Patents

Literature

620 results about "Porous coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

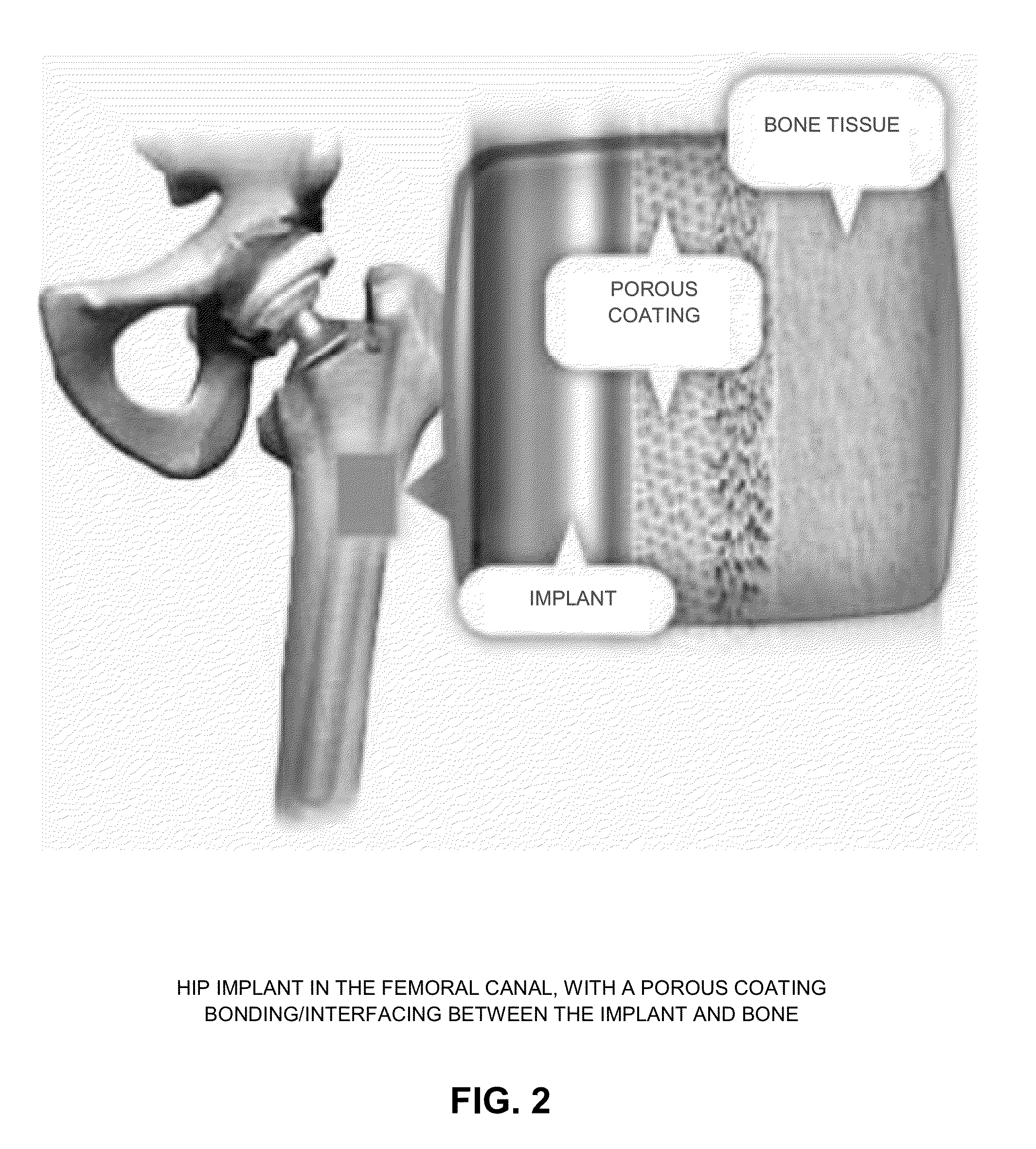

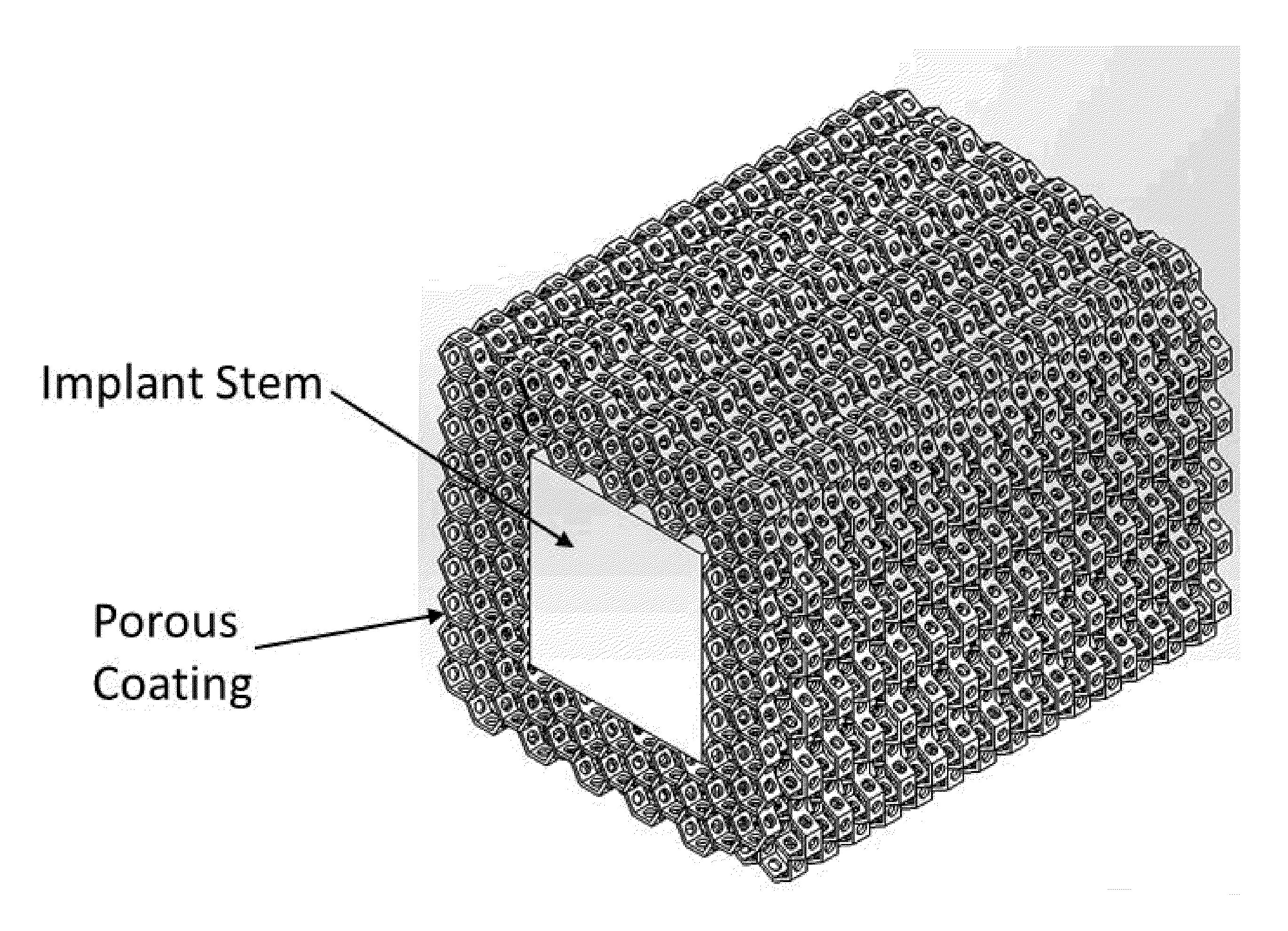

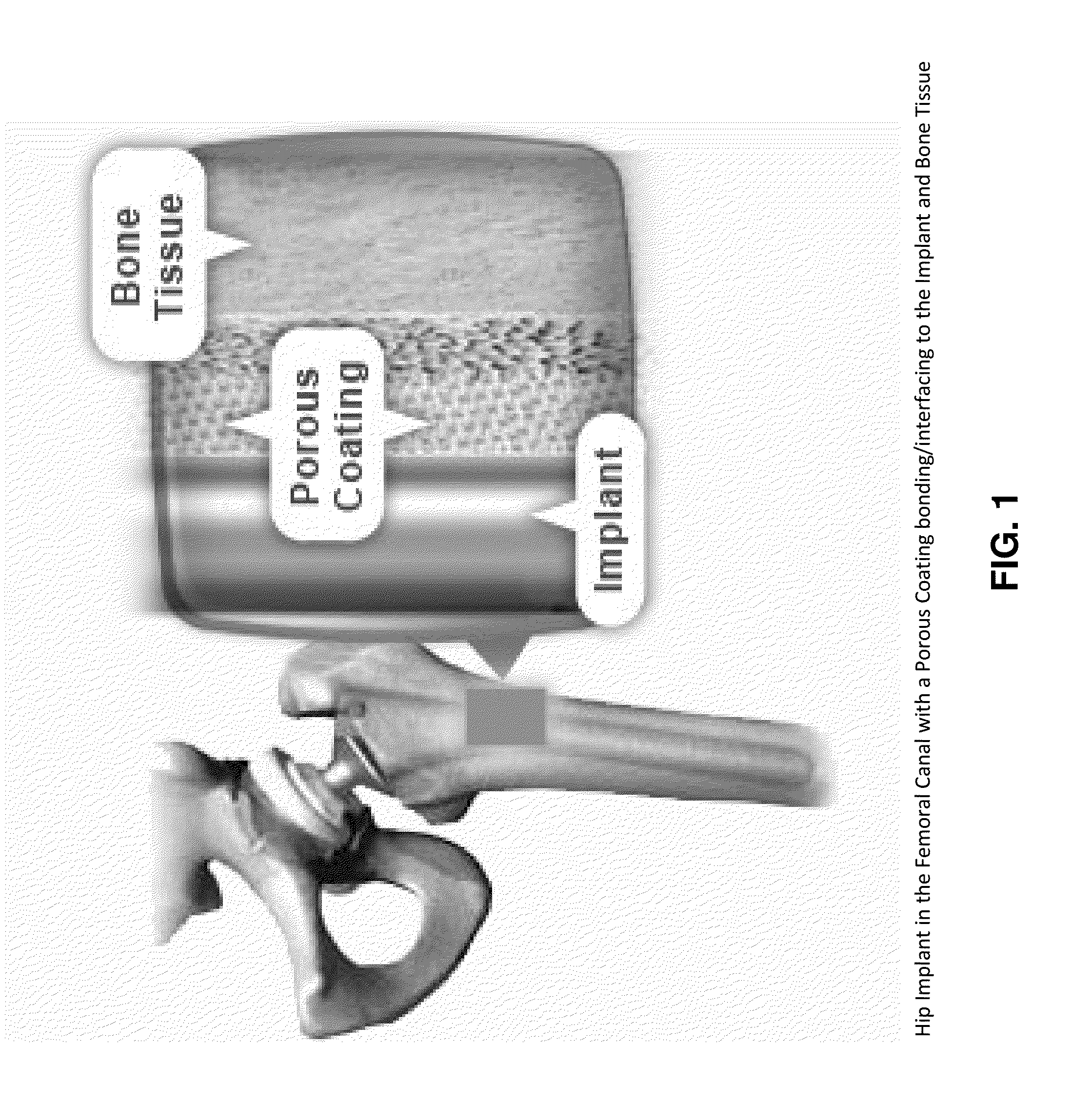

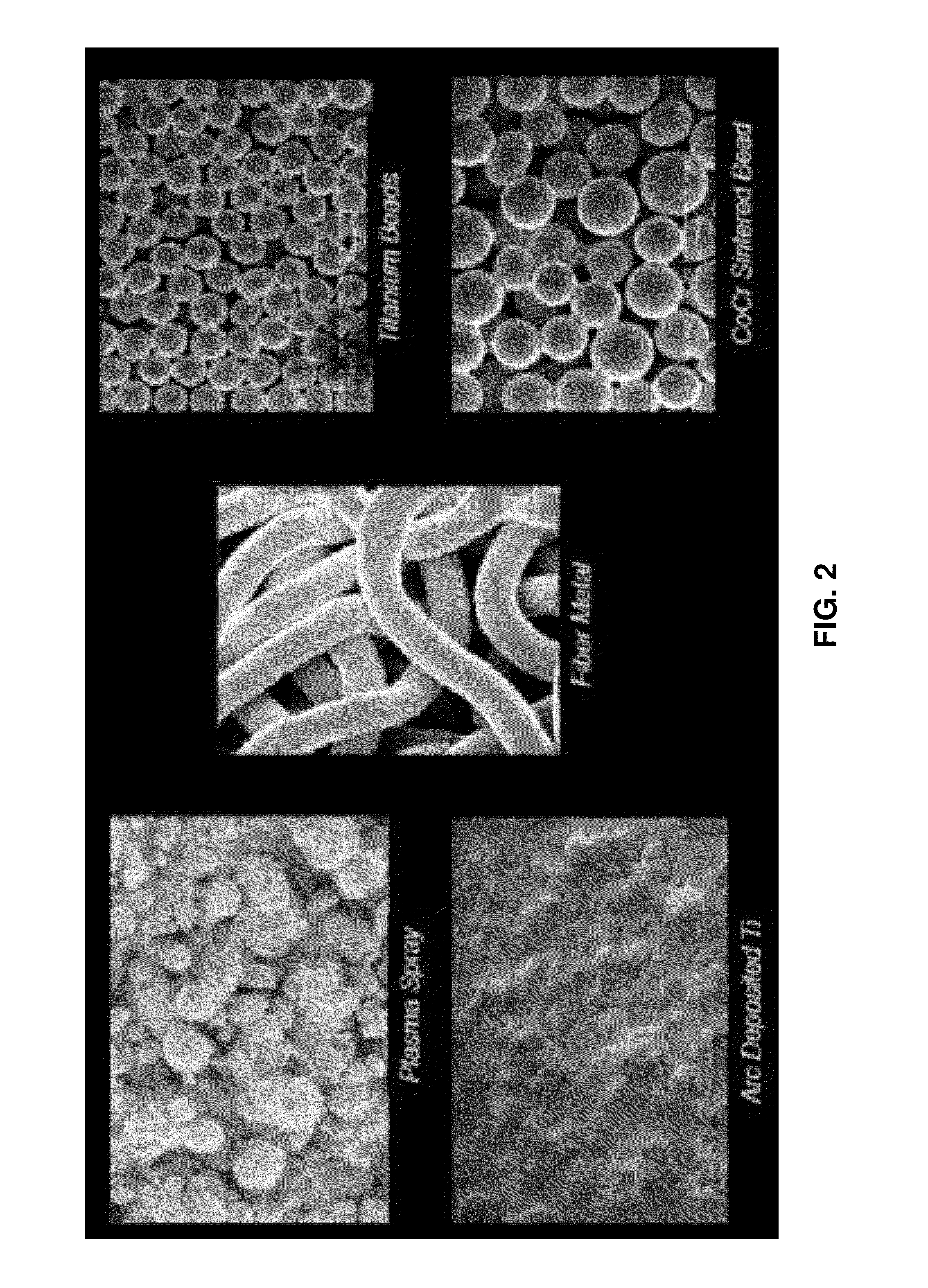

A porous coating is often applied to medical devices to enhance the fixation of an implant. Newer technologies also allow direct integration of porous structures in the base materials of devices.

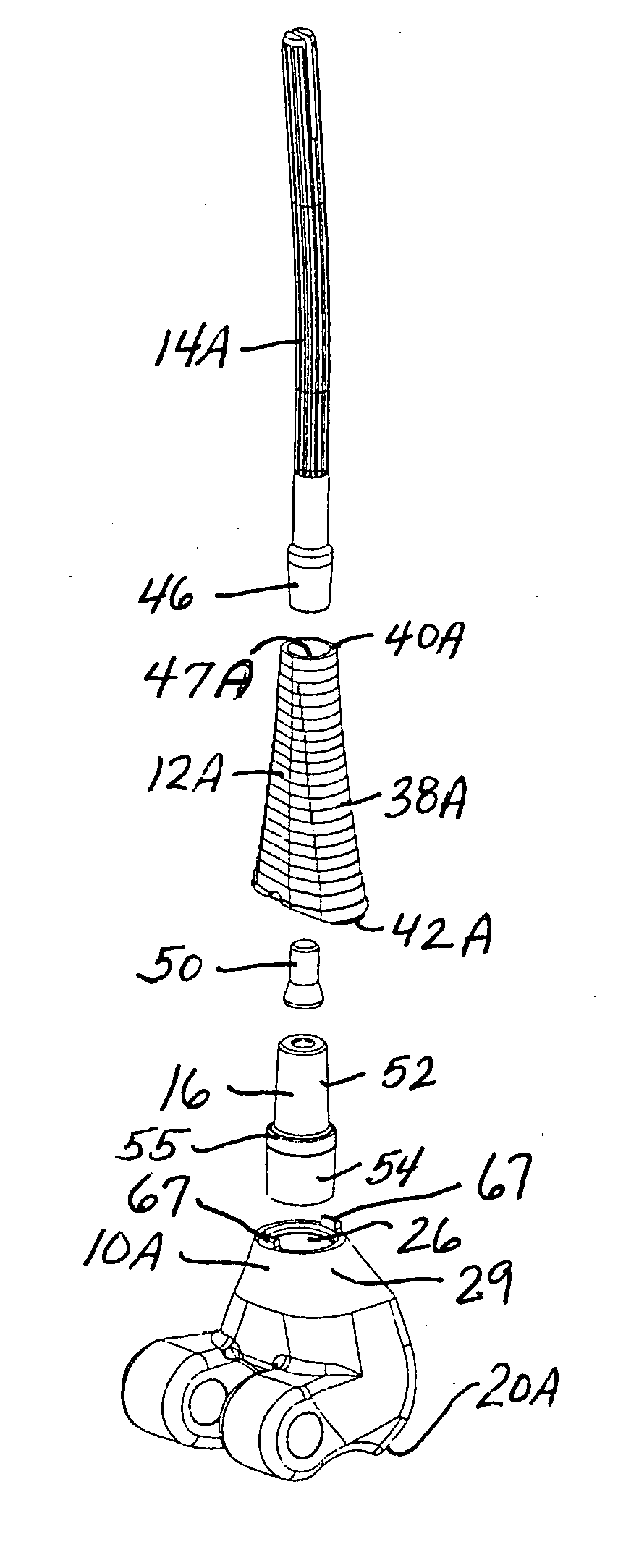

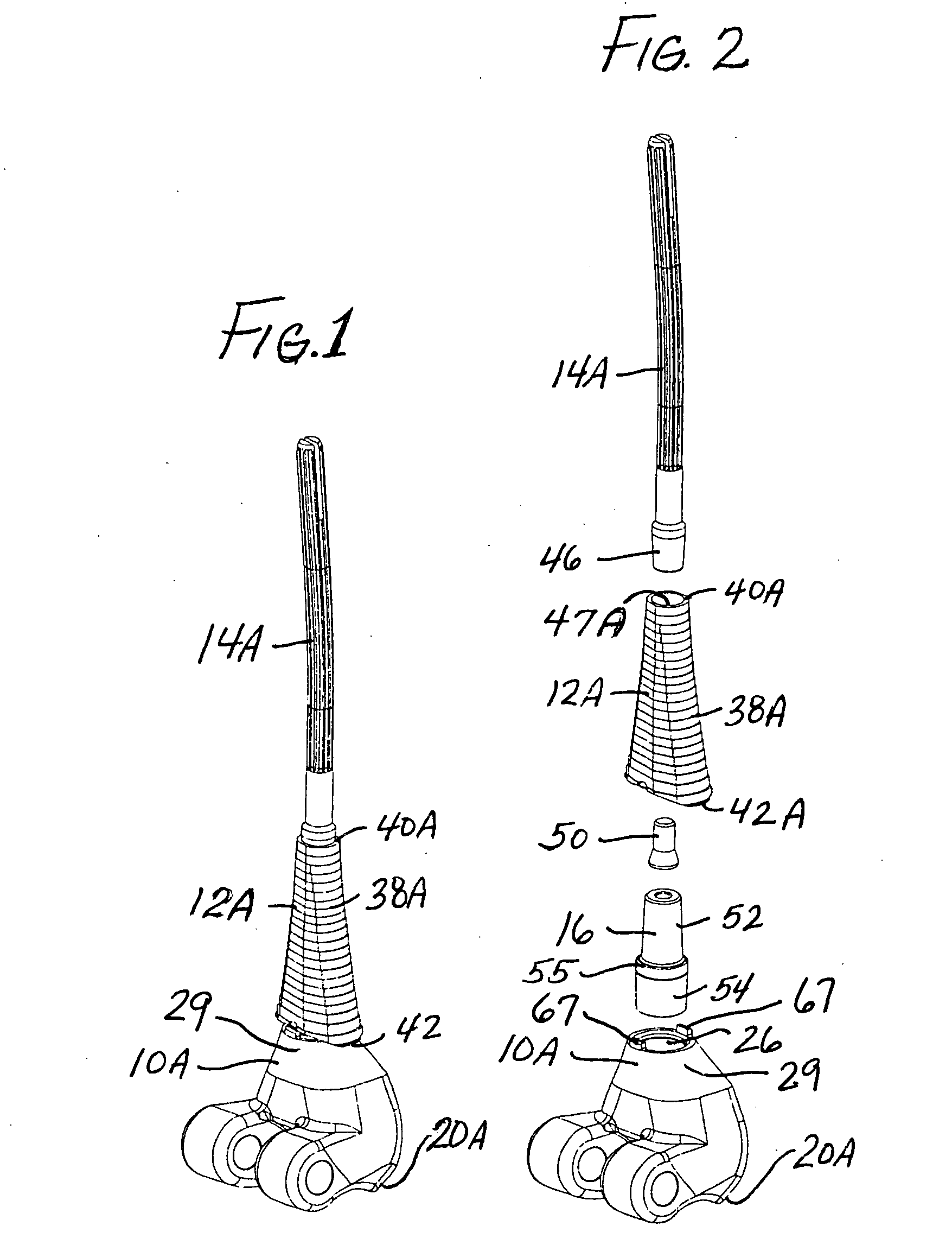

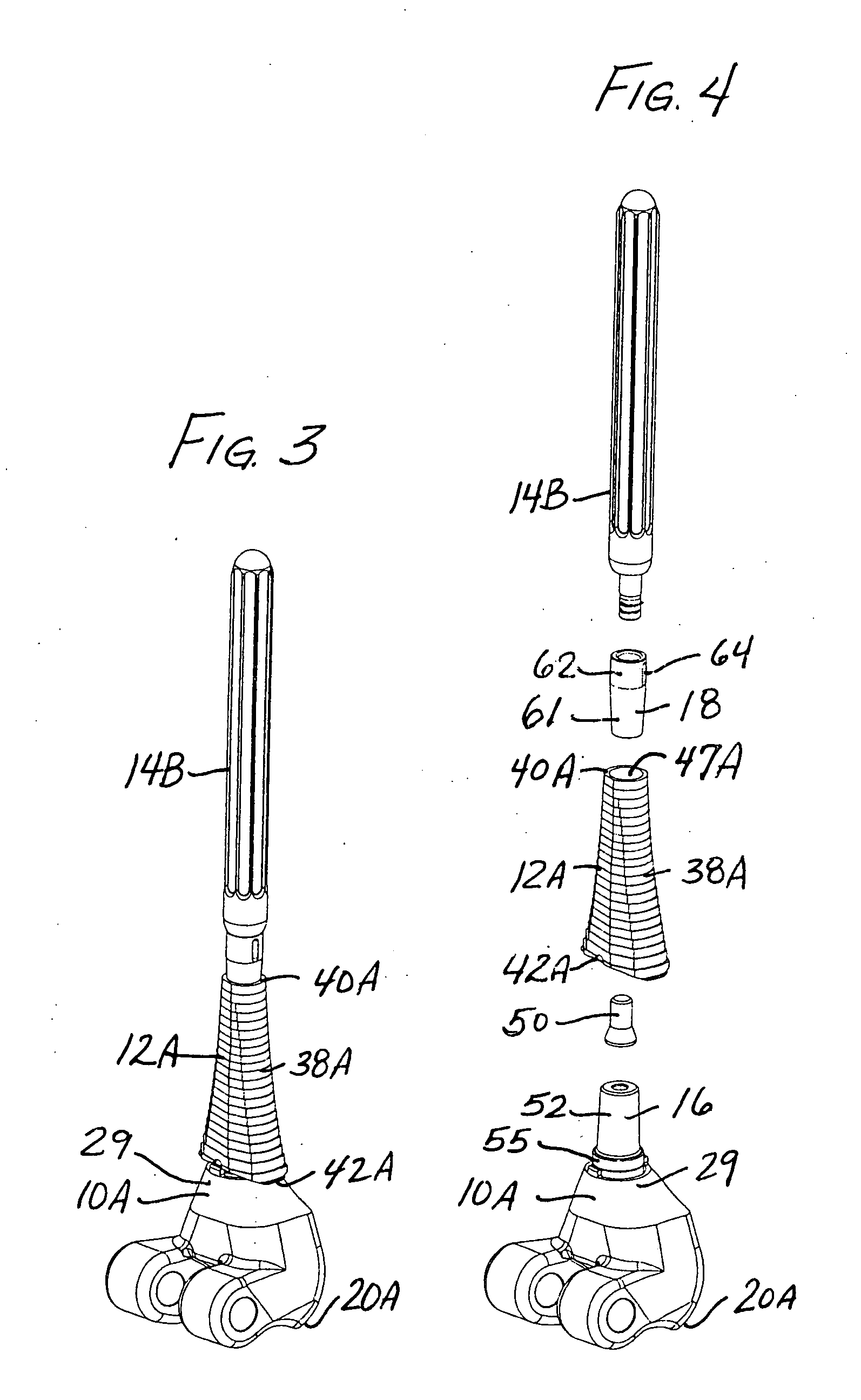

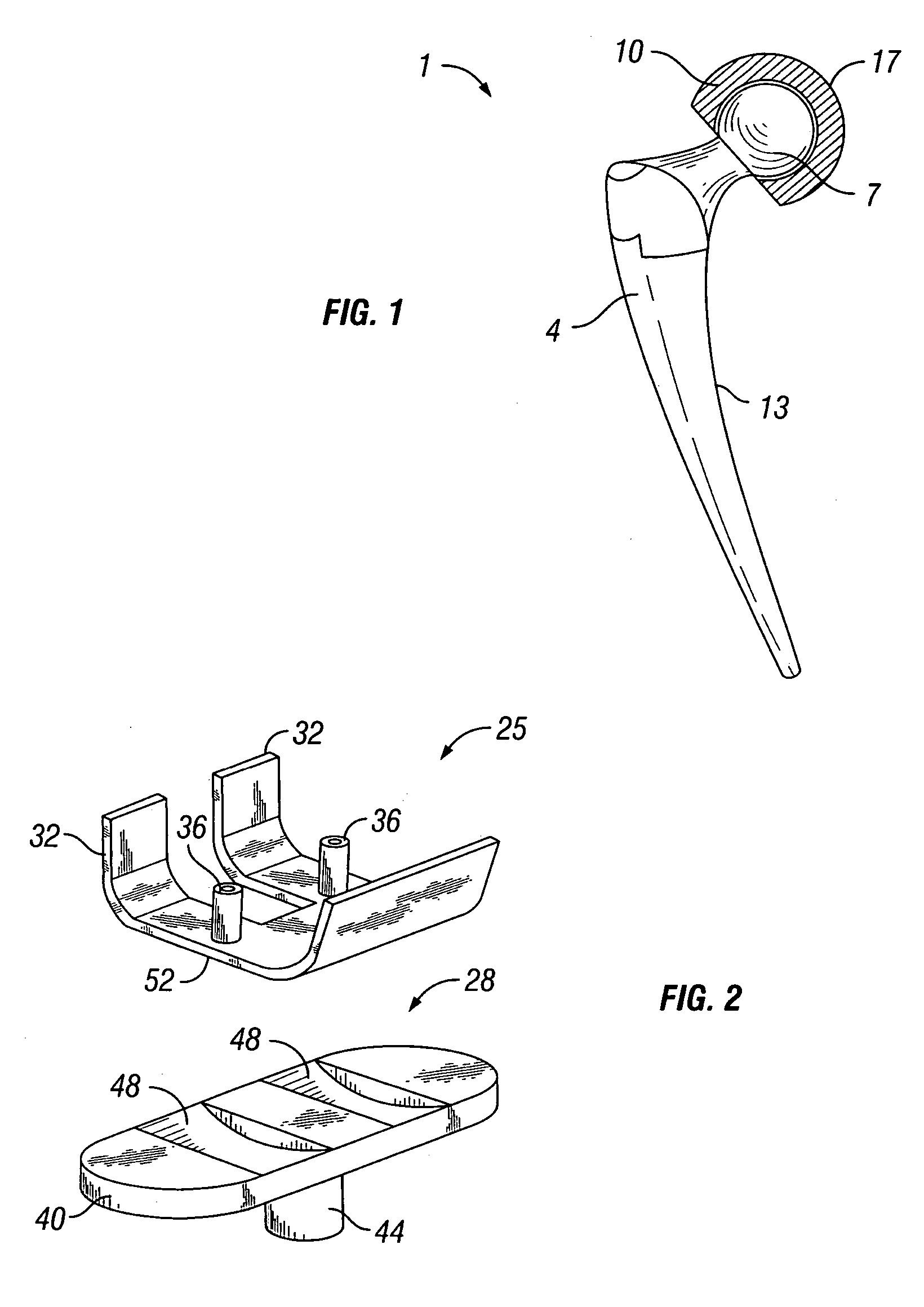

Modular implant system with fully porous coated sleeve

A modular knee implant system allows a surgeon to select between several different styles of distal femoral implant components and several different styles of stem extensions while also allowing for use of a metaphyseal component. The metaphyseal component can be a universal one that is usable with all of the styles of distal femoral implant components through use of an adapter. A second adapter allows for use of stem extensions with different types of connectors with the metaphyseal component. A separate metaphyseal component could also be provided with a distal Morse taper post to mate with a distal femoral component having a proximal Morse taper bore. The metaphyseal component may have an outer surface that is configured to maximize contact area with the patient's bone, and may have a surface finish over a substantial part of its overall length that is conducive to bone ingrowth.

