Patents

Literature

95results about How to "Easy to process precisely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

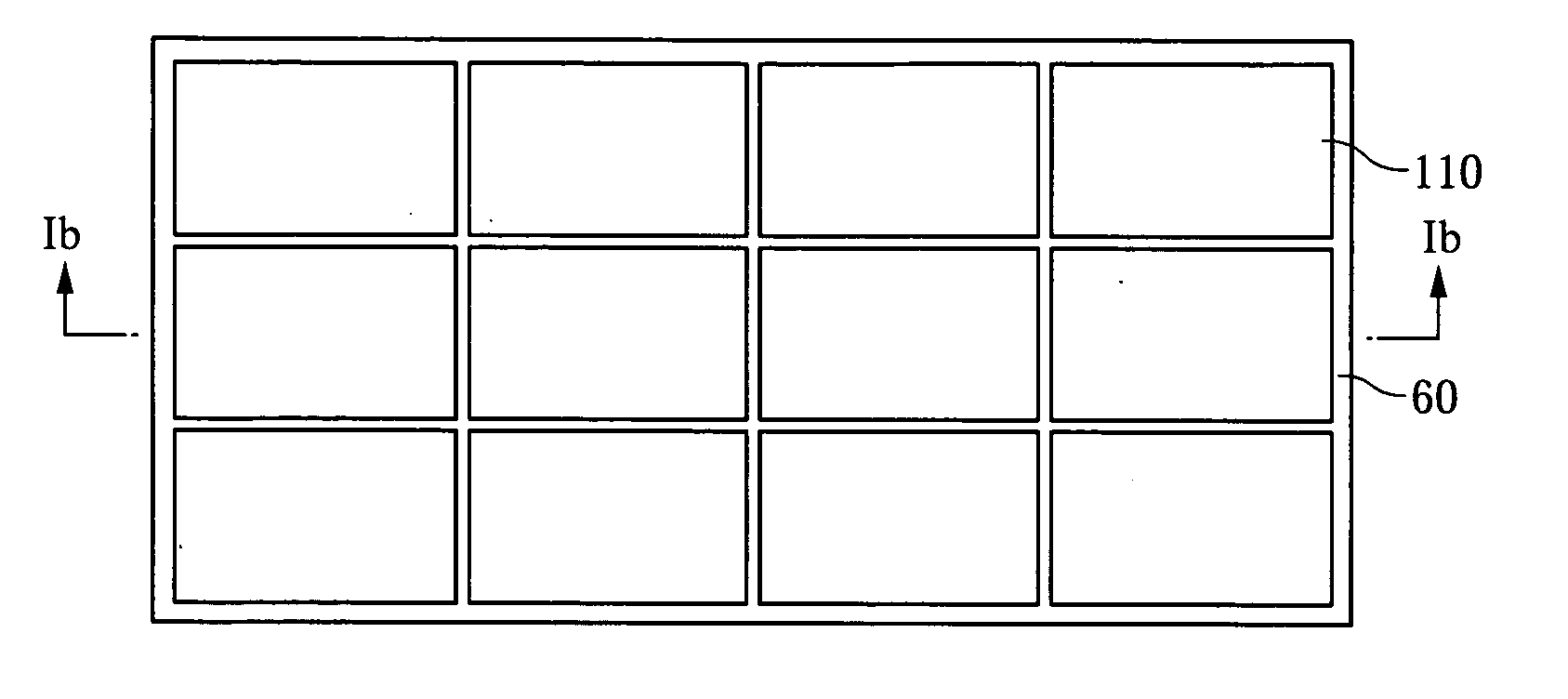

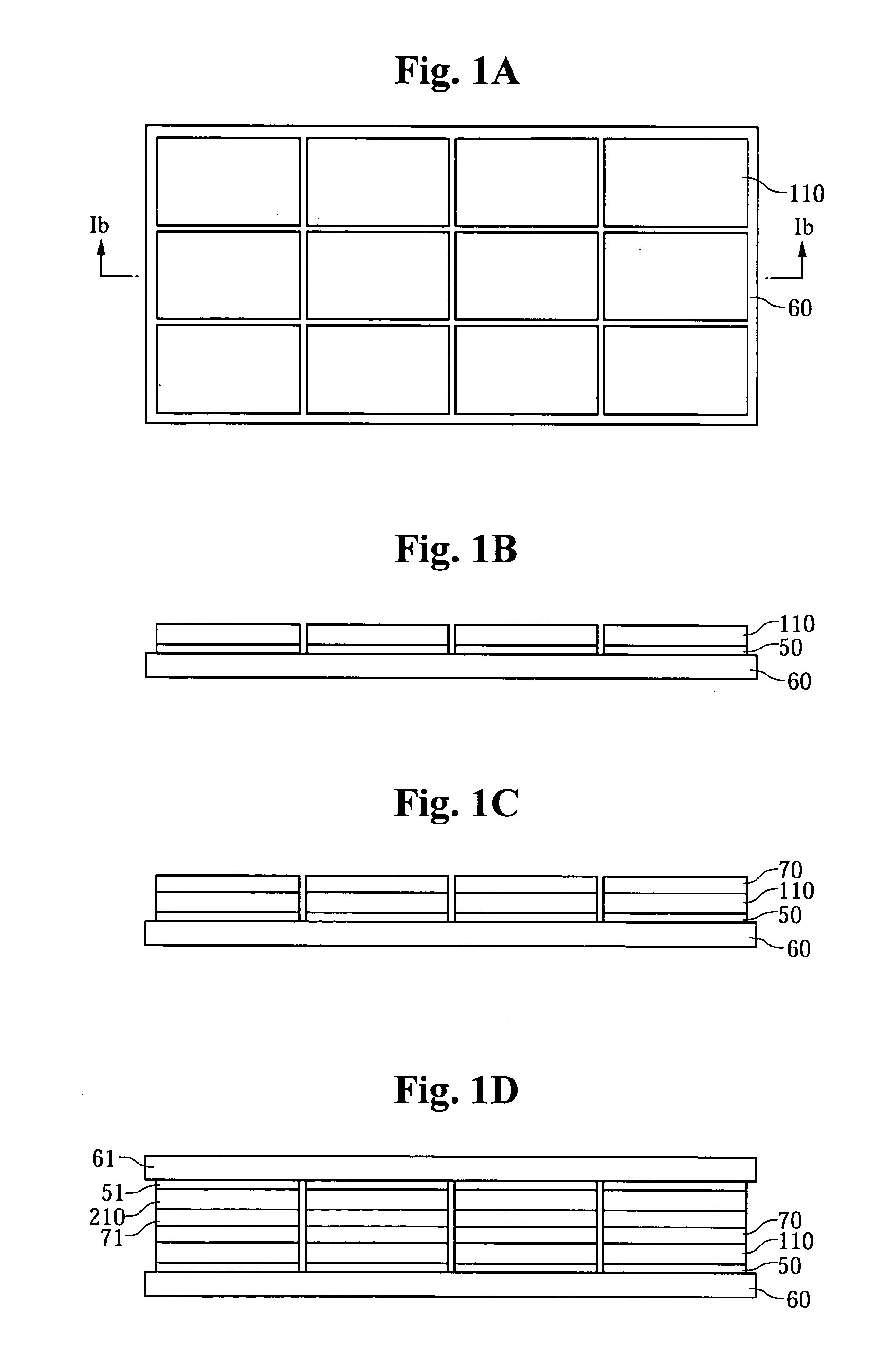

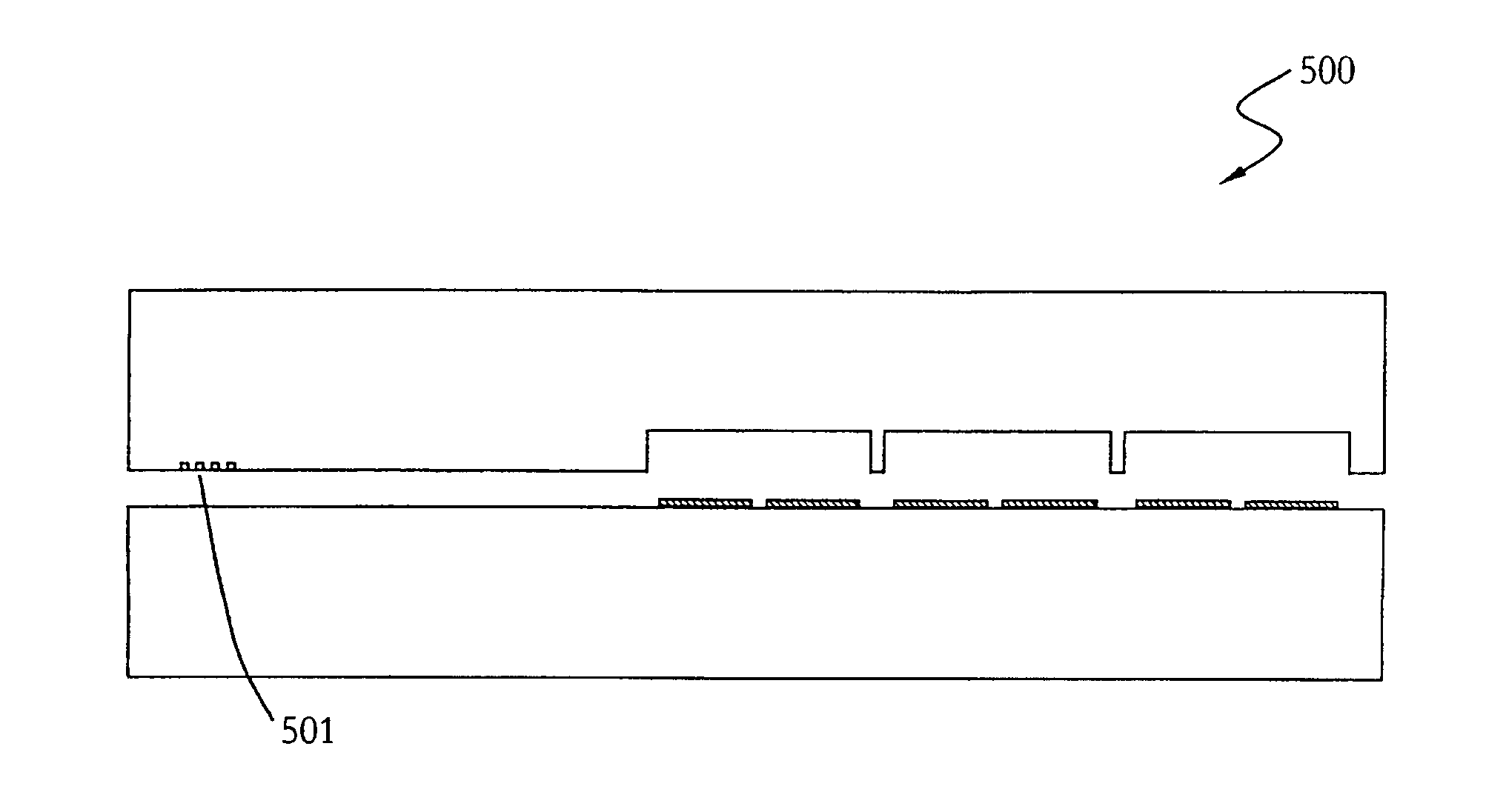

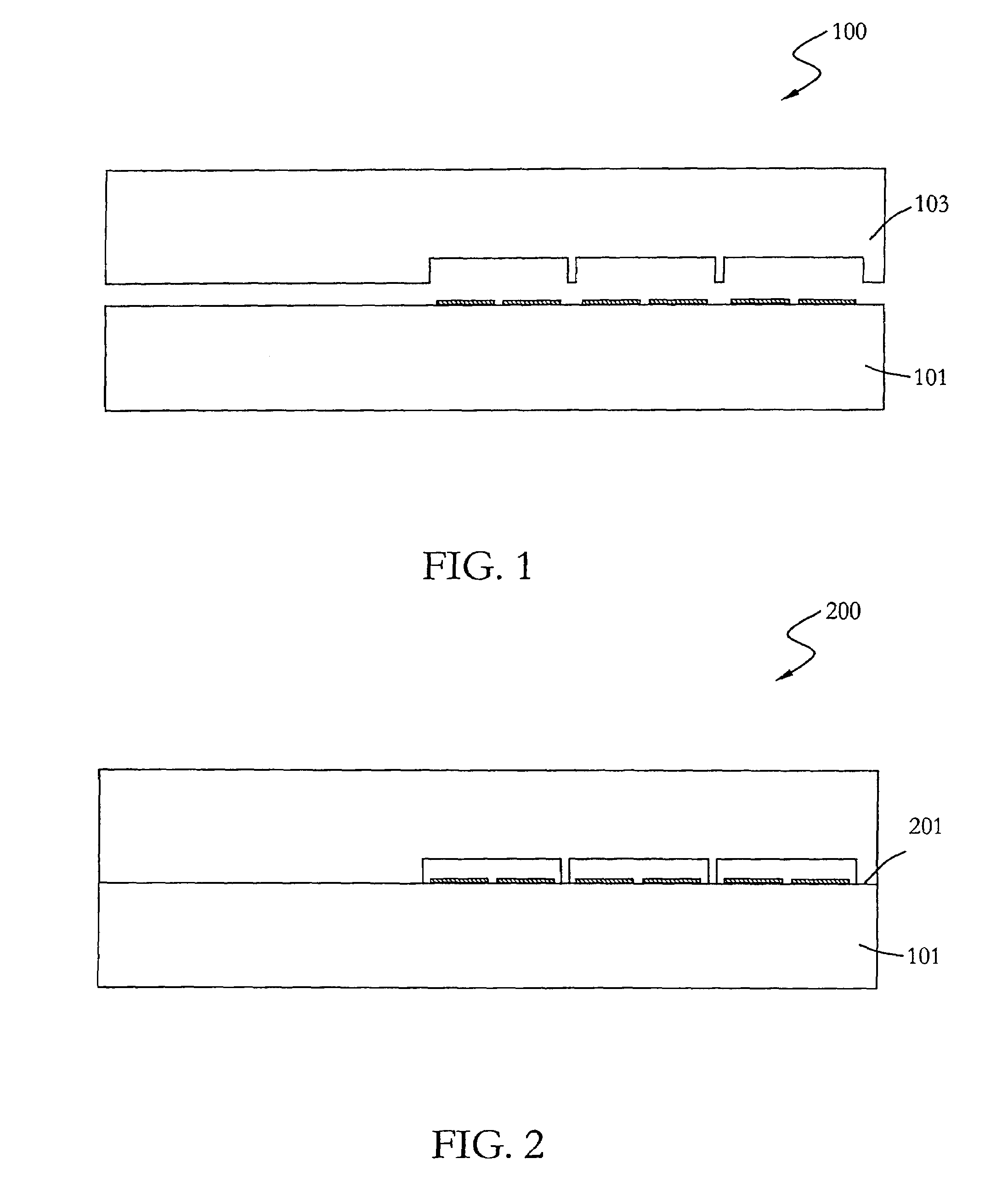

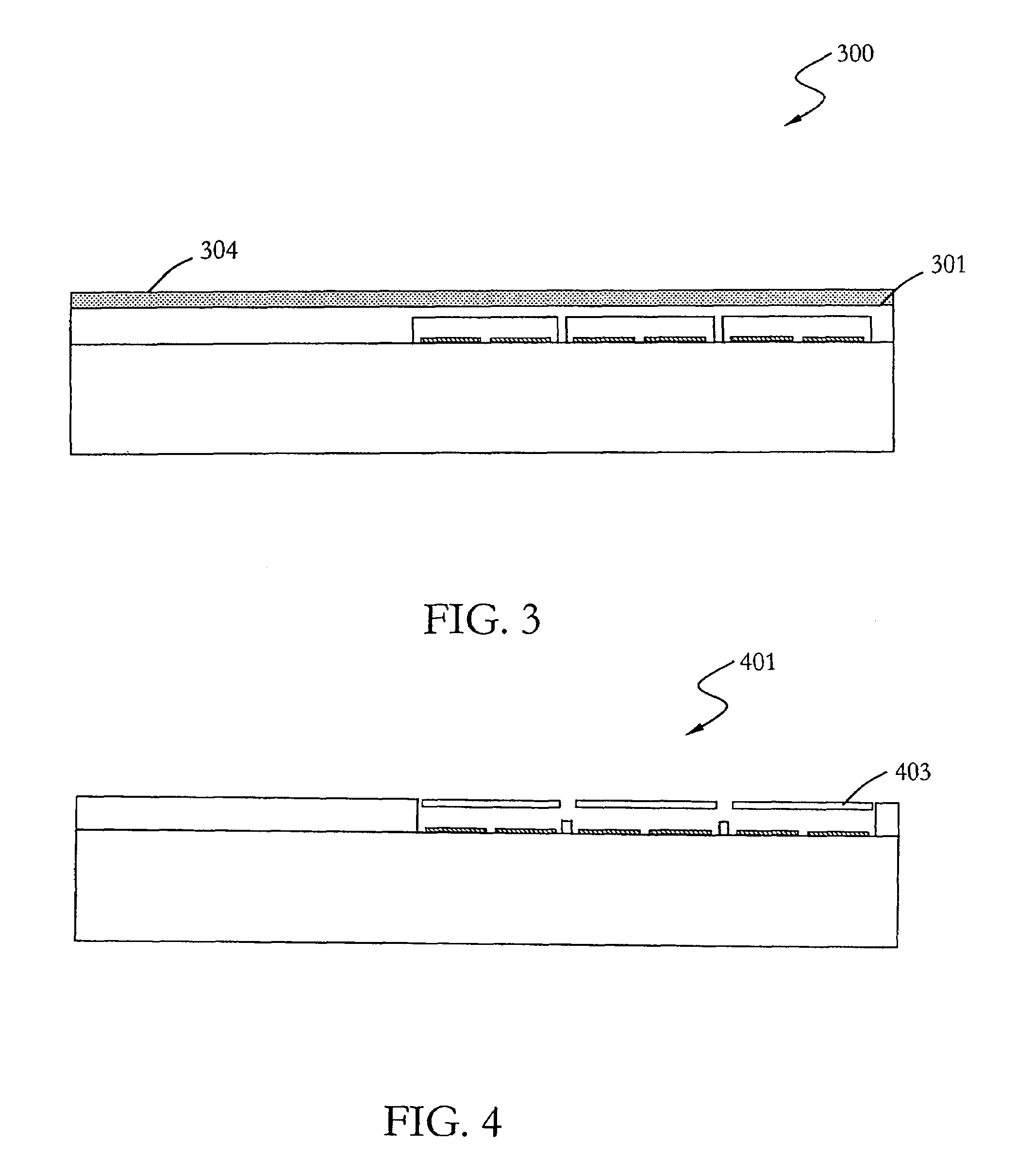

Method of manufacturing a flexible display device

InactiveUS20060278333A1Improve production yieldEasily and accuratelyLamination ancillary operationsLaminationManufacturing technologyEngineering

A method of manufacturing a flexible display is provided, which includes adhering a first flexible mother substrate to a first supporter, cutting the first flexible mother substrate to divide the first flexible mother substrate into a plurality of first substrates, and forming a thin film pattern on the first substrates. Thus, the production yield of a flexible display device may be improved and the manufacturing process is more precise and easier.

