Patents

Literature

2213results about "Material analysis using acoustic emission techniques" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

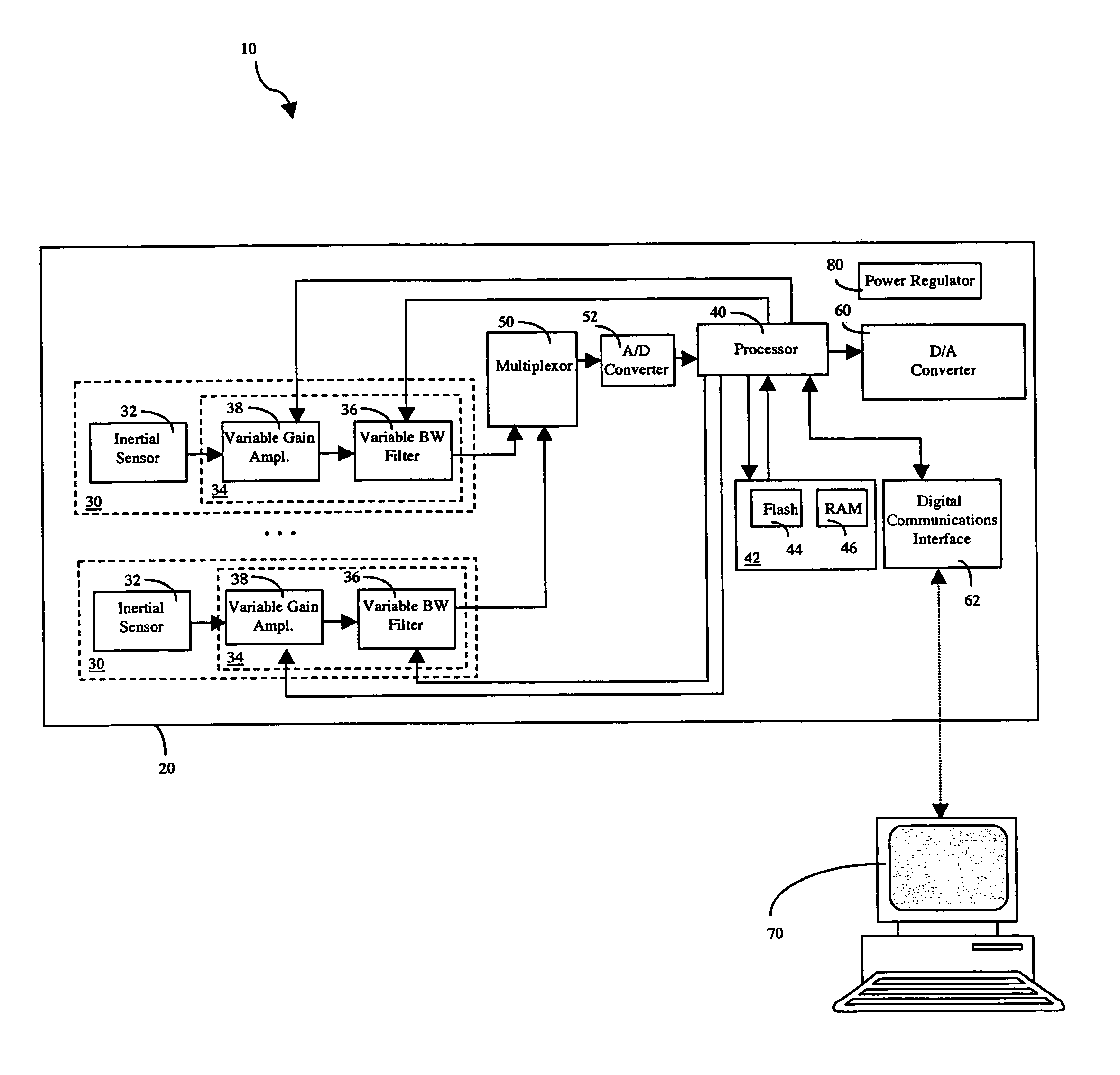

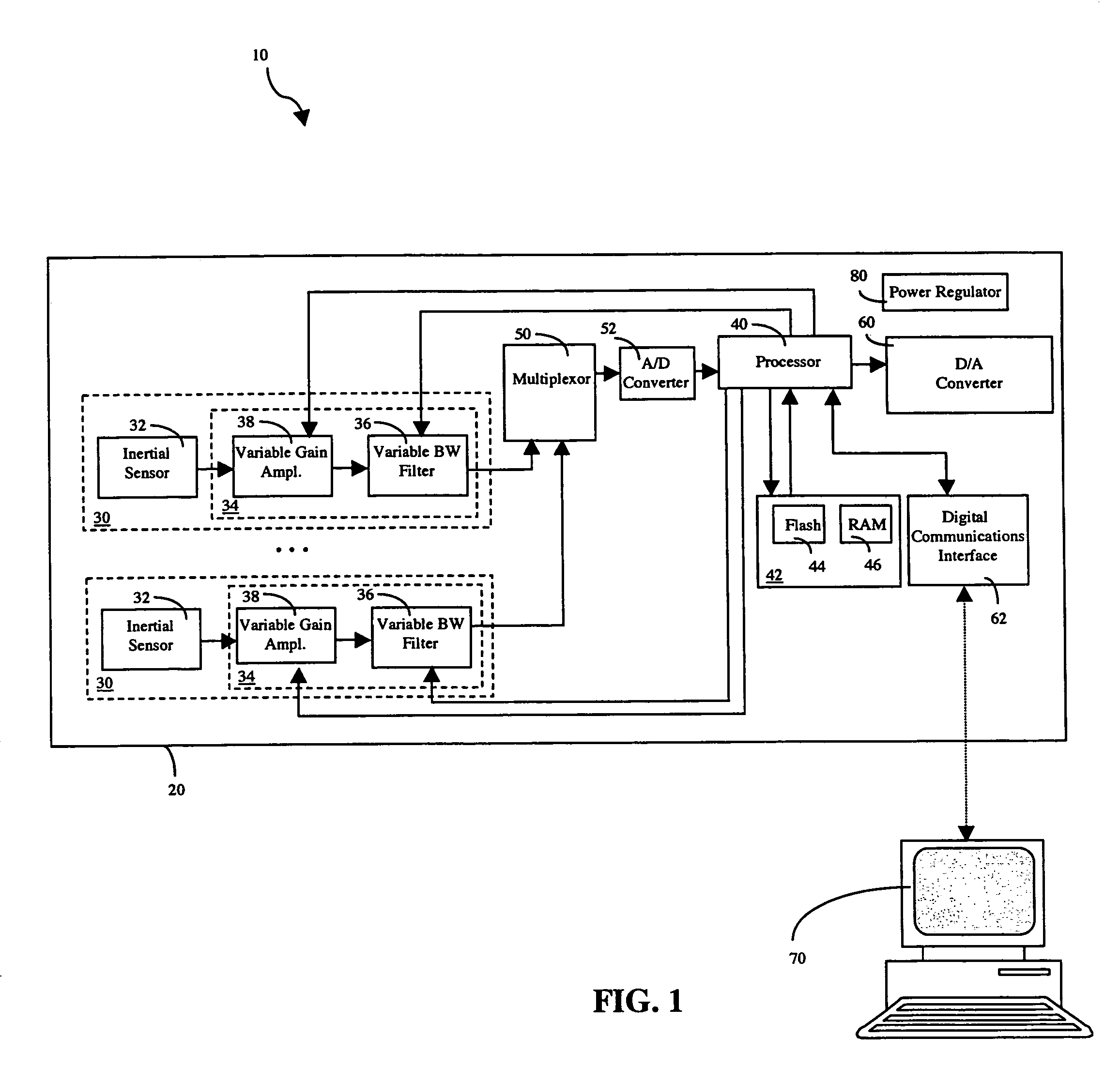

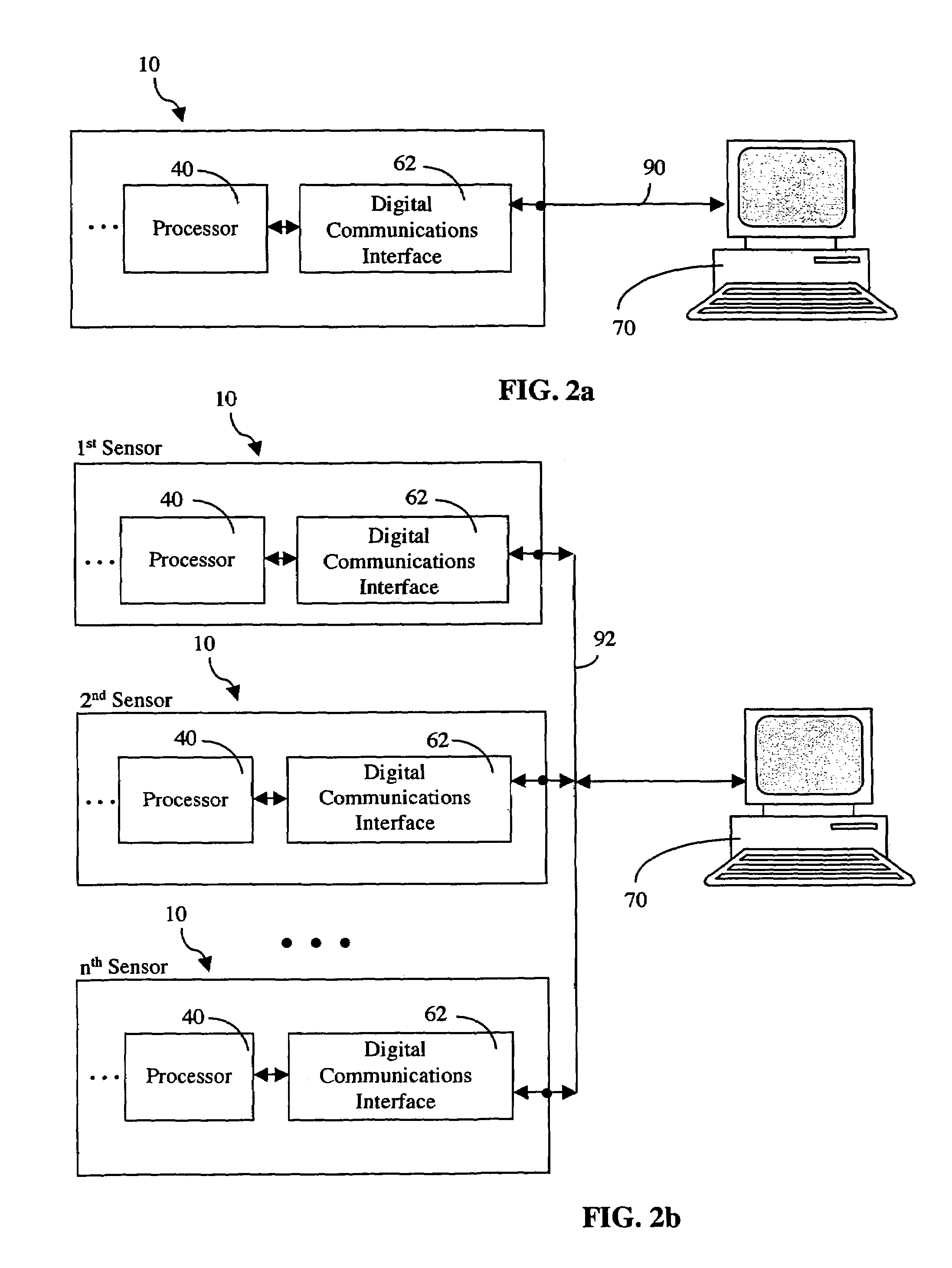

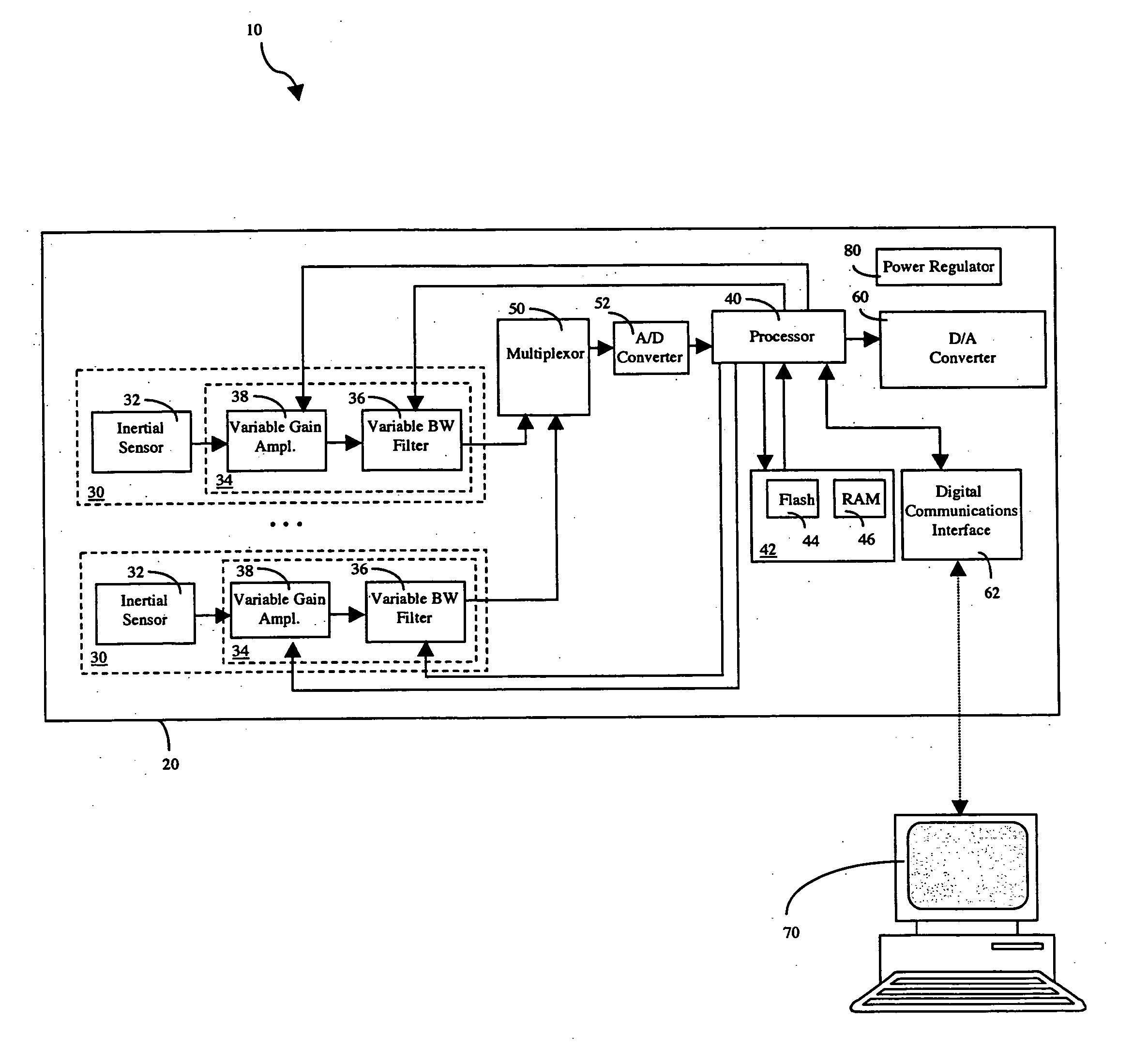

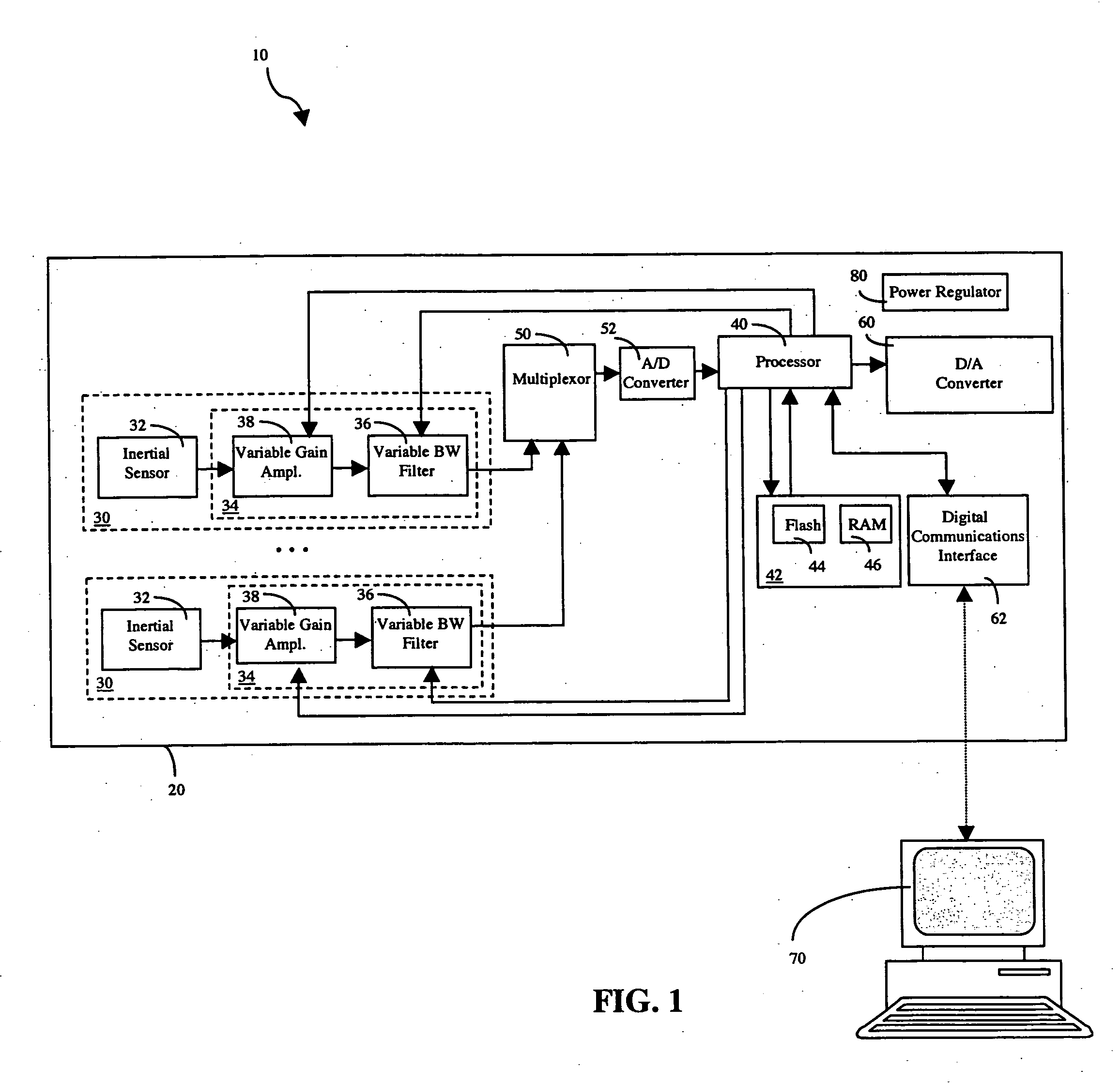

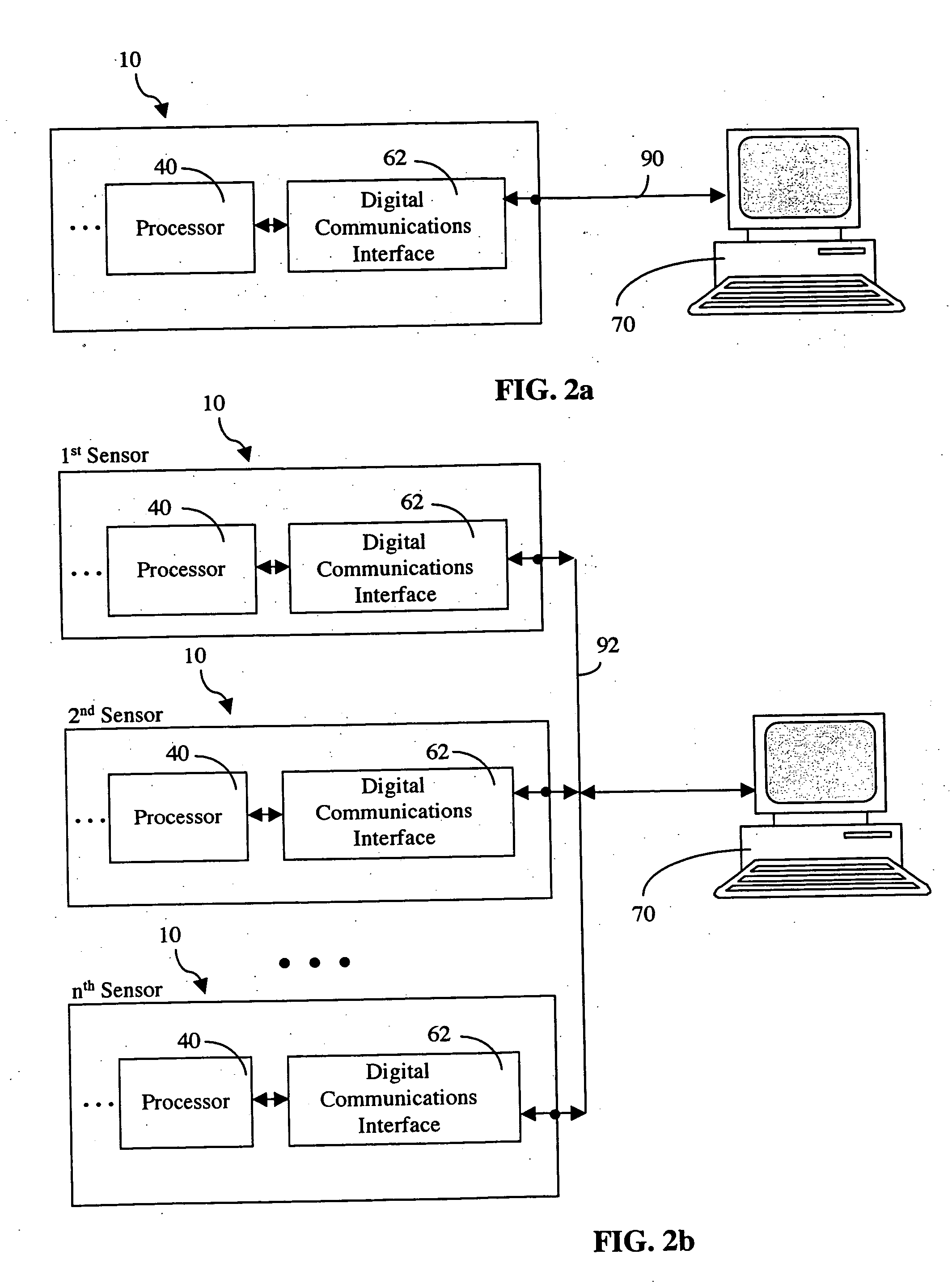

Configurable vibration sensor

InactiveUS7093492B2Vibration measurement in solidsMachine part testingVibration measurementVariable-gain amplifier

A configurable vibration sensor having a sensor circuit, an analog-to-digital converter and a processor is provided. The sensor circuit employs a vibration sensing element and a variable bandwidth filter controllable by the processor. In addition to the variable bandwidth filter, other configurable elements may also be employed in the sensor circuit, including a variable gain amplifier. These configurable elements allow the configurable vibration sensor to be configured for different vibration measurement applications when measuring vibrations from vibrating structures such as machinery and the like.

Owner:MECHWORKS SYST

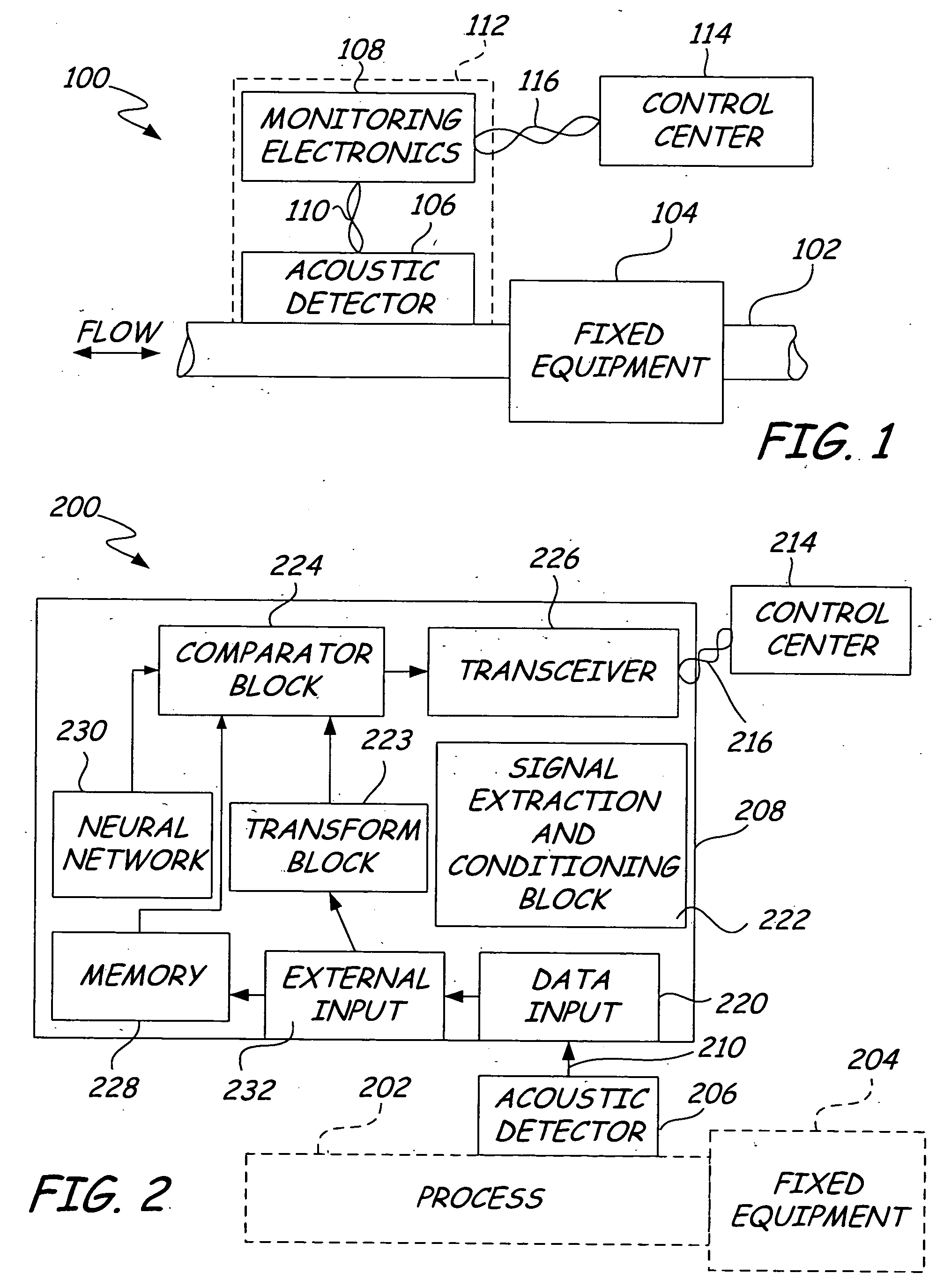

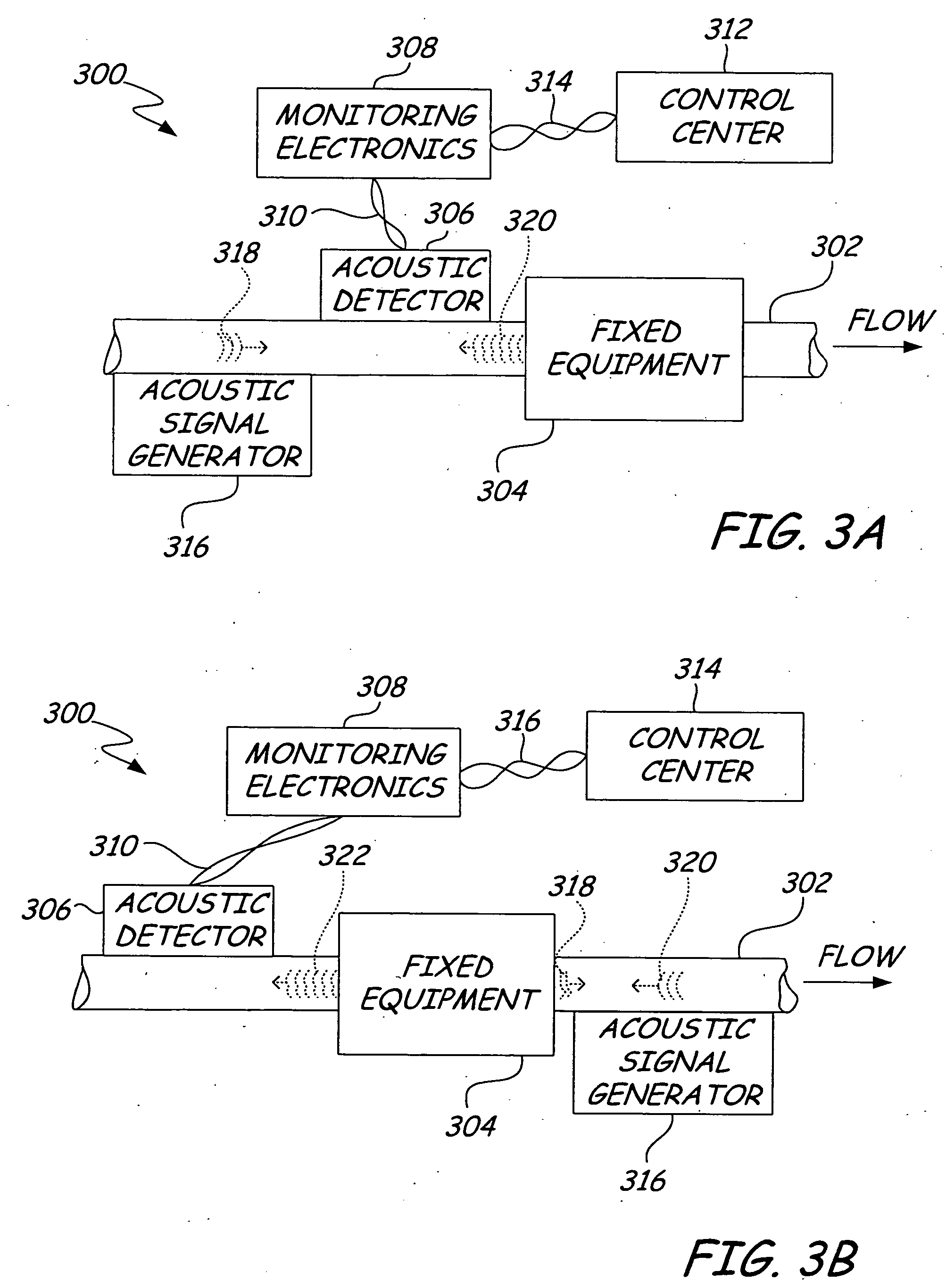

Process diagnostics

ActiveUS20050011278A1Improve abilitiesEasy to useVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

A diagnostic device for use in a industrial process includes monitoring electronics or diagnostic circuitry configured to diagnose or identify a condition or other occurrence in the industrial process. The system can be implemented in a process device such as a flowmeter, and in one example an acoustic flowmeter. A transducer can also be used and a frequency response, such as resonant frequency, can be observed.

Owner:ROSEMOUNT INC

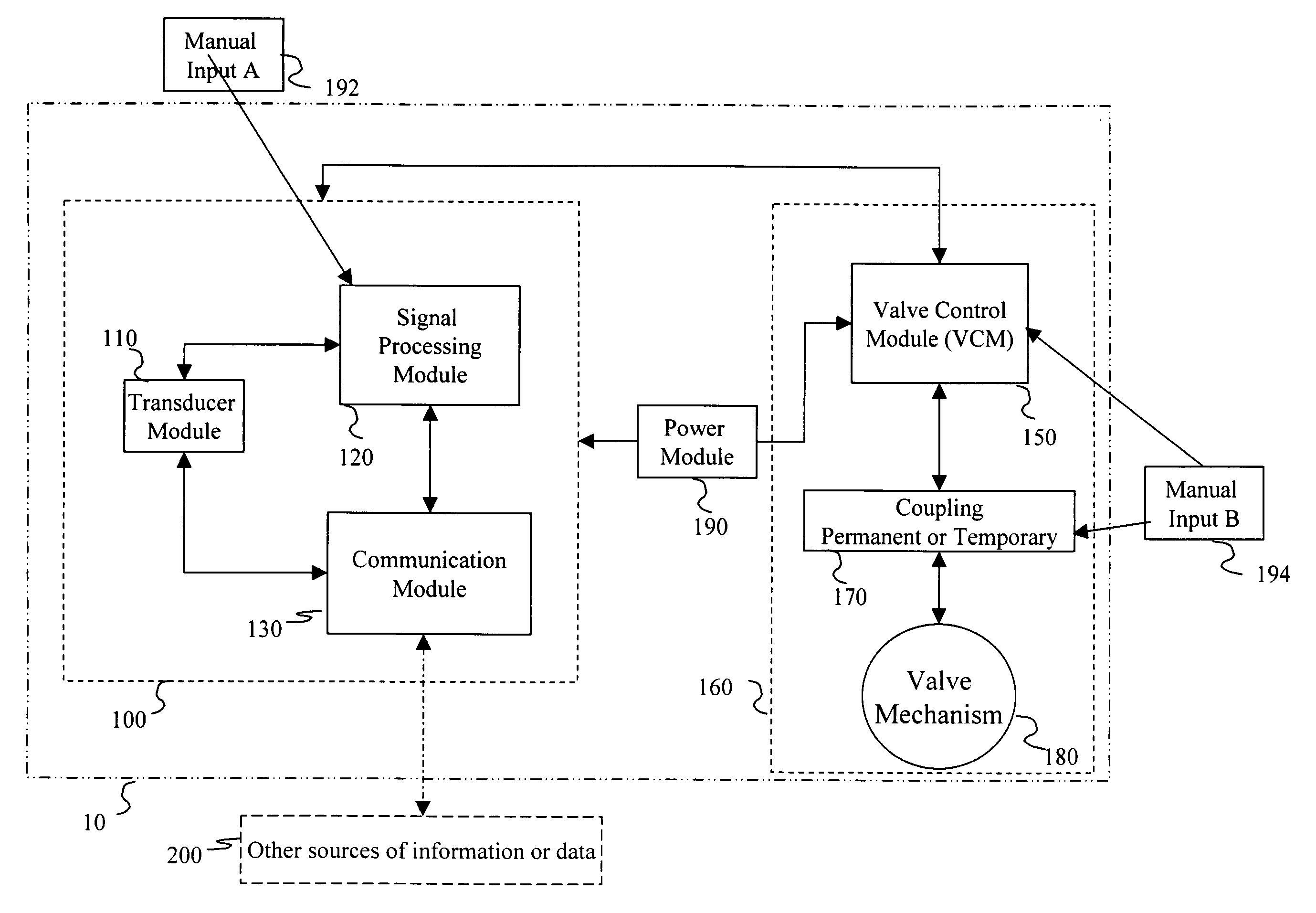

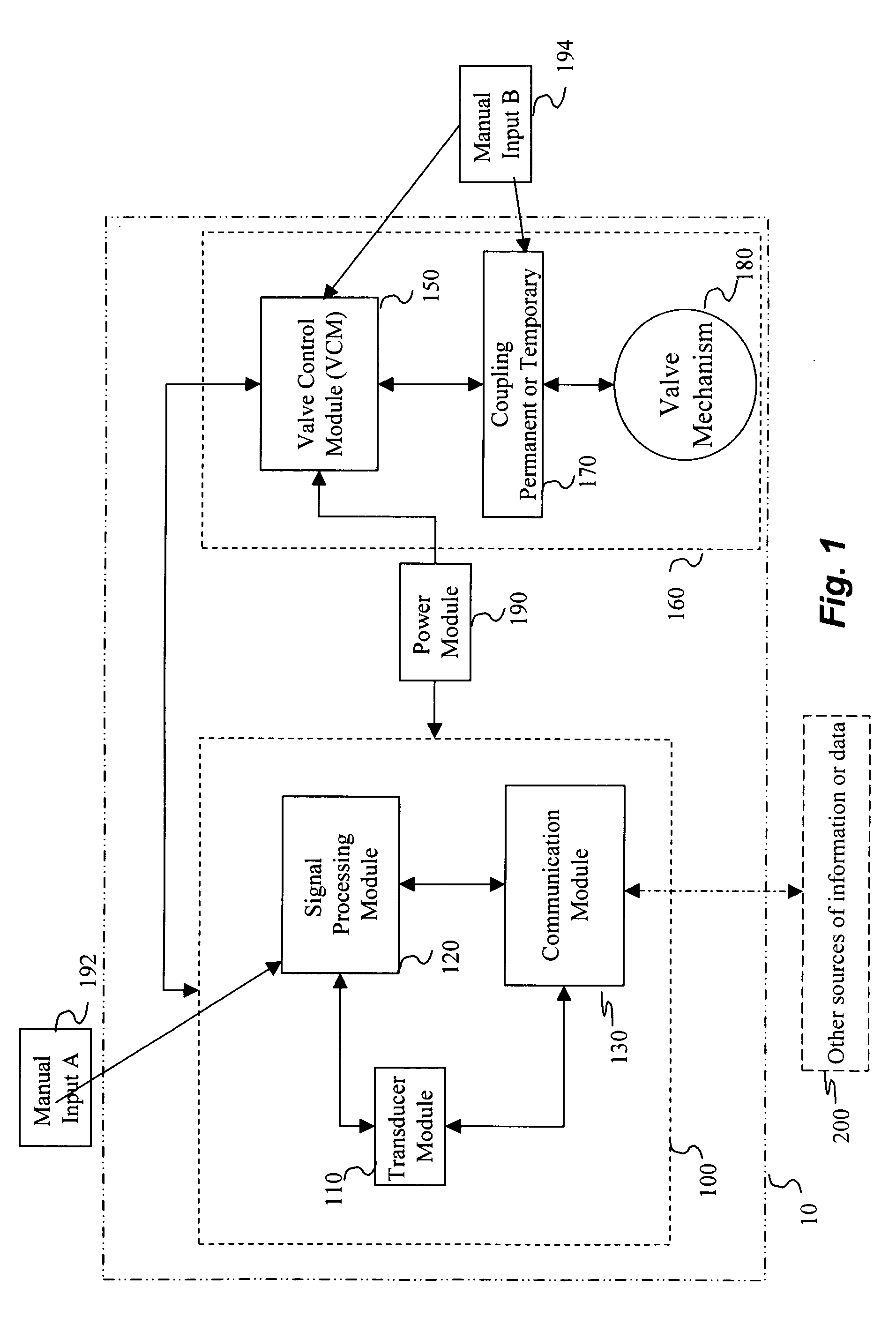

Intelligent valve control methods and systems

InactiveUS20060174707A1ConfidenceQuick couplingDetection of fluid at leakage pointVibration measurement in fluidSmoke detectorsElectricity

A method for determining a burst pipe that requires immediate feeding-valve closing using acoustic and / or vibration sensors coupled to the pipe lor detecting signals, a microprocessor for analyzing signals from said sensors in real-time, a memory coupled to said microprocessor for storing data, including digital signatures acoustic and / or vibration signatures, as well as an actuator electrically coupled to said microprocessor and mechanically coupled to said feeding-valve. When the sensor signals match stored leak-signatures or when a persistent sensor signal produces no match, the system of the present invention initiates a valve closing. To improve detection, signals from other sensors, i.e. water sensors, smoke detectors, heat sensors or acoustic / vibration sensors mounted on other pipes are also used. Some of the said systems have IP addresses and can communicate over the Internet or wirelessly with others.

