Patents

Literature

46results about How to "Reduce edge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

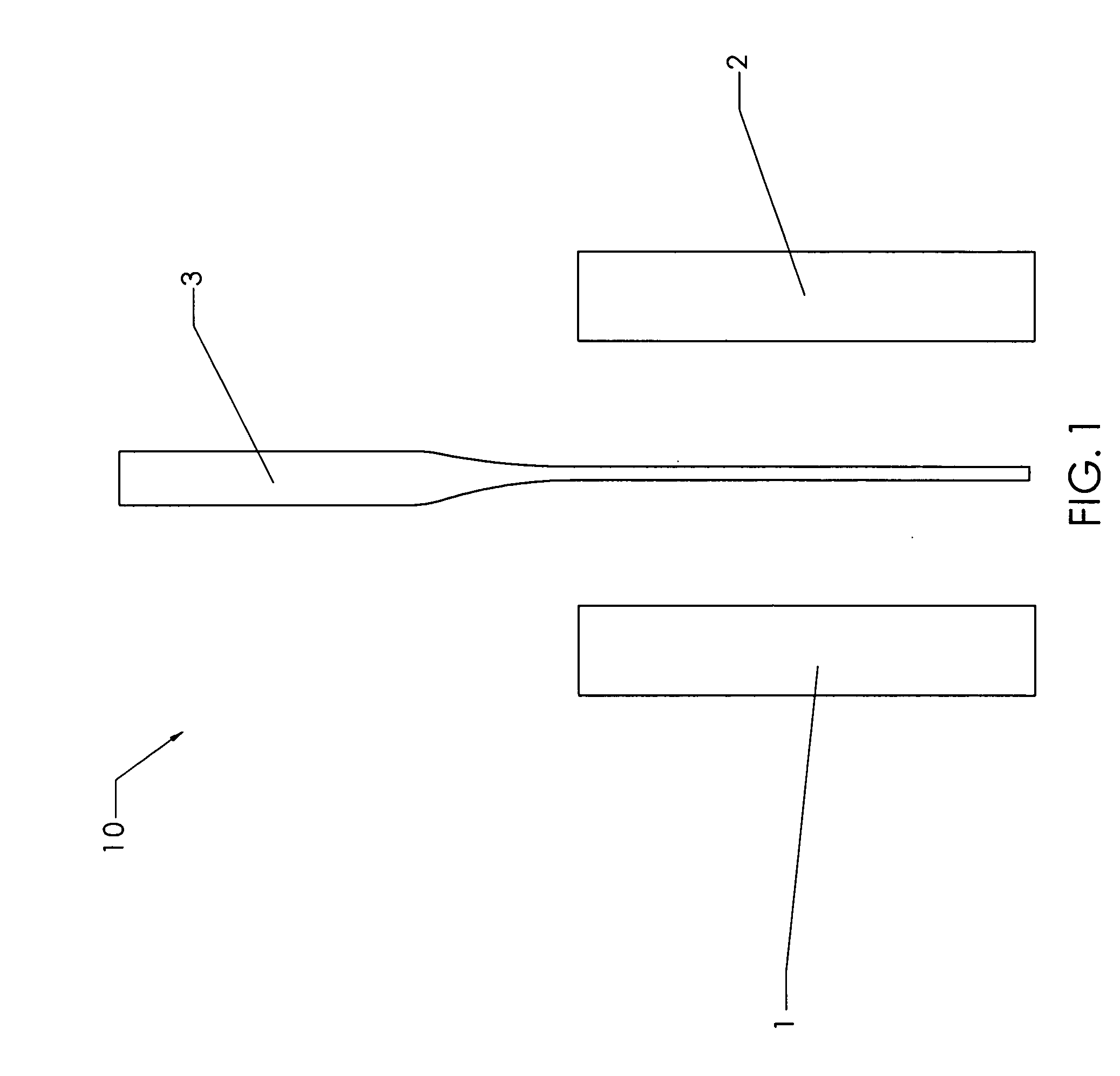

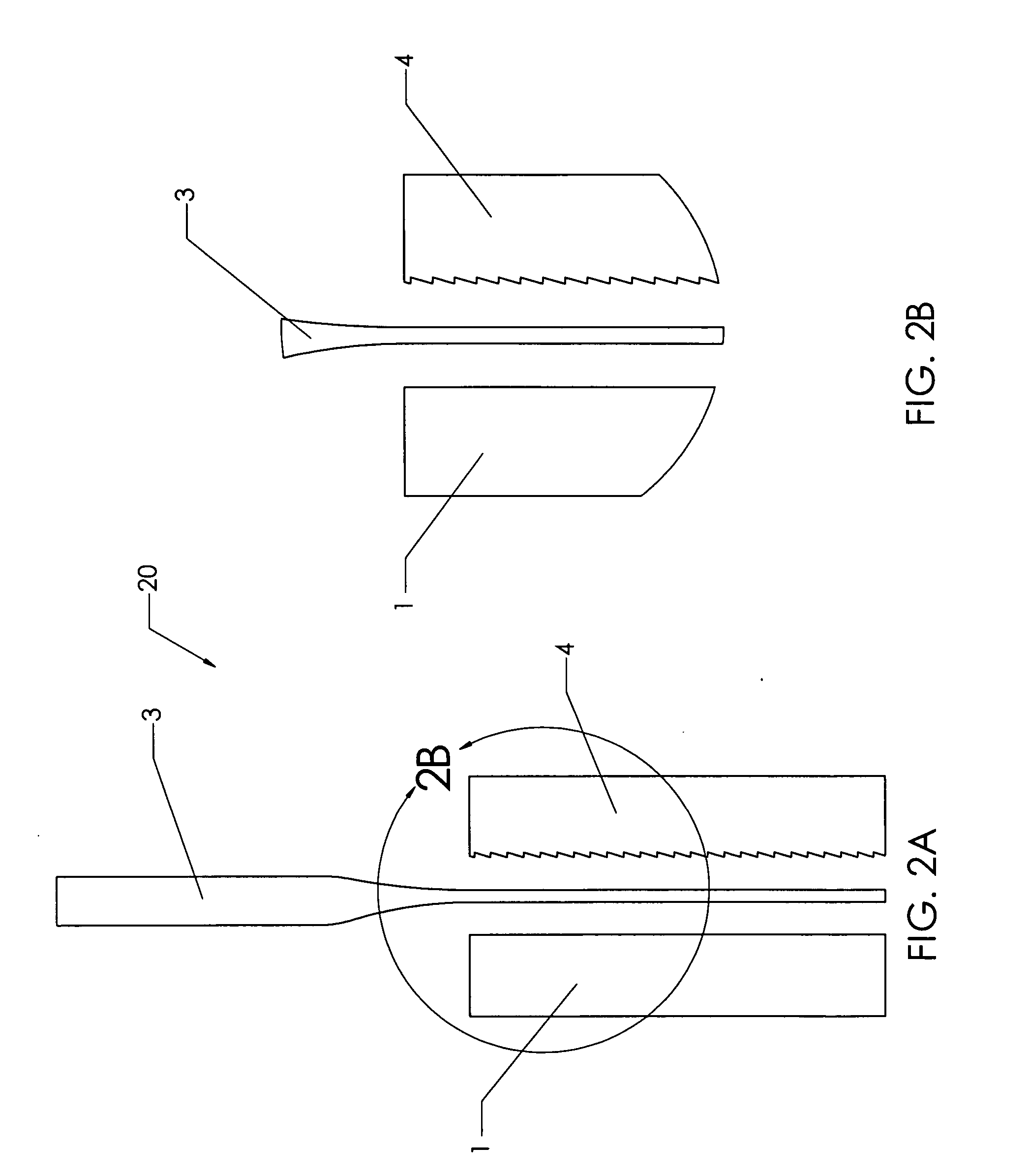

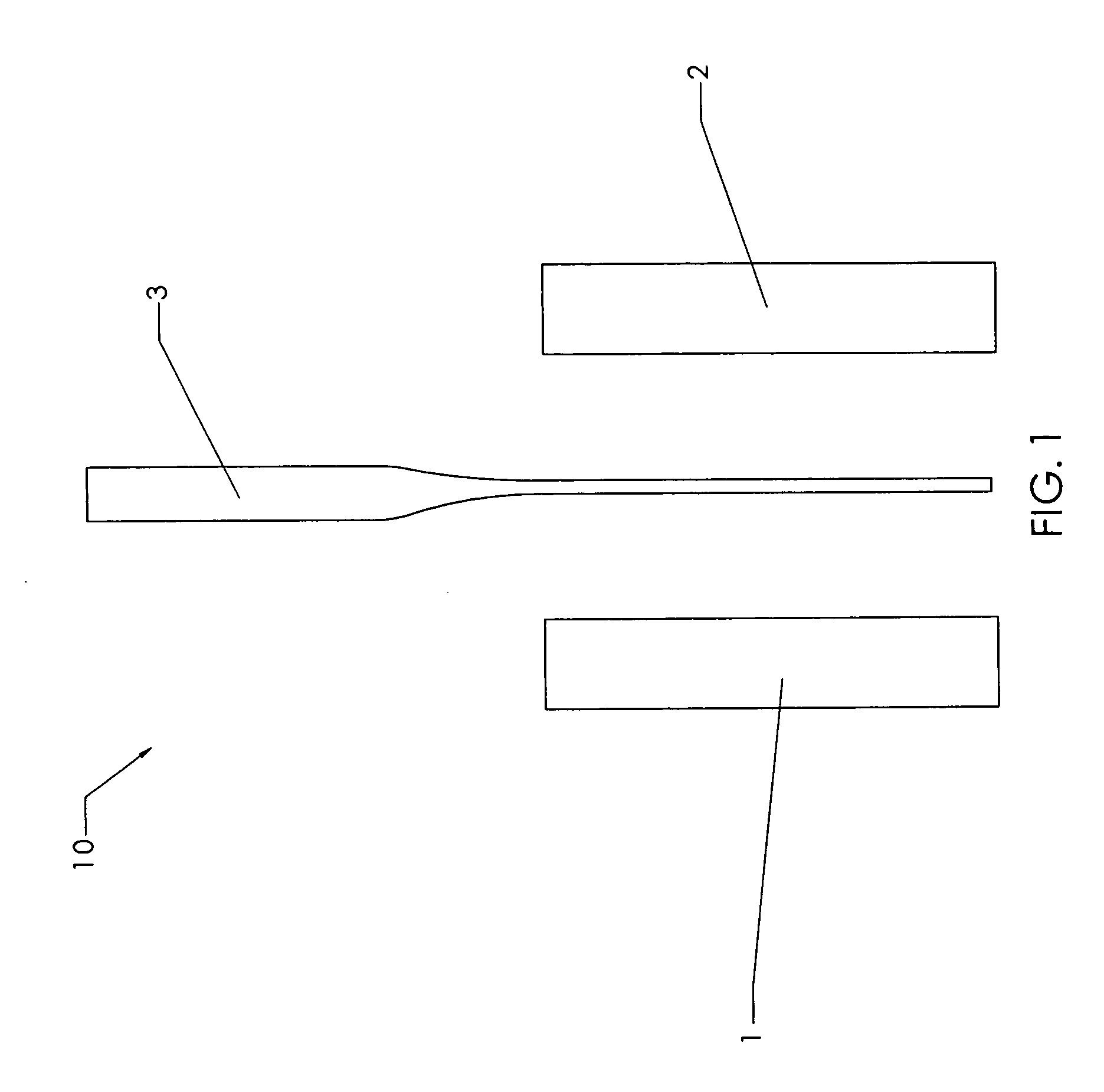

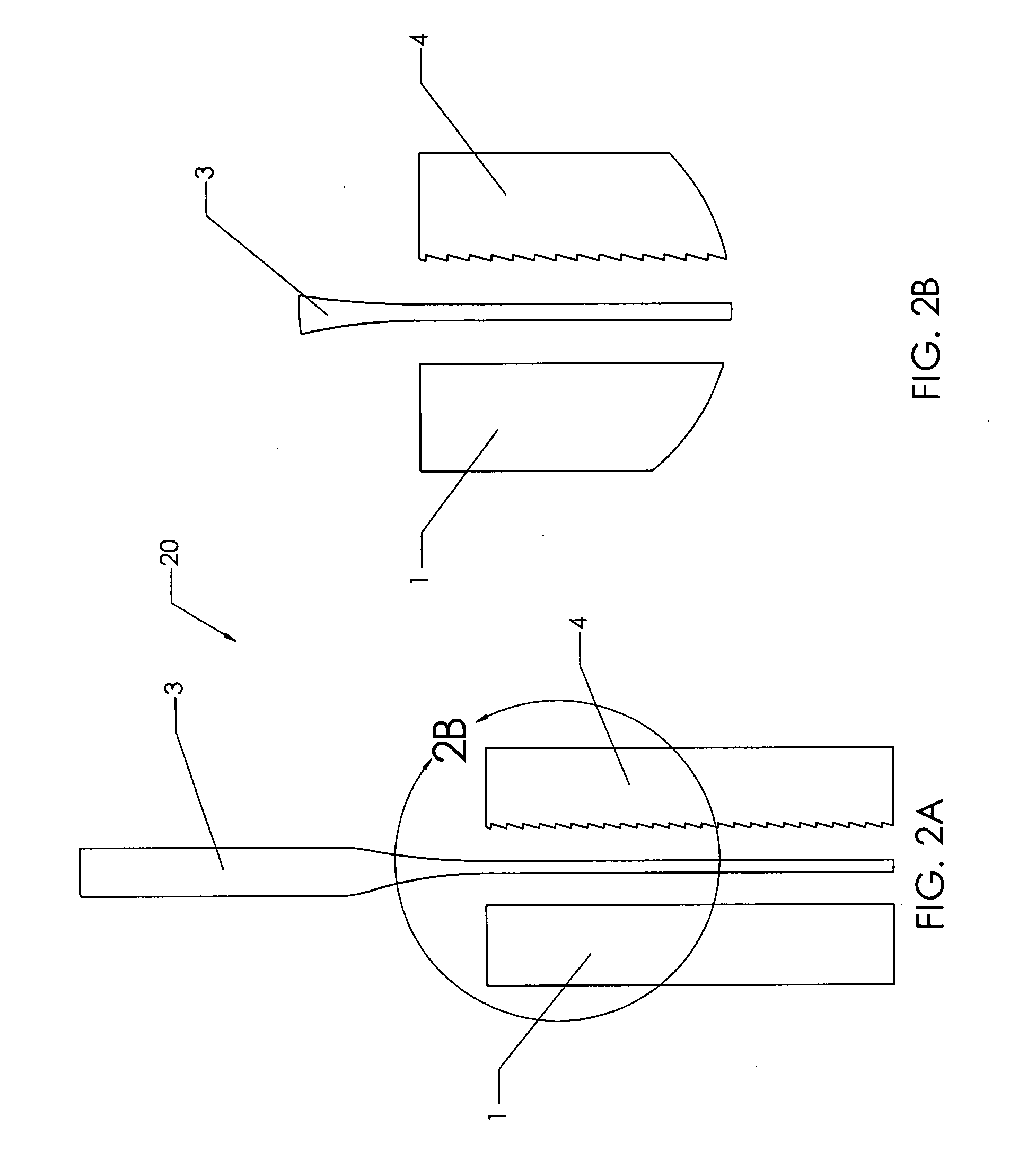

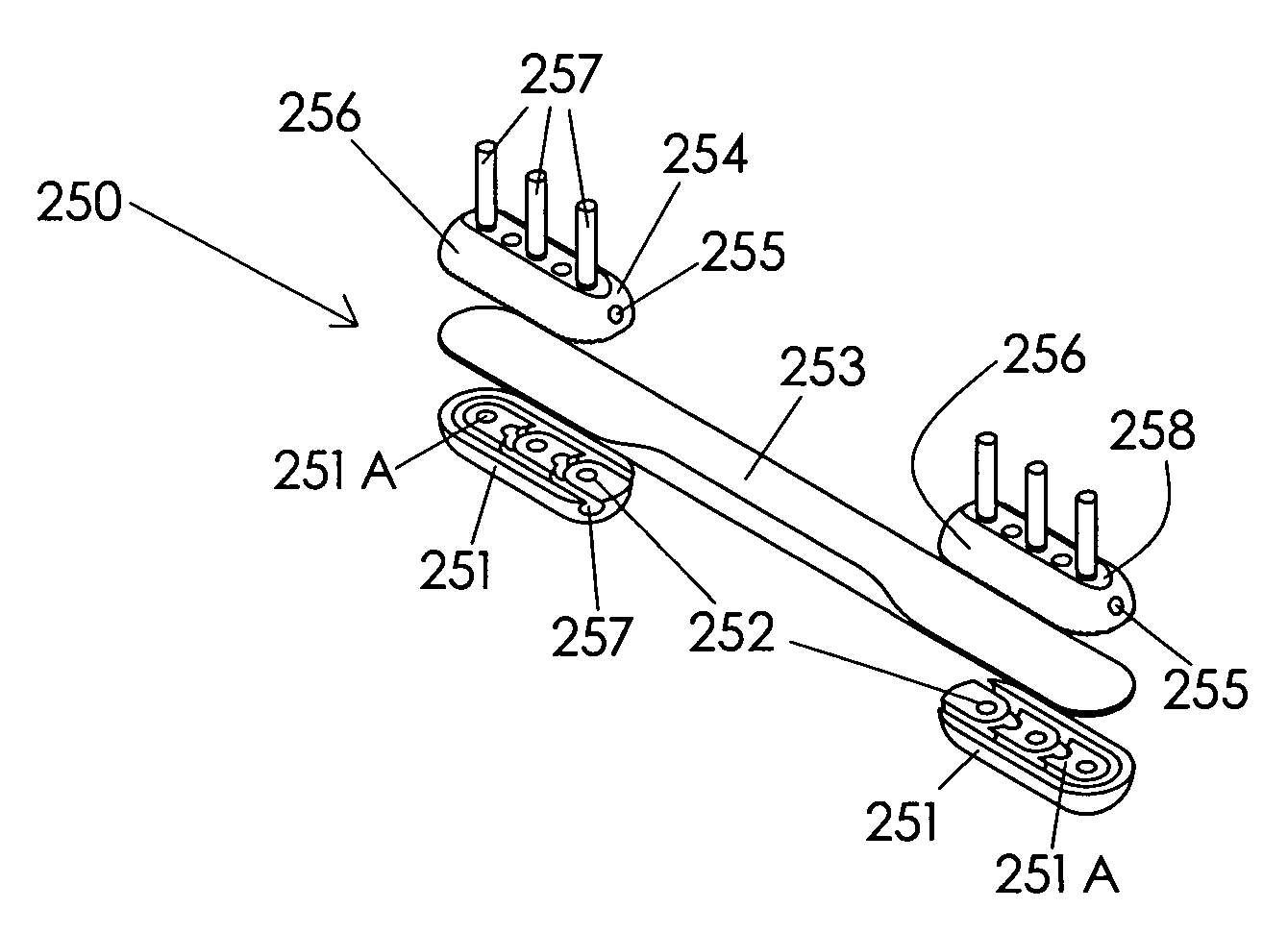

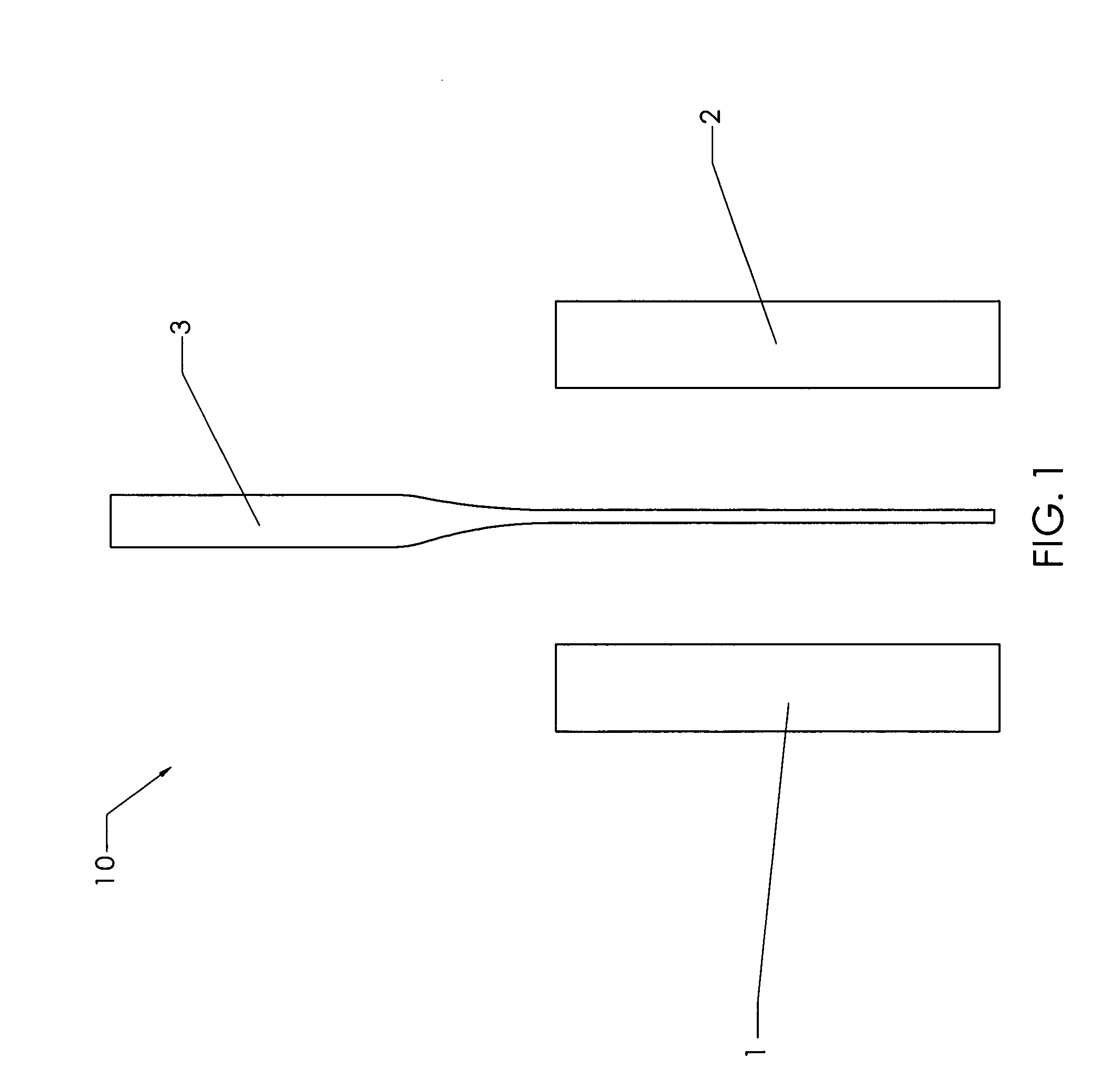

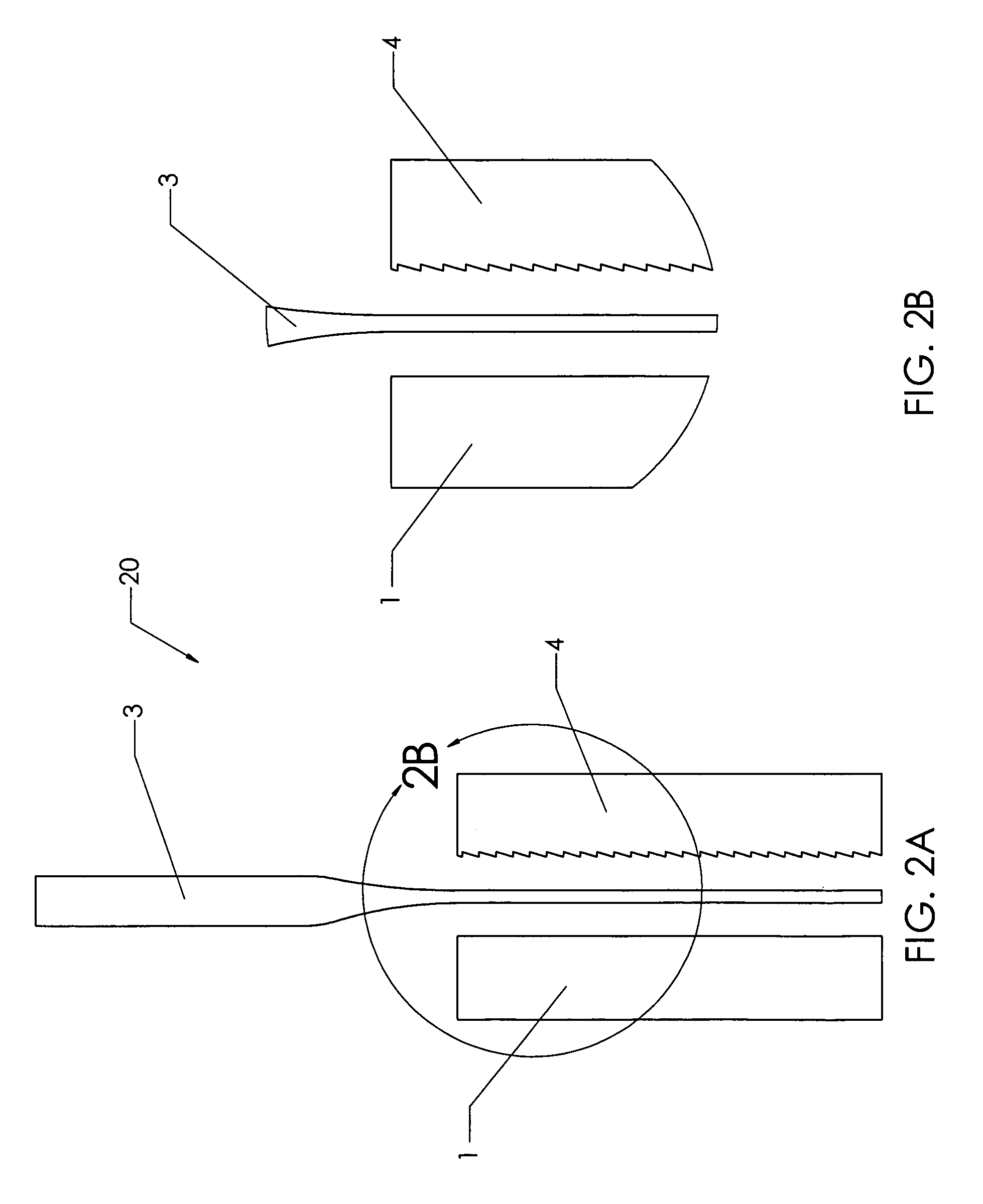

Assembled bone-tendon-bone grafts

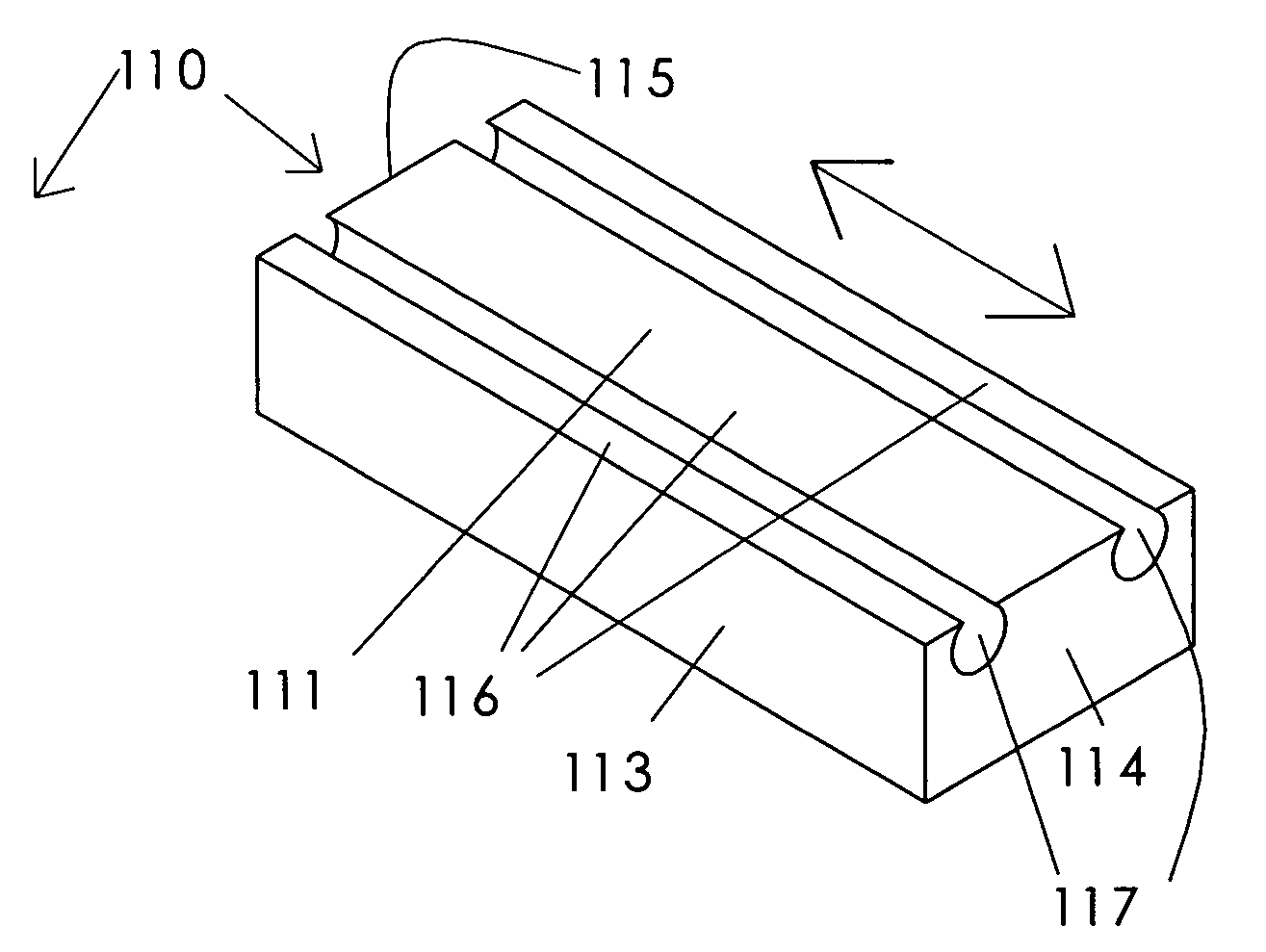

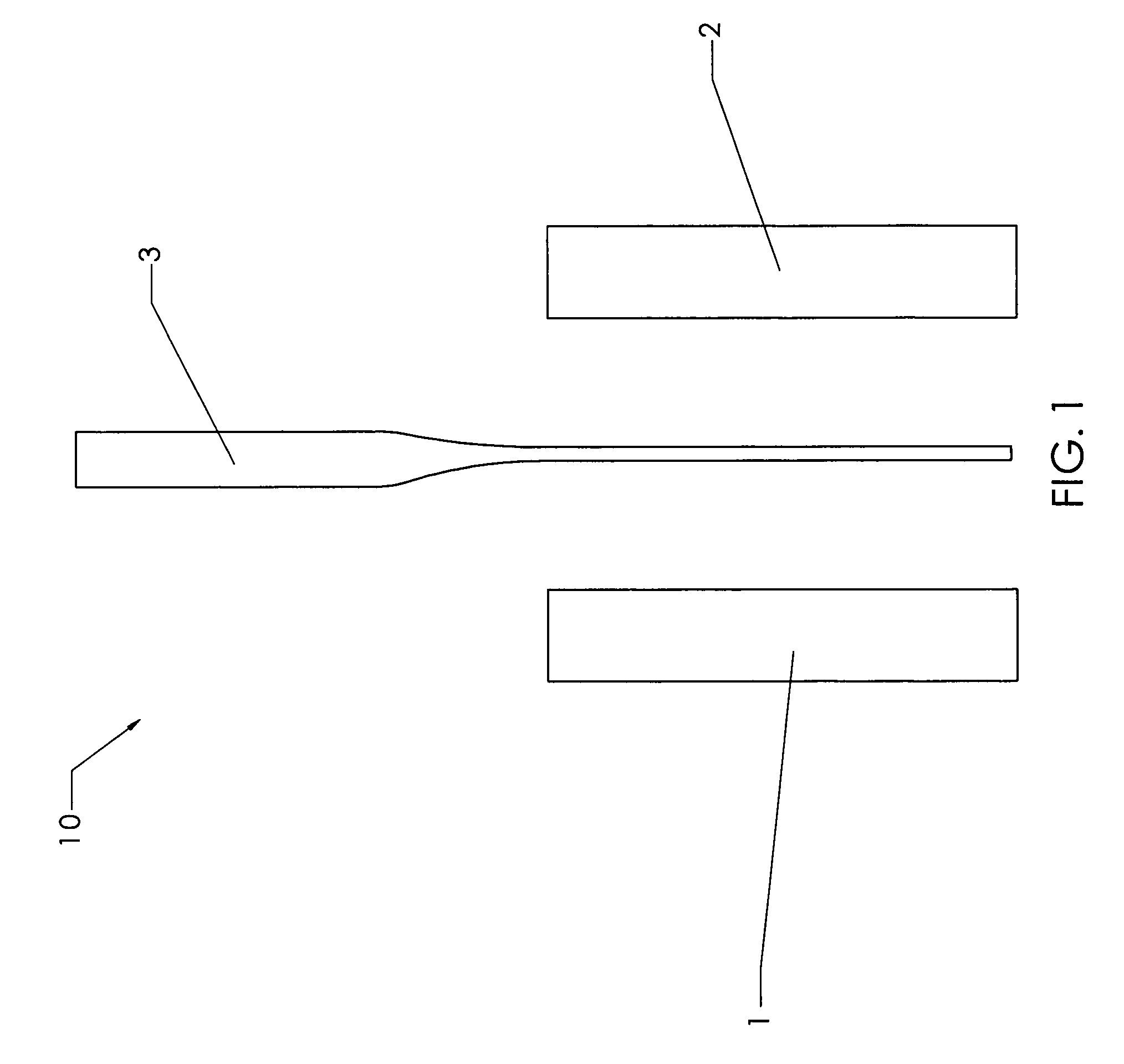

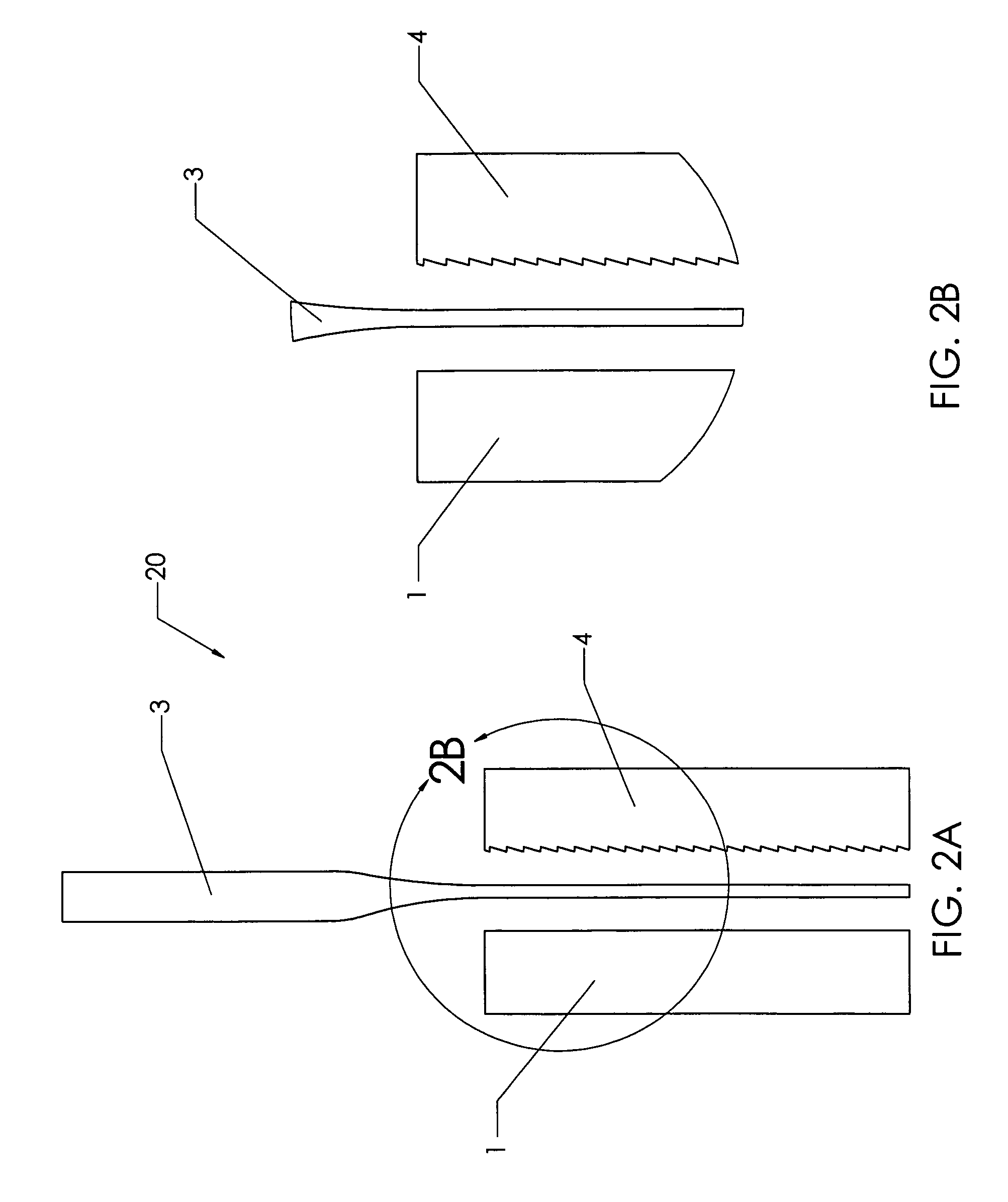

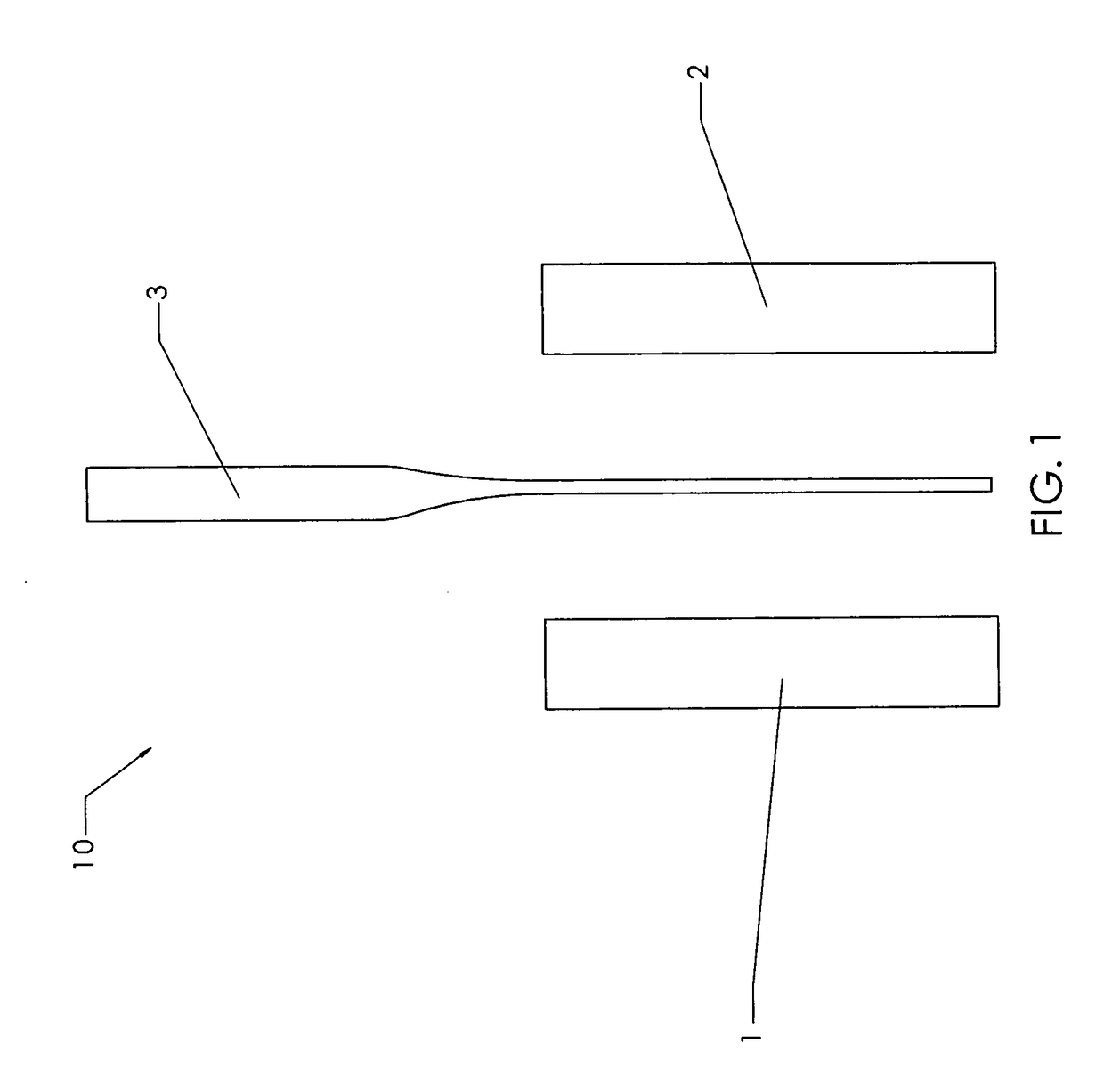

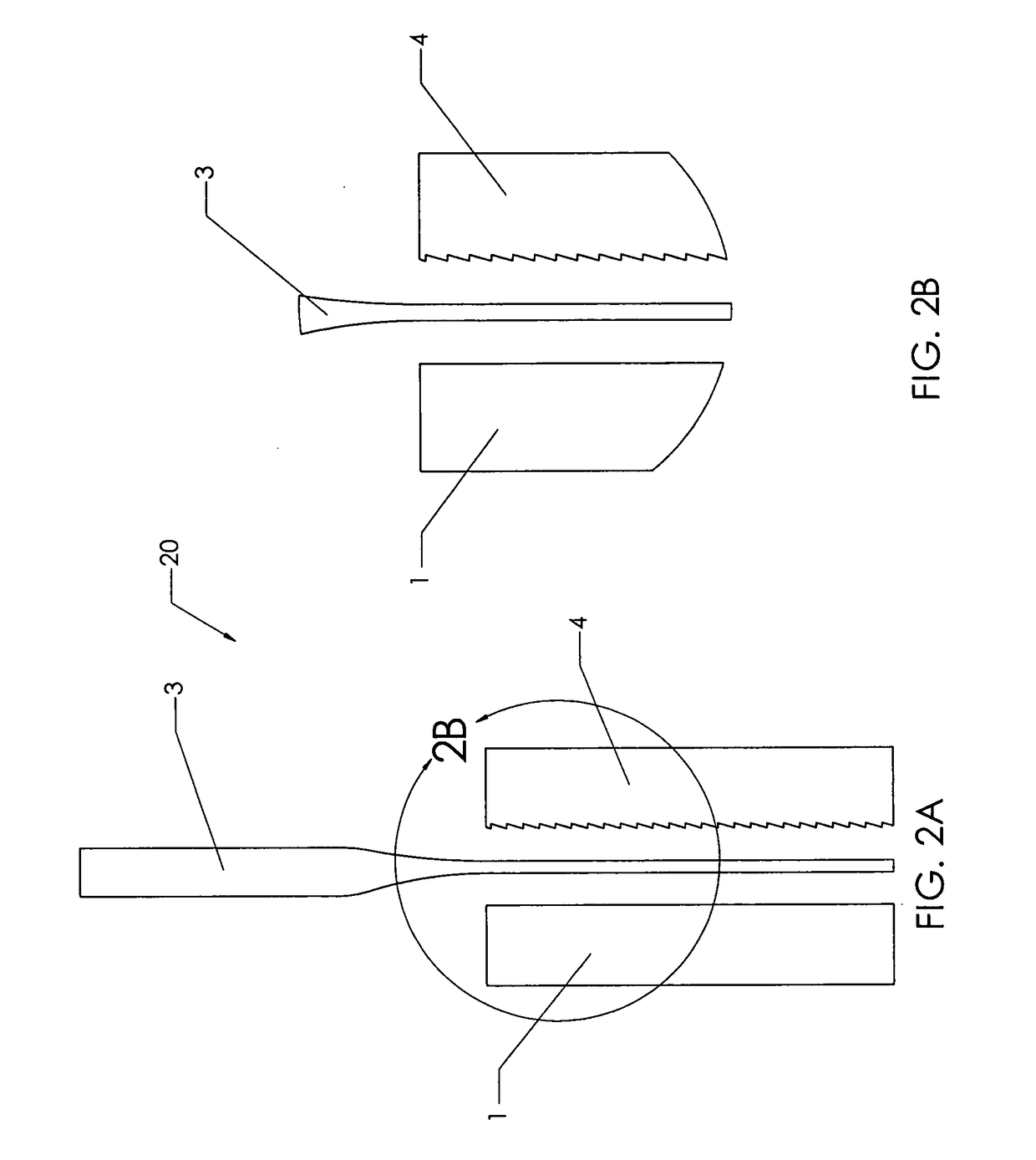

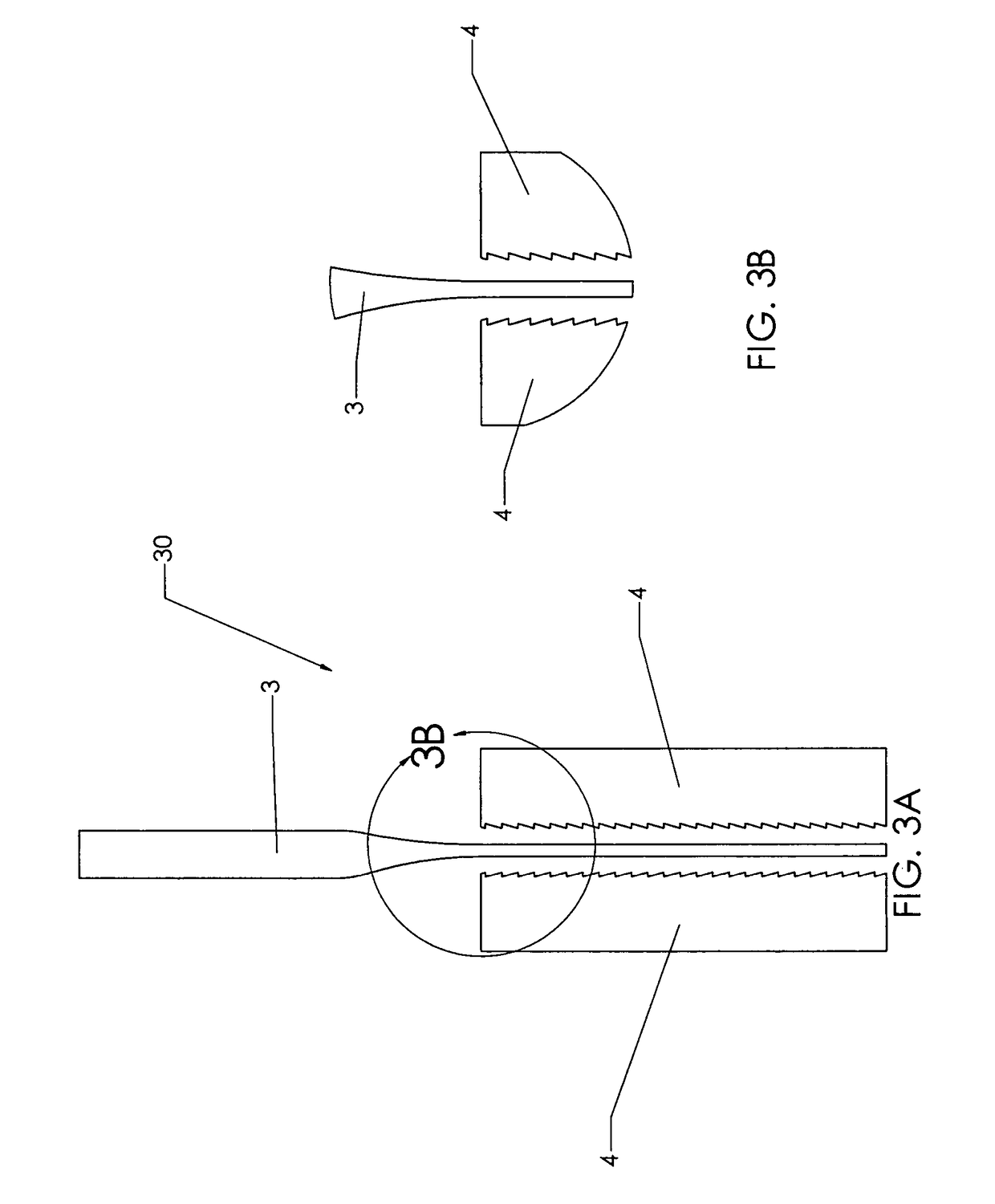