Owner:SAMSUNG ELECTRONICS CO LTD

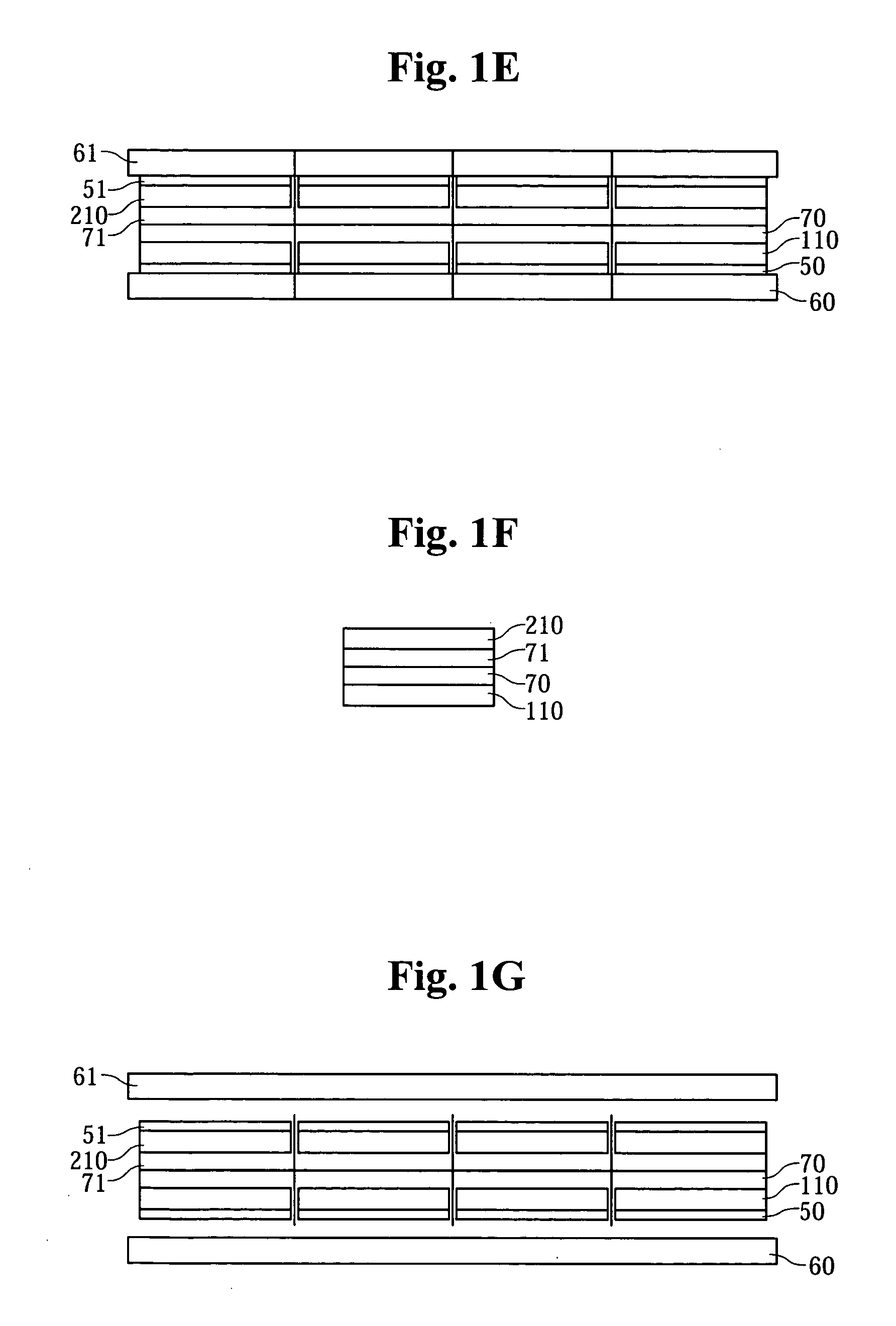

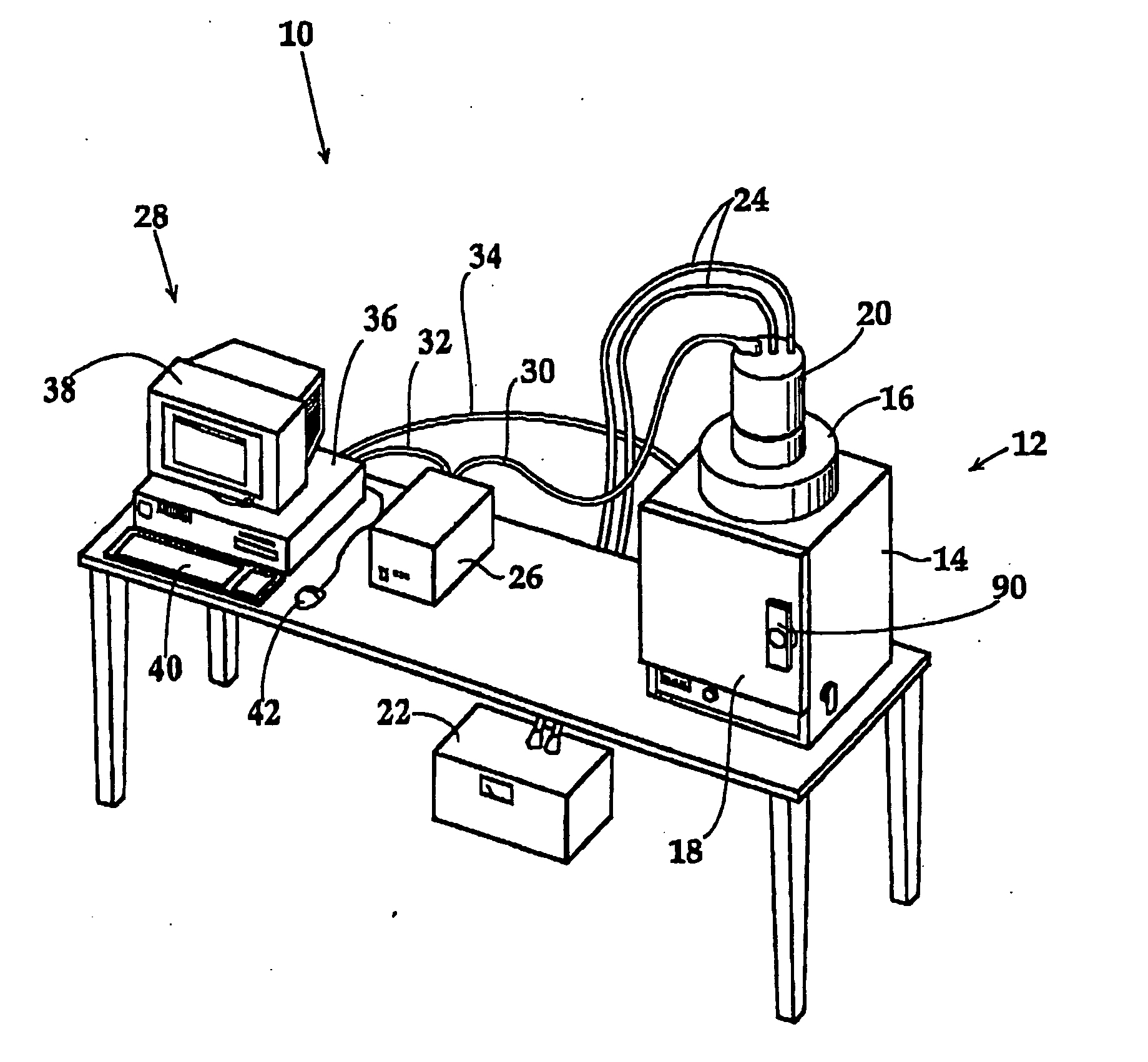

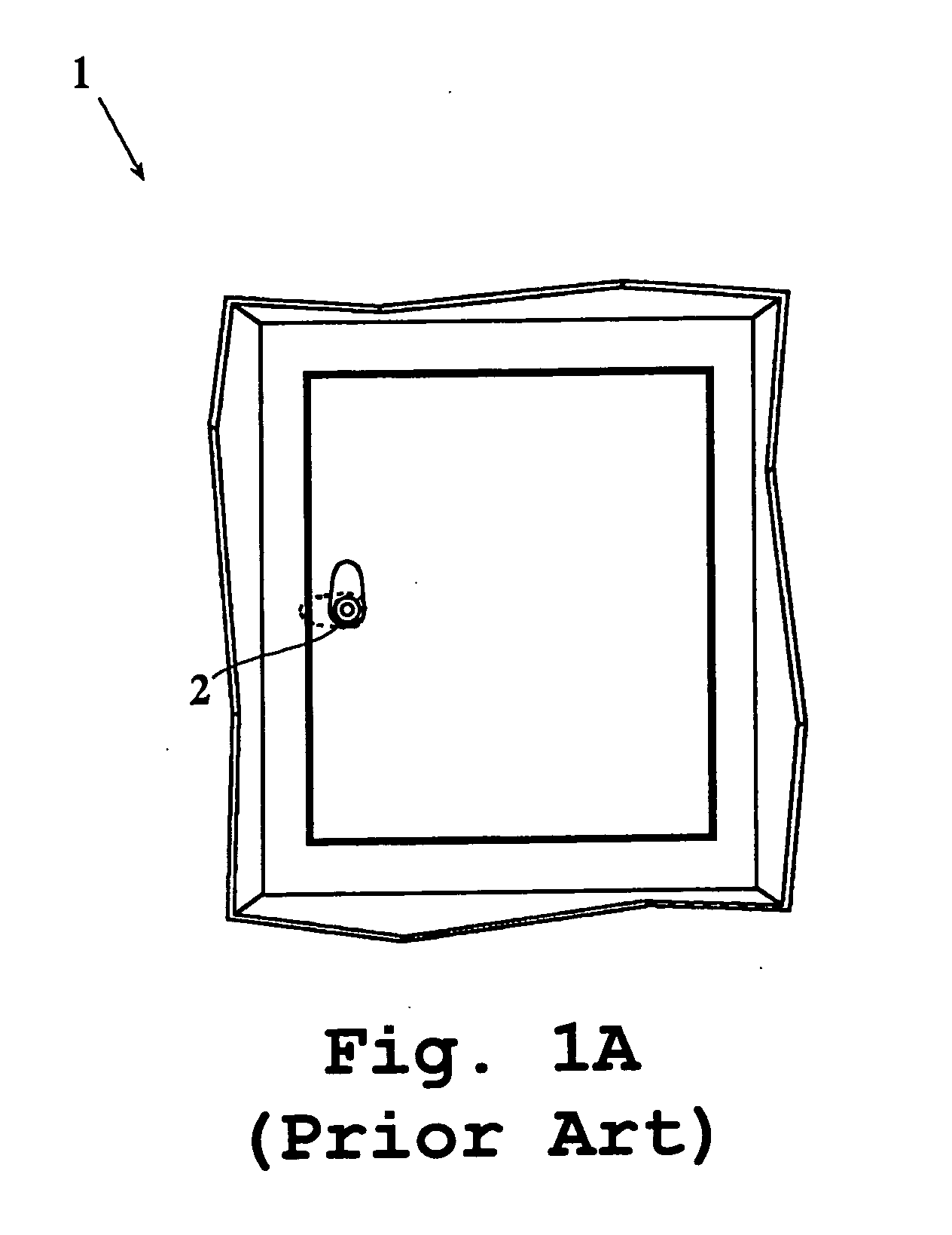

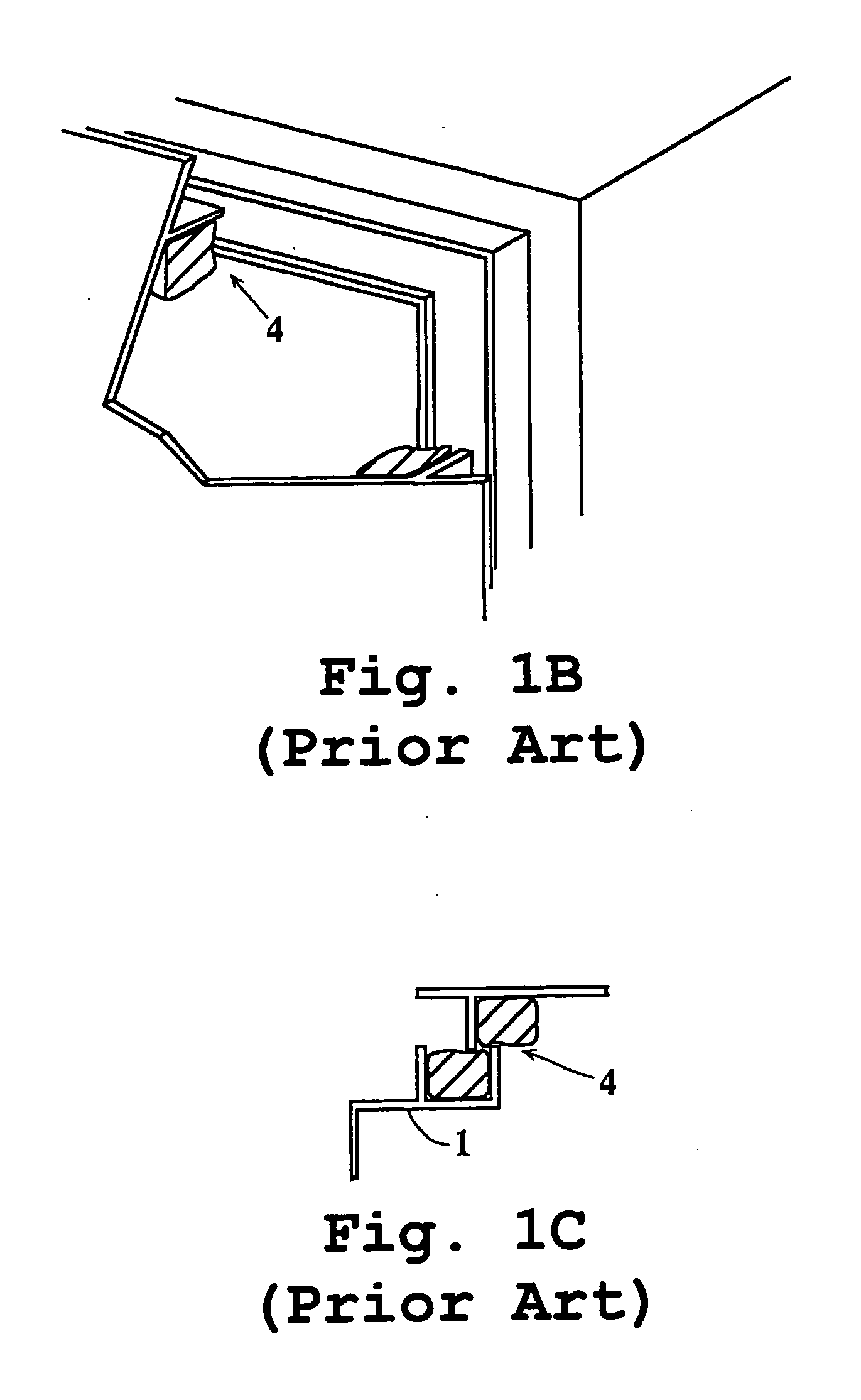

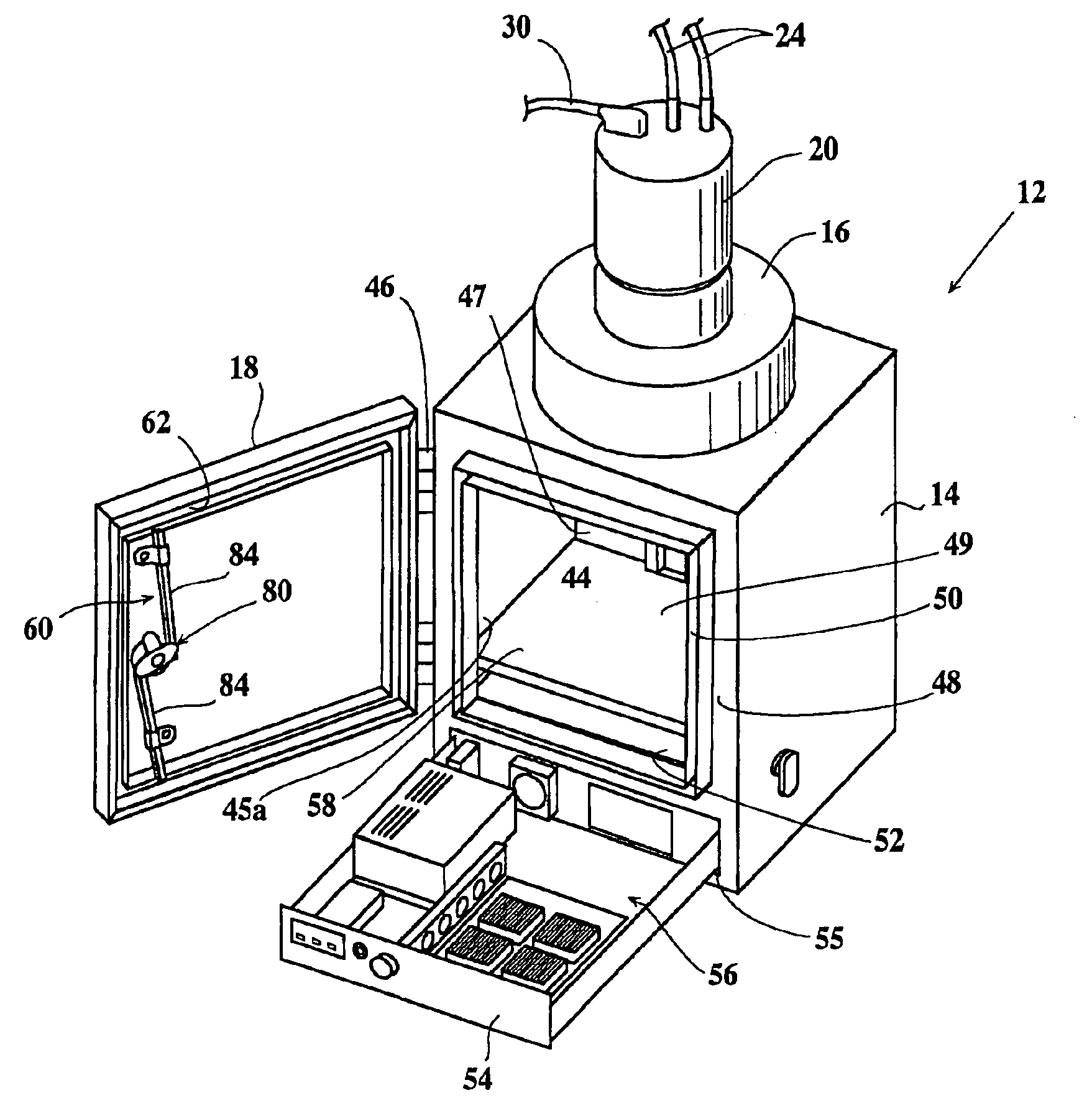

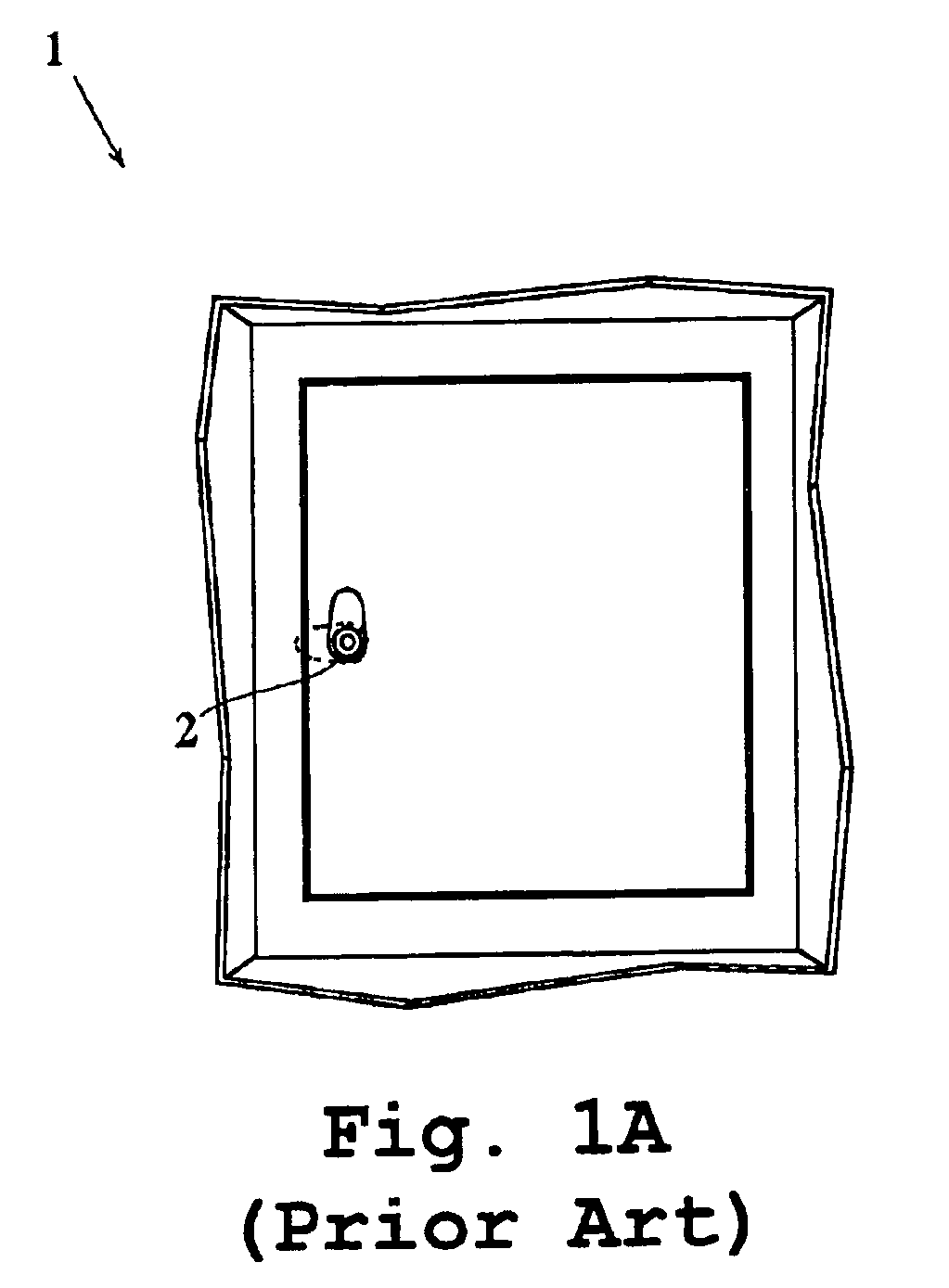

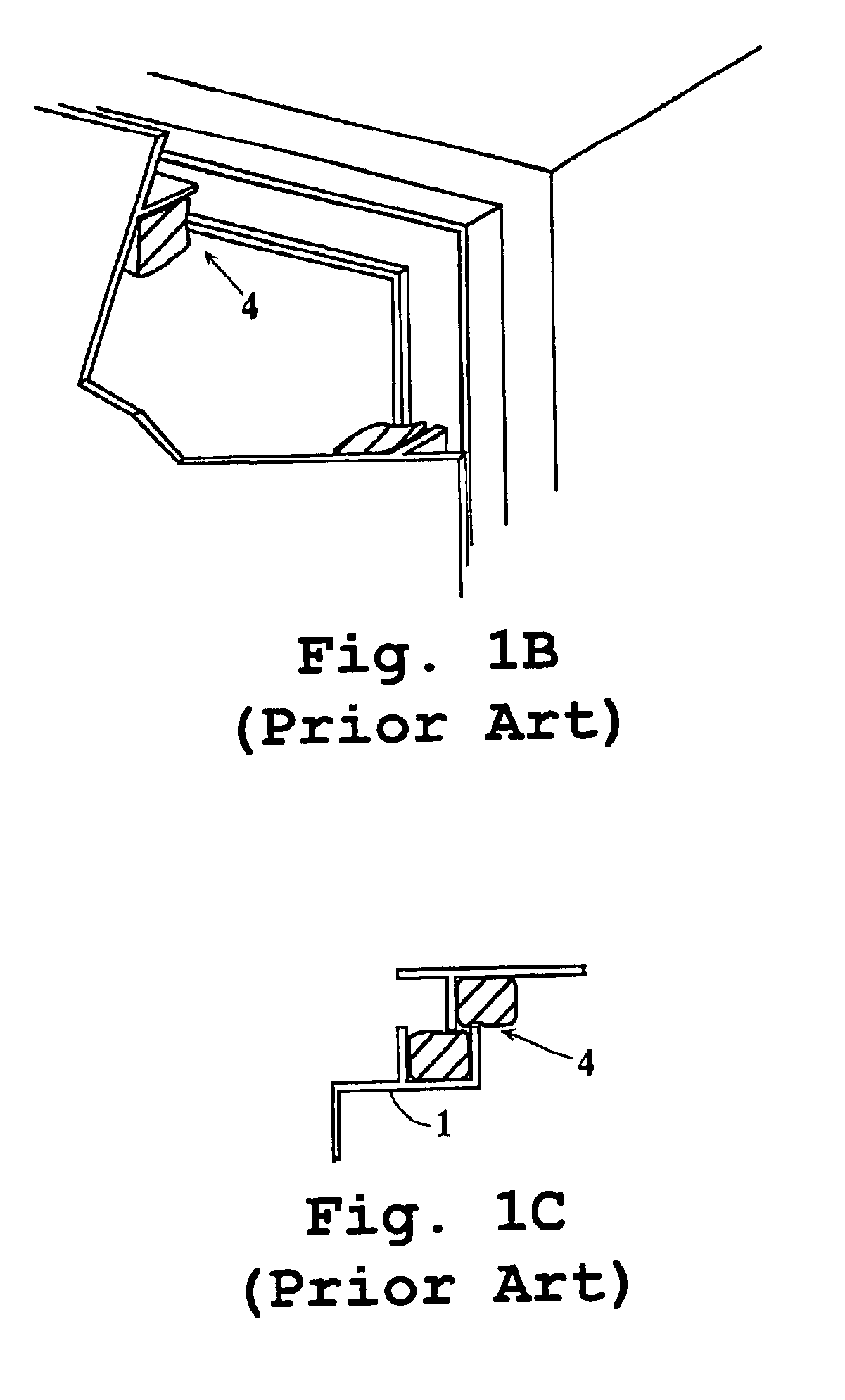

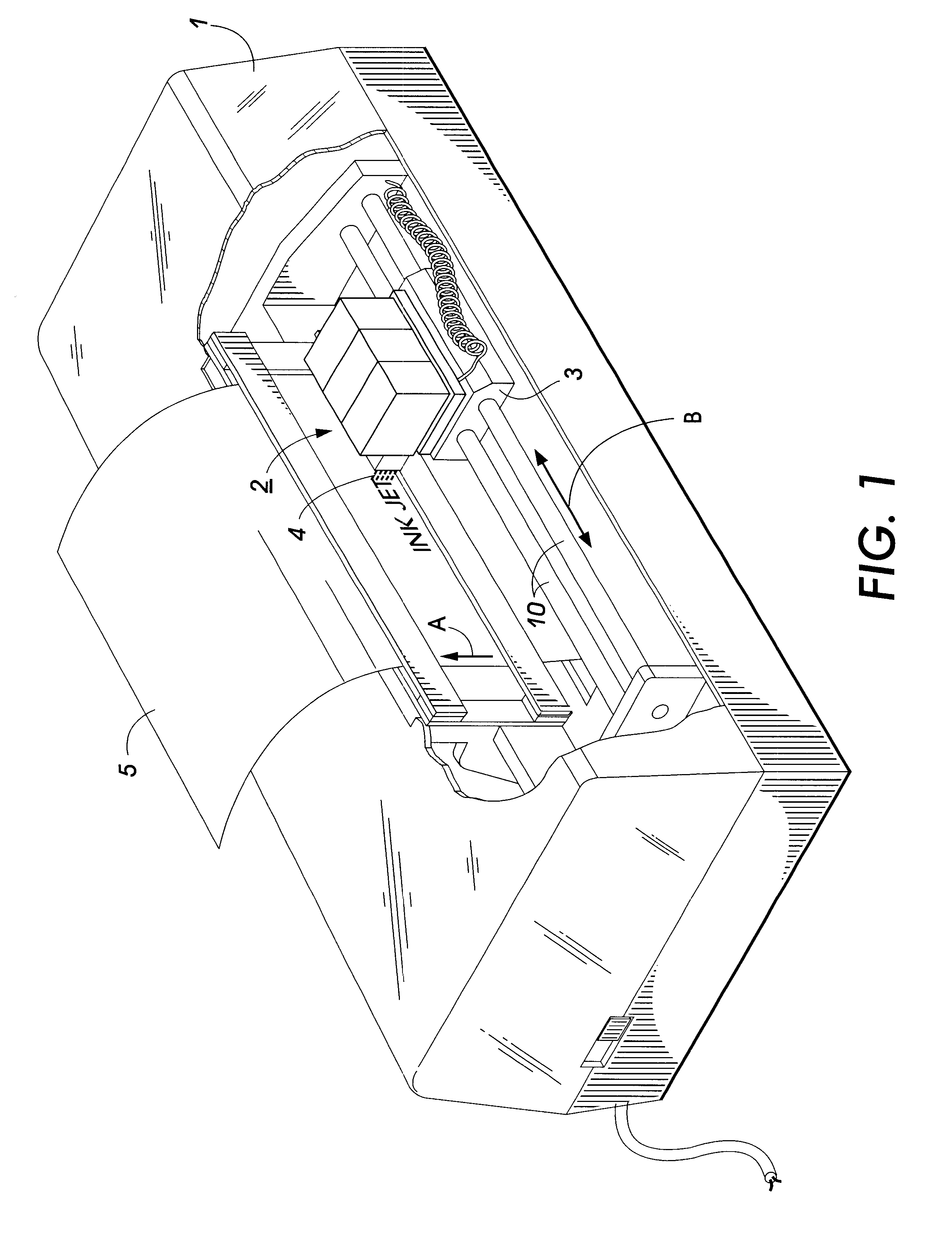

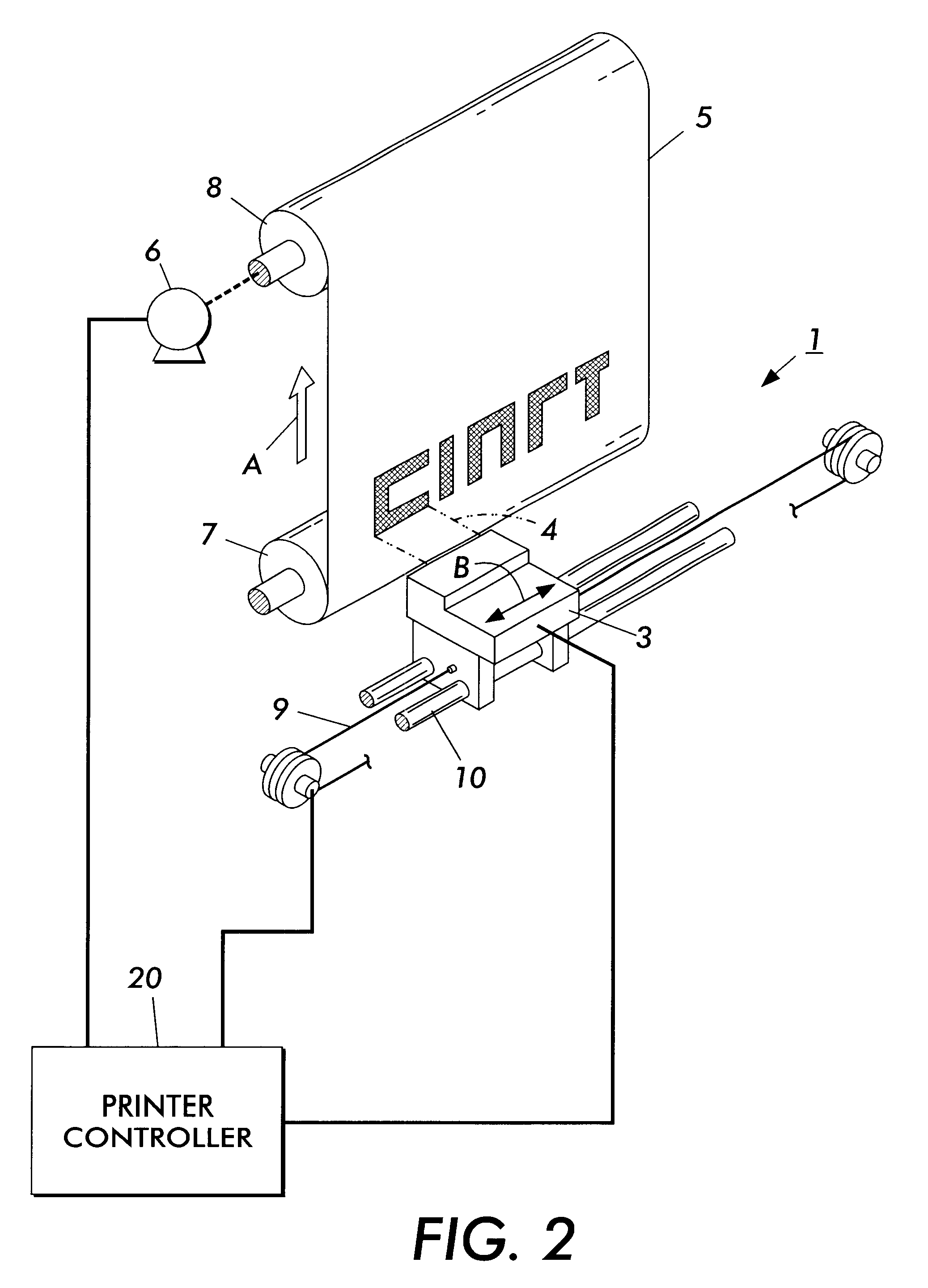

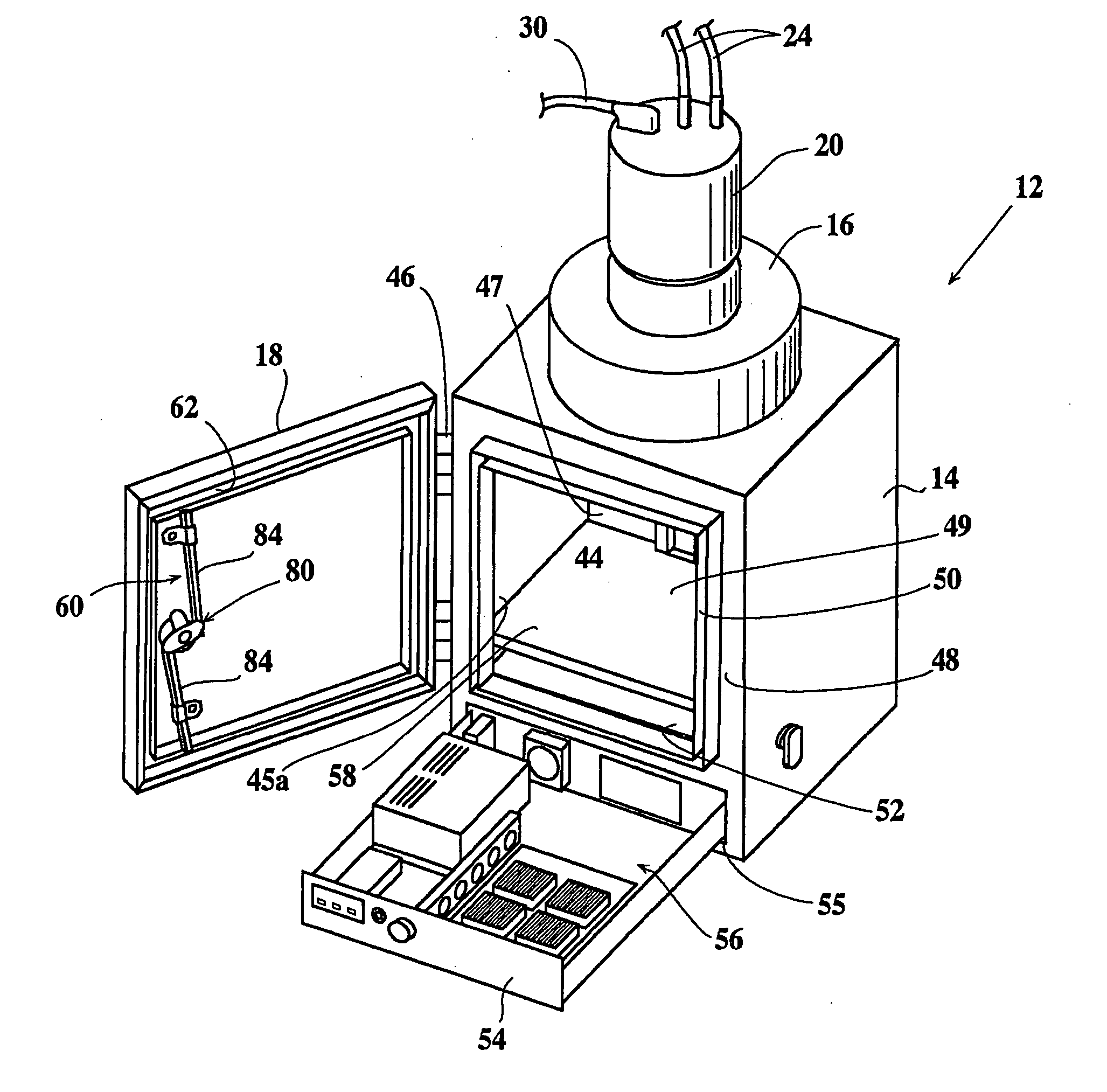

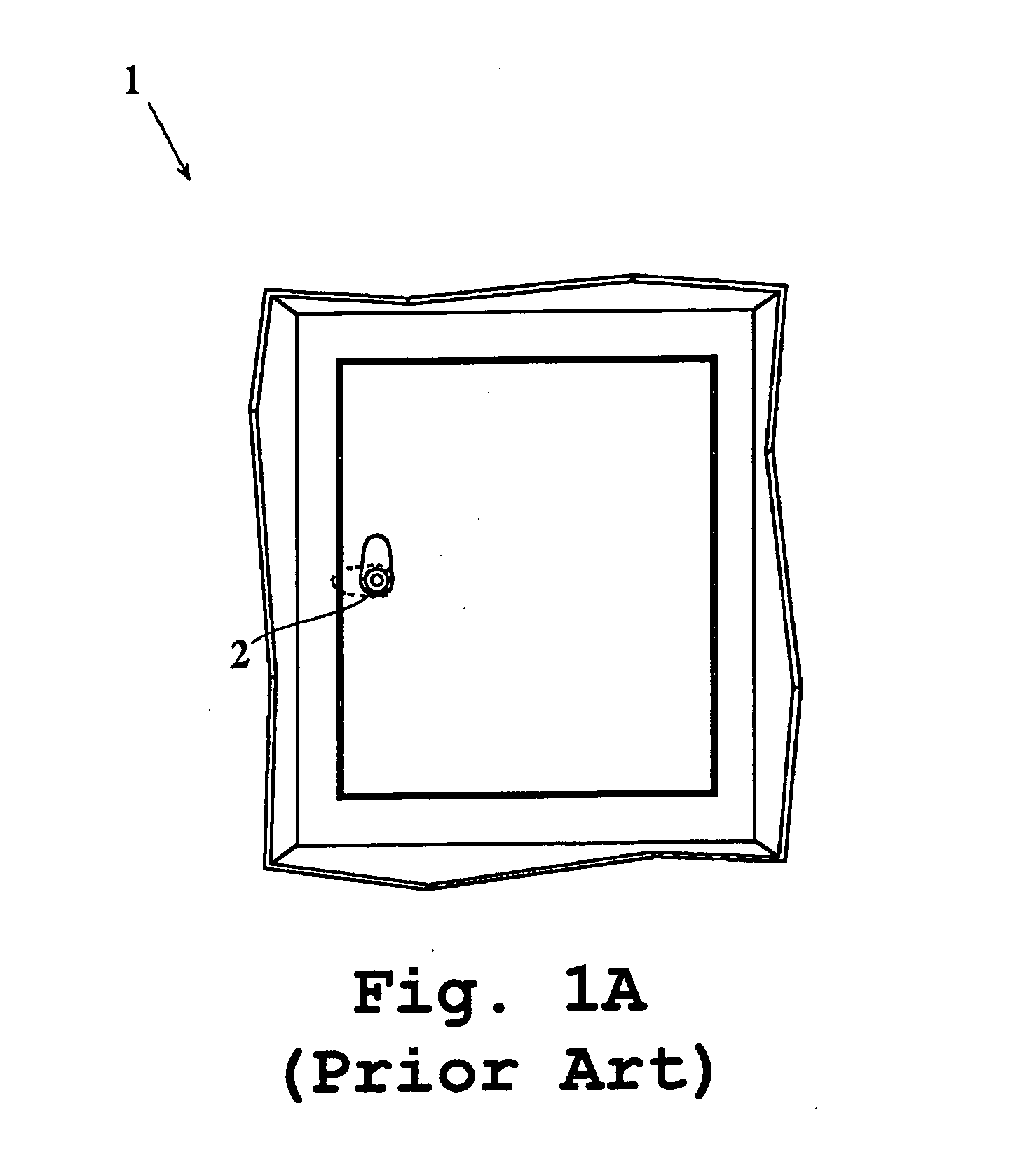

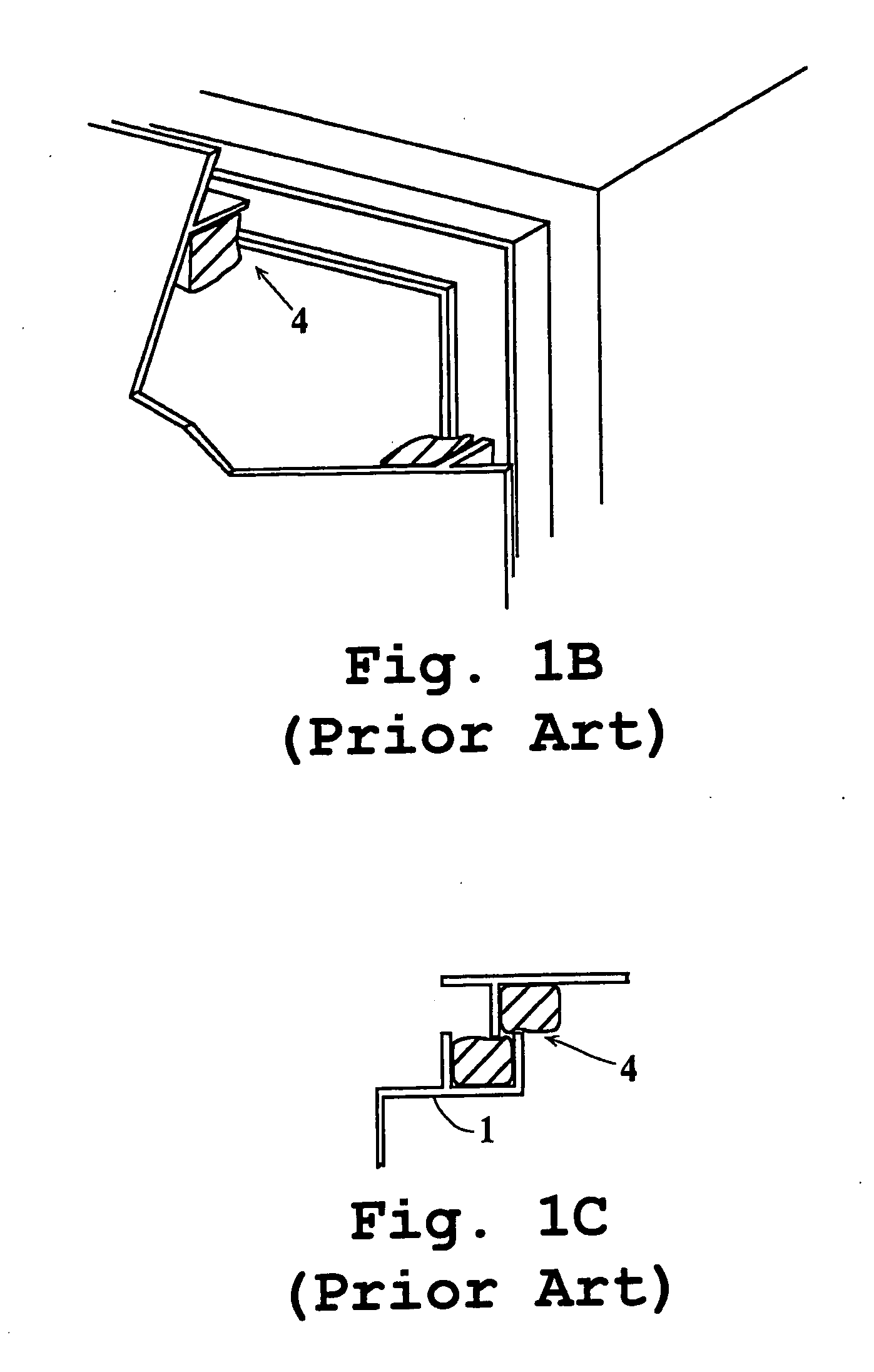

Imaging apparatus

InactiveUS20050148846A1Easy to controlImprove sealingTelevision system detailsChemiluminescene/bioluminescenceRadiologyImaging equipment

An improved imaging apparatus is disclosed that allows a user to perform numerous imaging operations. The imaging apparatus may include one or more improvements to imaging box design to improve illumination control within the imaging box, such as improved door seal arrangements, improved door closing mechanisms, and improved light seals. The present invention may also include one or more improvements to imaging apparatus design to facilitate image capture, such as: an automated filter select device, a moveable stage, automated focus control, f-stop adjustment and stage height, and improved internal illumination for capturing photographic images.

