Patents

Literature

107results about How to "Accuracy requirements met" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

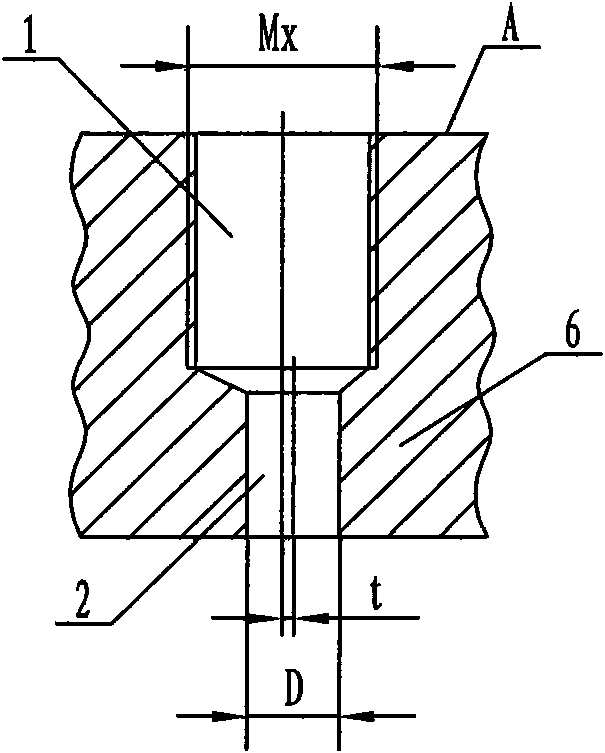

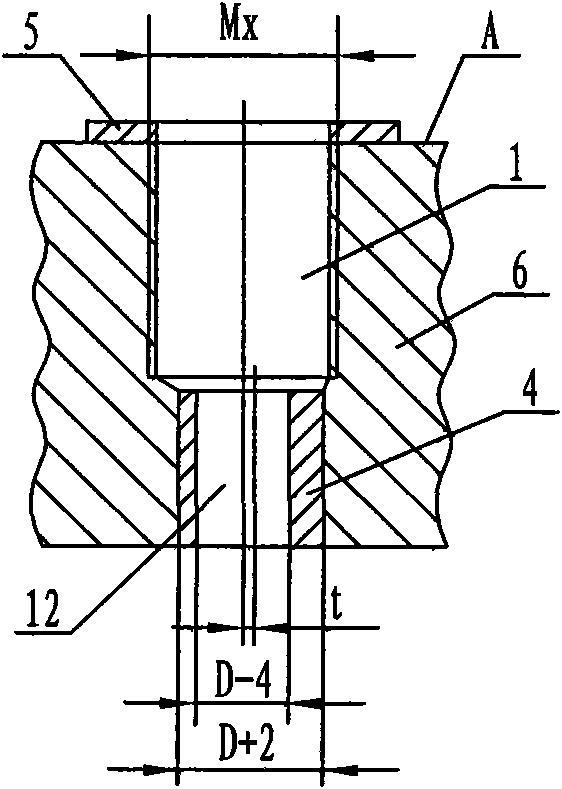

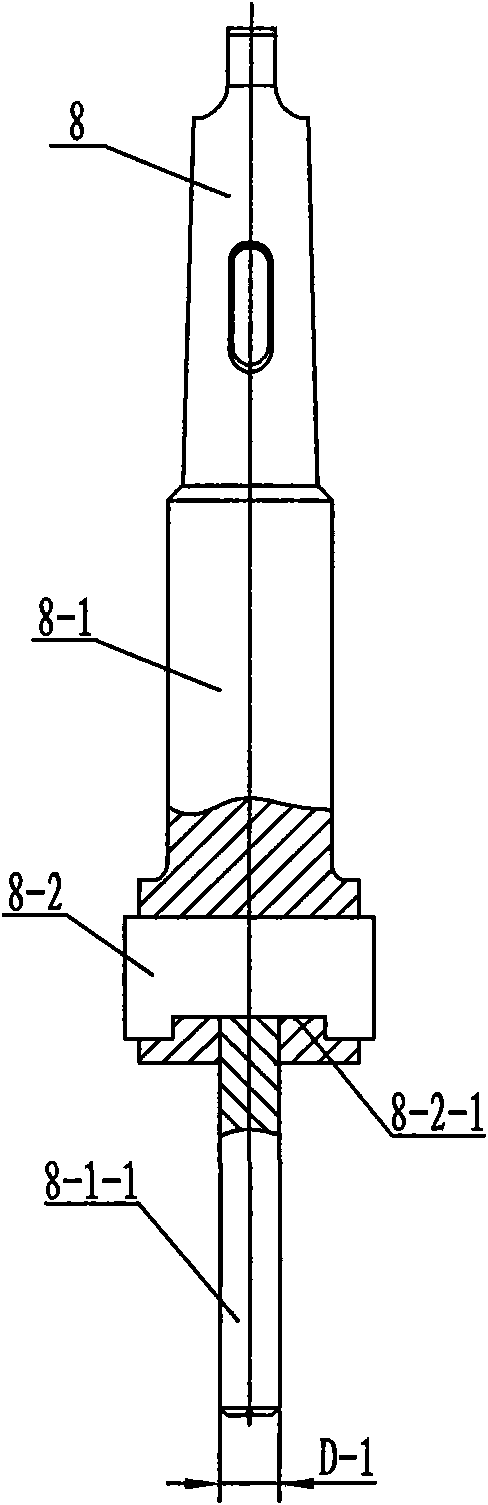

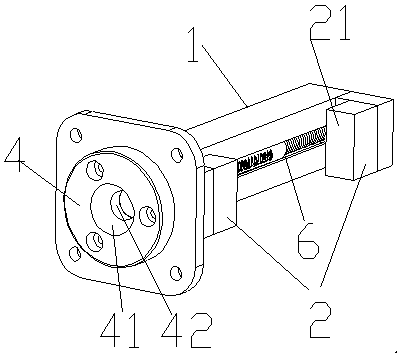

Method for repairing cylinder screw holes and special scraper and screw tap for implementing method

InactiveCN101941131AAvoid scrappingAccuracy requirements metThread cutting toolsTransportation and packagingEngineeringDrilling machines

The invention provides a method for repairing cylinder screw holes and a special scraper and a screw tap for implementing the method and relates to the method for repairing the cylinder screw holes, which solves the problem that a cylinder is scrapped owing to great repair processing difficulty of the cylinder screw holes and difficulty in achieving repair precision. The method comprises the following steps: 1. installing a radial drilling machine; 2. broaching; 3. boring holes; 4. scraping threaded holes; and 5. tapping. In the scraper, an upper end of a scraper blade is equipped with a groove matched with a shoulder, and the external diameter of the cutting edge of the scraper blade is Mx+1. In the screw tap, a tip is abutted with the center of a wrench, a connecting rod is symmetrically equipped with two first locating key slots, an upper end surface of a screw tap sleeve is symmetrically equipped with two second locating key slots width of which is equal to that of the first locating key slots, and two locating keys are respectively arranged in the first locating key slots at two sides of the connecting rod and the second locating key slots at two sides of the upper end surface of the screw tap sleeve. In the invention, the special scraper and the screw tap are used for processing the cylinder screw holes through the radial drilling machine so that the repaired cylinder screw holes conform to the precision requirement of the cylinder screw holes, thus avoiding the cylinder being scrapped.

Owner:HARBIN TURBINE

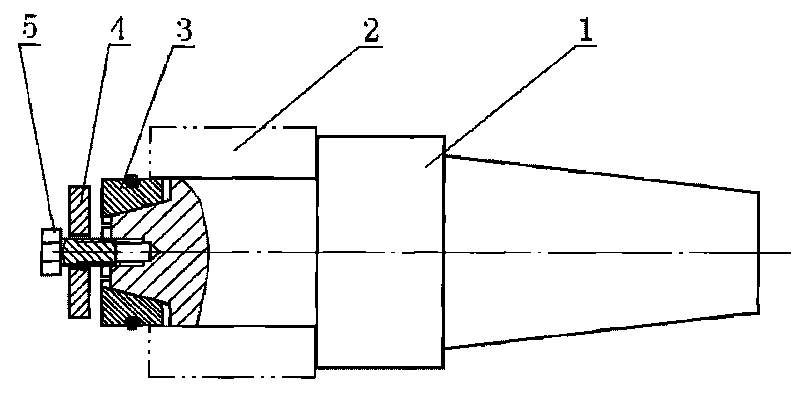

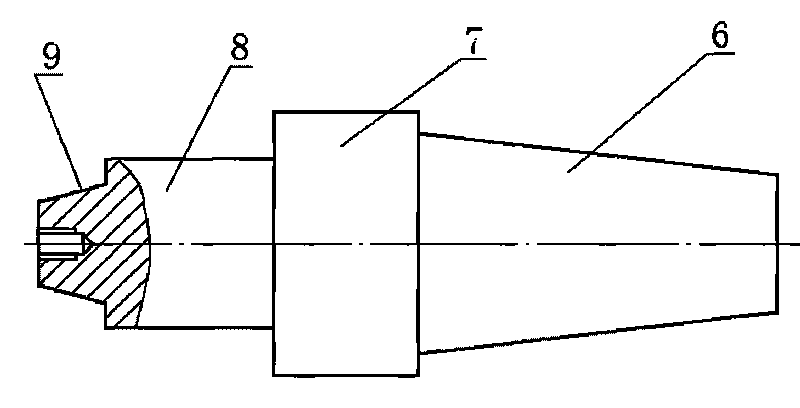

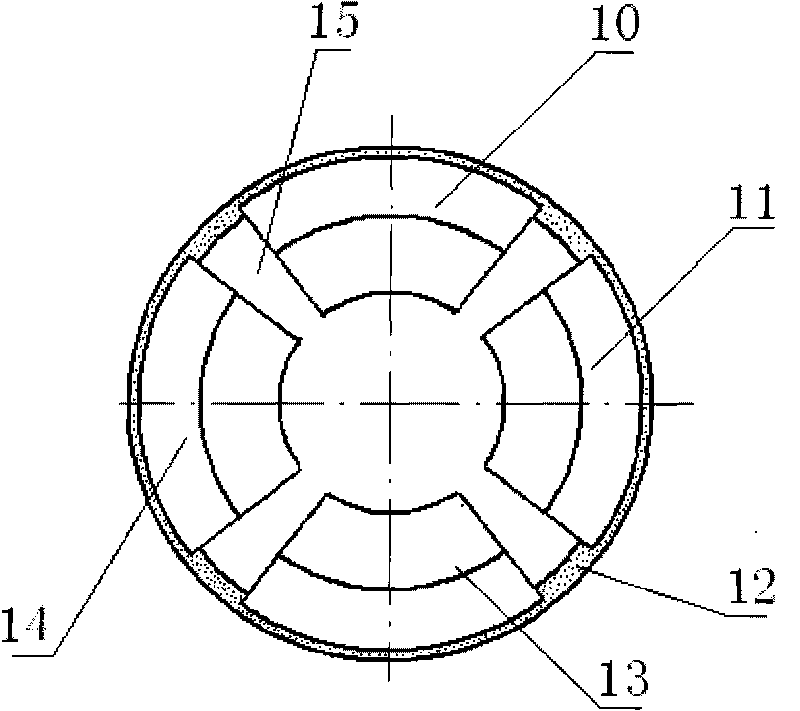

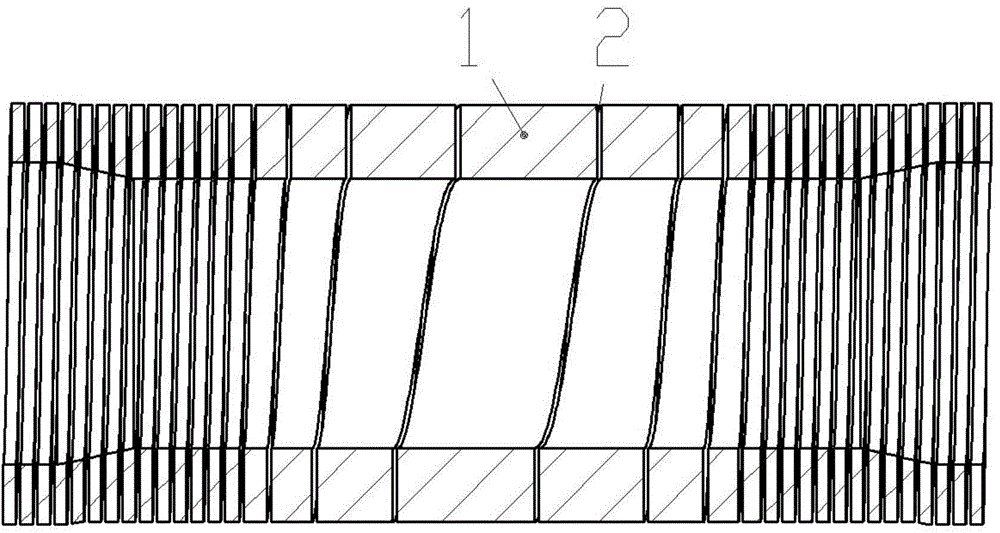

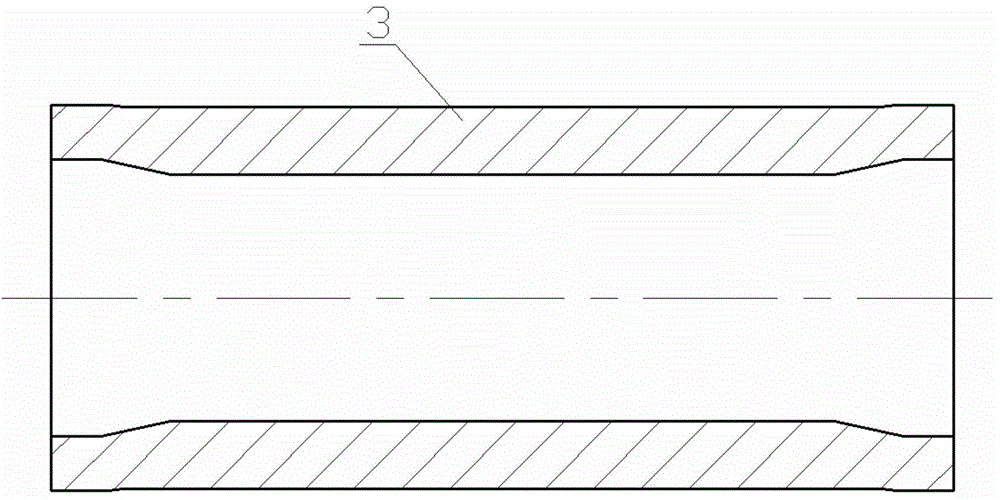

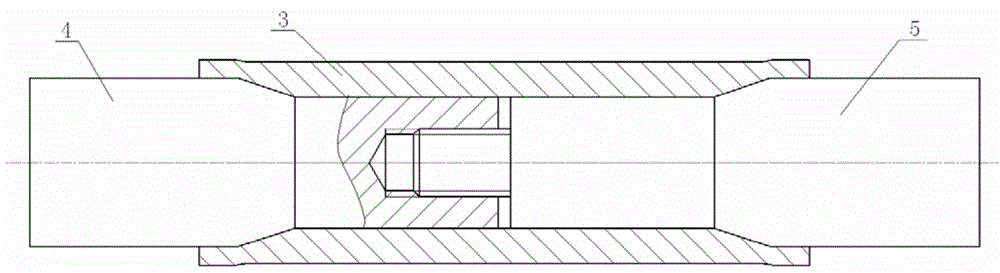

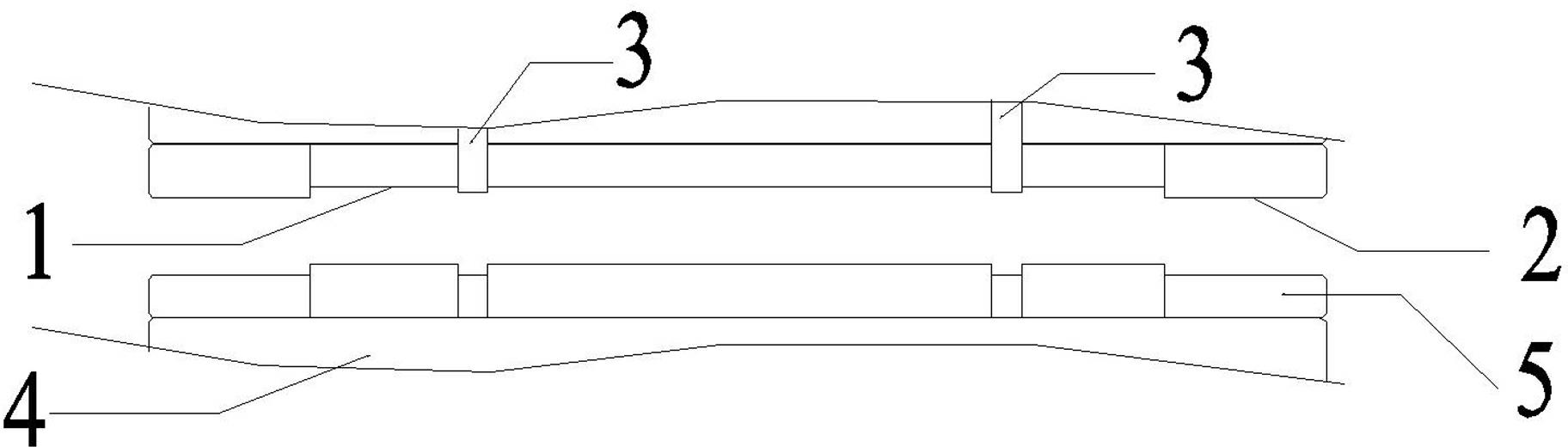

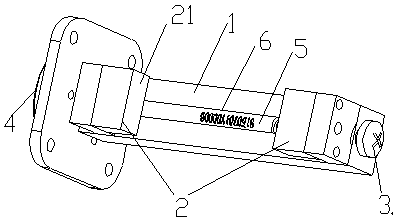

Workpiece internal-external circle concentricity lathe turning tooling and using method thereof

InactiveCN101758410AAccuracy requirements metImprove processing pass rateAuxillary equipmentPositioning apparatusCircular surfaceProcessing cost

The invention discloses a workpiece internal-external circle concentricity lathe turning tooling and a using method thereof; the workpiece internal-external circle concentricity lathe turning tooling is composed of a clamping body, a swelling piece, a baffle palate adjacent to the swelling piece and a set bolt; the clamping body is composed of a machine tool spindle fitting section, a transition section, a workpiece mounting section and a conical section sequentially, the swelling piece is composed of more than three swelling blocks which have the same structure and are provided with clearance respectively and elastic rings arranged on the surface of the external circle of the swelling block, each swelling block is provided with a high-precision inner circular surface adaptive to the conical section of the clamping body and a high-precision external circle ring surface which is adaptive to the inner circle of the workpeice after being swelled, a ring slot for placing the elastic ring is arranged in the middle part of the external circle ring surface of each swelling block, so as to lead the internal-external circle concentricity of the processed workpiece to be in accordance to the precision requirements, improve the processing passing percent and reduces the processing cost.

