Patents

Literature

76results about How to "Low acoustic impedance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piezoelectric resonator device having detuning layer sequence

InactiveUS6864619B2Optimization rangeIncreased acoustic impedanceImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAcousticsAcoustic impedance

A resonator device includes a piezoelectric resonator having a detuning layer sequence arranged on the piezoelectric resonator. The detuning layer sequence includes at least a first layer having a high acoustic impedance and a second layer having a low acoustic impedance.

Owner:AVAGO TECH INT SALES PTE LTD

Nanometer cellulose/polyvinyl alcohol gel composite material

ActiveCN102786642ALarge specific surface areaHigh porosityChemical industryChemical industryPolyvinyl alcohol

The invention relates to a nanometer cellulose / polyvinyl alcohol gel composite material, which is characterized by comprising hydrogel and aerogel. A preparation method of the nanometer cellulose / polyvinyl alcohol gel composite material comprises the following process steps of 1, nanometer cellulose preparation by a chemical combination mechanical treatment method; 2, composite hydrogel preparation; and 3, composite aerogel preparation. The nanometer cellulose / polyvinyl alcohol gel composite material has the advantages that the composite aerogel belongs to a porous amorphous solid material consisting of nanometer level colloid particles or high-polymer molecules, and a unique open nanometer level porous structure and a continuous three-dimensional reticular structure are adopted, so the density is extremely low, the specific surface area is high, and the porosity is high, wherein the solid phase of the aerogel accounts for 0.2 percent to 20 percent of the total volume percentage, the characteristics of high adsorption catalytic capability, low thermal conductivity, low sound resistance, low refractive index and the like are shown, and wide application prospects are realized in the fields of aviation, spaceflight, chemical industry, metallurgy, energy-saving building and the like.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

