are non-ionic surfactants; the clay stabilizer is potassium chloride, and the fluid preparation water is clear water or high-mineralization water or treated stratum flow-back fluid. The inverse-phase micro-emulsion polymer fracturing fluid system has the advantages that the inverse-phase micro-emulsion polymer fracturing fluid system is high in dispersing and swelling speed and can be prepared in a batch manner or can be continuously mixed, 'online construction' requirements even can be completely met by the inverse-phase micro-emulsion polymer fracturing fluid system, processes for constructing the inverse-phase micro-emulsion polymer fracturing fluid system are simple, and the fracturing cost can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

Static blasting fracturing method used for exploitation of shale gas and other low permeability oil and gas reservoirs

ActiveCN104005748ASimple construction, safe and environmentally friendlySafe and convenient to buyFluid removalHorizonOil shale gas

Owner:SOUTH CHINA UNIV OF TECH

Low-density ceramsite propping agent taking low-aluminum high-silicon alumyte as major raw material and preparation method thereof

ActiveCN102660252ASolve the problem of tight supplyReduce bulk densityFluid removalExpanded clay aggregateDolomite

The invention belongs to the technical field of solid propping agents for an oil / gas well fracturing technology, and discloses a low-density ceramsite propping agent taking low-aluminum high-silicon alumyte as a major raw material and a preparation method thereof. The low-density ceramsite propping agent is prepared from the following raw materials in percentage by mass: 90-96 percent of alumyte, 1-4 percent of manganese ore, 0.5-2 percent of hematite, 0-2 percent of clay and 0-2 percent of dolomite, wherein the alumyte is low-aluminum high-silicon alumyte; the mass percent of Al2O3 is 50-60 percent; and the mass percent of SiO2 is 12 percent. The method comprises the following steps of: smashing raw materials respectively; mixing according to a certain mixture ratio, grinding, and performing spray granulation; and sintering at the temperature of 1,320-1,380 DEG C for 0.5-2.5 hours. Crude low-aluminum high-silicon alumyte is adopted, so that the problem of supply tension of raw materials is solved, the production cost of alumyte is reduced by about 350 yuan / ton in comparison to alumyte of which the alumina content is over 65 percent, and the propping agent has a wide development prospect; and moreover, the bulk density and apparent density indexes of the ceramsite propping agent are reduced remarkably, and the cost of well fracturing is reduced simultaneously.

Owner:垣曲县方圆陶粒砂有限责任公司

Rotary control stepless ball fracturing sliding sleeve

ActiveCN106194110AEliminates grinding and milling operationsCompact and reasonable structureConstructionsFluid removalEngineeringMechanical engineering

The invention relates to the technical field of ball fracturing sliding sleeves, in particular to a rotary control stepless ball fracturing sliding sleeve. The rotary control stepless ball fracturing sliding sleeve comprises an upper connector, a sliding sleeve body, a lower connector, an inner sliding sleeve and a rotary control sliding sleeve. The outer side of the lower portion of the upper connector and the inner side of the upper portion of the sliding sleeve body are fixedly installed together. The inner side of the lower portion of the sliding sleeve body and the outer side of the upper portion of the lower connector are fixedly installed together. The lower portion of the inner sliding sleeve and the sliding sleeve body are fixedly installed together through shear pins. Two or more internal fracturing holes are distributed in the upper portion of the inner sliding sleeve along the circumference. The rotary control stepless ball fracturing sliding sleeve is reasonable and compact in structure and convenient to use, stepless ball fracturing is achieved, technical support is provided for opening all fracturing reservoirs through fracturing balls in the same size, the number of fracturing layers is not restrained by the diameters of fracturing balls, pressure loss at ball seats with different diameters in the existing fracturing operation process is reduced, ball seat grinding and milling procedures are omitted, fracturing efficiency is improved, fracturing cost is reduced, and the rotary control stepless ball fracturing sliding sleeve can be applied to underground fracturing production increase operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Coal gangue ceramsite proppant and preparation method thereof

InactiveCN109626960AHigh silicon contentReduce silicon contentFluid removalDrilling compositionExpanded clay aggregateComponents of crude oil

The invention relates to a coal gangue ceramsite proppant and a preparation method thereof. The proppant comprises, by weight, 30%-70% of coal gangue, 20%-65% of flint clay, 5%-10% of a sintering aidand 1-3% of a forming agent. The coal gangue is solid wastes which are discharged in coal collecting process and coal washing process, the silica content is higher, the aluminum content is lower, thecalorific value of the solid waste coal gangue is fully utilized in the preparation process, meta components of the coal gangue are completely utilized again to reduce the volume density of sintered ceramsite to better adapt to the technical demands of oil well fracturing construction, fracturing cost is reduced, and the use of high-grade bauxite resources is reduced to help to protect the environment.

