Patents

Literature

949results about "Tension/compression control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling hot rolling coiling tension

ActiveCN102125936ASolve the problem of narrowing the widthAvoid quality problemsTension/compression control deviceEngineeringStrip steel

The invention discloses a method for controlling hot rolling coiling tension. Strip steel coiling is controlled by a two-level tension control method. The method mainly comprises the following steps of: calculating a first level set value and a second level set value; starting first level tension control according to a calculating result when the head part of strip steel enters a coiling machine;when actually measured coil moment reaches the first level moment set value, delaying some time and starting second level tension control until the strip steel is completely coiled; detecting and determining the width and the coiling quality of the strip steel, and adjusting a tension coefficient if the detected width and coiling quality of the strip steel is unqualified; and performing a self-adapting step. The control method overcomes the defects of the prior art and well solves the problem that the width quality and the coiling quality of the strip steel cannot be qualified at the same time, and the width of the strip steel is ensured as well as the coiling quality of the strip steel.

Owner:BAOSHAN IRON & STEEL CO LTD

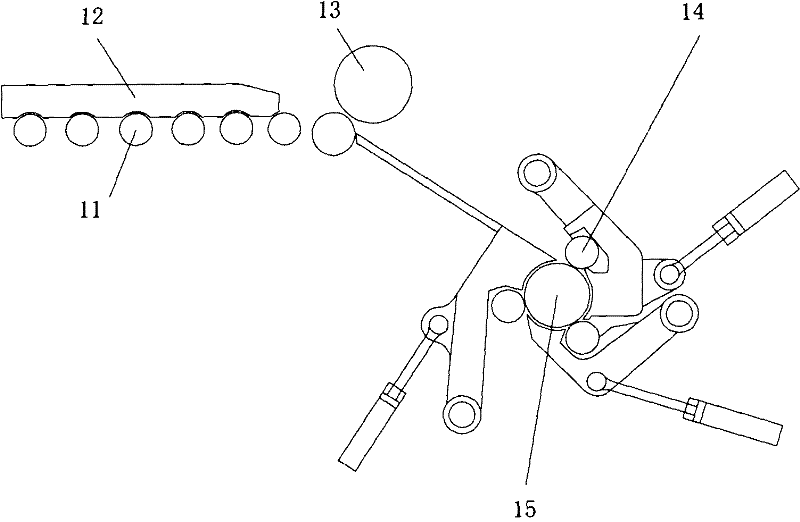

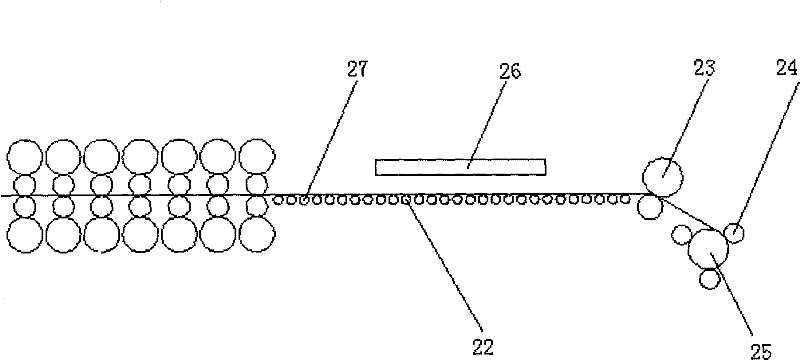

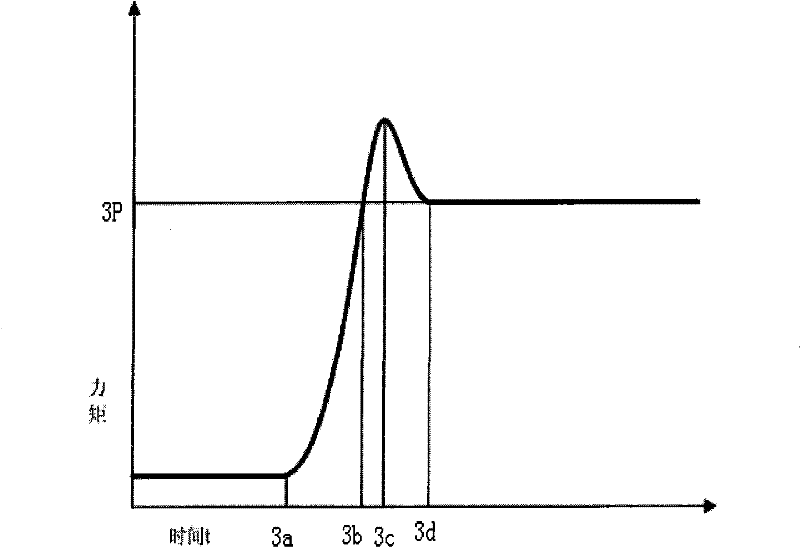

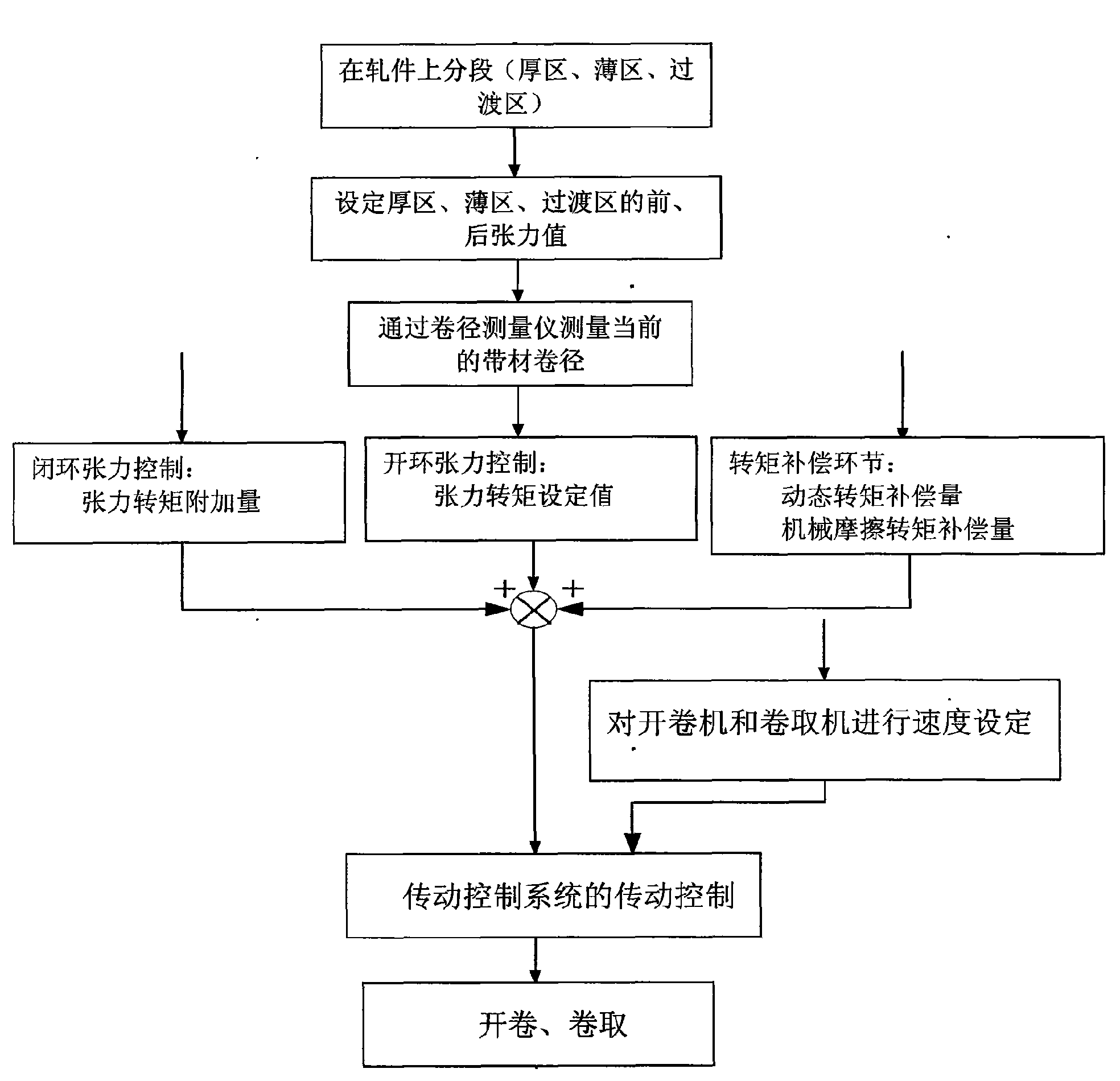

Control method and control system of tension in the process of rolling periodic variable-thickness strips

InactiveCN101602068AHigh precisionTension/compression control deviceMetal rolling arrangementsVariable thicknessMaximum torque

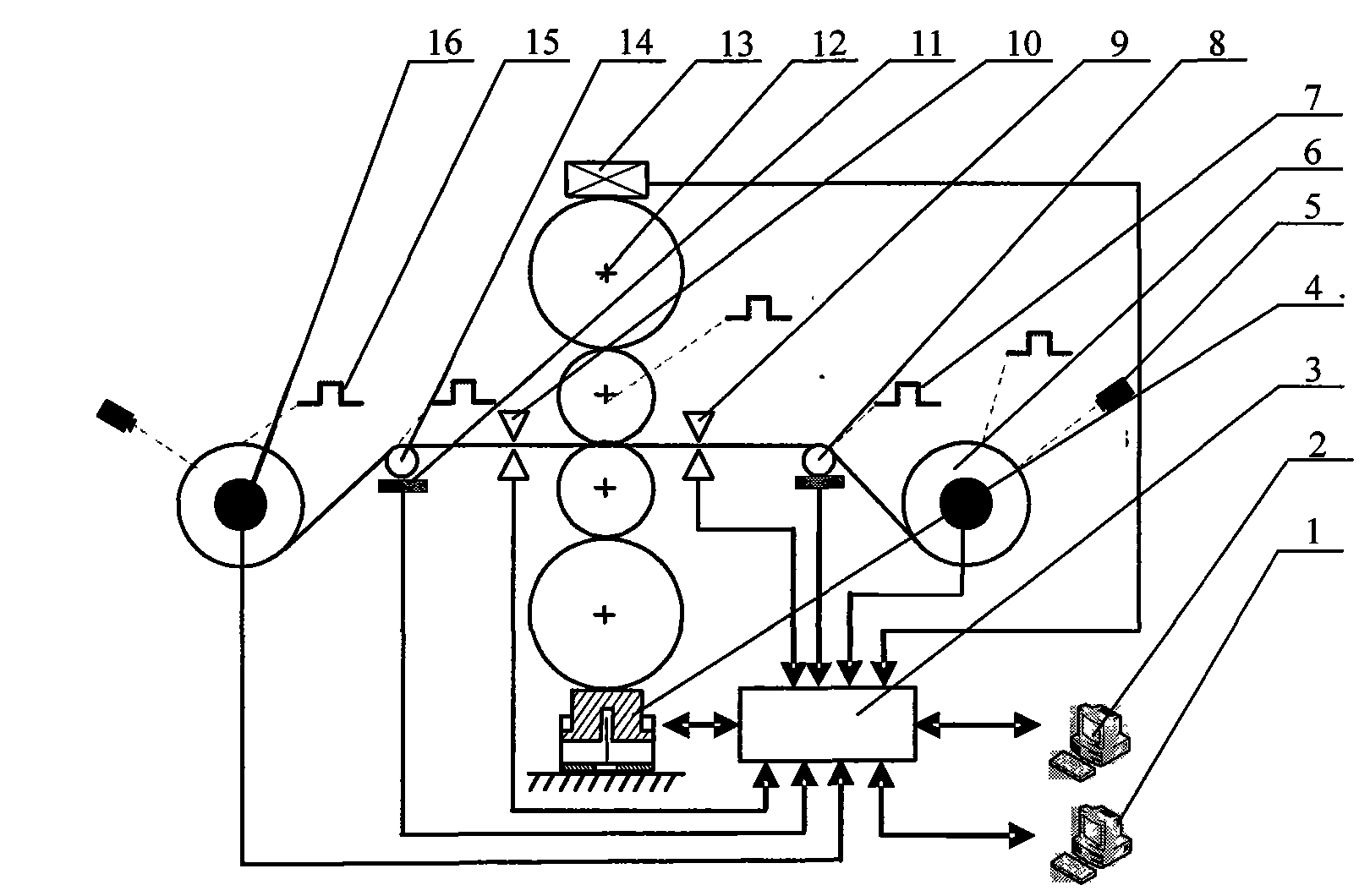

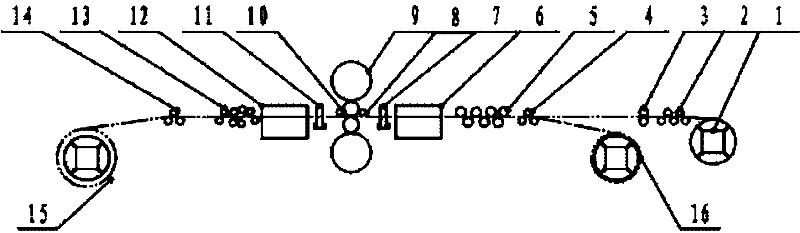

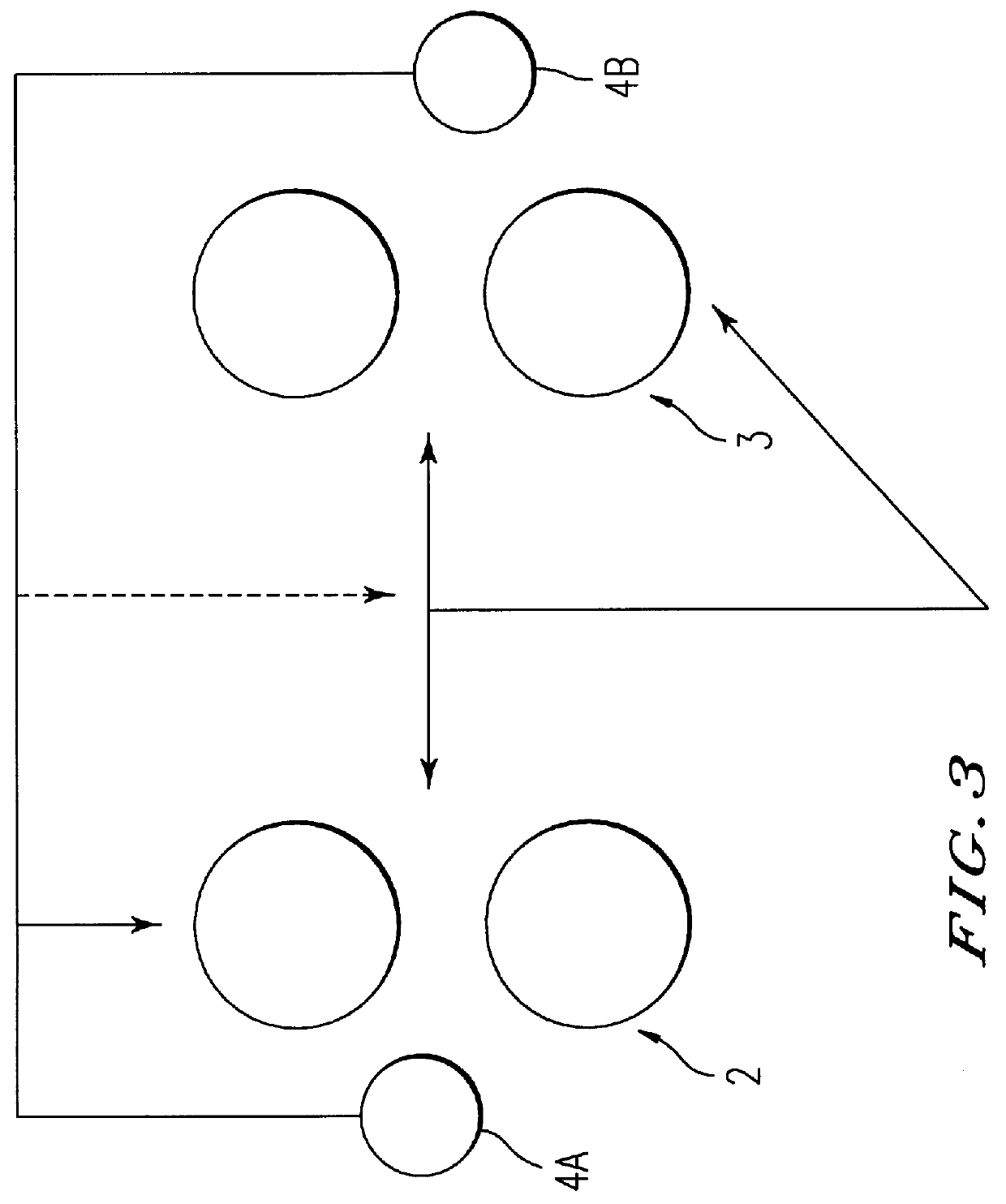

A control method and a control system of tension in the process of rolling periodic variable-thickness strips belong to the technical field of rolling. The method comprises the following steps: dividing segments on the rolled pieces, setting front and back tension values in each zone, realizing tension open-loop control and tension closed-loop control based on maximum torque limit and adding a dynamic torque compensation link and a mechanical friction torque compensation link; controlling torques of an uncoiler and a coiling machine motor and setting speed. The system comprises a rolling mill; coiling machines are arranged at both sides of the rolling mill respectively; length-measuring rollers are arranged between the coiling machines and the rolling mill; thickness gauges are arranged at both sides of the rolling mill respectively; coil diameter gauges are arranged on the coiling machines; a rolling force sensor and a hydraulic cylinder are arranged on the rolling mill; tensiometers are arranged below the length-measuring rollers and pulse coders are arranged on the length-measuring rollers; the thickness gauge, the coil diameter gauge, the rolling force sensor, a displacement sensor of the hydraulic cylinder, the tensiometer and the pulse coder are respectively connected with a computer control system.

Owner:NORTHEASTERN UNIV

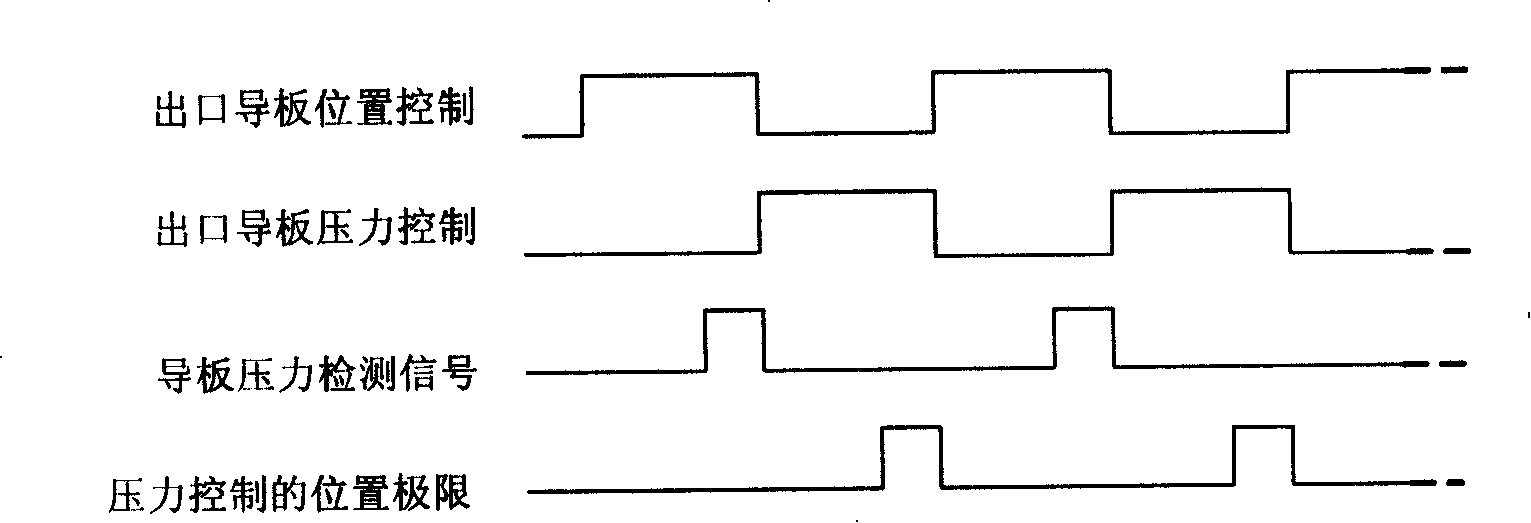

Controlling method of rough rolling breakdown bar camber

ActiveCN101224471APlay a guiding roleLow added valueGuiding/positioning/aligning arrangementsTension/compression control deviceAdditional valuesPosition control

