Patents

Literature

12603 results about "Hot press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct assembly process for fabrication of ionomeric polymer devices

InactiveUS20060266642A1Superior transduction performanceLarge strain generationEngine manufactureMachines/enginesPolymer scienceActuator

Ionomeric polymer sensors, actuators, and transducers and methods for fabricating them are disclosed. One embodiment of the sensors, actuators, and transducers possess a high surface area electrode layer that is applied by hot pressing and a highly conductive surface layer. Another embodiment of these sensors, actuators, and transducers possess a high surface area electrode layer that is penetrated by electronically conductive nanowires. Methods for fabricating these sensors, actuators, and transducers are disclosed. These methods involve the formation of the high surface area layer from a liquid mixture that contains ionomeric polymer, electronically conductive particles, and possibly diluent. This mixture is formed into layers either directly on an ionomeric polymer, on a separate transfer decal, or on an electronically conductive layer. This electronically conductive layer may also include an array of nanowires. These electrode layers are then attached to an ionomeric polymer membrane by hot pressing. The ionomeric polymer membrane may be swollen with a diluent either prior to the hot pressing or after the hot pressing step. Also, the ionomeric polymer membrane may be formed by casting from a liquid mixture containing ionomeric polymer and diluent.

Owner:VIRGINIA TECH INTPROP INC

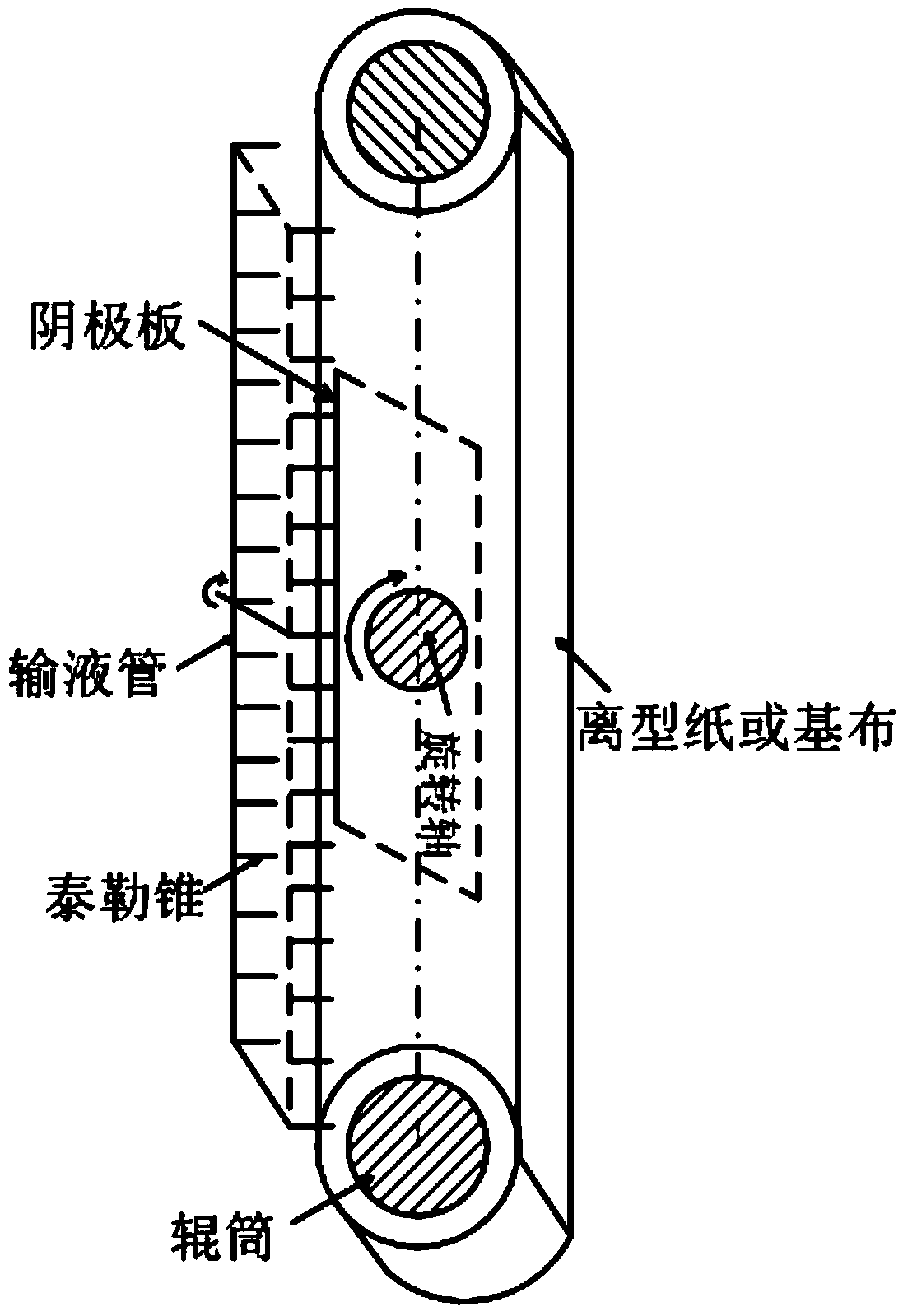

Electrostatic spinning nanofiber membrane as well as preparation method thereof

InactiveCN103437071AIncrease productivityReduce energy consumptionNon-woven fabricsChemical industryFiber

The invention provides an electrostatic spinning nanofiber membrane as well as a preparation method thereof. The electrostatic spinning nanofiber membrane provided by the invention comprises a fiber membrane obtained by electrostatically spinning a high-melting-point polymer and a fiber membrane obtained by electrostatically spinning a low-melting-point polymer, wherein the difference on the melting points of the high-melting-point polymer and the low-melting-point polymer is not less than 10 DEG C. The electrostatic spinning nanofiber membrane provided by the invention is multipurpose and can be applied to the fields such as biomedicines, energy and chemical industry, gas and liquid filtration, waterproofness and windproofness, windproofness and heat insulation, moisture permeability and ventilation, environmental management and semiconductor sensors. According to the electrostatic spinning nanofiber membrane provided by the invention, electrostatic spinning is respectively carried out on the high-melting-point polymer and the low-melting-point polymer, and the high-melting-point polymer fiber membrane and the low-melting-point polymer fiber membrane obtained are composited and hot-pressed to obtain the electrostatic spinning nanofiber membrane. The preparation method provided by the invention is high in production efficiency and low in energy consumption, and is suitable for industrial production.

Owner:ZHEJIANG WEIXING IND DEV

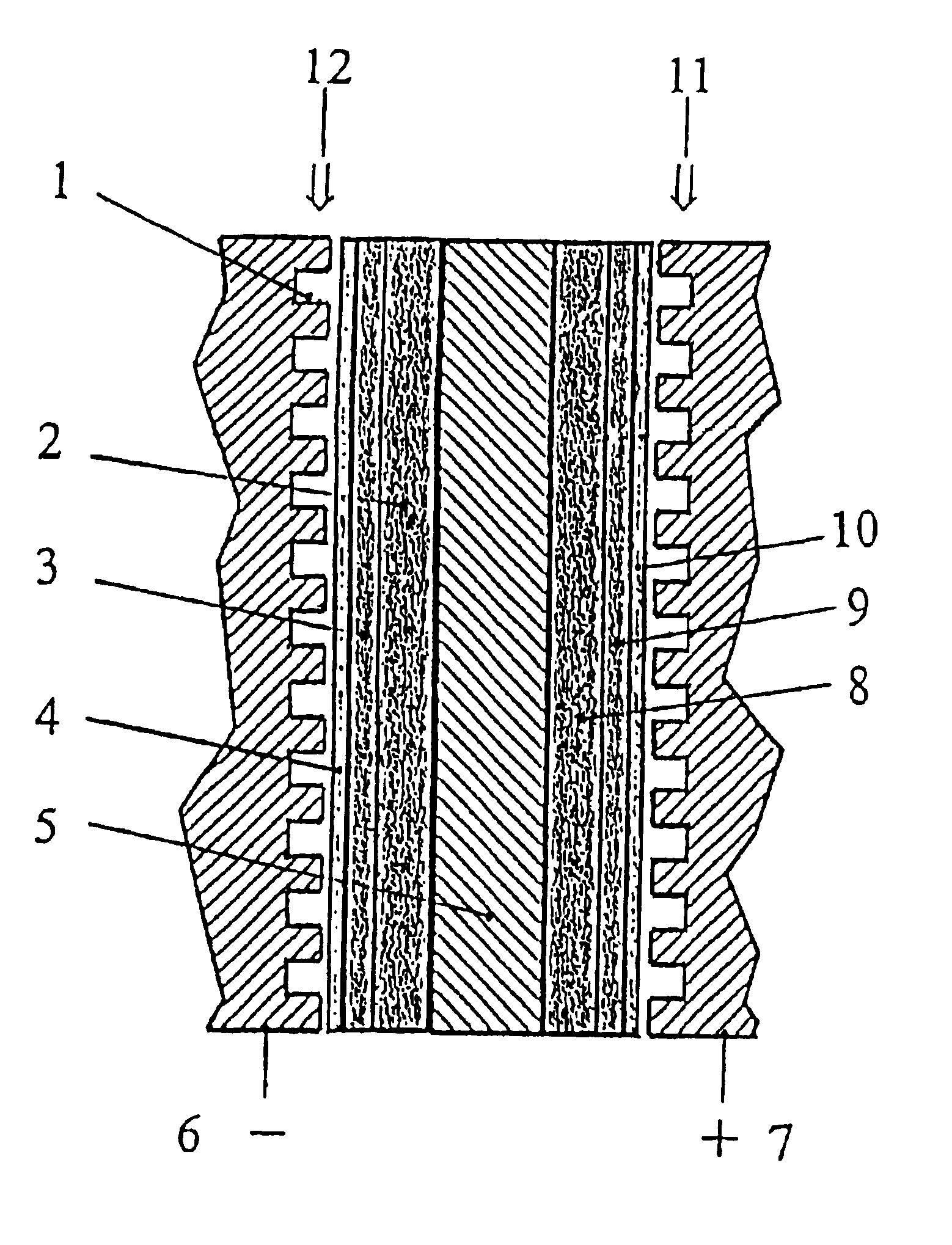

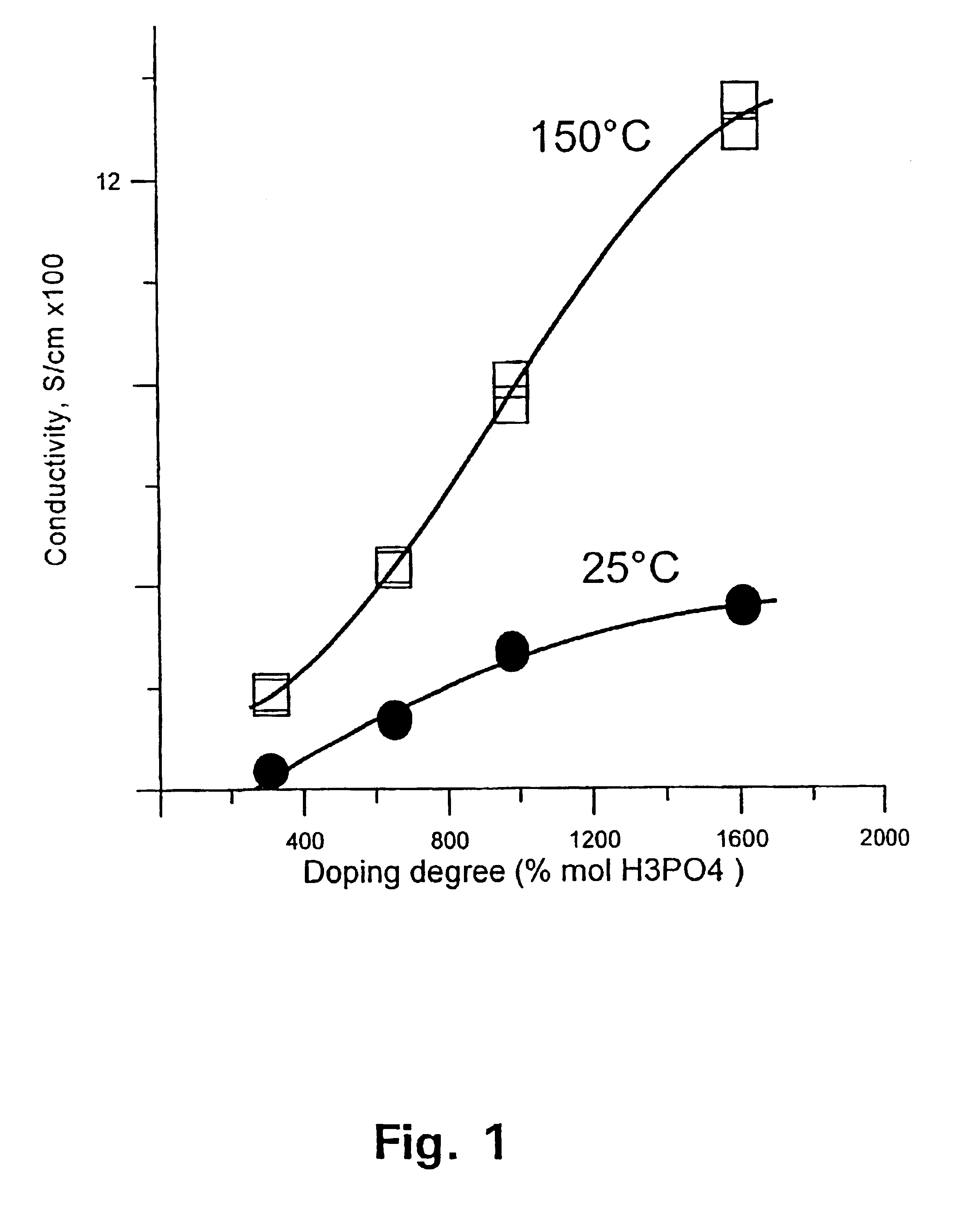

Polymer electrolyte membrane fuel cells

InactiveUS6946211B1Improve performanceImprove toleranceSolid electrolytesPrimary cellsThermoplasticGas diffusion electrode

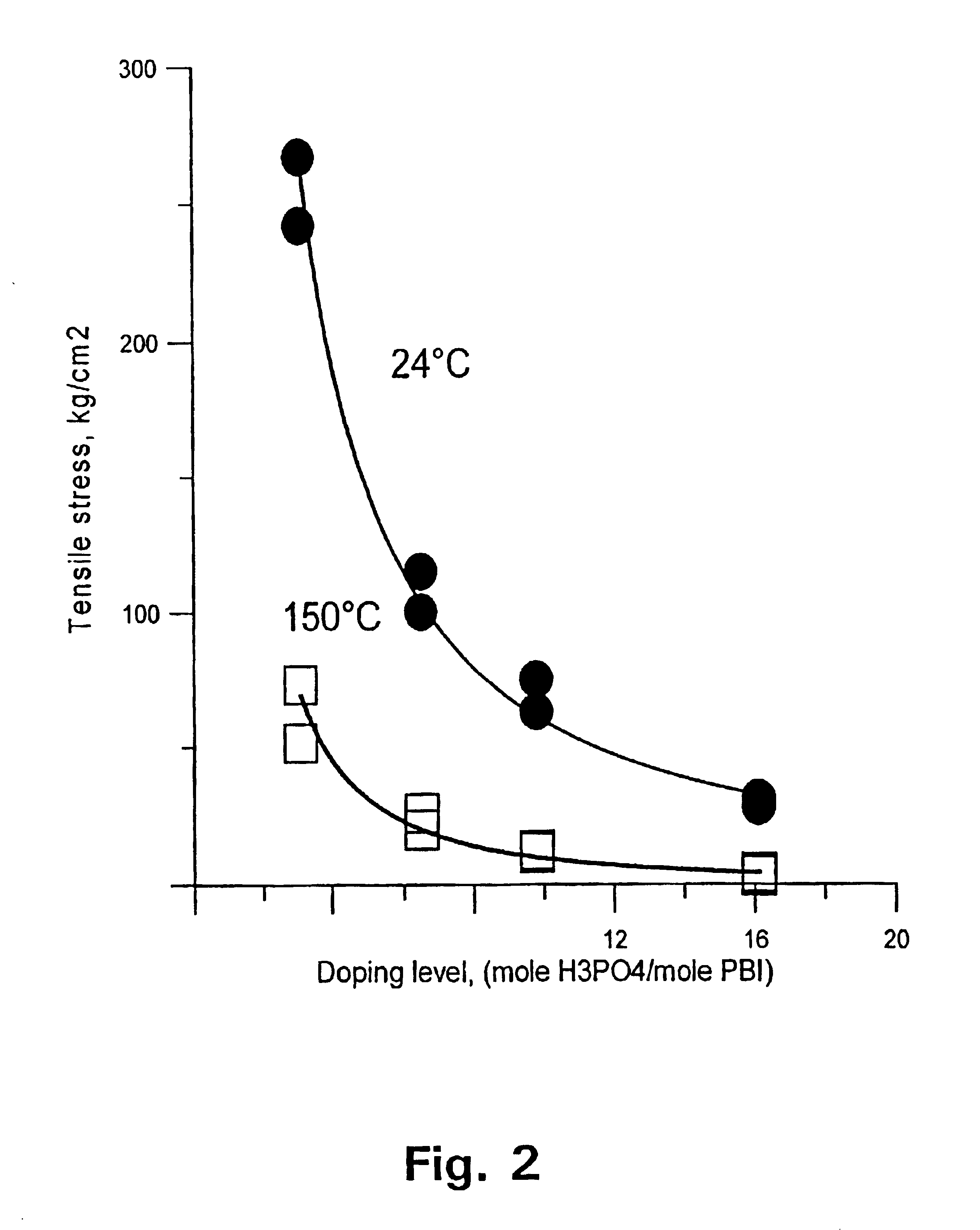

A method for preparing polybenzimidazole or polybenzimidazole blend membranes and fabricating gas diffusion electrodes and membrane-electrode assemblies is provided for a high temperature polymer electrolyte membrane fuel cell. Blend polymer electrolyte membranes based on PBI and various thermoplastc polymers for high temperature polymer electrolyte fuel cells have also been developed. Miscible blends are used for solution casting of polymer membranes (solid electrolytes). High conductivity and enhanced mechanical strength were obtained for the blend polymer solid electrolytes. With the thermally resistant polymer, e.g., polybenzimidazole or a mixture of polybenzimidazole and other thermoplastics as binder, the carbon-supported noble metal catalyst is tape-cast onto a hydrophobic supporting substrate. When doped with an acid mixture, electrodes are assembled with an acid doped solid electrolyte membrane by hot-press. The fuel cell can operate at temperatures up to at least 200° C. with hydrogen-rich fuel containing high ratios of carbon monoxide such as 3 vol % carbon monoxide or more, compared to the carbon monoxide tolerance of 10-20 ppm level for Nafion®-based polymer electrolyte fuel cells.

Owner:DANISH POWER SYST

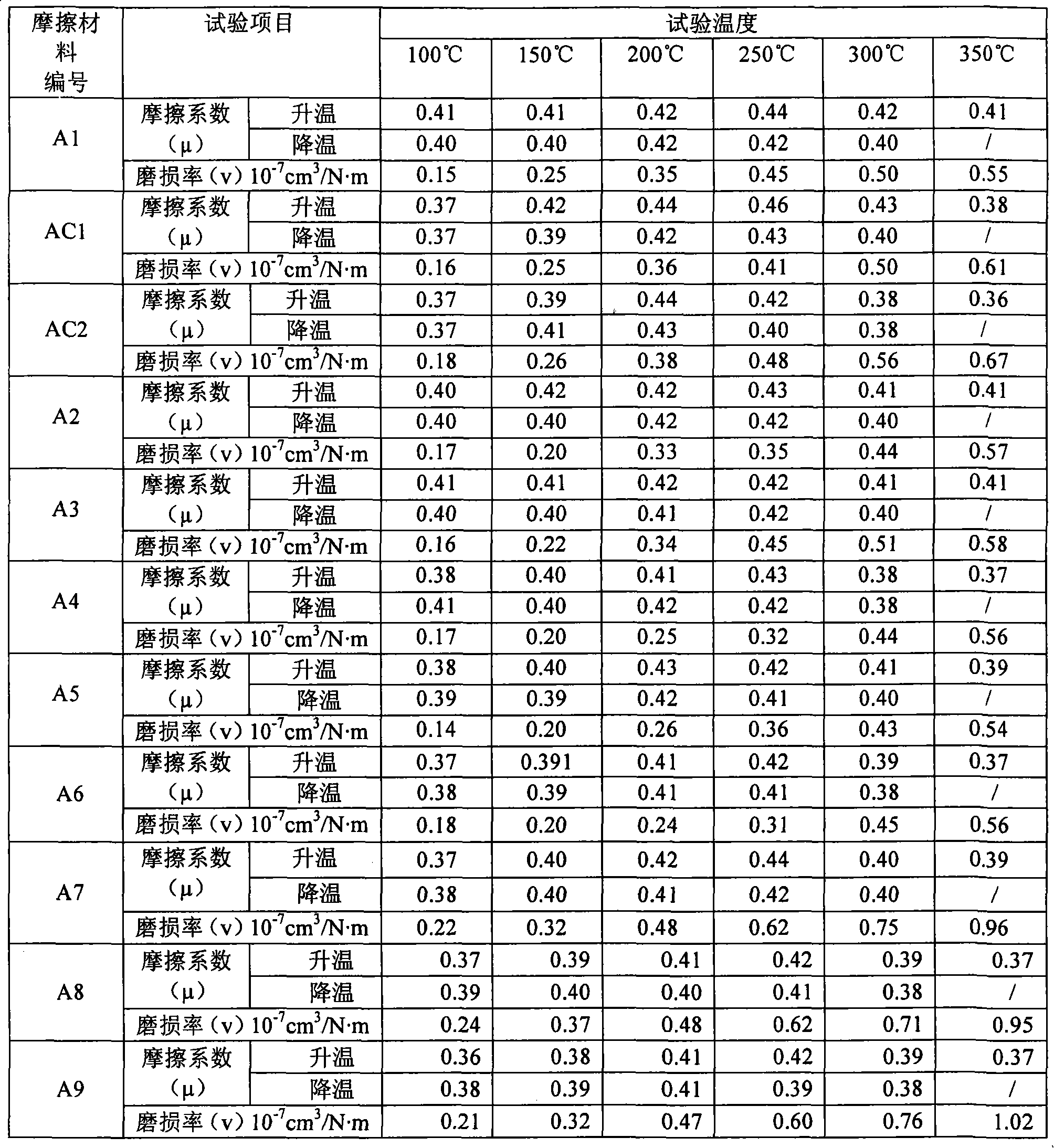

Environment-protection type high-performance automobile braking piece and making method

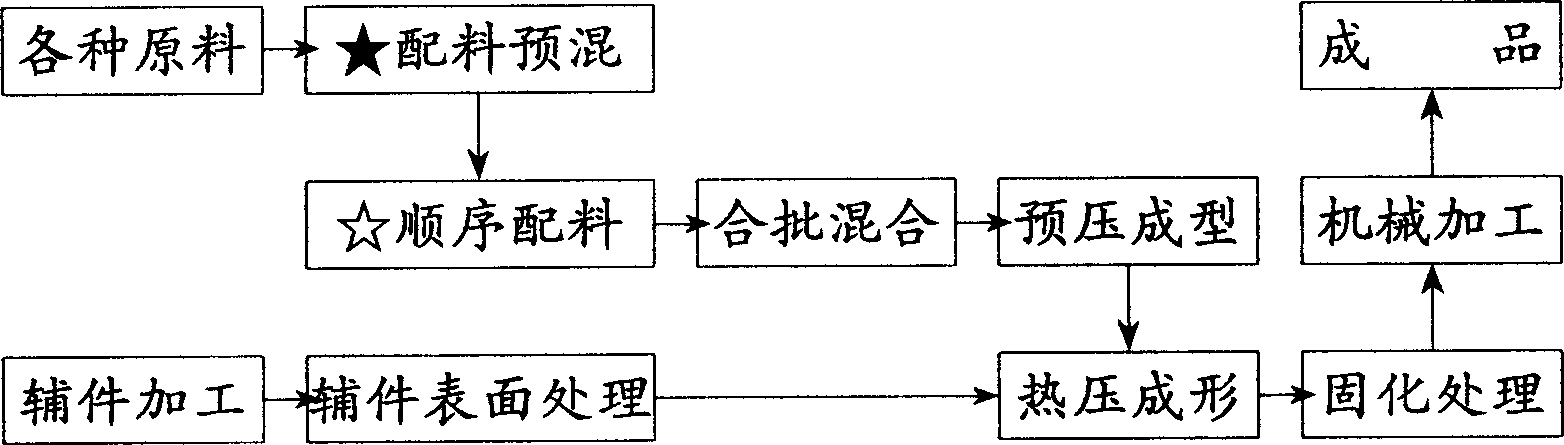

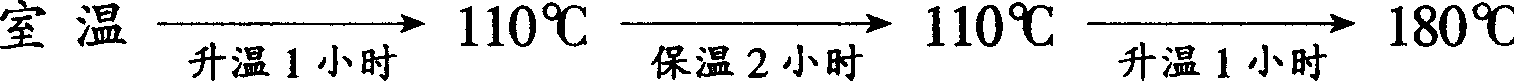

InactiveCN1814657AIncrease frictionOvercoming high temperature recession defectsFriction liningFiberAdhesive

This invention relates to a preparation technology for producing special products with plastic substances characterizing in mixing an adhesive agent, strengthened fibers, a regulator for friction performance and inorganic fillers in good match to process the surfaces of them with an anti-high temperature coupler to be hot-pressed to a format to get a high performance car brake plate of environmental protection, which replaces that made of asbestos fiber and overcomes the shortcoming of declining at high temperature of the asbestos car brake plates.