Owner:ZHANG JACK K

Integrated vibration measurement and analysis system

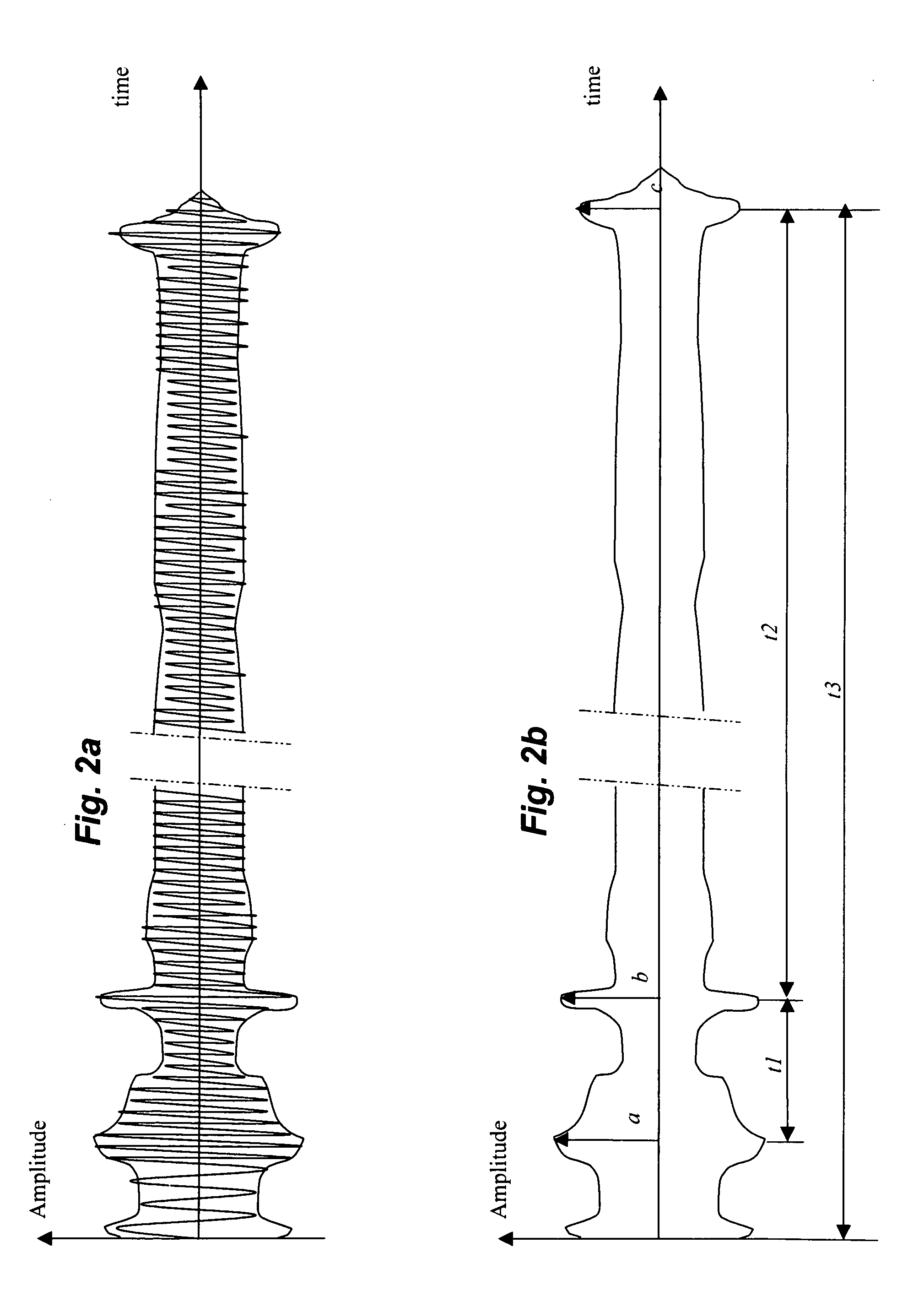

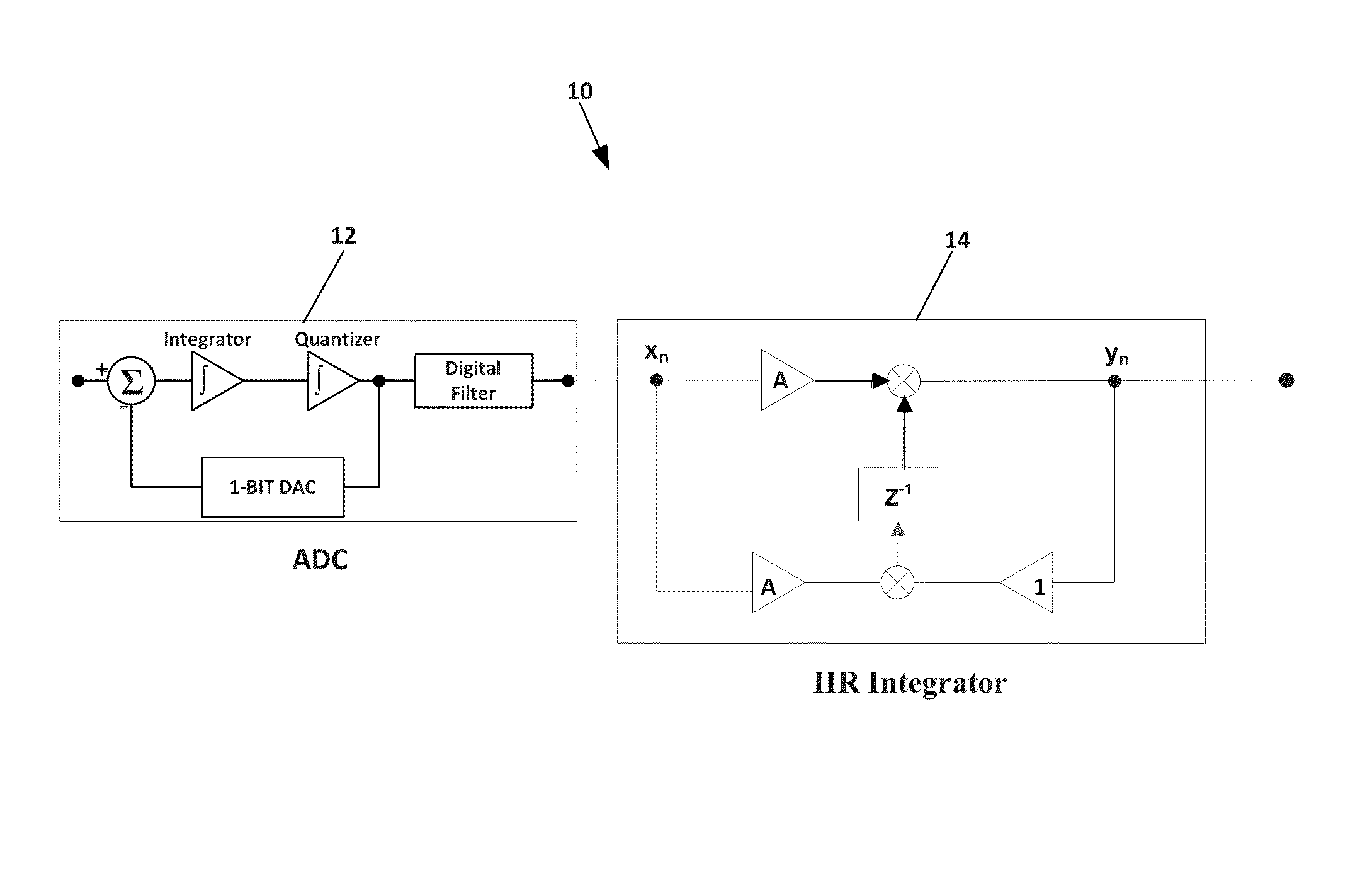

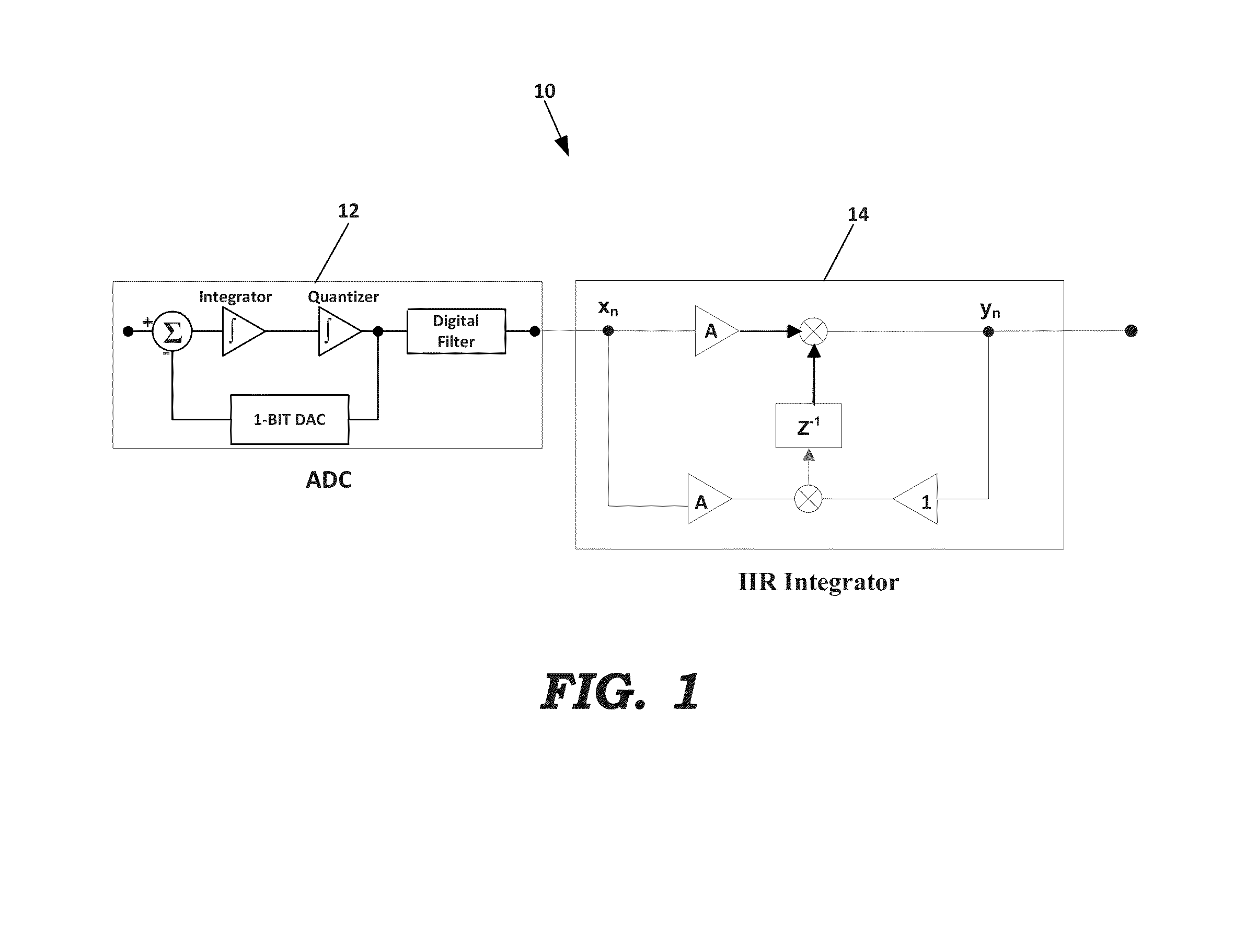

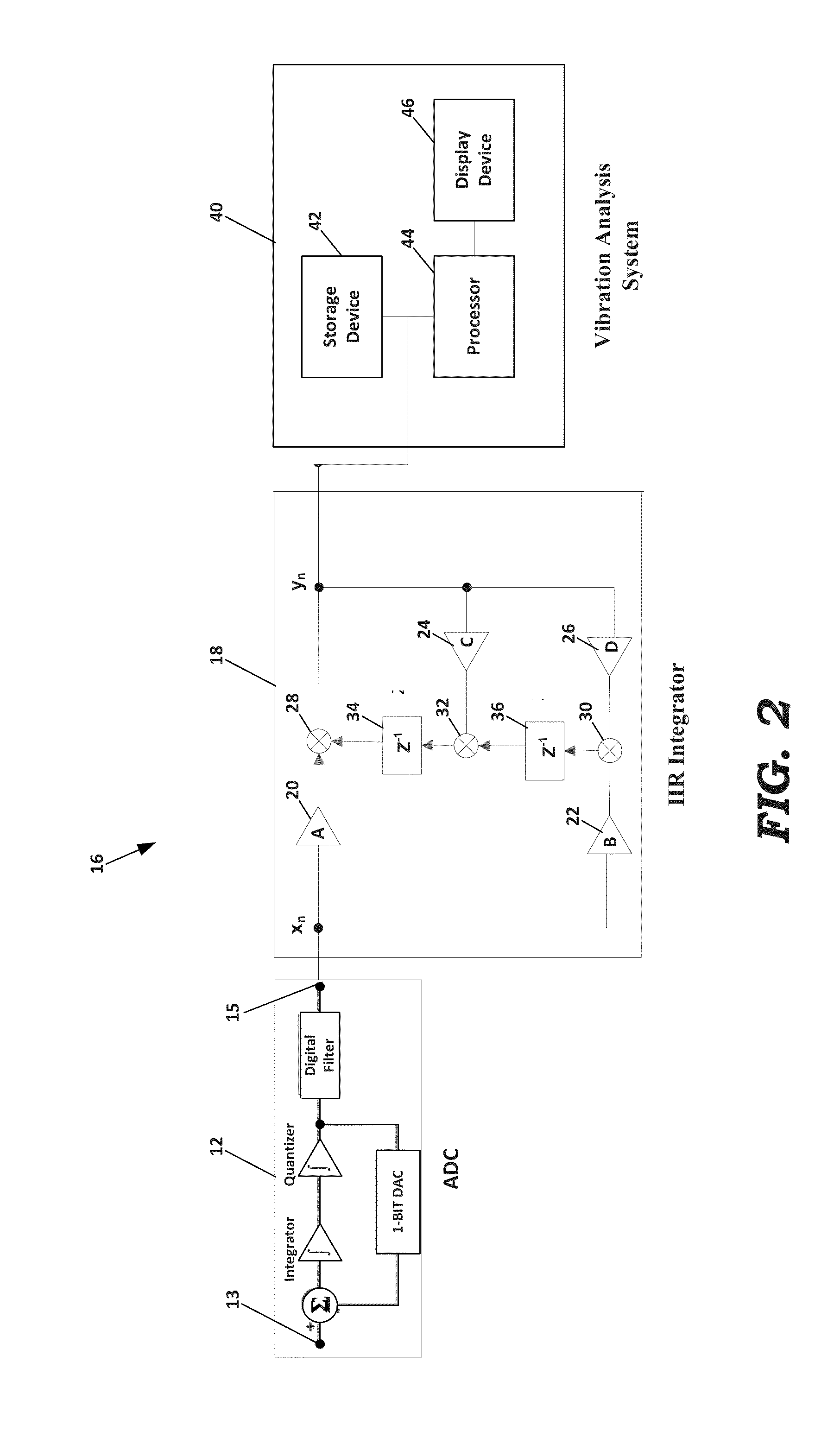

ActiveUS20140067289A1Reduce hardware complexityReduces data storage requirementVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurementData rate

A vibration data collection system performs an integration or differentiation process on incoming digitized vibration data in real time. The system uses a digital Infinite Impulse Response (IIR) filter running at the input data rate to provide the integration or differentiation function. With this approach, the system reduces hardware complexity and data storage requirements. Also, the system provides the ability to directly integrate or differentiate stored time waveforms without resorting to FFT processing methods.

Owner:COMPUTATIONAL SYST

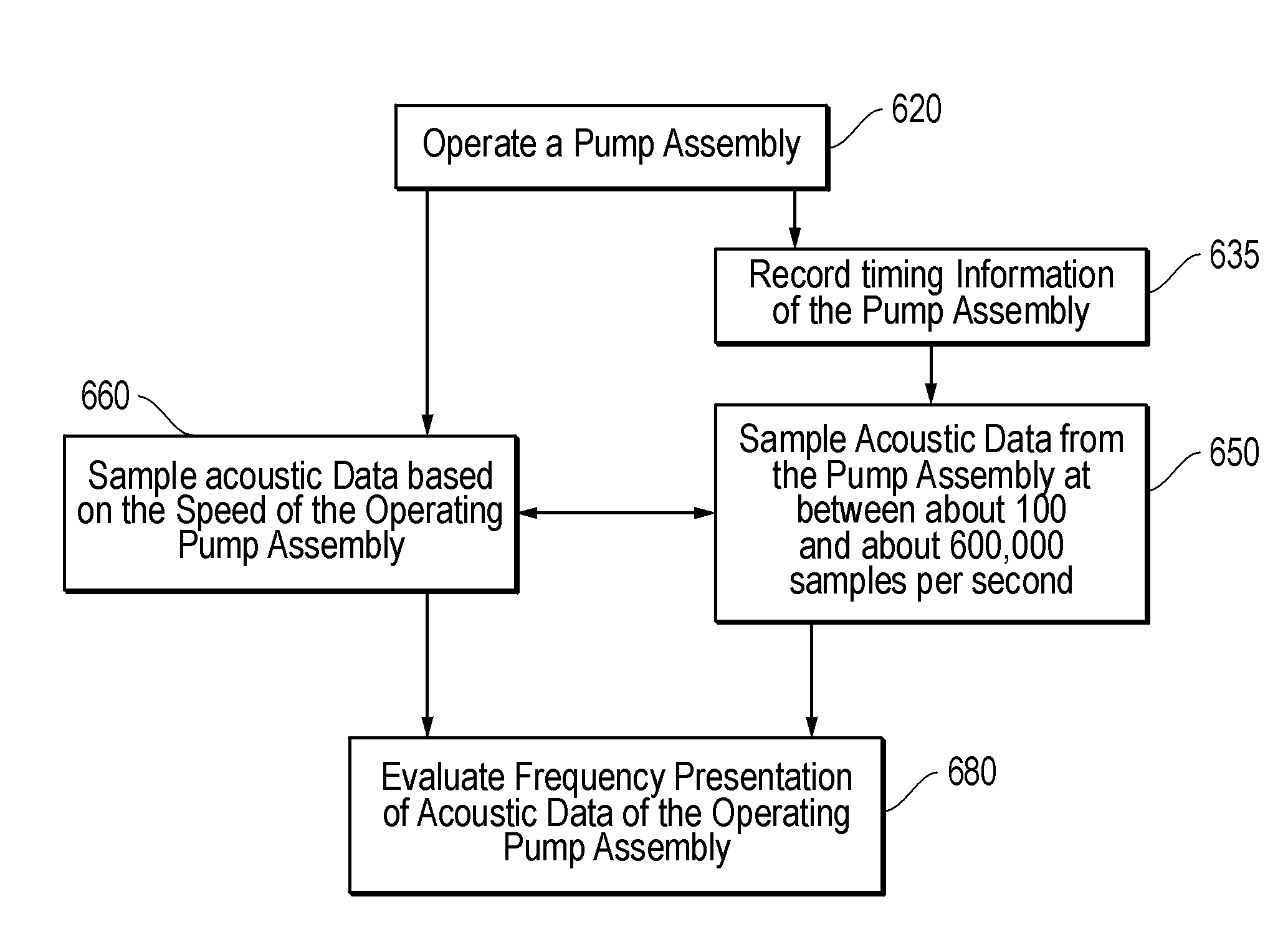

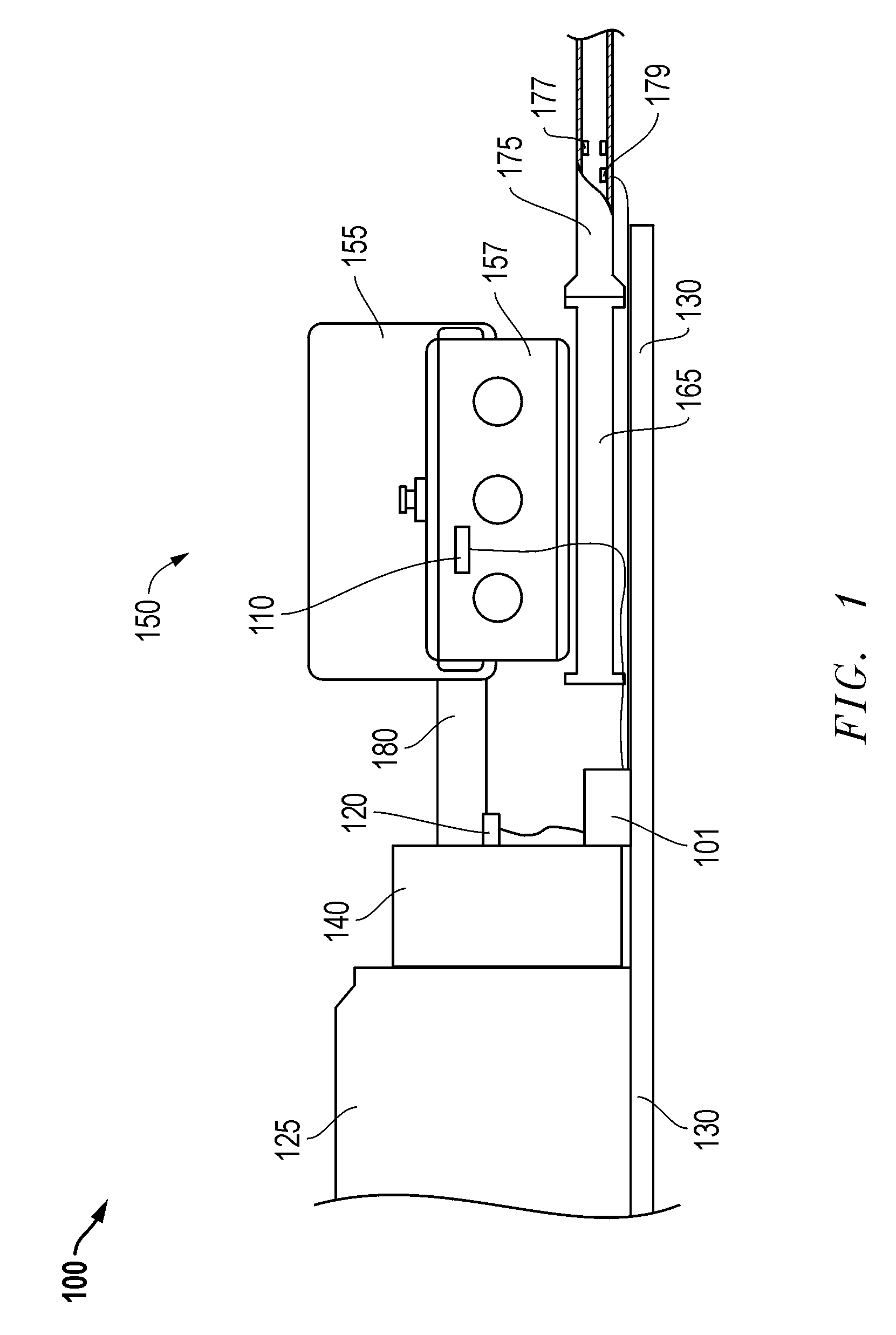

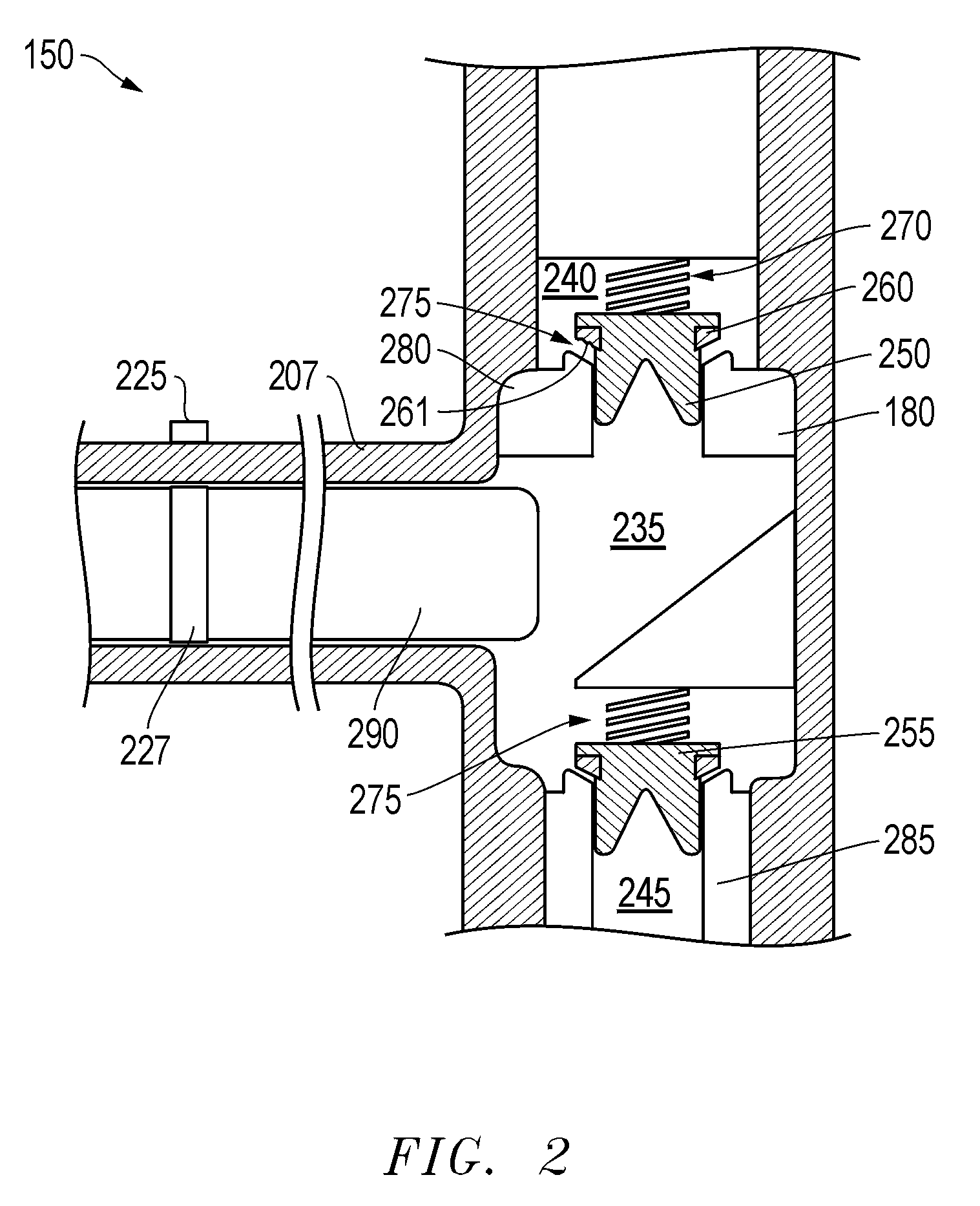

Pump integrity monitoring

InactiveUS20080006089A1Vibration measurement in solidsDetection of fluid at leakage pointImage resolutionComputer science

A method of monitoring integrity of a pump. The method may include recording timing information of the pump during operation while simultaneously sampling acoustic data with a high speed equidistant acquisition mechanism or at a rate based on the speed of the pump in operation. The acquisition of acoustic data is followed by evaluation thereof. Such techniques may improve resolution of acquired data while substantially increasing processor capacity for evaluation. A pump integrity monitor for carrying out such techniques is also described.

Owner:SCHLUMBERGER TECH CORP

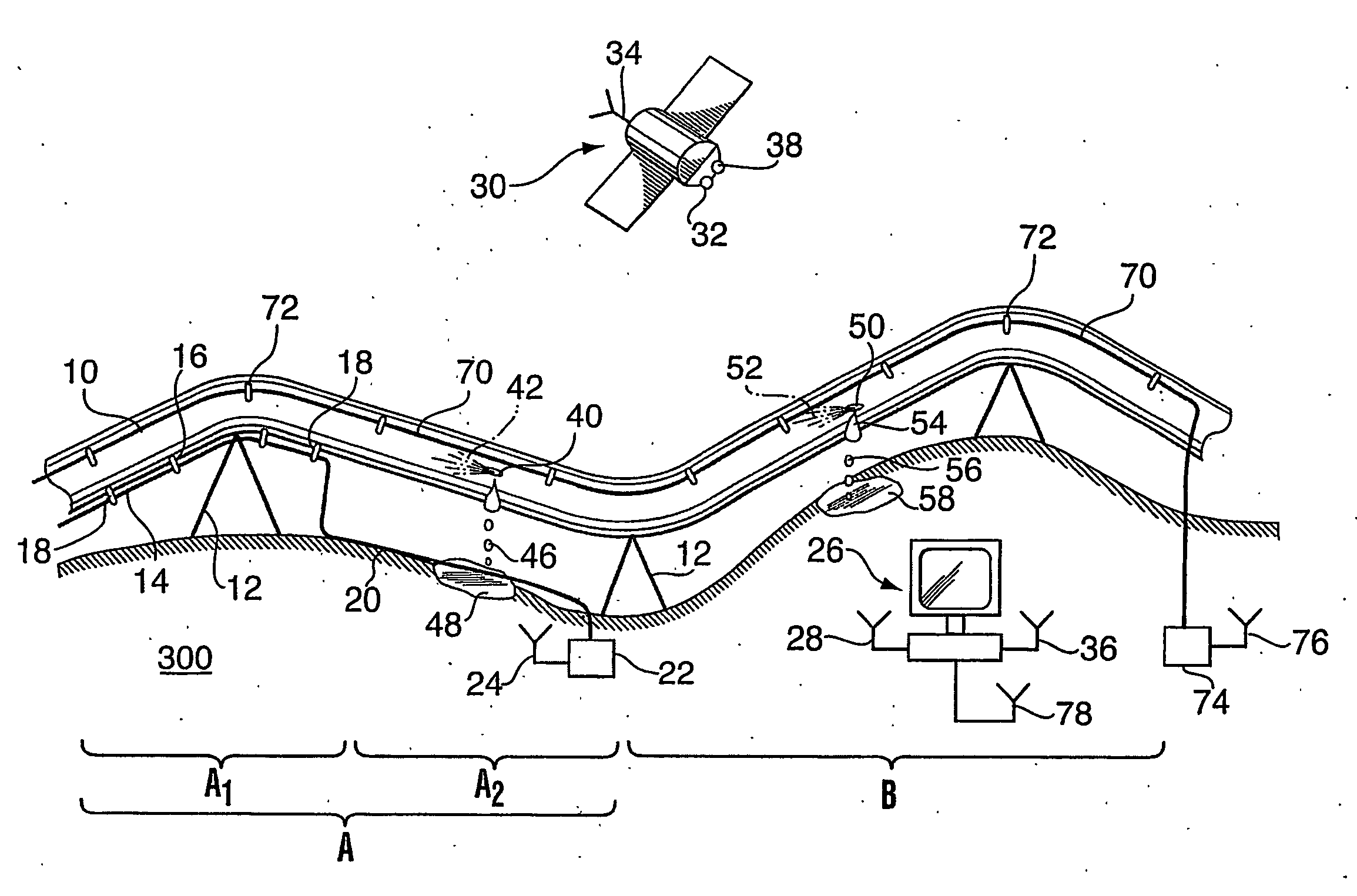

Pipeline monitoring system

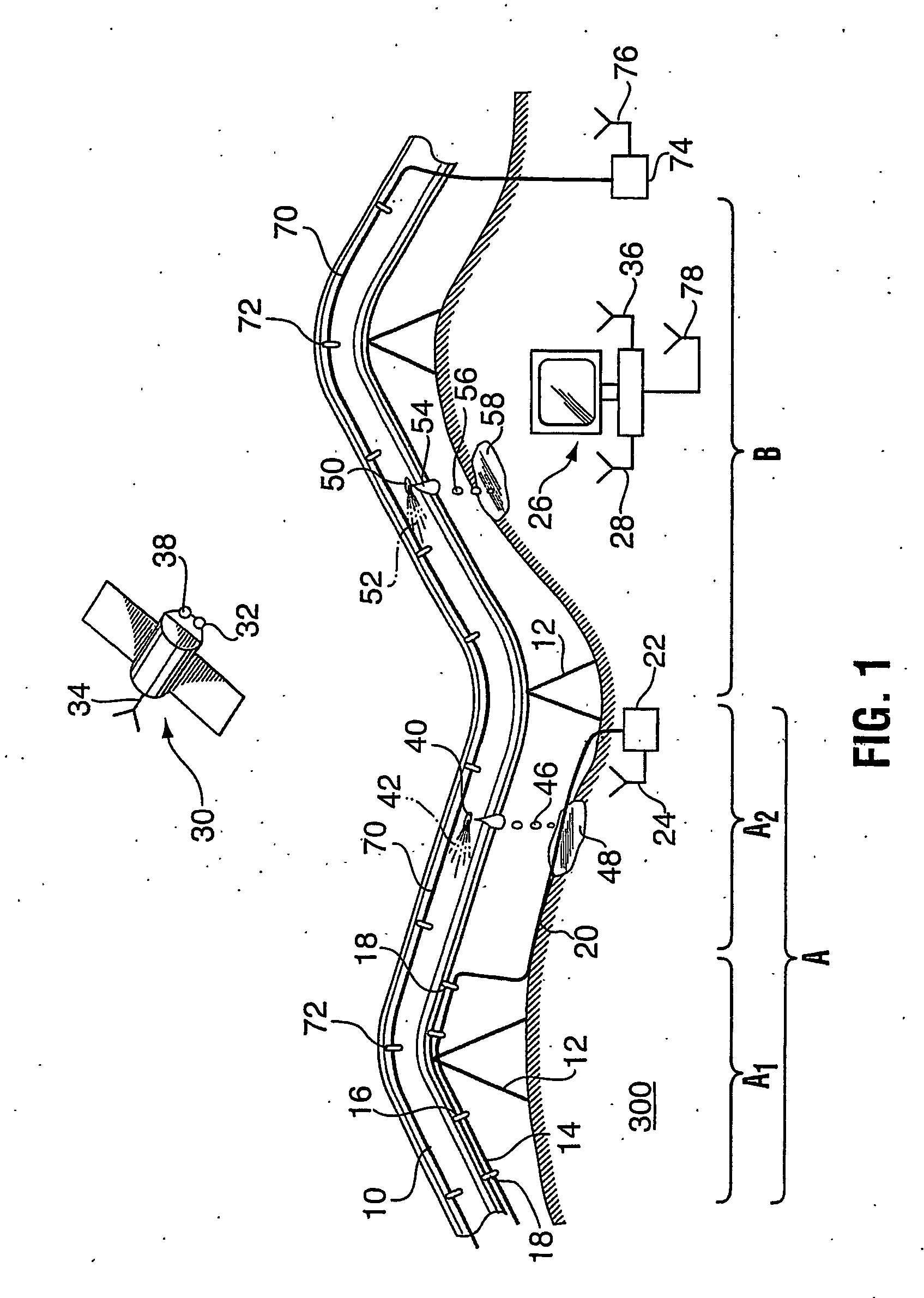

InactiveUS20060225507A1Convenient verificationDetection of fluid at leakage pointVibration measurement in fluidMonitoring systemEngineering

Process and apparatus for sensing possible leaks in a pipeline. The pipeline is monitored continuously by acoustic monitoring means, and acoustic events indicating a possible leak are noted. The pipeline is also equipped with temperature monitoring means, and is monitored for temperature either continuously, periodically or on demand. A leak is deemed probable at any location where there is an acoustic event indicating a possible leak, and at approximately the same time, a temperature difference greater than a pre-chosen amount between that location and adjacent locations

Owner:PURETECH VENTURES

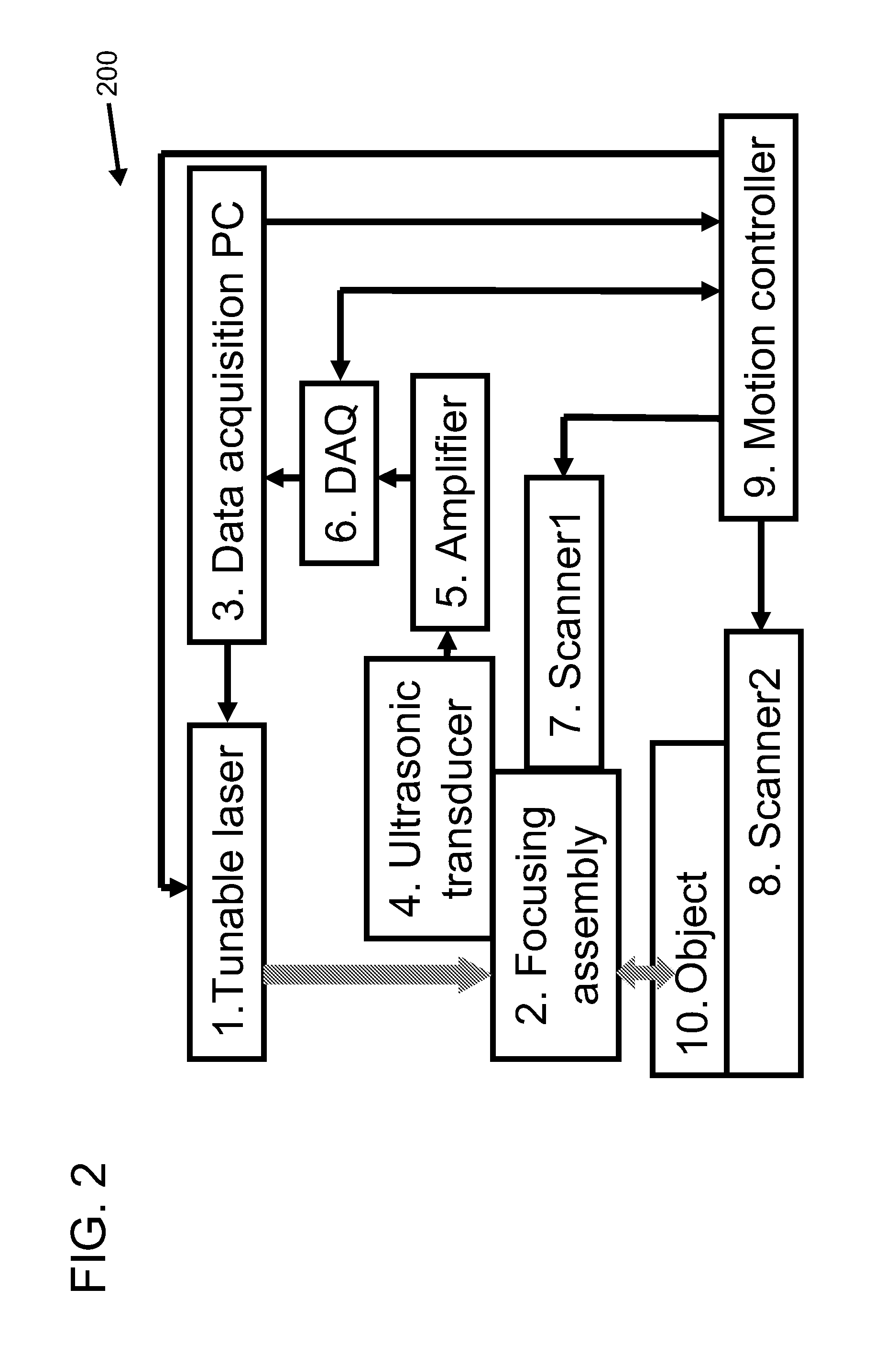

Confocal photoacoustic microscopy with optical lateral resolution

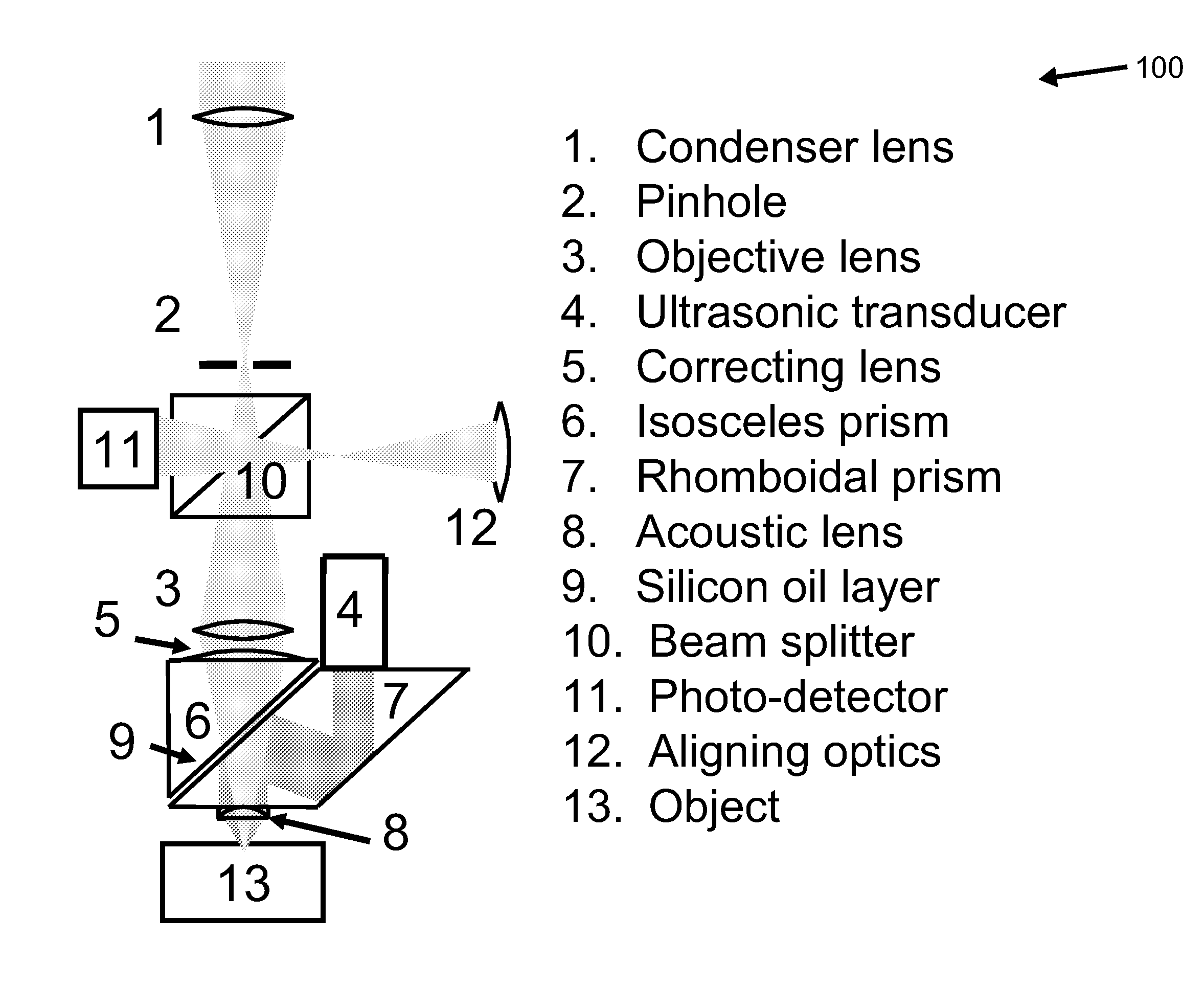

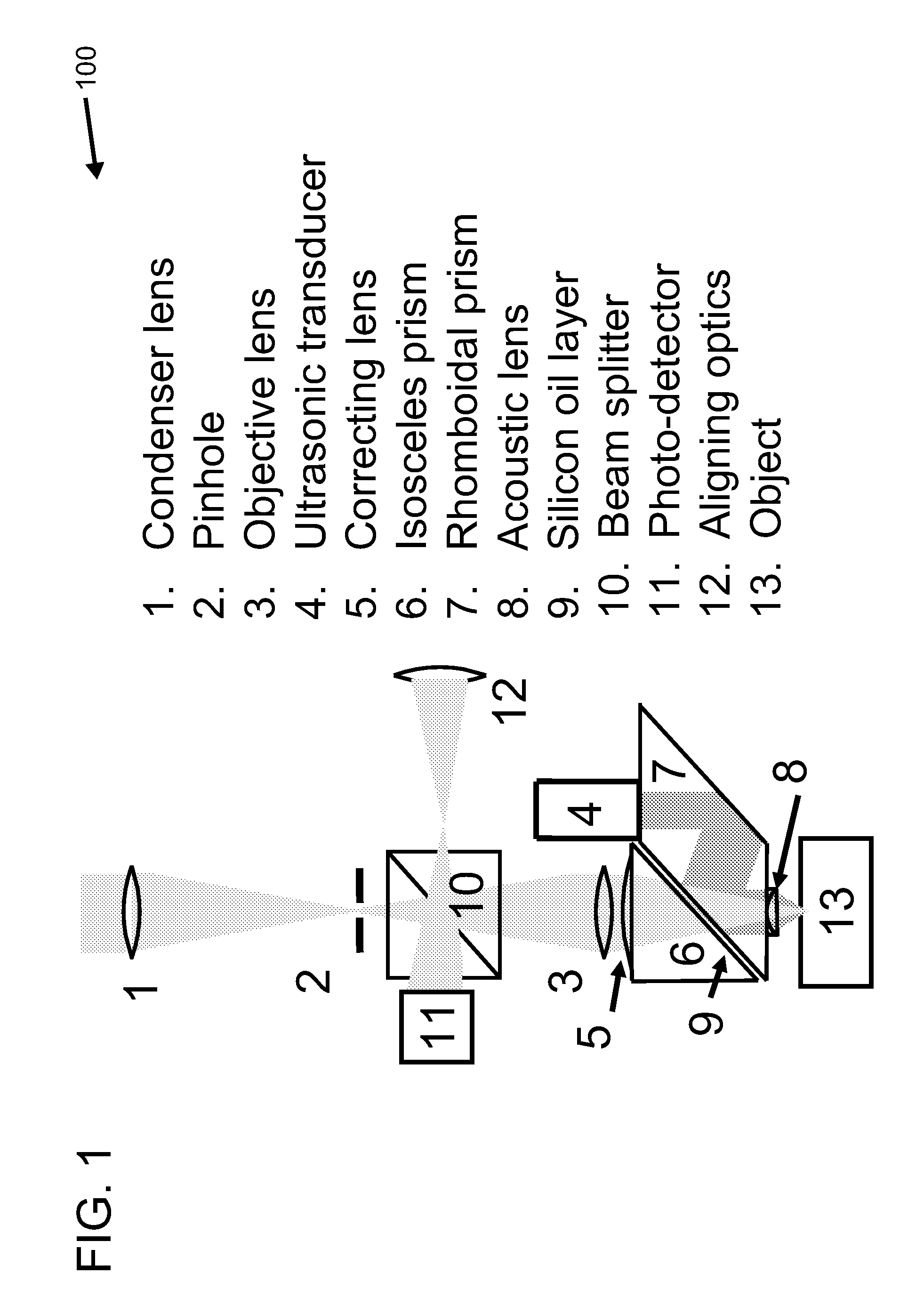

ActiveUS20100268042A1Vibration measurement in solidsUltrasonic/sonic/infrasonic diagnosticsPhotoacoustic microscopyUltrasonic sensor

A confocal photoacoustic microscopy system includes a laser configured to emit a light pulse, a focusing assembly configured to receive the light pulse and to focus the light pulse into an area inside an object, an ultrasonic transducer configured to receive acoustic waves emitted by the object in response to the light pulse, and an electronic system configured to process the acoustic waves and to generate an image of the area inside the object. The focusing assembly is further configured to focus the light pulse on the object in such a way that a focal point of the focusing assembly coincides with a focal point of the at least one ultrasonic transducer.

