Patents

Literature

871results about "Metal sawing tool making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brazed diamond tools and methods for making the same

Owner:SUNG CHIEN MIN

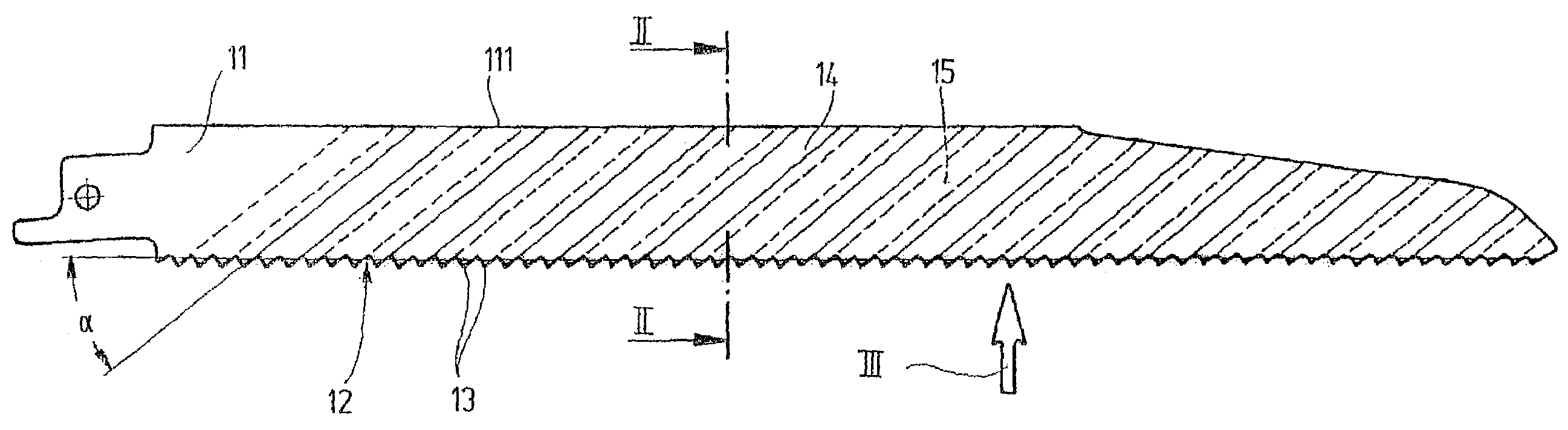

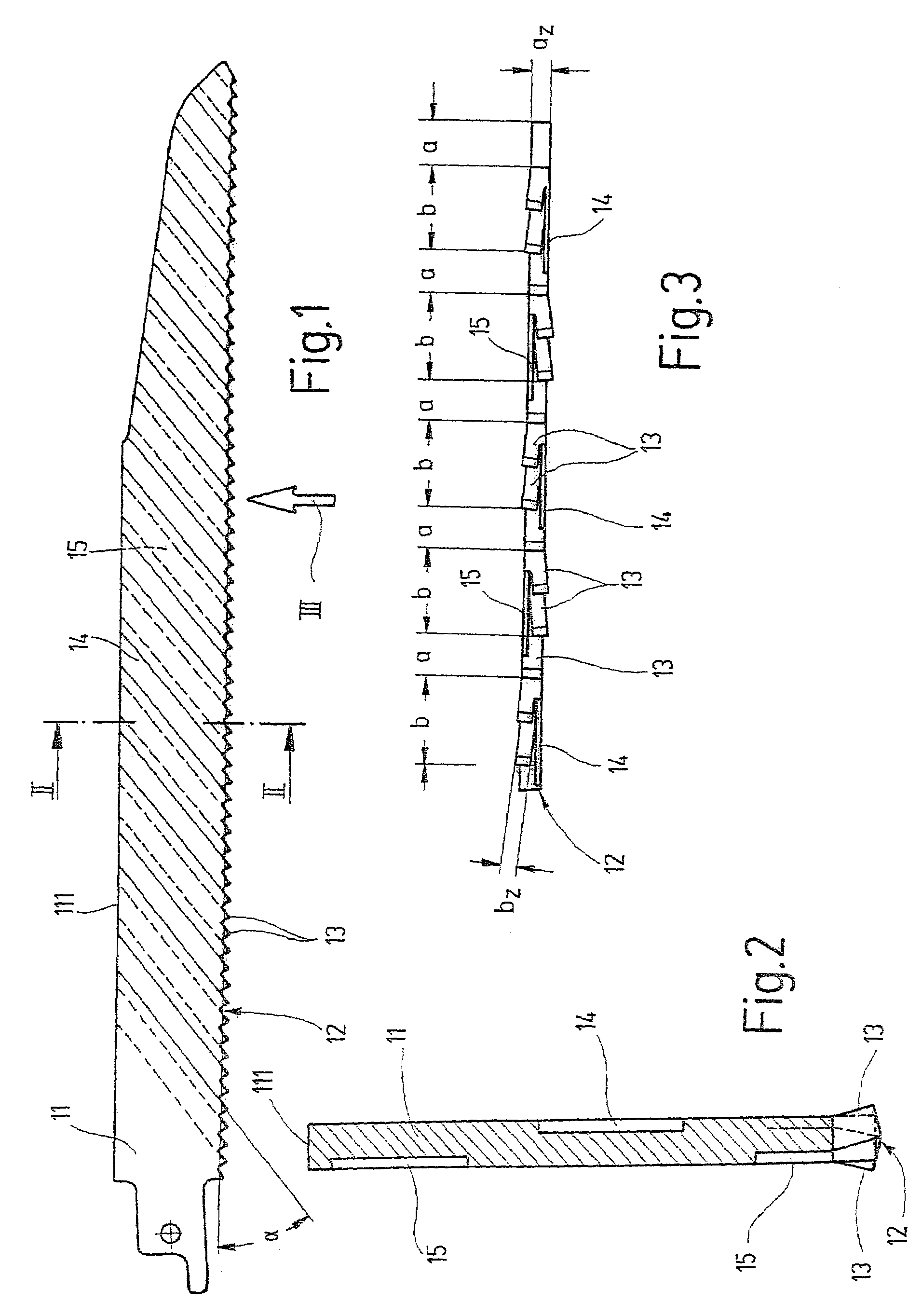

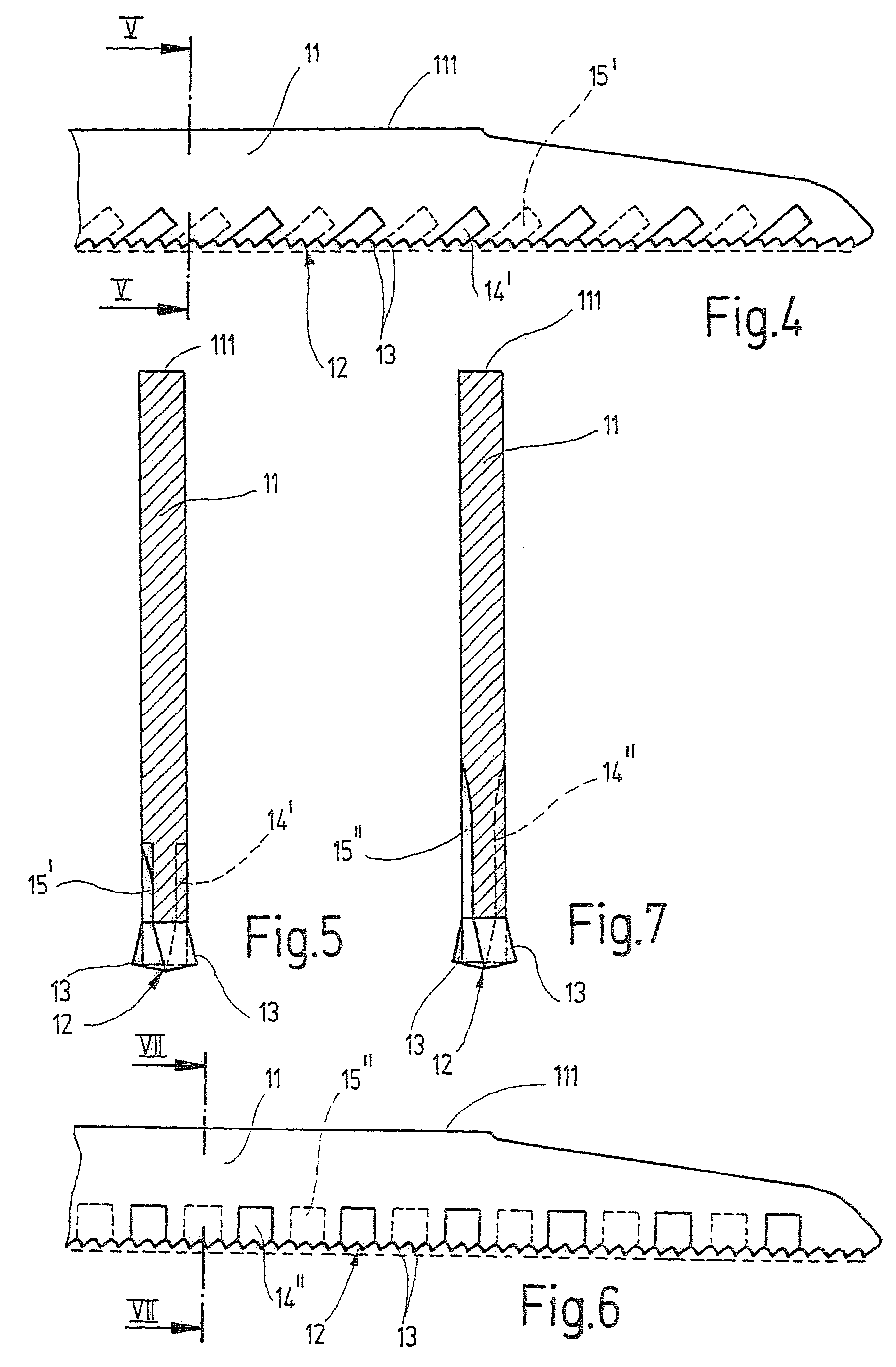

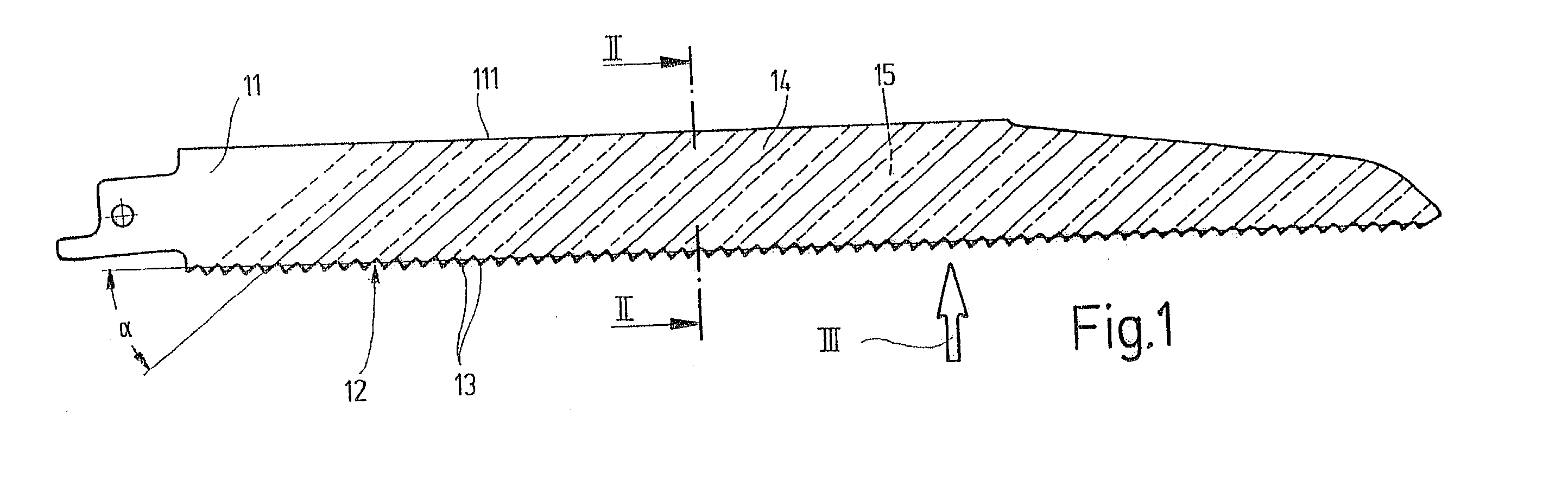

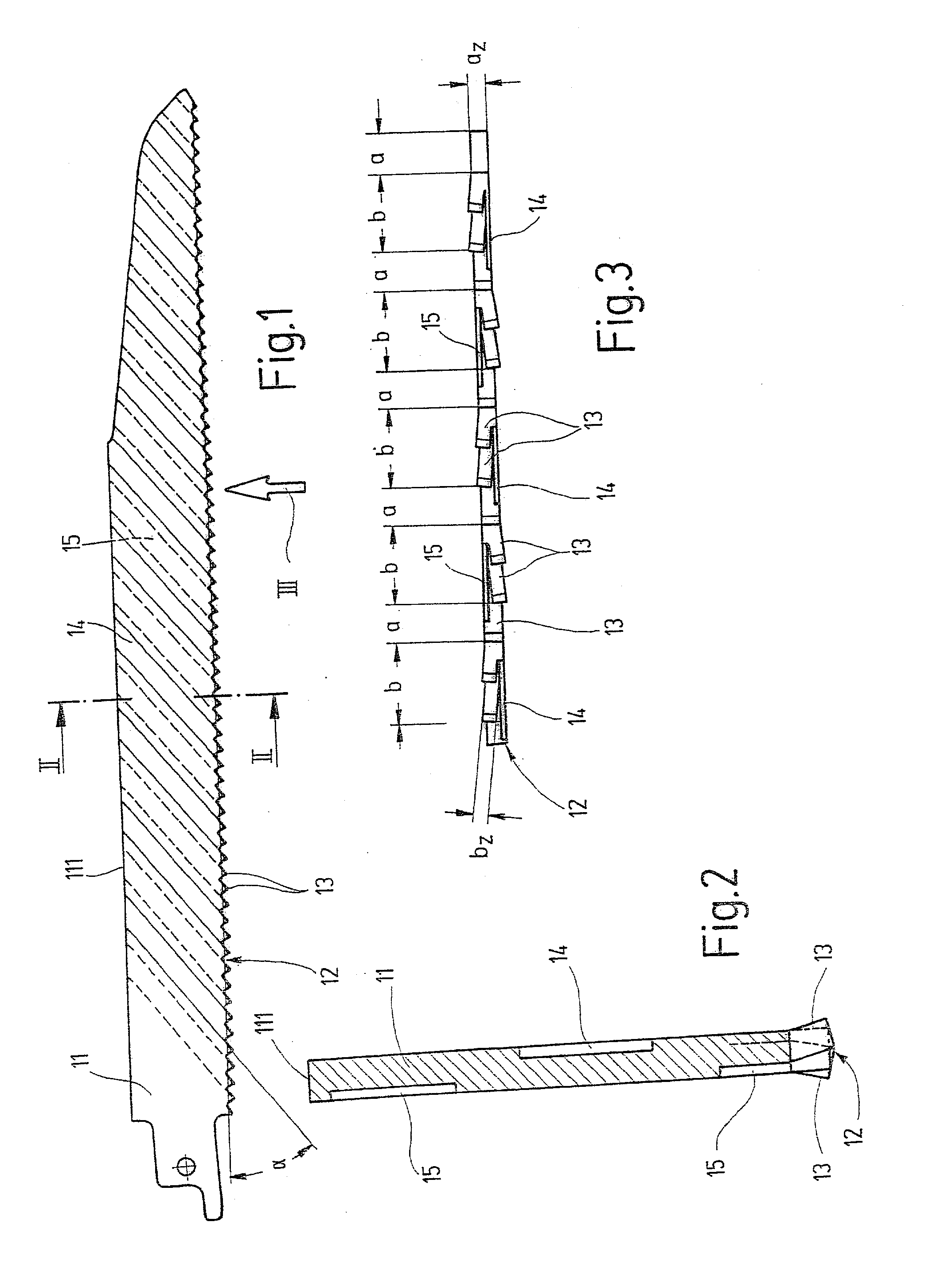

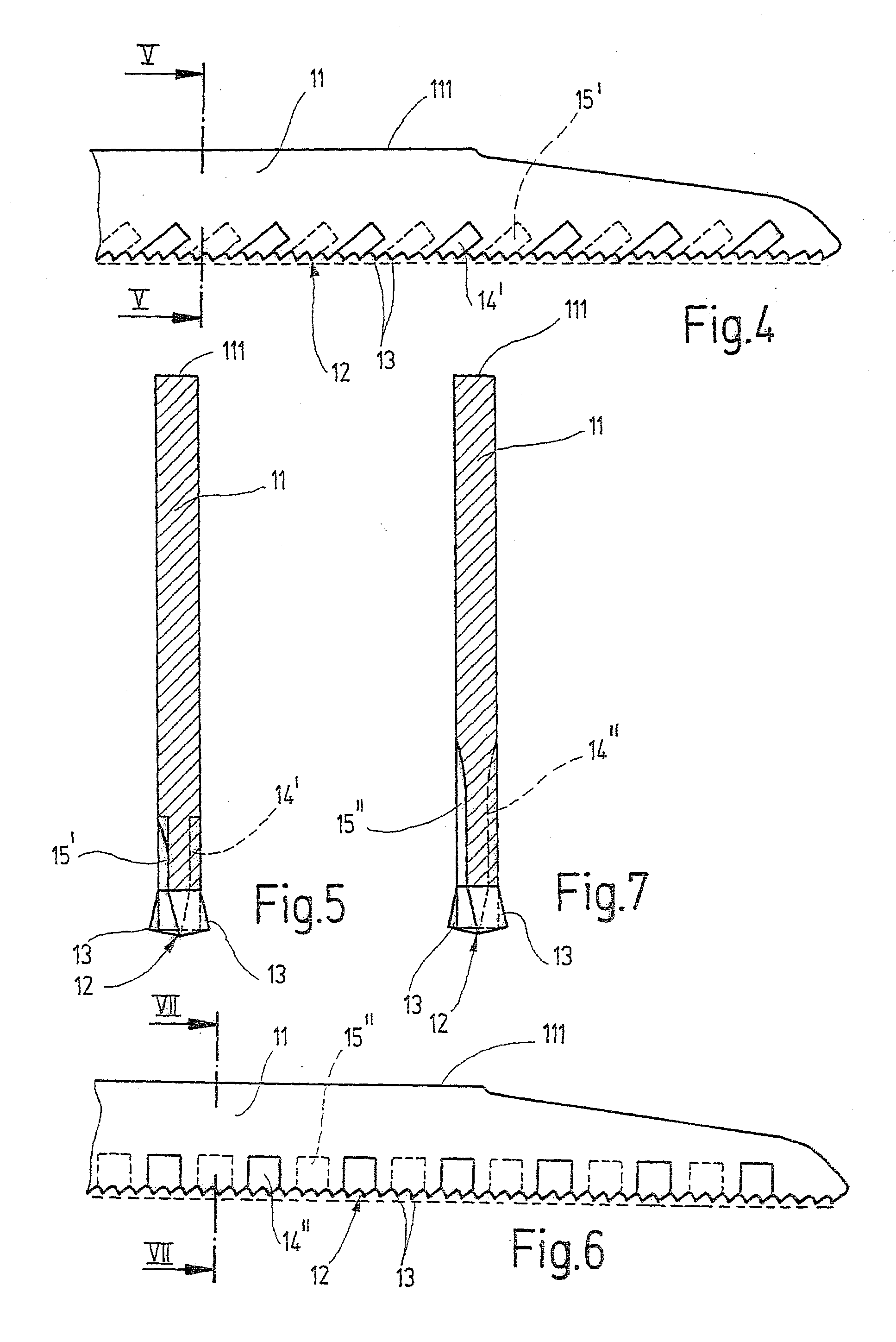

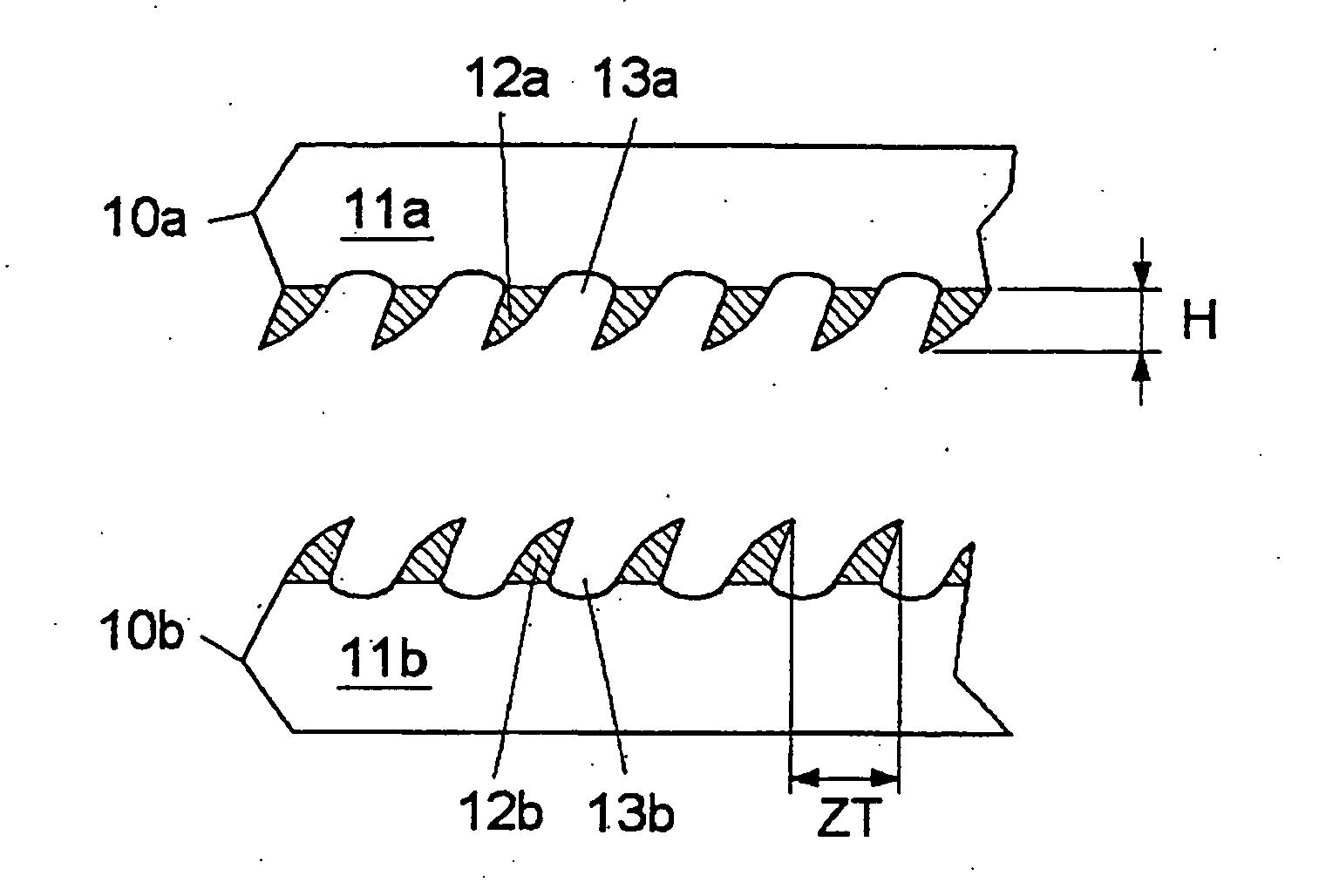

Saw blade for hand-held tools

InactiveUS7127979B2Prolong lifeIncrease forceMetal sawing devicesMetal sawing tool makingHand heldEngineering

Owner:ROBERT BOSCH GMBH

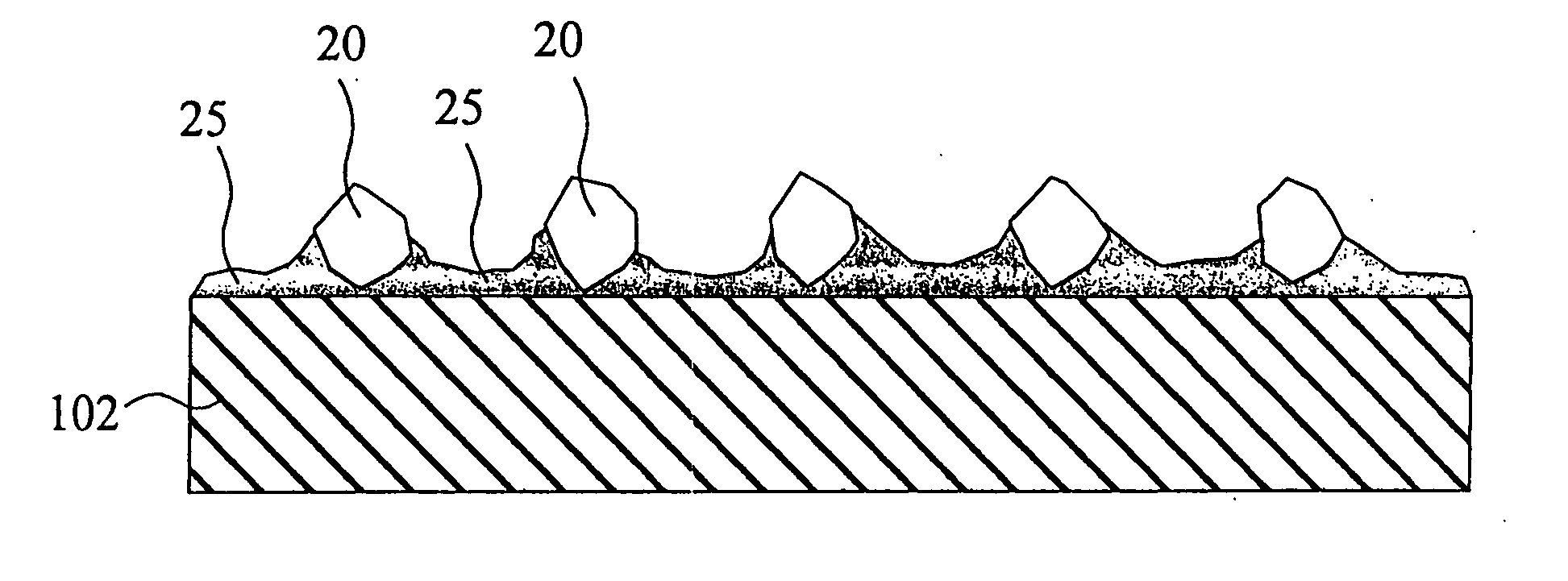

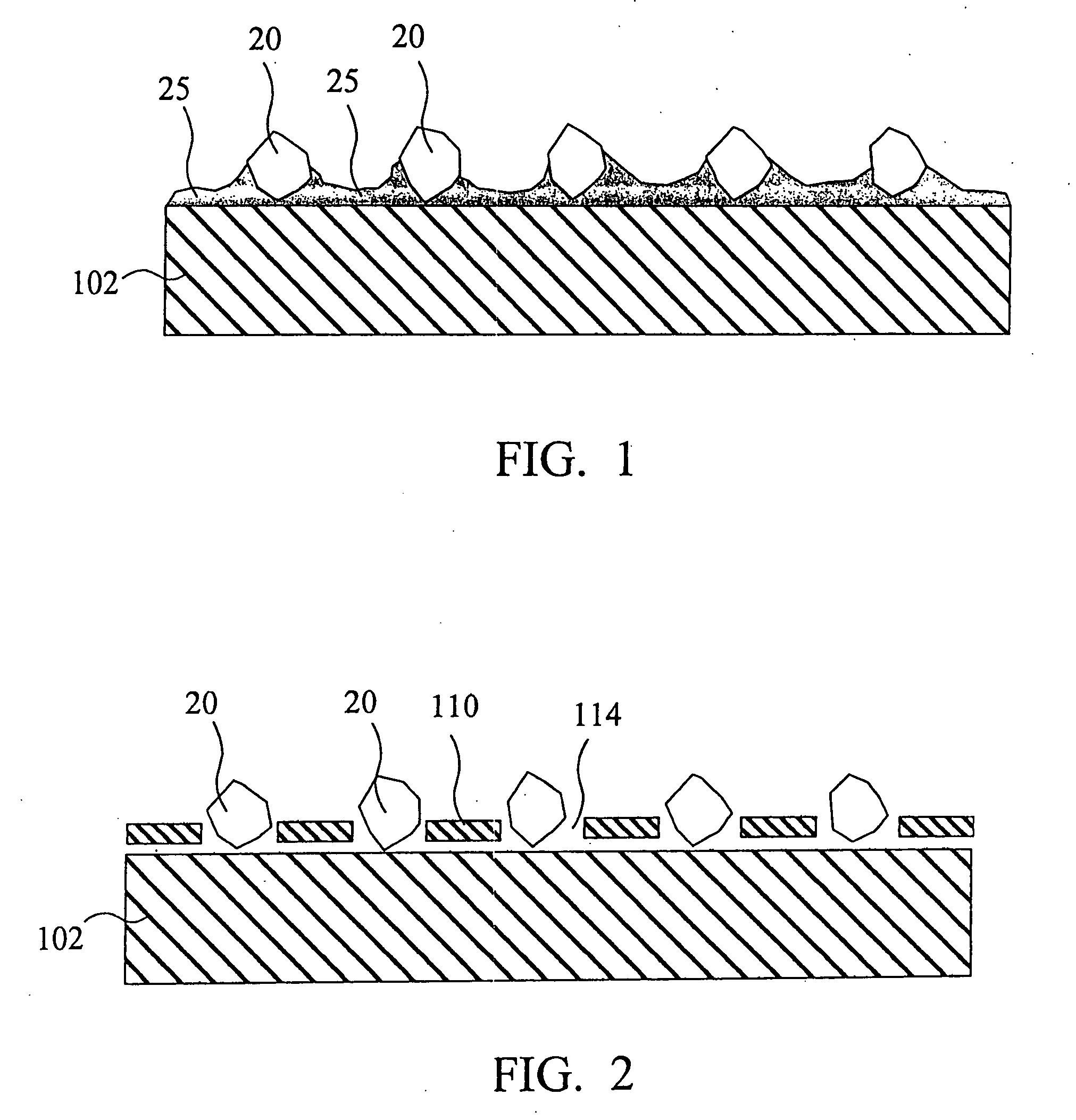

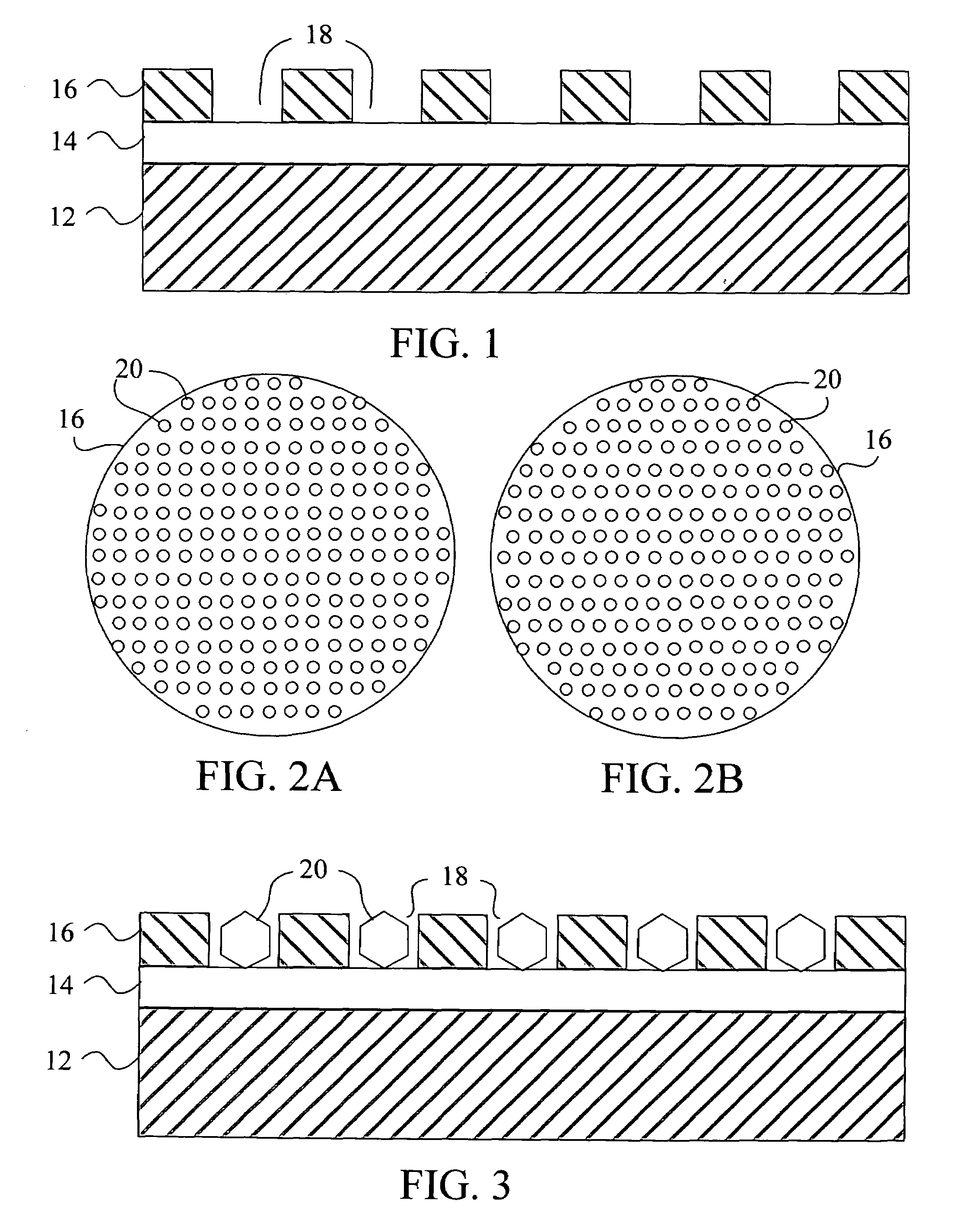

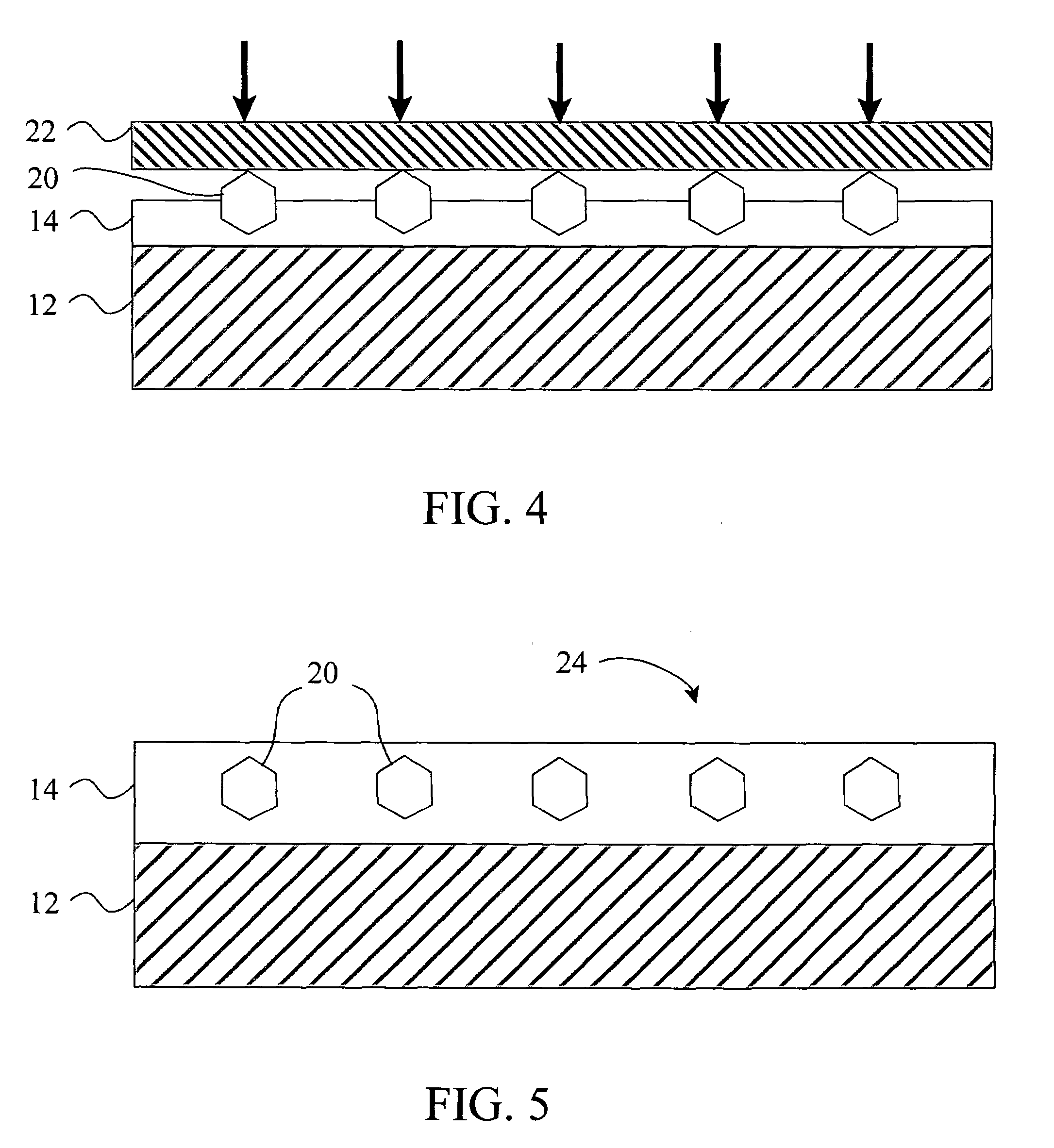

Brazed diamond tools and methods for making the same

InactiveUS20040112359A1Avoid large movementsImprove cutting efficiencyDrill bitsConstructionsChemical LinkageBraze alloy

