Patents

Literature

1794results about "Roll force/gap control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

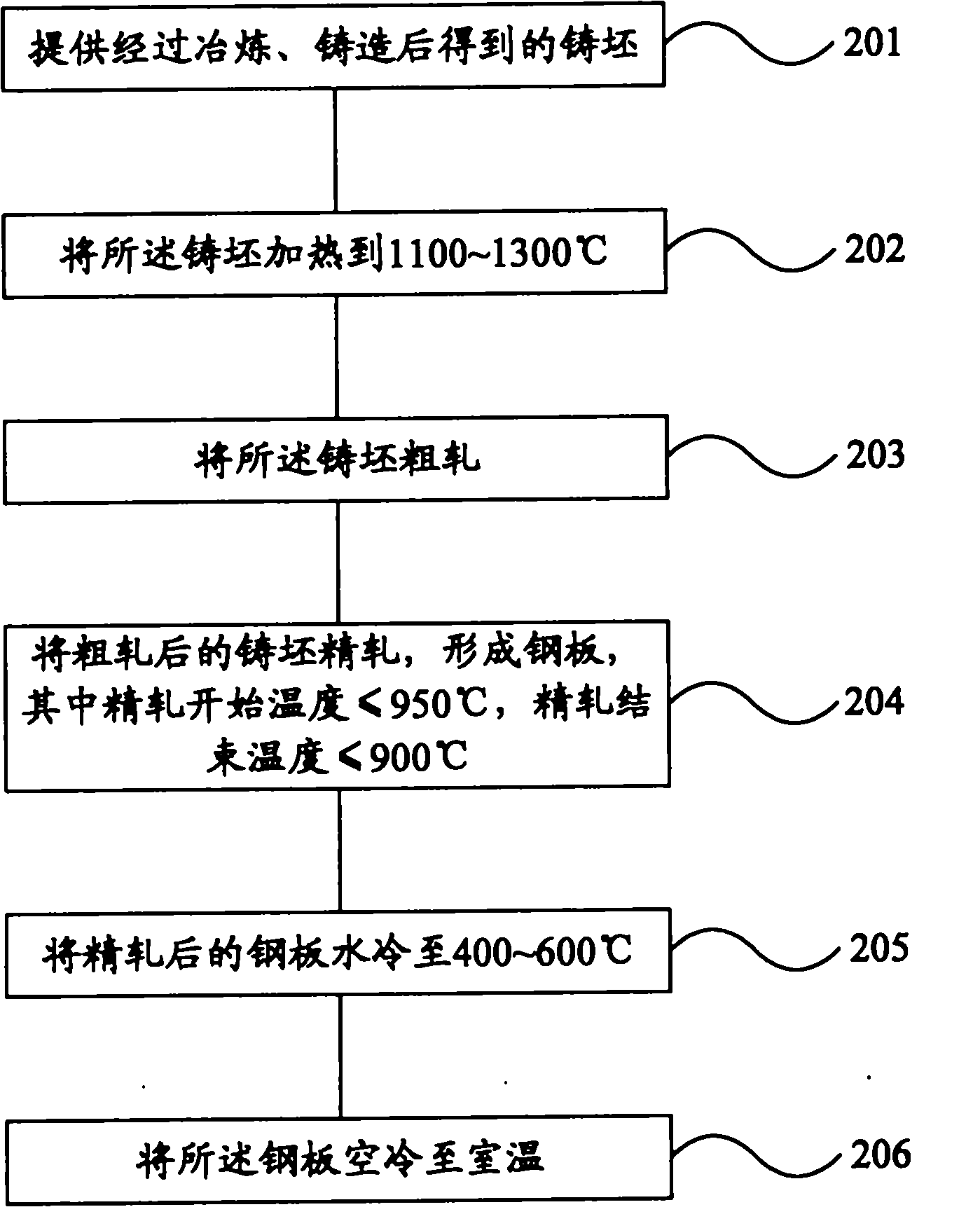

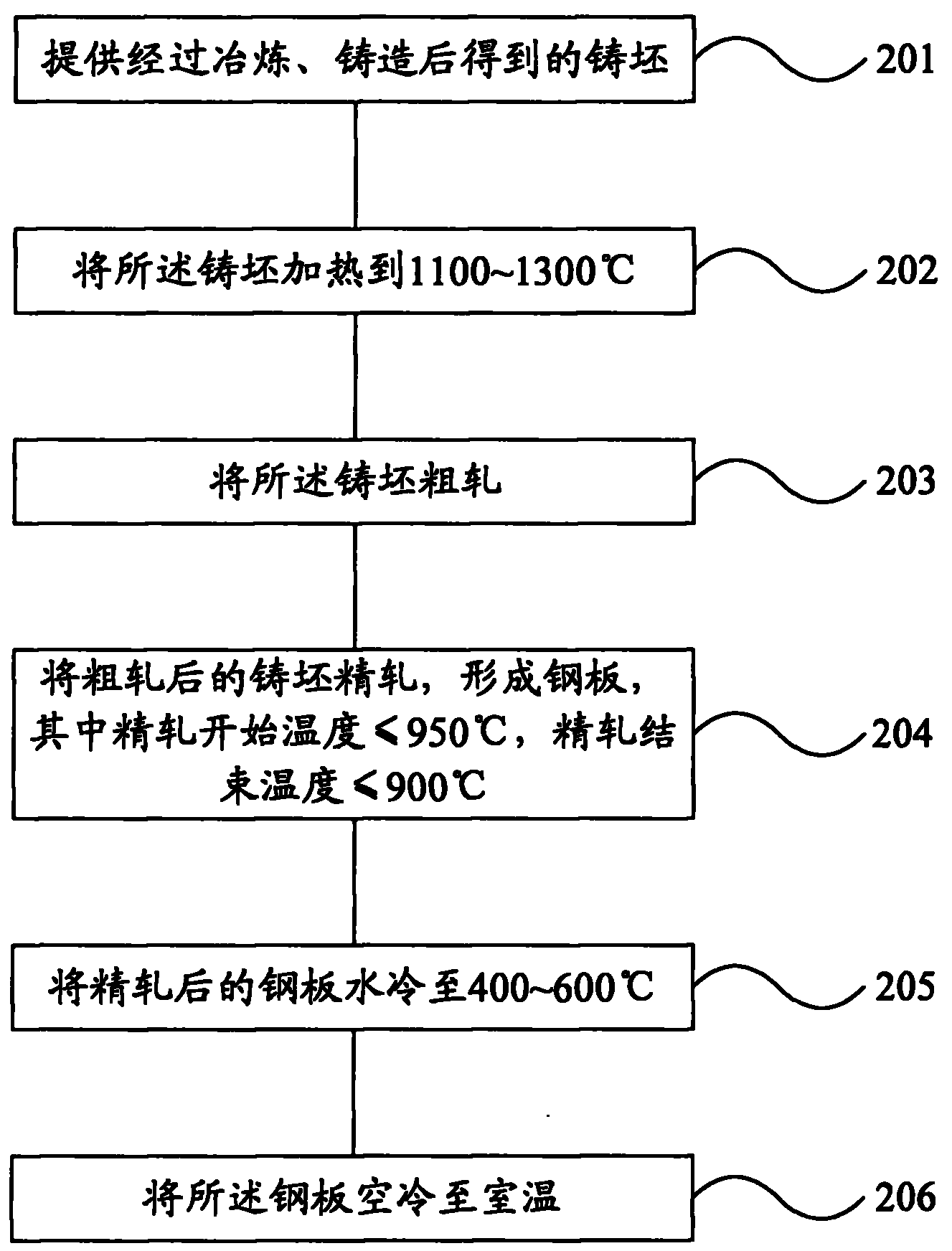

Weather resistant steel plate and manufacturing method thereof

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

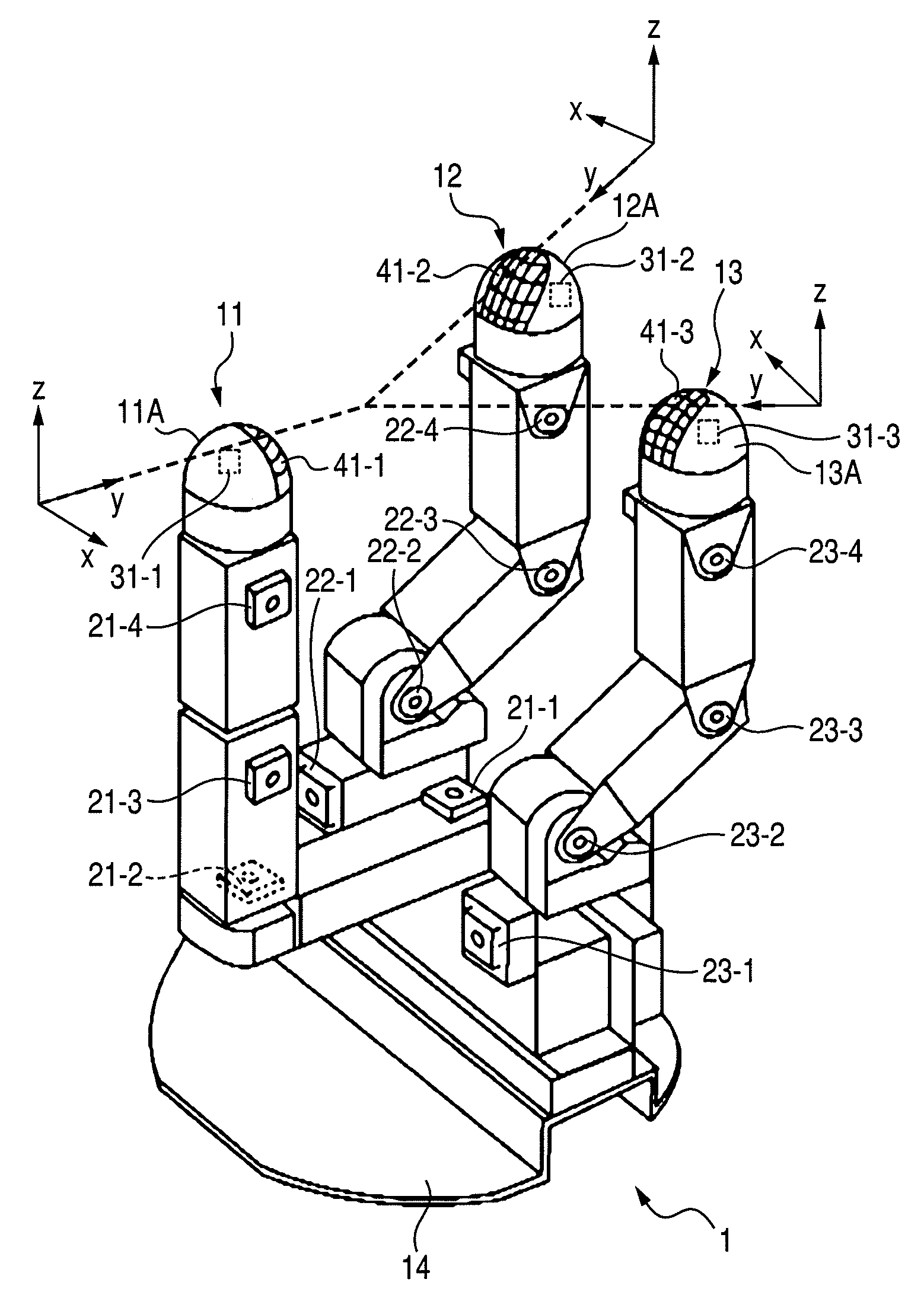

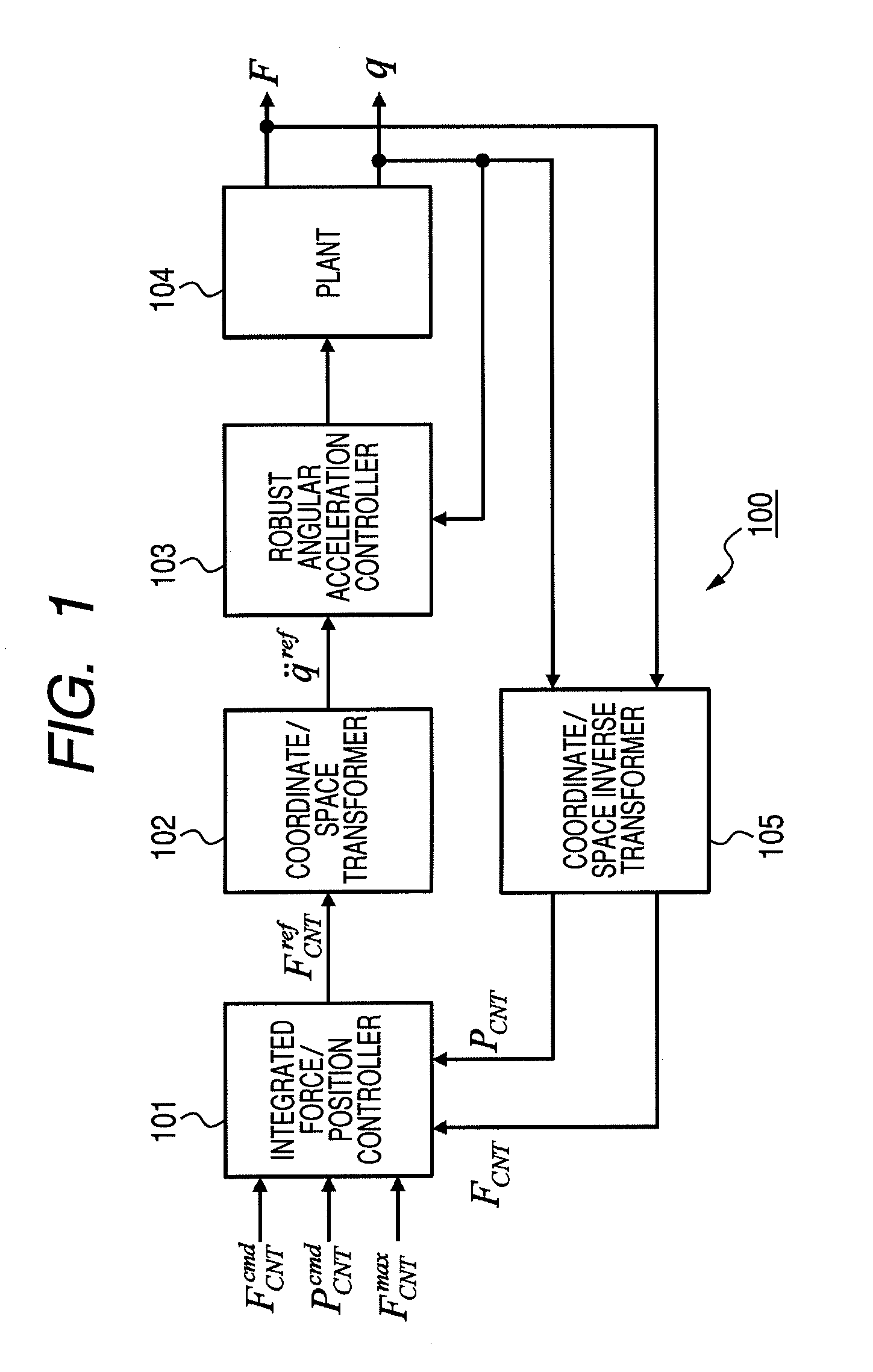

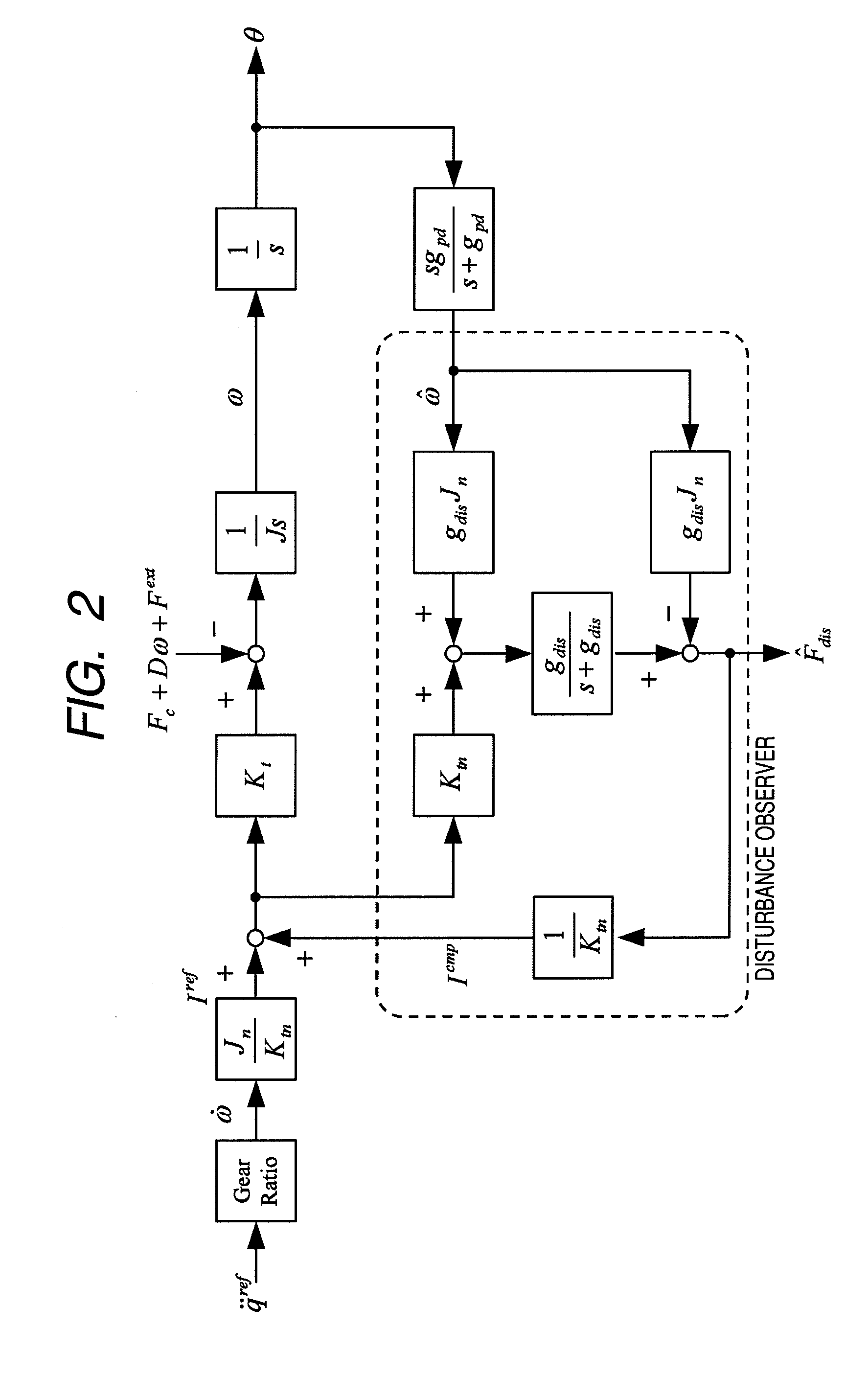

Robot apparatus and method of controlling the same

InactiveUS20090069942A1Easy to controlSmooth switchingProgramme-controlled manipulatorRoll force/gap control deviceMulti linkPosition control

A robot apparatus having a multi-link structure including a plurality of links and joints serving as link movable sections, and in which at least some of the links are driven by combination of position control and force control is disclosed. The apparatus includes: position control means for performing the position control on the links, which are driven by position control and force control; position control means with force constraint for placing the force control before the position control so as not to cause the magnitude of an external force to exceed a set value; force control means for performing the force control on the links; and integrated force / position control means for controlling driving of the joints by switching the position control means, the position control means with force constraint, and the force control means, and unifies the position control and the force control.

Owner:SONY CORP

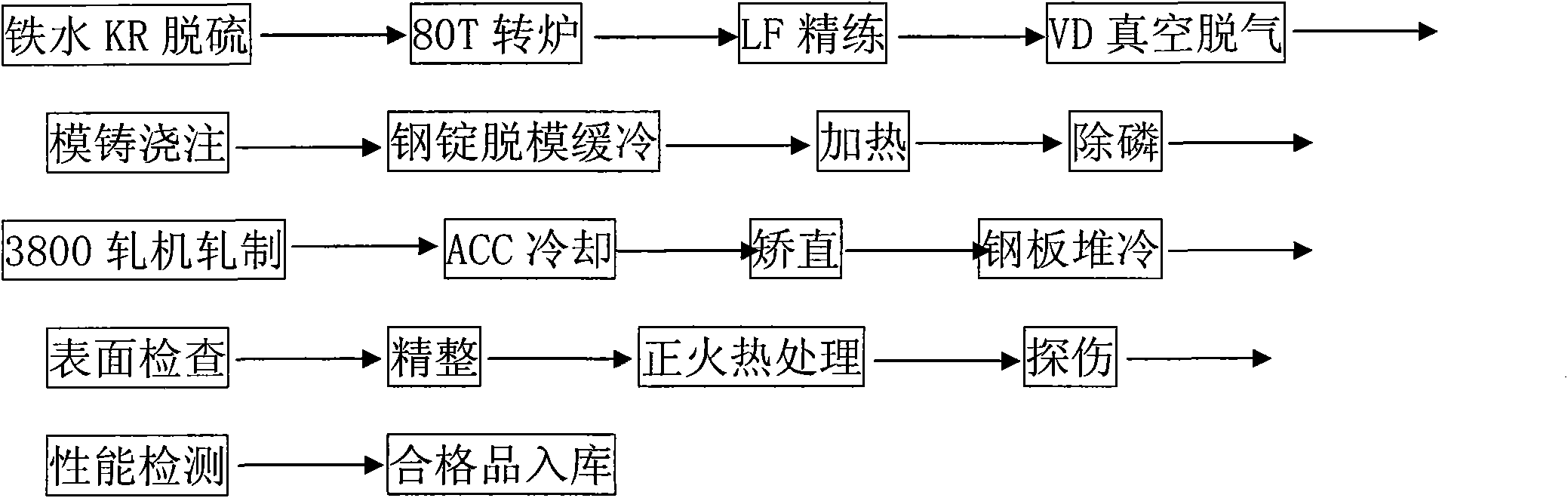

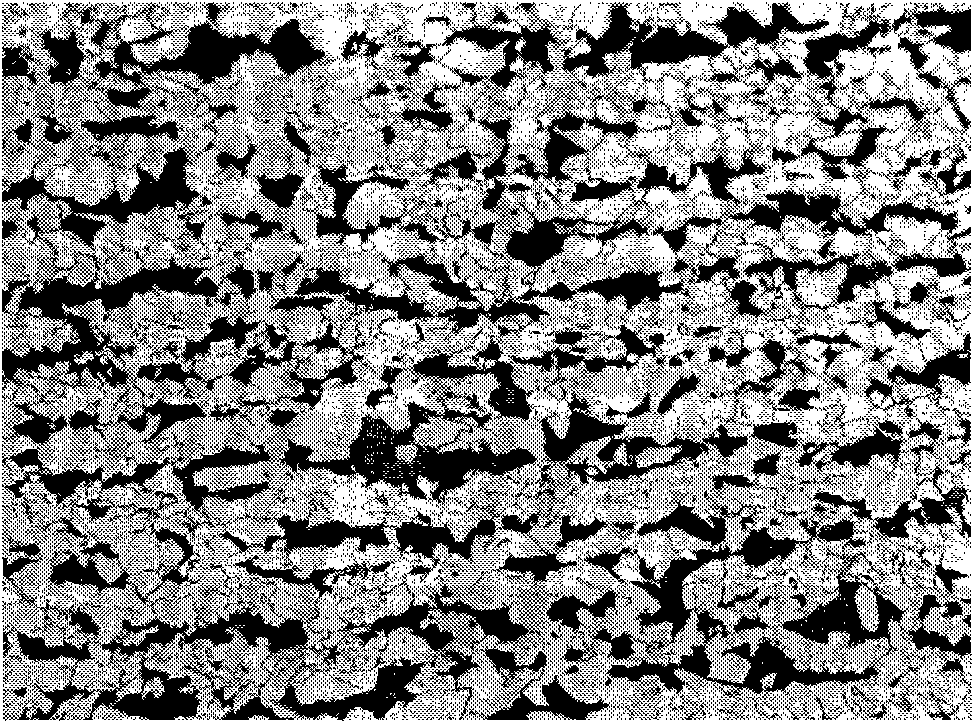

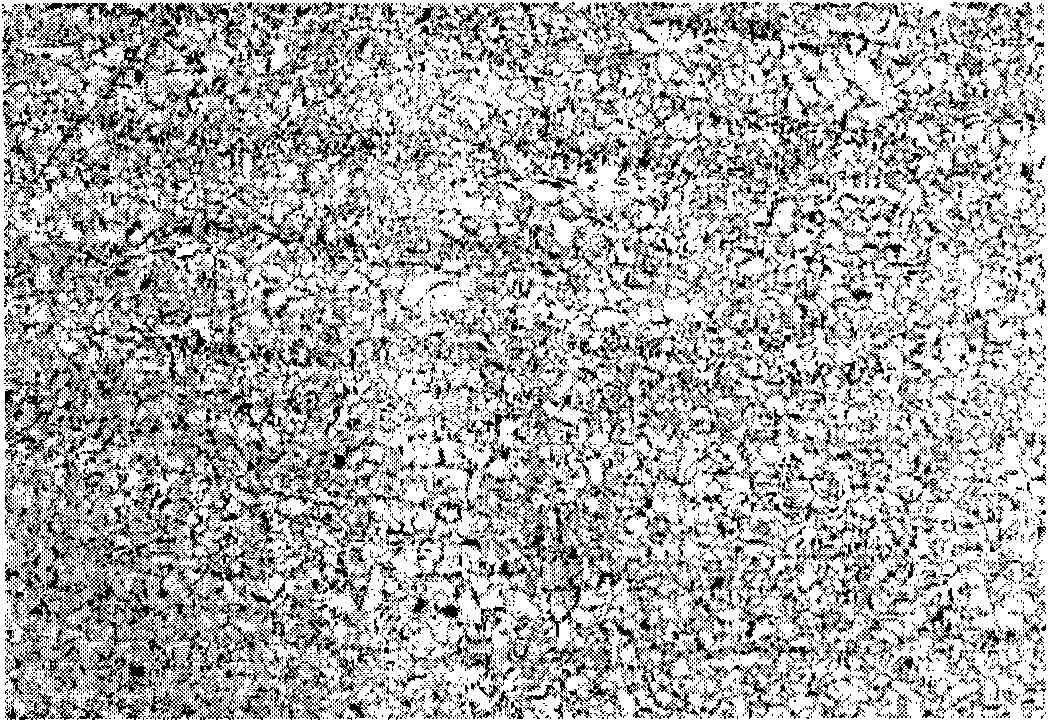

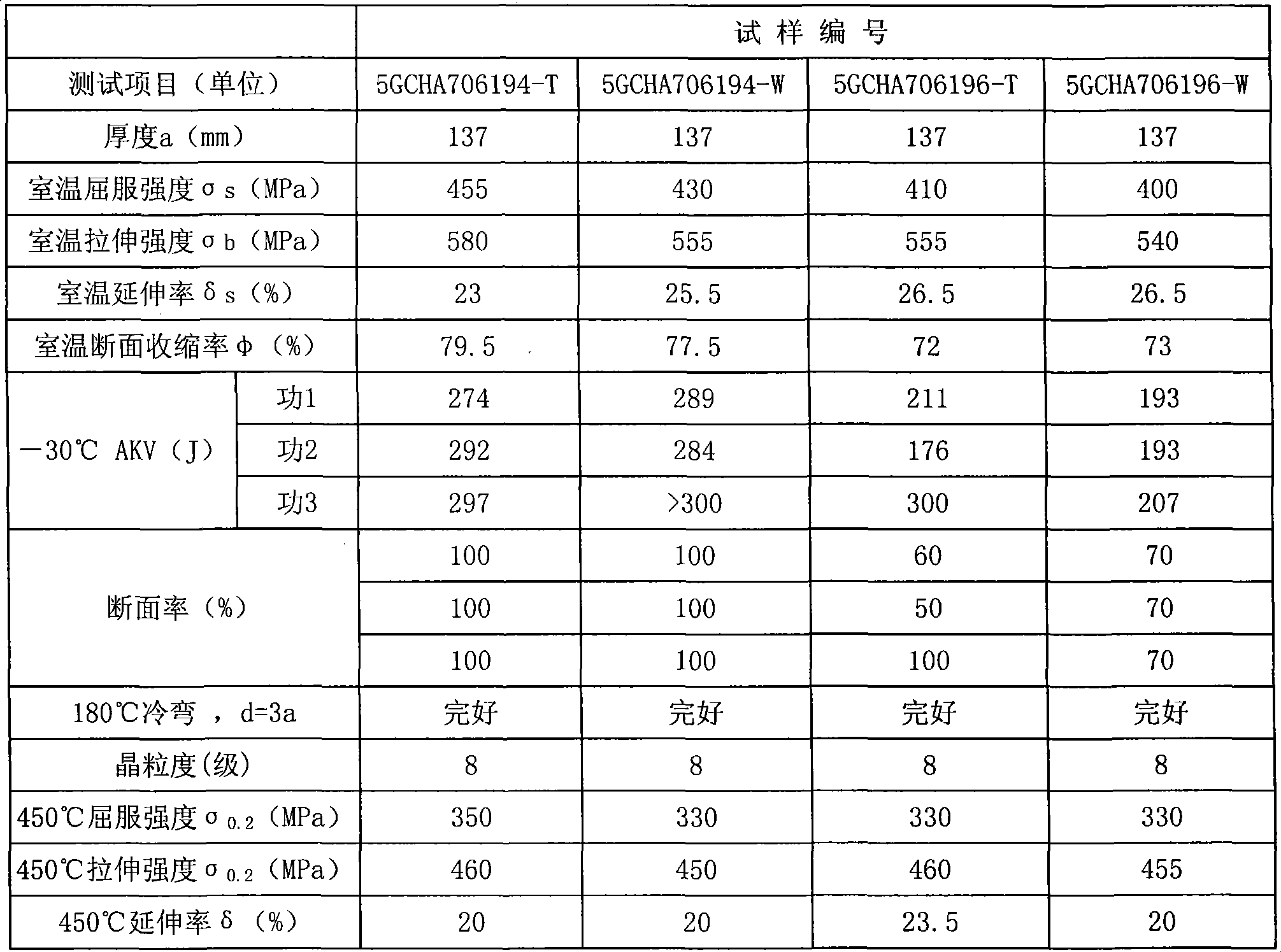

Q345q-series super-thick bridge steel plate and production method thereof

ActiveCN101880824AHigh standardRoll force/gap control deviceTemperature control deviceProduction lineChemical composition

The invention discloses a Q345q-series super-thick guaranteed performance and flaw detection bridge steel plate comprising the following chemical components in percentage by mass: 0.08-0.16 percent of C, 0.20-0.50 percent of Si, 1.15-1.60 percent of Mn, not more than 0.020 percent of P, not more than 0.010 percent of S, not more than 0.12 percent of microalloyed element (V+Nb+Ti+Ni), 0.010-0.050 percent of AlS and the balance of Fe and residual elements; and carbon equivalent is not more than 0.43. The invention also discloses a production method of the steel plate, comprising the steps of rolling, cooling, straightening, cooling in pile and thermal treatment. In the rolling, the cooling and the straightening, the 130 mm super-thick Q345qD(E) steel plate is successfully developed in the production line of a converter, die casting, mill rolling and normalization thermal treatment through carrying out reasonable composition design, die casting, TMCP (Thermal Mechanical Control Process) rolling and thermal treatment; the secondary flaw detection qualification rate reaches 90 percent, the performance initial test qualification rate reaches 100 percent, and the Z-direction performance of the entity of the steel plate can reach Z15 level. The development of the super-thick steel plate satisfies the higher requirements on bridge industry.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

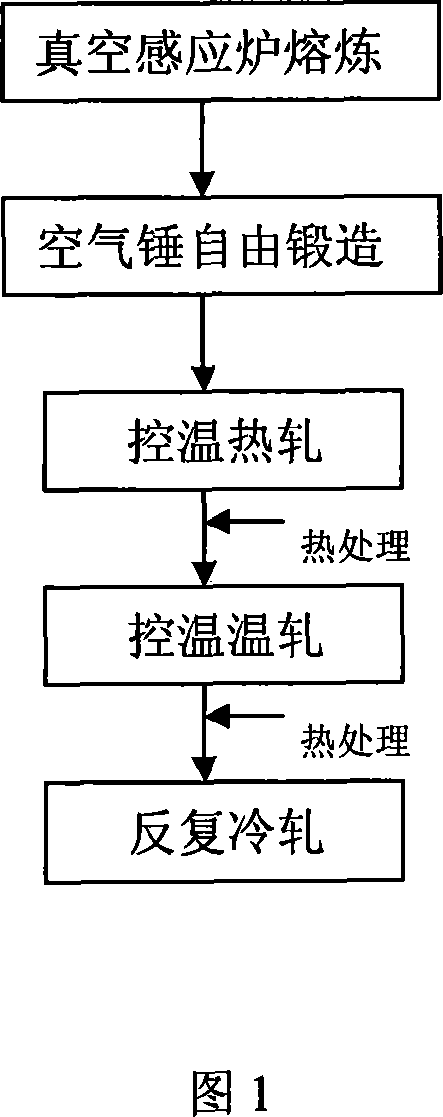

Preparation method for cold rolling sheet of duriron

InactiveCN101049669AWide applicabilityLow purityRoll force/gap control deviceTemperature control deviceAlloyThin sheet

A cold rolling method for preparing high-Si steel sheet containing Fe (85-96 Wt%) and Si (4-15) includes such steps as providing raw material containing Si, B and Fe, smelting, casting, forging, hot rolling, warm rolling, heat treating and cold rolling.

