Patents

Literature

67results about How to "Damage to material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

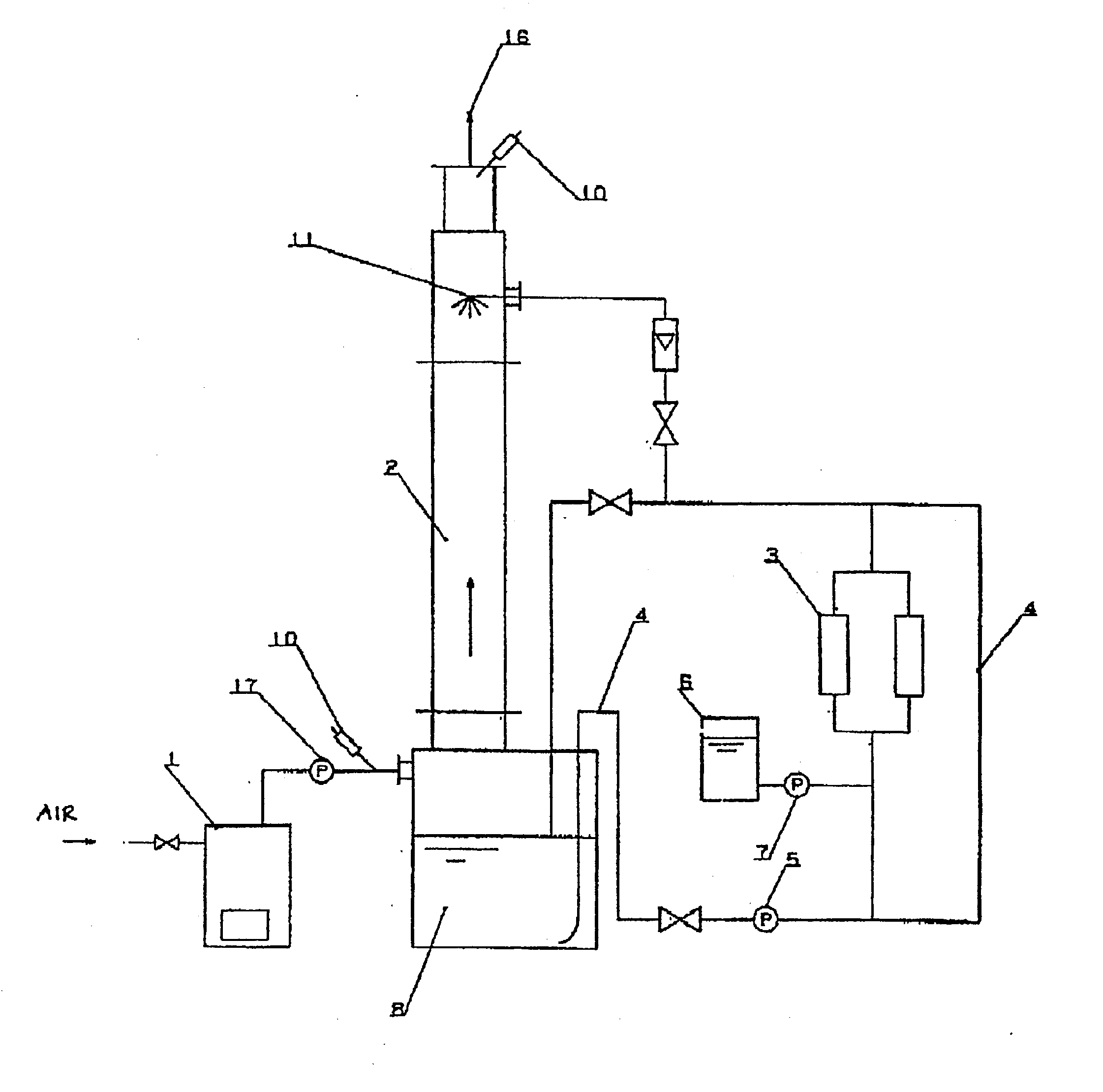

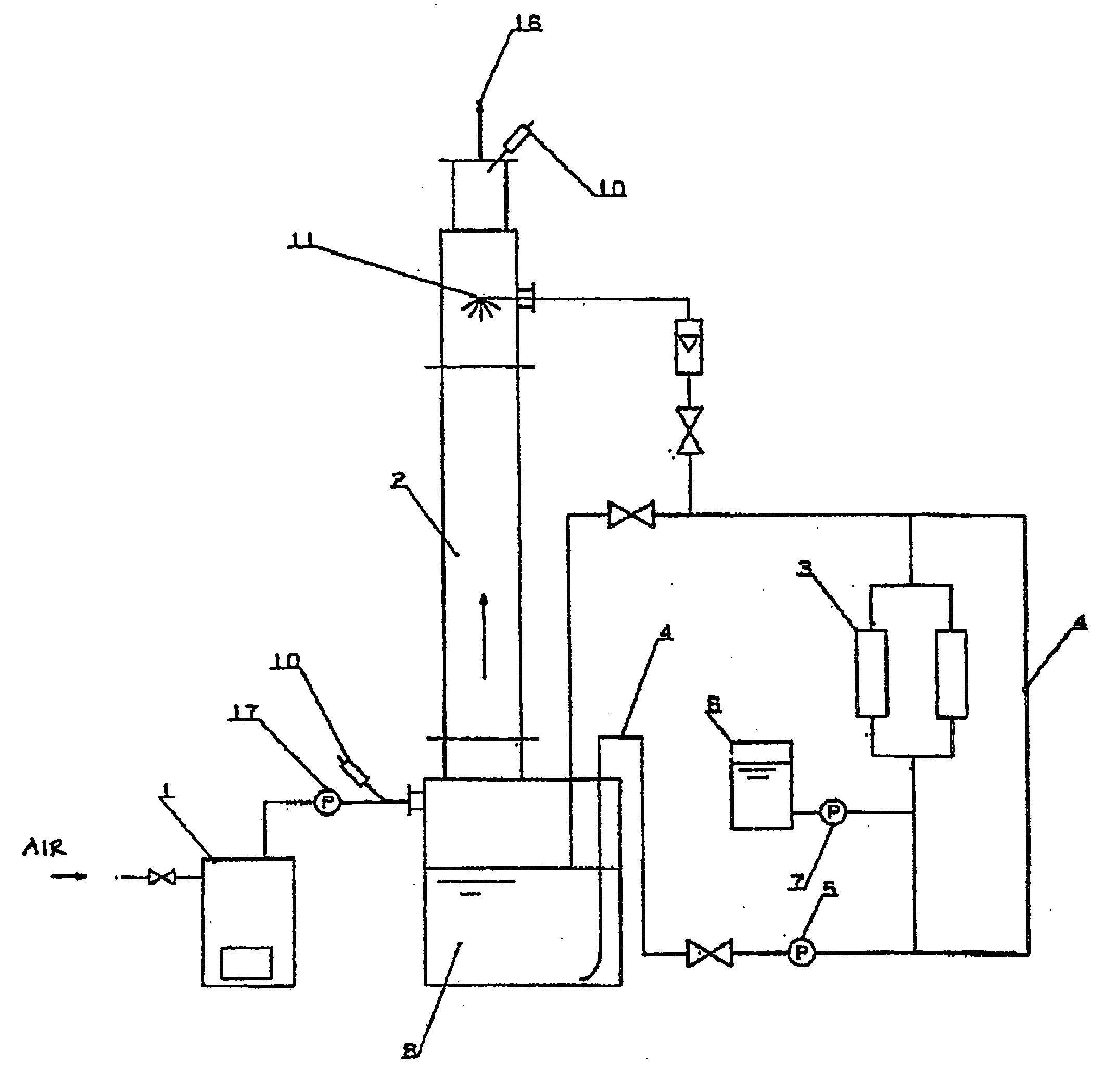

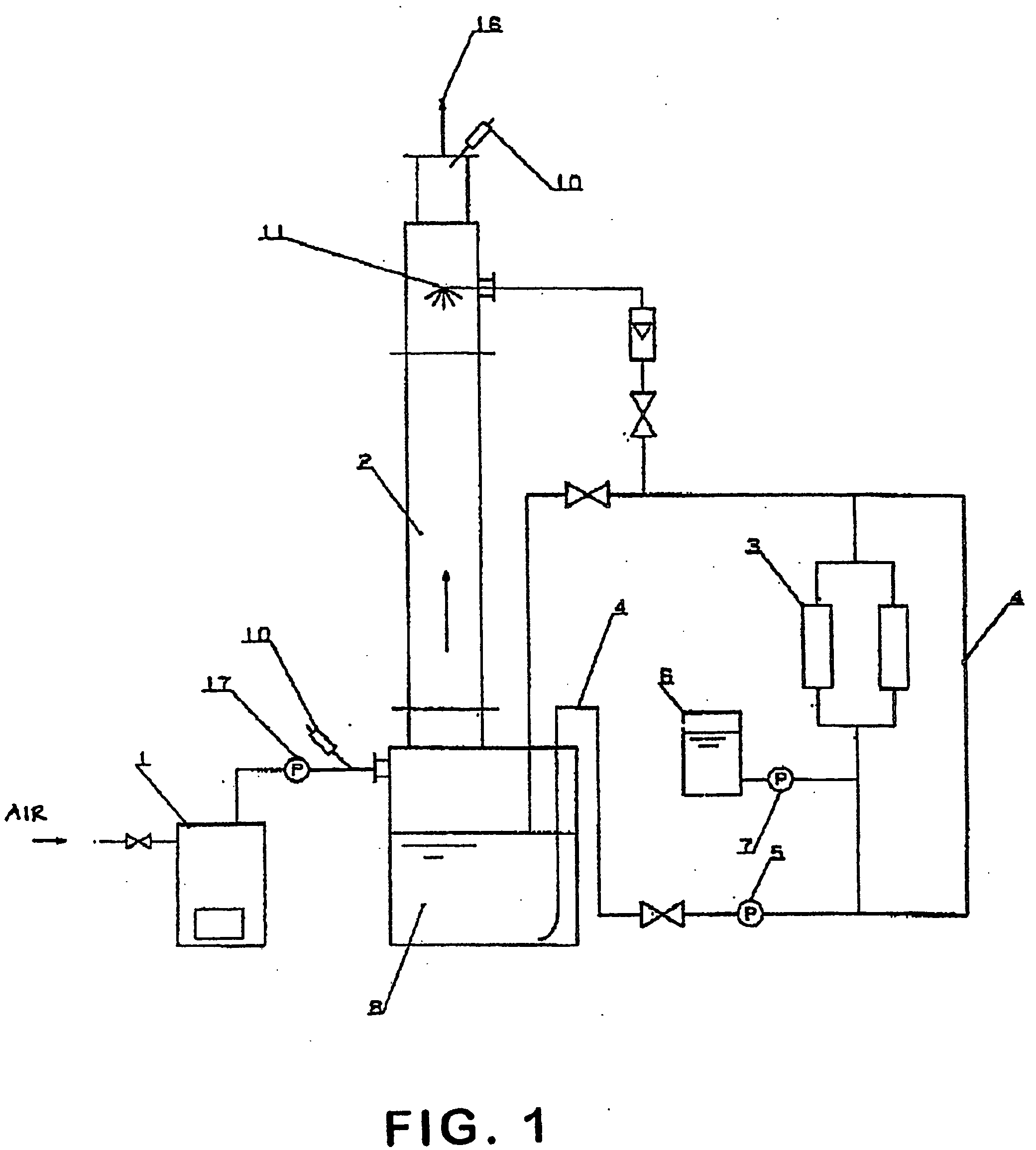

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20030164309A1Easy can be electrolyzedHigh densityCyanogen compoundsLighting and heating apparatusHazardous substancePotassium hydroxide

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogen acid such as hypochlorous acid soda, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:OMEGA CO LTD

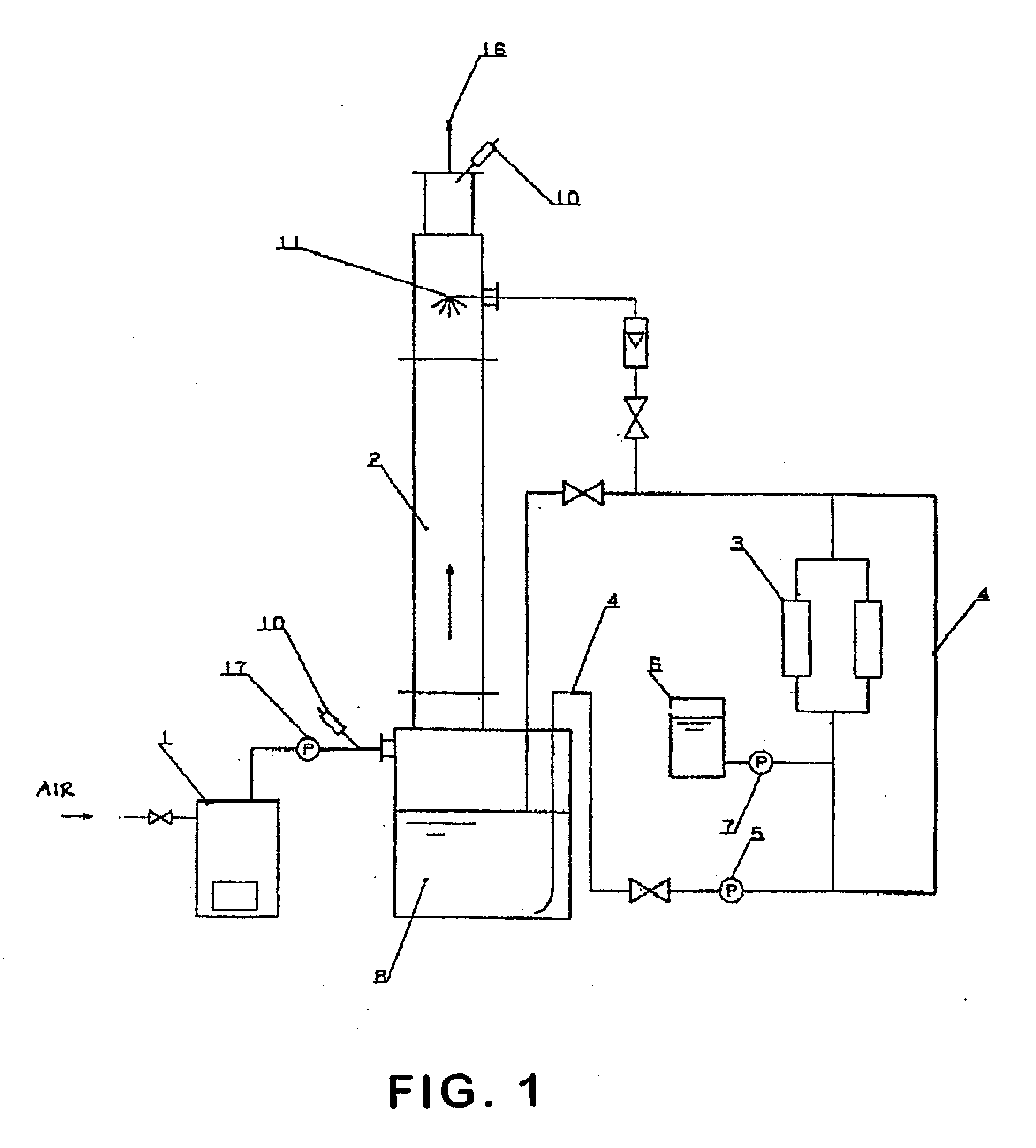

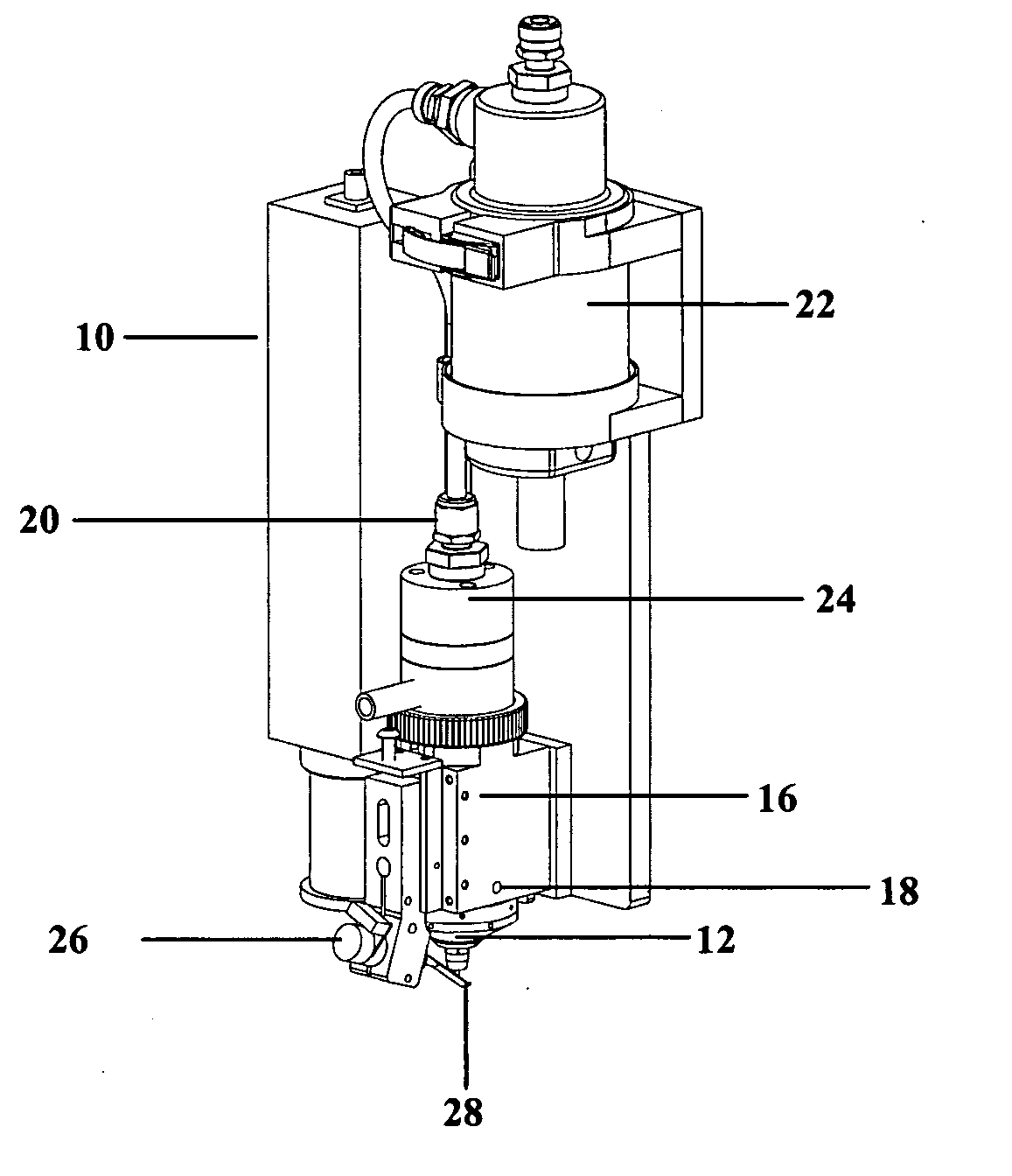

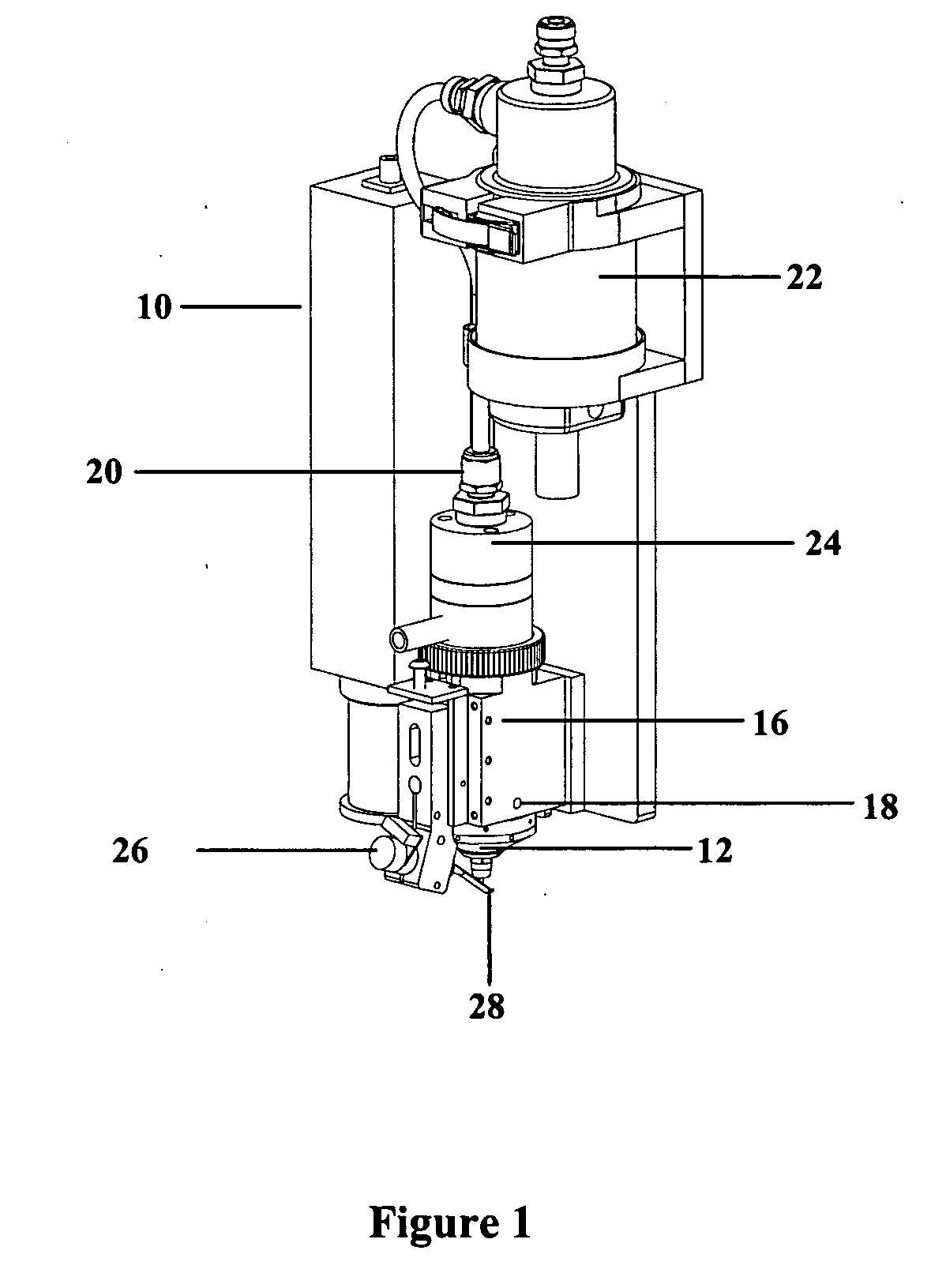

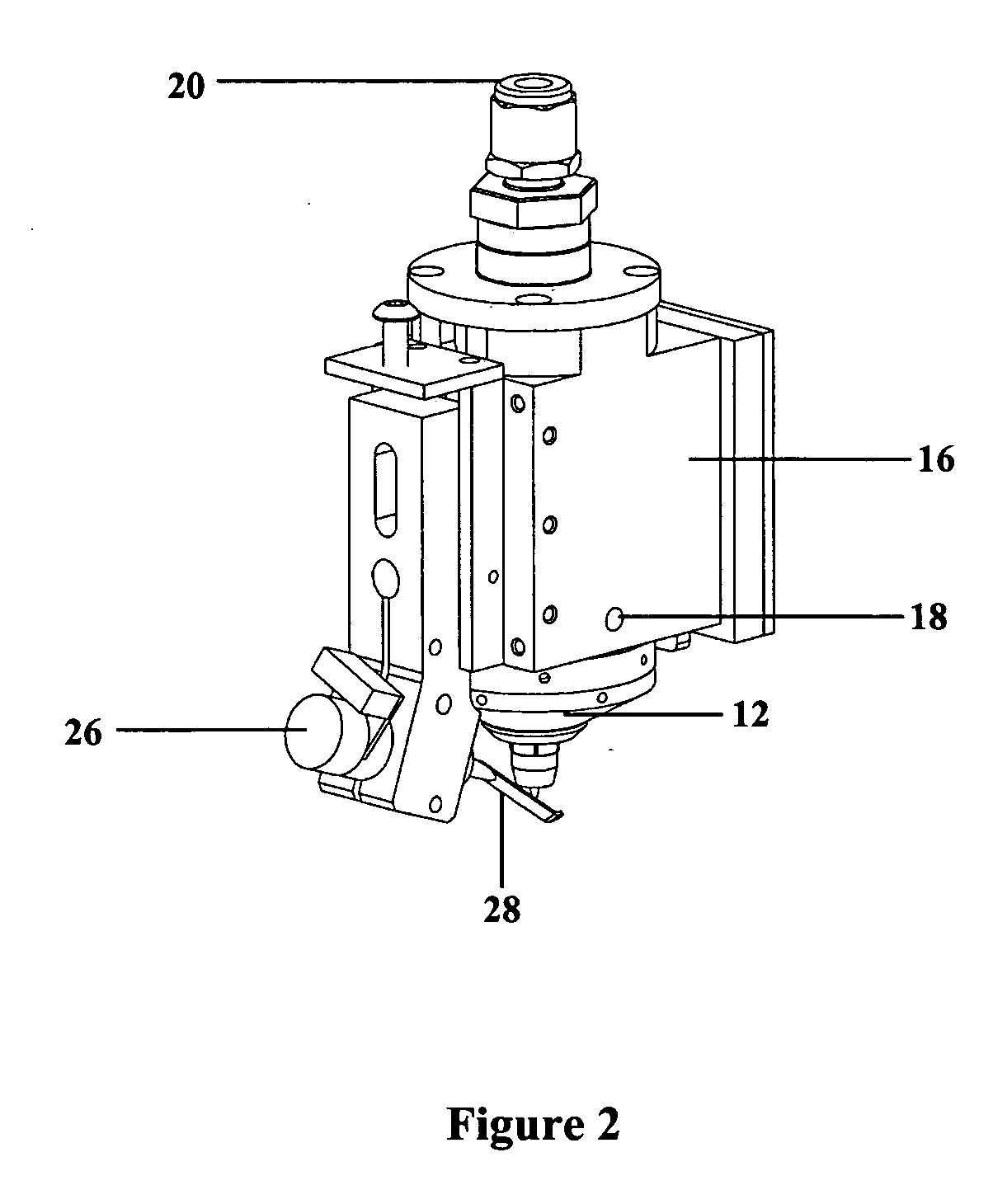

Laser processing for heat-sensitive mesoscale deposition of oxygen-sensitive materials

InactiveUS20070019028A1Damage to materialRadiation applicationsPretreated surfacesForming gasHeat sensitive

A method of depositing various materials onto heat-sensitive targets, particularly oxygen-sensitive materials. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts. Cover gases and / or forming gases may be used during thermal processing to change the material properties, for example by preventing oxidation.