Owner:CENT SOUTH UNIV +1

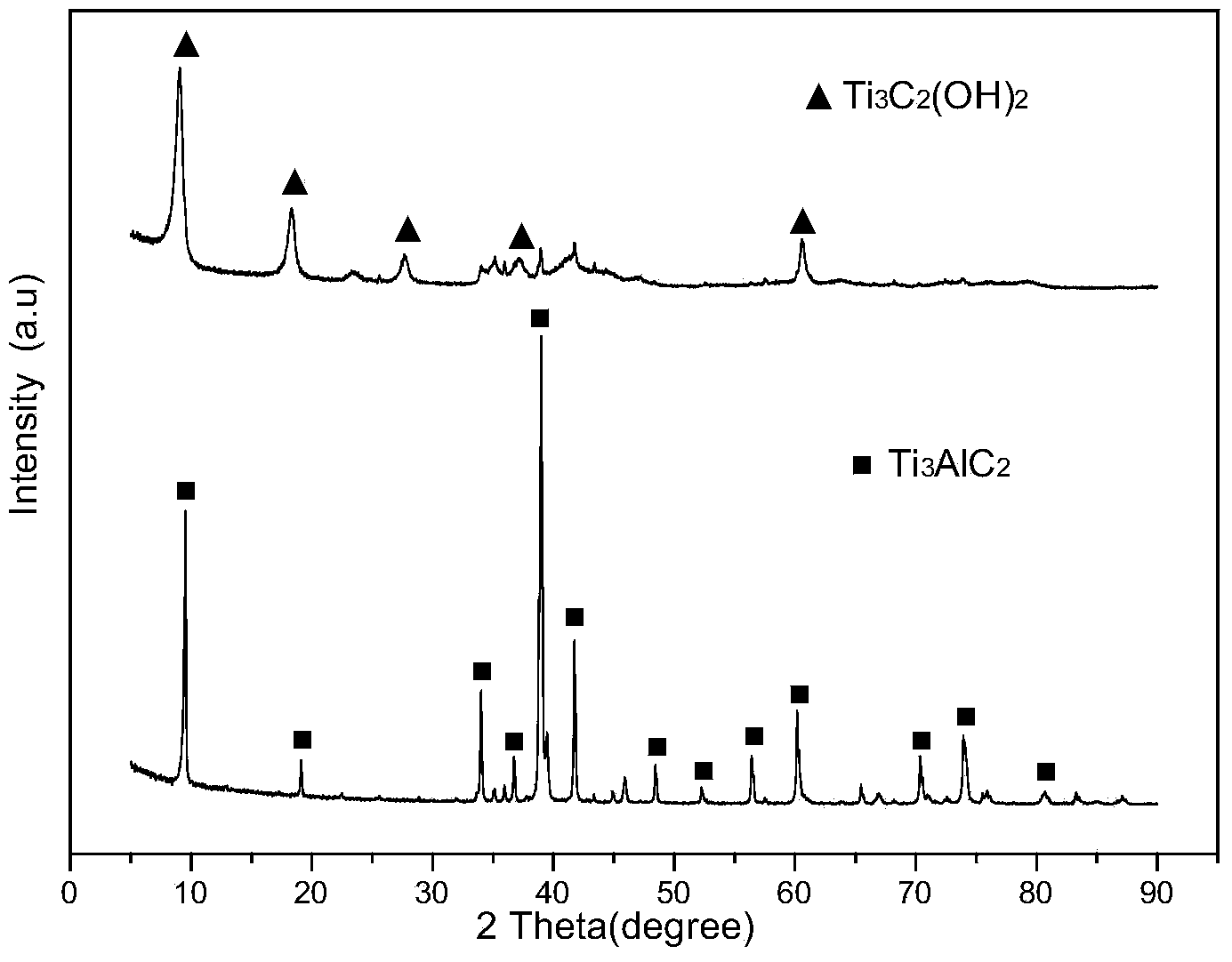

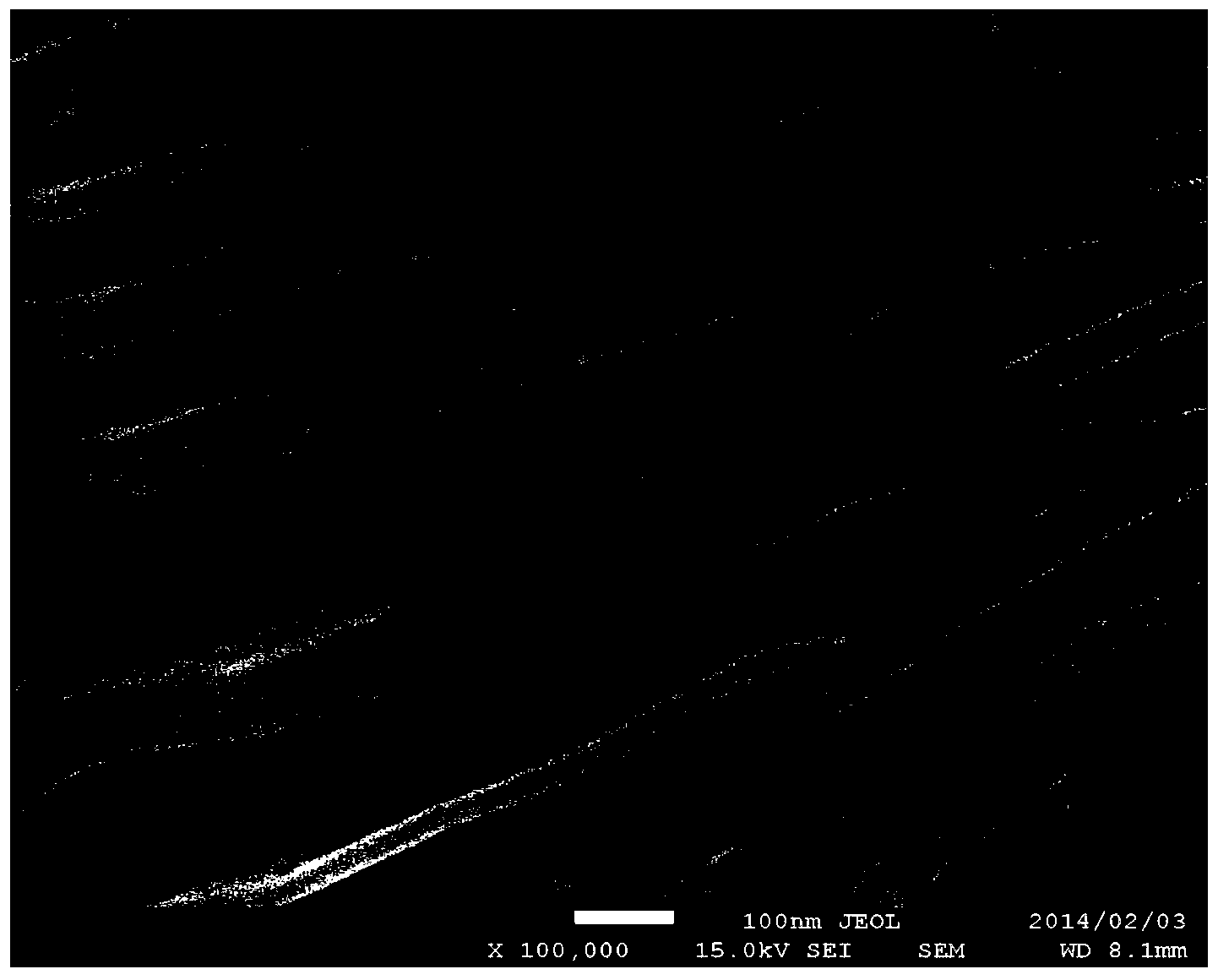

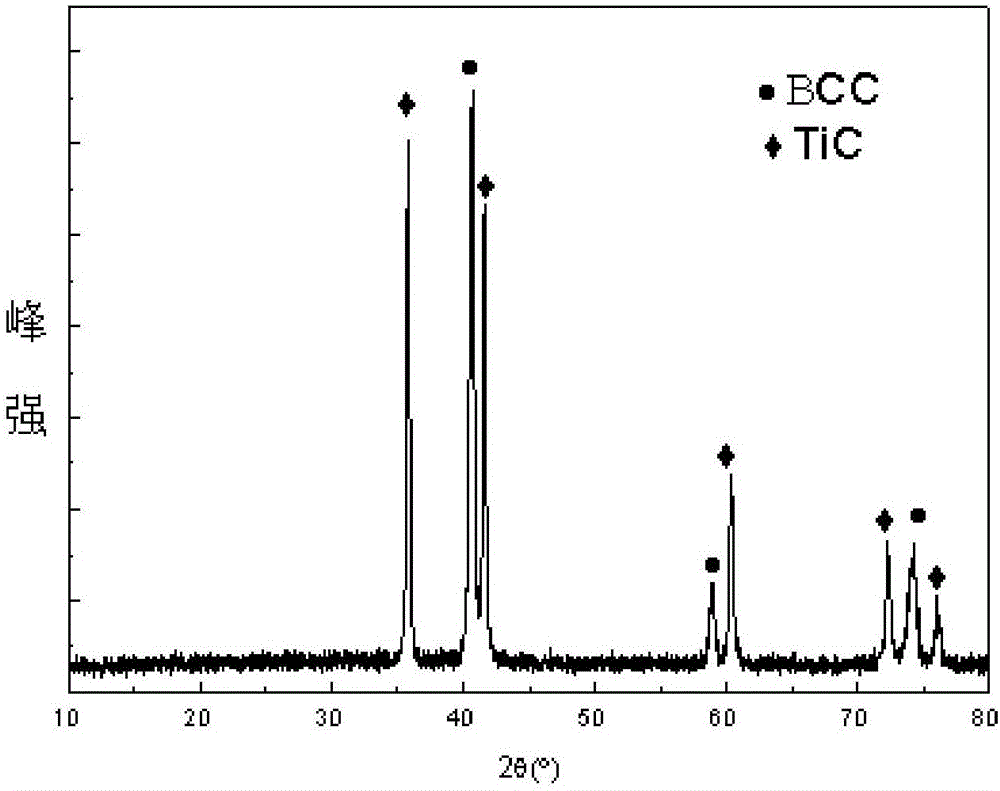

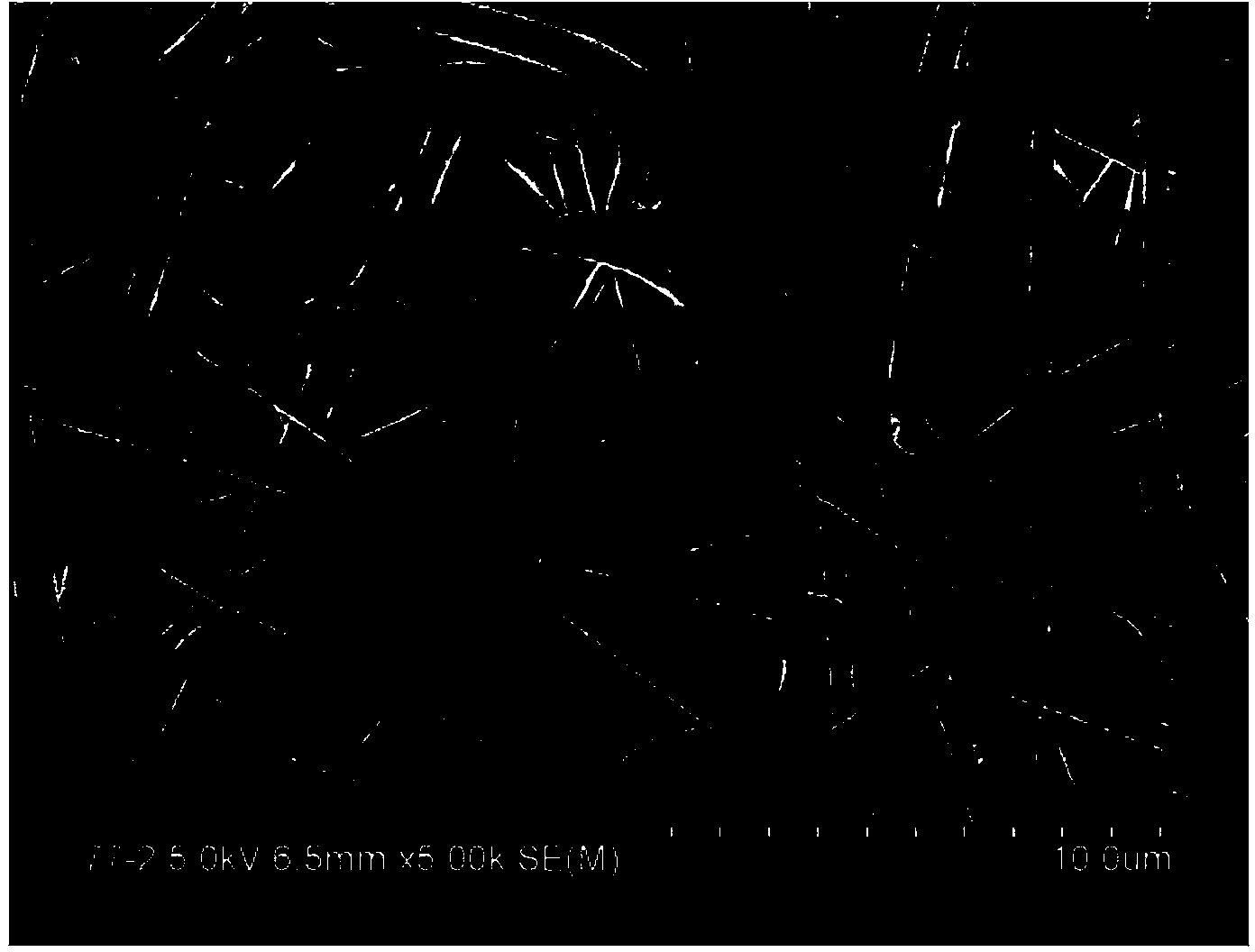

Method for preparing graphene-like two-dimensional laminar titanium carbide nanoplate

InactiveCN104016345AHigh purityHigh crystallinityMaterial nanotechnologyTitanium carbideSem micrographsCrystallinity

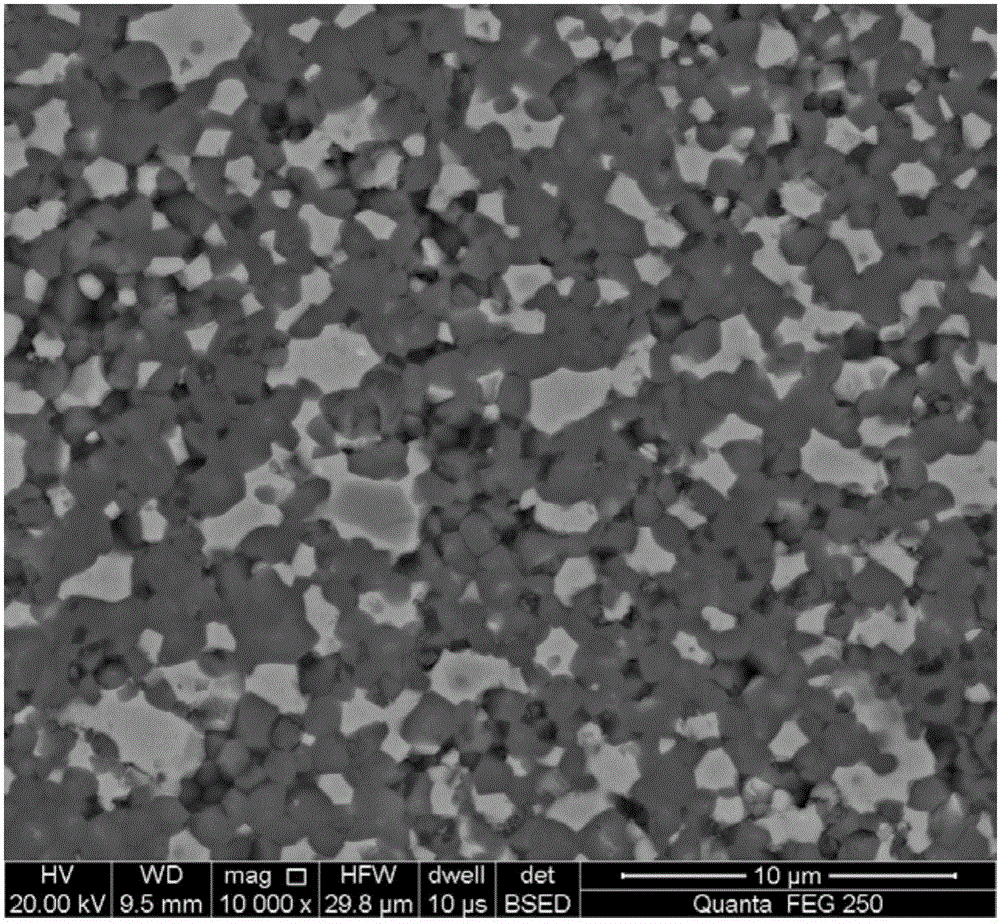

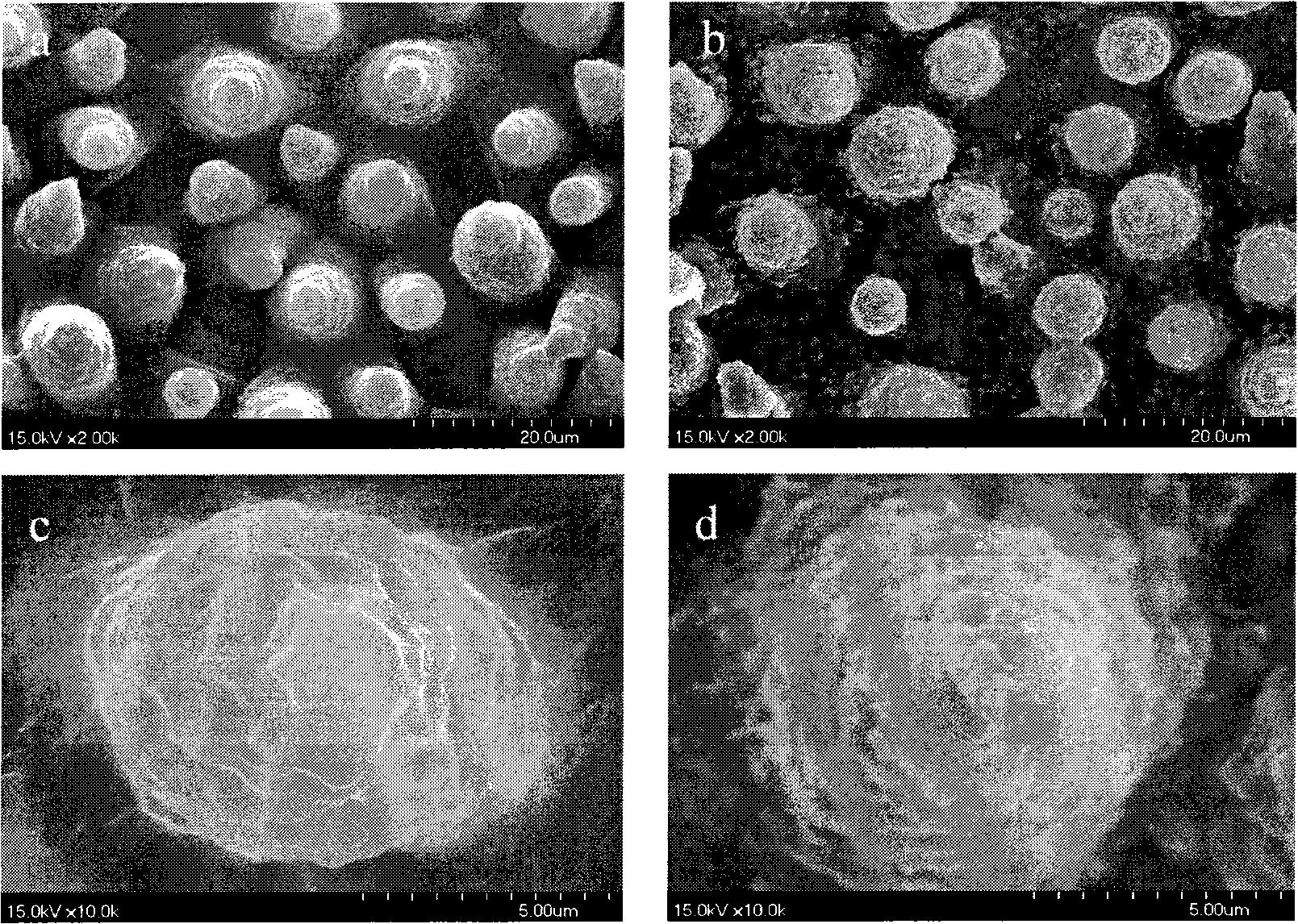

The invention discloses a method for preparing a graphene-like two-dimensional laminar titanium carbide nanoplate. The method comprises the following steps: preparing Ti3AlC2 powder by an in-situ hot-pressing solid-liquid reaction; preparing two-dimensional titanium carbide by a chemical liquid phase reaction; performing vacuum calcination post-treatment, and the like. The method can be used for preparing a Ti3AlC2 precursor with excellent crystallinity and high purity under simple process flow, stable process parameters, controllable process, high efficiency, low cost, short time and low pressure; the information that the transverse size of the two dimensional Ti3AlC2 nanoplate prepared by the method can be 5-10 microns, the average thickness of a single layer is about 10-20 nanometers can be found from an SEM picture, the inter-laminar spacing is remarkably enlarged after calcination treatment, and the laminar surface is regular and smooth.