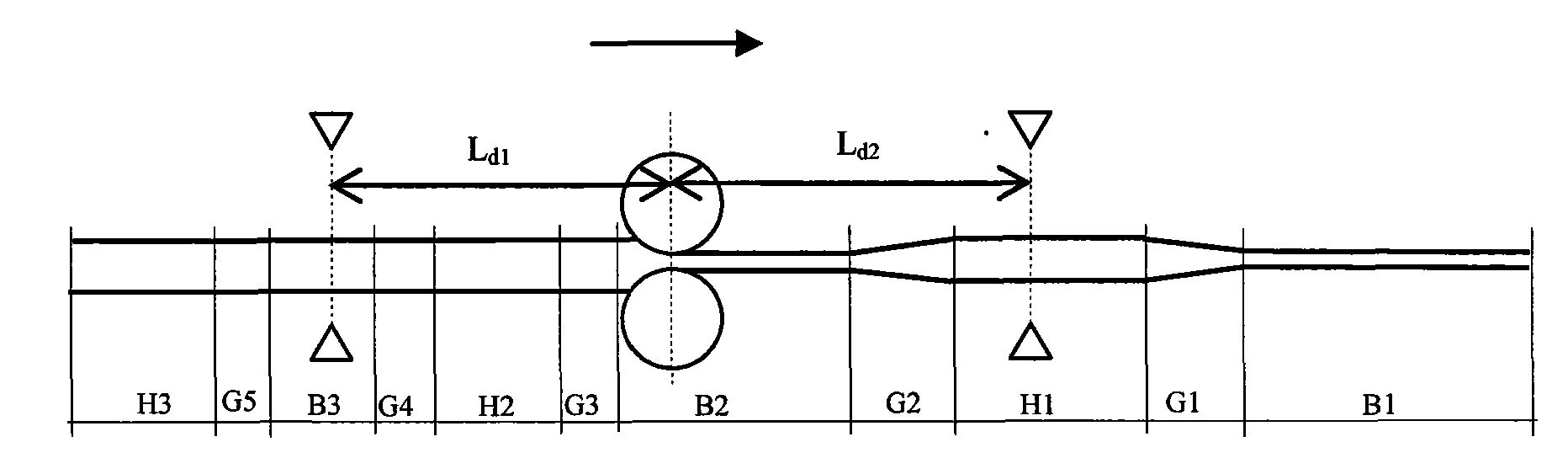

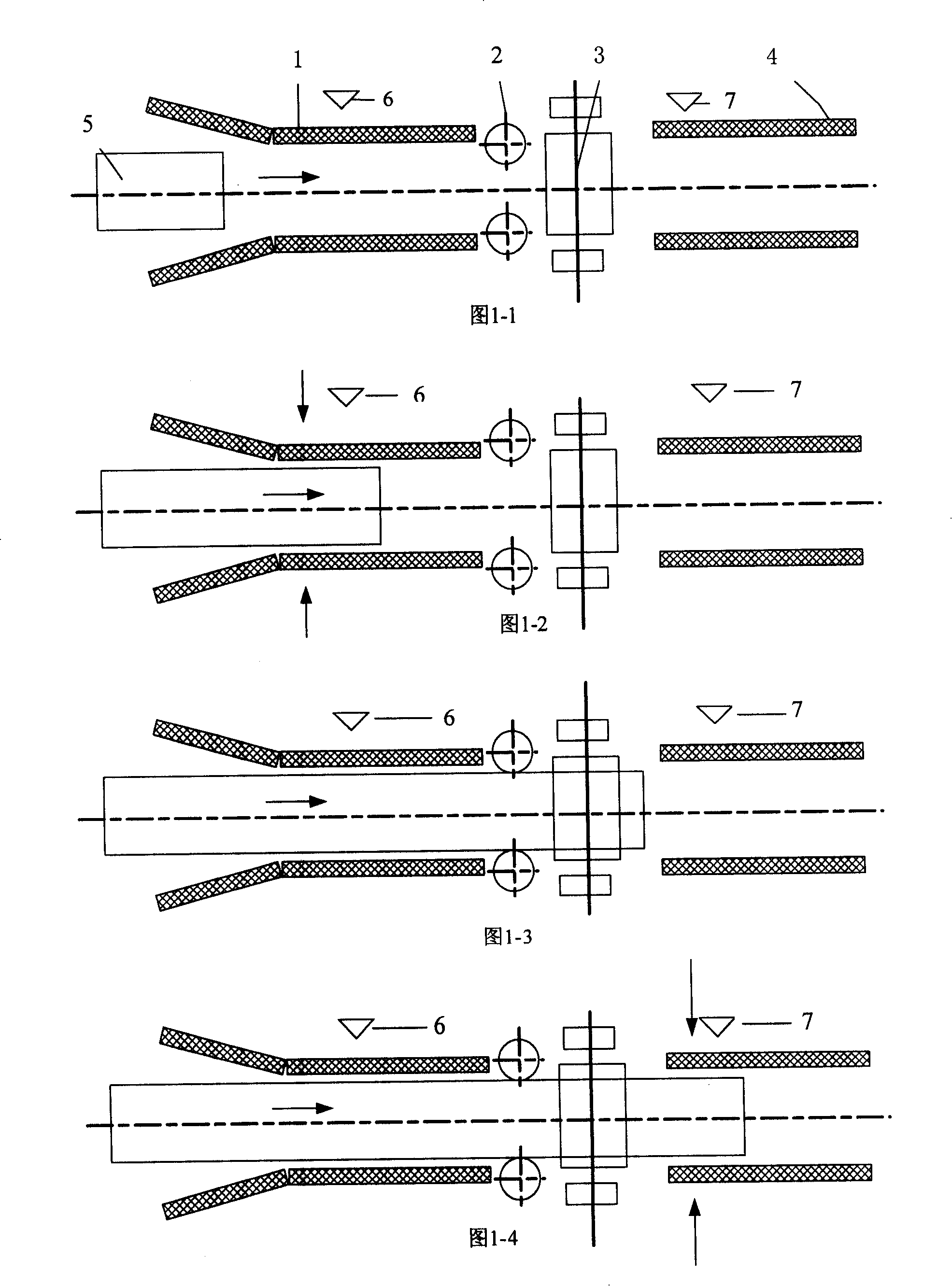

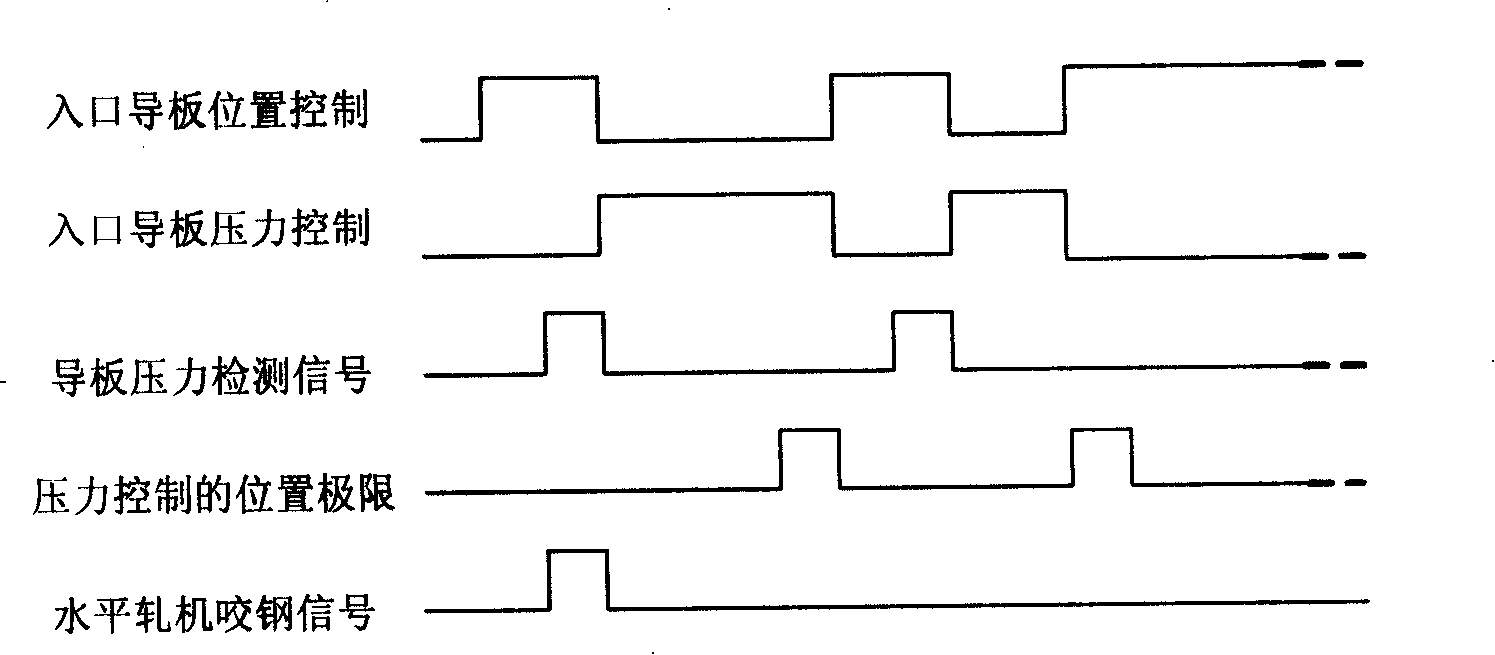

The invention relate to a control technique of the rolling process of a rolling steel. The invention discloses a control method of a rough rolling intermediate billet camber. The control method combines a position control with a pressure control; in a multi-pass rolling of the positive-pass and reverse-pass of a roughing mill, the camber generation of the intermediate billet is restricted. The control method of the invention can reduce the additional value of the openness of a side guide plate, leads the flexible deformation of the intermediate billet between the inlet and the outlet of the roughing mill in the horizontal direction to be restricted by the side guide plate, reduces the camber of the intermediate billet, and prevents the severe abrasion which is caused by the long-term contact of the side guide plate and the intermediate billet.

Owner:BAOSHAN IRON & STEEL CO LTD

Production process of precise stainless steel band for vehicle sealing pad

InactiveCN101716594AImprove quality requirementsThickness tolerance fluctuations are smallBell type furnacesTension/compression control deviceSolution treatmentStress relieving

The invention relates to a production process of a precise stainless steel band for a vehicle sealing pad. The production process comprises the following working procedures of: first cold rolling, solid solution, second cold rolling, spraying and degreasing, hot water spraying, hot wind drying, pre-bending straightening, stress relieving annealing, final bending straightening, finished product cutting, and the like. The production process adopts a 20-roller sendzimir mill and a unique rolling process to carry out cold rolling. Through the processes of degreasing, solid solution treatment, bending straightening, stress relieving annealing, and the like, the thickness tolerance undulation of a product is small, mechanical properties are stable, the plate flatness is good, the product is not easy to generate cracks and secondary deformation during stamping, and the quality of the product is obviously improved, thus the production process is suitable for industrial production and can meet the requirement for high quality of the vehicle part industry.

Owner:YONGXIN PRECISION MATERIAL WUXI

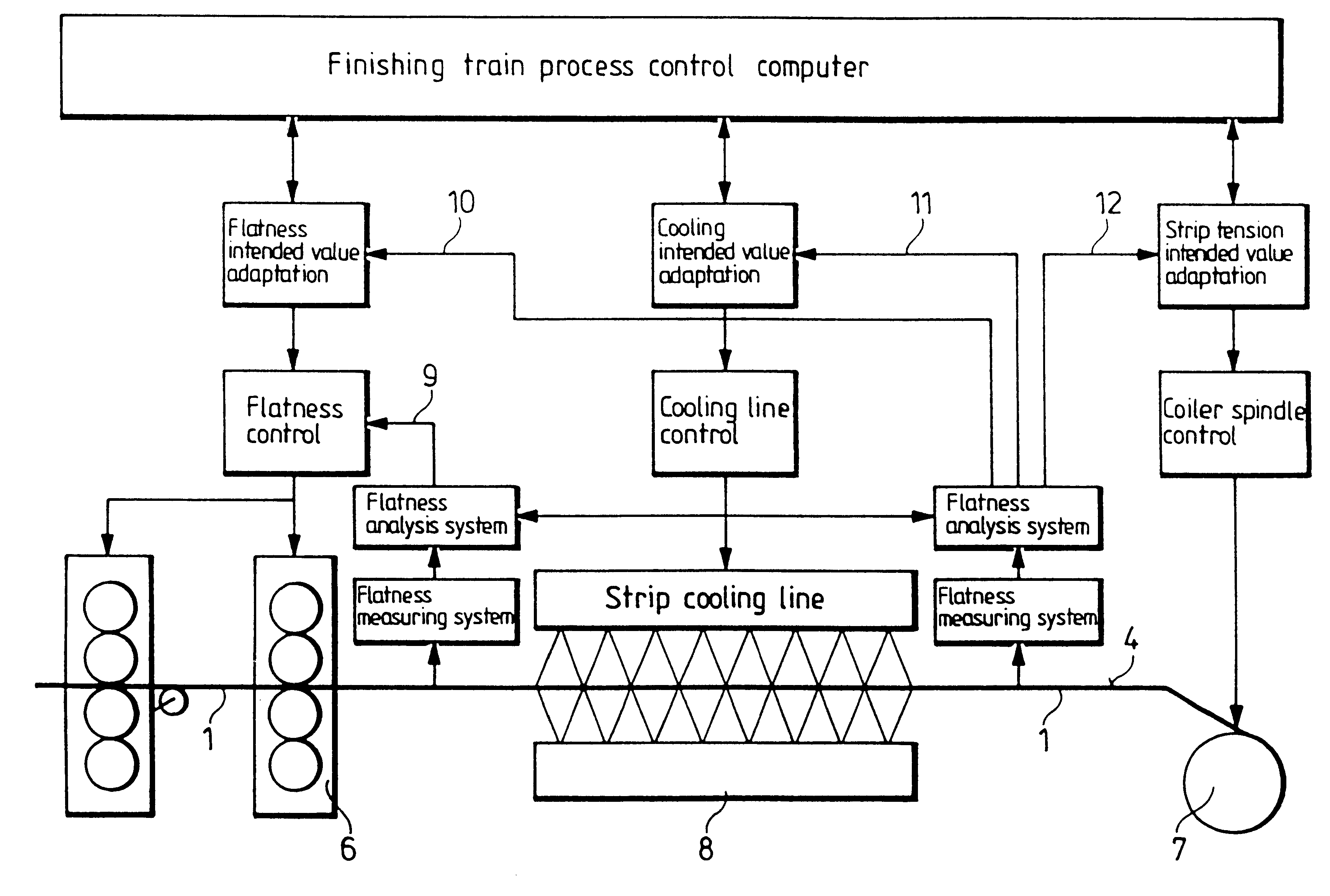

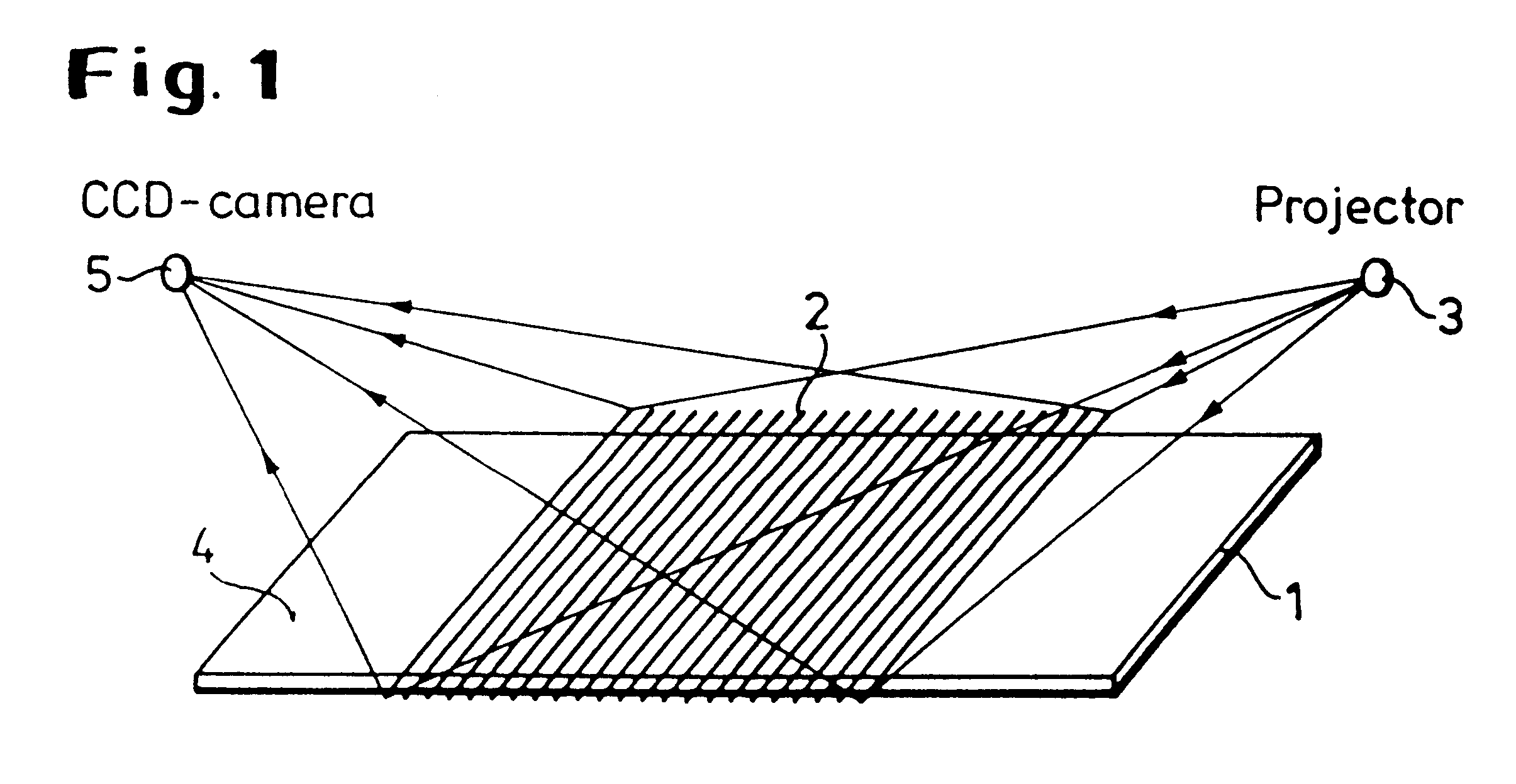

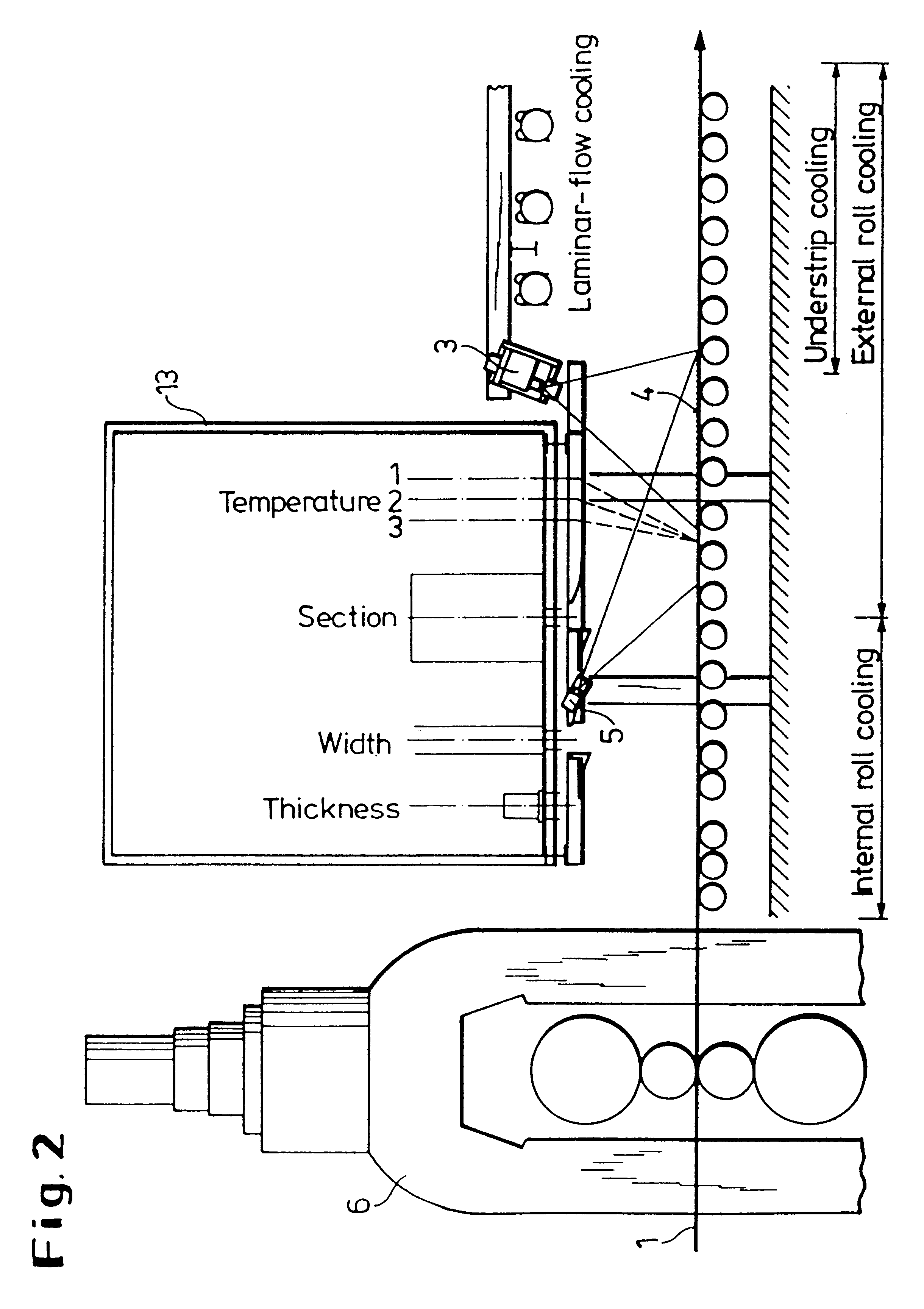

Flatness measurement system for metal strip

InactiveUS6286349B1Easy to measurePermit fine controlTemperature control deviceMeasuring devicesMetal stripsControl system

Owner:THYSSEN KRUPP STAHL AG +1

Production method of aluminum and copper composite metal band

ActiveCN101758071ASolve Oxidation ProblemsUniform thicknessTension/compression control deviceMetal rolling arrangementsCopperUltimate tensile strength

The invention discloses a production method of an aluminum and copper composite metal band. In the method, the aluminum and copper composite metal band is manufactured by anaerobic continuous casting and rolling of semisolid aluminum or aluminum alloy and a solid copper band. In the production method of the invention, the anaerobic metallurgical combination of the solid copper band and molten aluminum is realized, the aluminum oxidization problem is solved, the combined strength is high, and the aluminum and copper bonding strength is more than or equal to 100MPa; the continuous casting and rolling of the copper band and the molten aluminum are adopted to produce the aluminum and copper composite metal band, so the production efficiency is greatly improved by scores of times and the product quality is stable; the produced aluminum and copper composite metal band retains the original surface quality of the copper band, has a uniformly-thick copper layer and can be deeply processed by cold rolling; and the copper band and the molten aluminum, which comprise different components, can be used, and products are diversified and widely applicable. The method has the advantages that: the production process of the copper and aluminum composite band is advanced and comprises a few working procedures; and the energy-saving, material-saving and economic effects are obvious.

Owner:LUOYANG TONGYI METAL MATERIAL DEV +2

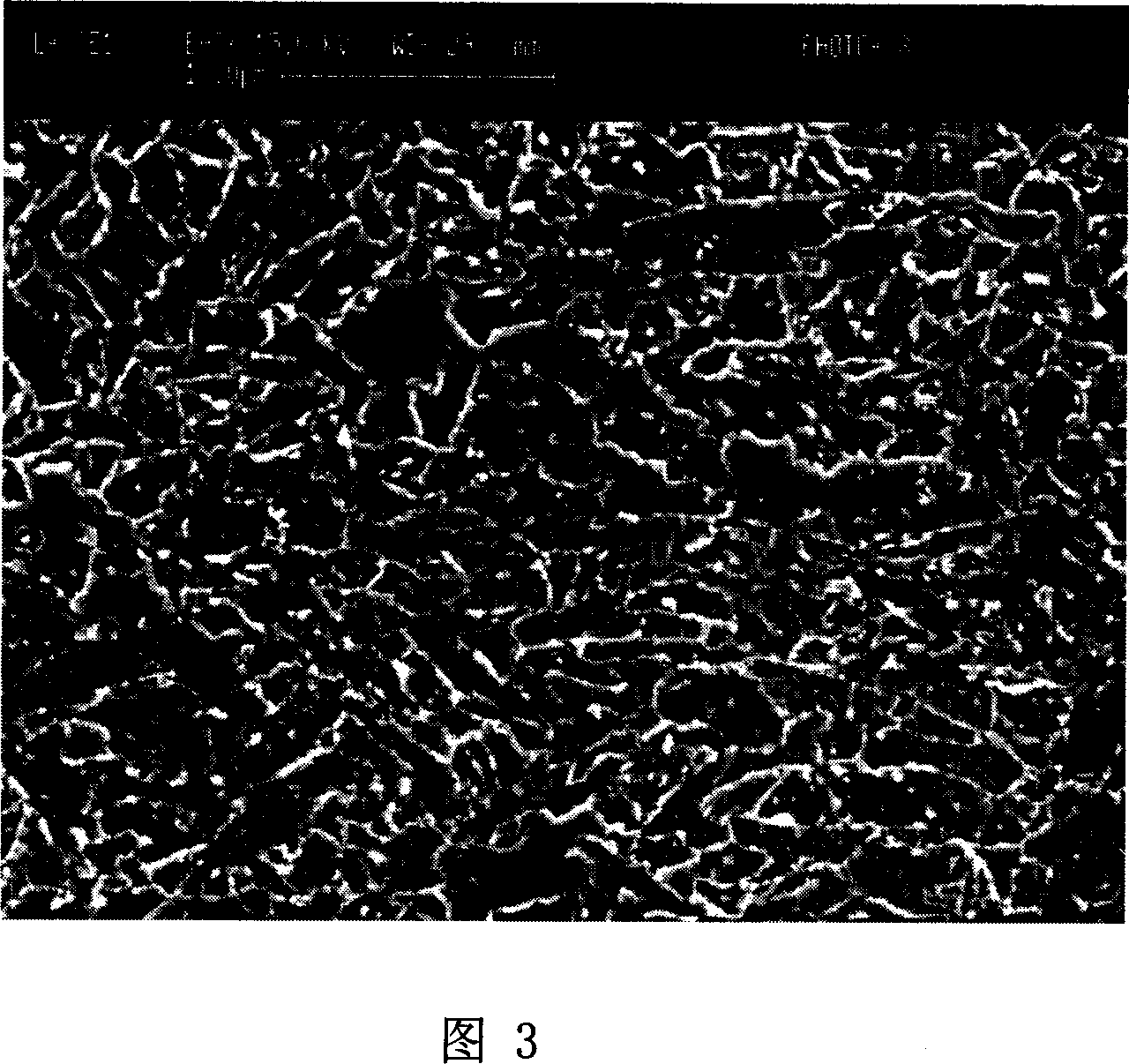

Wire rod used for ultrahigh-strength steel cord and manufacture method of wire rod

ActiveCN110629132AHigh wire breakage rateReduce wire breakage rateTemperature control deviceFurnace typesWire rodTemperature control

The invention discloses a wire rod used for an ultrahigh-strength steel cord and a manufacture method of the wire rod. The manufacture method includes the steel smelting stage, the blank casting stage, the cogging stage, the rolling stage and the controlled cooling stage which are sequentially conducted. In the steel smelting stage, molten steel is smelted, wherein the number density of inclusionswith the size being larger than or equal to 5 micrometers is smaller than or equal to 0.5 / mm<2>, and the inclusion size is smaller than or equal to 30 micrometers. In the blank casting stage, tappingmolten steel of the steel smelting stage is cast into an ingot blank with the central carbon segregation being 0.92 to 1.08. In the cogging stage, the ingot blank is made into an intermediate billetwith the central carbon segregation being 0.95 to 1.05 through cogging. In the rolling stage, the intermediate billet is rolled into the wire rod. In the controlled cooling stage, temperature-controlled cooling is conducted on the wire rod, and the wire rod which is high in cleanliness and high in homogeneity and has the tensile strength being smaller than or equal to 1150 MPa is obtained. The wire rod can be used for the ultrahigh-strength steel cord with the monofilament tensile strength being larger than or equal to 3600 MPa, the low drawing wire breaking rate, the low stranding wire breaking rate and the low mold consumption can be ensured, and the high yield is ensured.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Alloyed hot galvanizing bake hardening steel and method for manufacturing same

ActiveCN101230437ANot easy to produceImprove PlatabilityHot-dipping/immersion processesTemperature control deviceCooking & bakingSheet steel

The invention relates to an alloyed hot-galvanized baking-hardened steel plate and the manufacturing method thereof, which solves the problems of the anti-pulverization of the galvanized layer, the surface quality and the baking-hardened value. The mass percentage for the chemical components of a baseplate is as follows: C 0.0015 to 0.0025 percent, Si less than or equal to 0.030 percent, Mn 0.50 to 0.60 percent, P 0.050 to 0.060 percent, S less than or equal to 0.015 percent, N less than or equal to 0.003 percent, sol.Al 0.030 to 0.055 percent, Nb 0.004 to 0.015 percent, O less than or equal to 0.0050 percent and the rest are Fe and unavoidable impurities. The weight of the galvanized layer (for a single side) is 30-60g / m2 and the mass percentage for the Fe component of the galvanized layer is 8 to 12 percent. The steel plate of the invention has excellent anti-pulverization performance of the galvanized layer, excellent surface quality and appropriate baking-hardened value.