Owner:UNIV OF SCI & TECH BEIJING

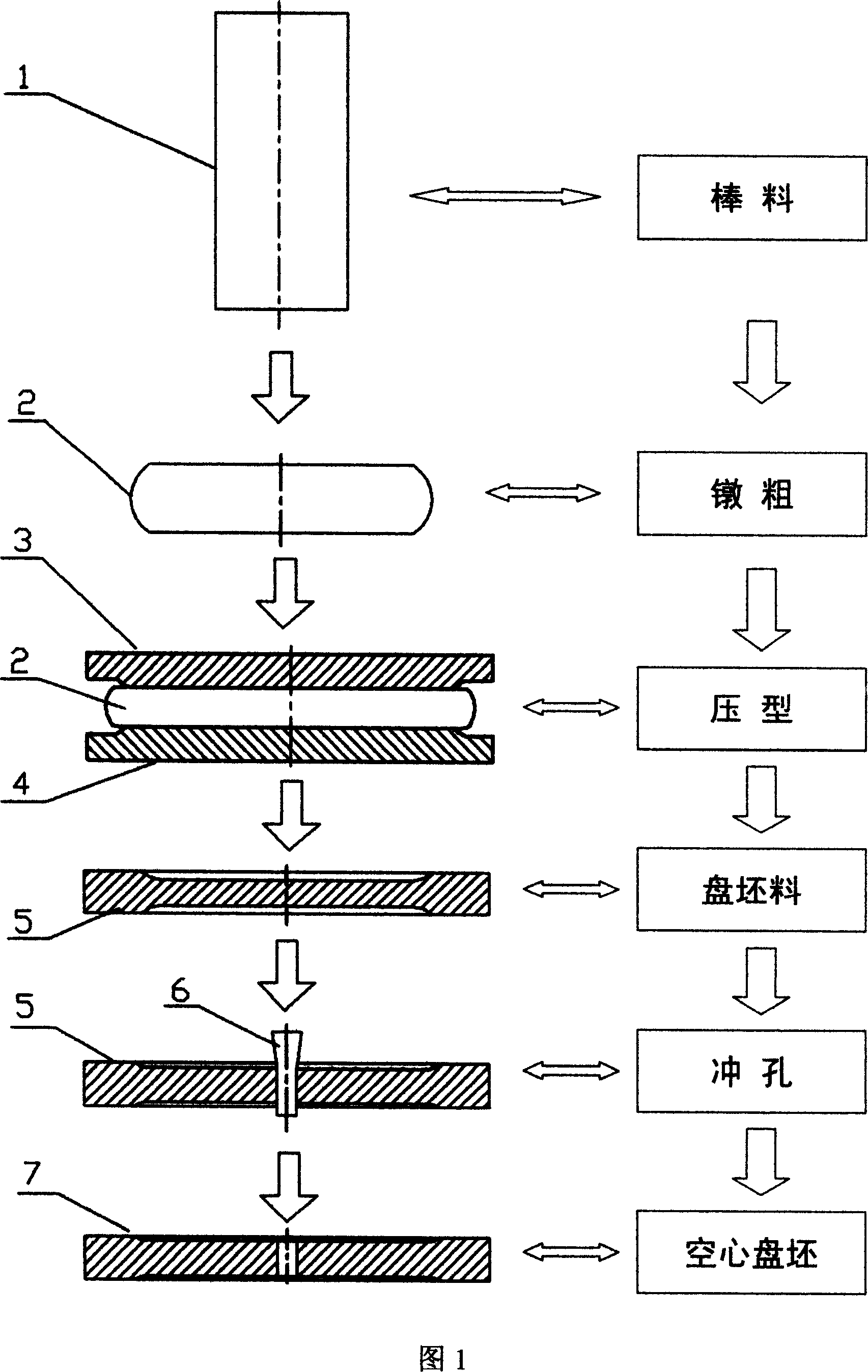

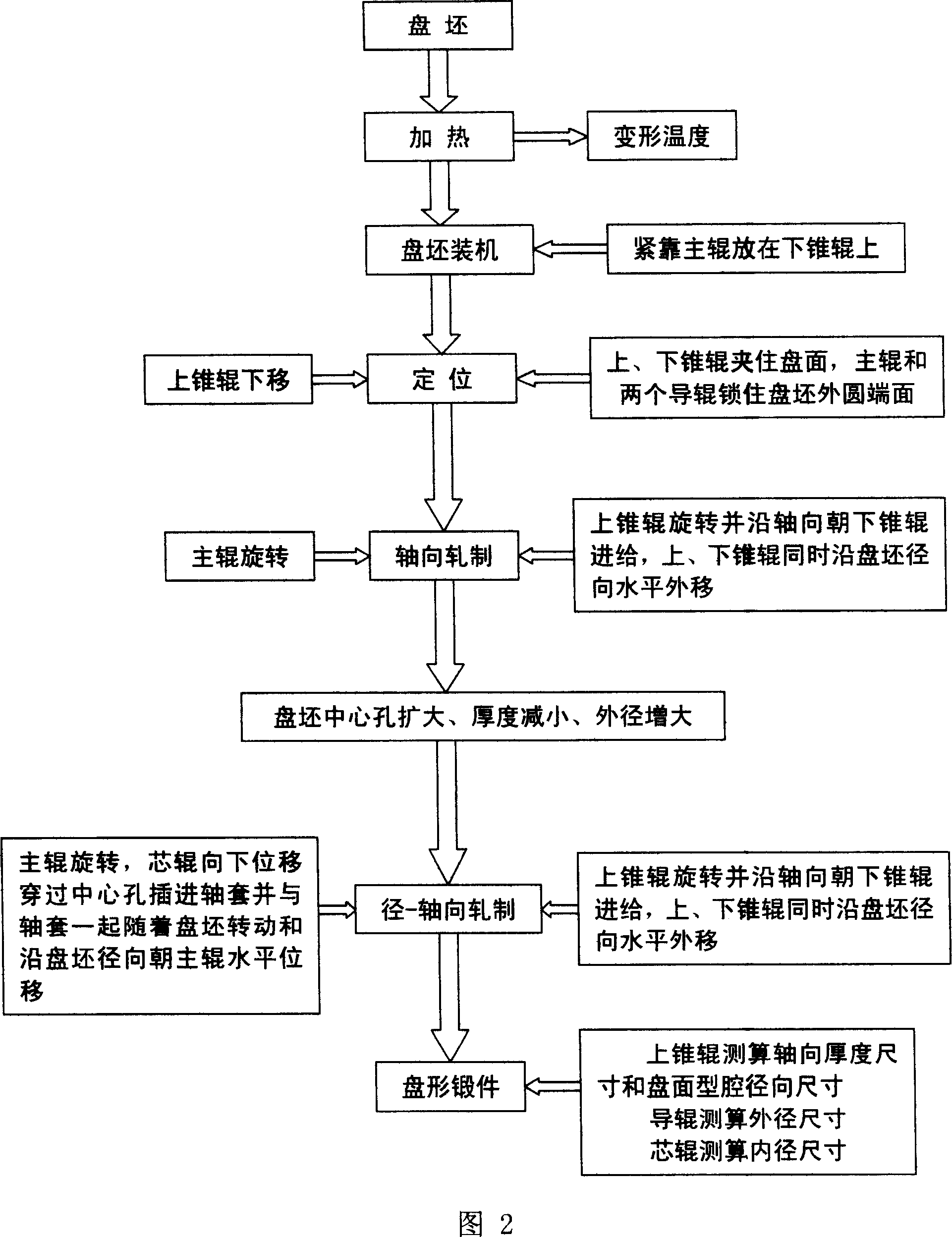

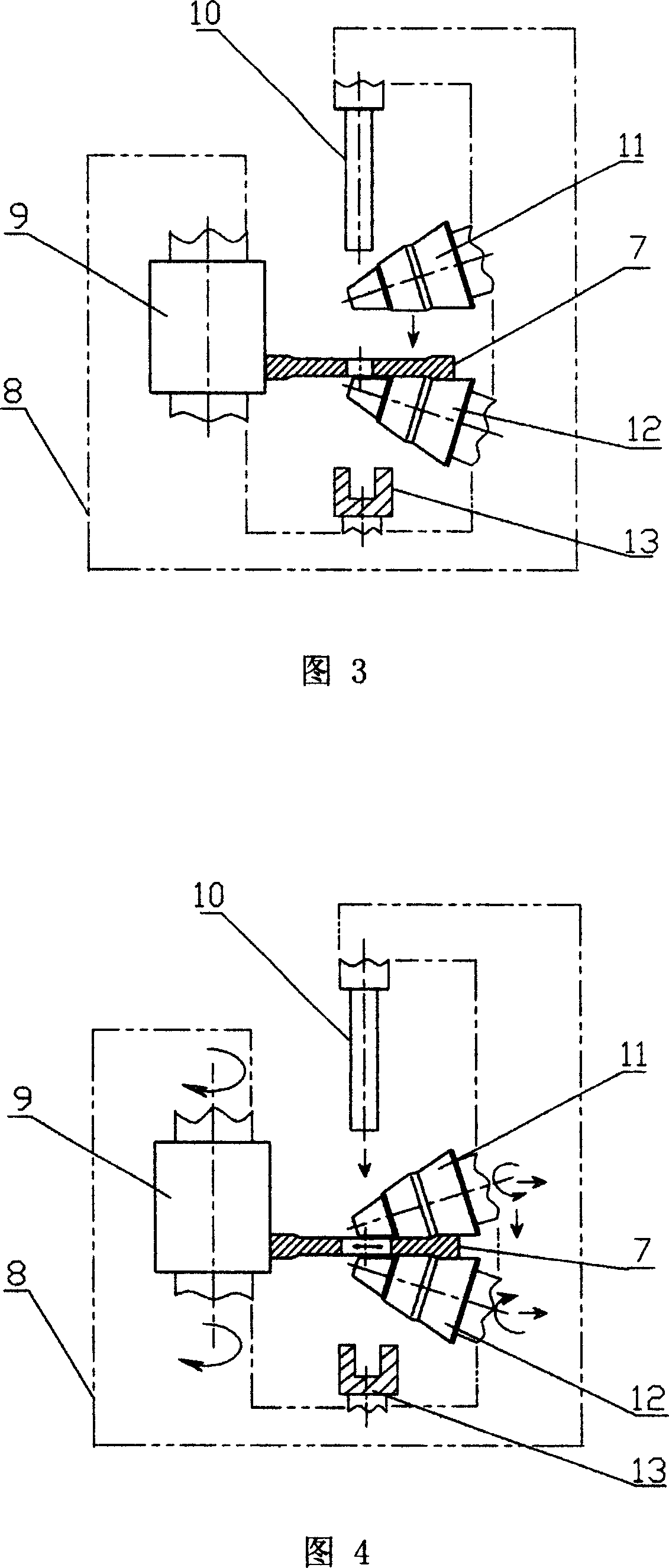

Rolling forming process for large hollow disc forging

ActiveCN101020282ARadial wall thickness reductionReduce axial thicknessRoll force/gap control deviceMeasuring devicesMaterials scienceMetal

The technological process of rolling and forming large hollow disc forging includes the steps of: deforming metal rod material, heating, upsetting to form cake blank, profiling to obtain disc blank, punching hole to obtain hollow disc blank, heating, locating, axial rolling, radial and axial rolling, and measuring size to obtain hollow disc forging. The rolling process has axial rolling force of (2-5)x10<5> kg, radial rolling force of (5-20)x10<4> kg, and broadening speed of 5-15 mm / s. The rolled disc forging has outer diameter of 800-3000 mm, inner diameter of 300-2000 mm and thickness of 30-250 mm. By means of altering the conic size and sizes of the conic roll, disc forgings of different sizes may be rolled. The present invention can form disc forging continuously and form large forging in small apparatus.

Owner:GUIZHOU ANDA AVIATION FORGING

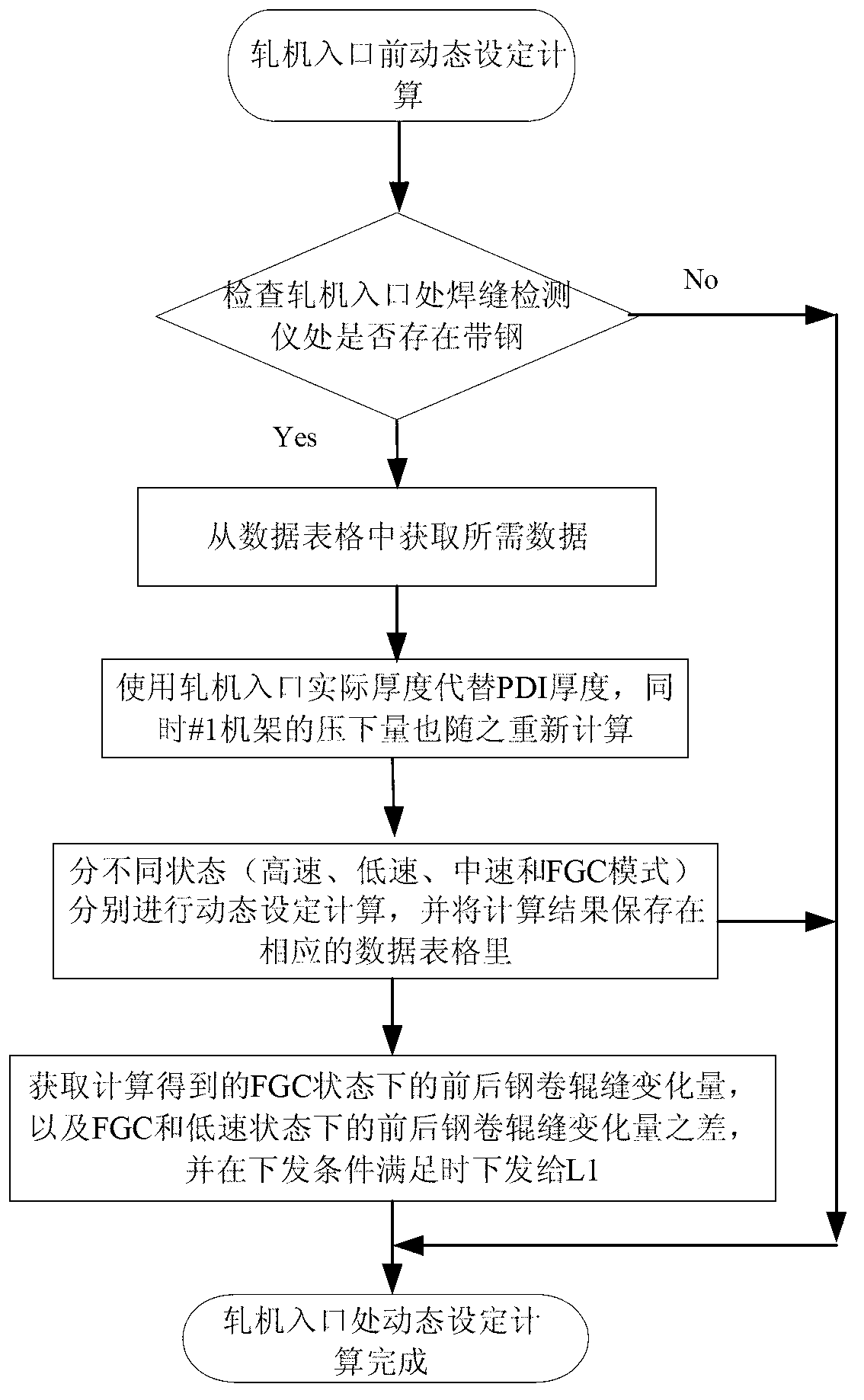

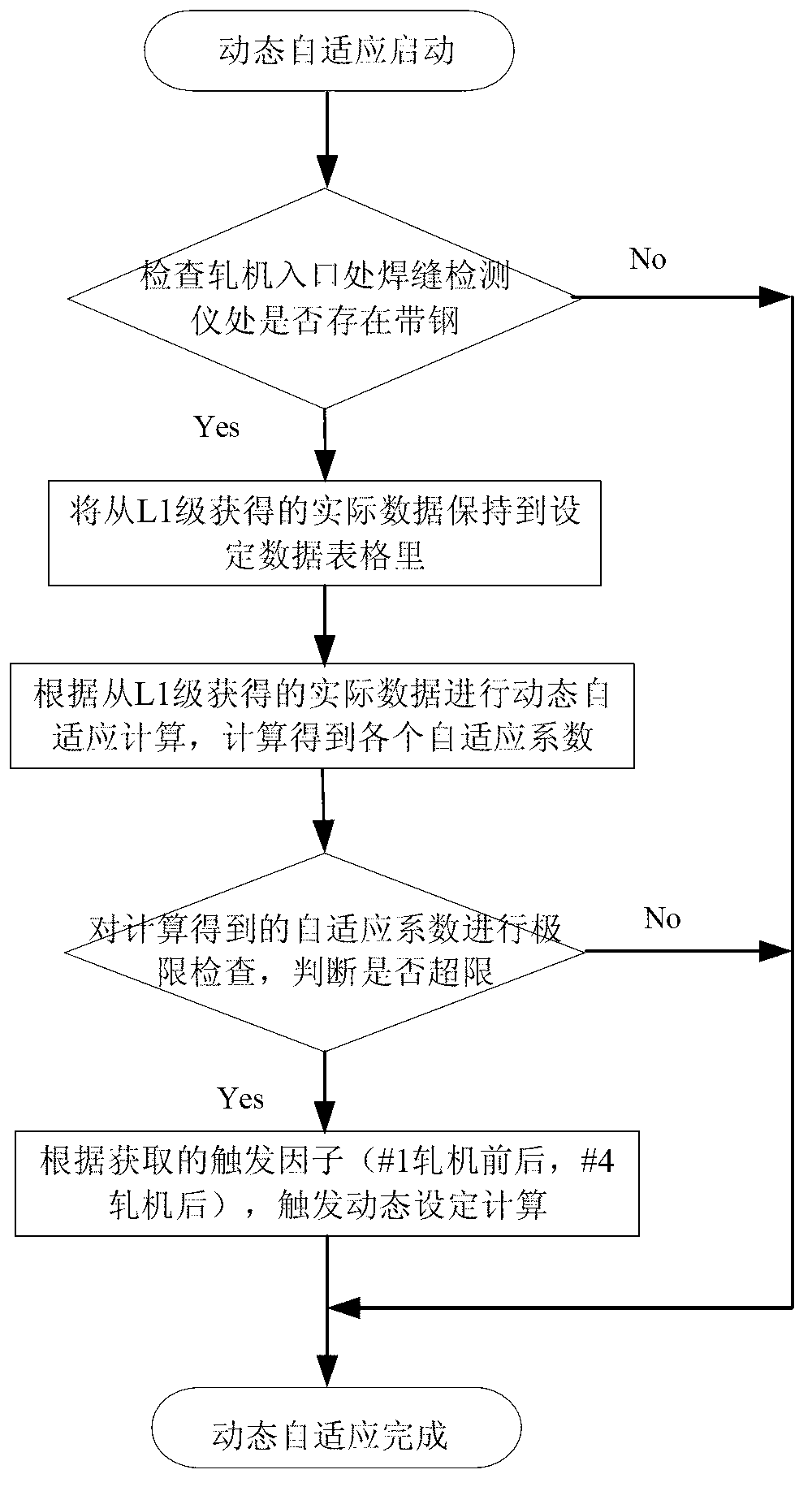

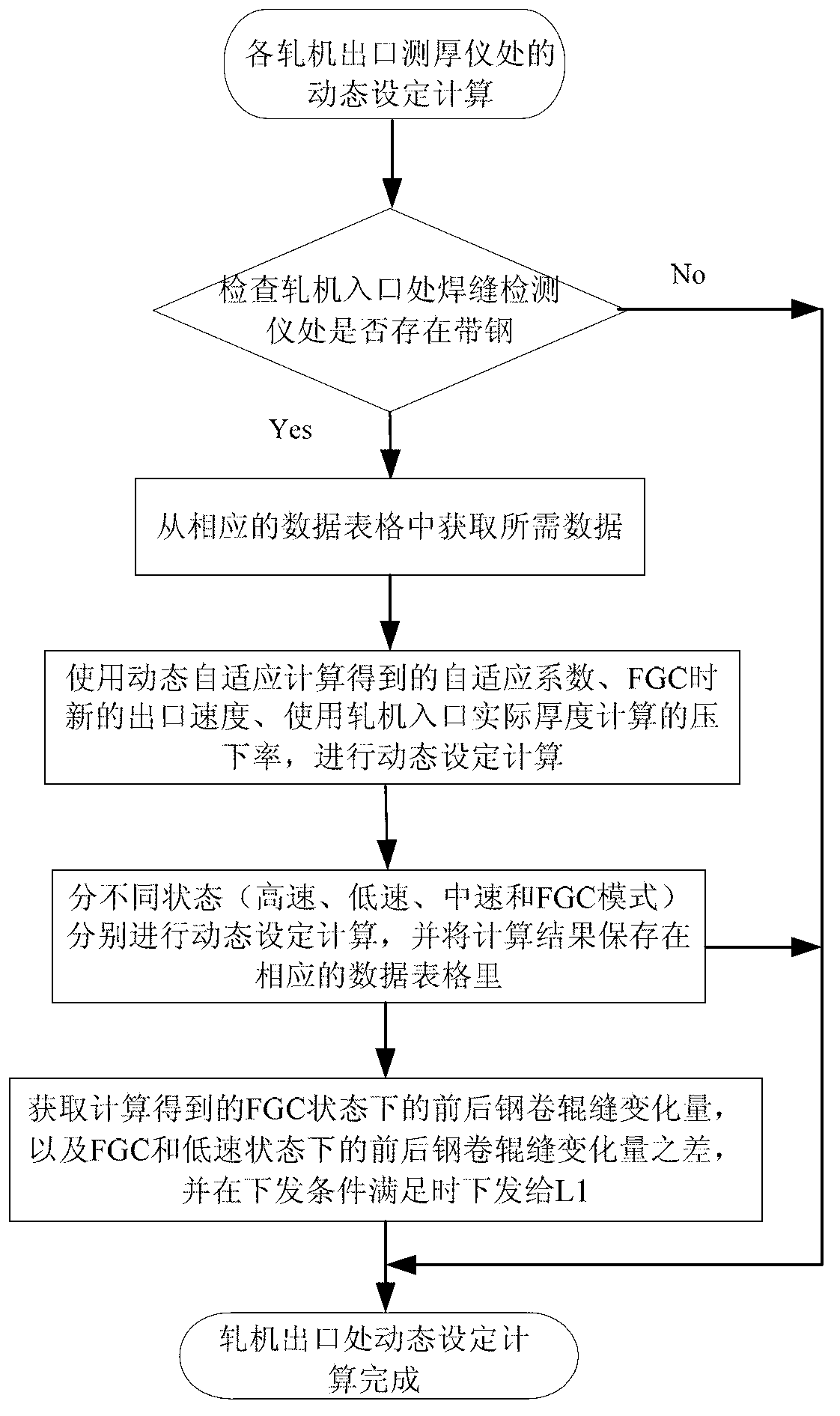

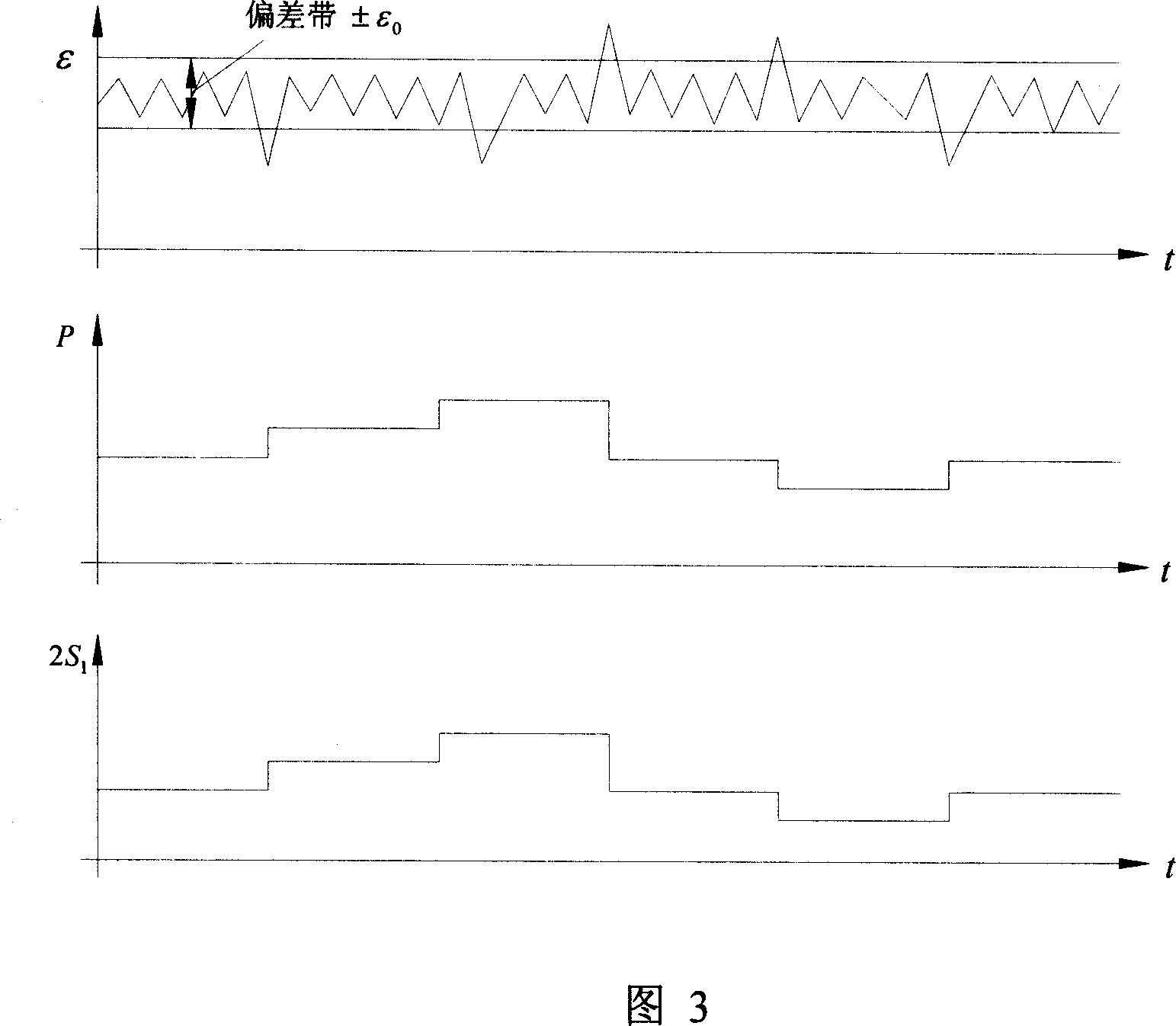

Dynamic roll gap compensation method during cold continuous rolling flying gauge control

ActiveCN103286142AImprove setting accuracyReduce head thickness deviationRoll force/gap control deviceAutomatic controlModel system

The invention discloses a dynamic roll gap compensation method during cold continuous rolling flying gauge control and belongs to the technical field of automatic control of cold continuous rolling. The method includes a part of roll gap compensation for a welding gap position at the position of a rolling mill inlet front thickness gauge and a part of roll gap compensation for the welding gap position at the positions of all rolling mill outlet thickness gauges. A roll gap adjustment value is determined by a model system of a process computer to a great degree due to the fact that a large part of AGC functions are not introduced during flying gauge control. Therefore, computational accuracy of the model system can directly affect thickness control accuracy during flying gauge control. A practical inlet thickness acquired by using a practical thickness gauge at the position of the rolling mill inlet front thickness gauge is adopted to replace a raw material thickness to improve initial data accuracy for setting a model, and a set value of a roll gap during FGC is corrected according to calculated deviation between a front steel coil roll gap and a back steel coil roll gap so as to improve setting accuracy of the roll gap. More accurate roll force is acquired in the method of dynamic self-adapting at the positions of all the rolling mill outlet thickness gauges, setting accuracy of the roll gap is improved, and then the roll gap value can be compensated during flying gauge control.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH +2

Titanium alloy TC4 cold-rolled tube and production method thereof

ActiveCN101824564AHigh strengthLow costRoll force/gap control deviceFurnace typesOxygenTitanium alloy

The invention relates to a titanium alloy, in particular to a titanium alloy TC4 cold-rolled tube and a production method thereof. By weight, the composition of the alloy is as follows: the balance of Ti, 5.5 percent to 6.75 percent of Al, 3.5 percent to 4.5 percent of V, less than or equal to 0.1 percent of Fe, less than or equal to 0.1 percent of C, less than or equal to 0.03 percent of N, less than or equal to 0.015 percent of H and less than or equal to 0.15 percent of O. The specification of the TC4 cold-rolled tube is outer diameter multiplied by wall thickness (however, the ratio of the outer diameter to the wall thickness is larger than 2). In the process of cold-rolling the titanium alloy tube, lubricant is added on the inner and the outer surfaces of the tube blank and the semi-finished tube, rolling is then carried out, the tube is annealed in oxygen after each rolling pass, a single edge is inwardly sheared by 0mm to 0.8mm, scale cinder and flaws are completely removed before the last one to two passes, the tube is washed by alkali and acid or acid and then by water and then rolled before a finished product is produced after 1 to 16 rolling passes, the rolled finished product is annealed in oxygen or vacuum, and the annealed finished product is washed by alkali and acid or acid again. The performance of the titanium alloy (TC4) cold-rolled tube is good, the metallographic structure is uniform, and the surface quality of the tube is good.