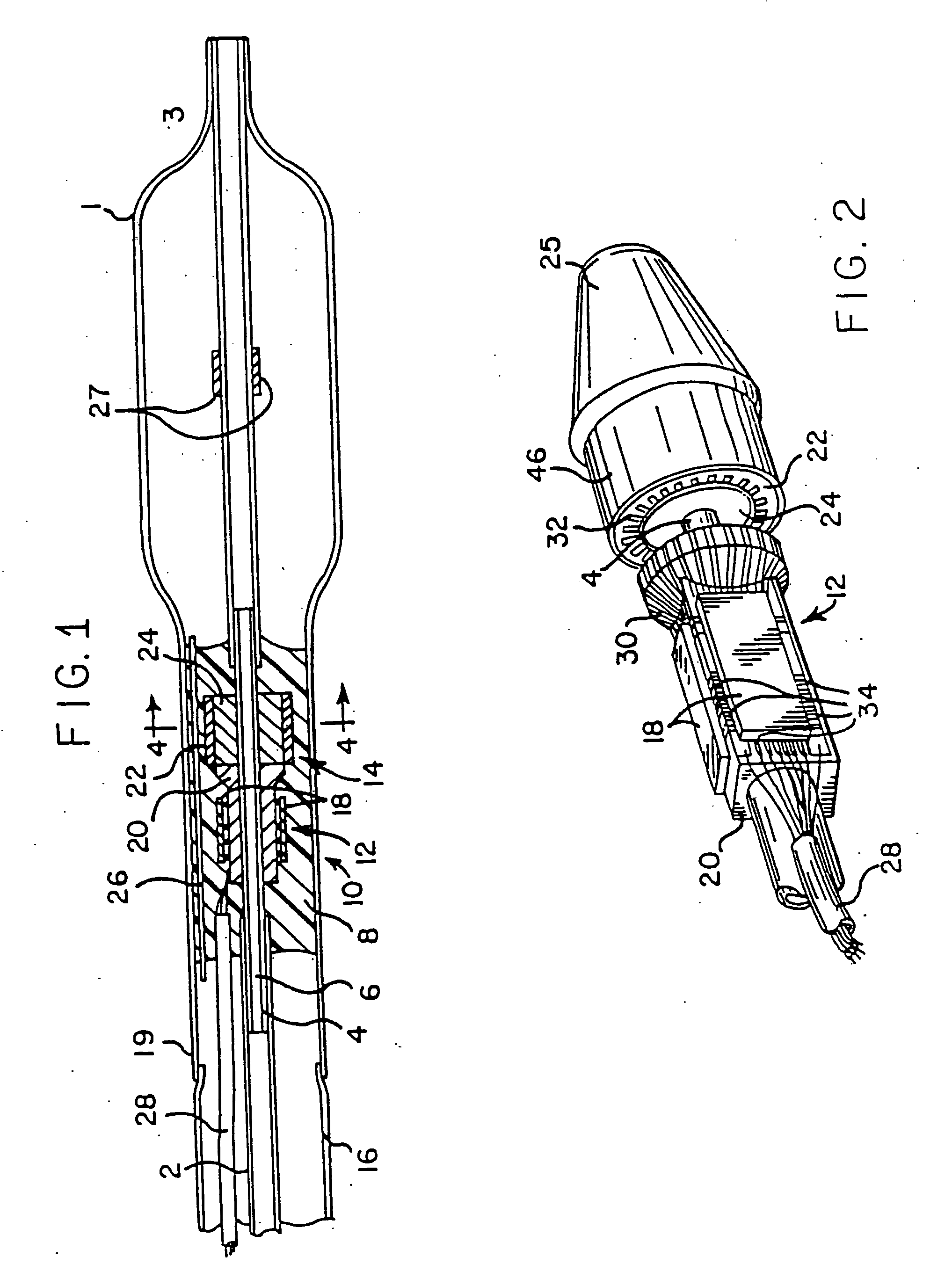

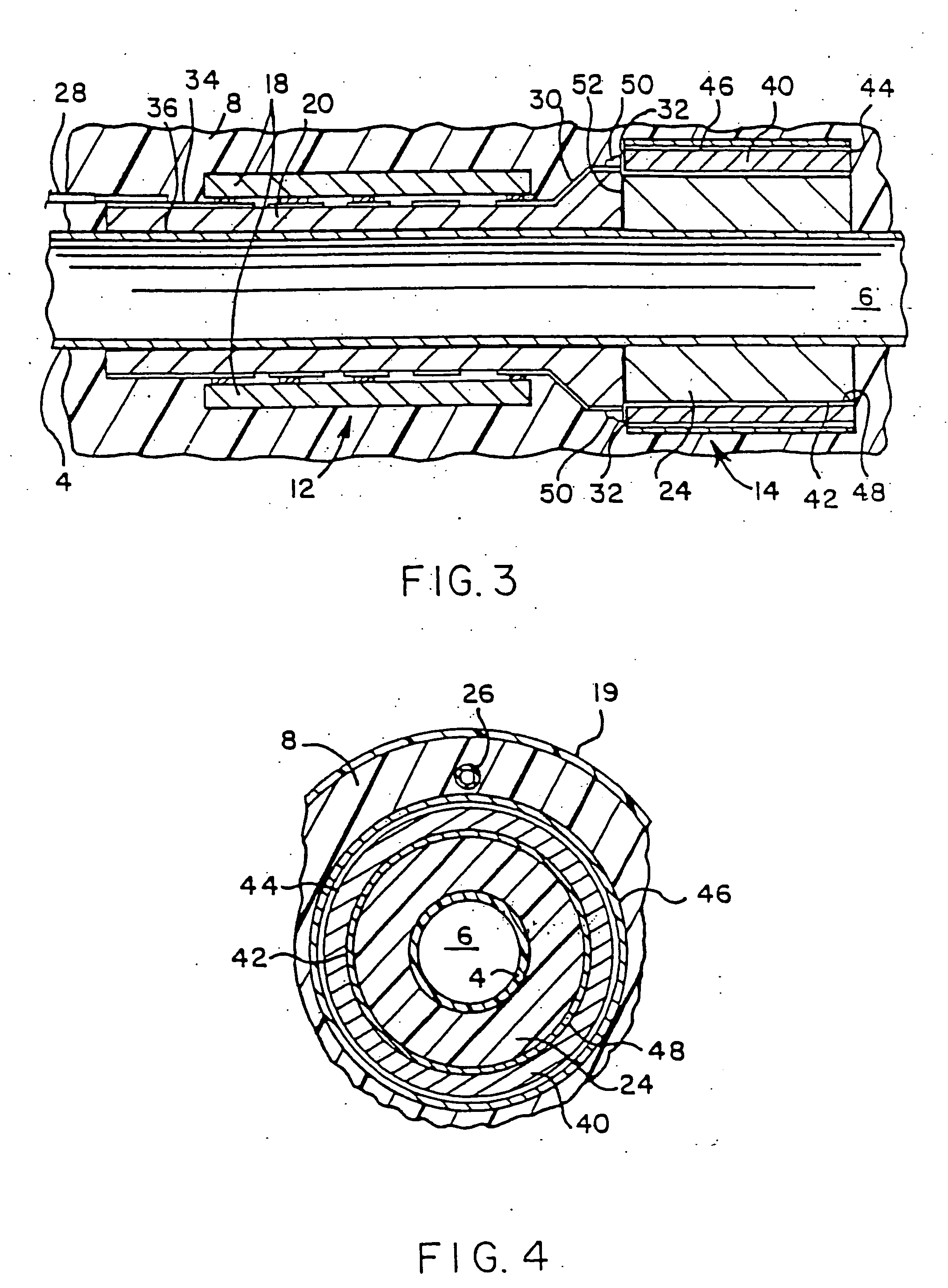

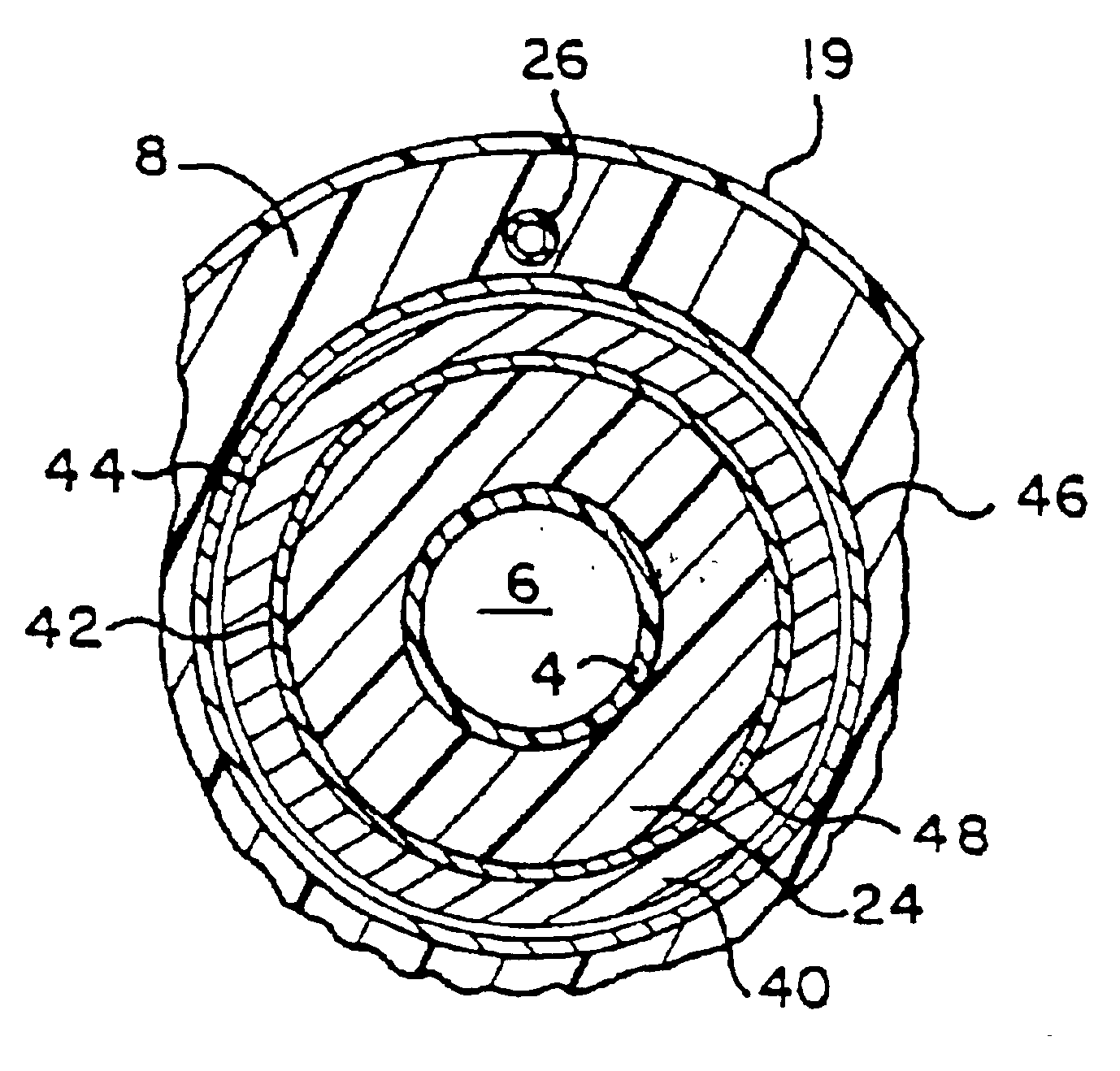

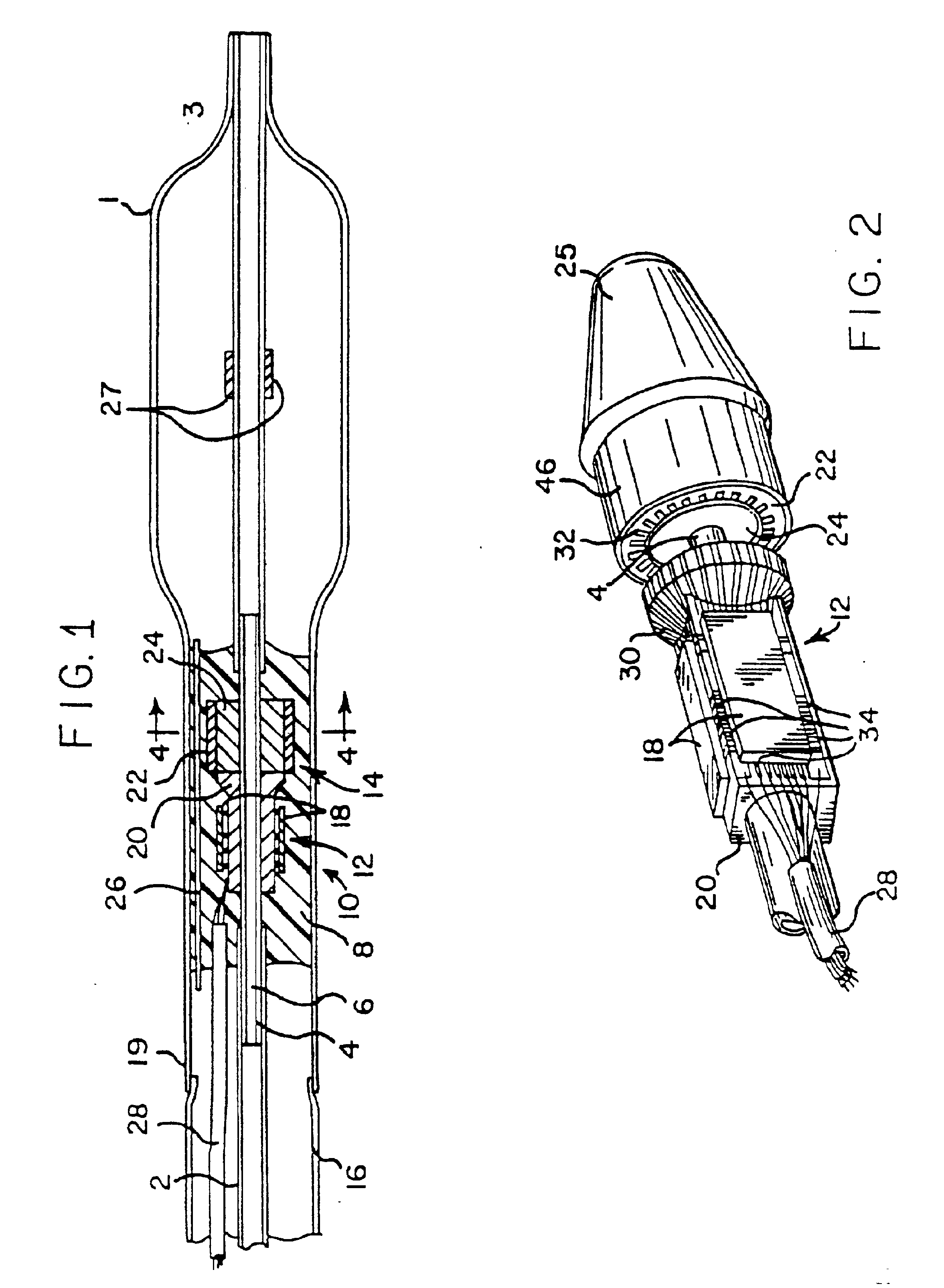

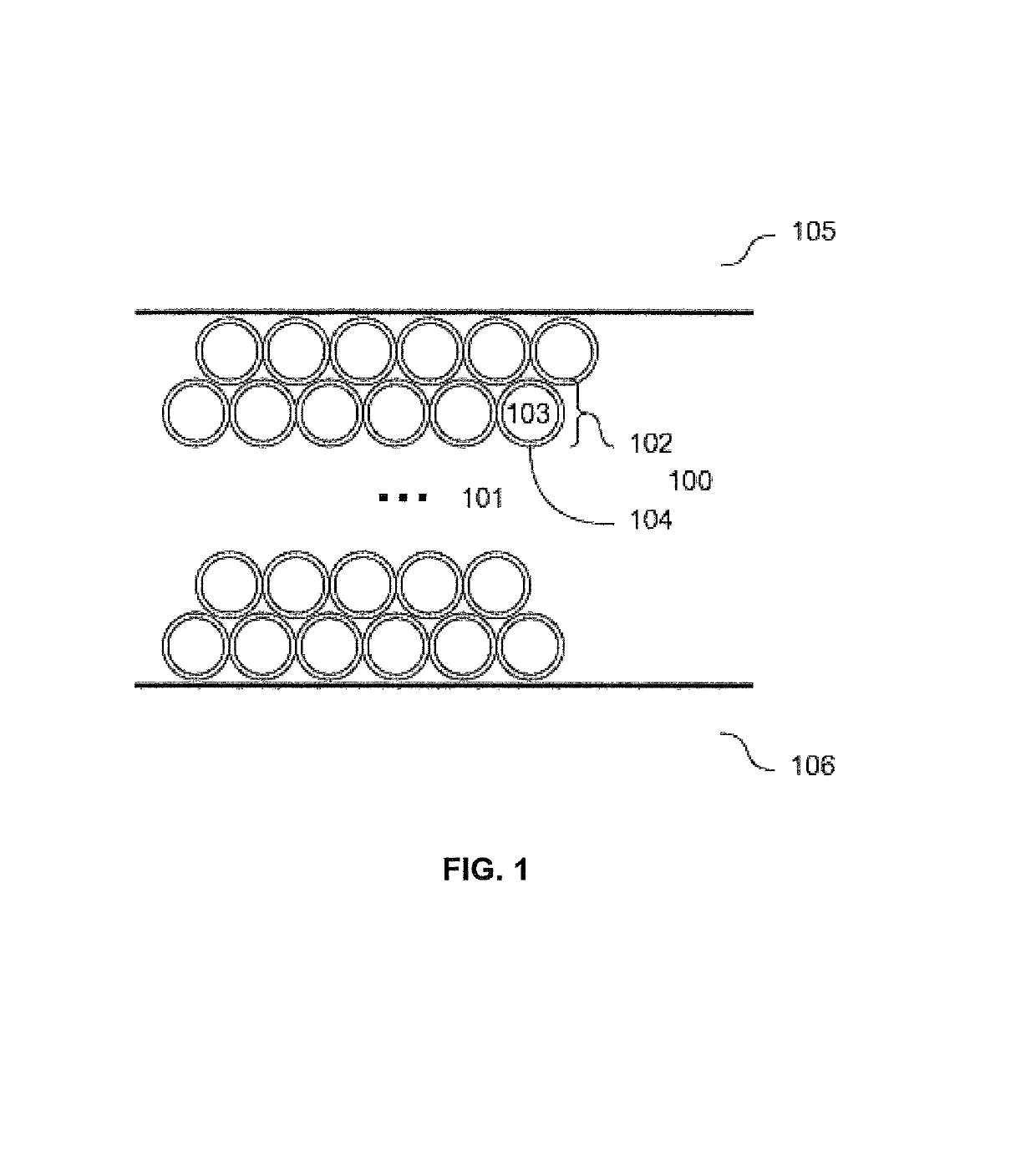

Ultrasound transducer assembly

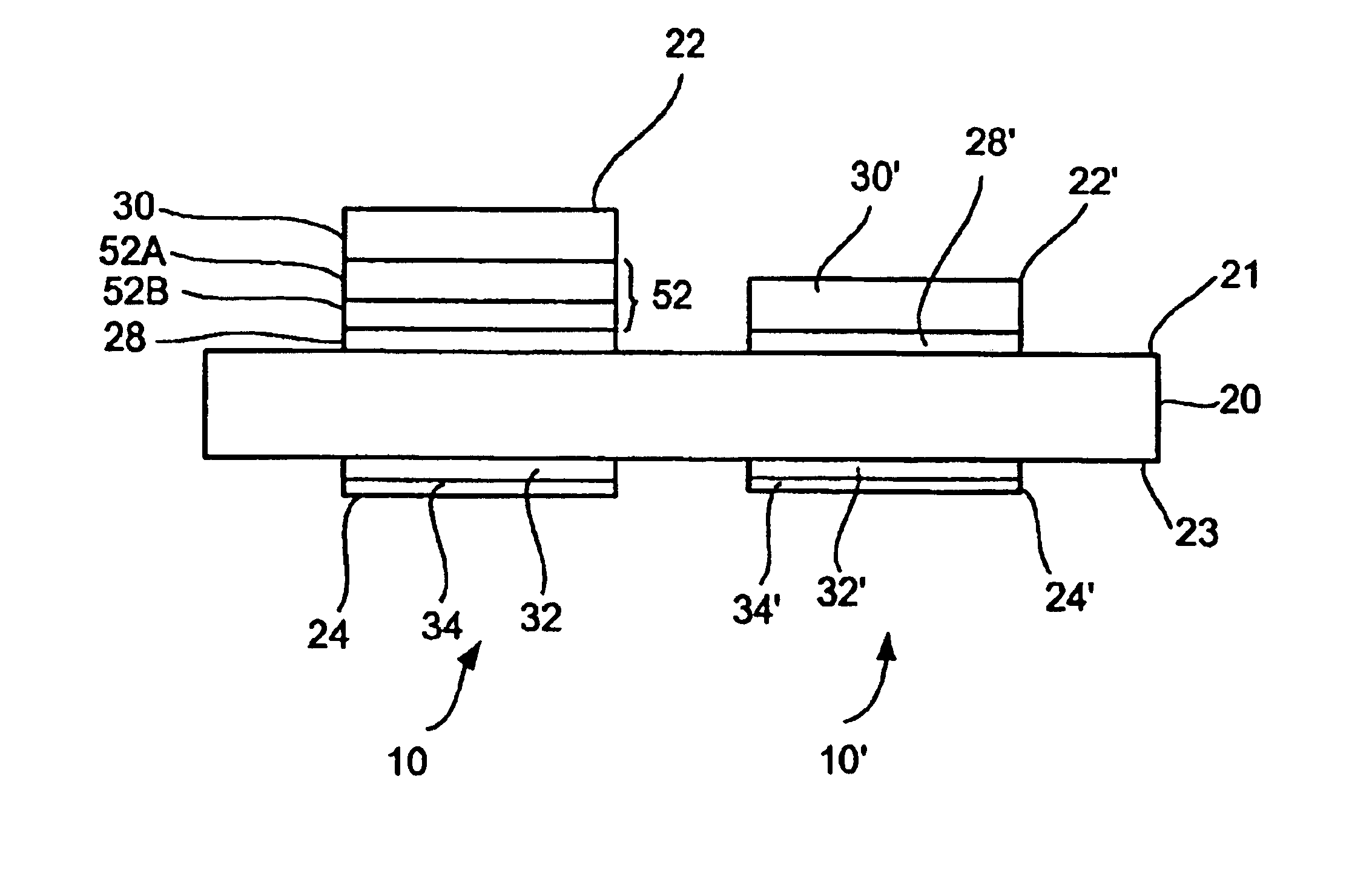

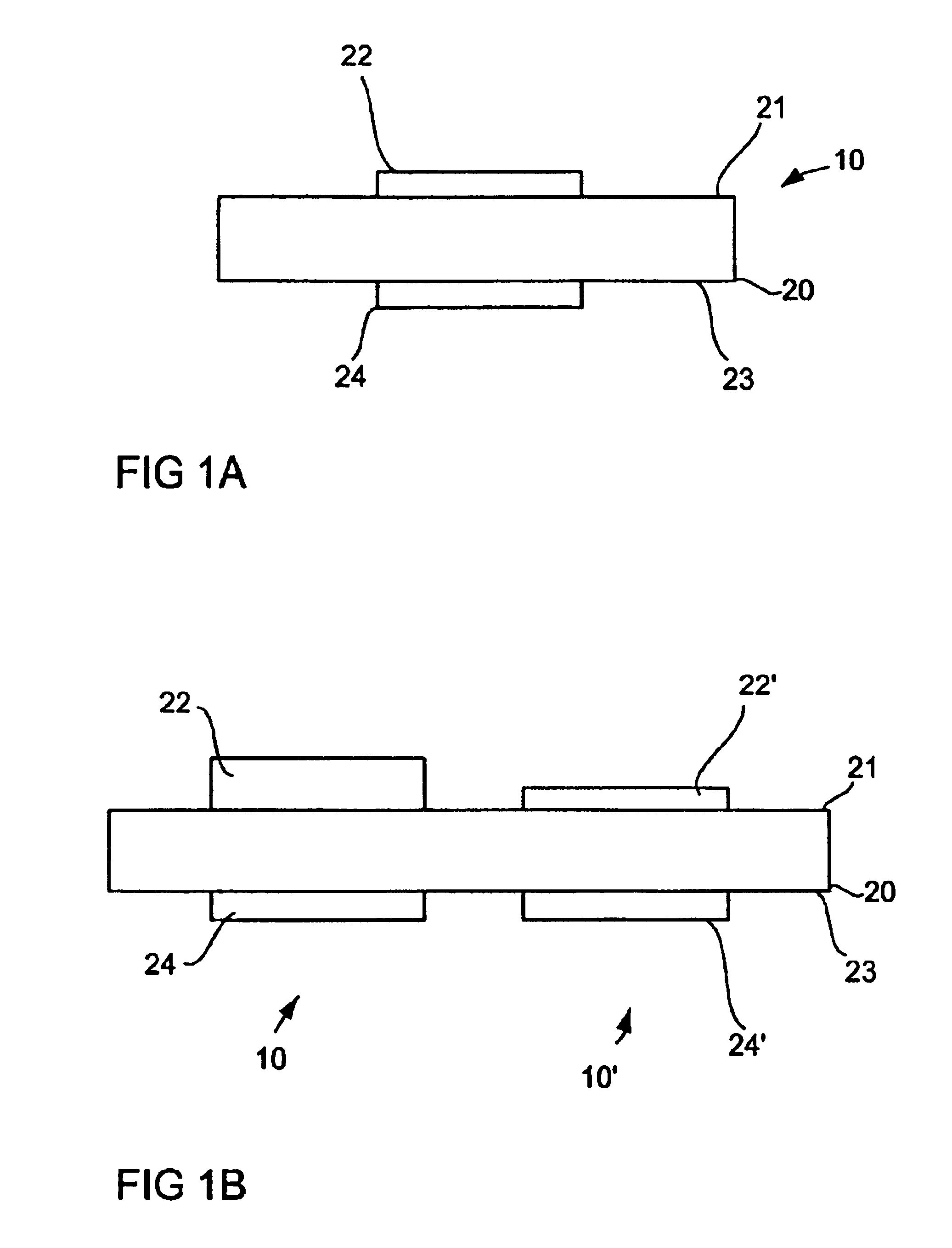

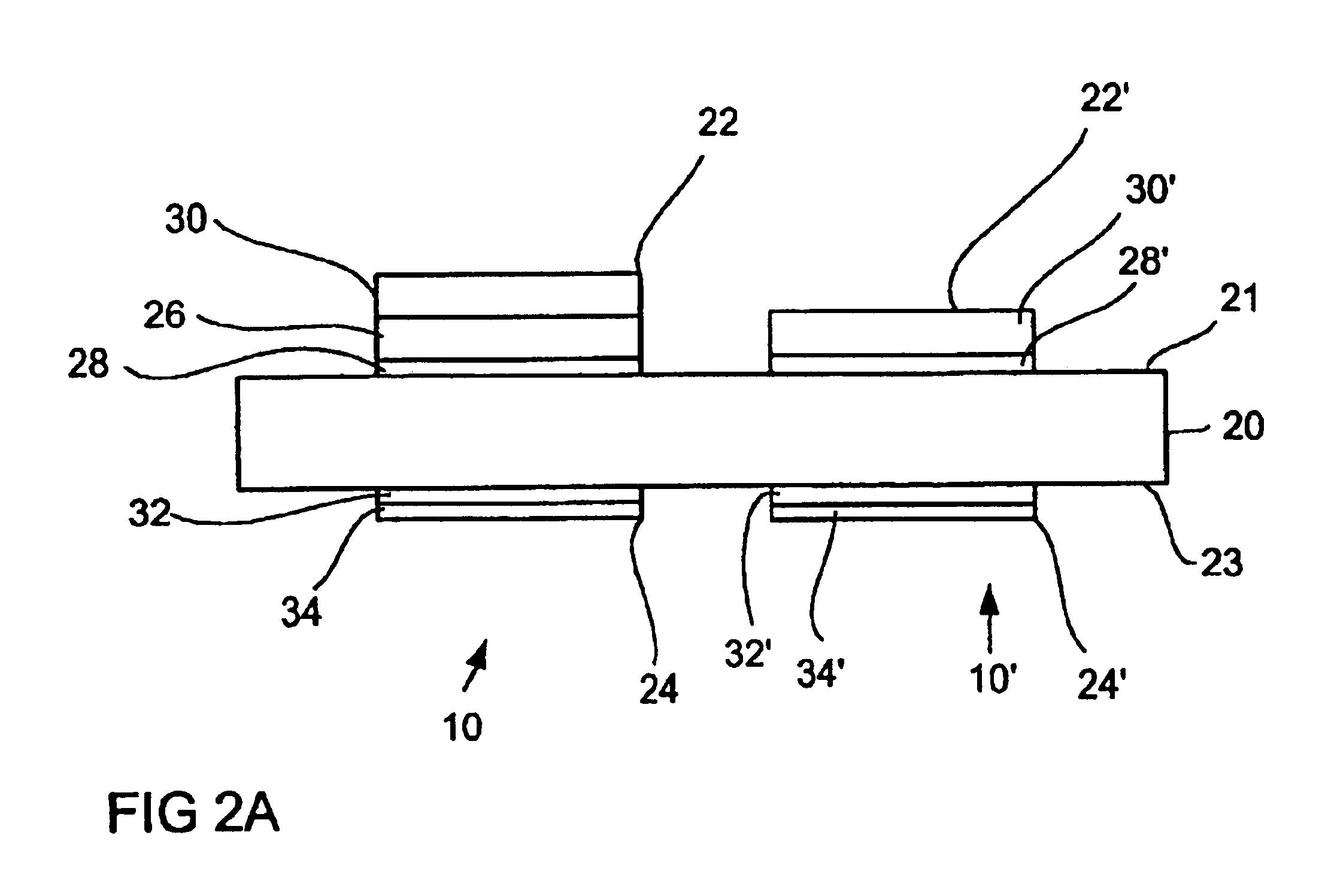

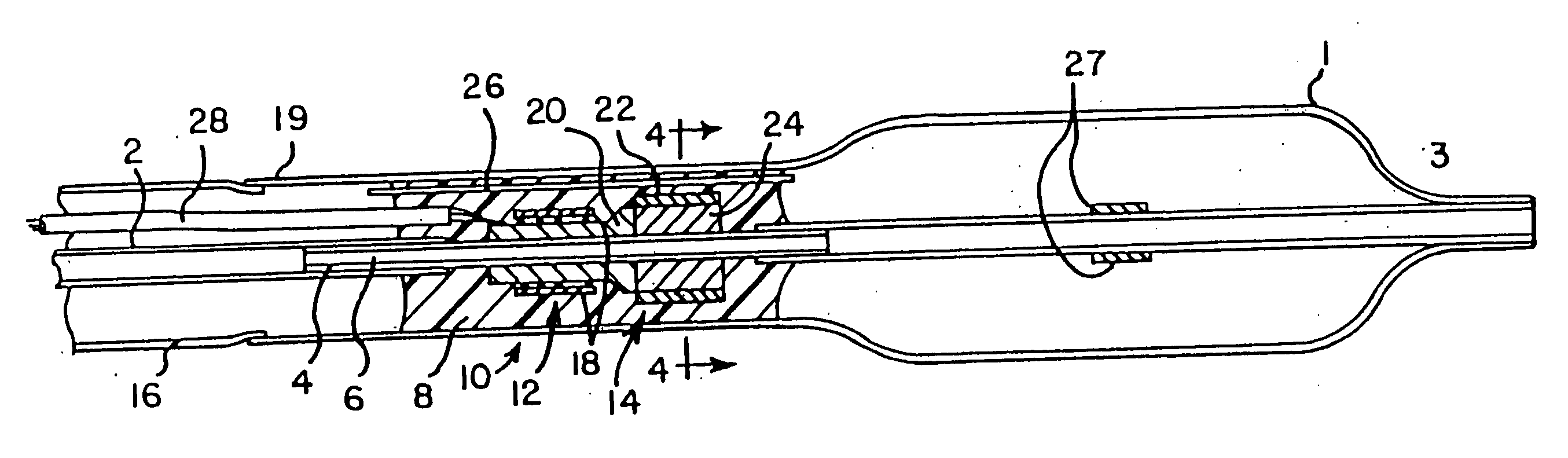

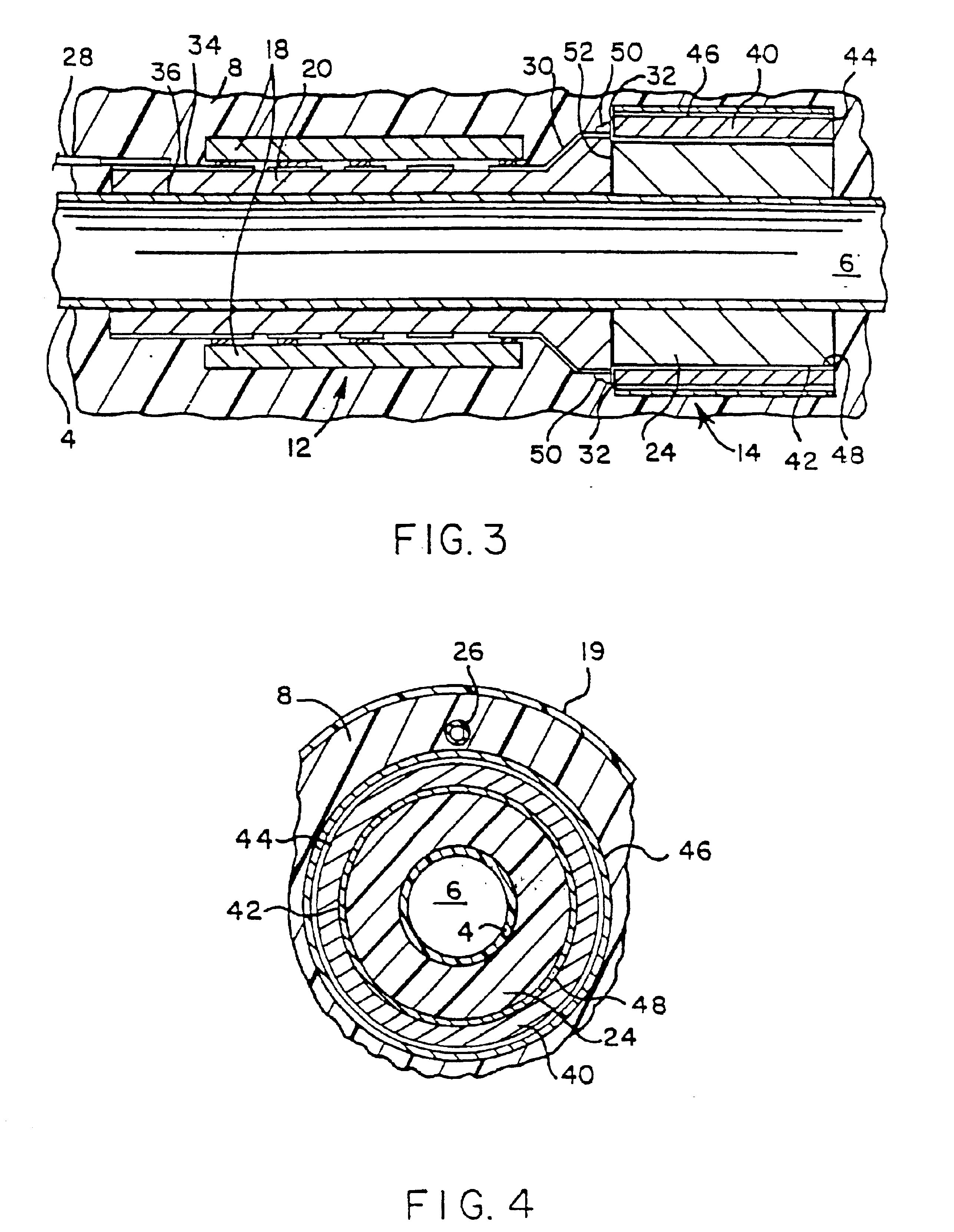

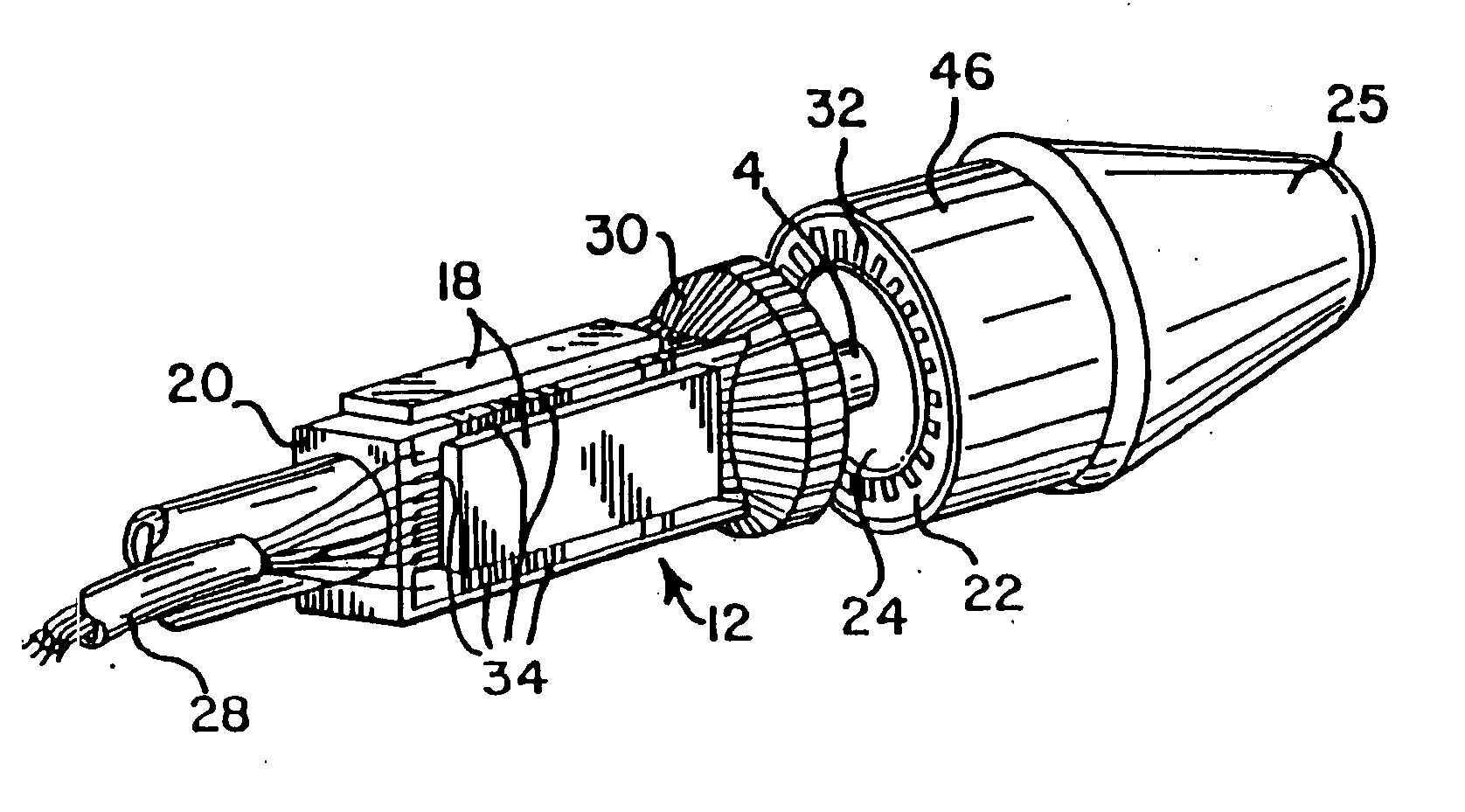

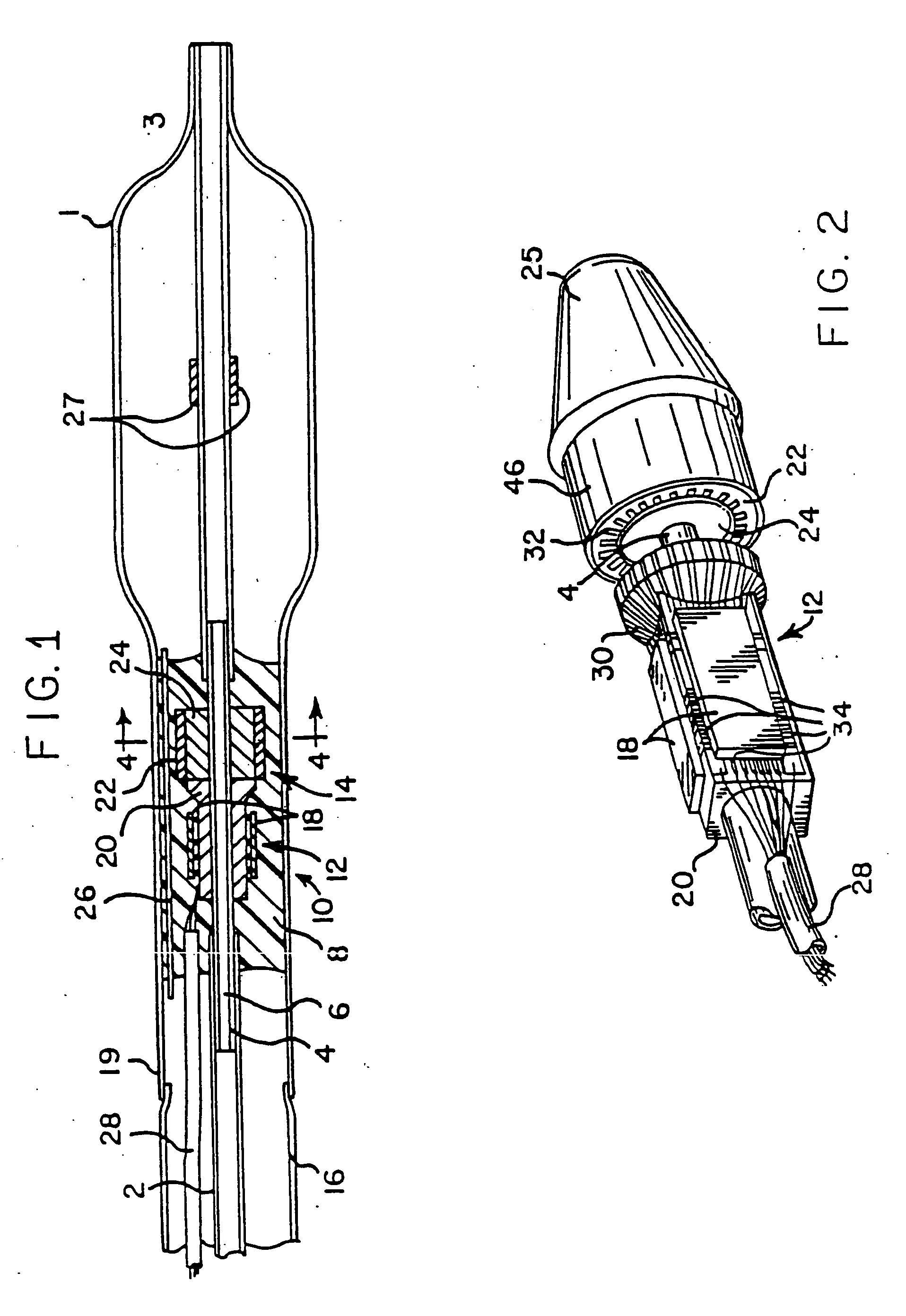

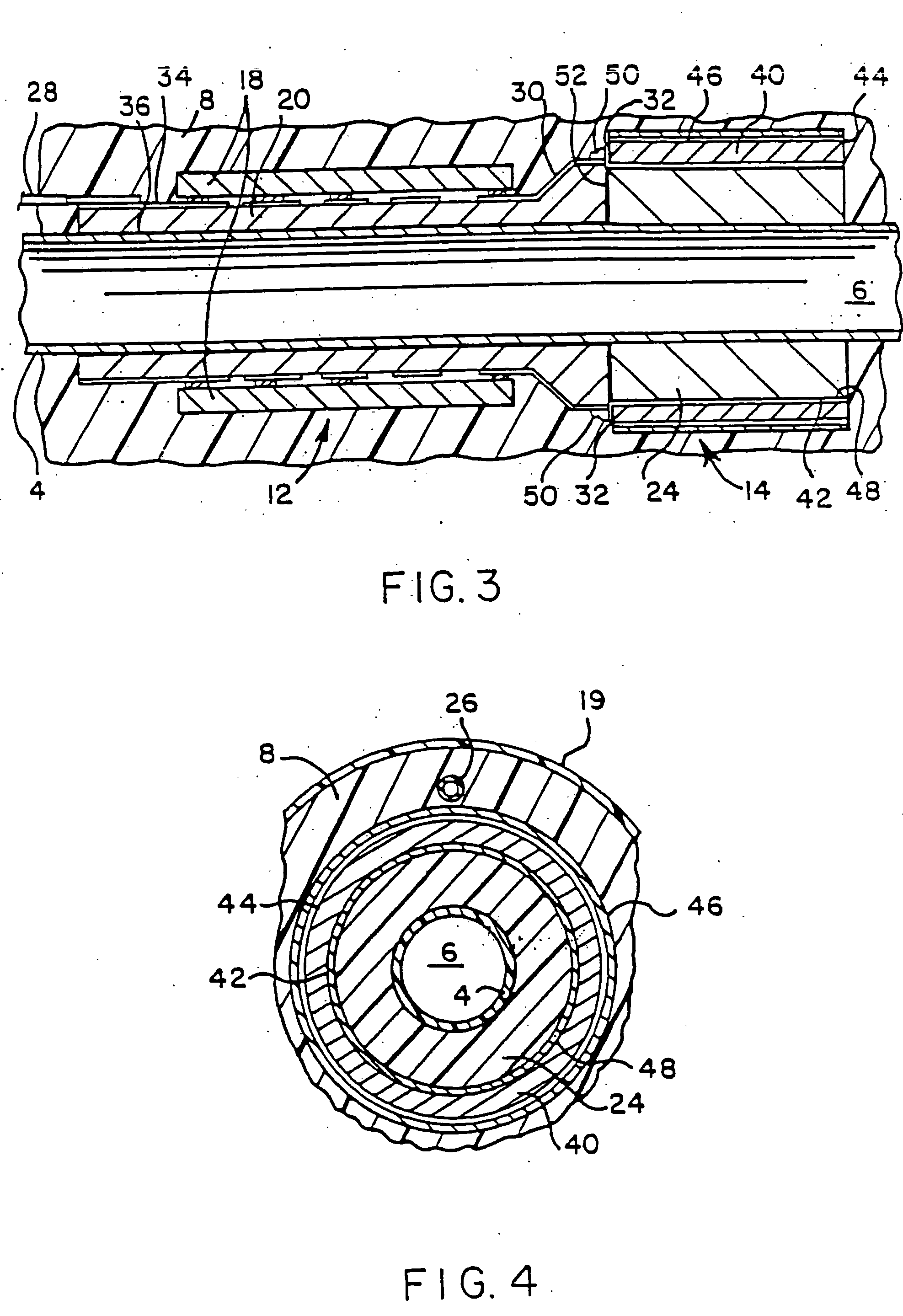

InactiveUS20070016071A1High sensitivityImprove imaging resolutionBlood flow measurement devicesSurgeryUltrasound deviceSonification

An ultrasound catheter is disclosed for providing substantially real-time images of small cavities. The ultrasound catheter is characterized by separate and distinct materials for backing the transducers and for carrying the electronics components. The separate materials comprise an electronics carrier meeting the requirements for holding the integrated circuitry of the ultrasound device and a backing material displaying superior characteristics relating to reducing ringing and minimizing the effect of other sources of signal degradation in the transducer assembly. Also, in accordance with the present invention, a technique is described for connecting the conductor lines of the separate transducer assembly and electronics body.

Owner:VOLCANO CORP

Ultrasound transducer assembly

InactiveUS6962567B2High sensitivityImprove imaging resolutionPiezoelectric/electrostrictive device manufacture/assemblyBlood flow measurement devicesUltrasound deviceSonification

An ultrasound catheter is disclosed for providing substantially real-time images of small cavities. The ultrasound catheter is characterized by separate and distinct materials for backing the transducers and for carrying the electronics components. The separate materials comprise an electronics carrier meeting the requirements for holding the integrated circuitry of the ultrasound device and a backing material displaying superior characteristics relating to reducing ringing and minimizing the effect of other sources of signal degradation in the transducer assembly. Also, in accordance with the present invention, a technique is described for connecting the conductor lines of the separate transducer assembly and electronics body.

Owner:VOLCANO CORP

Ultrasound transducer assembly

InactiveUS20060058681A1High sensitivityImprove imaging resolutionBlood flow measurement devicesSurgeryUltrasound deviceElectrical conductor

An ultrasound catheter is disclosed for providing substantially real-time images of small cavities. The ultrasound catheter is characterized by separate and distinct materials for backing the transducers and for carrying the electronics components. The separate materials comprise an electronics carrier meeting the requirements for holding the integrated circuitry of the ultrasound device and a backing material displaying superior characteristics relating to reducing ringing and minimizing the effect of other sources of signal degradation in the transducer assembly. Also, in accordance with the present invention, a technique is described for connecting the conductor lines of the separate transducer assembly and electronics body.