Owner:DEPUY PROD INC

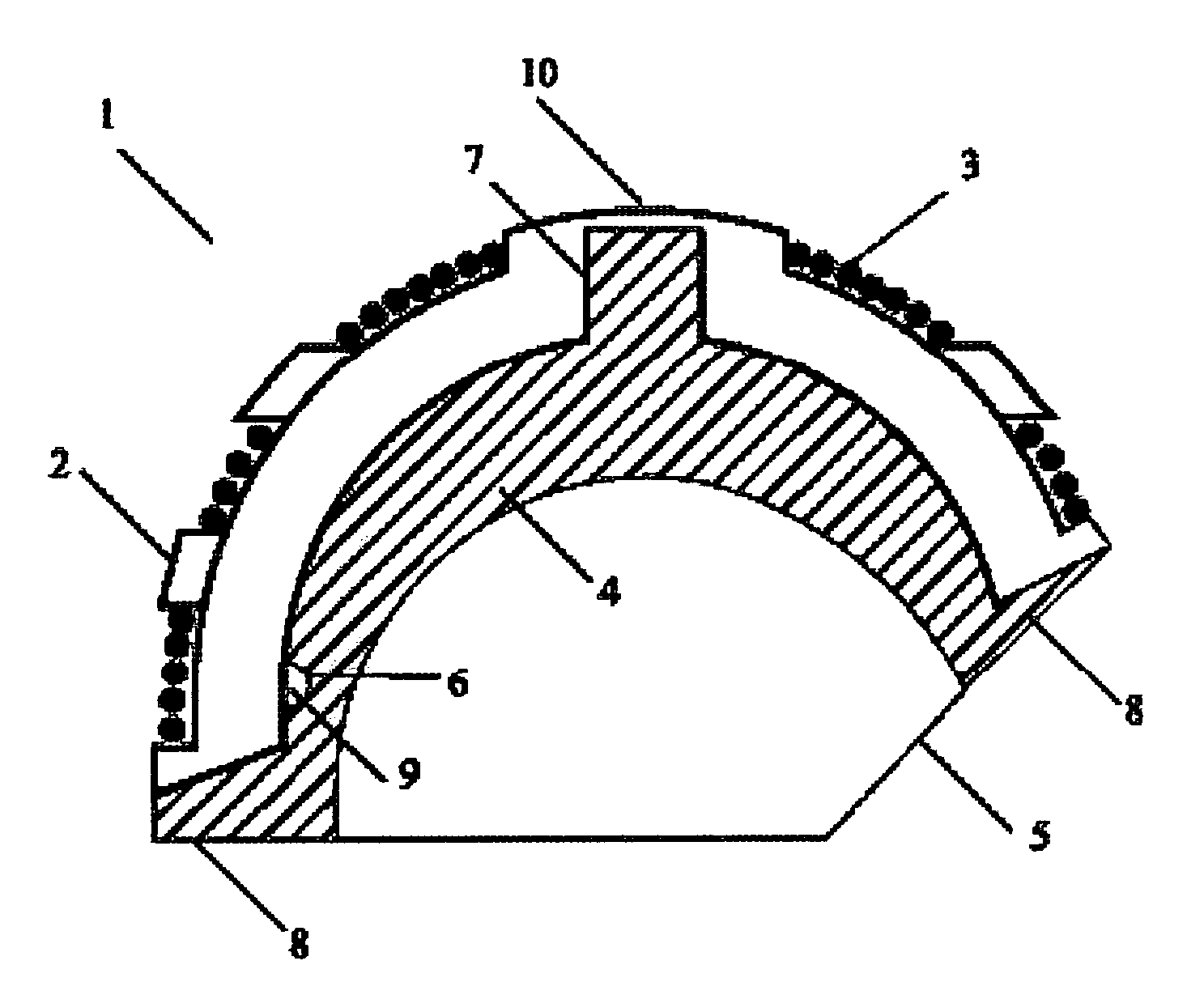

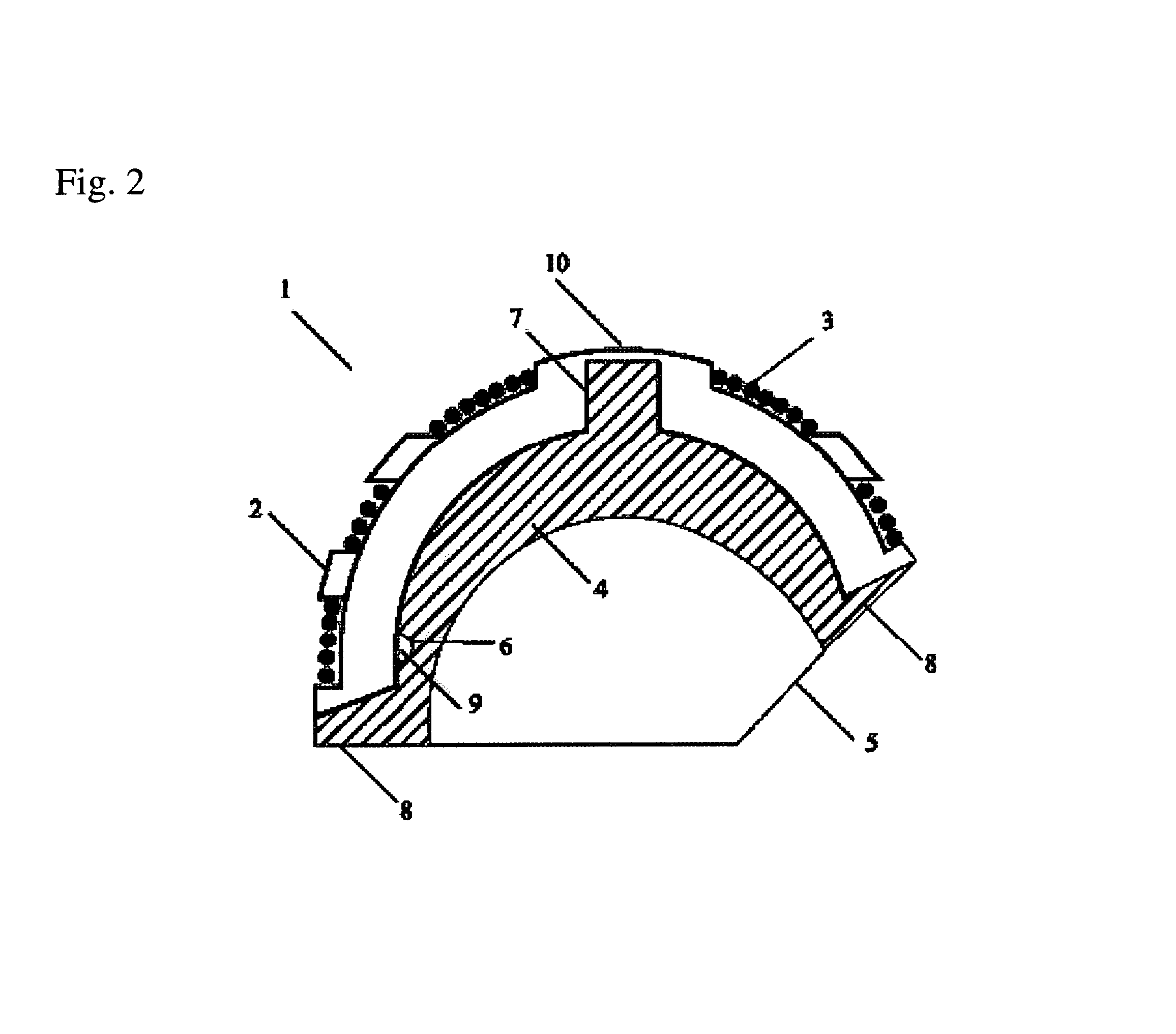

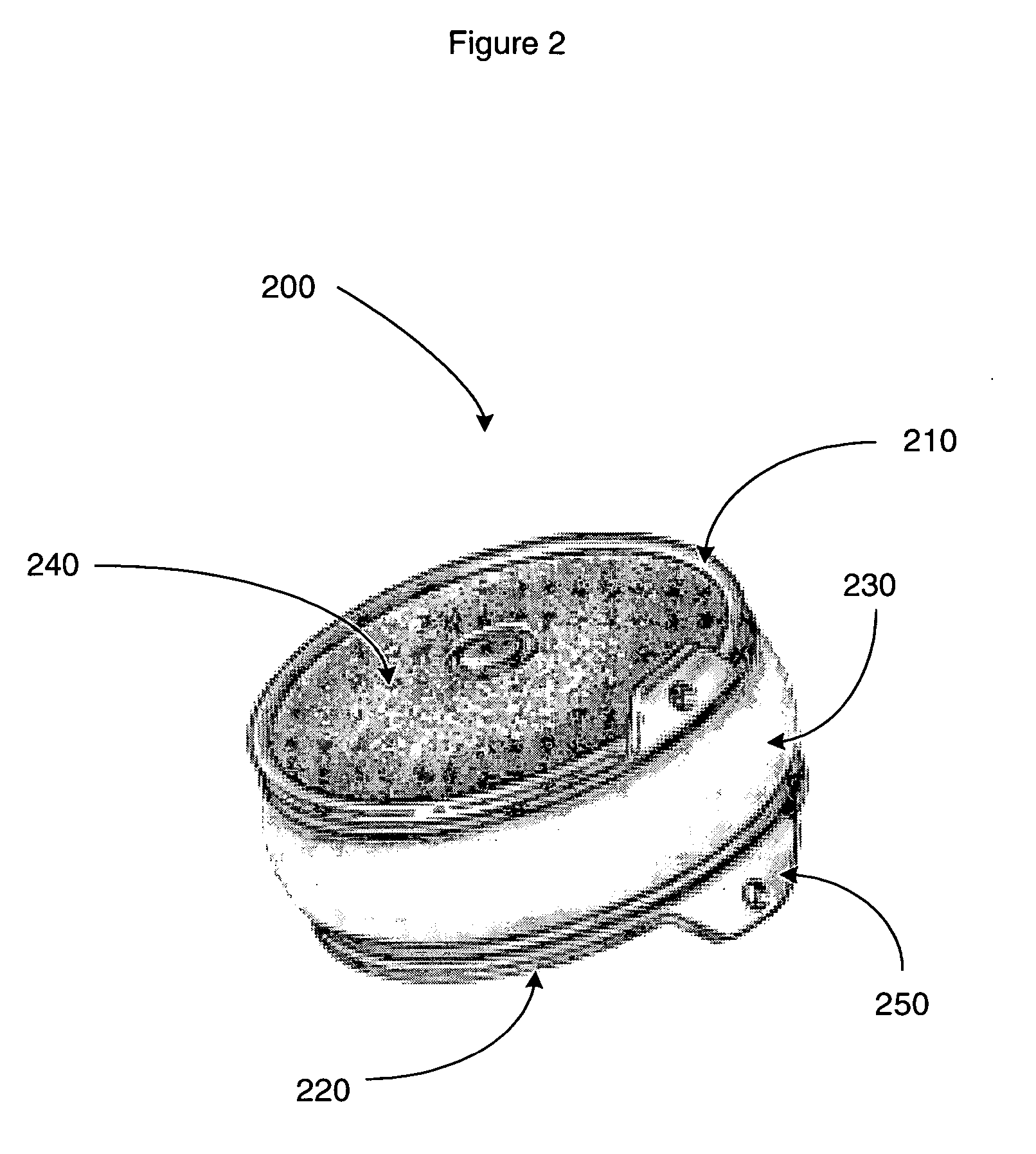

Canine acetabular cup

ActiveUS7169185B2Increase flexibilityLife maximizationSurgeryJoint implantsPorous coatingRight femoral head

Owner:IMPACT SCI & TECH

Coated vascular grafts and methods of use

InactiveUS6939377B2Provide strengthProvide compliancePharmaceutical containersPretreated surfacesPorous coatingMedicine

A vascular graft, such as an AAA stent graft, includes a core zone of PET fabric with a non-porous coating comprising a polyurethane, such as Thoralon®, disposed on at least one surface. The coating provides a barrier to prevent short and long term leakage of fluids through the pores of the PET fabric core zone. A method for sealing the pores of a porous PET graft includes the step of coating at least one surface of said graft with at least one polyurethane, or mixtures and combinations thereof. Preferably, the coating is Thoralon®. A method for making a vascular prosthesis includes the steps of providing a core zone of PET fabric, and coating at least one surface of the core zone with at least one polyurethane, or mixtures and combinations thereof, such as Thoralon®. Finally, a method of repairing or treating a defective vessel includes the step of reinforcing or replacing the defective vessel with a graft according to the invention.

Owner:TC1 LLC

Porous coatings for drug release from medical devices

InactiveUS20050079199A1Increase ratingsIncrease load capacityWound drainsSurgeryPorous coatingSurface layer

Extravascular implantable medical devices are described. The devices include a polymeric layer comprising a polymeric matrix and pores. Therapeutic agent is loaded in the matrix, in the pores, or in the matrix and the pores. The devices include a structural surface layer. Additional therapeutic agent may be loaded in or on the surface layer. The devices may also include one or more intermediate layer, into or onto which additional therapeutic agent may be loaded.

Owner:MEDTRONIC INC

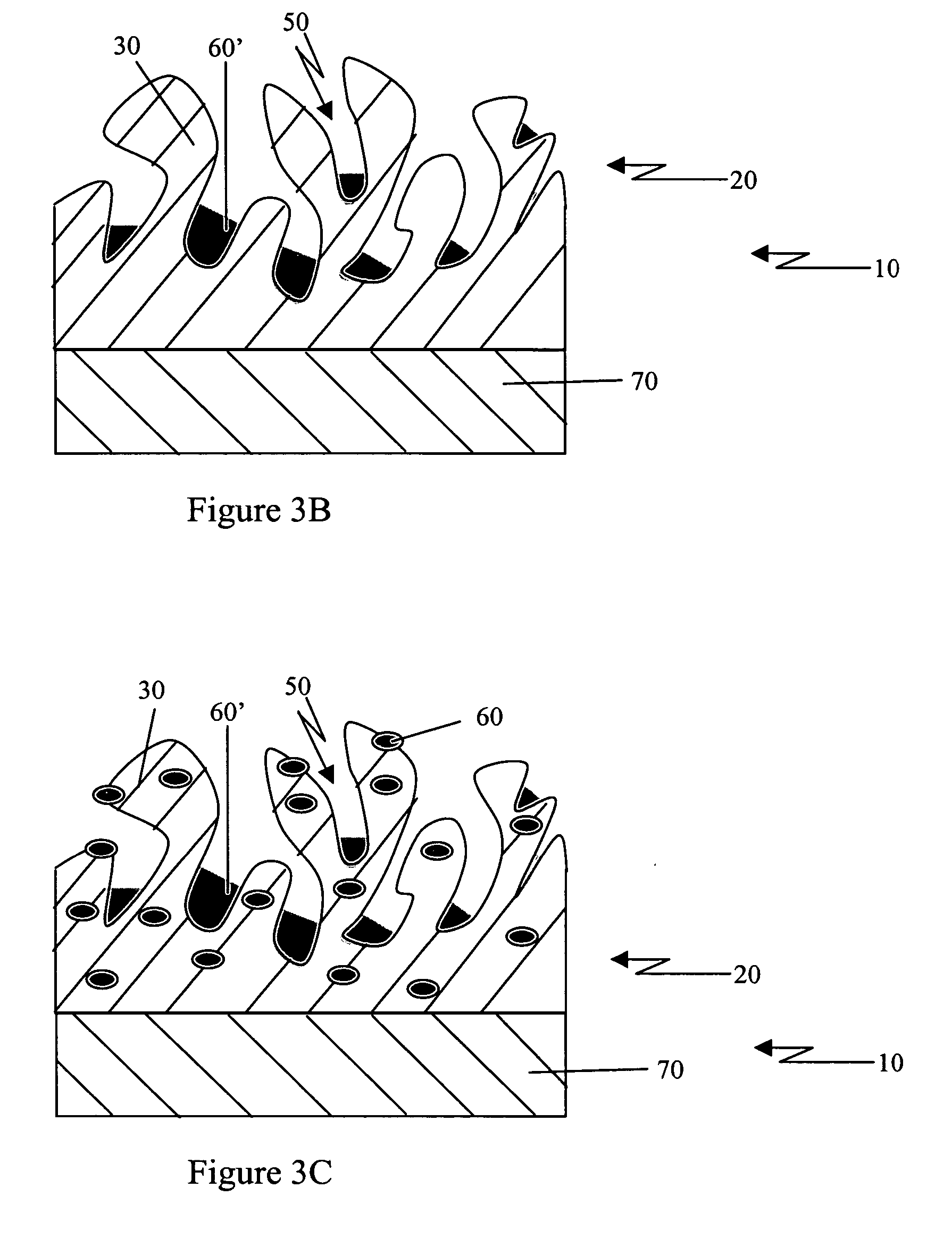

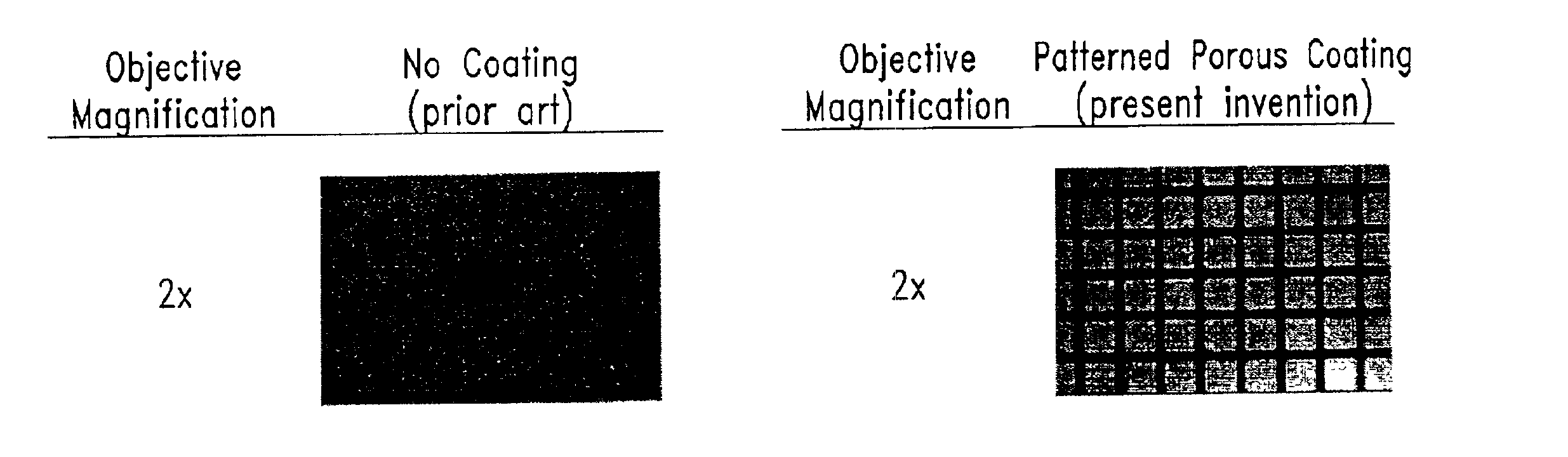

Porous coatings bearing ligand arrays and use thereof

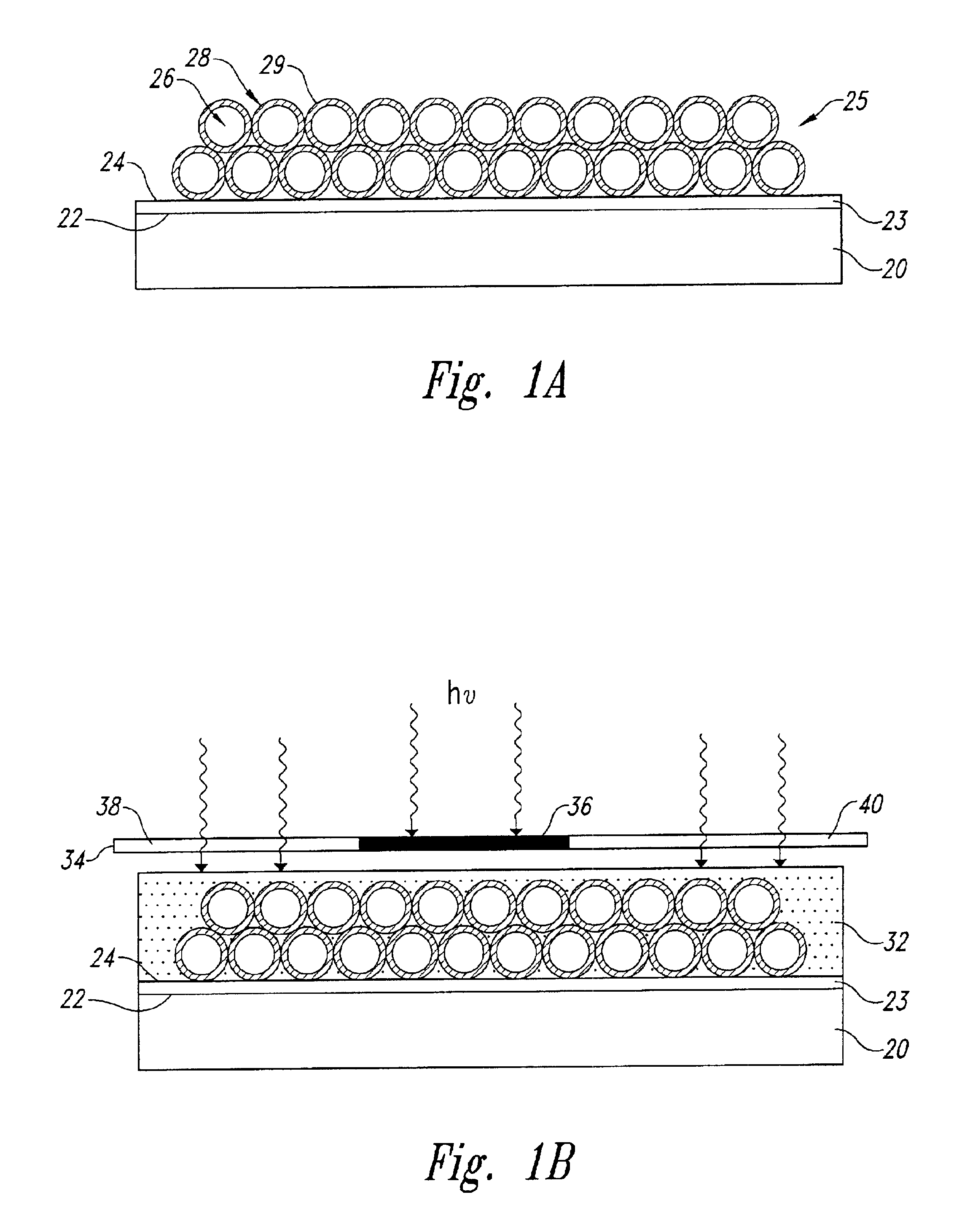

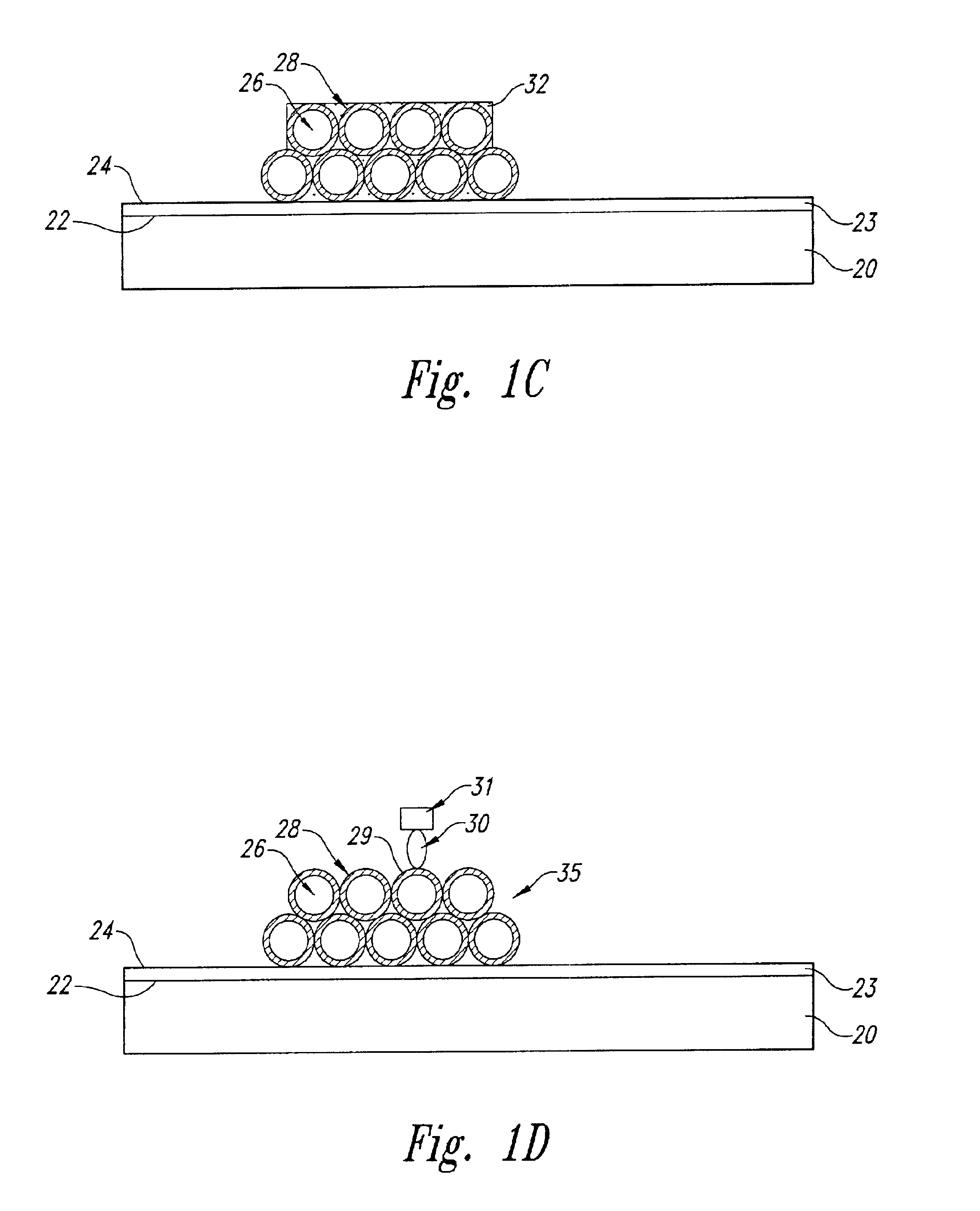

InactiveUS6951682B1Uniform thicknessHigh coating strengthBioreactor/fermenter combinationsMaterial nanotechnologyPorous coatingChemical synthesis

Articles comprising substantially uniform porous coatings, which may be photopatterned, are provided. The use of such porous coatings increases the surface density of attached compounds within, for example, ligand arrays prepared by methods such as regionally selective solid-phase chemical synthesis. Arrays prepared using the porous coatings may be used within a variety of diagnostic and drug discovery assays.

Owner:SYNTRIX BIOSYST

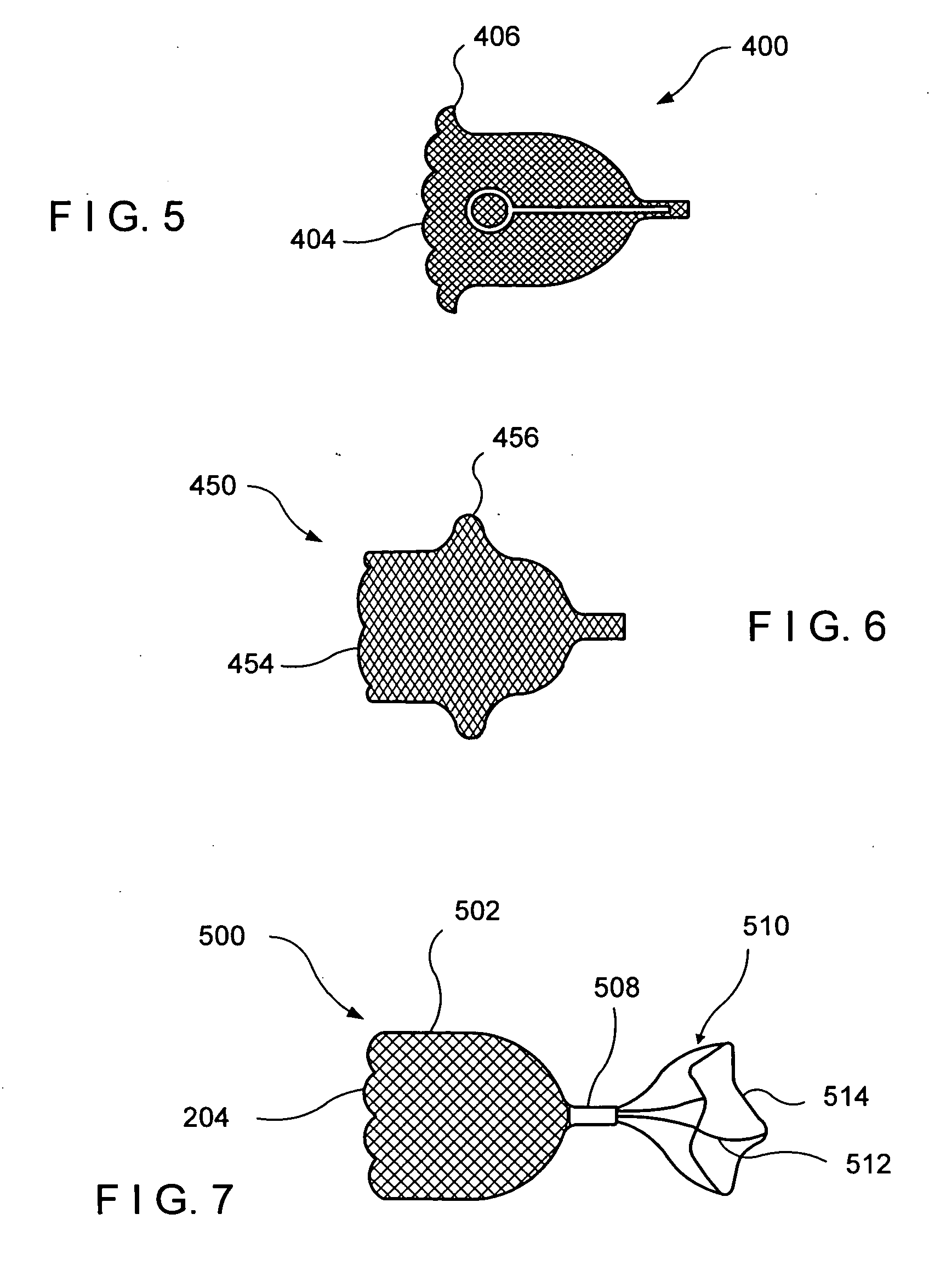

Bronchoscopic lung volume reduction valve

ActiveUS20070096048A1Permit flowAvoid flowStentsBronchiPorous coatingBronchoscopic lung volume reduction

A valve to perform lung volume reduction procedures is described. The valve is formed of a braided structure that is adapted for endoscopic insertion in a bronchial passage of a patient's lung. The braided structure has a proximal end and a distal end and is covered with a non porous coating adapted to prevent flow of air into the. A constricted portion of the braided structure is used to prevent flow of air through a central lumen of the structure, and to define at least one funnel shaped portion. The funnel shaped portion blocks the flow of air towards the constriction, i.e. towards the core of the lung. At least one hole is formed in the braided structure to permit flow of mucus from the distal end to the proximal end, to be expelled out of the lungs.