Owner:BAOSHAN IRON & STEEL CO LTD

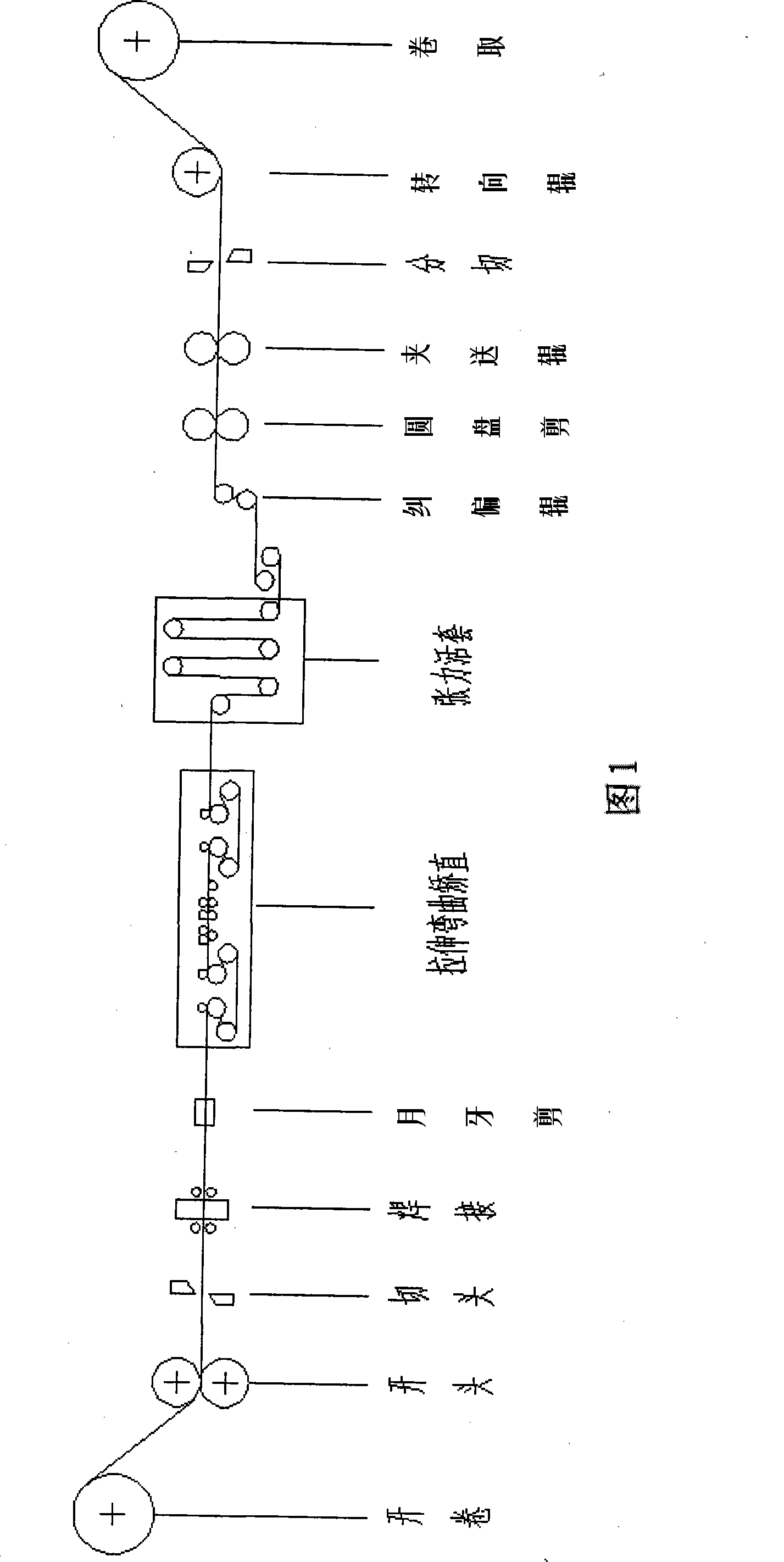

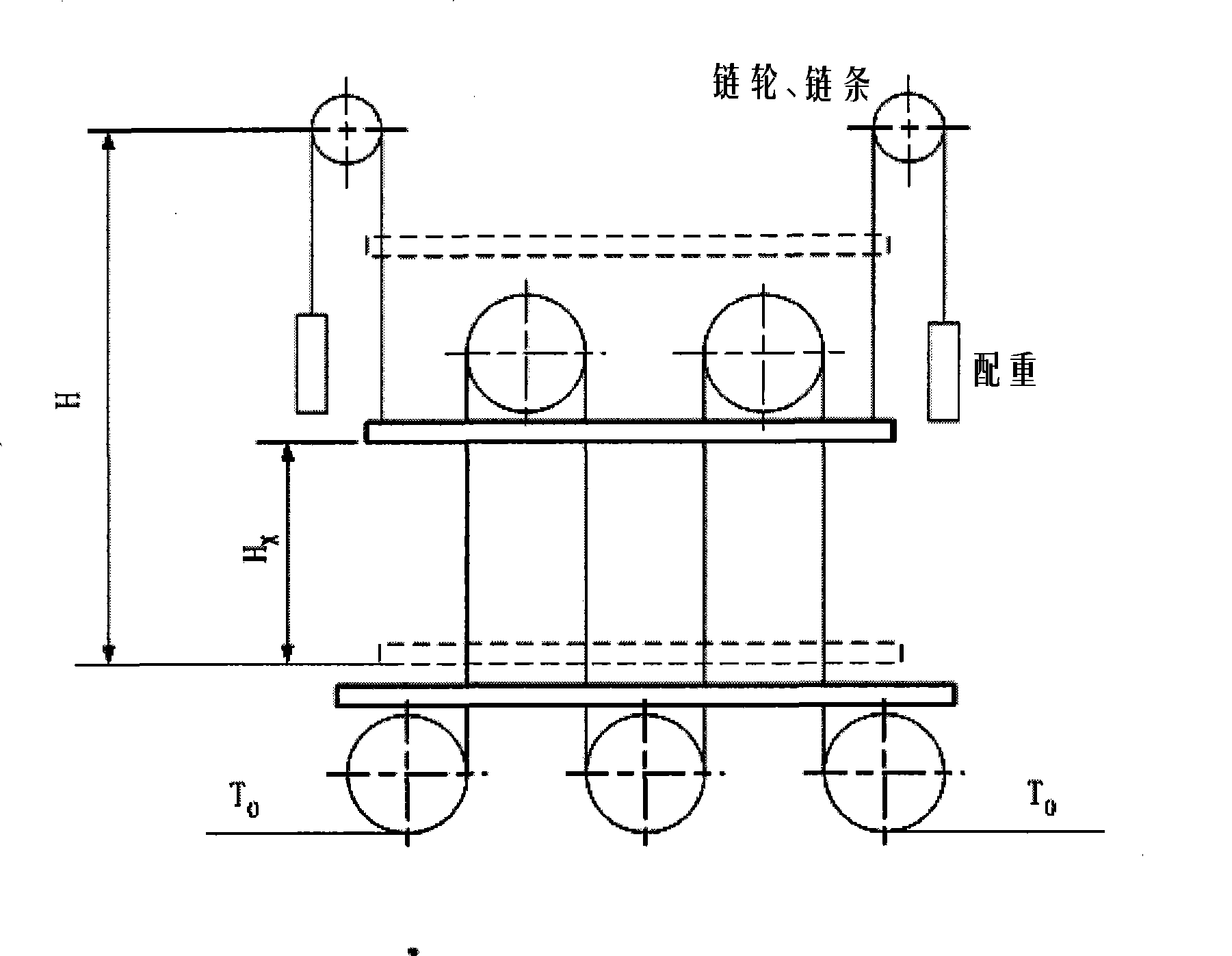

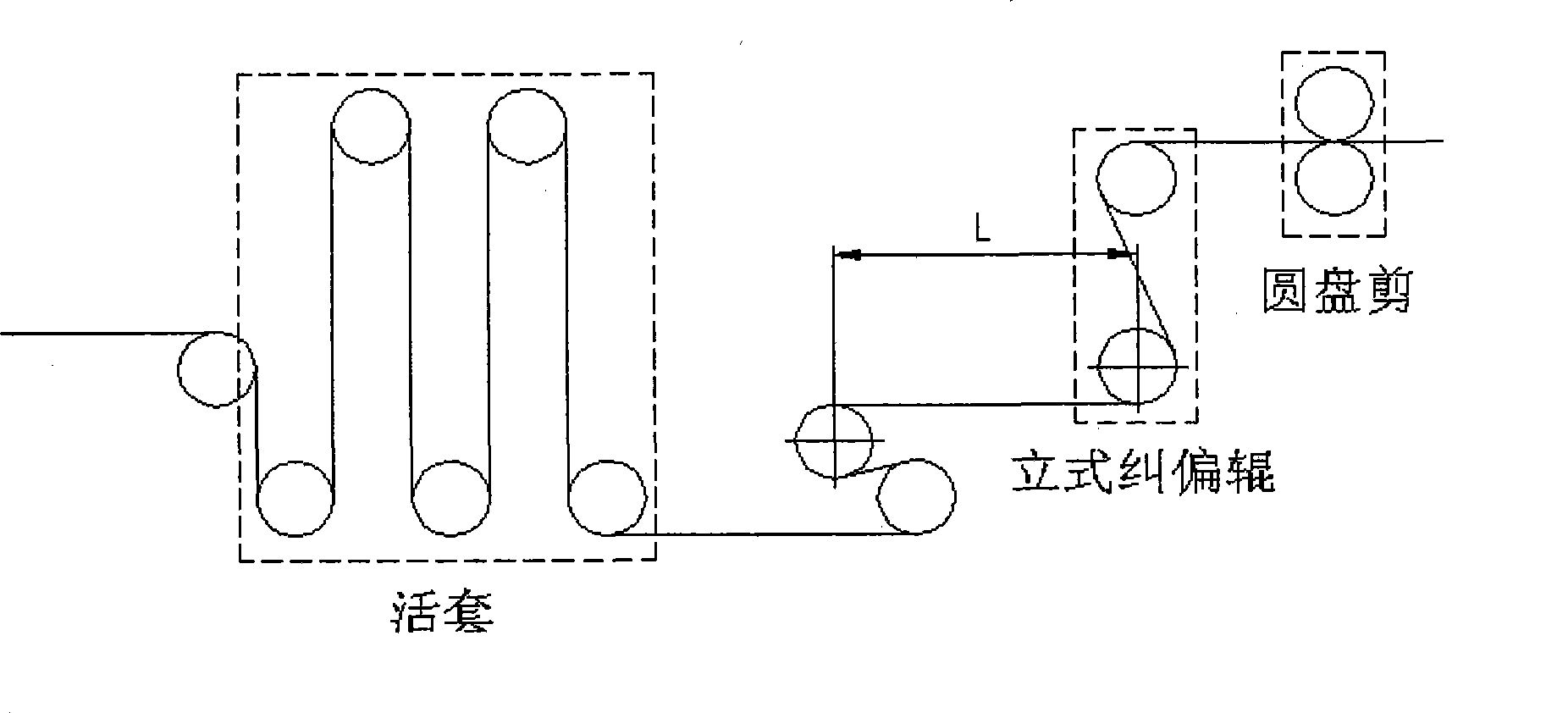

Machine unit process for stretch bending, straightening and rewinding

InactiveCN101439468AEliminate tension changesConstant tensionOther manufacturing equipments/toolsFlexible work arrangmentsCircular discLower limit

The invention provides a unit process used for finishing, tension-bending, straightening, and recoiling the metallurgical cold-rolling strips. The process is characterized in that the process comprises at least the steps as follows: roll-up, uncoiling, head cutting, welding, tension-bending and straightening, tensioning piston, rectification, trimming, separating, coiling and coil removing. When the unit produces normally, a coiler provides initial tension for an outlet tension roller; when the production line is shut down for coil separating, the coiler is shut down, the tensioning piston provides the initial tension equivalent to the coiling tension during the normal production for the outlet tension roller and a tension-bending, and straightening machine continues to straighten the strips; the straightened strips are stored in the tensioning piston; when the coiler removes the coils and re-produces the next finished coils, the straightened strips stored in the piston are coiled, the lifting roller unit of the movable sleeve falls to a lower limit position, the coiler loads the tension and shifts the initial tension of the tension-bending and straightening machine from the tensioning piston to the coiler at the same time, and then the whole unit produces at an accelerated speed. The process can overcome the defects generated on the disc shear by the strips when the tension is shifted between the coiler and the tensioning piston owning to the shutdown of the coil separating.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Integrate optimized controlling means for planisher elongation roll-force, tension, and roll-bending force

ActiveCN1923391AGuaranteed accuracyGuarantee the shape qualityRoll force/gap control deviceTension/compression control deviceControl systemClosed loop

The invention relates to a method for optimizing and controlling the rolling tensioning roller of finisher. Wherein, it is in the extending rate control system; the inner ring of control closed loop is rolling pressure closed loop and tension closed loop; based on the difference of adjustment sequence of tension and rolling pressures, first adjusting tension or first adjusting rolling pressure to control the extending rate, to control extending rate and plate shape; the method that first adjusting tension is that optimizes the tension to control extending rate, when it is over limited range, keeps it constant, and adjusts the rolling force; and the method that first adjusting rolling pressure is that optimizes the rolling pressure to control extending rate, when it is over limited range, keeps it constant and adjusts the tension force. The invention can confirm the accuracy of extending rate and the quality of sheet shape.

Owner:BAOSHAN IRON & STEEL CO LTD +1

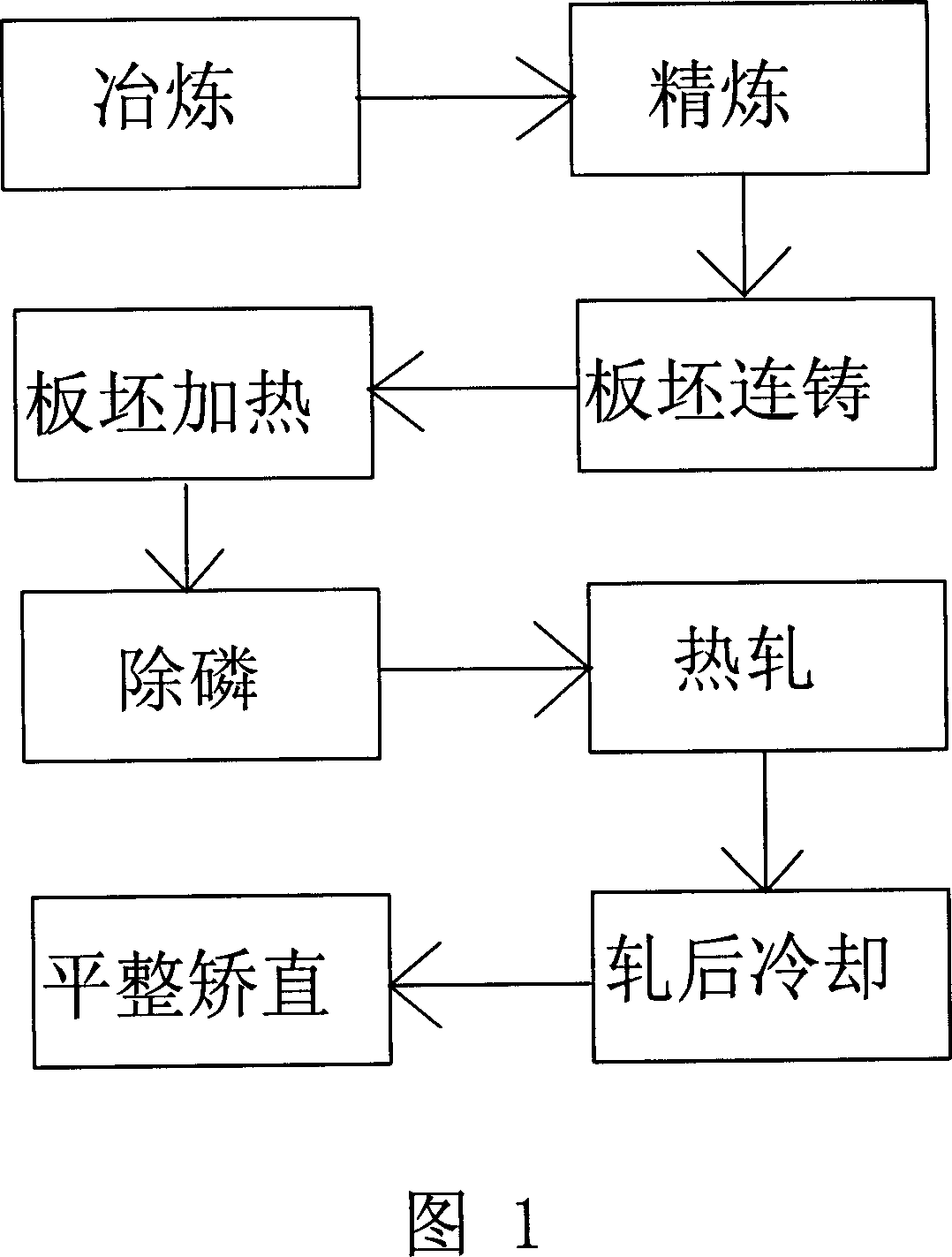

Manufacturing technique of low compression ratio high grade pipe line steel

InactiveCN1927486AImprove performanceRoll force/gap control deviceTemperature control deviceNiobiumHeating temperature

The invention relates to a method for producing high-strength low-alloy steel. Wherein, it comprises smelting, refining, casting sheet blank, heating blank, removing phosphor, cooling and flattening; the smelting step uses pure steel, low phosphor, and low sulfur; in the casting step, the loose of blank and the aliquation are lower than B0.5level; in the heating step, vanadium+niobium+ titanium0.15%, nickel+chromium+copper<=0.50%, and the heating temperature is 1180-1220Deg. C; in the thermal rolling step, in the crystallize process, the deformation temperature is 1070-1000Deg. C, the deformation amount is 40-60%, and the rolling speed is 1.5-2.5m / s, and in the second step that rolling the non-crystallized area, the pressure is 200-400MPa, the rolling speed is 5-1.5m / s, and the deformation amount is 60-75%; and the interlayer cooling speed in the cooling step is 15Deg. C / s-25Deg. C / s.

Owner:NANJING IRON & STEEL CO LTD +1

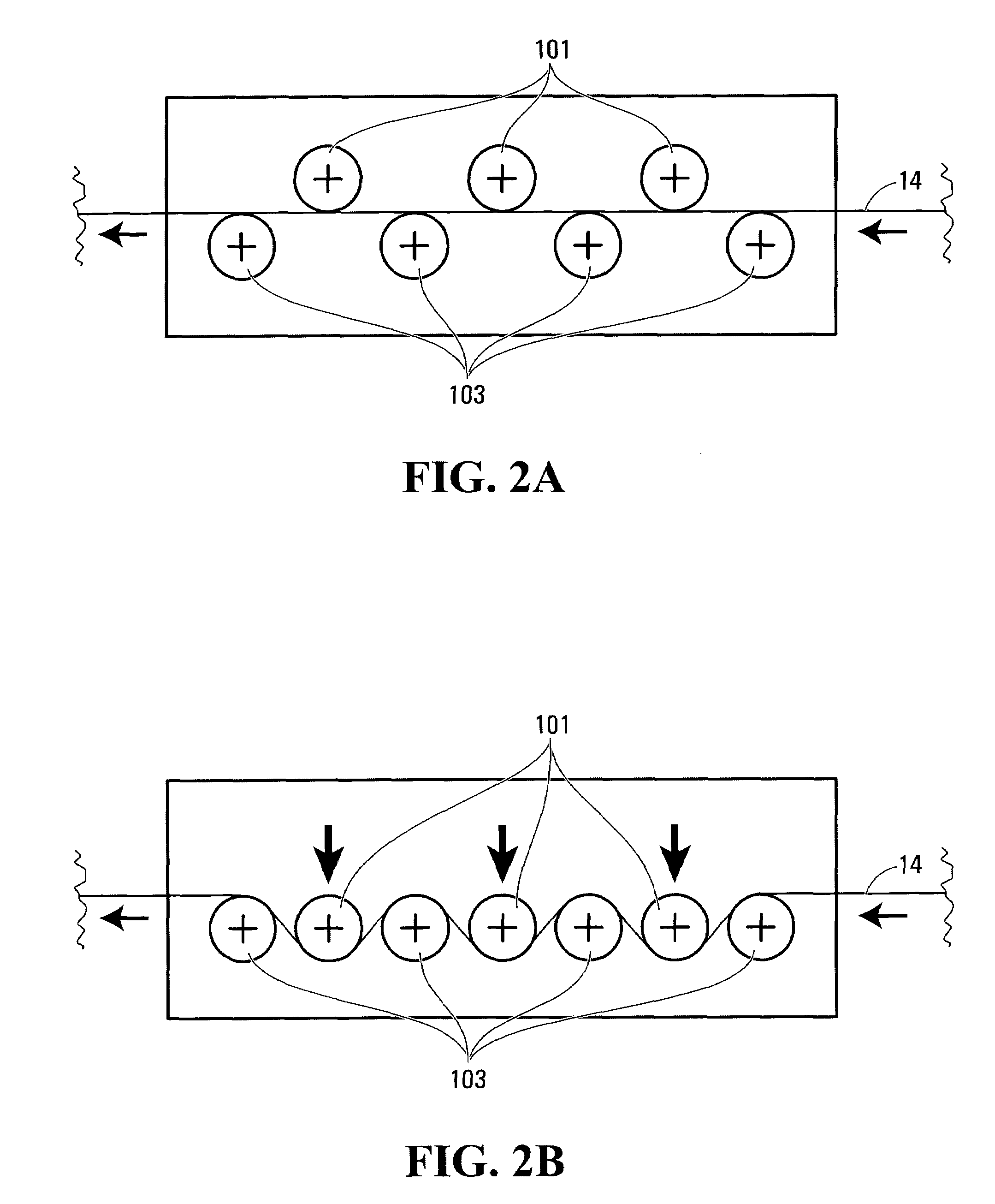

Lamination process and apparatus for alkali metals or alloys thereof

ActiveUS7513136B2Reduce thicknessElectrode rolling/calenderingRoll force/gap control deviceLithiumElectrical battery

An apparatus for and method of manufacturing lithium or lithium alloy anodes for electrochemical cells by a lamination process wherein a lithium or lithium alloy sheet is reduced into a thin lithium or lithium alloy film. The method and apparatus provide adjustments of the profile defined by the meeting surfaces of a pair of working rollers to compensate for thermal dilation of the working rollers or to compensate for irregular thickness of the lithium or lithium alloy sheet to control the shape and profile of the lithium or lithium alloy film being laminated.