Owner:XENOGEN CORP

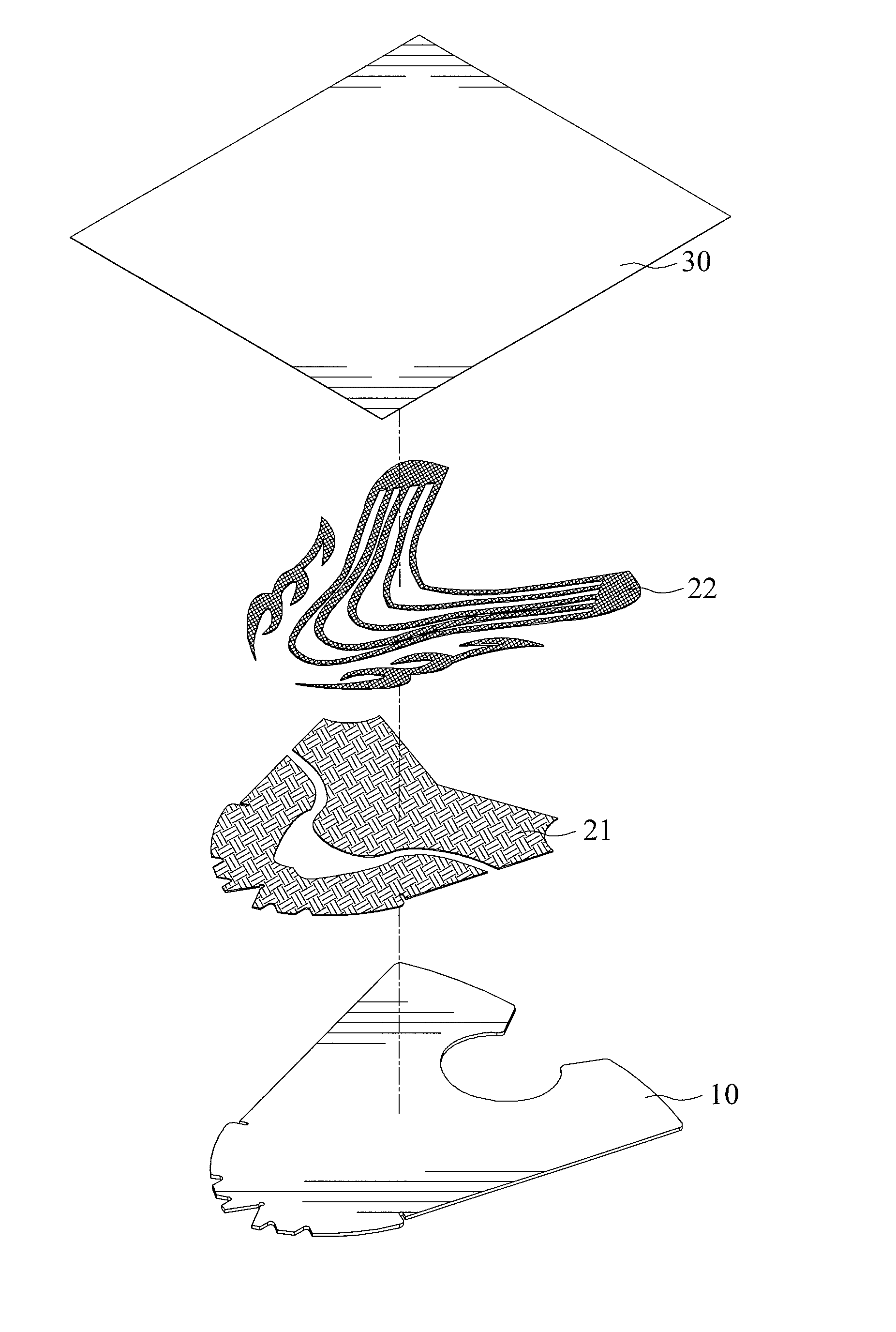

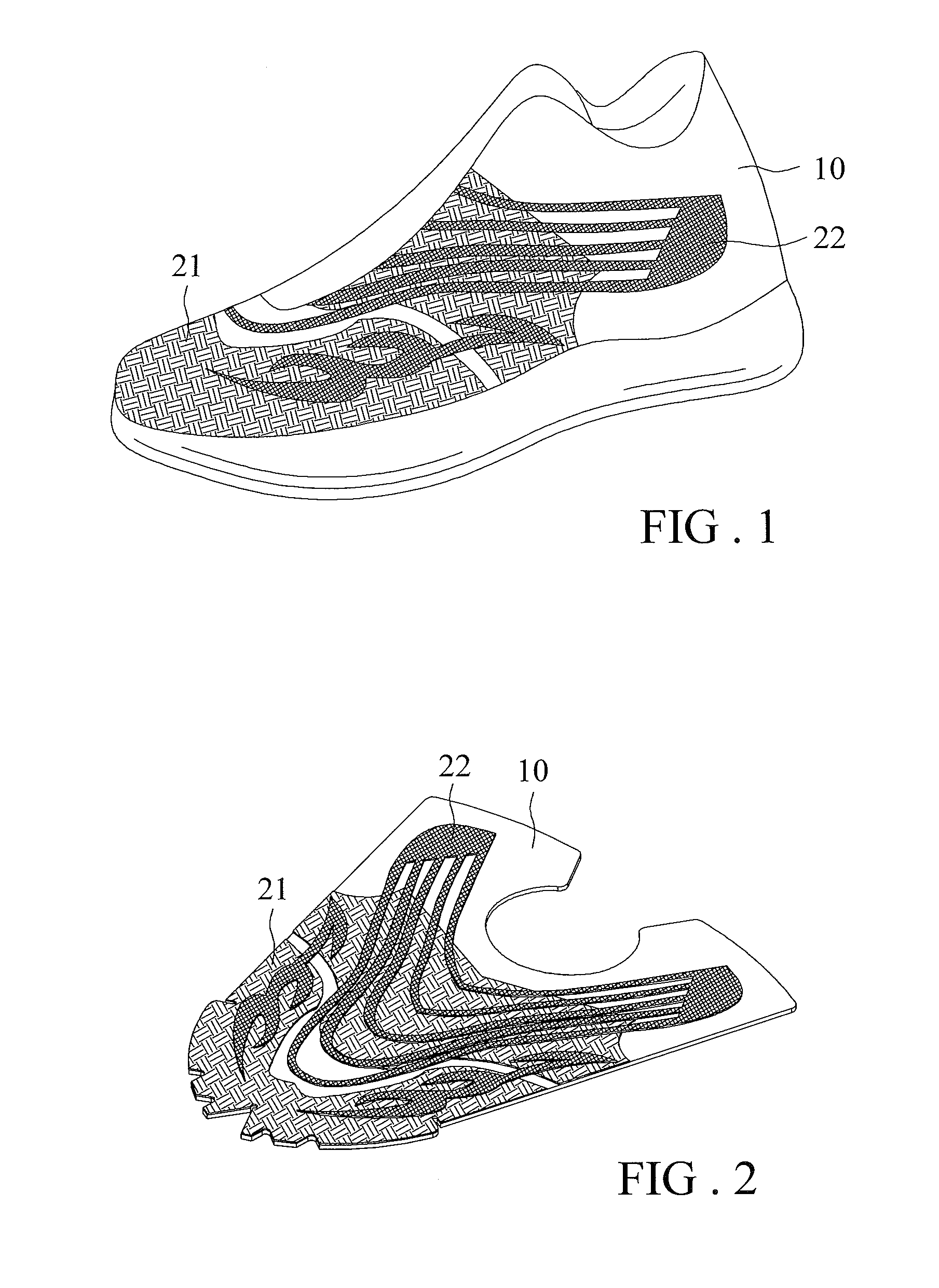

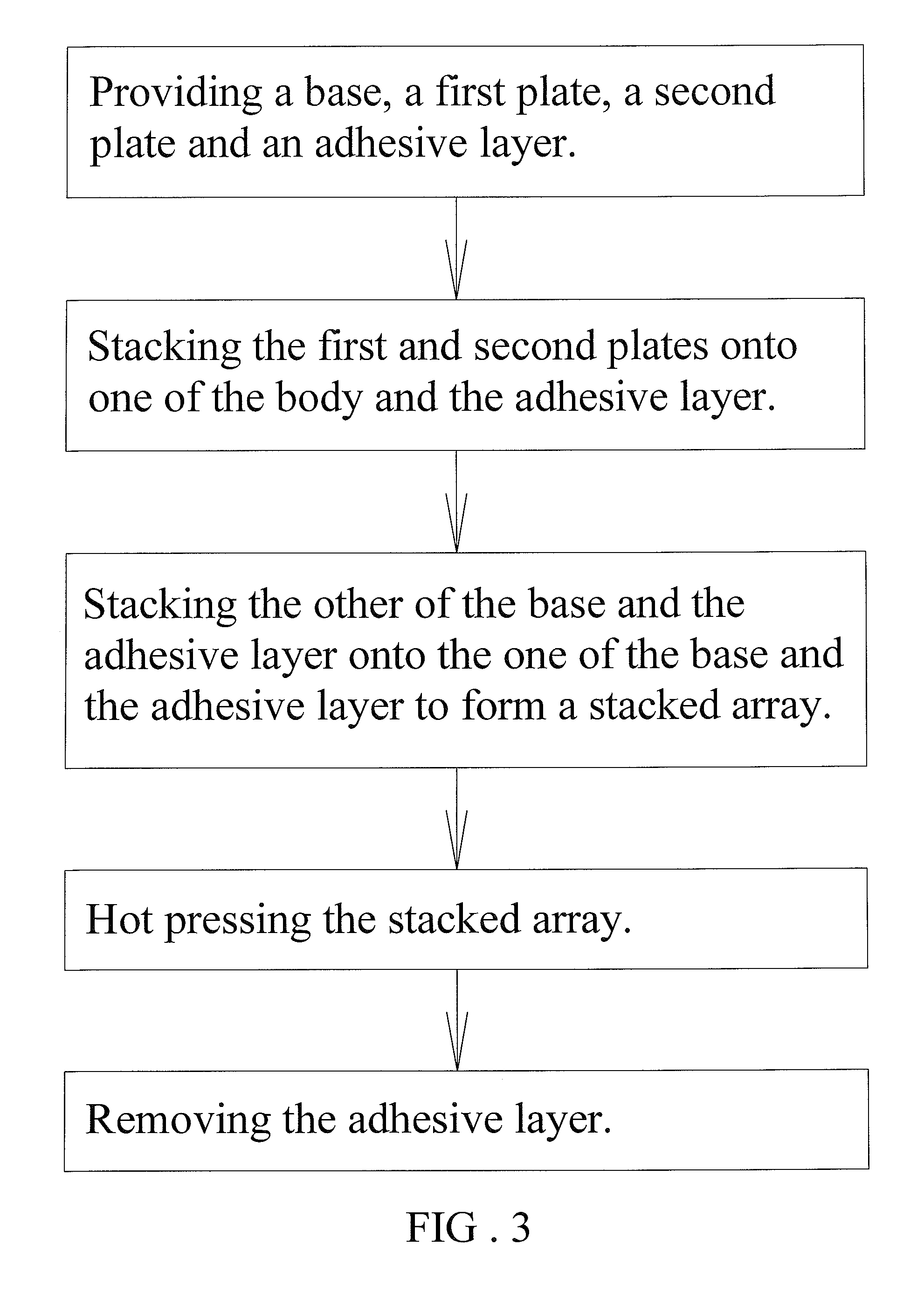

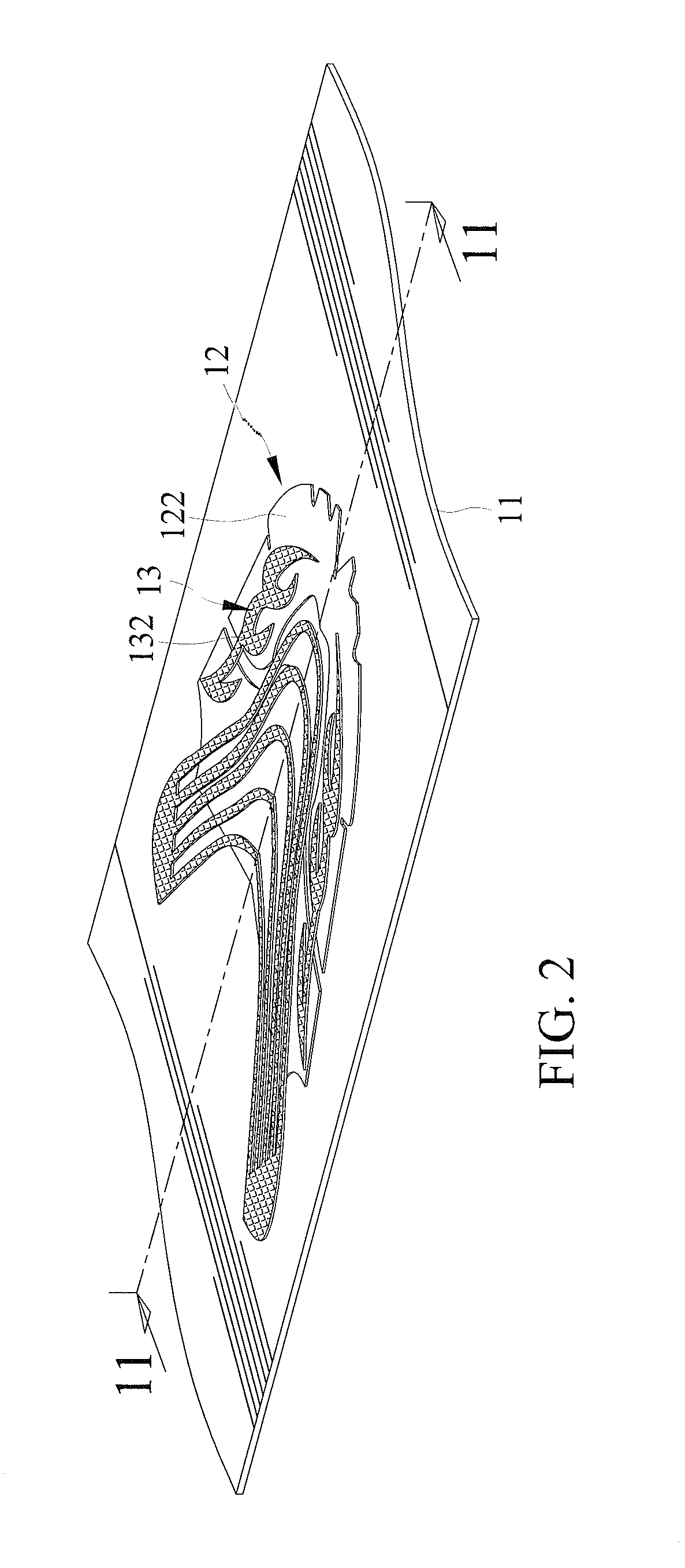

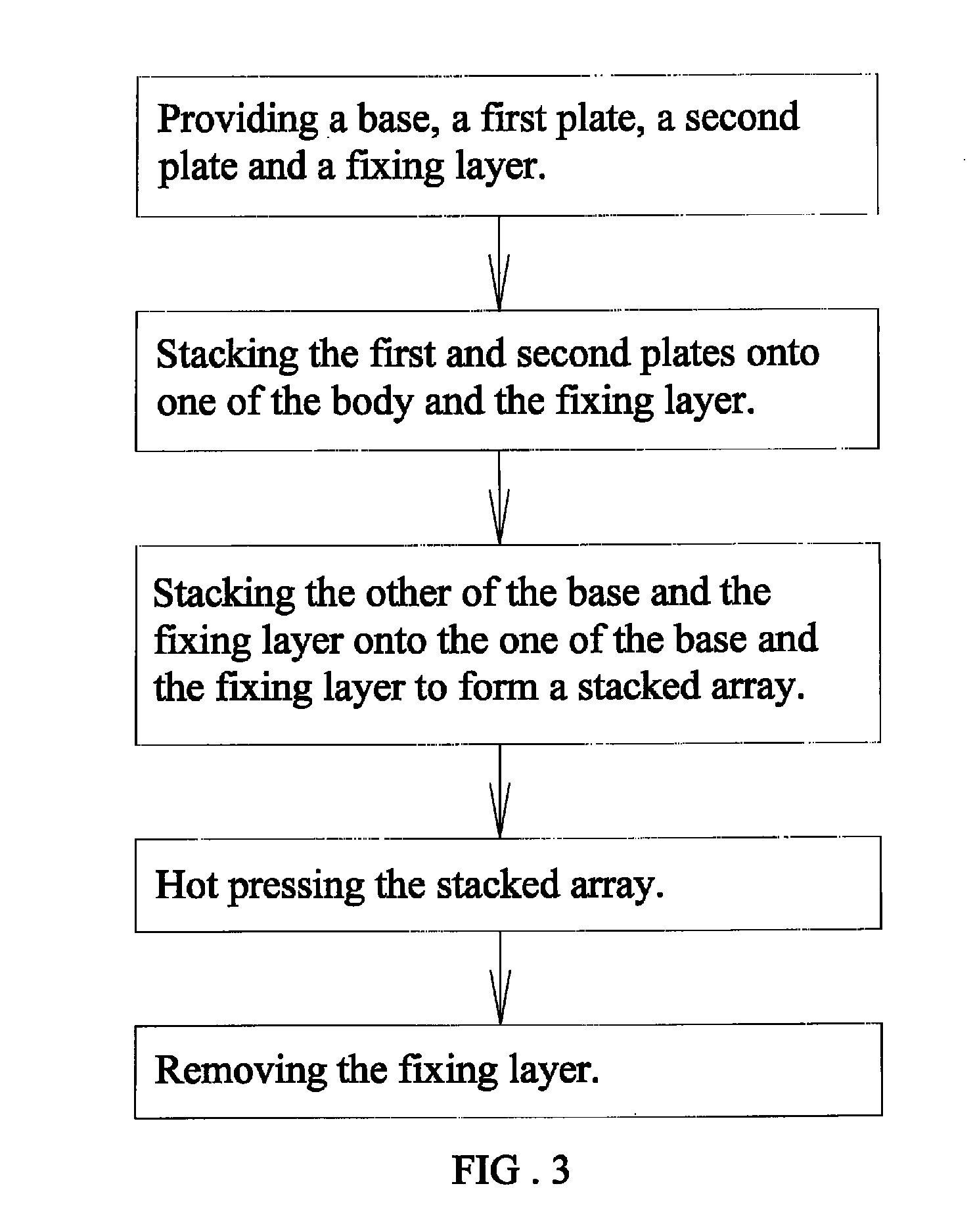

Multi-layer Decorating Element and Method of its Manufacture

ActiveUS20120189852A1Precise processingEasy to process preciselyLamination ancillary operationsDecorative surface effectsEngineeringHot press

A method for producing a multi-layer decorating element includes the steps of: (a) providing a base, a first plate, a second plate and an adhesive layer; (b) stacking the first and second plates onto one of the base and the adhesive layer; (c) stacking the other of the base and the adhesive layer onto one of the base and the adhesive layer to form a stacked array; (d) hot pressing the stacked array; and (e) removing the adhesive layer.

Owner:JAH YIH ENTERPRISE

Optical filter, optical filter system, spectrometer and method of fabrication thereof

ActiveUS20200064195A1Simple processEasy to manufactureSpectrum investigationOptical filtersDetector arrayRefractive index

A nano-structured optical wavelength transmission filter is provided. The optical filter includes a patterned substrate on which a high refractive index dielectric waveguide is arranged. A low index dielectric layer is arranged on the high refractive index dielectric waveguide, on which an array of metallic nanostructures is arranged. The layers of the optical filter have conformal shapes defined by a patterned surface of the substrate. An optical filter system includes the optical transmission filter and a detector array fixed to the substrate. A spectrometer includes at least one optical transmission filter and / or at least one said optical transmission filter system, and has a spectral resolution of lower than 30 nm for incident light having a wavelength between 300 nm and 790 nm. A method of fabrication of an optical filter, an optical filter system and a spectrometer is also described.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

Imaging apparatus

InactiveUS6901279B2Easy to controlImprove sealingTelevision system detailsChemiluminescene/bioluminescenceEngineeringImaging equipment

An improved imaging apparatus is disclosed that allows a user to perform numerous imaging operations. The imaging apparatus may include one or more improvements to imaging box design to improve illumination control within the imaging box, such as improved door seal arrangements, improved door closing mechanisms, and improved light seals. The present invention may also include one or more improvements to imaging apparatus design to facilitate image capture, such as: an automated filter select device, a moveable stage, automated focus control, f-stop adjustment and stage height, and improved internal illumination for capturing photographic images.

Owner:XENOGEN CORP

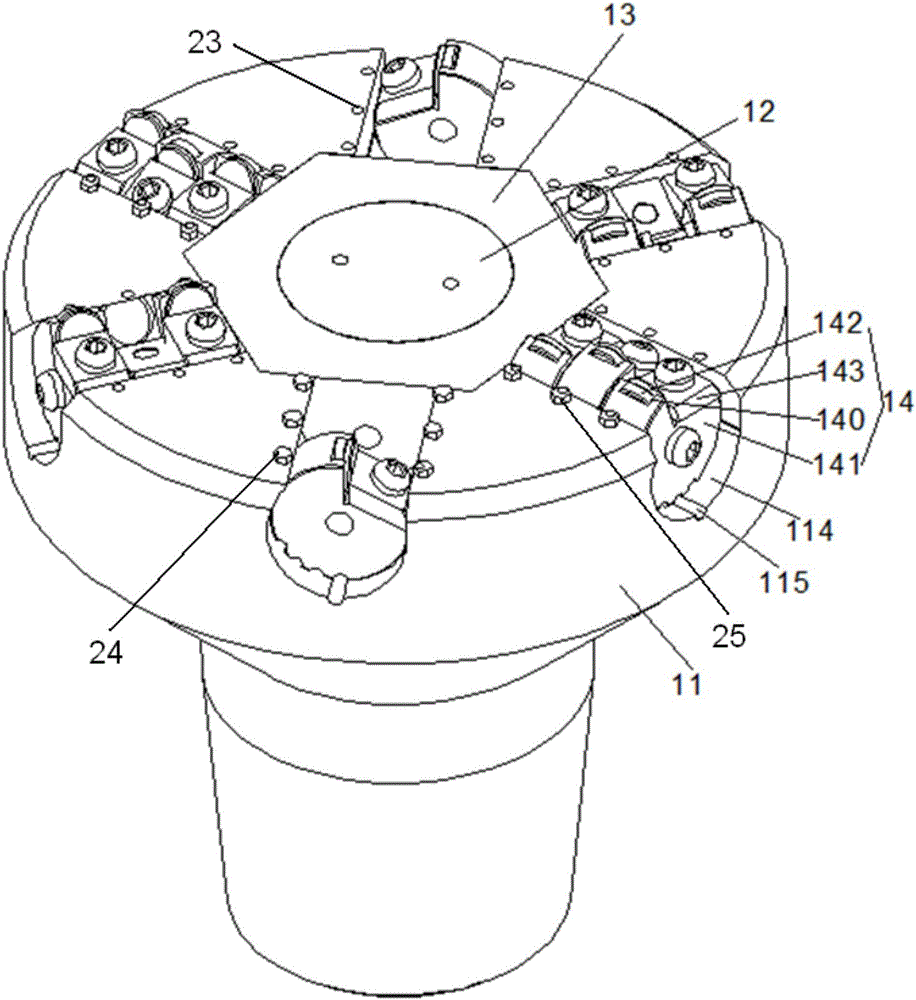

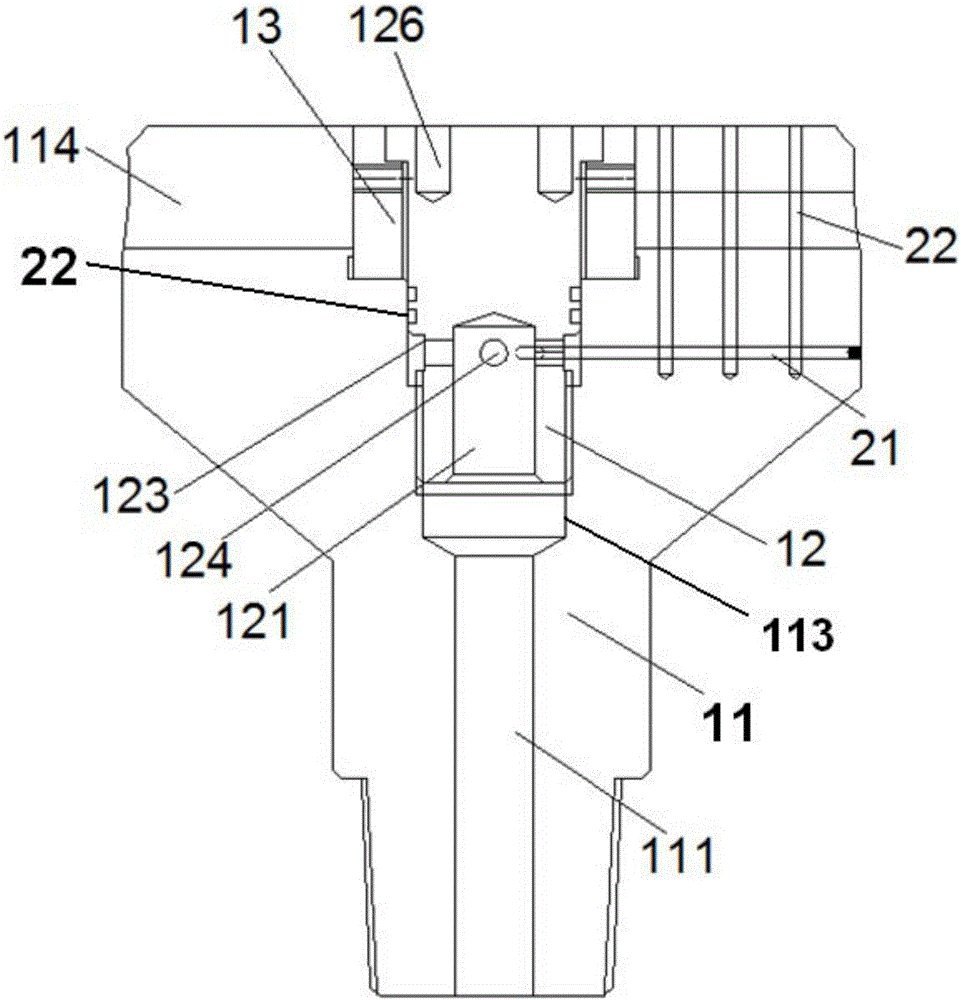

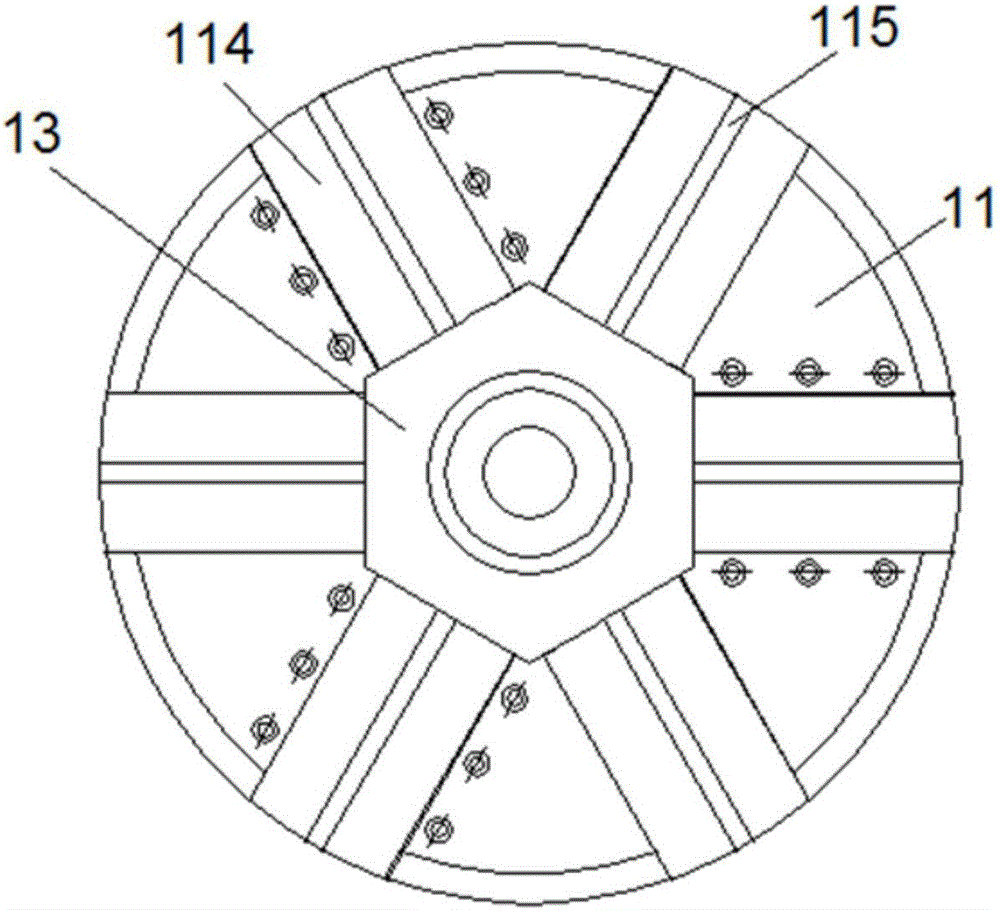

Multifunctional high-pressure water jet-PDC tooth combined rock-breaking experiment drill bit

The invention provides a multifunctional high-pressure water jet-PDC tooth combined rock-breaking experiment drill bit. The drill bit comprises a drill bit body and clamping devices. A plurality of clamping device installation grooves are formed in the upper end face of the drill bit body, the clamping devices are installed in the clamping device installation grooves respectively, the clamping devices are detachably provided with cutting teeth, and the relative angles and the positions of the clamping devices and the installation grooves are adjustable. Rock breaking behaviors and efficiency of individual teeth and the drill bit under different teeth distribution modes can be researched, the use efficiency of the drill bit is improved, and the experiment cost is reduced. Nozzles can be detached, whether jet nozzles are installed or not can be determined according to requirements, and jet flow channels at different angles are machined in different nozzles, so that efficiency during rock impacting and rock debris carrying relative to different jet angles of tooth pieces is researched. The jet flow channels are machined in the two sides of each tooth piece on the drill bit body respectively, so the nozzles can be installed at different relative positions of the tooth pieces to research the influence of the PDC tooth and water jet relative position matching relationship on rock breaking.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