Owner:BOSTON SCI SCIMED INC

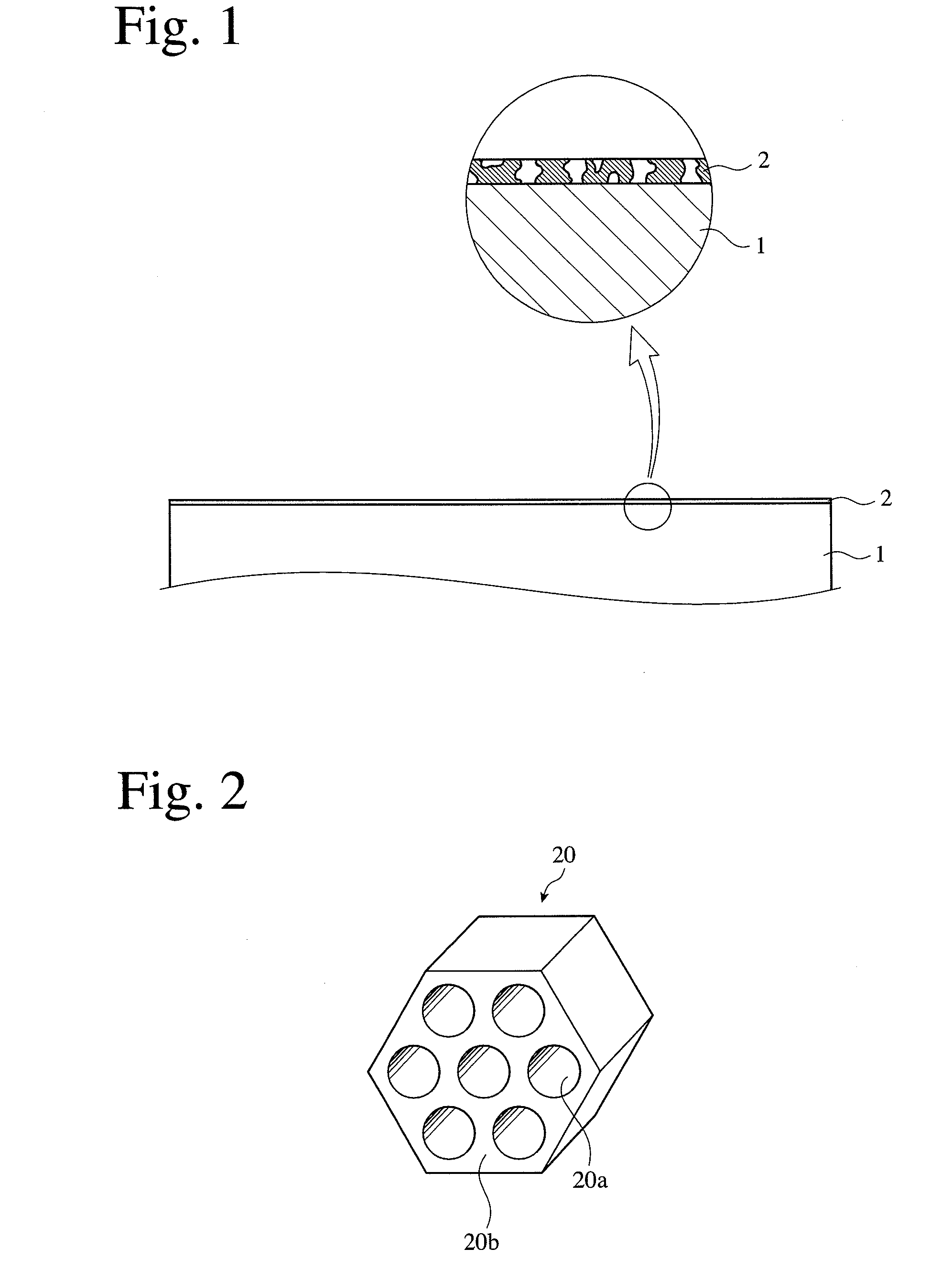

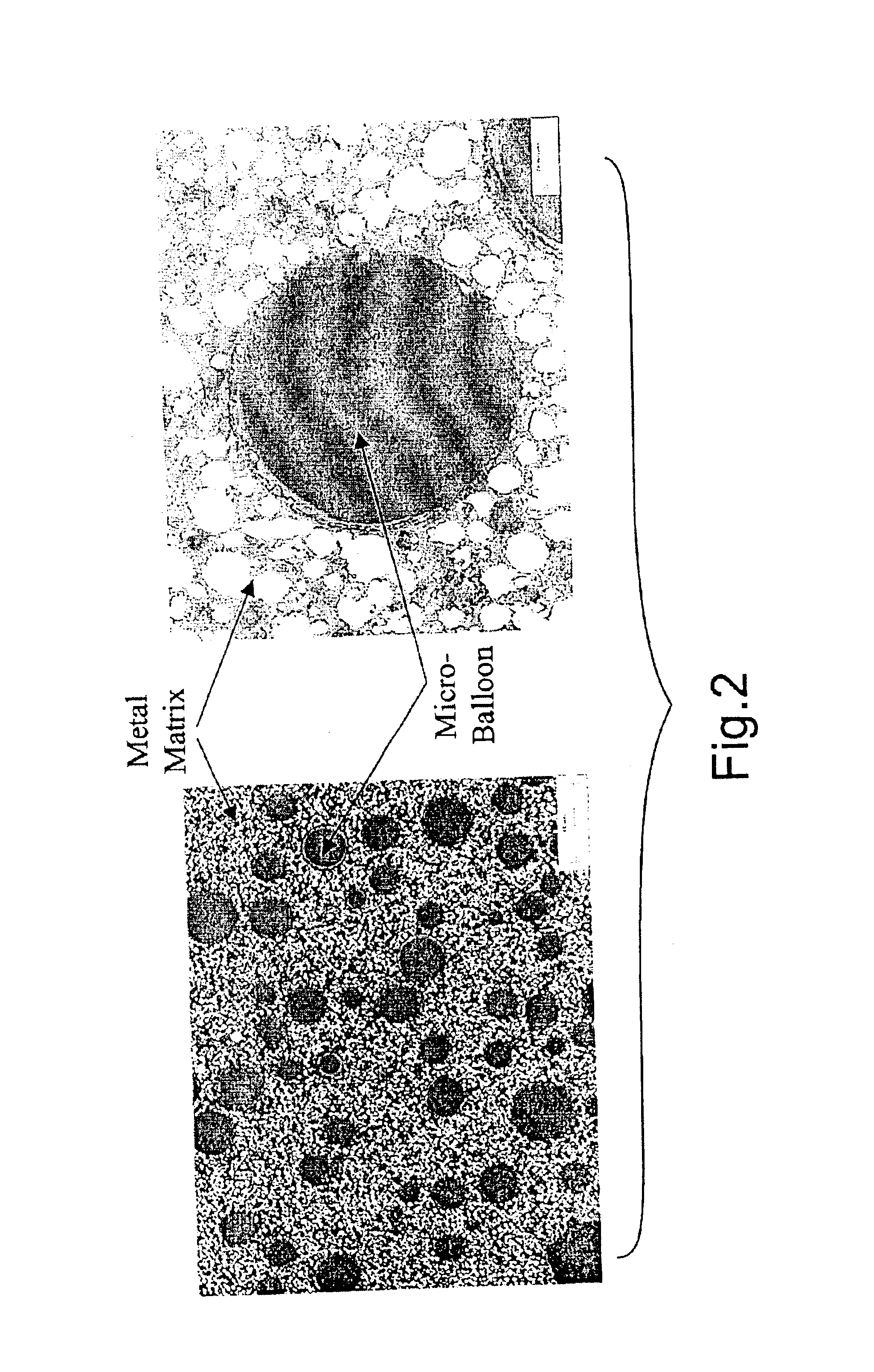

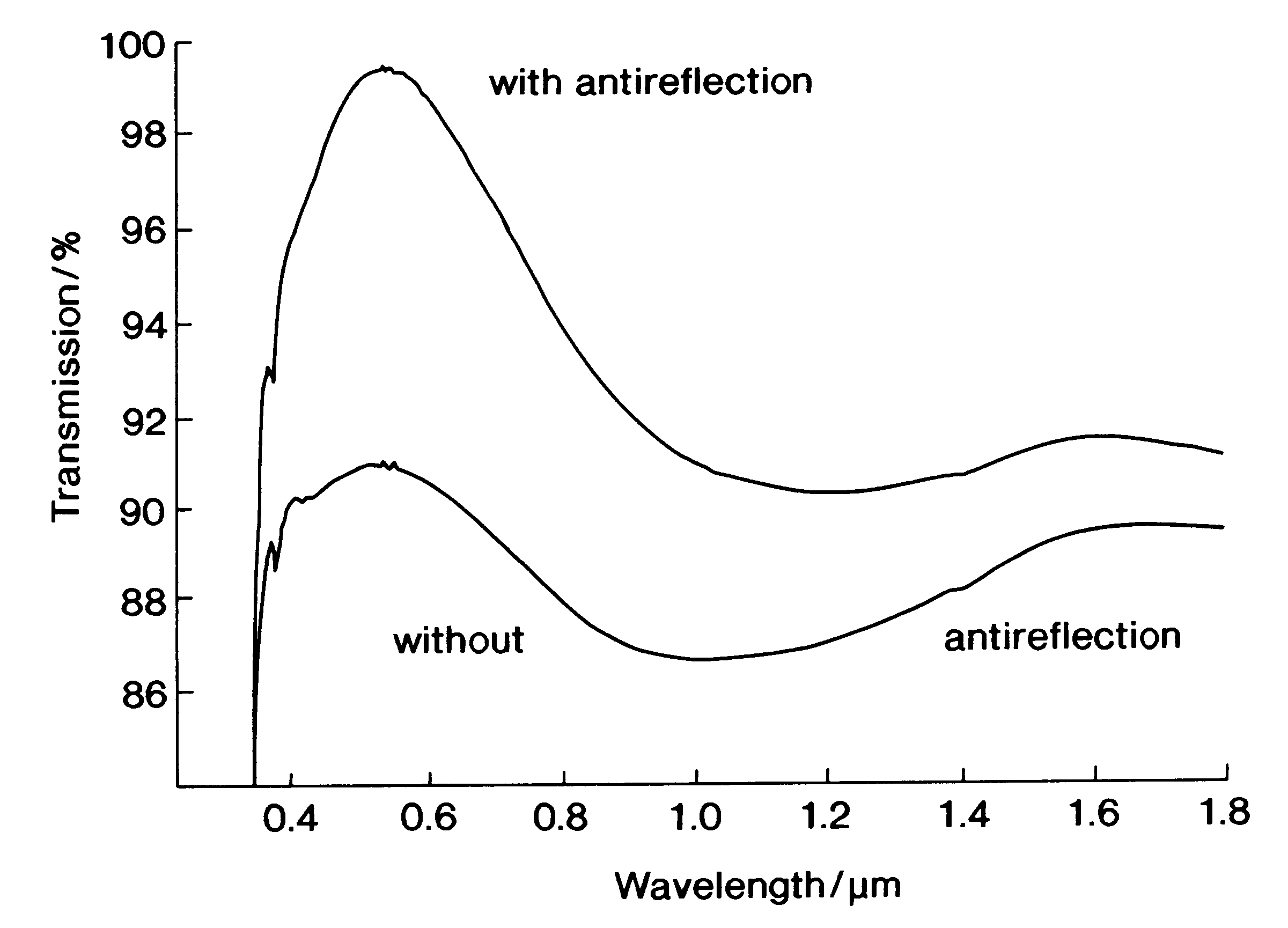

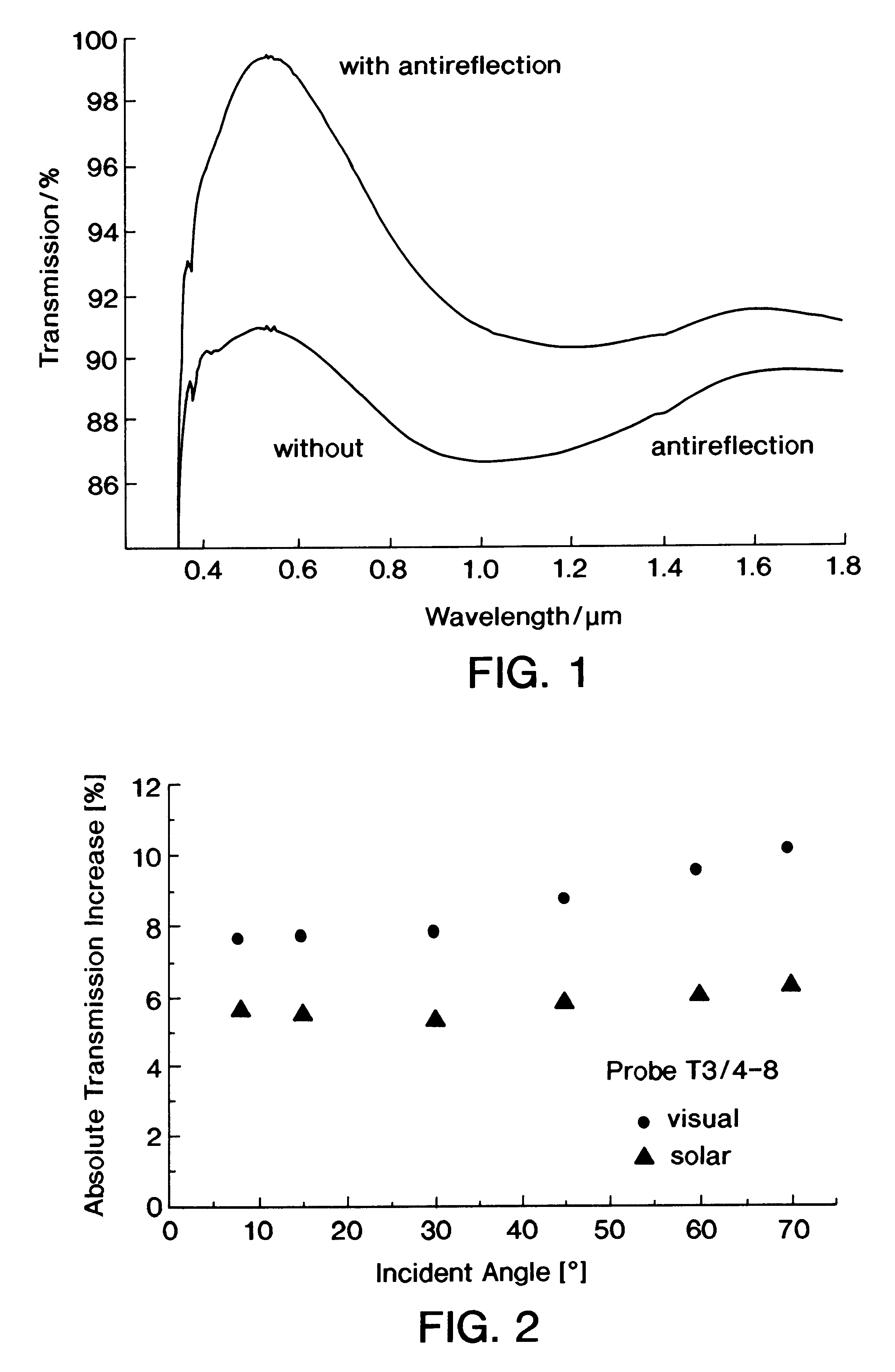

Method for forming mesoporous silica layer, its porous coating, Anti-reflection coating, and optical member

InactiveUS20100136319A1Low refractive indexLayered productsPretreated surfacesPtru catalystActive agent

A method for forming a mesoporous silica layer composed of nanometer-sized, mesoporous silica particles on an optical substrate or a dense layer formed thereon, comprising the steps of (1) hydrolyzing and polycondensing alkoxysilane in a solvent containing a catalyst, a cationic surfactant and a nonionic surfactant to prepare composites comprising nanometer-sized, mesoporous silica particles and these surfactants, (2) applying a solution containing the composites to the substrate or the dense layer, (3) drying the solution to remove the solvent, and (4) removing both surfactants by baking the resultant coating at 120-250° C. in an oxygen-containing gas atmosphere, or plasma-treating it using an oxygen-containing gas.

Owner:RICOH IMAGING COMPANY +1

Medical devices composed of porous metallic materials for delivering biologically active materials

InactiveUS20050266040A1Increase surface areaFacilitated releaseAntibacterial agentsBiocidePorous coatingInsertion stent

A medical device, such as a stent, for delivering a biologically active material to body tissue of a patient, and a method for making such a medical device are described. The medical device has a coating layer on its surface. The coating layer includes a metal having a plurality of pores and a biologically active material dispersed in the pores. The pores are connected to the outer surface of the coating layer. The coating layer may be formed by applying a coating composition comprising two or more metals (such as a gold and silver) to the surface of the medical device and removing one of the metals to form the porous coating layer. This coating layer may be radiopaque, and may be substantially free of a polymeric material. The coating layer of the disclosed medical device has an increased surface area and, thus, can be loaded with a greater amount of biologically active material than a medical device without such coating.

Owner:BOSTON SCI SCIMED INC

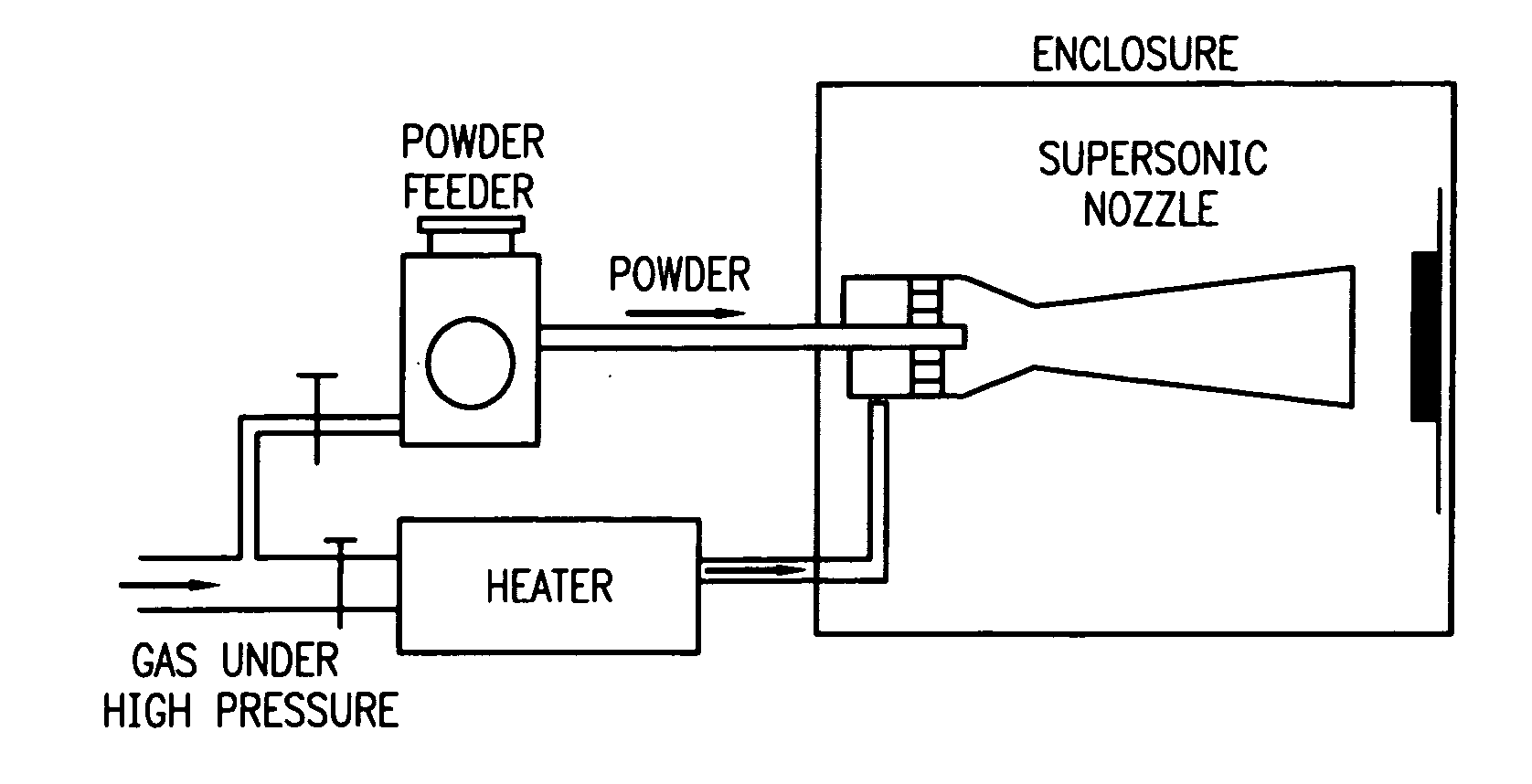

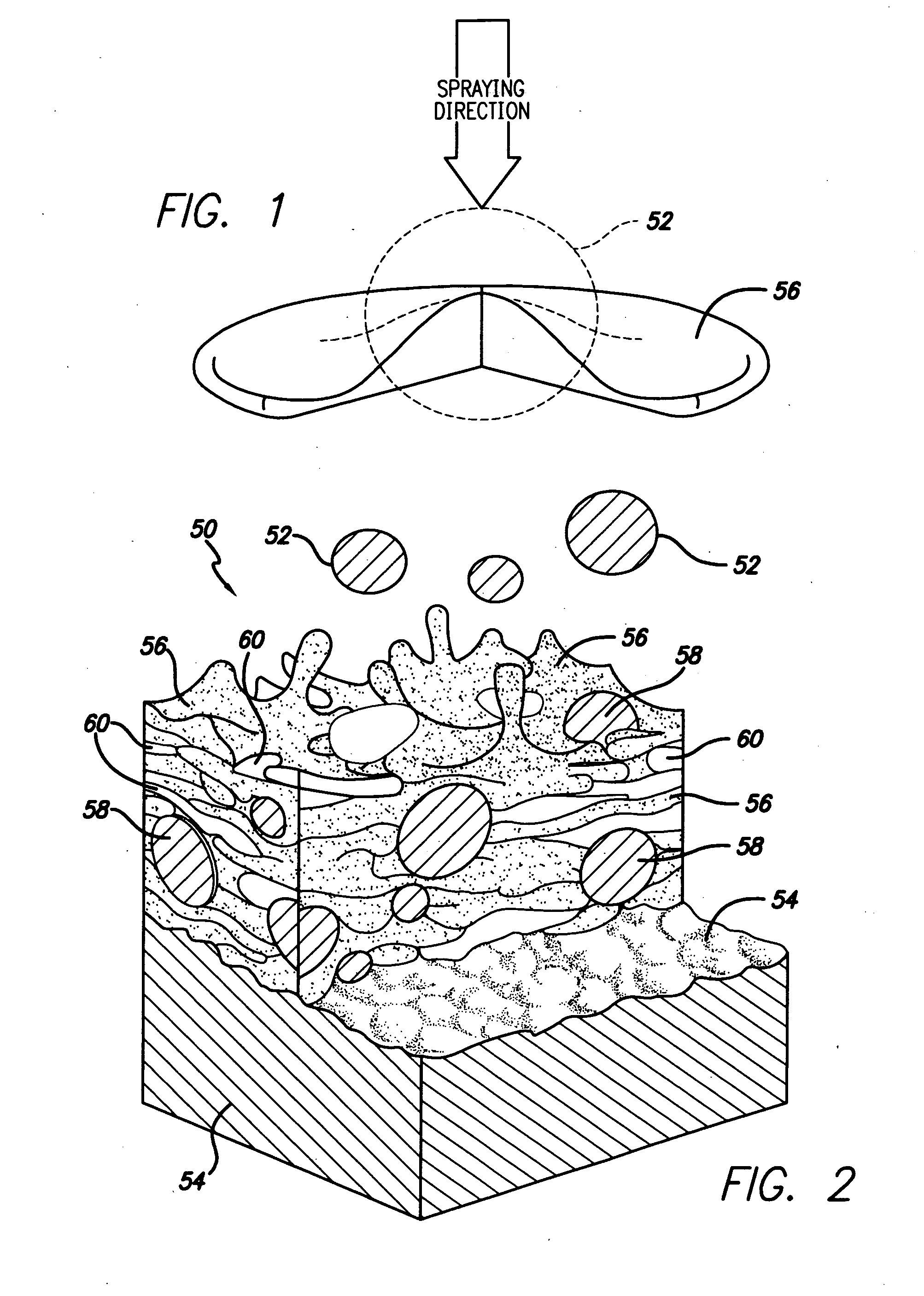

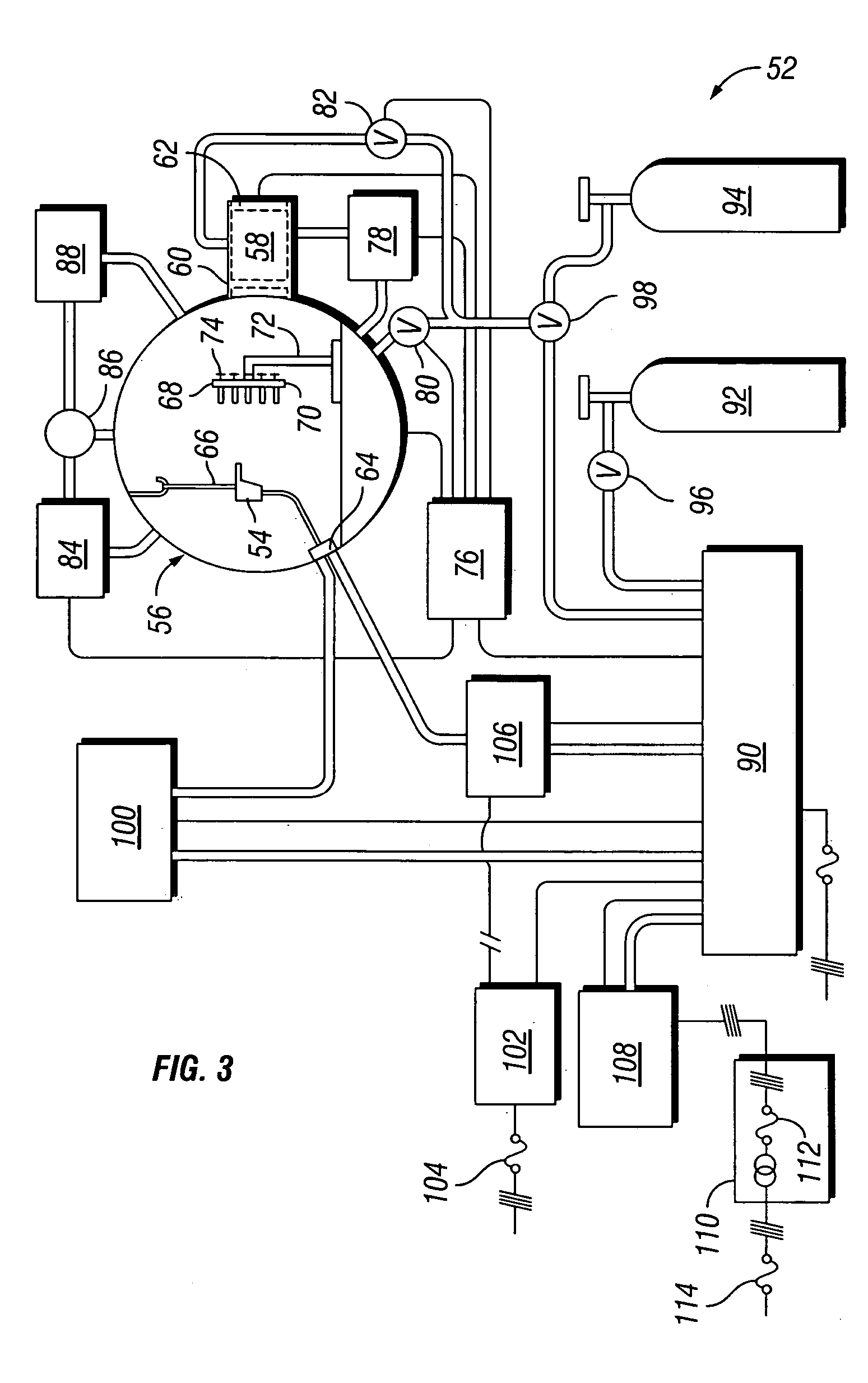

Method and apparatus for spray processing of porous medical devices

InactiveUS20070036905A1Minimize contaminationMinimize oxidationMolten spray coatingPretreated surfacesPorous substrateThermal spraying