Owner:忠世高新材料股份有限公司

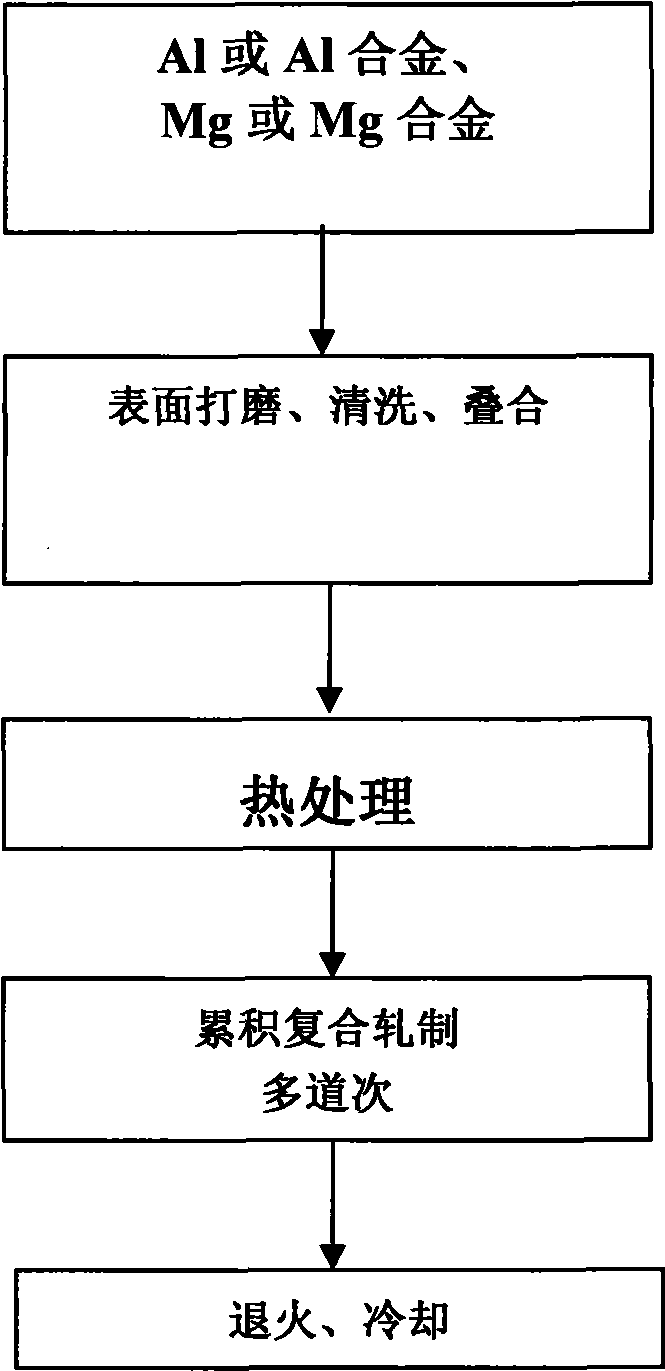

Method for preparing aluminum-magnesium ultrafine crystal composite plate with multilayer structure

InactiveCN101530860AImprove organizationHigh bonding strengthRoll force/gap control deviceHeat treatment process controlRoom temperatureAlloy

The invention relates to a method for preparing an aluminum-magnesium ultrafine crystal composite plate with a multilayer structure. The method selects a plate material Al or an Al alloy and Mg or a Mg alloy as raw materials; a structural layer of the prepared aluminum-magnesium ultrafine crystal composite plate with the multilayer structure is the Al / the Mg / the Al, or the Al alloy / the Mg alloy / the Al alloy or the Al / the Mg alloy / the Al in sequence; the preparation method adopts an accumulated composite rolling method which comprises the steps: polishing, cleaning, removing metal chips or impurities on the surface of the plate material, stacking in a hamburger mode, and positioning the stacked steel plate in a resistance furnace for heat treatment; taking out the plate material subjected to heat treatment, placing the plate material on a rolling machine, and rolling the plate material with 50 percent of rolling reduction in every pass; cutting cracked edges and burr in the edge part of the rolled plate material, cutting the plate material into two equivalent parts, and carrying out multipass accumulated composite rolling repeatedly; placing the plate material subjected to accumulated composite rolling in an air protection annealing furnace for heat treatment, cooling the plate material to the room temperature along the furnace and taking out the plate material; and the Al / Mg / Al composite steel plate with the multilevel structure can be obtained.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

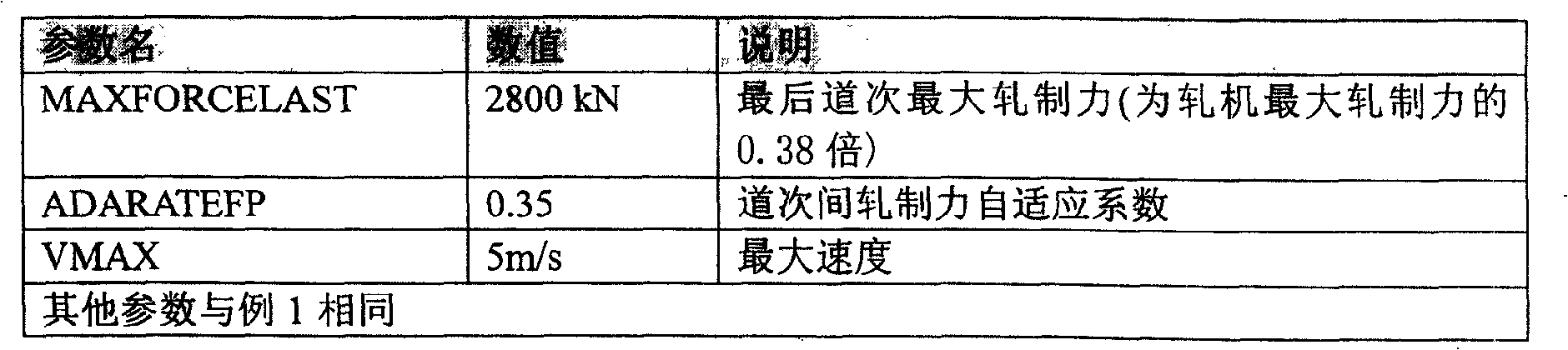

6mm steel plate rolling technique

InactiveCN101259482APrevent lateral movementStable rolling processRoll force/gap control deviceTemperature control deviceSheet steelEngineering

The invention provides a rolling technique for rolling a steel plate of 6mm by using a middle-thickness rolling mill which carries out corresponding settlements on the furnace discharge temperature of a stock, the stock thickness, rolling gates, an automatic gauge control, a rolling force, the self-adaptation coefficients of the rolling force between the gates, an opposite convexity and the matching between the linear speed of a transmission roller gate and the linear speed of the working roller of a rolling mill. The technique solves the problems of waves, bending, camber, frame scraping and waste rolling appearing in the plank stuffs during the testing rolling of 6mm plates of the existing middle-thickness rolling mill, leads the rolling to be stable and can manufacture qualified products in batch.

Owner:XINYU IRON & STEEL CO LTD

Hot-rolled fine-grained steel for electrostatic enamel and manufacturing method thereof

ActiveCN101063189AHigh strengthGood formabilityRoll force/gap control deviceTemperature control deviceManganeseAlloy

The invention discloses a preparing method of electrostatic enamel hot-roller fine-grained steel, which is characterized by the following: allocating mass percent as 0. 02-0. 10 carbon, not more than 0. 10 silicon, 0. 4-1. 0 manganese, not more than 0. 05 phosphor, 0. 02-0. 05 sulfur, 0. 01-0. 10 aluminum, 0. 003-0. 010 nitrogen, 0. 03-0. 10 titanium, surplus ferric and unavoidable impurity; setting the content of TiN at 0. 013-0. 044; setting ferrite tissue grain fineness number not less than 10 grade. This invention possesses good enamel adherence property and against squama knock property.

Owner:BAOSHAN IRON & STEEL CO LTD

Integrate optimized controlling means for planisher elongation roll-force, tension, and roll-bending force

ActiveCN1923391AGuaranteed accuracyGuarantee the shape qualityRoll force/gap control deviceTension/compression control deviceControl systemClosed loop

The invention relates to a method for optimizing and controlling the rolling tensioning roller of finisher. Wherein, it is in the extending rate control system; the inner ring of control closed loop is rolling pressure closed loop and tension closed loop; based on the difference of adjustment sequence of tension and rolling pressures, first adjusting tension or first adjusting rolling pressure to control the extending rate, to control extending rate and plate shape; the method that first adjusting tension is that optimizes the tension to control extending rate, when it is over limited range, keeps it constant, and adjusts the rolling force; and the method that first adjusting rolling pressure is that optimizes the rolling pressure to control extending rate, when it is over limited range, keeps it constant and adjusts the tension force. The invention can confirm the accuracy of extending rate and the quality of sheet shape.

Owner:BAOSHAN IRON & STEEL CO LTD +1

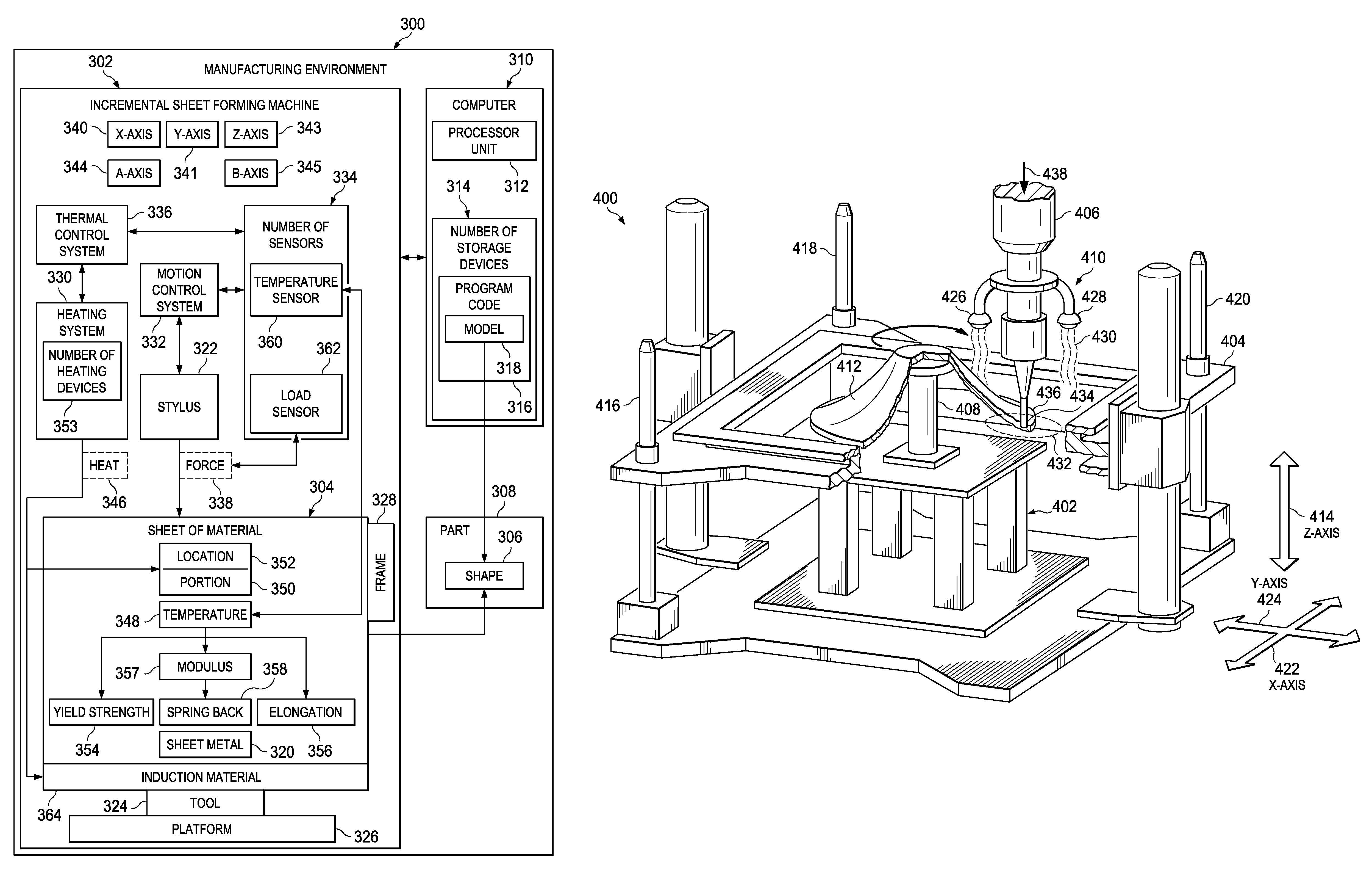

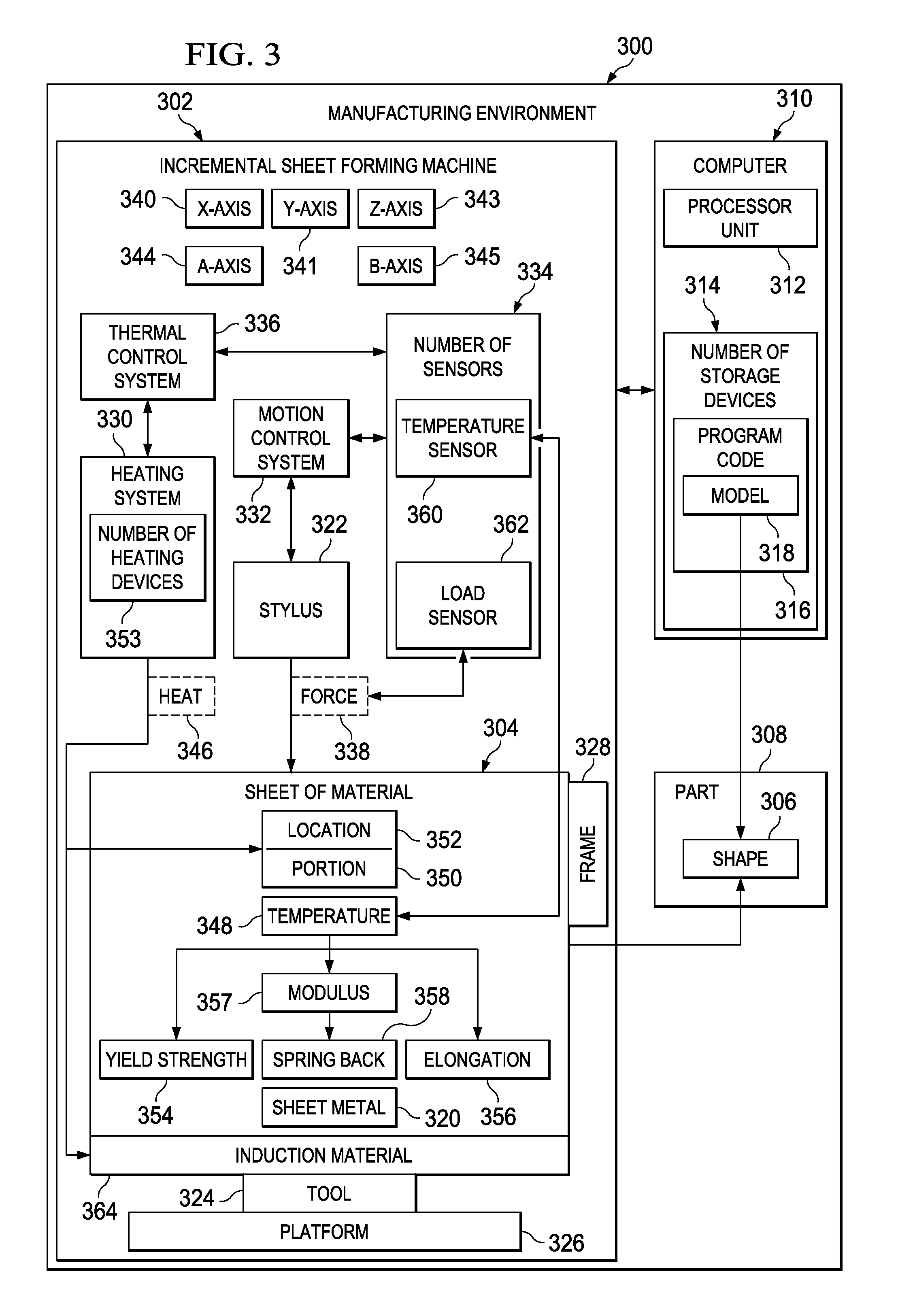

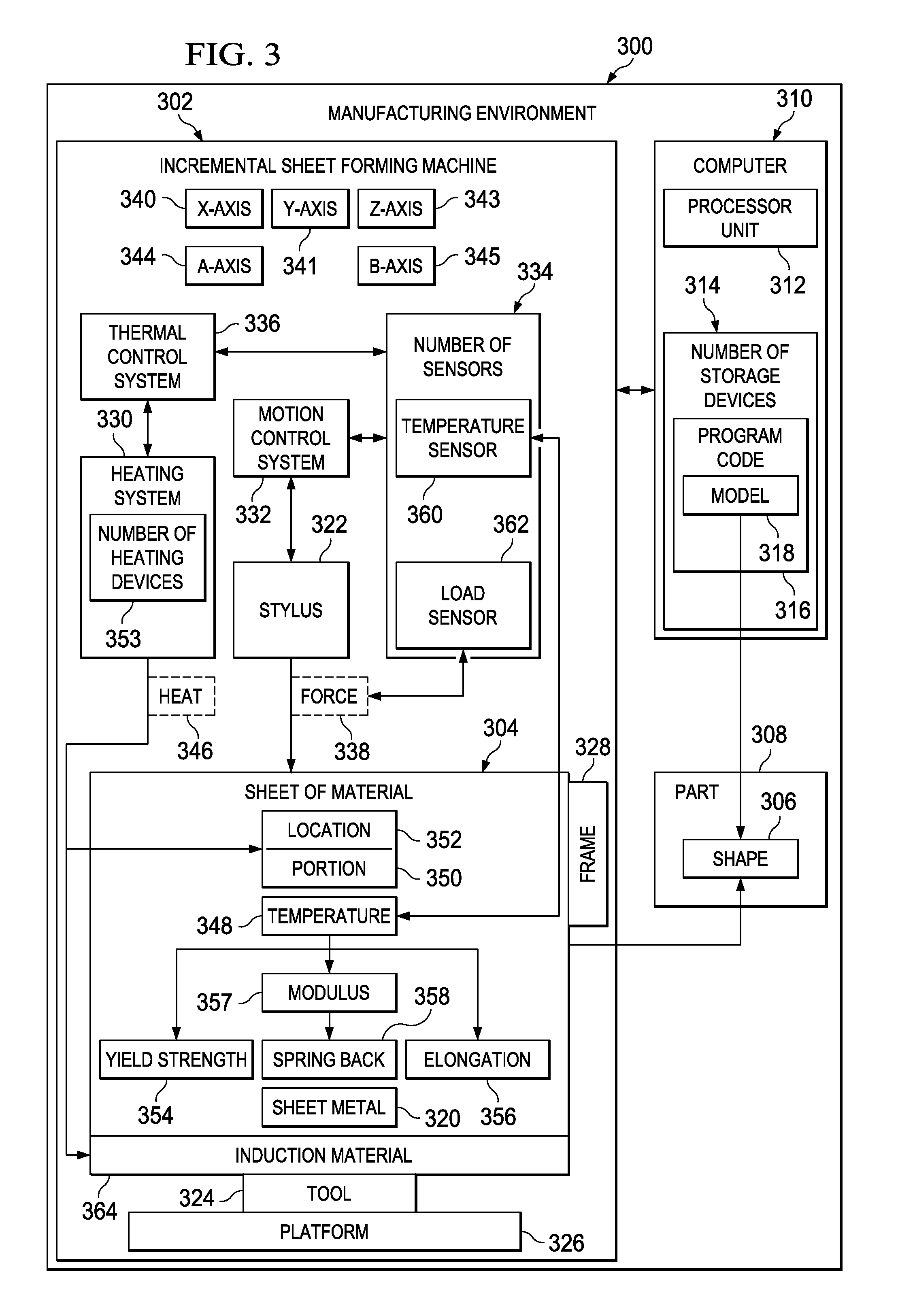

Reducing force needed to form a shape from a sheet metal

An apparatus comprises a platform, a stylus, and a heating system. The platform is capable of holding a sheet of material. The stylus is capable of impinging the sheet of the material to incrementally form a shape for a part. The heating system is capable of heating at least a portion of the sheet of material in a location on the sheet of material prior to the stylus impinging the location.

Owner:THE BOEING CO

Quenched and tempered steel sheet and manufacturing method thereof

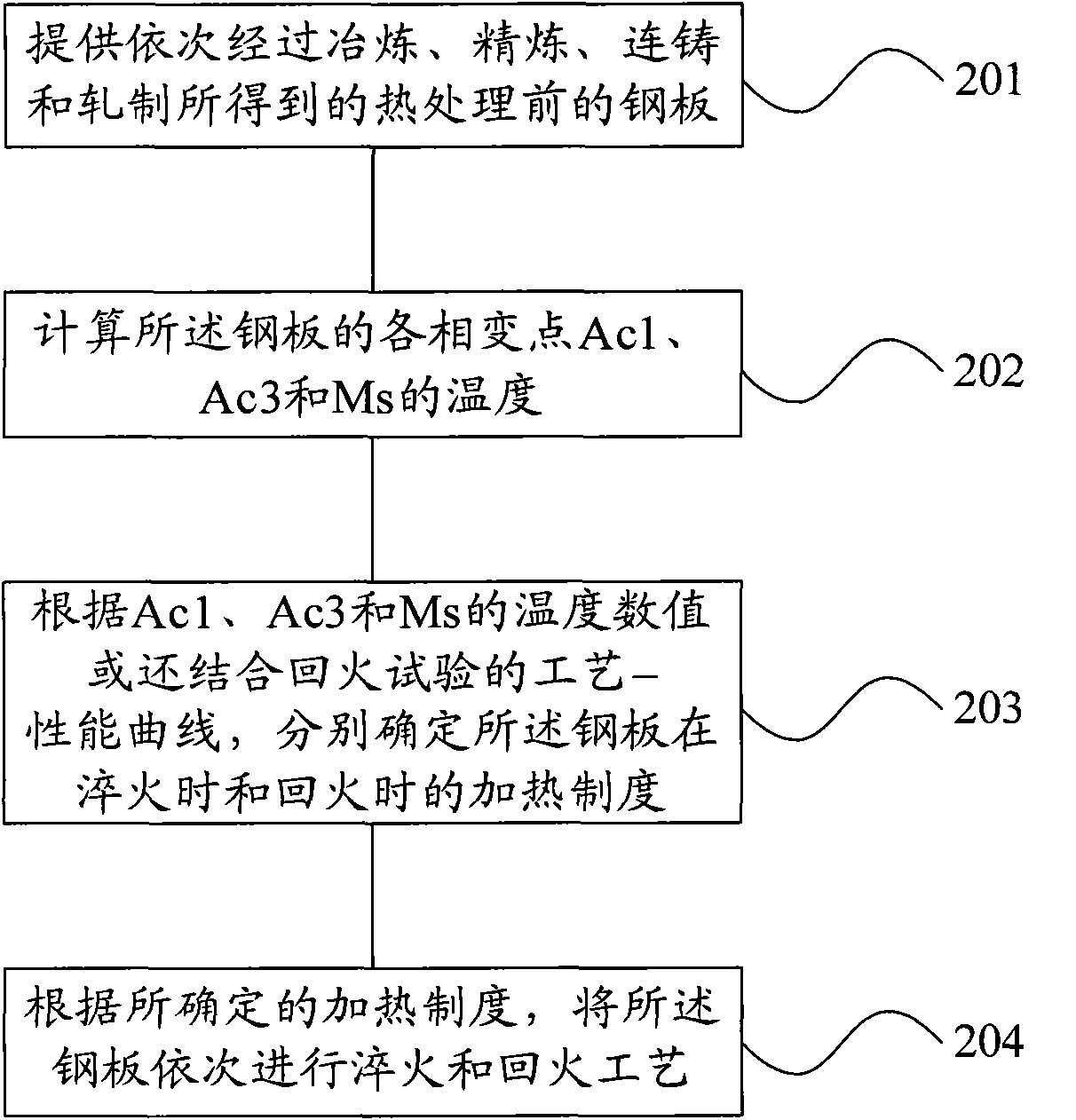

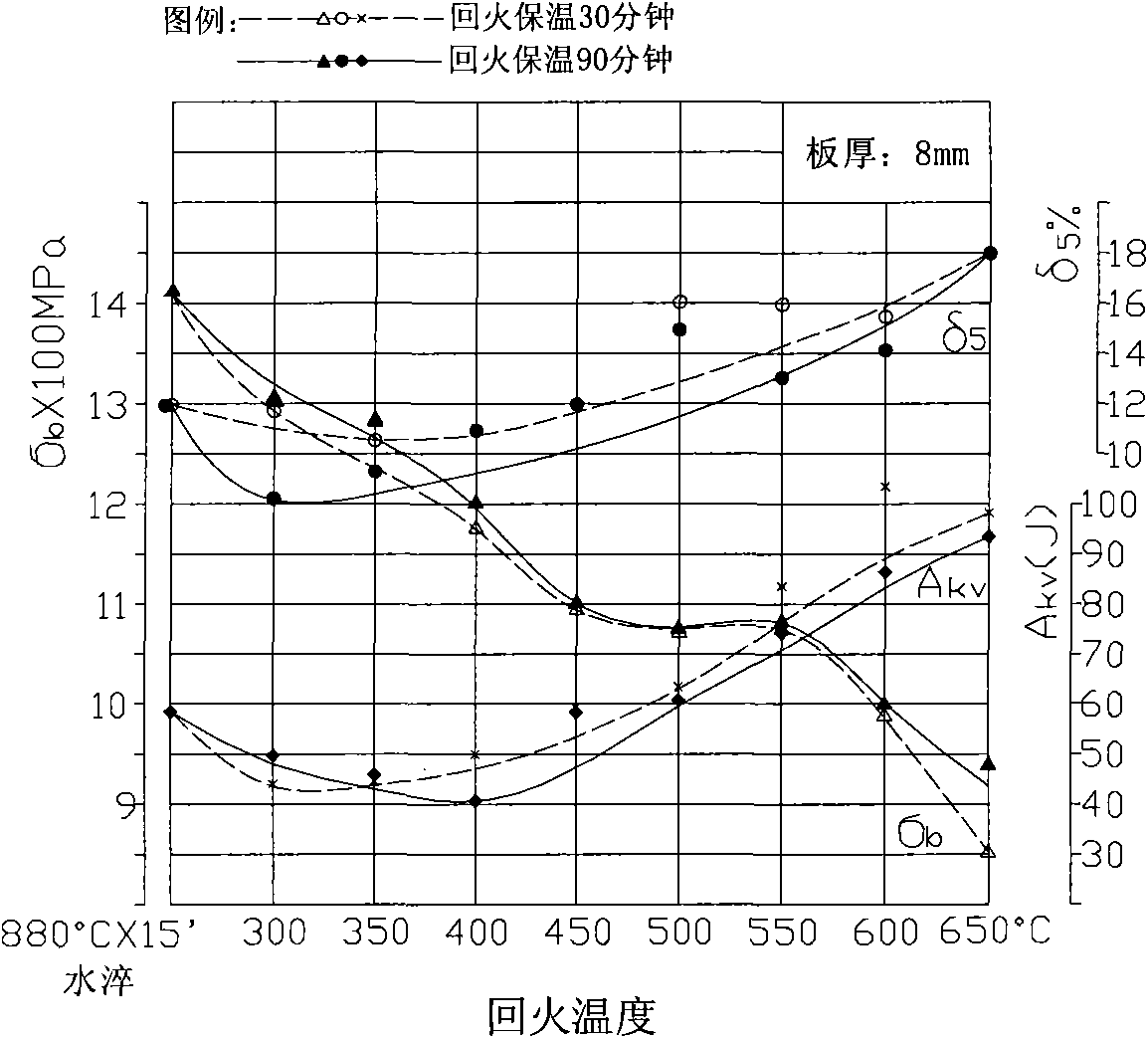

ActiveCN101962741AStrong plastic matchingSimple welding processRoll force/gap control deviceMolten metal pouring equipmentsSheet steelChemical composition