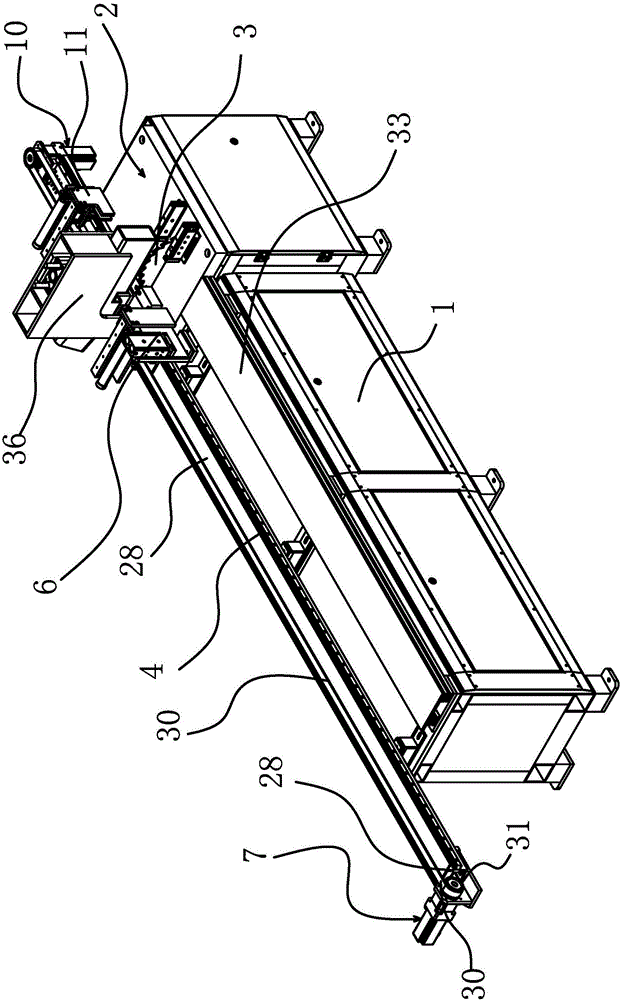

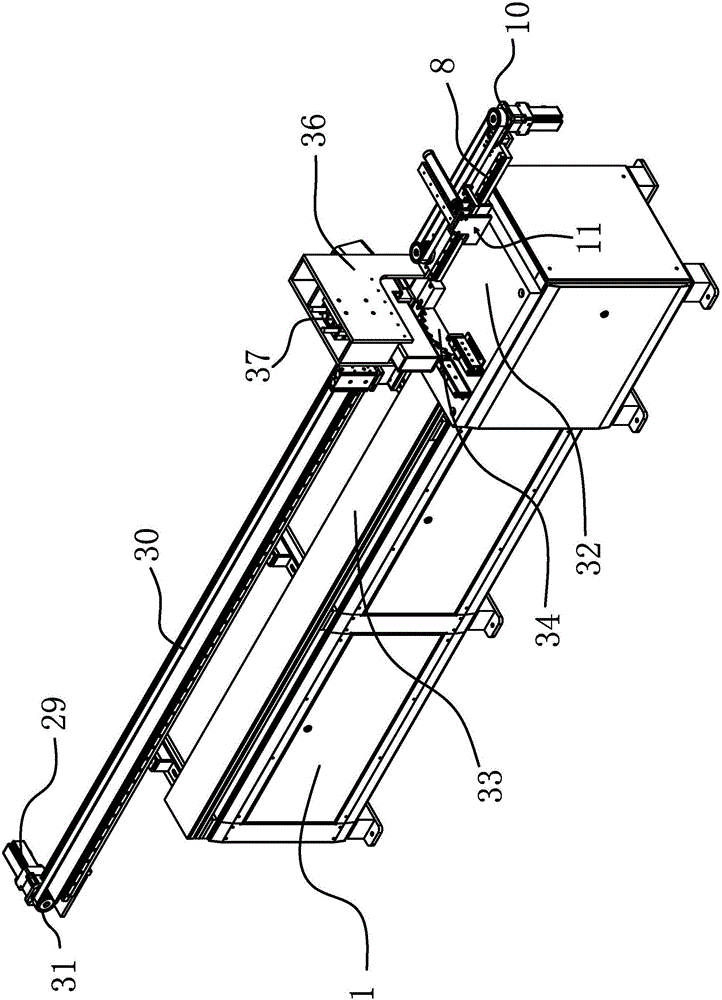

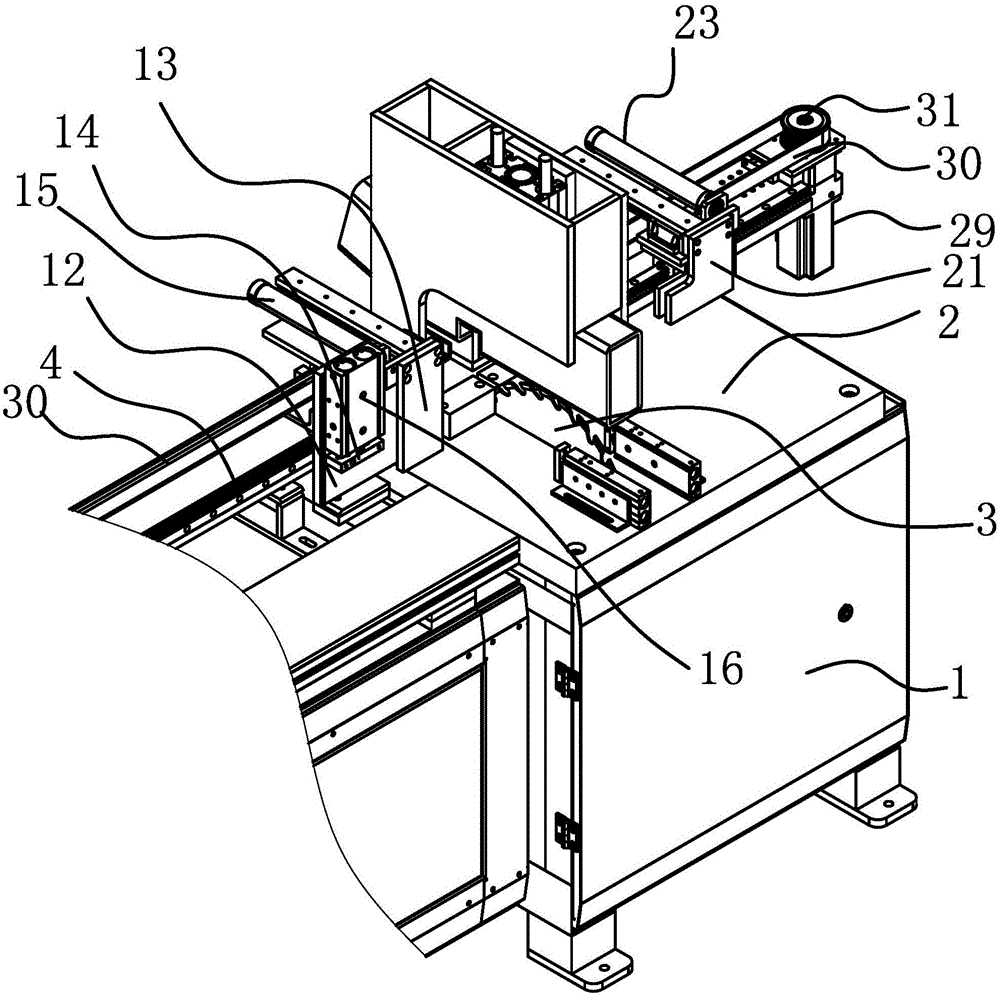

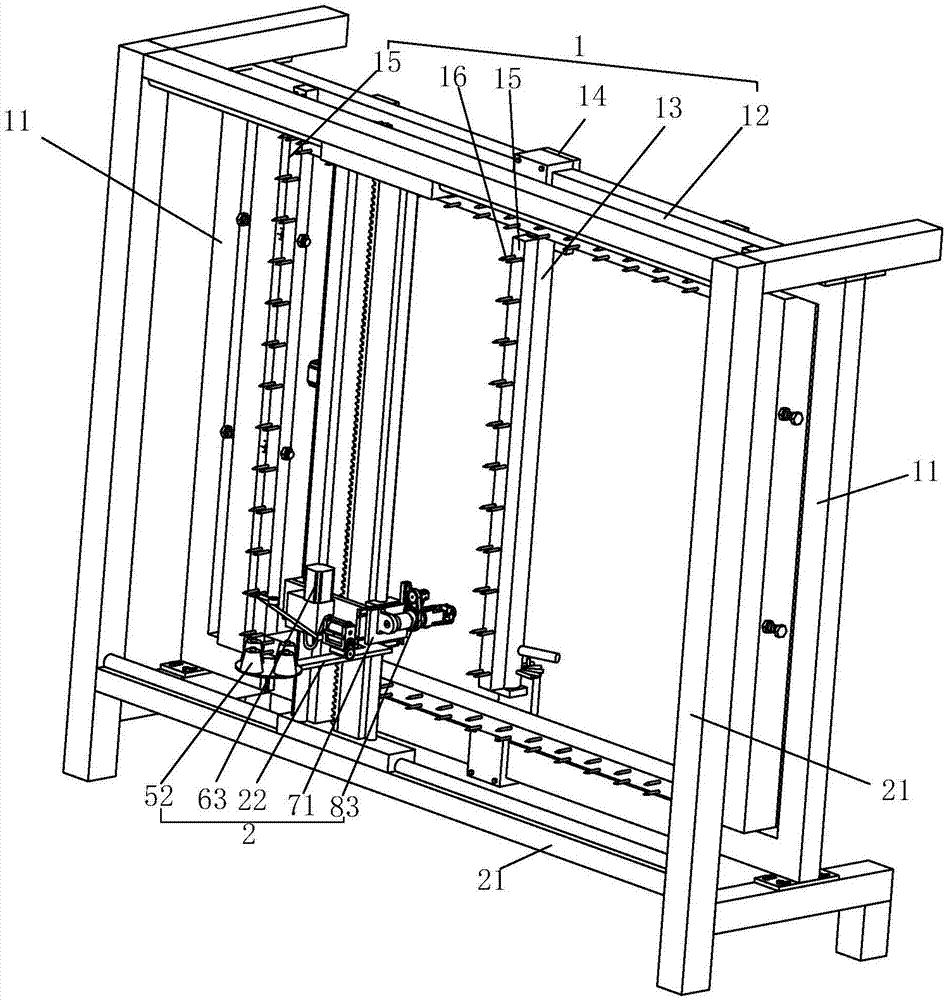

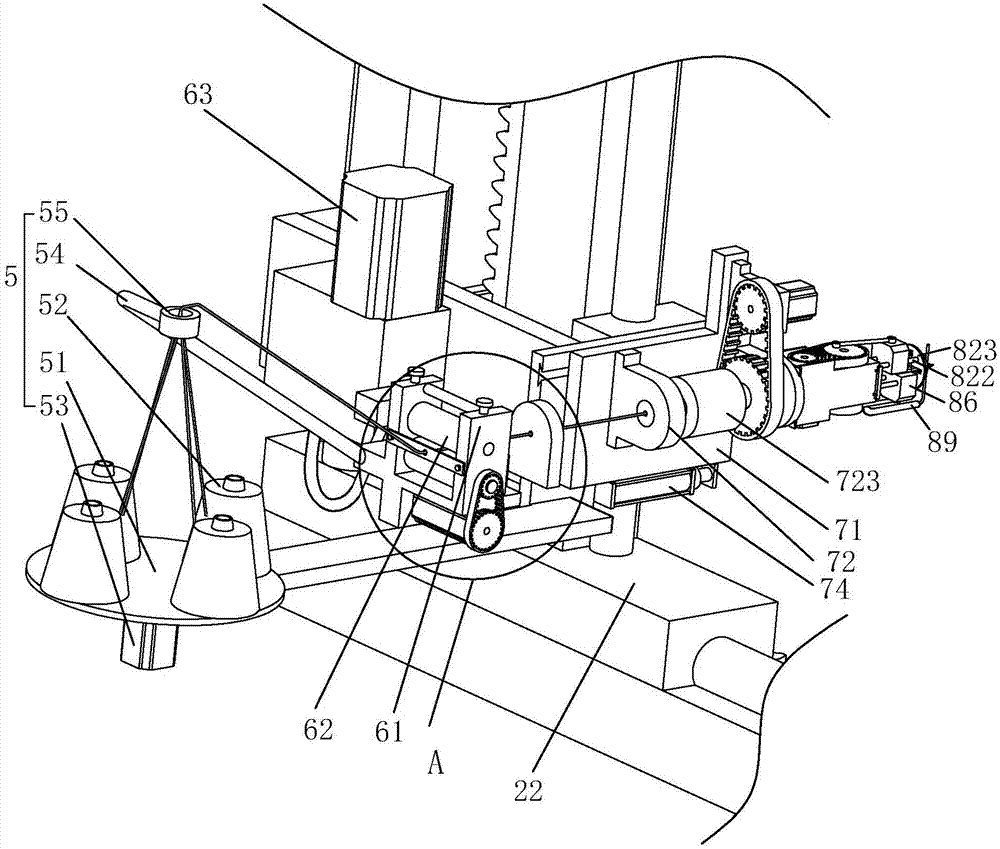

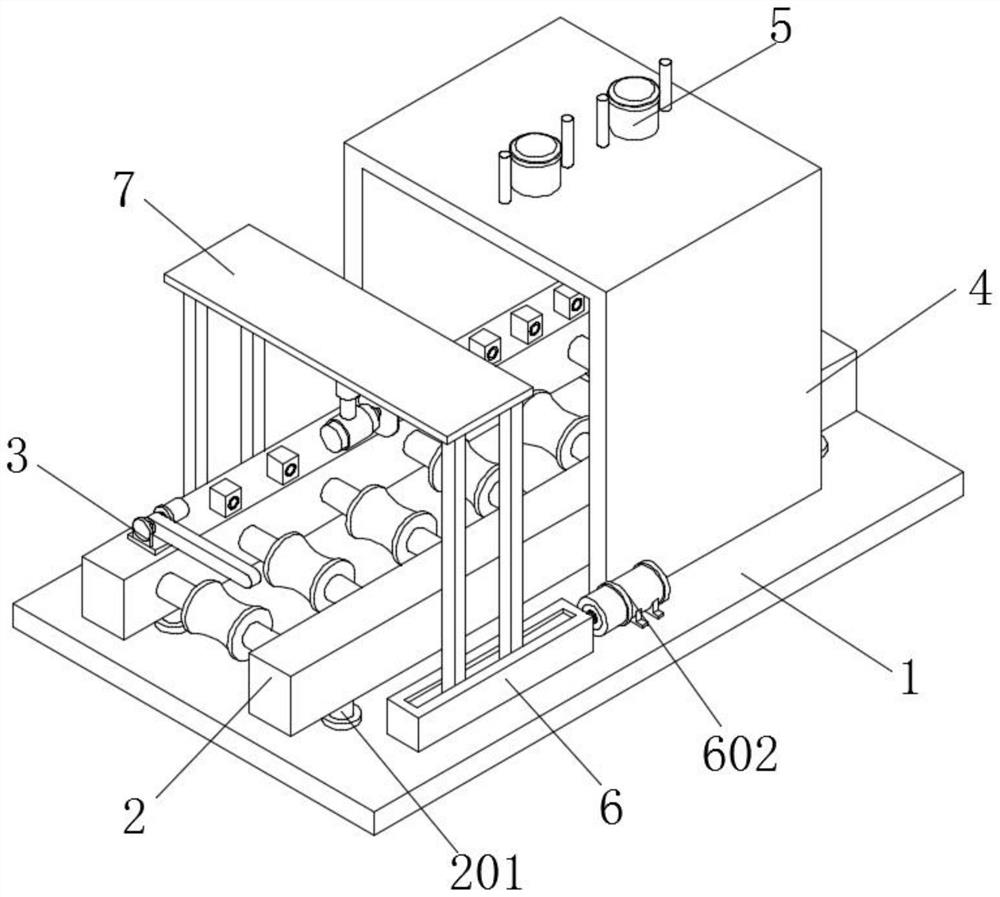

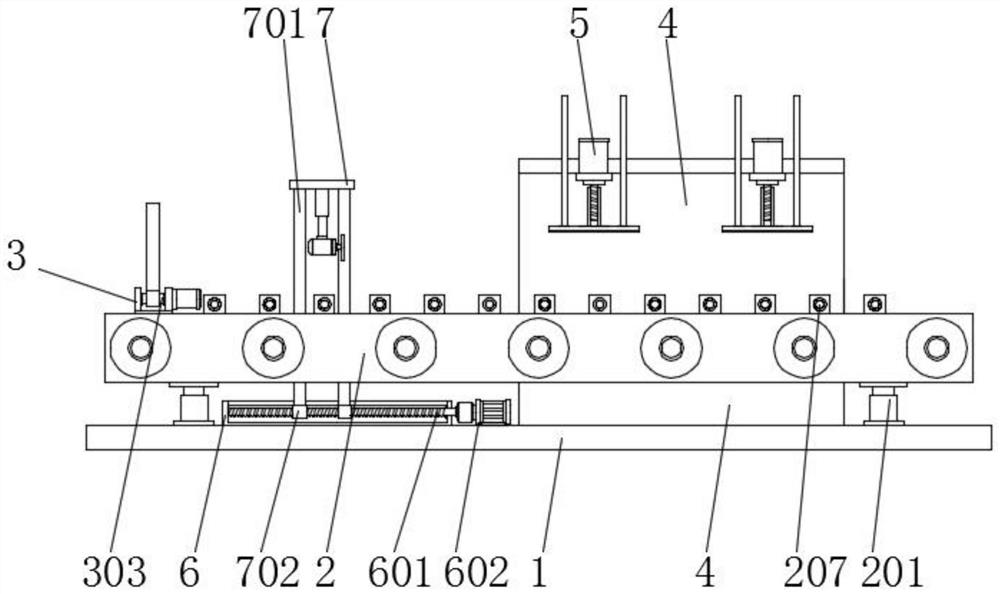

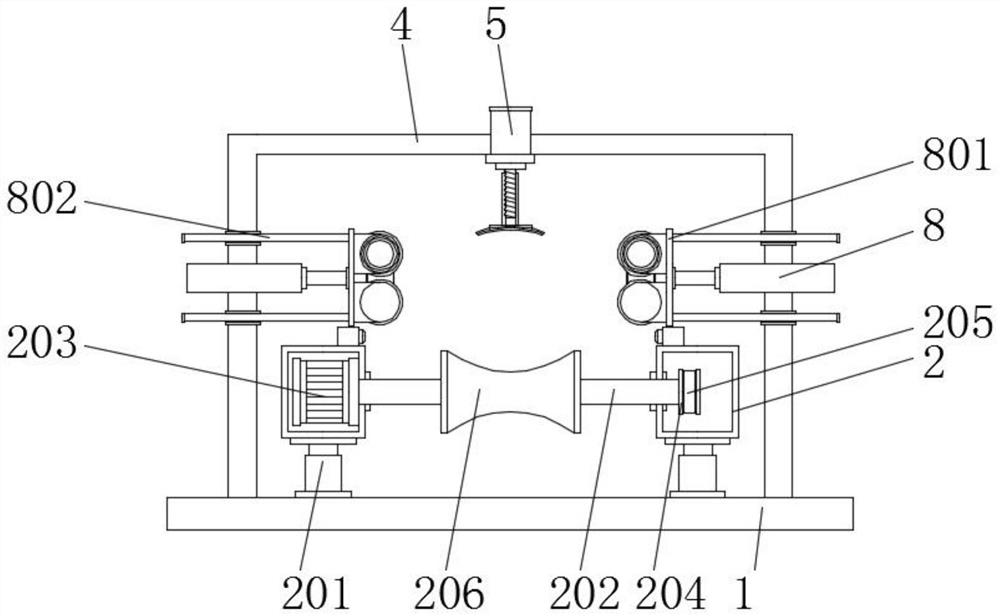

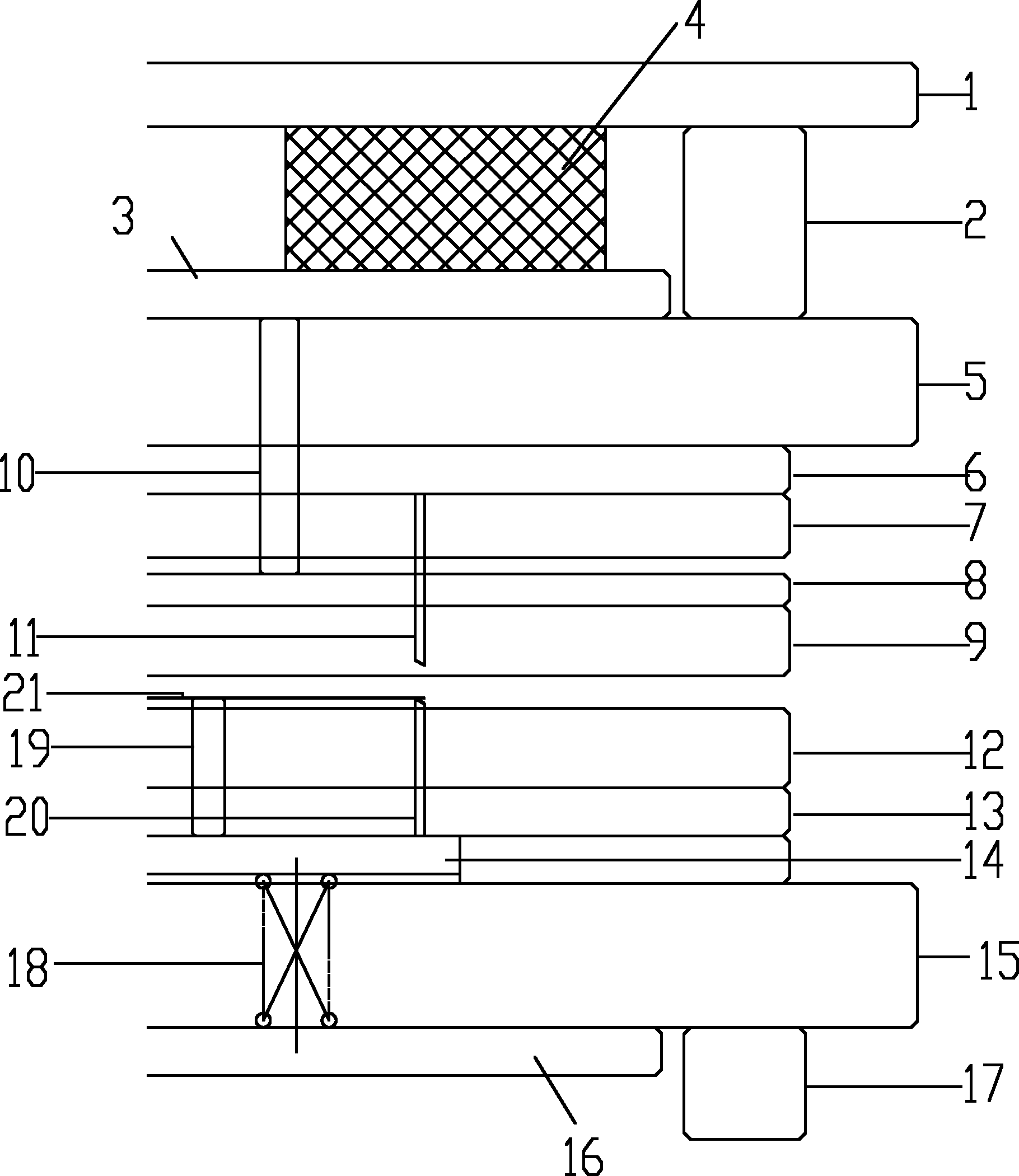

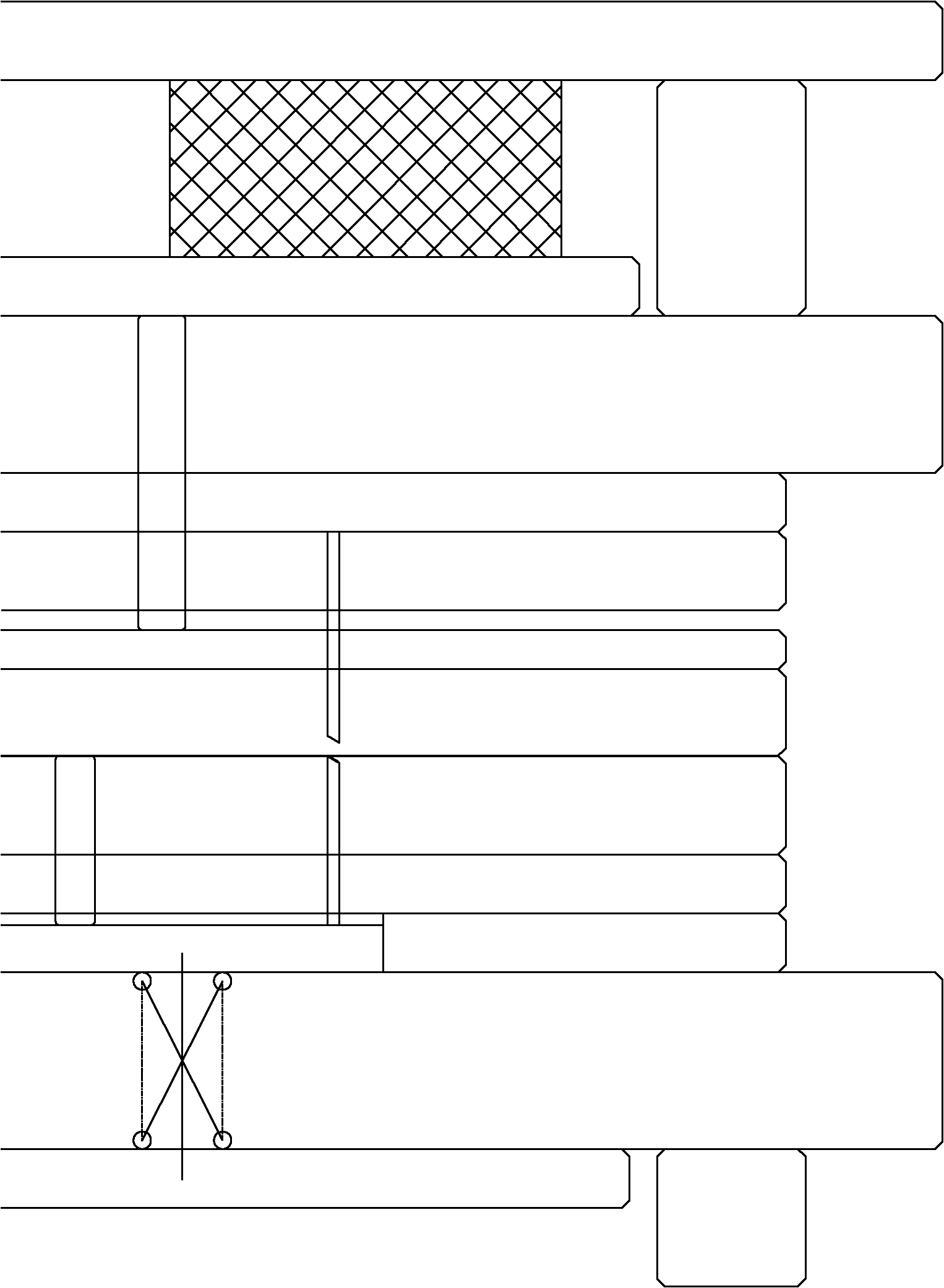

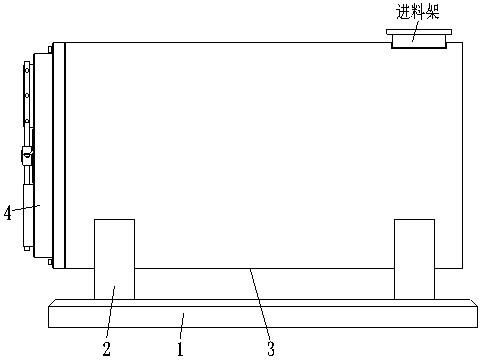

Timber discharging machine with tailing material dragging function

ActiveCN106078931AReduce wasteAvoid the defect of excessive marginFeeding devicesCircular sawsEngineeringMechanical engineering

The invention provides a timber discharging machine with a tailing dragging function and belongs to the technical field of machines. The technical problem that a last section of tailing material is seriously wasted when an existing discharging sawing machine is used for cutting a batten is solved. The timber discharging machine comprises a rack. A horizontal worktable is arranged on the rack. An electric saw is arranged on the rack. A first horizontal guide rail is further fixed to the rack. A first sliding block is connected to the first horizontal guide rail in a sliding manner. The rack is provided with a first driving source used for driving the first sliding block to move along the first horizontal guide rail. A first clamping claw is fixed to the first sliding block. A second horizontal guide rail is further fixed to the rack. A second sliding block is connected to the second horizontal guide rail in a sliding manner. The rack is provided with a second driving source used for driving the second sliding block to move along the second horizontal guide rail. A second clamping claw is fixed to the second sliding block. The first clamping claw and the second clamping claw are located on the two sides of the electric saw correspondingly and can clamp the same piece of timber at the same time. According to the timber discharging machine with the tailing material dragging function, the waste of the tailing material of the timber can be reduced, and the utilization rate of the last section of tailing material of the timber is increased when the batten is cut.

Owner:TAIZHOU EVOK MASCH CO LTD

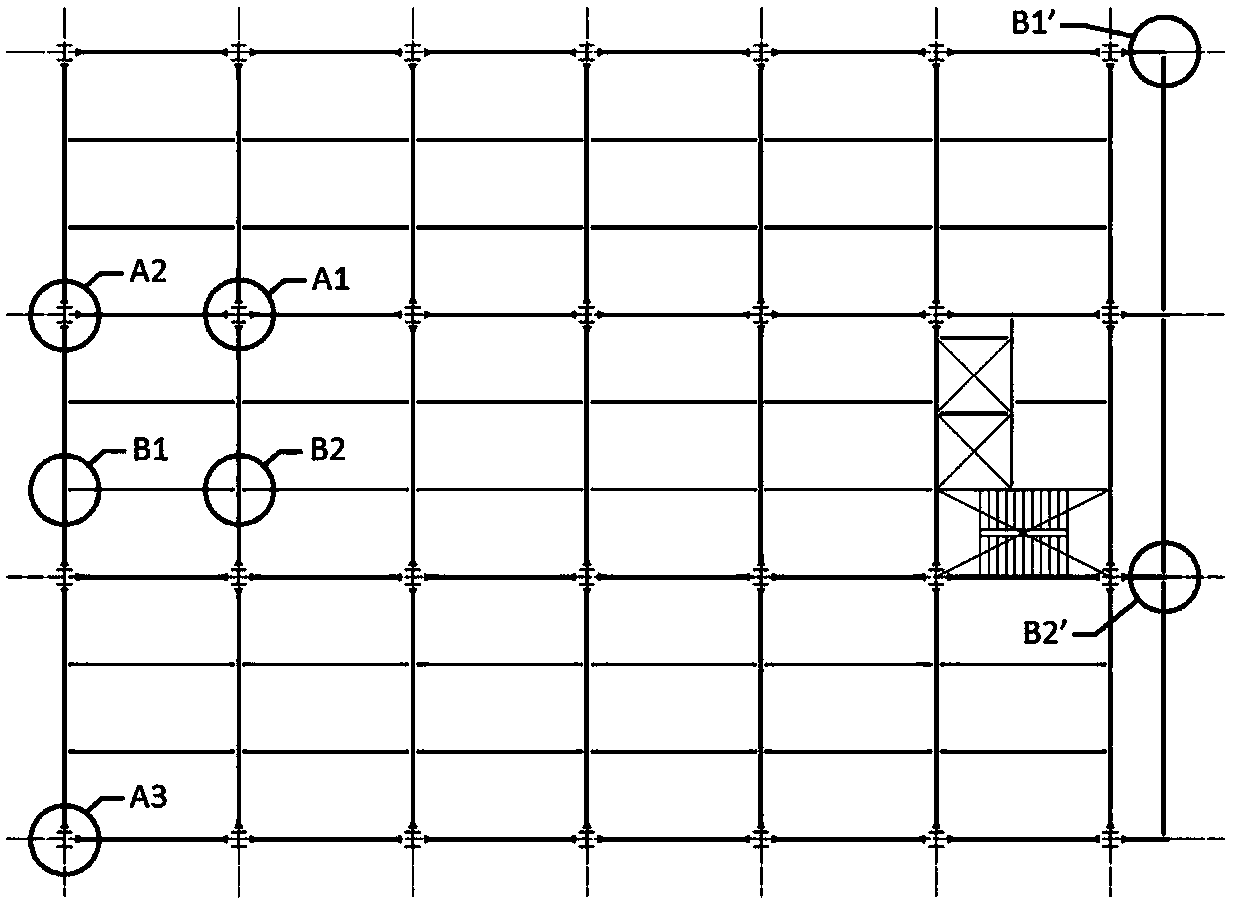

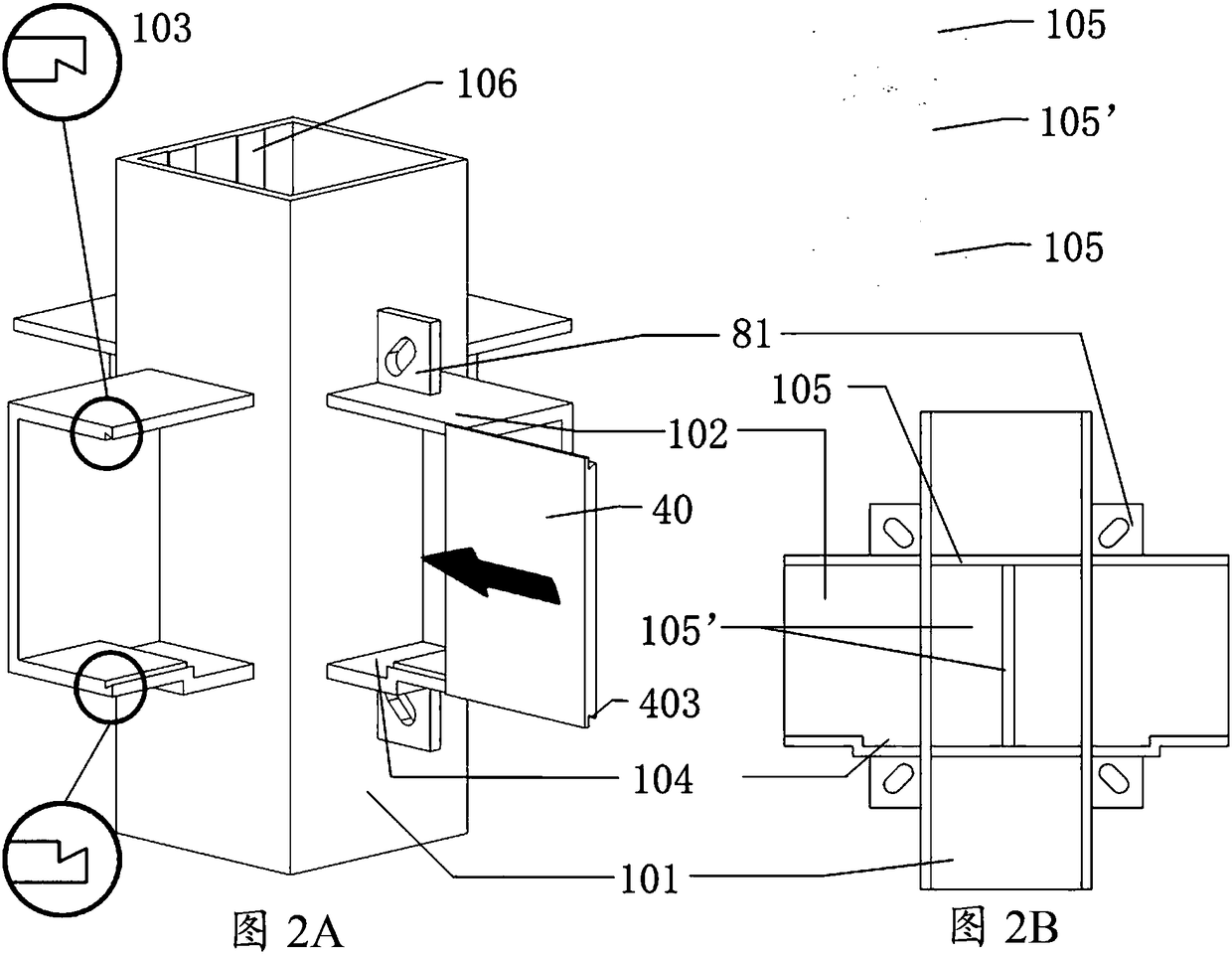

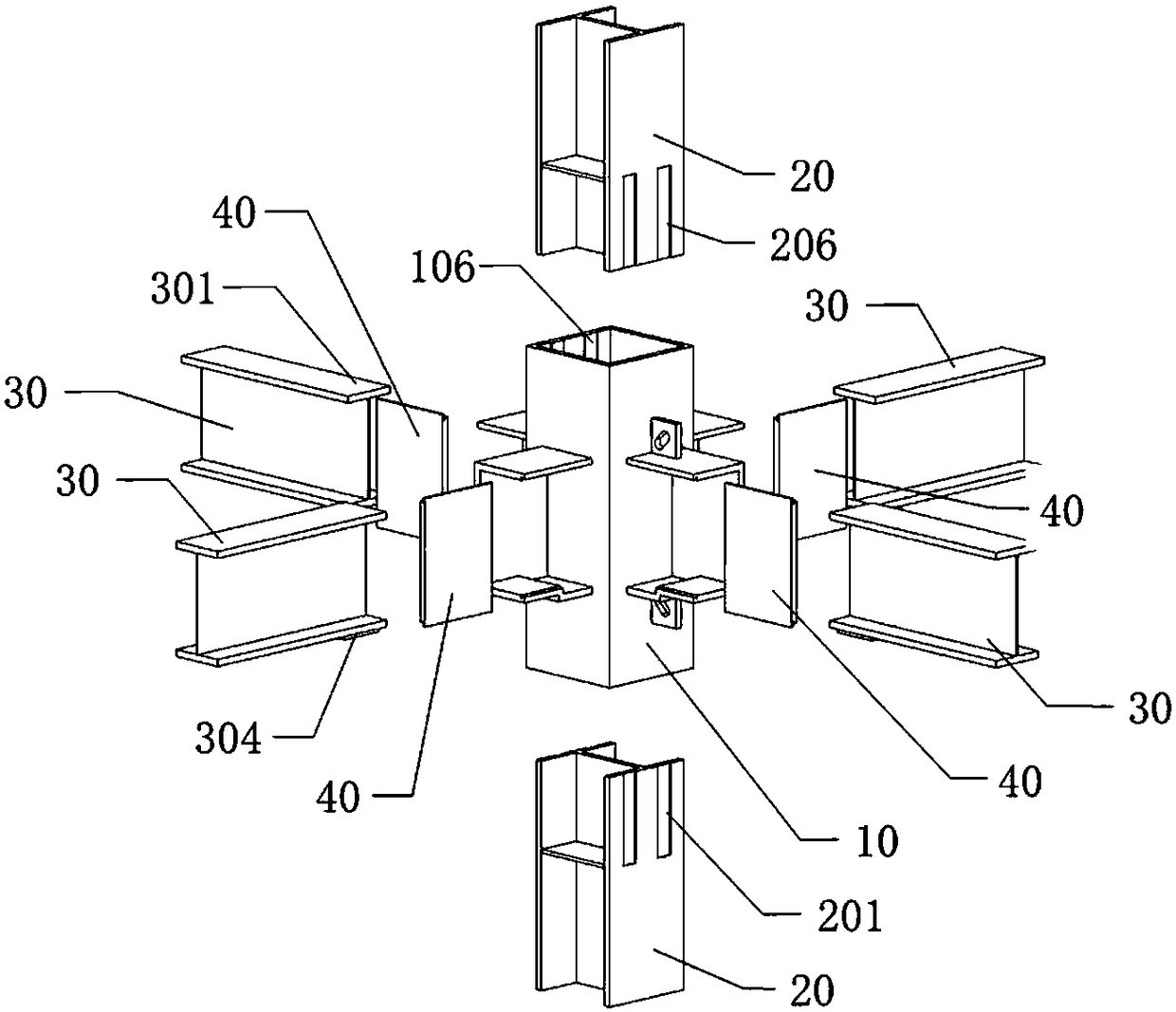

Prefabricated fabricated structure system and assembling method thereof

InactiveCN108505619ASmall sizeReduce weightBuilding constructionsReinforced concreteMortise and tenon

The present invention provides a prefabricated fabricated structure system and an assembling method thereof. The prefabricated fabricated structure system can be used for a steel structure, a reinforced concrete structure and a wood structure. When used for the steel structure, the prefabricated fabricated structure system comprises steel structure joints and related elements. The steel structurejoints and related elements further comprise beam-column connection sleeves, vertical columns, main beams and fixed steel plates for the main beams. The beam-column connection sleeves comprise first box-shaped steel tubes and first C-shaped sleeves vertically extending from the outer surfaces of the first box-shaped steel tubes. First wedge-shaped concave parts are arranged at the ends of the upper and lower flanges of the first C-shaped sleeves. The vertical columns are provided with column connection ends which are inserted into the first box-shaped steel tubes. The main beams are provided with main beam connection ends which are inserted into the first C-shaped sleeves. First wedge-shaped protruding parts matched with the first wedge-shaped concave parts of the first C-shaped sleeves ina mortise and tenon joint mode are arranged on the two sides of the fixed steel plates for the main beams. The application range of the beam-column connection sleeves of the prefabricated fabricatedsteel structure system can be further extended from the steel structure to the reinforced concrete structure and the wood structure.

Owner:NEW WORLD CHINA LAND

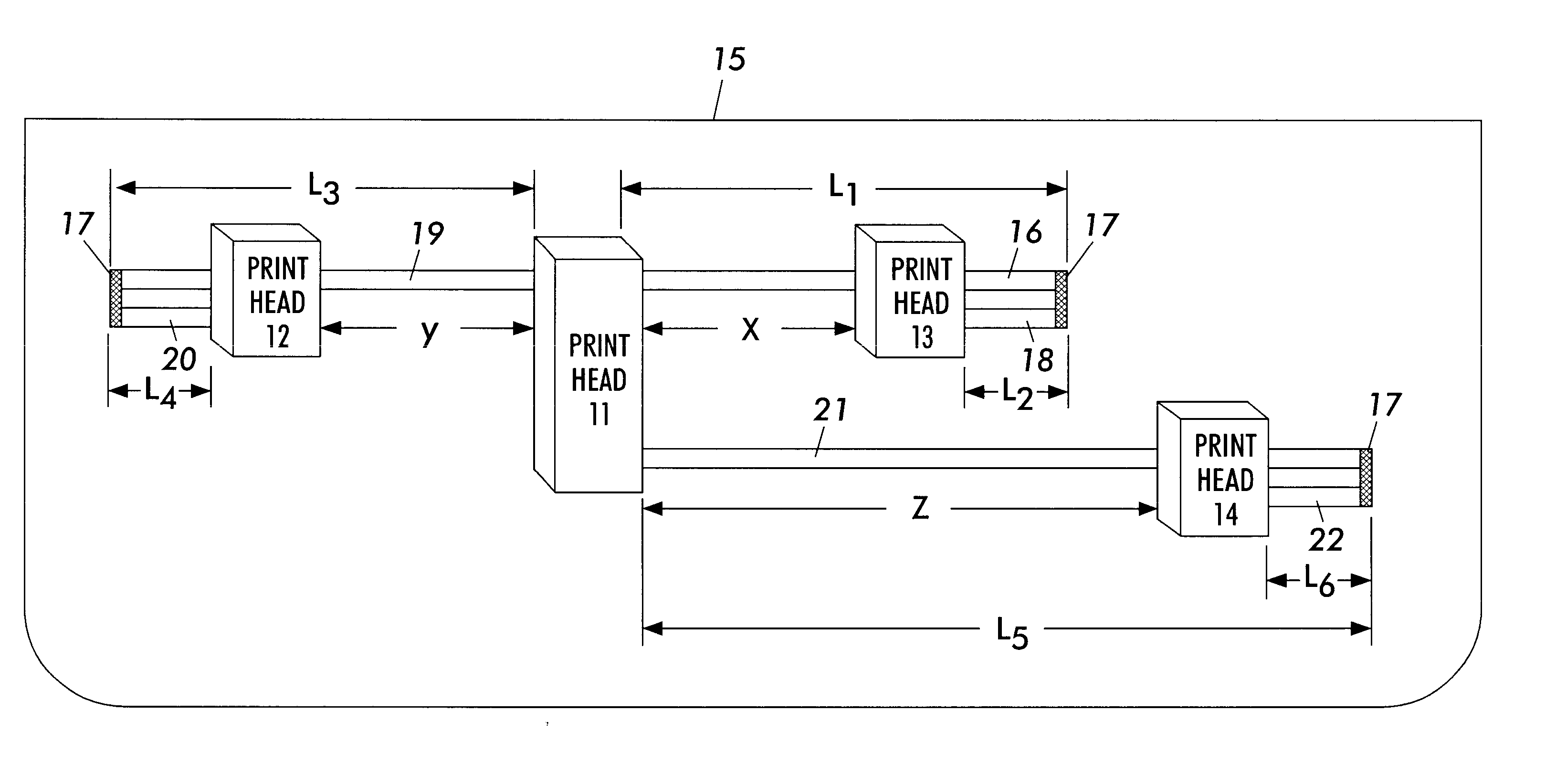

Methods and apparatus for thermally-insensitive mounting of multiple actuators

InactiveUS6338543B1Reduce generationImprove placement accuracyInking apparatusPower drive mechanismsEngineeringThermal expansion

A method and apparatus for controlling the spacing of actuators within a common carriage or frame of a multiple actuator device is provided to render the actuator spacing insensitive to thermal deviations occurring among actuators due to variable thermal conditions within the carriage or frame. A first fixed actuator is connected to an underlying carriage or frame supporting a plurality of actuators and to each additional actuator via links of at least two dissimilar material, such that the respective coefficients of thermal expansion of the dissimilar materials enables the actuators to maintain their original spacing with respect to one another regardless of the thermal conditions within the carriage or frame.