Owner:WASHINGTON UNIV IN SAINT LOUIS

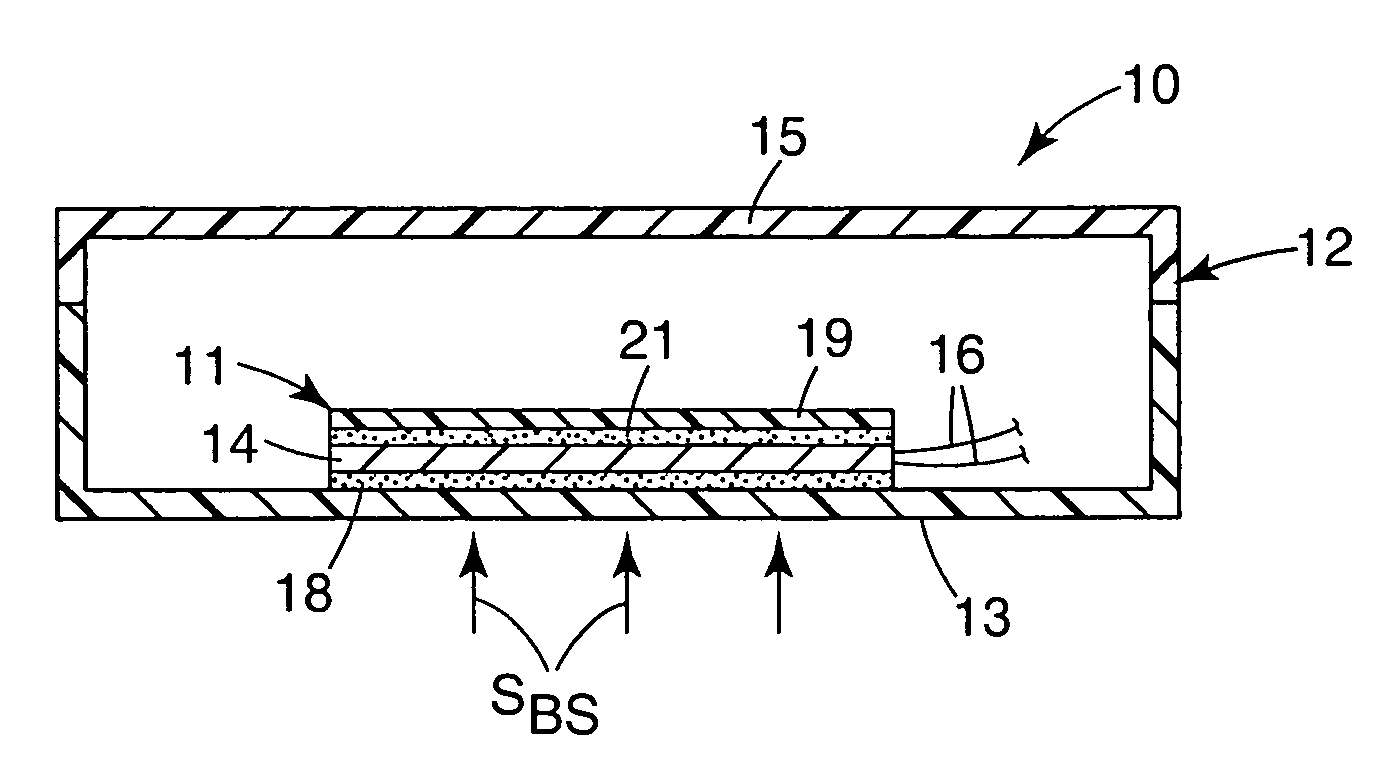

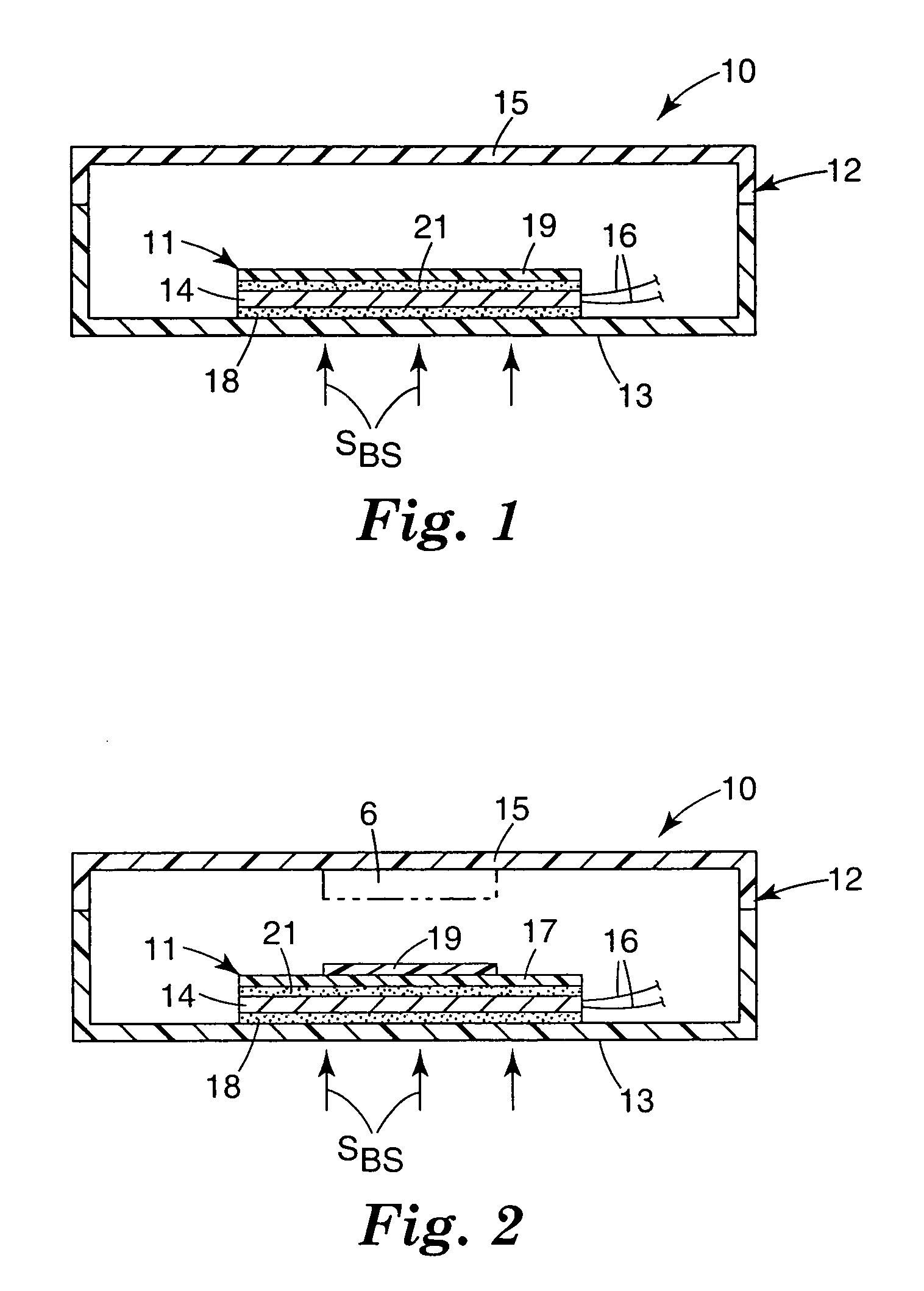

Configurable vibration sensor

InactiveUS20050204820A1Vibration measurement in solidsMachine part testingVibration measurementAudio power amplifier

A configurable vibration sensor comprising a sensor circuit, an analog-to-digital converter and a processor, where each sensor circuit comprises a vibration sensing element and a variable bandwidth filter controllable by the processor. In addition to the variable bandwidth filter, other configurable elements may also be employed in the sensor circuit, including a variable gain amplifier. These configurable elements allow the configurable vibration sensor to be configured for different vibration measurement applications when measuring vibrations from vibrating structures such as machinery and the like.

Owner:MECHWORKS SYST

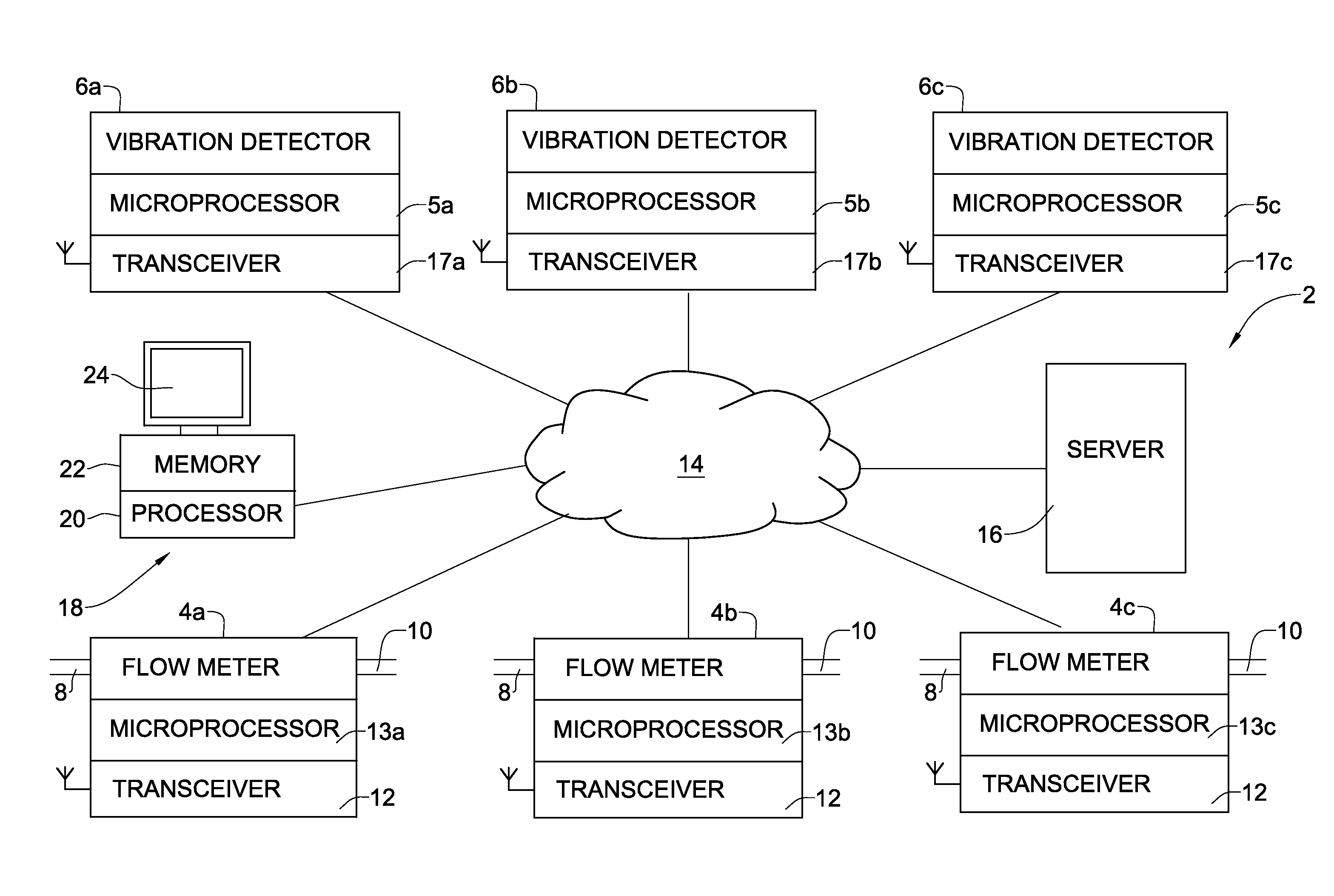

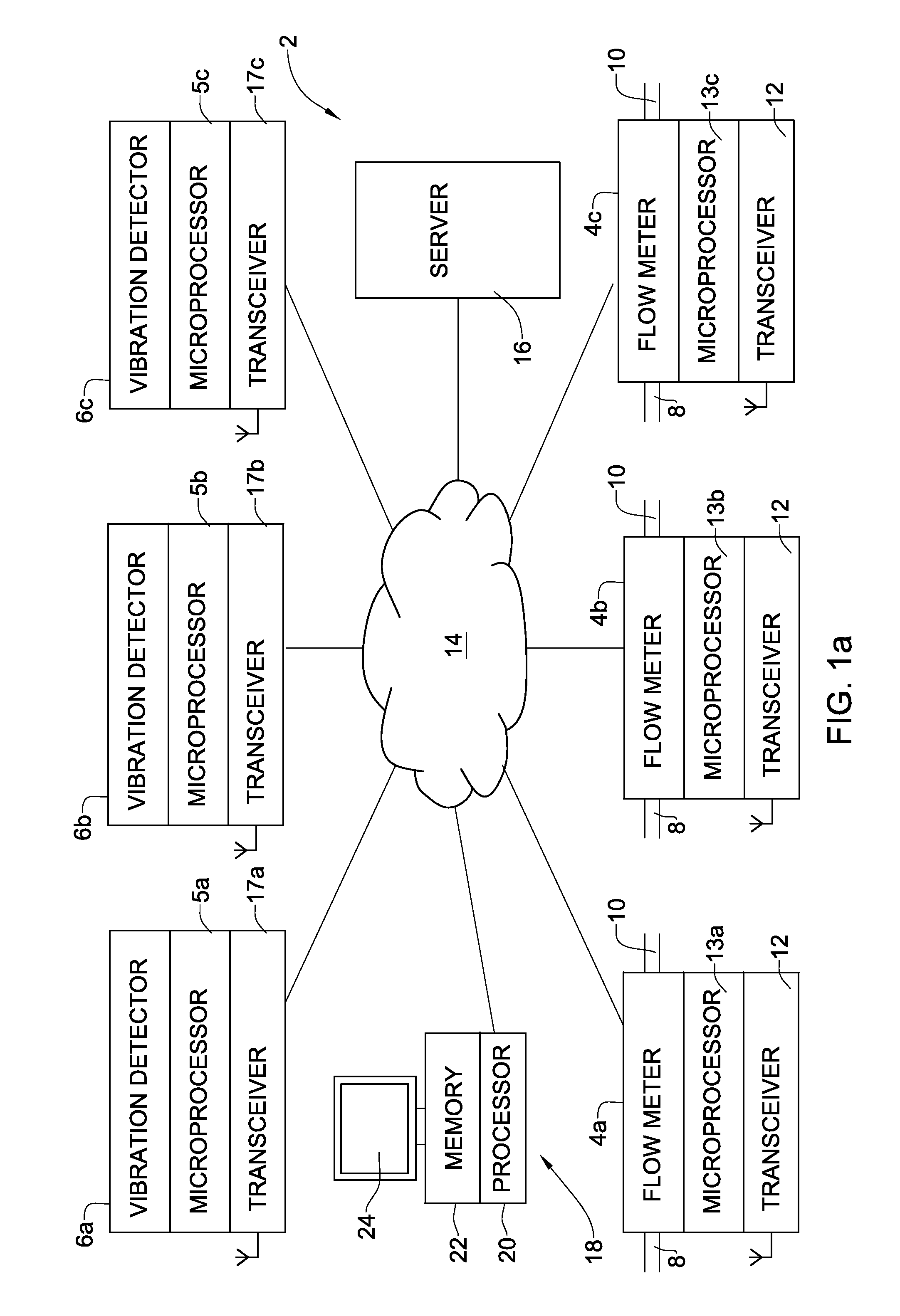

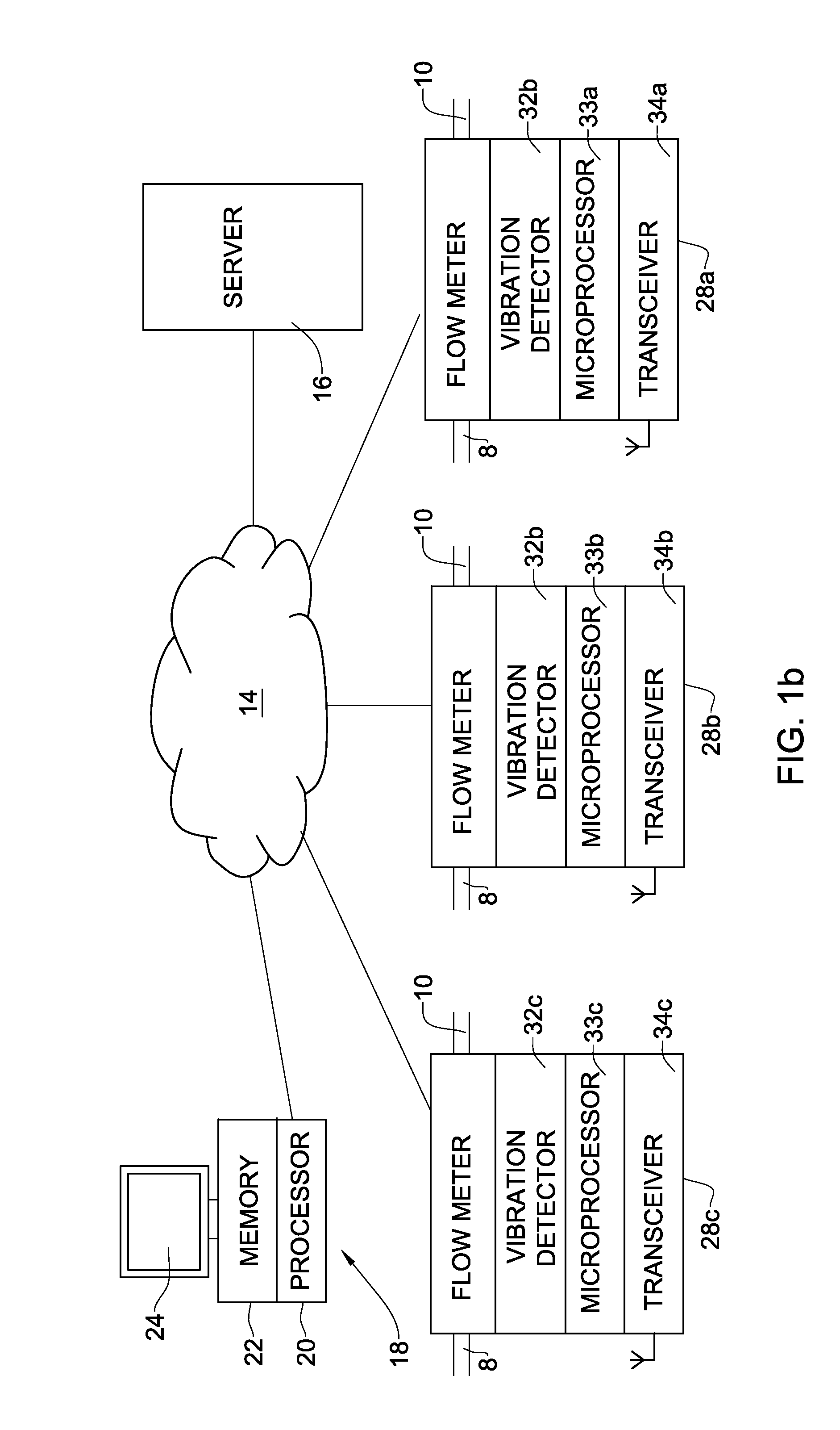

System method and device for leak detection and localization in a pipe network

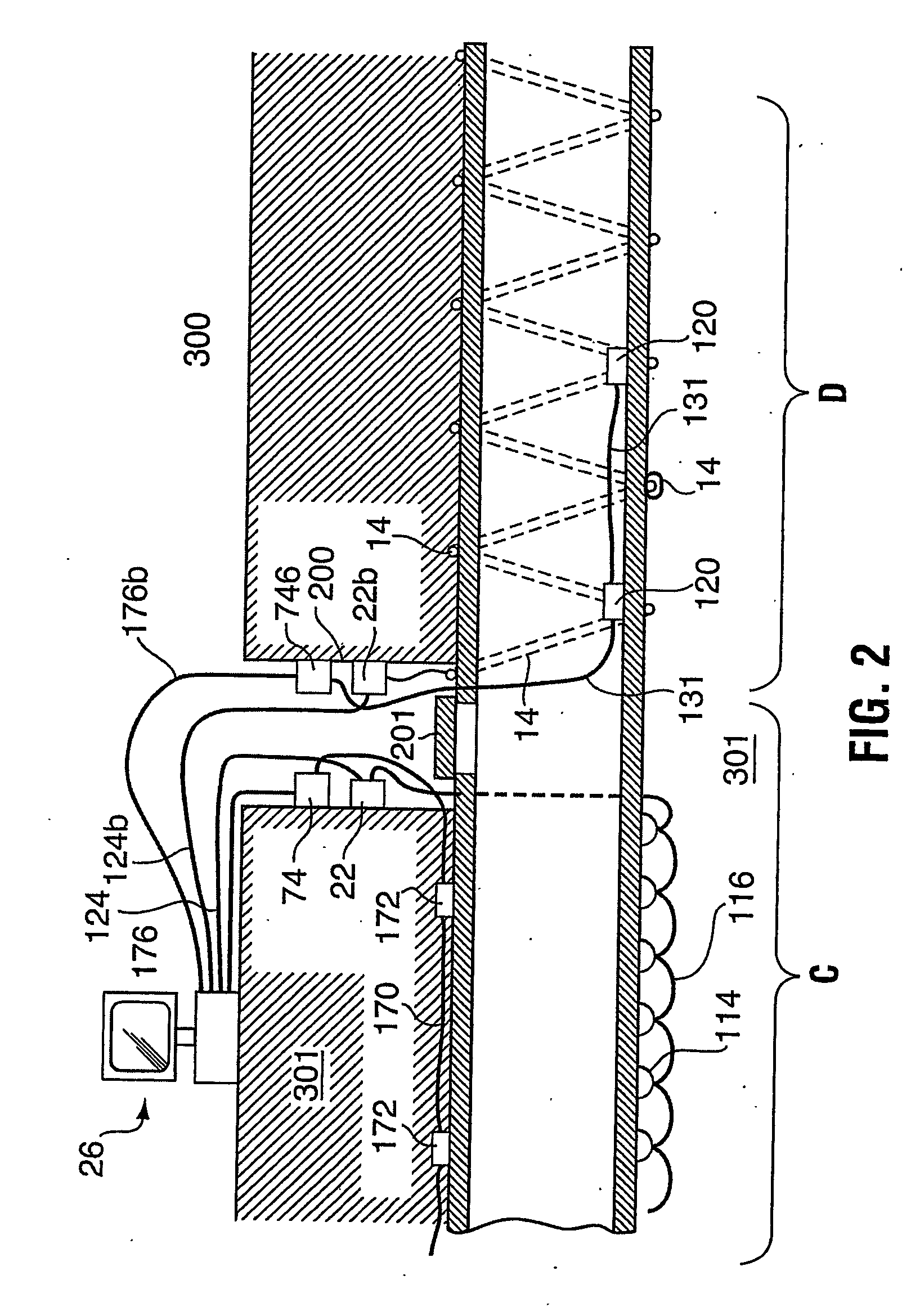

ActiveUS20120007743A1Reduce vibration measurement artifactReduce artifactsDetection of fluid at leakage pointMaterial analysis using acoustic emission techniquesEngineeringLeak detection

The invention provides a system for leak detection of a fluid in a pipe network. The system includes flow meters, and vibration detectors adapted to be attached to a pipe at a location in the pipe network. A processor analyzes signals generated by the flow meters and vibration detectors to identify the presence of one or more leaks in the pipe network. The invention also provides a method for detecting and localizing leaks in a pipeline network, and a device comprising a flow meter integral with a vibration detector for use in the system of the invention.

Owner:AQUARIUS SPECTRUM

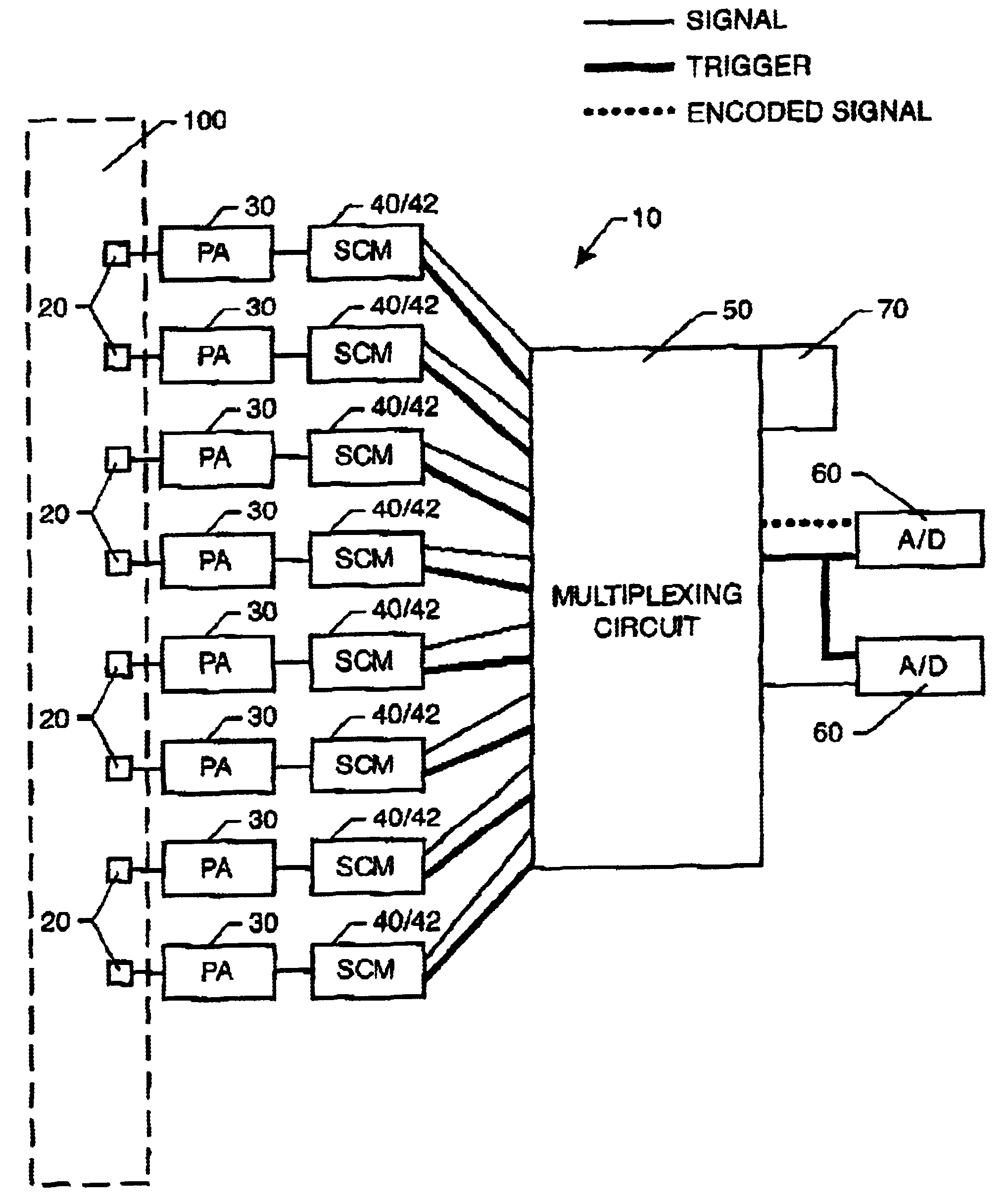

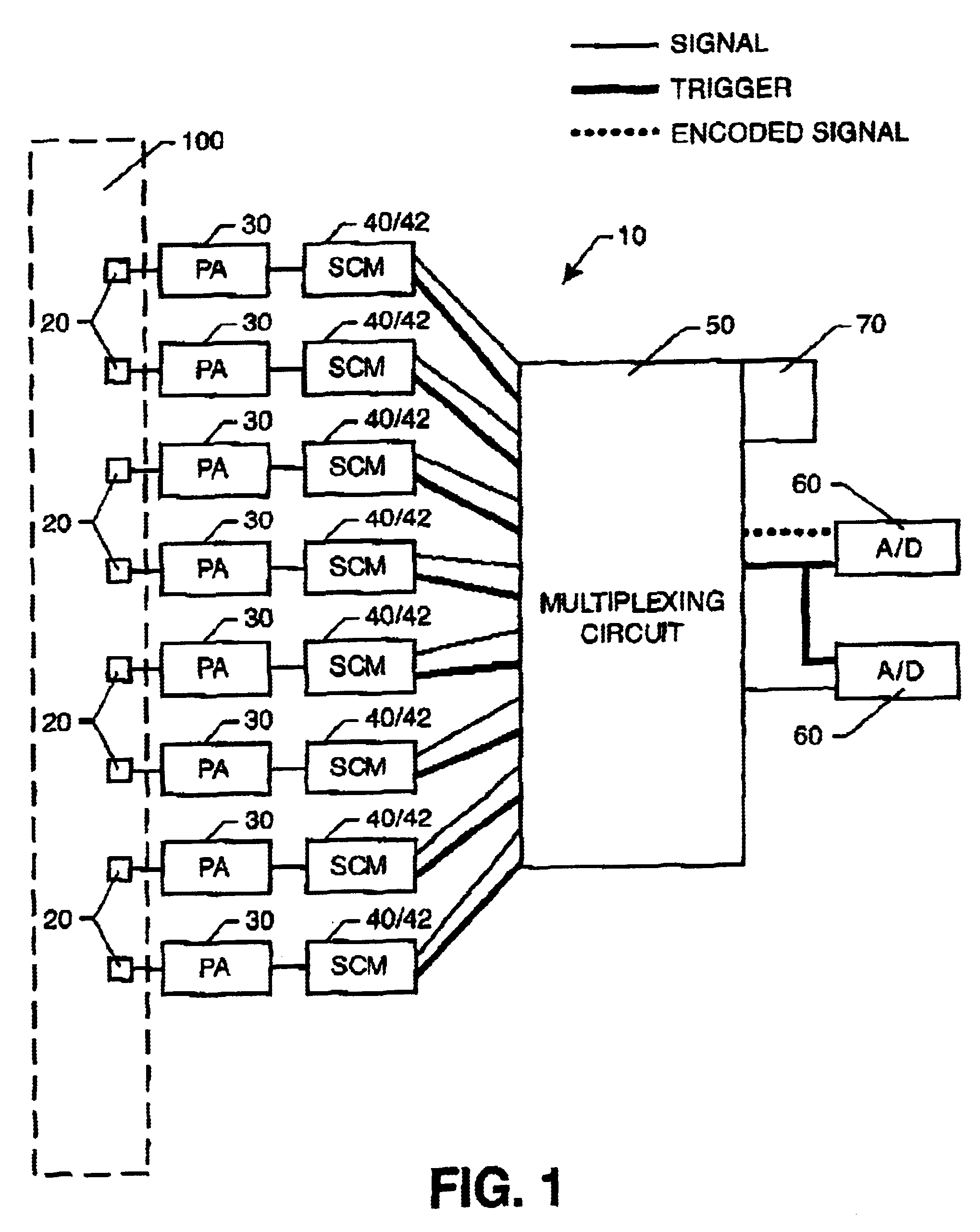

System for multiplexing acoustic emission (AE) instrumentation

InactiveUS6628567B1Vibration measurement in solidsMaterial analysis using acoustic emission techniquesMultiplexingAcoustic emission

An acoustic monitoring device has at least two acoustic sensors with a triggering mechanism and a multiplexing circuit. After the occurrence of a triggering event at a sensor, the multiplexing circuit allows a recording component to record acoustic emissions at adjacent sensors. The acoustic monitoring device is attached to a solid medium to detect the occurrence of damage.

