Patents

Literature

1740results about "Metal sawing tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

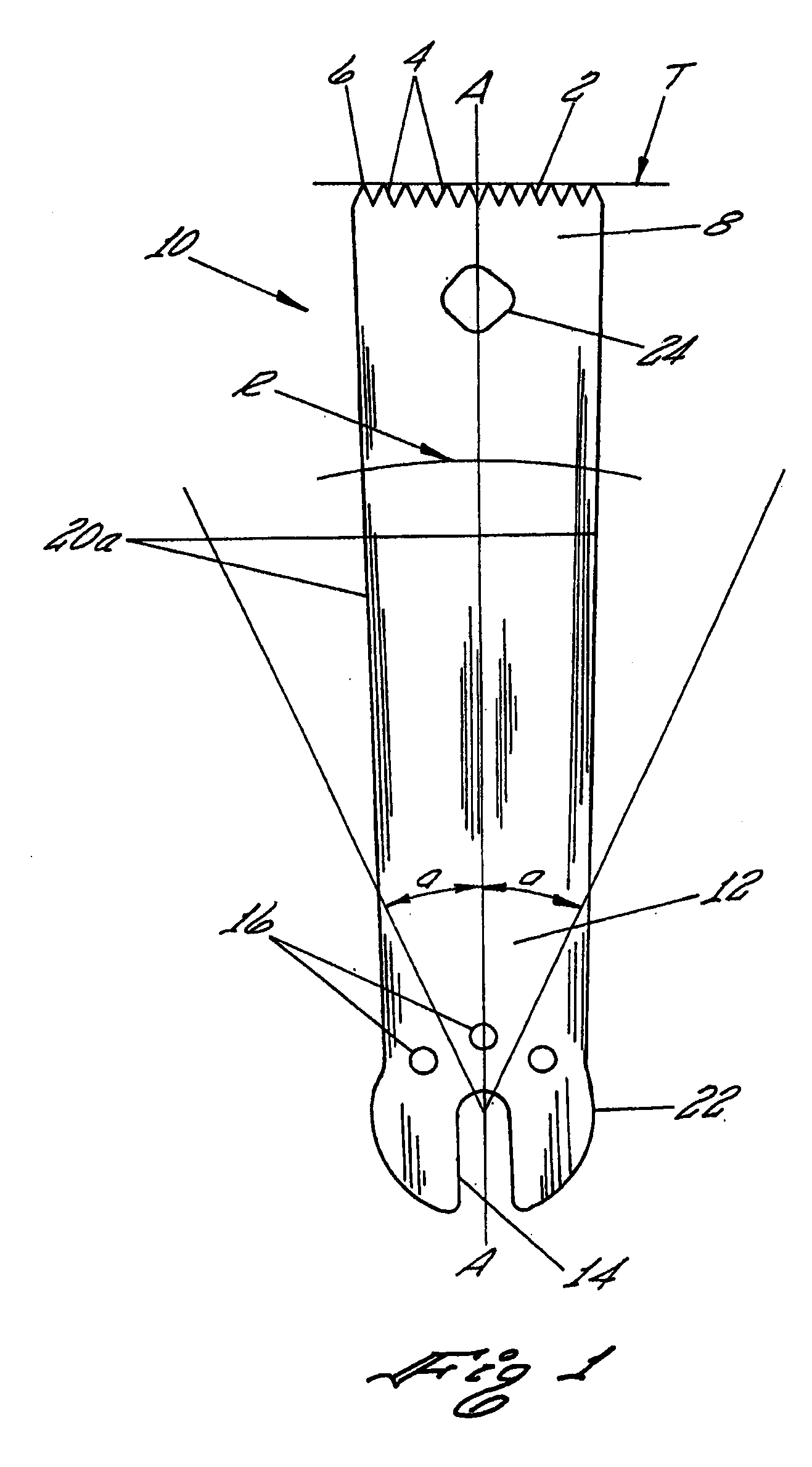

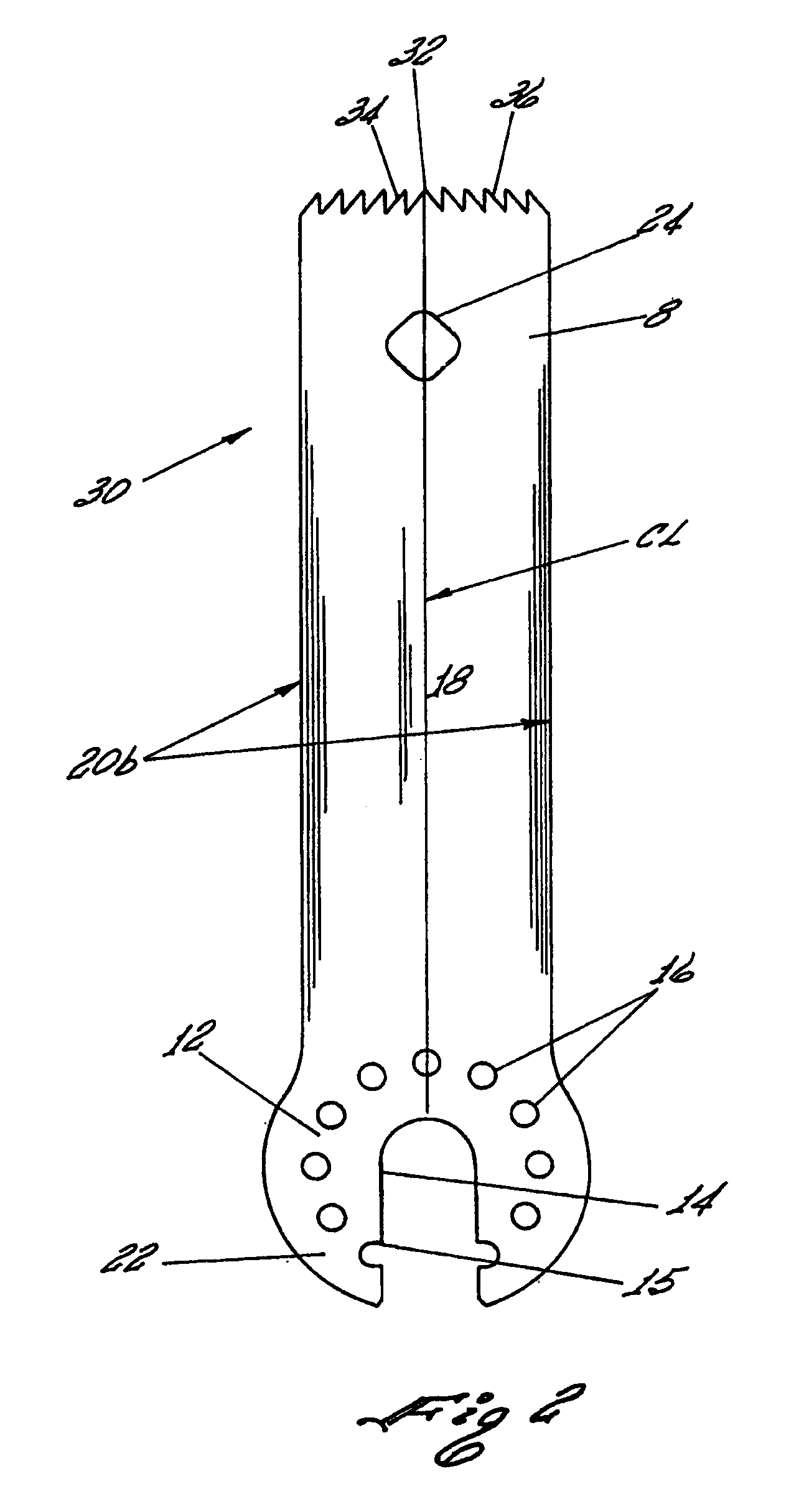

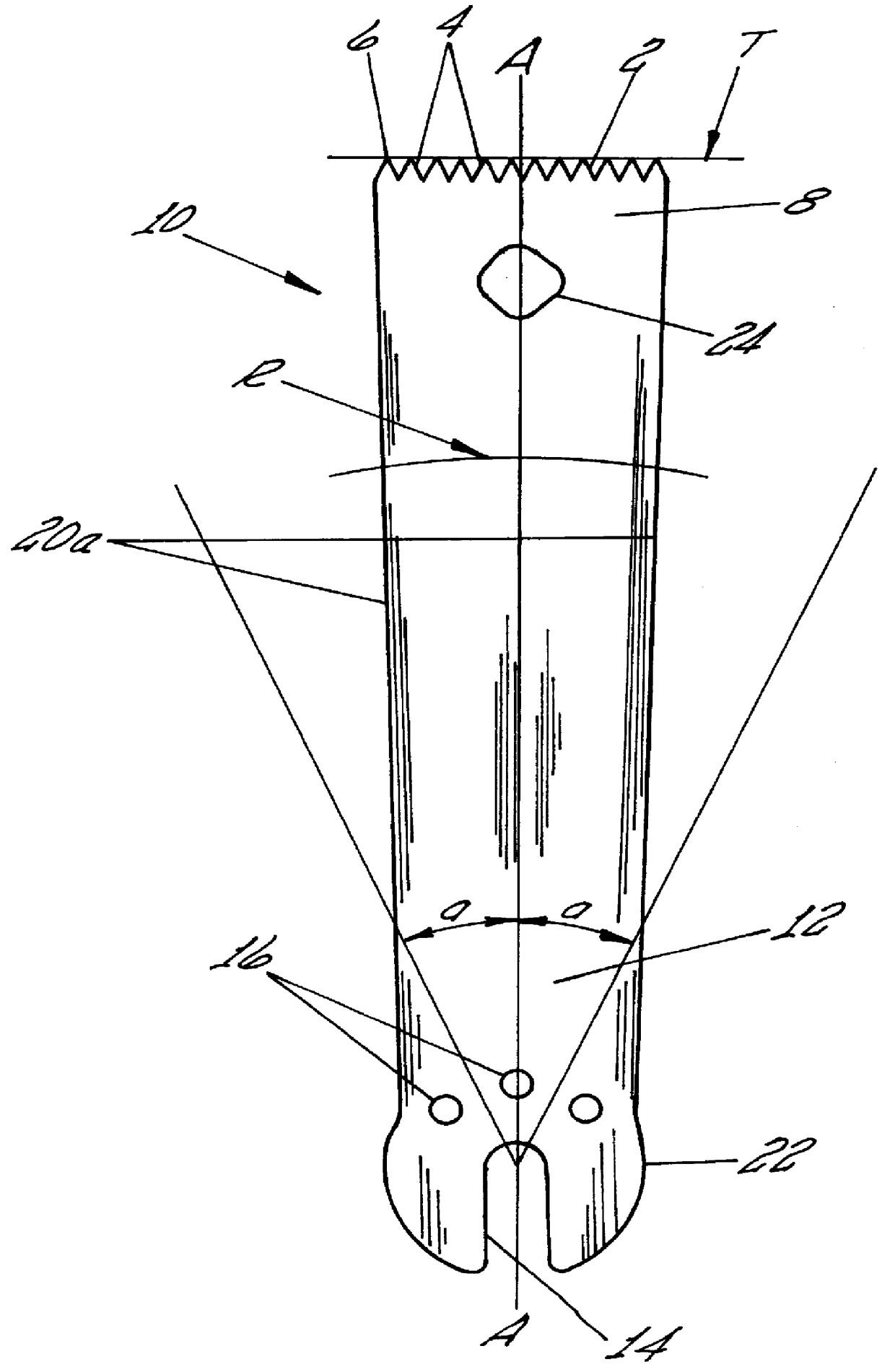

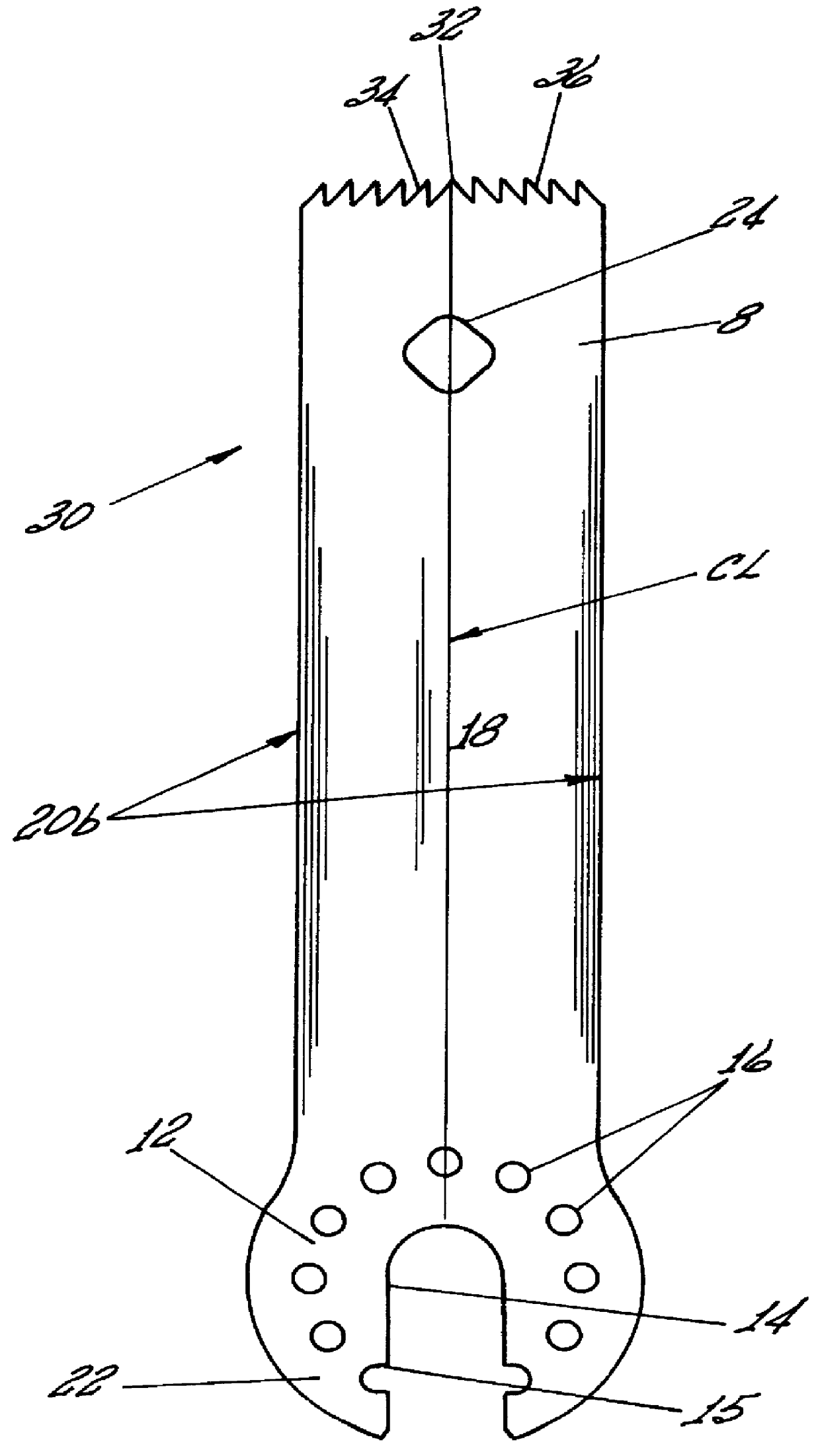

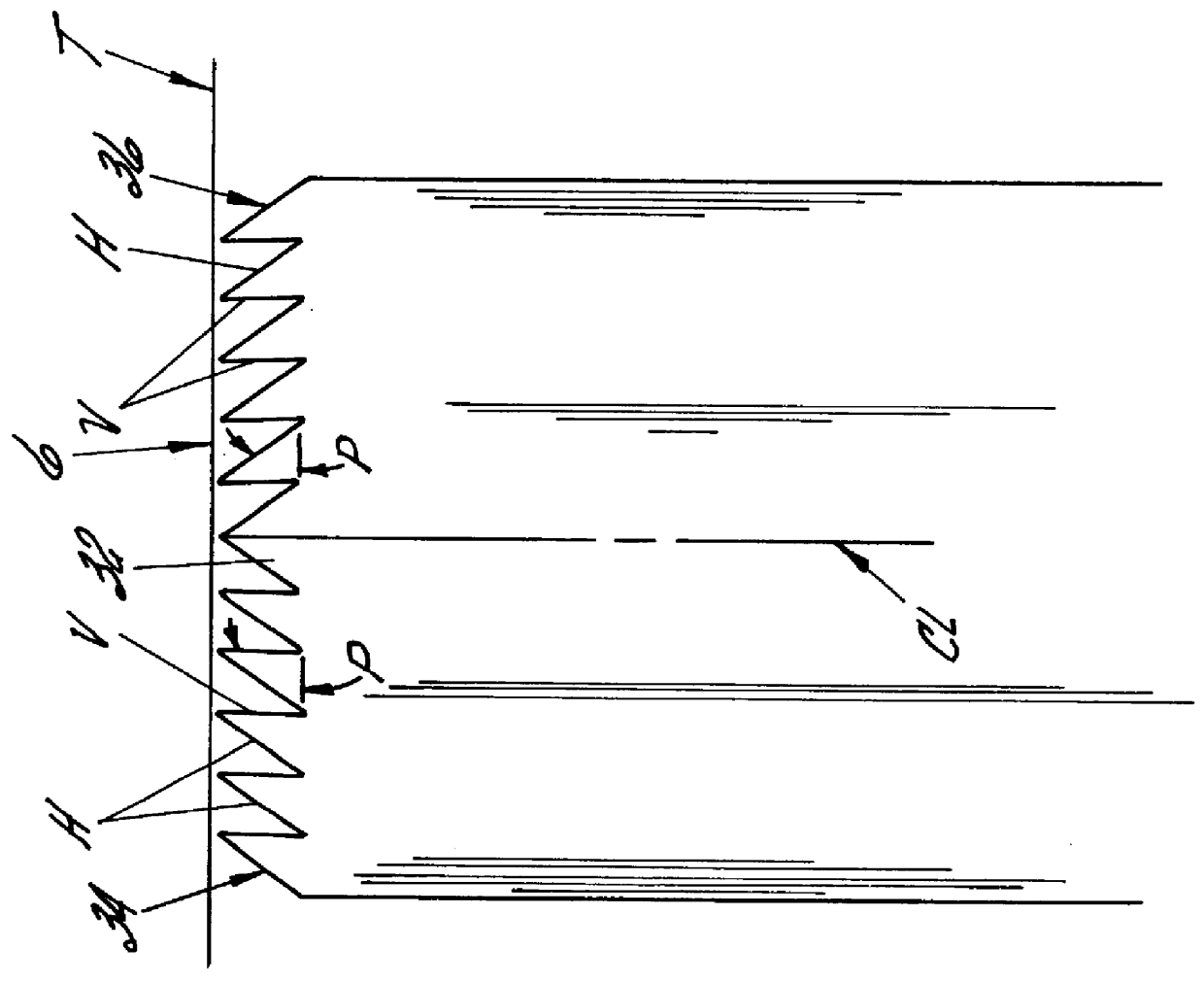

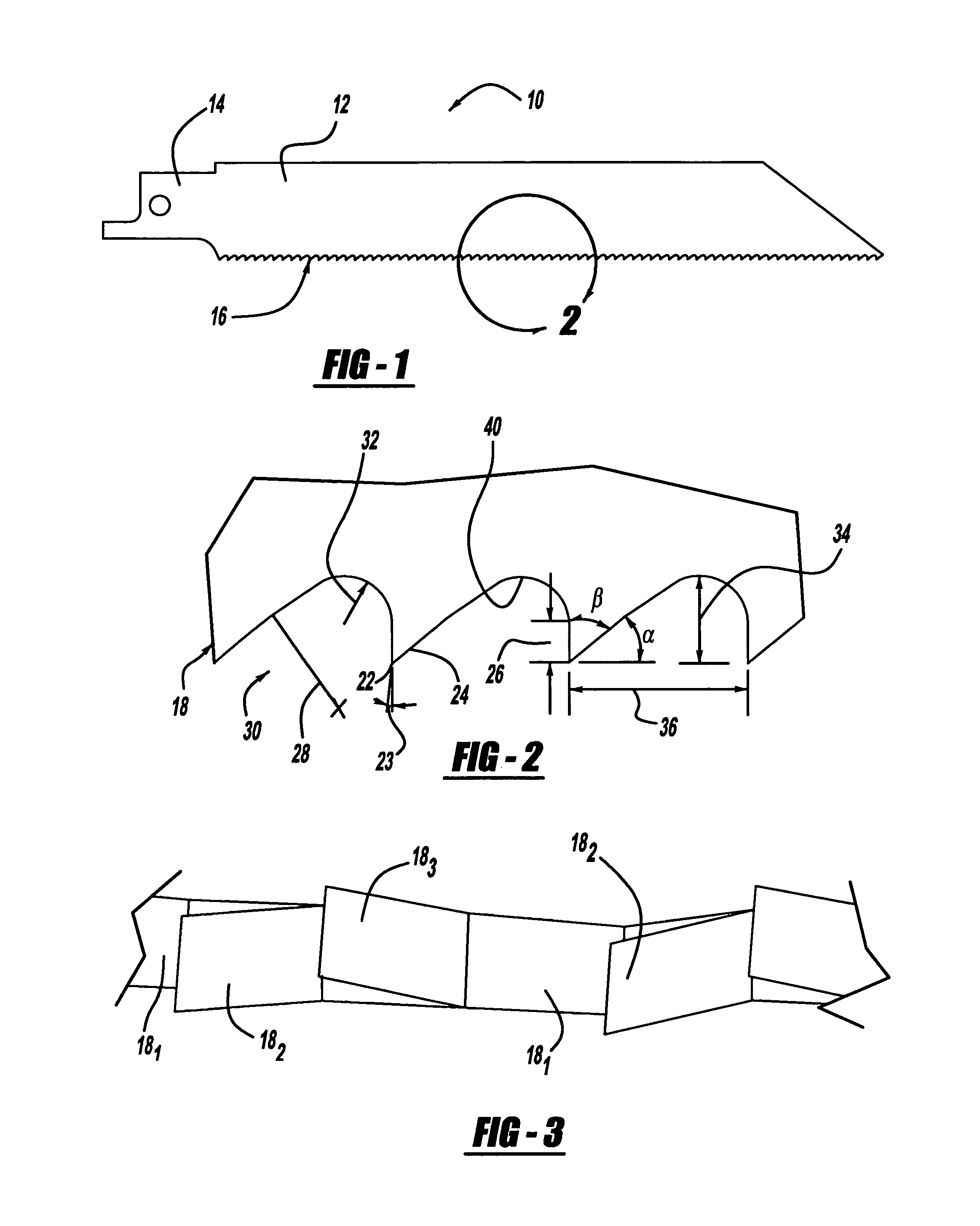

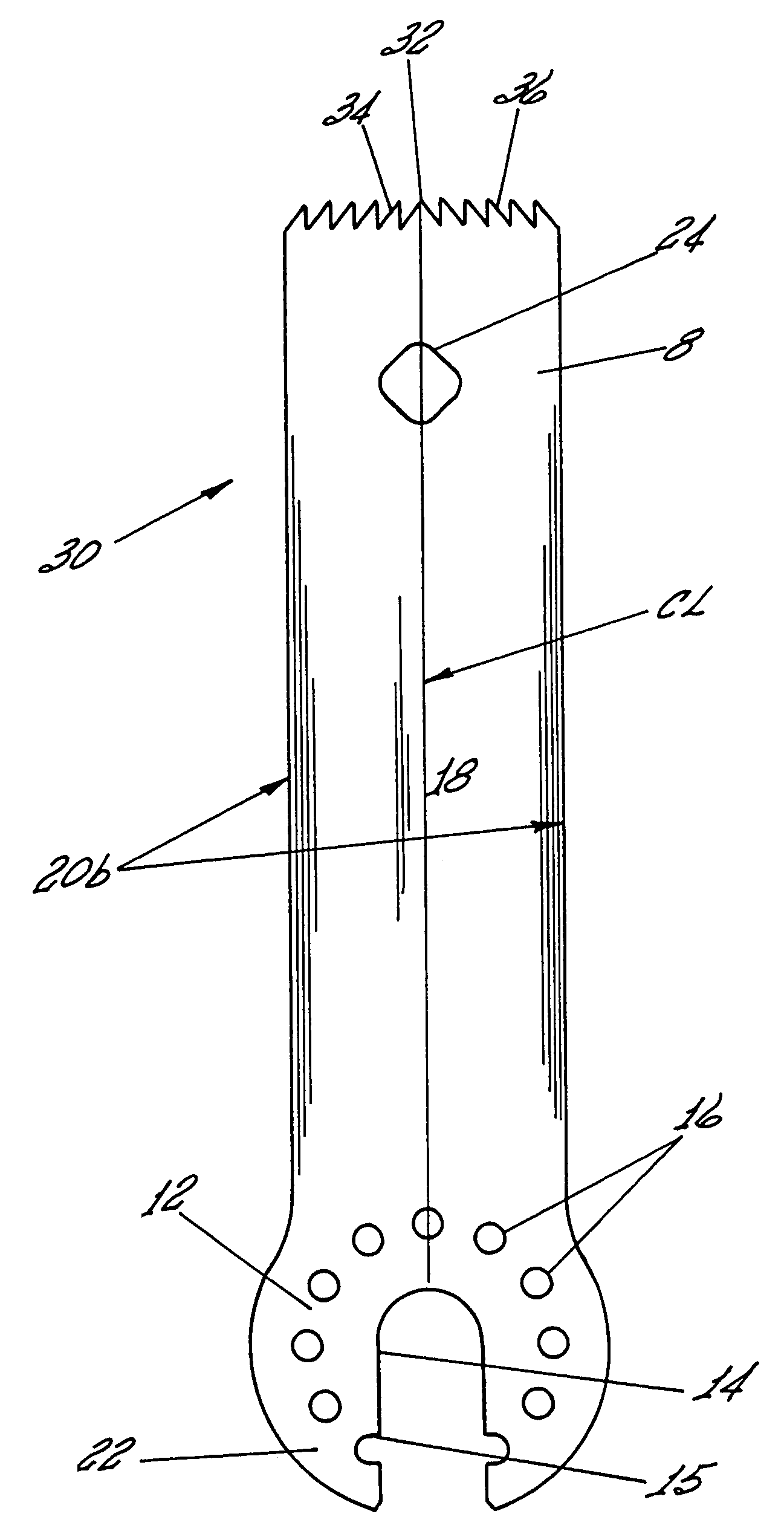

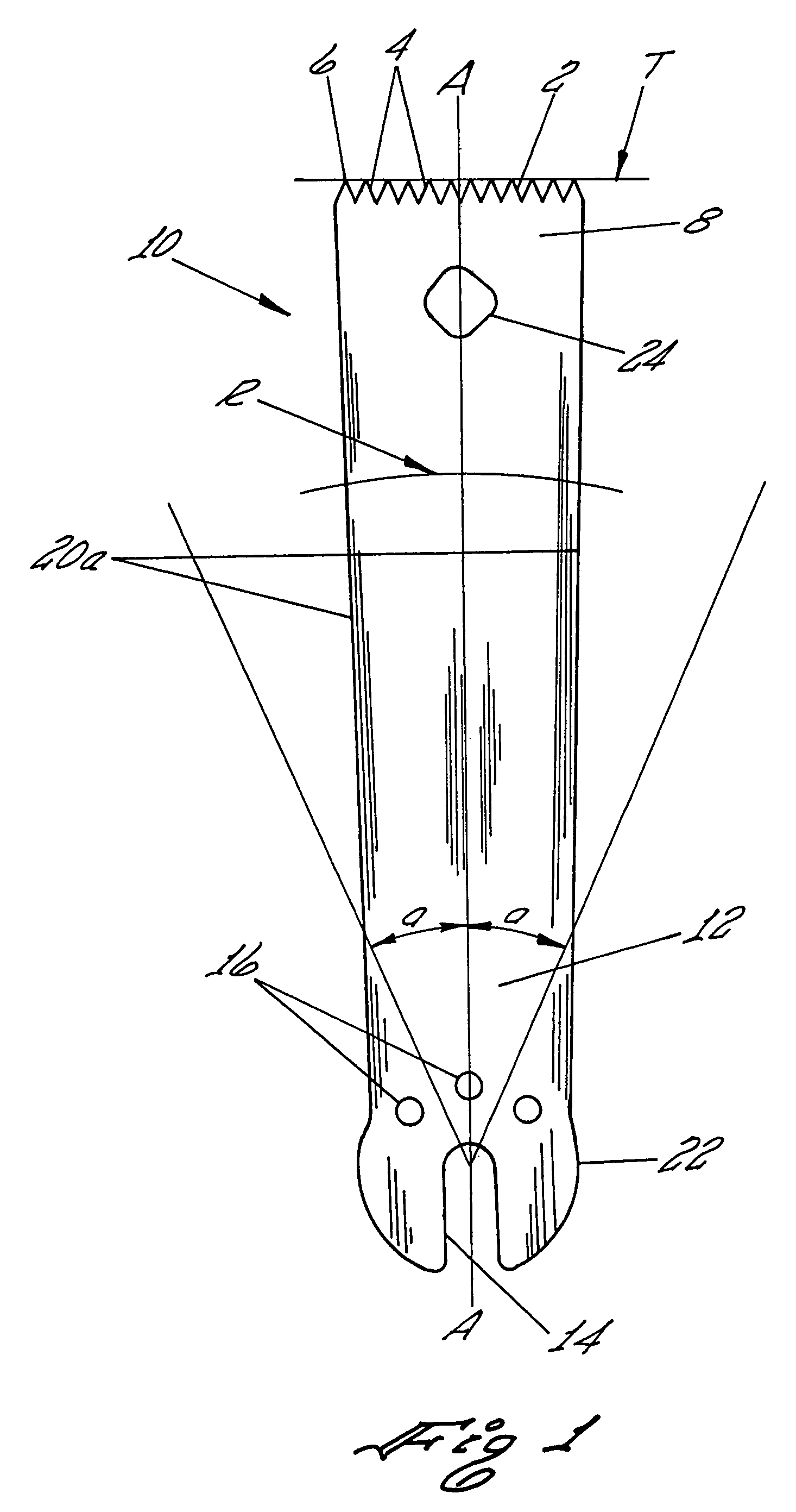

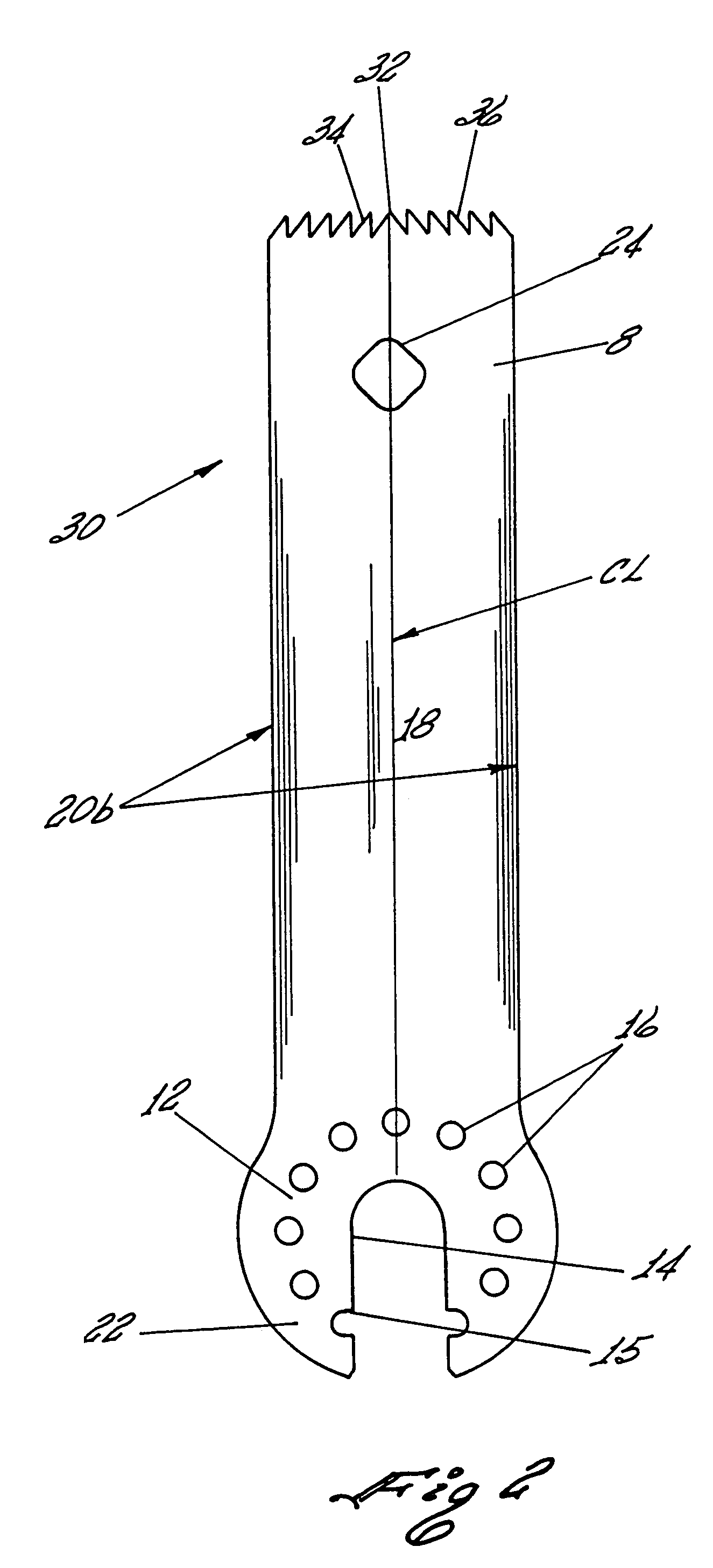

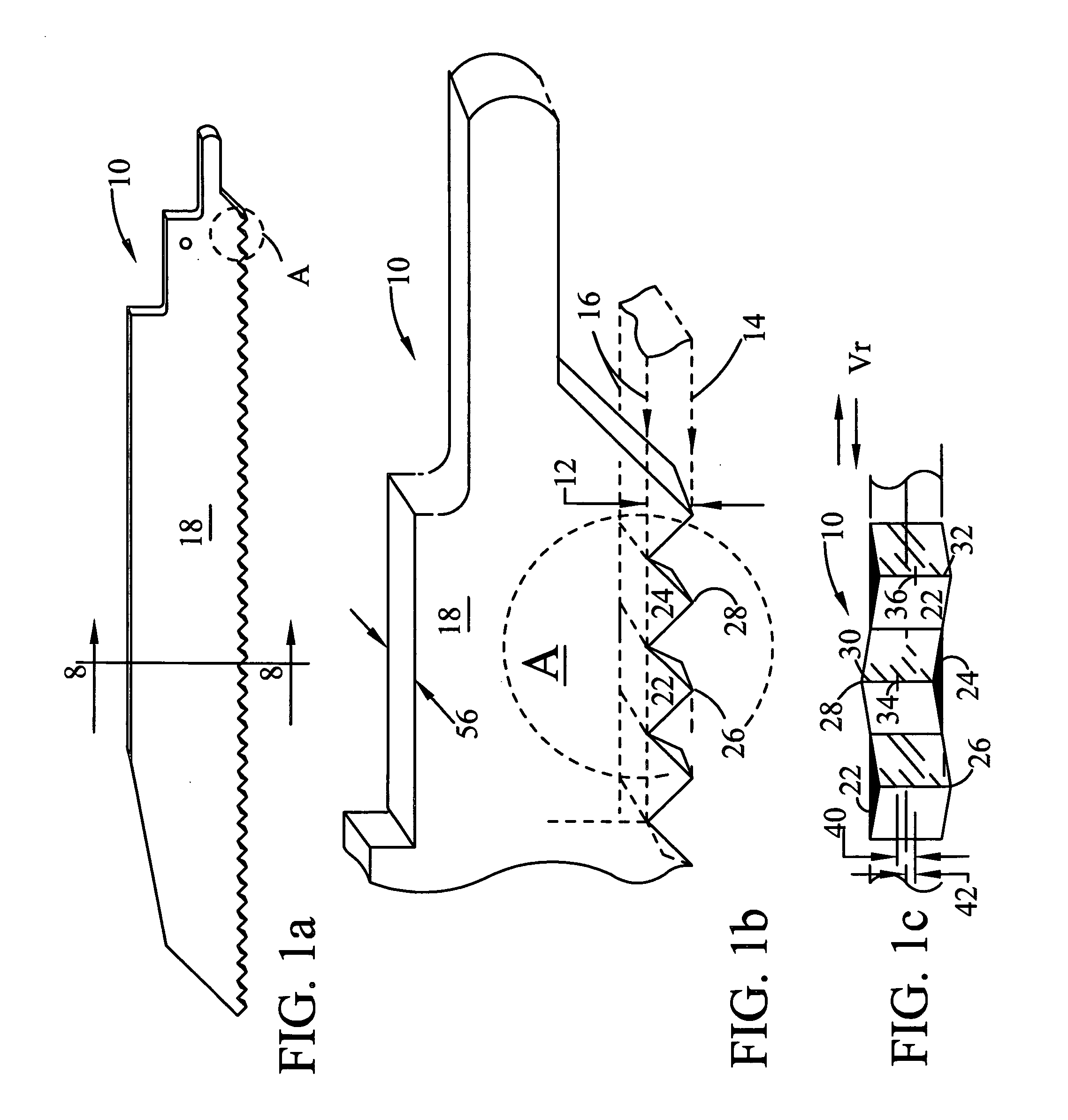

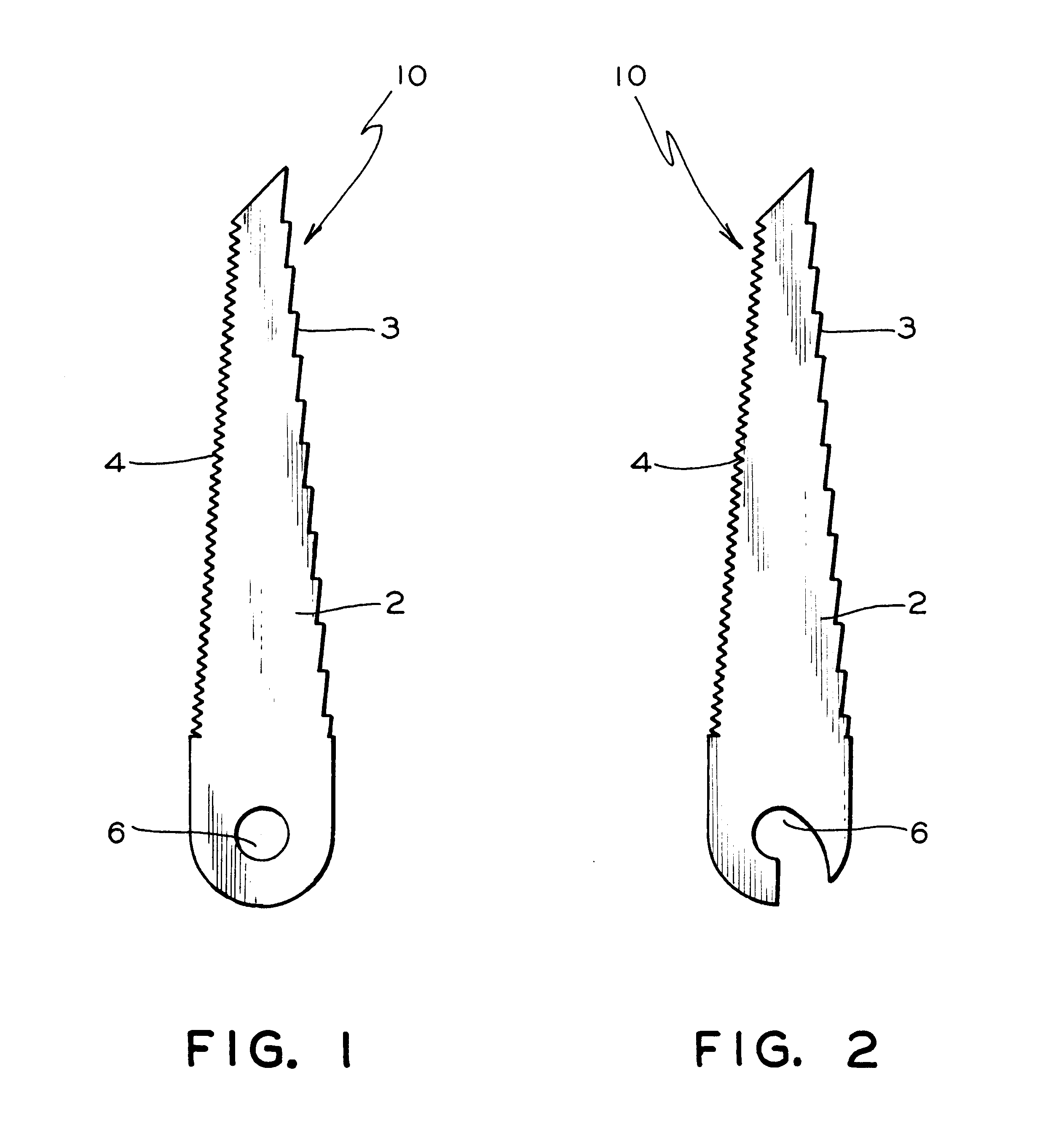

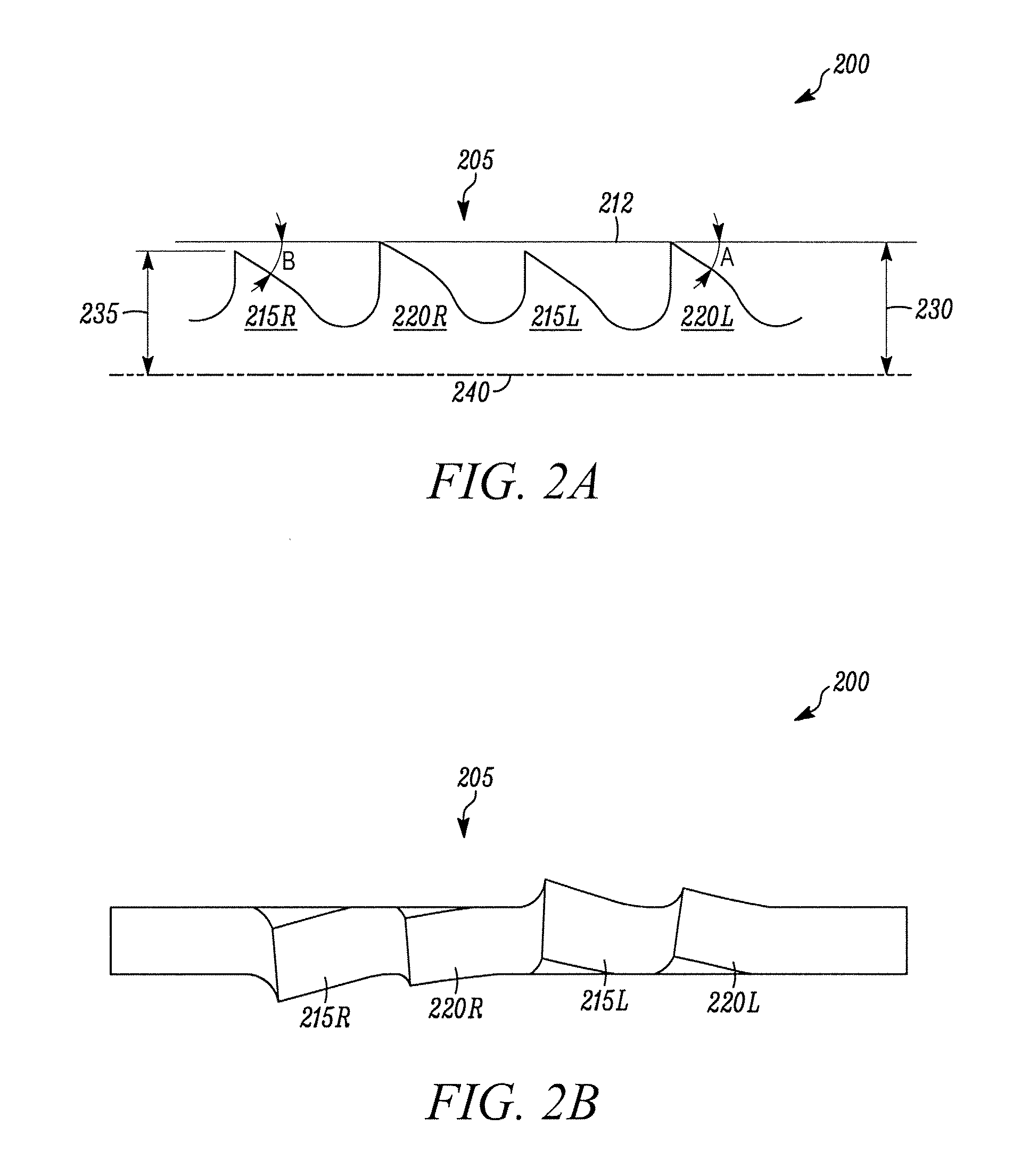

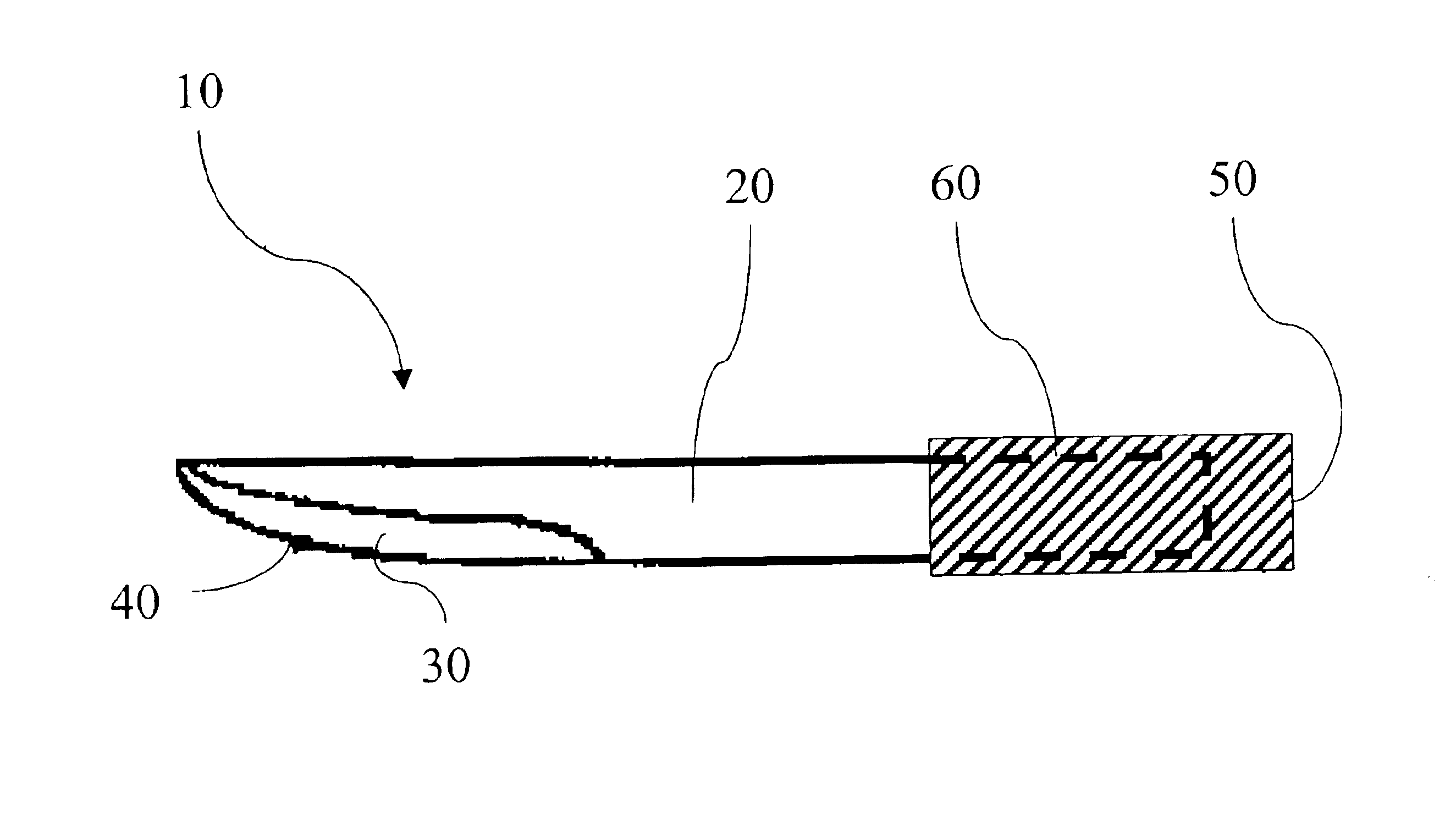

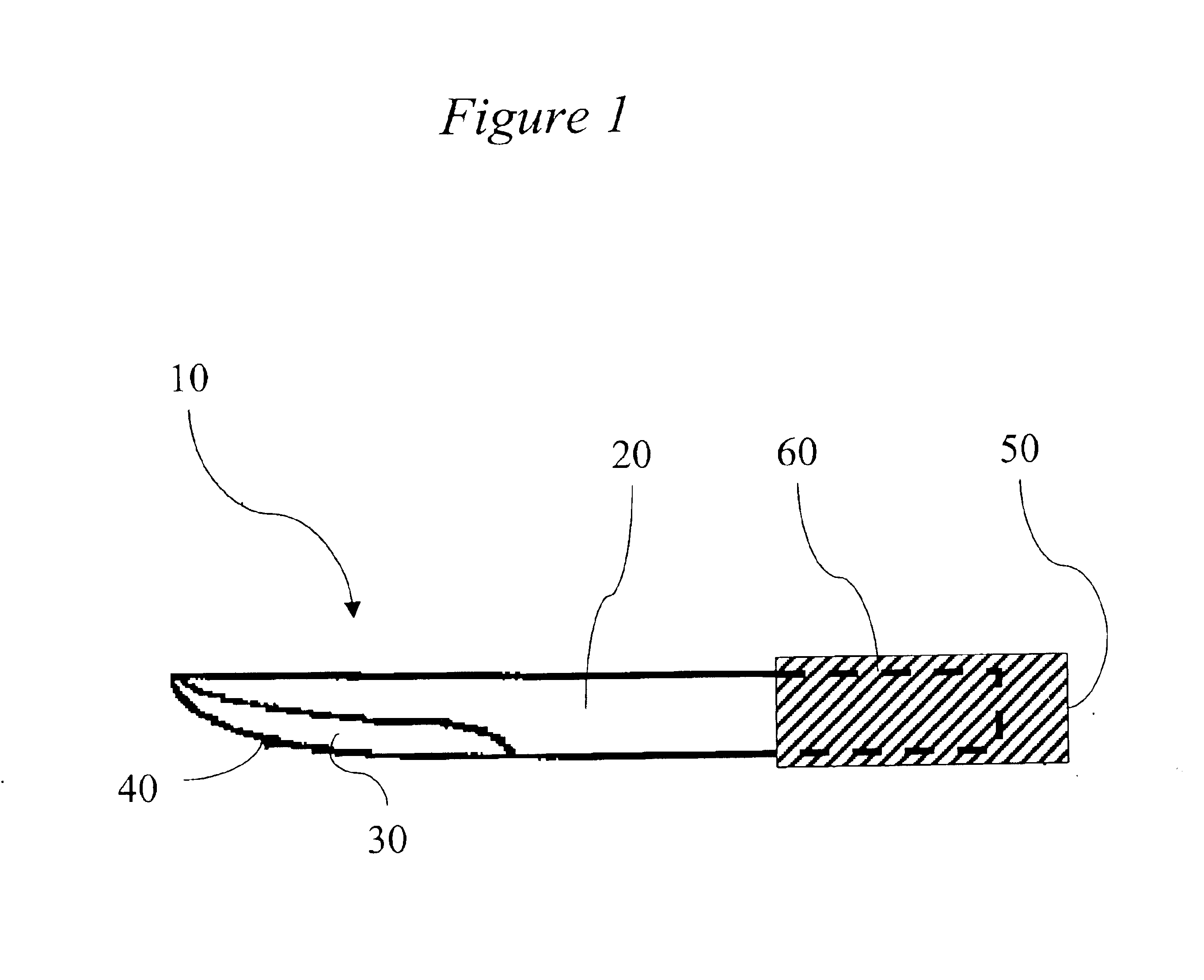

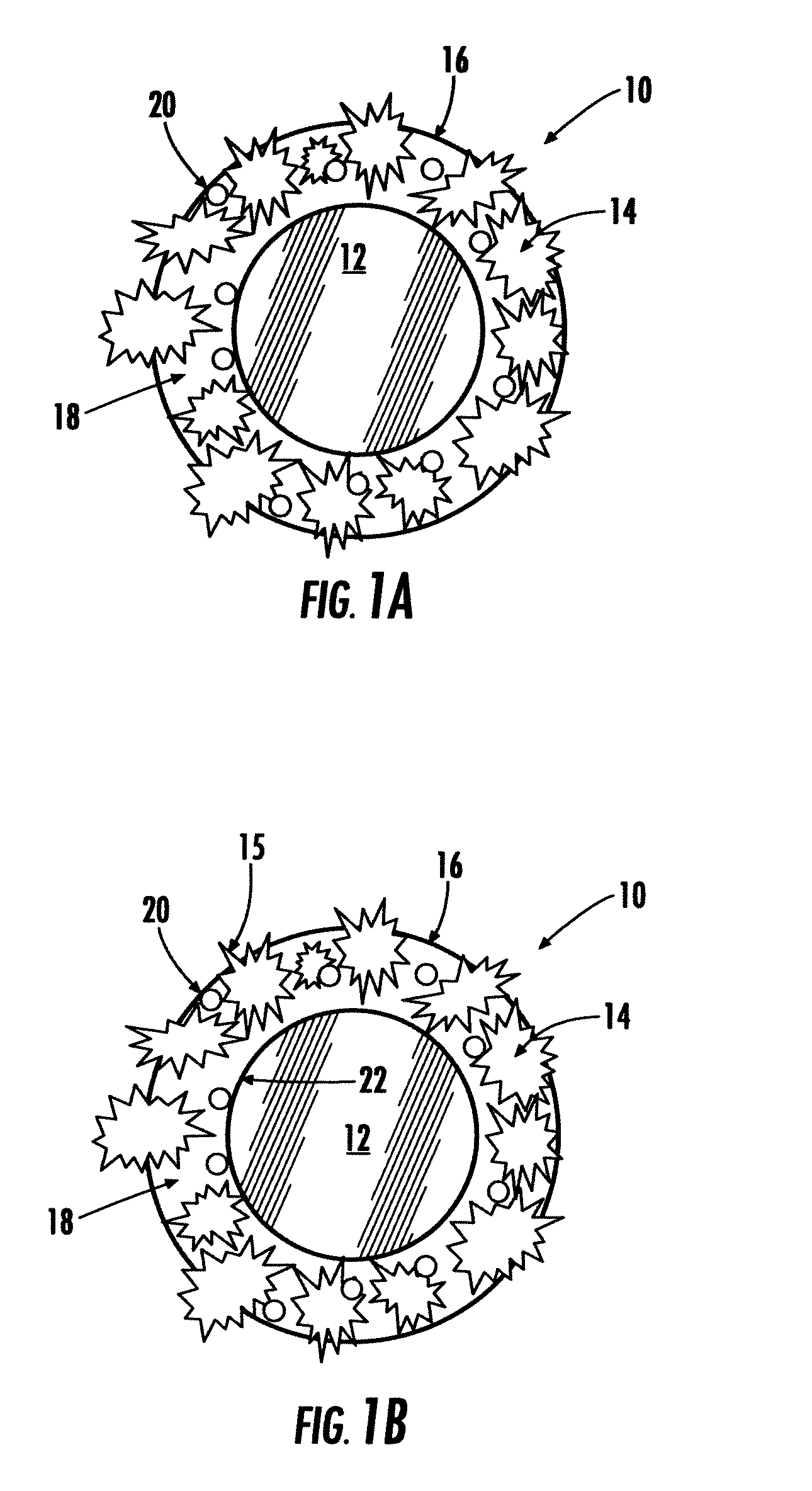

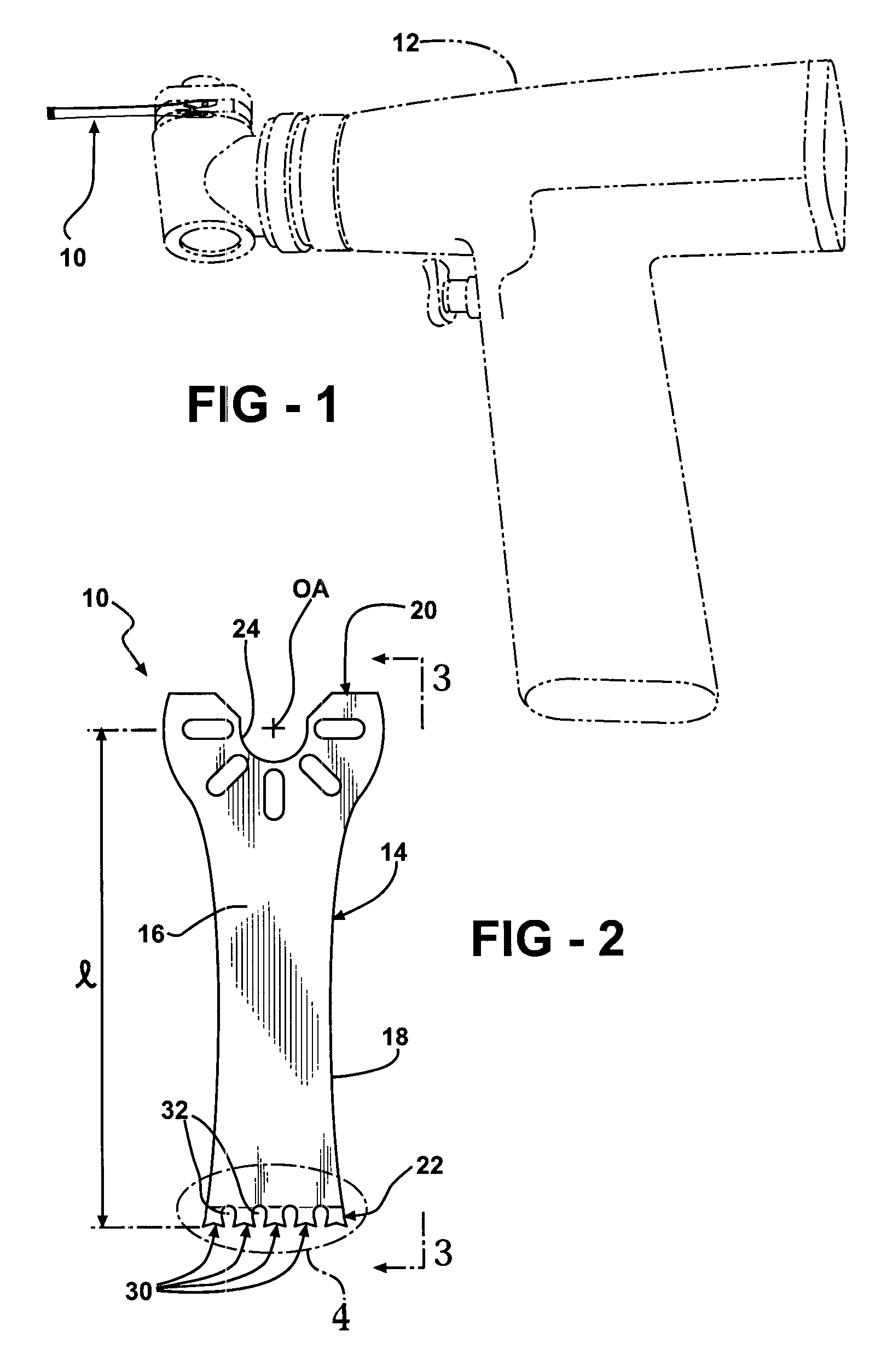

Surgical saw blade having at least one pair of opposed teeth shaped as right triangles

InactiveUS20090093815A1Reduce fatigueEasy to trackDot-and-dash transmission apparatusMetal sawing devicesRight triangleLong axis

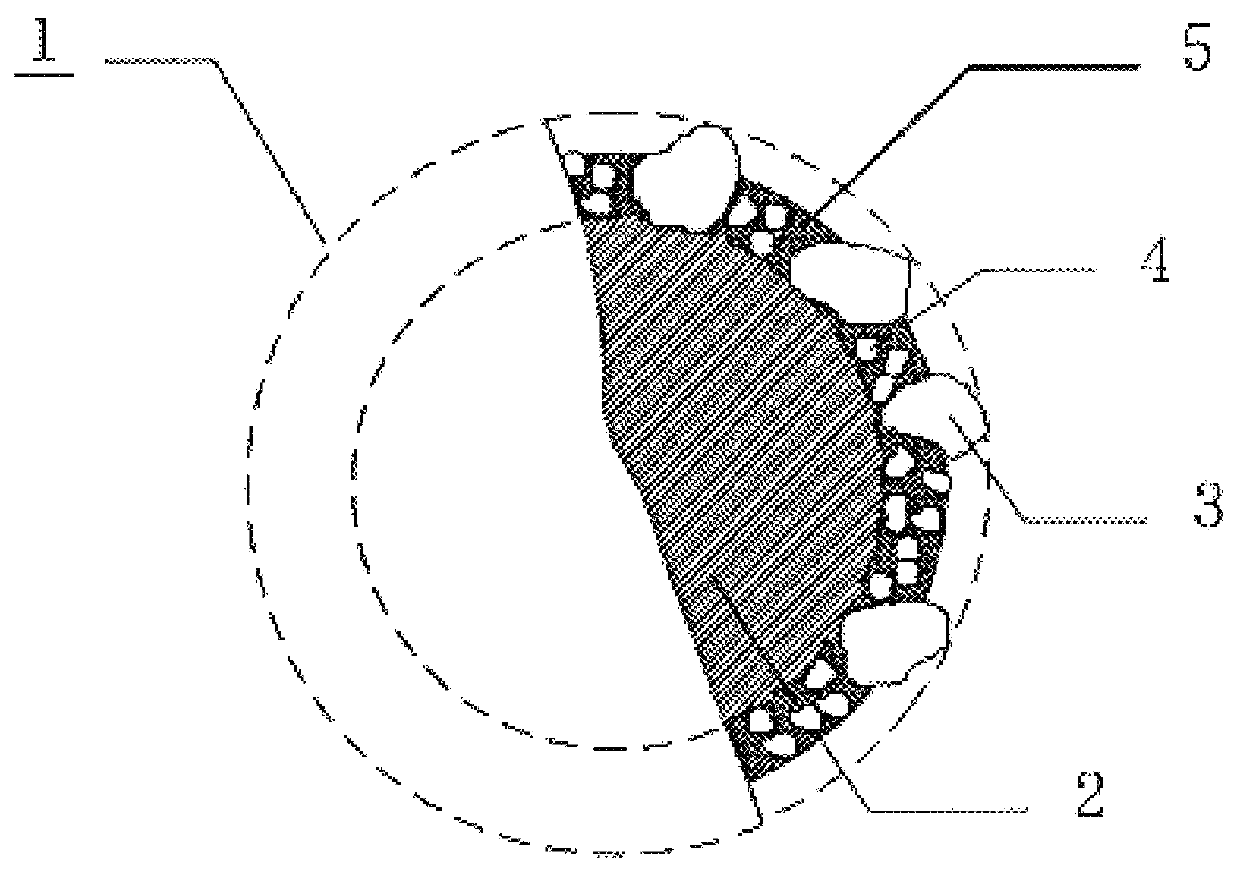

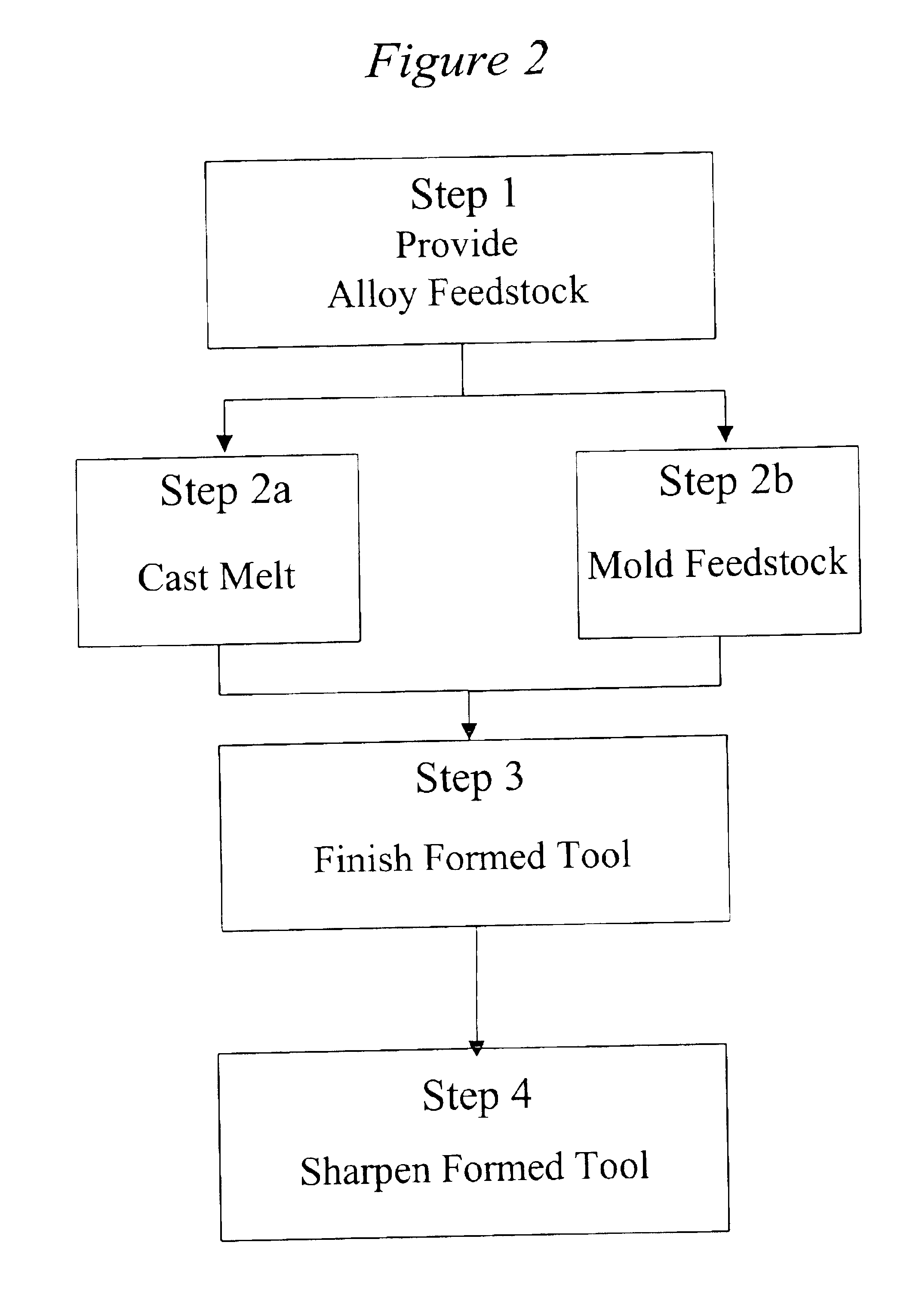

A cutting saw blade for use with an oscillatory power tool used in surgical bone cutting procedures including a blade having a distal end provided with teeth whose tips are located on a tangent line perpendicular to the long axis of the blade. The teeth are configured substantially as right triangles with their hypotenuses facing either towards the center of the blade or away from the center of the blade. A central tooth can be optionally provided. The surgical saw blade may have a distal end having at least one pair of teeth configured to be adjacent to each other and each of the pair of teeth is configured as a right triangle each having a hypotenuse which is oriented at least one of towards and away from the centrally positioned long axis.

Owner:SYNVASIVE TECH

Surgical saw blade

InactiveUS6022353AMinimizes degree of heat buildupReduce the thermal necrosisMetal sawing devicesMetal sawing toolsRight triangleLong axis

A cutting saw blade for use with an oscillatory power tool used in surgical bone cutting procedures including a blade having a distal end provided with teeth whose tips are located on a tangent line perpendicular to the long axis of the blade. The teeth are configured substantially as right triangles with their hypotenuses facing either towards the center of the blade or away from the center of the blade. A central tooth can be optionally provided.