Owner:XEROX CORP

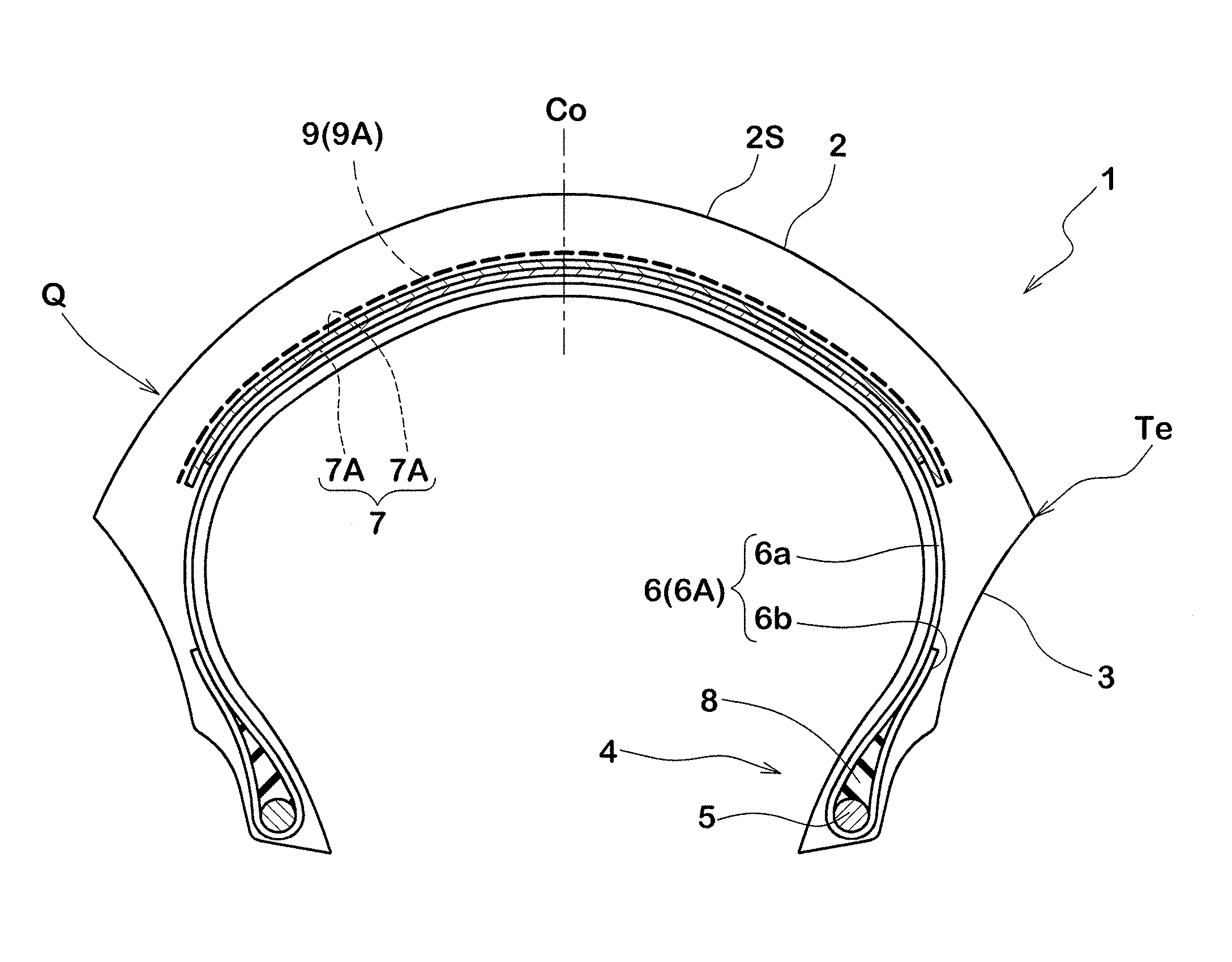

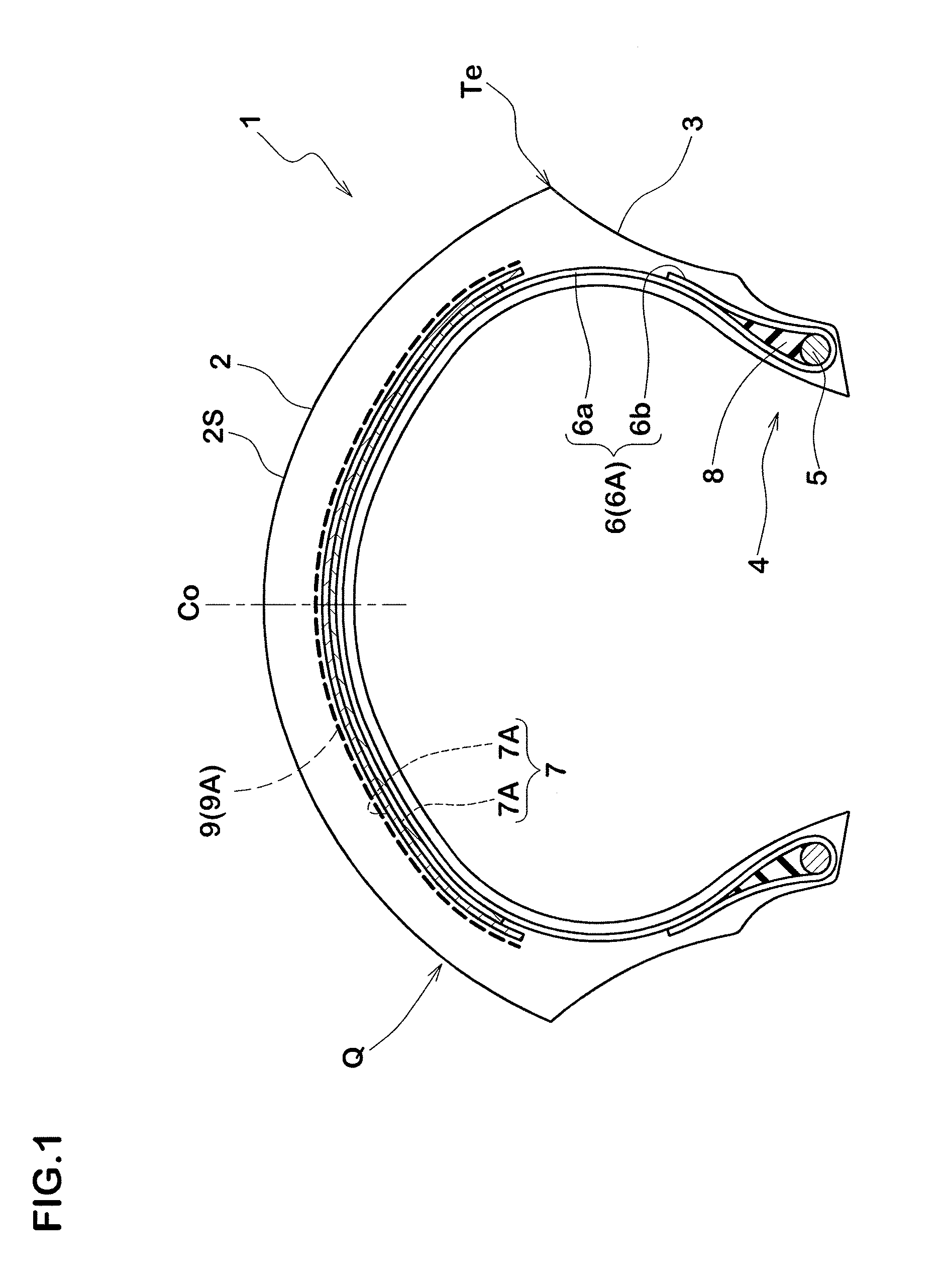

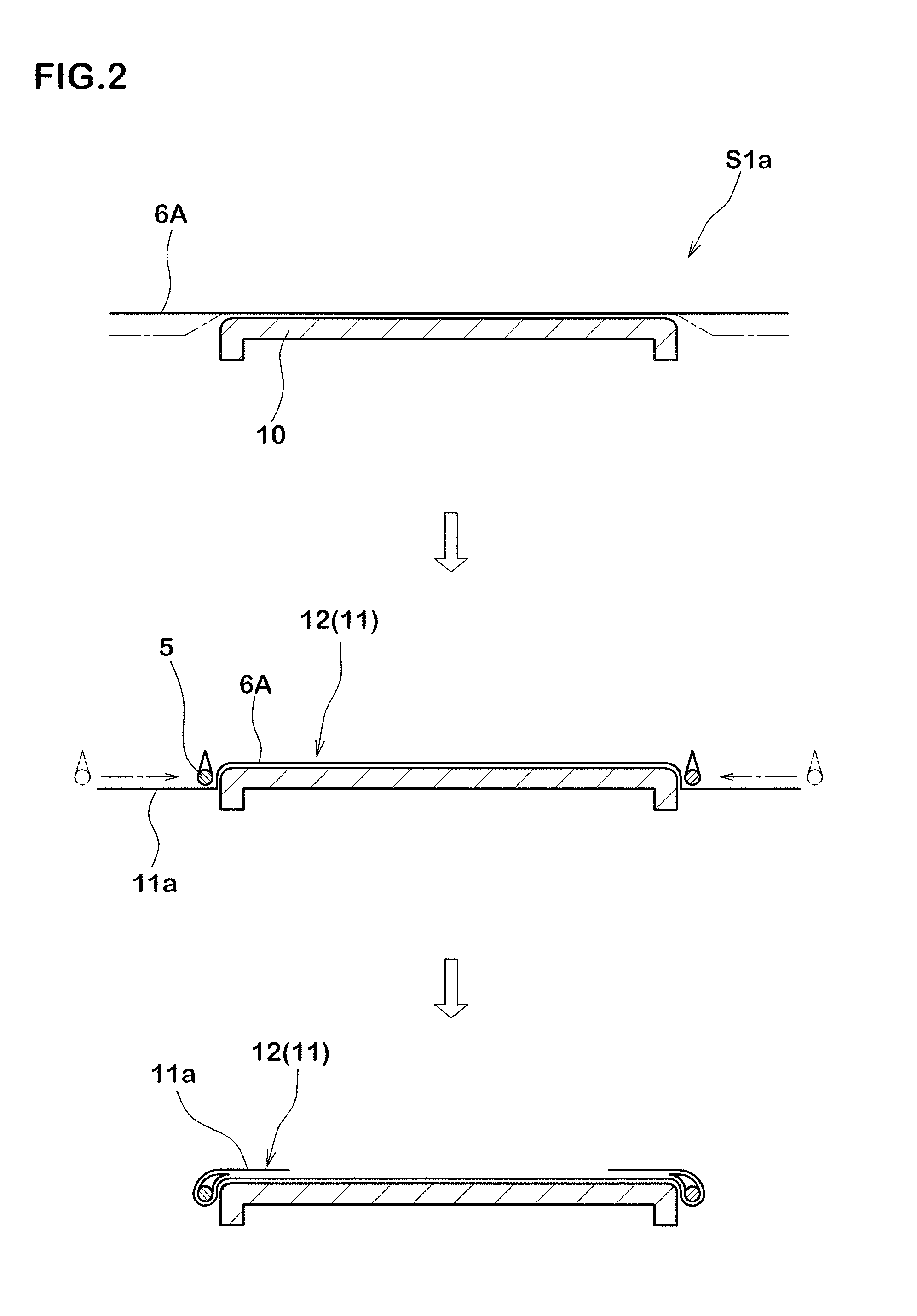

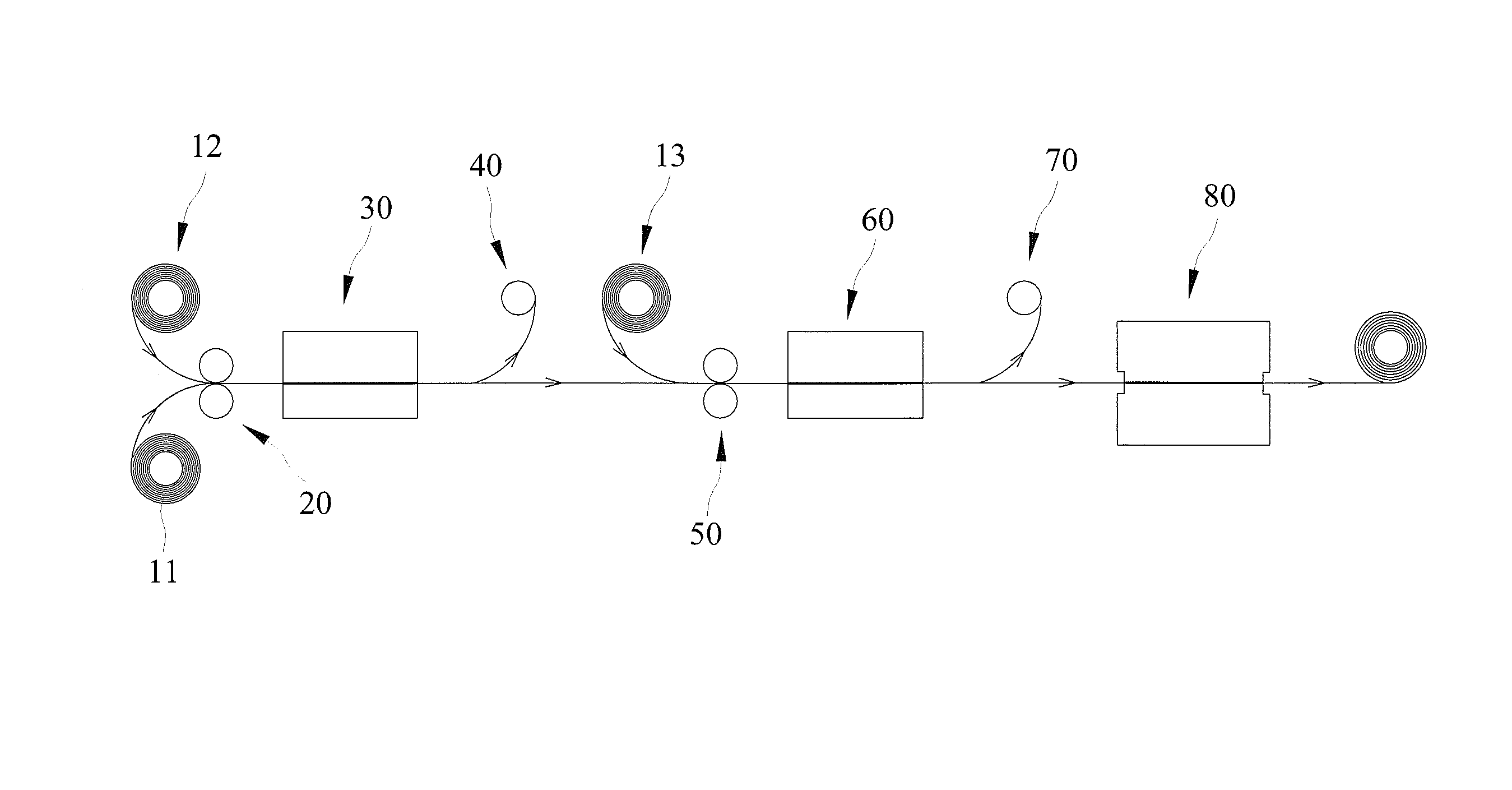

Method for manufacturing motorcycle tire

ActiveUS20140338818A1Improving uniformity of tirePreventing of disarrangementTyresMotorcycle tyreCircuit breaker

Owner:SUMITOMO RUBBER IND LTD

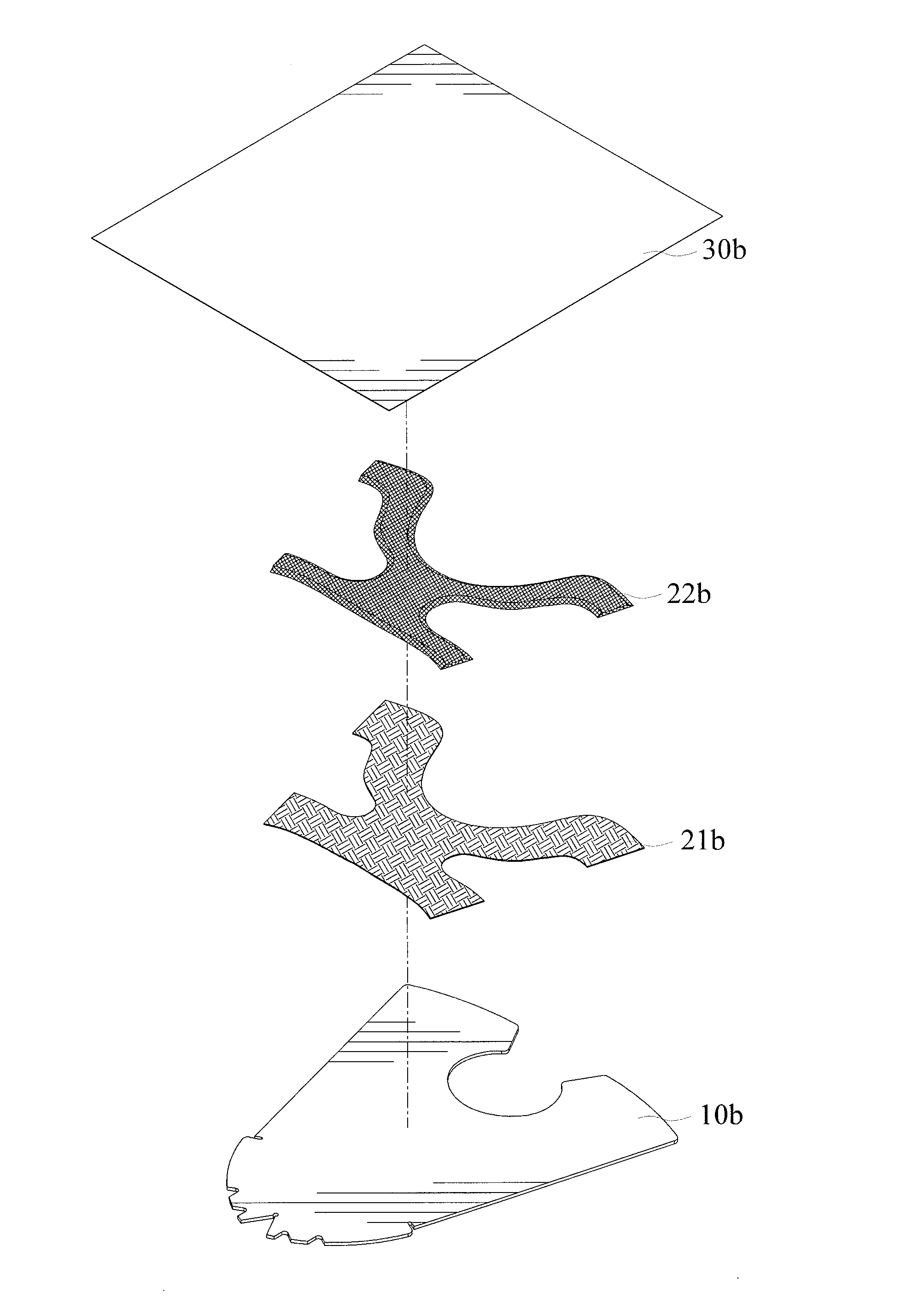

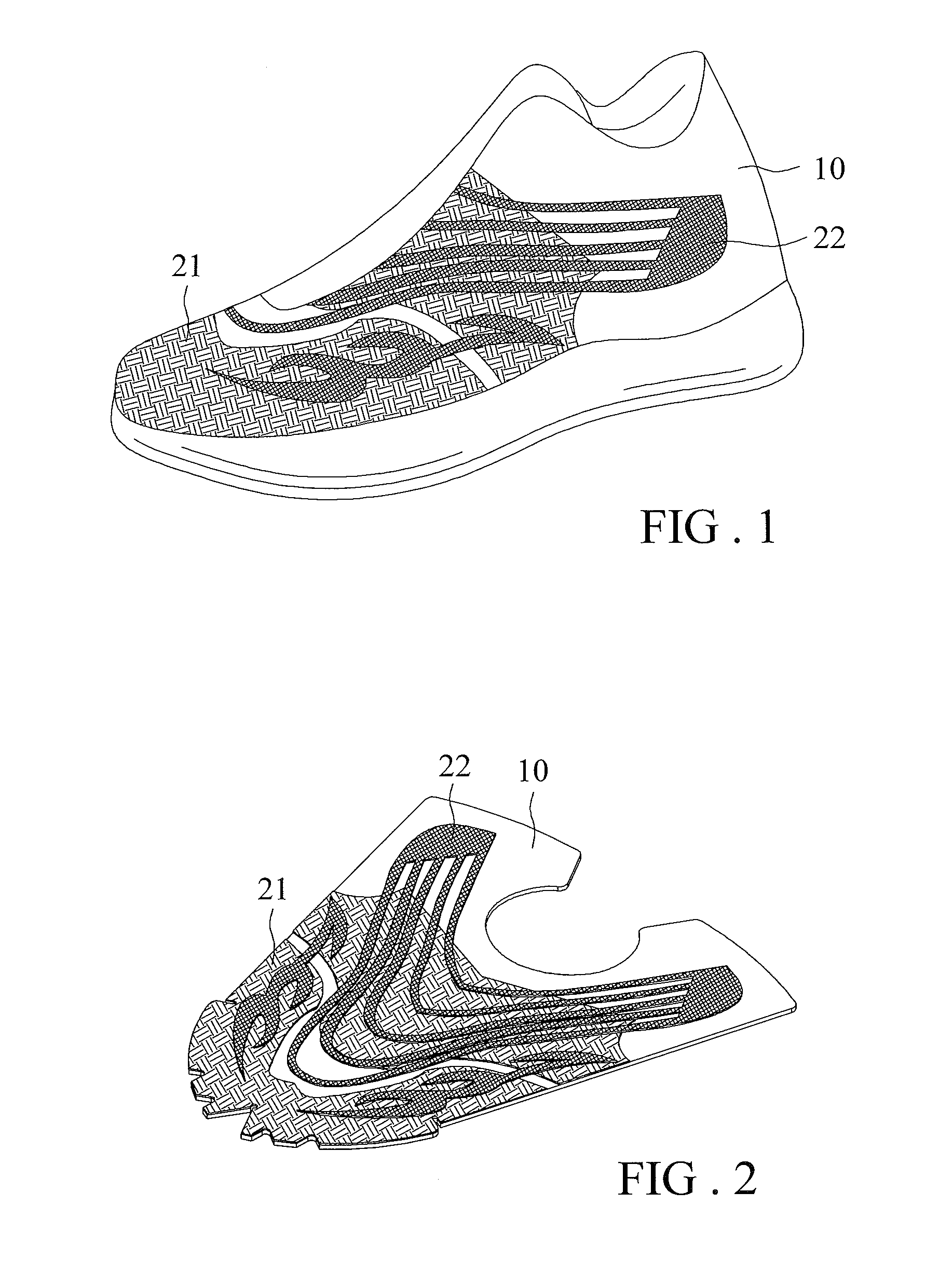

Decorating accessory and method of its manufacture

ActiveUS8366856B2Easy to process preciselyLamination ancillary operationsLaminationEngineeringElectrical and Electronics engineering

A method for manufacturing a decorating accessory includes the steps of: (a) preparing a base, a first film and a second film; (b) attaching the first film to the base; (c) cutting the first film; (d) removing a remaining portion of the first film; (e) attaching the second film to the first film; (f) cutting the second film; (g) removing a remaining portion of the second film to form a stacked array; (h) hot pressing the stacked array to get a finished decorating accessory; (i) collecting the finished decorating accessory.

Owner:JAH YIH ENTERPRISE

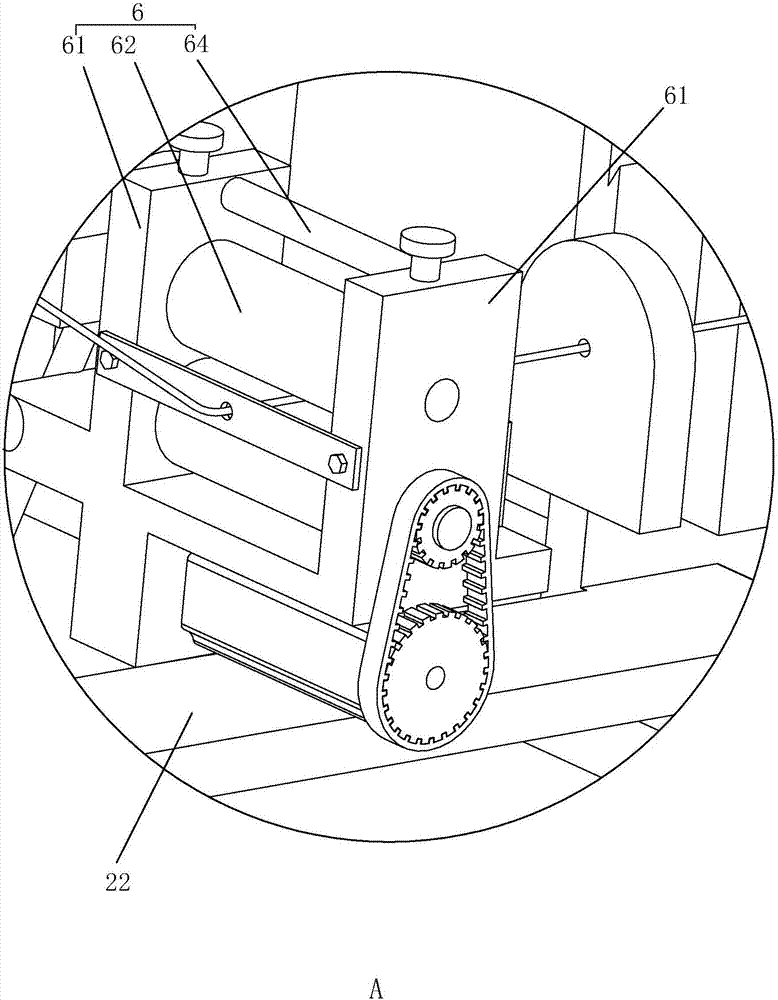

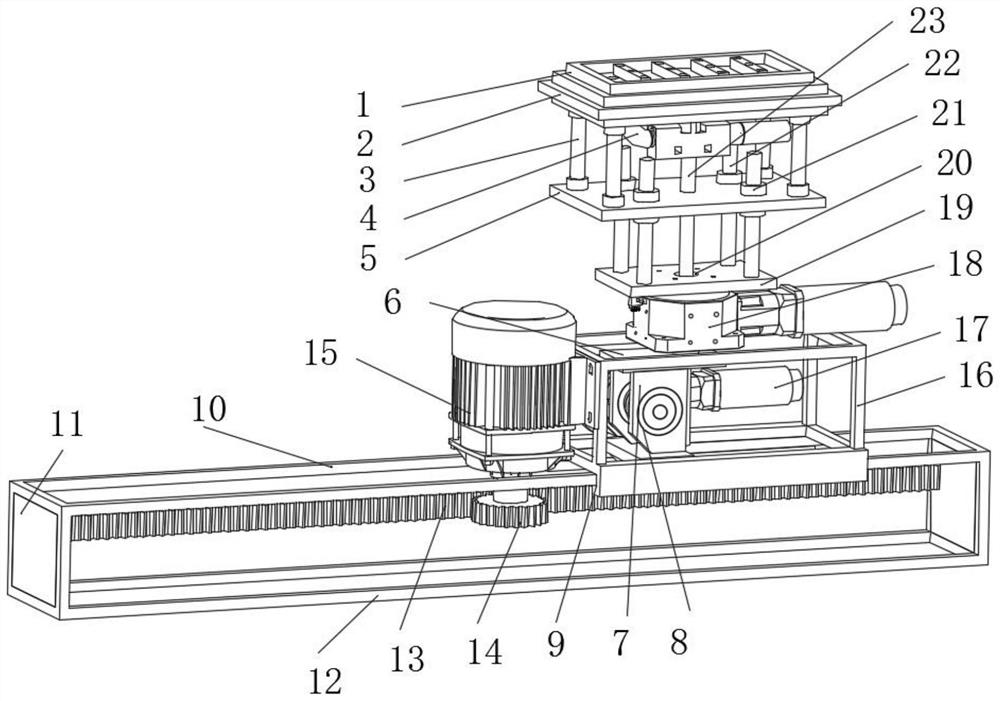

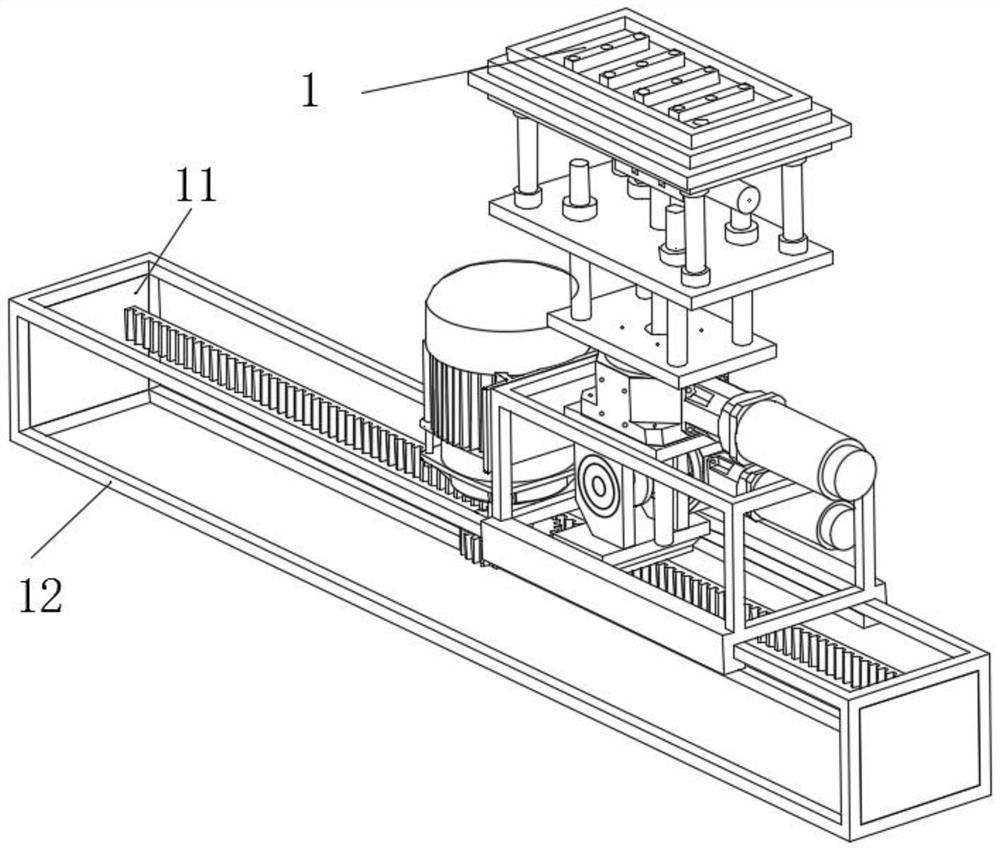

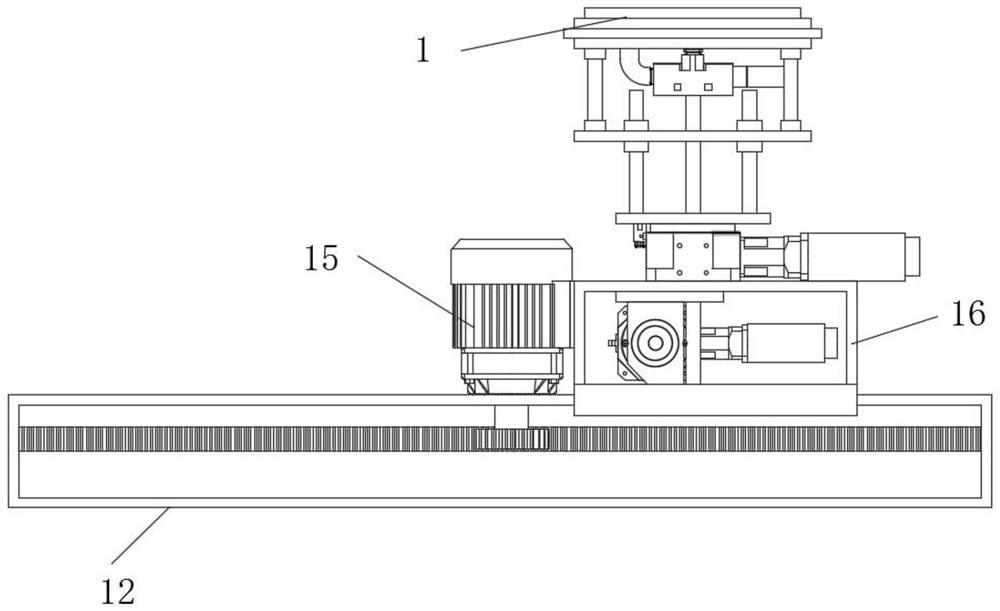

Carpet tufting machine

The invention discloses a carpet tufting machine and belongs to the technical field of textile machinery. The carpet tufting machine has the advantage that an arc-shaped pattern can be embroidered ona carpet; the technical scheme is as follows: the carpet tufting machine comprises a tensioning bracket for fixing the carpet and further comprises a tufting machine head and a fixed bracket for enabling the tufting machine head to move, wherein the tufting machine head comprises a rack, and a thread storage device, a thread feeding device, a movement device and a needle punching device which arefixed on the rack in sequence; the movement device comprises a feeding plate which is in sliding connection with the rack, a mounting platform which is in rotary connection onto the feeding plate, anda driver for driving the mounting platform to rotate; the rack is provided with a retracting device for driving the feeding plate to slide; the driver is fixed on the mounting platform; the needle punching device is fixedly connected with one side, close to the tensioning bracket, of the mounting platform.

Owner:天津市奥丰地毯有限公司

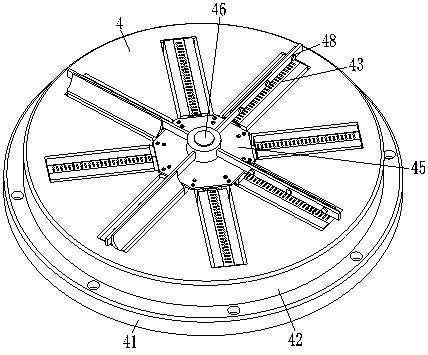

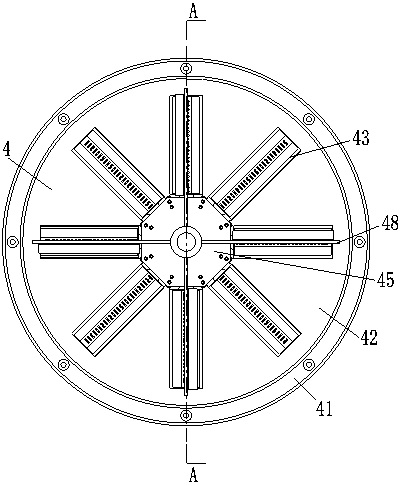

Rotary location type gear shaft gear tooth end chamfering grinding processing device

InactiveCN105618866AReduce lossSimple structureGear-cutting machinesGear teethGear wheelLocking mechanism

The invention discloses a rotary location type gear shaft gear tooth end chamfering grinding processing device which comprises a workbench, wherein a grinding wheel mounting and adjusting tooling and a gear clamping tooling are arranged on the workbench; the grinding wheel mounting and adjusting tooling comprises a base; vertical guide rods are arranged on the base; a sliding seat is arranged on the guide rods; a grinding wheel mounting seat is arranged on the sliding seat; a grinding wheel mechanism is mounted on the grinding wheel mounting seat; the grinding wheel mechanism comprises a pneumatic motor and a grinding wheel mounted on a rotating shaft of the pneumatic motor; a locking mechanism used for locking the sliding seat and the guide rods is arranged between the sliding seat and the guide rods; the grinding wheel mounting seat comprises two mutually parallel mounting plates; the pneumatic motor is mounted between the two mounting plates in a rotary matching manner; the axis of the rotating shaft of the pneumatic motor is horizontal; a driving mechanism used for driving the pneumatic motor to rotate is arranged on the grinding wheel mounting seat; the gear clamping tooling comprises a mounting base; a liquid expansion fixture which is mounted in a central hole of a gear workpiece in a sleeving manner is vertically mounted on the base; and a locating meshing mechanism is arranged on the mounting base.