ActiveUS20060200235A1Enhanced gripping featureHigh tensile strengthBone implantLigamentsBone CortexBone tendon bone

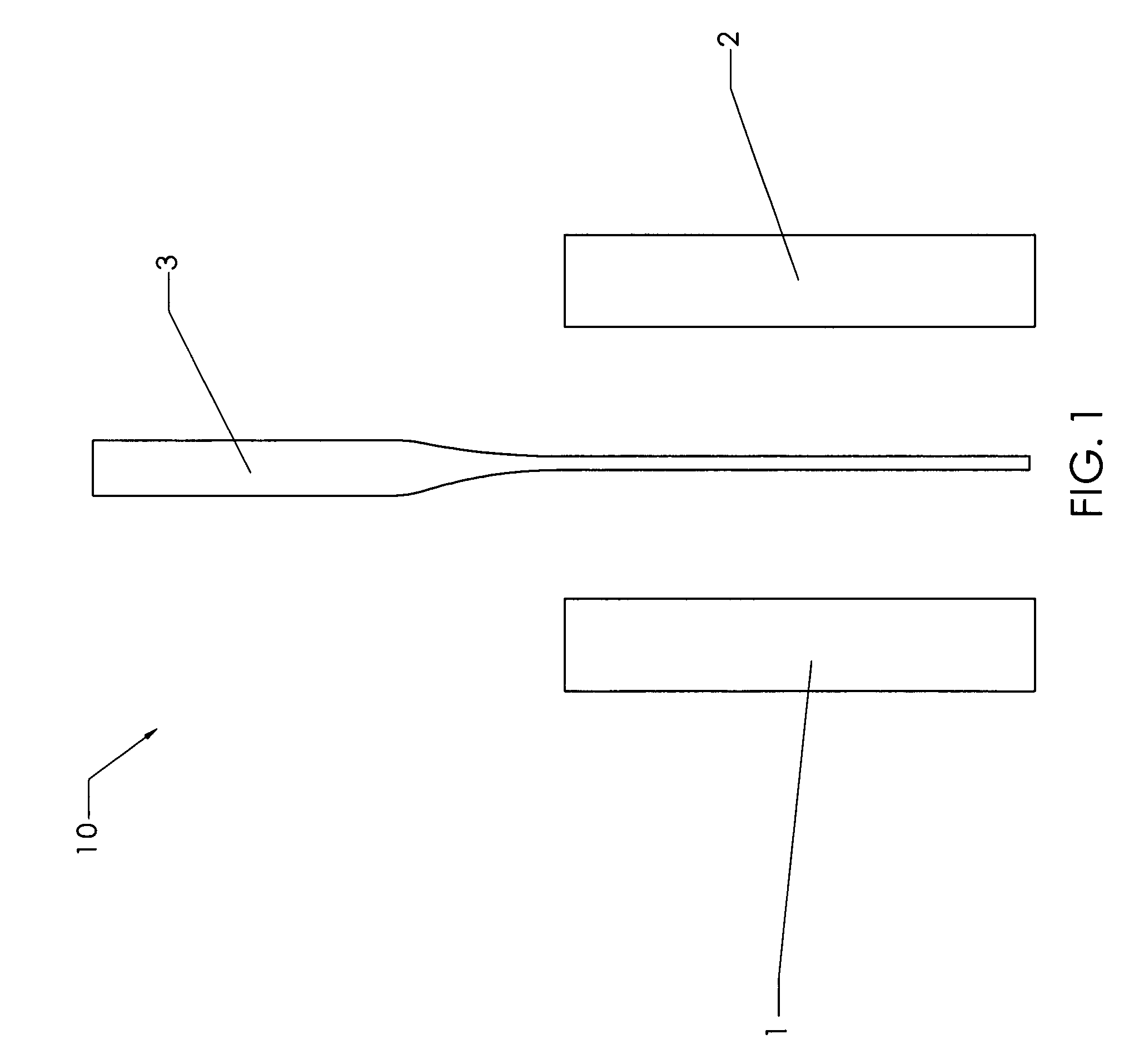

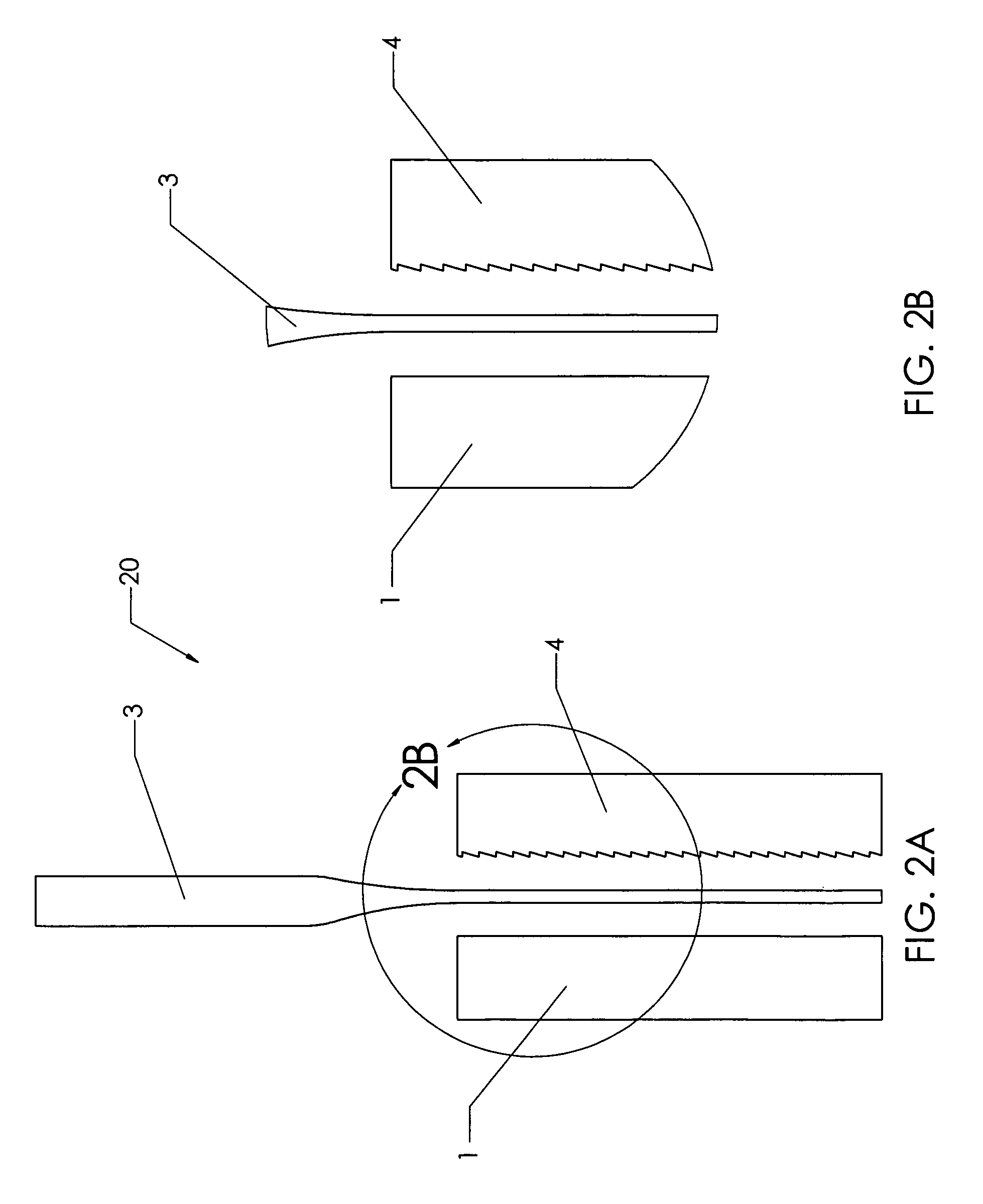

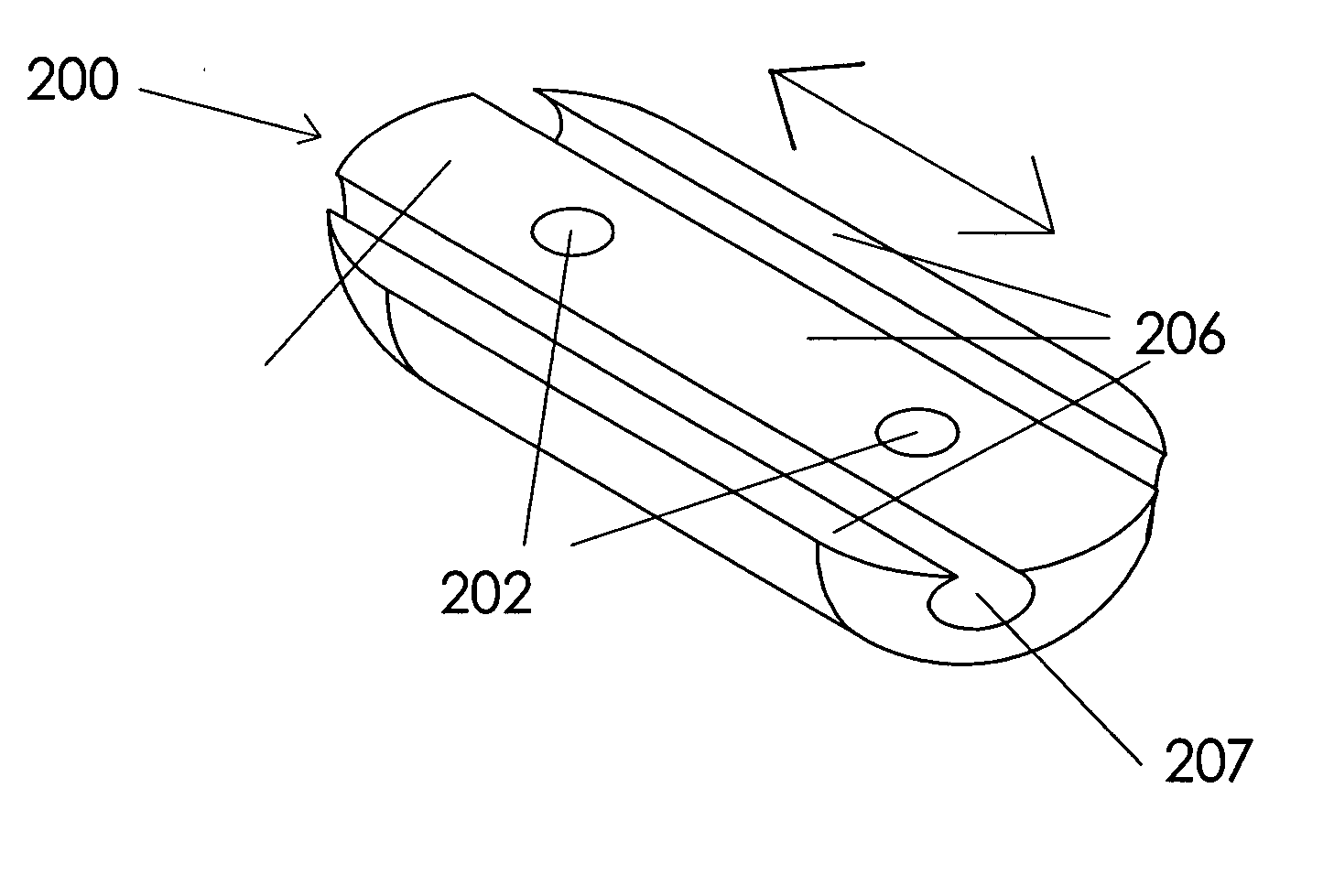

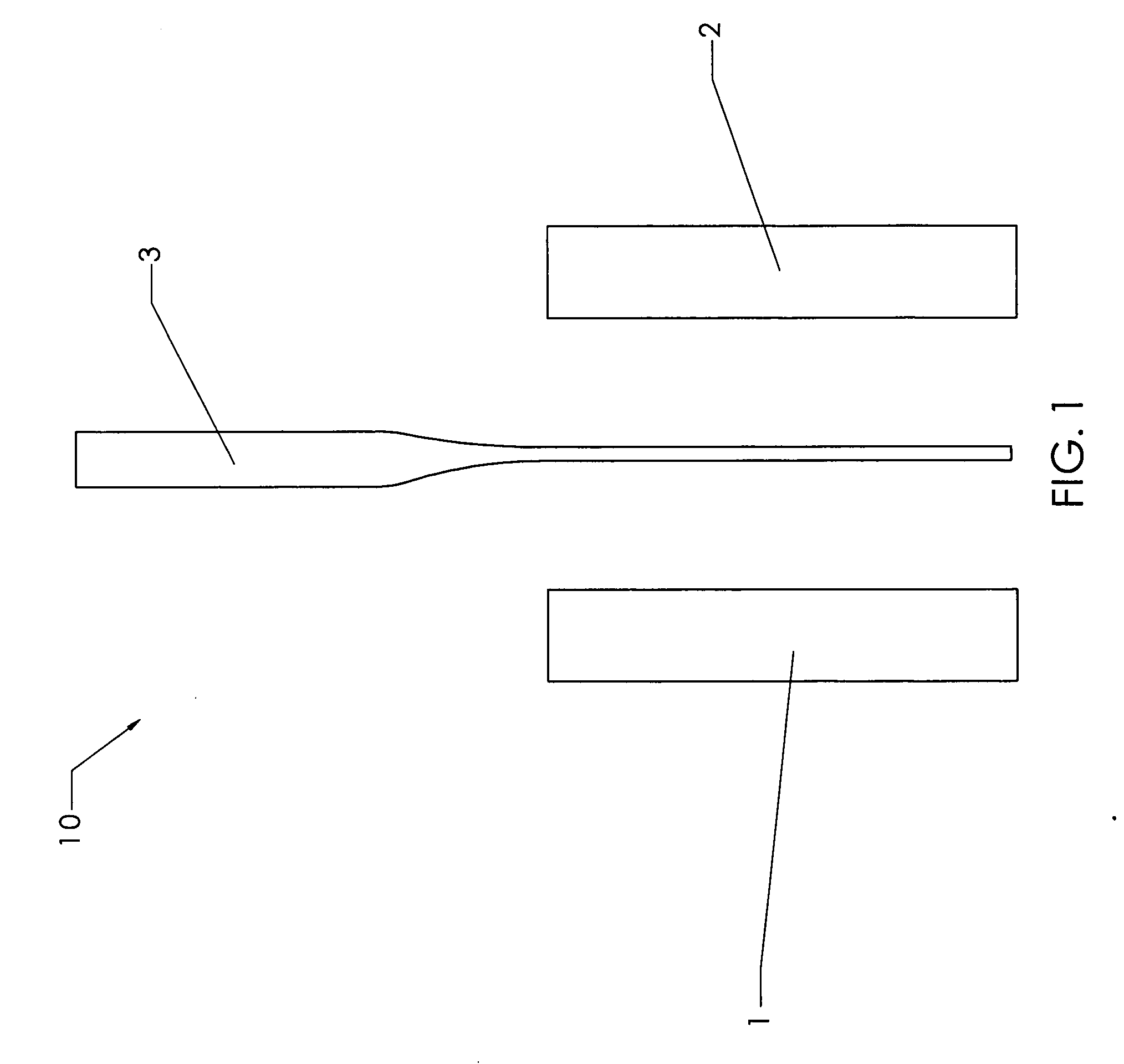

The present invention has multiple aspects. In its simplest aspect, the present invention is directed to an intermediate bone block comprising a machined segment of cortical bone, cancellous bone or both, the intermediate having a face comprising one to ten compression surfaces and one to ten cavities, the compression surfaces suitable for compressing soft tissue, the cavities for receiving and holding overflow soft tissue. The cavities are preferably channels, and more preferably channels having an omega cross-sectional profile. Surprisingly, the cavities and channels, which reduced the compressed surface area between the intermediate bone block and the tendon, significantly improved tendon load at failure. In standardized tests, an intermediate bone block of this invention, when combined with high surface area bone blocks of the prior art bone blocks, unexpectedly increased their load at failure. The invention is also directed to bone block assemblies suitable for binding to a soft tissue to form an implantable graft, and to such implantable grafts. A particularly preferred graft is a bone-tendon-bone graft.