Owner:芜湖长胜机械制造有限公司

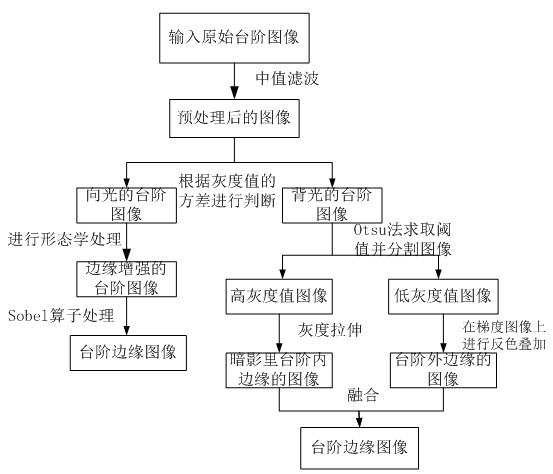

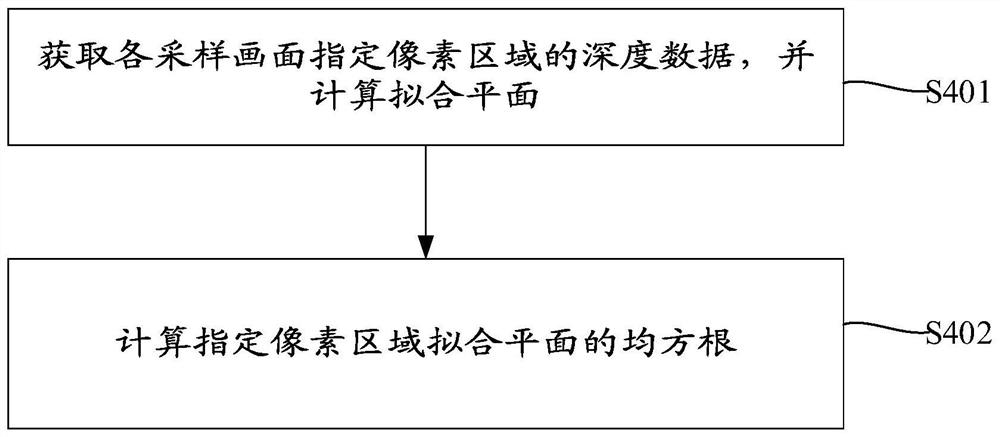

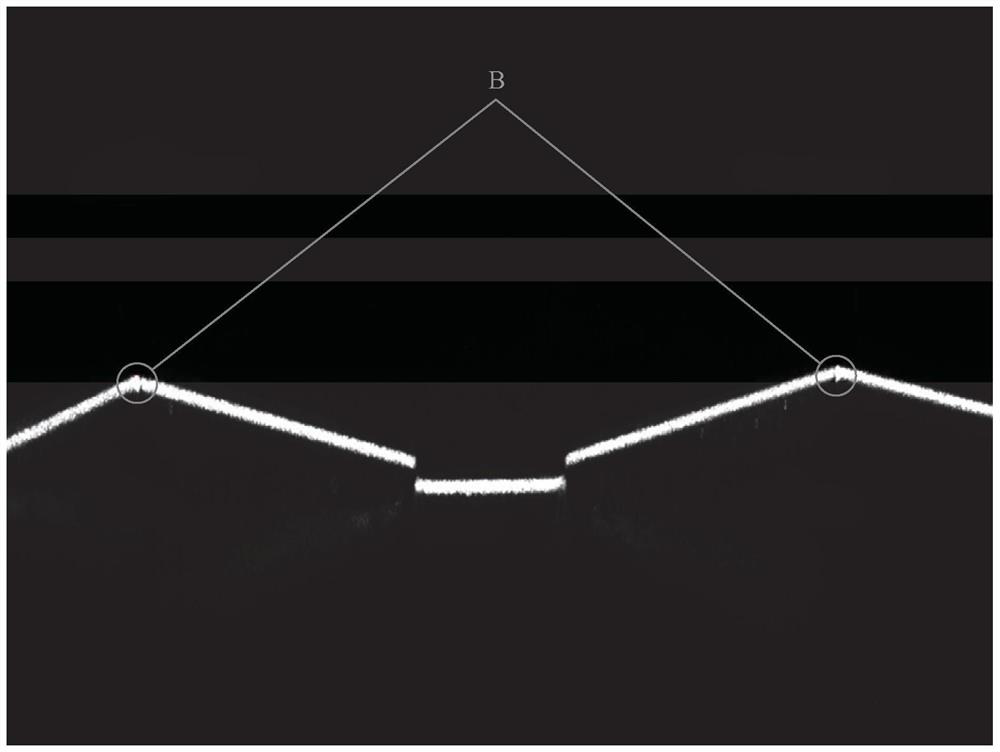

Step edge detection method oriented to humanoid robot

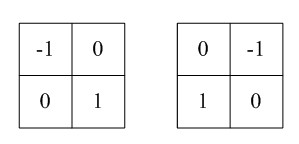

InactiveCN102324099ATimelinessAccuracy requirements metImage analysisMorphological processingHumanoid robot

The invention relates to a step edge detection method oriented to a humanoid robot, which comprises the following steps of: 1) preprocessing an image to the detected; 2) judging the image; 3) conducting morphological processing to the image; 4) processing the image to obtain the edges of phototropic steps; 5) seeking threshold values and converting the image into a binary image to obtain the edges of apheliotropic steps; 6) using edge lines at the step 5 to segment the image at the step 2 and conducting gray stretching to parts with high gray values to obtain a new image; 7) conducting gradient transform according to the new image obtained at the step 6 to obtain a gradient image; 8) conducting invert color transform according to the new image obtained at the step 6 and then conducting gradient transform to obtain another gradient image; 9) adding the corresponding pixel points of the two gradient images respectively obtained at the step 7 and the step 8 to obtain the edges of the image; and 10) fusing the edges obtained at the step 5 and the edges obtained at the step 9 into one image. The edge detection method provided by the invention can satisfy the requirements on the timeliness and the accuracy of the vision of the robot.

Owner:GUANGDONG UNIV OF TECH

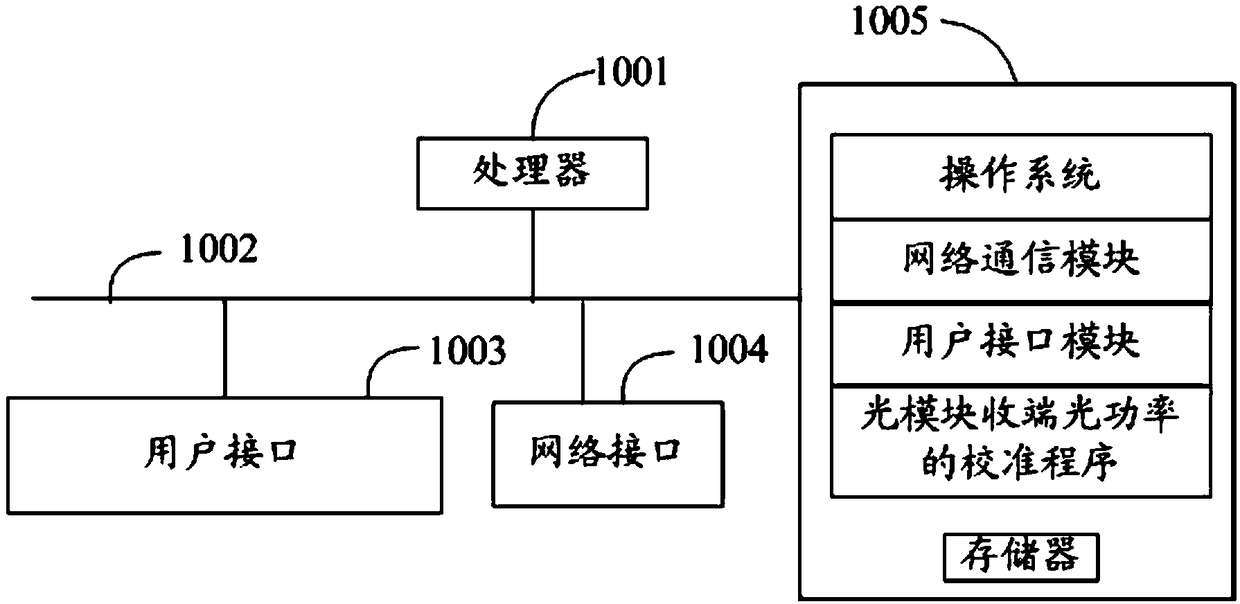

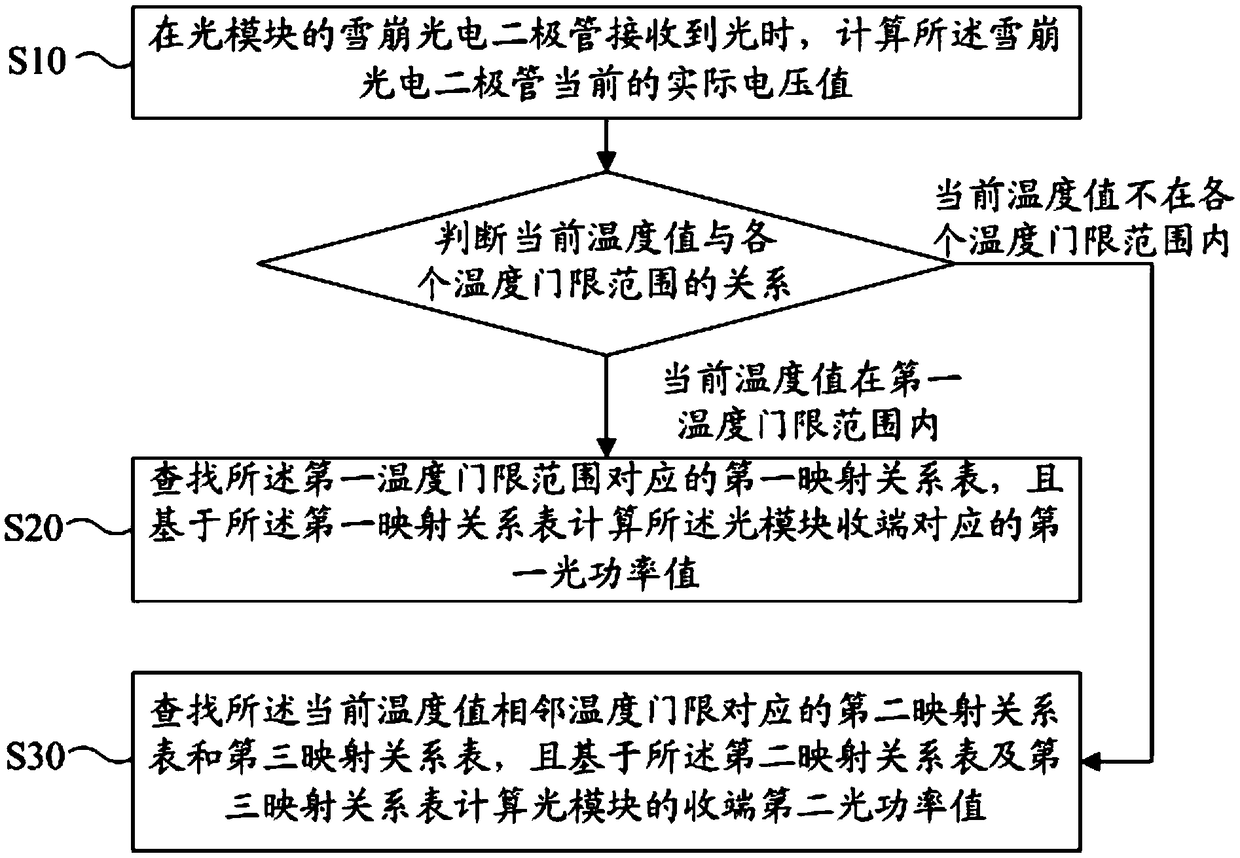

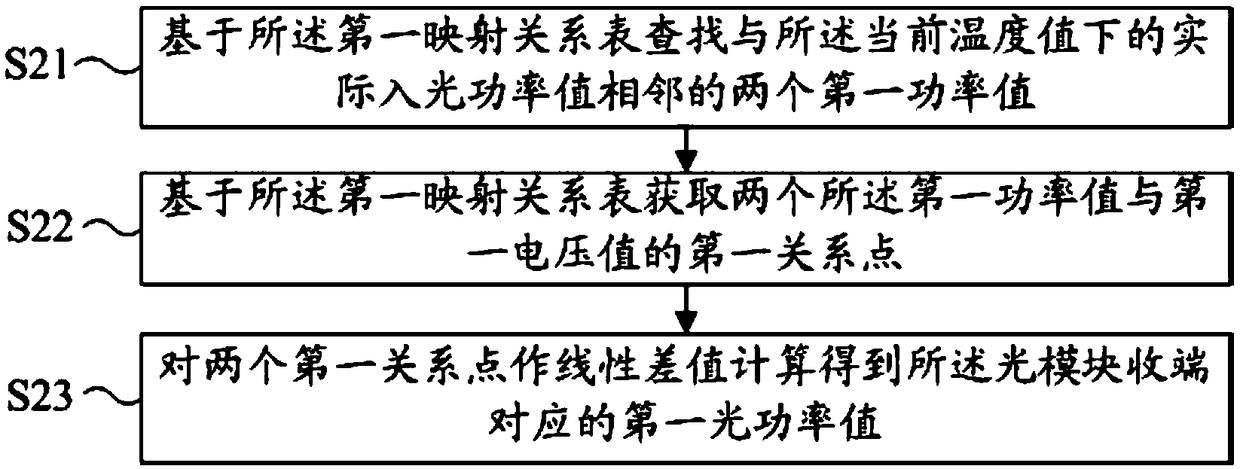

Method and device for calibrating optical module receiving end optical power, and readable storage medium

InactiveCN109327258AAccuracy requirements metReduce mistakesElectromagnetic transmissionOptical ModuleOptical power

The invention discloses a method and device for calibrating optical module receiving end optical power, and a readable storage medium. The method for calibrating the optical module receiving end optical power comprises the following steps: calculating a current actual voltage value of an avalanche photodiode when the avalanche photodiode of an optical module receives a light, and judging the relationship between the current temperature value and each temperature threshold range; calculating a first optical power value corresponding to the optical module receiving end according to a first mapping relationship table if the current temperature value is within a first temperature threshold range of each temperature threshold range; and calculating a second optical power value of the optical module receiving end based on a second mapping relationship table and a third mapping relationship table if the current temperature value is not within each temperature threshold. Both the difference between the first optical power value in the invention and the incoming optical power corresponding to the light and the difference between the second optical power value in the invention and the incoming optical power corresponding to the light are small; therefore, the error between the incoming optical power and the received optical power is effectively reduced, and high-precision requirements for optical power reported by the receiving end are realized.

Owner:APAT OPTOELECTRONICS COMPONENTS

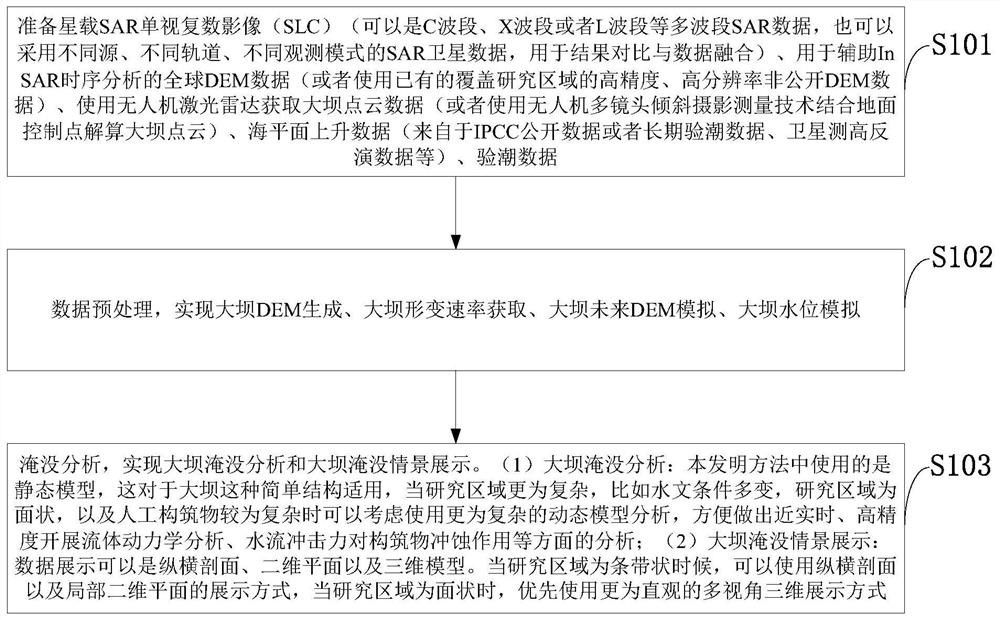

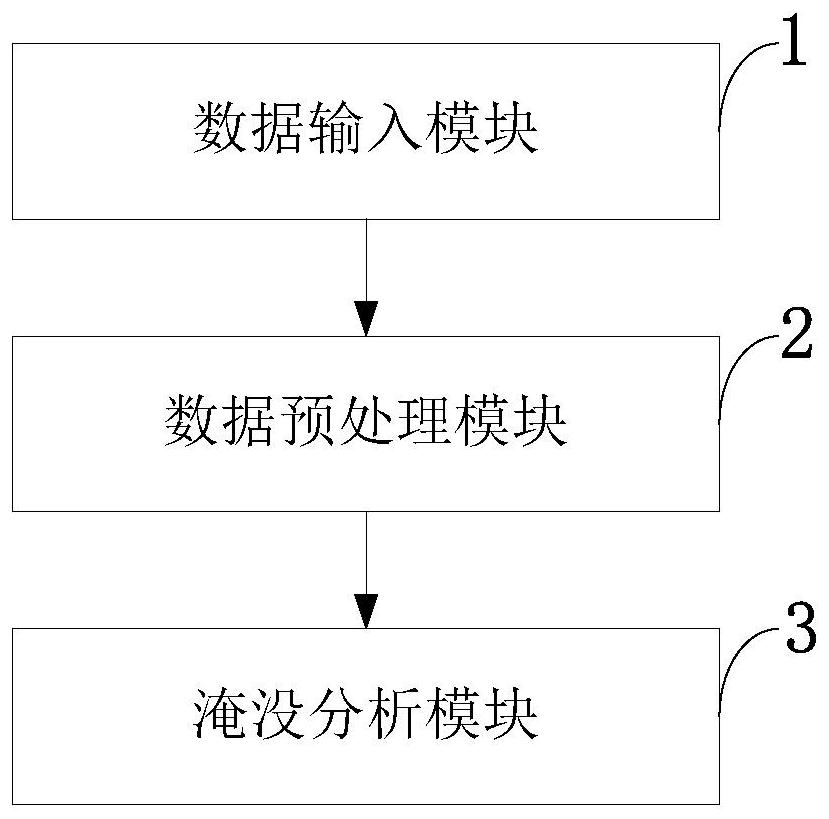

Coastal zone dam stability monitoring and flooding vulnerability evaluation method and system

ActiveCN111999733AEnsure accuracy andEnsure observation efficiencyClimate change adaptationSatellite radio beaconingSea level riseEngineering

The invention belongs to the technical field of coastal zone dam monitoring, and discloses a coastal zone dam stability monitoring and flooding vulnerability evaluation method and system. The method comprises the steps of preparing a satellite-borne SAR single look complex image and global DEM data for assisting the InSAR time sequence analysis, and obtaining dam point cloud data, sea level risingdata and tide inspection data through employing an unmanned plane laser radar; carrying out data preprocessing to realize dam DEM generation, dam deformation rate acquisition, dam future DEM simulation and dam water level simulation; and performing flooding analysis to realize dam flooding analysis and dam flooding scene display. According to the invention, the combination of the satellite-borneInSAR time sequence analysis deformation rate and the unmanned aerial vehicle-mounted laser radar DEM is realized, and high observation precision and space-time resolution are ensured. According to the invention, three components (tidal component, storm water increase and sea level rise) are synthesized for flooding water level simulation, daily conditions and extreme conditions are simulated at the same time, and over-high water level estimation is avoided.

Owner:OCEAN UNIV OF CHINA

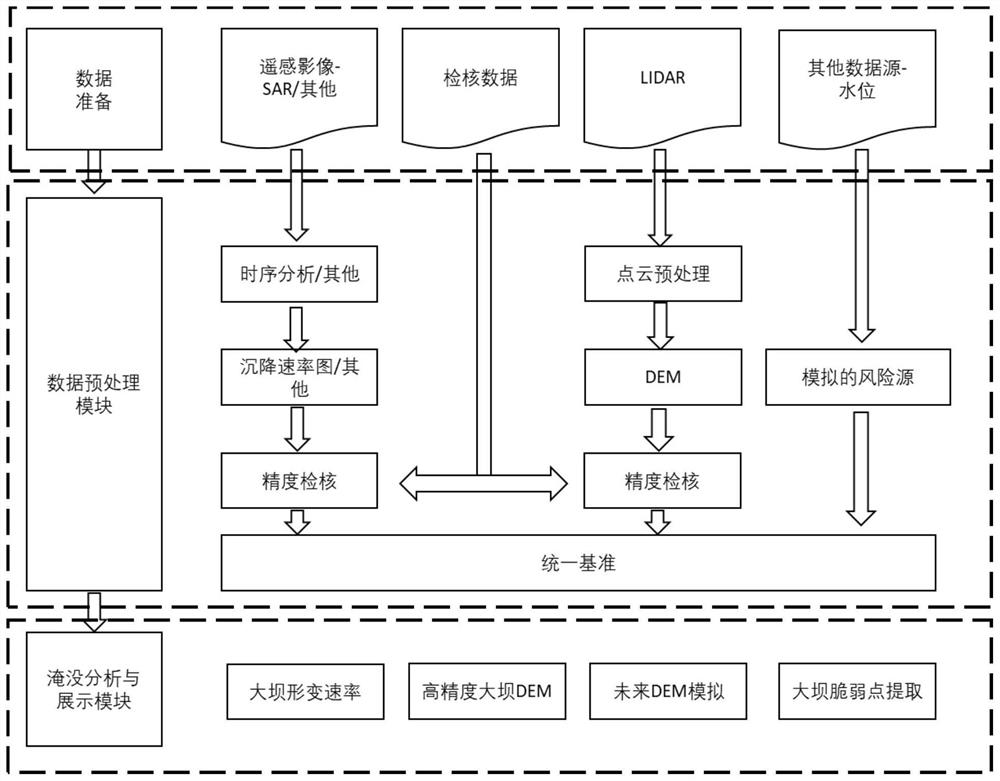

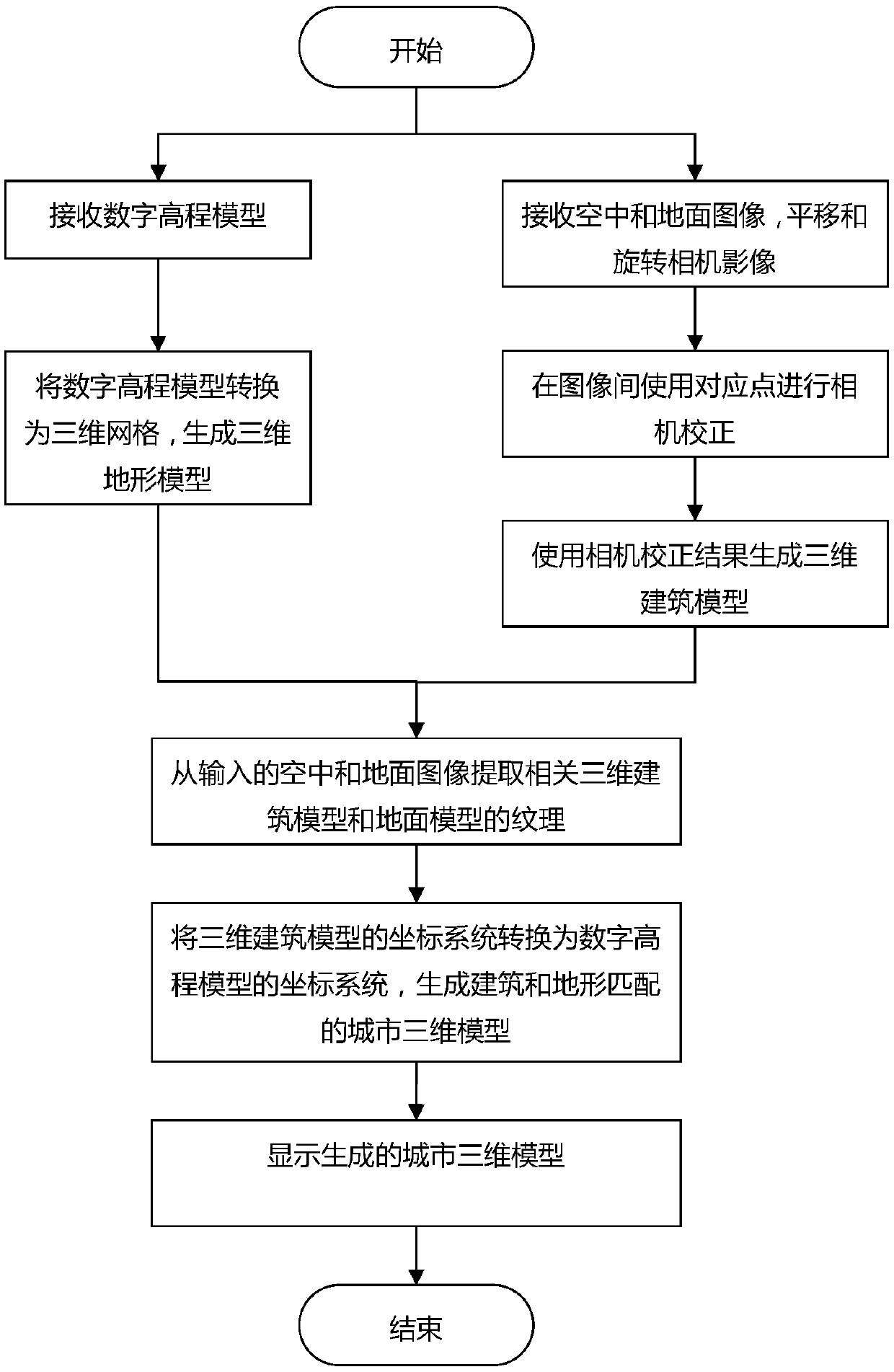

Novel city three-dimensional modeling control system and method

InactiveCN108053474AHigh resolutionFine simulationImage generation3D modellingTexture extractionLandform

