Patents

Literature

89 results about "Knee implant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

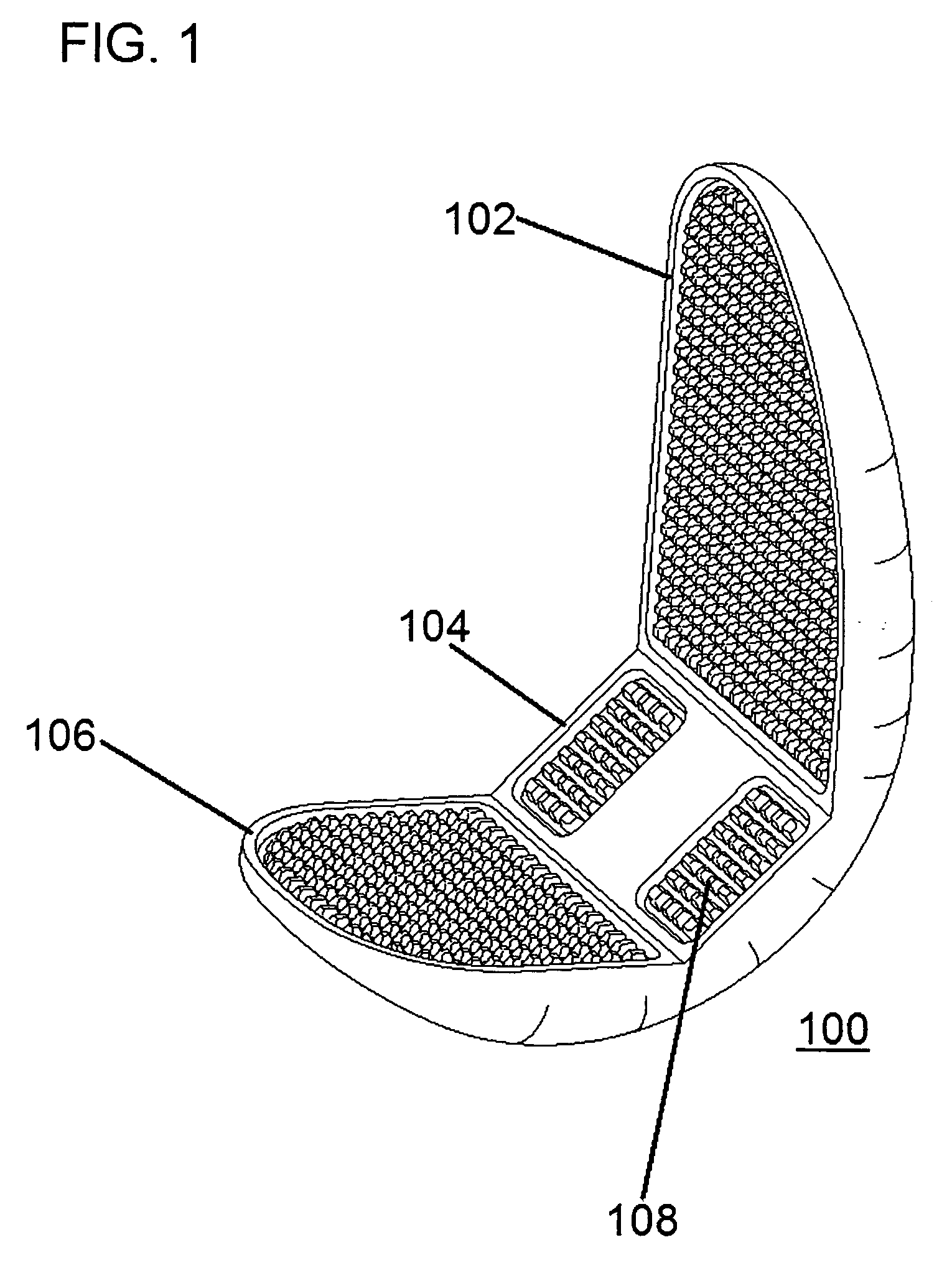

Unicompartmental Implants. Although replacing the total knee joint is the most common procedure, some people can benefit from just a partial knee replacement. If only one side of the knee joint is damaged, smaller implants can be used (unicompartmental knee replacement) to resurface just that side.