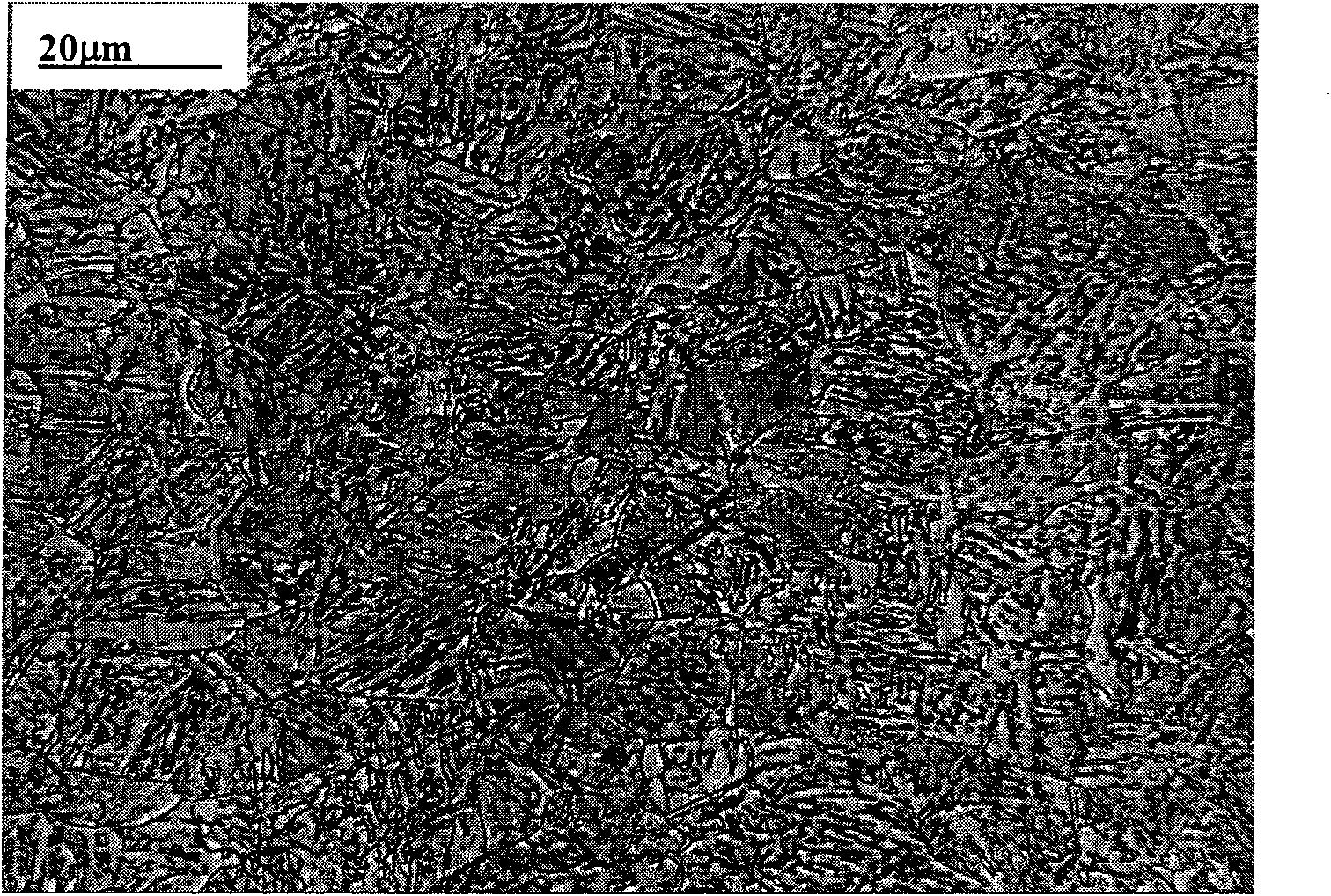

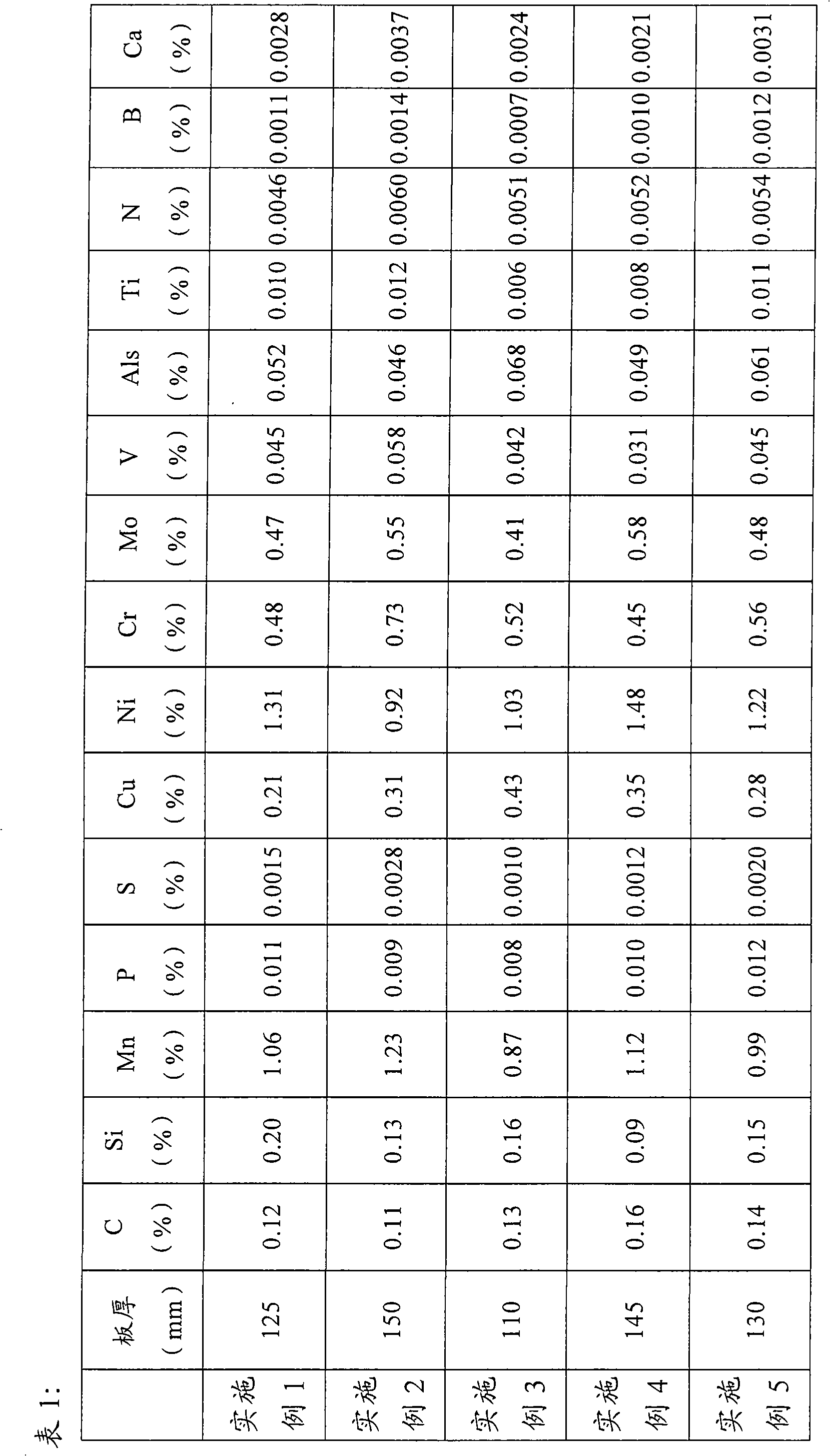

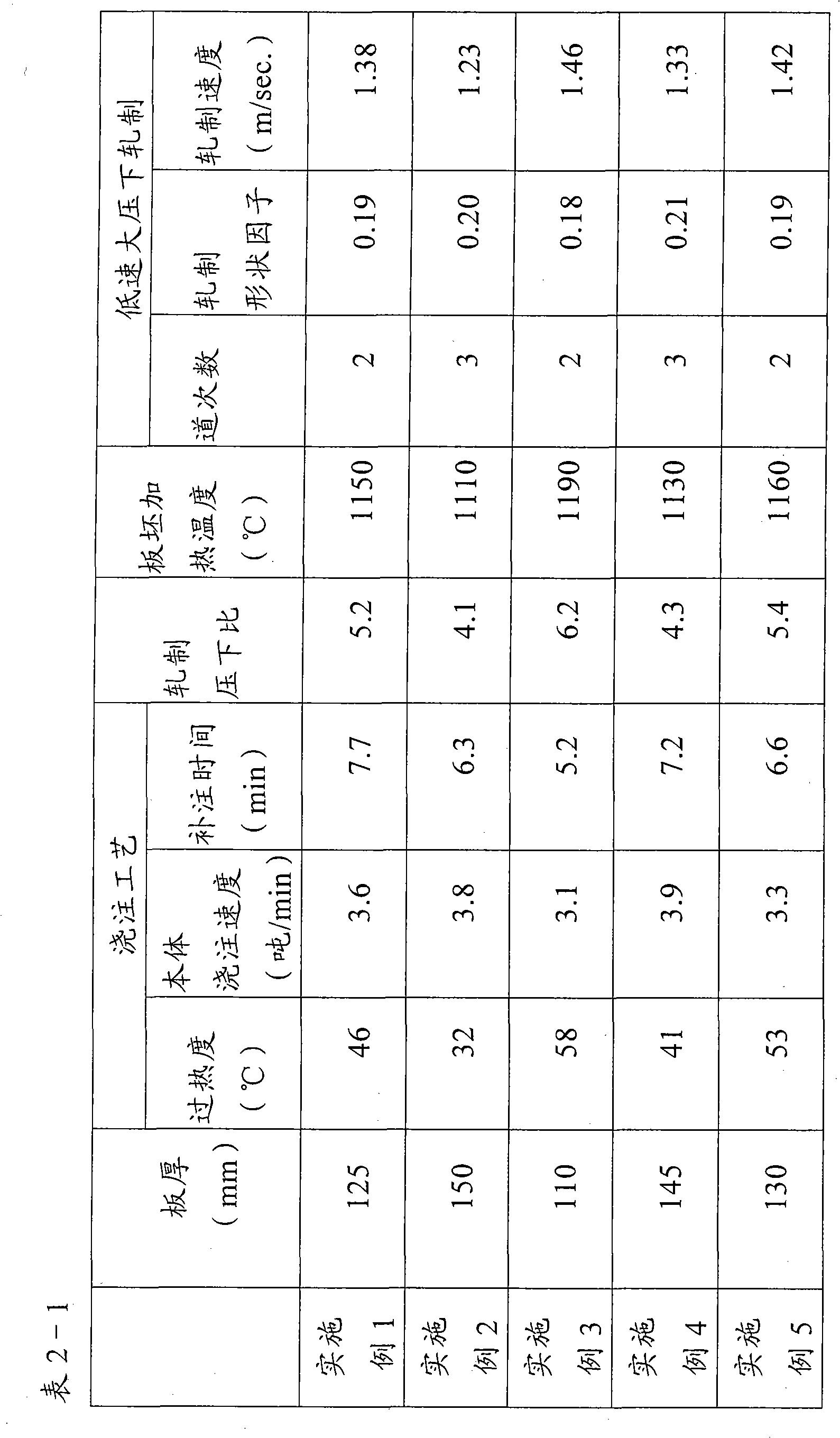

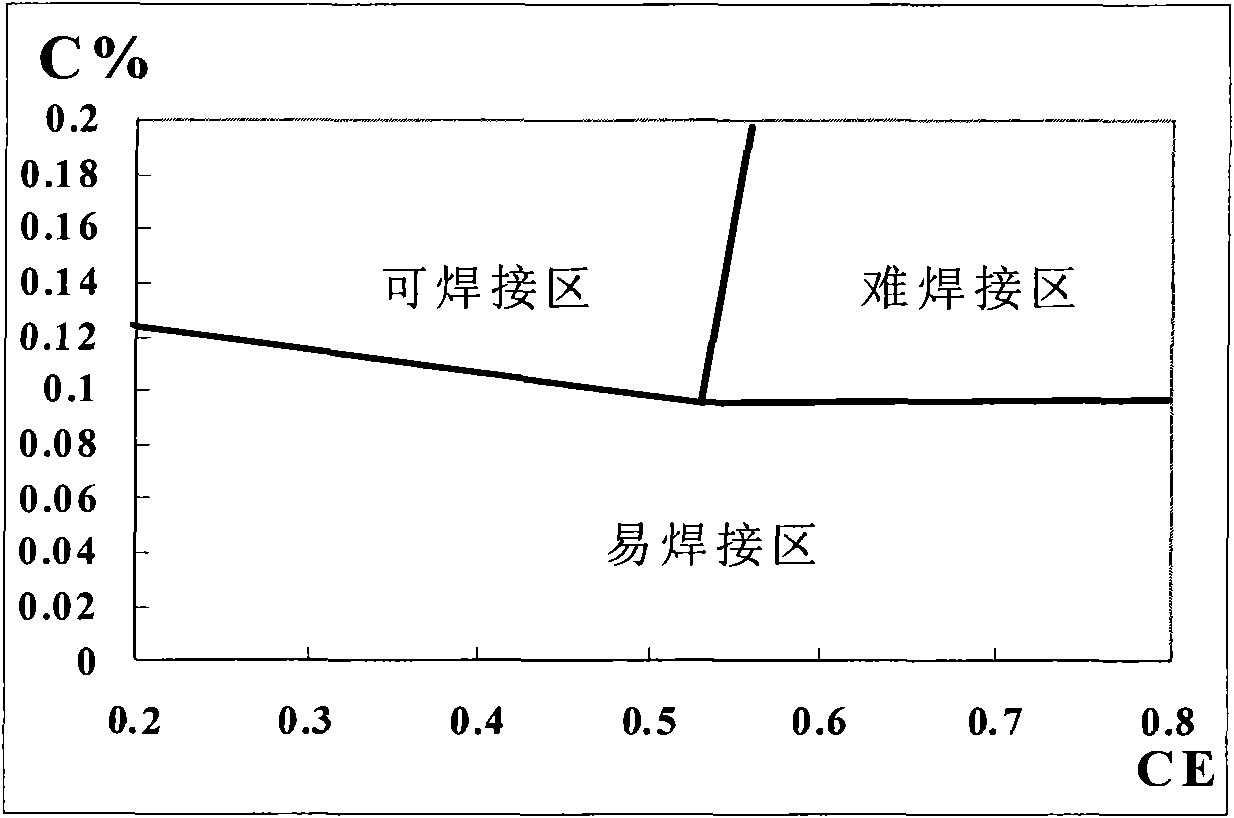

The invention provides a 80kg extra-thick quenched and tempered steel sheet. The steel sheet comprises the following chemical compositions: 0.10 to 0.16 percent of C, less than or equal to 0.20 percent of Si, 0.85 to 1.25 percent of Mn, less than or equal to 0.013 percent of P, less than or equal to 0.0030 percent of S, 0.20 to 0.45 percent of Cu, 0.90 to 1.50 percent of Ni, 0.45 to 0.75 percent of Cr, 0.40 to 0.65 percent of Mo, 0.030 to 0.060 percent of V, 0.045 to 0.070 percent of Als, 0.006 to 0.012 percent of Ti, less than or equal to 0.0060 percent of N, 0.0006 to 0.0014 percent of B, 0.001 to 0.005 percent of Ca, and the balance of iron and inevitable impurities, wherein the chemical compositions meet the following conditions that: the Mn equivalent / C is more than or equal to 10 and less than or equal to 20; the Als is more than or equal to (Mn equivalent / c)*(N-0.292Ti); the Ni equivalent is more than or equal to 1.15 percent; the Mo equivalent is more than or equal to 0.25 percent; Ca / S is more than or equal to 0.80 and less than or equal to 3.00, and (Ca)(S)0.18 is more than or equal to 5*10<-4> and less than or equal to 2.5*10<-3>; and F*DI equals to the effective hardenability index Deff and is more than or equal to 1.00*t. The invention also relates to a method for manufacturing the quenched and tempered steel sheet. The technology of optimal recrystallization controlled rolling+offline quenching and tempering is adopted to ensure that the microstructure of the finished product steel sheet is a fine tempered bainite and tempered martensite, the average colony size is less than 25mu m, and excellent obdurability / plasticity matching and uniform mechanical performance along the direction of the sheet thickness can be acquired.

Owner:BAOSHAN IRON & STEEL CO LTD

High-silicon-steel thin belt and preparation method thereof

InactiveCN101935800AEasy to processImprove magnetismRoll force/gap control deviceTemperature control deviceChemical compositionTransformer

The invention belongs to the fields of metallurgical technology and material science, and in particular relates to a high-silicon-steel thin belt and a preparation method thereof. High silicon steel is mainly applied to manufacture iron cores in a high-frequency motor, a transformer and a high-frequency choke coil and comprises the following chemical components in percentage by weight: 6.5 percent of Si, 0.01-0.6 percent of Al, 0.4-0.8 percent of Mn, no more than 0.003 percent of N, no more than 0.005 percent of S, no more than 0.01 percent of P, no more than 0.003 percent of O, no more than 0.004 percent of C and the balance of Fe and unavoidable impurities. The content of the impurities and harmful gases is reduced in the high silicon steel by vacuum melting to ensure the purity of molten steel, then, the high silicon steel is cast and rolled with the casting temperature of 1470-1510 DEG C, and the thickness of a cast belt is 1.5-2.0mm; after being taken out of a cast roll, cooling by spraying water, heat insulating and warm rolling are carried out on the cast belt, and finally, a product is obtained by recrystallization annealing. When being used for producing the high silicon steel, the technology of the invention has the advantages of small investment, energy saving, environmental protection, high lumber recovery and good product magnetism.

Owner:NORTHEASTERN UNIV

Quenching steel plate for engineering machinery with 900MPa-grade yield strength and production method thereof

InactiveCN101899630AHigh strengthImprove toughnessRoll force/gap control deviceTemperature control deviceSheet steelHigh intensity

The invention provides a quenching steel plate for engineering machinery with 900MPa-grade yield strength, comprising the following components in percentage by mass: 0.13 to 0.18 percent of C, 1.20 to 1.60 percent of Mn, not more than 0.010 percent of S, not more than 0.020 percent of P, not more than 0.50 percent of Si, not more than 0.50 percent of Cr, not more than 0.50 percent of Ni, 0.30 to 0.60 percent of Mo, not more than 0.003 percent of B, not more than 0.05 percent of V, not more than 0.03 percent of Ti, not more than 0.03 percent of Nb, not less than 0.018 percent of Al and the balance of Fe and other unavoidable impurities; and the mass percentages of all the components in the steel plate also need to satisfy the condition that the value of the carbon equivalent is not more than 0.56 percent. The invention also provides a production method of the quenching steel plate for engineering machinery with 900MPa-grade yield strength. The steel plate has favorably-matched strength and tenacity, and the welding performance of the steel plate can satisfy the construction requirements on steels for manufacturing high-strength welding structures of the engineering machinery; meanwhile, the strength, the tenacity and the plasticity of the provided steel plate are all superior to similar WELDOX900-standard products in foreign countries.

Owner:BAOSHAN IRON & STEEL CO LTD

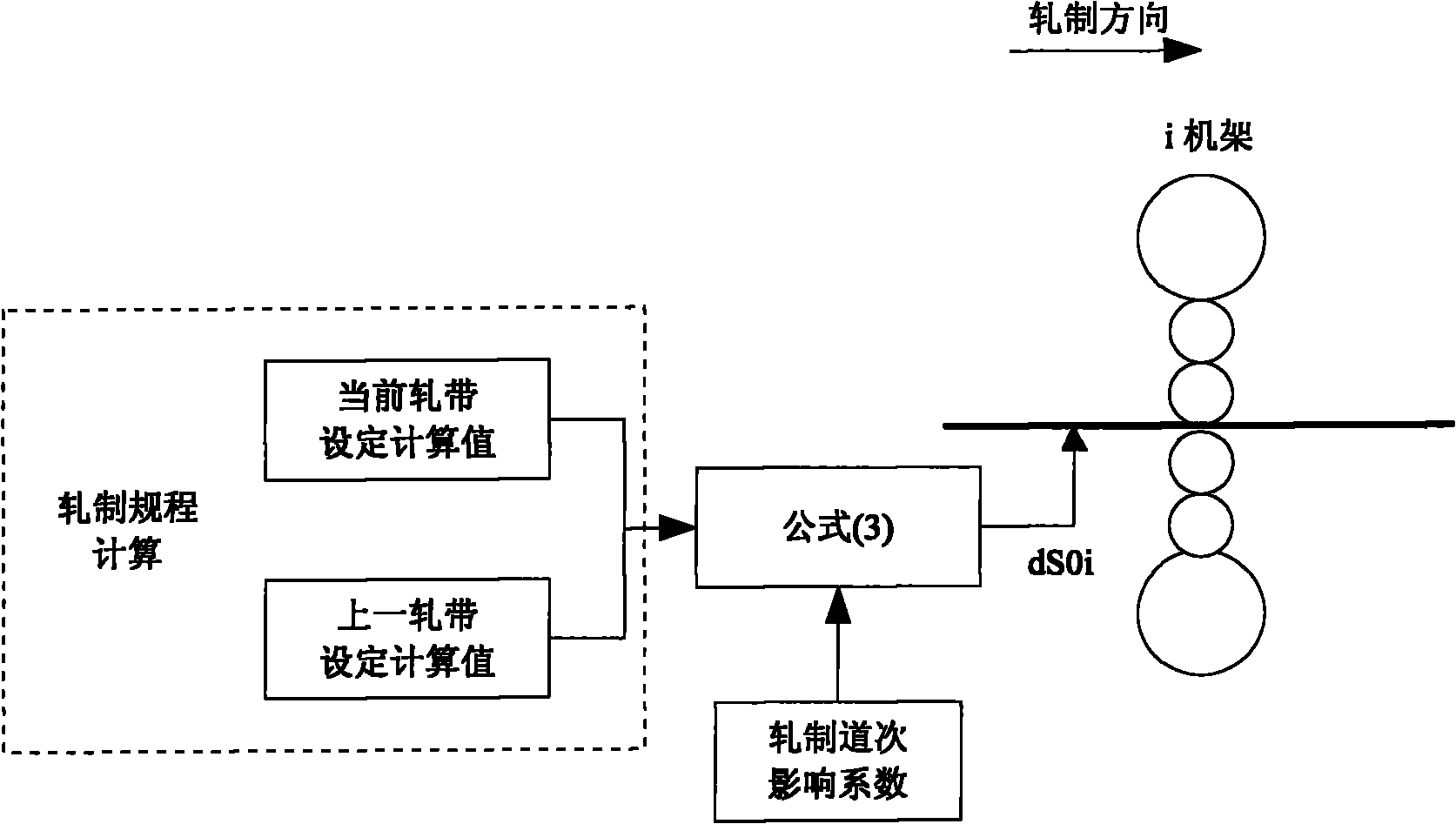

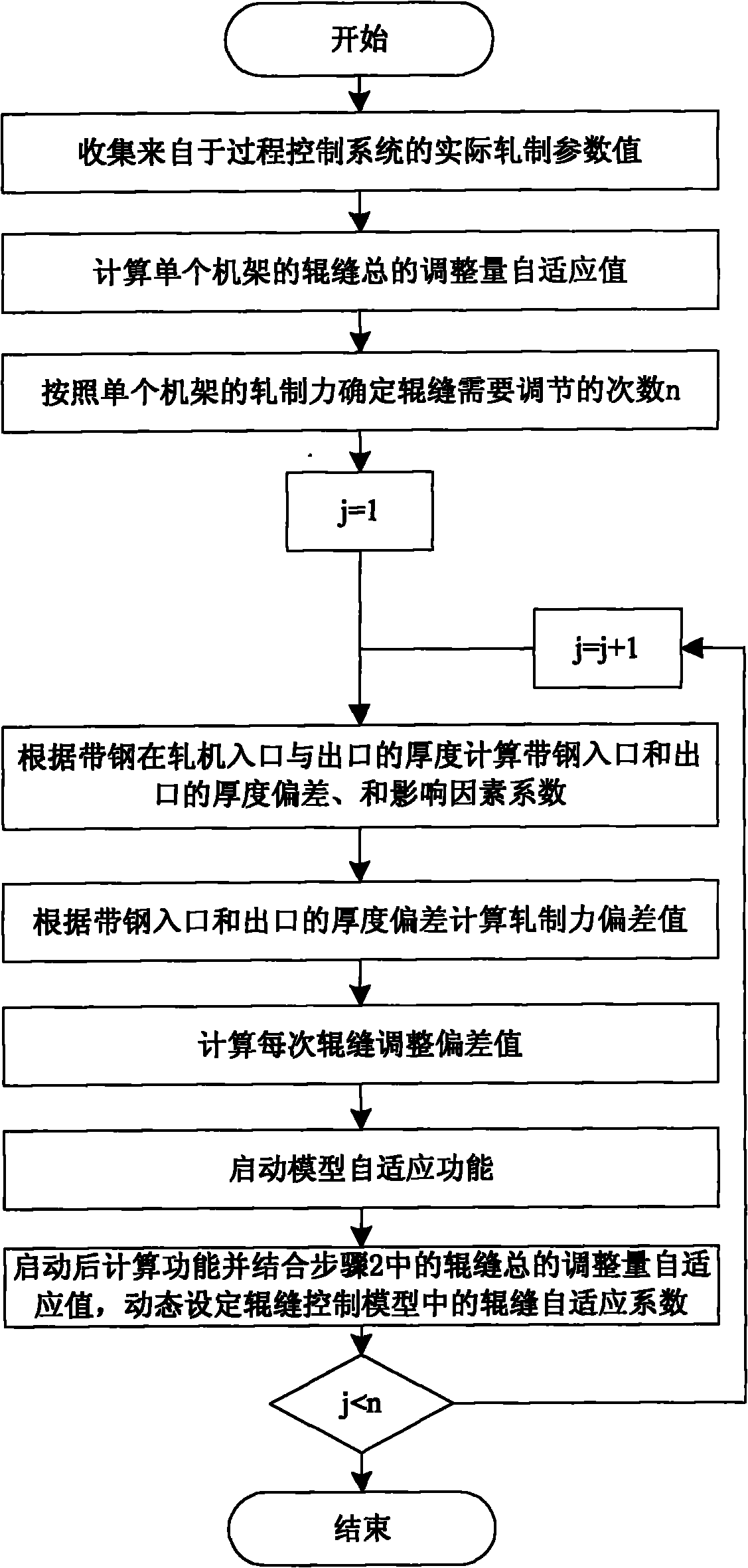

Thickness control compensation method of strip steel head part when welding line passes through rack

ActiveCN101780480AThickness tolerance length controlHigh thickness accuracyRoll force/gap control deviceControl systemStrip steel

The invention introduces a thickness control compensation method of a strip steel head part when a welding line passes through a rack, which comprises the following steps: 1, collecting actual rolling parameter values from a process control system; 2, calculating the total adjustment amount self-adaption value of roll-gaps of a single rack; 3, determining the required adjustment time n of the roll-gap according to the roll force of the single rack; 4, setting j to be equal to 1; 5, calculating thickness deviation delta hj-1, delta hj and influencing coefficient factor of the inlet and the outlet of the strip steel according to the thickness of the strip steel at the inlet and the outlet of a rolling mill; 6, calculating rolling force deviation value according to the thickness deviation of the inlet and outlet of the strip steel; 7, calculating roll-gap adjustment deviation value of each time; 8, starting the self-adaptation function of a model; 9, starting calculating function, and dynamically setting roll-gap self-adaptation coefficients in a roll-gap control model by combing the total adjustment quantity self-adaptation value of the roll-gap in the step 2; and 10, carrying out the step 5 when j is less than n and j=j+1; and finishing the process when j is more than or equal to n. The method ensures that the indication error length of thickness of the strip steel head part is controlled.