Owner:OPTOMEC DESIGN CO

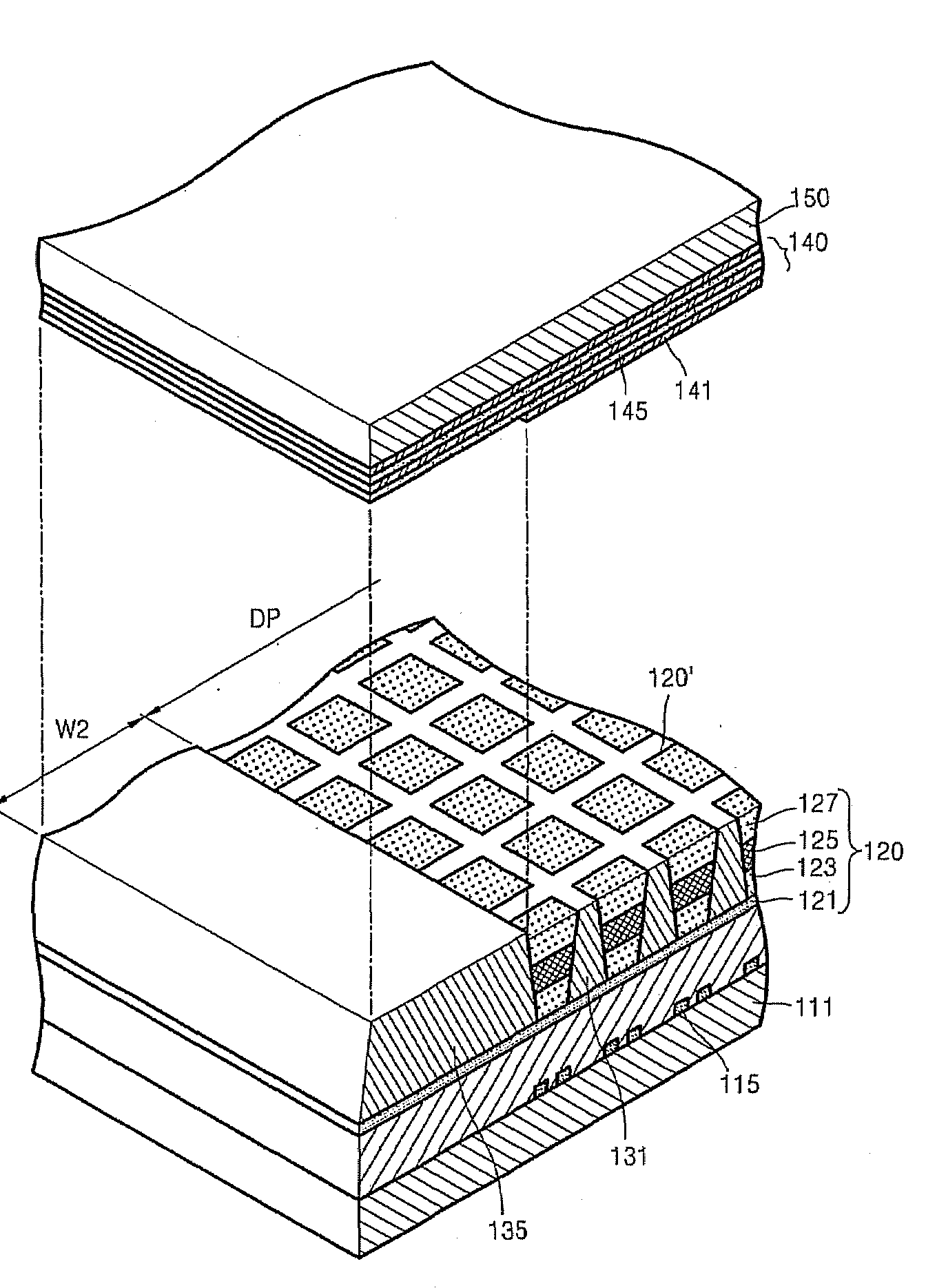

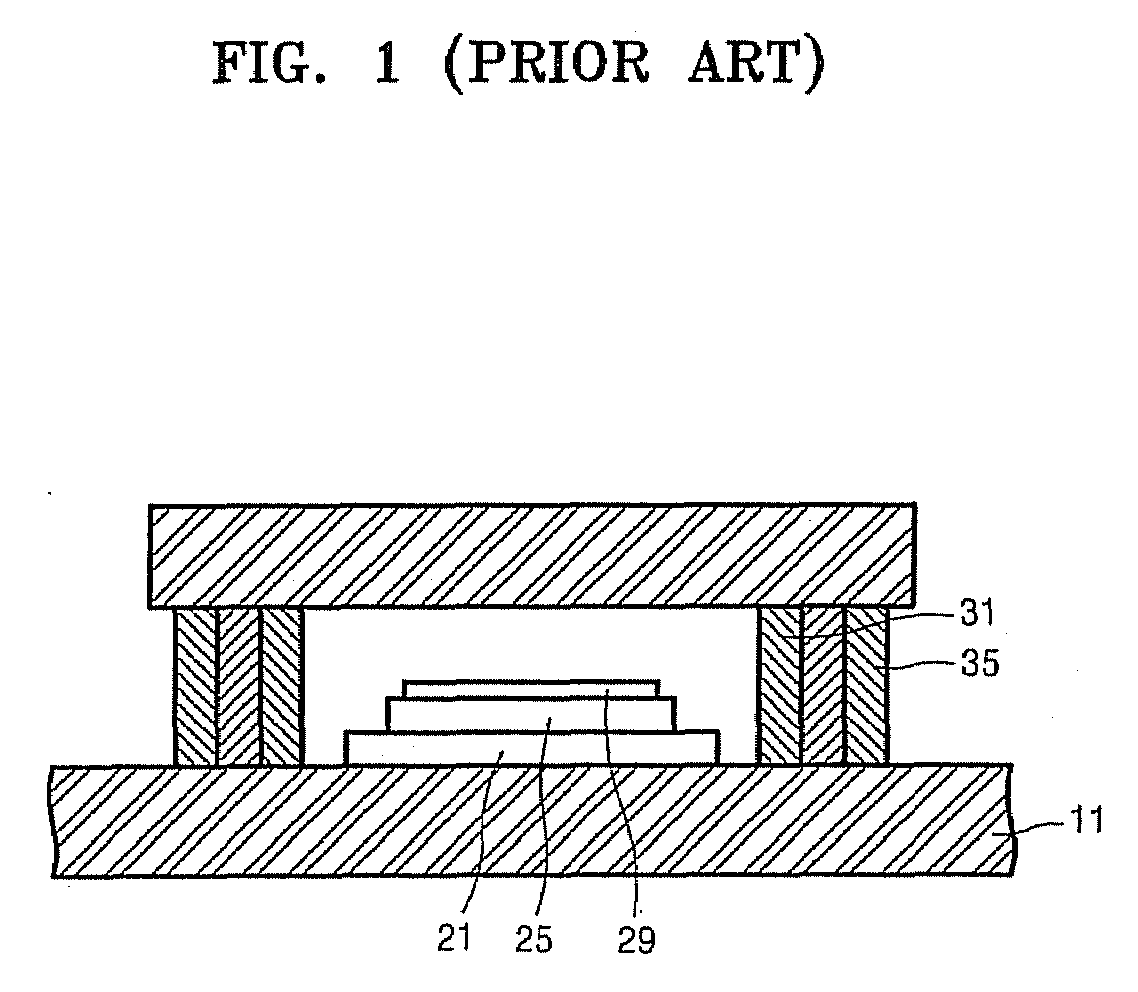

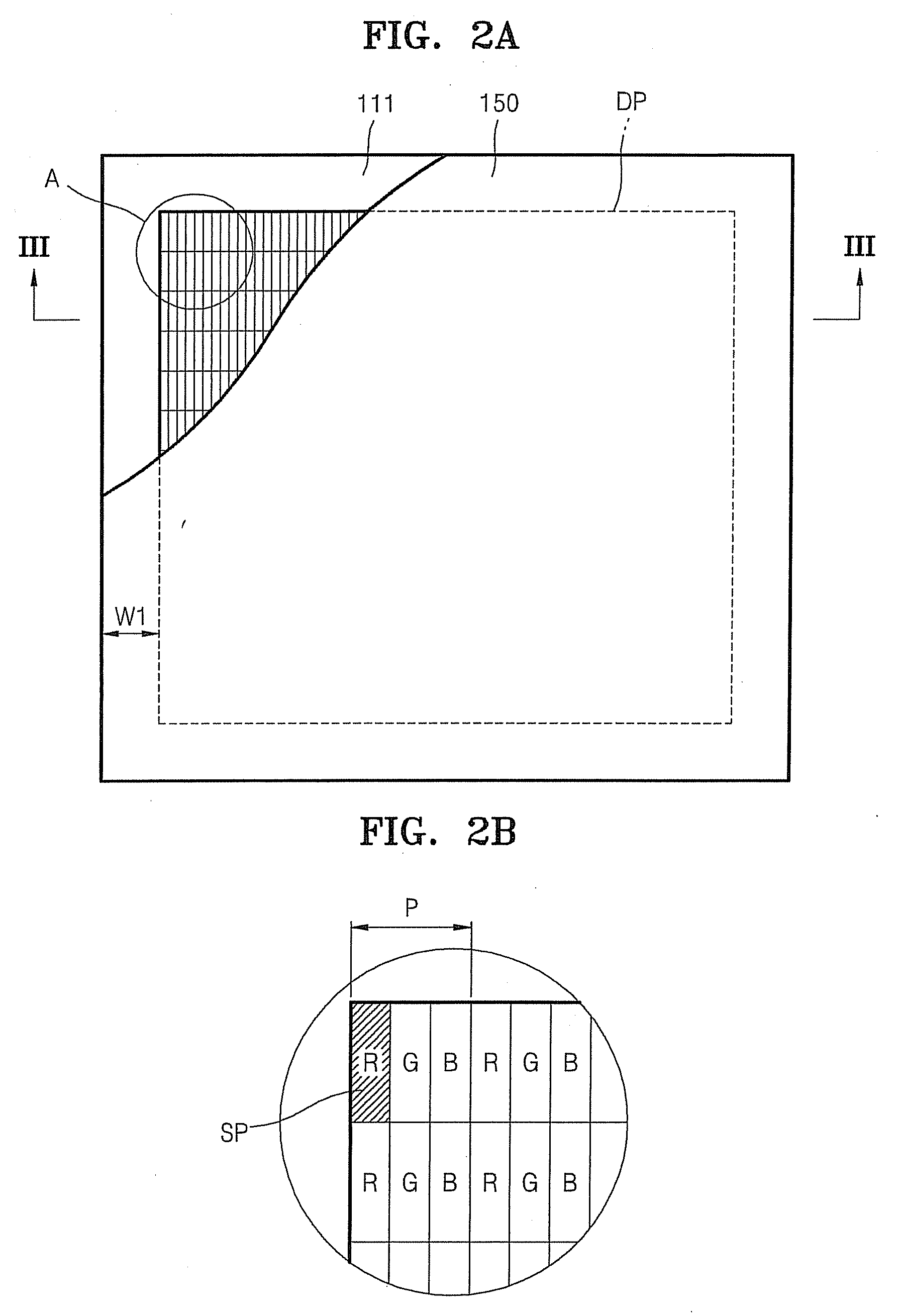

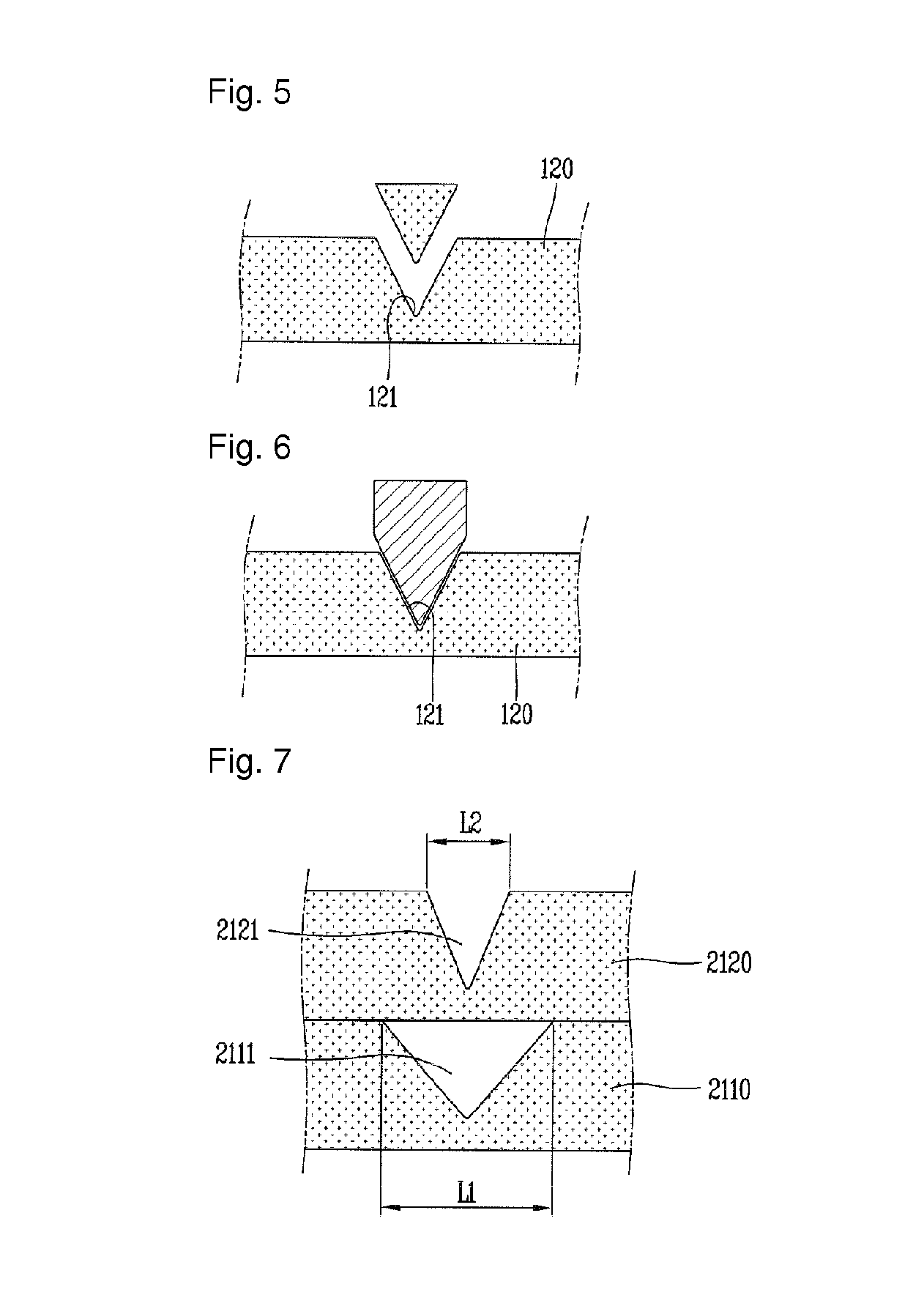

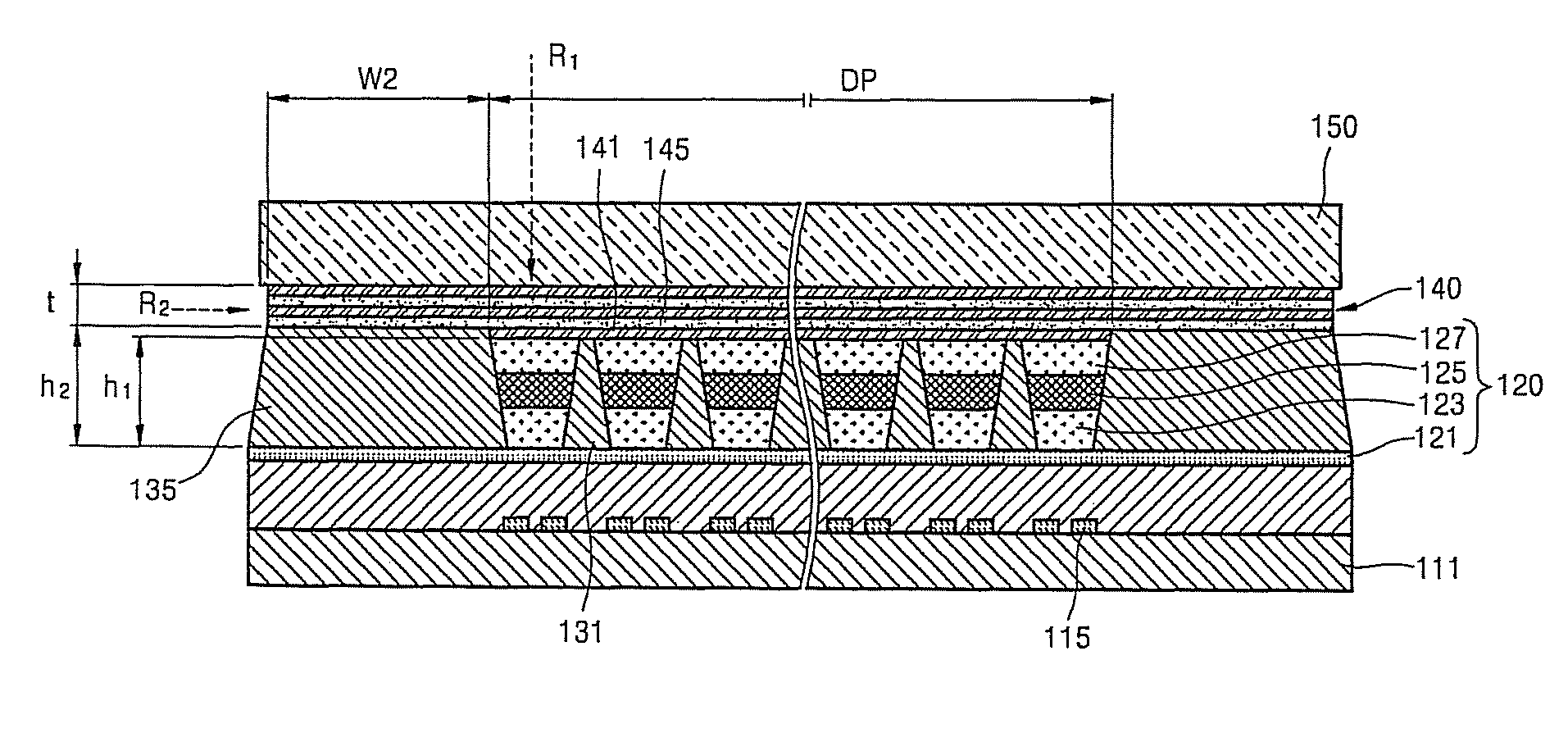

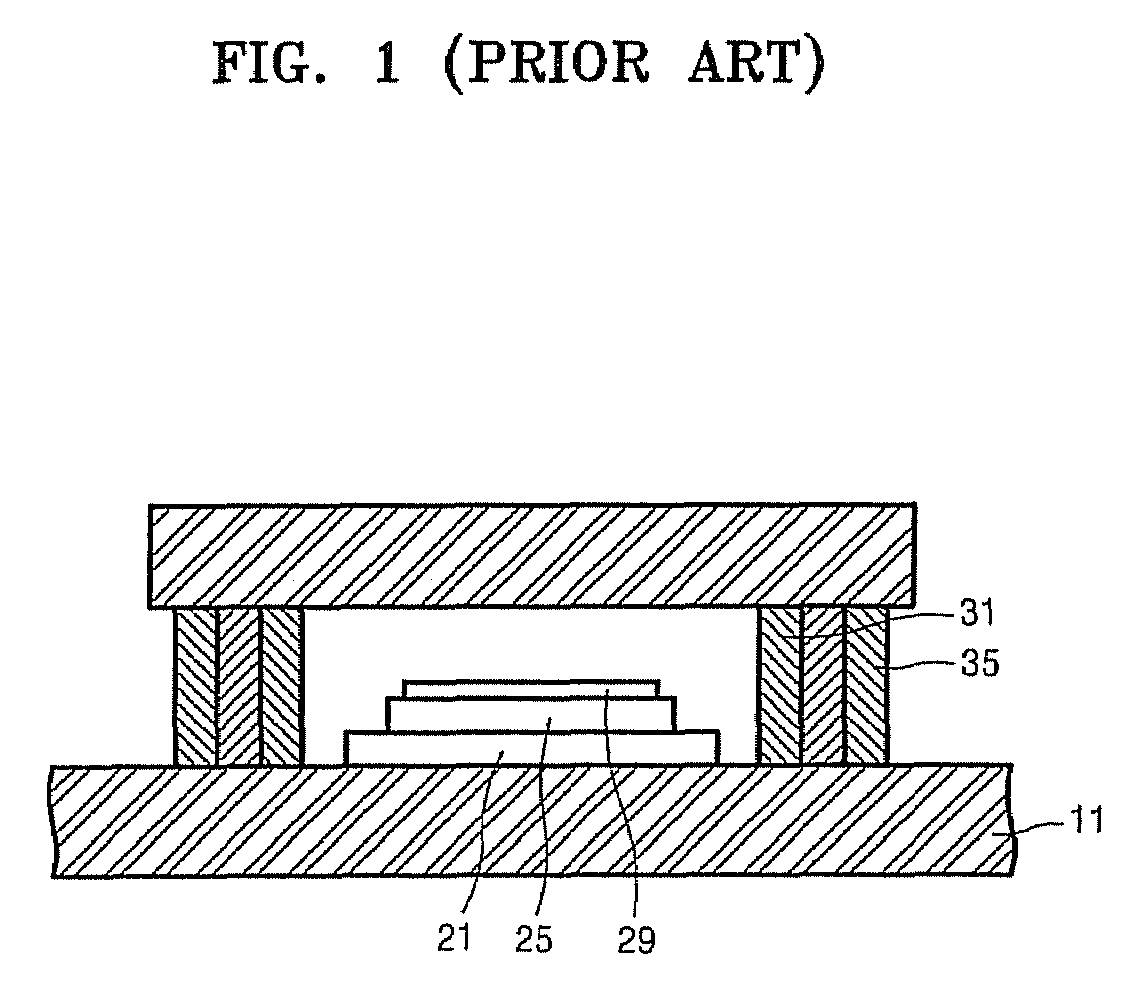

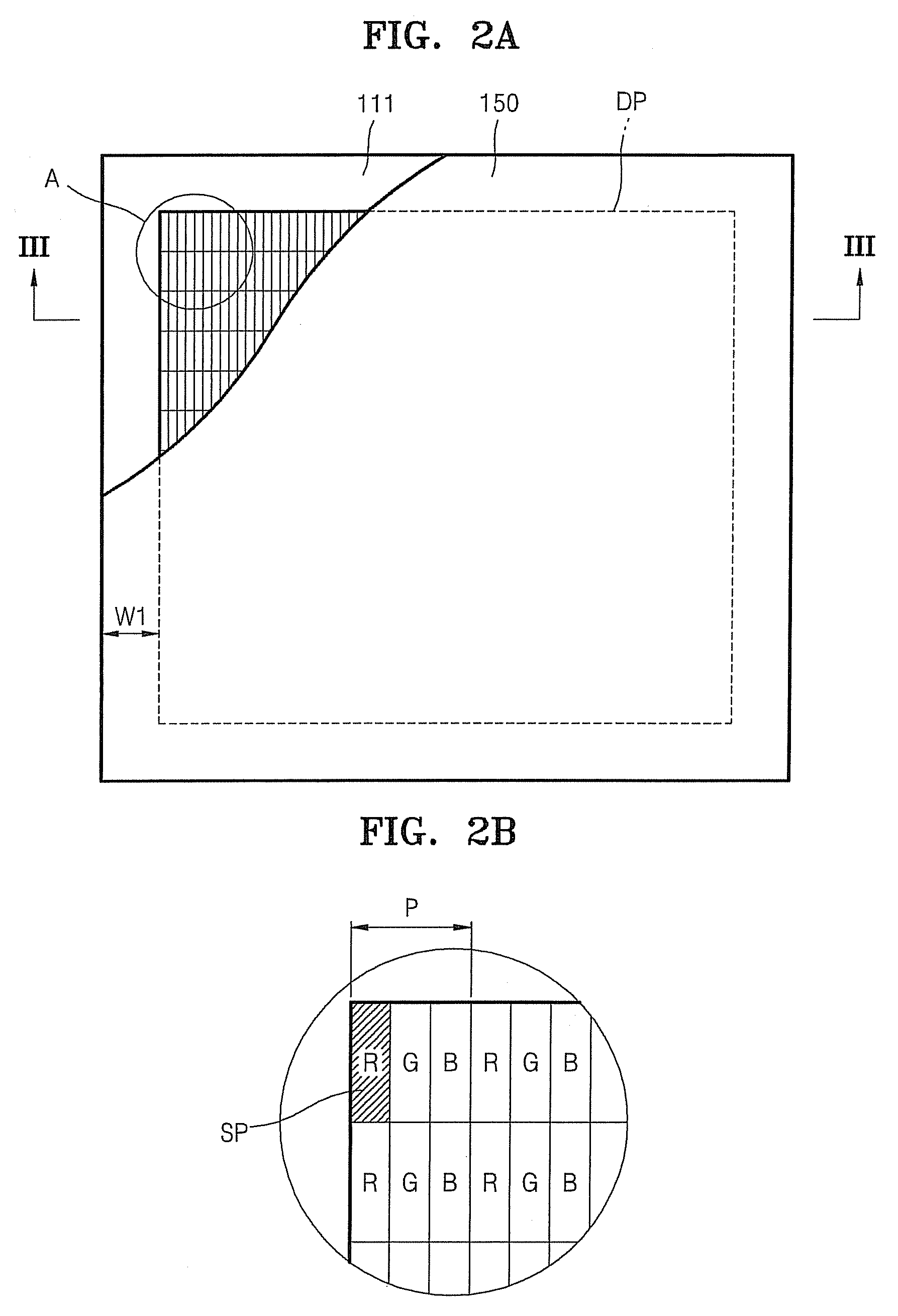

Flat panel display device and method thereof

ActiveUS20070159094A1Damage to materialAvoid performance degradationSolid-state devicesBristleOrganic filmEngineering

A flat panel display device including a display area where an image is displayed and a non-display area located at an outside of the display area includes bank portions arranged in a pattern in the display area and partitioning a plurality of openings, emission elements located in the openings, dummy bank portions formed in the non-display area and integrated therewith, and a sealing passivation layer having a multi-layered structure of organic films and inorganic films alternately arranged, one organic film being located at an interface directly contacting the emission element and one inorganic film located firstly on an outermost portion of the dummy bank portions when the sealing passivation layer extends from the display area to the non-display area.