Owner:SYNVASIVE TECH

Brazed diamond tools and methods for making the same

Owner:SUNG CHIEN MIN

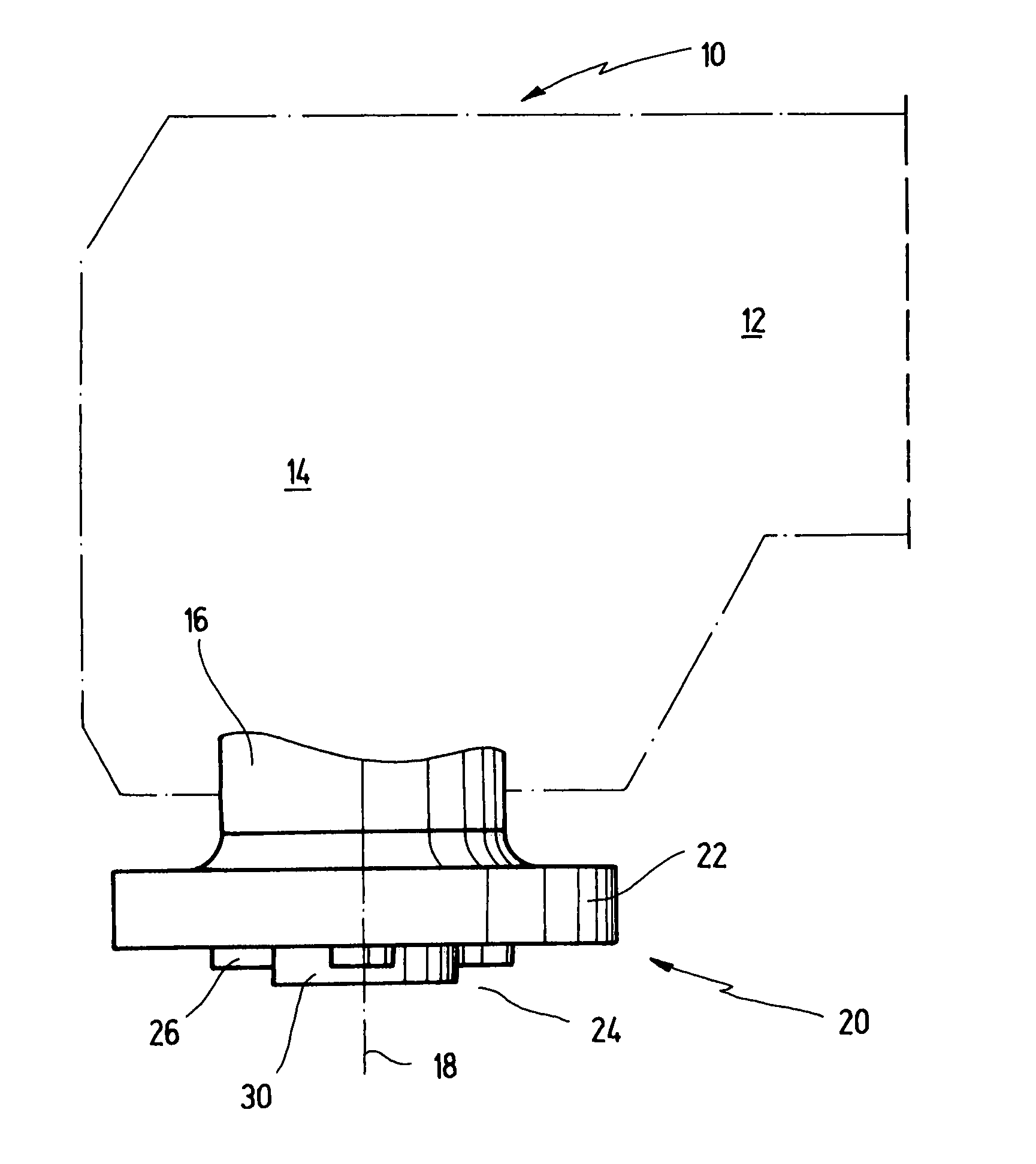

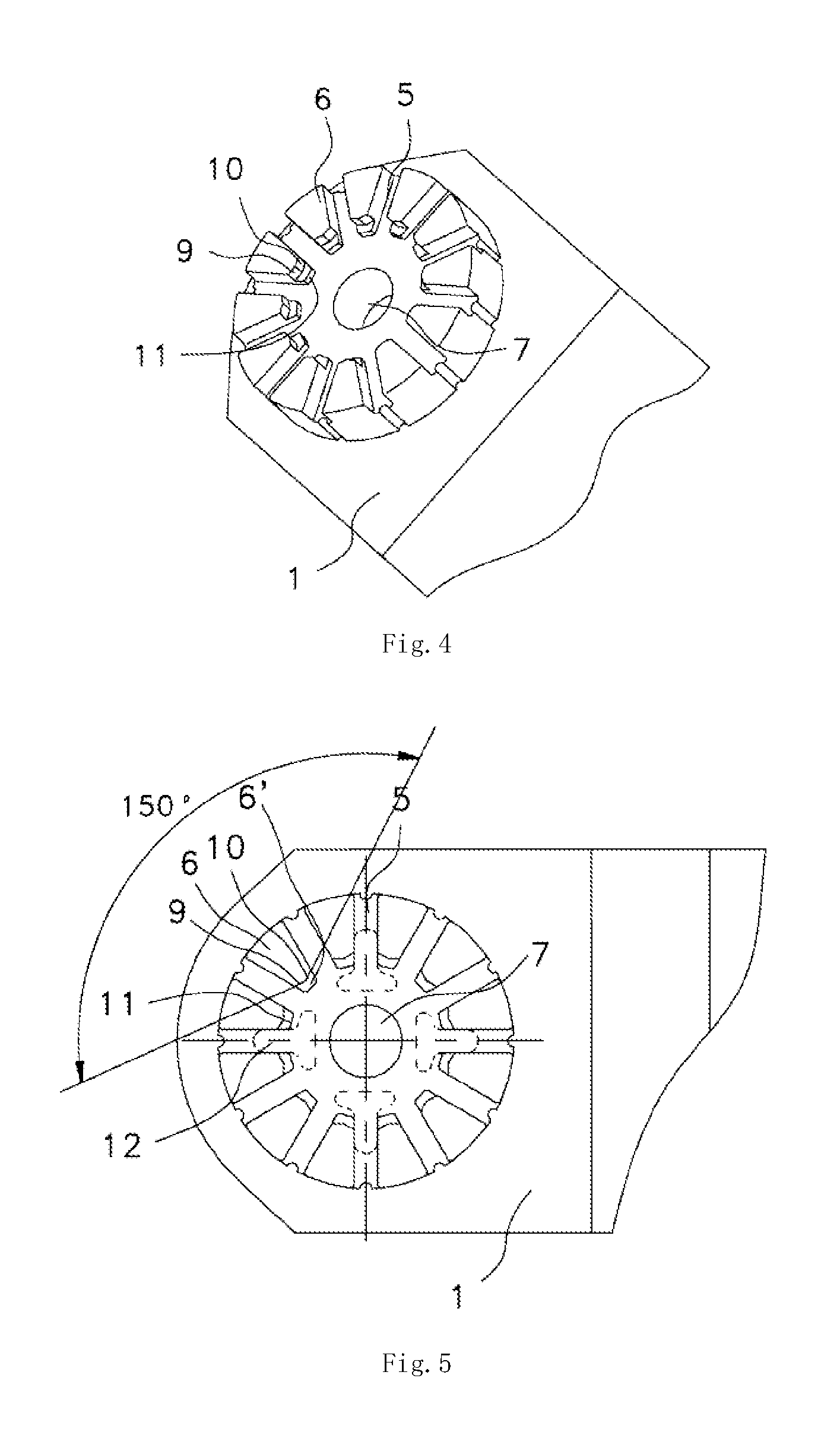

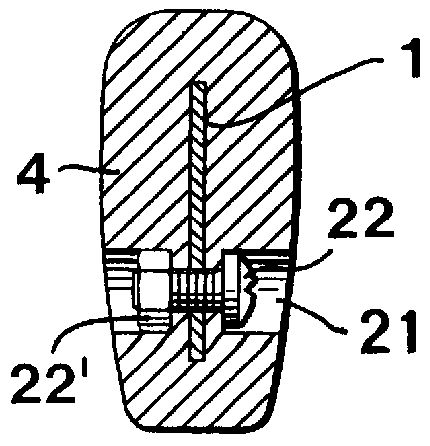

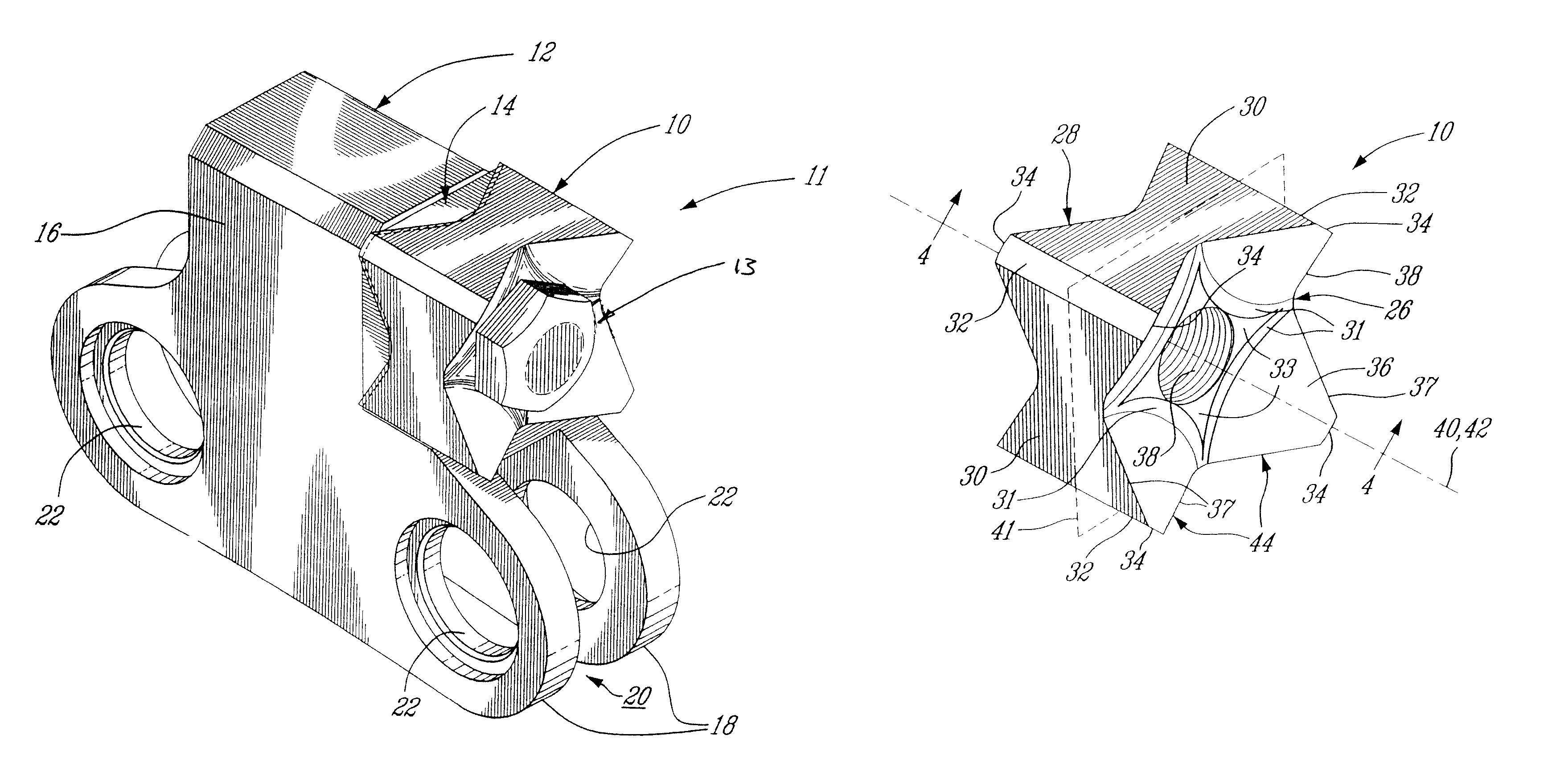

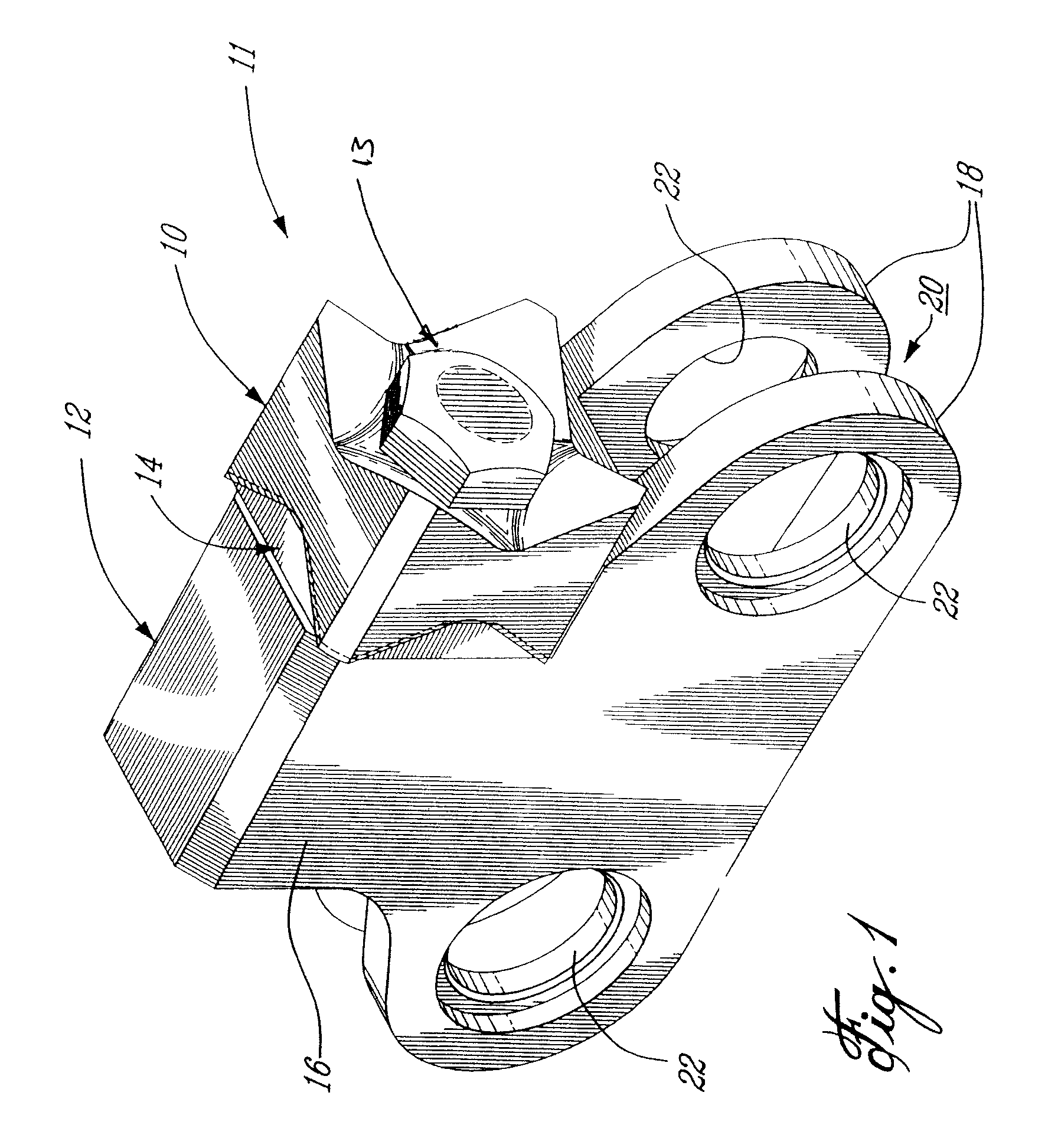

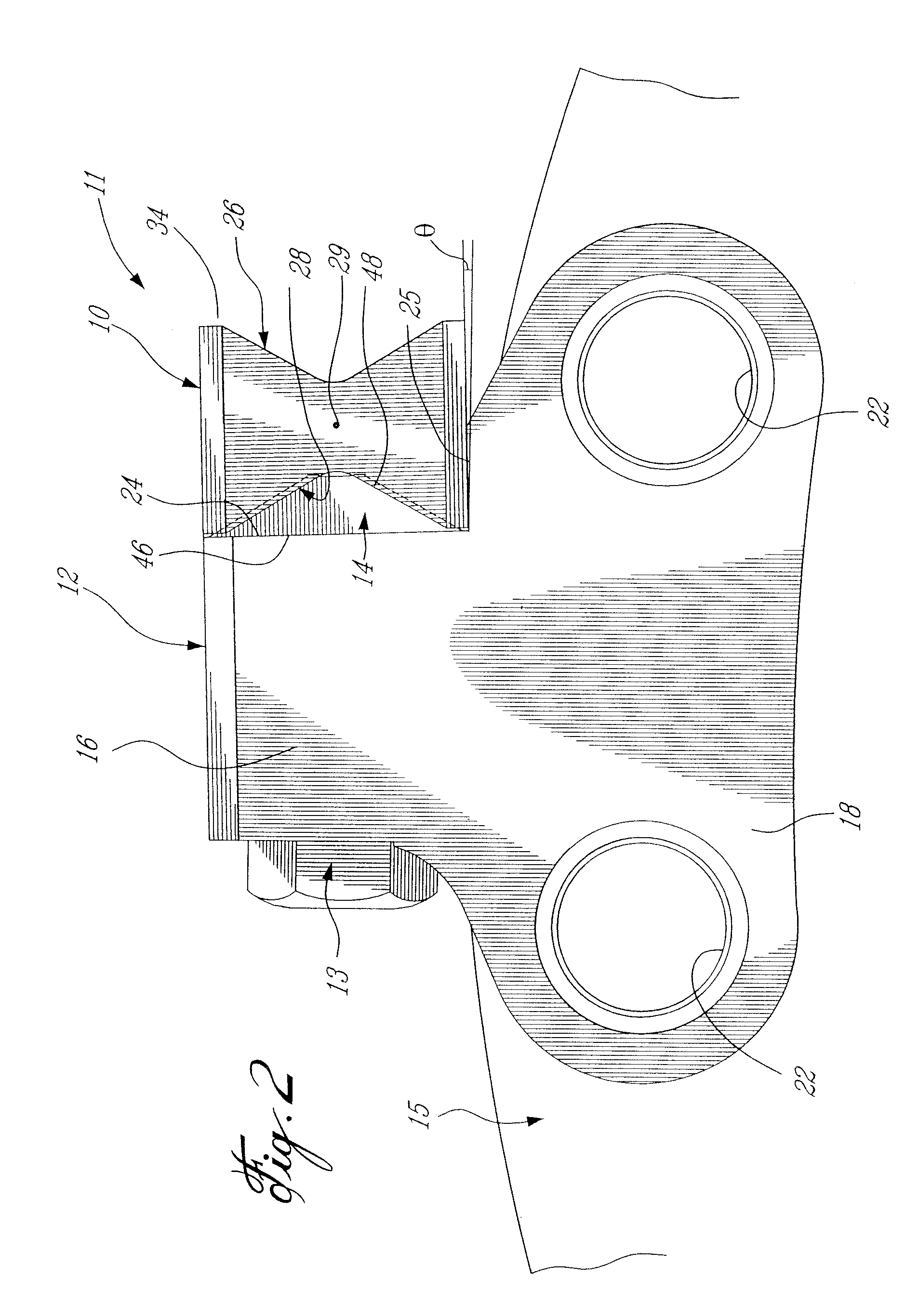

Power tool having a receptacle for securing a tool

InactiveUS6945862B2Reduce riskImprove transmittanceGrinding wheel securing apparatusMetal sawing toolsDrive shaftPower tool

A power tool having a receptacle for securing a tool to a drive shaft thereof is disclosed. The receptacle comprises a receiving opening, preferably being arranged on the tool. The receiving opening engages a securing section preferably being provided in a raised fashion on the drive shaft of the power tool, thereby effecting a positive fit. The securing section comprises a plurality of rounded tips arranged at even radial distances from said longitudinal axis, at angular intervals between each other, each rounded tip having a pair of lateral flanks extending from a common apex toward an intermediate section connecting lateral flanks of a pair of adjacent rounded tips. Preferably the receiving opening comprises a number of rounded tips which is twice the number of rounded tips provided on the raised section.

Owner:C & E FEIN GMBH & CO KG

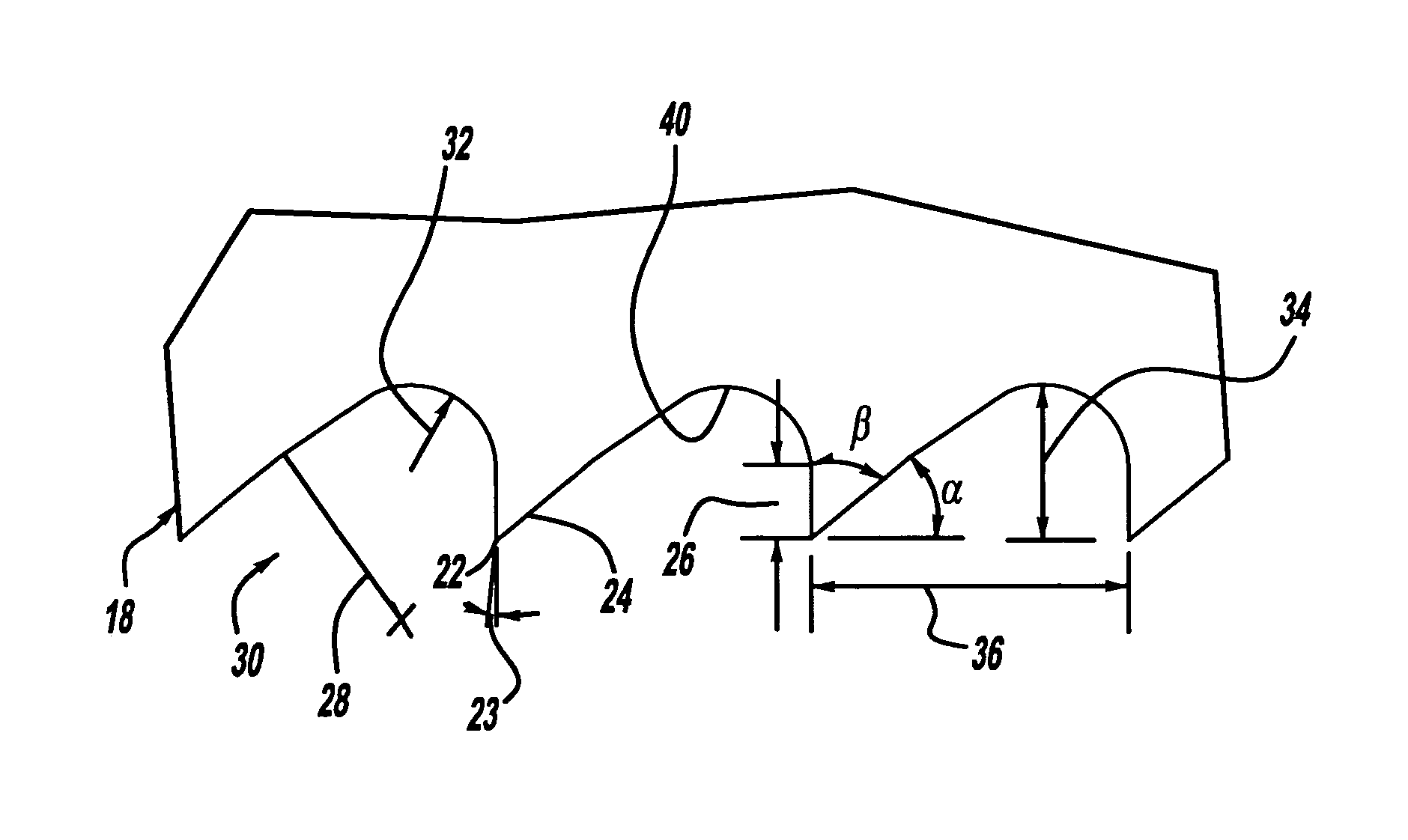

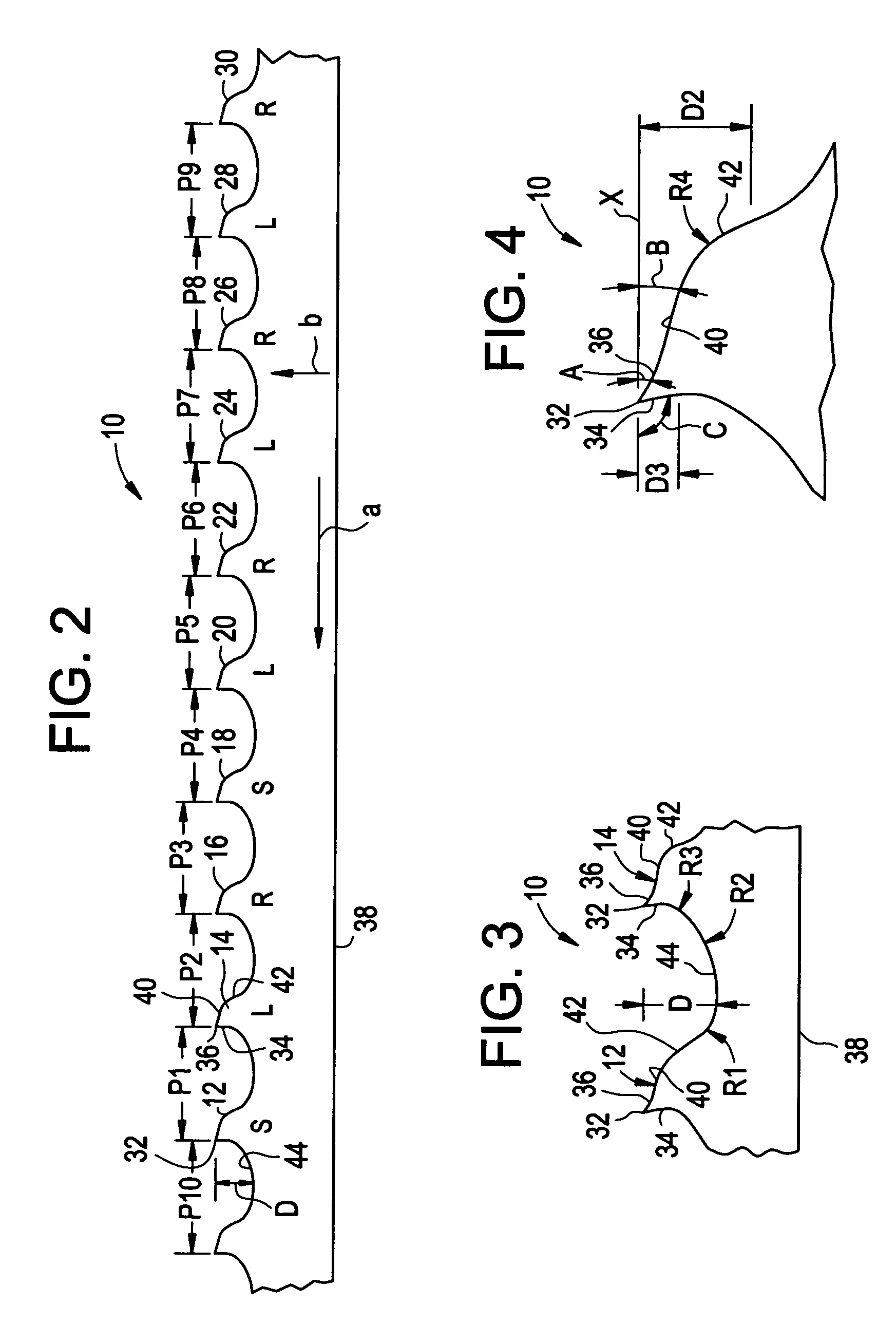

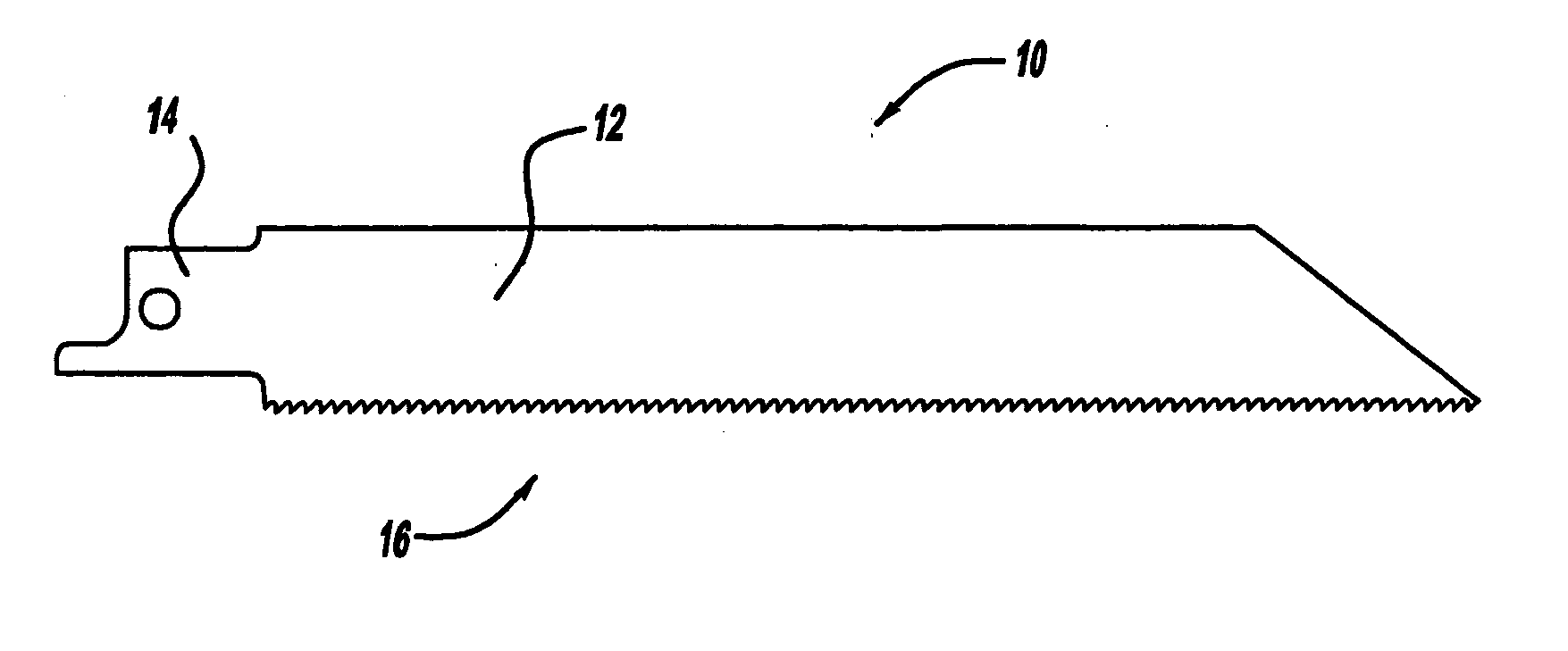

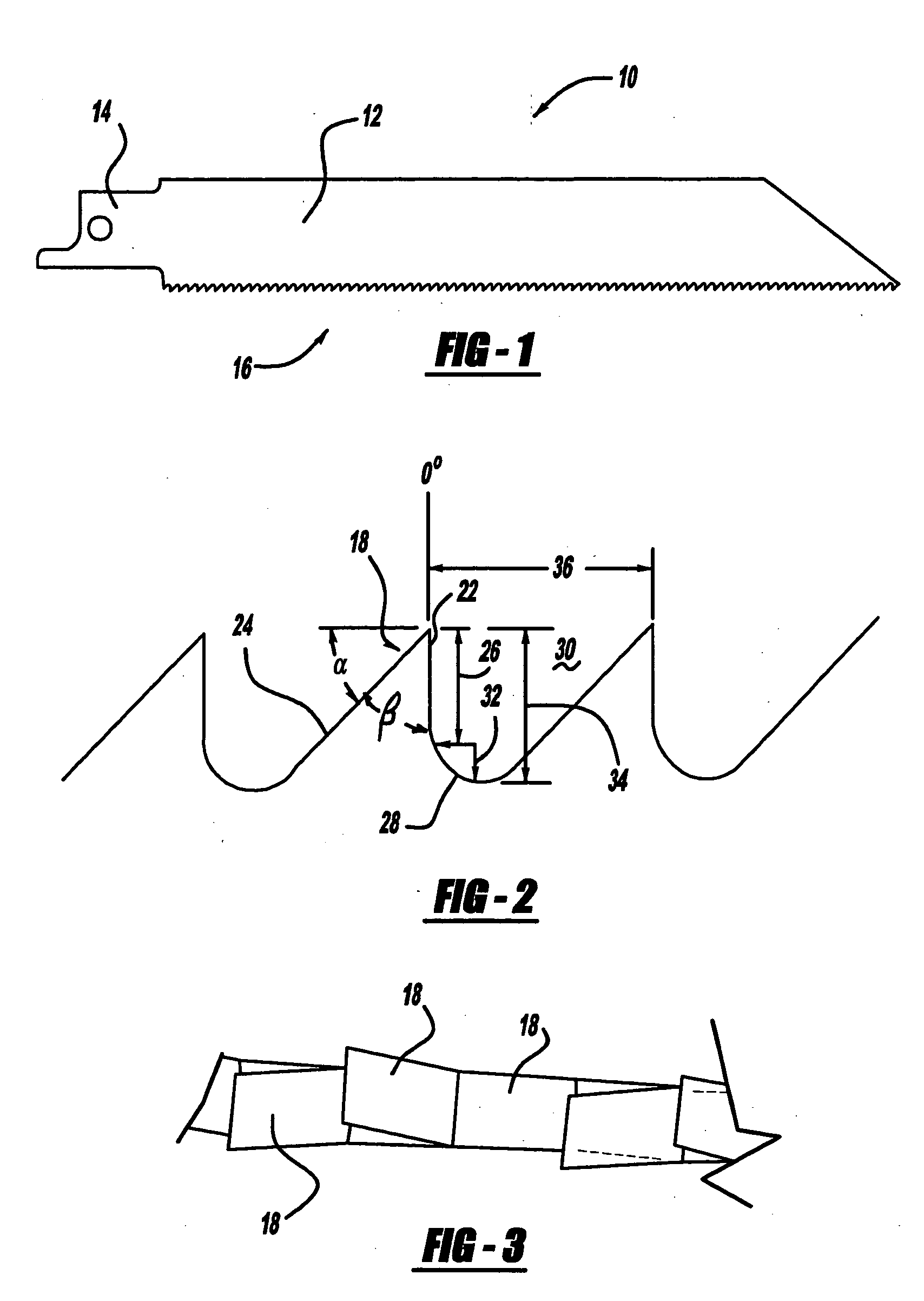

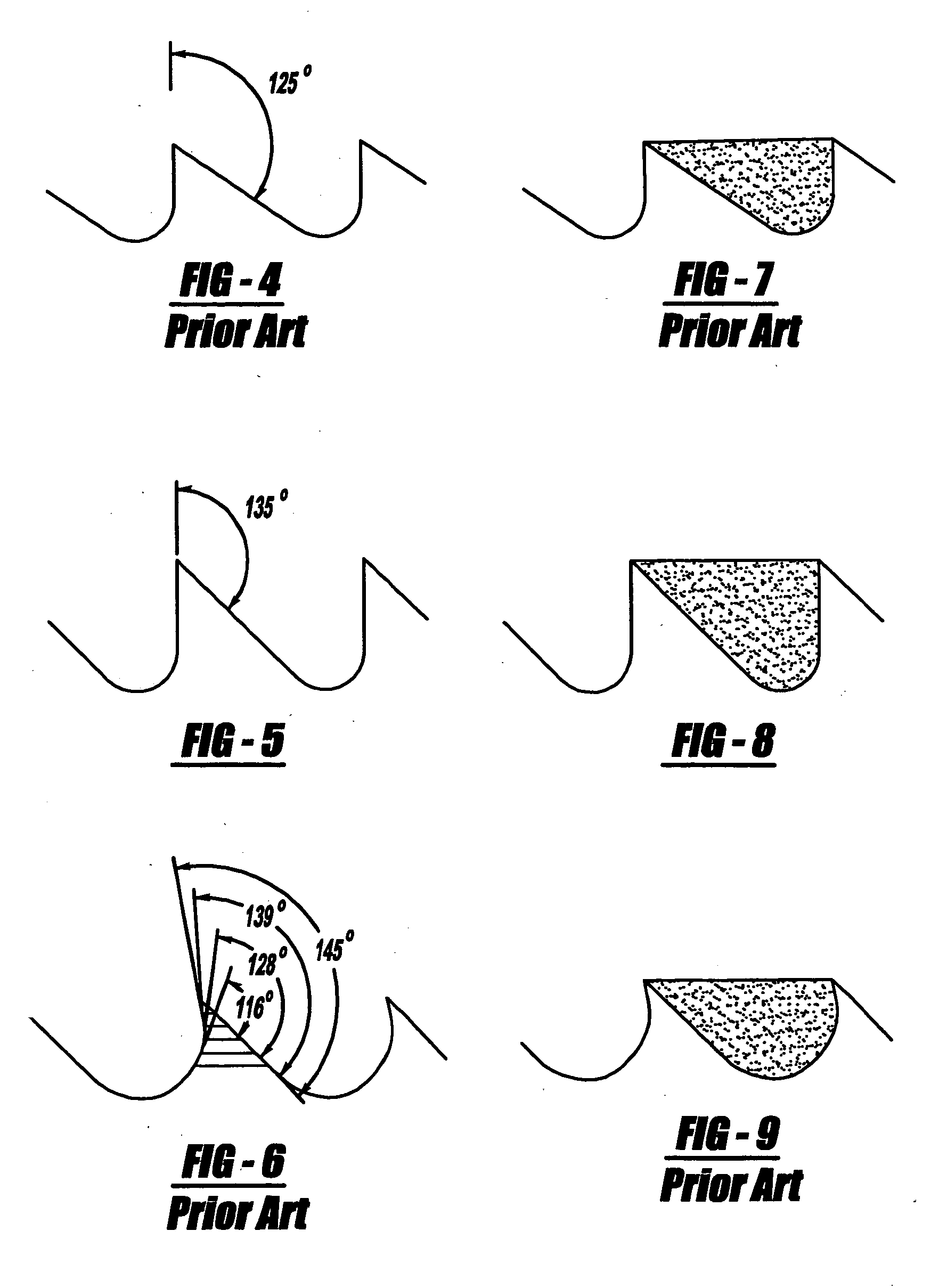

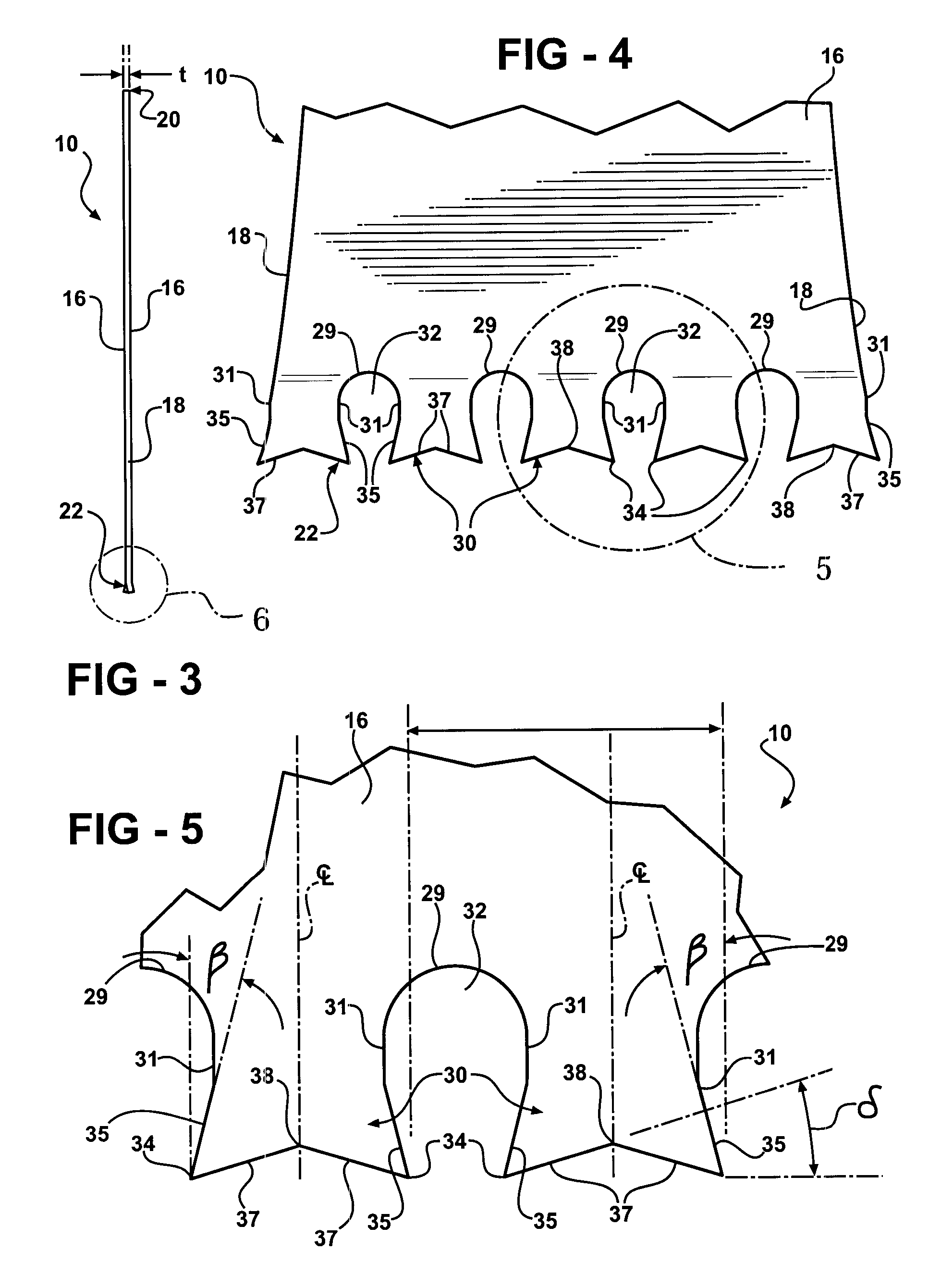

Tooth form design for reciprocating saw blade

A reciprocating saw has a tooth form that decreases the cutting time of the saw blade and extends the life of the saw blade. The tooth height is longer than conventional metal cutting reciprocating saws. Also, the tooth form has a larger gullet. The tooth rake angle remains substantially constant during the life of the saw blade.