Owner:ABBOTT CARDIOVASCULAR

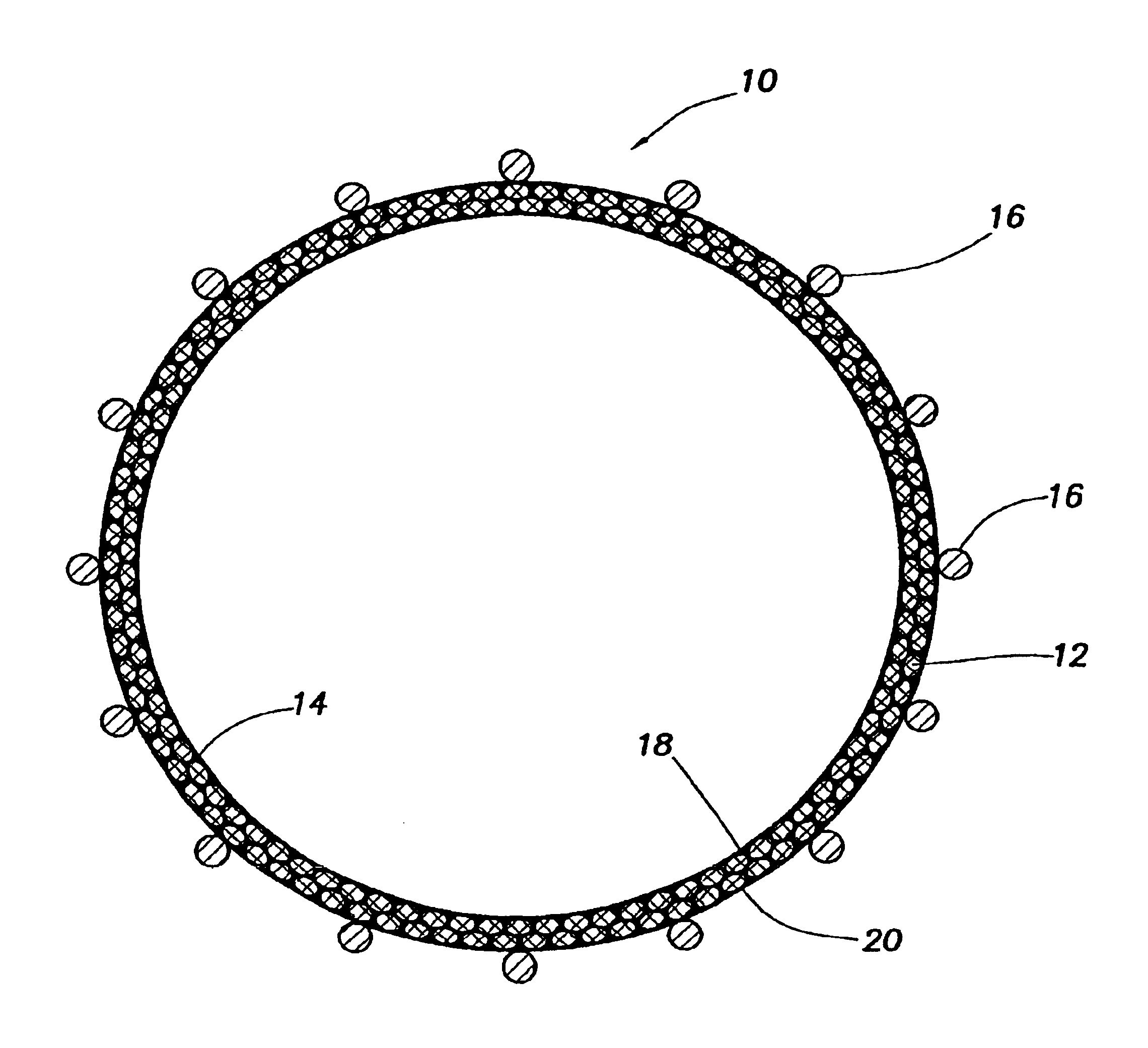

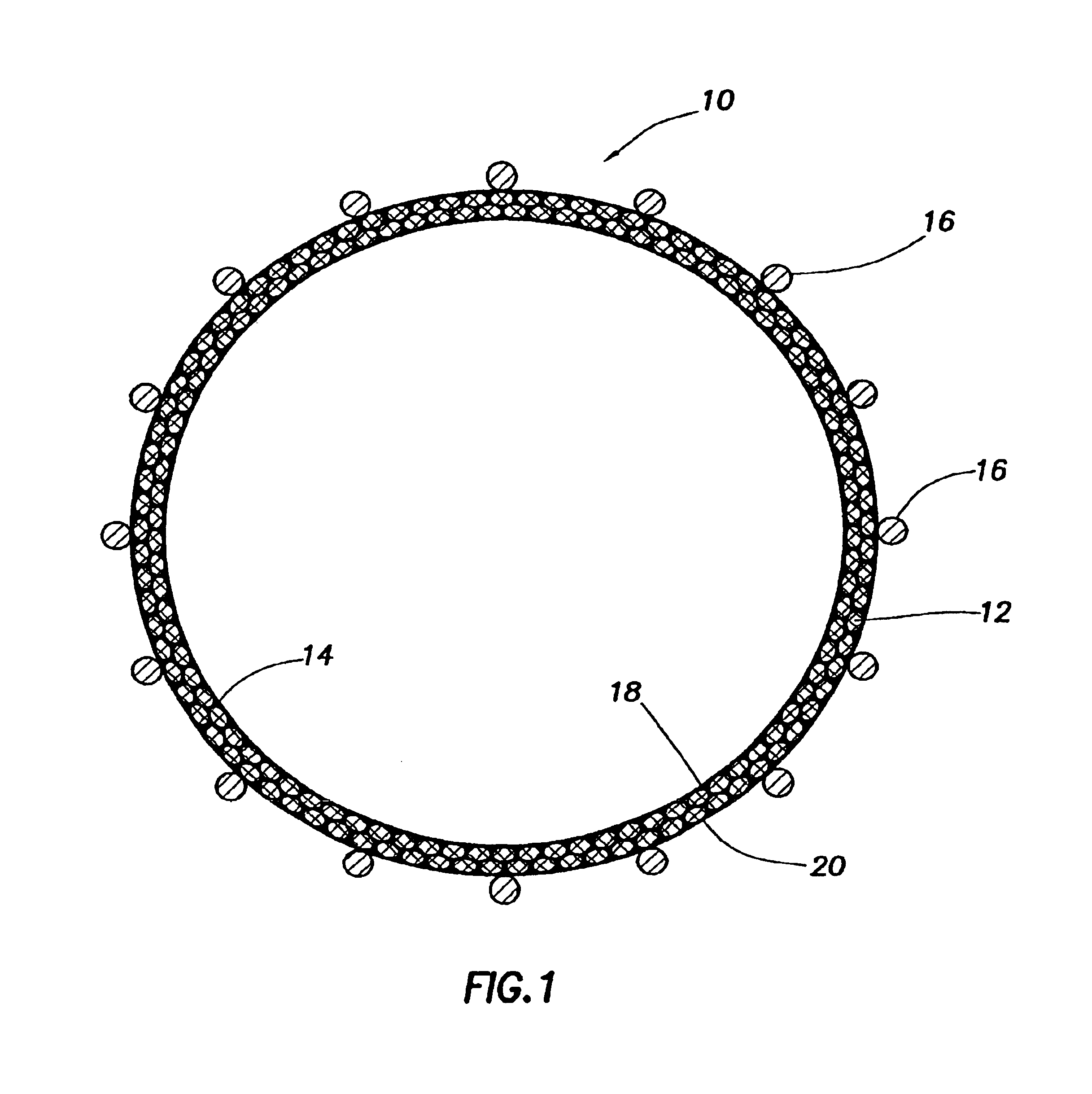

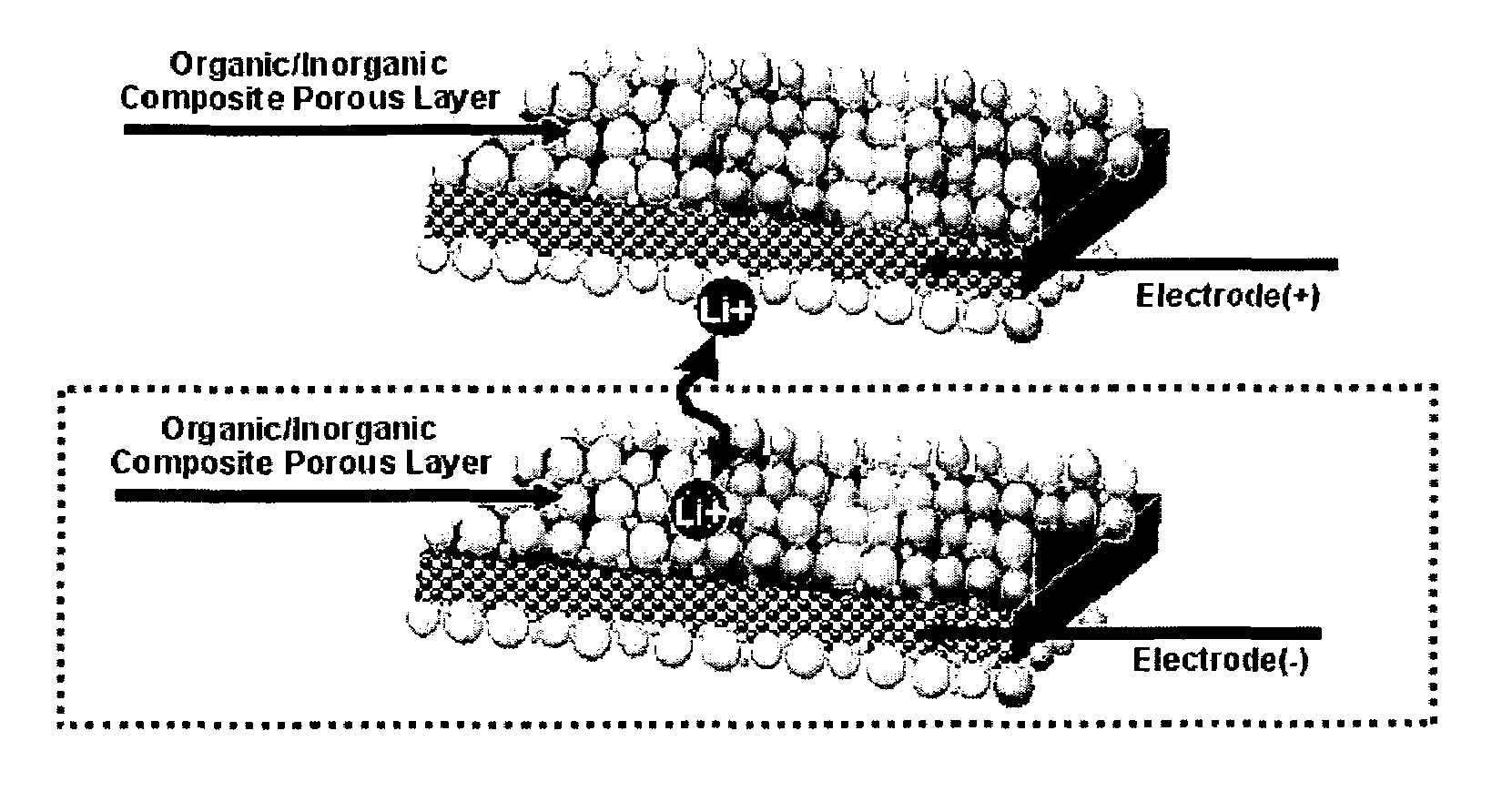

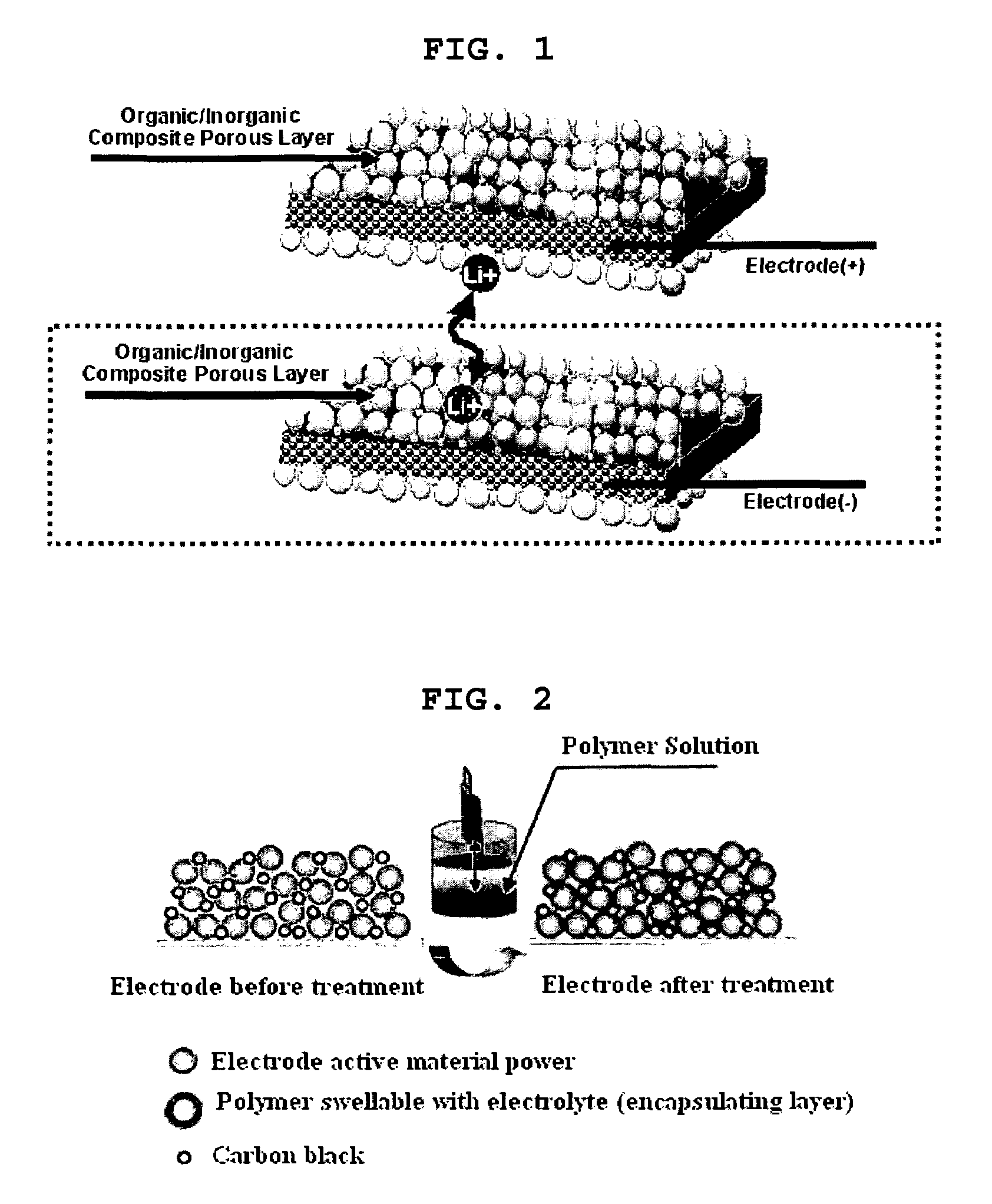

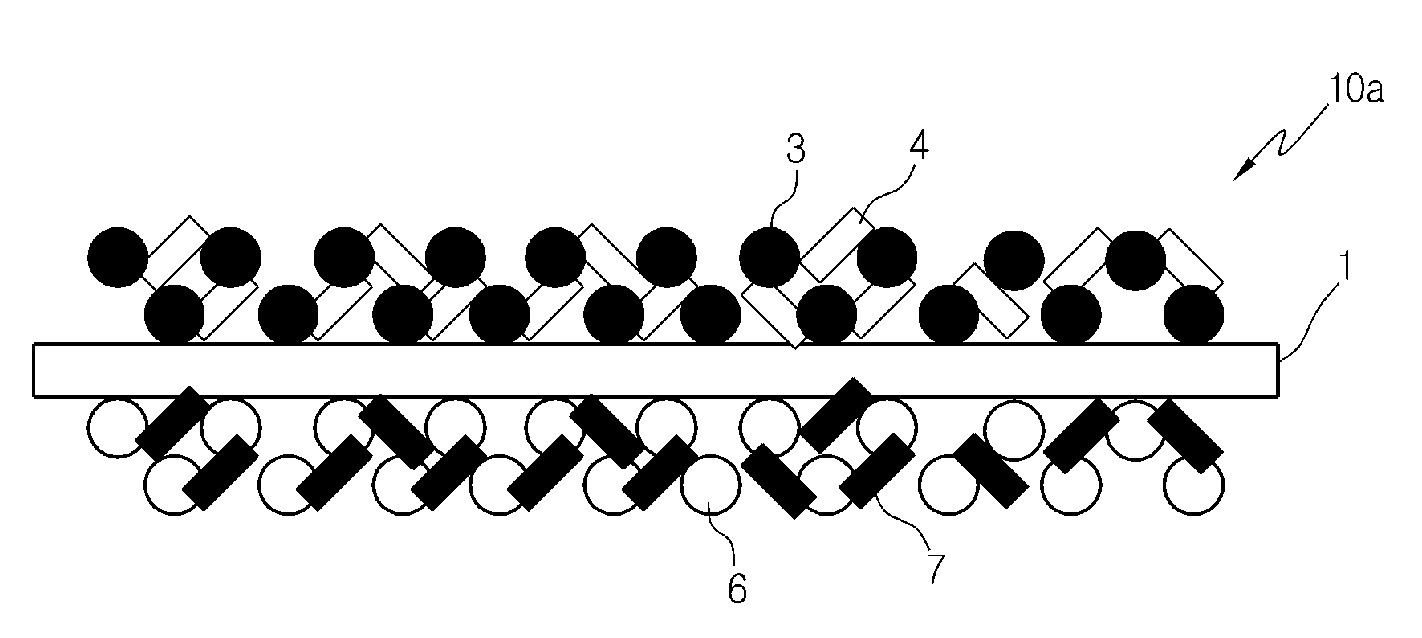

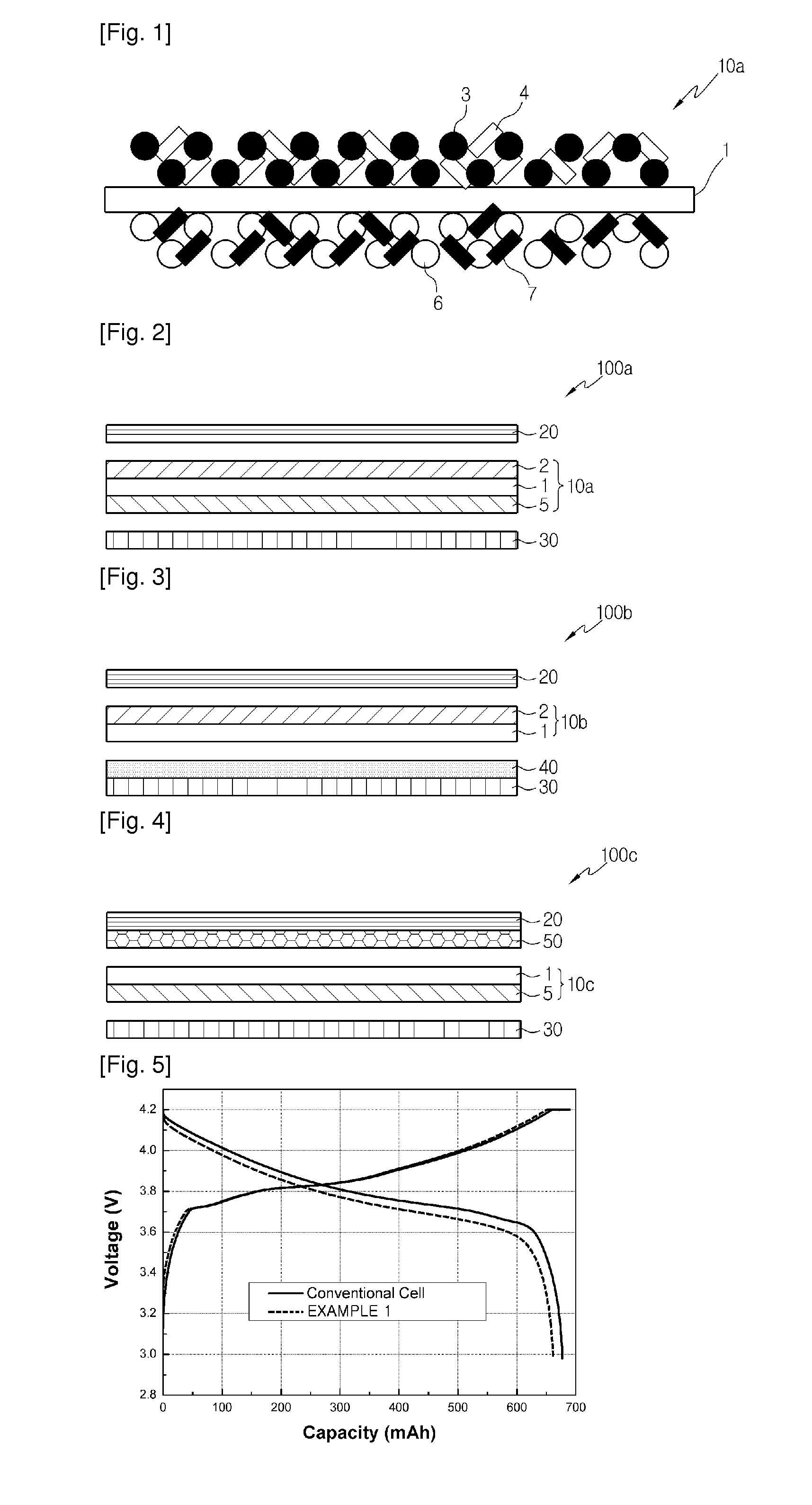

Organic/inorganic composite porous layer-coated electrode and electrochemical device comprising the same

ActiveUS7682740B2Improve performanceImprove securityElectrode rolling/calenderingNon-aqueous electrolyte accumulator electrodesPorous coatingInorganic particle

Disclosed is an electrode comprising a first organic / inorganic composite porous coating layer formed on its surface, wherein the first coating layer includes inorganic particles and a binder polymer for interconnecting and fixing the inorganic particles, and has micropores formed by interstitial volumes among the inorganic particles. An electrochemical device including the same electrode is also disclosed. Further, disclosed is a method for manufacturing an electrode having an organic / inorganic composite porous coating layer on the surface thereof, comprising the steps of: (a) coating a current collector with slurry containing an electrode active material and drying it to provide an electrode; and (b) coating the surface of electrode obtained from step (a) with a mixture of inorganic particles with a binder polymer. A lithium secondary battery including the electrode shows improved safety and minimized degradation in battery performance.

Owner:LG ENERGY SOLUTION LTD

Method of manufacturing a medical device having a porous coating thereon

Methods of manufacturing drug-coated medical devices having a porous coatings thereon. The pores are created by solid particle additives added to a mixture comprising a solvent, a drug, and a polymer to create a suspension, which is applied to the medical device. The method includes adding a surfactant to the mixture to prevent or decrease flocculation of the solid particle additives. Another method is provided that includes spraying a suspension on a medical device that comprises solid particle additives, a drug, and a polymer and analyzing the distribution of the solid particle additives in the suspension.