Owner:DIGITAL WAVE CORP +1

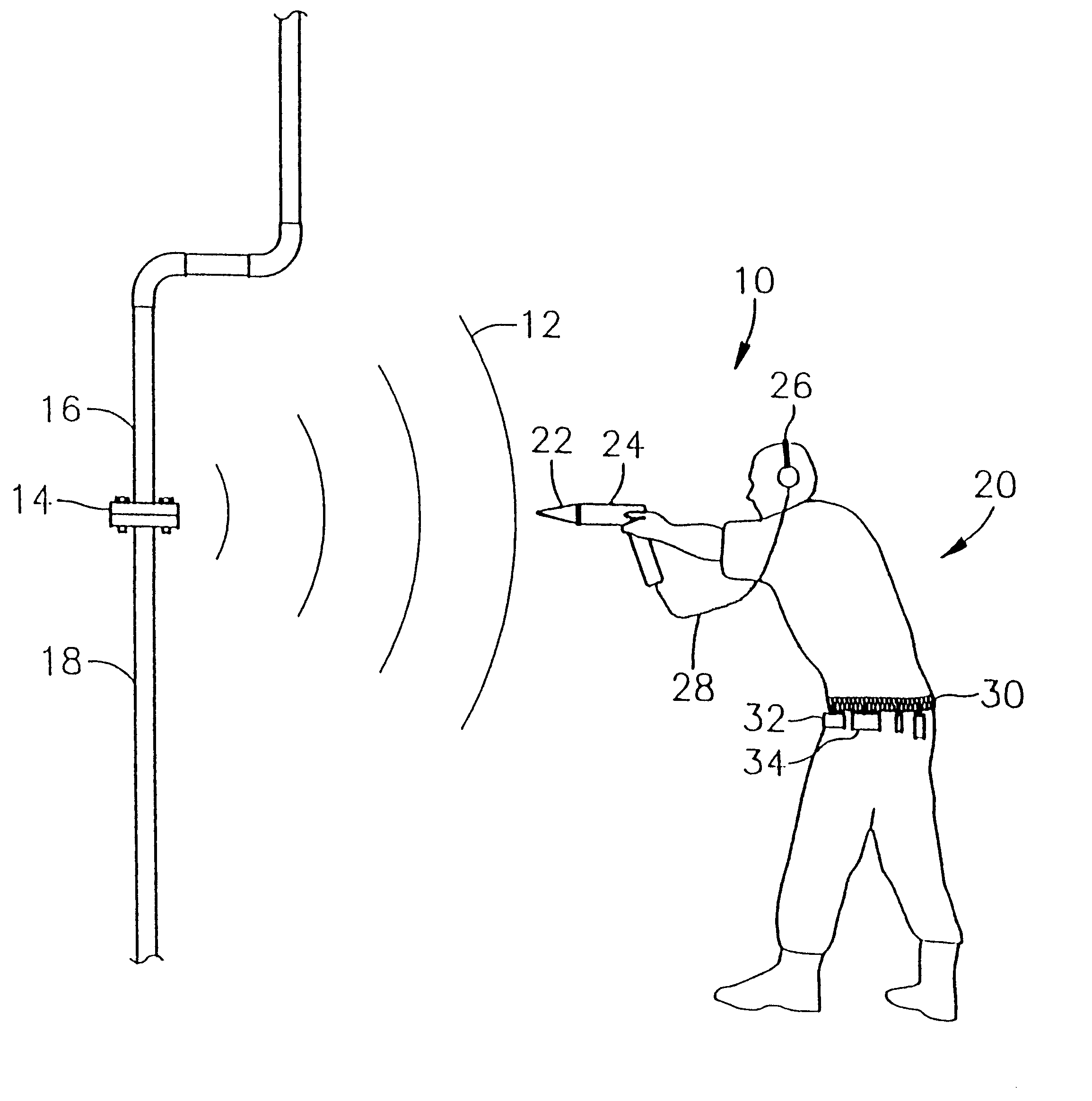

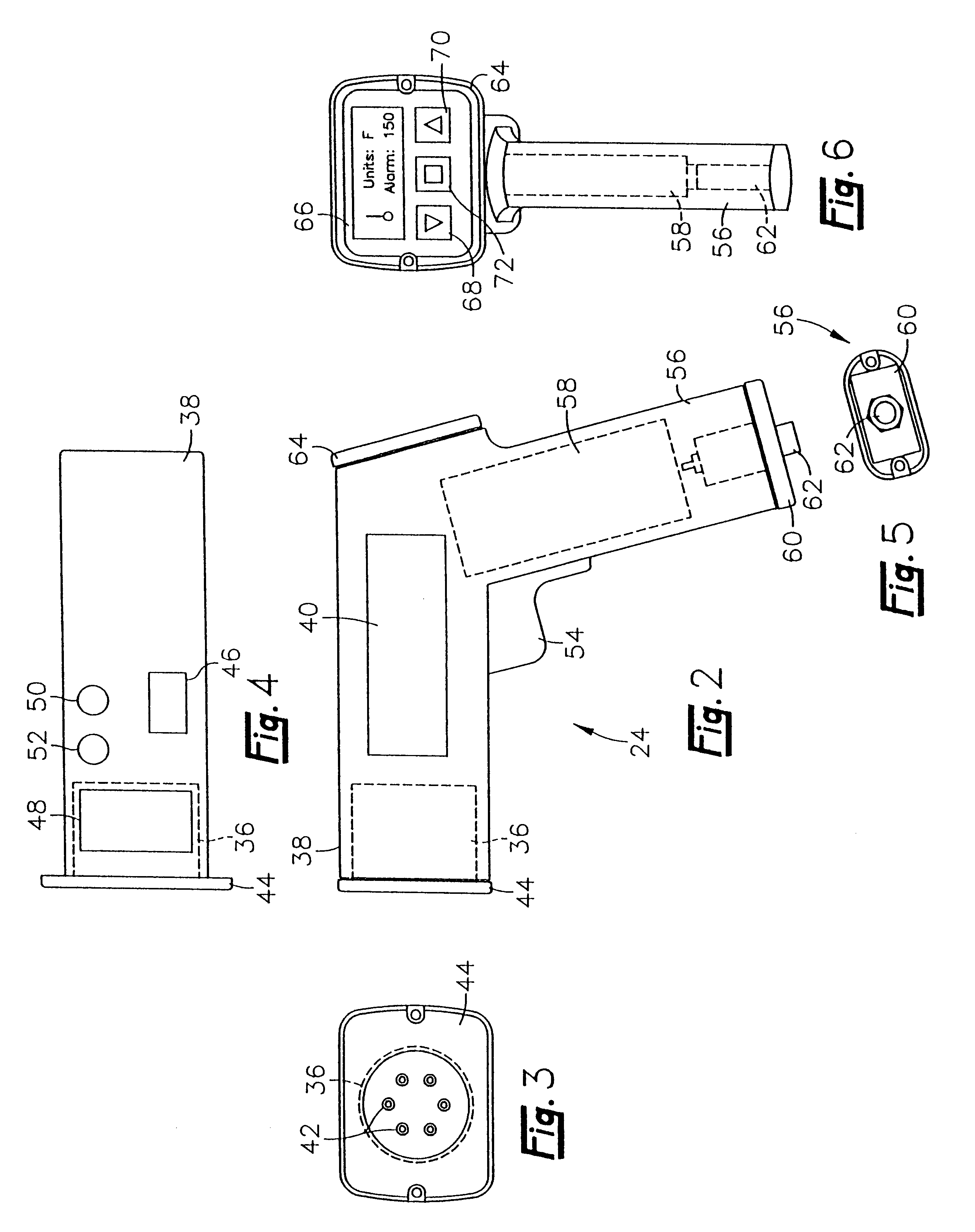

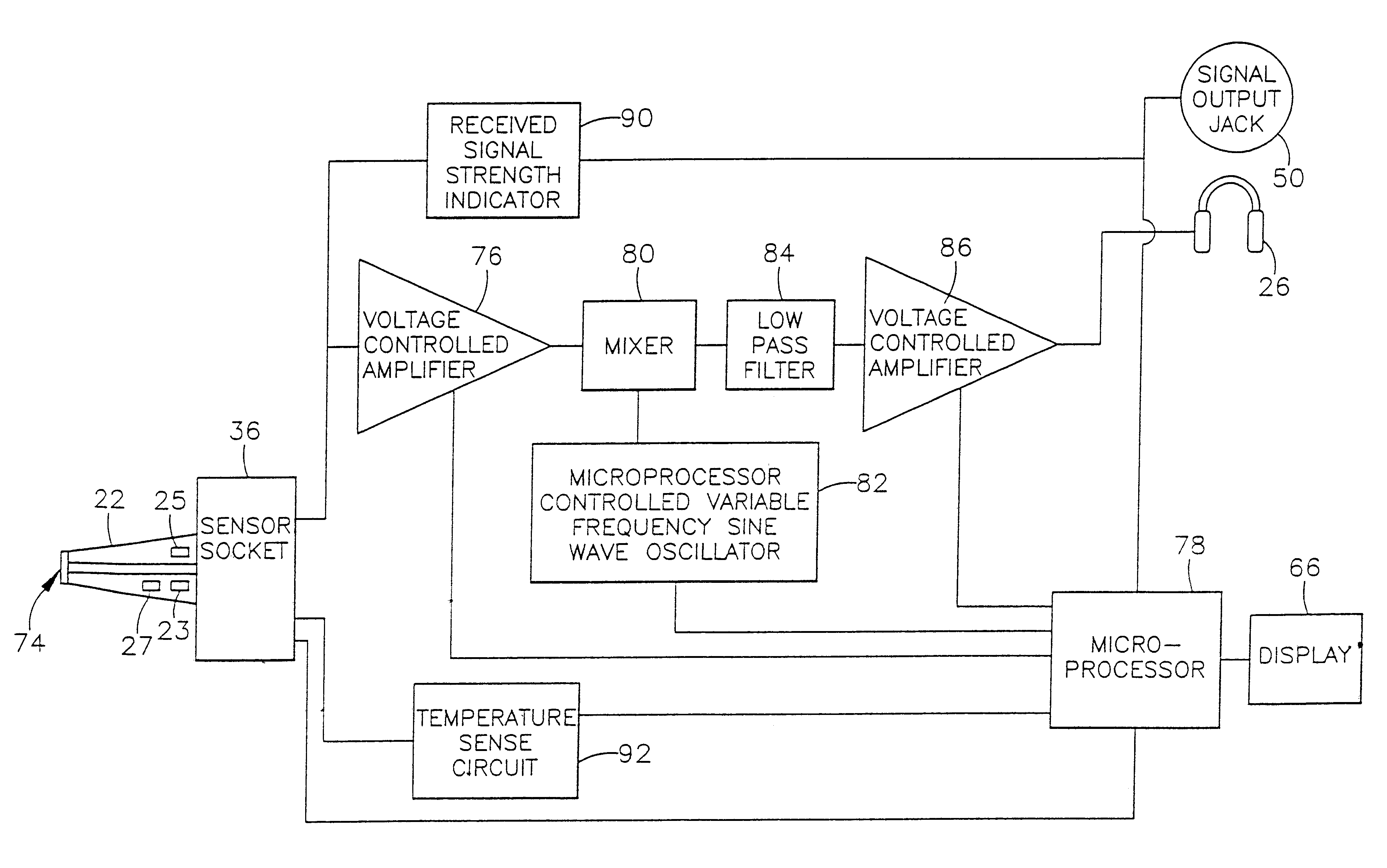

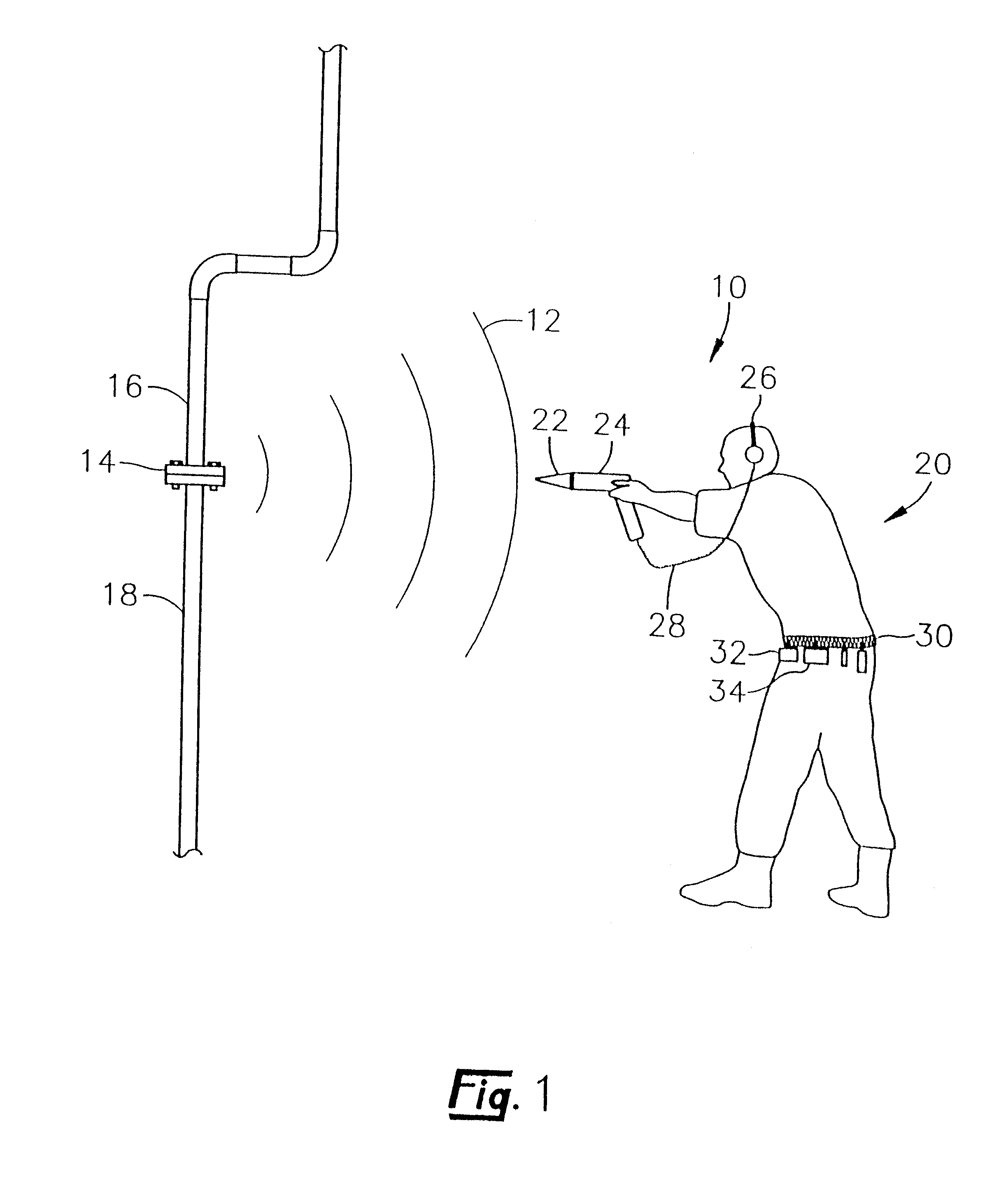

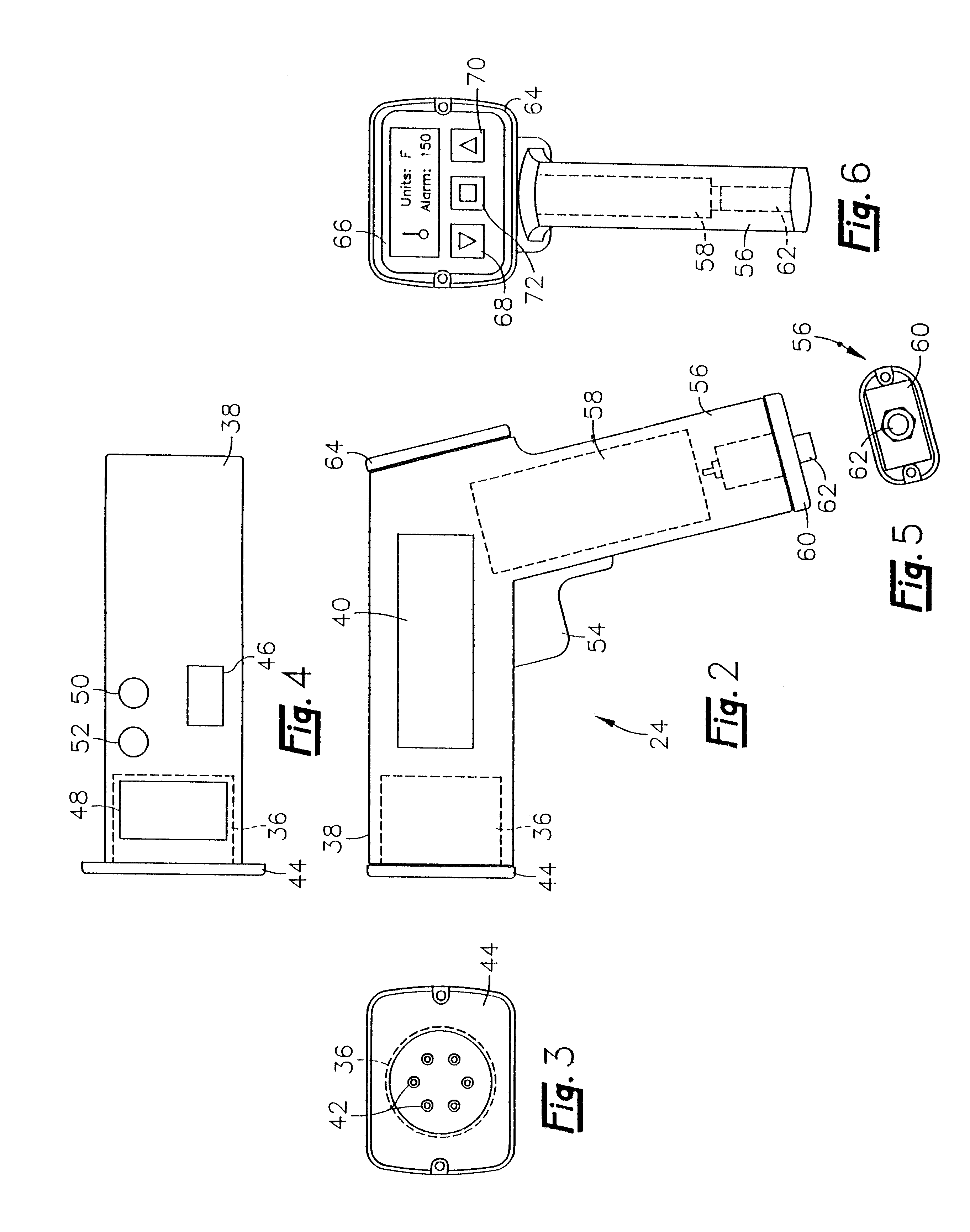

Multiple sensor ultrasonic monitoring device

InactiveUS6220098B1High thermal and ultrasonic conductivityMinimize intrinsic thermal time constantVibration measurement in solidsMachine part testingHand heldMultiple sensor

An ultrasonic monitoring apparatus is provided for use by an operator in detecting ultrasonic vibrations and sound waves. The ultrasonic monitoring apparatus consists of a hand held device with a sensor socket that allows a variety of different types of sensors to be interchangeably installed in the hand held device. These sensors include both contact and airborne ultrasonic sensors as well as a combination temperature and ultrasonic sensor that allows the operator to simultaneously monitor the surface temperature of an object and the ultrasonic vibrations produced by the object. Identification information corresponding to the type of sensor is encoded on the individual sensors. The identification information is read by an identification circuit located in the hand held device. This identification information allows the hand held device to configure itself to operate with the type of sensor installed in the socket.

Owner:COMPUTATIONAL SYST

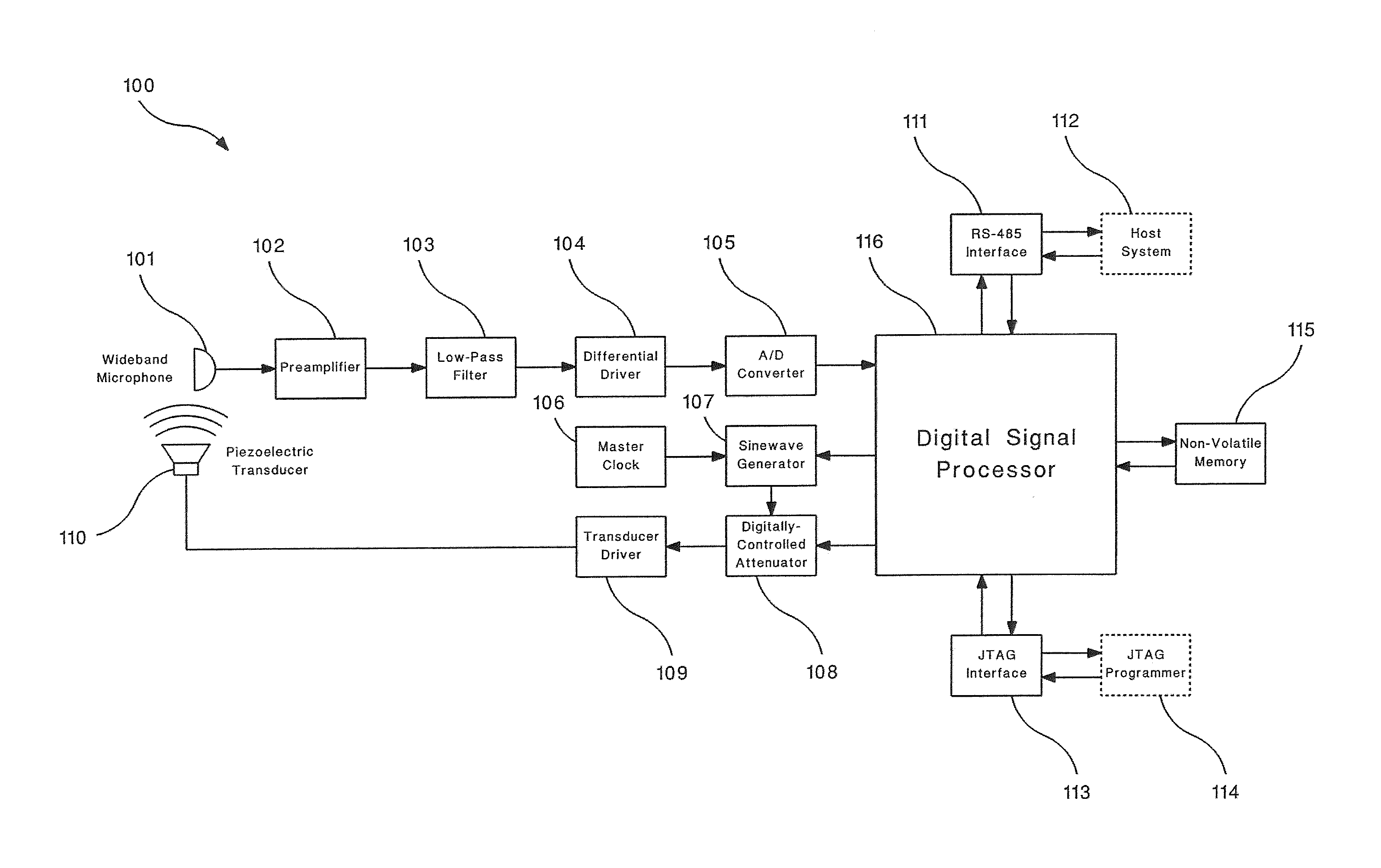

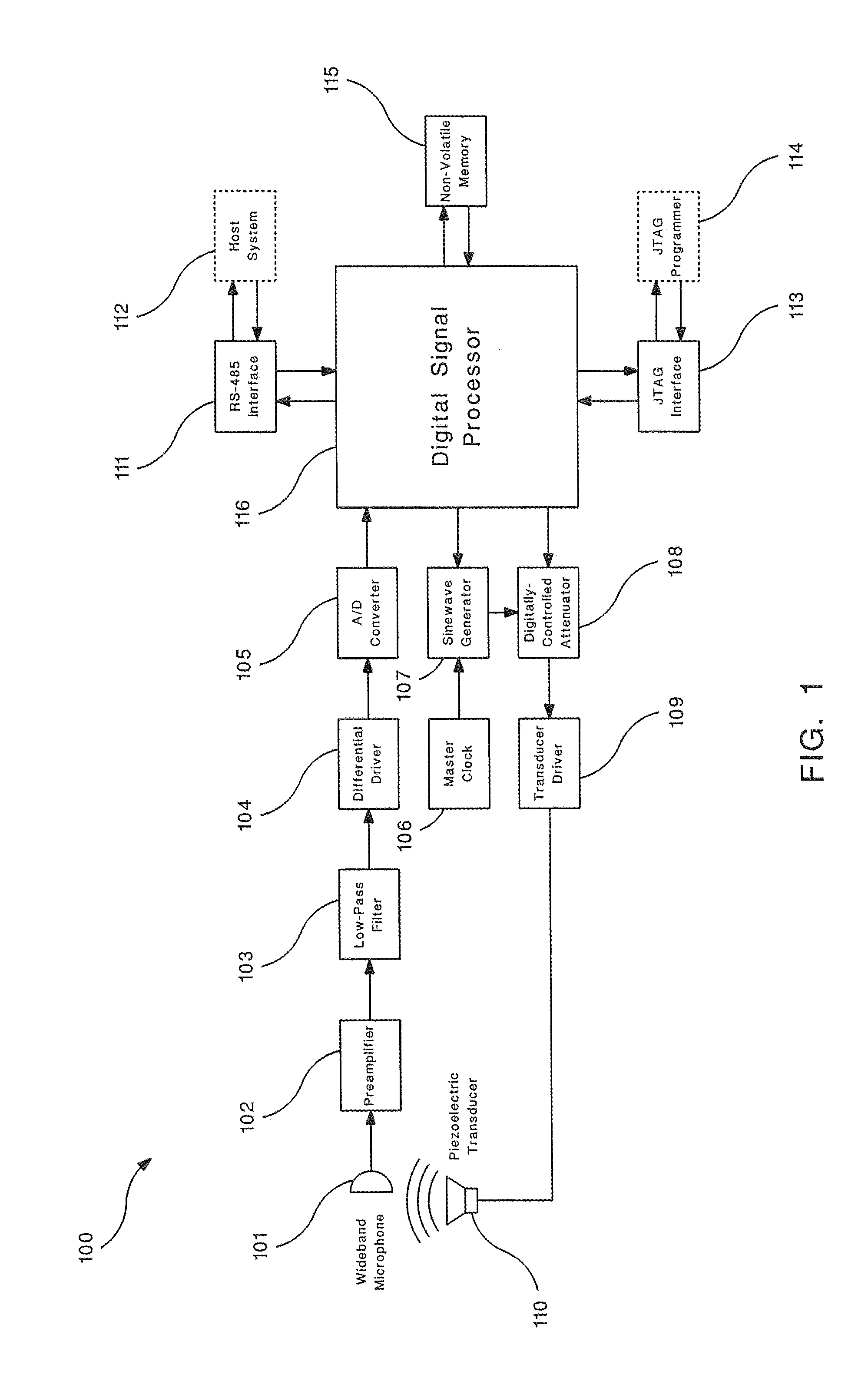

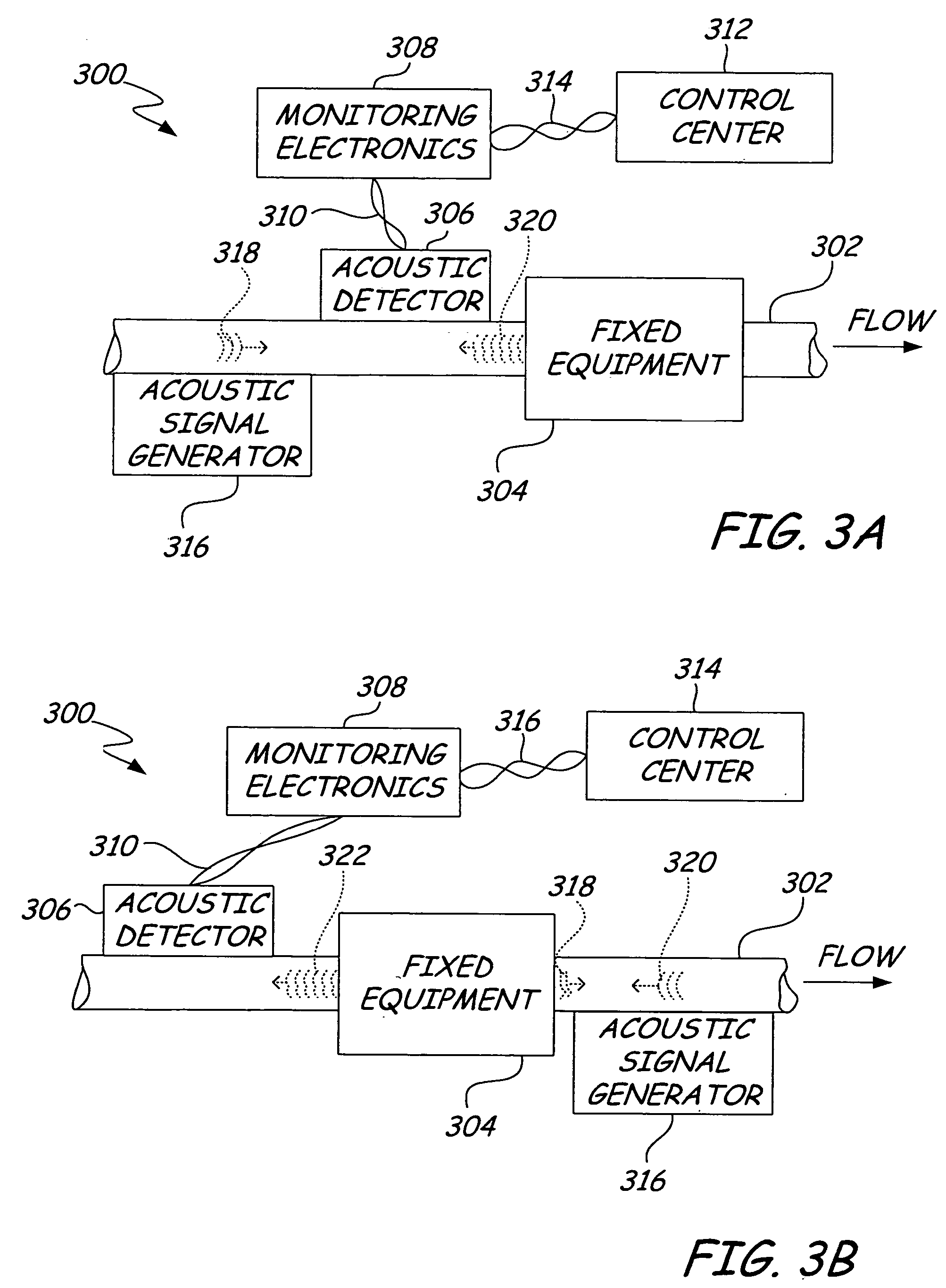

System and method for an acoustic monitor self-test

InactiveUS20130166227A1Material analysis using acoustic emission techniquesFlow propertiesUltrasound attenuationAnalog signal

A system for self-testing an acoustic monitor includes a memory that stores a reference acoustic power of a reference acoustic signal; a digital signal processor (DSP) that computes a real-time acoustic power spectrum of background noise in a frequency range of about 20 Hz to about 80 kHz; a microphone including analog signal conditioning circuitry that receives an acoustic test signal at a test frequency and sound pressure level (SPL), the SPL including an attenuation level; and a processor that compares a measured acoustic power at the test frequency with a calculated acoustic power of the acoustic test signal, the calculated acoustic power including the reference acoustic power and the attenuation level; where the acoustic monitor includes the DSP in signal communication with the microphone.

Owner:UTC FIRE & SECURITY AMERICAS CORPORATION INC

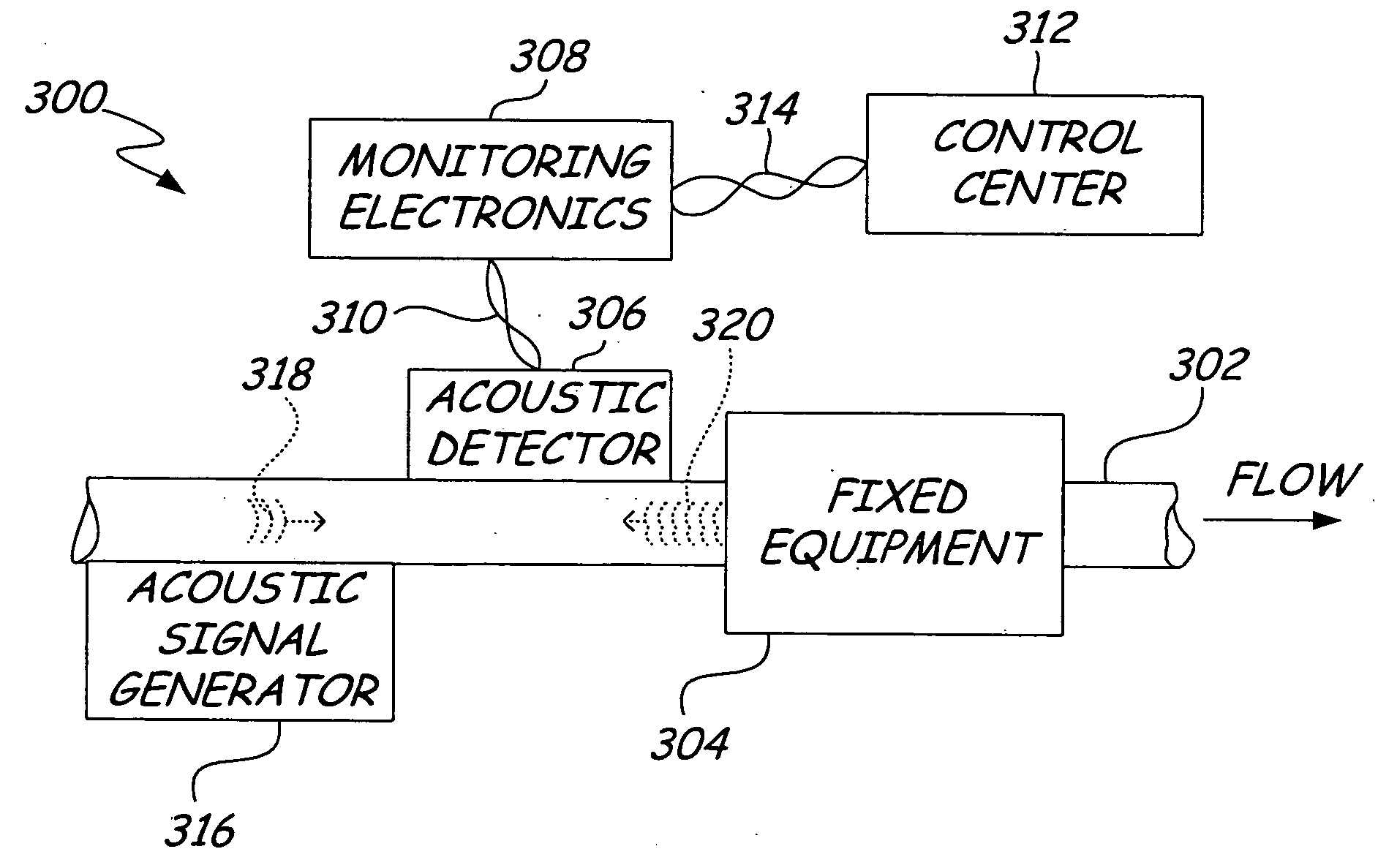

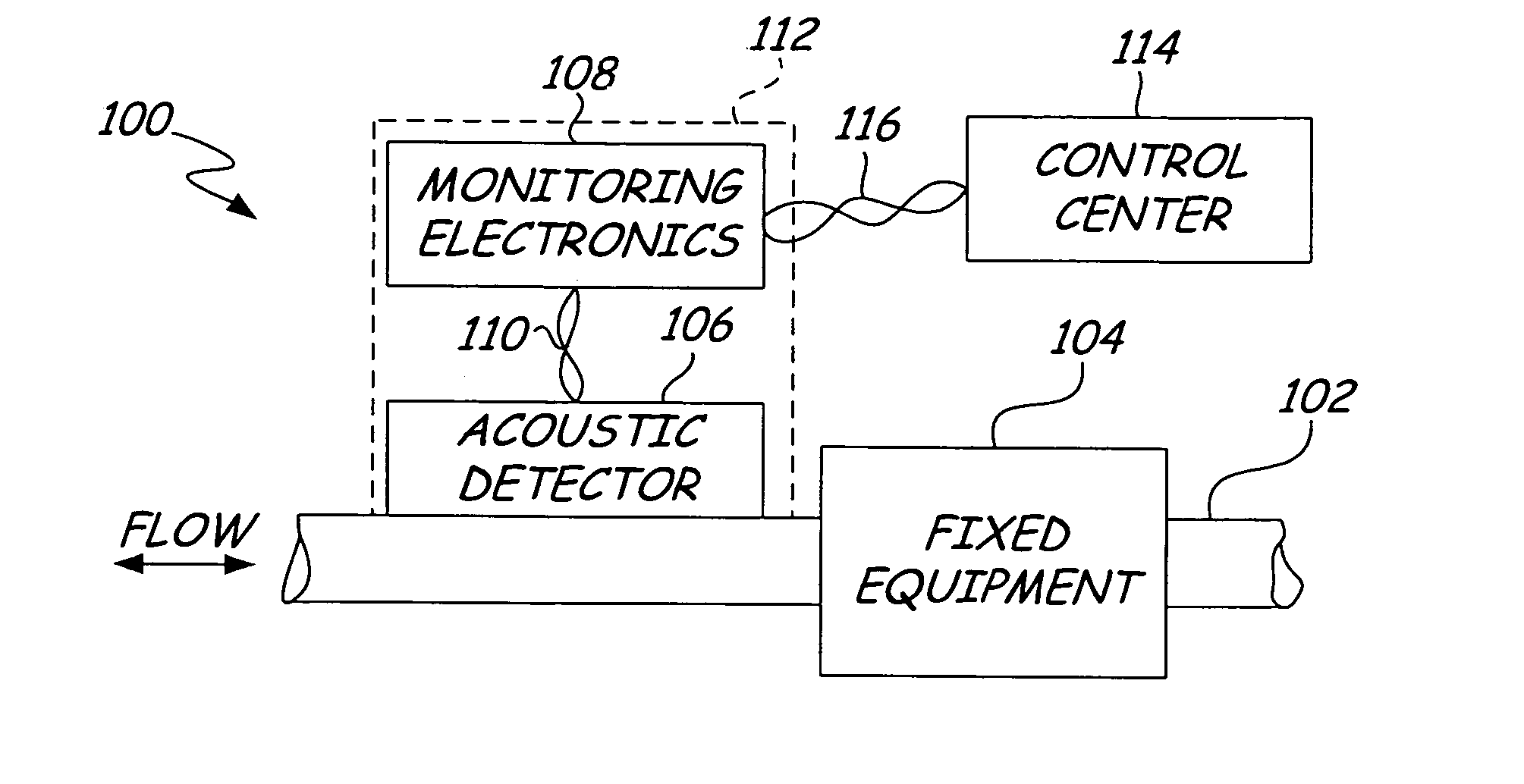

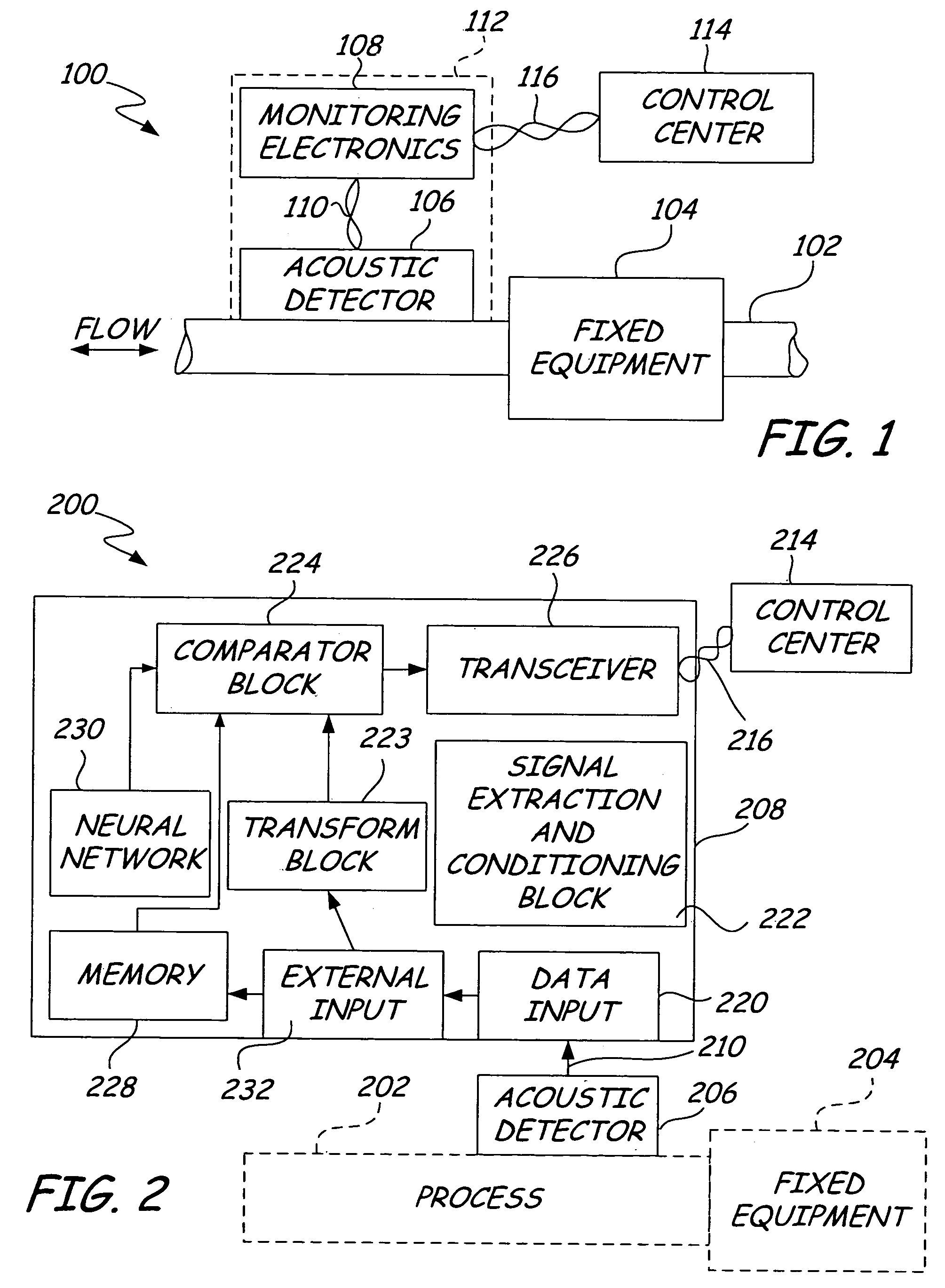

Process diagnostics

ActiveUS7290450B2Improve abilitiesEasy to useVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

A diagnostic device for use in a industrial process includes monitoring electronics or diagnostic circuitry configured to diagnose or identify a condition or other occurrence in the industrial process. The system can be implemented in a process device such as a flowmeter, and in one example an acoustic flowmeter. A transducer can also be used and a frequency response, such as resonant frequency, can be observed.

Owner:ROSEMOUNT INC

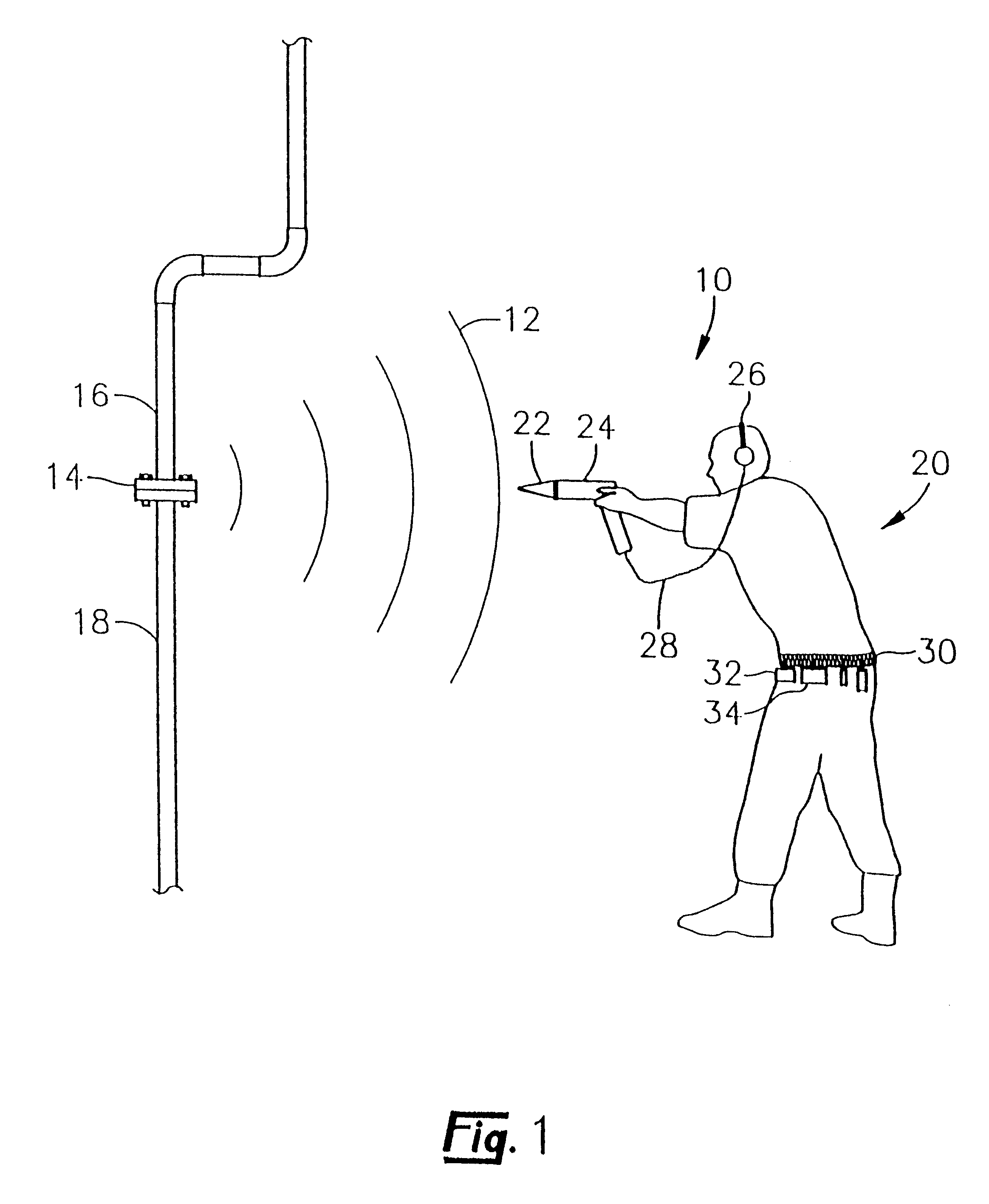

Digital ultrasonic monitoring system and method

InactiveUS6247353B1Easily readable formatVibration measurement in solidsDetection of fluid at leakage pointSonificationDisplay device

A portable digital ultrasonic monitoring system and method for use by an operator in detecting the ultrasonic waves and temperature variations produced by sources such as leaks in pipes, arcing, electrical corona and machinery defects is provided. The digital ultrasonic monitoring system includes a microprocessor based system in a hand held elongate housing that digitally analyzes and stores information received from its sensors. The digital ultrasonic monitoring system provides a referenced decibel output reading of the signal strength of the received ultrasonic signals. In addition, a heterodyned type audio signal that is related to the sensed ultrasonic signals is provided to the operator through a pair of headphones. The portable device has user input keys that allow the operator to select from a variety of different operating modes. A display displays a variety of different readings depending upon the operating mode of the device.