Owner:BLACK & DECKER INC

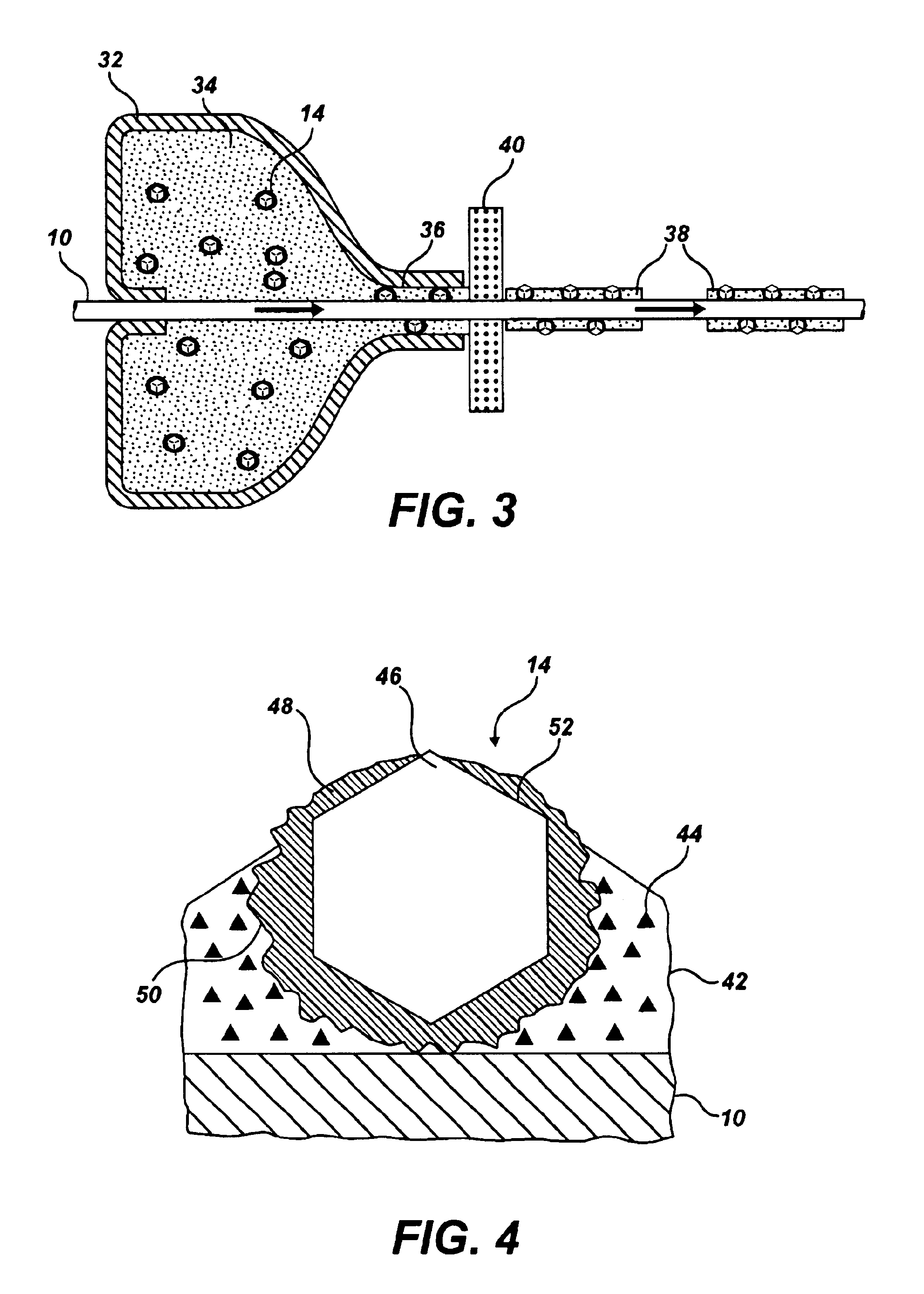

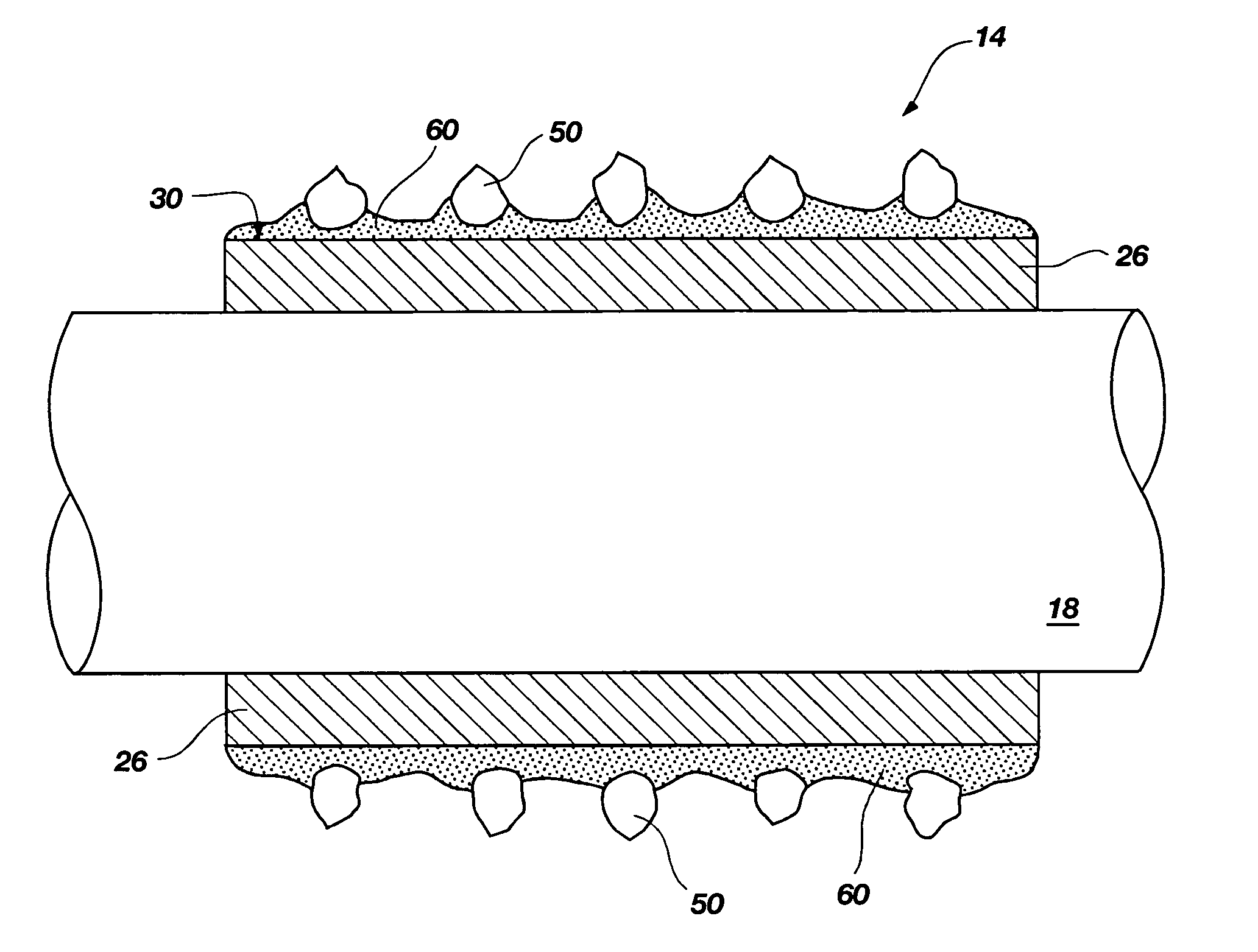

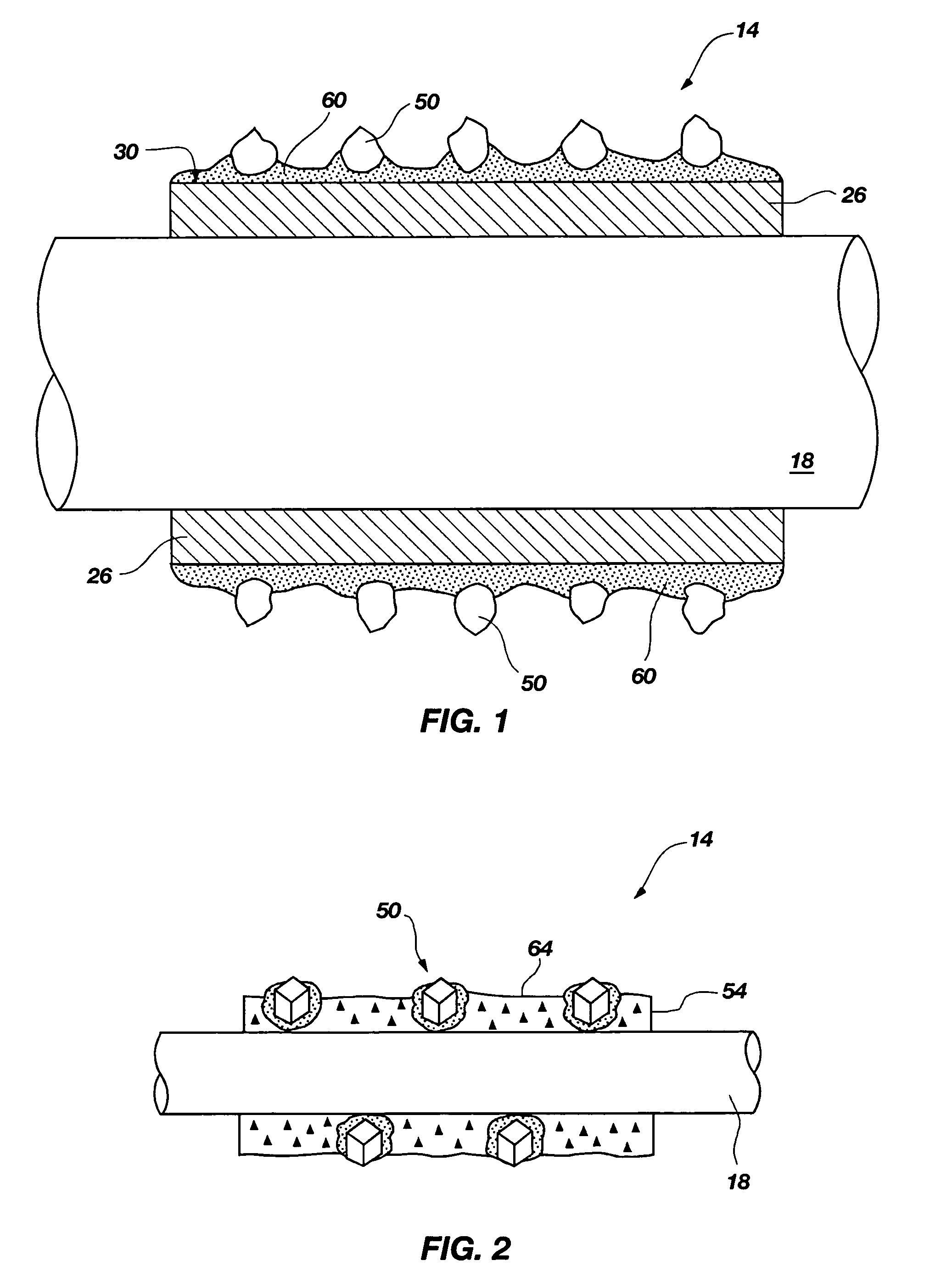

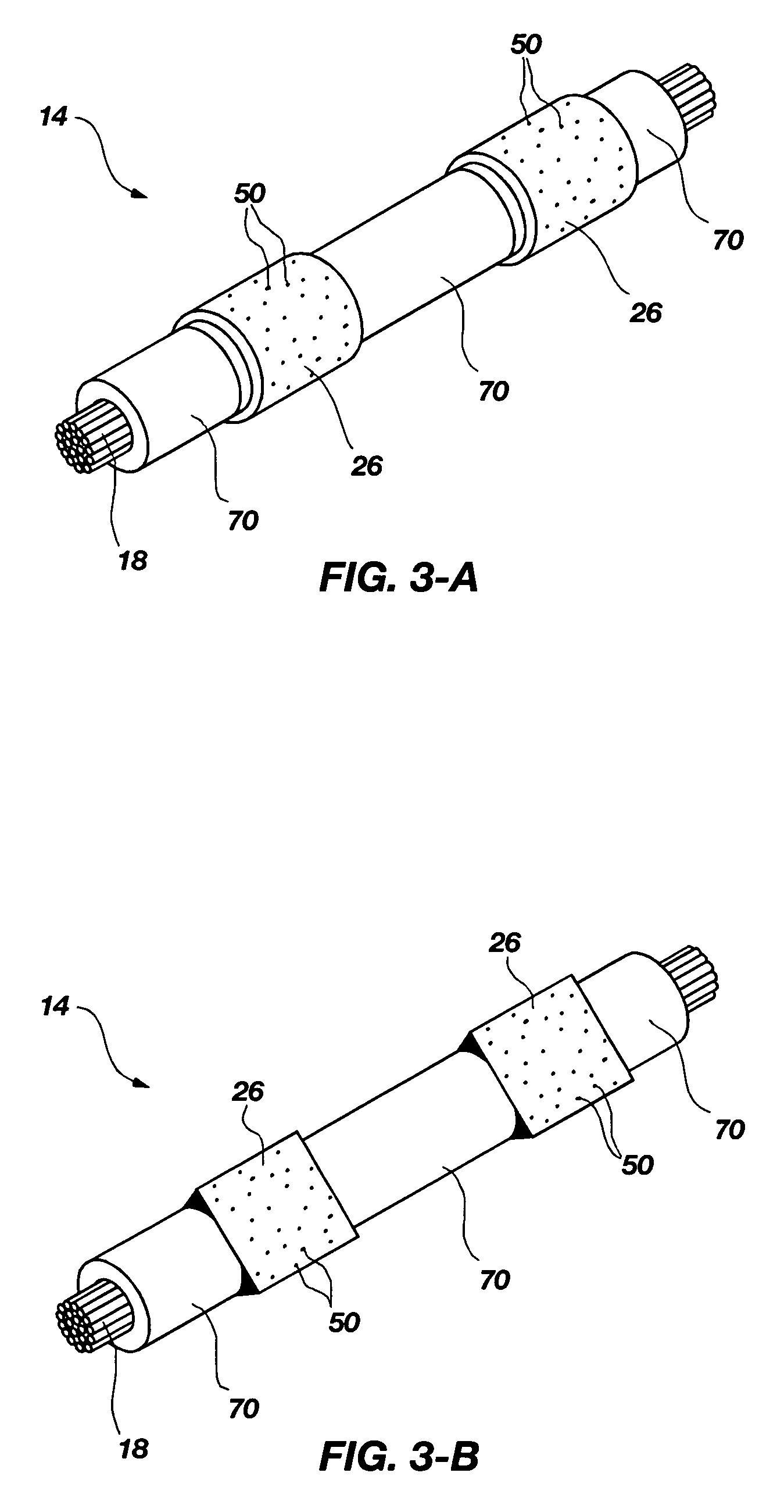

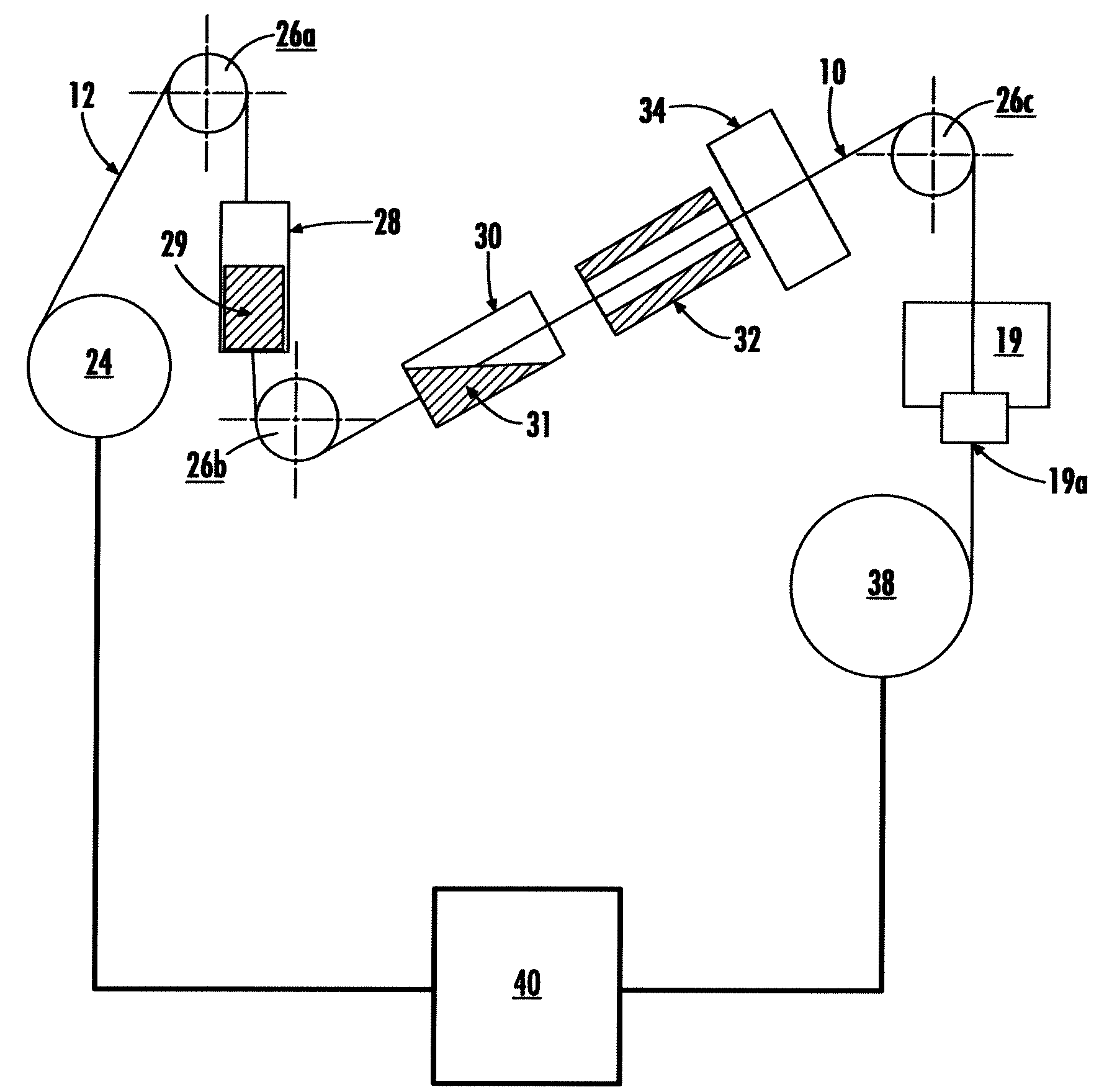

Superabrasive wire saw and associated methods of manufacture

InactiveUS6915796B2Improving particle retentionHigh material removal ratePigmenting treatmentOther chemical processesWire rodAlloy

A superabrasive wire saw having a plurality of individual coated superabrasive particles attached to a wire with an organic binder is disclosed and described. The superabrasive particle can be coated with a solidified coating of a molten braze alloy that is chemically bonded to the superabrasive particle. The organic binder can optionally contain filler materials and / or an organometallic coupling agent to improve the retention of coated superabrasive particles. The resulting superabrasive wire saws can be produced having diameters of less than 0.5 mm which significantly reduce kerf loss. Various methods for making and using such a superabrasive wire saw are additionally disclosed and described.

Owner:SUNG CHIEN MIN

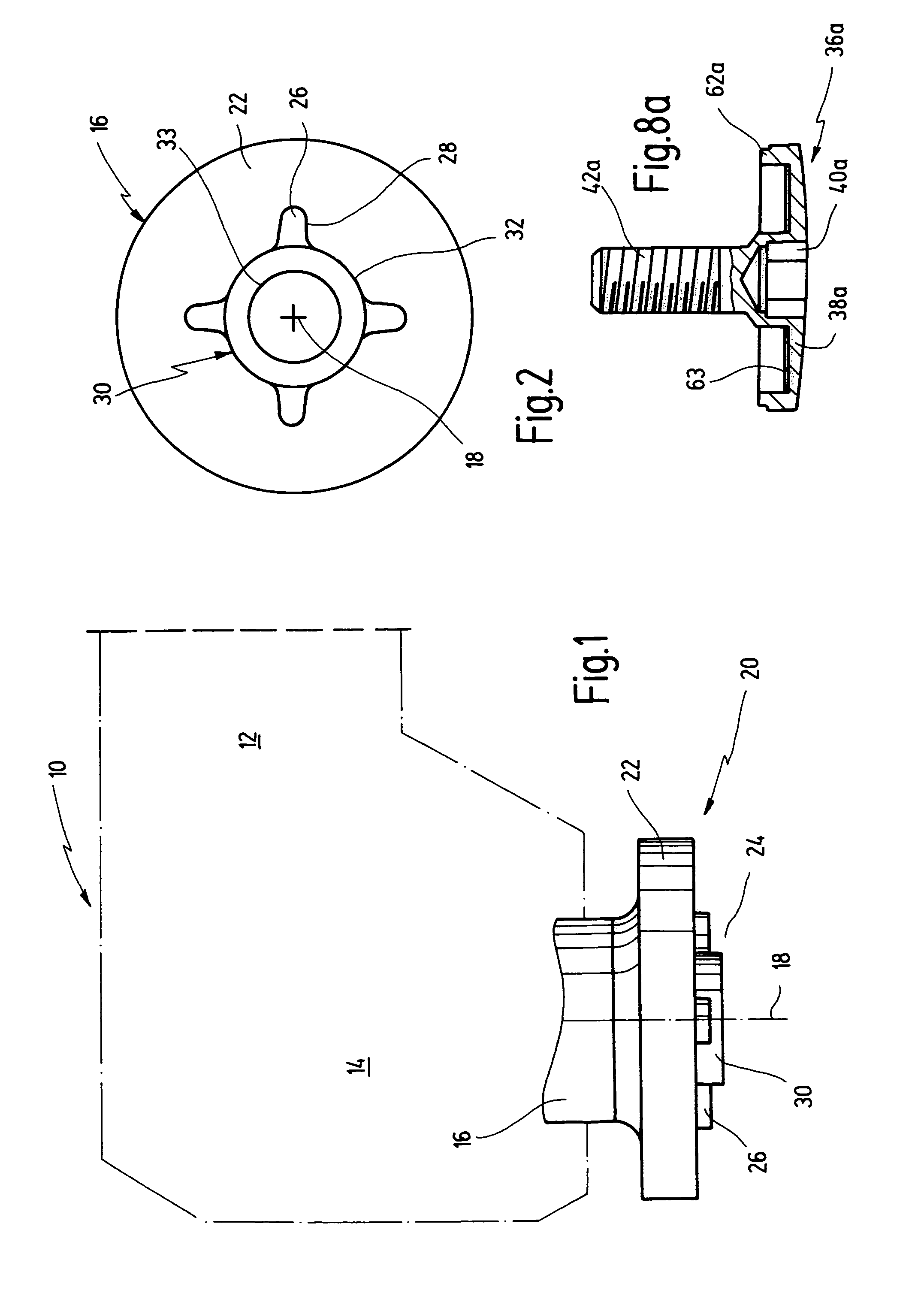

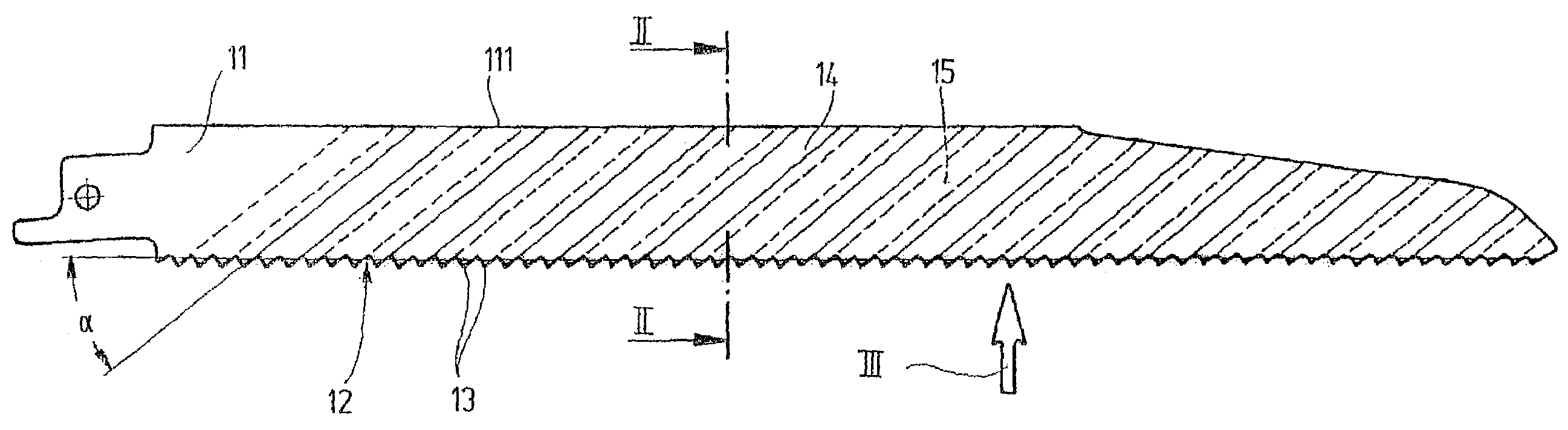

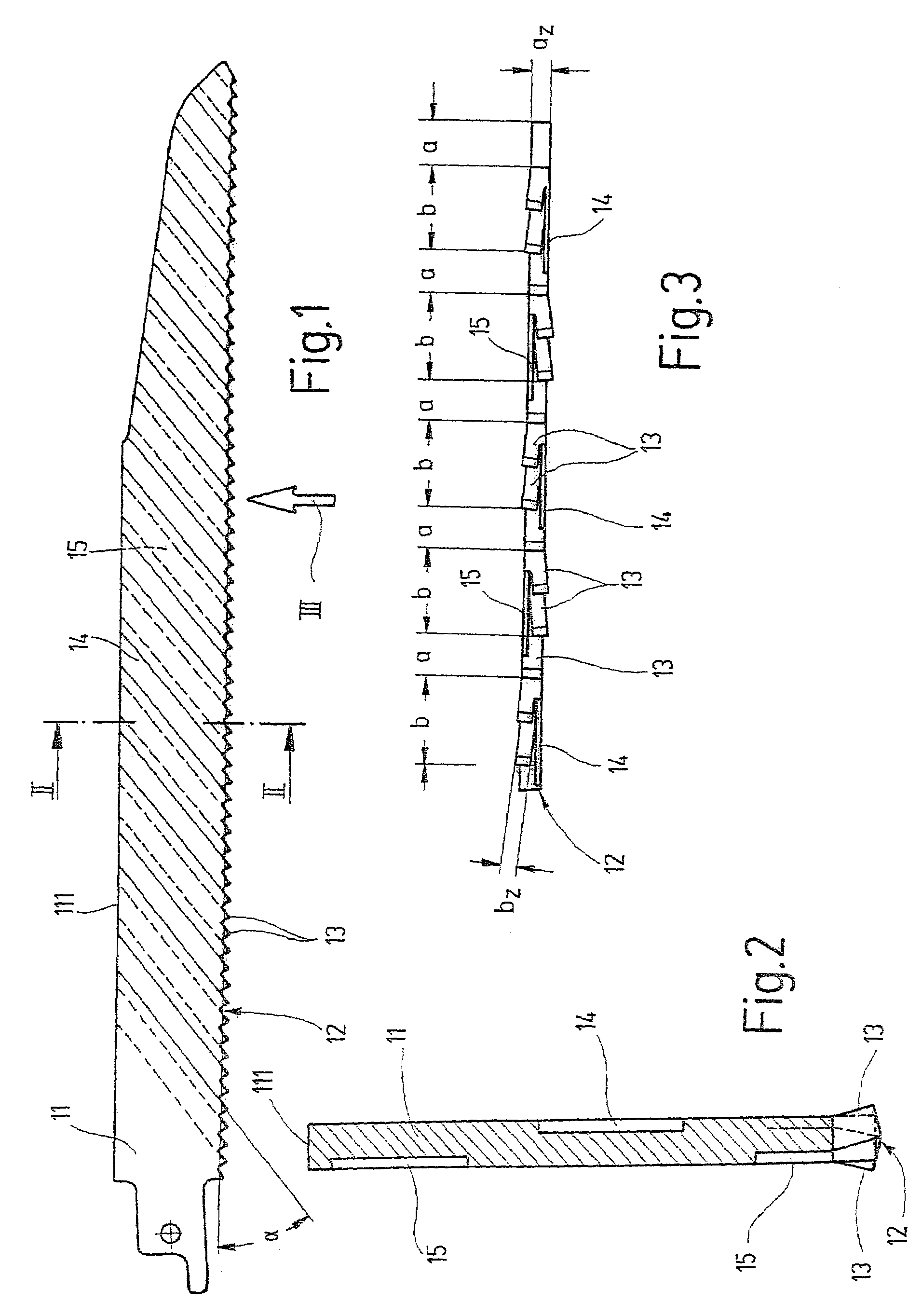

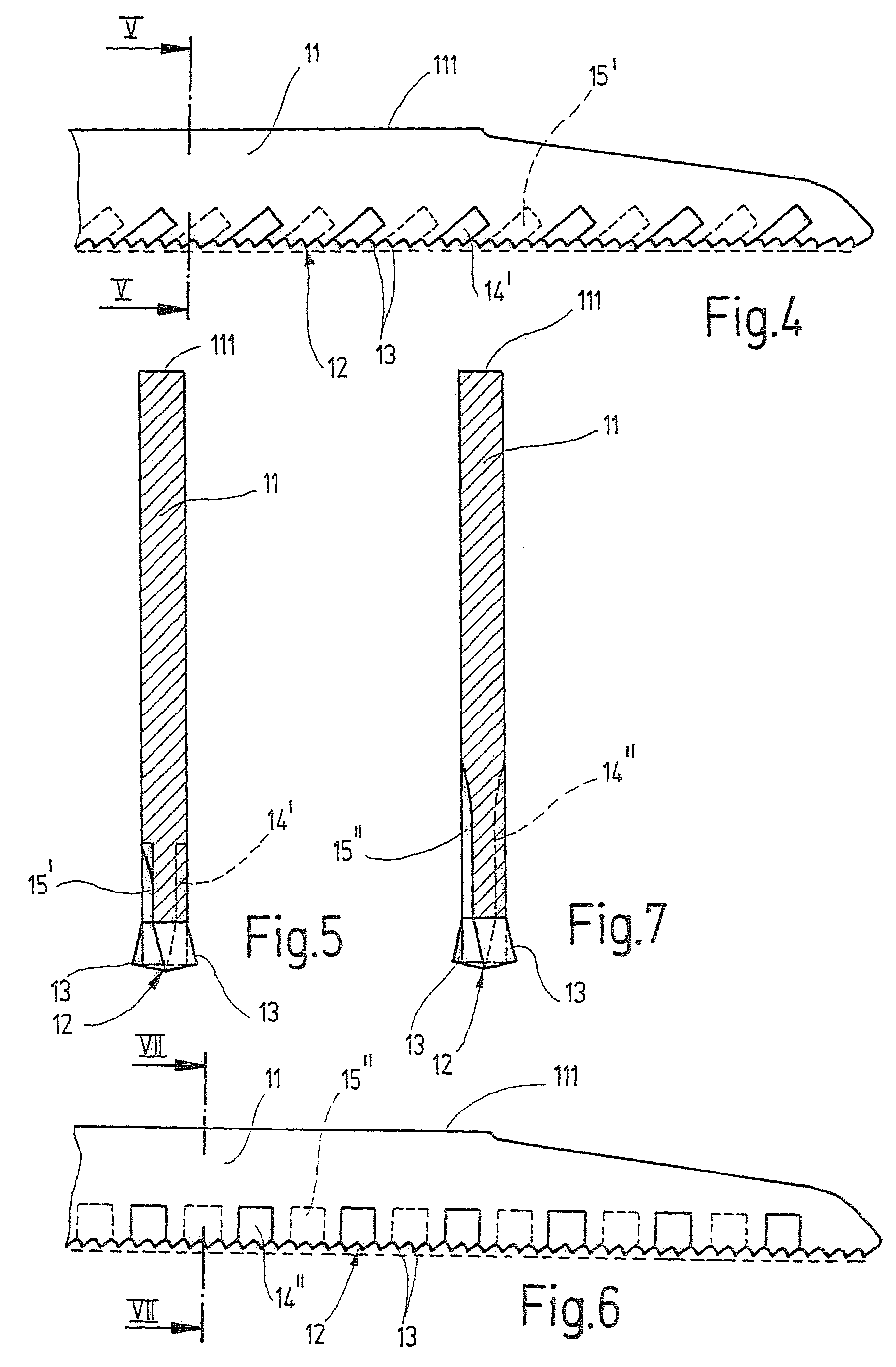

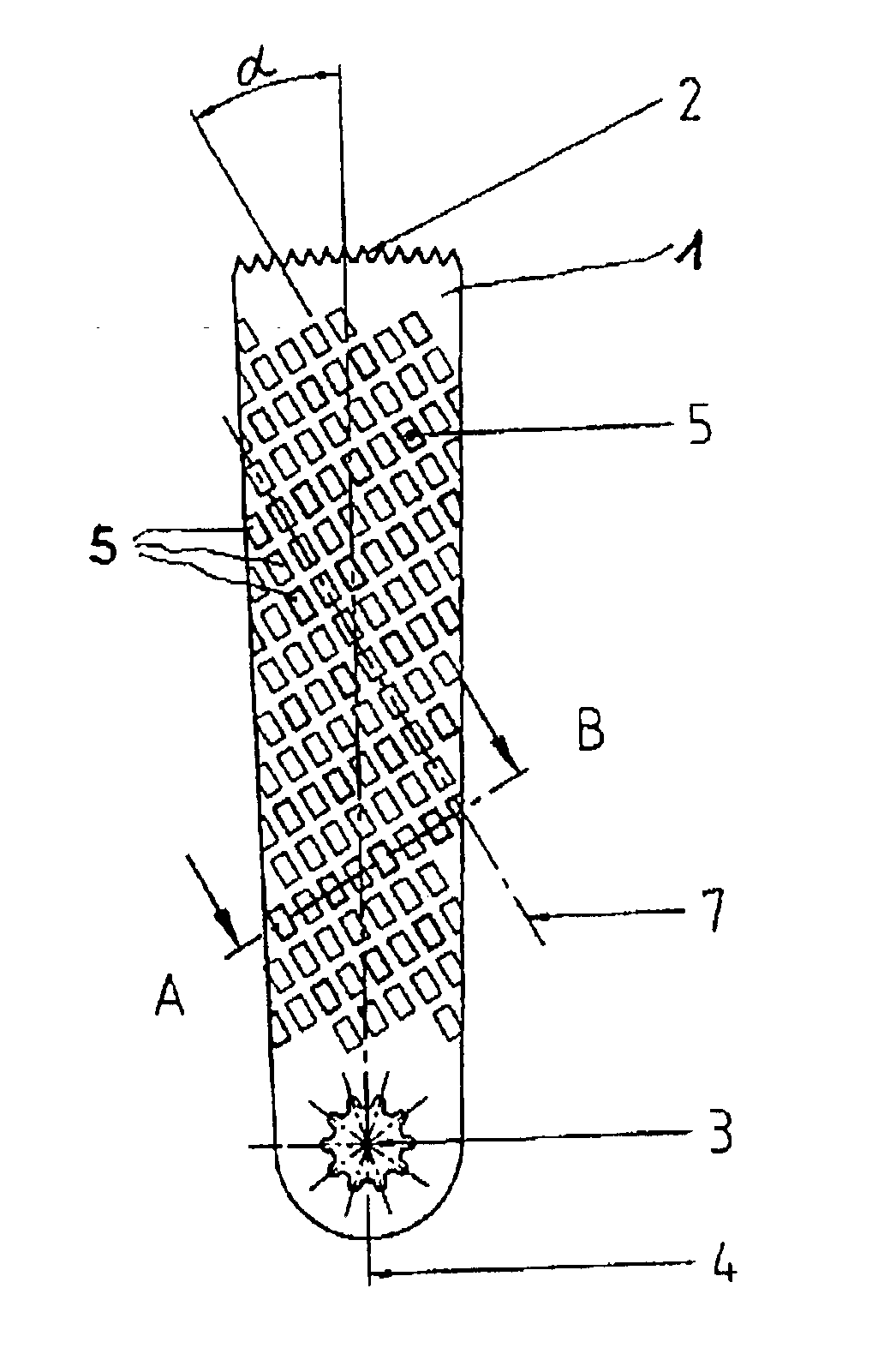

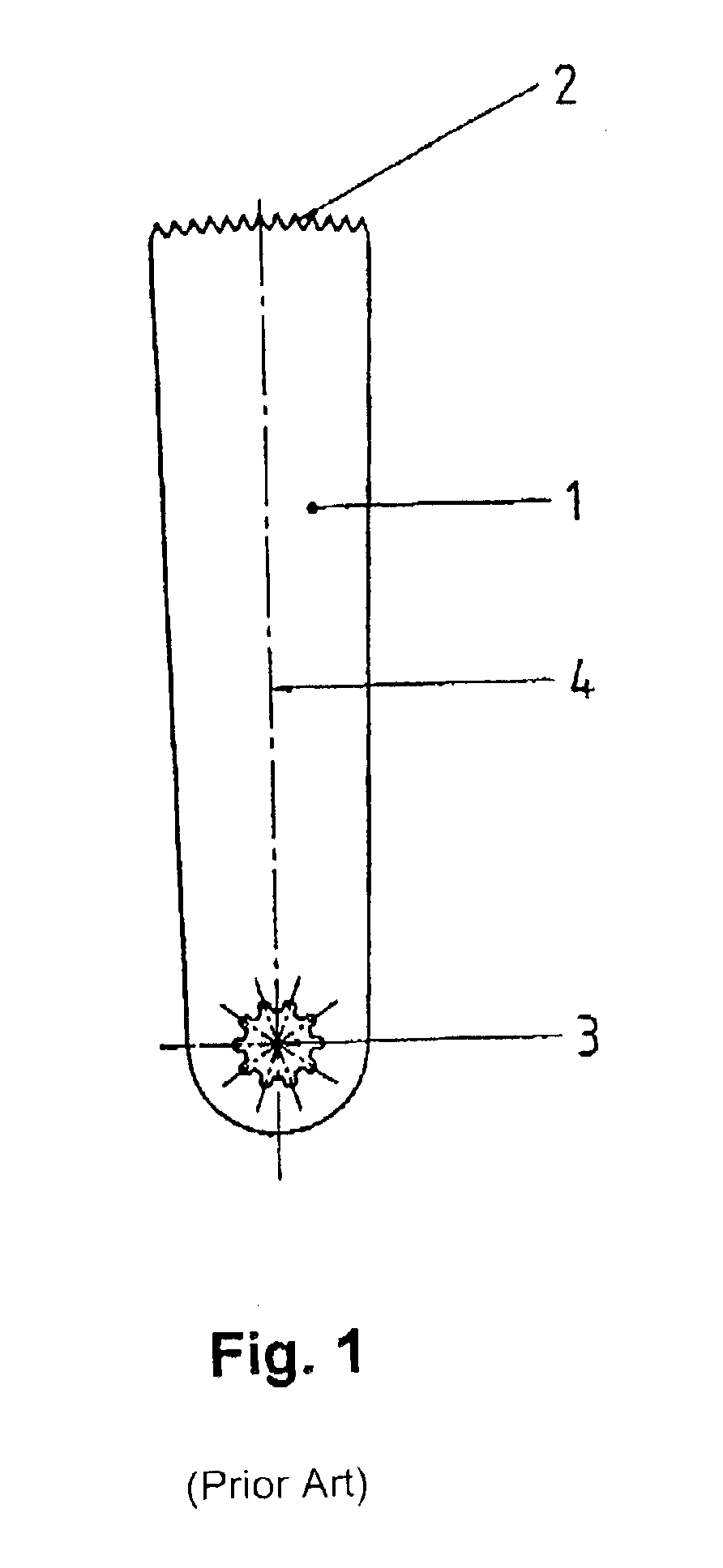

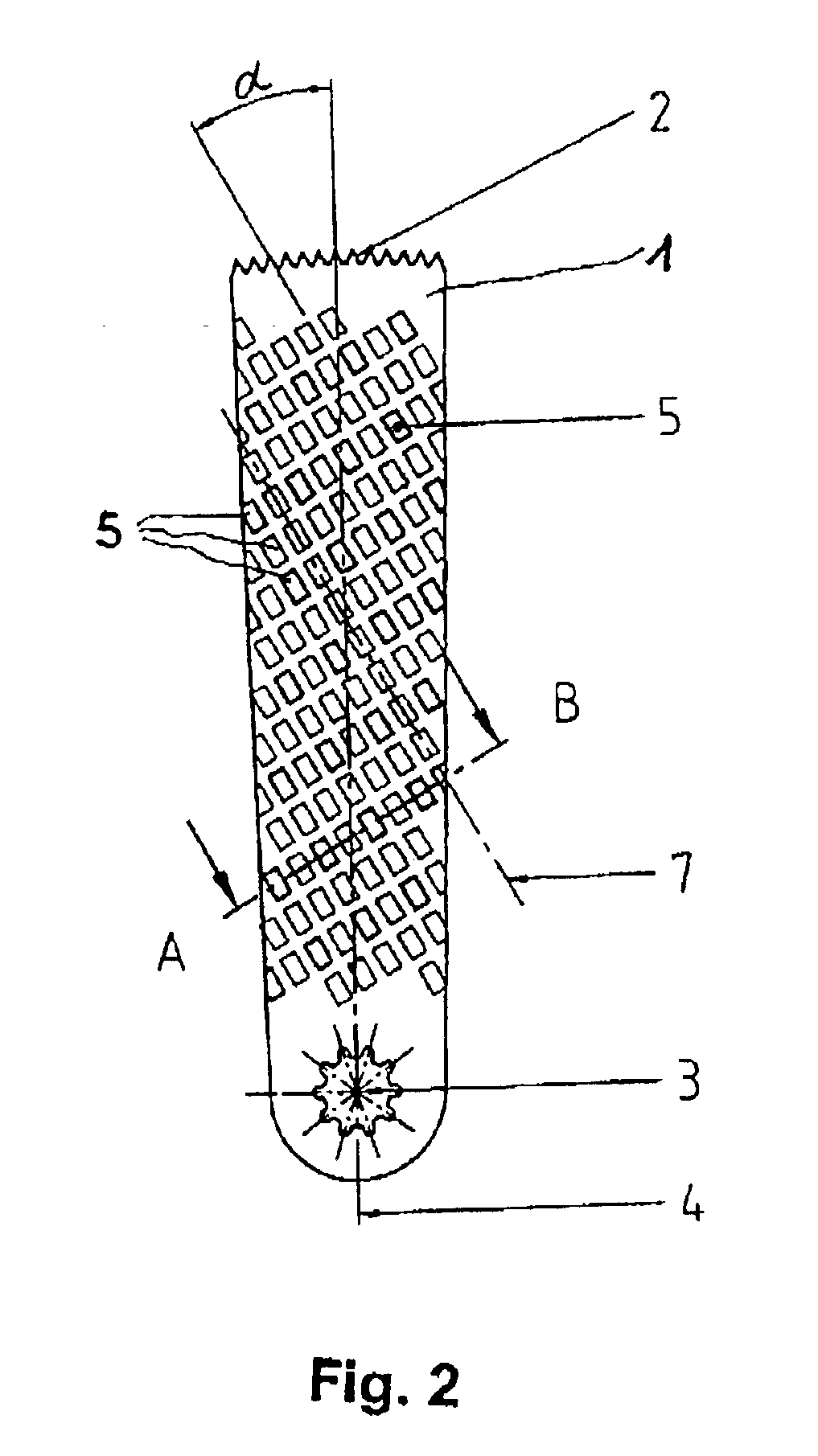

Saw blade for hand-held tools

InactiveUS7127979B2Prolong lifeIncrease forceMetal sawing devicesMetal sawing tool makingHand heldEngineering

Owner:ROBERT BOSCH GMBH

Surgical saw blade having at least one pair of opposed teeth shaped as right triangles

InactiveUS7527628B2Reduce fatigueEasy to trackMetal sawing devicesMetal sawing toolsRight triangleLong axis

A cutting saw blade for use with an oscillatory power tool used in surgical bone cutting procedures including a blade having a distal end provided with teeth whose tips are located on a tangent line perpendicular to the long axis of the blade. The teeth are configured substantially as right triangles with their hypotenuses facing either towards the center of the blade or away from the center of the blade. A central tooth can be optionally provided. The surgical saw blade may have a distal end having at least one pair of teeth configured to be adjacent to each other and each of the pair of teeth is configured as a right triangle each having a hypotenuse which is oriented at least one of towards and away from the centrally positioned long axis.