Owner:綦江县飞达重型汽车齿轮厂

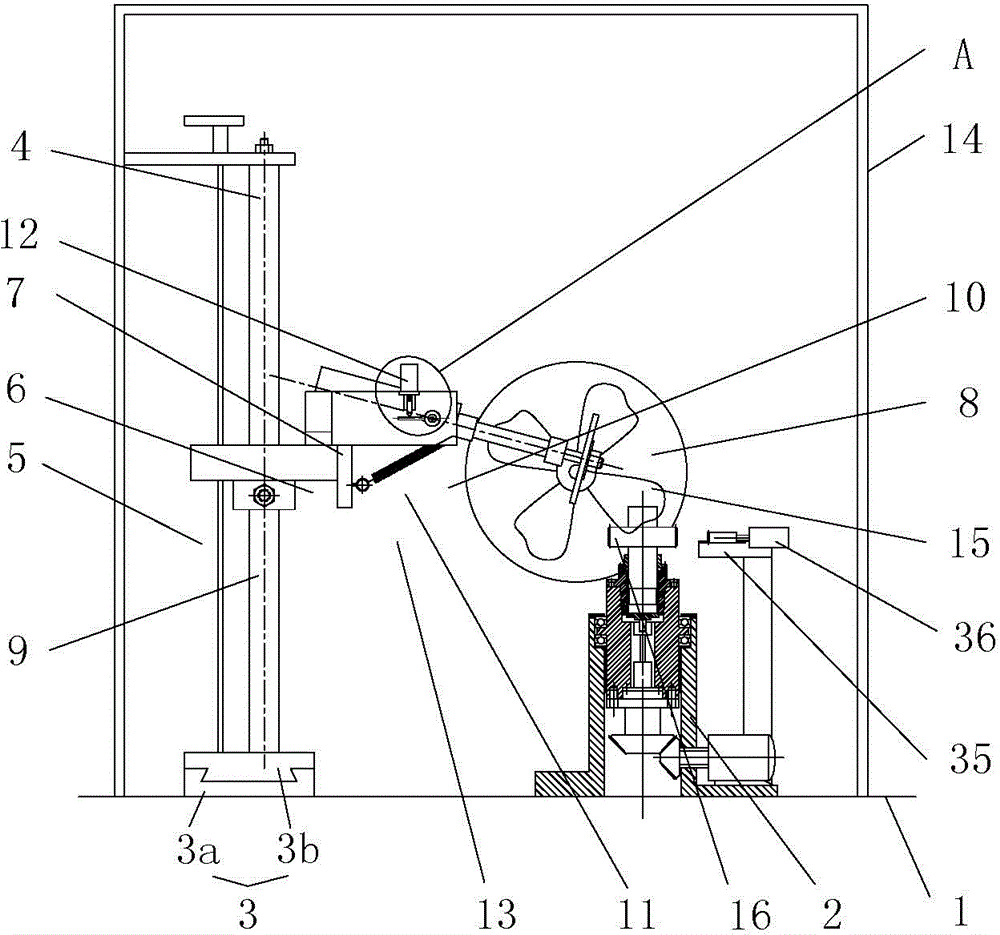

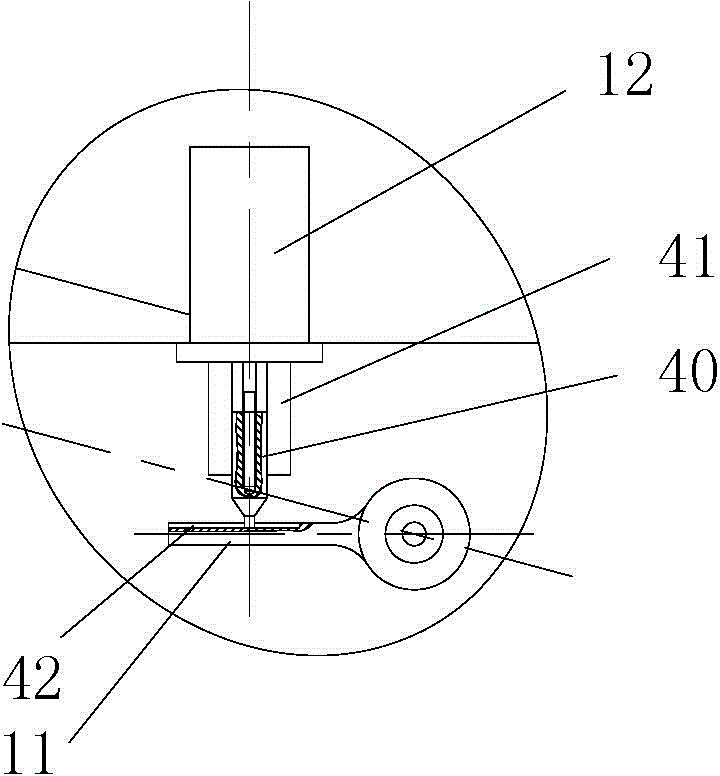

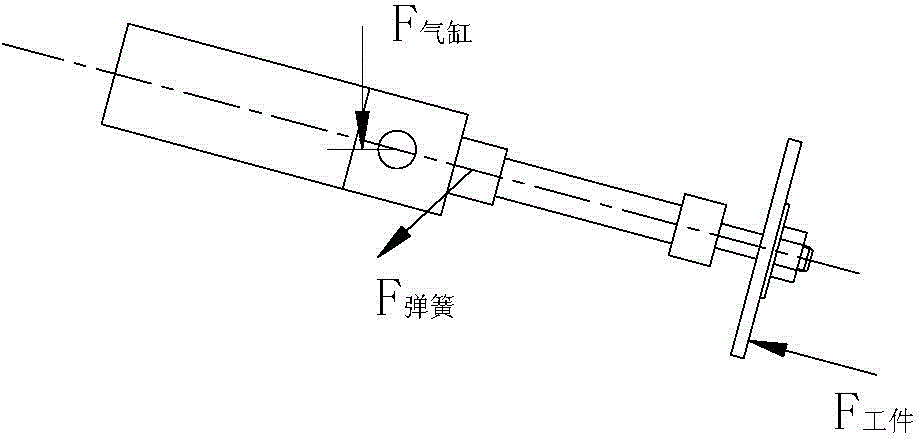

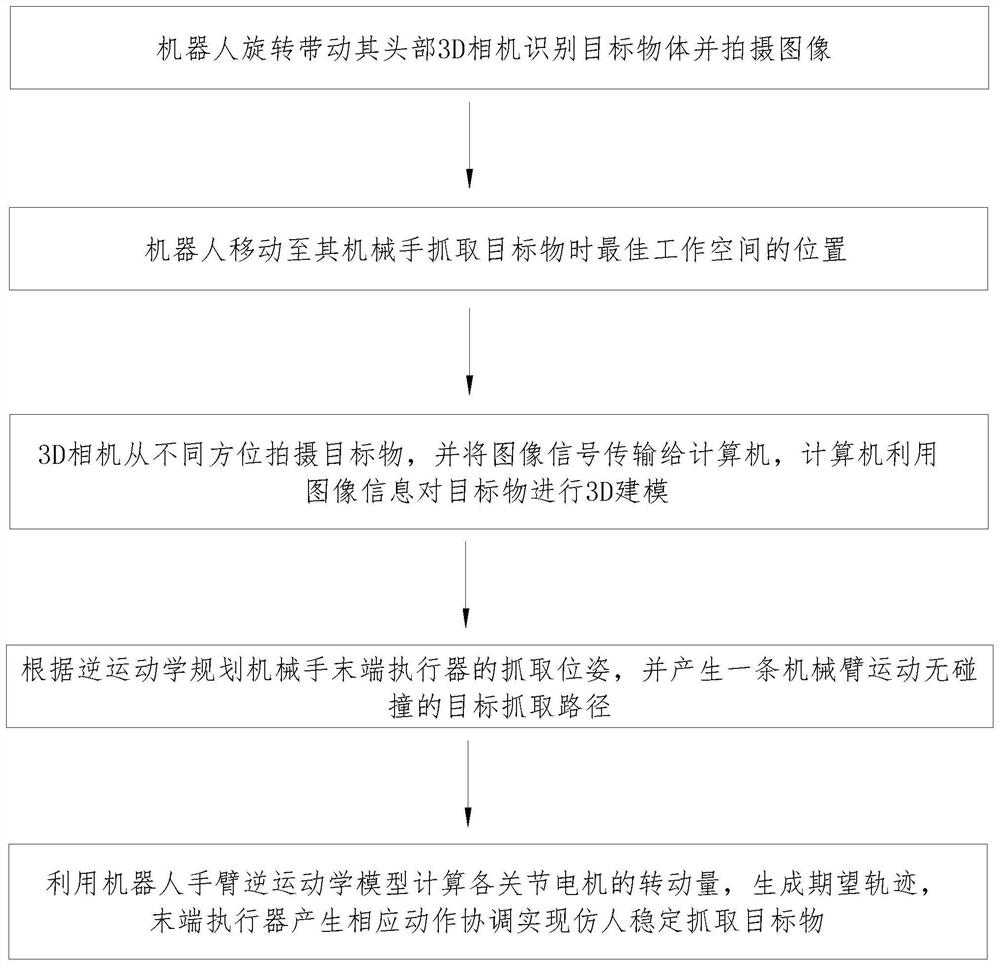

Robot target image capturing method

PendingCN112109074AAccurate and convenient positioningEasy image processingProgramme-controlled manipulatorEngineeringVisual feedback

The invention discloses a robot target image capturing method. The robot target image capturing method comprises the following steps that a robot rotates to drive a 3D camera at the head of the robotto recognize a target object and shoot an image; the robot moves to the optimal working space when a manipulator of the robot grabs the target object; the 3D camera shoots the target object from different directions and transmits an image signal to a computer, and the computer carries out 3D modeling on the target object by using image information; a grabbing pose of an end effector of the manipulator is planned according to inverse kinematics, and a target grabbing path with no collision during movement of the manipulator is generated; and an inverse kinematics model of the manipulator is used for calculating the rotation quantity of each joint motor, an expected track is generated, and the end effector generates corresponding action to coordinate so as to stably grab the target object ina humanoid manner. According to the robot target image capturing method, the 3D camera is used for shooting the image, a visual feedback method is used for positioning the target object, and the expected track for grabbing the target object is calculated according to the inverse kinematics so that an imitation hand can perform human-machine interaction better and can work in a complex environmentmore flexibly.

Owner:SHENZHEN SANBOT INNOVATION INTELLIGENT CO LTD

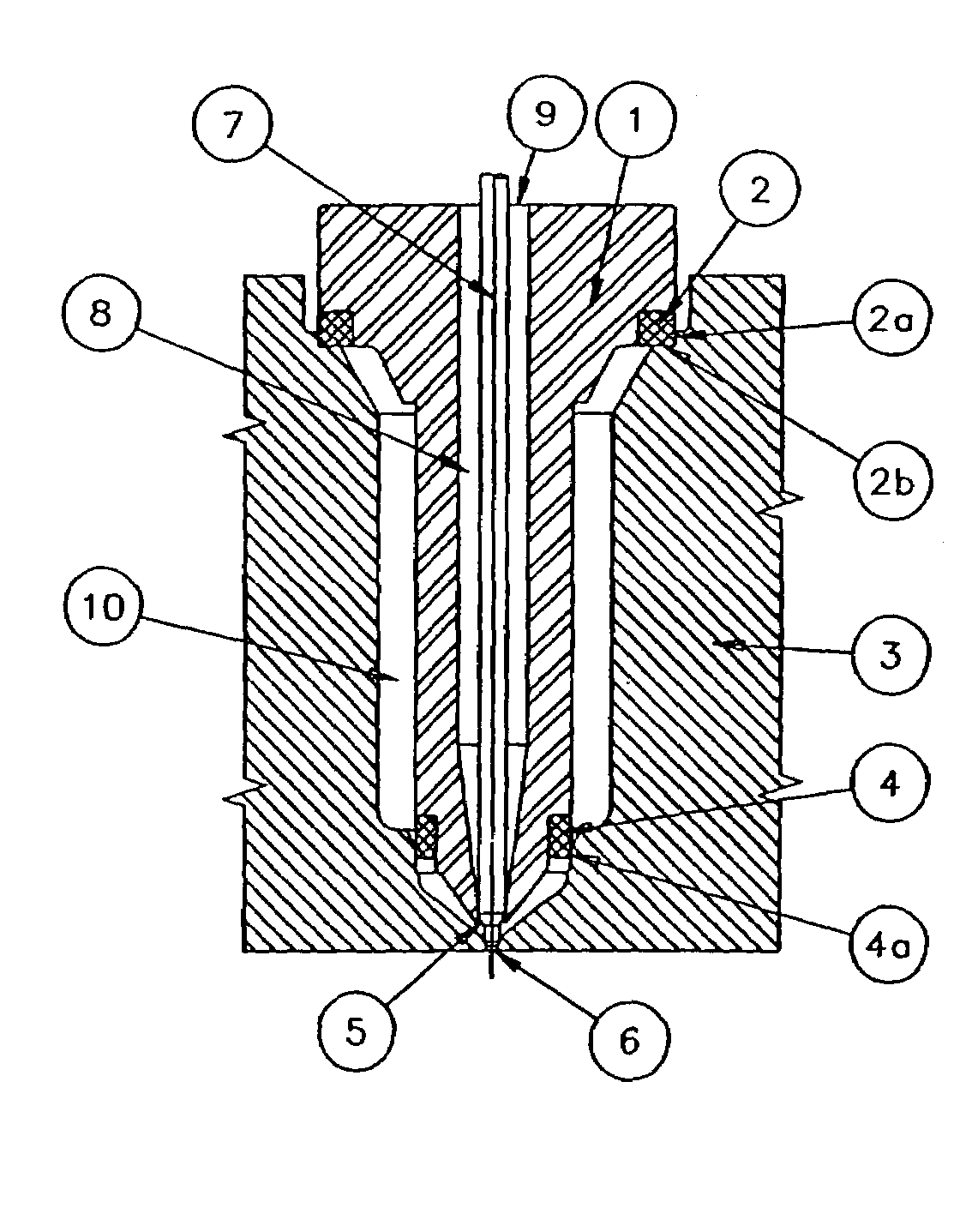

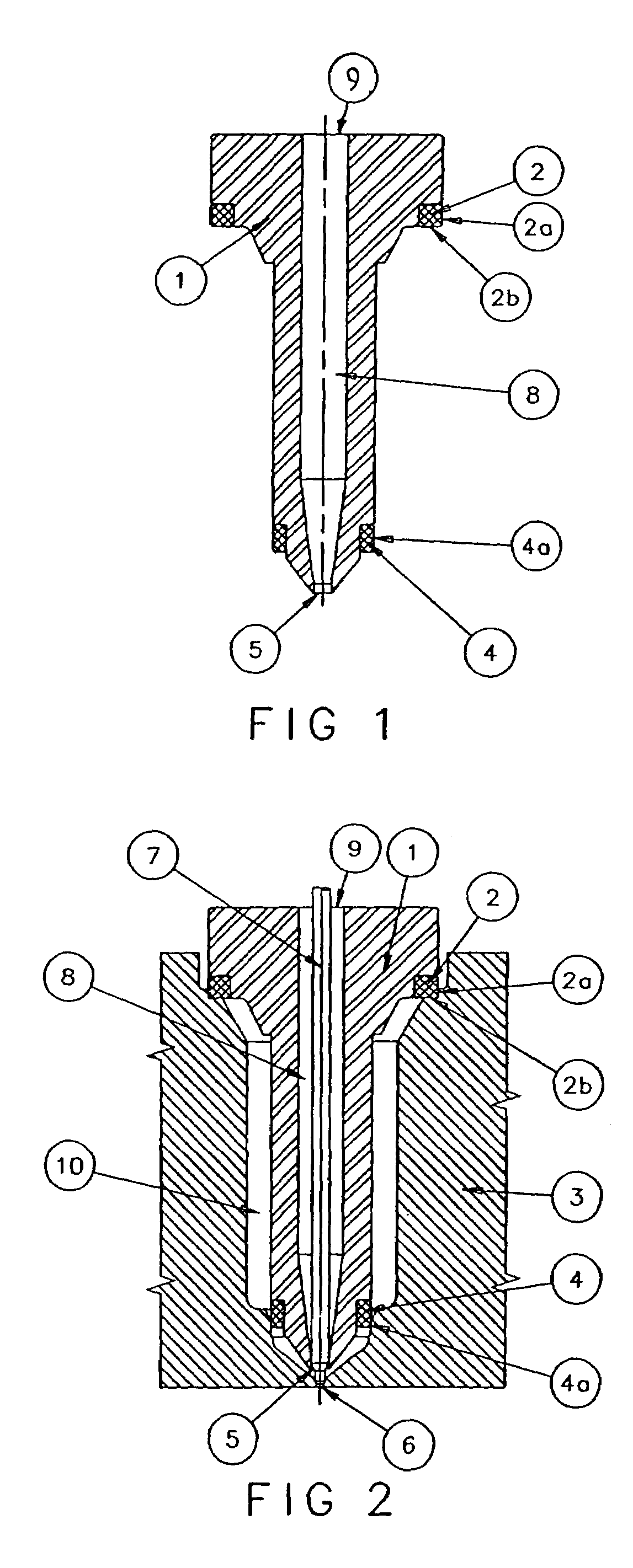

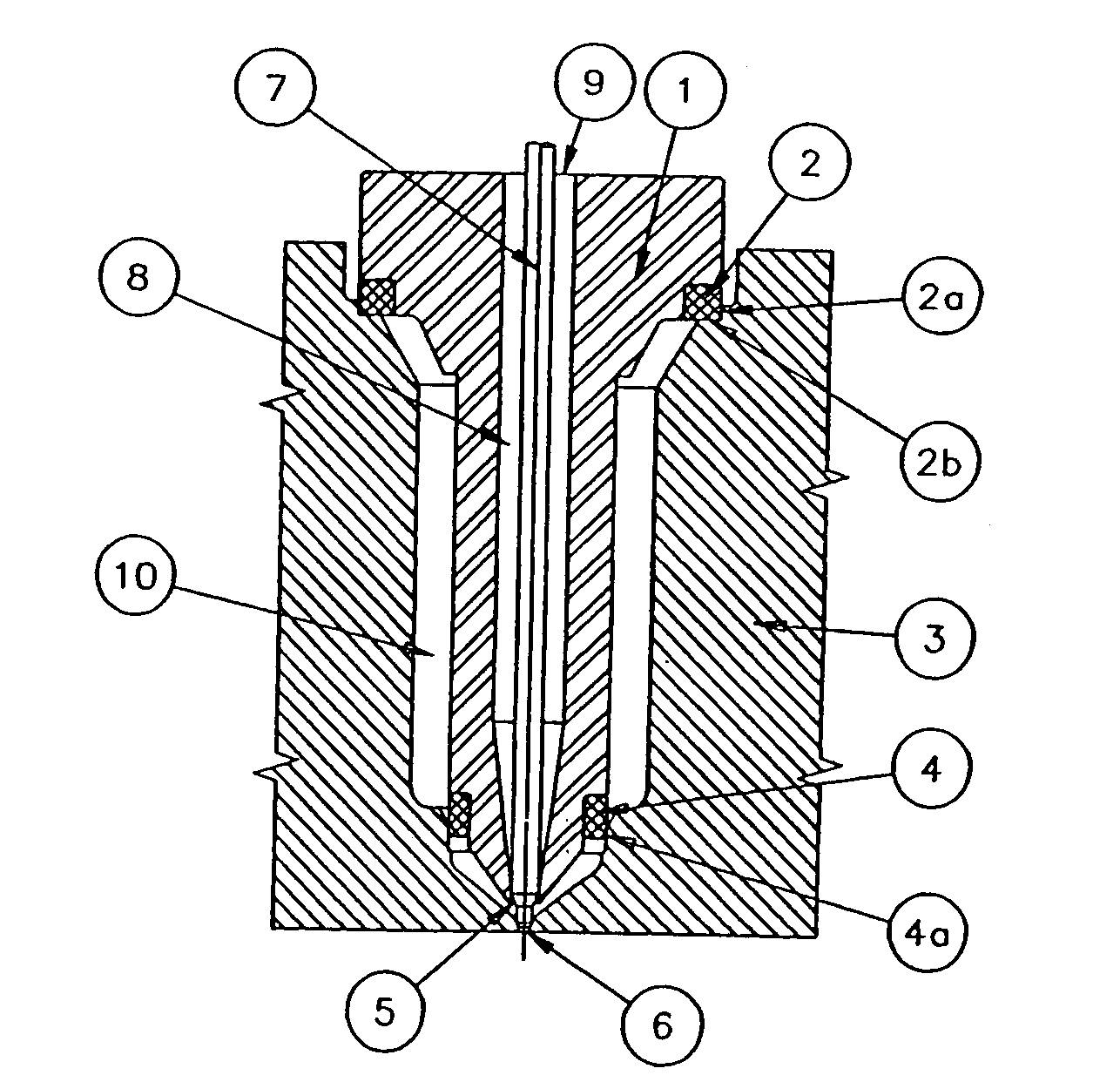

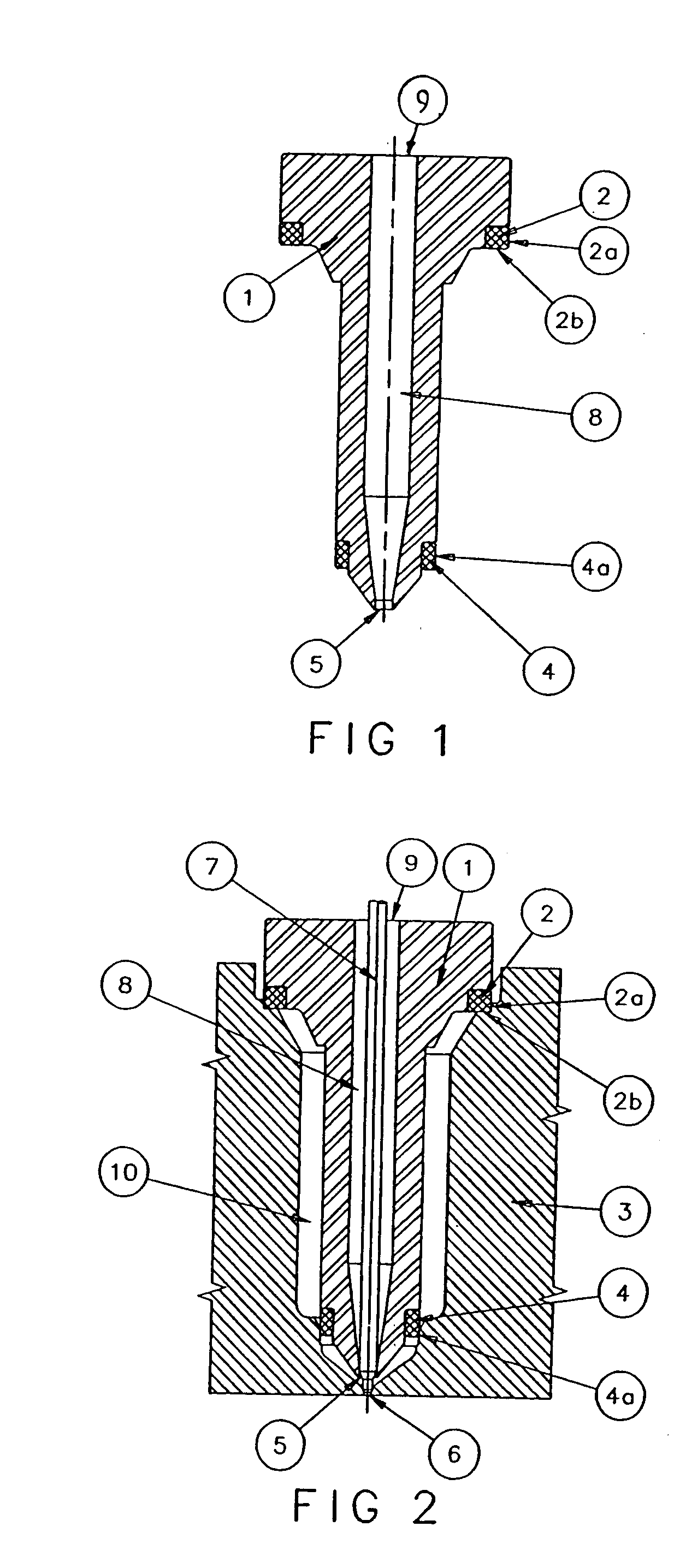

Injection molding tool

ActiveUS7306453B2Improve accuracyHigh precision machiningFood shapingEngineeringInjection molding machine

In an injection molding nozzle for an injection molding tool having an opening for receiving the injection molding nozzle, at least a first mounting element of low heat conductivity is firmly connected to the injection molding nozzle so as to permit accurate machining of the mounting element together with the nozzle such that the nozzle can be installed in the opening of the molding tool by an accurate press fit without directly contacting the base body of the molding tool.

Owner:OTTO MANNER INNOVATIONS

Adjustable efficient cutting and grinding device for pipeline machining

PendingCN113752036AStable supportAvoid going forwardMeasurement/indication equipmentsOther manufacturing equipments/toolsElectric machineryScrew thread

The invention discloses an adjustable efficient cutting and grinding device for pipeline machining. The adjustable efficient cutting and grinding device for pipeline machining comprises a bottom plate, wherein two groups of symmetrically-arranged lifting rods are installed at the top of the bottom plate through bolts, supporting pipes are installed at the tops of the lifting rods, and installation seats are installed at the tops of the supporting pipes through bolts; and a supporting frame is installed at the top of the bottom plate through bolts and located at the outer sides of the lifting rods, a control motor is installed at the top of the supporting frame in a penetrating mode, and adjusting rods are installed on the outer walls of the two sides of the supporting frame in a penetrating mode. According to the invention, a screw rod is installed, an adjusting motor operates to drive the screw rod at an output end to rotate, the screw rod rotates to drive a lantern ring at the outer side to move through threads, and the lantern ring drives a supporting rod to move in the moving process, so that the position of a cutting device at the top is adjusted, and quantitative cutting for a pipeline by the device according to needs is facilitated.

Owner:NANTONG SHUGUANG ELECTROMECHINCAL ENG

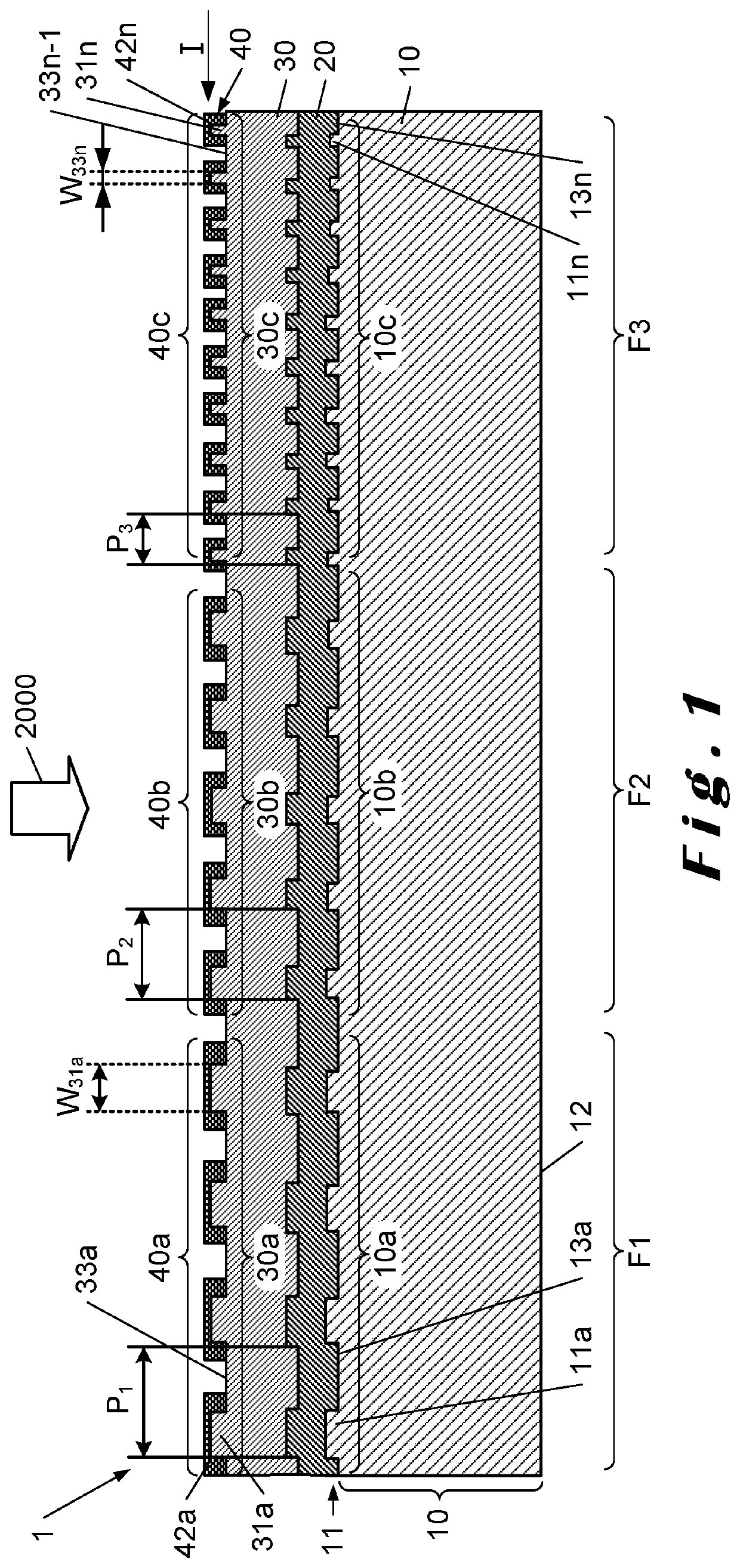

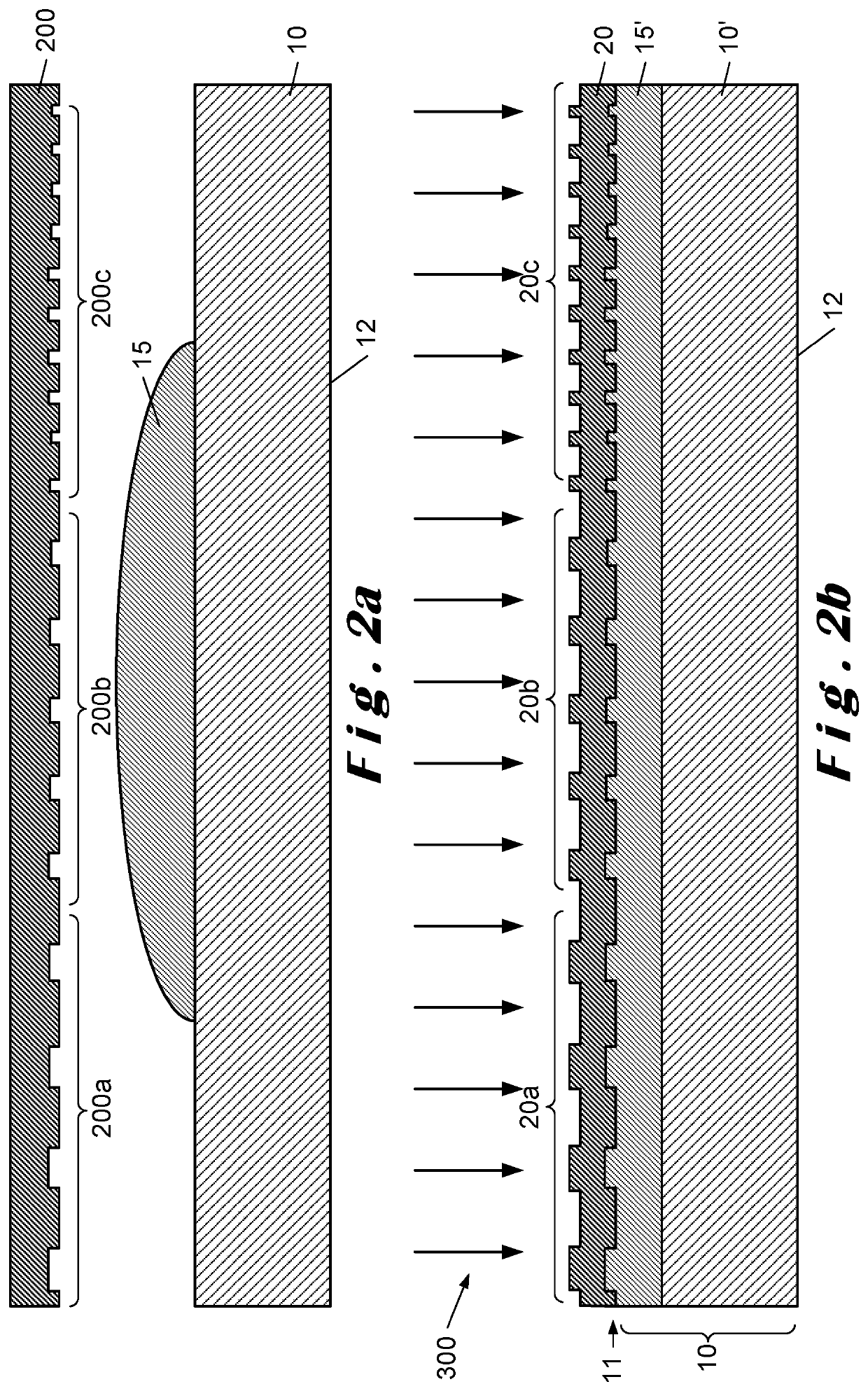

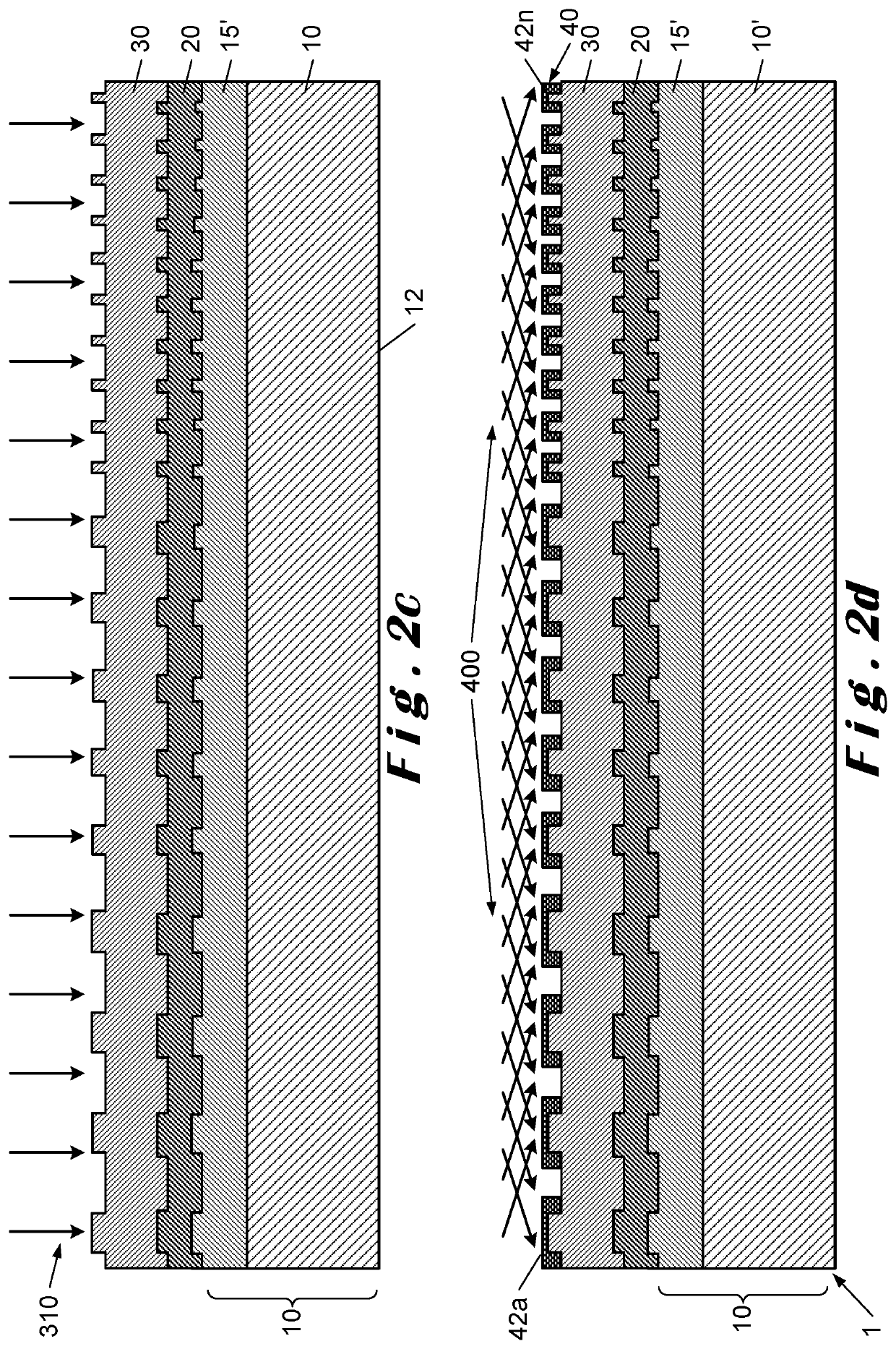

Multi-layer decorating element and method of its manufacture

ActiveUS8496777B2Easy to process preciselyLamination ancillary operationsDecorative surface effectsEngineeringHot pressing

Owner:JAH YIH ENTERPRISE

Method for preparing cooling film hole in turbine blade with thermal barrier coating

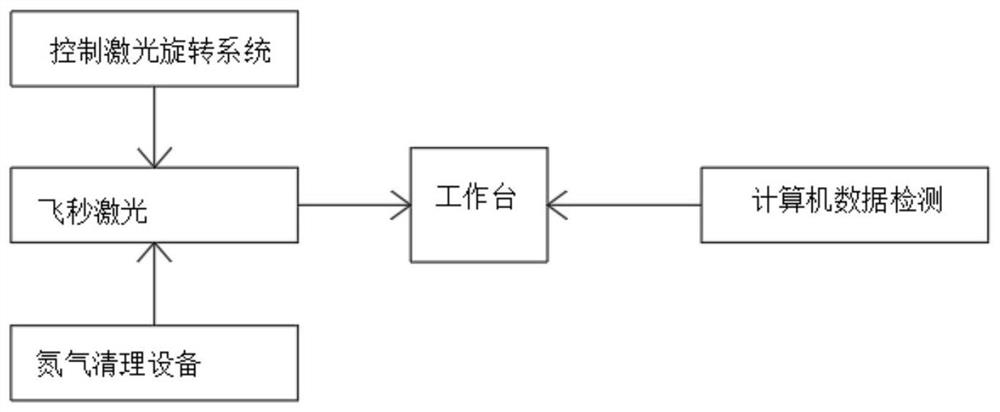

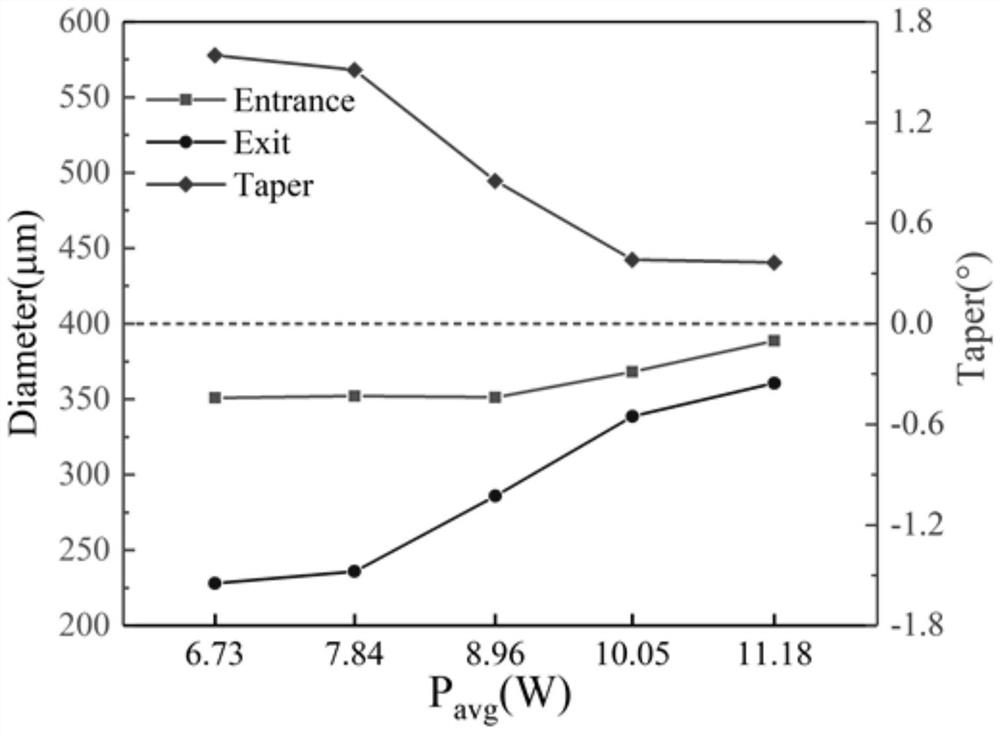

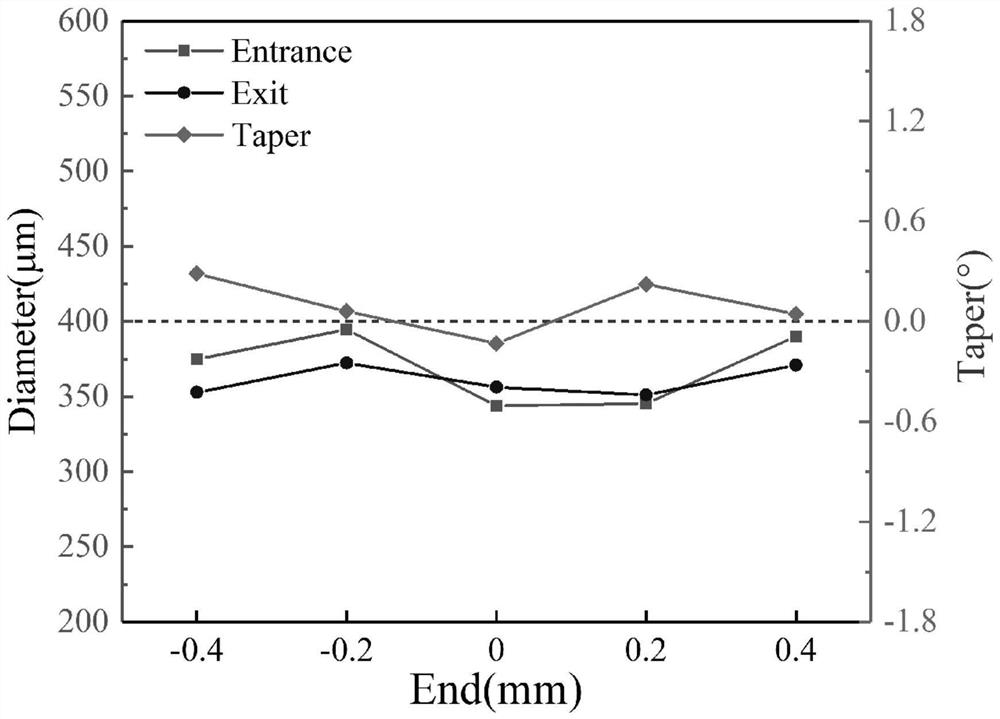

ActiveCN114749806AStable control shapeBlow off and clean up in timeLaser beam welding apparatusFemto second laserControl system

The invention discloses a method for preparing a cooling film hole in a turbine blade with a thermal barrier coating, and the method for preparing the cooling film hole in the turbine blade with the thermal barrier coating comprises the following steps: firstly, placing the turbine blade to be processed on a workbench, and fixing; then adjusting the included angle between femtosecond laser and the turbine blade through the angle of the cooling film hole, starting the femtosecond laser and setting laser parameters as follows: the pulse width is 290fs-10ps, the peak power is 12-14KW and the pulse frequency is 1kHz-1MHz, programming a laser rotary cutting route in a control system, setting the rotary cutting speed to 0.4-0.5 mm / s and the rotary cutting frequency to three times, preheating the turbine blade by utilizing high frequency, and then, carrying out rotary cutting on the turbine blade by utilizing high frequency; external nitrogen is conveyed to the workbench and the surface of the turbine blade through the nitrogen pipe, residues left during punching can be blown away and cleaned away, the situation that machining of the turbine blade by femtosecond laser is affected due to the fact that the residues move into a film hole is avoided, and high film hole machining quality is achieved.

