Preparation method of composite piezoelectric material based on PVDF-TrFE

A technology of piezoelectric materials and piezoelectric ceramics is applied in the preparation of composite piezoelectric materials and the preparation of new piezoelectric composite materials, which can solve the problem of acoustic impedance ultrasonic loss, low piezoelectric strain constant and electromechanical coupling coefficient, and low acoustic impedance and other problems, to achieve the effect of improving performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

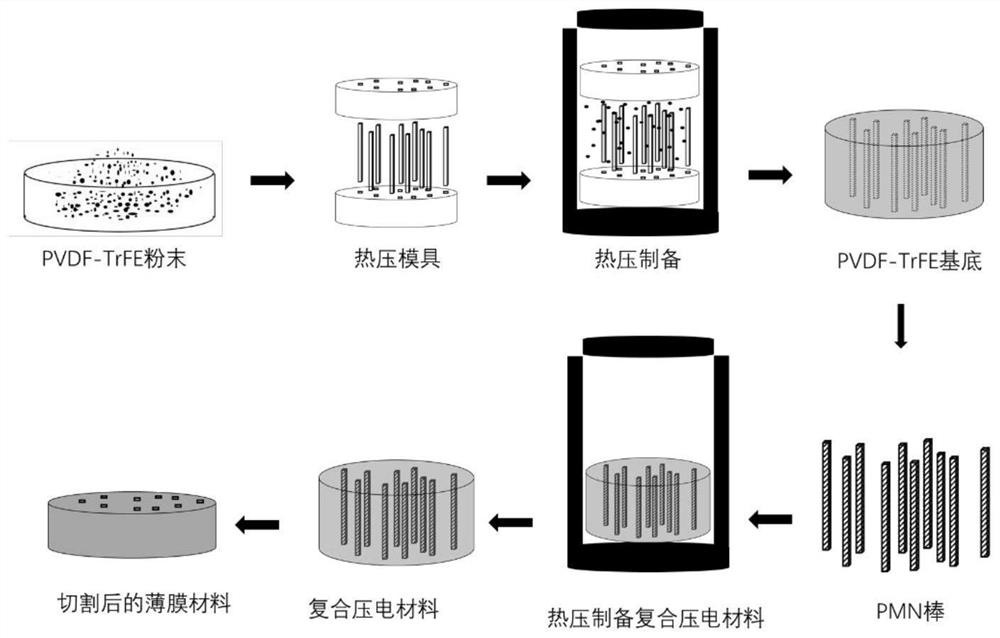

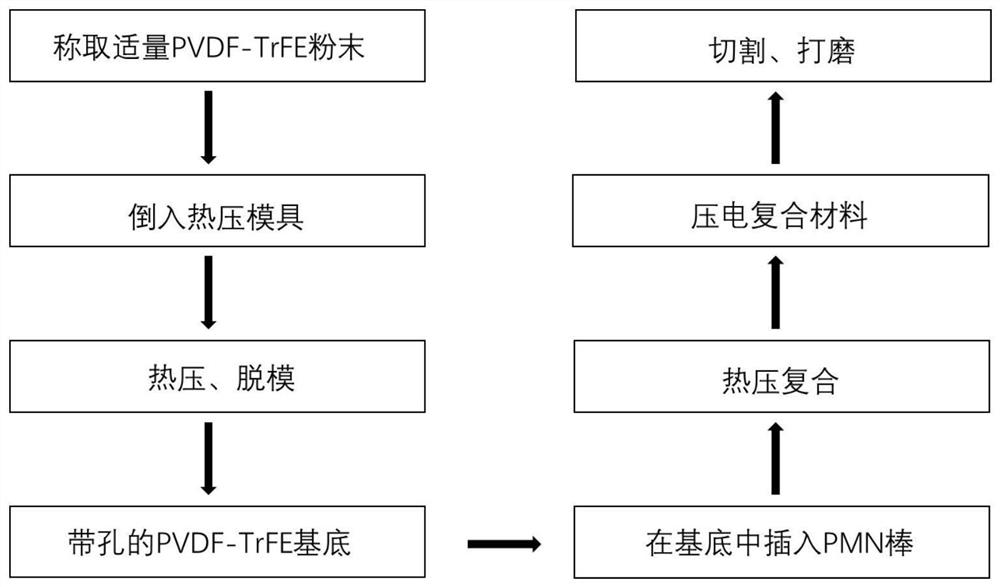

[0026] For details, see figure 1 , an embodiment of the present invention provides a schematic diagram of a method for preparing a type 1-3 piezoelectric composite material.