Owner:BATHIUM CANADA

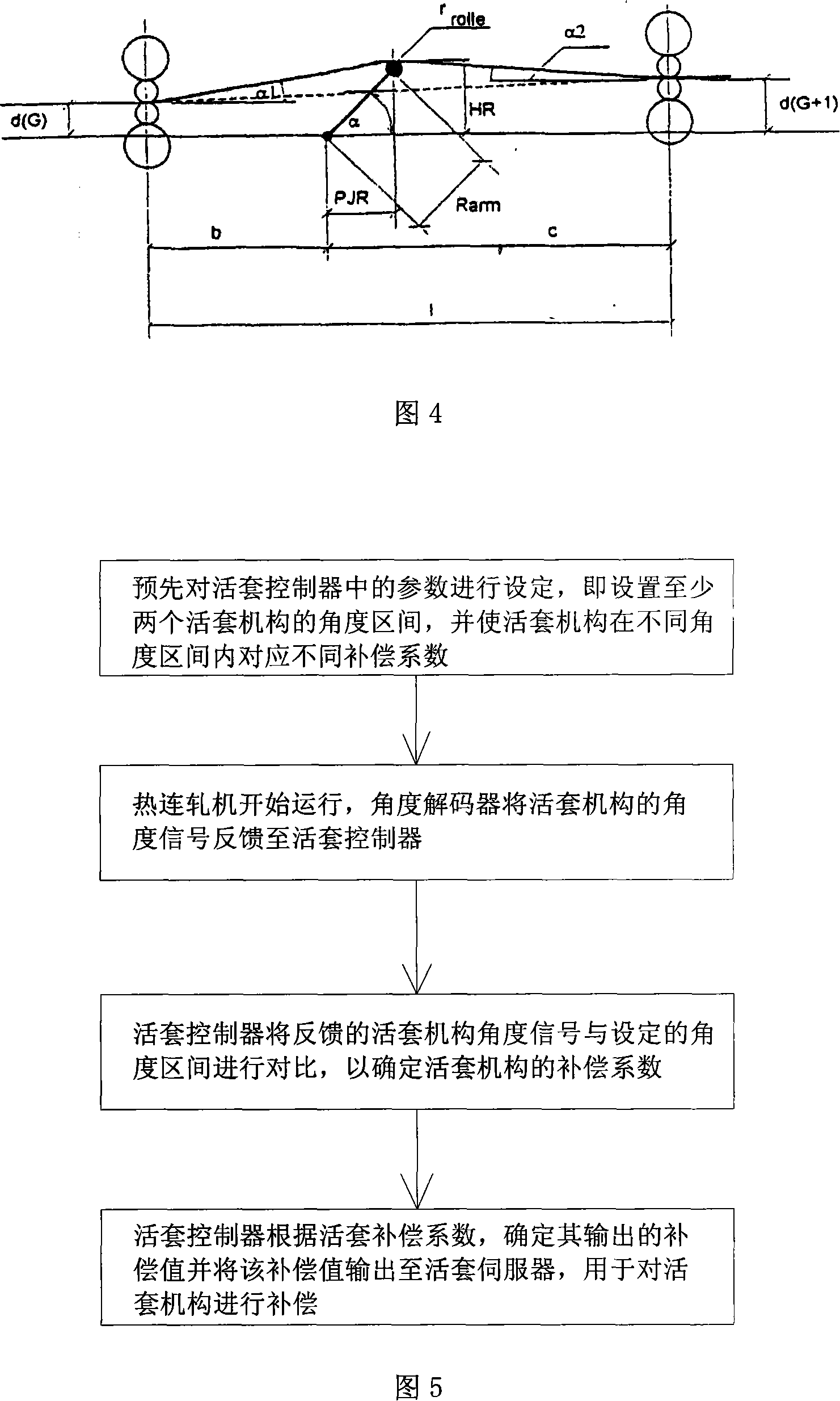

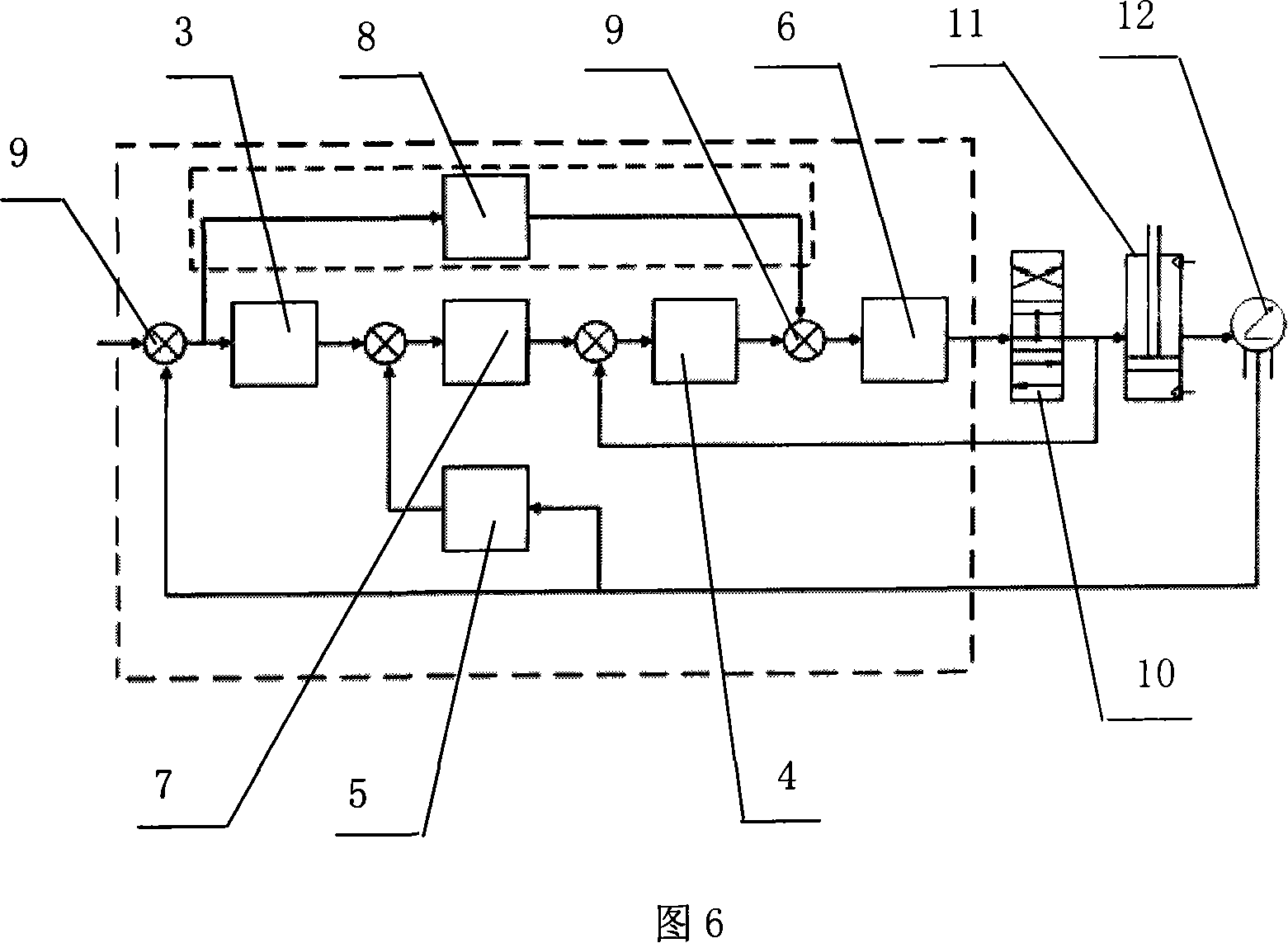

Hot continuous rolling mill loop control method and used controller

InactiveCN101219438AImprove control effectHigh control precisionFlexible work arrangmentsTension/compression control deviceLoop controlContinuous rolling

The invention discloses a control method for the loose cover of a hot strip mill, which comprises the steps that: a. the parameter in a controller of the loose cover is set in advance, namely at least two angle intervals of the loose cover device are set and the loose cover is arranged in different angle intervals with different corresponding compensation factors; b. the angle signals of the loose cover device are sent to the controller of the loose cover by an angle decoder when the hot strip mill starts to work; c. comparison is made between the angle signals of the loose cover and the set angle interval by the controller of the loose cover to determine the compensation factor of the loose cover device; d. an output compensation value is determined by the controller of the loose cover based on the compensation factor of the loose cover and output to a servo valve of the loose cover to make compensation to the loose cover device. The invention modifies the control property of the loose cover and promotes the stability thereof.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

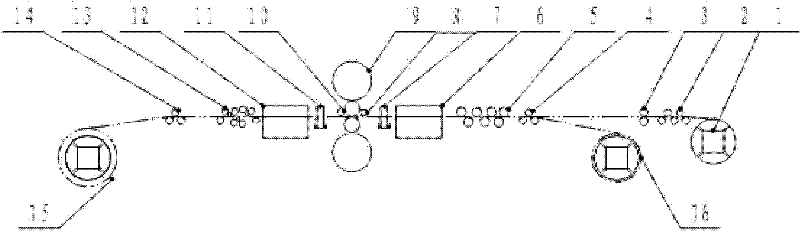

Rolling device for preparing high-toughness high-formability magnesium alloy sheet strip coil

ActiveCN102240676ARealize continuous temperature-controlled rollingImprove mechanical propertiesMeasuring devicesTension/compression control deviceMetallic materialsFeedback control

The invention relates to a rolling device for preparing a high-toughness high-formability magnesium alloy sheet strip coil and belongs to the field of metal material rolling. The rolling device provided by the invention comprises a rolling machine, an uncoiling machine, a left-right recoiling machine, a front online heating insulating device of the roll machine, a rear online heating insulating device of the roll machine, a straightening machine, a bending rectifying machine, a thickness measuring device, a steering tension roll, a guide roll, a roller heating and lubricating device and the like. In the invention, an online continuous heating device and an advanced PLC (programmable logic control) feedback control system are adopted, and continuous temperature control rolling on the magnesium alloy strip coil is realized. The rolling device provided by the invention has the advantages of uniform heating temperature, high heating efficiency and high temperature control accuracy, and high-quality thin wrought magnesium alloy strip coils are efficiently produced by virtue of a roller preheating insulating system, a technical lubricating system, a strip shape control system and a tension straightening device, thus the geometric quality and structure properties of rolled metal can meet operating requirements.

Owner:江苏永良镁业科技有限公司

Process for producing accurate stainless steel band applied in electronic industry

InactiveCN101716595AImprove quality requirementsThickness tolerance fluctuations are smallFurnace typesTension/compression control deviceSolution treatmentThermal water

The invention relates to a process for producing an accurate stainless steel band applied in an electronic industry. The process comprises the following steps of: the first cold rolling process; the first spray degreasing process; the first hot-water spraying process; the first hot-wind drying and solid dissolving process; the second cold rolling process; the second spray degreasing process; the second hot-water spraying process; and the second hot-wind drying process, bending stretching and straightening process and the process of cutting into finished products. According to the production process, a twenty-Hi sendzimir rolling mill and an unique rolling process are adopted for cold rolling; and the processes such as degreasing, solid dissolving treatment, bending stretching, straightening, and the like are performed, so that the product has little tolerance fluctuation of the thickness, stable performance, uniform surface color and roughness and no color difference, good plate flatness, improved quality and capacity of meeting the requirements of the electronic industry on top quality.

Owner:YONGXIN PRECISION MATERIAL WUXI

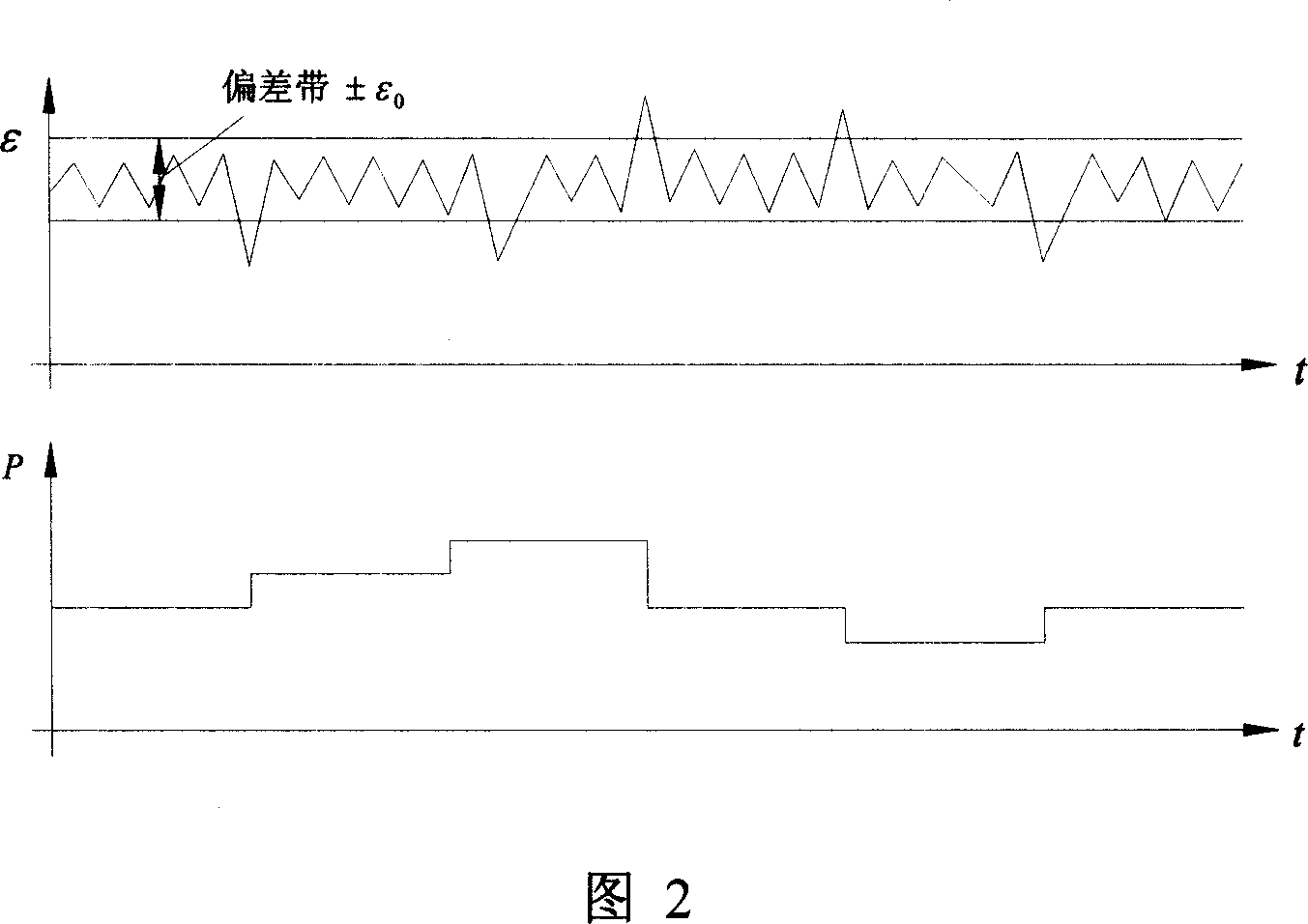

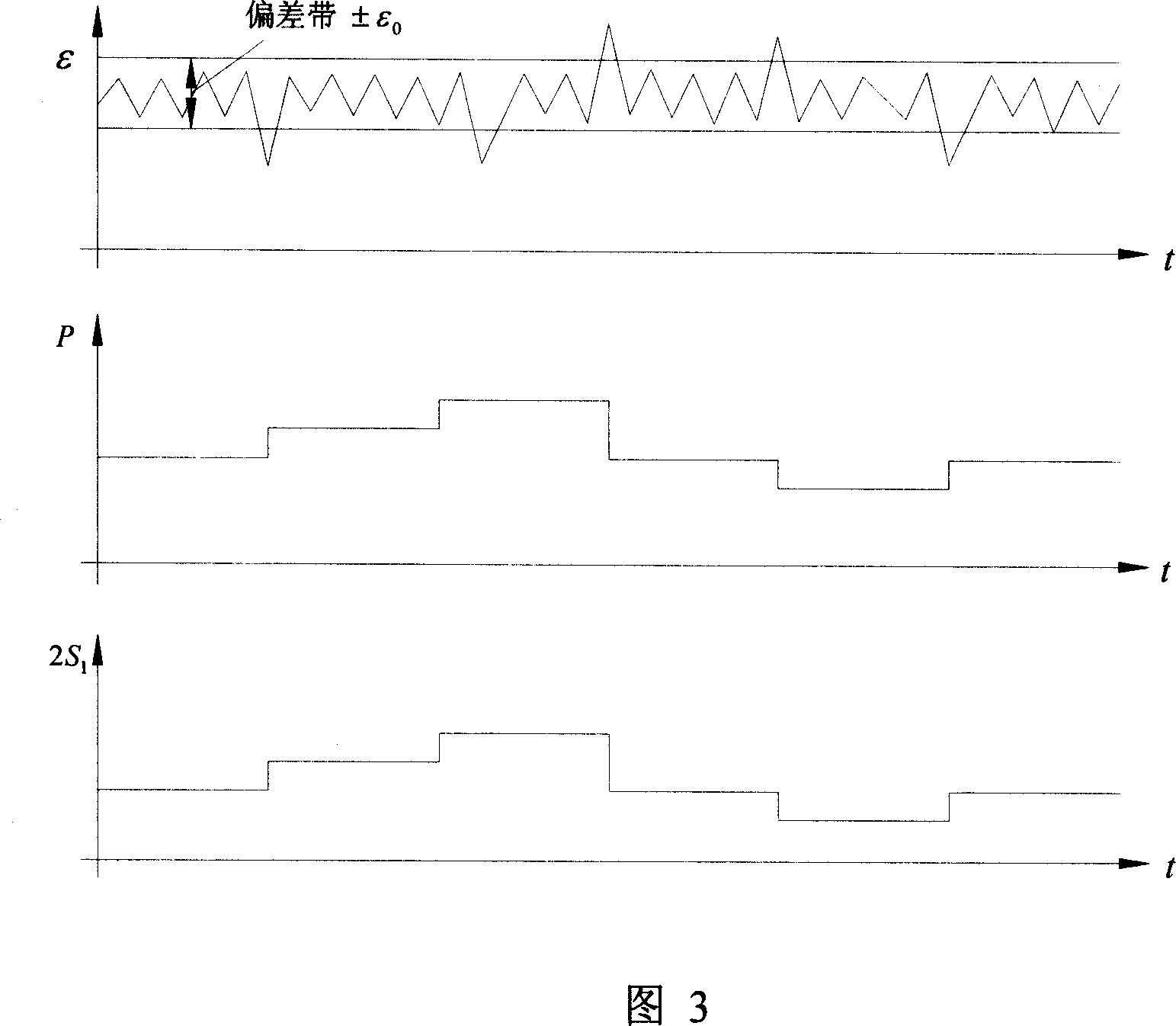

Strip steel tension dynamic control method based on loop quantity deviation and control system using strip steel tension dynamic control method

ActiveCN103920720ARealize dynamic controlHigh control precisionTension/compression control deviceControl systemStrip steel

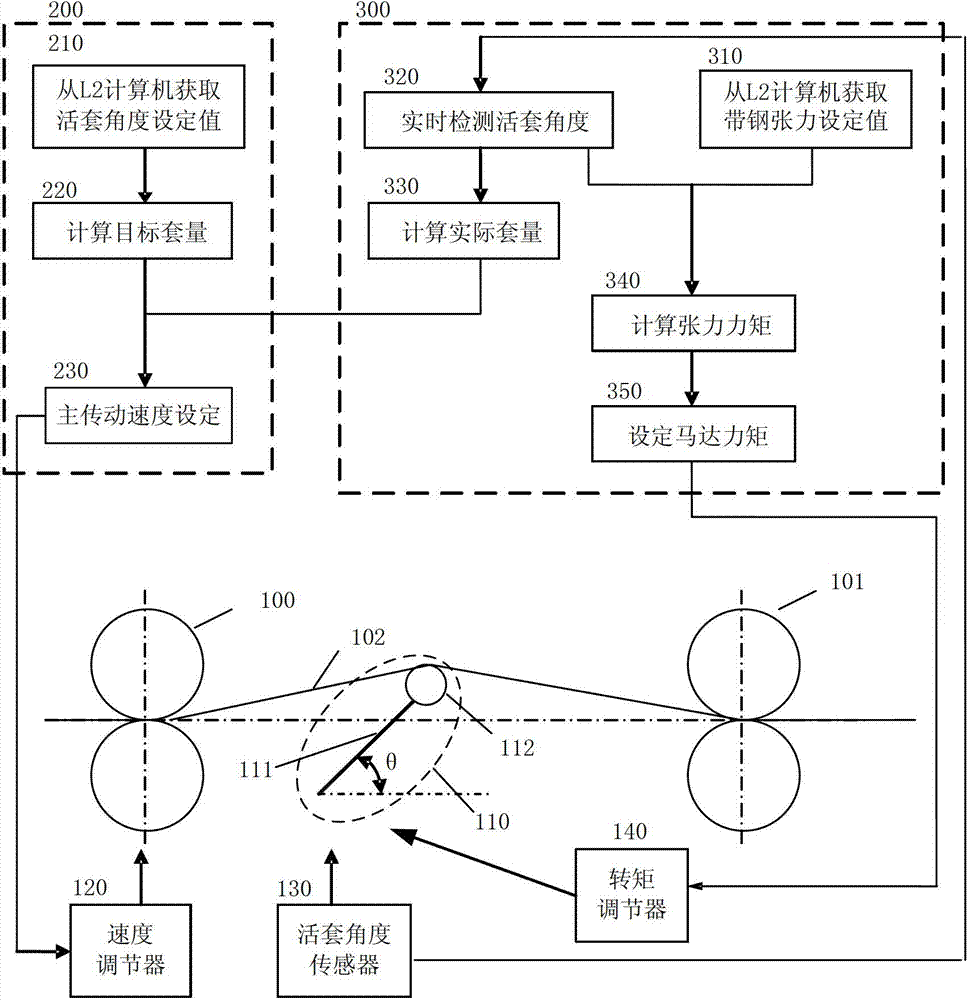

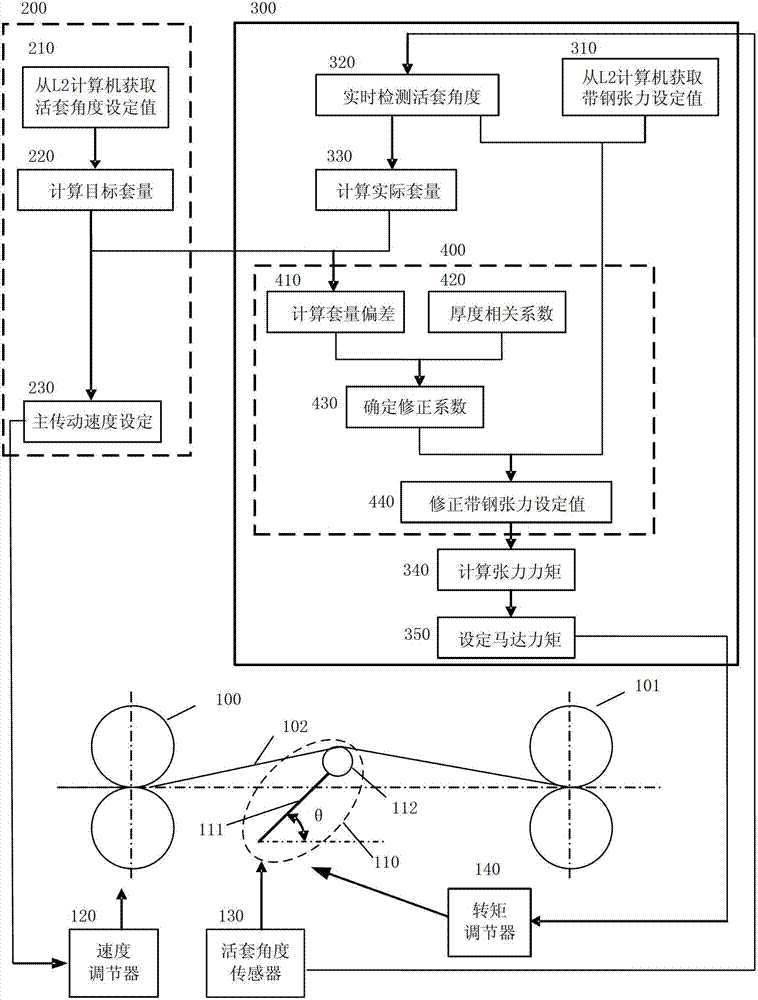

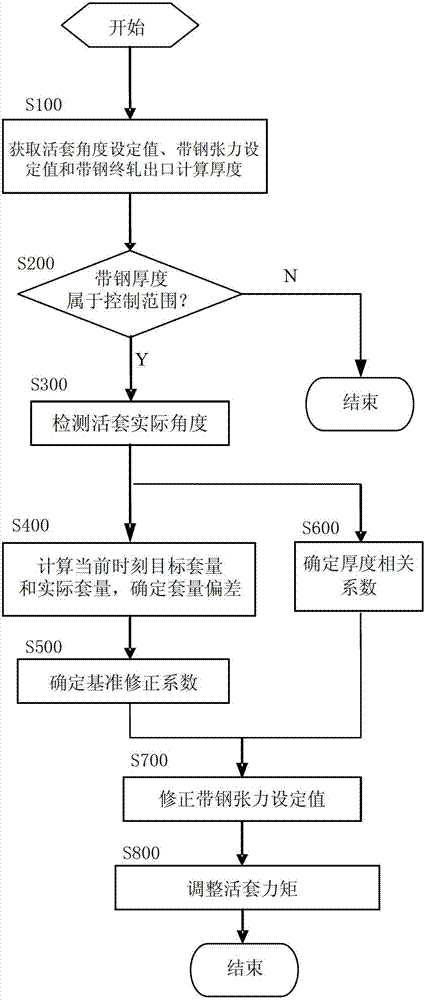

The invention discloses a strip steel tension dynamic control method based on loop quantity deviation and a control system using the strip steel tension dynamic control method, and relates to a control device or method which is specially applicable to a metal rolling mill or products machined by the metal rolling mill, in particular to dynamic control of hot-rolled strip steel tension through a loop. The control system comprises a main transmission speed control module, a tension adjusting module and a tension set value correction module, a strip steel tension set value is corrected by computing loop quantity deviation between a target loop quantity and an actual loop quantity in real time and according to the loop quantity deviation, the strip steel tension set value is increased if the actual loop quantity is higher than the target loop quantity, the strip steel tension set value is decreased if the actual loop quantity is lower than the target loop quantity, tension moment is computed according to the corrected strip steel tension set value and transmitted to a torque adjuster of an electric loop, the strip steel tension is dynamically controlled, and the problem of internal deviation of strip steel in a frame or narrow reduction of the strip steel due to easy deviation of the actual loop quantity of the loop caused by fluctuation of technological parameters in constant tension control of an existing strip steel tension control system is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