Owner:AIR FORCE UNIV PLA

Injection molding tool

In an injection molding nozzle for an injection molding tool having an opening for receiving the injection molding nozzle, at least a first mounting element of low heat conductivity is firmly connected to the injection molding nozzle so as to permit accurate machining of the mounting element together with the nozzle such that the nozzle can be installed in the opening of the molding tool by an accurate press fit without directly contacting the base body of the molding tool.

Owner:OTTO MANNER INNOVATIONS

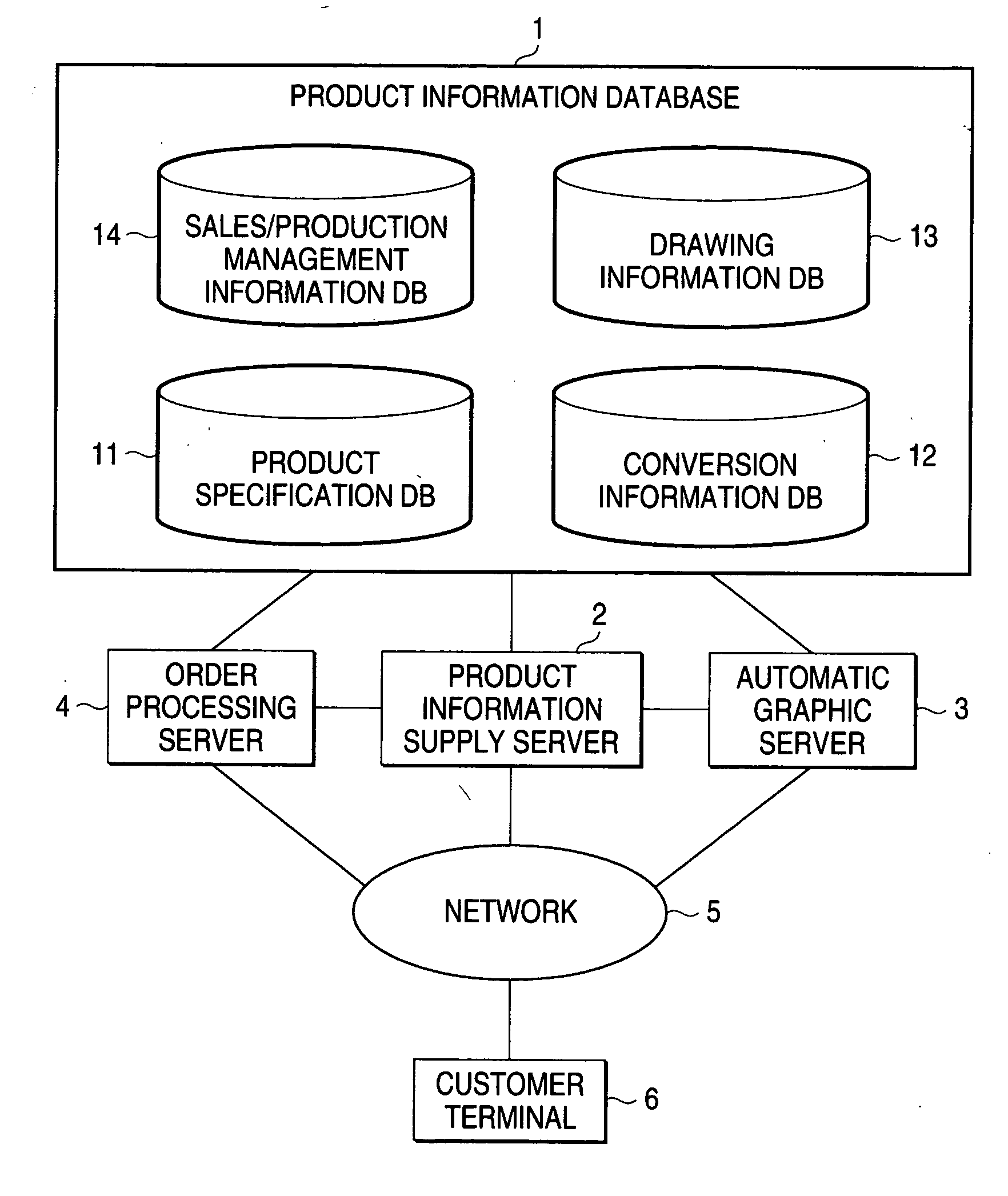

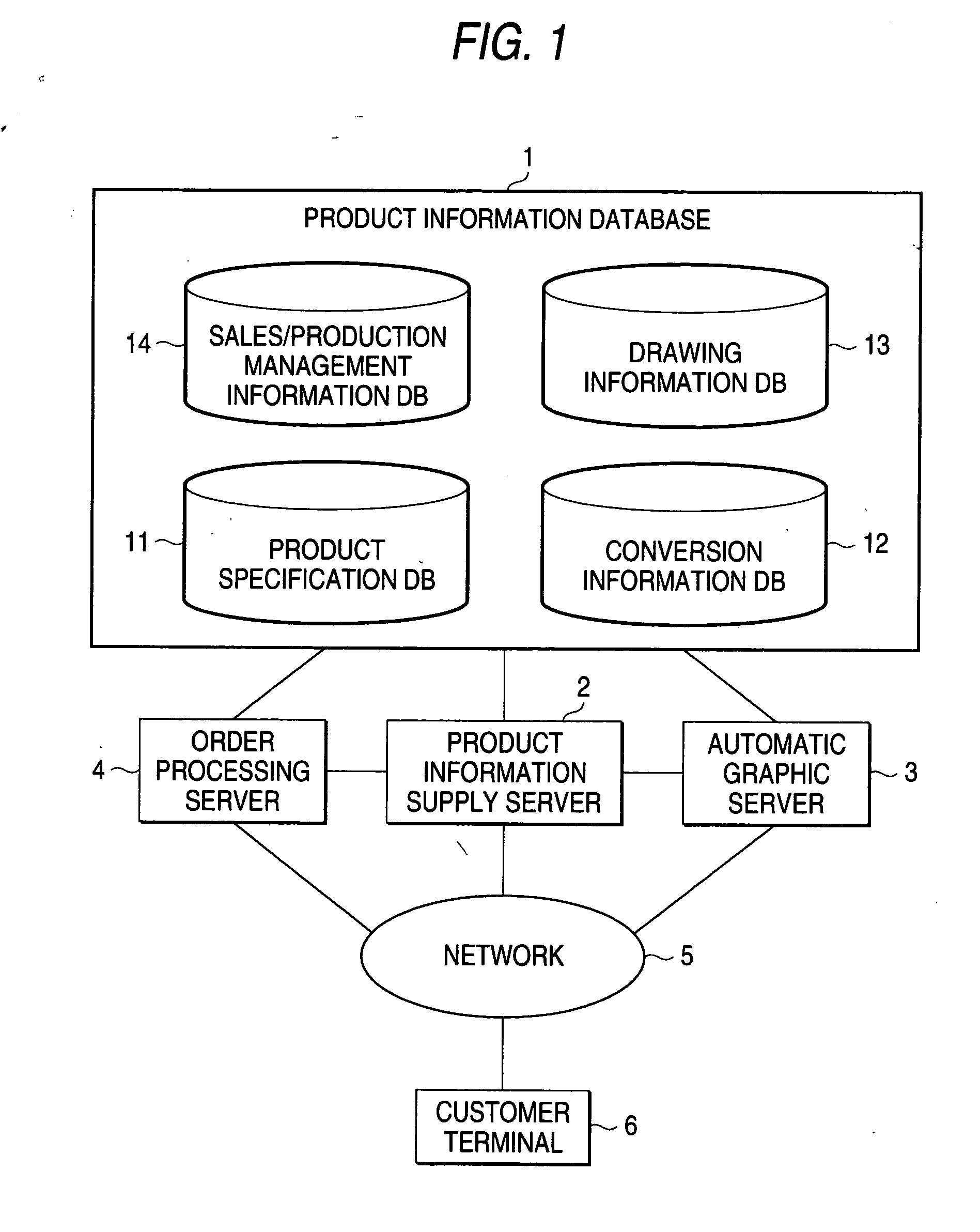

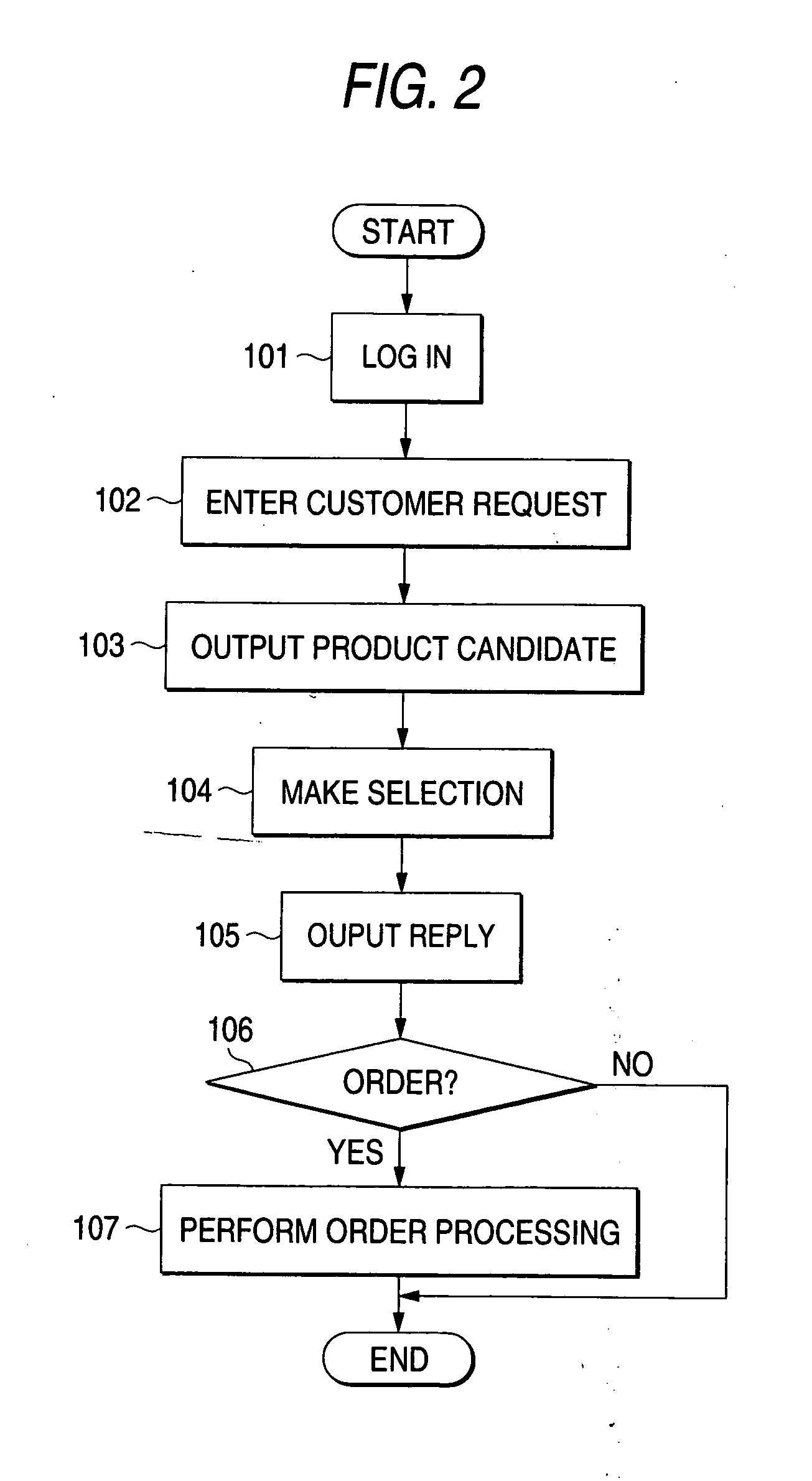

Product purchase supporting system

InactiveUS20070005455A1Easy and accurate order processingEasy to process preciselyMarketingSupporting systemOrder processing

A system constituted by a product information supply server 2, an automatic graphic server 3, an order processing server 4 and a product information database 1. The servers 2, 3 and 4 may be connected to product information database 1 on a network 5, wherein product information is supplied and an order is accepted on the basis of a request from a customer terminal 6. The product information supply server 2 searches and supplies various pieces of product information in accordance with the request from the customer terminal 6. The product information supply server 2 searches a product specification database 11 on the basis of the product specification information entered from the customer terminal 6, extracts a call number of a relevant product from the product specification database 11, and supplies the call number of the relevant product together with price information and delivery to the customer terminal 6.

Owner:NSK LTD

Imaging apparatus

InactiveUS20050010101A1Facilitate image captureImprove illumination controlTelevision system detailsChemiluminescene/bioluminescenceEngineeringImaging equipment

An improved imaging apparatus is disclosed that allows a user to perform numerous imaging operations. The imaging apparatus may include one or more improvements to imaging box design to improve illumination control within the imaging box, such as improved door seal arrangements, improved door closing mechanisms, and improved light seals. The present invention may also include one or more improvements to imaging apparatus design to facilitate image capture, such as: an automated filter select device, a moveable stage, automated focus control, f-stop adjustment and stage height, and improved internal illumination for capturing photographic images.

Owner:XENOGEN CORP

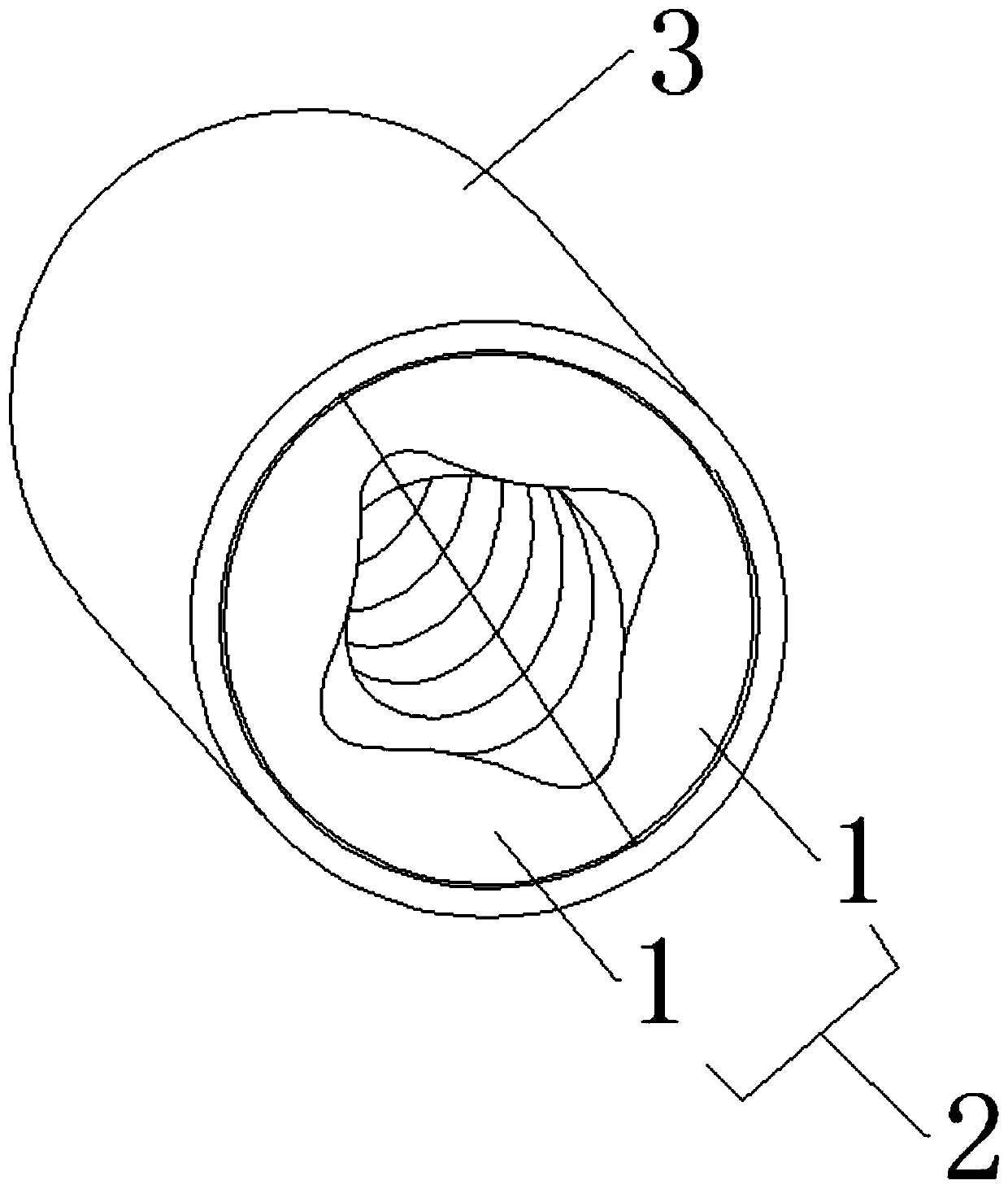

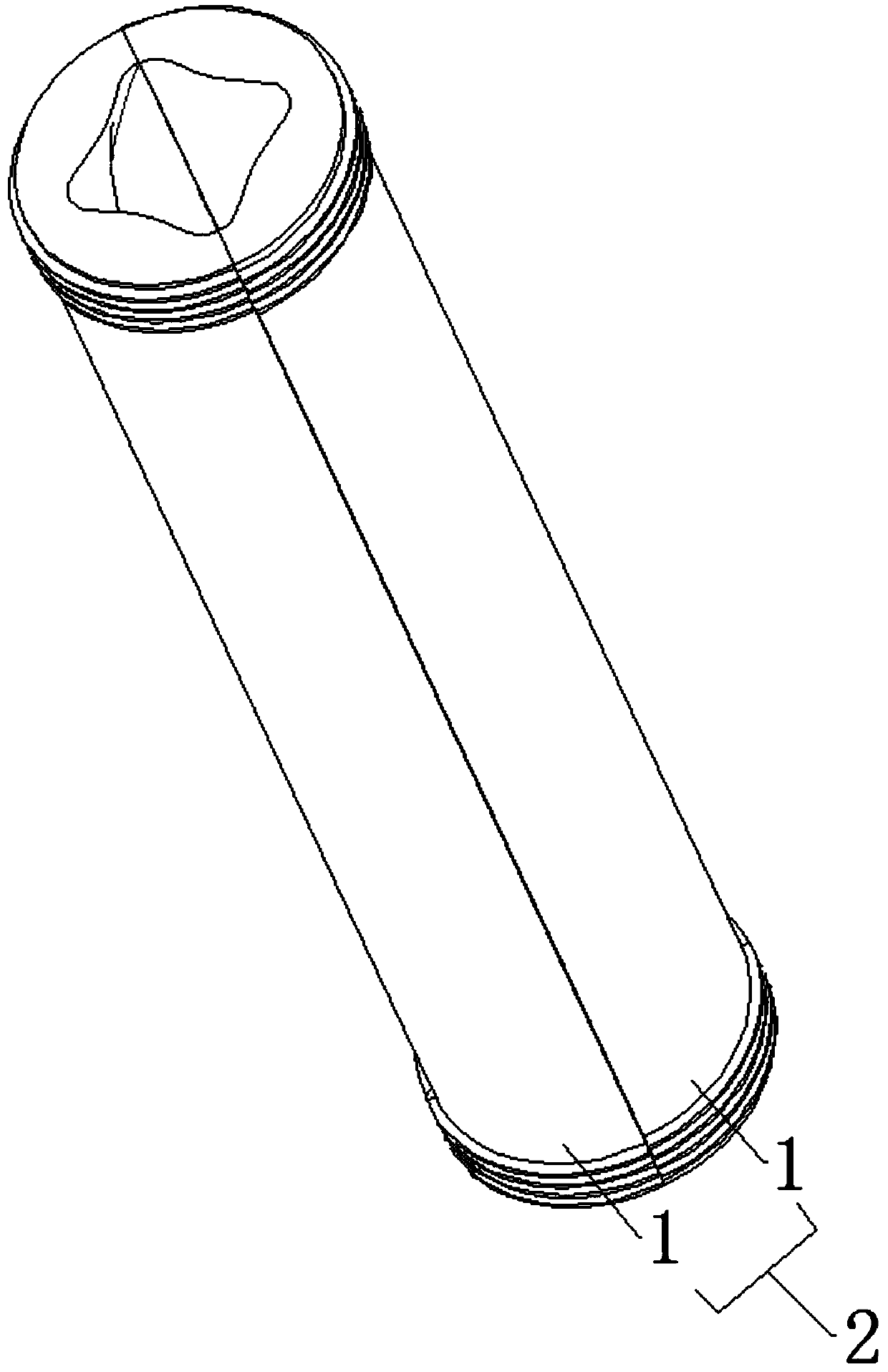

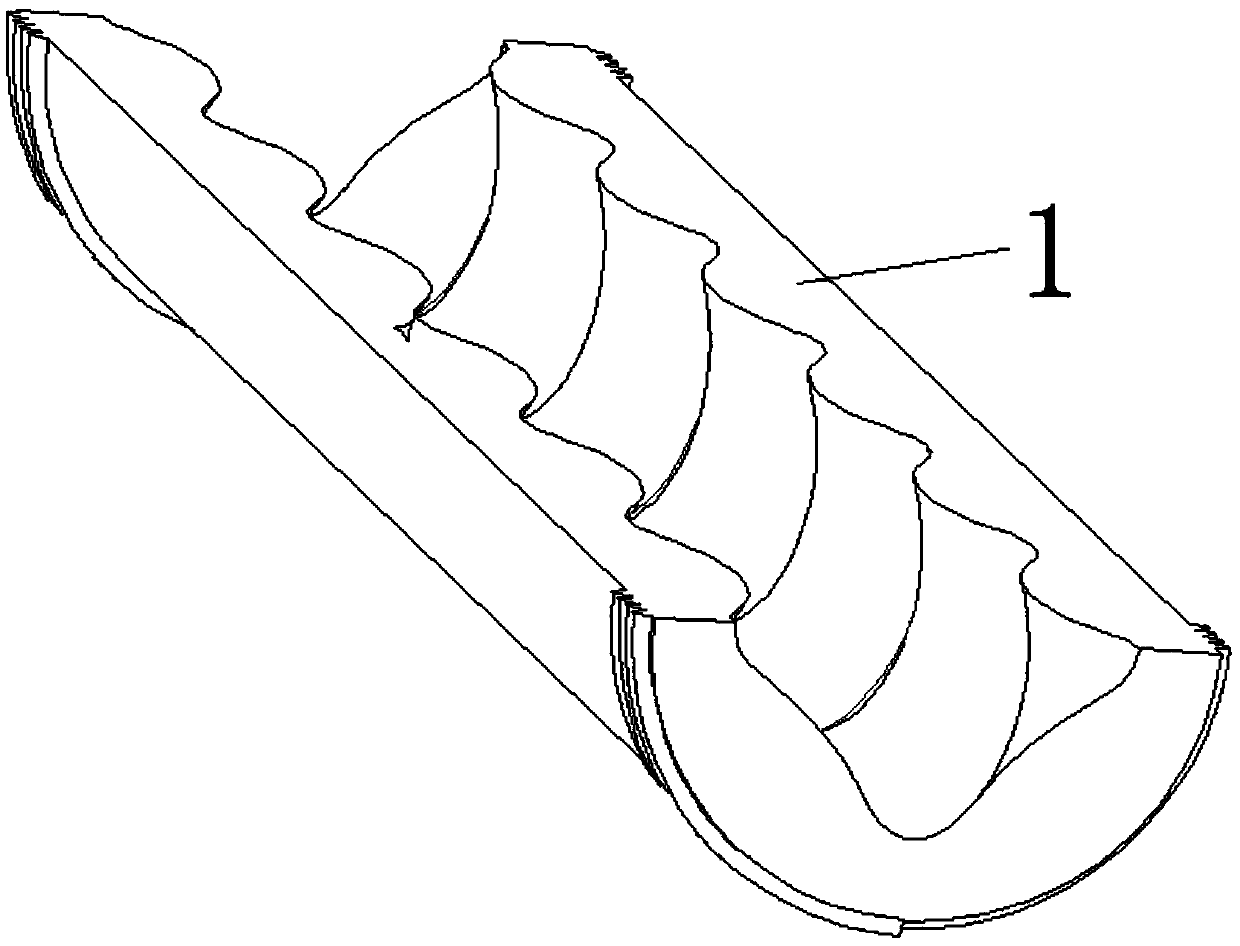

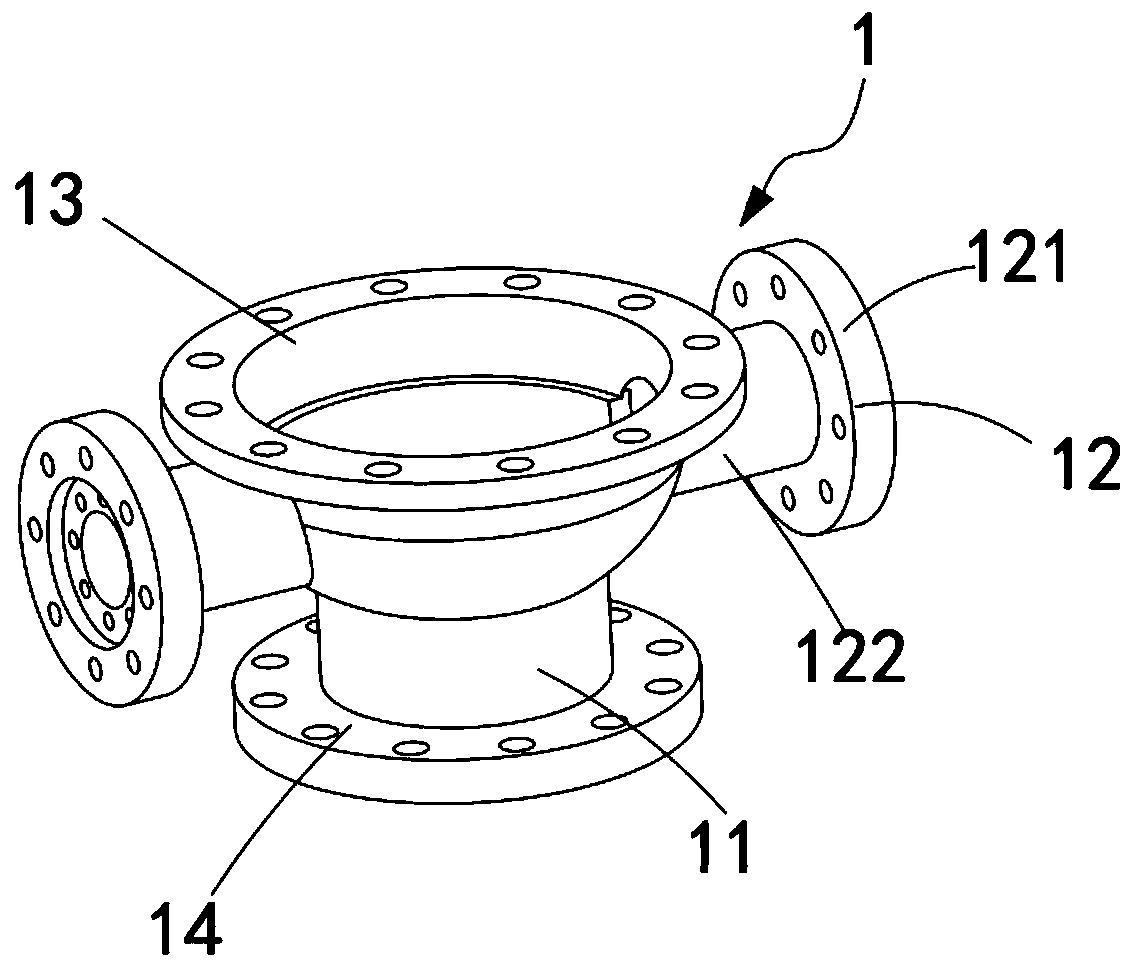

Sleeving splicing type full-metal screw stator and machining method thereof

PendingCN109538112AReduce processing difficultyEasy and precise processingBorehole drivesRotary piston enginesPipe fittingEngineering

The invention discloses a sleeving splicing type full-metal screw stator and a machining method thereof. According to the stator, a half-cylinder metal stator blank with the length being two stator leads is cut and machined to form an inner helix and then cut into two half-cylinder spliced parts, after the planes of the two half-cylinder spliced parts fit each other, soldering tin is pressed intoa matching gap for welding, and finally a cylindrical metal stator inner core is formed; male thread lines with the same rotating direction are milled at the two ends of the stator inner core, and then the stator inner core is inserted into a metal pipe fitting; female thread lines are milled at the positions, corresponding to the stator inner core, of the inner walls of the two ends of the metalpipe fitting, and the stator inner core is fixed in the metal pipe fitting through a thread meshed with the metal pipe fitting. The machining method adopts thread locking fixing and metal stator splitmachining, the inner helix surface of the stator is machined more conveniently and accurately, in this way, the machining difficulty of the stator can be lowered greatly, matching precision is improved, then the working performance of the full-metal screw drilling tool is improved, and the service life of the full-metal screw drilling tool is prolonged.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Spring plate puncture forming device

The invention discloses a spring plate puncture forming device which has the following beneficial effects: according to the sizes of the processed spring plates, the required number of springs are arranged below a lower die knock plate and the lower die knock plate is utilized to support puncture inner strippers. By means of the invention, the problem that when the spring plates are processed in the prior art, the puncture positions of the spring plates are liable to broken holes, thus affecting subsequence processing of the spring plates is solved. The spring plate puncture forming device issimple to operate, has high efficiency, can not cause broken holes, and utilizes the springs to ensure the plates to float up and down to replace ejector pins to strip materials.