[0027] A method for preparing a composite piezoelectric material is provided in this embodiment, comprising the following steps:

[0028] 1). Weigh an appropriate amount of polymer PVDF-TrFE powder, the powder quality can be determined according to the demand and the size of the mold.

[0029] 2).Will figure 1 The 9-hole mold liner is put into a tableting mold with a suitable diameter, and the diameter can be 10 in one embodiment, and then the weighed polymer powder is poured into the hot-pressing mold.

[0030] 3). Put the mold poured into the polymer powder into the hot-pressing device, and carry out hot-pressing preparation under appropriate temperature, pressure and holding time. In one embodiment, the hot pressing preparation conditions may be 120-250° C., 1-10 MPa, and heating for 30-120 minutes...

Embodiment 2

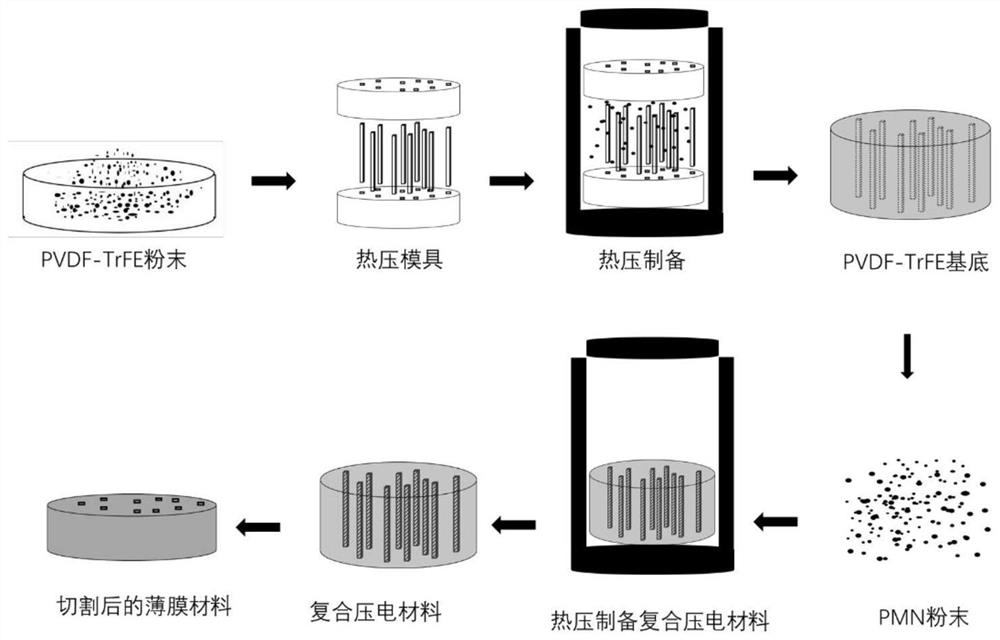

[0037] For details, see figure 2 , another embodiment of the present invention provides a schematic diagram of a method for preparing a type 1-3 piezoelectric composite material.

[0038] In another embodiment, a method for preparing a composite piezoelectric material is provided, comprising the following steps:

[0039] 1). Weigh an appropriate amount of polymer PVDF-TrFE powder, the powder quality can be determined according to the demand and the size of the mold.

[0040] 2).Will figure 2 The 9-hole die liner of the 1000 is placed into a tableting die of an appropriate diameter, which may be 10 in one embodiment. Then pour the weighed polymer powder into the hot pressing mold.

[0041] 3). Put the mold poured into the polymer powder into the hot-pressing device, and carry out hot-pressing preparation under appropriate temperature, pressure and holding time. In one embodiment, the hot pressing preparation conditions may be 120-250° C., 1-10 MPa, and heating for 30-120 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com