Owner:VOLCANO CORP

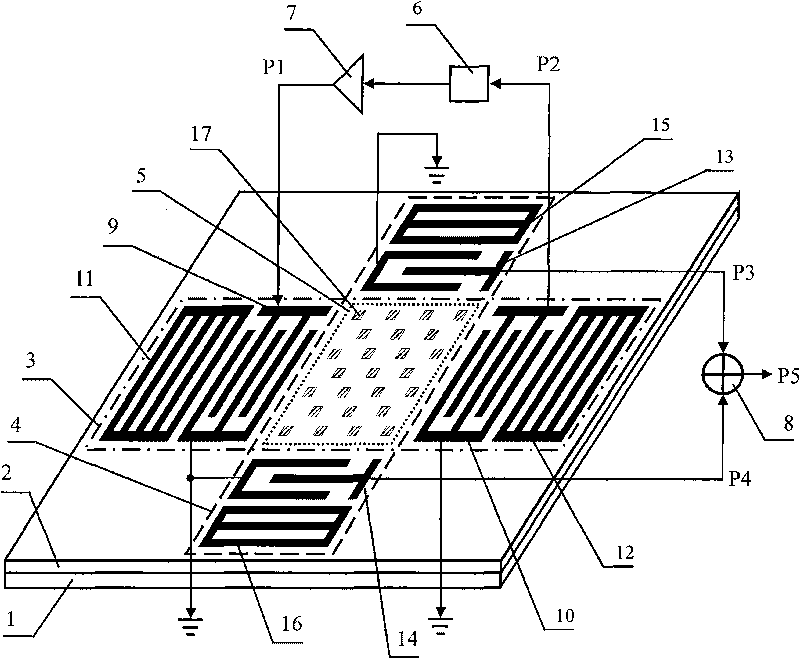

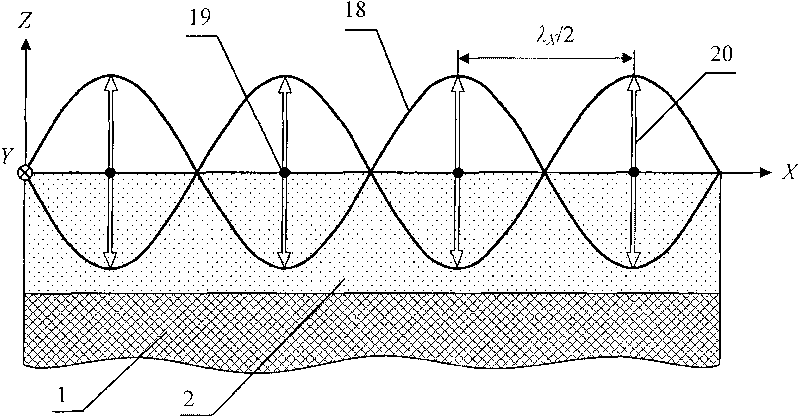

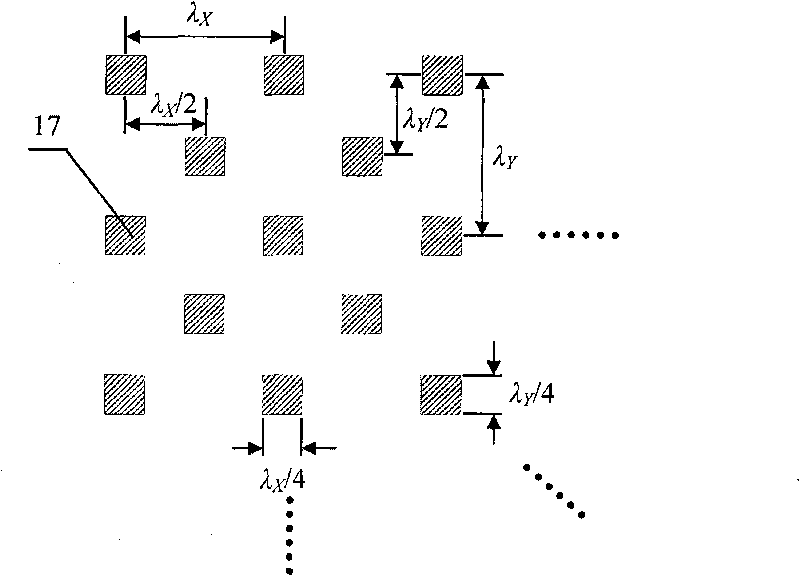

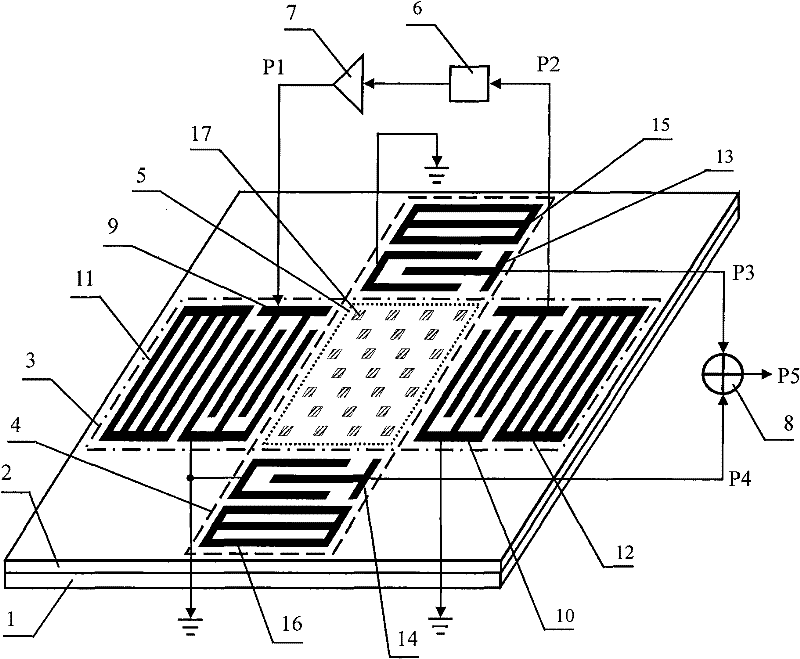

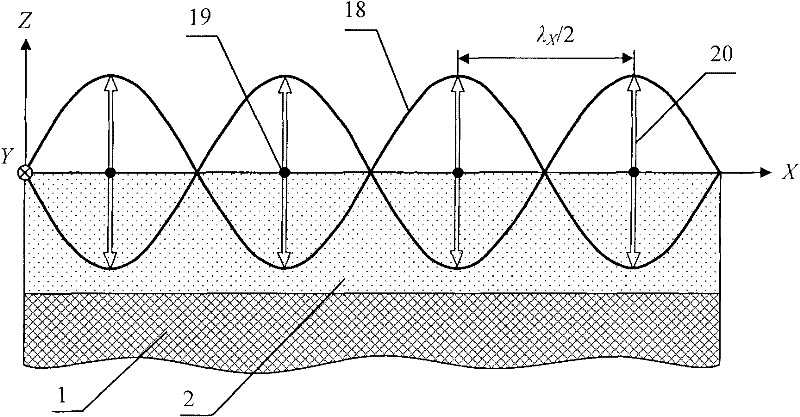

Composite film-based frequency-adjustable surface acoustic wave gyro

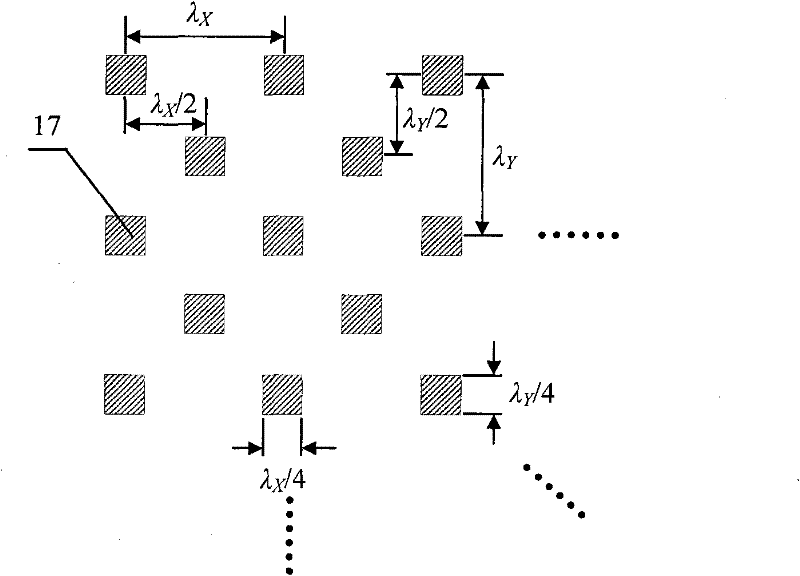

ActiveCN101738183AHigh strengthHigh sensitivitySpeed measurement using gyroscopic effectsTurn-sensitive devicesRadio frequencyPhase shifted

The invention discloses a composite film-based frequency-adjustable surface acoustic wave gyro, which comprises a magnetostrictive substrate, a piezoelectric film, a surface acoustic wave resonator, a surface acoustic wave detector, a metal dot matrix, a phase-shift network and a radio-frequency amplifier. The piezoelectric film is covered on the magnetostrictive substrate; the surface acoustic wave resonator, the surface acoustic wave detector and the metal dot matrix are arranged on the surface of the piezoelectric film; the surface acoustic wave resonator, the phase-shift network and the radio-frequency amplifier form a surface acoustic wave oscillator together; the surface acoustic wave resonator and the surface acoustic wave detector are arranged in a mutually perpendicular crossing way; the surface of the piezoelectric film at the intersection of the surface acoustic wave resonator and the surface acoustic wave detector forms a blank; and the metal dot matrix is positioned at the blank. The gyro has the advantages of simple and compact structure, low cost, easy and simple operation and the like, can adjust the working frequency of the surface acoustic wave gyro in a certain range, can realize matching of the working frequency of the oscillator and the working frequency of the detector, and effectively improves the sensitivity and accuracy of the surface acoustic wave gyro.

Owner:NAT UNIV OF DEFENSE TECH

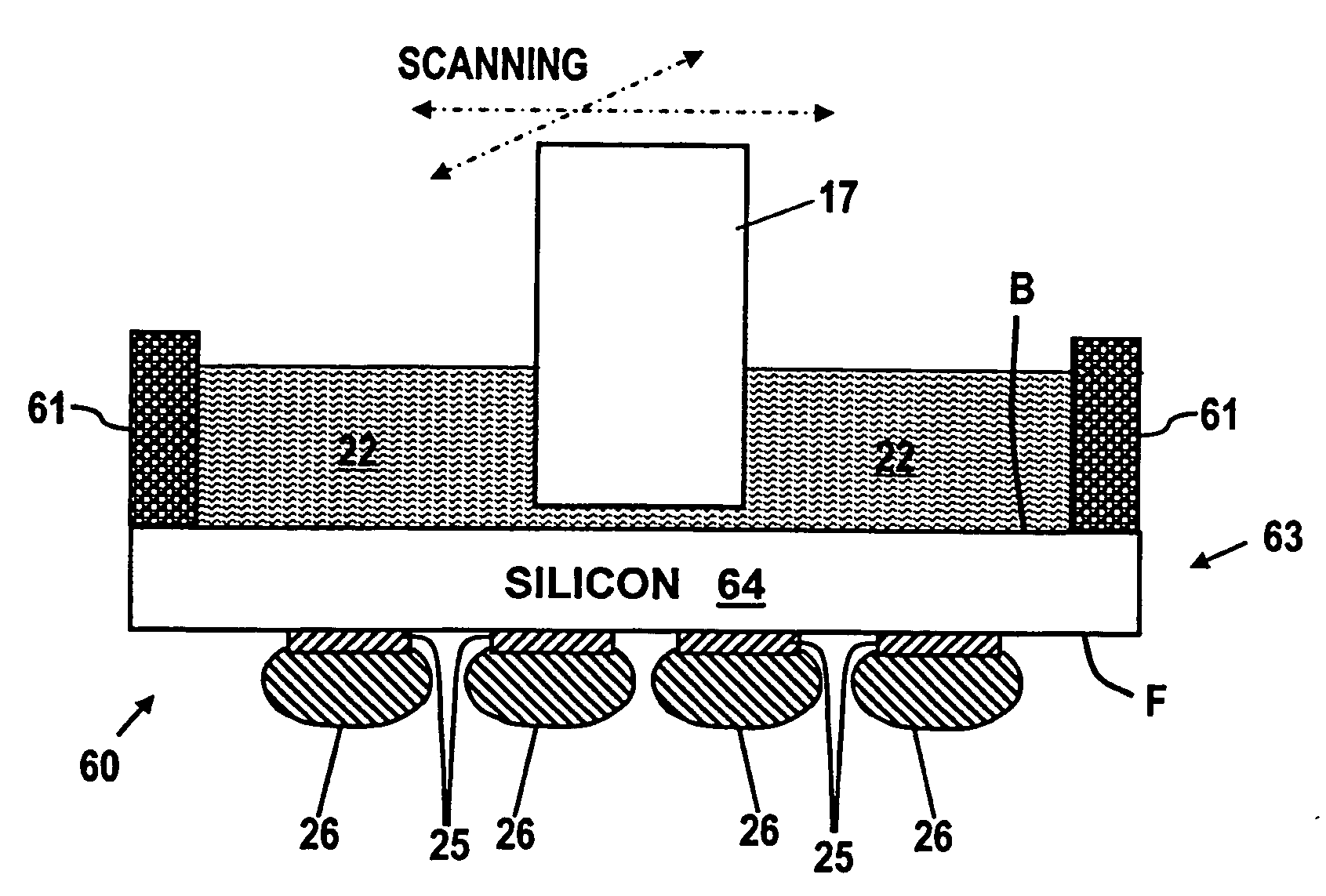

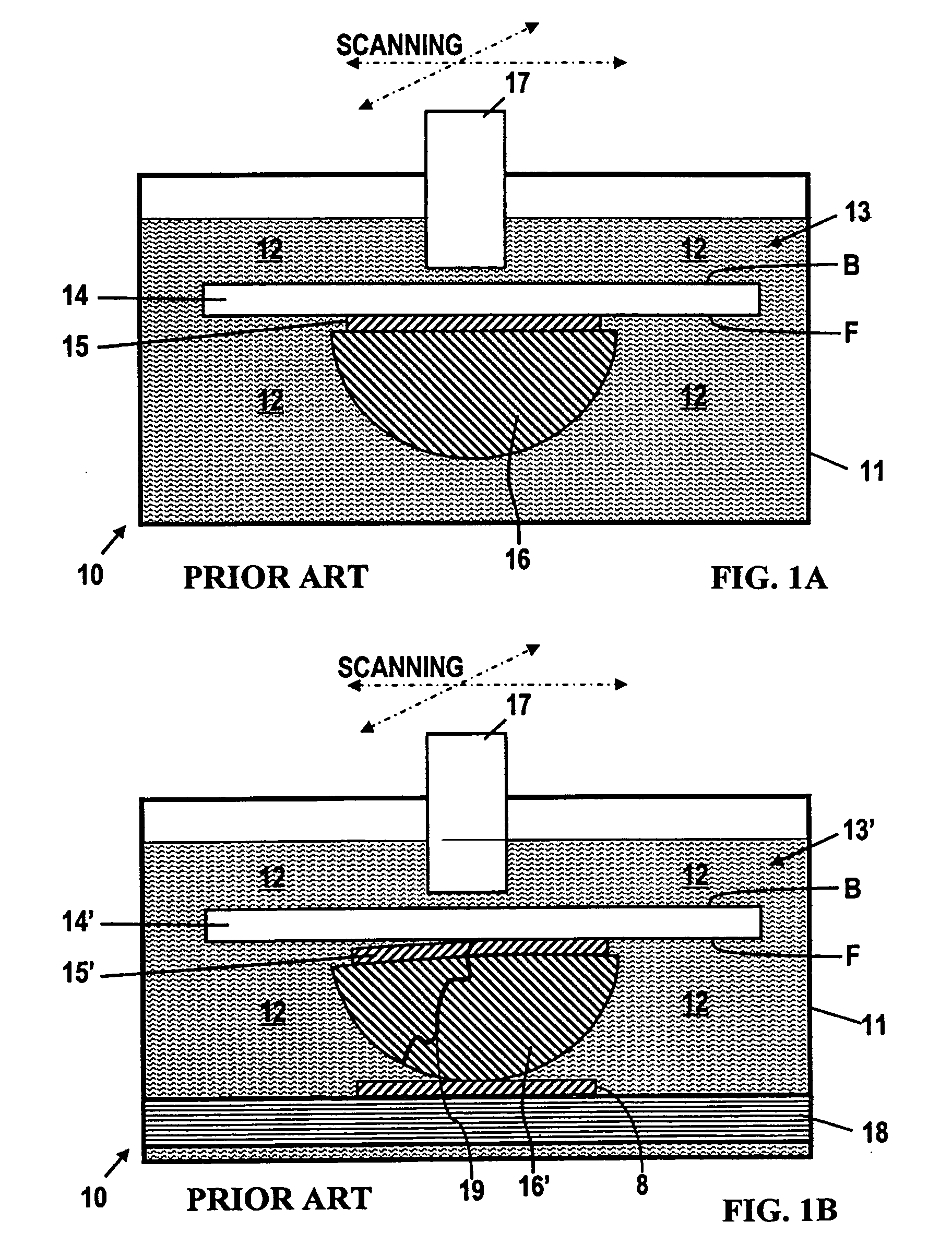

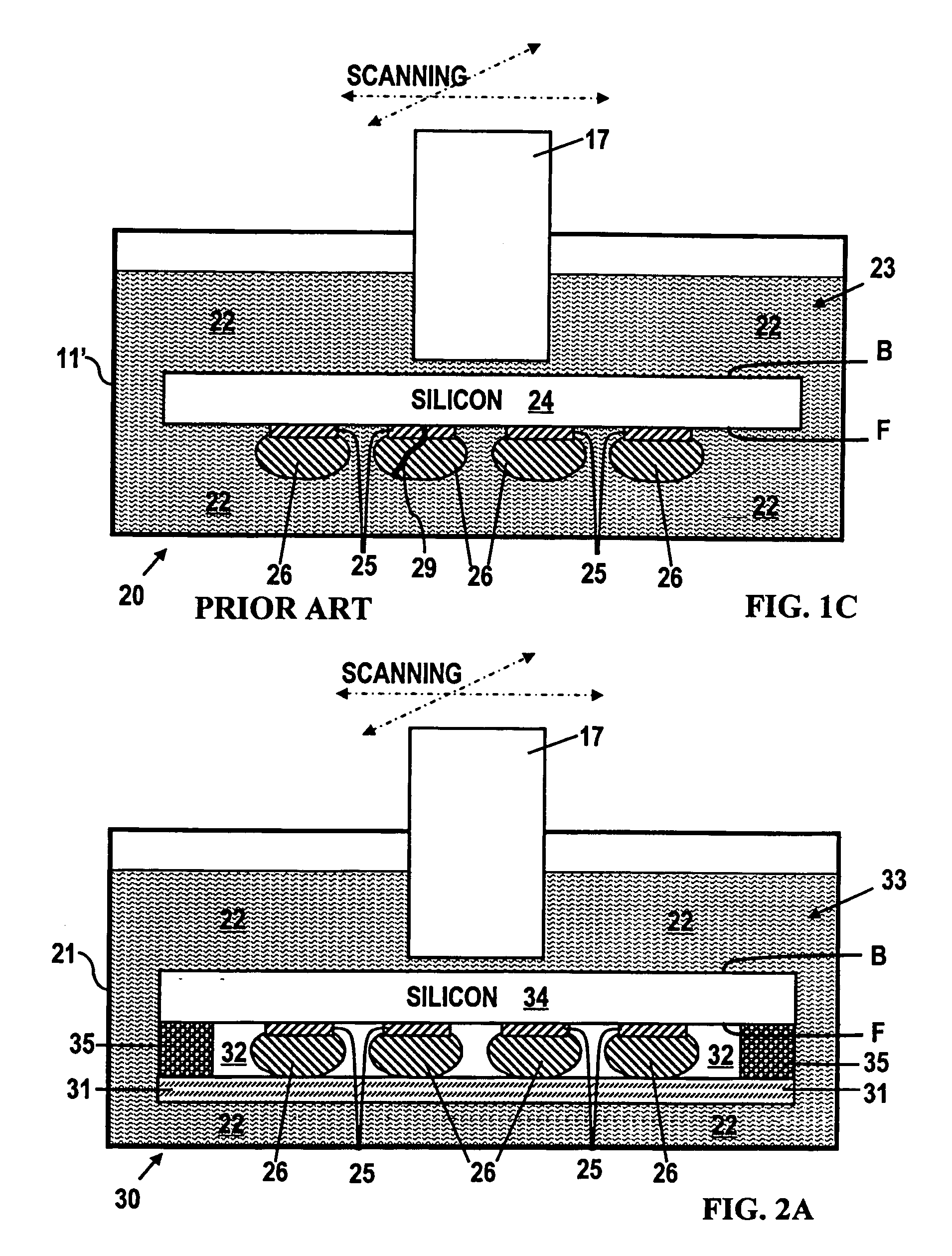

Imaging thin film structures by scanning acoustic microscopy

InactiveUS20080022774A1Avoid interior spacesIncrease contrastAnalysing solids using sonic/ultrasonic/infrasonic wavesSpecific gravity measurementAcoustic transmissionSemiconductor

A method and apparatus for Scanning Acoustic Microscopy (SAM) for testing of a semiconductor device having a first surface and a second surface with bonding features secured to said first surface are provided. An impervious fixture comprising a dam or a tank retains acoustic transmission fluid in contact with the second surface. Acoustic transmission fluid is excluded from admission to the space surrounding the bonding features where an atmosphere of gas or a vacuum is provided by isolating the first surface from the acoustic transmission fluid either by providing a sealed chamber protecting the first surface or by providing a dam surrounding the second surface.

