Heat cover type grinding device for machining sealing ring with regularly conical surface

A surface sealing and shrink-fitting technology, which is applied in the direction of grinding workpiece support, metal processing equipment, grinding/polishing equipment, etc., can solve the problem that it is difficult to effectively obtain sealing rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

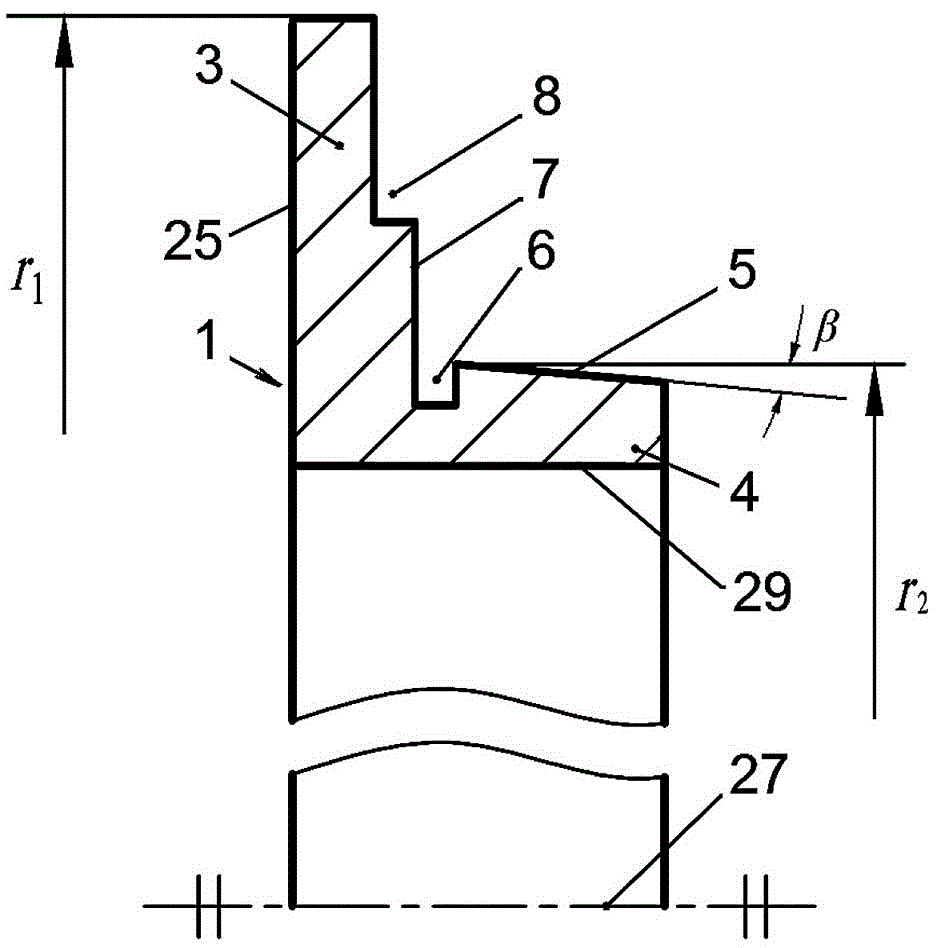

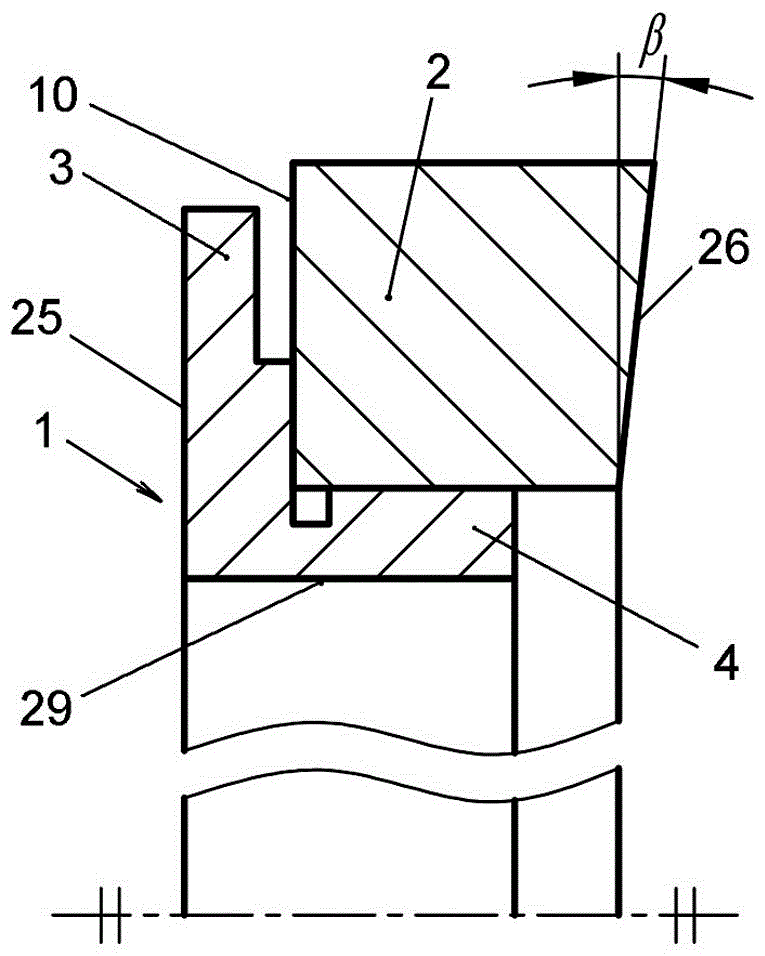

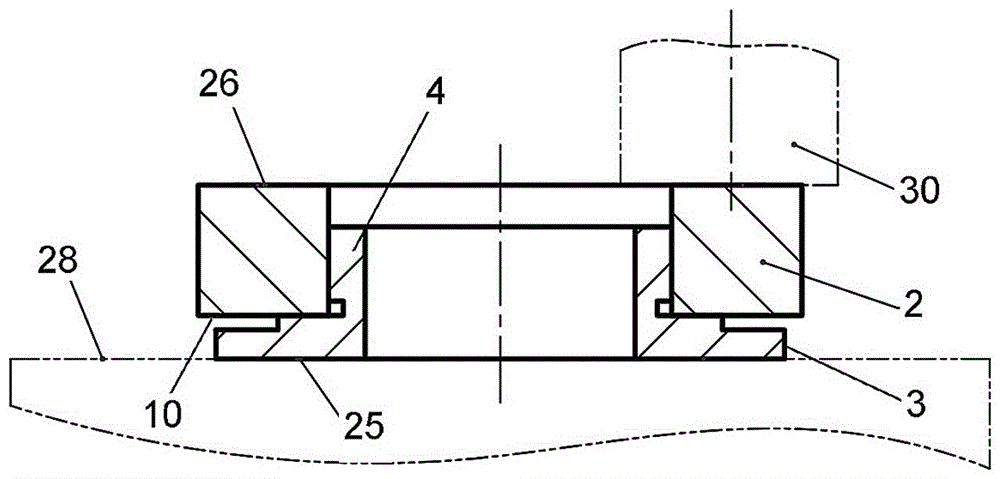

[0021] Figure 1 ~ Figure 4 Shown is a structure of the present invention for processing a grinding device 1 with a positive conical sealing ring, including an integral disc body 3 with a central axis 27 as the center of rotation and a radially outwardly extending disc body 3 with a central hole , and a cylindrical axially extending structure 4 with a central hole at one end having the same inner hole surface 29 at its radially inner side.

[0022] The two axial end faces of the disc body 3 are the reference plane 25 perpendicular to the central axis 27 and the positioning working surface 7 that can be in contact with the non-sealing end face of the processed sealing ring 2, and the outer peripheral radius r1 of the disc body 3 is smaller than the processed The outer peripheral radius r5 of the sealing ring 2 is at least 2 mm. On the axial extension structure 4 adjacent to the positioning working surface 7, a radial groove 6 is provided. The ratio to the thickness is 0.01-0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com