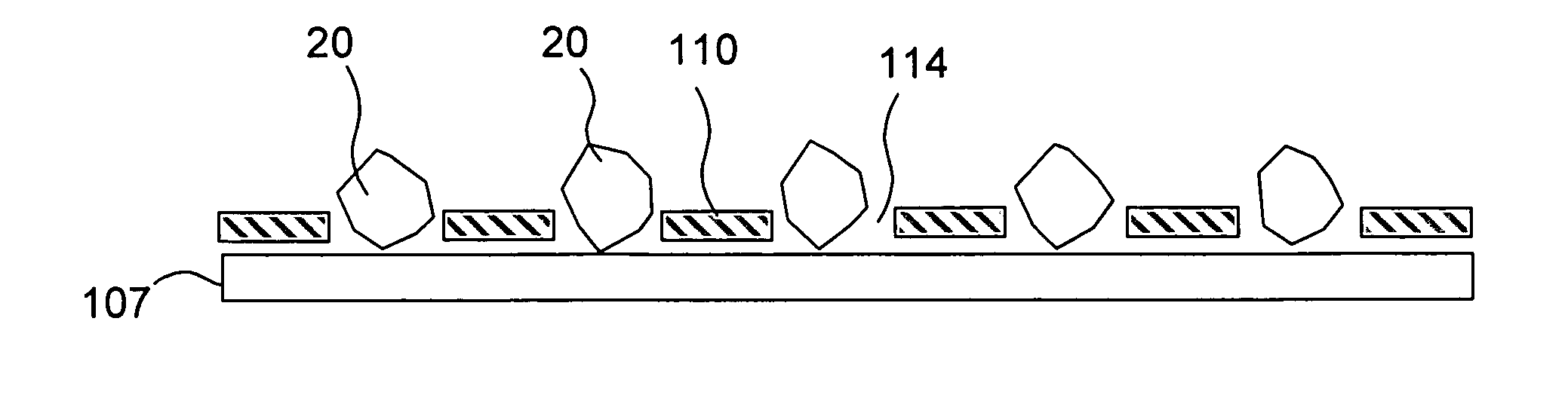

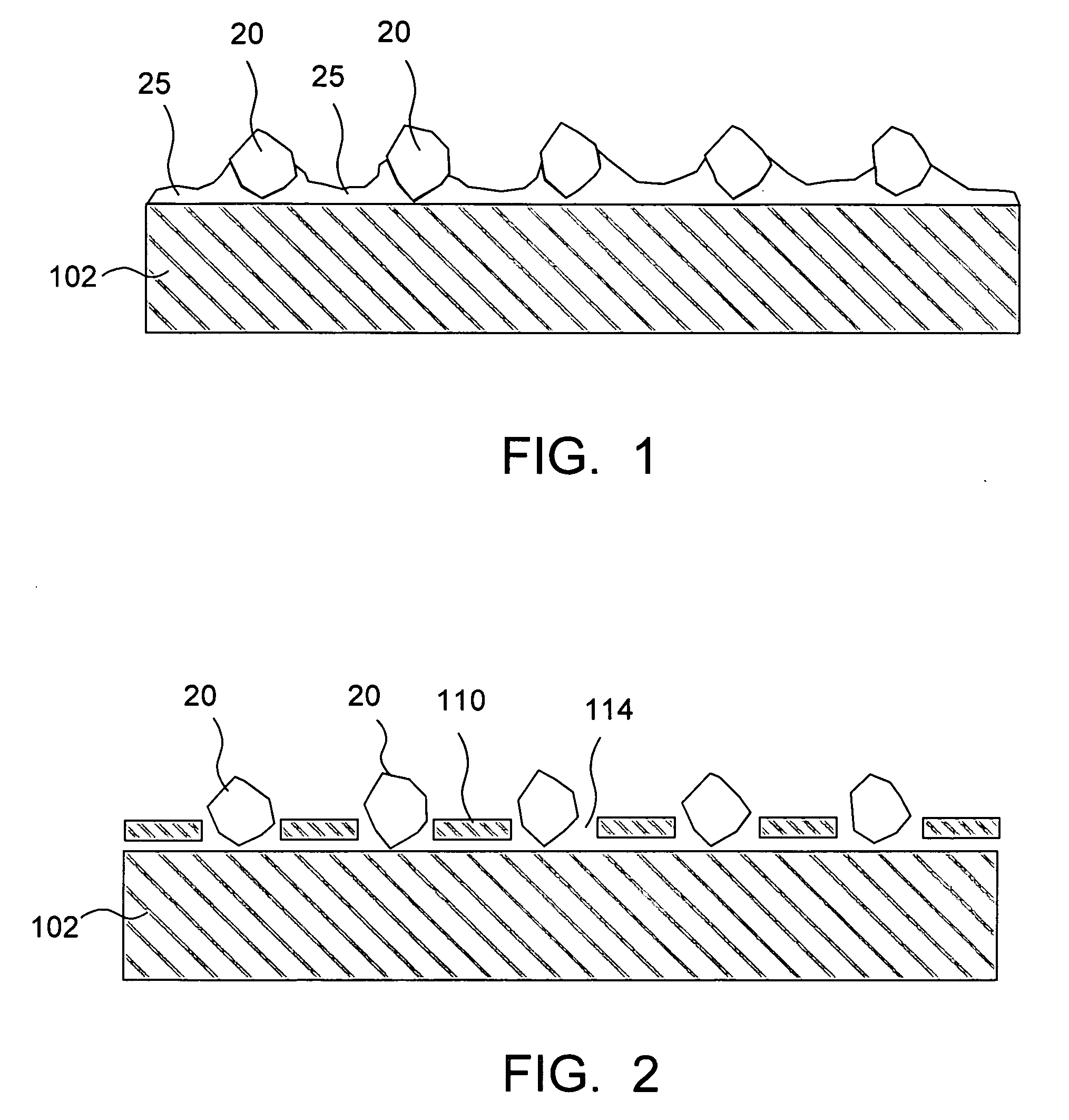

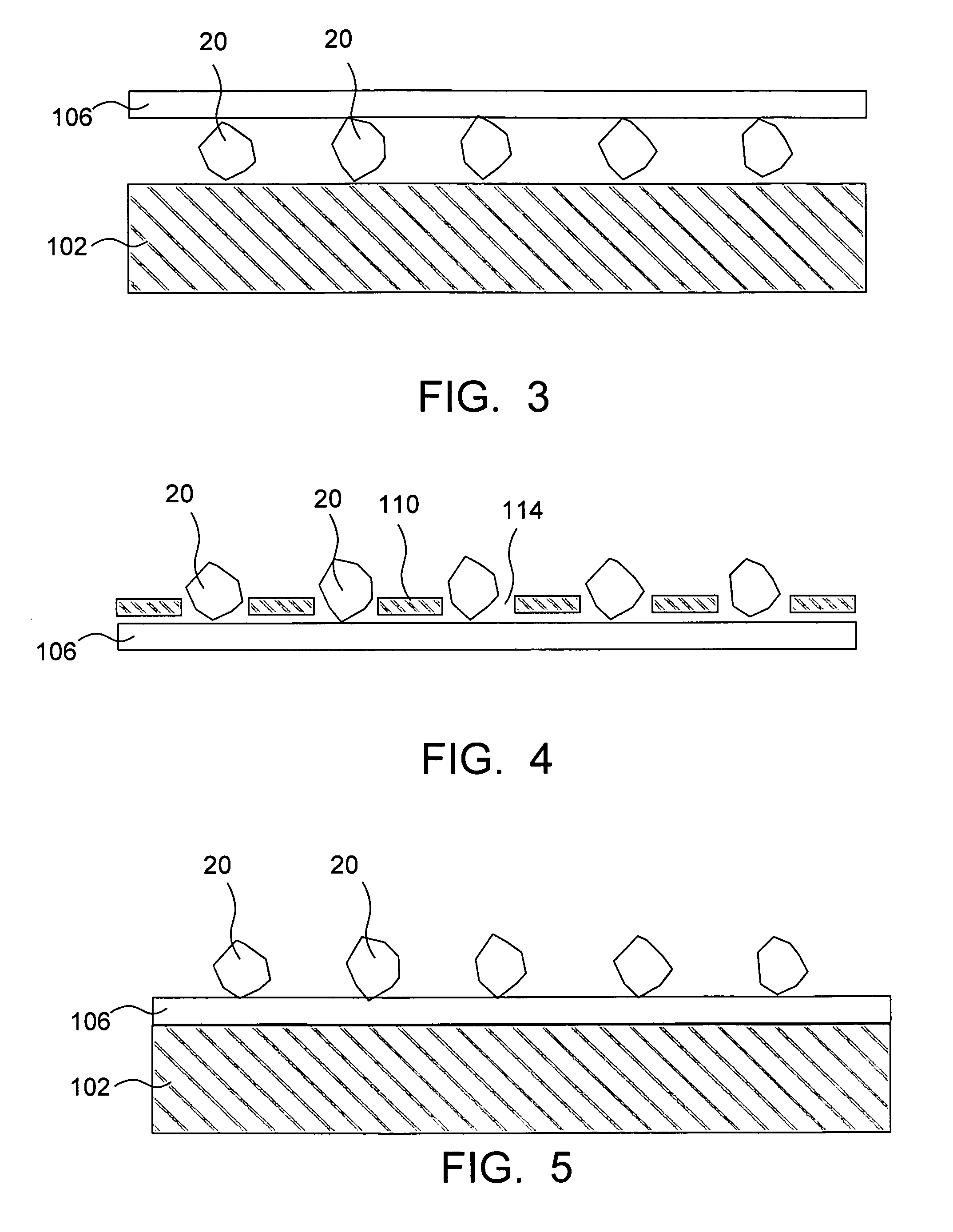

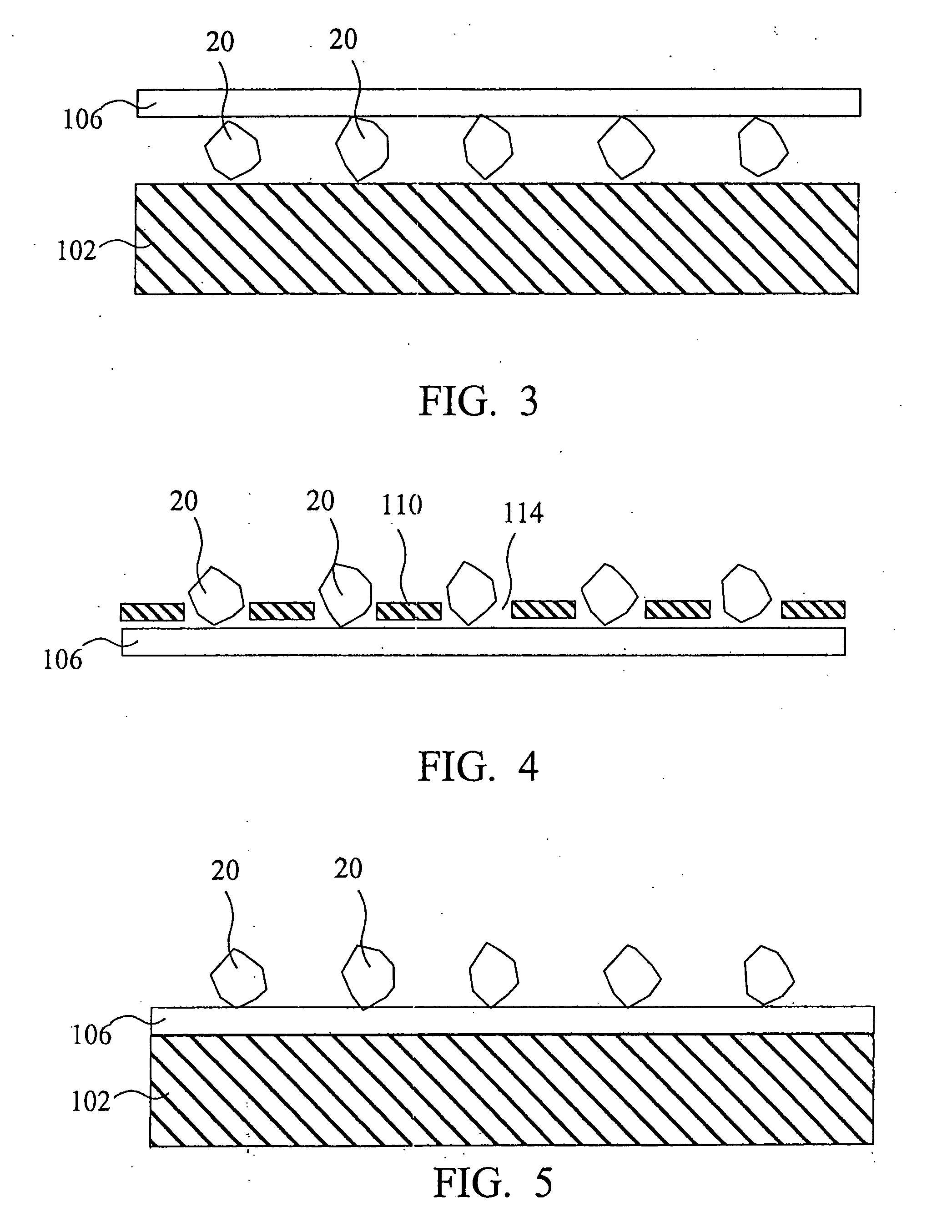

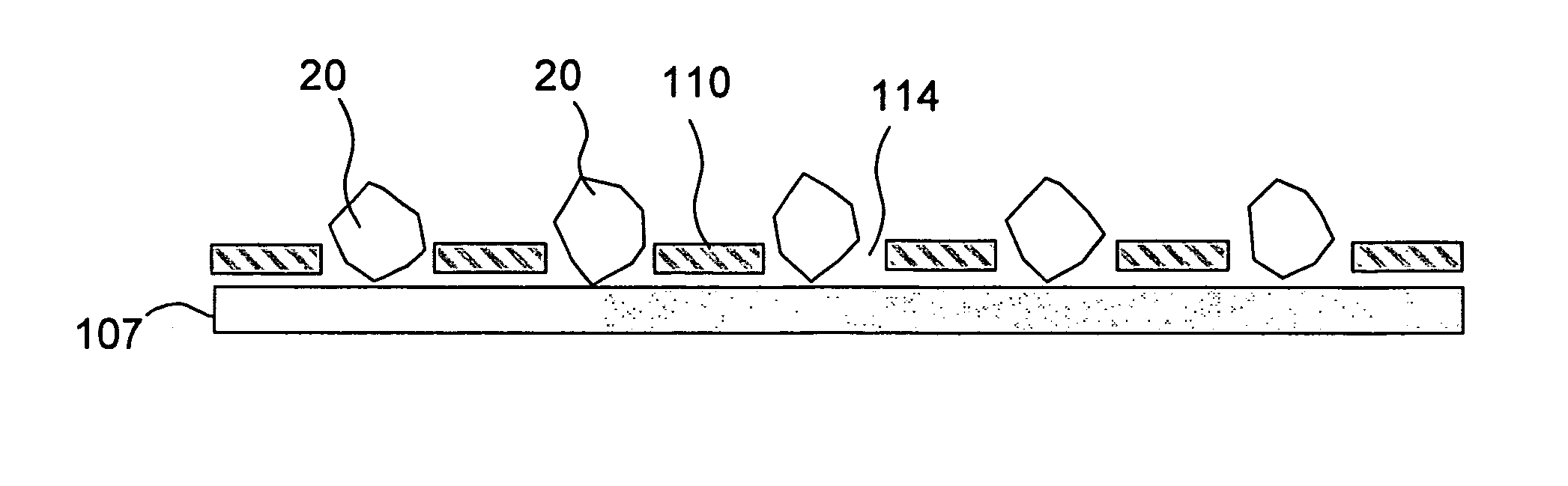

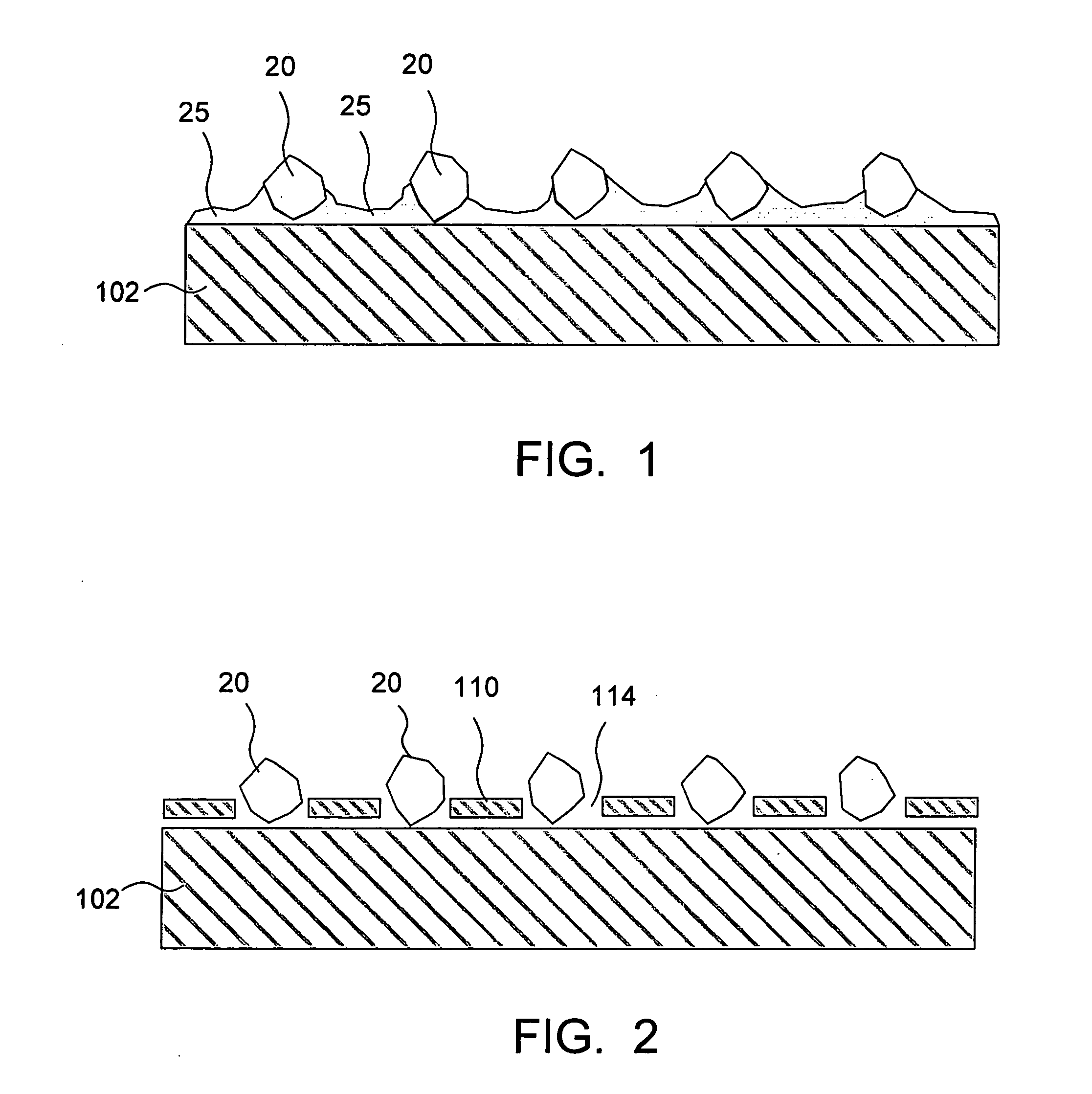

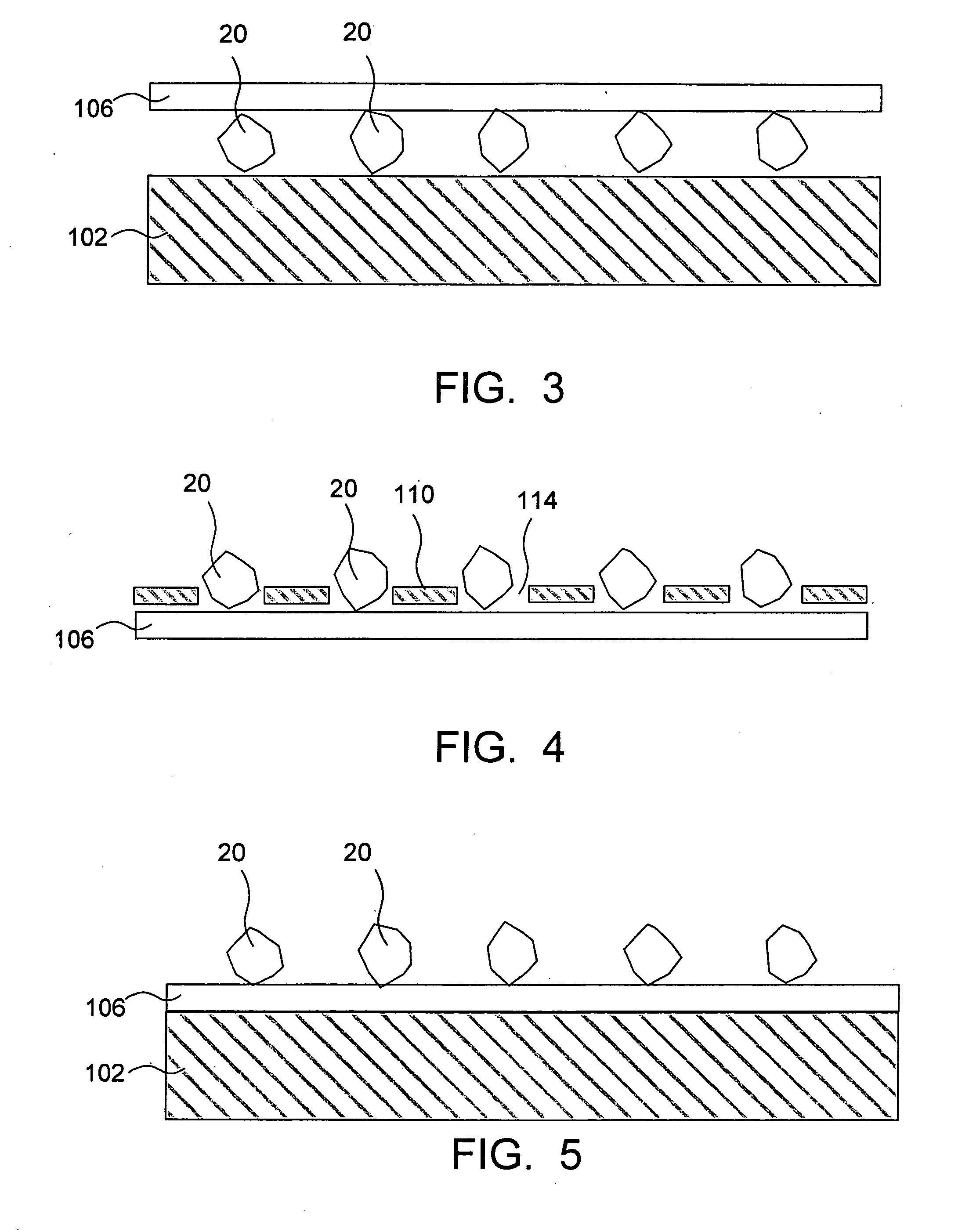

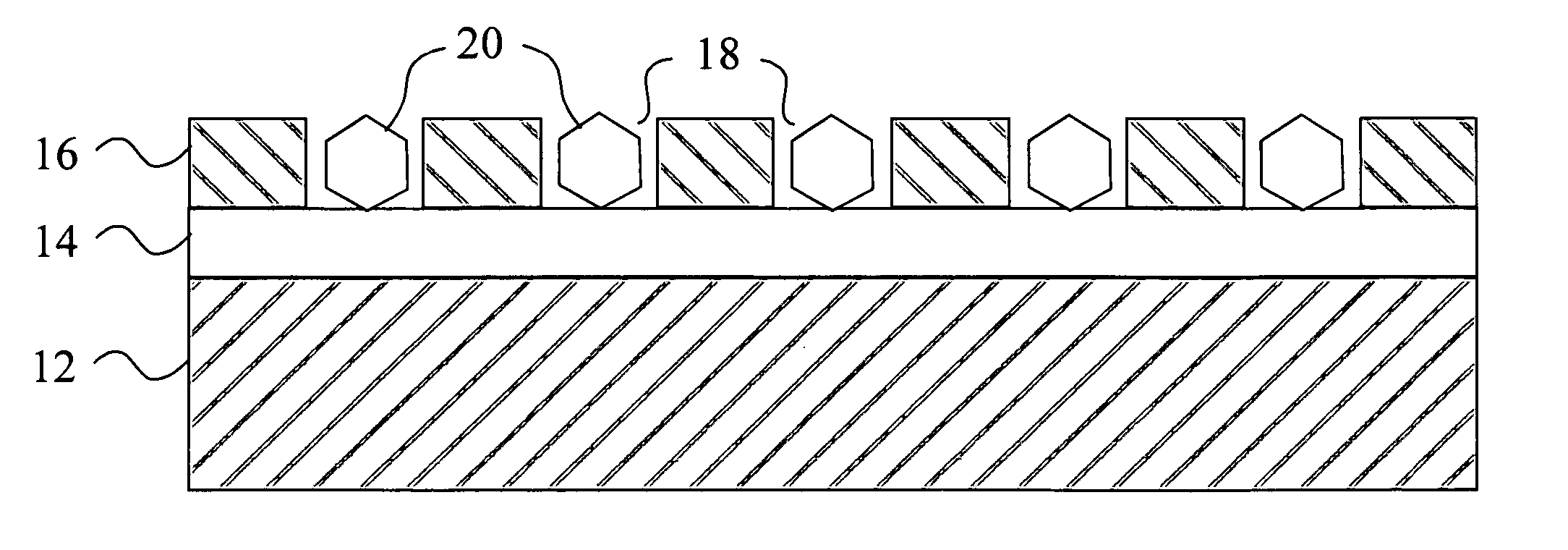

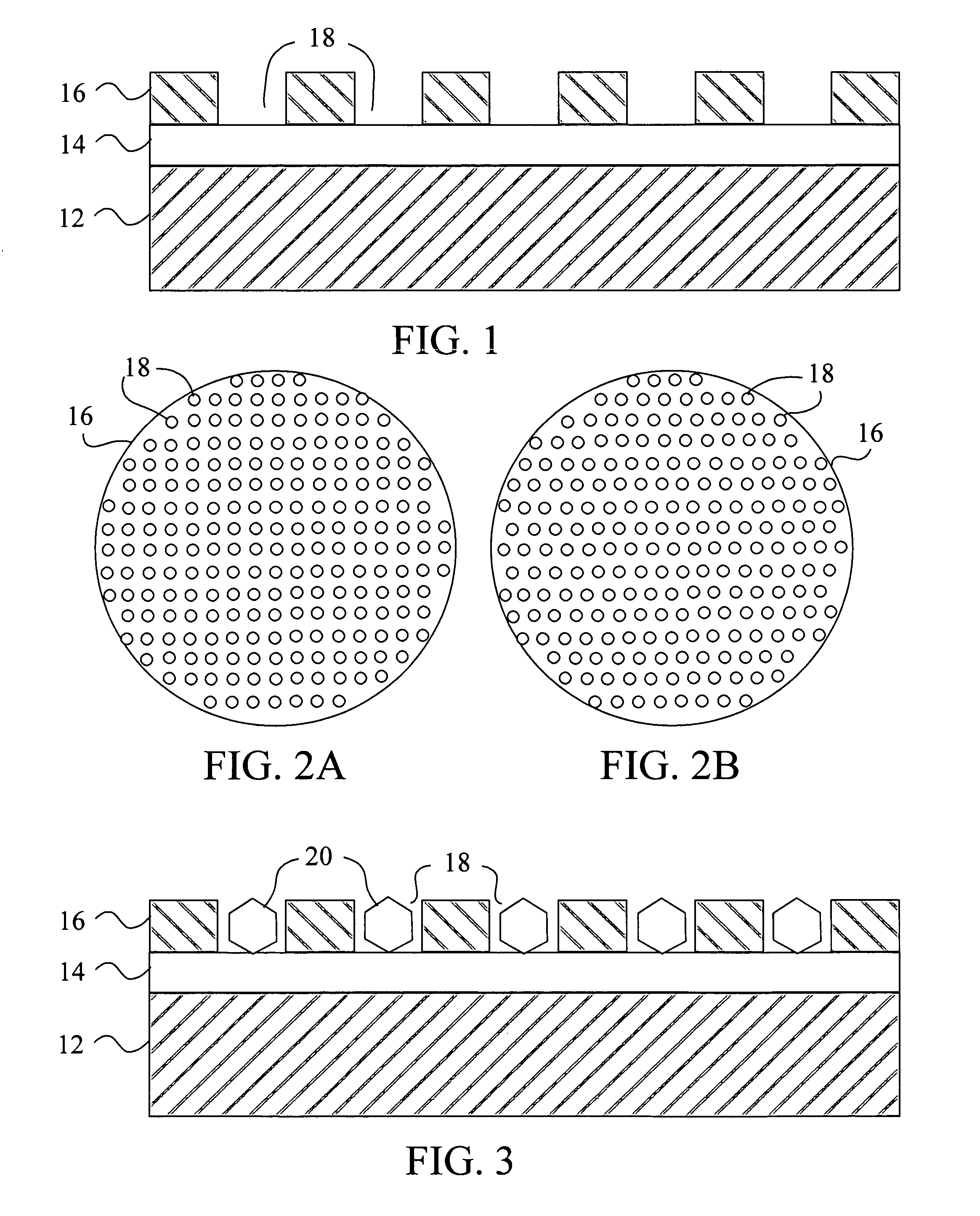

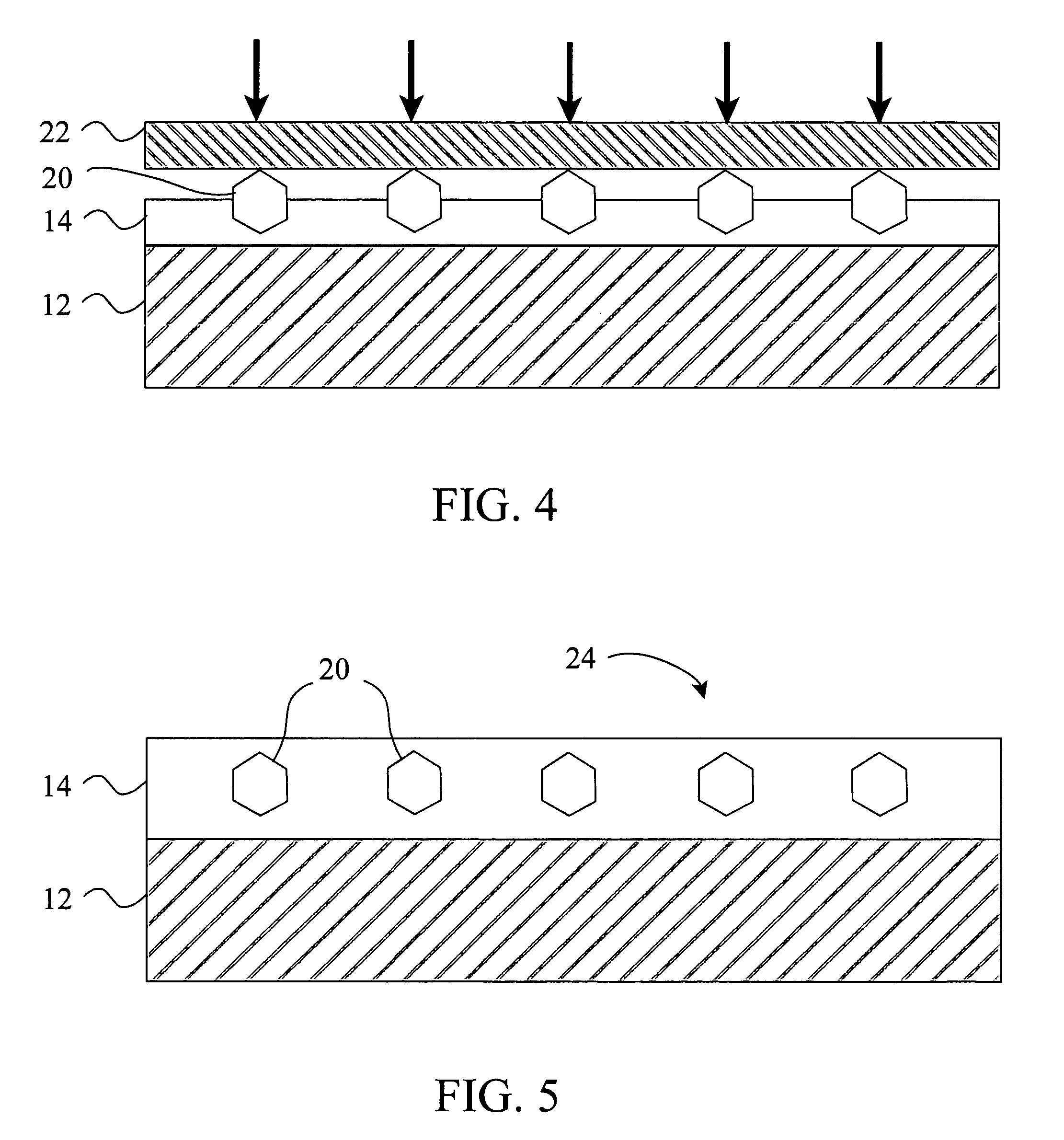

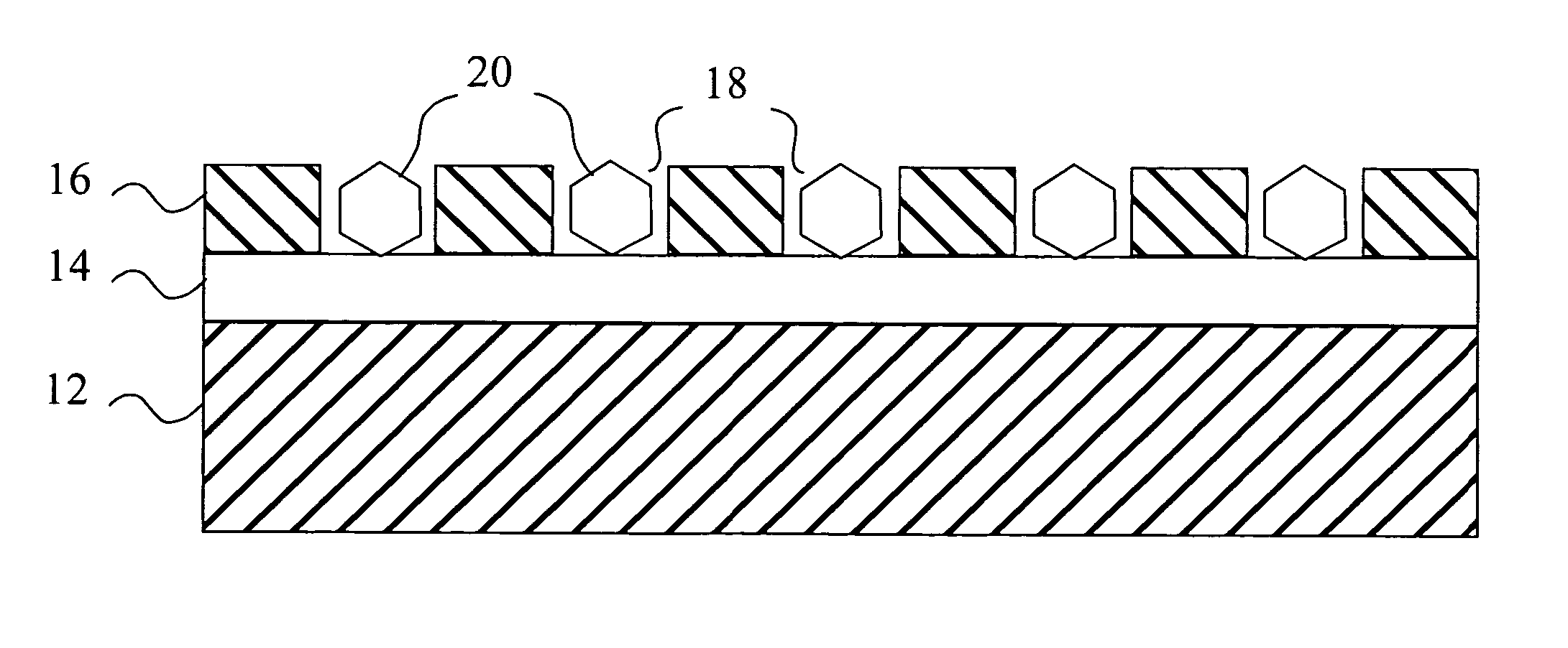

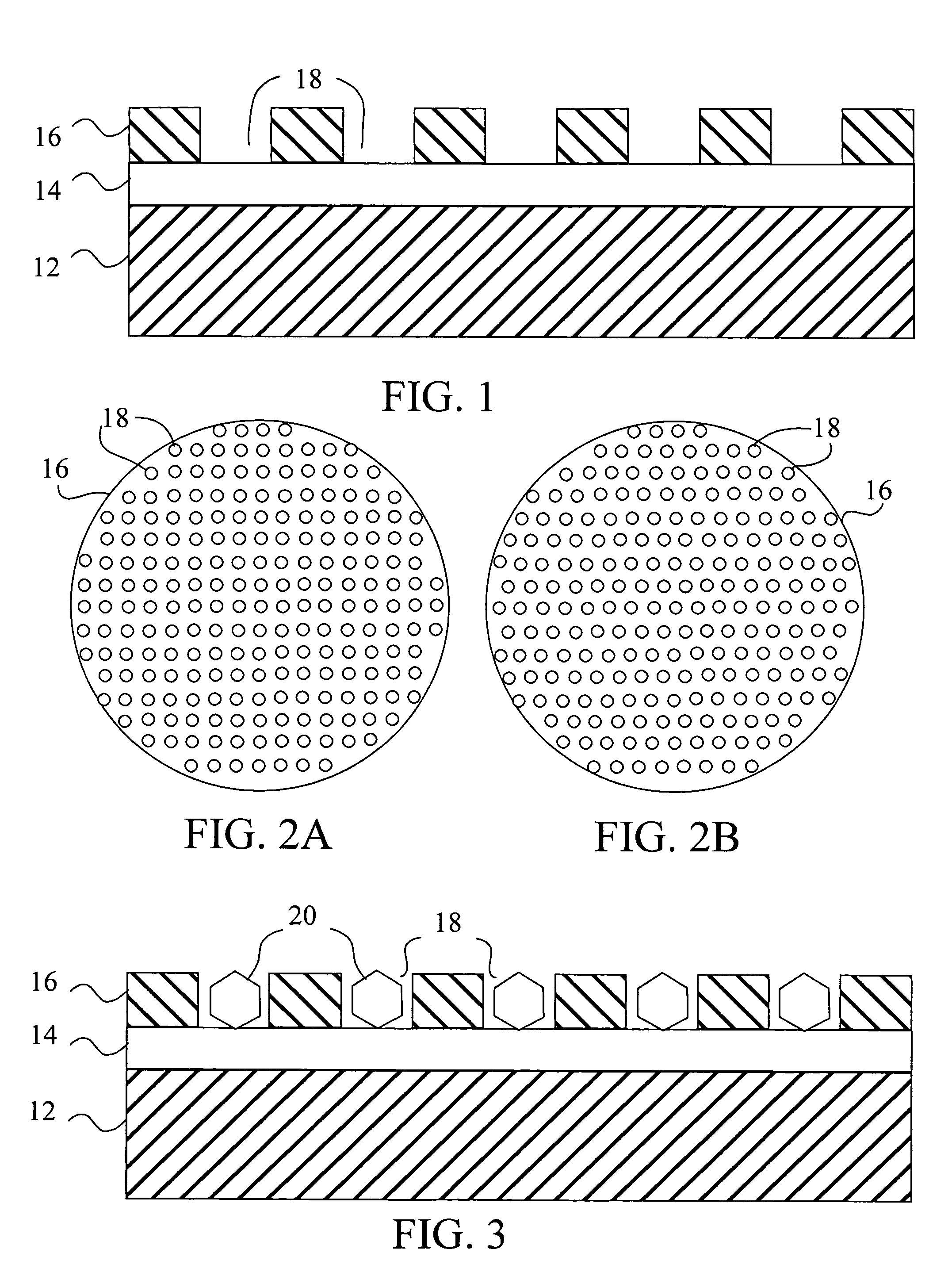

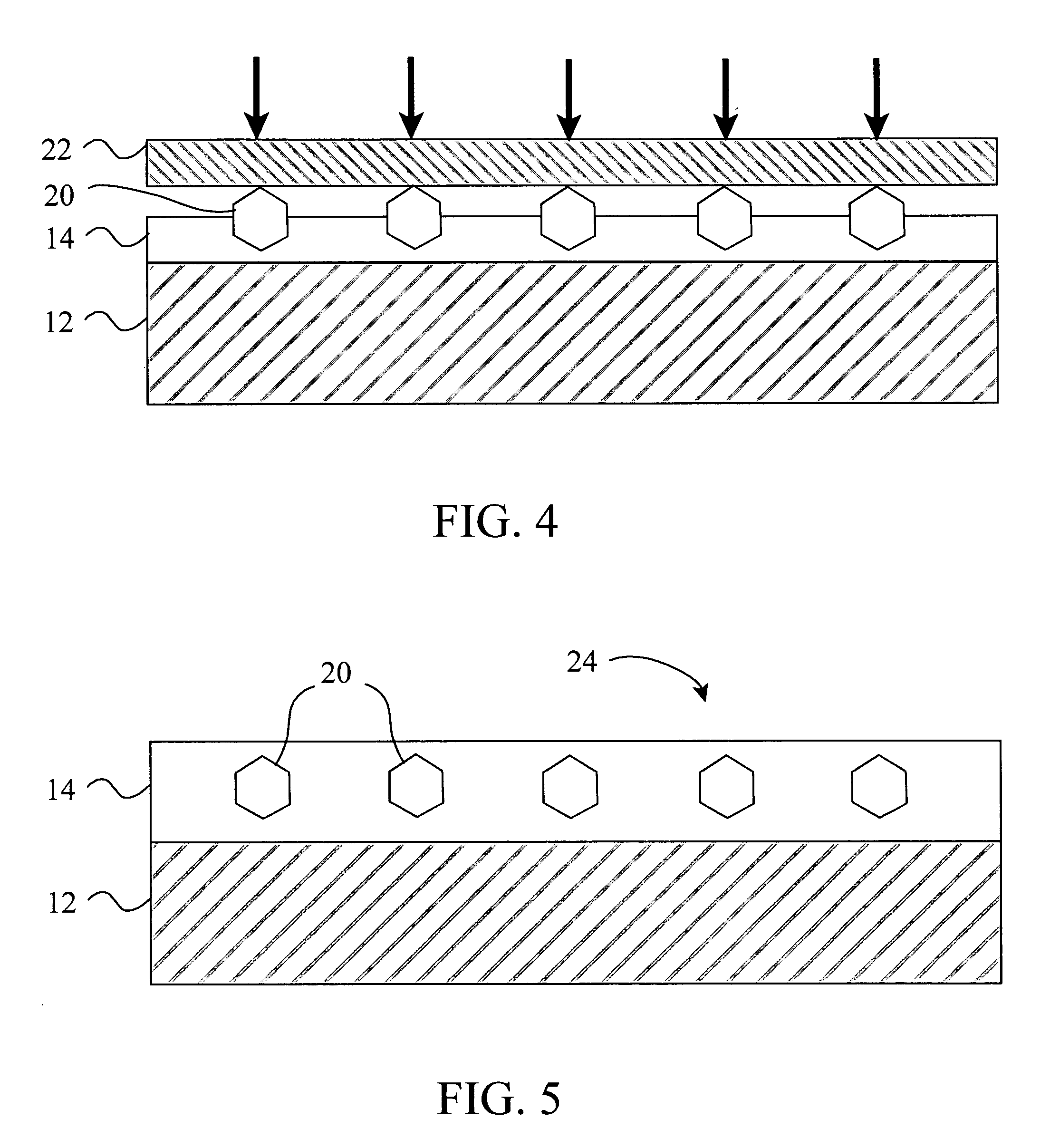

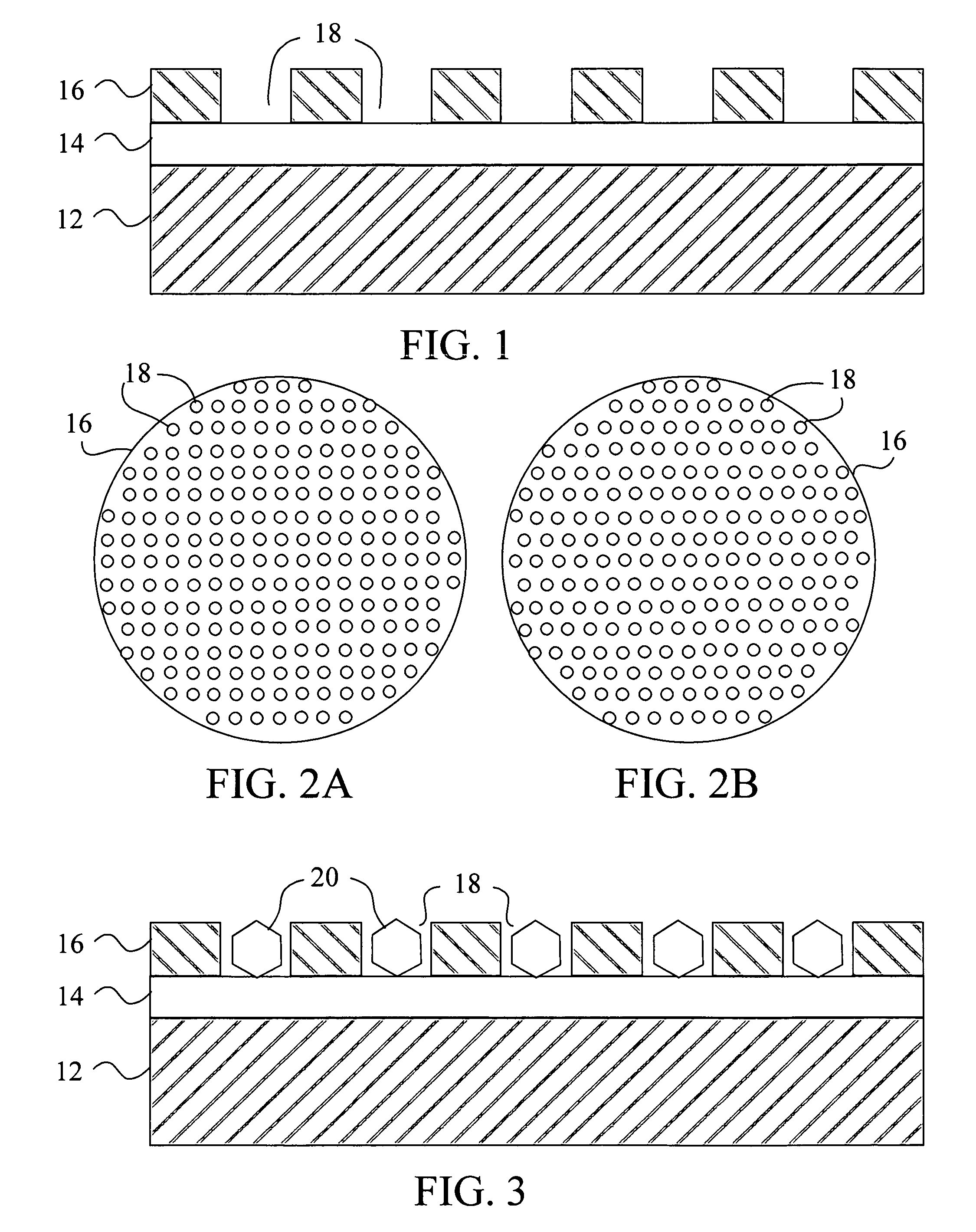

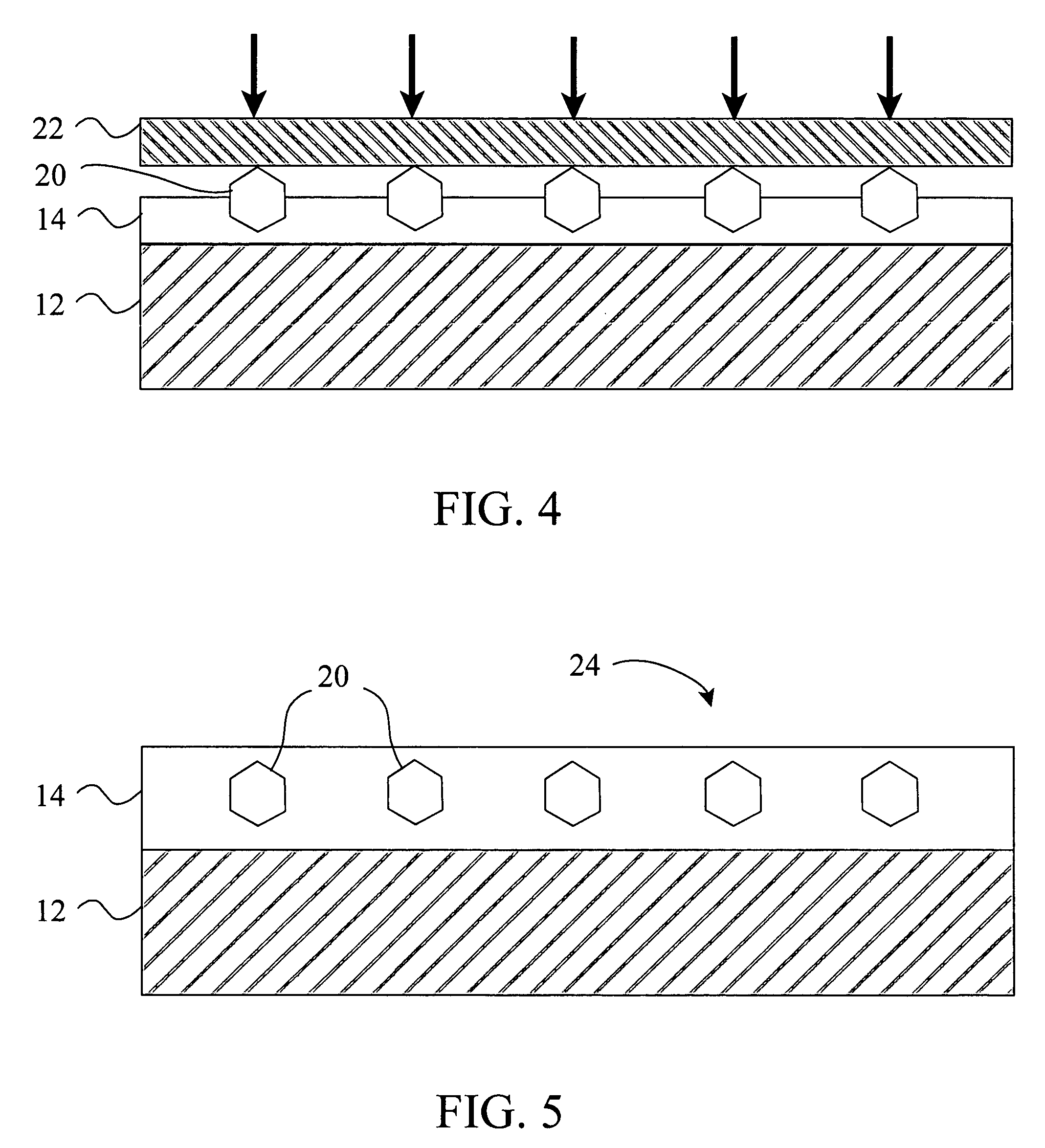

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

Brazed diamond tools and methods for making the same