Owner:IBM CORP

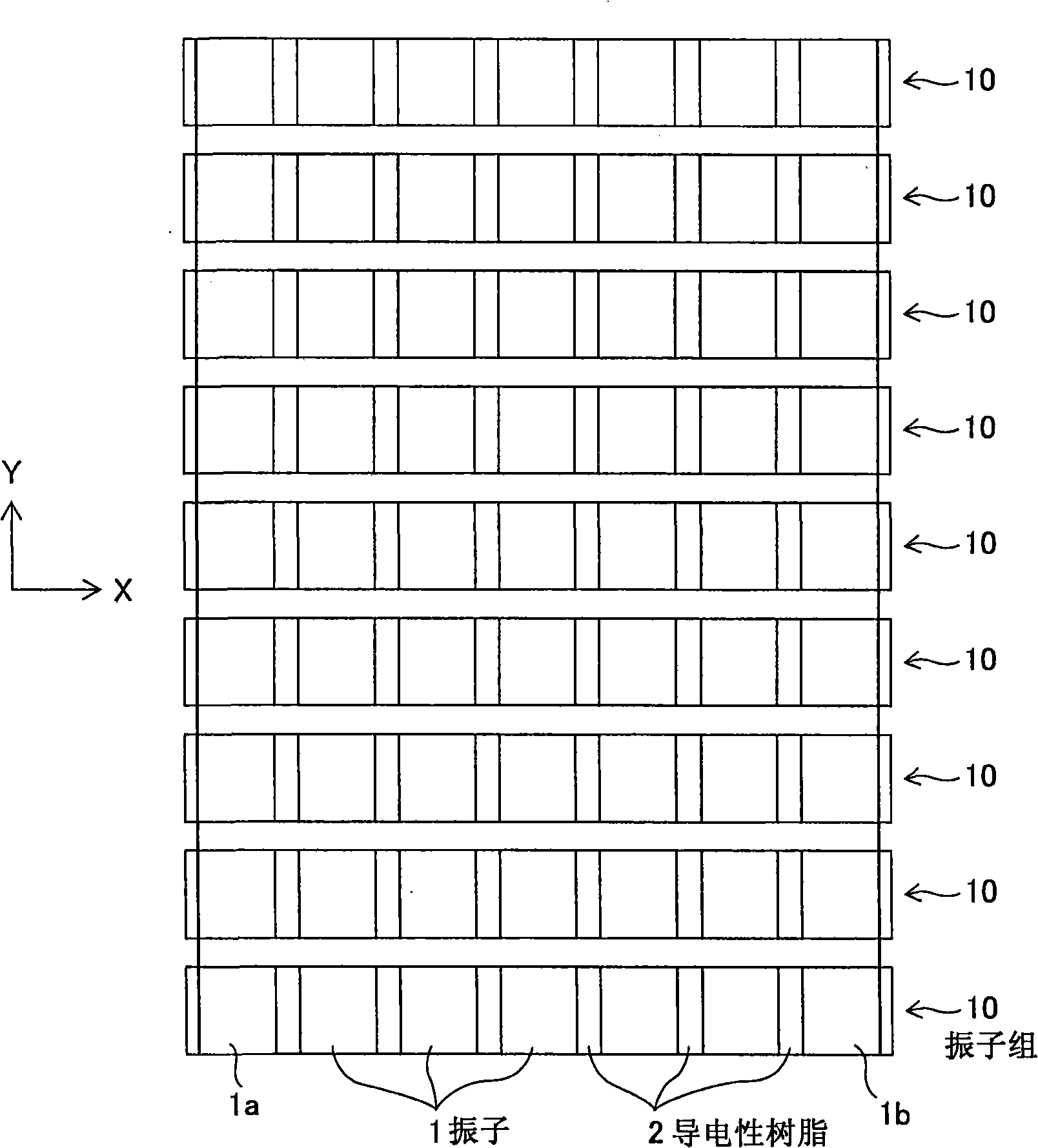

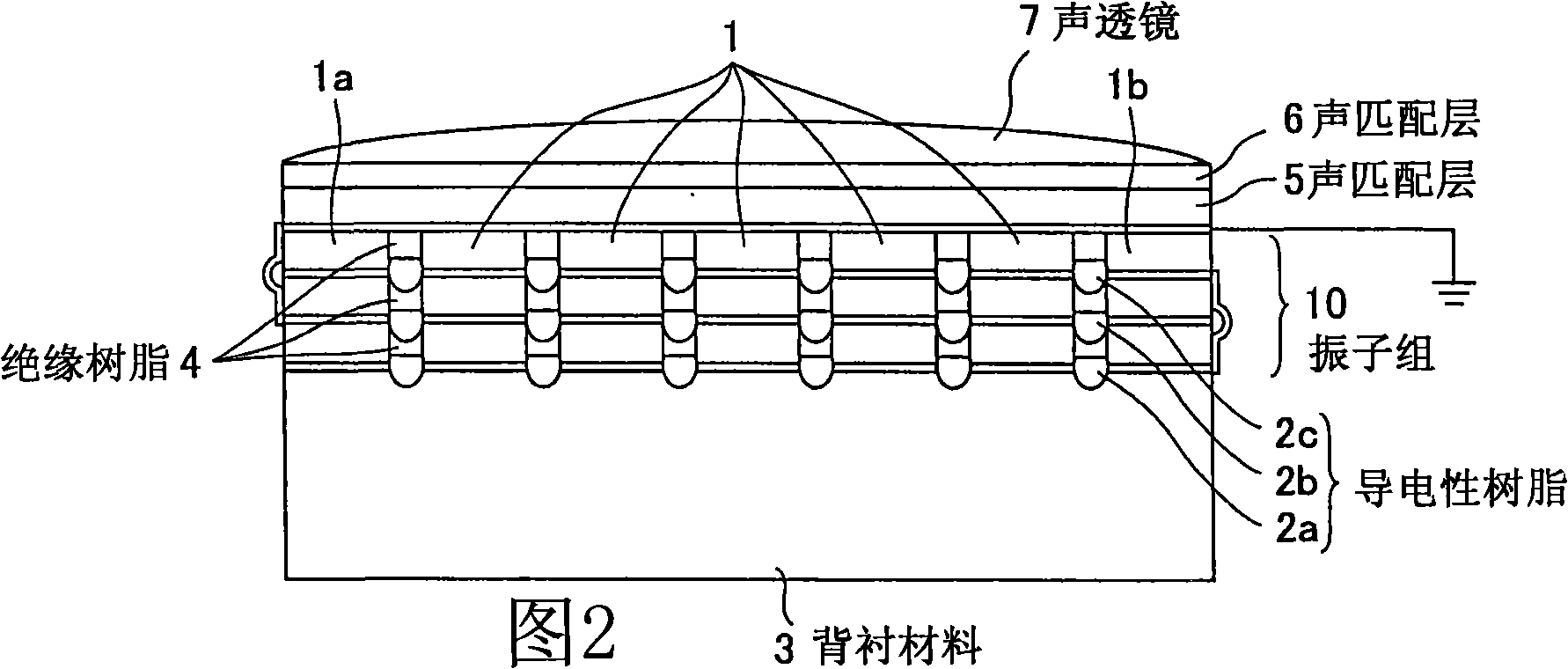

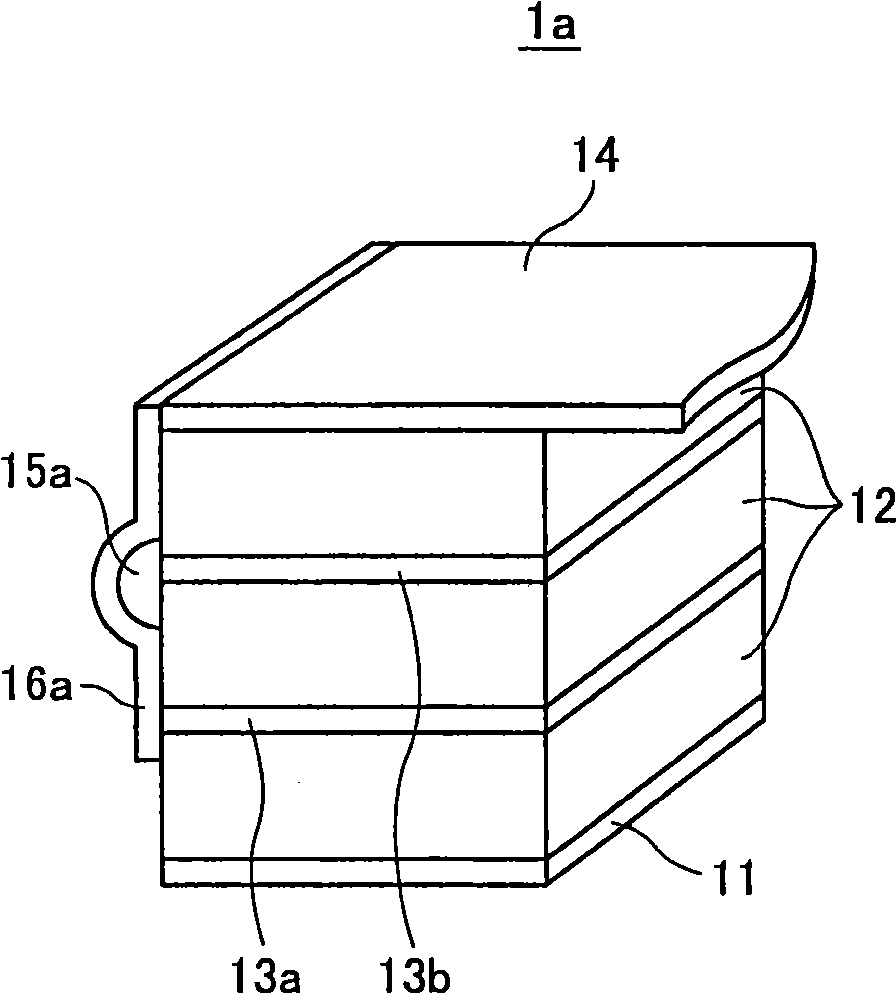

Ultrasonic probe and production method thereof

InactiveCN101278843AHigh sensitivityHigh electromechanical coupling coefficientUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectricityTransducer

An ultrasonic probe realizing a high sensitivity and a wide band thereof while miniaturizing a transducer and also taking into consideration a measure against generated heat. The ultrasonic probe includes: a backing material; a transducer array having a multi-layered structure in which a plurality of transducers are arranged in a first direction to compose a transducer group and a plurality of the transducer groups are arranged in a second direction different from the first direction; a first layer of conductive resin electrically connecting the first electrode layers of adjacent transducers with each other in each transducer group; a second layer of conductive resin electrically connecting the internal electrode layers of adjacent transducers with each other in each transducer group; and an insulating resin disposed in a predetermined region among the plurality of transducers in each transducer group.

Owner:FUJIFILM CORP

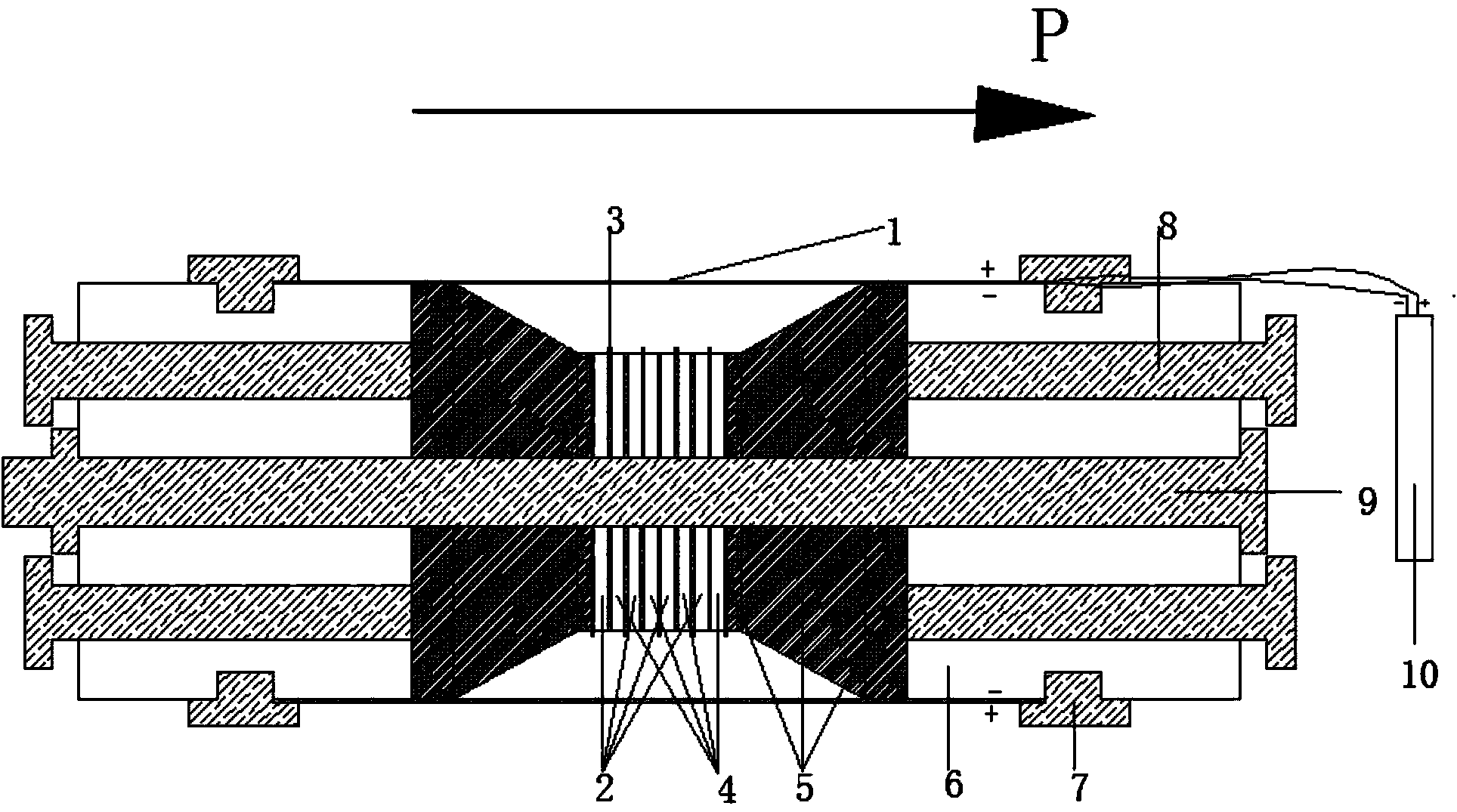

A flextensional transducer using a PVDF piezoelectric film

ActiveCN103646643AImprove energy conversion efficiencyImprove receiver sensitivitySound producing devicesBroadband transmissionTransducer

The invention relates to a flextensional transducer using a PVDF piezoelectric film. The flextensional transducer comprises a piezoelectric ceramic wafer stack and a PVDF film. The PVDF film surrounds the piezoelectric ceramic wafer stack. A connecting piece is arranged between the PVDF film and the piezoelectric ceramic wafer stack. The flextensional transducer further comprises a device for enabling the PVDF film to generate prestress. The metallic housing of a conventional flextensional transducer is replaced by the PVDF film. The PVDF film and the piezoelectric ceramic wafer stack are used as sensitive elements. The PVDF film uses a film flexural vibration mode under a simple boundary condition. The piezoelectric ceramic wafer stack uses a longitudinal vibration mode. A wide bandwidth can be acquired by mode coupling so as to achieve broadband transmission sound waves. The flextensional transducer has characteristics of low frequency, a wide band, high receiving sensitivity, large acoustic radiation power, and horizontal omnidirectional directivity.

Owner:武汉国科舰航传感科技有限公司

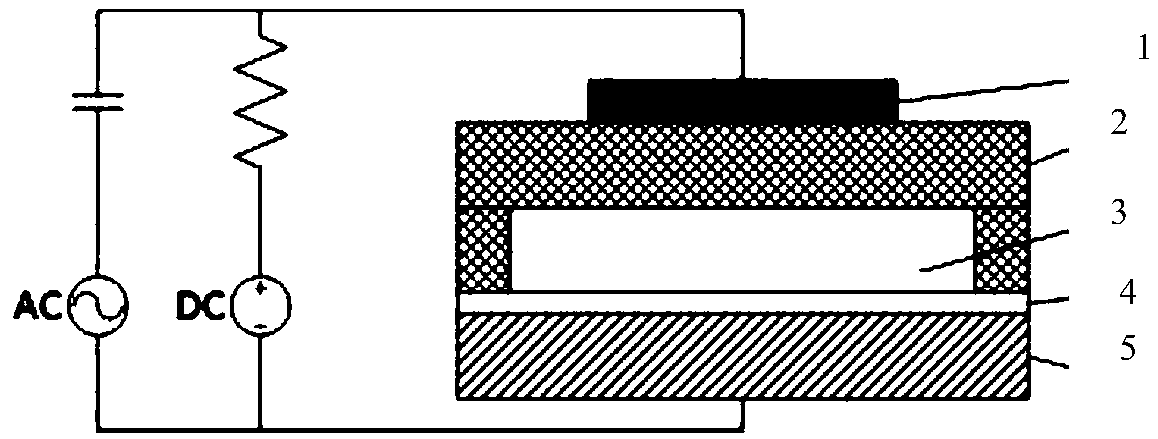

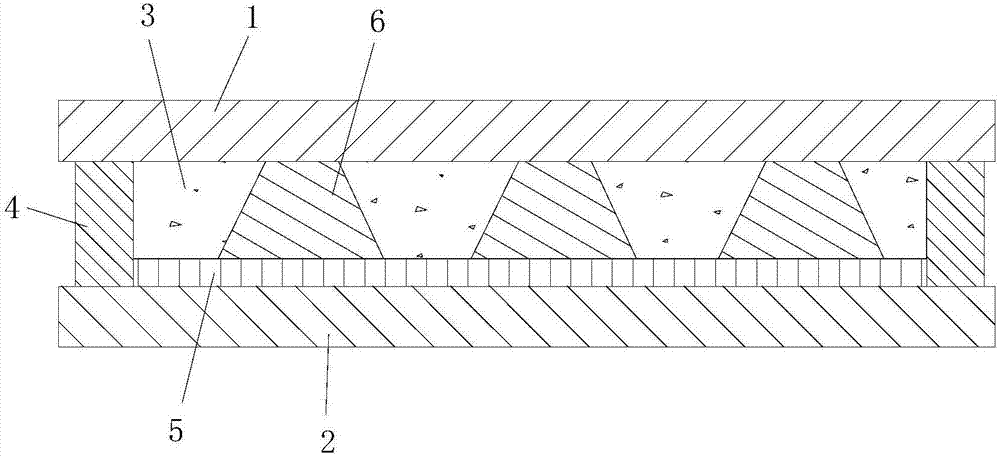

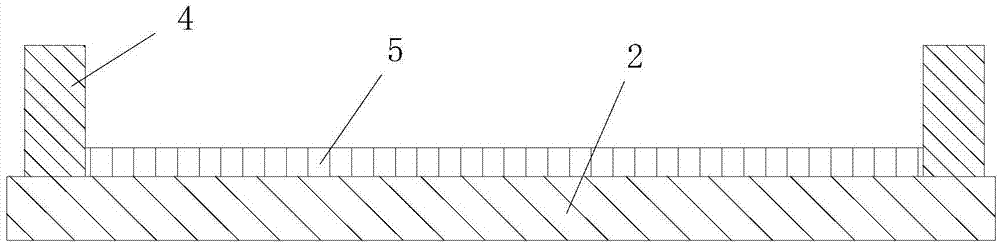

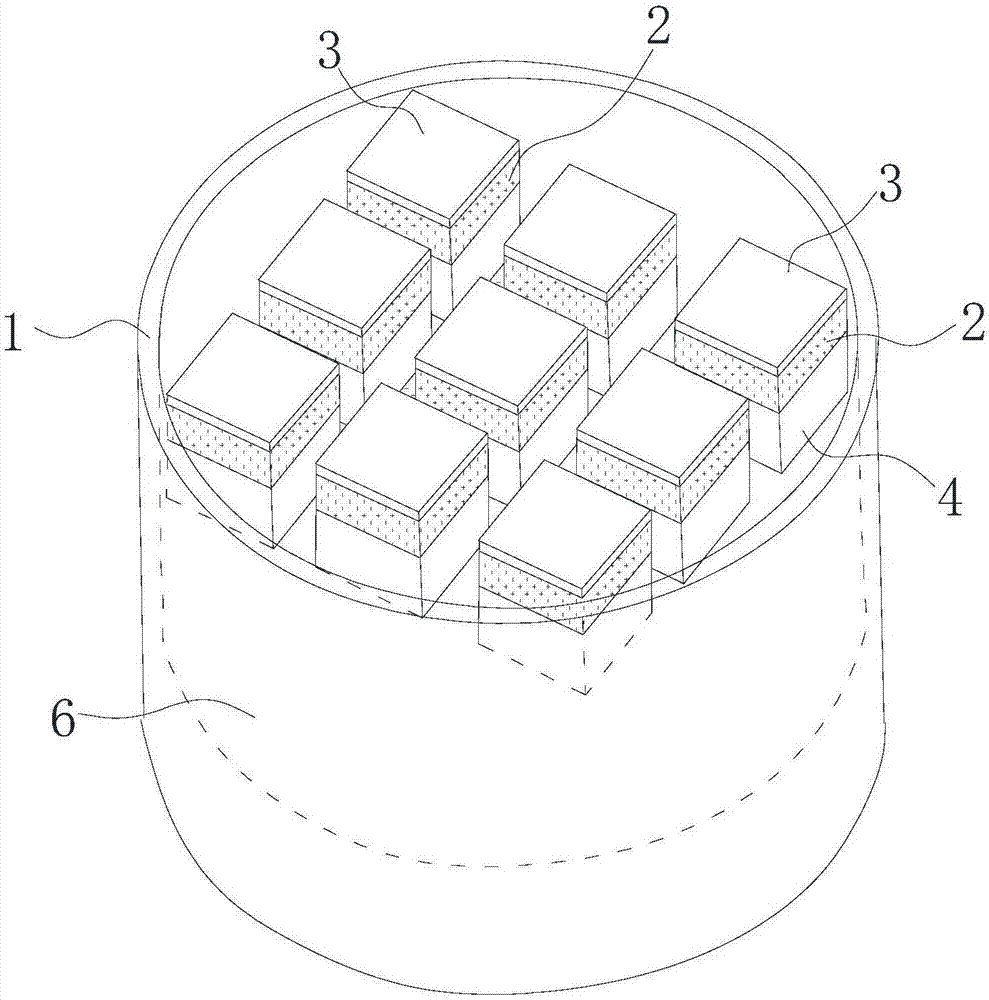

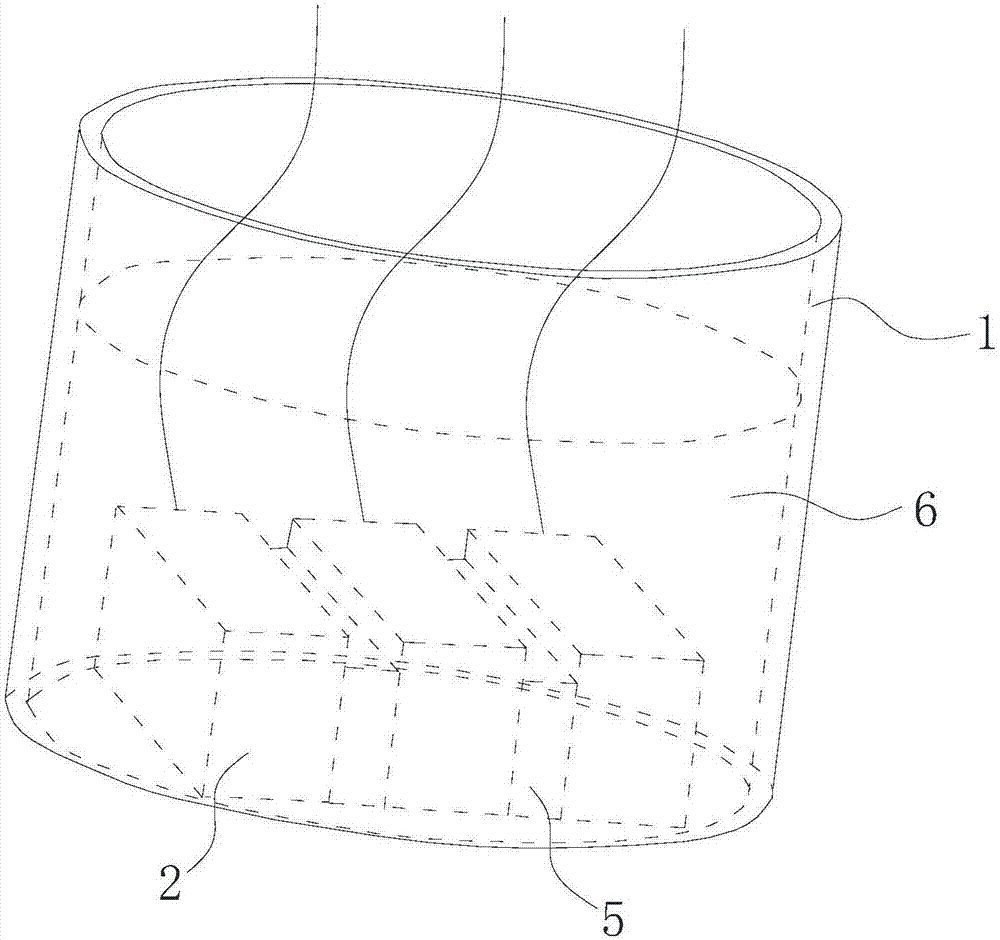

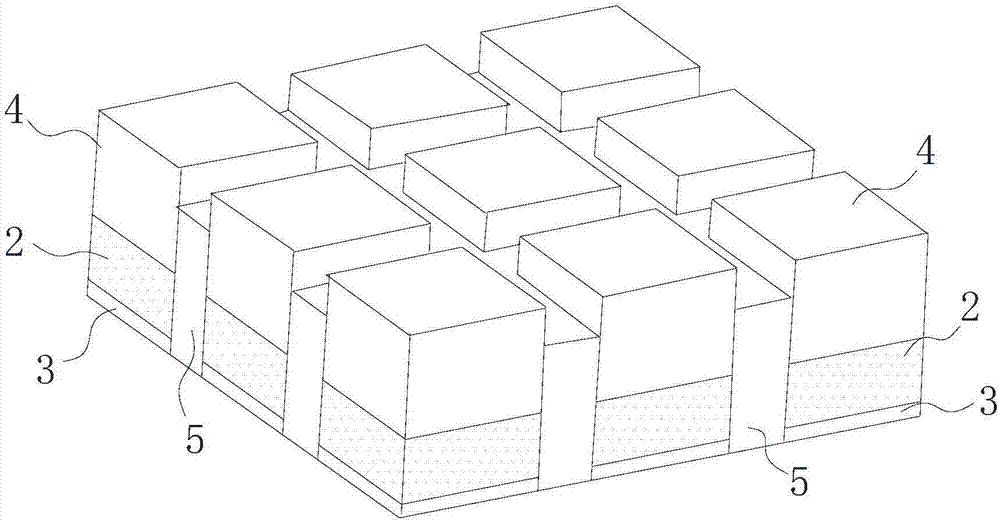

Air-coupled capacitive micromachining ultrasonic transducer, preparation method and application

ActiveCN108704827AHigh electromechanical coupling efficiencyLow acoustic impedanceAfter-treatment detailsVacuum evaporation coatingSilicon nitrideAluminium

The invention relates to an air-coupled capacitive micromachining ultrasonic transducer, a preparation method and application. A transducer array comprises 16 array elements; each array element is formed by multiple sensing units; each sensing unit is structurally formed by an upper electrode 1, a vibrating diaphragm 2, a cavity 3 and a base 5 sequentially from top to bottom; and each base is usedas a lower electrode. The working frequency of the designed transducer is 100kHz to 2MHz. The transducer array is manufactured based on an SOI bonding process; each vibrating diaphragm is made of monocrystalline silicon; each upper electrode is gold or aluminum; an insulating layer 4 is silicon dioxide or silicon nitride; and the array elements of the transducer are divided through etching the low-resistance-silicon bases to form grooves, so that the array with the multiple array elements is formed. According to the air-coupled ultrasonic transducer, an ultrasonic wave in a metal plate or a composite plate is excited through an air coupling manner and is used for nondestructively detecting internal defects of the plate. The transducer is matched with a phased array system, and pulse drivesignals of the array elements are delay-controlled, so that the phase-controlled deflection and the focusing of an acoustic beam are adjusted, and the freedom degree of detecting is increased.

