Carpet tufting machine

A gun stabbing machine and carpet technology, applied in the field of textile machinery, can solve the problems of unclear drawing and inaccurate arc pattern processing and drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

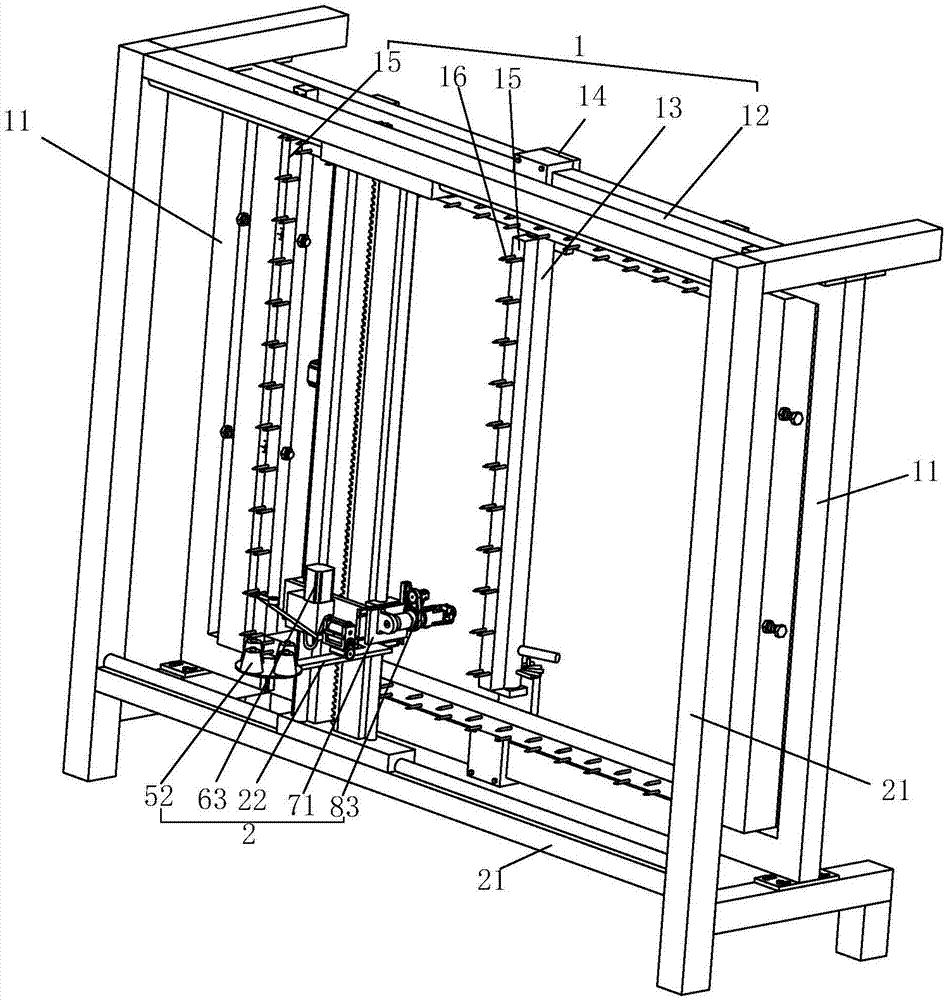

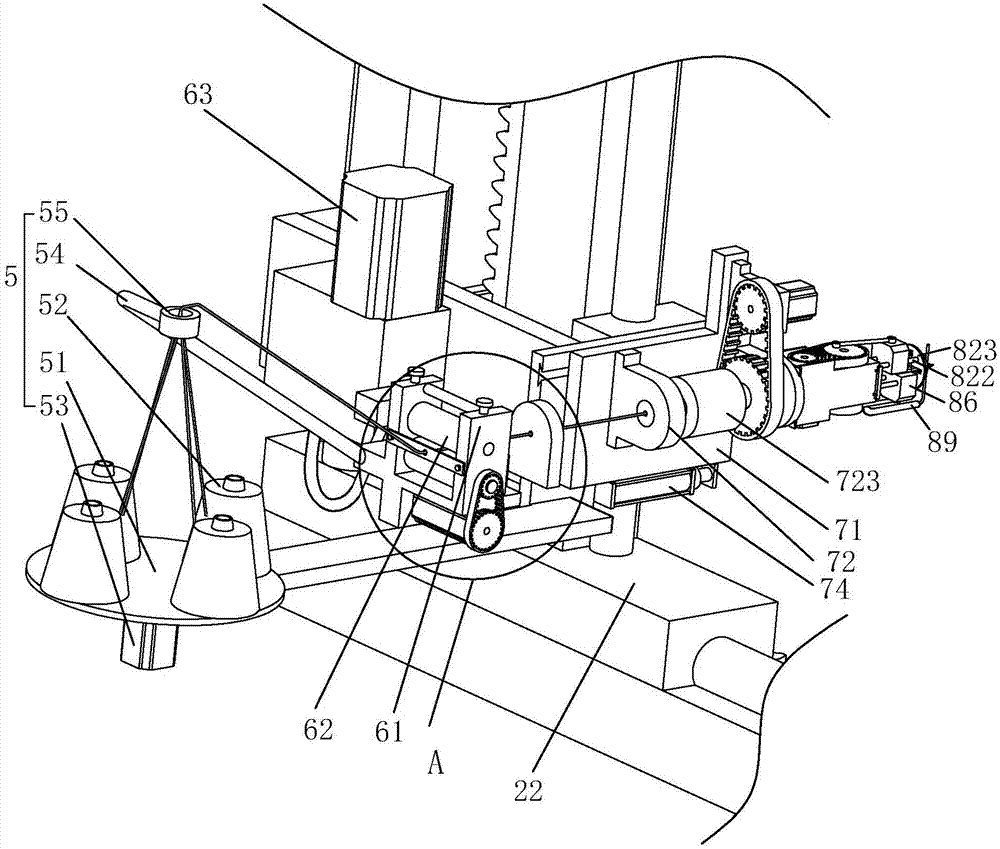

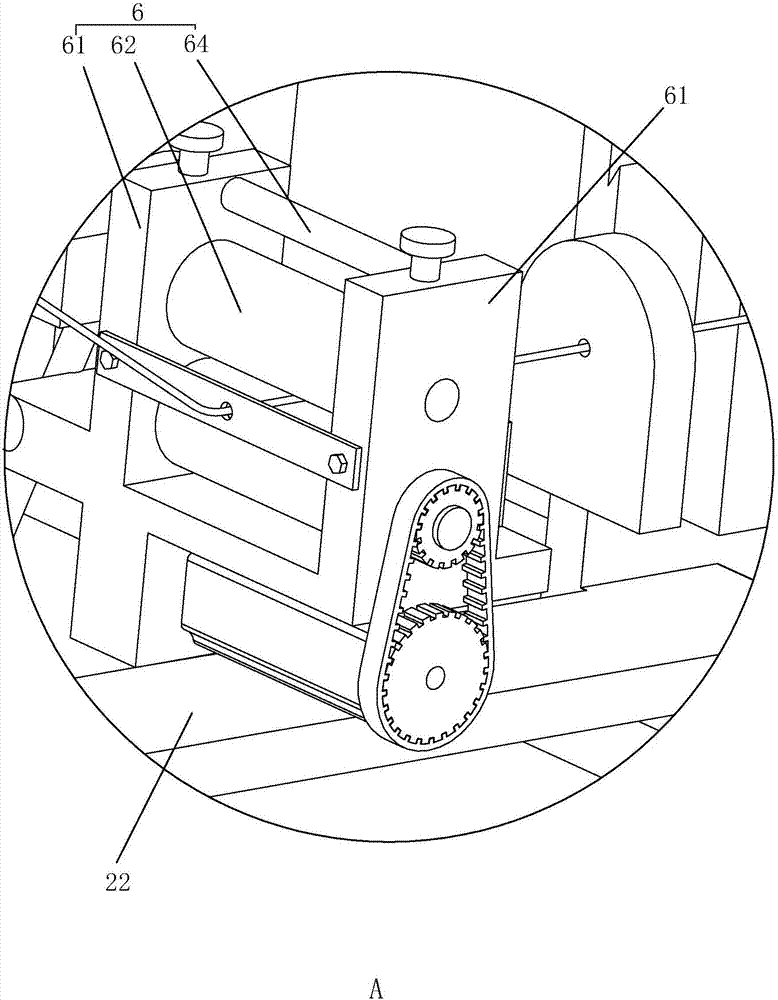

[0042] A carpet stabbing machine such as figure 1 , 8 As shown, it includes a tensioning support 1 for fixing the carpet, a stabbing head 2, and a fixed support 21 for the stabbing head 2 to move, wherein the tensioning support 1 includes two fixed support rods 11, and the two fixed supports The rods 11 are connected by two slide rails 12, and a slide plate 14 is connected with each other on the two slide rails 12. A mobile support rod 13 is arranged on the slide rail 12, and the two ends of the mobile support rod 13 are respectively Rotationally connected on the two slides 14, when sliding the slides 14, the movable support bar 13 can be driven to move, so that the position of the movable support bar 13 on the tensioning bracket 1 can be adjusted, and on the edge of the tensioning bracket 1 and All are provided with the cloth bar 15 that has barbed needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com