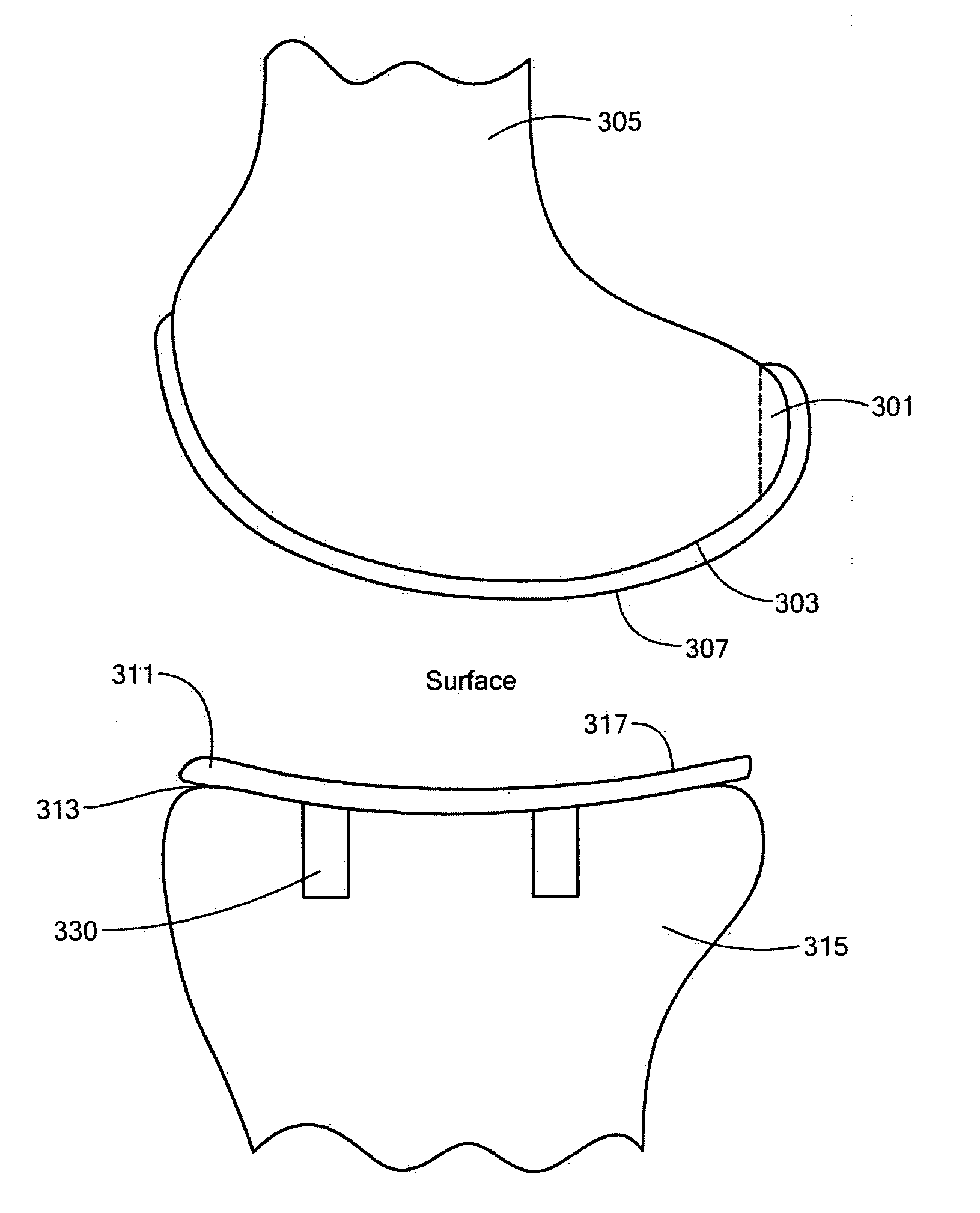

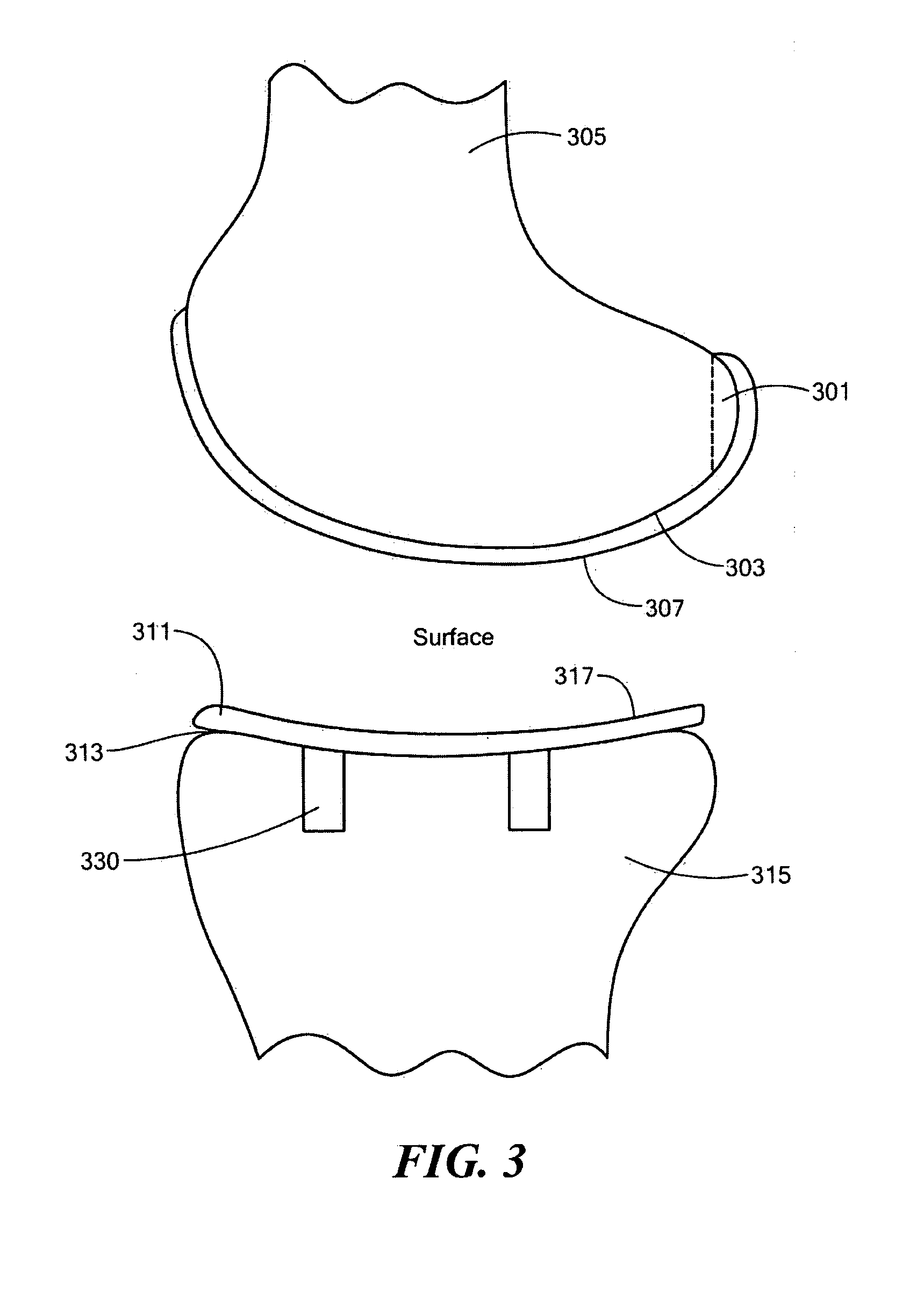

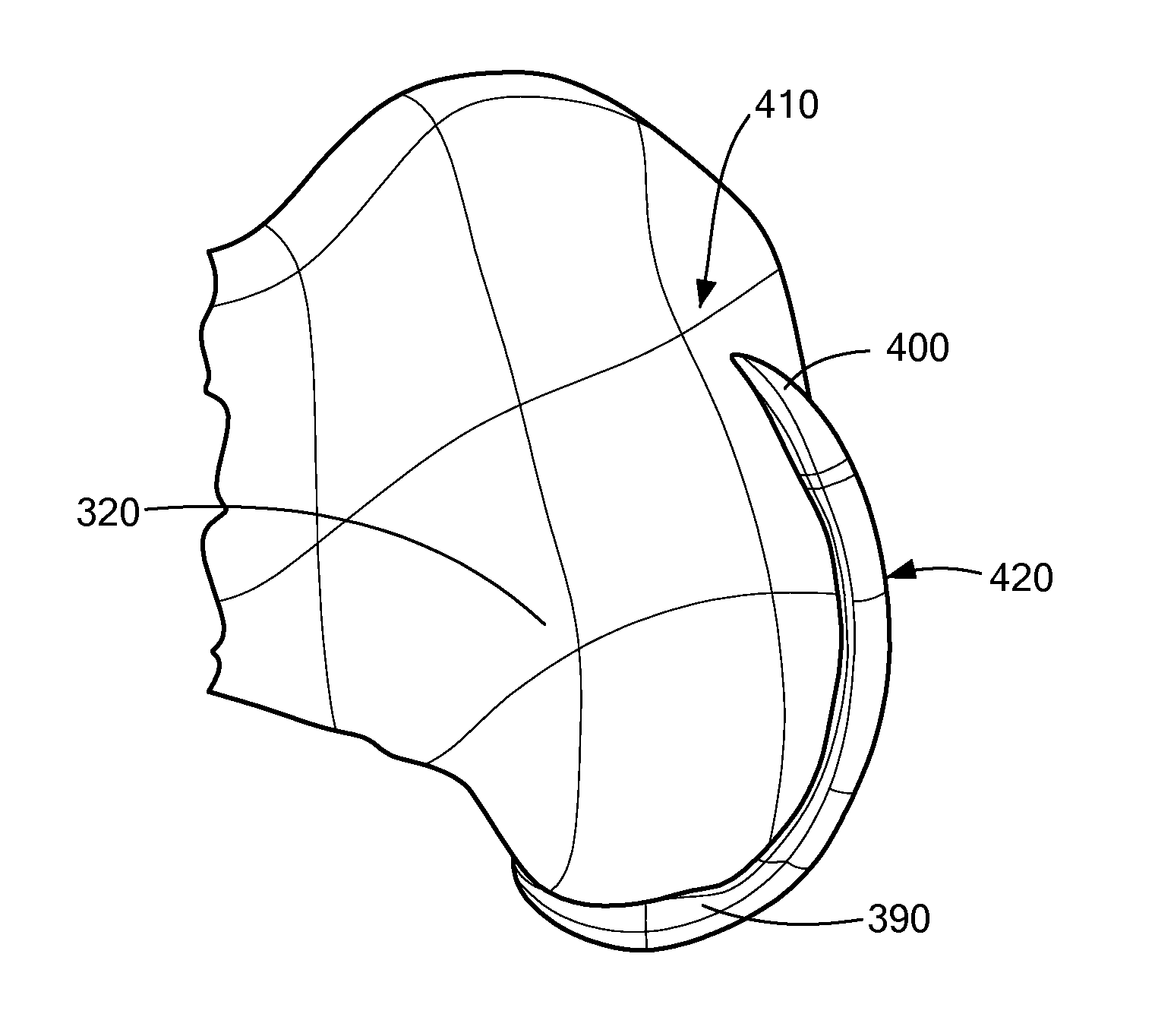

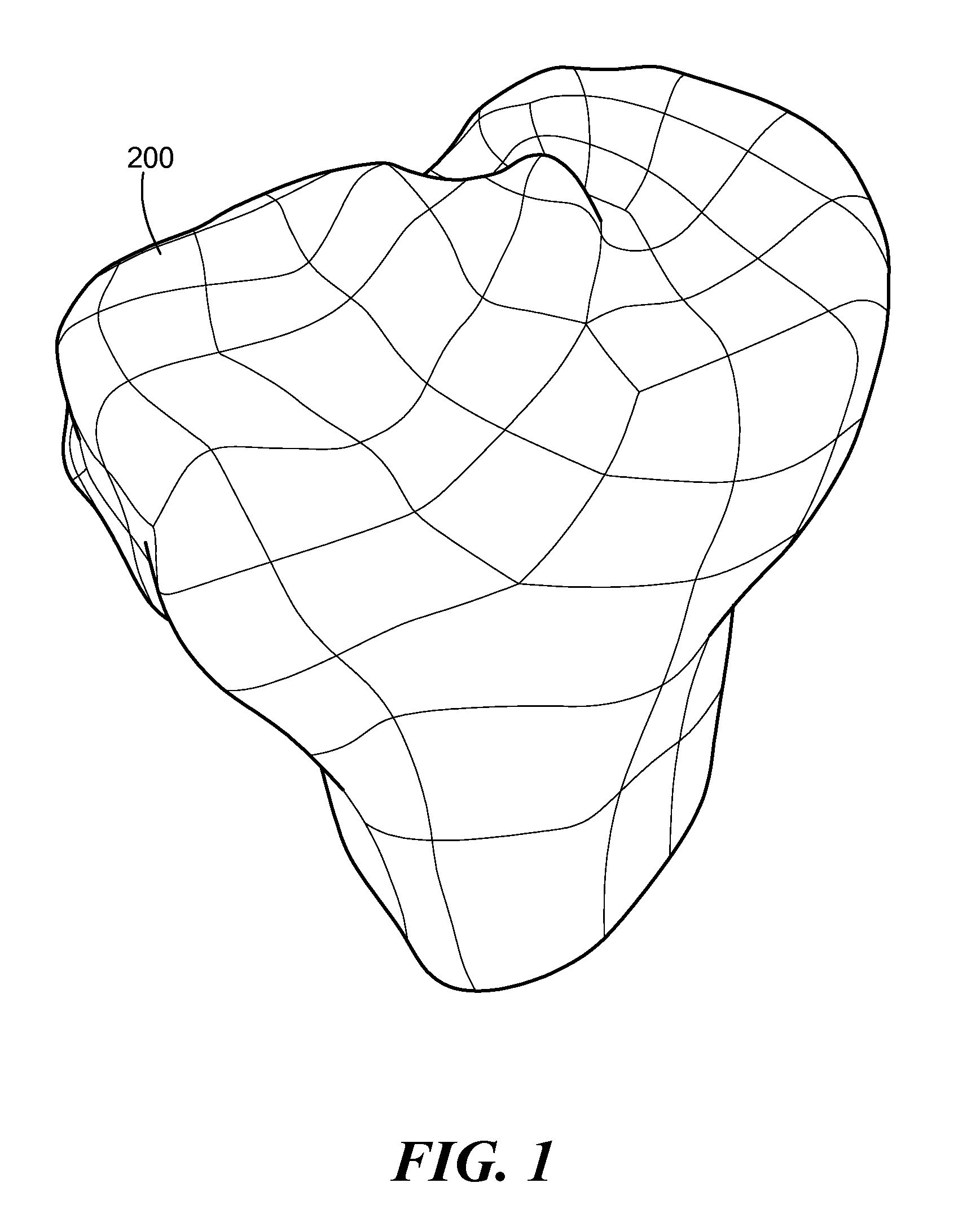

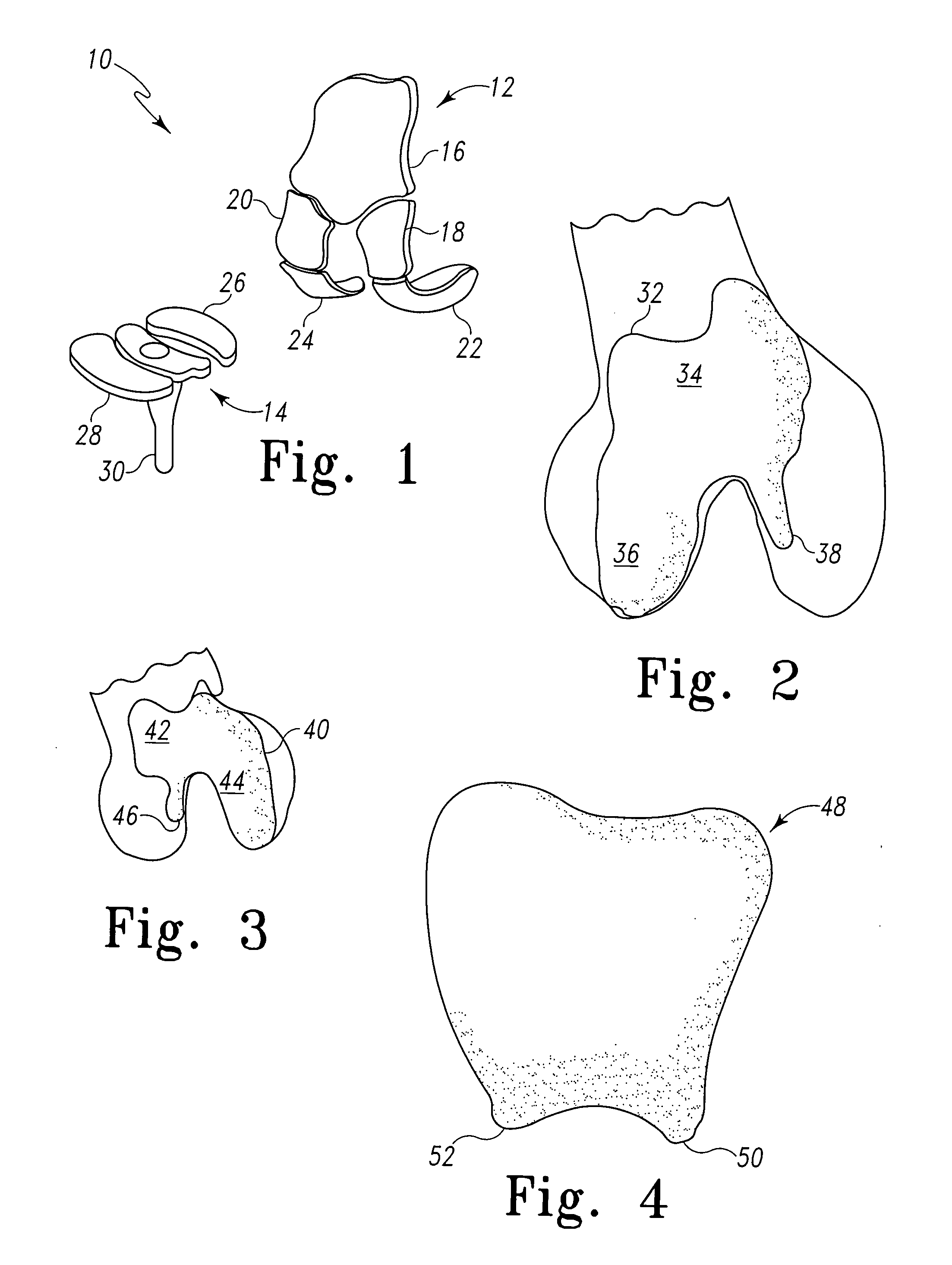

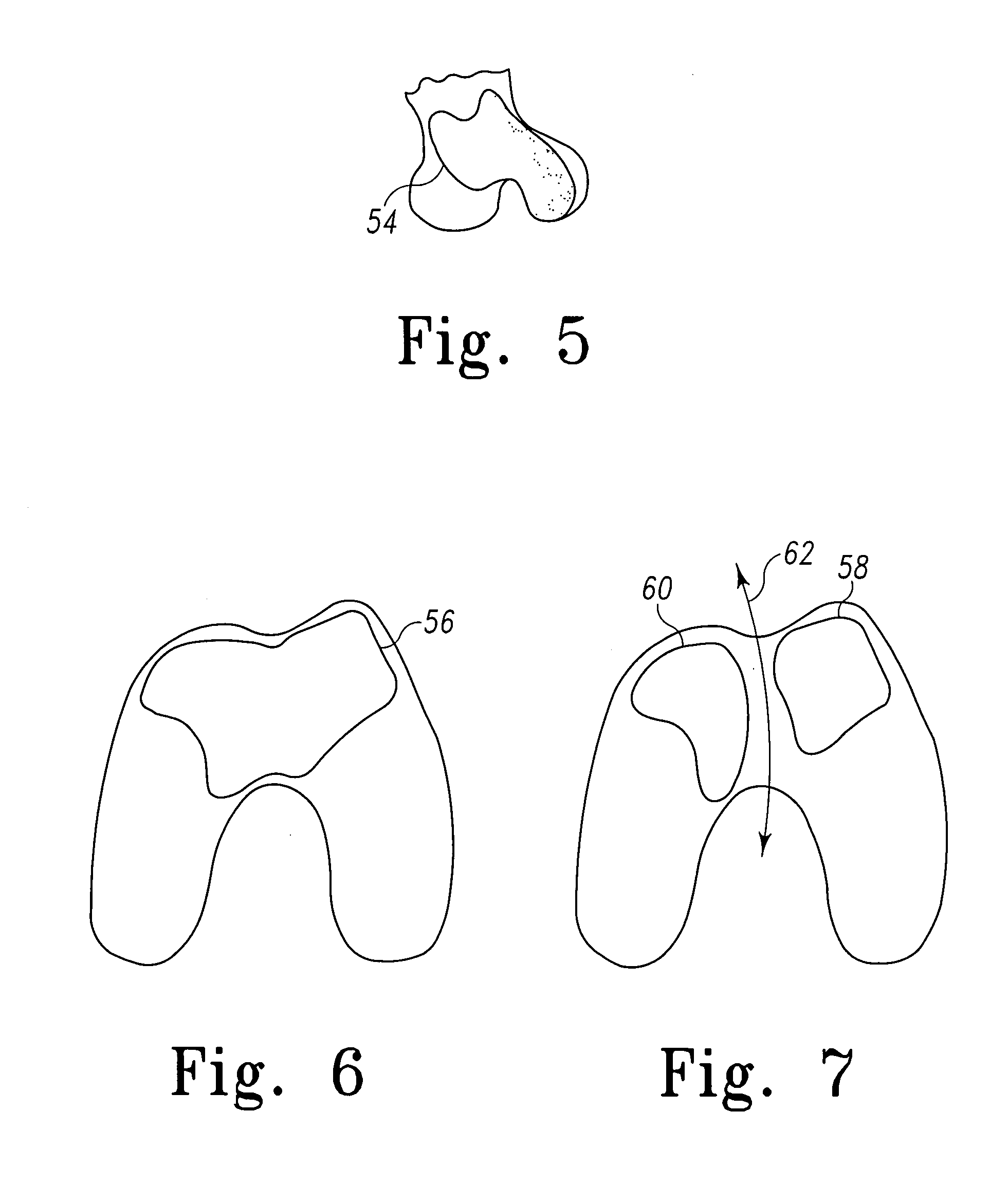

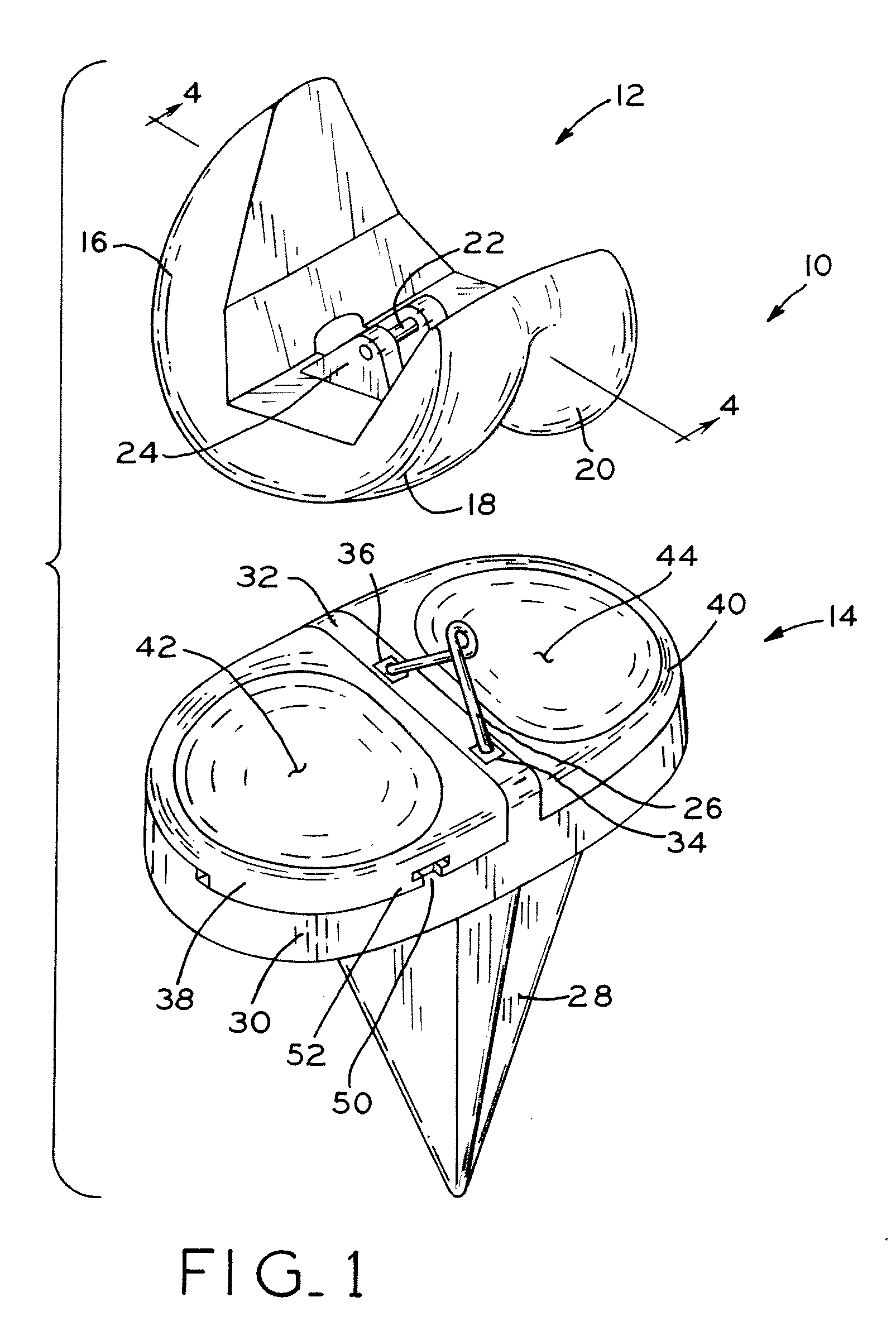

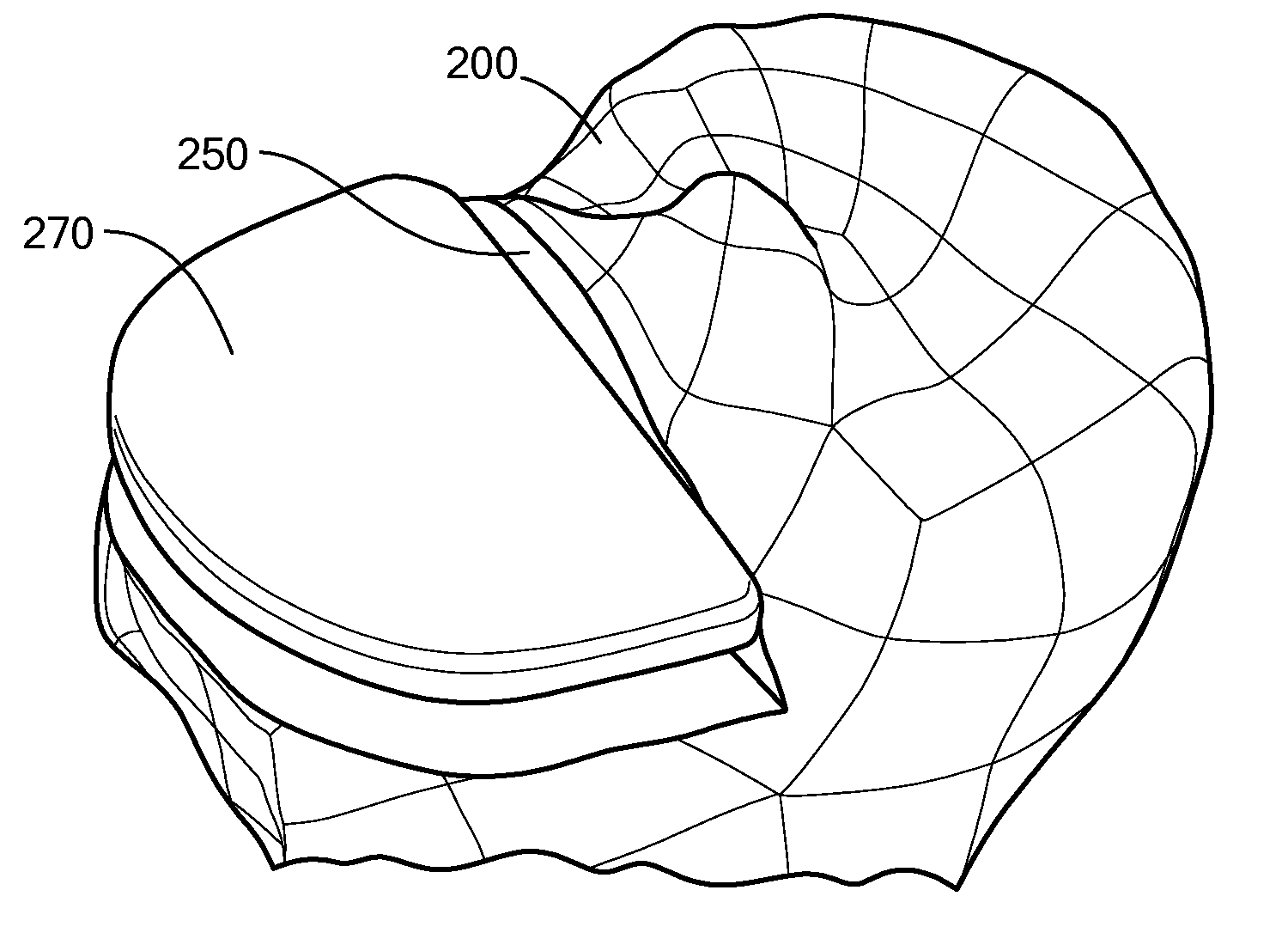

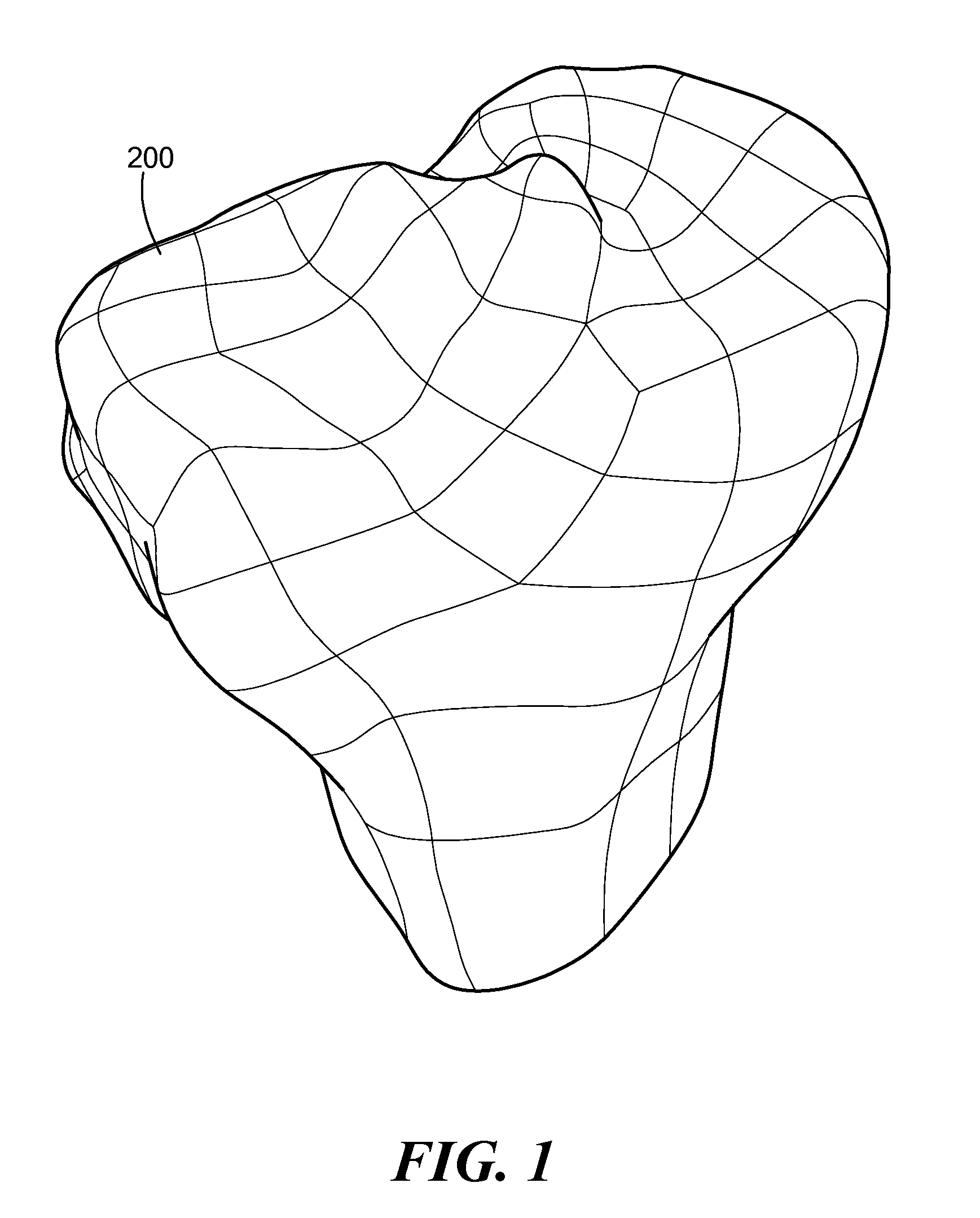

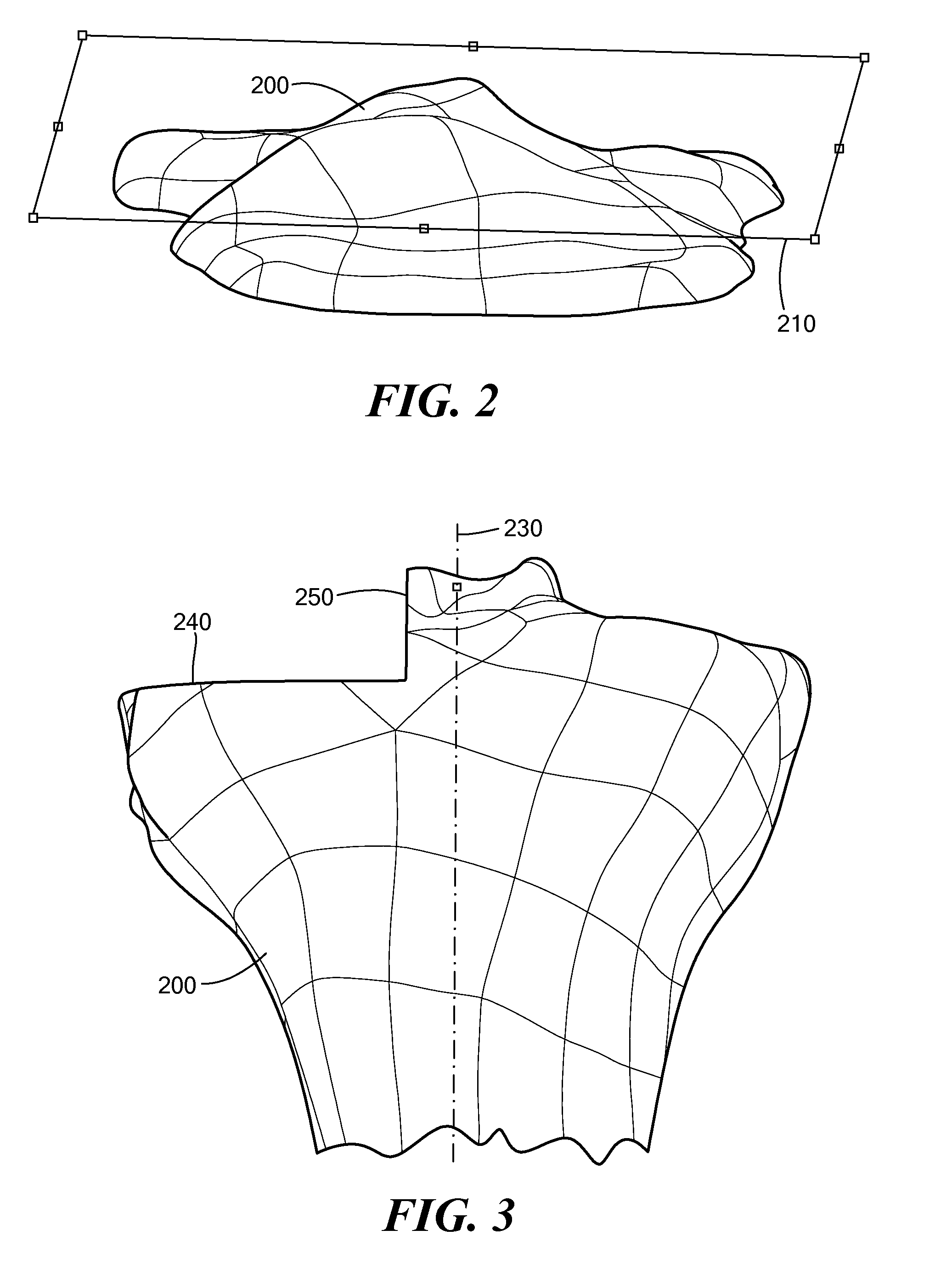

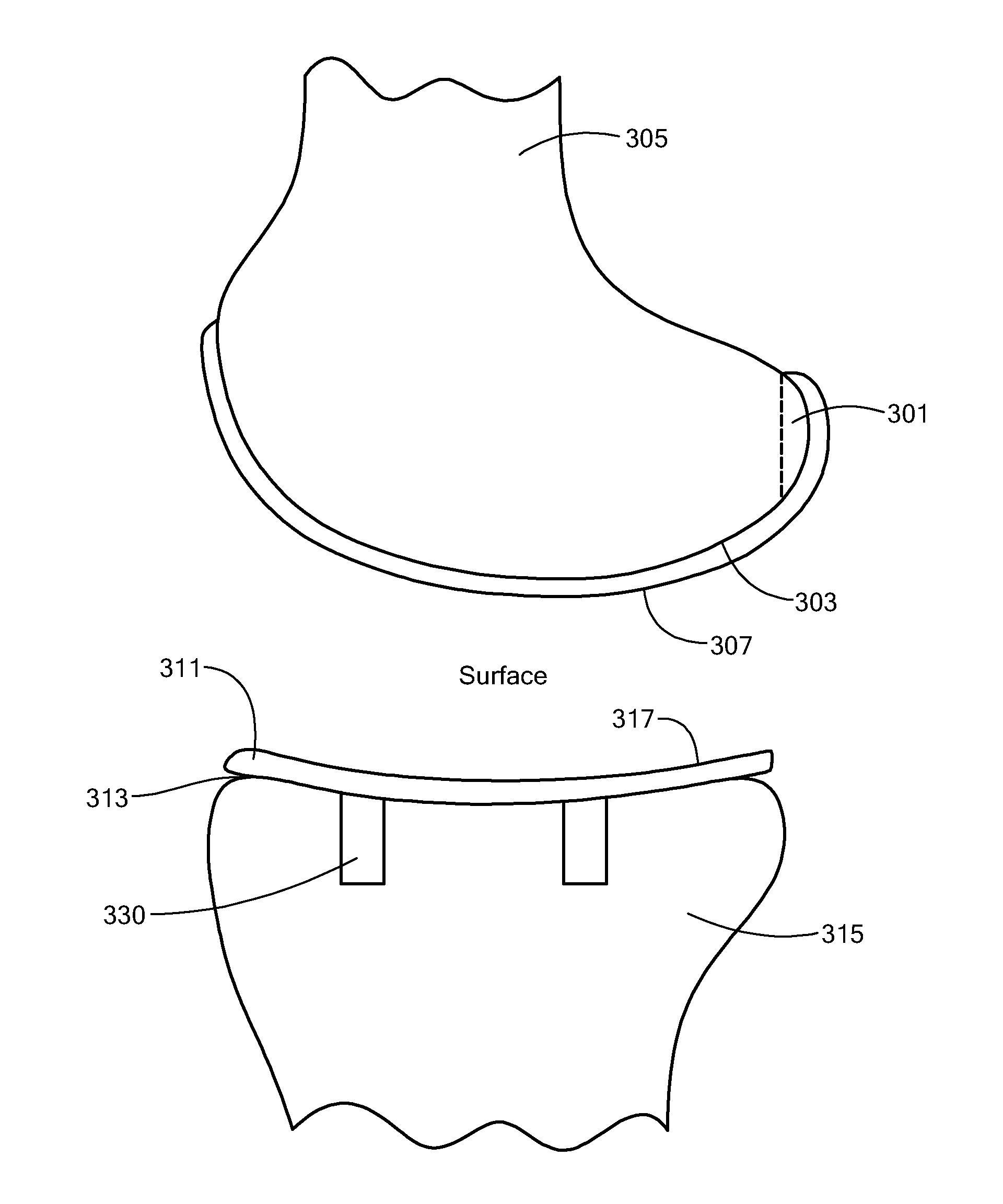

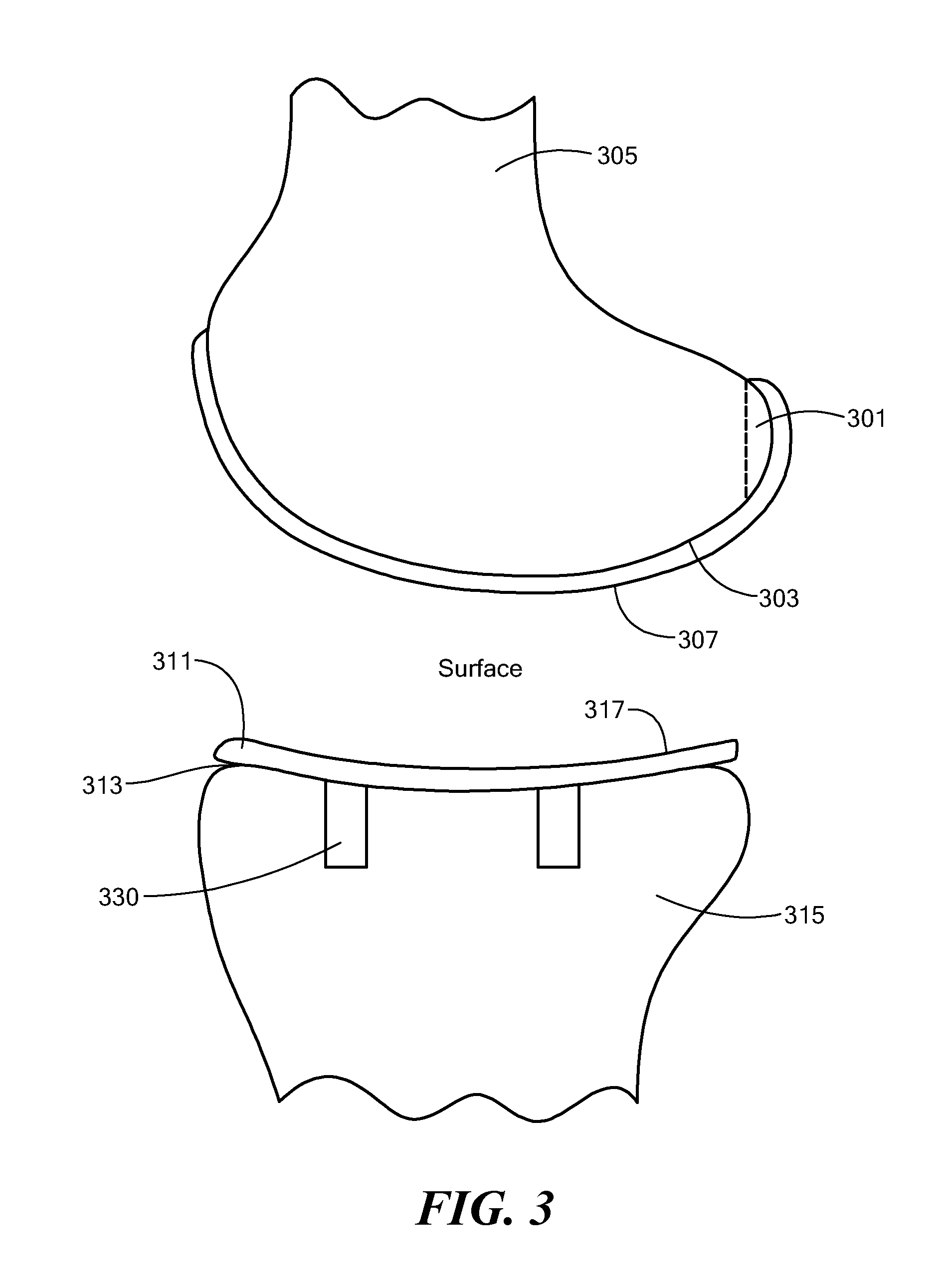

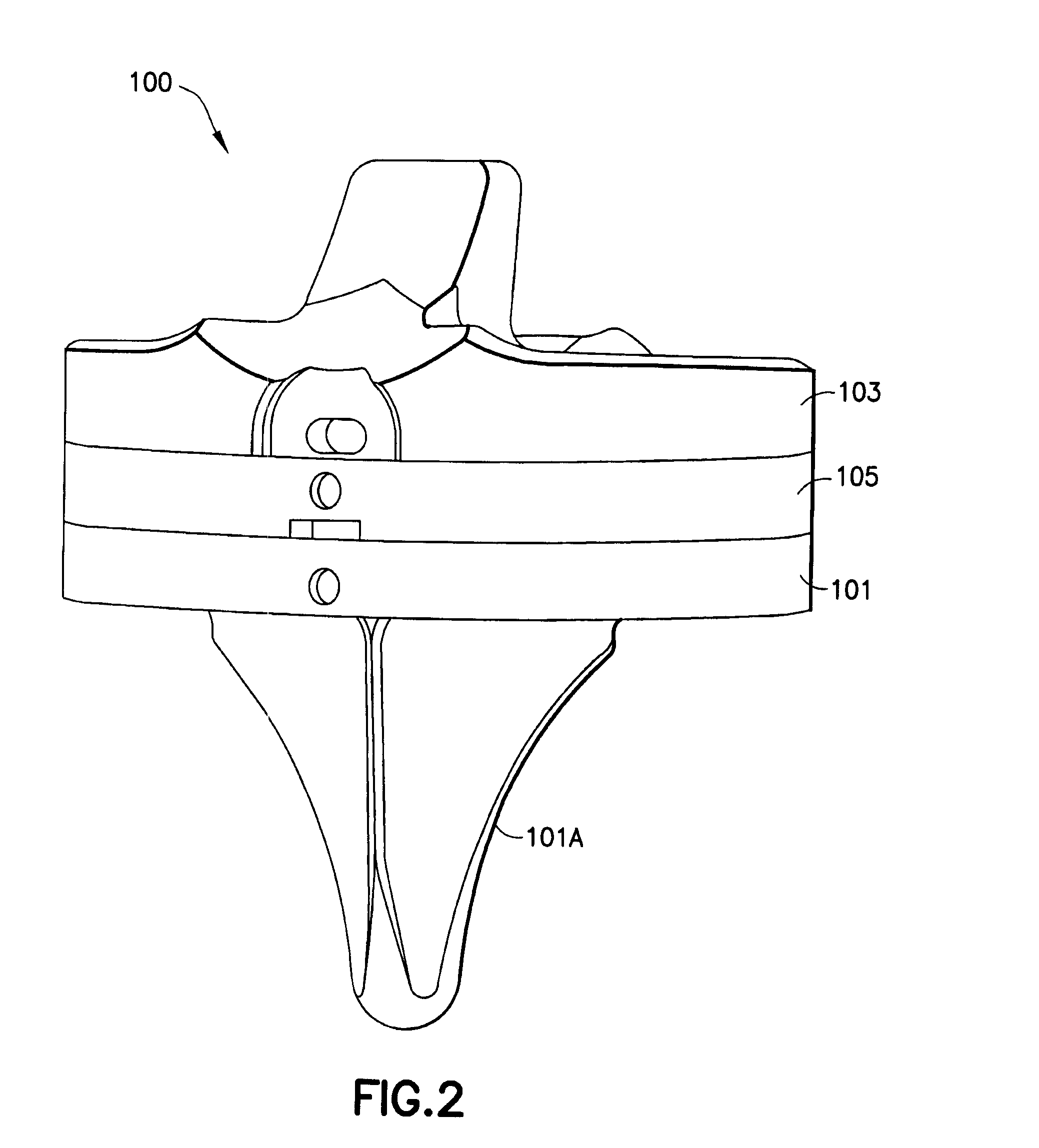

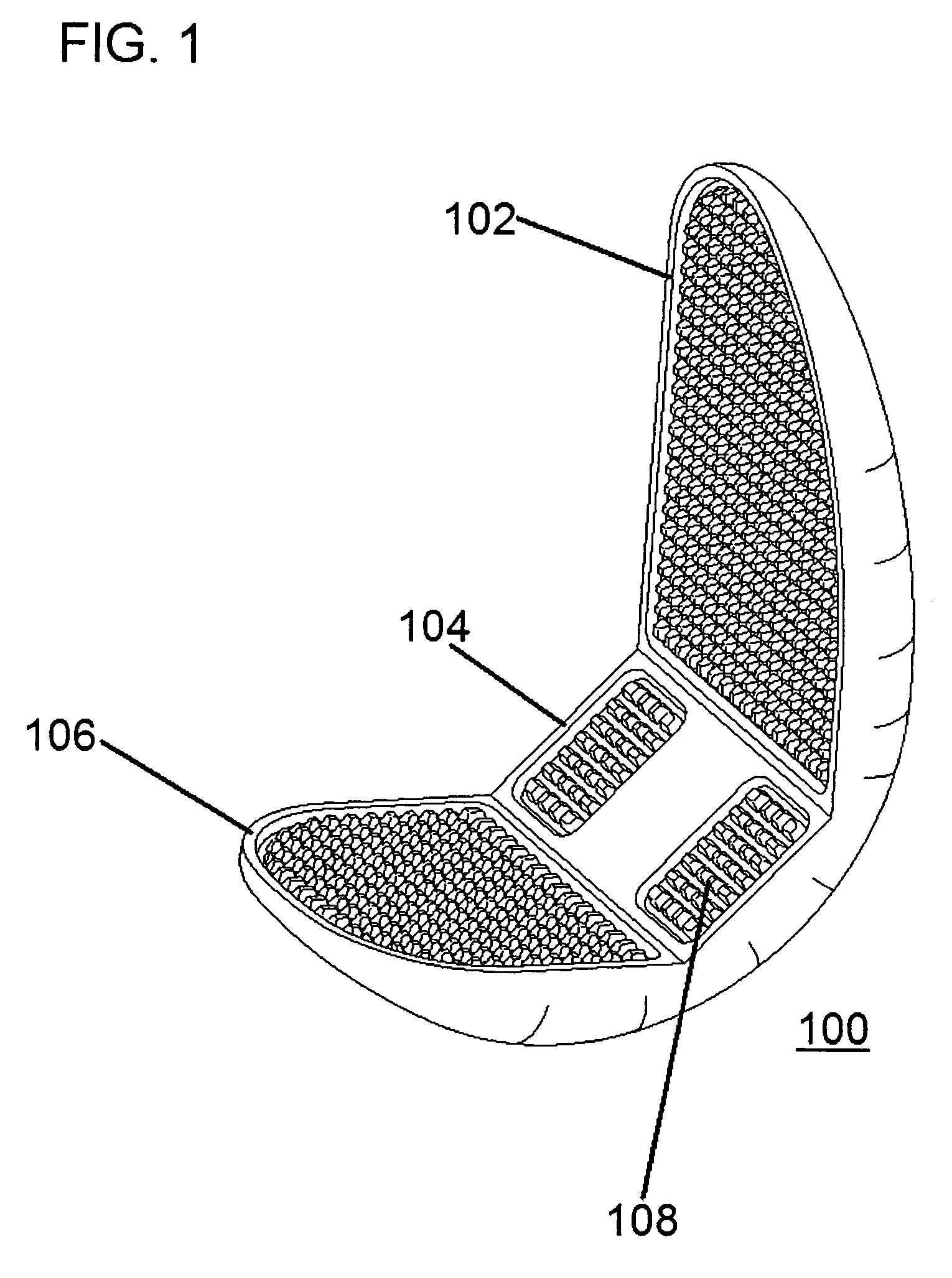

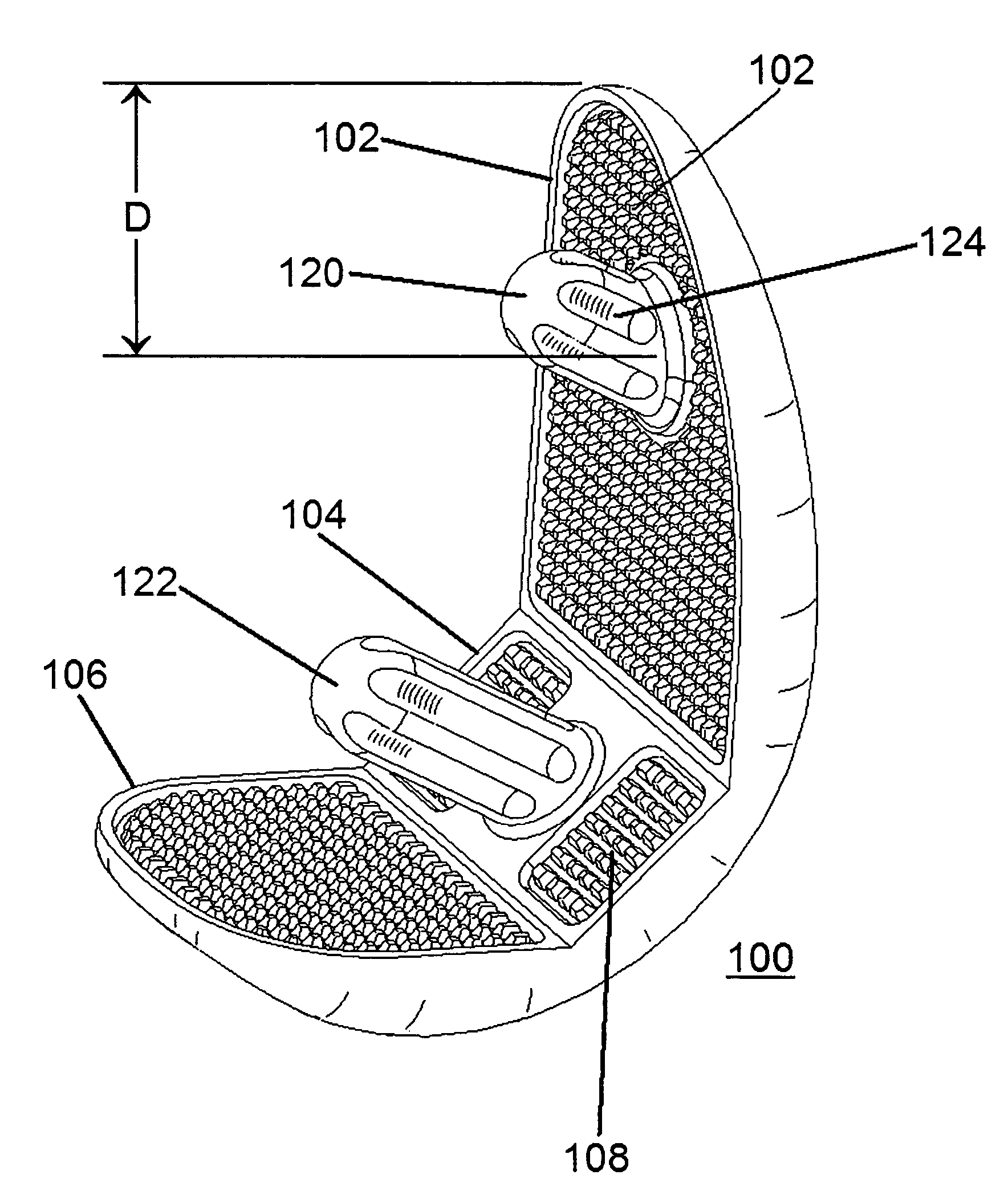

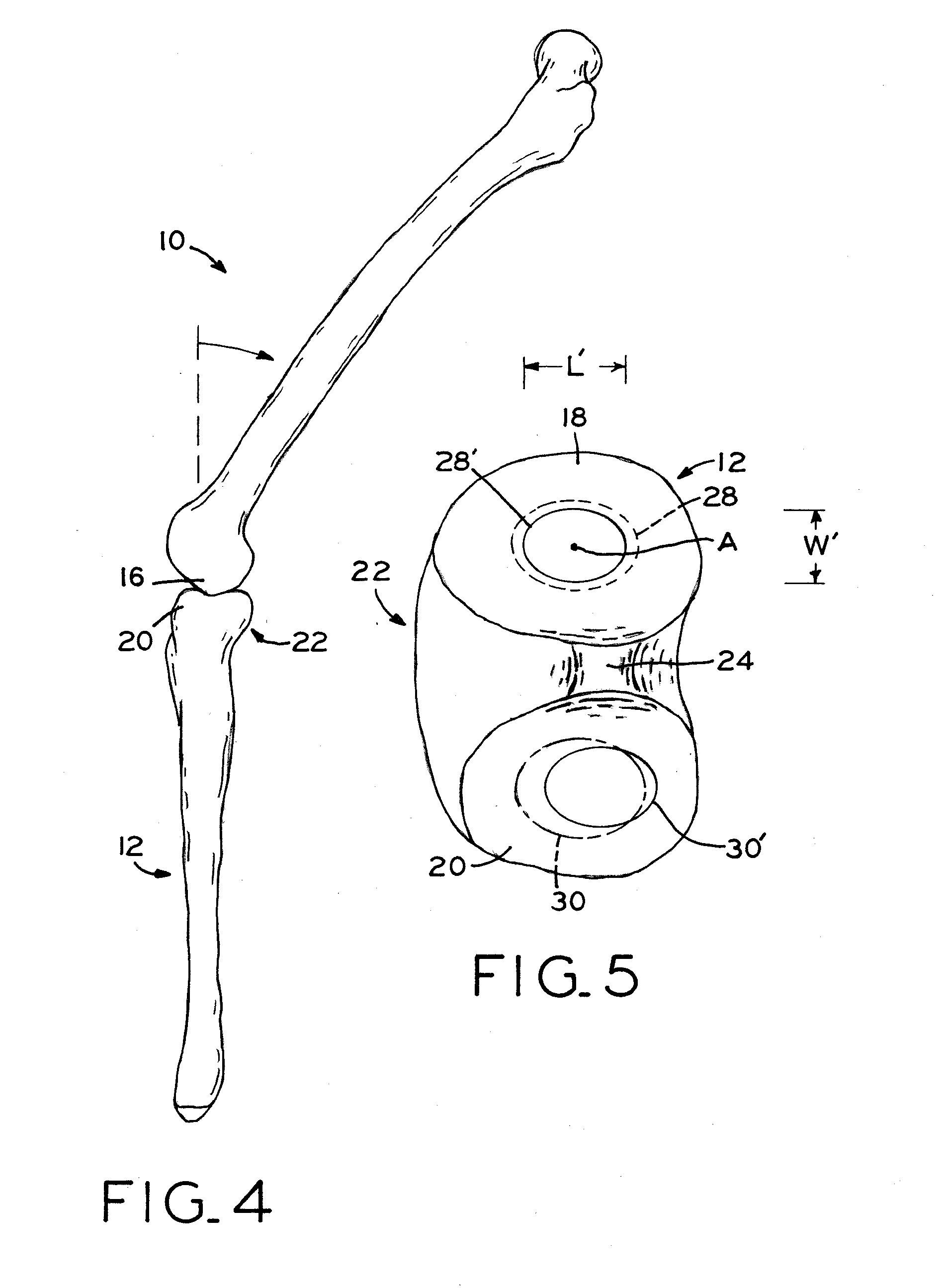

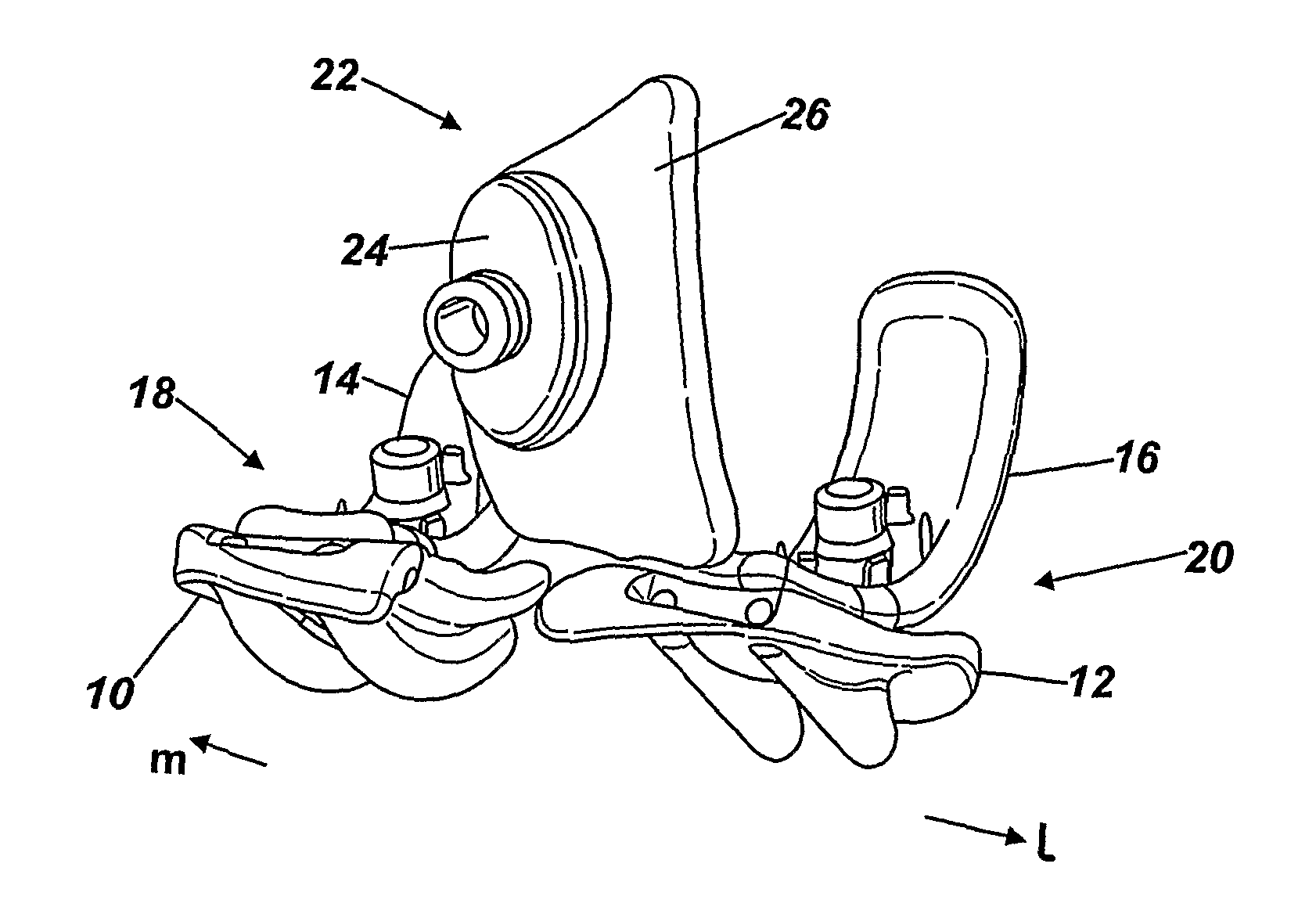

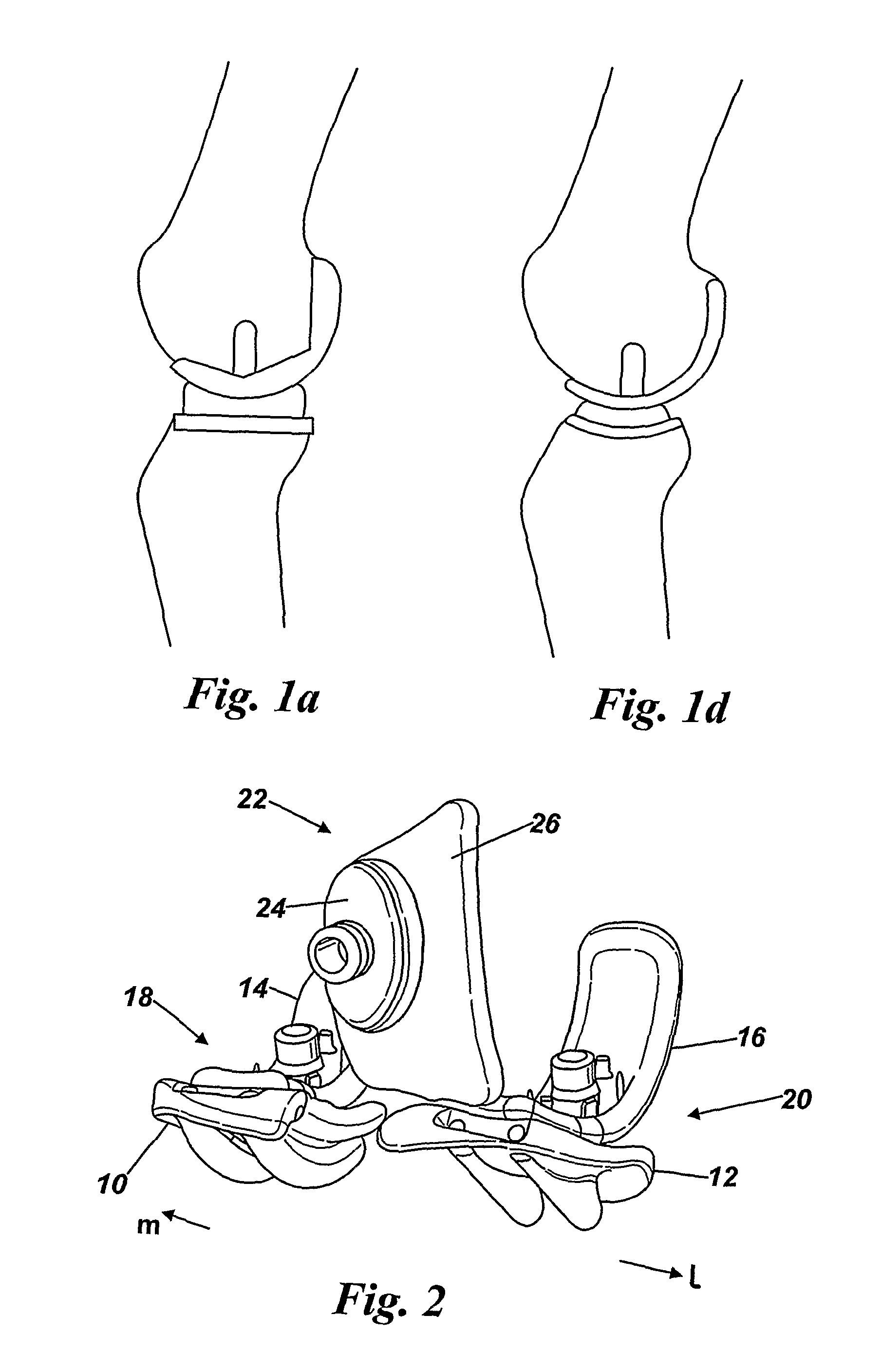

Implant Device and Method for Manufacture

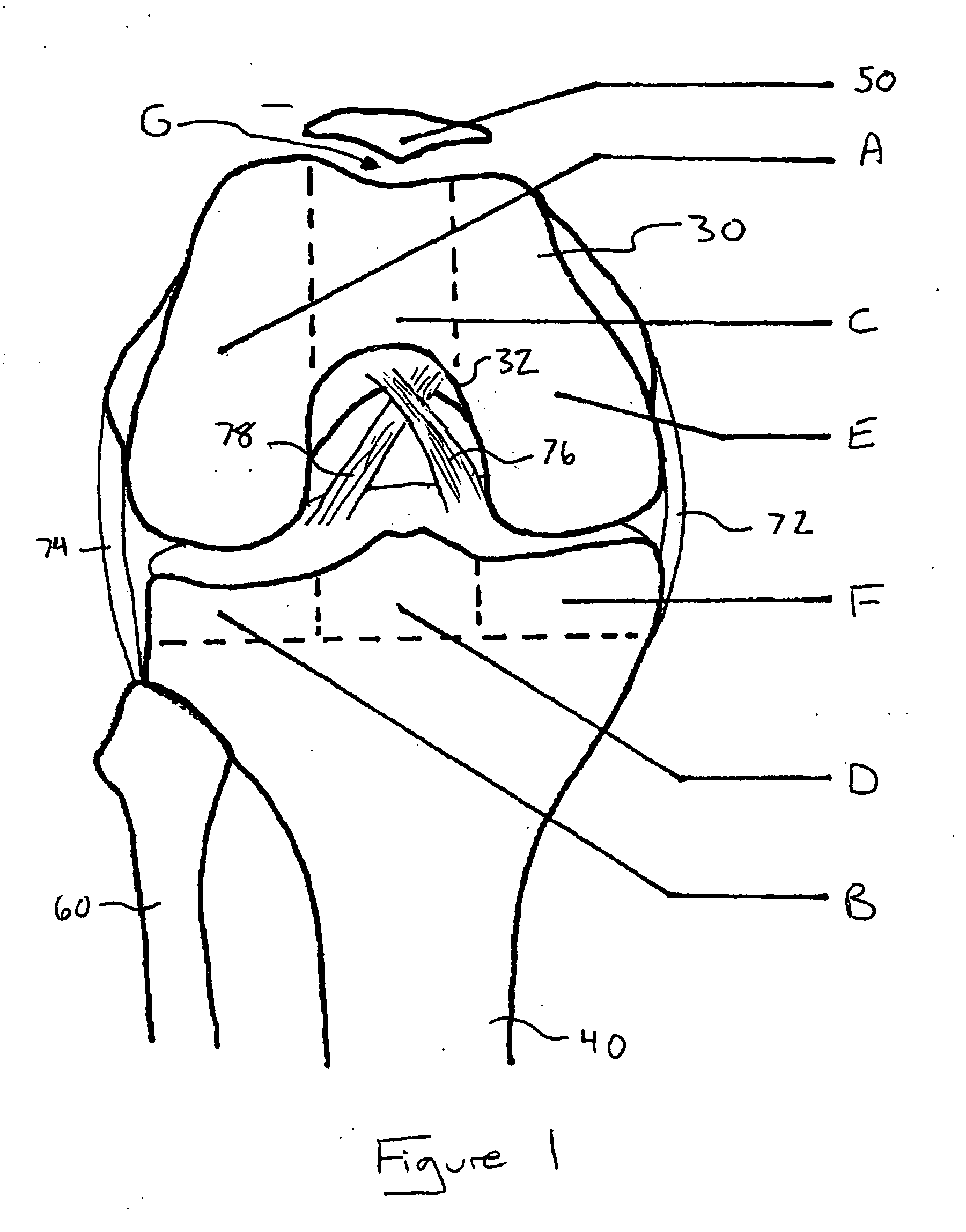

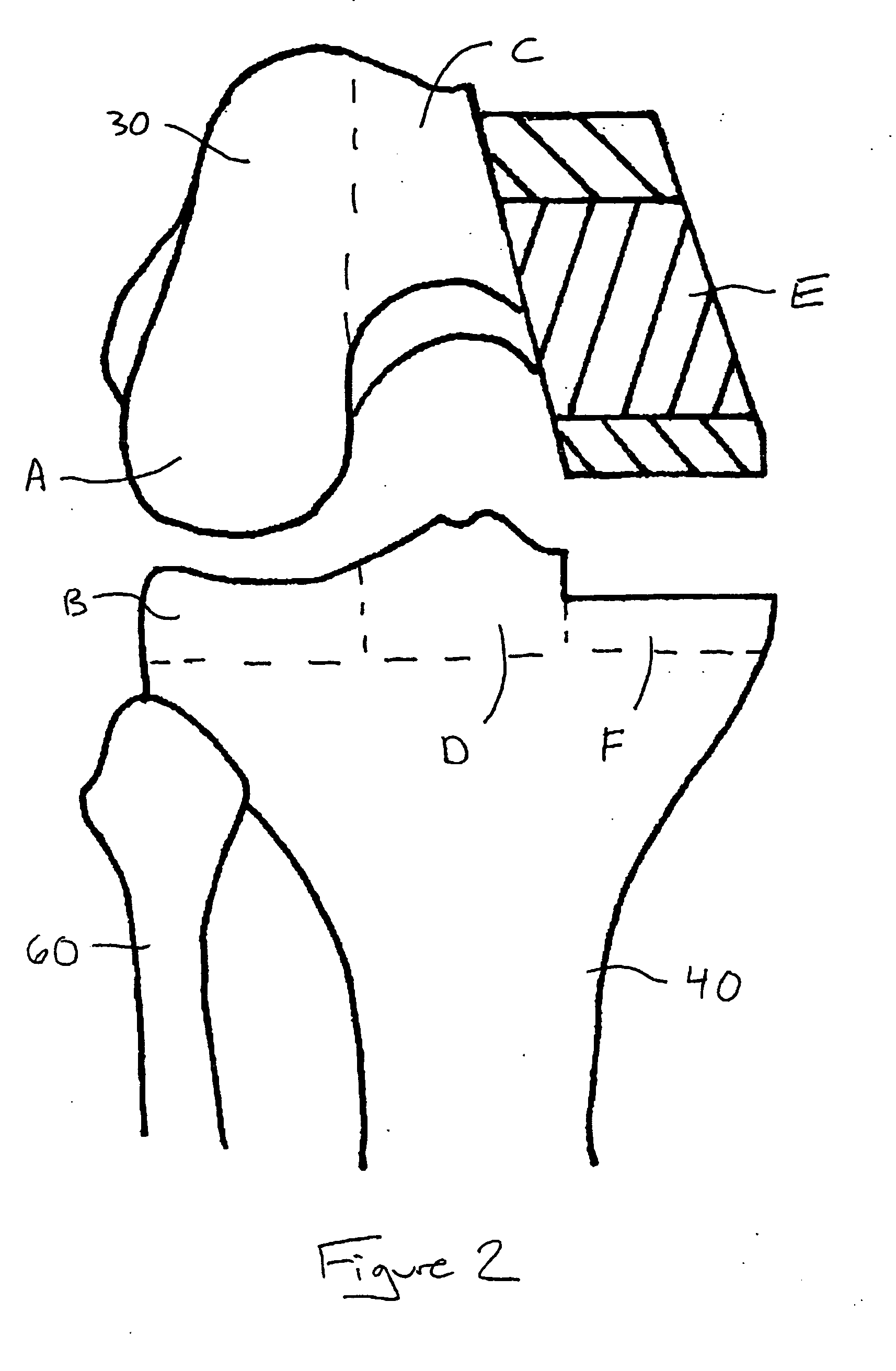

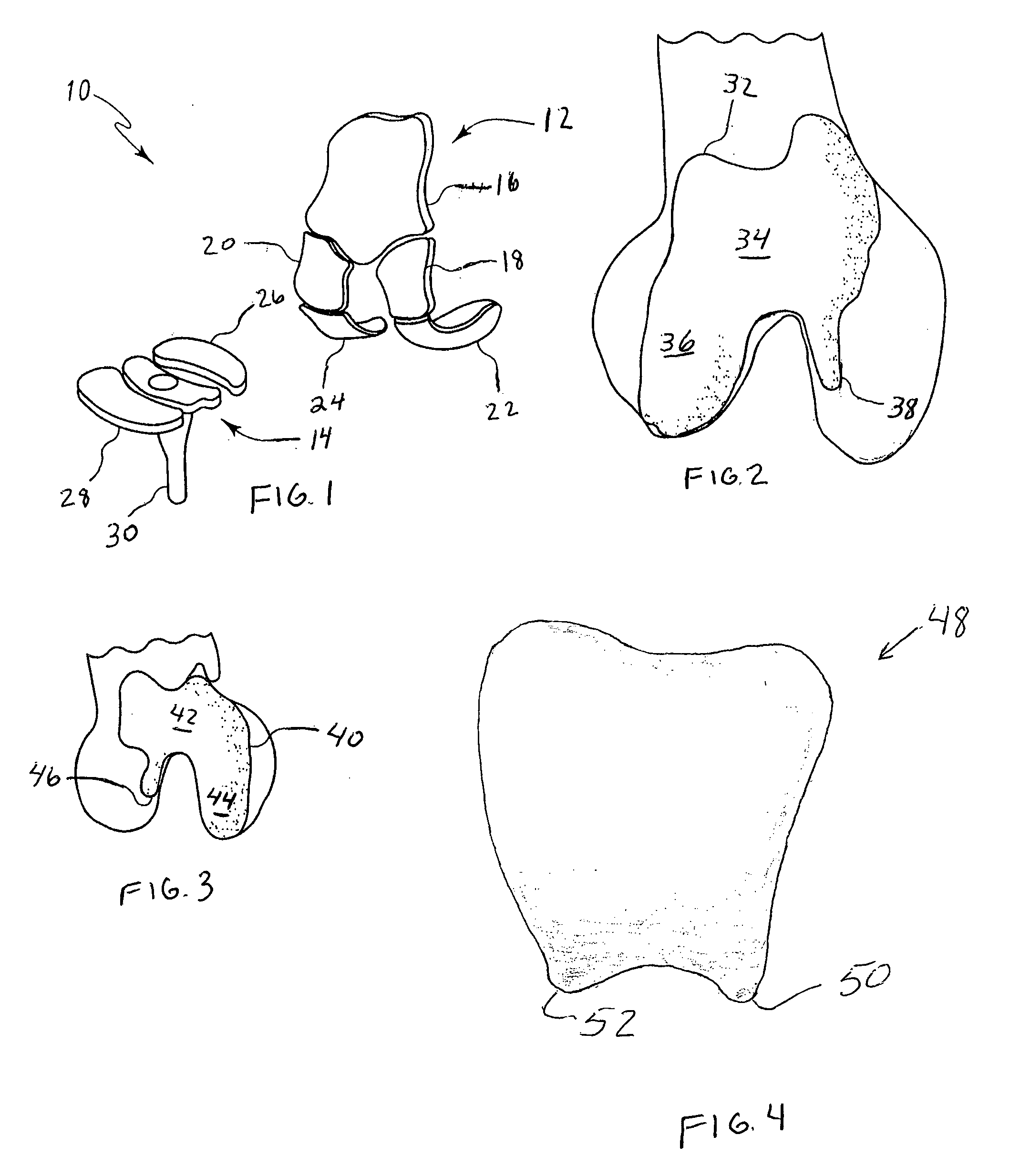

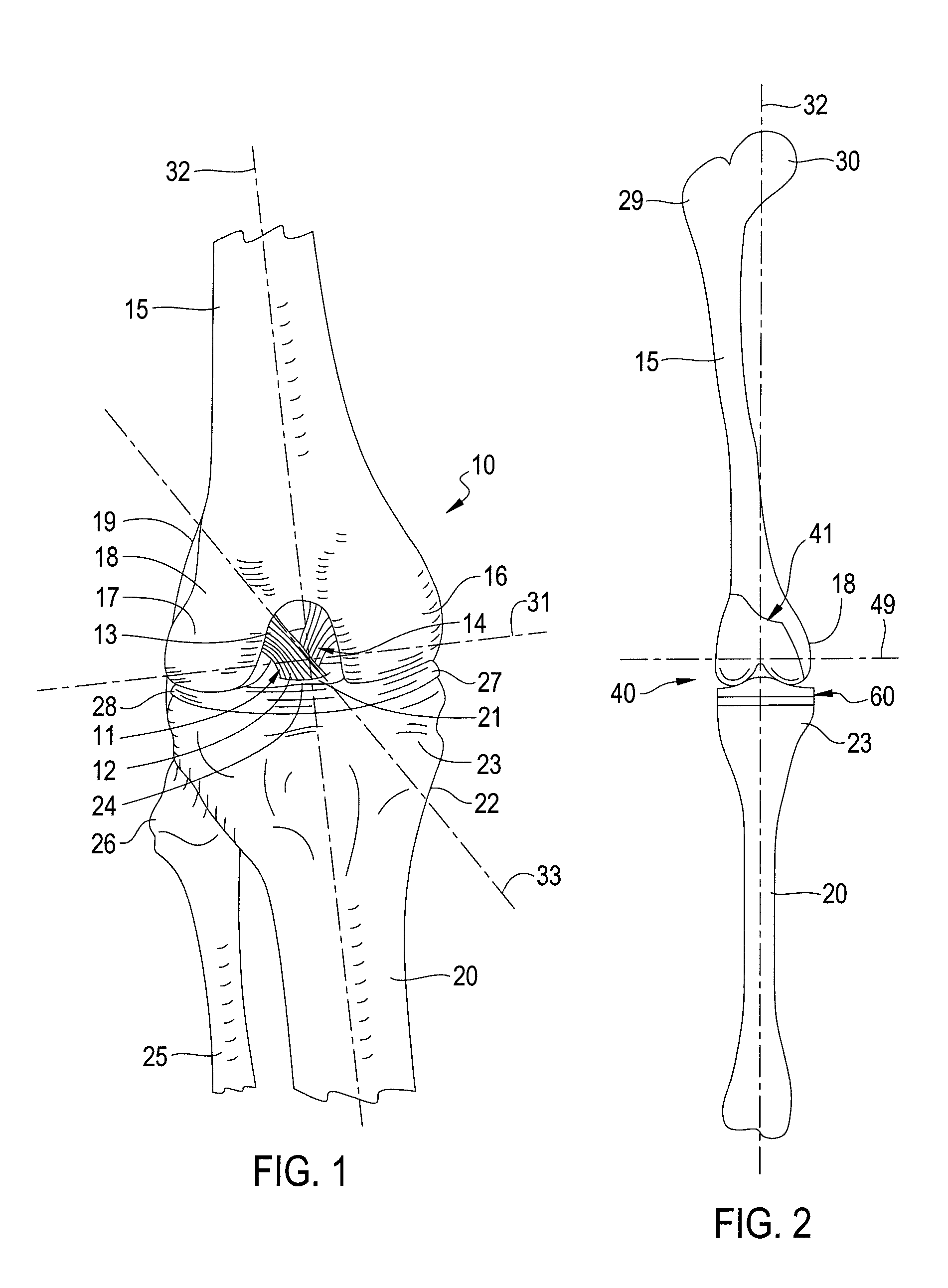

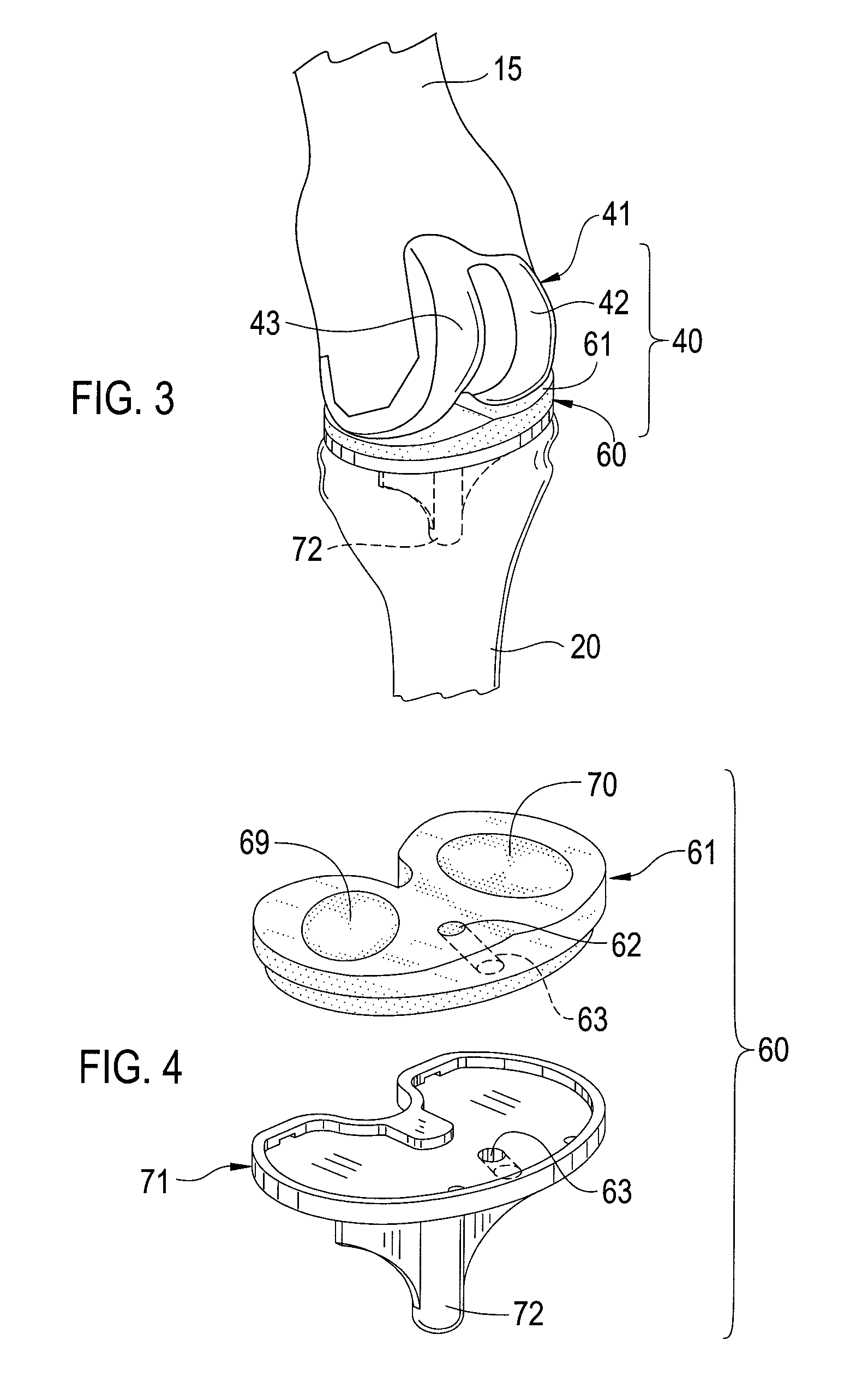

A knee implant includes a femoral component having first and second femoral component surfaces. The first femoral component surface is for securing to a surgically prepared compartment of a distal end of a femur. The second femoral component surface is configured to replicate the femoral condyle. The knee implant further includes a tibial component having first and second tibial component surfaces. The first tibial component surface is for contacting a proximal surface of the tibia that is substantially uncut subchondral bone. At least a portion of the first tibial component surface is a mirror image of the proximal tibial surface. The second tibial component surface articulates with the second femoral component surface.

Owner:CONFORMIS

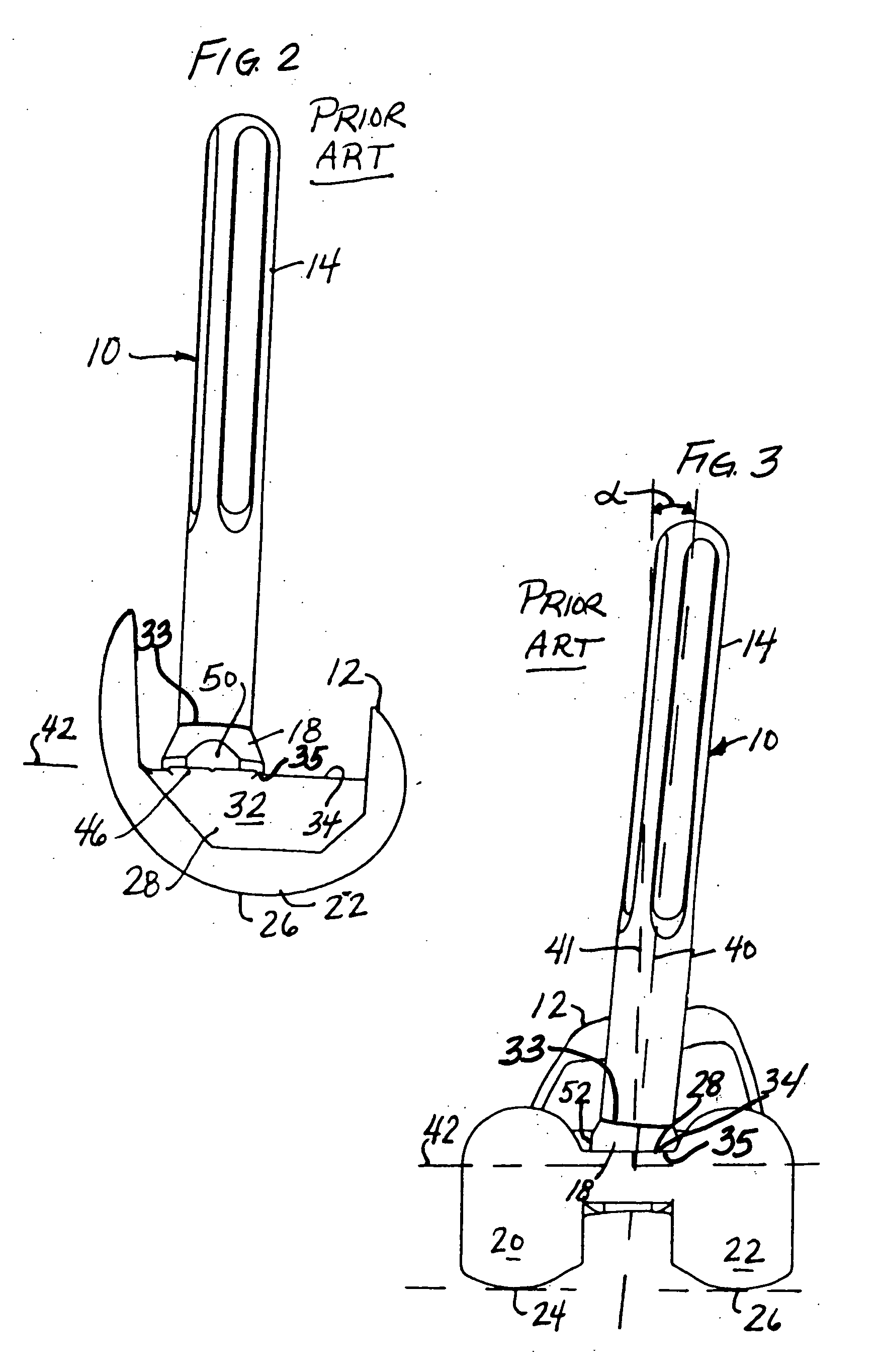

Unicondylar knee implant

InactiveUS20050171604A1Reduce frictionMinimal incisionSuture equipmentsSurgical needlesFiberSide effect

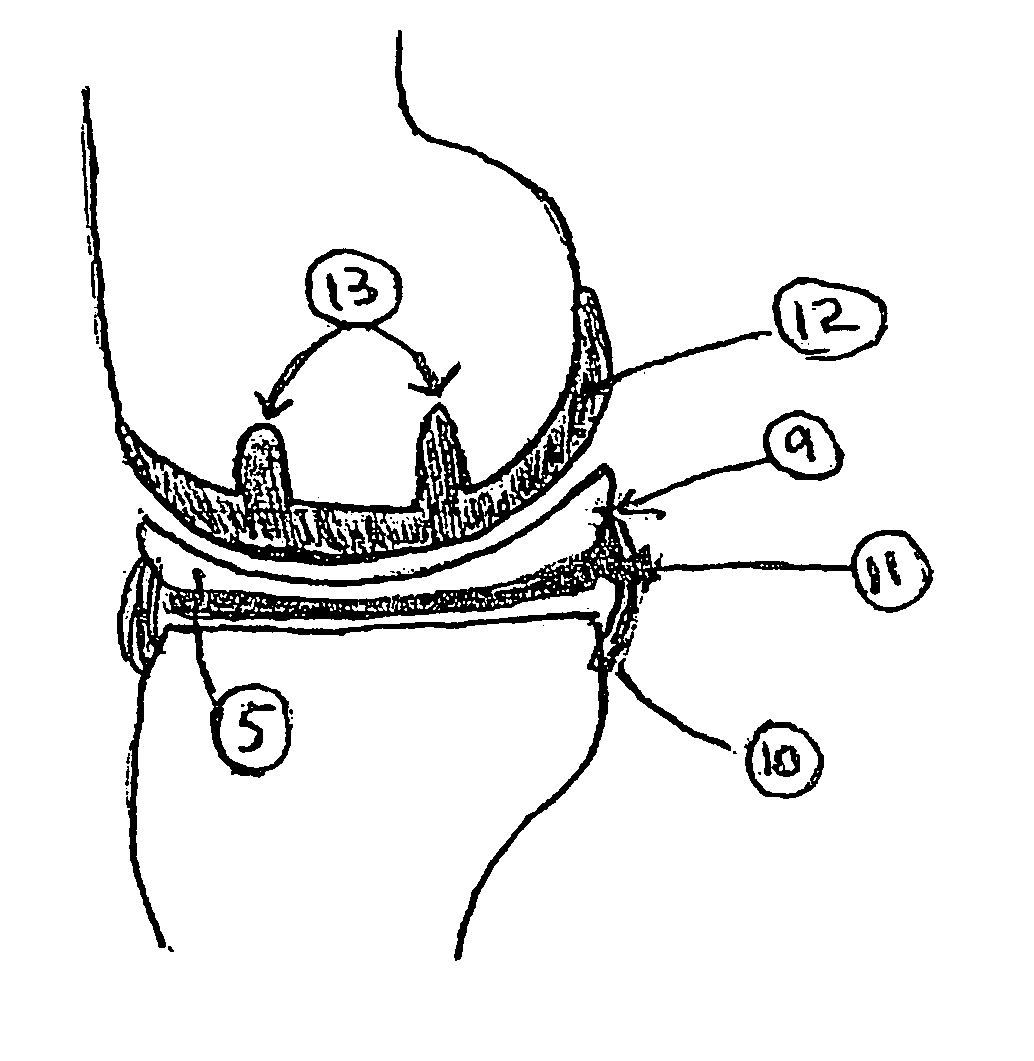

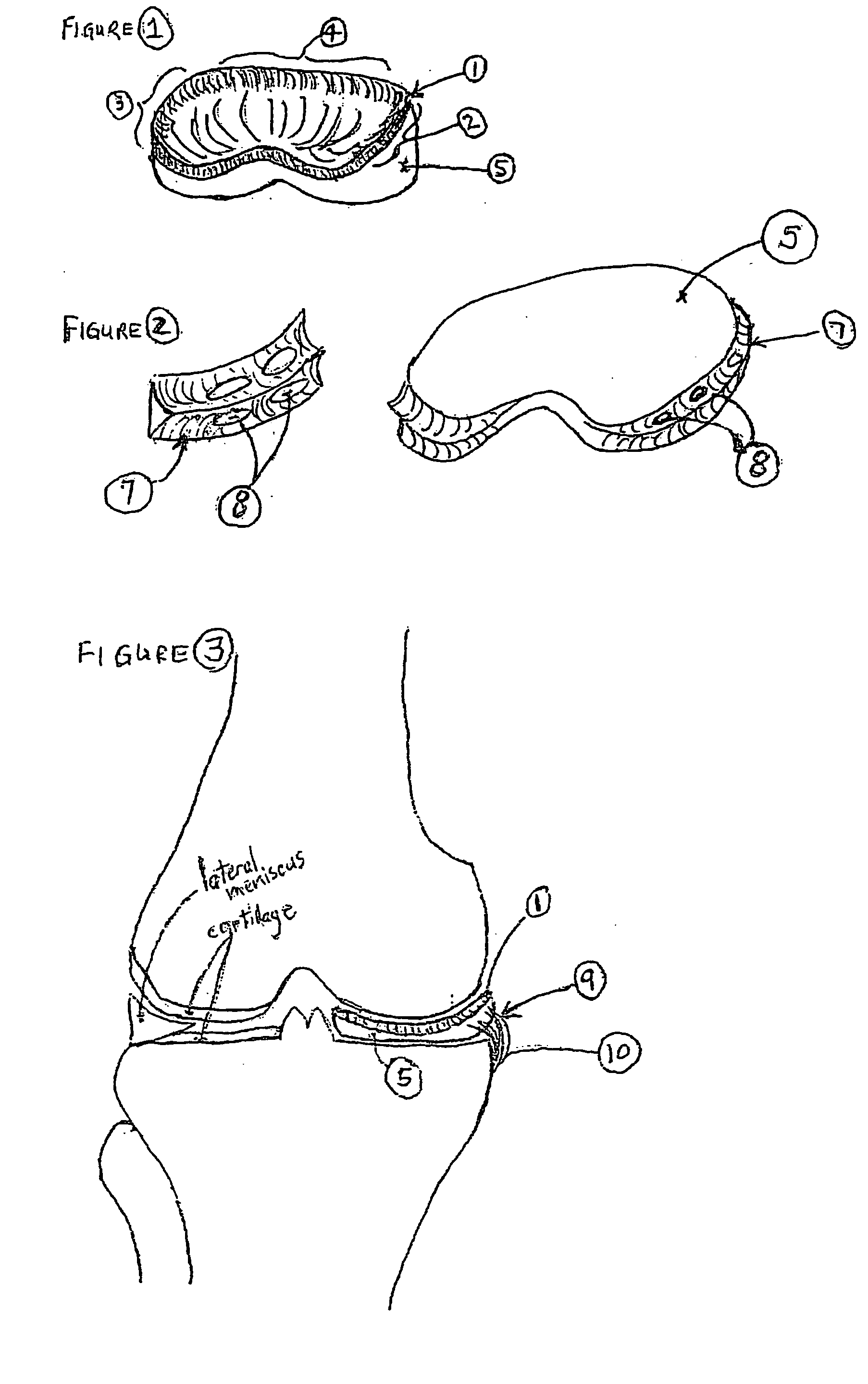

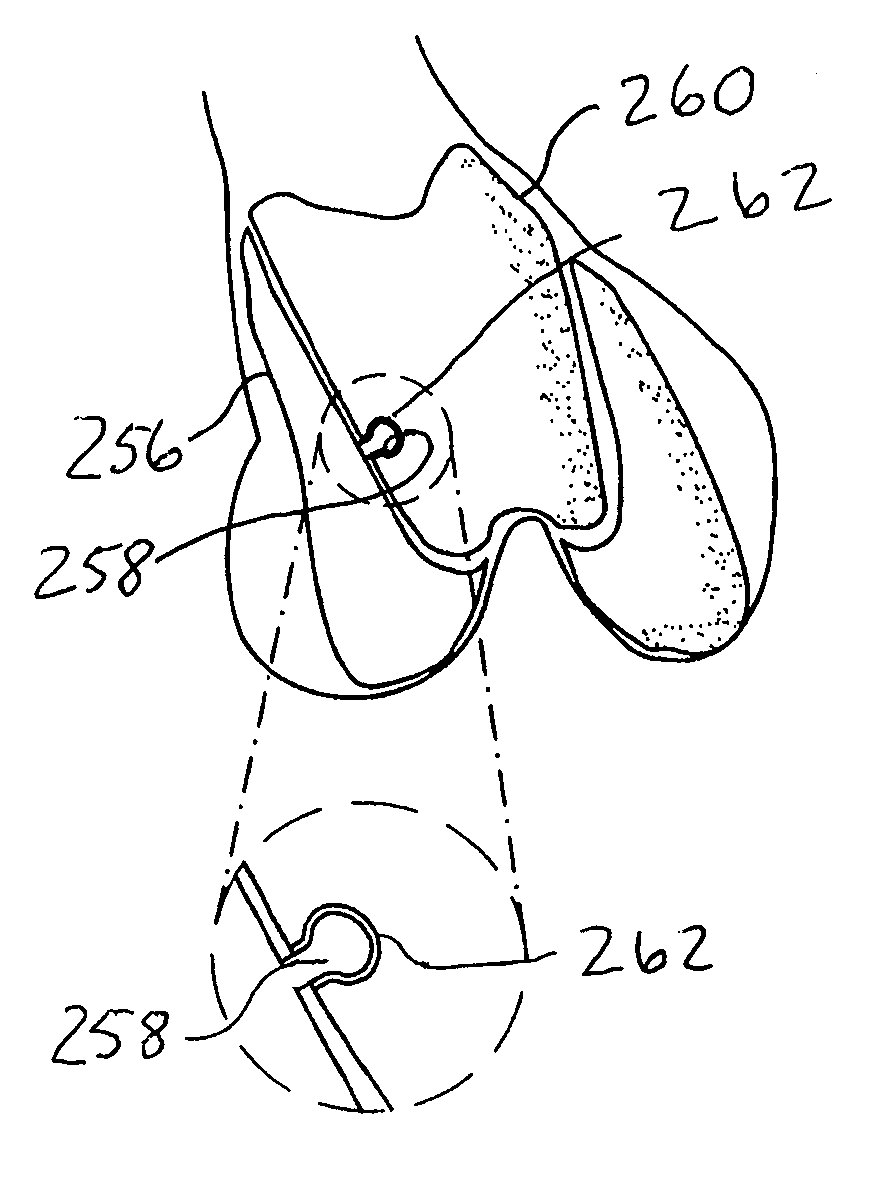