Owner:BAOSHAN IRON & STEEL CO LTD

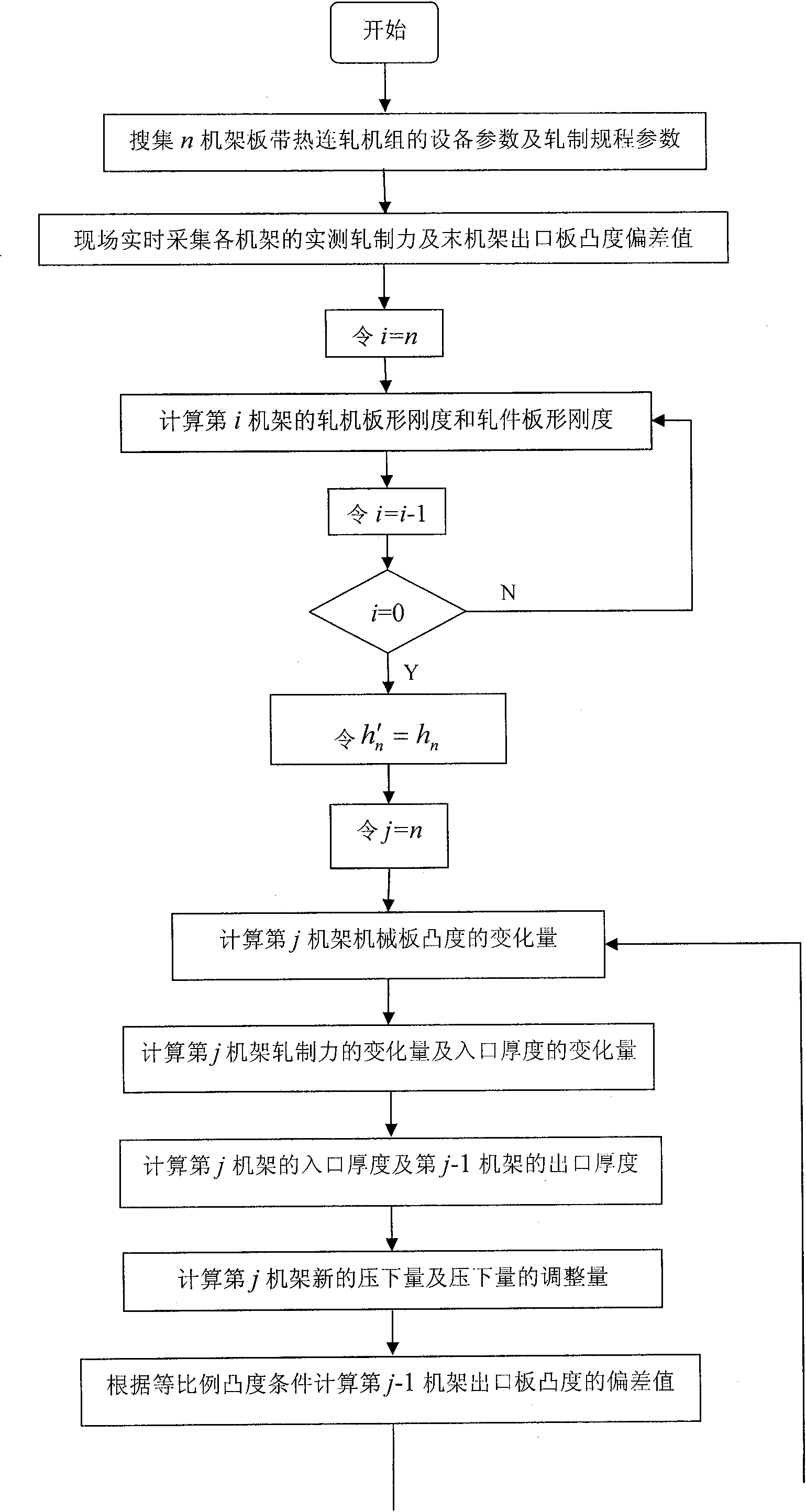

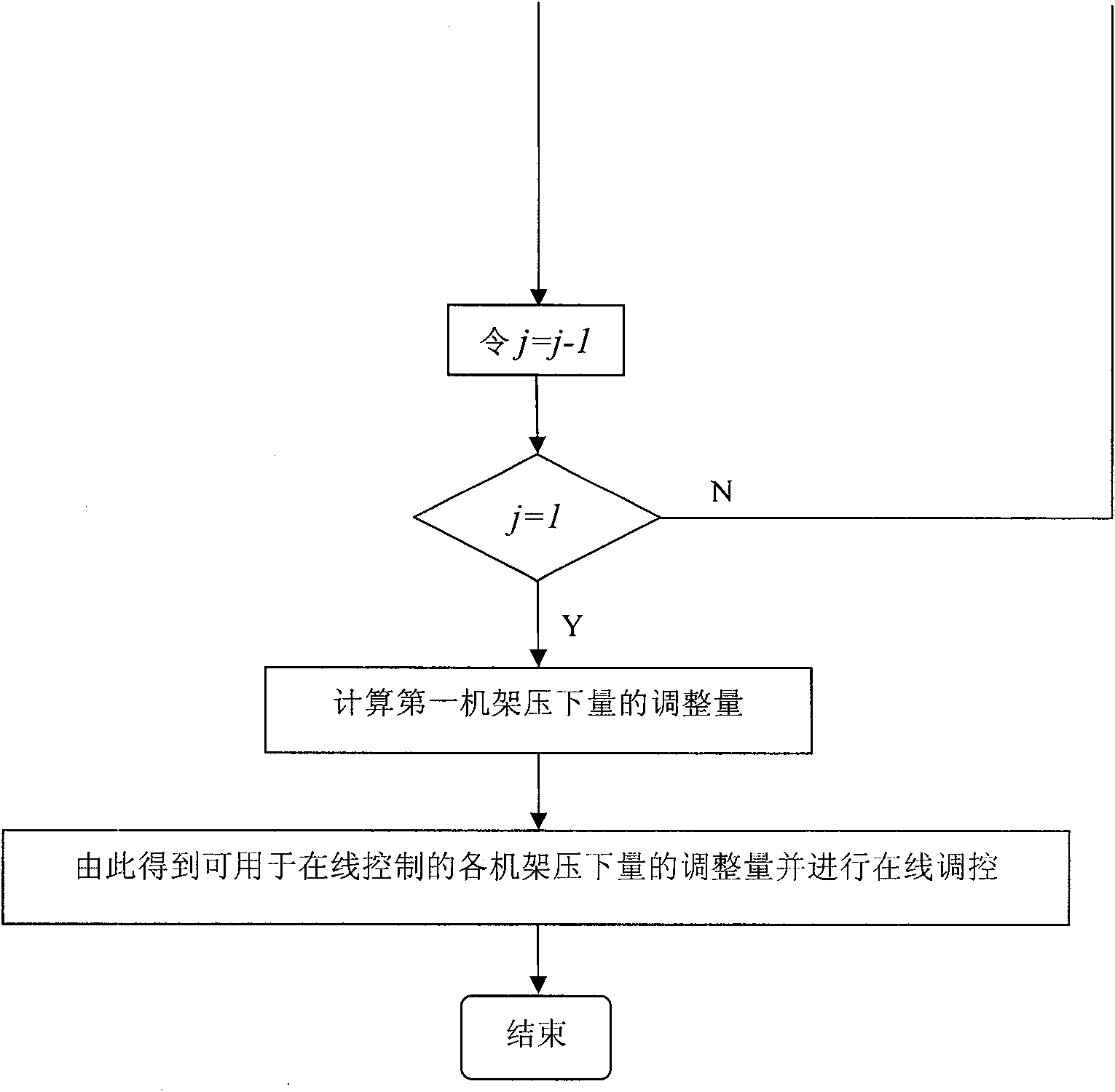

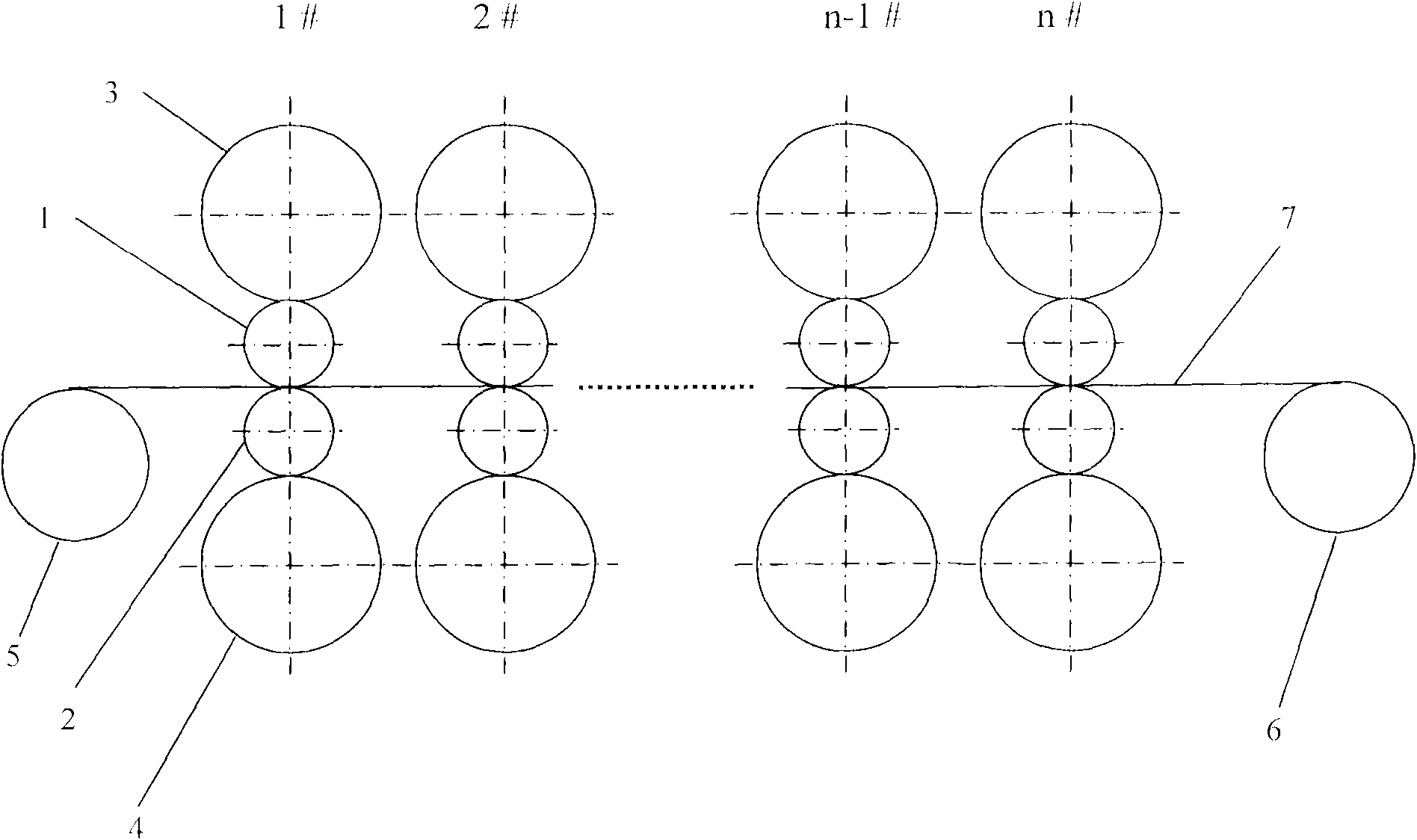

On-line coordination control method for plate shape and plate thickness of strip tandem hot continuous rolling mill

InactiveCN101890433ALower control costsSimple control methodRoll force/gap control deviceProfile control deviceSlice thicknessEngineering

The invention discloses an on-line coordination control method for the plate shape and plate thickness of a strip tandem hot continuous rolling mill, belonging to the technical filed of hot continuous rolling of sheets and strips. The method is characterized by comprising the following steps: (1) collecting n rack hot continuous rolling mill equipment and rolling schedule parameters; (2) collecting the roll force and the convexity offset value of a last rack plate in situ; (3) calculating the plate shape stiffness of each rack; (4) keeping the thickness of the outlet of the tail rack to be constant; (5) inversely calculating the convexity variable quantity of the mechanical plate of the i rack from the tail rack; (6) calculating the roll force and the variable quality of the thickness of the inlet of the i rack; (7) calculating the thickness of the new inlet and outlet of the i rack; (8) calculating the rolling reduction and adjusted quantity of the i rack; (9) calculating the convexity variable quantity of the outlet plate of the (i-1) rack according to the equi-proportional convexity condition; (10) repeating steps from (5) to (9) to obtain the rolling reduction and adjusted quantities of 2nd to n racks; (11) calculating the rolling reduction and adjusted quantity of the first rack; and (12) carrying out on-line coordination control according to the rolling reduction and adjusted quantities, thereby achieving the purpose of coordination control on the plate shape and plate thickness.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low-yield-ratio high-tenacity steel plate and manufacture method thereof

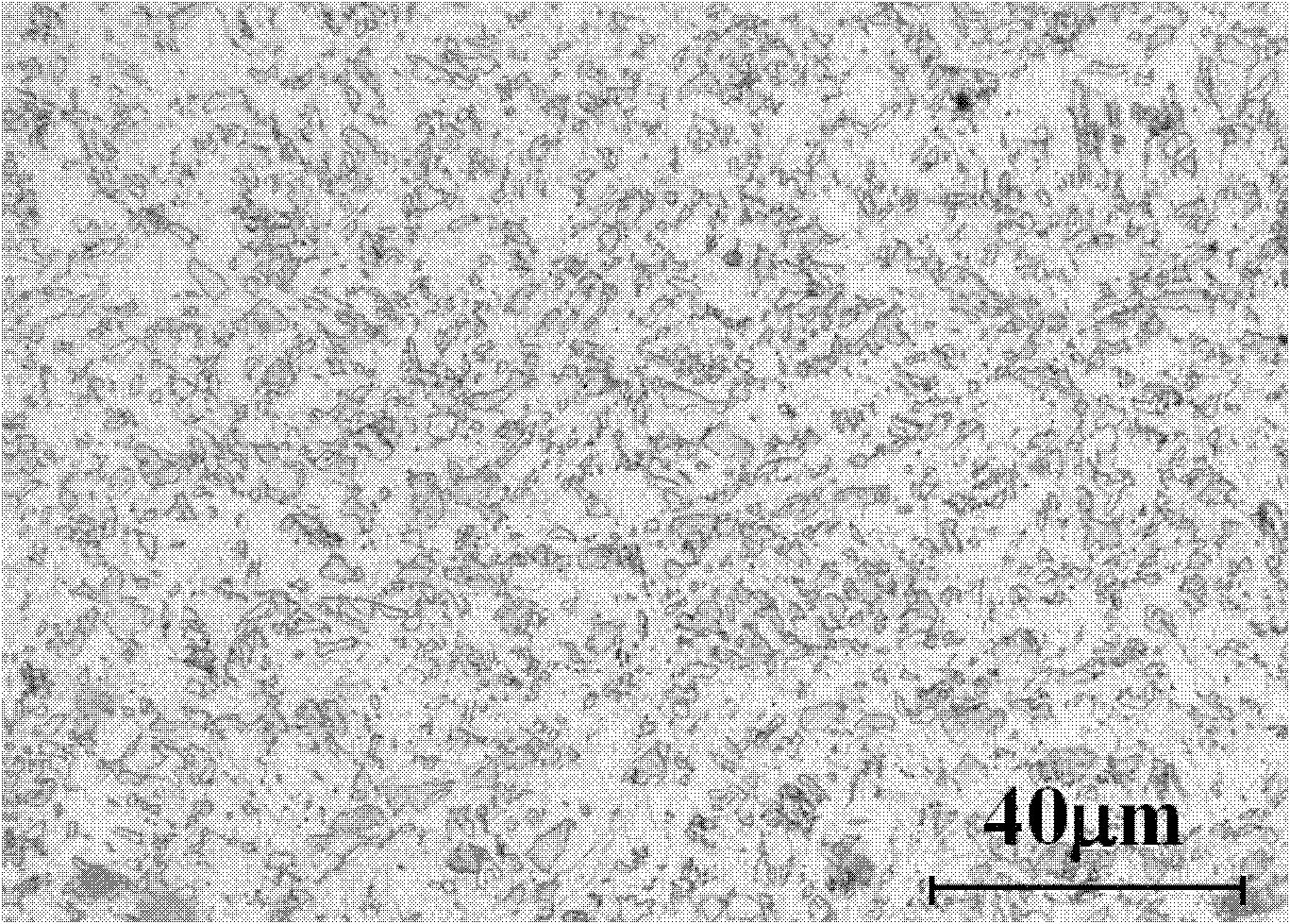

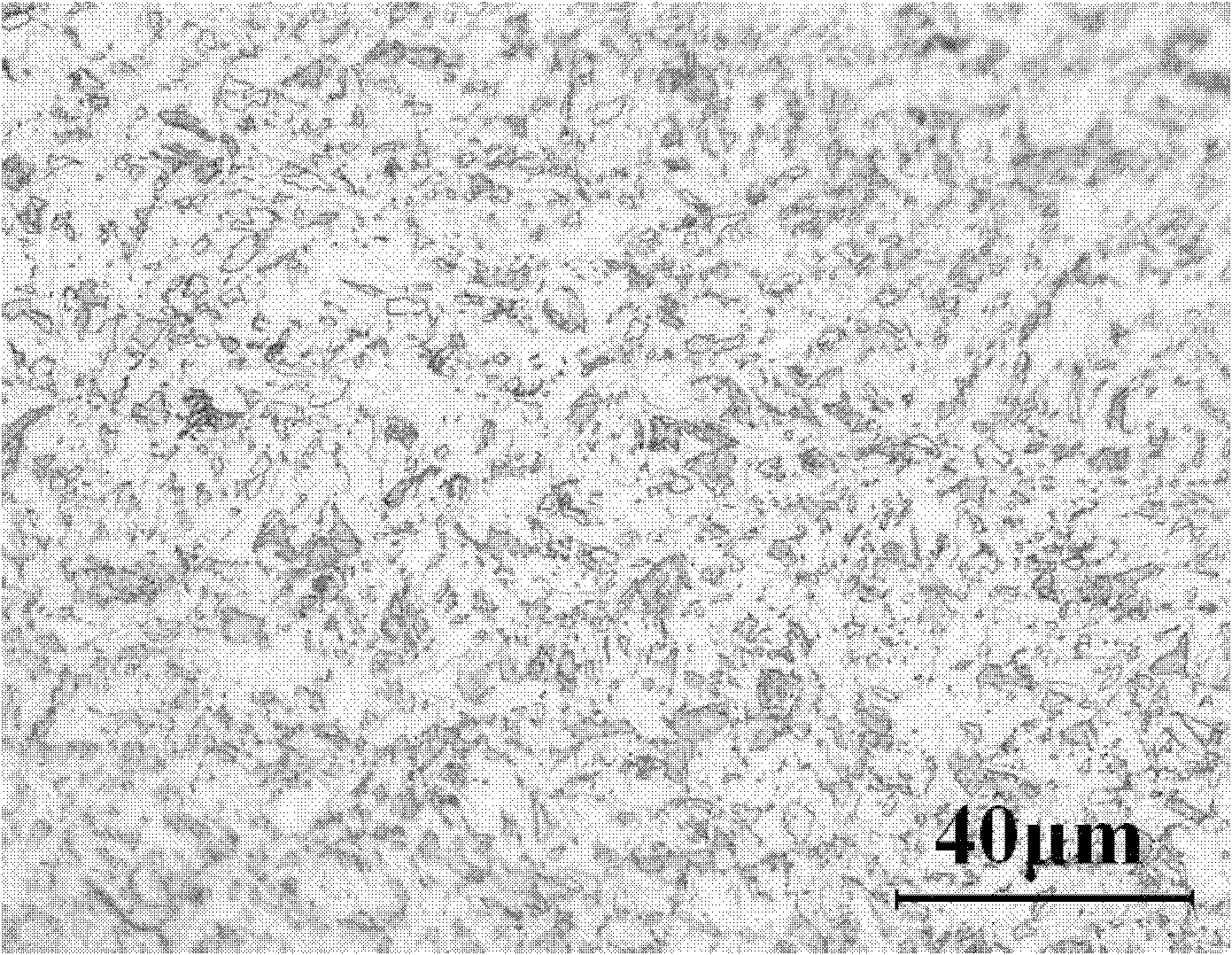

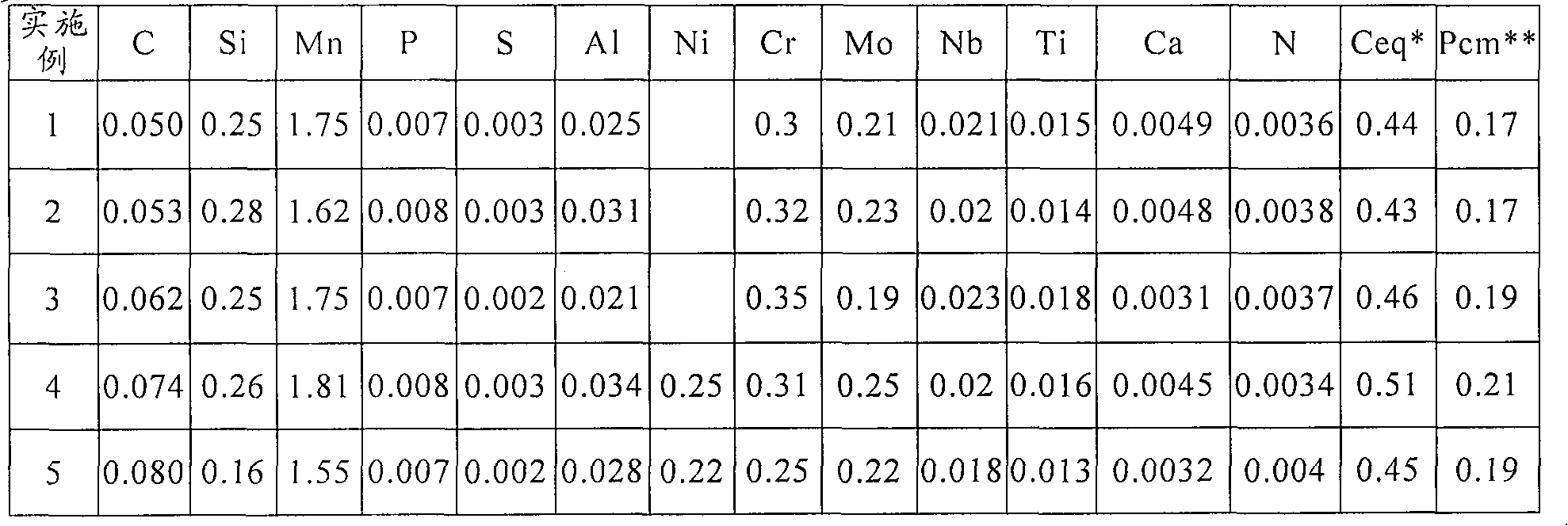

ActiveCN103014554AGood cold bending performanceRoll force/gap control deviceTemperature control deviceReduction rateYield ratio

The invention relates to a low-yield-ratio high-tenacity steel plate. The steel plate comprises the following chemical constituents in percentage by weight: 0.05 to 0.08 percent of C, 0.15 to 0.30 percent of Si, 1.55 to 1.85 percent of Mn, smaller than or equal to 0.015 percent of P, smaller than or equal to 0.005 percent of S, 0.015 to 0.04 percent of Al, 0.015 to 0.025 percent of Nb, 0.01 to 0.02 percent of Ti, 0.20 to 0.40 percent of Cr, 0.20 to 0.30 percent of Mo, smaller than or equal to 0.006 percent of N, smaller than or equal to 0.004 percent of O, smaller than or equal to 0.005 percent of Ca, smaller than or equal to 0.40 percent of Ni, and the balance of iron and inevitable impurities, wherein Ca / s is larger than or equal to 1.5. The steel plate is manufactured through the following method: heating a continuous casting or steel billet at 1150 to 1220 DEG C and performing multi-pass rolling, wherein the total reduction rate is larger than or equal to 80 percent, and the finish rolling temperature is larger than or equal to 850 DEG C; performing rapid water cooling on a rolled steel plate at the speed of 15 to 50 DEG C / s to a temperature range from Bs-60 DEG C to Bs-100 DEG C, and then performing air cooling for 5 to 60 seconds; and heating the cooled steel plate in an on-line induction heating furnace to Bs plus 20 DEG C at the speed of 1 to 10 DEG C / s, tempering for 40 to 60 seconds, then discharging from the furnace and performing air cooling. The thickness of the steel plate is 10 to 25mm, the yield strength is larger than or equal to 500MPa, the yield ratio is smaller than or equal to 0.75, the ductility A50 is larger than or equal to 20 percent, and Akv at minus 60 DEG C is larger than or equal to 200J.

Owner:BAOSHAN IRON & STEEL CO LTD

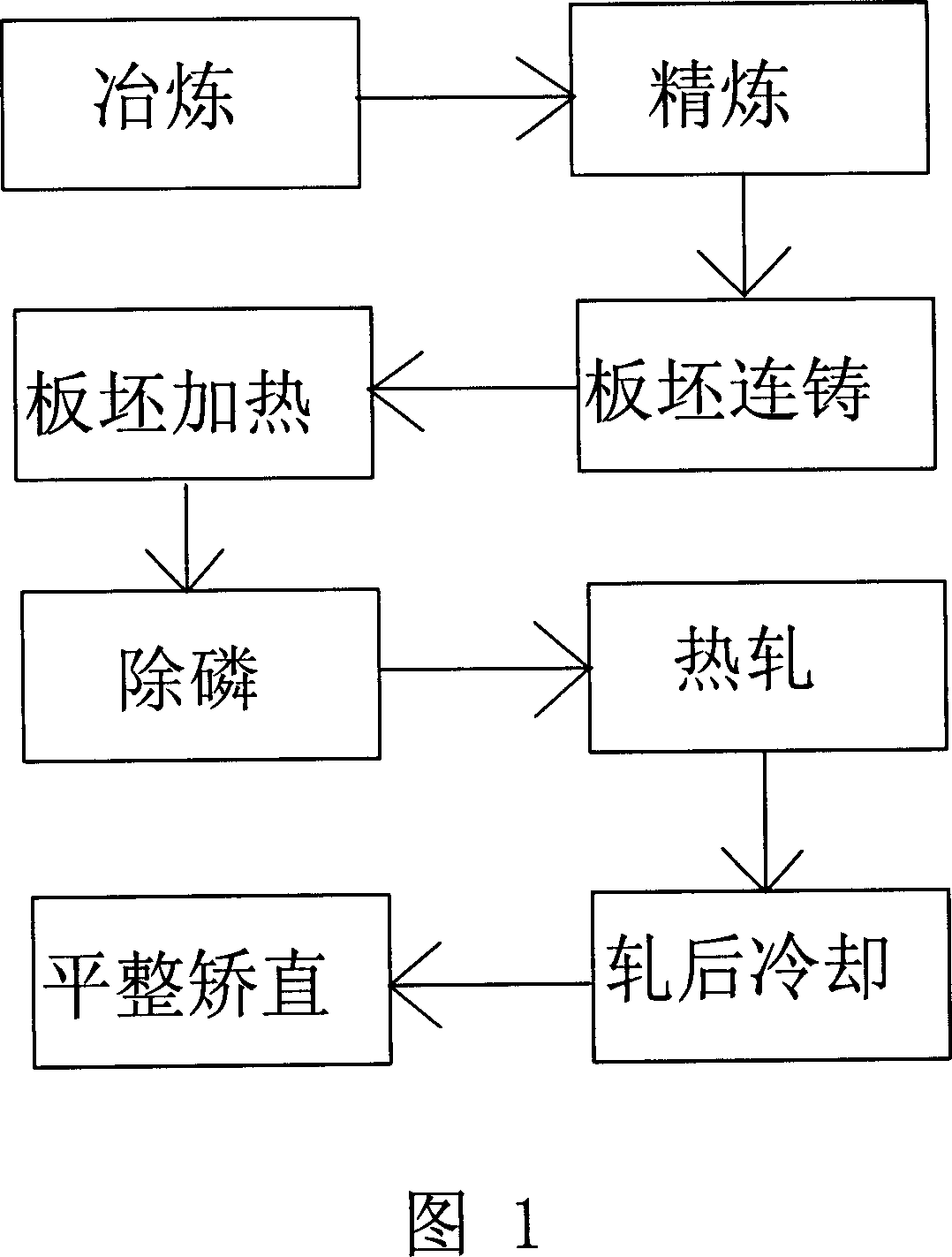

Manufacturing technique of low compression ratio high grade pipe line steel

InactiveCN1927486AImprove performanceRoll force/gap control deviceTemperature control deviceNiobiumHeating temperature

The invention relates to a method for producing high-strength low-alloy steel. Wherein, it comprises smelting, refining, casting sheet blank, heating blank, removing phosphor, cooling and flattening; the smelting step uses pure steel, low phosphor, and low sulfur; in the casting step, the loose of blank and the aliquation are lower than B0.5level; in the heating step, vanadium+niobium+ titanium0.15%, nickel+chromium+copper<=0.50%, and the heating temperature is 1180-1220Deg. C; in the thermal rolling step, in the crystallize process, the deformation temperature is 1070-1000Deg. C, the deformation amount is 40-60%, and the rolling speed is 1.5-2.5m / s, and in the second step that rolling the non-crystallized area, the pressure is 200-400MPa, the rolling speed is 5-1.5m / s, and the deformation amount is 60-75%; and the interlayer cooling speed in the cooling step is 15Deg. C / s-25Deg. C / s.