Owner:TIANJIN UNIV

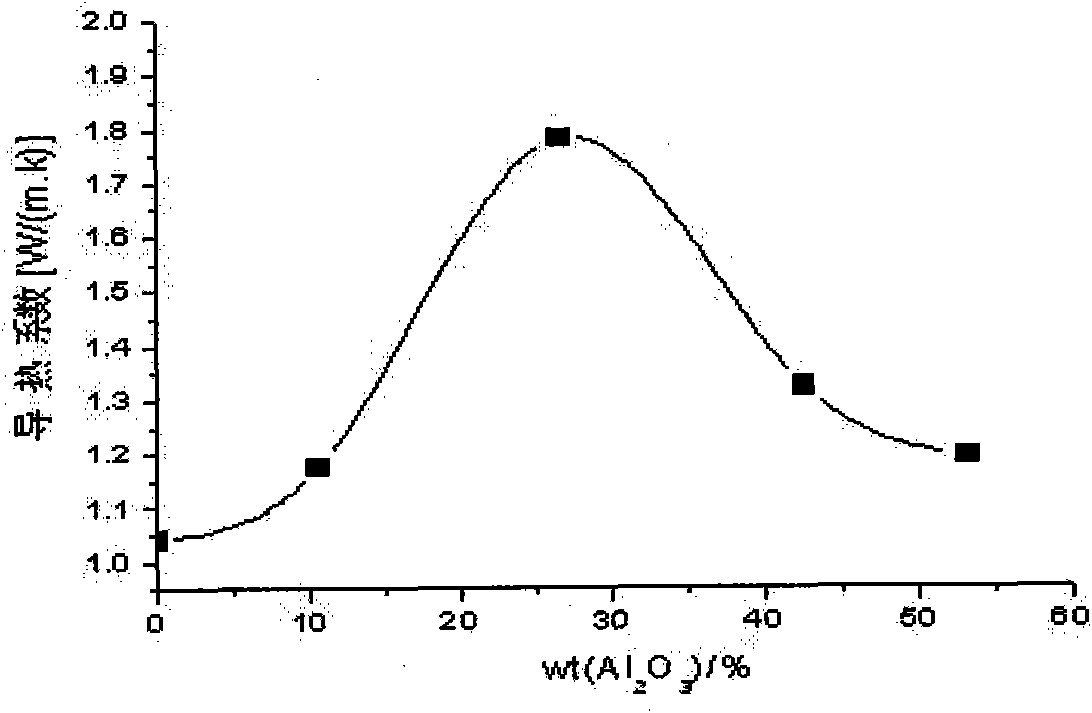

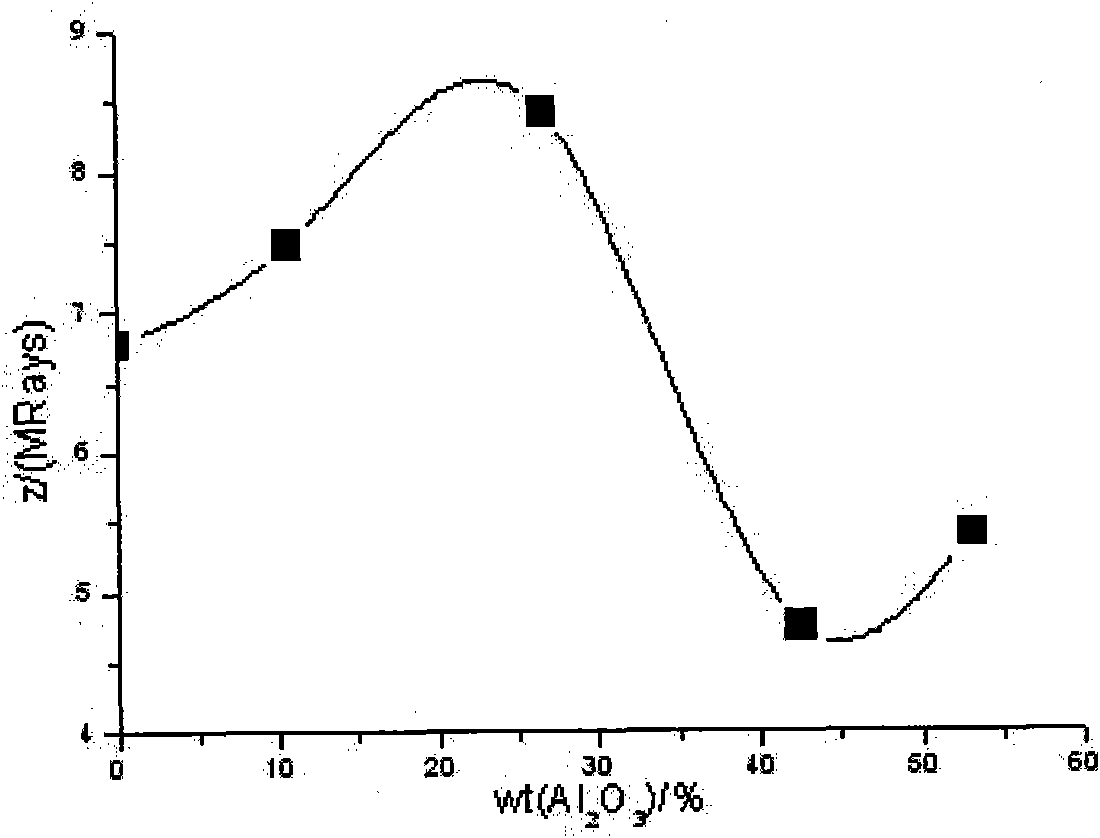

High heat conduction and high attenuation backing material for ultrasonic phased array probe and manufacturing method thereof

InactiveCN102338777AConvenient source of raw materialsLow priceMaterial analysis using sonic/ultrasonic/infrasonic wavesHeat-exchange elementsThermal conductivityImage resolution

A high heat conduction and high attenuation backing material for ultrasonic phased array probe is made from lutecium oxide, alumina, a tungsten compound material and an epoxy adhesive and is characterized in that the epoxy adhesive is prepared by mixing epoxy resin E-54 and triethanolamine; the tungsten compound material is prepared by mixing rubber and a tungsten powder; and the alumina accounts for 10.48-53.04wt% of the backing material. A manufacturing method of the backing material comprises the following steps of: (a) mixing the epoxy resin E-54, lutecium oxide, alumina and the tungsten compound material with stirring, wherein the epoxy resin E-54 accounts for 6.22% the total weight of the backing material and alumina accounts for 10.48-53.04wt% of the backing material; (b) adding triethanolamine which accounts for 0.95% the total weight of the backing material into the above composite particles with stirring; (c) putting the composite particles into a die, and extruding the composite particles into the required backing material by the use of a powder pressing machine; and (d) putting the pressed backing material into an air-blasting heating oven of 65 DEG C for heating-curing. The thermal conductivity of the backing material is 1.782W / (m.k), its specific acoustic impedance is 8.42*106Pa.s / m and its acoustic attenuation coefficient at 5MHz is 294.4dB / cm. The backing material has high thermal conductivity and high attenuation. In addition, the sensitivity and resolution of the phased array probe produced by the use of the backing material can satisfy the requirement for application.

Owner:广州多浦乐电子科技股份有限公司

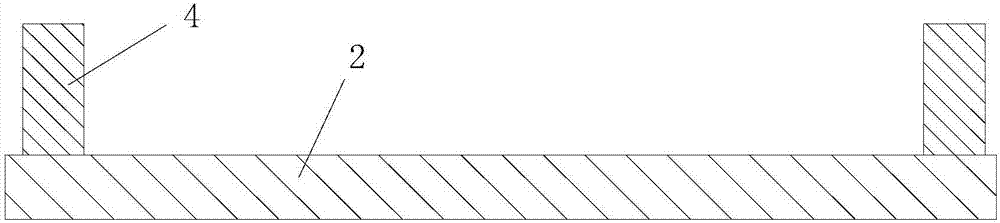

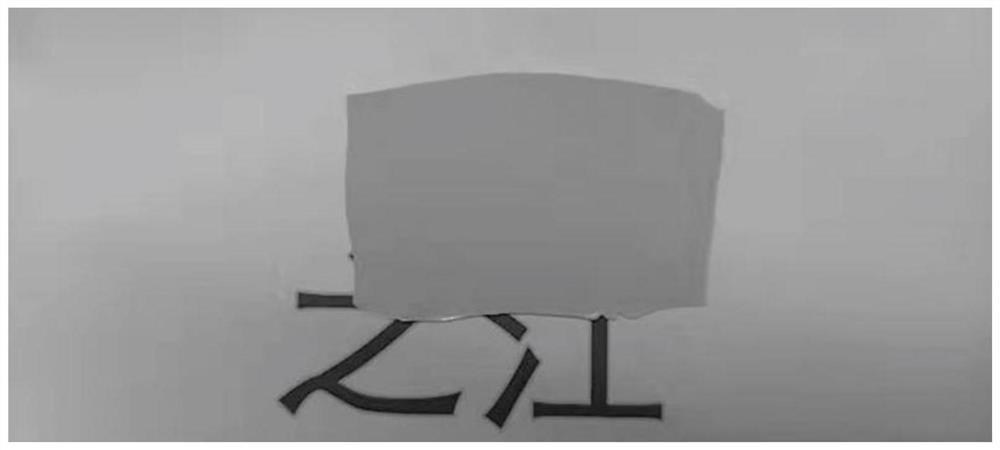

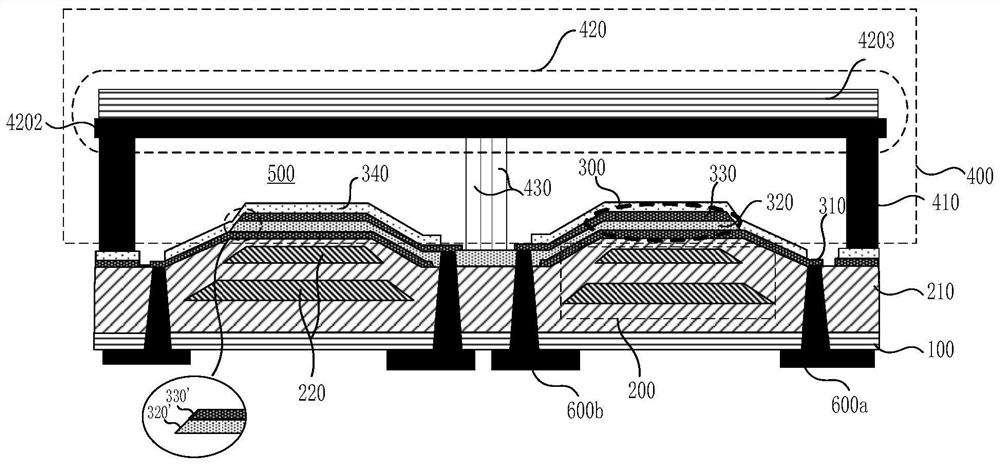

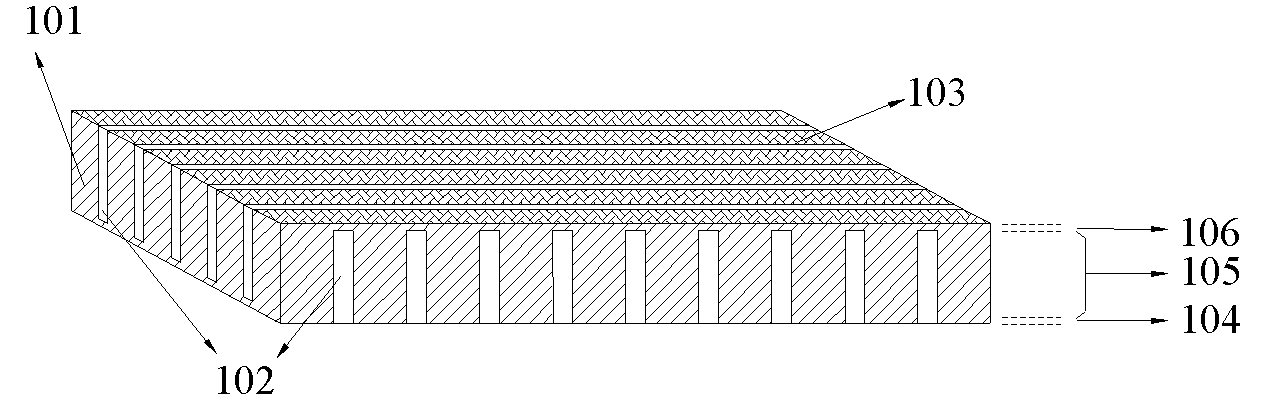

Display screen, electronic device and production method of display screen

InactiveCN107329303ALow acoustic impedanceImprove recognition ratePrint image acquisitionPhotovoltaic energy generationEngineeringTransistor

The invention provides a display screen, an electronic device and a production method of the display screen. The display screen comprises an upper glass substrate, a lower glass substrate, supporting parts, a thin film transistor and filling layers; the supporting parts are arranged between the upper glass substrate and the lower glass substrate, and the supporting parts are used for supporting and fixing the upper glass substrate and the lower glass substrate; the thin film transistor is arranged on one surface, towards the upper glass substrate, of the lower glass substrate; the filling layers are formed between the upper glass substrate and the lower glass substrate and allow light rays or ultrasonic waves to penetrate, and the filling layers are in a flowing state or solid state. The display screen can be applied to a scheme that an ultrasonic wave fingerprint is used on the screen, so that the screen rate of the electronic device is larger, and the user requirements are met.

Owner:LENOVO (BEIJING) LTD

Flexible transparent piezoelectric composite film, transparent stretchable ultrasonic transducer and preparation method thereof

ActiveCN113801412AImprove piezoelectric performanceImprove local voltage distributionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesHeterojunctionComposite film

The invention discloses a flexible transparent piezoelectric composite film, a transparent stretchable ultrasonic transducer and a preparation method thereof. The flexible composite transparent film is mainly obtained by constructing a chemical heterojunction and designing the structure of each phase ferroelectric domain wall in the composite piezoelectric film. According to the method, firstly, a chemical heterojunction is formed in a composite film precursor solution through an in-situ synthesis method, the chemical heterojunction can improve voltage distribution of an inorganic piezoelectric phase dispersion unit in the composite film when the inorganic piezoelectric phase dispersion unit is polarized, and dipole moment orientation under the action of an electric field is remarkably improved; and then, applying an alternating electric field to the formed non-transparent flexible composite film for polarization, so continuous ferroelectric domains are fused with each other, and the number of the ferroelectric domains is reduced. And finally, the flexible composite piezoelectric film with high transparency, high piezoelectric property and low acoustic impedance is prepared and is finally applied to a transparent stretchable ultrasonic transducer, particularly applied to photoacoustic imaging of non-planar tissues such as craniocerebral tissues and the like, the light transmission efficiency in photoacoustic imaging is improved, and the imaging quality is improved.

Owner:ZHEJIANG LAB

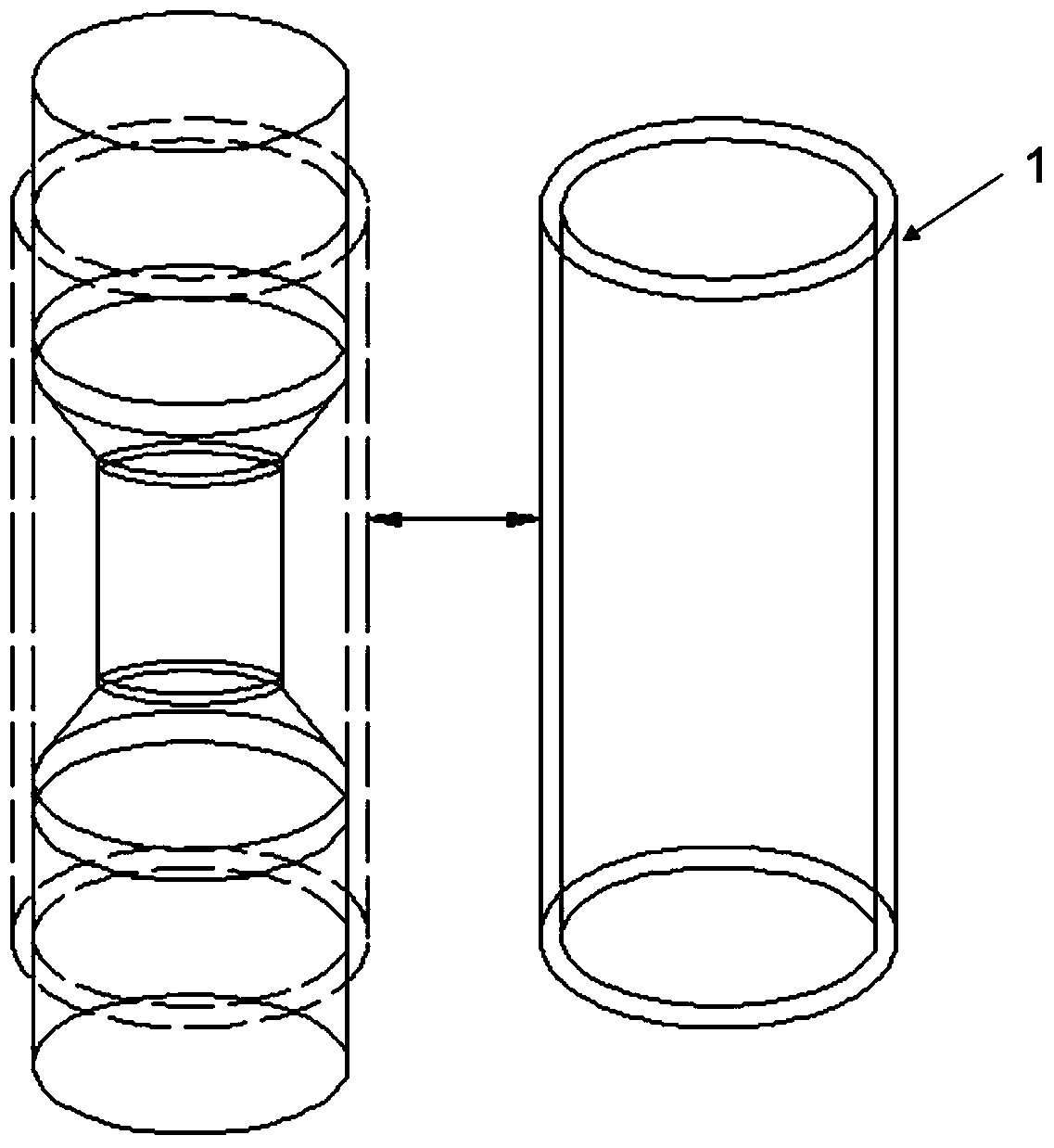

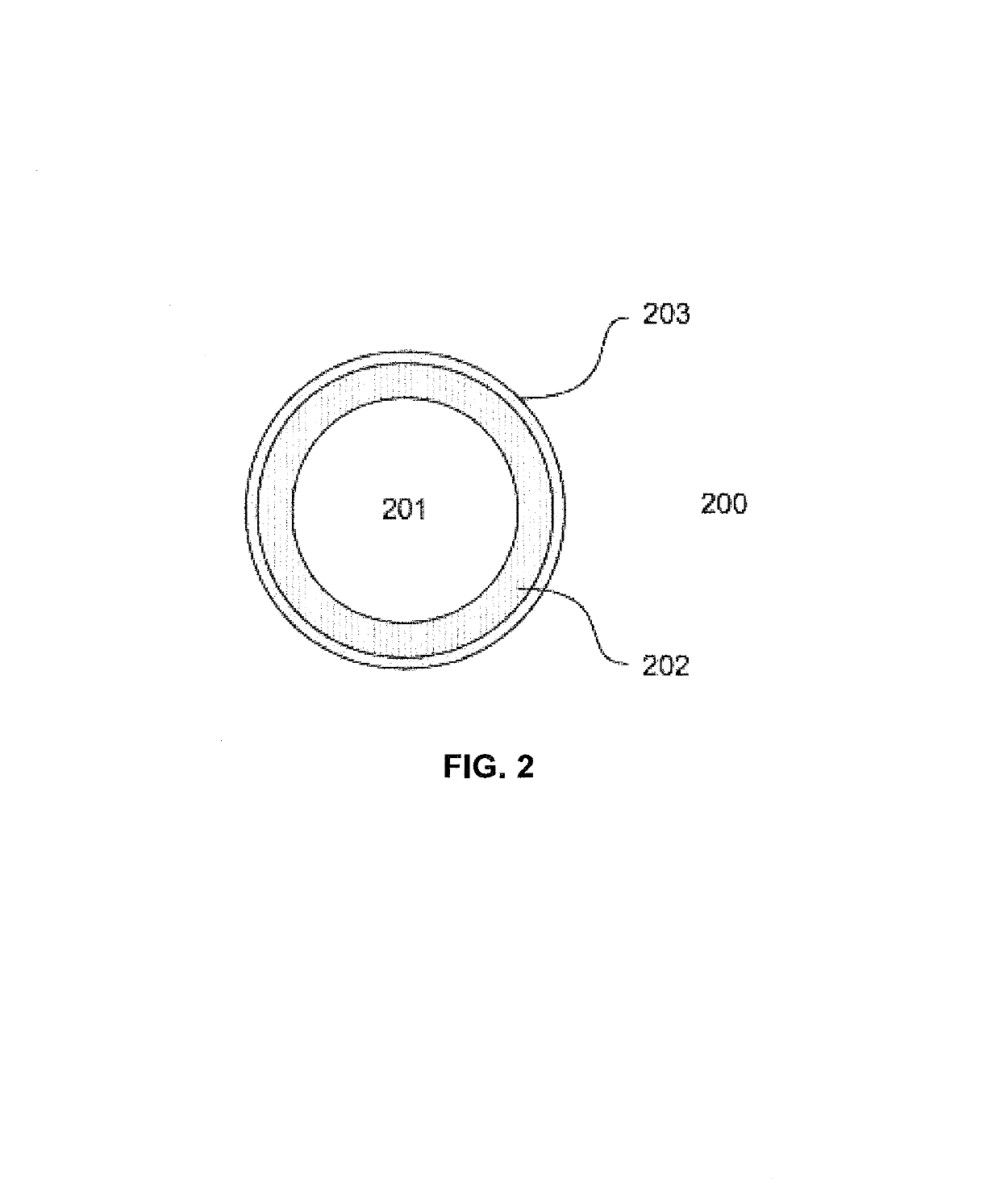

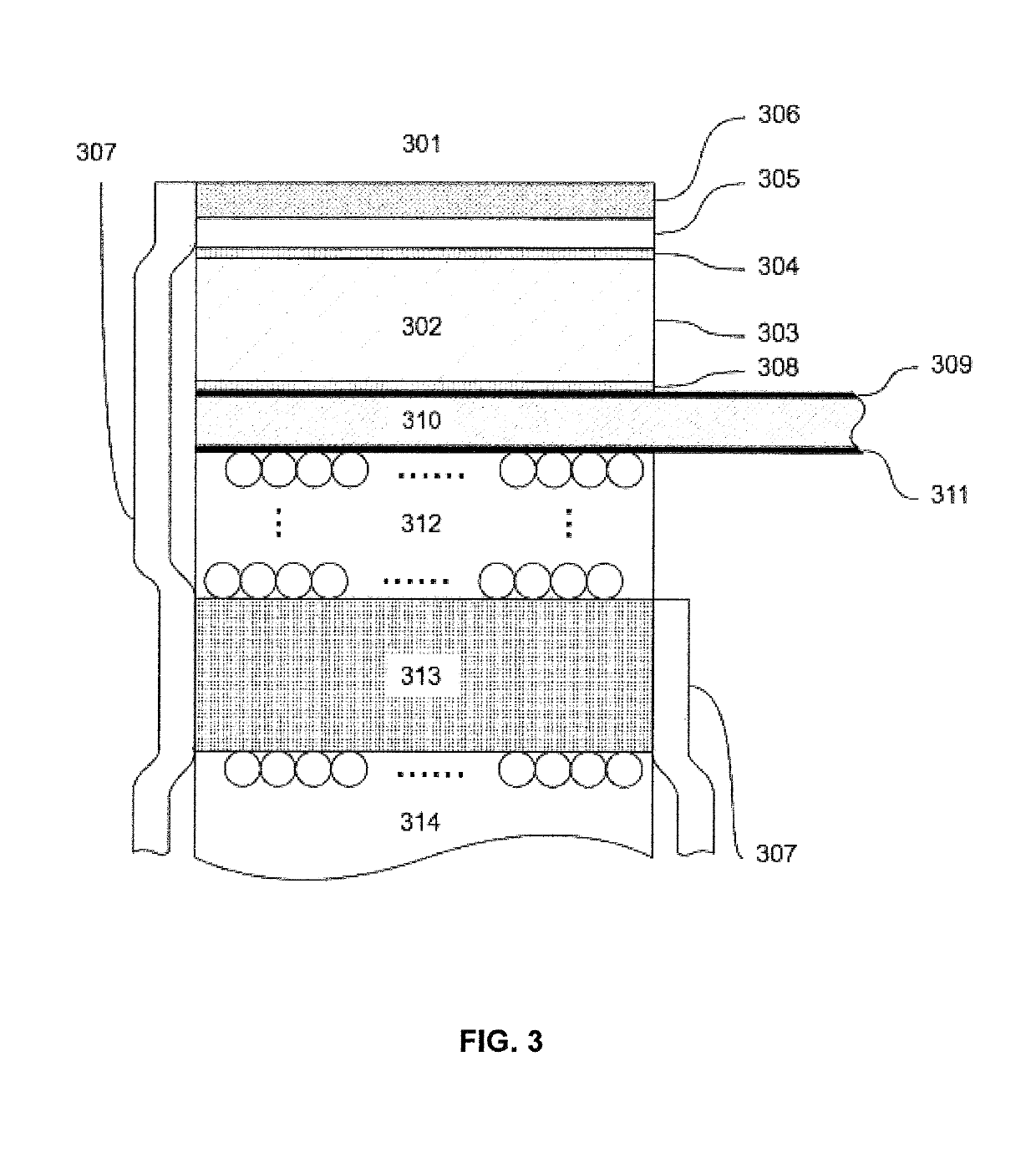

Ultrasonic transducer, focused transducer and focused transducer manufacturing method

ActiveCN107981887AImprove resolutionSmall focus rangeUltrasonic/sonic/infrasonic diagnosticsElectrical transducersSonificationTransducer

The invention provides an ultrasonic transducer, a focused transducer and a focused transducer manufacturing method and relates to the technical field of ultrasonic detection. The ultrasonic transducer comprises a tube sleeve; at least two piezoelectric components are dispersedly disposed in the tube sleeve; the piezoelectric component comprises a piezoelectric vibrator and a matching layer, wherein the matching layer is located on the same end of the tube sleeve, and the frequency of the piezoelectric vibrator is not the same. The focused transducer comprises the above-mentioned ultrasonic transducer, and the matching layer forms a concave spherical surface in the tube sleeve. The focused transducer manufacturing method includes the following steps of heating and softening insulating filler, pressing the piezoelectric component with a part of a convex spherical surface until the piezoelectric component is recessed in the insulating filler and forms a concave spherical surface, coolingand solidifying the insulating filler, and then taking out the part of the convex spherical surface. With the piezoelectric vibrator in the piezoelectric component of different frequency, the frequency of the obtained corresponding ultrasonic wave is also different, and thus, the ultrasonic transducer is widened to obtain ultrasonic frequency bandwidth, and application range and practicality thereof are increased.