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

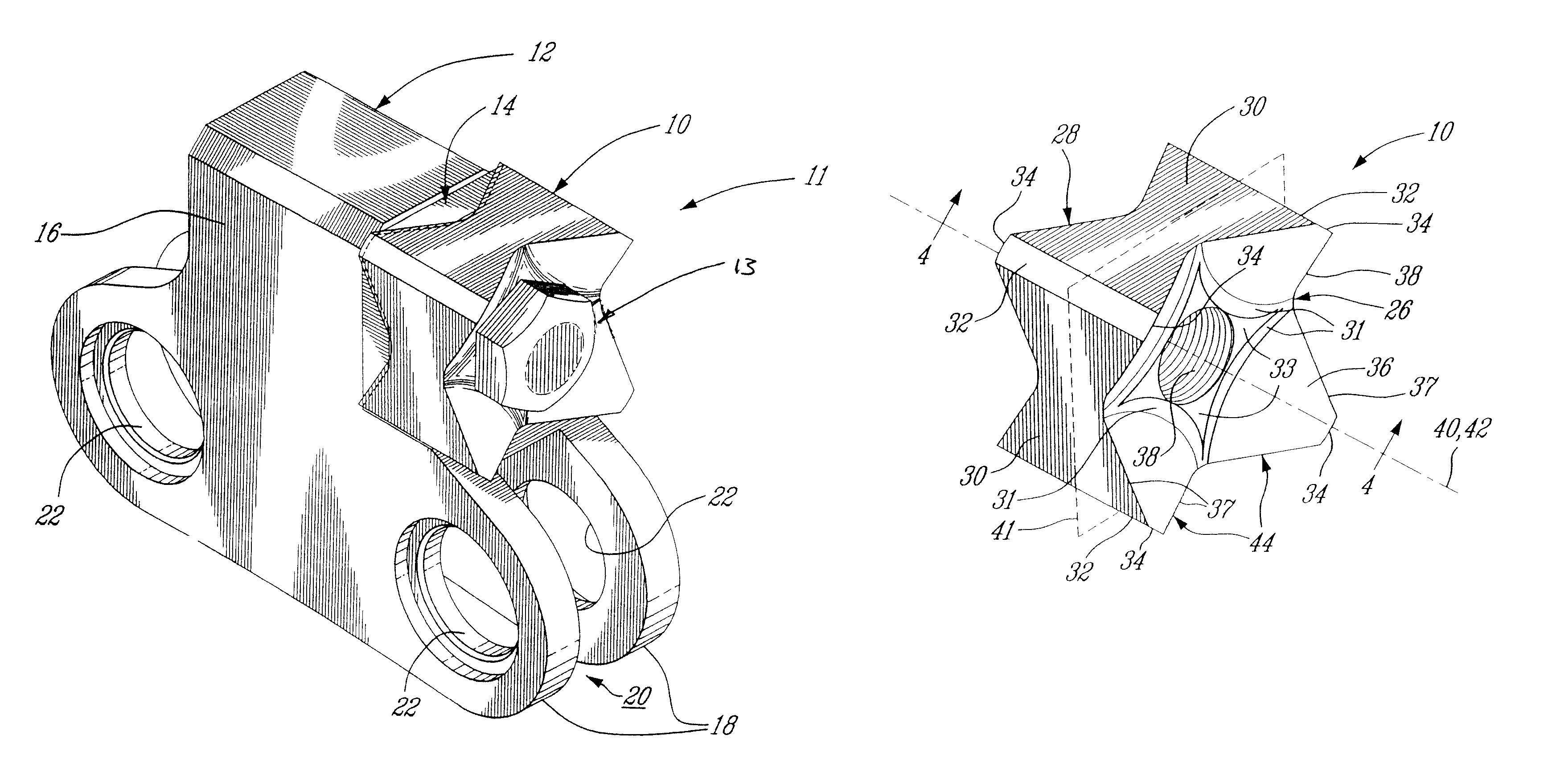

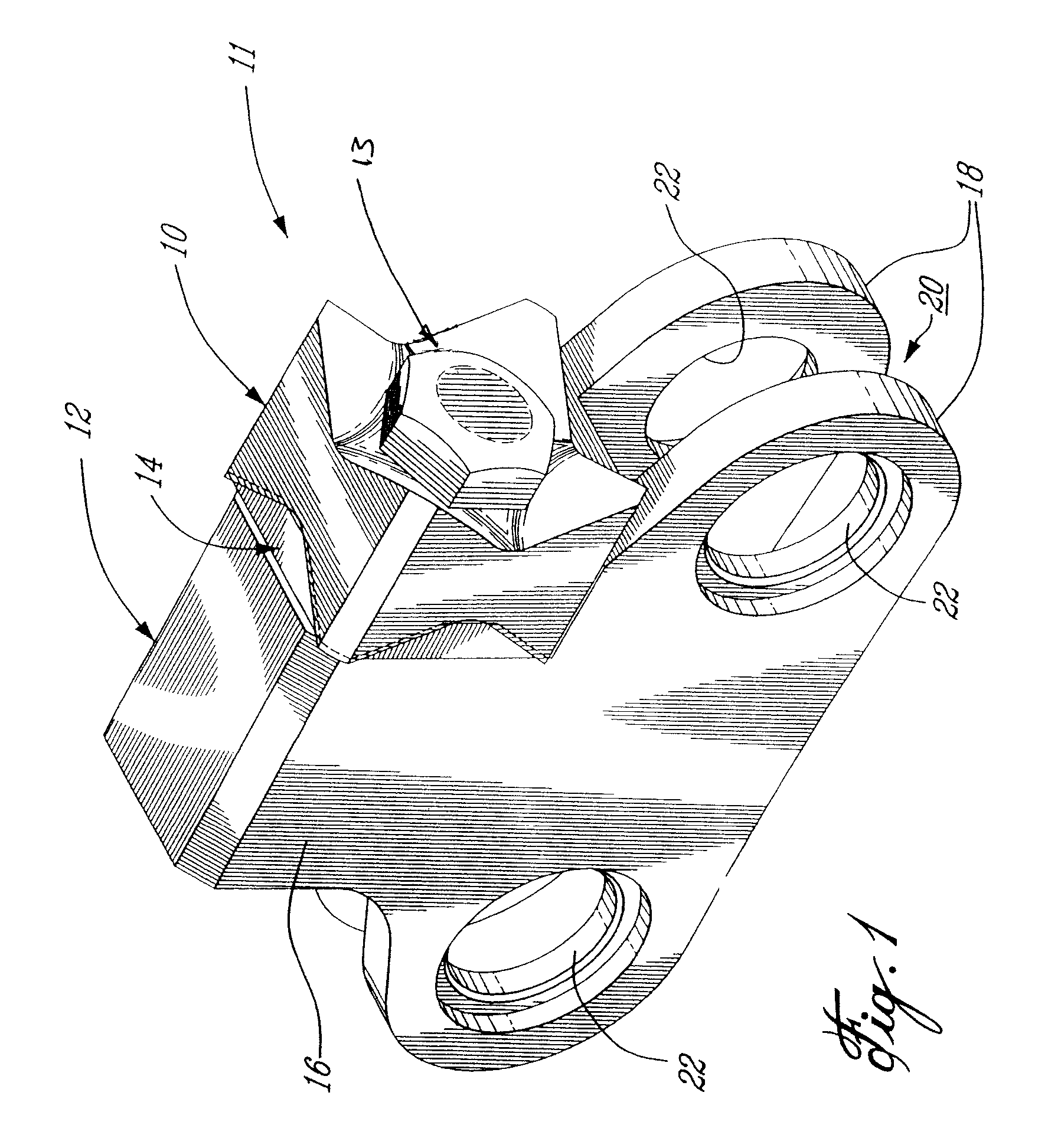

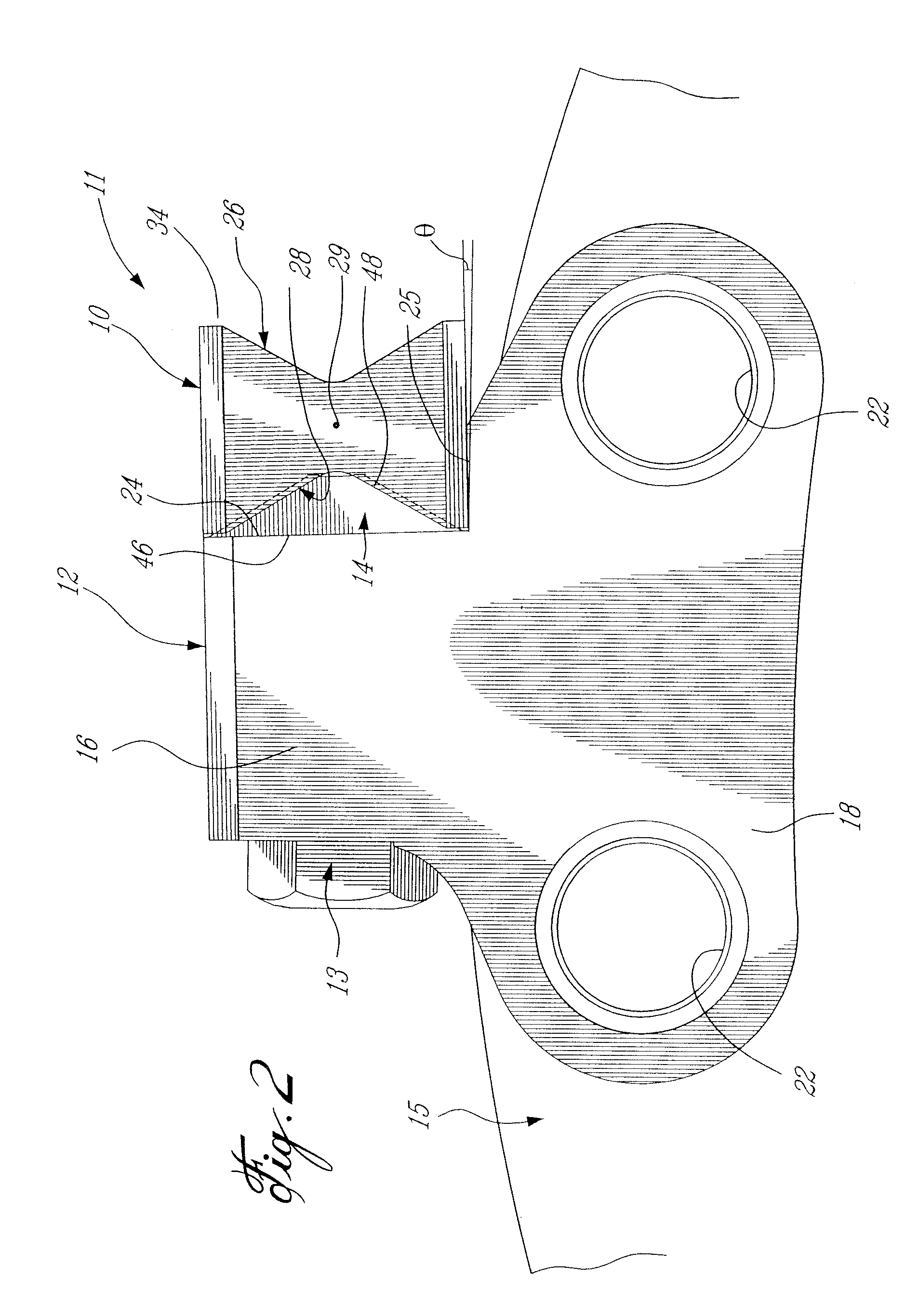

Reversible saw tooth

A replaceable saw tooth for a rotary cutting machine. The saw tooth comprises more than two cutting edges on each of two opposed faces thereof. More specifically, the saw tooth may comprise a body having two cutting faces disposed opposite each other and spaced apart by at least four side faces which are each parallel to an opposite one of the side faces. The side faces are parallel to a central axis extending between the two cutting faces. Four cutting edges are defined between the side faces and each of the two cutting faces.