Owner:攀枝花秉扬科技股份有限公司

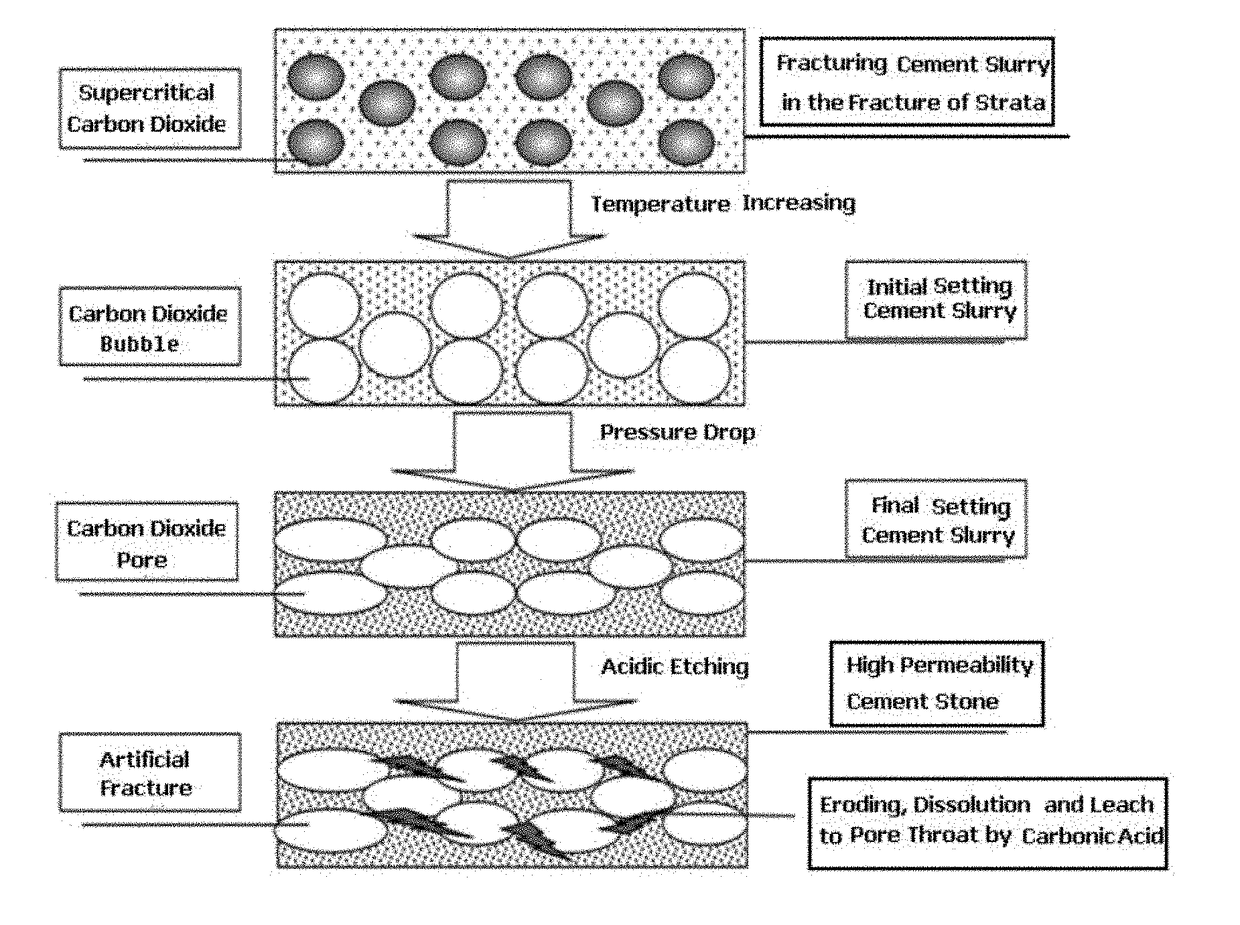

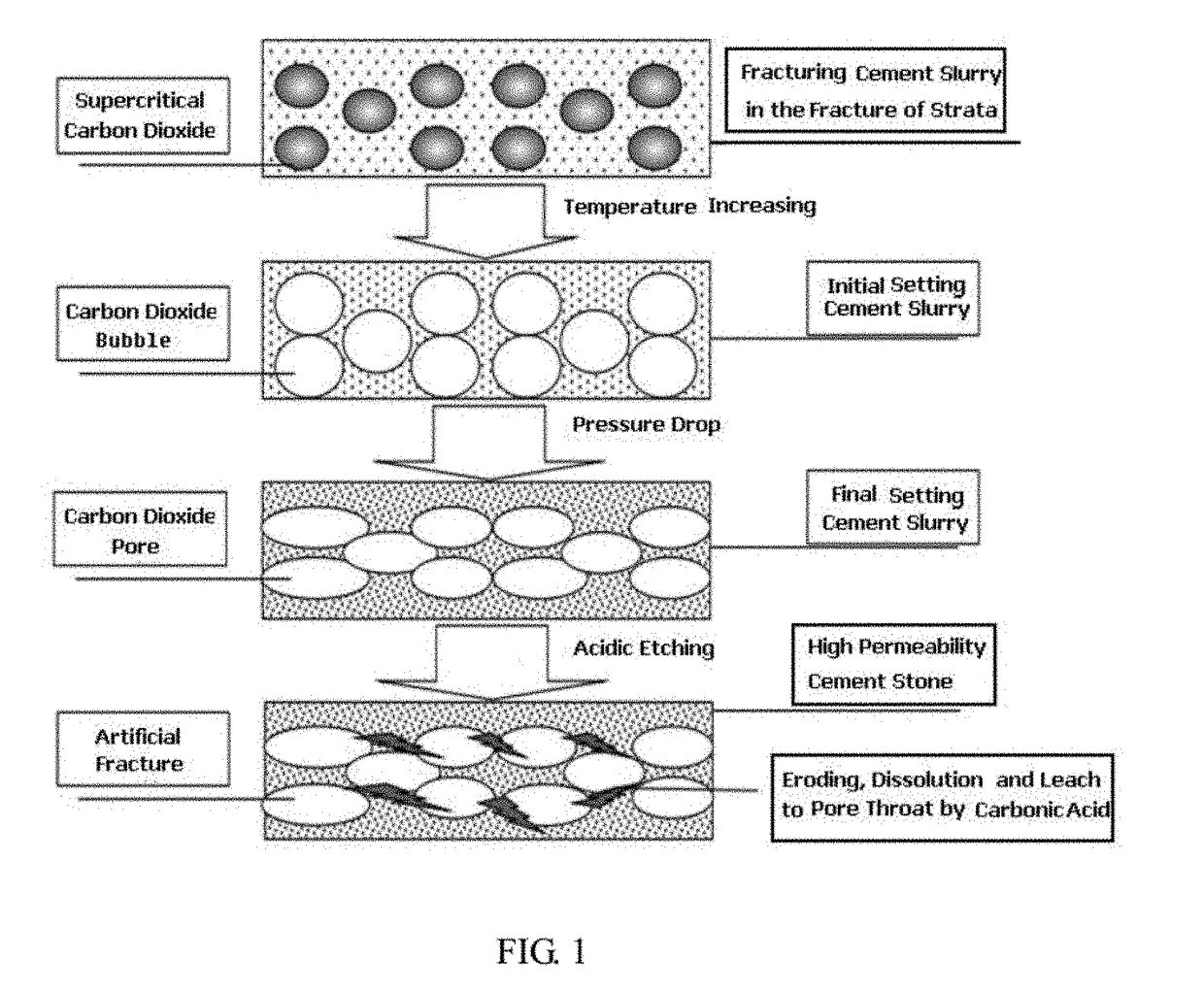

Permeable cement stone fracturing exploitation method for non-conventional oil and gas layer

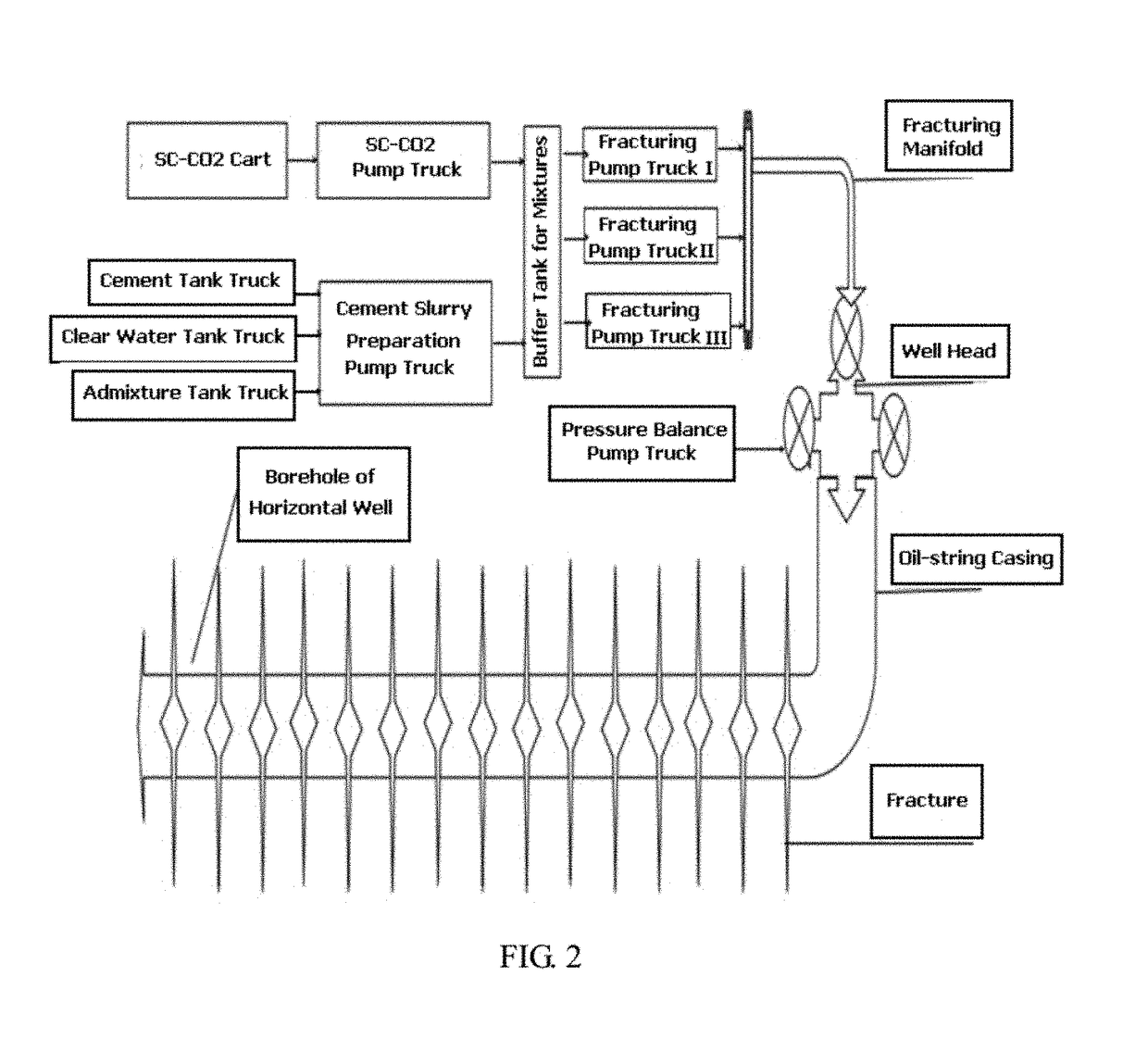

ActiveUS20180238157A1High Effective PermeabilityStimulated is largeConstructionsOther gas emission reduction technologiesTight oilFracturing fluid

Disclosed is a permeable cement stone fracturing exploitation method for non-conventional oil and gas layer such as tight oil and gas, shale gas, coal-bed gas, combustible ice and so on. The method comprises the following complementary processes and embodiments: transporting, storing and pumping process for supercritical carbon dioxide; transporting, storing, preparing and pumping process for fracturing cement slurry; process for mixing the supercritical carbon dioxide and the cement slurry; process of fracturing the supercritical carbon dioxide and the cement slurry on ground; process of forming a permeable cement stone under the ground; and so on. The present invention provides a method for non-conventional oil and gas layer fracturing exploitation without using conventional fracturing proppant and fracturing fluid, having advantages of no flow-back fluid, less water, less material, less equipment, smaller area of well site, lower cost, better stimulation effect, environmental protection, and wide application.