Owner:RTI BIOLOGICS INC

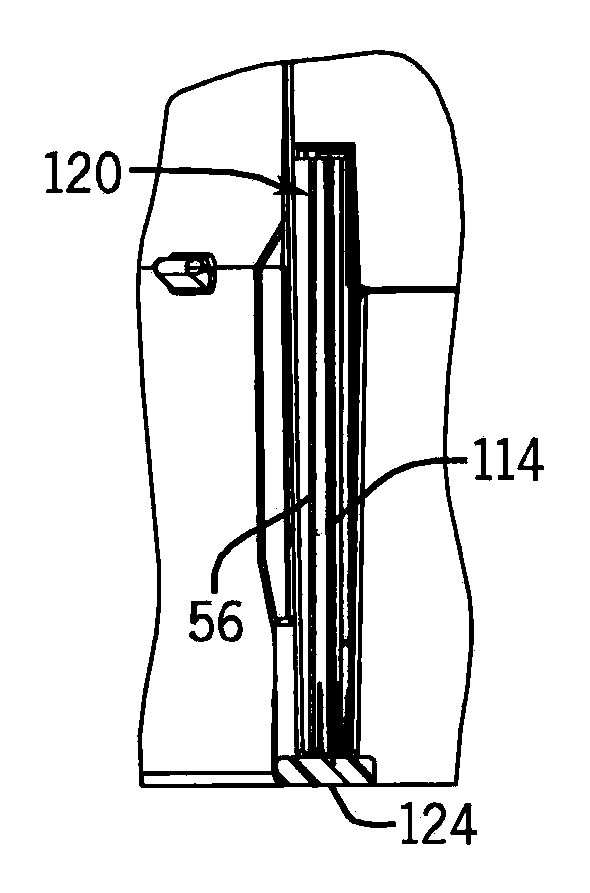

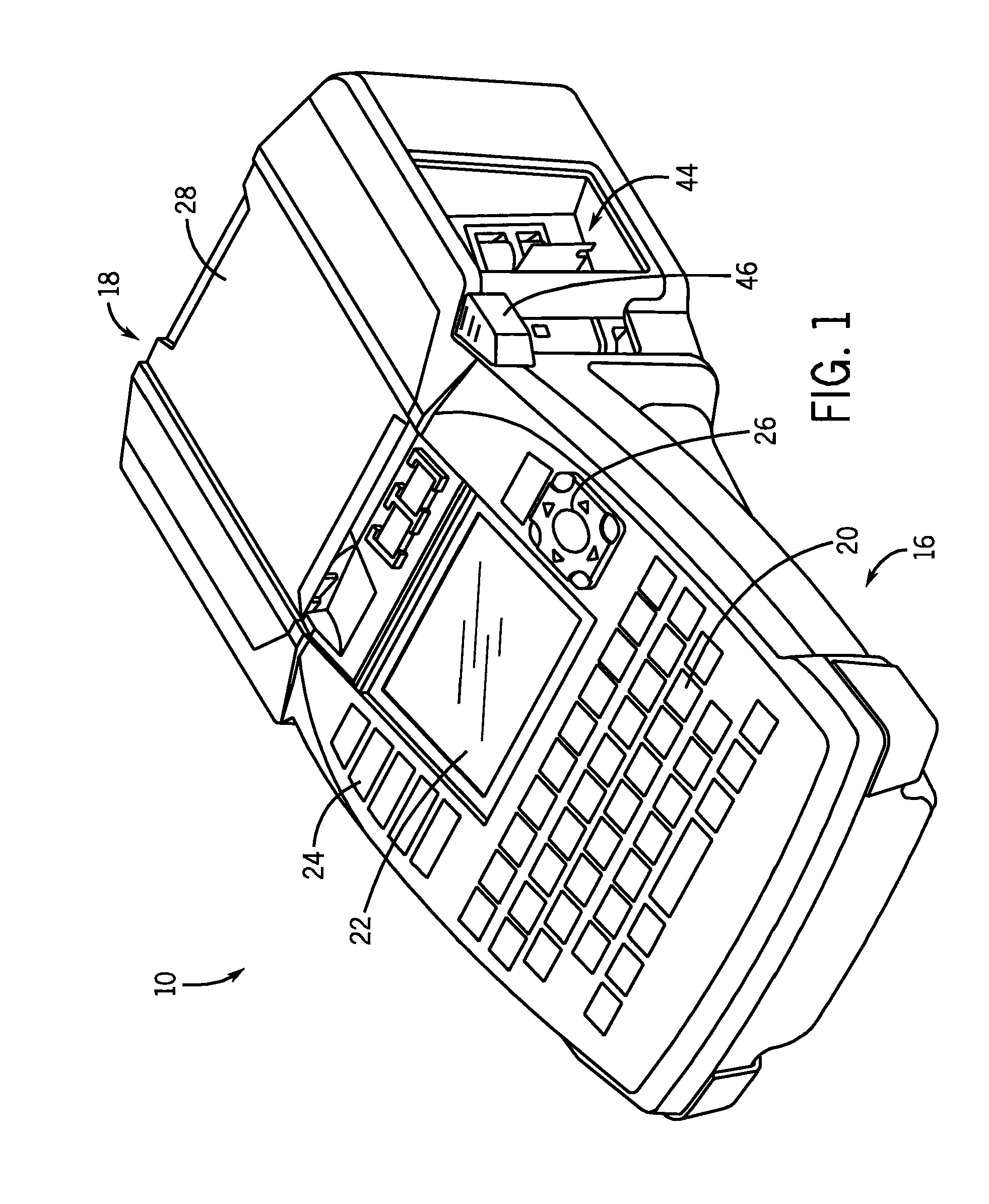

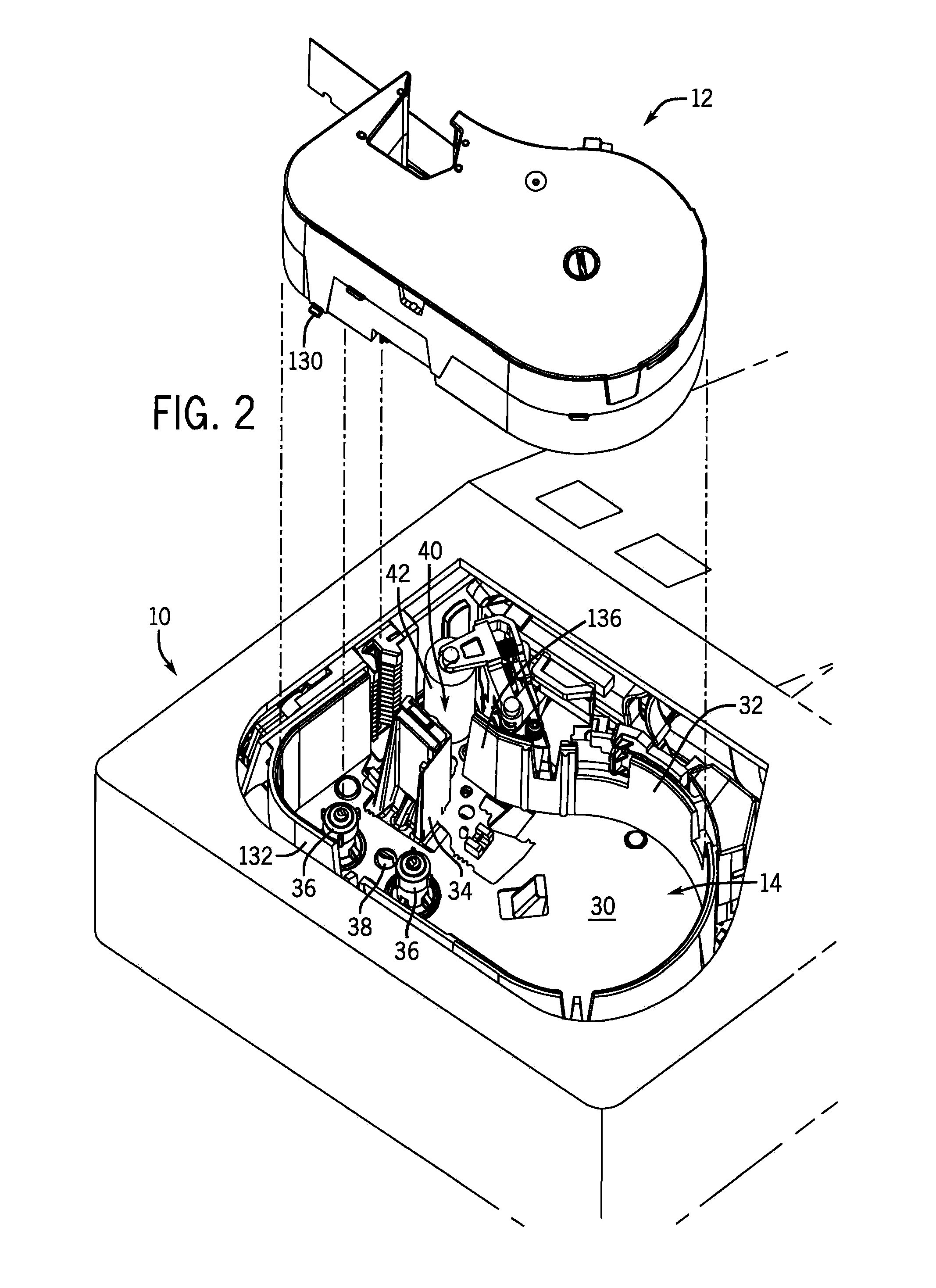

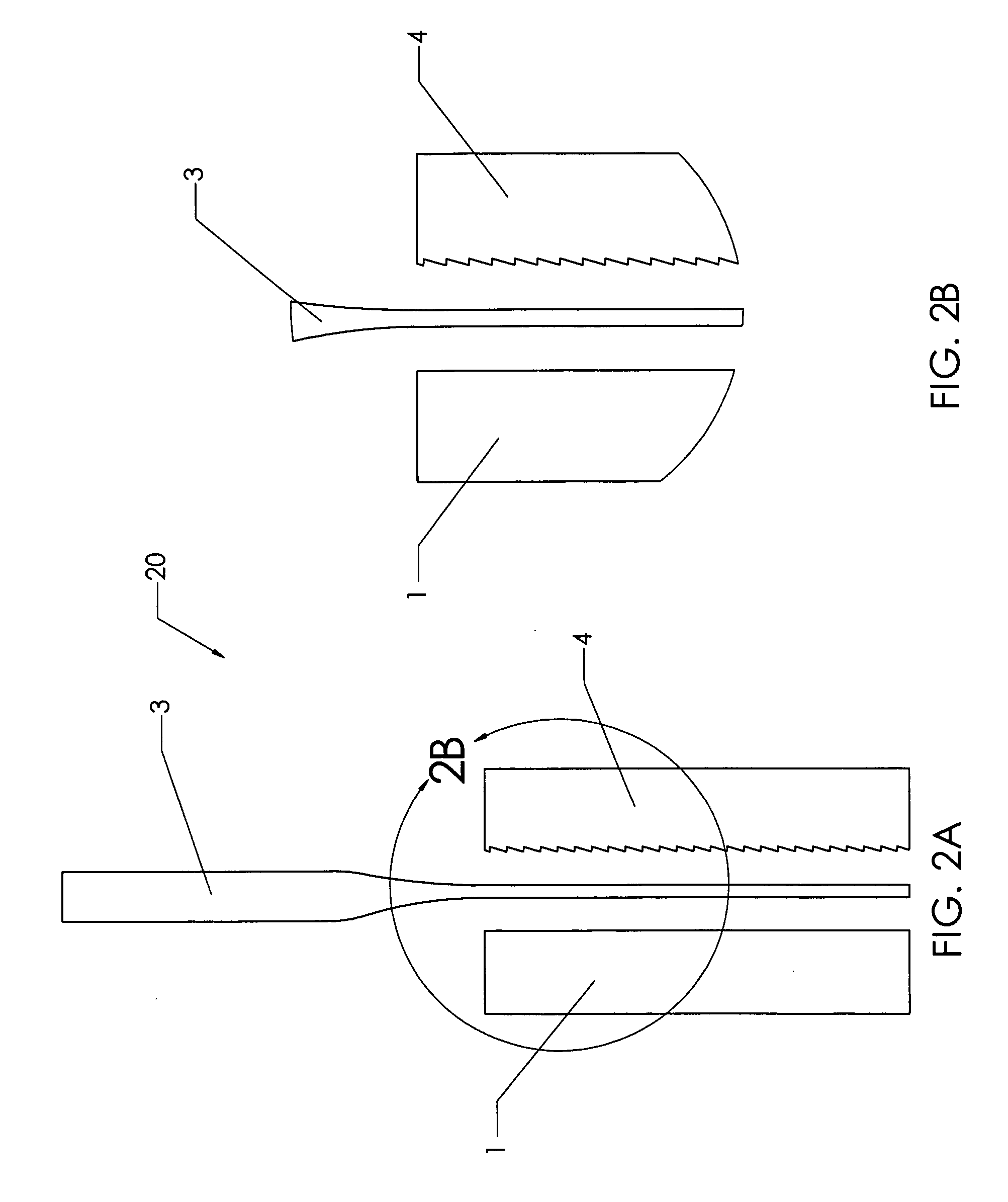

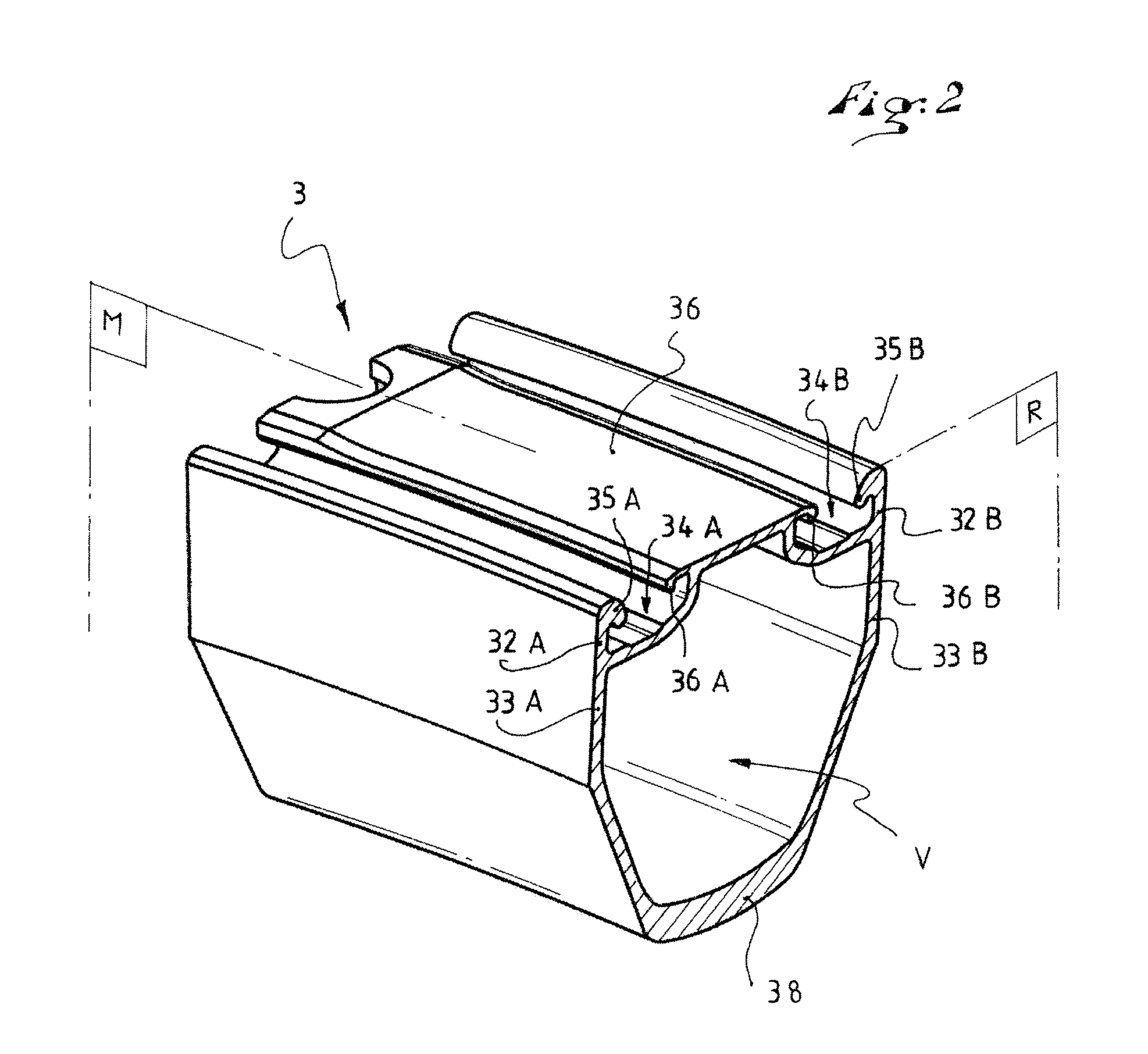

Cartridge assembly with edge protector

ActiveUS20120027487A1Improve protectionReduce edgeInking apparatusOther printing apparatusEngineeringMechanical engineering

A cartridge assembly is disclosed with improved protection of its media and / or ink ribbon. The cartridge assembly includes a cartridge housing for receiving media. The cartridge housing includes an exit opening through which the media exits the cartridge housing along a media path. A media guide is also located on the media path and is spaced from the exit opening a predetermined distance. An edge protector extends between the exit opening and the media guide adjacent a lower edge of the media path to protect a lower edge of the media.

Owner:BRADY WORLDWIDE INC

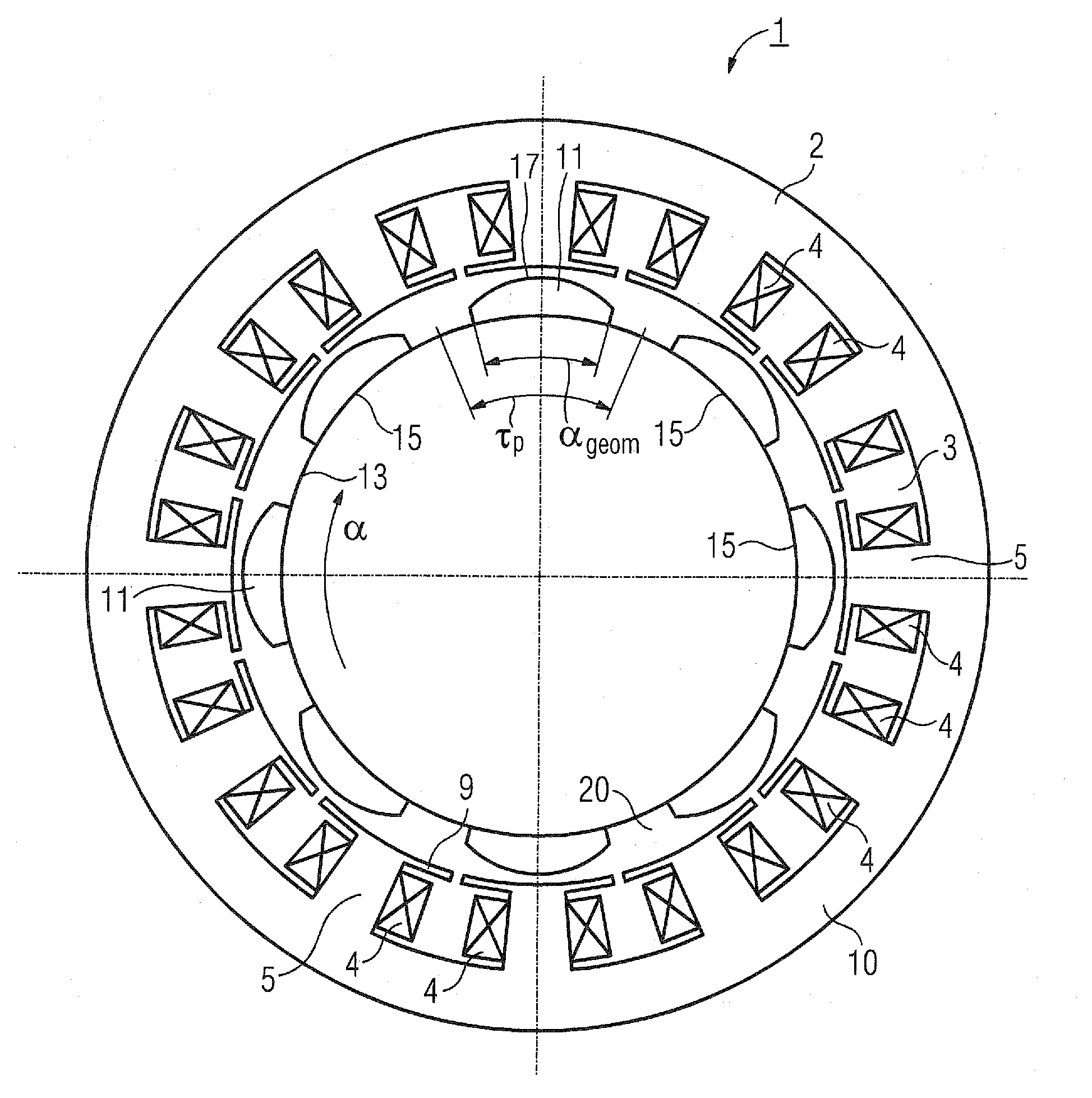

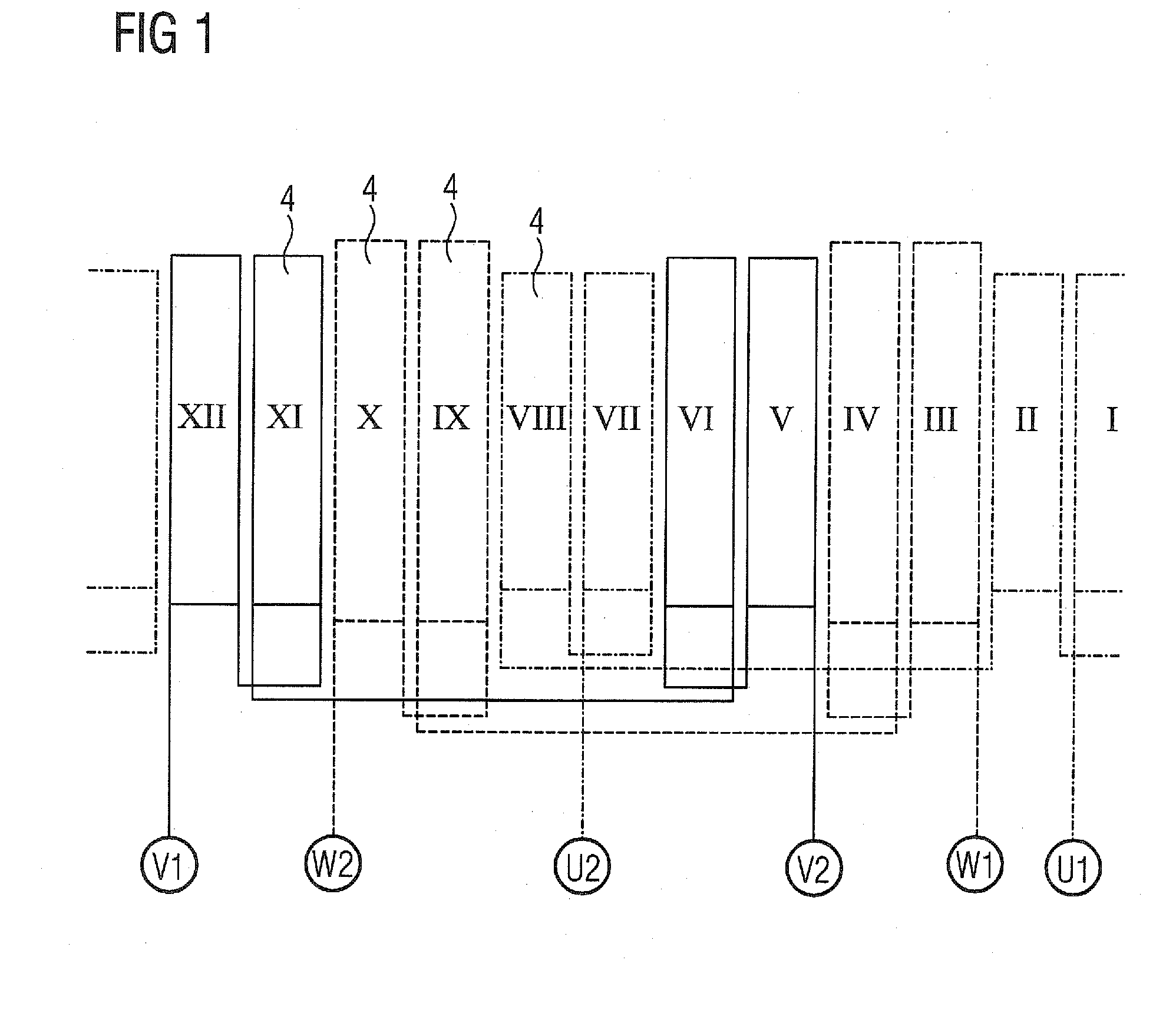

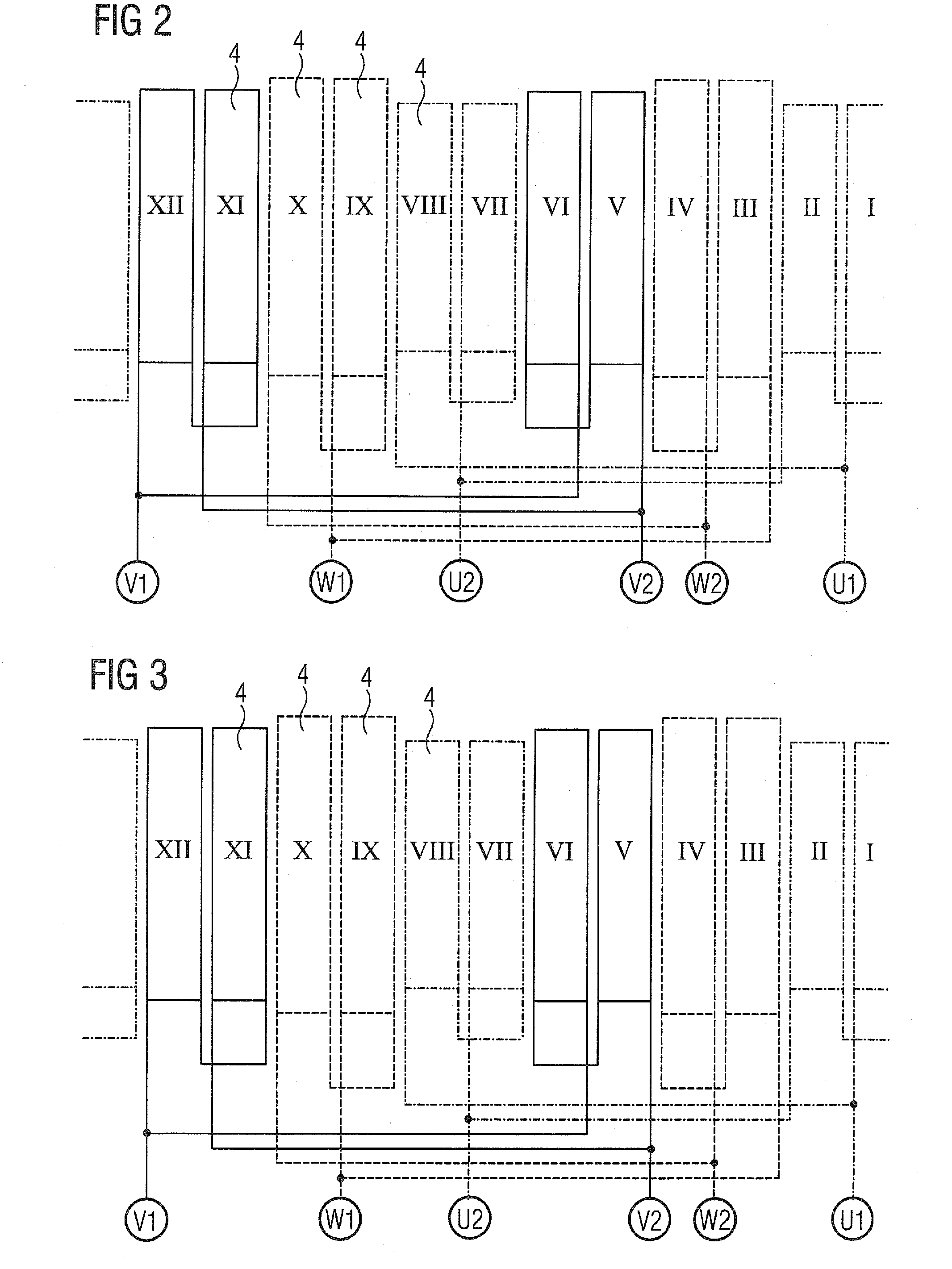

Three-phase dynamoelectrical permanently excited synchronous machine

InactiveUS20100133940A1Reduce edgeReduction in detentMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsWind systemThree-phase