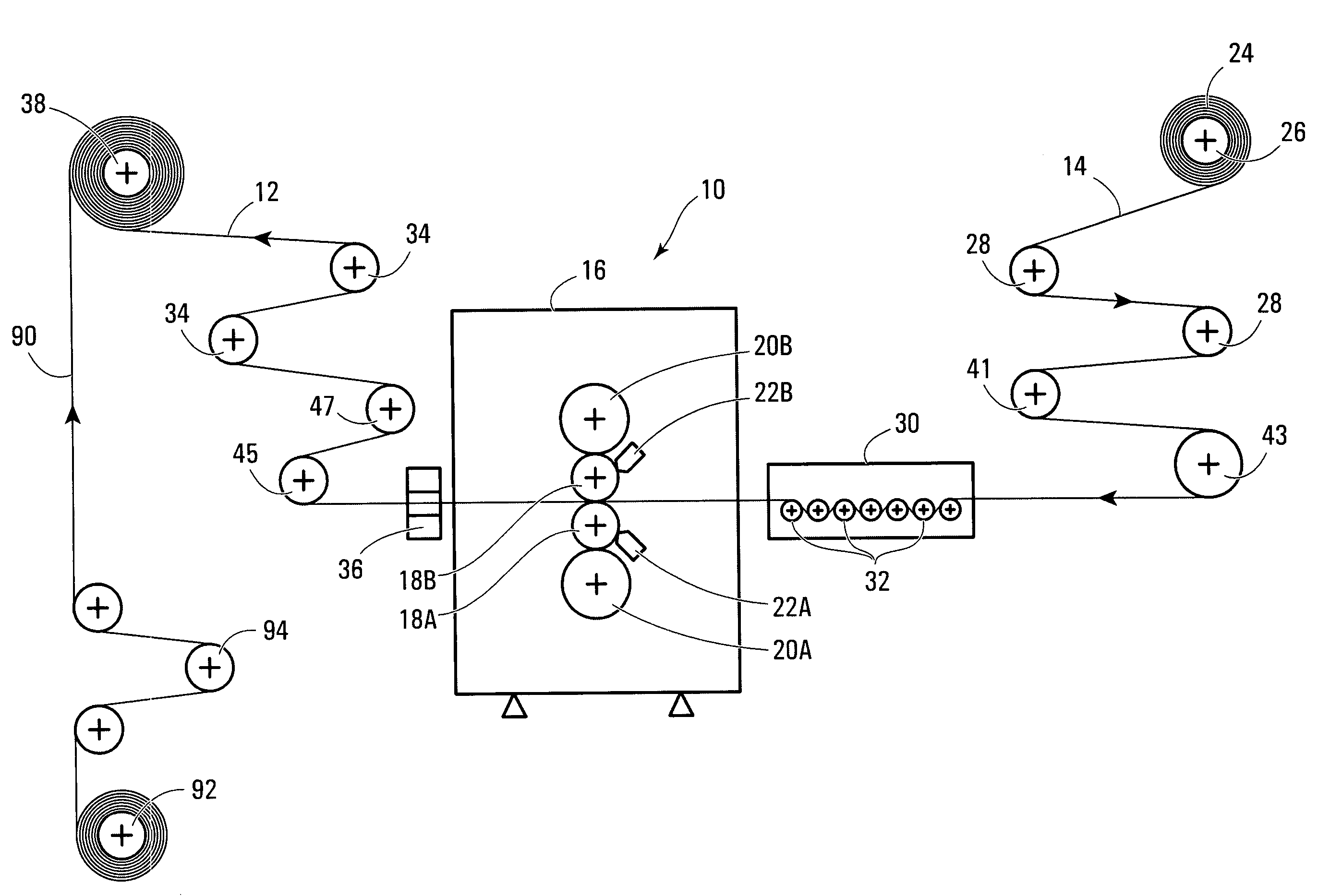

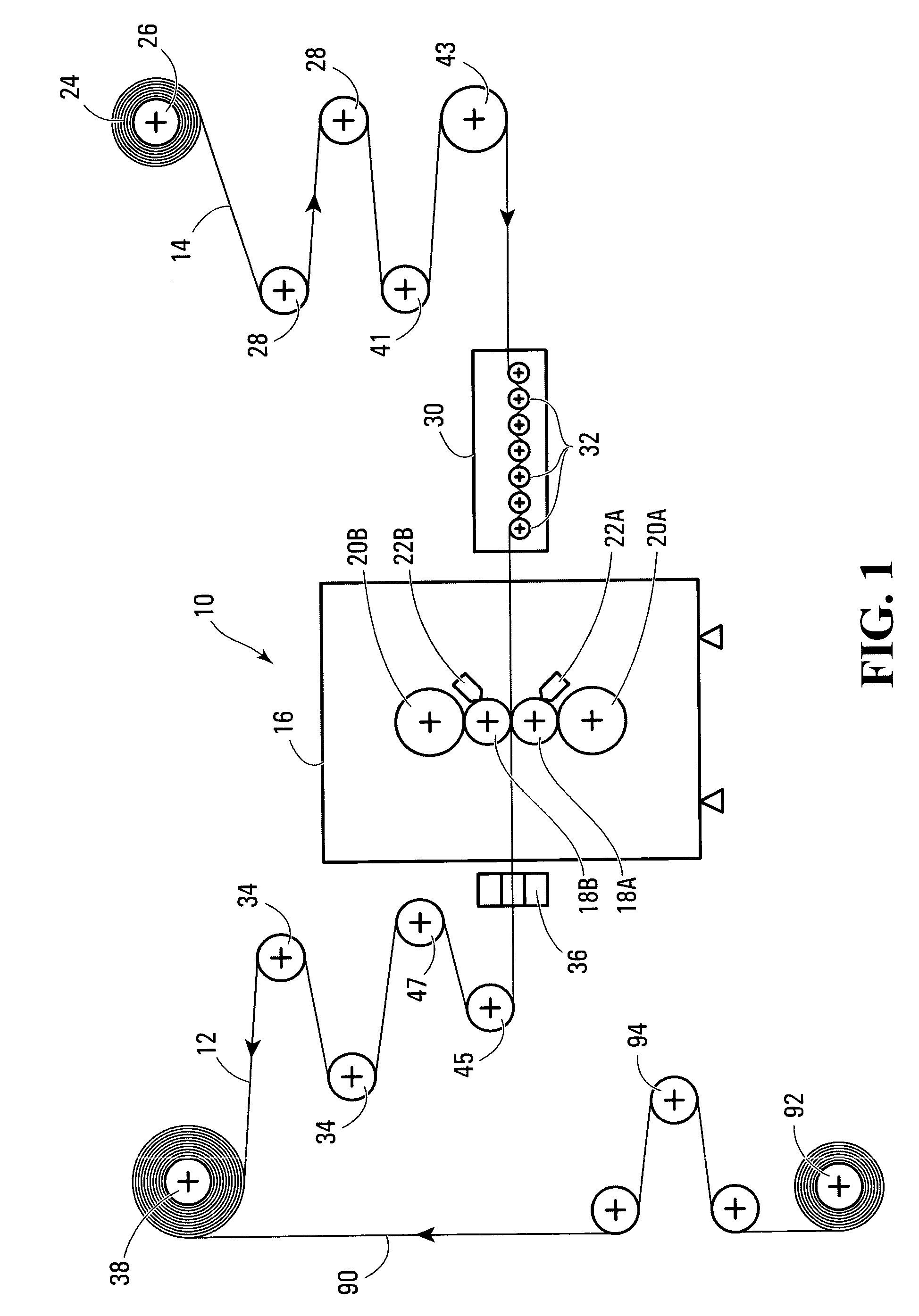

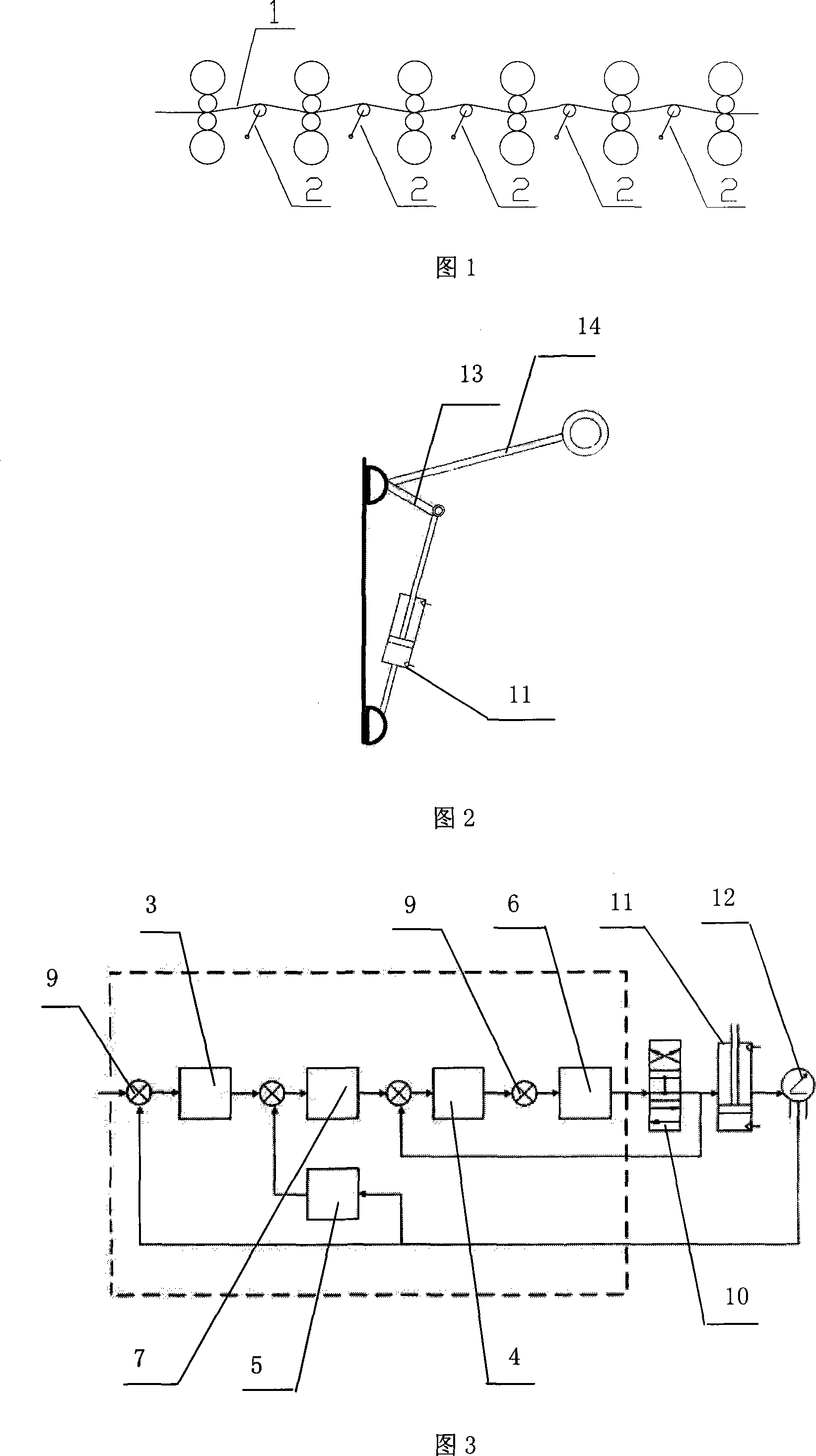

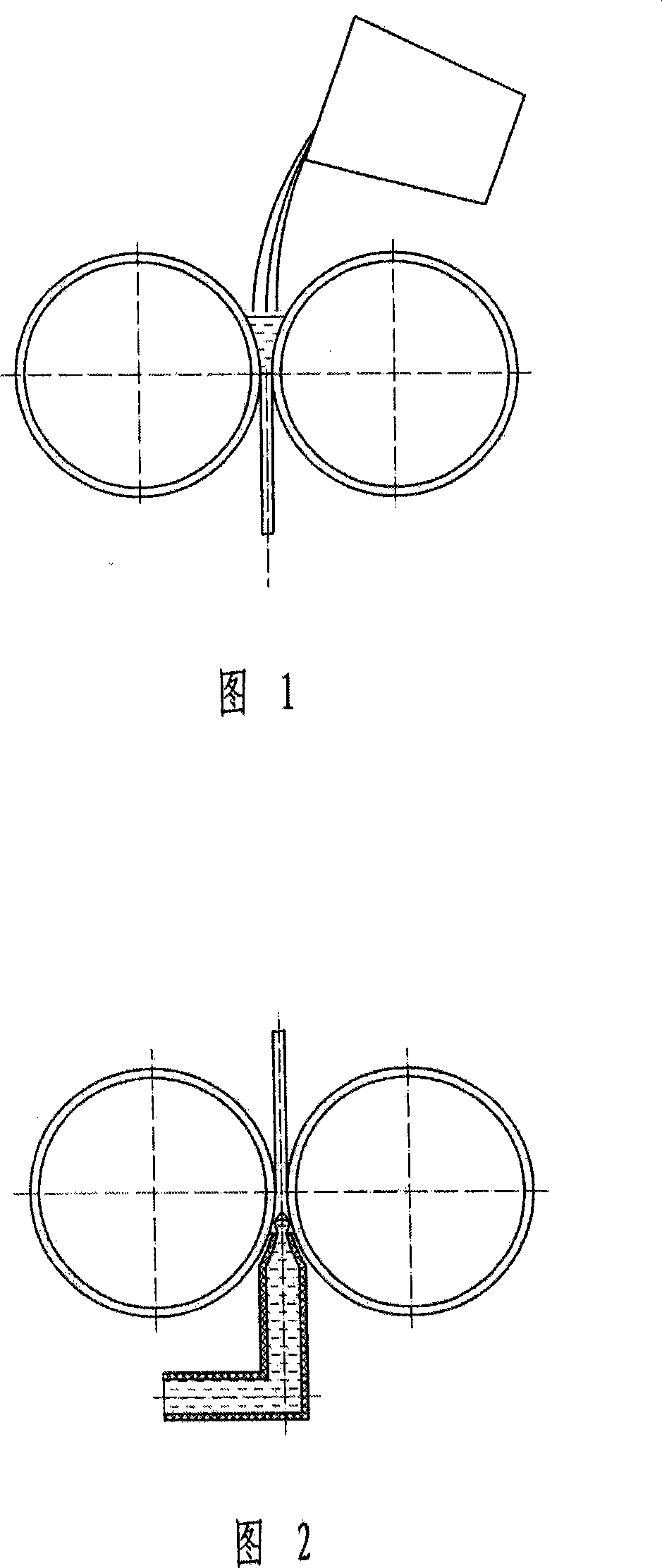

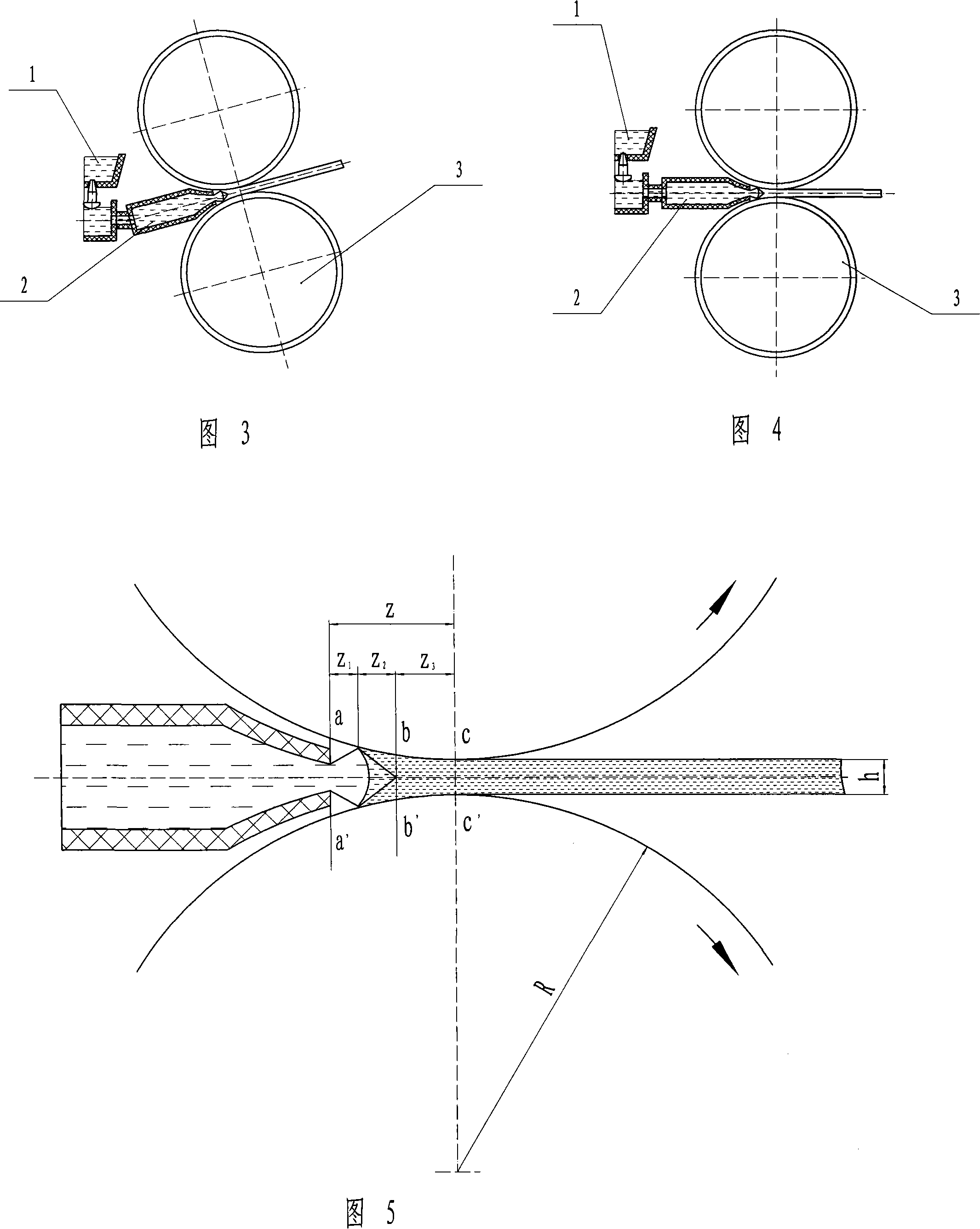

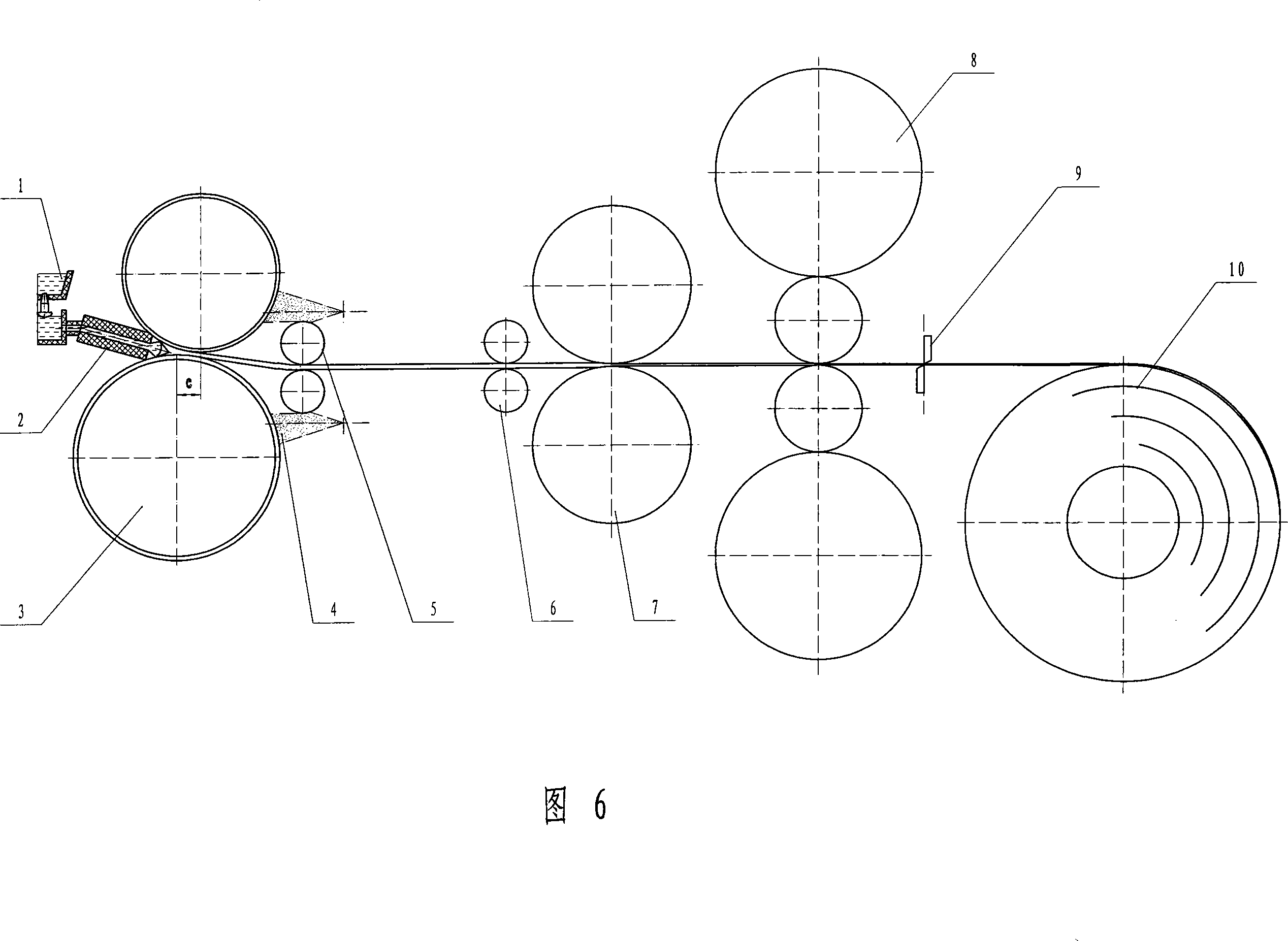

Double-roller casting rolling-hot continuous rolling method and equipment

ActiveCN101239358AIncrease productionHigh dimensional accuracyTemperature control deviceMetal rolling stand detailsProduction lineUltimate tensile strength

The invention provides a method and device for double-roller cast rolling-thermal tandem rolling, which are a method and device for producing aluminum and aluminum alloy plate blank. By using the method, thick cast rolling plate blank can be produced, and coiled material with quality corresponding to that of thermal rolling plate is produced by large rolling amount of thermal rolling, transmitting and coiling. The invention provides a method and device for producing aluminum and aluminum alloy coiled material with high efficiency and greatly improved property by modification aiming at shortcoming of limited cooling space and cooling intensity of the double-roller cast rolling mill in prior art. The invented device enlarges the cast rolling space of the cast rolling mill in prior art with 1.8-4.0 times, enlarges the roller gap thereof with 1.5-2.5 times, enhances the cast rolling speed thereof with 1.5-3.0 times, cast rolls the casting blank continuously with a temperature ranging from 310 DEC C to 510 DEG C, and the integral processing amount is controlled in the range of 40-85, thereby the yield, size accuracy and mechanical property are greatly improved, and the product range is enlarged. The invented device is: inclination angle adjustable off-centering reducing double-roller cast rolling-thermal tandem rolling- cutting-coiling production line.

