Step type pulse circulation temporary plugging complex fracture network fracturing method for deep low-permeability reservoir

A pulse-circulating, step-type technology, applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as difficulty in forming complex fracture networks, reduce the number of operations, save fracturing costs, and improve fracturing. The effect of crack transformation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

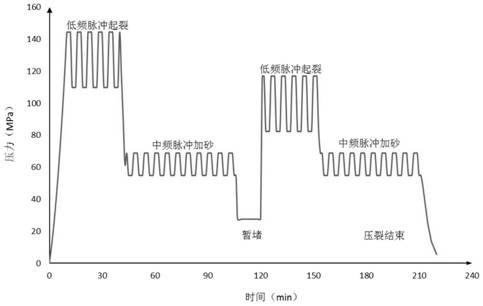

[0039] Embodiment 1 adopts the method of the present invention to carry out fracturing

[0040] Specifically include the following steps:

[0041] Step 1, surface and wellbore preparation: prepare the first surface fracturing vehicle group, the second surface fracturing vehicle group, supporting tools and fracturing fluid, and perform well drilling and well cleaning operations.

[0042] Step 2, perforation operation: use coiled tubing to run the connected downhole pulse hydraulic energy generation tool into the designated perforation section, and use the first ground fracturing crew to provide 120MPa pressure and 0.8m 3 The first fluid with displacement per minute makes the downhole pulsed hydraulic energy generating tool with bottom seal generate ultra-high pressure pulsed water jet, and the pressure of the first fluid increases to 200-250MPa to complete the perforation.

[0043] Step 3, Reservoir initiation: use the second ground fracturing unit to pump 1.0-3.0m 3 / min low...

Embodiment 2

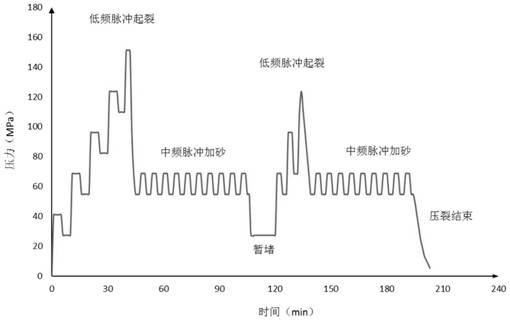

[0050] Embodiment 2 adopts the method of the present invention to carry out fracturing

[0051] Specifically include the following steps:

[0052] Step 1, surface and wellbore preparation: prepare the first surface fracturing vehicle group, the second surface fracturing vehicle group, supporting tools and fracturing fluid, and perform well drilling and well cleaning operations.

[0053] Step 2, perforation operation: use coiled tubing to run the connected downhole pulse hydraulic energy generation tool into the designated perforation section, and use the first ground fracturing unit to generate downhole pulse hydraulic energy with bottom seal according to the predetermined perforation plan. The generation tool provides 80~140MPa pressure, 0.2~1.0m 3 The first fluid with a displacement of 1 / min forms an ultra-high pressure pulsed abrasive water jet downhole, and the pressure of the first fluid increases to 200-250 MPa to complete the perforation.

[0054] Step 3, Reservoir in...

Embodiment 3

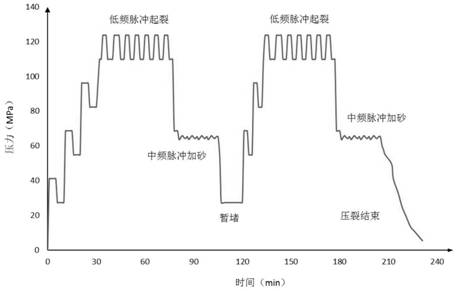

[0061] Embodiment 3 adopts the method of the present invention to carry out fracturing

[0062] Include the following steps:

[0063] Step 1, surface and wellbore preparation: prepare the first surface fracturing vehicle group, the second surface fracturing vehicle group, supporting tools and fracturing fluid, and perform well drilling and well cleaning operations.

[0064] Step 2, perforation operation: use coiled tubing to run the connected downhole pulse hydraulic energy generation tool into the designated perforation section, and use the first ground fracturing unit to generate downhole pulse hydraulic energy with bottom seal according to the predetermined perforation plan. The generation tool provides 80~140MPa pressure, 0.2~1.0m 3 The first fluid with a displacement of 1 / min forms an ultra-high pressure pulsed abrasive water jet downhole, and the pressure of the first fluid increases to 200-250 MPa to complete the perforation.

[0065] Step 3, Reservoir initiation: use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com