Owner:QUADCO

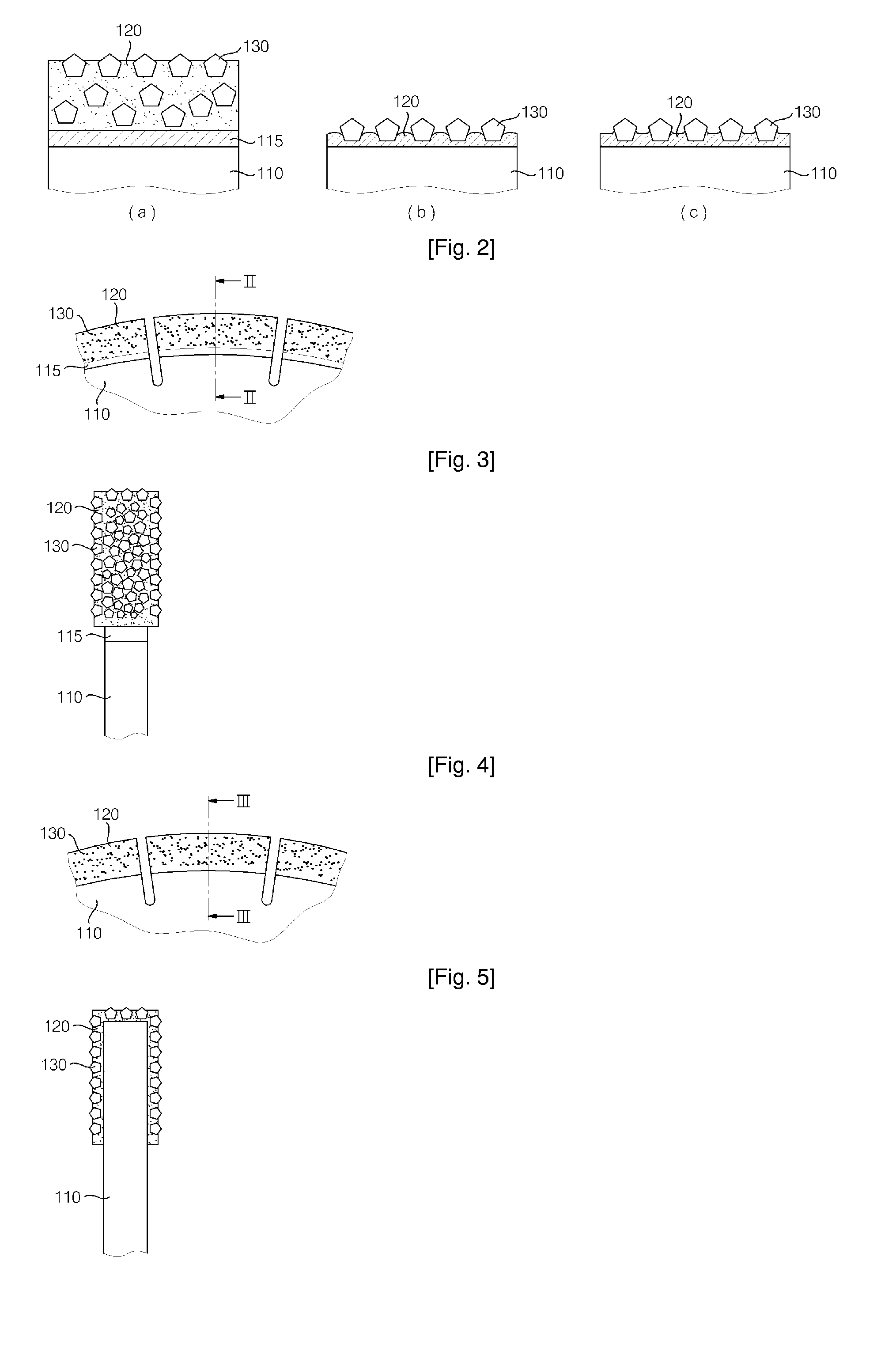

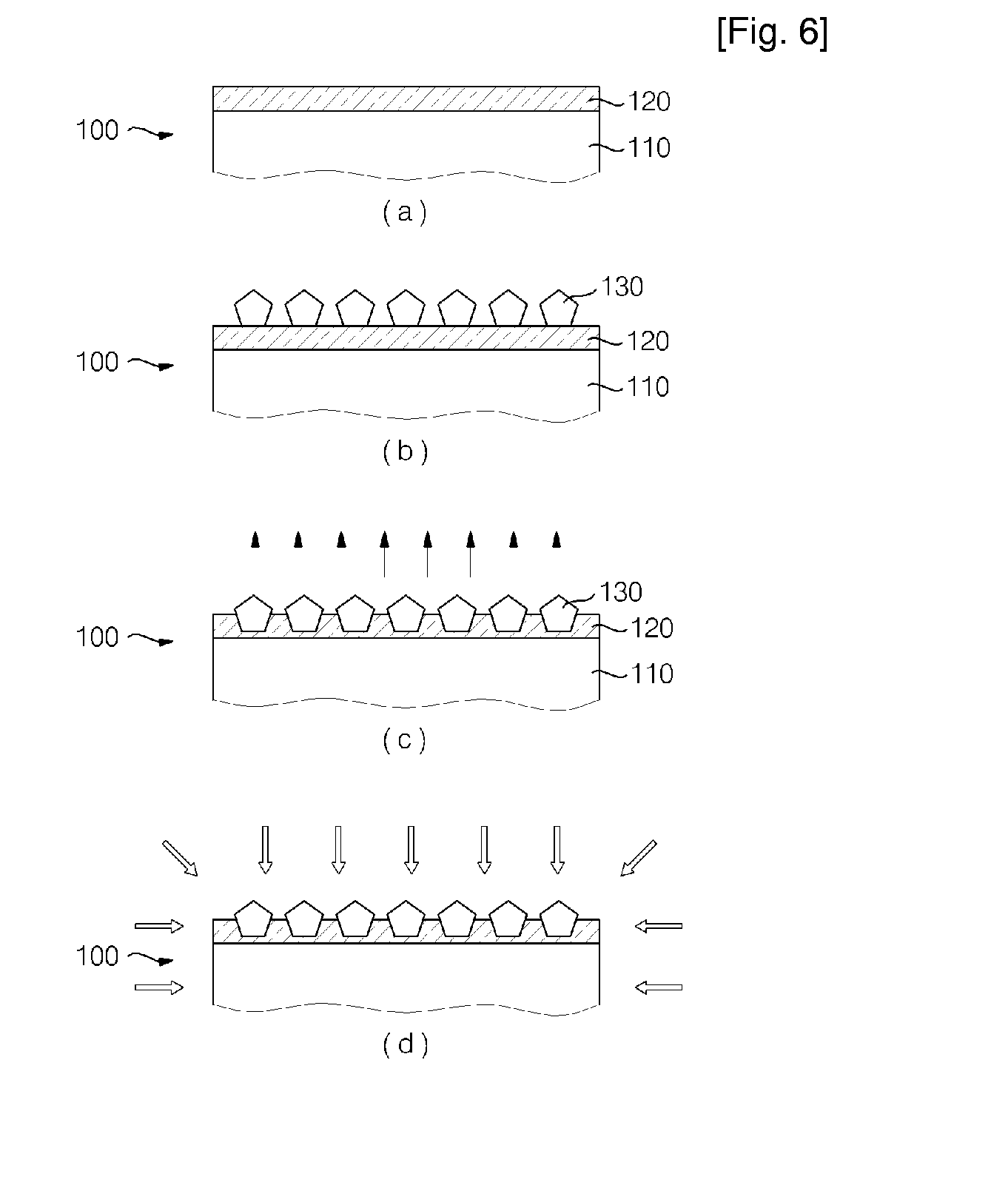

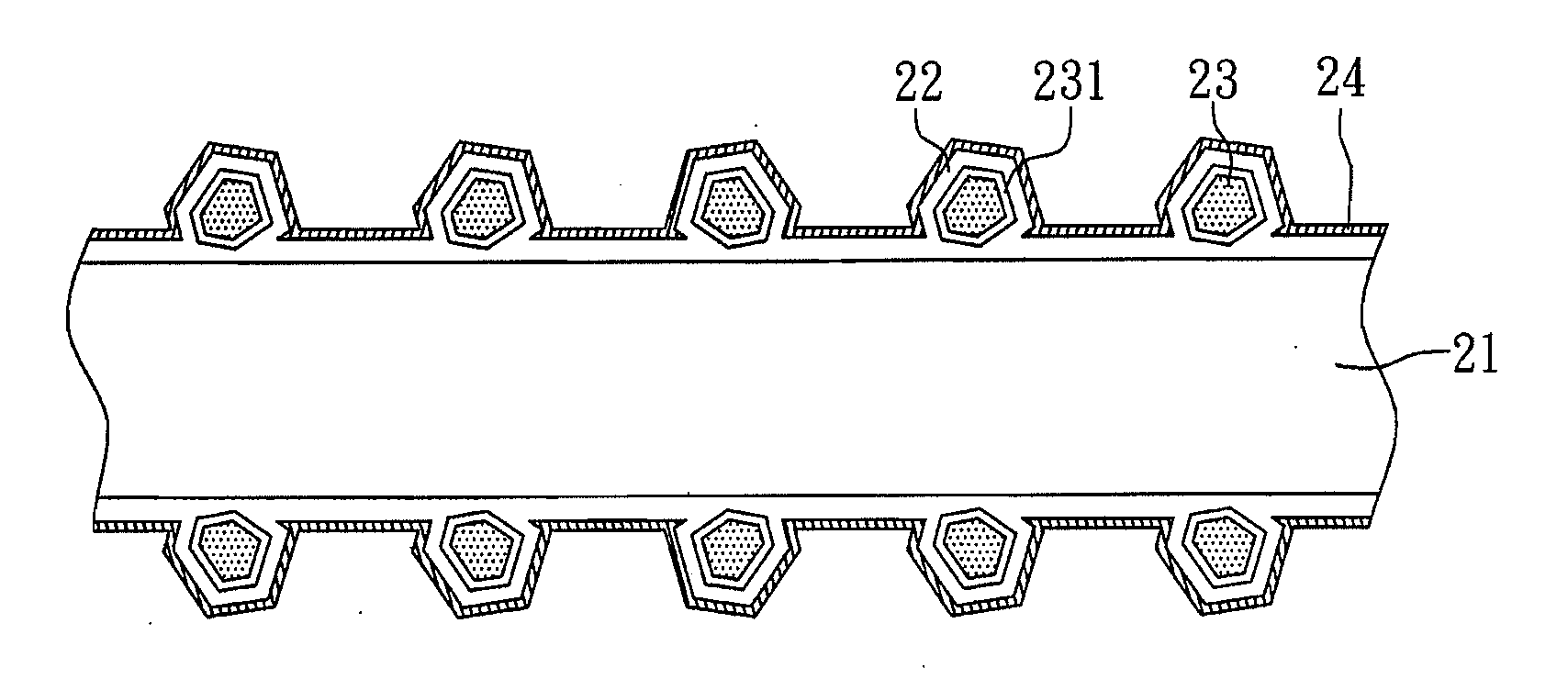

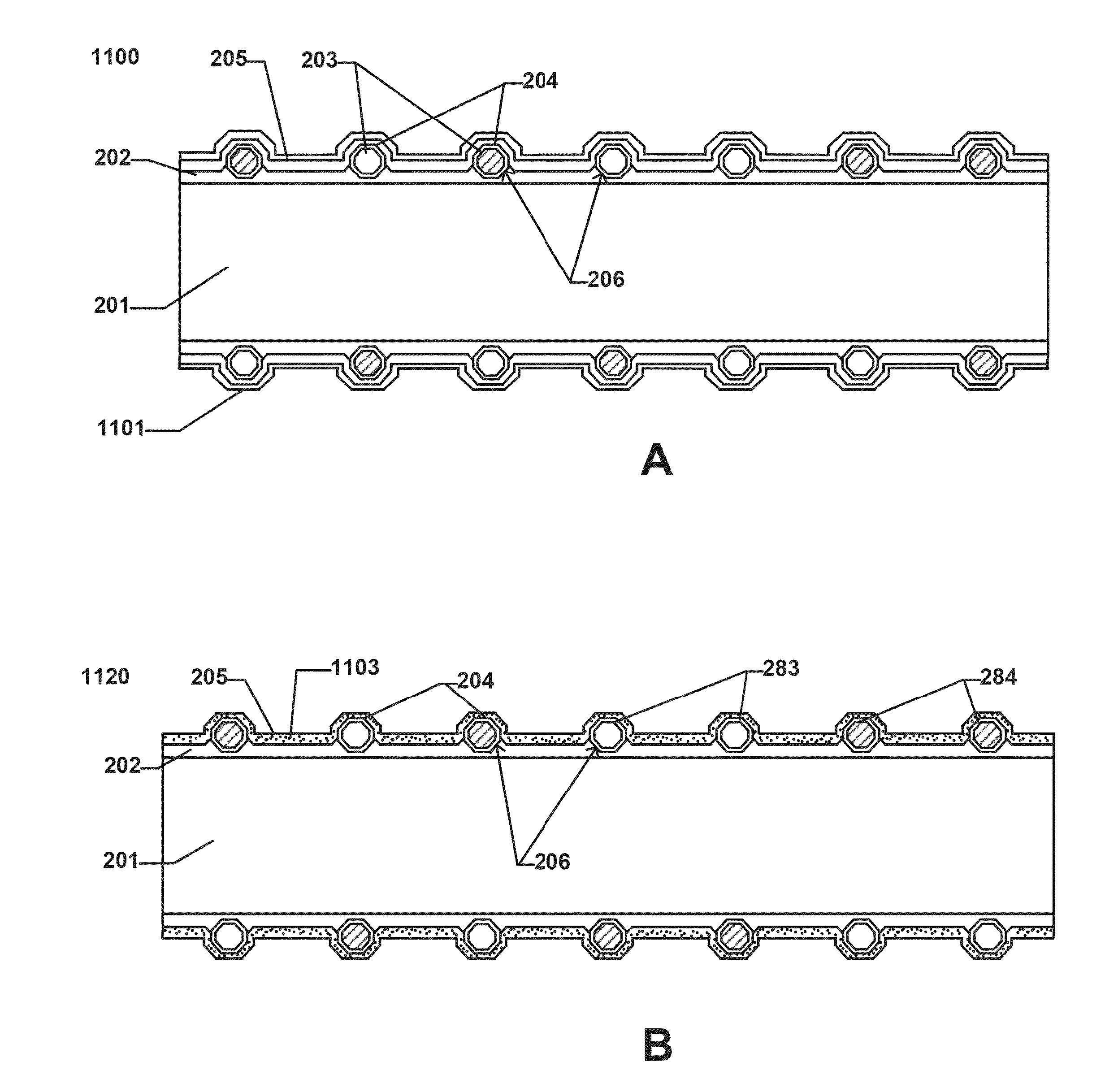

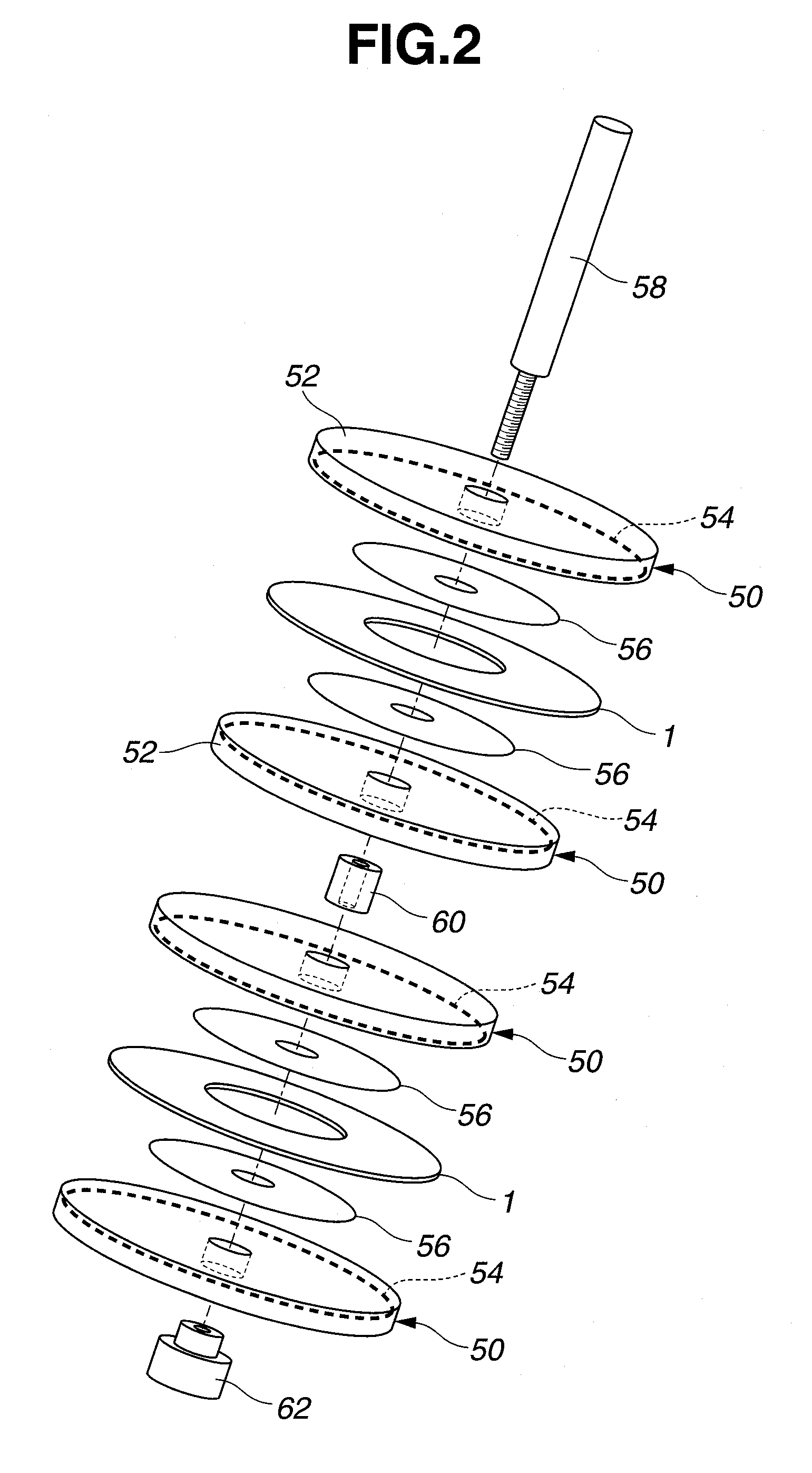

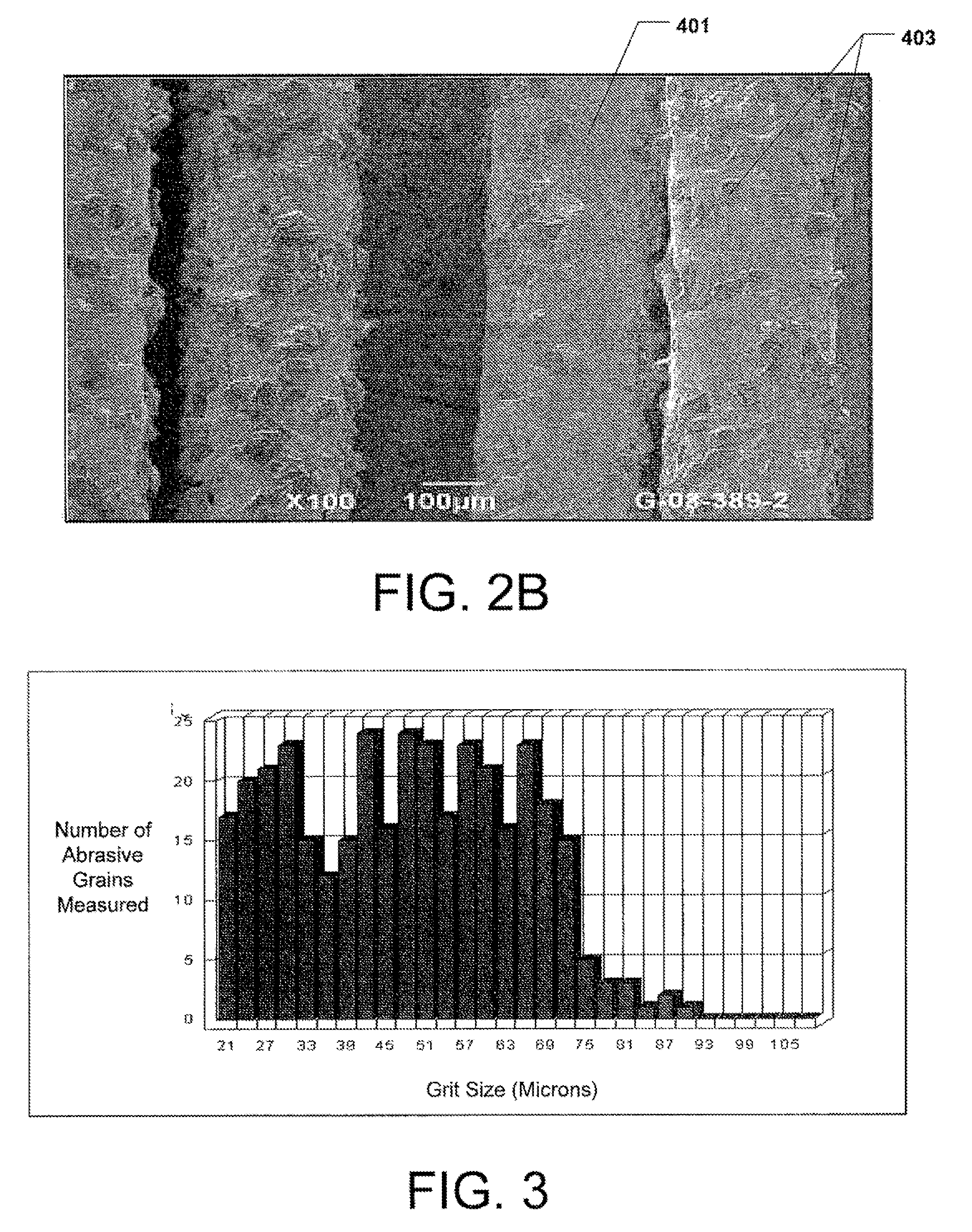

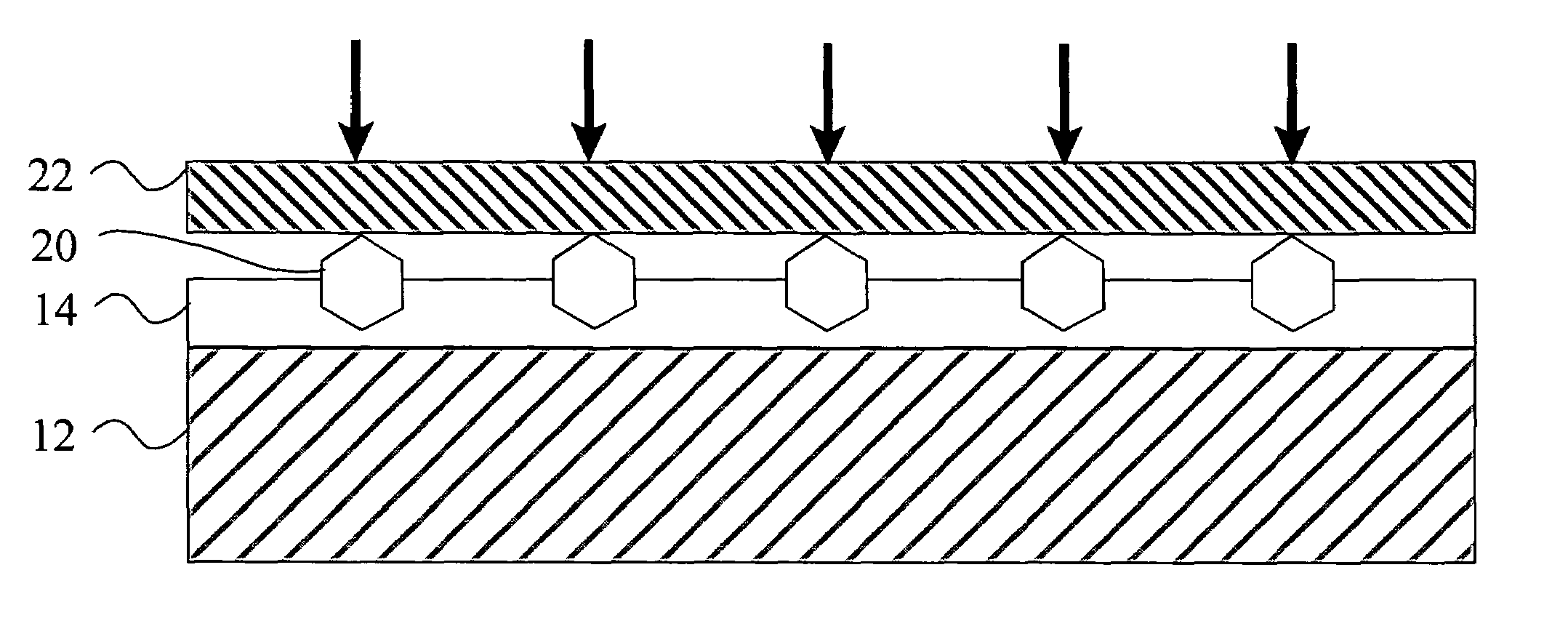

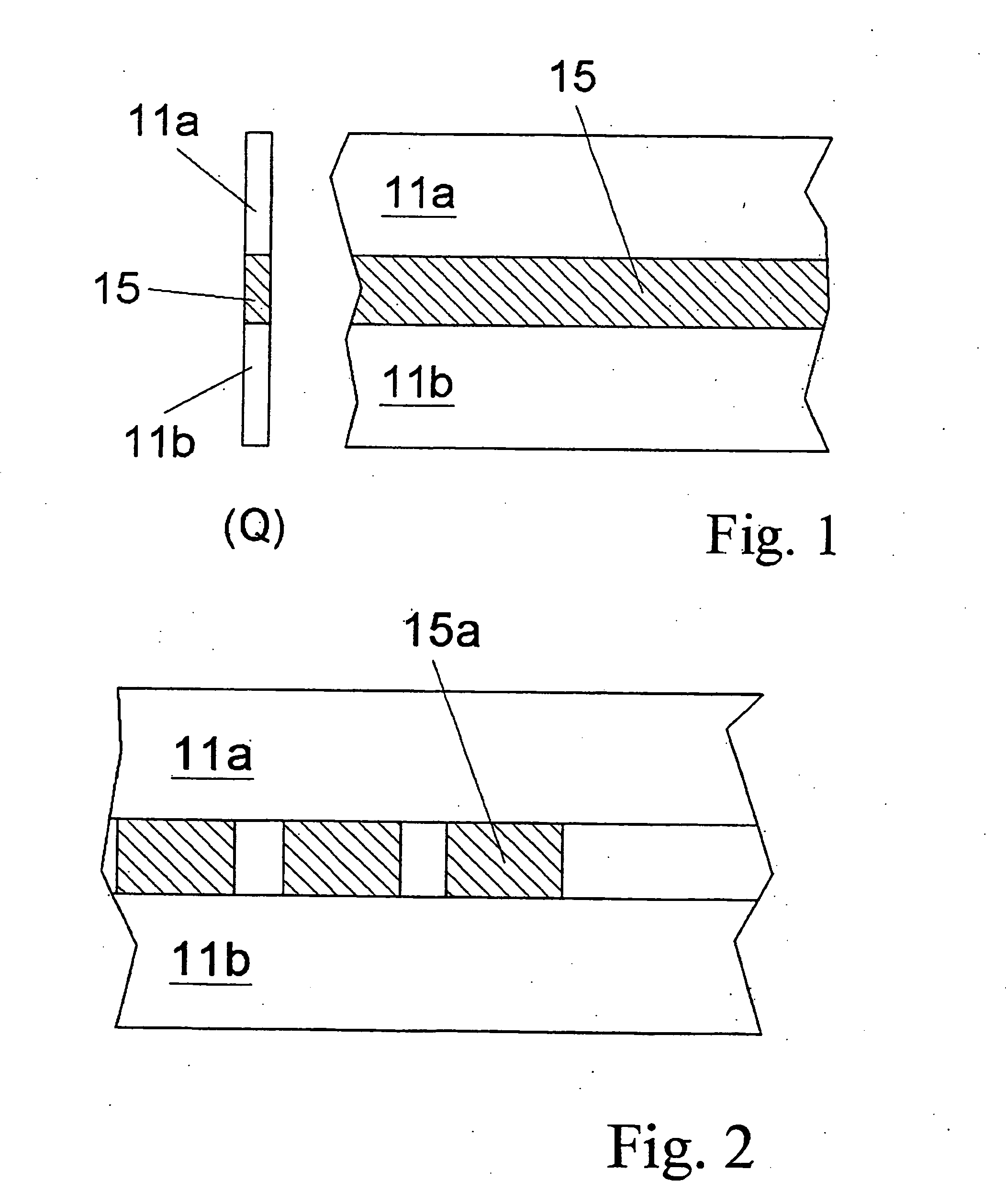

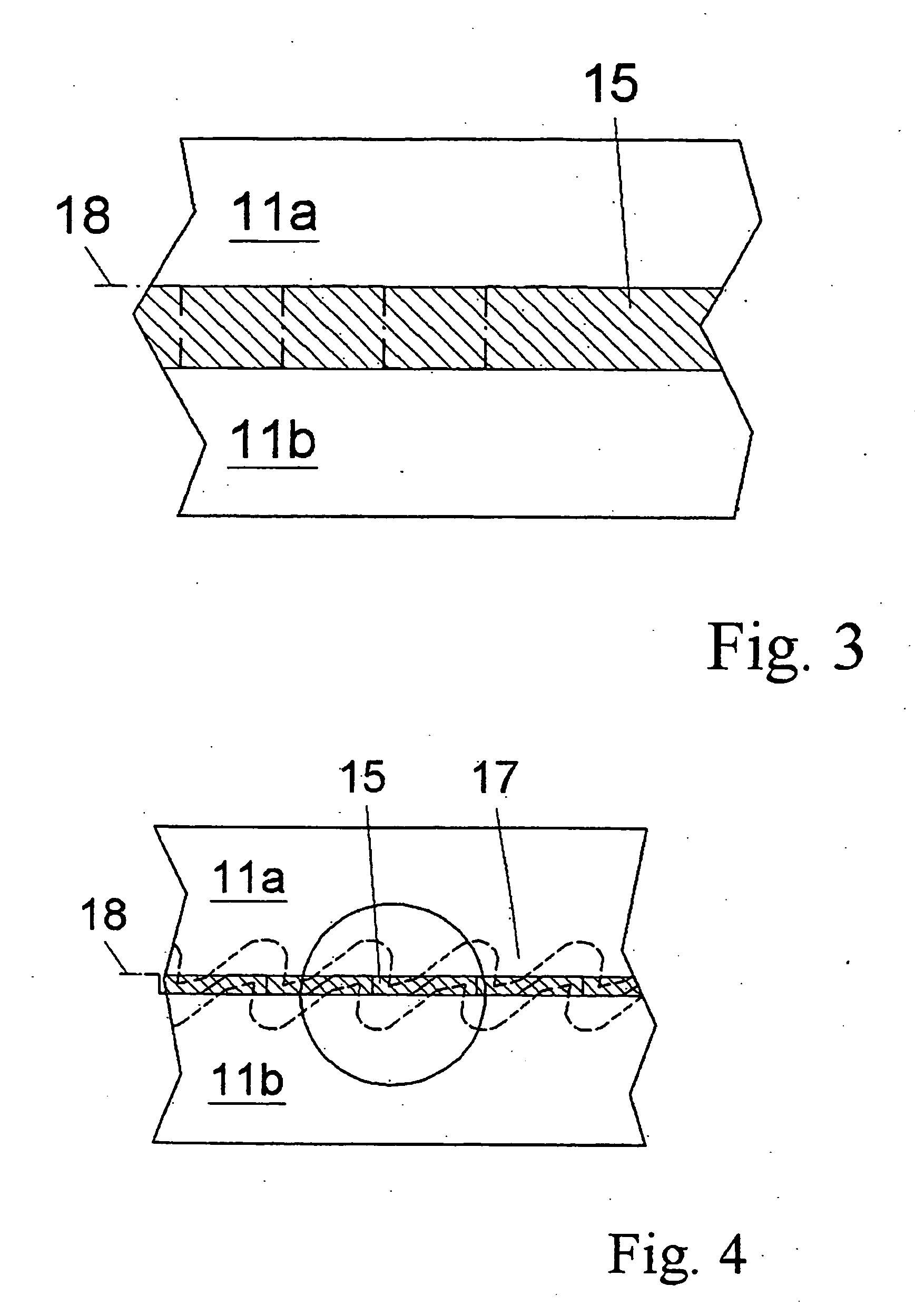

Diamond tools with multilayers of abrasive grain and method for manufacturing the same

ActiveUS20070151554A1Evenly distributedUniform thicknessBonded abrasive wheelsGrinding devicesElectroplatingHeat treated

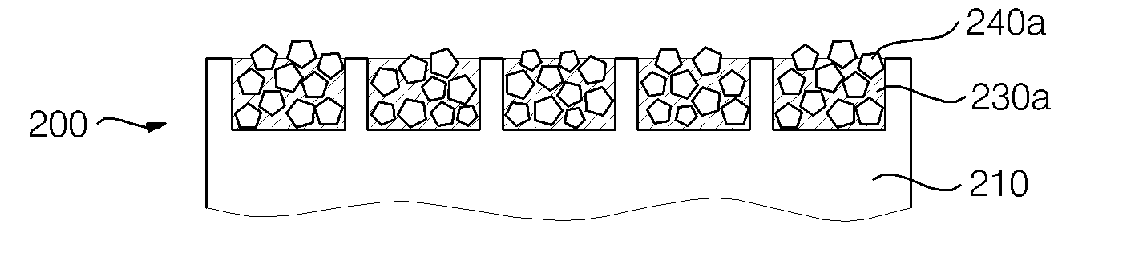

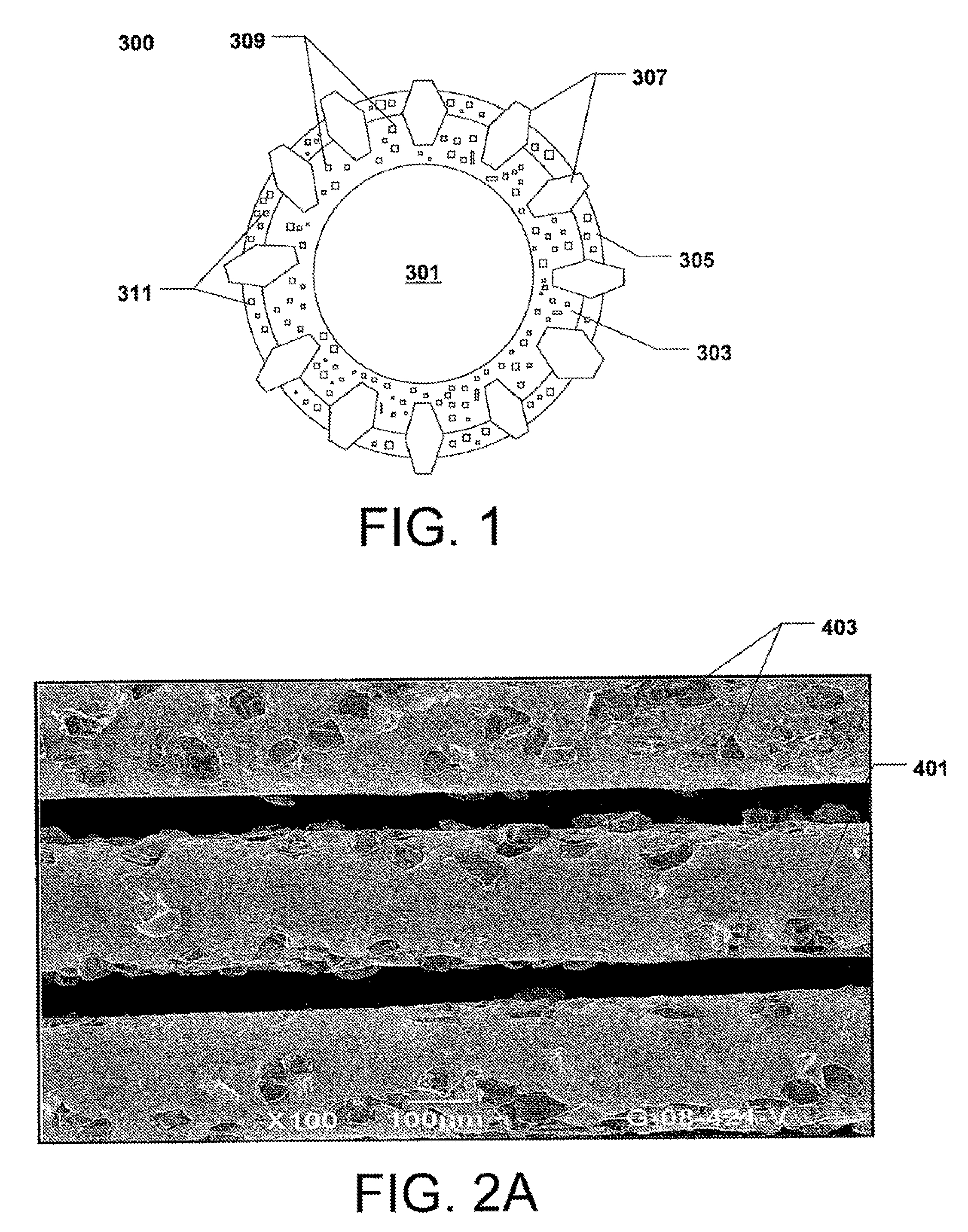

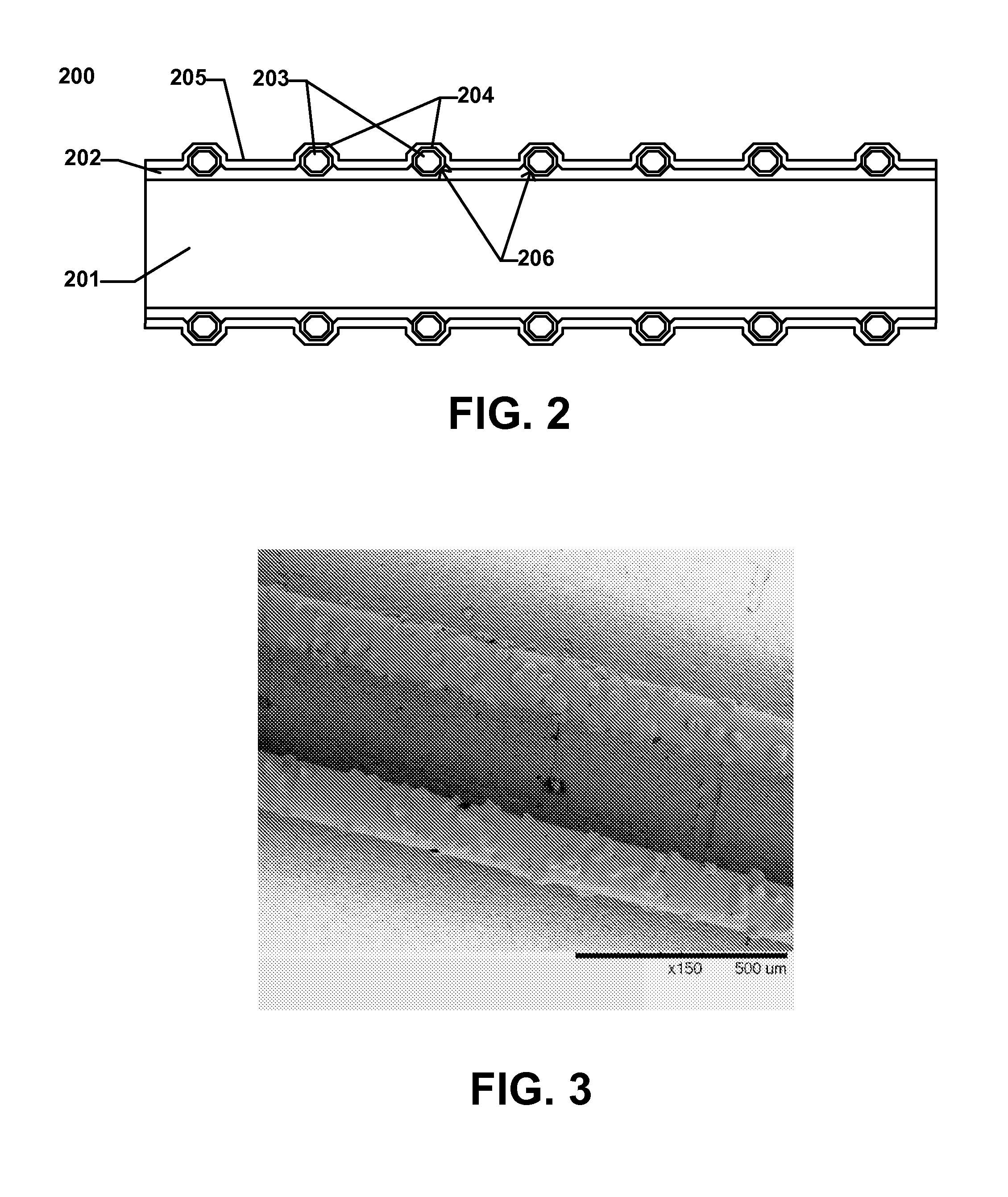

The present invention relates to a diamond tool and a method of manufacturing the same, wherein multiple abrasive layers are formed through a brazing or electroplating method, thereby improving the performance and service life of the tool. According to the method of the present invention, a plurality of concave portions are formed in a surface of the shank. A bonding paste is coated into the concave portions and abrasives are dispersed in the bonding paste to thereby form a lower abrasive layer. Again, a bonding material is coated on the lower abrasive layer and abrasives are dispersed in the bonding material to thereby form an upper abrasive layer. Then, a heat treatment is executed to fusion-bond the bonding material and abrasives onto the surface of the shank. Therefore, the diamond tools manufactured through a multiple brazing or electroplating method according to the invention can significantly extend the service life thereof, which has been a detrimental weakness of the conventional diamond tools having a single abrasive layer, in spite of various advantages of the brazing and electroplating methods. Furthermore, multiple abrasive layers can be formed inside the concave portions having a desired spacing, width and depth, thereby significantly improving the service life and the cutting performance of diamond tools.