Owner:HOHAI UNIV

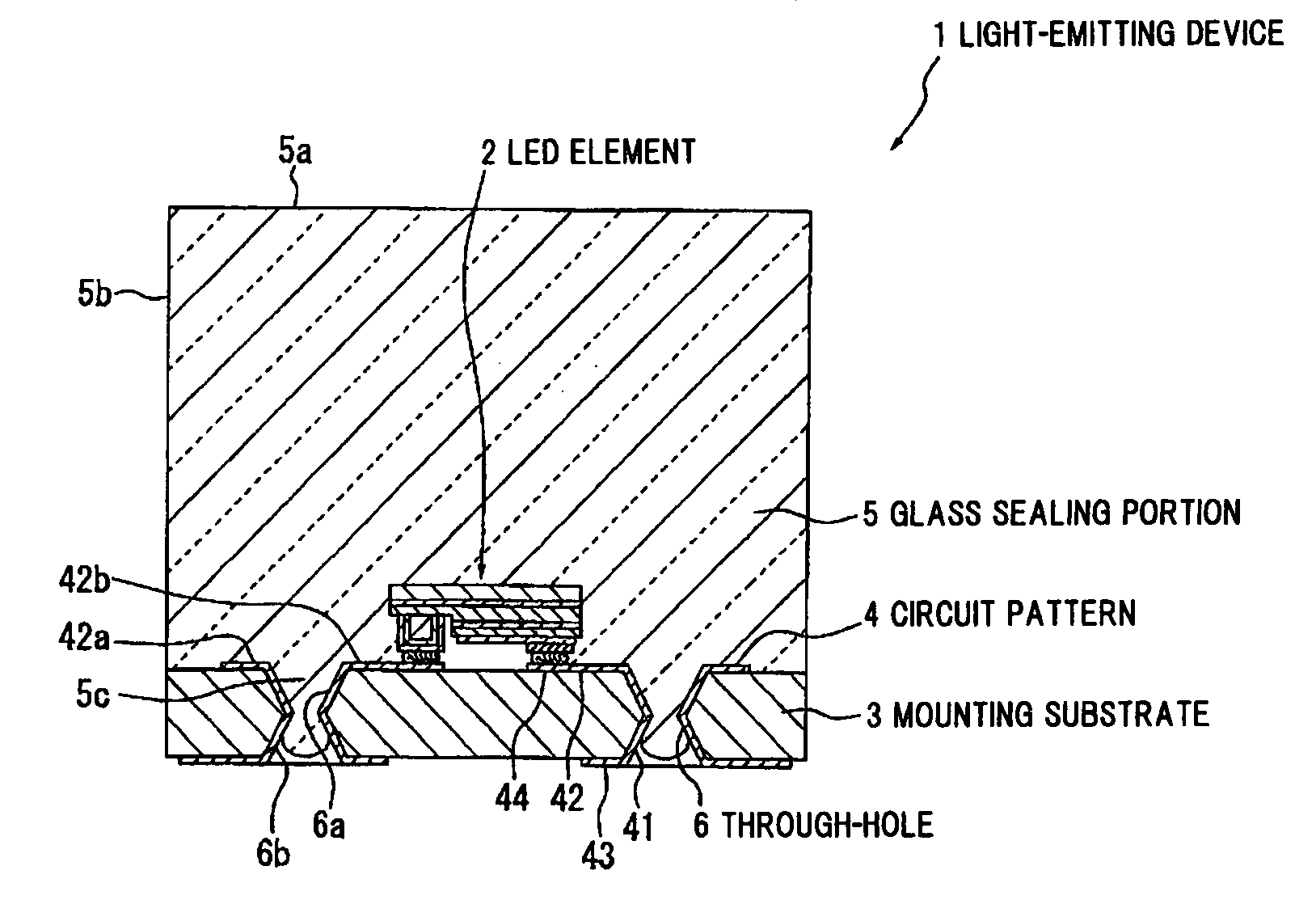

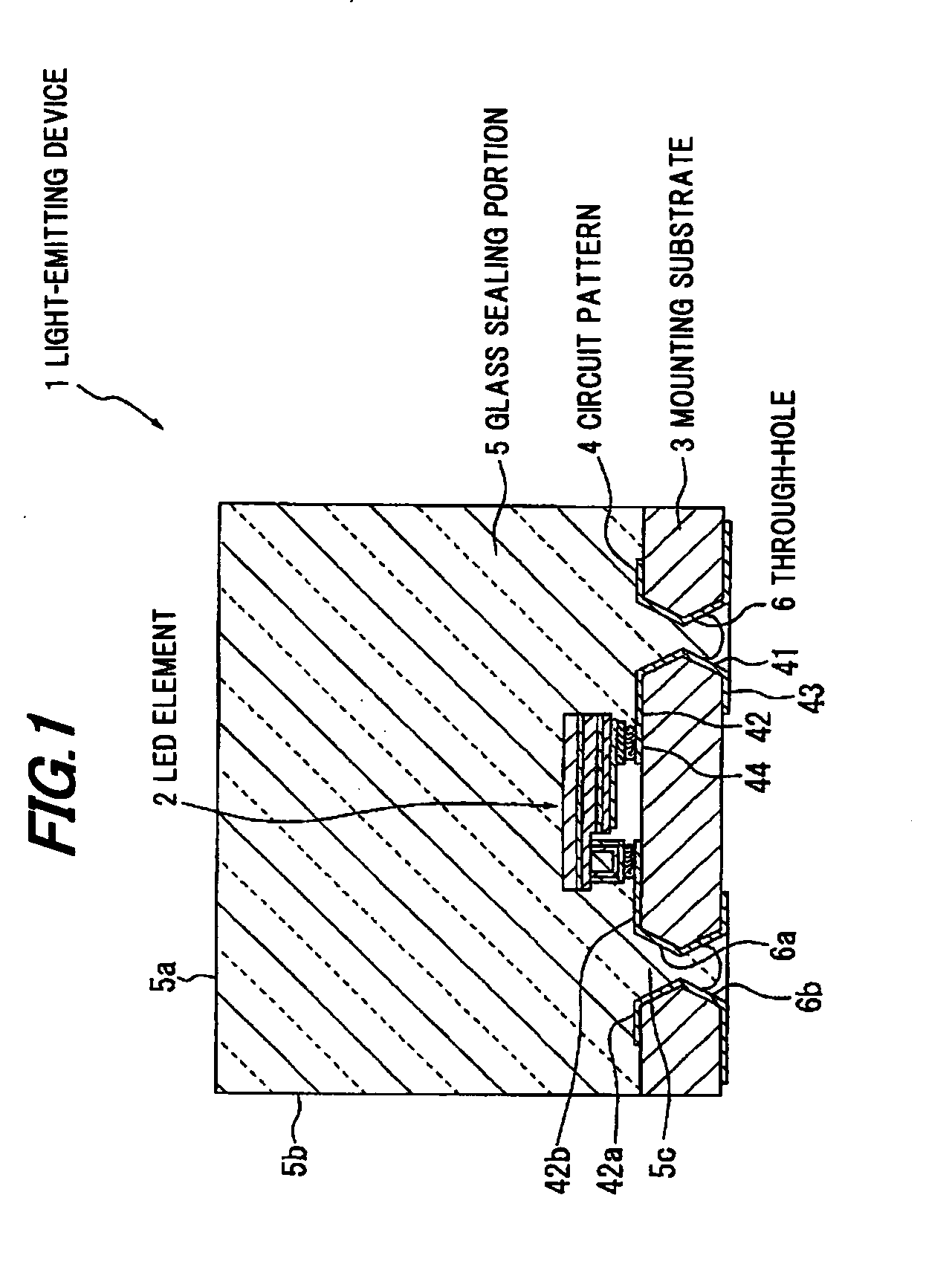

Light-emitting device, method of manufacturing the same, method of mounting the same and lighting device

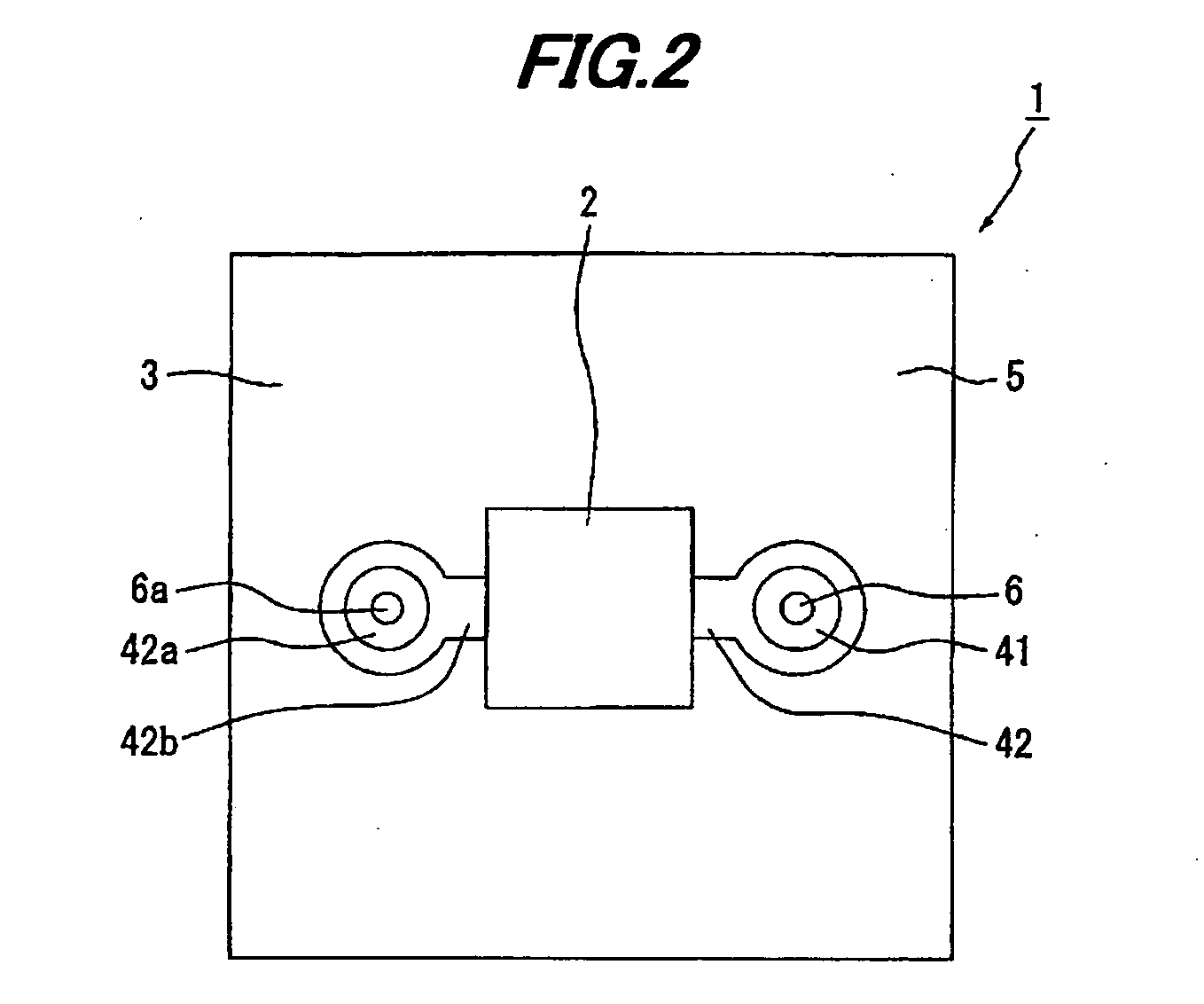

ActiveUS20110114989A1Improve reliabilityFix tightSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringInorganic materials

A method of manufacturing a light-emitting device includes a hole forming process for forming a through-hole that continues from a front surface to a back surface of a mounting substrate, a pattern forming process for continuously forming a circuit pattern on an inner surface of the through-hole in the mounting substrate, from an end portion of the through-hole on the front surface of the mounting substrate to a mounting portion of a light-emitting element, and on a periphery of the through-hole on the back surface of the mounting substrate, a mounting process for mounting the light-emitting element on the mounting portion, and a hot pressing process in that an inorganic material softened by heating is placed on the surface of the mounting substrate and is advanced into the through-hole while sealing the light-emitting element by pressing and bonding the inorganic material to the surface of the mounting substrate.