A knee prosthesis, methods of implanting the prosthesis, method of treating arthritis of the knee, and a kit therefore are provided. The prosthesis answers many of the limitations of current knee prosthetic devices by providing a two-component (or alternatively, an optional three-component) device, as either a single structure, or as separate pieces. One of the components is constructed of low friction material, while the second is composed of a weight-dissipating cushioning material; the optional third component is constructed of low friction material. The prosthesis is initially attached to surrounding soft tissue in the knee by biodegradable sutures; it is held permanently in place by fibrous ingrowth into a porous collagen rim in the cushioning component. Major improvements provided by the present invention over currently available prostheses include minimal incisions, minimal or no bone cuts, minimal overall dissection (these improvements lead to shorter hospital stays and rapid rehabilitation and fewer potential for side effects), less prosthetic wear, greater longevity, fewer activity restrictions, able to be used on young, large, active patients, ease of revision, ease of conversion into a total knee arthroplasty if needed.

Owner:MICHALOW ALEXANDER

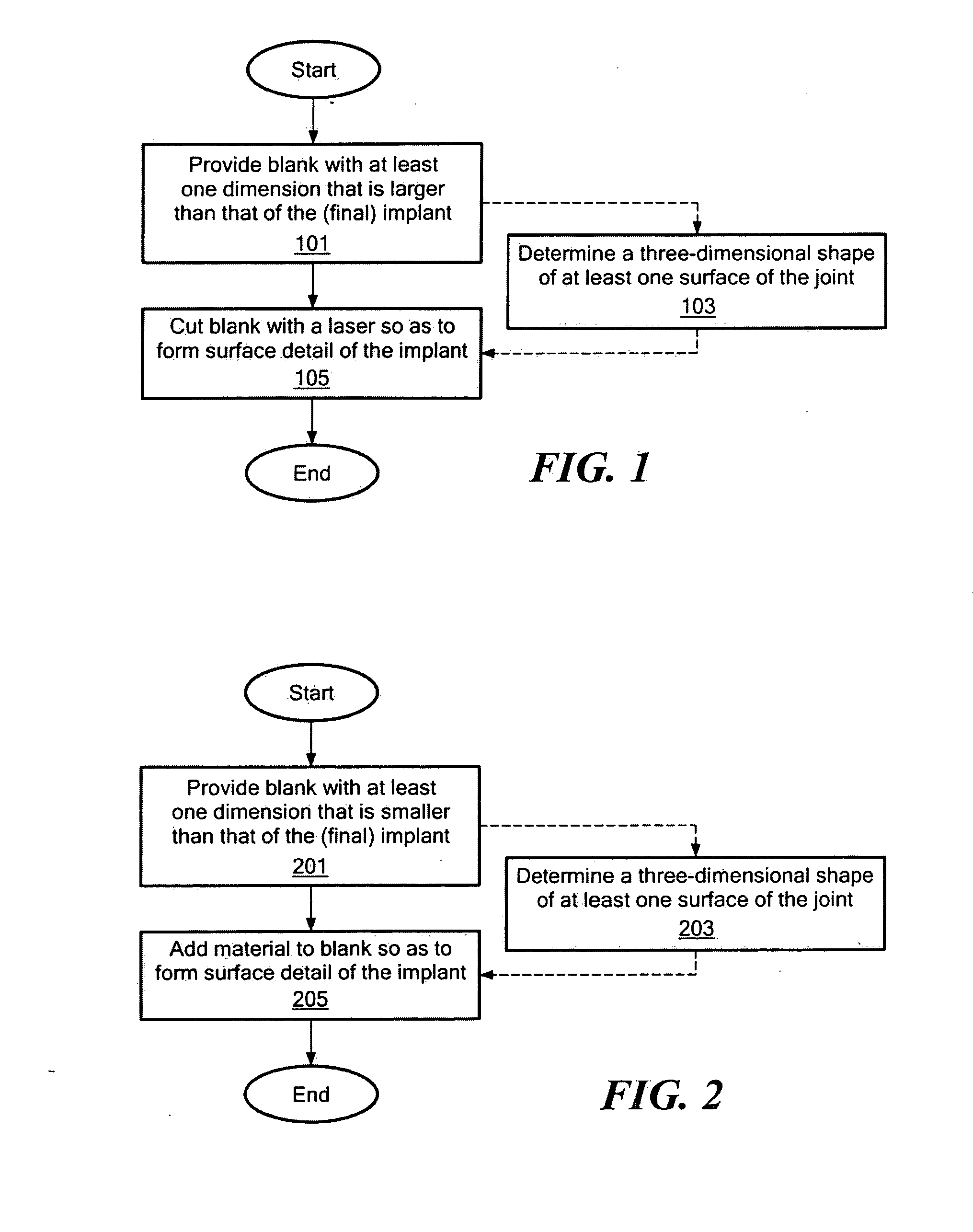

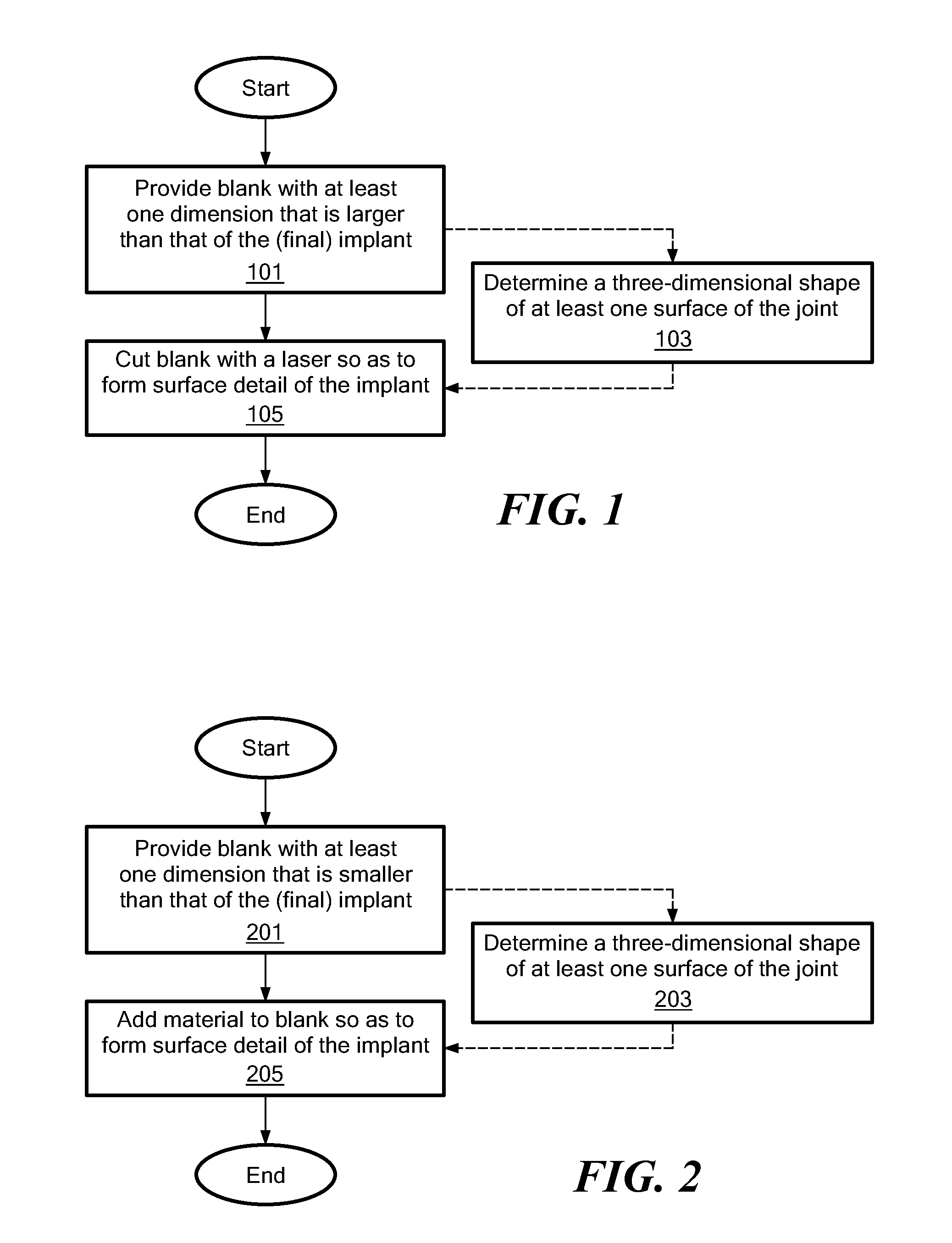

Integrated Production of Patient-Specific Implants and Instrumentation

InactiveUS20100217270A1Easy and efficient to manufactureManufactured efficiently and inexpensivelySurgical furnitureDiagnosticsPlastic surgeryTarsal Joint

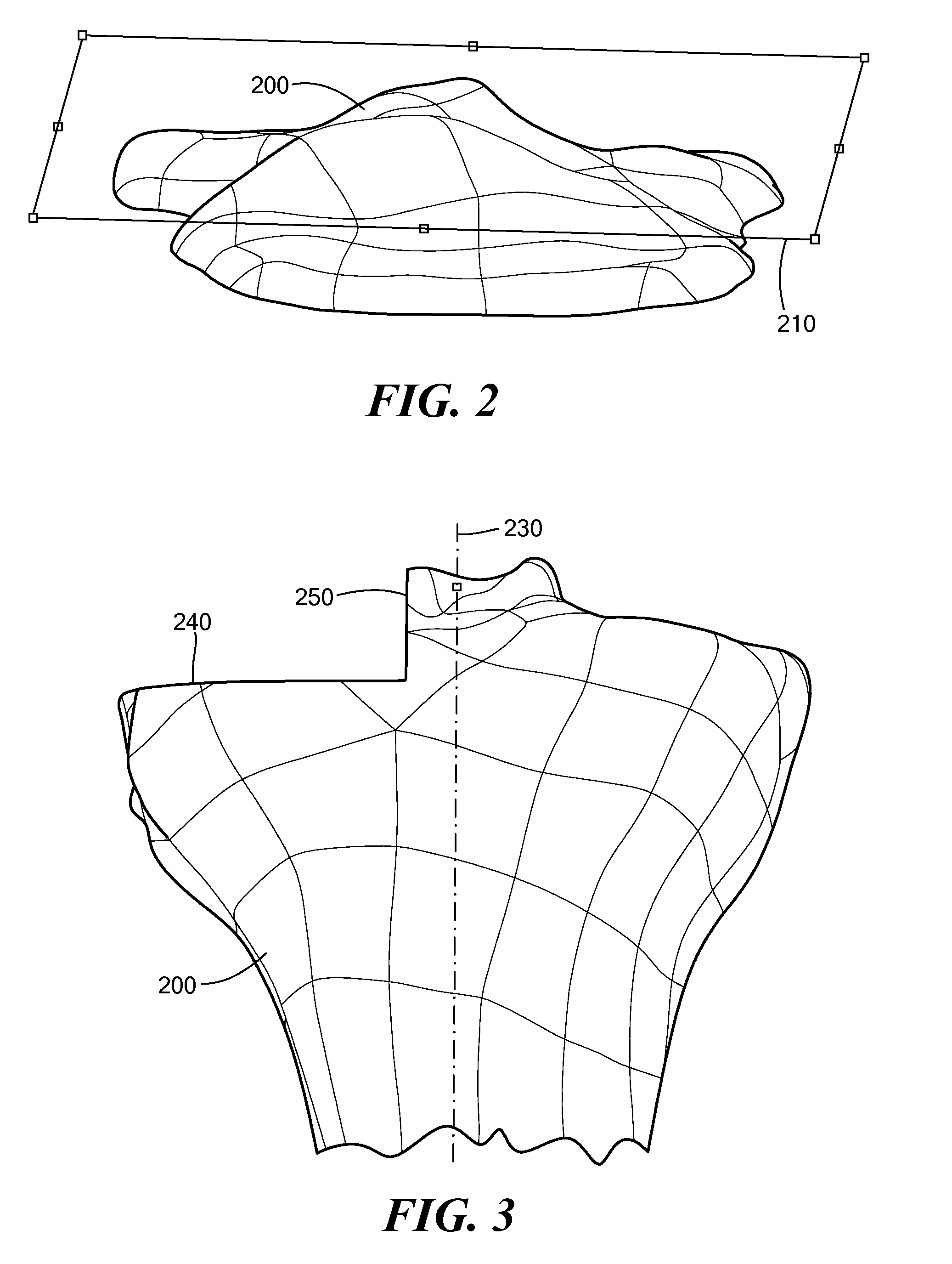

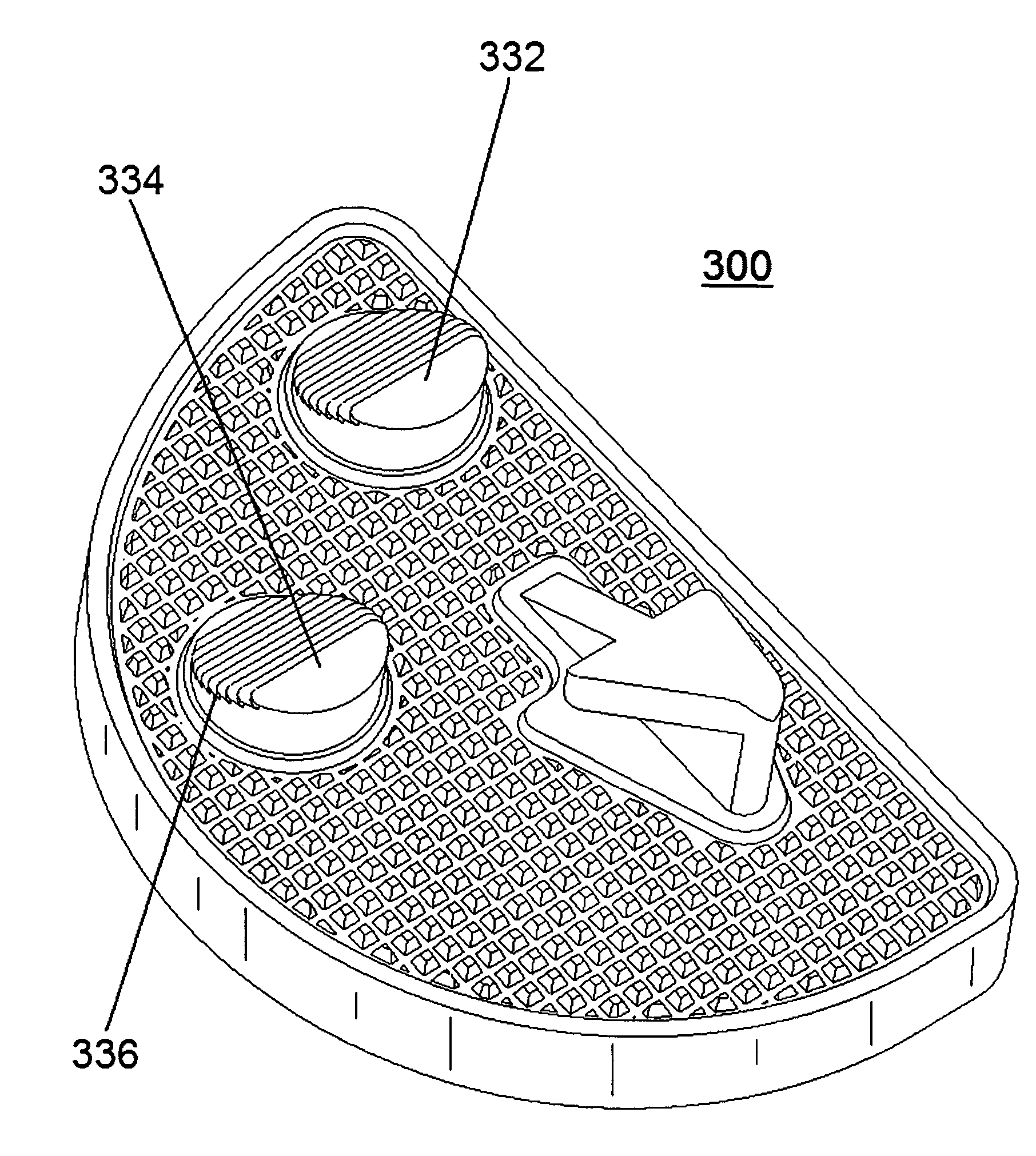

Disclosed herein are devices, systems and methods for the automated design and manufacture of patient-specific / patient-matched orthopedic implants. While the embodiments described herein specifically pertain to unicompartmental resurfacing implants for the knee, the principles described are applicable to other types of knee implants (including, without limitation, other resurfacing implants and joint replacement implants) as well as implants for other joints and other patient-specific orthopedic applications.