Owner:SICHUAN XINGZHI ZHIHUI INTPROP OPERATION CO LTD +1

Single-pipeline pressure-adjustment type double-end-blocked fracturing machine and fracturing method

PendingCN110984940ARealize blockingAchieve regulationFluid removalSealing/packingThermodynamicsEngineering

The invention relates to a single-pipeline pressure-adjustment type double-end-blocked fracturing machine and a fracturing method. The single-pipeline pressure-adjustment type double-end-blocked fracturing machine comprises a tail hole sealing machine, a communicating pipe and a front part hole sealing machine which sequentially communicate with one another in a drilling direction; a fracturing unit is arranged between the front part hole sealing machine and the tail hole sealing machine; the fracturing unit consists of a pressure adjustment part and a fracturing part; before fracturing of anore deposit is carried out, the pressure adjustment part is used for setting the opening pressure of the fracturing part; the tail hole sealing machine is connected with a high-pressure water fillingdrill rod; the high-pressure water filling drill rod is connected with a pump station and extends into a drilled hole so that the fracturing unit is placed at a to-be-fractured position; the tail holesealing machine and the front part hole sealing machine are expanded and are tensioned on the wall of the drilled hole with increment of the water filling pressure; the water filling pressure continues to be increased until the water filling pressure is equal to the opening pressure; at the moment, the tail hole sealing machine, the pressure adjustment part and the fracturing part communicate with one another; and high-pressure water enters the fracturing part to realize fixed-point fracturing. The single-pipeline pressure-adjustment type double-end-blocked fracturing machine provided by theinvention changes the traditional double-pipeline fracturing way, makes the hydraulic fracturing operation be simpler by only one pump station and only one pressurization operation, and can greatly lower the fracturing cost.

Owner:CCTEG CHINA COAL RES INST

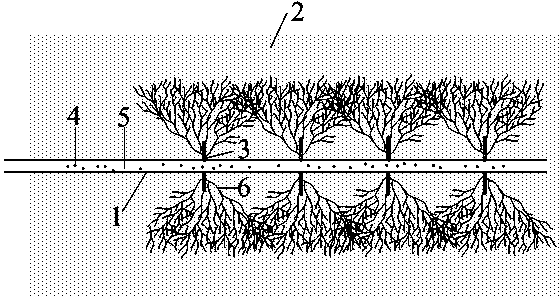

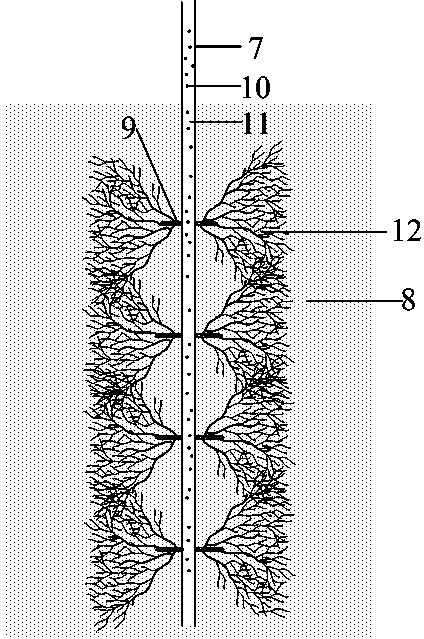

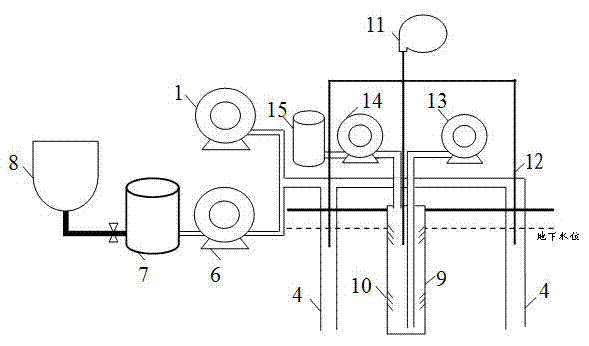

Underground water pollution in-situ restoration device based on synchronous shattering and hydrodynamic circulating

ActiveCN103043862ASolve the narrow channelImprove repair effectMultistage water/sewage treatmentContaminated groundwater/leachate treatmentPipeflowRestoration device

An underground water pollution in-situ restoration device based on synchronous shattering and hydrodynamic circulating comprises more than two hydrodynamic shattering wells and more than one pneumatic stripping circulating well; each pneumatic stripping circulating well is a double-layer well, an upper-layer screen stencil and a lower-layer screen stencil are arranged in the pneumatic stripping circulating well, an air pump is connected to the inner well of the pneumatic stripping circulating well, and the outer well of the pneumatic stripping circulating well is connected to an extraction pump and is in pipe connection with a gas treatment device outside the pneumatic stripping circulating well; each hydrodynamic shattering well is provided with a fracture layer in a low-permeability soil layer, the fracture layer is formed through hydrodynamic fracturing, and fracturing propping agent is injected into fractures; the fractures are formed through synchronous hydrodynamic fracturing of each two paired hydrodynamic shattering wells; and the device further comprises a hydrodynamic fracturing pump, a surface active agent adding tank and the like. The device provided by the invention has the advantages that the defect of narrow underground soil layer aperture passage is effectively solved due to the synchronous fracturing wells (namely the hydrodynamic shattering wells), pneumatic stripping of VOC (Volatile Organic Compounds) can be performed by the pneumatic stripping circulating wells under a hydrodynamic circulating condition, and the VOC restoration capability is greatly improved in combination with synchronous injection of surface active agent.

Owner:陈和平

Spinel high-strength petroleum fracturing proppant and production method thereof

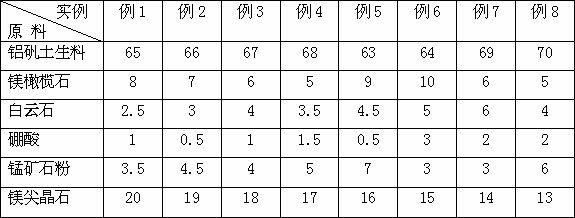

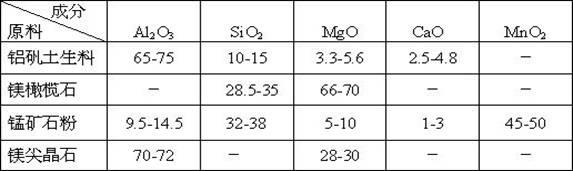

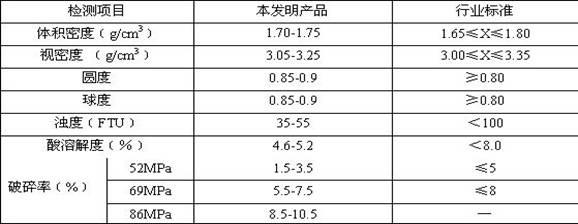

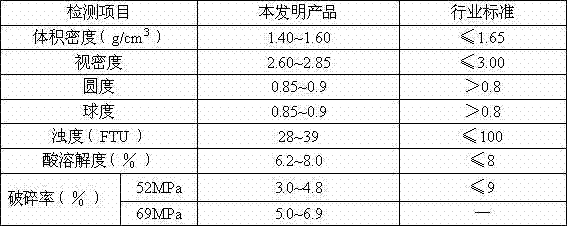

The invention relates to spinel high-strength petroleum fracturing proppant and a production method thereof. The proppant comprises the following raw materials: 63-70% of raw bauxite, 5-10% of forsterite, 2.5-6% of dolomite, 0.5-3% of boric acid, 3-7% of manganese ore powder and 13-20% of magnesium spinel. The production method comprises the following steps of: respectively grinding each raw material into fine powder during the preparation and screening by a 320-mesh sieve; mixing uniformly to obtain a mixture, then feeding the mixture to a rotary granulator while adding atomized moisture, preparing the mixed material into round grains and screening by a sieve with 18-30 meshes to obtain a half-finished product; drying the half-finished product till the moisture content is less than 6%; and transferring the dried half-finished product to a rotary kiln to bake, controlling temperature of a kiln head to be 1285 to 1400 DEG C and temperature of a kiln end to be 280 to 325 DEG C and burning for 6-8h and the discharging out of the kiln. According to the invention, the raw materials form a large amount of magnesium aluminate spinel phases at high temperature so as to play a supporting role of a skeleton; the obtained spinel high-strength petroleum fracturing proppant has the advantages of good compactness and strong anti-crushing capacity; the breakage rates of the spinel high-strength petroleum fracturing proppant at 52 MPa, 69 MPa and 86 MPa respectively are respectively less than 3.5%, less than 7.5% and less than 10.5%, the strength of the spinel high-strength petroleum fracturing proppant is higher than that of the products of the same kind and the performance of the spinel high-strength petroleum fracturing proppant is excellent; and meanwhile, the production techniqueis optimized, low in cost and easy to promote and implement.