Owner:KUNSHAN ESON PRECISION ENGINEERING CO LTD

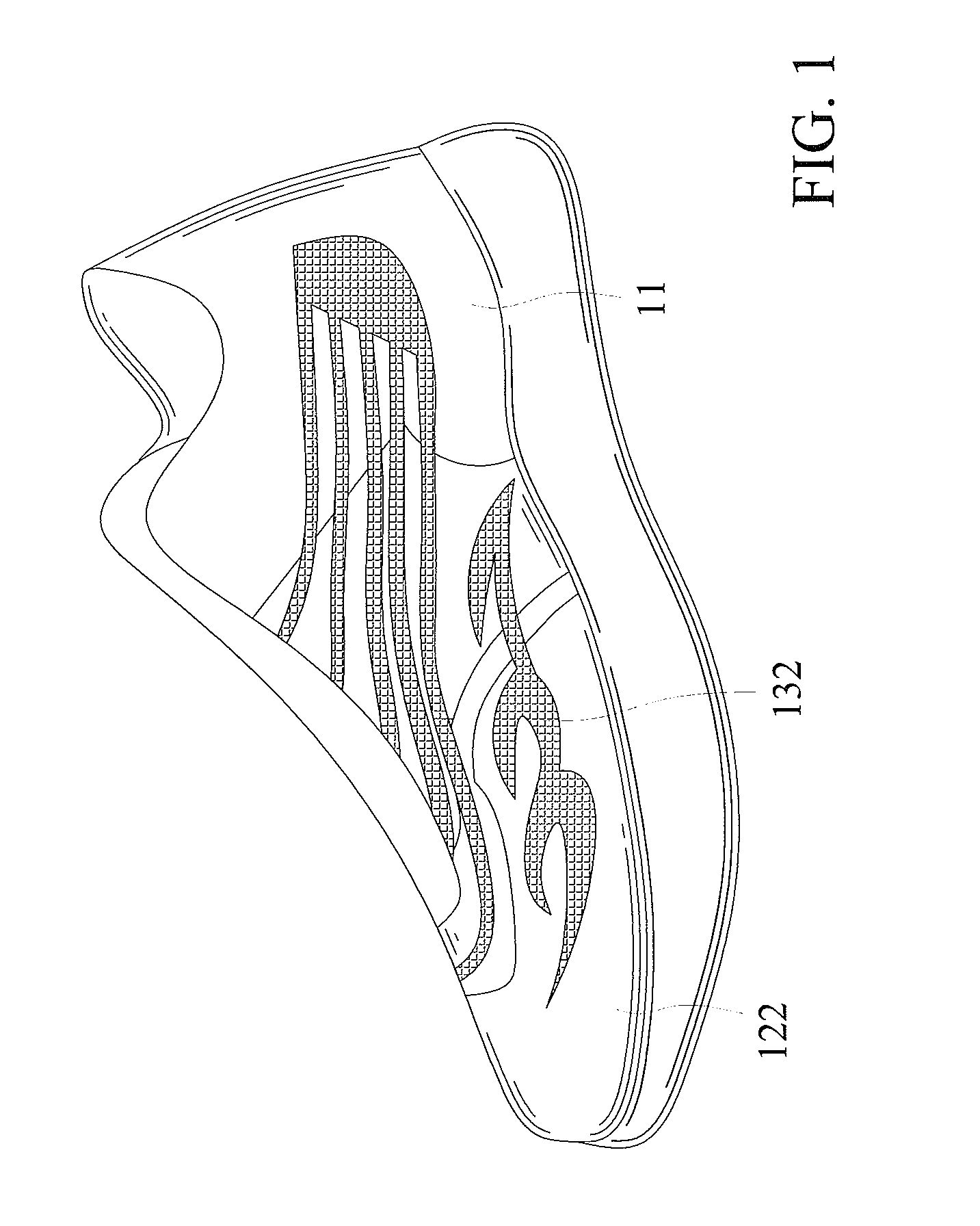

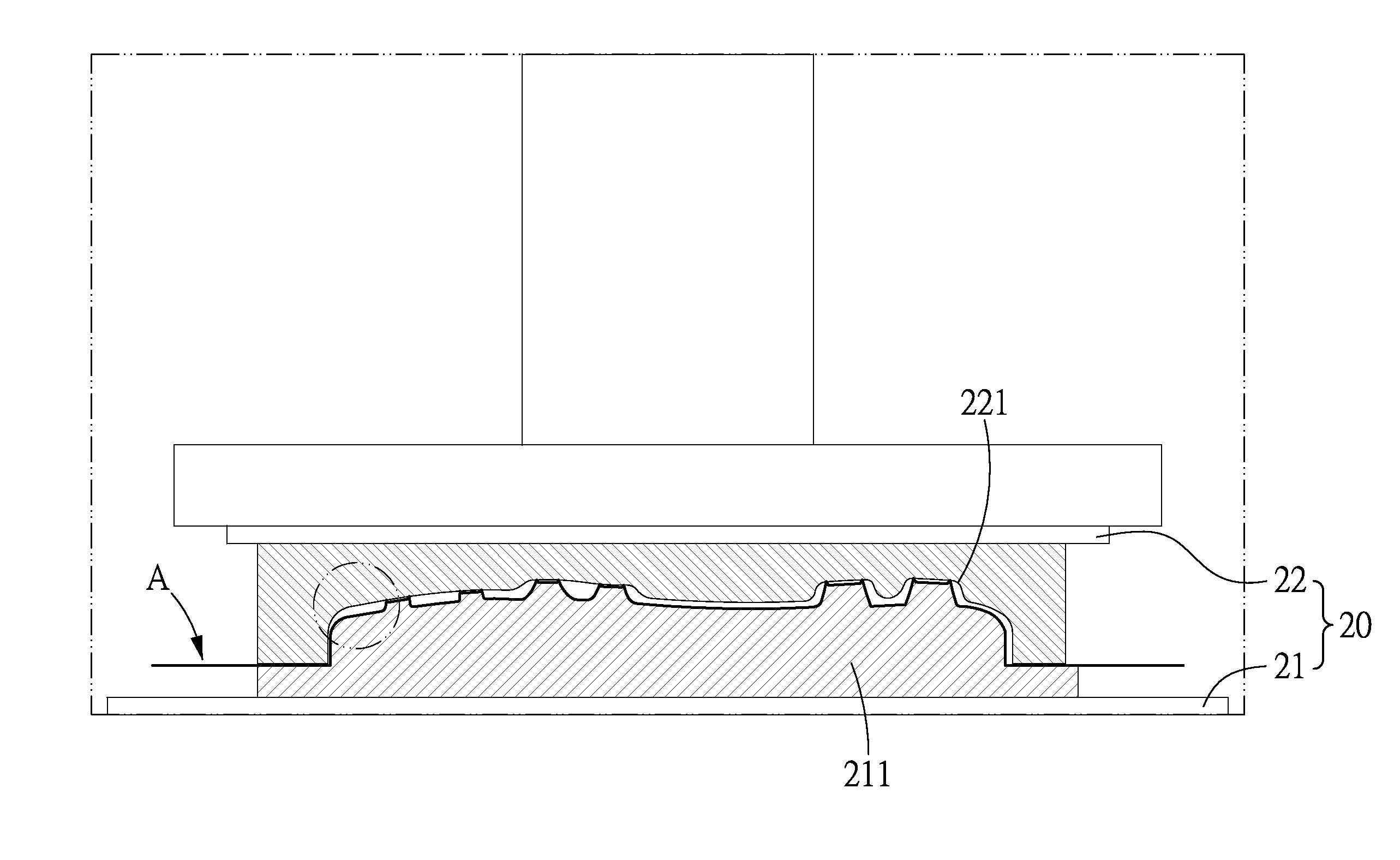

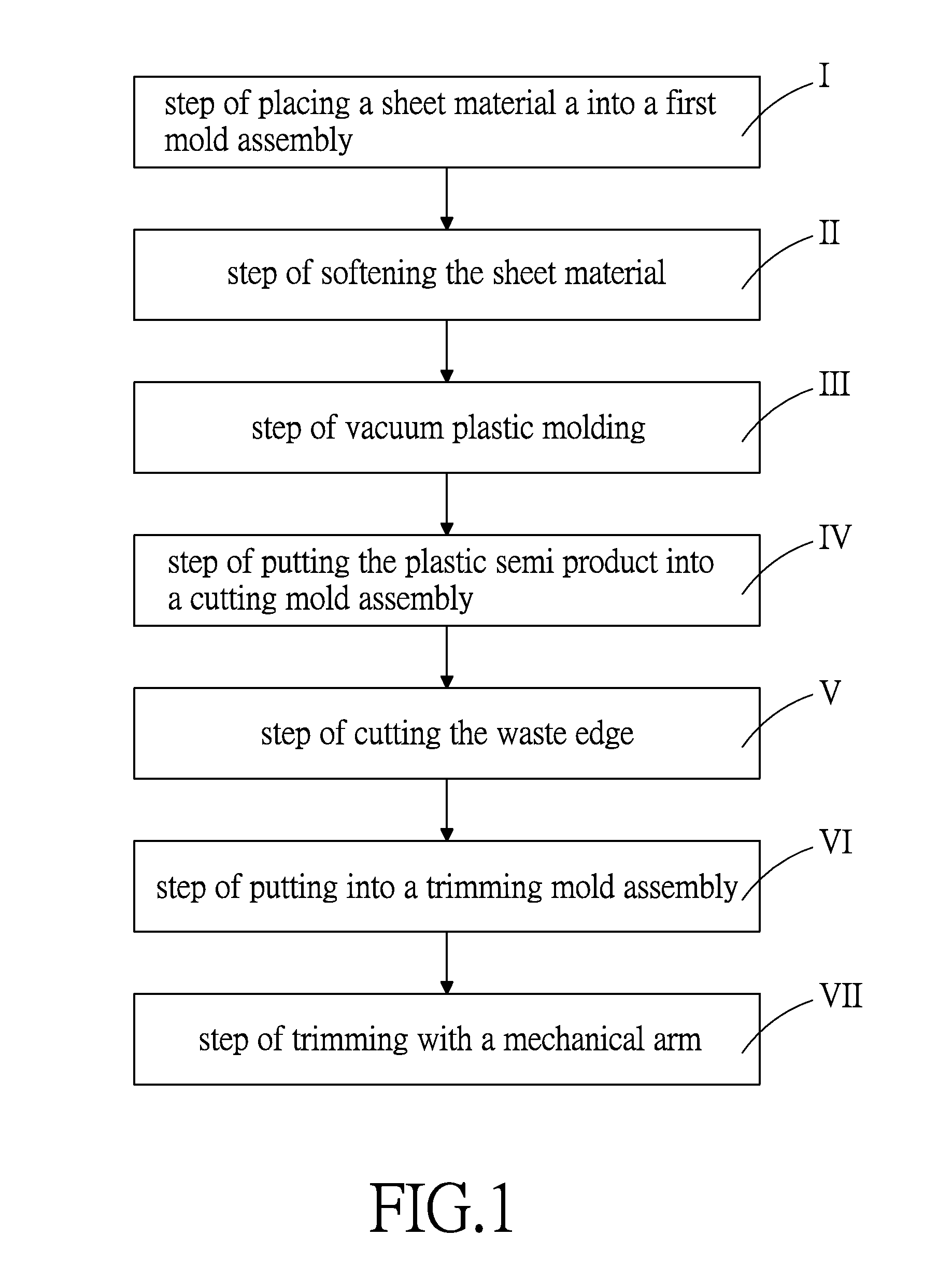

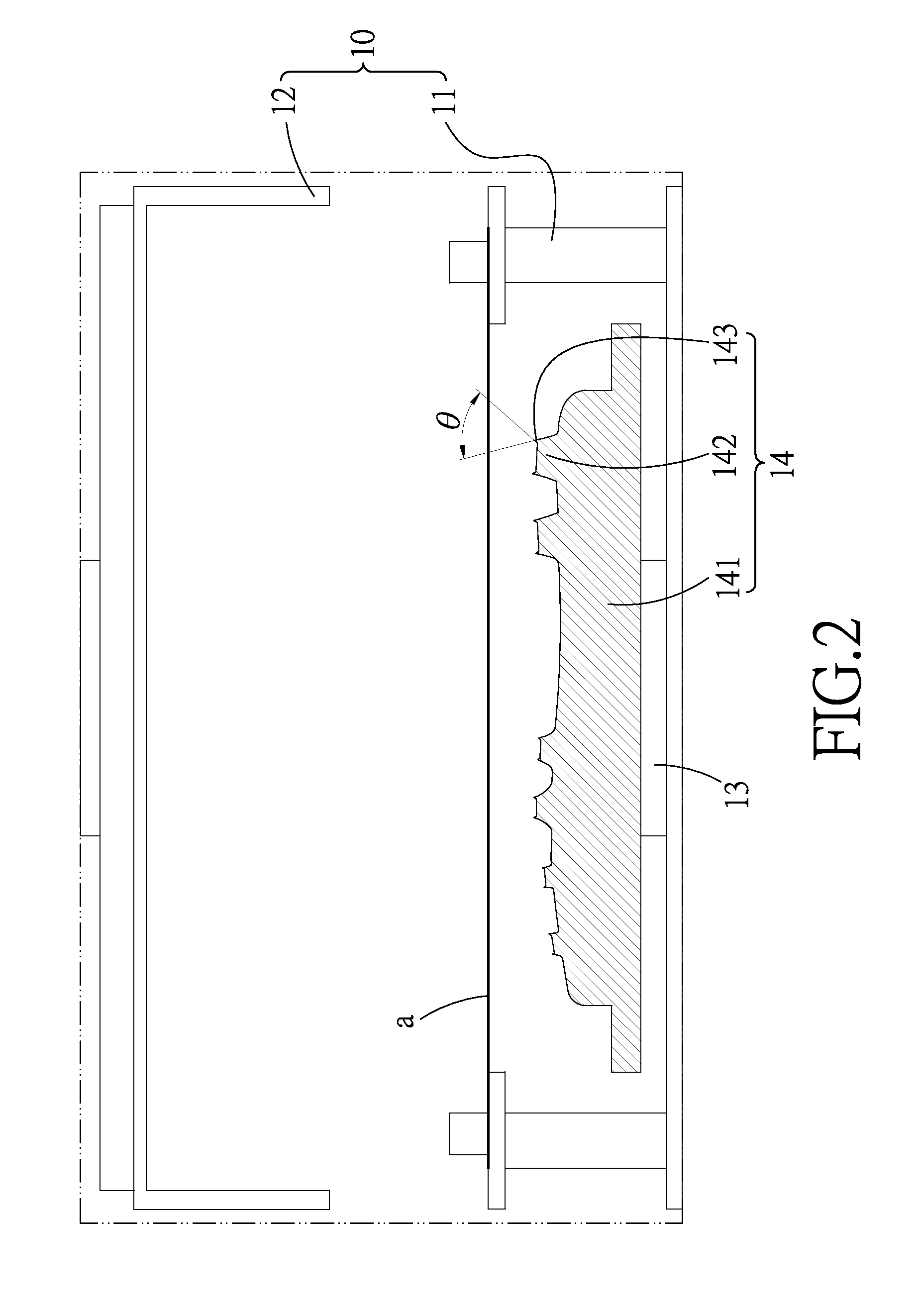

Method for forming a plastic support shell of a sole

InactiveUS20160368183A1Easy to makeEasy to process preciselyDomestic footwearDomestic articlesEngineeringPlastic molding

A method for forming a plastic support shell of a sole includes the steps of placing a sheet material into a first mold assembly; softening the sheet material; vacuum plastic molding; putting the plastic semi product into a cutting mold assembly; cutting the waste edge; putting into a trimming mold assembly; and trimming with a mechanical arm. The carrying mold and the pressing mold press against the inner and outer surfaces of the plastic semi product, and the restricting edge and the support edge are used to define a cutting line. Therefore, the plastic semi product can be firmly positioned and held tight, and then the mechanical arm can trim the plastic semi product under the guiding of the restricting edge and the support edge, which makes the trimming process easy and precise.

Owner:YANG TENG JEN

Refrigerator liner positioning device based on vacuum technology and operation method thereof

InactiveCN112621564ASolve the problem of subsequent processingGuaranteed angular rotation requiresGrinding drivesPositioning apparatusIceboxEngineering

The invention discloses a refrigerator liner positioning device based on a vacuum technology and an operation method thereof, and relates to the technical field of refrigerator machining equipment. An upper positioning panel comprises a lower positioning base plate fixed to the upper side of a fixed connecting plate, a positioning frame and inner positioning plates are fixedly arranged on the upper side surface of the lower positioning base plate, the inner positioning plates are located in the positioning frame, and the multiple inner positioning plates are arranged in the positioning frame; the surfaces of the inner positioning plates and the surface of the lower positioning base plate are all provided with air pumping holes, the air pumping holes in the lower positioning base plate communicate with the interiors of the air pumping holes in the inner positioning plates, the positioning frame is of an integrated frame structure, air in a cavity between the positioning frame and a refrigerator liner is pumped away through a vacuum generation device, and then the formed pressure difference is used for positioning, so that the problems that traditional positioning for a refrigerator liner piece is unstable in the machining process, the precision is poor, and subsequent machining of the liner piece is affected are solved.

Owner:滁州力通机械装备股份有限公司

Method and structure for fabricating mechanical mirror structures using backside alignment techniques

InactiveUS7449284B2Easy to useHigh device yieldPhoto-taking processesPhotoprinting processesElectromagnetic radiationSilicon

A method for fabricating mechanical structures from bonding substrates. The method includes providing a bonded substrate structure, which includes a first substrate having a first thickness of silicon material and a first face. The bonded substrate also includes a second substrate having a second thickness and a second face. At least the first substrate or at least the second substrate (or both) has an alignment mark comprising a front-size zero mark within a portion of either the first thickness or the second thickness. The method includes applying a layer of photomasking material overlying a first backside surface of the first substrate. The method includes illuminating electromagnetic radiation using a coherent light source through the layer of photoresist material and through a portion of the first thickness. The method includes detecting an indication of the alignment mark using a signal associated with a portion of the electromagnetic radiation from a second backside of the second substrate. The method also includes exposing a portion of the layer of photomasking material once a pattern a portion of a reticle structure has been aligned using the alignment mark.

Owner:MIRADIA INC

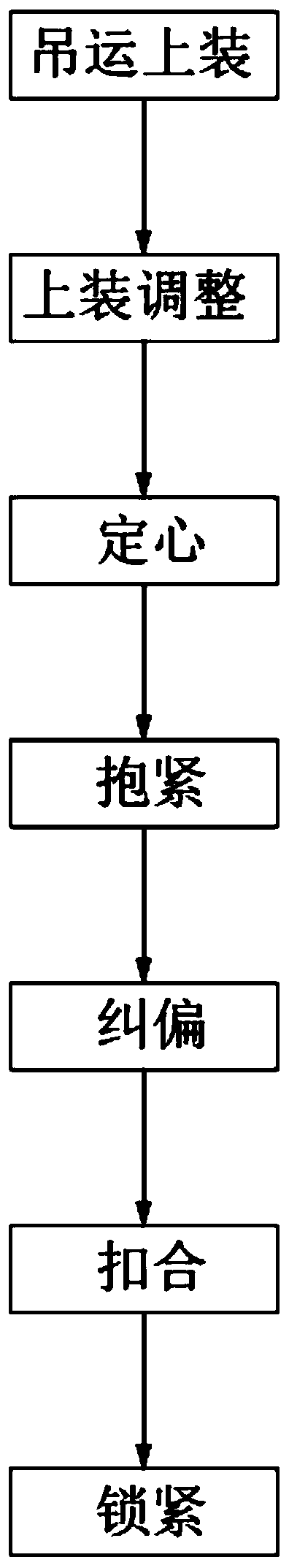

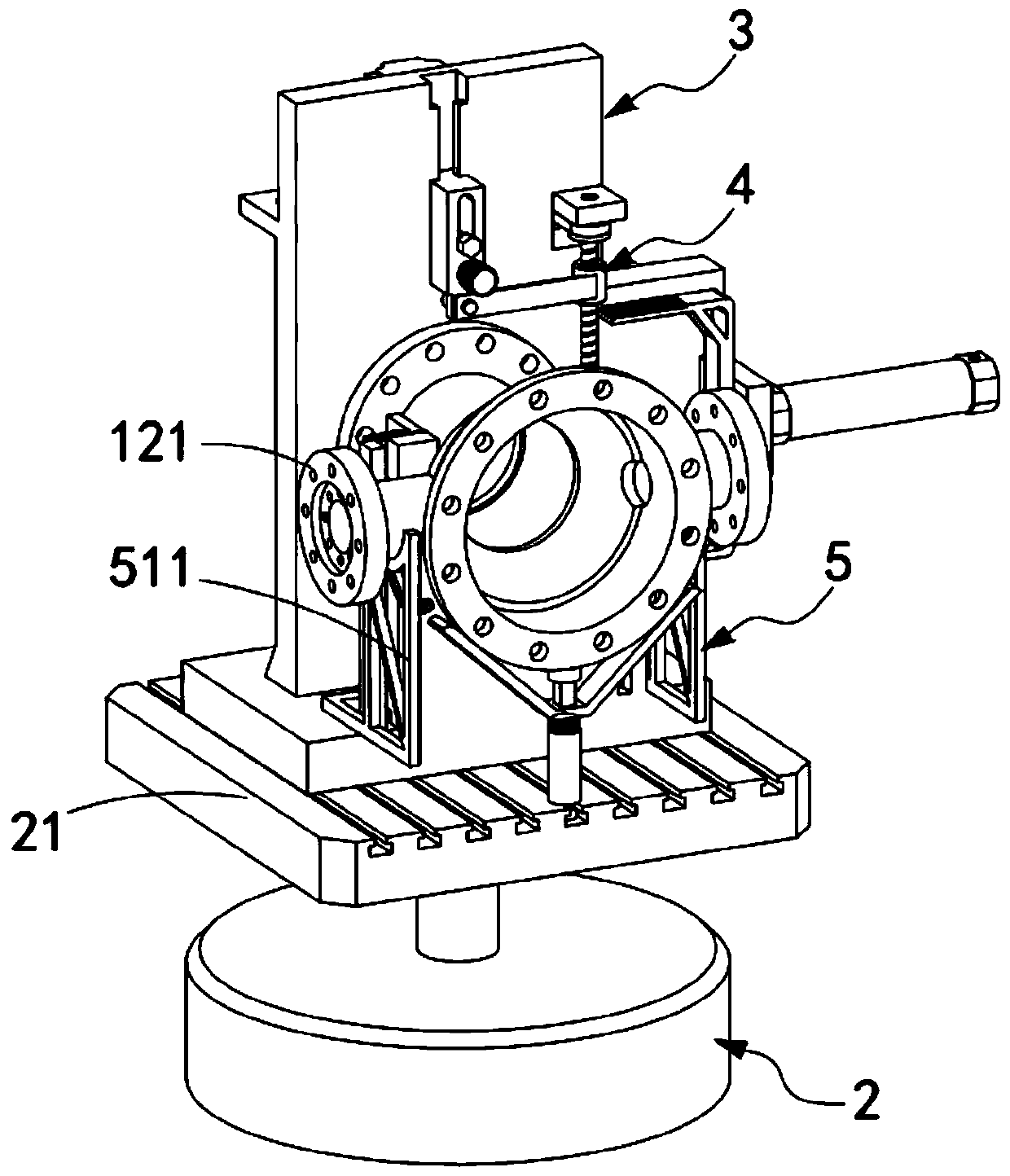

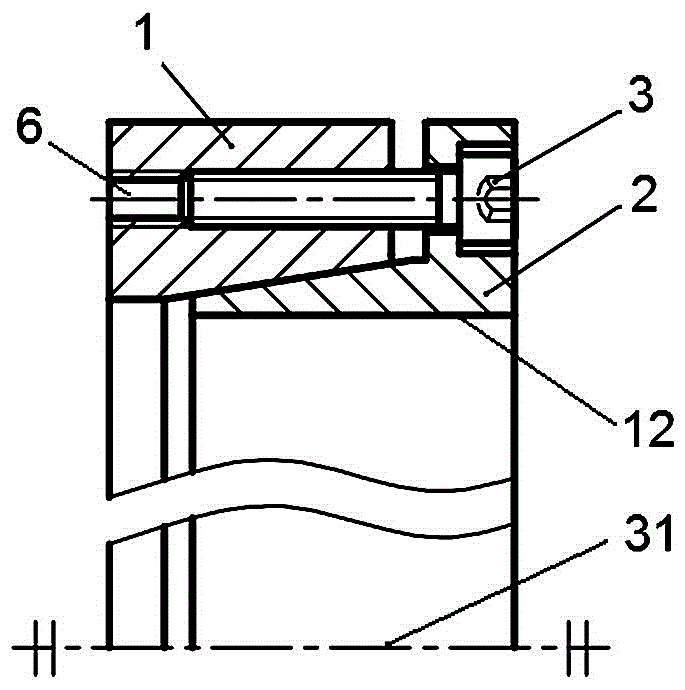

Processed upper tool positioning method special for valve body

ActiveCN111376098AGuaranteed vertical setting of the flangeEasy to process preciselyChucksMetal working apparatusProcessing accuracyVALVE PORT

The invention relates to the technical field of valve processing, in particular to a processed upper tool positioning method special for a valve body. The processed upper tool positioning method comprises the steps of upper tool lifting and transporting, upper tool adjusting, centering, holding tightly, deviation correcting, buckling and locking. According to the processed upper tool positioning method, in the step of centering, an installation and clamping mechanism is utilized to clamp and fix the valve body, the steps of holding tightly and deviation correcting are synchronously utilized, connecting ends on the two sides of the valve body are tightly held and buckled by a holding claw and a positioning claw in a deviation correcting mechanism, thus the axis of a connecting end part is arranged horizontally, it is guaranteed that the flanging of the connecting end part is arranged vertically, the subsequent accurate processing is convenient, and the technical problem of low processing accuracy of the connecting end caused by clamping and fixing is solved.

Owner:惠州联合阀控液压技术有限公司

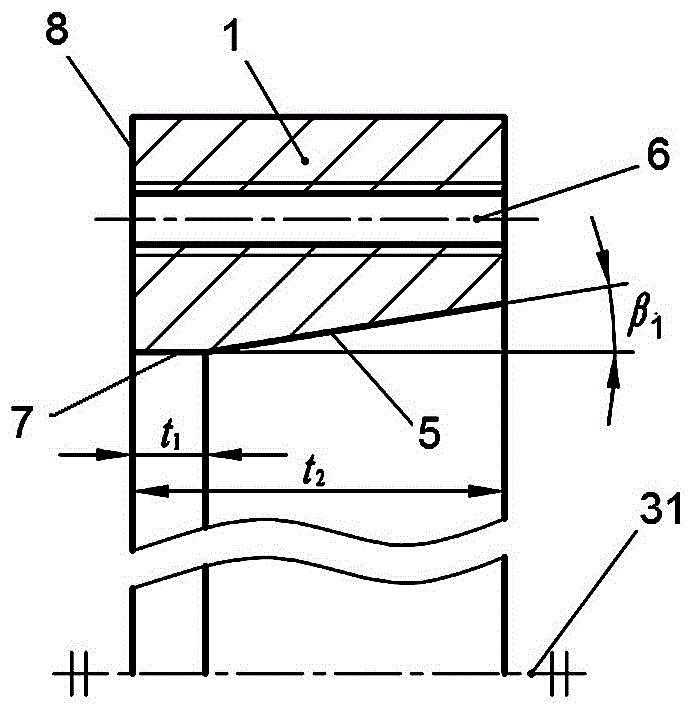

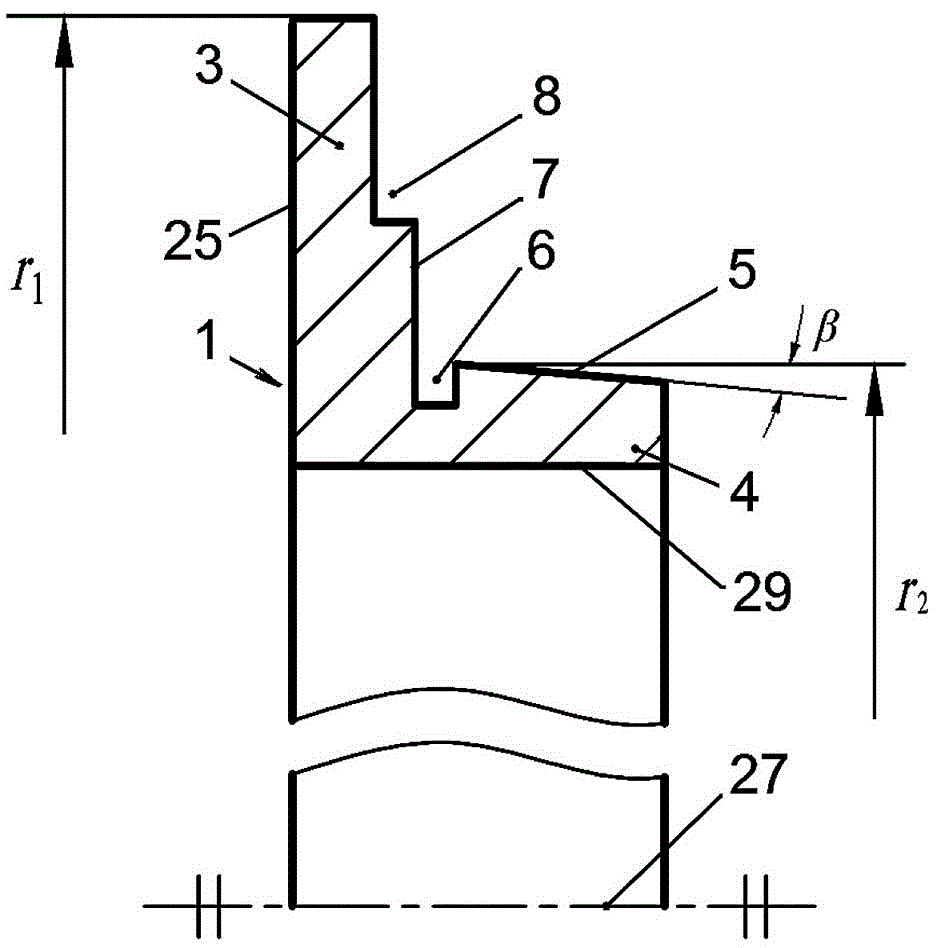

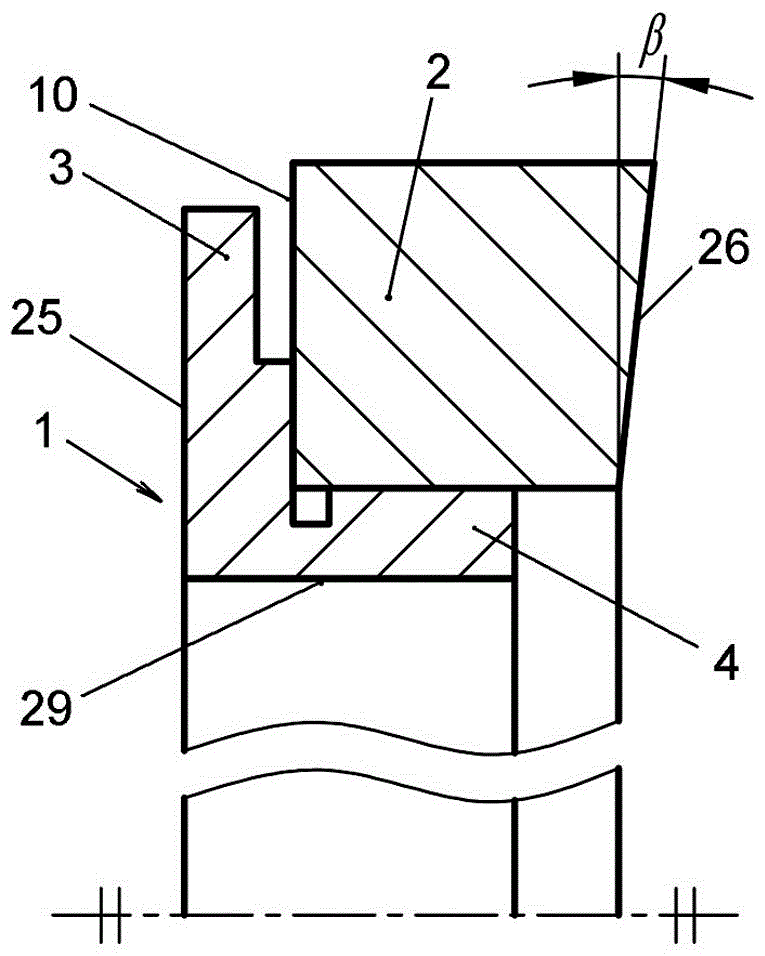

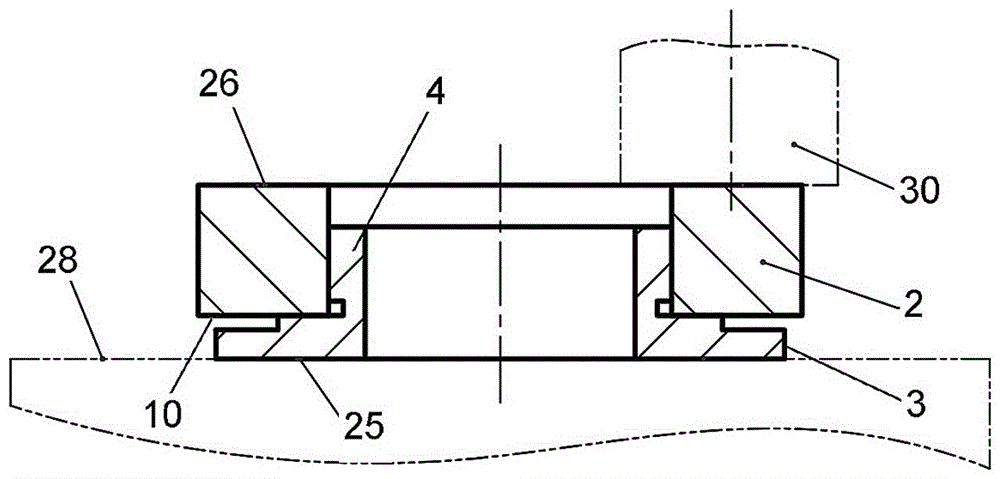

Taper sleeve type grinding device for machining inverted cone sealing ring

ActiveCN106826475AHigh surface quality requirementsEasy to process preciselyGrinding machinesGrinding work supportsEngineeringFrustum

The invention discloses a taper sleeve type grinding device for machining an inverted cone sealing ring. The device comprises a group including an outer sleeve structure and an inner insertion structure, wherein the outer sleeve structure and the inner insert structure can be connected and fastened to each other through a connecting structure in a way that the opposite ends of the outer sleeve structure and the inner insert structure are matched in a socket way along the axial direction; the socket matching parts of the outer sleeve structure and the inner insert structure are rotation matching surfaces including an inner concave conical hole surface and an outer convex frustum surface; each rotation matching surface takes a central axis as a rotation center; the inner concave conical hole surface is provided with a taper angle beta 1; the outer convex frustum surface is provided with a taper angle beta 2; the taper angle beta 1 of the rotation surface of the outer sleeve structure is more than or equal to the taper angle beta 2 of the rotation surface of the inner insertion structure; the other end surface, in the backward direction of the socket end, of the outer sleeve structure is a reference surface; an axial internal concave structure of a cylindrical internal hole surface is arranged in the inner insertion structure; the cylindrical internal hole surface also takes an axis as a rotation center; and the internal diameter of the cylindrical internal hole surface is adaptive to the outer diameter of the machined sealing ring. The grinding device can be used to conveniently and accurately machine a sealing surface on a sealing end surface, wherein the taper angle is only about a few minutes or tens of minutes, the maximal cut amount along the axial direction is only tens of micrometers, the requirement on the surface quality of the sealing end surface is very high, and especially the sealing surface has an inverted cone surface.

Owner:XIHUA UNIV

Extrusion molding granulator

ActiveCN113427661AEffective extrusionExtrude evenlyPlastic recyclingProcess engineeringIndustrial engineering

The invention relates to an extrusion molding granulator. The extrusion molding granulator comprises a mounting frame, supporting frames, a conveying charging barrel and a granulation die head, the supporting frames are symmetrically mounted at the upper end of the mounting frame, the conveying charging barrel is mounted in the middle of the upper ends of the supporting frames, a conveying screw is mounted in the conveying charging barrel, and the granulation die head is mounted at the left end of the conveying charging barrel through screws. The extrusion molding granulator can solve the problems that the extrusion effect of raw materials is poor, the processing efficiency is low, the production cost of enterprises is increased due to the fact that the existing equipment cannot quickly adjust the size of extruded granules according to use requirements and generally needs to replace dies with different sizes when used for granulating waste plastics, meanwhile, when the existing equipment is used for granulating the waste plastics, the extruded raw materials cannot be accurately granulated, the cutting effect is poor, the cutting is not uniform, the cut raw materials are prone to adhering to a cutter, and the subsequent use of the cutter is influenced.

Owner:邓益民

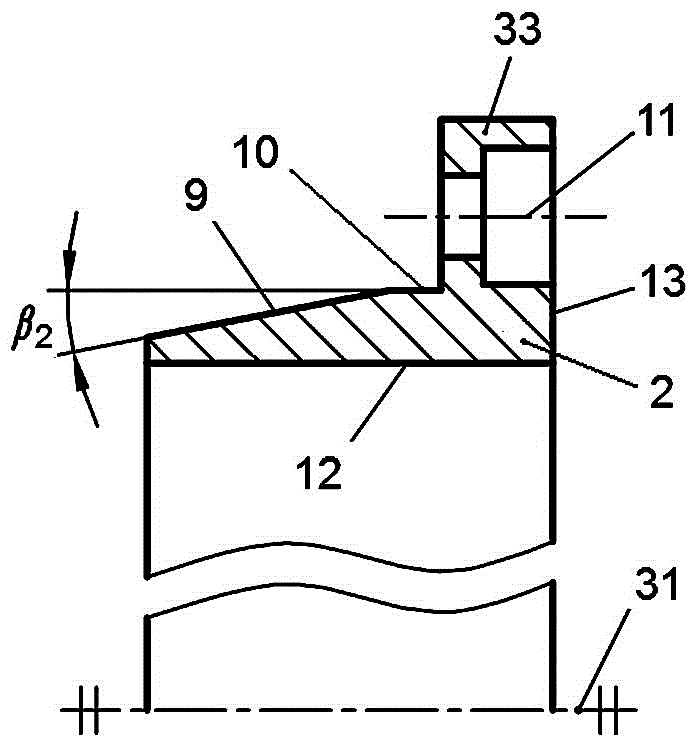

Heat cover type grinding device for machining sealing ring with regularly conical surface

ActiveCN106670909AHigh surface quality requirementsEasy to process preciselyGrinding work supportsPlane surface grinding machinesMicrometerEngineering

A heat cover type grinding device for machining a sealing ring with a regularly conical surface comprises a radial extended disc body and an axial extension structure, wherein a central axis is used as the gyration center of the radial extended disc body; the axial extension structure extends to one side in the axial direction on the radial inner side ; the outer diameter of the axial extension structure can be matched with the diameter of an inner hole of a machined sealing ring; two axial end surfaces of the disc body are respectively a reference surface and a positioning working surface; the reference surface is perpendicular to the central axis; the positioning working surface can be in surface contact with a non-sealed end of the machined sealing ring; a radial groove is formed in a part, which is adjacently connected with the positioning working surface, of the axial extension structure; a peripheral surface of the axial extension structure is a cylindrical or conical gyration surface; and the diameter of a peripheral surface of a root in the direction of the positioning working surface is greater than or equal to the diameter of an axial extension end. By the grinding device, a sealing surface which has the size of several fen to dozens of fen, has the maximum stock removal of only dozens of micrometers in the axial direction and has quite high requirements on surface quality, particularly a regularly conical sealing surface, can be machined on a sealing end surface conveniently and accurately.

Owner:XIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com