The invention belongs to the technical field of three-dimensional modeling, and discloses a novel city three-dimensional modeling control system and method. The system comprises an image input unit, acamera calibration unit, a parallel moving and rotating data input unit, a digital elevation model input unit, a landscape model generation unit, a texture extraction unit, an architectural model generation unit, an architecture model storage unit, a model matching unit and a display unit. According to the system, by using the digital elevation model (DEM) and images acquired from an aerial vehicle and the ground, modeling of three-dimensional appearance of city architectures and three-dimensional landscape is achieved, and realistic textures are extracted from the images; three-dimensional architecture models can be generated by using the images taken from the air in vertical and inclined directions except for the DEM, textures of the related three-dimensional models can be extracted, the three-dimensional models generated by the images acquired from the ground can be simulated more accurately, or the textures with higher definition can be extracted.

Owner:HUNAN CITY UNIV

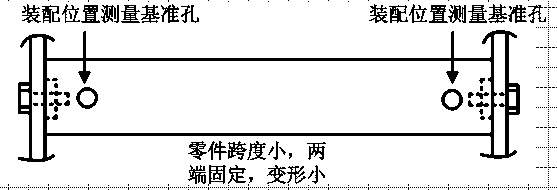

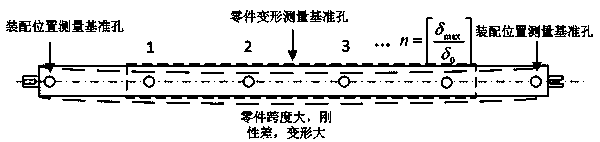

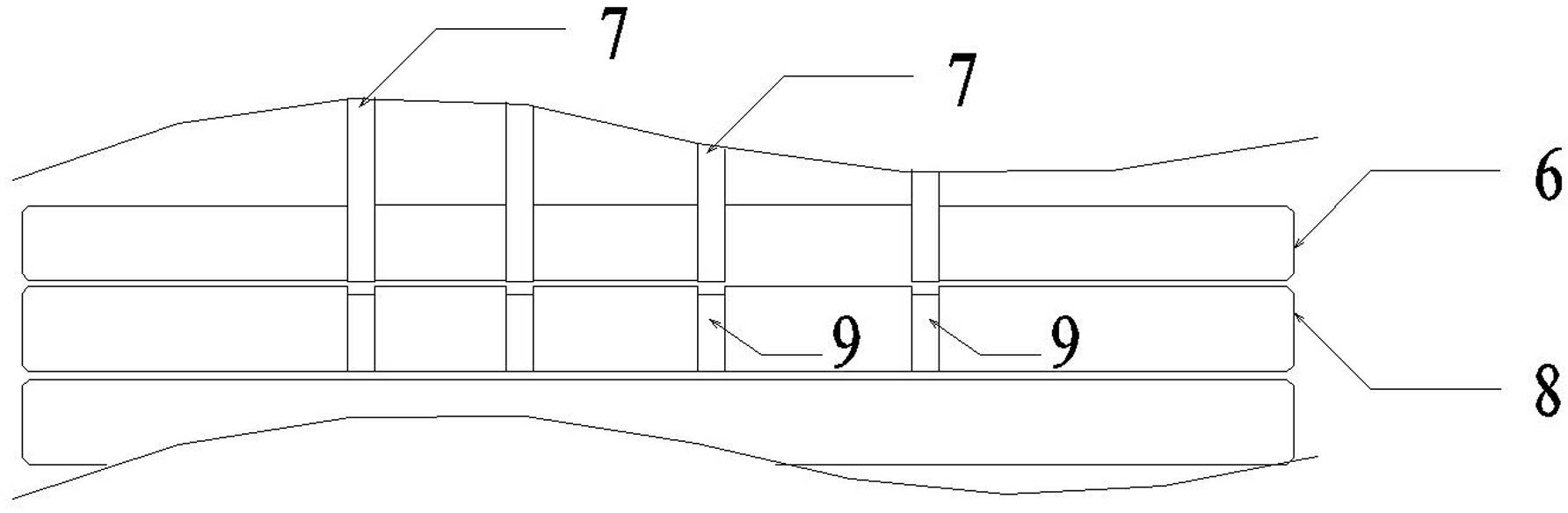

Reference hole arrangement method

ActiveCN110530326AImprove the accuracy of hole positionReduce in quantityMeasurement devicesAircraft assemblyDrilling systemEngineering

The invention discloses a reference hole arrangement method. The method comprises the steps of (S1) measuring the deformation of an assembled segment-mounted part through a measuring instrument, (S2)dividing reference holes into two types which comprises (1) part assembly position measurement reference holes for feeding back an actual assembly position of a part and (2) part deformation measurement reference holes for feeding back the deformation condition of the part, and (S3) arranging the reference holes in the part according to an error allocated to a hole site correction link, wherein ahole error distributed to the hole site correction link through tolerance is delta 0 when measured part maximum deformation is delta max, the reference holes are only arranged in two ends of the partwhen the deformation of the part is small and a condition (delta max) / (delta 0) is smaller than 1 is satisfied, the reference holes are arranged in the two ends of the part when a condition (delta max) / (delta 0) is larger than or equal to 1 is satisfied, and the reference holes for measuring the deformation of the part are arranged between the reference holes in the two ends. The reference hole arrangement method has the advantages that the actual assembly condition of the part can be accurately reflected to an automatic drilling system, the drilling hole position precision is improved, that corrected drilling hole positions meet a precision requirement is guaranteed, meanwhile, the number of the reference holes can be effectively reduced, the reference hole measurement complexity is reduced, and the production efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

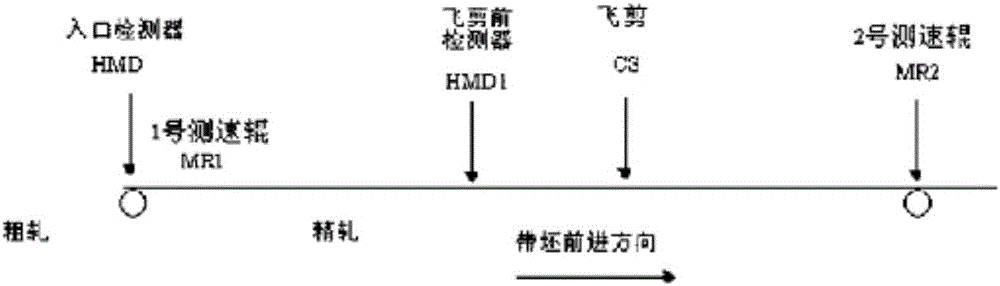

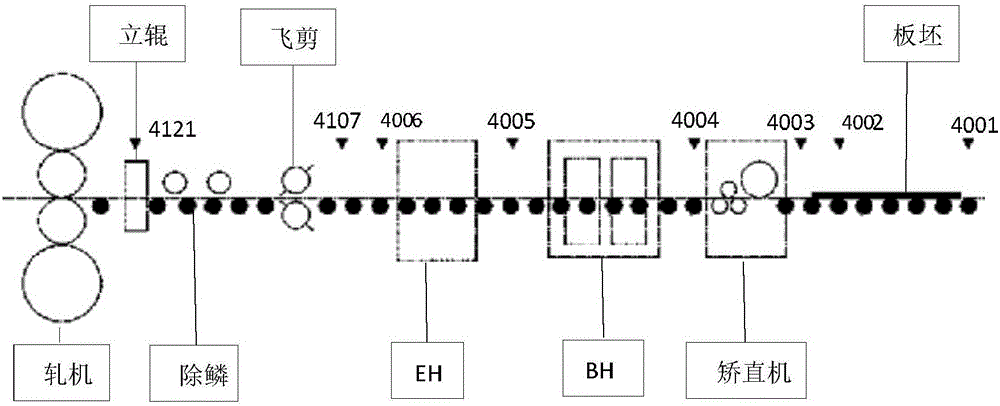

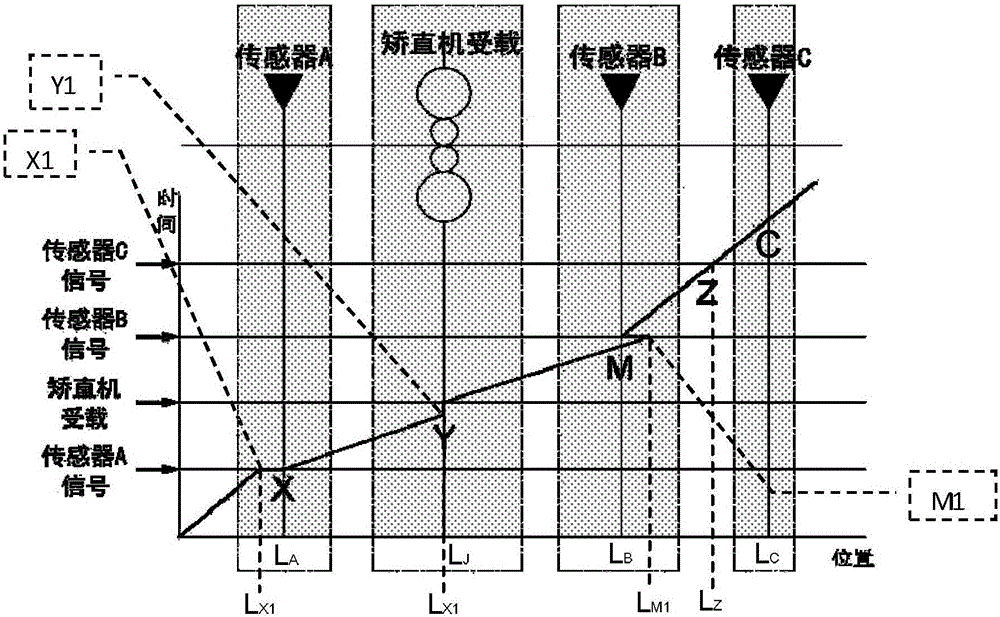

Hot-rolled flying shear head and tail initial shearing position dynamic control method

ActiveCN107433287ARealize dynamic controlAccuracy requirements metRare end control deviceMetal rolling arrangementsProduction lineSite location

The invention relates to control over a steel billet flying shear of a hot rolling machine, in particular to an initial shearing position dynamic control method applicable to a hot rolling machine flying shear. The method comprises the following steps of determining a position tracking detection range; determining dynamic detection points; calculating the distance from each dynamic detection point to a flying shear start point; determining the width of a tracking travel window; determining the practical running position of a strip steel; determining the calculated shearing length of the strip steel; comparing the calculated shearing length of the strip steel with a strip steel shearing length set value; and starting the flying shear to shear the strip steel. The detection areas of the head and tail positions of the strip steel are controlled through a finish rolling inlet of a hot continuous rolling production line; through combination with arrangement of the strip steel head and tail position tracking travel window and correction of the basic displacement of the strip steel, position tracking integrated initial points are switched dynamically, and dynamic control over strip steel initial shearing position control points is realized. Position tracking data are more aligned with the requirement for the practical site location precision.