Owner:郑州德赛尔陶粒有限公司

Low-density high-strength andalusite fracturing proppant and production method thereof

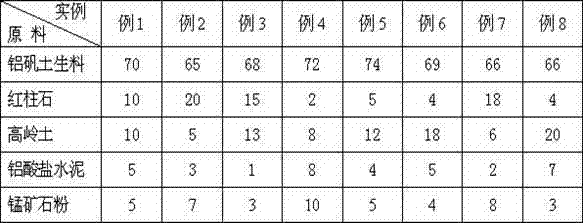

ActiveCN102268248ACompatibility is reasonableHigh compressive strengthFluid removalKaolin clayEngineering

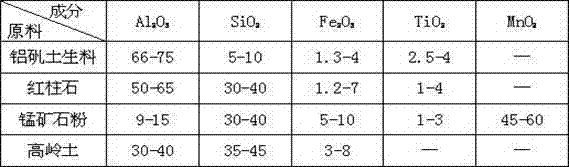

The invention relates to a low-density high-strength andalusite fracturing propping agent and a production method thereof. The raw materials comprise: 65-75% of bauxite raw meal, 2-20% of andalusite, 5-20% of kaolinite, 1-8% of calcium aluminate cement, 3-10% of manganese ore powder. The production method comprises the following steps: weighing raw materials, grinding into fine powder, sieving, well mixing, adding into a rotating granulator for granulation, adding atomized aqueous vapor till the mixture becomes a spherical semifinished product, drying; sintering the semifinished product in a rotary kiln for 6-10 h with a kiln head temperature of 1300-1400 DEG C and a kiln tail temperature of 280-320 DEG C, taking the product out of the kiln to obtain a finished product. The product of theinvention has broken rates of 4.8% and 6.9% under pressures of 52 MPa and 69 MPa respectively, and has strength higher than that of other products of the same kind; the product has bulk density of 1.40-1.60 g / cm3, and apparent density of 2.60-2.85 g / cm3, and the density is lower than industrial standard; the product has high surface fineness, and can effectively reduce cost of petroleum fracturing.