A three-phase dynamoelectrical permanently excited synchronous machine includes a stator with teeth which point to a rotor, wherein twelve slots are formed between the teeth. The slots have coil sides of coils of a winding system in such a manner that two coil sides of different coils are situated in each slot. The rotor has a cylindrical support structure which is provided with permanent magnets defined by an inner radius which corresponds to a radius of the support structure, and by an outer radius which is smaller than their inner radius. The permanent magnets are formed with ten magnet poles when viewed in a circumferential direction.

Owner:SIEMENS AG

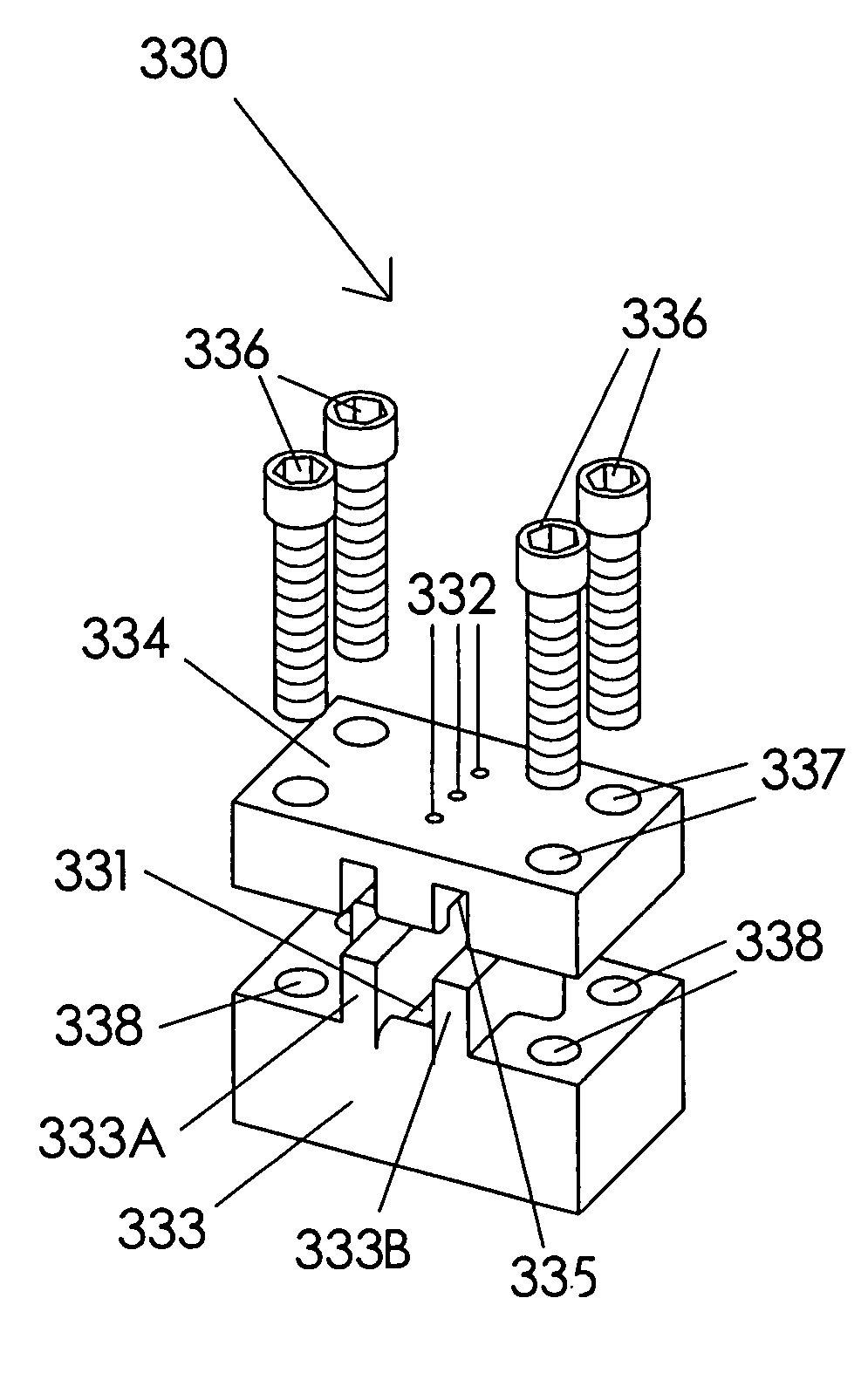

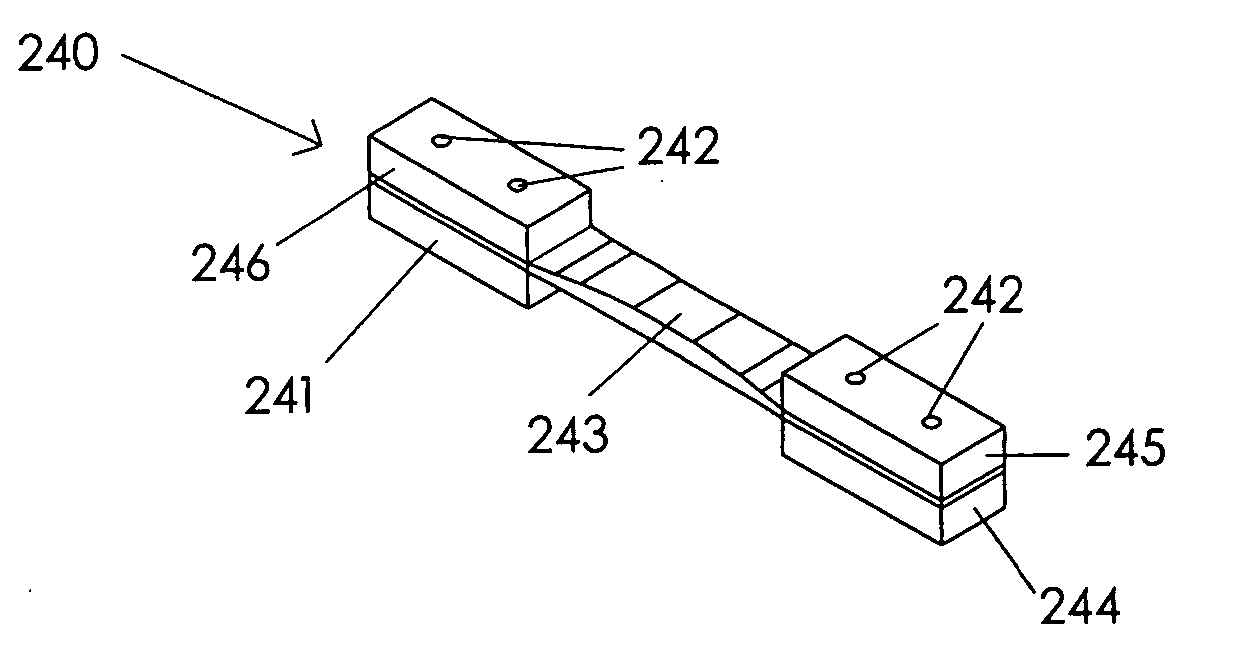

Adjustable and fixed assembled bone-tendon-bone graft

ActiveUS20060229722A1Increase tensile strengthEnhance gripping featureBone implantLigamentsBone tendon boneCancellous bone

The present invention has multiple aspects relating to a bone-tendon-bone graft and components thereof. Embodiments of the present invention comprise an intermediate bone block that is used to adjustably secure soft tissue (e.g., tendon) in a patient. Preferred intermediate bone blocks comprise at least one machined segment of cortical bone, cancellous bone or both. Embodiments of intermediate bone blocks of the present invention are used singly or in combination with one or more bone blocks to form a bone block assembly for securing soft tissue. The present invention further relates to an assembled bone-tendon-bone graft suitable for implantation in humans comprising the intermediate bone block and a length of soft tissue. In a preferred embodiment, a bone-tendon-bone graft comprises a length of soft tissue (e.g., tendon) extending from a first assembled bone block to a second bone block and then doubles back to said first assembled bone block. Depending upon the embodiment, the second bone block fixedly or slideably attaches to the length of soft tissue and facilitates it doubling back to the first assembled bone block.