Owner:SHINHAN DIAMOND IND

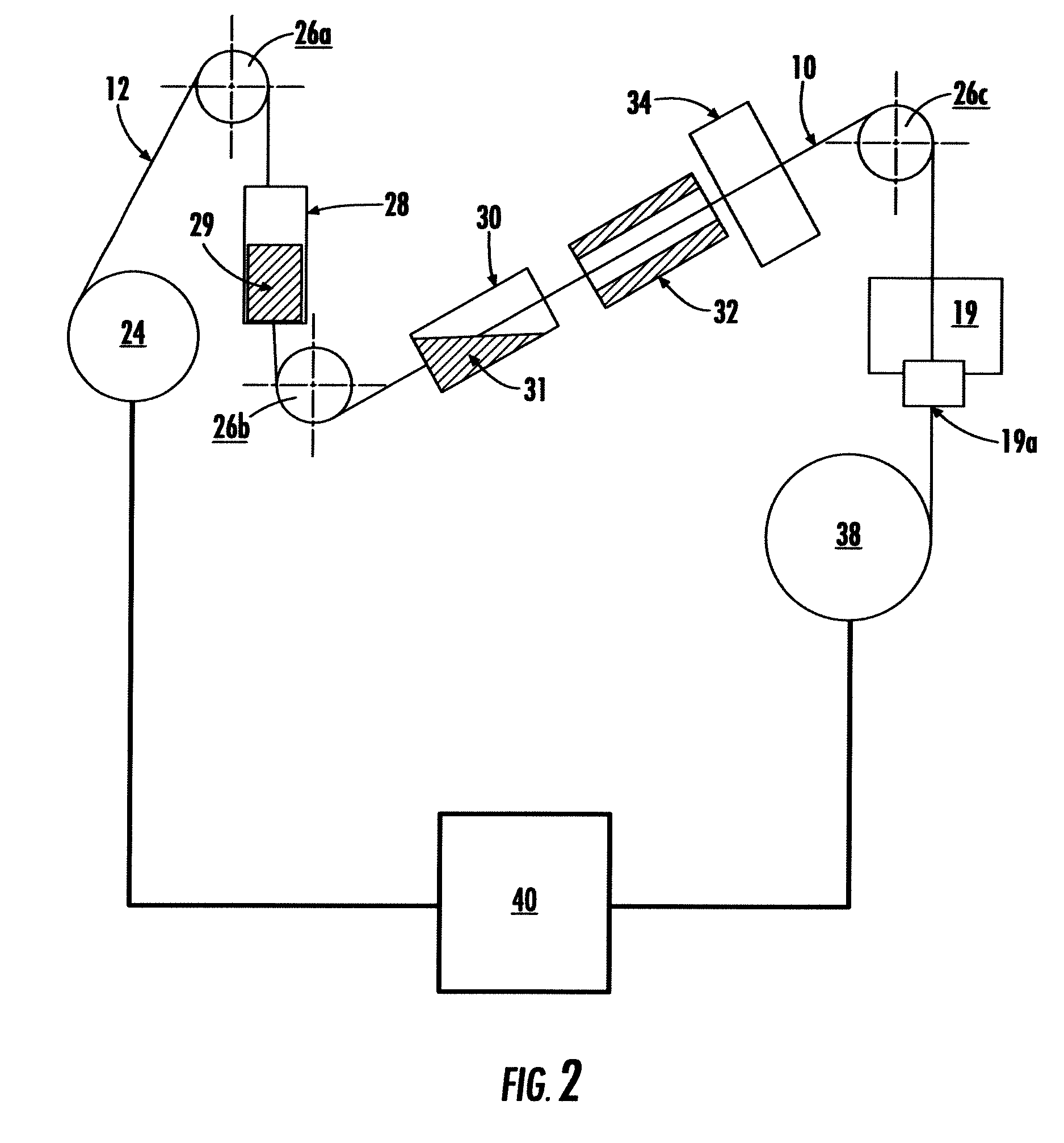

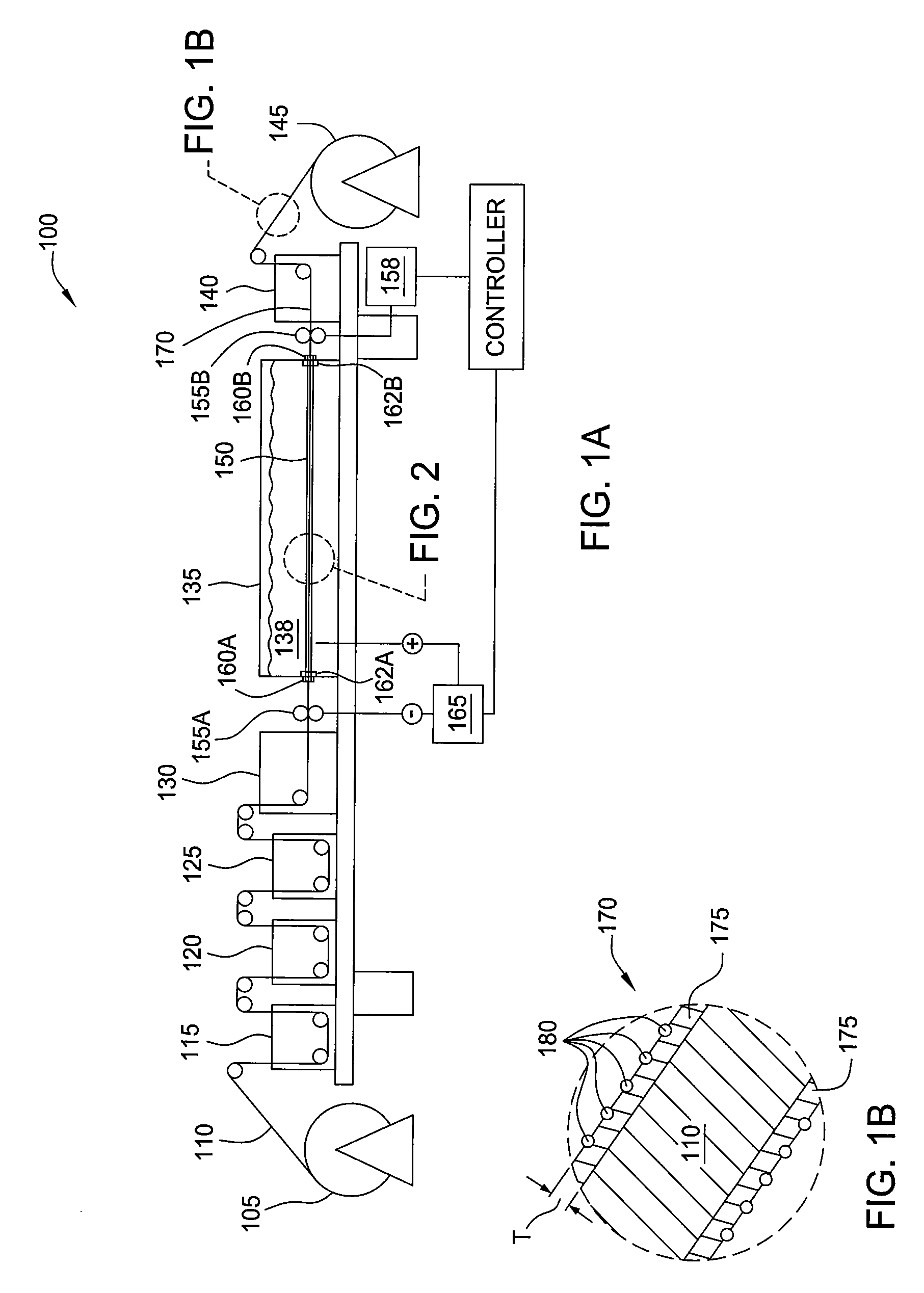

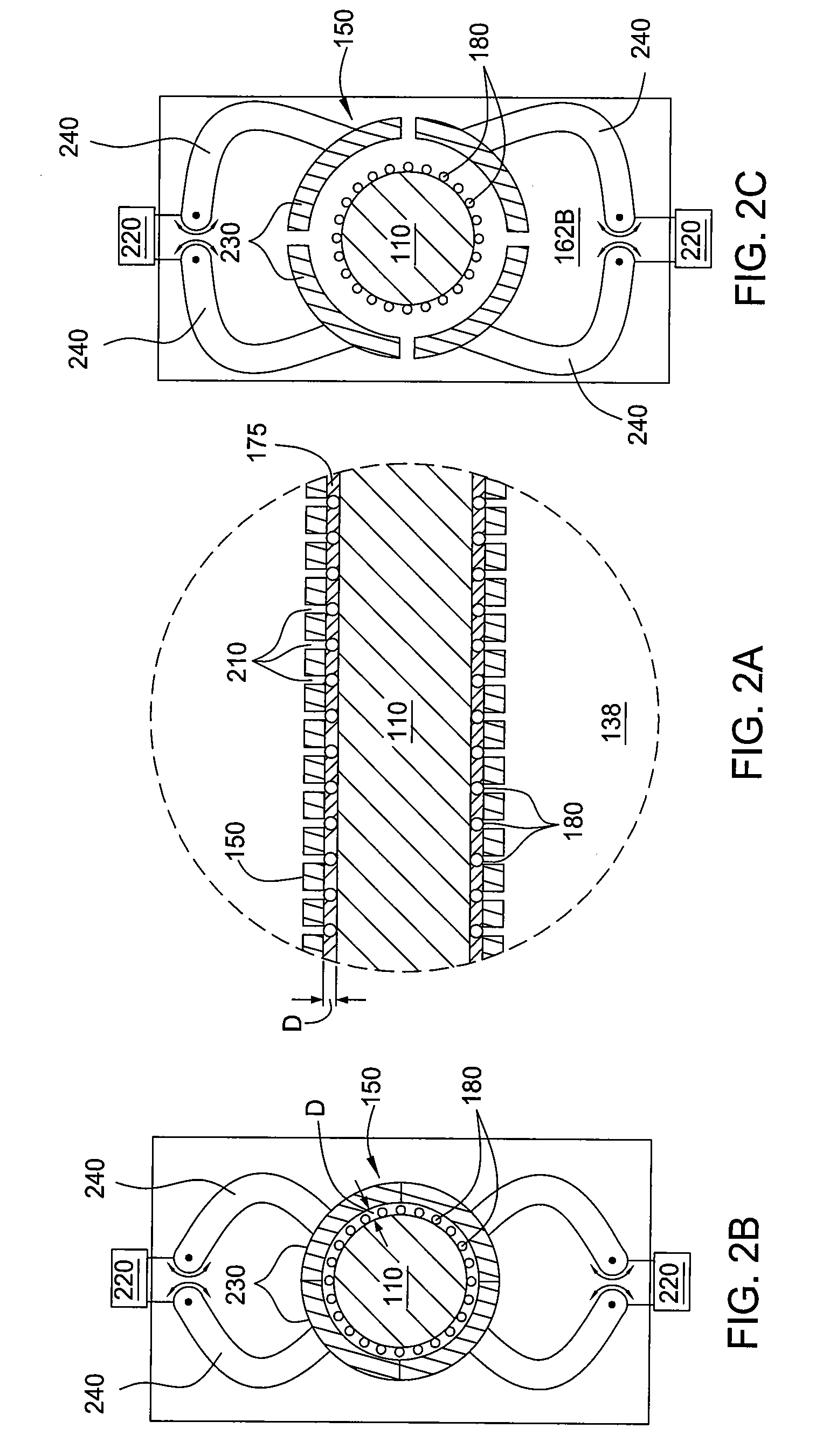

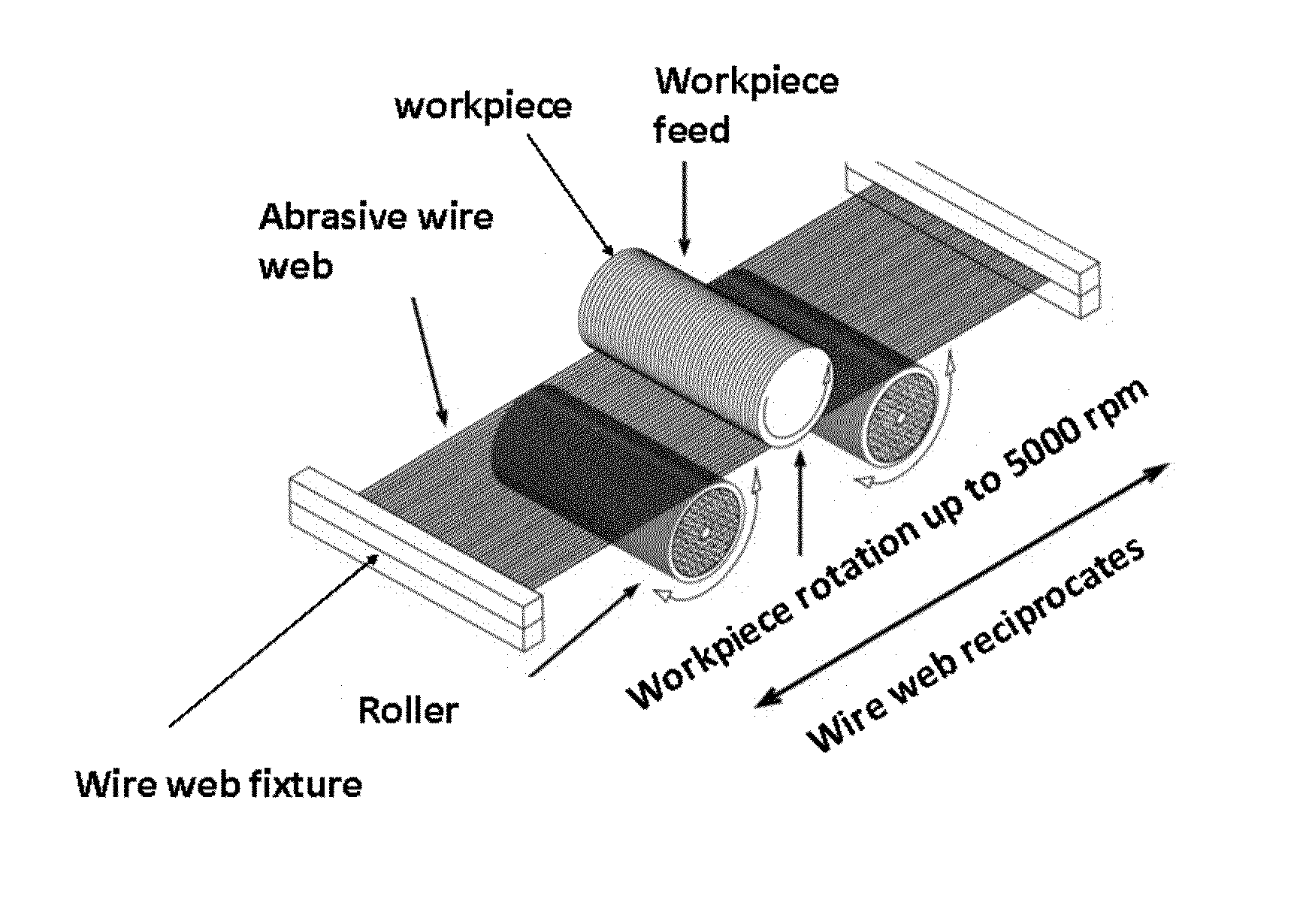

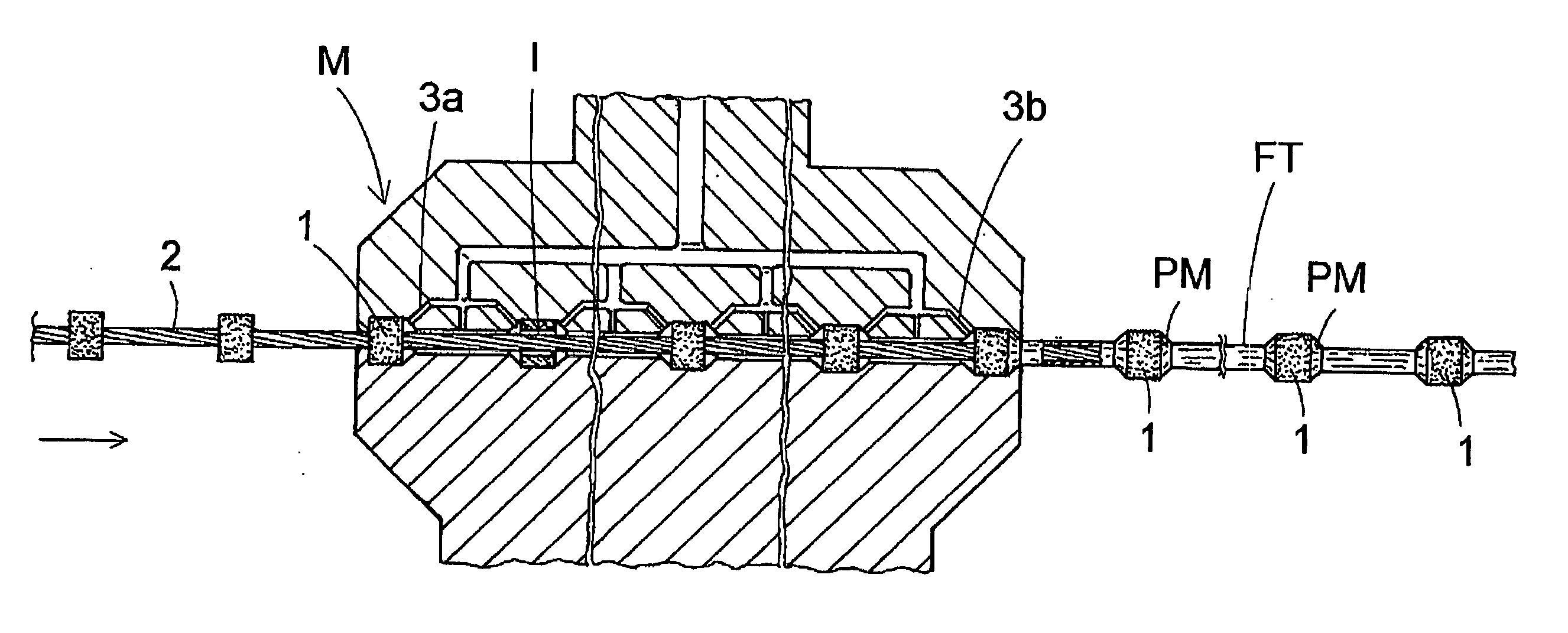

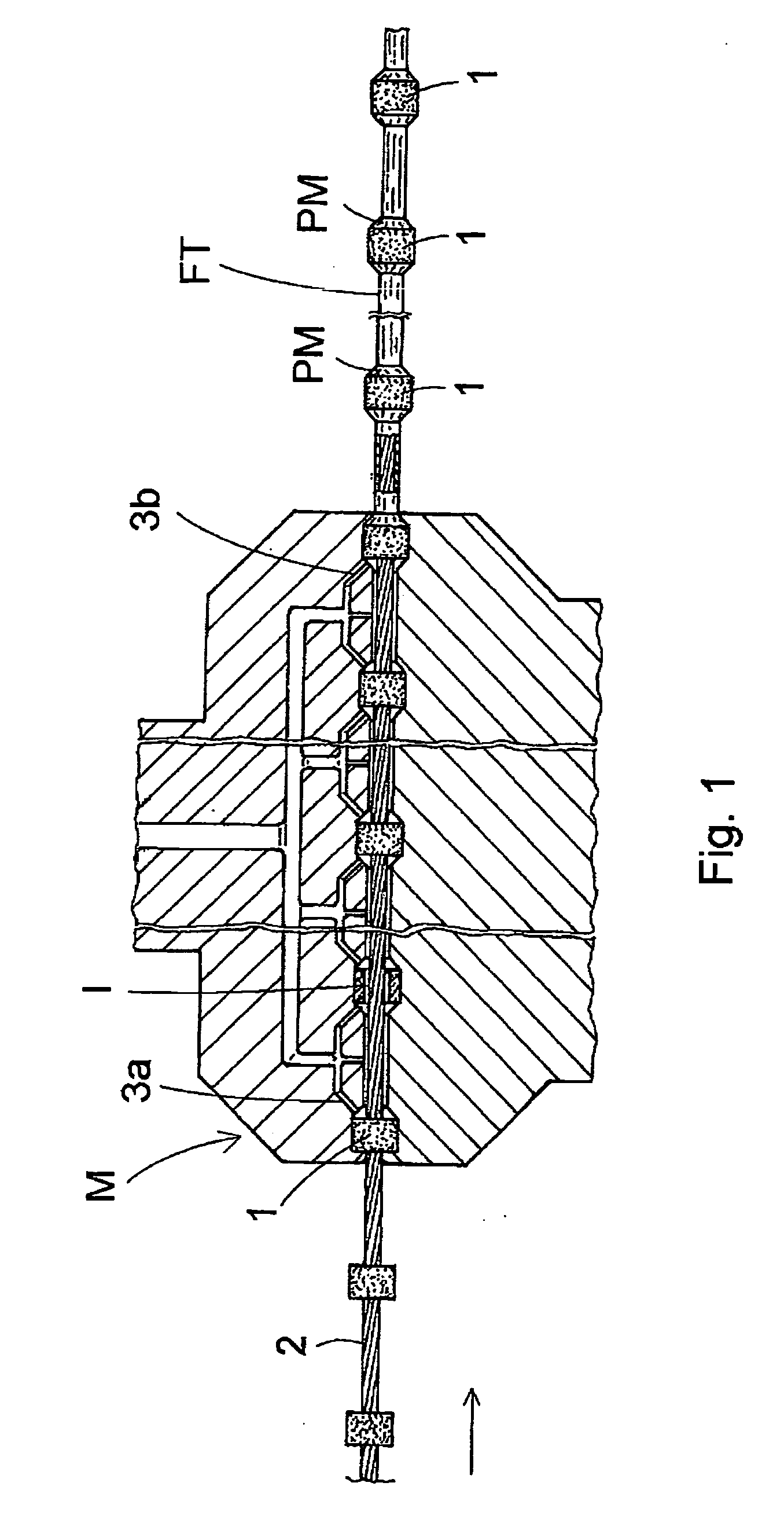

Methods, Wires, and Apparatus for Slicing Hard Materials

Methods, wires, and apparatus for use in cutting (e.g., slicing) hard, brittle materials is provided. The wire can be a super-abrasive wire that includes a wire core and super-abrasive particles bonded to the wire core via a metal bonding layer. This wire, or another type of wire, can be used to slice workpieces useful for producing wafers. The workpieces can be aligned within a holder to produce wafers using the device and methods presently provided. The holder rotates about its central axis, which translates to workpieces moving in orbit around this axis. A single abrasive wire, or multiple turns of wire stretched tightly between wire guides, is then contacted with the rotating holder to slice the workpieces.

Owner:UNIVERSITY OF SOUTH CAROLINA

Superabrasive particle synthesis with controlled placement of crystalline seeds

InactiveUS20050136667A1Narrow size distributionQuality improvementDrill bitsOther chemical processesOctahedronSynthesis methods

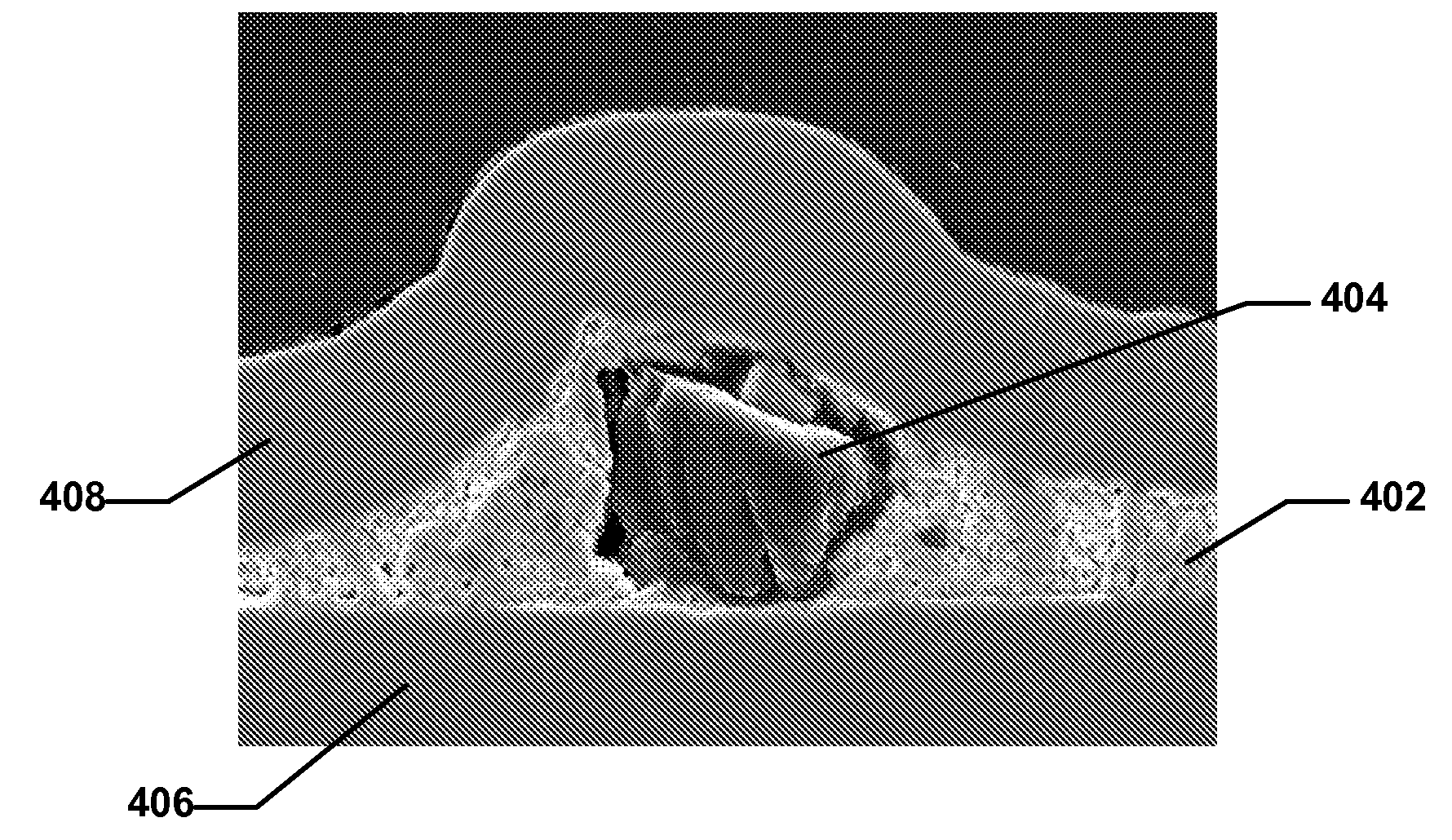

An improved method for synthesizing superabrasive particles provides high quality industrial superabrasive I-,articles with high yield and a narrow size distribution. The synthesis method includes forming a substantially homogeneous mixture of raw material and catalyst material or layers of raw material and metal catalyst. A plurality of crystalline seeds is placed in a predetermined pattern in the mixture or one of the layers to form a growth precursor. The growth precursor is maintained at a temperature and pressure at which the superabrasive crystal is thermodynamically stable for a time sufficient for a desired degree of growth. Advantageously, the patterned placement of crystalline seeds and disclosed processes allow for production of synthetic octahedral diamonds and improved growth conditions generally. As a result, the grown superabrasive particles typically have a high yield of high quality particles and a narrow distribution of particle sizes.

Owner:SUNG CHIEN MIN

Saw blade for hand-held tools

InactiveUS20020121023A1Prolong lifeIncrease forceMetal sawing devicesMetal sawing tool makingPower toolEngineering

Owner:ROBERT BOSCH GMBH

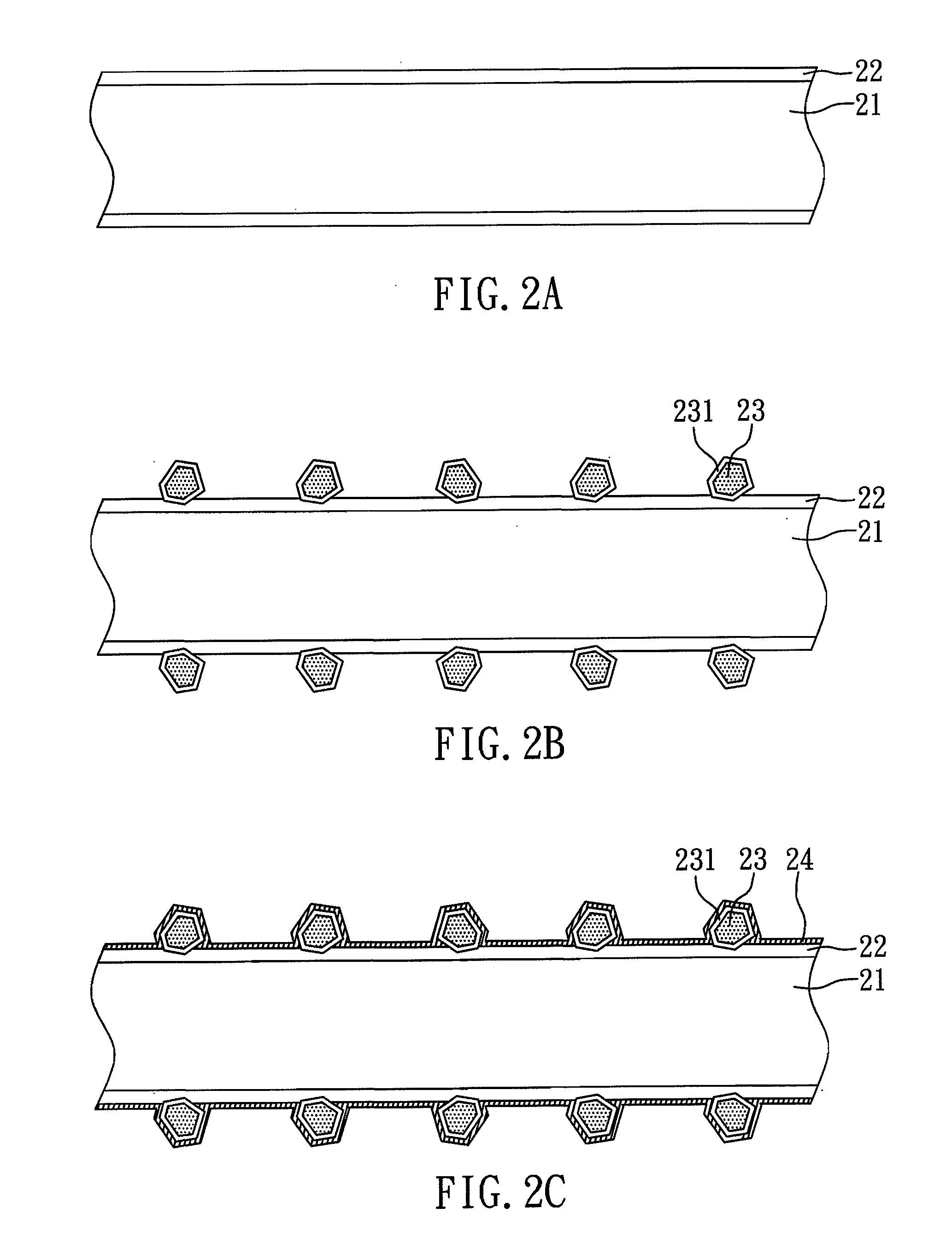

Wire saw and method for fabricating the same

The present invention relates to a wire saw and a method for fabricating the same. The method for fabricating a wire saw according to the present invention includes: providing a core wire; coating an intermediate layer over the core wire, and embedding a plurality of abrasives in the intermediate layer; and plating a metal protective layer over the abrasives. Accordingly, the present invention can resolve the conventional problem of abrasives in the plating bath aggregating during electroplating deposition, so as to enhance cutting quality and precision.

Owner:KINIK

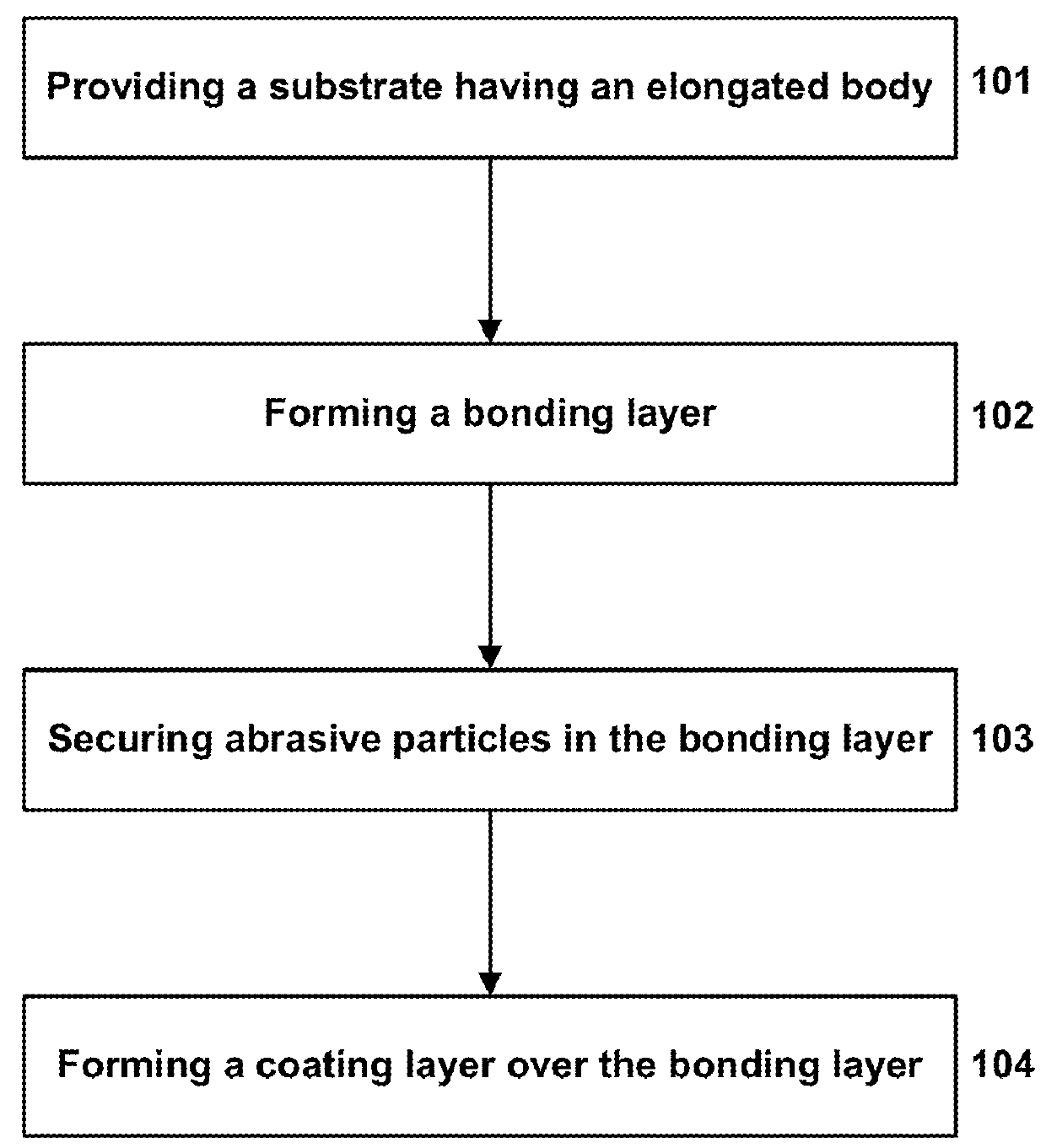

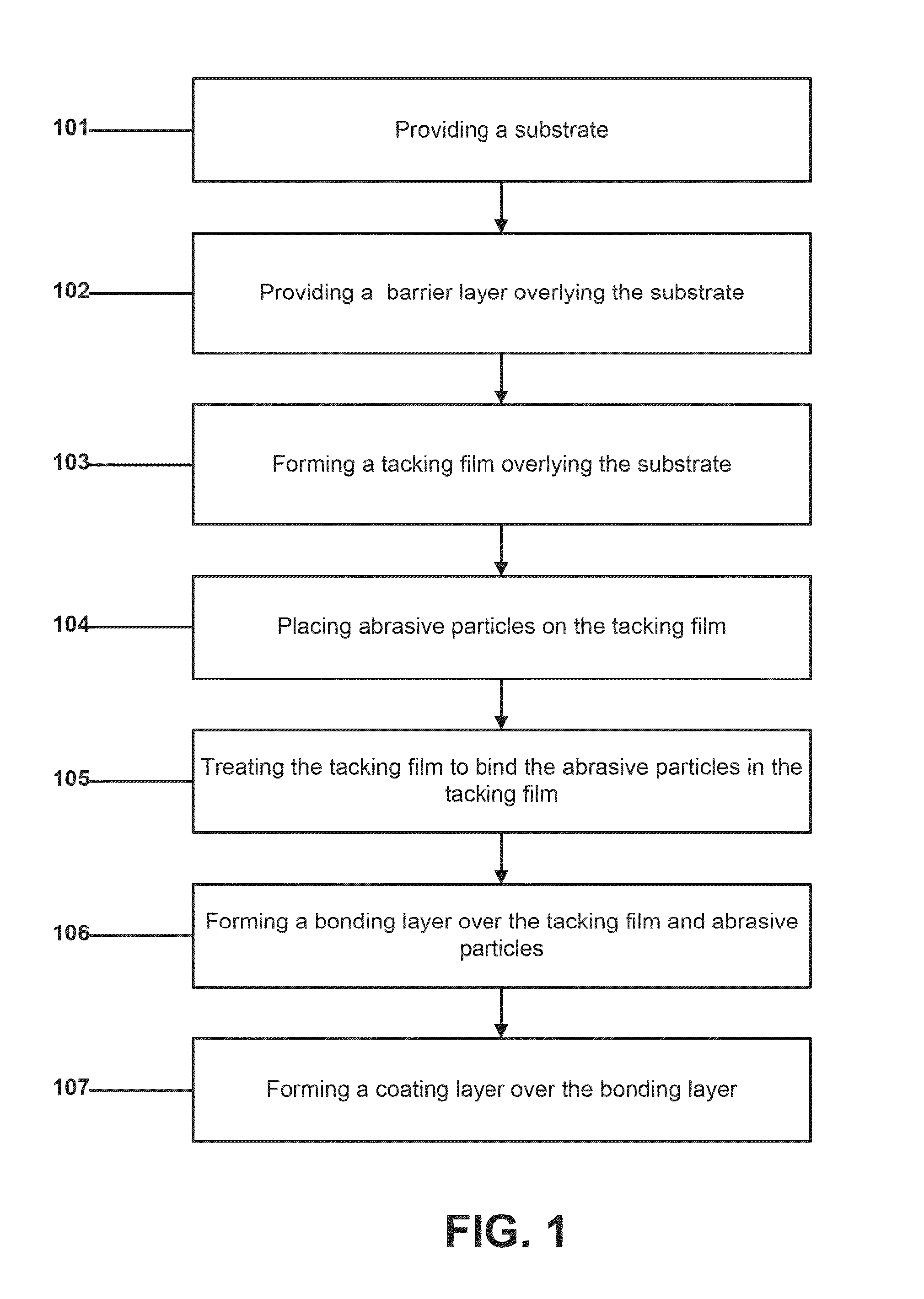

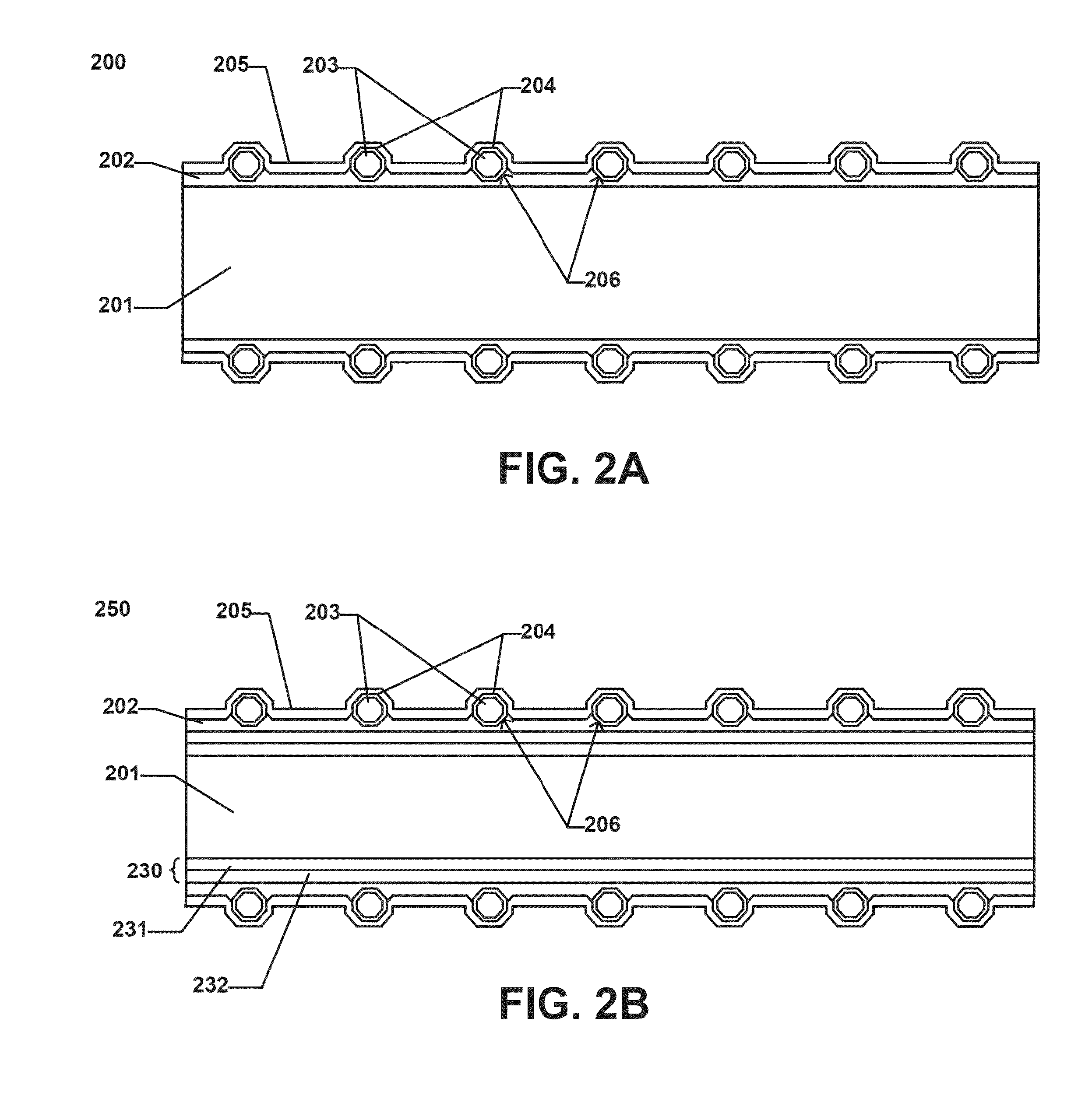

Abrasive Articles Including Abrasive Particles Bonded to an Elongated Substrate Body Having a Barrier Layer, and Methods of Forming Thereof

An abrasive article including a substrate in the form of an elongated member having a core and a barrier layer in direct contact with an peripheral surface of the core. The barrier layer consists essentially of tin. A bonding layer is overlying the elongated substrate and abrasive particles are secured in the bonding layer

Owner:SAINT GOBAIN ABRASIVES INC +1

Superabrasive particle synthesis with controlled placement of crystalline seeds

InactiveUS20060016127A1Narrow size distributionQuality improvementDrill bitsConstructionsOctahedronSynthesis methods

An improved method for synthesizing superabrasive particles provides high quality industrial superabrasive particles with high yield and a narrow size distribution. The synthesis method can include forming a growth precursor of a substantially homogeneous mixture of raw material and catalyst material or layers of raw material and metal catalyst. The growth precursor can have a layer of adhesive over at least a portion thereof. A plurality of crystalline seeds can be placed in a predetermined pattern on the layer of adhesive. The growth precursor can be maintained at a temperature and pressure at which the superabrasive crystal is thermodynamically stable for a time sufficient for a desired degree of growth. Advantageously, the patterned placement of crystalline seeds and disclosed processes allow for production of various morphologies of synthetic diamonds, including octahedral and cubic diamonds, and improved growth conditions generally. As a result, the grown superabrasive particles typically have a high yield of high quality particles and a narrow distribution of particle sizes.

Owner:SUNG CHIEN MIN

Saw blade

InactiveUS20080264231A1Metal sawing devicesMetal sawing tool makingEngineeringMechanical engineering

A saw blade comprises a plate having a plurality of teeth. Each of the teeth includes a tip where the tip has a smooth curved surface welded to the plate. The tip comprises a solid piece of hard material and has a generally rounded wedge shape. A method of forming a saw blade having cutting tips welded to the plate is also provided.