Owner:郑州德赛尔陶粒有限公司

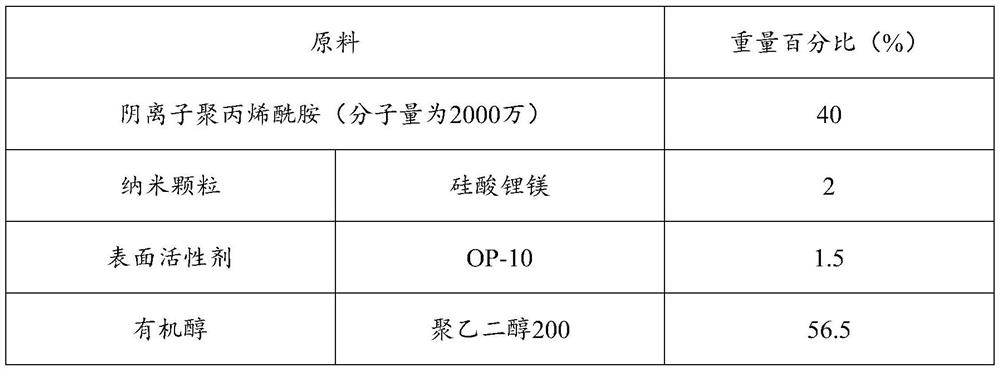

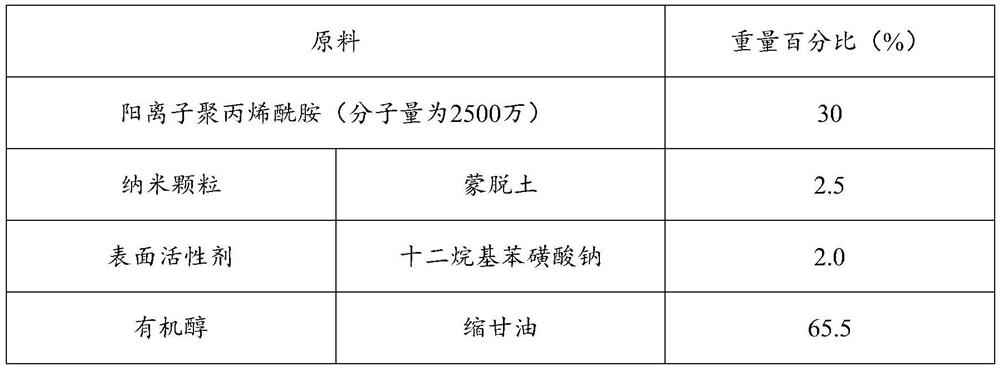

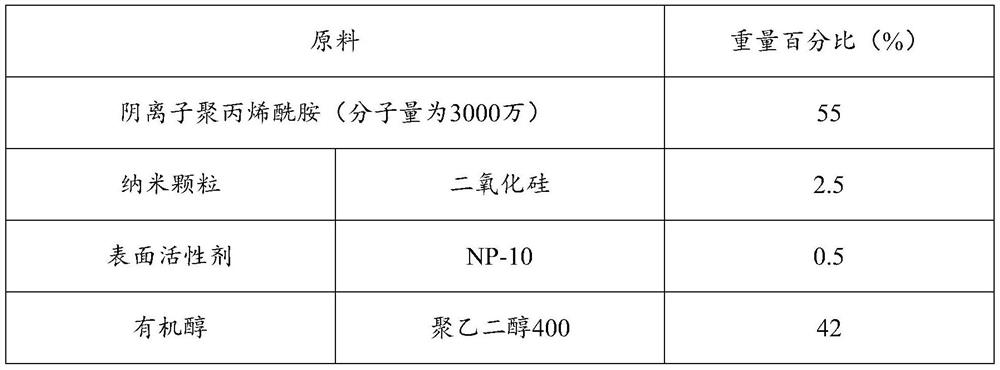

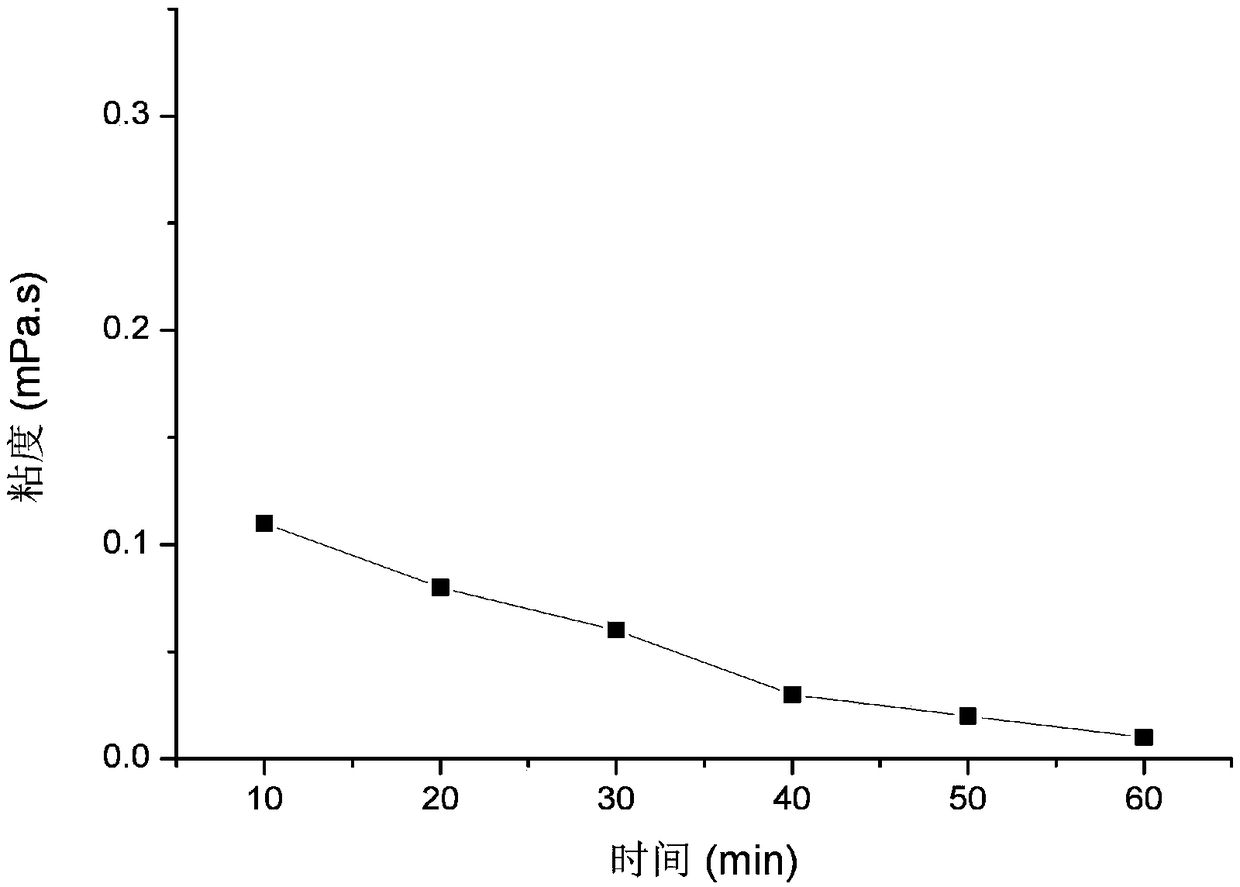

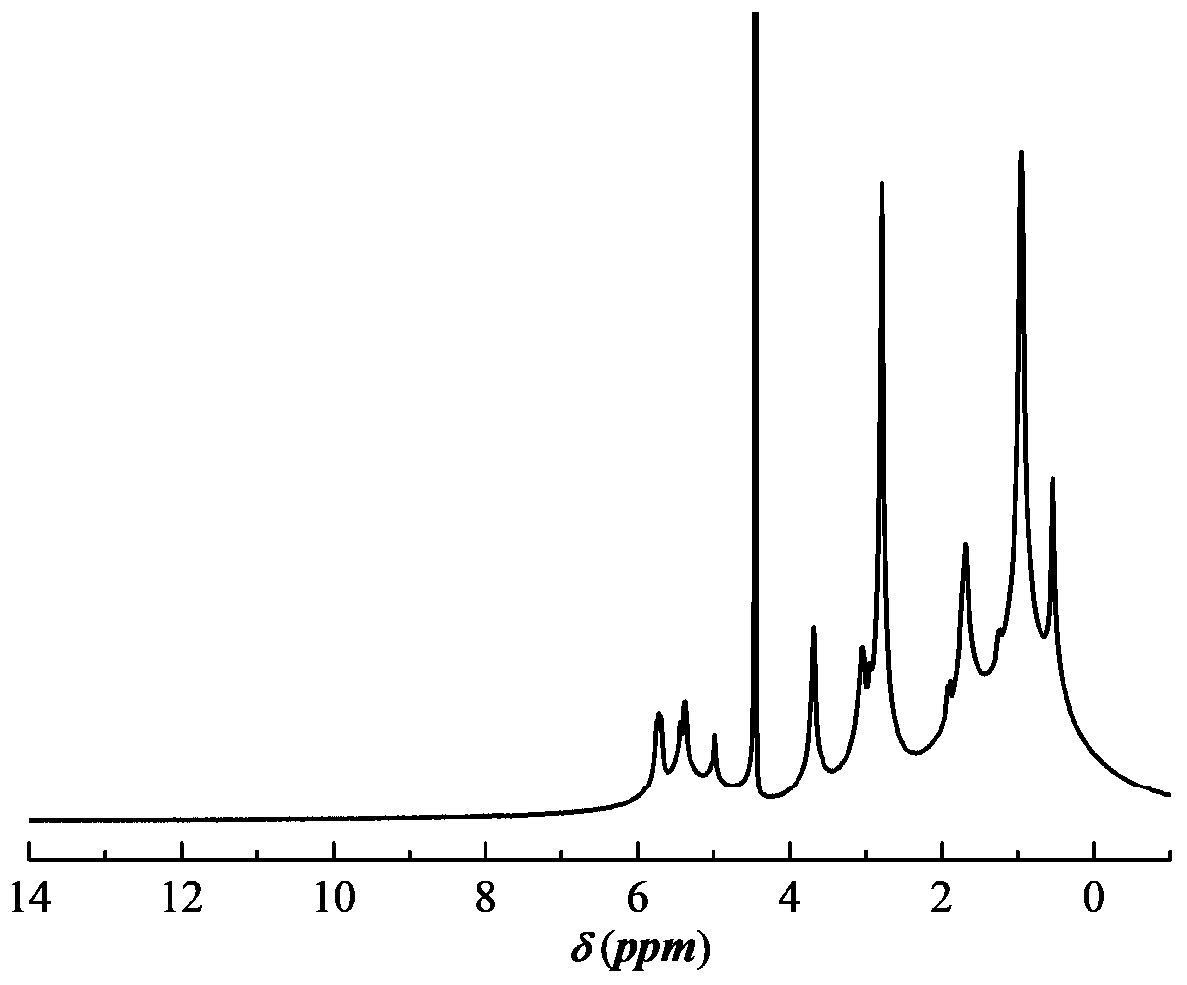

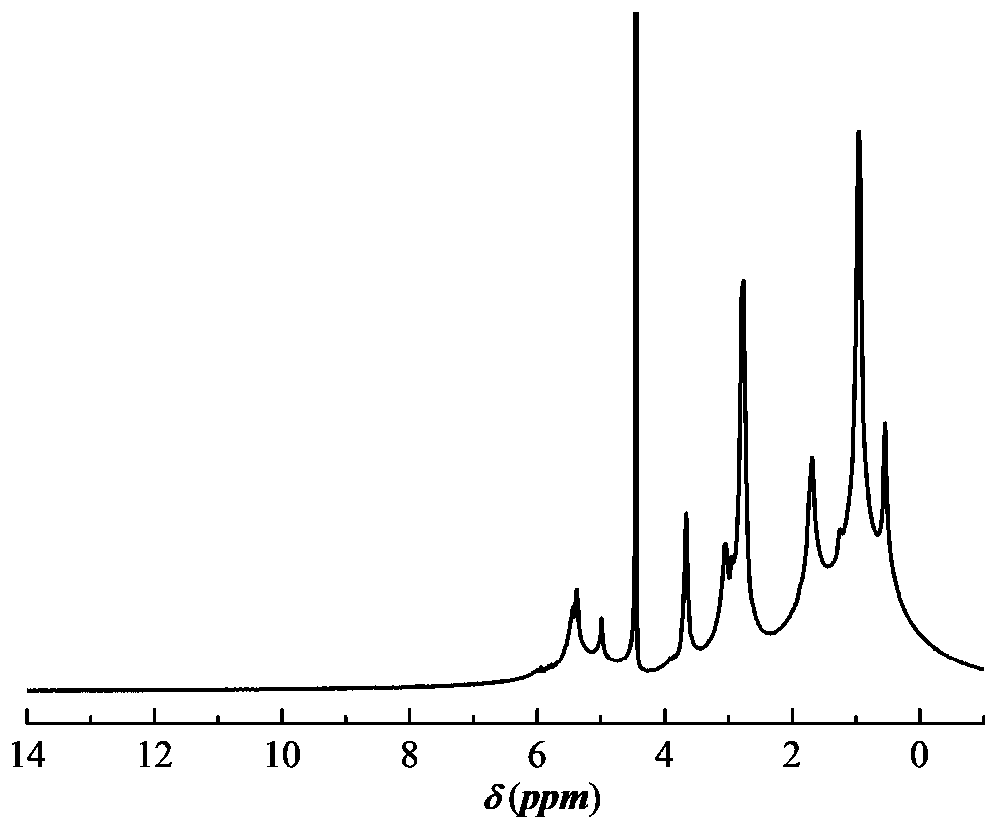

Alcohol-soluble slickwater system for fracturing as well as preparation method and application of alcohol-soluble slickwater system

ActiveCN112375557AImprove thixotropyImprove suspension abilityGeneral water supply conservationDrilling compositionAcid fracturingAlcohol

The invention discloses an alcohol-soluble slickwater system for fracturing as well as a preparation method and application of the alcohol-soluble slickwater system, and relates to the technical fieldof acid fracturing agents. The slickwater system is composed of the following components in percentage by weight: 20.0-60.0% of a polyacrylamide polymer, 0.5-4.0% of nano particles, 0.1-3% of a surfactant, and the balance of organic alcohol.