Owner:慧威医疗科技(台州)有限公司

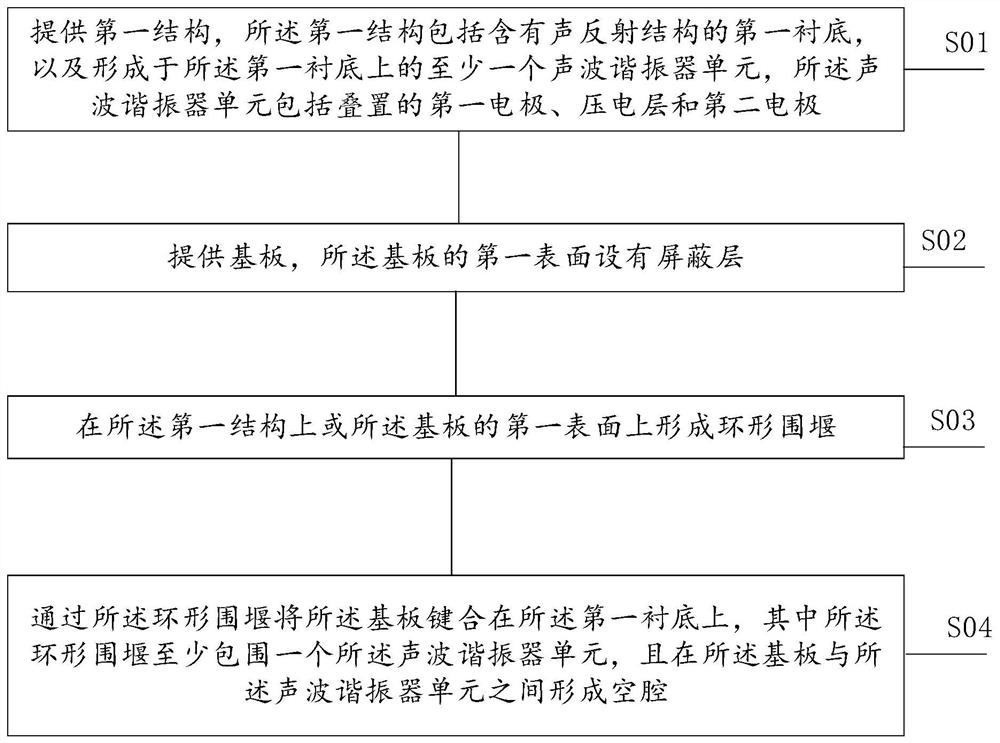

Film acoustic resonator and manufacturing method thereof

PendingCN112350680ASuppresses external electromagnetic radiationBlock or attenuate external transmissionImpedence networksThin membraneAcoustic wave

The present invention provides a film acoustic resonator and a manufacturing method thereof, the film acoustic resonator comprising: a first substrate including an acoustic reflection structure; an acoustic resonator unit at least part of which is located on the acoustic reflection structure, and which sequentially comprises a first electrode, a piezoelectric layer and a second electrode which arestacked from bottom to top; and a substrate bonded with the first substrate through an annular cofferdam, wherein a cavity is formed between the substrate and the acoustic resonator unit, the cavityat least comprises one acoustic resonator unit therein, and at least one of the substrate and the annular cofferdam has an effect of shielding electromagnetic waves. According to the film acoustic resonator, the external propagation of electromagnetic waves generated by the resonator unit is effectively blocked or attenuated, so that the external electromagnetic radiation of the resonator unit isinhibited.

Owner:NINGBO SEMICON INT CORP

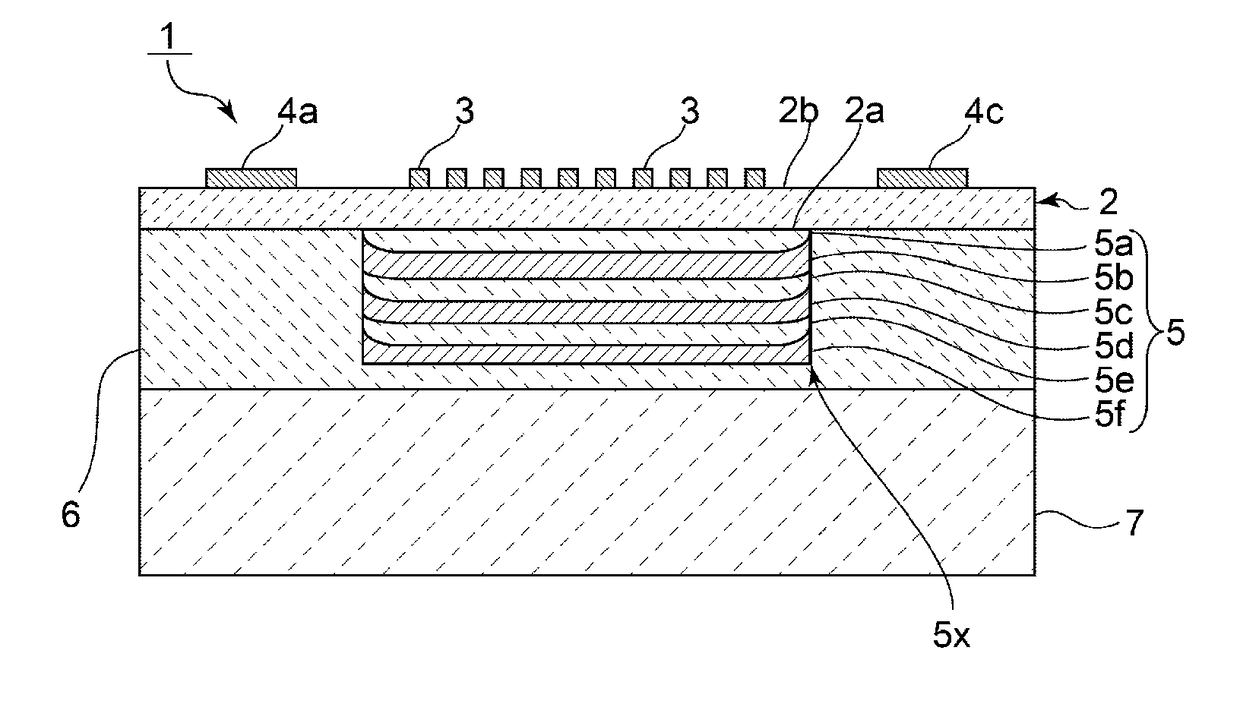

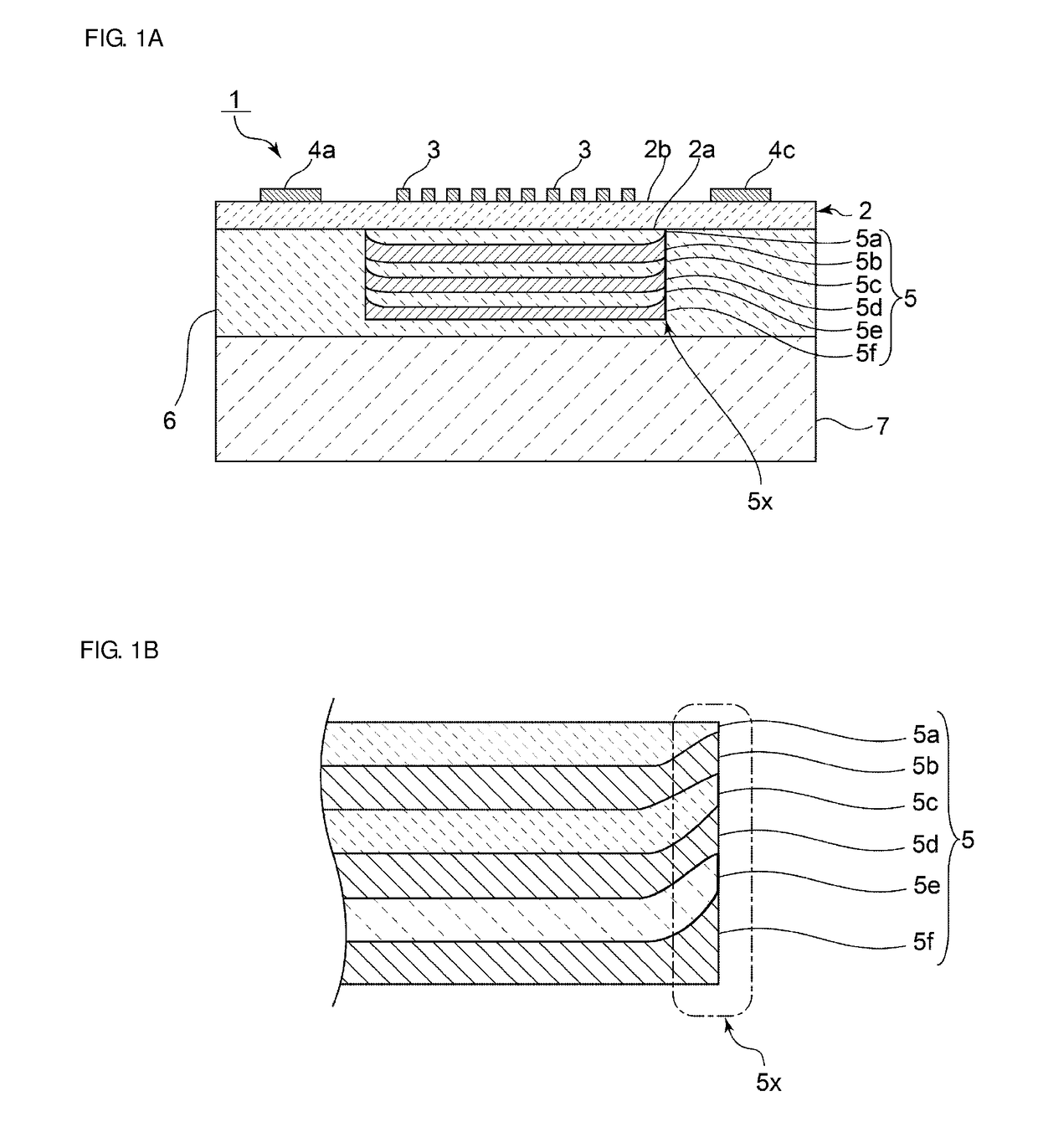

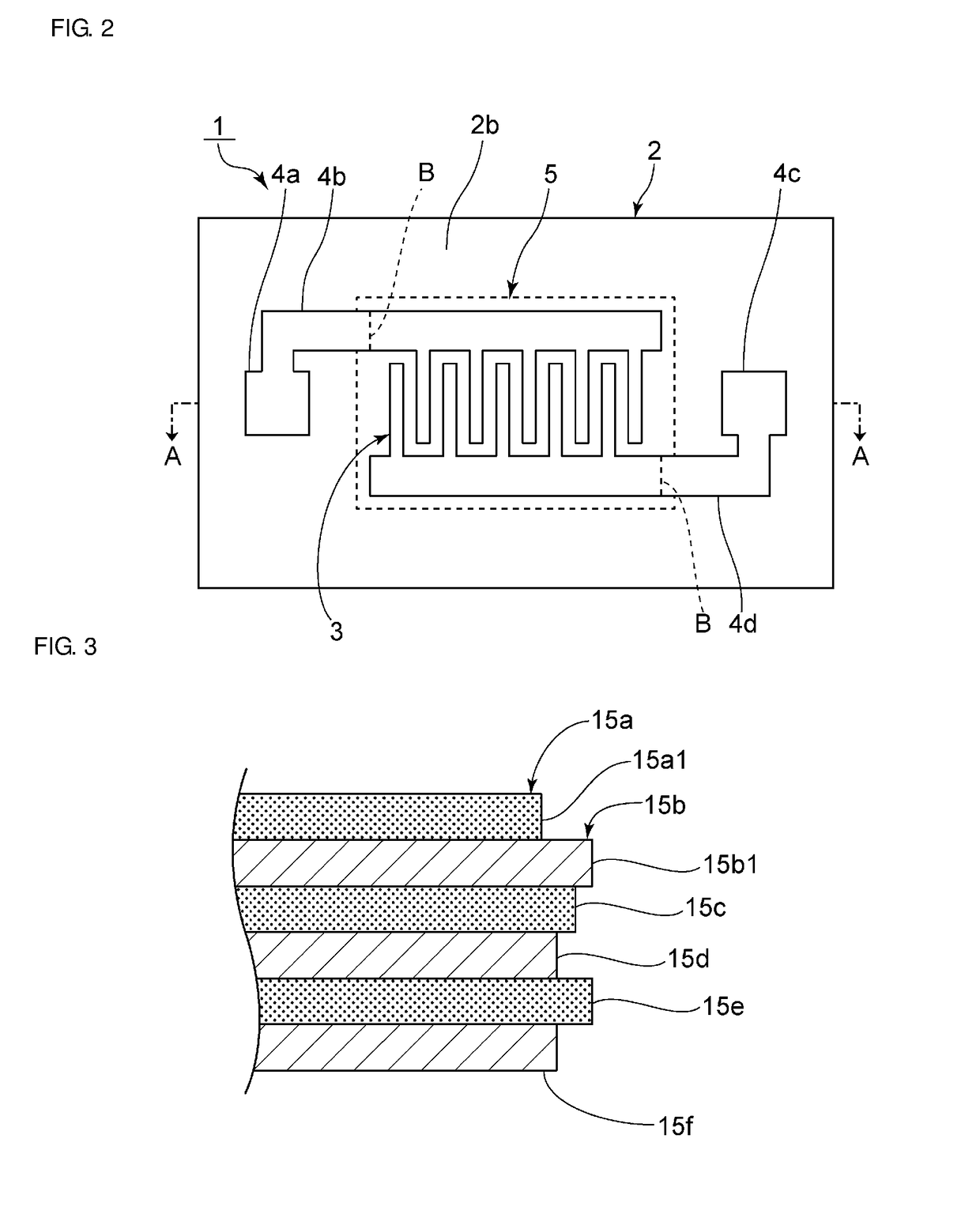

Elastic wave device and manufacturing method therefor

ActiveUS20170366160A1Influence of unwanted is reducedReduce and prevent reflectionPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic impedanceElectrode

An elastic wave device in which an IDT electrode defines an excitation electrode on a piezoelectric layer, an acoustic reflection layer is laminated on a first main surface of the piezoelectric layer, the acoustic reflection layer includes high acoustic impedance layers with a relatively high acoustic impedance and low acoustic impedance layers with a relatively low acoustic impedance, and the acoustic reflection layer has an unwanted wave reflection suppression structure in which reflection of unwanted waves toward the piezoelectric layer side is significantly reduced or prevented.

Owner:MURATA MFG CO LTD

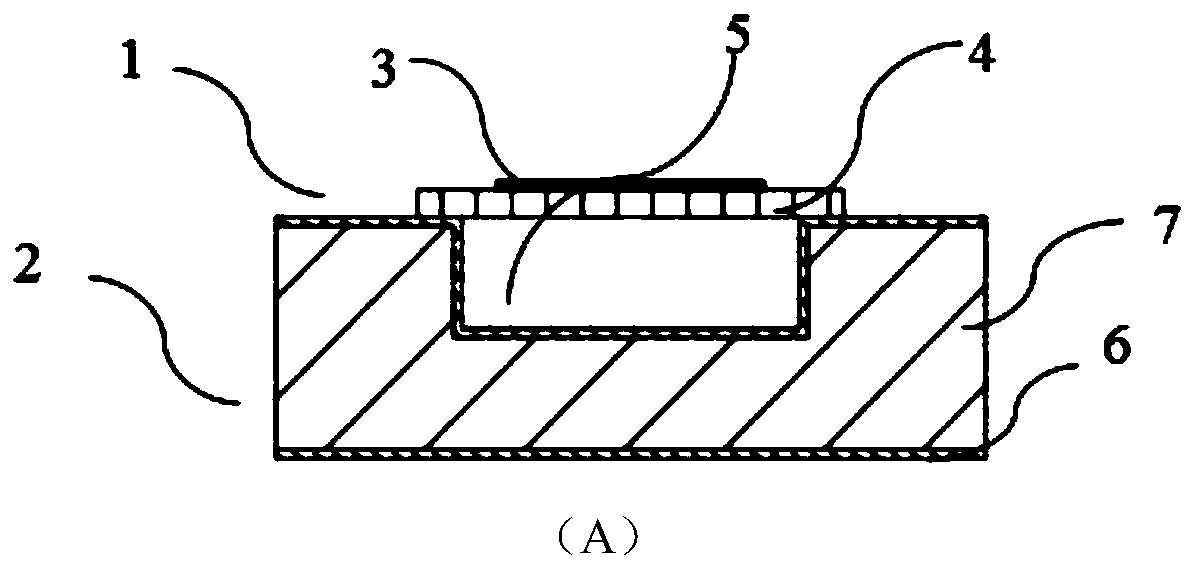

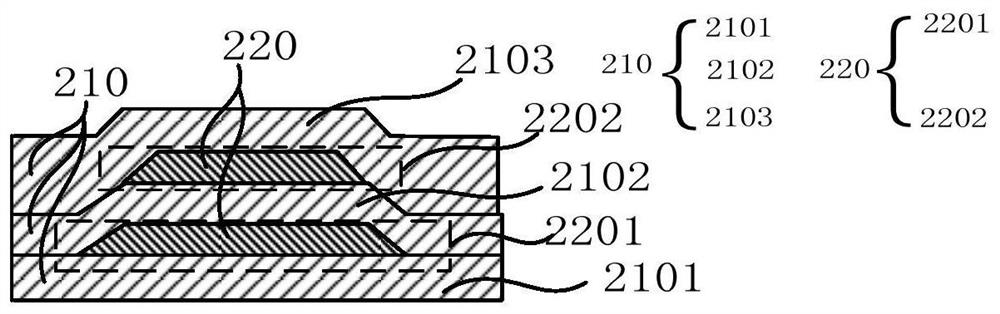

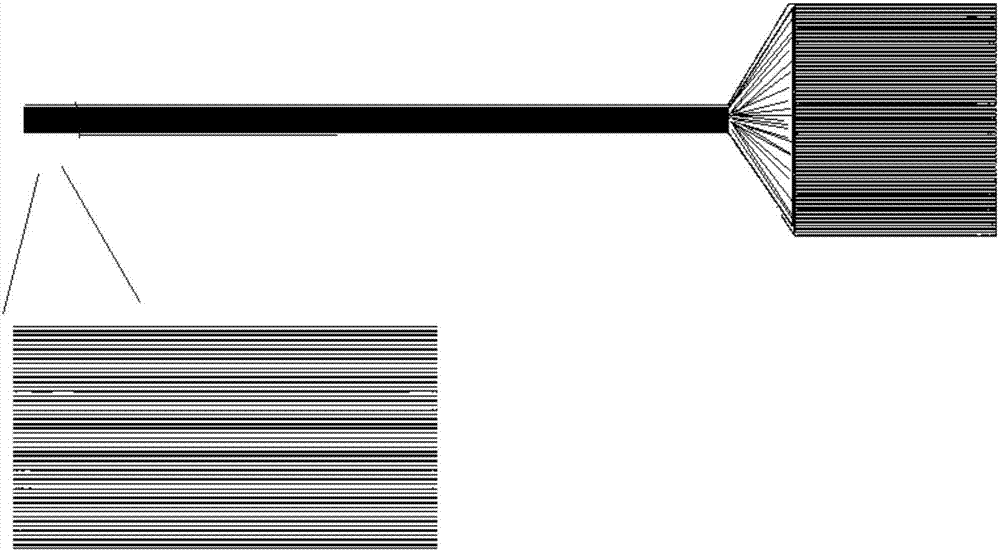

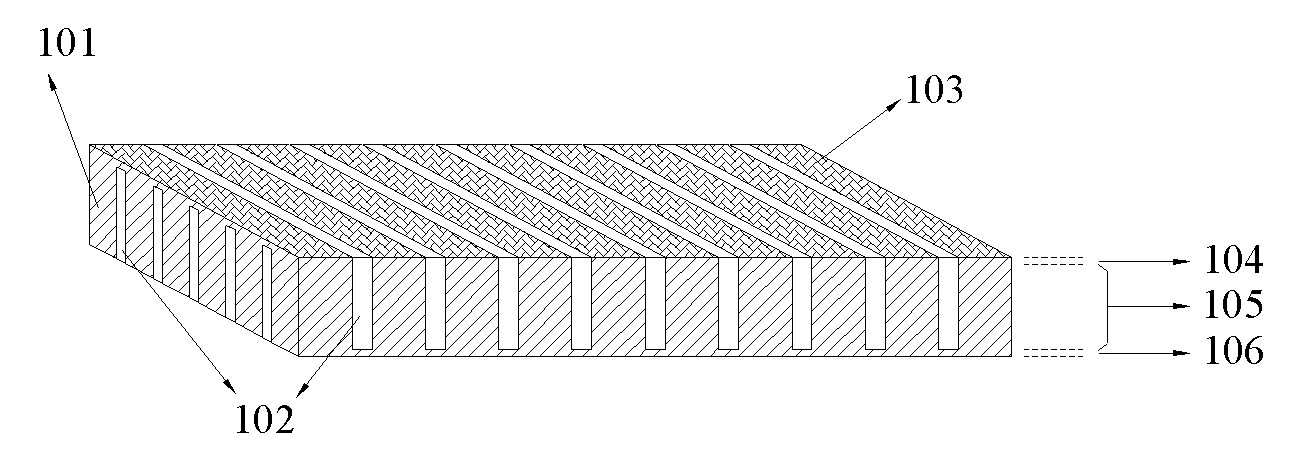

One dimensional ultrasound phased array probe based on PIN-PMN-PT (lead indium niobate-lead magnesium niobate-lead titanate) ternary system piezoelectric monocrystalline and preparing method

InactiveCN106890783AImprove performanceHigh curie temperatureMechanical vibrations separationIndiumFlexible circuits

The invention discloses a one dimensional ultrasound phased array probe based on a PIN-PMN-PT (lead indium niobate-lead magnesium niobate-lead titanate) ternary system piezoelectric monocrystalline and a preparing method thereof. The phased array probe comprises a lower electrode, a 1-3 composite PIN-PMN-PT piezoelectric monocrystalline array, an upper electrode array and a flexible circuit board which are laminated from bottom to top in sequence; array elements of the upper electrode array and the array elements of the piezoelectric monocrystalline array correspond one to one, and print circuit passages on the flexible circuit board correspond to the array elements on the upper electrode array; a preparing method comprises adopting a photoetching and etching method for grooving to form the 1-3 composite PIN-PMN-PT piezoelectric monocrystalline array, and forming the lower electrode on a piezoelectric plate of the lower bottom surface of the PIN-PMN-PT piezoelectric monocrystalline array through a sputtering process, forming upper electrodes on the upper surface of the piezoelectric monocrystalline array and adopting the flexible circuit board to provide a lead for the electrodes to be connected to an external circuit. The one dimensional ultrasound phased array probe can bear higher working temperature and electric field.