Owner:SAMSUNG DISPLAY CO LTD

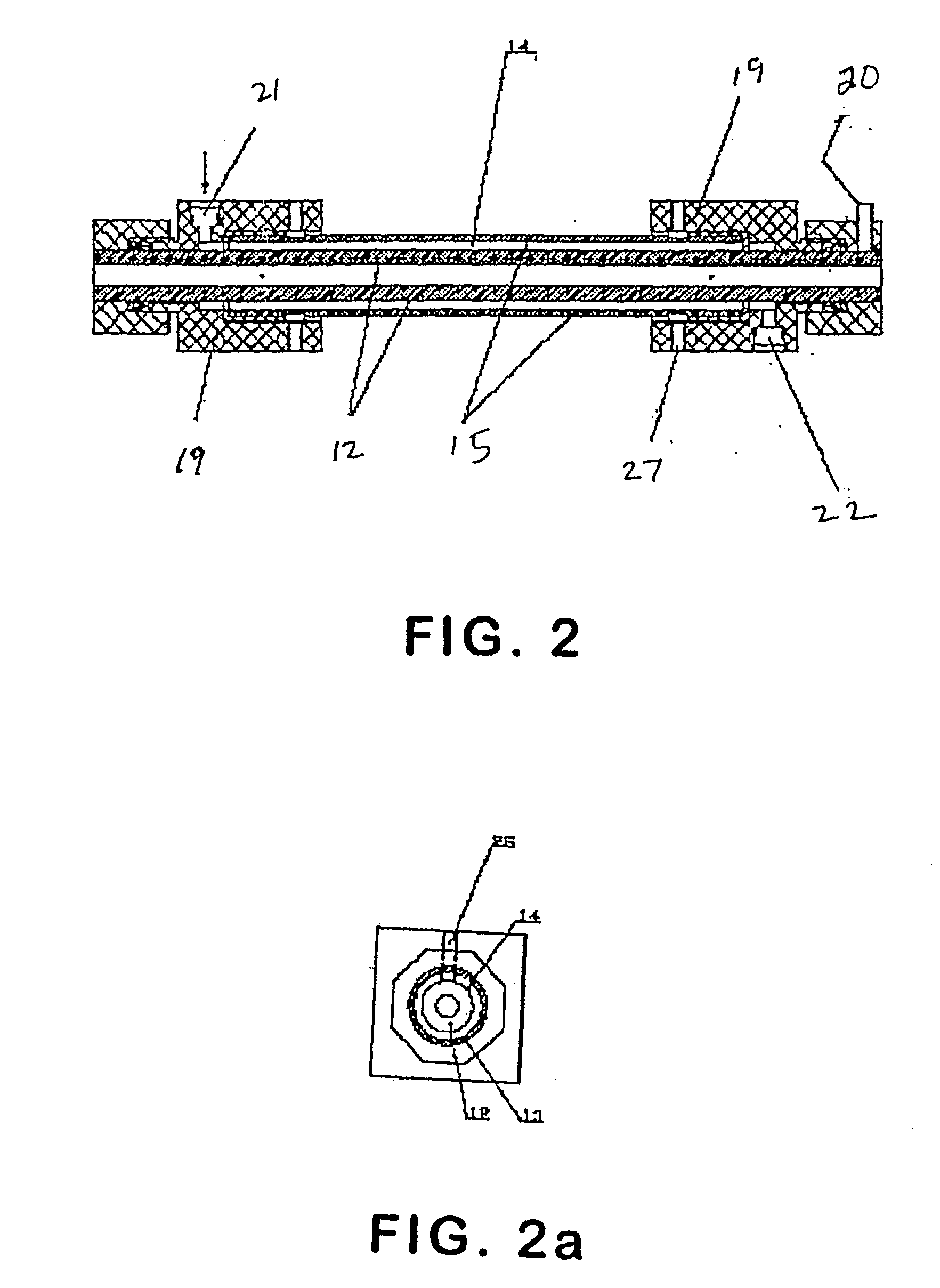

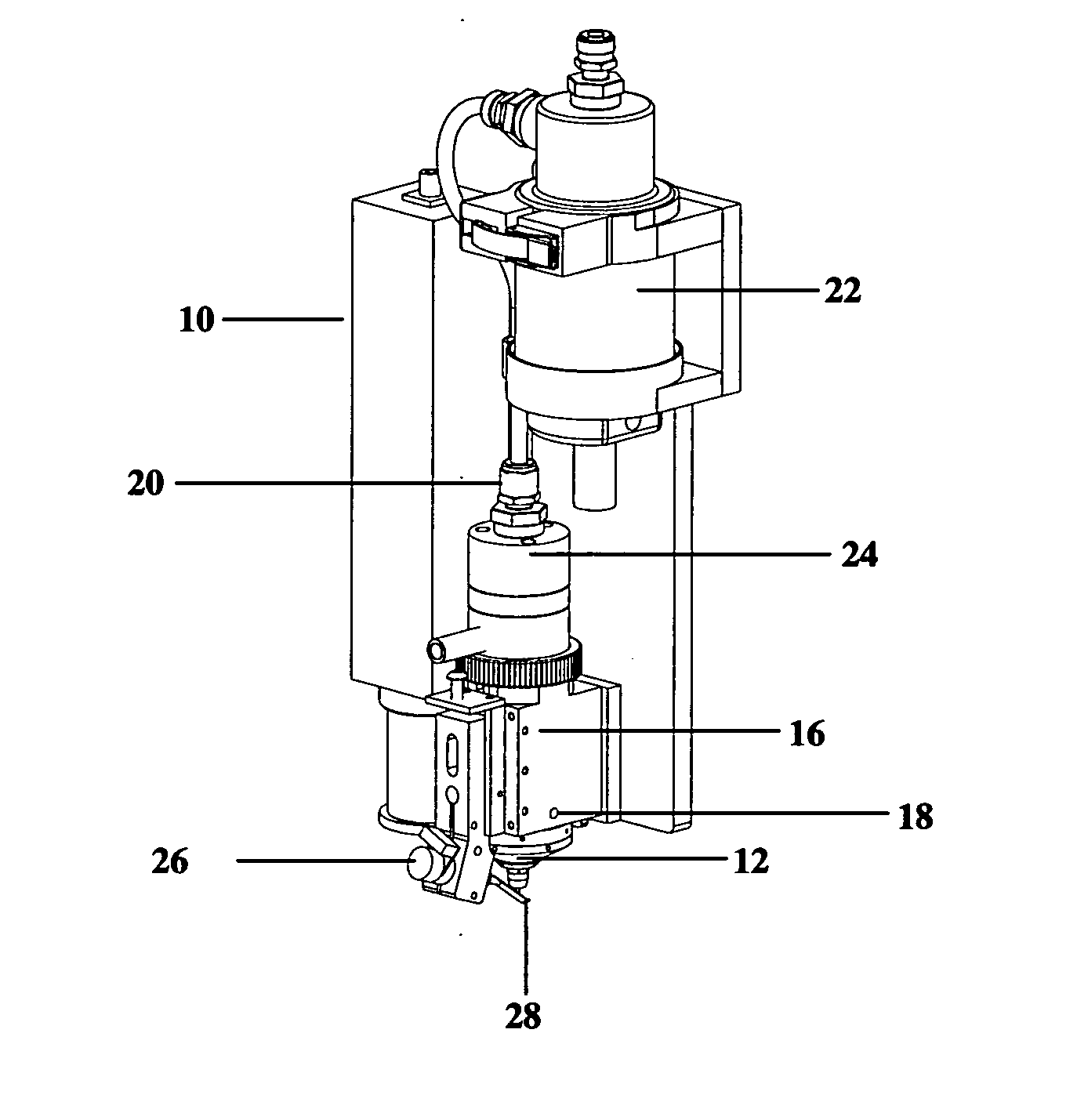

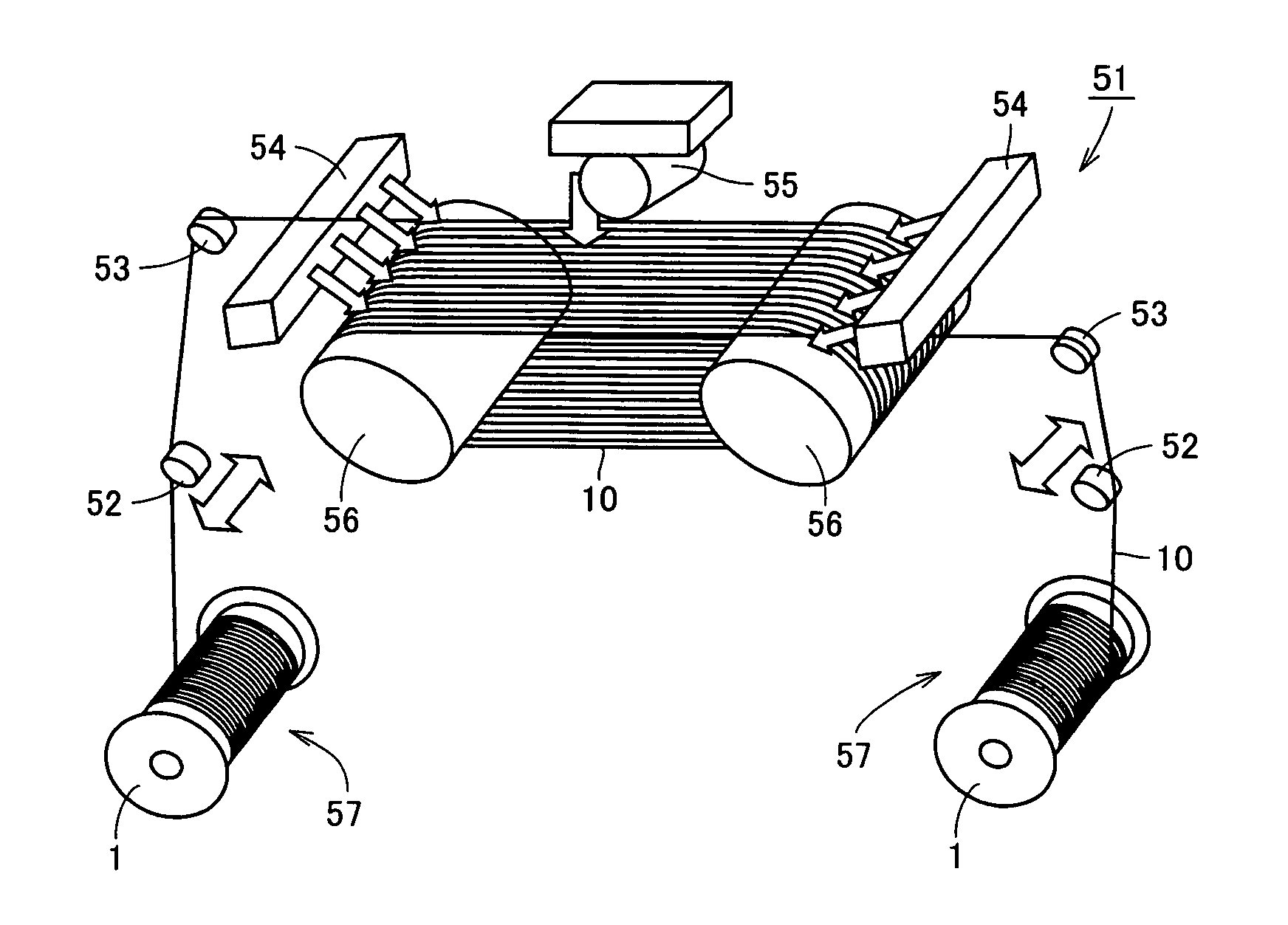

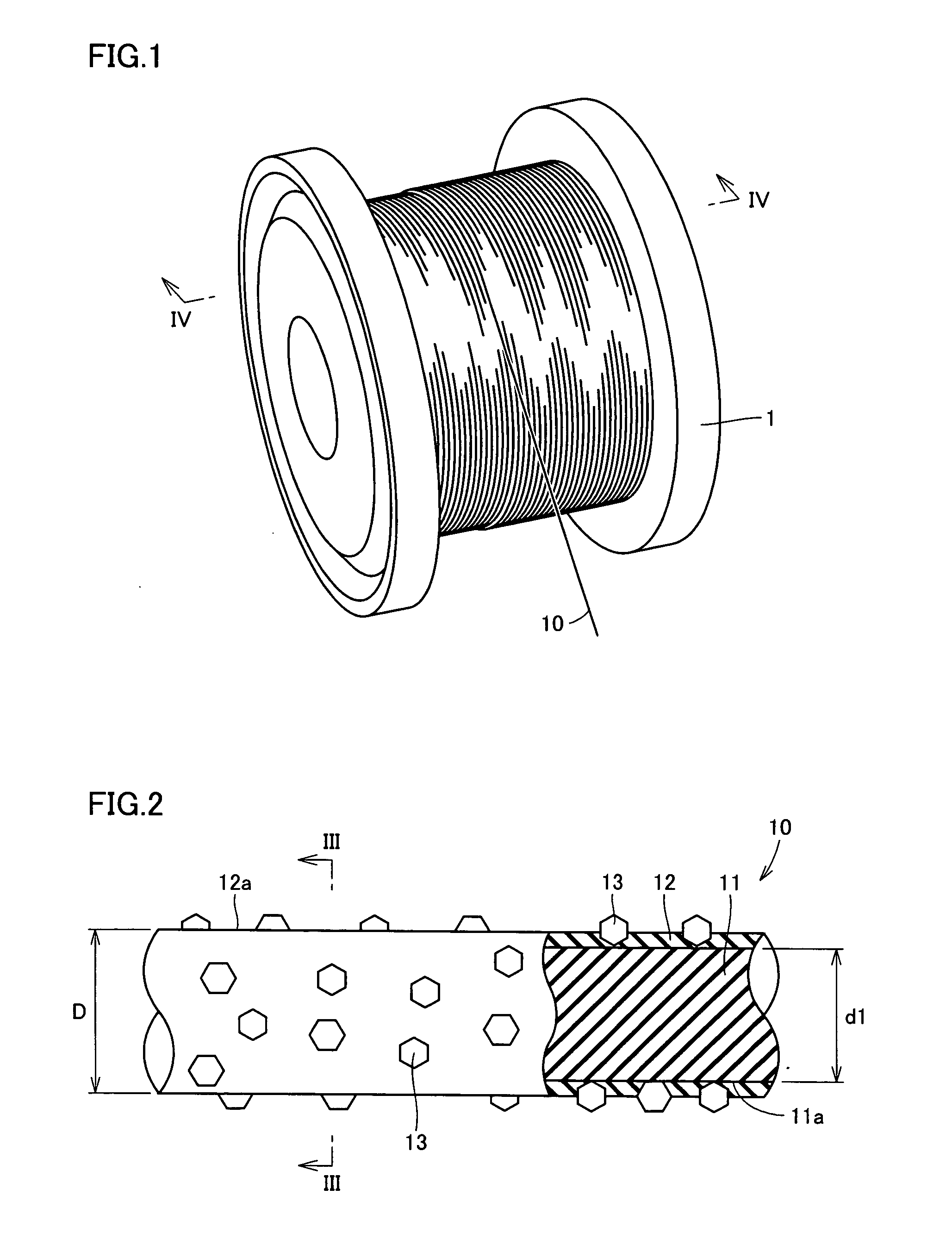

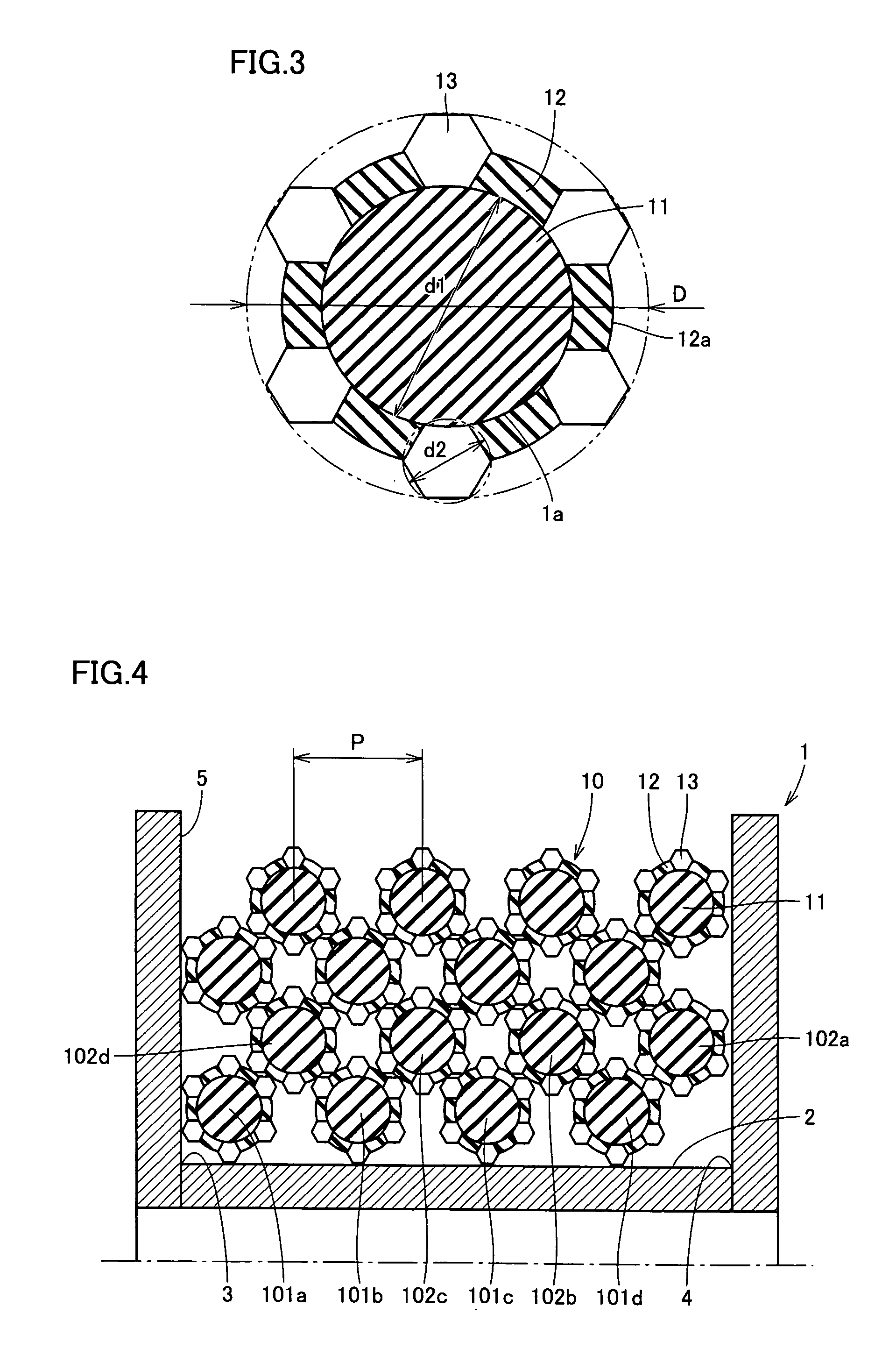

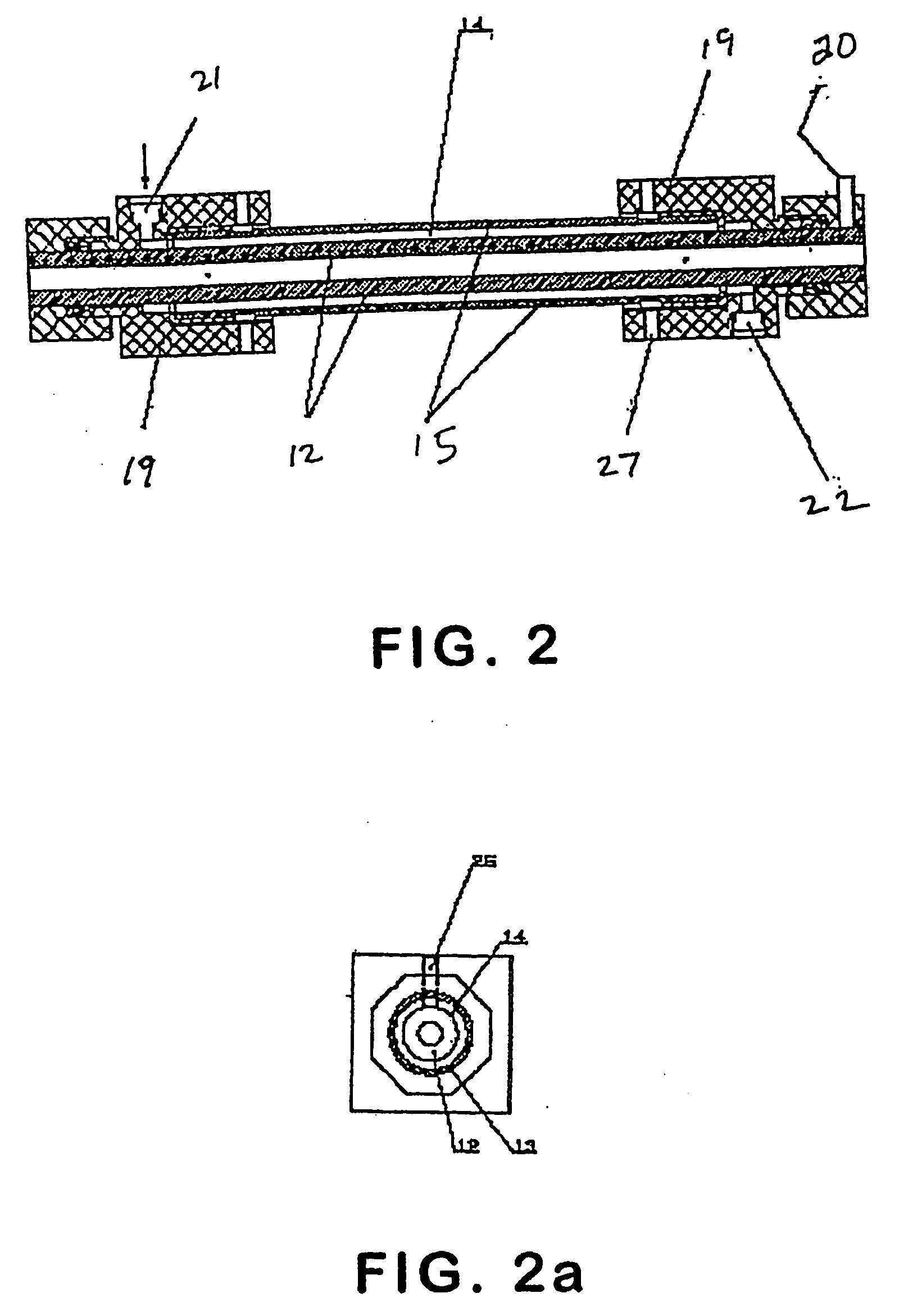

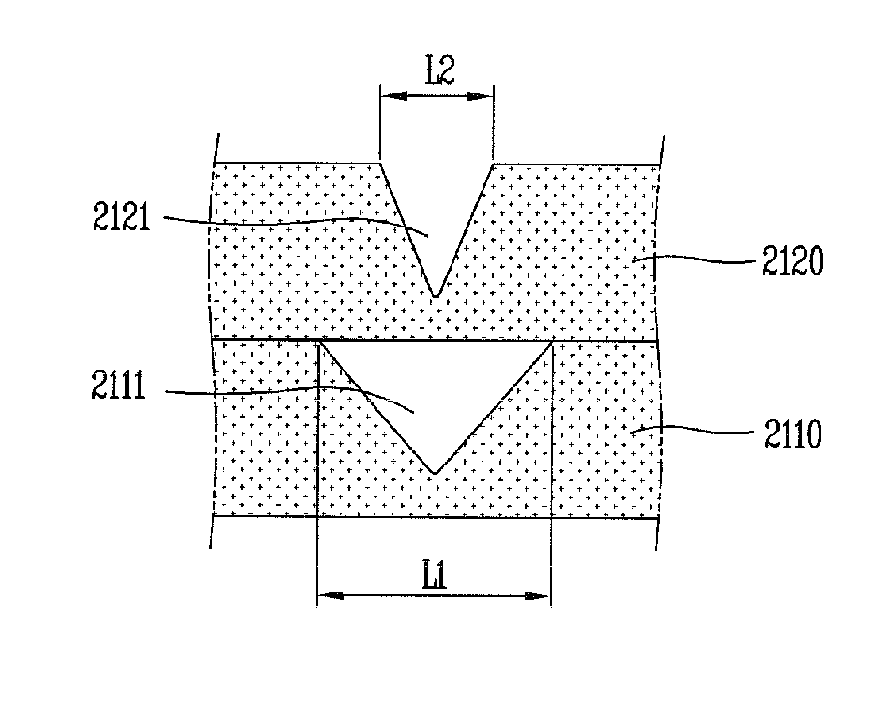

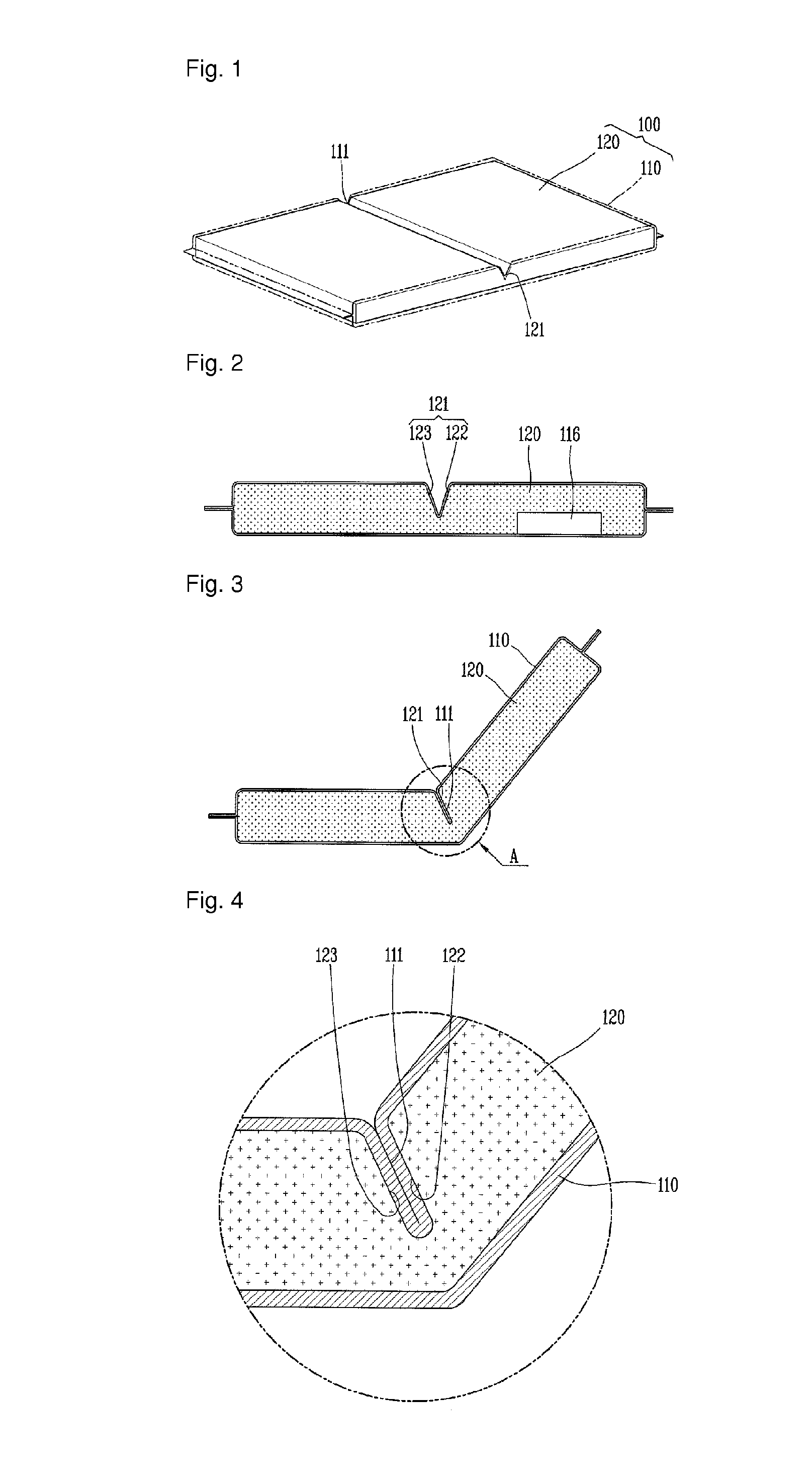

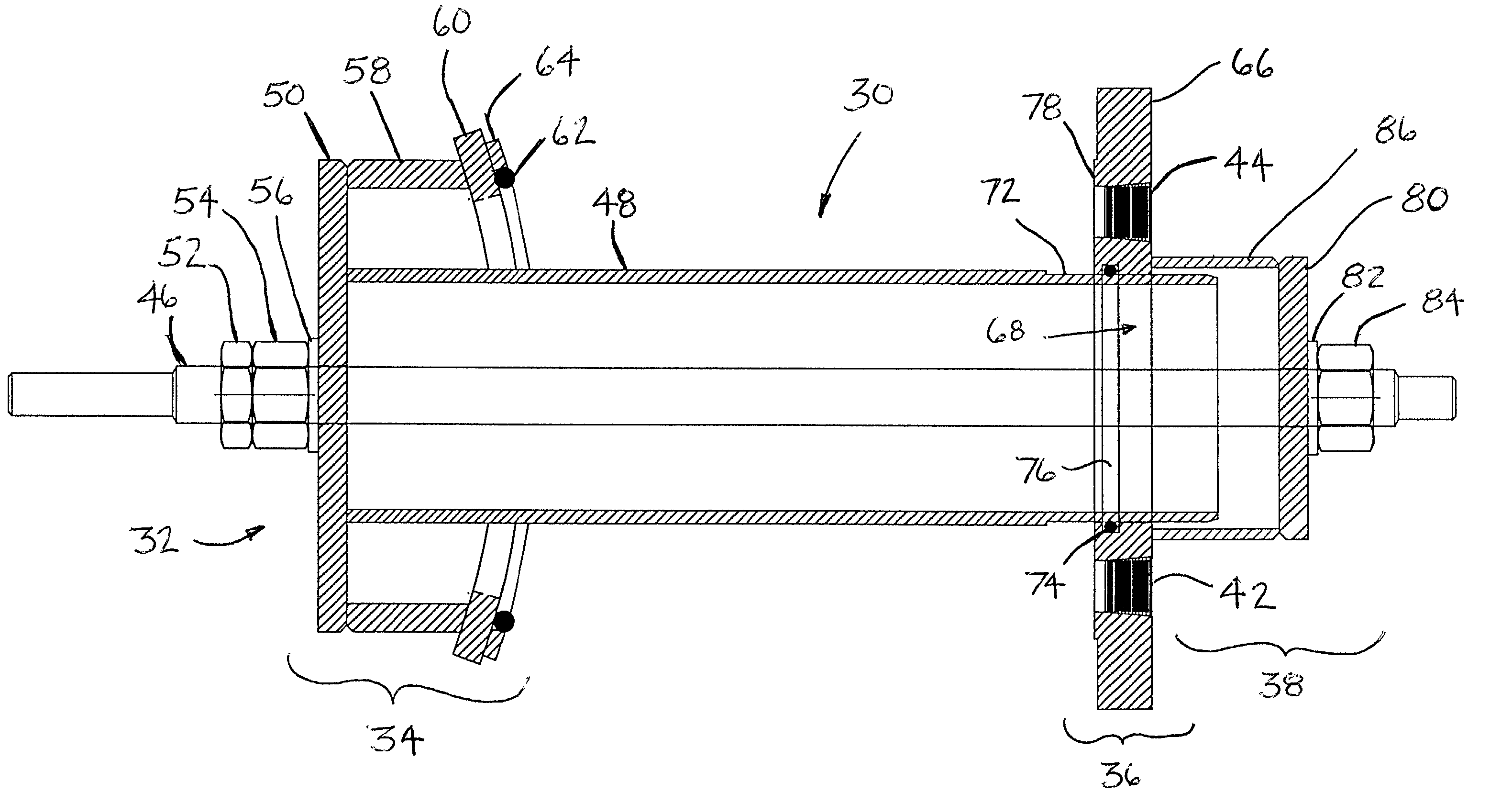

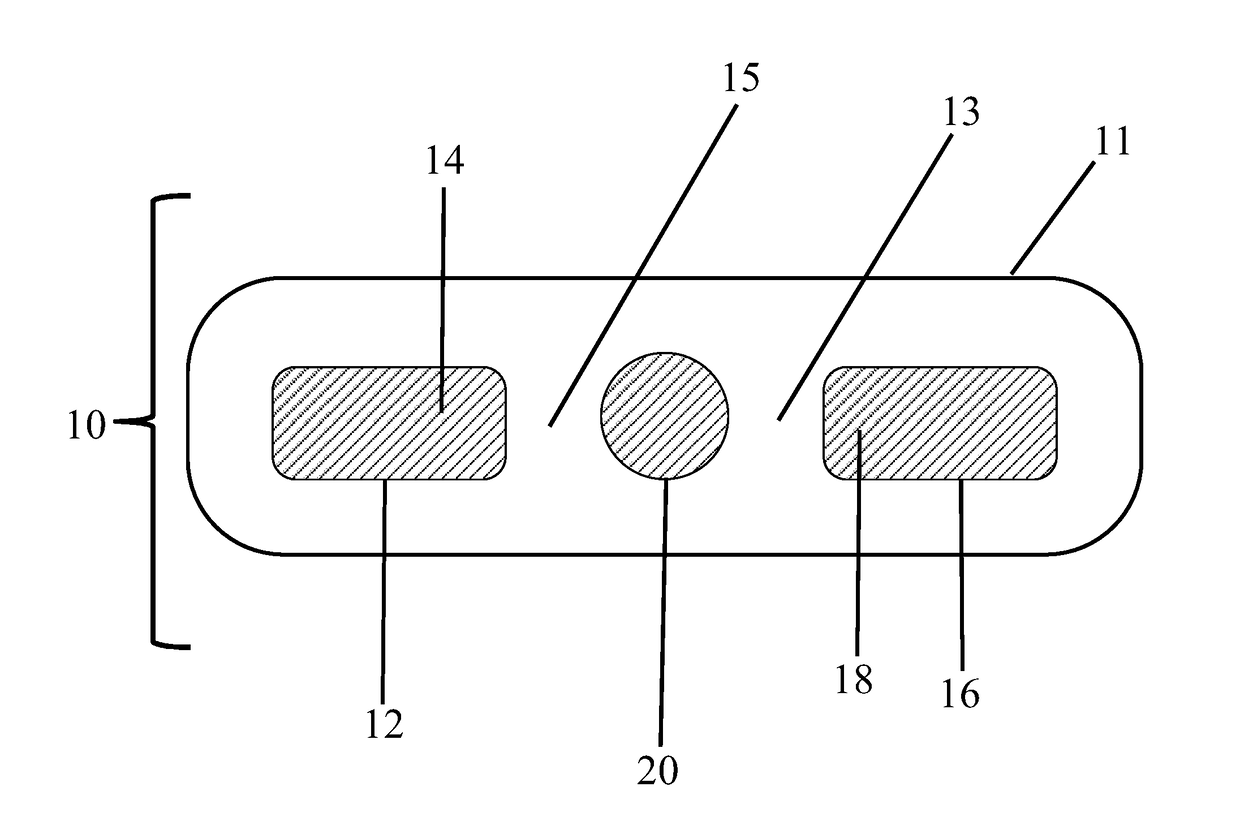

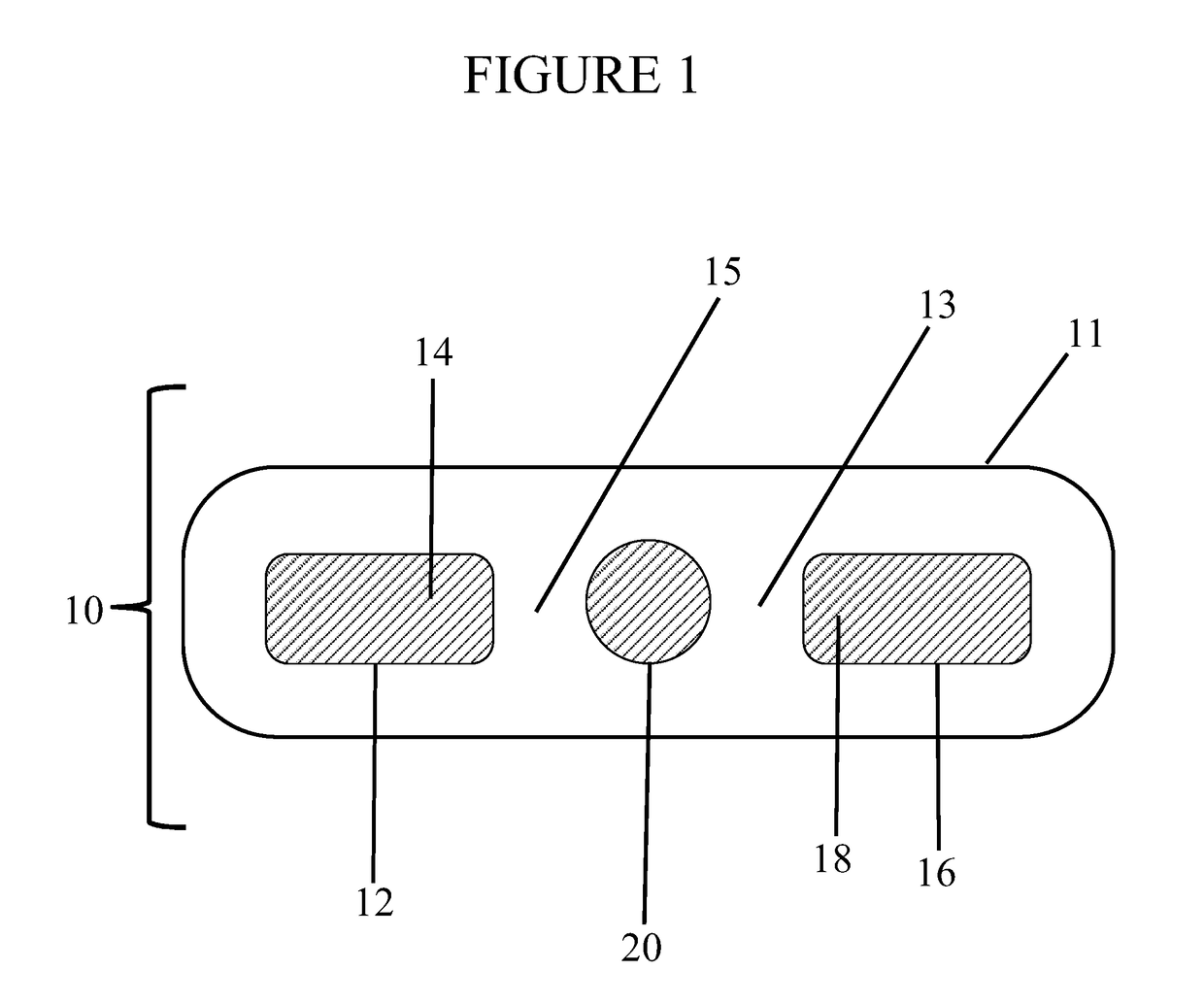

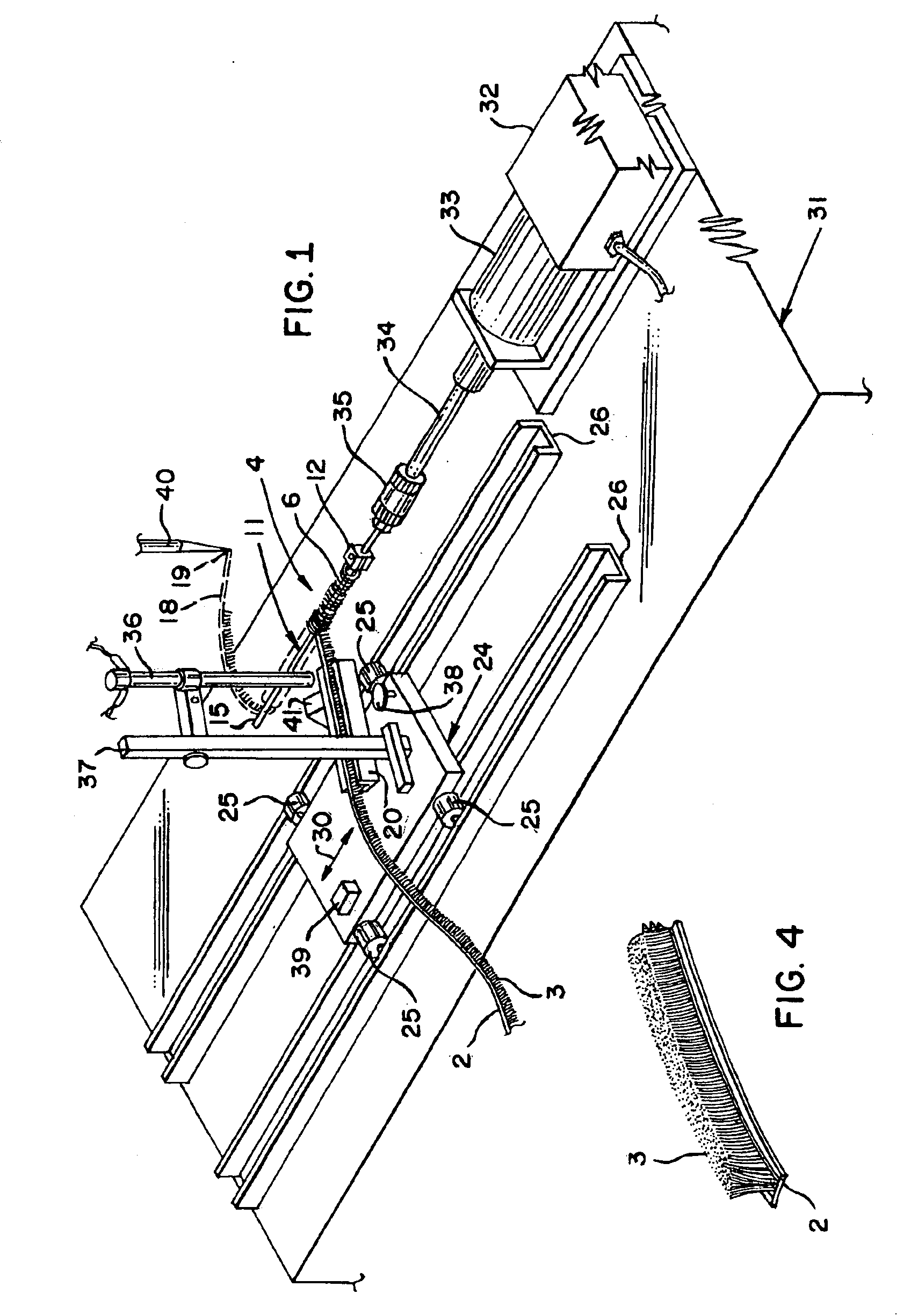

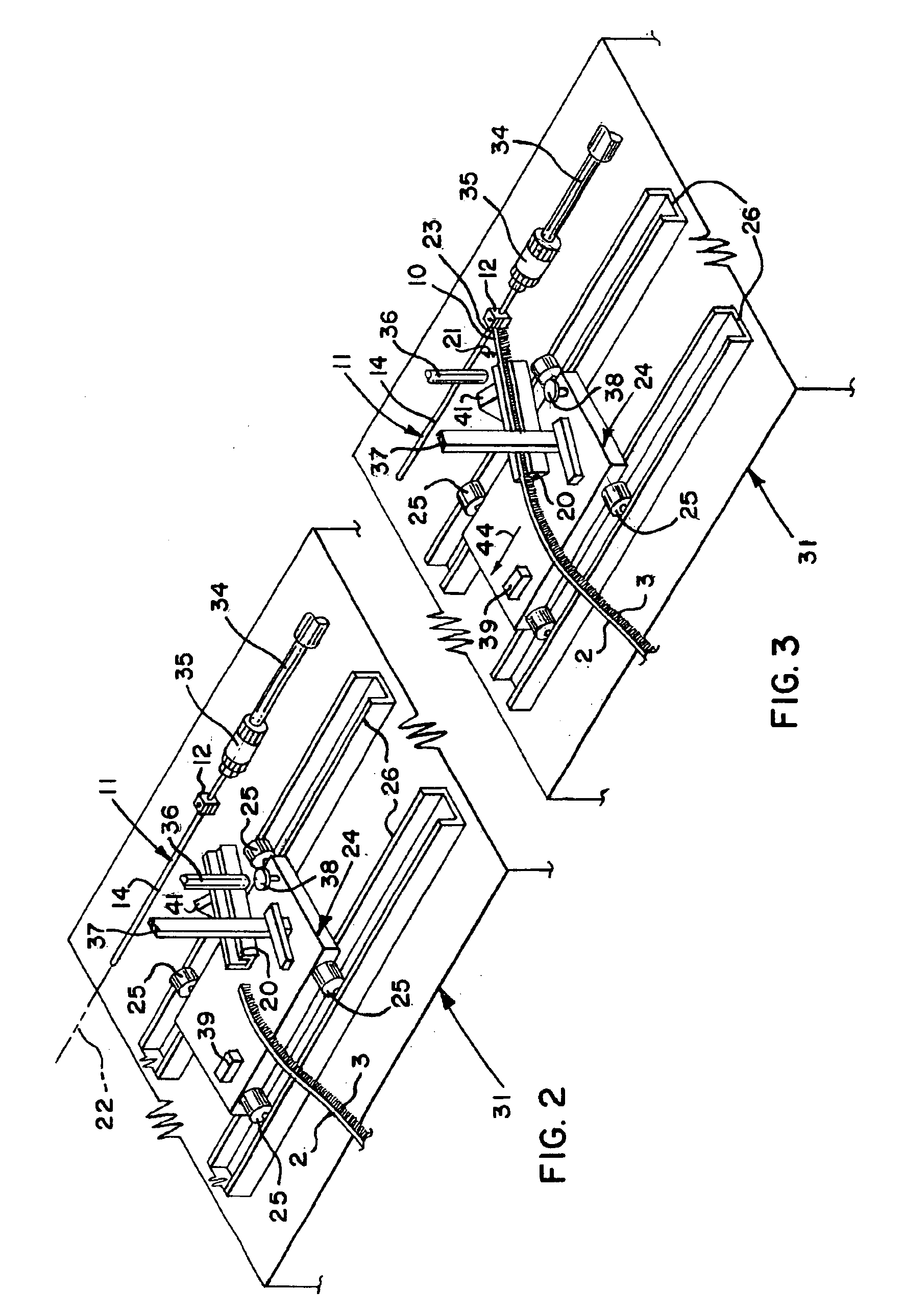

Super abrasive grain wire saw winding structure, super abrasive grain wire saw cutting device, and super abrasive grain wire saw winding method

InactiveUS20070023027A1Friction can be so intenseDamage to materialMetal sawing devicesEdge grinding machinesConductor CoilWire saw

A superabrasive wire saw-wound structure includes a superabrasive wire saw (10) formed with an average diameter D and a reel (1). The superabrasive wire saw (10) includes a core wire (11), a bonding material (12) surrounding a surface of the core wire (11), and a plurality of superabrasive grains (13) bonded to the surface of the core wire (11) with the bonding material (12). The reel (1) includes a peripheral surface (2) having one end (3) and the other end (4). The superabrasive wire saw (10) which is to be unreeled successively toward a workpiece is wound around the peripheral surface (2) reciprocatingly between the one end (3) and the other end (4) to be multi-layered. A pitch P for winding the superabrasive wire saw (10) around the peripheral surface (2) between the one end (3) and the other end (4) satisfies a relation of D<P<2D. According to the present invention, there can be provided a superabrasive wire saw-wound structure, a cutting device with a superabrasive wire saw, and a method of winding a superabrasive wire saw which can reduce damage to a bonding material and falling of a superabrasive grain.

Owner:ALLIED MATERIAL

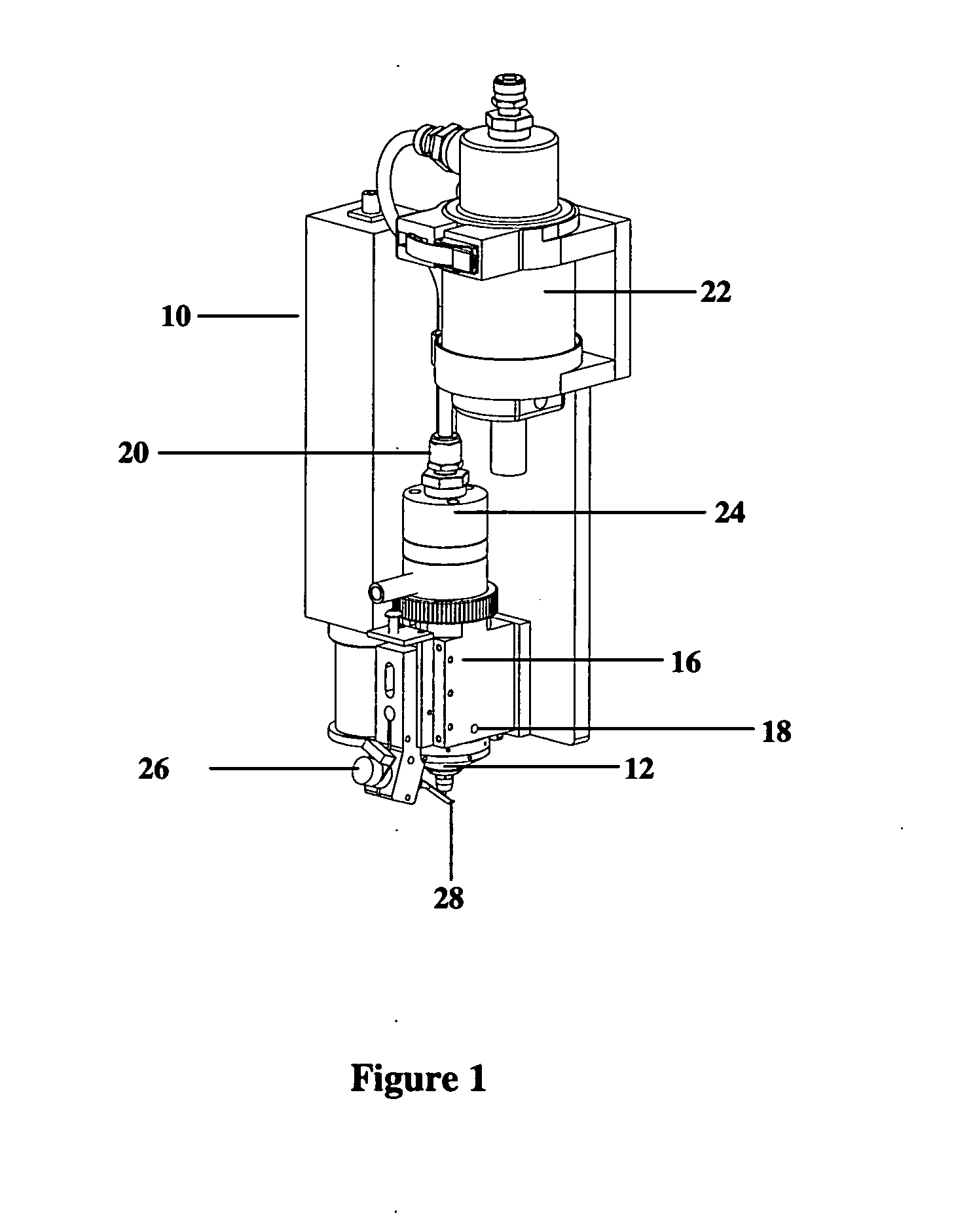

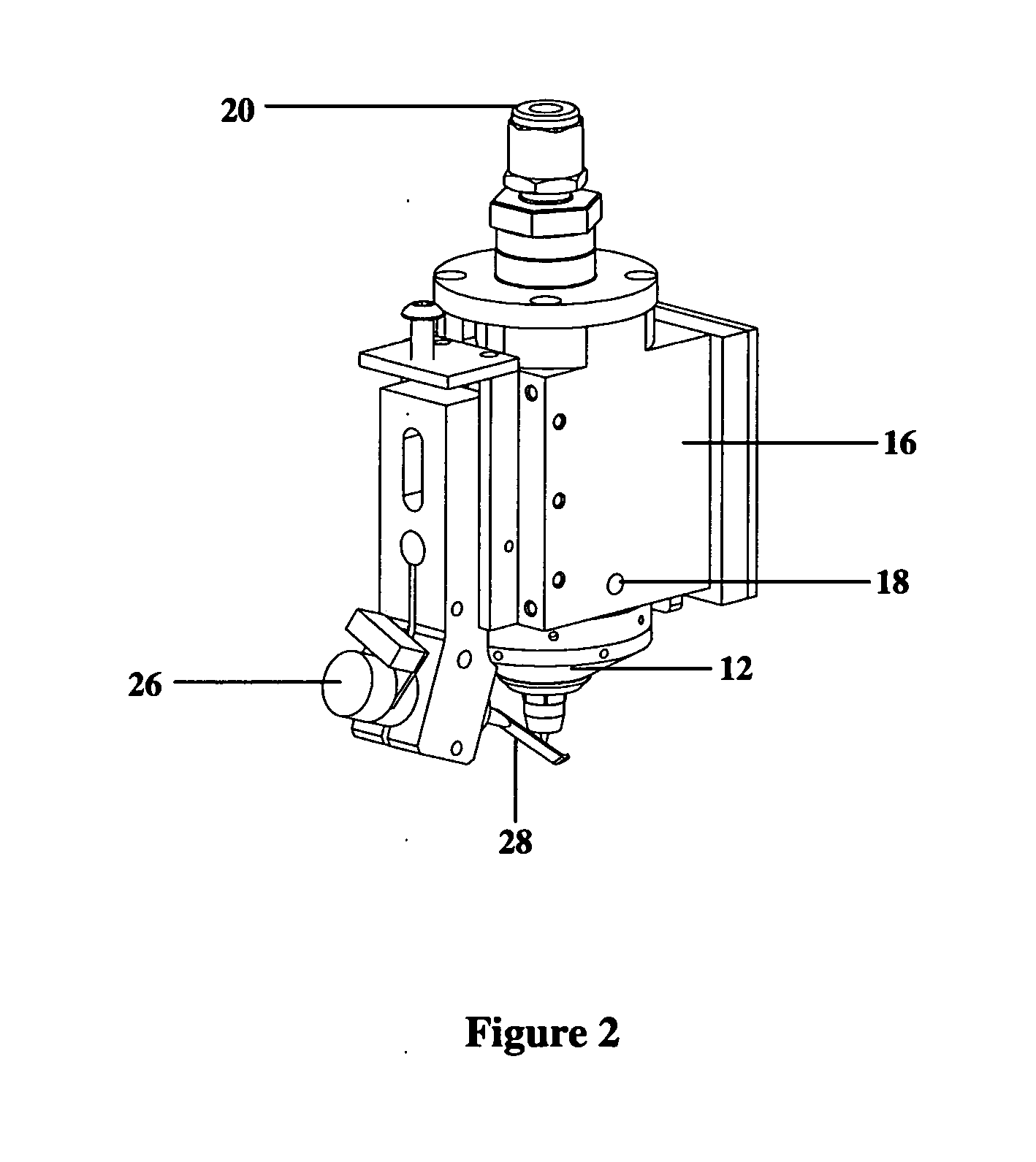

Laser processing for heat-sensitive mesoscale deposition

InactiveUS20050129383A1Low damage thresholdDamage to materialSolid-state devicesMetal-working apparatusLaser processingHeat sensitive

A method of depositing various materials onto heat-sensitive targets. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts.

Owner:OPTOMEC DESIGN CO

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20060124444A1Reduce needRemove films of protein oil and fatsLighting and heating apparatusExhaust apparatusElectrolysisHazardous substance

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogenous acid compounds such as sodium hypochlorite, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:NAKAMURA SHINICHI +2

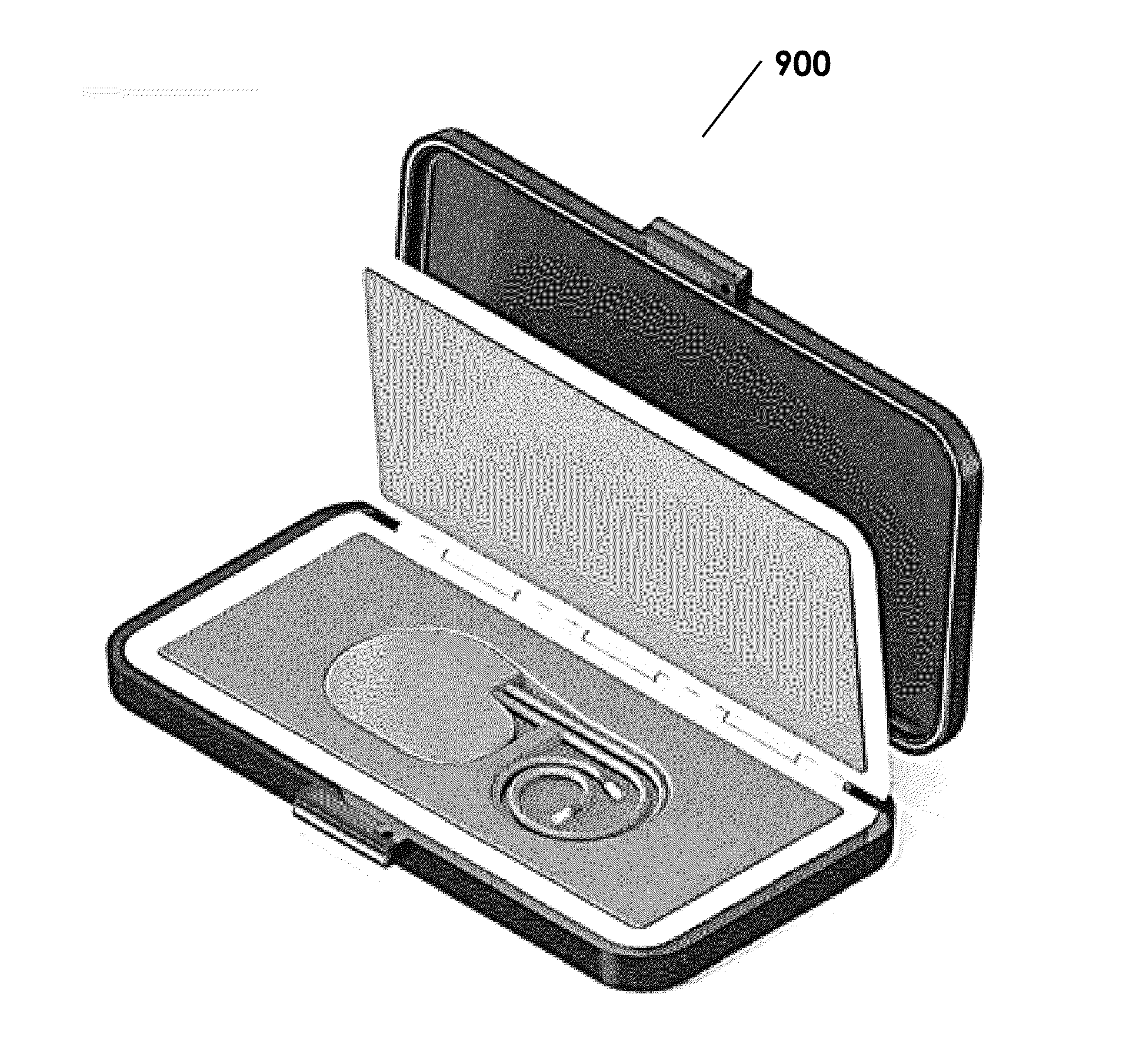

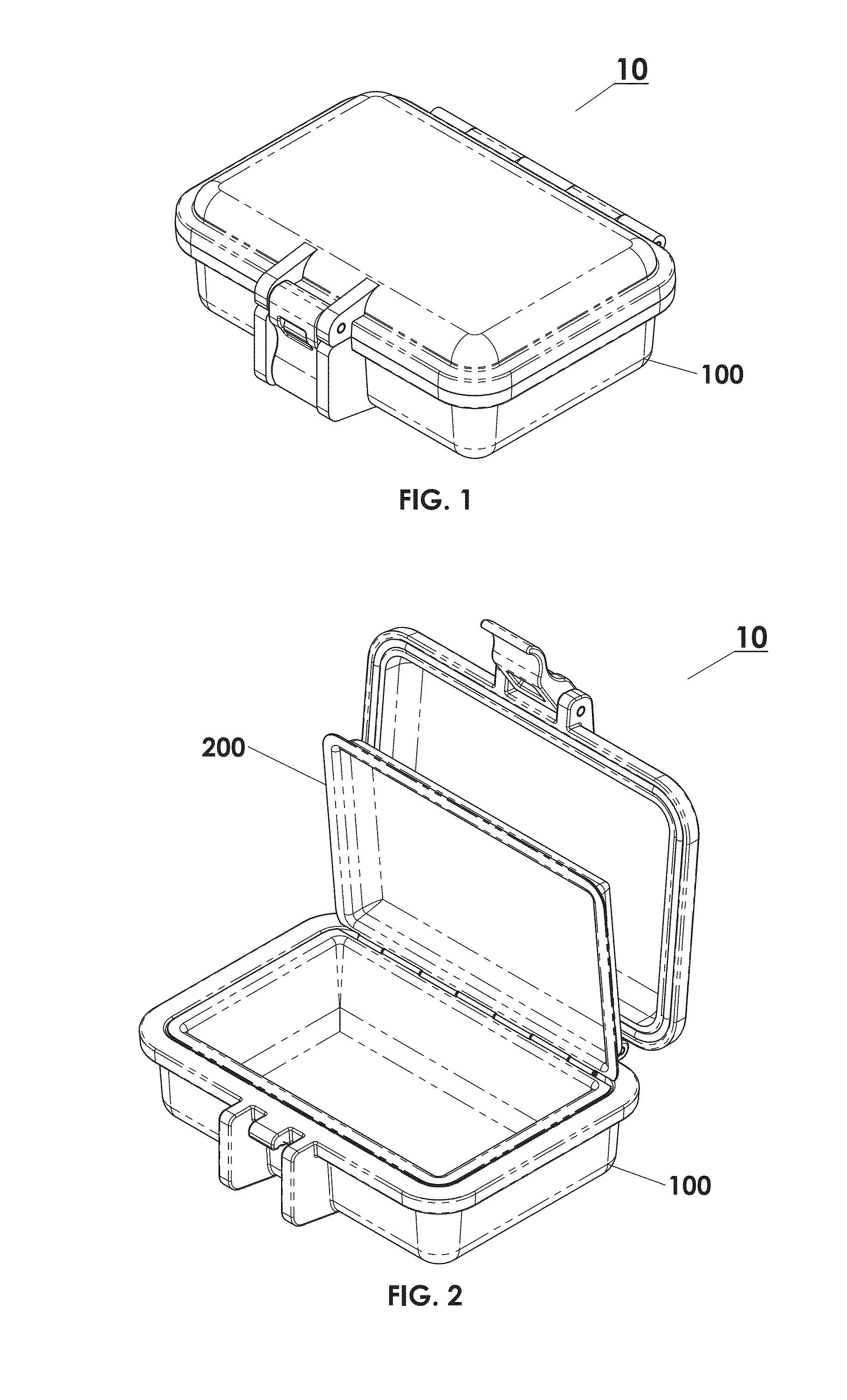

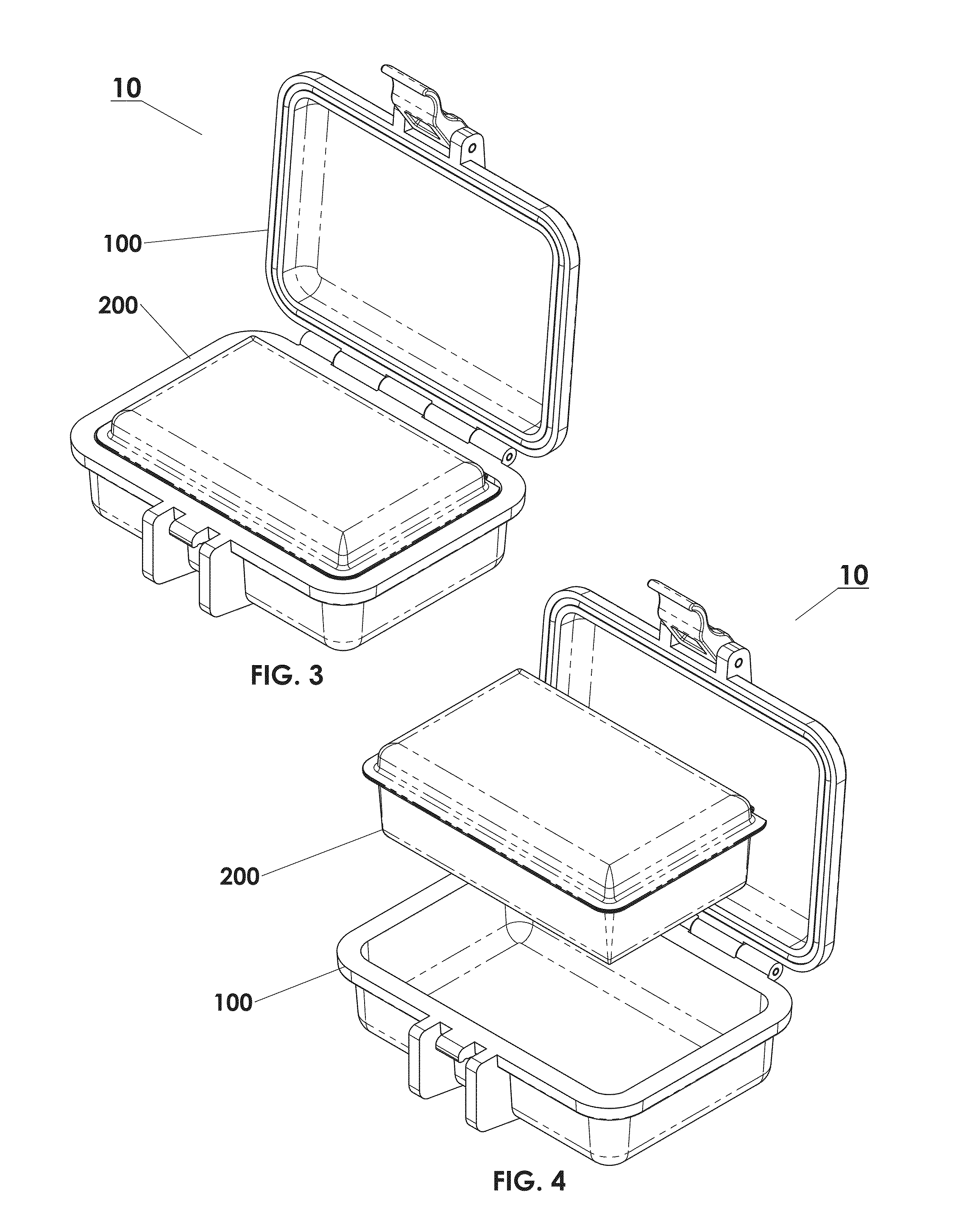

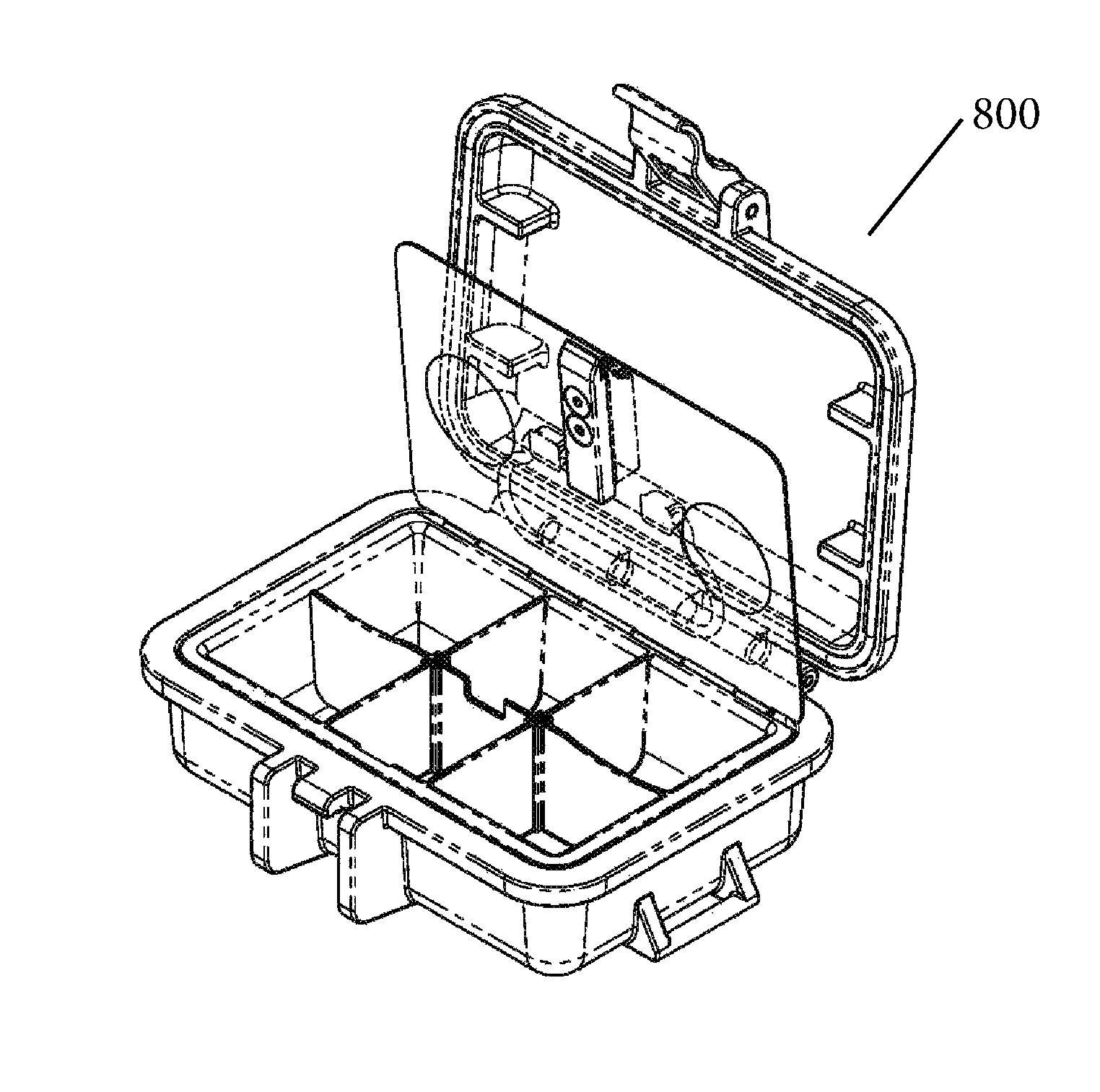

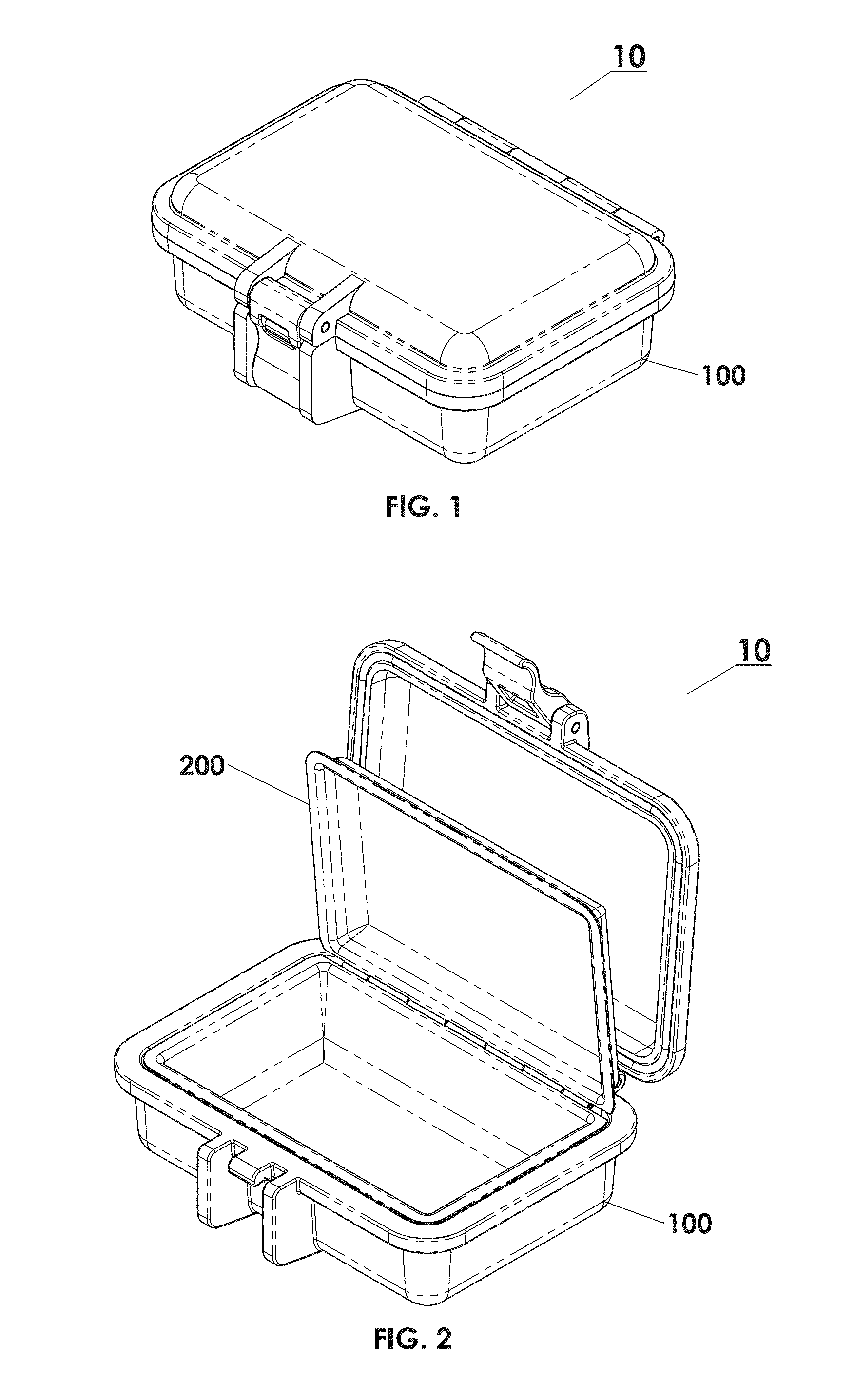

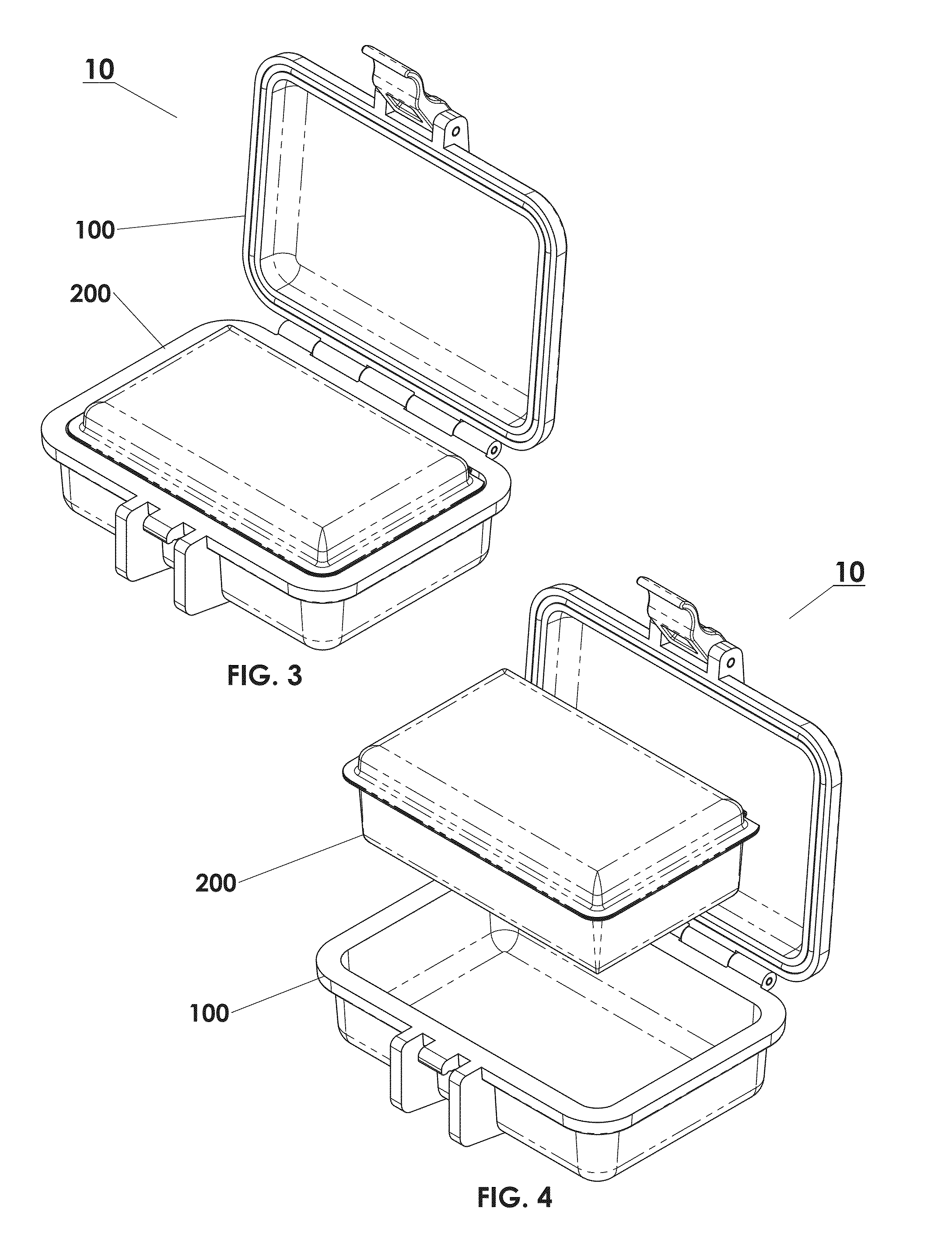

Protective Box for Surgery

ActiveUS20140346072A1Readily availableContamination damageSurgical furnitureDiagnosticsSurgical GraftSTERILE FIELD

The present invention is directed to providing a sterile container protecting various surgical grafts, implants and devices from incidental contamination and damage during operative procedures. The design includes an inner box to contain the items, and an outer box to protect the exterior of the inner box from contamination in the event of fall or other contamination, such as from airborne particles or liquids, fall from the sterile field, or by non-sterile handling. In the event of fall or contamination of the outer box, the surgical staff will be able to recover the inner box and its contents in sterile and unspoiled condition without difficulty.