Owner:四川川庆井下科技有限公司

Liquid and supercritical carbon dioxide tackifying switch surfactant and compounding system thereof

InactiveCN108728074AGood viscosity increasing effectGreenDrilling compositionBulk chemical productionPolyesterProtonation

The invention discloses a liquid and supercritical carbon dioxide tackifying switch surfactant and a compounding system thereof. The switch surfactant is a nonionic surfactant with a tertiary amine group; the switch surfactant is a polyhydric alcohol type or polyoxyethylene type nonionic surfactant with the tertiary amine group. The compounding system which is prepared on the basis of the switch surfactant and is applied to liquid and supercritical carbon dioxide tackifying comprises the switch surfactant and a tackifying polymer; the tackifying polymer is a long-chain fatty acid or a polyester with at least one of groups of amino, ether and alcoxyl, or polysiloxane which is modified by using at least one of groups of amino, polyether, acrylic acid, aryl and alkyl. According to the switchsurfactant, inverse phase wormlike micelle tackifying can be achieved, the hydrophilcity of the switch surfactant is improved through protonation of the tertiary amine, flowback can be achieved, finally recycling and repeated use of the surfactant can be achieved through deprotonation, and the fracturing cost can be reduced.

Owner:成都菲尔特技术开发有限公司

High-salt-resistant viscoelastic surfactant cleaning fracturing fluid and preparation method thereof

ActiveCN109705835AResistant to high saltHigh viscosityOrganic compound preparationCarboxylic acid amides preparationCarbon numberInorganic salts

The invention discloses a high-salt-resistant viscoelastic surfactant cleaning fracturing fluid and a preparation method thereof. The fracturing fluid contains a cationic surface active agent, and thestructural formula of the cationic surface active agent is shown as the following formula. In the formula, R<1>' is selected from saturated alkyls with a carbon number n meeting a relationship of 16<=n<=24, unsaturated alkyls with a carbon number n meeting a relationship of 16<=n<=24, and a compound as shown in the following formula, wherein R<1> is selected from saturated alkyls with a carbon number n meeting a relationship of 16<=n<=24, and unsaturated alkyls with a carbon number n meeting a relationship of 16<=n<=24; and R<2> is selected from saturated alkyls with a carbon number C meetinga relationship of 3<=C<=7, unsaturated alkyls with a carbon number C meeting a relationship of 3<=C<=7, and short-chain alkylbenzene (C<=5). The cationic surfactant has good resistance to inorganic salts, and the principle is that the R<2> substituent groups block mutual proximity between polar head groups of the cationic surface active agent under a high-mineralization-degree condition, and thenprecipitation of the cationic surface active agent is avoided, so that the micelle continues keeping a dense three-dimensional network structure, and tackifying performance is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

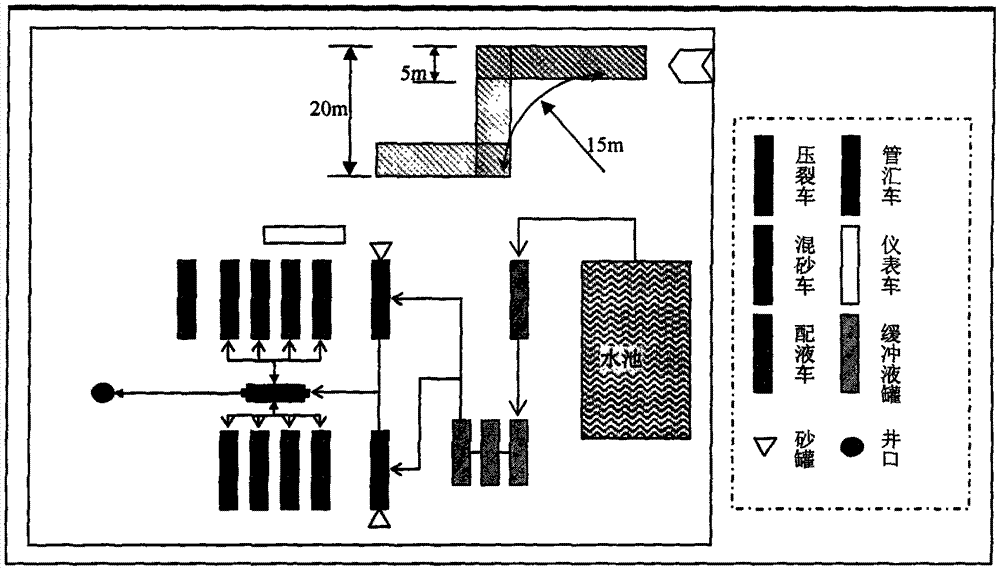

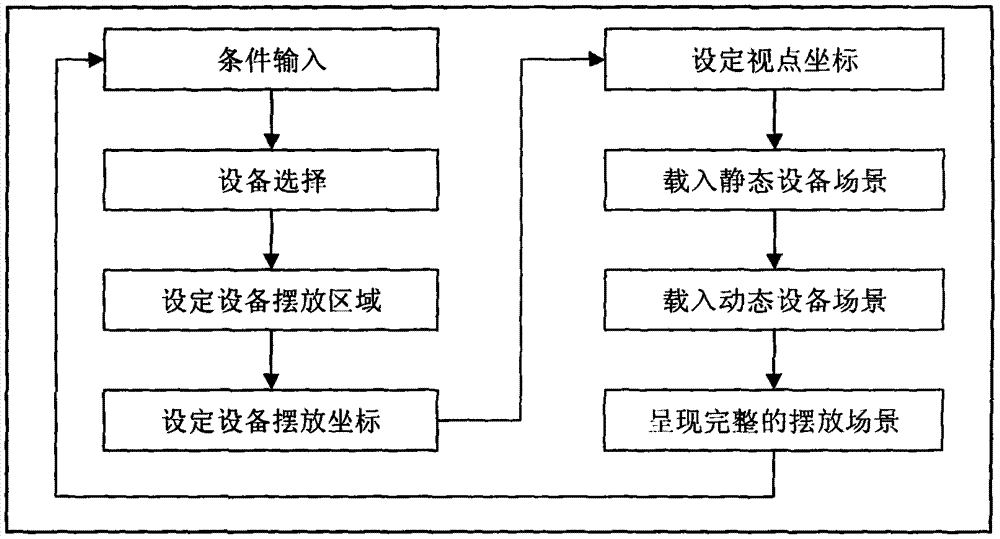

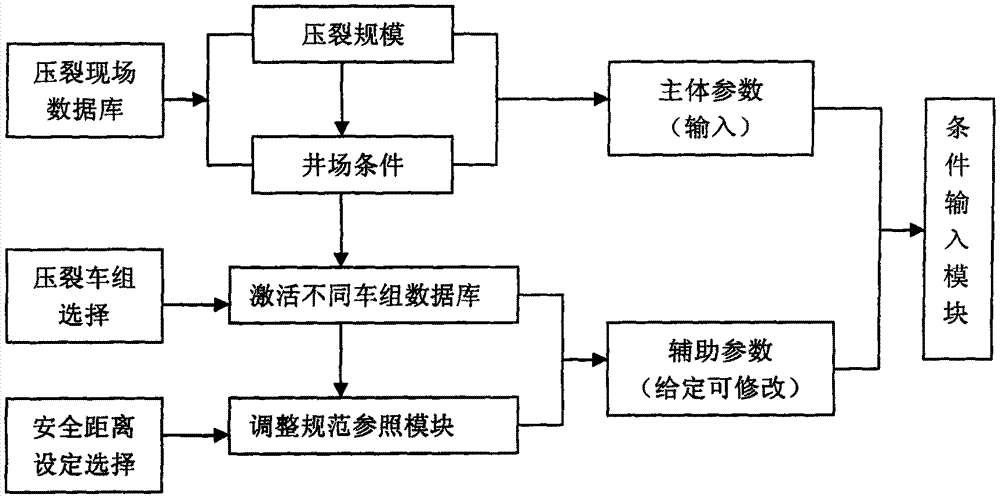

Shale gas fracturing construction 3000 type equipment placing simulation method and realization

InactiveCN104123406AReduced fracturing costsImprove realismSpecial data processing applicationsShale gasInterface design

