Unicondylar knee implants and insertion methods therefor

a knee implant and unicondylar technology, applied in the field of implants, can solve the problems of limited access to damaged joints, affecting the extent of intrusion required to complete an effective implant,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

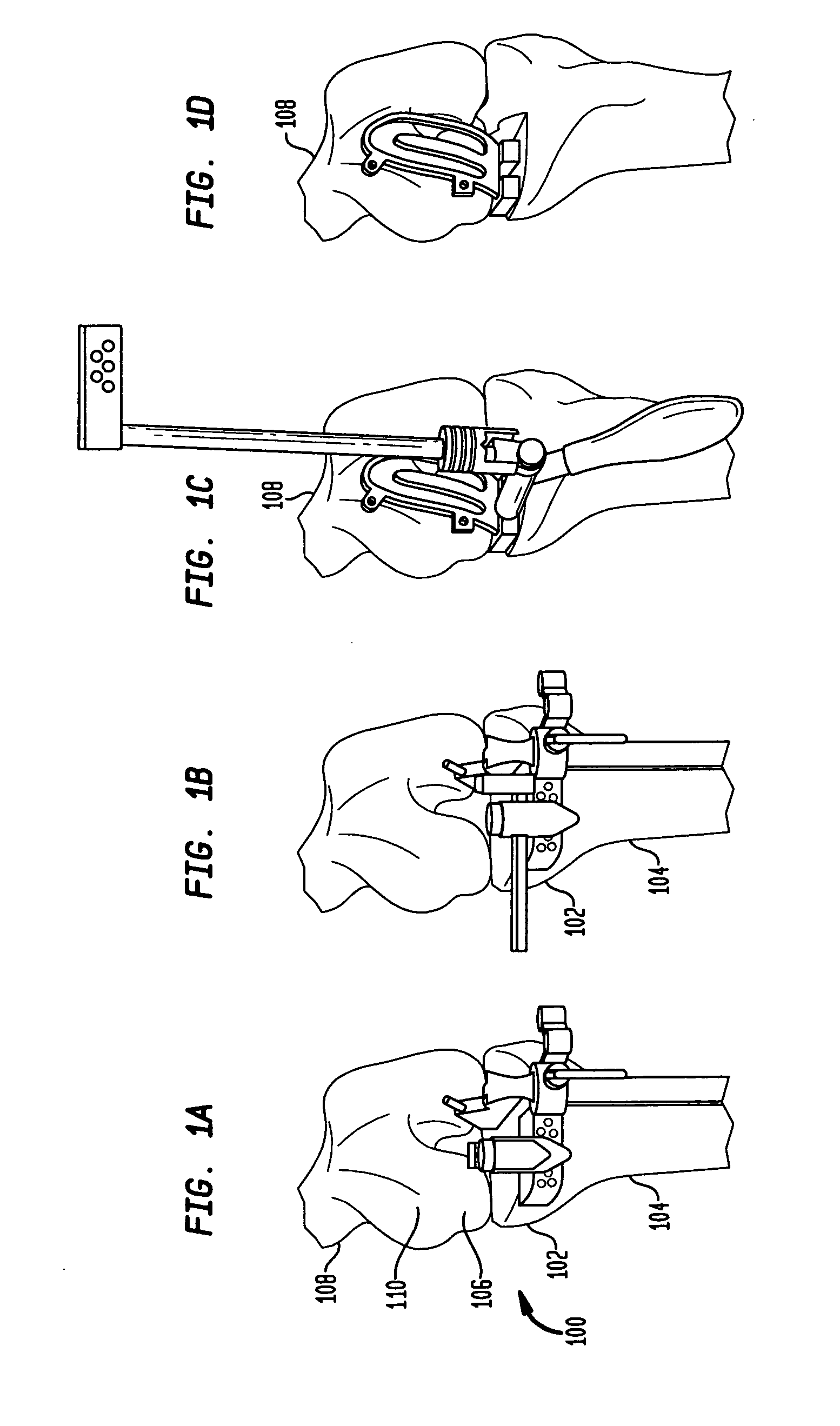

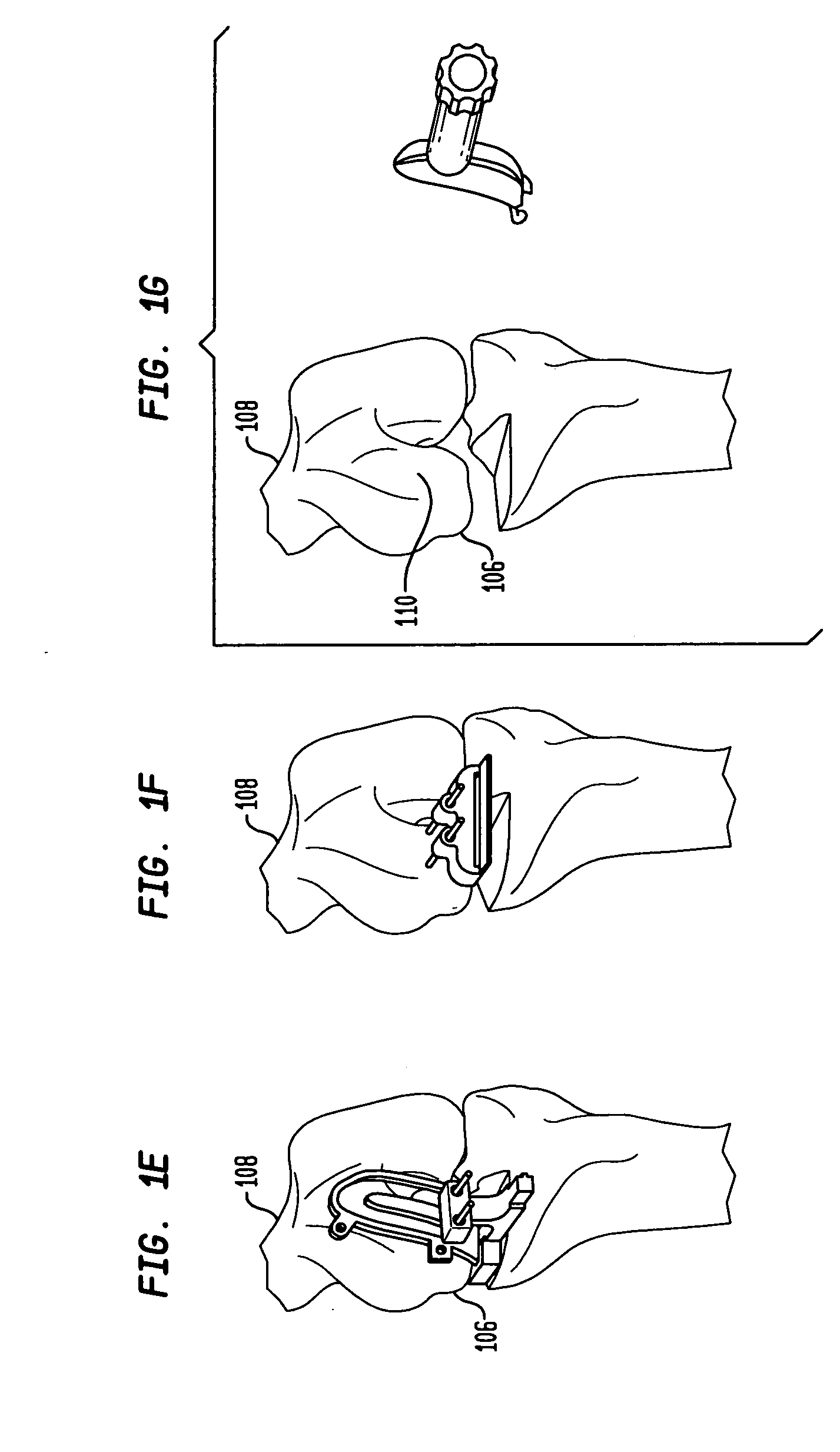

[0075]FIGS. 1A-1J show a method of preparing a knee for receiving an implant, in accordance with certain preferred embodiments of the present invention. In particular preferred embodiments, the method is used for preparing a knee to receive a knee implant such as a unicondylar knee implant. Referring to FIG. 1A, a knee joint 100 is located between a proximal end 102 of a tibia 104 and a distal end 106 of a femur 108. The distal end 106 of the femur 108 includes a distal condyle 110, which is the curved surface on a bone where it forms a joint with another bone. The femur 108 also has a posterior region of the femoral condyle.

[0076]In FIG. 1A, a tibial resection is performed on the proximal end 102 of the tibia 104. FIG. 1B shows a saggital resection being performed on the proximal end 102 of the tibia 104. FIG. 1C shows the positioning and alignment of a combination bur template and spacer block in a knee joint. The combination bur template and spacer block includes a spacer block t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com