Owner:JACOBSON DANIEL R

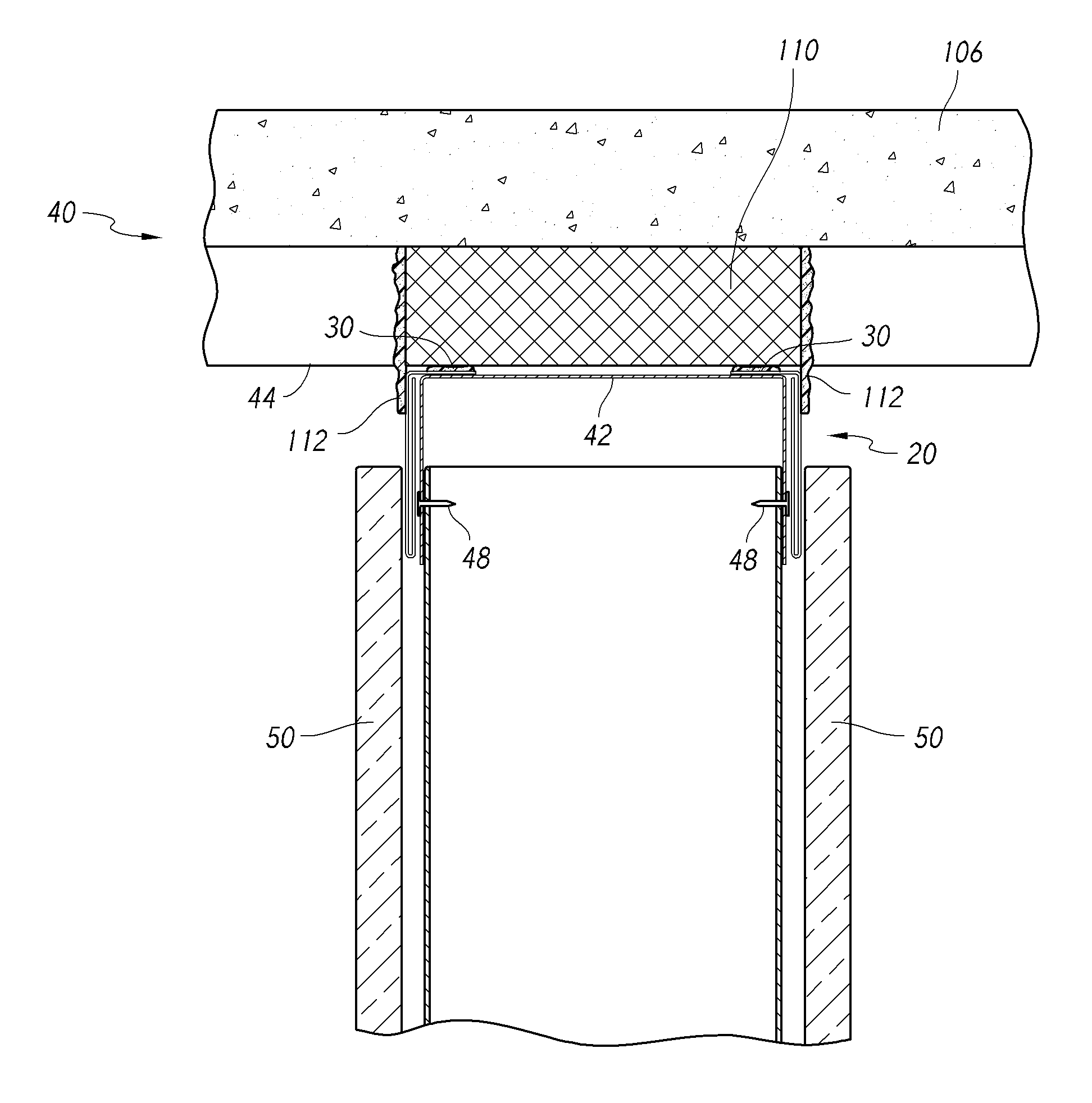

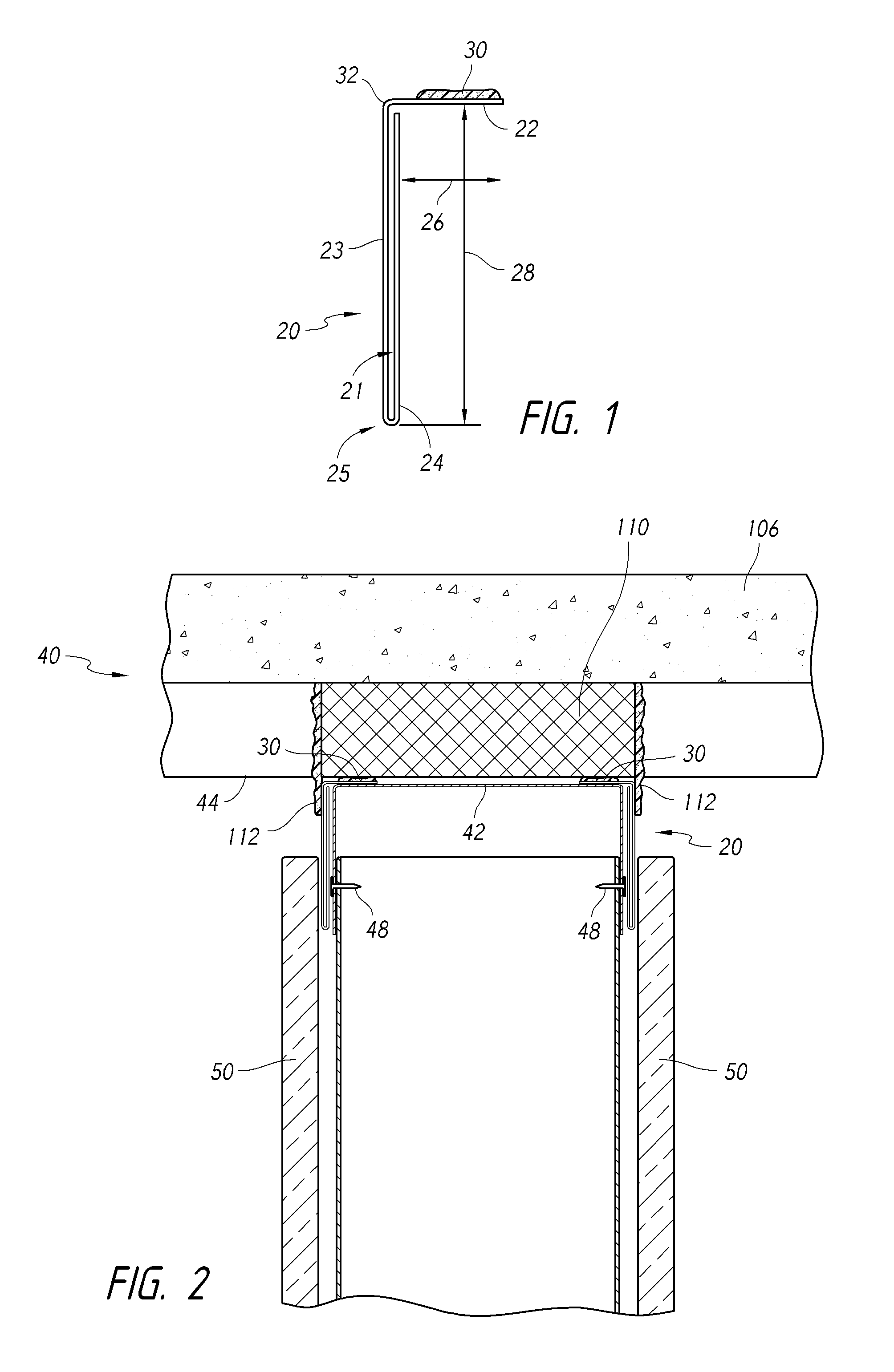

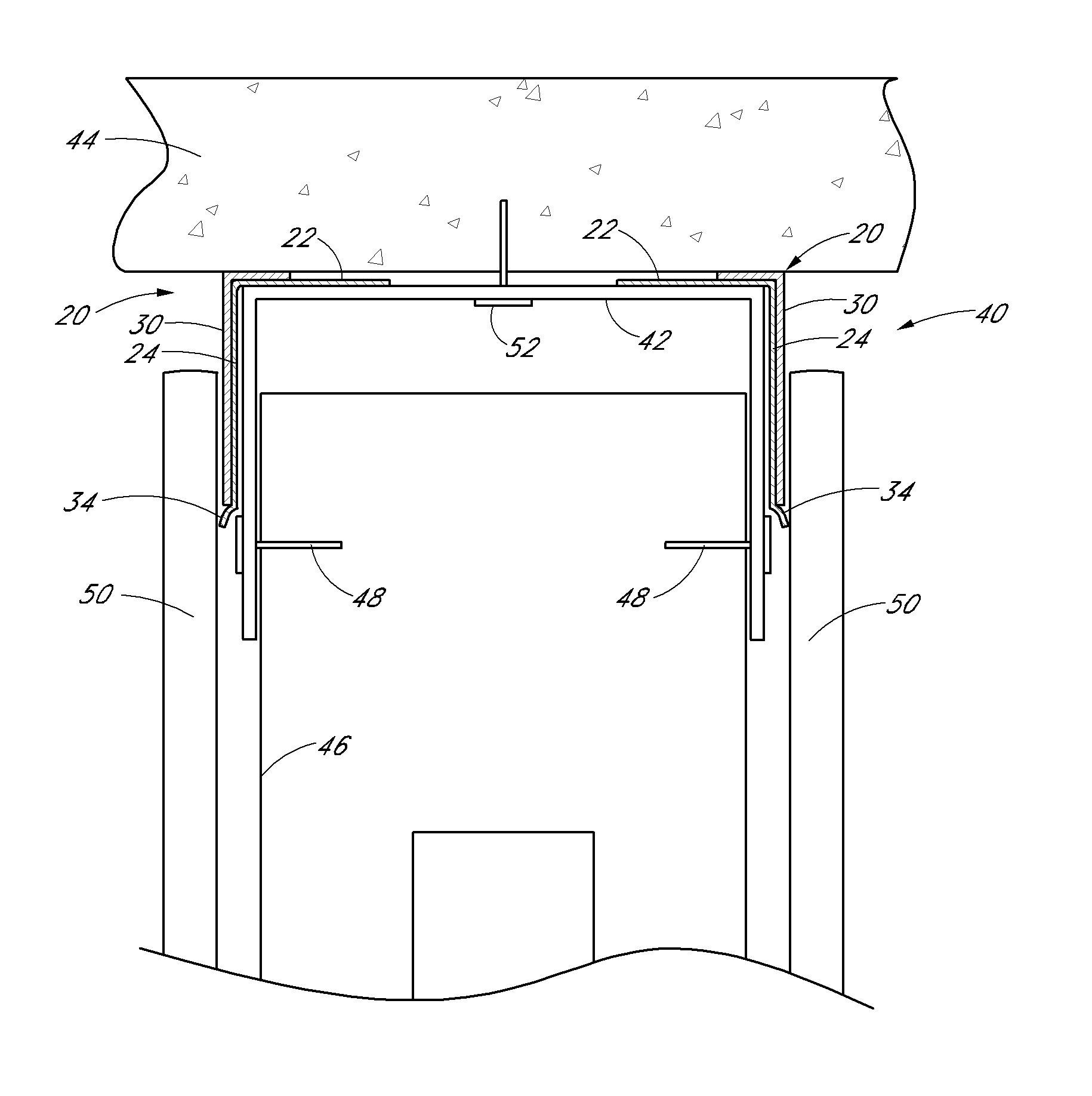

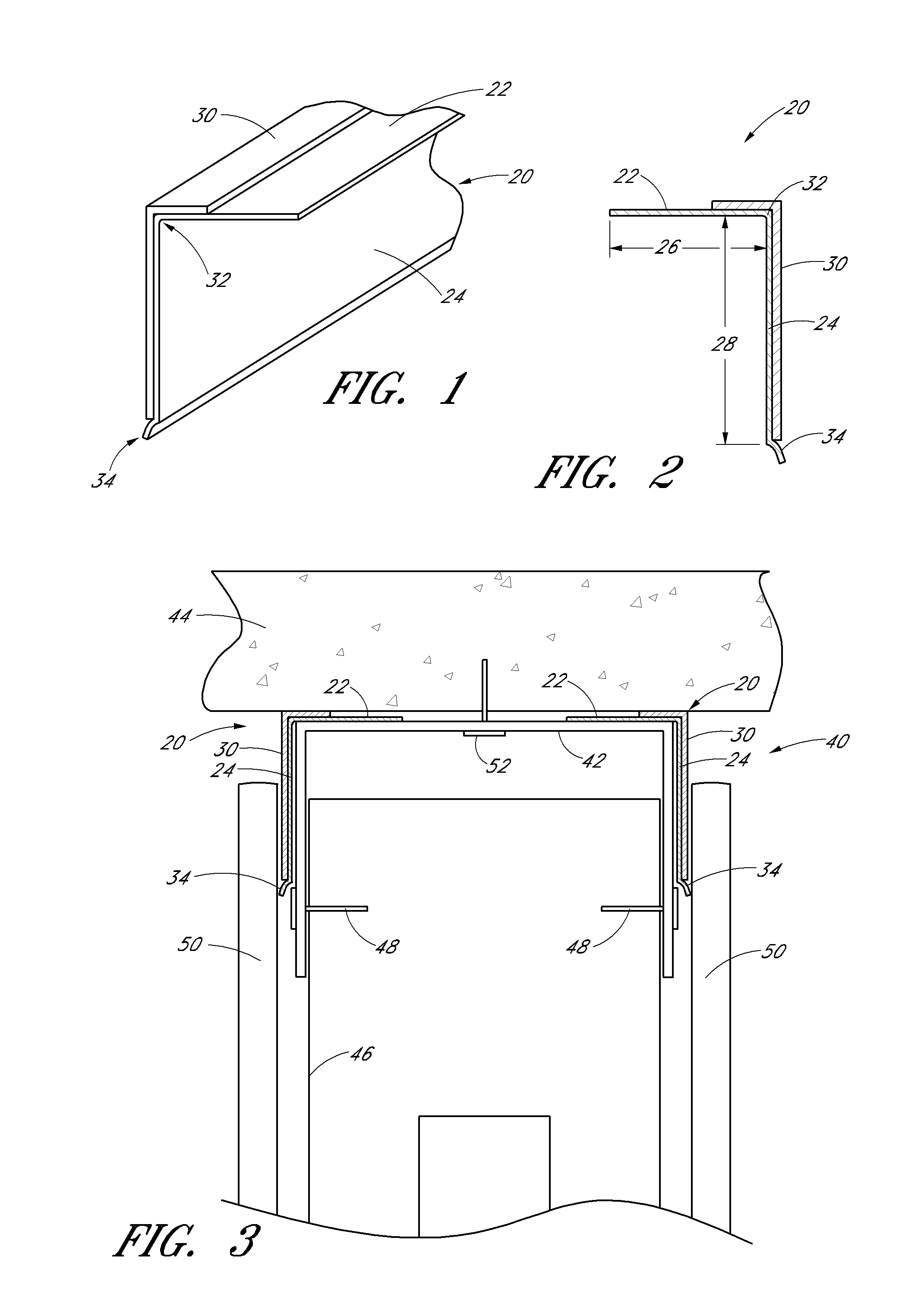

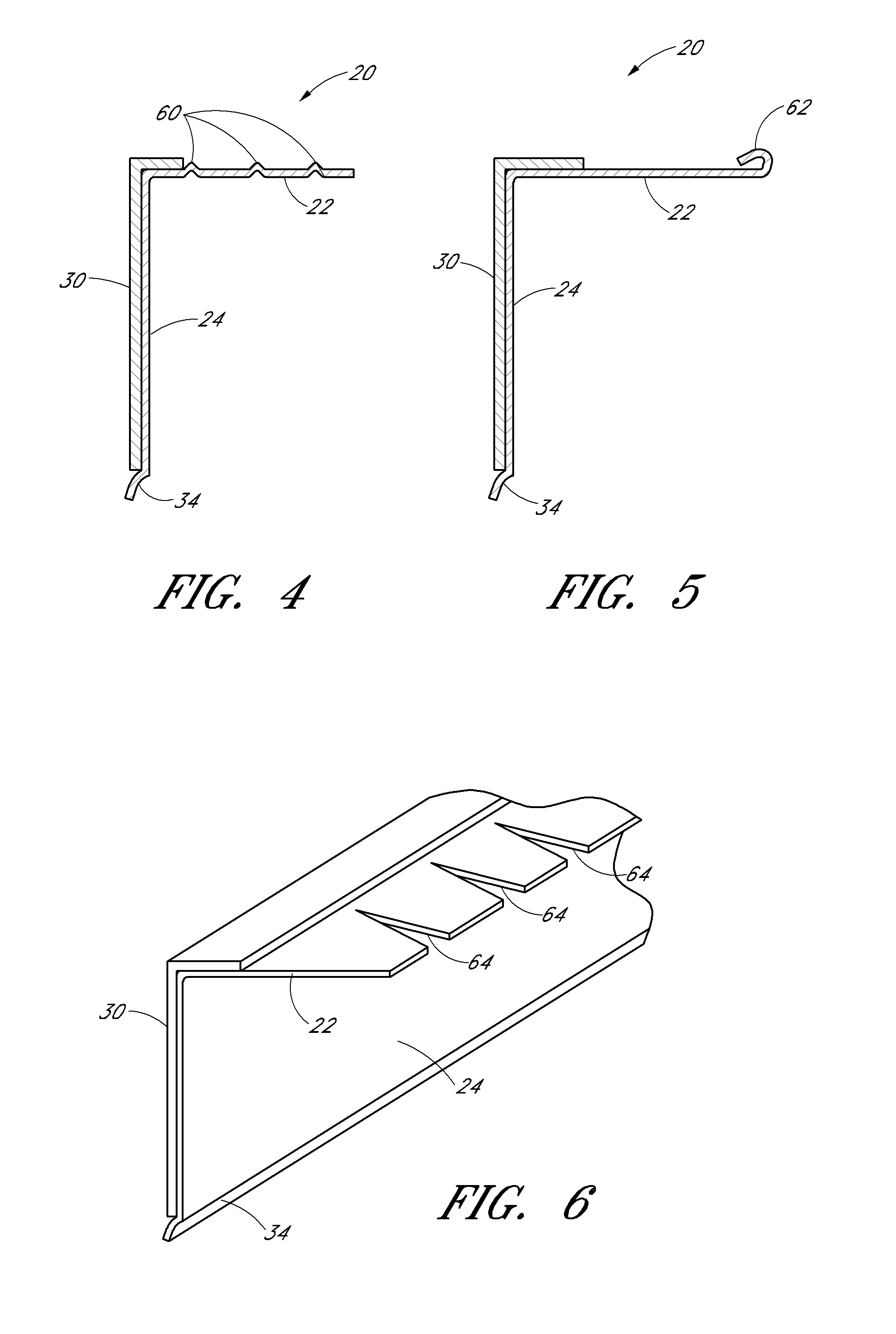

Fire-resistant angle and related assemblies

ActiveUS20160097197A1Efficient and cost-effectiveDamage to materialCeilingsWallsIntumescentEngineering

A fire-resistance angle piece and related assemblies include at least one multi-layer portion, which can provide an insulation space and / or a sacrificial layer of the angle piece. The angle piece can comprise vent openings to a space between adjacent layers of the angle piece. In some configurations, adjacent layers of the angle piece can be sealed to one another, such as along an edge portion that can be opposite the vent openings (if present) and / or a fold of the angle piece or other closed end that creates adjacent layers. Intumescent may or may not be included on the angle piece.

Owner:CEMCO LLC

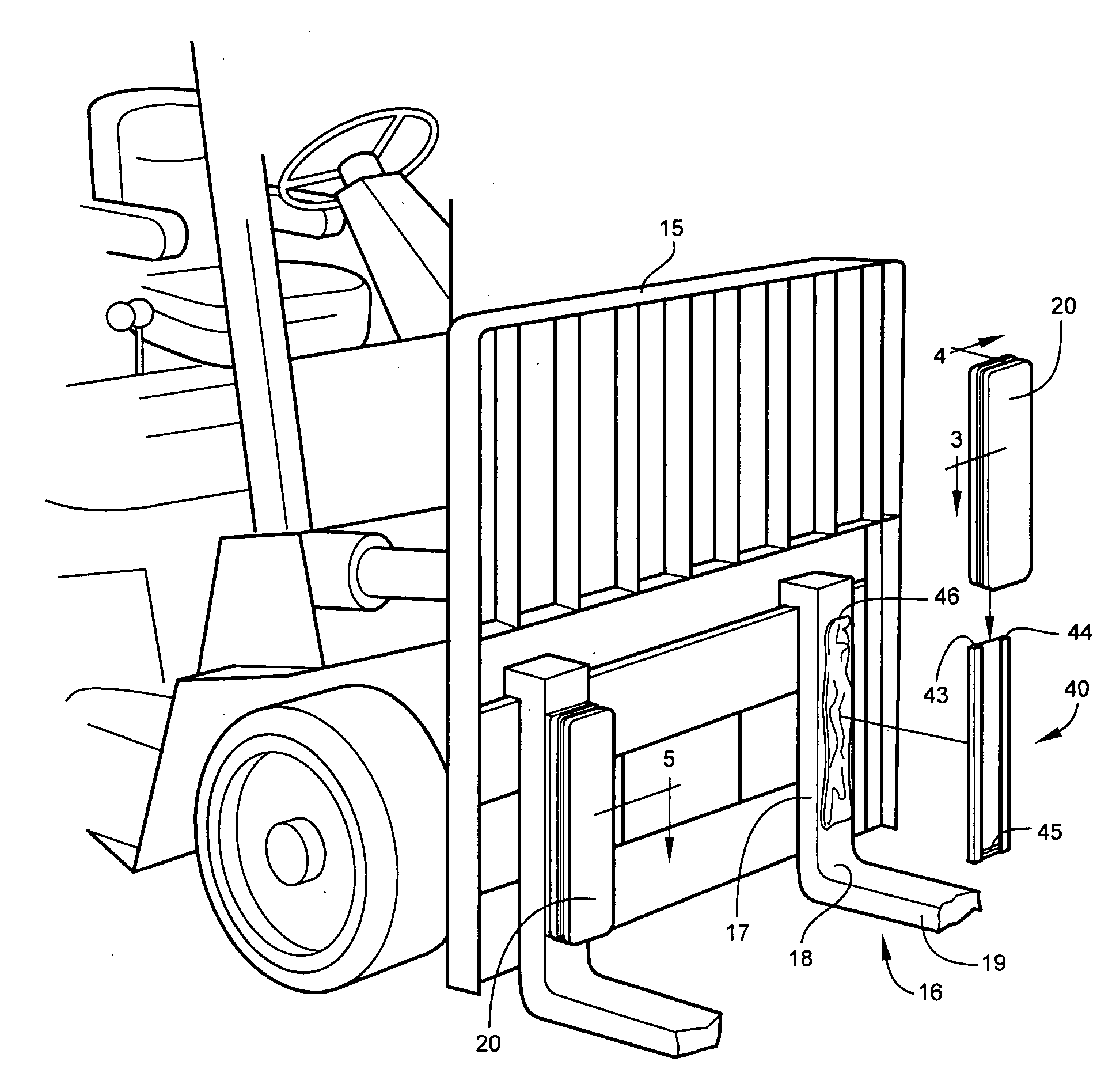

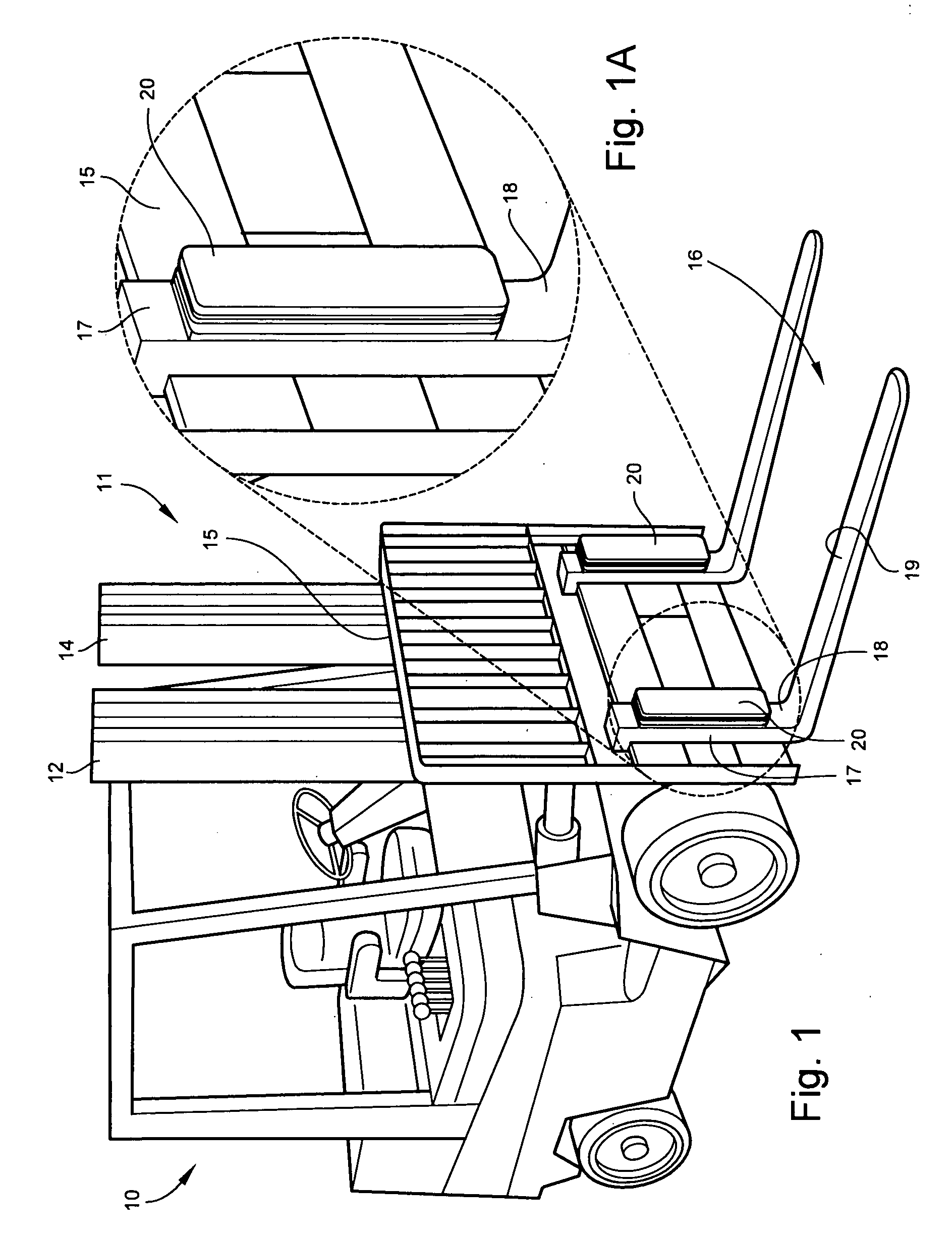

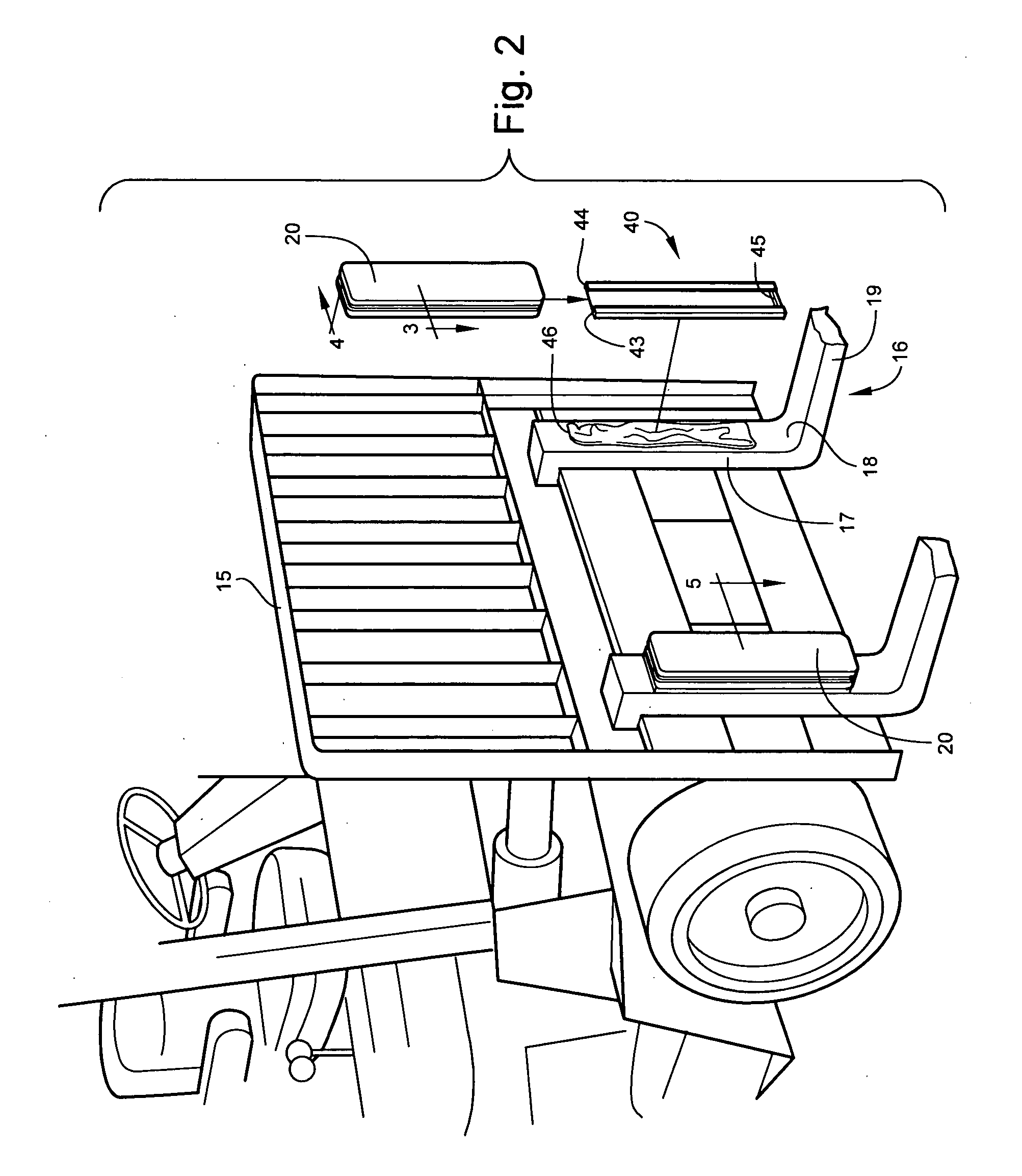

Protective bumper adapted for minimizing damage to materials carried by a materials handling vehicle

InactiveUS20090008951A1Reduce material damageLow costSolid-state devicesSemiconductor/solid-state device manufacturingElastomerMechanical lift

A materials handling vehicle incorporates a mechanical lift including a horizontal extension and a vertical back. The vehicle has a protective bumper designed for engaging and protecting materials carried by the vehicle. The protective bumper includes a base located on the vertical back of the lift. A compressible, resilient body is located adjacent the base, and is adapted for absorbing impact of materials loaded onto the lift.