Owner:COMPUTATIONAL SYST

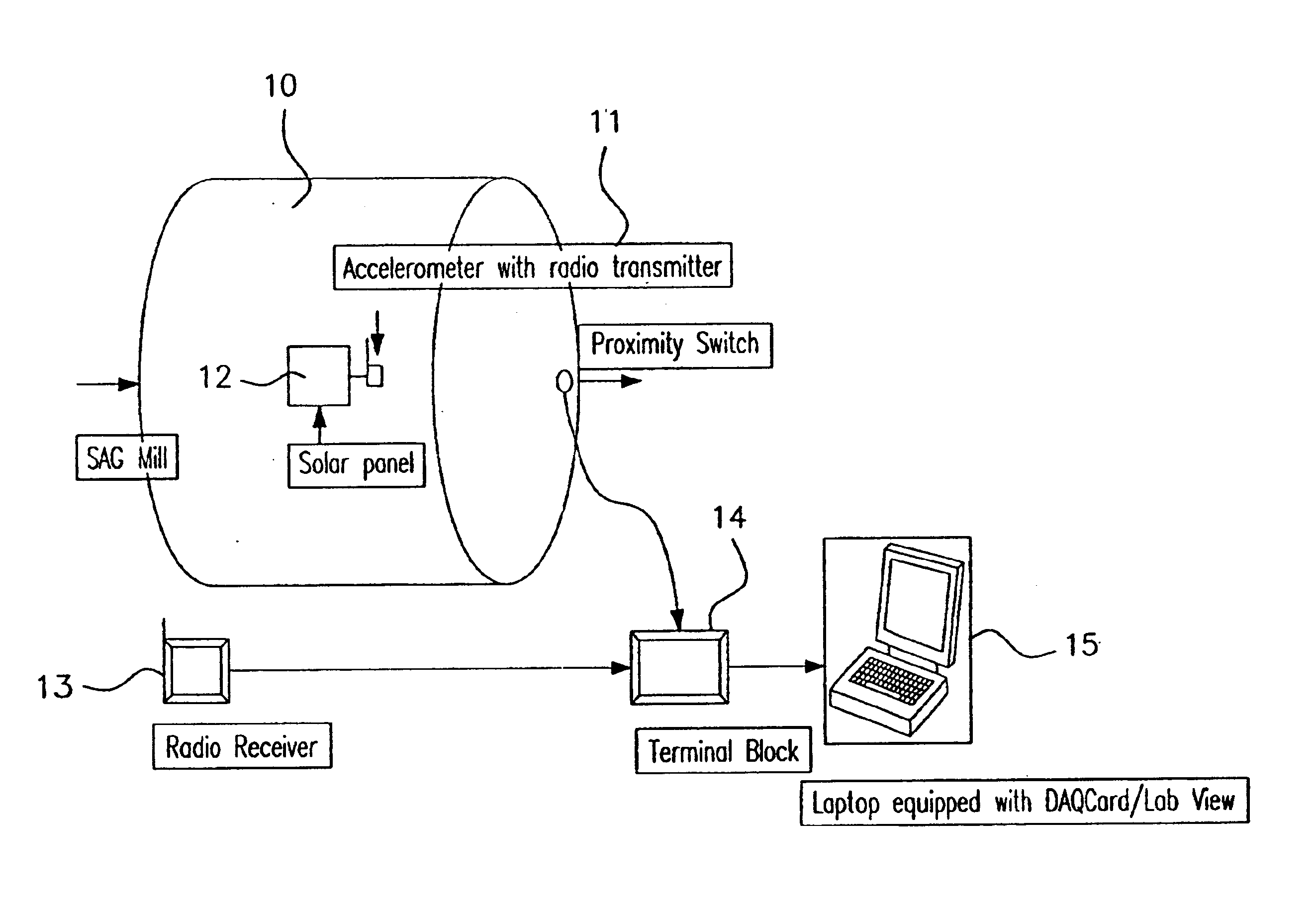

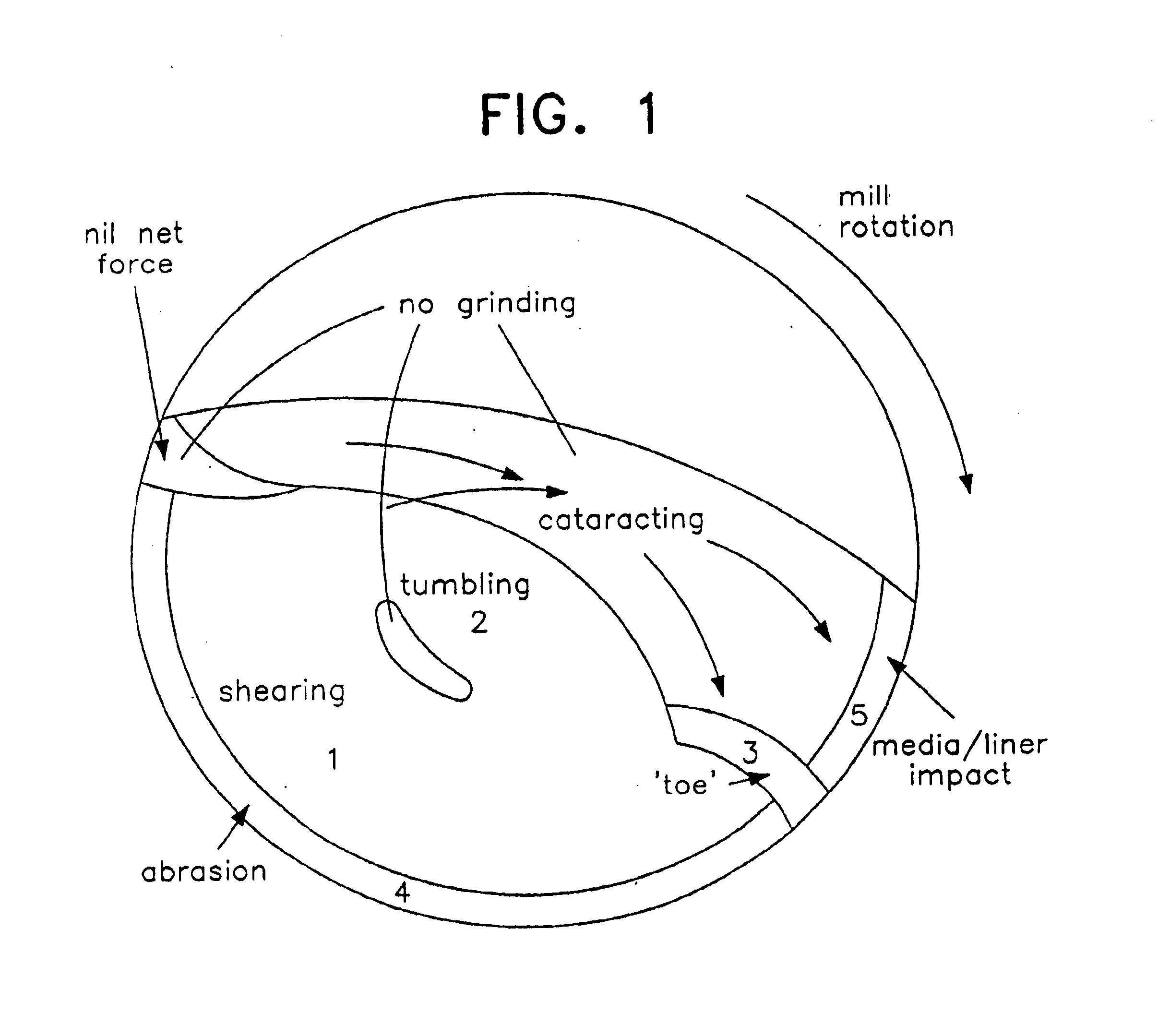

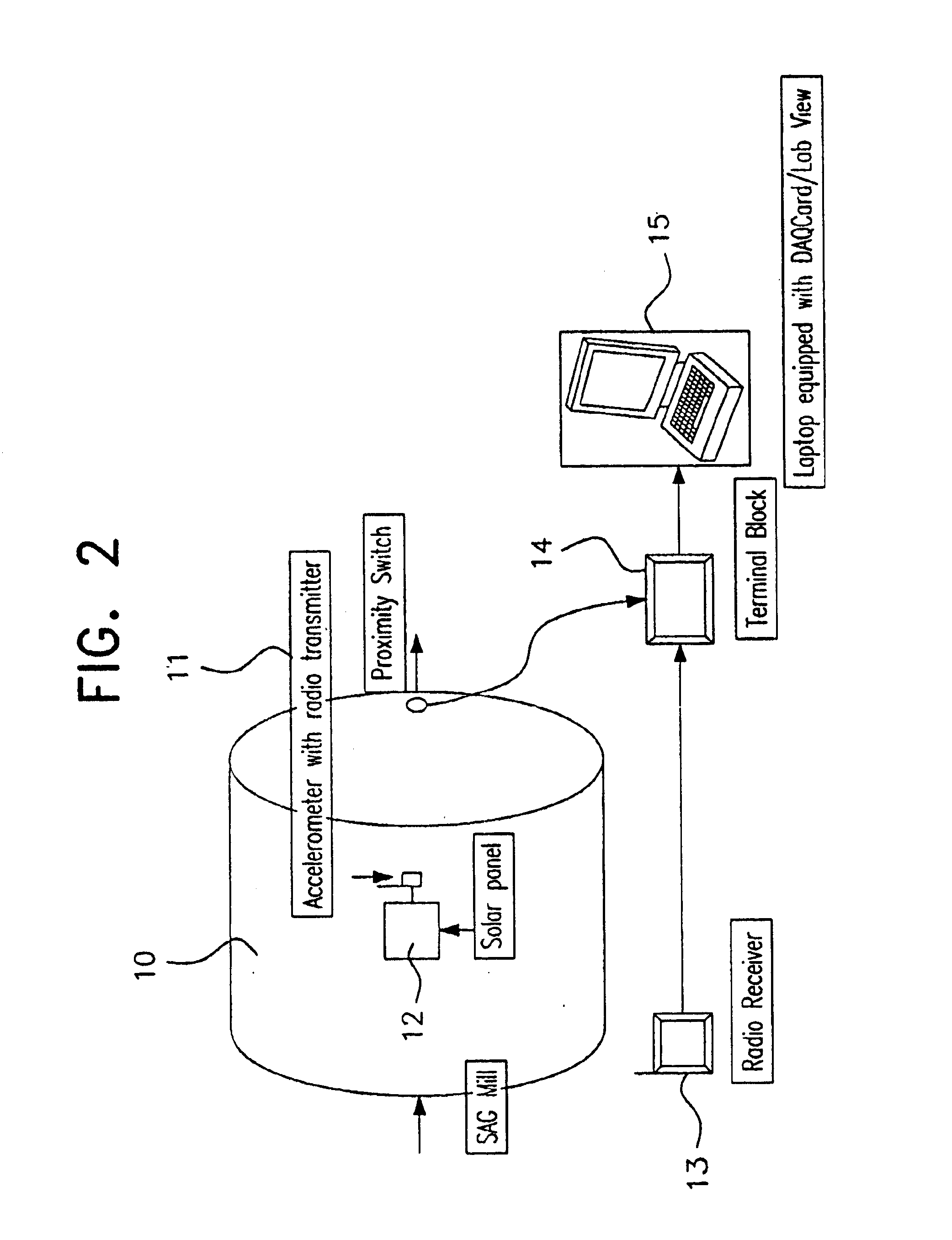

System for monitoring mechanical waves from a moving machine

InactiveUS6874364B1Minimise number/amplitude/frequencyMinimizes valueVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesParticulatesEngineering

A system for monitoring mechanical waves from a machine which in operation has moving particulate matter therein, the system including at least one sensor located on the machine at a location away from the central axis of the machine, the sensors being for sensing acoustic waves and including a transmitter for transmitting signals representing the sensed mechanical waves to a receiver at a location remote from the sensor(s), a data processor connected to the receiver for receiving signals from the receiver which signals represent the mechanical waves and processing the signals to produce output signals for display on a display means, wherein the output signals for display represent one or more parameters indicative of mechanical waves emitted from the machine over a predetermined period of time.

Owner:COMMONWEALTH SCI & IND RES ORG

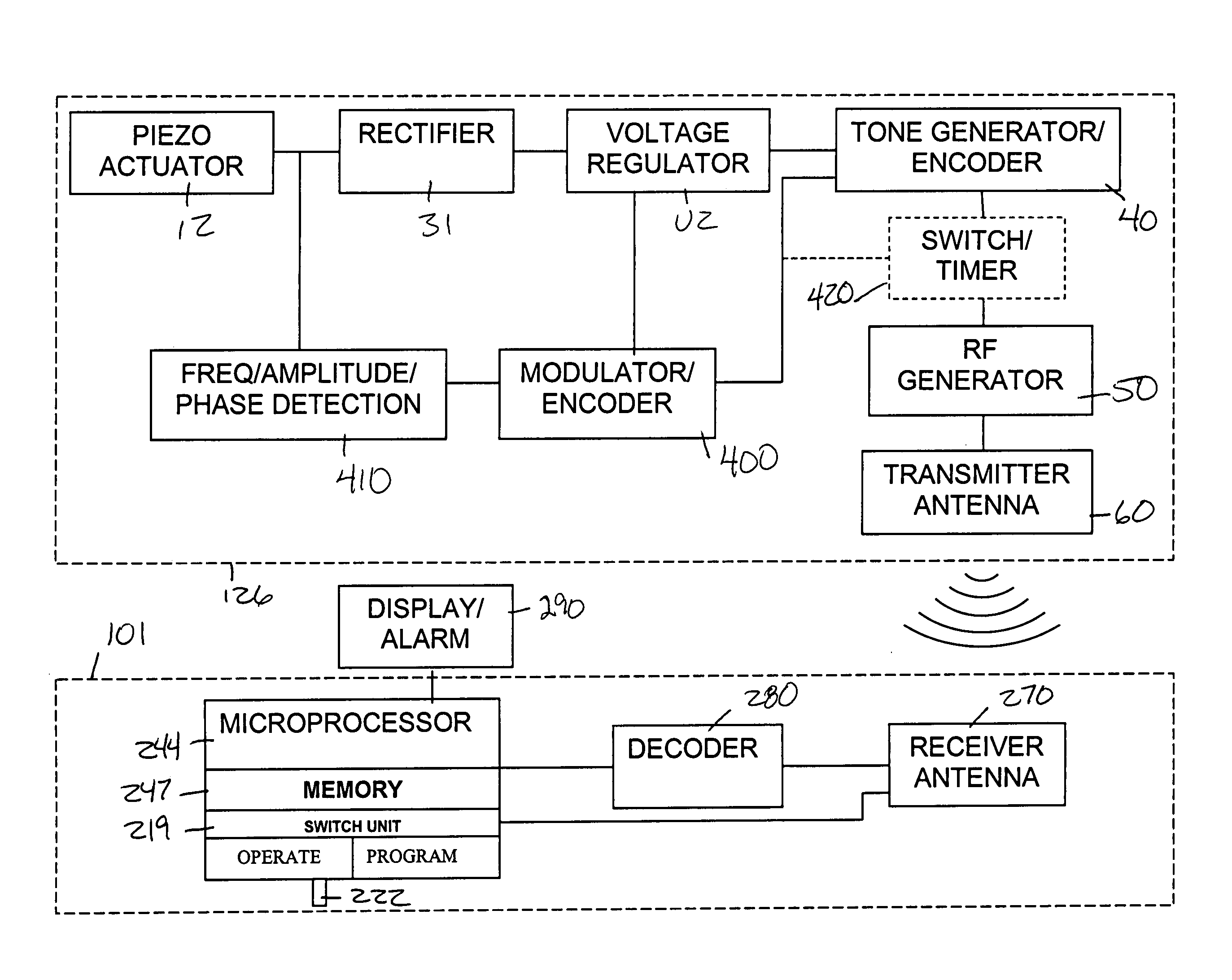

Self-powered vibration monitoring system

InactiveUS20050087019A1Sufficient magnitudeEasy to useSubsonic/sonic/ultrasonic wave measurementMaterial analysis using acoustic emission techniquesElectricityMonitoring system

A system for monitoring the vibration of electrical and mechanical equipment. More particularly, the present invention relates to a self-powered vibration monitoring device and system that generates an electrical signal that not only powers the device(s), but also is indicative of the frequency and / or amplitude of vibration of the equipment to which it is attached. The power is preferably generated through a piezoelectric element and is sent through signal generation circuitry coupled to a transmitter for sending RF signals indicative of the vibrational status of the equipment to one or more receivers for further display or processing.

Owner:FACE BRADBURY R

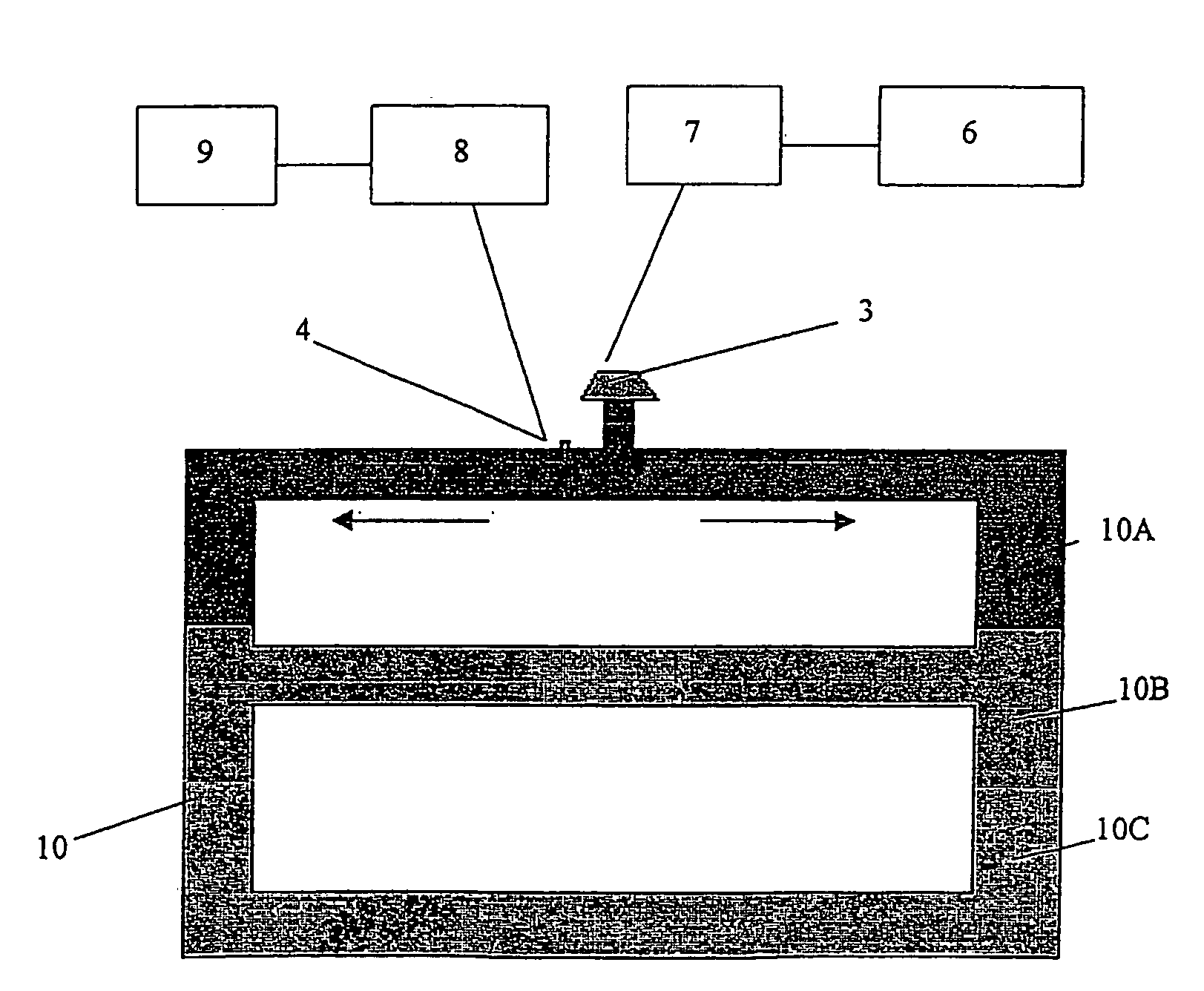

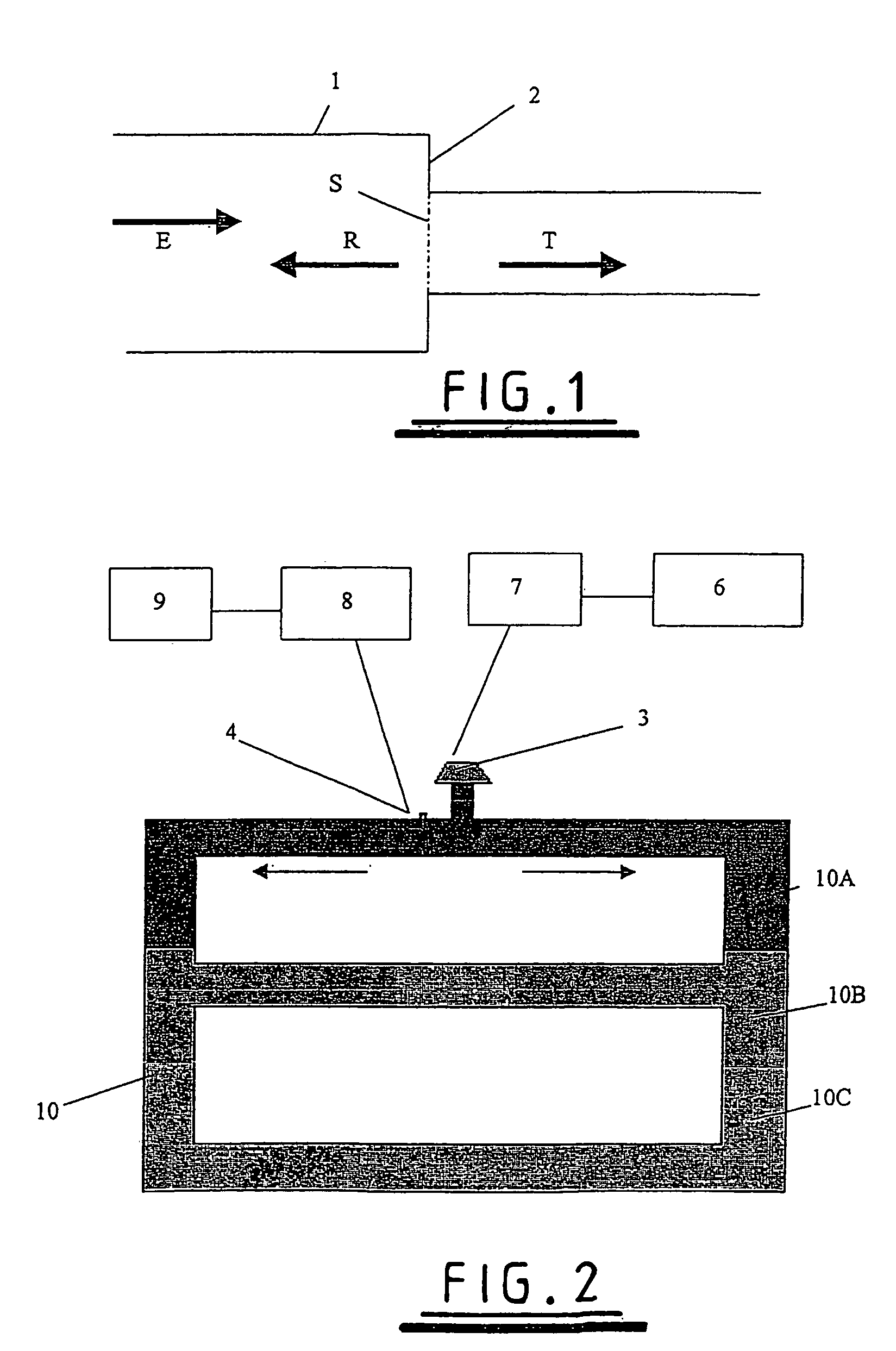

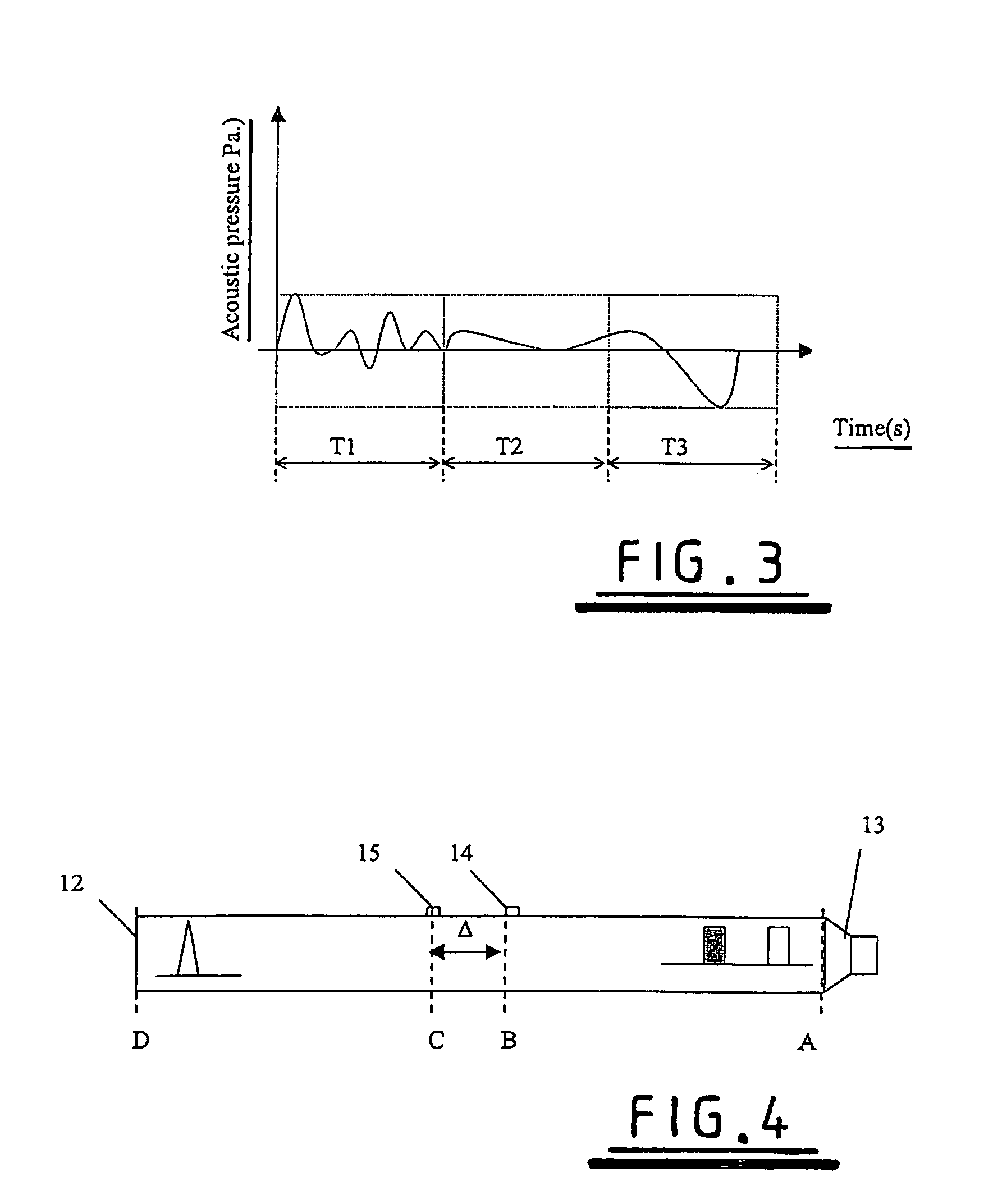

Remote pipeline acoustic inspection

InactiveUS7266992B2Reduce complexityReduce the amount requiredDetection of fluid at leakage pointAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineering

A pipe inspection apparatus comprising an acoustic source (3) for location at a first position in a pipe or pipe network, one or more acoustic or pressure detectors (4) for location at one or more positions in the pipe or pipe network, means for recording and / or displaying a signal detected by the one or more detectors following the generation of an acoustic pulse, and means for allowing the comparison of the detected signal with a predetermined reference signal, differences between the detected and reference signals being indicative of a blockage or leakage in the pipe or pipe network (10).

Owner:UNIV OF MANCHESTER

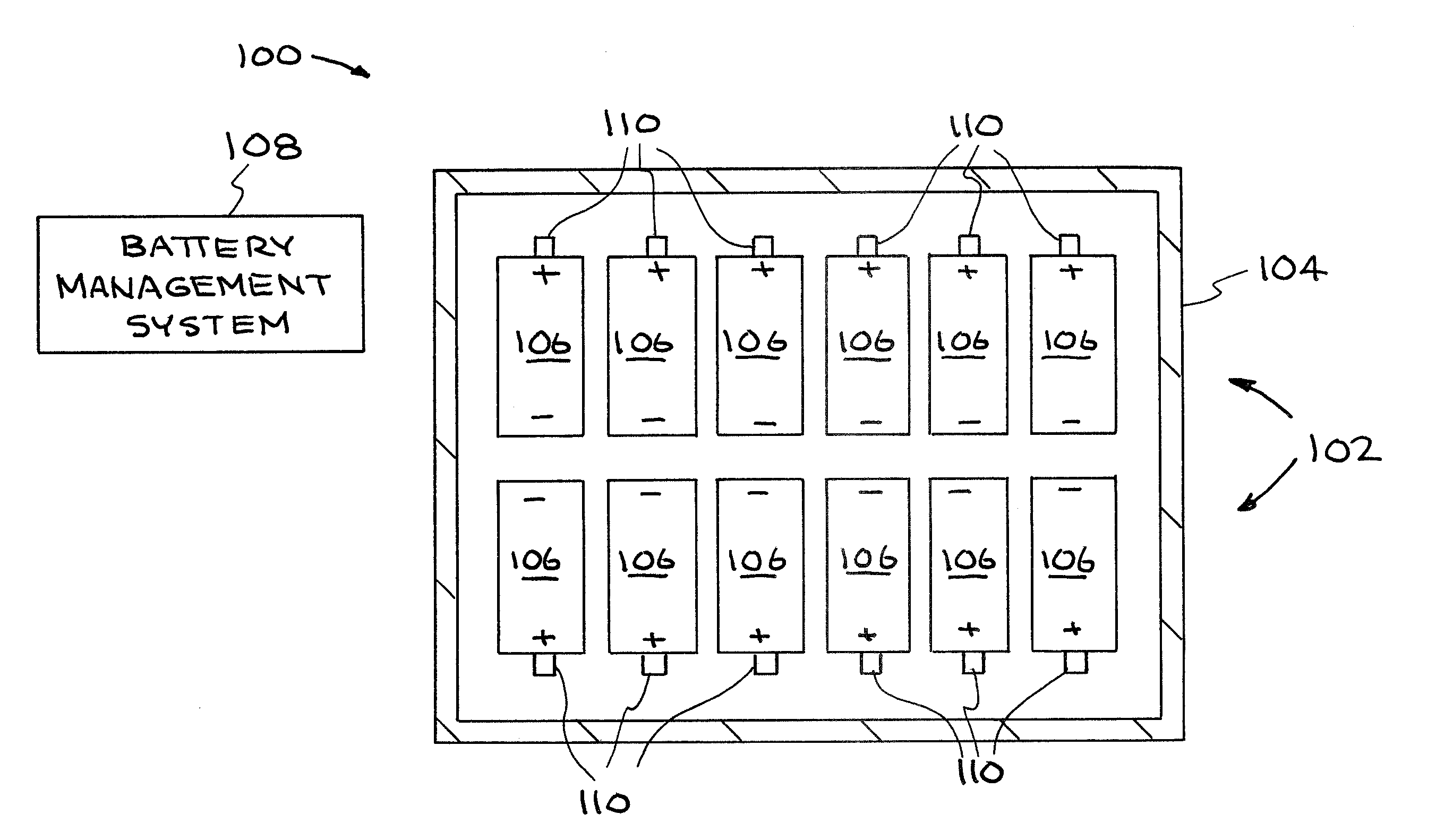

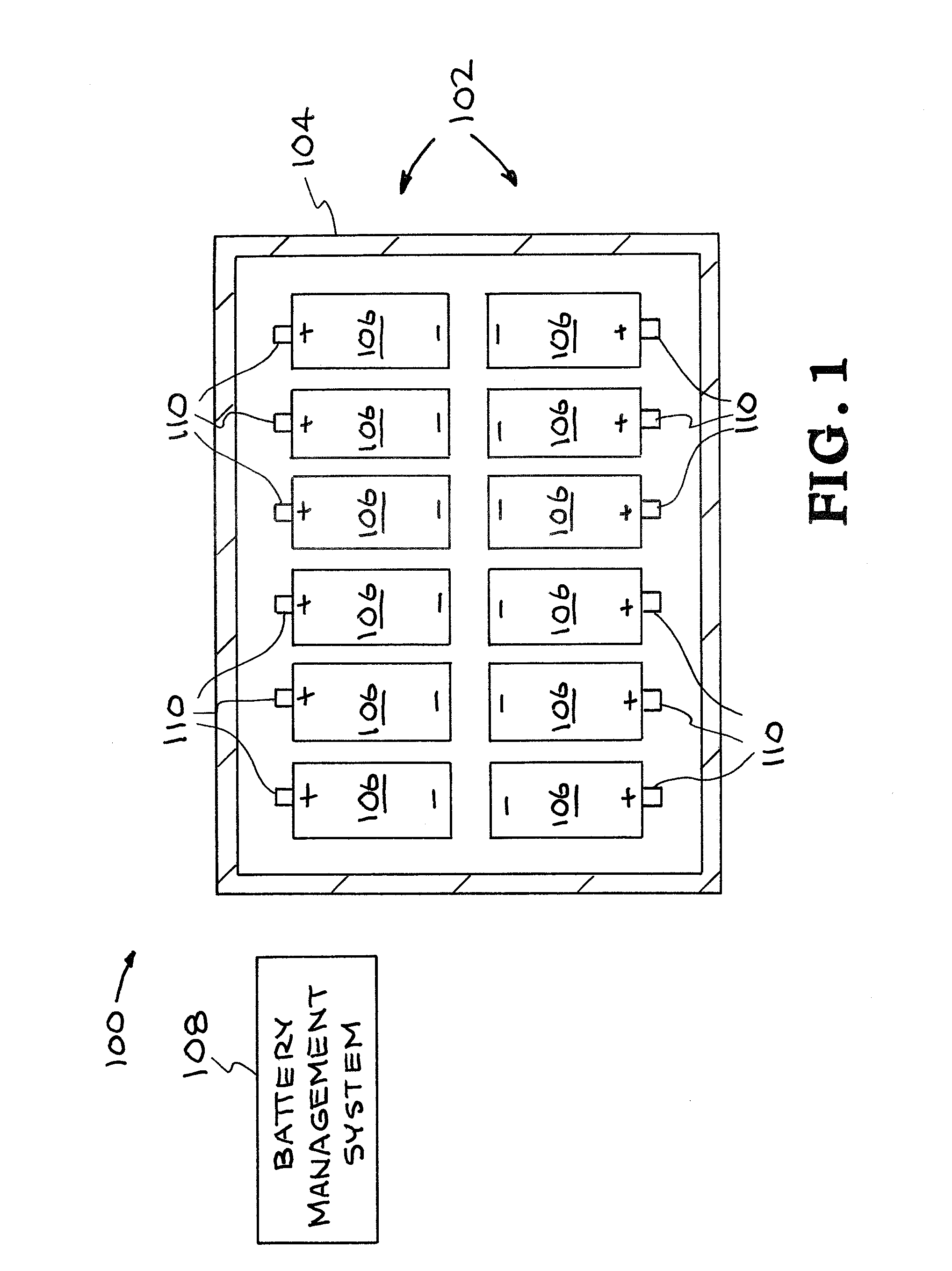

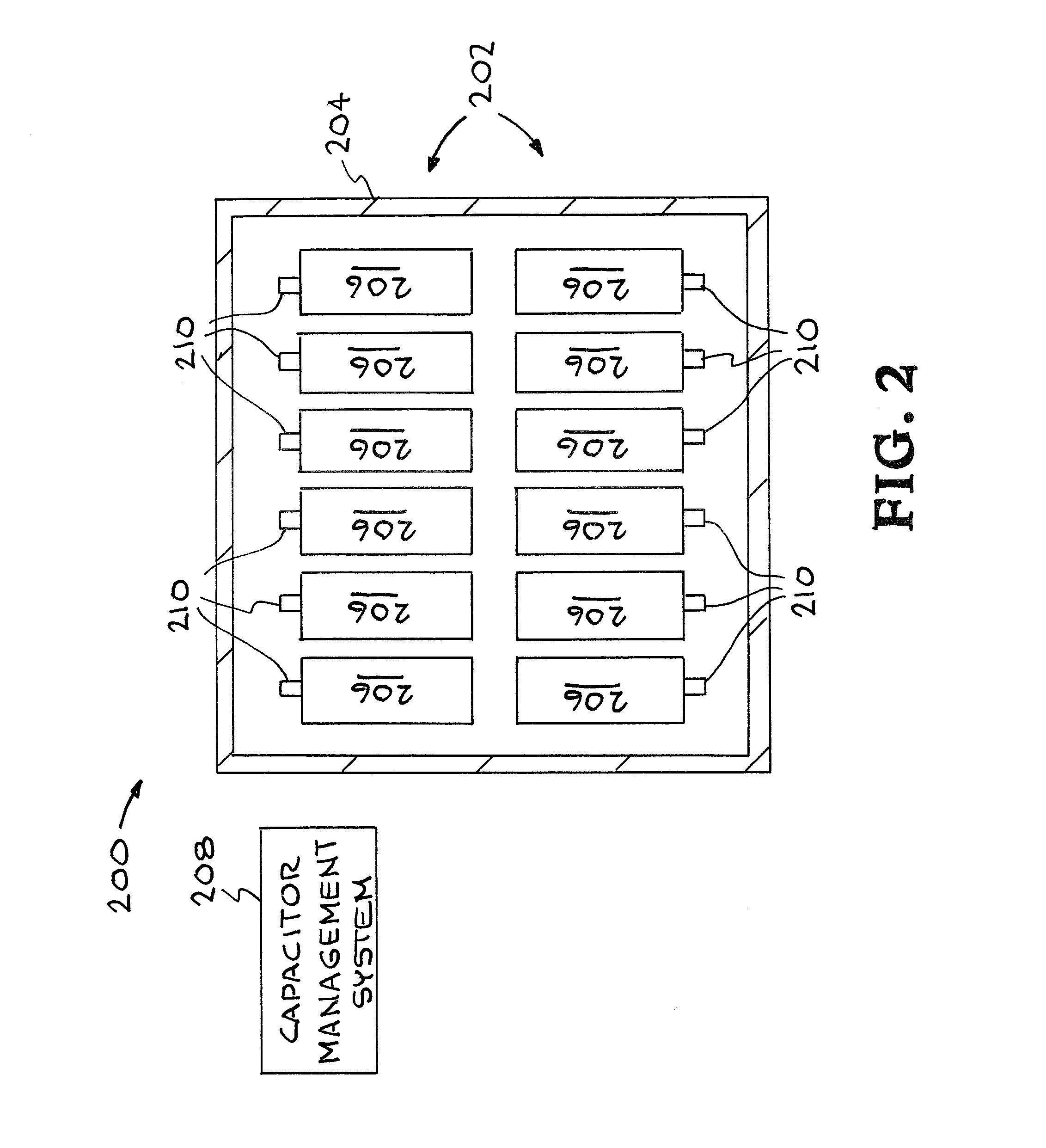

Battery management system with distributed wireless sensors

ActiveUS20130314094A1Vibration measurement in solidsMaterial analysis using acoustic emission techniquesEngineeringRadio frequency

A system for monitoring parameters of an energy storage system having a multiplicity of individual energy storage cells. A radio frequency identification and sensor unit is connected to each of the individual energy storage cells. The radio frequency identification and sensor unit operates to sense the parameter of each individual energy storage cell and provides radio frequency transmission of the parameters of each individual energy storage cell. A management system monitors the radio frequency transmissions from the radio frequency identification and sensor units for monitoring the parameters of the energy storage system.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