Owner:TOYODA GOSEI CO LTD

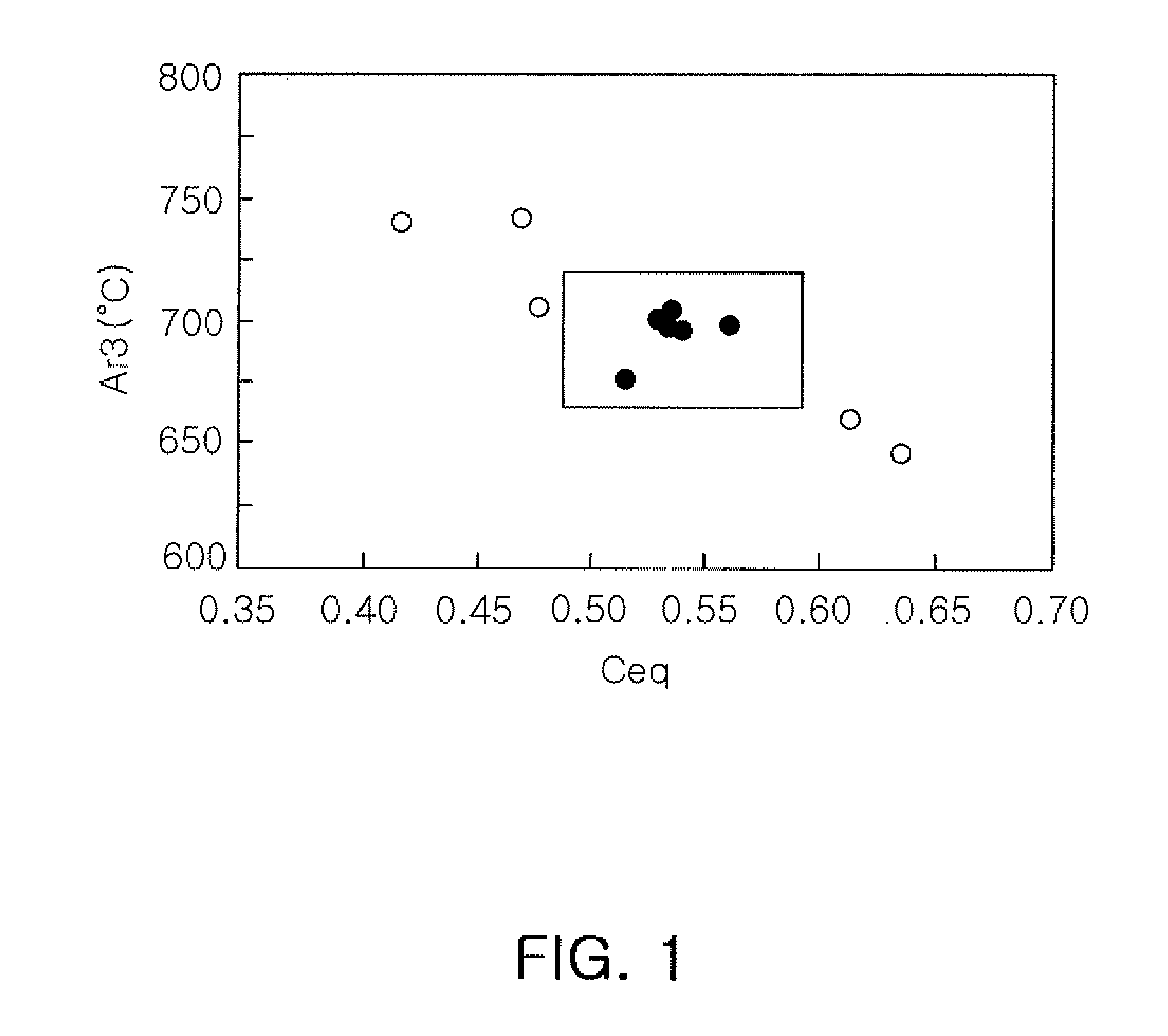

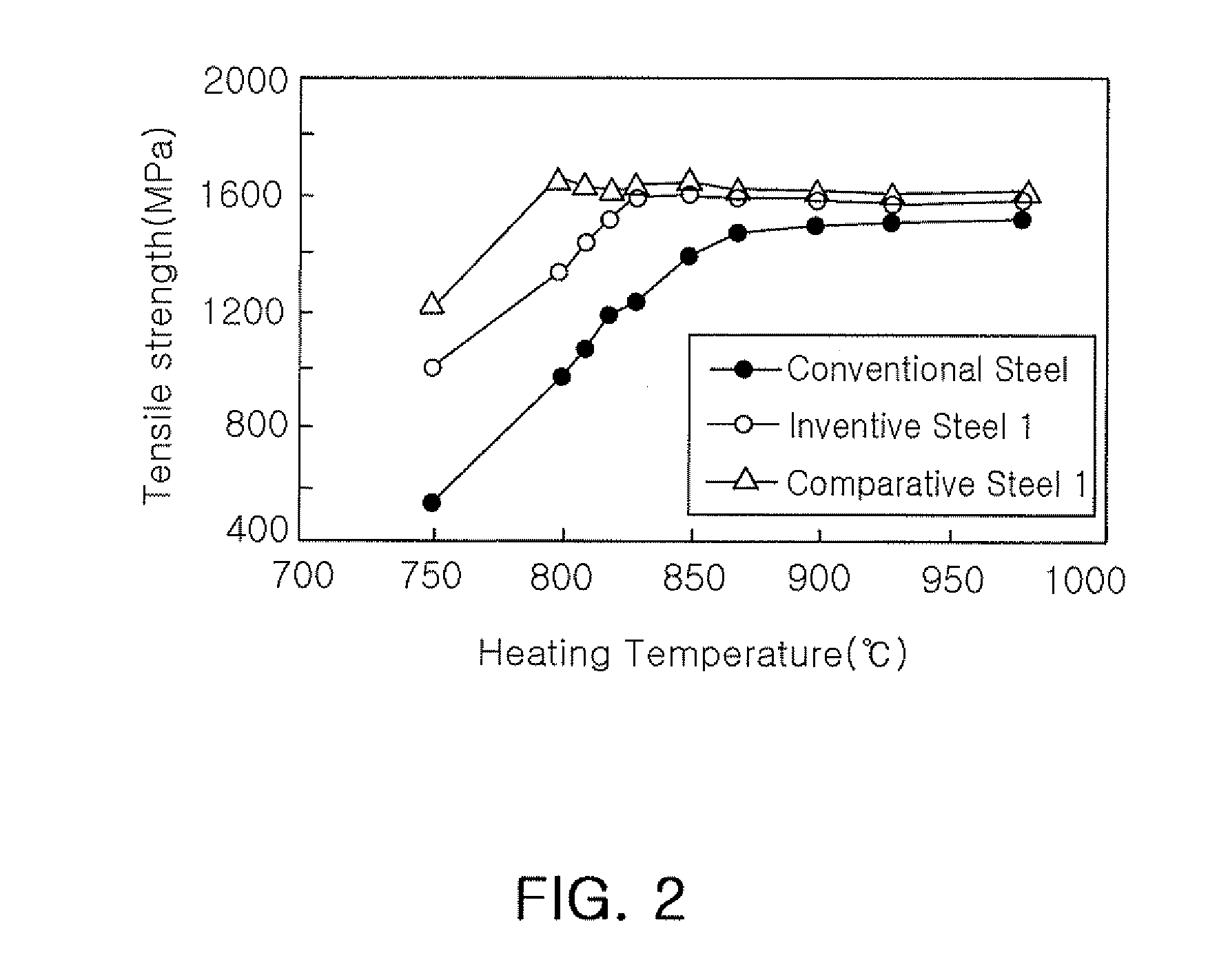

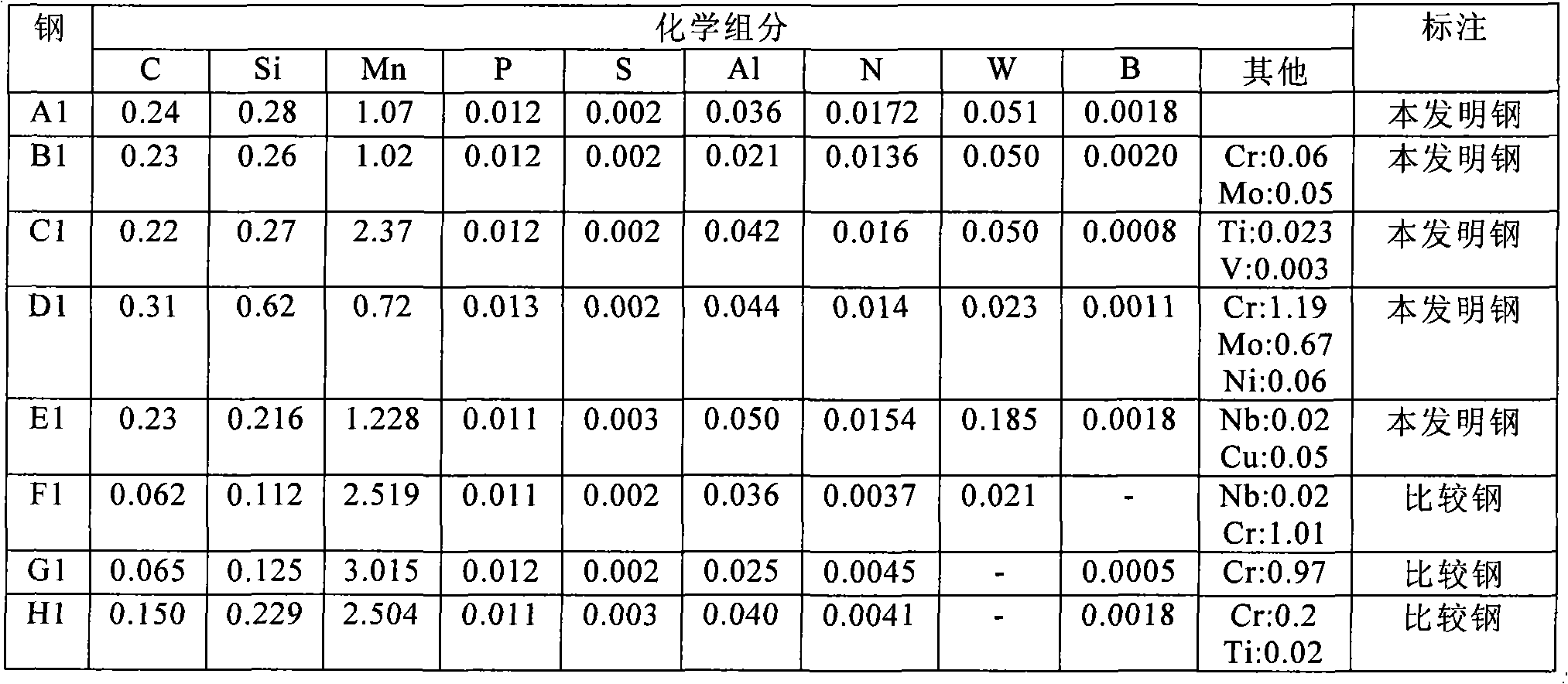

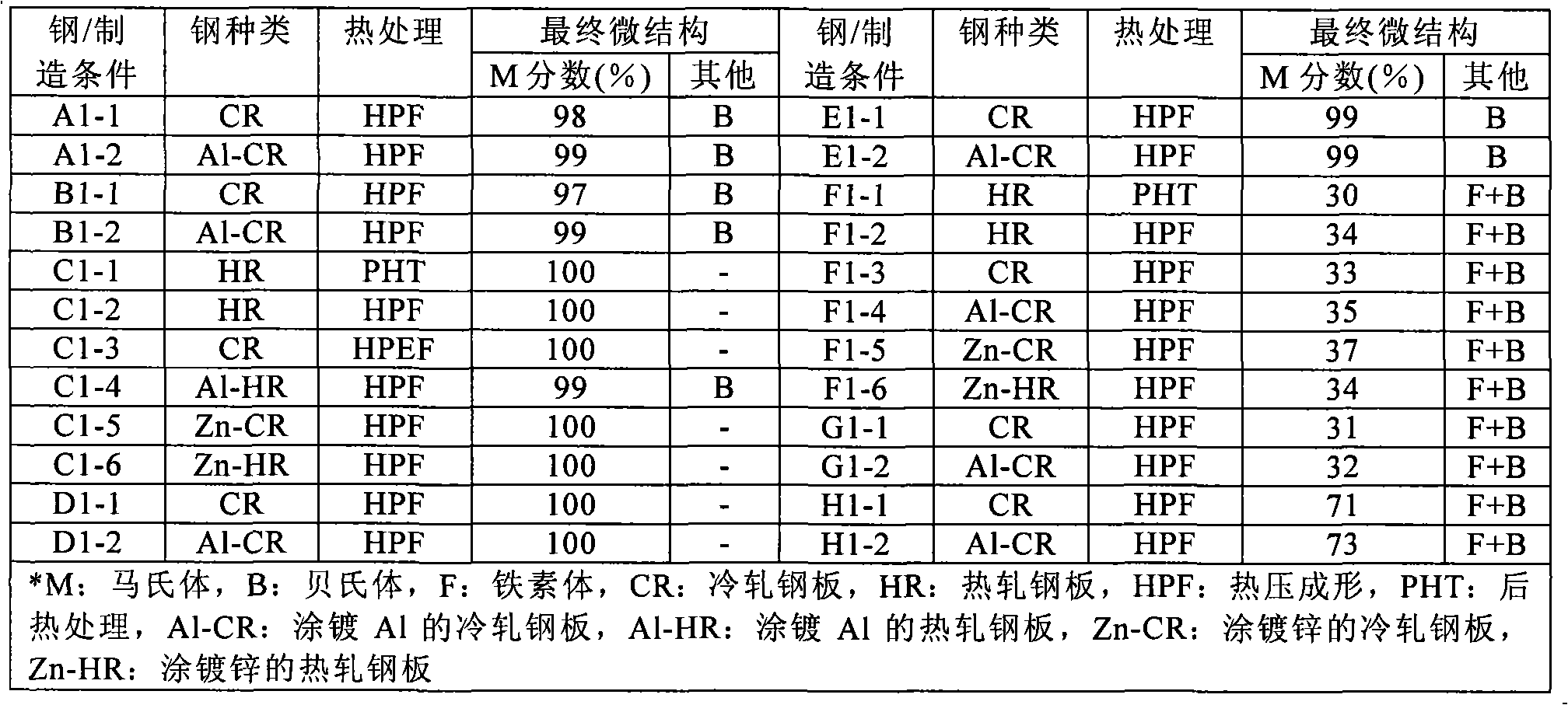

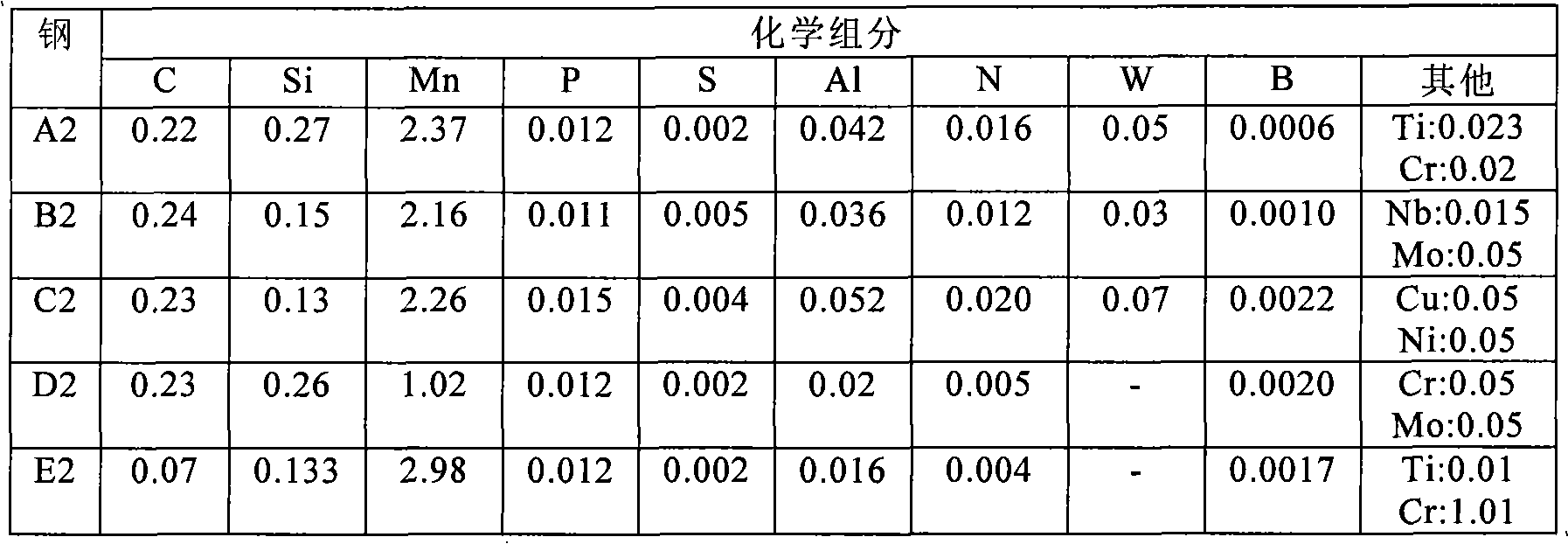

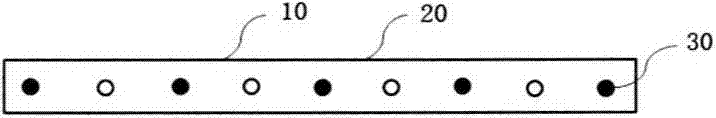

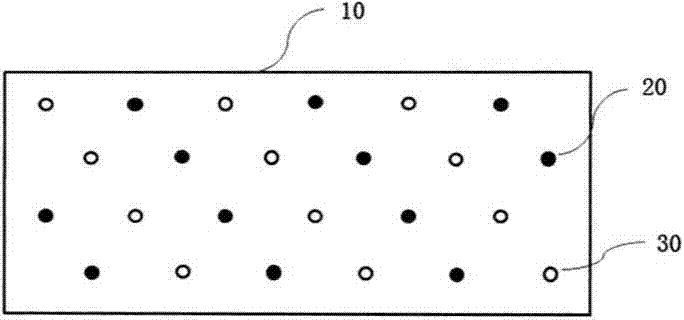

Steel sheet for hot press forming having low-temperature heat treatment property, method of manufacturing the same, method of manufacturing parts using the same, and parts manufactured by the same

ActiveUS20090238715A1Reduced strengthHigh yield strengthMetal rolling stand detailsFurnace typesManganeseHeat treated

A steel sheet for forming having low-temperature heat treatment property, in which heat treatment is performed within a range of lower temperature than a conventional steel sheet in the event of hot press forming or post-heat treatment after cold forming, a method of manufacturing the same, and a method of manufacturing parts using the same. The steel sheet has a composition of, by weight, carbon (C): 0.15 to 0.35%, silicon (Si): 0.5% or less, manganese (Mn): 1.5 to 2.2%, phosphorus (P): 0.025% or less, sulfur (S): 0.01% or less, aluminum (Al): 0.01 to 0.05%, nitrogen (N): 50 to 200 ppm, titanium (Ti): 0.005 to 0.05%, tungsten (W): 0.005 to 0.1%, and boron (B): 1 to 50 ppm, wherein Ti / N: less than 3.4, where Ti / N is the atomic ratio of the corresponding elements, Ceq expressed by the following formula ranges from 0.48 to 0.58, and temperature Ar3 ranges from 670° C. to 725° C. Wherein Ceq=C+Si / 24+Mn / 6+Ni / 40+Cr / 5+V / 14 where C, Si, Mn, Ni, Cr and V indicate the contents (wt %) of the respective elements.

Owner:POHANG IRON & STEEL CO LTD

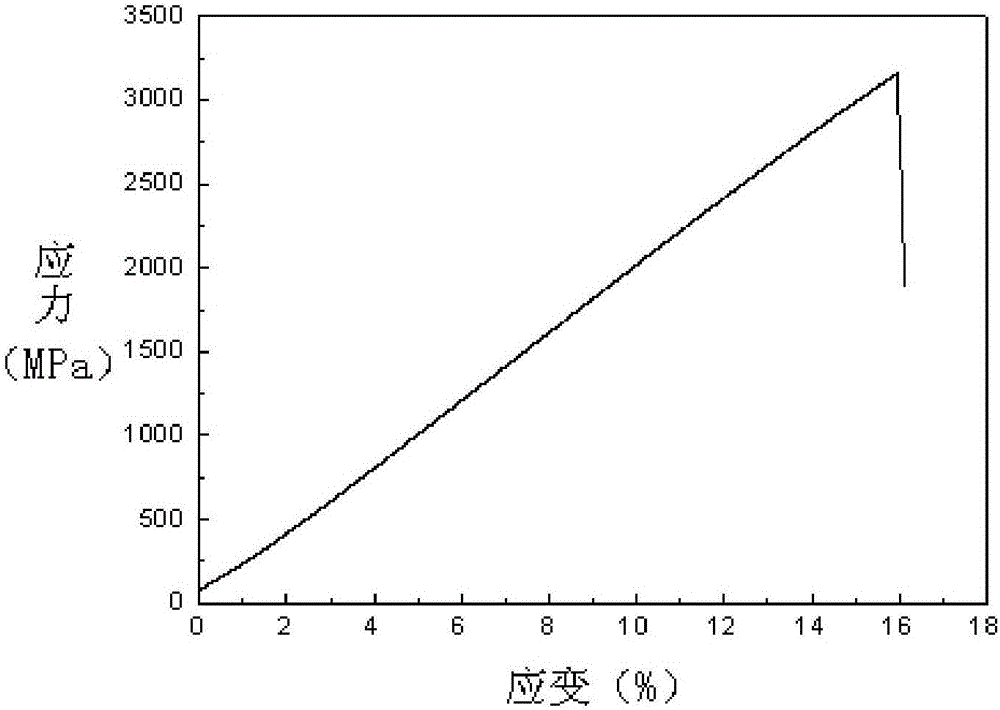

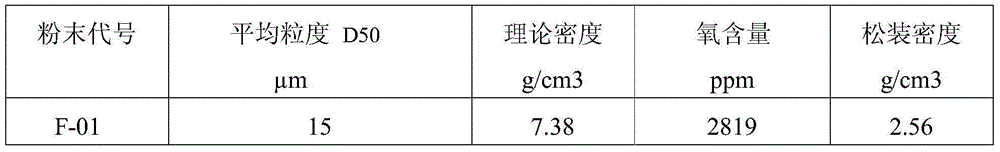

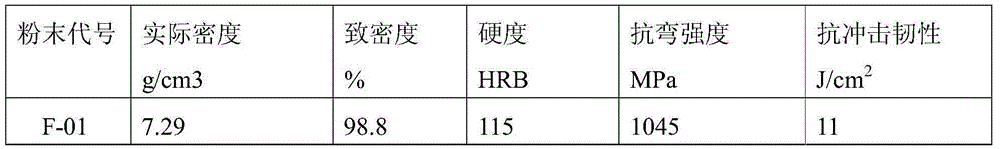

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

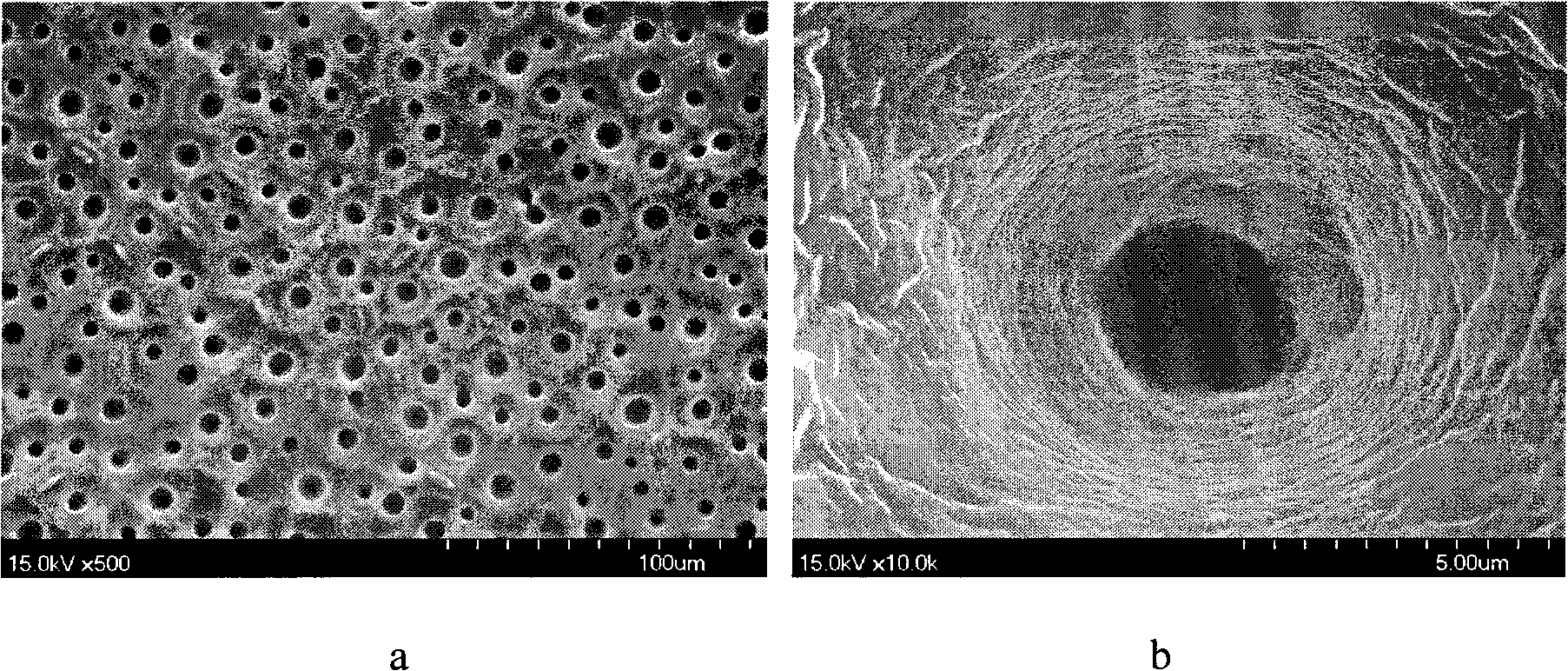

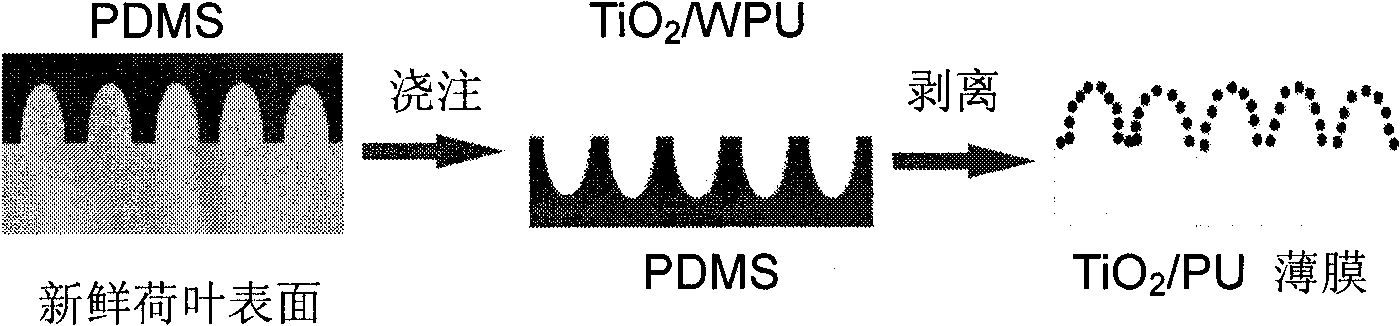

Method for preparing superhydrophobic surface by using nano-particles for assisting micromolding

The invention provides a method for preparing a polymer superhydrophobic surface by using nano-particles for assisting micromolding. The method firstly uses a PDMS as a raw material for copying a micro-structure on the surface of a fresh lotus leaf to be used as a soft template, then casts or hot presses the modified nano particles and a polymer on the surface of the PDMS soft template and strips after molding, thereby obtaining the polymer superhydrophobic surface which contains a micro / nano second-order structure on the surface and has a certain function. The method has simple operation process, high efficiency and good controllability and repeatability; as the obtained surface contains the functional nano-particles, the method not only gives the superhydrophobic property to the polymer surface, but also gives a certain function to the superhydrophobic surface, thereby providing a simple and effective way for preparing the superhydrophobic surface and having wide application value and broad market prospect.

Owner:ZHEJIANG UNIV OF TECH

Preparation method for silicon carbide ceramic tube or rod

ActiveCN101560104AEvenly dispersedUniform moisture contentCeramic shaping apparatusClay processing apparatusShielding gasSlurry

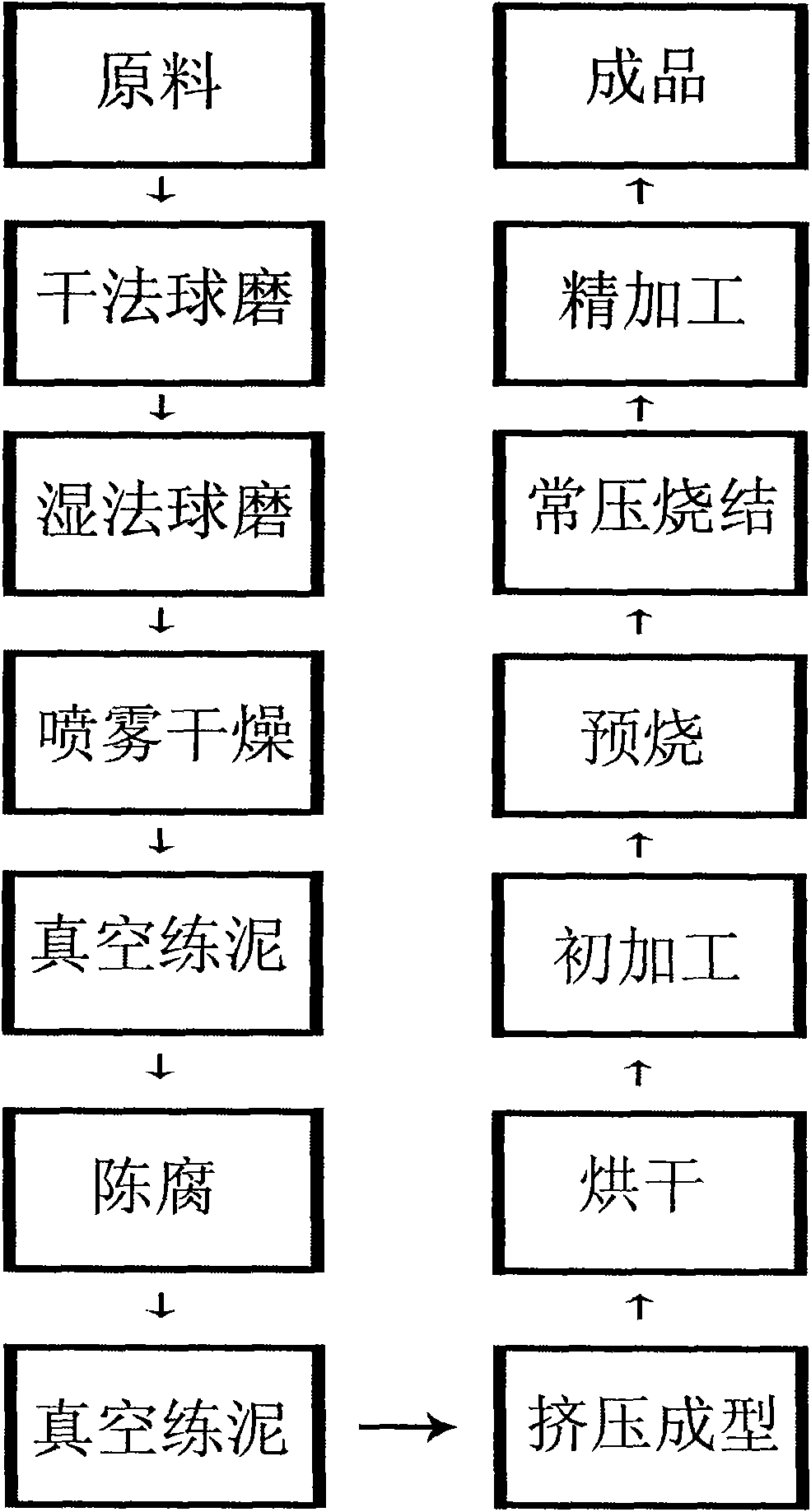

The invention relates to a preparation method for a silicon carbide ceramic tube or rod. An extrusion moulding method is adopted to form a blank body; a normal pressure sintering method is adopted for sintering; and submicron level silicon carbide powder and additives are taken as main raw materials. The preparation method comprises the following steps: 1) carrying out ball milling on the main raw materials by a dry method, adding water, a dispersant, a plasticizer, a lubricant and a liquid state binder, and then carrying out ball milling by a wet method; 2) adopting a spray granulation process to granulate silicon carbide slurry; 3) extruding the blank body by a one-shot direct extrusion moulding method after vacuum pug, corrosion, and vacuum pug; 4) drying the molded blank body by a stage drying mechanism; and 5) placing the blank body of the silicon carbide ceramic tube or rod in a vacuum furnace and carrying out sintering for two times by taking argon gas as protective gas. The high temperature resisting strength and the corrosion resistance of the silicon carbide ceramic tube or rod prepared by the method are both better than those of a reactive sintered product. Compared with a hot press sintering method, the method has lower limit on the product shape and size, and lower cost. The method is suitable for the industrialized production.

Owner:宁波欧翔精细陶瓷技术有限公司

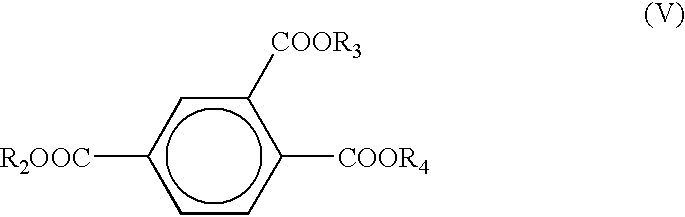

Toner

A toner, particularly a color toner suitable for full-color image formation through a substantially oil-less heat-pressure fixing device, is formed from at least a binder resin, a colorant and a wax. The binder resin comprises a polyester-based resin selected from the group consisting of (a) a polyester resin, (b) a hybrid resin having a polyester unit and a vinyl polymer unit, and (c) a mixture of these resins. The wax is characterized by including a structural unit including an OH group, an amide, or an ester group at a specific position.