Owner:BAOSHAN IRON & STEEL CO LTD

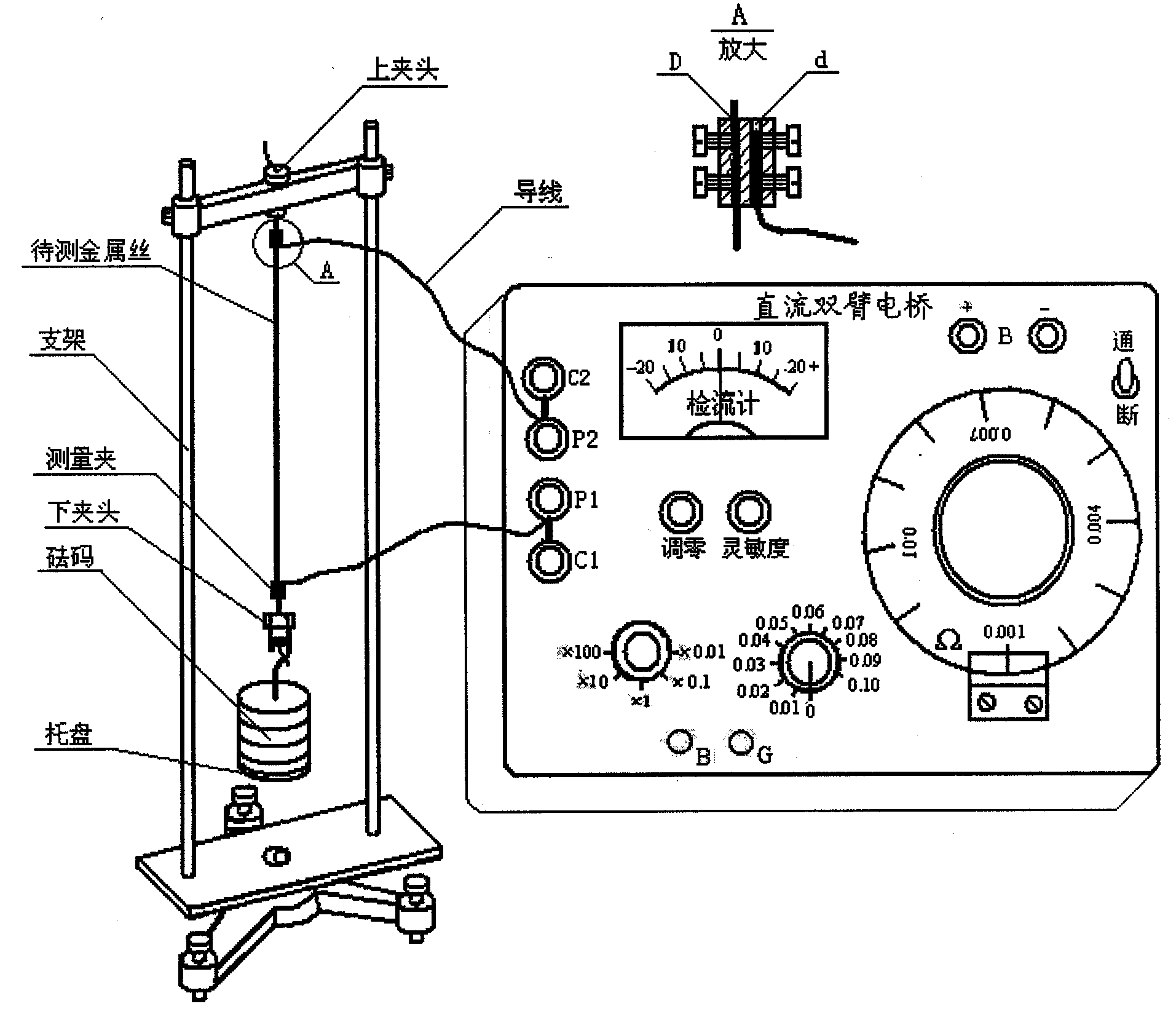

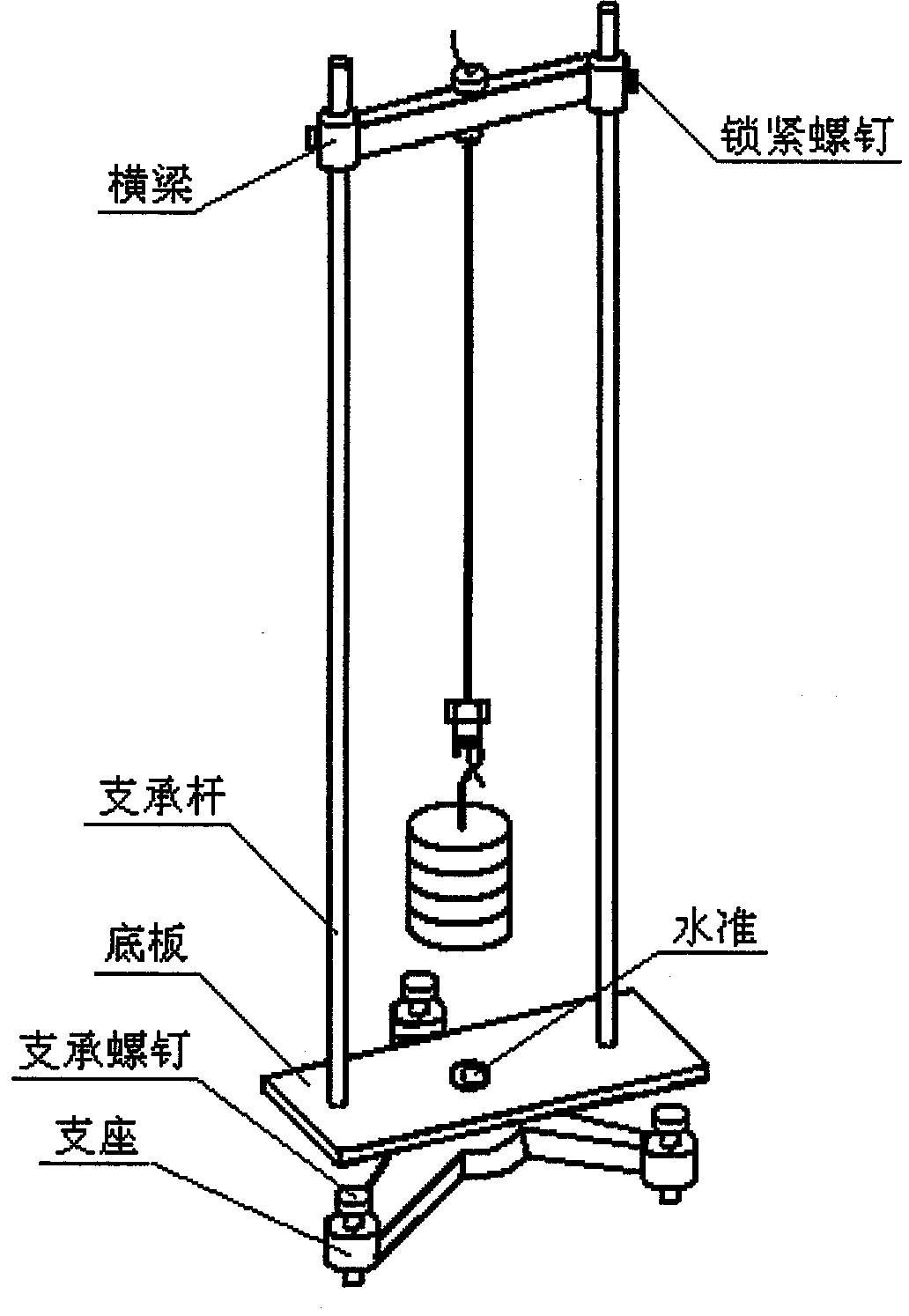

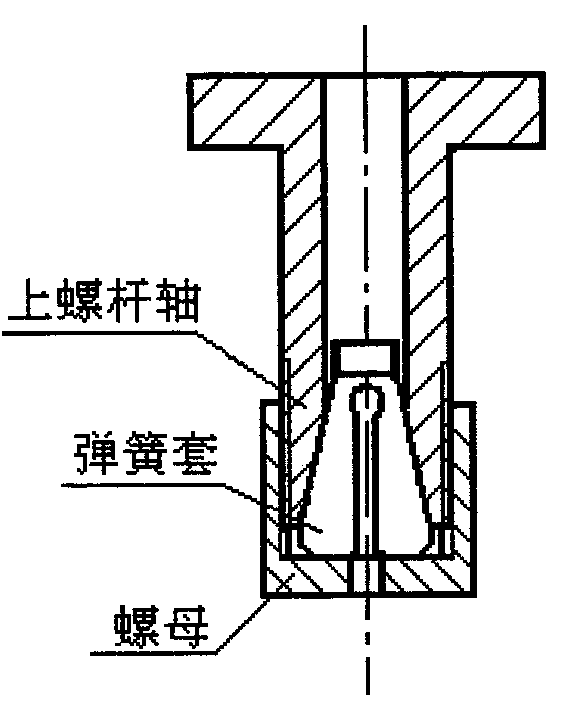

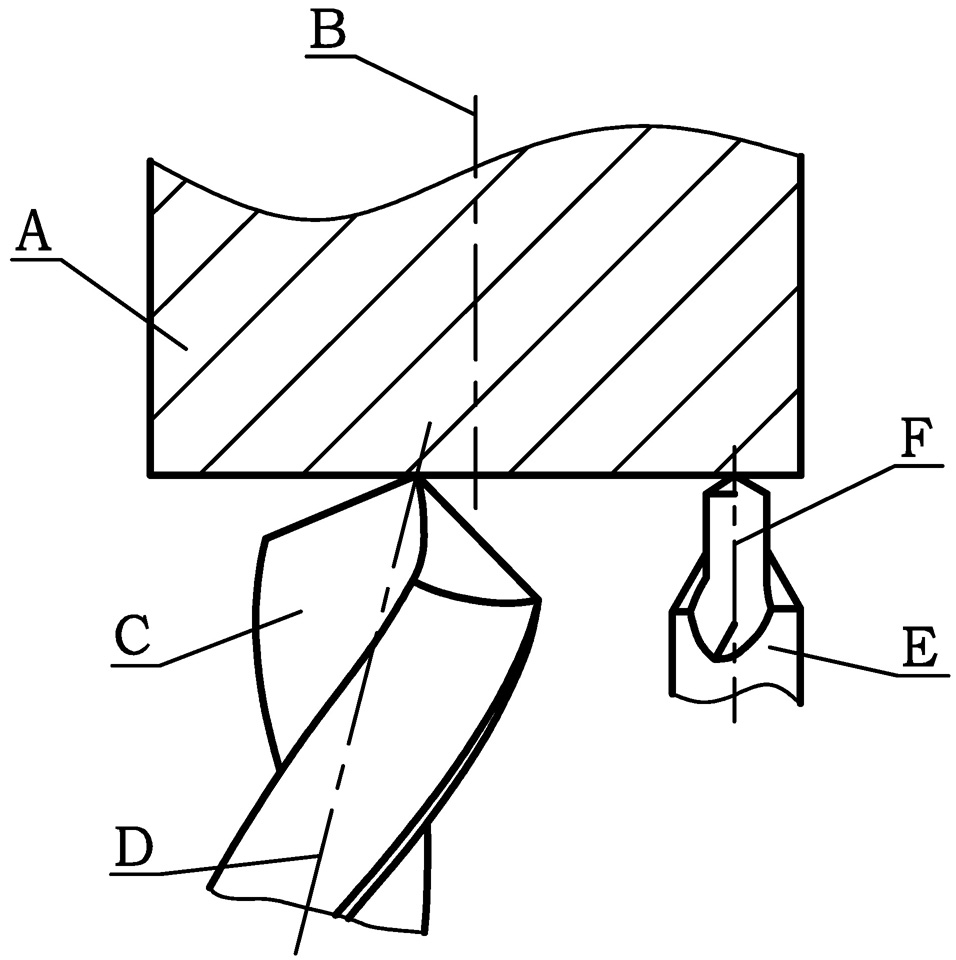

Device and method for measuring elasticity modulus of metallic material

ActiveCN103411837AClamping is convenient for testingFast clamping to be testedMaterial strength using tensile/compressive forcesElectrical resistance and conductanceObservational error

The invention relates to a device and a method for measuring the elasticity modulus of a metallic material. The device comprises a bracket, weights, a tray, an upper chuck, a lower chuck, a measuring clamp, a direct-current double-arm bridge, a screw-thread micrometer, a measuring tape and a metal wire to be measured. The measuring method comprises the following steps: deriving a new formula for solving the elasticity modulus of the metallic material; keeping the measuring distance of the metal wire to be unchanged; increasing or decreasing same load for the metal wire step by step; measuring data of the change of the corresponding load at a detection section of the metal wire along with the micro change of resistance of the metal wire by using the direct-current double-arm bridge in every time, measuring data of the change of corresponding load at the detection section of the metal wire along with micro change of resistance of the metal wire by using the screw-thread micrometer in every time, substituting the data into correlation formulas to solve the elasticity modulus of the metallic material. According to the device and the method, the metal wire to be measured is convenient and quick to clamp, the measuring error is small, and the device and the method are used for researching properties of the metallic material or experiment teaching of mechanics of materials.

Owner:桐乡市恒达经编股份有限公司

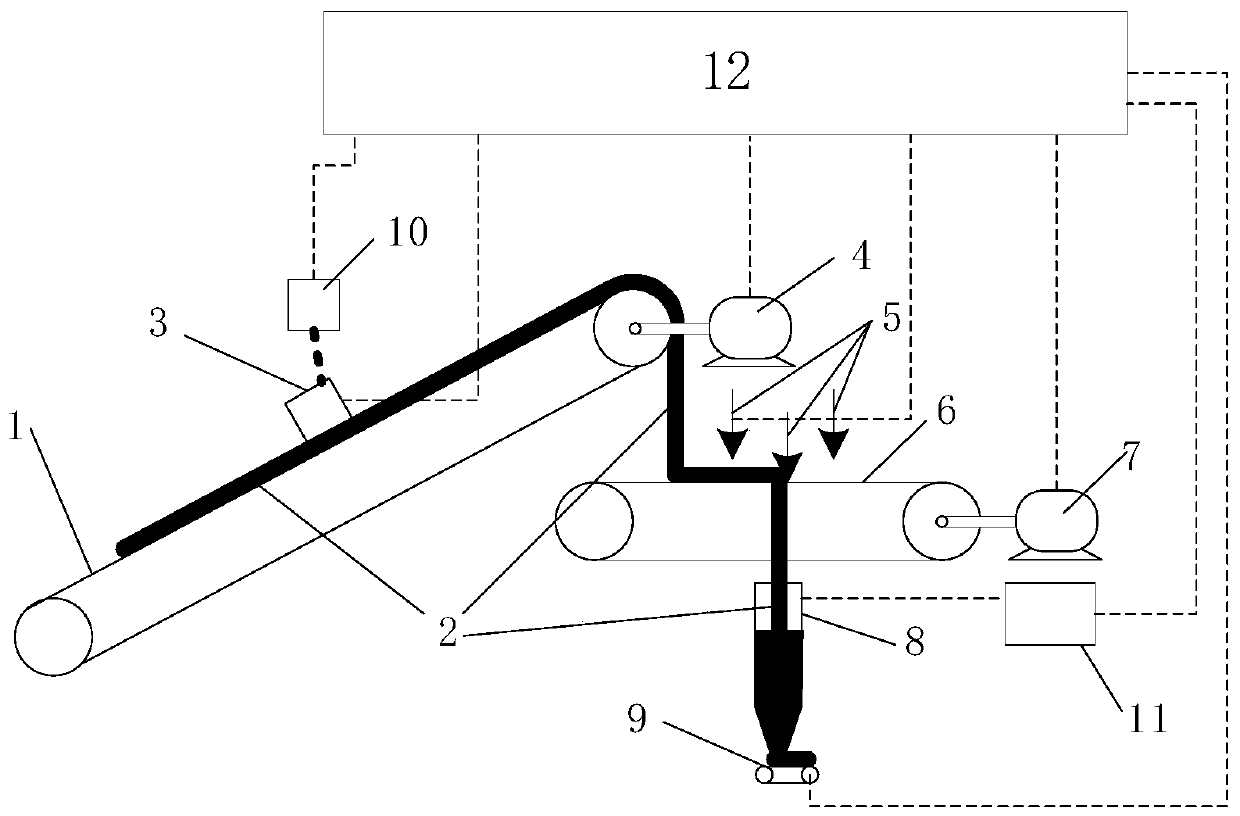

As-fired coal quality online monitoring system and method for real-time operation control

PendingCN110554164AReal-time accessMeet the requirements of coal quality precisionFuel testingLarge containersMotor driveElectric machine

The invention relates to an as-fired coal quality online monitoring system and method for real-time operation control. The system comprises a coaling belt motor; a coaling belt driven by the coaling belt motor; delivered fuel coal; a sampler arranged on the coaling belt; a horizontal belt used for distributing coal bunkers; a horizontal belt motor driving the horizontal belt to operate; a plurality of coal ploughing devices mounted on the horizontal belt; a coal feeder; a coal feeder inlet bunker; a coal quality online detection device receiving a coal sample produced by the sampler and used for coal quality analysis; a material level change grading correction filtering module used for receiving signals of a material level sensor and correcting the material level; and a real-time as-firedcoal quality calculation device used for receiving signal data of all parts and outputting real-time quality of the as-fired coal. The invention further discloses the online monitoring method. The coal quality online detection device installed on the coaling belt at present can obtain as-fired coal quality online data meeting the requirement for real-time operation control, a low-cost solution isprovided for solving the common problem caused by coal quality fluctuations, and the practical value is remarkable.

Owner:HUADIAN LAIZHOU POWER GENERATION +1

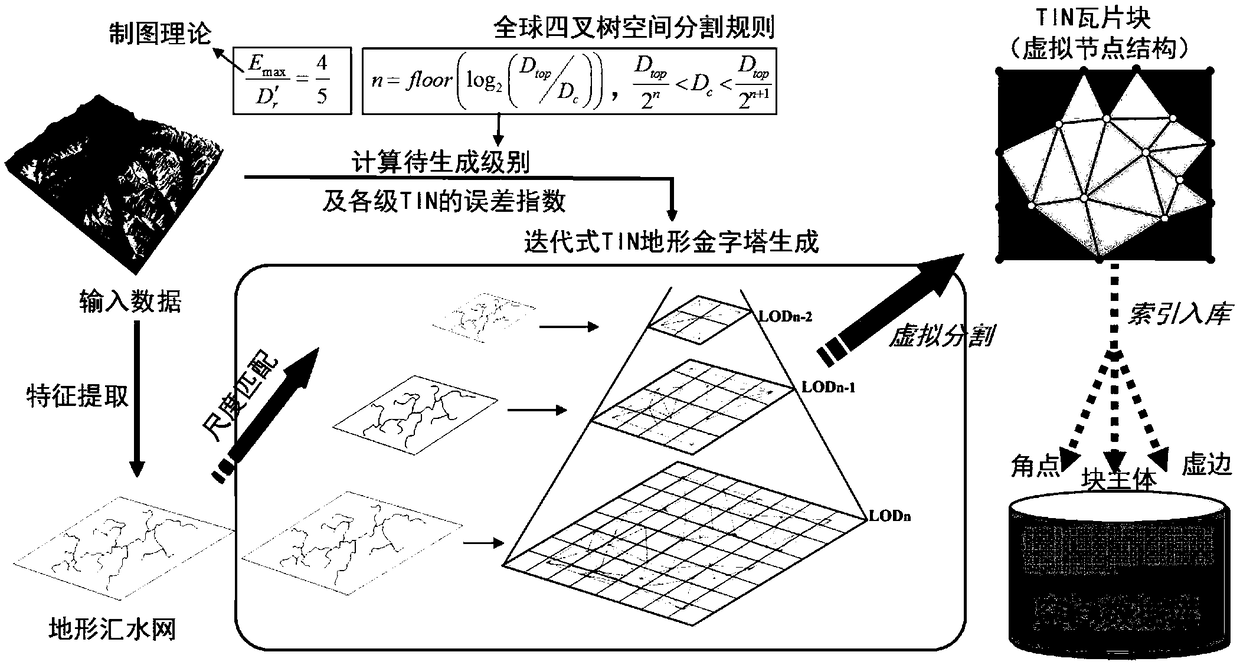

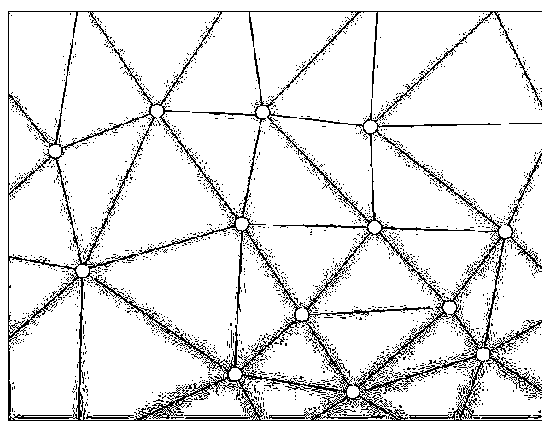

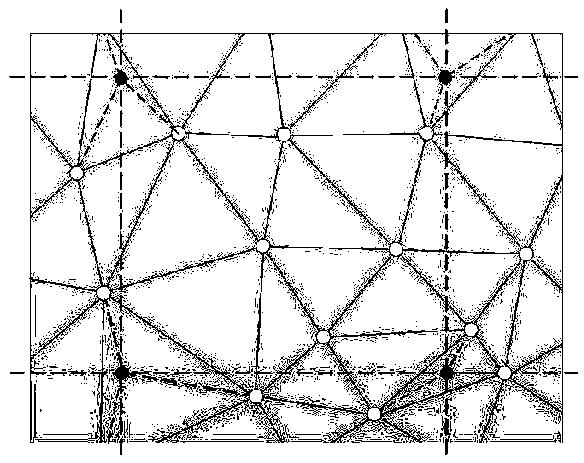

Terrain multi-scale TIN (Triangulated Irregular Network) online visualization method oriented to virtual earth

InactiveCN108717729AAccuracy requirements metImplement schedulingSpecial data processing applications3D-image renderingMathematical modelLandform

The invention provides a terrain multi-scale TIN (Triangulated Irregular Network) online visualization method oriented to the virtual earth. The method comprises the following steps of global multi-scale TIN scale parameter mathematical model construction, terrain multi-scale TIN automatic construction and virtual segmentation under characteristic constraints, the online visualization of a multi-scale TIN topography spherical surface and real-time crack elimination, wherein the step of the terrain multi-scale TIN automatic construction and virtual segmentation under characteristic constraintsis realized as follows; the step of the online visualization of the multi-scale TIN topography spherical surface comprises the step of carrying out calculation to obtain visual terrain blocks of different levels according to point-of-sight information; and the step of the real-time crack elimination comprises the following step of carrying out quick decoding during real-time visualization to finish the edge connection of the adjacent boundary of terrain blocks of different levels. By use of the method, while the structural flexibility of the TIN is kept, the multi-scale irregular modeling andthe quadtree segmentation of a large-scale terrain are realized, meanwhile, the seamless real-time rendering of a mixed scale TIN terrain is supported, the terrain data processing and expression accuracy of the virtual earth can be greatly improved, a seamless fusion ability for irregular GF spatial data is also greatly improved, so that the high-fidelity expression requirement of a geographical environment can be met, and each category of reliable geographical analysis application can be supported.

Owner:WUHAN UNIV

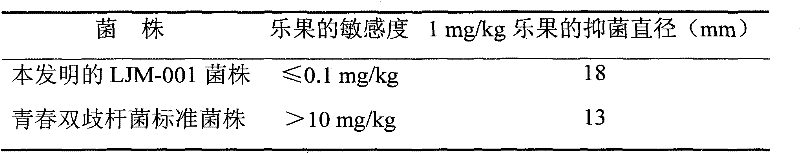

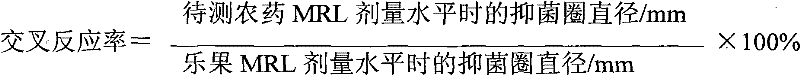

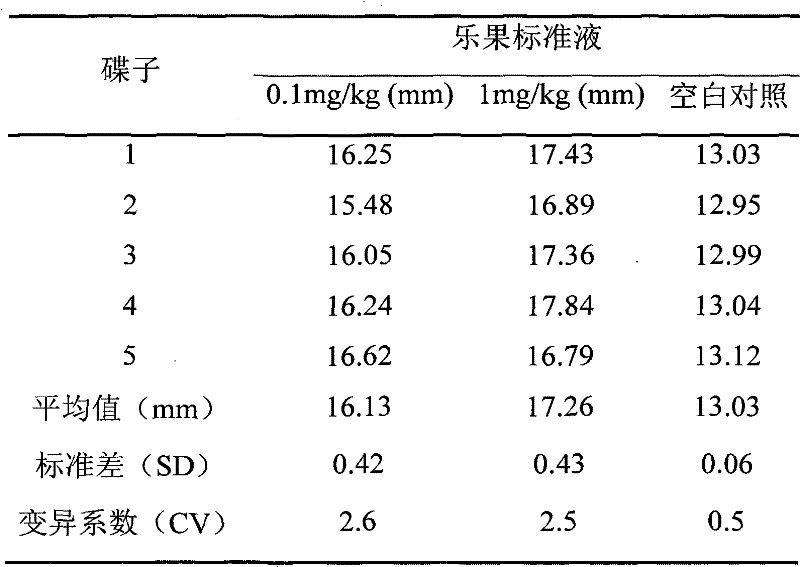

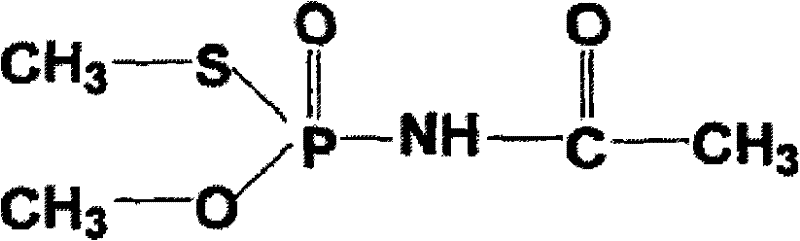

A kind of microbiological method for screening dimethoate residues in food

InactiveCN102286604AIncreased sensitivityStrong specificityBacteriaMicrobiological testing/measurementBifidobacteriumMicroorganism

The invention provides a bifidobacterium LJM-001 strain. The collection number of the bifidobacterium LJM-001 strain is CGMCC No.4090. The LJM-001 strain is hypersensitive to dimethoate and is a working strain for detecting dimethoate residues in food. The invention also provides a microbiological method for screening dimethoate residues in food. According to the size of antibacterial rings on a screening culture medium, whether the residual quantity of the dimethoate in food samples exceeds the standard or not can be judged. The method for screening the dimethoate residues in food has the characteristics of simpleness and convenience for operation, low cost, high sensitivity and suitability for sample screening, and the screening requirement of a large number of samples in the pesticide residue detection department in China is met.