Owner:BOSTON SCI SCIMED INC

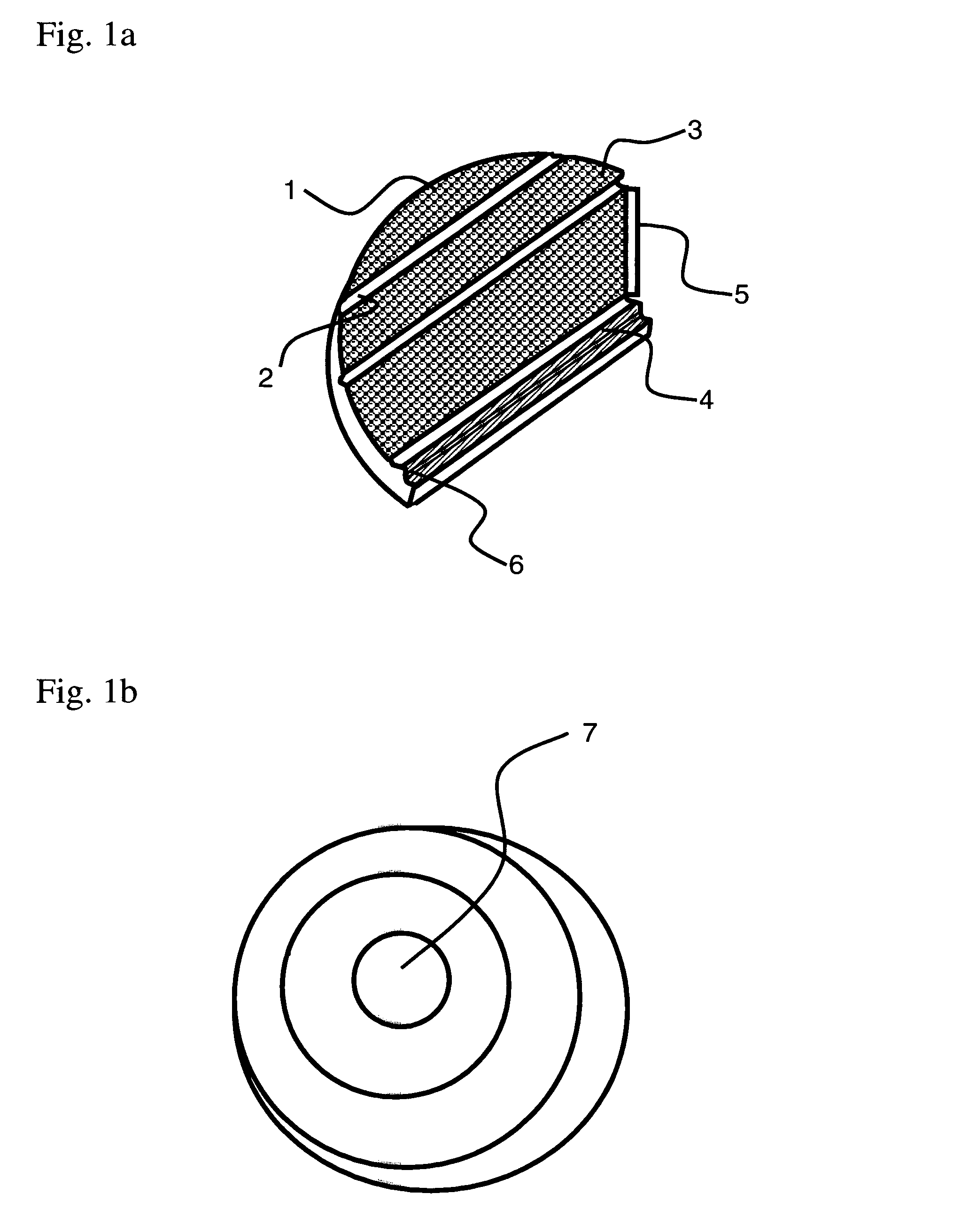

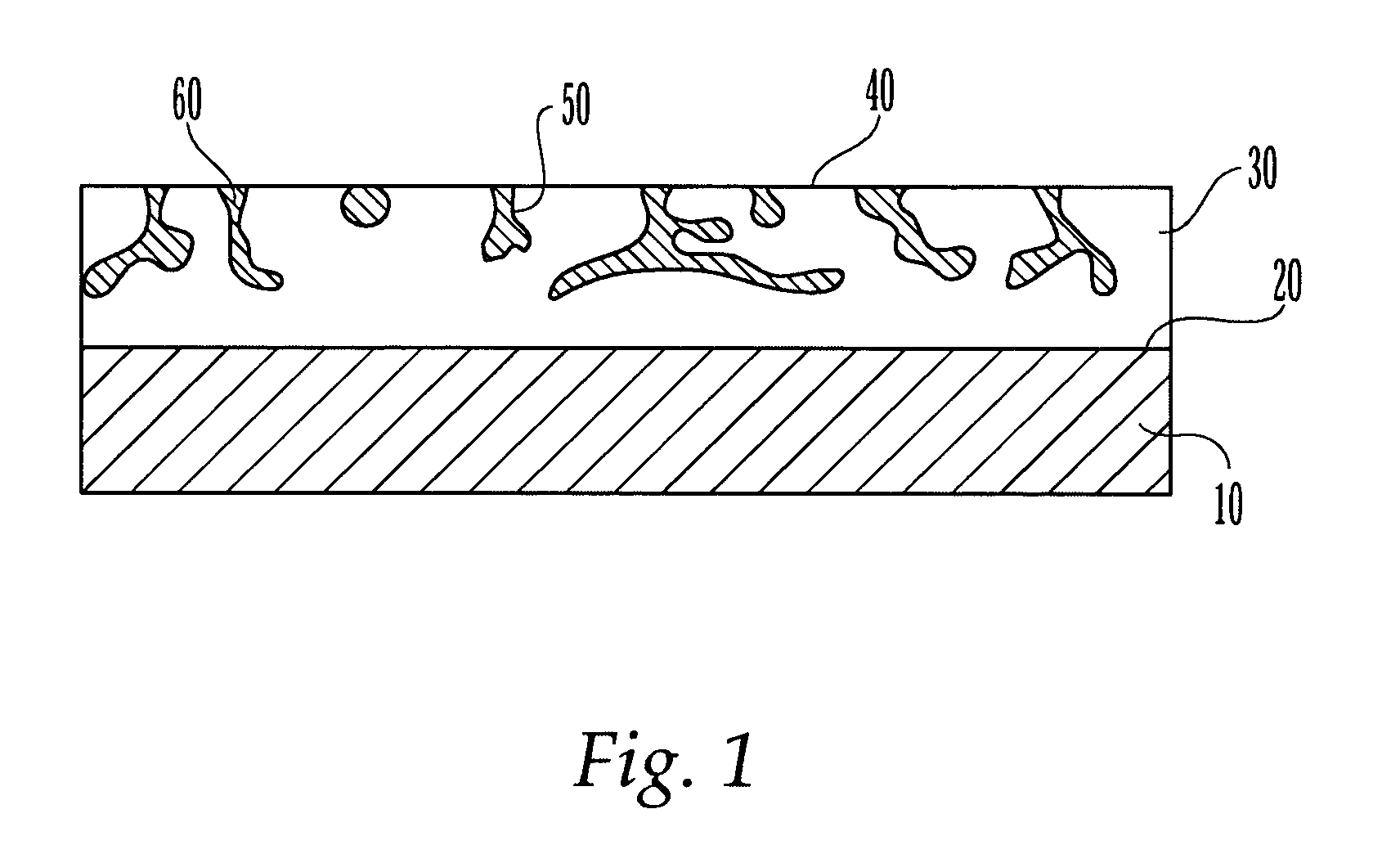

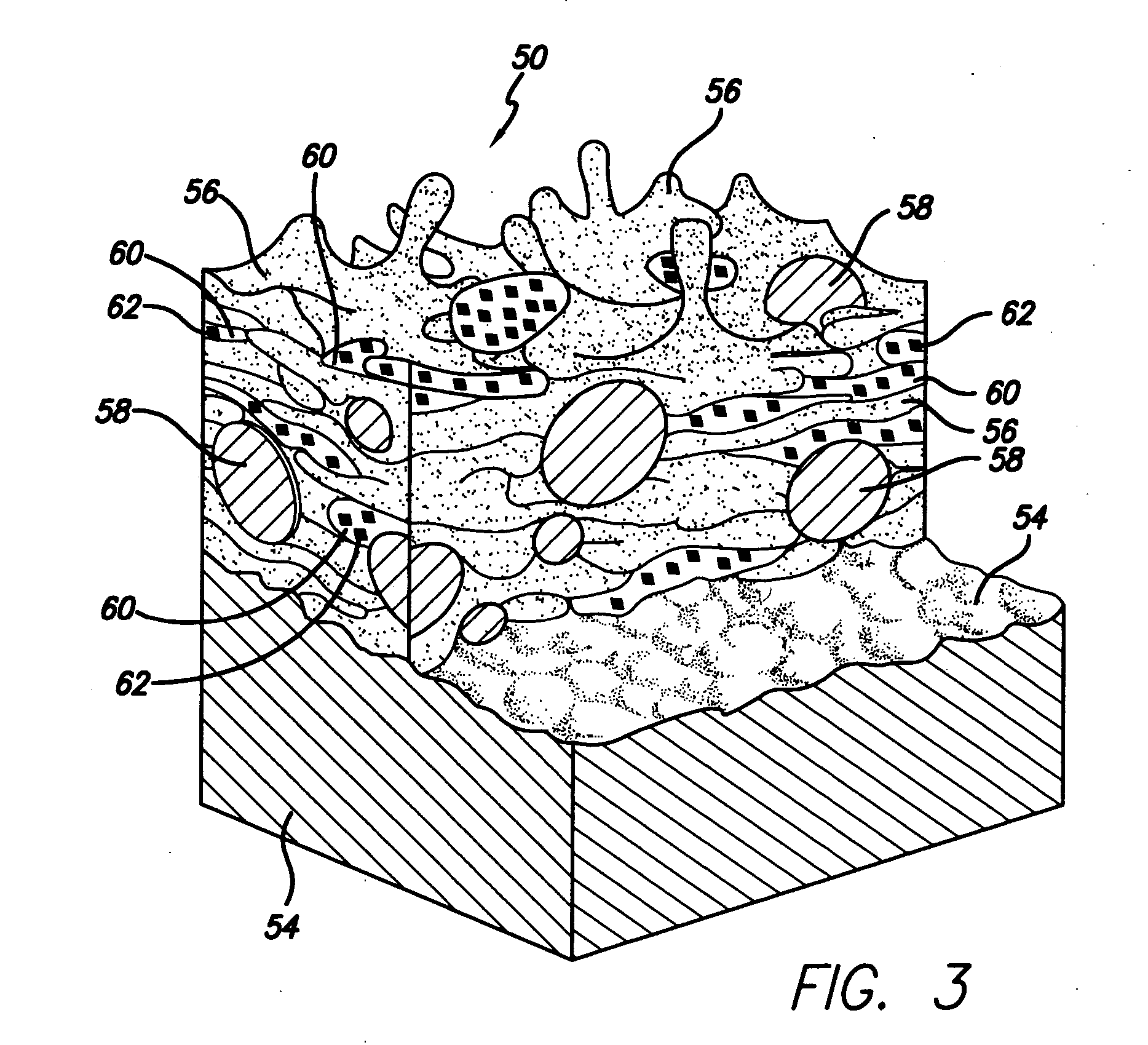

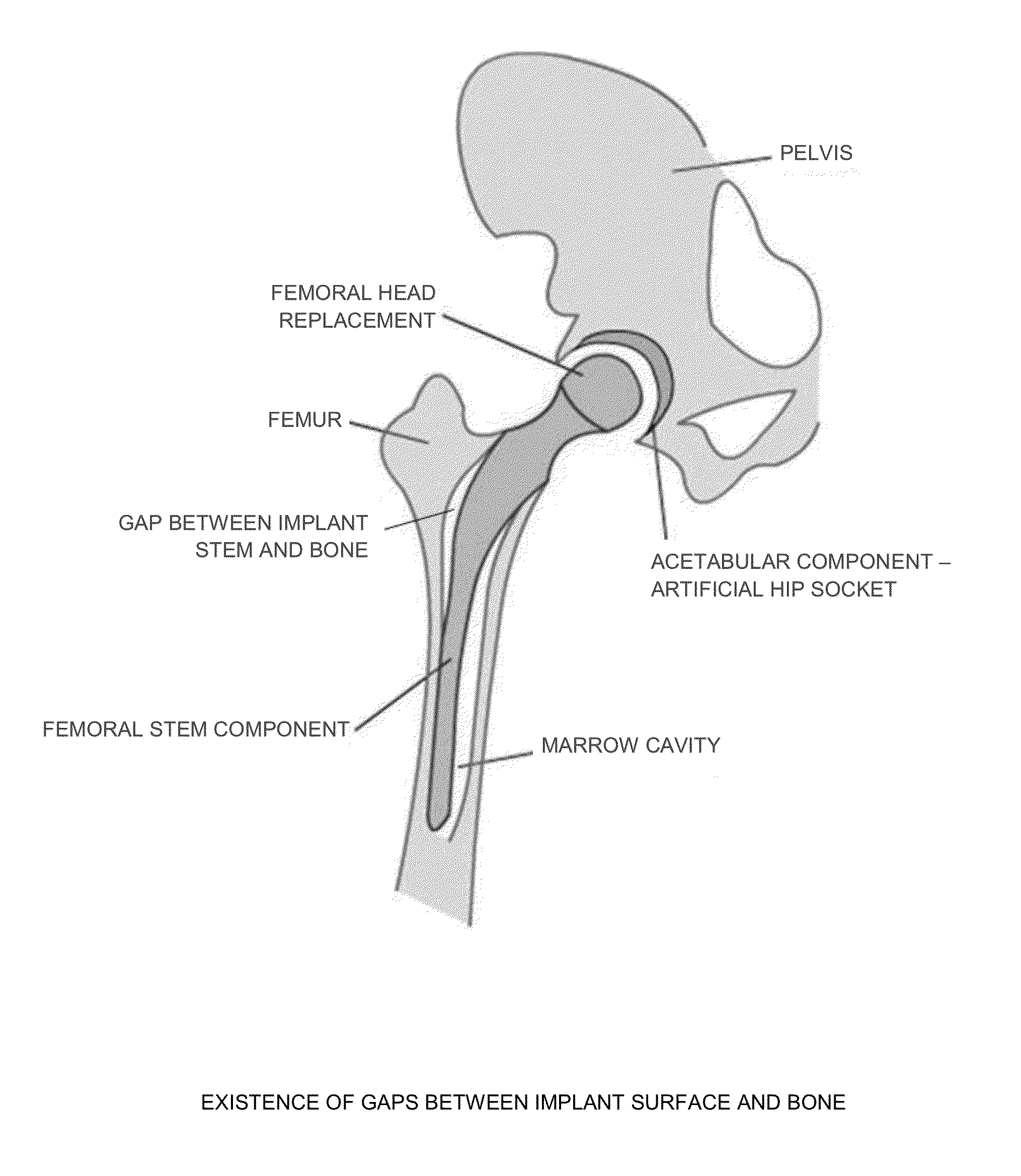

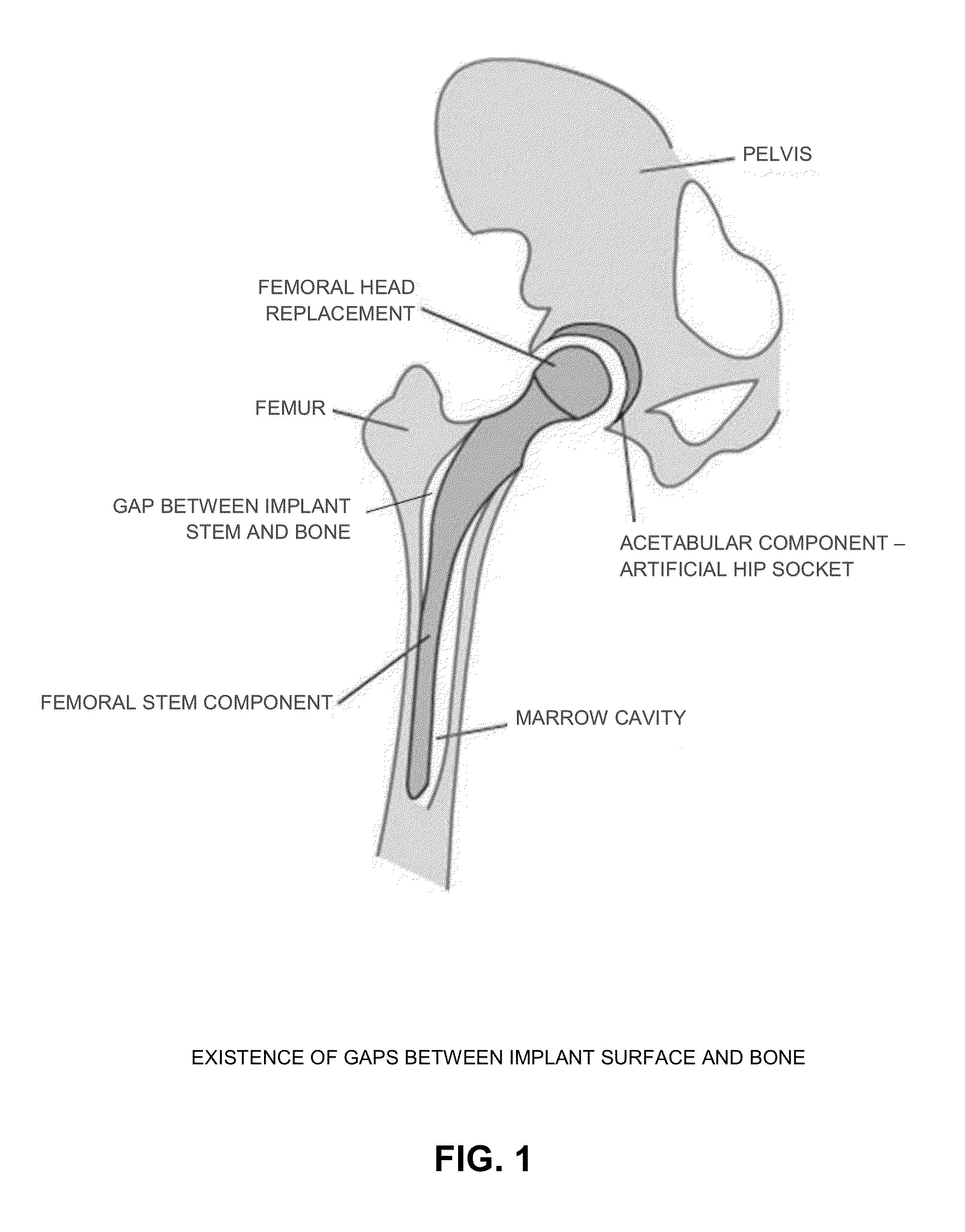

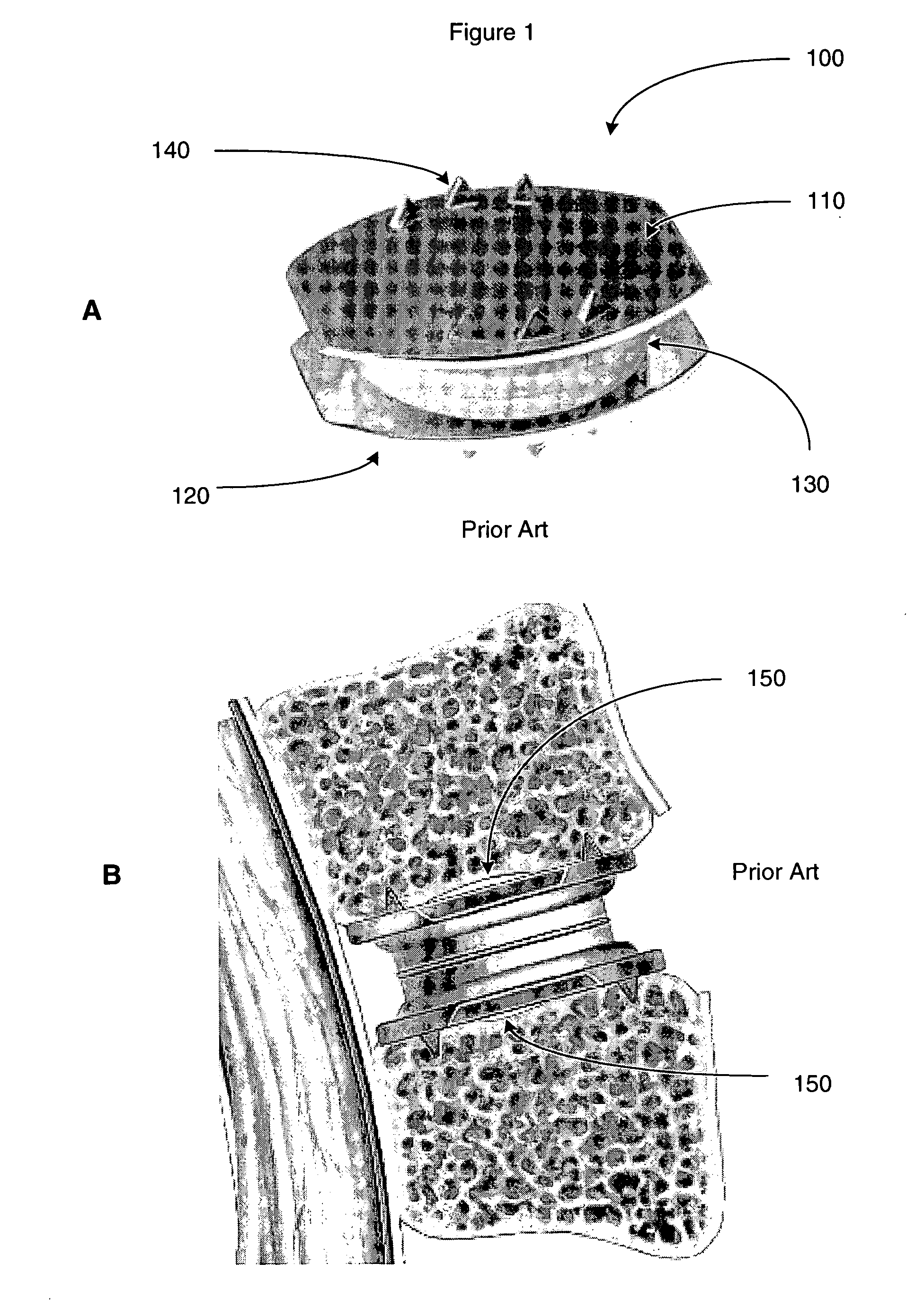

Dynamic porous coating for orthopedic implant

ActiveUS20130218288A1Improve performancePromotes bone remodelingBone implantPharmaceutical delivery mechanismPorous coatingInterference fit

A dynamic porous coating for an orthopedic implant, wherein the dynamic porous coating is adapted to apply an expansive force against adjacent bone so as to fill gaps between the dynamic porous coating and adjacent bone and to create an interference fit between the orthopedic implant and the adjacent bone.

Owner:ARTHREX

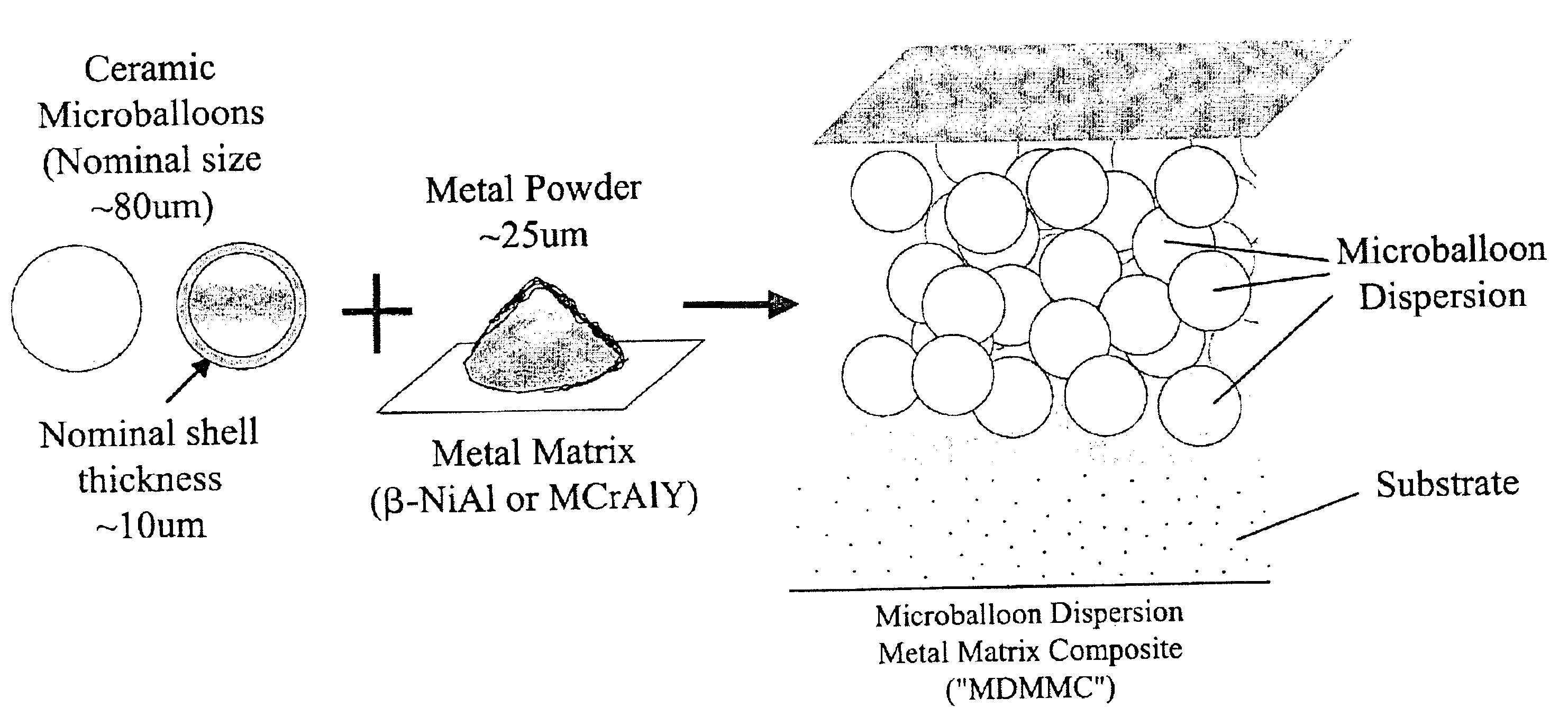

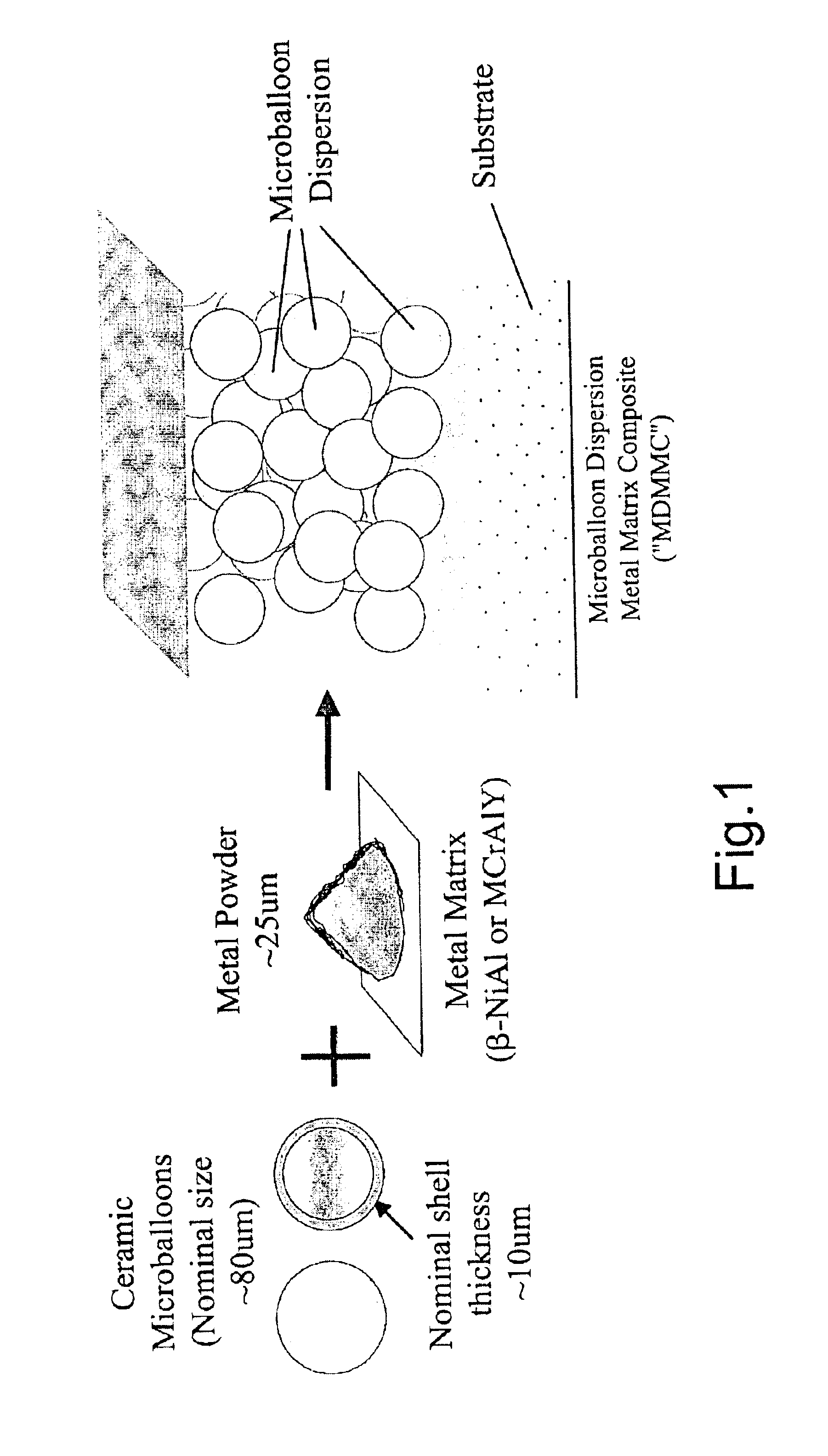

High temperature, oxidation-resistant abradable coatings containing microballoons and method for applying same

InactiveUS6916529B2Effective timeReducing hot gas leakageMolten spray coatingPropellersThermal sprayingMicrosphere

An abradable coating composition for use on shrouds in gas turbine engines or other hot gas path metal components exposed to high temperatures containing an initial porous coating phase created by adding an amount of inorganic microspheres, preferably alumina-ceramic microballoons, to a base metal alloy containing high Al, Cr or Ti such as β-NiAl or, alternatively, MCrAlY that serves to increase the brittle nature of the metal matrix, thereby increasing the abradability and oxidation resistance of the coating at elevated temperatures. Coatings having a total open and closed porosity of between 20% and 55% by volume due to the presence of ceramic microballoons ranging in size from about 10 microns to about 200 microns have been found to exhibit excellent abradability for applications involving turbine shroud coatings. An abradable coating thickness in the range of between 40 and 60 ml provides improved performance for turbine shrouds exposed to gas temperatures between 1380° F. and 1800° F. Abradable coatings in accordance with the invention can be used for new metal components or to repair existing equipment. The coatings can be applied to the metal shroud using thermal spray, processes that integrate sintering and brazing, or direct write techniques.

Owner:GENERAL ELECTRIC CO

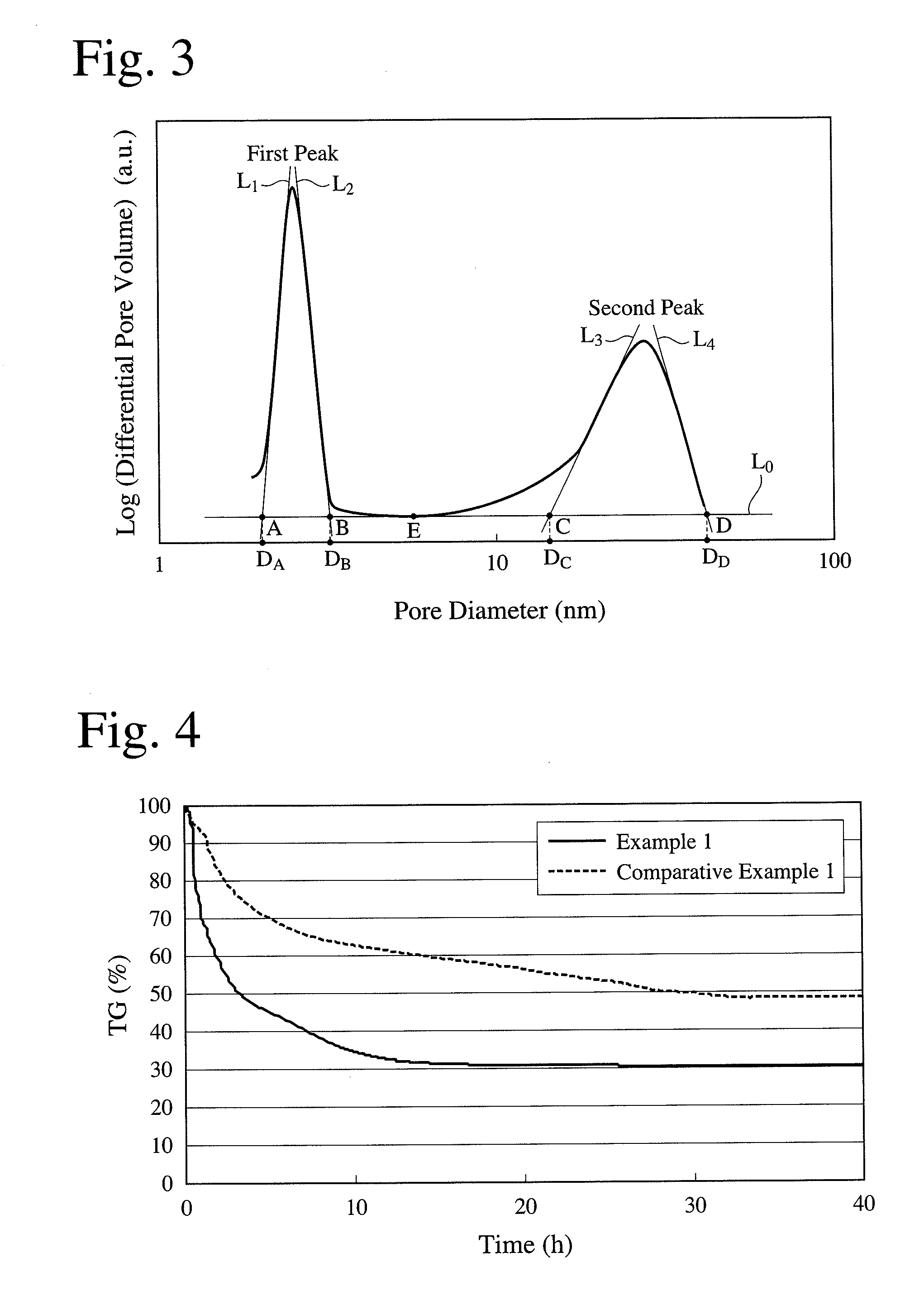

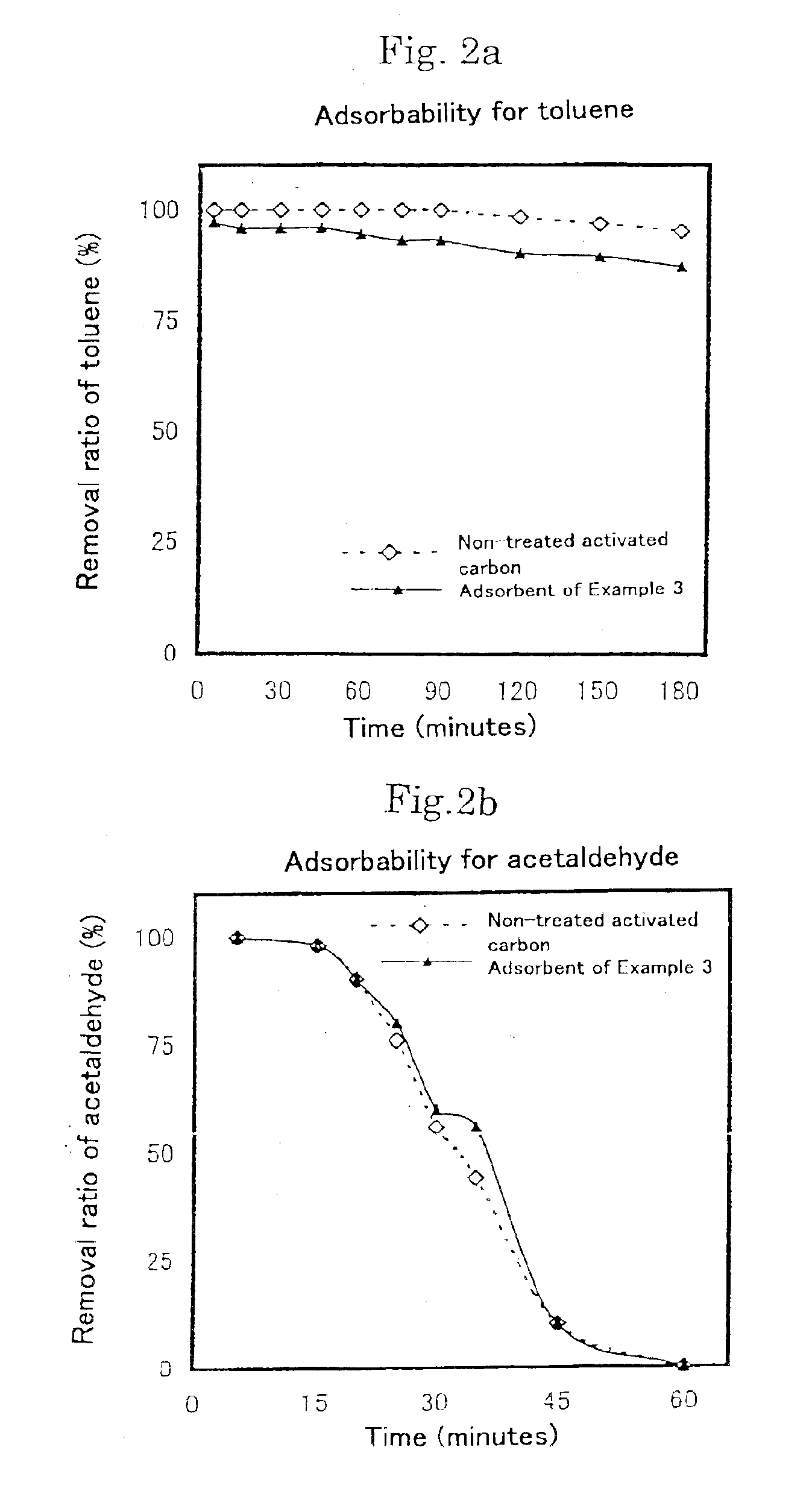

Adsorbents, process for producing the same, and applications thereof

InactiveUS6890373B2Prevent leakageImprove abilitiesCombination devicesIsotope separationPorous coatingSorbent

An adsorbent includes core particles containing an adsorbing material; a porous coating layer including a polymer material that coats the core particles; and an underlying layer containing a metal compound and disposed between the core particles and the porous coating layer. The porous coating layer is formed by spraying and applying a suspension or a solution containing the polymer material over the adsorbing material, or by immersing the adsorbing material into the suspension or the solution.