Owner:CANON KK

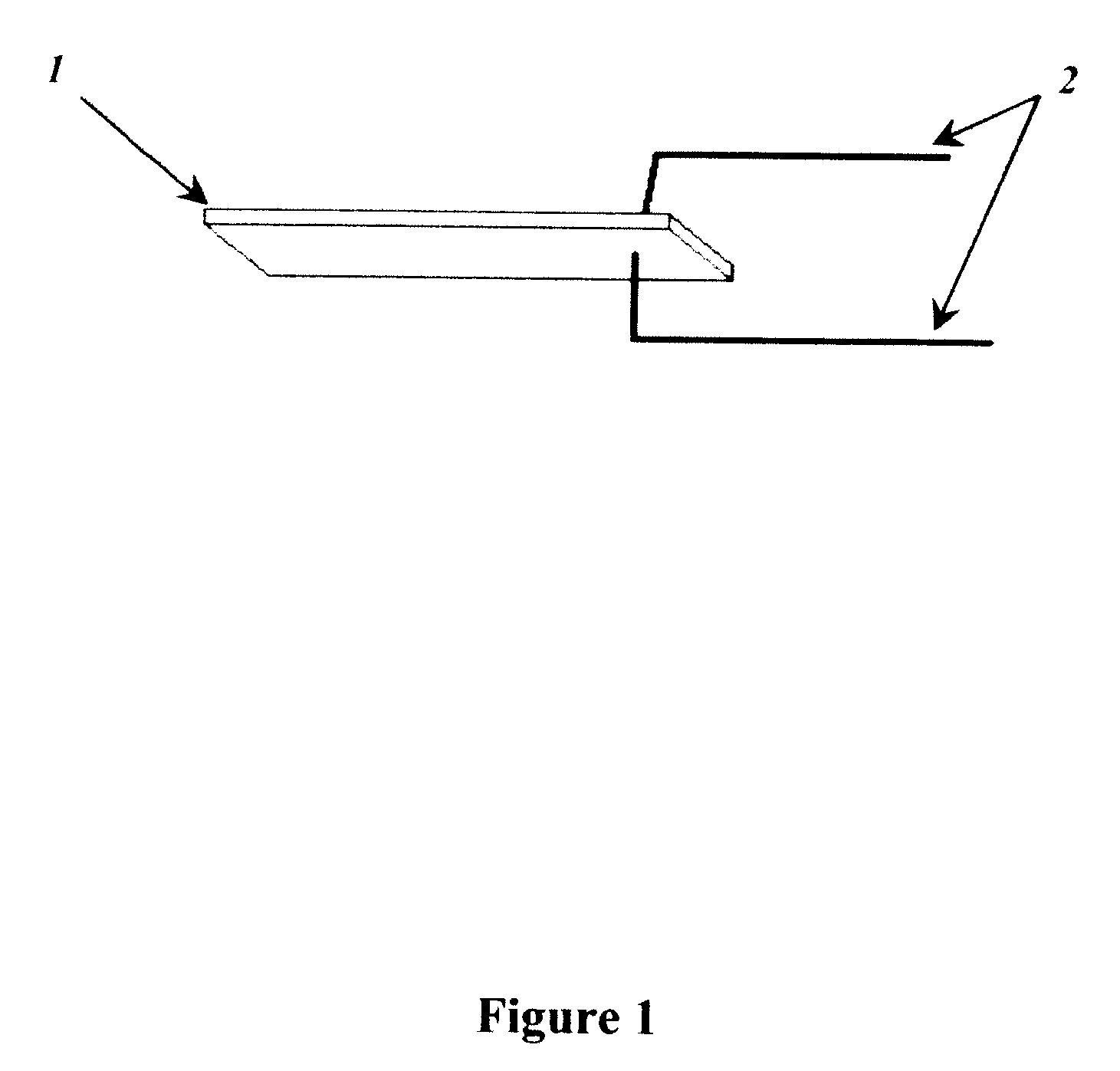

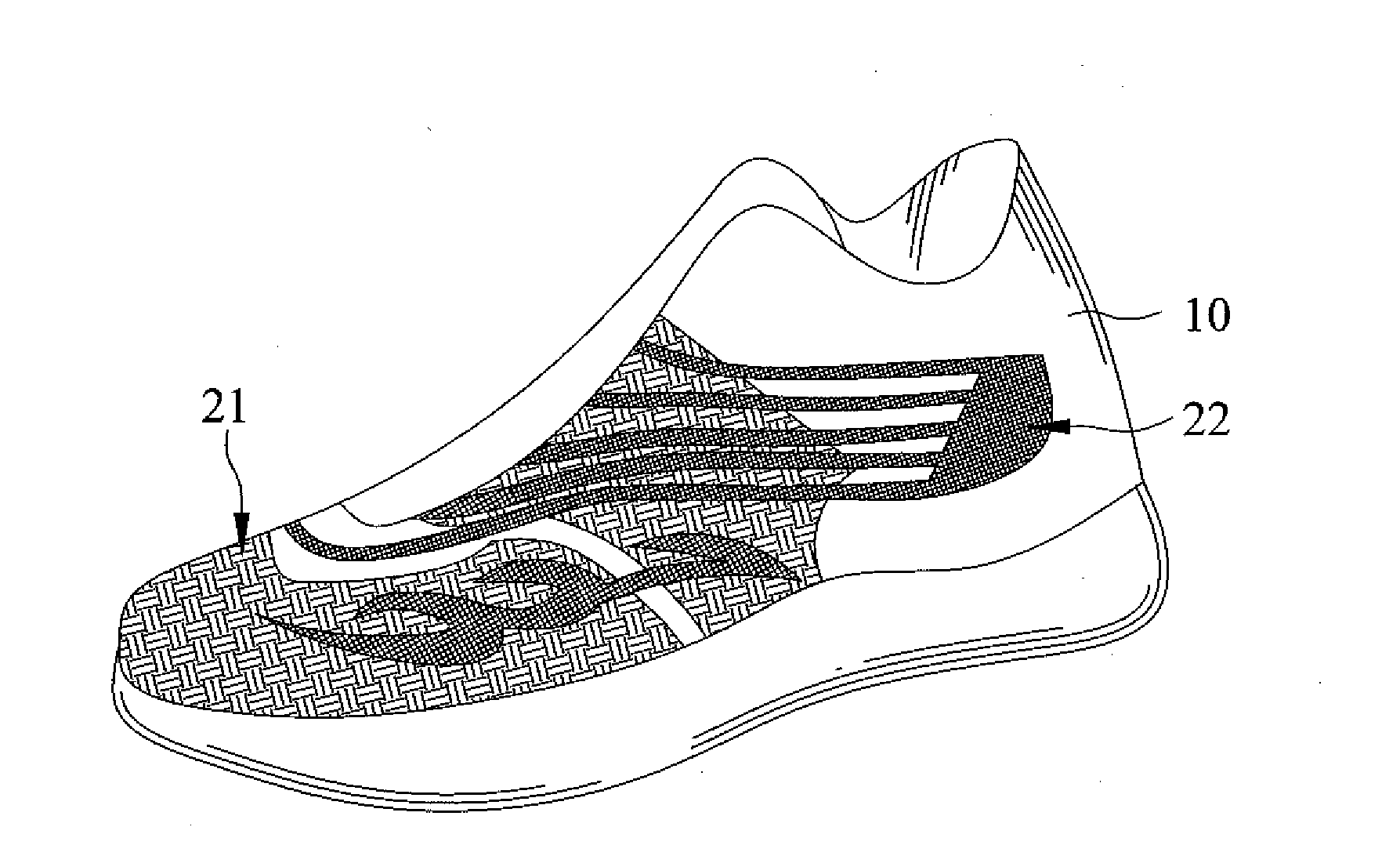

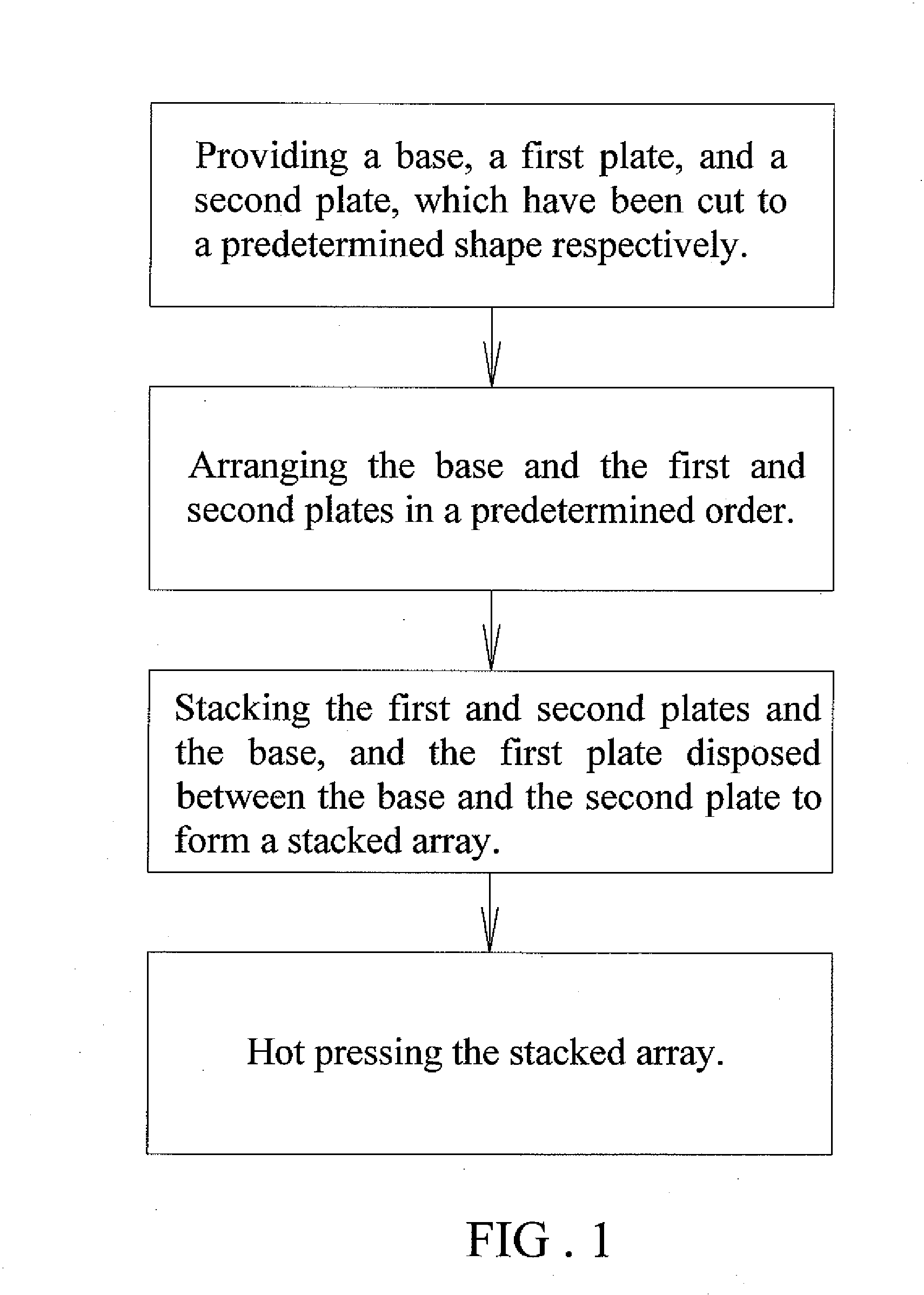

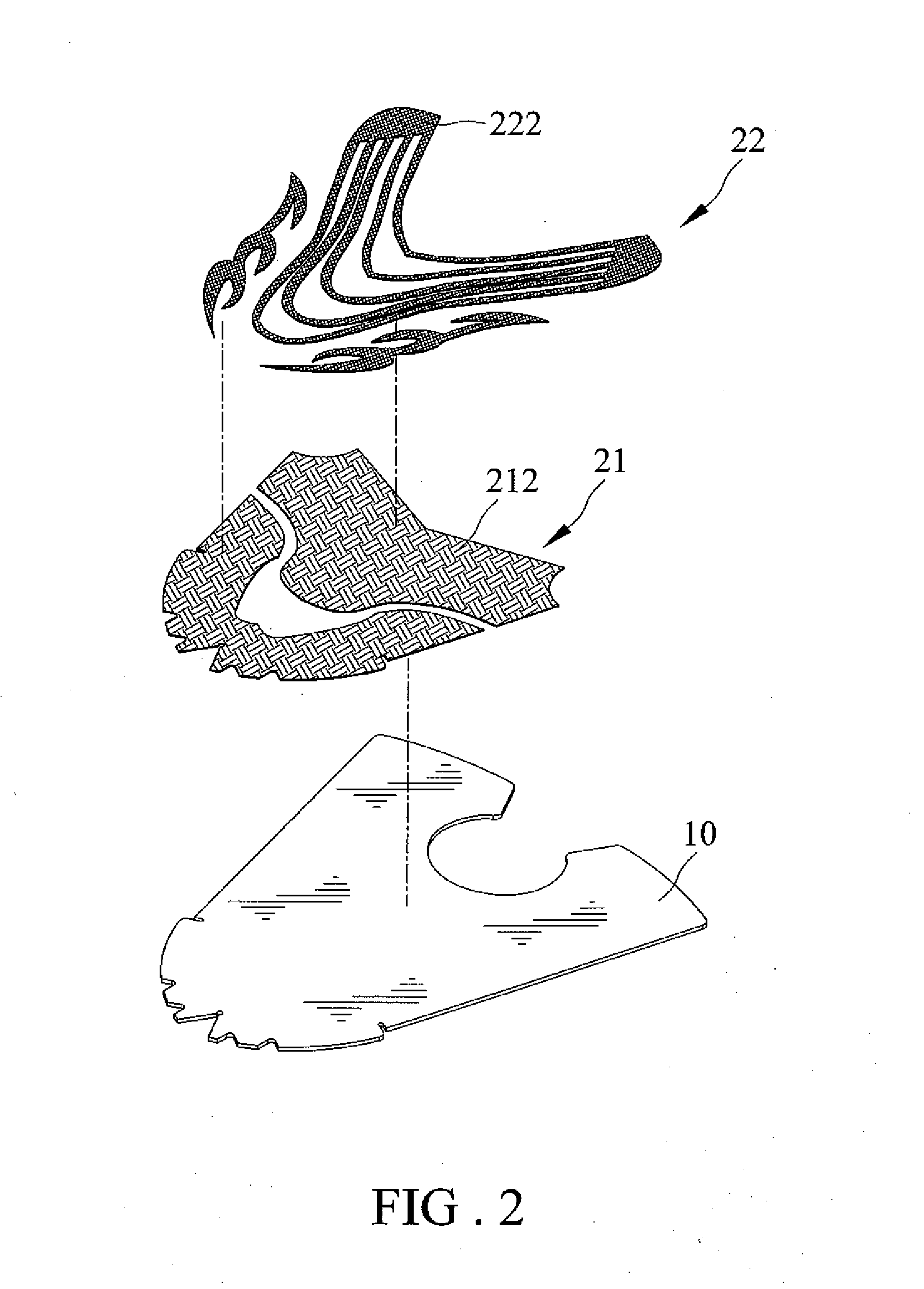

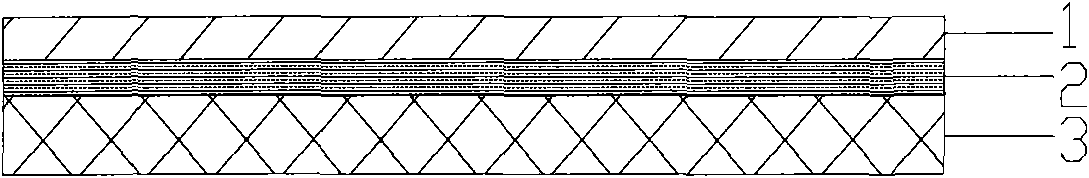

Multi-layer Decorative Vamp and method of its Manufacture

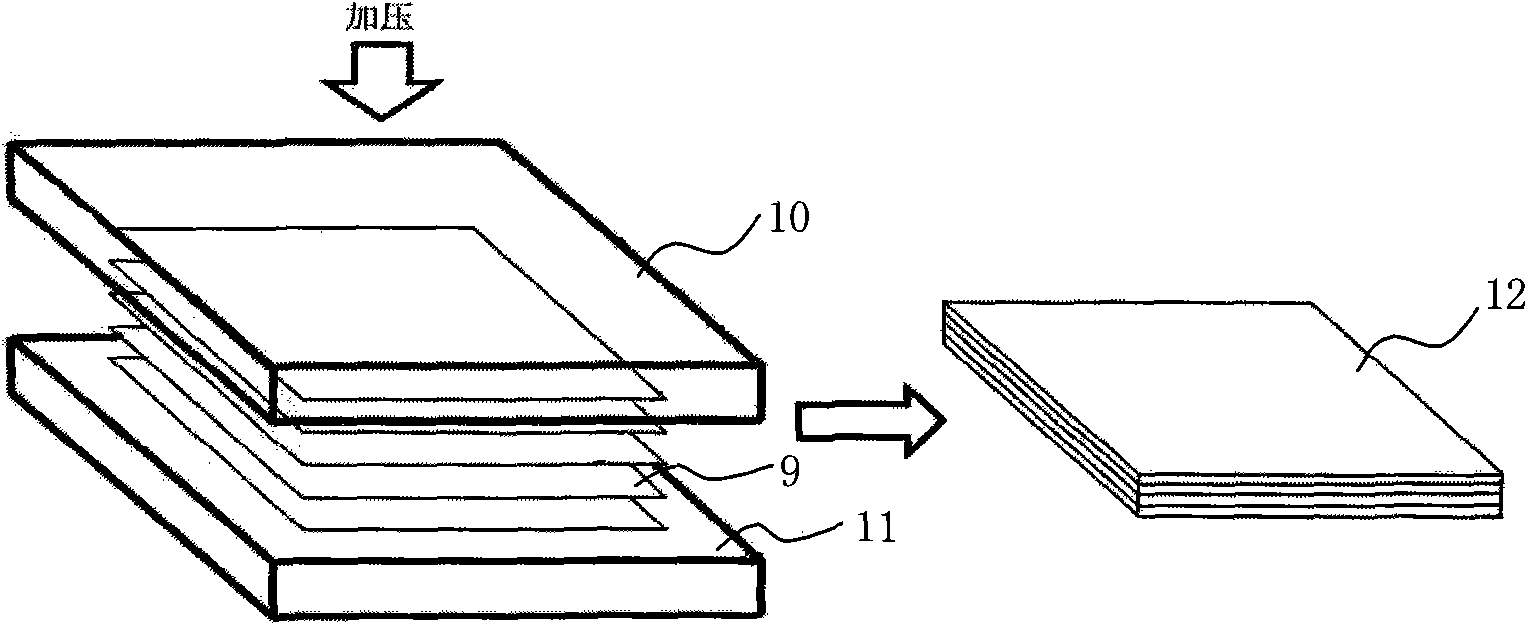

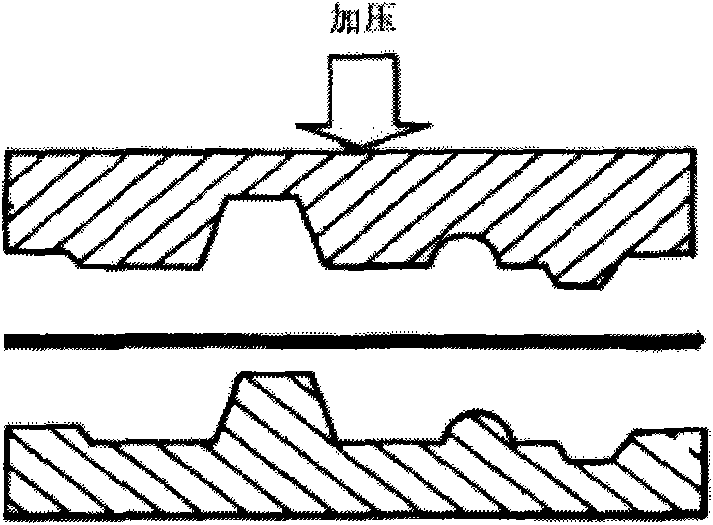

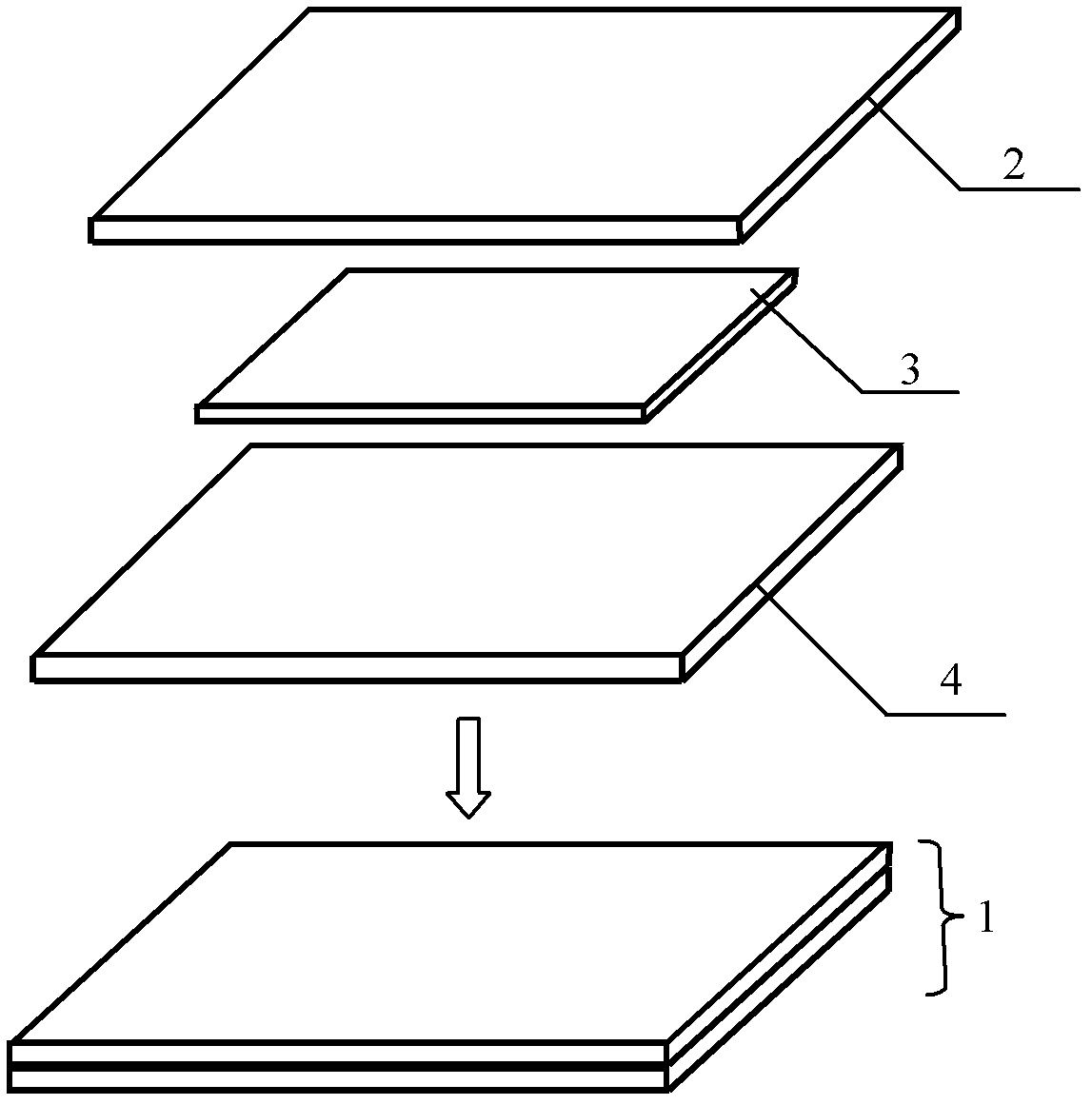

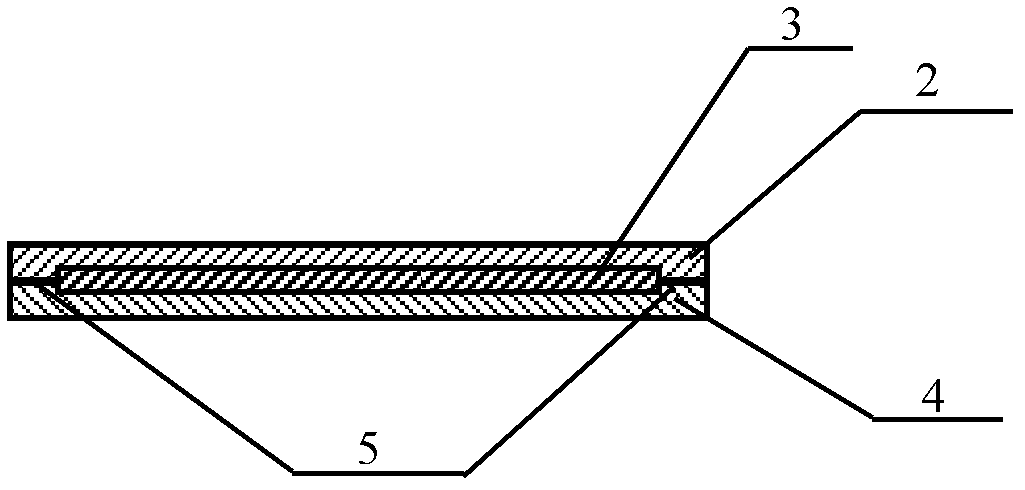

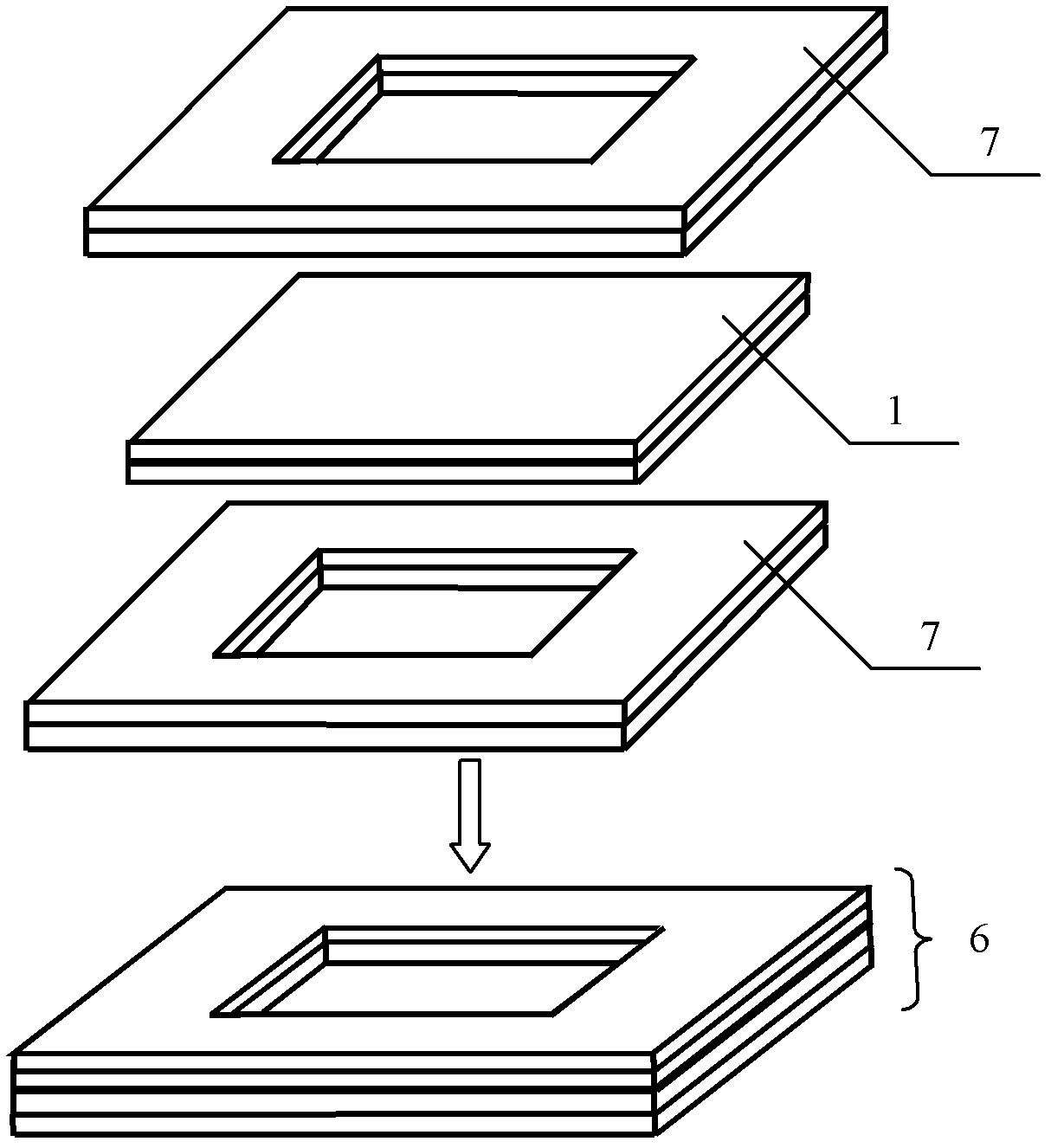

A method for producing the multi-layer decorative vamp according to the first embodiment includes the steps of (a) providing a base, a first plate, and a second plate, which have been cut to a predetermined shape respectively; (b) arranging the base and the first and second plates in a predetermined order; (c) stacking the first and second plates and the base, and the first plate disposed between the base and the second plate to form a stacked array; (d) hot pressing the stacked array.

Owner:JAH YIH ENTERPRISE

Method for recycling copper, nickel, chromium, zinc and iron from plating sludge

The invention relates to a method for recycling copper, nickel, chromium, zinc and iron from plating sludge, belonging to the technical field of chemical engineering and metallurgy. The method comprises the following steps: acid leaching, vulcanizing for separation and enrichment, hot-pressure leaching, extracting for separation, hot-press oxidizing chromium, purifying chromium solution, extracting ferric chloride and the like. The method has obvious advantages of strong adaptability to different kinds of plating sludge, high utilization of metal resources, high value-added content of product,less process waste residue, thorough deintoxication and the like.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

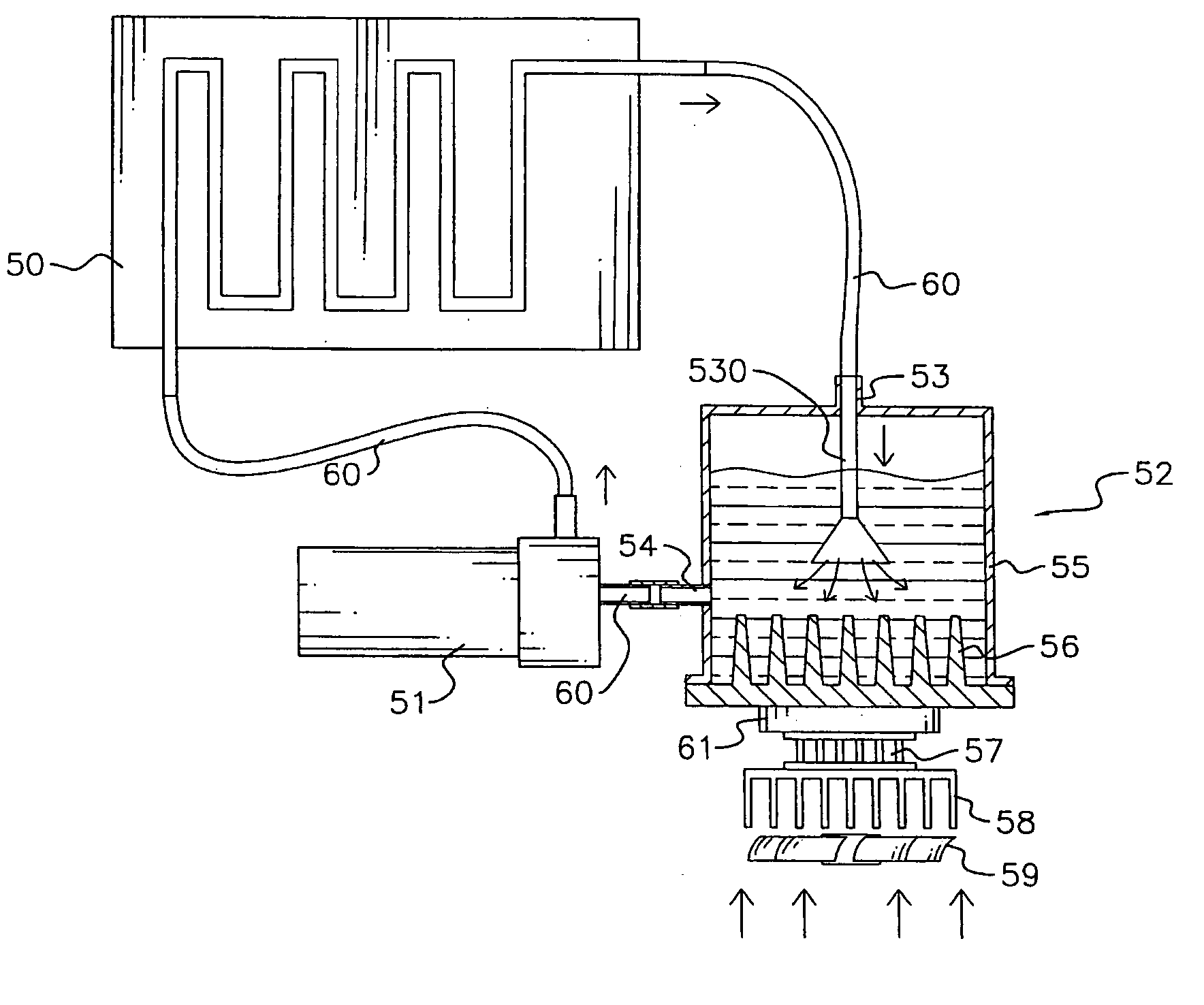

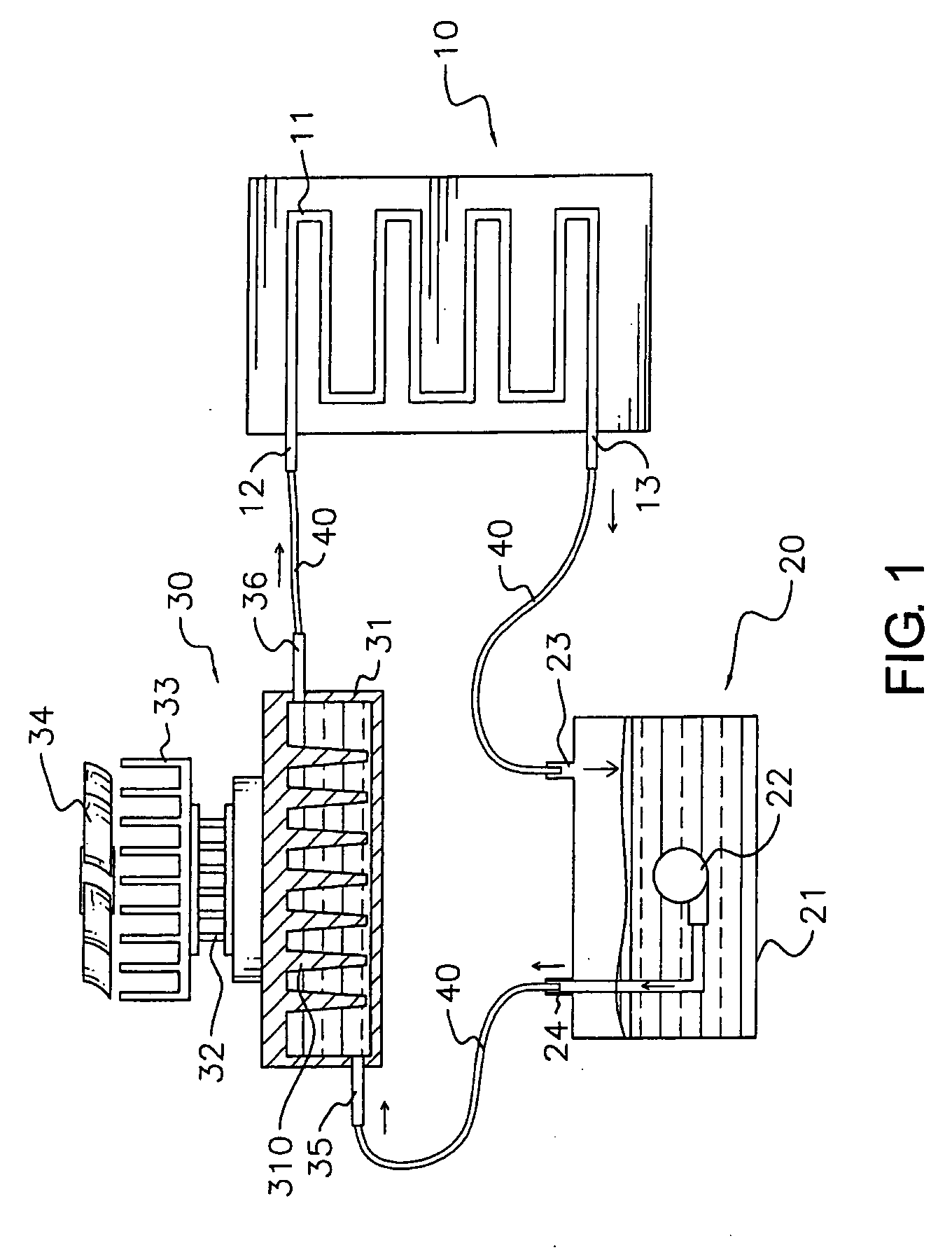

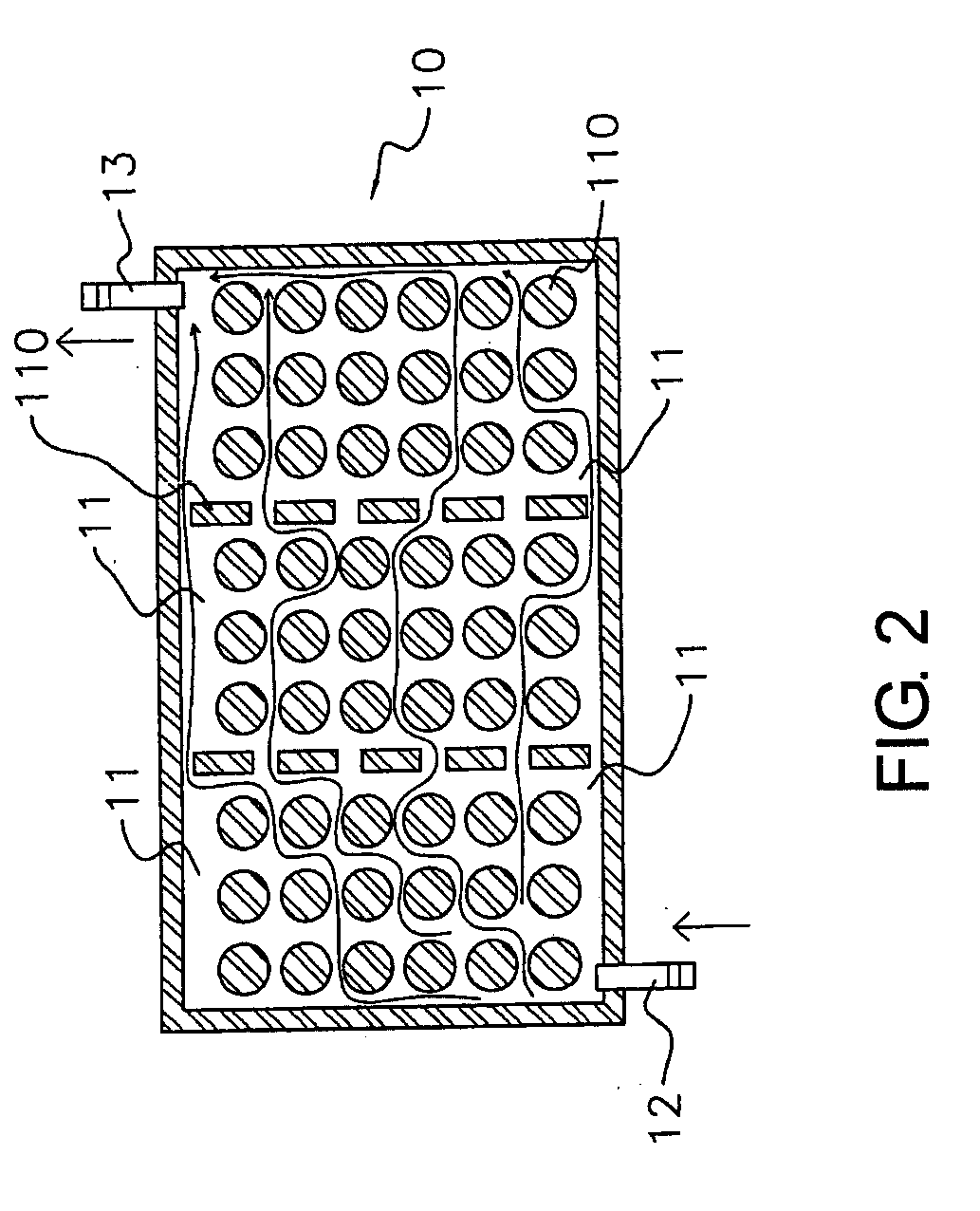

Cooling/heating pad

InactiveUS20060048520A1Reduce weightUsing liquid separation agentMachines/enginesElectrical conductorWater channel

A cooling / heating pad of the present invention includes a pad portion, a water reservoir system and a heat exchanger, wherein the pad portion has the pad portion is a foldable, thin, double-layered bag and has a plurality of adhered regions formed by a hot-press or ultrasonic hot melting process to form the water channel between the adhered regions; the water reservoir system has a water reservoir and a water circulating pump, the water reservoir having a water inlet and a water outlet, the water inlet of the water reservoir connected to the water outlet of the water channel, and the water circulating pump moving the cooling water in the water reservoir from the water outlet of the water reservoir to the water inlet of the water channel; and the heat exchanger includes an electrical heating semiconductor chip, and a thermal conductor mounted on one side of the electrical heating semiconductor chip; wherein the thermal conductor directly contacts the cooling water in the water reservoir, or is mounted on a water path between the water outlet of the water reservoir to the water inlet of the water channel, so that the cooling water is capable of exchanging heat with the thermal conductor.

Owner:U LONG

Thermoplastic resin-based carbon fiber composite and preparation method thereof

