Porous Coated Member and Manufacturing Method Thereof Using Cold Spray

a coating member and coating technology, applied in the field of coating members, can solve the problems of thermal impact on the mother material, process limits in application, stress may occur,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

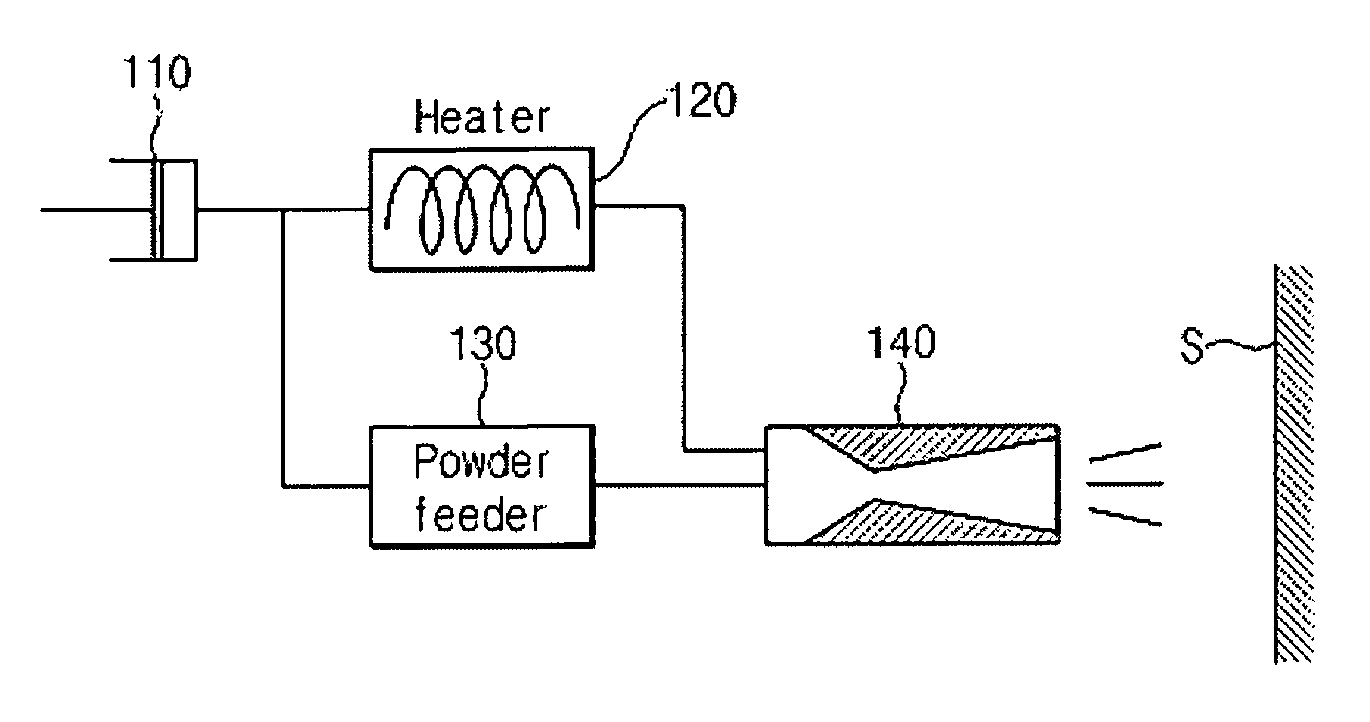

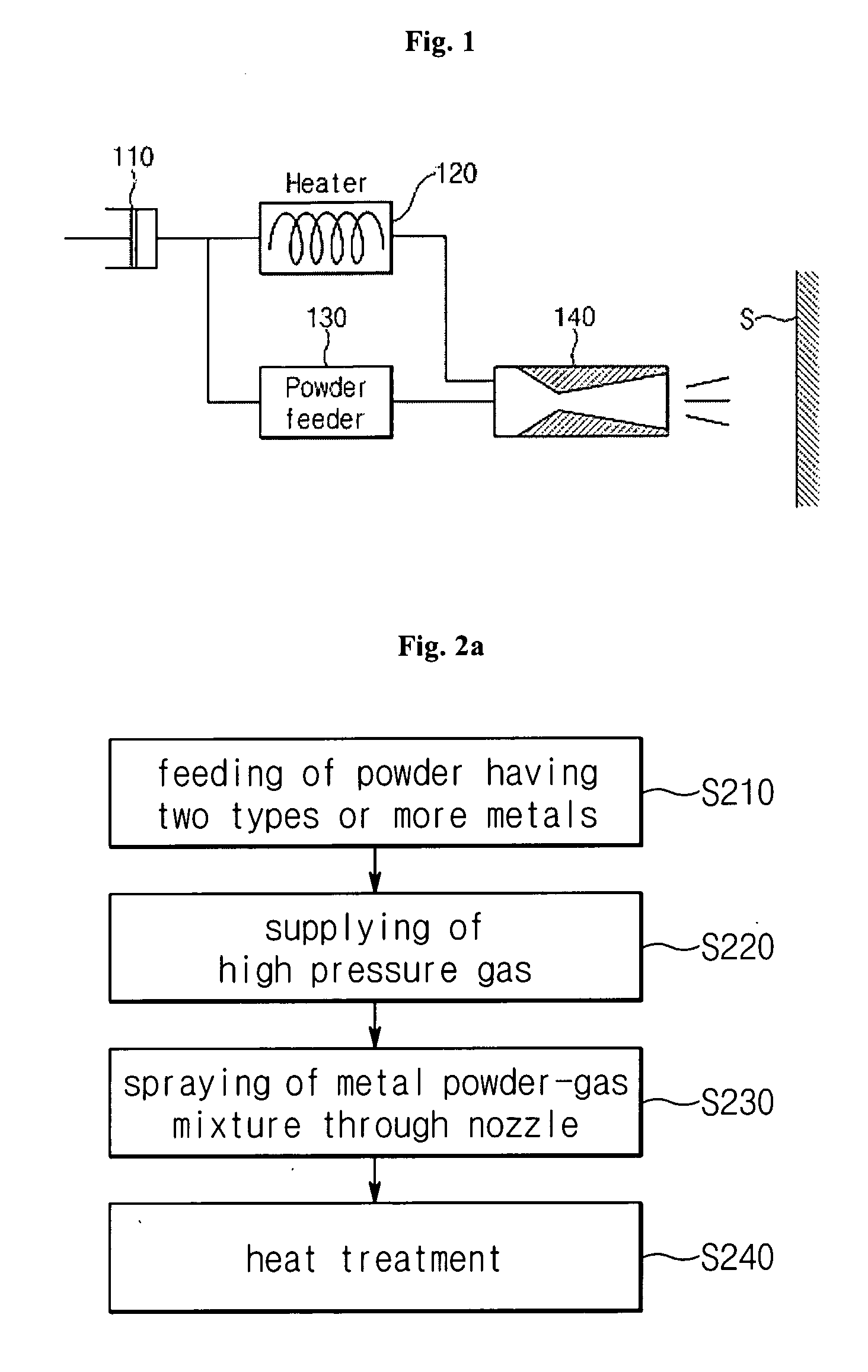

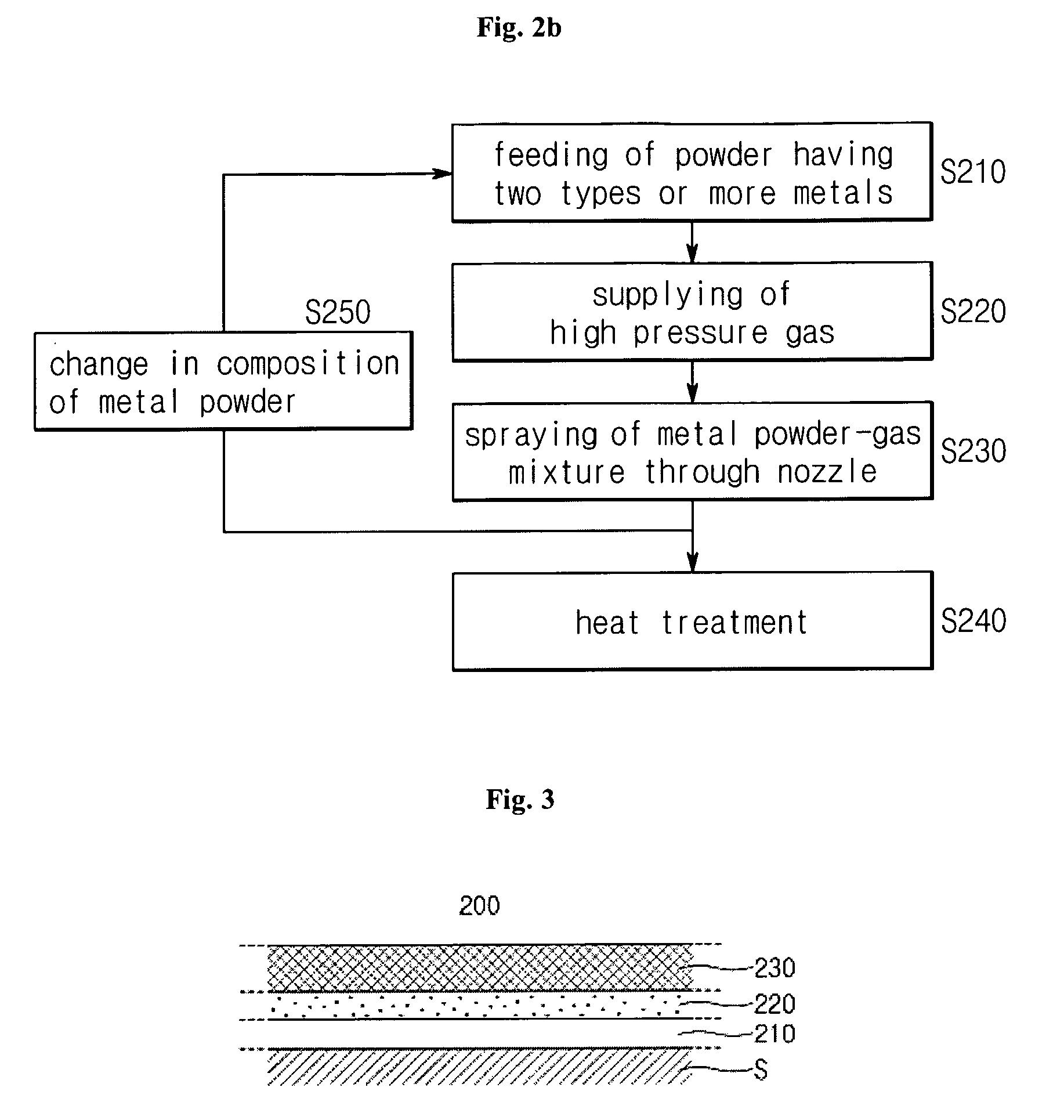

Method used

Image

Examples

example 1

[0061] Mixture powder which includes Al powder and AlMg powder (eutectic temperature of about 400° C.) in a weight ratio of 50:50 (i.e. 0.5Al-0.5AlMg) and air at 7 atm were fed into a spraying nozzle to be applied on an aluminum substrate.