Owner:BRIDGESTONE CORP

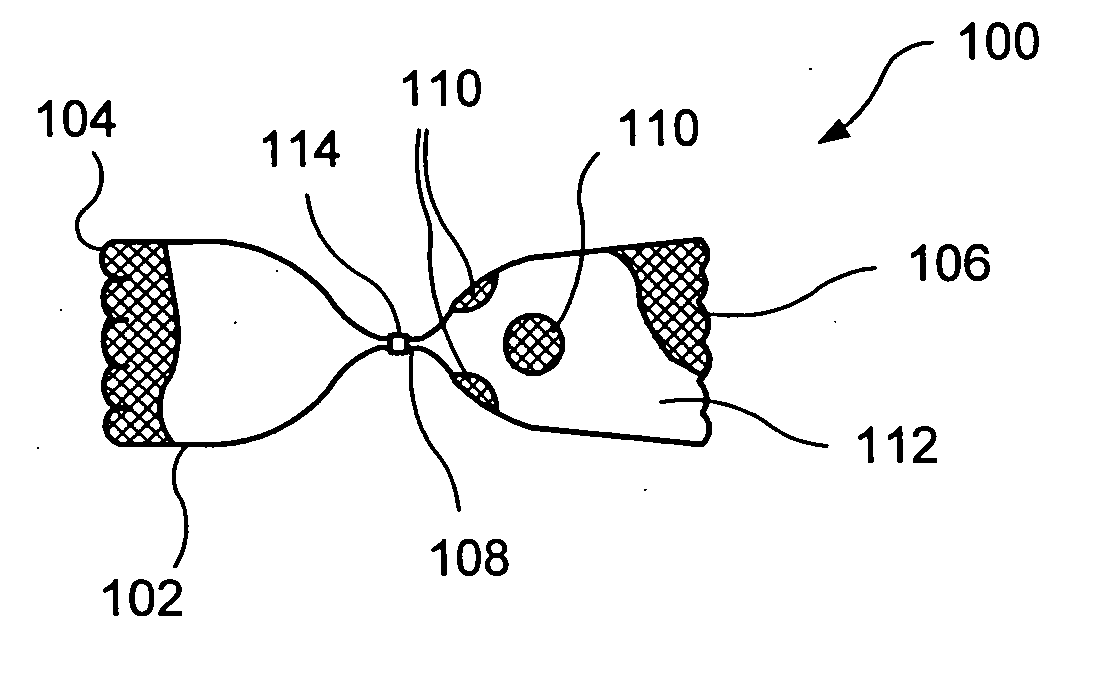

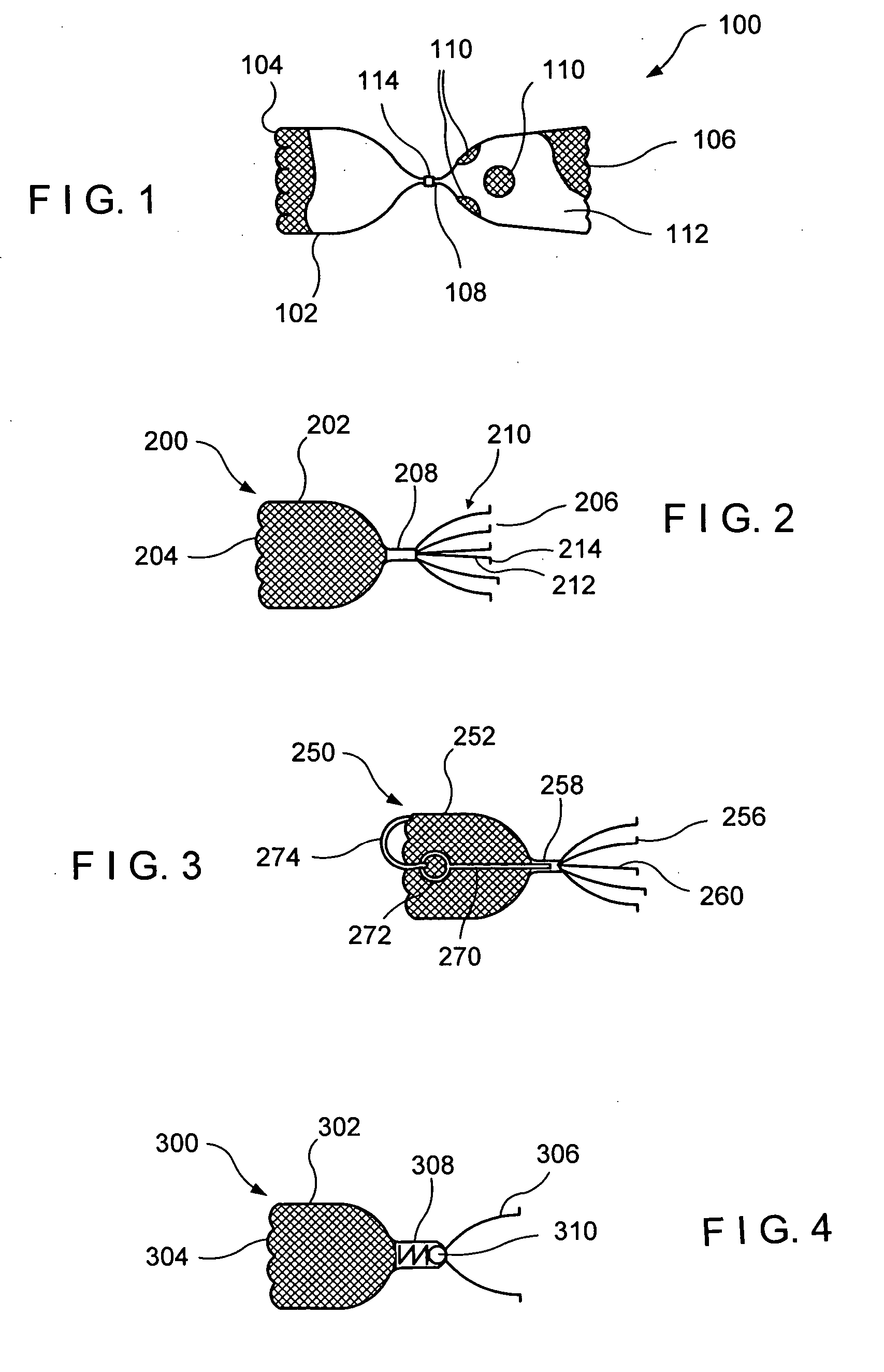

Compliant porous coating

InactiveUS20060282166A1Easy to adaptEasy to implantBone implantSpinal implantsPorous coatingBiomedical engineering

Intervertebral implant components having compliant coatings, and methods of making and implanting the implant components are provided. The embodiments relate to compositions, methods and devices having a compliant surface coating that permits application of the device in areas without significant bone reformation to accept the device.

Owner:WARSAW ORTHOPEDIC INC

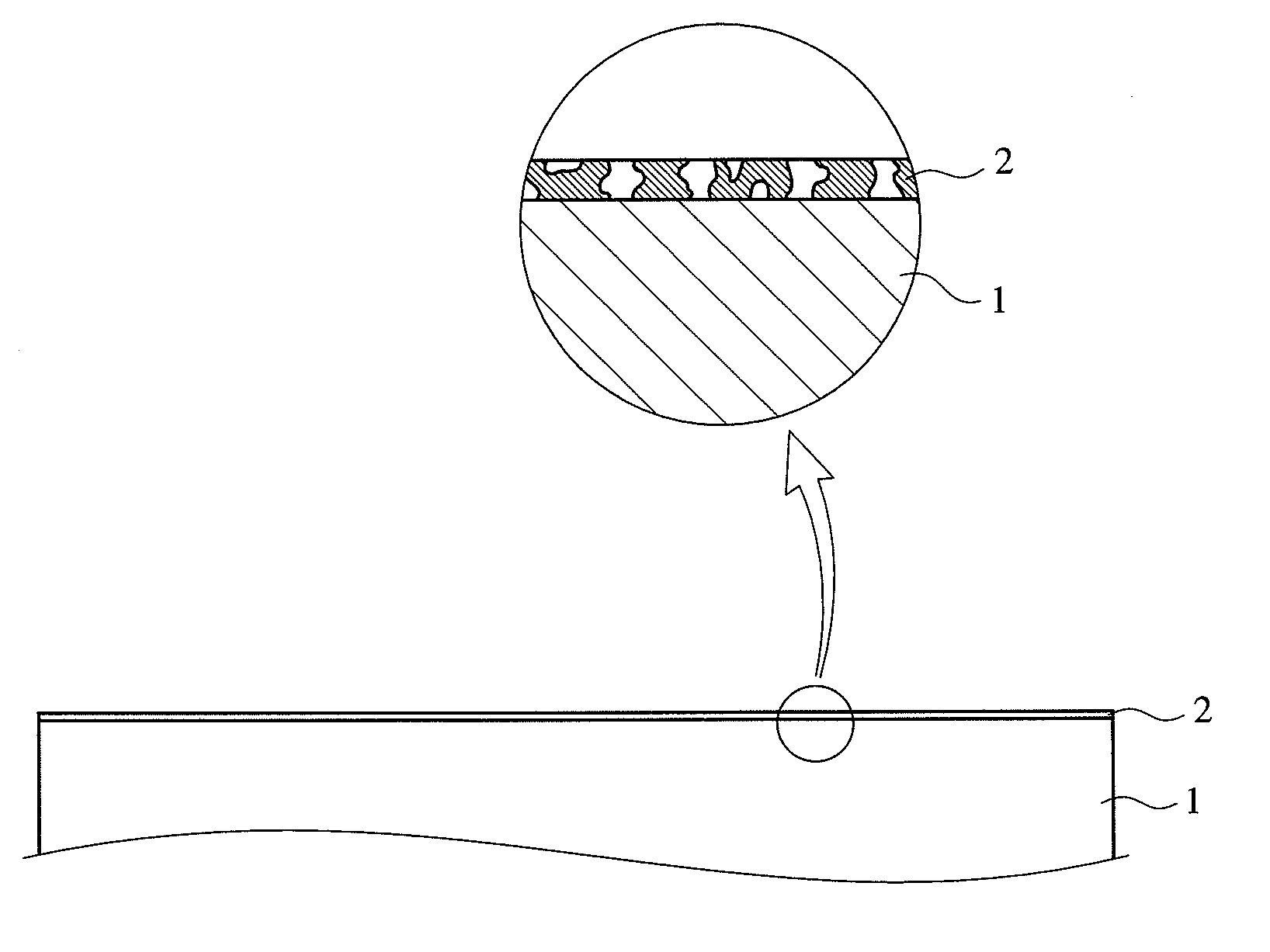

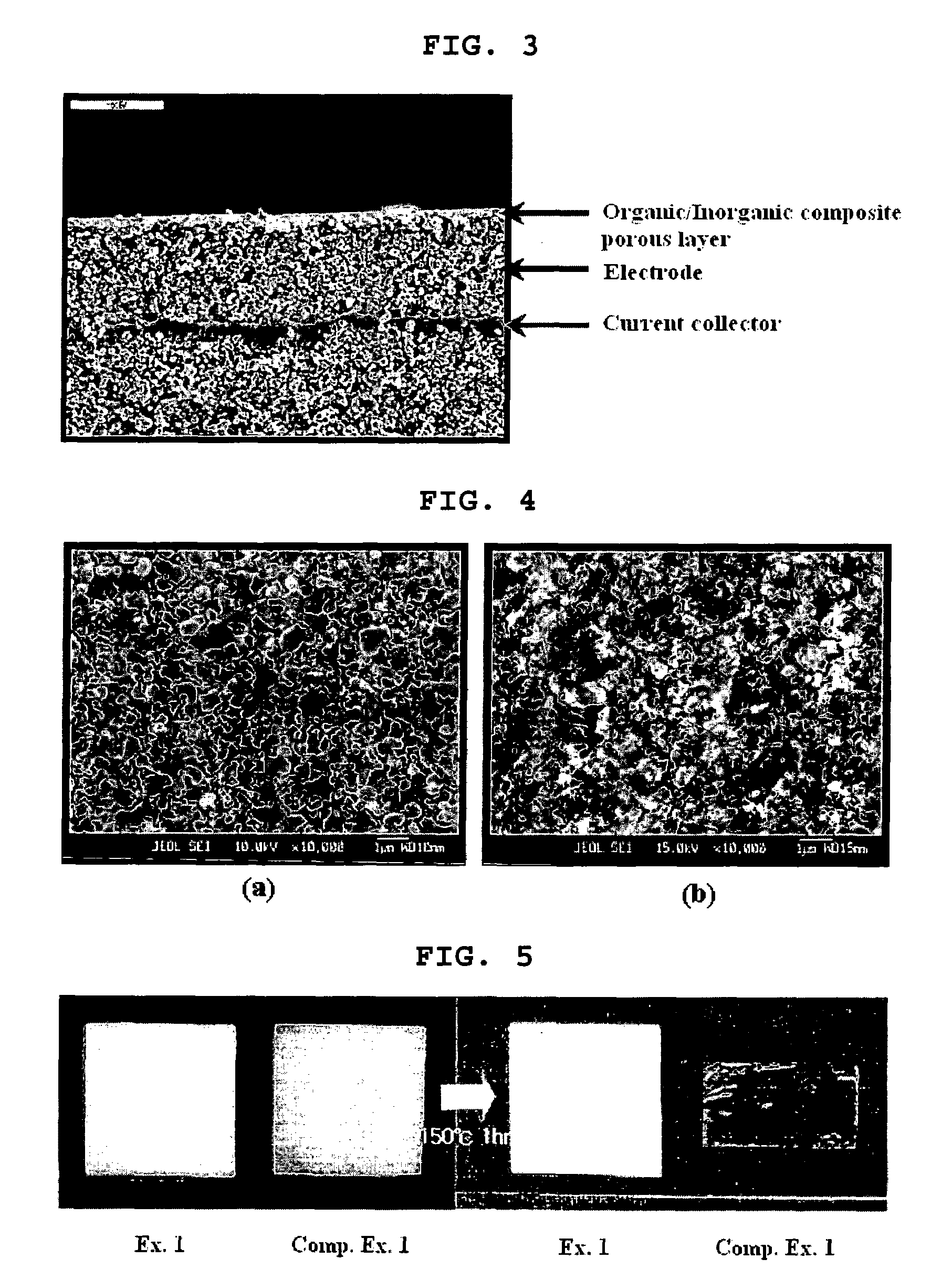

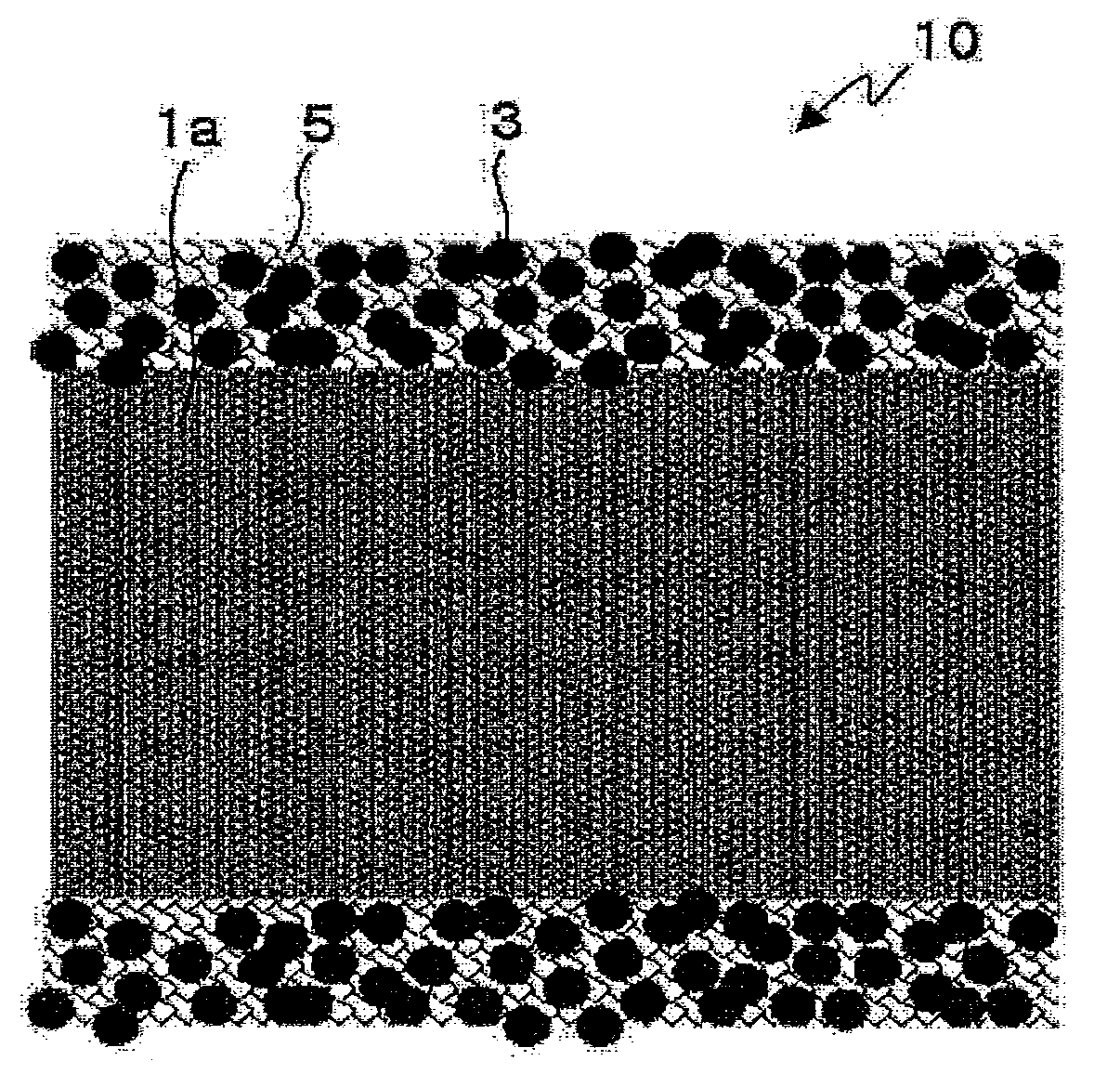

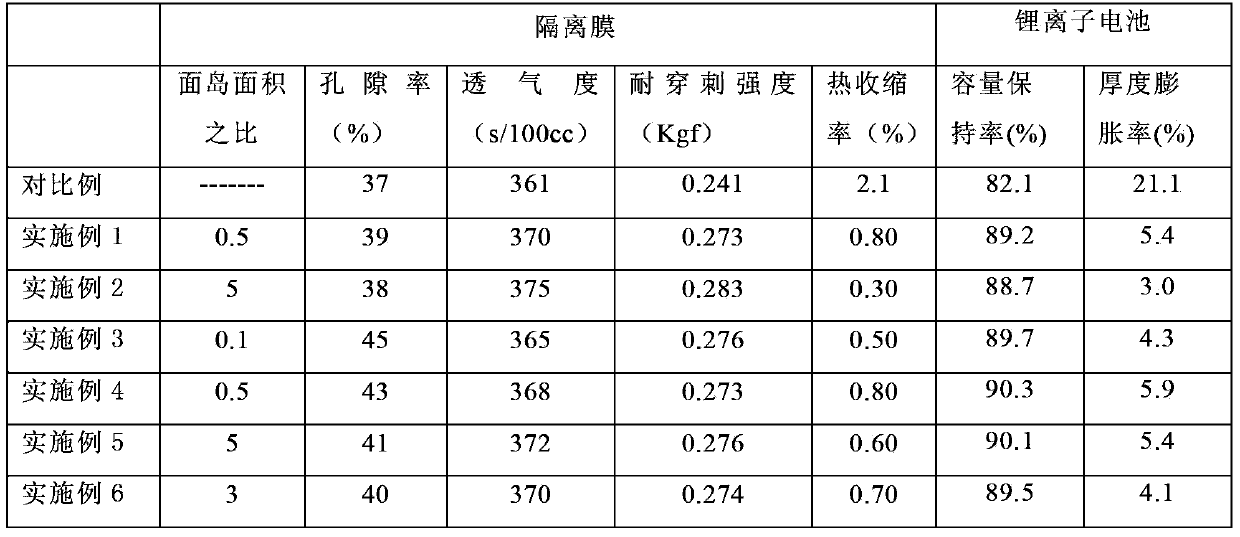

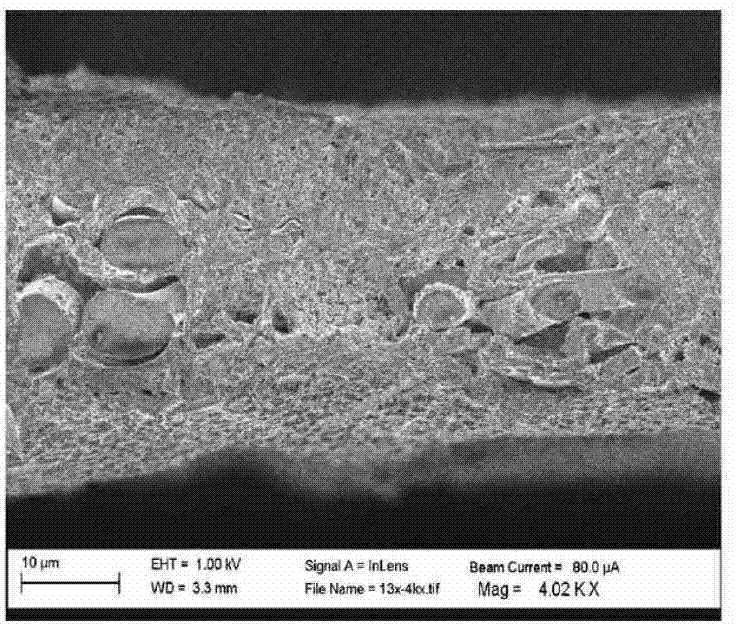

Separator having porous coating layer, method for manufacturing the same and electrochemical device having the same

InactiveUS20100316903A1Excellent characteristicsImprove performanceFinal product manufactureLi-accumulatorsPorous coatingPorous substrate

A separator includes a porous substrate having a plurality of pores; and a porous coating layer formed on at least one surface of the porous substrate and made of a mixture of a binder and a plurality of inorganic particles, wherein the binder includes a crosslinked binder. This separator may improve high temperature cycle performance, discharge characteristics and thermal resistance of an electrochemical device since the separator exhibits improved insolubility and impregnation to electrolyte and improved thermal resistance.

Owner:TORAY BATTERY SEPARATOR FILM

Method of making an anti-reflection coating

InactiveUS6177131B1Reducing and eliminating reflectionReduce and even reflectionSolar heat devicesPretreated surfacesSilanesRefractive index

A method of and a solution for making a highly porous optical antireflection coating of a selectively designed index of refraction, by applying a colloidal dispersion derived from hydrolytically condensing, in the presence of water and a catalyst, one or more silicon compounds of the general formula RaSiX4-a, or precondensates derived therefrom, to a substrate. In the formula, R is an organic group having from 1 to 10 carbon atoms which may be interrupted by oxygen atoms and / or sulfur atoms and / or amino groups, X is hydrogen, halogen, hydroxy, alkoxy, acyloxy, alkylcarbonyl, alkoxycarbonyl or NR'2, R' being hydrogen, alkyl or aryl and a being 0, 1 or 2. The solution also contains colloidally dispersed organic polymers at a molar ratio, relative to the silane, between 0.1 mmol / mol silane and 100 mmol / mol silane, the median molecular mass of the polymer being between 200 and 500,000. Sol-vents, preferably alcohol, may also be present in the solution. After being applied to an optical substrate, the solution is dried and organic components are removed from it to leave a porous coating of predetermined index of refraction.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Organic/inorganic composite porous isolating membrane, preparation method thereof and electrochemical device

ActiveCN103441230AImprove breathabilityImprove conductivityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersPorous coatingInorganic particle

The invention provides an organic / inorganic composite porous isolating membrane, a preparation method thereof and an electrochemical device. According to the first aspect of the invention, the organic / inorganic composite porous isolating membrane comprises a porous base material and an organic / inorganic composite porous coating coated on at least one surface of the porous base material, wherein the organic / inorganic composite porous coating comprises inorganic particles, a binding agent and organic particles with at least two swelling degrees, and the organic particles are swelled by a plasticizer. The preparation method of the organic / inorganic composite porous isolating membrane is used for preparing the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. According to the third aspect of the invention, the electrochemical device comprises the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. Therefore, the organic / inorganic composite porous isolating membrane can form an excellent interface, so that a risk that the risk of blocking holes by the organic particles is reduced, breathability of the organic / inorganic composite porous isolating membrane is improved, and electrical conductivity of the organic / inorganic composite porous isolating membrane is improved.