Owner:张明

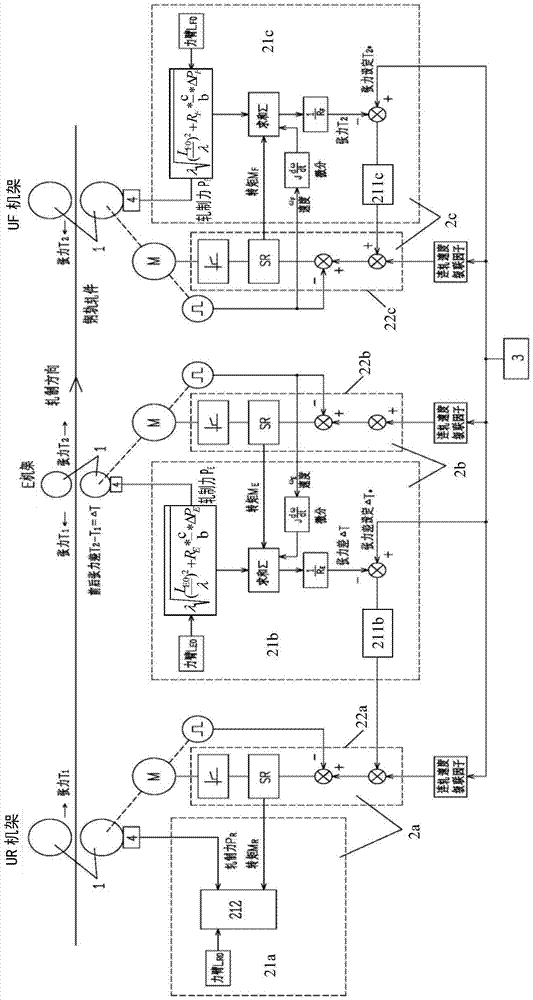

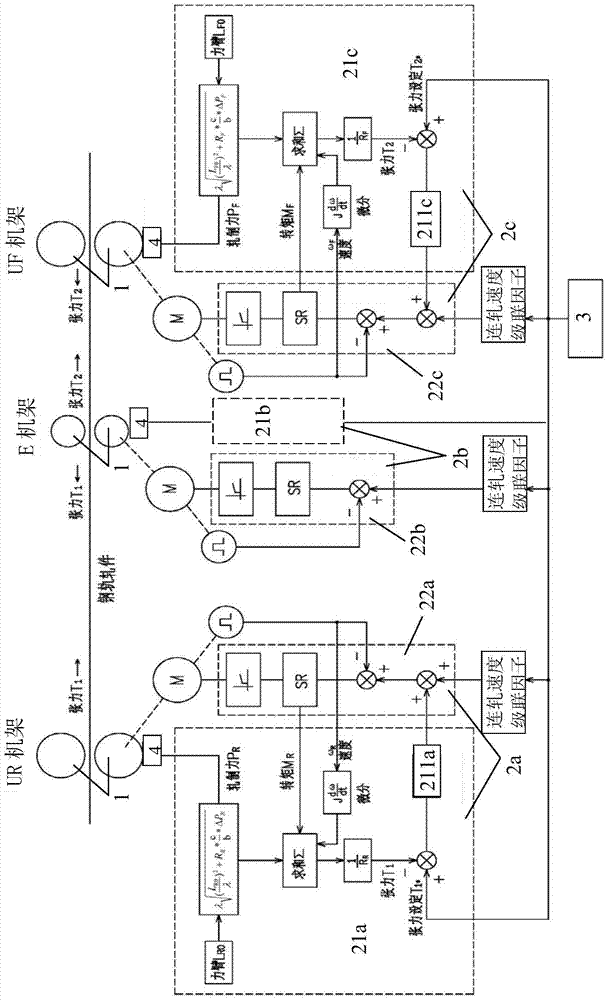

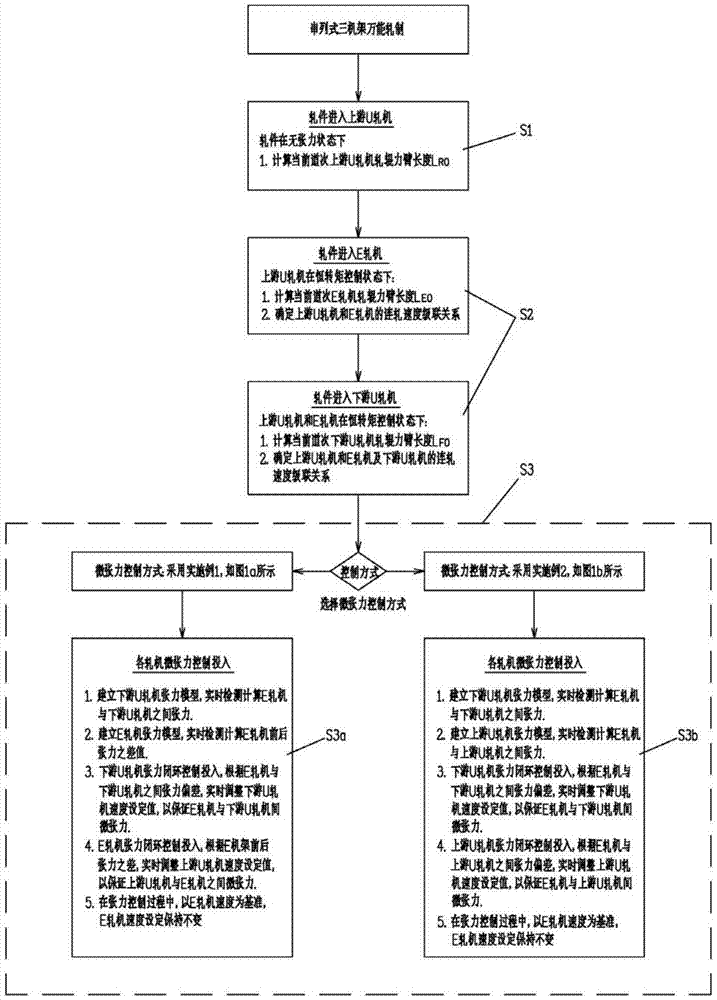

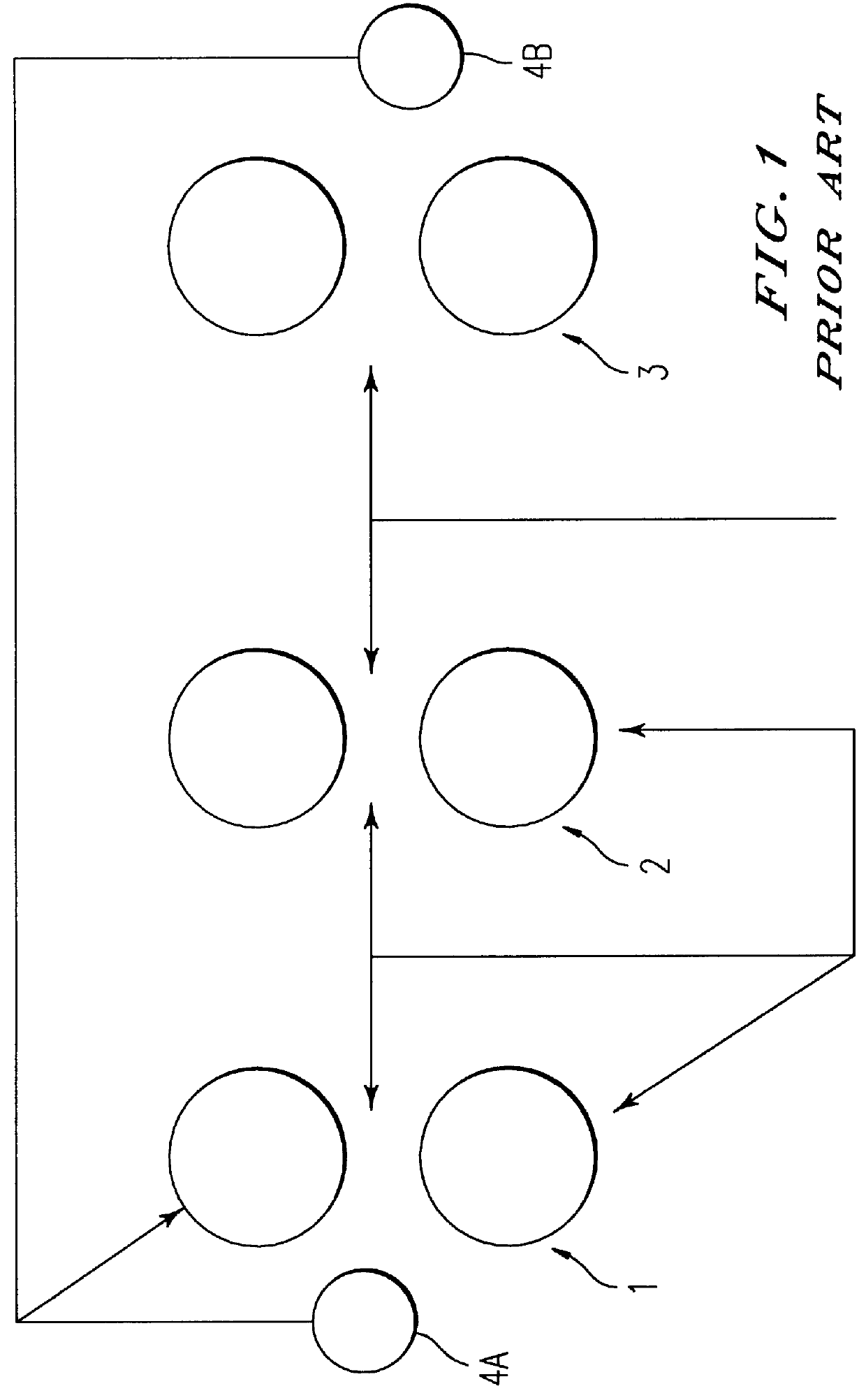

Micro-tension control system and method

ActiveCN103567230AGuaranteed tension control accuracyGeometry out-of-tolerance reductionMeasuring devicesTension/compression control deviceLoop controlClosed loop

The invention discloses a micro-tension control system and method. In the hot continuous rolling process, when a rolled piece enters a current machine frame and is stably bitten, the current machine frame is kept under speed control, speed control of main motors of machine frames on the upstream of the current machine frame is switched to constant torque control, on the basis, the torque and the rolling force of a main motor of the current machine frame are sampled to calculate the initial length of a rolling force arm, and the tension measurement calculating accuracy is improved. Each machine frame is provided with a pressure measuring head device to directly detect the rolling force, and consideration is given to the situation that the length of the rolling force arm is changed along with changes of the rolling force. Tension between the machine frames is obtained in real time through tension calculating models to form micro-tension closed-loop control to adjust the speeds of the machine frames so as to correct the tension deviations between the machine frames. As for a serial type universal rolling mill, the speed of the E machine frame serves as a standard, the rolling speed of the E machine frame is kept unchanged while speed set values of the other machine frames are adjusted, and real-time control is carried out on dynamic instantaneous values of the tension difference of the E machine frame before and after the adjustment process to guarantee micro-tension rolling of series universal rolling.

Owner:BERIS ENG & RES CORP

Method for preventing strip breakage on startup

ActiveCN103785694AThe number of times to prevent the start of the car from breaking the beltReduce tensile stressRoll force/gap control deviceTension/compression control deviceEngineeringBending force

The invention discloses a method for preventing strip breakage on startup. The method includes, before strip winding, processing sheets with broken strips at first after stopping of a cold rolling mill due to strip breakage, compressing roll gaps of various frames and regulating the minimum rolling force of the roll gaps of the different frames after finishing the strip winding, generating exit tension of the different frames prior to regulating roll bending force of working rolls and intermediate rolls after finishing compressing of the roll gaps, and then, starting the cold rolling mill. The method for preventing strip breakage on startup includes control of the roll gaps of the cold rolling mill, selection of rolling force and tension and generation of tension, regulation of actual inclination and tension deviation of different frames, control of bending conditions of the working rolls and the intermediate rolls after startup, thereby effectively controlling times of startup strip breakage of sheets with the thickness lower than 0.6mm and improving production efficiency.

Owner:SHOUGANG CORPORATION

Method for producing metallic titanium plate using medium-wide strip hot rolling machine set

ActiveCN101412038ALow investment costRoll force/gap control deviceTemperature control deviceSocial benefitsProduction line

The invention discloses a method for producing a metallic titanium plate by adopting a medium-wide band heat rolling set. The method comprises the following steps: heating a titanium plate blank with a thickness of between 50 and 90 millimeters in a roller-hearth type soaking furnace to between 800 and 1,000 DEG C, controlling inlet temperature of the titanium plate blank entering the medium-wide band heat rolling set at a temperature of between 800 and 950 DEG C, controlling process temperature to between 700 and 950 DEG C, and keeping final rolling temperature at a temperature of between 700 and 800 DEG C after fine rolling for seven times; and well controlling roll gap width, depressing rate, roll force and roll (rolling) speed of each stander of the heat rolling set, controlling the rolling speed of the titanium plate rolled by the tail stander of the heat rolling set at between 4.0 and 8.0 meters per second, and coiling the titanium plate by a coiling machine after cooling the titanium plate by water, wherein the coiling temperature is between 550 and 680 DEG C. The method uses a CSP production line to produce the non-ferrous metallic titanium plate (coil) for domestic initiation, and has extremely great economic and social benefits.

Owner:湖南湘投金天钛金属股份有限公司 +1

Control process for continuous skin pass operation for metal strip

InactiveUS6079242AEliminate disadvantagesRoll force/gap control deviceTensioning/braking arrangementsMechanical engineeringEngineering

A method of controlling a continuous skin-pass and reduction operation for a metal strip includes the steps of passing a strip through a gap between working rollers of at least two successive rolling stands, only an upstream one of the stands providing substantial thickness reduction of the strip; determining an extension rate of the strip provided by the upstream stand; determining a tension of the strip downstream of the upstream stand; adjusting the speed of the working rollers of the upstream stand compared to the speed of the working rollers of a downstream one of said stands according to the determination of the extension rate; and adjusting the squeezing force of the upstream stand according to the downstream tension determination. A response time to the step of adjustment of the squeezing force is longer than a response time to the step of adjusting the speed of the working rollers.

Owner:SOLLAC (SA)

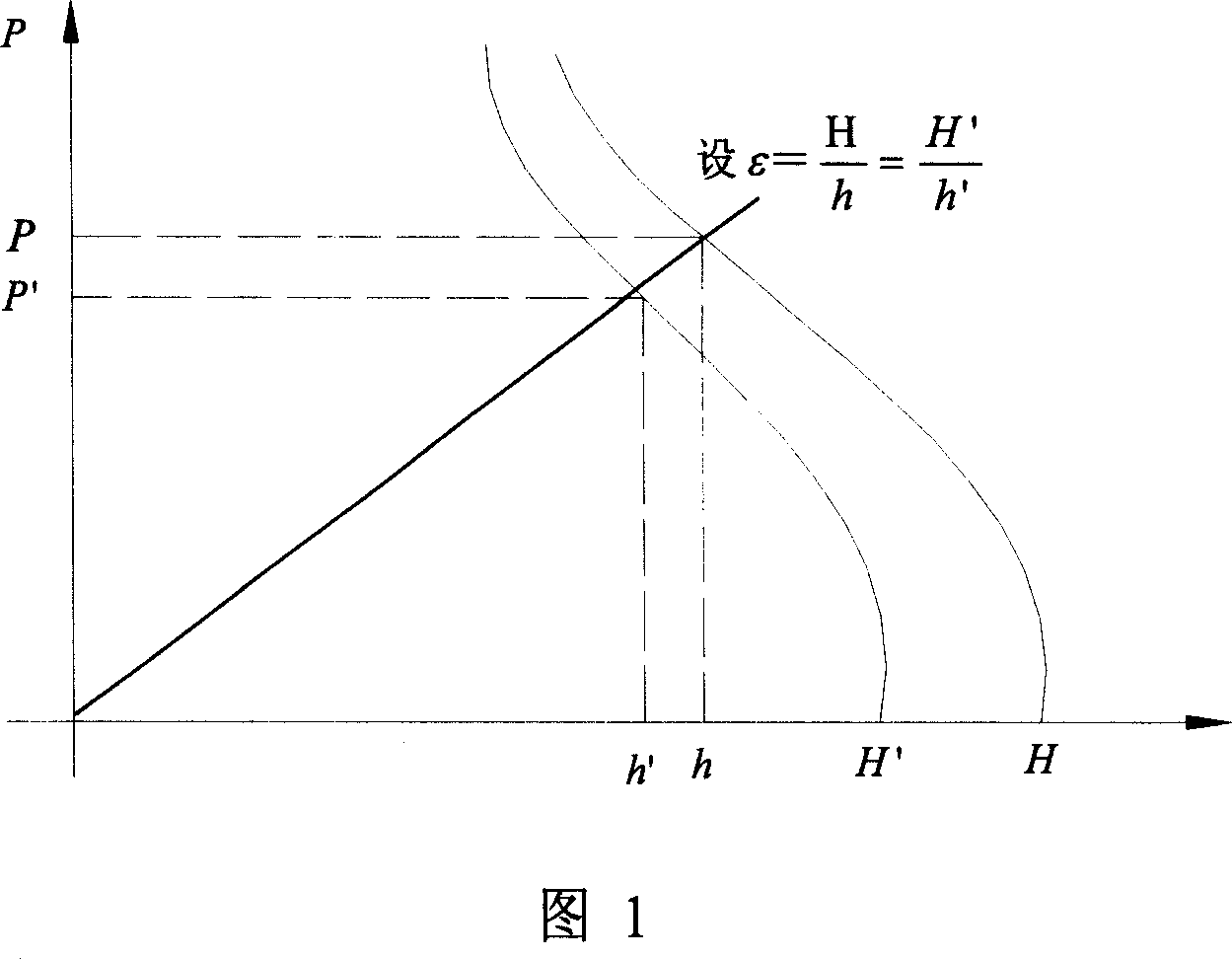

Extension coefficient and plate shape integrated control method in steel strip flattening process

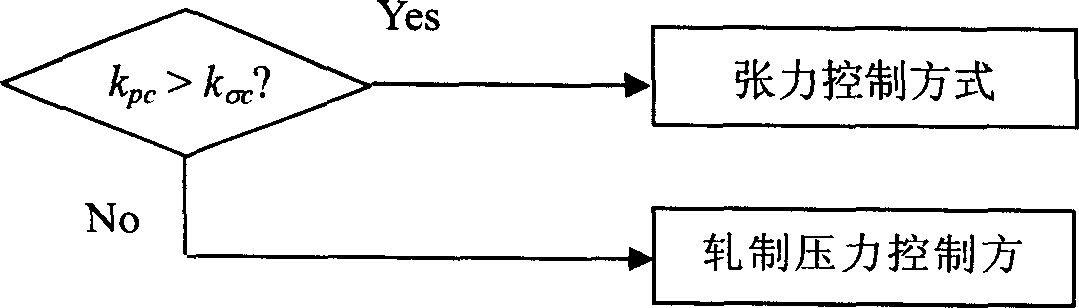

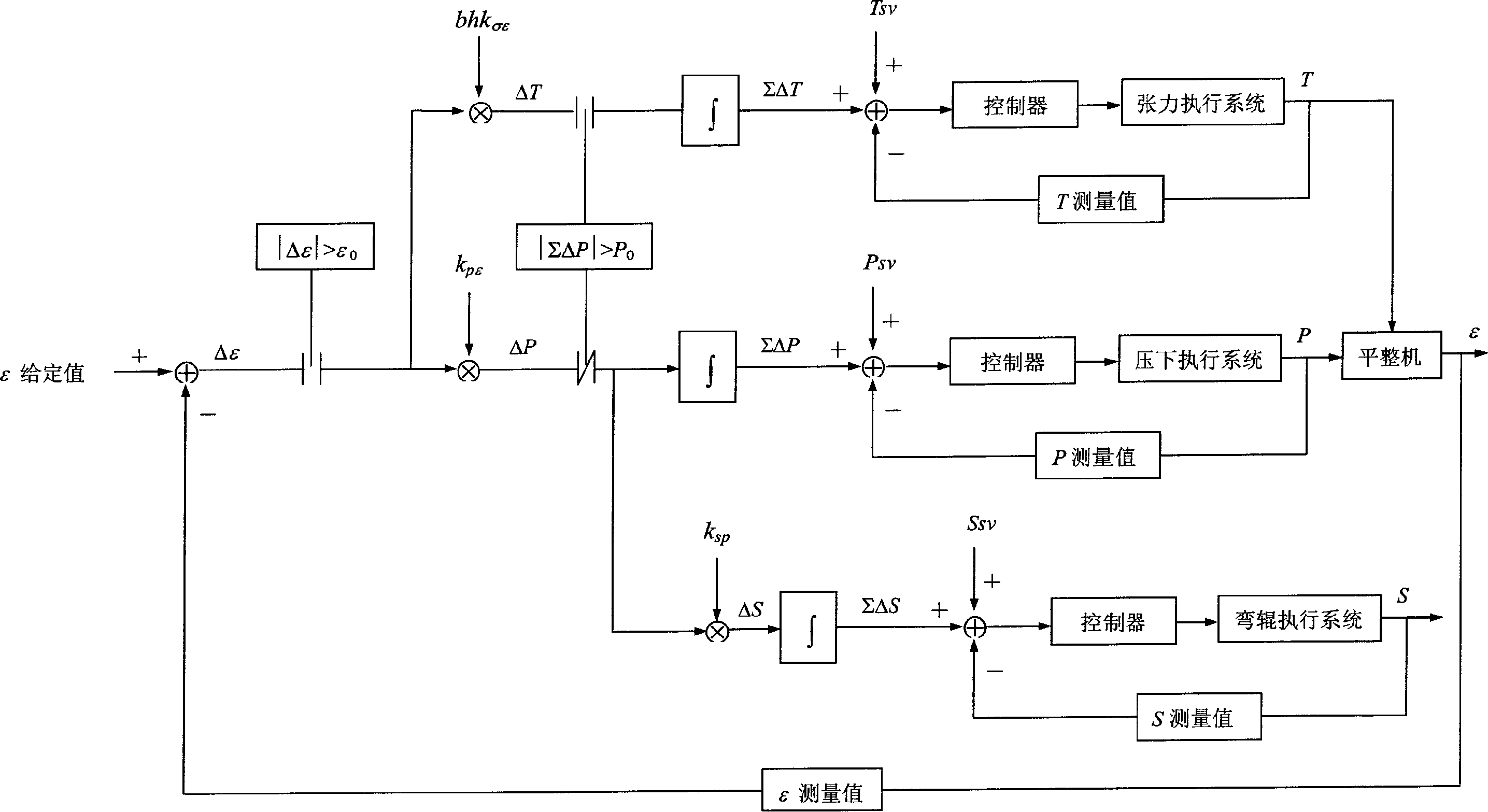

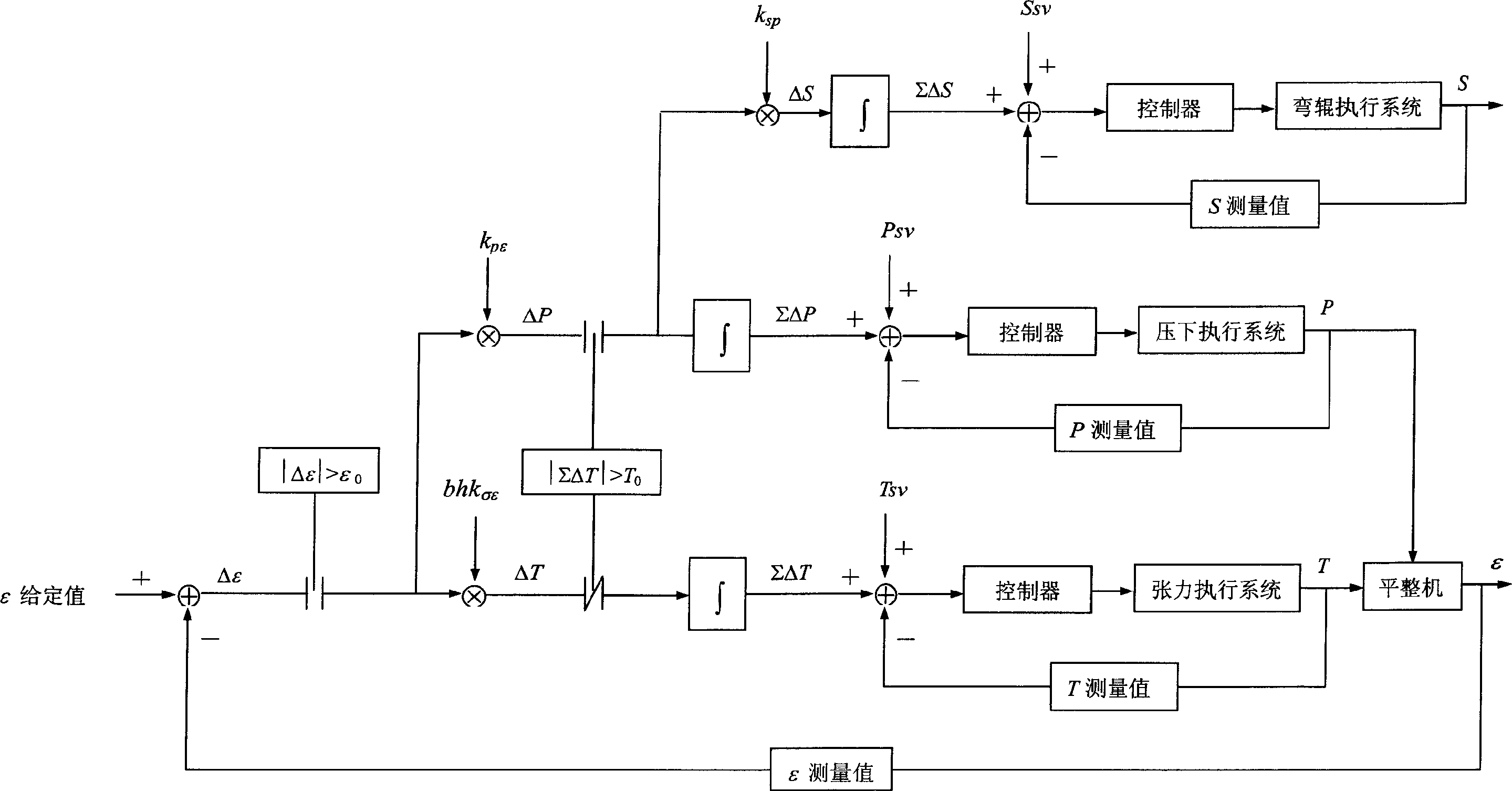

ActiveCN1840255AHigh elongationHigh precisionRoll force/gap control deviceTension/compression control deviceSet pointTension control

The invention discloses a belt steel flattening elongation and slab-shaped complex control method, which is characterized by the following: the invention can choose draught pressure mode by comparing draught pressure adjusting elongation algebraic system and tension adjusting elongation algebraic system or use tension mode to control elongation, which can control rolling process of planisher according to set point of every processing parameter and relevant on-line measured value; the tension is controlled in draught pressure control mode, when the draught pressure accumulation regulating variable is over finite limit and the draught pressure keeps constant; the draught pressure is adjusted in tension control mode, when the tension accumulation regulating variable is over finite limit and the tension keeps constant; the curve roll force is adjusted when adjusting draught pressure.