Owner:WHETSTINE ROBERT D

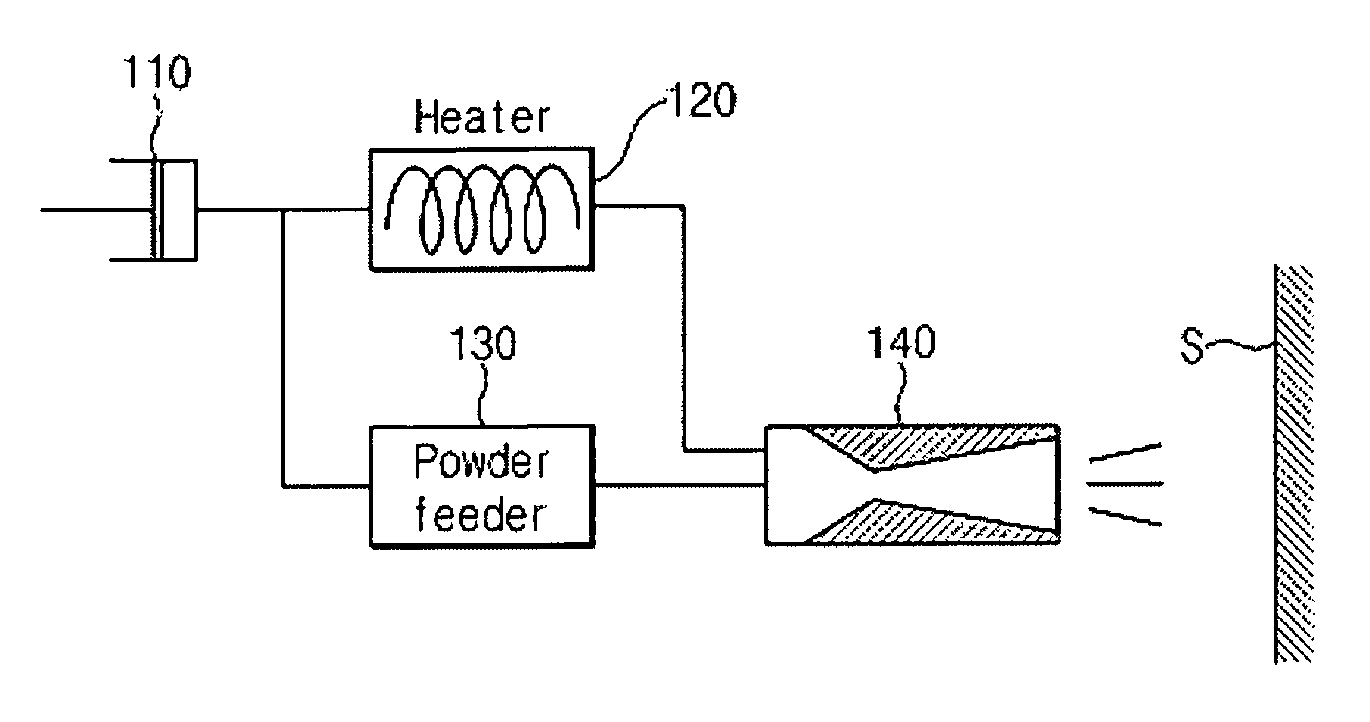

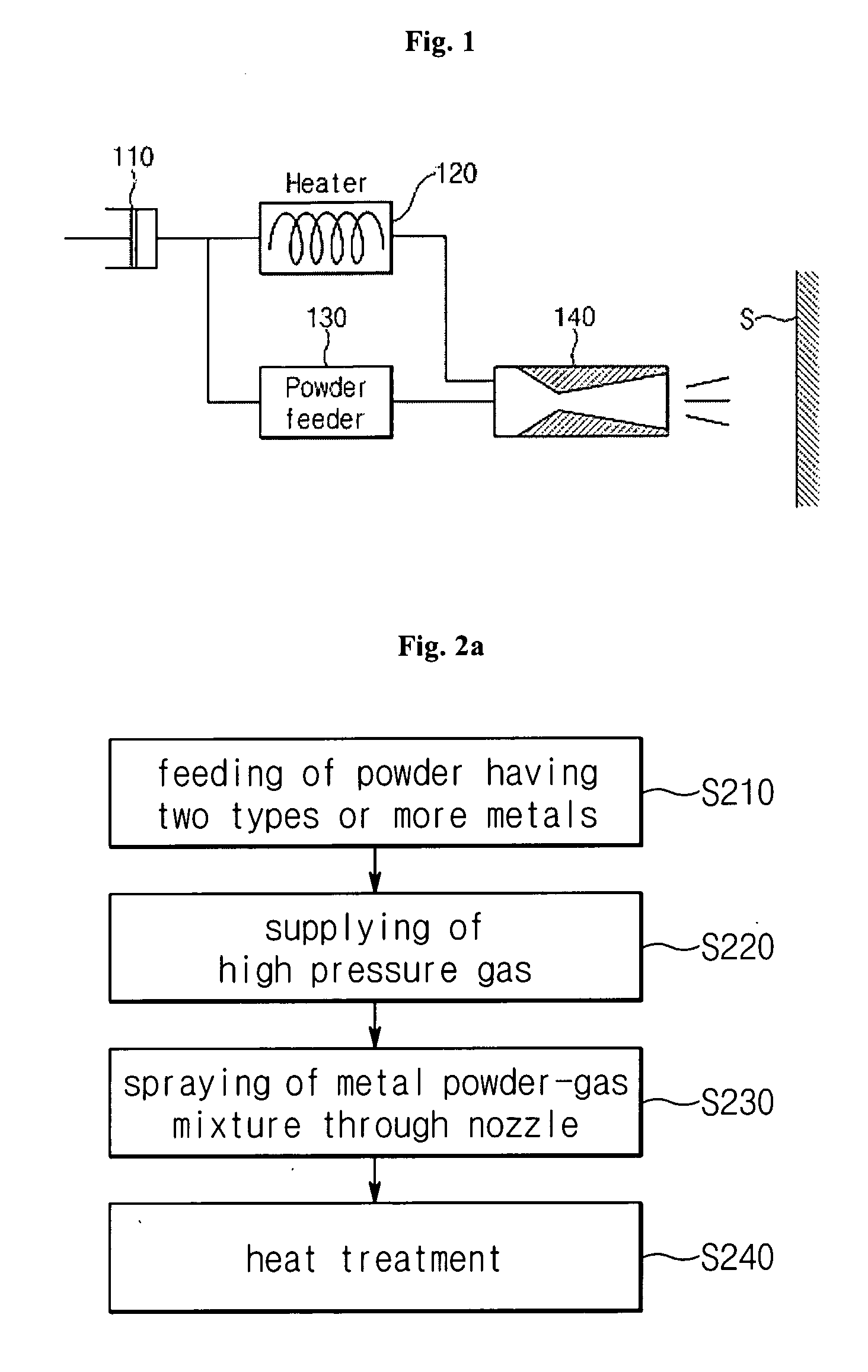

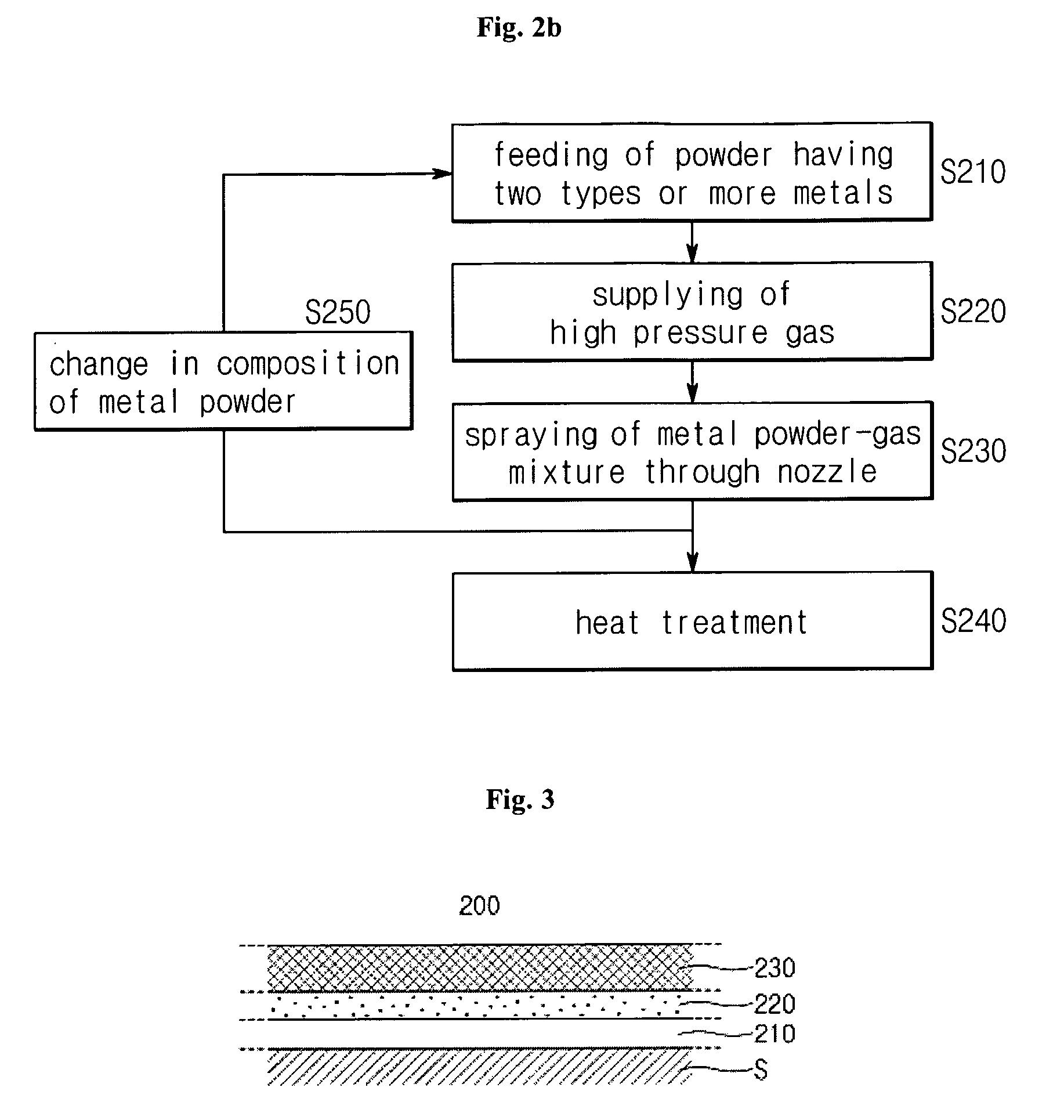

Porous Coated Member and Manufacturing Method Thereof Using Cold Spray

InactiveUS20070240603A1Damage to materialImprove thermal conductivityMolten spray coatingLighting elementsPorous coatingHigh pressure

Disclosed is a coated member on which a porous metal coating layer is formed and a method of producing the same. The method comprises providing the mother material, feeding powder having a metal composition, which includes at least two different metals selected from the group consisting of Al, Mg, Zn, and Sn and which is expressed by xA-(1−x)B (0<x<1, where x is a weight ratio of A and B), onto the mother material, supplying high pressure gas to the powder, applying the metal powder using on the mother material by spraying the metal powder using the high pressure gas through an supersonic nozzle, and heat-treating the coated mother material to form the porous coating layer. In the method, it is possible to freely control the pore size and porosity of the coated member. Accordingly, it is available to various members for thermal and mechanical applications.

Owner:SKC SOLMICS

Protective box for surgery

ActiveUS9414893B2Contamination damageDamage to materialSurgical furniturePackaging protectionSurgical GraftSTERILE FIELD

The present invention is directed to providing a sterile container protecting various surgical grafts, implants and devices from incidental contamination and damage during operative procedures. The design includes an inner box to contain the items, and an outer box to protect the exterior of the inner box from contamination in the event of fall or other contamination, such as from airborne particles or liquids, fall from the sterile field, or by non-sterile handling. In the event of fall or contamination of the outer box, the surgical staff will be able to recover the inner box and its contents in sterile and unspoiled condition without difficulty.

Owner:JACOBSON DANIEL R

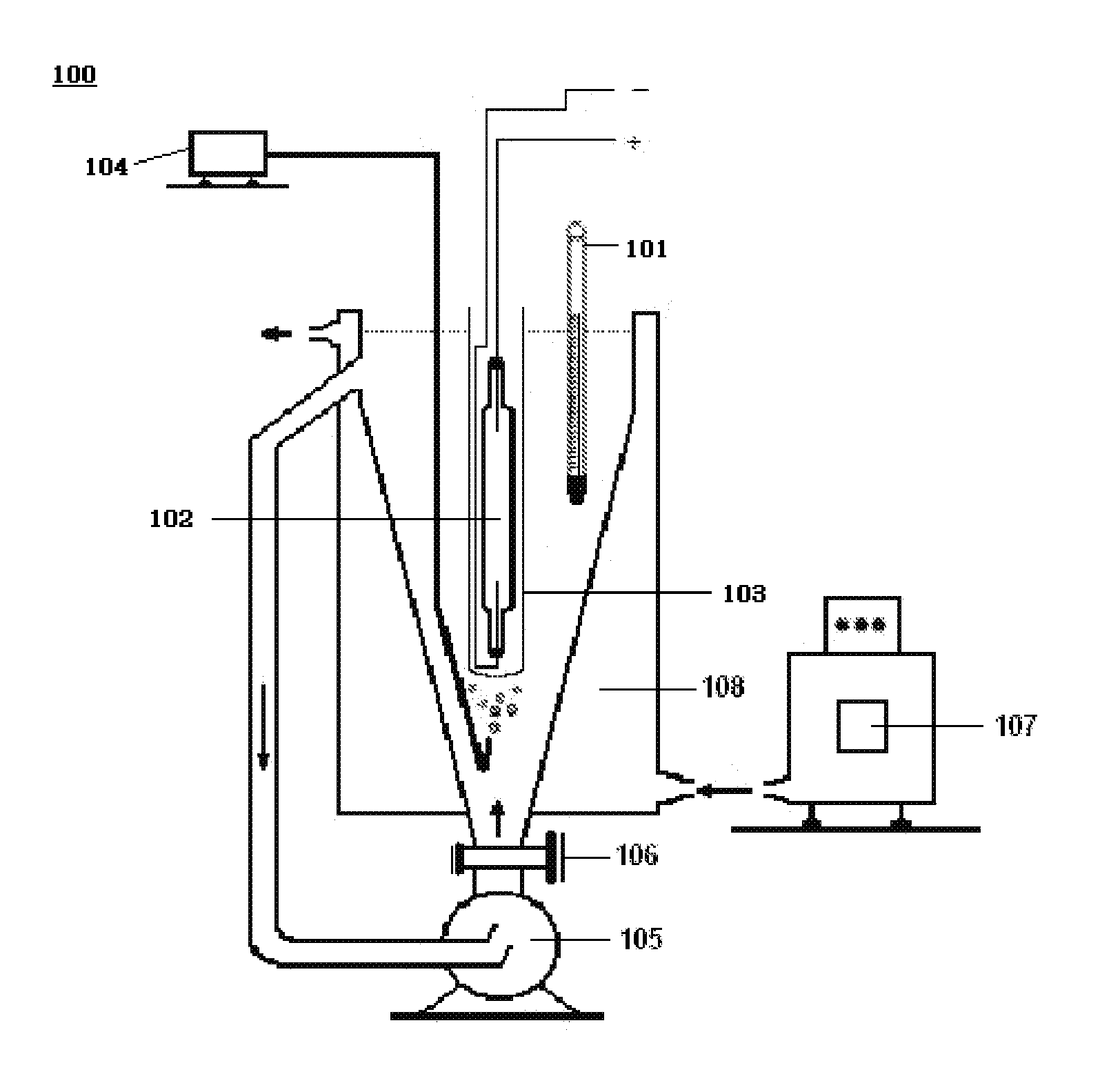

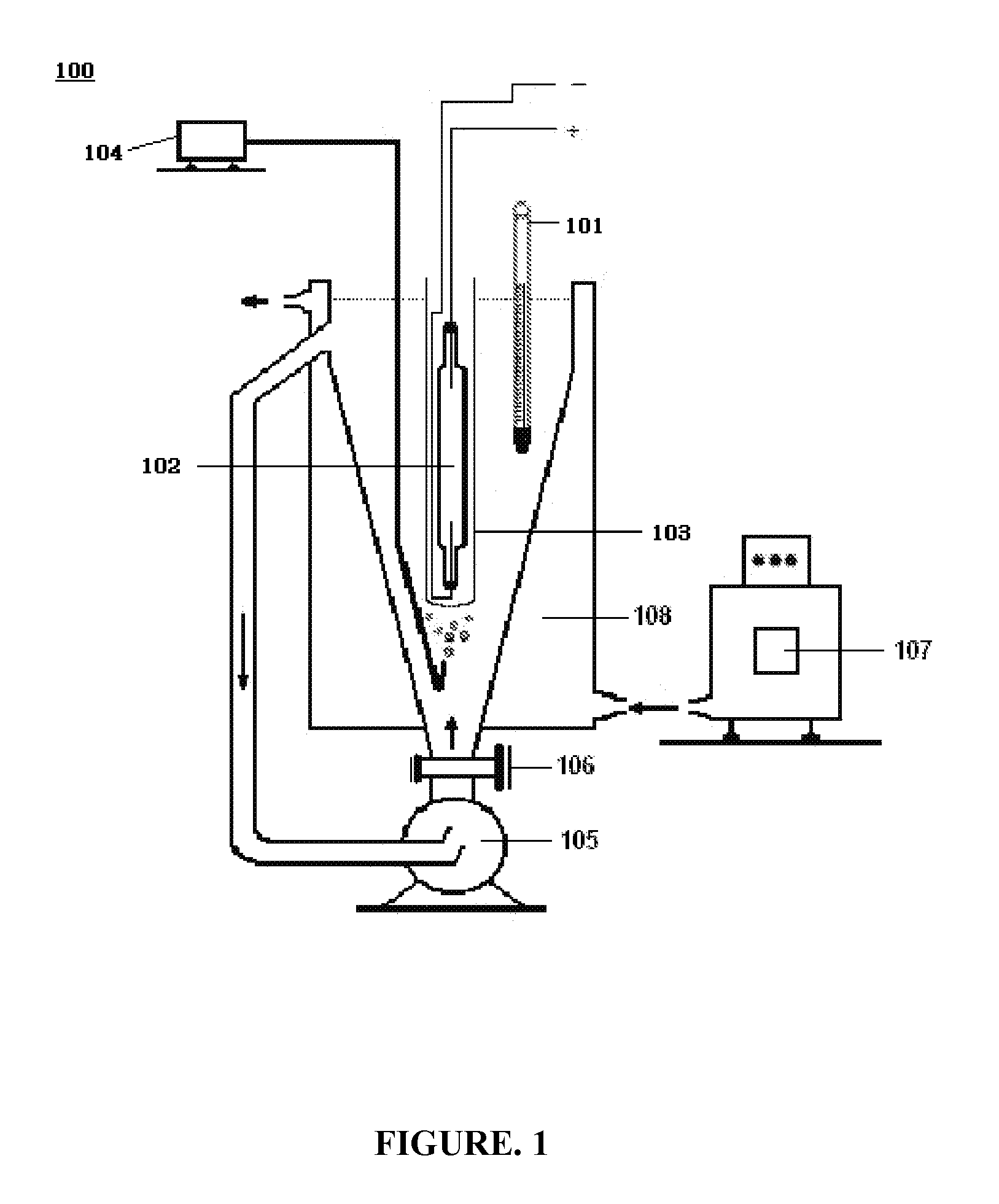

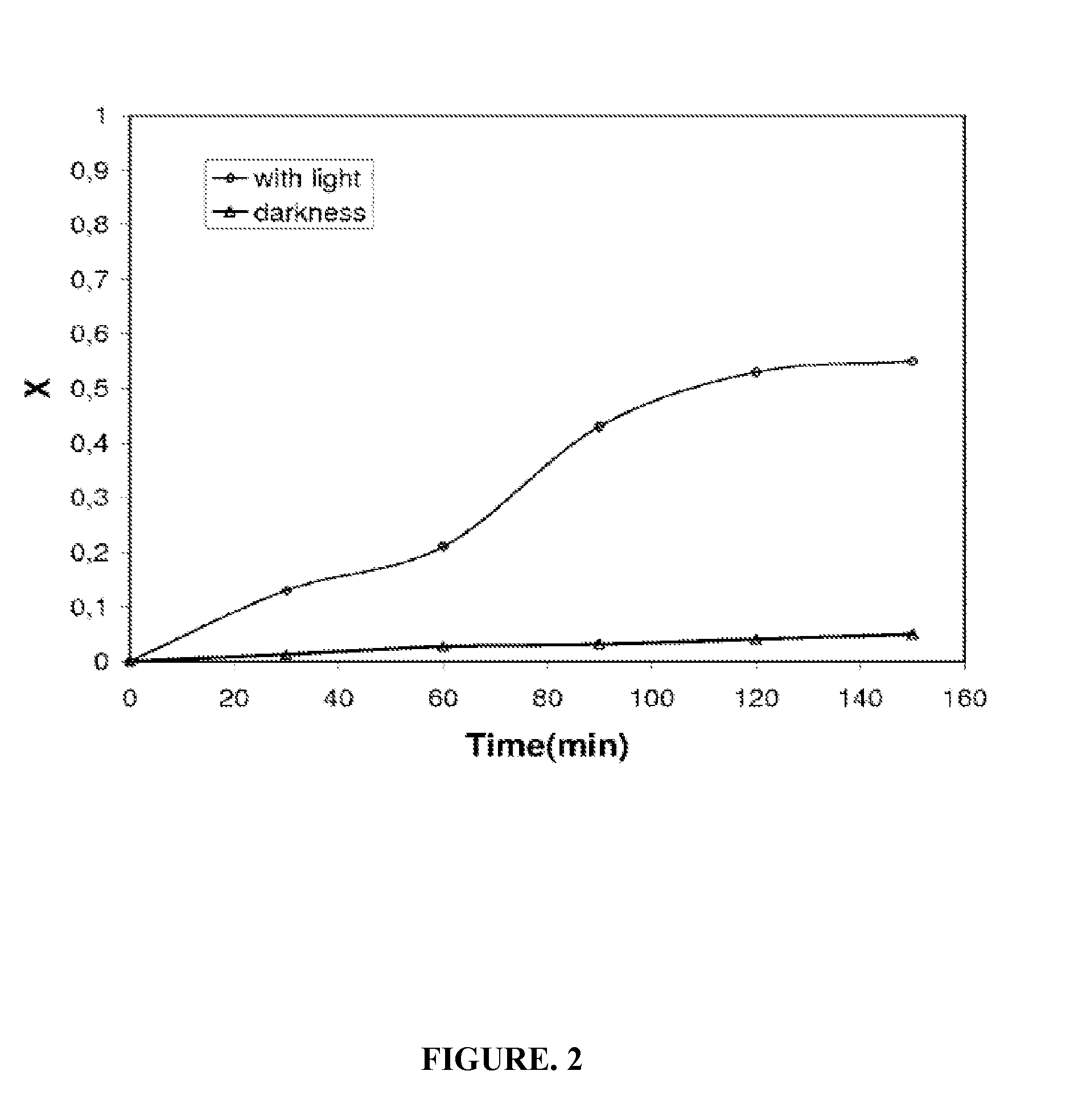

Treatment of the refinery wastewater by NANO particles of tio2

InactiveUS20100200515A1Improve efficiencyPromote degradationWater/sewage treatment by irradiationWater treatment compoundsReactor systemPhotocatalytic reaction

The embodiments herein relate to a photocatalytic reactor system and photo-degrading method for eliminating organic and high molecular oil contaminant (or pollutants) from industrial wastewater. A more economical and stable titanium dioxide (TiO2) having a diameter of 21±10 nm is used as the photocatalyst. Method and system of present invention is highly efficient, compatibles with the environment and does not require secondary or additional treatments. In one embodiment, an optimal and very low catalyst concentration (100 ppm) is used for high degradation of the pollutant which is irradiated for utmost 120 min using UV light. This has an industrially interest as this method is considered as an alternative or synergetic process for biological degradation, having high residence times, required to provide significant COD removal. The analysis of the contained materials showed that the efficiency of the applied degradation system is high for all the identified present organic pollutants.

Owner:IRANIAN ACADEMIC CENT FOR EDUCATION CULTURE & RES ACECR

Fire-rated joint system

ActiveUS20130186020A1Efficient and cost-effectiveDamage to materialWallsPublic buildingsWall plateIntumescent

A fire-rated angle piece and wall assemblies or other assemblies that incorporate the fire-rated angle piece, in which the angle piece includes an intumescent or other fire-resistant material strip. The angle can be attached adjacent to a corner of a framing member, such as metal tracks, headers, header tracks, sill plates, bottom tracks, metal studs, wood studs or wall partitions, and placed between the framing member and a wall board member at a perimeter of a wall assembly to create a fire block arrangement.

Owner:CEMCO LLC

Vacuum insulation panel, refrigerator with vacuum insulation panel and manufacturing method for vacuum insulation panel

ActiveUS8986805B2Good adhesionDamage to materialThermometer detailsThermal insulationEngineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

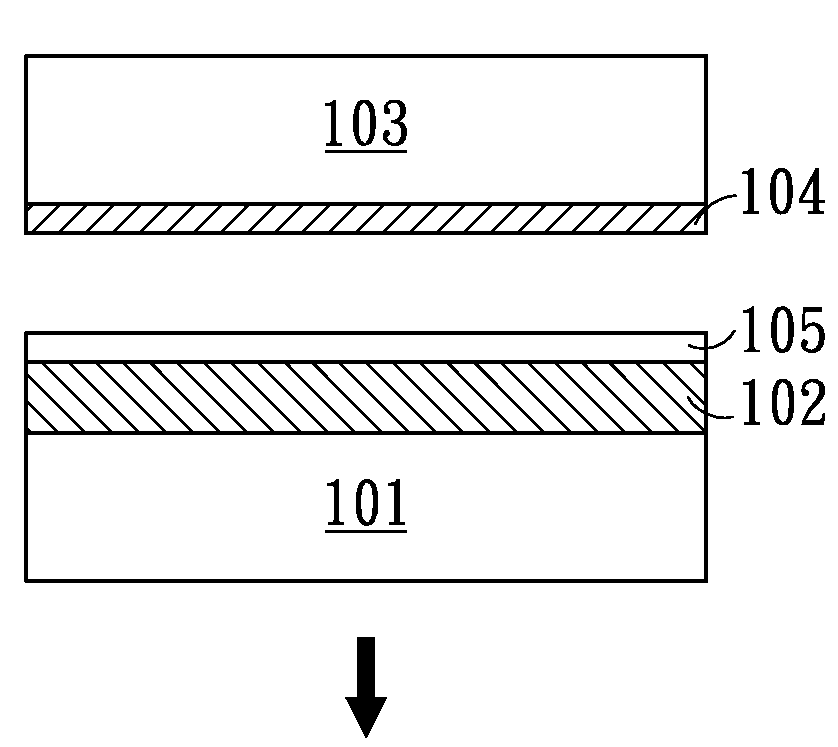

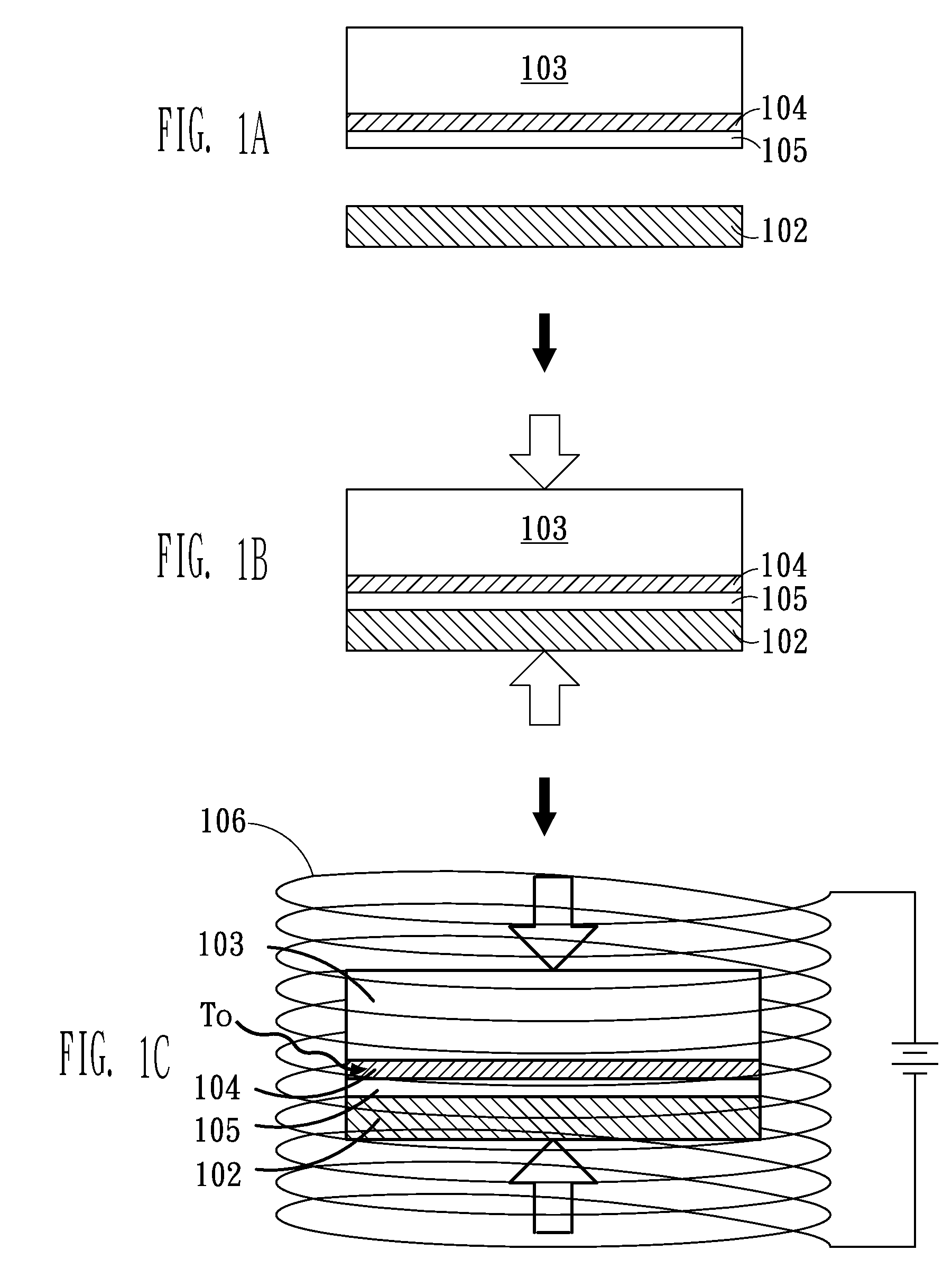

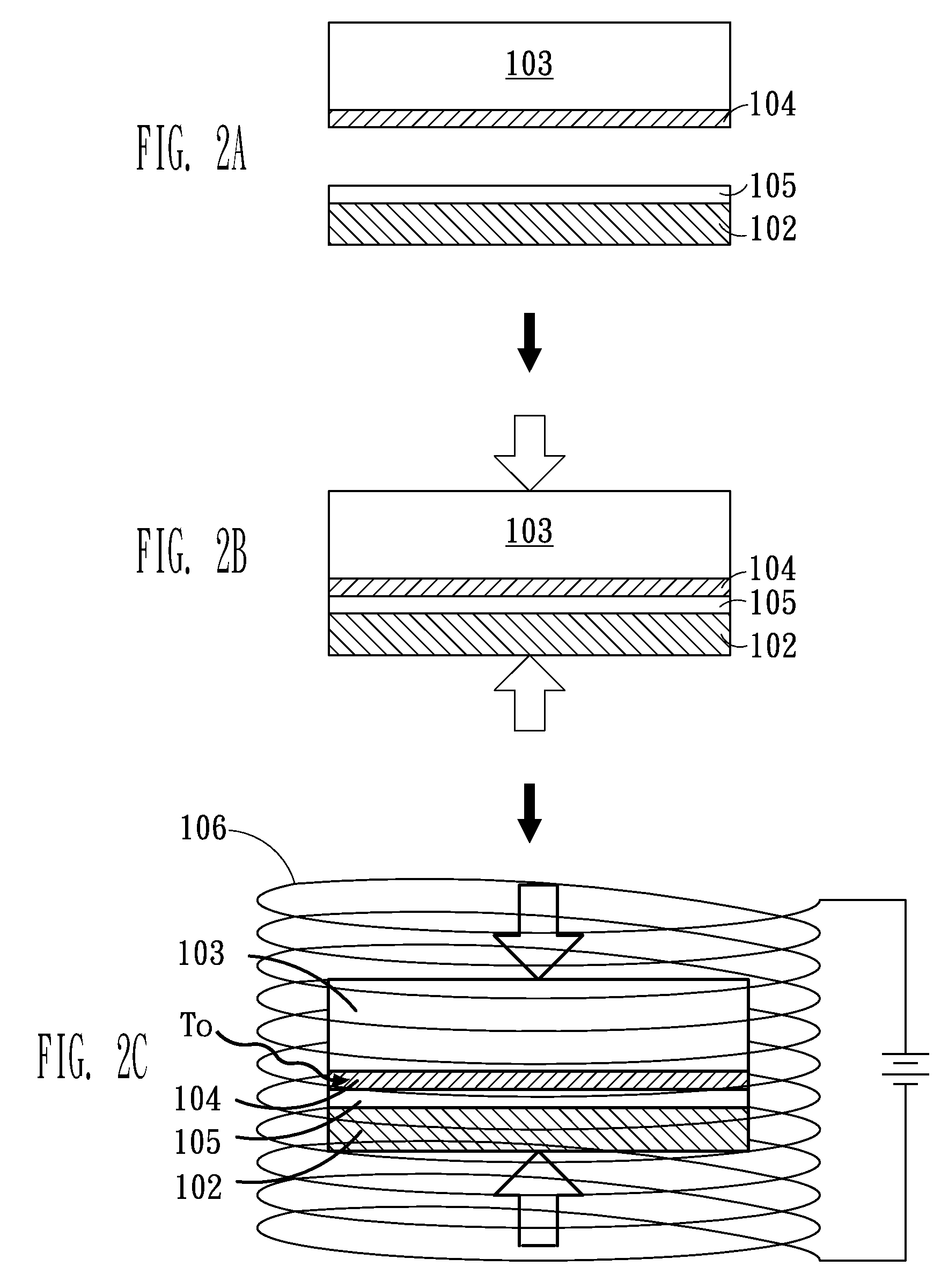

Method for bonding two materials

InactiveUS20100170936A1Relieve stressDamage to materialSemiconductor/solid-state device manufacturingHigh frequency current welding apparatusRadio frequency energyMaterials science

A method for bonding two materials uses radio frequency energy to swiftly induce heat in a high permeability material for heating a medium to the bonding temperature of the medium so as to bond the two materials with each other.

Owner:ADVANCED OPTOELECTRONICS TECH

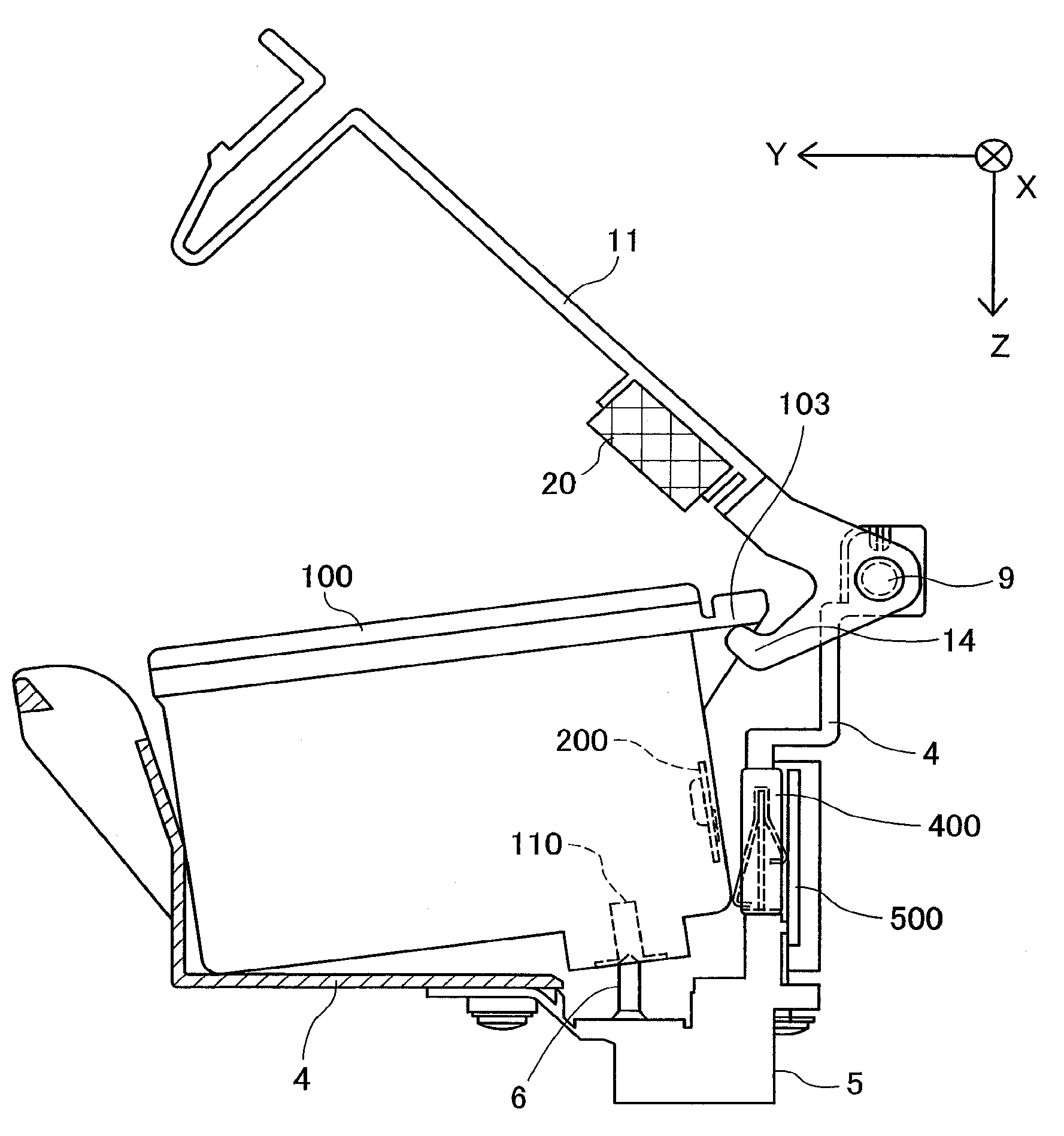

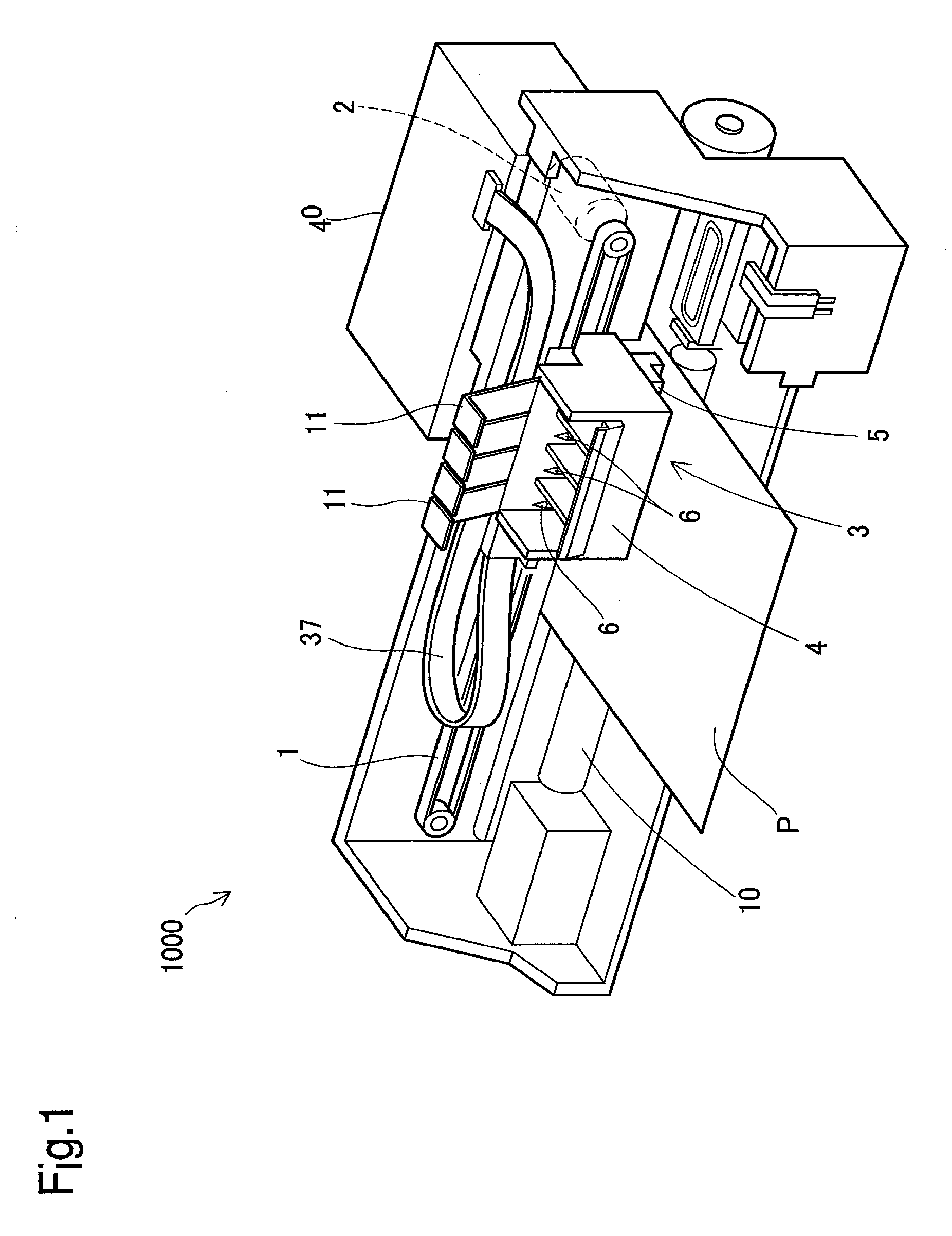

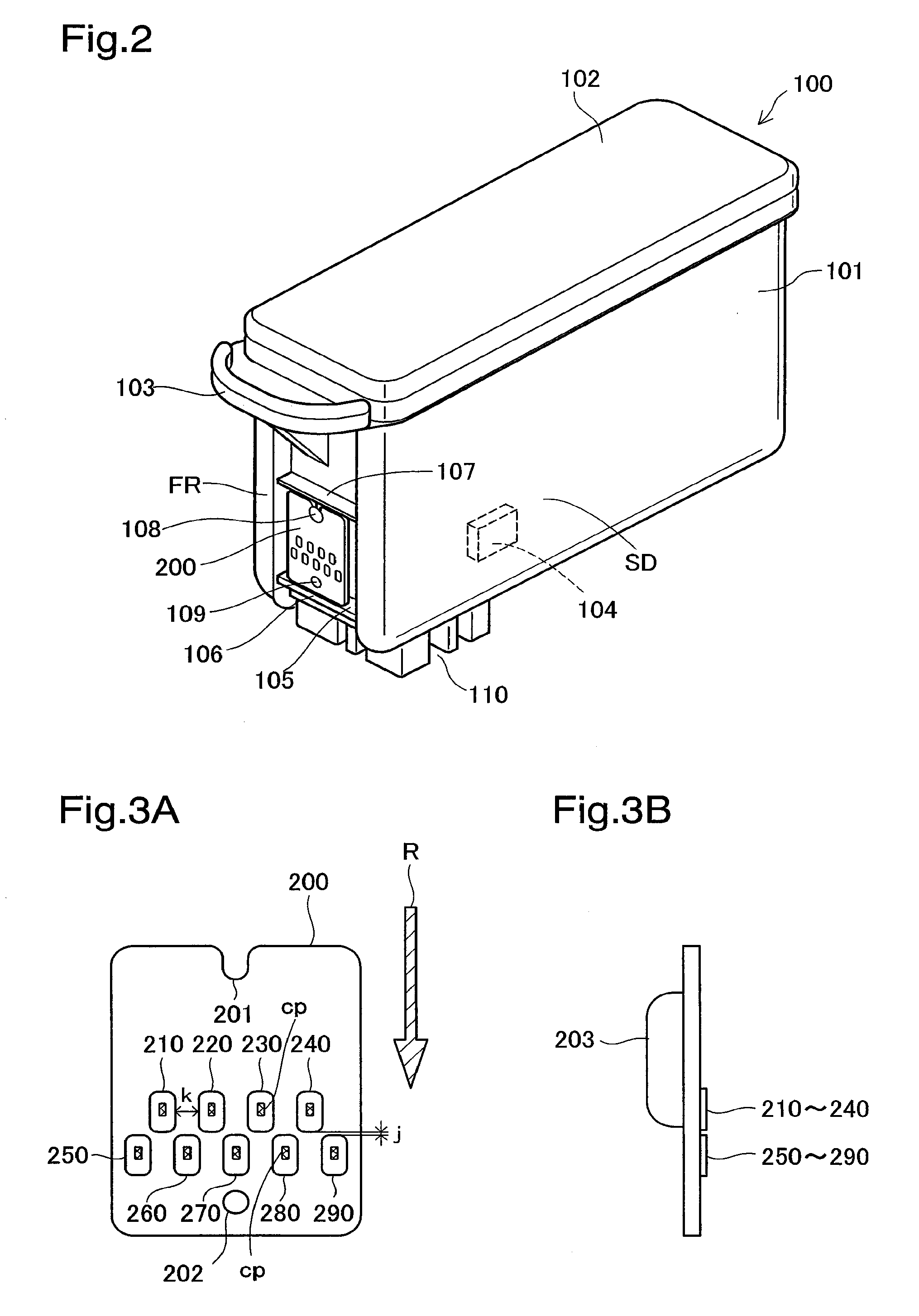

Printing material container, and board mounted on printing material container

ActiveUS20080158318A1Damage to materialPrevent and reduce damageCoupling device detailsPrintingMechanical engineeringShort circuit