Owner:HUAZHONG UNIV OF SCI & TECH

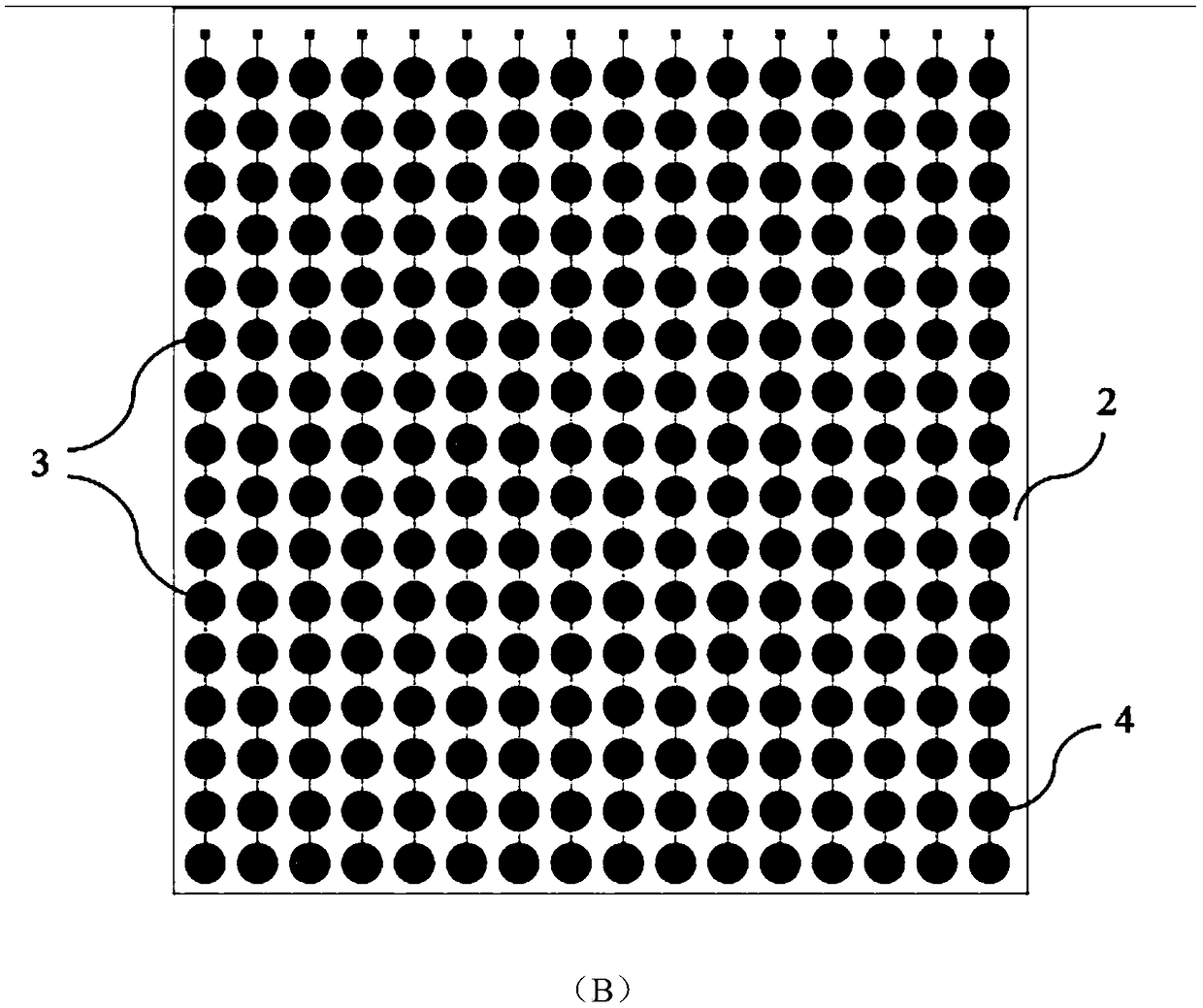

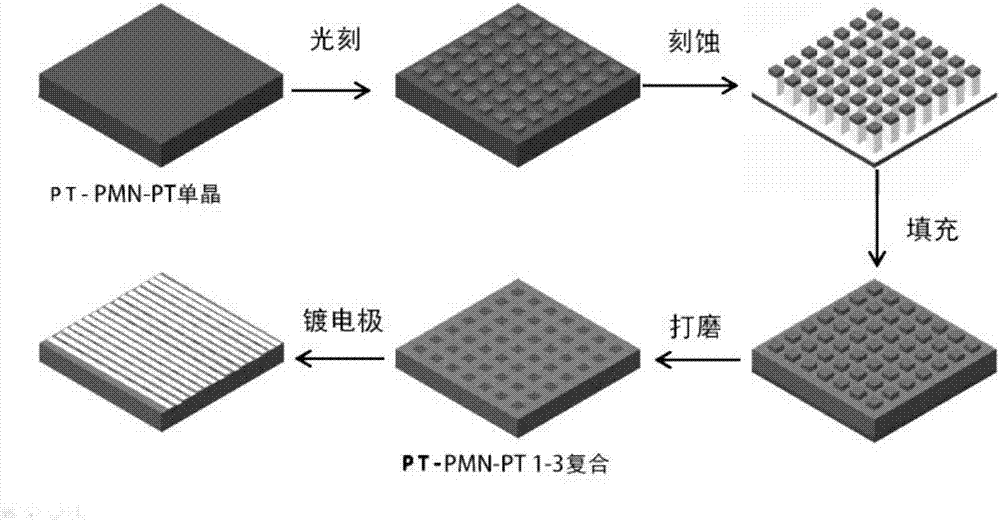

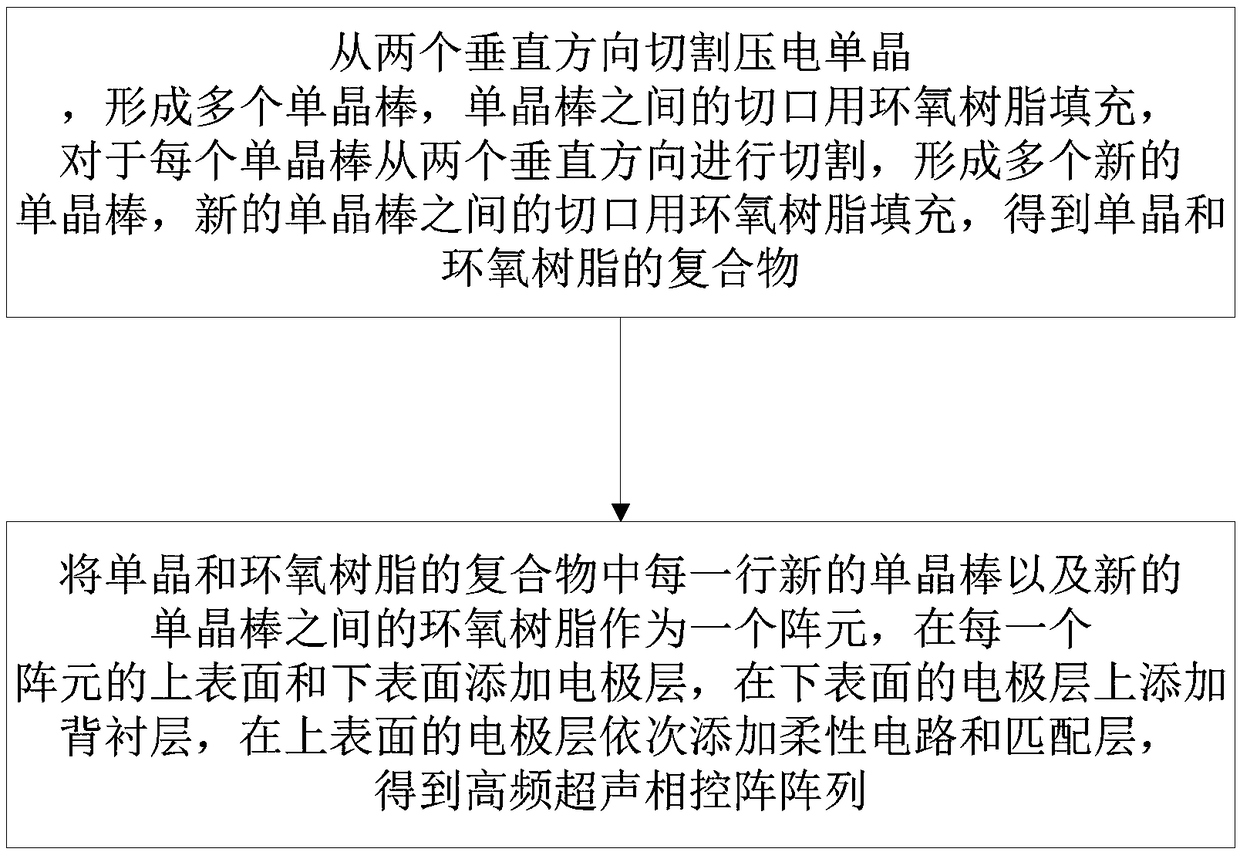

High-frequency ultrasonic phased array for ophthalmology and preparation method thereof

InactiveCN108903975AHigh electromechanical coupling coefficientImprove image qualityBlood flow measurement devicesEye diagnosticsEpoxyFlexible circuits

The invention discloses a high-frequency ultrasonic phased array for ophthalmology and a preparation method thereof, wherein the preparation method includes: cutting piezoelectric monocrystal from twovertical directions to form multiple monocrystal rods, filling cuts of the monocrystal rods with epoxy resin, cutting each monocrystal rod from two vertical directions to form a plurality of new monocrystal rods, and filling cuts of the new monocrystal rods with epoxy resin to obtain monocrystal-epoxy resin complex; using the new monocrystal rods of each row in the monocrystal-epoxy resin complexand the epoxy resin between the new monocrystal rods as an array element, adding electrode layers to upper and lower surfaces of each array element, adding a backing layer to an electrode layer of each lower surface, and adding a flexible circuit and a matching layer to the electrode layer of each upper surface so that the high-frequency ultrasonic phased array is obtained. The high-frequency ultrasonic phased array has high resolving power for imaging and can monitor fundal blood flow condition in real time.

Owner:HUAZHONG UNIV OF SCI & TECH

Ultrasound transducer and method of manufacturing

ActiveUS10310061B2Low acoustic impedanceImprove thermal conductivityWave based measurement systemsSemiconductor electrostatic transducersThermal conductivityPolymer particle

Owner:SURF TECH AS

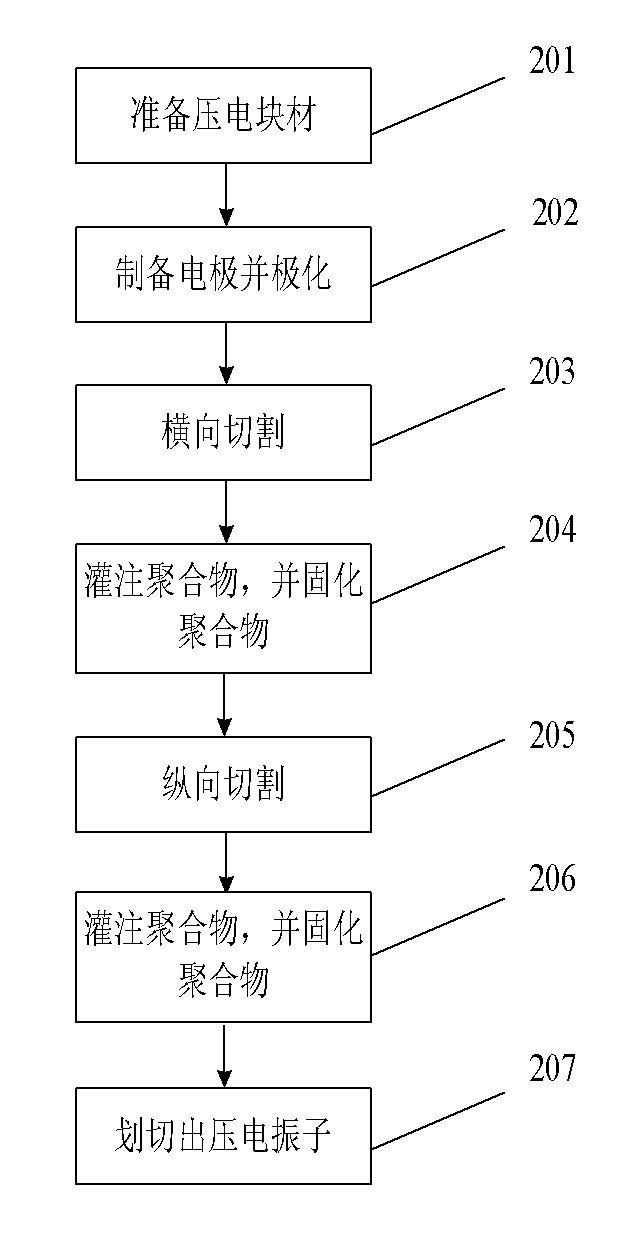

Piezoelectric vibrator preparation method and piezoelectric vibrator prepared thereby

ActiveCN103078600ALow acoustic impedanceHigh electromechanical conversion performanceImpedence networksEngineeringAcoustics

The invention relates to a piezoelectric vibrator preparation method and a piezoelectric vibrator prepared thereby. The piezoelectric vibrator is respectively provided with a plurality of first direction slots and a plurality of second direction slots vertical to the first direction slots in the lateral direction and the longitudinal direction, wherein the depth of the first direction slots and the second direction slots is less than the thickness of a piezoelectric bulk; the inside of the first direction slots and the second direction slots is filled with solidified polymers; the upper end surface and the lower end surface of the piezoelectric bulk are successively provided with piezoelectric thin strips and polymer thin strips at an interval in parallel; meanwhile, electrodes reserved by the upper layer of the piezoelectric thin strips and the lower layer of the piezoelectric thin strips can be directly subjected to lead welding so as to omit factors, such as the complex technology of preparing the electrode on the surface of the composite structure and instability; meanwhile, the piezoelectric vibrator has the advantages of low acoustic impedance and high electro-mechanical transformation performance of the common composite material, as well as high smoothness; and because of the support of the inner piezoelectric bulk of the piezoelectric vibrator, the piezoelectric vibrator is unlikely to deform if being heated and impacted by external force.

Owner:EDAN INSTR

High mechanical property low impedance polymer bonded explosive and preparation method thereof

ActiveCN110304978ALower impedanceImprove mechanical propertiesNon-explosive fillers/gelling/thickening agentsExplosive working-up apparatusPolymer scienceHigh energy

The invention relates to a high mechanical property low impedance polymer bonded explosive and a preparation method thereof, and belongs to the technical field of composite energetic materials. The high mechanical property low impedance polymer bonded explosive is prepared from the components of polymer binder polyuria, an energetic material and an explosive performance modifier in a certain proportion. According to the high mechanical property low impedance polymer bonded explosive, a novel binder two-component slow reaction polyuria is introduced, high explosive and the like are effectivelyrecombined, the mechanical property of the energetic compound is obviously improved, and meanwhile the problems of low adhesive force and high acoustic impedance of the high energy composite explosiveare solved. According to the high mechanical property low impedance polymer bonded explosive, the bonding strength between the explosive components, and between the explosive and surrounding containing materials is improved, and important application value is achieved for improvement of the mechanical properties of the energy containing compound and the comprehensive performance of charging. In addition, the high mechanical property low impedance polymer bonded explosive is prepared at normal temperature, waste water, waste liquid or waste gas is not generated, and the advantages of safety, environmental protection, and simple technology are achieved.

Owner:ZHONGBEI UNIV

Flame-retardant and environment-friendly polystyrene foam material and preparation method thereof

The invention discloses a flame-retardant and environment-friendly polystyrene foam material and a preparation method thereof and belongs to the field of polystyrene foam materials. The polystyrene foam material is prepared from raw materials in parts by weight as follows: 90-100 parts of polystyrene / SiO2 core-shell composite particles, 80-90 parts of phenolic resin, 15-20 parts of a curing agent,4-5 parts of a nitrogen-phosphorus intumescent flame retardant and 1-2 parts of sodium dodecyl benzene sulfonate. Expandable core-shell composite bead particles are prepared through suspension polymerization with SiO2 aerogel as a core and polystyrene as a shell, the defects that polystyrene has high heat conductivity coefficient and poor corrosion resistance and is inflammable are overcome, SiO2aerogel and polystyrene are compounded, advantages are enhanced while disadvantages are avoided, advantages of SiO2 aerogel and polystyrene are played simultaneously, a SiO2 aerogel composite board has heat insulation property higher than that of common foam polystyrene boards and has substantially improved flame retardance. The nitrogen-phosphorus intumescent flame retardant has the advantages of smoke inhibition, low toxicity and no corrosive gas, the flame retardance of the material is improved with non-halogenation, no-toxic and flame-retardant technologies and environmental pollution iseffectively reduced.

Owner:苏州巴鸣泡沫塑料制品有限公司

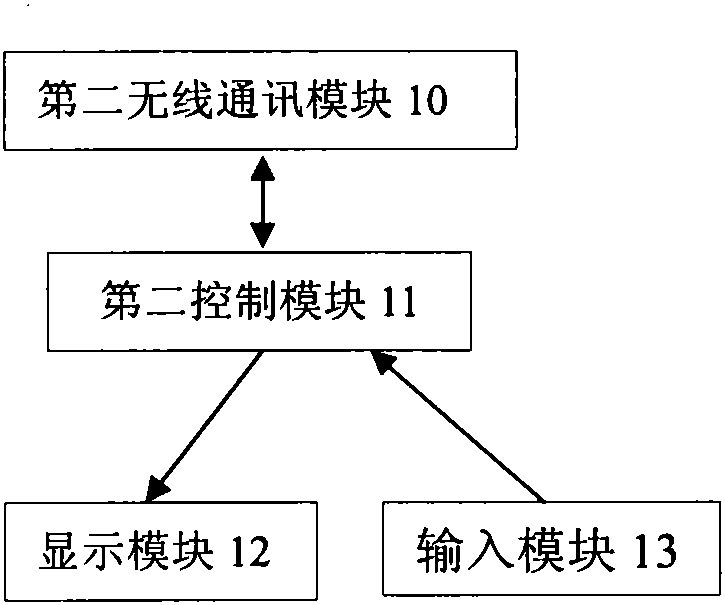

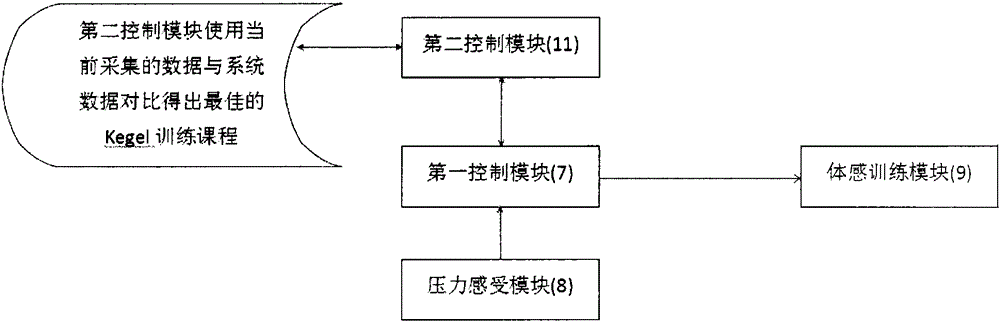

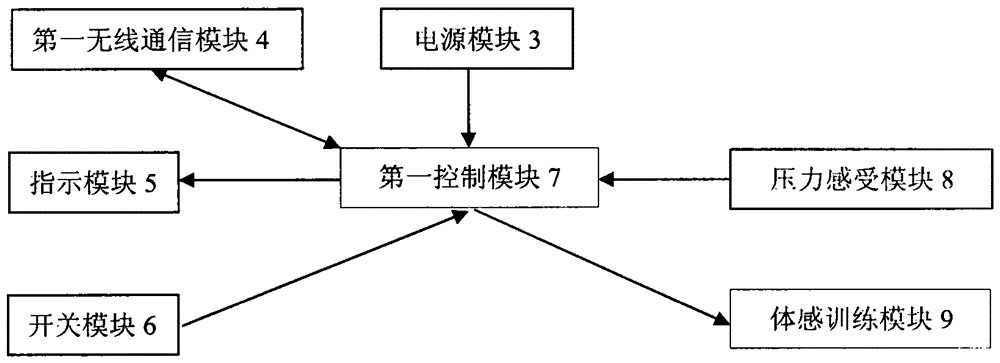

A wireless intelligent kegel pelvic floor muscle training device and its control method

InactiveCN104436544BPromote recoveryQuick treatmentGymnastic exercisingPelvic diaphragm muscleNon traumatic

Owner:BEIJING LINGXIAN GONGCHUANG ENTERPRISE MANAGEMENTCO

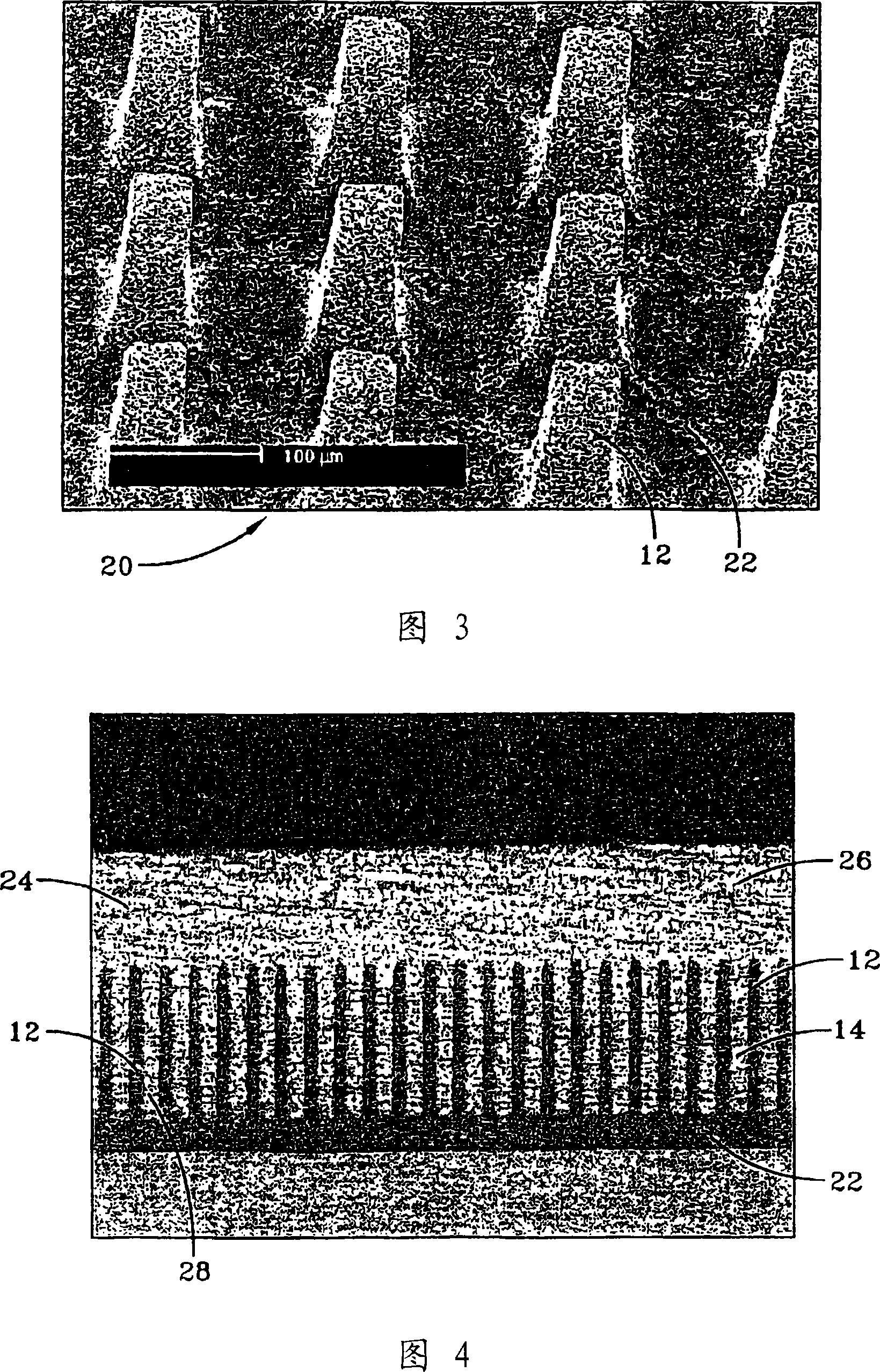

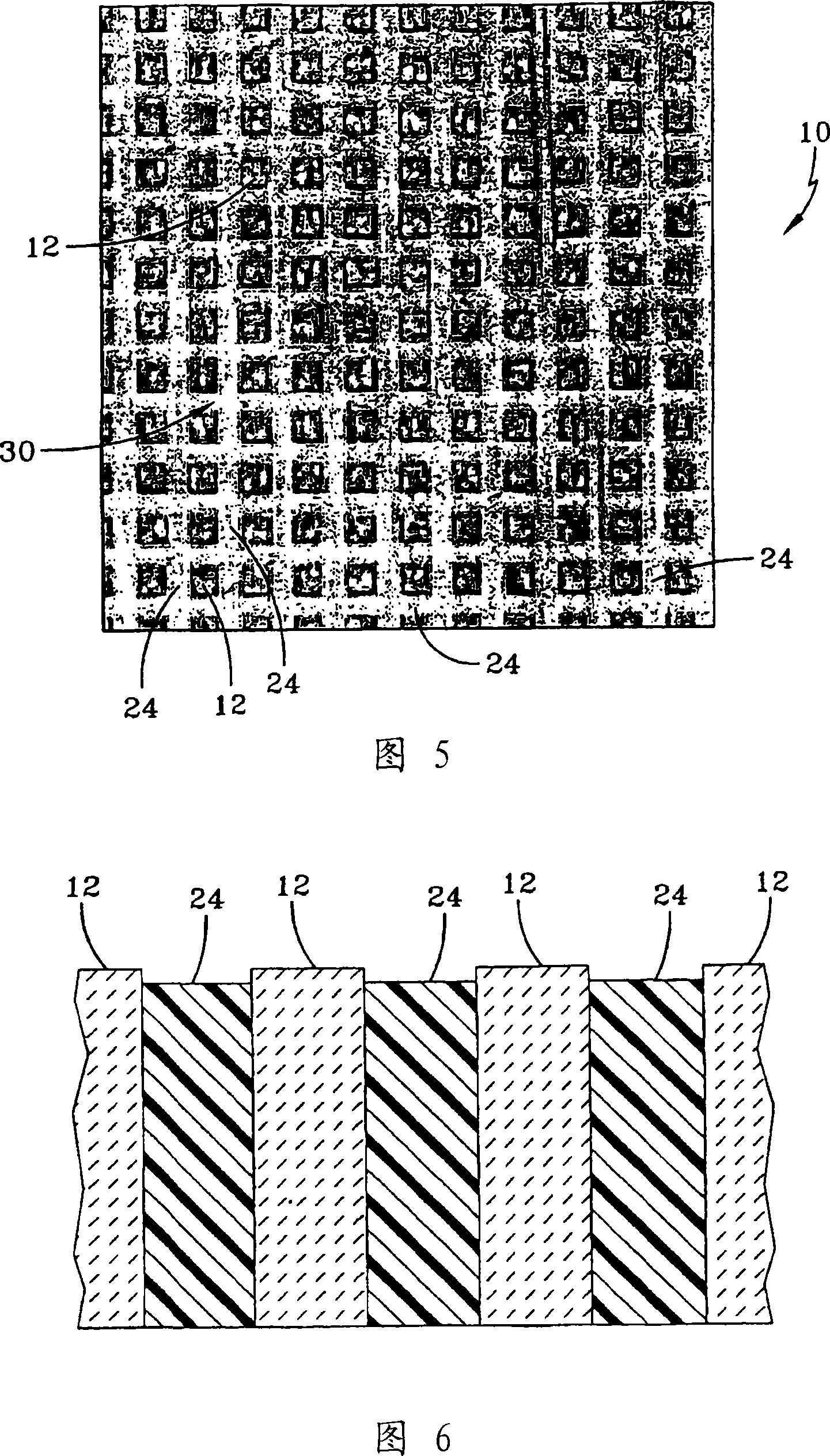

Method for plating piezoelectric composite

InactiveCN101115572AEasy to manufactureImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyMechanical vibrations separationEpoxyAcid etching

A method of manufacturing a piezo-composite element comprising a ceramic element (12) embedded in a polymer (14) such as epoxy for use in an ultrasonic transducer (10) includes first grinding the face of the composite and removing damaged ceramic (12) by acid etching the ceramic (12). The epoxy is then removed by plasma etching so that the ceramic (12) is slightly elevated above the epoxy. The composite is sputter plated so that a maximum temperature that could damage the p1a ting is not exceeded. The ceramic (12) is then poled so that a maximum temperate re that could damage the plating is not exceeded. Contacts (16) are then attached to the plating adjacent the ceramic (12). In an array, the ceramic elements (1 2) may be in the form of posts. The plurality of ceramic elements (12) is in staggered arrangement with the polymer (14).