Owner:CONFORMIS

Inlaid articular implant

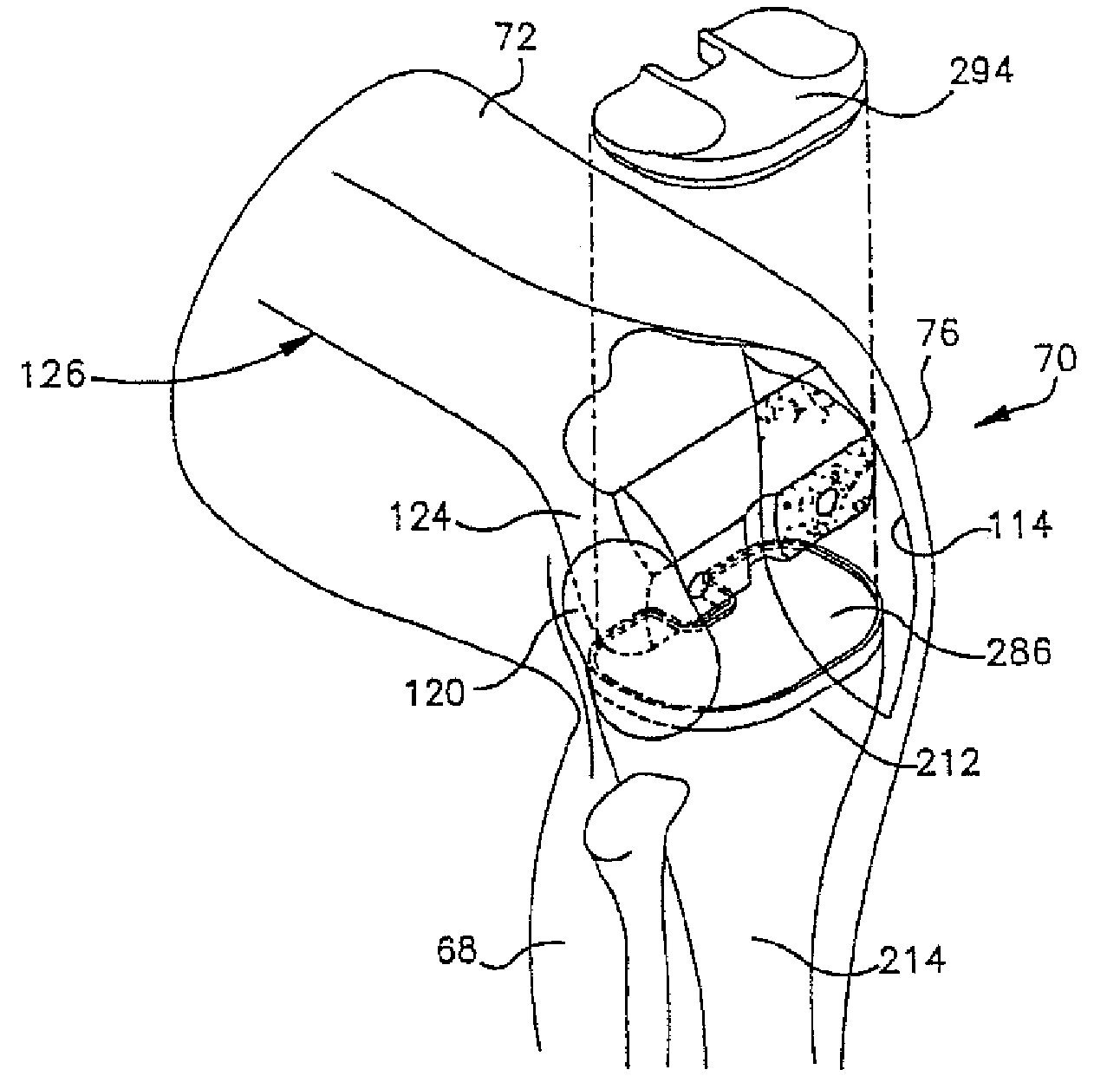

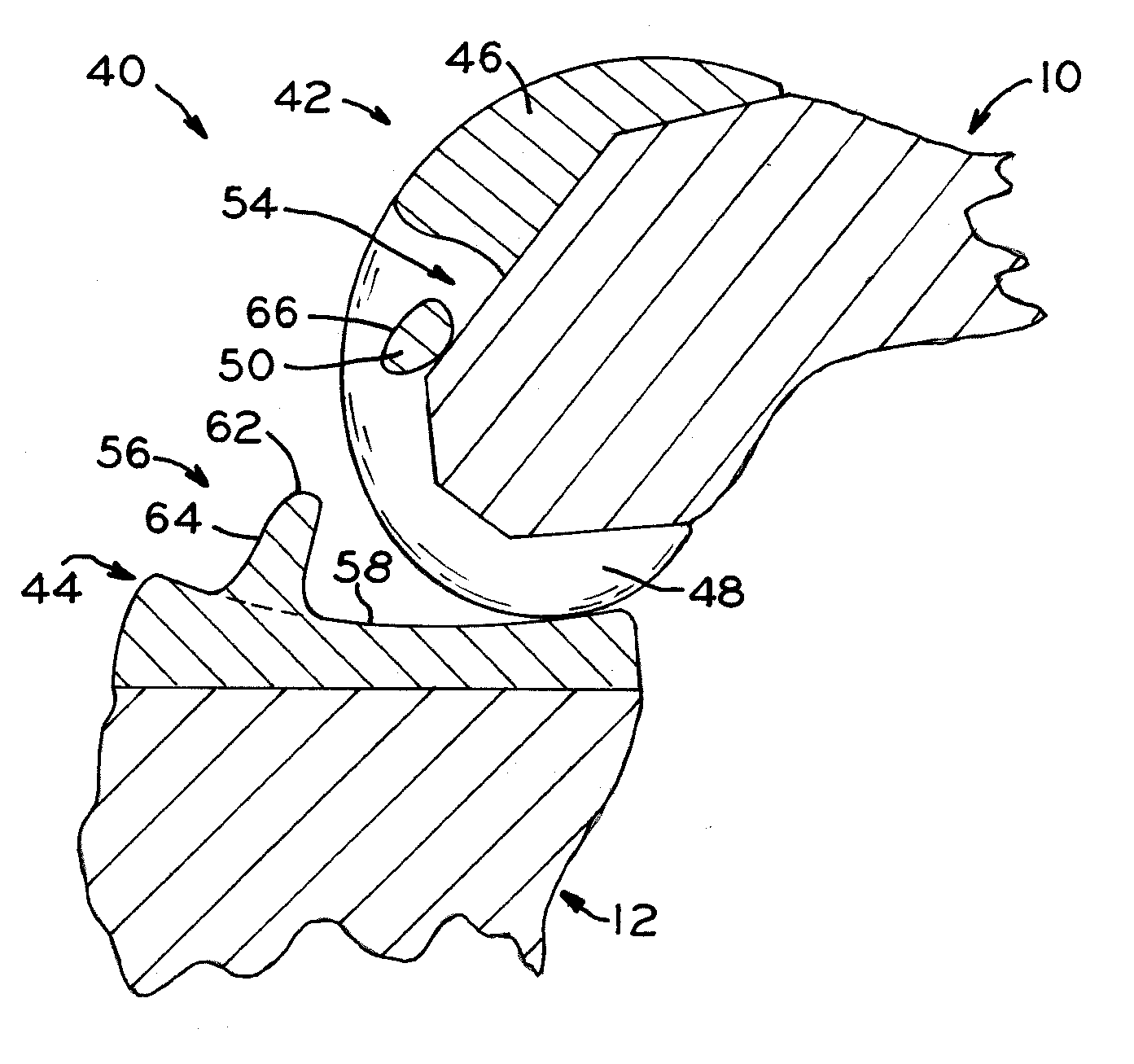

InactiveUS20070173946A1Promote balance between supply and demandSuture equipmentsDiagnosticsKnee JointFemoral component

A method is provided for performing a total knee arthroplasty. The method includes making a primary incision near a knee joint of a patient and resecting medial and lateral condyles of the femur of the leg to create at least one femoral cut surface. The resecting step is performed without dislocating the knee joint. The method also includes balancing various ligament tensions to obtain desired tension and moving a femoral component of a total knee implant through the primary incision. The method further includes positioning the femoral component with respect to the at least one femoral cut surface.

Owner:BONUTTI SKELETAL INNOVATIONS

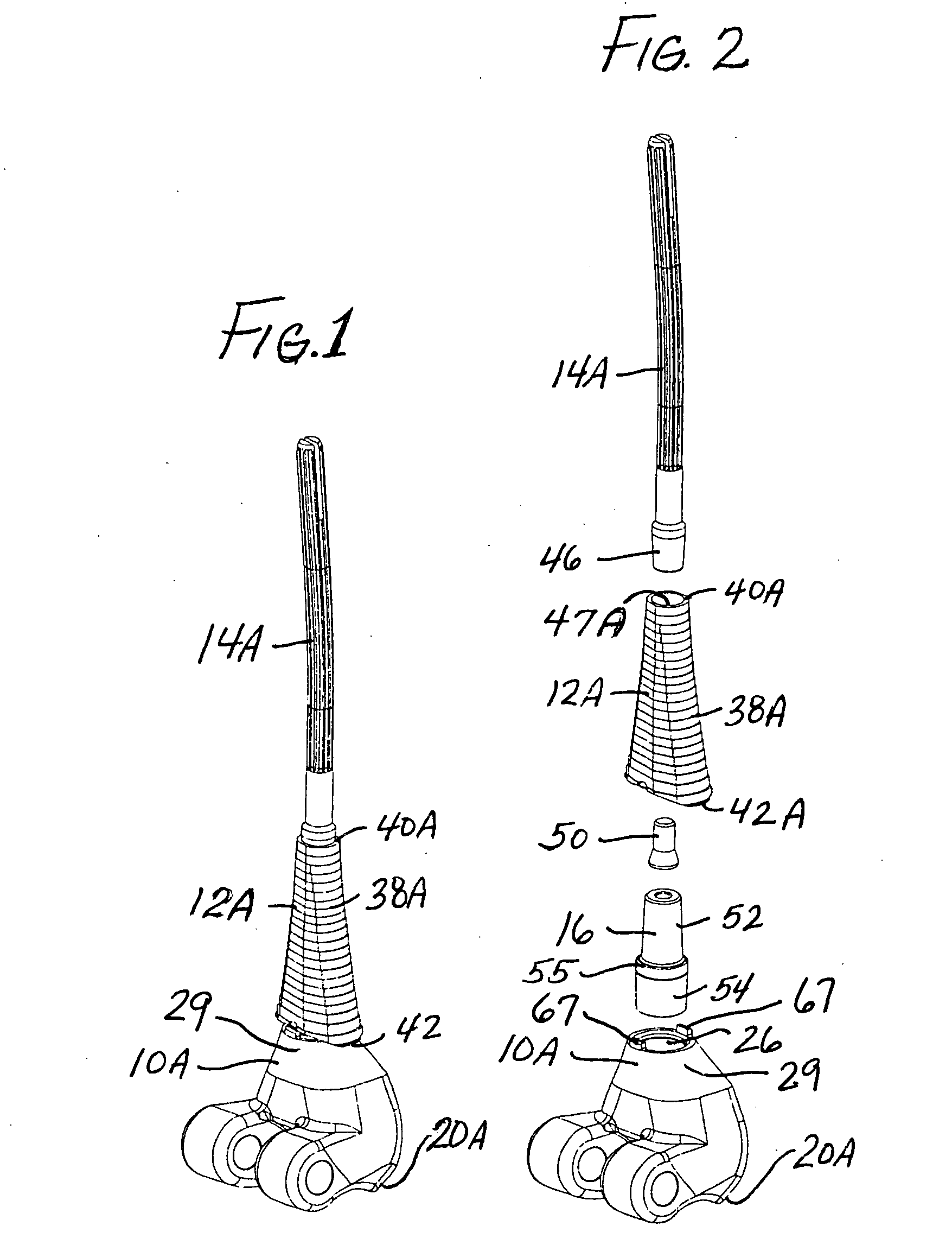

Knee implant

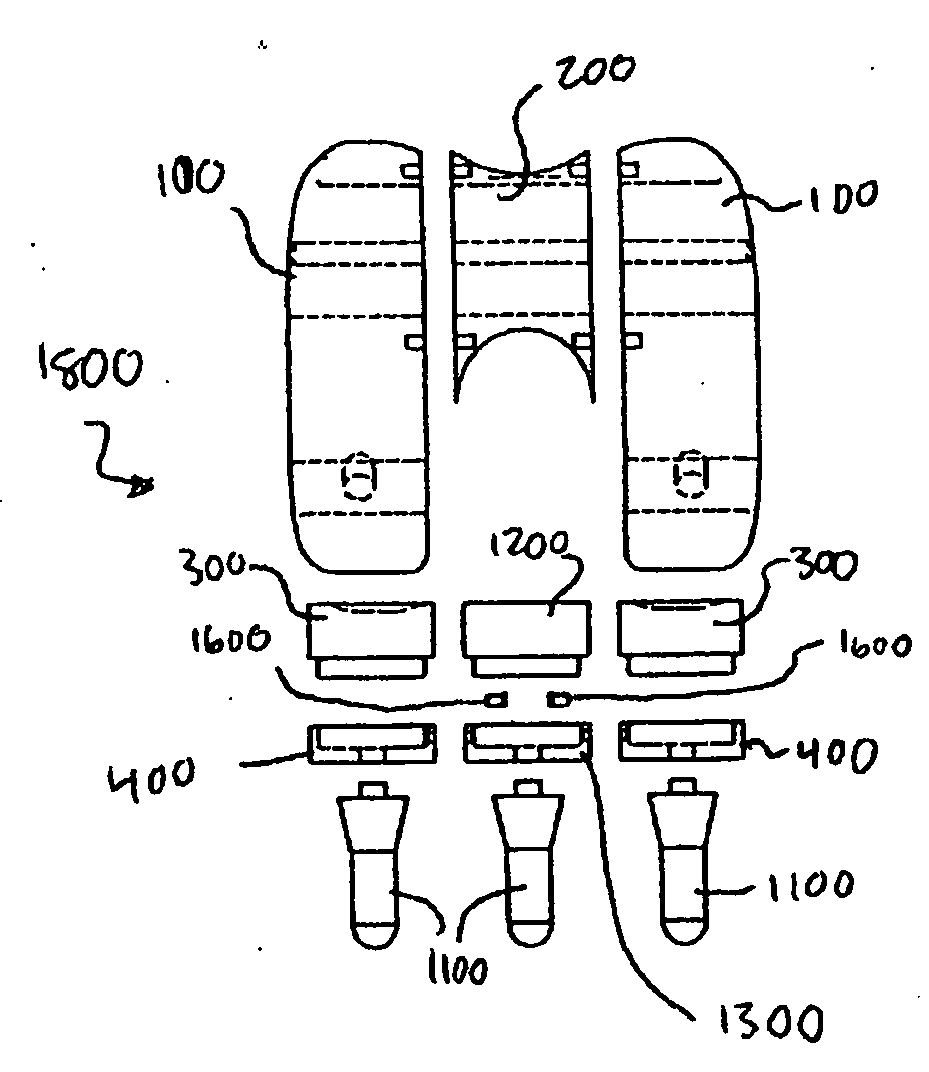

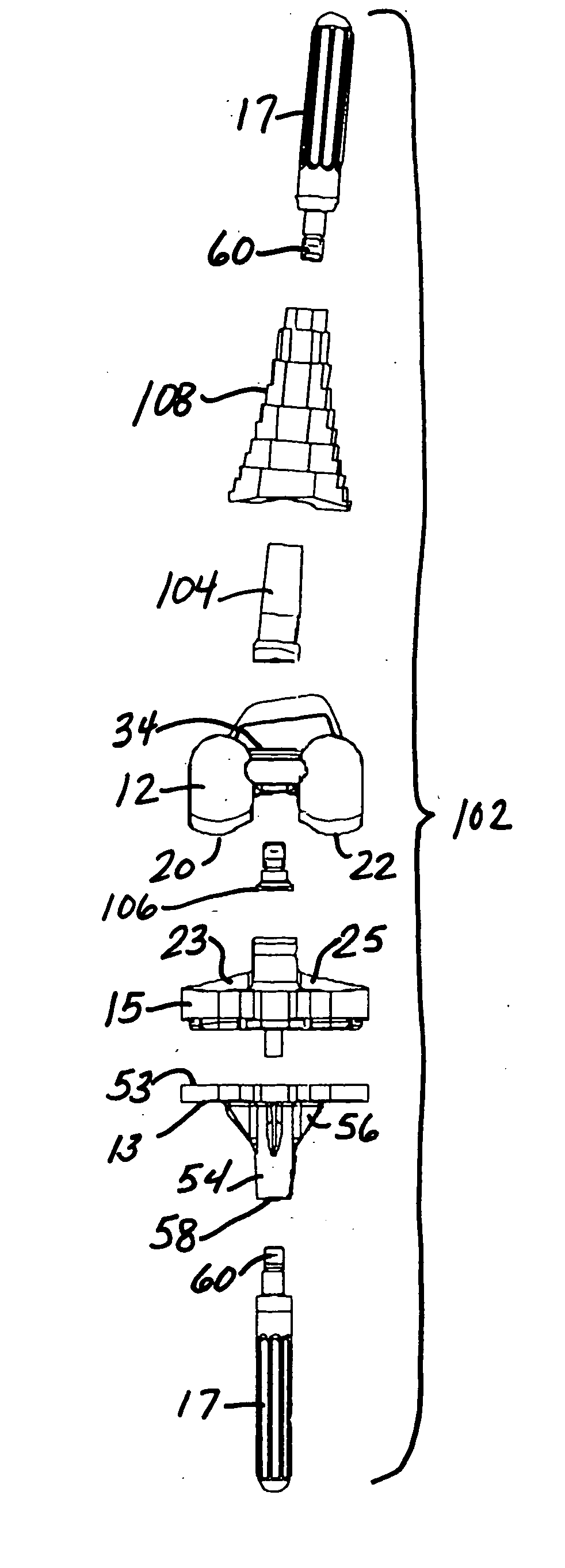

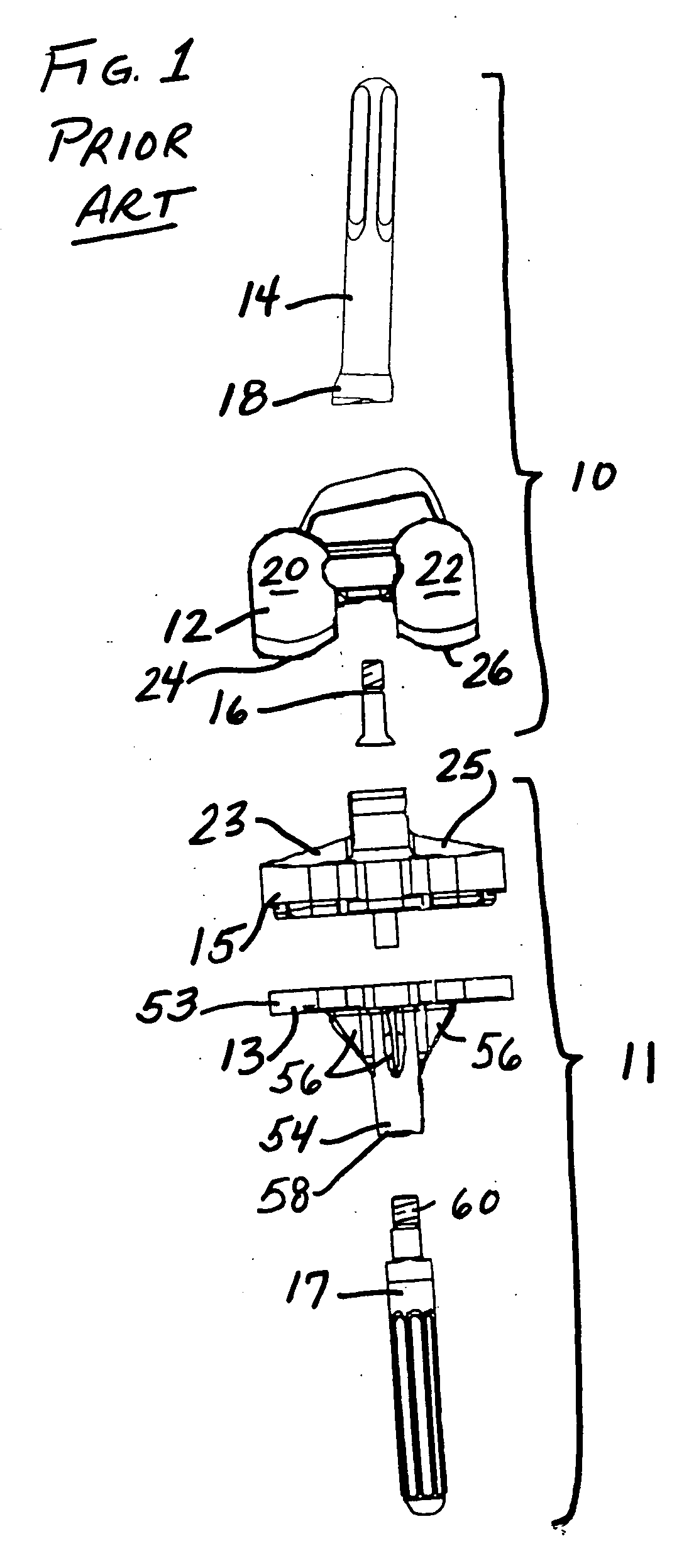

A modular prosthetic device is provided for replacement of the knee. The device is assembled from a plurality of components, each of which can be inserted through a small incision. After inserting the components through the incision, the device can be assembled within the knee cavity. The modularity of the device enables a surgeon to replace only those regions of the knee that are diseased or damaged, thereby avoiding a complete knee replacement. If, at a later time, additional regions of the knee become diseased or damaged, those additional regions of the knee can be replaced by additional device components and those additional components can be connected to the previously implanted components. By replacing only those regions of the knee that are diseased or damaged and by implanting each of the components through the small incision, the surgery is minimally invasive and, therefore, requires reduced time for healing and rehabilitation.

Owner:MAKO SURGICAL CORP

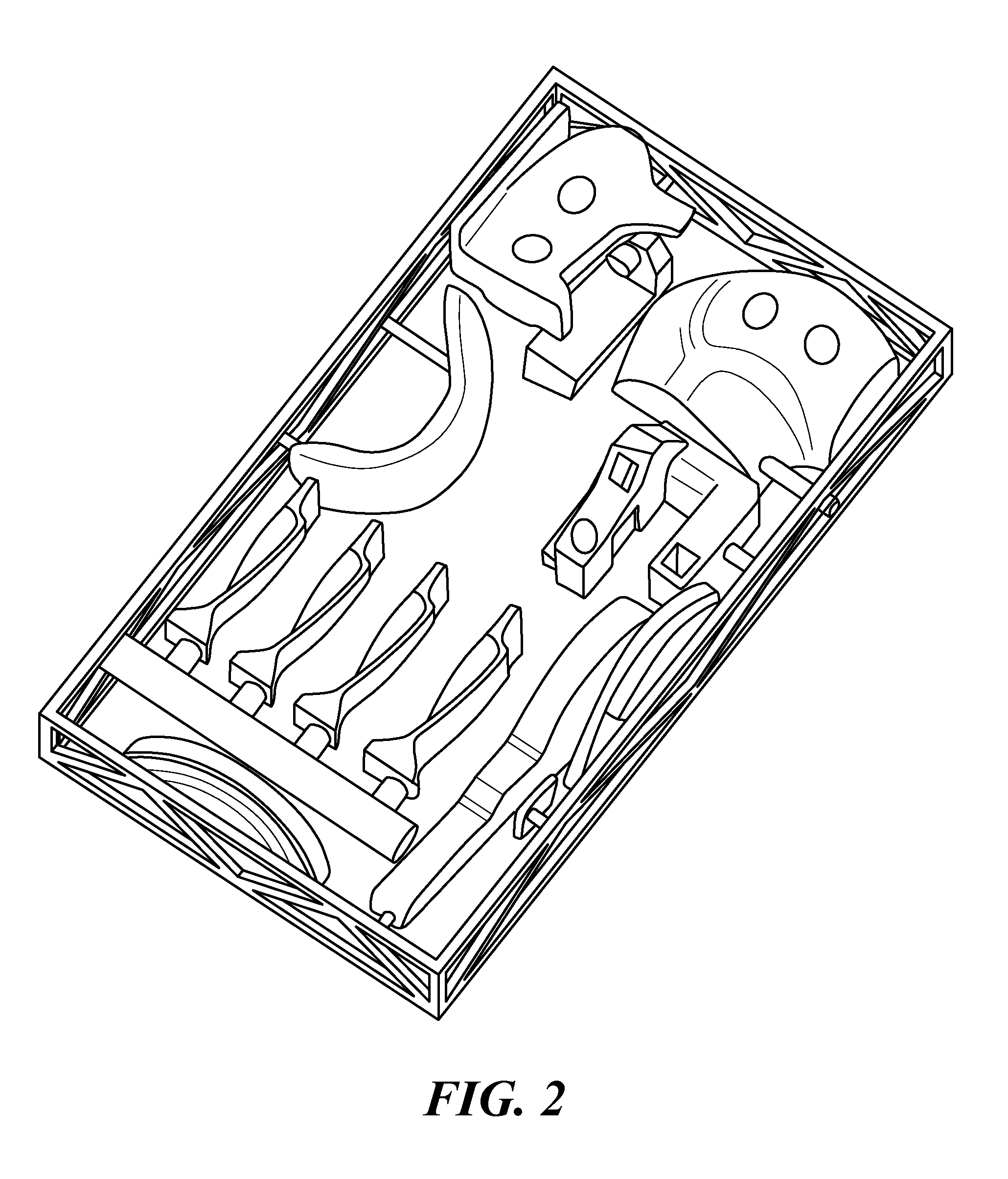

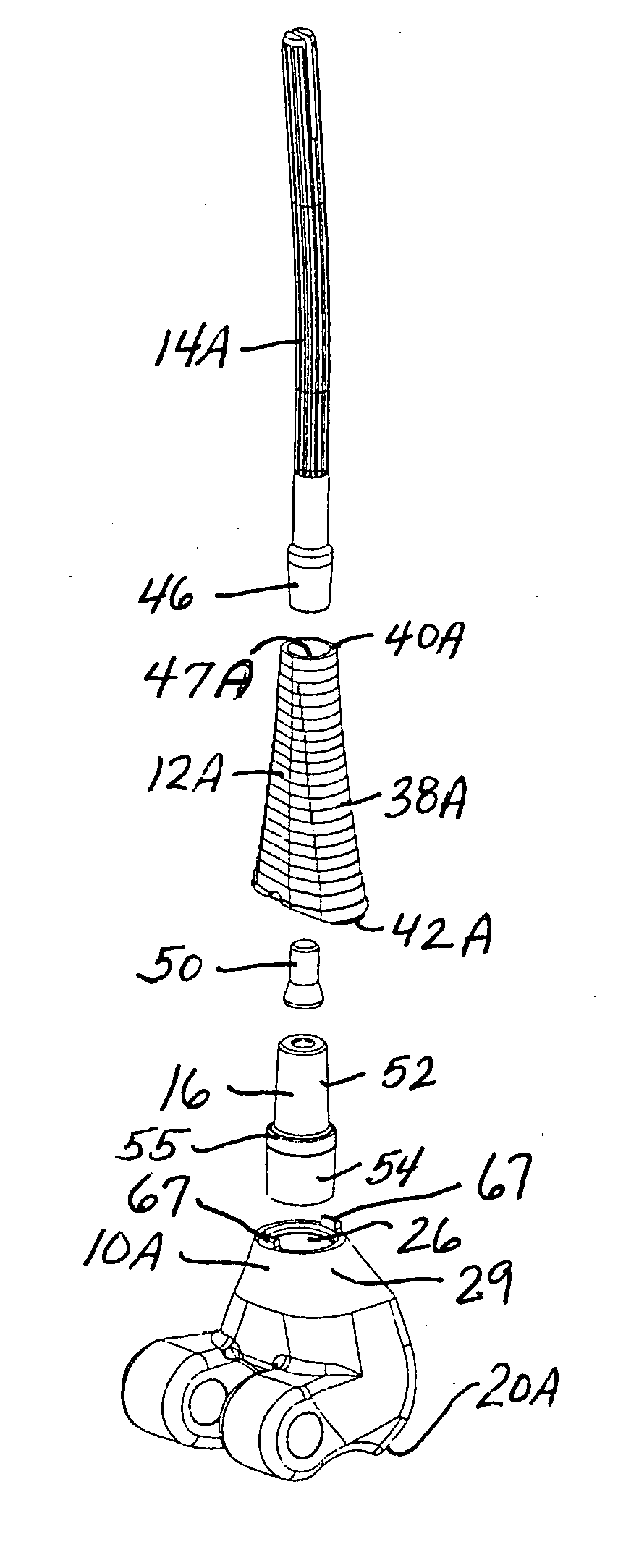

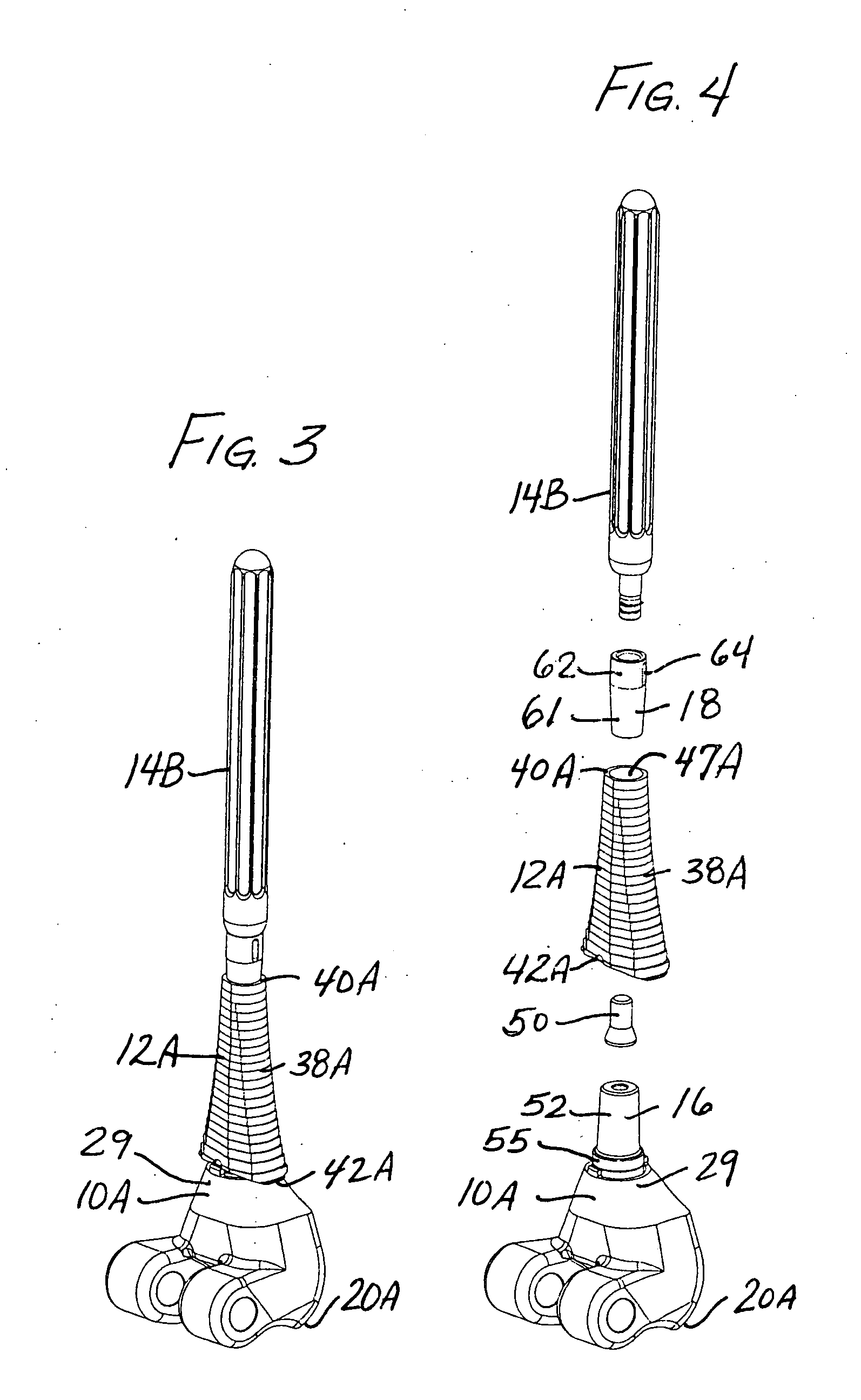

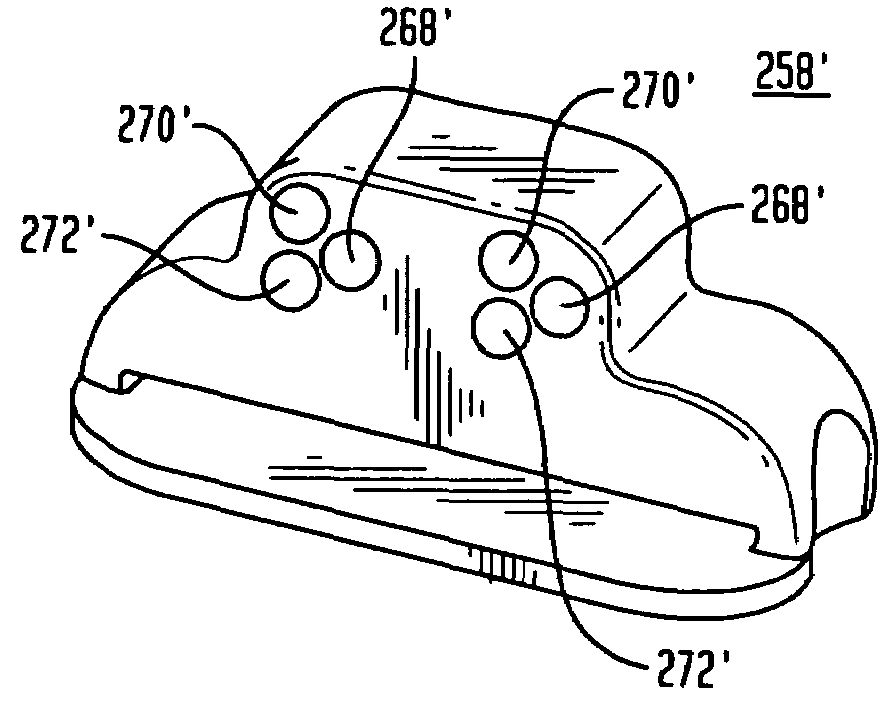

Modular implant system with fully porous coated sleeve

A modular knee implant system allows a surgeon to select between several different styles of distal femoral implant components and several different styles of stem extensions while also allowing for use of a metaphyseal component. The metaphyseal component can be a universal one that is usable with all of the styles of distal femoral implant components through use of an adapter. A second adapter allows for use of stem extensions with different types of connectors with the metaphyseal component. A separate metaphyseal component could also be provided with a distal Morse taper post to mate with a distal femoral component having a proximal Morse taper bore. The metaphyseal component may have an outer surface that is configured to maximize contact area with the patient's bone, and may have a surface finish over a substantial part of its overall length that is conducive to bone ingrowth.

Owner:DEPUY PROD INC

Automated systems for manufacturing patient-specific orthopedic implants and instrumentation

InactiveUS8234097B2Provide real-time feedbackAnalogue computers for chemical processesJoint implantsSurgical implantPlastic surgery

Disclosed herein are devices, systems and methods for the automated design and manufacture of patient-specific / patient-matched orthopedic implants. While the embodiments described herein specifically pertain to unicompartmental resurfacing implants for the knee, the principles described are applicable to other types of knee implants (including, without limitation, other resurfacing implants and joint replacement implants) as well as implants for other joints and other patient-specific orthopedic applications.