Owner:温州医科大学仁济学院

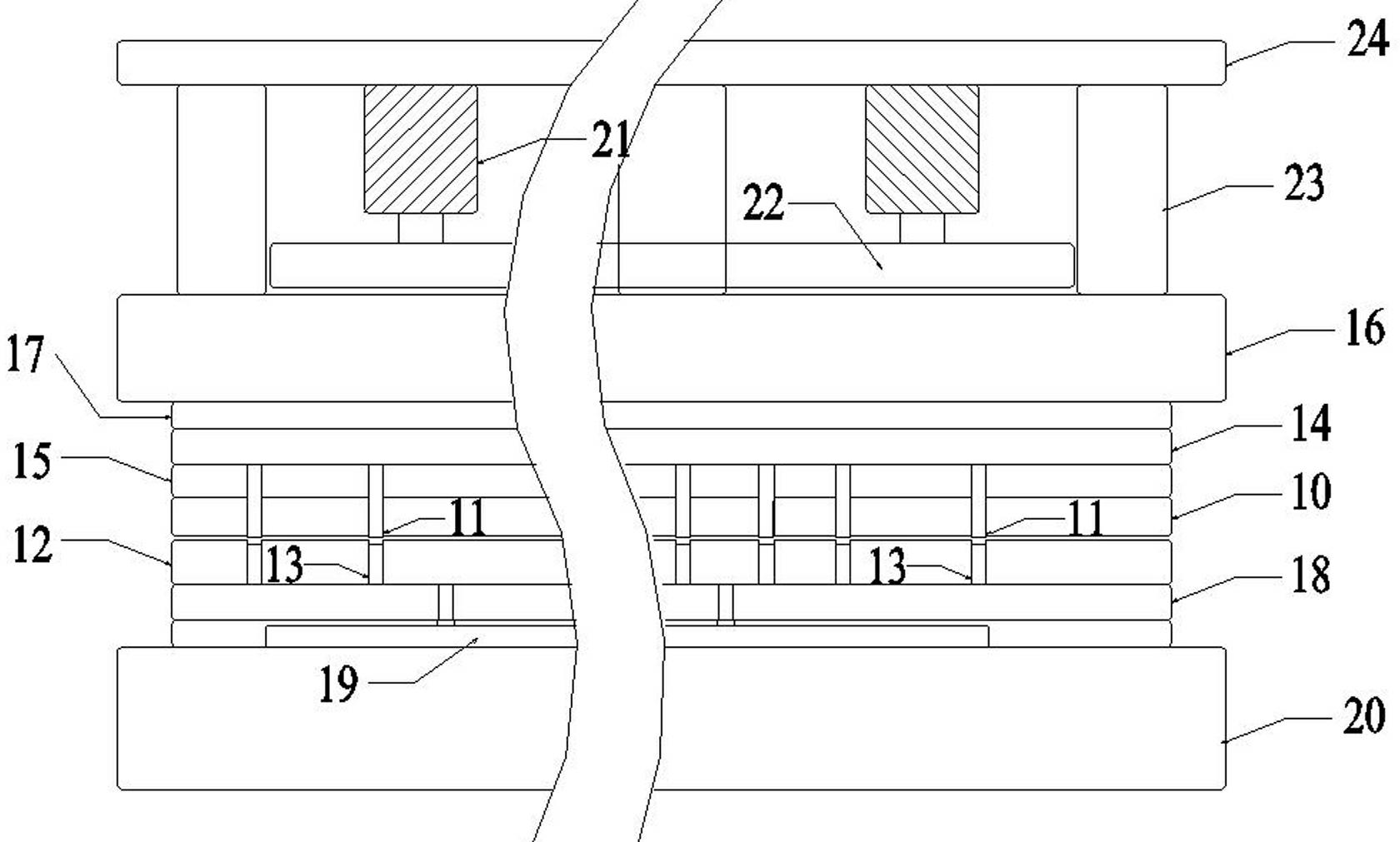

Manufacturing method of special-shaped spring

ActiveCN104624876AIncrease productivityGuaranteed machining accuracyWire springsNumerical controlWork in process

The invention discloses a manufacturing method of a special-shaped spring. The manufacturing method comprises the steps of spring semi-finished product machining, spring semi-finished product heat treatment strengthening and sizing. A spring semi-finished product is a spiral workpiece with a spiral gap formed by machining larger than a spring spiral gap required by the technology. After the spring semi-finished product is machined, the spring semi-finished product is compressed through a spring compressing sizing clamp first, a sizing sheet is placed in the spiral gap of the spring semi-finished product for pressing, the thickness of the sizing sheet is equal to the special-shaped spring spiral gap required by the technology, then the spring semi-finished product is subjected to vacuum heat treatment sizing, and heat treatment comprises the steps of vacuum hardening and secondary tempering. A numerical control technique is used for being combined with heat treatment for machining a special-shaped spring, production efficiency is high, machining accuracy is guaranteed, and the production efficiency of special-shaped springs, especially section-variable special-shaped springs is improved.

Owner:CENT SOUTH UNIV

Punching mould and punching method suitable for labtop keyboard frame

The invention discloses a punching mould and a punching method suitable for labtop keyboard frame, wherein the mould comprises a group of blanking modules for blanking, a plurality of groups of coarse punching mouldes, and a group of fine punching modules for finally and finely processing. According to the punching method of the invention, the modules cooperated with each other, the side walls of the punched keyboard frame has enough euphotic belts, the positive and negative surfaces of a keyboard hole are acute angles and have no singk angle. At the same time, the punching mould of the invention uses a punching head and a lower mould inlet block processed by PG (profile grinding) optical grinding, and further is provided with a nitrogen spring so that the products have good euphotic belt and flatness.

Owner:KUNSHAN SANJING SCI & TECH

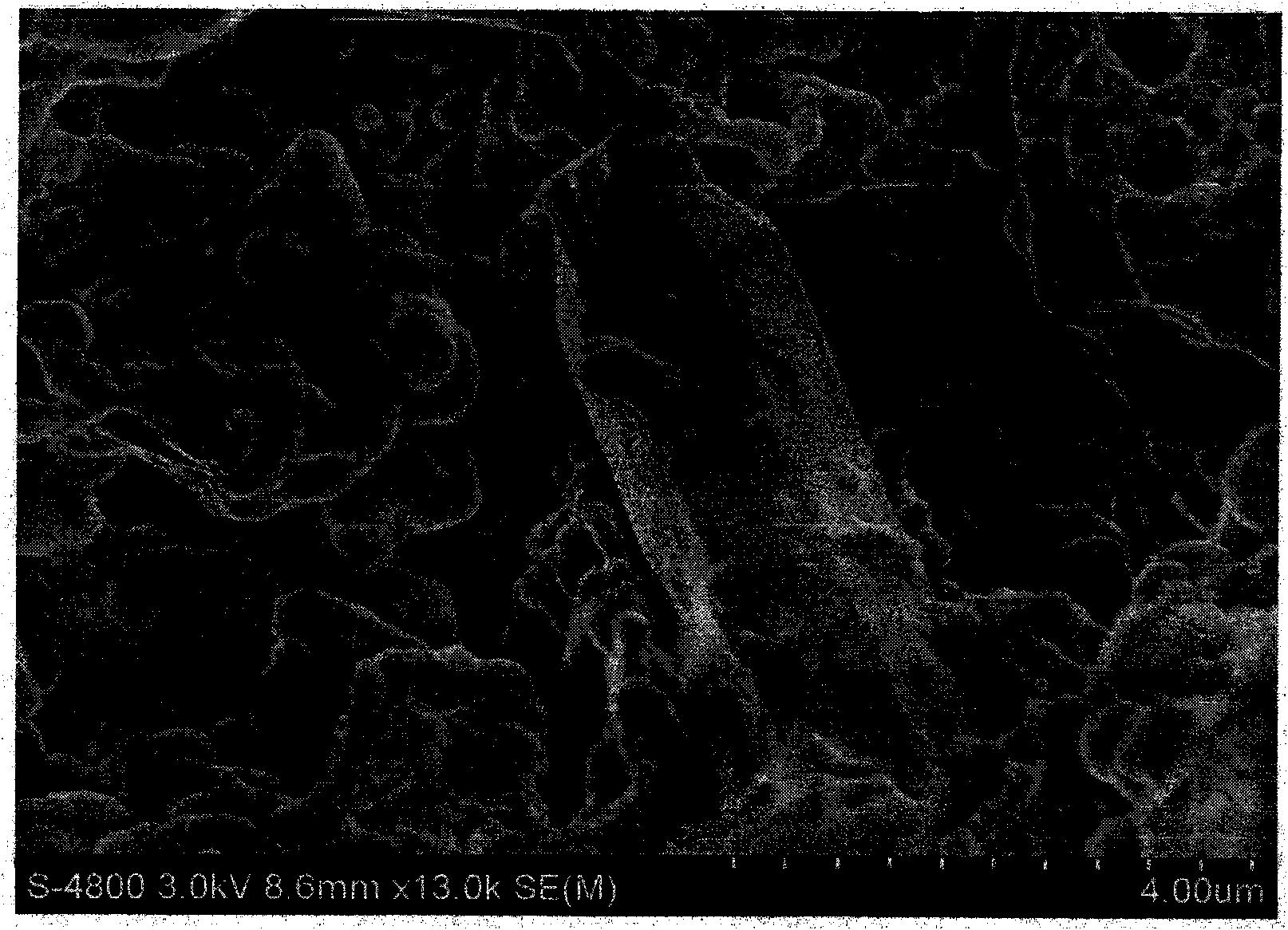

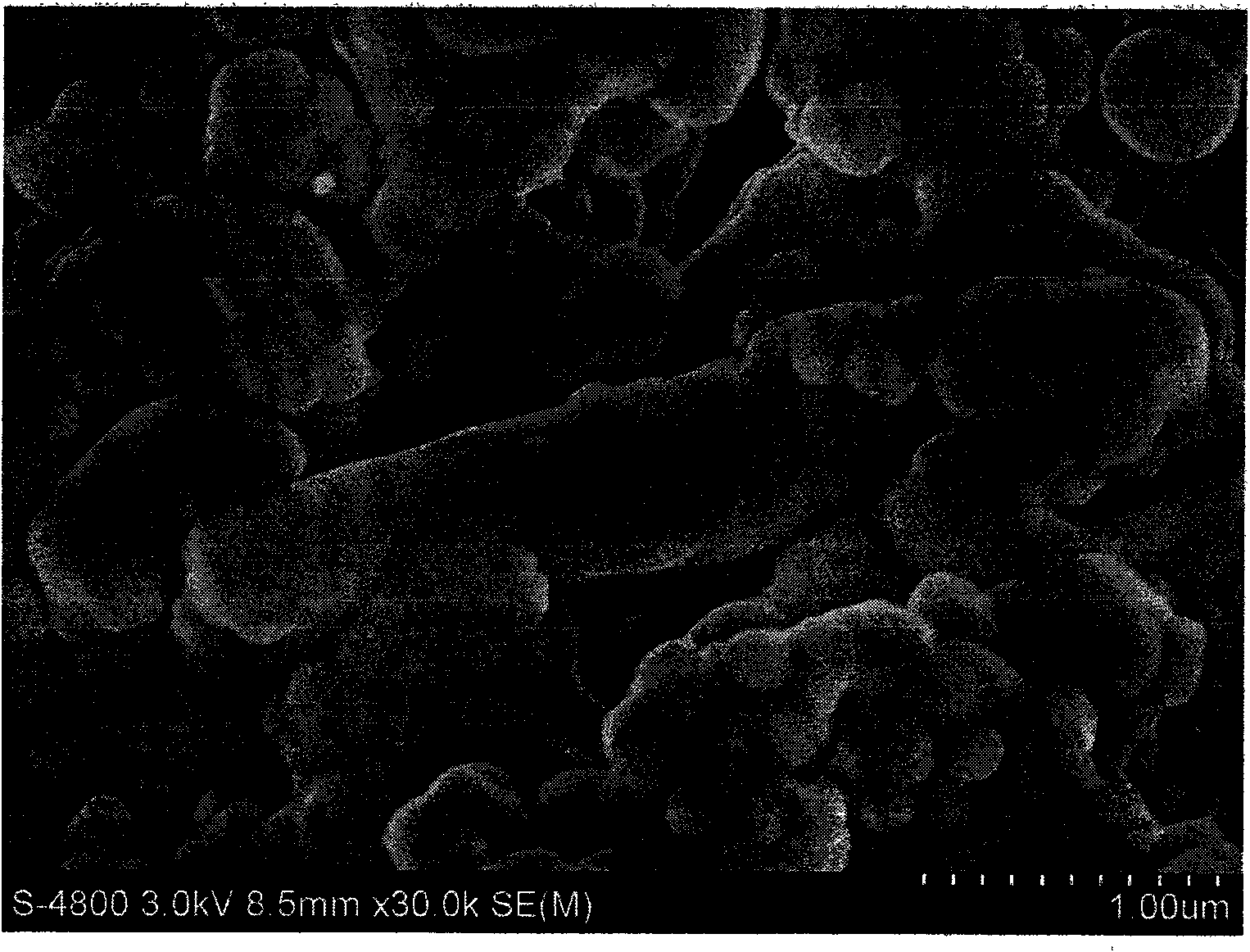

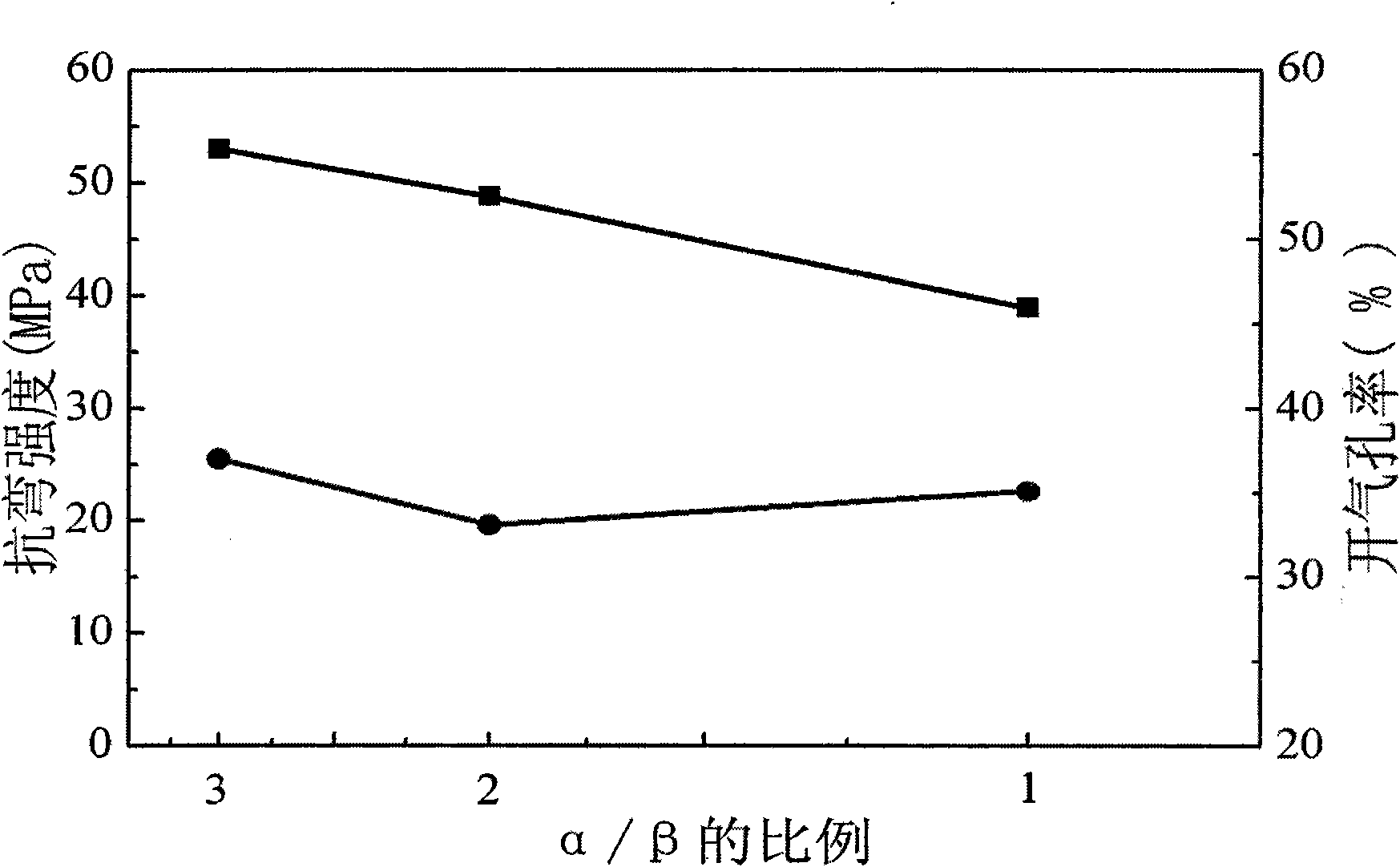

Method for producing porous ceramic materials by adopting low-temperature hydrothermal method

InactiveCN101570436ANo reduction in dielectric propertiesDoes not cause oxidationCeramicwareSilica particleNon oxide ceramics

The invention discloses a method for producing porous ceramic materials by adopting the low-temperature hydrothermal method. The method utilizes the hydrothermal reaction to immerse a ceramic formed body in silicon dioxide sol; according to the dissolution-precipitation mechanism, part of silicon dioxide particles can be precipitated on the surfaces of ceramic grains to play a bonding role, thereby producing the porous ceramic materials. The hydrothermal temperature in the preparation method is lower and can not cause the oxidation of non-oxide ceramics during the sintering process.

Owner:BEIHANG UNIV

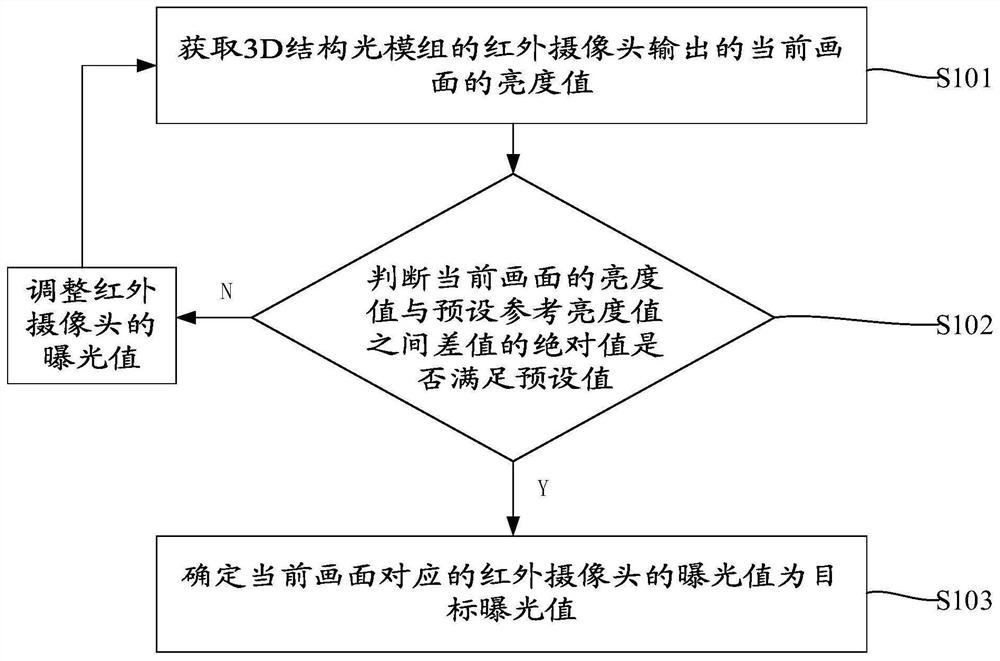

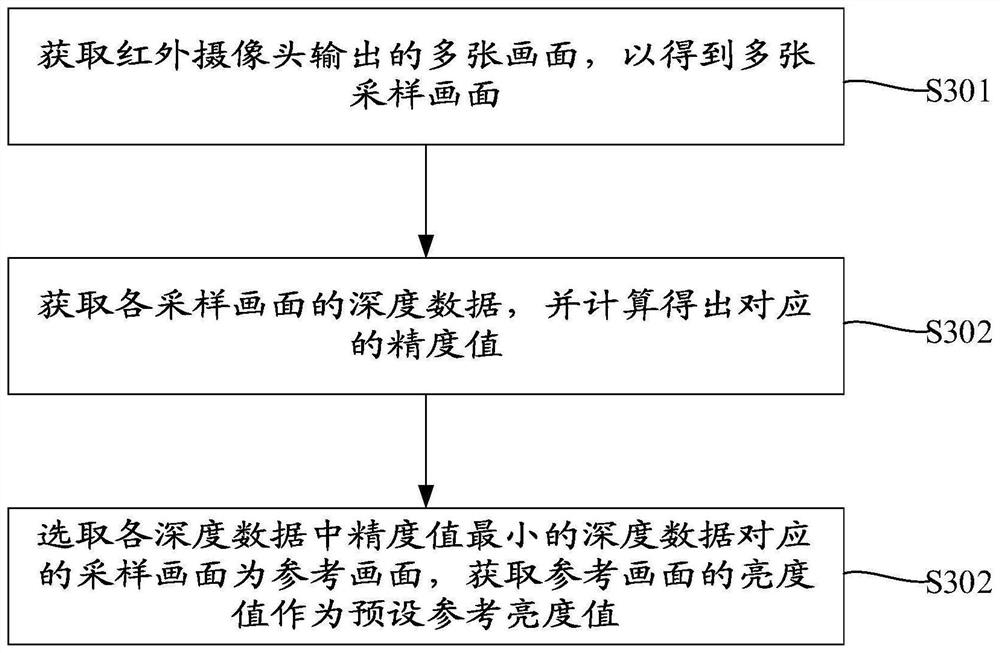

Infrared camera exposure adjustment method and device, electronic equipment and storage medium

ActiveCN111885311AMeet the precision requirementsAccuracy requirements metTelevision system detailsColor television detailsExposure valueEngineering

The invention provides an infrared camera exposure adjustment method and device, electronic equipment and a storage medium, and belongs to the technical field of deep sensing detection. The infrared camera exposure adjustment method comprises the following steps: acquiring a brightness value of a current picture output by an infrared camera of a 3D structured light module; judging whether the absolute value of the difference value between the brightness value of the current picture and a preset reference brightness value meets a preset value or not, wherein the depth data of the picture corresponding to the preset reference brightness value meets the precision requirement; if not, adjusting the exposure value of the infrared camera, and obtaining the brightness value of the current pictureoutput by the infrared camera of the 3D structured light module again; if so, determining the exposure value of the infrared camera corresponding to the current picture as a target exposure value. The infrared camera is enabled to shoot images of to-be-measured objects with different distances in a working range and maintain good brightness so that depth calculation of the 3D structured light module in the working range is enabled to always meet the precision requirement.