Owner:BAOSHAN IRON & STEEL CO LTD

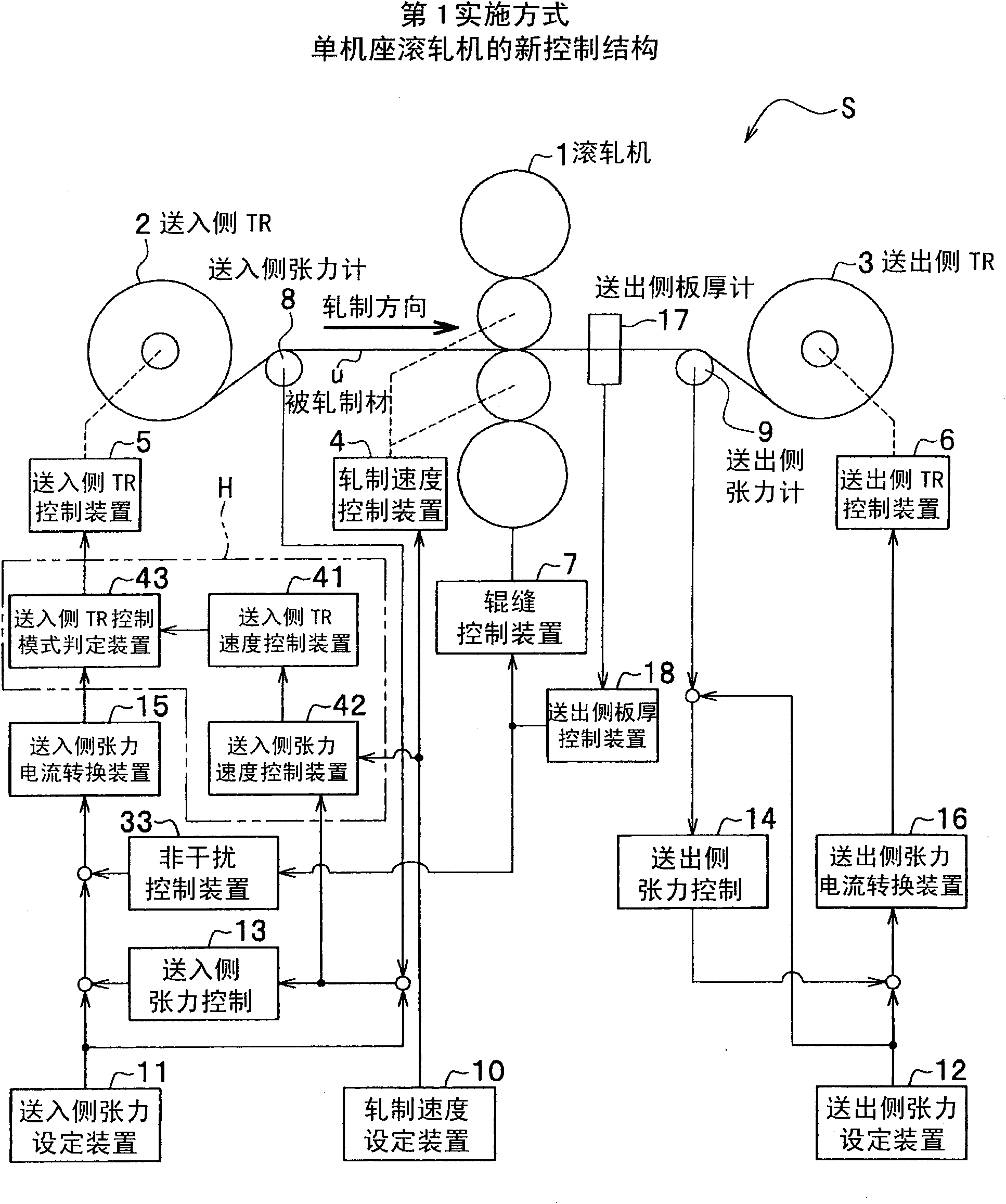

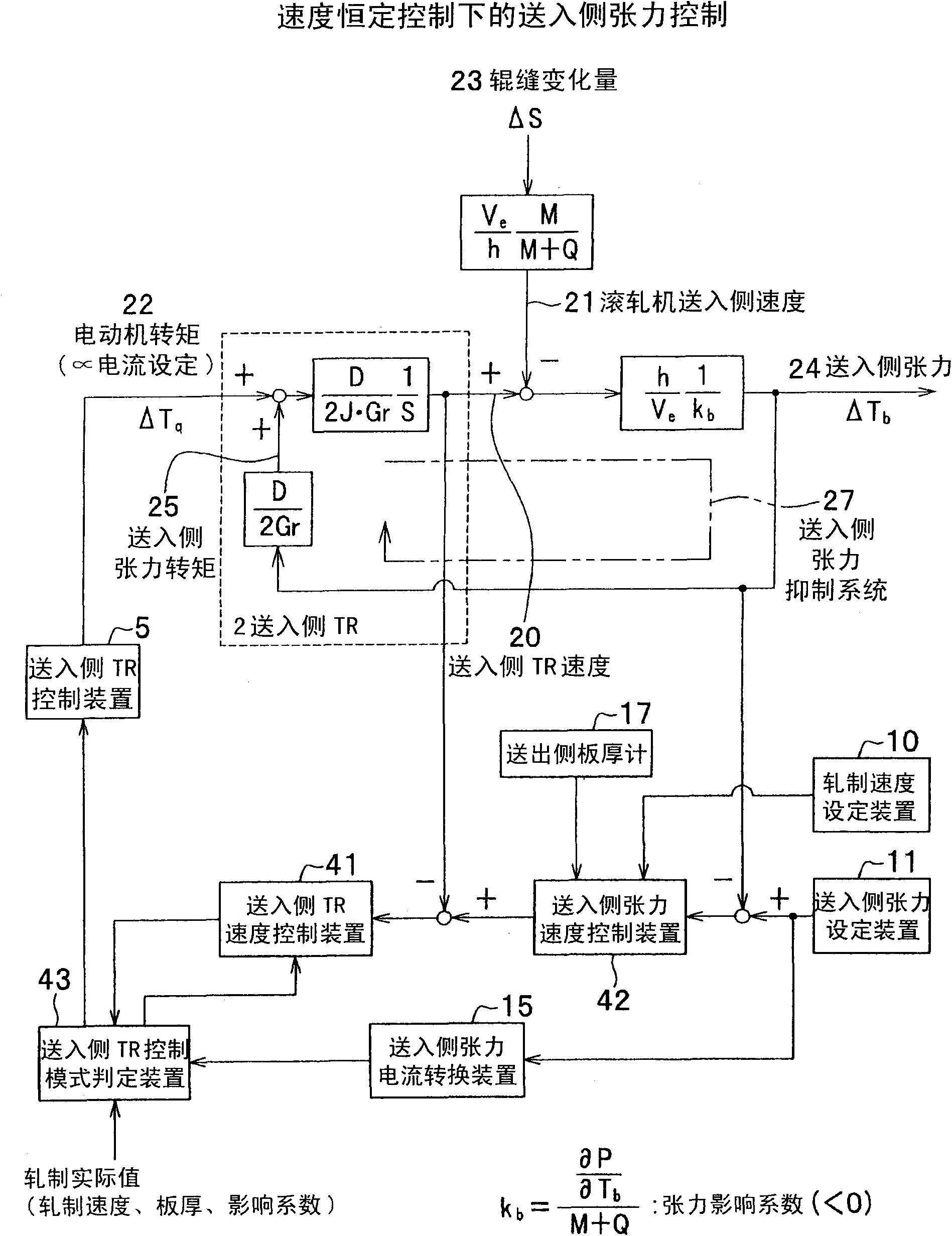

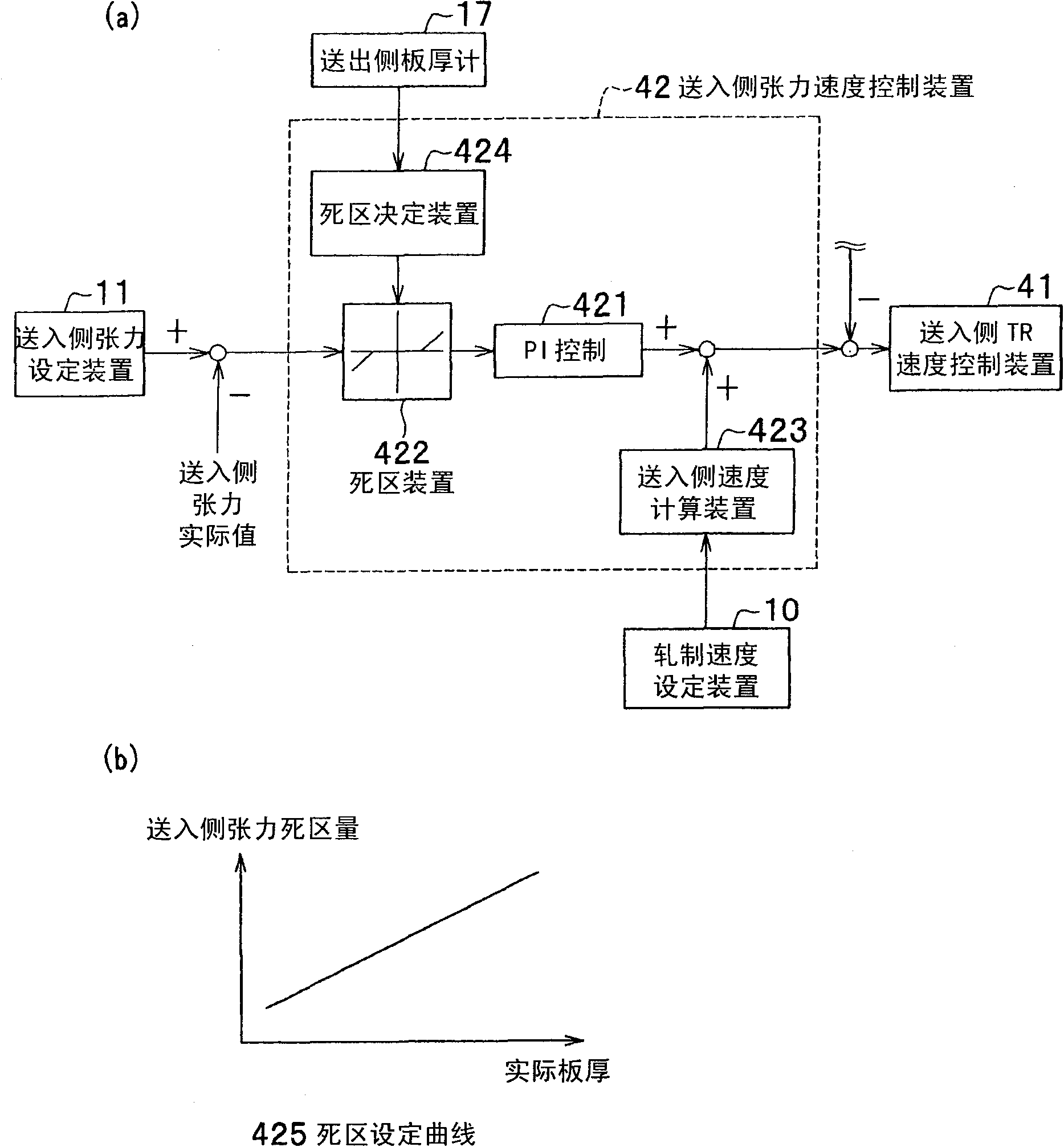

Control device of rolling machine and control method thereof

ActiveCN101856670ATension/compression control deviceMetal rolling arrangementsEngineeringMechanical engineering

The present invention provides a control device of a rolling machine, which restrains the plate thickness variation of rolling machine generated by the speed variation of a tension reel at the feeding-in / feeding-out side. In the rolling machine, the feeding-in / feeding-out side of the rolling machine (1) is provided with the tension reel (2) for unreeling and reeling the rolled material (u). The control device is provided with a tension and speed control unit (41) which sustains the tension between the tension reel (2) and the rolling machine (1) to an expected value. On the other hand, for the derivation to a preset tension value in the preset range, the speed of the tension reel is fixed to a constant value without modifying the tension error for restricting the speed variation of the tension reel.

Owner:HITACHI LTD +1

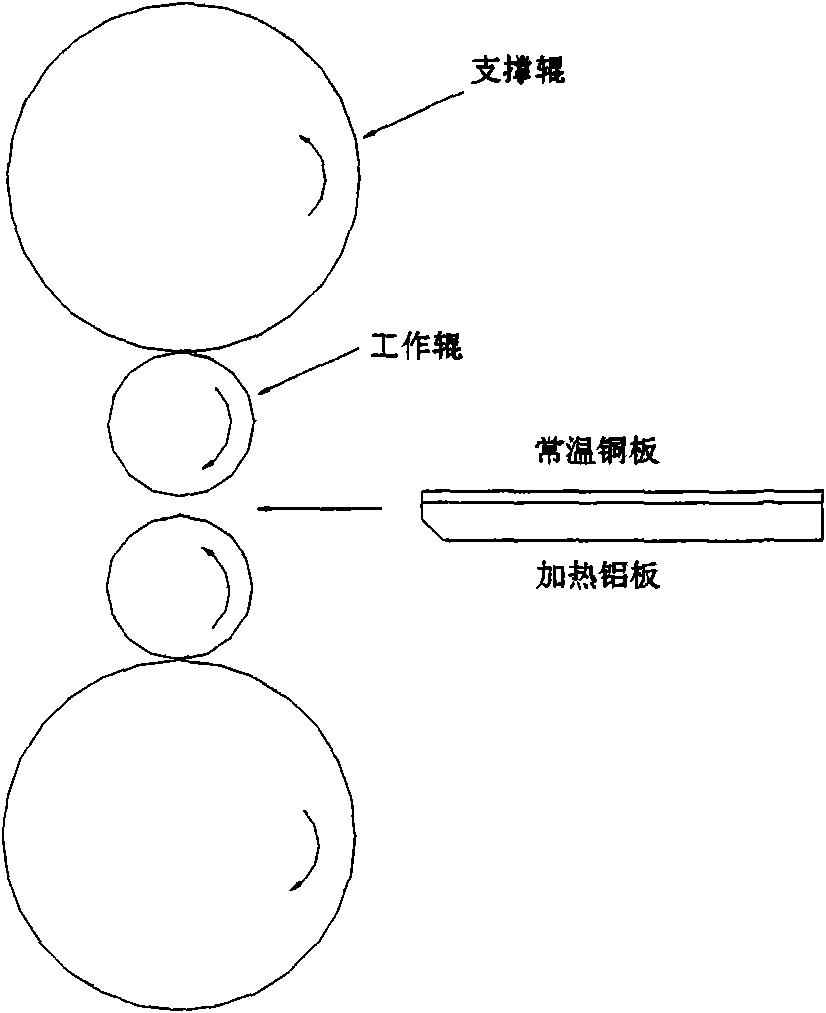

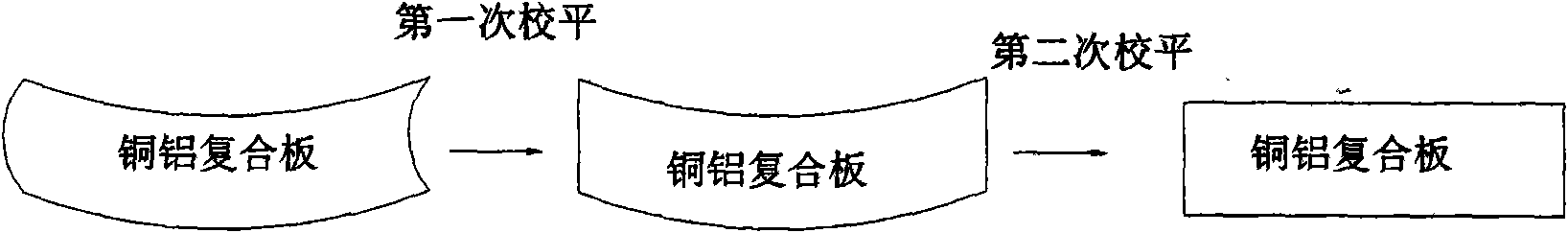

Manufacturing method of copper-aluminum composite board

InactiveCN101559557APrevent oxidationImprove bindingTemperature control deviceTension/compression control deviceCopperAluminum composites

The invention discloses a manufacturing method of a copper-aluminum composite board, comprising the following steps: 1. removing oil for preliminary treatment; 2. grinding a junction surface; 3. heating an aluminum board, not heating a copper board and performing inreversible and isodromic rolling in one pass; 4. adopting a common leveler with fifteen rollers to carry out twice leveling; and 5. cutting to form into finished products. The invention solves the problem that the bonding strength of copper and aluminum is lower and achieves the beneficial effects of producing the high-quality copper-aluminum composite boards in batch with low cost.

Owner:上海新东蒸发器有限公司

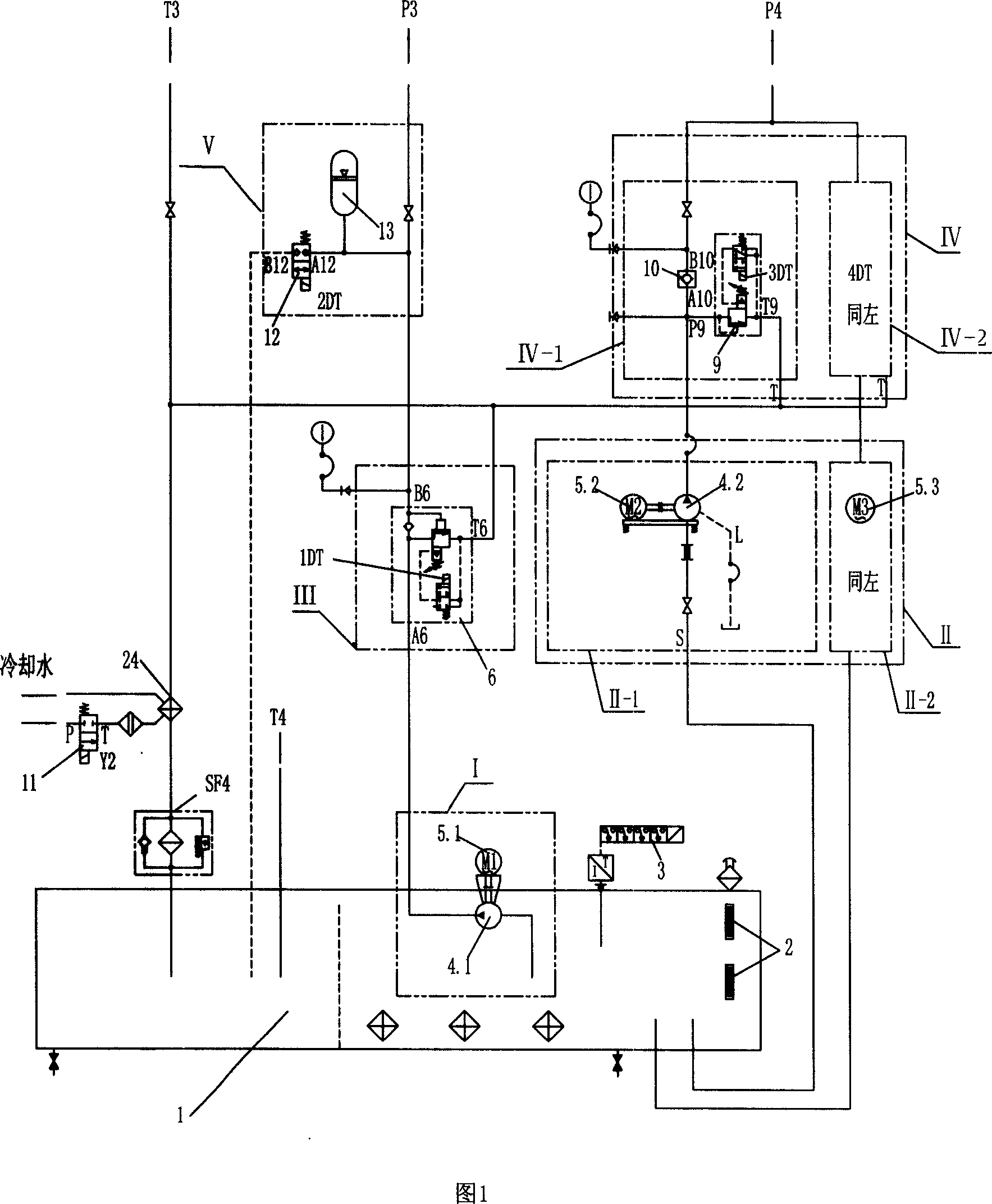

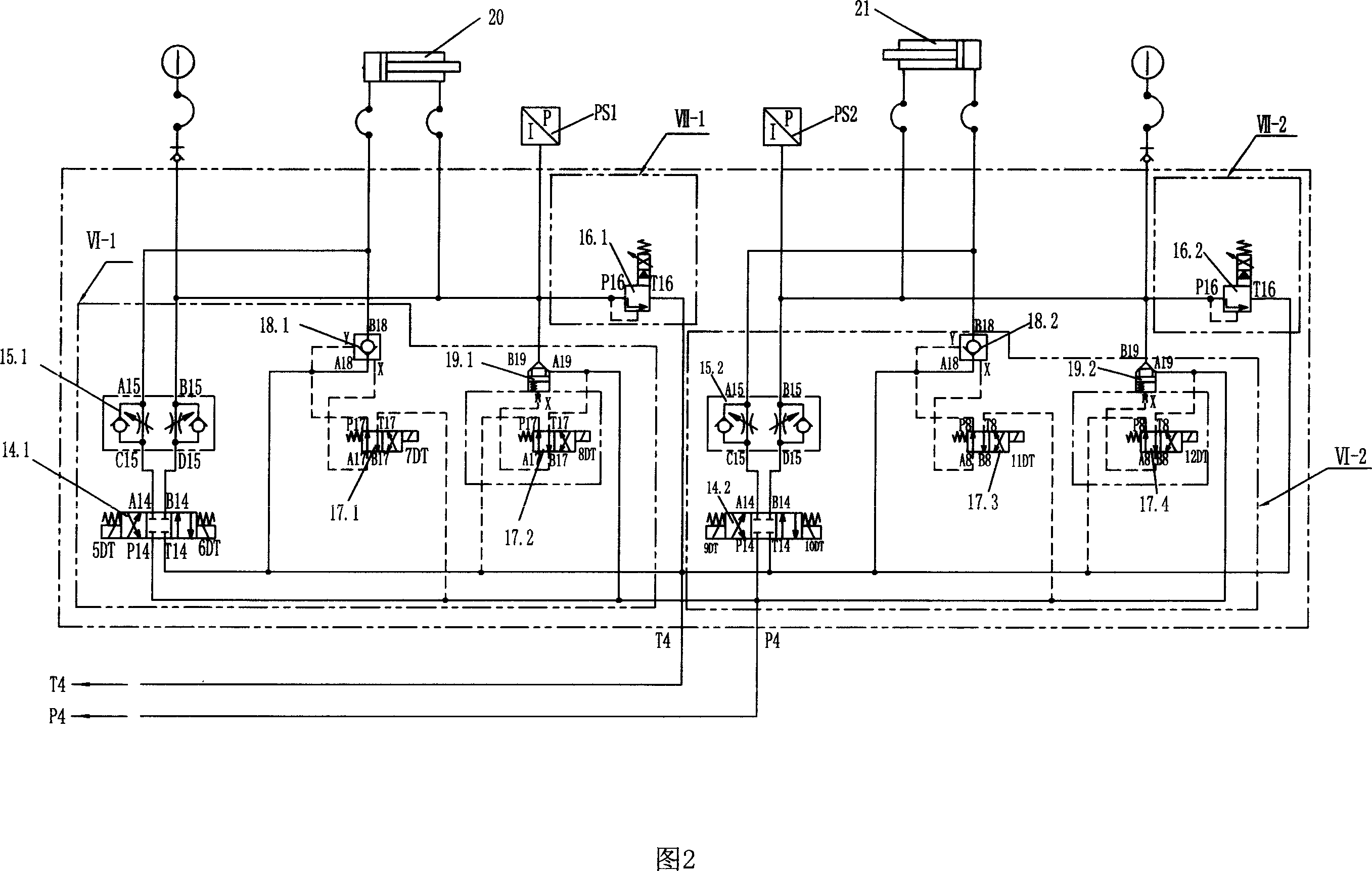

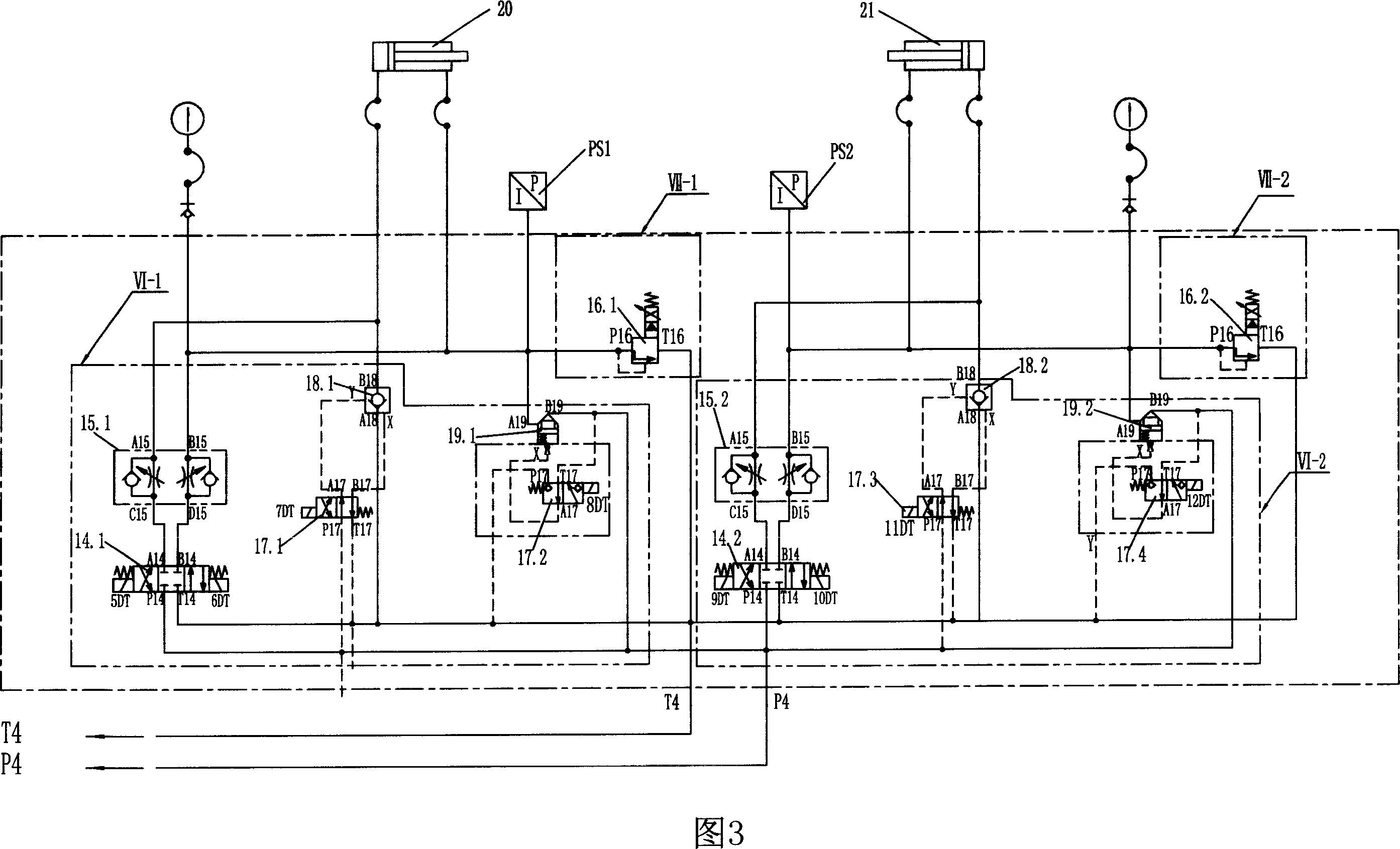

Ratio control hydraulic pressure system for implementing belt steel rolling constant-tension control

InactiveCN101011709AAchieve energy saving effectGuaranteed cleanlinessFluid-pressure actuatorsTension/compression control deviceHydraulic cylinderProportional control

The proportional control hydraulic system with steel rolling constant tension control comprises tension hydraulic cylinder, pressure sensor, tension hydraulic cylinder control, hydraulic fixture, with the tension hydraulic cylinder control composed of high pressure oil source, high pressure safety pressure control, tension hydraulic action control and proportional control, with the high pressure oil source connecting with two tension hydraulic cylinder control device and proportional control, tension hydraulic action control device, proportional control device connecting with hydraulic cylinder bar free cavity and with bar cavity, the clamping control composed of low pressure oil source, low pressure control device, energy accumulation device, clamping cylinder action control, with the low pressure oil source connecting with two clamping hydraulic cylinder through low pressure control device, energy accumulation device and clamping cylinder action control device, tension hydraulic cylinder with bar cavity connected with pressure sensor, and each oil return opening and discharge opening connecting with the oil tank.

