Strip steel tension dynamic control method based on loop quantity deviation and control system using strip steel tension dynamic control method

A technology of dynamic control and tension control, which is applied in the direction of tension/pressure control, etc., can solve problems such as strip steel frame deviation width, narrowing, looper amount deviation, etc., so as to improve the quality of strip steel rolling products and improve control The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

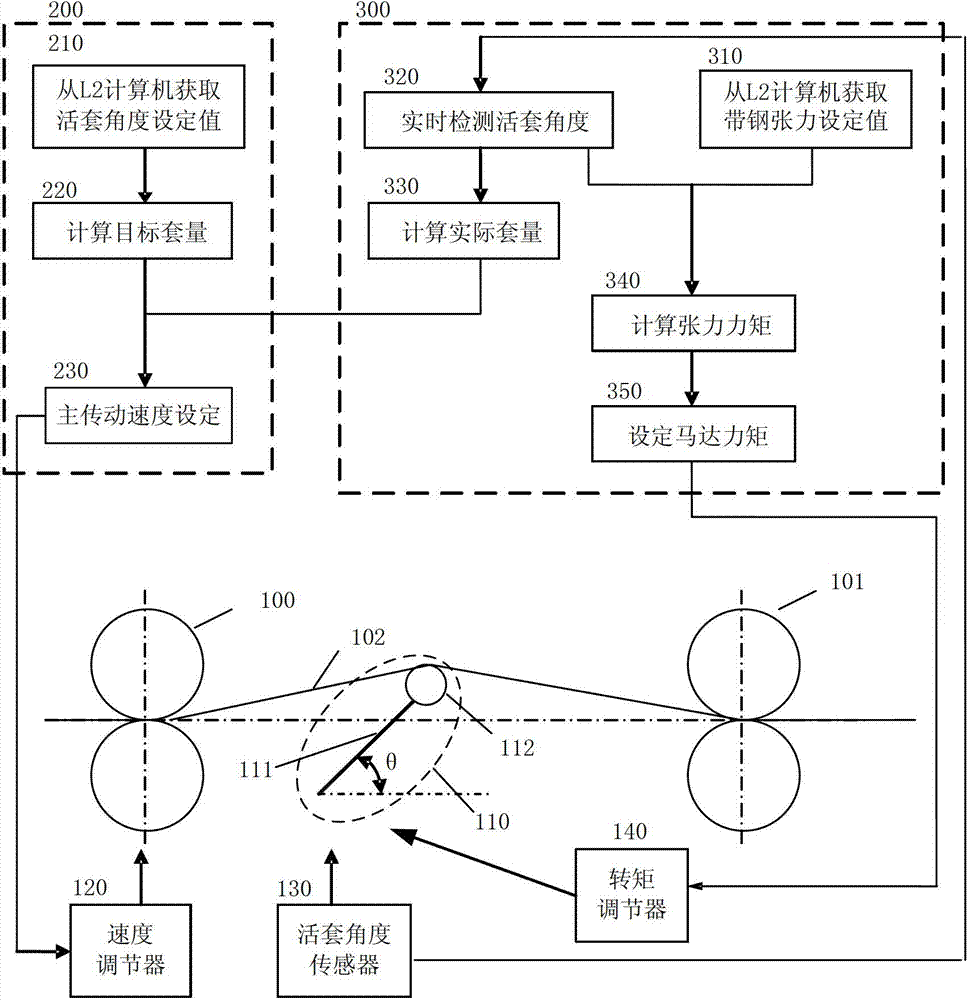

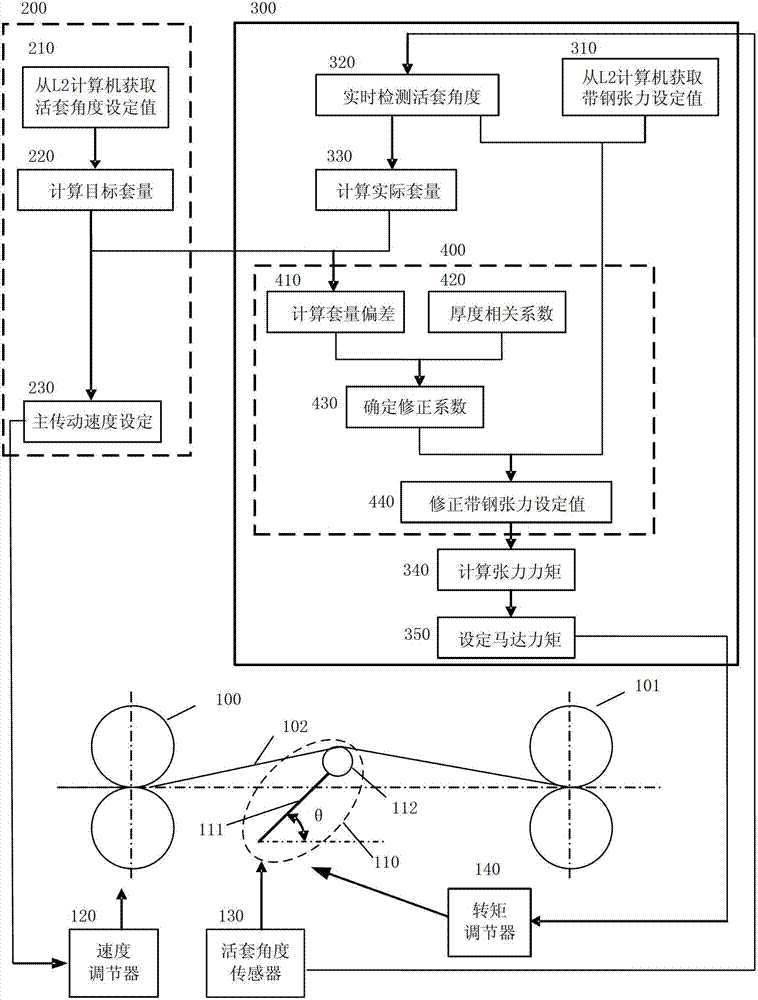

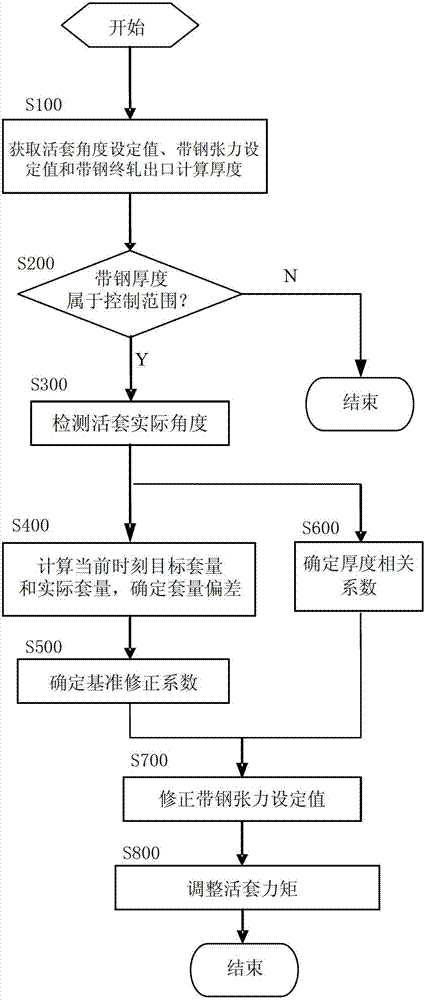

[0095] figure 2 It is a structural schematic diagram of an embodiment of a strip tension control system using a strip tension dynamic control method of the present invention. The strip tension control system is used for strip tension control of a hot rolling mill. In this embodiment, The hot rolling unit has rolling stands F3, F4, F5 and F6 arranged in sequence, and each group of front and rear adjacent front stands form three groups of front and rear adjacent front stands and rear stands of F34, F45 and F56 , between each group of front and rear adjacent front and rear frames, respectively equipped with strip tension control system and strip tension control system of the present invention, figure 2 Only a group of rolling stands and their strip tension control systems are shown in figure 2 The front frame 100 and the rear frame 101 can represent any group in the three groups of adjacent frames of F34, F45 and F56, and each group is equipped with an electric looper 110 for...

Embodiment 2