Owner:DONGGUAN VISIONX-TECH CO LTD

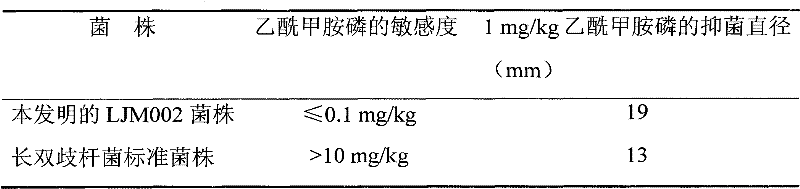

Cifidobacterium longum strain

InactiveCN102304482AIncreased sensitivityStrong specificityBacteriaMicrobiological testing/measurementMicroorganismPesticide residue

The invention provides a bifidobacterium longum LJM002 strain, the preservation No. of which is CGMCC No. 4900. The LJM002 strain is ultra-sensitive to acephate and is a work strain for detecting the residue of the acephate in foods. The invention also provides a microorganism method for screening the residue of the acephate in the foods, which comprises the step of judging whether the residue limit of acephate in food samples to be detected exceeds the standard according to the size of a bacteriostatic ring on a screening medium. The method for screening the residue of the acephate in the foods has the characteristics that the method is simple to operate, has low cost and high sensitivity and is suitable for sample screening. The method conforms to the screening requirements of China's pesticide residue detection department for a large quantity of samples.

Owner:WENZHOU MEDICAL UNIV

Saw grinding belt and processing method

ActiveCN102773560AAccuracy requirements metSimple processMetal sawing tool makingMetal sawing toolsEngineeringMechanical engineering

The invention discloses a saw grinding belt. The technical problem to be solved is to provide a saw grinding belt which can not only saw but also grind. In order to solve the problem, the saw grinding belt utilizes the technical scheme that the saw grinding belt comprises a belt saw blade body, and one side of the belt saw blade body is provided with sawteeth. The saw grinding belt is characterized in that at least one surface of the saw blade body is adhered with a grinding layer. The grinding layer consists of an upper grinding layer and a lower grinding layer. The saw grinding belt disclosed by the invention overcomes the problem, can saw and simultaneously grind, also has the advantages that the process is simplified, the efficiency is greatly improved, and the equipment investment is decreased. The grinding geometric accuracy of the saw grinding belt can reach + / -0.01mm, and the level of cleanliness is 12 to fully meet the accuracy requirements of industries; simultaneously, 50% of cost and 60% of time are saved.

Owner:上海康嘉怡医疗器材服务有限公司

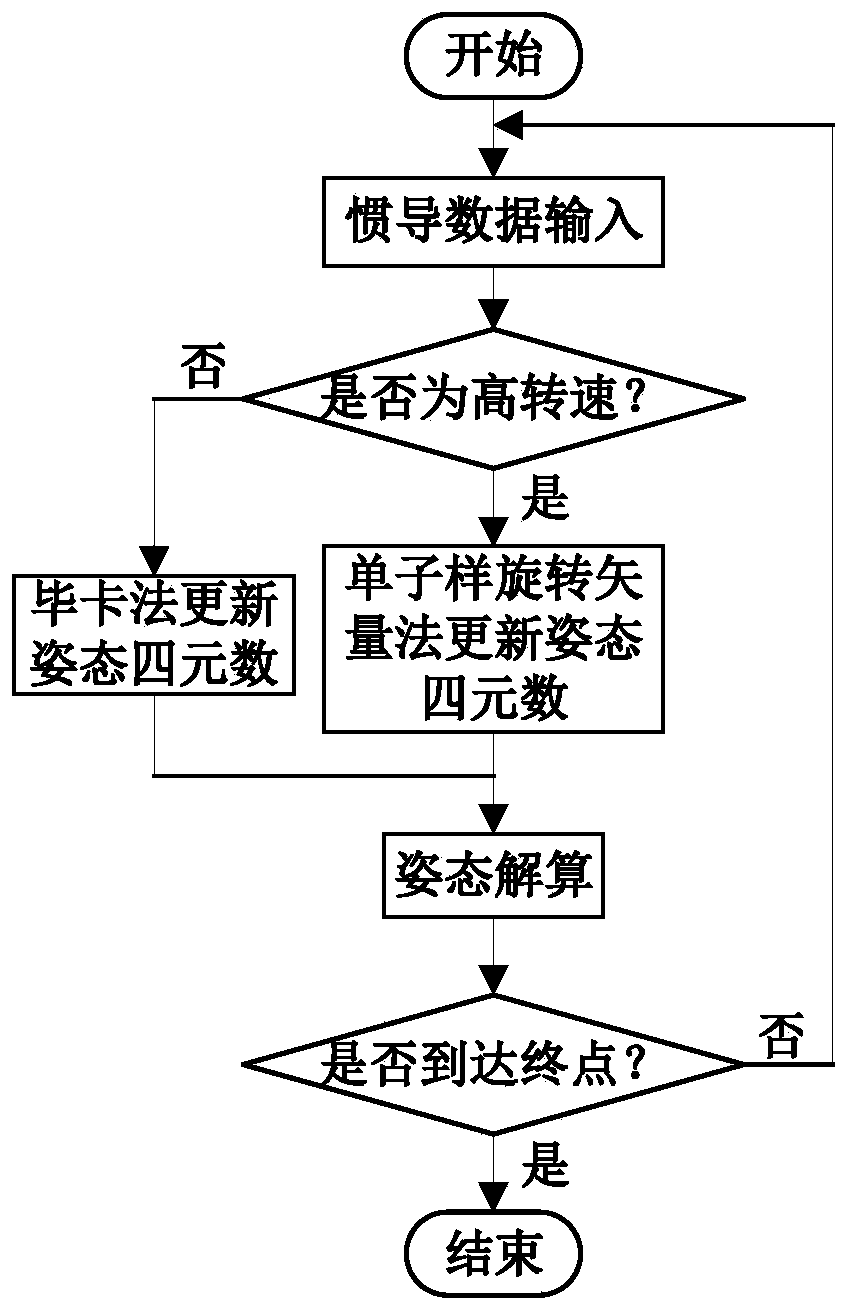

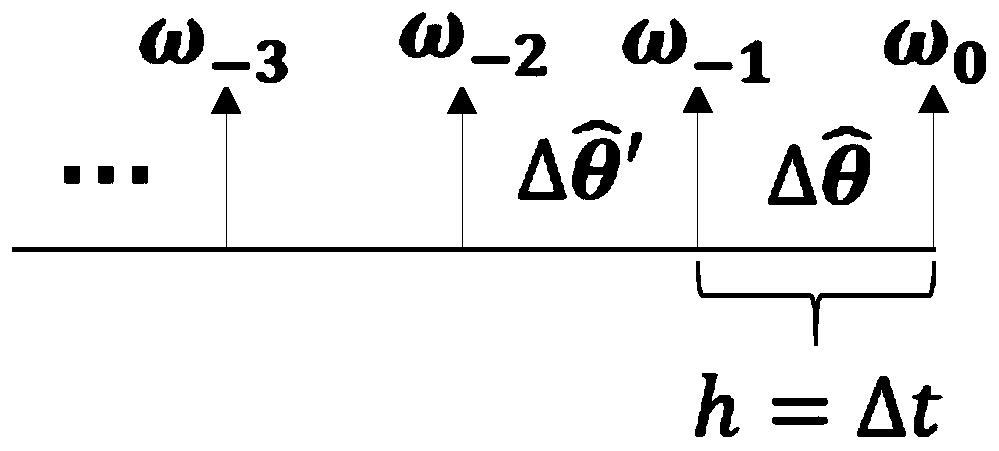

Attitude calculation method for high-dynamic variable-speed carrier

ActiveCN110851776AReduce the sampling frequencyAccuracy requirements metNavigation by speed/acceleration measurementsComplex mathematical operationsInertial navigation systemClassical mechanics

The invention discloses an attitude calculation method for a high-dynamic variable-speed carrier, and belongs to the field of inertial navigation. According to the method, the process of judging the rotating speed of a carrier is added in the process of resolving the attitude, so that when the rotating speed of the carrier is high, an inertial navigation system adopts higher sampling frequency toensure that a resolving result meets the precision requirement; when the carrier rotates at a low speed, the sampling frequency of the inertial navigation system is properly reduced so as to reduce the burden of hardware. When at high rotational speed, the invention provides a single subsample rotation vector algorithm based on angular rate output, the attitude can be updated according to the sampling frequency of the inertial navigation system, meanwhile, the current and previous attitude update cycle angle increment information and the current and previous angular rate information are used for compensating cone errors, and an error compensation coefficient can be obtained by solving a linear equation set. The method can effectively solve the problem of attitude solution of the high-dynamic variable-speed carrier.

Owner:SOUTHEAST UNIV

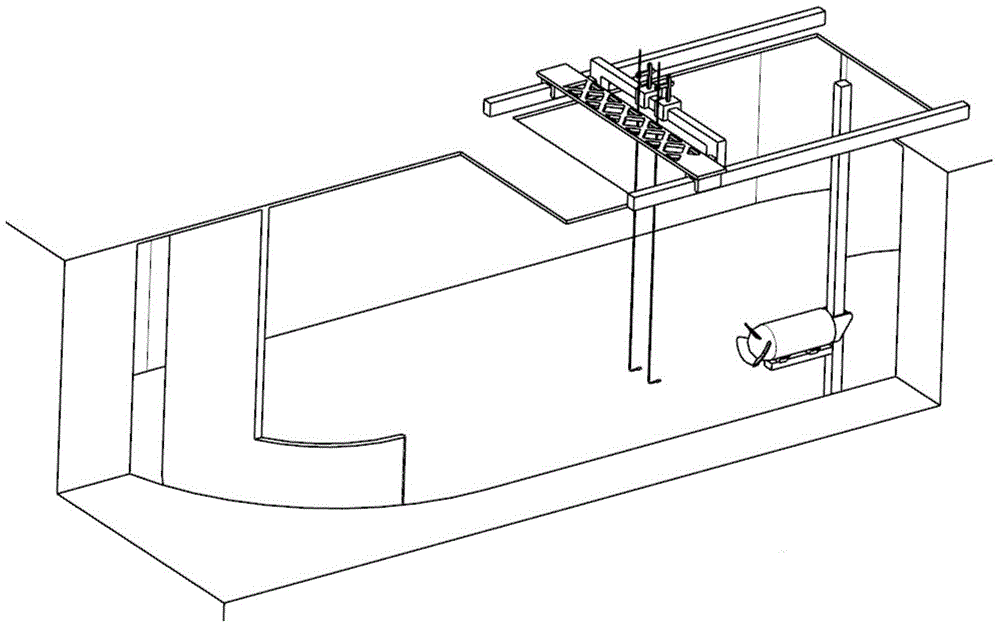

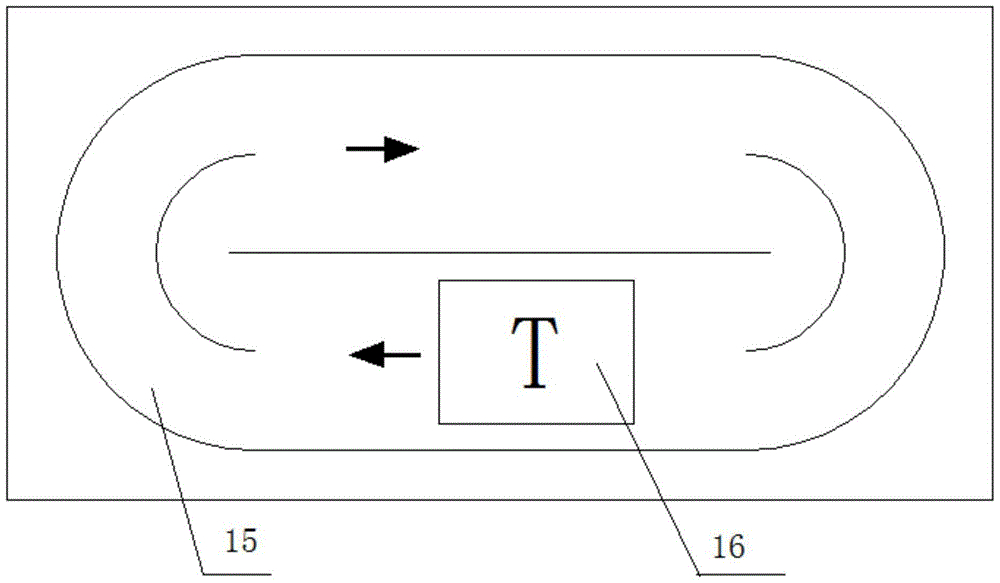

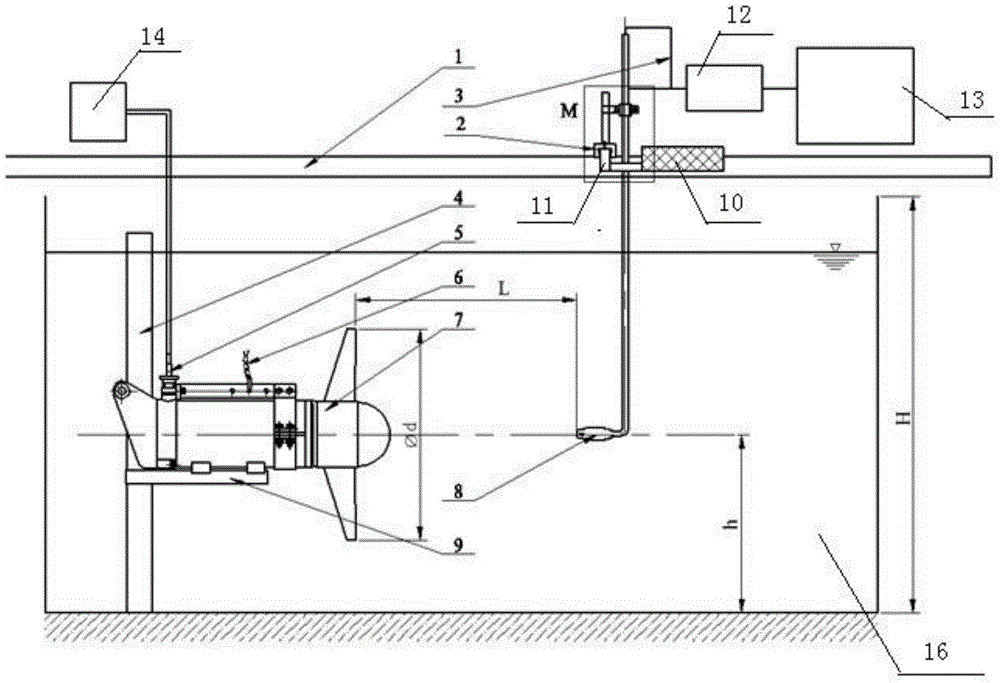

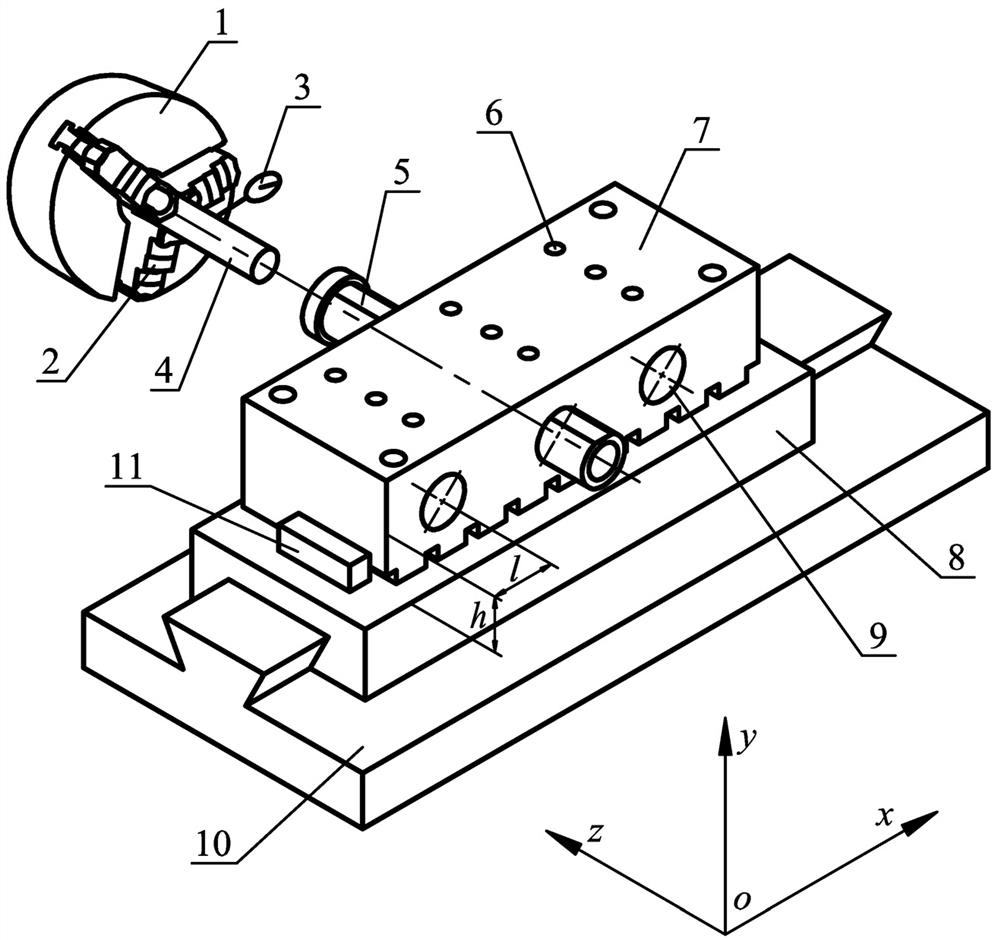

Test board for measuring overall flow velocity of submersible mixer, and method for measuring overall flow velocity of submersible mixer

ActiveCN105044382AAvoid backmixingFlow field stabilityFluid speed measurementMaximum diameterSubmersible mixer

The invention belongs to the technical field of fluid and chemical engineering, and relates to a test board for measuring the overall flow velocity of a submersible mixer and a method for measuring the overall flow velocity of a submersible mixer. The test board comprises a submersible mixer and a cone-shaped five-hole probe which are arranged in a sewage treatment pool, wherein the sewage treatment pool is a road-shaped pool; the cone-shaped five-hole probe is connected with an input end of a signal collector through a pressure sensor; and an output end of the signal collector is connected with a computer. The test board for measuring the overall flow velocity of a submersible mixer can measure the overall flow velocity of a submersible mixer by means of the integral principle, wherein the measuring process includes starting measurement from the position which is about 40mm apart from an impeller axis of the submersible mixer (dmin=40mm); moving to two sides point by point by the increment (each d=80) to measure the mean flow velocity in each anchor ring until the measured mean flow velocity is less than the minimum flow velocity Vmin so as to determine the maximum diameter dmax of a circle; and then obtaining the overall flow velocity. The invention provides the method for measuring the overall flow velocity of the submersible mixer, and designs the test board for measuring the overall flow velocity of the submersible mixer for the measuring method, thus being able to provide accurate experimental data for a factory inspection report of the mixer.