Owner:SYNVASIVE TECH

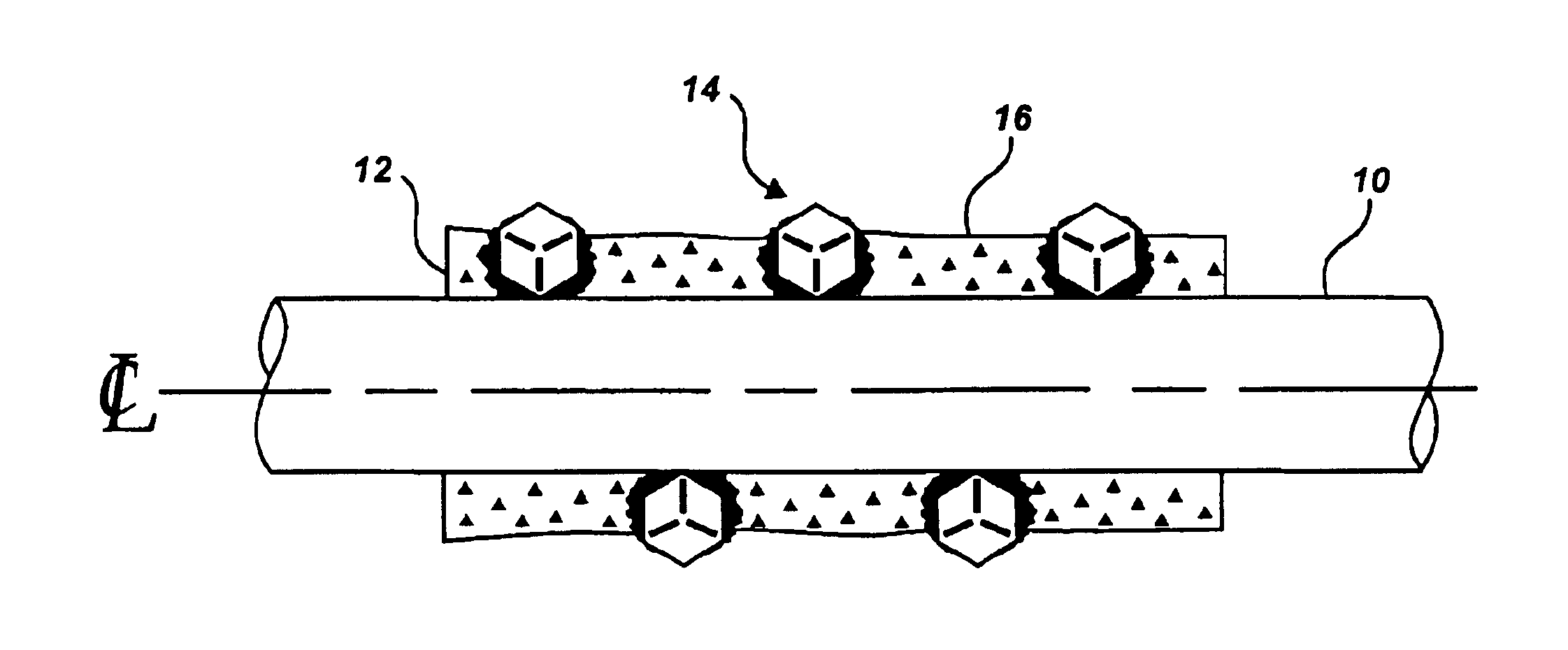

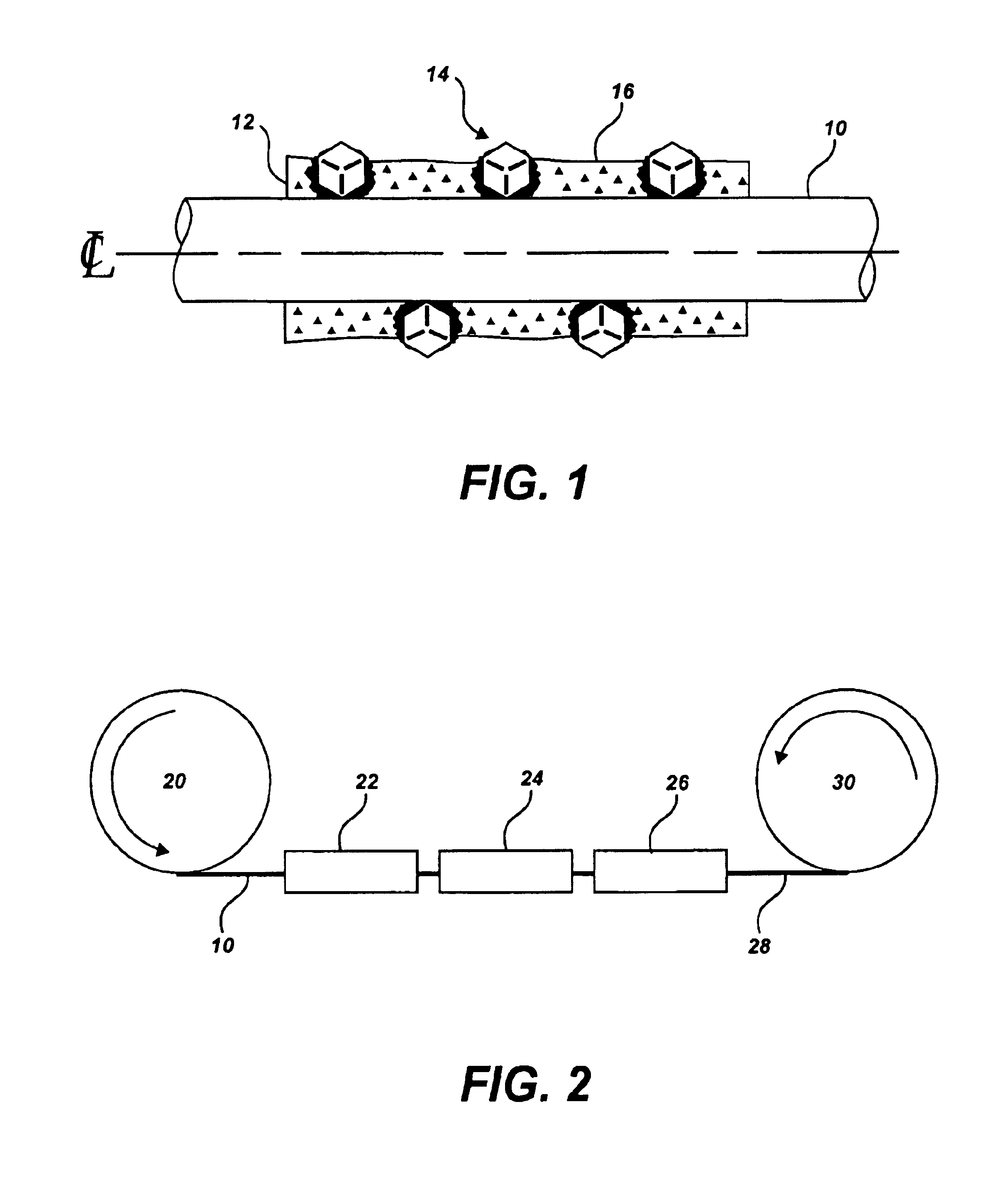

Reciprocating wire saw for cutting hard materials

InactiveUS7089925B1Low costIncrease valueBelt grinding machinesMetal sawing toolsEngineeringWire saw

The present invention features a reciprocating wire saw particularly adapted or configured for cutting hard materials. In one aspect, the reciprocating wire saw comprises (a) a flexible wire; (b) a plurality of cutting segments fittable onto the flexible wire, wherein each of the cutting segments comprises an outer surface; and a (c) plurality of superabrasive particles braze bonded onto the outer surface of the cutting segments to form a cutting wire. In another aspect, the reciprocating wire saw comprises a plurality of superabrasive particles braze bonded directly to the wire itself to form a cutting wire. The cutting wire is unique in that it comprises a pre-determined superabrasive particle concentration and is configured to cut various materials, such as granite, in a reciprocating manner.

Owner:KINIK

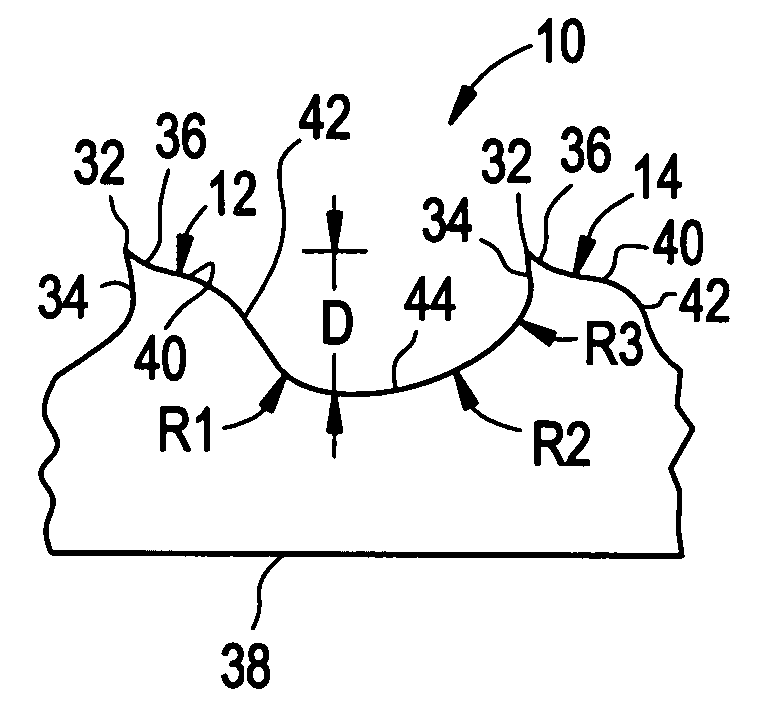

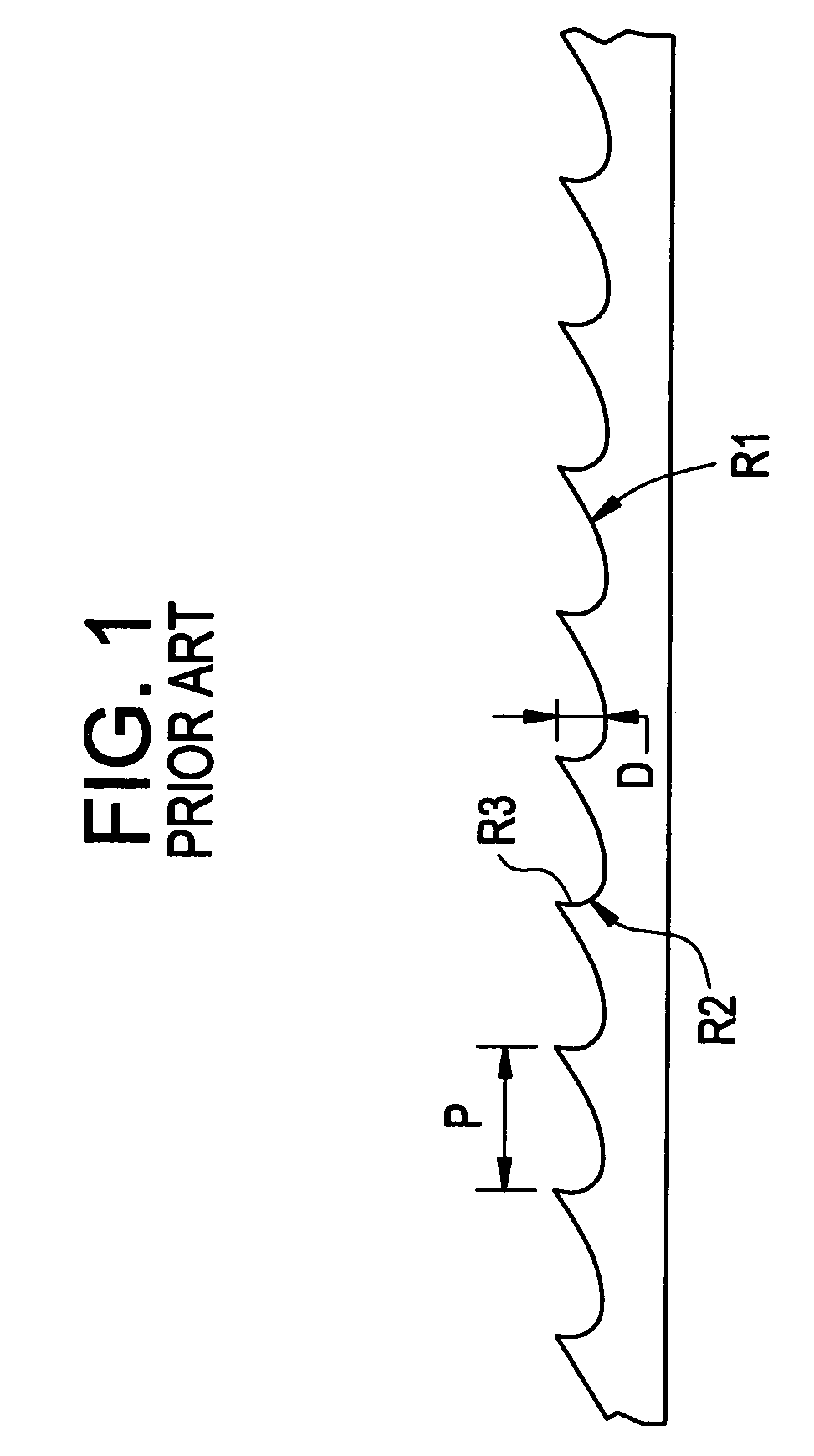

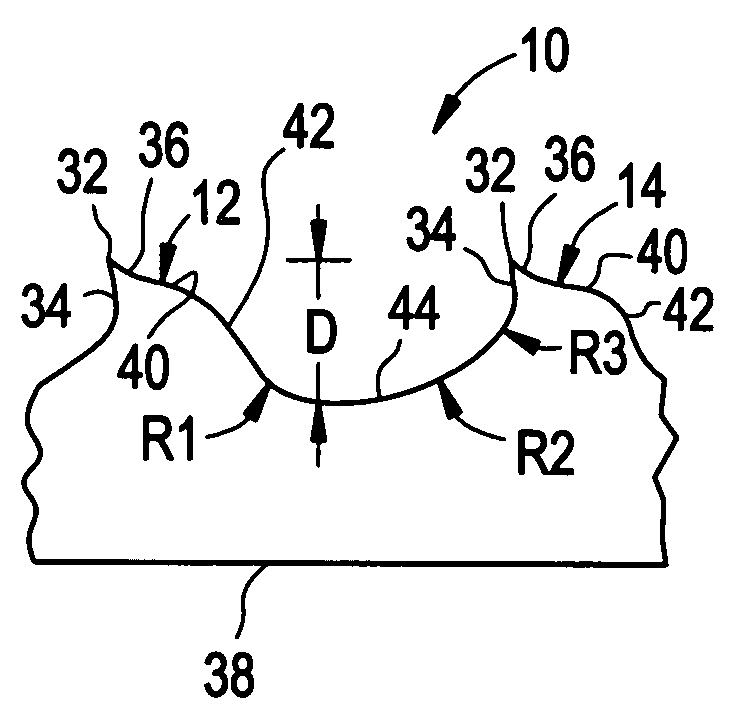

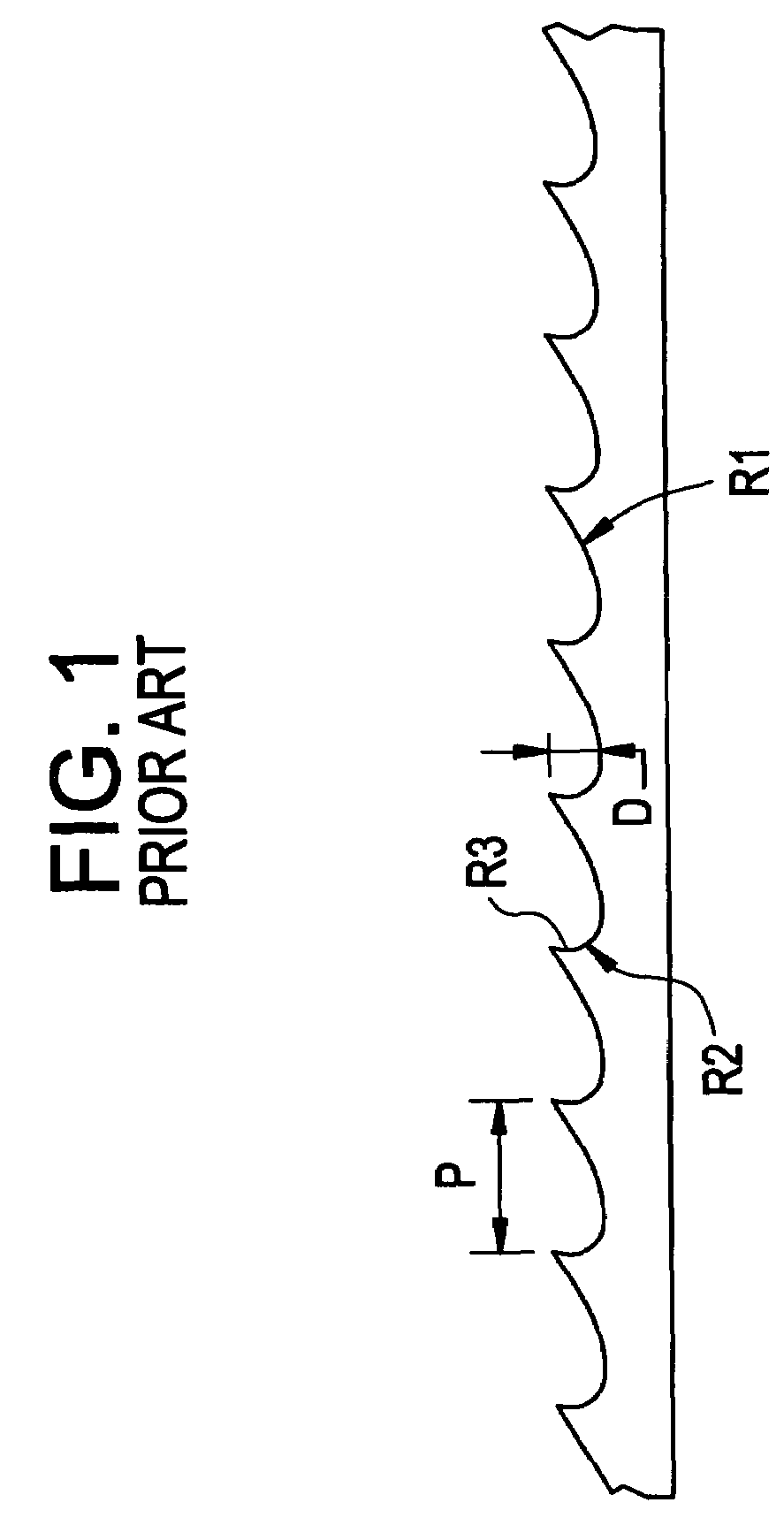

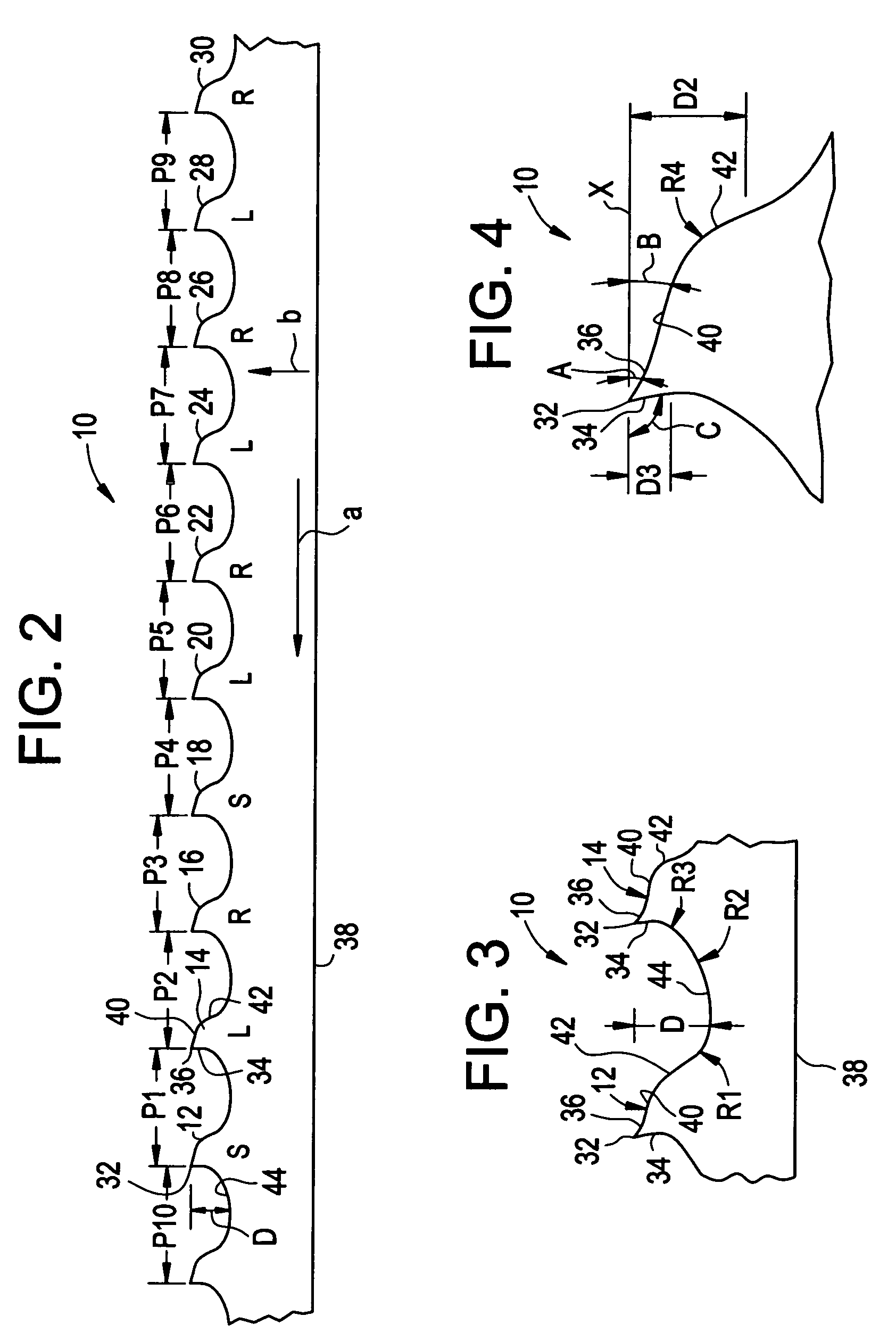

Saw blade having increased tooth stiffness and resistance to fatigue failure

InactiveUS20060065098A1Increase Section WidthPrevent set collapseMetal sawing devicesMetal sawing toolsEngineeringWood cutting

A wood-cutting band saw blade includes a cutting edge defined by a plurality of teeth spaced relative to each other, wherein each tooth includes a tip; a rake face formed on one side of the tip; a primary clearance surface formed on an opposite side of the tip relative to the rake face; a secondary clearance surface formed on an opposite side of the primary clearance surface relative to the tip; a tertiary clearance surface formed on an opposite side of the secondary clearance surface relative to the primary clearance surface; and a gullet located on an opposite side of the rake face relative to the tip and defining a depth (D) between a base surface of the gullet and the tip. Each tooth further defines a first gullet radius (R1) located between the gullet and tertiary clearance surface; a second gullet radius (R2) extending between a base surface of the gullet and the rake face; and a pitch (P) between the respective tooth and a preceding tooth in a cutting direction of the saw blade. In each tooth, R2>D>R1, D / P is within the range of about 25% to about 35% and R2 / R1≧about 1.4. R1 defines a minimum radius (Rmin) at a base of the gullet and Rmin / D>about 20%.

Owner:IRWIN IND TOOL CO

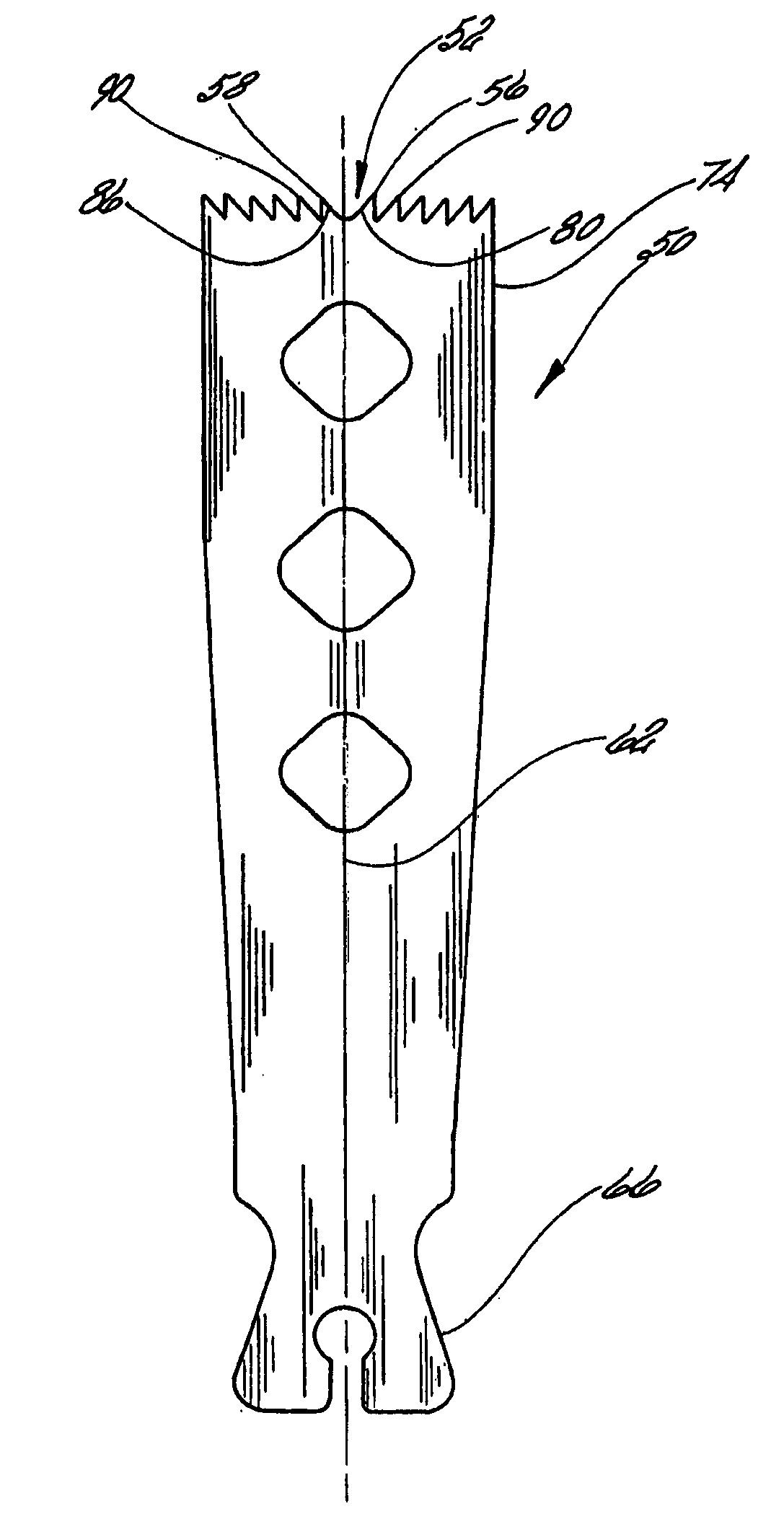

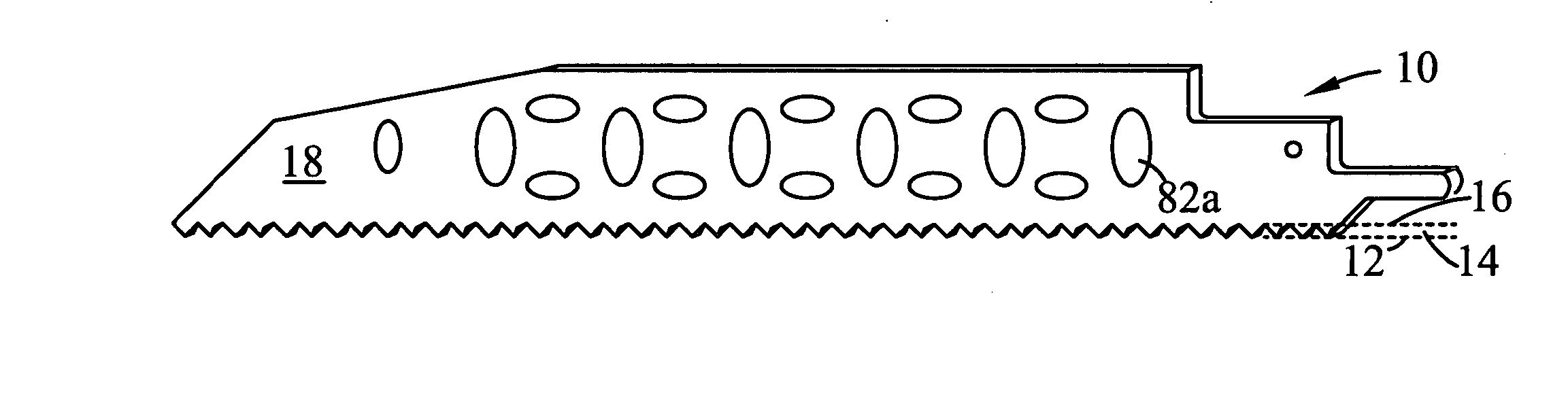

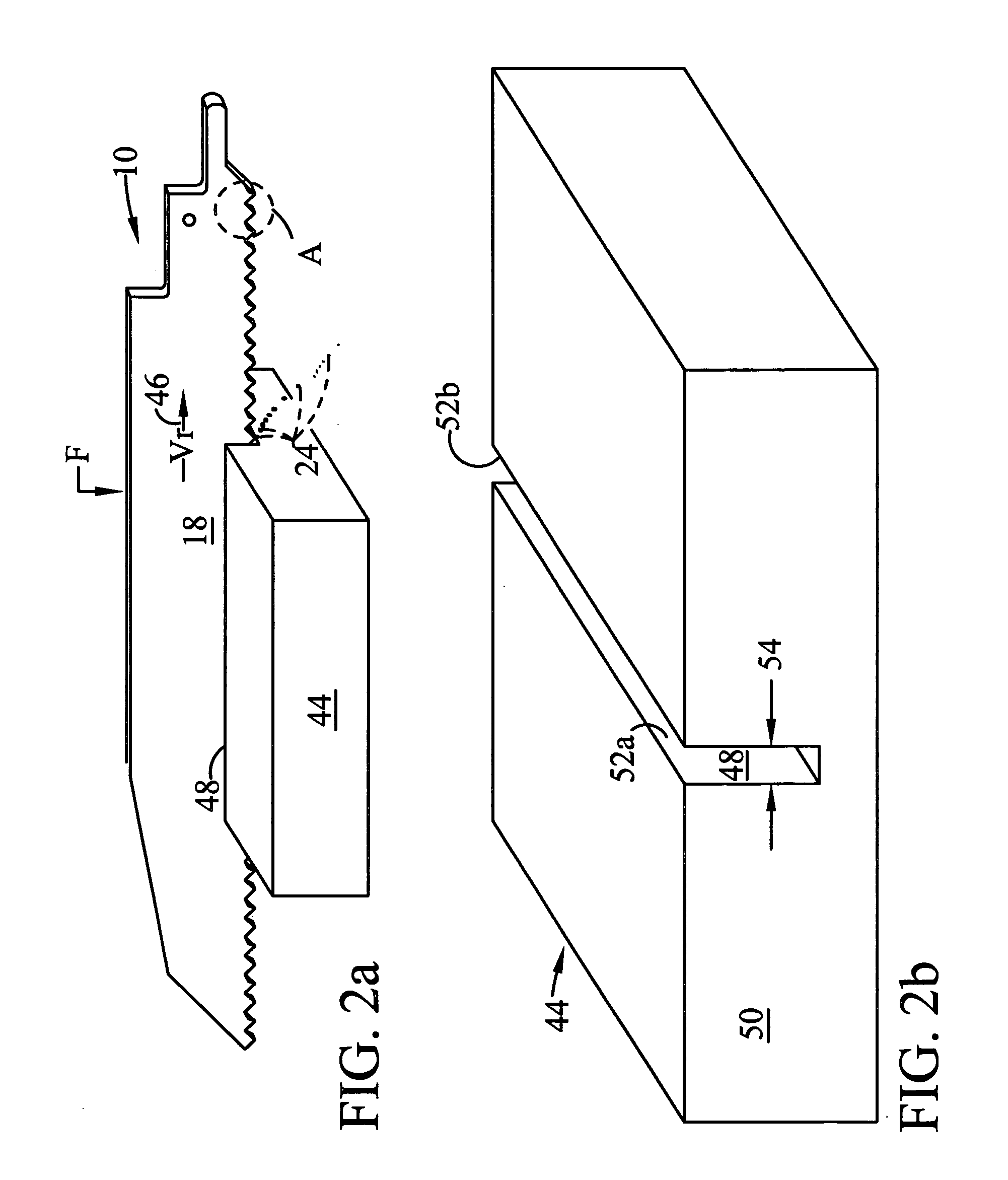

Saw cutting blade

InactiveUS20060016315A1Small sizeGood removal effectMetal sawing devicesMetal sawing toolsLinear motionEngineering

A saw blade having blade body supporting a leading cutting edge for cutting through a workpiece. A force and motion are applied to drive the cutting edge against the work piece as the body of the saw blade is driven with a reciprocating, rotational or linear motion transverse to the applied direction of the force. The solid rectangular cross section of a saw blade is modified to improve its ability to cut through a workpiece. The body of the blade is characerized as having cut out areas distributed throughout the blade body to capture and remove the debris from the kerf. This improved cutting performance can be further enhanced by reducing the cross section of the body. Secondary cutting edges may also be incorporated around the perimeter of the cutouts and as part of the reduced geometry portion of the blade body.