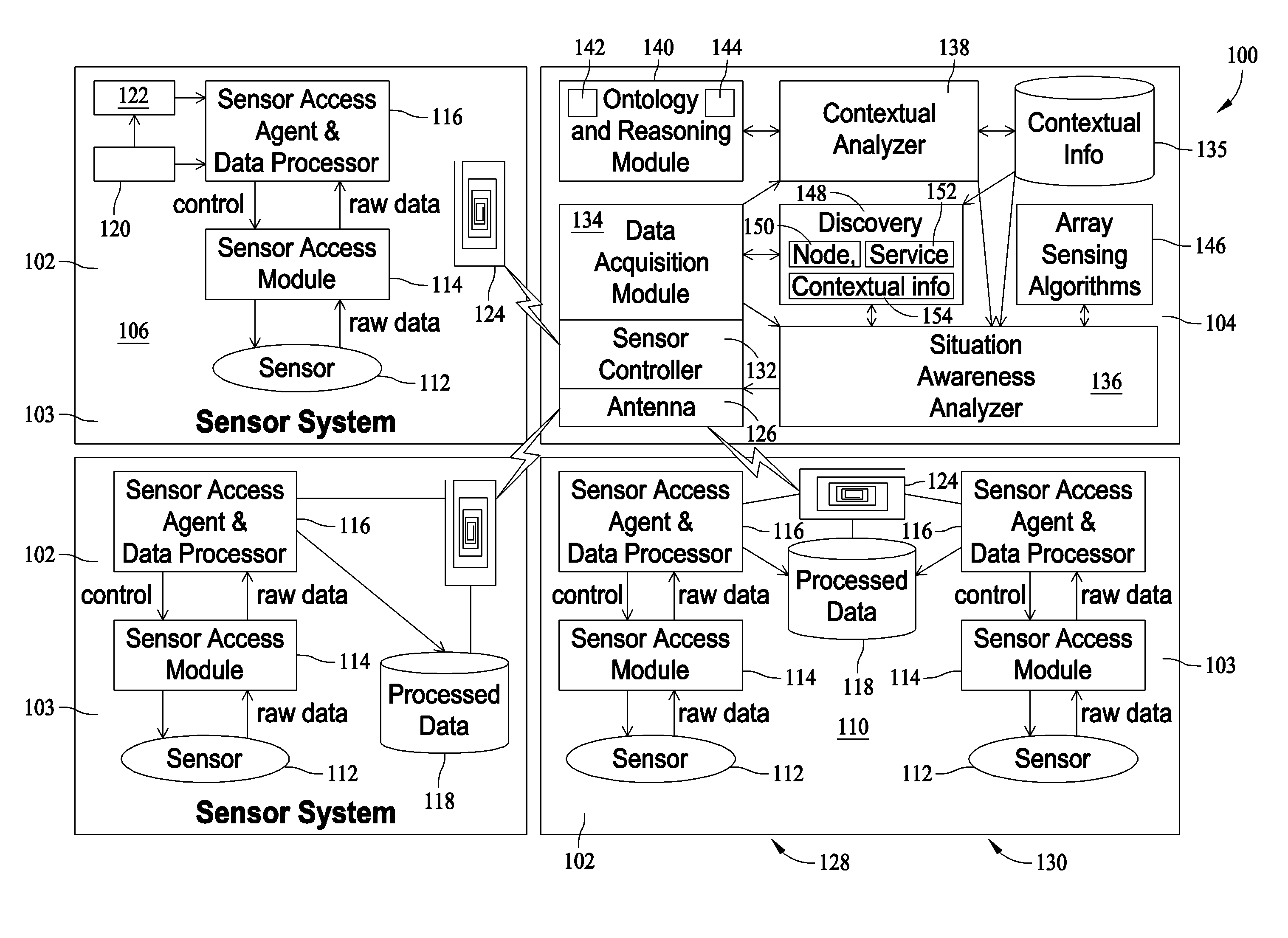

Vibration condition monitoring system and methods

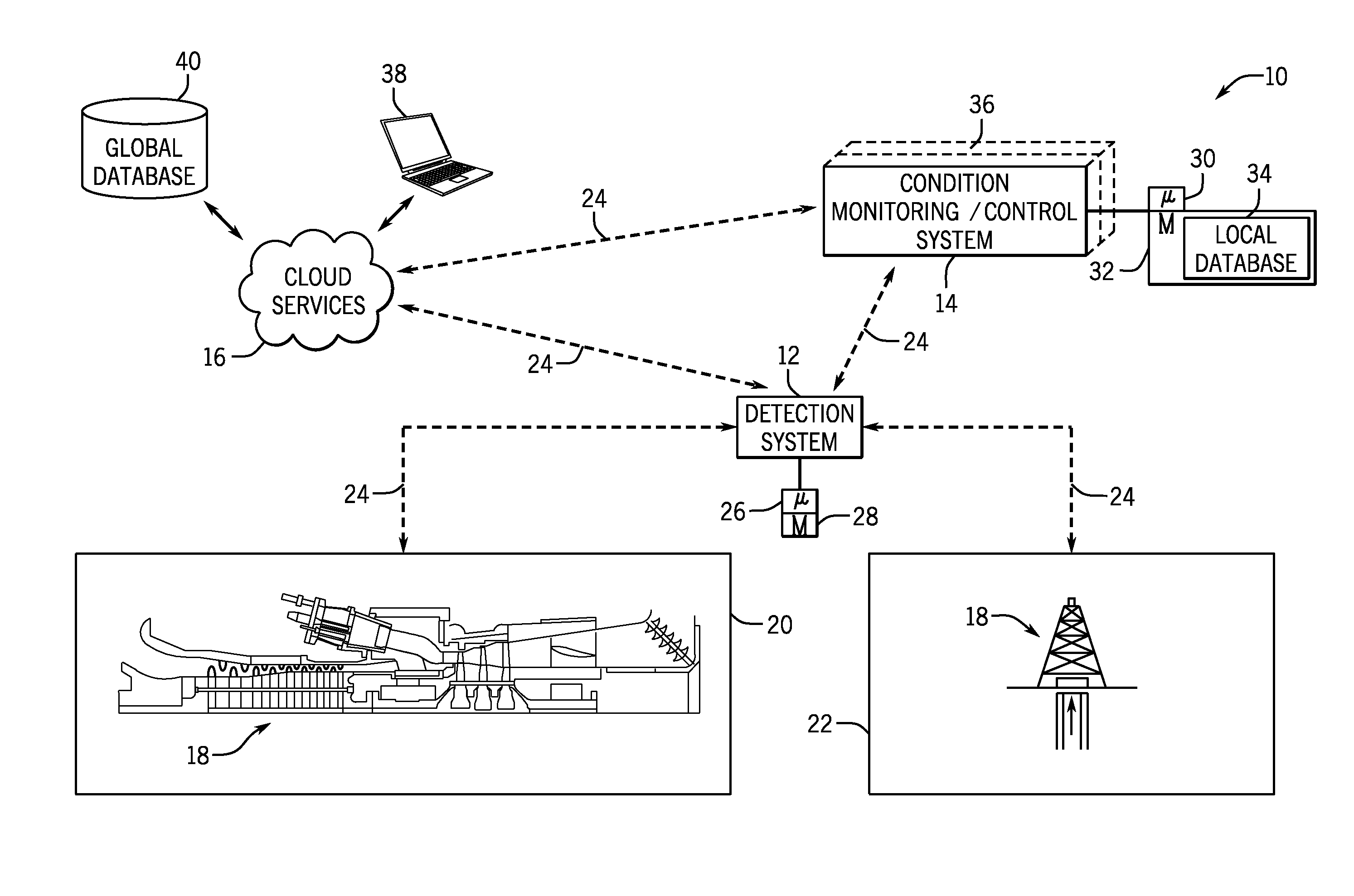

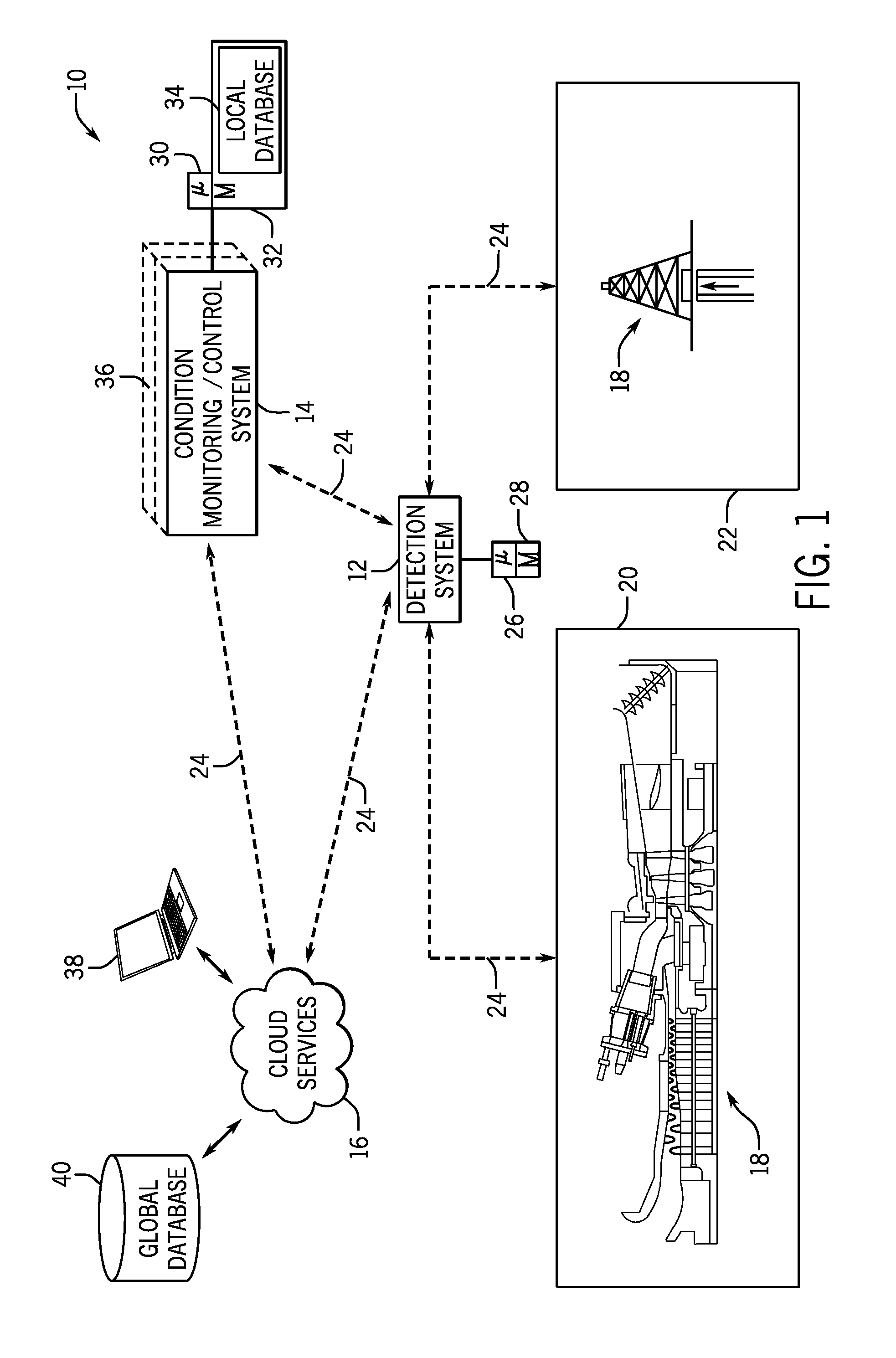

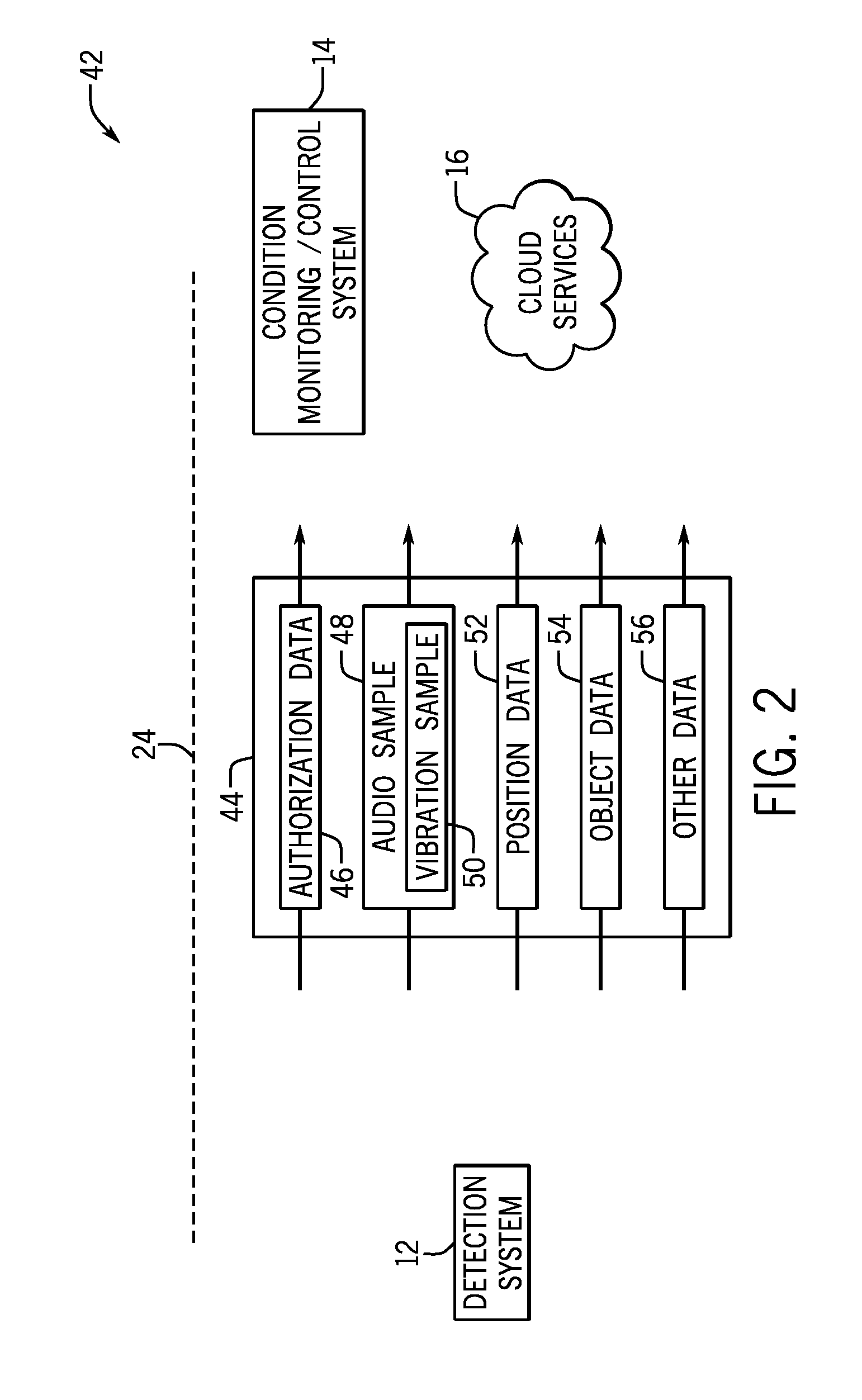

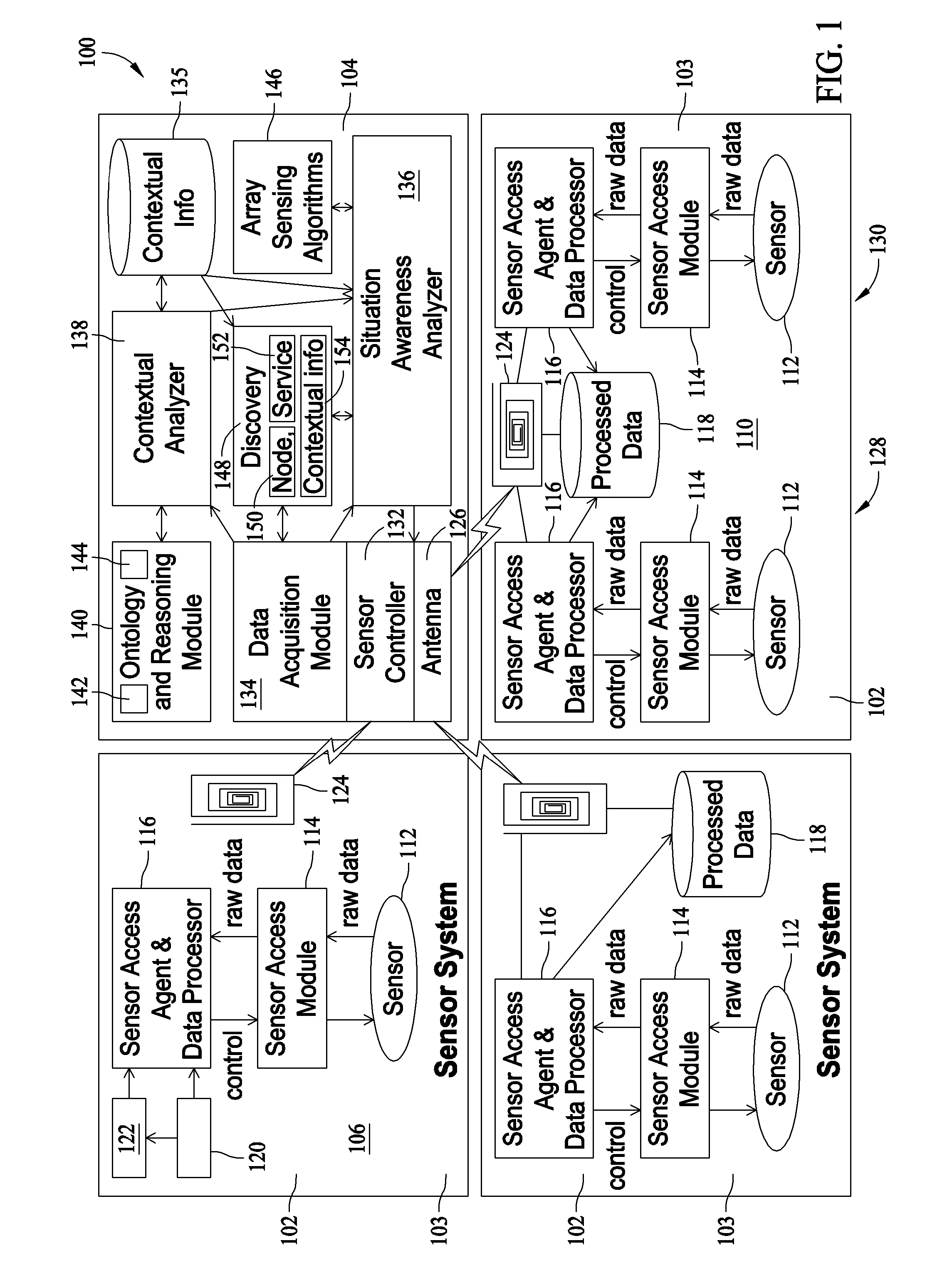

ActiveUS20150039250A1Electrical apparatusMaterial analysis using acoustic emission techniquesContext basedComputing systems

In one embodiment, a diagnostics system is provided. The diagnostics system include a detection system configured to capture acoustic information and contextual information related to a machine component defect. A computing system is coupled to a processor configured to receive the acoustic information and the contextual information from the detection system, select one or more algorithms based at least in part on the contextual information, and retrieve and execute the one or more algorithms to extract one or more characteristic features of the acoustic information. The processor is further configured to generate an acoustic fingerprint based at least in part on the one or more characteristic features of the acoustic information, such that the one or more characteristic features correspond to the machine component defect.

Owner:BAKER HUGHES INC

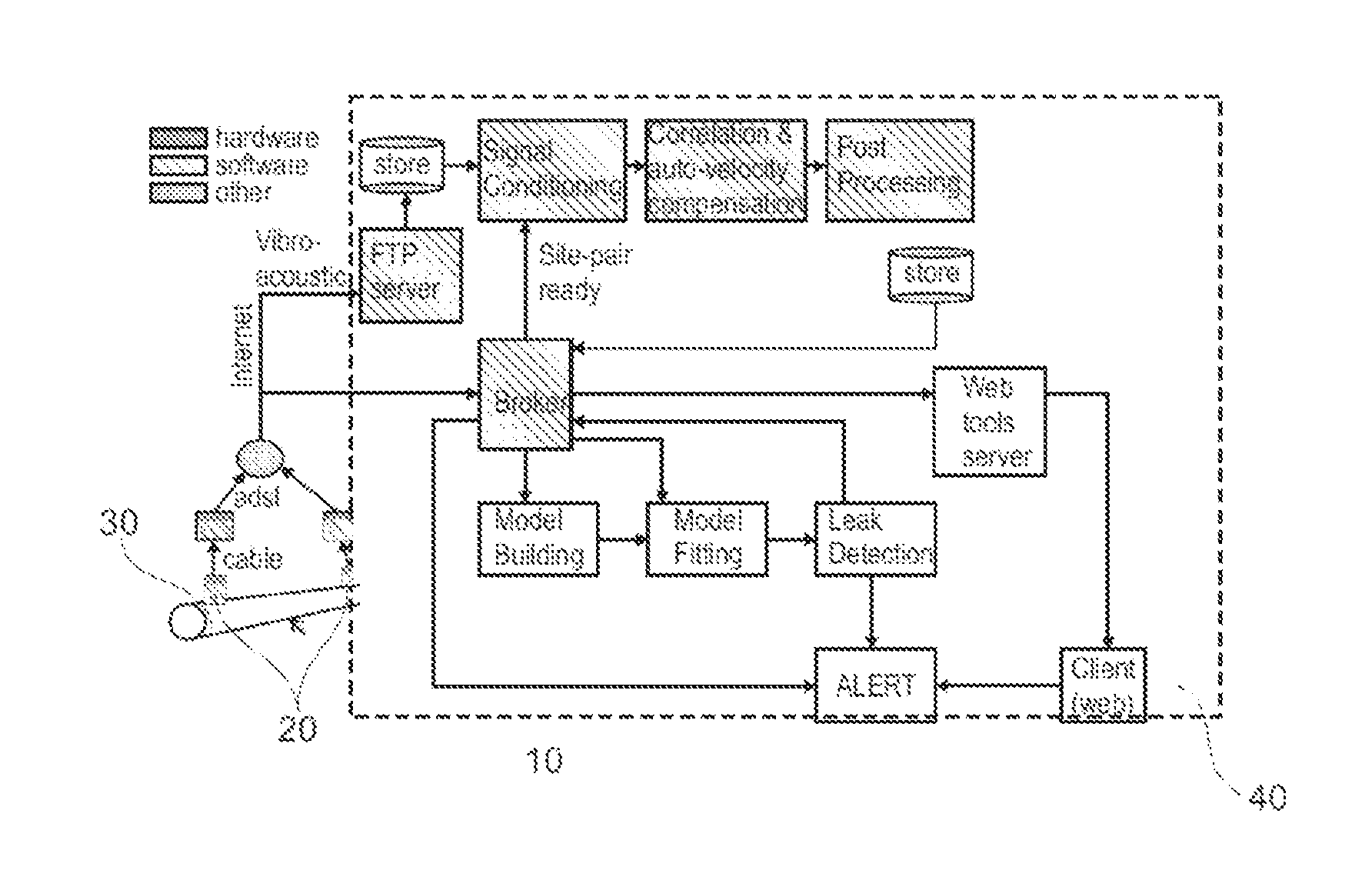

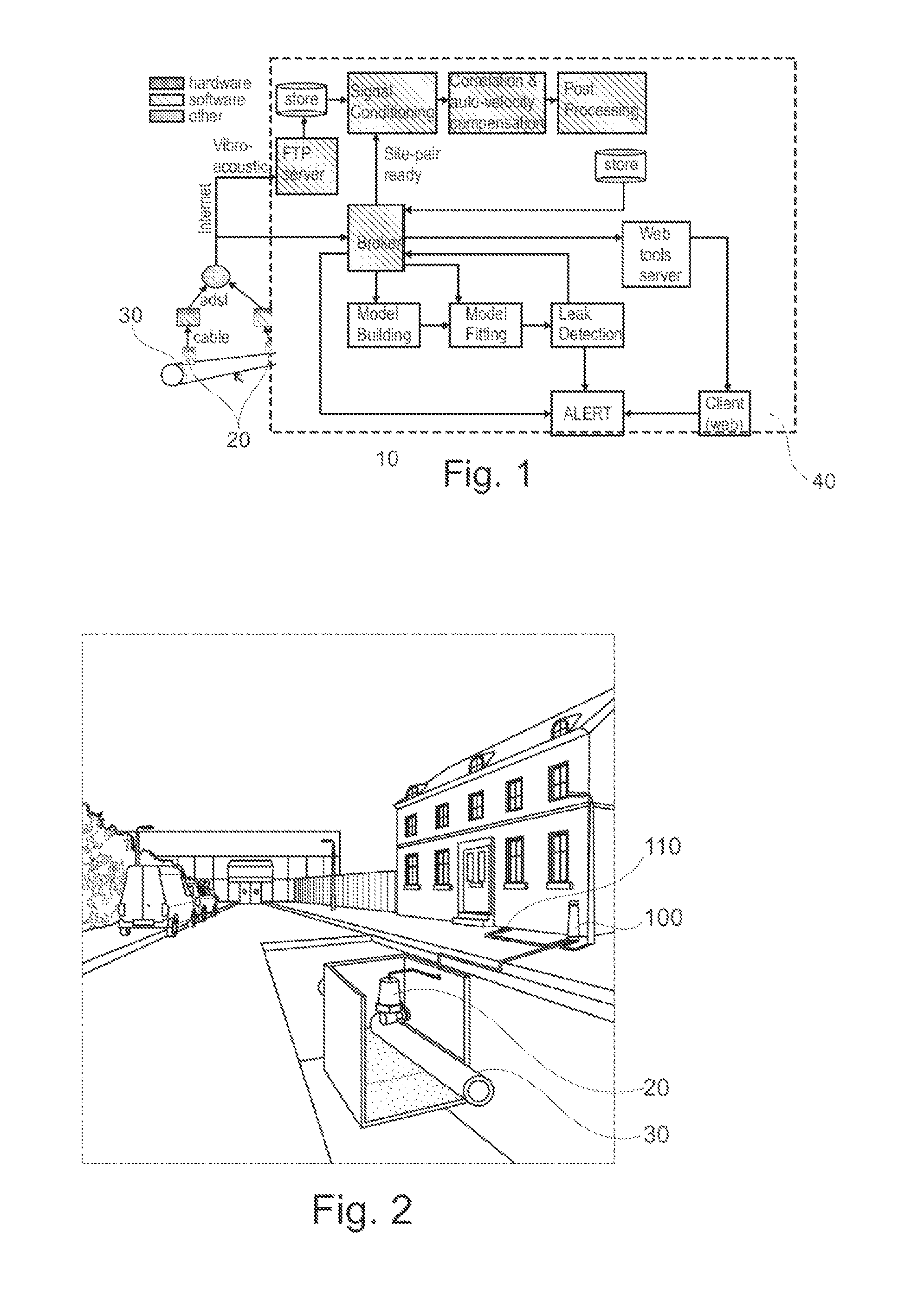

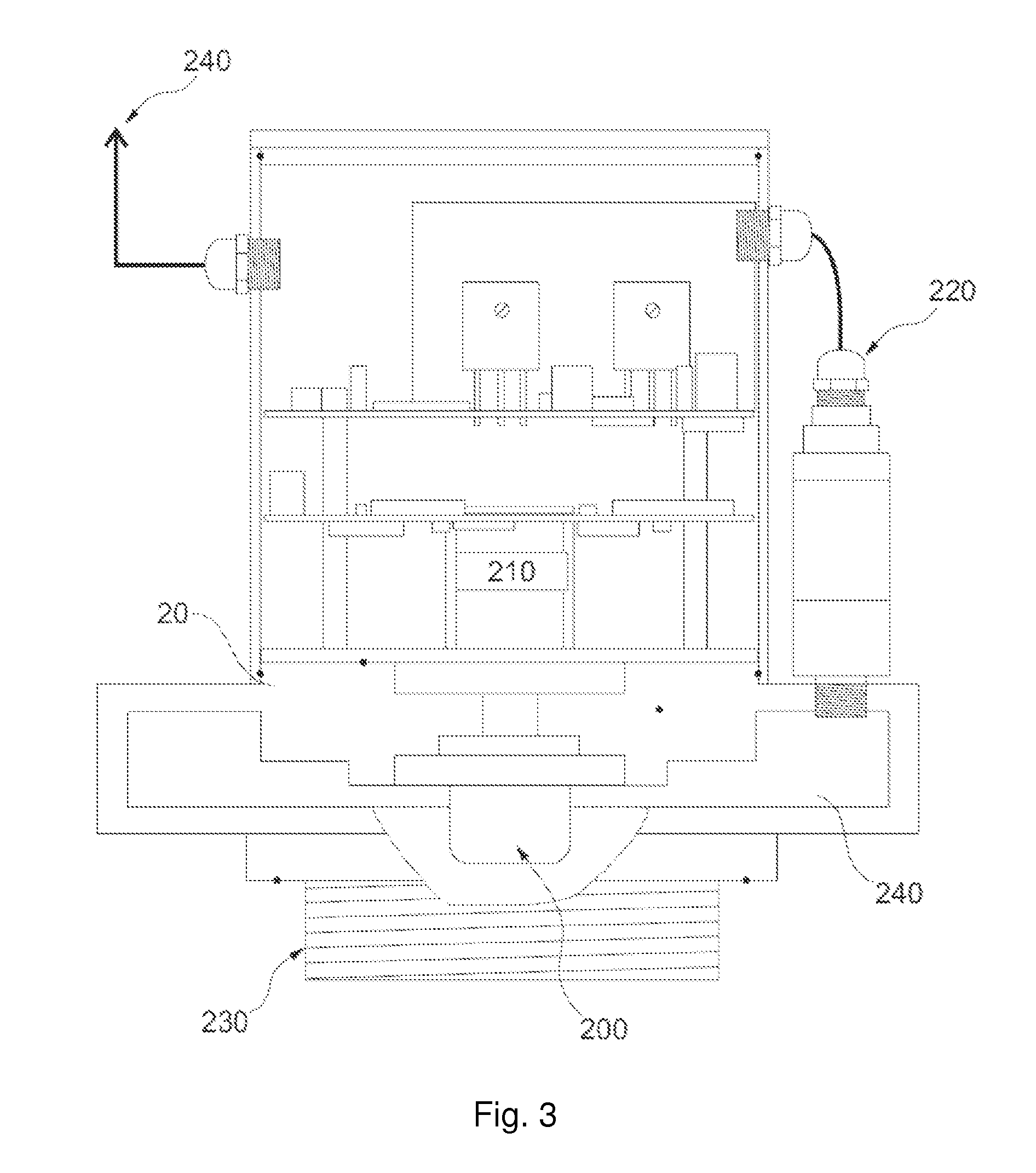

Pipeline fault detection system, sensor head and method of detecting pipeline faults

ActiveUS20140165731A1Avoid spendingComplete understandingAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidMonitoring systemAcoustic property

A pipeline fault detection system, method and sensor head suitable for use in the system are disclosed. The system comprises a vibro-acoustic sensor connectable to a fluid path of a pipeline and a remote monitoring system, the sensor being operable to measure one or more predetermined vibro-acoustic properties of the fluid and / or fluid path and communicate data on said measurements to the remote monitoring system, the remote monitoring system being arranged to monitor said data over time and being further arranged to screen the monitored data for characteristics representing a fault type to identify occurrence of a fault type in the pipeline.

Owner:SYRINIX

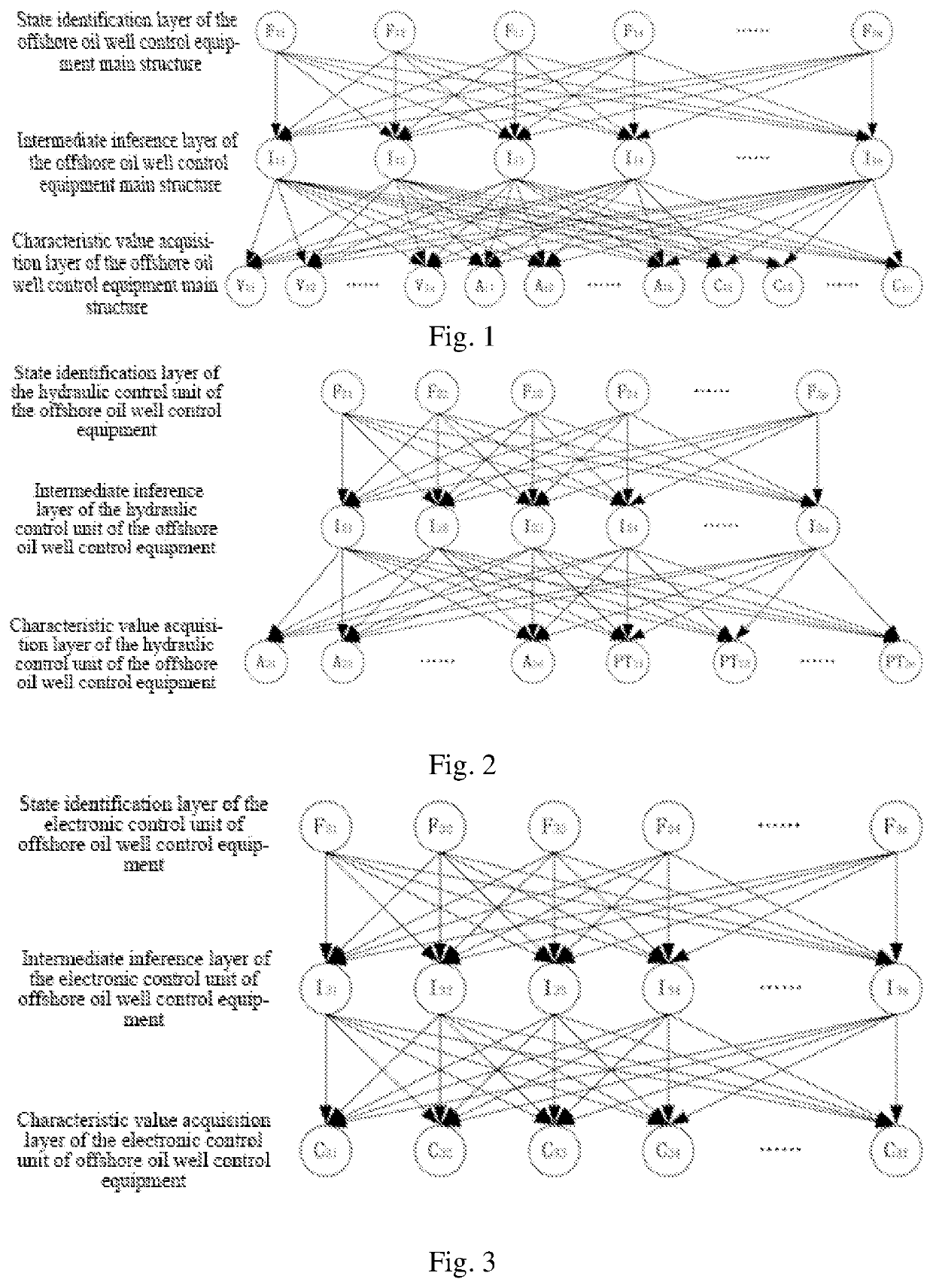

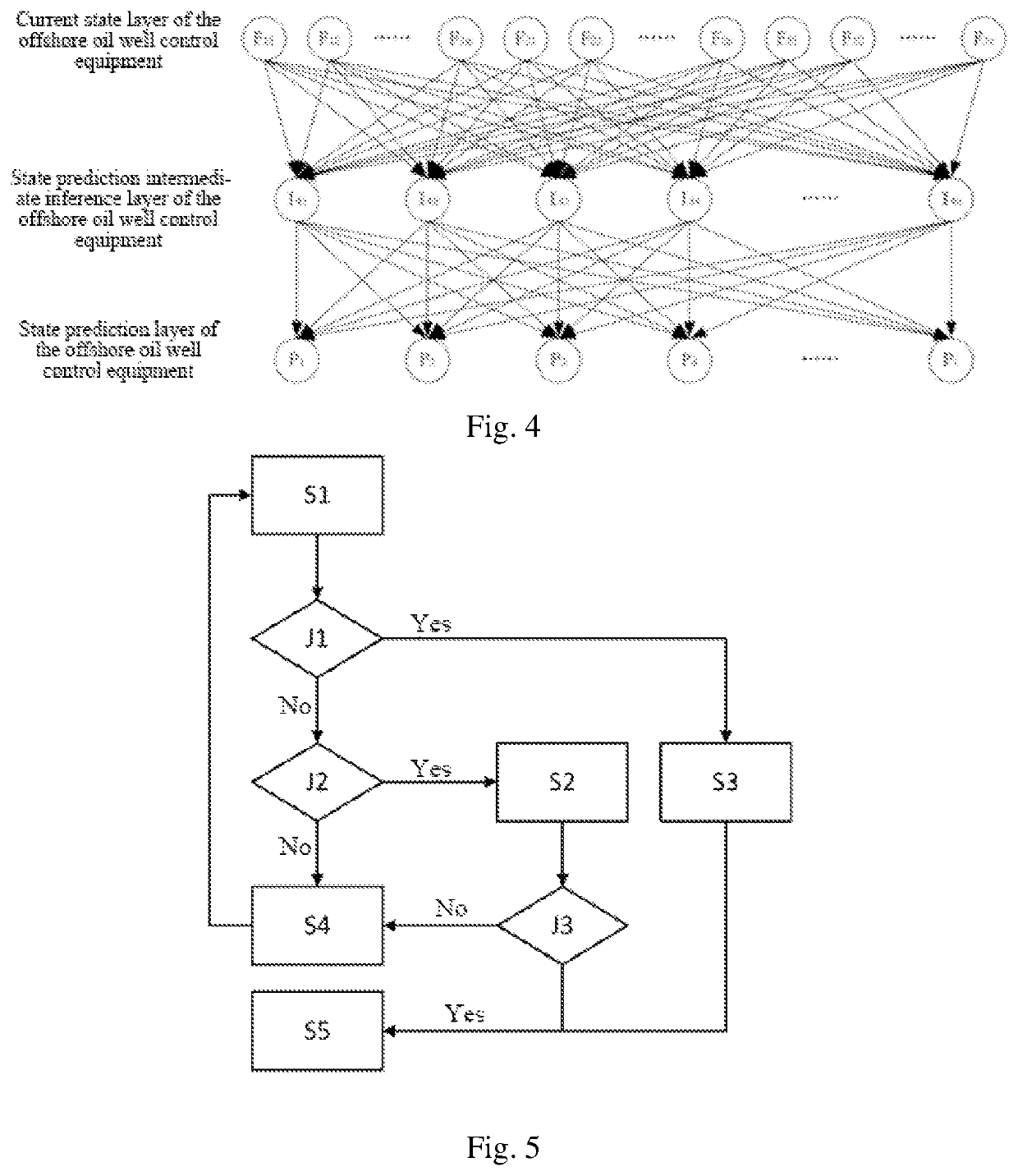

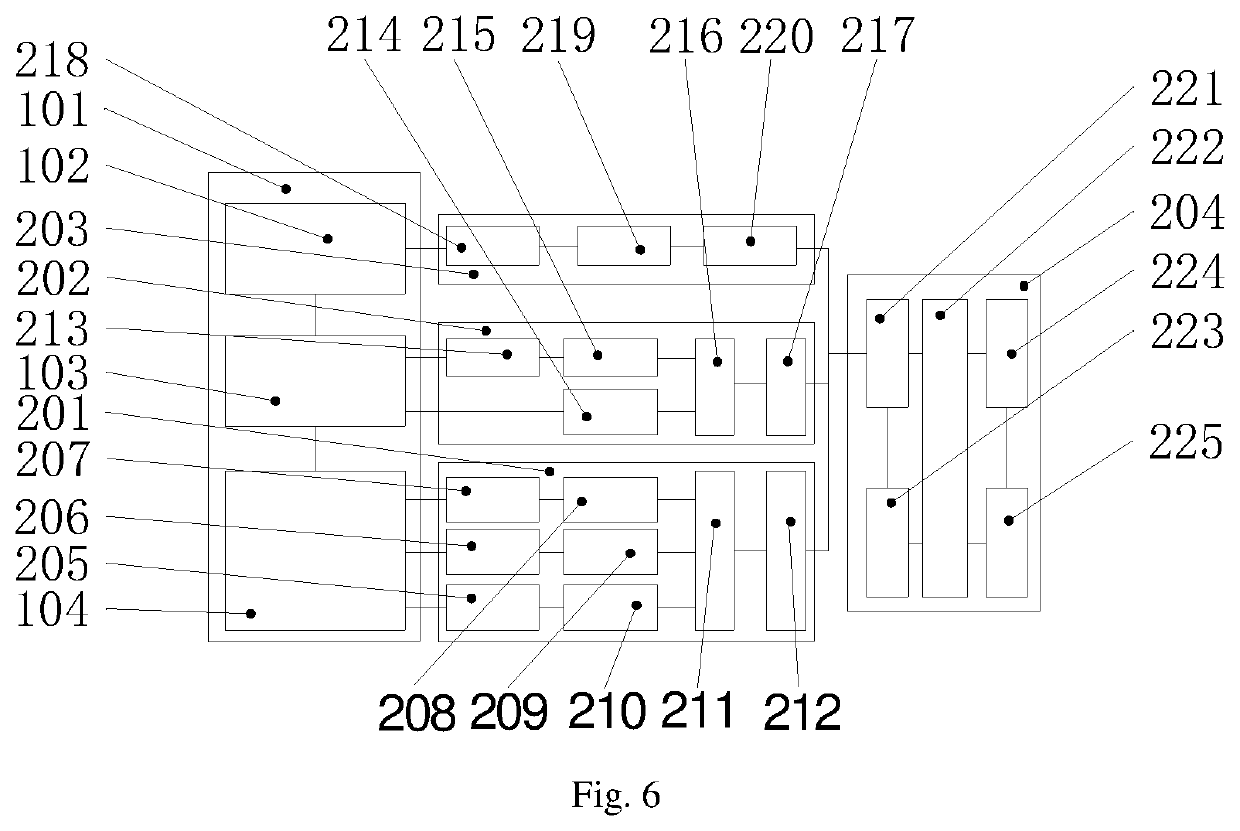

Method and system for guaranteeing safety of offshore oil well control equipment

The present disclosure belongs to the field of marine engineering, and in particular relates to a method and system for guaranteeing the safety of offshore oil well control equipment. The method comprises: identifying the state of a main structure of the offshore oil well control equipment, identifying the state of a hydraulic control unit of offshore oil well control equipment, identifying the state of an electronic control unit of offshore oil well control equipment, predicting the state of the offshore oil well control equipment and making a real-time decision based on existing information; and the system for guaranteeing the safety of the offshore oil well control equipment comprises a state identification subsystem of a main structure, a state identification subsystem of the hydraulic control unit, a state identification subsystem of the electronic control unit and a state prediction and real-time decision subsystem.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

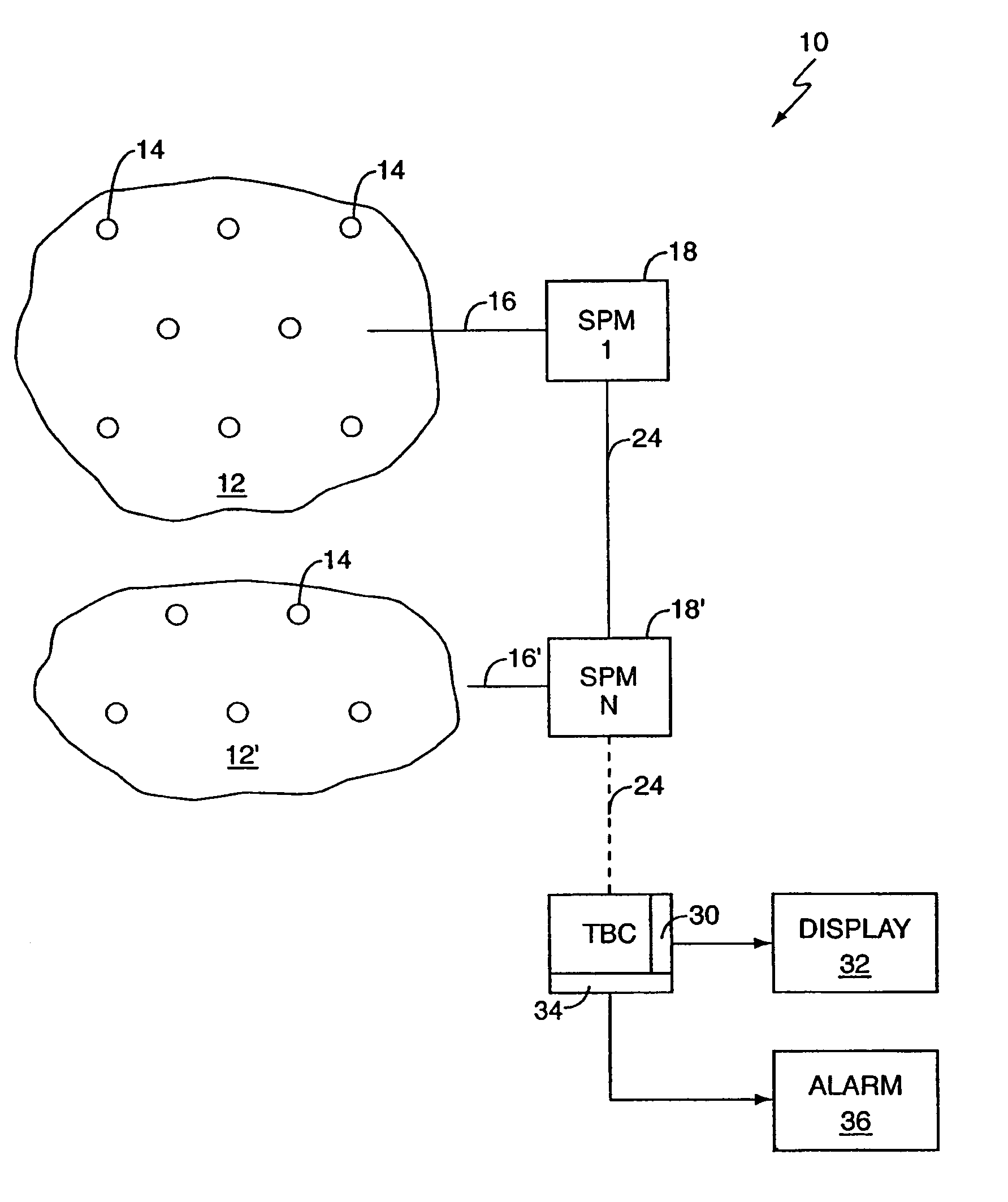

System for damage location using a single channel continuous acoustic emission sensor

InactiveUS7075424B1Material analysis using acoustic emission techniquesProcessing detected response signalSensor arrayElectricity

A sensor array for non-destructively monitoring a structure to detect a critical structural event. The sensor array includes a plurality of discrete sensor nodes, each of the discrete sensor nodes producing an electrical signal in response to a structural event. A signal adder is electrically connected to the plurality of discrete sensor nodes for receiving and combining the electrical signal from each of the discrete sensor nodes to form a single sensor array output signal. A signal processing module then receives and processes the single sensor output signal. In the preferred embodiment, the signal processing module uses the time interval between the electrical signals from each of the discrete sensor nodes formed into a single sensor array output signal to calculate the location of the critical structural event. Also, in the preferred embodiment, a data collection system is located downstream of the sensor processing module.