Owner:JIANGSU UNIV

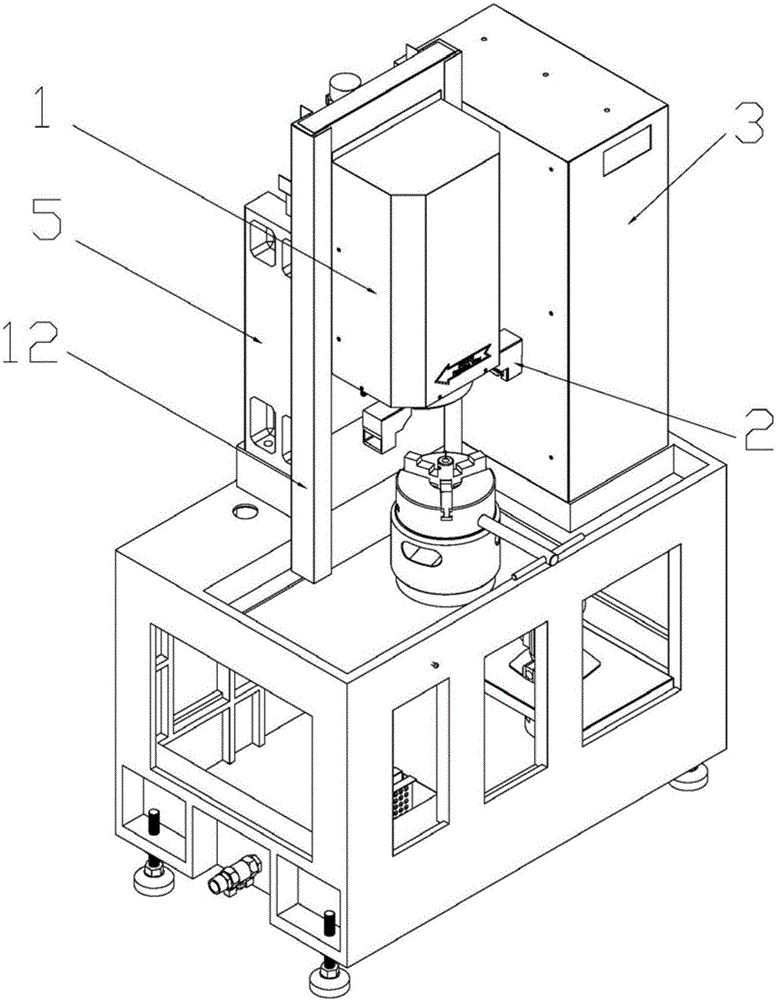

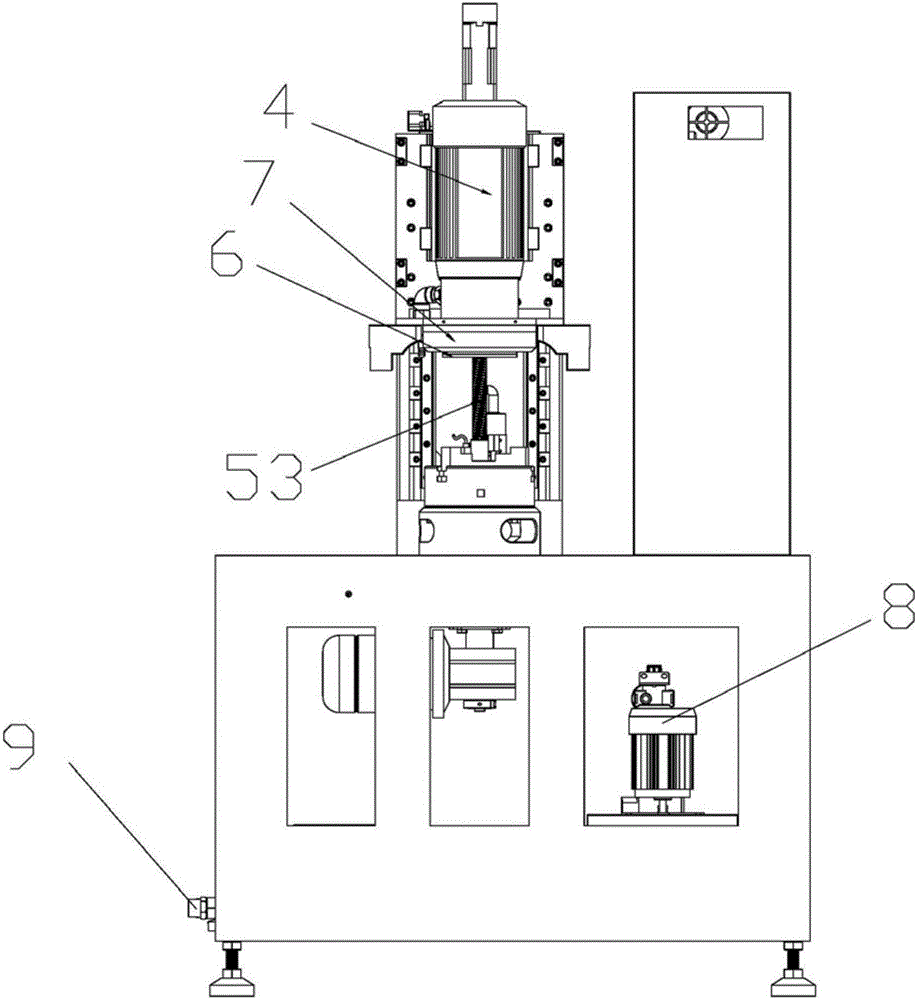

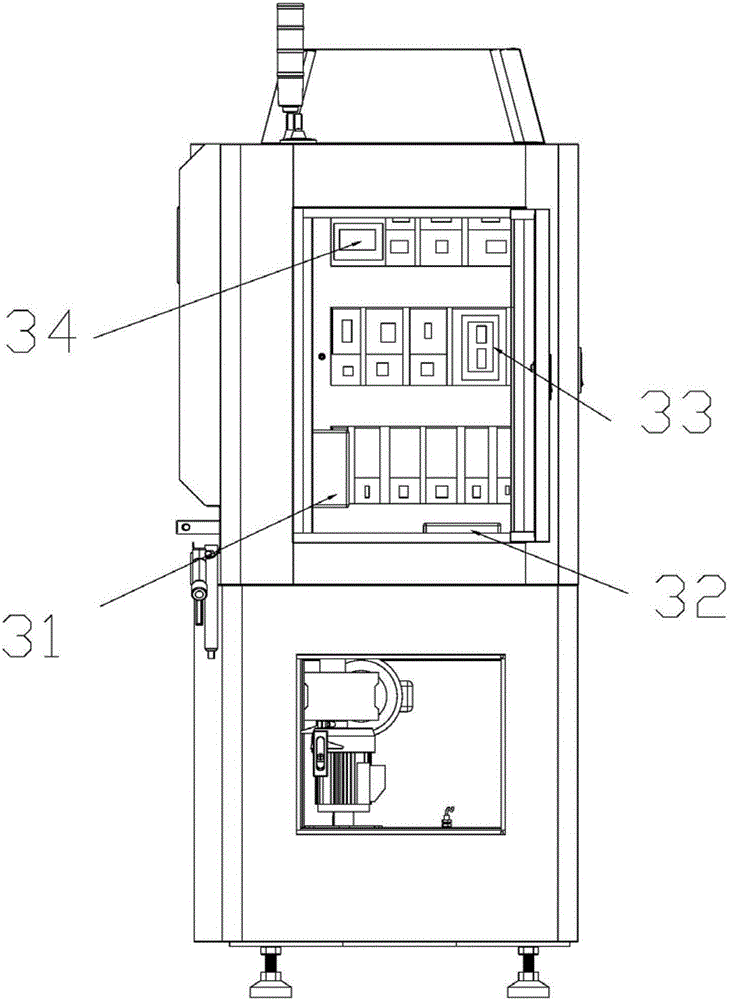

Automatic numerical control grinding machine for punch press die machining and using method thereof

ActiveCN105666288AExtended service lifeAvoid harmGrinding drivesGrinding feed controlNumerical controlAutomatic train control

The invention discloses an automatic numerical-control grinding machine for punch press die machining and a using method thereof and belongs to the field of grinding machines. The problem that an existing grinding machine is poor in cooling effect, severe in grinding environment, short in service life and low in machining precision is solved. The automatic numerical-control grinding machine comprises a spindle grinding wheel seat, a grinding head motor arranged on the spindle grinding wheel seat and a grinding wheel arranged on the grinding head motor and further comprises a cooling water pan, wherein the cooling water pan is in a shape of a hollow disc and is arranged between the grinding head motor and the grinding wheel and surrounds the spindle between the grinding head motor and the grinding wheel. Water spraying holes are formed in the inner wall of the cooling water pan. The automatic numerical-control grinding machine can effectively improve the cooling efficiency and improve a grinding environment, accordingly the service life of the machine is prolonged, the grinding precision is improved, and the automatic numerical-control grinding machine has higher safety performance and provides guarantee for safe production.

Owner:安徽雷默模具制造有限公司

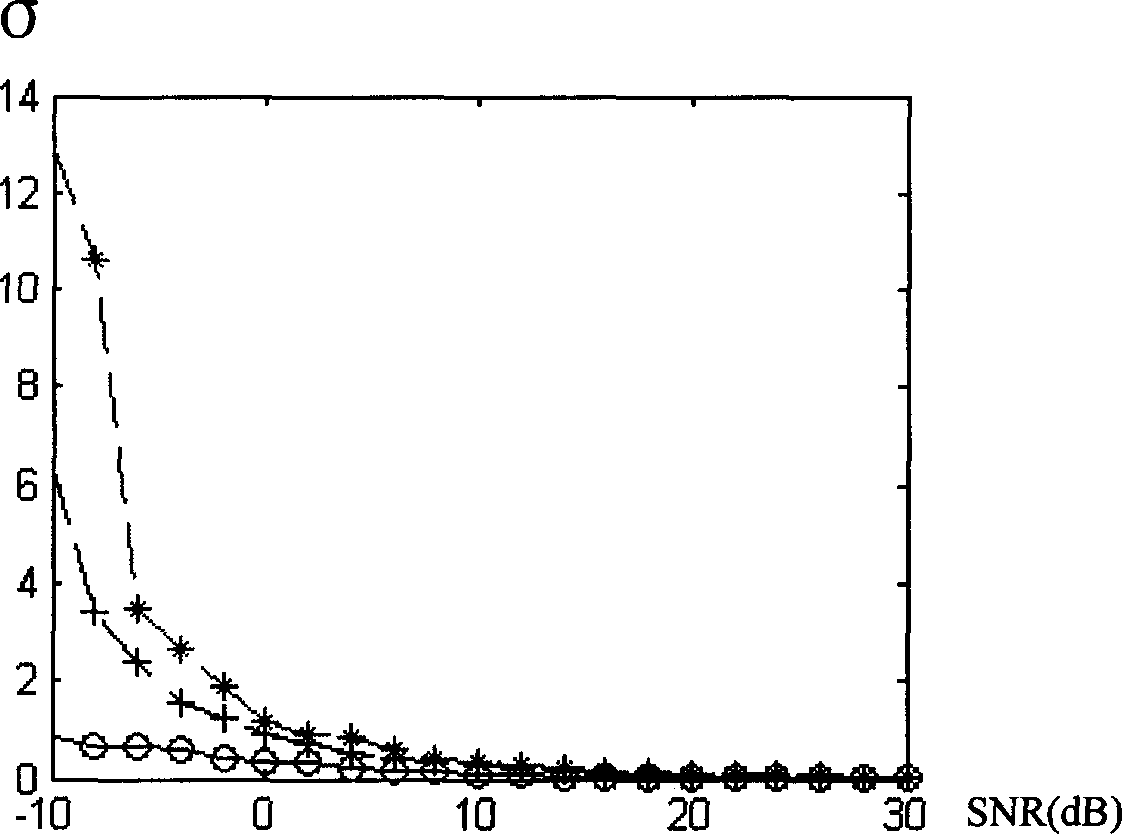

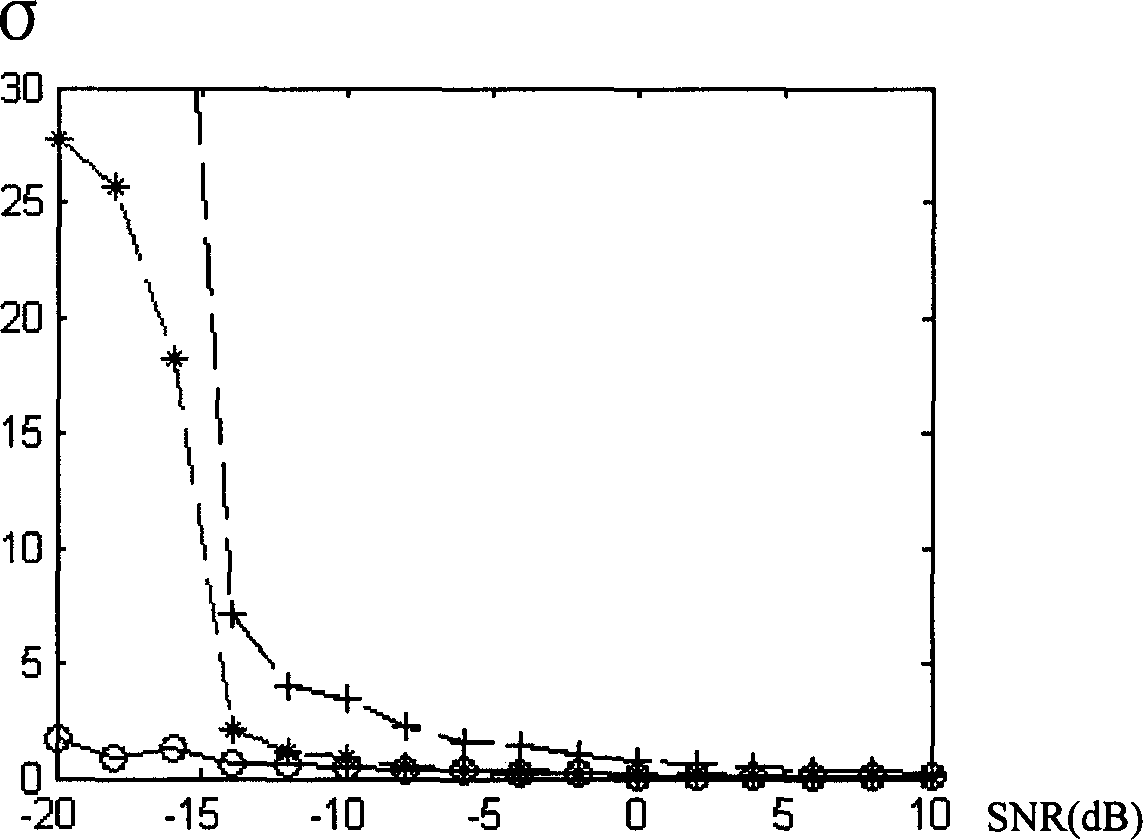

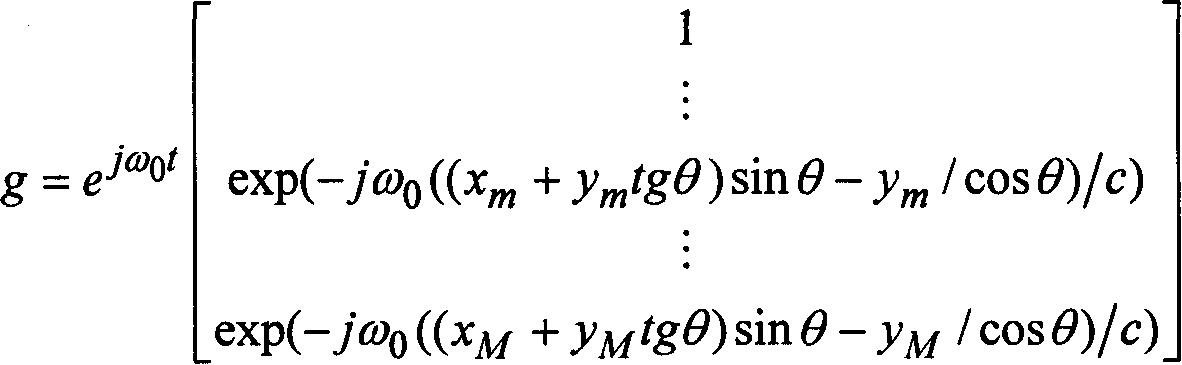

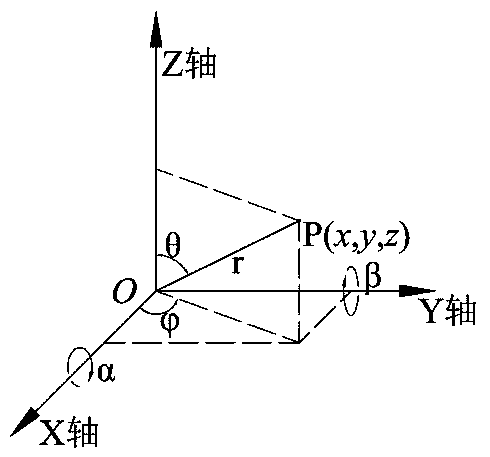

Space radiation source DOA estimation method based on non-orthogonal decomposition

InactiveCN1881838ALow environmental requirementsHigh precisionAntenna arraysDirection finders using radio wavesDecompositionEuclidean vector

The invention relates to a spatial radiation source reach angle estimate method, based on non-orthogonality decomposition, wherein the method that treating the antenna array collected data comprises: based on the carrier frequency of spatial radiation source signal, the character of antenna array and the formula of atom vector g, building the non-orthogonality over-maturity atom vector base G; then matching the data vector X received by antenna array in the non-orthogonality over-maturity atom base G; projecting the data received by antenna array in the non-orthogonality over-maturity atom base G, to select the atom vector with maximum projected component as the optimized atom vector; said spatial reach angle parameter theta of said optimized atom vector is the estimated value of spatial radiation source reach angle. The invention has high accuracy, the application in low signal / noise rate, and non-sensitive to the antenna array error, with low calculation consumption.

Owner:SOUTHWEST JIAOTONG UNIV

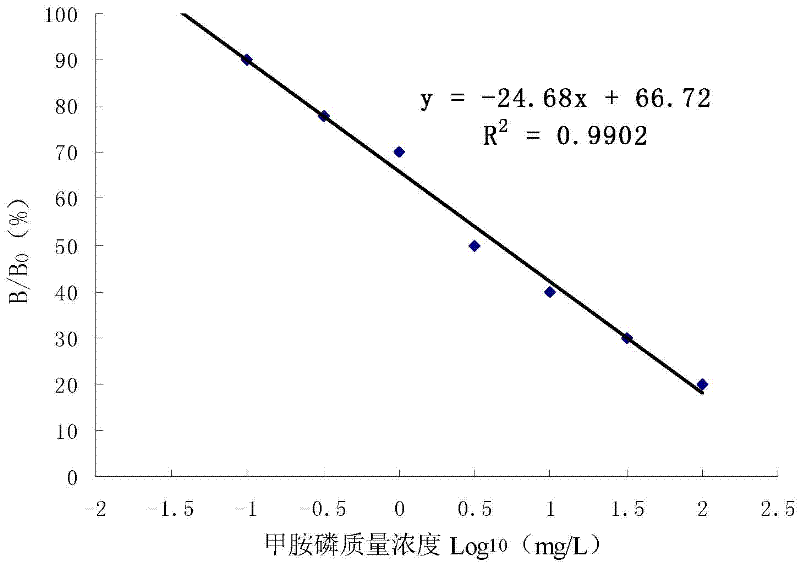

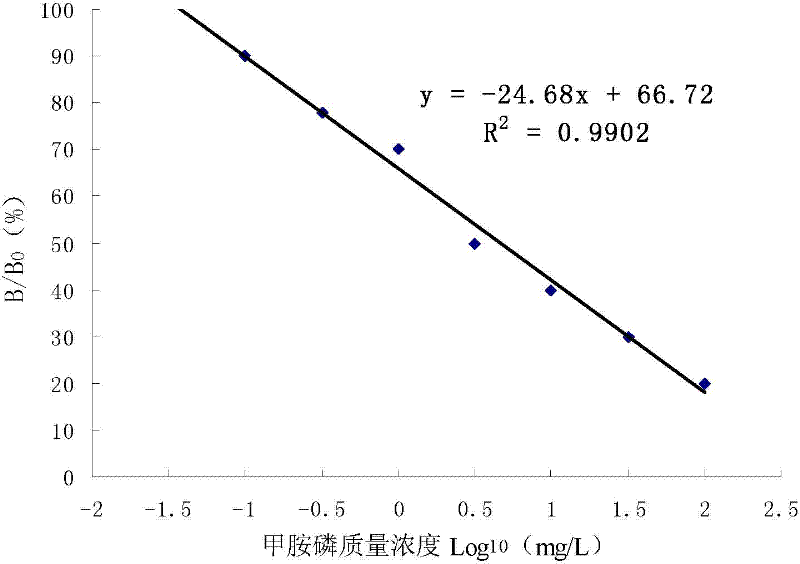

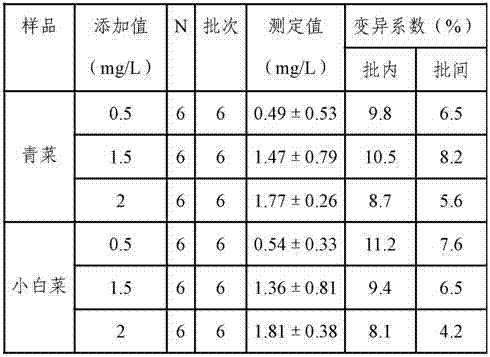

Bifidobacterium breve and detection method of methamidopho pesticide residue in foodstuff

InactiveCN102517230AIncreased sensitivityImprove stabilityBacteriaMicrobiological testing/measurementPesticide residueMicrobiology

The invention relates to bifidobacterium breve and a method for detecting methamidopho pesticide residue in foodstuff by using bifidobacterium breve. According to the invention, a selected strain is an LJM-006 strain with a collection number of CGMCC No. 5418. The LJM-006 strain is hypersensitive to methamidopho. The methamidopho residue detection method established employing the strain as a working strain comprises the steps of: (1) strain activation, (2) strain suspension preparation, (3) detection tube preparation, (4) standard curve drawing and regression equation establishing, (5) sample pretreatment, (6) sample detection, and the like. The detection method provided by the invention is advantaged in simple operation, low cost, and high sensitivity. The result of detection is easy to determine. Compared to a high-efficiency liquid chromatography method, a result coincidence rate is high. Therefore, the method is suitable for sample detection. The method satisfies the requirement by the national pesticide residue detection department for large-batch sample screening.