Owner:NORTHEASTERN UNIV

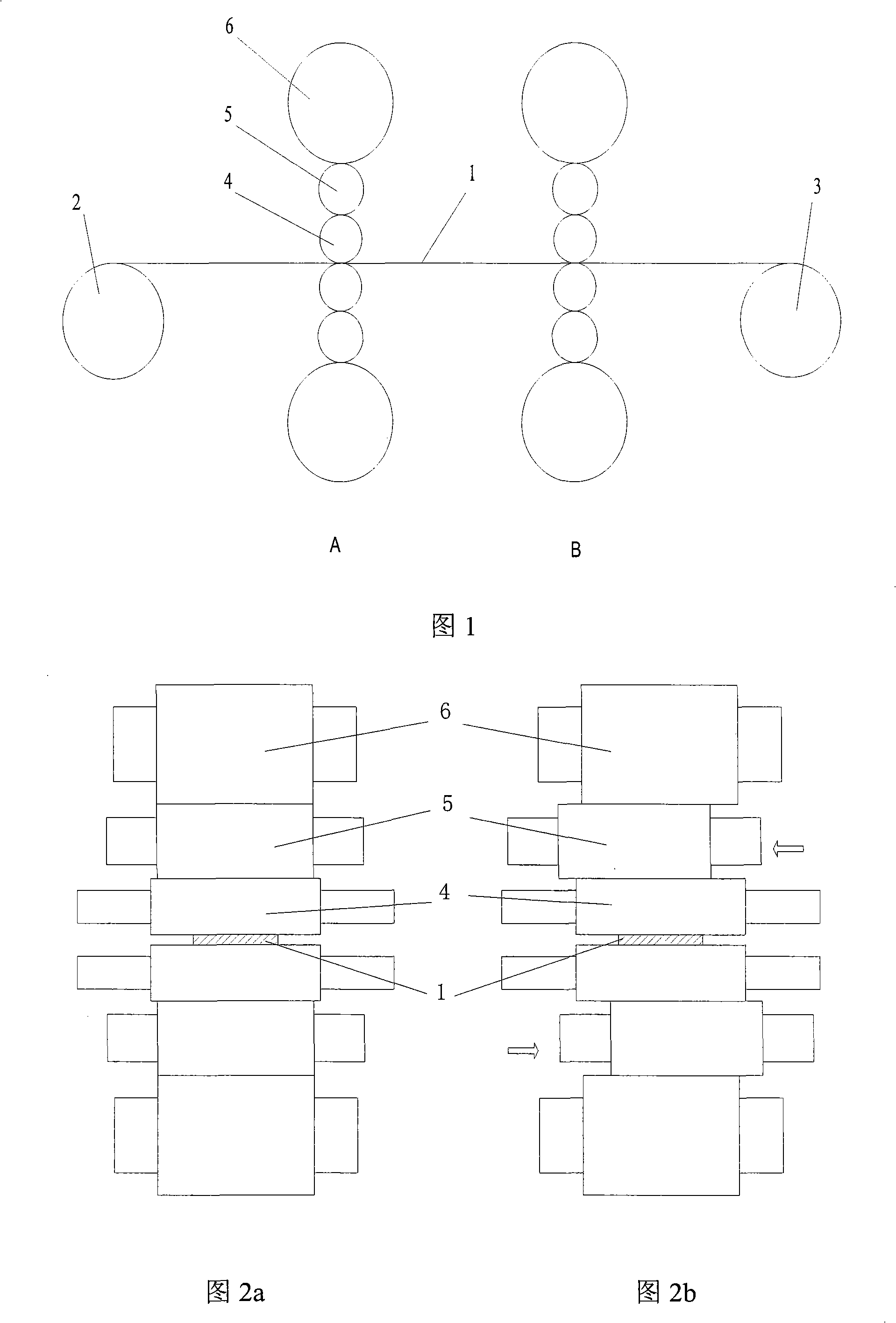

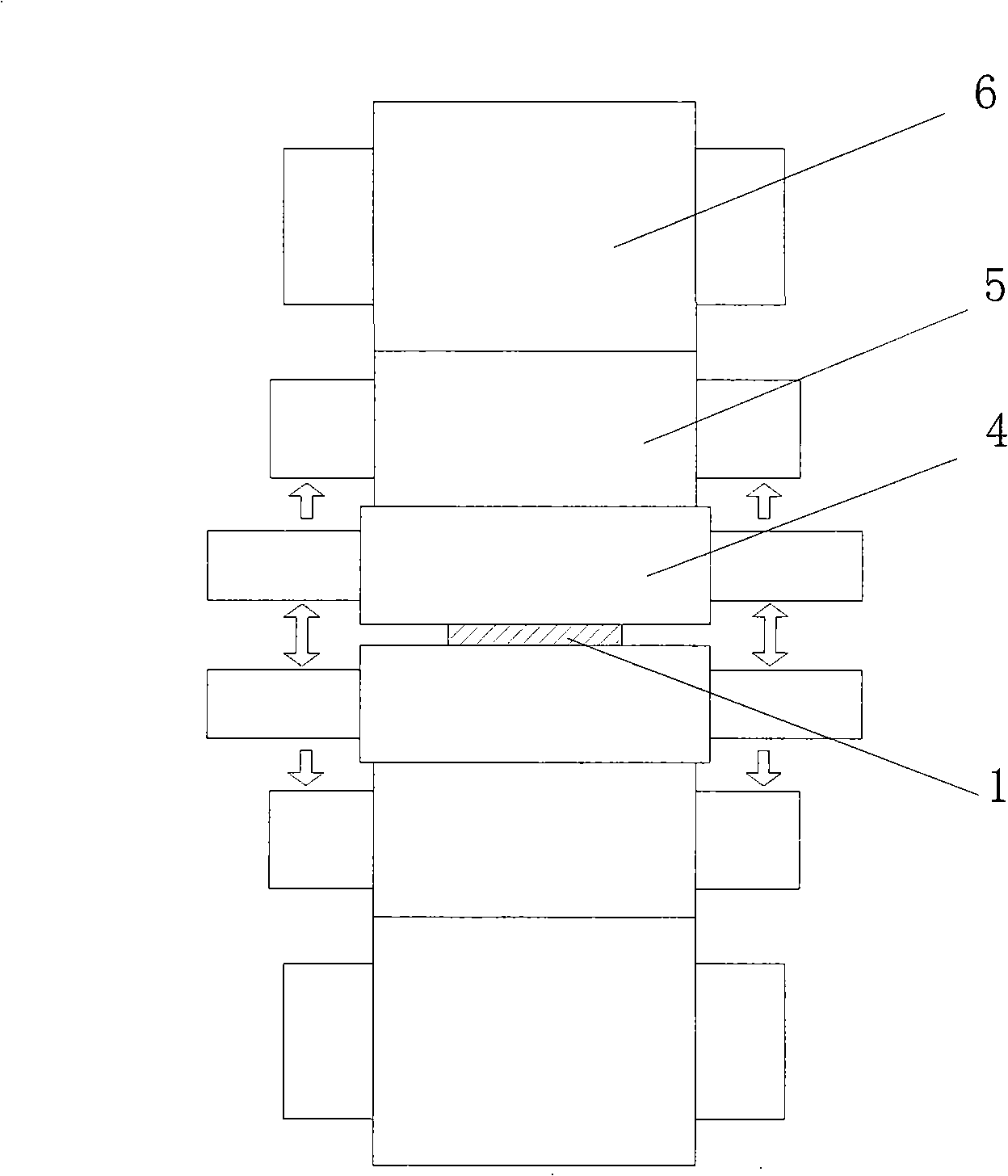

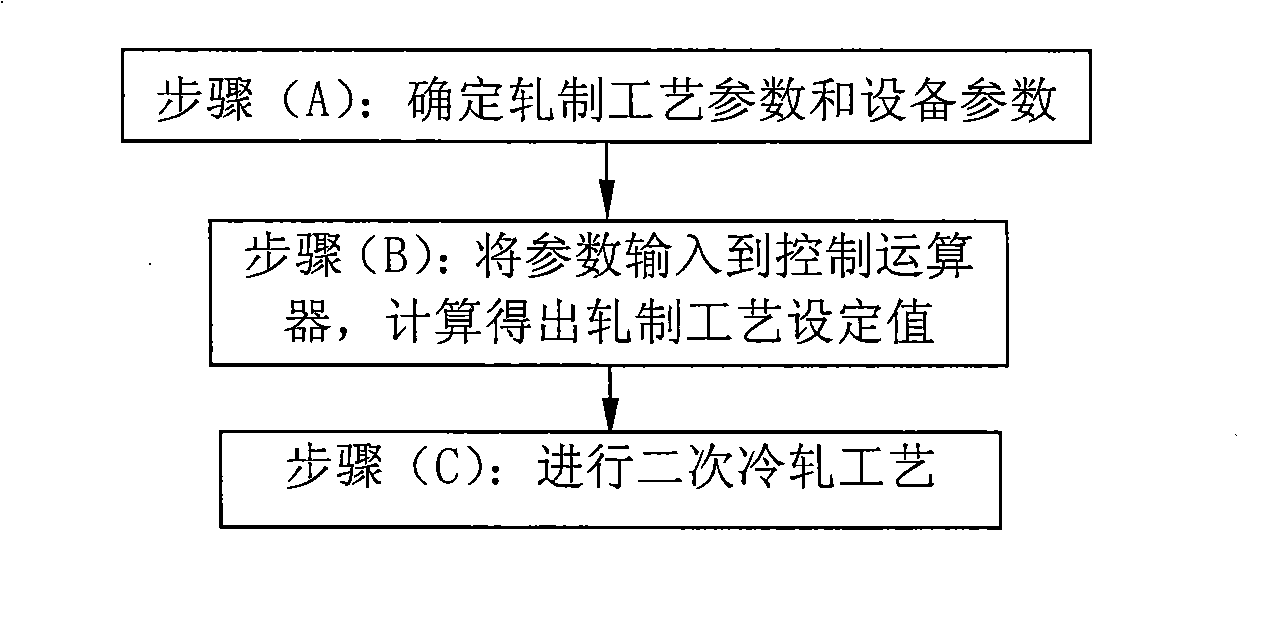

Method for leveling strip produced by secondary cold rolling unit

ActiveCN101513647AEasy to shapeQuality improvementTension/compression control deviceProfile control deviceHorizontal distributionWork roll

The invention provides a method for leveling a strip produced by a secondary cold rolling unit, which controls the surface roughness of the strip by reasonably setting the partition coefficients of the roughness and elongation of the working rolls of first and second machine frames and controls the shapes of finished strips other possible surface defects by reasonably setting a bending-roller force, a roll shifting rate and the tension of the front, middle and rear sections of the machine frames to achieve uniform front tension of finished strips and uniform horizontal distribution of a rolling force, thereby establishing effectively improved technology for leveling high-brightness micro plates produced by a secondary cold rolling unit. The principle of the method is clear, a secondary cold rolling process is carried out smoothly according to obtained rolling process set values, the quality of the shape and surface of leveled strips is high, the calculation is quick, and the method issuitable for online use.

Owner:BAOSHAN IRON & STEEL CO LTD

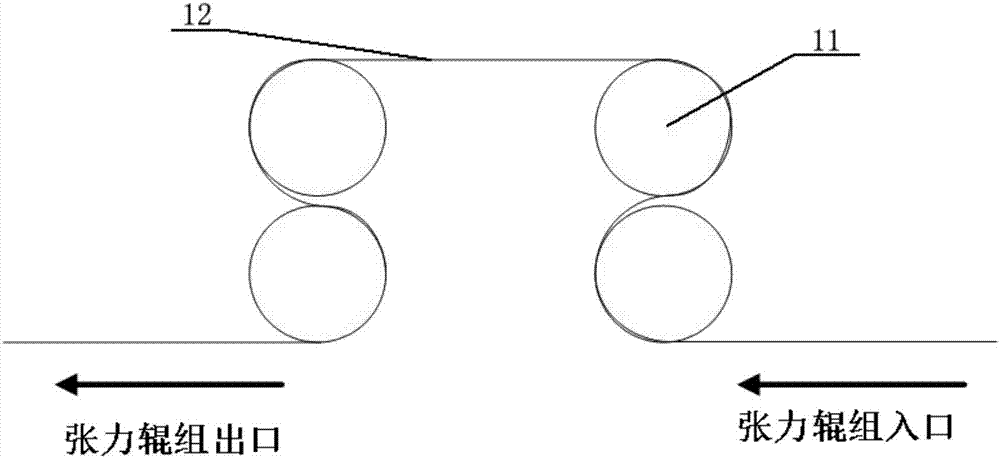

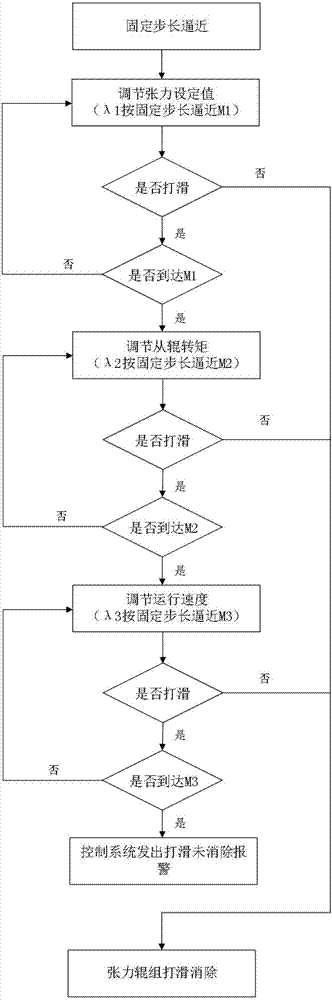

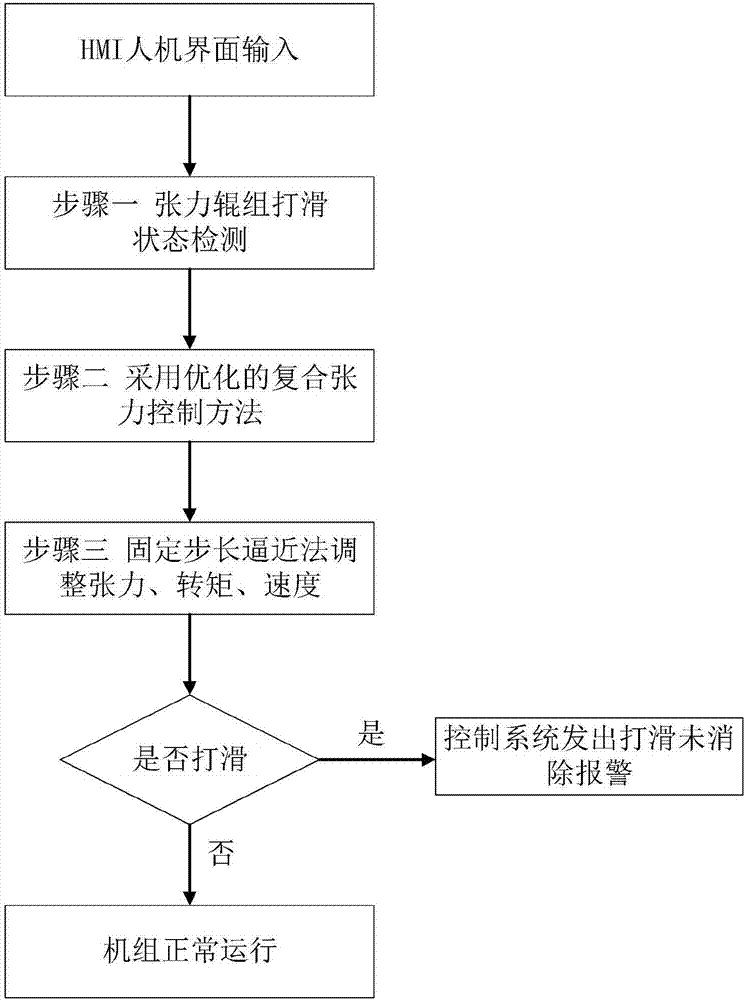

Control method for reducing influence of slipping of tension roll set

ActiveCN107952799AReal-time monitoring of slippageEliminate slippageTension/compression control deviceProduction lineControl system

The invention provides a control method for reducing the influence of slipping of a tension roll set. The control method is characterized by comprising the following steps of 1, monitoring of the tension roll set slipping state, 2, formulating of a tension roll set tension control method, and 3, reducing and even eliminating of the tension roll set slipping state through a fixed-step approach method. According to the control method for reducing the influence of slipping of the tension roll set, in a control system, through three slipping judgment strategies, whether the tension roll set in a cold rolling strip material production line slips or not and which tension roll slips are monitored in real time, and according to the production state, the tension roll set in the production line is controlled through the formulated composite control method. When the slipping state occurs, through the fixed-step approach method, the tension, torque and speed are adjusted so as to reduce and finally eliminate the occurring slipping phenomenon of the tension roll set.

Owner:WUHAN UNIV OF SCI & TECH

Stainless steel band production method for mobile telephone

InactiveCN101386024AImprove surface roughnessEliminate the need for frostingFurnace typesTension/compression control deviceMaterials preparationSolution treatment

The invention discloses a method for producing a stainless steel band for a mobile phone, in particular relates to a method for producing the stainless steel band for processing the mobile phone shell. The method is characterized by comprising the steps of material preparation, primary rolling, solution treatment, primary cleaning, secondary rolling, secondary cleaning and straightening and withdrawal, etc. The stainless steel band produced by the method is further processed into the mobile phone shell which produces no fingerprint after being touched by hands and is beautiful. The method can meet the demand of the mobile phone shell while the production cost is reduced.

Owner:无锡华生精密材料股份有限公司

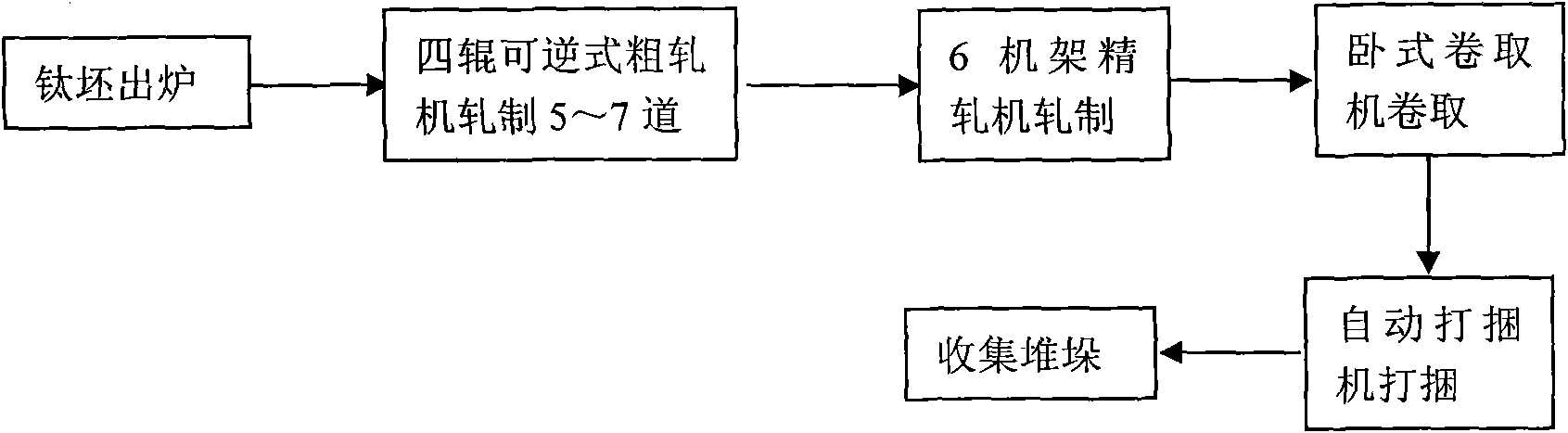

Method for producing titanium strip by adopting conventional hot continuous rolling machine set

InactiveCN101811135AAbundant resourcesReduce manufacturing costTemperature control deviceTension/compression control deviceSocial benefitsTitanium

The invention discloses a method for producing a titanium strip by adopting a conventional hot continuous rolling machine set, wherein the method comprises the following steps: heating a titanium plate blank with the thickness of 150 to 250mm to the temperature of 800 to 900 DEG C in a walking beam type heating furnace, manufacturing the titanium strip with the thickness of 2.5 to 20mm through five passes of rough rolling and continuous rolling of six stands, and coiling into a strip coil through a coiler, wherein the finishing temperature is larger than 650 DEG C, the coiling temperature is larger than 550 DEG C, and the coil weight is 5 to 15 tons. Producing the titanium strip through the conventional hot continuous rolling machine set belongs to domestic initiation and has great economic and social benefits.

Owner:SHANDONG IRON & STEEL CO LTD

Method for leveling titanium board coil

InactiveCN101486051AStress reliefEliminate its influenceTension/compression control deviceRoll speed control deviceNational standardTitanium

The invention provides a method for levelling a titanium plate coil, which comprises the following steps: delivering the titanium plate coil subjected to annealing treatment to a levelling machine, and directly carrying out levelling extension on the titanium plate coil by a levelling roll on the levelling machine or carrying out wet levelling on the titanium plate coil by the levelling roll under the conditions that the rolling speed is 50 to 200 meters per minute, the uncoiling tension is 0.5 and 4 tons, the curling tension is between 3.0 and 5.0 tons, and the extension rate is between 0.80 and 2.0 percent. After the cold-rolled and annealed titanium plate coil is subjected to leveling extension by the levelling roll on the levelling machine, the levelling method can eliminate stress and influence of the stress, level plate surfaces, and obtain better surface quality; and all the plate shape, dimension, surface quality, mechanical property, and the like of the leveled titanium plate coil achieve national standard requirements, and completely meet market demand.

Owner:YUNNAN TITANIUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com