Owner:NORTH CAROLINA AT&T STATE UNIV

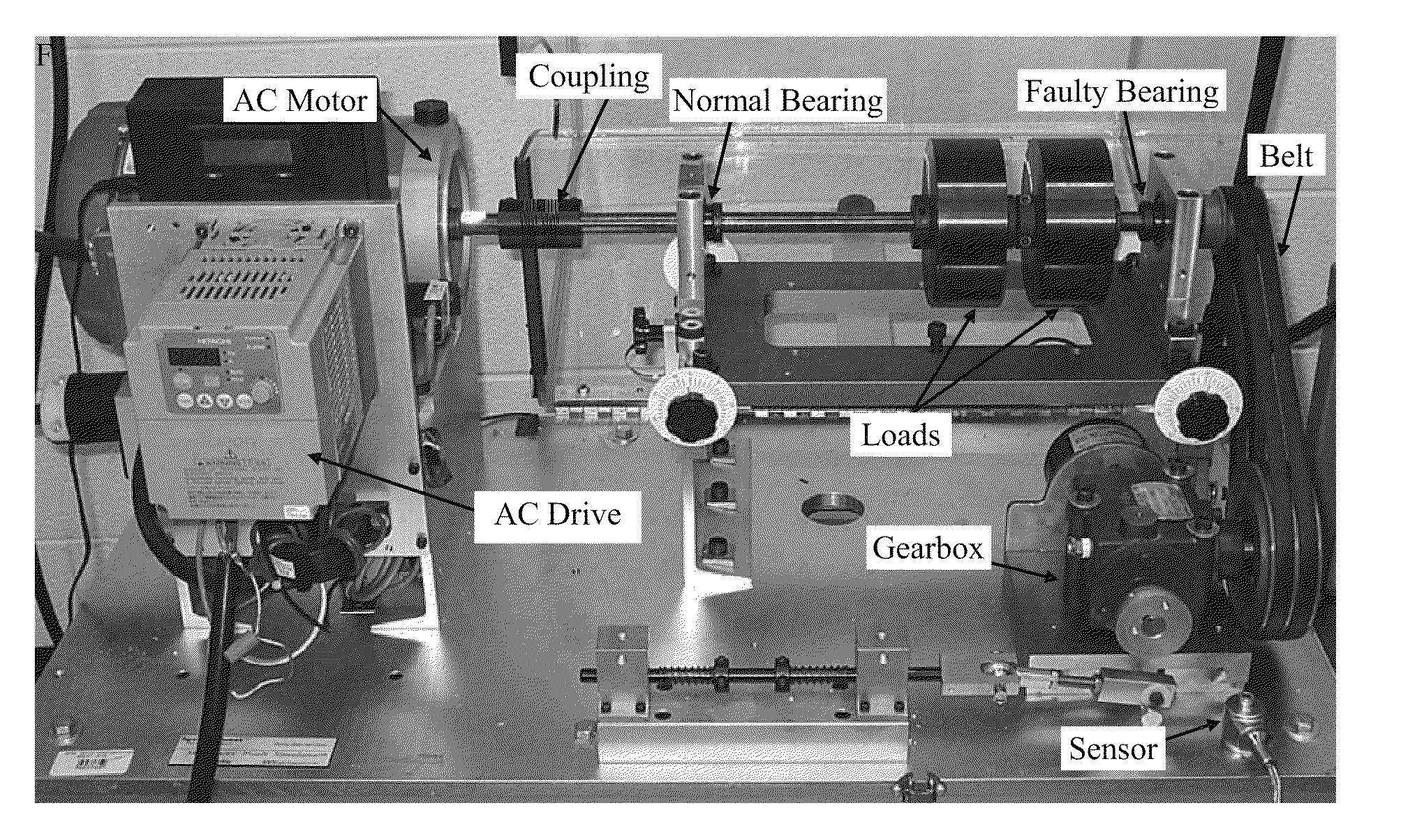

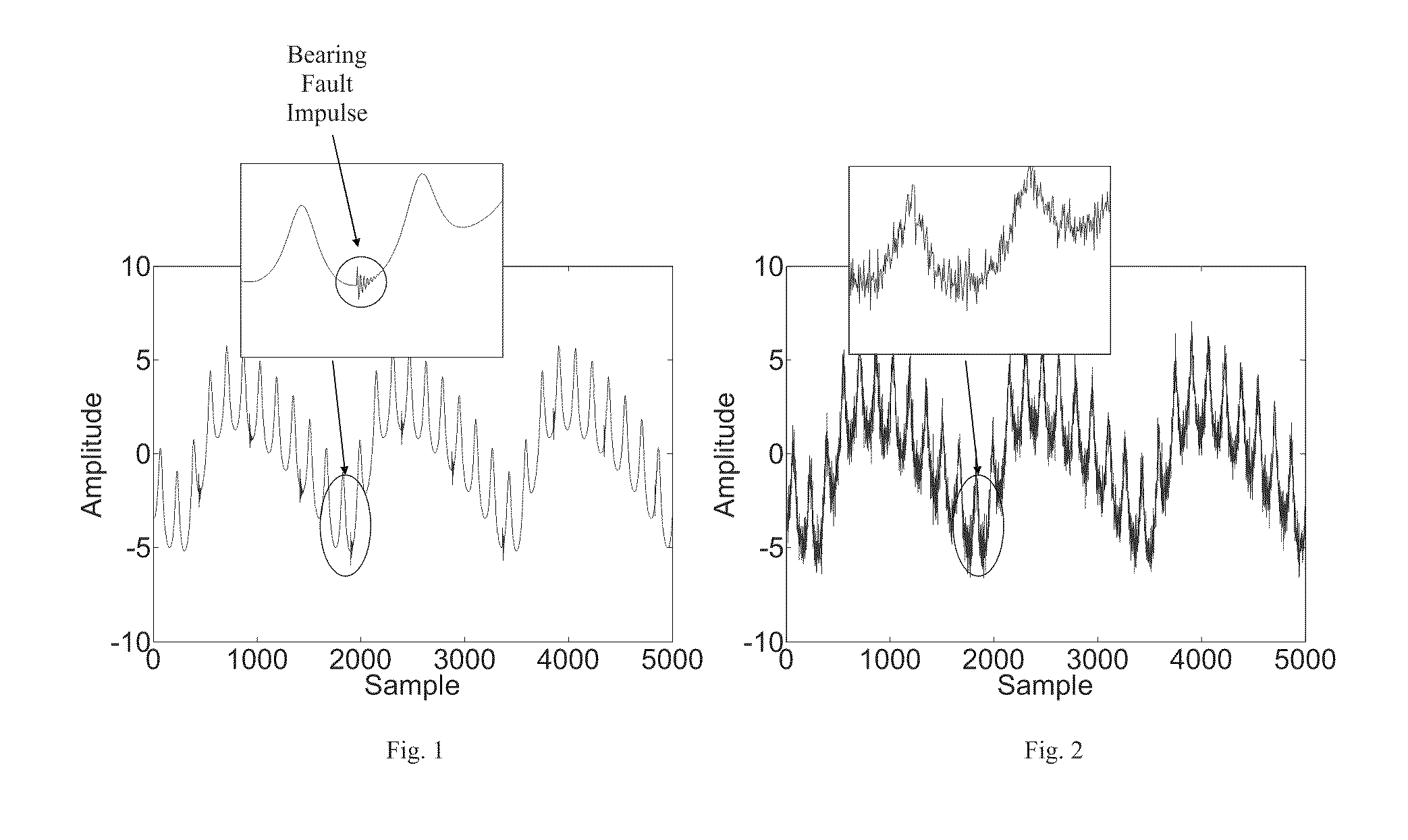

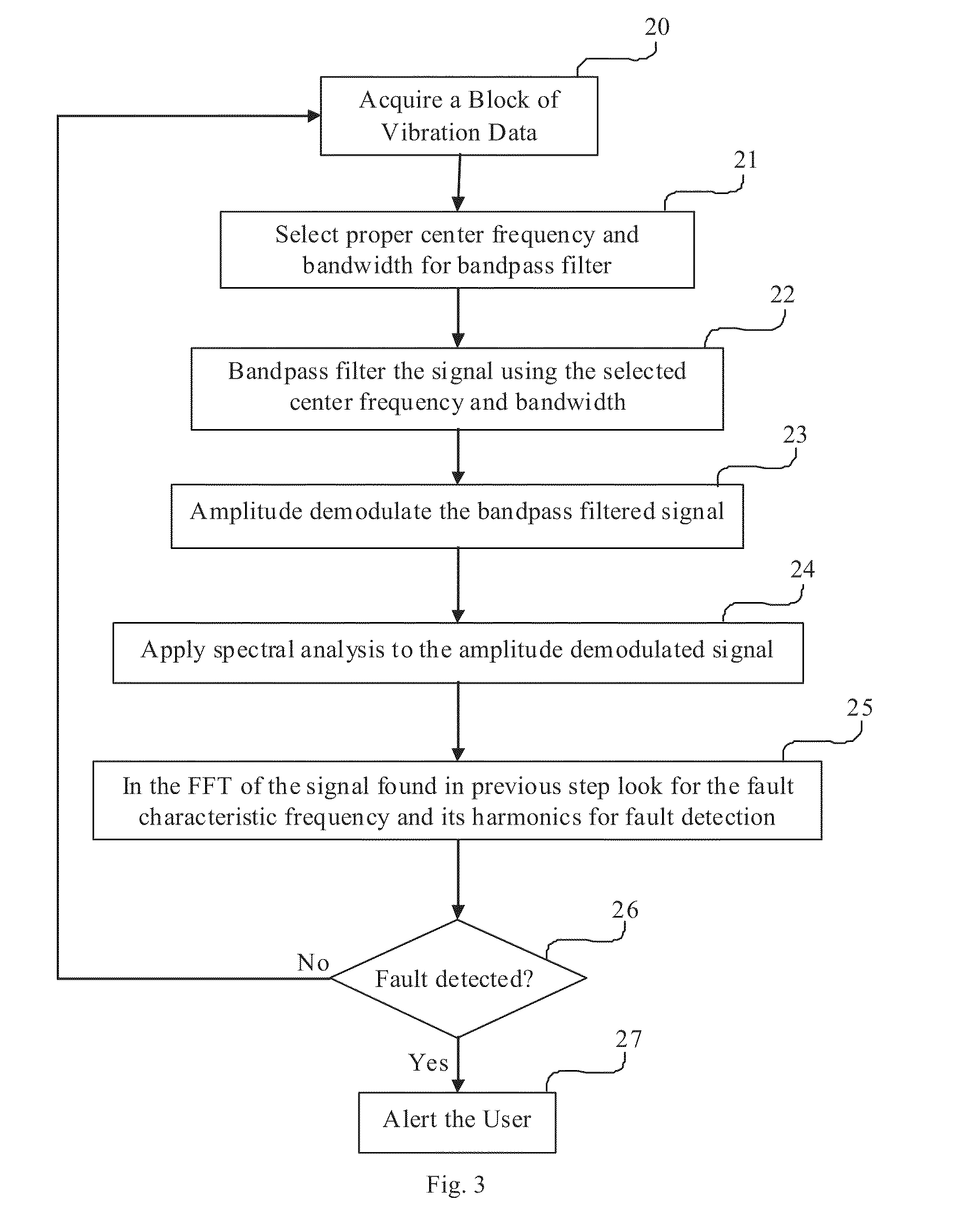

Parameter independent detection of rotating machinery faults

InactiveUS20100139403A1Efficient implementationVibration measurement in solidsMachine part testingMechanical componentsAmplitude demodulation

A parameter-free method to analyze sensor signals incorporates two or more of frequency demodulation, amplitude demodulation and phase demodulation of the raw signal data. The resulting signal is transformed to a frequency domain, and target fault characteristics from the demodulated signal are identified. The method is used to detect faults in bearings, gears and other mechanical components.

Owner:UNIVERSITY OF OTTAWA

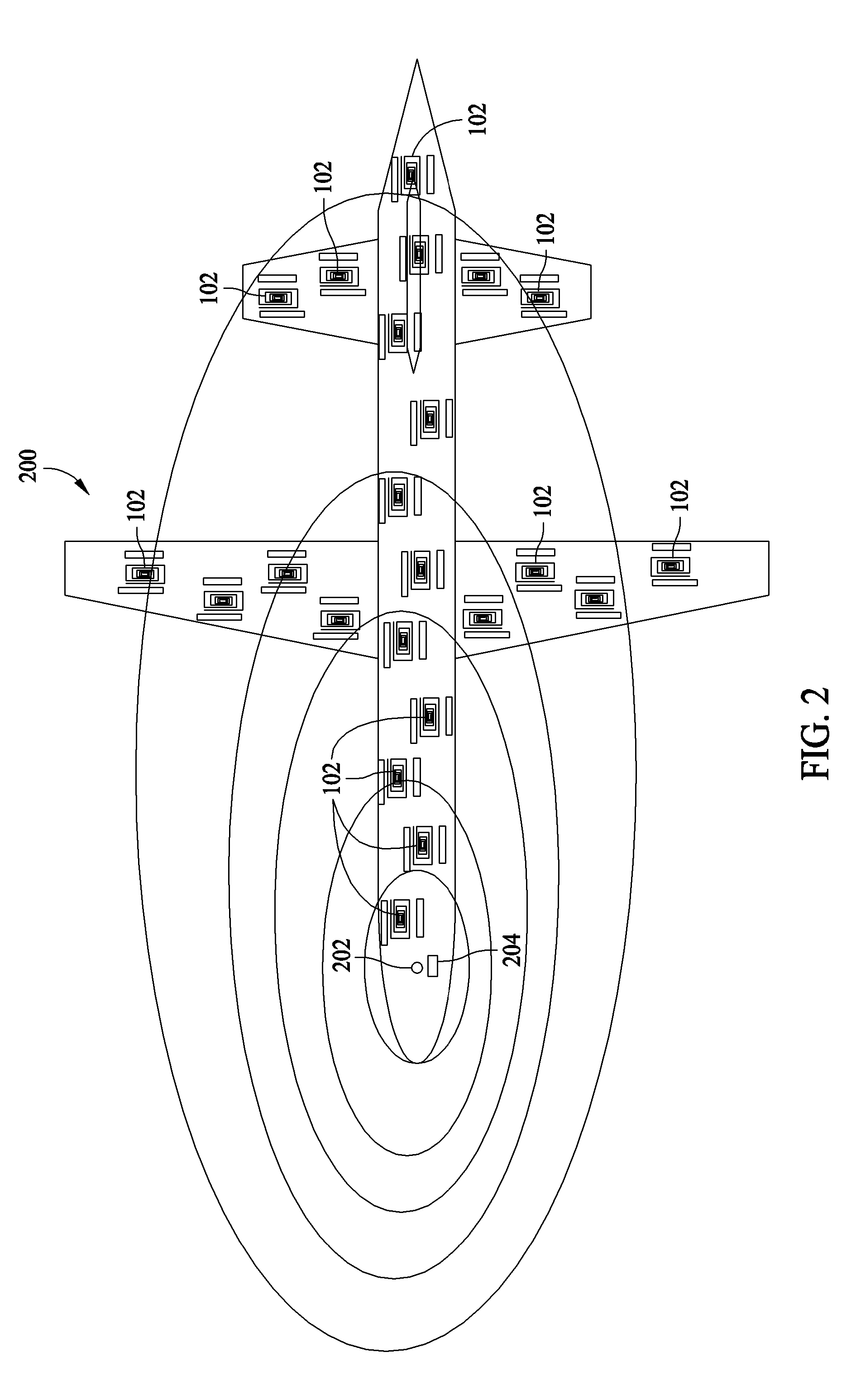

Methods and systems for monitoring structures and systems

ActiveUS20080167833A1Material analysis using acoustic emission techniquesRegistering/indicating working of vehiclesHandling systemData mining

Methods and systems for structural and component health monitoring are provided. A system includes a plurality of sensor systems positioned about an object to be monitored and a processing system communicatively coupled to at least one of said plurality of sensor systems wherein the processing system includes an ontology and reasoning module configured to model the object to be monitored, reason about the received sensor data associated with the object to be monitored and reason about the relationships between the received sensor data to fuse the data into contextual information for the overall object to be monitored and a contextual analyzer configured to transmit the received sensor data to said ontology and reasoning module and to store the information into a contextual information database.

Owner:THE BOEING CO

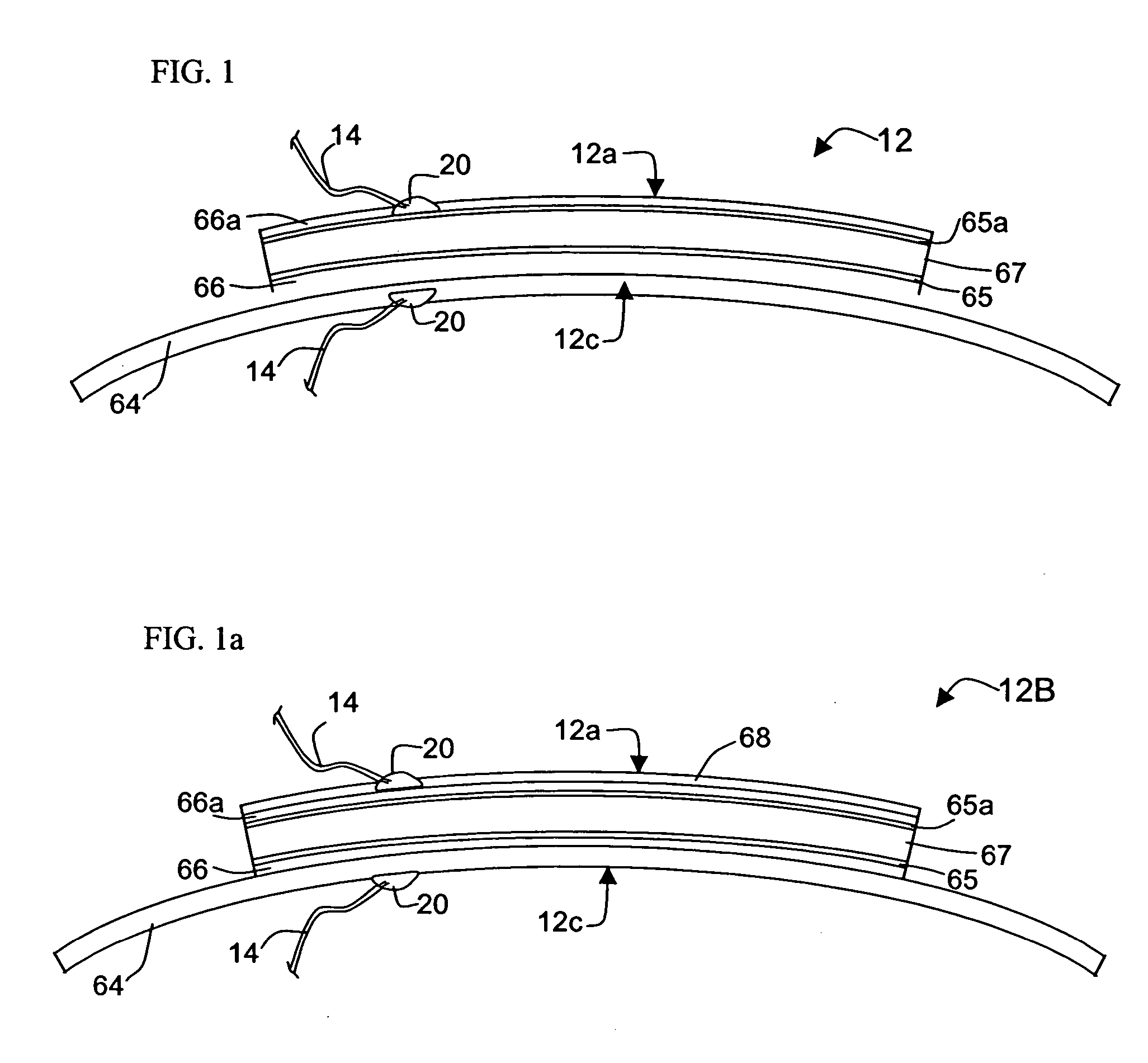

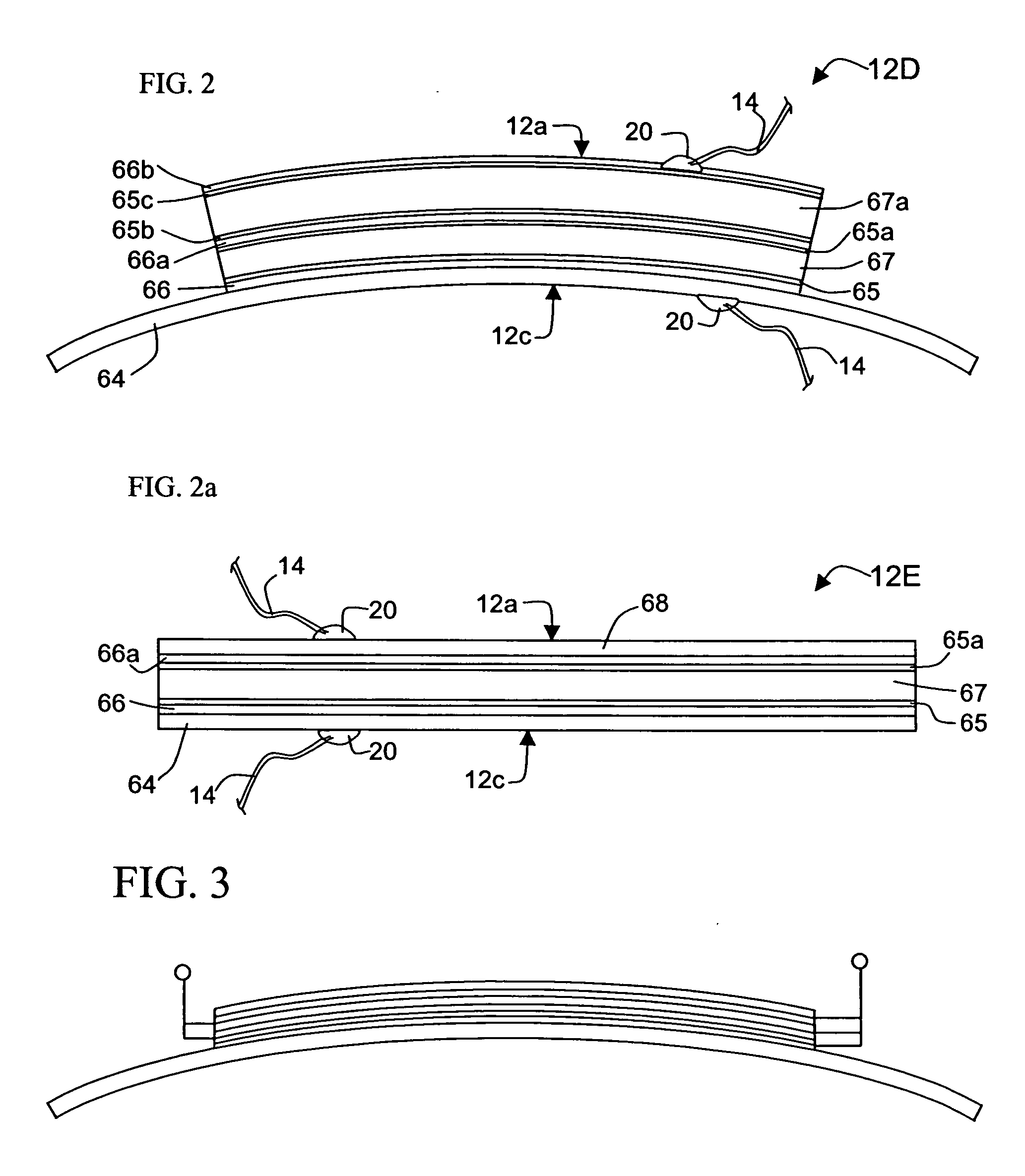

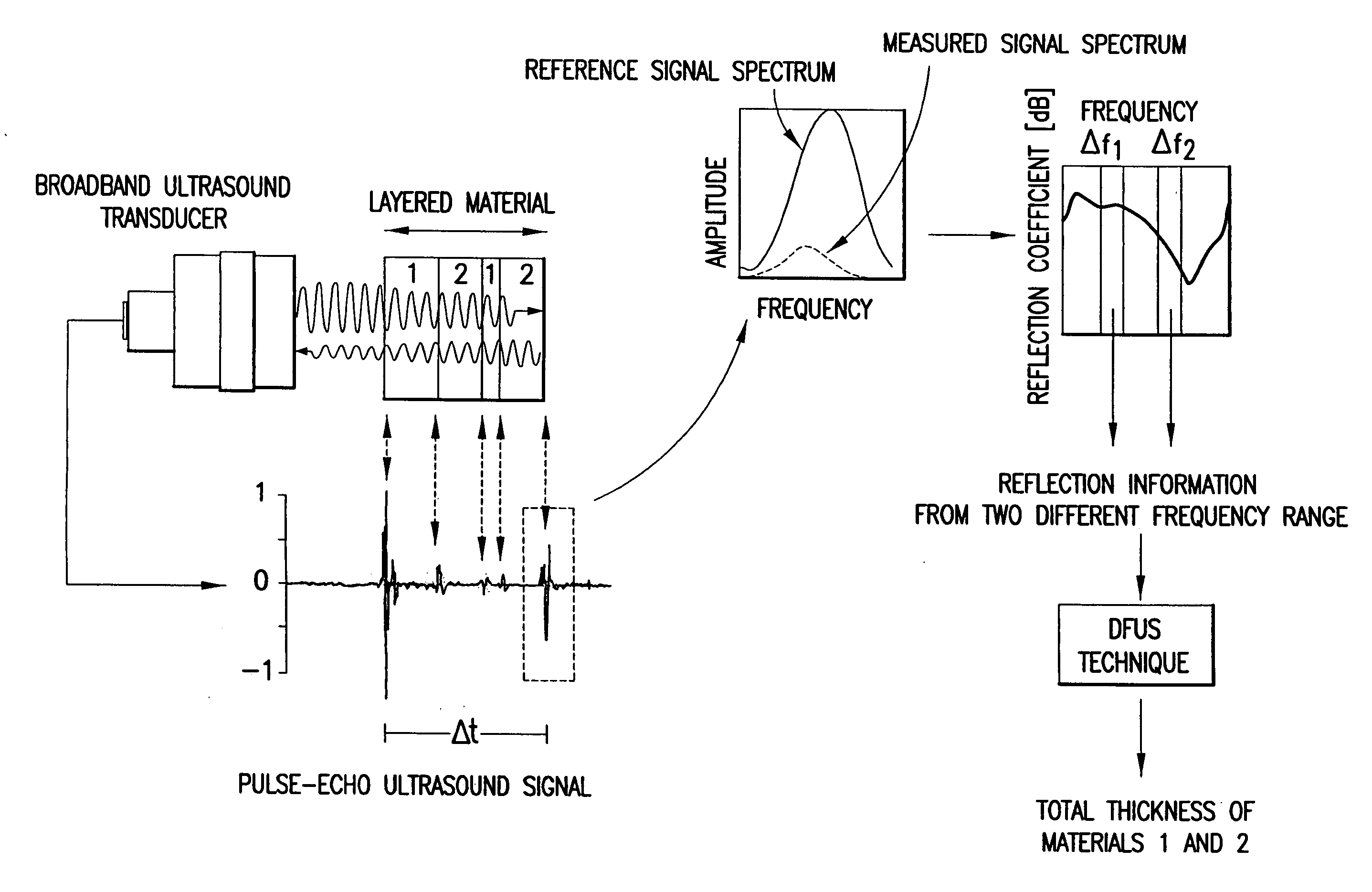

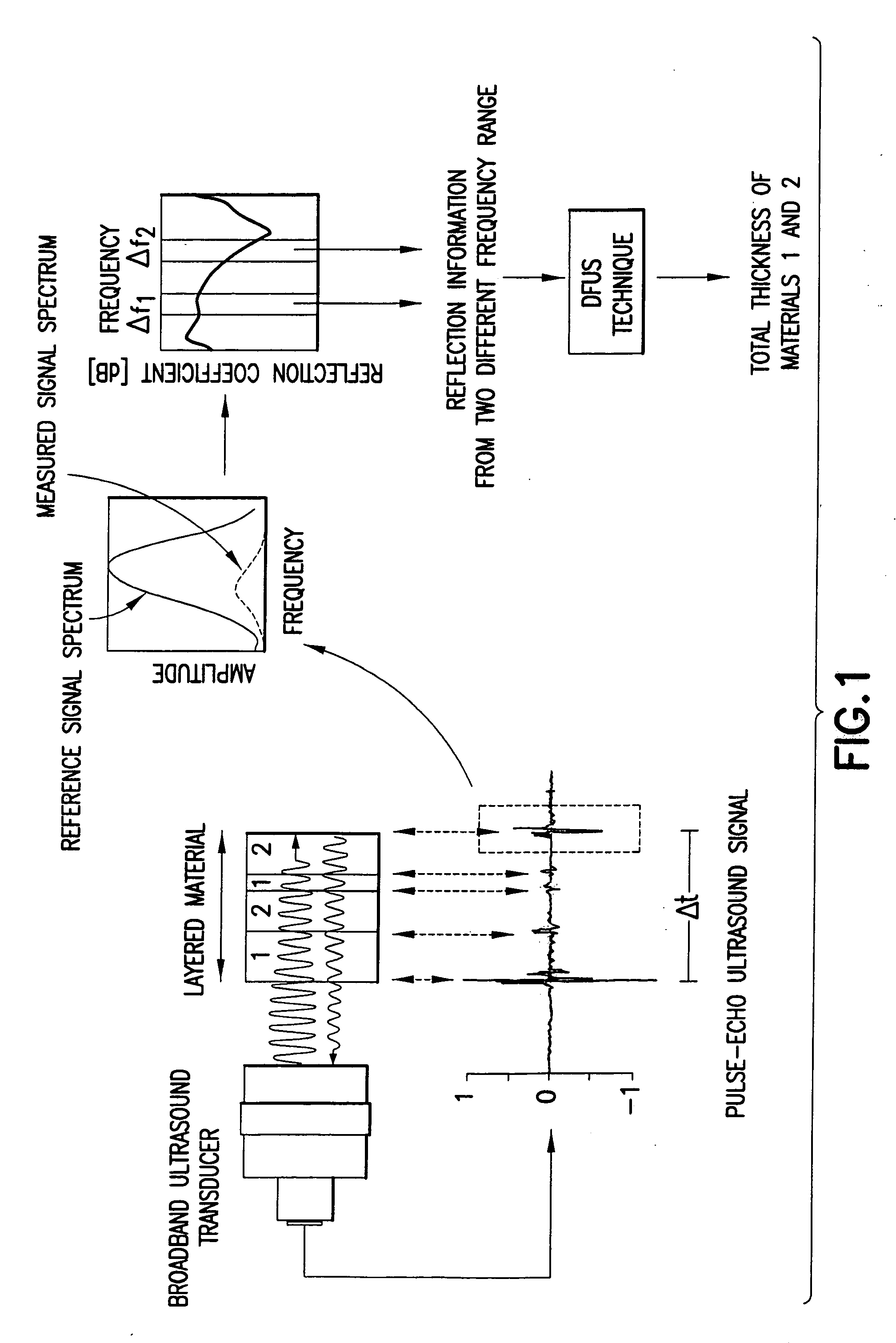

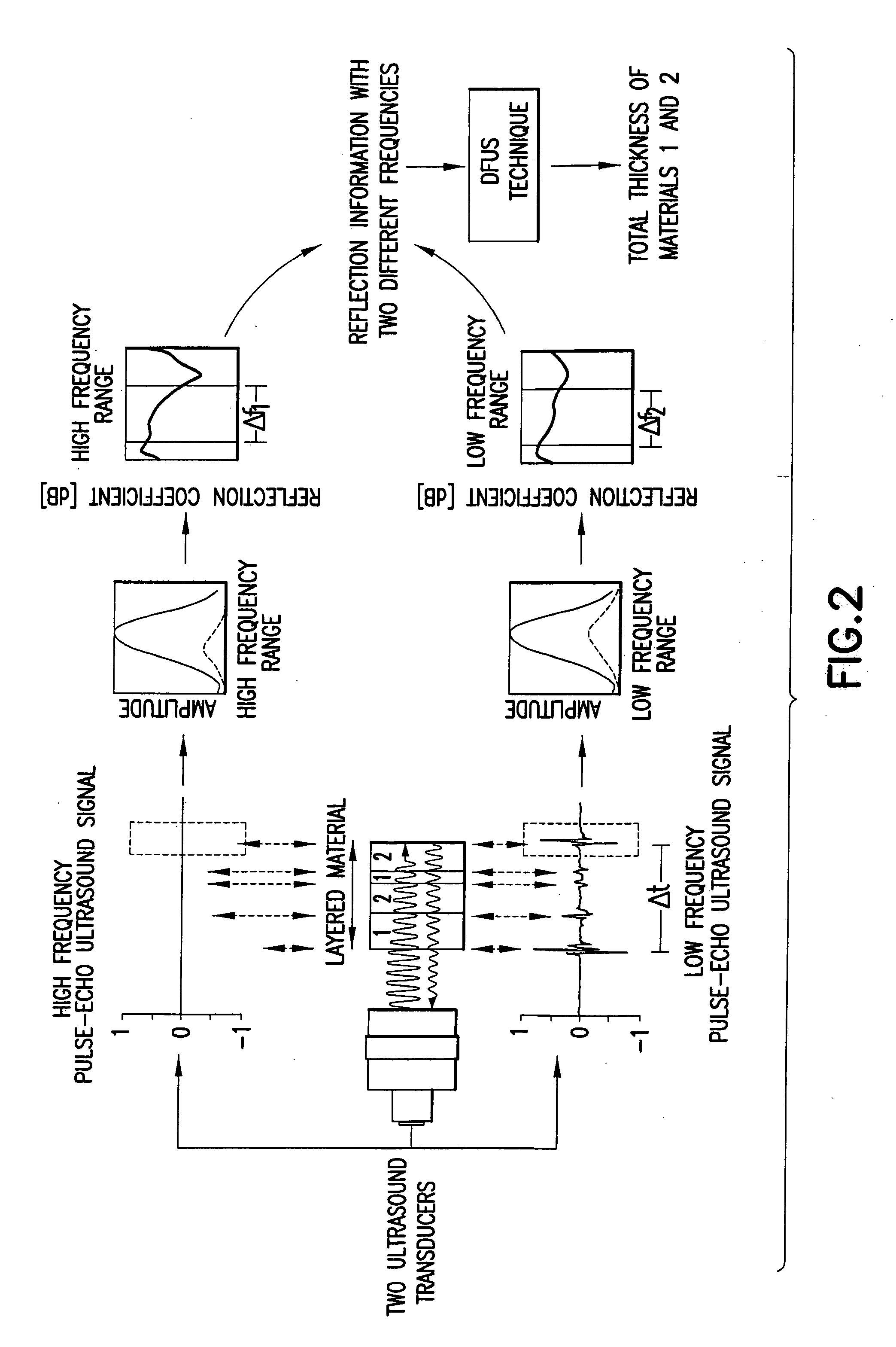

Method for measuring of thicknesses of materials using an ultrasound technique

ActiveUS20090143681A1Improve accuracyEliminate disadvantagesUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorUltrasound techniques

The invention relates to a method for measuring thicknesses of materials of multilayered structure. This method includes transmitting one or more ultrasound signals including different frequencies into a multilayered structure consisting of two or more materials with one or more ultrasound transducers, measuring materials, acoustic properties for which are different at the frequencies in use, measuring ultrasound signals reflected from the front surface and back surface of the multilayered structure with one or more ultrasound transducer and determining thicknesses of the materials within multilayered structure from the reflected ultrasound signals.

Owner:BONE INDEX FINLAND

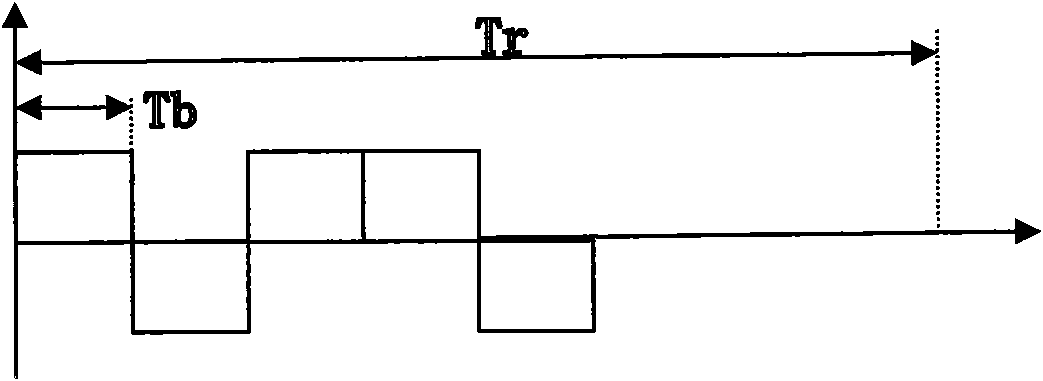

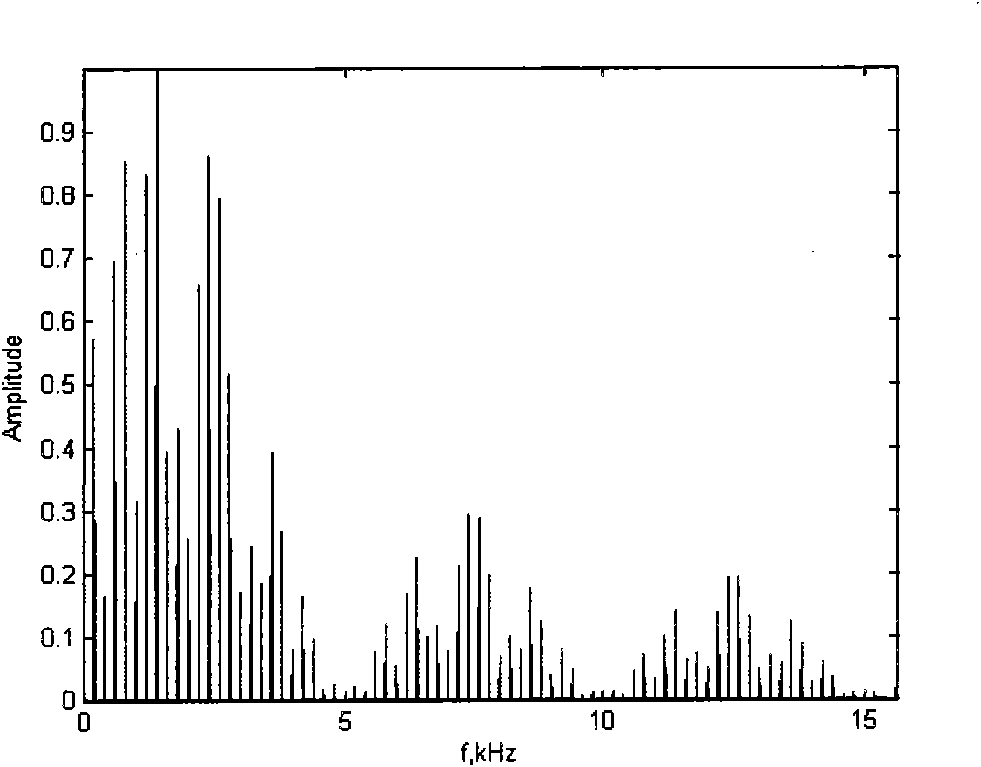

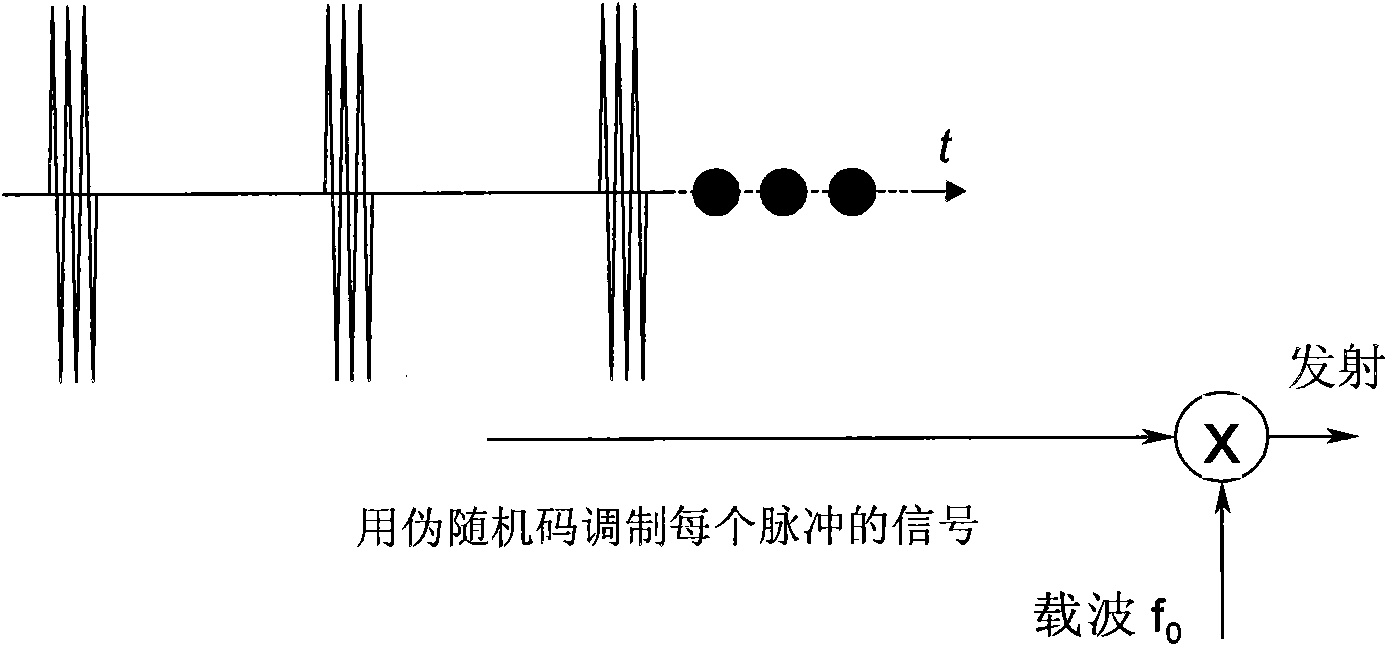

Ultrasonic imaging method and device

InactiveCN101869485AHigh energyGood cross-correlationUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using acoustic emission techniquesAcoustic radiation forceSignal-to-noise ratio (imaging)

The invention discloses ultrasonic imaging method and device. The method comprises the following steps of: firstly carrying out coded modulation on a pulse generating an acoustic radiation force, and exciting a probe to emit an ultrasonic wave to generate a multi-frequency acoustic radiation force to generate tissue vibration; then adopting the coded modulation different from an exciting pulse for the pulse detecting the tissue vibration, ensuring the good correlation between two code words, and eliminating the interference caused by an exciting pulse echo generating the acoustic radiation force for a detection echo by utilizing a CDMA (Code Division Multiple Access) technology similar to communication, thereby improving the signal-to-noise ratio and increasing the energy of the acoustic radiation force by more fully utilizing the pulse width and the frequency band width resources of a system.