The invention relates to a shale gas fracturing construction 3000 type equipment placing simulation method and realization which are used for shale gas pool fracturing construction and in the field of the petroleum industry. The simulation method mainly solves the problem of shale gas fracturing construction 3000 type equipment placing in current conditions. The simulation method mainly comprises the steps that a. for 3000 type fracturing equipment, 3D Studio Max is used for completing an equipment 3D model, and after the equipment 3D model and an established equipment placing generalized principle are subjected to datamation, the equipment 3D model and the established equipment placing generalized principle are used as a simulation database together; b. interface designing and function relation are set, wherein fracturing scale and well site condition parameters are input and recognized, and fracturing equipment and placing modes are optimized; c. an MFC class wizard and an interface are selected, and site construction parameter and database calling is completed; and d. timer events are used, and dynamic-static state loading of the 3000 equipment is completed. Practice shows that the realization of the method has certain economic benefit and obvious social benefit.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

A Fracturing Technology Realizing Ultra-High Conductivity

ActiveCN103306659BLow effective concentrationReduce the overall heightFluid removalOrder of magnitudeMaterial Perforation

The invention relates to a fracturing technology for implementing the ultrahigh flow conductivity, which comprises the following steps: 1, judging whether geomechanics parameters of a target reservoir is suitable for the fracturing technology disclosed by the invention or not; 2, judging whether completion perforation of a target well is suitable for the fracturing technology disclosed by the invention or not, and if no, changing a perforating scheme of a well bottom; 3, before fracturing, selecting related fracturing materials; 4, carrying out fracturing on the target well by using a unique pumping program of the fracturing technology disclosed by the invention. According to the fracturing technology, proppant struts are formed in a stratum; flow conductivity of a stratum fracture is not improved by a filling layer of a proppant, but oil gas passes through by passages between the proppant struts; the flow conductivity is obviously improved by the open flowing passages; the flow conductivity of an existing conventional fracturing technology is not more than 200mum<2>*cm generally, but the flow conductivity of the fracturing technology for implementing the ultrahigh flow conductivity, which is disclosed by the invention, is higher than that of the conventional fracturing technology by 1 to 3 orders of magnitude; the fracturing technology reduces a pressure drop in the fracture, is helpful for improving drainage capacity and increases the effective fracture half-length and the production increase volume of the reservoir so as to improve yield.

Owner:凯泽未来(无锡)新材料研究院有限公司

Step type pulse circulation temporary plugging complex fracture network fracturing method for deep low-permeability reservoir

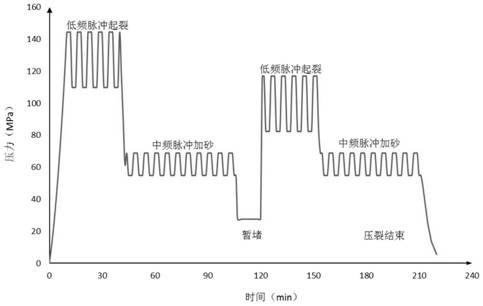

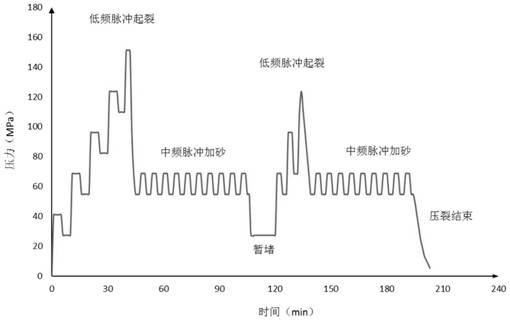

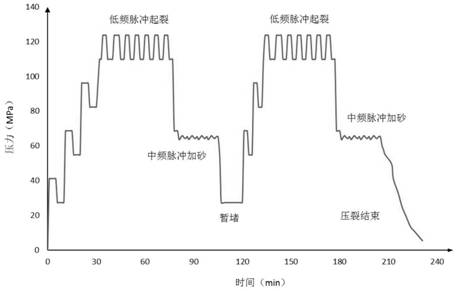

PendingCN112253073ASolve the problem that it is difficult to form a complex seam networkReduced induced microseismic amplitudeFluid removalSealing/packingFatigue damagePetroleum oil

The invention belongs to the field of petroleum and natural gas fracturing transformation, and relates to a step type pulse circulation temporary plugging complex fracture network fracturing method for a deep low-permeability reservoir. The method includes the steps of ground and borehole preparation; perforation; cracking; complex fracture network generation; sand adding; temporary plugging; circulation pulse fracturing and the like. A pulse hydraulic energy generation tool with a bottom seal is matched, and a complex fracture network is formed in the deep reservoir through pulse circulationimpact fracturing, fatigue damage and temporary plugging steering, so that the problem that the complex fracture network is difficult to form in the deep reservoir is solved, the induced microseism amplitude is reduced under the low crack initiation fracturing condition, and the fracturing transformation operation efficiency, effectiveness and earthquake safety are improved. The step type pulse circulation temporary plugging complex fracture network fracturing method for the deep low-permeability reservoir is also suitable for repeated fracturing transformation of the low-permeability reservoir.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

Ejector with telescopic nozzles

InactiveCN106351616AImprove accuracyIncrease perforation depthFluid removalHydraulic fracturingPulp and paper industry

The invention provides an ejector with telescopic nozzles. The ejector comprises an ejector body, preservation holes are formed in the ejector body, the telescopic nozzles are arranged in the preservation holes and are composed of an outer layer nozzle, a middle layer nozzle and an inner layer nozzle which are arranged in a sleeving mode from outside to inside in sequence, the lower parts of the outer layer nozzle, the middle layer nozzle and the inner layer nozzle are fixed through nozzle connecting pins, a large-diameter sealing ring is arranged between the outer layer nozzle and the ejector body, a middle-diameter sealing ring is arranged between the outer layer nozzle and the middle layer nozzle, a small-diameter sealing ring is arranged between the middle layer nozzle and the inner layer nozzle, the outer layer nozzle is pressed through a gland, and the gland is fixed to the ejector body through gland pins. The ejector can carry out ejecting and feeding at the same time, a radial horizontal hole with a certain hole diameter and depth is finally formed, and the accuracy of opening a crack at a fixed point of a wellbore wall and the depth of an ejection hole are improved; the influence of the stress of a near wellbore area is reduced, the partial pressure probability is increased, and the reliability of hydrofracture self-packing is improved; the purposes of improving fracturing effects and reducing the fracturing cost are achieved.

Owner:PETROCHINA CO LTD

Fracturing method for controlling opening of shale near-well fine natural cracks

InactiveCN112240192AEnsure the degree of expansionGuaranteed expansion volumeFluid removalFiltrationExpanded clay aggregate

The invention discloses a fracturing method for controlling the opening of shale near-well fine natural cracks, and belongs to the technical field of oil and gas field development. The method is characterized by comprising the following steps of a, controlling the on-site fracturing displacement to be 9-10m<3> / min in a prepad fluid injection stage at the initial stage of fracturing, and enabling the fracturing displacement to open a reservoir and an artificial crack to extend; b, after prepad fluid is injected, adding 10-15 tons of 100-mesh quartz sand into slickwater to fill the artificial crack and micro cracks; c, increasing the fracturing displacement by 1-2m<3> / min, and continuously adding 10-20 tons of 100-mesh quartz sand; d, increasing the displacement to a designed displacement, and continuously adding more than 10 tons of 100-mesh quartz sand; and e, transferring in 40-70-mesh ceramsite and sand until fracturing construction is finished. The fracturing method \is beneficial to filling and plugging the natural cracks, reducing liquid filtration loss, ensuring the expansion degree of artificial cracks and achieving the purposes of smoothly adding sand and ensuring the expansion volume of the artificial cracks.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation raw material, preparation method and application of online concentrated drag reduction liquid for fracturing

The invention discloses a preparation raw material, preparation method and application of online concentrated drag reduction liquid for fracturing. The preparation raw material is composed of the following components: a polymer, a high-efficiency water diversion agent, a micropore generating agent, base oil, a main emulsifier and an auxiliary emulsifier. The preparation method comprises the following steps: (1) diluting a polymer with deionized water until the mass percentage concentration is 50-80% to obtain a stock solution; (2) slowly adding an efficient water diversion agent into the stocksolution prepared in the step (1); (3) slowly adding a micropore generating agent into the solution prepared in the step (2) to obtain a water phase part; (4) mixing the main emulsifier and the auxiliary emulsifier to obtain an oil phase part; and (5) adding the oil phase part in the step (4) and the water phase part in the step (3) into a reactor to obtain the online concentrated drag reductionliquid for fracturing. The drag reduction liquid has the advantages of being high in effective content, safe, environmentally friendly, rapid to dissolve, multipurpose, good in gel breaking effect andlow in residue content.