Owner:CONFORMIS

Systems and methods for compartmental replacement in a knee

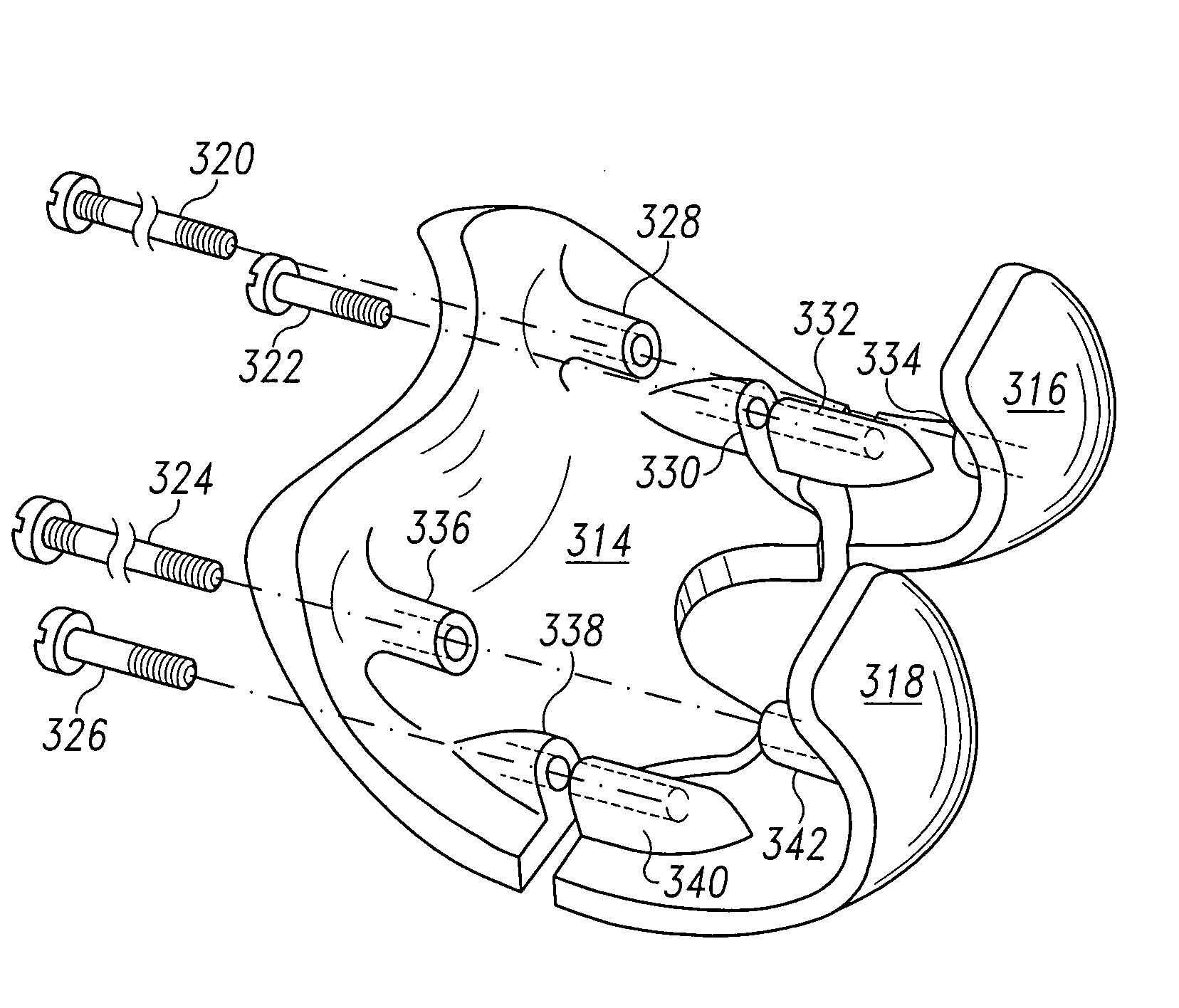

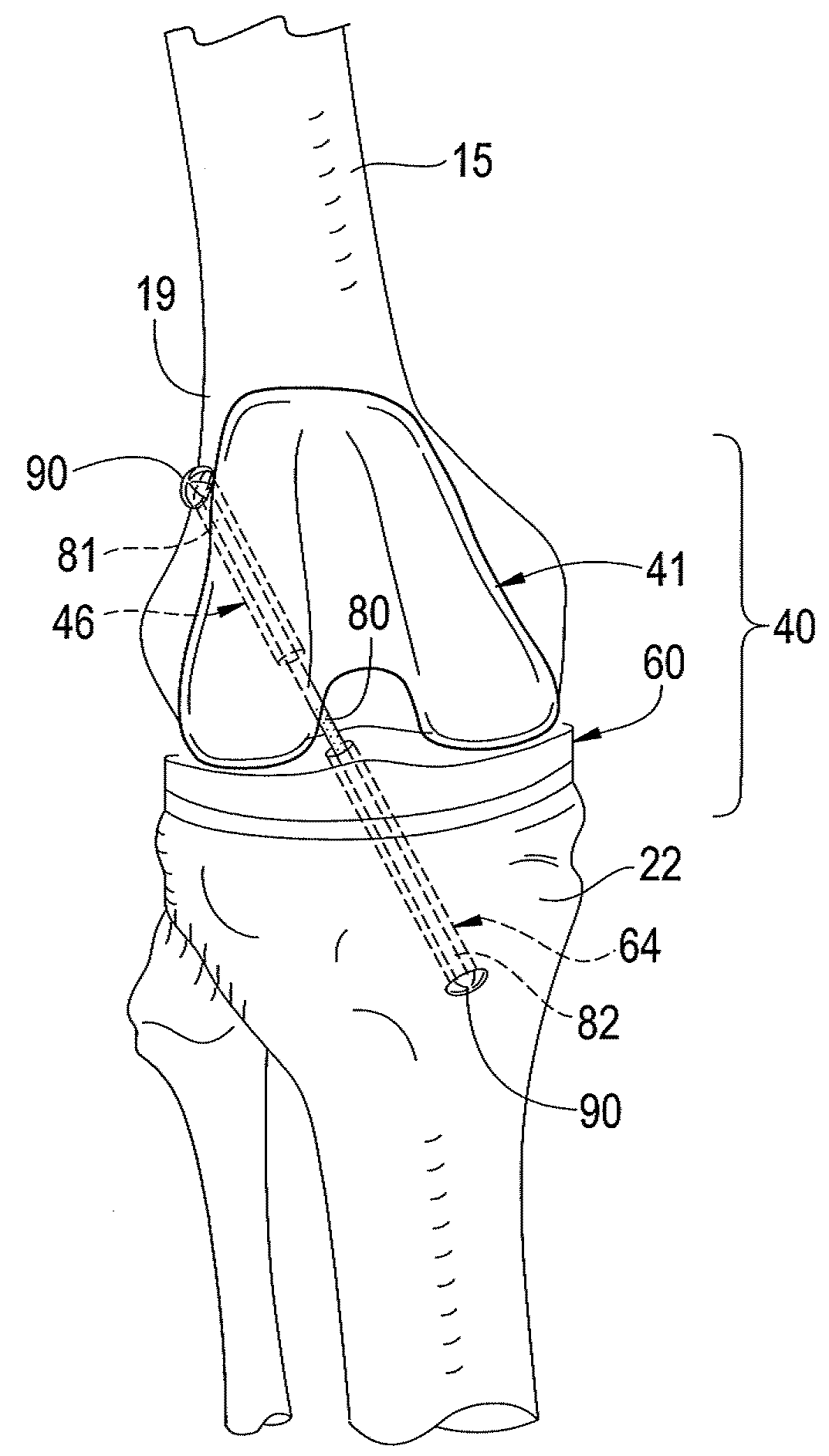

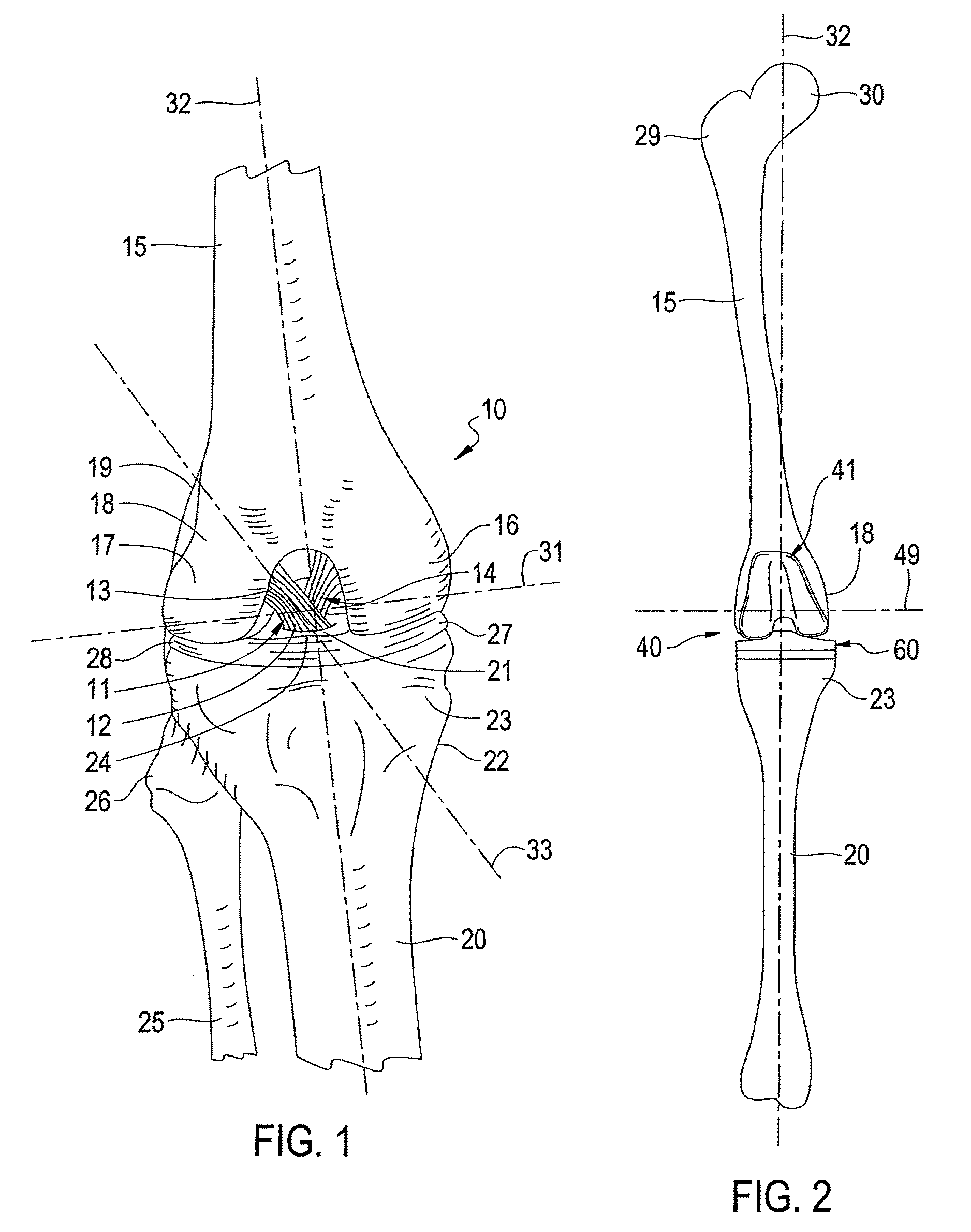

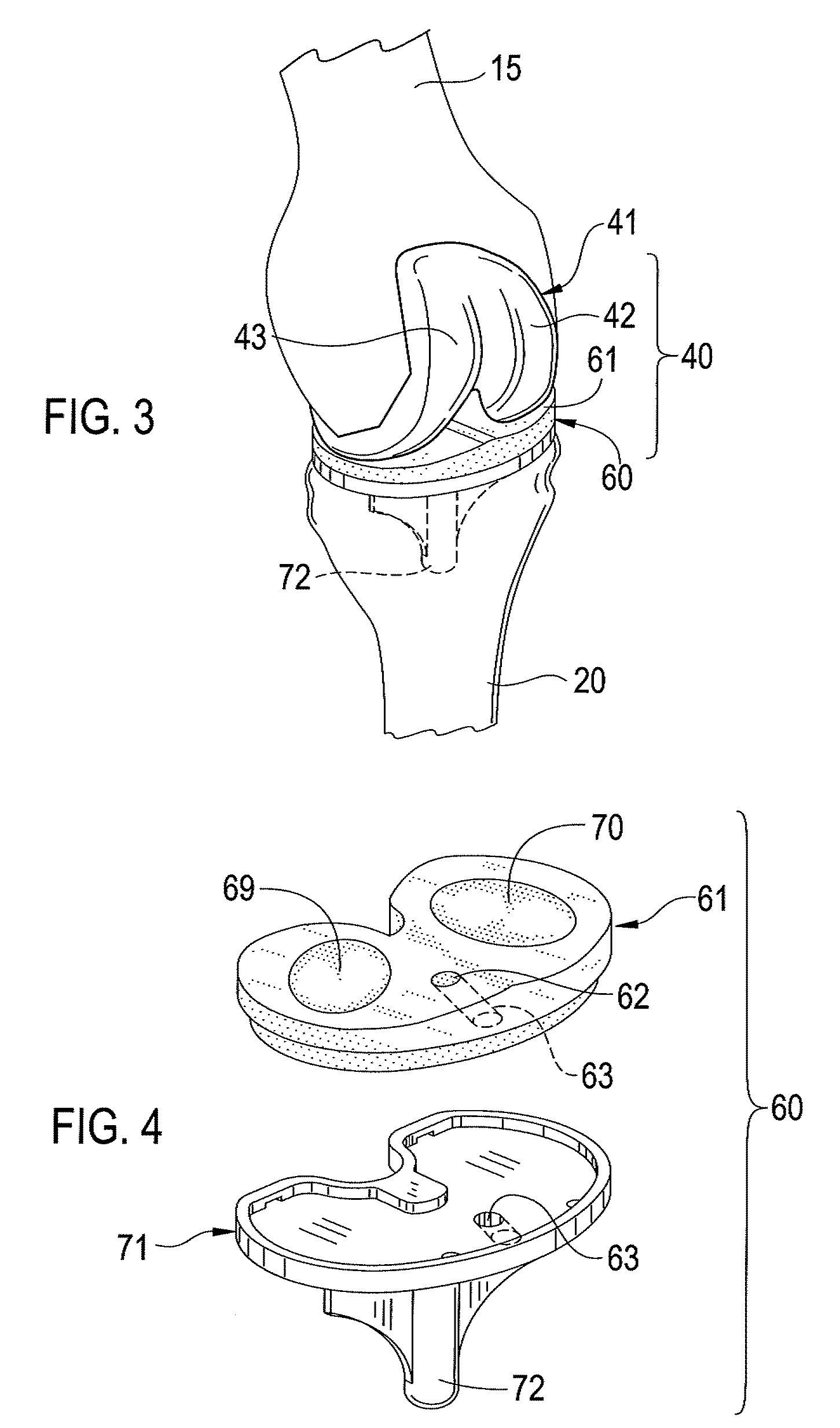

A knee replacement system provides a knee implant that may be used to more accurately replicate the diameter of a natural knee. In one embodiment, a patellofemoral component is connected to the posterior portion of a condylar component by screws that pass through the femur allowing the patellofemoral component and the condylar component to be torqued against opposing sides of the femur. Two additional screws are used to connect the patellofemoral component to an anterior portion of the condylar component. A gap may be left between the patellofemoral component and the anterior portion of the condylar component if needed to provide precise replication of the diameter of the natural knee from the patellofemoral component to the condylar component.

Owner:DEPUY PROD INC

Systems and methods for compartmental replacement in a knee

A knee replacement system provides a knee implant that may be used to more accurately replicate the diameter of a natural knee. In one embodiment, a patellofemoral component is connected to the posterior portion of a condylar component by screws that pass through the femur allowing the patellofemoral component and the condylar component to be torqued against opposing sides of the femur. Two additional screws are used to connect the patellofemoral component to an anterior portion of the condylar component. A gap may be left between the patellofemoral component and the anterior portion of the condylar component if needed to provide precise replication of the diameter of the natural knee from the patellofemoral component to the condylar component.

Owner:DEPUY PROD INC

Total knee implant

A knee prosthesis is provided for use in knee arthroplasty. In one exemplary embodiment, the present invention provides a tibial prosthesis having a tibial baseplate with a fixed medial bearing component and a mobile lateral bearing component. In one exemplary embodiment, the lateral bearing component is secured to the lateral portion of the tibial baseplate utilizing at least one prosthetic ligament. Additionally, in one exemplary embodiment, a stop is provided to limit anterior or posterior movement of the lateral bearing component relative to the tibial baseplate. For example, the stop may be defined by cooperating shoulders formed on the lateral bearing and the tibial baseplate.

Owner:ZIMMER INC

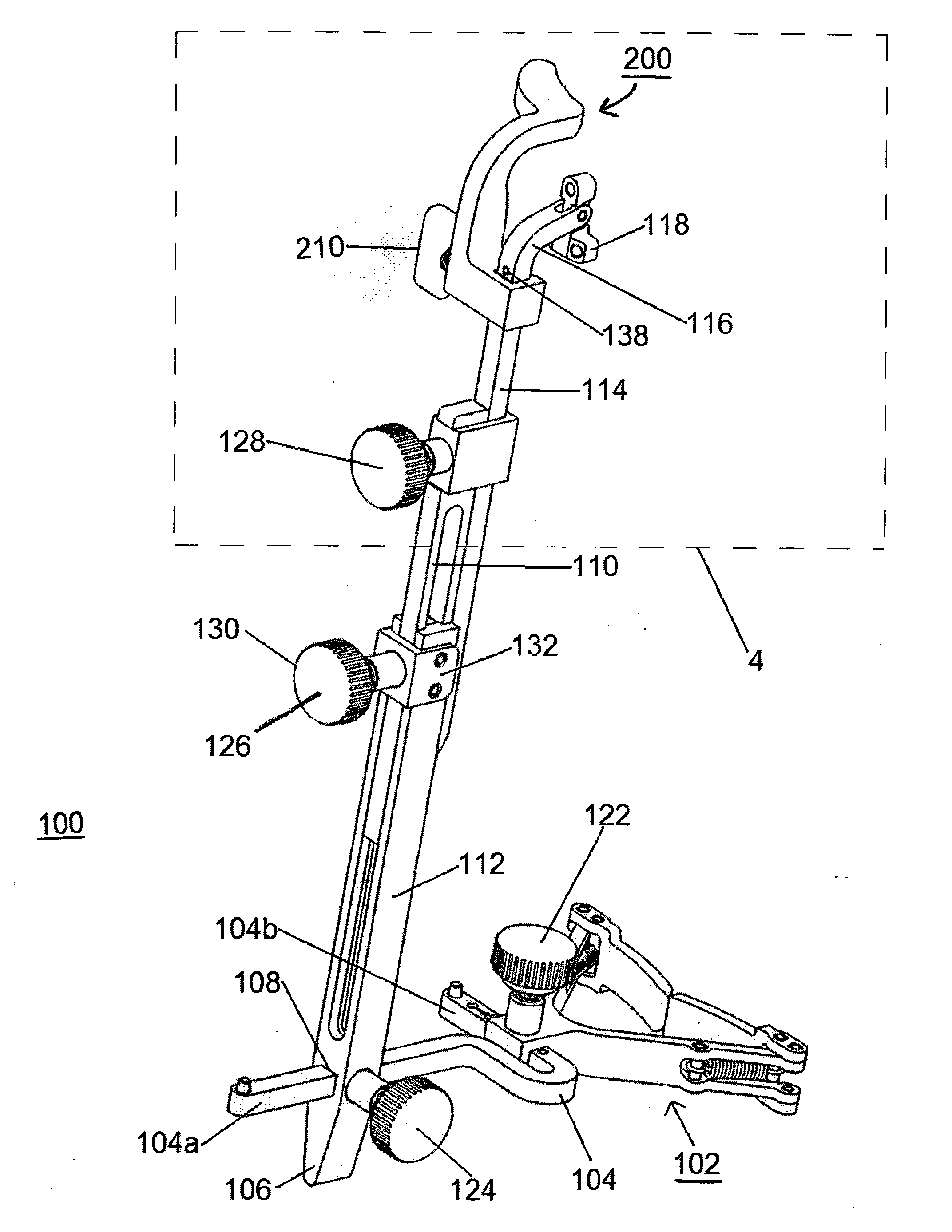

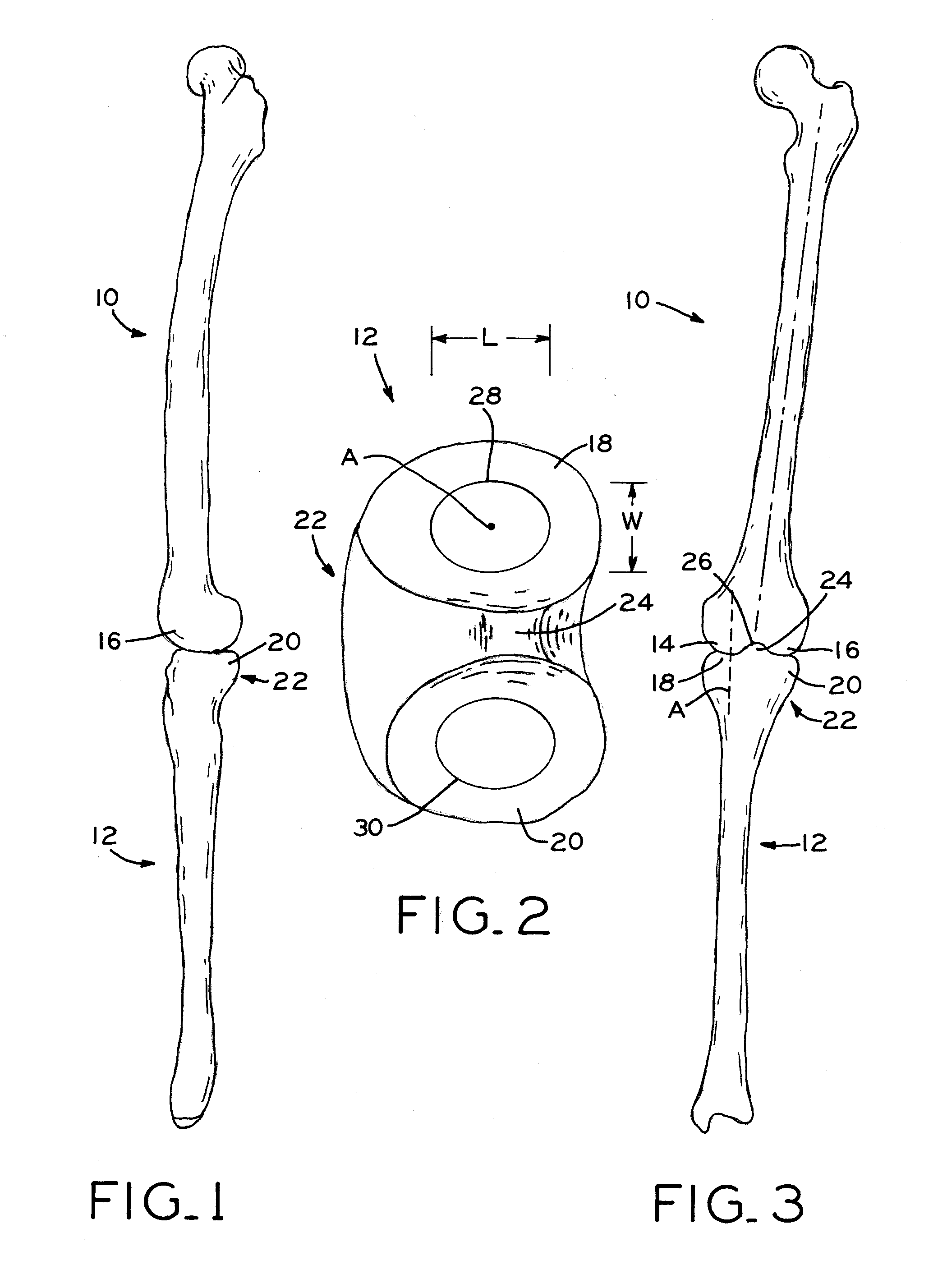

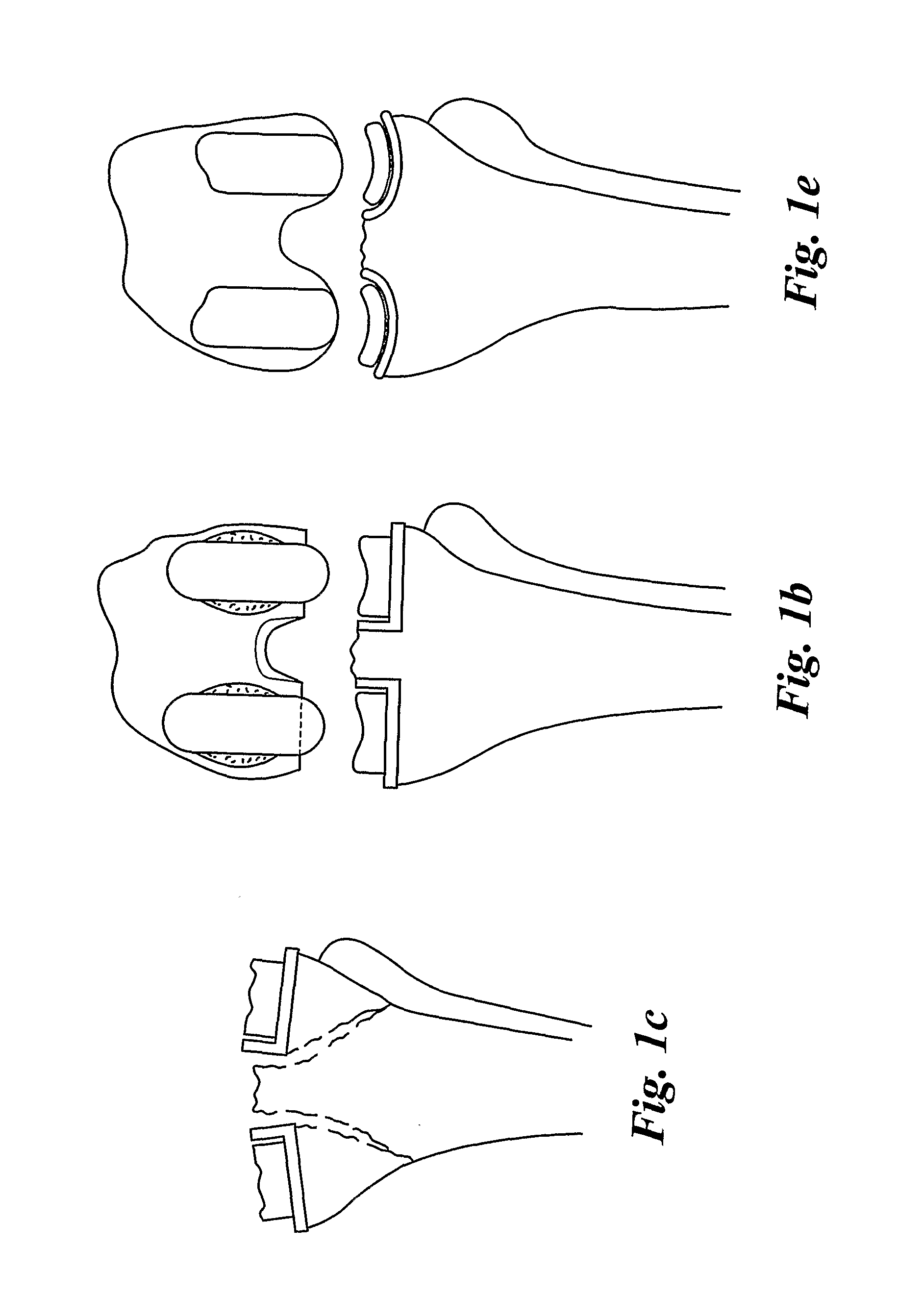

Unicondylar knee implants and insertion methods therefor

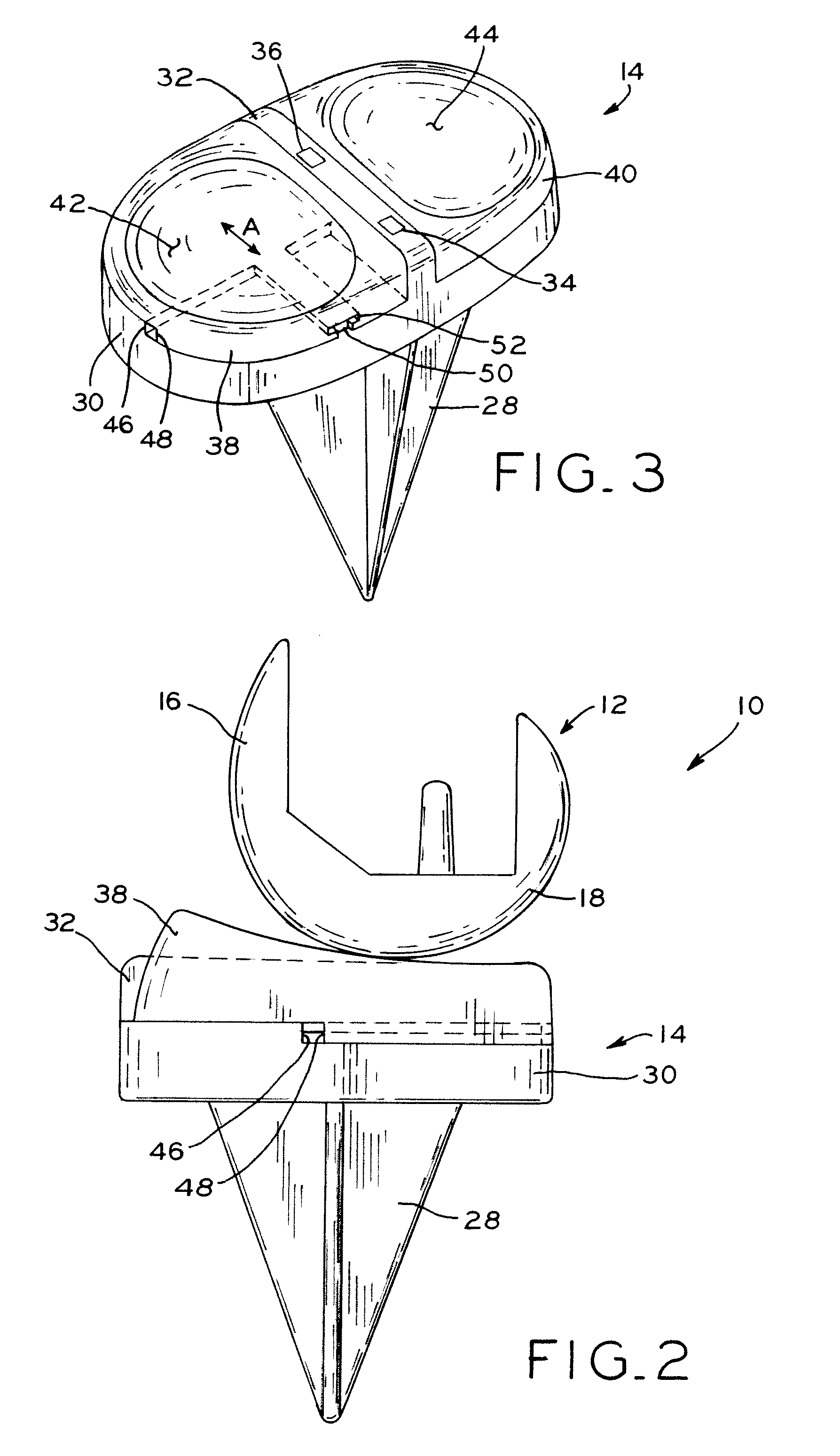

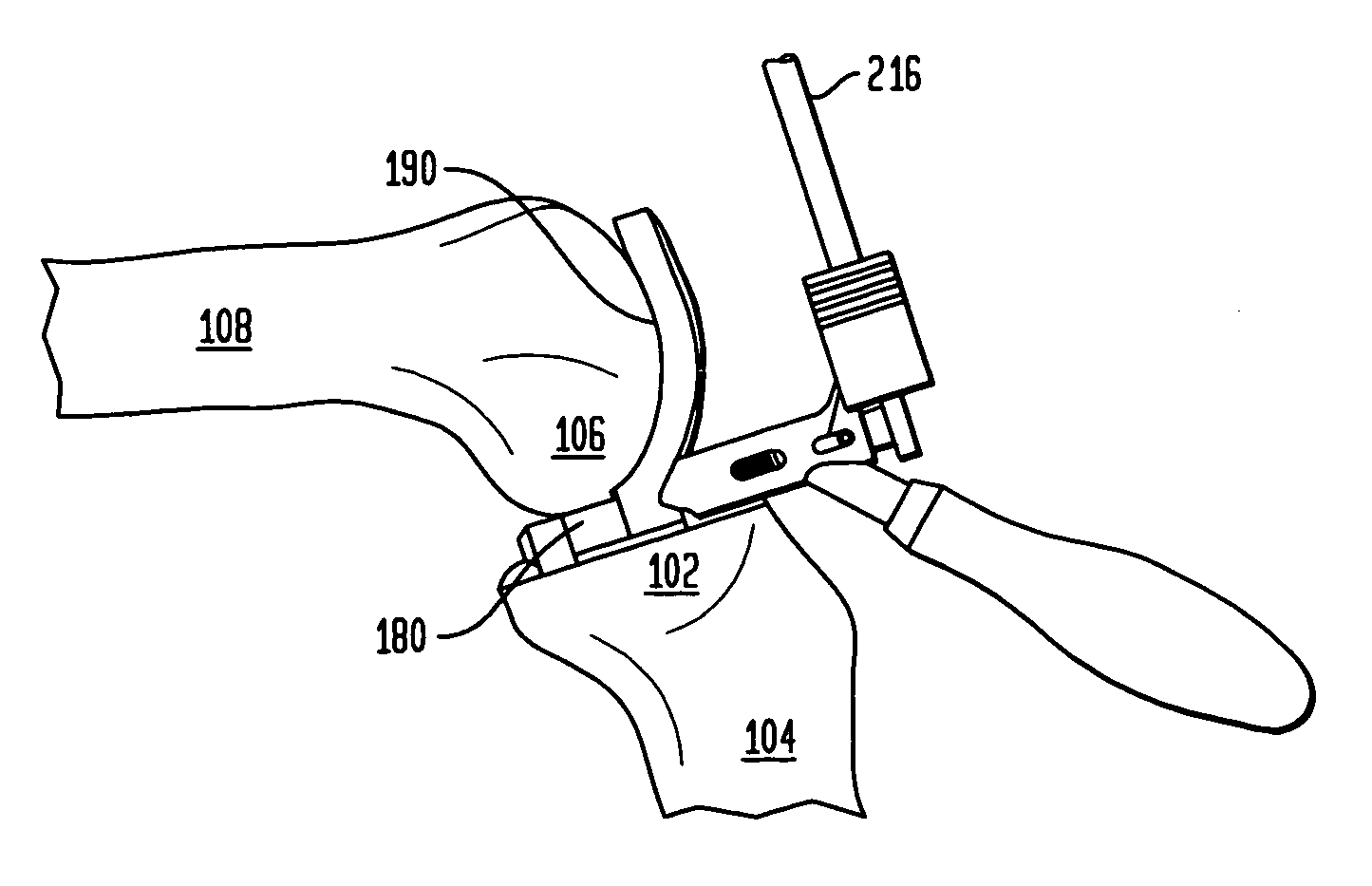

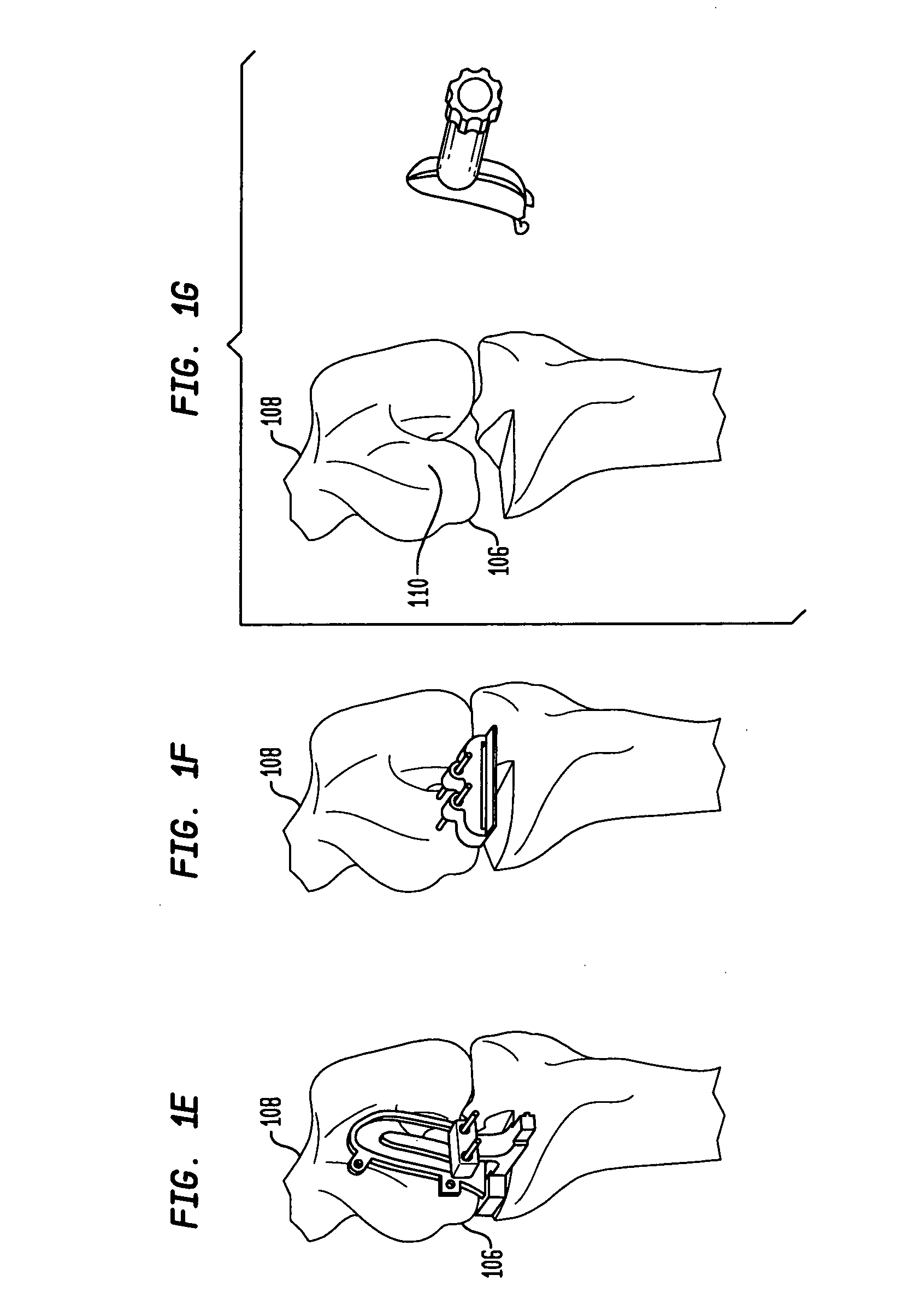

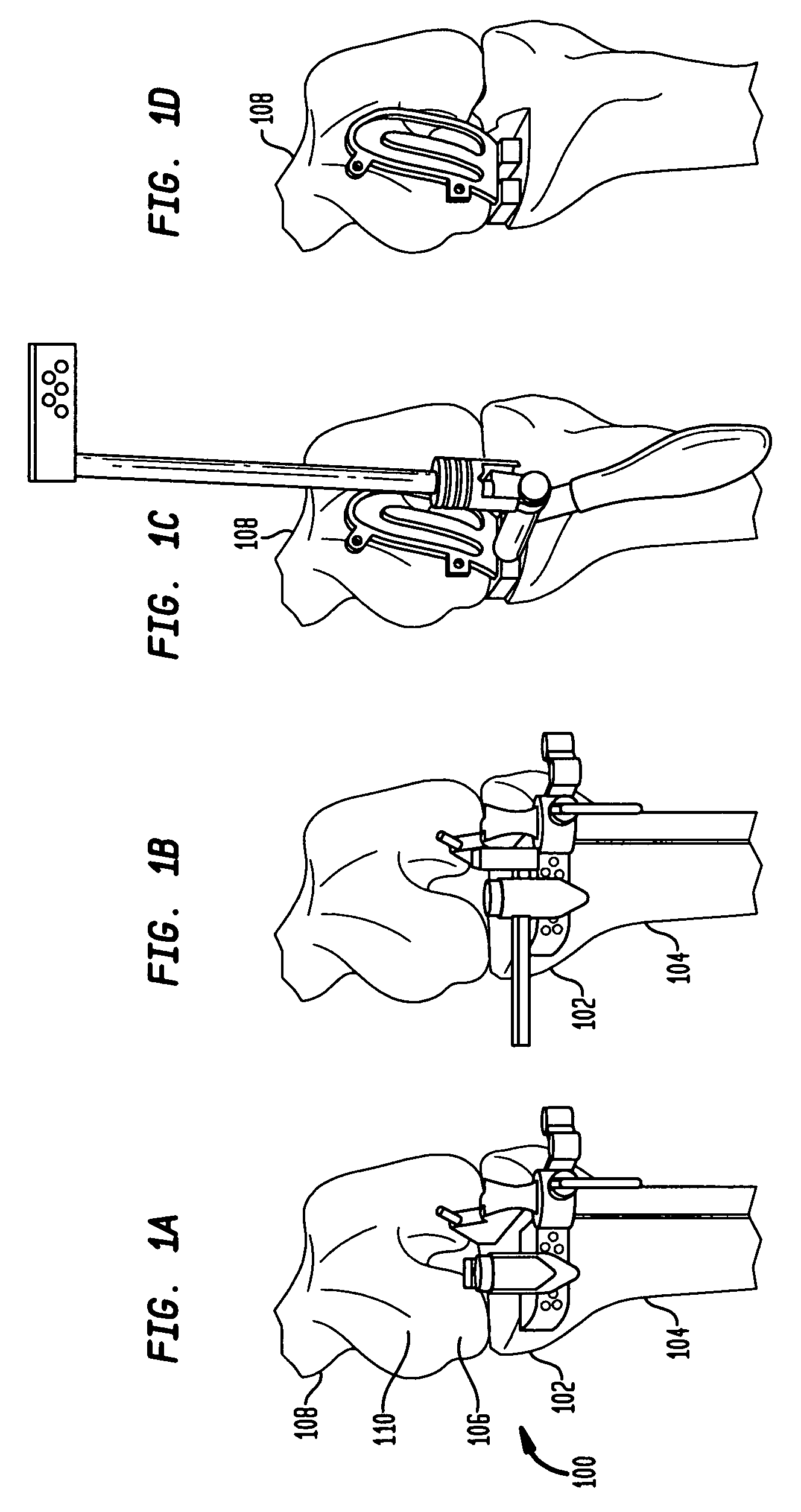

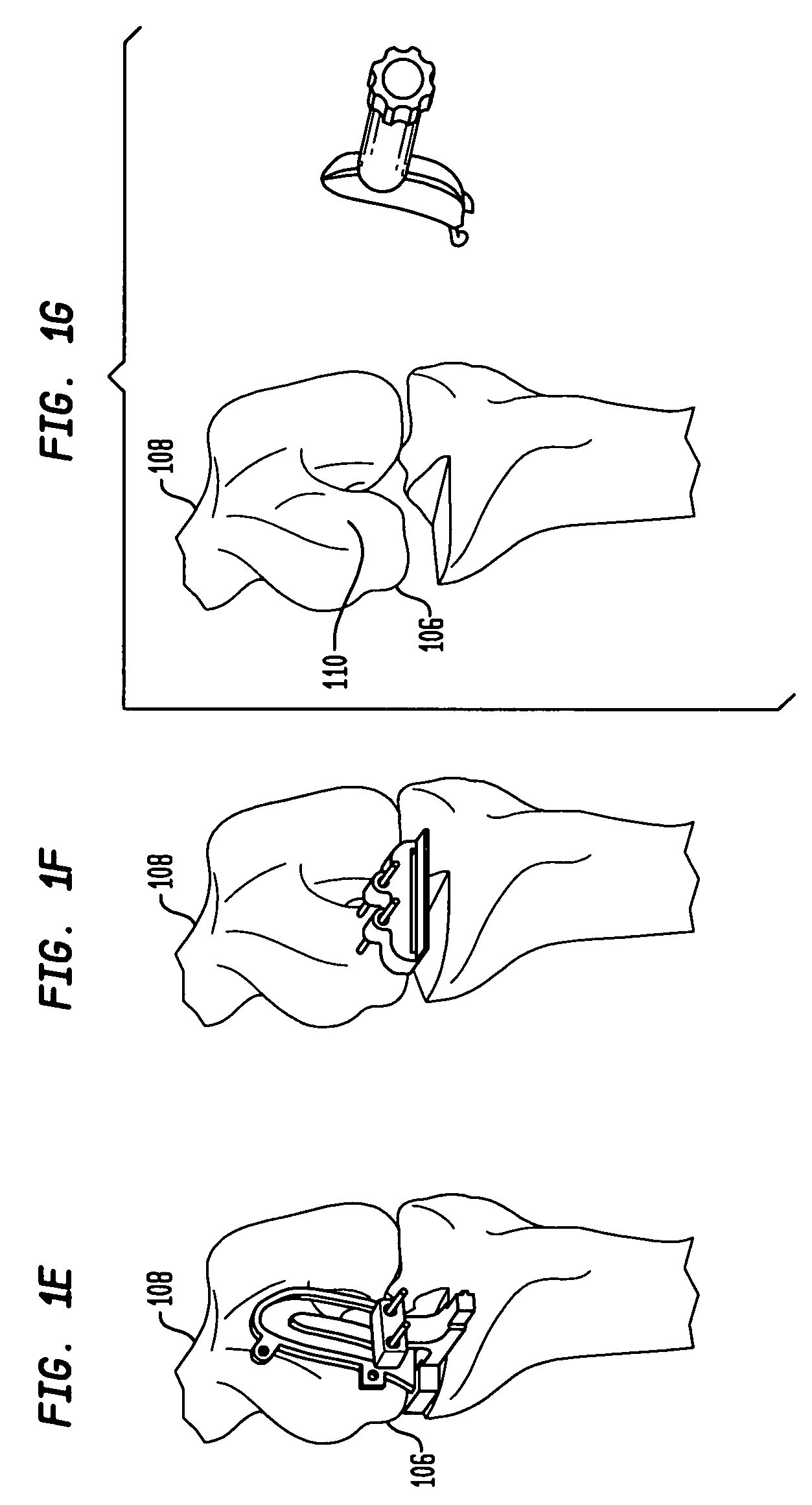

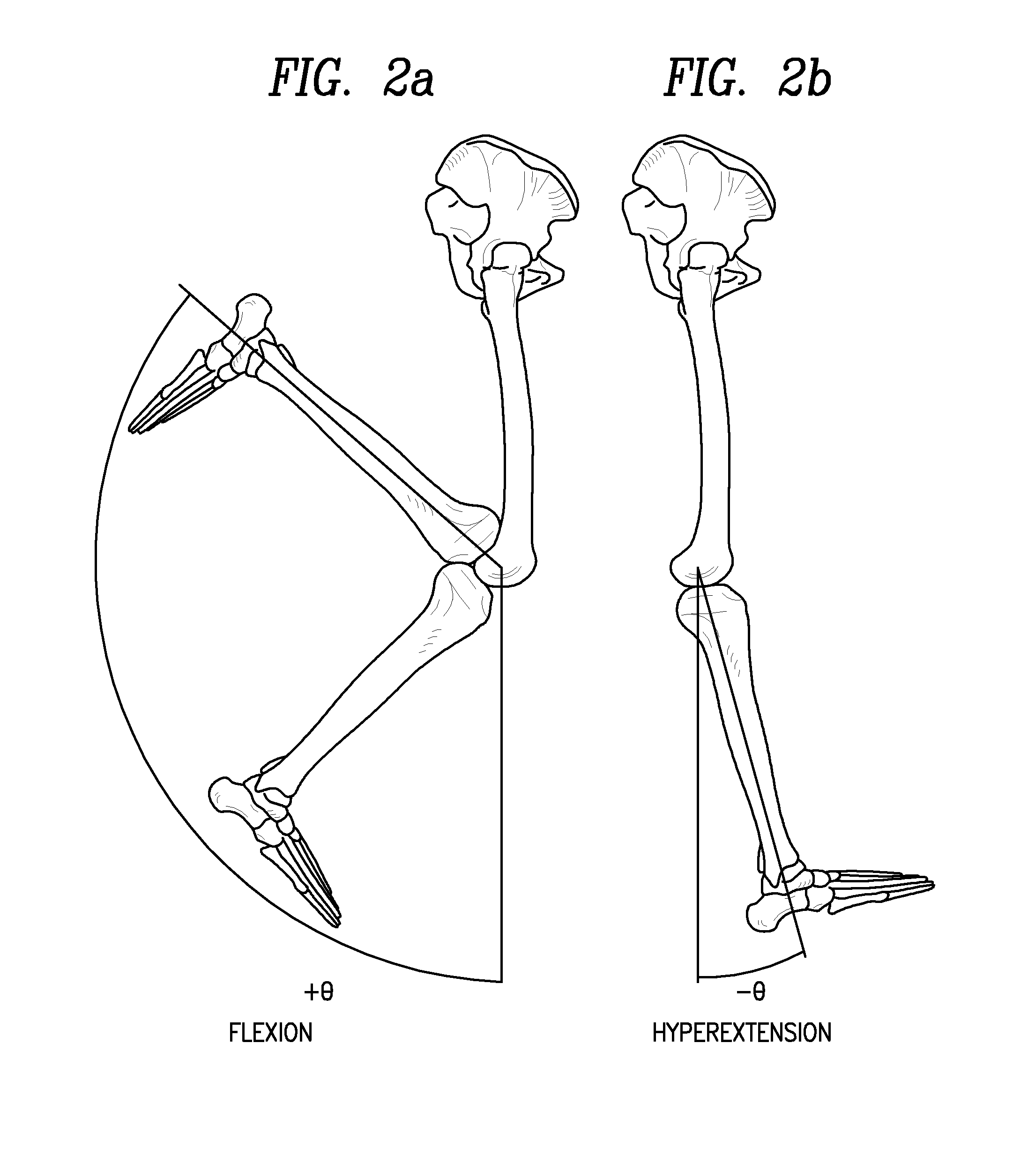

A method of preparing a knee joint for receiving a unicondylar knee implant includes preparing a first seating surface at a proximal end of a tibia, and providing a combination bur template and spacer block, the bur template having an upper end, a lower end and a curved surface extending between the upper and lower ends thereof that is adapted to conform to a femoral condyle of a femur and the spacer block extending from the lower end of the bur template and having top and bottom surfaces. The method includes flexing the knee joint so that the prepared first seating surface at the proximal end of the tibia opposes a posterior region of the femoral condyle and inserting the combination bur template and spacer block into the knee joint so that the top surface of the spacer block engages the posterior region of the femoral condyle and the bottom surface of the spacer block engages the first seating surface at the proximal end of the tibia. While the spacer block is maintained between the femur and the tibia, the knee joint is extended until the curved surface of the bur template engages the femoral condyle of the femur. The bur template is anchored to the femur and used to guide burring of the femoral condyle for preparing a second seating surface on the femur. After burring the distal end of the femoral condyle, the posterior region of the femoral condyle is resected.