Owner:温州医科大学仁济学院

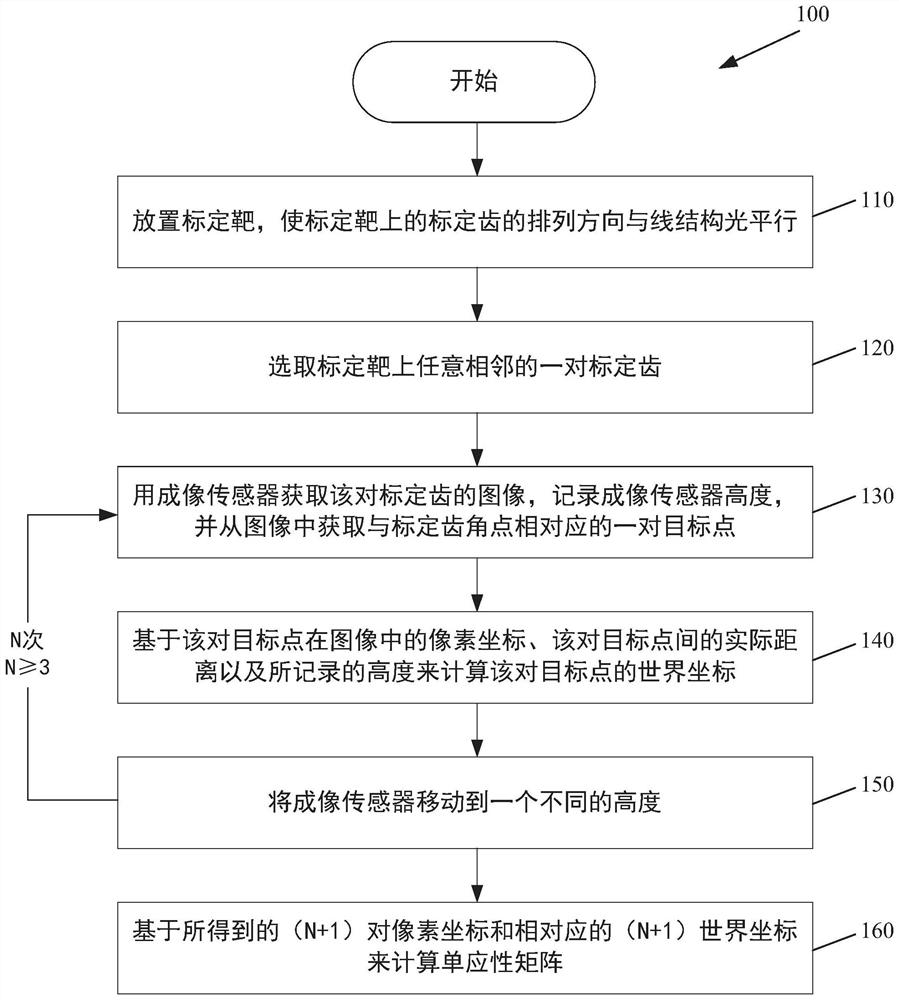

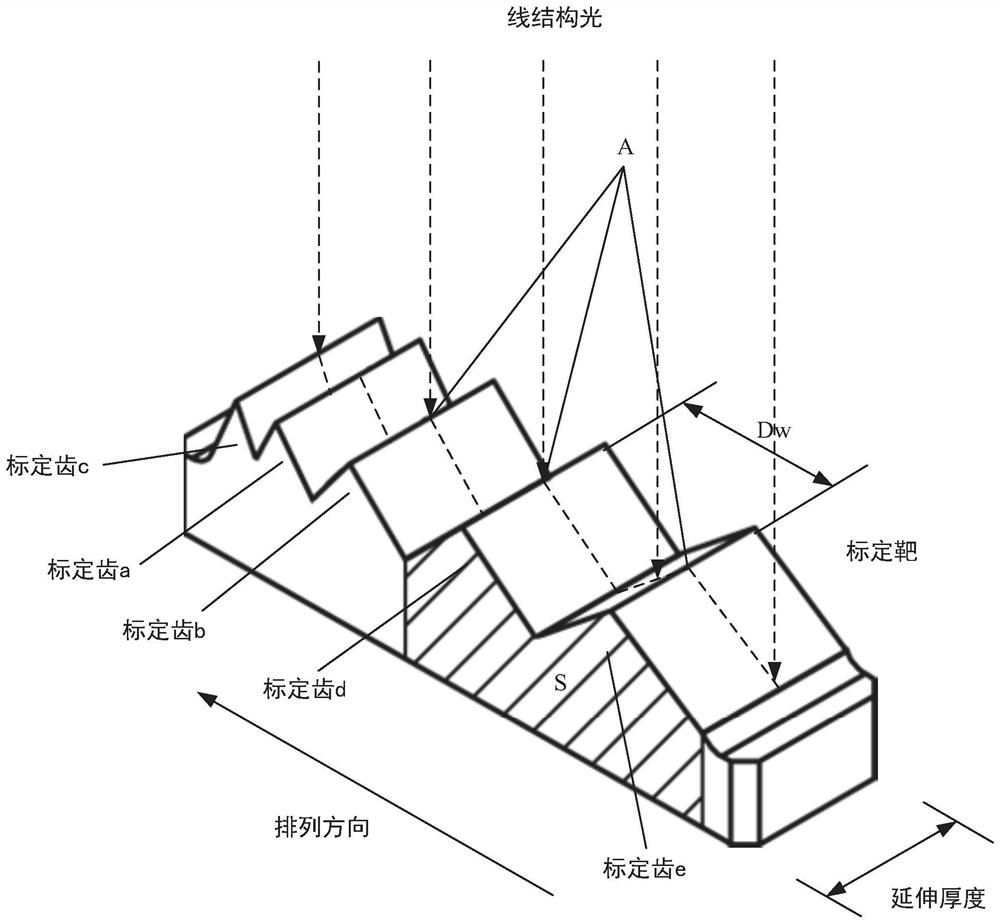

Calibration method, calibration system and calibration target for linear structured light imaging and measurement system using calibration target

PendingCN114241061AGuaranteed accuracyAccuracy requirements metImage enhancementImage analysisStructured light

The invention relates to a line structured light imaging calibration method, a calibration system, a calibration target and a measurement system using the calibration target. The calibration method comprises the following steps: a, placing a calibration target so that the arrangement direction of calibration teeth on the calibration target is parallel to the line structure light; b, selecting any pair of adjacent calibration teeth on the calibration target; c, an image of the pair of calibration teeth is obtained through an imaging sensor, the height of the imaging sensor in the Z-axis direction perpendicular to the placement plane of the calibration target is recorded, and the image comprises a pair of angular points, irradiated by the line structured light, of the pair of calibration teeth serving as a pair of target points; d, world coordinates of the pair of target points are calculated based on the pixel coordinates of the pair of target points in the image, the actual distance between the pair of target points and the recorded height; e, the imaging sensor is moved to different heights N times in the Z-axis direction, the steps c-d are executed again after each time of movement, and N is larger than or equal to 3; and f, calculating a homography matrix based on the (N + 1) pair pixel coordinates and the corresponding (N + 1) pair world coordinates obtained in the steps c-e.

Owner:上海柏楚电子科技股份有限公司

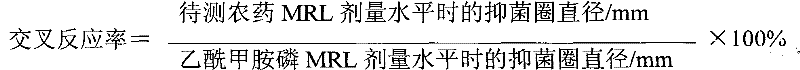

Method for quick screening and assessment of pesticide residues in tea

ActiveCN106222235AIncreased sensitivityStrong specificityMicroorganismsMicrobiological testing/measurementInhibition zoneInterference resistance

The invention provides a method for quick screening and assessment of pesticide residues in tea. The invention provides a microbial method for screening carbamate pesticide residues in tea by using clostridum butyricum WZ001 as a working strain. The size of inhibition zone on a screening medium is employed to determine whether the acephate residues in a food sample to be measured exceeds the standards. The method for quick screening and assessment of pesticide residues in tea has the characteristics of simple operation, low cost, high sensitivity, and suitability for screening sample characteristics, is superior to the current national standards for rapid screening of pesticide residues, fully meets the requirements for maximum residue limit in food of national food safety standards, has good ability of matrix interference resistance, and can effectively avoid false positive results.

Owner:WENZHOU MEDICAL UNIV

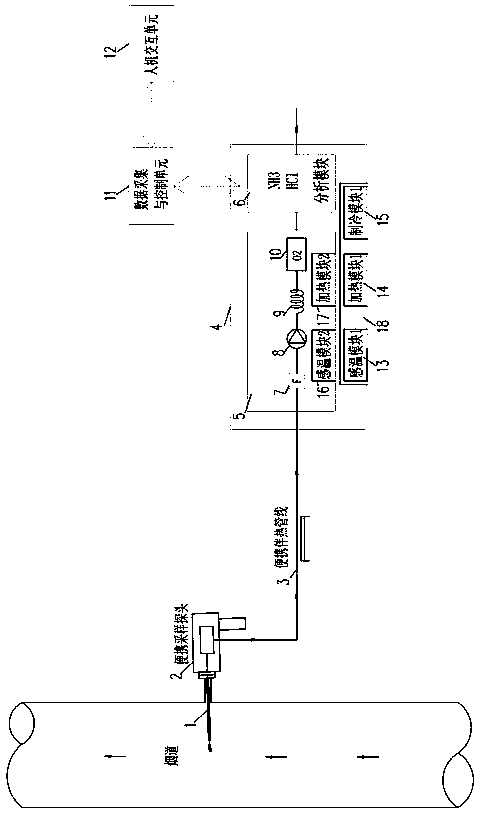

Portable NH3 and HCl analysis system for comparison monitoring

PendingCN108956529AReduce distractionsHigh speedColor/spectral properties measurementsGas analysisBlood gas analysis

The invention belongs to the field of gas analysis and relates to a portable NH3 and HCl analysis system for comparison monitoring. The portable NH3 and HCl analysis system comprises a portable heating and sampling probe, a tracing heat pipeline and a portable analysis unit, wherein the tracing heat of a whole sampling analysis process of the portable NH3 and HCl analysis system is 220 DEG C and gas sampling temperature is higher than a acid dew point of a flue gas to be detected; the portable analysis unit comprises a temperature control unit, a high-temperature pre-treatment box, an oxygen analysis module, an NH3 and HCl analysis module, a data acquisition and control unit and a man-machine exchange unit. The analysis system has the characteristics of small interference, rapid speed, high sensitivity and high measurement precision, and field comparison monitoring work is extremely convenient to realize.

Owner:NANJING HOPES TECH

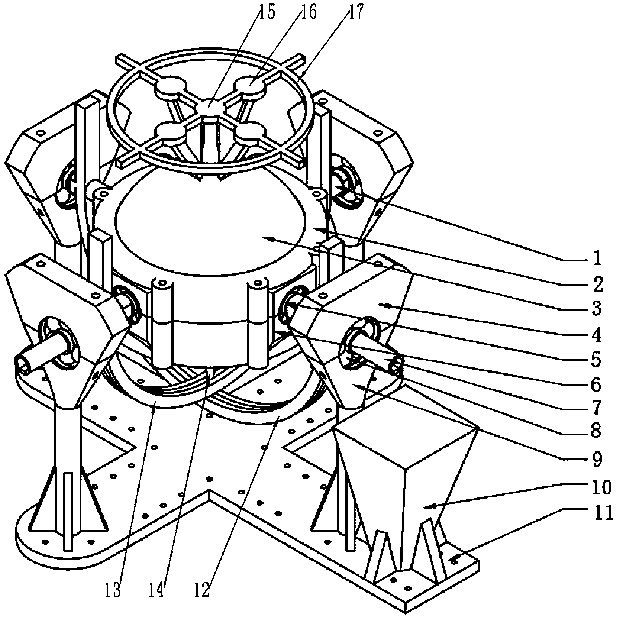

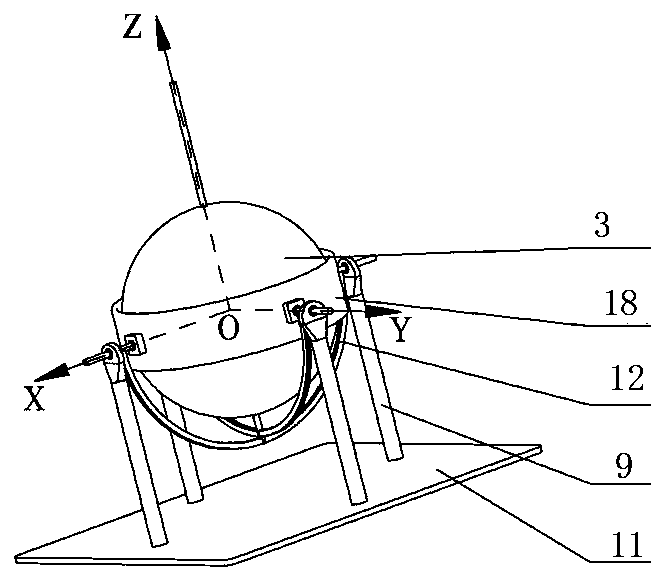

Spherical joint movement sensor

The invention relates to a spherical joint movement sensor and belongs to the field of spatial rotation angle measurement technologies. The invention aims to provide a special measurement system for measuring the rotation angle of a spherical joint. According to the technical schemes of the invention, the spherical joint movement sensor includes a sphere, a supporting bracket, an outer slide rail,an inner slide rail and single-axis angle encoders; the equator portion of the sphere is surrounded by the supporting bracket; the sphere is in rotatable fit with the supporting bracket; the top endof the sphere is provided with an action receiving portion; the bottom end of the sphere is provided with a decoupling slider; each of the outer slide rail and the inner slide rail is a semi-circulararc rail with a slit formed in the middle; two sides of each of the outer slide rail and the inner slide rail are hinged to the supporting bracket through coupling devices; the decoupling slider passes through the slit of the inner slide rail and is hinged to the slit of the outer slide rail; and the outer ends of the coupling devices are connected with the single-axis angular encoders.

Owner:ZHONGBEI UNIV

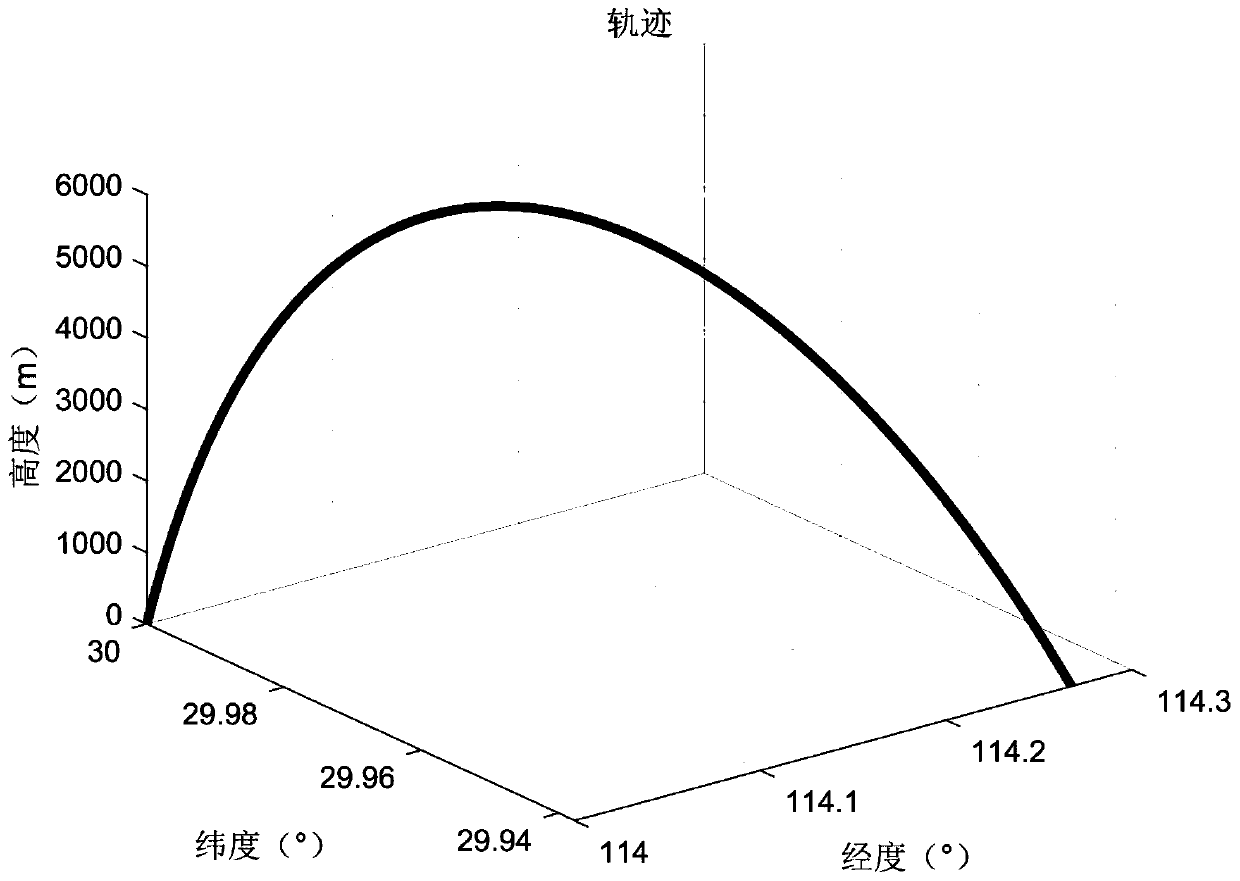

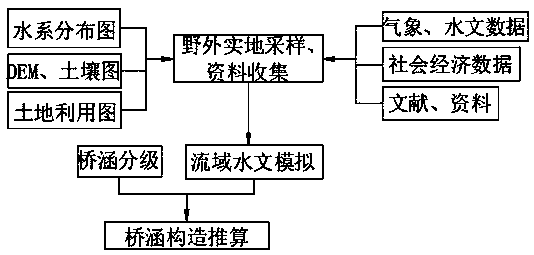

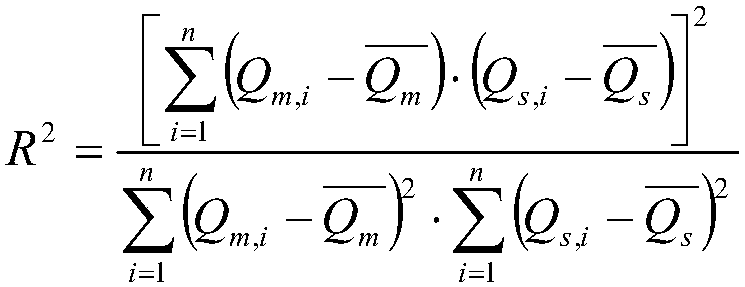

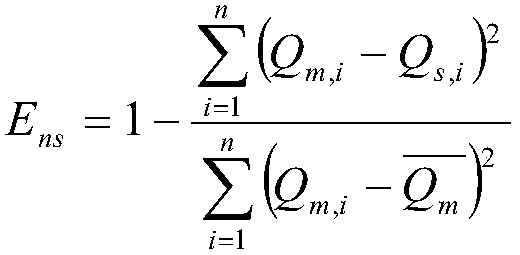

A method for estimating bridge and culvert structure based on Mayi River basin

ActiveCN109472102AAccuracy requirements metHigh simulationClimate change adaptationDesign optimisation/simulationDischarge dataDecision-making

The invention discloses a method for estimating bridge and culvert structure based on Mayi river basin, belonging to the field of hydrology environment. Including the establishment of SWAT hydrological model and the calculation of bridge and culvert structure, using hydrological data to calibrate and verify the model, to obtain daily discharge data of small watershed, Within a relatively large watershed, it is difficult to investigate the structure of bridges and culverts, The selection and construction of bridges and culverts by means of bridge and culvert structure estimation and the selection of appropriate types of bridges and culverts can provide theoretical support for river ecological management decision-making, provide reasonable distribution for future bridge and culvert construction, and also provide convenient operation for studying the quantification process of cold water fish migration affected by bridges and culverts in Mayi River Basin.

Owner:BEIJING NORMAL UNIVERSITY

Detonator lateral illumination recognition structure

PendingCN109387995AQuick identificationEfficient Information ManagementAmmunition fuzesPhotographyDetonatorComputer module

The invention discloses a detonator lateral illumination recognition structure, comprising a detonator support main body and illumination modules. The detonator support main body comprises a chamber conforming to the outer dimension of the detonator, and the chamber has a visible opening communicating with the outside. The detonator is visible to the outside through the opening, and the illumination modules are mounted on outer sides of both ends of the visible opening of the detonator support main body. According to the invention, the conventional manual recording of a detonator code is converted into illumination photographing mode, the detonator logo can be effectively and quickly identified; through connection of systems of the related equipment and a database, information of the civilexplosives of detonators can be quite highly efficiently managed; various flow directions of the quantity and of types of civil explosives can be ensured; real-time position monitoring and loss can be effectively controlled; and the strict management and control of civil explosives can be effectively ensured.

Owner:GUANGZHOU BENAN INFORMATION TECH CO LTD

Lathe gang tool rest installation precision adjusting method

ActiveCN112571096AHigh coaxiality requirementsSolve the accuracy problemAuxillary equipmentLarge fixed membersProcess engineeringSlide plate

The invention provides a lathe gang tool rest installation precision adjusting method. According to the lathe gang tool rest installation precision adjusting method, a targeted gang tool rest structure is designed by analyzing the machining characteristics of lathe holes, and the gang tool rest installation precision adjusting method is formulated according to the structural characteristics and precision of a lathe; by additionally arranging the tool positions on a sliding plate, the machining capacity is improved, the designed gang tool rest installation precision adjusting method is suitablefor increasing the number of the lathe tool positions, the precision obtained through the gang tool rest installation precision adjusting method can meet the precision requirement of a machine tool,the machining precision of a refitted gang tool rest is improved to the maximum extent, rapid tool replacing is achieved, the toolsetting error is eliminated, the production efficiency is improved, the hole machining precision is improved to the maximum extent, and the high-precision and high-efficiency operation requirements of modern production and manufacturing are met.

Owner:SUZHOU SABO IND DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com