Owner:BLACK & DECKER INC

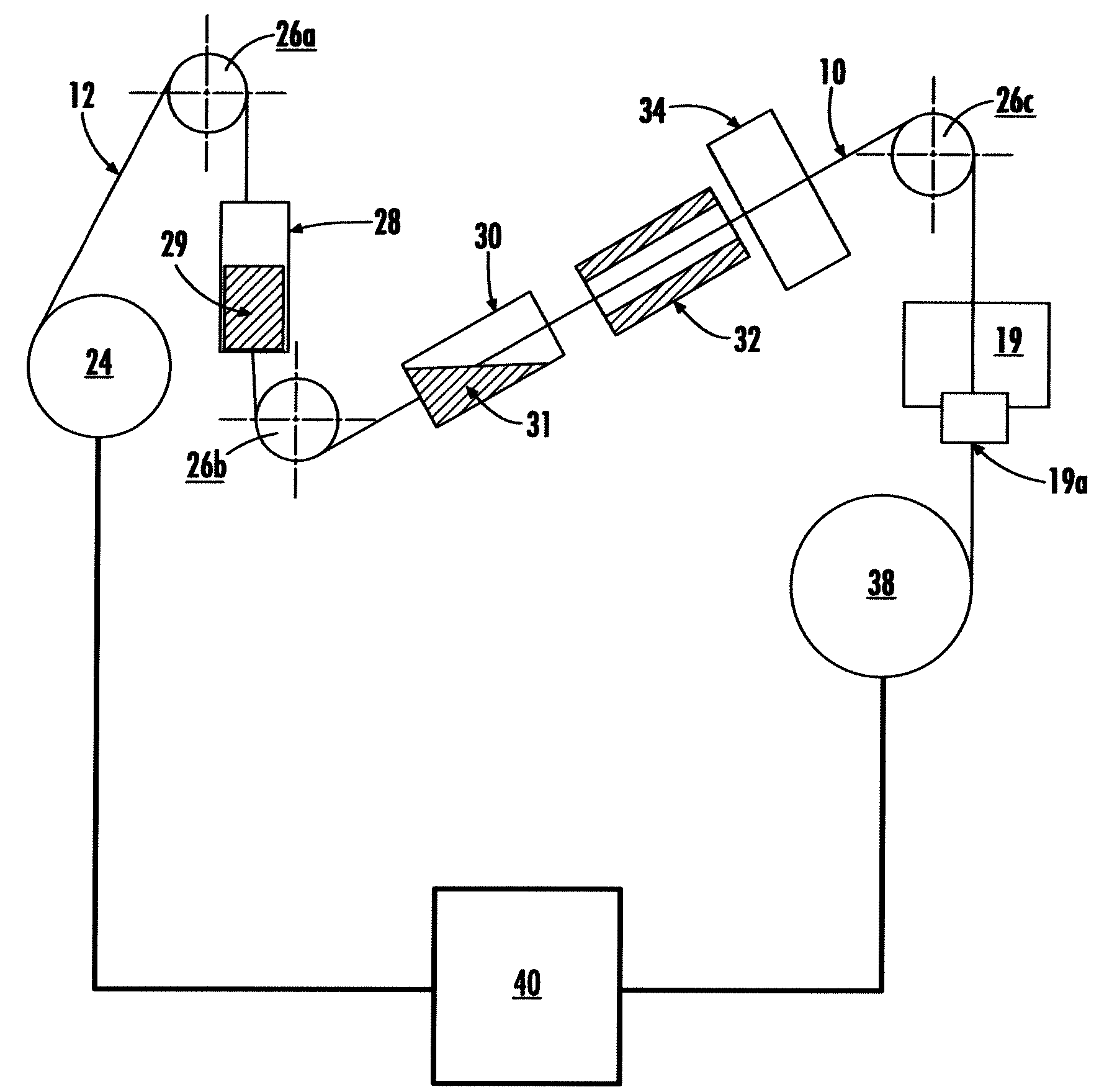

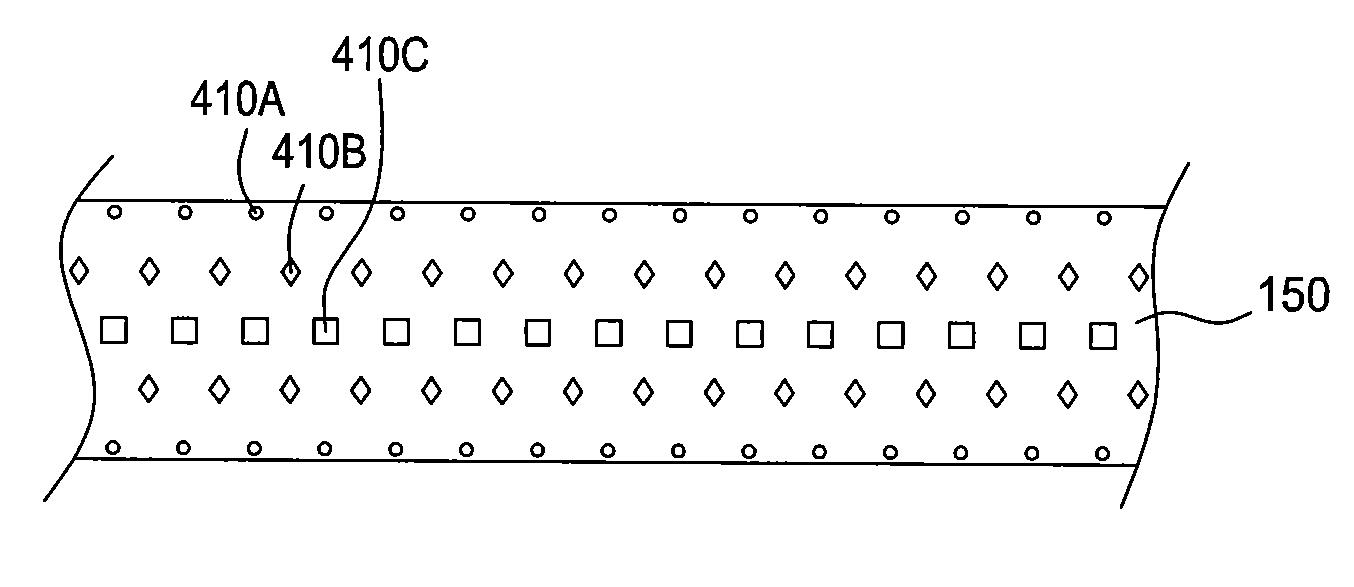

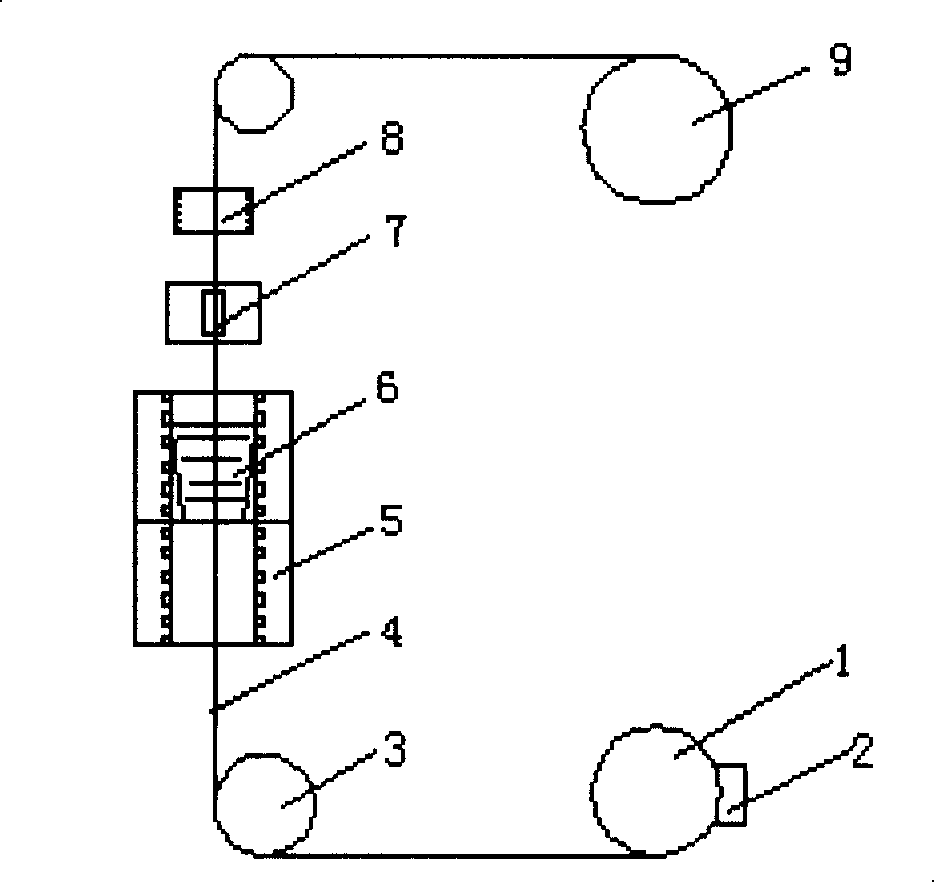

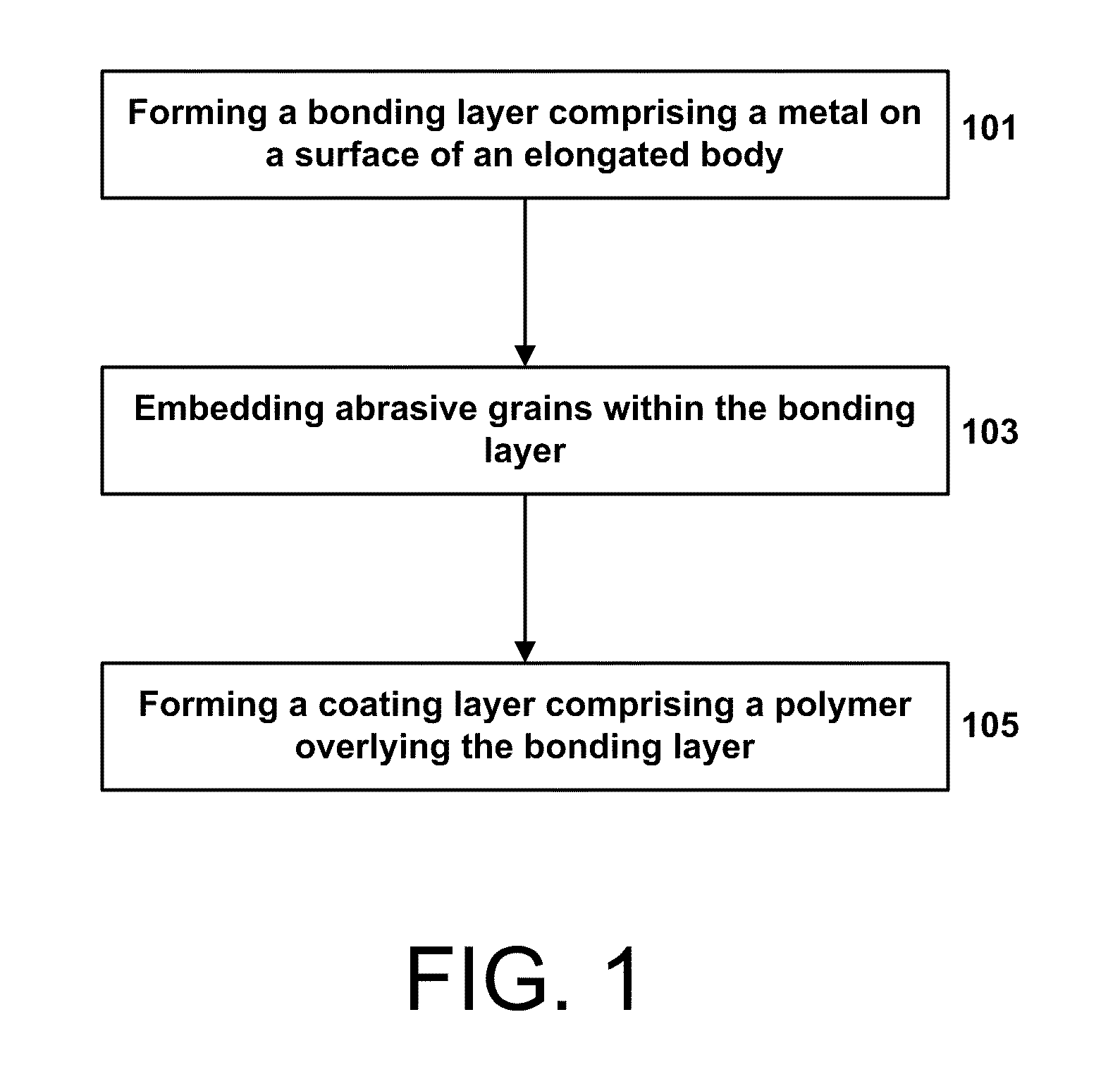

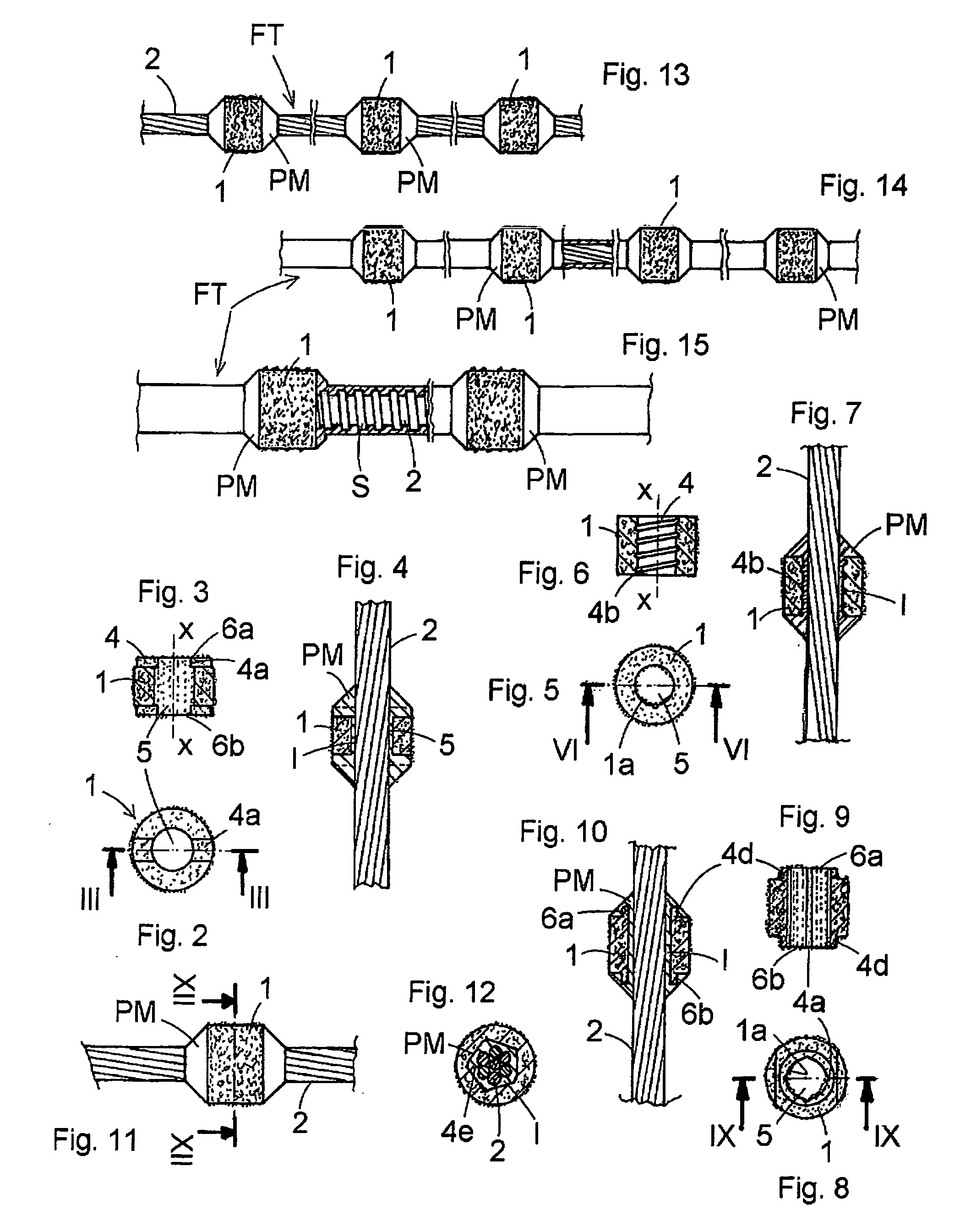

Method and apparatus for manufacturing an abrasive wire

A method and apparatus for an abrasive laden wire is described. In one embodiment, an abrasive coated wire is described. The wire includes a core wire having a symmetrical pattern of abrasive particles coupled to an outer surface of the core wire, and a dielectric film covering portions of the core wire between the abrasive particles.

Owner:APPLIED MATERIALS INC

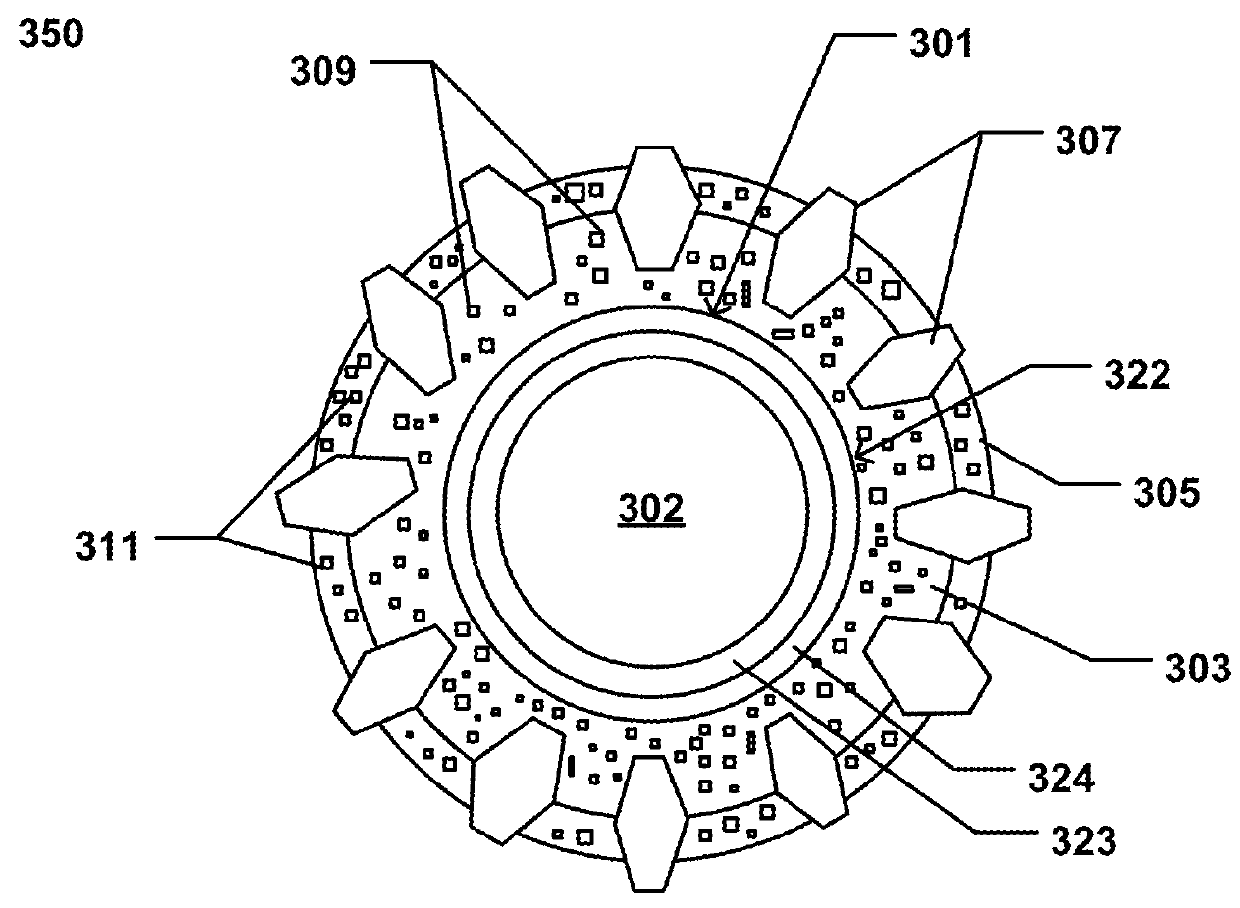

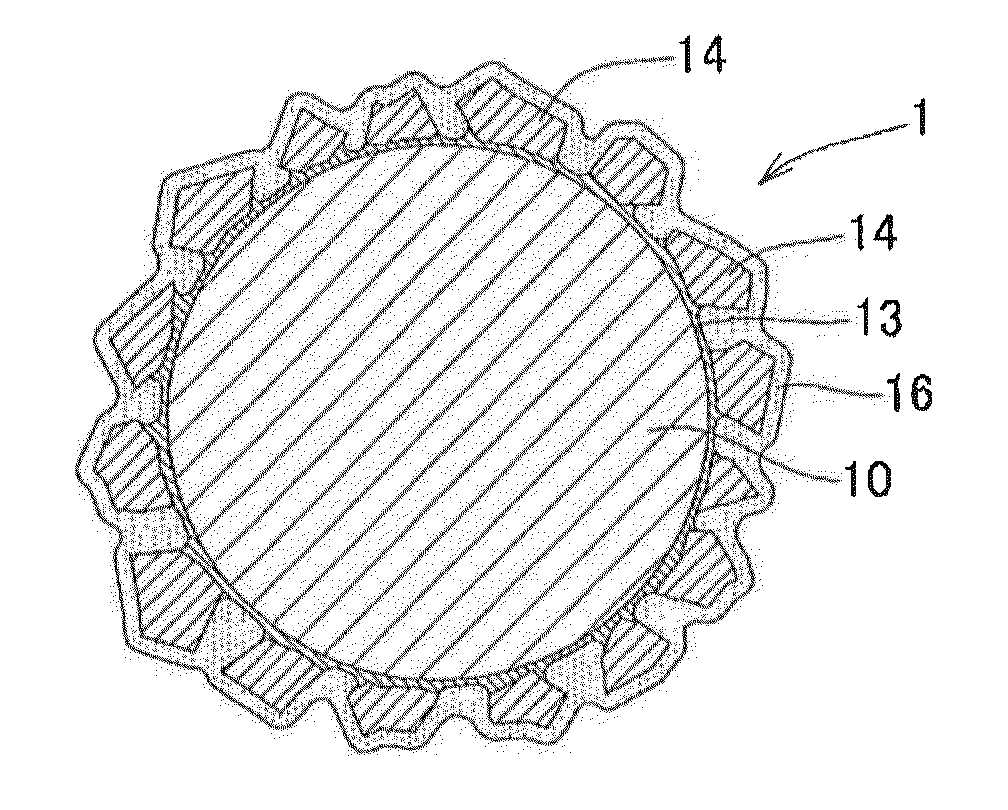

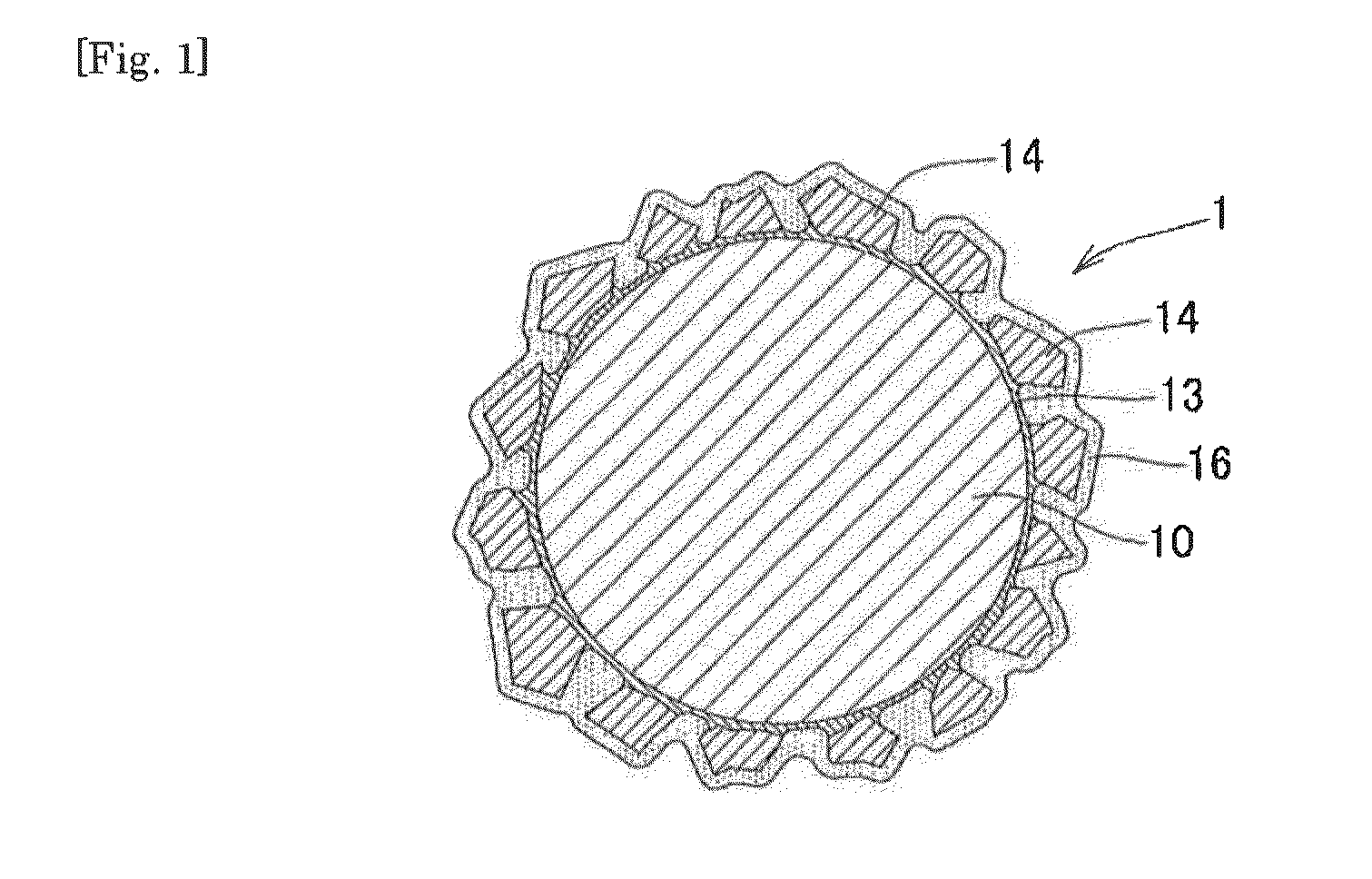

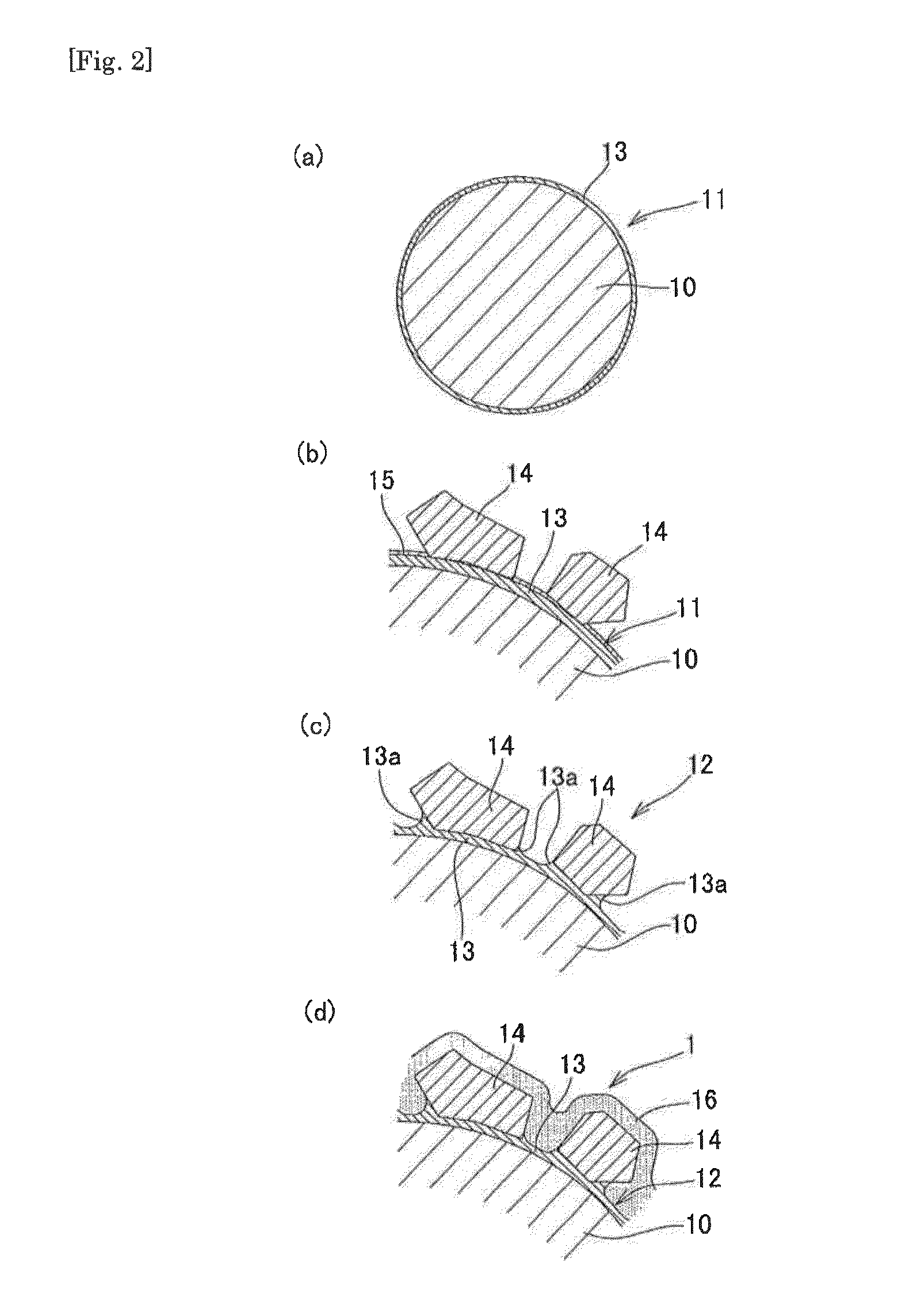

Super-abrasive grain fixed type wire saw, and method of manufacturing super-abrasive grain fixed type wire saw

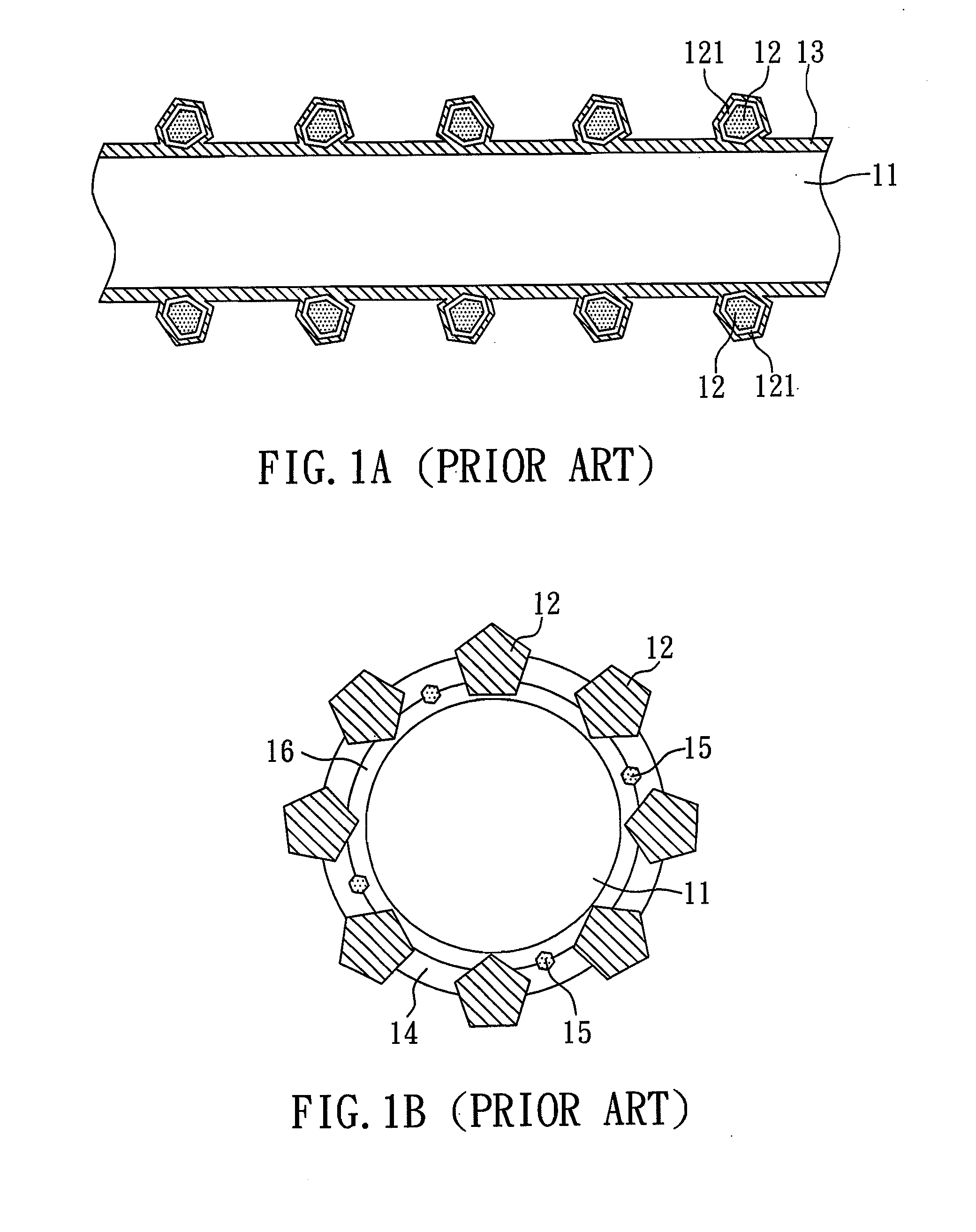

InactiveUS20130032129A1Improve retentionFast productionMetal sawing tool makingAbrasion apparatusWire sawMetal

The super-abrasive grain fixed type wire saw is equipped with two layers consisting of a brazing material layer (13) and a metal plating layer (16), the aforementioned brazing material layer (13) serving to temporarily fix super-abrasive grains (14), and the aforementioned metal plating layer (16) serving to hold the super-abrasive grains (14). The thickness of the brazing material layer (13) is 10% or less of the average grain diameter of the super-abrasive grains (14). The brazing material layer (13) is formed on the surface of a wire (10) in advance. The super-abrasive grains (14) are dispersed and adhered in a single layer onto the brazing material layer (13). Subsequently, the surface of the brazing material layer (13) is melted and solidified, resulting in a super-abrasive-grains-temporarily-adhered wire (12) such that super-abrasive grains (14) are joined to the adhesion surface of the brazing material layer (13). Thereafter, the super-abrasive-grains-temporarily-adhered wire (12) is metal-plated.