Owner:DONGGUAN AMPEREX TECH +1

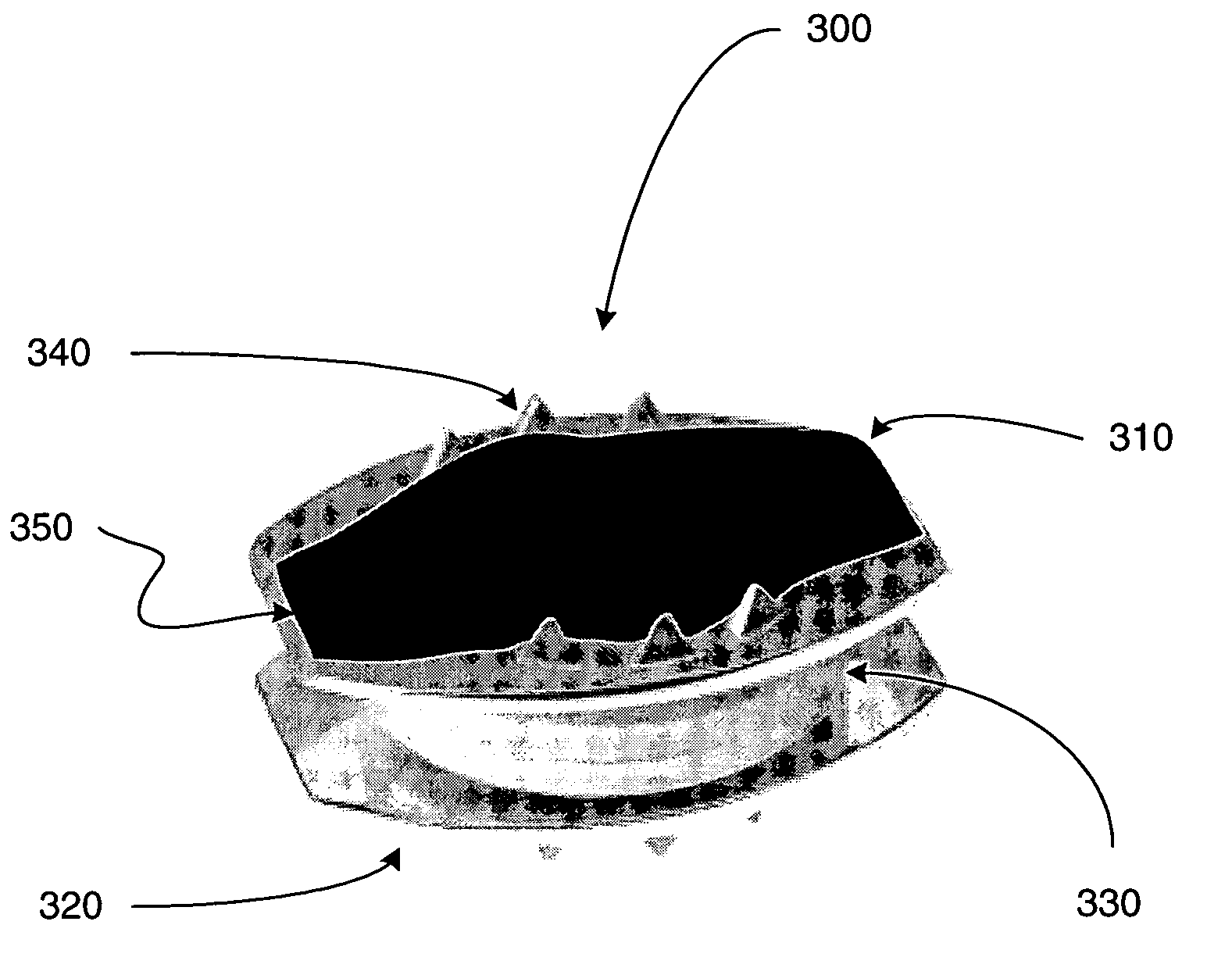

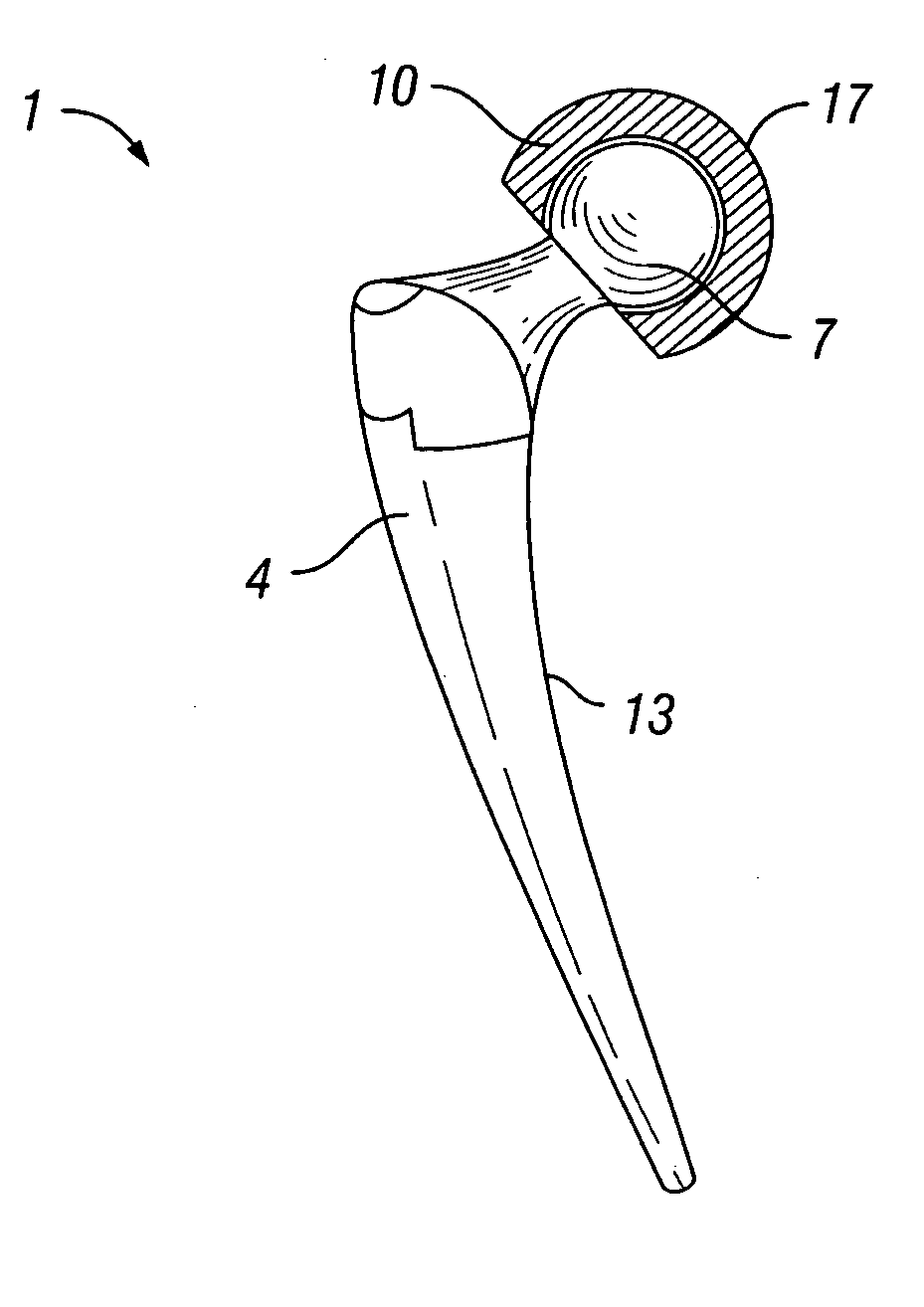

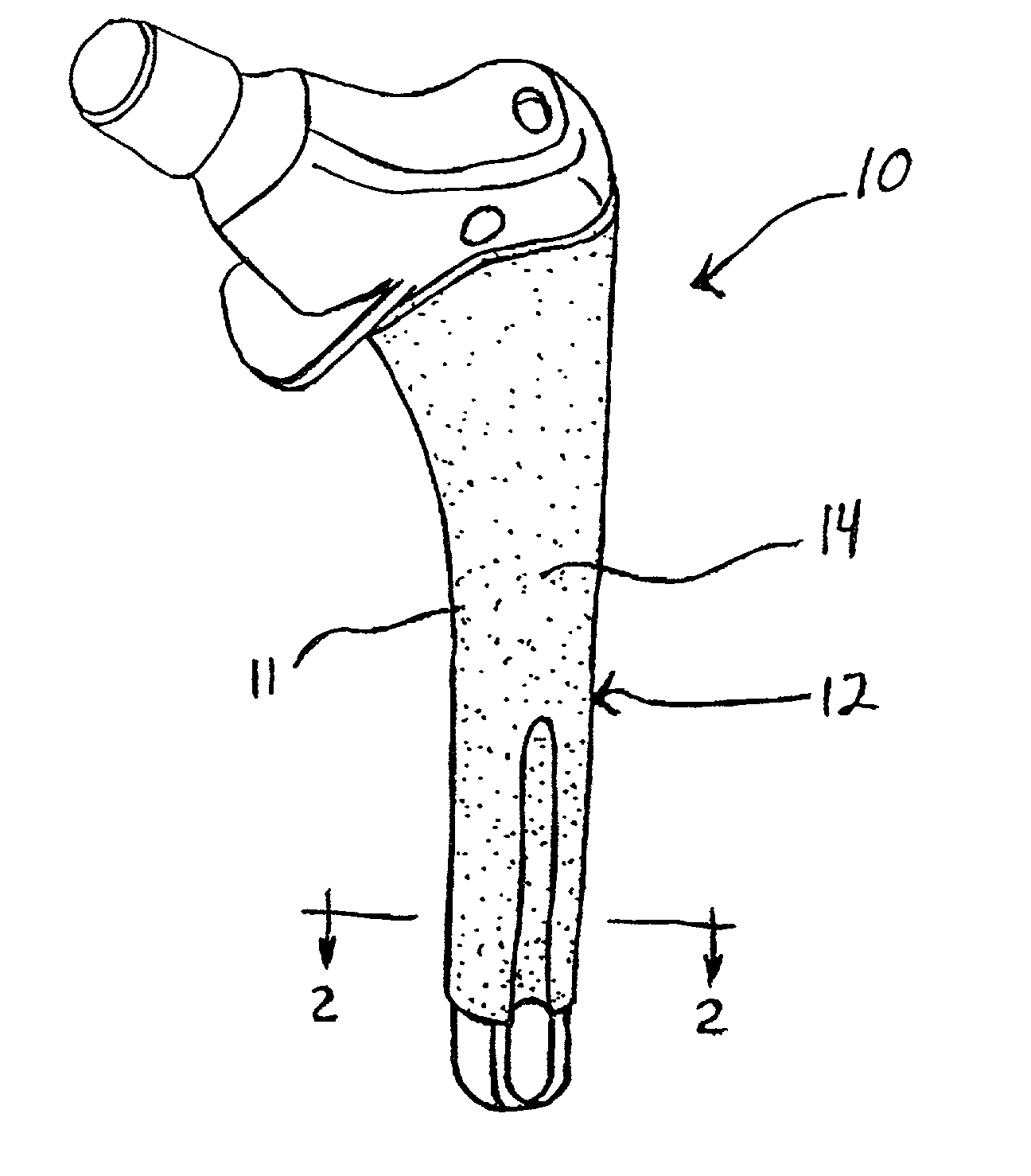

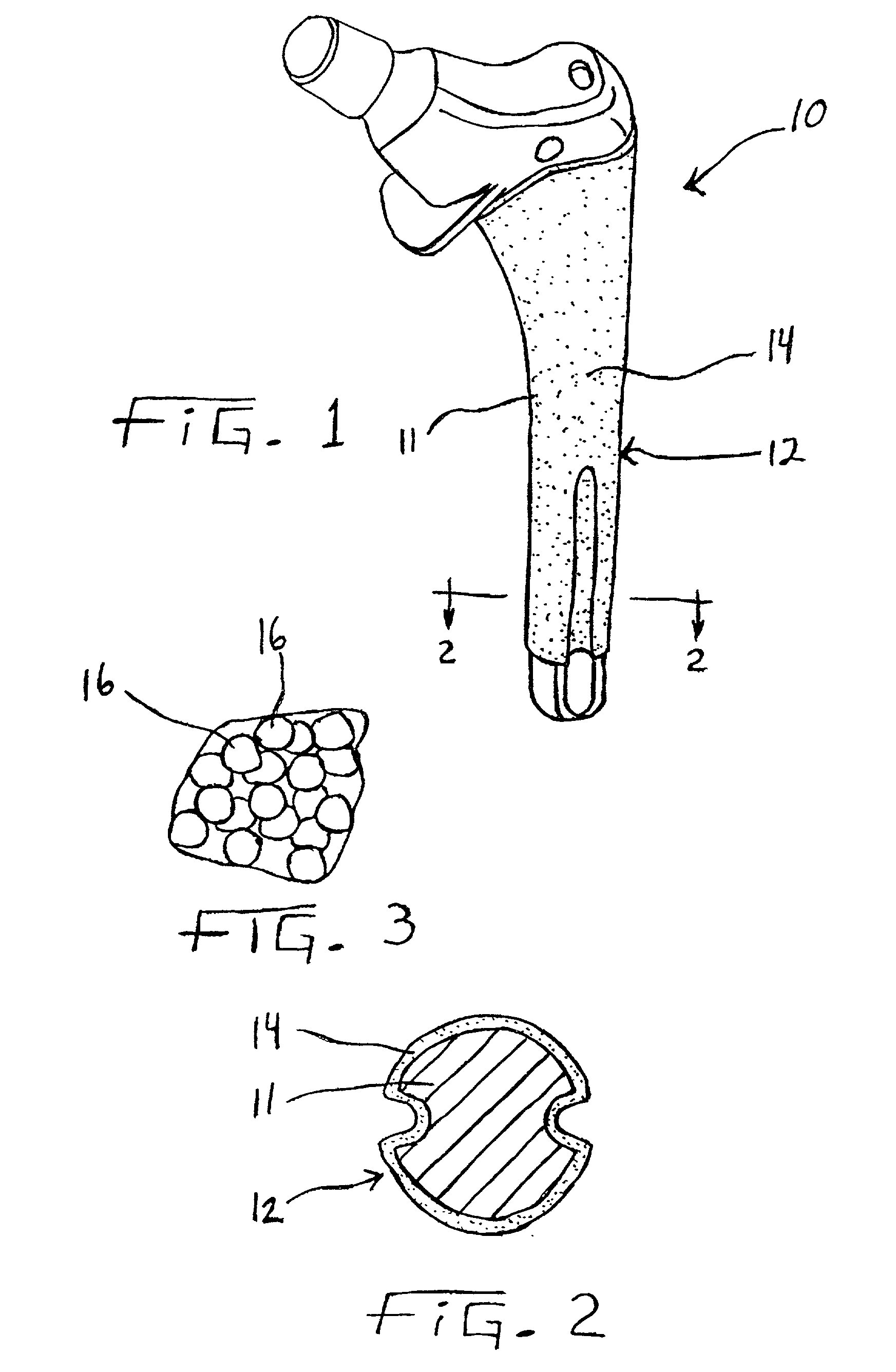

Porous coating for orthopedic implant utilizing porous, shape memory materials

ActiveUS20160184103A1Reduce stiffnessFacilitate proximal load transferBone implantPharmaceutical delivery mechanismPorous coatingBiomedical engineering

A porous coating for a medical implant, wherein the porous coating comprises a porous, shape memory material.

Owner:ARTHREX

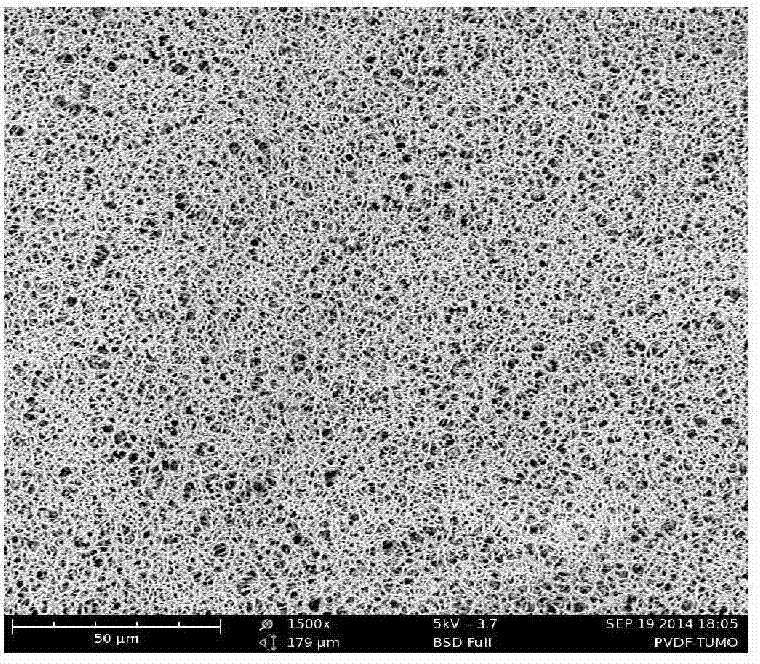

Lithium-ion battery diaphragm and preparation method thereof

InactiveCN105140451AUniform pore sizePorosity is easy to controlCell component detailsPorous coatingPorous substrate

The invention discloses a lithium-ion battery diaphragm. The lithium-ion battery diaphragm is prepared by coating the upper surface and the lower surface of a porous base material with one or more porous coatings, wherein the thickness of the porous base material is 4-80 microns; the porosity of the porous base material is 30%-90%; and each porous coating comprises the following raw materials in parts by weight: 30-100 parts of a polymer material, 0-70 parts of inorganic powder and a surface treating agent and 0-50 parts of a compatibilizer. The invention further discloses a preparation method of the lithium-ion battery diaphragm. The battery diaphragm disclosed by the invention is controllable in pore size and porosity and uniform in pore size; the finished diaphragm product is high in high-grade rate, good in wettability and high in safety; and the diaphragm is good in heat resistance, and has a thermal closing function.

Owner:郑少华

Assembly for the preparation of a medical device having a coating comprising hydrogen peroxide

InactiveUS20060263404A1Maintain good propertiesEliminate the effects ofPeroxide active ingredientsPretreated surfacesUrinary catheterUpper urinary tract infection

The present invention provides an assembly for the preparation of a medical device having a porous coating comprising hydrogen peroxide. Particularly interesting medical devices are catheters (such as urinary catheters), endoscopes, laryngoscopes, tubes for feeding, tubes for drainage, guide wires, condoms, urisheaths, barrier coatings e.g. for gloves, stents and other implants, extra corporeal blood conduits, membranes e.g. for dialysis, blood filters, devices for circulatory assistance, dressings for wound care, and ostomy bags. The coating is in particular a hydrophilic coating formed from cross-linked polyvinylpyrrolidone. In one embodiment, the assembly holds a dry catheter element in one compartment of a package and an aqueous hydrogen peroxide solution in another compartment. The solution may also comprise stabilizers, e.g. chelators, and osmolality increasing agents. The catheter for insertion in the urethra is useful for the treatment, alleviation or prophylaxis of microbial infections such as urinary tract infections (UTI).

Owner:COLOPLAST AS

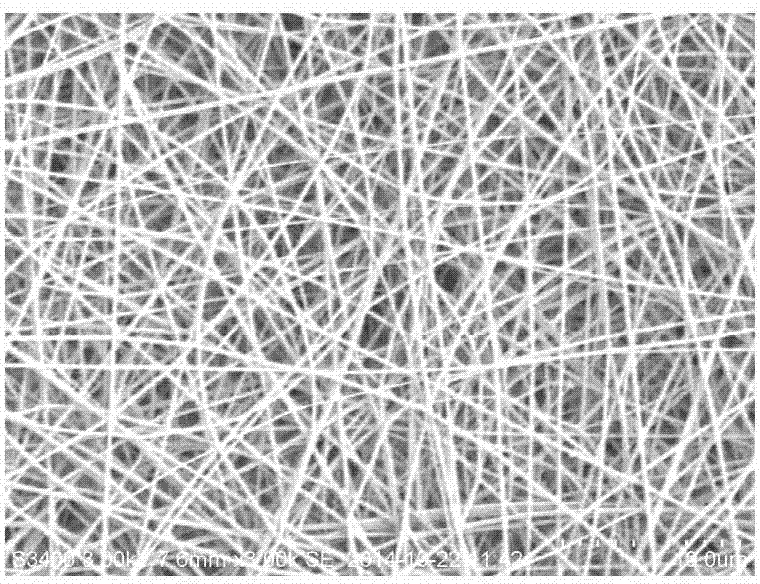

Composite lithium ion battery diaphragm and preparation method thereof

InactiveCN104766938AReduce the probability of short circuitImprove performanceCell seperators/membranes/diaphragms/spacersSecondary cellsNonwoven fabricLithium-ion battery

The invention discloses a composite lithium ion battery diaphragm comprising a nonwoven fabric substrate layer, an electrostatic spinning layer and a polymer porous coating, and the structure compound mode is as follows: polymer porous coating / electrostatic spinning layer / nonwoven fabric substrate layer / electrostatic spinning layer / polymer porous coating; nonwoven fabric substrate layer / electrostatic spinning layer / polymer porous coating; or polymer porous coating / nonwoven fabric substrate layer / electrostatic spinning layer / polymer porous coating. The composite lithium ion battery diaphragm uses nonwoven fabric as a substrate to ensure the diaphragm high porosity and heat resistance, electrostatic spinning layers are arranged on the upper and lower surfaces of the nonwoven fabric substrate, the nonwoven fabric pore diameter can be reduced, the pore diameter is uniform, and the problem of short circuit caused by local macropore of the nonwoven fabric diaphragm can be solved, and by the arrangement of the polymer porous coating, the absorption and electrolyte maintaining capacity of the diaphragm can be improved, battery positive and negative electrodes can be bonded, battery mechanical properties can be improved, and the battery safety can be ensured. The prepared composite lithium ion battery diaphragm can satisfy the security requirements of large current charging discharging and running in harsh environments of a high-capacity high-power power battery.