Owner:HOWMEDICA OSTEONICS CORP

Automated Systems for Manufacturing Patient-Specific Orthopedic Implants and Instrumentation

InactiveUS20100274534A1Provide real-time feedbackAnalogue computers for chemical processesJoint implantsPlastic surgerySacroiliac joint

Disclosed herein are devices, systems and methods for the automated design and manufacture of patient-specific / patient-matched orthopedic implants. While the embodiments described herein specifically pertain to unicompartmental resurfacing implants for the knee, the principles described are applicable to other types of knee implants (including, without limitation, other resurfacing implants and joint replacement implants) as well as implants for other joints and other patient-specific orthopedic applications.

Owner:CONFORMIS

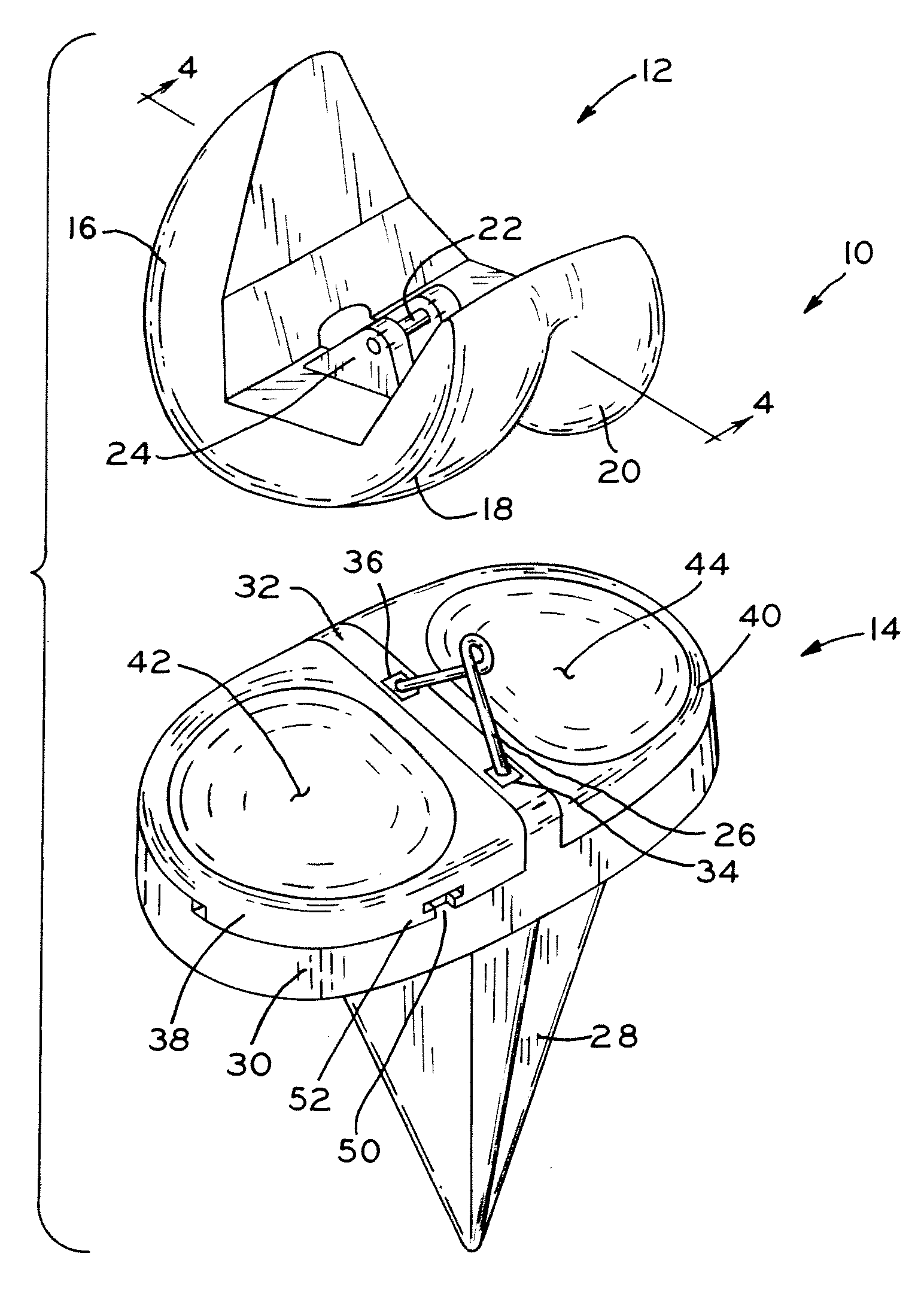

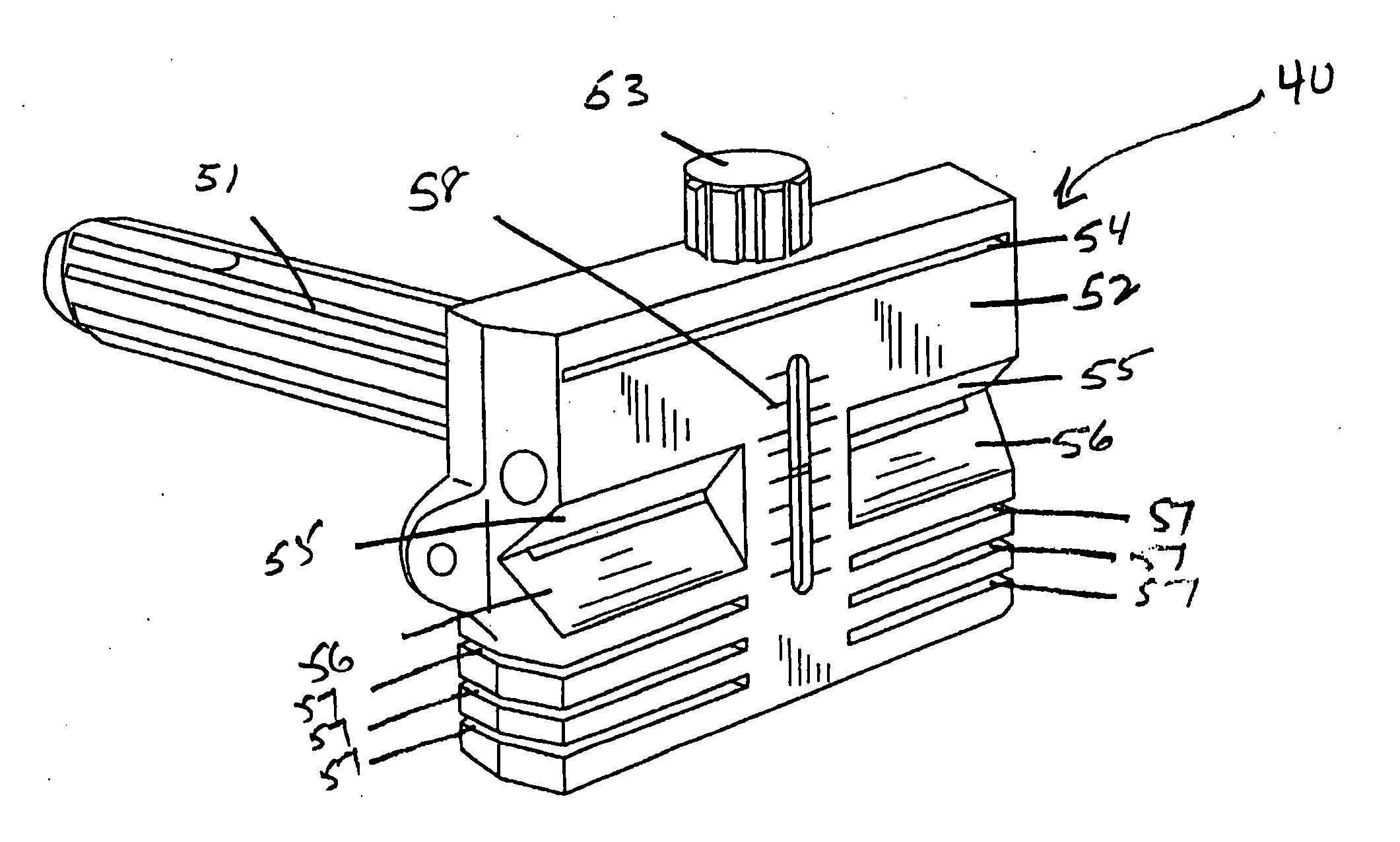

Modular orthopaedic implant system with multi-use stems

A knee implant system includes a femoral adapter. The femoral adapter has a threaded bore so that a stem extension can be threaded onto the proximal end of the adapter. The same stem extension can be threaded onto the distal end of the tibial tray so that the number of stem extensions required in the system is reduced. The femoral adapter has a tapered exterior surface so that a metaphyseal sleeve can be frictionally connected to the femoral adapter. The metaphyseal sleeve has a threaded bore so that the same type of stem extension can be threaded onto the metaphyseal sleeve. The system can include a group of adapters to give the surgeon the option of selecting the appropriate valgus angle and anterior-posterior position of the stem extension.

Owner:DEPUY SYNTHES PROD INC

Total knee prosthesis and method for total knee arthroplasty

A prosthetic knee implant for implantation into a mammal, which accommodates an anterior cruciate ligament substitute to provide stability to the knee implant. The prosthetic knee implant includes a femoral component having a pair of condylar surfaces and a tibial component having a surface portion adapted to slidably engage the femoral component upon rotation of the same. The femoral component further includes a recess between the condyles defining an aperture through the femoral component. The tibial component further includes a center portion defining an aperture through the tibial component substantially at its center. The femoral aperture and the tibial aperture are adapted to receive an anterior cruciate ligament substitute for biasing the mammalian femur and tibia together. Also disclosed is a method used to replace the total knee joint in a mammal with the improved prosthetic knee implant of the present invention.

Owner:BLUM MICHAEL F

Surfaces and processes for wear reducing in orthopaedic implants

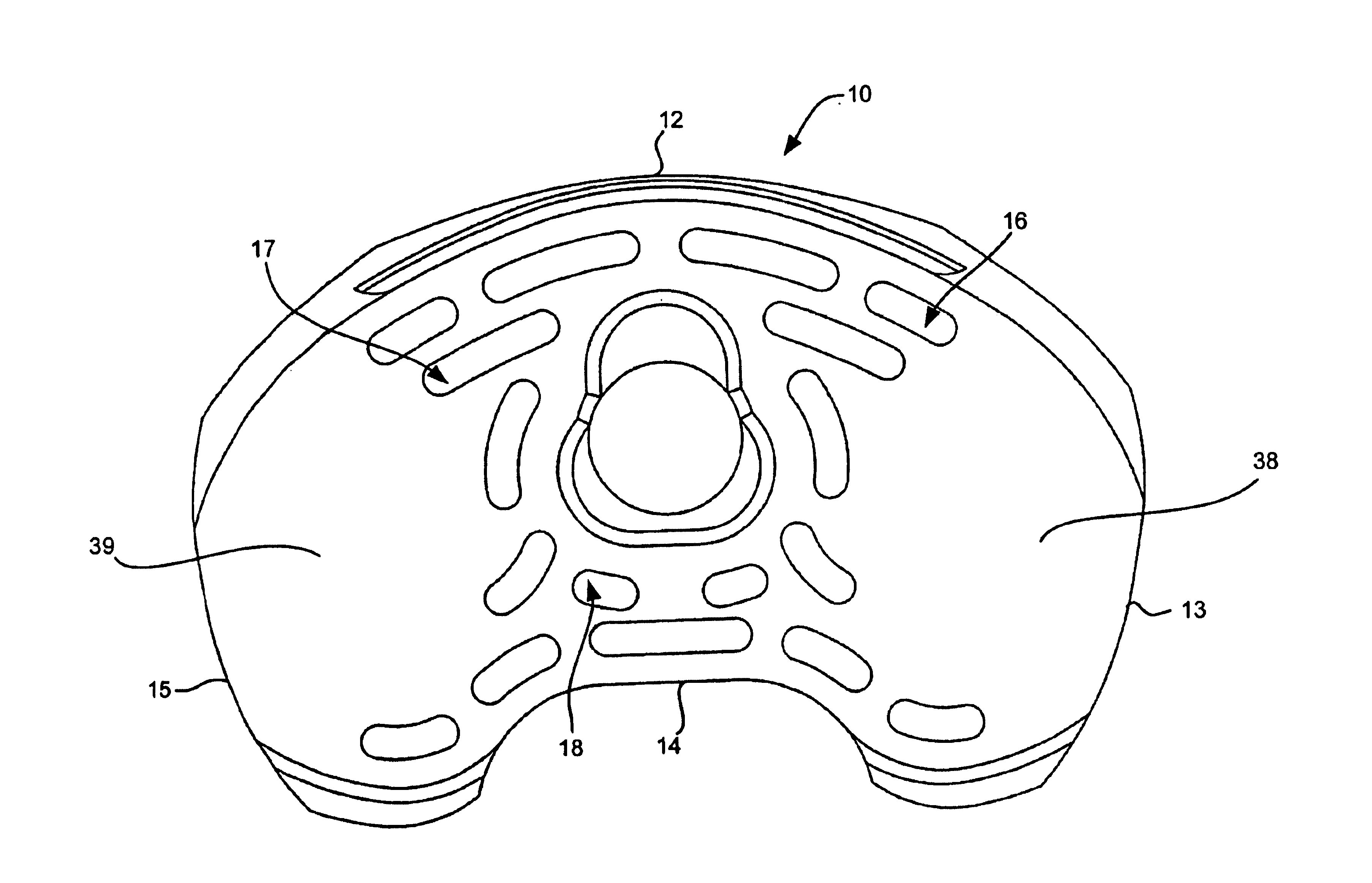

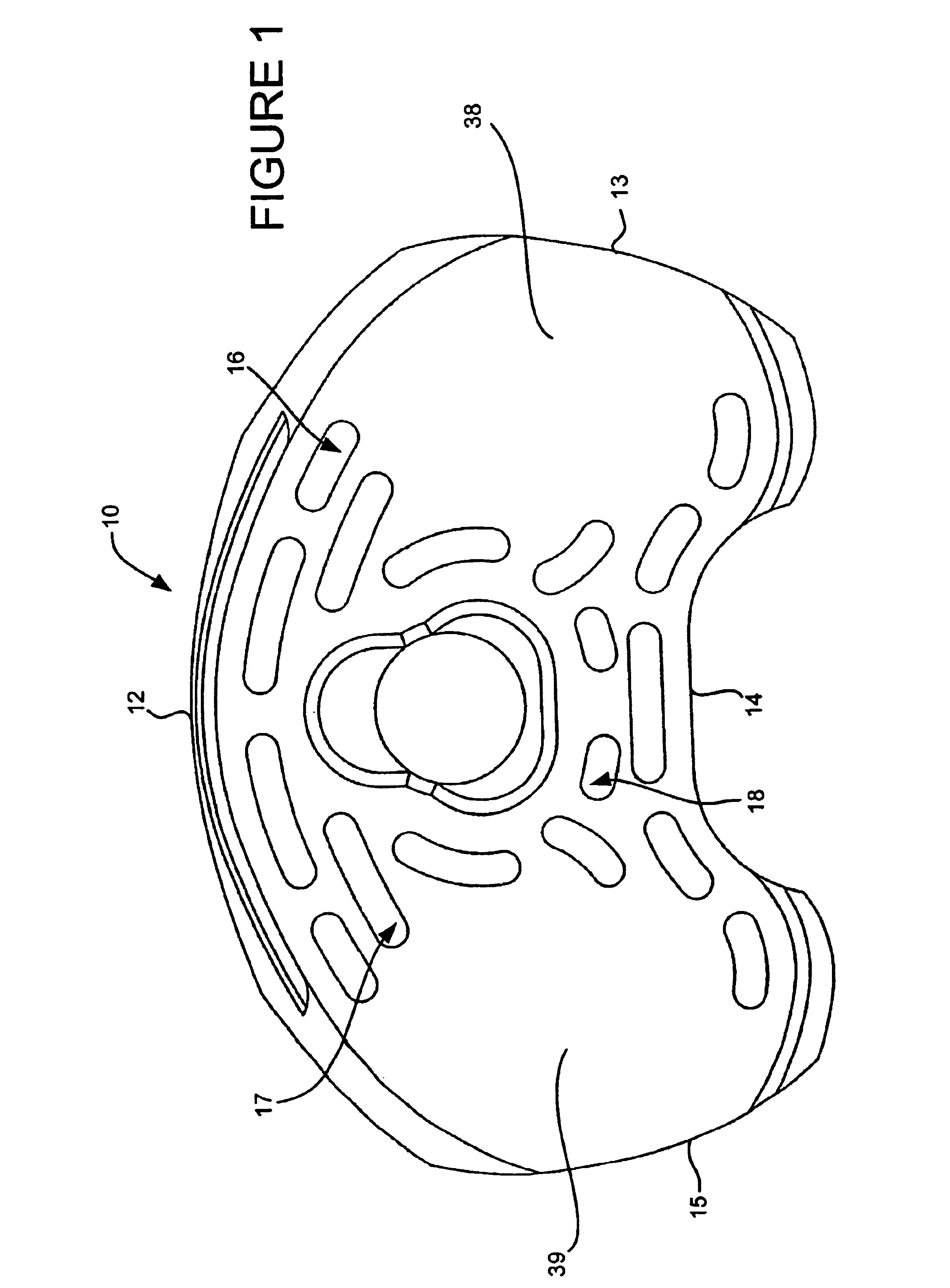

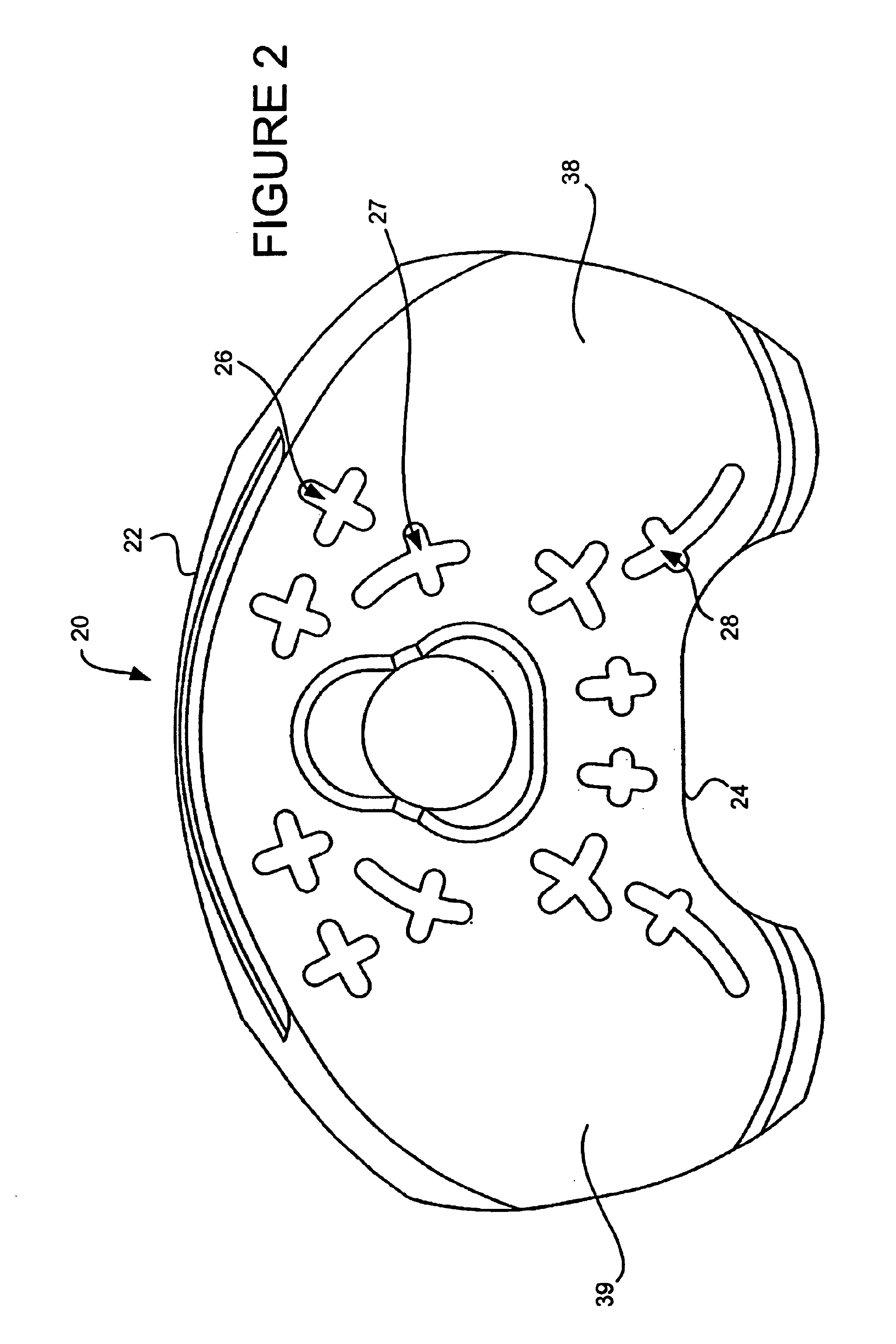

Artificial implants having reduced area to provide reduced wear are provided. The reduced area is particularly located at areas where greatest wear is exhibited. In a particular embodiment of a mobile bearing knee implant, the area is reduced on the mobile bearing insert underside, where it contacts a tibial component. The reduced area may be any shape of indentations, for example, grooves, dimples, straight patterns, curved patterns, crossing patterns, holes, channels or slots. The indentations may be various sizes, and have been found to be particularly effective if covering about 10% to about 20% of the insert at depths between about 1-2 mm.

Owner:SMITH & NEPHEW INC

Unicondylar knee implants and insertion methods therefor

A system for resecting a posterior region of a femoral condyle includes a posterior resection guide having a main body with an upper end and a lower end, a cutting instrument guide surface provided on the main body, and a series of anchor pin holes extending through the main body. The series of anchor pin holes includes a first pair of pin holes located a first distance from the upper end of the main body, a second pair of pin holes located a second distance from the upper end of the main body that is less than the first distance, and a third pair of anchor pin holes located a third distance from the upper end of the main body that is more than the first distance. Anchor pins are insertable through the anchor pin holes for coupling the posterior resection guide with a femoral condyle of a femur.

Owner:HOWMEDICA OSTEONICS CORP

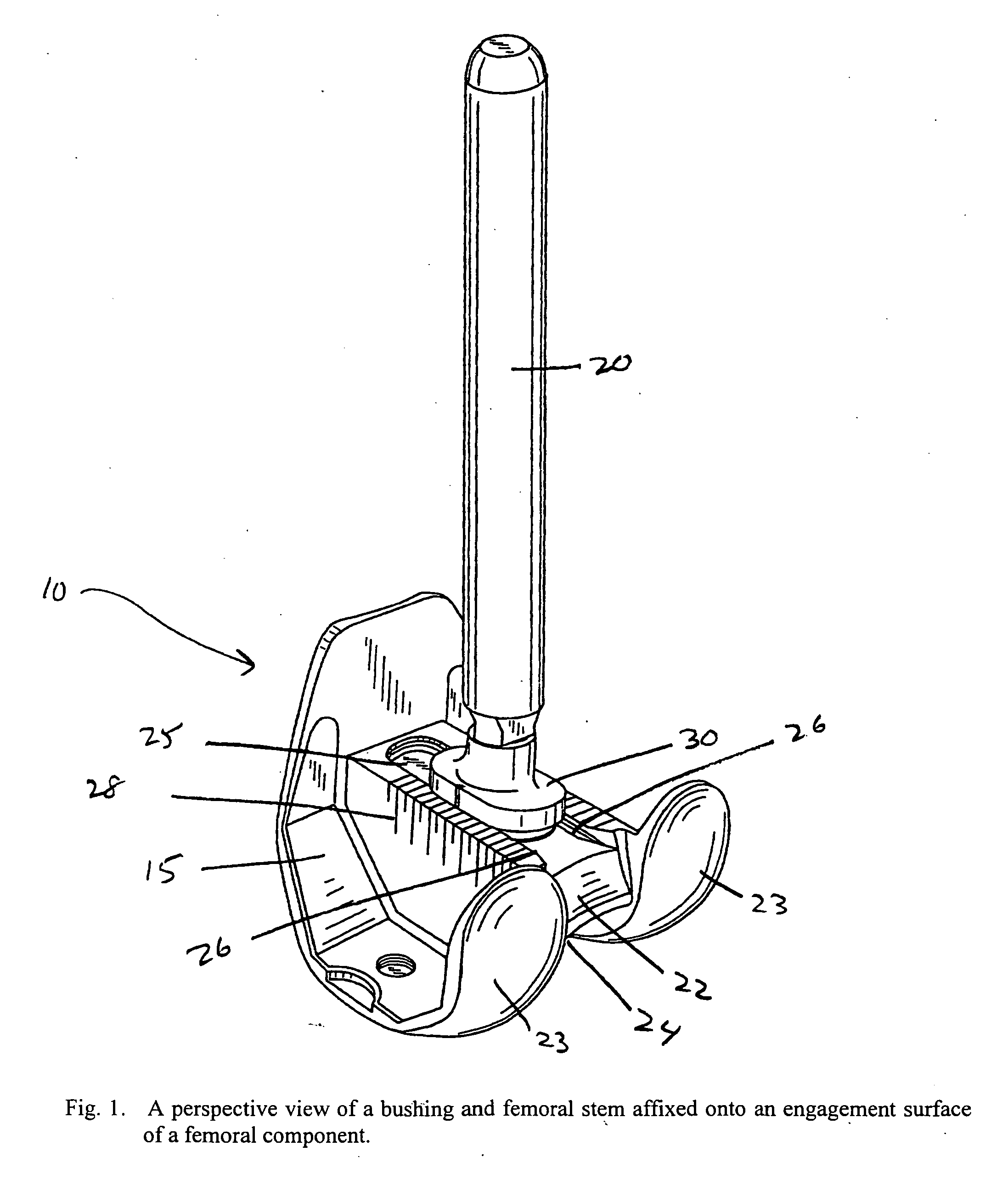

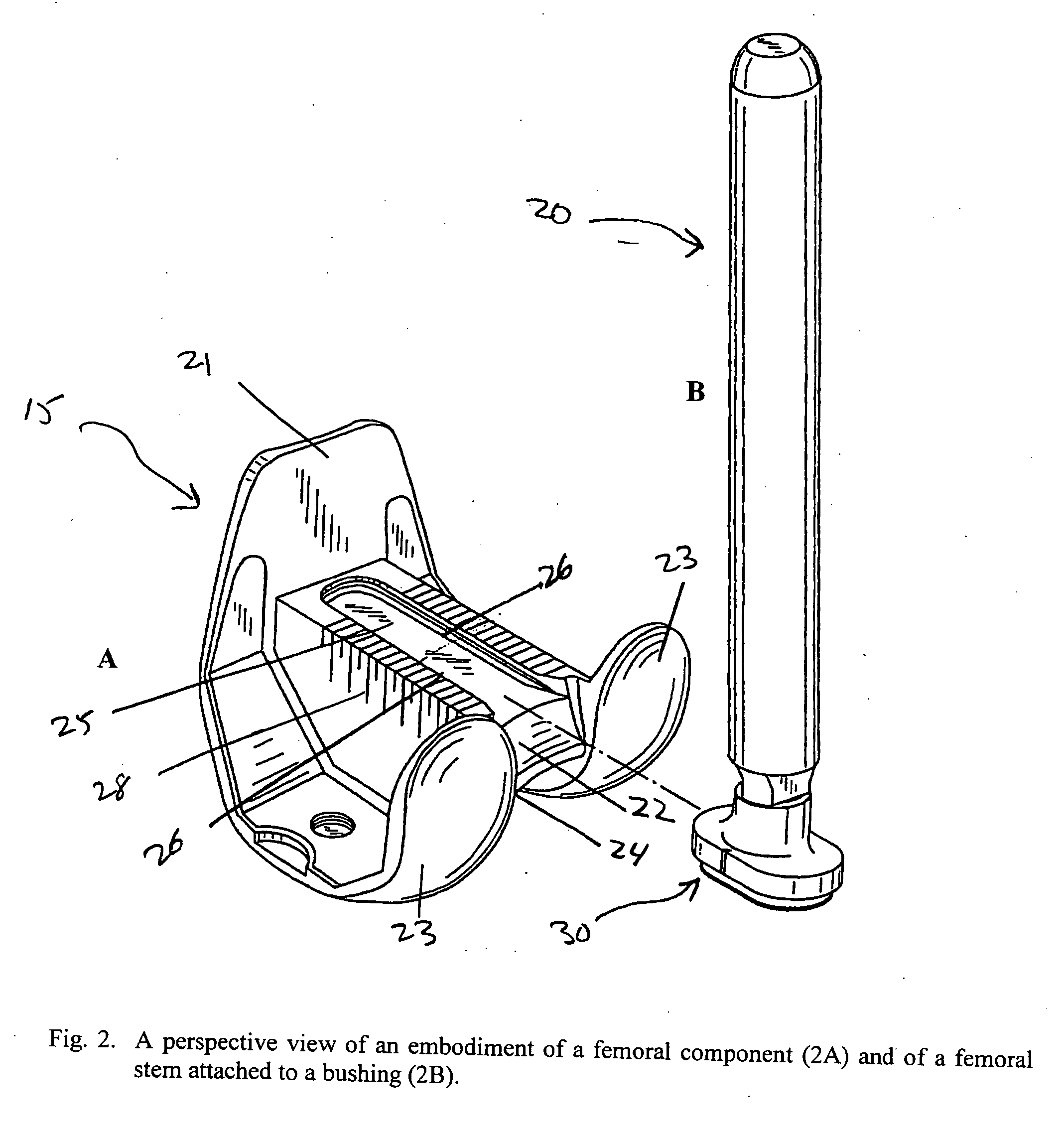

Prosthetic revision knee system

The present invention provides a femoral component, and a method for surgical implantation of a femoral prosthesis, comprised of a revision knee implant and corresponding cutting block system. In particular, the revision knee implant, comprised of a femoral component having incremental markings thereon and a femoral stem, and corresponding cutting block system having corresponding incremental markings thereon, enables a surgeon maximally to position the cutting block adjacent as much area as possible of a distal femur of a patient and to infinitely position the femoral component in the exact position indicated by the cutting block.

Owner:GLOBUS MEDICAL INC

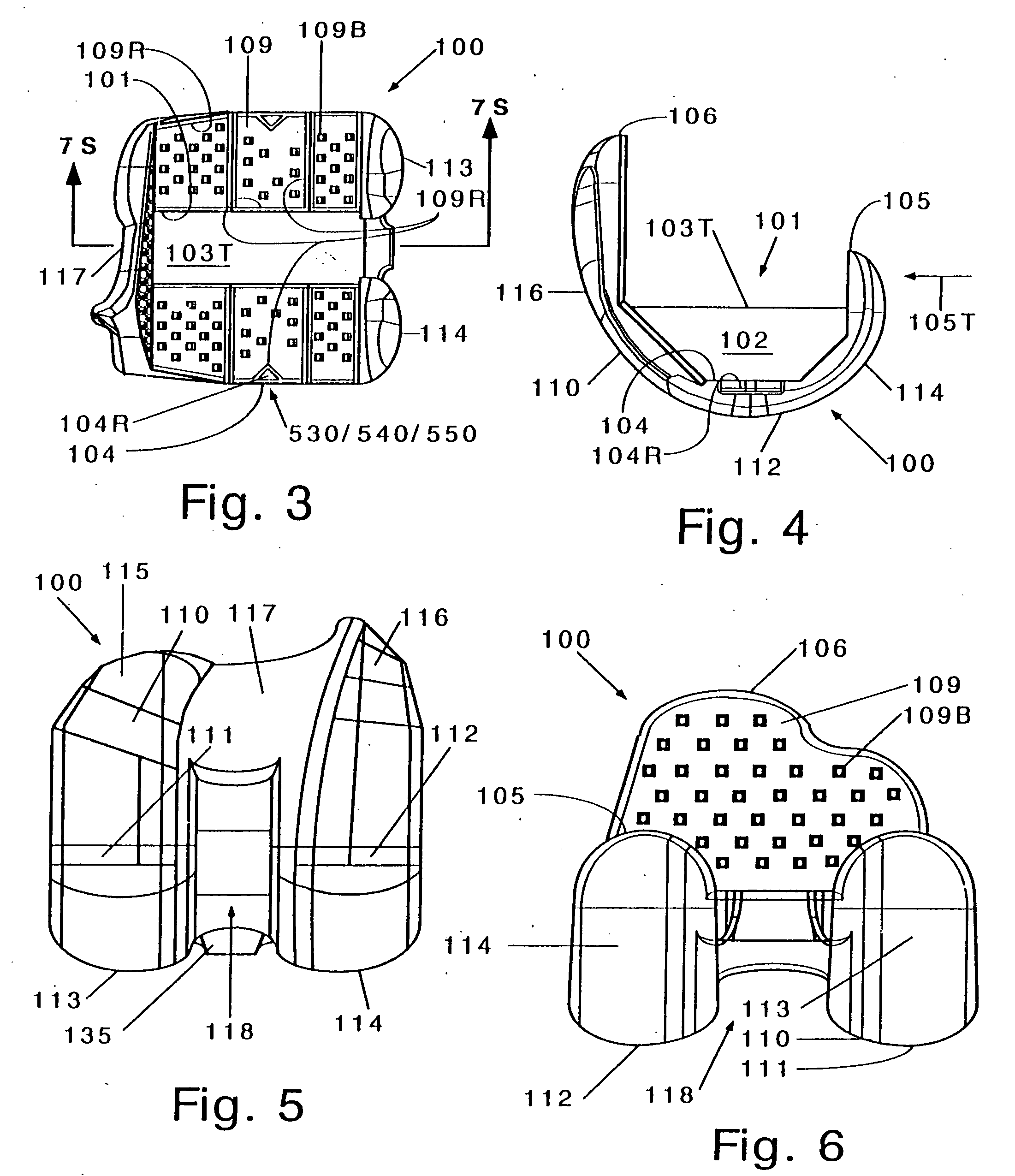

Implant device and method for manufacture

A knee implant includes a femoral component having first and second femoral component surfaces. The first femoral component surface is for securing to a surgically prepared compartment of a distal end of a femur. The second femoral component surface is configured to replicate the femoral condyle. The knee implant further includes a tibial component having first and second tibial component surfaces. The first tibial component surface is for contacting a proximal surface of the tibia that is substantially uncut subchondral bone. At least a portion of the first tibial component surface is a mirror image of the proximal tibial surface. The second tibial component surface articulates with the second femoral component surface.

Owner:CONFORMIS

System and method for adjusting the thickness of a prosthesis

The present invention relates to a system and method for adjusting a thickness of a prosthesis (e.g., a knee implant). In one embodiment, a knee prosthesis for implantation in a patient is provided, comprising: a tibial tray, wherein the tibial tray comprises an upper surface and a lower surface, and the lower surface of the tibial tray is disposed adjacent a tibia of the patient; a tibial insert, wherein the tibial insert comprises an upper surface and a lower surface; a tibial spacer, wherein the tibial spacer comprises an upper surface and a lower surface, and wherein the tibial spacer is disposed between the tibial tray and the tibial insert such that the lower surface of the tibial spacer is adjacent the upper surface of the tibial tray and the upper surface of the tibial spacer is adjacent the lower surface of the tibial insert; and at least one locking mechanism, wherein the locking mechanism locks the tibial spacer to the tibial tray to form a locked spacer / tray assembly such that the locking mechanism substantially prohibits at least relative up-down movement between the tibial spacer and the tibial tray when the locked spacer / tray assembly is implanted in the patient. In one example, the locking mechanism may further lock the tibial spacer to the tibial insert to form a locked insert / spacer / tray assembly such that the locking mechanism substantially prohibits at least relative up-down movement between the tibial spacer and the tibial insert when the locked insert / spacer / tray assembly is implanted in the patient. In another embodiment, a method for implanting a knee prosthesis in a patient is provided, comprising: providing a tibial tray, wherein the tibial tray comprises an upper surface and a lower surface, and the lower surface of the tibial tray is disposed adjacent a tibia of the patient; providing a tibial insert which has a shelf life and which is not readily re-sterilizable after the shelf life has expired, wherein the tibial insert comprises an upper surface and a lower surface; and providing a tibial spacer which has a shelf life and which is re-sterilizable after the shelf life has expired, wherein the tibial spacer comprises an upper surface and a lower surface, and wherein the tibial spacer is disposed between the tibial tray and the tibial insert such that the lower surface of the tibial spacer is adjacent the upper surface of the tibial tray and the upper surface of the tibial spacer is adjacent the lower surface of the tibial insert.

