Apparatus for preparing stainless steel cutting line by composite electric spraying apparatus and method thereof

A diamond cutting wire and stainless steel technology, which is applied in the manufacture of grinding devices, knives of sawing machine devices, and tool manufacturing of sawing machine devices, can solve the problem of high process cost and achieve the effect of simple process, good wear resistance, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

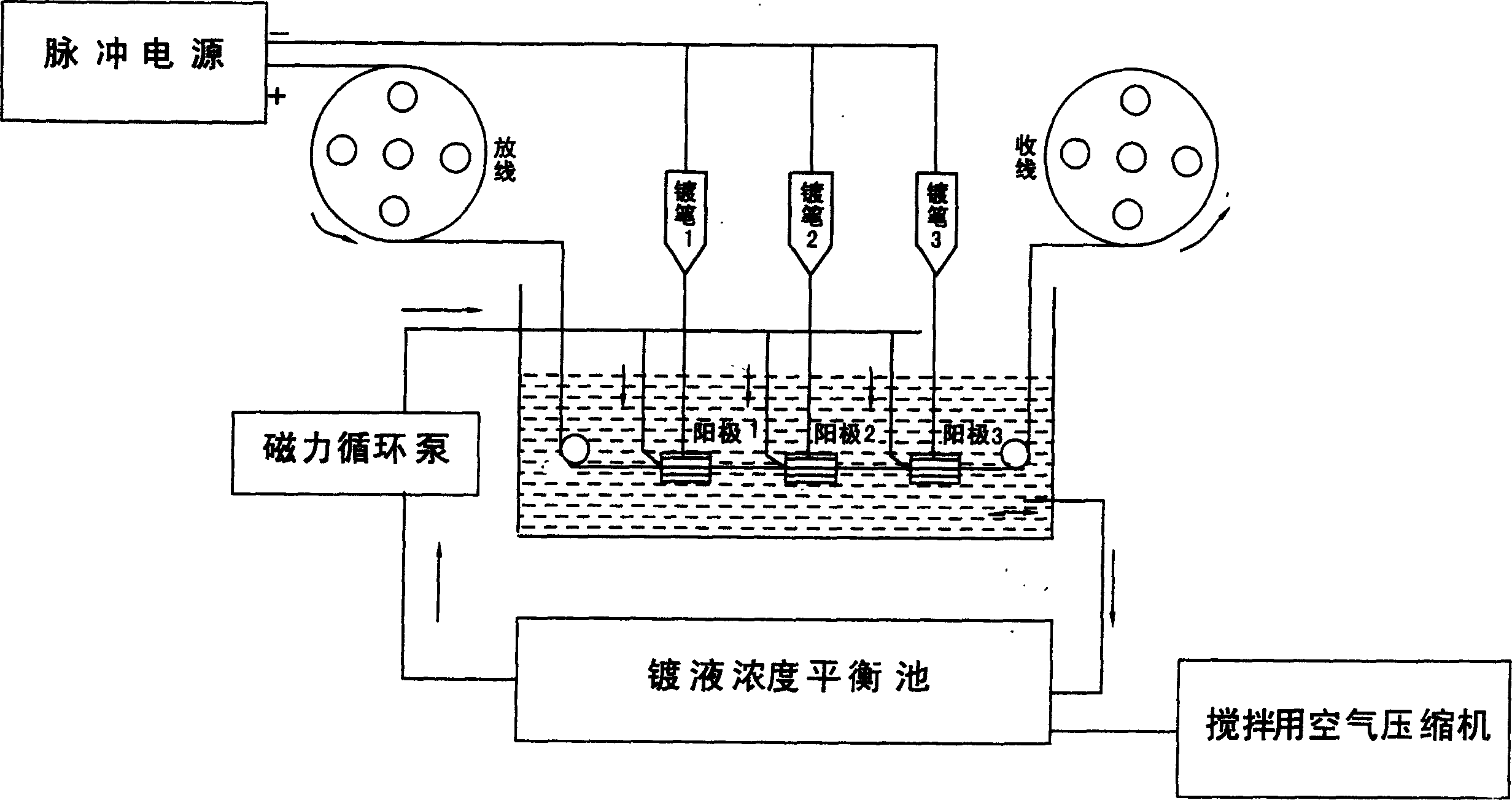

Method used

Image

Examples

Embodiment 1

[0017] Take nickel sulfate 100 kg / kl, nickel chloride 5 kg / kl, sodium hypophosphite 20 kg / kl, sodium sulfate 20 kg / kl, sodium acetate 10 kg / kl, sodium citrate 3 kg / kl liters, lactic acid 60 kg / kl, diamond powder mixed particles 5-100μm 20 kg / kl. The pH value of the above-mentioned solution is between 1.5 and 6, and the temperature is controlled between 70 and 90°C, and it is ready for use.

[0018] Clean the stainless steel wire (generally 0.1-1mm) for degreasing and impurity removal, heat treatment at a temperature of 200-500°C for about half an hour, and then clean it with water for de-impurity removal. When performing electrospraying, the winding wire passes through the cathode and anode plating solution pool, and the relative movement is 5-30 m / min, and then the coating is inspected. Generally, the thickness of the coating can be controlled between 5-80 μm. After testing, heat treatment is carried out at 200-500°C for about half an hour, and then cleaning with water to re...

Embodiment 2

[0021] Take nickel sulfate 150 kg / kl, nickel chloride 17.5 kg / kl, sodium hypophosphite 25 kg / kl, sodium sulfate 35 kg / kl, sodium acetate 15 kg / kl, sodium citrate 6.5 kg / kl liters, lactic acid 70 kg / kl, lead nitrate 0.0025 kg / kl, diamond powder mixed particles 5-100μm 60 kg / kl. The pH value of the above-mentioned solution is between 1.5 and 6, and the temperature is controlled between 70 and 90°C, and it is ready for use.

[0022] Clean the stainless steel wire (generally 0.1-1mm) for degreasing and impurity removal, heat treatment at a temperature of 200-500°C for about half an hour, and then clean it with water for de-impurity removal. When performing electrospraying, the winding wire passes through the cathode and anode plating solution pool, and the relative movement is 5-30 m / min, and then the coating is inspected. Generally, the thickness of the coating can be controlled between 5-80 μm. After testing, heat treatment is carried out at 200-500°C for about half an hour, an...

Embodiment 3

[0025] Take nickel sulfate 200 kg / kl, nickel chloride 20 kg / kl, sodium hypophosphite 30 kg / kl, sodium sulfate 50 kg / kl, sodium acetate 20 kg / kl, sodium citrate 10 kg / kl liters, lactic acid 80 kg / kl, lead nitrate 0.005 kg / kl, diamond powder mixed particles 5-100 μm 100 kg / kl, adjust the pH value between 1.5-6, control the temperature between 70-90°C, and reserve .

[0026] The stainless steel wire (generally 0.1-1mm) is degreased, de-impured, cleaned, heat-treated at a temperature of 200-500°C for about half an hour, and then cleaned with clean water for de-impurity. When performing electrospraying, the winding wire passes through the cathode and anode plating solution pool, and the relative movement is 5-30 m / min, and then the coating is inspected. Generally, the thickness of the coating can be controlled between 5-80 μm. After testing, heat treatment is carried out at 200-500°C for about half an hour, and then cleaning with water to remove impurities is carried out. After pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com