Owner:NANJING IRON & STEEL CO LTD +1

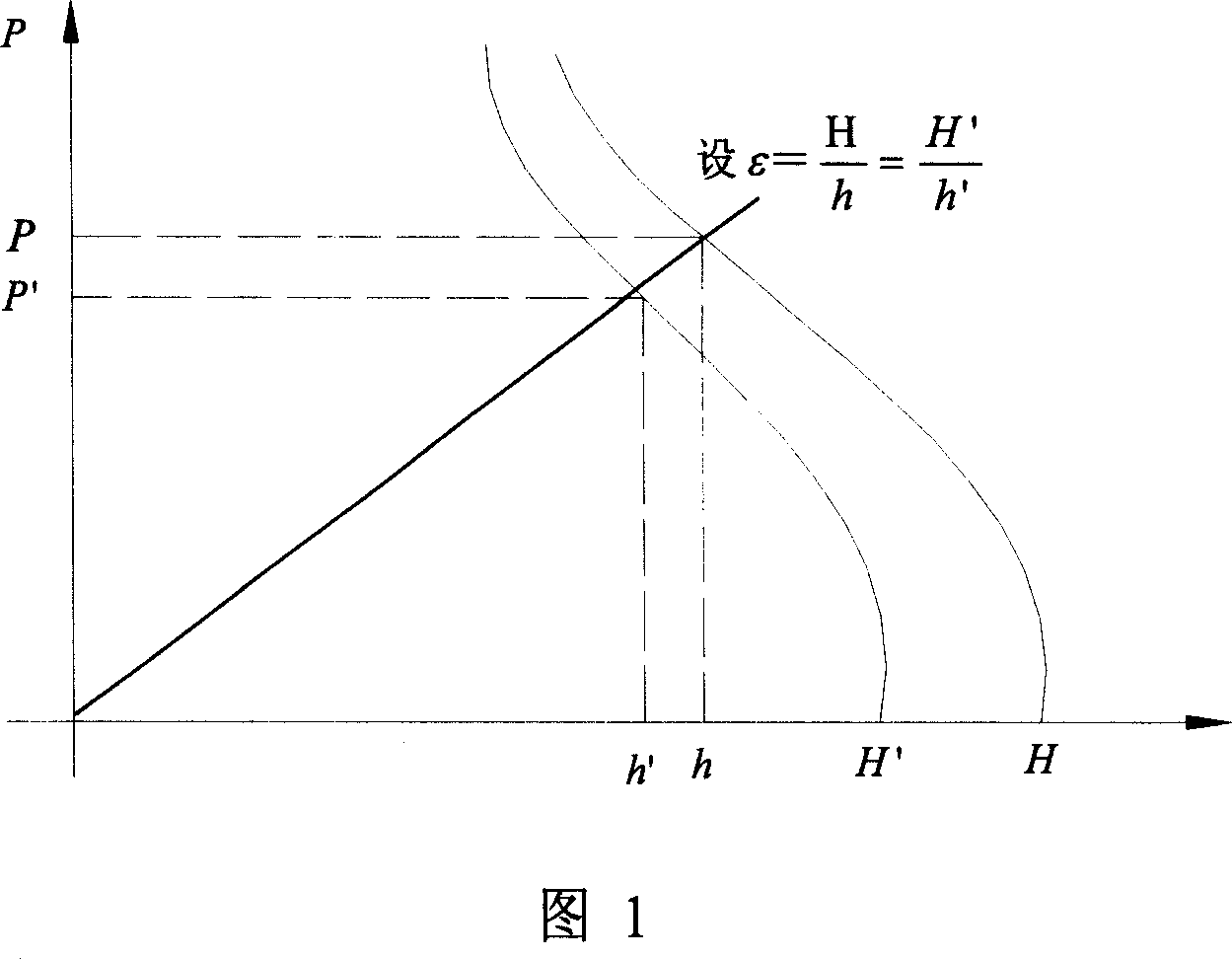

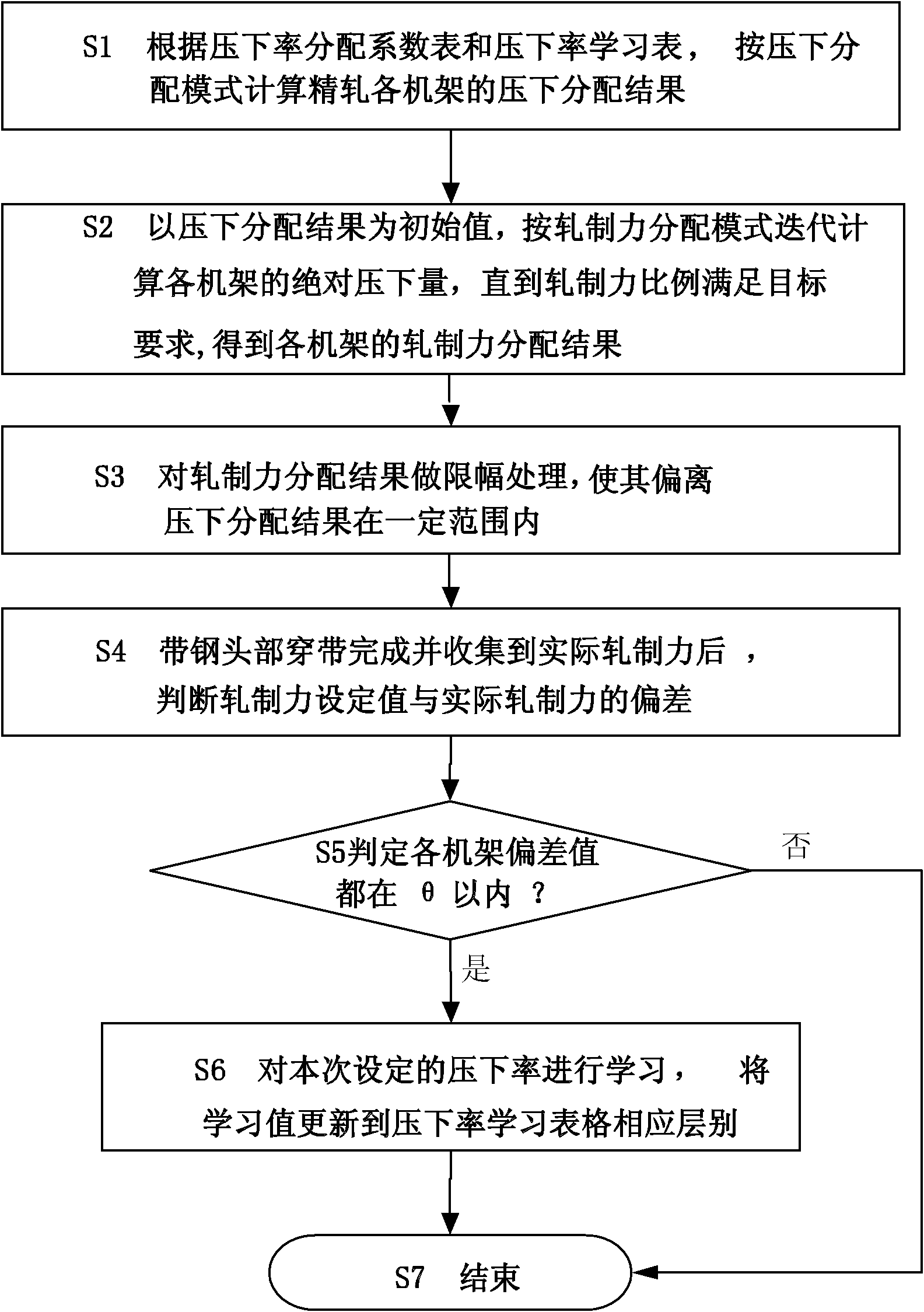

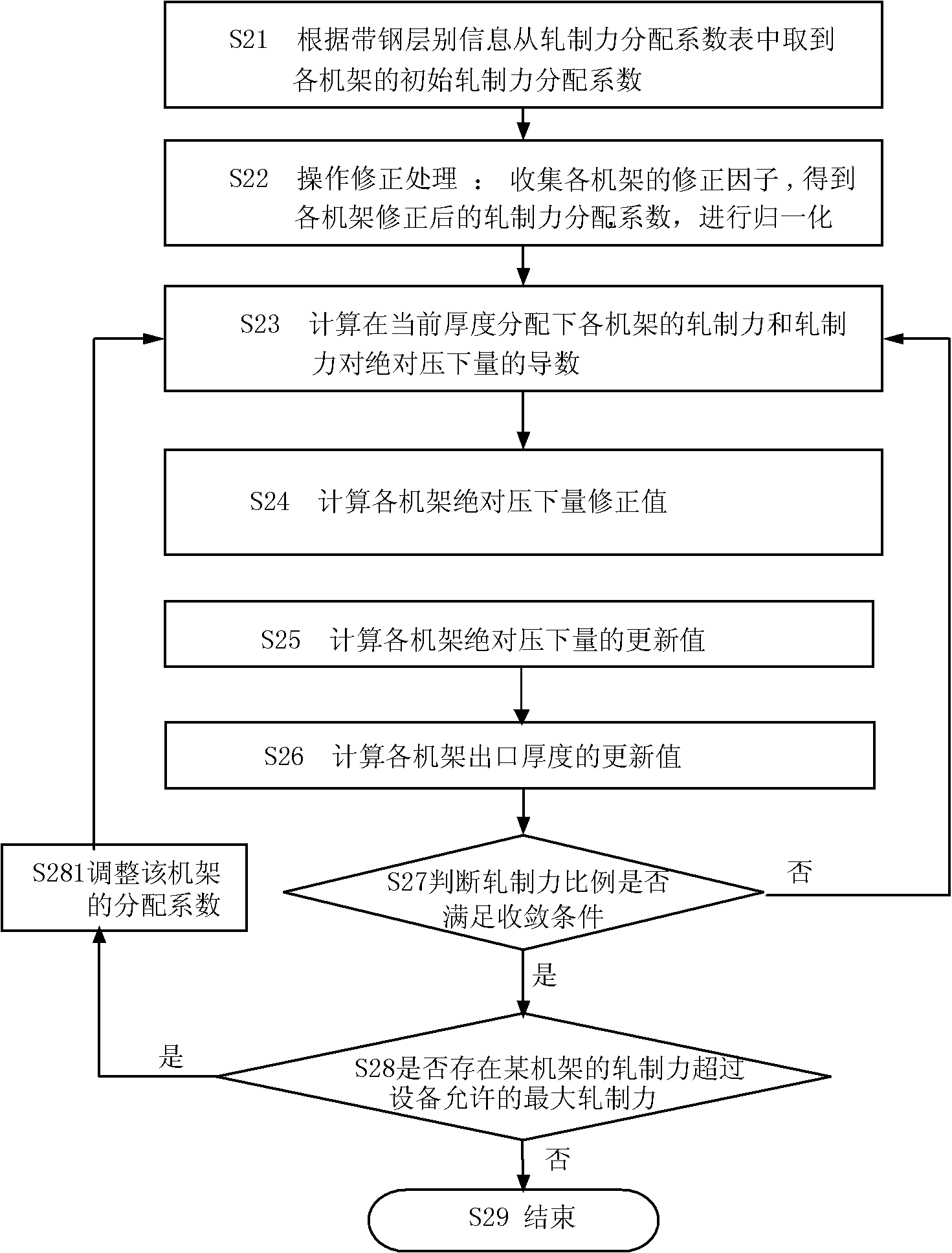

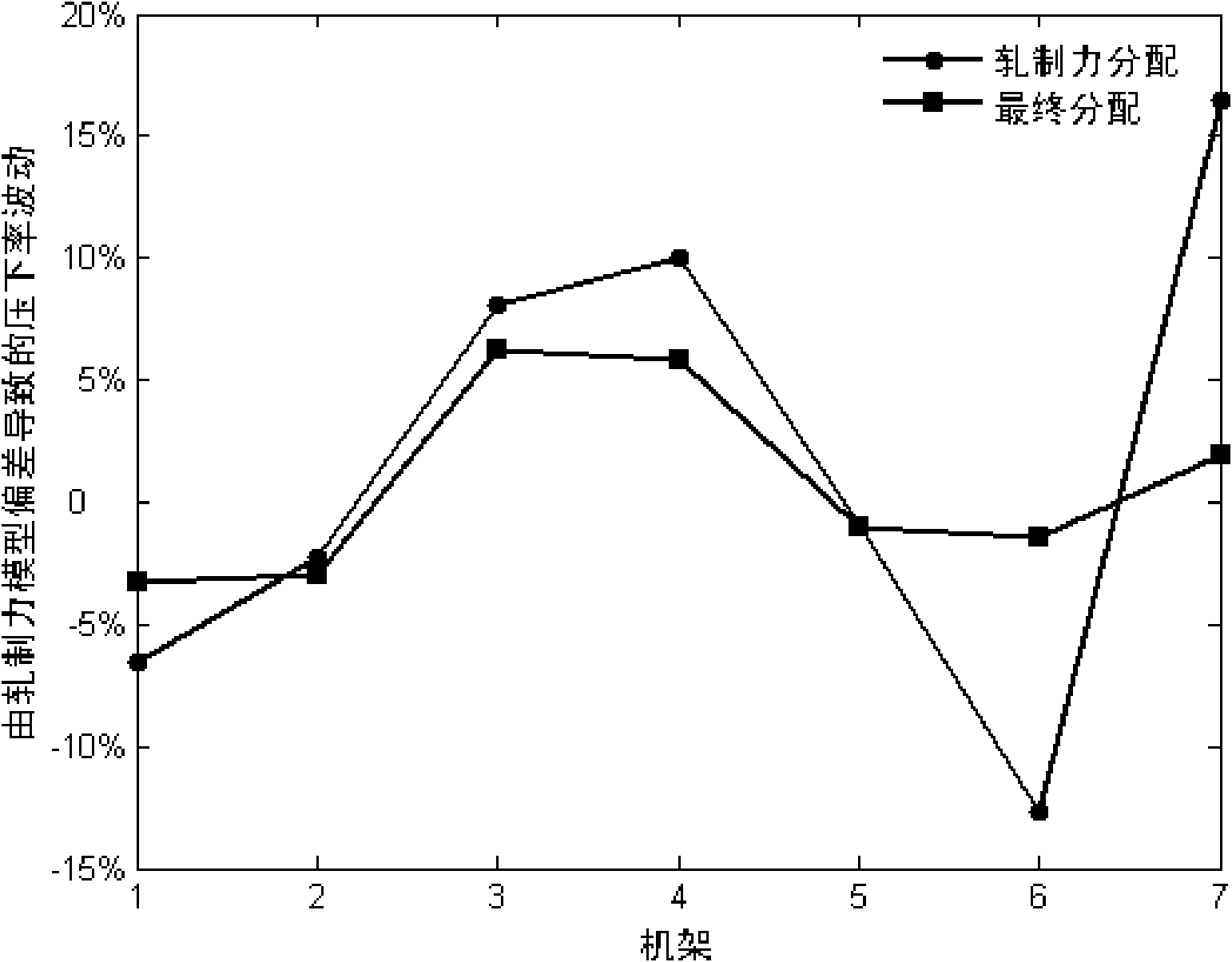

Method for setting load distribution of finish rolling band steel

ActiveCN102728624AHigh precisionImprove rolling stabilityRoll force/gap control deviceMetal rolling arrangementsLoad distributionMaterials science

The invention relates to a method for setting the load distribution of finish rolling band steel, belonging to the field of production control of finish rolling band steel, and solving the problems that the rolling force proportion of stands is large in fluctuation when the rolling condition is changed under the pressed-down distribution mode, and the thickness distribution of the stands is large in fluctuation when the rolling force model is large in deviation under the rolling force distribution mode. According to the invention, the pressed-down distribution mode and the rolling force distribution mode are combined; the rolling force distribution result is restricted by the distribution range determined by pressed-down distribution; the requirement that the rolling force of stands is decreased according to proportion is met while the thickness distribution fluctuation of the stands is reduced; the results of two distribution modes are gradually consistent, and the iterations are gradually reduced by learning a pressed-down rate learning table when the deviation of the rolling force model is small; and the fluctuation range of the pressed-down rate of the stands is effectively controlled through the pressed-down distribution amplitude limit when the deviation of the rolling force model is large. By adopting the method, the advantages of the two modes are combined and the shortages are overcome, so that the rolling schedule setting precision and the rolling stability of the finish rolling band steel are effectively improved.

Owner:BAOSHAN IRON & STEEL CO LTD

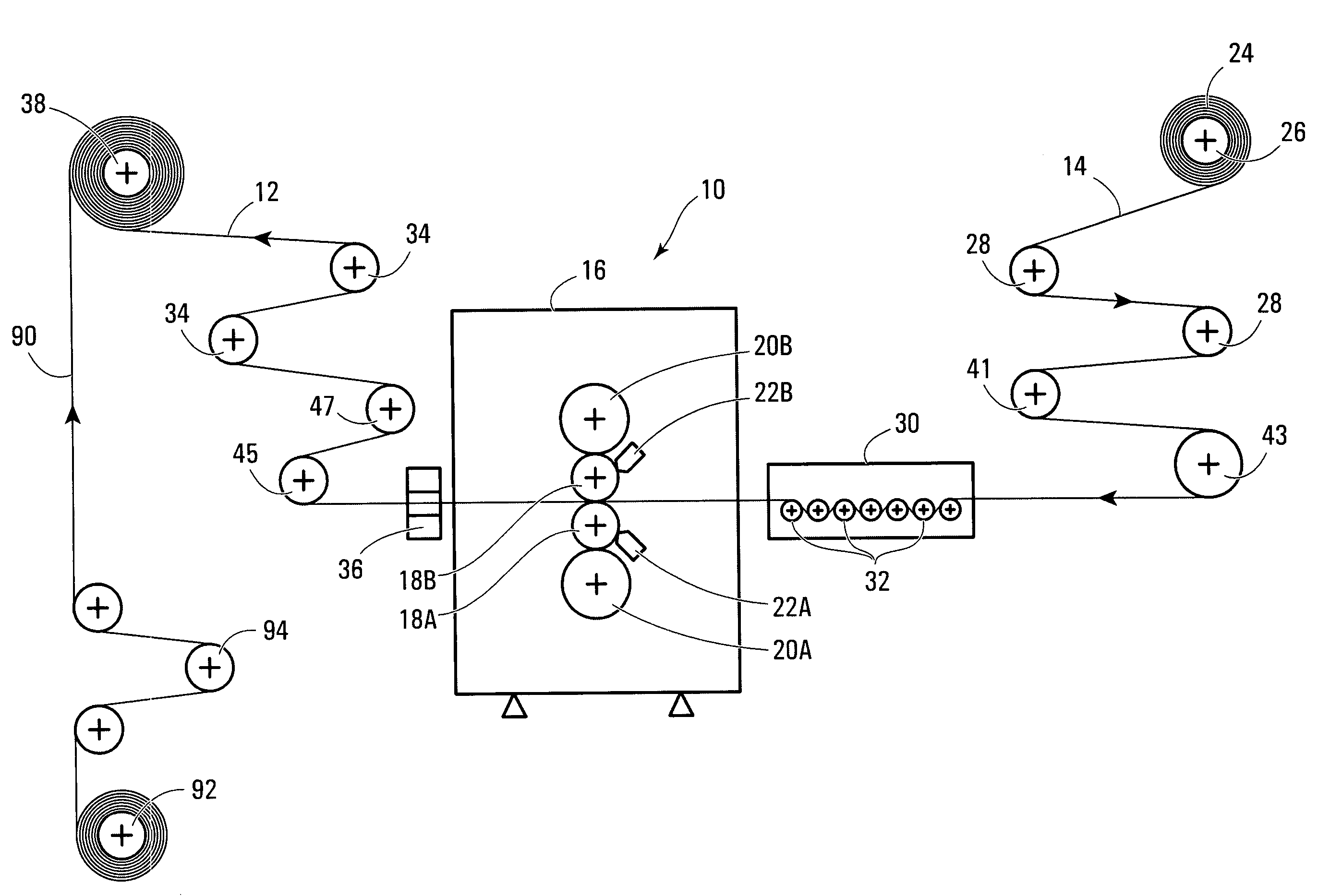

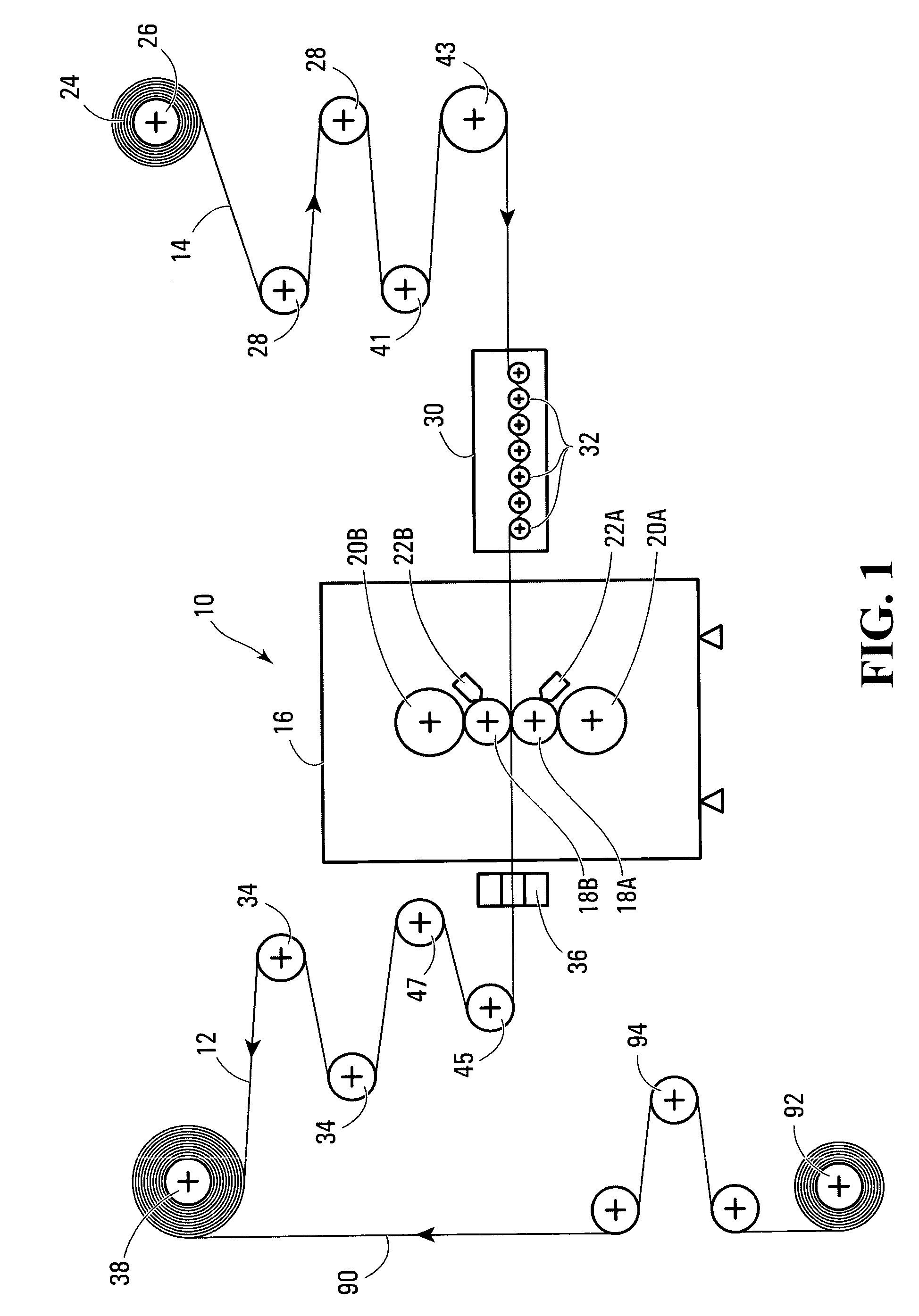

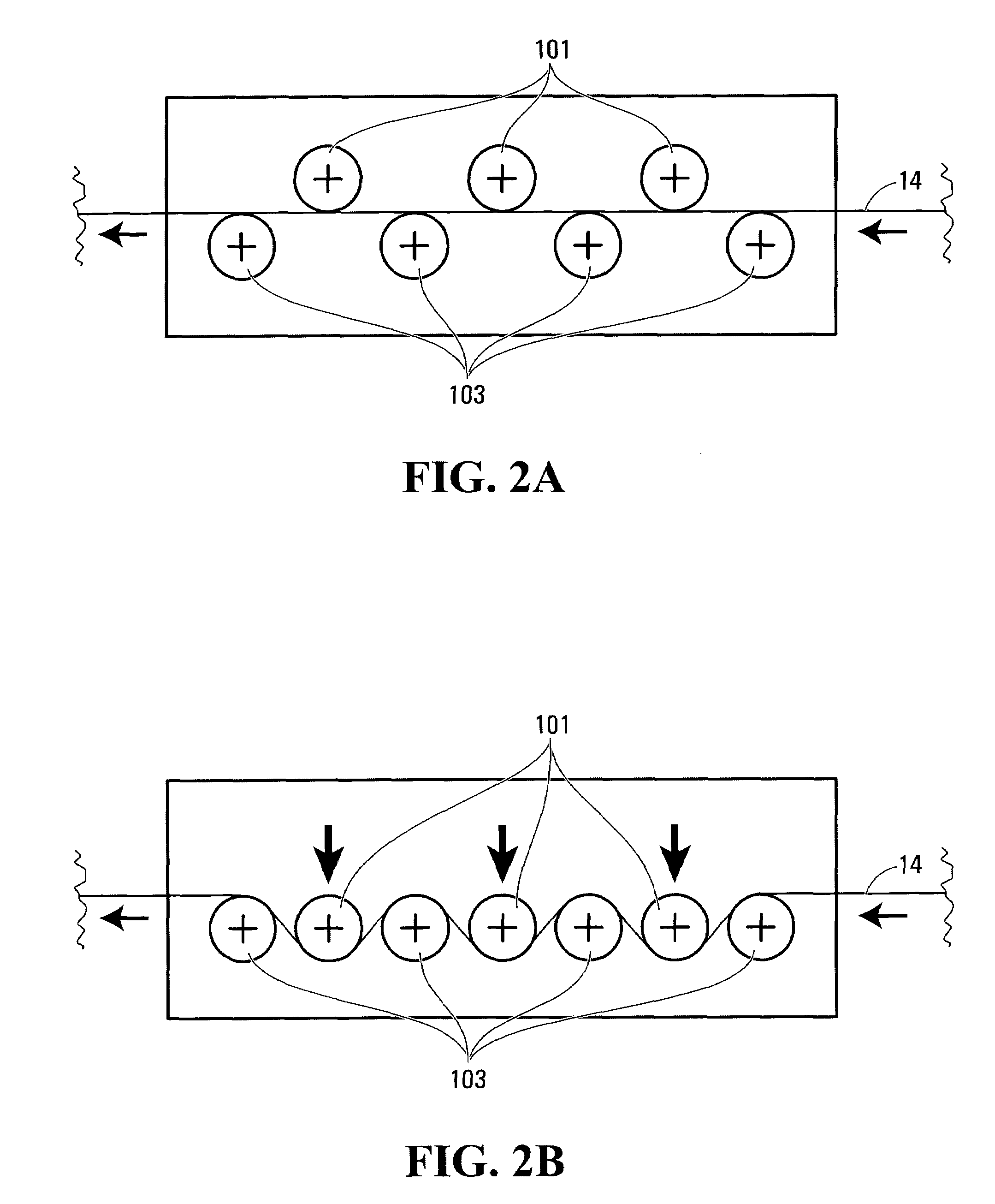

Lamination process and apparatus for alkali metals or alloys thereof

ActiveUS7513136B2Reduce thicknessElectrode rolling/calenderingRoll force/gap control deviceLithiumElectrical battery

An apparatus for and method of manufacturing lithium or lithium alloy anodes for electrochemical cells by a lamination process wherein a lithium or lithium alloy sheet is reduced into a thin lithium or lithium alloy film. The method and apparatus provide adjustments of the profile defined by the meeting surfaces of a pair of working rollers to compensate for thermal dilation of the working rollers or to compensate for irregular thickness of the lithium or lithium alloy sheet to control the shape and profile of the lithium or lithium alloy film being laminated.

Owner:BATHIUM CANADA

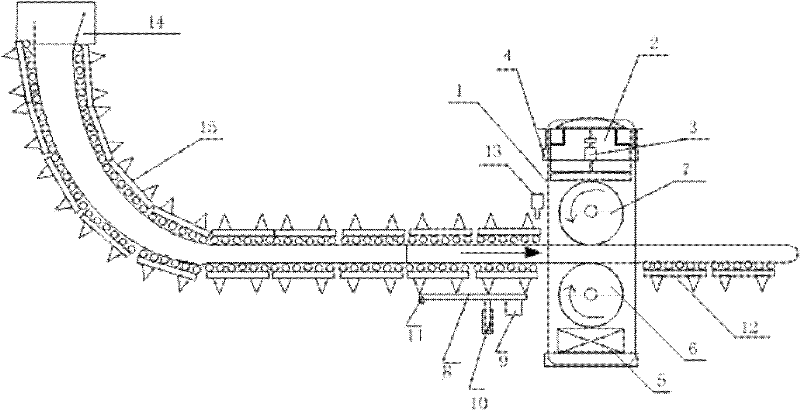

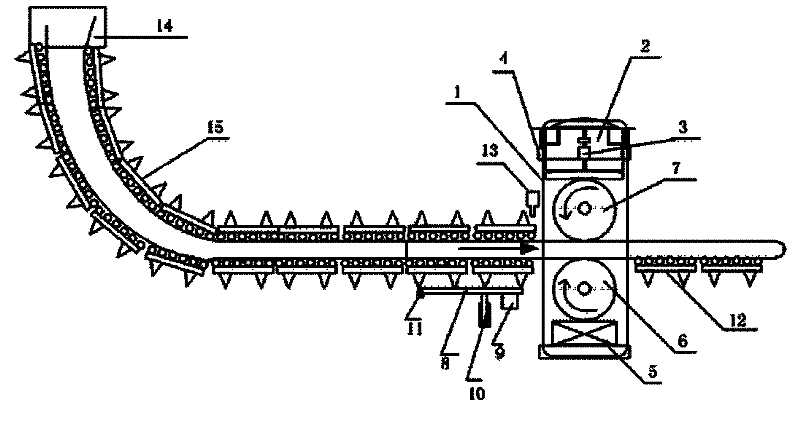

Method for rolling liquid core under heavy reduction rate by virtue of online thickness regulating roll by utilizing continuous casting machine

ActiveCN102189102AQuality improvementExempt from reheatingRoll force/gap control deviceMetal rolling arrangementsReduction rateLiquid core

The invention relates to a method for rolling a liquid core under heavy reduction rate by virtue of an online thickness regulating roll by utilizing a continuous casting machine. The method comprises the following steps of: when two rolling mills are loaded, setting a target thickness, feeding back the thickness value in real time and detecting oil pressure, carrying out conversion on a rolling force to judge whether the rolling force is higher than a limit value, if the rolling force is lower than the limit value, stabilizing rolling until the rolling is finished; if the rolling force is higher than the limit value, regulating and judging the rolling force again; if the target thickness is changed in the rolling process, calculating thickness variation by virtue of a rolling process computer, regulating roll gap of the two rolling mills to be the target thickness, and judging whether the rolling force is higher than the limit value again. In the method provided by the invention, a rolling signal can be changed to change the target thickness in the rolling process, and a wedge-shaped blank is rolled. By applying the method provided by the invention, the quality of a continuous casting can be better improved, the continuous casting and the wedge-shaped blank can be rolled, and the time of a process is reduced while the yield is improved; meanwhile, structure of equipment is simple, investment is less, control is simple, reliability is high, and energy can be greatly saved, thus the method has a good popularization and application prospect.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