Owner:SEIKO EPSON CORP

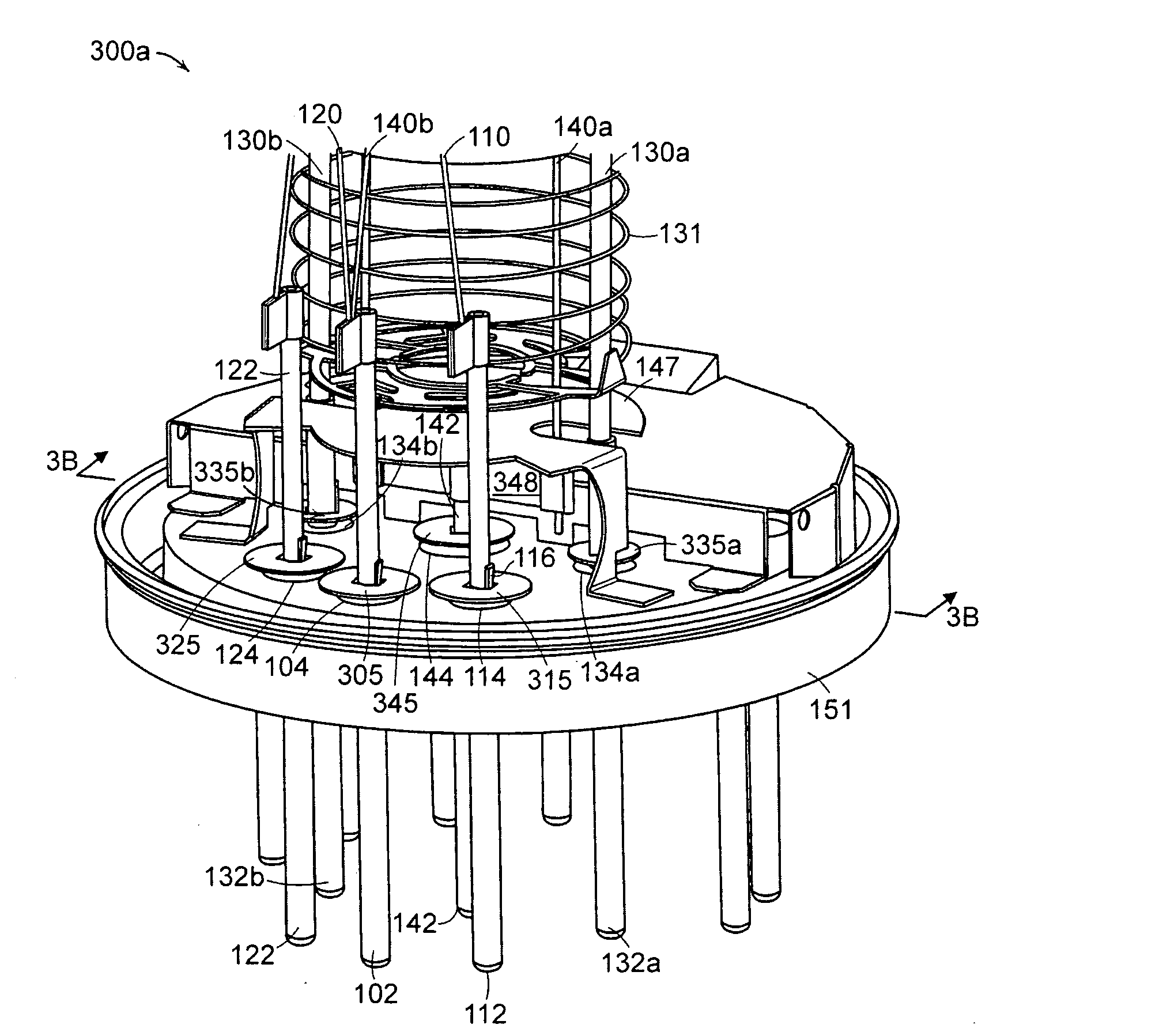

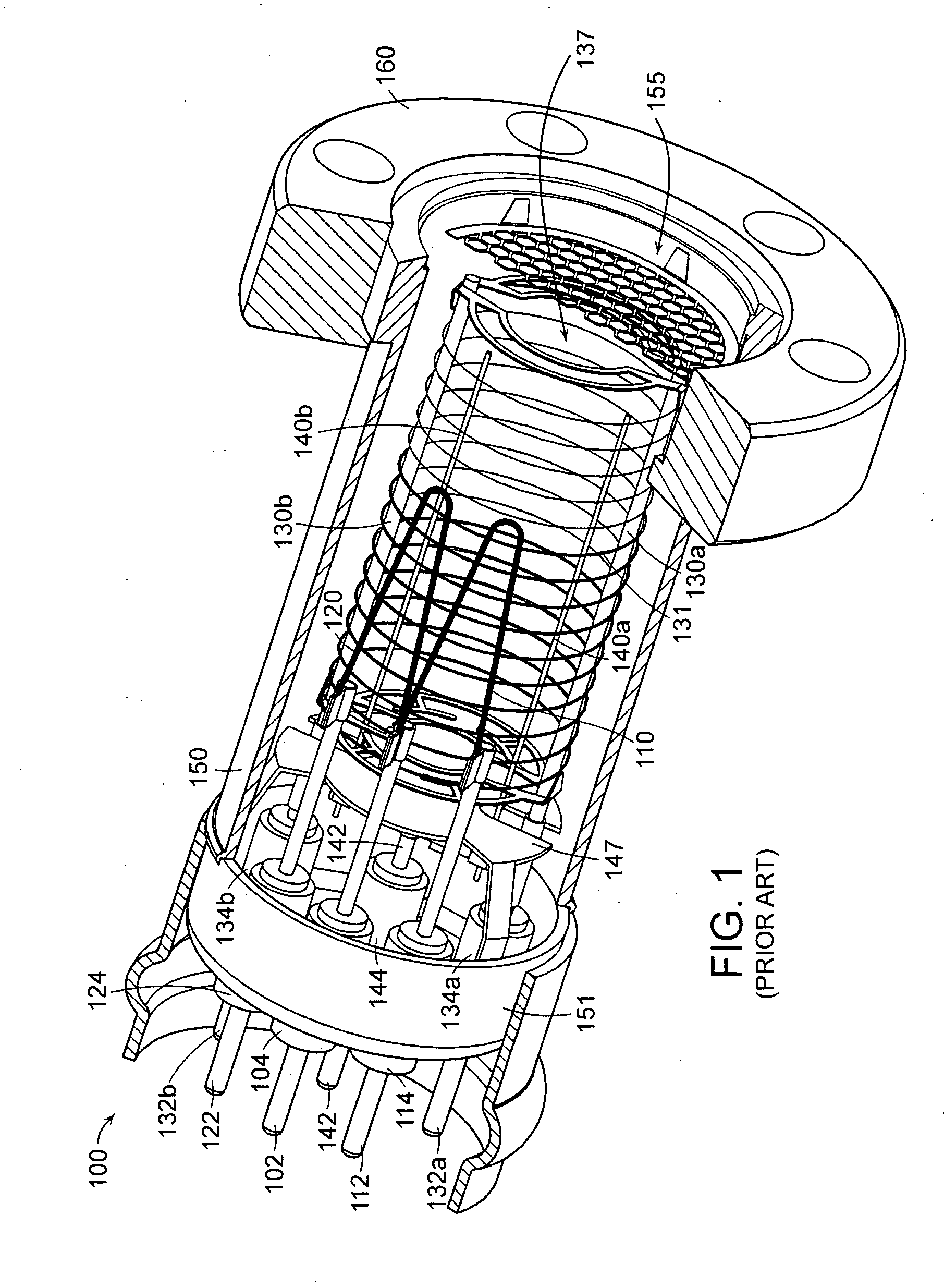

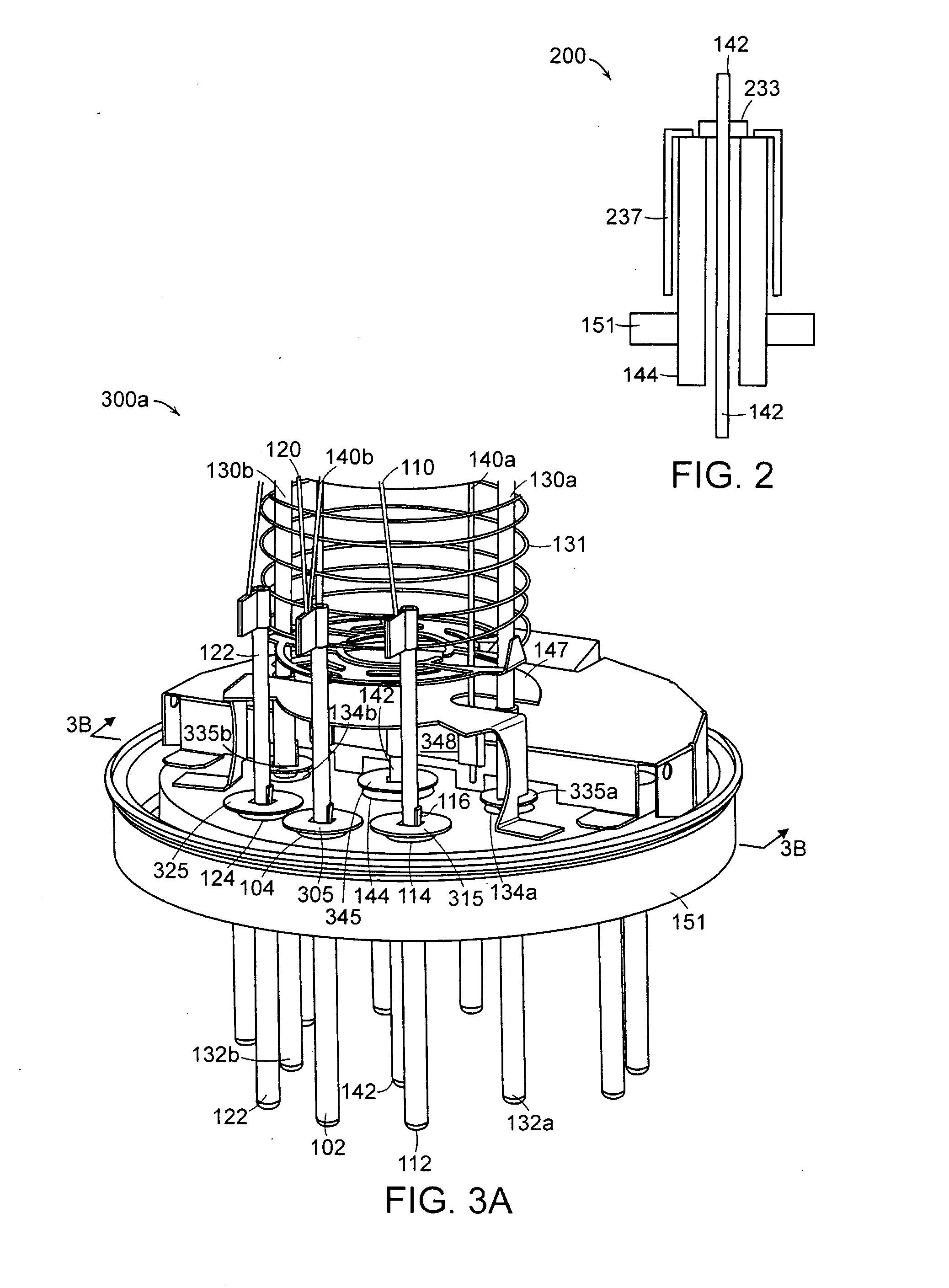

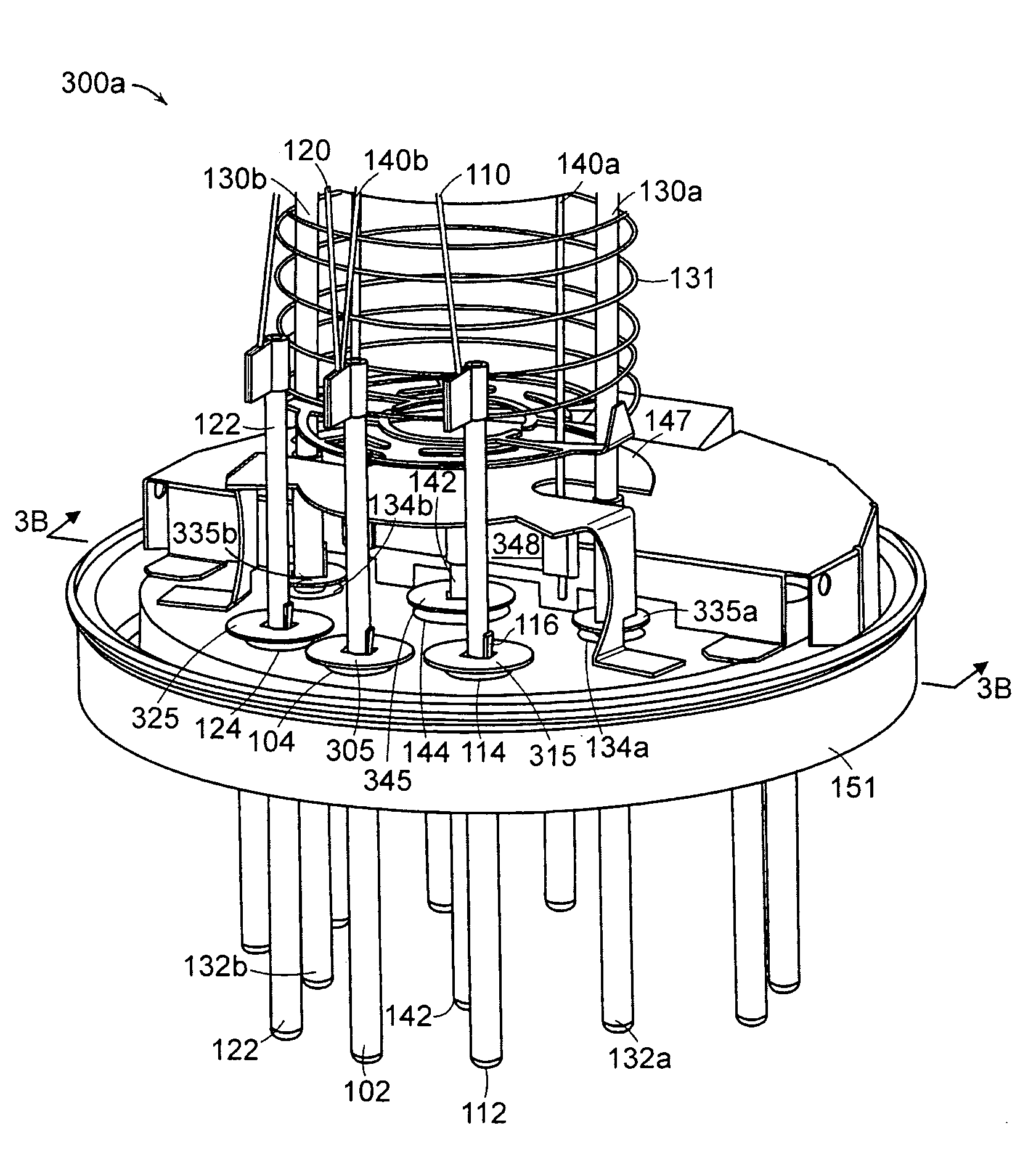

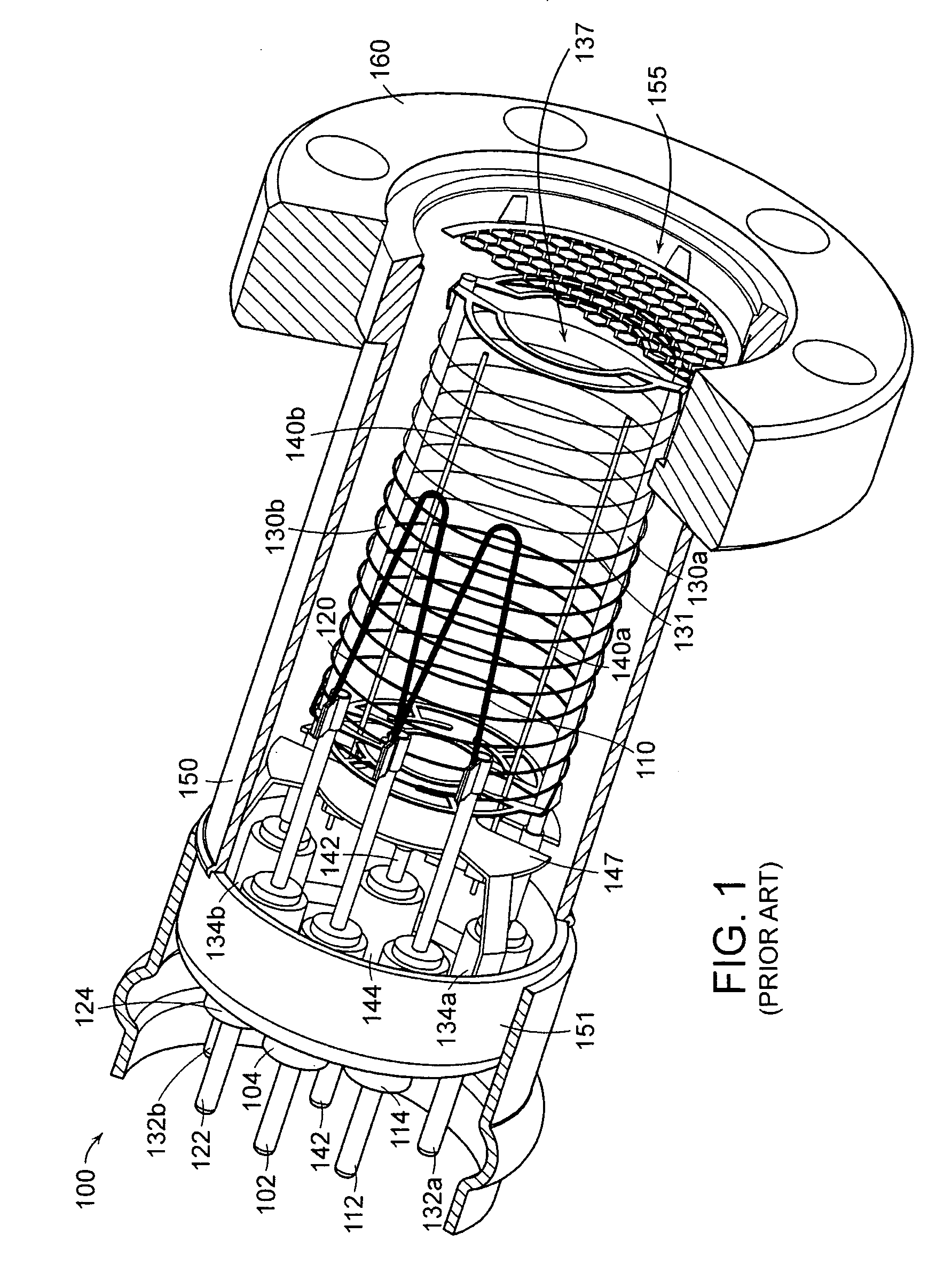

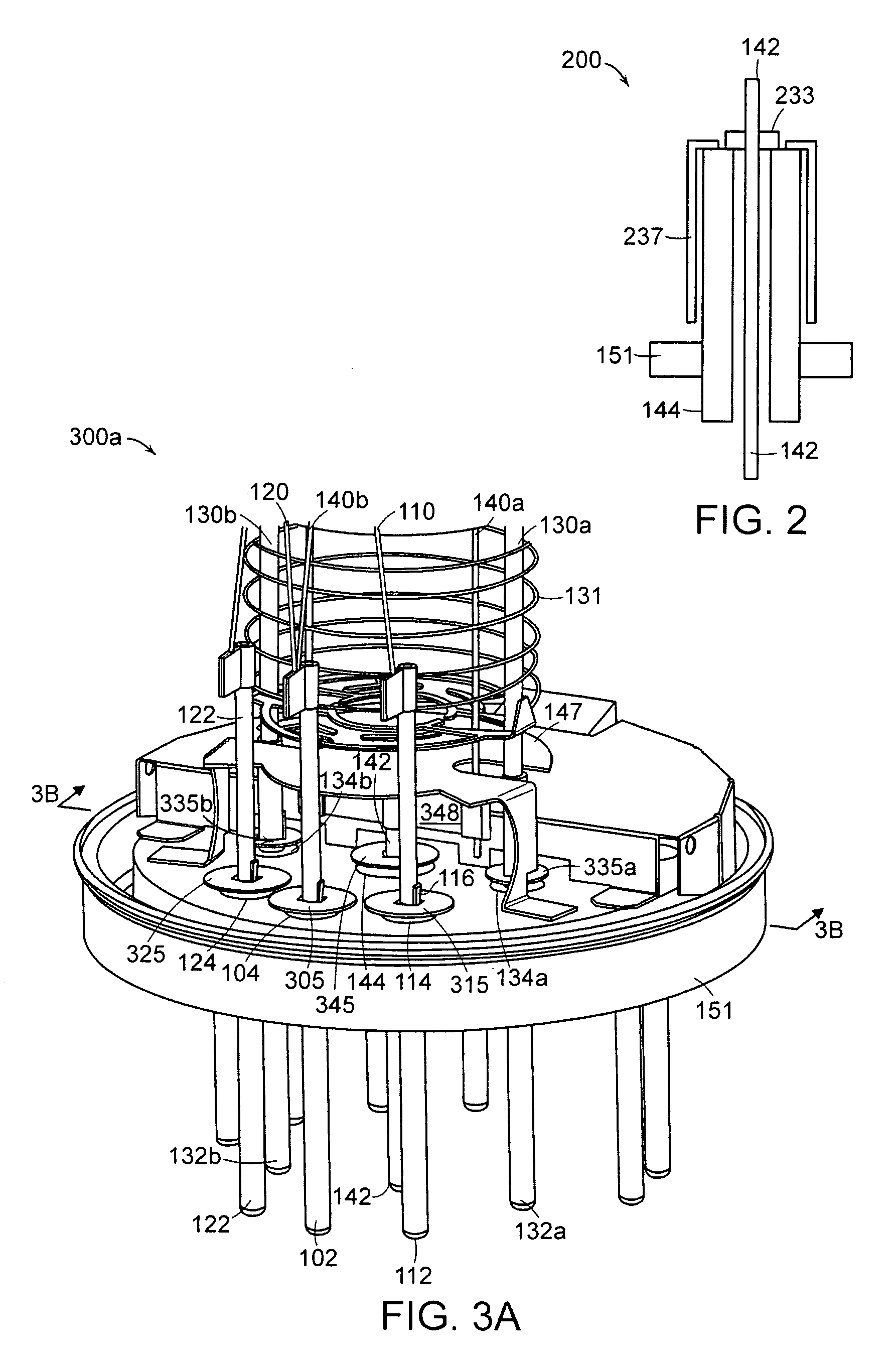

Method and apparatus for shielding feedthrough pin insulators in an ionization gauge operating in harsh environments

InactiveUS20080100301A1Easy to operateDamage to materialVacuum gauge using ionisation effectsDischarge tube/lamp detailsEngineeringIonization

Shields for feedthrough pin insulators of a hot cathode ionization gauge are provided to increase the operational lifetime of the ionization gauge in harmful process environments. Various shield materials, designs, and configurations may be employed depending on the gauge design and other factors. In one embodiment, the shields may include apertures through which to insert feedthrough pins and spacers to provide an optimal distance between the shields and the feedthrough pin insulators before the shields are attached to the gauge. The shields may further include tabs used to attach the shields to components of the gauge, such as the gauge's feedthrough pins. Through use of example embodiments of the insulator shields, the life of the ionization gauge is extended by preventing gaseous products from a process in a vacuum chamber or material sputtered from the ionization gauge from depositing on the feedthrough pin insulators and causing electrical leakage from the gauge's electrodes.

Owner:MKS INSTR INC

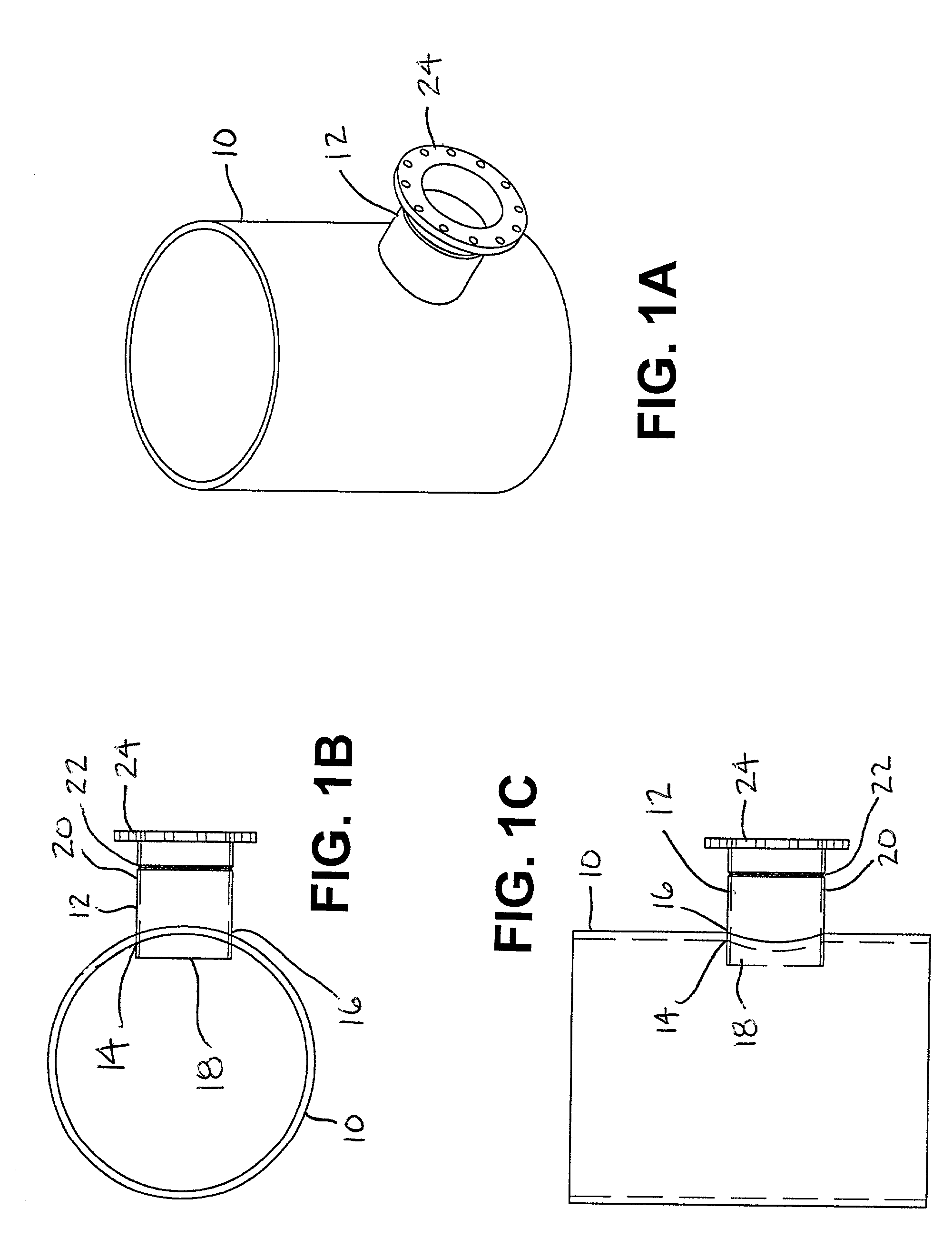

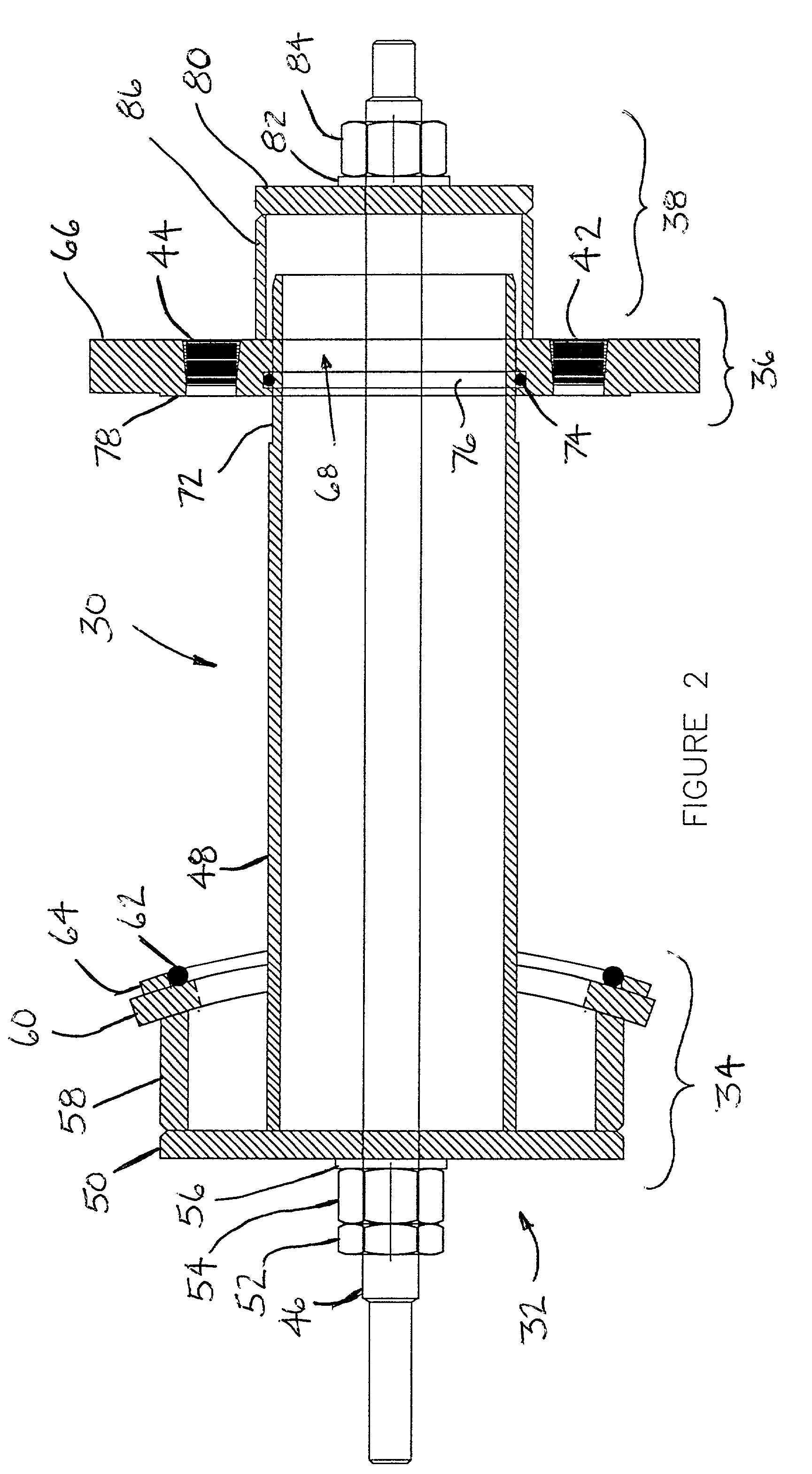

Branch pipe/tank nozzle test plug and method of use

InactiveUS20030167827A1Damage to materialReliable and ready and efficient installationDetection of fluid at leakage pointMeasurement of fluid loss/gain rateLeak testingWaste management

A test plug and method for isolating and testing a connection, such as a welded connection, which interconnects a wall of tank, vessel, or pipe to a branch pipe or nozzle. The test plug isolates the connection from the remainder of the tank, vessel or piping system and enables pressure / leak testing of the connection without requiring pressurization of the entire tank or vessel or a large section of the piping system. Further, the test plug can be utilized during welding operations to isolate harmful materials, vapors or fumes existing within tanks, vessels or piping systems from the weld location and to permit the flow of an inert gas to safely flush any potentially harmful vapors or the like away from the welding area.

Owner:EST GROUP

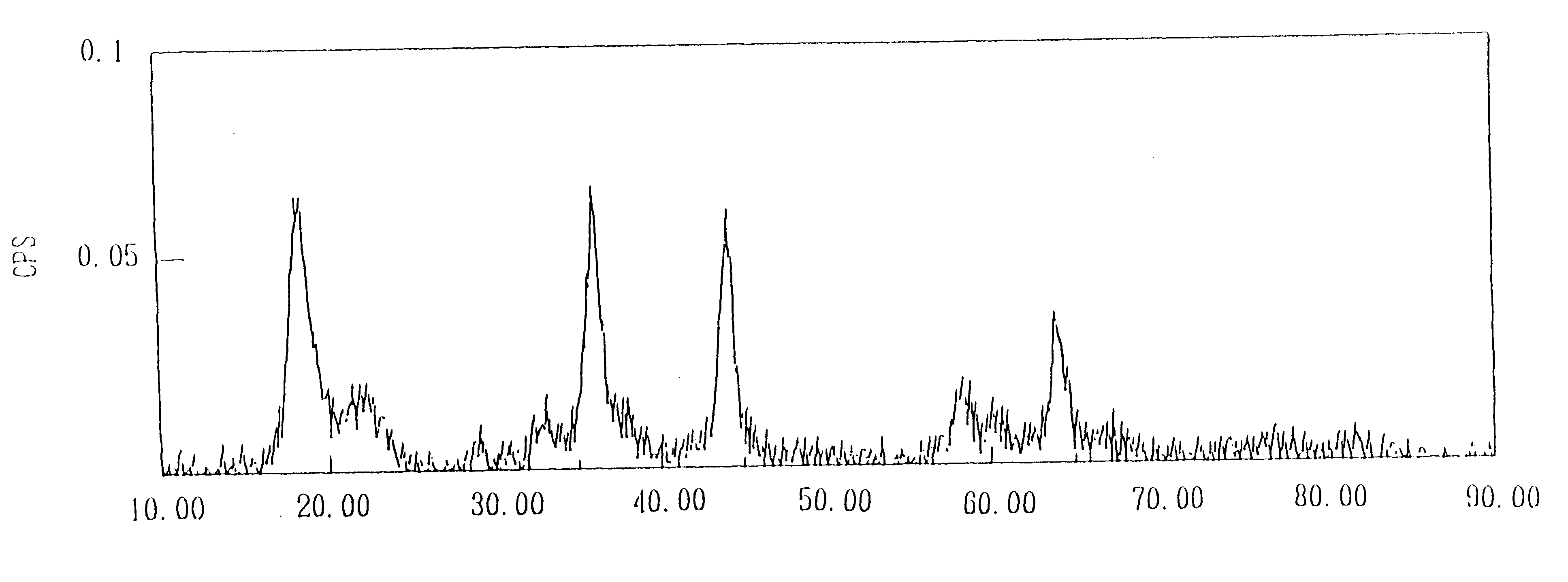

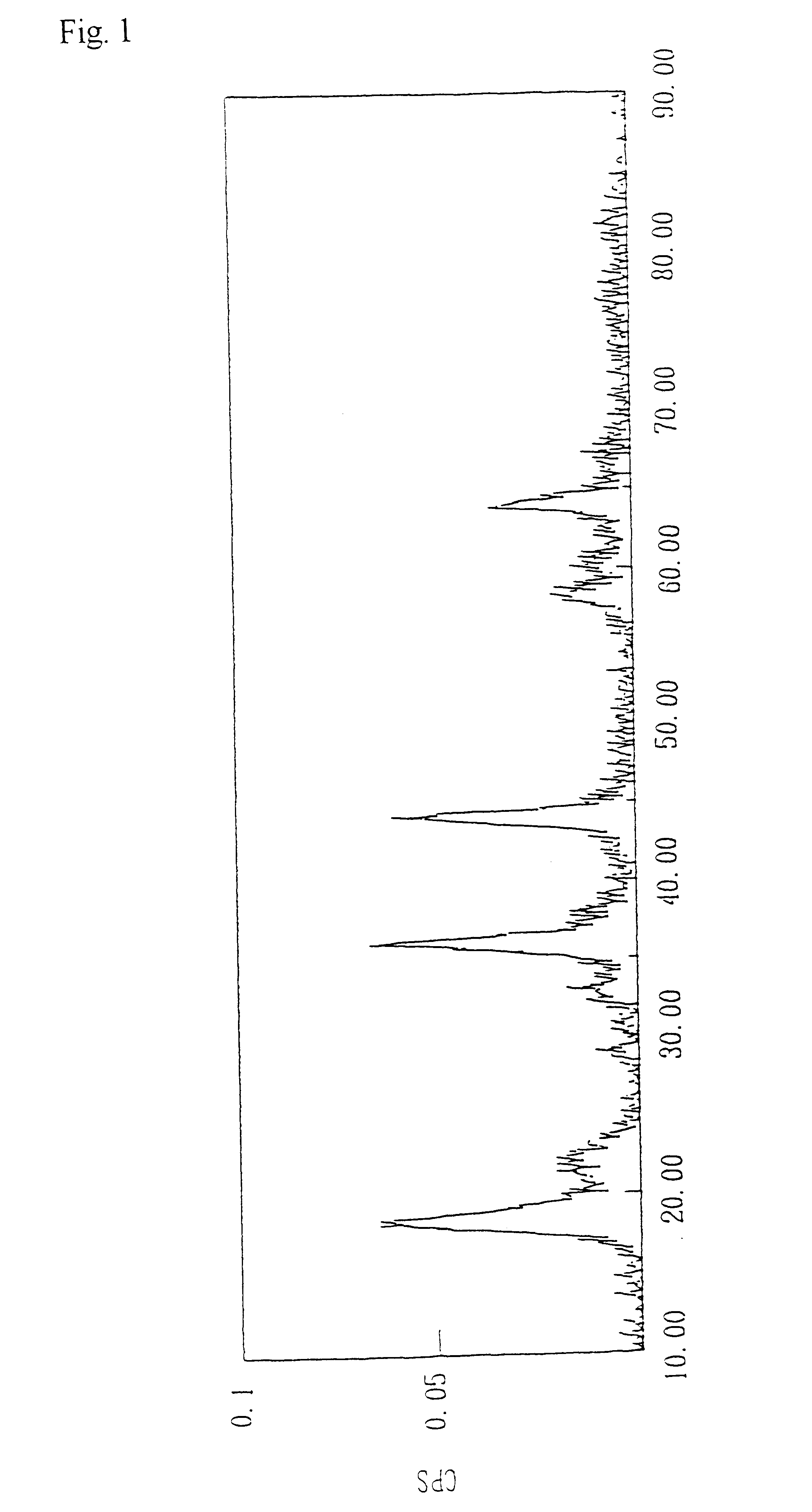

Method for preparing lithium manganate and positive electrode for lithium secondary cell containing the same

InactiveUS6699297B1Low costImprove charge and discharge performanceElectrode manufacturing processesPrimary cellsSpinelManganate

A method for preparing lithium manganate having spinel structure which comprises contacting a manganese halide and lithium compound at a temperature of 100° C. or less in a liquid phase to react with each other; a lithium manganate which is prepared according to the method, is represented by the formula LixMnOy, wherein x represents a real number satisfying 0<x<=0.8, and y represents a real number satisfying 1.8<=y<=2.4, and has an average particle diameter of 1 to 50 mum and a specific surface area of 10 to 15 m<2> / g; a positive electrode for a lithium secondary cell comprising the lithium manganate as an active material; and a lithium secondary cell using the positive electrode.

Owner:TOHO TITANIUM CO LTD

Method and apparatus for shielding feedthrough pin insulators in an ionization gauge operating in harsh environments

InactiveUS7456634B2Easy to operateDamage to materialVacuum gauge using ionisation effectsDischarge tube/lamp detailsEngineeringIonization

Shields for feedthrough pin insulators of a hot cathode ionization gauge are provided to increase the operational lifetime of the ionization gauge in harmful process environments. Various shield materials, designs, and configurations may be employed depending on the gauge design and other factors. In one embodiment, the shields may include apertures through which to insert feedthrough pins and spacers to provide an optimal distance between the shields and the feedthrough pin insulators before the shields are attached to the gauge. The shields may further include tabs used to attach the shields to components of the gauge, such as the gauge's feedthrough pins. Through use of example embodiments of the insulator shields, the life of the ionization gauge is extended by preventing gaseous products from a process in a vacuum chamber or material sputtered from the ionization gauge from depositing on the feedthrough pin insulators and causing electrical leakage from the gauge's electrodes.