The invention discloses a thermoplastic resin-based carbon fiber composite and a preparation method thereof. The thermoplastic resin-based carbon fiber composite comprises the following components in percentage by volume: 50 to 70 percent of carbon fibers and 30 to 50 percent of thermoplastic resin. In the preparation method, according to rheological properties of the thermoplastic resin, the thermoplastic resin-based carbon fiber composite with good interface binding property is prepared by utilizing hot-roller hot-pressing continuous equipment and adjusting process conditions such as machining temperature, machining pressure, machining time and the like. Compared with the prior art, the thermoplastic resin-based carbon fiber composite has the advantages of simple structure, good interface binding property, high impact resistance and recycling property; and the preparation method can realize the uniform distribution of the carbon fibers and the thermoplastic resin and ensure the carbon fibers are immersed by the thermoplastic resin completely, so that the defect of the conventional method is overcome.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Bipolarity current collector and preparation method

ActiveCN103219521AEasy to packImprove securityFinal product manufactureElectrode carriers/collectorsHigh voltage batteryCopper

The invention discloses a bipolarity current collector and a preparation method, which belongs to the chemical energy storage battery technical field. The provided bipolarity current collector comprises aluminum foil, a non-aluminum conducting layer and a polymer barrier layer positioned between aluminum foil and non-aluminum conducting layer; the edges of the aluminum foil and the non-aluminum conducting layer are partially or wholly conductively contacted, the width of a conductive contact area of the edges are 0.1-1.5 centimeters. The bipolarity current collector can avoid the occurrence of internal short circuit and cathode oxidation of the current copper aluminum laminated foils under the condition that a hole is existed; composite insulation frames are hot-pressed on the bipolarity current collector, and can avoid the occurrence of short circuit of the marginal part of the composite current collector, and the security of high voltage battery can be increased.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

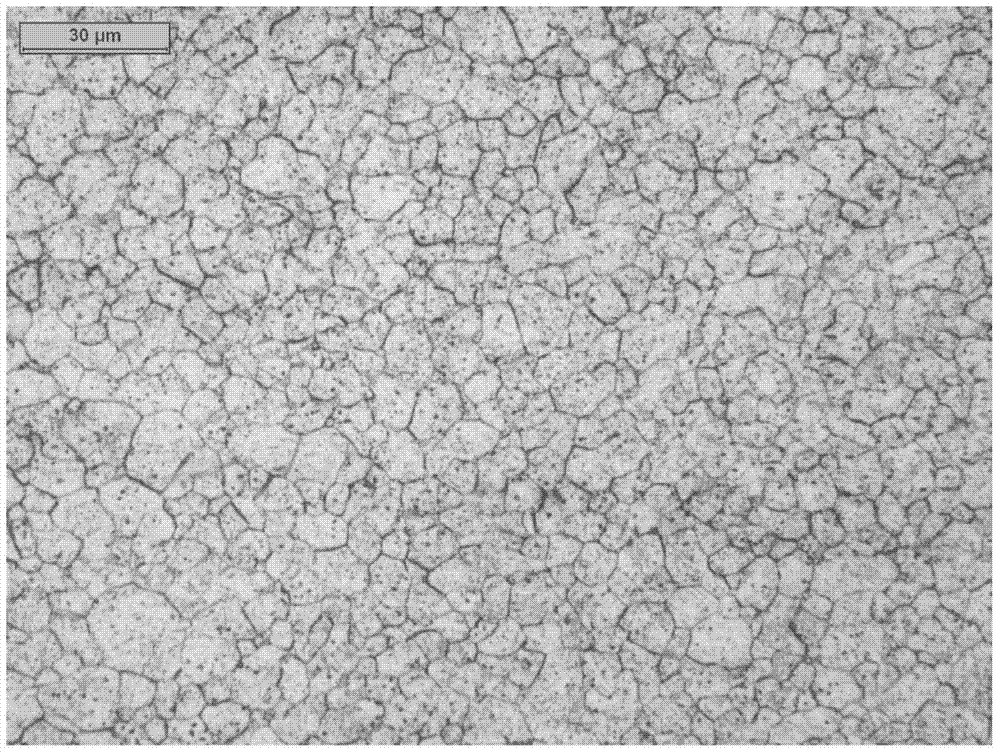

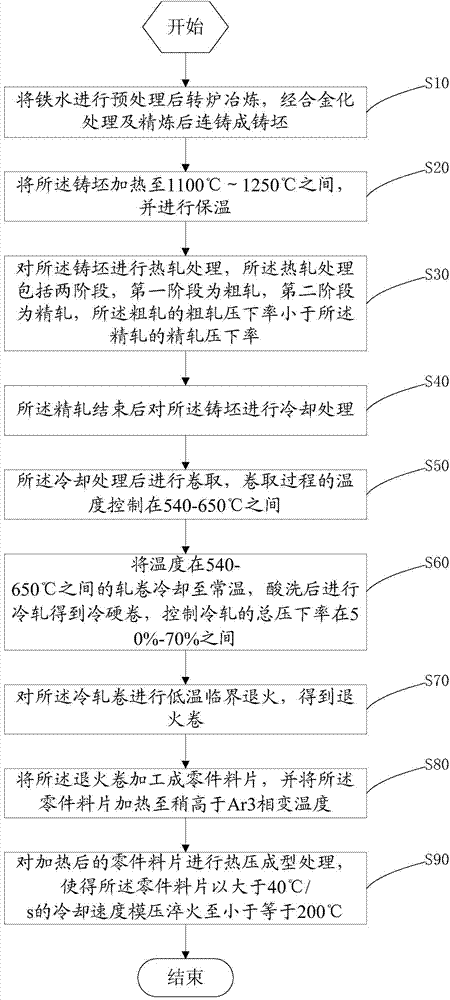

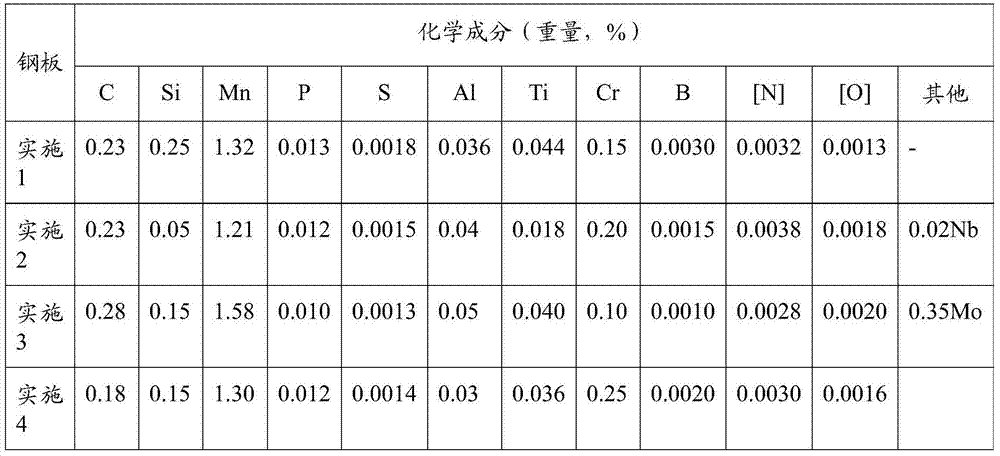

High-flexural-behavior hot-formed steel used for automobiles and manufacturing method thereof

The invention belongs to the technical field of steel rolling, and particularly relates to high-flexural-behavior hot-formed steel used for automobiles and a manufacturing method thereof. The steel comprises following trace elements by mass: 0.18-0.3% of C, not more than 0.3% of Si, 1-1.6% of Mn, not more than 0.015% of P, not more than 0.002% of S, 0.1-0.3% of Cr, 0.02-0.06% of Ti, 0.02-0.06% of Al, 0.0005-0.004% of B, not more than 0.004% of [N] and not more than 0.003% of [O]. The manufacturing method includes: heating a casting blank at a low temperature, performing controlled rolling in two stages, rapidly cooling, reeling up at a low temperature, preparing a steel coil by cold rolling and low-temperature critical annealing, shearing to prepare component tablets and performing hot press molding. By the manufacturing method, steel crystal grains are refined and ductility and toughness of the steel are enhanced, so that more energy is absorbed during deformation of the steel and automobile safety performance is enhanced.