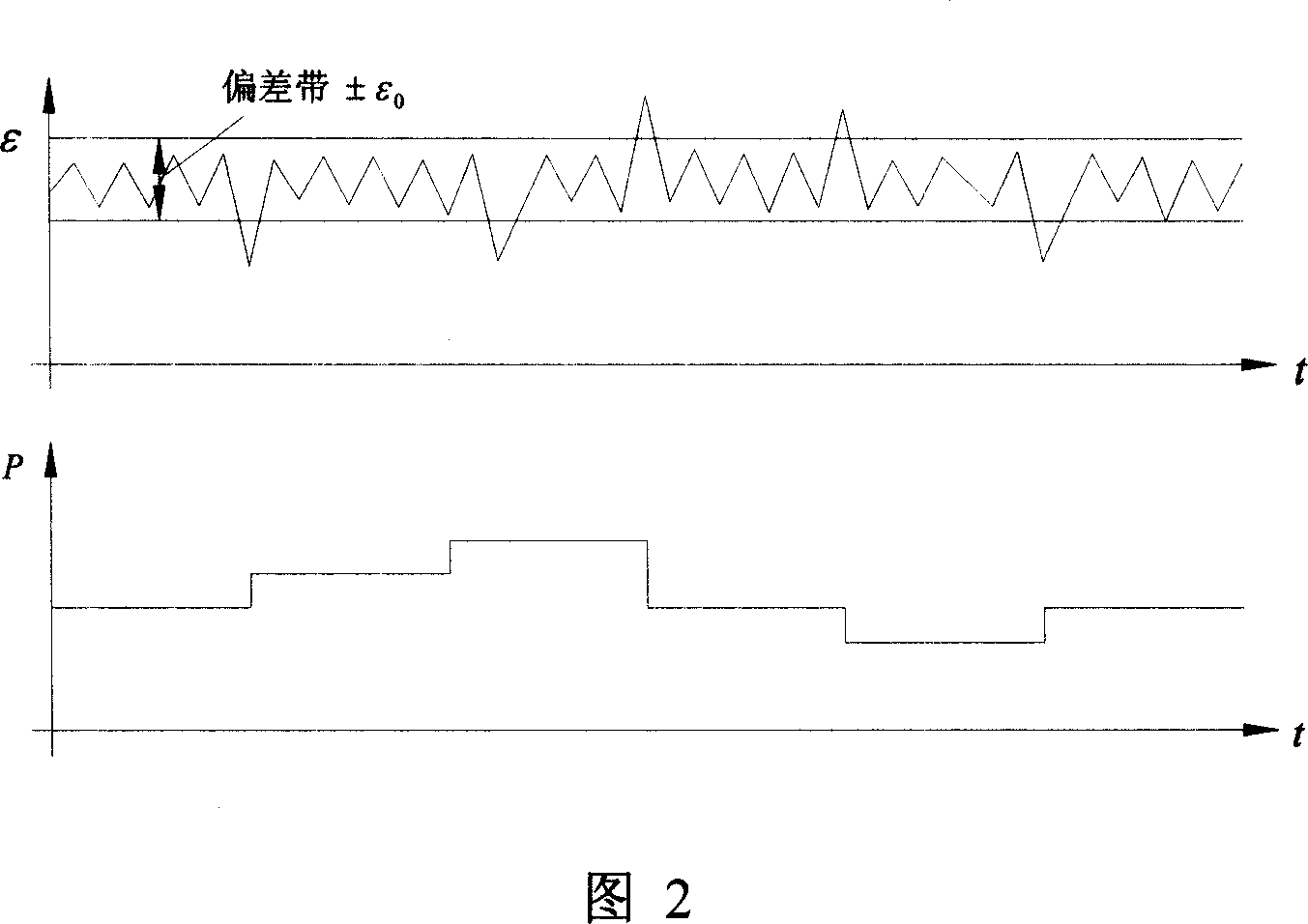

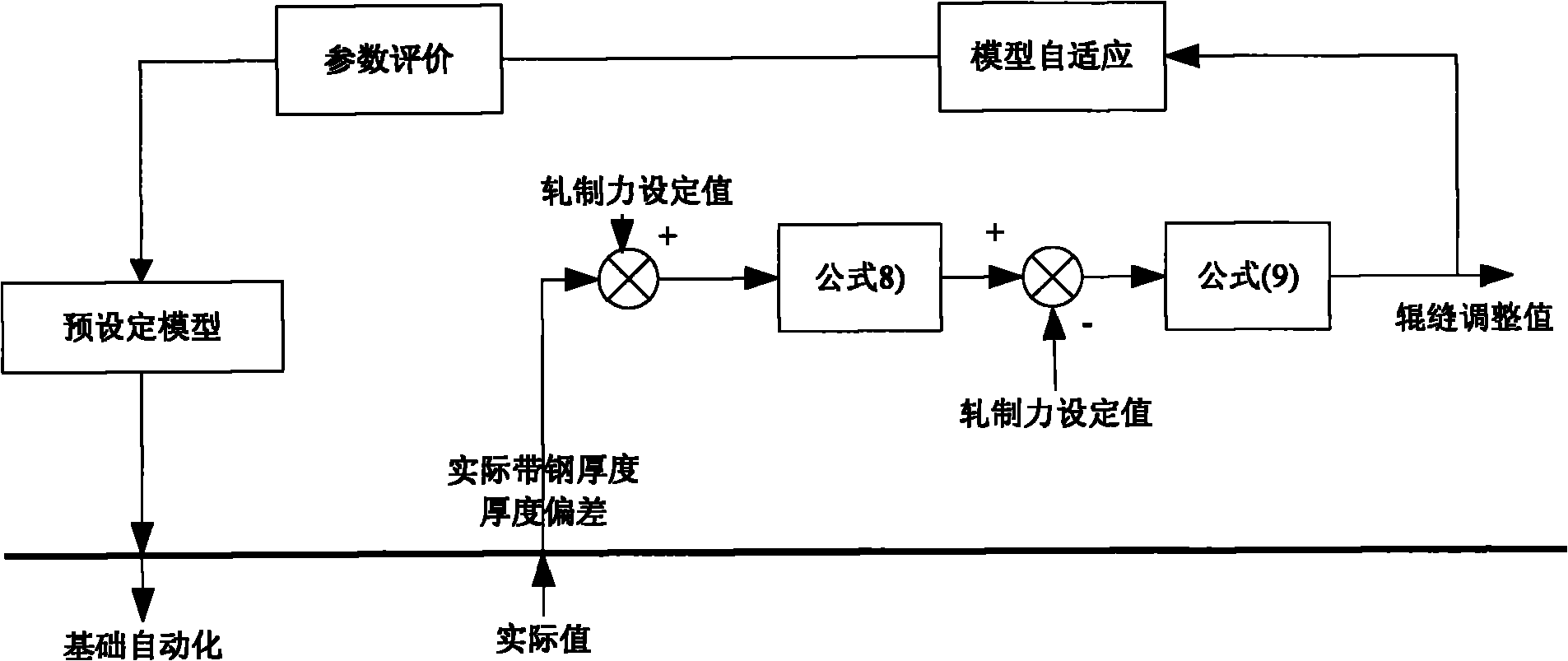

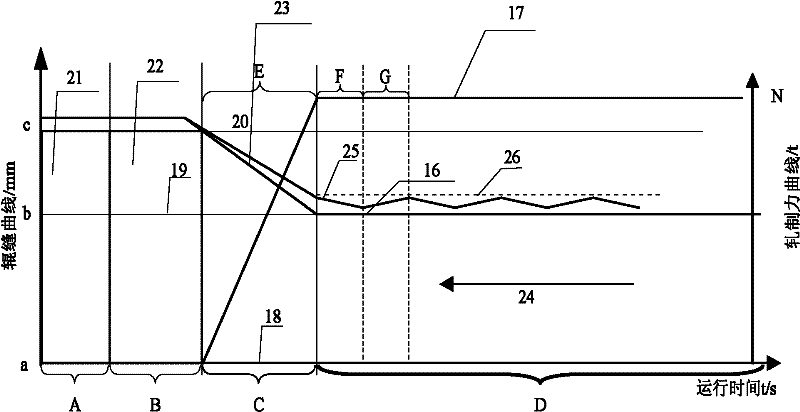

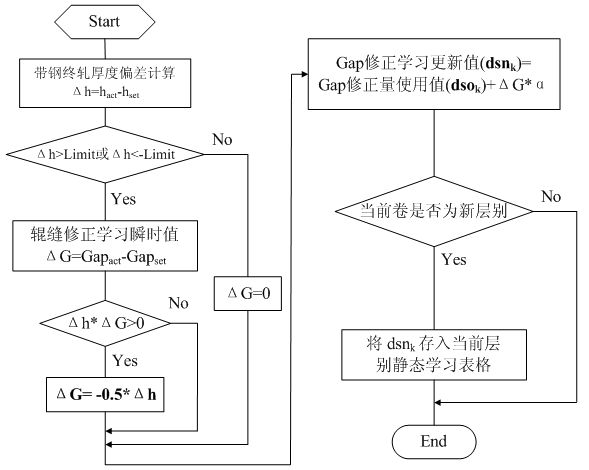

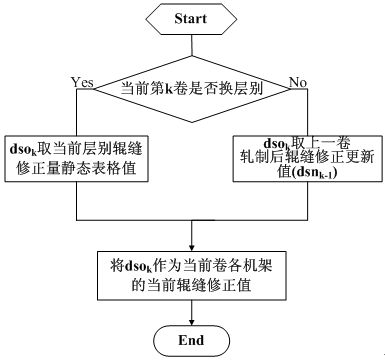

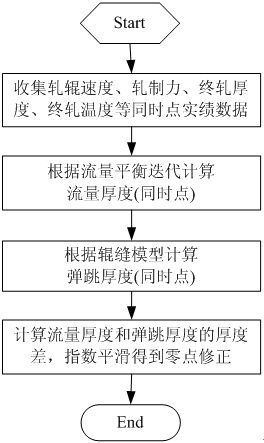

Adaptive control method for increasing thickness precision of finish-rolled band steel by utilizing roll gap

ActiveCN102371279AEasy to controlEliminate dynamic errorsRoll force/gap control deviceModel learningEngineering

The invention relates to the field of production and control of a finish-rolled band steel, in particular to a method for controlling a thickness of a finish-rolled band steel. An adaptive control method for increasing the thickness precision of a finish-rolled steel band by utilizing a roll gap is characterized in that the method comprises the following steps of establishing a roll gap modification quantity static table which performs indexing according to the layers of band steels; before rolling the band steels, identifying the layer of the current rolling band steel, determining the roll gap modification current value, summing the roll gap modification current value with the zero point modification current values of racks, obtaining a roll gap model learning coefficients of the racks used for rolling setting pre-calculation; after rolling the band steels, detecting the obtained band steel final rolling thickness value and the actual roll gap value of the rack at the finish-rollingend, calculating the values, obtaining the band steel final rolling thickness deviation, the initial roll gap deviation value and the roll gap modification update value, for example, when the layer of the same coil of band steel is different with that of the former coil of band steel, the roll gap modification update value is saved in the roll gap modification quantity static table; and collecting the roller speed, roll gap, rolling force and final rolling thickness actually measured data of each rack, and then performing zero point modification of the roll gap. According to the method provided by the invention, the roll gap modification value and zero point modification are used jointly, so that the adaptive capability of the roll gap model under the condition that the rolling planning specification is variable can be improved, thereby improving the setting precision of the model and realizing accurate control to the thickness of the band steel.

Owner:BAOSHAN IRON & STEEL CO LTD

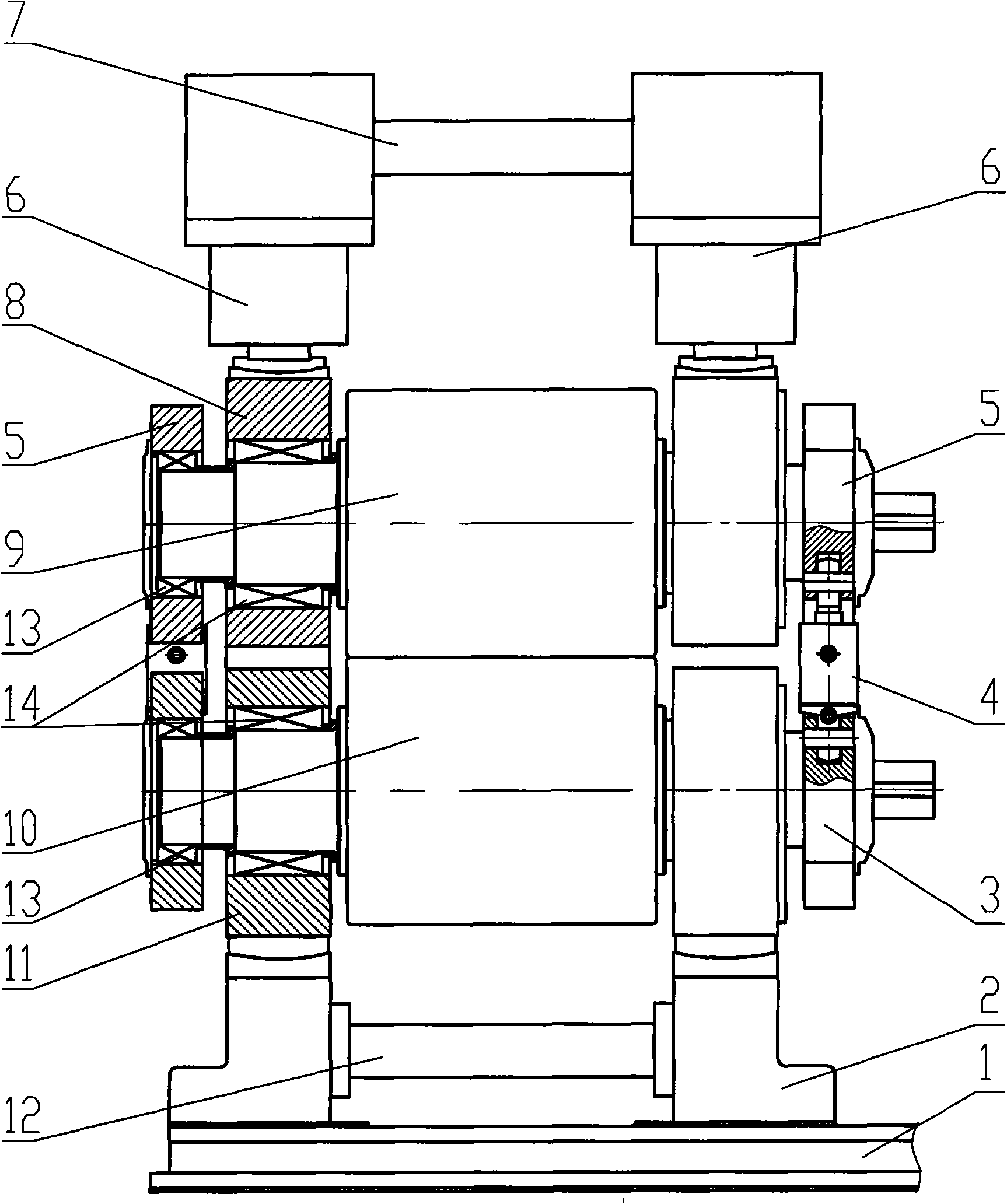

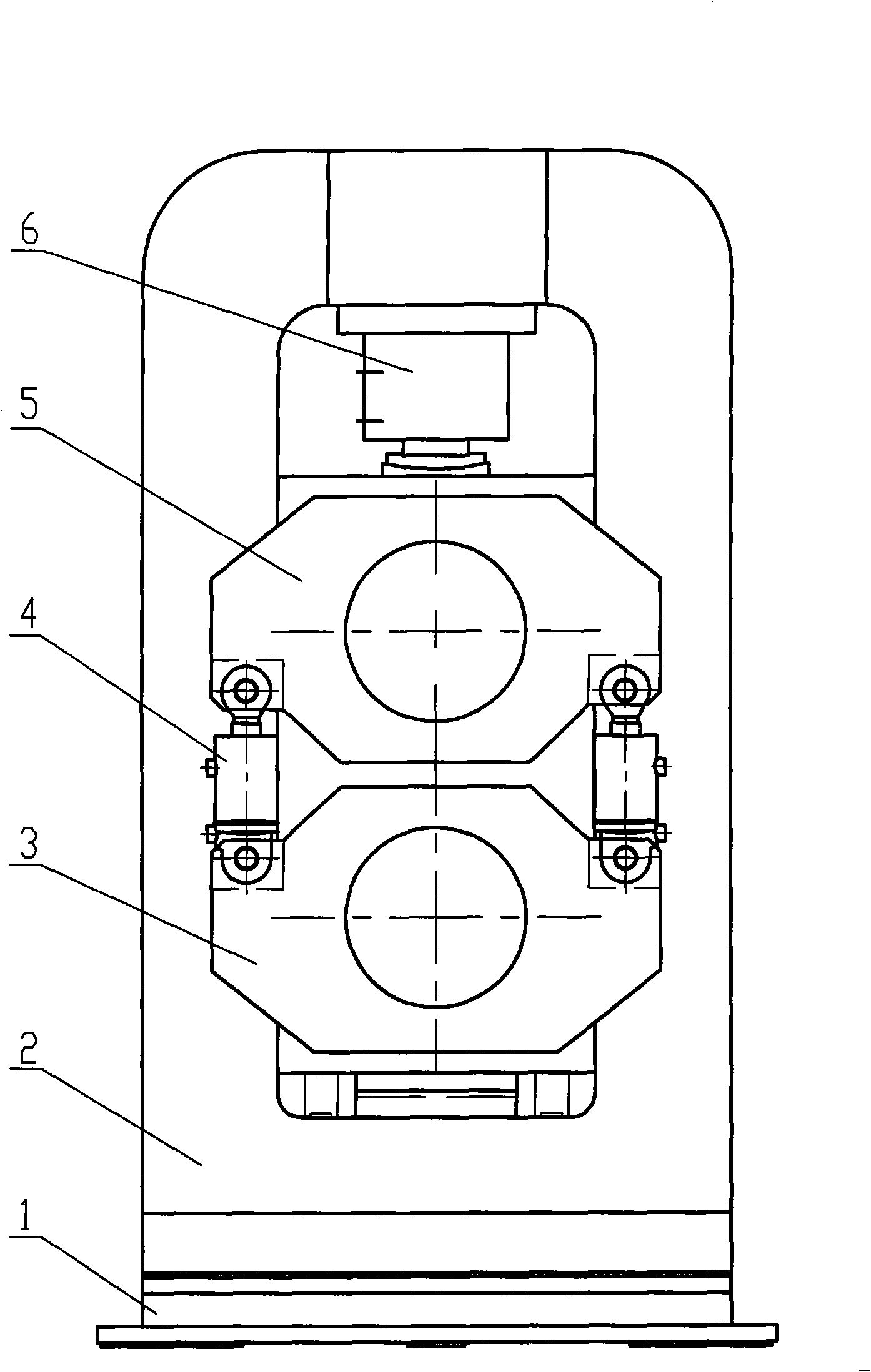

Hydraulic servo battery pole piece rolling mill

ActiveCN101254509ASimple structureHigh sensitivityRoll force/gap control deviceMetal rolling stand detailsHydraulic cylinderControl manner

The invention discloses a hydraulic servo rolling mill for producing battery pole sheets, which comprises a pedestal, a frame arranged on the pedestal, a lower mill roller and an upper mill roller both arranged inside the frame, a computer-controlled press-down servo hydraulic cylinder connected on a bearing seat for holding the rollers, and computer-controlled roller-bending hydraulic cylinders respectively arranged outside the lower bearing seat of the lower mill roller and the upper bearing seat of the upper mill roller to adjust the bearing clearance between the lower and the upper mill rollers. The invention has three control modes of constant-pressure, constant-clearance and constant-thickness rolling of battery pole sheets, achieves on-line real-time control of position and pressure of the roller and the thickness of the battery pole sheet, ensures the arbitrary switch among the three control modes, thereby meeting higher requirement for the accuracy of battery pole sheets.

Owner:邢台纳科诺尔精轧科技股份有限公司

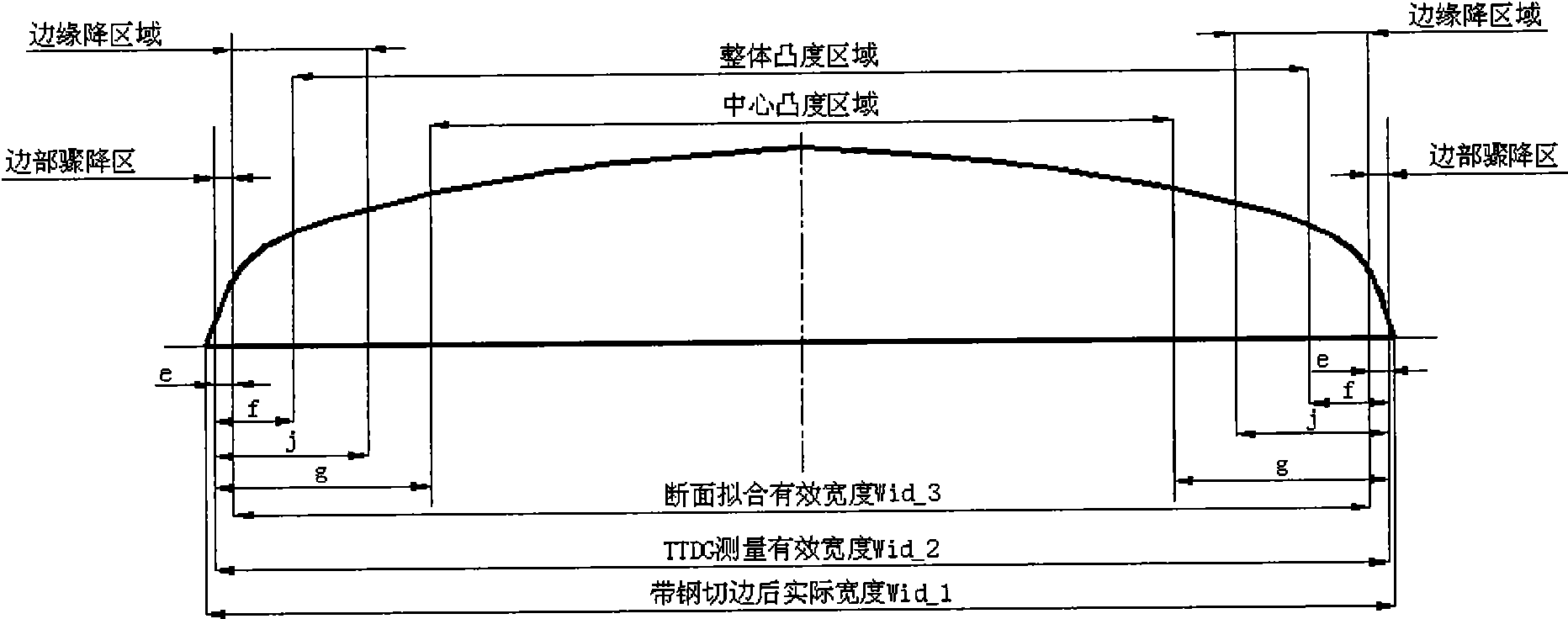

Control method of lateral thick difference of cold-rolling strip steels

ActiveCN102029294AReal-time acquisition of lateral thickness fluctuationsTimely responseRoll force/gap control deviceMeasuring devicesStrip steelEngineering

The invention discloses a control method of the lateral thick difference of cold-rolling strip steels, which realizes the feedforward control of the lateral thick difference of the cold-rolling strip steels by detecting the shapes of the profiles of hot-rolling supplied materials in real time on the basis of a profiler configured on an inlet of a No.1 rack. The control method mainly comprises thefollowing steps of: (1) configuring a strip steel profile shape detector on the inlet of the No.1 rack of a cold-rolling mill, and detecting the shapes of the profiles of the hot-rolling supplied materials in real time; (2) calculating to obtain the characteristic value vectors of the profiles of the cold-rolling strip steels positioned on the inlet of the No.1 rack through the measured values ofthe shapes of the profiles of the hot-rolling supplied materials; (3) respectively determining the compensation amount of a working bending roll, an intermediate bending roll, a supporting tilting roll, an upper shifting roll, a lower shifting roll and an intermediate shifting roll of the No.1 rack according to the difference of the actual values of the characteristic vectors of the profiles of the cold-rolling strip steels positioned on the inlet of the No.1 rack and the target values of the characteristic vectors; and (4) when the lateral thick difference is output in a controlling way, adopting the actual distribution of the flatness of a roll gap outlet as a constraint condition. The invention can further enhance the quality of the cold-rolling strip steels of cold-rolling mill products and ensure the stability of a cold-rolling production process.

Owner:BAOSHAN IRON & STEEL CO LTD

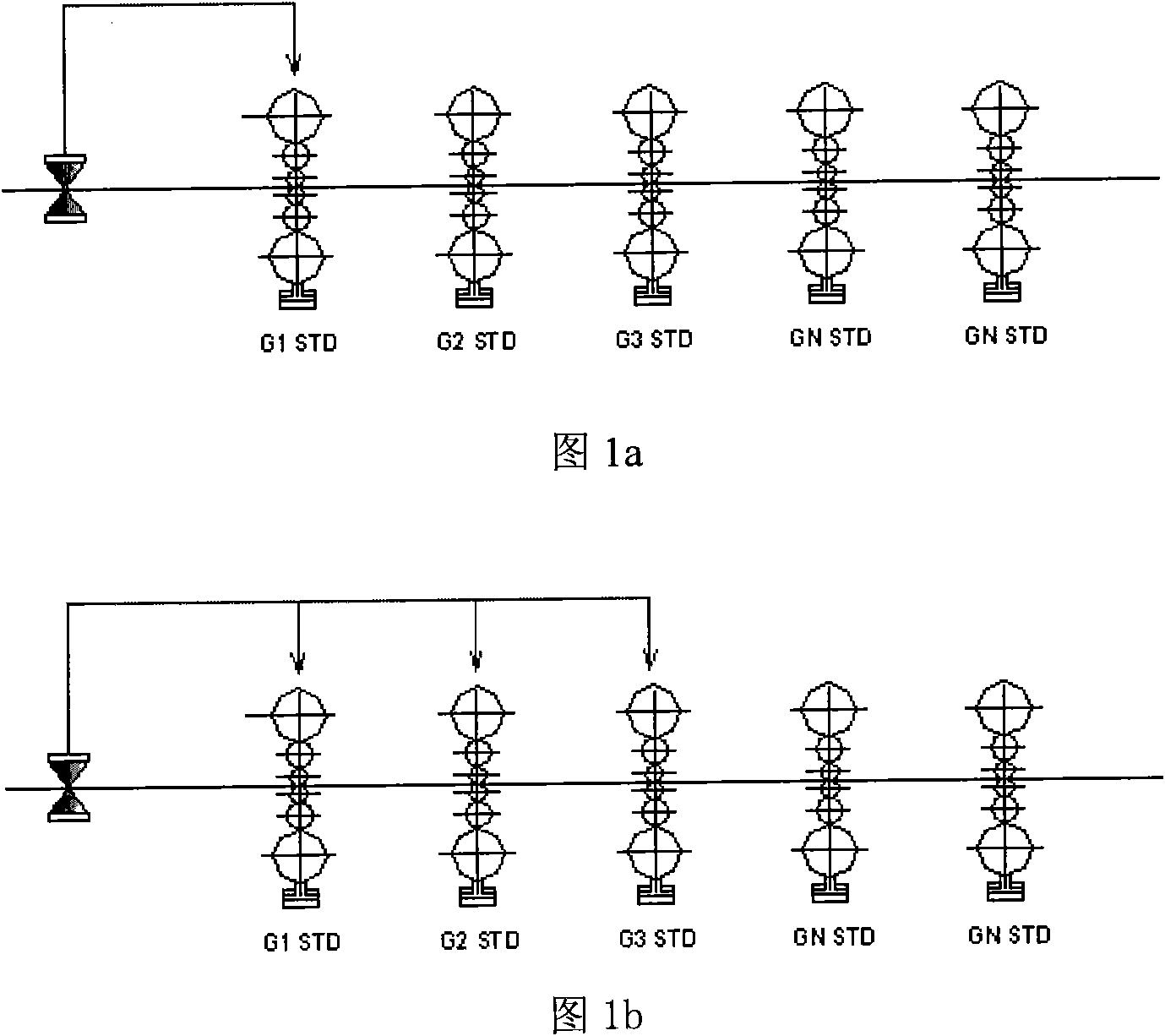

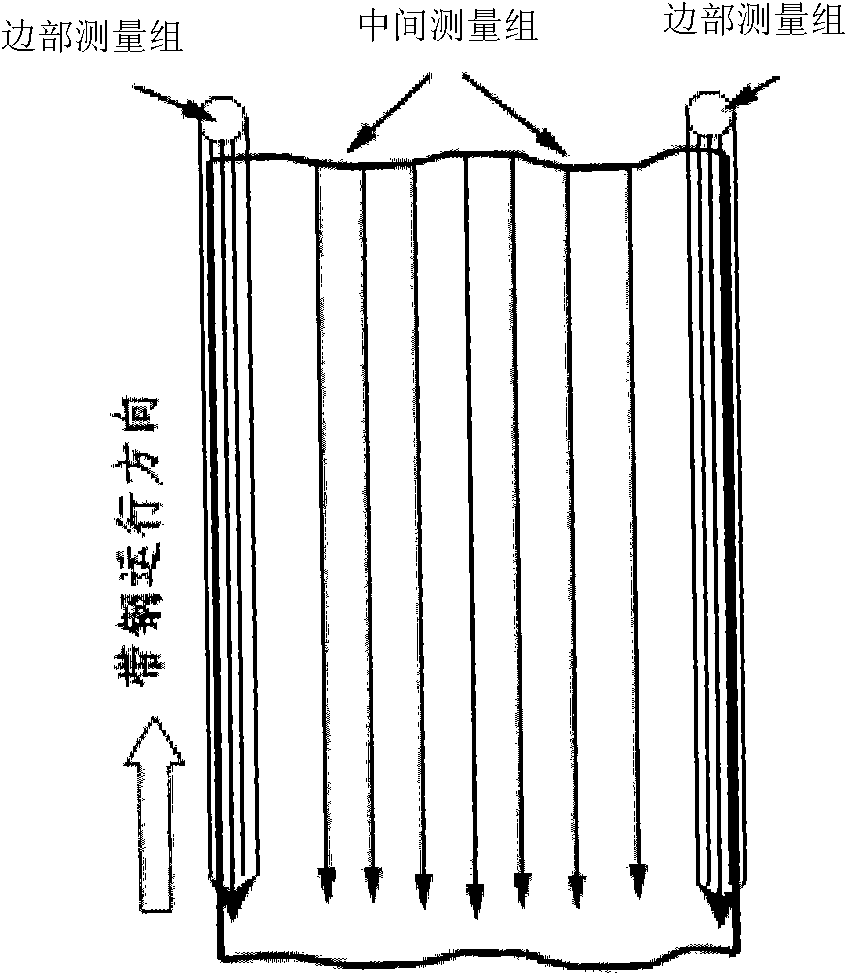

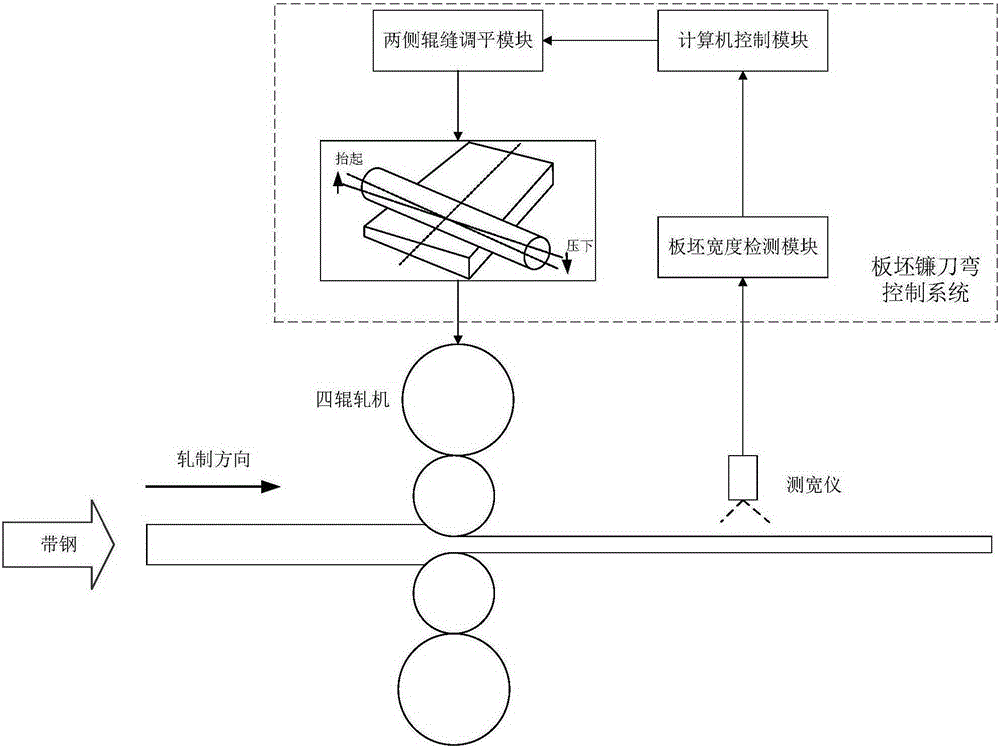

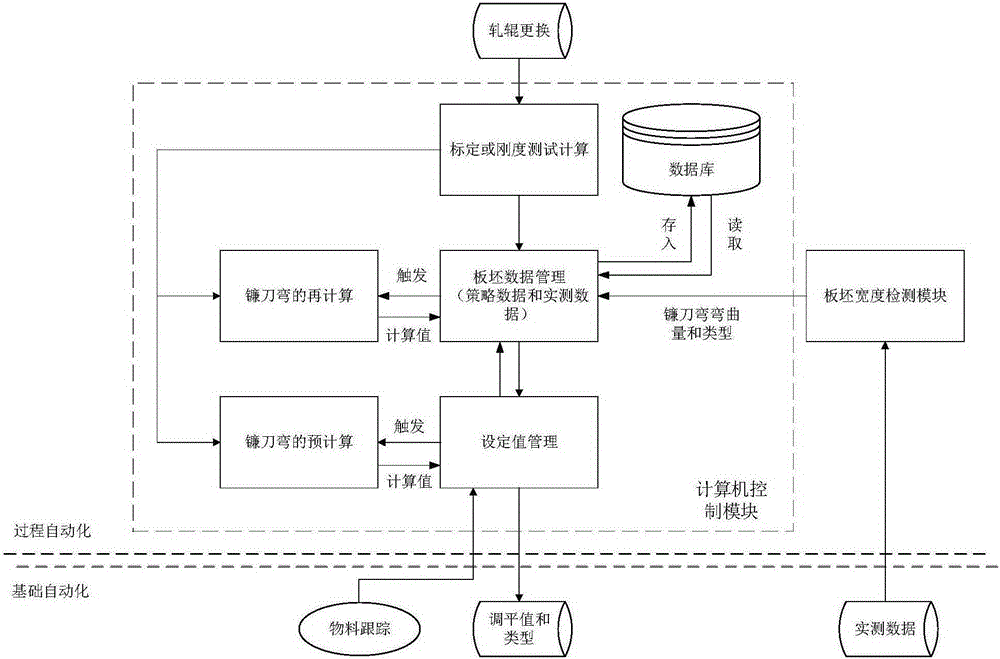

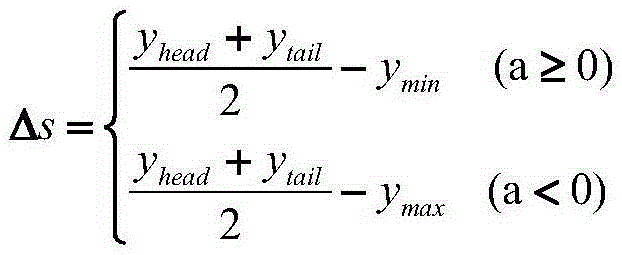

Slab sickle bending control system and method used for roughing mill

InactiveCN105234189AIncreased level of controlInhibition defectRoll force/gap control deviceAutomatic controlStrip mill