Owner:LONGYAN ZIJIN INNOVATION RES INST +1

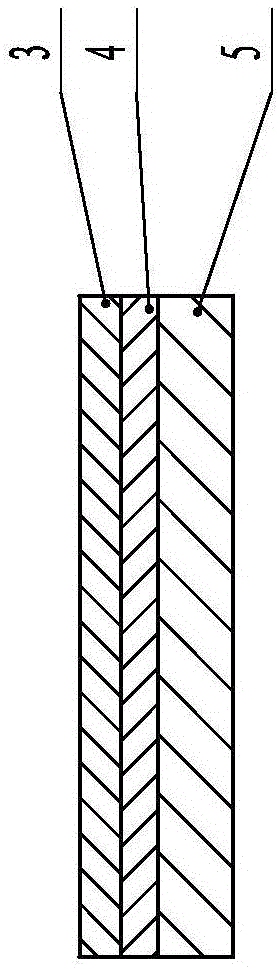

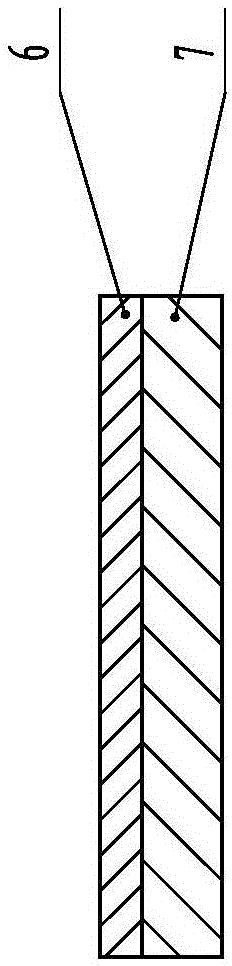

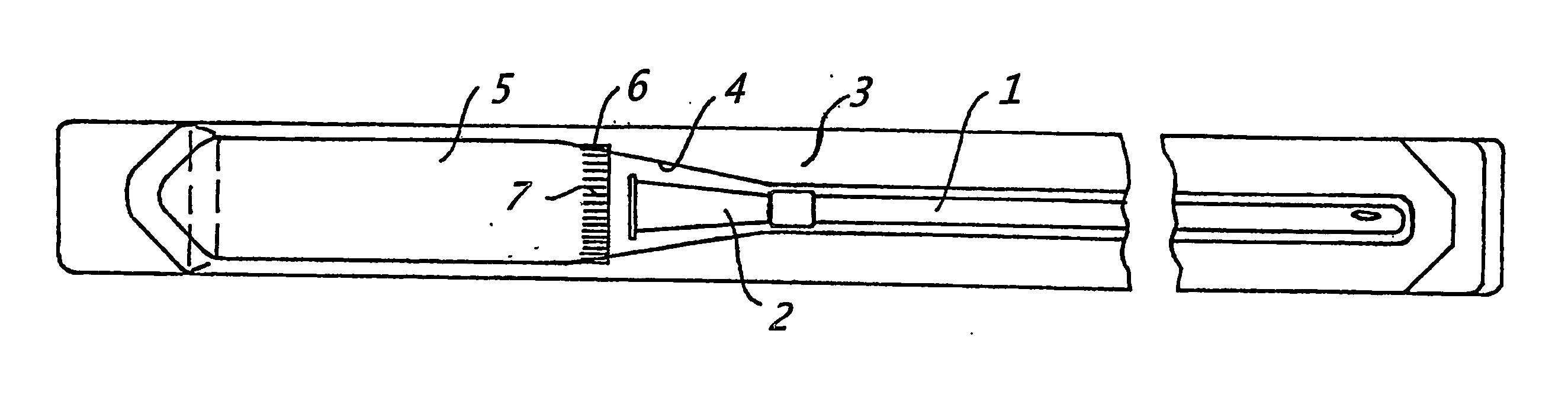

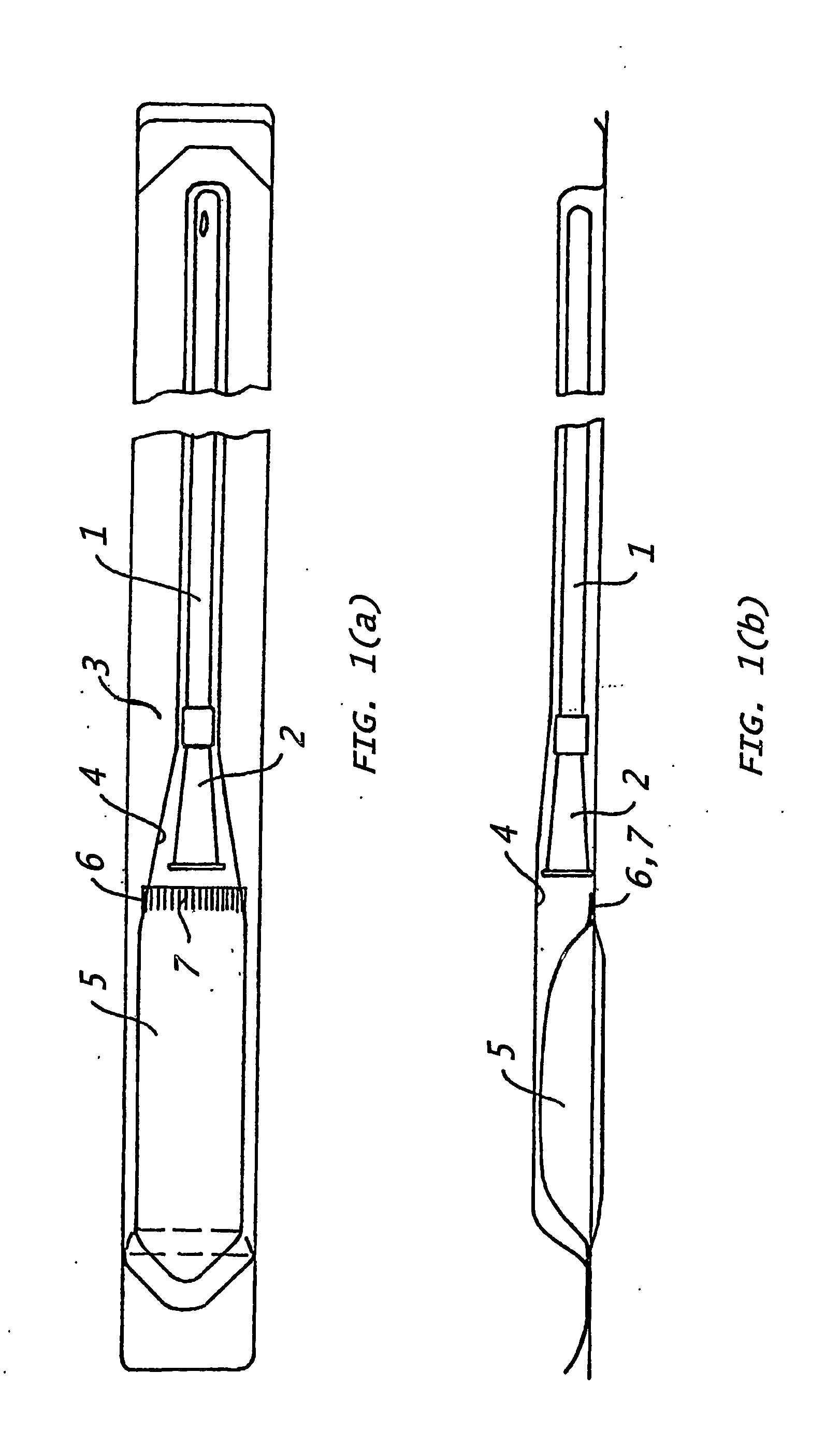

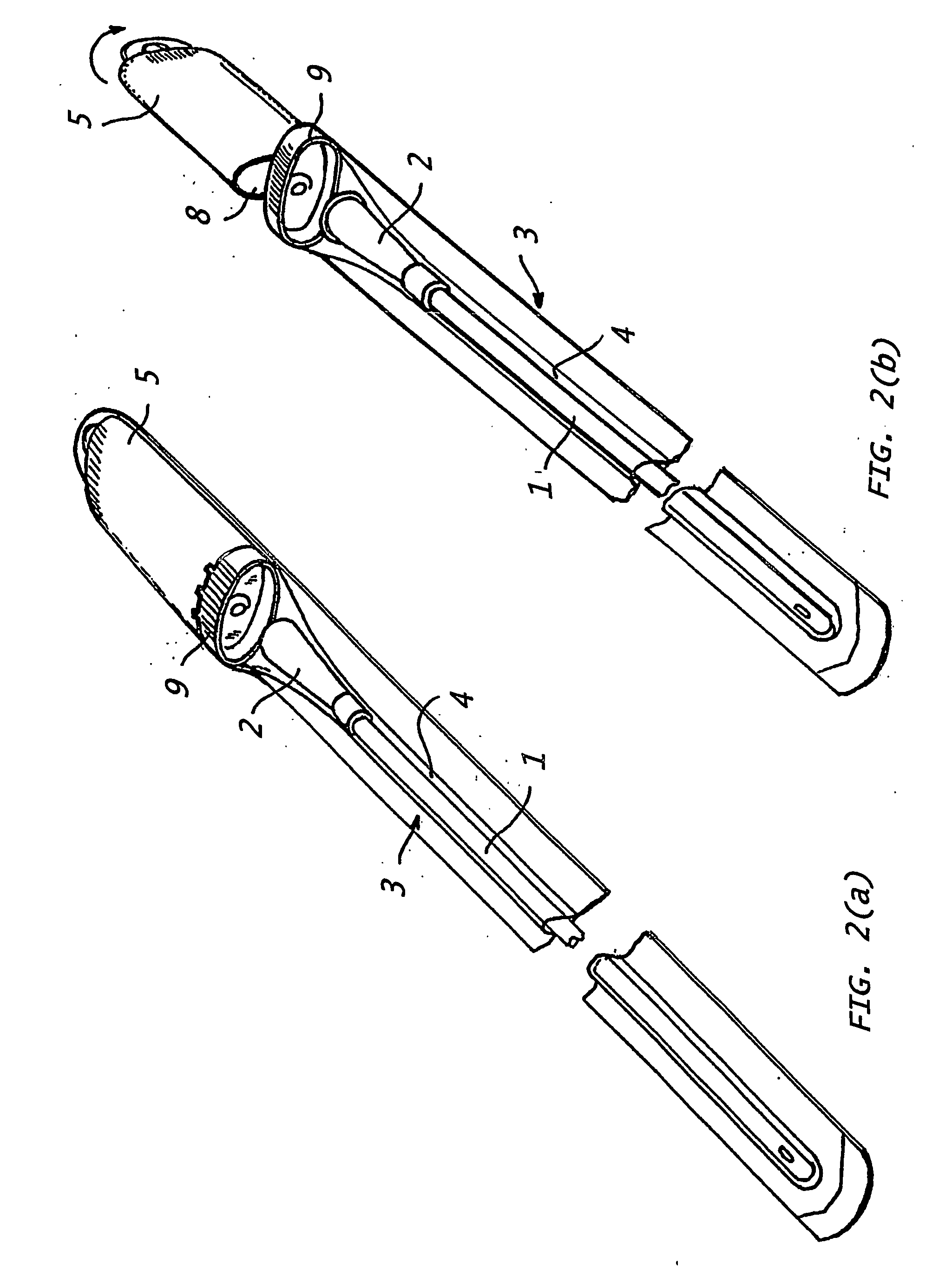

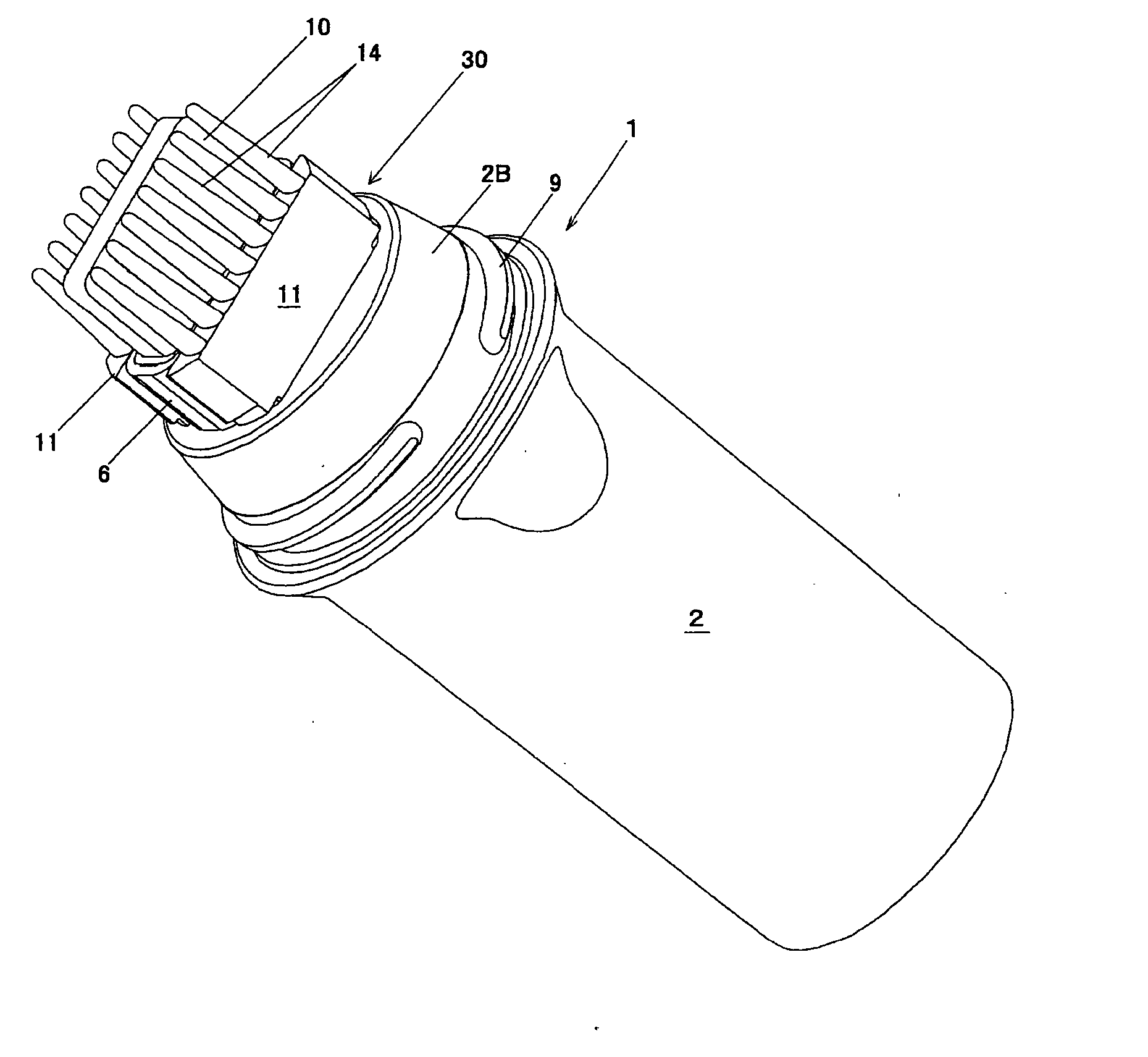

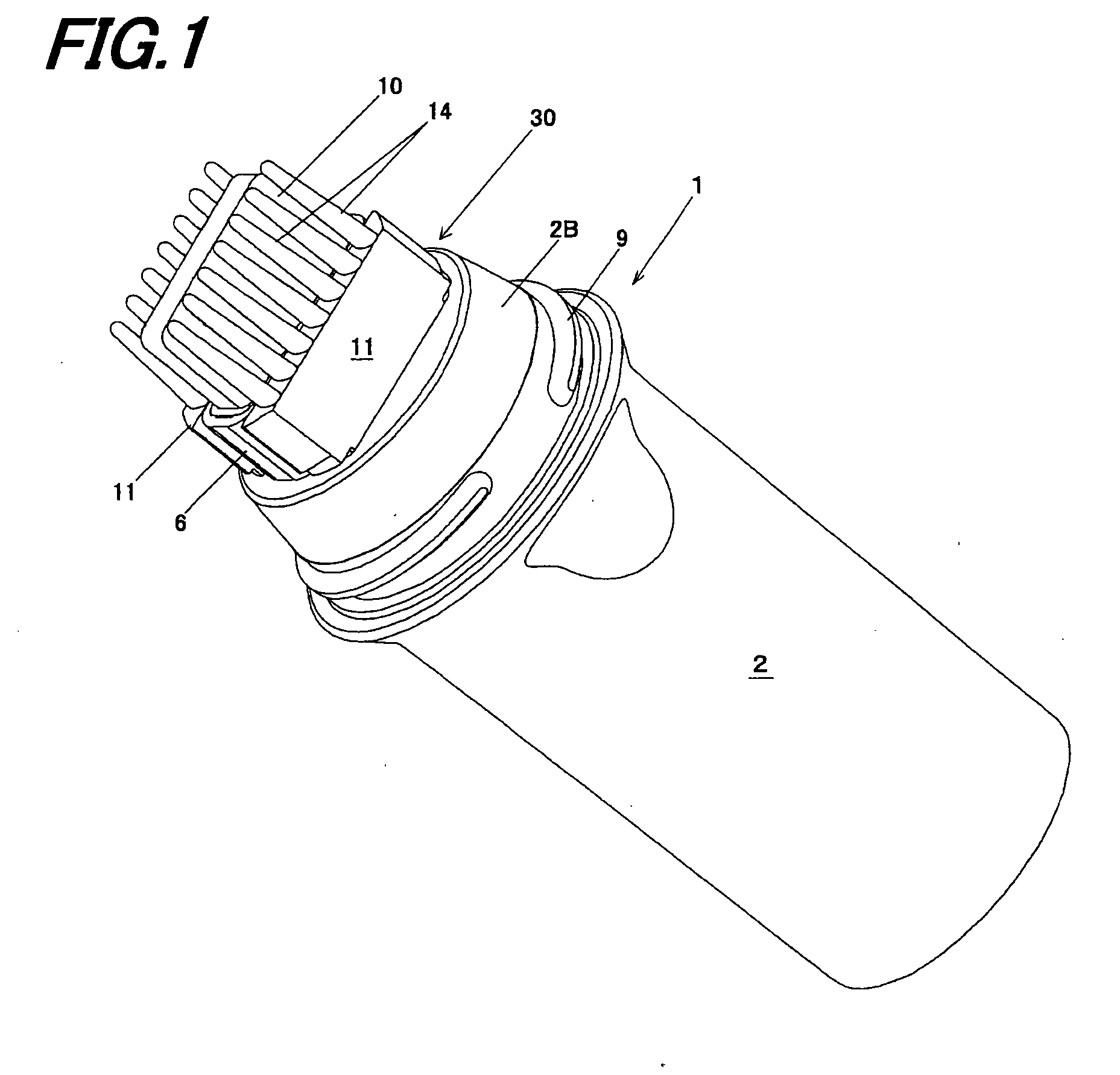

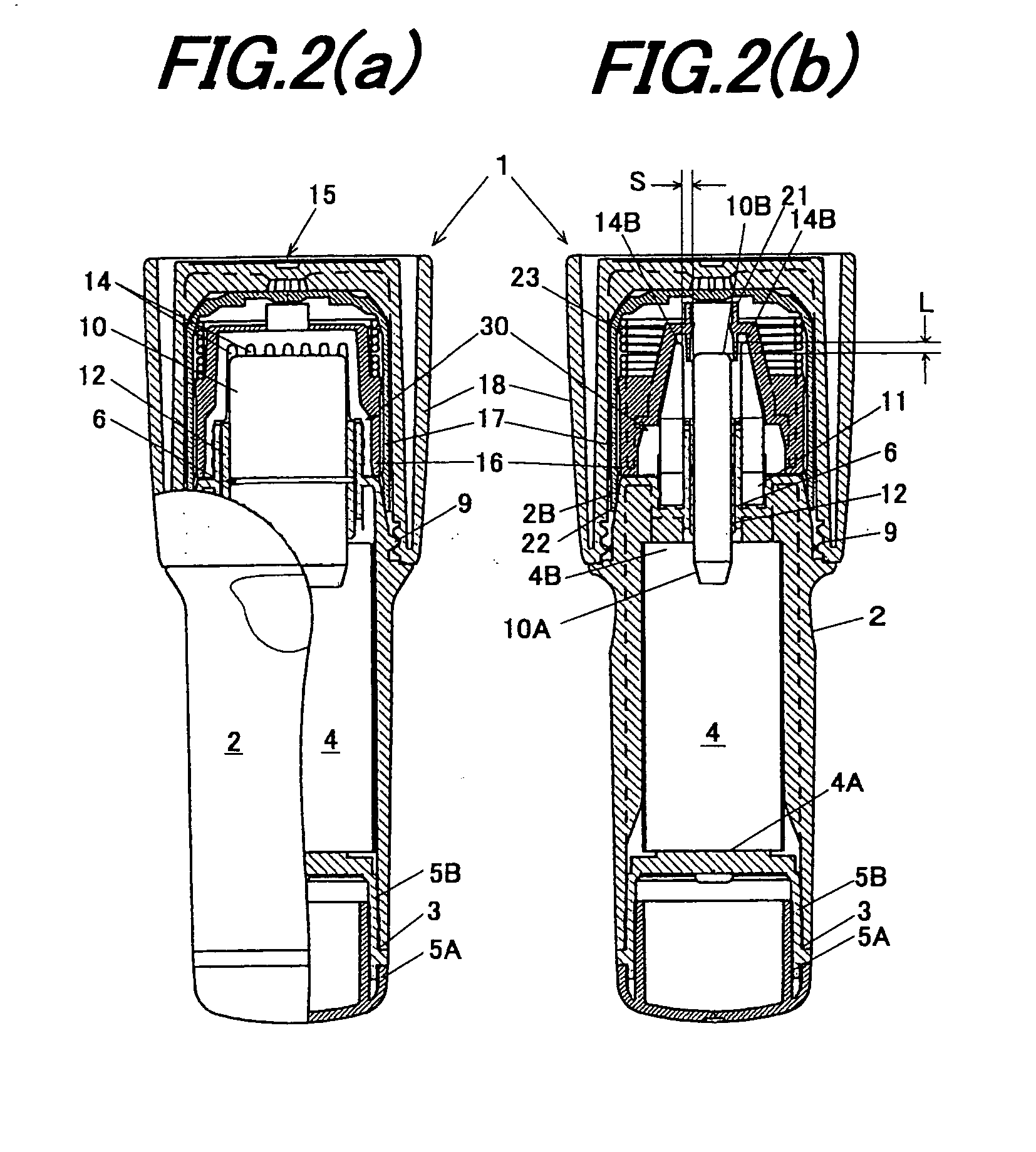

Coater for Hair and Cosmetic Paint Container with the Coater

InactiveUS20080060665A1Sufficient paint performancePrevent liquid leakageLiquid surface applicatorsBristlePorous coatingBiomedical engineering

The present invention is a hair coater which appropriately delivers an paint liquid without liquid leakage of the paint liquid, and which, in addition, can assure sufficient paint performance, preventing the paint liquid or the like from being directly applied to the scalp, and the hair coater, which while combing hair by a comber made up of comb members and a multiple number of porous coating elements arranged comb-like in a row along the comb members, is able to apply the paint liquid in a container being attached to the hair by means of the porous coating elements, and is characterized in that the paint liquid retention force of the porous coating elements falls within a range of 120 to 250 mm. The present invention also includes a coater-equipped cosmetic container with the aforementioned hair coater.

Owner:MITSUBISHI PENCIL CO LTD

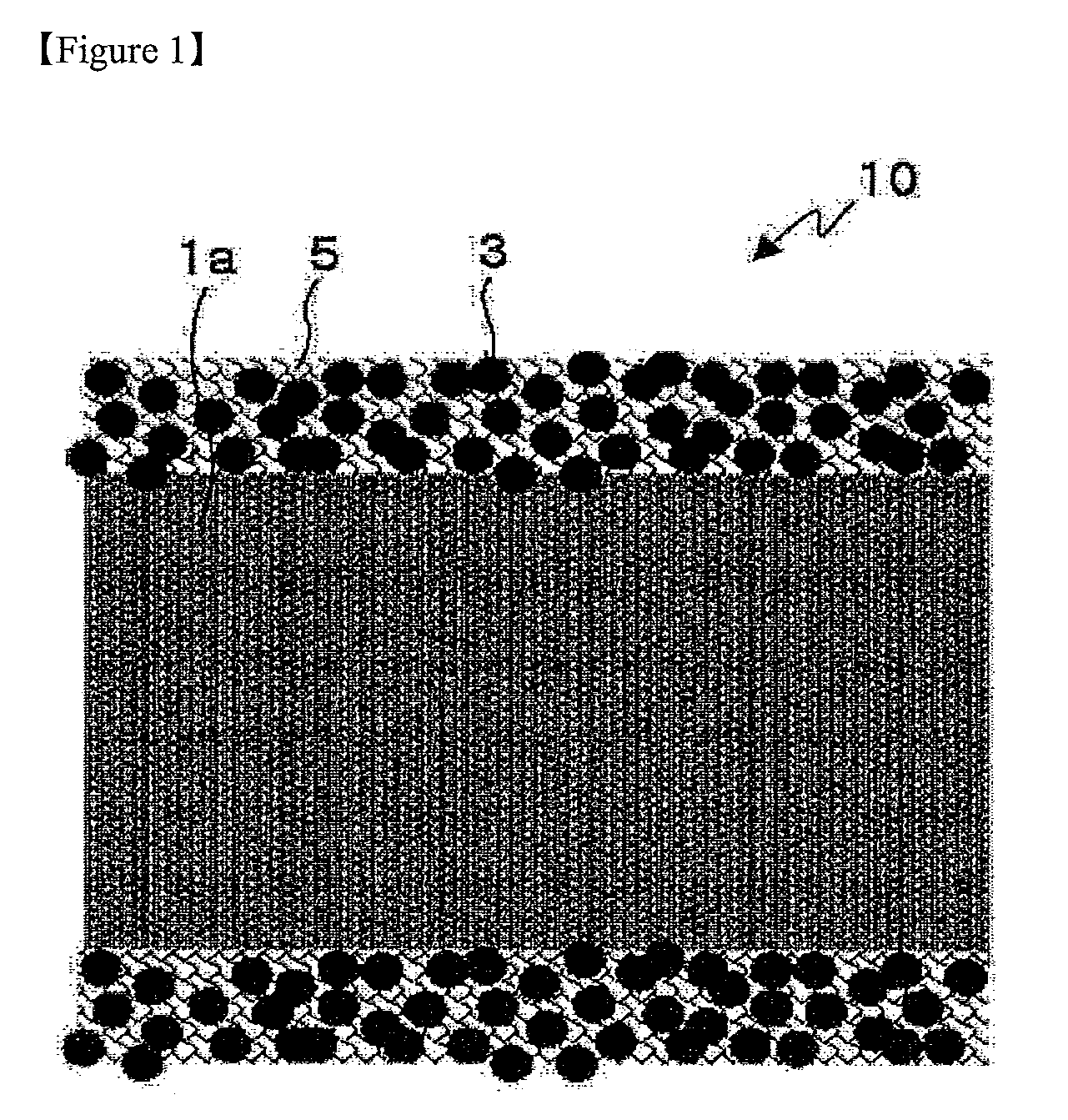

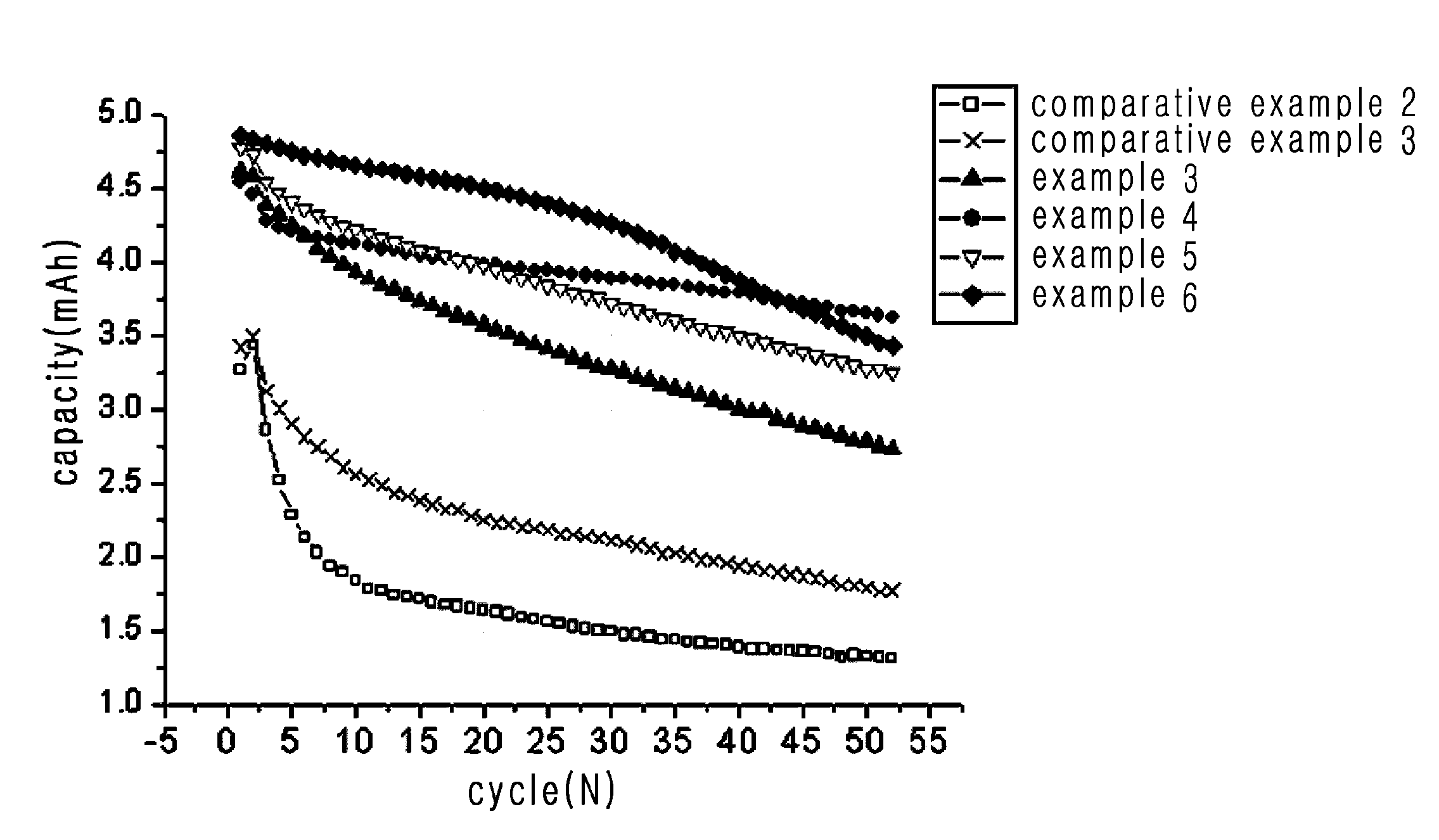

Lithium secondary battery

ActiveUS20110064988A1Improve wettabilityImprove securityCell seperators/membranes/diaphragms/spacersCell electrodesPorous coatingPorous substrate

A lithium secondary battery includes a cathode, an anode, a separator interposed between the cathode and the anode, and a non-aqueous electrolytic solution obtained by dissolving lithium salt to a non-aqueous solvent. The separator includes a porous substrate having pores; and a porous coating layer located on at least one surface of the porous substrate and having inorganic particles and a binder polymer, the inorganic particles being connected and fixed to each other by means of the binder polymer, the porous coating layer having pores therein formed by interstitial volumes among the inorganic particles. The non-aqueous solvent is a high-viscous non-aqueous solvent having a viscosity of 1.4 cP or above at 25° C. This lithium secondary battery gives improved safety and excellent charging / discharging characteristics since it has the high-viscous non-aqueous solvent and the separator with good wettability against the solvent.

Owner:TORAY BATTERY SEPARATOR FILM +1

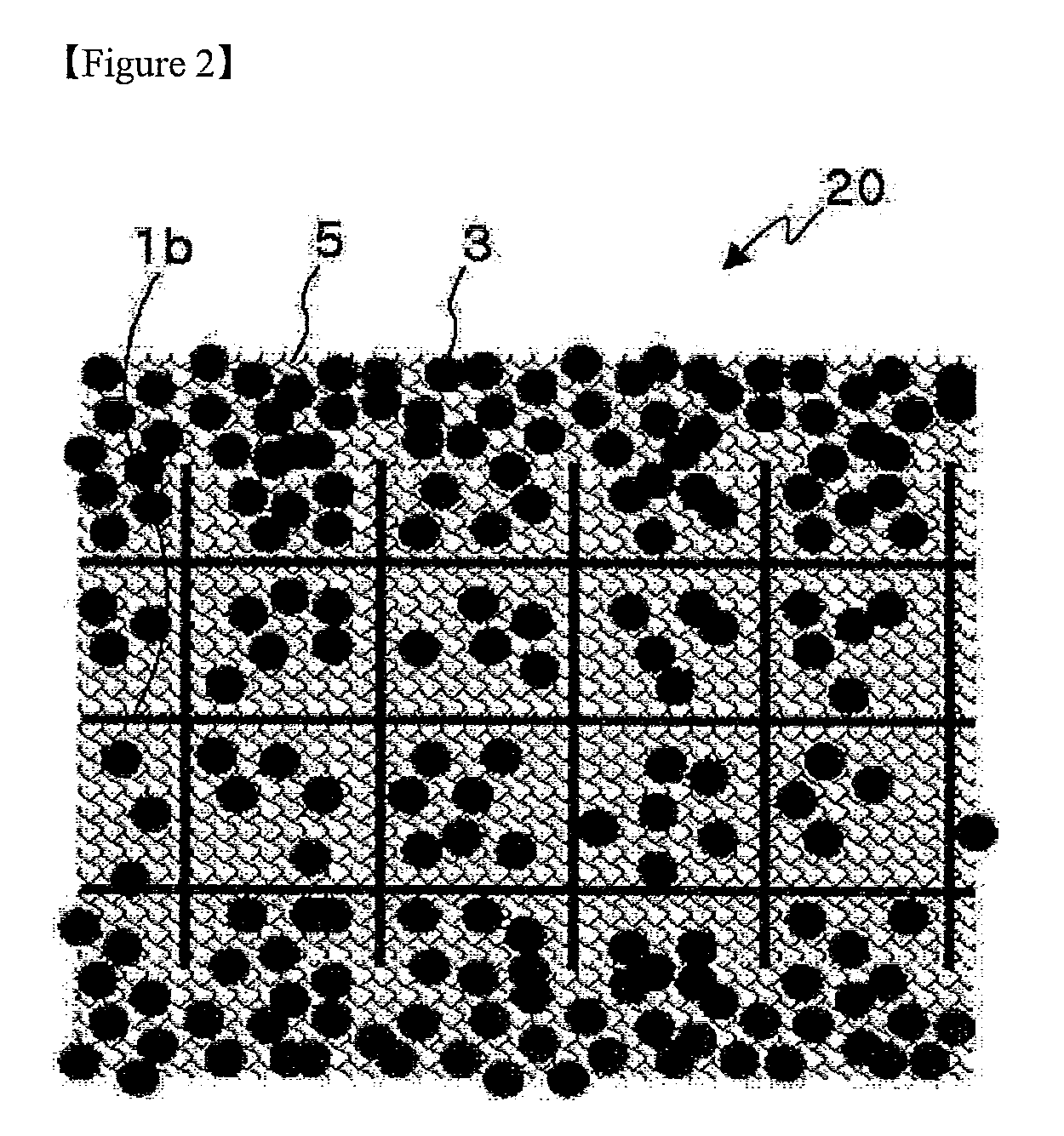

Separator having porous coating layer, and electrochemical device containing the same

ActiveUS20120034509A1High porosityThermal shrinkage of the separator may be further loweredLi-accumulatorsCell component detailsPorous coatingPolyolefin

A separator includes a monolayer-type polyolefin-based micro-porous film having a porosity of 40 to 60%, an average pore diameter of 60 nm or less, and an air permeability of 350 s / 100 mL or less; and a porous coating layer formed on at least one surface of the micro-porous film and made of a mixture of a plurality of inorganic particles and a binder polymer. An electrochemical device having the above separator has excellent thermal stability and allows a high power while minimizing the occurrence of leak current.

Owner:LG ENERGY SOLUTION LTD +1

Separator including porous coating layer, method for manufacturing the separator and electrochemical device including the separator

ActiveUS20120015228A1Avoid it happening againInhibit the electrochemical reaction processFinal product manufacturePretreated surfacesPorous coatingInorganic particle

A separator includes a non-woven fabric substrate having pores, fine thermoplastic powder located inside the pores of the non-woven fabric substrate, and a porous coating layer disposed on at least one surface of the non-woven fabric substrate. The fine thermoplastic powder has an average diameter smaller than that of the pores and a melting point lower than the melting or decomposition point of the non-woven fabric substrate. The porous coating layer includes a mixture of inorganic particles and a binder polymer whose melting point is higher than the melting or decomposition point of the fine thermoplastic powder. In the porous coating layer, the inorganic particles are fixedly connected to each other by the binder polymer and the pores are formed by interstitial volumes between the inorganic particles. Previous filling of the large pores of the non-woven fabric substrate with the fine thermoplastic powder makes the porous coating layer uniform.

Owner:LG ENERGY SOLUTION LTD +1

Electrochemical device and its manufacturing method

ActiveUS20100003590A1Improve thermal stabilityEconomic efficiency is excellentFinal product manufacturePrimary cellsPorous substratePorous coating

An electrochemical includes an electrode structure provided with a composite separator having a porous substrate with a plurality of pores and a porous coating layer formed on at least one surface of the porous substrate and made of a mixture of electrode active material particles and a binder polymer. The porous coating layer of the composite separator improves thermal stability of the porous substrate and plays a function of electrode active material layer of the electrochemical device. Accordingly, this electrochemical device has excellent stability and good economical efficiency since the electrode structure does not need coating of an electrode active material layer on a surface of a current collector.

Owner:LG ENERGY SOLUTION LTD

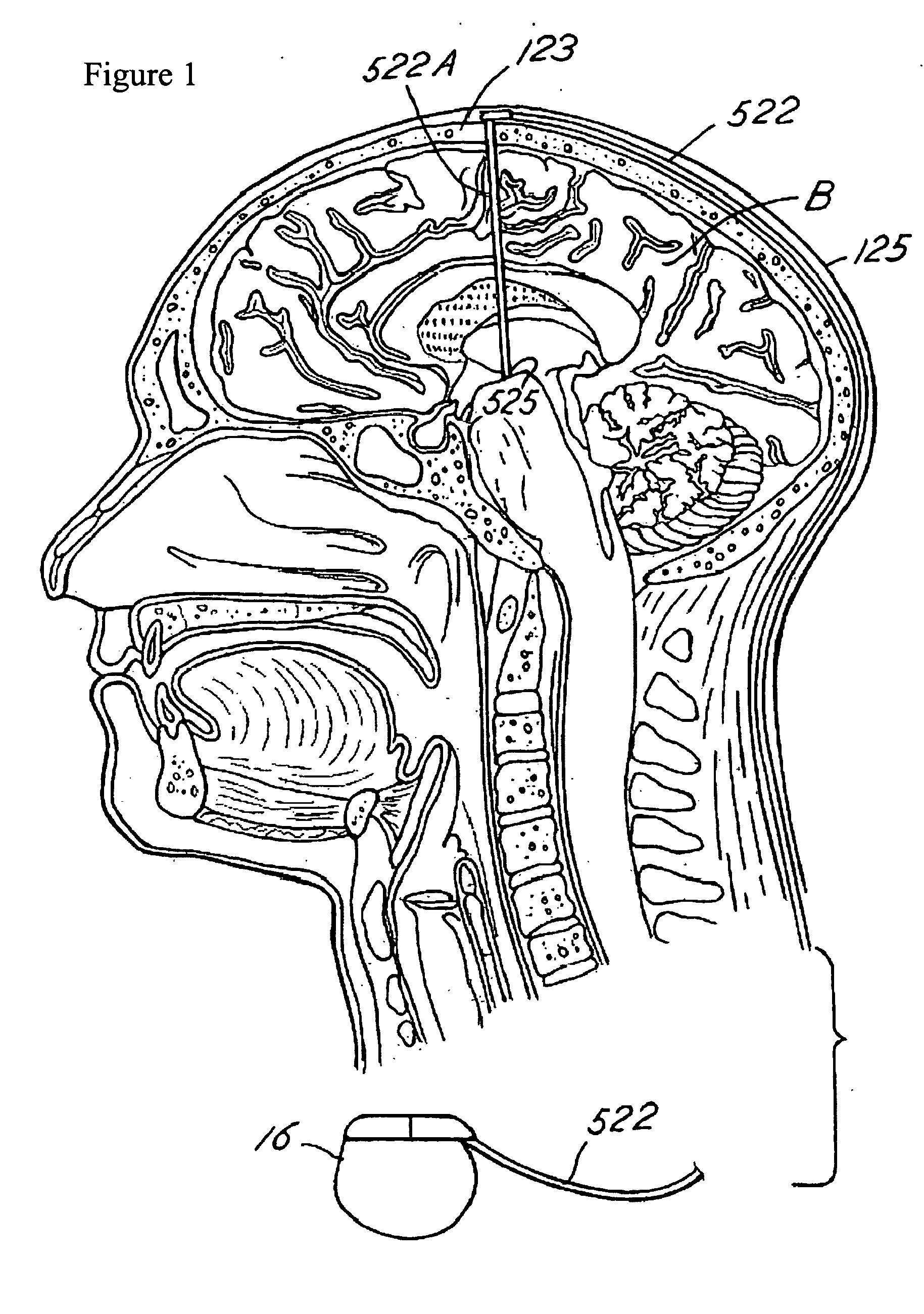

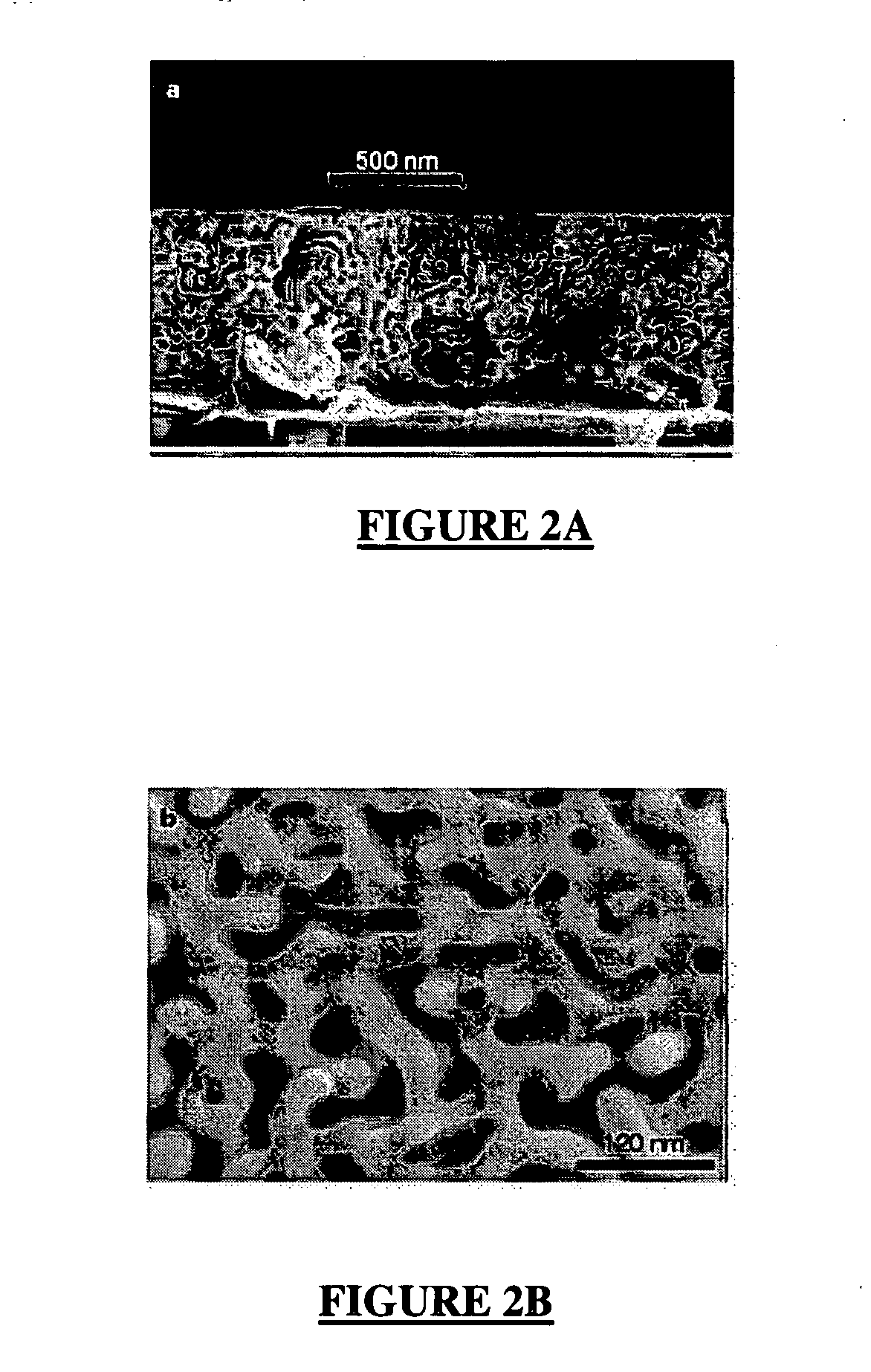

Plasma sprayed porous coating for medical implants

A prosthesis having an oxidized zirconium surface and a porous textured surface is described. A major advantage of the prosthesis is increased service life. Additionally, a process of manufacturing the prosthesis is described.

Owner:SMITH & NEPHEW INC

Method of producing coated engine components

InactiveUS20050016489A1Reduce frictionProvide wear resistanceMolten spray coatingPlungersPorous coatingEngineering

To improve engine performance and reduce wear and friction, a porous coating is applied to piston skirts and cylinder bores via a thermal spray process. The porous nature of the coating allows for oil to be held on the surfaces enhancing lubrication.

Owner:WIDE OPEN COATINGS

Enhanced fatigue strength orthopaedic implant with porous coating and method of making same

InactiveUS20020151983A1Improve fatigue strengthBone implantJoint implantsMetal particleBone ingrowth

A method for producing an orthopedic implant having enhanced fatigue strength. A forged implant substrate having an elongated stem is incorporated with a melting point lowering substance. Then, metal particles are sintered to the substrate, forming a porous layer on the substrate which enhances bone ingrowth or the mechanical interlock with bone cement. Advantageously, the sintering occurs at a lower temperature than if the substance were not incorporated into the substrate, which in turn results in an enhanced fatigue strength of the inventive implant. The fatigue strength of a forged or cast implant can also be improved by nitrogen diffusion hardening and / or thermally processing the implant after the porous coating is adhered by sintering. Further, the fatigue strength can be further improved by combining incorporating the melting point lowering substance with nitrogen diffusion hardening and / or aging treatment subsequent to sintering.

Owner:ZIMMER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com