Owner:ZORICH TIMOTHY A +1

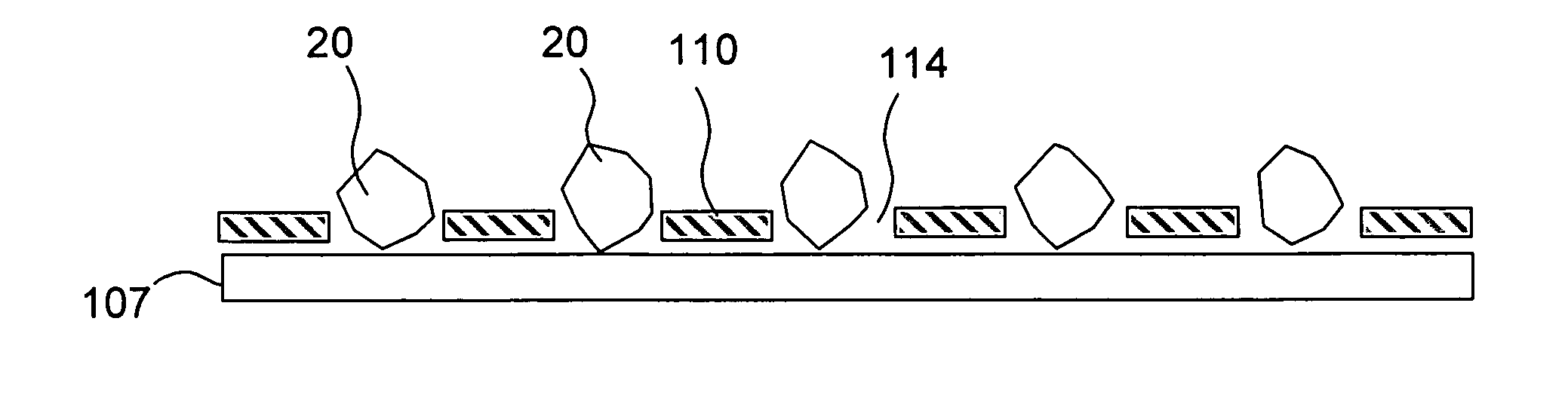

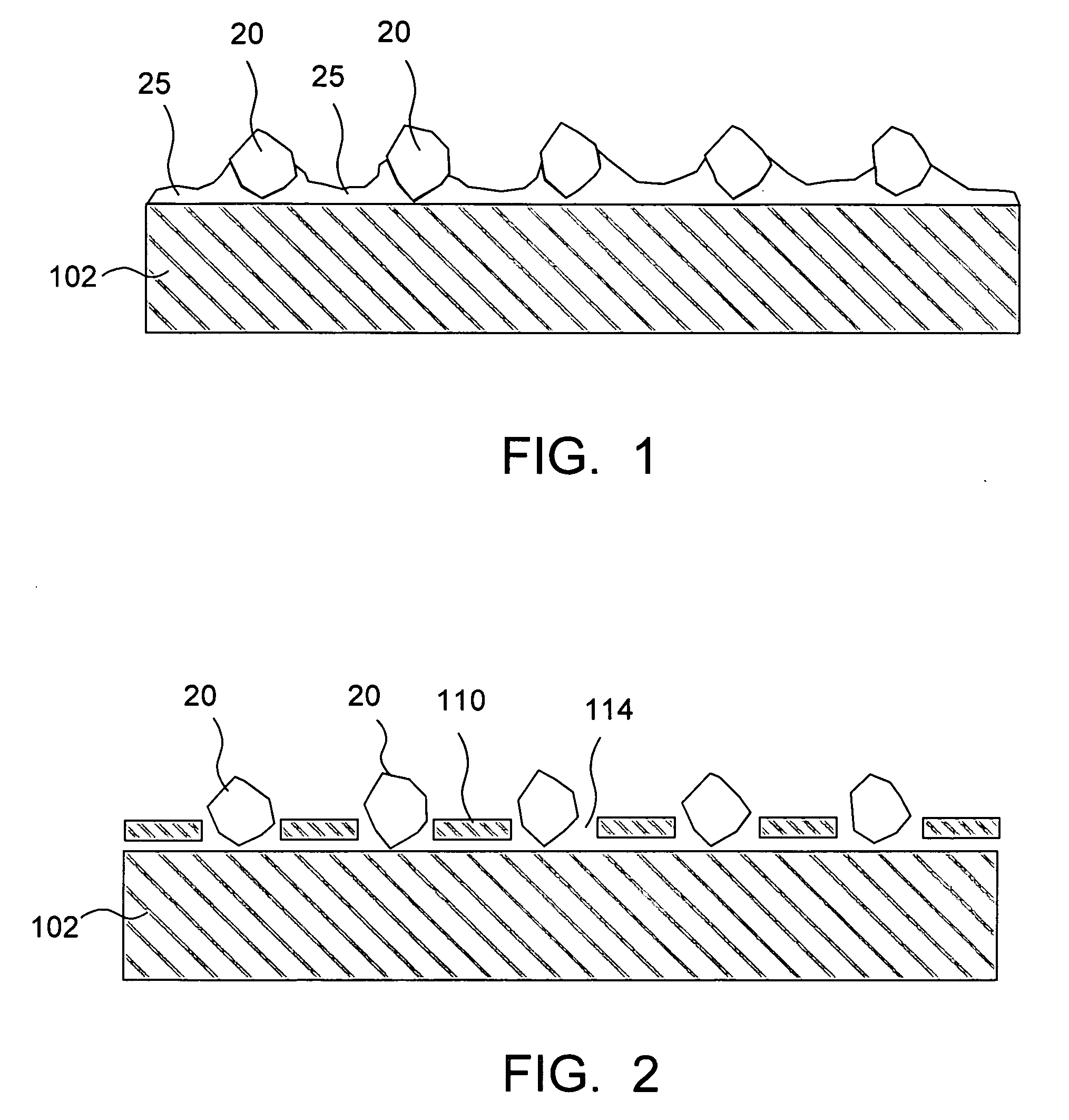

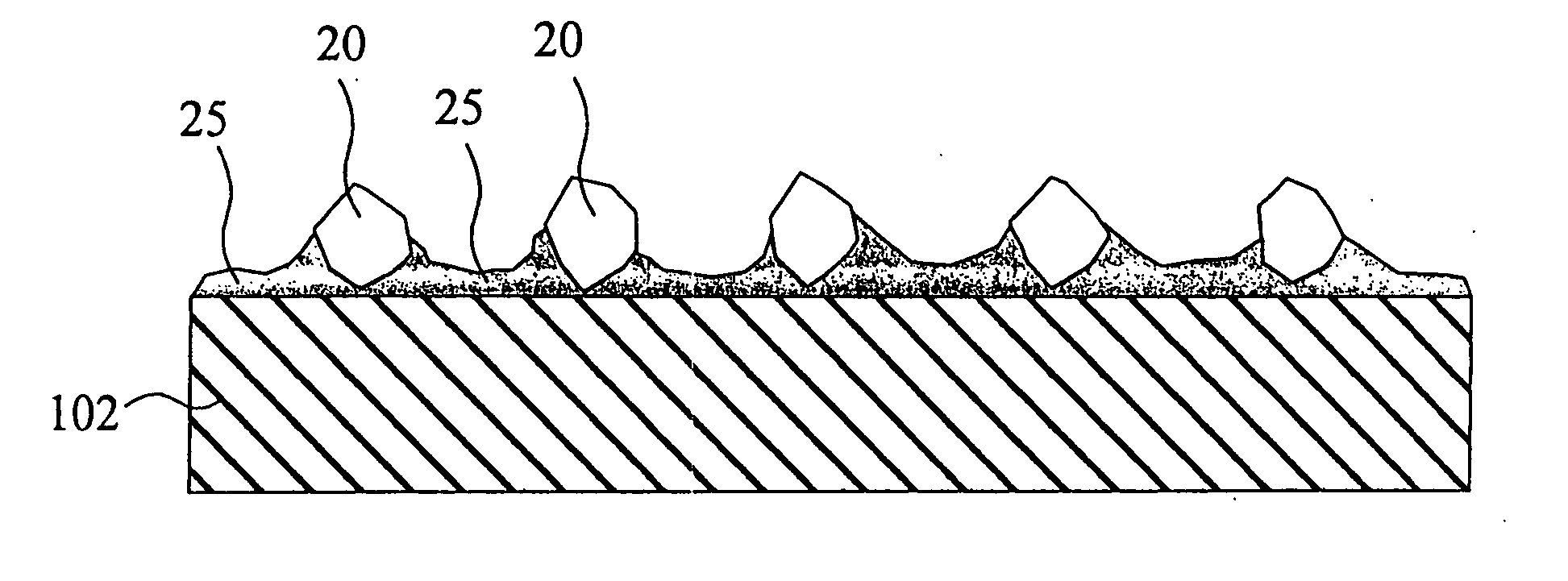

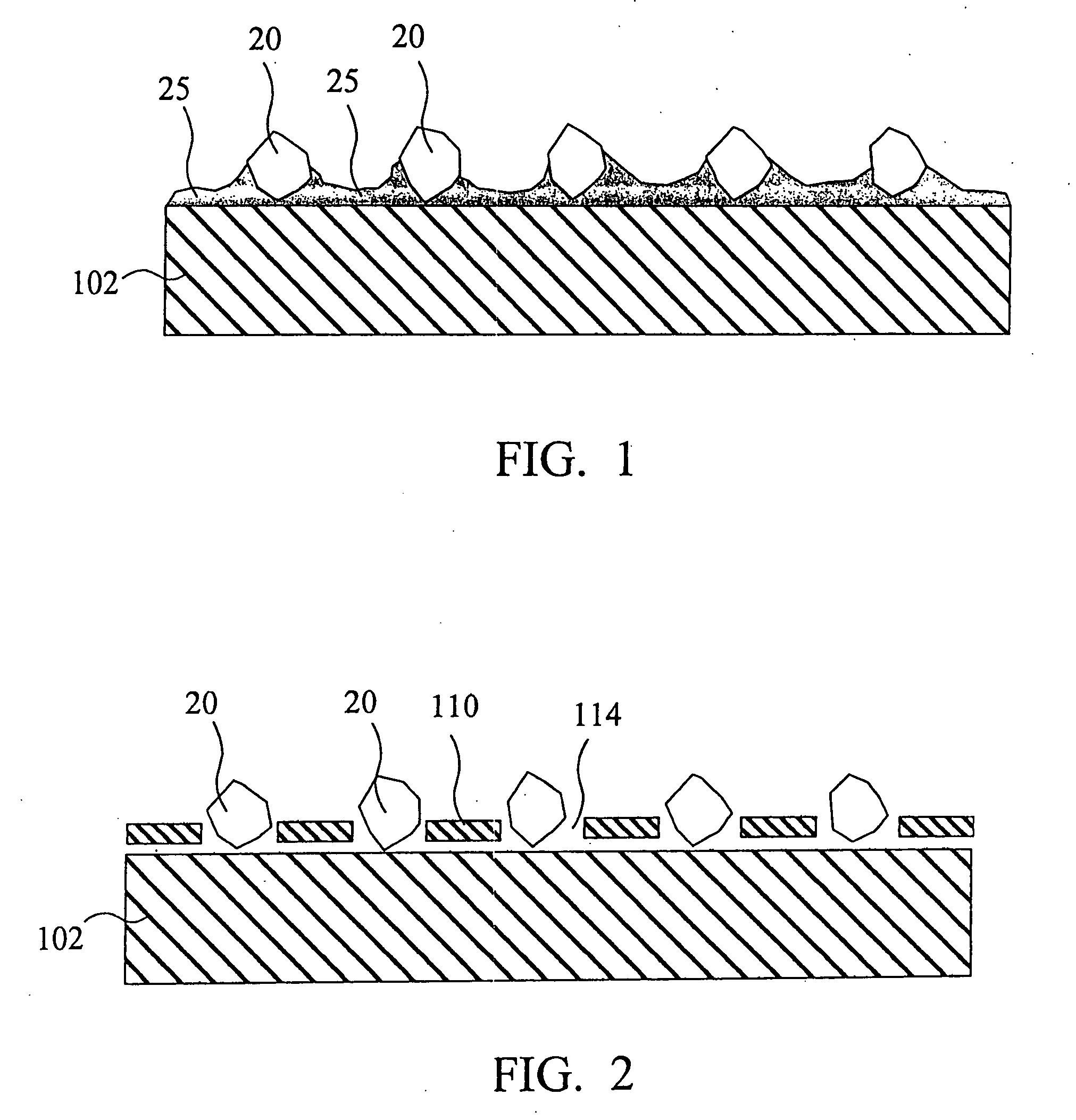

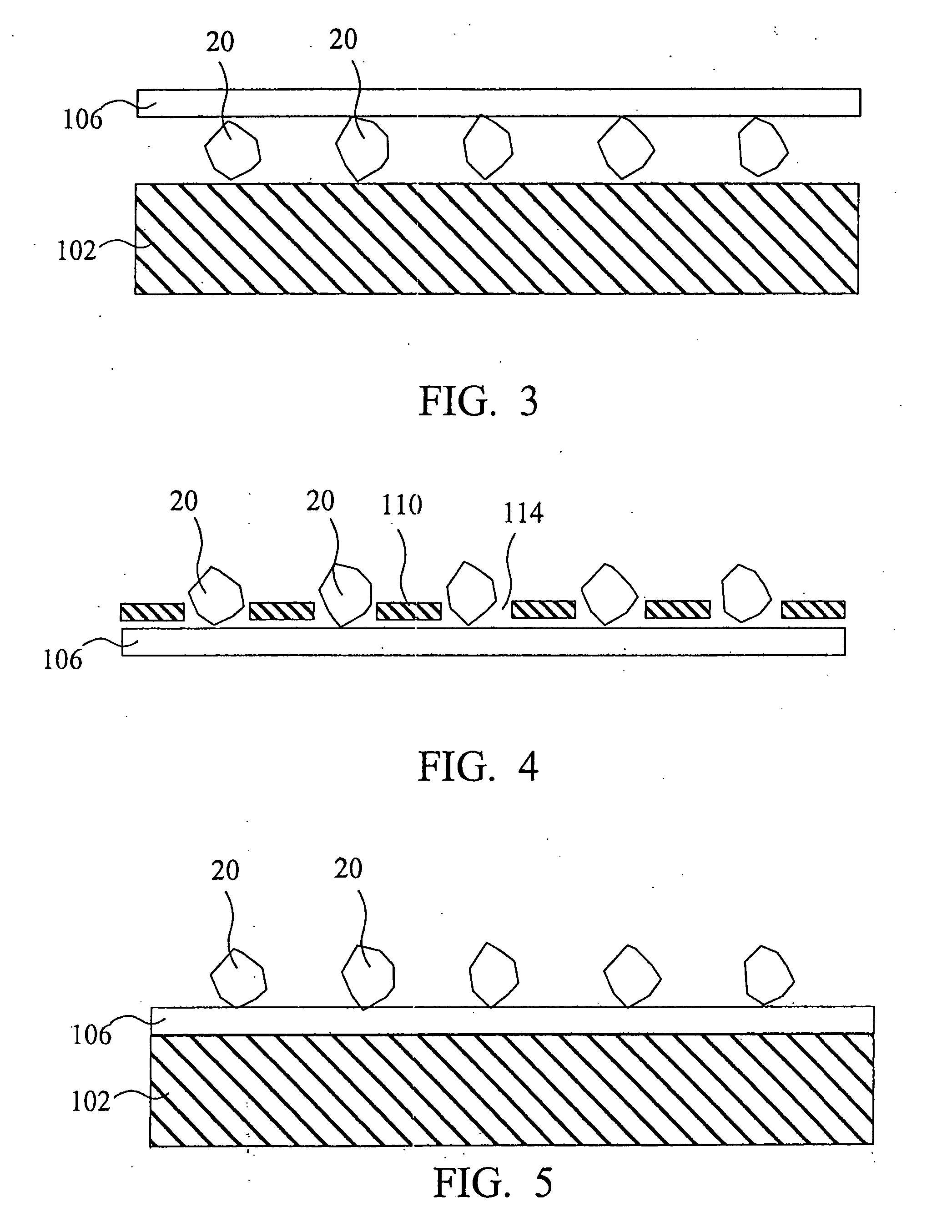

Brazed diamond tools and methods for making the same

InactiveUS20040112359A1Avoid large movementsImprove cutting efficiencyDrill bitsConstructionsChemical LinkageBraze alloy

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

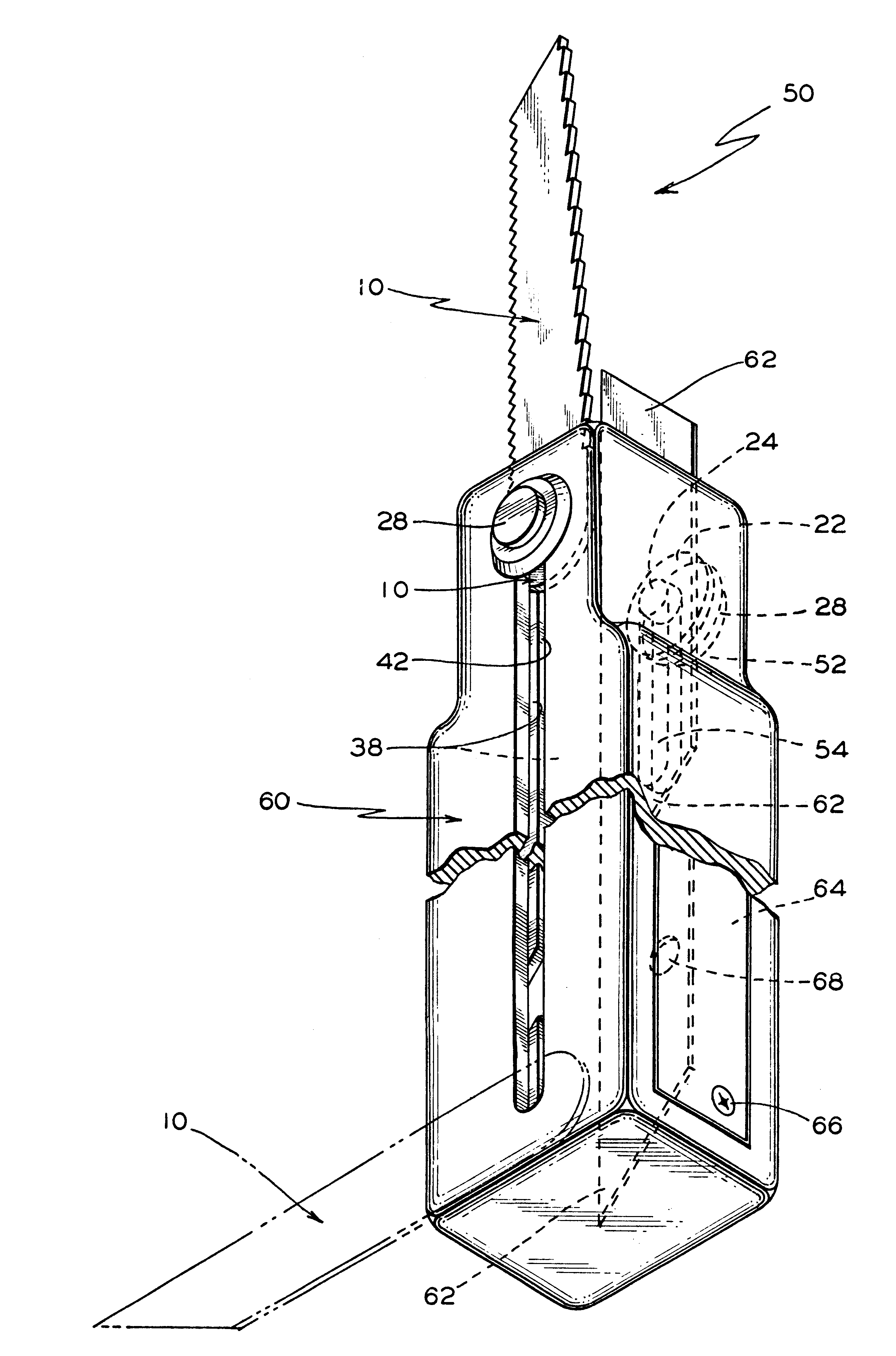

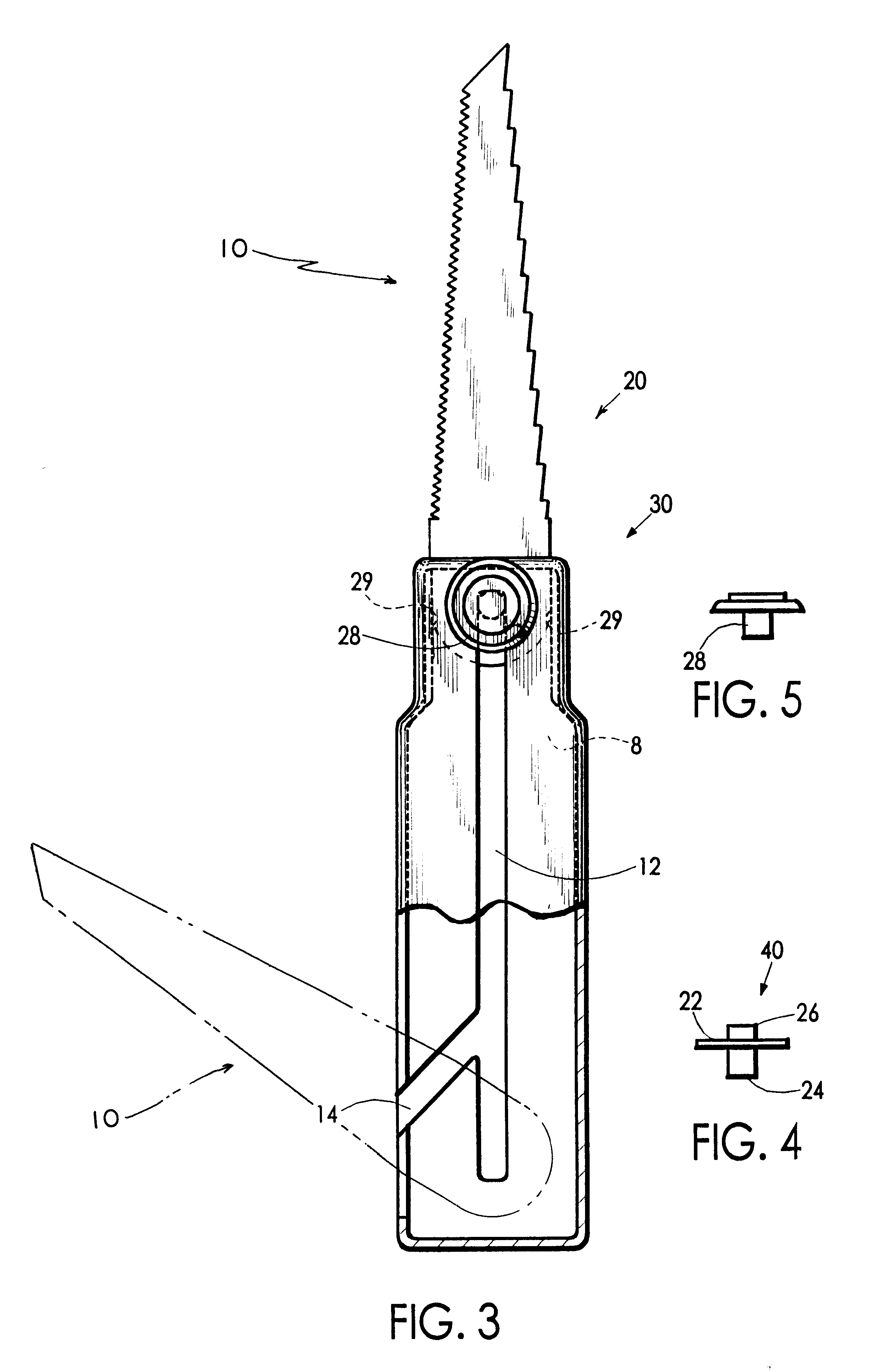

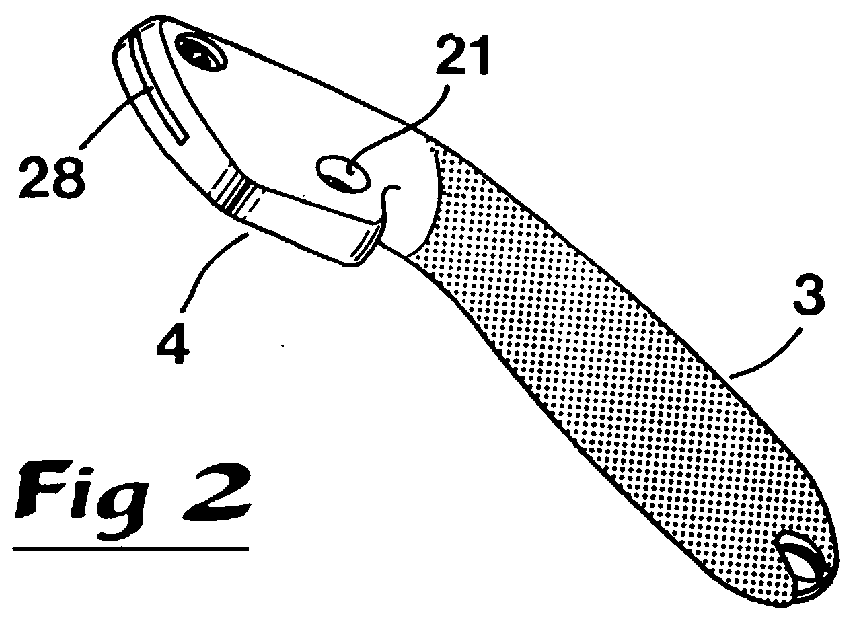

Combination utility retractable saw and knife device

The present invention provides a combination utility retractable saw and knife device that comprises a handle member having a predetermined configuration and a knife blade disposed within a cavity formed in the handle member when in a retracted position. The knife blade member has a predetermined configuration. It further includes a saw blade disposed within a radially opposed cavity of such handle member when in a retracted position. Such combination device further includes a means engageable with the saw blade for connecting it with the handle and a means engageable with the knife blade for connecting it with the handle. There is also a means engageable with the saw blade for at least one of slidably moving and pivotably rotating the saw blade to an operable position, the means being at least partially disposed within the handle and a means engageable with the knife blade for slidably moving the knife blade member to an operable position, such means also being at least partially disposed within the handle. There is further a means engageable with the saw blade and the handle for locking the saw blade in an operable position and in a retracted position, such means being at least partially disposed within the handle and a means engageable with the knife blade and the handle for locking the knife blade in an operable and a retracted position, such means being at least partially disposed within said handle member.

Owner:UMSTEAD GEORGE H +1

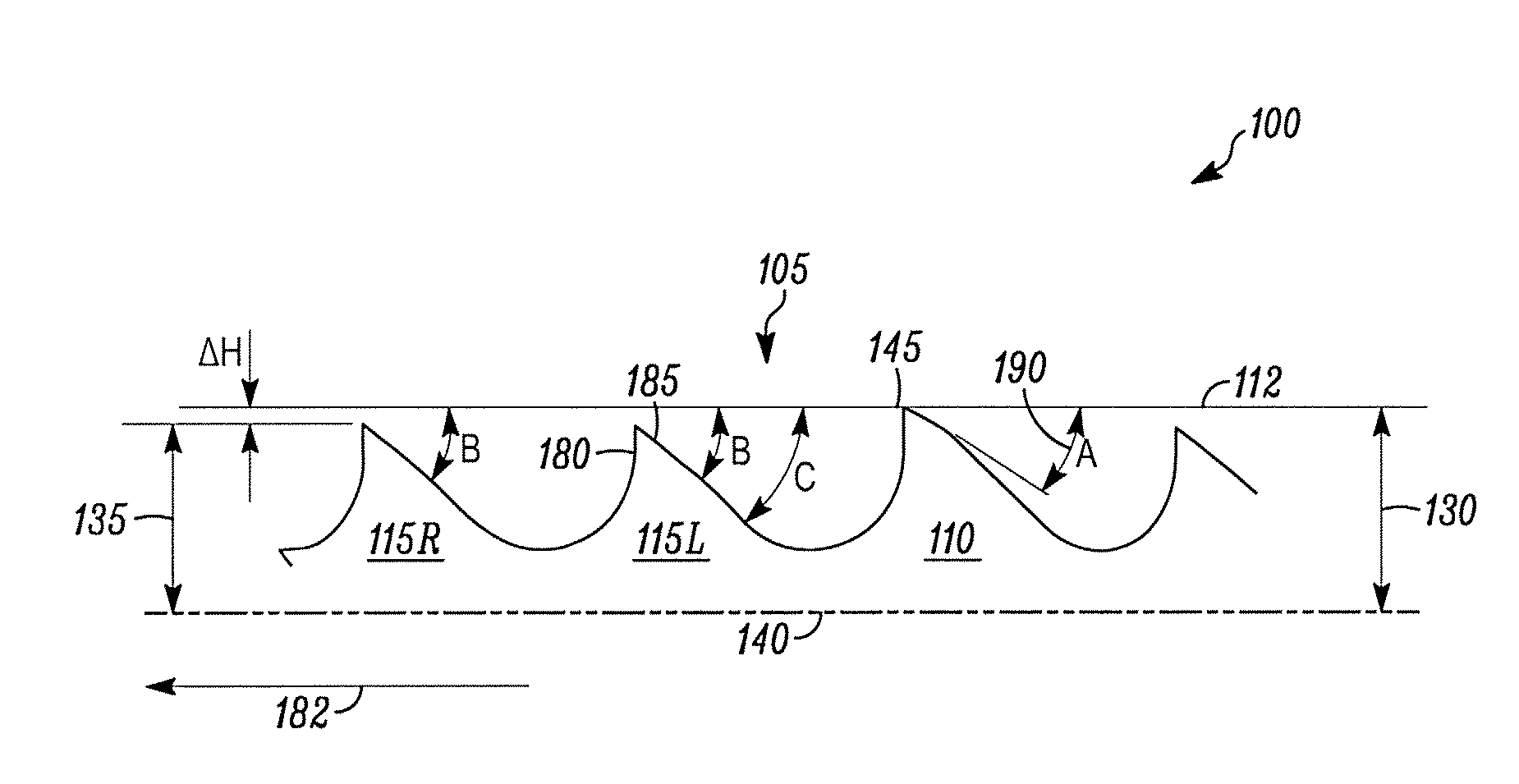

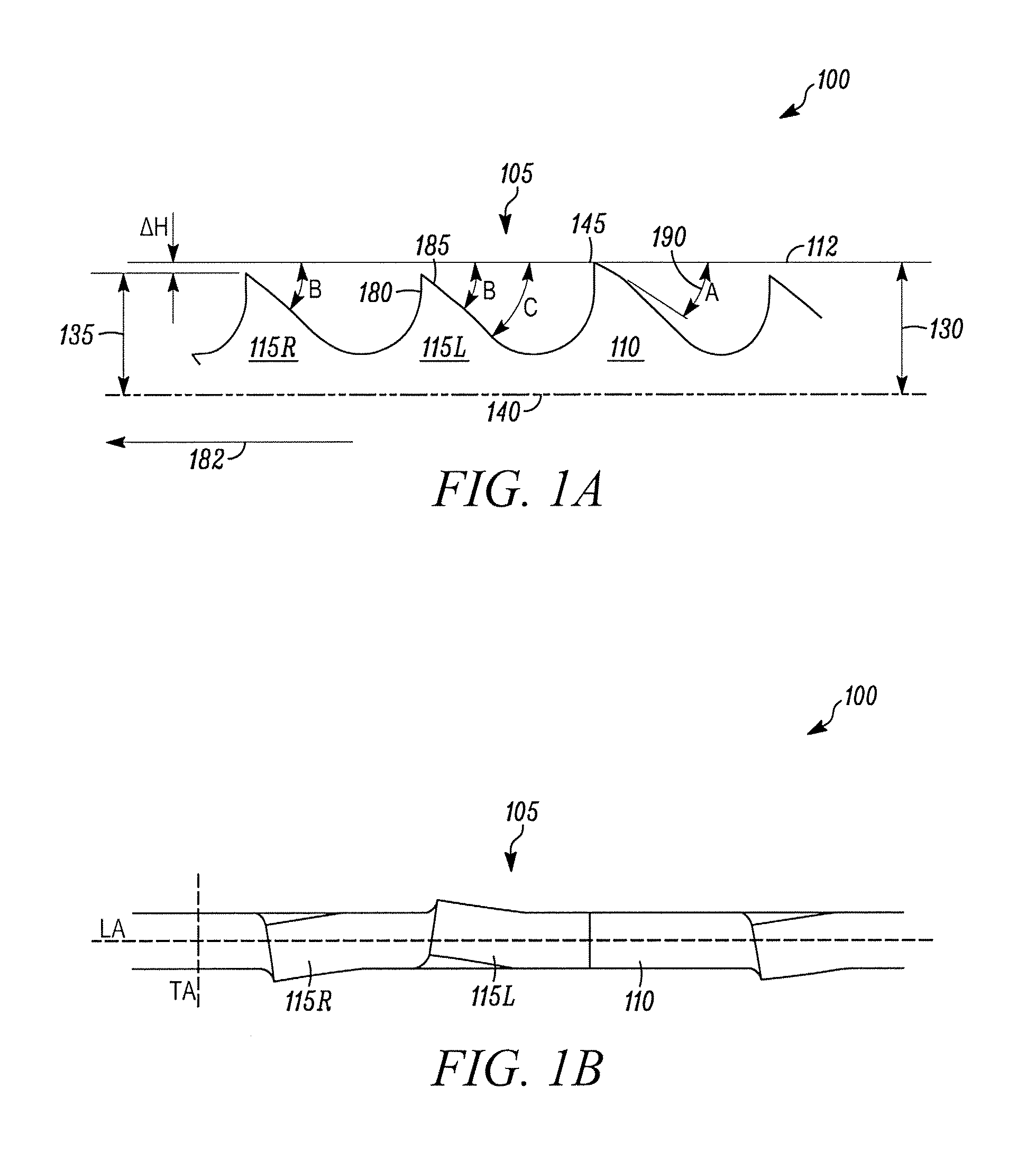

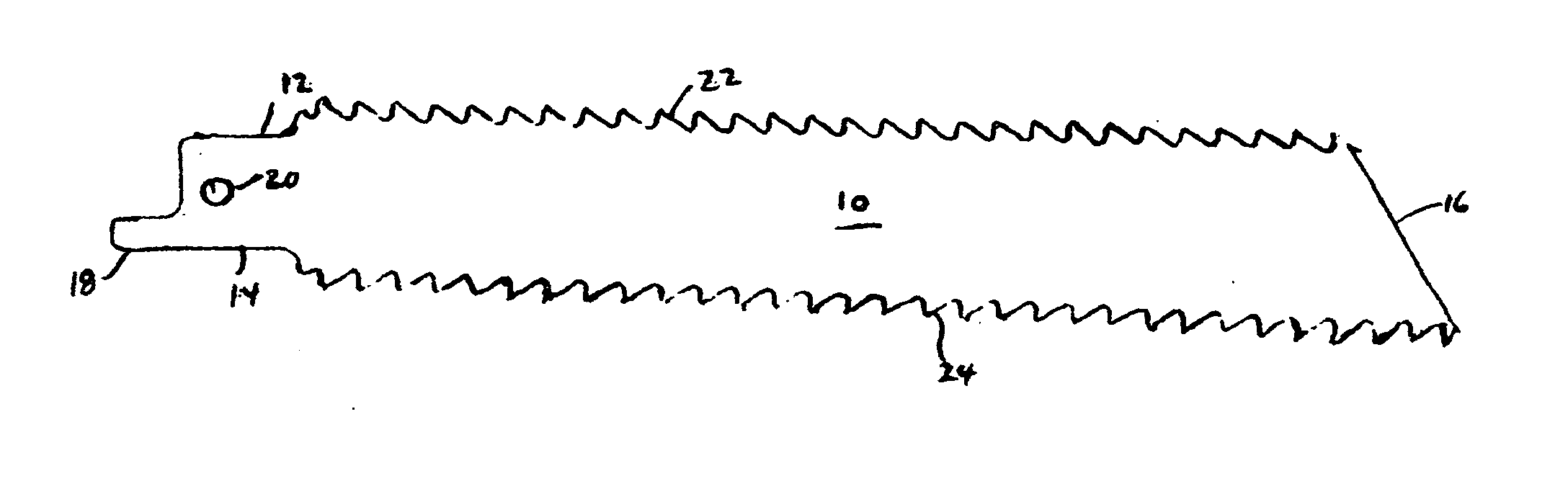

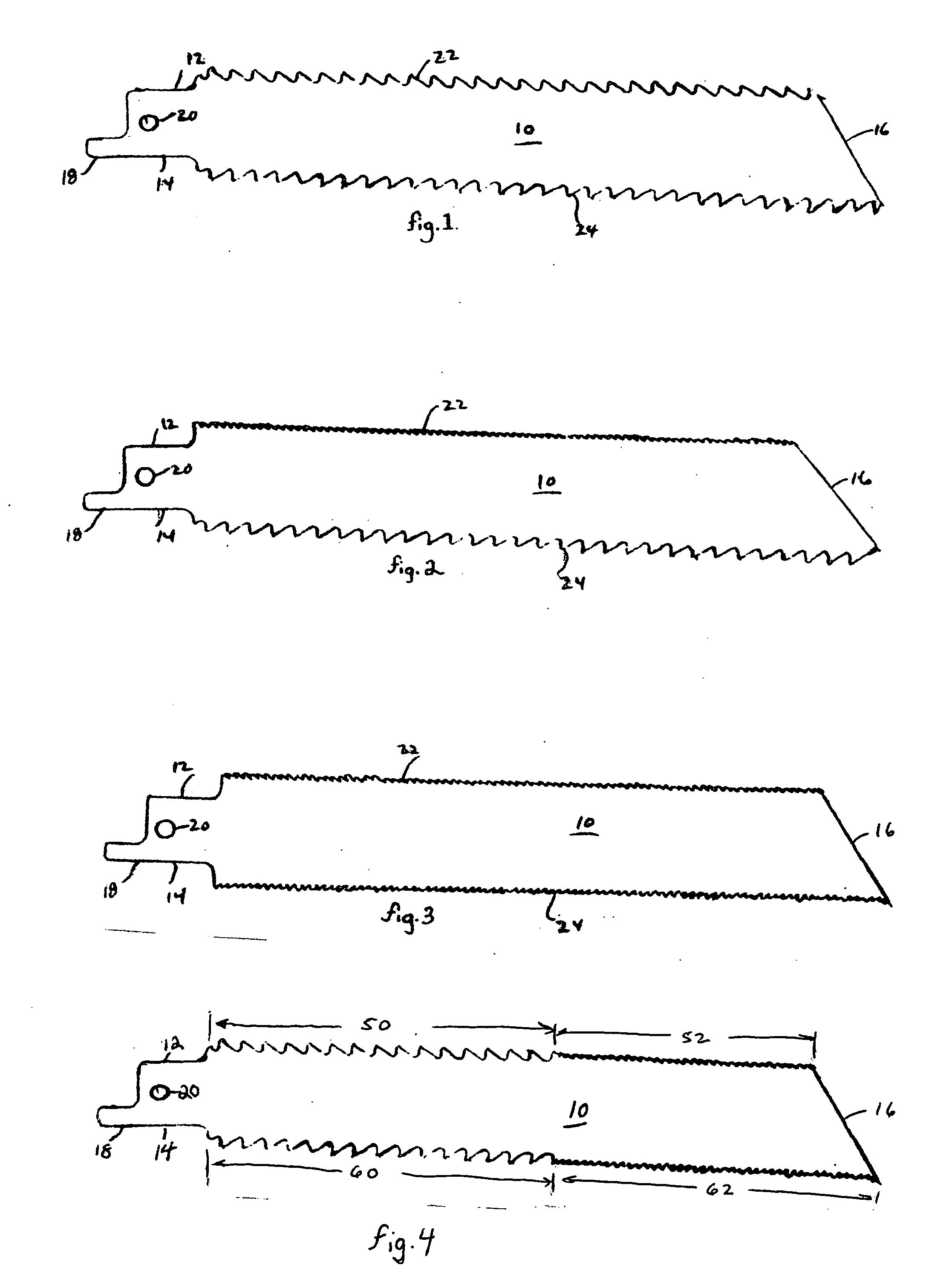

Reciprocating Saw Blade Having Variable-Height Teeth and Related Method

ActiveUS20080307936A1Improve performanceIncrease cutting forceMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

Construction saw blade

A construction saw blade having pluralities of cutting teeth along upper and lower edge surfaces thereof, an aperture transversely extending through the blade adjacent its rearwardly facing back end of a configuration and dimension to receive a fastener to removably secure the blade to a reciprocating saw for use, and wherein each plurality of cutting teeth include rake angles for cutting substantially only on a pull stroke of the reciprocating saw.

Owner:HAWTHORN JOHN E

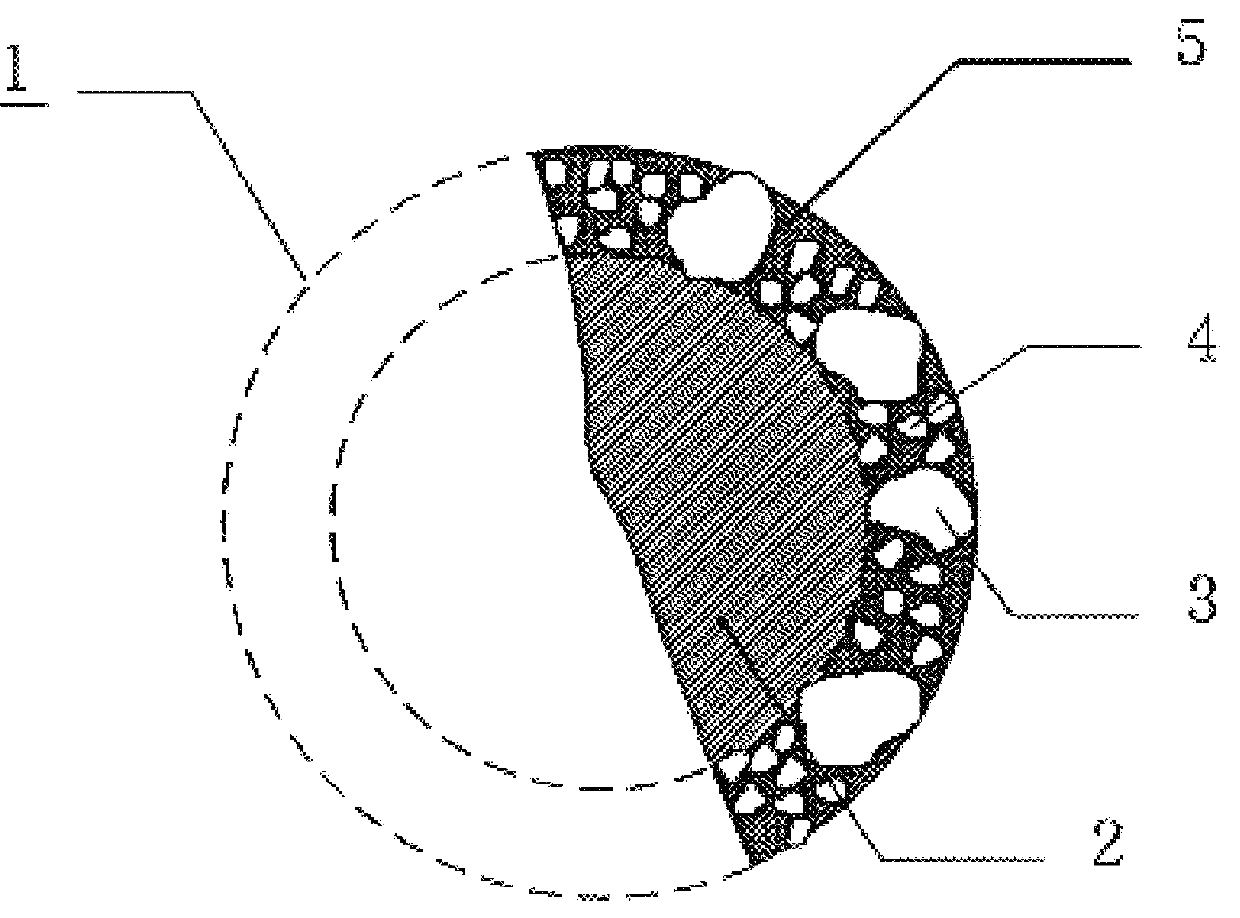

Wire-saw and its manufacturing method

InactiveUS6070570AReadily worked and finishedImprove homogeneityMetal sawing toolsGrinding devicesEngineeringElectronic materials

PCT No. PCT / JP98 / 00532 Sec. 371 Date Mar. 9, 1999 Sec. 102(e) Date Mar. 9, 1999 PCT Filed Feb. 9, 1998 PCT Pub. No. WO98 / 35784 PCT Pub. Date Aug. 20, 1998The present invention provides a wire saw for use in cutting works of electronics materials or optical materials and a method for manufacturing the same, said wire saw having the following characteristic features. Namely, onto a high-strength core wire 2, abrasive grains 3 having a grain size not smaller than two-thirds the thickness of a layer of resin bond 4 on said core wire 2 but not exceeding a half the diameter of said core wire are fixed with said resin bond, said resin bond containing a filler having a grain size smaller than two-thirds the thickness of said resin bond layer. The thus structured and arranged wire saw has an improved efficiency and precision in cutting. The wire saw can be manufactured readily by using an enamelling oven.

Owner:ALLIED MATERIAL +1

Tooth form design for reciprocating saw blade

A reciprocating saw has a tooth form that decreases the cutting time of the saw blade and extends the life of the saw blade. The tooth height is longer than conventional metal cutting reciprocating saws. Also, the tooth form has a larger gullet. The tooth rake angle remains substantially constant during the life of the saw blade.