The invention discloses a slab sickle bending control system and a slag sickle bending control method used for a roughing mill, and belongs to the field of mechanical automatic control. The control system comprises a slab width detecting module, two side roller beam leveling modules, a computer control module and a storage unit. The slag width detecting module is used for processing centre line offset data detected by a width detector and sending the processed centre line offset data to the computer control module; the computer control module is used for calculating a leveling value of each gate by collecting a set value of slag and practically measured value data, and sending the leveling value to the two side roller beam leveling modules; and the two side roller beam leveling modules are used for regulating two side roller beams of the roughing mill according to the leveling value, and controlling the slab sickle bending. The control system is applicable on the roughing mill, capable of calculating the leveling value of each gate more accurately, and capable of effectively controlling slag sickle bending and guaranteeing stability of finishing rolling unit production, thereby relieving steel scrap caused by off-tracking, shifting and the like, increasing yield and bringing direct economic benefits for enterprises.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

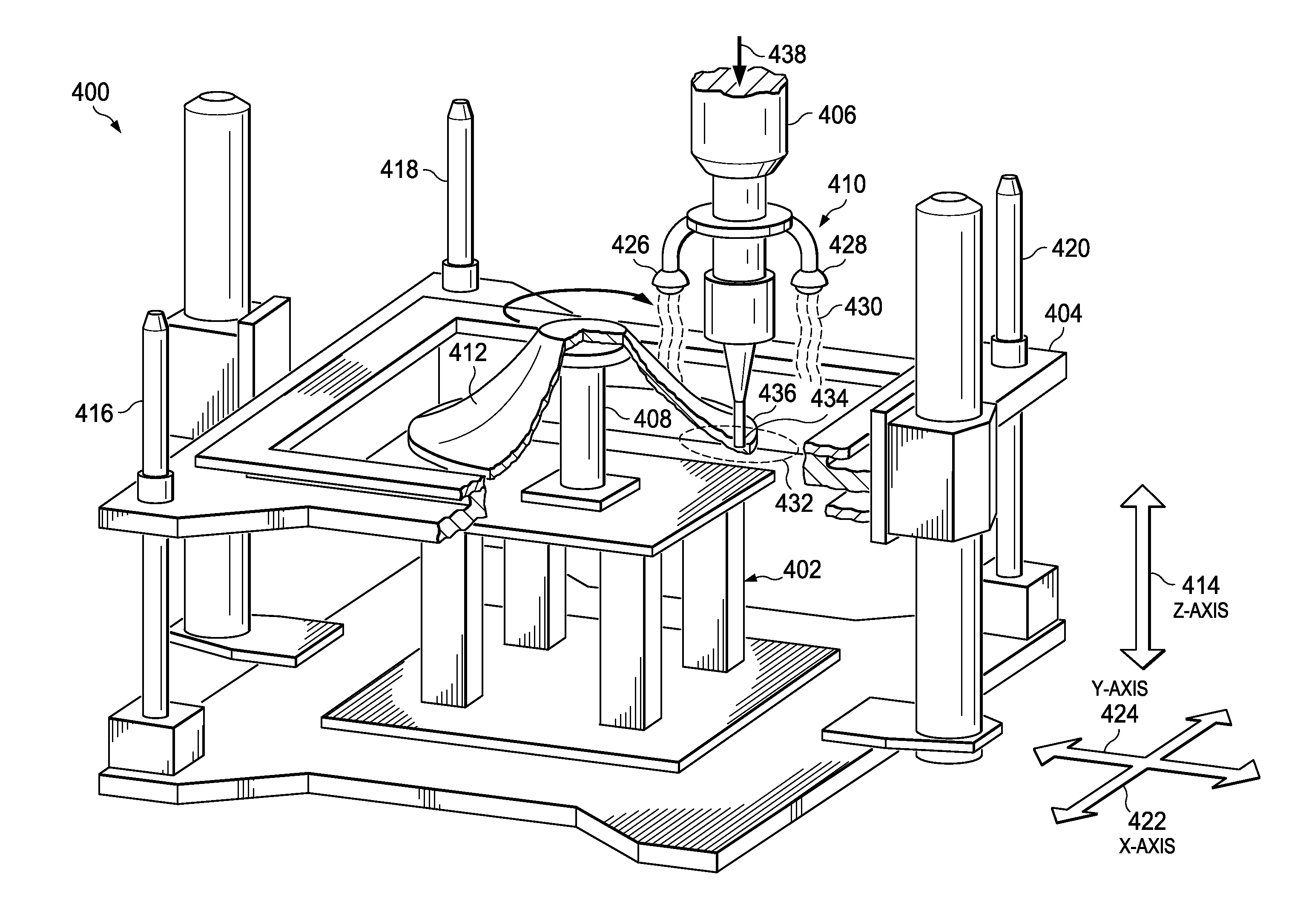

Method and Apparatus for Reducing Force Needed to Form a Shape from a Sheet Metal

ActiveUS20100257909A1Reduction in yield strengthHigh elongationShaping toolsRoll force/gap control deviceHeating systemSheet material

An apparatus comprises a platform, a stylus, and a heating system. The platform is capable of holding a sheet of material. The stylus is capable of impinging the sheet of the material to incrementally form a shape for a part. The heating system is capable of heating at least a portion of the sheet of material in a location on the sheet of material prior to the stylus impinging the location.

Owner:THE BOEING CO

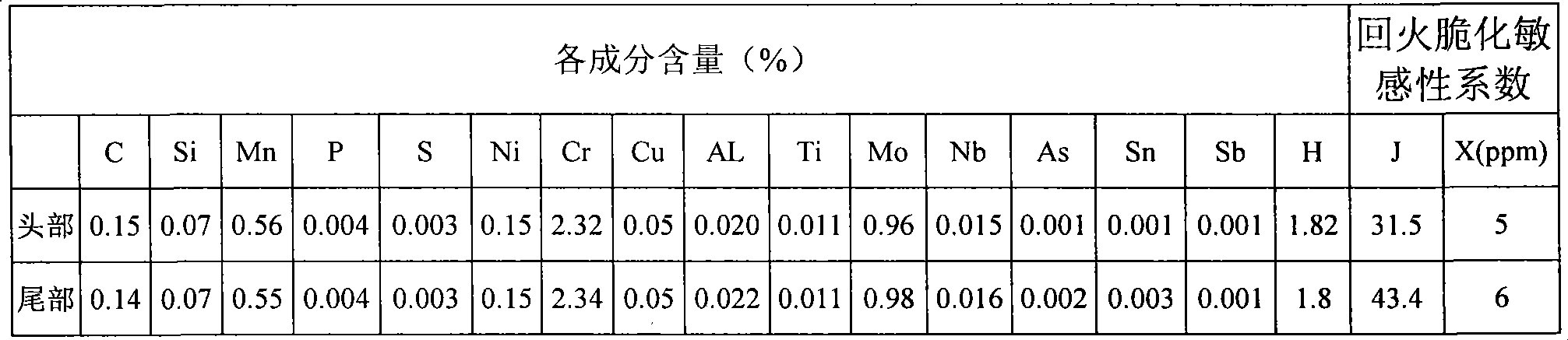

Steel plate for large-thickness hydrogen-contacting equipment and its production technology

InactiveCN101368251AExcellent resistance to hydrogen corrosionHigh strengthRoll force/gap control deviceTemperature control deviceSheet steelHydrogen

The invention relates to a steel plate used for a large-thickness hydro-device which belongs to the technical field of steel-making. Counted by weight percentage, the steel plate consists of the following elements: 0.13 to 0.15 percent of C, equal to less than 0.10 percent of Si, 0.50 to 0.60 percent of Mn, equal to or less than 0.008 percent of P, equal to or less than 0.007 percent of S, 0.14 to 0.18 percent of Ni, 2.30 to 2.50 percent of Cr, equal to or less than 0.15 percent of Cu, 0.95 to 1.10 percent of Mo, 0.015 to 0.020 percent of Nb, 0.010 to 0.020 percent f Ti, 0.020 to 0.045 percent of Al, equal to or less than 0.016 percent of As, equal to or less than 0.015 percent of Sn, equal to or less than 0.003 percent of Sb and the rest is Fe as well as unavoidable impurities. The delivery state of the steel plate is normalizing plus annealing; the quality of the steel is pure; the capacity for resisting the corrosion of hydrogen is excellent; besides, the steel plate has excellent weldability and comprehensive mechanical properties.

Owner:WUYANG IRON & STEEL

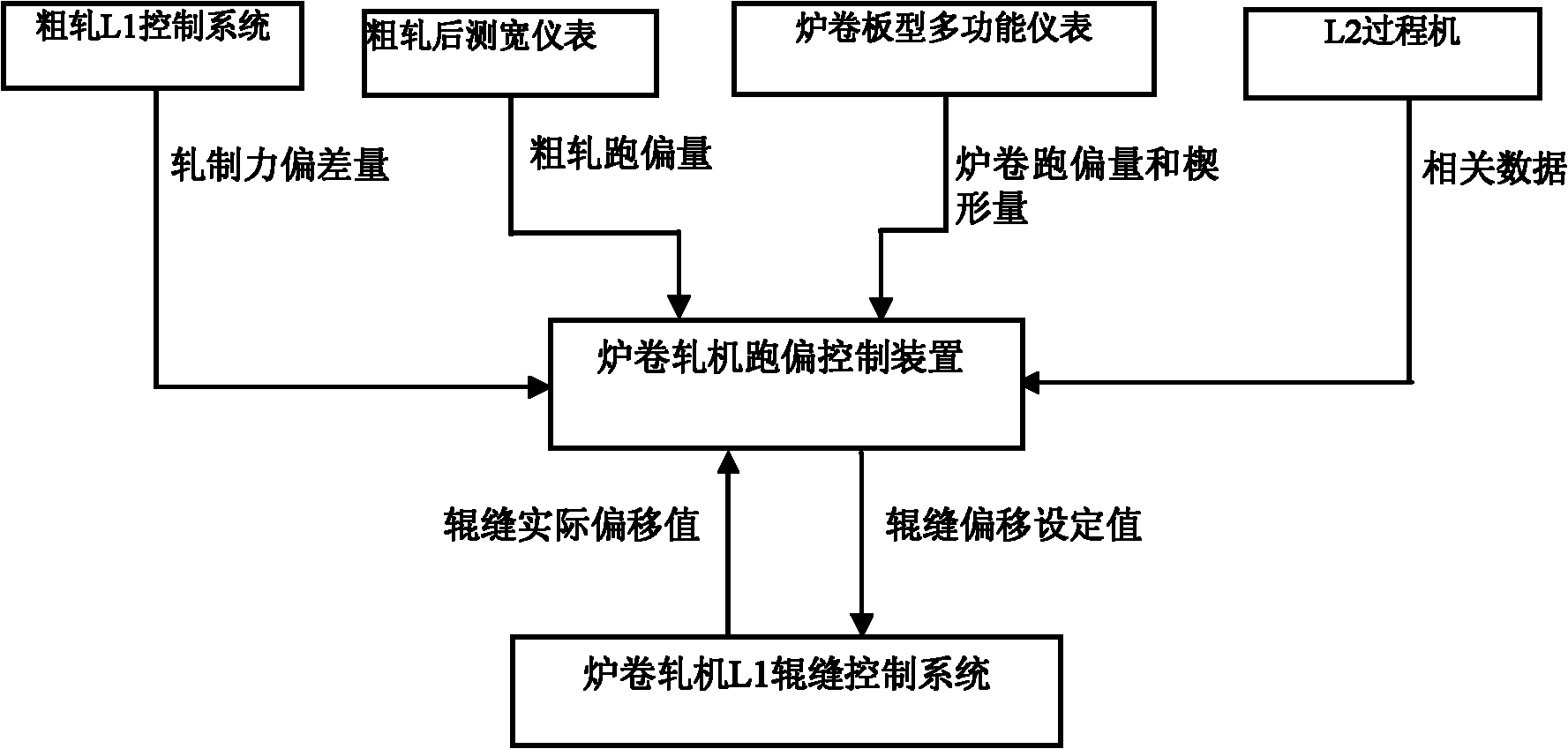

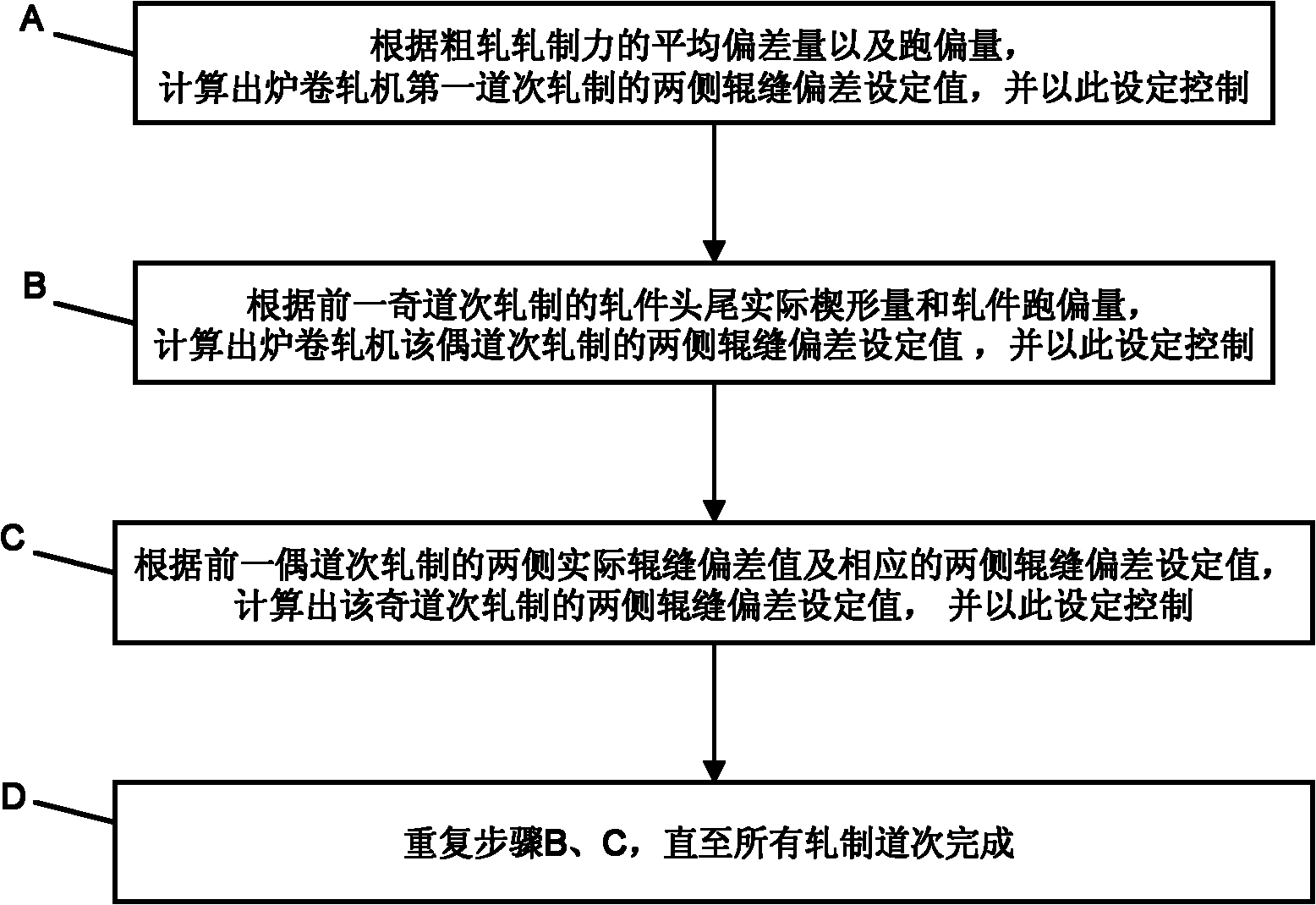

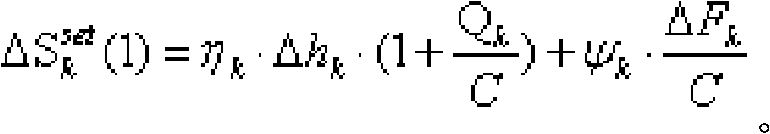

Steckel mill rolled piece head-and-tail deviation control method

InactiveCN102641903AImprove rolling stabilityPrevent set controlRare end control deviceRoll force/gap control deviceStrip millStrip steel

The invention discloses a steckel mill rolled piece head-and-tail deviation control method which comprises the following steps that: based on existing equipment configuration, different modes are distinguished by integrating the rolling information of a steckel mill according to the rolled piece deviation and rough rolling force in the final step of rough rolling, then the deviation controlled by roll gaps on both sides of the steckel mill is determined, and roll gap setting control for preventing deviation is carried out. Through the method, the hand-and-tail deviation of strip steel can be reduced, shut-down accidents caused by the deviation of strip steel can be prevented, and the rolling stability of the steckel mill can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

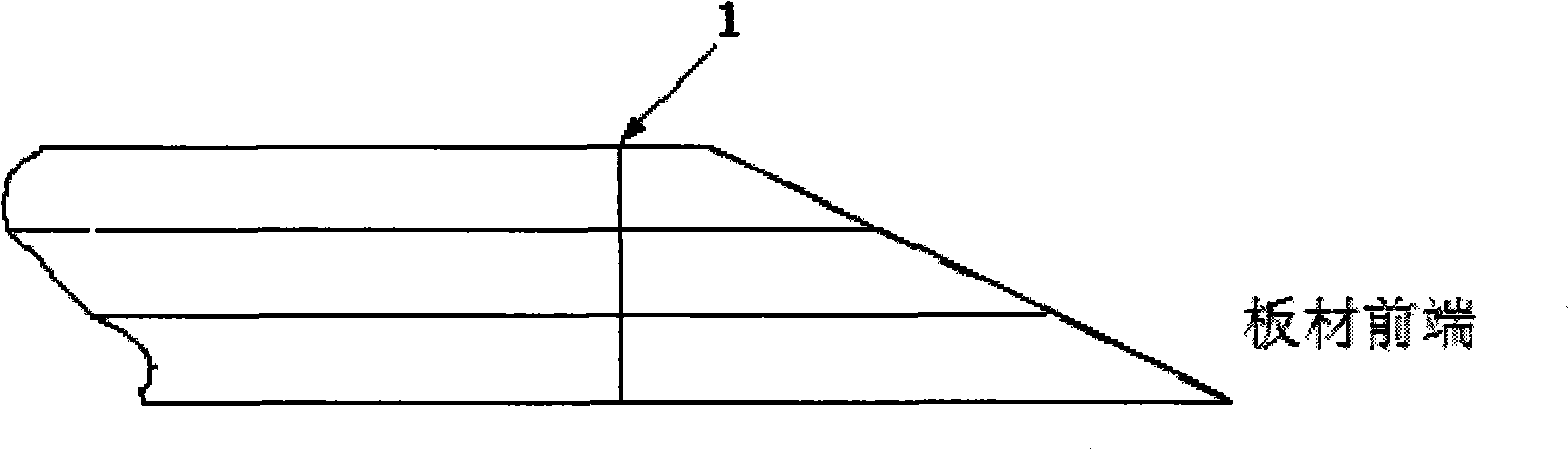

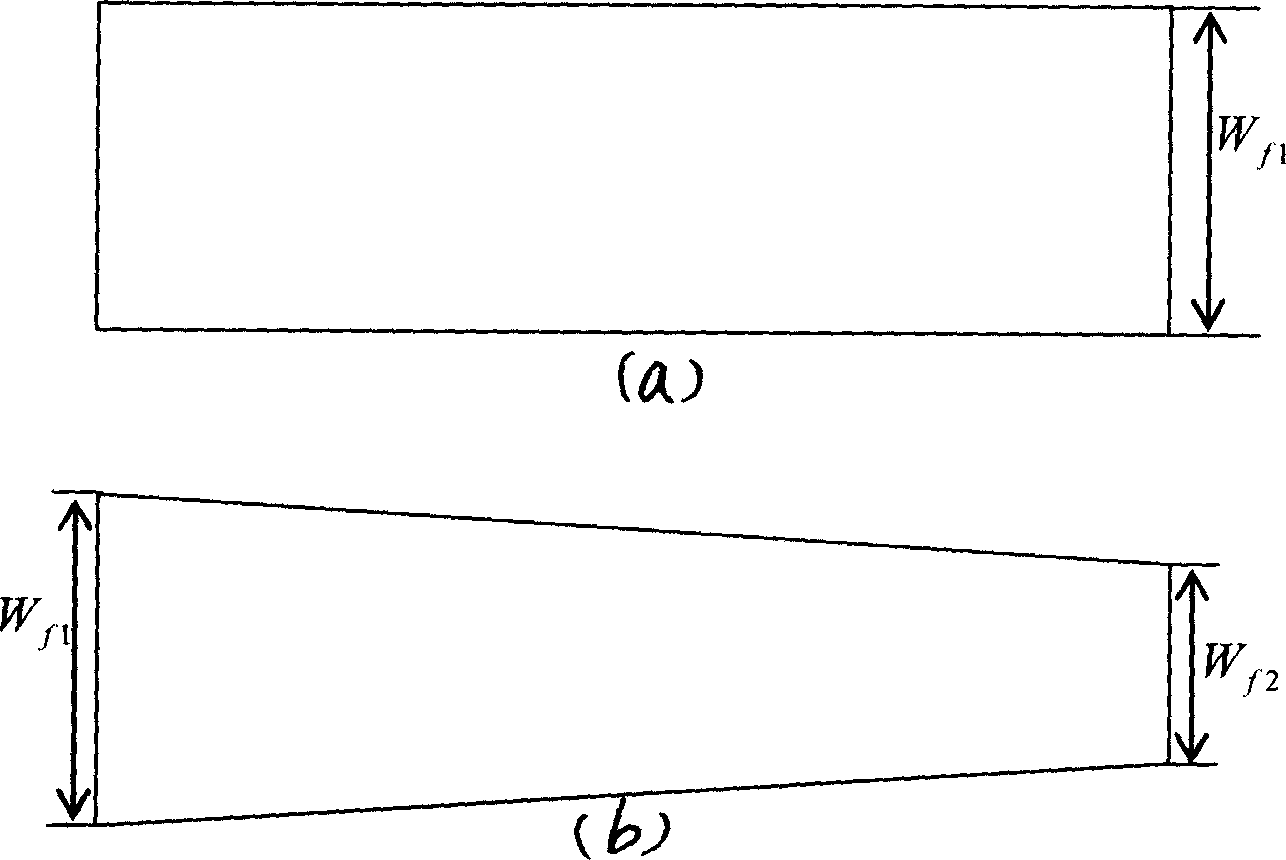

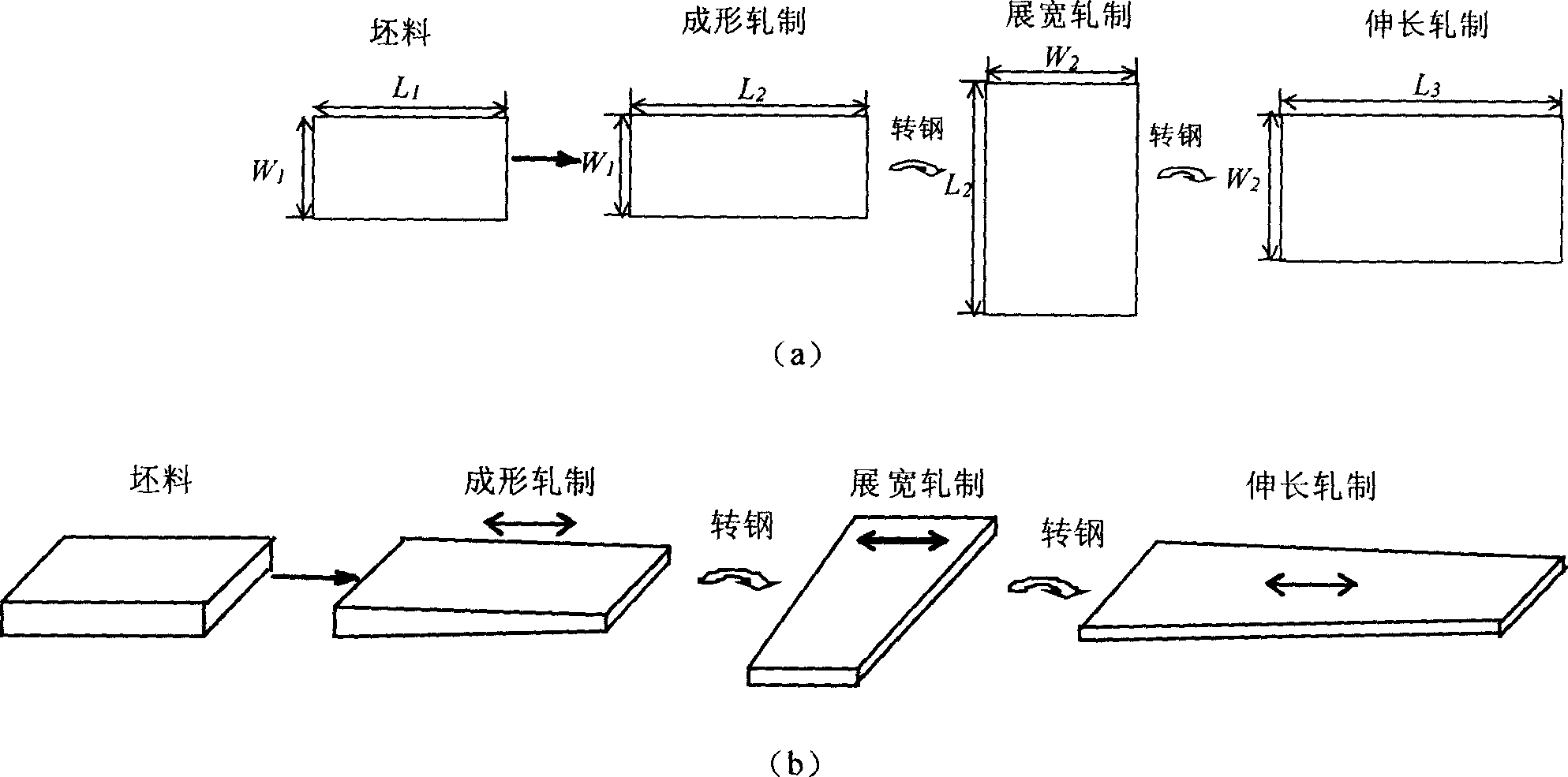

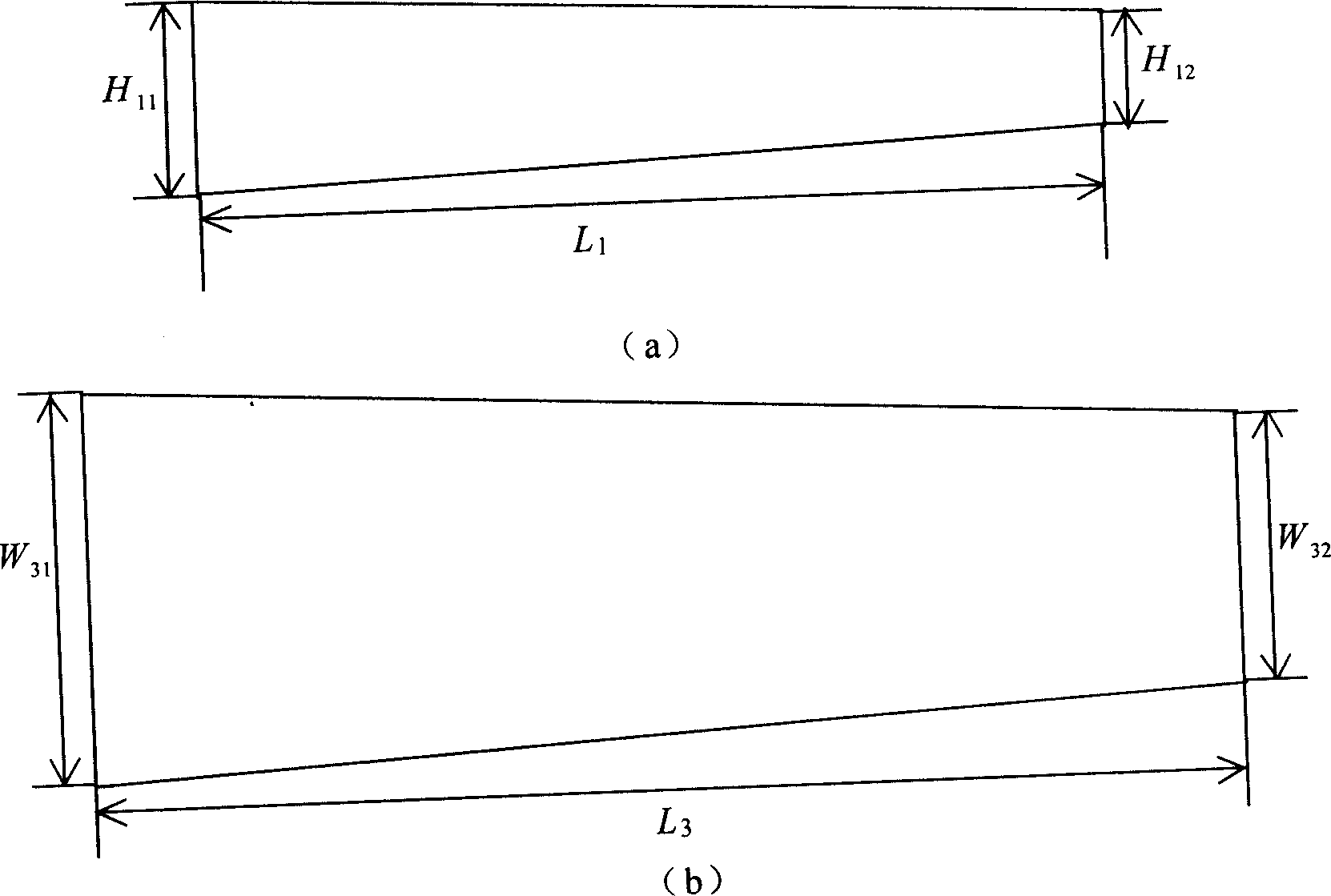

Method for rolling trapezoidal width steel plate

InactiveCN1850376AGood workmanshipRoll force/gap control deviceMetal rolling stand detailsVariable thicknessSheet steel

The present invention relates to a rolling method of stepped width steel plate. It utilizes longitudinal-transverse-longitudinal rolling tactics of heavy and medium plate to produe variable width steel plate. Said method includes the following steps: firstly, rolling the steel plate into variable thickness steel plate in last pass of forming stage, before rolling defining size of variable thickness steel plate, according to conventional rolling method making forming rolling, rolling steel plate to make its thickness size be above 2-10 mm, then utilizing rolling method of variable thickness steel plate, adding a pass and rolling steel plate to make its thickness meet size requirement, then making widening rolling operation so as to obtain the invented stepped width steel plate.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com