Owner:MKS INSTR INC

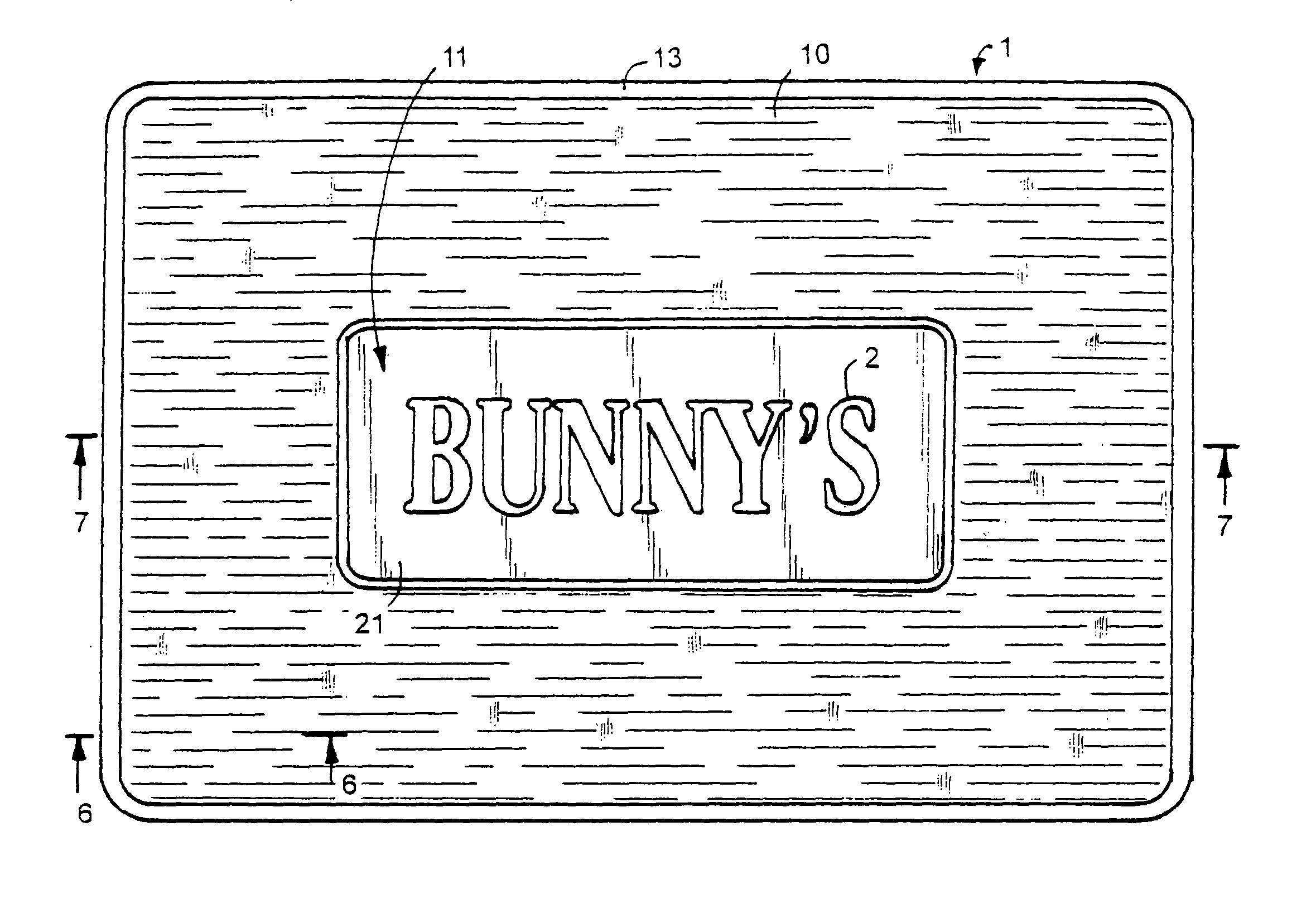

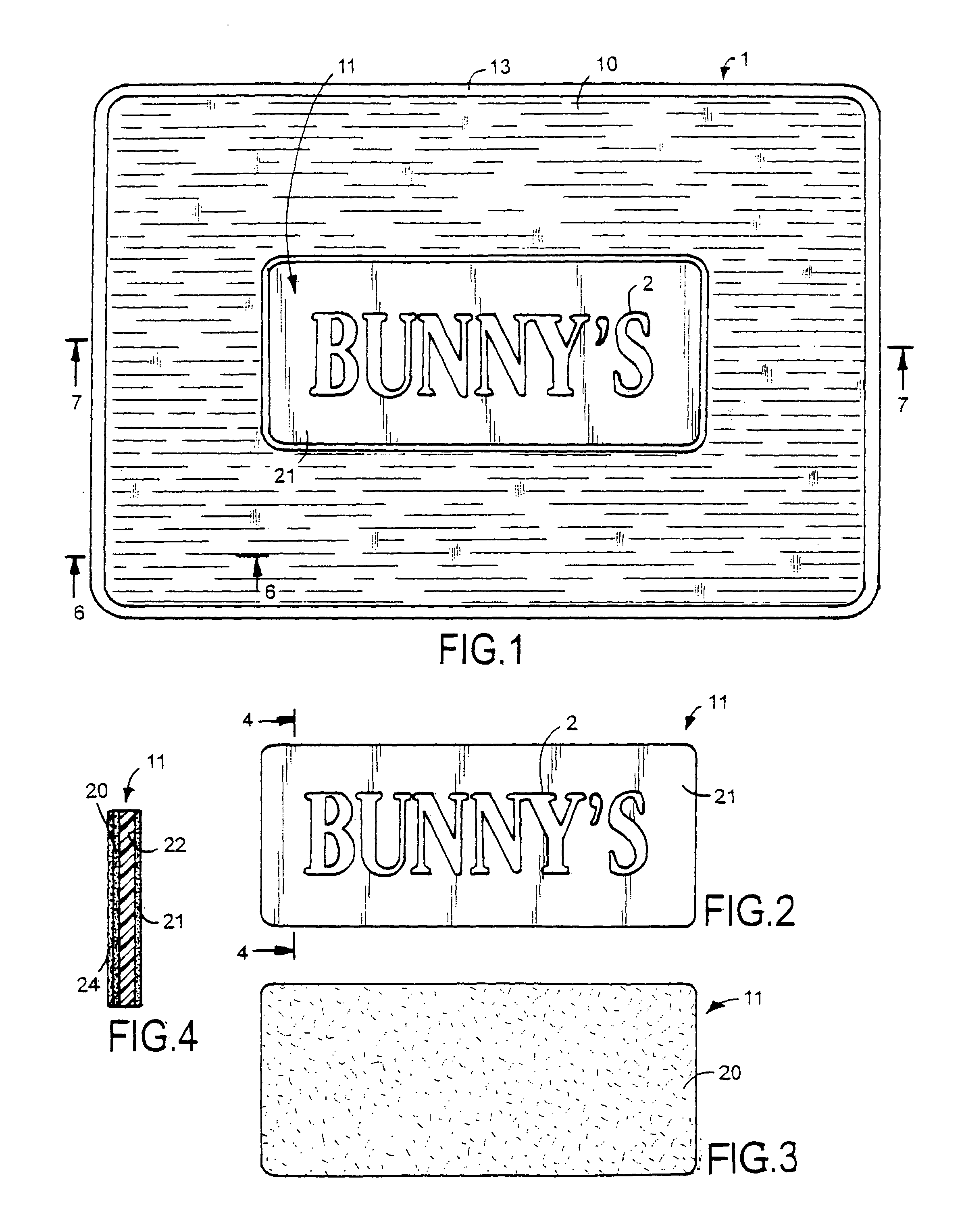

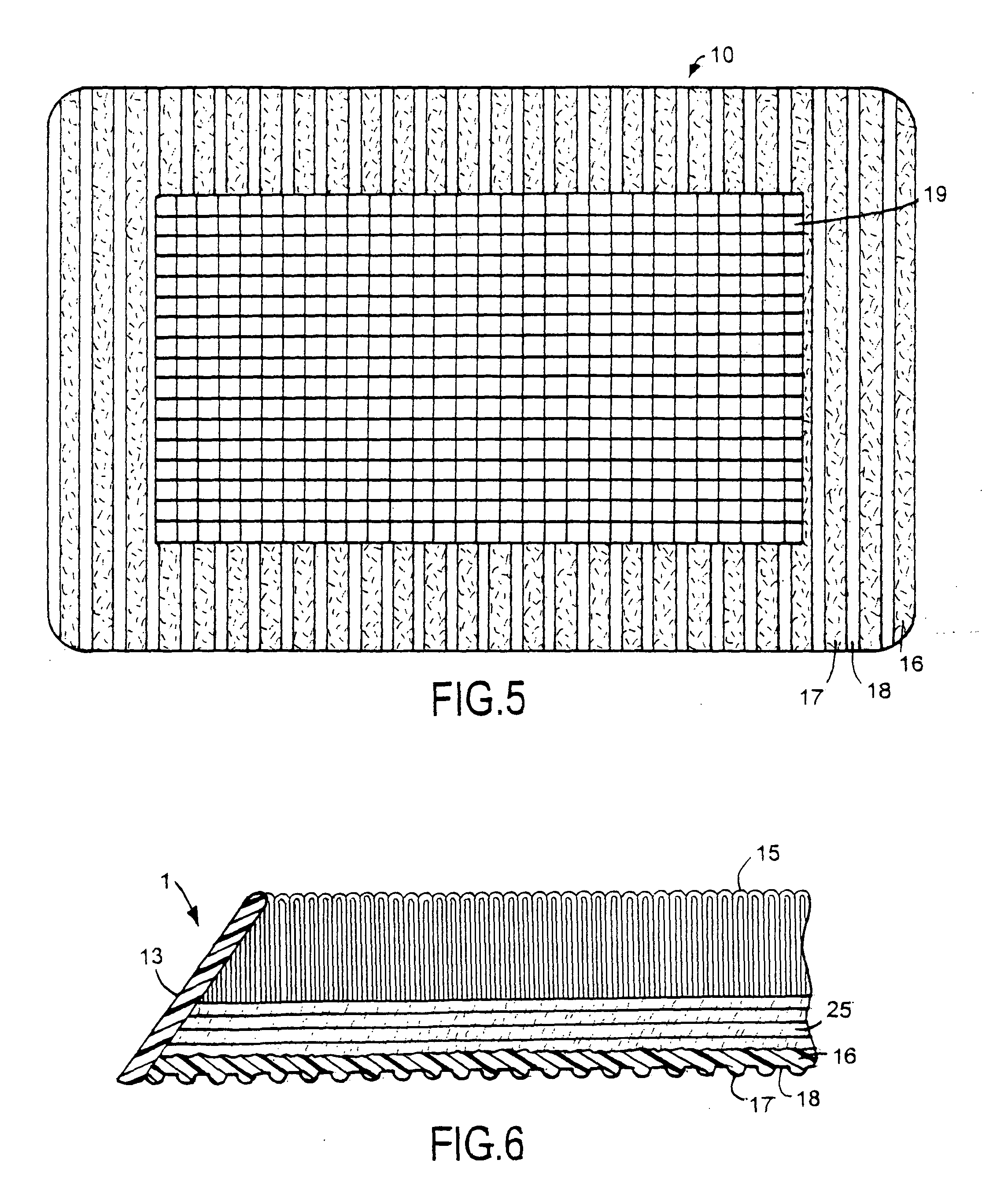

Graphic floor mat and method of making mat

InactiveUS8859073B1Increase frictionAvoid deformationResonant long antennasLayered productsAdhesiveMechanical engineering

A floor mat has a cavity accommodating an insert supporting a releasable sheet member. An adhesive releasably attaches the sheet member to the insert to allow the sheet member to be removed from the mat and replaced with another sheet member. The sheet member has visual indicia providing persons with information. Signal transmitter and receiver antennas of an electronic article surveillance system are located within the floor mat.

Owner:CALLAS ENTERPRISES

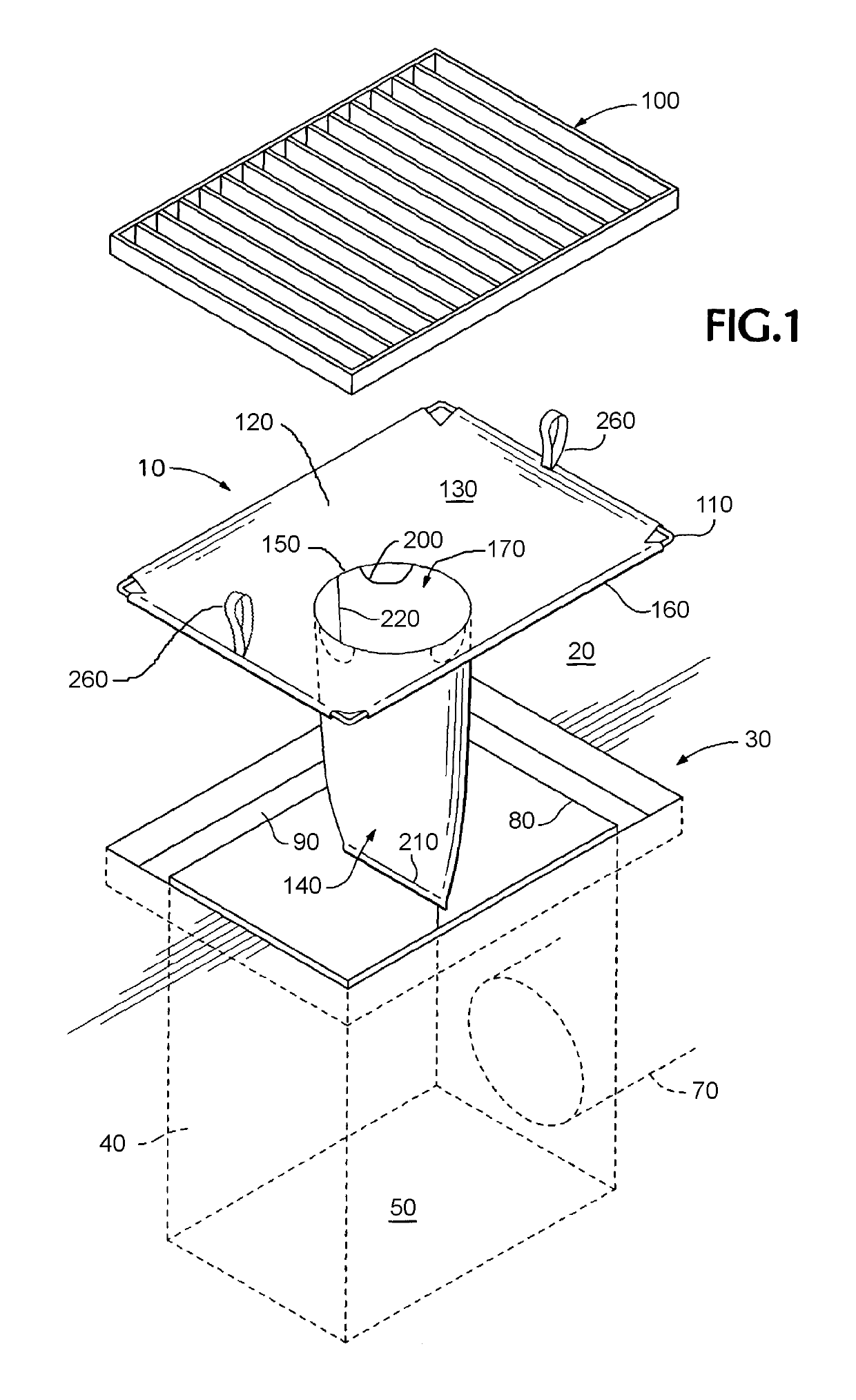

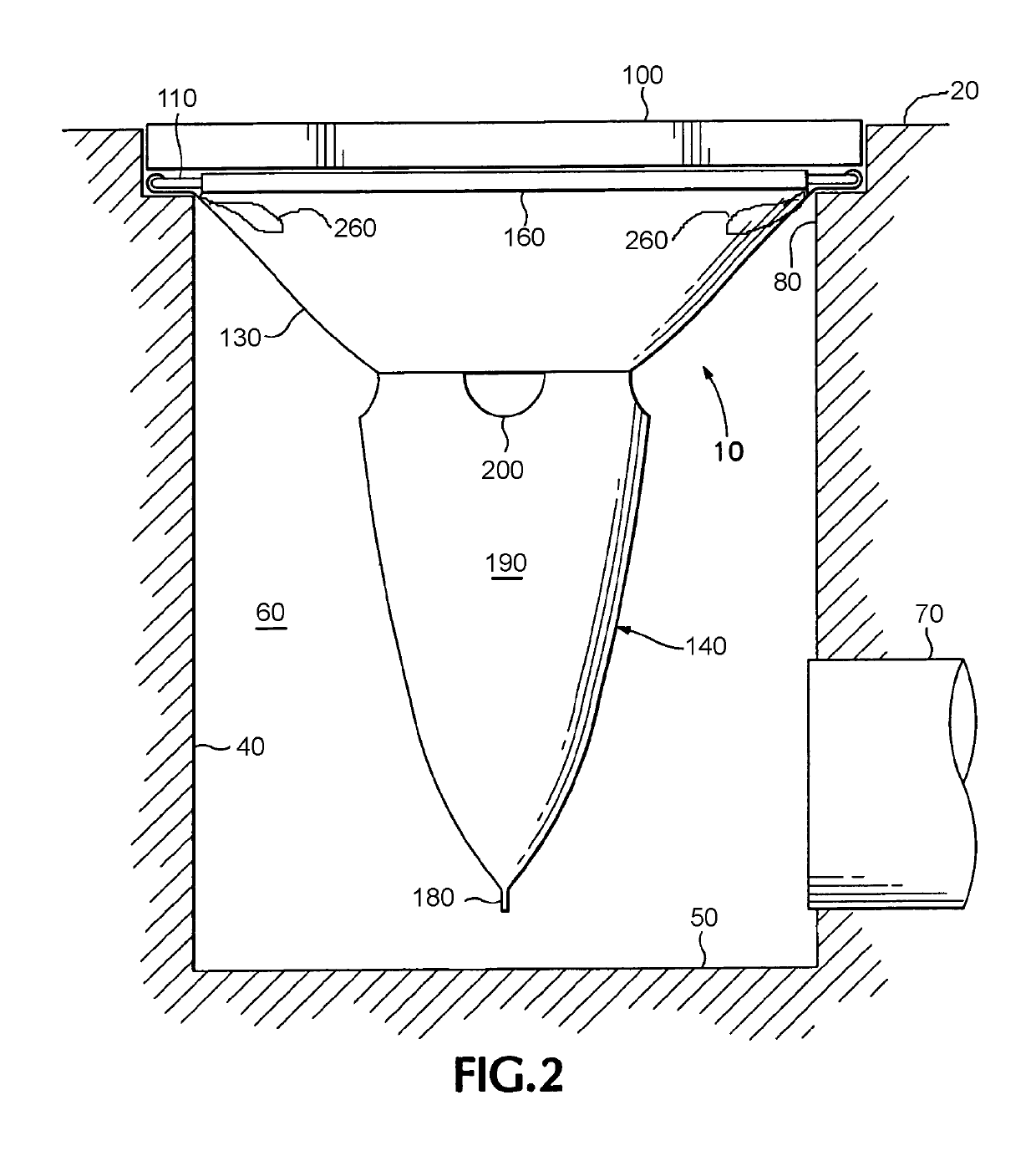

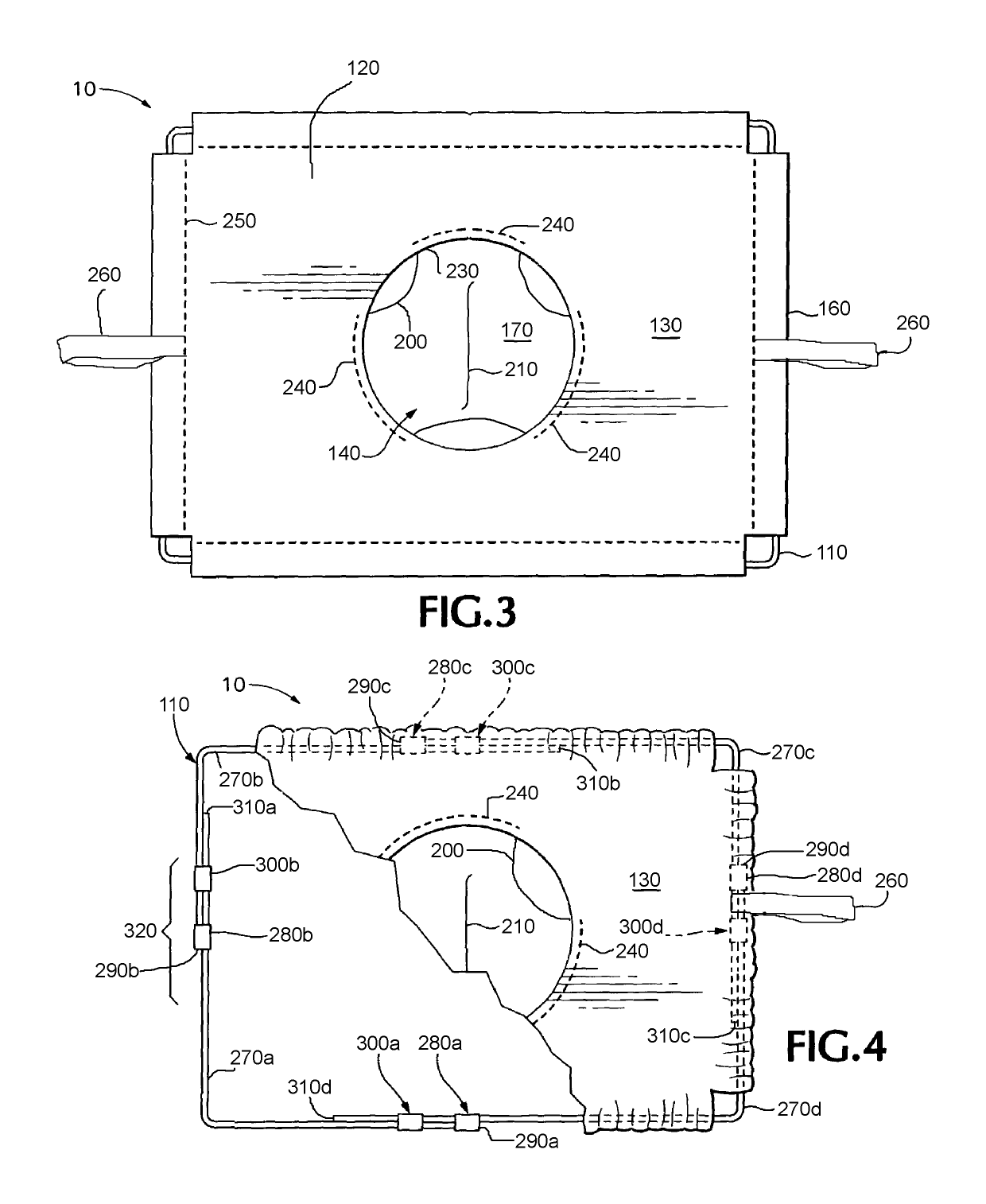

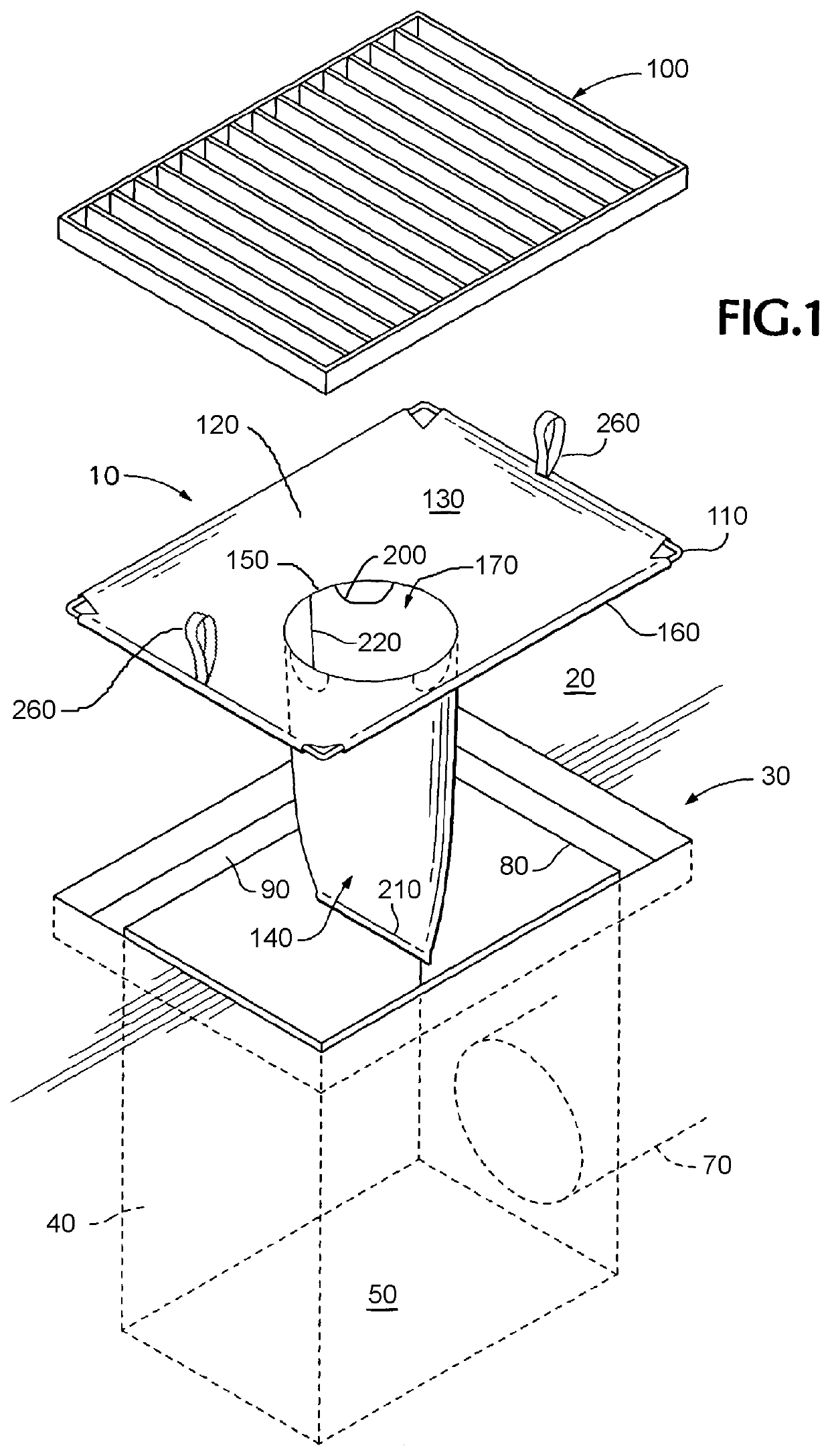

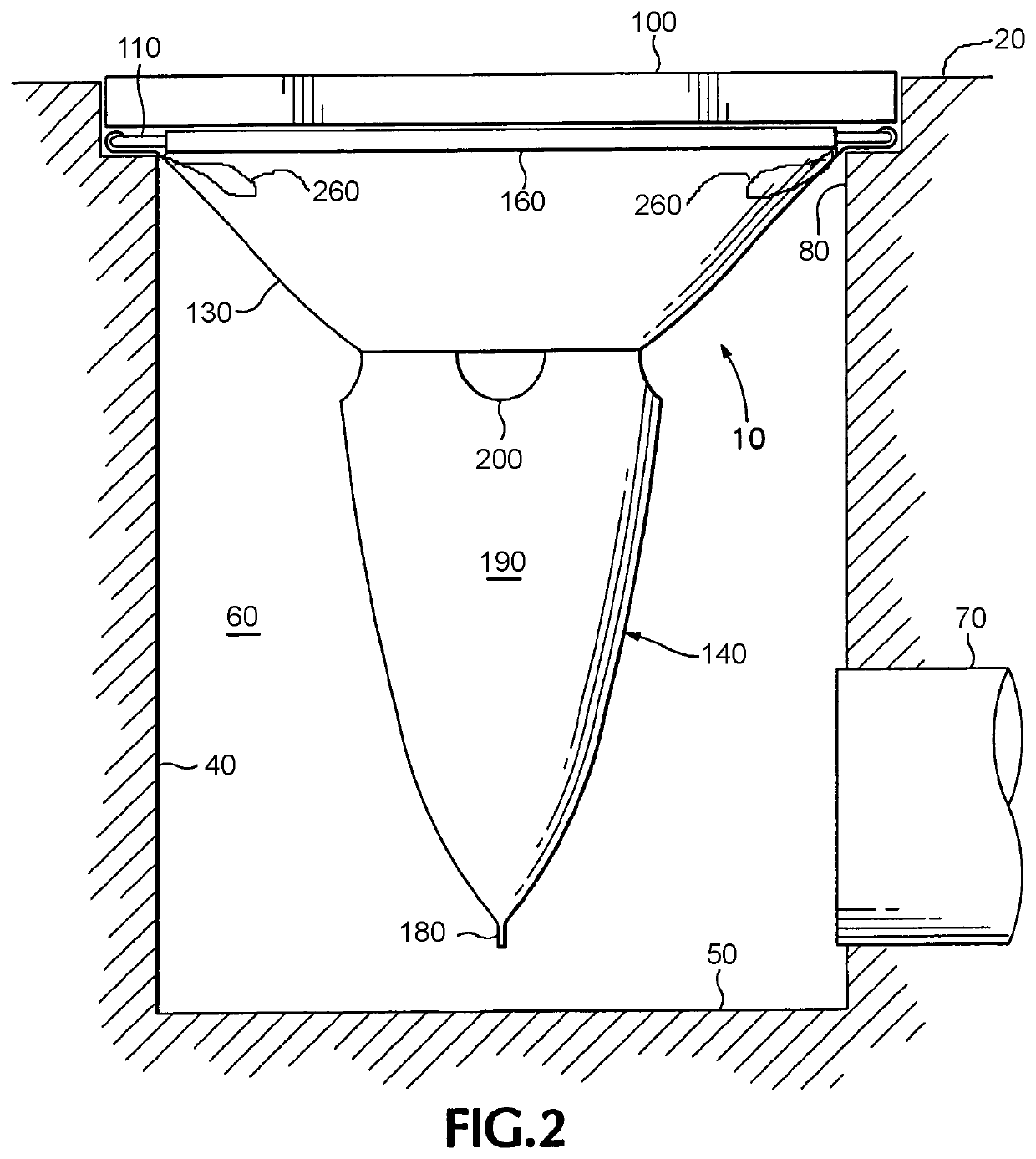

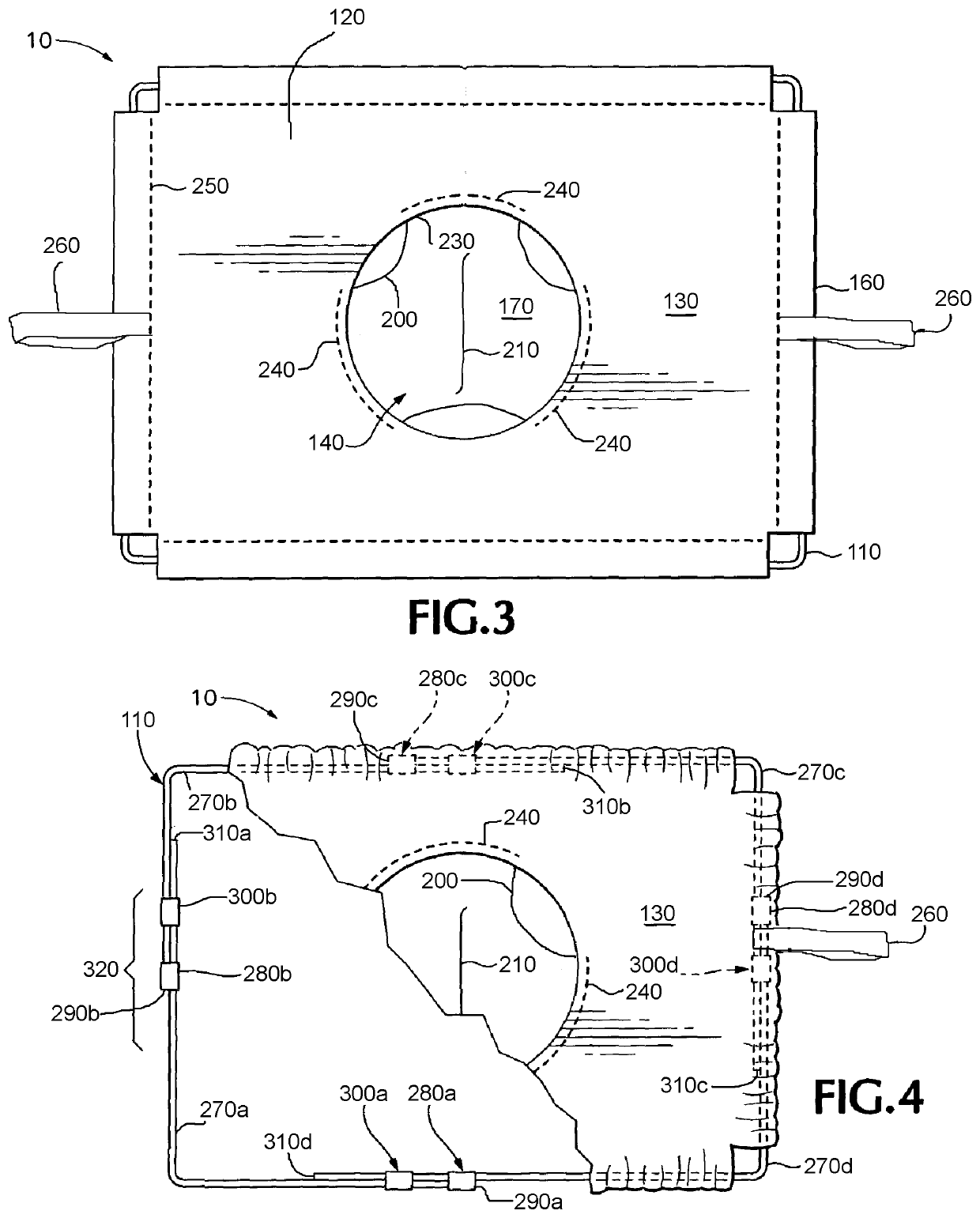

Storm drain sediment filter

ActiveUS10384155B1Prevent exitDamage to materialSewerage structuresGravity filtersStorm drainMaximum dimension

A storm drain sediment filter that can be adapted to cover a catch basin and be held in place by a perforated grate. In one embodiment, the filter includes a frame including four L-shaped rigid members, each of which is provided with at least two spaced apart retaining members. The four L-shaped rigid members are arranged such that a rectangular frame is formed having a total of four overlapping sections. The retaining members engage one of the overlapping portions of the frame but slidably receives the other. No retaining ends are formed at the distal end of the slidably engaged L-shaped members to serve as a sliding boundary. Instead, the dimensions of the filter bag are such that the filter bag serves to define the maximum dimension of the frame and thereby maintain the overlapping L-shaped rigid members in slidable engagement with each other. A circular embodiment is also disclosed.

Owner:ENPAC

Probiotic delivery systems

ActiveUS20170173091A1Healthy immune systemDamage to materialPeptide/protein ingredientsInorganic non-active ingredientsSuppositoryRoom temperature

Suppository compositions are provided combining a pharmaceutically acceptable matrix material that is solid outside of the human body and in a dry environment, but which melts at body temperature; and apple cider vinegar and one or more species of probiotic bacteria dispersed within the matrix material; wherein the matrix material contains a mixture of fatty acids that are solid at room temperature. Methods for supplementing and nourishing the microbiome of the rectum of a male or female and the microbiome of the vagina of a female are also disclosed. Oral dosage forms of the compositions of the present invention are also provided.

Owner:PROBIOTECH LLC

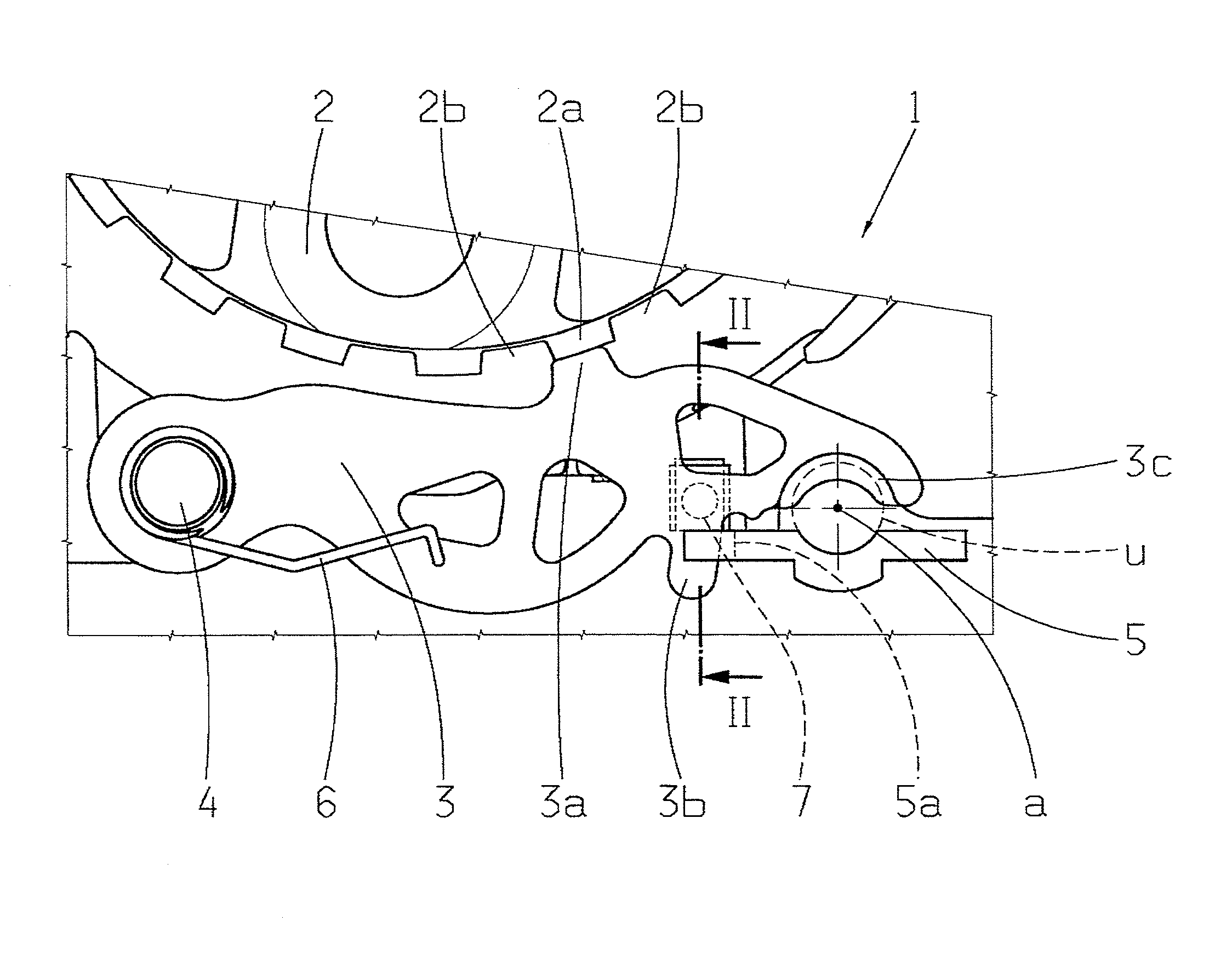

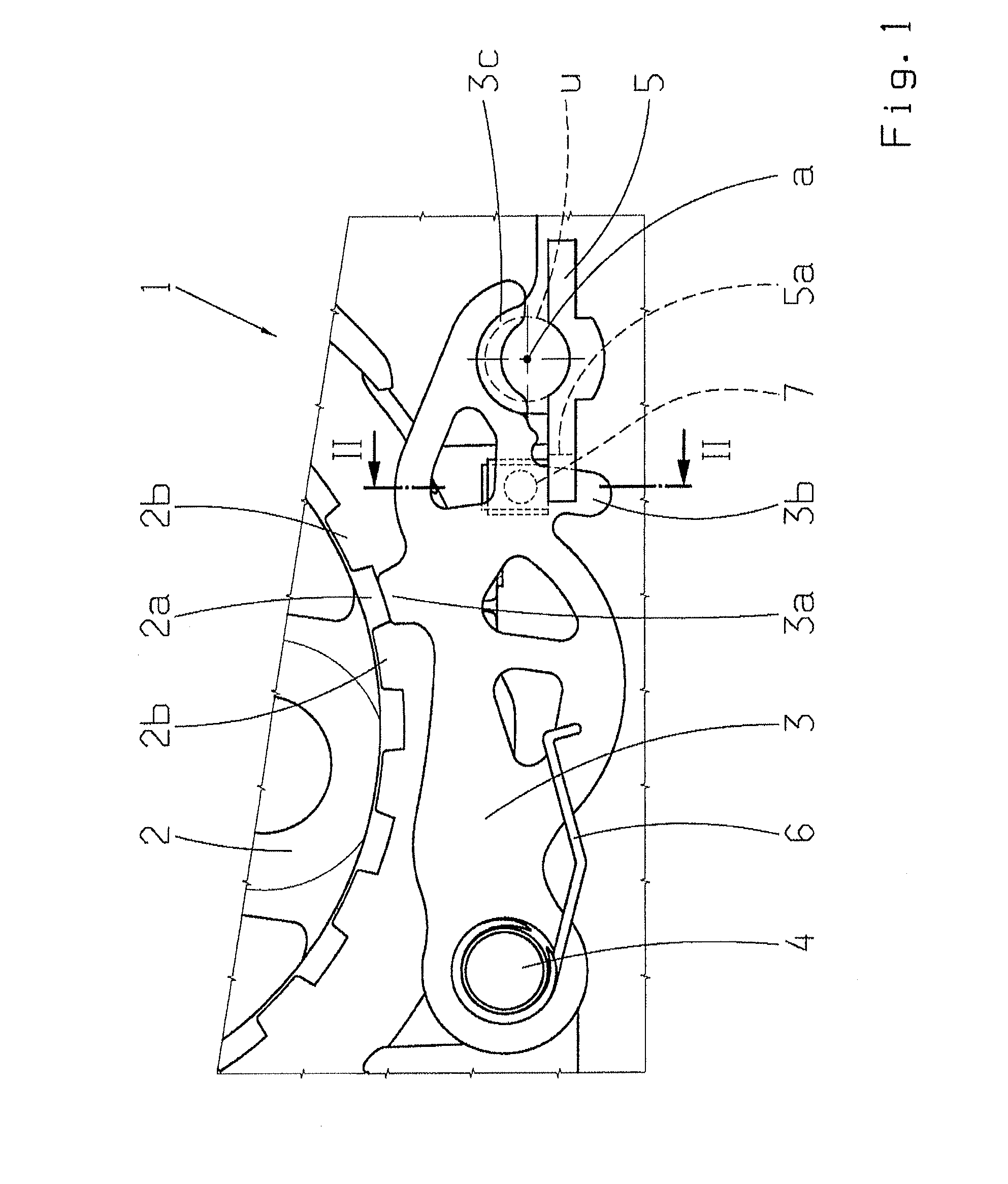

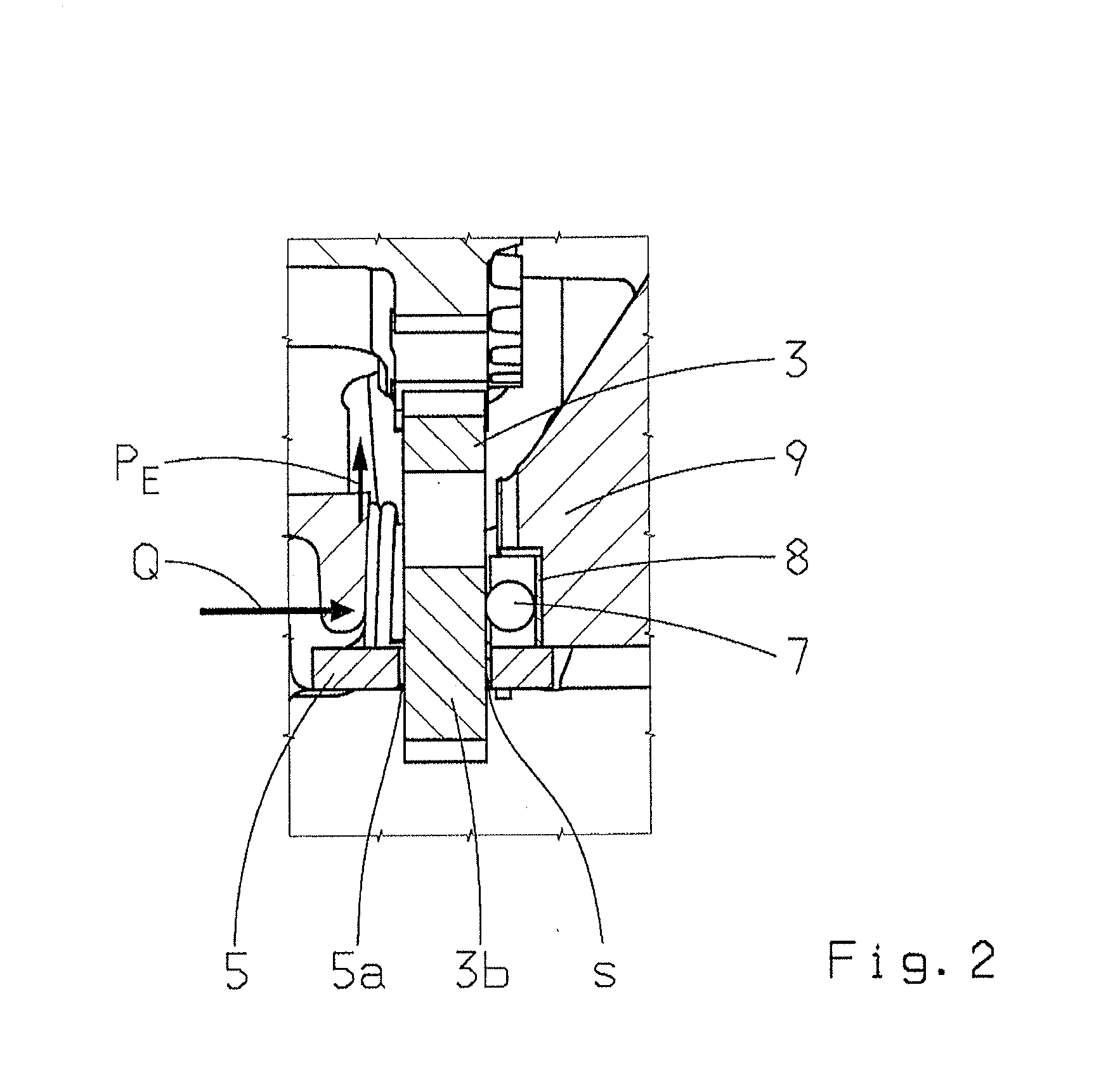

Parking lock device for an automatic transmission of a motor vehicle

ActiveUS20110278132A1Improve securityReduce frictionGearing controlFriction clutchesAutomatic transmissionMotorized vehicle

A parking lock device (1) for an automatic transmission of a motor vehicle. The parking lock device (1) comprises a locking pawl (3) that is fixed to the transmission housing and mounted so that the locking pawl (3) can pivot. The parking lock device (1) has a guiding element (3b) and a guide plate (5) fixed to and supported by the housing in which the guide element (3b) of the locking pawl (3) is guided laterally. One of a low-friction supporting element (7, 8) and an electrically insulating supporting element in a form of an insulating body (107) laterally guides the locking pawl (3).