Owner:NAKAMURA CHOKO

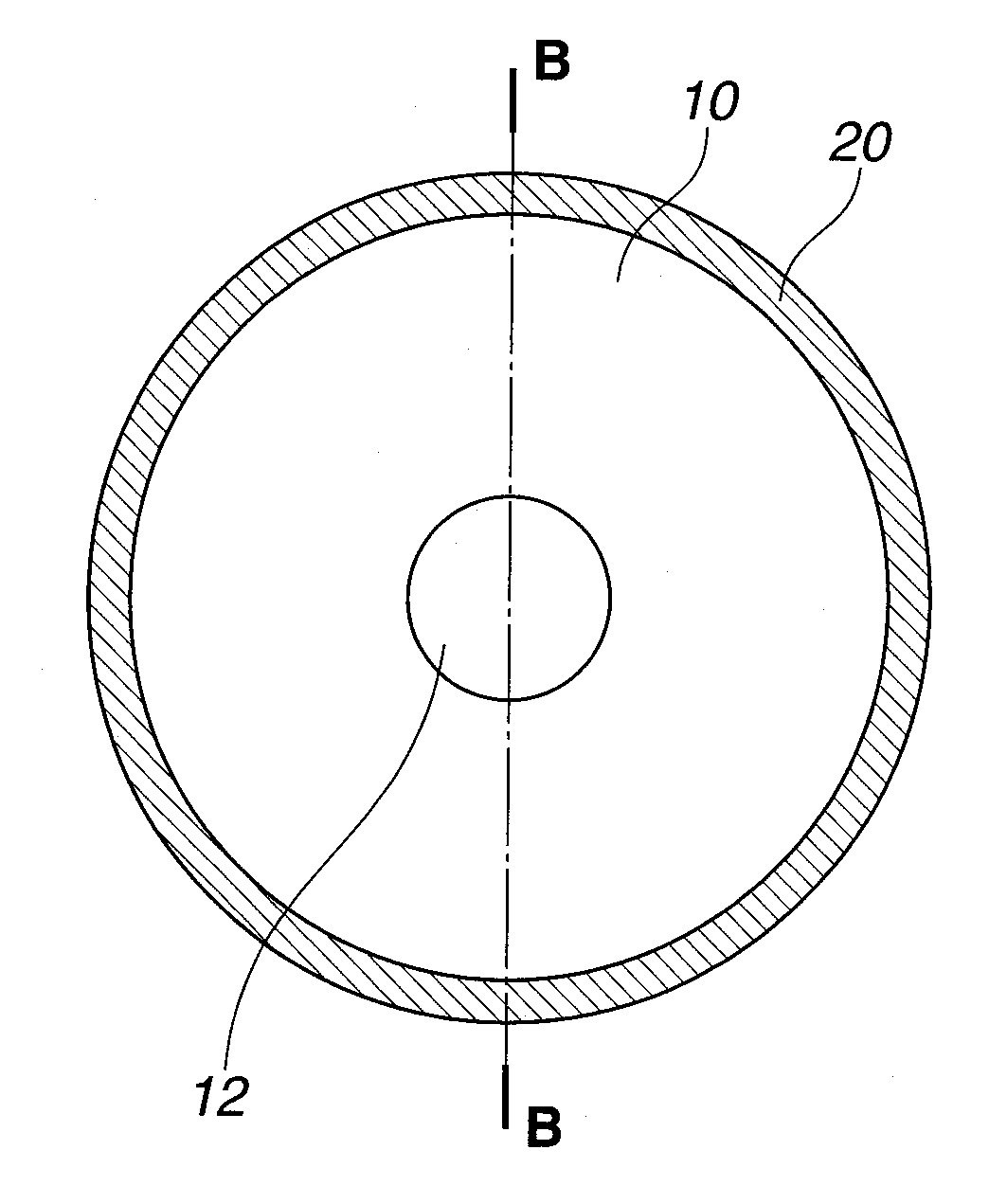

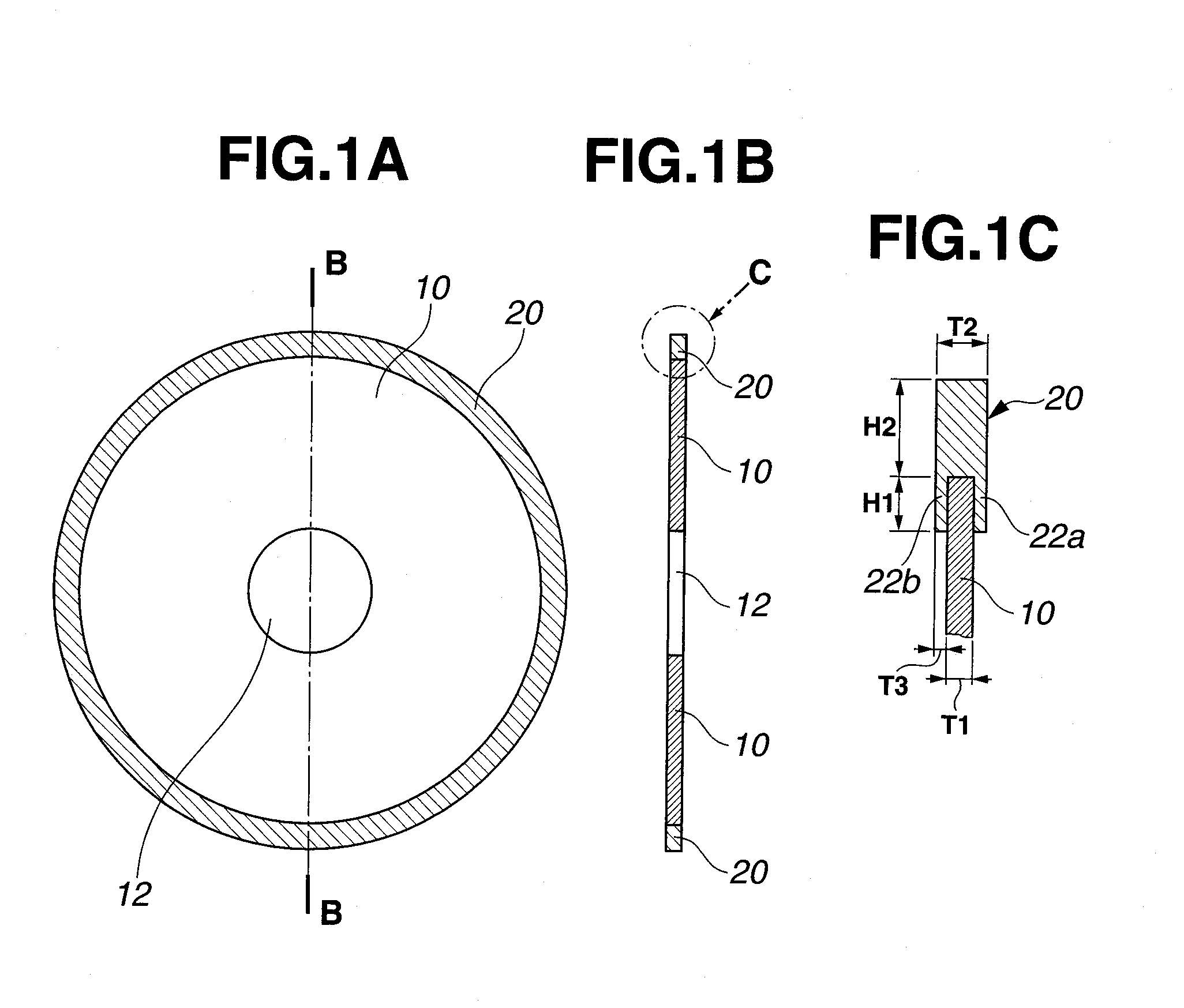

Method and jig assembly for manufacturing outer blade cutting wheel

ActiveUS20100275522A1Low costHigh yieldElectrolysis componentsElectrolytic coatingsCemented carbideElectroplating

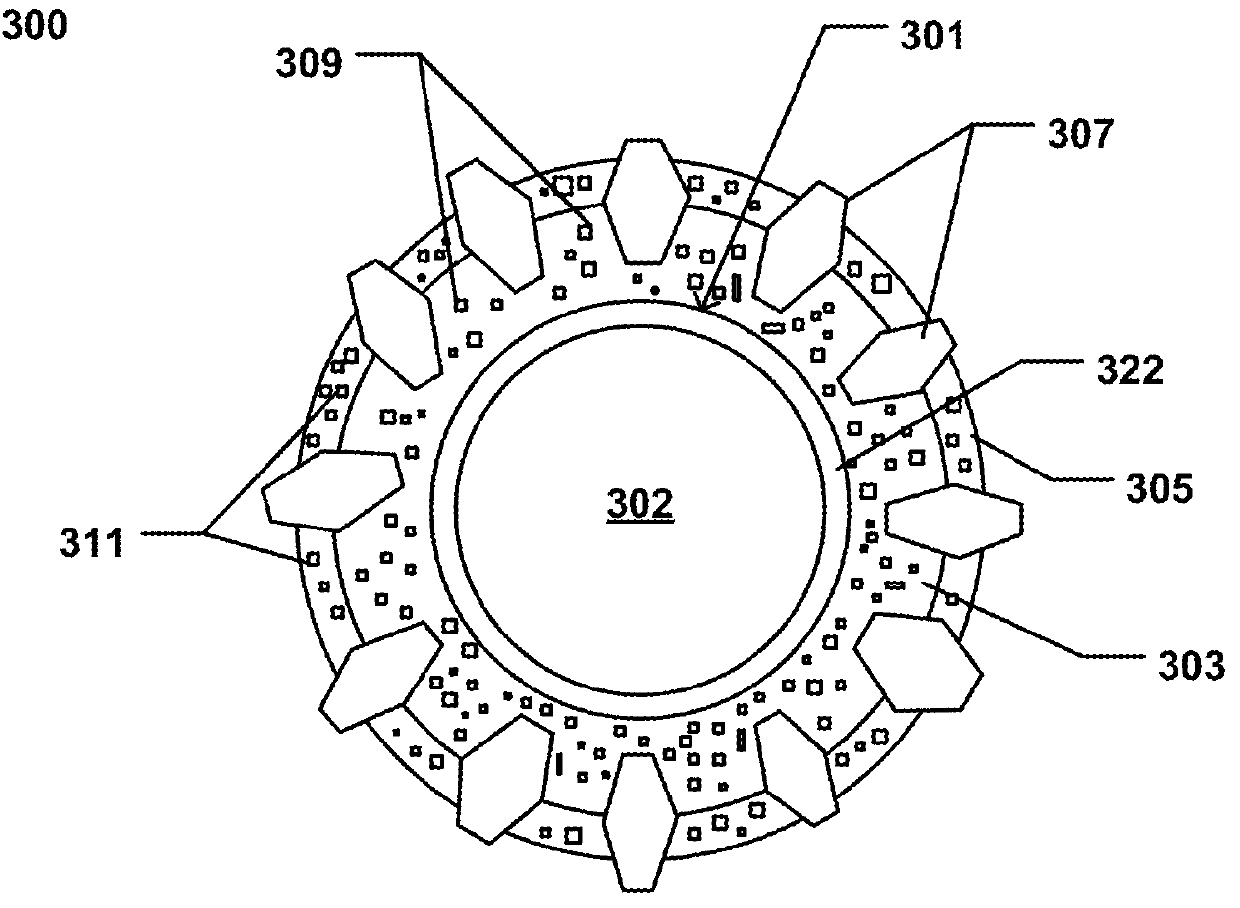

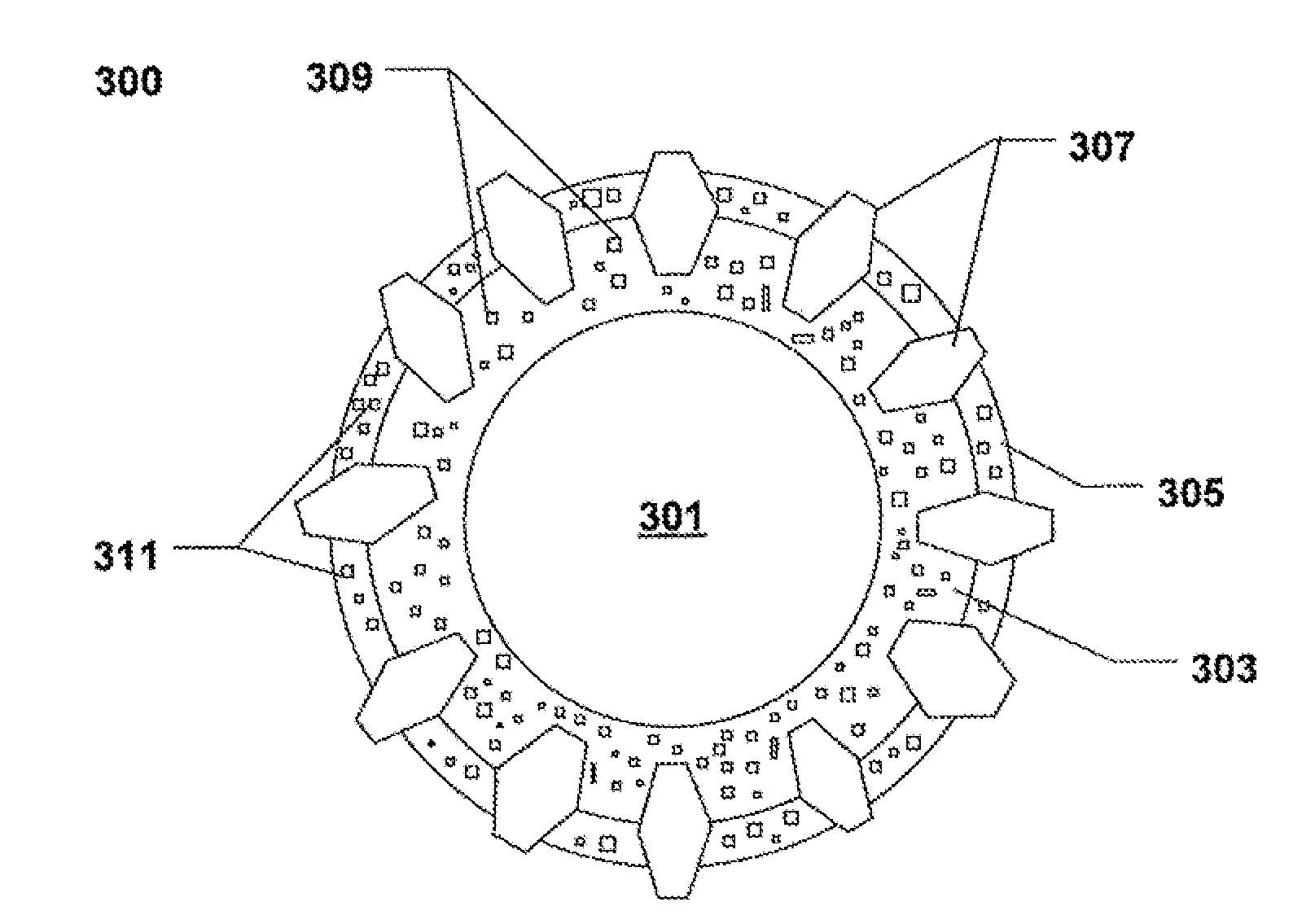

An outer blade cutting wheel comprising an annular thin disc base of cemented carbide and a blade section is manufactured by disposing permanent magnet pieces on the side surfaces and inward of the outer periphery of the base to produce a magnetic field, providing magnetic coated diamond and / or CBN abrasive grains such that the magnetic field may act on the grains, causing the grains to be magnetically attracted to the base outer periphery, and electroplating or electroless plating whereby the abrasive grains are bound to the base outer periphery to form the blade section.

Owner:SHIN ETSU CHEM IND CO LTD

Superabrasive particle synthesis with controlled placement of crystalline seeds

InactiveUS7404857B2Narrow size distributionQuality improvementDrill bitsConstructionsOctahedronMetal catalyst

An improved method for synthesizing superabrasive particles provides high quality industrial superabrasive particles with high yield and a narrow size distribution. The synthesis method includes forming a substantially homogeneous mixture of raw material and catalyst material or layers of raw material and metal catalyst. A plurality of crystalline seeds is placed in a predetermined pattern in the mixture or one of the layers to form a growth precursor. The growth precursor is maintained at a temperature and pressure at which the superabrasive crystal is thermodynamically stable for a time sufficient for a desired degree of growth. Advantageously, the patterned placement of crystalline seeds and disclosed processes allow for production of various morphologies of synthetic diamonds, including octahedral and cubic diamonds, and improved growth conditions generally. As a result, the grown superabrasive particles typically have a high yield of high quality particles and a narrow distribution of particle sizes.

Owner:SUNG CHIEN MIN

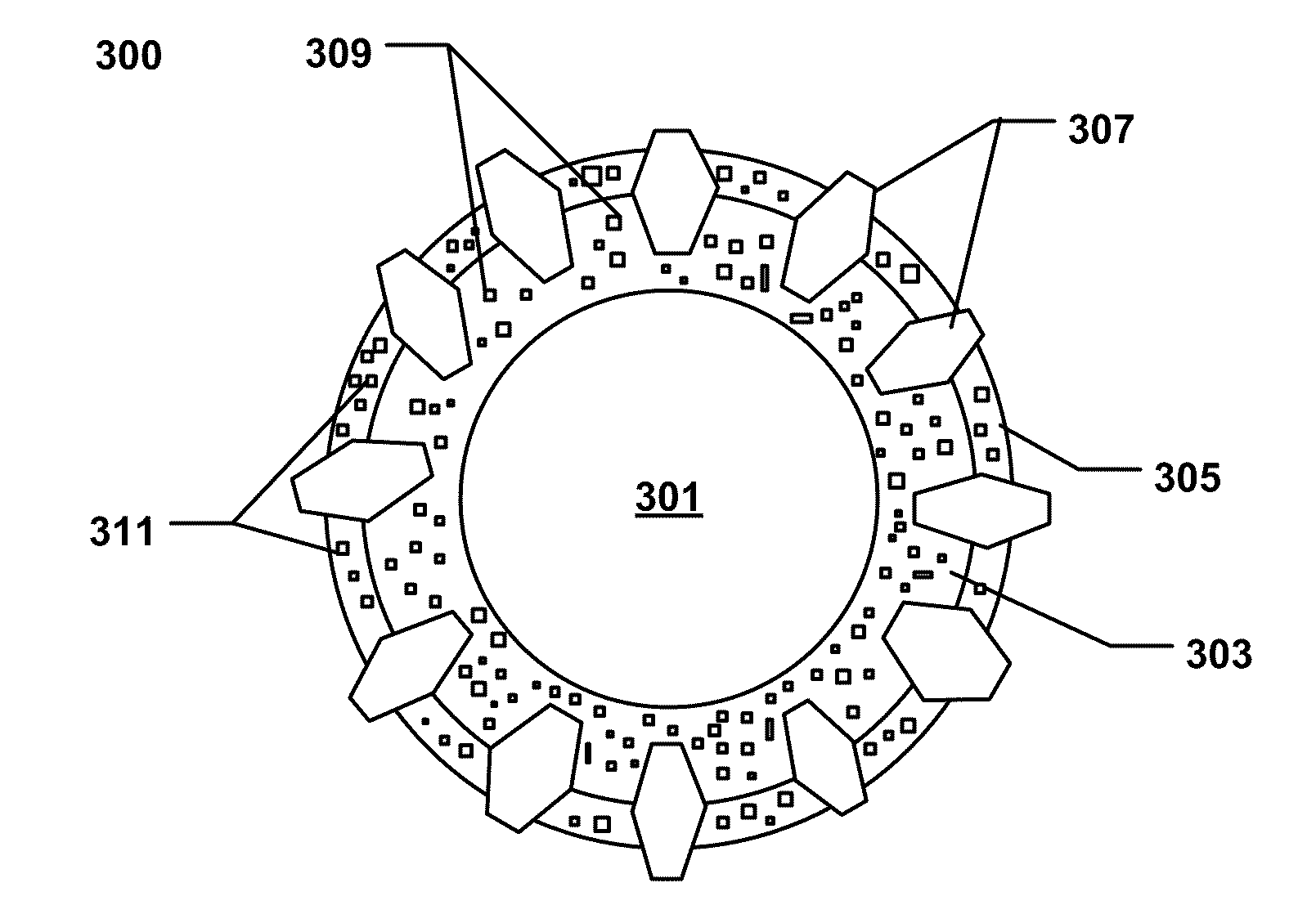

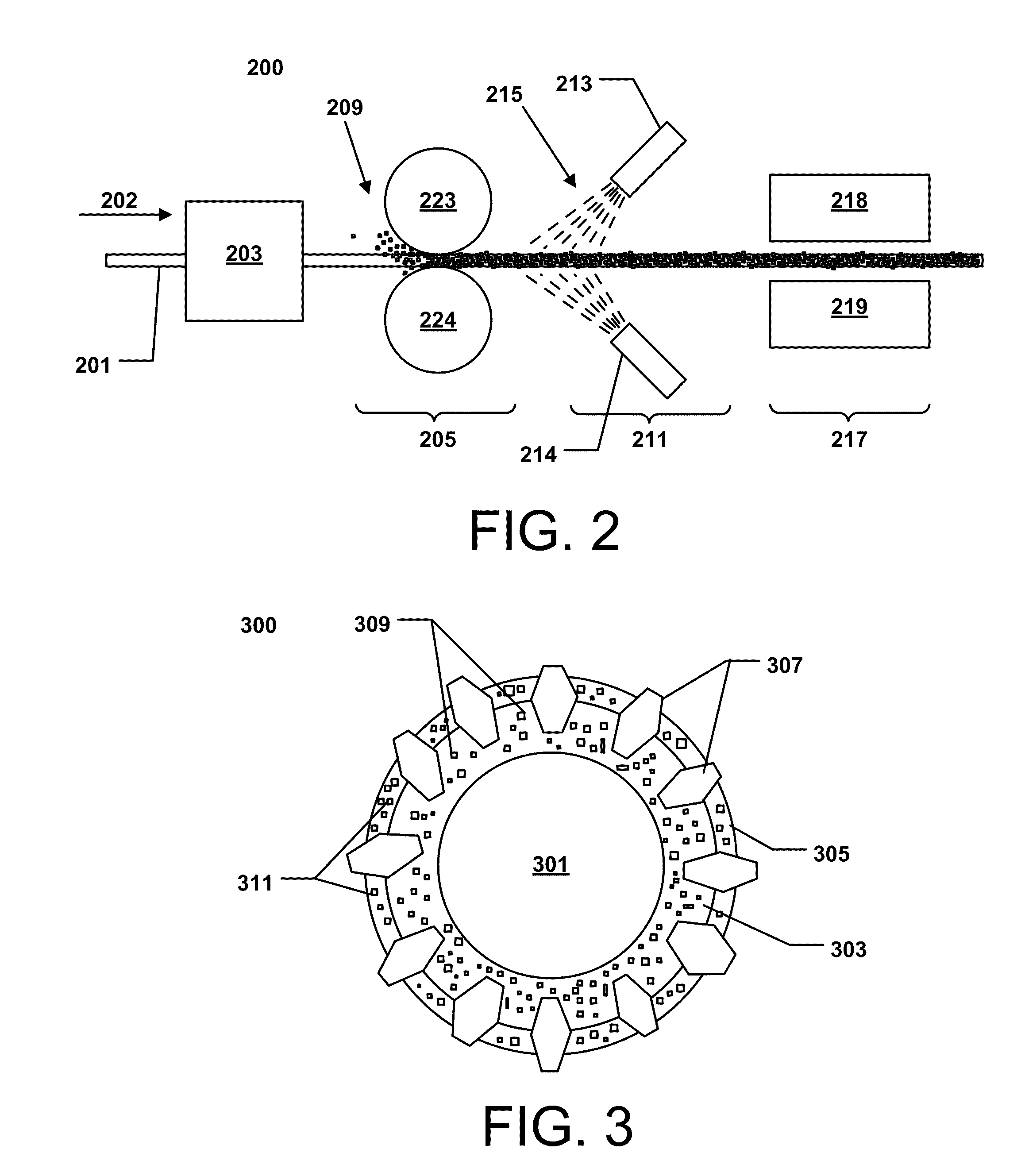

Abrasive articles including abrasive particles bonded to an elongated body

Owner:SAINT GOBAIN ABRASIVES INC +1

High pressure superabrasive particle synthesis

InactiveUS7323049B2Narrow size distributionQuality improvementDrill bitsConstructionsParticulatesSynthesis methods

An improved method for controlling nucleation sites during superabrasive particle synthesis can provide high quality industrial superabrasive particles with high yield and a narrow size distribution. The synthesis method can include forming a raw material layer, forming a particulate catalyst layer adjacent the raw material layer, and placing crystalline seeds in a predetermined pattern at least partially in the catalyst layer or raw material layer to form a growth precursor. Alternatively, the raw material and catalyst material can be mixed to form a particulate crystal growth layer and then placing the crystalline seeds in a predetermined pattern in the growth layer. Preferably, seeds can be substantially surrounded by catalyst material. The growth precursor can be maintained at a temperature and pressure at which the superabrasive crystal is thermodynamically stable for a time sufficient for a desired degree of growth. The crystalline seeds can be placed in a predetermined pattern using a template, a transfer sheet, vacuum chuck or similar techniques. The superabrasive particles grown using the described methods typically have a high yield of high quality industrial particles and a narrow distribution of particle sizes.

Owner:SUNG CHIEN MIN

Method for preparing metal binding agent diamond scroll saw

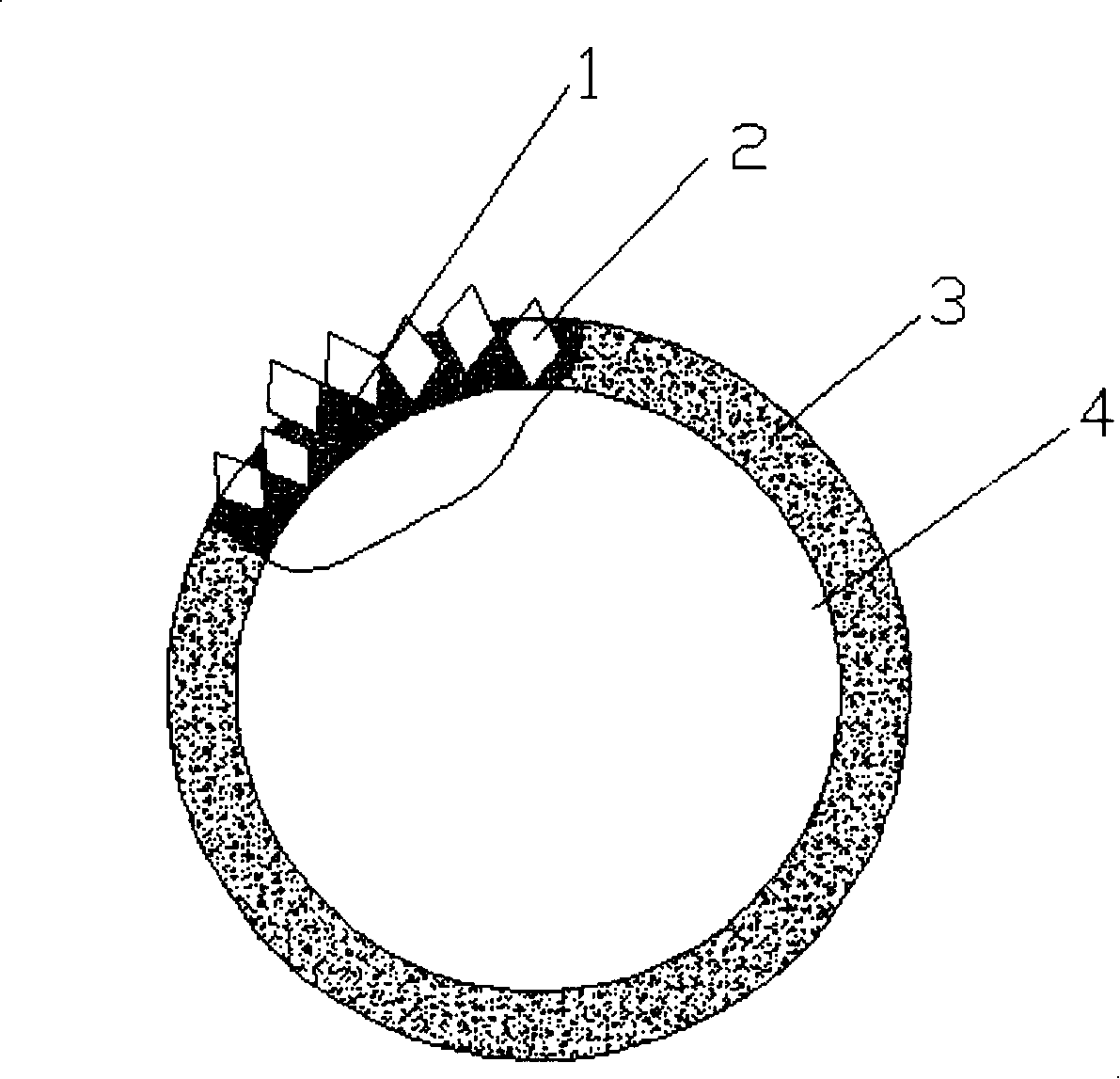

InactiveCN101209505ATo achieve the purpose of cuttingImprove bindingMetal sawing tool makingMetal sawing toolsDiamond wire sawDiffusion reaction

The invention provides a preparation method and the product of a metal binder diamond wire saw, comprising the preparation steps of (1) steel wire surface, (2) plating auxiliary disposal of the steel wire, (3) burdening, (4) plating of steel wire and (5) post-processing. The thickness of the binder coating ranges from 1 / 2 to 2 / 3 of the grain diameter of the diamond. By a series of chemical and diffusion reaction, the surface of the steel wire is covered by a layer of uniform and firm coating 3; a diamond mill grain 2 is also uniformly held in a metal binding layer 1, thus achieving the cutting object.