Owner:彭辉 +2

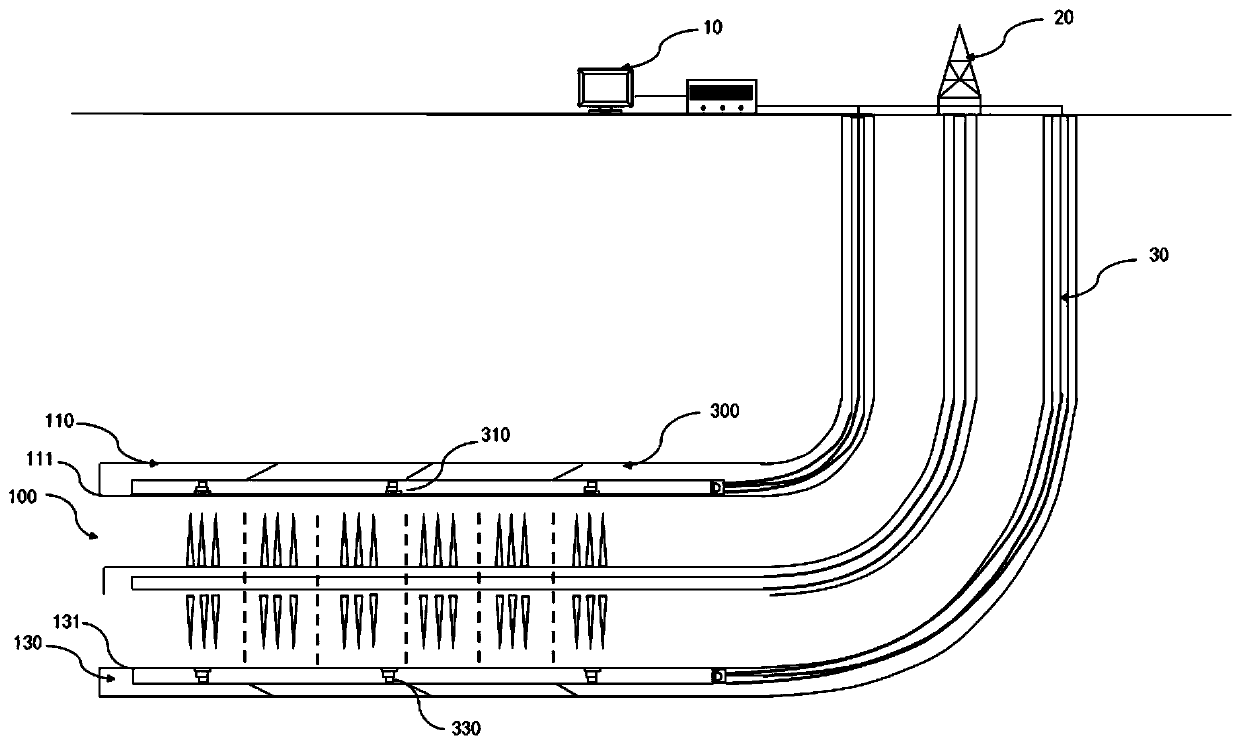

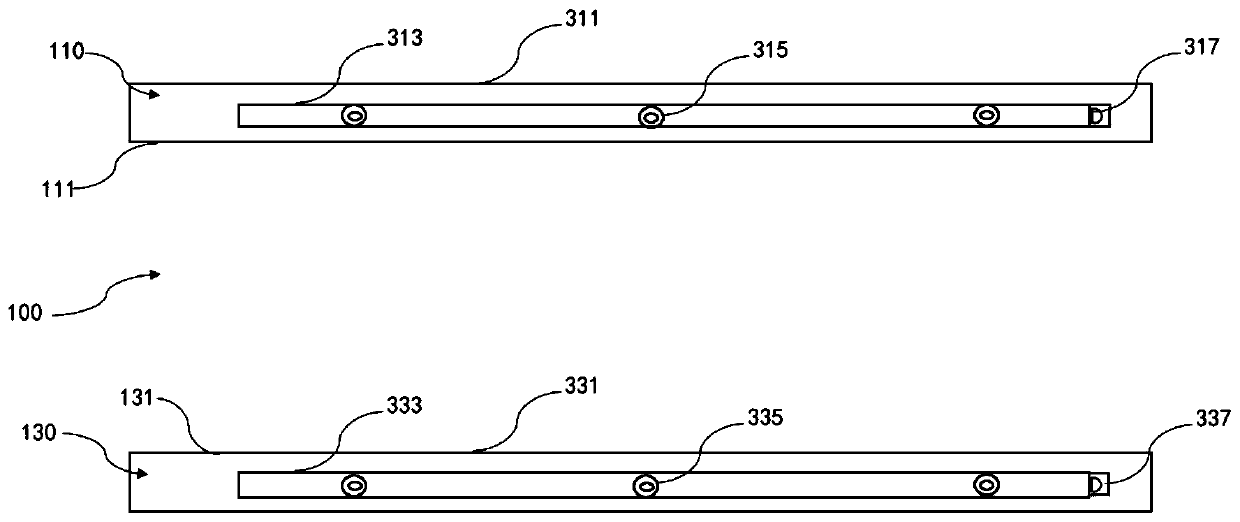

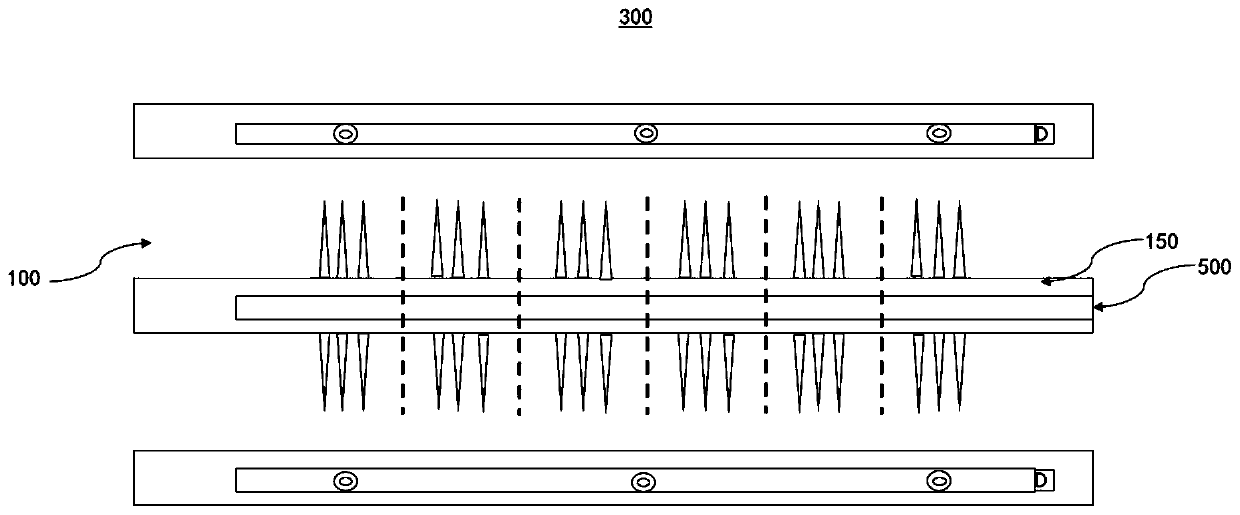

Reservoir mining incentive structure and shale gas reservoir mining method

ActiveCN109973037AIncrease pressureRelieve pressureFluid removalVibration devicesAuditory radiationDesorption

The invention provides a reservoir mining incentive structure and a shale gas reservoir mining method, and belongs to the technical field of resource mining. A first vibrator and a second vibrator arearranged on the upper interface and lower interface of a shale gas reservoir by the the mining incentive structure, and the first vibrator and the second vibrator separately release energy into the shale gas reservoir to drive the vibration of the shale gas reservoir. Under the action of acoustic vibration incentive, rock damage occurs, the rock strength decreases, the fracture pressure of the shale reservoir is reduced, and in the later stage of hydraulic fracturing transformation, the cost of hydraulic fracturing is reduced; meanwhile, the change of a stress state of the shale gas reservoiris conducive to the formation of a fracture net in the process of hydraulic fracturing transformation, the volume transformation of the shale gas reservoir is facilitated, the flow of shale gas is accelerated, and the decrease of shale gas reservoir pressure is accelerated; and the desorption of methane is prompted, the acoustic radiation effect can further promote the desorption of the methane,the production of shale gas wells is improved, the mining time of the shale gas reservoir is shortened, and the mining cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com