[0062] The resulting coating was heat treated at about 620° C. for 1 hour. The heat treated substrate was cut and polished, and cross section was observed using an optical microscope. FIG. 4 illustrates a picture of the cut surface of the resultant substrate.

[0063] From FIG. 4, it can be seen that the coating layer is nicely attached to the Al substrate. An interface between the Al substrate and the coating layer is apparent due to pores (black portions) trapped in the coating layer. The pores were not observed during the coating, but were generated after the heat treatment.

example 2

[0064] A coating layer was produced under the same conditions as example 1 except that the weight of AlMg increased in the mixture powder so that the metal powder had a composition of 0.3Al-0.7AlMg. The coating layer was heat treated, a section was observed using an optical microscope, and the results are shown in FIG. 5.

[0065] In comparison with FIG. 4, from FIG. 5, it can be seen that the size of the pore is increased, and an increase in porosity can be confirmed even with the naked eye.

example 3

[0066] A coating layer was formed in such a way that Al powder / AlMg powder / Al powder / AlMg powder / Al powder were sequentially layered. The remaining coating conditions were the same as example 1. Subsequently, the resulting coating layer was heat treated at 620° C. for 1 hour.

[0067]FIG. 6 is an optical microscope picture showing a section of a heat treated substrate. As shown in the drawing, pores were scarcely observed in the Al layer, but frequently observed in the AlMg layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com