Owner:ZF FRIEDRICHSHAFEN AG

Flat panel display device and method thereof

ActiveUS8350467B2Avoid performance degradationPrevent penetrationDischarge tube luminescnet screensElectroluminescent light sourcesOrganic filmEngineering

A flat panel display device including a display area where an image is displayed and a non-display area located at an outside of the display area includes bank portions arranged in a pattern in the display area and partitioning a plurality of openings, emission elements located in the openings, dummy bank portions formed in the non-display area and integrated therewith, and a sealing passivation layer having a multi-layered structure of organic films and inorganic films alternately arranged, one organic film being located at an interface directly contacting the emission element and one inorganic film located firstly on an outermost portion of the dummy bank portions when the sealing passivation layer extends from the display area to the non-display area.

Owner:SAMSUNG DISPLAY CO LTD

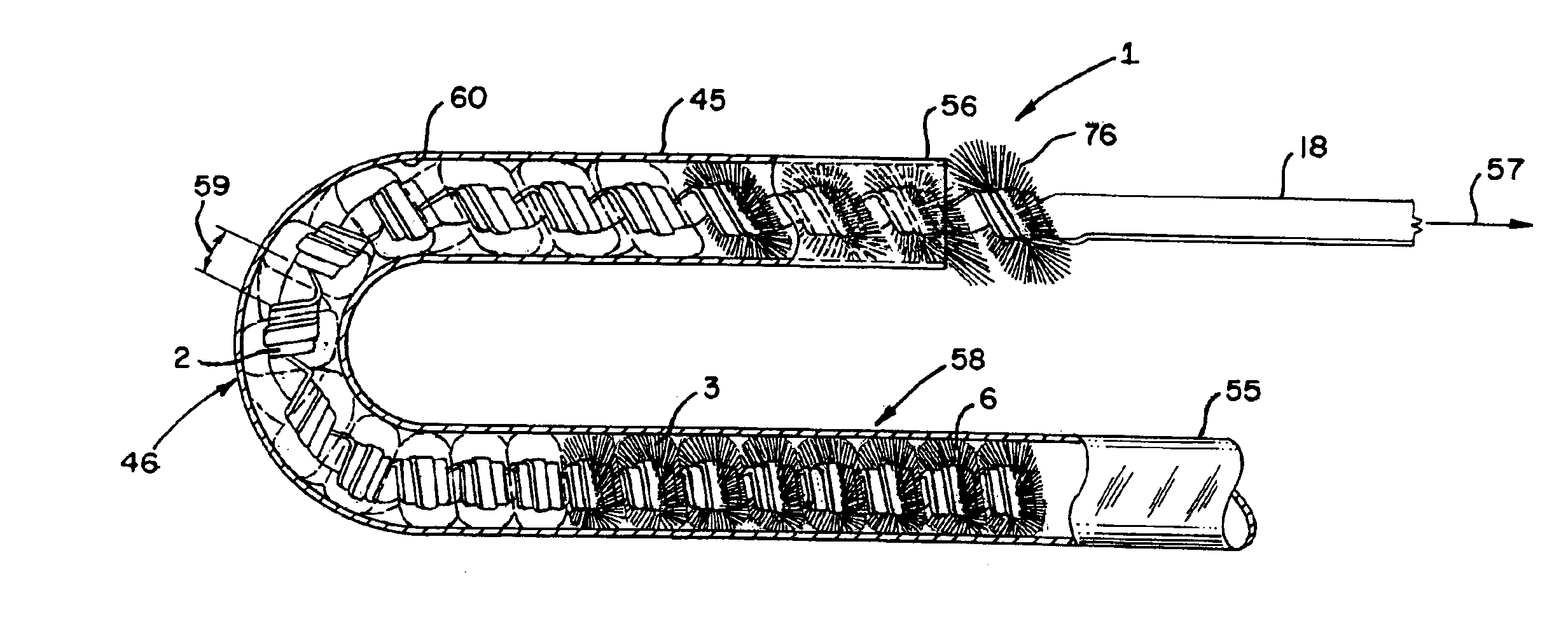

Cleaning device

InactiveUS6868575B2Damage to materialInexpensive and easy to useBrush bodiesHollow article cleaningEngineeringFiber

A cleaning device and method for making which is constructed from a flexible base member of thermoplastic material to which a plurality of fibers are fused and protrude therefrom, and formed into a curvilinear configuration such as a helix-like, or U-shaped-like configuration. The method includes the steps of heating the base until it is softened and bent to a U-shape like configuration and then cooling the base member, or helically winding the base onto a rotating mandrel; stopping the mandrel and severing an end of the base member; and cooling the base member so that it retains its U-shape or helical configuration. A core member may also be inserted through the opening in the helix-like configuration and attached at one or more points of the base member permitting the cleaning device to be pushed through tubular members.

Owner:KOREGELOS GEORGE H W PROD

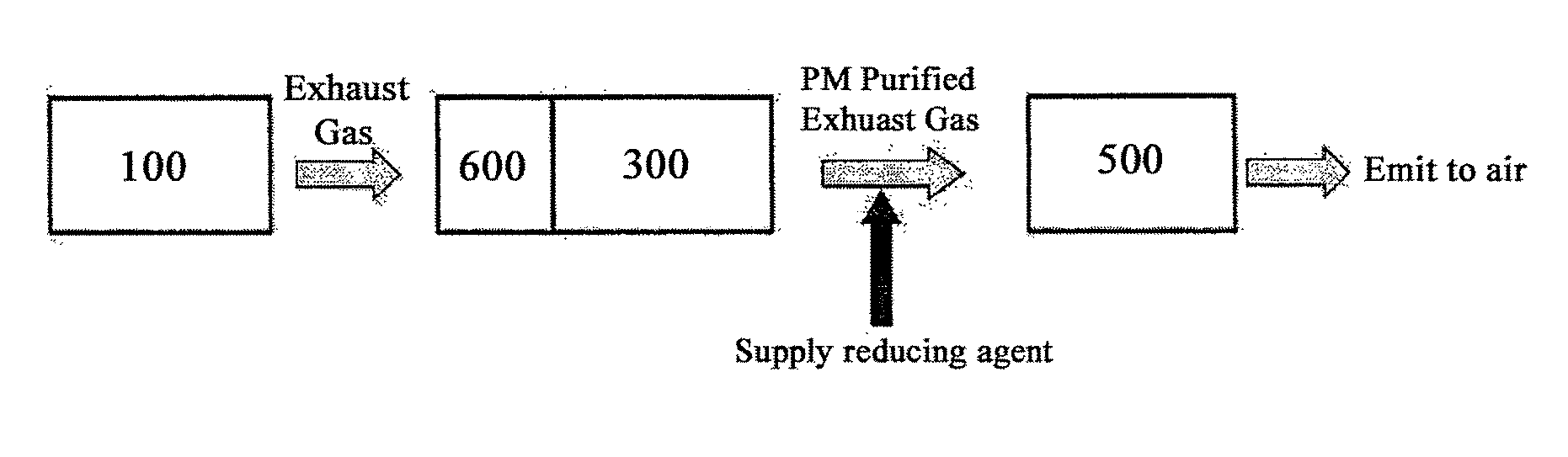

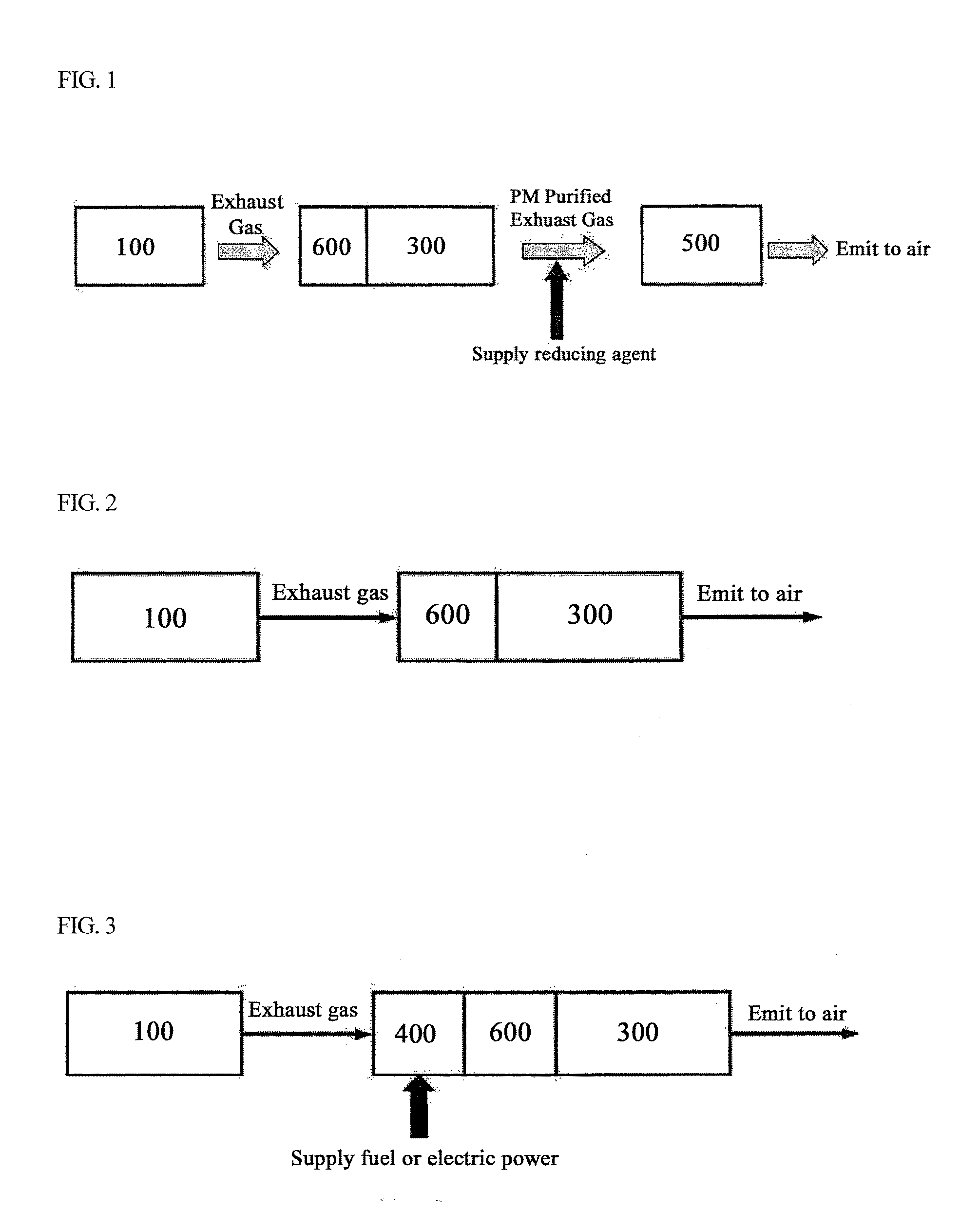

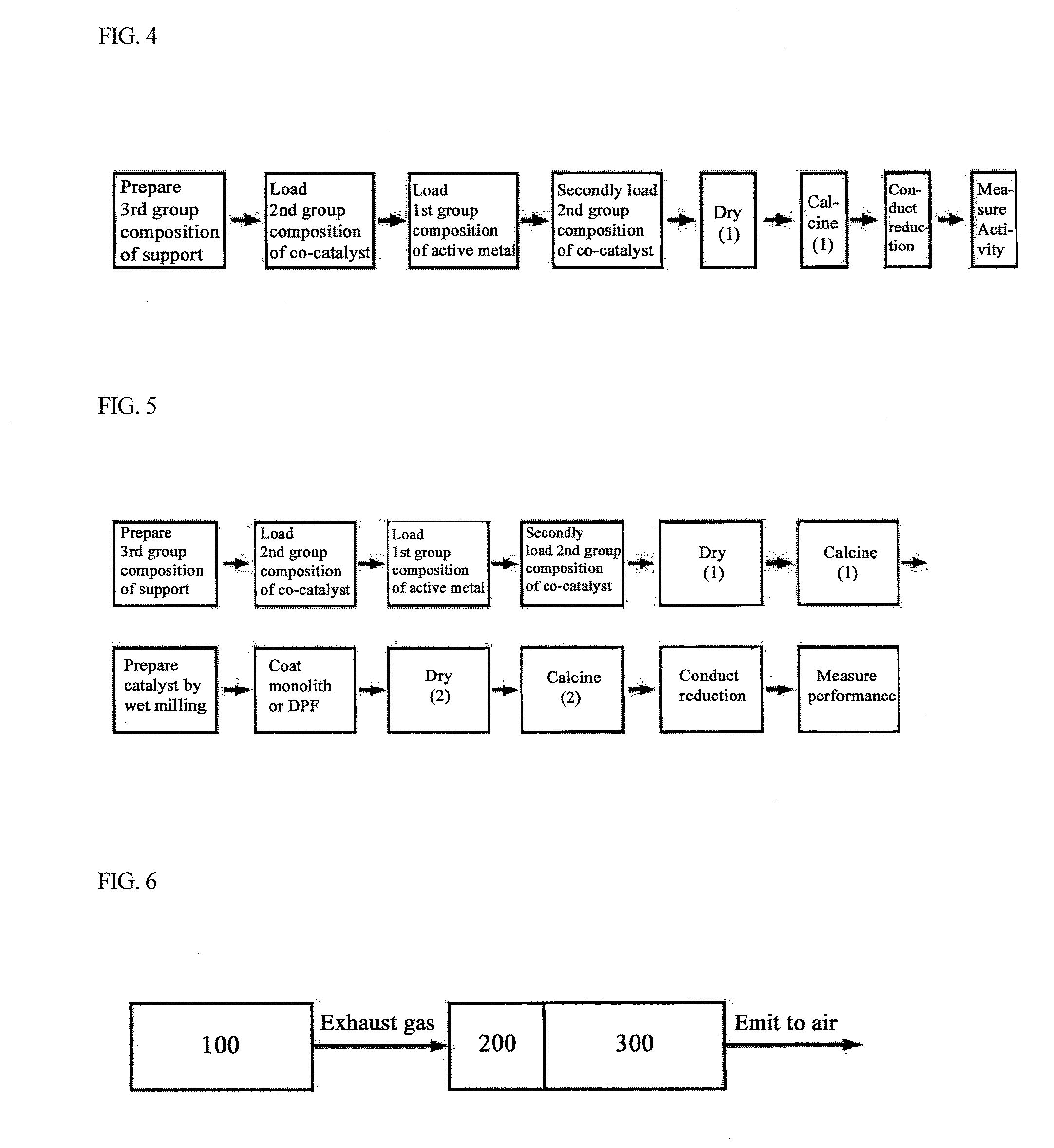

Bifunctional Catalyst for Decomposition and Oxidation of Nitrogen Monoxide, Composite Catalyst Including the Same for Apparatus to Decrease Exhaust Gas, and Method for Preparation Thereof

InactiveUS20110258994A1Improve efficiencyLarge particle sizeGas treatmentMolecular sieve catalystsPtru catalystNitrogen monooxide

Disclosed are a bifunctional catalyst for simultaneously removing nitrogen oxide and particulate matters, capable of decomposing nitrogen monoxide and generating nitrogen dioxide through oxidation of nitrogen monoxide, a composite catalyst including the catalyst for simultaneously removing nitrogen oxide and particulate matters used for an apparatus to decrease exhaust gas of diesel vehicles, and a method for preparation thereof. The catalyst and the composite catalyst can be used in a device for reducing exhaust gas contaminants mounted on a diesel vehicle and an exhaust gas purification system comprising the device.

Owner:KOREA INST OF ENERGY RES

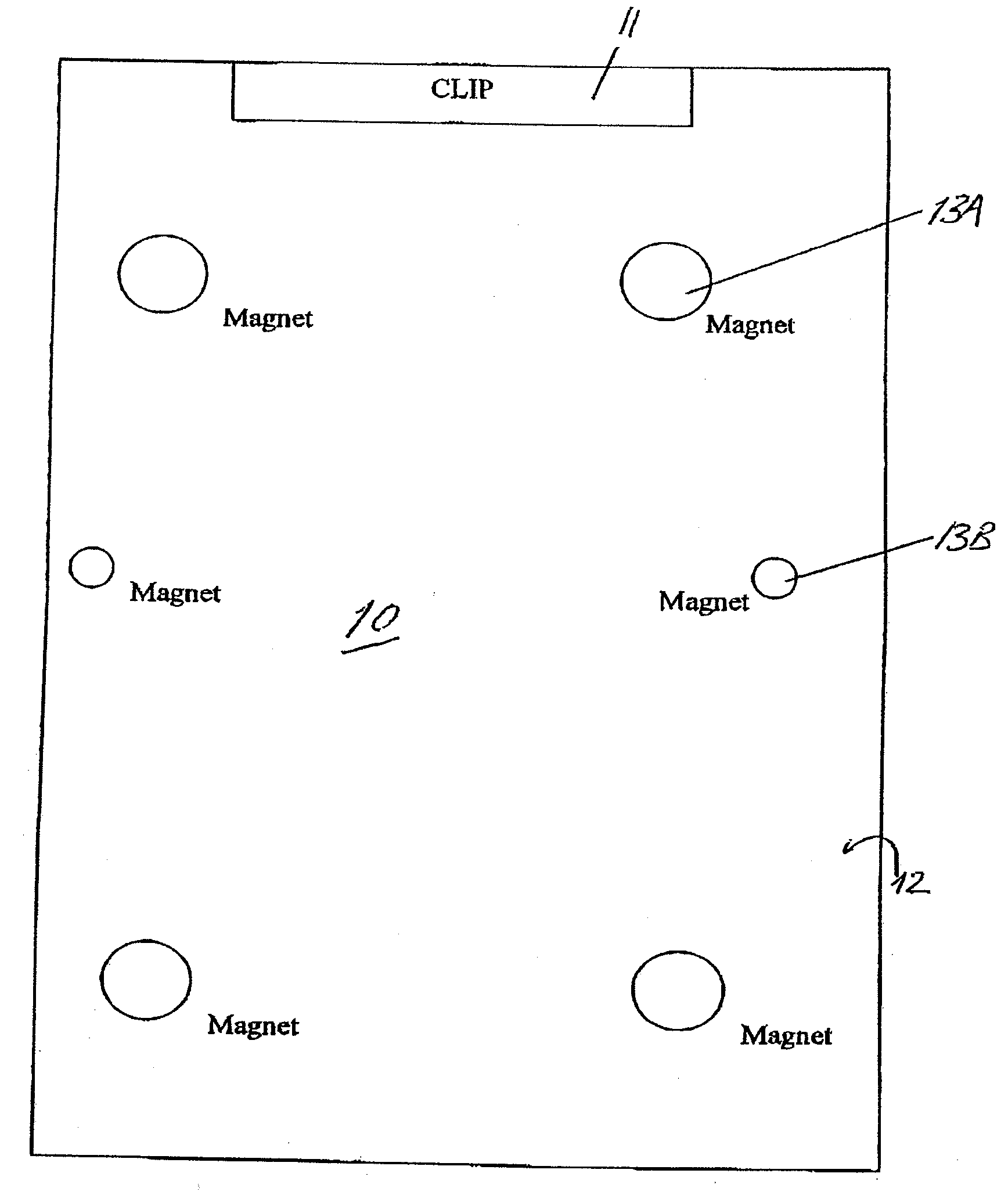

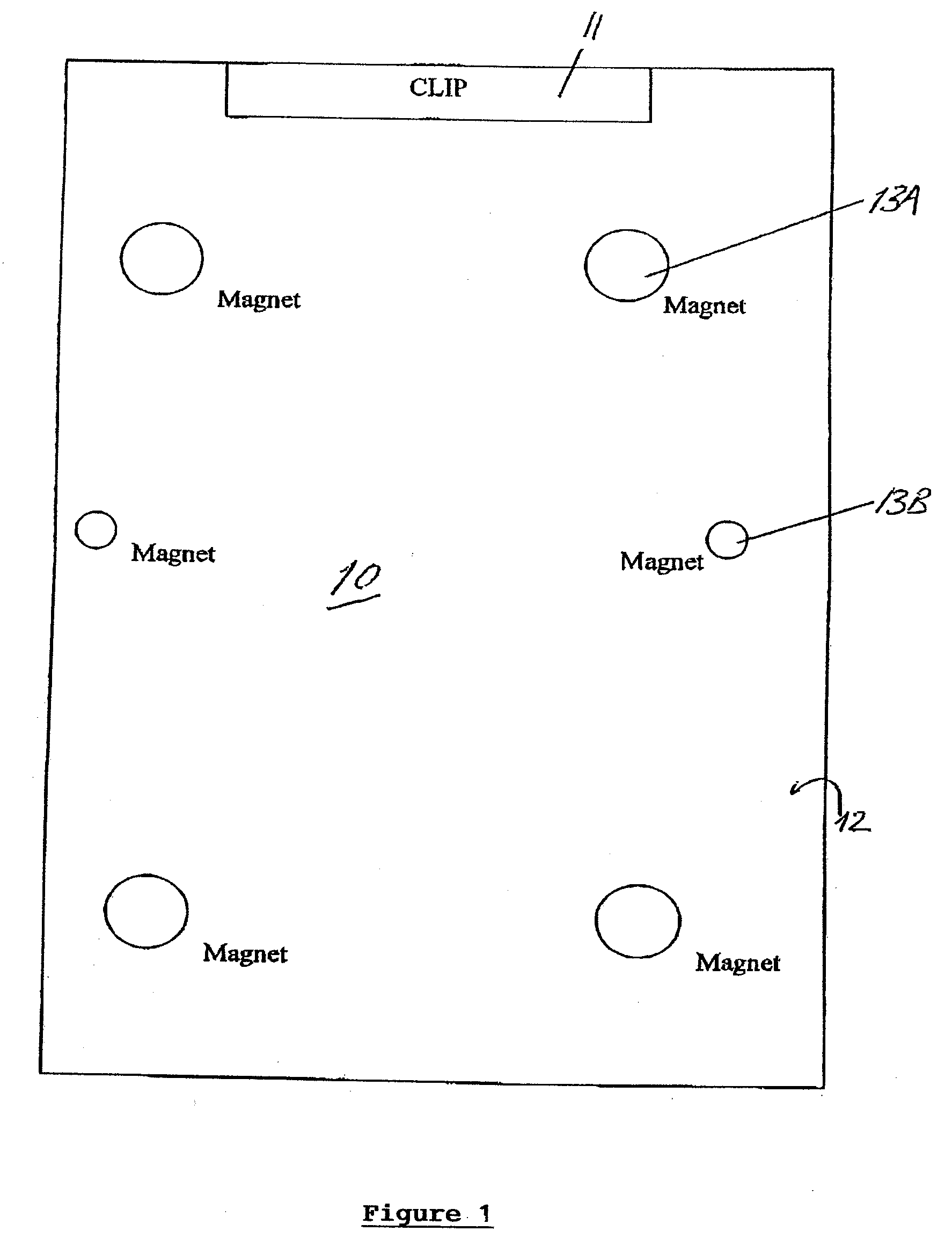

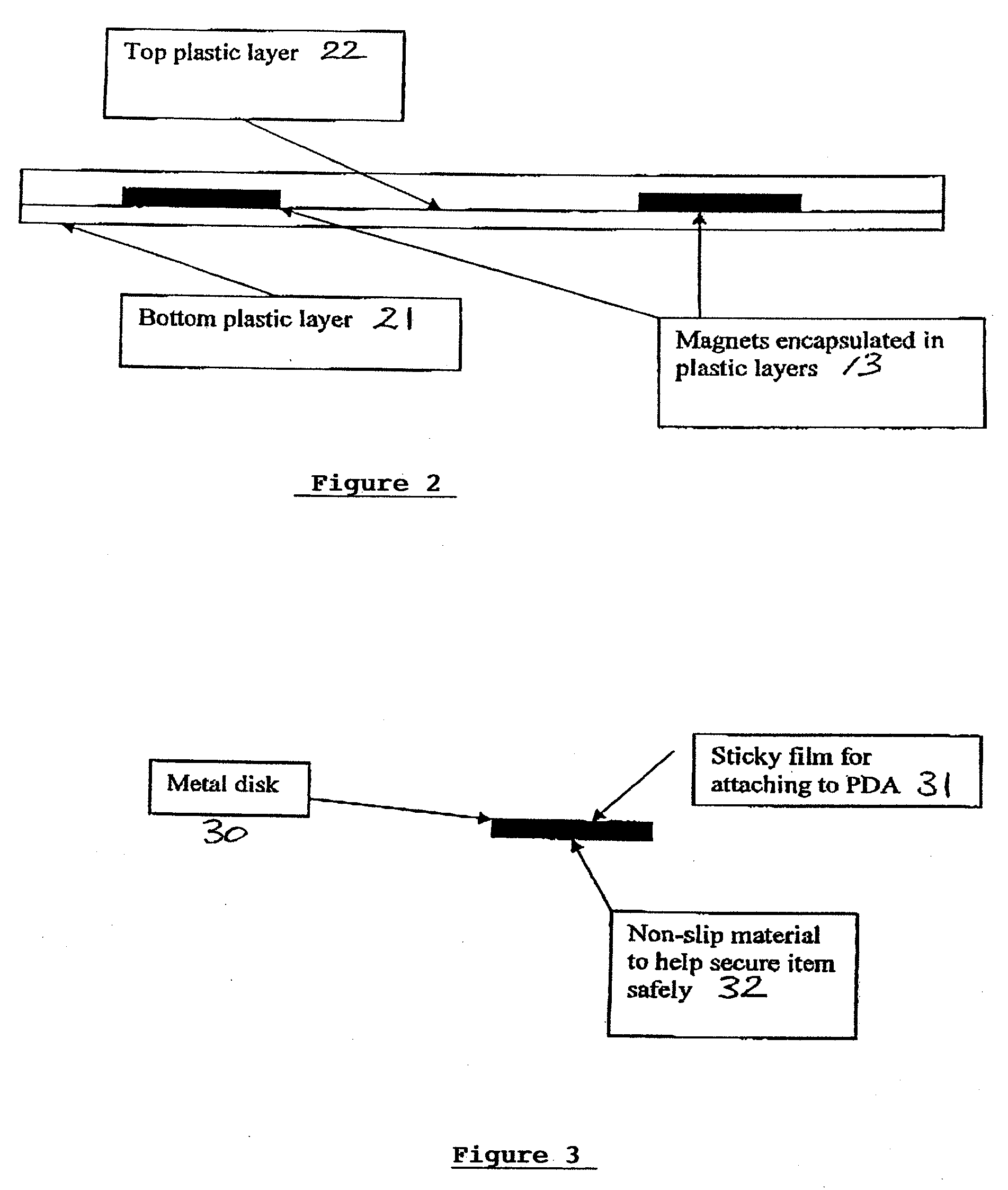

Clipboard

InactiveUS20090206592A1Easy accessEasily cleanableHanging devicesWriting connectorsPlastic materialsMobile phone

A pad is disclosed to assist a user to carry a number of small articles such as a mobile telephone, calculator, personal digital assistant etc. The pad, typically about the size of A4 paper, has a flat surface having plurality of magnets associated therewith. The magnets can be located beneath the surface of the pad protected by a layer of plastics material or can be flush with the surface. Typically, a magnet is disc-shaped but can also be in the form of a strip for particular uses. A bulldog clip or the like can be included in order to retain papers or forms on the pad. If necessary, a magnet or magnetizable element can be affixed to an article to be carried to provide the article with engagement with the magnets.

Owner:SUMMERHAYES STEPHEN

Storm drain sediment filter

ActiveUS20190358564A1Prevent exitDamage to materialSewerage structuresGravity filtersMaximum dimensionSediment Filter

A storm drain sediment filter that can be adapted to cover a catch basin and be held in place by a perforated grate. In one embodiment, the filter includes a frame including four L-shaped rigid members, each of which is provided with at least two spaced apart retaining members. The four L-shaped rigid members are arranged such that a rectangular frame is formed having a total of four overlapping sections. The retaining members engage one of the overlapping portions of the frame but slidably receives the other. No retaining ends are formed at the distal end of the slidably engaged L-shaped members to serve as a sliding boundary. Instead, the dimensions of the filter bag are such that the filter bag serves to define the maximum dimension of the frame and thereby maintain the overlapping L-shaped rigid members in slidable engagement with each other. A circular embodiment is also disclosed.

Owner:ENPAC

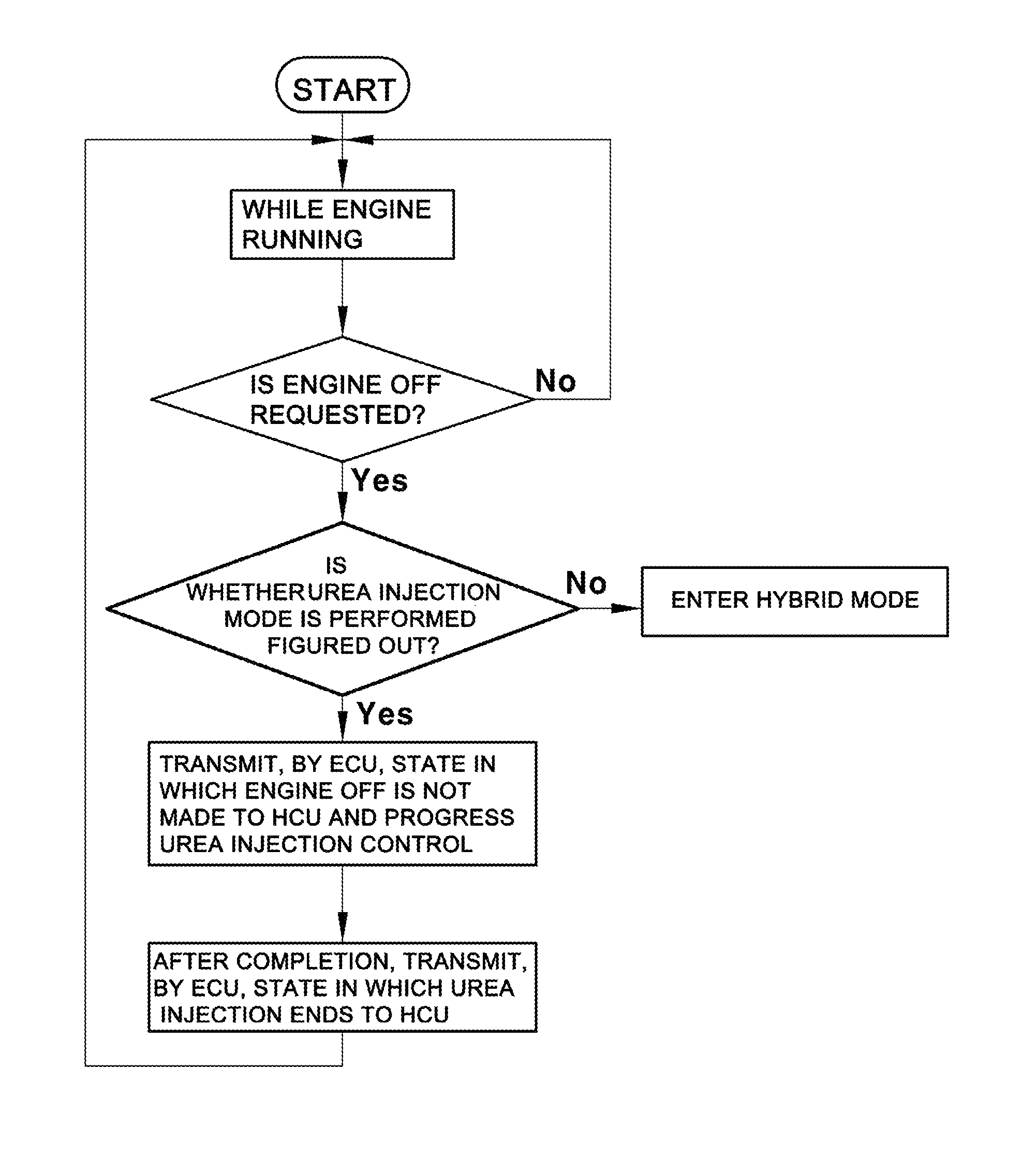

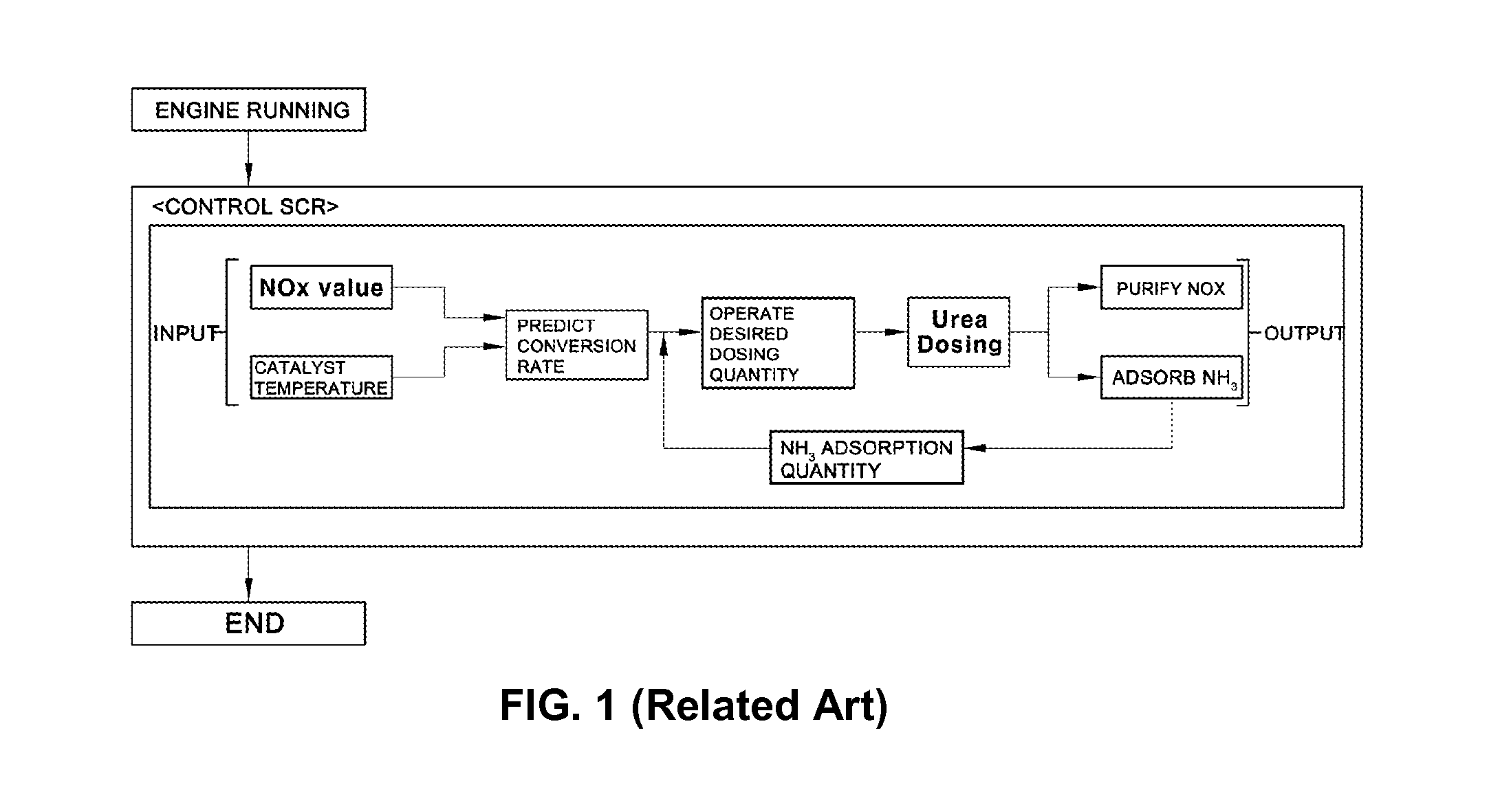

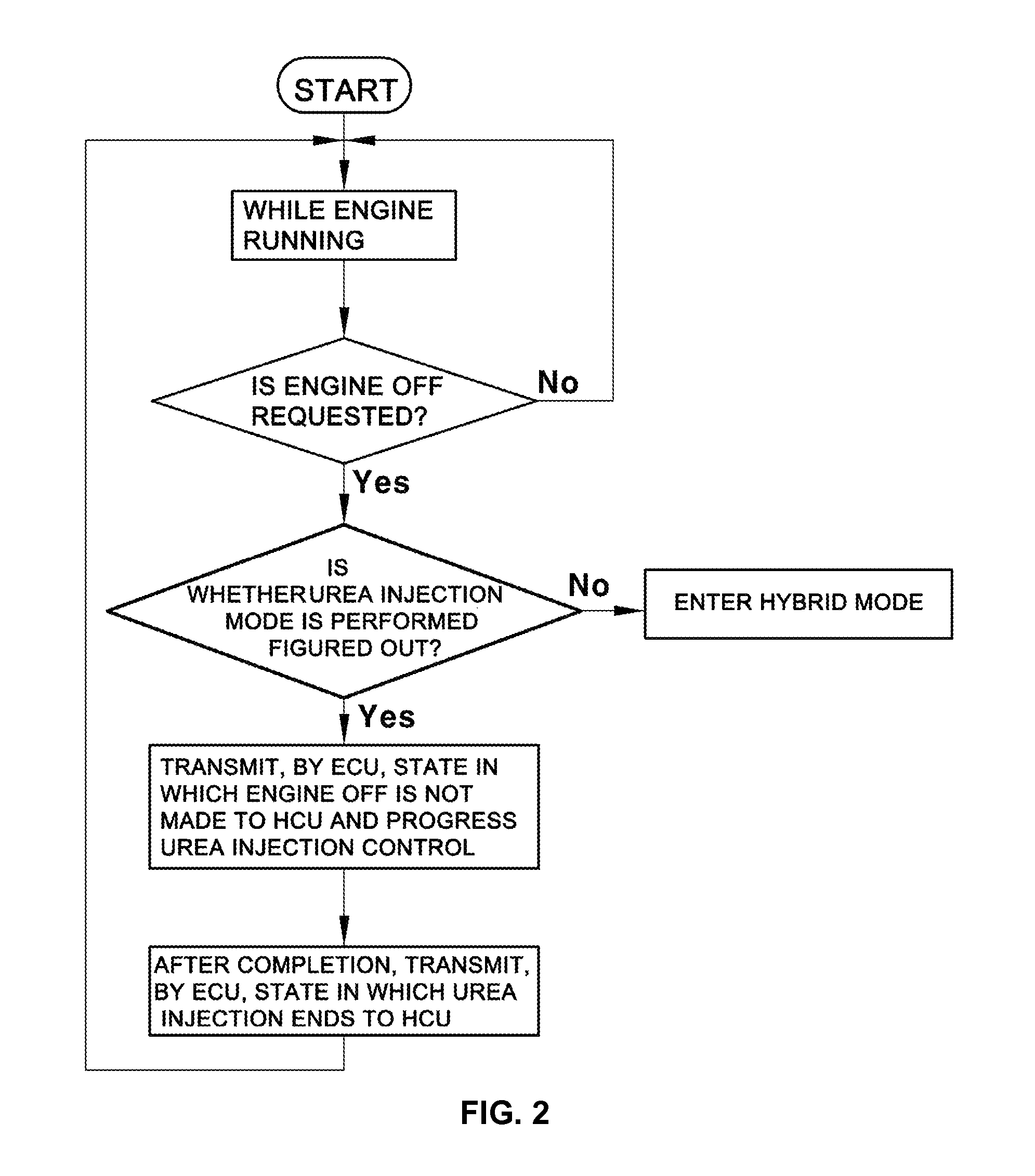

System for improving exhaust gas purifying performance of diesel hybrid electric vehicle

InactiveUS20160082949A1Improve exhaust gas purification performanceImprove performanceHybrid vehiclesElectrical controlNitrogen oxideElectric vehicle

A system for improving exhaust gas purification performance of a diesel hybrid electric vehicle in which an SCR catalyst is equipped in an exhaust line to reduce nitrogen oxide within exhaust gas may include a hybrid control unit configured to request an engine control unit to turn off an engine to make the diesel hybrid electric vehicle enter a hybrid driving mode, and an engine control unit configured to determine whether urea is required to be injected into a front of the SCR catalyst when receiving a request of an engine off from the hybrid control unit.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com