Owner:SHOUGANG CORPORATION

Drainage plate for silt consolidation, filter cloth and drainage plate core

The invention is the improvement on a longitudinal drainage plate for silt consolidation, filter cloth and a drainage plate core, which is characterized in that fibrous hot-pressed microporous filter cloth is planar filter cloth hot-rolled by a flat roller, the filter cloth is adhered to the surfaces of convex ribs of the drainage plate core through thermal thawing or a chemical way, the filter cloth adopts silk reeling and hot-press forming separation technology, and the drainage plate core is made of co-polypropylene, thereby overcoming the disadvantages of the prior art; and the aperture of the filter cloth can be adjusted according to treated silt, the drainage plate is difficult to block, the engineering on a soft foundation after the treatment cannot have the settlement after the construction and has smooth drainage and high drainage efficiency, and the plate core has long effective service life.

Owner:JIANGSU XINTAI GEOTECHNICAL TECH CO LTD

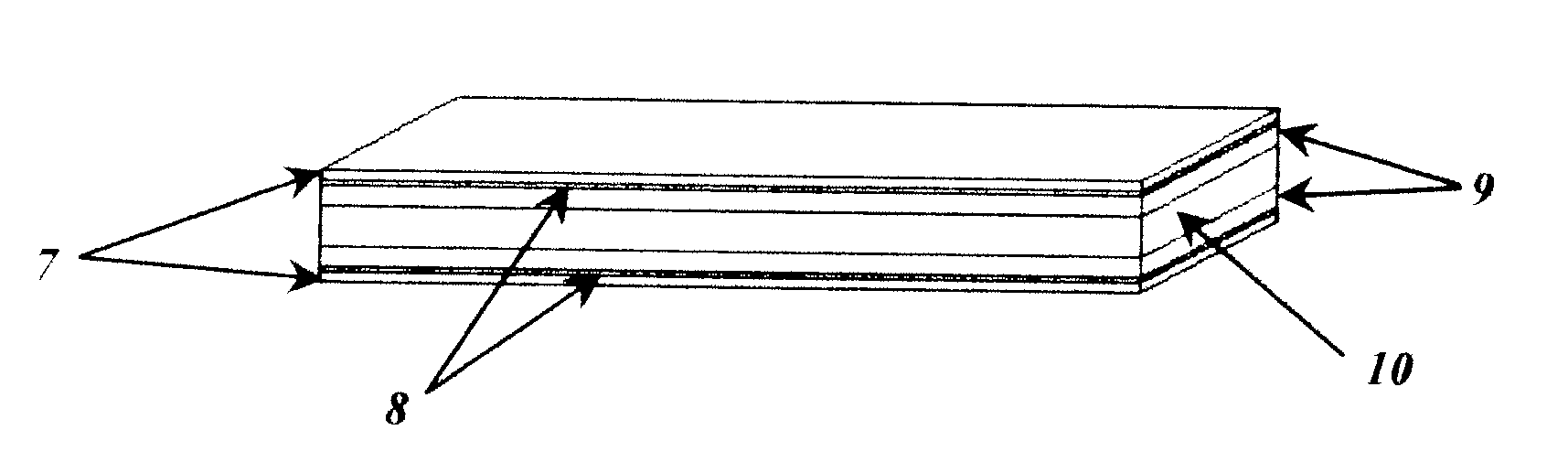

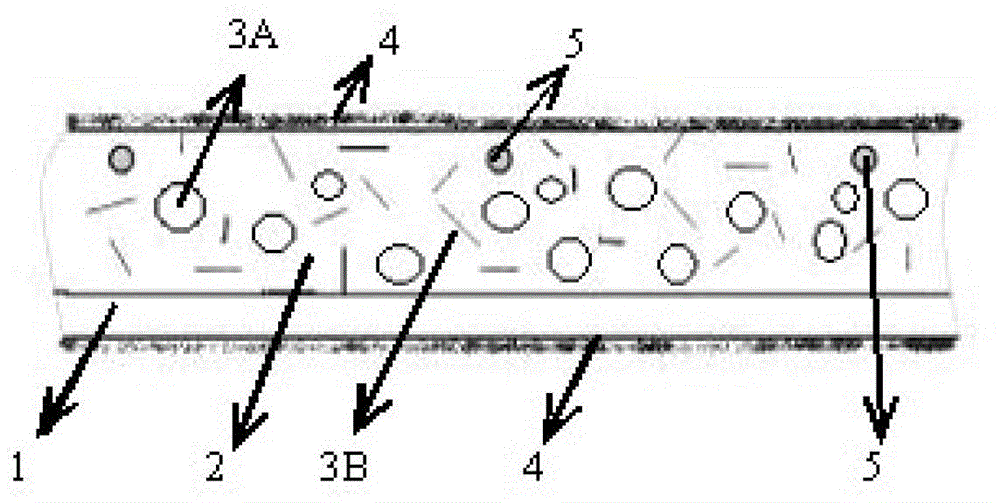

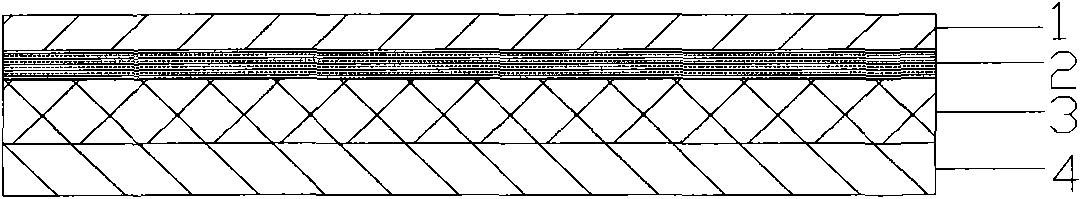

Low-resistance and high-strength ion exchange membrane for chlor-alkali industry and preparation method of low-resistance and high-strength ion exchange membrane

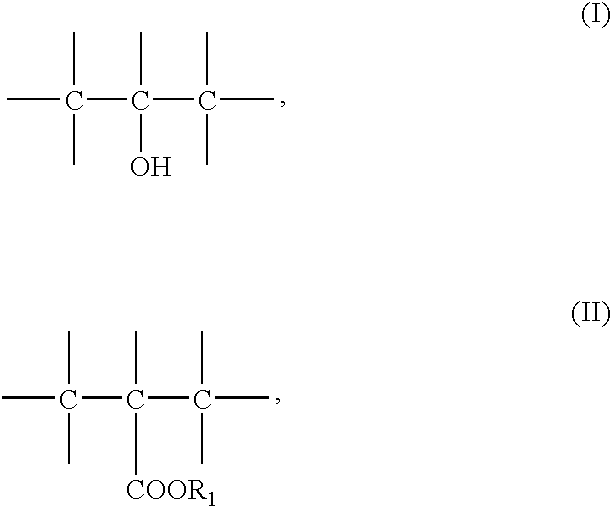

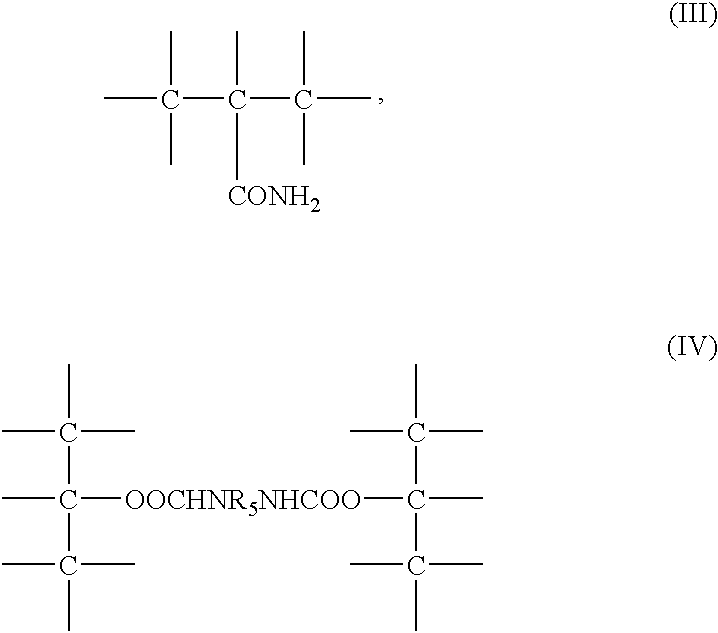

ActiveCN102978654AHigh mechanical strengthAvoid formingOrganic diaphragmsPhysical chemistryIon-exchange membranes

The invention relates to a low-resistance and high-strength ion exchange membrane for the chlor-alkali industry and a preparation method of the low-resistance and high-strength ion exchange membrane. The low-resistance and high-strength ion exchange membrane is a multi-layer composite membrane comprising a perfluorosulfonic ion exchange resin layer, a perfluoropropionate ion exchange resin layer, reinforced screen cloth and gas release coatings, wherein the perfluorosulfonic ion exchange resin layer with the thickness of 80-150 micrometers and the perfluoropropionate ion exchange resin layer with the thickness of 8-12 micrometers form a perfluorosulfonic ion exchange resin base membrane, the gas release coatings with 3-12 micrometers are arranged on two outer side surfaces of the base membrane, the reinforced screen cloth is arranged in the perfluorosulfonic ion exchange resin layer, and the perfluorosulfonic ion exchange resin layer is also internally provided with a nano pore and a nano cavity. The low-resistance and high-strength ion exchange membrane can be prepared through a melt co-extruding or multi-layer hot-pressing compounding process, can be used in an ion exchange membrane in the chlor-alkali industry, and has good mechanical property and electrochemical performance.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method for preparing sharp type epoxide resin binding agent diamond abrasive tool

ActiveCN103056788AImprove bindingInhibit sheddingAbrasion apparatusGrinding devicesFirming agentEpoxide

The invention discloses a method for preparing a sharp type epoxide resin binding agent diamond abrasive tool. A working layer is mainly made of diamond abrasive, an epoxide resin binding agent, a curing agent, an auxiliary abrasive, a filler and an auxiliary assistant. The method comprises steps of uniformly mixing 5-20 parts by mass of self-sharpening diamond, 5-28 parts by mass of auxiliary abrasive, 10-40 parts by mass of filler and 0.5-10 parts by mass of auxiliary assistant through a machine; uniformly mixing the mixture, 17-25 parts by mass of liquid epoxide resin and 5-25 parts of curing agent; injecting the fluid mixture to a plastic die through a pouring mode; and obtaining the sharp type epoxide resin binding agent diamond abrasive tool after curing. Compared with the method for preparing the abrasive tool through hot press molding, the method has the advantages that the process is simple, the energy is saved, the emission is reduced, the pollution of solid powder on the environment is reduced, the method is environment-friendly, the production speed is quick, the sharpening degree is high, the self-sharpening performance is good, the polishing effect is good and the service life is long.

Owner:惠安宇信金刚石工具有限公司

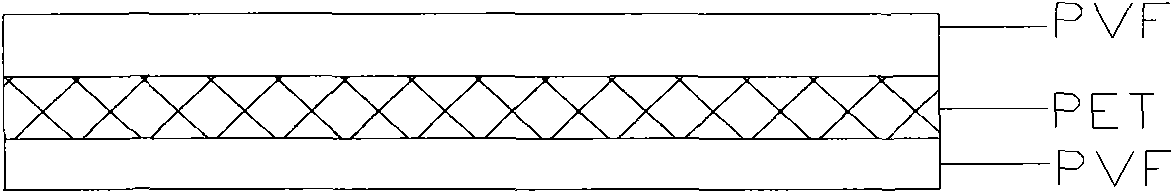

Solar battery back panel film and preparation method thereof

InactiveCN101997038AEasy to prepareGood weather resistanceLamination ancillary operationsFinal product manufactureAdhesiveElectric breakdown

The invention relates to a solar battery back panel film and a production method thereof. The solar battery back panel film comprises a PET (Polyethylene Terephthalate) thin film substrate layer and at least one polyvinylidene fluoride film layer, wherein the polyvinylidene fluoride film layer and the PET thin film substrate layer are compounded through an adhesive layer. The solar battery back panel film also comprises an EVA (Ethylene Vinyl Acetate Copolymer) film layer, and the EVA film layer and the PET thin film substrate layer are compounded by adopting a composite laminating process. The preparation method of the solar battery back panel film comprises the following steps of: carrying out surface corona treatment on the PET thin film substrate layer and the polyvinylidene fluoride film layer; coating an adhesive layer on the PET thin film substrate layer; and carrying out hot-pressing compounding on the adhesive-coated surface of the PET thin film substrate layer and the polyvinylidene fluoride film layer and then solidifying. The preparation method of the solar battery back panel film is simple, and the product has excellent weather fastness, higher lamination peel strength, good barrier property and good electric breakdown resistance.

Owner:NANJING NAQUAN HI TECH MATERIAL

Circular diamond saw blade bit and manufacturing method thereof

The invention discloses a circular diamond saw blade bit and a manufacturing method thereof. The circular diamond saw blade bit is made of diamond particles and matrix powder used for consolidation of the diamond particles. The matrix powder comprises, by mass percent, 40%-80% of Fe, 15%-30% of Cu, 0%-10% of Ni, 2%-8% of Sn, 0%-10% of Co, 0%-5% of Me and the balance inevitable impurities. Me is at least one of Mn, Ti, Si, Cr, P and Al. The manufacturing method comprises the steps of mixing raw materials, conducting cold-press molding and free sintering. The manufacturing method is simple and can effectively avoid the loss of a graphite mould and reduce manufacturing cost. Meanwhile, a volume production requirement can be met, and blade bits in complicated shapes can be produced; production efficiency is prolonged, and the service life of the tool is similar to that of a tool manufactured through a hot-press sintering method; the purpose that high-quality diamond cutting tools are produced under the condition of low cost can be achieved; and the circular diamond saw blade bit and a manufacturing method thereof are easy to popularize in an industrialized manner.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

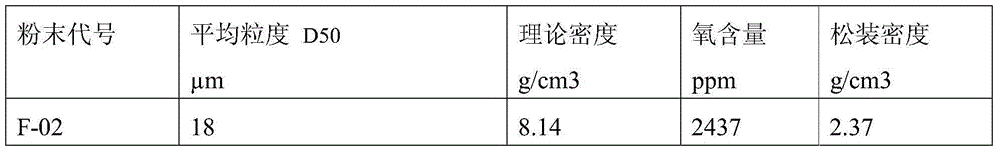

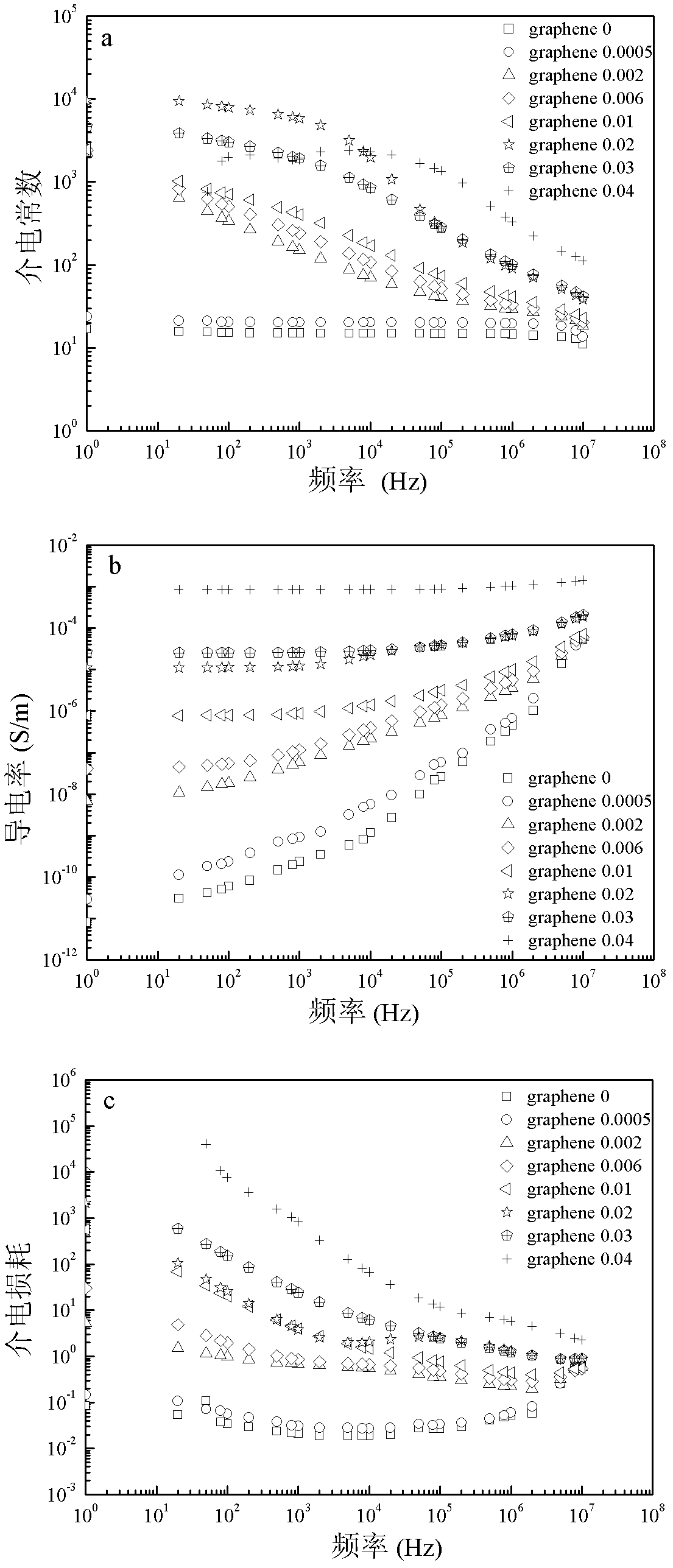

Polyvinylidene fluoride/graphene composite and preparation method thereof

ActiveCN102604275AHigh dielectric constantImprove toughnessFixed capacitorsDielectricPolyvinylidene difluoride

The invention discloses polyvinylidene fluoride / graphene composite and a preparation method thereof. The preparation method includes: reducing oxidation graphene by reductant, mixing the reduced graphene and polyvinylidene fluoride with N, N-dimethylacetamide solvent to be solution, drying and hot-pressing the solution to obtain the polyvinylidene fluoride / graphene composite. The prepared polyvinylidene fluoride / graphene composite has the following advantages that 1) dielectric constant of the polyvinylidene fluoride / graphene composite is high and can reach 7940 on the condition of 100Hz frequency and the weight percentage of the graphene is 0.02; and 2) flexibility is fine. Meanwhile, the preparation method has the advantages of simple operation and high stripping and dispersing degree of graphene and the like.

Owner:嘉善县国创新能源研究院

Steel sheet for hot press forming having excellent heat treatment and impact property, hot press parts made of it and the method for manufacturing thereof

Disclosed is a steel sheet that exhibits an ultra-high strength after hot press forming followed by rapid cooling, and an enhanced yield strength after painting. The steel sheet has a composition comprising 0.1% to 0.5% by weight of C, 0.01% to 1.0% by weight of Si, 0.5% to 4.0% by weight of Mn, 0.1 % by weight or less of P, 0.03% by weight or less of S, 0.1 % by weight of soluble Al, 0.01% to 0.1% by weight of N, 0.3% by weight or less of W, and the balance Fe and other inevitable impurities. Further disclosed are a hot-pressed part made of the steel sheet and a method for manufacturing the hot-pressed part. The hot-pressed part achieves a high increment in yield strength after heat treatment for painting while ensuring an ultra-high tensile strength. Furthermore, the hot-pressed part exhibits superior adhesion to a coatinglayer, good surface appearance and improved corrosion resistance after painting.

Owner:POHANG IRON & STEEL CO LTD

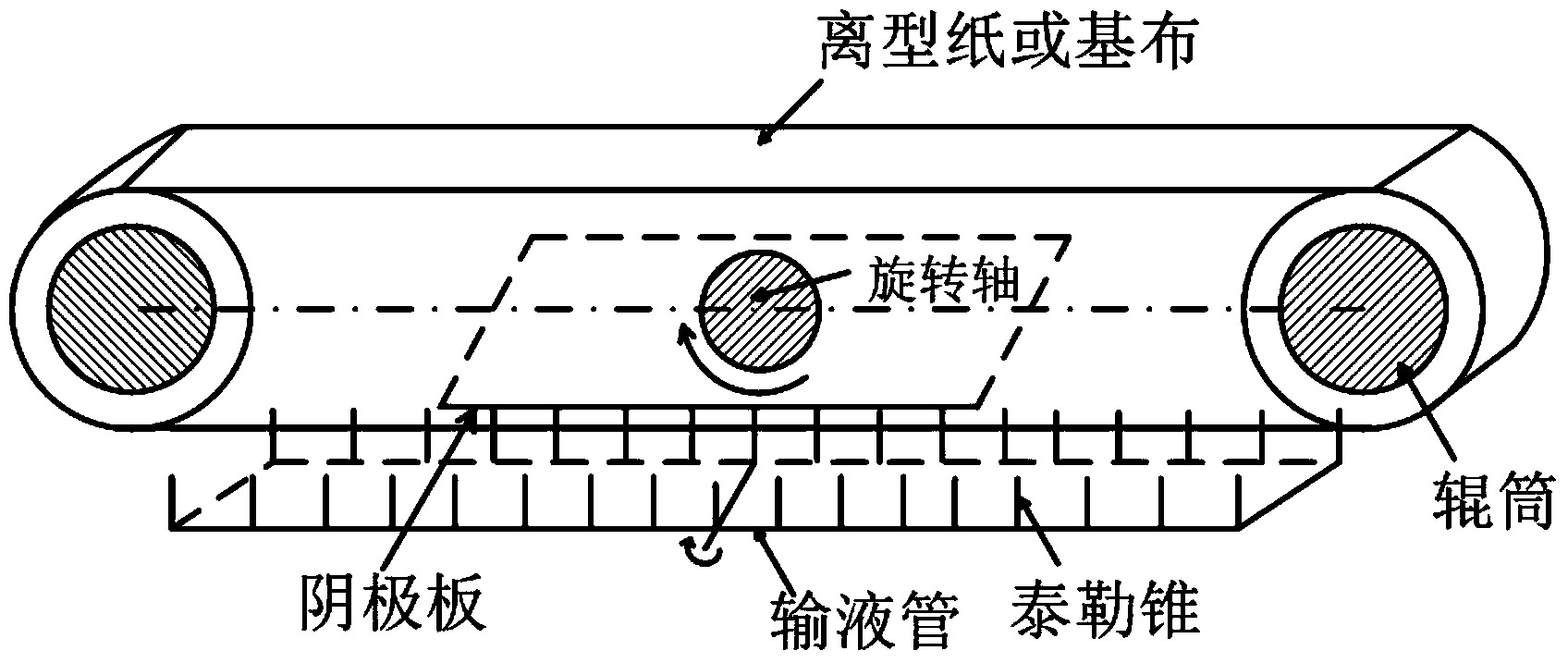

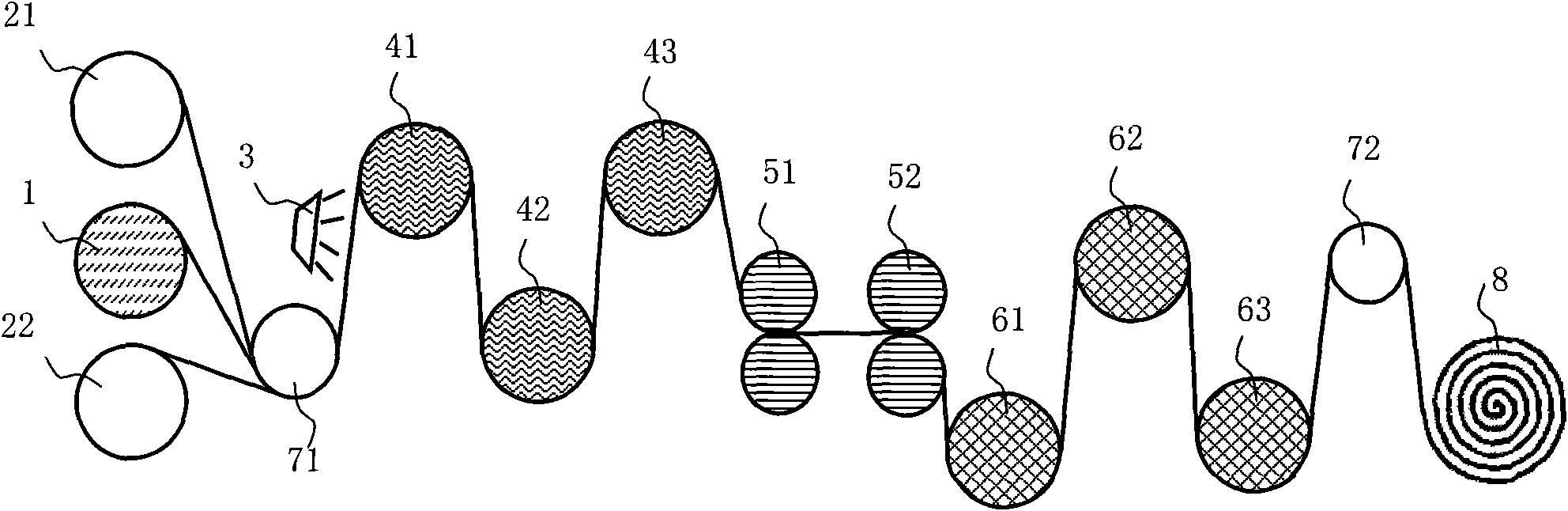

Method for enhancing electrostatic spinning nanofiber membrane

ActiveCN103541149AImprove mechanical propertiesEasy to manufactureElectro-spinningNon-woven fabricsFiberPolymer science