Owner:RTI BIOLOGICS INC

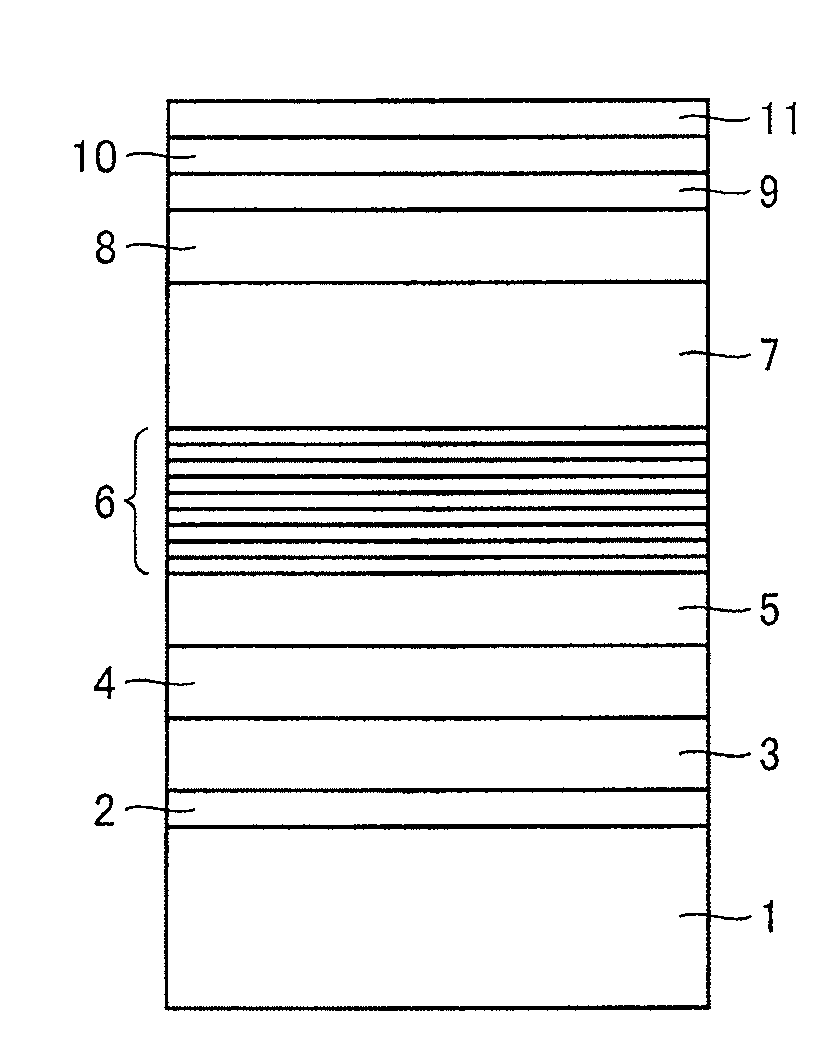

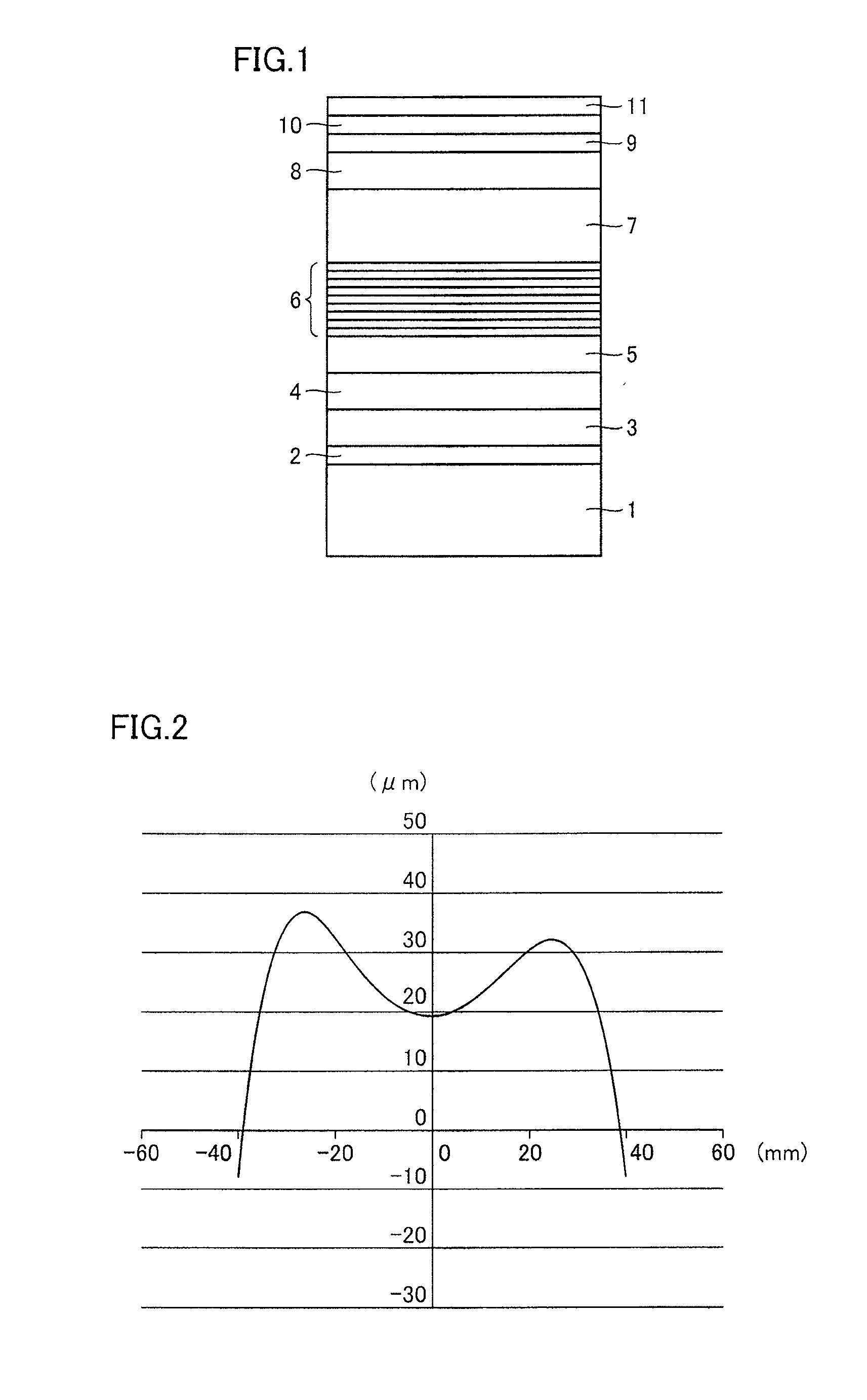

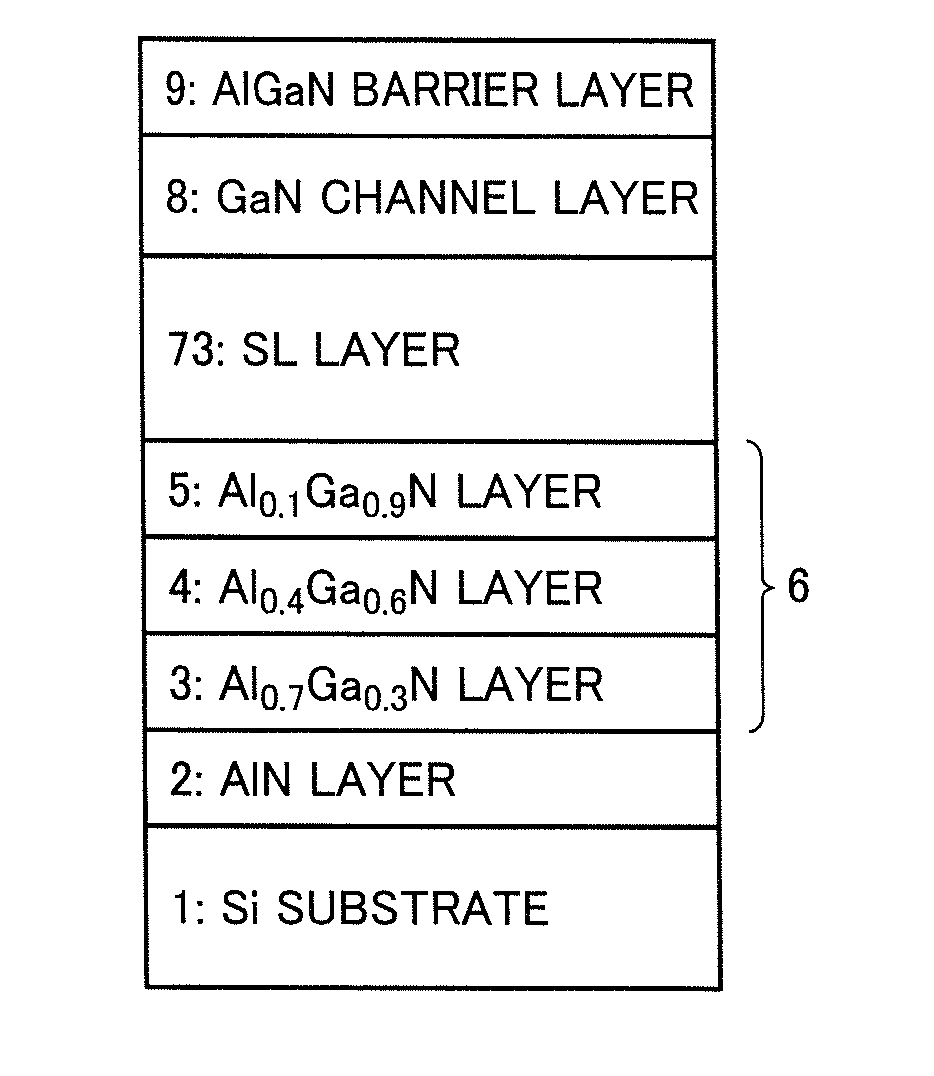

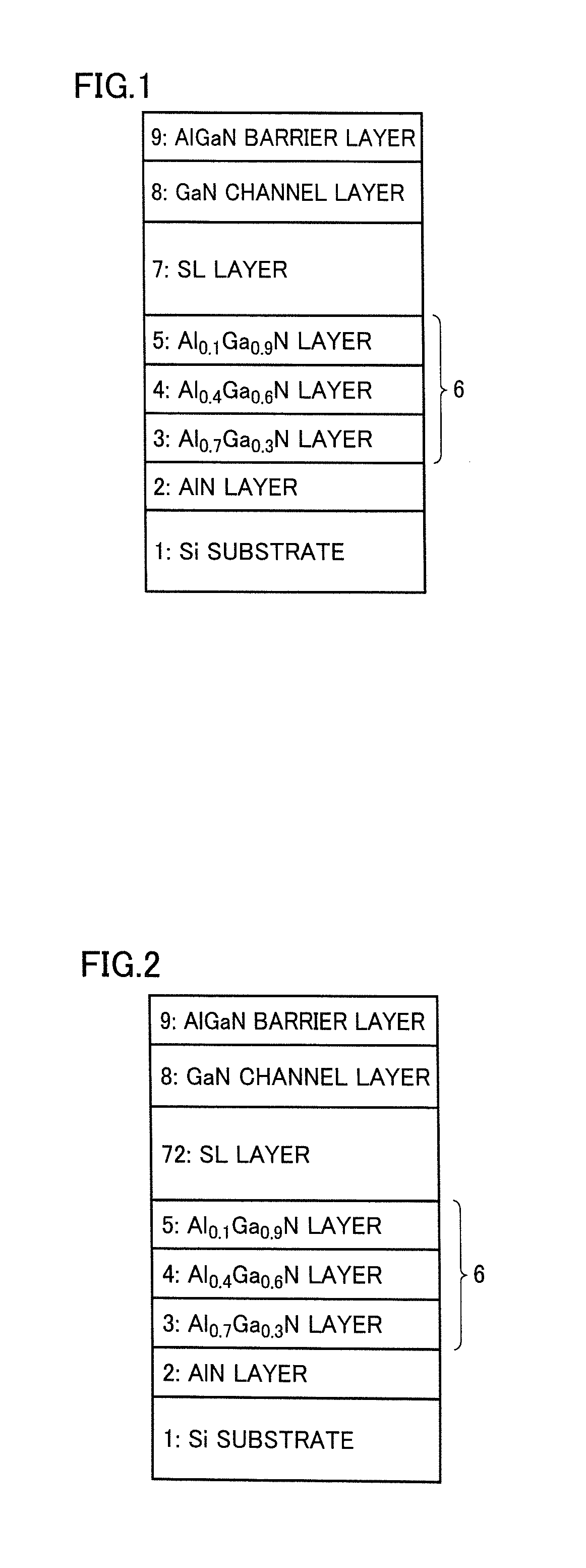

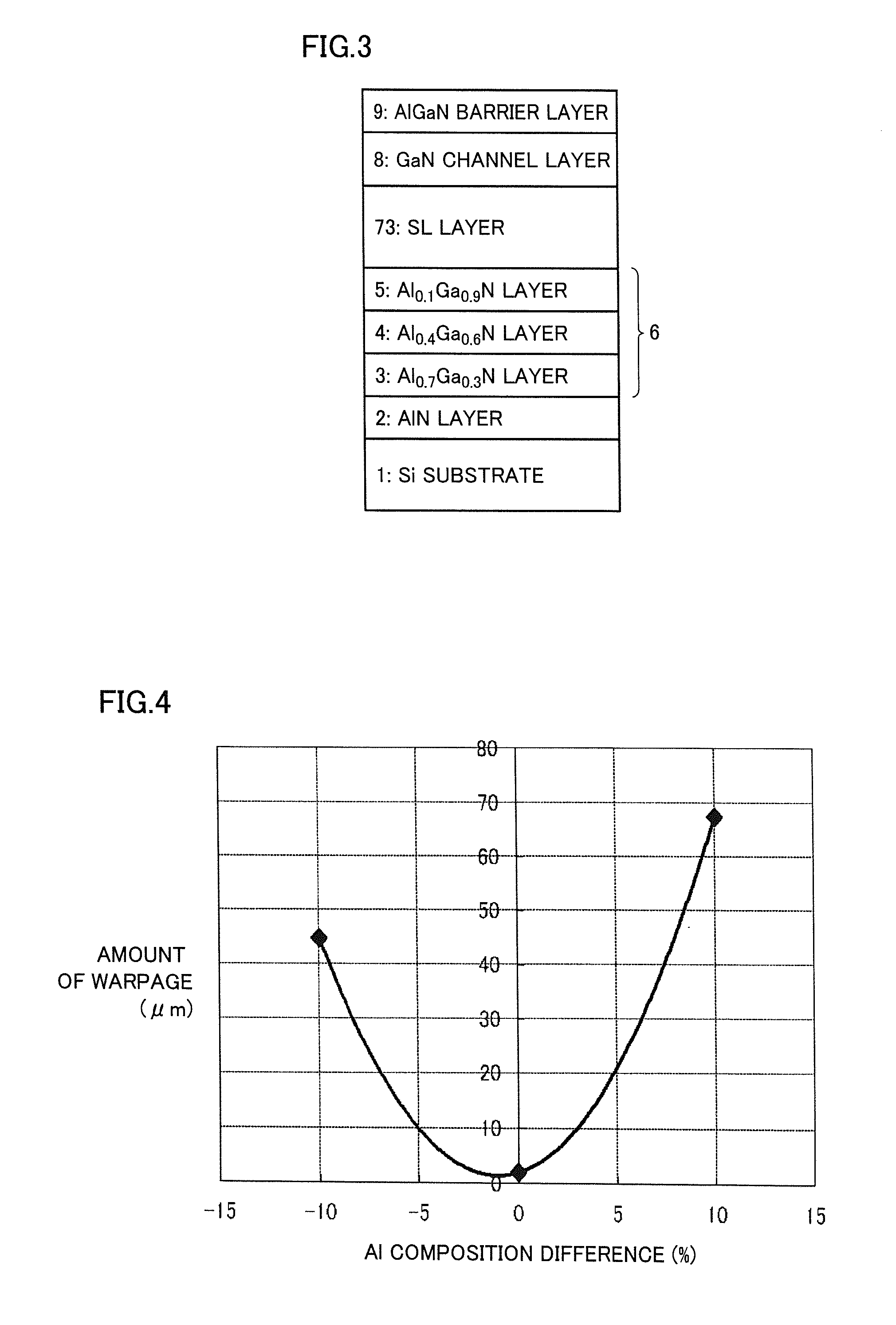

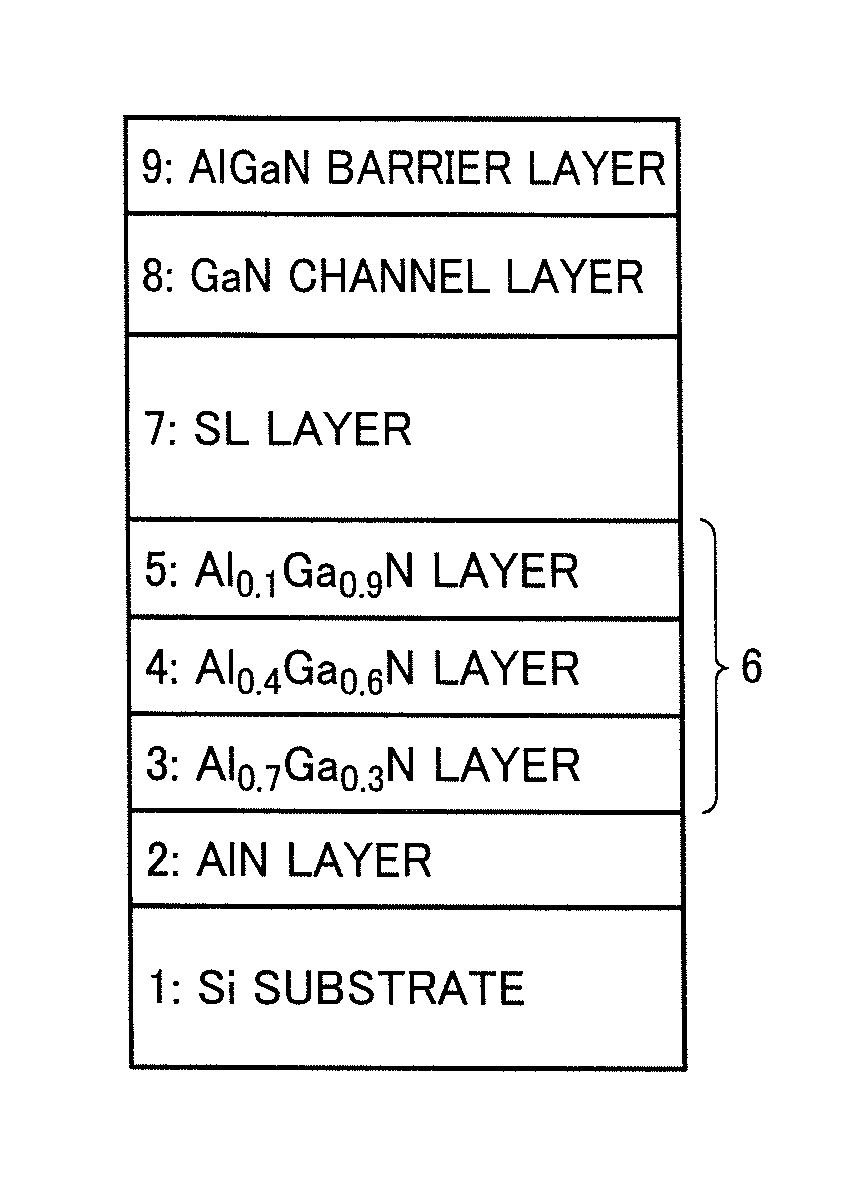

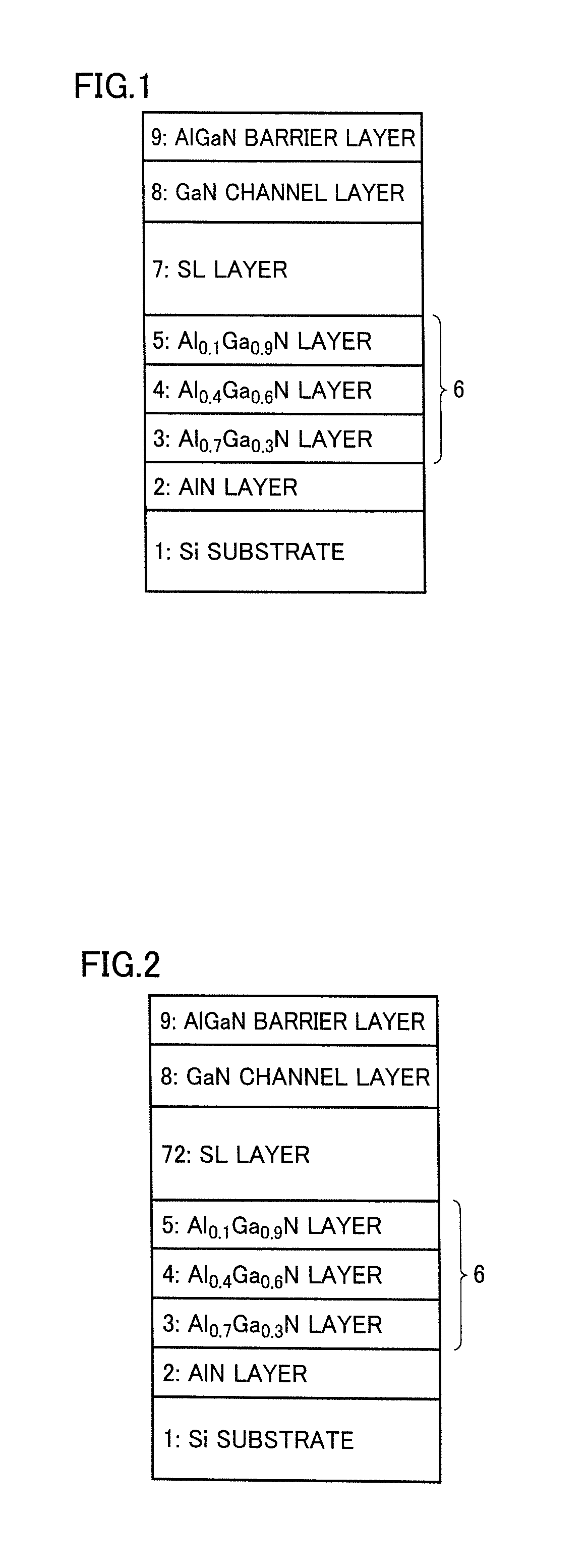

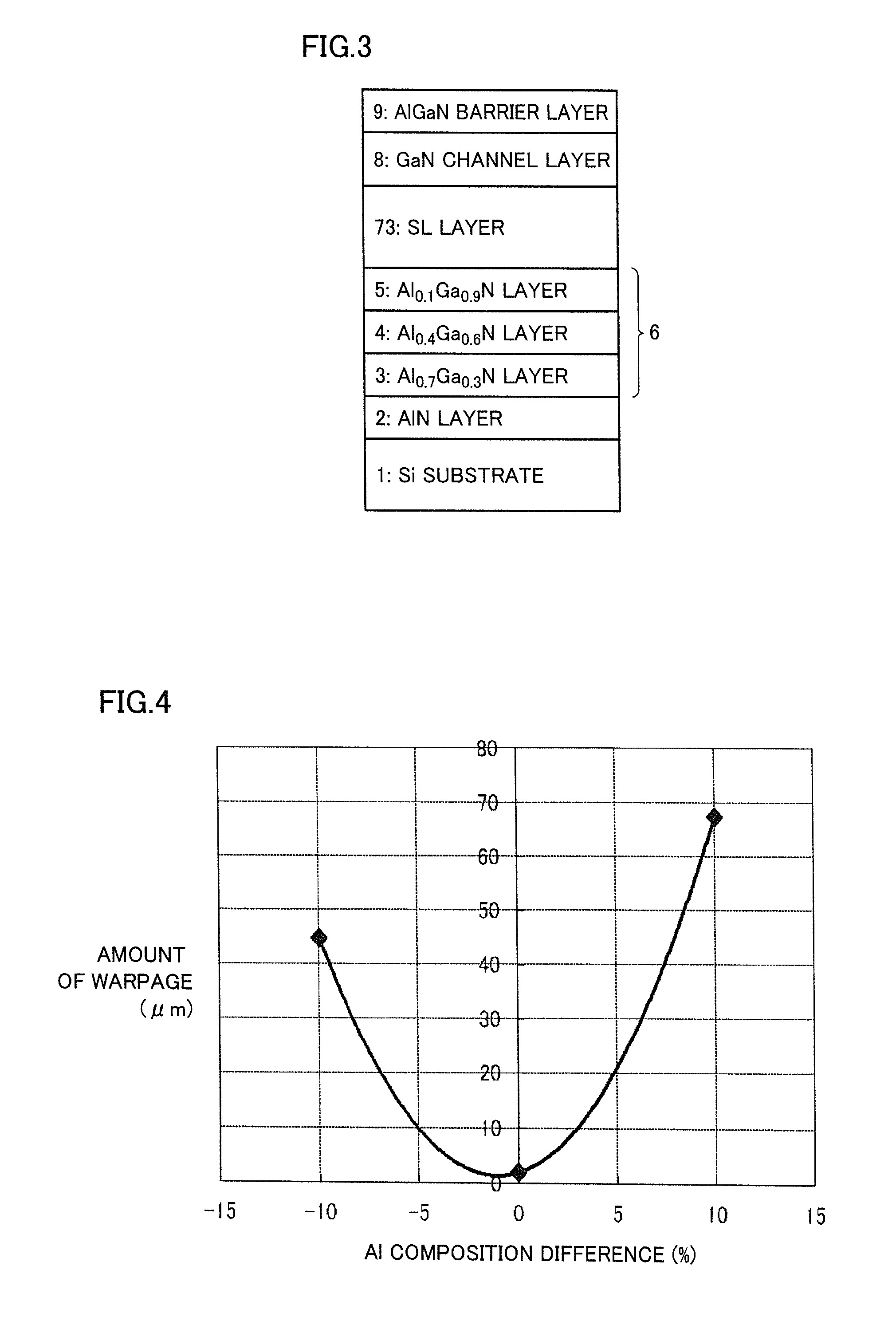

Epitaxial wafer including nitride-based semiconductor layers

InactiveUS20130020581A1Improve warpageHigh crystallinitySemiconductor/solid-state device manufacturingSemiconductor devicesNitrideSemiconductor

An epitaxial wafer including nitride-based semiconductor layers usable for a hetero-junction field effect type transistor, includes a first buffer layer of AlN or AlON, a second buffer layer of AlxGa1-xN having its Al composition ratios decreased in a stepwise fashion, a third buffer layer including a multilayer of repeatedly stacked AlaGa1-aN layers / AlbGa1-bN layers disposed on the second buffer layer, a GaN channel layer, and an electron supply layer in this order on a Si substrate, wherein the Al composition ratio x in the uppermost part of the second buffer layer is in a range of 0≦x≦0.3.

Owner:SHARP KK

Bone block assemblies and their use in assembled bone-tendon-bone grafts

ActiveUS7763071B2Add featureHigh tensile strengthSuture equipmentsSkin implantsBone CortexBone tendon bone

The present invention has multiple aspects. In its simplest aspect, the present invention is directed to an intermediate bone block comprising a machined segment of cortical bone, cancellous bone or both, the intermediate having a face comprising one to ten compression surfaces and one to ten cavities, the compression surfaces suitable for compressing soft tissue, the cavities for receiving and holding overflow soft tissue. The cavities are preferably channels, and more preferably channels having an omega cross-sectional profile. The invention is also directed to bone block assemblies suitable for binding to a soft tissue to form an implantable graft, and to such implantable grafts. A particularly preferred graft is a bone-tendon-bone graft.

Owner:RTI BIOLOGICS INC

Intermediate bone block and its use in bone block assemblies and assembled bone-tendon-bone grafts

ActiveUS20060200236A1Enhanced gripping featureHigh tensile strengthBone implantLigamentsBone CortexBone tendon bone

The present invention has multiple aspects. In its simplest aspect, the present invention is directed to an intermediate bone block comprising a machined segment of cortical bone, cancellous bone or both, the intermediate having a face comprising one to ten compression surfaces and one to ten cavities, the compression surfaces suitable for compressing soft tissue, the cavities for receiving and holding overflow soft tissue. The cavities are preferably channels, and more preferably channels having an omega cross-sectional profile. Surprisingly, the cavities and channels, which reduced the compressed surface area between the intermediate bone block and the tendon, significantly improved tendon load at failure. In standardized tests, an intermediate bone block of this invention, when combined with high surface area bone blocks of the prior art bone blocks, unexpectedly increased their load at failure. The invention is also directed to bone block assemblies suitable for binding to a soft tissue to form an implantable graft, and to such implantable grafts. A particularly preferred graft is a bone-tendon-bone graft.

Owner:RTI BIOLOGICS INC

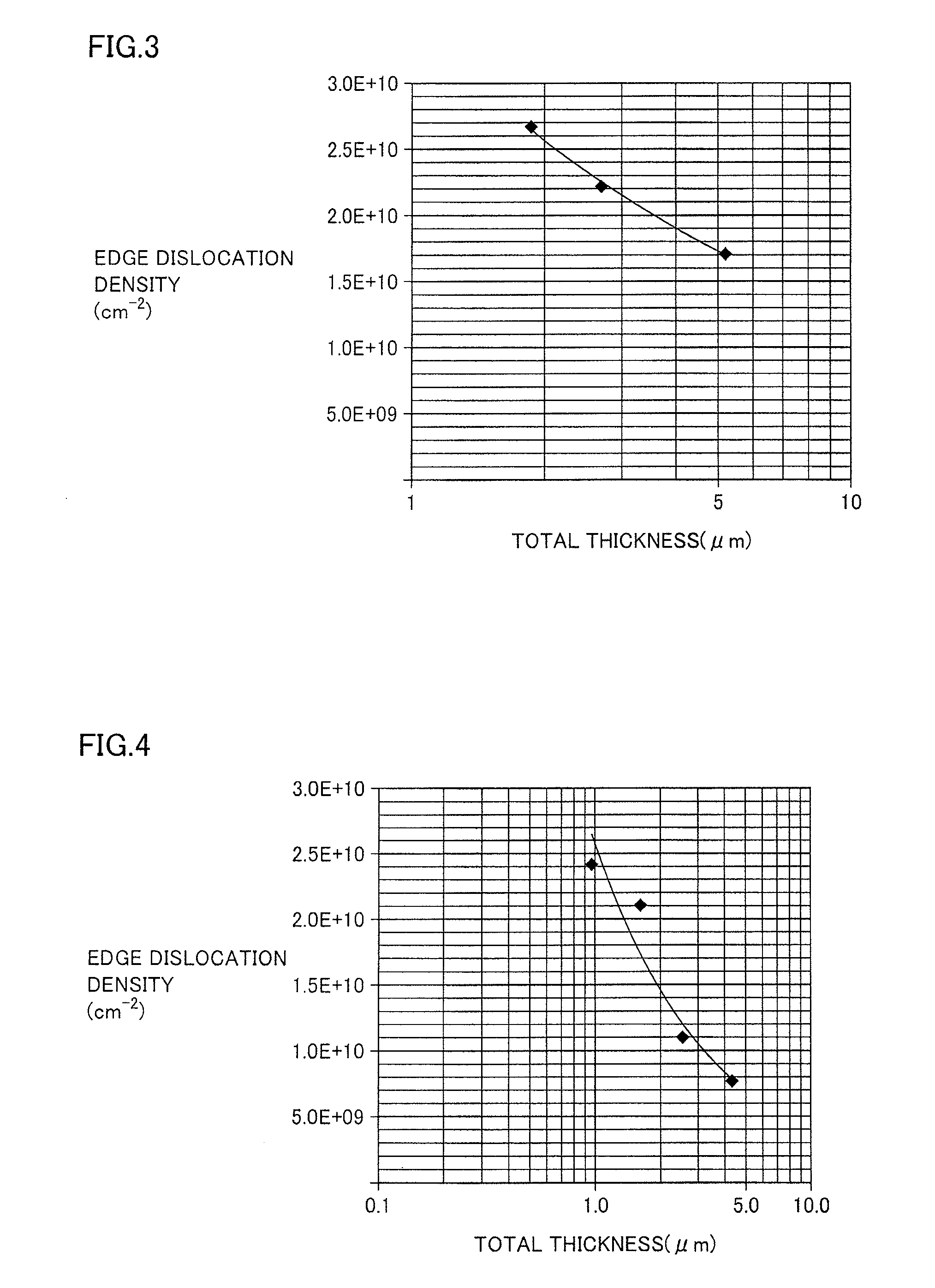

Epitaxial wafer for heterojunction type field effect transistor

ActiveUS20140353587A1Reduce dislocation densityReduce edgeSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionEngineering

An epitaxial wafer for a heterojunction type FET includes an AlN primary layer, a stepwisely composition-graded buffer layer structure, a superlattice buffer layer structure, a GaN channel layer, and a nitride semiconductor electron supply layer, which are sequentially provided on a Si substrate, the stepwisely composition-graded buffer layer structure including a plurality of AlGaN buffer layers provided on each other such that an Al composition ratio is sequentially reduced, an uppermost layer thereof having a composition of AlxGa1—xN (0<x), a plurality of sets of an AlyGa1−yN (y≦1) superlattice constituting layer and an AlzGa1−zN (0<z<y) superlattice constituting layer being provided on each other alternately starting from one of the AlyGa1−yN superlattice constituting layer and the AlzGa1−zN superlattice constituting layer in the superlattice buffer layer structure, the AlxGa1−xN buffer layer and the AlzGa1−zN superlattice constituting layer satisfying x−0.05≦z≦x+0.05.