Owner:GE INSPECTION TECH LP

Piezoelectric ceramic composite material and preparation method thereof

ActiveCN105837136ALow acoustic impedanceHigh compressive strengthHydration reactionCeramic composite

The invention provides a piezoelectric ceramic composite material and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing and stirring Portland cement, aluminate cement, octadecanamide, beeswax, bisphenol A epoxy resin, bisphenol F epoxy resin, erythritol, 651 low-molecular polyamide, m-phenylenediamine, polyvinyl acetal, calcium propionate, sodium carboxymethyl cellulose, absolute ethyl alcohol and water, vacuumizing, and eliminating gas; then putting a piezoelectric ceramic sheet into a mold, pouring the mixture into the mold and vibrating, and continuing pouring to make the mold full of the mixture; and putting the mold into a vacuum system, vacuumizing, eliminating gas, then putting the mold into a standard curing room, curing, demolding, and continuing curing; and finally cutting until the piezoelectric ceramic sheet is exposed at two surfaces of the sample. The piezoelectric ceramic composite material has relatively low acoustic impedance rate and relatively high compressive strength, besides, noise can be effectively shielded, the sensor receiving performance is good, and in addition, a cement hydration reaction can be effectively detected.

Owner:福建省德化县成艺陶瓷有限公司

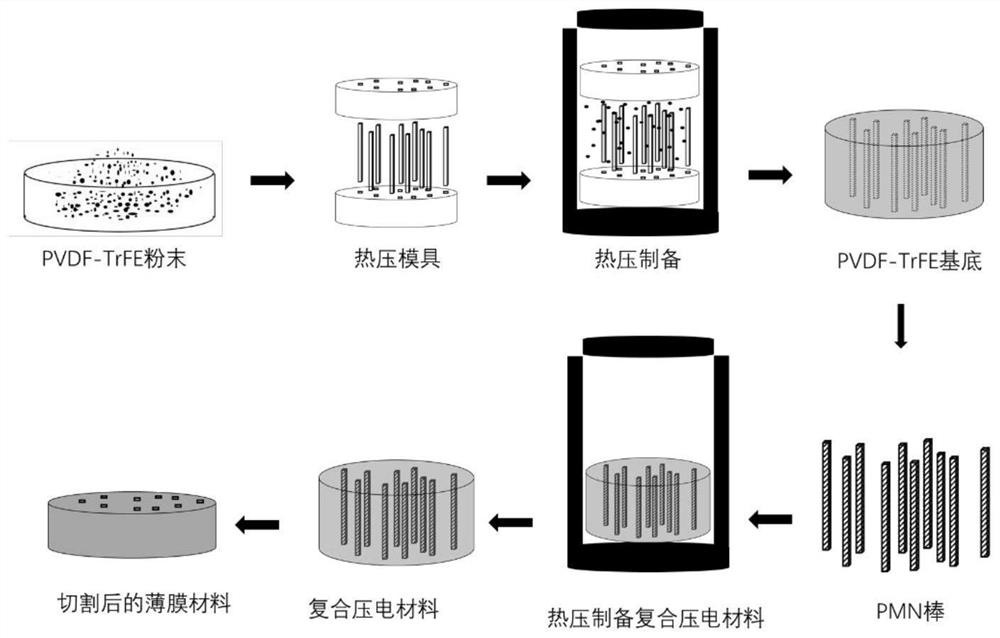

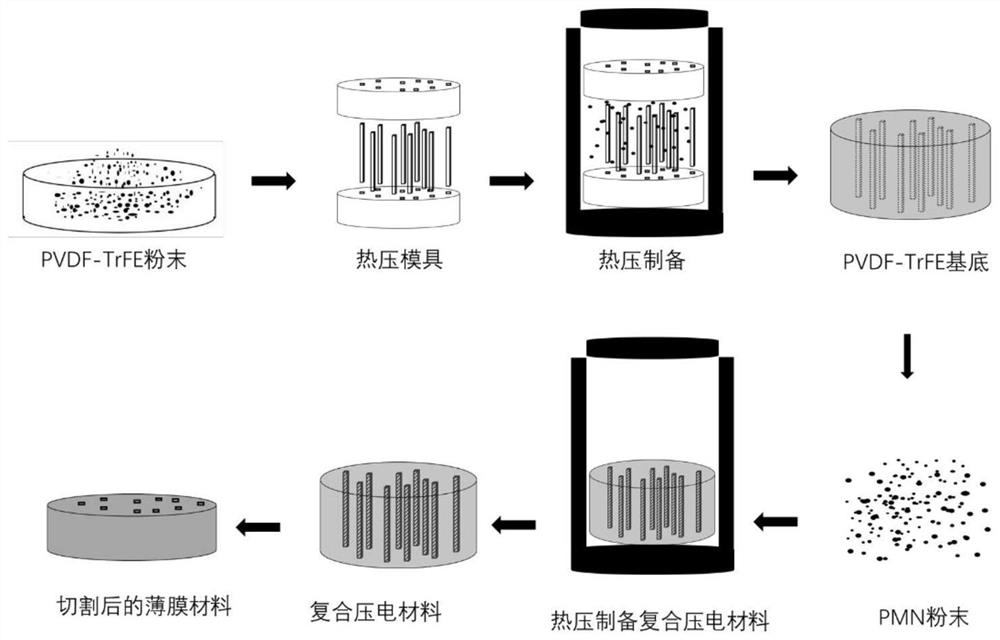

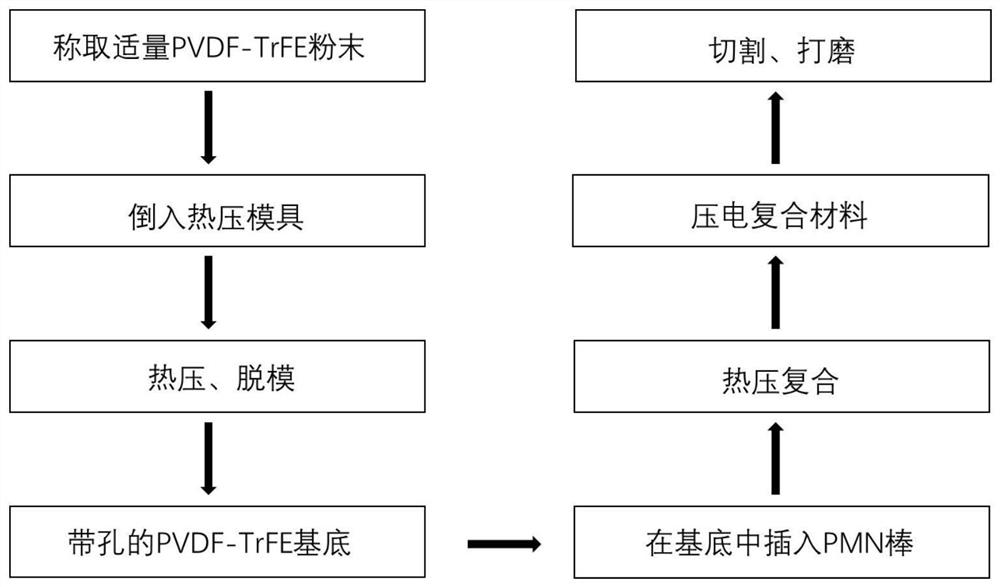

Preparation method of composite piezoelectric material based on PVDF-TrFE

ActiveCN112563407AImprove performanceLow acoustic impedancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionSingle crystalPiezoelectric composite

The invention relates to a preparation method of a composite piezoelectric material based on PVDF-TrFE. The preparation method comprises the following steps: weighing a polymer PVDF-TrFE powder; putting a mold liner into a tabletting mold, and pouring the weighed polymer PVDF-TrFE powder into a hot pressing mold; putting the prepared mold into a hot-pressing device, carrying out hot-pressing preparation, and then demolding to obtain a PVDF-TrFE matrix; carrying out hot-pressing shaping on the prepared composite piezoelectric material under a certain condition; cutting the prepared composite piezoelectric material by using a cutting machine, and carrying out hot-pressing shaping under the condition that a thickness is 0.5-2 mm; and using abrasive paper to carry out polishing, exposing a piezoelectric single crystal phase, and finally preparing a 1-3-type composite piezoelectric thin plate with certain flexibility. The performance of the PVDF-TrFE piezoelectric composite material is effectively improved, and therefore the composite material has wider application prospects in the aspects of transducers, energy collection and the like.

Owner:ZHEJIANG LAB

Composite film-based frequency-adjustable surface acoustic wave gyro

ActiveCN101738183BHigh sensitivityChange working frequencySpeed measurement using gyroscopic effectsTurn-sensitive devicesComposite filmDot matrix

Owner:NAT UNIV OF DEFENSE TECH

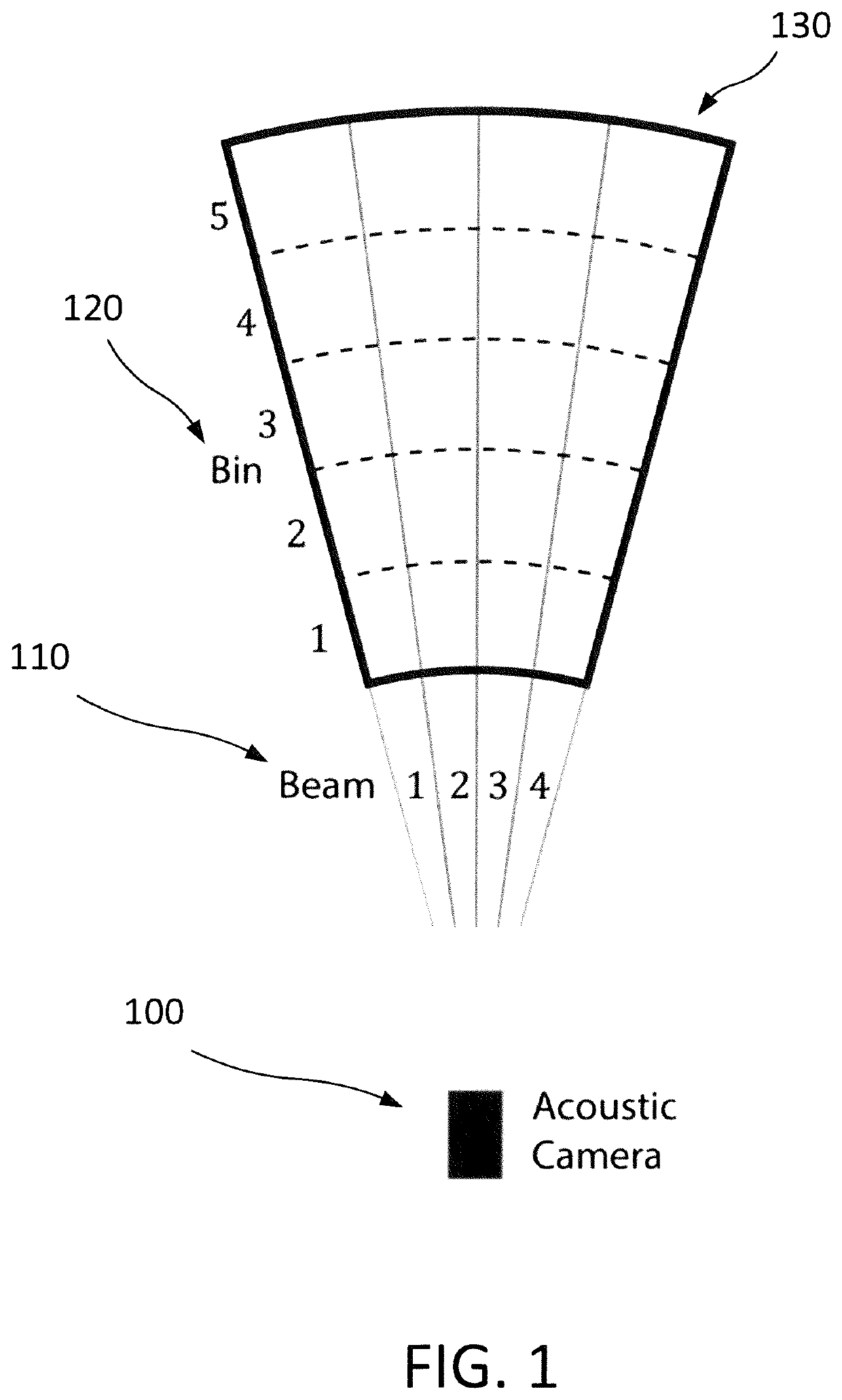

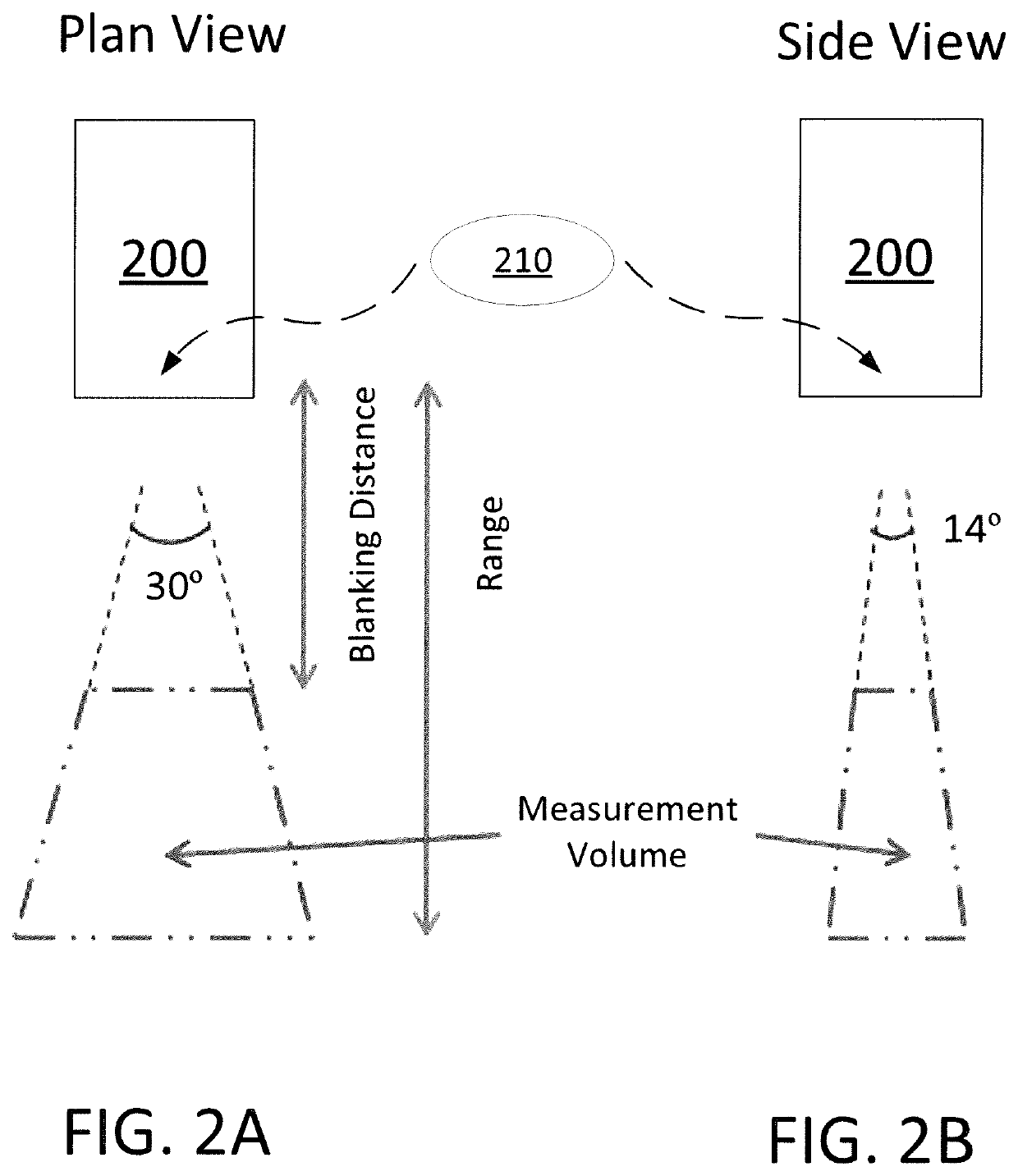

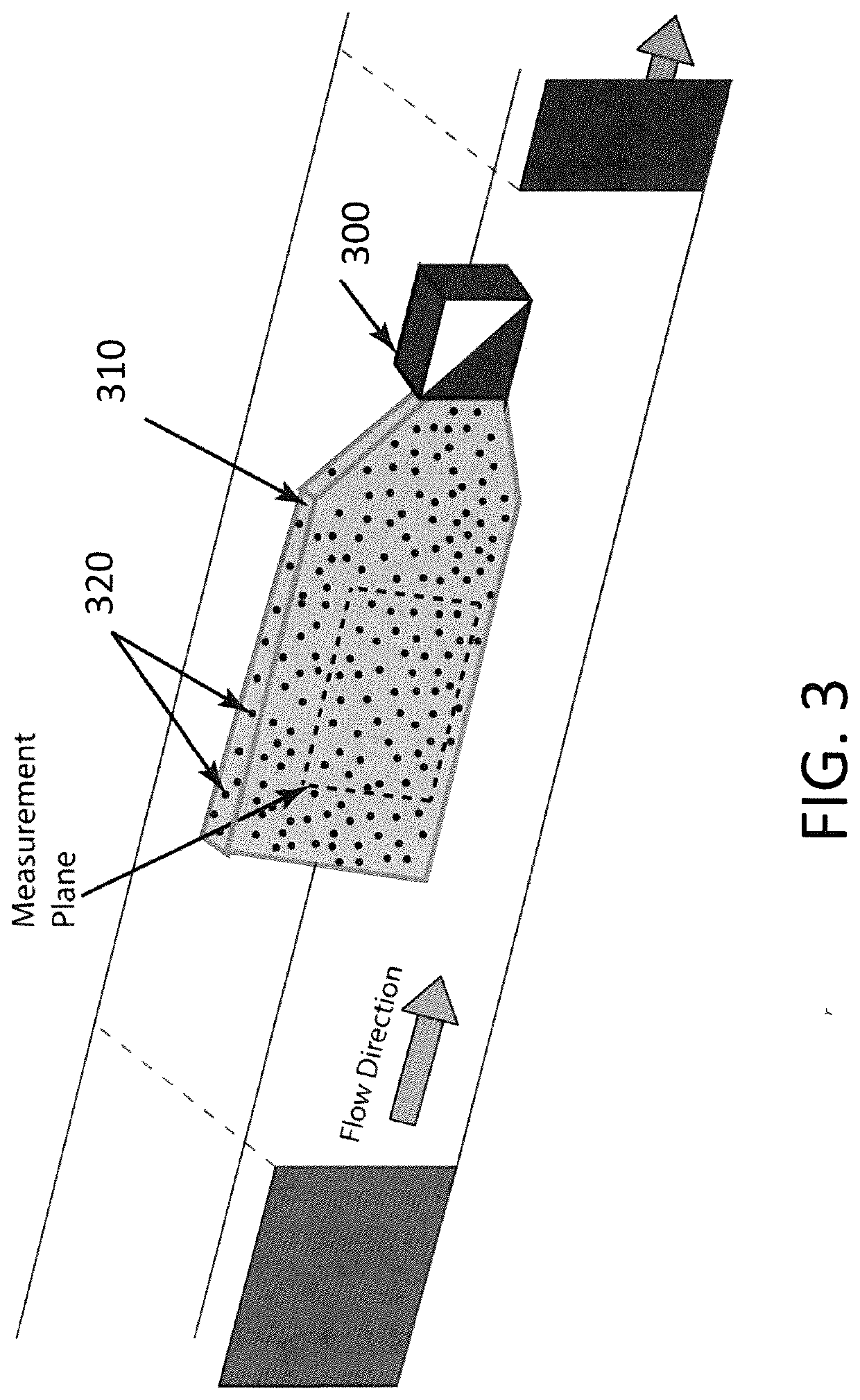

Acoustic camera systems and methods for large scale flow analysis in turbid field environments

InactiveUS20200217702A1Lower effective “ side lobes ”High resolutionVolume/mass flow measurementFull-field flow measurementSuspended particlesAtmospheric sciences

In one embodiment, a field-deployable acoustic camera system is provided for measuring a two-dimensional velocity field in a large scale flow in a turbid environment. The system includes an acoustic camera and a concentrator lens. The concentrator lens operates to reduce a spreading angle of the acoustic camera. The system is configured to apply planar cross-correlation velocimetry to collected images of native micro-bubble and / or suspended particle motion collected in turbid environments such as lake circulation, riverine, estuarine, and coastal flows, as well as turbid flows that occur near dredging operations.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Dual-frequency integrated ultrasonic transducer based on piezoelectric composite film

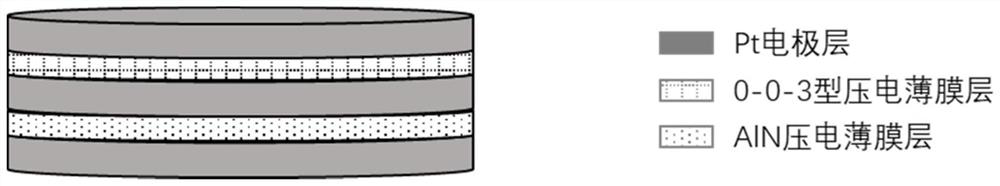

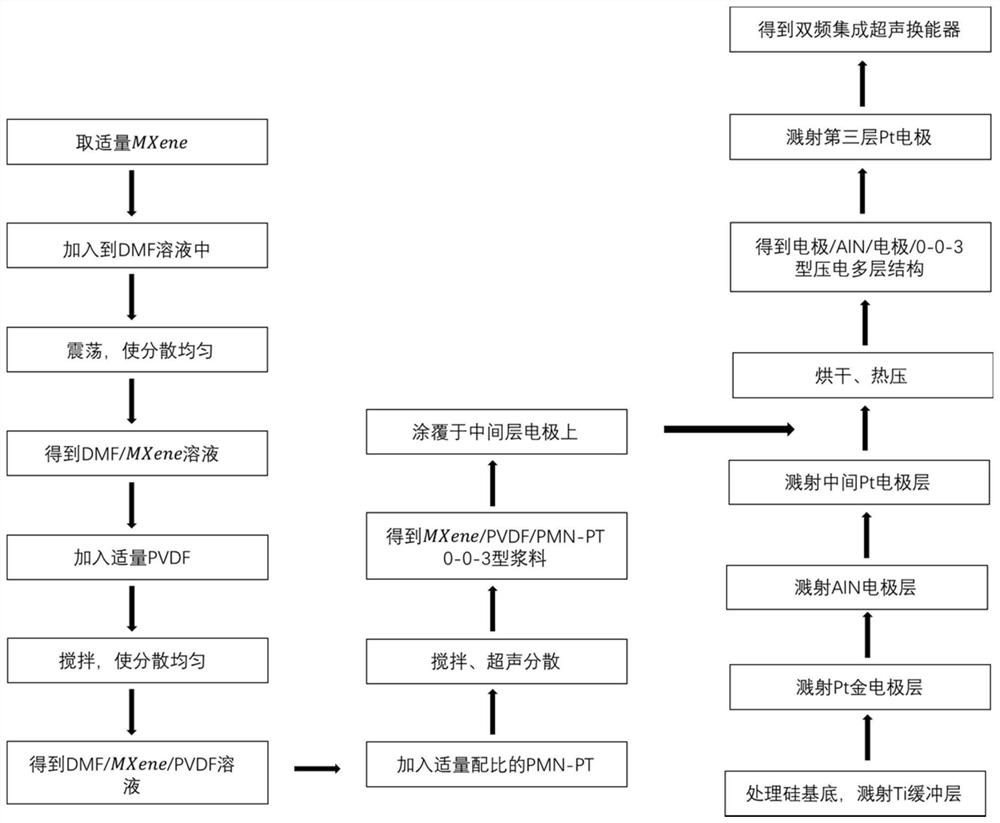

PendingCN113594352ARaise Alignment OrientationImprove piezoelectric performancePiezoelectric/electrostrictive device material selectionMechanical vibrations separationUltrasonic sensorImage resolution

The invention discloses a dual-frequency integrated ultrasonic transducer based on a piezoelectric composite film. The basic structure is a multi-layer structure of a 0-0-3 type piezoelectric composite film (a high-frequency piezoelectric composite film), an AlN piezoelectric film (an ultrahigh-frequency piezoelectric film) and three layers of electrodes. The structure comprises a metal upper electrode layer, the 0-0-3 type piezoelectric composite film, a middle metal electrode layer, an AlN piezoelectric film layer, a lower electrode layer and the like from top to bottom. The frequency range of the 0-0-3 type piezoelectric composite film layer ultrasonic transducer is dozens of MHz to hundreds of MHz, and the frequency range of the AlN layer ultrasonic transducer is GHz so that through the design of the dual-frequency integrated ultrasonic transducer, the frequency and resolution use requirements of different scenes can be met by switching different transducer layers, therefore, the frequency application range of the ultrasonic transducer is widened, and the transducer has multiple purposes.

Owner:ZHEJIANG LAB

Nanometer cellulose/polyvinyl alcohol gel composite material

ActiveCN102786642BLarge specific surface areaHigh porosityChemical industryChemical industryPolyvinyl alcohol

The invention relates to a nanometer cellulose / polyvinyl alcohol gel composite material, which is characterized by comprising hydrogel and aerogel. A preparation method of the nanometer cellulose / polyvinyl alcohol gel composite material comprises the following process steps of 1, nanometer cellulose preparation by a chemical combination mechanical treatment method; 2, composite hydrogel preparation; and 3, composite aerogel preparation. The nanometer cellulose / polyvinyl alcohol gel composite material has the advantages that the composite aerogel belongs to a porous amorphous solid material consisting of nanometer level colloid particles or high-polymer molecules, and a unique open nanometer level porous structure and a continuous three-dimensional reticular structure are adopted, so the density is extremely low, the specific surface area is high, and the porosity is high, wherein the solid phase of the aerogel accounts for 0.2 percent to 20 percent of the total volume percentage, the characteristics of high adsorption catalytic capability, low thermal conductivity, low sound resistance, low refractive index and the like are shown, and wide application prospects are realized in the fields of aviation, spaceflight, chemical industry, metallurgy, energy-saving building and the like.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com