Owner:EXACTECH INC

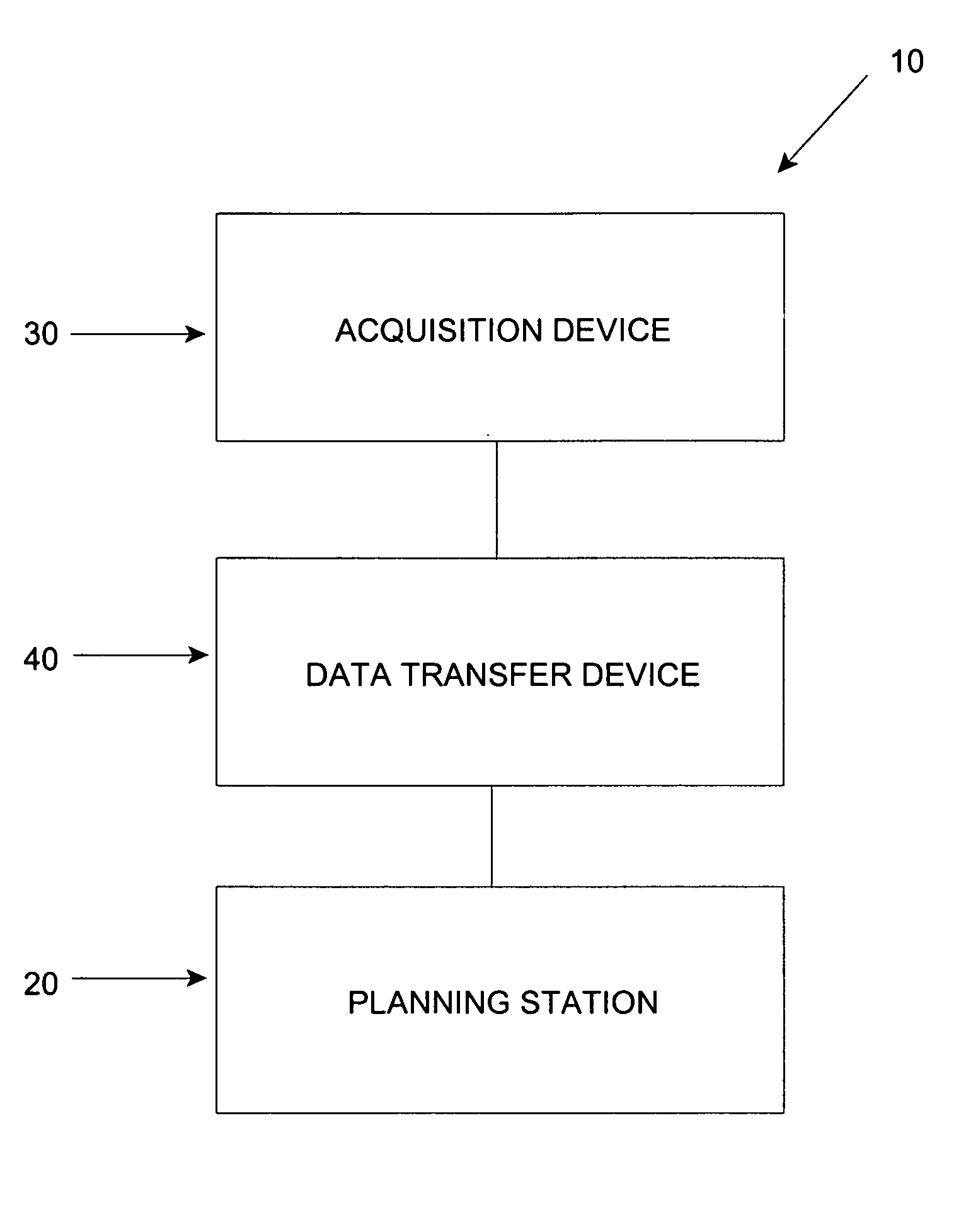

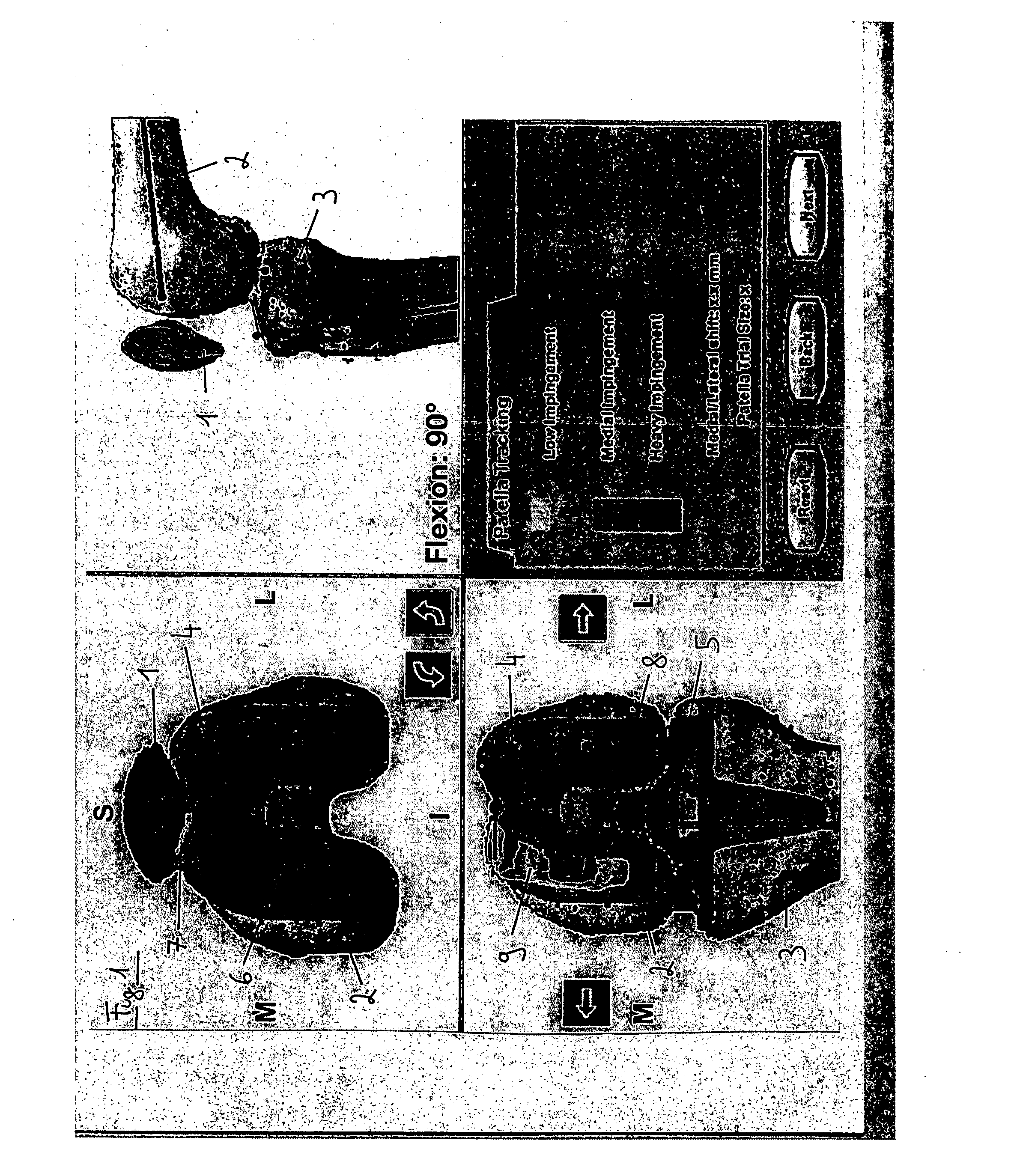

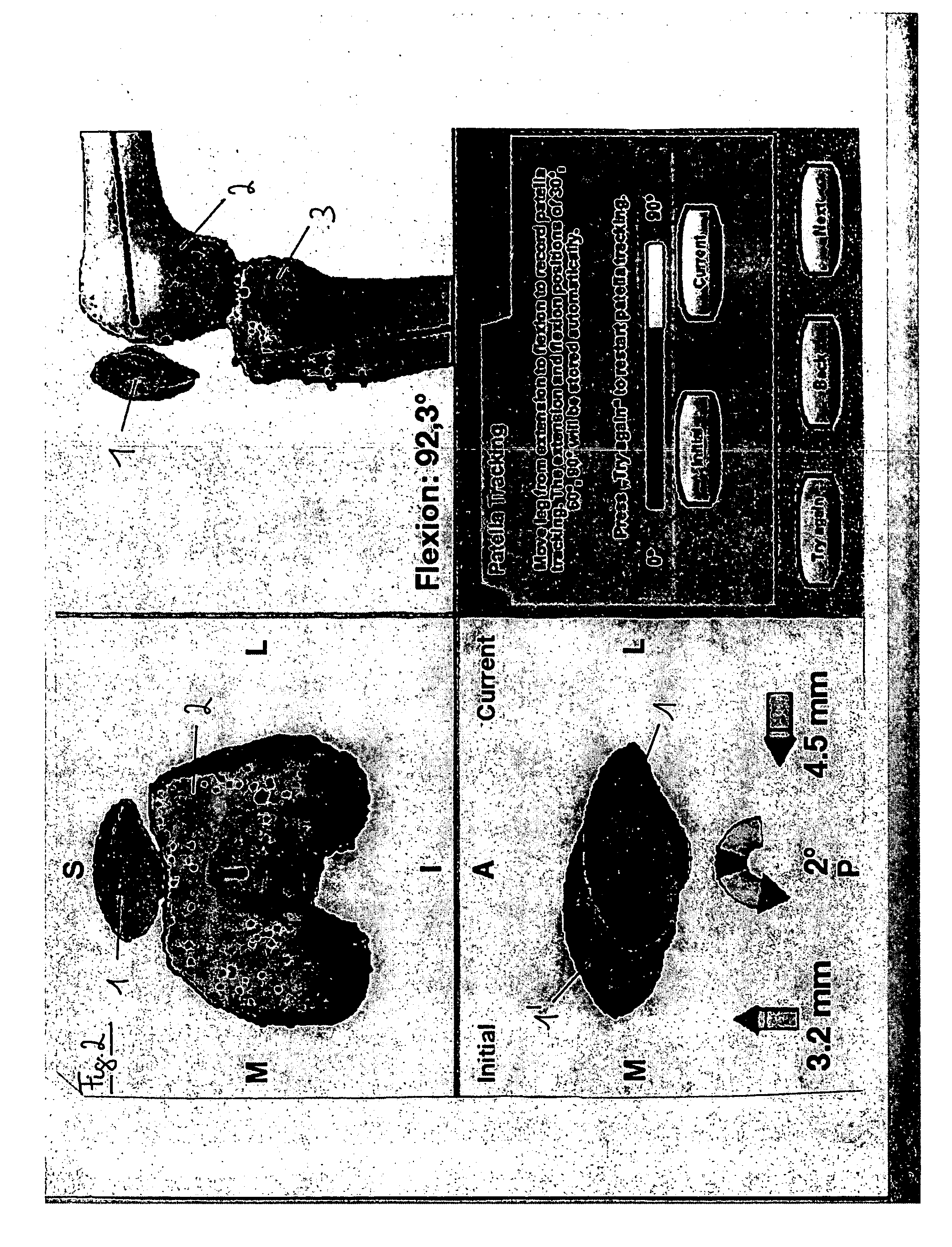

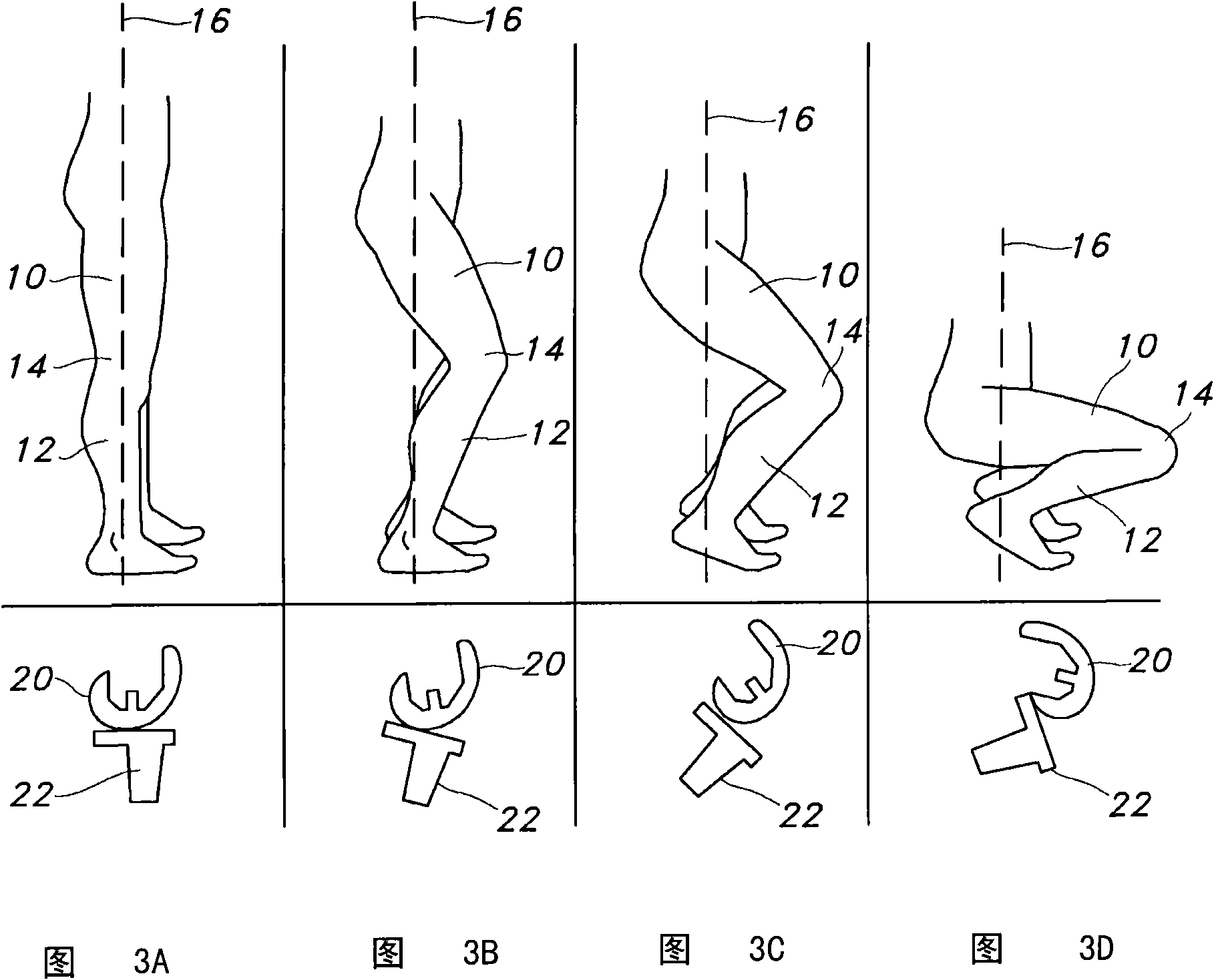

Planning method and planning device for knee implants

ActiveUS20050251065A1Overcome disadvantagesSurgical navigation systemsPerson identificationTibiaKnee Joint

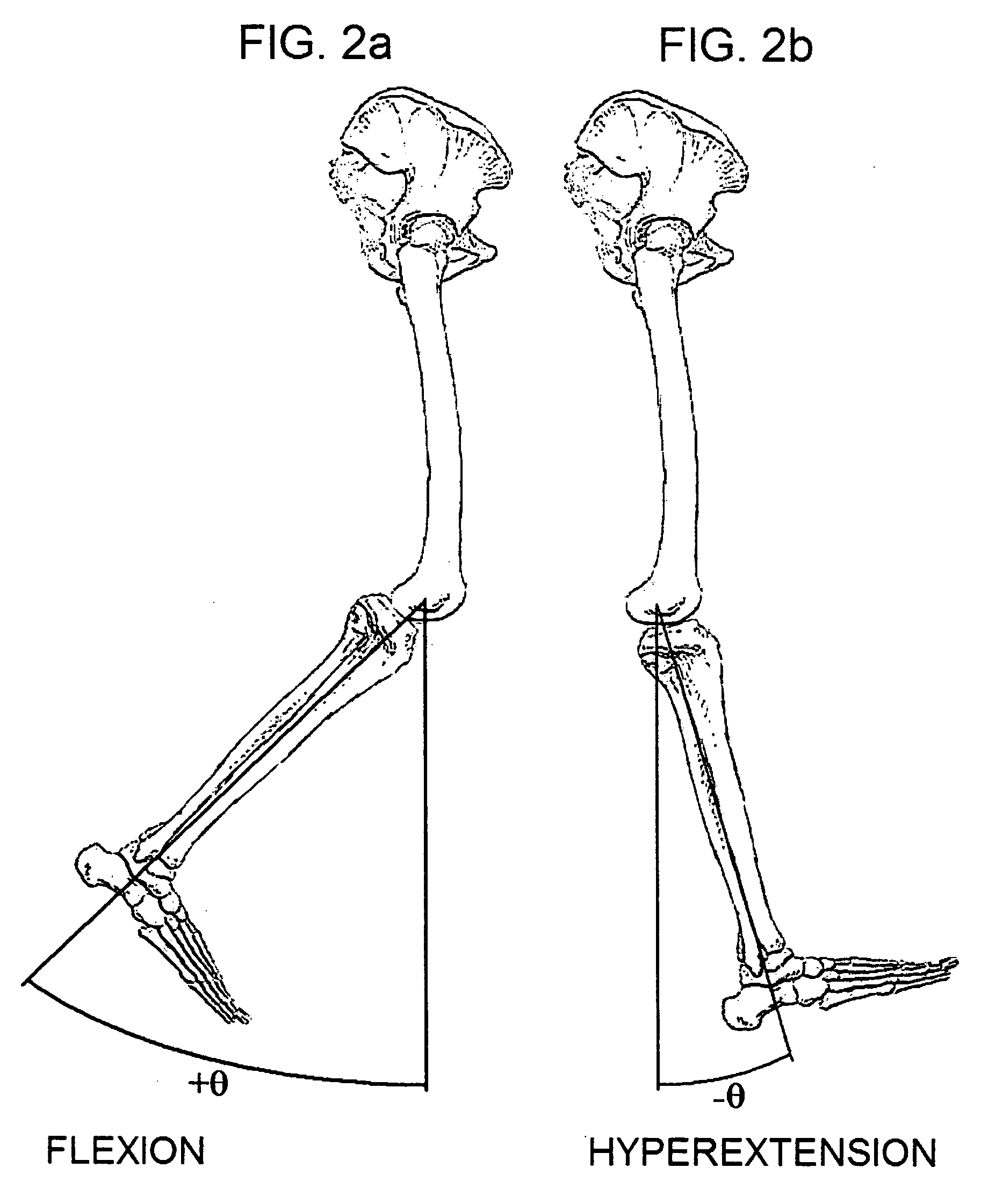

A planning method and device for knee implants, wherein spatial data on the configuration of a patient's genicular anatomy, in particular of at least a part of the femur and / or the patella and / or the tibia, are captured in order to be inputted into a computer-assisted planning station; the movement of the parts of the genicular anatomy is recorded using a tracking and / or motion capturing method; the captured anatomical and movement data are made available to the computer-assisted planning station; a part of the patient's genicular anatomy is virtually replaced in the planning station by a sample implant and movements of the knee together with the sample implant are simulated; contact and impingement between the non-replaced parts of the genicular anatomy and the implant during the virtual movement is ascertained according to its magnitude; and wherein an adjustment of the positioning, shape or orientation of the implant or of a number of these parameters is determined until the contact and impingement become non-critical and the adjustment thus determined is defined as a suitable adjustment.

Owner:BRAINLAB

Unicondylar knee implant

Owner:ARTHREX

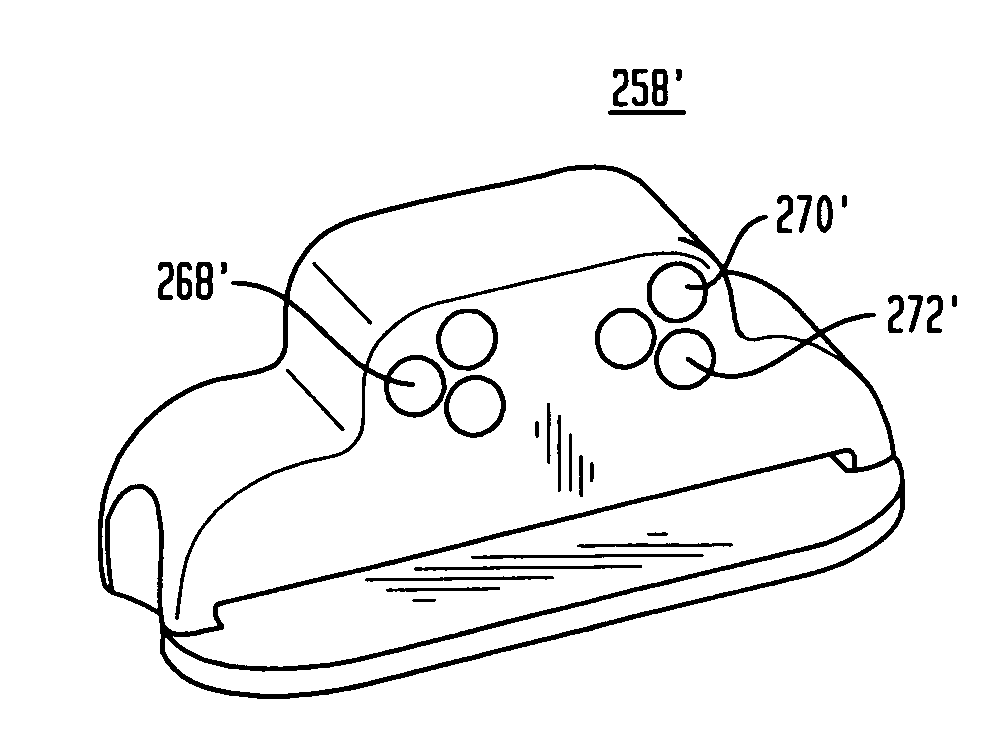

Unicondylar knee implant

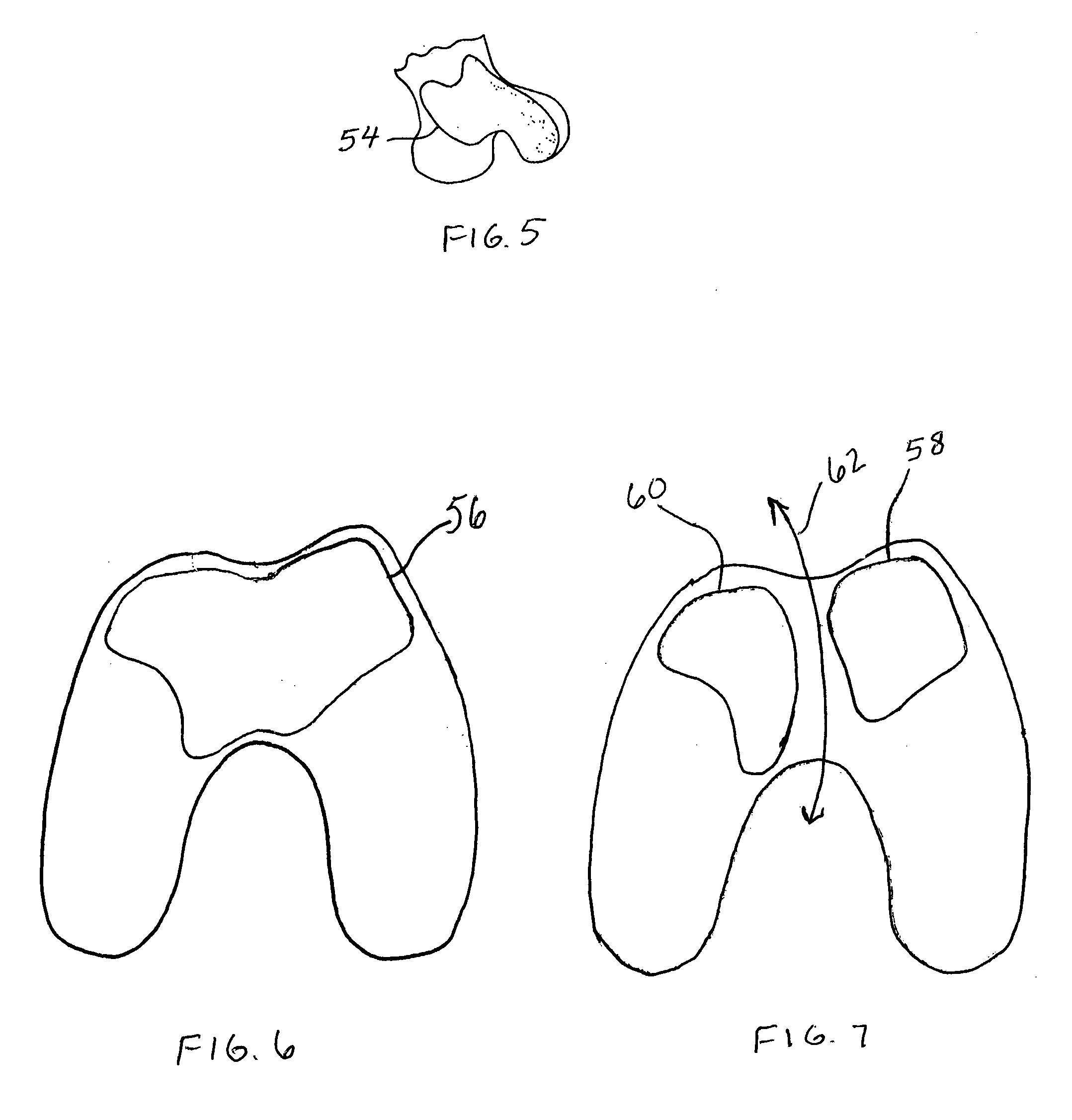

A unicondylar knee implant system according to one embodiment includes a unicondylar femoral knee component having a single sagittal radius, a tibial bearing component, and a tibial tray component having a self-locking keel. The unicondylar knee implant system also provides for a locking mechanism for securing the tibial bearing component onto the tibial tray component. The unicondylar knee system allows for a simplified surgical technique, complete interchangeability between sizes, and a more MIS compatible implant system.