Owner:MURATA MFG CO LTD

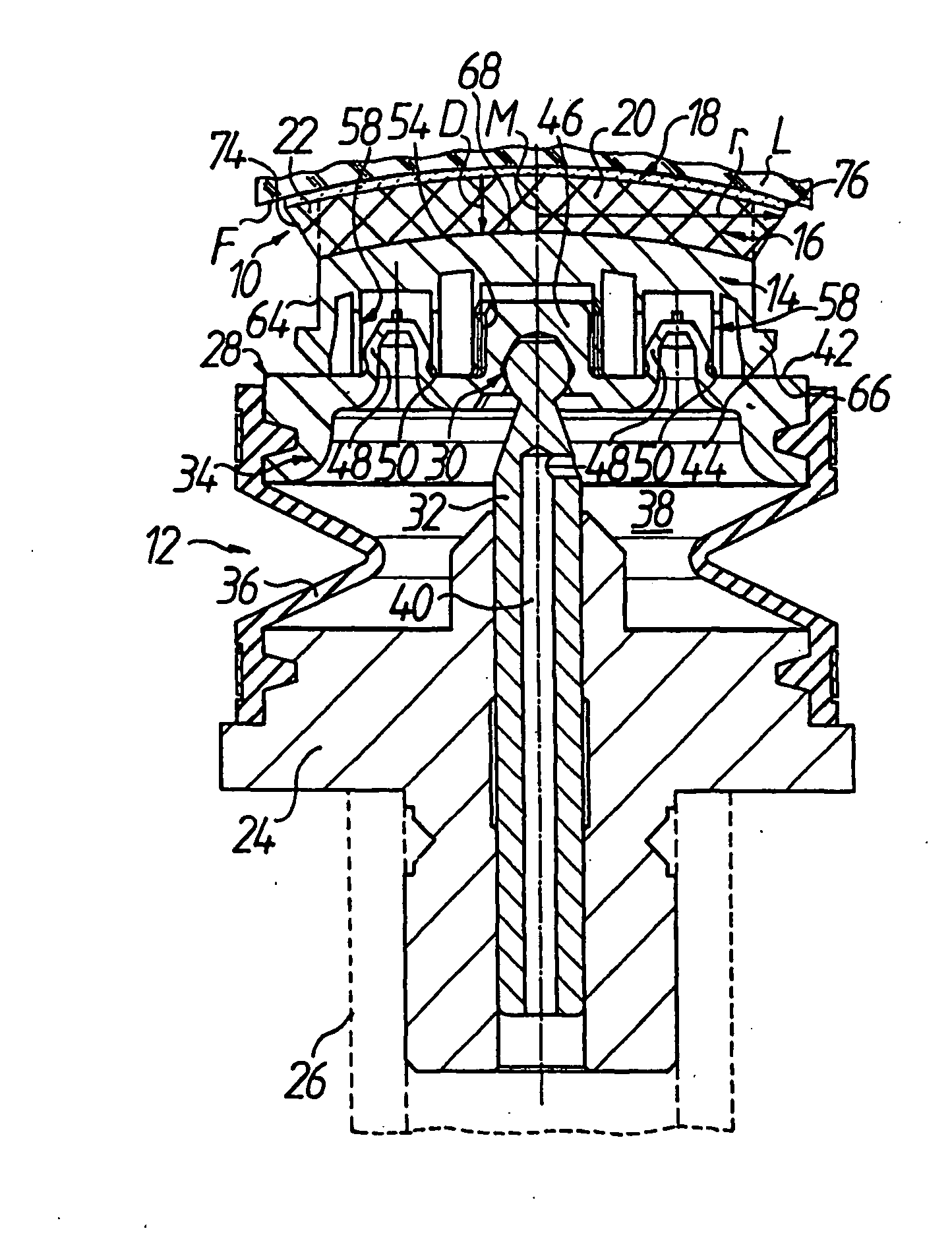

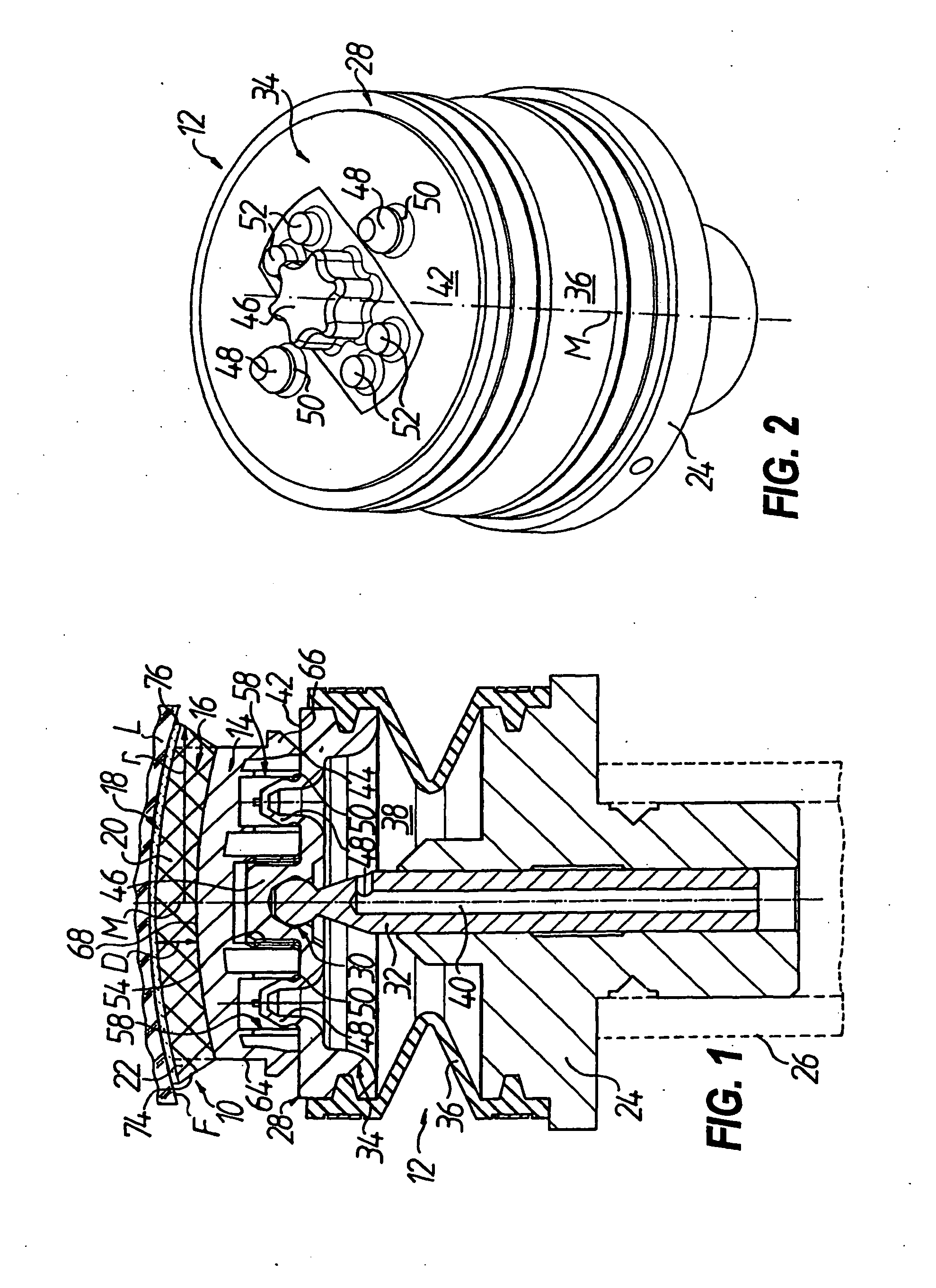

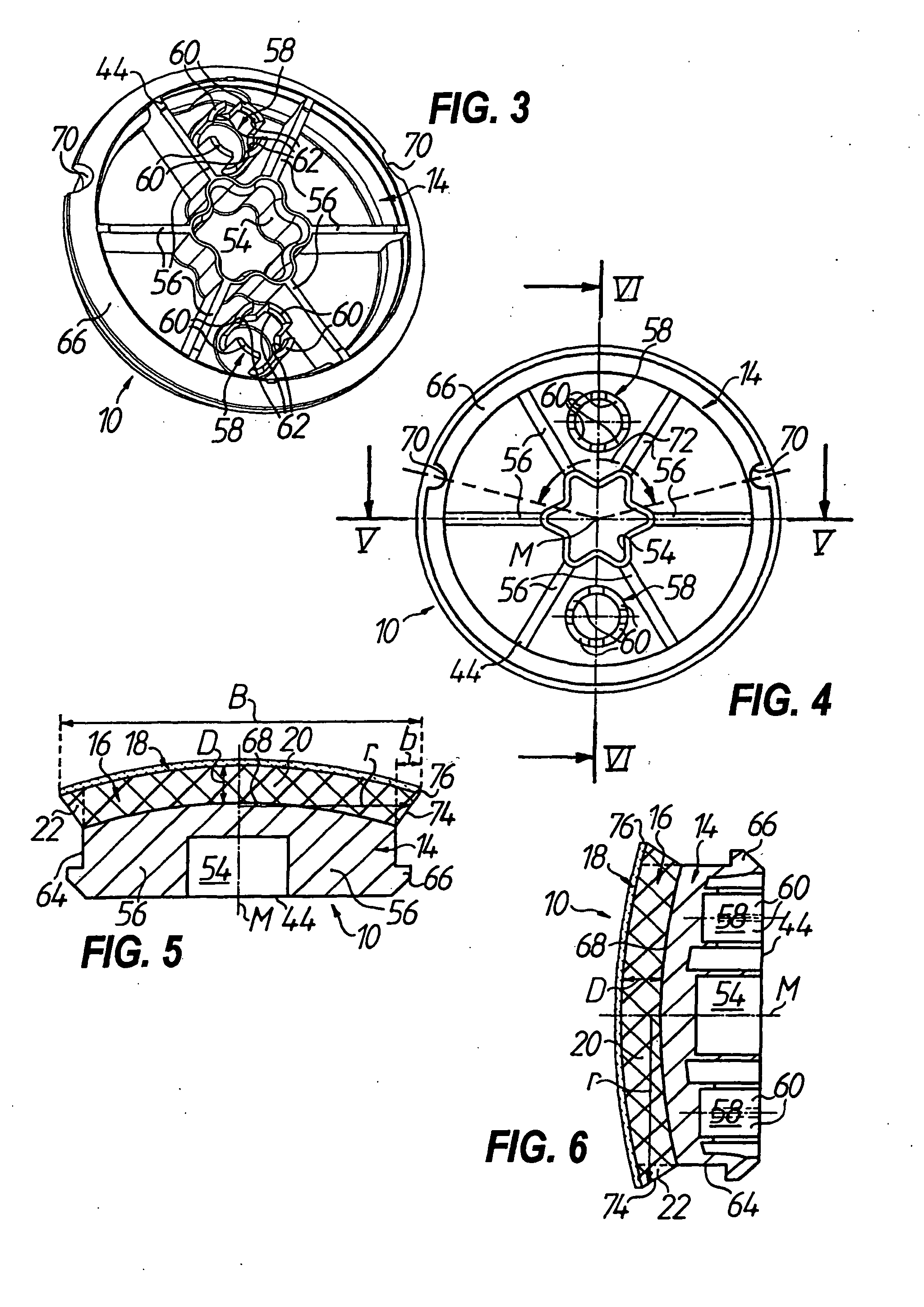

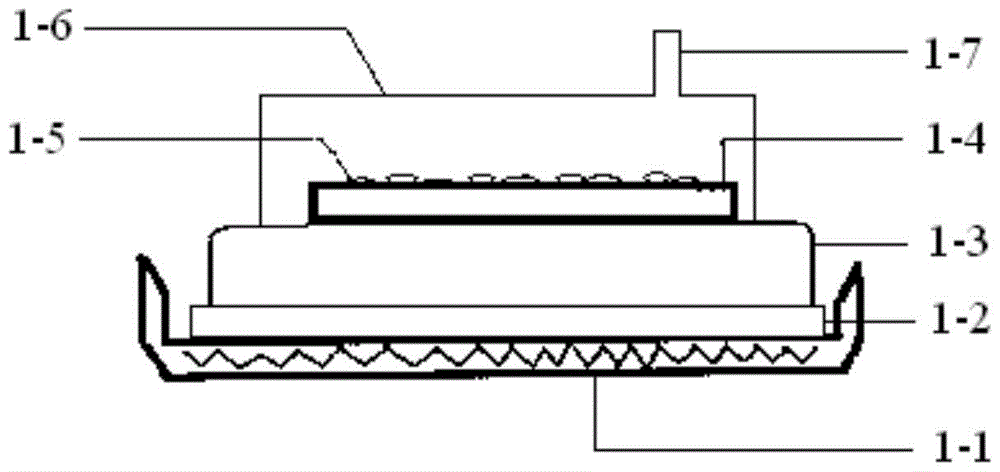

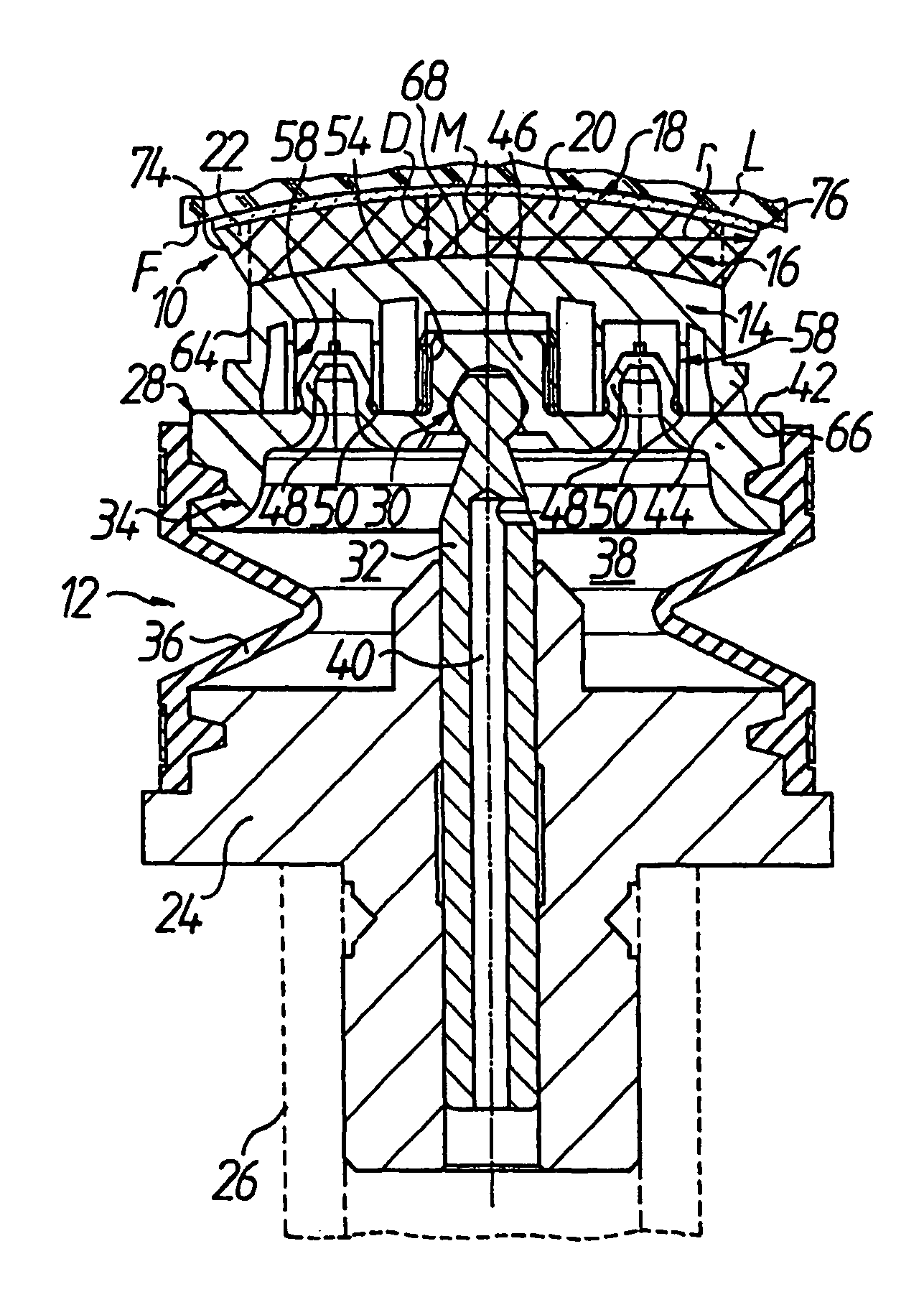

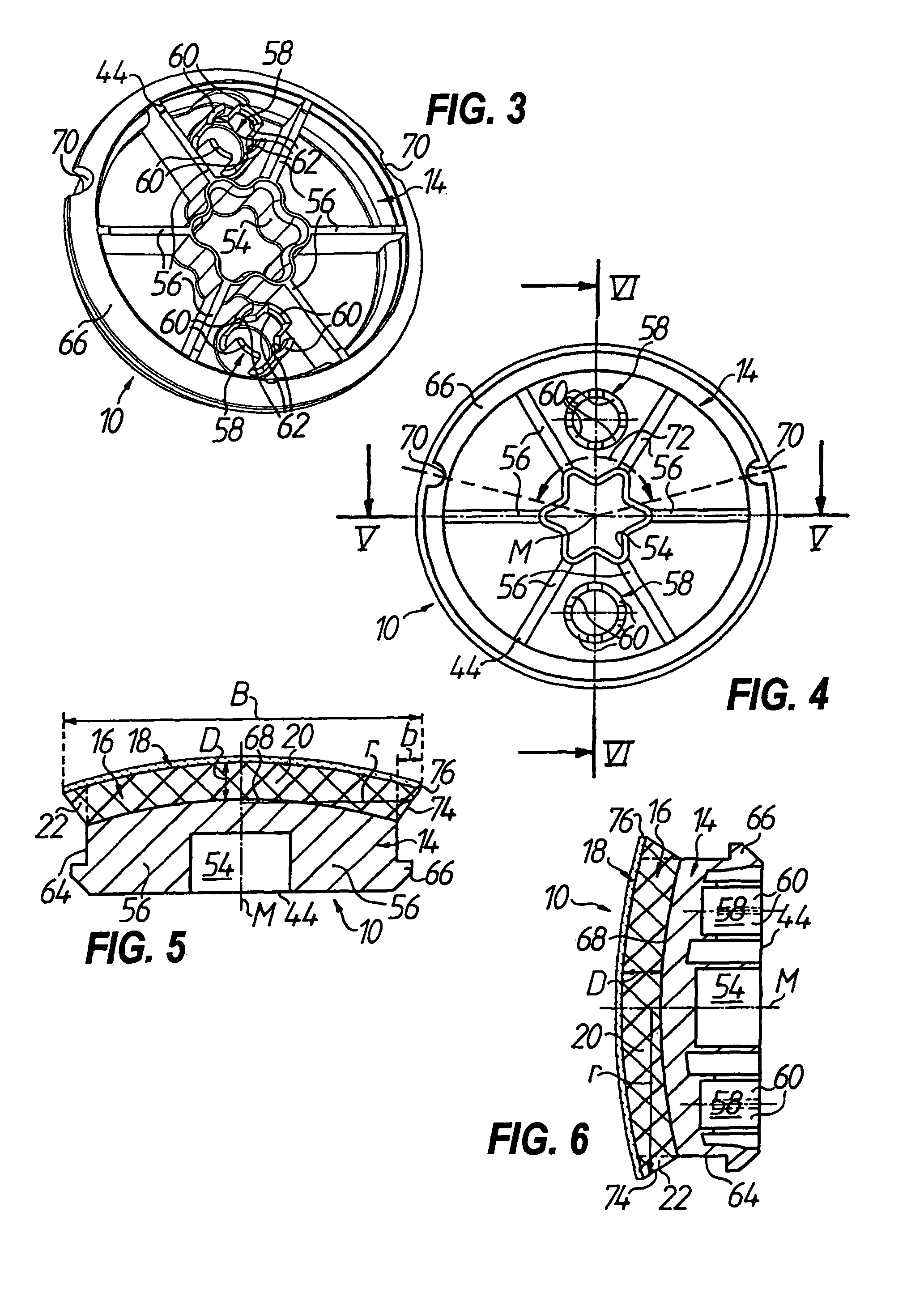

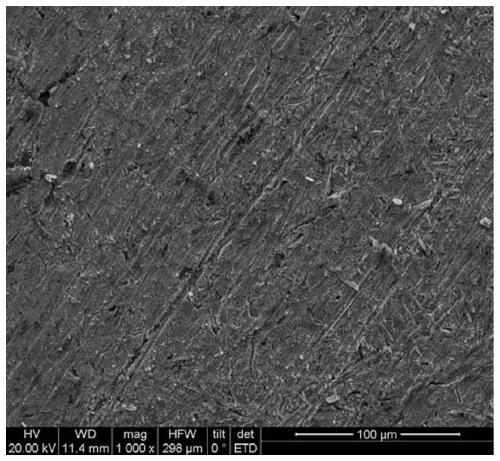

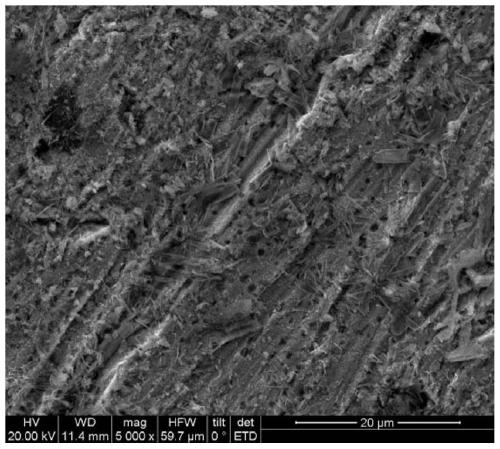

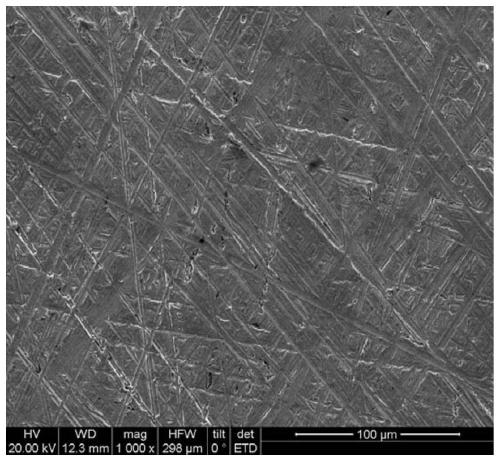

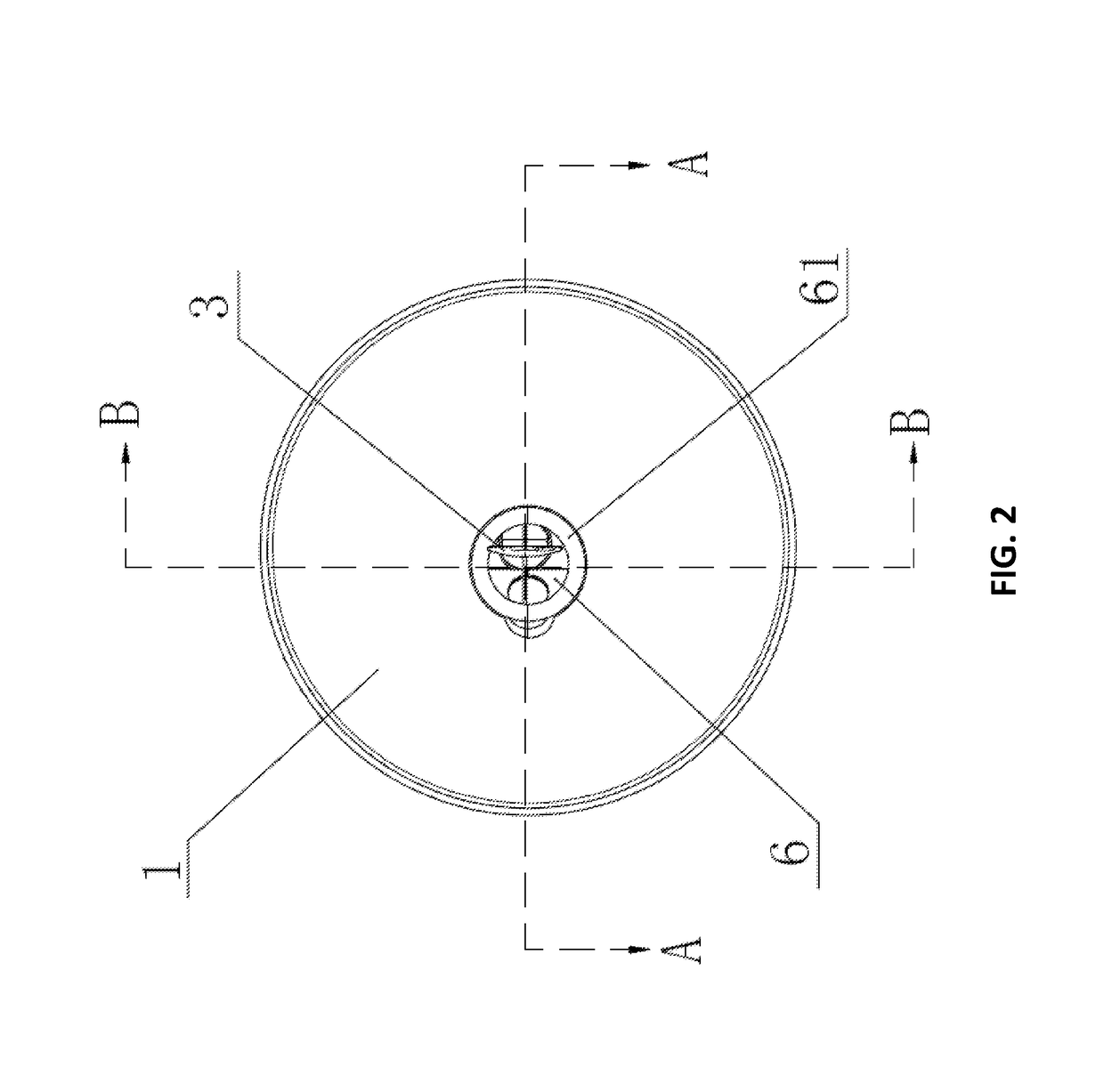

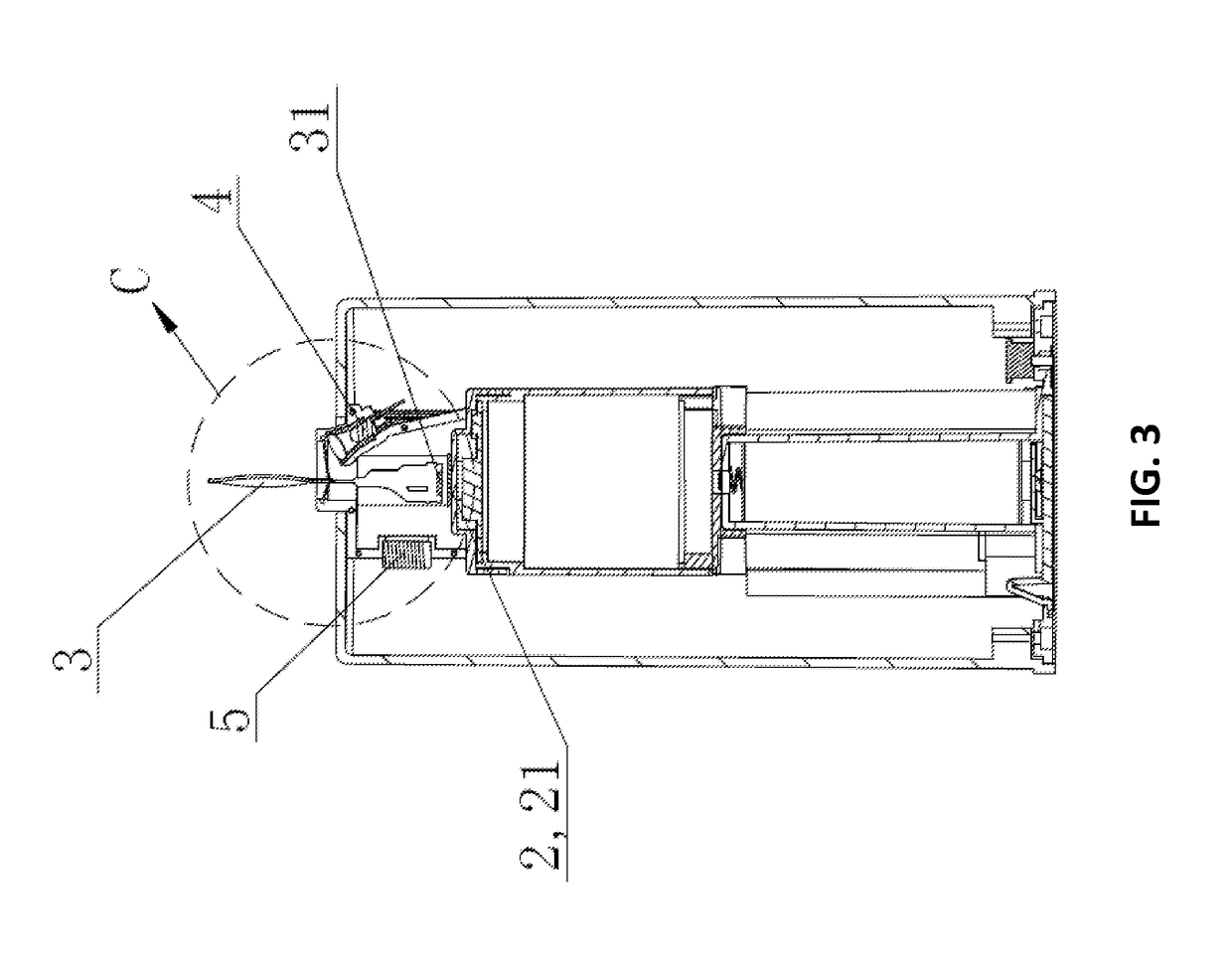

Polishing disc for a tool for the fine machining of optically active surfaces particularly on spectacle lenses and method for its production

ActiveUS20080305723A1Rapid and accurate productionDegradation takes placeGrinding machine componentsFlexible-parts wheelsMachined surfaceEngineering

A polishing disc for a tool for the fine machining of optically active surfaces, particularly on spectacle lenses as workpieces, comprises a main body which has a center axis and on which there is fixed an intermediate layer which is softer than the main body and on which a polishing agent carrier rests. The intermediate layer has, with respect to the center axis, a radial inner region of substantially constant axial thickness and an adjoining radial outer region. The latter is formed or is fixed to the main body in a particular way so as to prevent the edge of the polishing disc from being imprinted on the machined surface of the workpiece in the form of very fine, scratch-like microstructures. Also proposed is a simple method which can be used to produce such a polishing disc.

Owner:SATISLOH AG

Bone block assemblies and their use in assembled bone-tendon-bone grafts

ActiveUS20060212036A1Enhanced gripping featureHigh tensile strengthSuture equipmentsSkin implantsBone CortexBone tendon bone

The present invention has multiple aspects. In its simplest aspect, the present invention is directed to an intermediate bone block comprising a machined segment of cortical bone, cancellous bone or both, the intermediate having a face comprising one to ten compression surfaces and one to ten cavities, the compression surfaces suitable for compressing soft tissue, the cavities for receiving and holding overflow soft tissue. The cavities are preferably channels, and more preferably channels having an omega cross-sectional profile. Surprisingly, the cavities