Owner:BLACK & DECKER INC

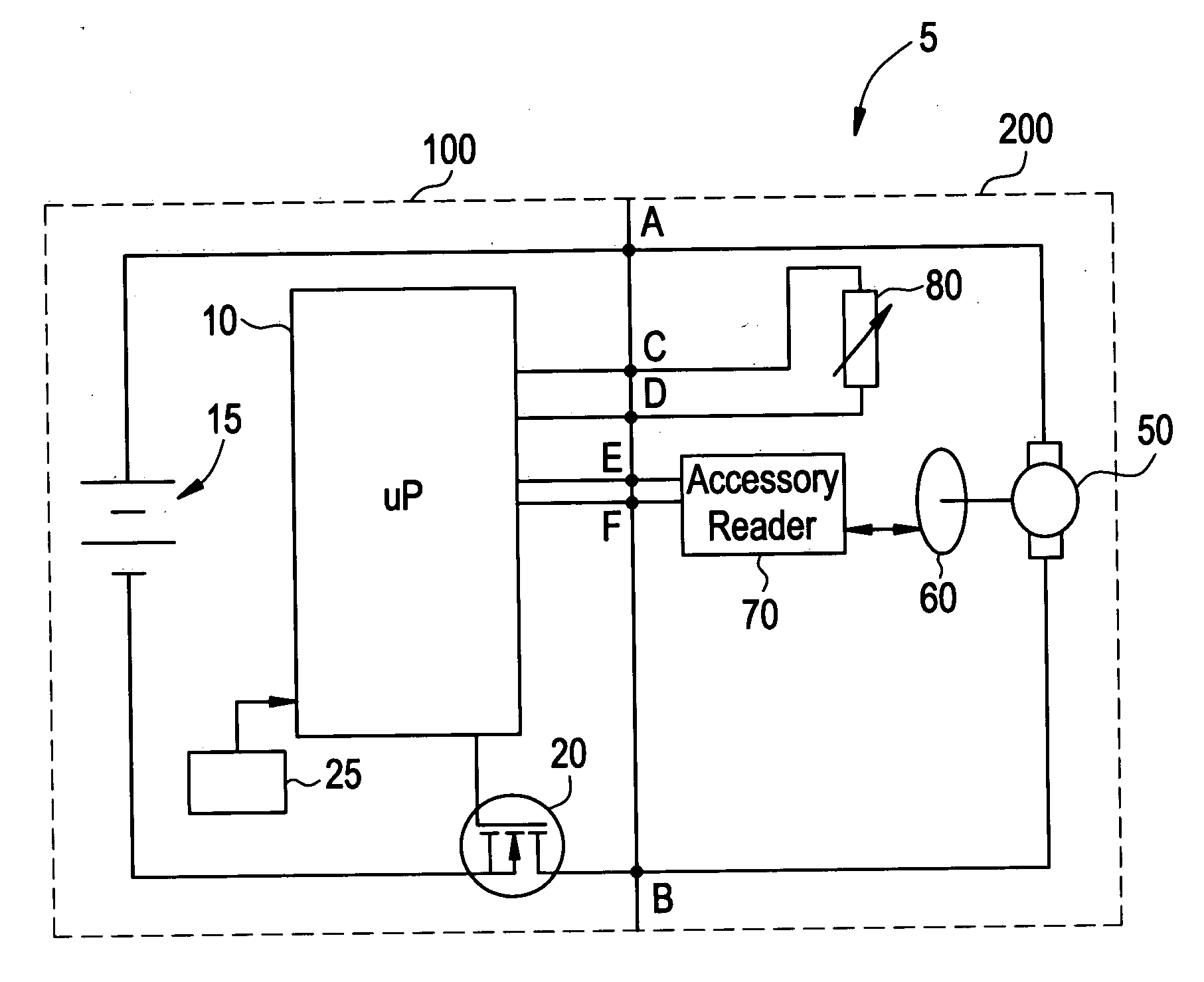

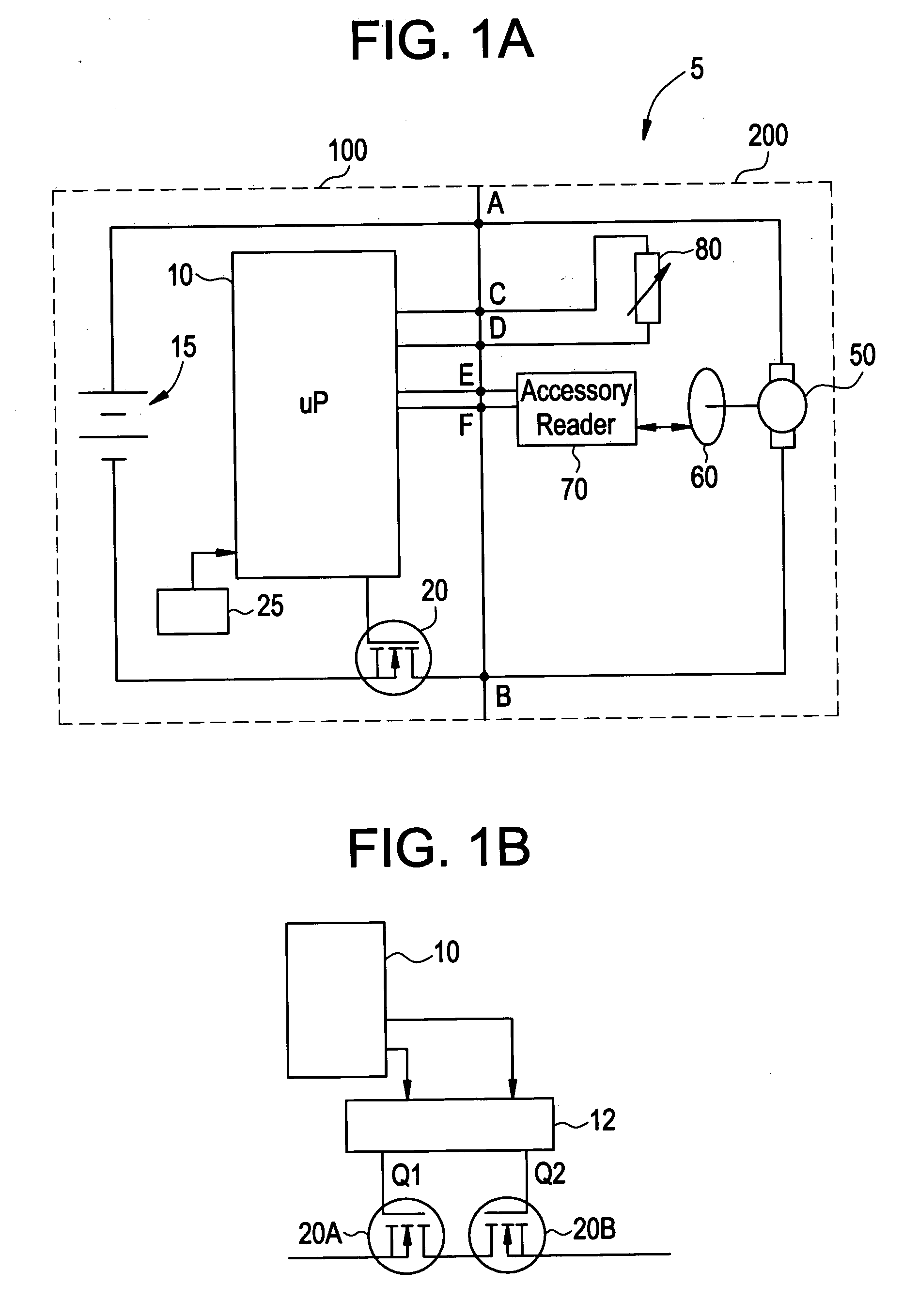

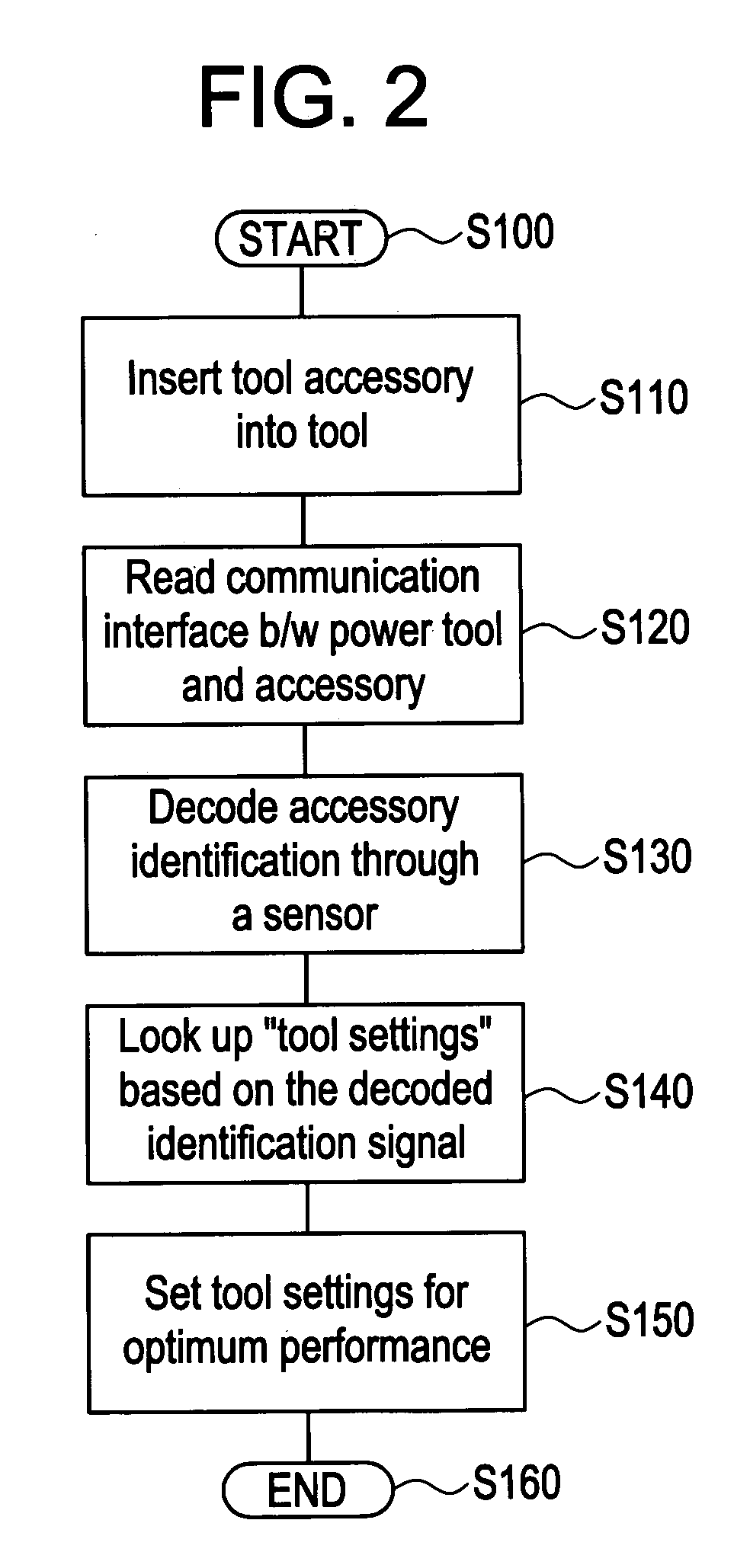

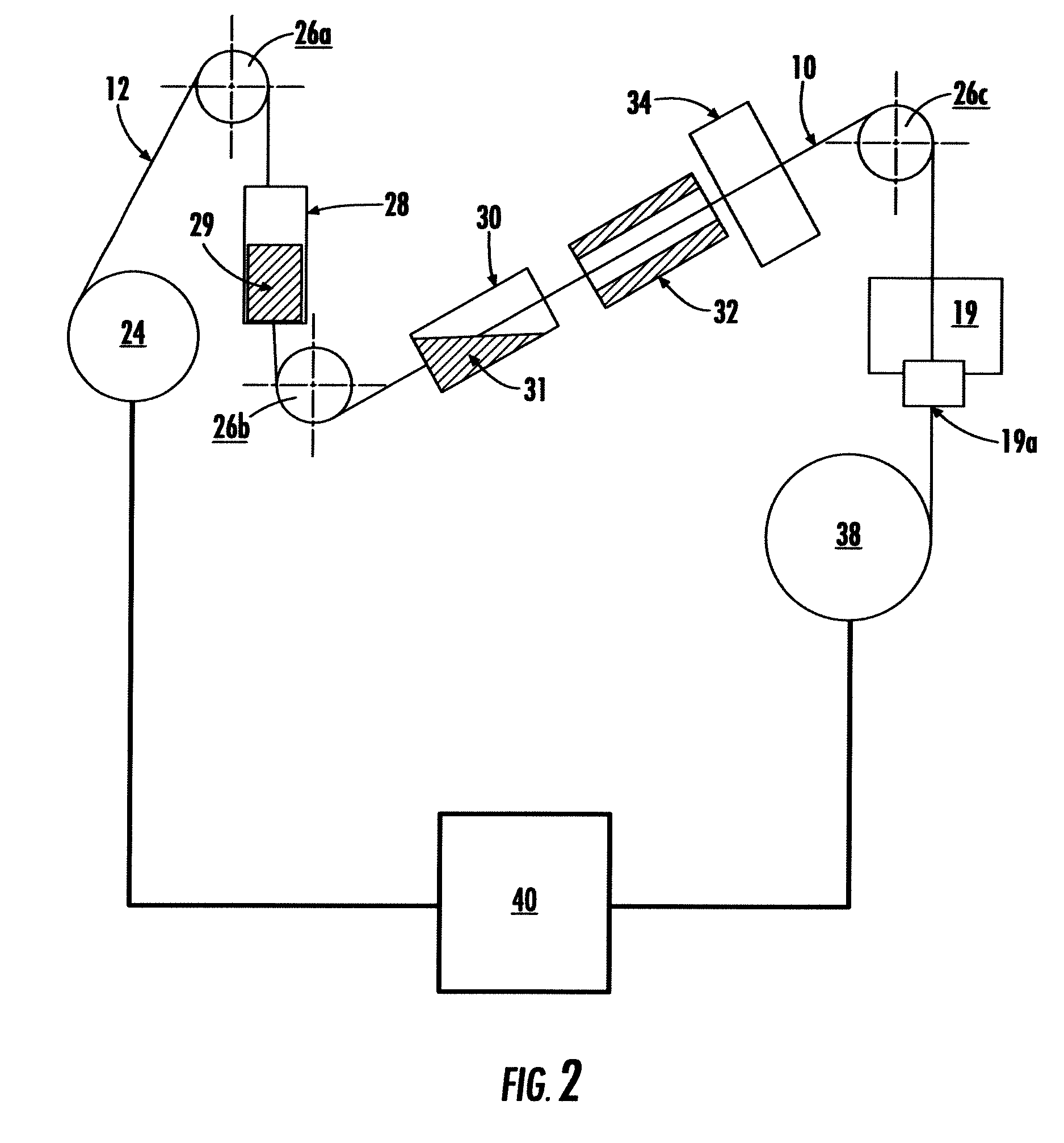

Power tool accessory identification system

A power tool accessory identification system includes a power tool which has a motor, an output spindle actuatable by the motor, and a tool holder connected to the spindle and configured to hold an accessory therein. The power tool includes an accessory reader to decoding an identification device on the accessory. In a method of controlling the power tool with an accessory operatively coupled thereto, the accessory is inserted in the tool and a communication interface between the accessory and tool is read. An accessory identification is decoded via an accessory reader of the tool. A tool setting for the power tool is accessed based on the decoded accessory identification.

Owner:BLACK & DECKER INC

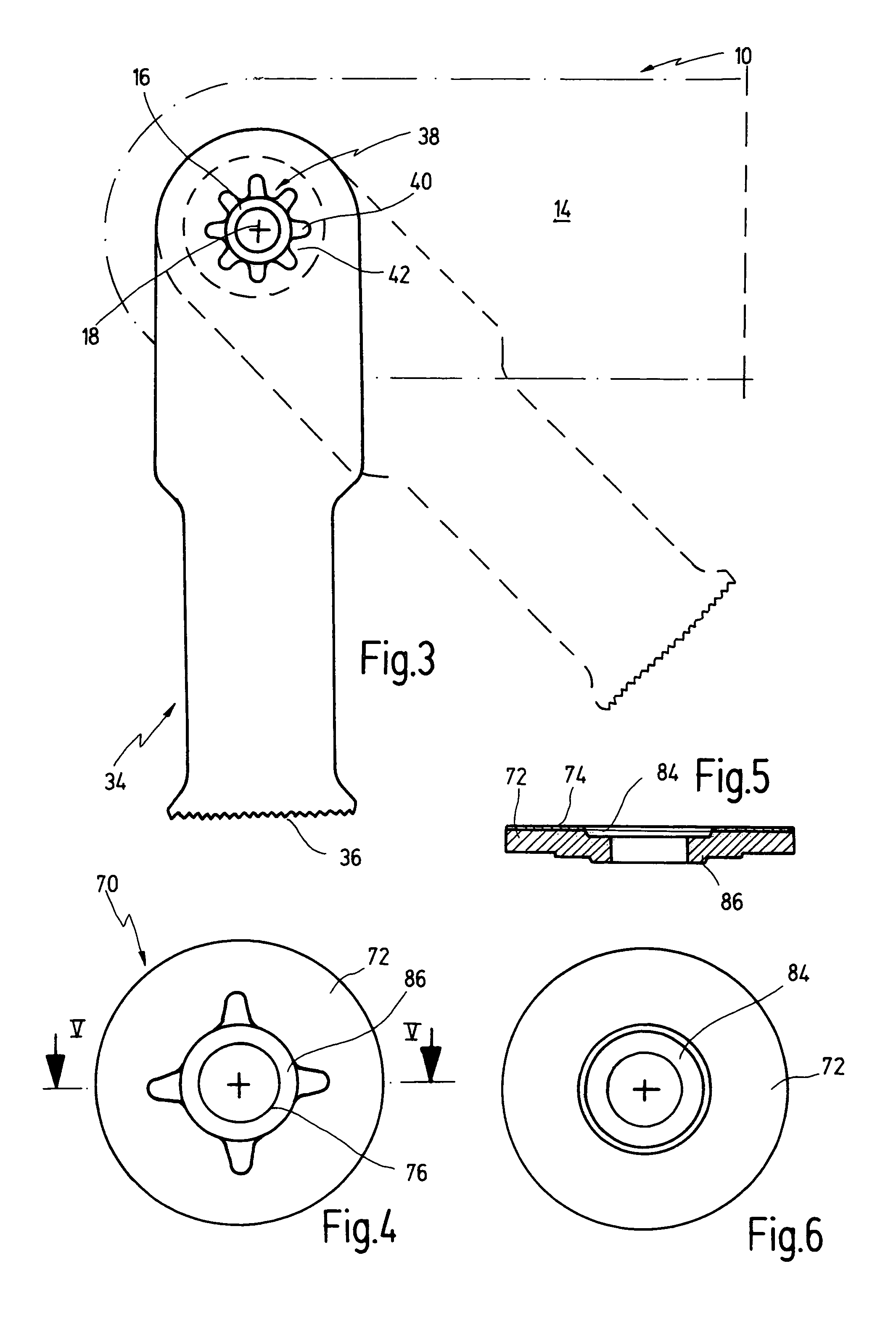

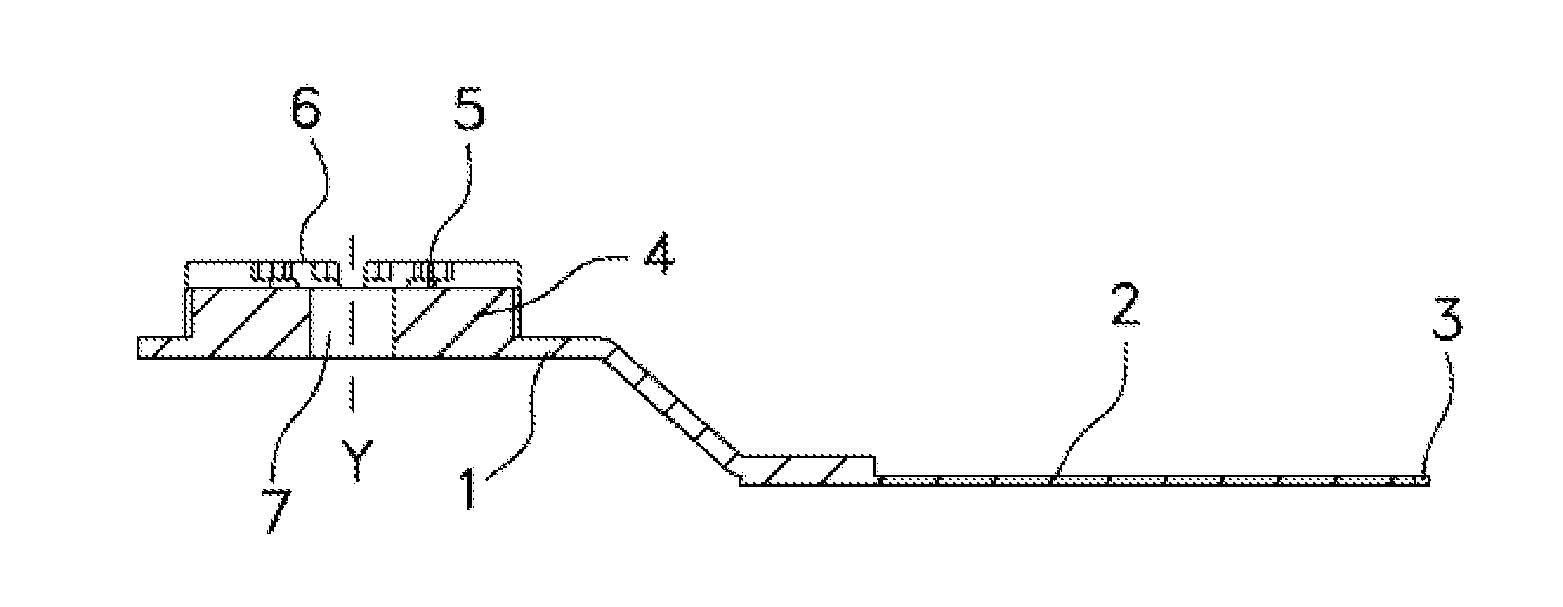

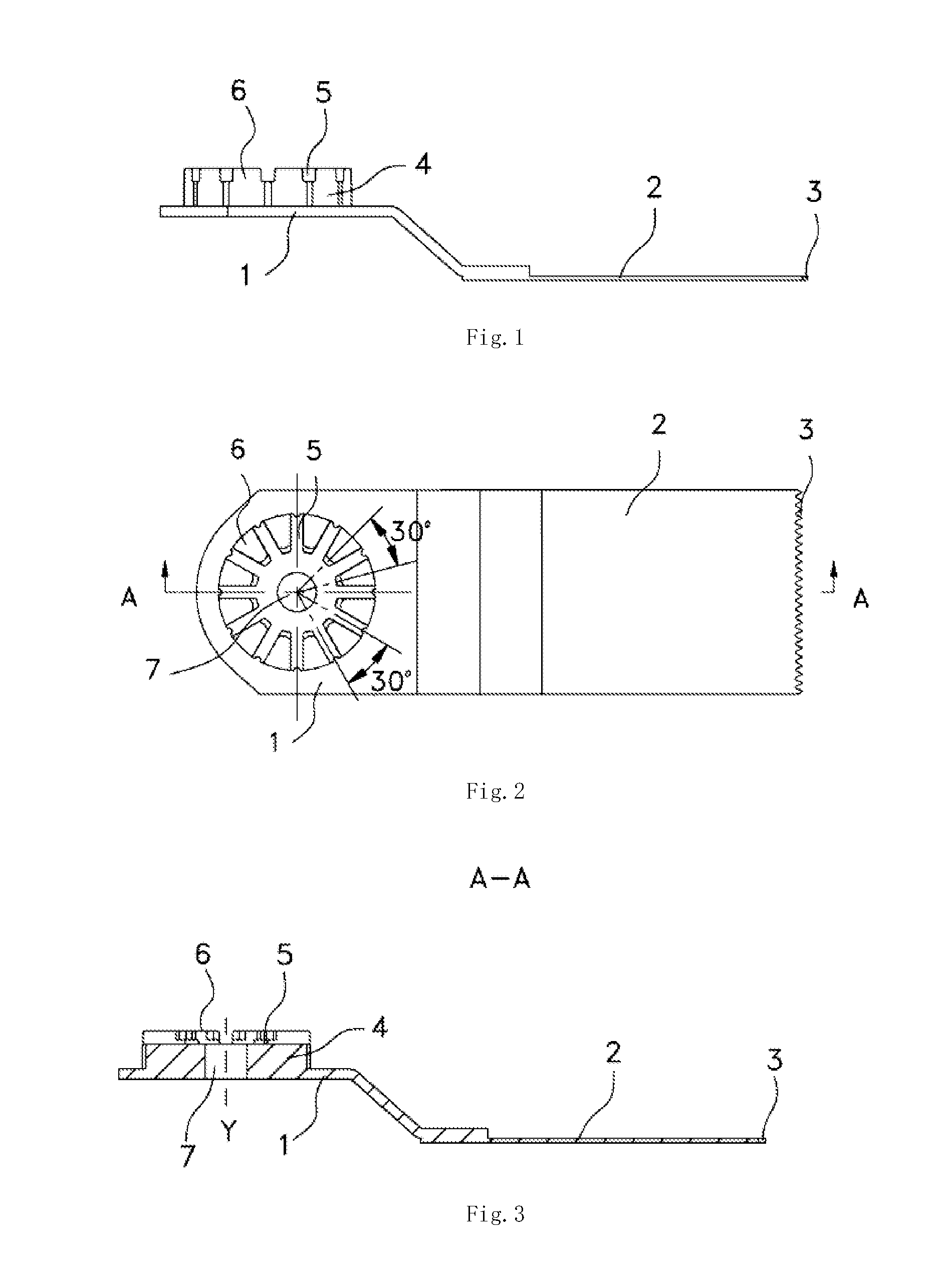

Working component for mating with multiple shaft ends

ActiveUS20110316241A1Reduce in quantityImprove portabilitySleeve/socket jointsGrinding wheel securing apparatusMechanical engineeringPhysics

A working component for mating with multiple shaft ends includes a body portion and a clamping portion which is connected to the body portion and suitable for mounting the working component to the shaft ends. The body portion has a work piece processing area for acting on the work piece to be processed and the clamping portion has a mounting hole with a longitudinal axis Y. The clamping portion includes a support portion and a mating portion which are overlapped along the direction of the longitudinal axis Y.

Owner:CHERVON HK LTD WANCHAI

Saw blade having increased tooth stiffness and resistance to fatigue failure

InactiveUS7174823B2Increase Section WidthIncrease stiffnessMetal sawing devicesMetal sawing toolsEngineering

A band saw blade comprising a plurality of teeth, wherein each tooth comprises a tip; a rake face formed on one side of the tip; a primary clearance surface formed on an opposite side of the tip relative to the rake face; a secondary clearance surface formed on an opposite side of the primary clearance surface relative to the tip; and a gullet located on an opposite side of the rake face relative to the tip and defining a depth (D) between a base surface of the gullet and the tip. Each tooth further defines a first gullet radius (R1) located between the gullet and the secondary clearance surface; a second gullet radius (R2) extending between a base surface of the gullet and the rake face; and a pitch (P) between the respective tooth and a preceding tooth. In each tooth, R2>D>RQ, and D / P is between about 25% and 35%.

Owner:IRWIN IND TOOL CO

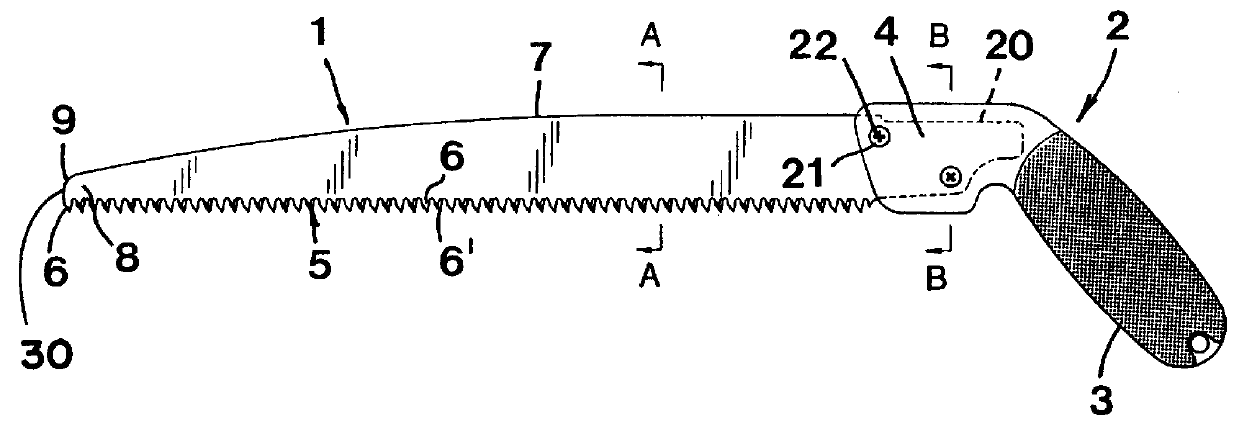

Pruning saw

A pruning saw includes an elongated sawblade which has a line of cutting teeth. Opposite sides of the blade extending between the line of teeth and the back edge are concave. A thinnest waist between the concave sides is located closer to the line of teeth than to the back where the blade has its maximum height. A front edge of the blade forms a rounded corner where it intersects the back edge.

Owner:SANDVIK AB

Saw blade for medical applications

InactiveUS7001403B2Precise cuttingDamped reliablyMetal sawing devicesNon-rotary toothed toolsMechanical engineeringMedical treatment

Owner:HAUSMANN THOMAS +1

Brazed diamond tools and methods for making the same

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

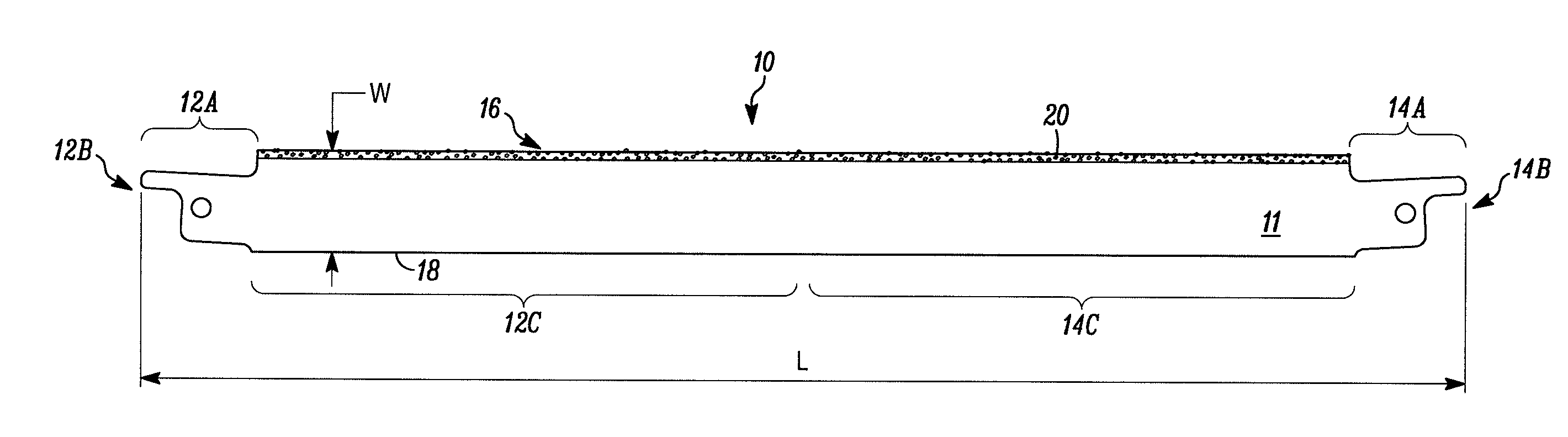

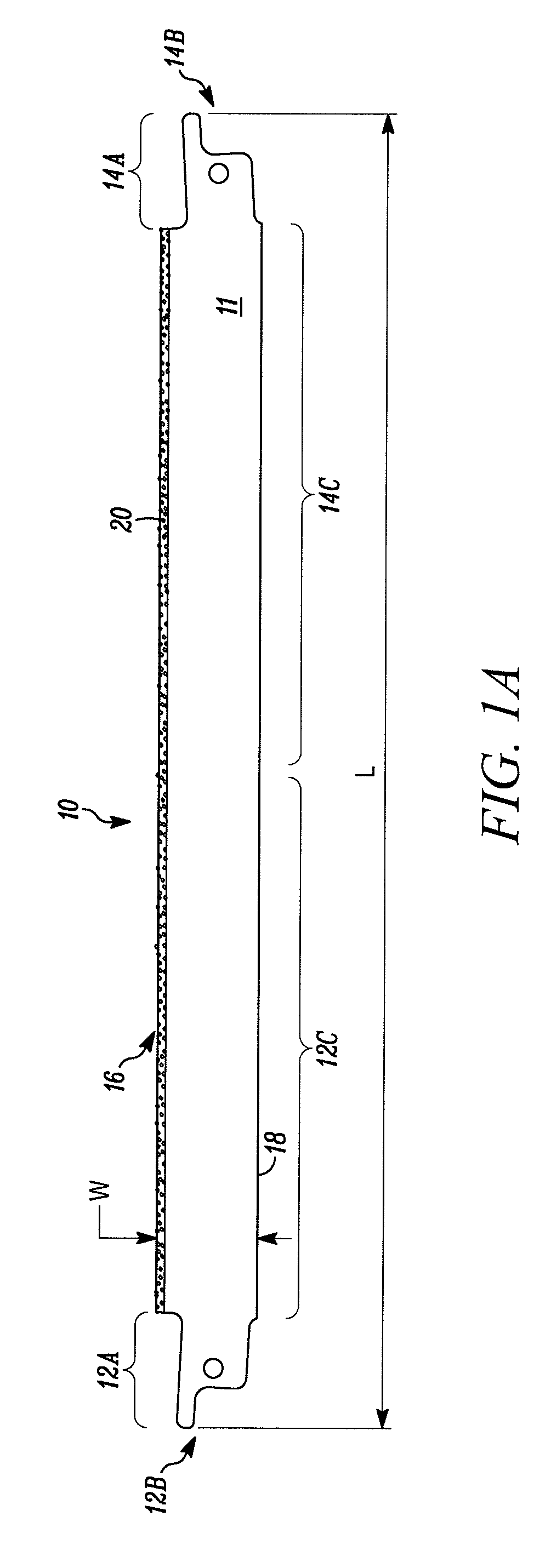

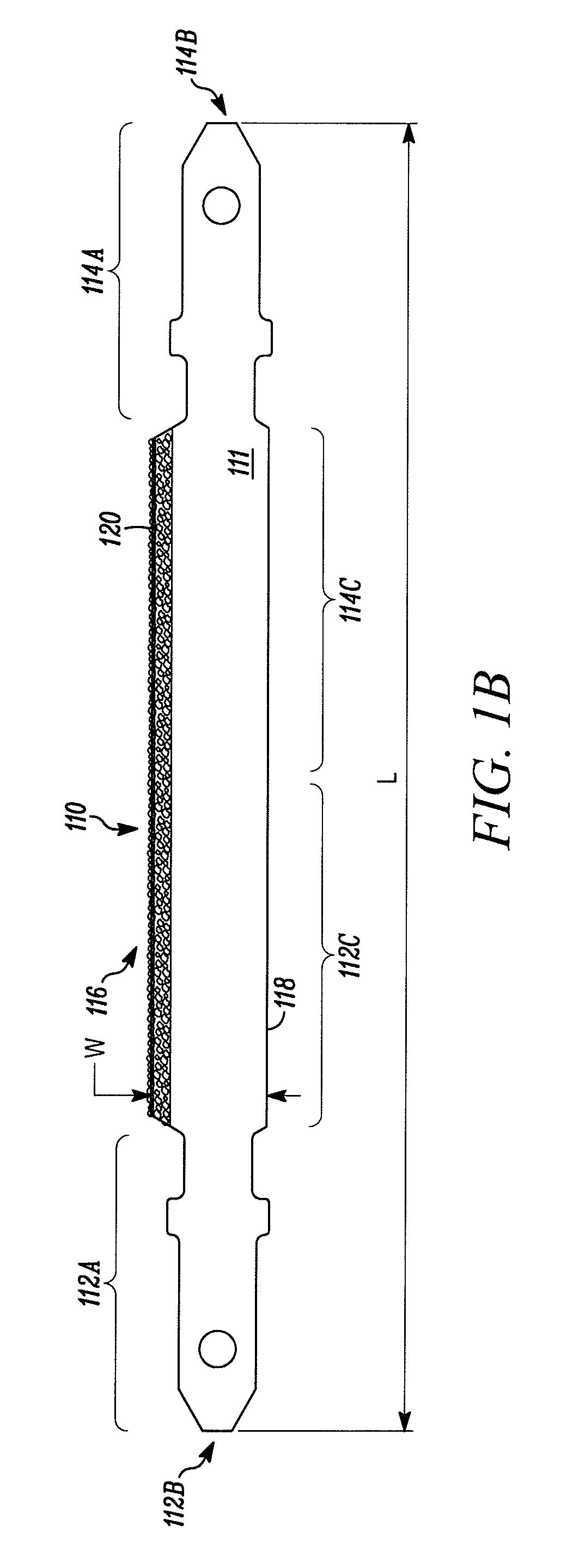

Reciprocating Saw Blade With Tangs On Each End And Related Method

ActiveUS20100218389A1Improve wear lifeReadily apparentMetal sawing devicesMetal sawing toolsReciprocating motionEngineering

A reciprocating saw blade has a first end with a first tang and a second end with a second tang. The first and second tangs are alternatively engageable with the chuck of a reciprocating saw. The reciprocating saw blade defines a substantially uniform cutting edge extending from approximately the first end to approximately the second end of the blade. The first tang is engageable with the chuck of the reciprocating saw for fixedly securing the first end of the blade to the reciprocating saw and forming with the second tang the free end of the saw blade. Alternatively, the second tang is engageable with the chuck of the reciprocating saw for fixedly securing the second end of the blade to the reciprocating saw and forming with the first tang the free end of the reciprocating saw blade drivable in a reciprocating motion by the reciprocating saw.

Owner:BLACK & DECKER INC

Reversible saw tooth

A replaceable saw tooth for a rotary cutting machine. The saw tooth comprises more than two cutting edges on each of two opposed faces thereof. More specifically, the saw tooth may comprise a body having two cutting faces disposed opposite each other and spaced apart by at least four side faces which are each parallel to an opposite one of the side faces. The side faces are parallel to a central axis extending between the two cutting faces. Four cutting edges are defined between the side faces and each of the two cutting faces.