Owner:ZHEJIANG UNIV OF TECH

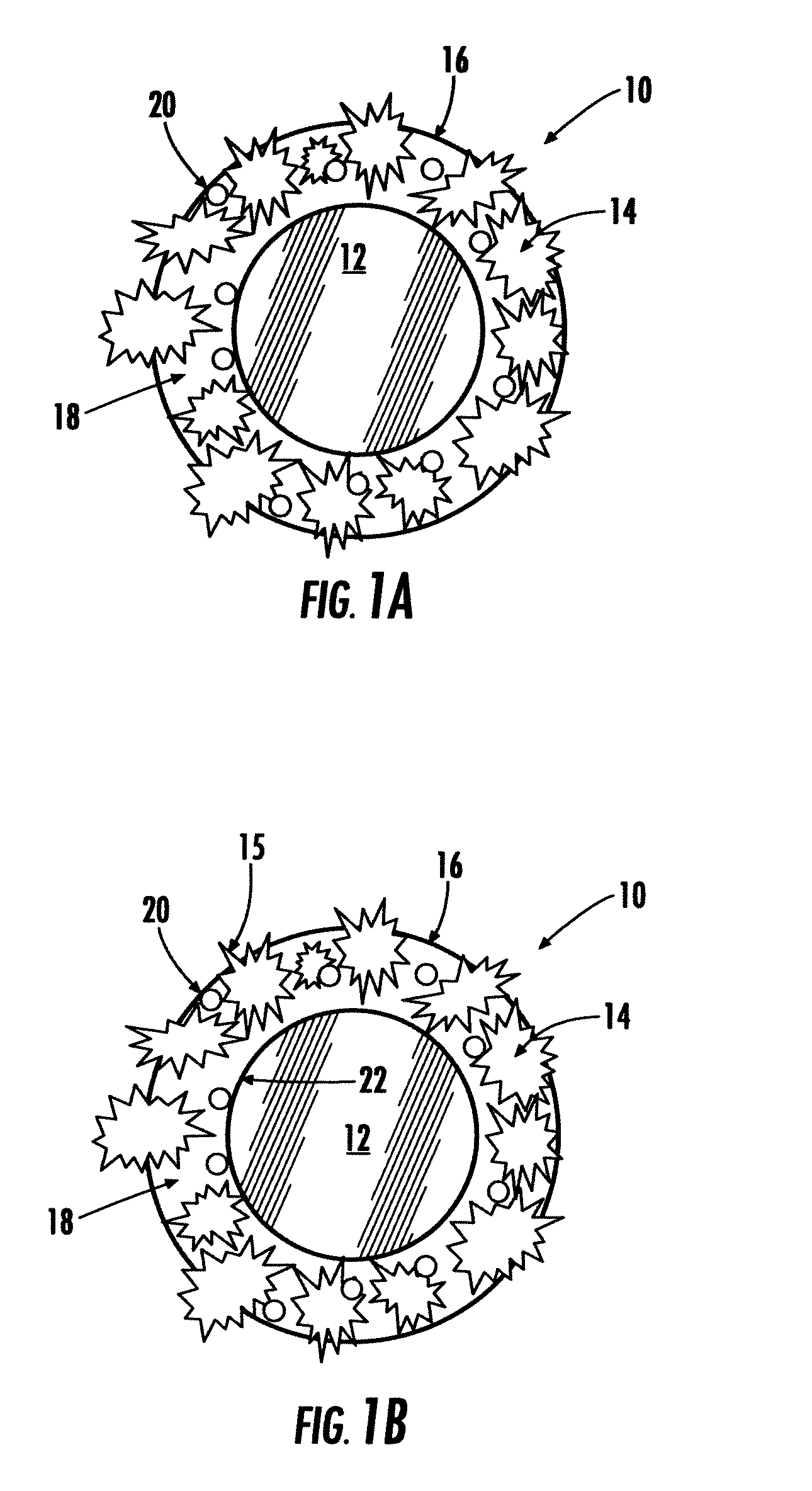

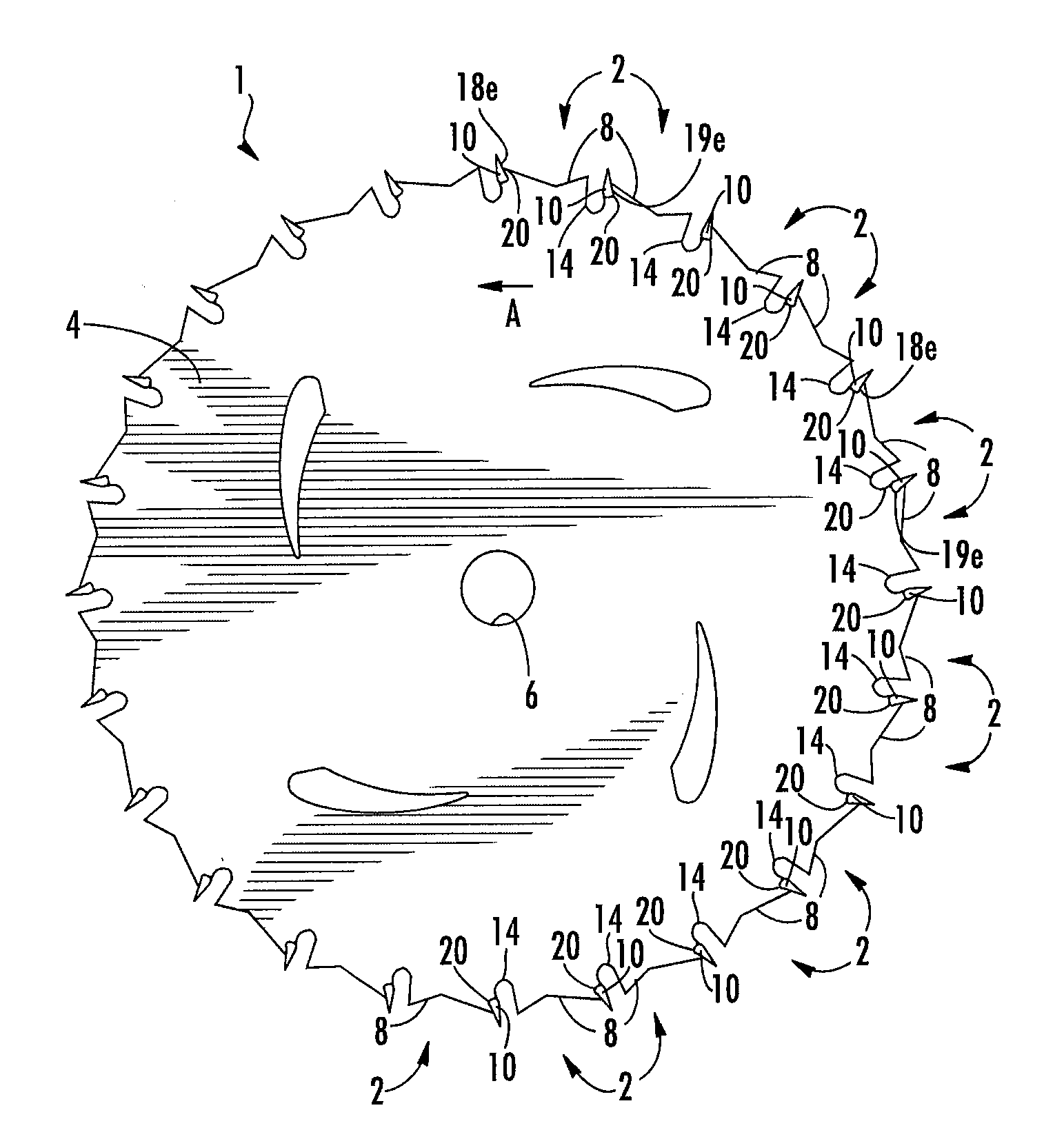

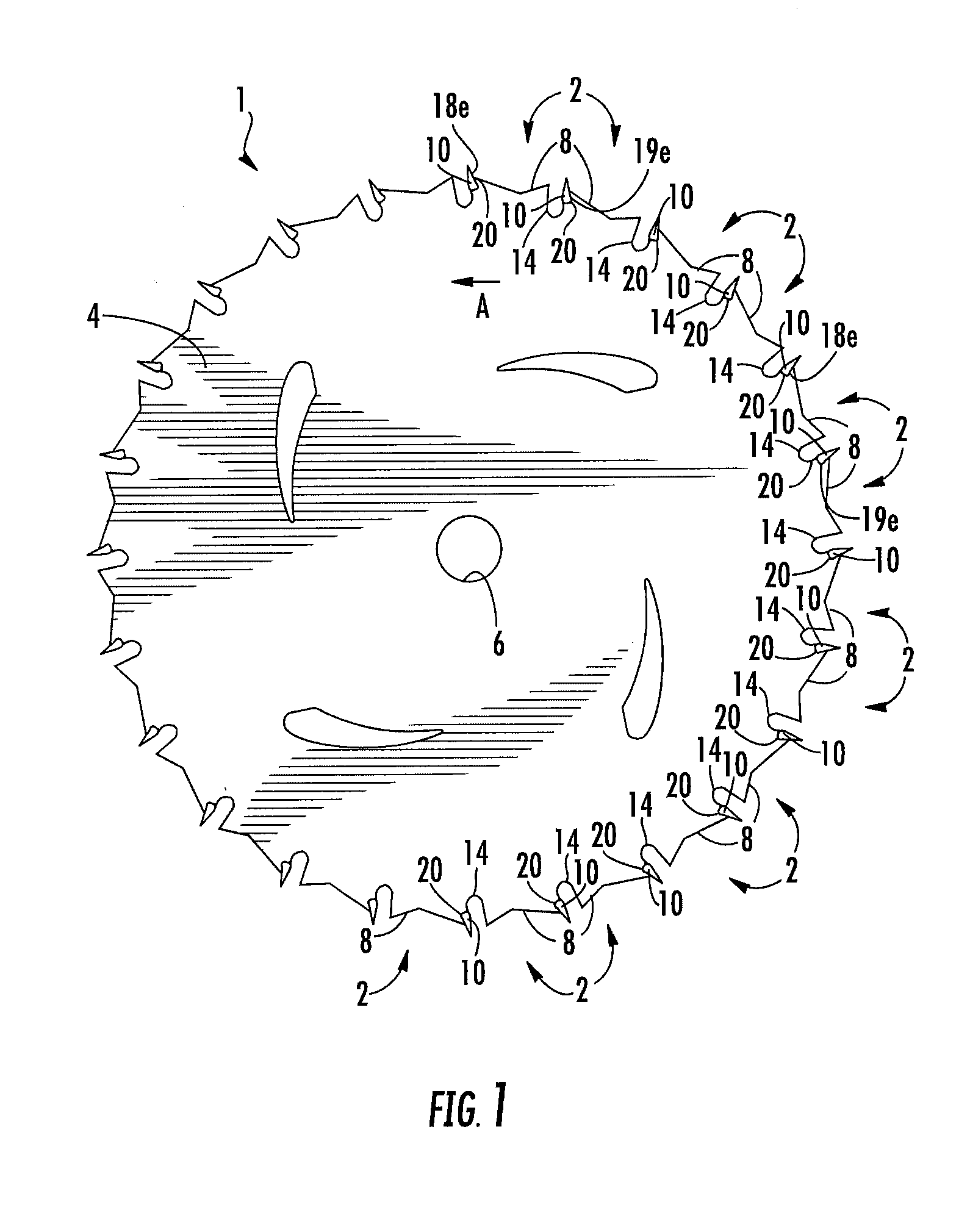

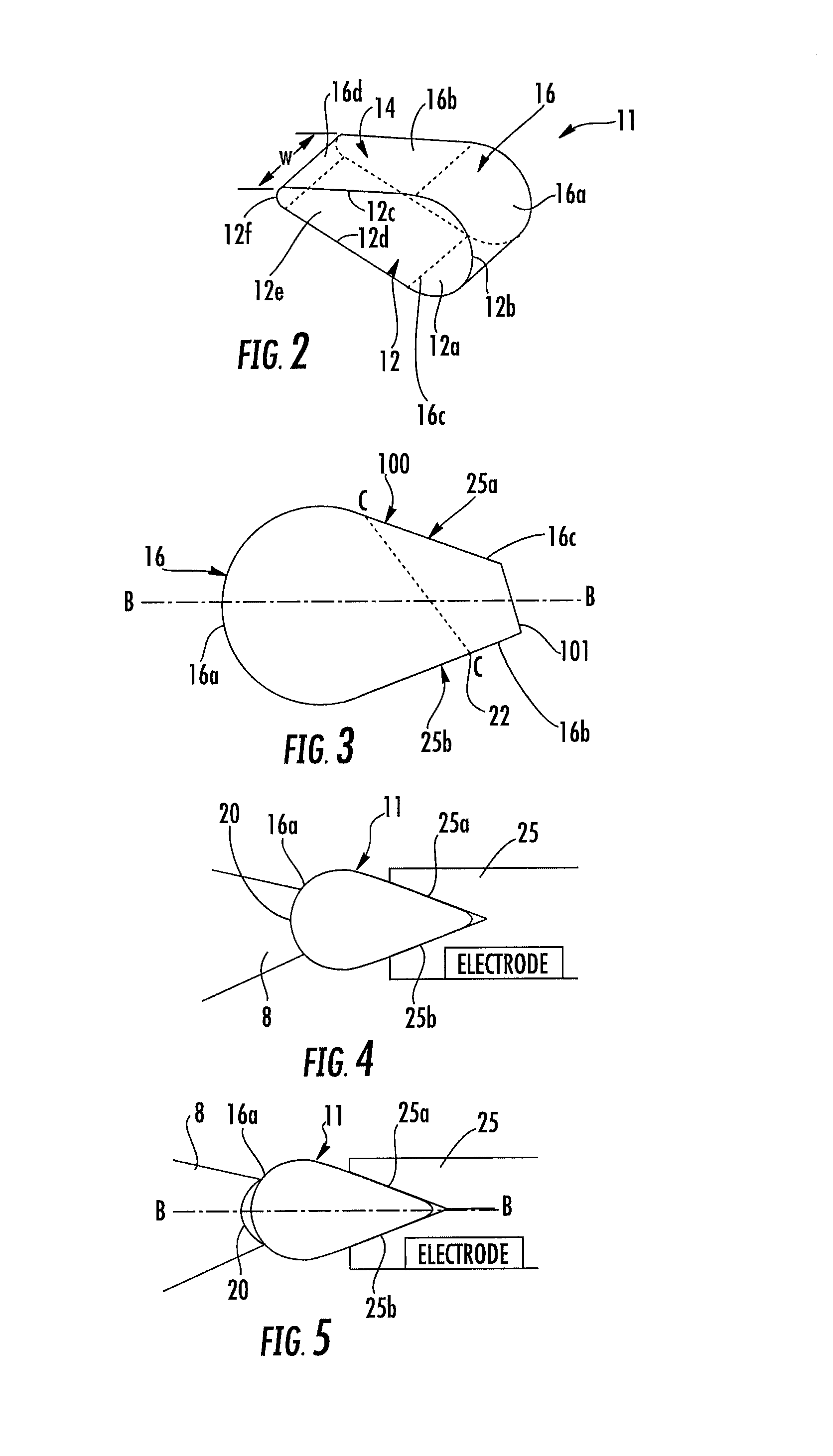

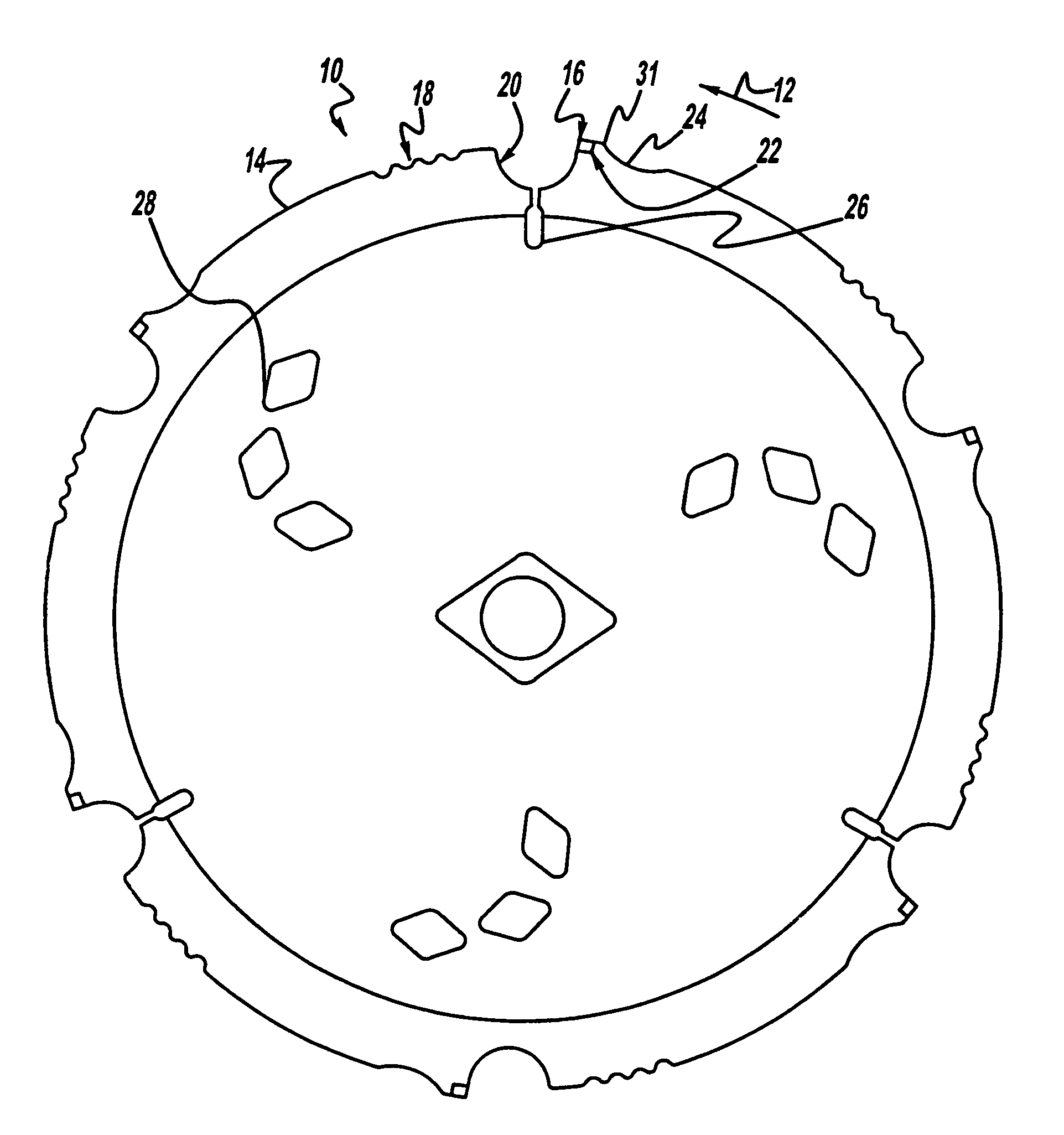

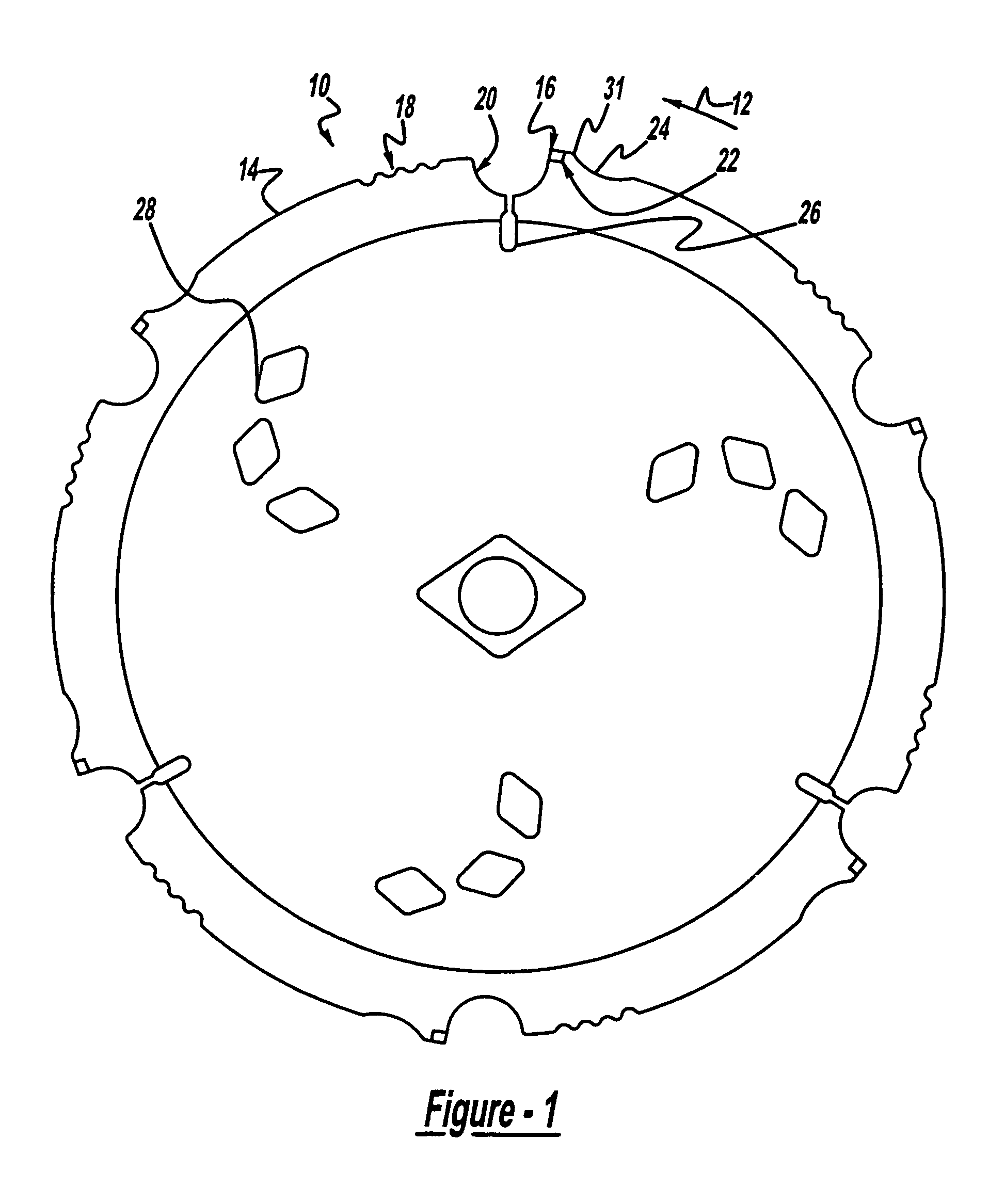

Saw blade for cutting fiber cement

InactiveUS7117863B1Reduce the amount requiredReduce the level of dustRevolution surface grinding machinesAnimal feeding devicesFiberCircular saw

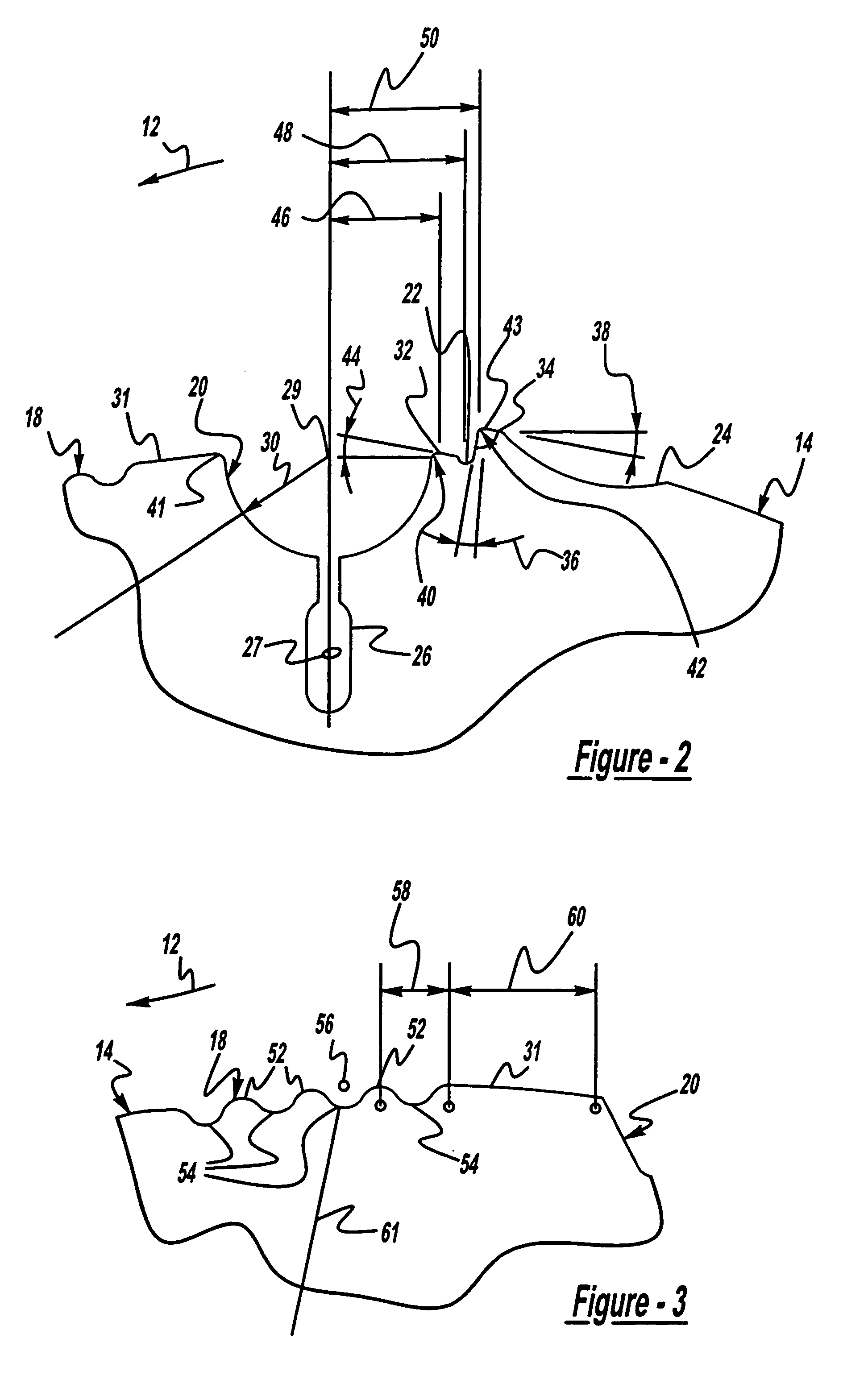

An improved circular saw blade designed for cutting fiber cement workpieces, which are becoming more and more prevalent on the construction site, includes a PCD / carbide tip (16) mounted in the rim (31) of the saw blade (10) at six, rather than the usual for locations, equally spaced around the blade. The tips are mounted adjacent a relatively large-diameter, semi-circular gullet (20), which itself is preceded by a chip and dust minimizer (18). The minimizer includes several alternating hills (52) and valleys (54) formed in the rim of the saw blade, each hill and valley having the same radius, producing a sinuous array essentially centered on the rim of the blade. It has been discovered that such a dust and chip minimizer reduces the level of dust and chips produced by the blade and clears the same from the kerf generated in the blade-workpiece interface. Ideally, all of the parameters and relief angles for the surfaces on the saw blade tip can be generated by cutting an array of such tips from a large-diameter blank (110) of PCD fused to a layer of tungsten carbide (72), and by mounting the tips onto the blade in such an orientation as to present, preferably, a negative hook or rake angle (74) to the workpiece.

Owner:BLACK & DECKER INC

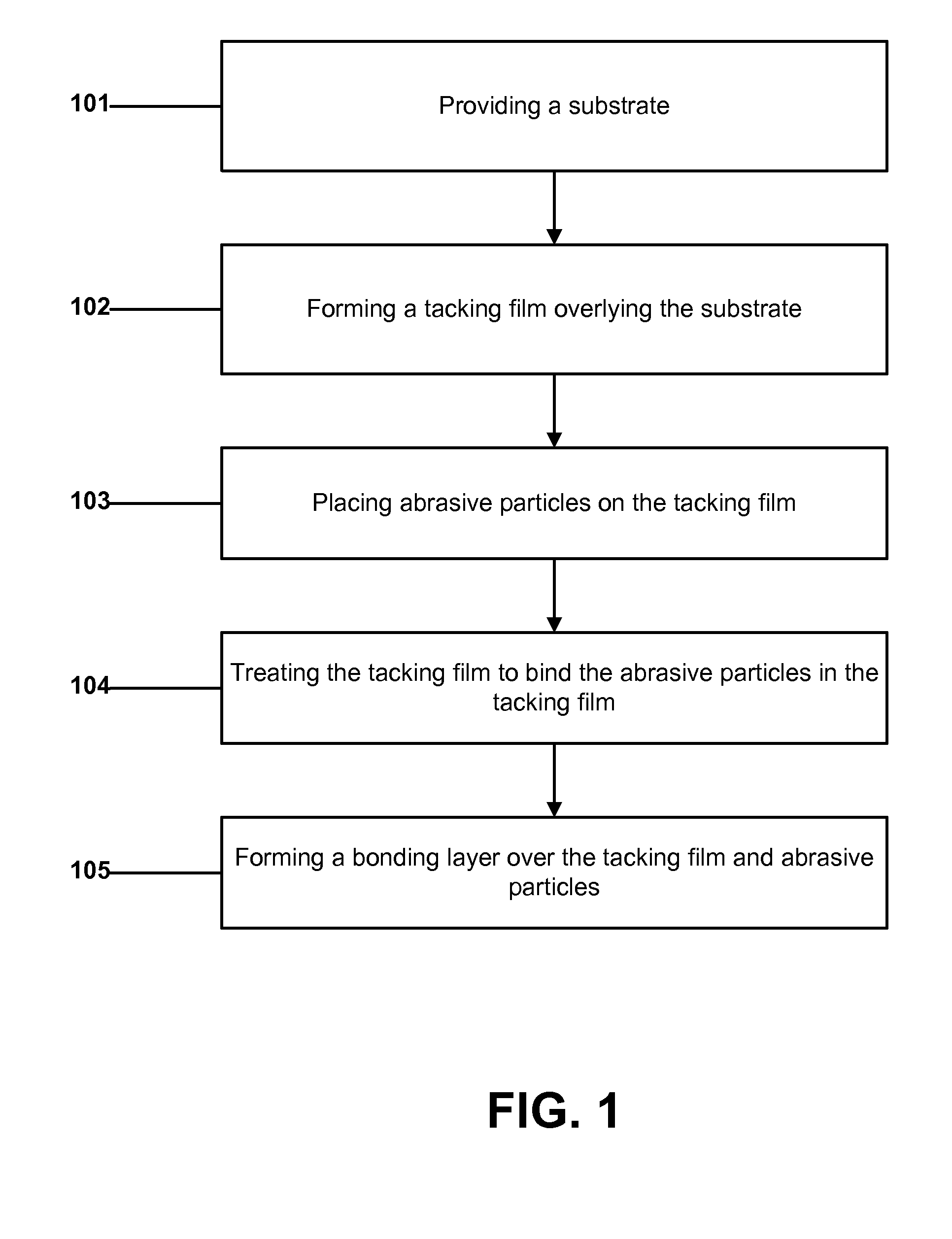

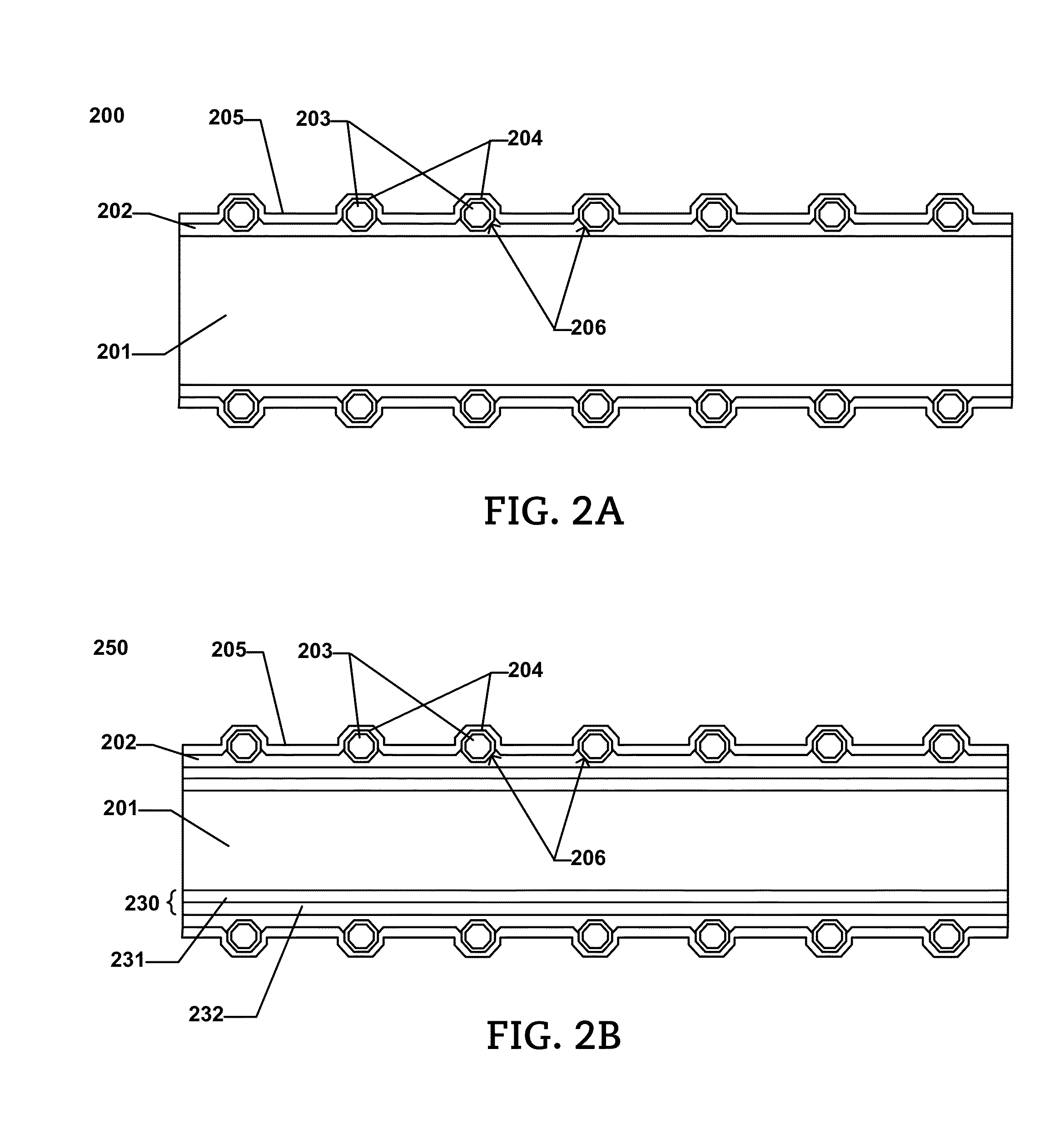

Abrasive article and method of forming

An abrasive article having a substrate, a tacking film overlying the substrate, abrasive particles comprising a coating layer bonded to the tacking film such that a bond between the coating layer and the tacking film defines a metallic bonding region, and a bonding layer overlying the abrasive particles and the tacking film,

Owner:SAINT GOBAIN ABRASIVES INC +1

Abrasive articles including abrasive particles bonded to an elongated body, and methods of forming thereof

An abrasive article includes an elongated body, a bonding layer including a metal overlying a surface of the elongated body, and a coating layer including a polymer material overlying the boding layer. The abrasive article further includes abrasive grains contained within the bonding layer and coating layer, and wherein the bonding layer comprises an average thickness (tbl) at least about 40% of the average grit size of the abrasive grains.

Owner:SAINT GOBAIN ABRASIVES INC +1

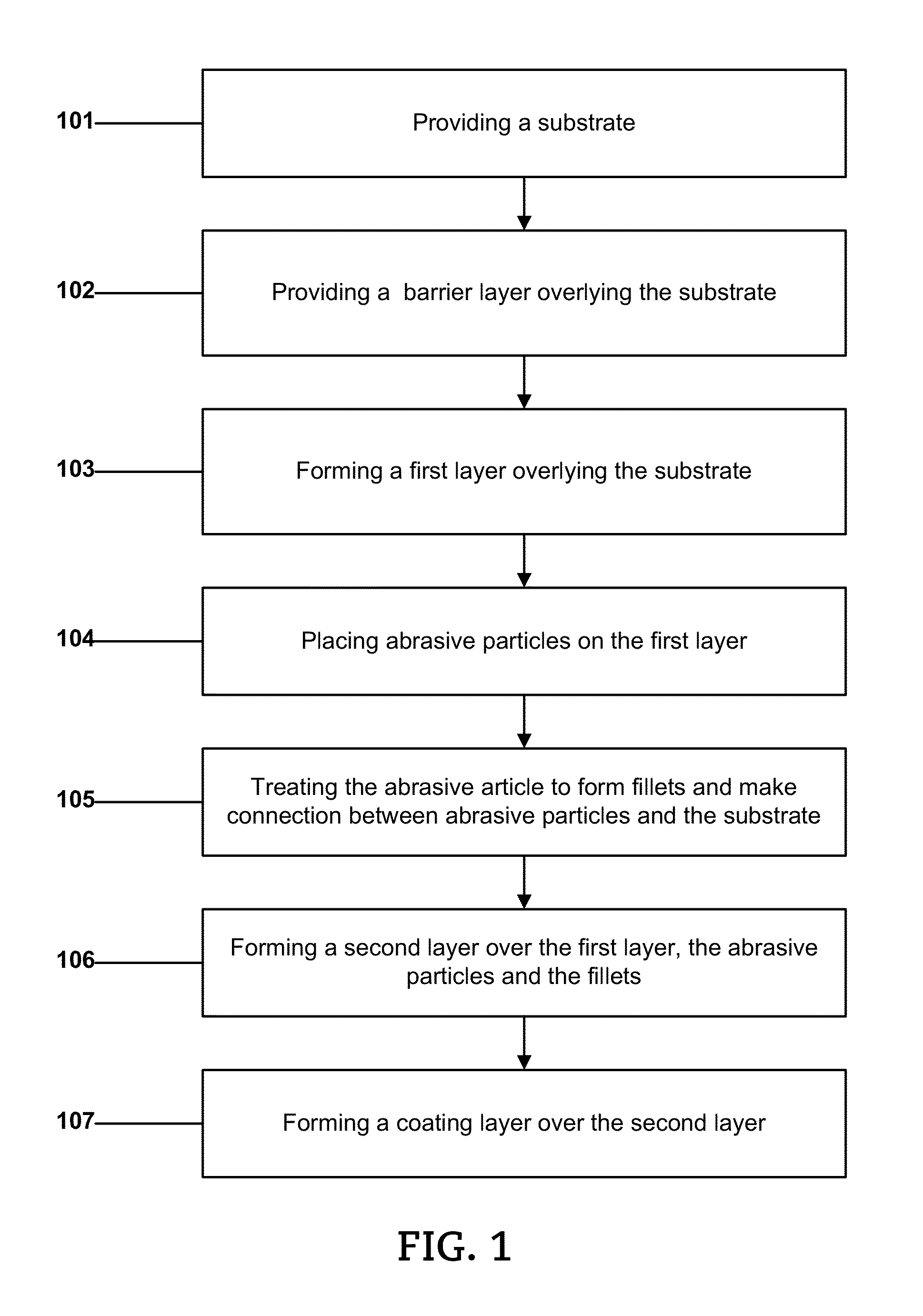

Abrasive Article and Method of Forming

An abrasive article including a substrate as an elongated member, a first layer overlying the substrate, abrasive particles overlying the first layer, fillets connecting the first layer and the abrasive particles, a bonding layer overlying the abrasive particles, the first layer and the fillets, and the fillets have a fillet characteristic relative to an abrasive application, the fillet characteristic selected from the group consisting of tacking factor (tfl / tf), a fillet-to-particle factor (tf / dab), a fillet-to-bonding layer factor (tf / tbl), a contact factor (Ab / Af), a fillet size variance (Vf), and a combination thereof.

Owner:SAINT GOBAIN ABRASIVES INC +1

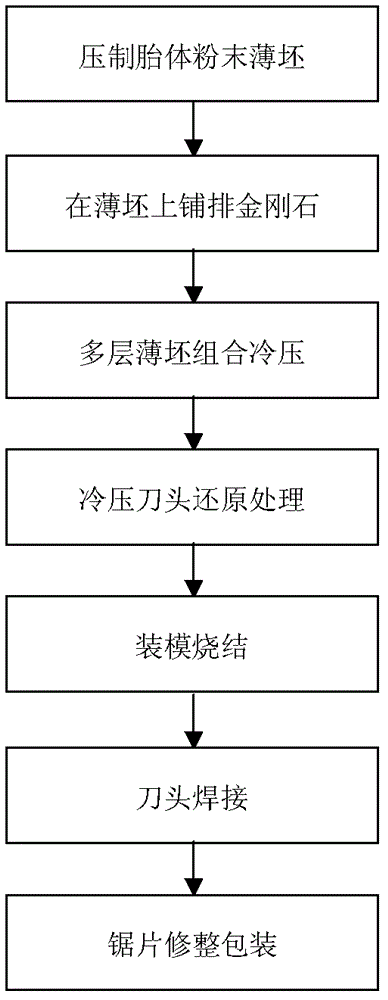

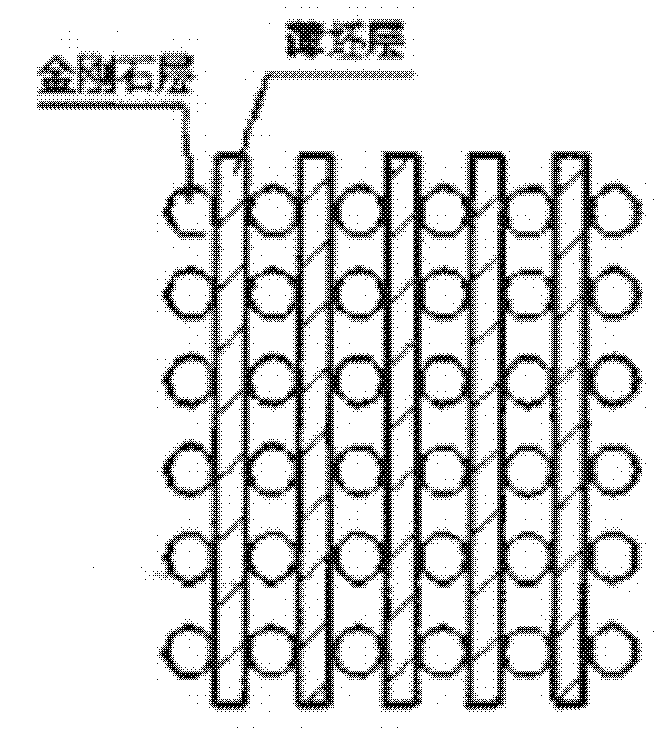

Manufacture method evenly distributing and orderly arranging diamond saw blades

InactiveCN103056450AImprove sharpnessExtended service lifeMetal sawing tool makingThree-dimensional spaceGraphite

The invention relates to a manufacture method evenly distributing and orderly arranging diamond saw blades. The manufacture method mainly resolves the problems that diamond saw blade segments are low in sharpness and short in service life caused by the fact that diamond particles are arranged and distributed unevenly and disorderly in existing diamond saw blade segments. The manufacture method includes the steps: enabling casing powder to be mixed evenly, manufacturing casing-sheet-shaped thin stocks through a cold-pressing forming technology; designing the methods of even distribution and order arrangement, adopting laser boring to manufacture red copper frameworks, spraying one layer of thin and special pressure-sensitive glue on the surfaces of the casing-sheet-shaped thin stocks, enabling the red copper frameworks to be placed on the surfaces of the casing-sheet-shaped thin stocks, and then enabling diamonds to be released on the red copper frameworks and using a steel flat plate to slightly sweep the diamonds, guaranteeing that a diamond can fall into each hole in each red copper framework, cleaning extra diamonds on the red copper frameworks, uncovering the red copper frameworks, due to the fact that pressure-sensitive agents on the casing-sheet-shaped thin stocks play a cementing action to the diamonds, and the diamonds can be fixed on the surface of the casing-sheet-shaped thin stocks and form even distribution and orderly arrangement; enabling the casing thin stocks with a multiple layers with the diamond particles to be overlapped together to combine metal segments to be installed inside a graphite mould, and forcing power-on sintering on a hot pressing machine. Therefore, the obtained diamond segments not only have the structure of even distribution and orderly arrangement of three-dimensional space, but also improve sharpness of the diamond blades and prolong service life of the diamond blades.

Owner:HUNAN FEIYUE NEW MATERIAL TECH

High-strength diamond saw blade

The present invention is a high-strength diamond saw blade, which includes a substrate and a diamond cutter head. The substrate of the diamond saw blade includes the following components by weight: 28-37 parts of copper powder, 0-5 parts of aluminum powder, and 2-6 parts of tin powder , 2-4 parts of zinc powder, 5-8 parts of rare earth, 15-18 parts of titanium powder, 11-15 parts of nickel powder, 8-12 parts of cobalt powder, 1-3 parts of manganese powder, 0-1 part of phosphorus powder, silicon 1-3 parts of vanadium powder, 0.2-0.9 parts of vanadium powder, 2-5 parts of silver powder, 2-6 parts of molybdenum powder, 0.1-2 parts of tungsten powder, 0.5-3 parts of chromium powder, and the rest are iron and unavoidable impurities; diamond The cutter head of the saw blade includes the following components by weight: copper powder 35‑40 parts, tin powder 8‑11 parts, zinc powder 1‑2 parts, titanium powder 6‑10 parts, diamond 13‑18 parts, iron powder 9‑ 14 parts, nickel powder 1-5 parts, rare earth 1-4 parts, tungsten powder 1-3 parts. The invention can effectively improve the cutting performance of the diamond saw blade, and has high strength, high wear resistance, firmness and durability, great pressure resistance and low cost.

Owner:JIANGSU SUPER PEAK TOOLS CO LTD

Process for making an annular abrasion bead element for a cutting wire for cutting relatively hard materials

InactiveUS20070194492A1Save materialCompetitive costMetal sawing tool makingMetal sawing toolsMetallic materialsMetal

The present invention relates to a process for making an annular abrasion bead element for a cutting wire for cutting relatively hard materials, comprising the following sequential steps: loading a mixture of metal material powder and abrasive granular material into at least one annular seat of a first mold; forming said mixture in said mold, thus obtaining at least one formed annular element with inner through opening (5); and sintering each formed annular element to obtain a finished annular abrasive element.

Owner:AROS

Starting Component For The Production Of Saw Blades Or Bands And Method For The Production Thereof

The present invention relates to a precursor component for the manufacturing of saw blades respectively saw bands, a method for the production of this precursor component, as well as a method for the production of saw blades, respectively saw bands. The above mentioned precursor component comprises at least a pre-manufactured carrier band respectively a pre-manufactured carrier disc, preferably a steel band respectively a steel disc and at least one pre-manufactured segment comprising of a precursor material for a cutting contour of saw blades respectively saw bands, wherein the carrier band respectively the carrier disc as well as the segment comprise a first and second face side, respectively and the first face side is more narrow than the second face side; and wherein the at least one carrier band respectively the at least one carrier disc is connected with the at least one segment via its respective narrow face side, such that by means of a separation of the final precursor component along a separation line which runs through the at least one segment two bi-metal bands respectively bi-metal discs can be generated which comprise one part of the at least one segment, respectively.

Owner:BOEHLER UDDEHOLM PRECISION STRIP GMBH

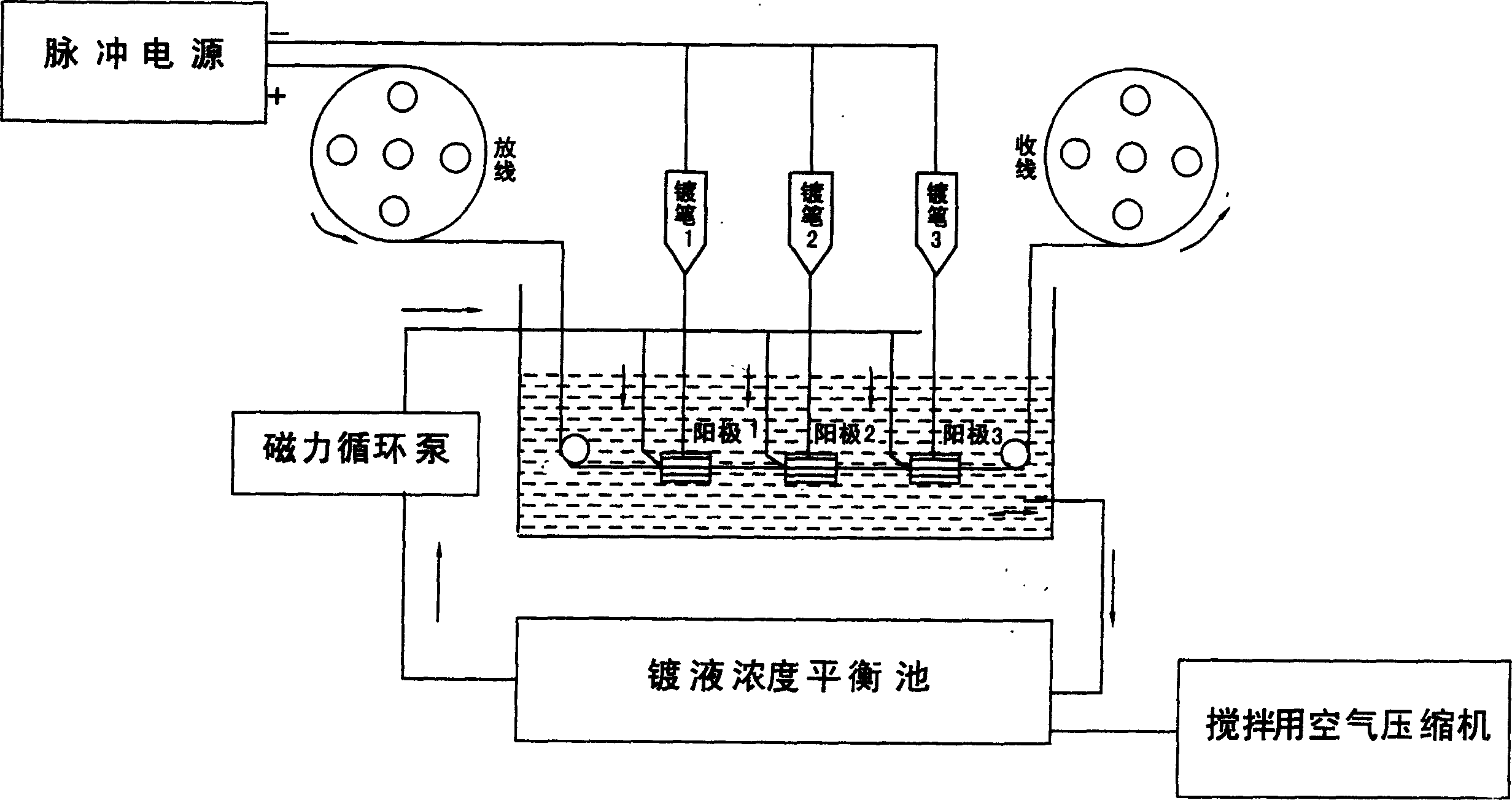

Apparatus for preparing stainless steel cutting line by composite electric spraying apparatus and method thereof

InactiveCN1583336AHigh tensile strengthNot easy to fall offMetal sawing tool makingMetal sawing toolsSpray methodManufacturing line

An apparatus for preparing the stainless steel-diamond wire used to cut crystal steel by electric coat-spray method is composed of pulse power supply, coating pen, magnetic circulating pump, plating liquid concentration balancing pool, air compressor, and wire paying off and winding unit. Its method includes such steps as washing stainless steel wire, heat treating, washing, coating while spraying, testing, heat treating, washing and examining.

Owner:SHENYANG CITY JINGTONG DIAMOND COMPOSITE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com