Owner:ARTHREX

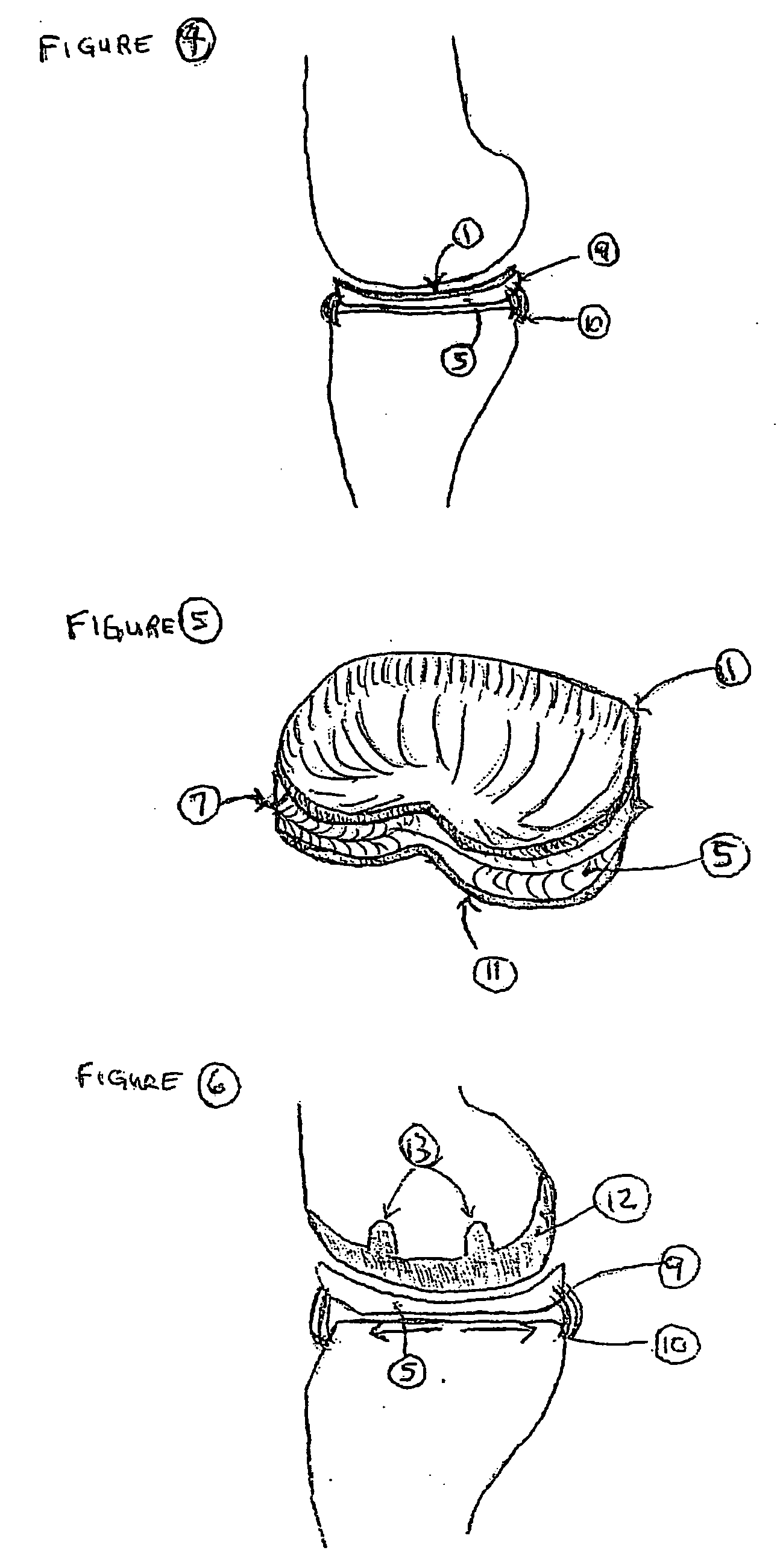

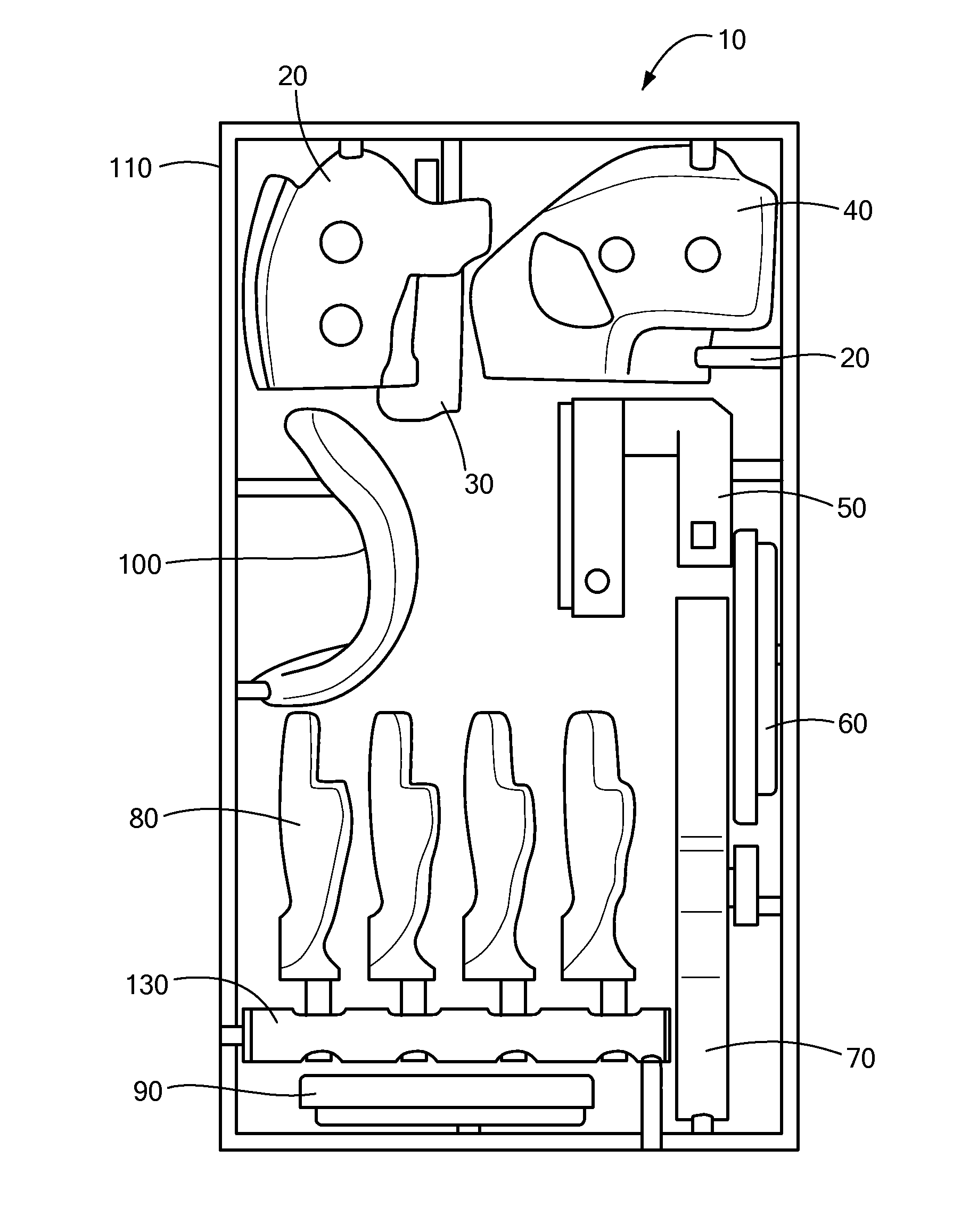

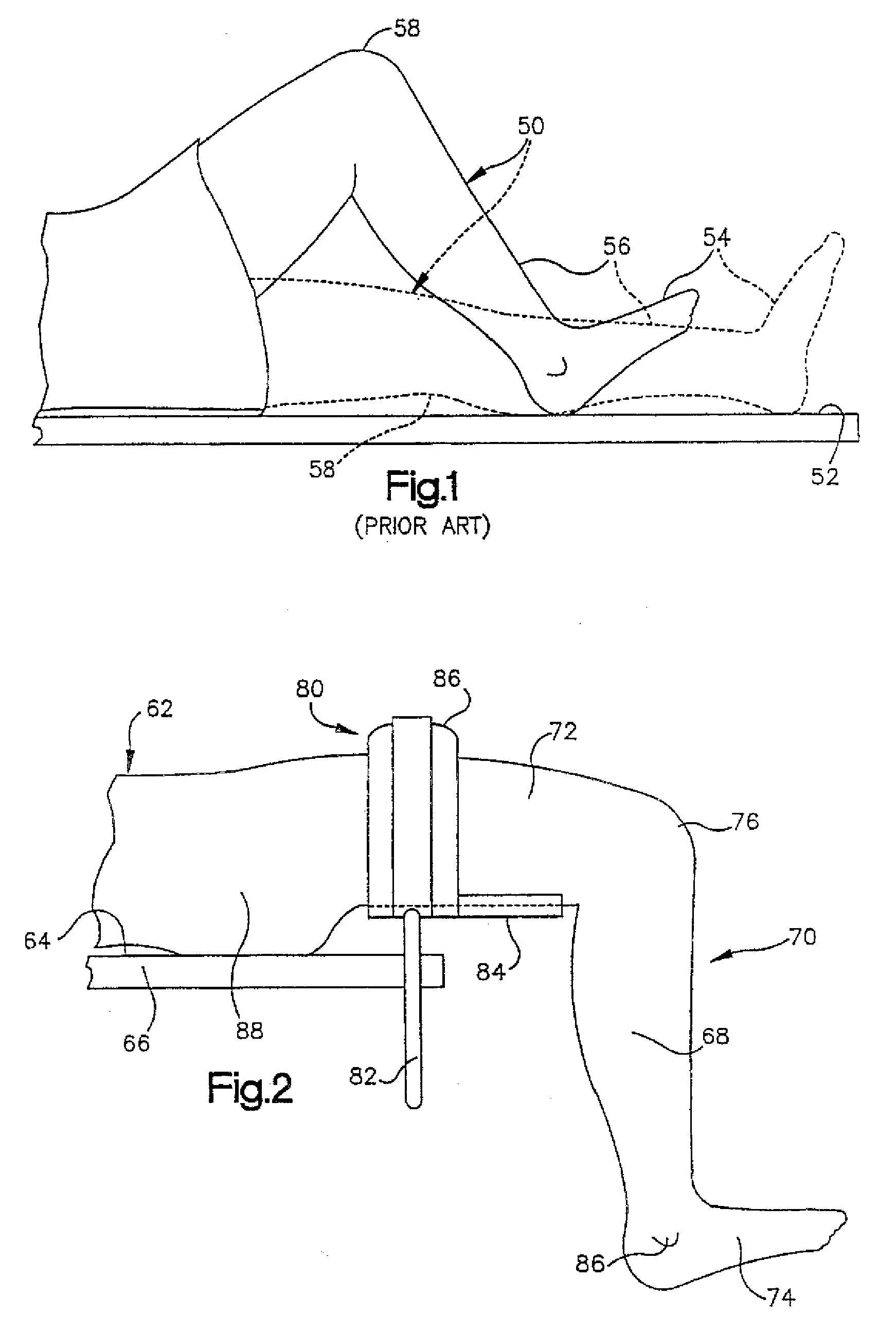

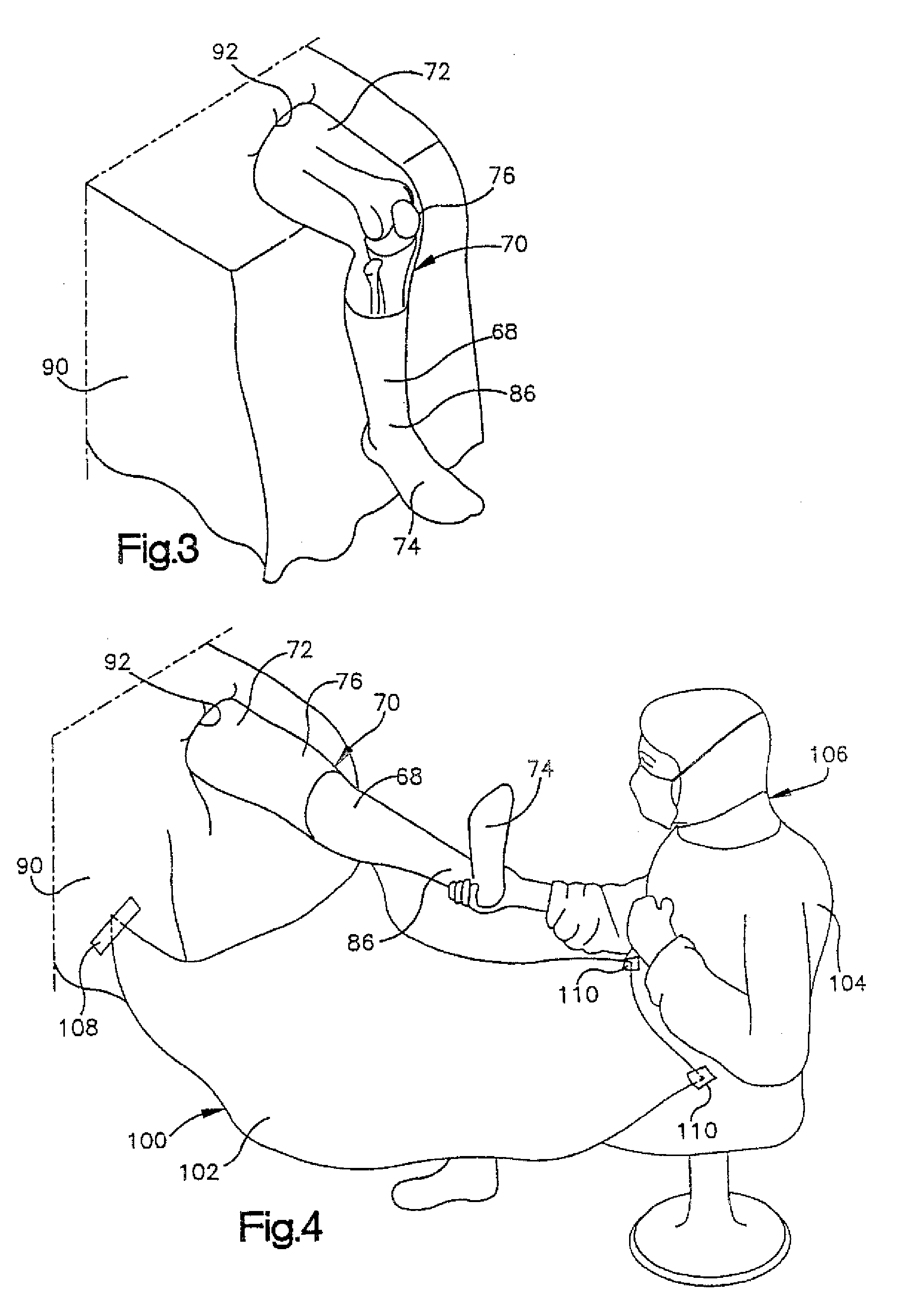

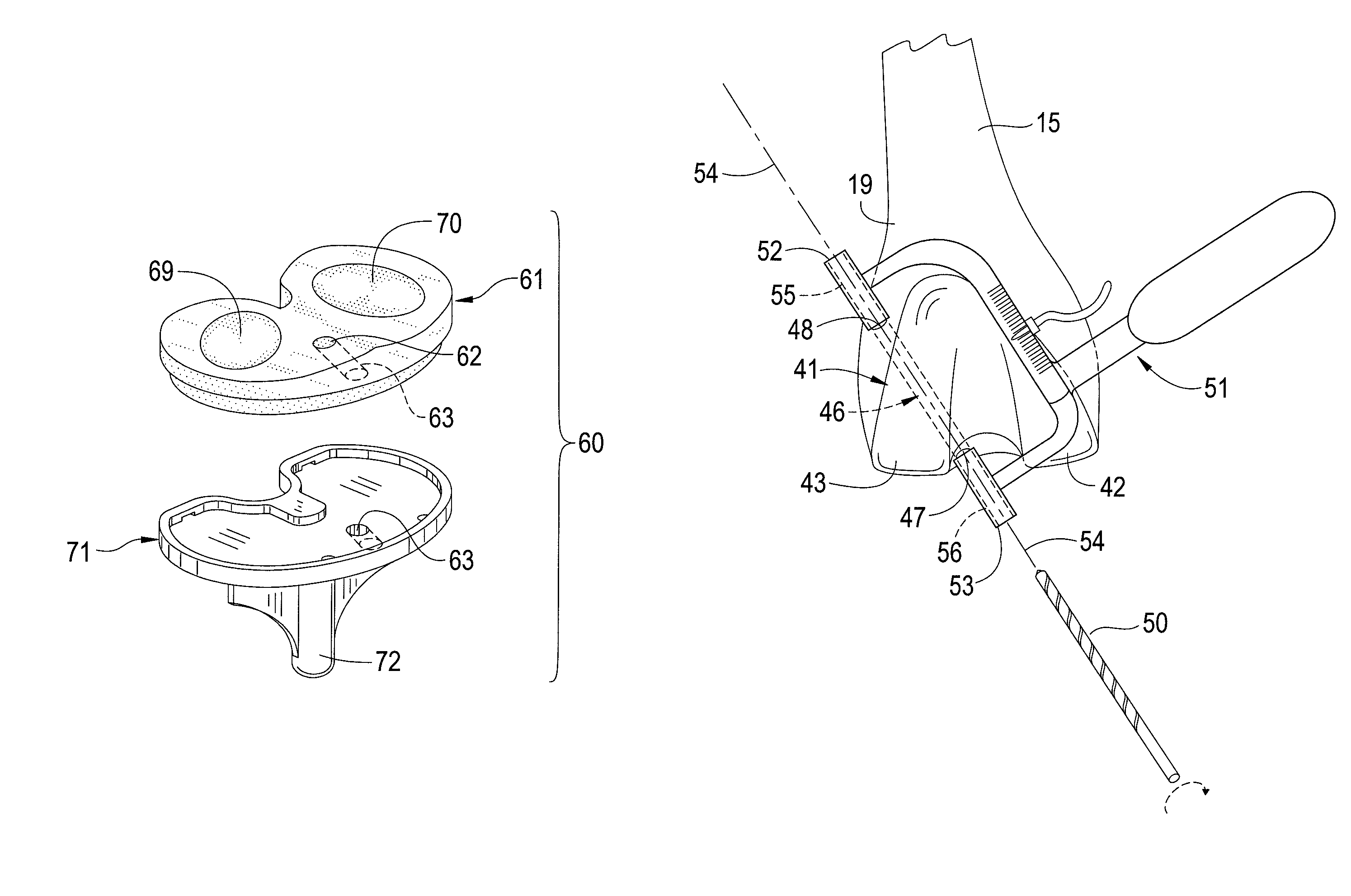

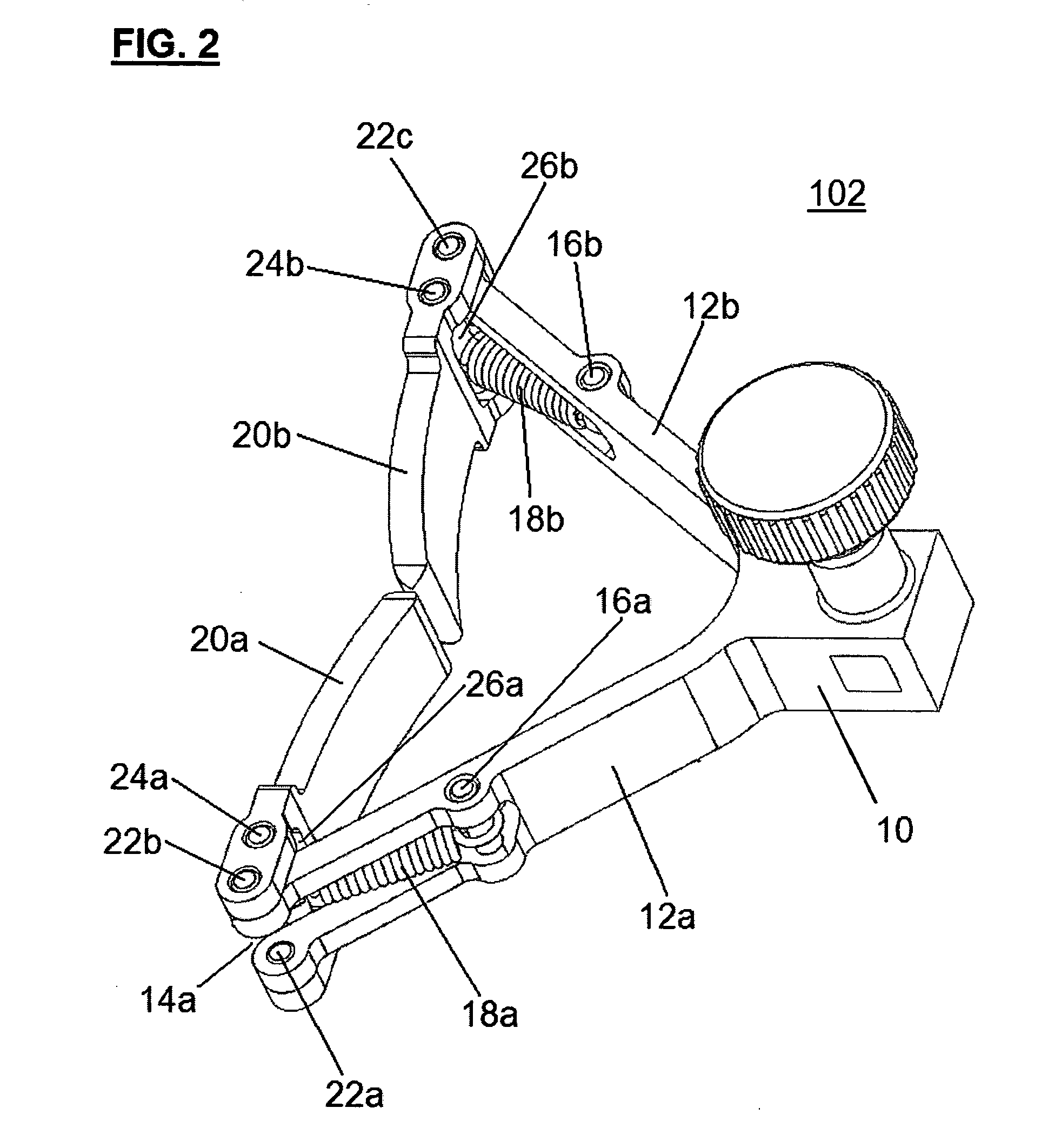

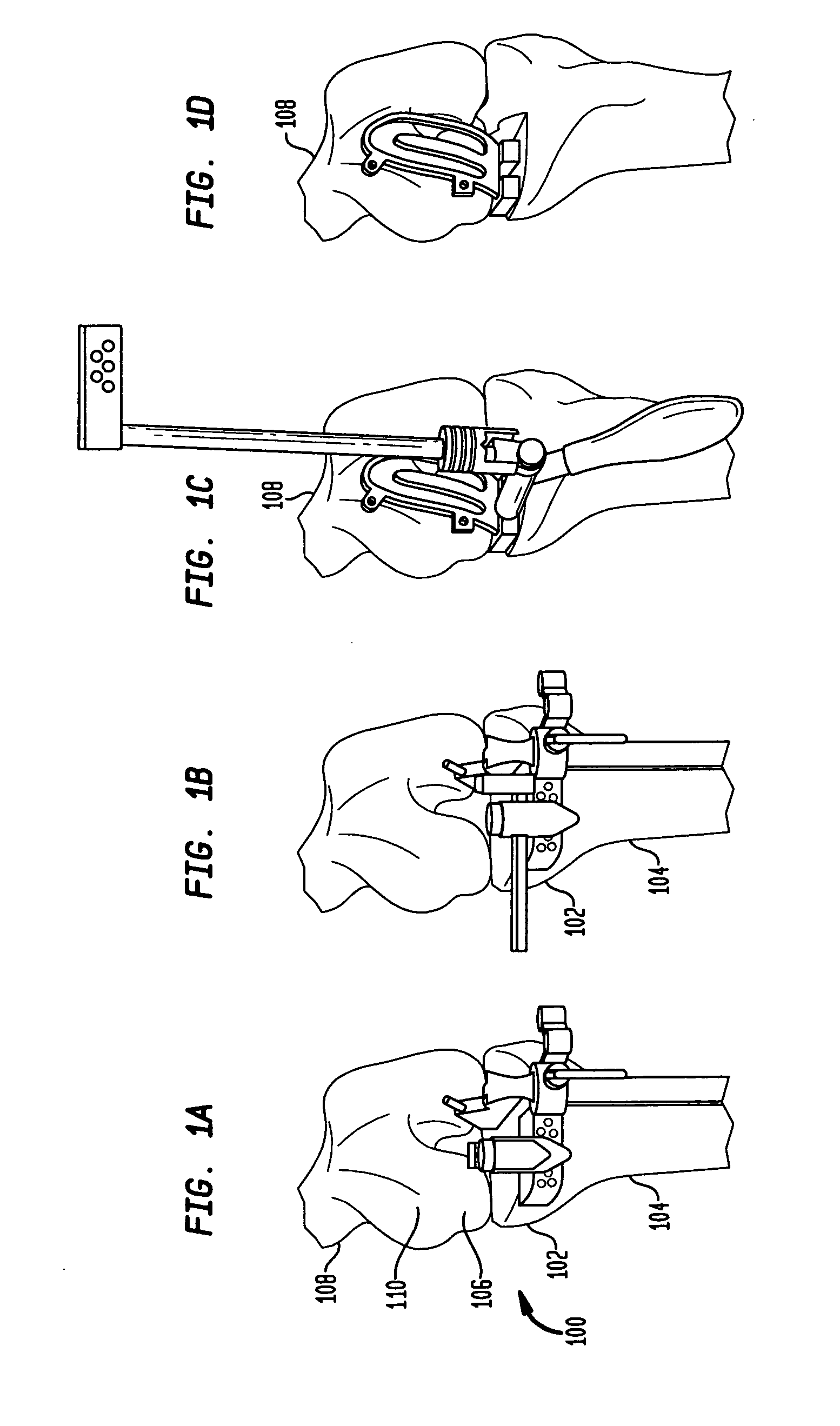

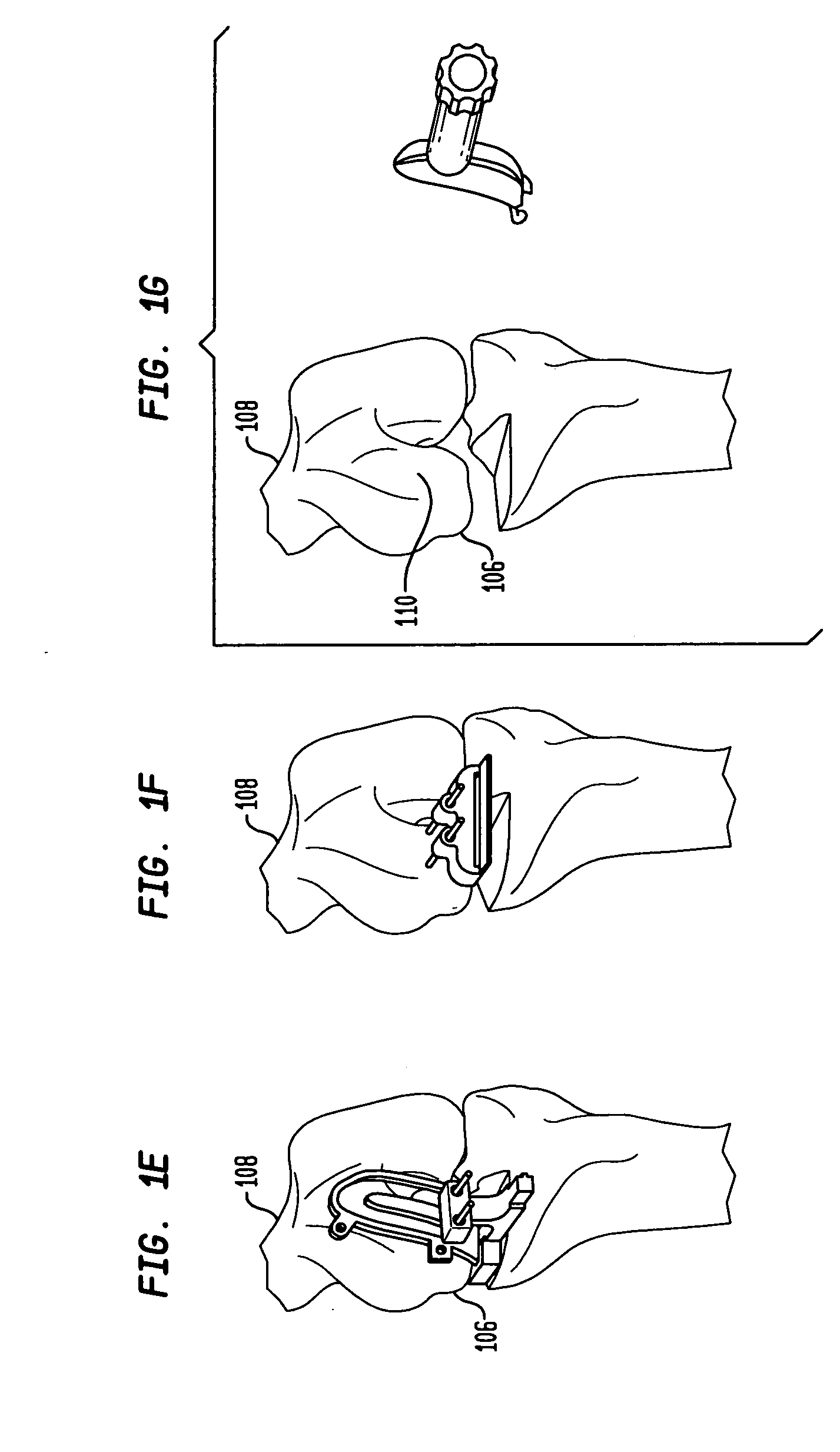

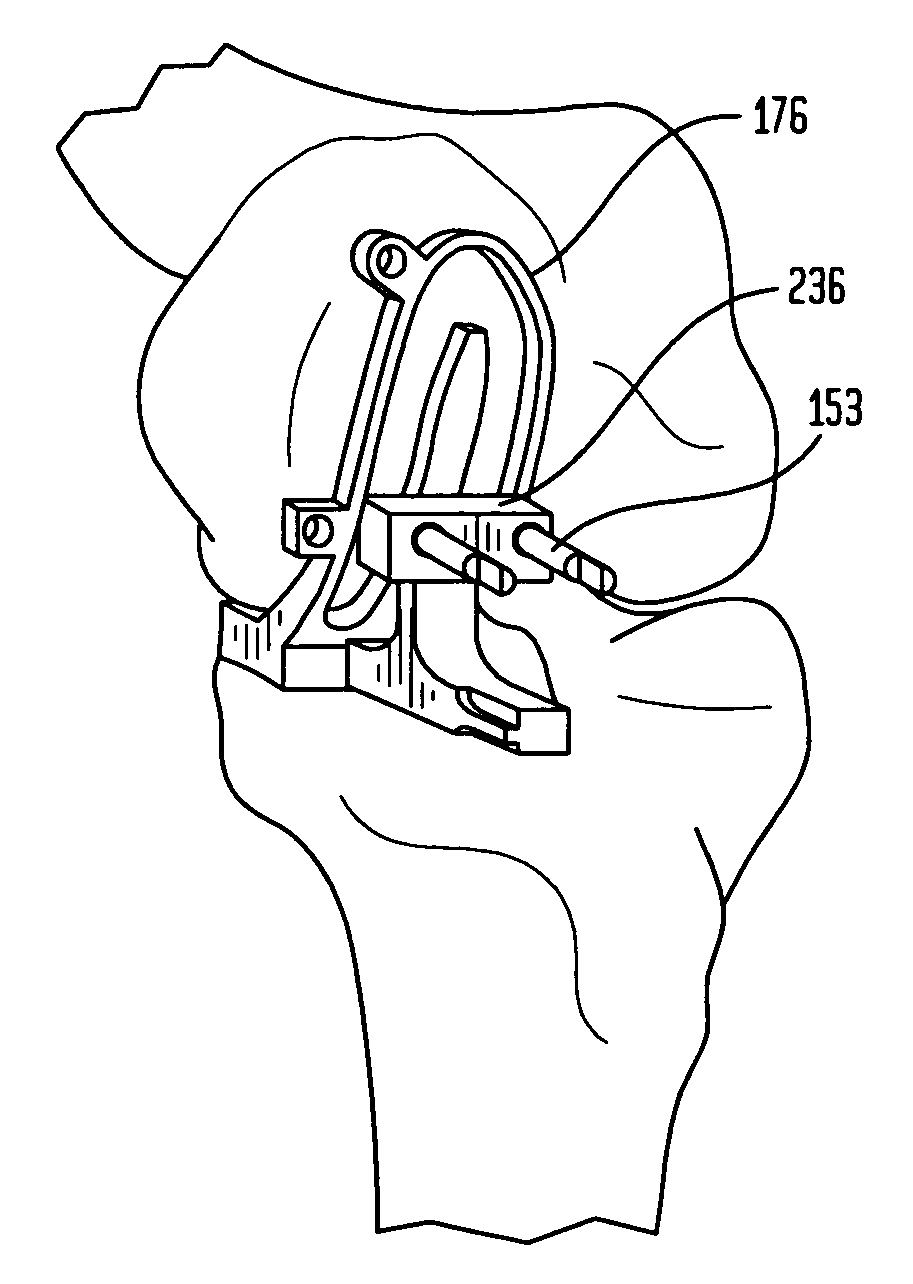

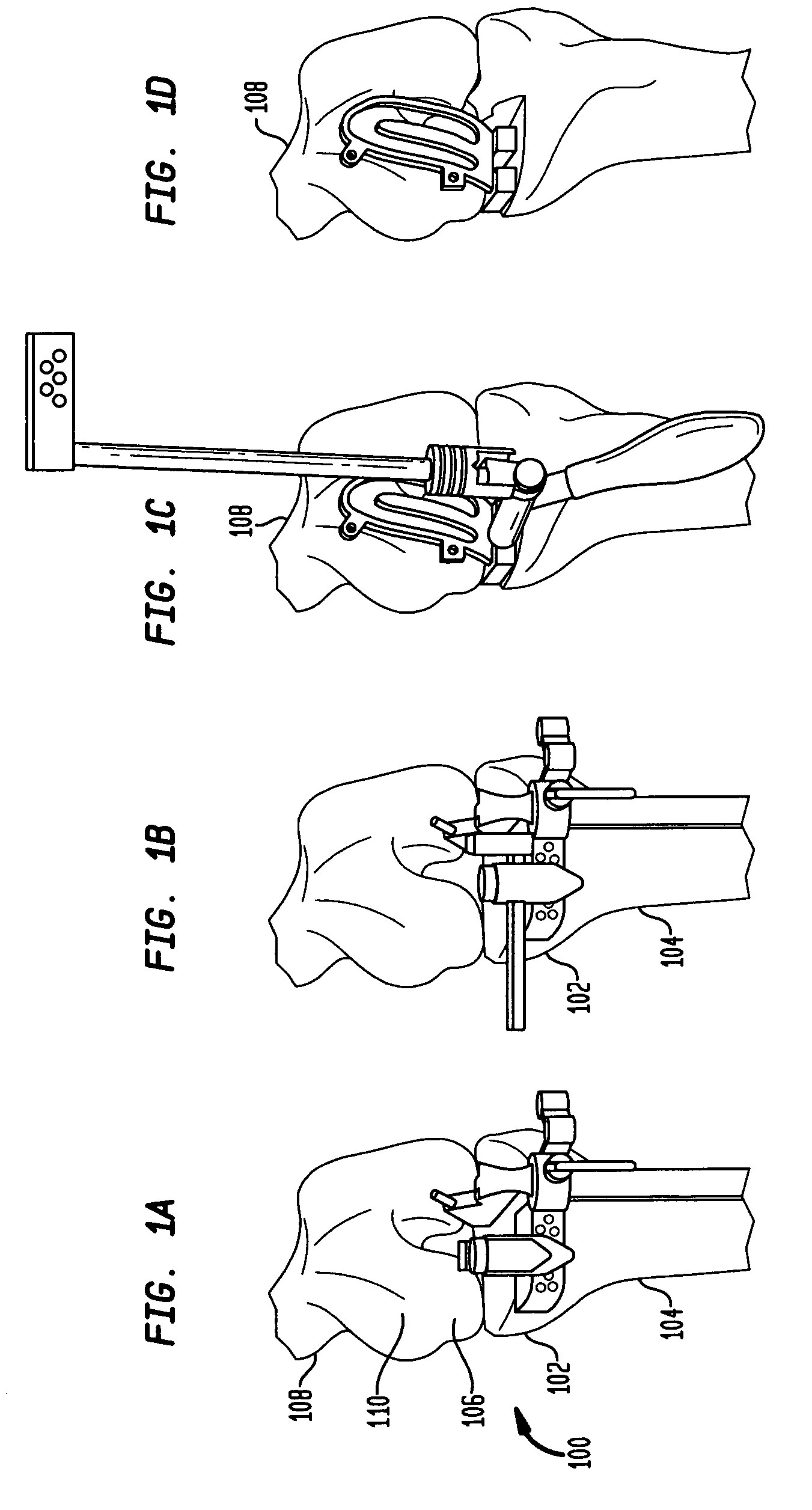

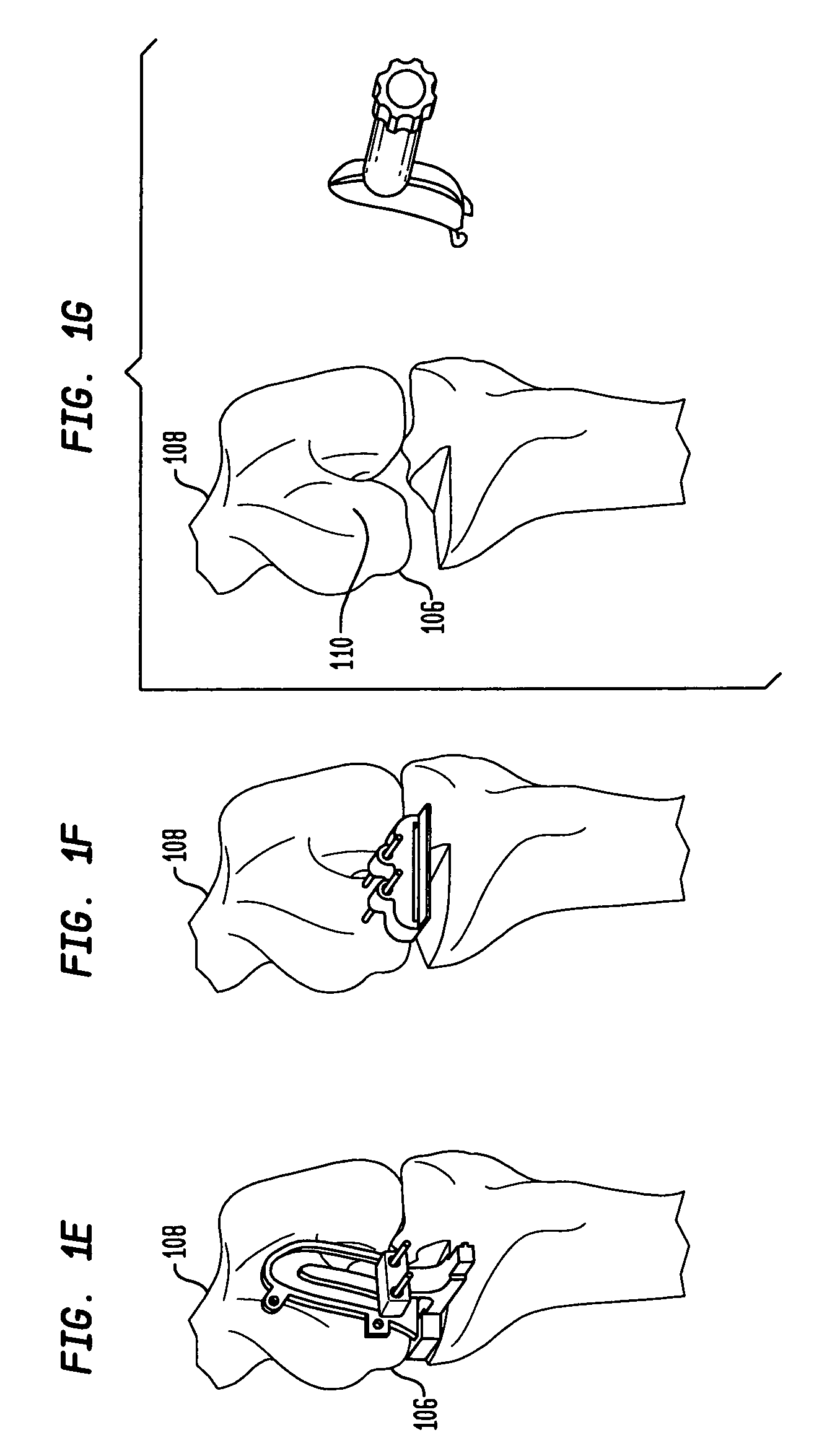

Unicondylar knee instrument system

The present invention provides for an apparatus for cutting a tibia, a stylus, an apparatus for cutting a femur, an apparatus for aligning a femoral cutting guide, and an ankle clamp in support of a unicondylar knee surgery. The present invention further provides for a method of preparing a femoral condyle of a femur for the implantation of a unicondylar femoral knee implant. The apparatus for cutting a tibia includes a unicondylar tibial resection guide that is adjustably connectable to a unicondylar tibial alignment guide and configured to operate concurrently with the tibial alignment guide. The apparatus for cutting a femur includes a spacer block and a cutting guide configured to operate concurrently with the spacer block.

Owner:ARTHREX

Anterior stabilized knee implant

A posterior cruciate ligament retaining knee implant prosthesis comprising a femoral component including a medial condyle and a lateral condyle separated from one another by an intercondylar channel adapted to accommodate throughput of a native cruciate ligament, both the medial condyle and the lateral condyle posteriorly terminate individually, the medial condyle including a medial condyle bearing surface and the lateral condyle including a lateral condyle bearing surface, the femoral component including an anterior cam, and a tibial component including a medial condyle receiver having a medial condyle receiver bearing surface, the tibial component also including a lateral condyle receiver having a lateral condyle receiver bearing surface, the tibial component also including an anterior post.

Owner:DEPUY (IRELAND) LTD

Total Knee Prosthesis and Method for Total Knee Arthroplasty

A prosthetic knee implant for implantation into a mammal, which accommodates an anterior cruciate ligament substitute to provide stability to the knee implant. The prosthetic knee implant includes a femoral component having a pair of condylar surfaces and a tibial component having a surface portion adapted to slidably engage the femoral component upon rotation of the same. The femoral component further includes a central femoral recess between the condyles providing access to the femur for drilling a channel through which a cruciate ligament substitute may be integrated into the femur. The tibial component further includes a center portion defining an aperture through which the ligament substitute maybe threaded through the tibia and integrated therein, or anchored upon its surface. Also disclosed is a method used to replace the total knee joint in a mammal with the improved prosthetic knee implant of the present invention.

Owner:BLUM MICHAEL F

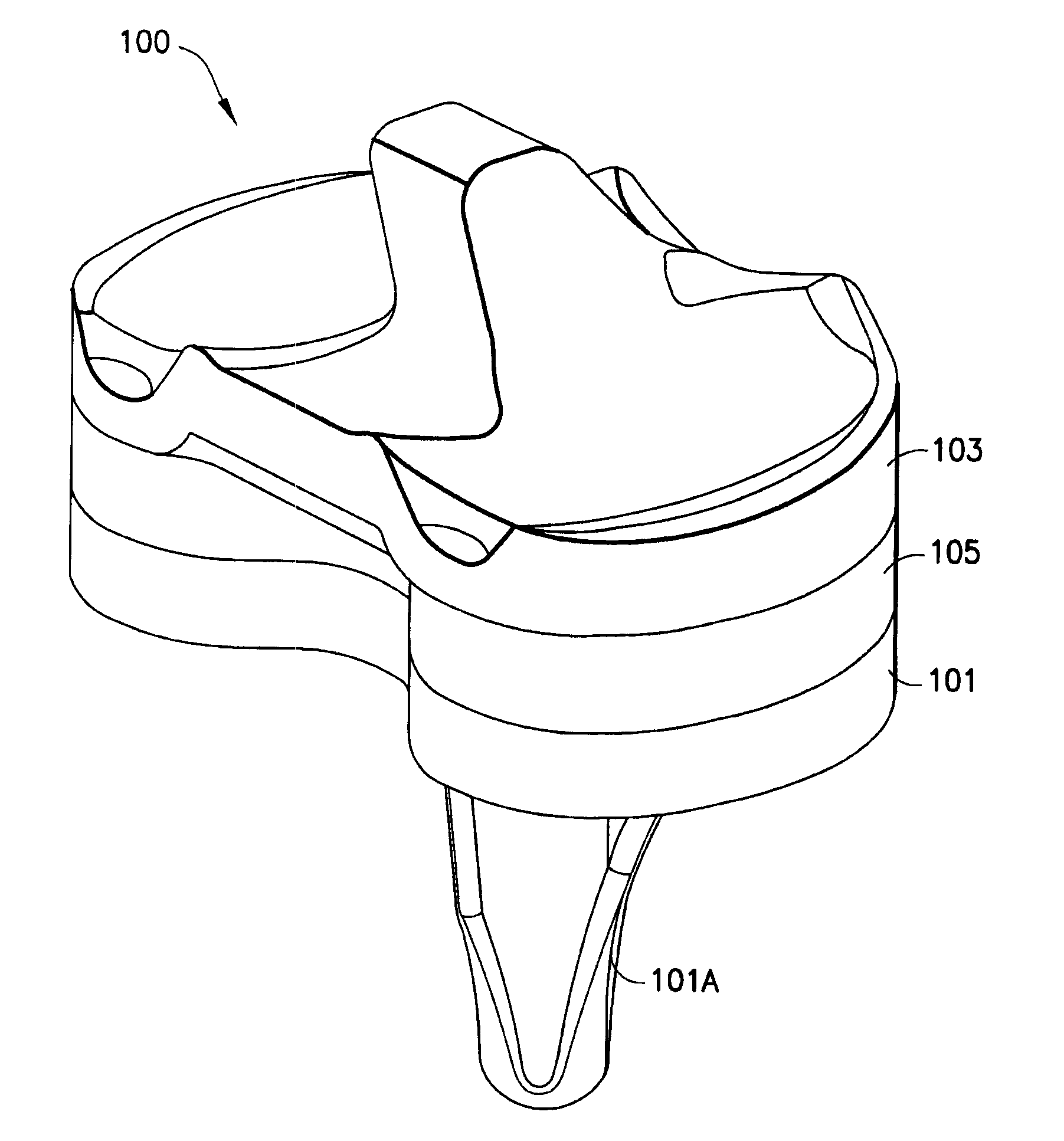

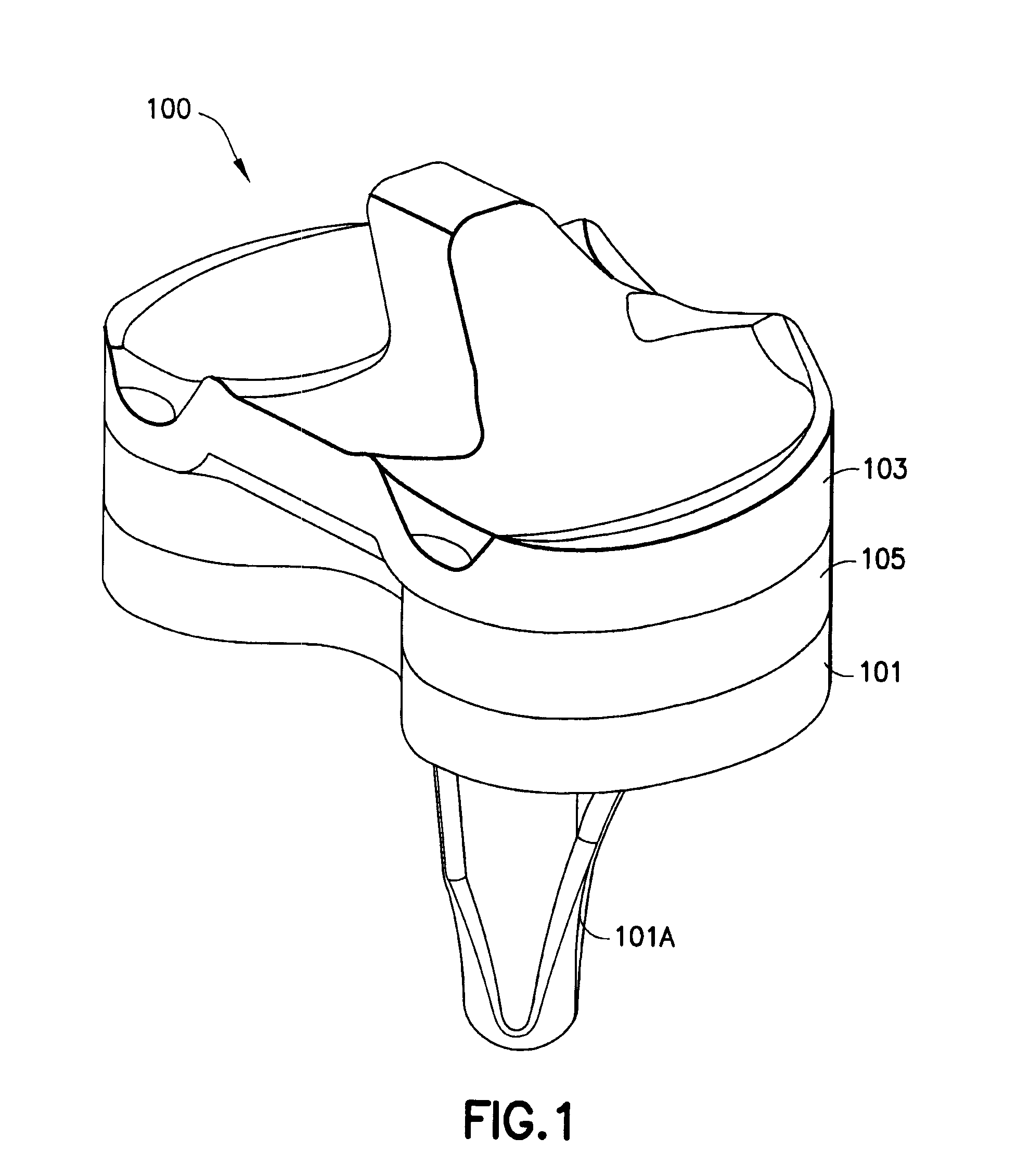

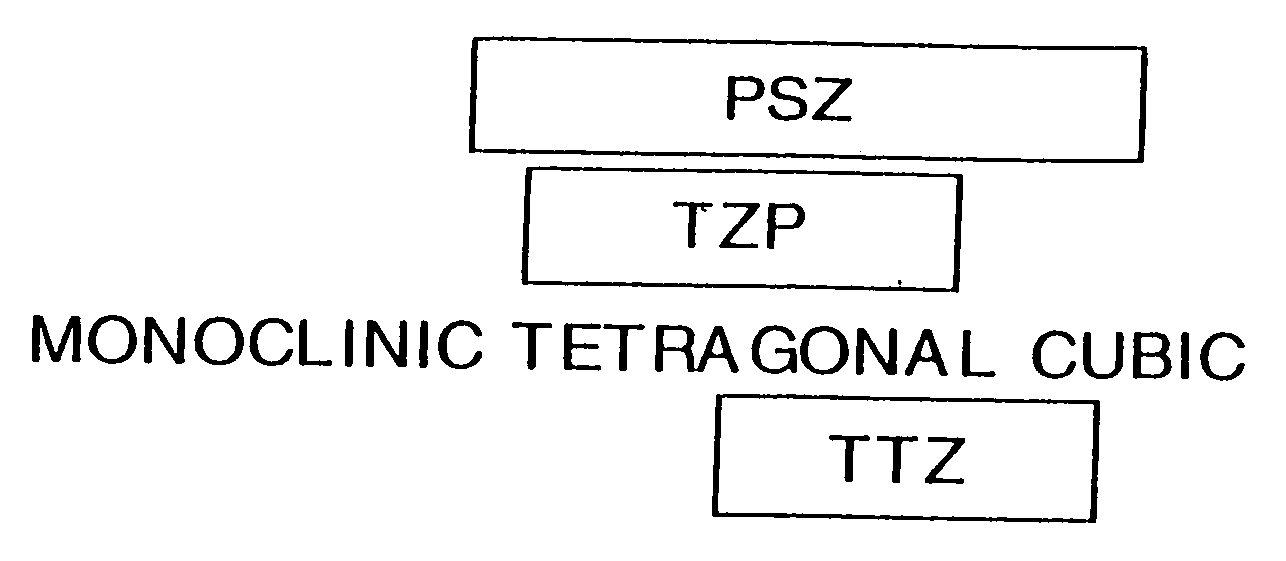

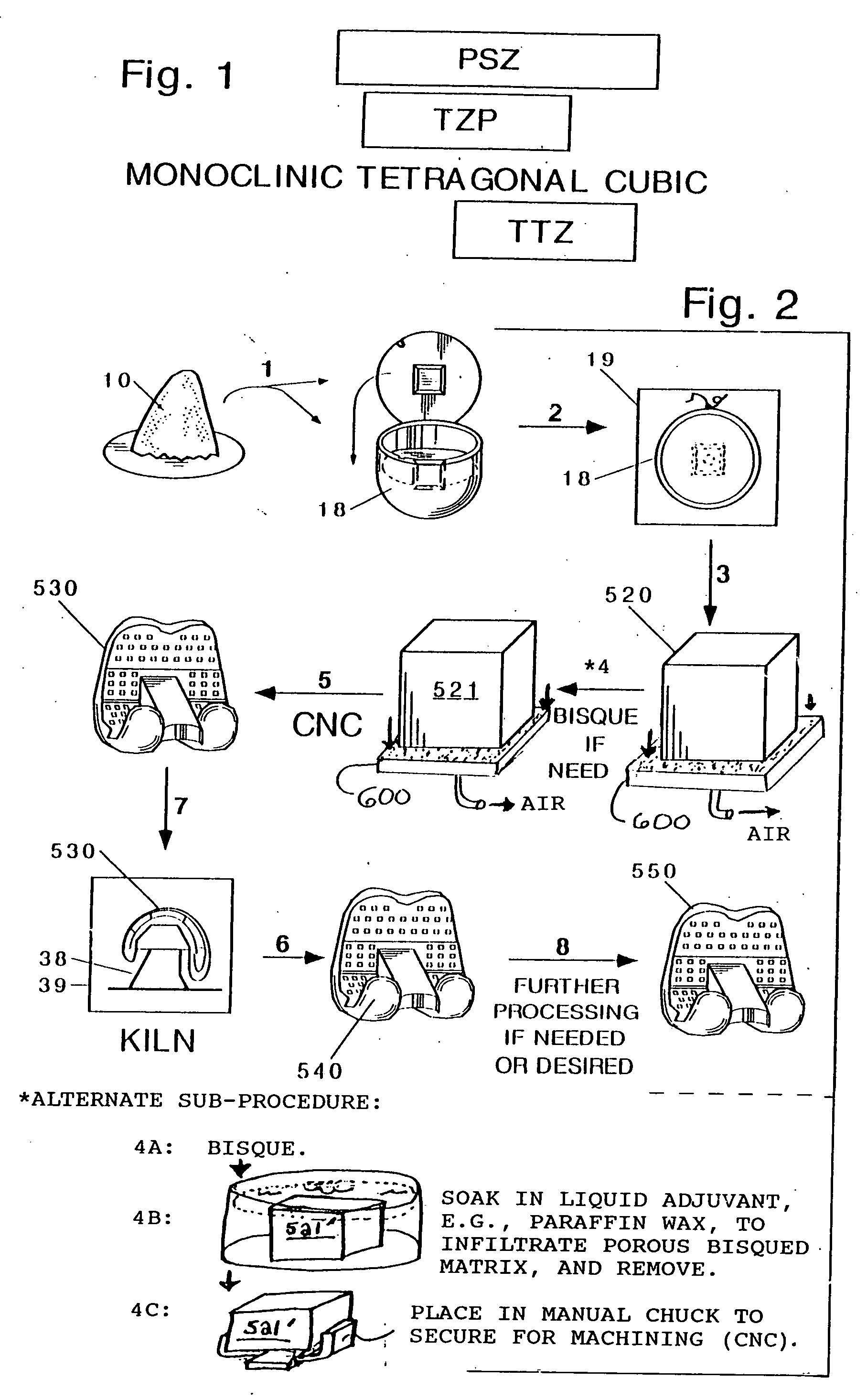

Ceramic manufactures

Ceramic bodies can be made by providing an initial green body of ceramic; and machining the initial green body to provide a machined green ceramic body. Embedding the initial green body in an embedding mass can be avoided. The initial green body can be bisqued, infiltrated an adjuvant such as machining wax, removing the infiltrated body, and machining it. Highly detailed ceramic products can be generated. The machined green ceramic body may be fired and / or further processed to provide a more finished ceramic body. Examples include a femoral component for a posterior stabilized knee implant, a component body for an artificial rotation device containing knee implant prosthesis a dental implant or bridge, an ice skating blade, and so forth. Zirconia ceramics are advantageously employed, for an example, Mg-TTZ.

Owner:LOUIS A SERAFIN JR TRUST +1

Anterior cruciate ligament substituting knee implants

The present disclosure provides knee prostheses that replicate at least a portion of the function of an individual patient's anterior cruciate ligament (ACL). An exemplary knee prosthesis includes a femoral component configured to be implanted on the distal end of the patient's femur and a tibial component configured to be implanted on the proximal end of the patient's tibia. In extension, the femoral component and the tibial component may cooperate to limit anterior movement of the tibial component relative to the femoral component. In flexion, the femoral component may be free to rotate relative to the tibial component.

Owner:ZIMMER INC

Unicondylar knee implants and insertion methods therefor

A method of balancing extension and flexion gaps in a knee joint includes preparing a tibial component seating surface at a proximal end of a tibia, extending the knee joint and measuring an extension gap between the tibial component seating surface and a distal end of a femur, and flexing the knee joint and measuring a flexion gap between the tibial component seating surface and a posterior region of the femur. The extension gap is compared with the flexion gap to determine an amount of bone that is to be removed from the posterior region of the femur for balancing the extension gap with the flexion gap.

Owner:HOWMEDICA OSTEONICS CORP

Modular knee implants

An implant for bone re-surfacing in a joint, the implant having a bearing platform having a front surface which forms a bearing surface and a back surface, and securing apparatus projecting from the back surface, the securing apparatus having a locking surface arranged to bear against an undercut surface of the bone to secure the implant against the bone.

Owner:IMPERIAL INNOVATIONS LTD

Unicondylar knee implants and insertion methods therefor

A method of preparing a knee joint for receiving a unicondylar knee implant includes preparing a first seating surface at a proximal end of a tibia, and providing a combination bur template and spacer block, the bur template having an upper end, a lower end and a curved surface extending between the upper and lower ends thereof that is adapted to conform to a femoral condyle of a femur and the spacer block extending from the lower end of the bur template and having top and bottom surfaces. The method includes flexing the knee joint so that the prepared first seating surface at the proximal end of the tibia opposes a posterior region of the femoral condyle and inserting the combination bur template and spacer block into the knee joint so that the top surface of the spacer block engages the posterior region of the femoral condyle and the bottom surface of the spacer block engages the first seating surface at the proximal end of the tibia. While the spacer block is maintained between the femur and the tibia, the knee joint is extended until the curved surface of the bur template engages the femoral condyle of the femur. The bur template is anchored to the femur and used to guide burring of the femoral condyle for preparing a second seating surface on the femur. After burring the distal end of the femoral condyle, the posterior region of the femoral condyle is resected.

Owner:HOWMEDICA OSTEONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com