The invention discloses a method for enhancing an electrostatic spinning nanofiber membrane. The blending electrostatic spinning-hot rolling bonding net fixing technology which can effectively improve the strength of the electrostatic spinning nanofiber membrane is provided. The method for enhancing the electrostatic spinning nanofiber membrane is characterized in that interphase blending electrostatic spinning is conducted through multiple types of thermoplastic high polymers with the fusion point at least 20 DEG C lower than that of other components or low-fusion-point thermoplastic high polymers and non-thermoplastic high polymers, electrostatic spinning jet flows of the components are distributed frontwards and backwards in the moving direction of a receiving device, and fibers are distributed randomly in a staggered mode; after hot rolling is conducted on a blending electrostatic spinning fiber membrane, the blending electrostatic spinning fiber membrane is treated, the hot pressing temperature is slightly higher than the fusion starting temperature of the low-fusion-point thermoplastic high polymers, time ranges from 1min to 10min, the pressure ranges from 1MPa to 20MPa, after hot pressing is conducted, part of the low-fusion-point thermoplastic high polymers is fused, point adhesion is generated on the nanofiber intersection portions, and a hole is not blocked. The method for enhancing the electrostatic spinning nanofiber membrane has the advantages that the strength of the prepared enhanced electrostatic spinning nanofiber membrane is far higher than that of a common electrostatic spinning membrane and original good performance of the electrostatic spinning nanofiber membrane can be kept.

Owner:TIANJIN POLYTECHNIC UNIV

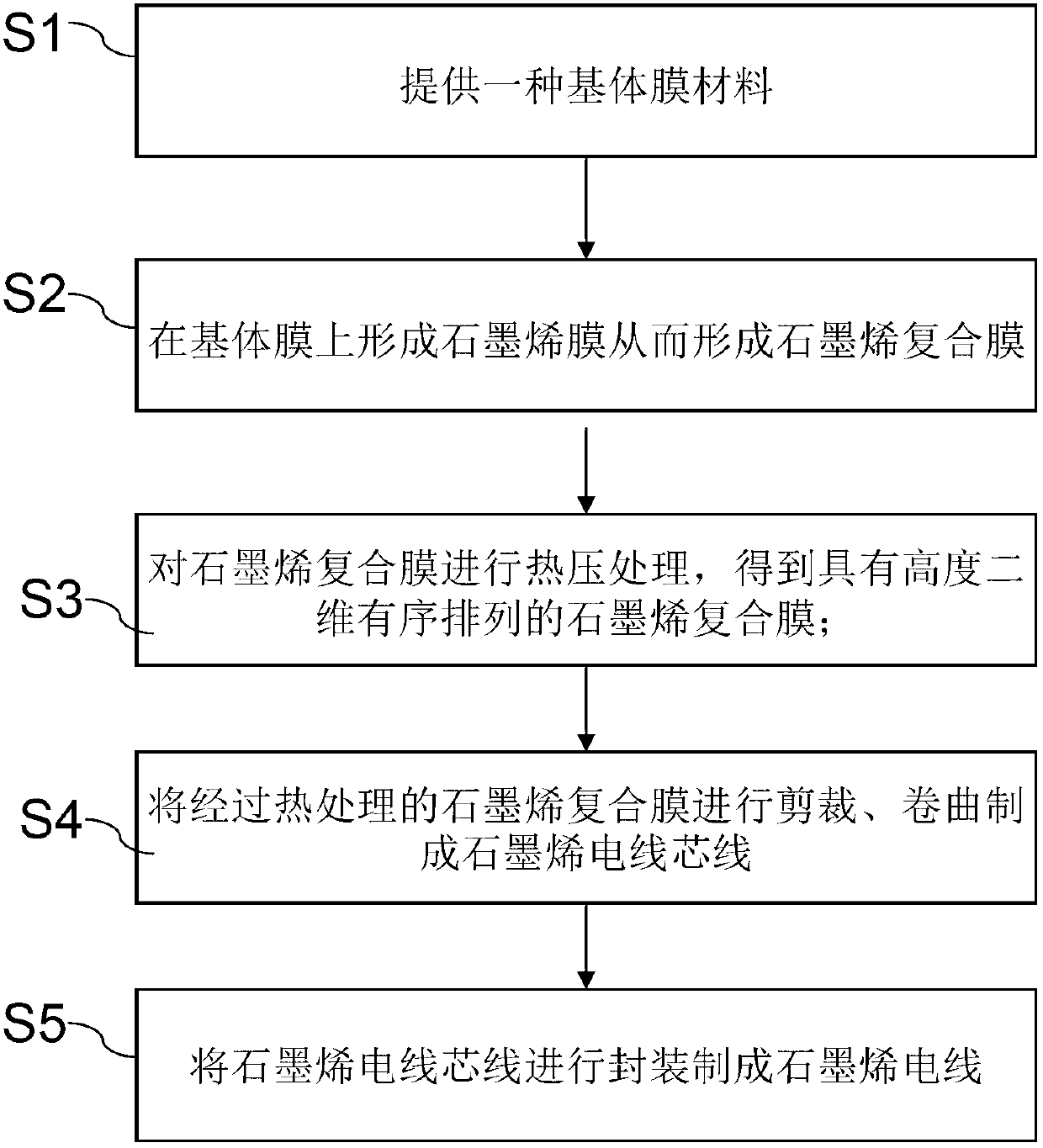

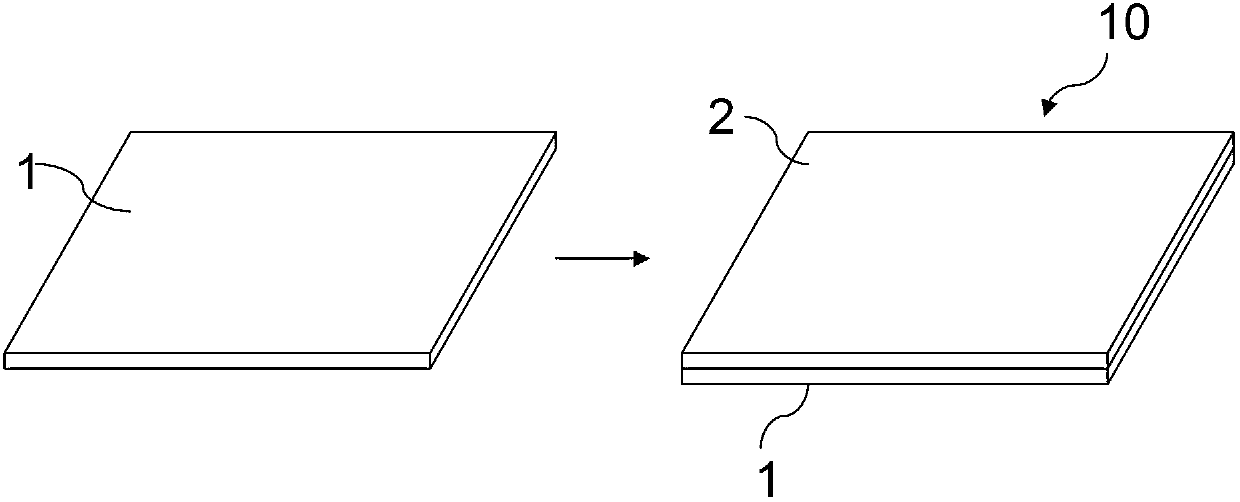

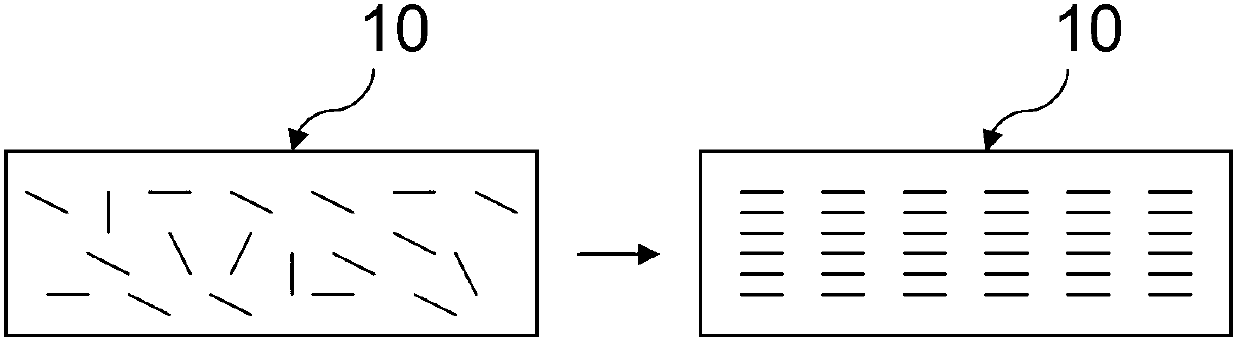

Method for preparing graphene wire and cable

InactiveCN103123830AExcellent two-dimensional conductive propertiesHigh conductivity densityCable/conductor manufactureElectrical conductorTemperature resistance

The invention provides a method for preparing a graphene wire and cable. The method comprises the following steps of: spraying or growing a graphene functional material with superior two-dimensional conduction characteristic on a substrate membrane material, and converting disordered graphene nanosheets into highly ordered two-dimensional graphene membranes through treatment of a hot pressing technology so as to prepare the graphene membrane material with the superior two-dimensional conduction characteristic; and then winding the two-dimensional graphene membrane material into the graphene wire with superior one-dimensional conduction characteristic through a winding technology. The graphene wire has the advantages of low resistance, high conduction density, superior conduction characteristic to that of metal conductors such as copper and silver, light weight, high temperature resistance and good chemical stability; and the graphene wires can be assembled and packaged to prepare a high-current graphene cable.

Owner:青岛科孚纳米技术有限公司

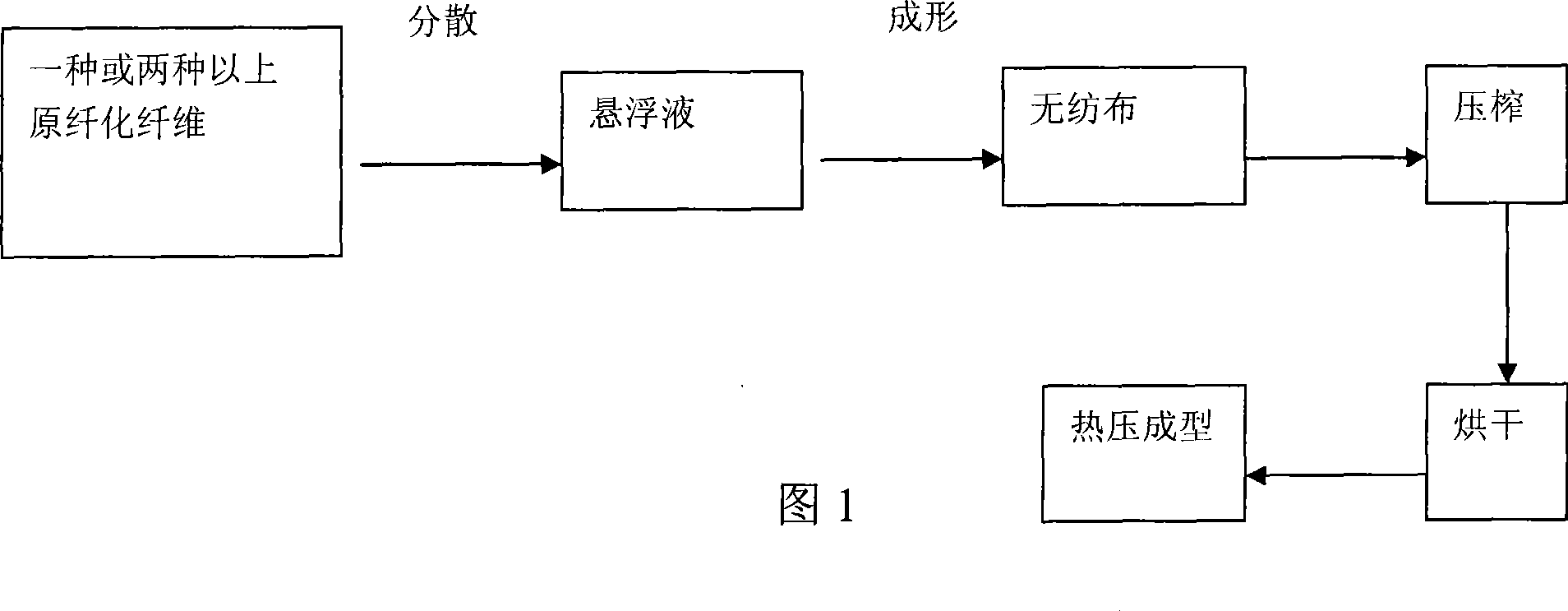

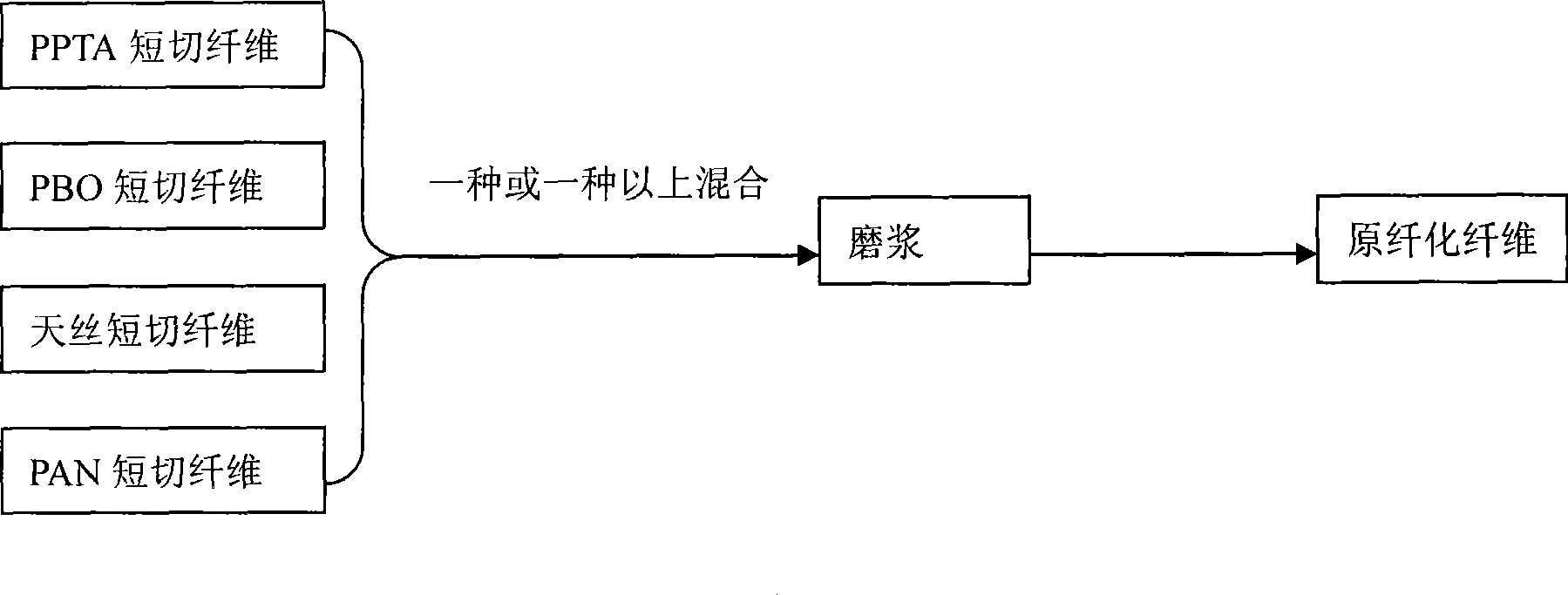

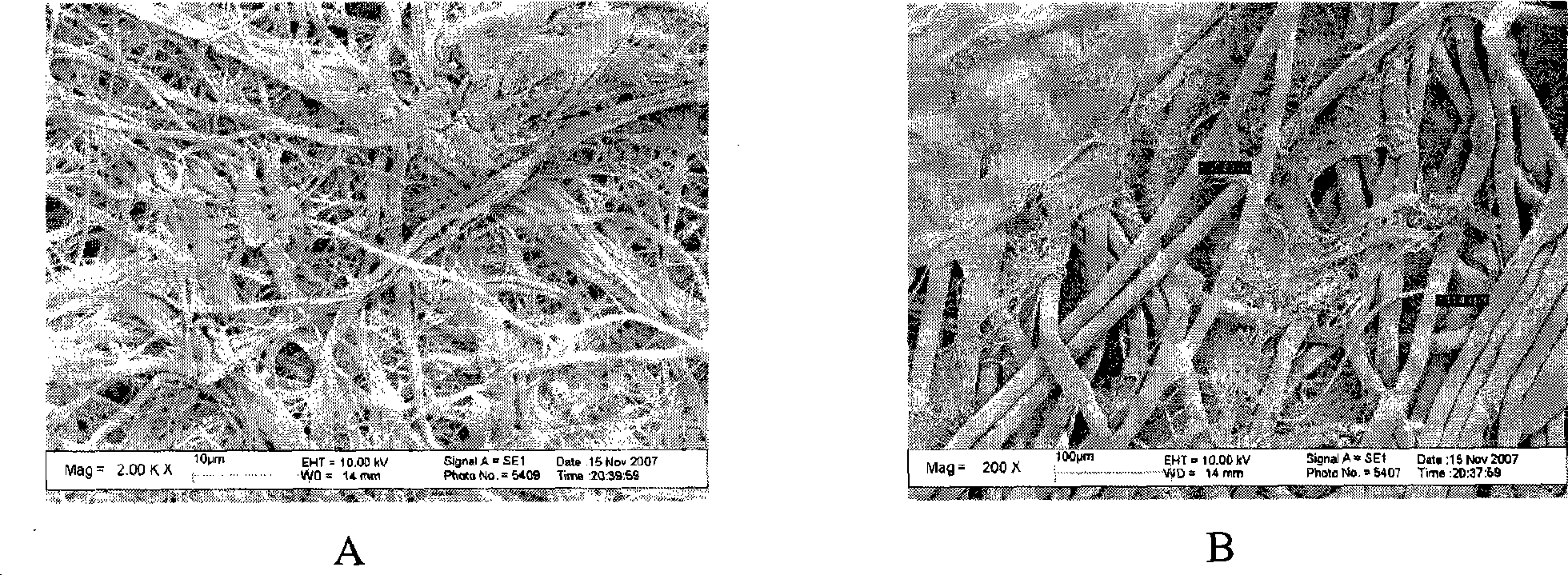

Multiple layer composite micropore filtration separation material and preparation method and use thereof

ActiveCN101380535AImprove uniformityUniform pore size distributionSemi-permeable membranesCell component detailsMicropore FilterElectrical battery

The invention relates to a multi-layer composite micropore filter separation material, a method for preparing the material and the application thereof, wherein, the preparation method comprises the following steps: (1) the fiber which can be fibrillated is prepared into fully fibrillated fiber material by pulping process; (2) the slurry is obtained after the fully fibrillated fiber material is dispersed in water; (3) advancing to the net and shaping are carried out, a layer of nonwoven fabric is placed on a shaping net, the above slurry is dehydrated on the nonwoven fabric directly for compound molding; (4) drying is carried out for obtaining the product. The product can also be processed by hot press molding. The method can be operated easily, is applicable for application of large scale, the obtained multi-layer composite high temperature resistance micropore filter separation material has the outstanding performance of high temperature resistance, meanwhile the uniformity of the holes is excellent, the average aperture can reach 10nm-1mum, and the method can be used in such fields as preparing filter material, battery septum material, electrolytic capacitor paper and double electric layers capacitor septum, etc.

Owner:ZHUZHOU TIMES FIBER PIONEER MATERIAL TECH CO LTD

Friction material composition and friction material for preparing brake pad

The invention provides a friction material composition for preparing a brake pad. The composition contains binding agent, reinforced materials, friction increase agent, lubricating agent and filler, wherein the binding agent contains the binary modified phenolic resin of cashew nut shell oil and chemigum. The invention also provides a friction material for preparing the brake pad. The friction material is obtained in such a way that the friction material composition carries out heat treatment after being molded by hot press, wherein the friction material composition is provided by the invention. The friction material composition for preparing the brake pad can obviously improve the stability of the friction coefficient of the friction material.

Owner:BYD CO LTD

Waterproof and moisture permeable membrane, preparation method of waterproof and moisture permeable membrane, waterproof and moisture permeable fabric and preparation method of waterproof and moisture permeable fabric

InactiveCN104207390AImprove waterproof performanceGood moisture permeabilitySynthetic resin layered productsNon-woven fabricsFiberElectrospinning

The invention provides a waterproof and moisture permeable membrane which sequentially comprises a nano-fiber hydrophilic layer and a nano-fiber hydrophobic layer. The nano-fiber hydrophilic layer is prepared from a hydrophilic polymer by electrostatic spinning; the nano-fiber hydrophobic layer is prepared from a hydrophobic polymer by electrostatic spinning. The waterproof and moisture permeable membrane provided by the invention has good moisture permeability and air permeability; an experiment result shows that the moisture permeability of the waterproof and moisture permeable membrane provided by the invention can reach 10,000g / m<2>24h, and the air permeability of the waterproof and moisture permeable membrane can reach 0.29mL / cm<2>s. The invention also provides a preparation method of the waterproof and moisture permeable membrane. According to the preparation method provided by the invention, the nano-fiber hydrophilic layer and the nano-fiber hydrophobic layer which are prepared by electrostatic spinning are subjected to hot-pressing compounding, so that the obtained waterproof and moisture permeable membrane has better performance and can be integrally formed without being adhered by an adhesive; the production process is simplified; the waterproof and moisture permeable membrane is easy for industrial production. The invention also provides a waterproof and moisture permeable fabric and a preparation method thereof.

Owner:ZHEJIANG WEIXING IND DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com