[0106] In Embodiment 2, in the strip tension dynamic control method based on the deviation of the set amount of the present invention, step S400 uses a table lookup method to determine the reference correction coefficient corresponding to the set amount deviation; step S500 uses a table lookup method to determine the strip thickness corresponding to The thickness correlation coefficient. In this embodiment, the amount deviation is divided into 6 levels, and the reference correction coefficients corresponding to the amount deviation are stored in the standard correction coefficient classification data table shown in Table 1. The strip thickness is divided into 4 grades, and the thickness correlation coefficient corresponding to the strip thickness is stored in the thickness correlation coefficient classification data table shown in Table 2.

[0107] Table 1: Benchmark correction coefficient classification data table

[0108]

[0109] Table 2: Thickness correlation coefficie...

Embodiment 3

[0112] Embodiment 3 is the strip tension dynamic control method based on the set weight deviation of the present invention. It is an application example of the strip tension control system of the hot rolling production line finishing mill group in embodiment 1. The hot rolling group includes F34, F45 and F56 Three groups of front and rear adjacent front frames and rear frames are respectively equipped with electric loopers for controlling strip steel tension and the strip steel tension of the present invention between each group of front and rear adjacent front frames and rear frames. In the control system, the dynamic tension control parameters of the three groups of adjacent racks are stored in the two-dimensional data tables shown in Table 3, Table 4 and Table 5 with comprehensive correction coefficients. Among them, the comprehensive correction coefficient is the product of the reference correction coefficient and the thickness correlation coefficient. The computer at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com