Owner:QUADCO

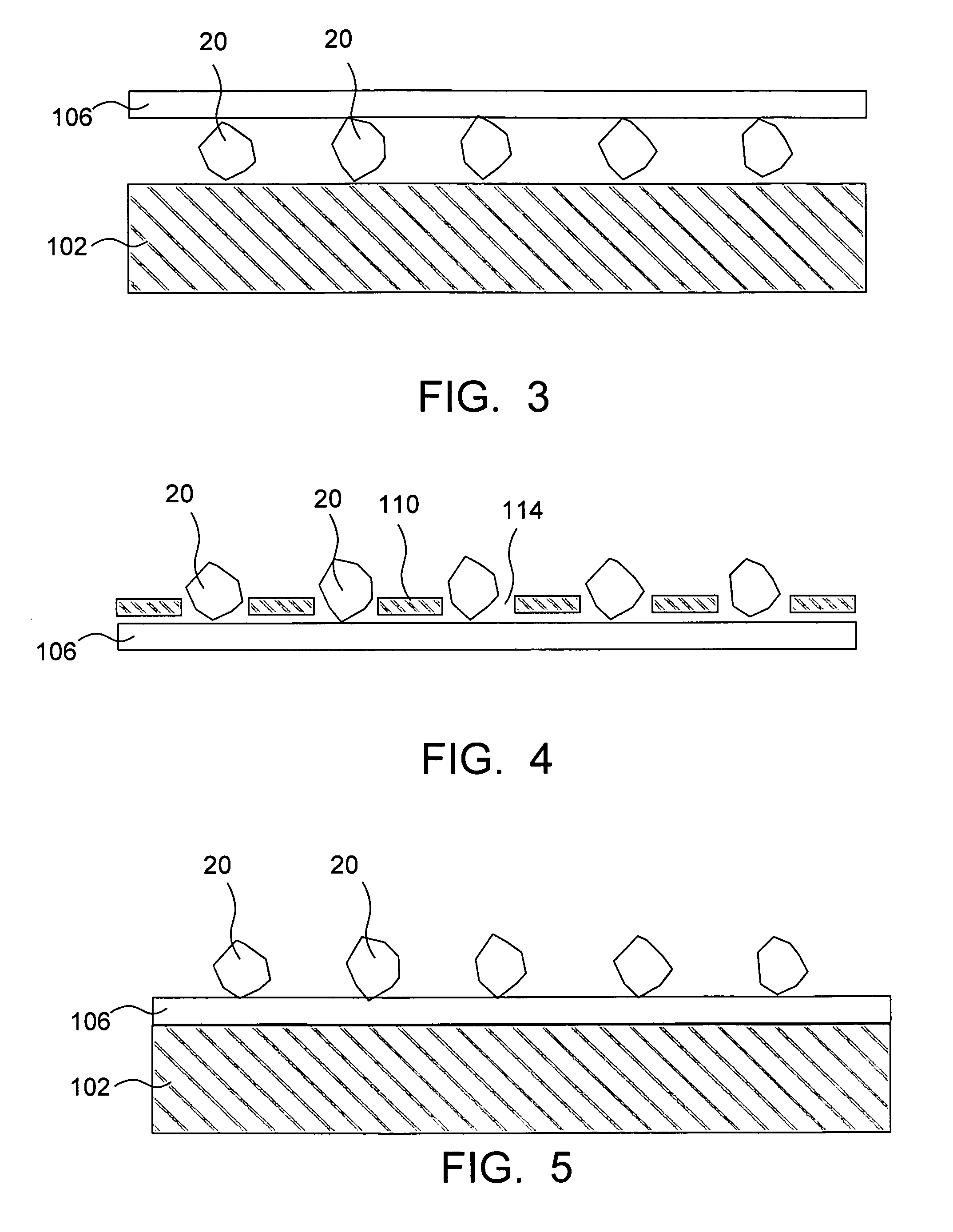

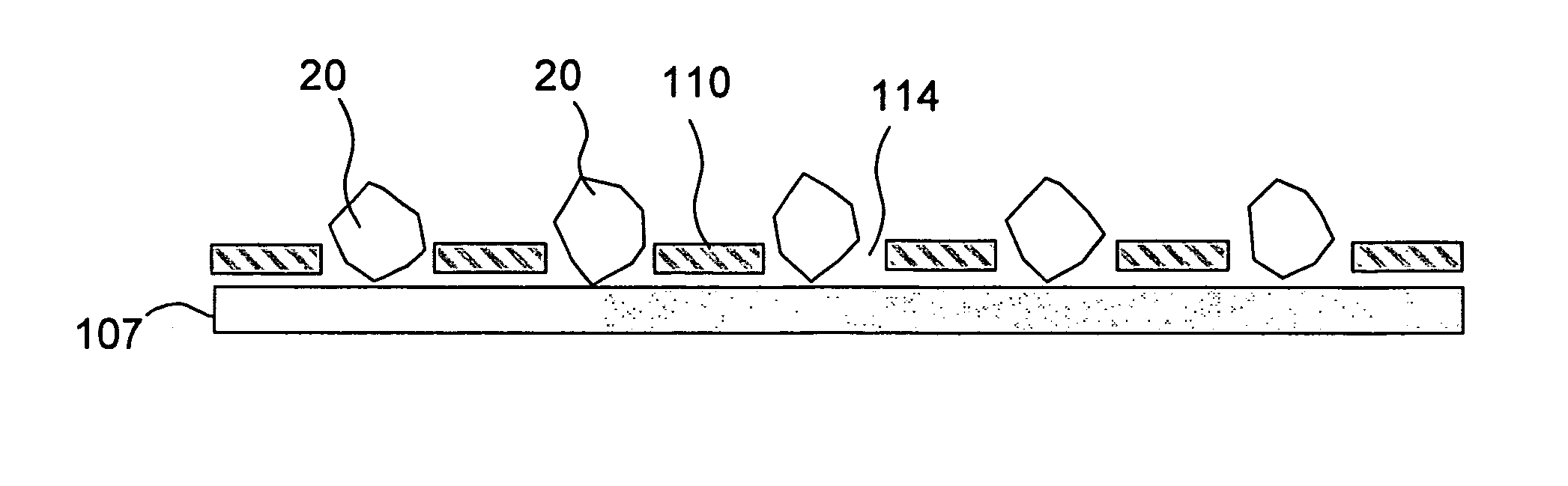

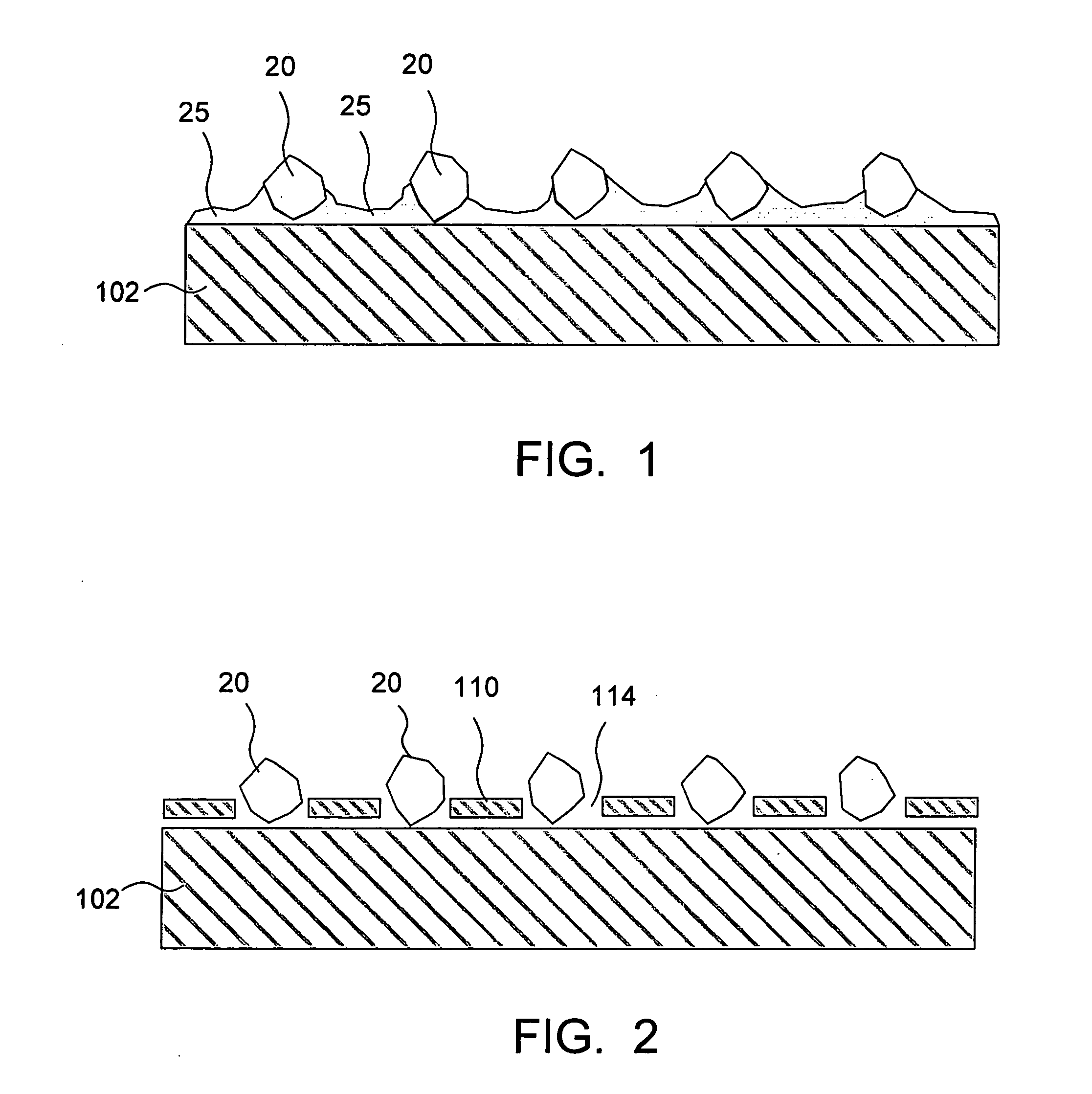

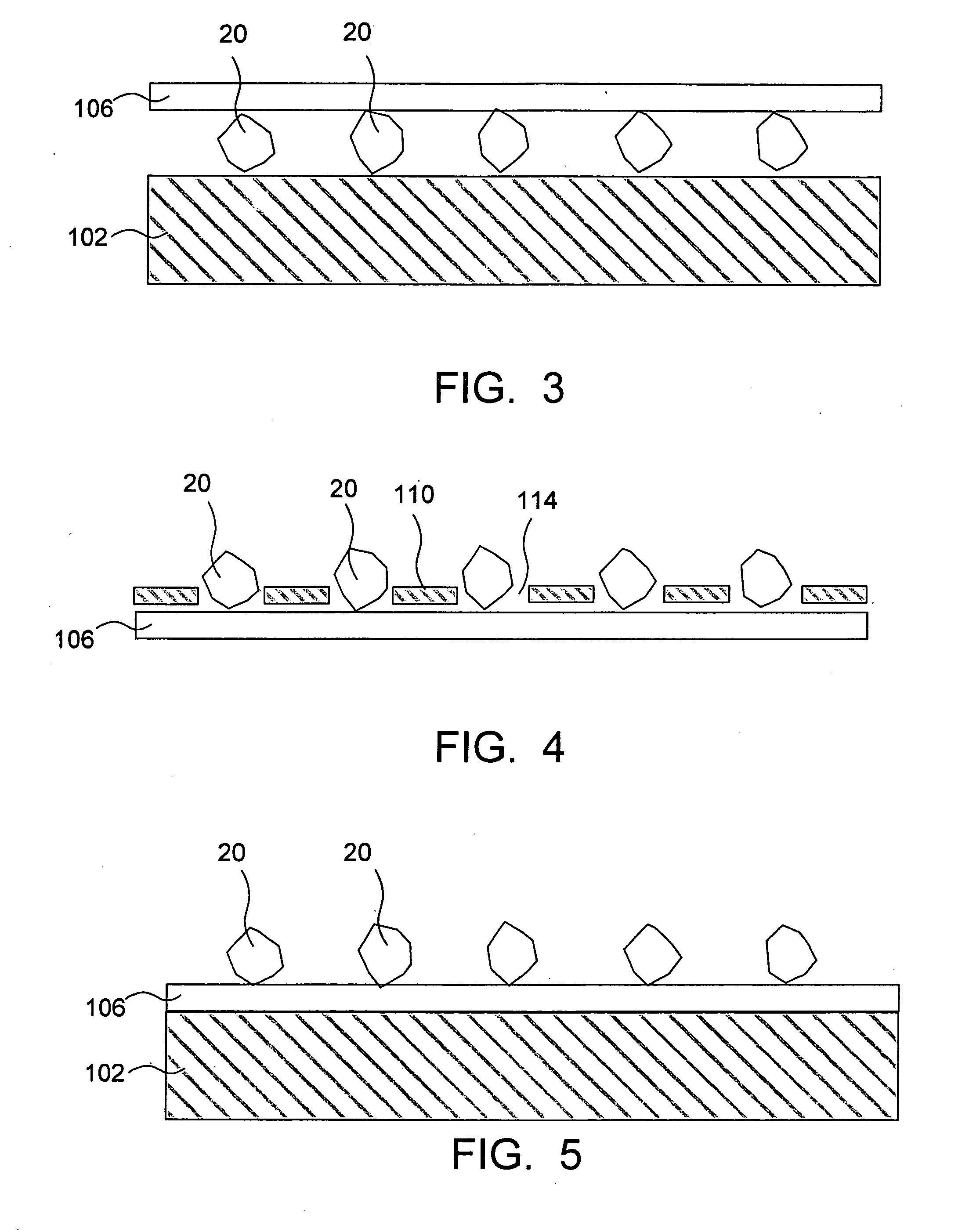

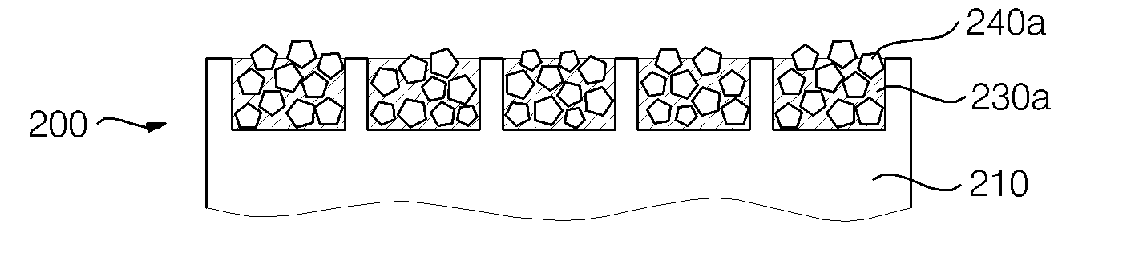

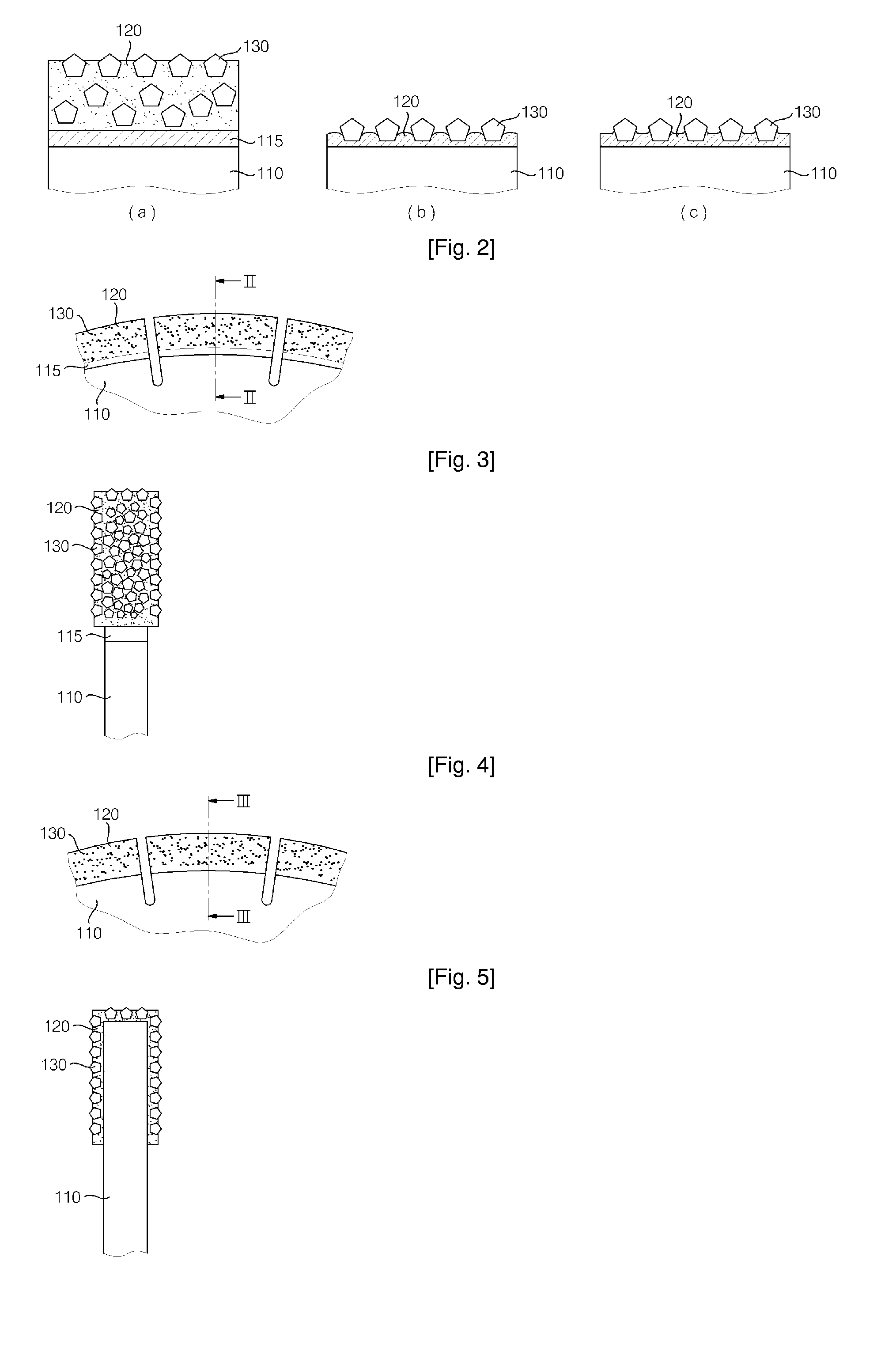

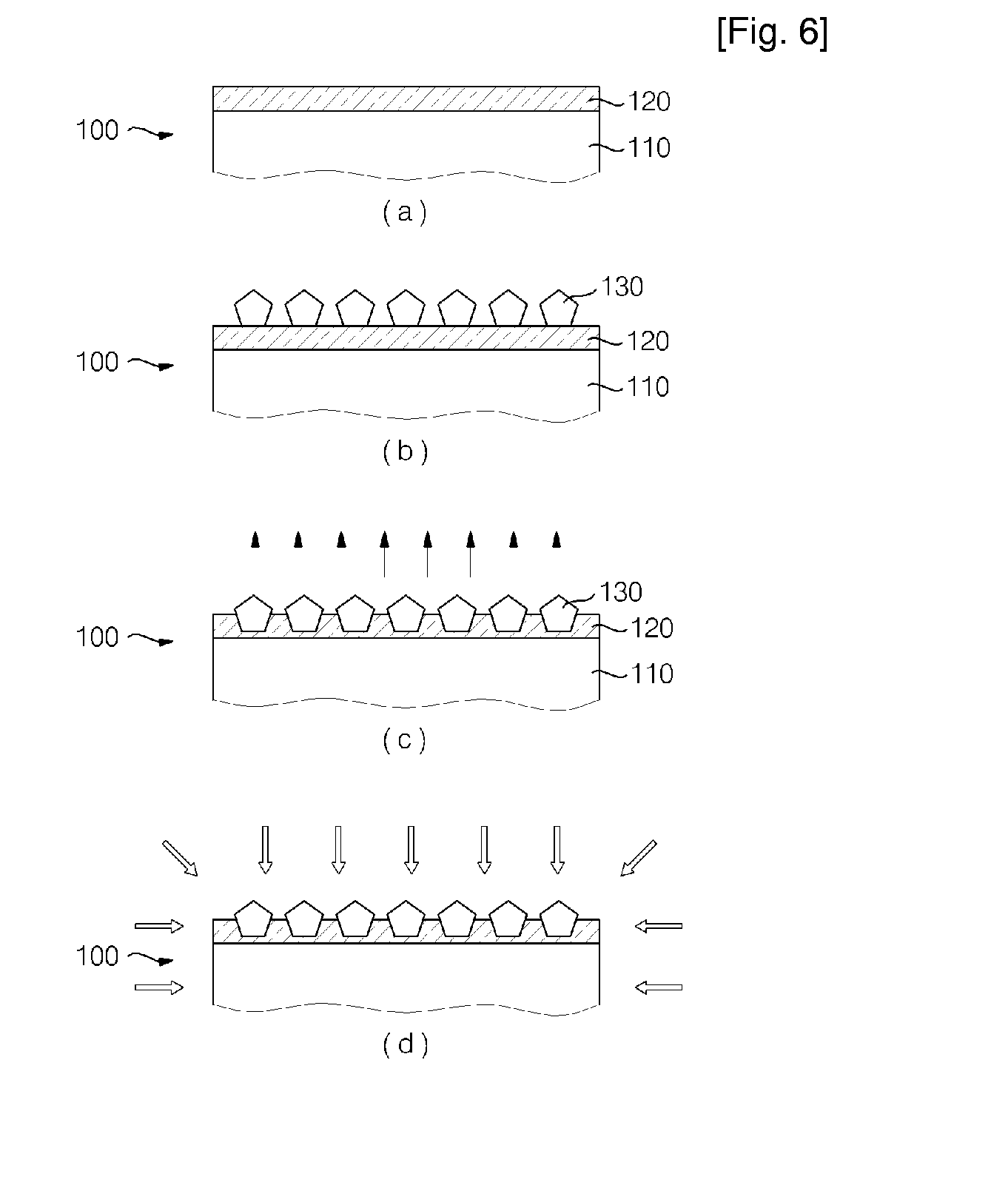

Diamond tools with multilayers of abrasive grain and method for manufacturing the same

ActiveUS20070151554A1Evenly distributedUniform thicknessBonded abrasive wheelsGrinding devicesElectroplatingHeat treated

The present invention relates to a diamond tool and a method of manufacturing the same, wherein multiple abrasive layers are formed through a brazing or electroplating method, thereby improving the performance and service life of the tool. According to the method of the present invention, a plurality of concave portions are formed in a surface of the shank. A bonding paste is coated into the concave portions and abrasives are dispersed in the bonding paste to thereby form a lower abrasive layer. Again, a bonding material is coated on the lower abrasive layer and abrasives are dispersed in the bonding material to thereby form an upper abrasive layer. Then, a heat treatment is executed to fusion-bond the bonding material and abrasives onto the surface of the shank. Therefore, the diamond tools manufactured through a multiple brazing or electroplating method according to the invention can significantly extend the service life thereof, which has been a detrimental weakness of the conventional diamond tools having a single abrasive layer, in spite of various advantages of the brazing and electroplating methods. Furthermore, multiple abrasive layers can be formed inside the concave portions having a desired spacing, width and depth, thereby significantly improving the service life and the cutting performance of diamond tools.

Owner:SHINHAN DIAMOND IND

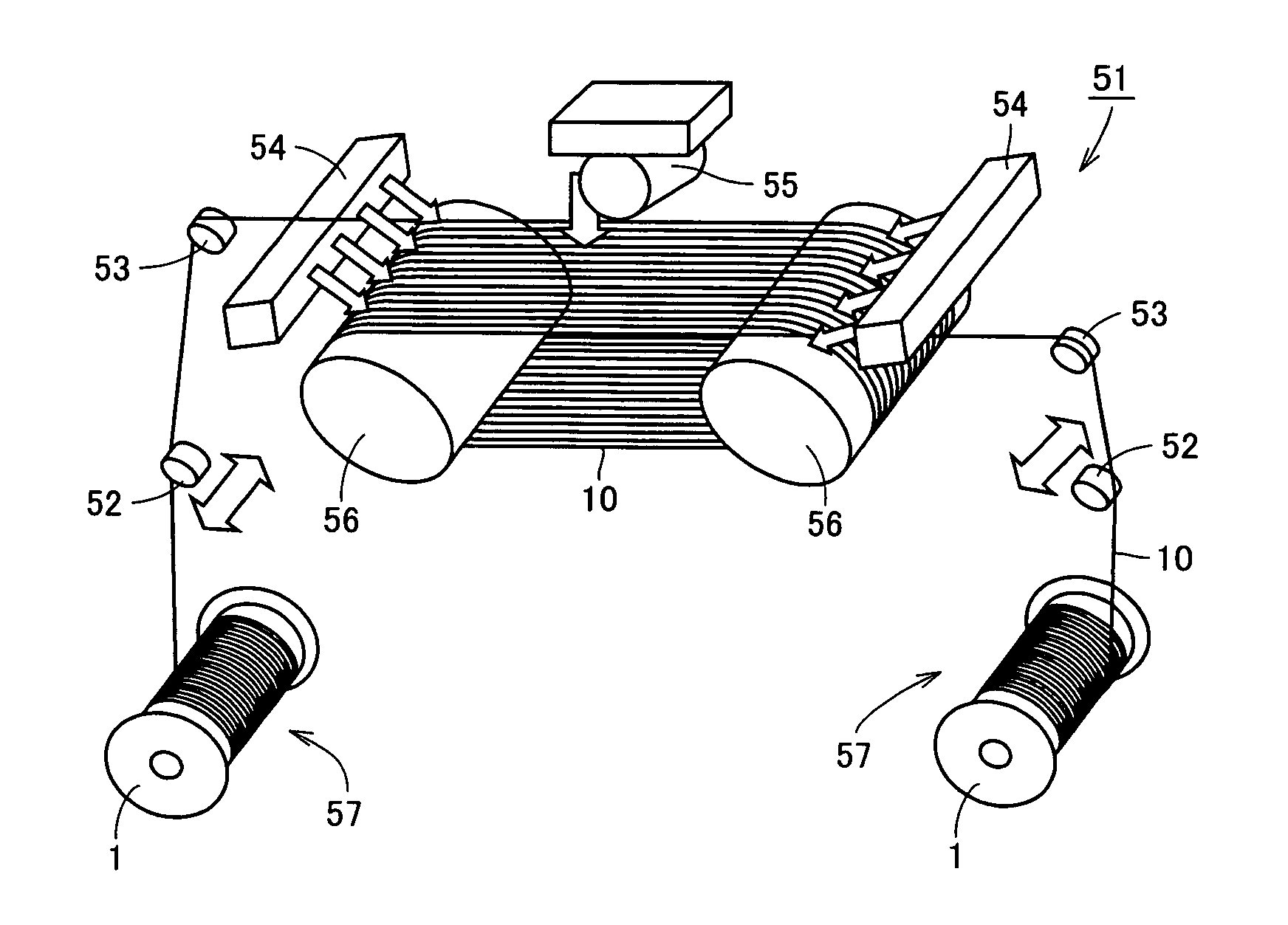

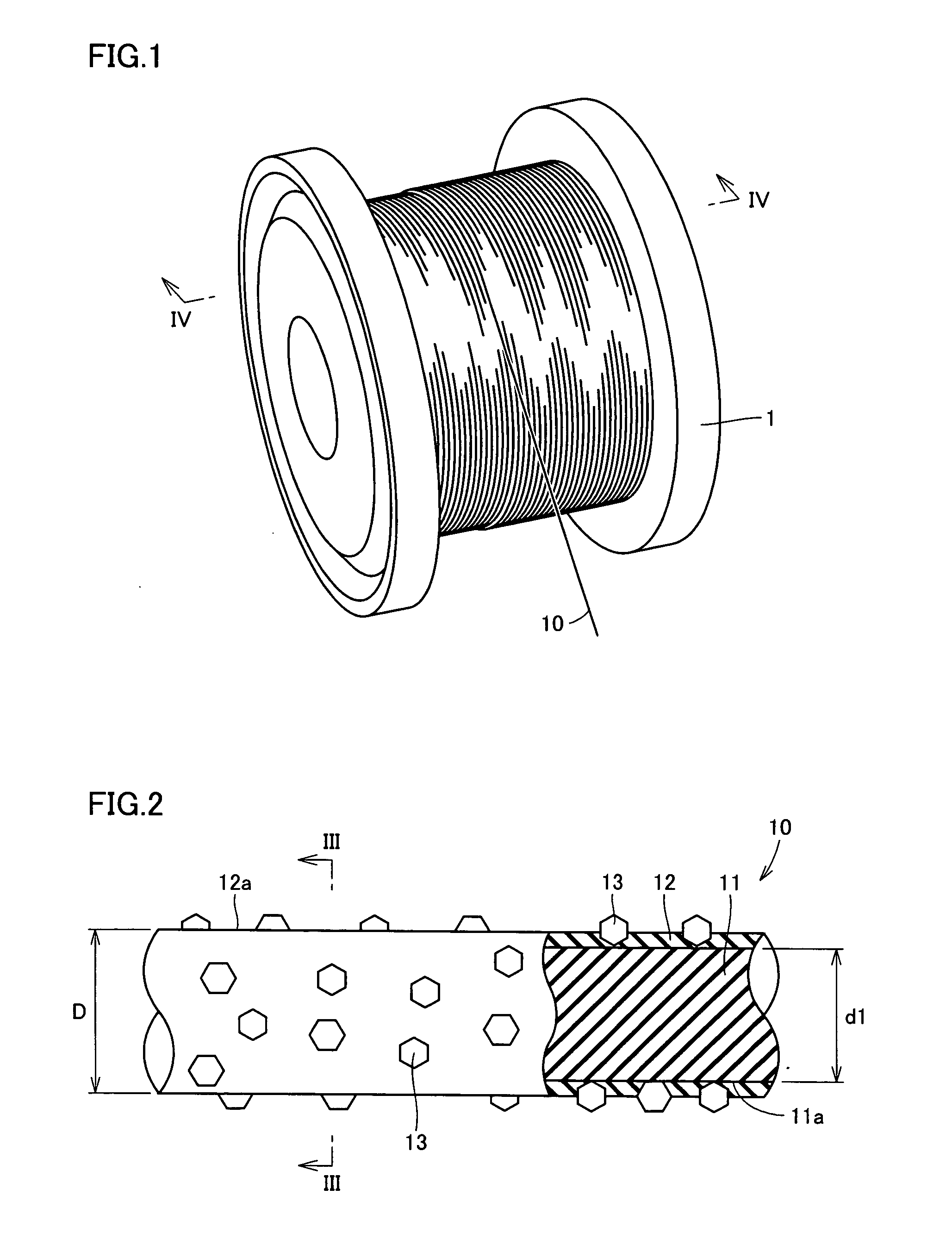

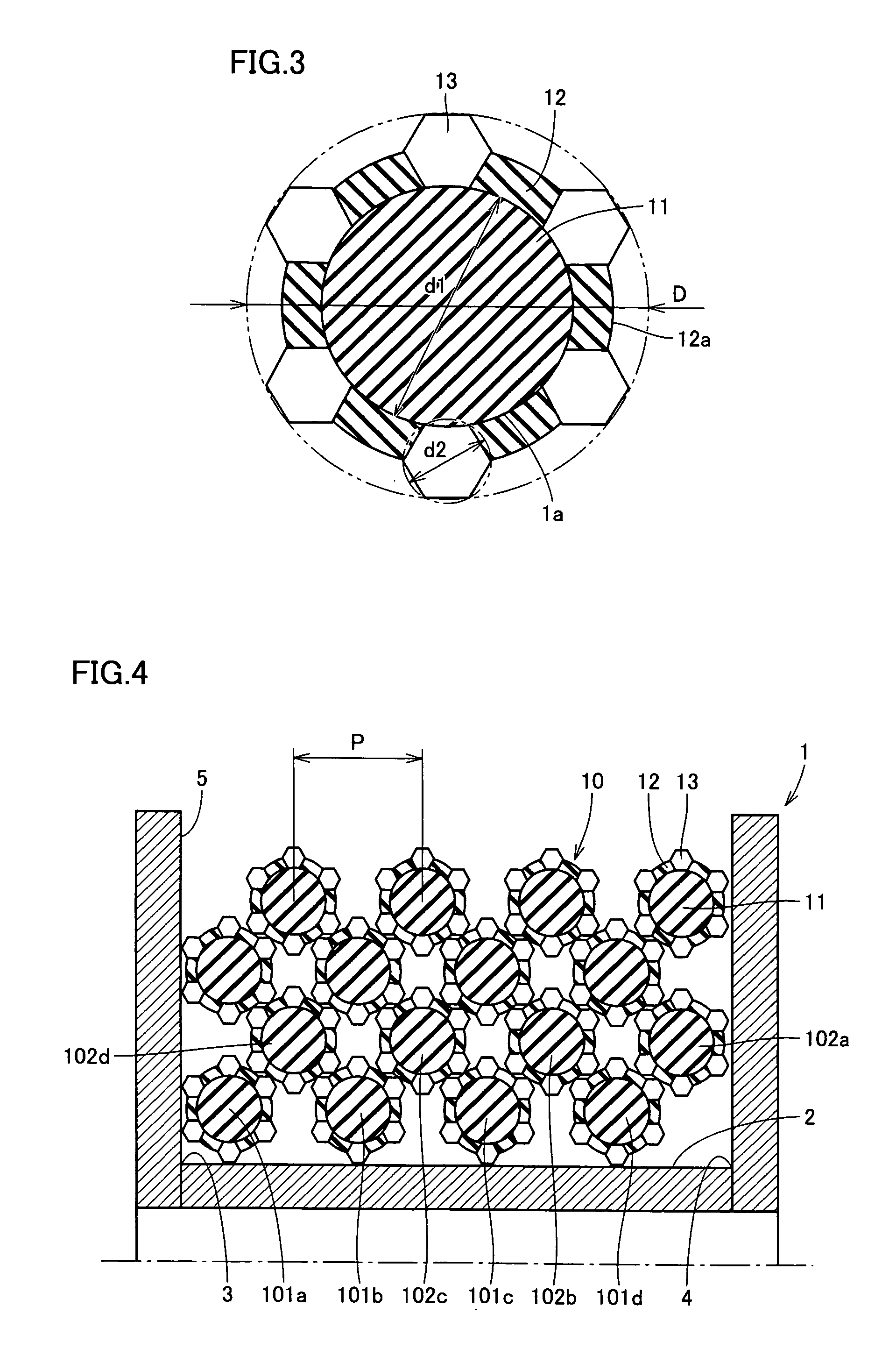

Super abrasive grain wire saw winding structure, super abrasive grain wire saw cutting device, and super abrasive grain wire saw winding method

InactiveUS20070023027A1Friction can be so intenseDamage to materialMetal sawing devicesEdge grinding machinesConductor CoilWire saw

A superabrasive wire saw-wound structure includes a superabrasive wire saw (10) formed with an average diameter D and a reel (1). The superabrasive wire saw (10) includes a core wire (11), a bonding material (12) surrounding a surface of the core wire (11), and a plurality of superabrasive grains (13) bonded to the surface of the core wire (11) with the bonding material (12). The reel (1) includes a peripheral surface (2) having one end (3) and the other end (4). The superabrasive wire saw (10) which is to be unreeled successively toward a workpiece is wound around the peripheral surface (2) reciprocatingly between the one end (3) and the other end (4) to be multi-layered. A pitch P for winding the superabrasive wire saw (10) around the peripheral surface (2) between the one end (3) and the other end (4) satisfies a relation of D<P<2D. According to the present invention, there can be provided a superabrasive wire saw-wound structure, a cutting device with a superabrasive wire saw, and a method of winding a superabrasive wire saw which can reduce damage to a bonding material and falling of a superabrasive grain.

Owner:ALLIED MATERIAL

Methods, Wires, and Apparatus for Slicing Hard Materials

Methods, wires, and apparatus for use in cutting (e.g., slicing) hard, brittle materials is provided. The wire can be a super-abrasive wire that includes a wire core and super-abrasive particles bonded to the wire core via a metal bonding layer. This wire, or another type of wire, can be used to slice workpieces useful for producing wafers. The workpieces can be aligned within a holder to produce wafers using the device and methods presently provided. The holder rotates about its central axis, which translates to workpieces moving in orbit around this axis. A single abrasive wire, or multiple turns of wire stretched tightly between wire guides, is then contacted with the rotating holder to slice the workpieces.

Owner:UNIVERSITY OF SOUTH CAROLINA

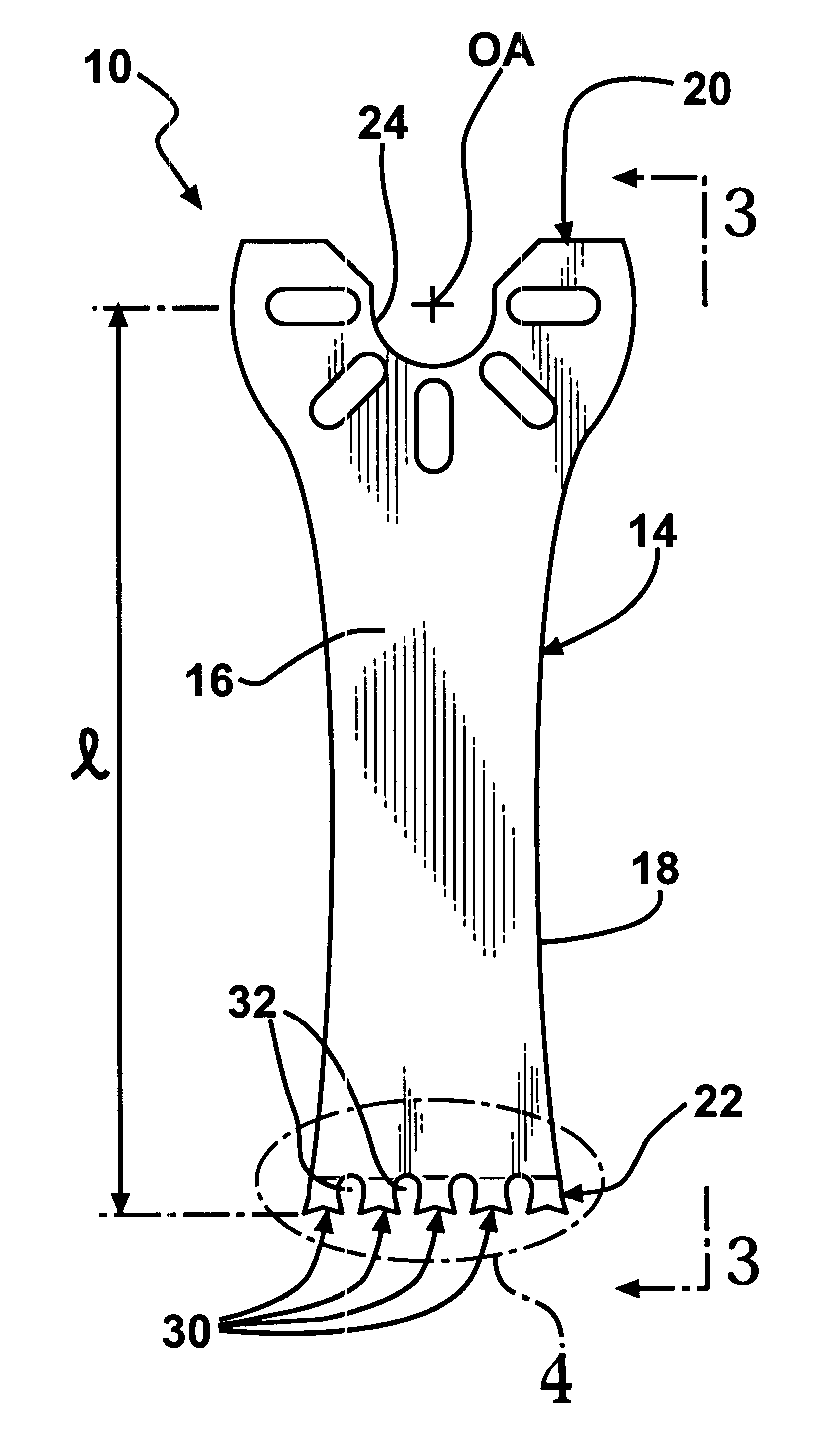

Dual cut surgical saw blade

InactiveUS20060272468A1Less stressEasy to controlMetal sawing devicesMetal sawing toolsEngineeringSurgical saw

A surgical saw blade operatively couples to an oscillatory power tool for oscillation about an oscillation axis (OA). The saw blade includes a plurality of cutting teeth separated from one another by a clean out opening along a distal end. The clean out opening comprises an arcuate closed end and straight side walls extending from the closed end. Each tooth comprises first and second rake surfaces and first and second relief surfaces intersecting to define first and second cutting edges, respectively. The first and second cutting edges are oppositely disposed from one another. One cutting tooth protrudes a distance (de) from one side face of the blade and the next adjacent cutting tooth protrudes the same distance (de) from the other side face of the blade to cut a groove having a width (dg) wider than the thickness (t) of the blade.

Owner:STRYKER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com