Owner:SHENZHEN UNIV

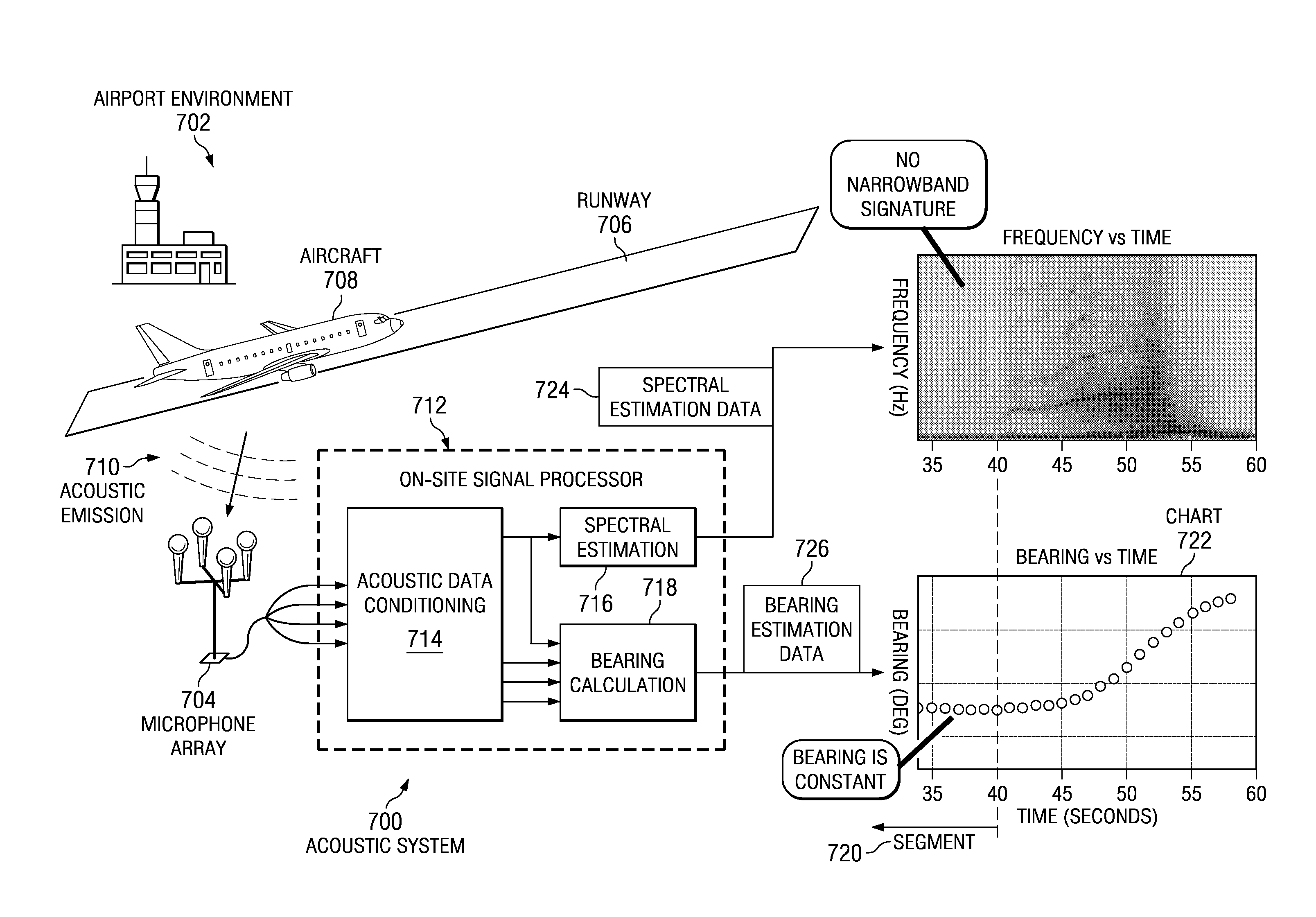

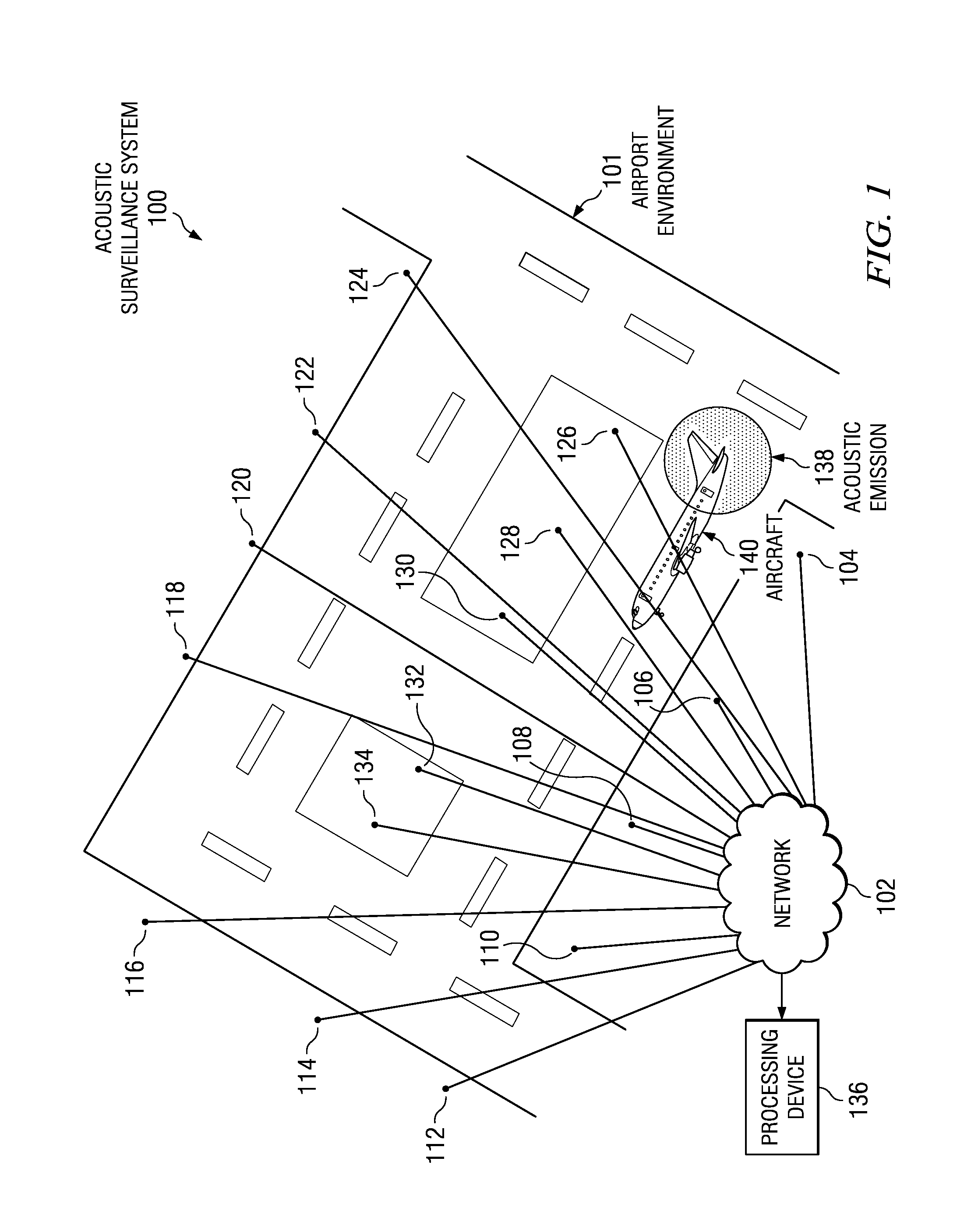

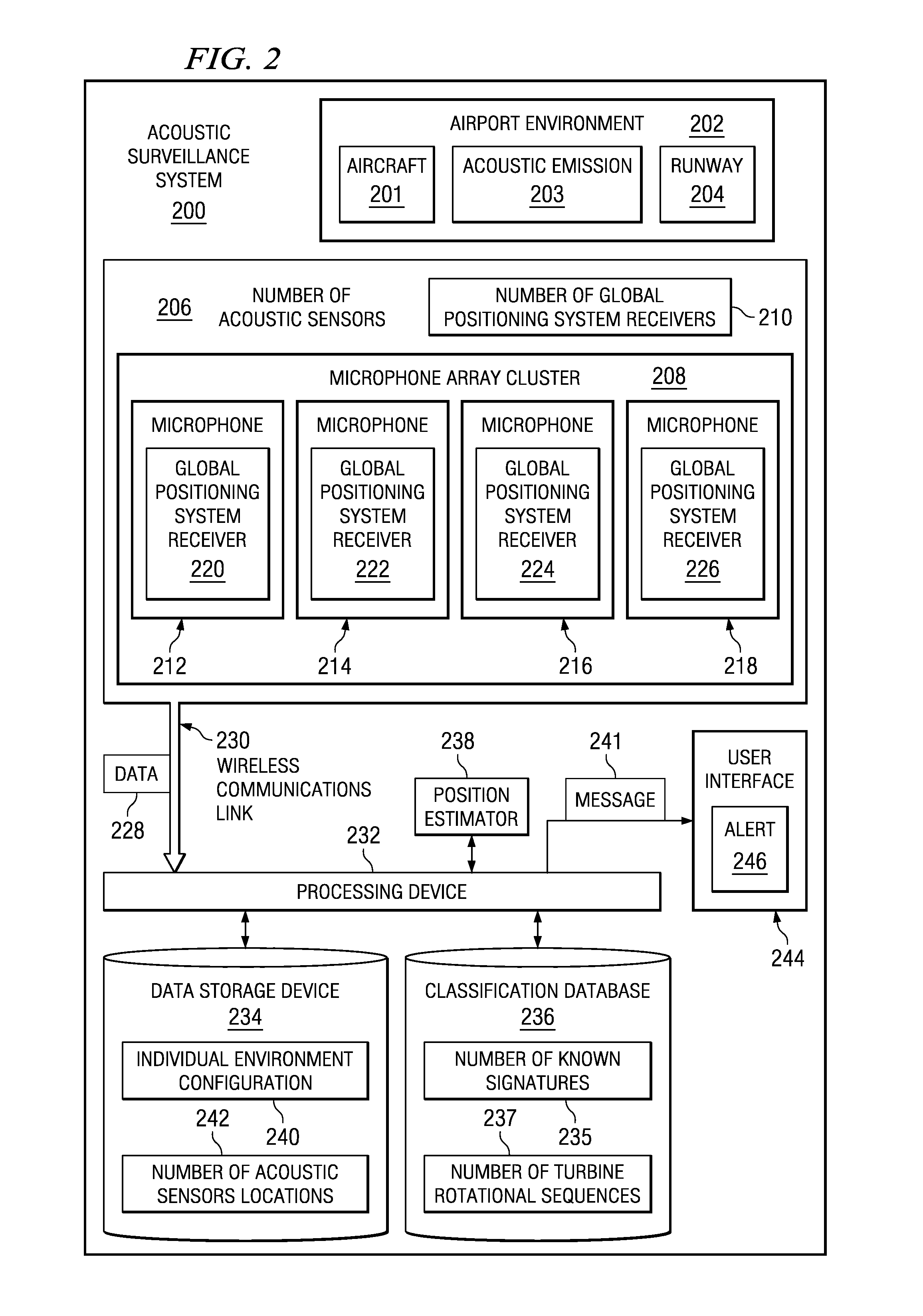

Acoustic airport surveillance system

ActiveUS8059489B1Material analysis using acoustic emission techniquesProcessing detected response signalAcoustic emissionMonitoring system

The different advantageous embodiments provide a method and apparatus for detecting an aircraft. The different advantageous embodiments may provide a method for detecting an acoustic emission emitted by the aircraft using a number of acoustic sensors to form a detected acoustic emission. The aircraft may be identified from the detected acoustic emission to form an identified aircraft. A bearing may be estimated for the identified aircraft using the detected acoustic emission.

Owner:THE BOEING CO

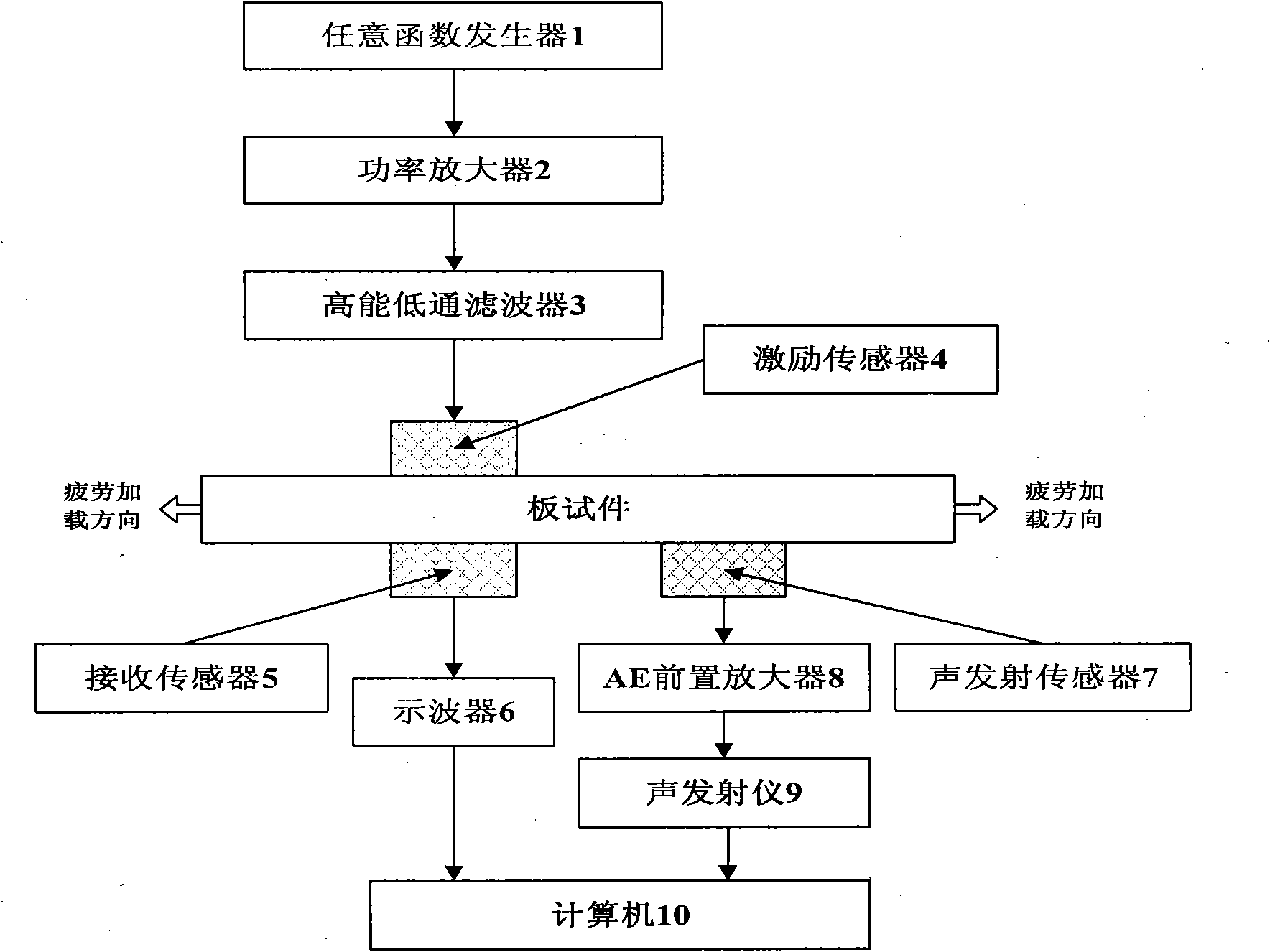

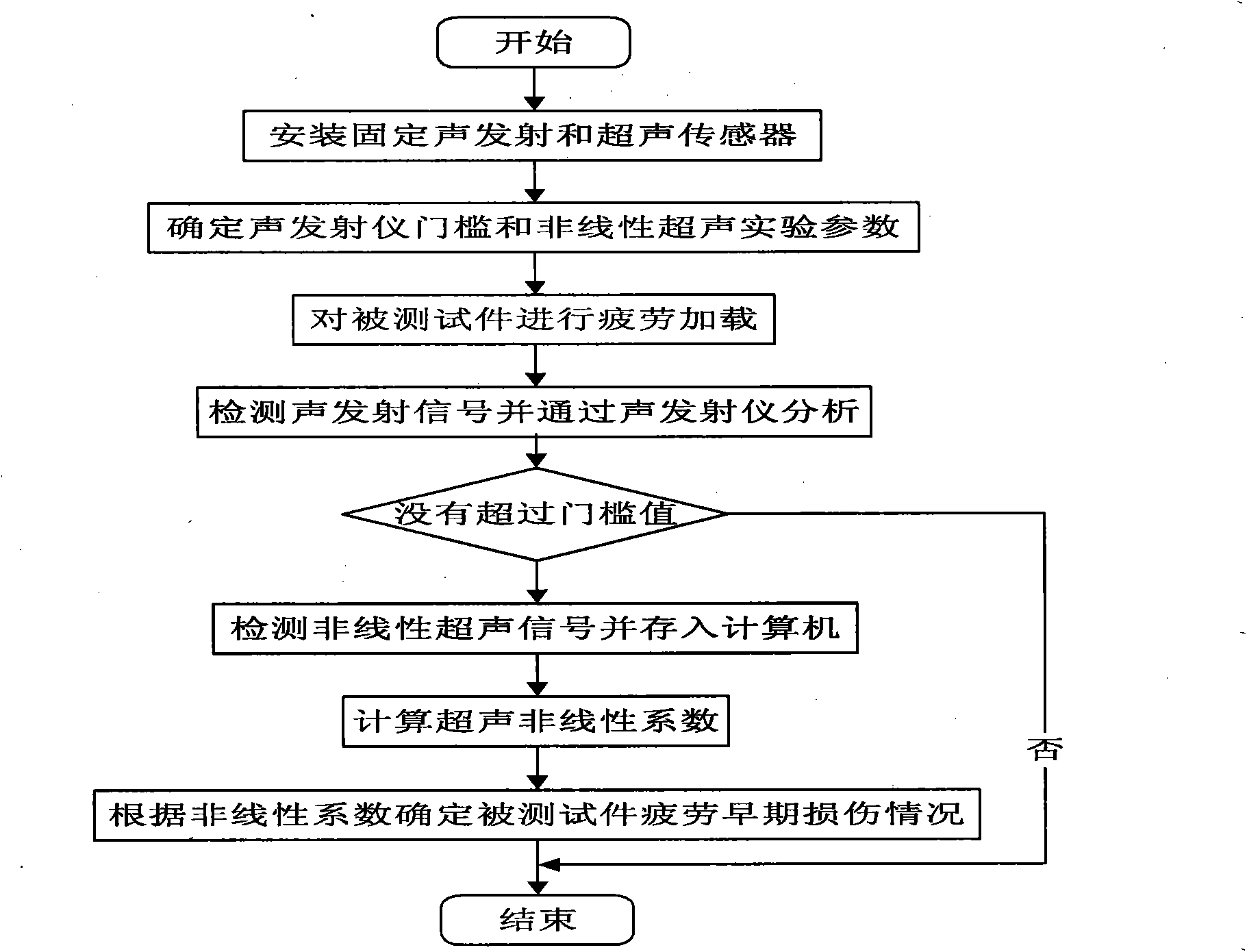

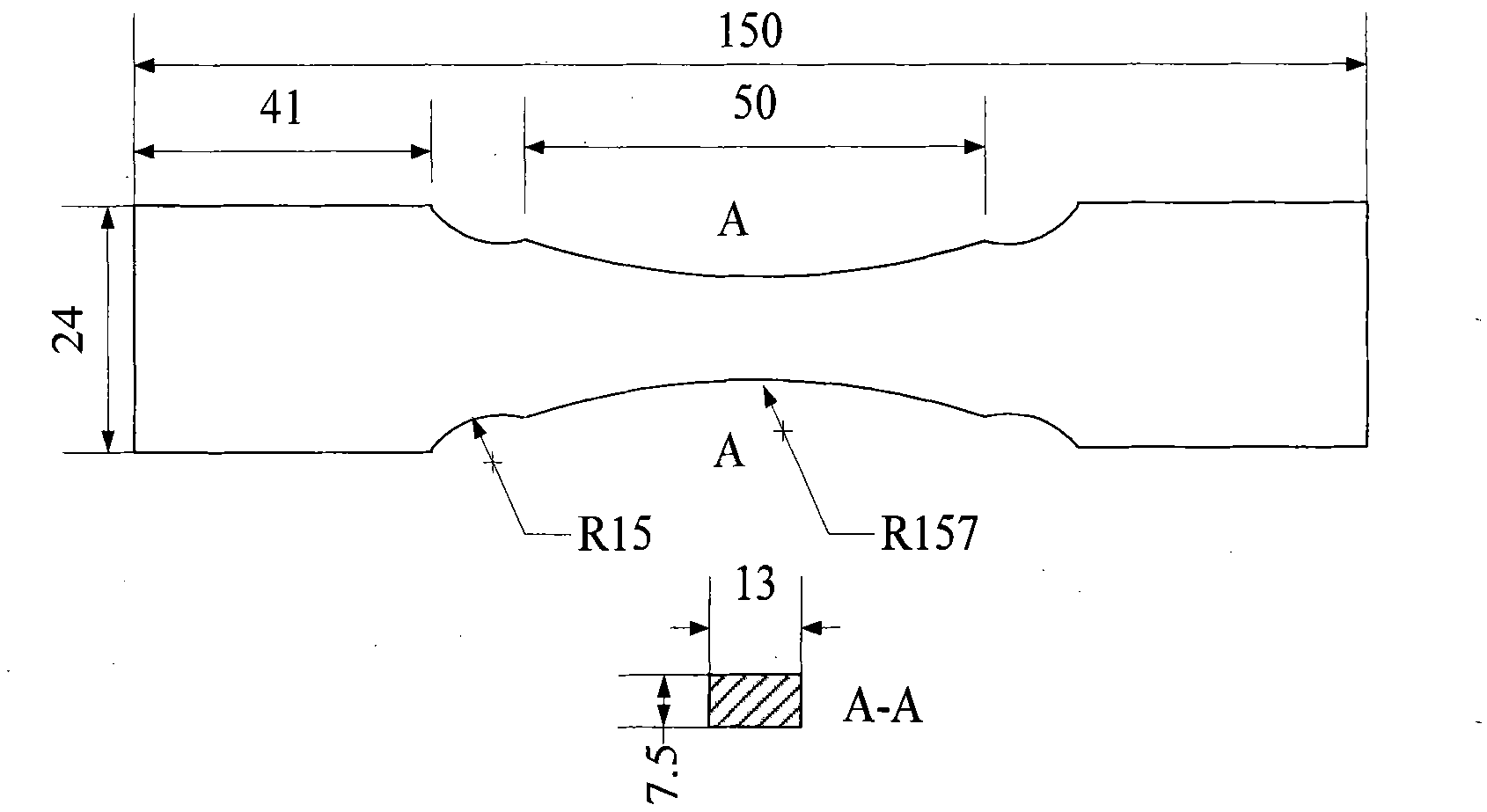

Method for non-linear ultrasonic online detection of early fatigue damage to metal material

InactiveCN101806778ARealize the whole process of fatigue detectionSolve misjudgmentMaterial analysis using acoustic emission techniquesFatigue damageSonification

A method for the non-linear ultrasonic online detection of early fatigue damage to a metal material belongs to the field of nondestructive detection. The method comprises the following steps: determining an excitation signal parameter according to the thickness of a tested piece and inputting the parameter to an arbitrary function generator to generate a sound signal; determining a threshold value of an acoustic emission instrument according to the amplitude of a no-load noise signal; performing fatigue loading on the tested piece, continuously detecting an acoustic emission signal in real time with an acoustic emission sensor, amplifying the acoustic emission signal, inputting the acoustic emission signal into the acoustic emission instrument, and judging ring with the acoustic emission instrument when the amplitude of the acoustic emission signal exceeds the preset the threshold value of the acoustic emission instrument; detecting a non-linear ultrasonic signal at equal time interval if the acoustic emission instrument does not display the ring or the times of the continuous ring is not more than an empirical value; and stopping detection if the displayed ring times is more than the empirical value, because fatigue cracks are generated and develop. On the basis of non-linear ultrasonic nondestructive detection, the method of the invention introduces acoustic emission technique, so the method does not make incorrect judgment when detecting the early fatigue damage to the metal material and realizes continuous online detection.

Owner:BEIJING UNIV OF TECH

Weighted bioacoustic sensor and method of using same

InactiveUS20070113654A1Low acoustic impedanceEfficient amplificationAcceleration measurement using interia forcesSamplingElectrical conductorTransducer

A sensor for sensing bioacoustic energy includes a housing comprising an interfacing portion configured to establish coupling with a body part during use. The sensor includes a transducer element coupled to the interfacing portion of the housing and configured to sense sounds produced by matter of biological origin. One or more conductors are coupled to the transducer element. A mass element is compliantly coupled to a surface of the transducer element. Intervening material is disposed between the transducer element surface and the mass element, and allows for differential motion between the transducer element surface and the mass element during excitation of the transducer element.

Owner:3M INNOVATIVE PROPERTIES CO

Method for determining the location of impacts by acoustic imaging

ActiveUS8692810B2Material analysis using acoustic emission techniquesDirection finders using ultrasonic/sonic/infrasonic wavesComputer scienceFourier transform

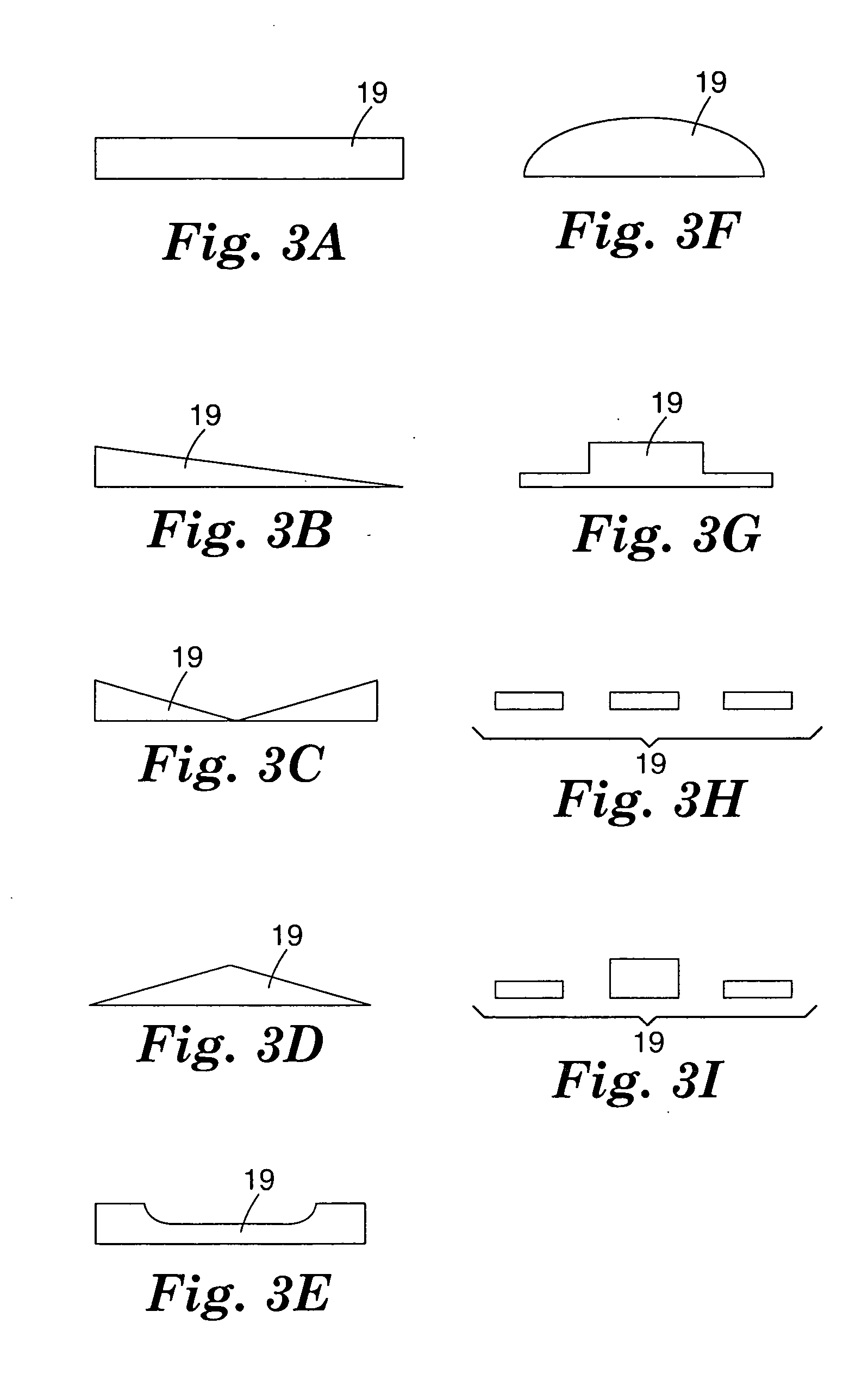

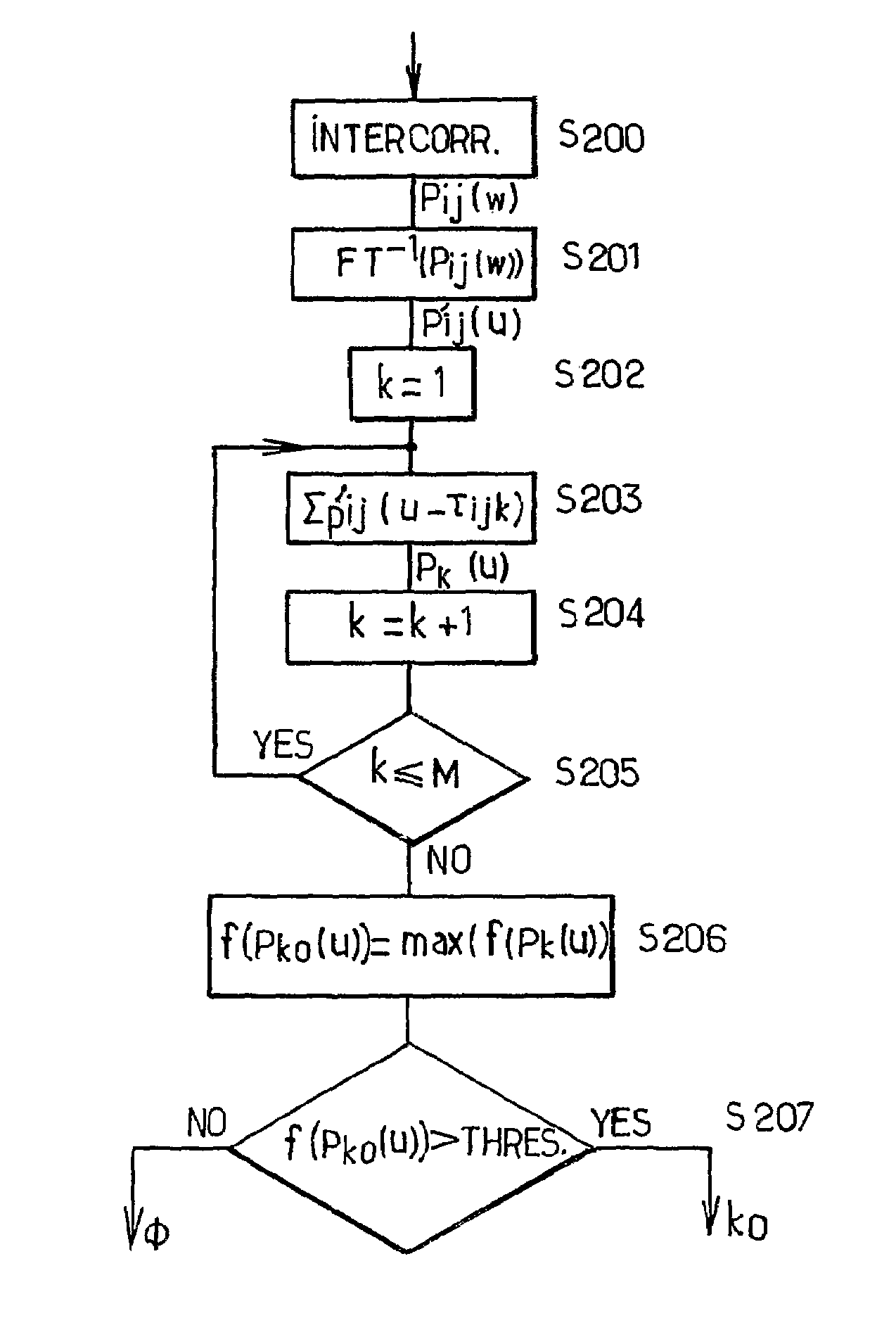

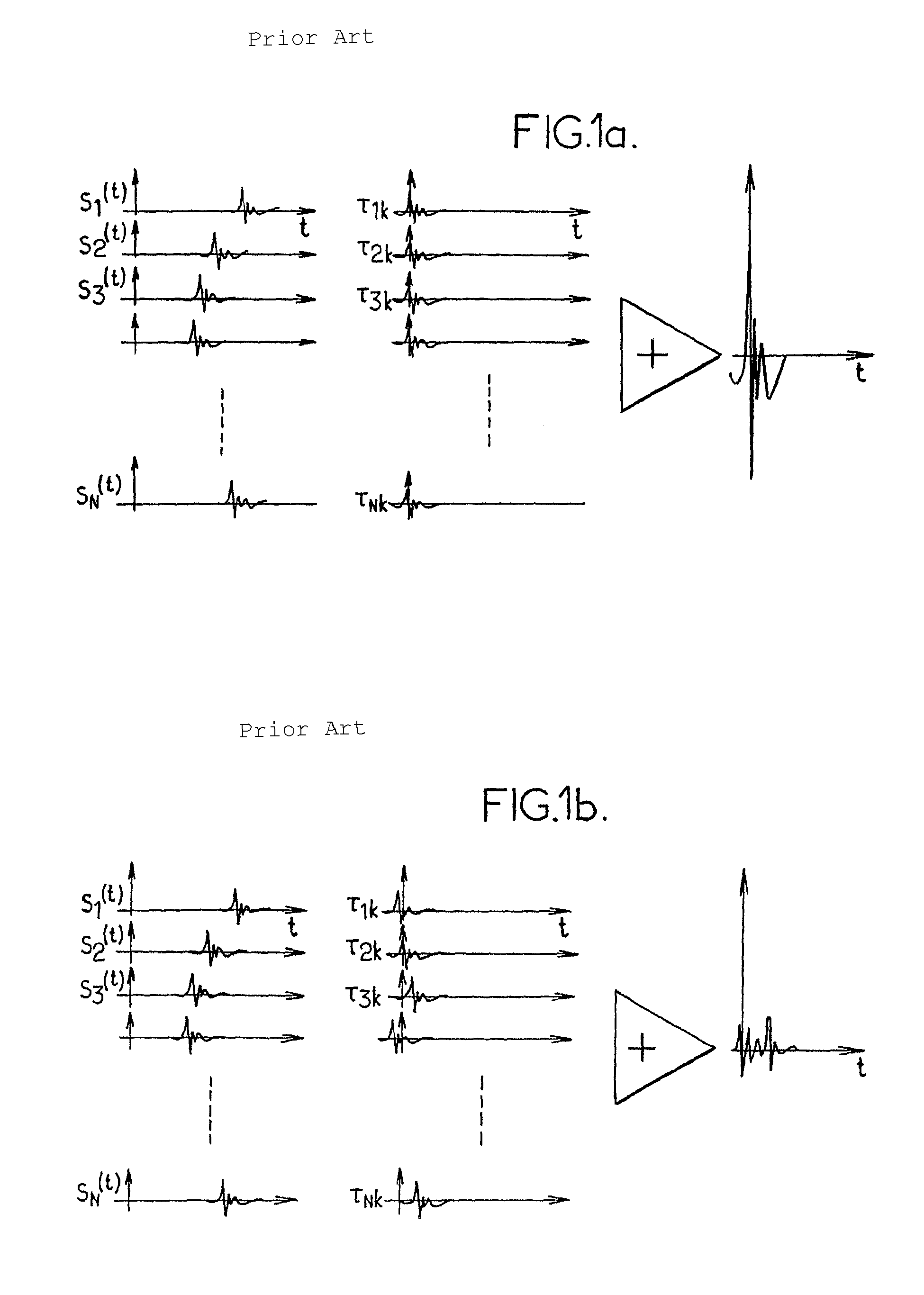

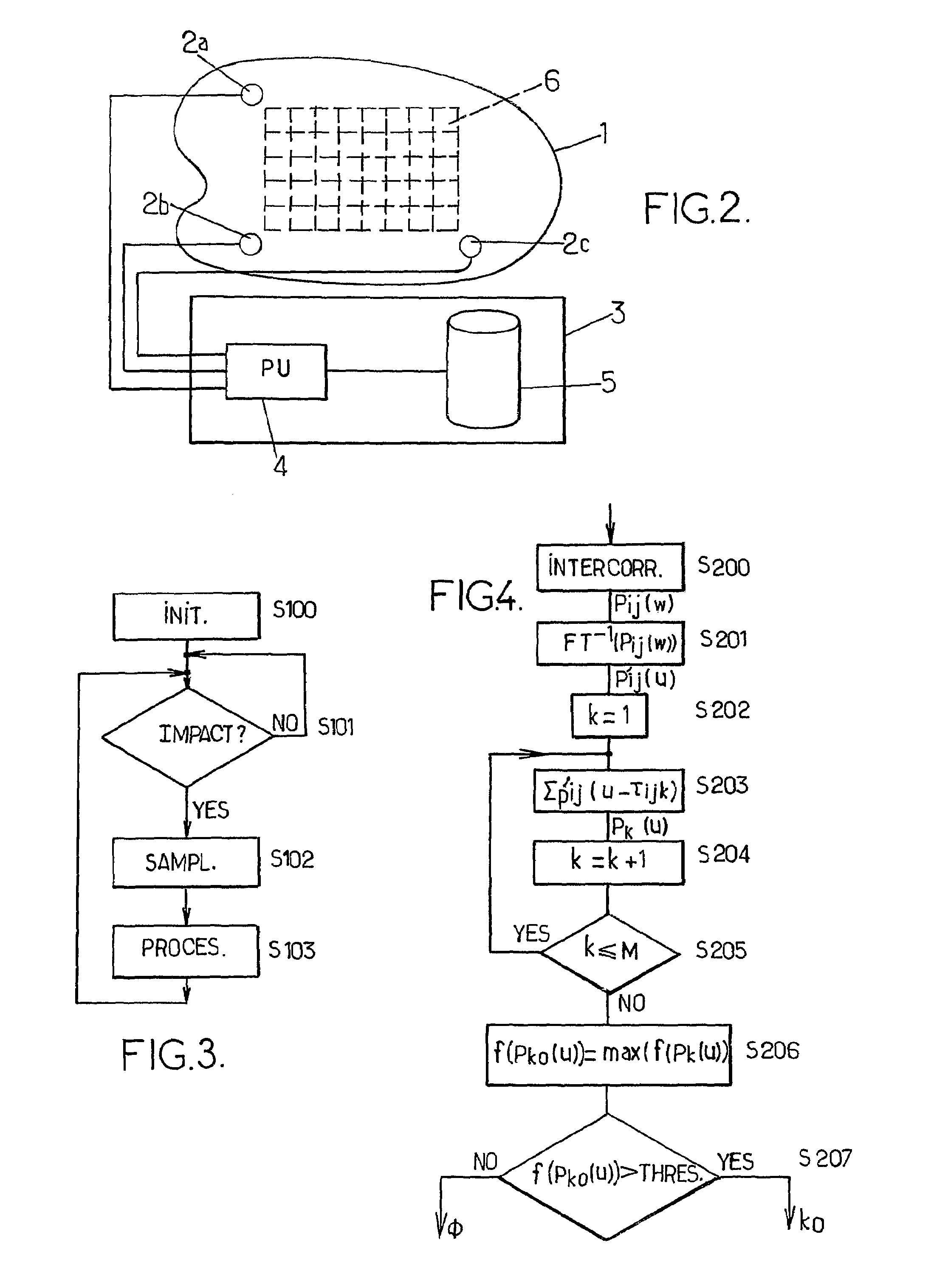

A method for determining the location of an impact on a surface (1) comprising N acoustic sensors (2a, 2b, 2c), transmitting a sensed signal si(t) to a processing unit (4) comprises the following steps (a) computing P intercorrelation products (b) calculating P inverse Fourier transforms p′ij (u) (c) computing for each area k, Pk(u)=ΣP′ij (u−τijk); d) finding k0, where a characterizing value of Pk0 (u) is greater than a given threshold value.

Owner:ELO TOUCH SOLUTIONS INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com