and channels, which reduced the compressed surface area between the intermediate bone block and the tendon, significantly improved tendon load at failure. In standardized tests, an intermediate bone block of this invention, when combined with high surface area bone blocks of the prior art bone blocks, unexpectedly increased their load at failure. The invention is also directed to bone block assemblies suitable for binding to a soft tissue to form an implantable graft, and to such implantable grafts. A particularly preferred graft is a bone-tendon-bone graft.

Owner:RTI BIOLOGICS INC

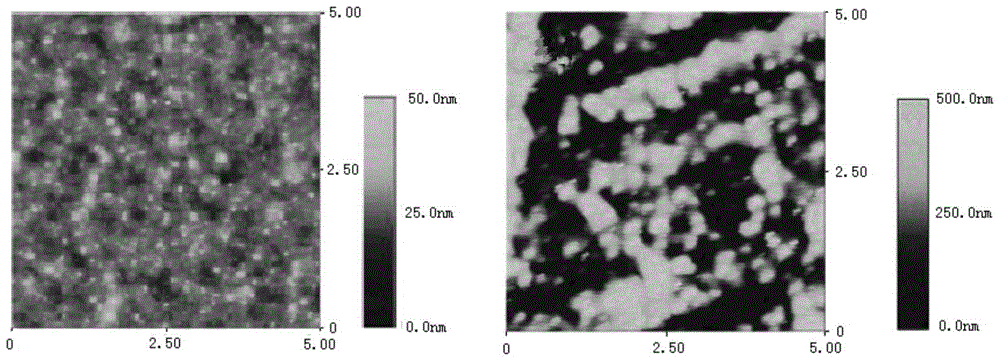

Solution film formation method and device of organic material

InactiveCN105679935ASmall differenceAlleviate unevennessSolid-state devicesSemiconductor/solid-state device manufacturingSolvent moleculeBoiling point

The invention belongs to the technical field of preparation of a film material, and discloses a solution film formation method and device of an organic material. The method comprises the following stages of dissolving the organic material in a mixed solvent containing a high-boiling point solvent and a low-boiling point solvent, and depositing the organic material on a substrate by a film formation technology to obtain a liquid film; and carrying out normal-pressure evaporation on the substrate containing the liquid film under conditions of rotation, variable frequency vibration and programmable temperature rise to remove the low-boiling point solvent, stopping rotating and vibrating, evaporating the high-boiling solvent under conditions of vacuum and programmable temperature rise to obtain an organic material film. The substrate is shaken in a reciprocating way through rotation and variable frequency vibration, so that the solution keeps flowing, the difference between the edge and the middle of the solution is reduced, and the difference of the surface and the interior of the solution is reduced; and meanwhile, the thermal motion of solvent molecules is accelerated by programmable temperature rise, and the film formation quality of the solvent during the drying process is improved.

Owner:SOUTH CHINA UNIV OF TECH

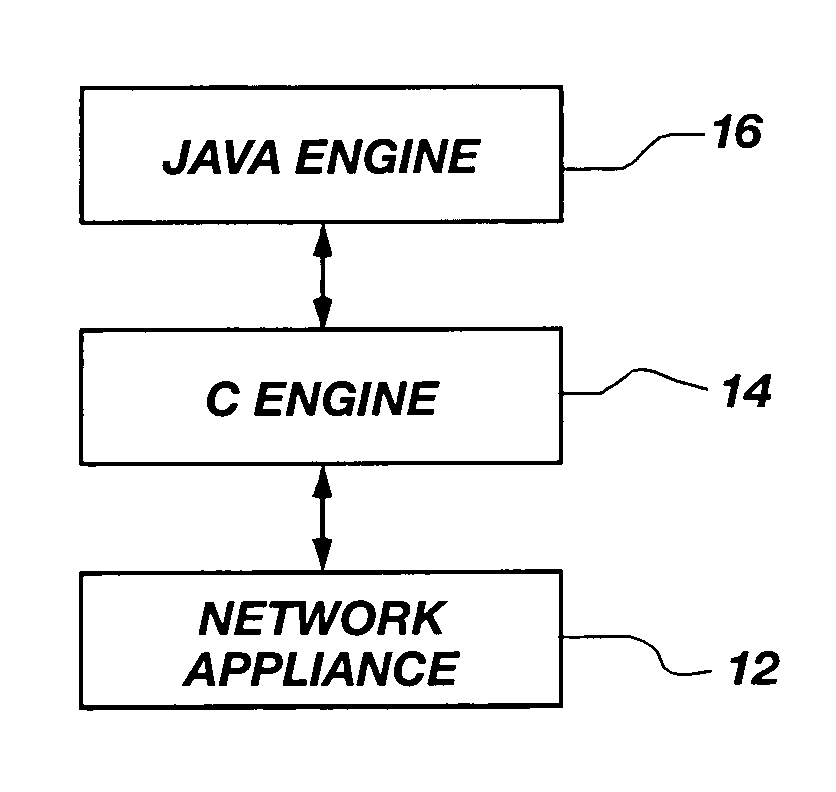

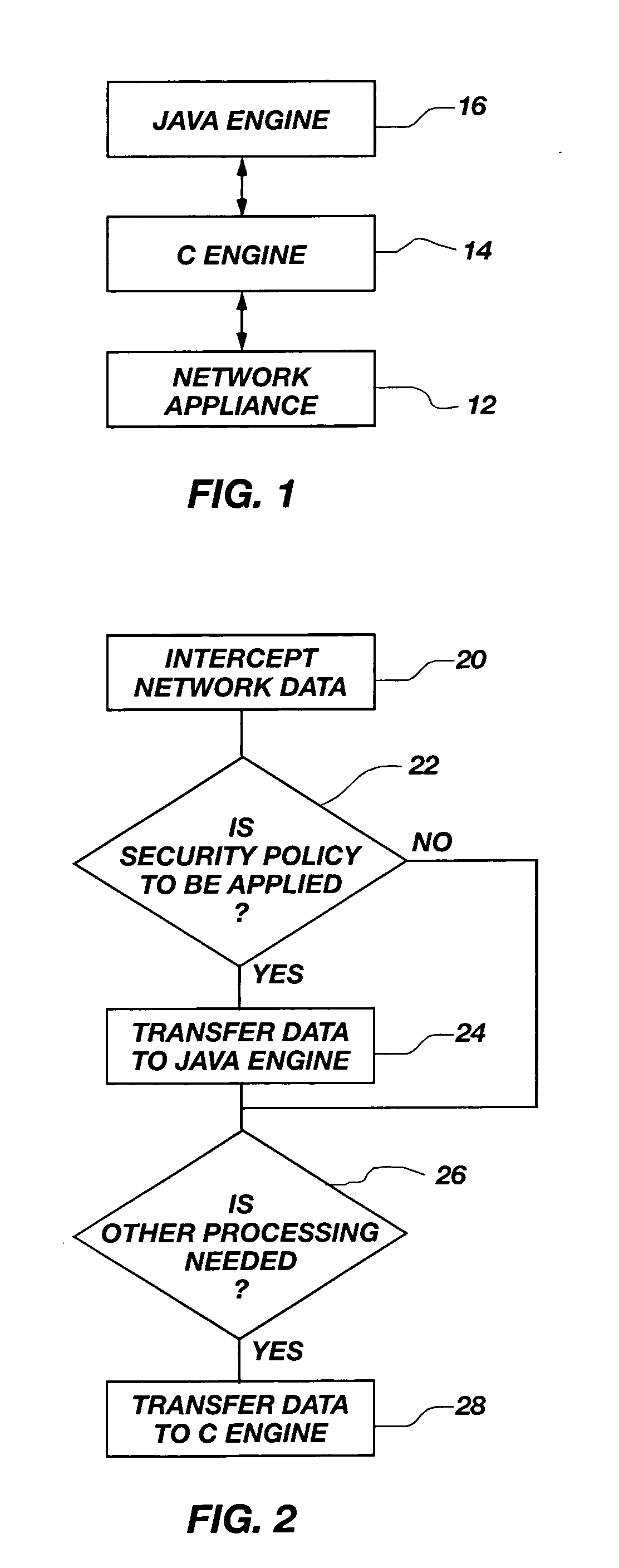

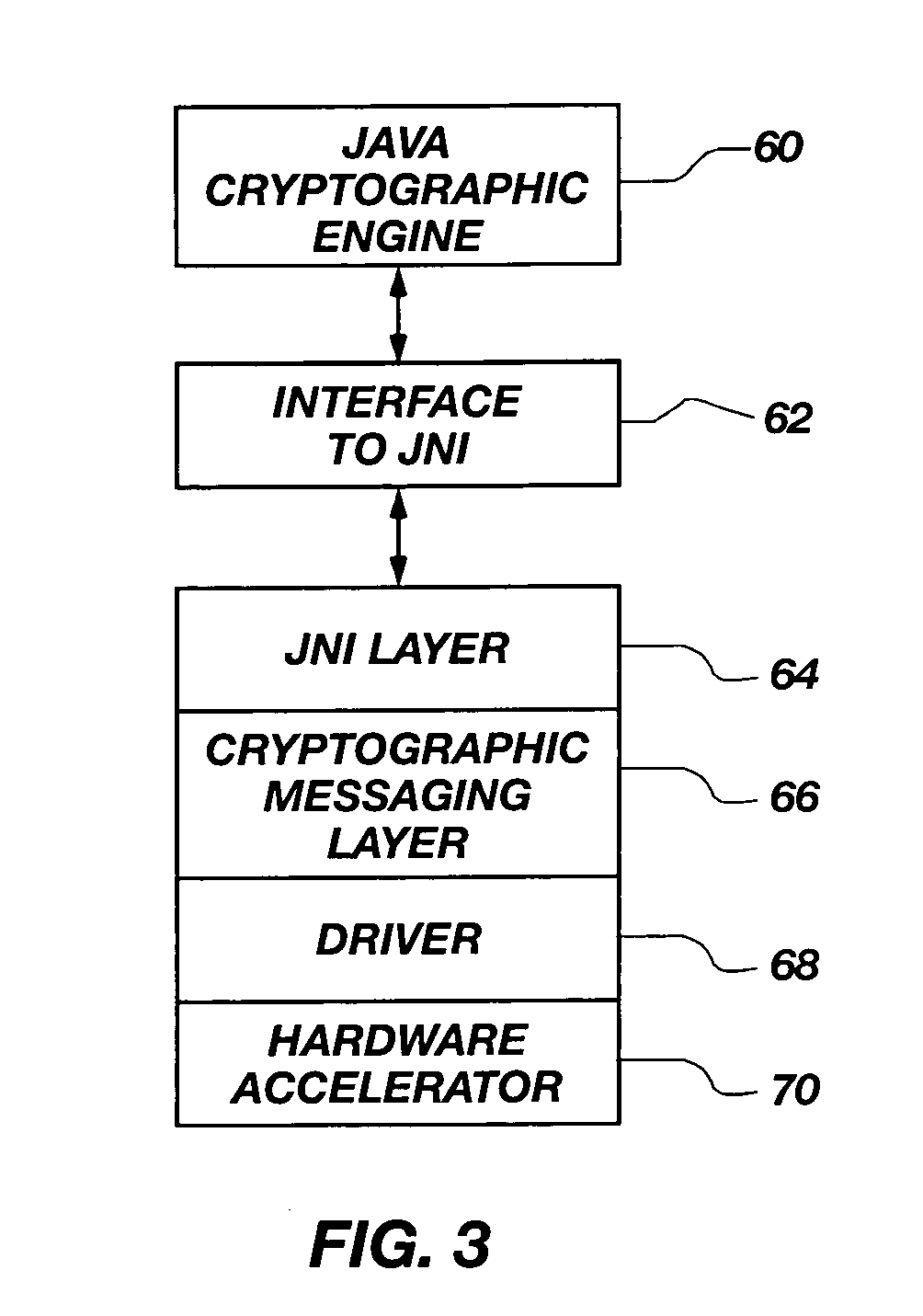

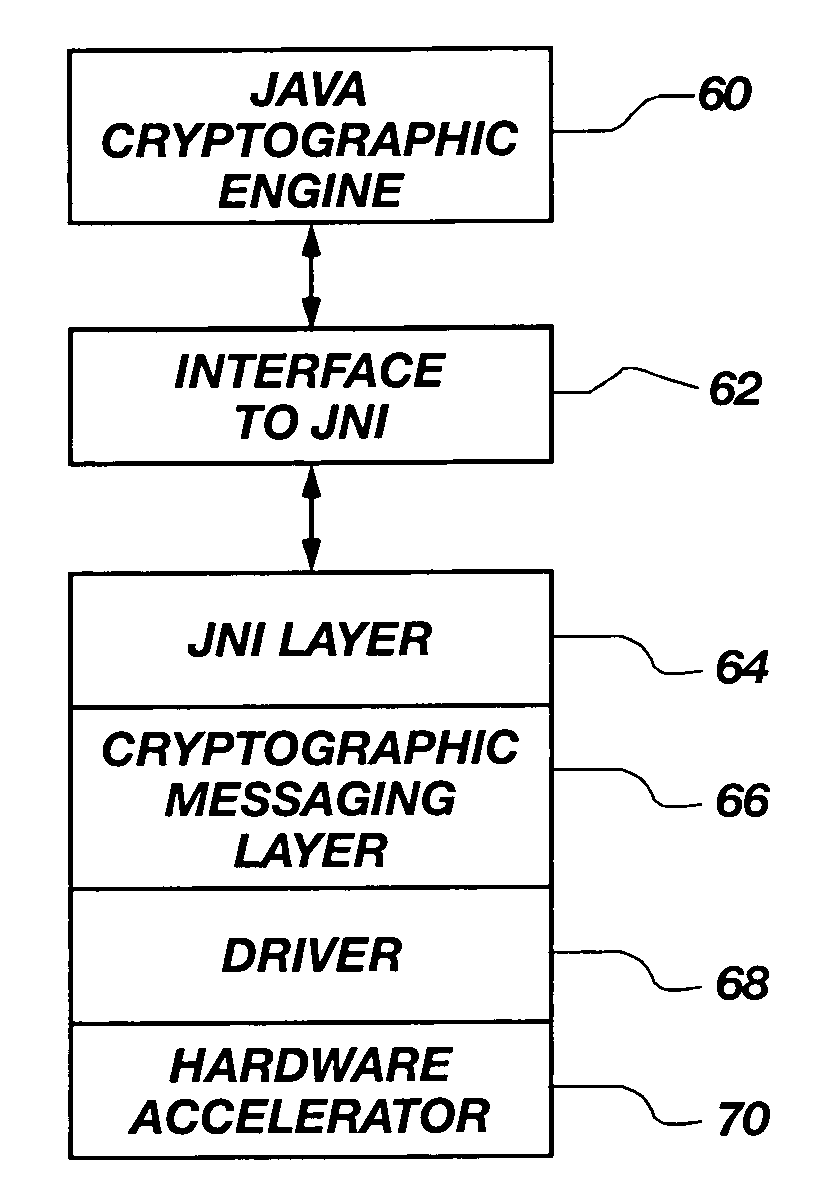

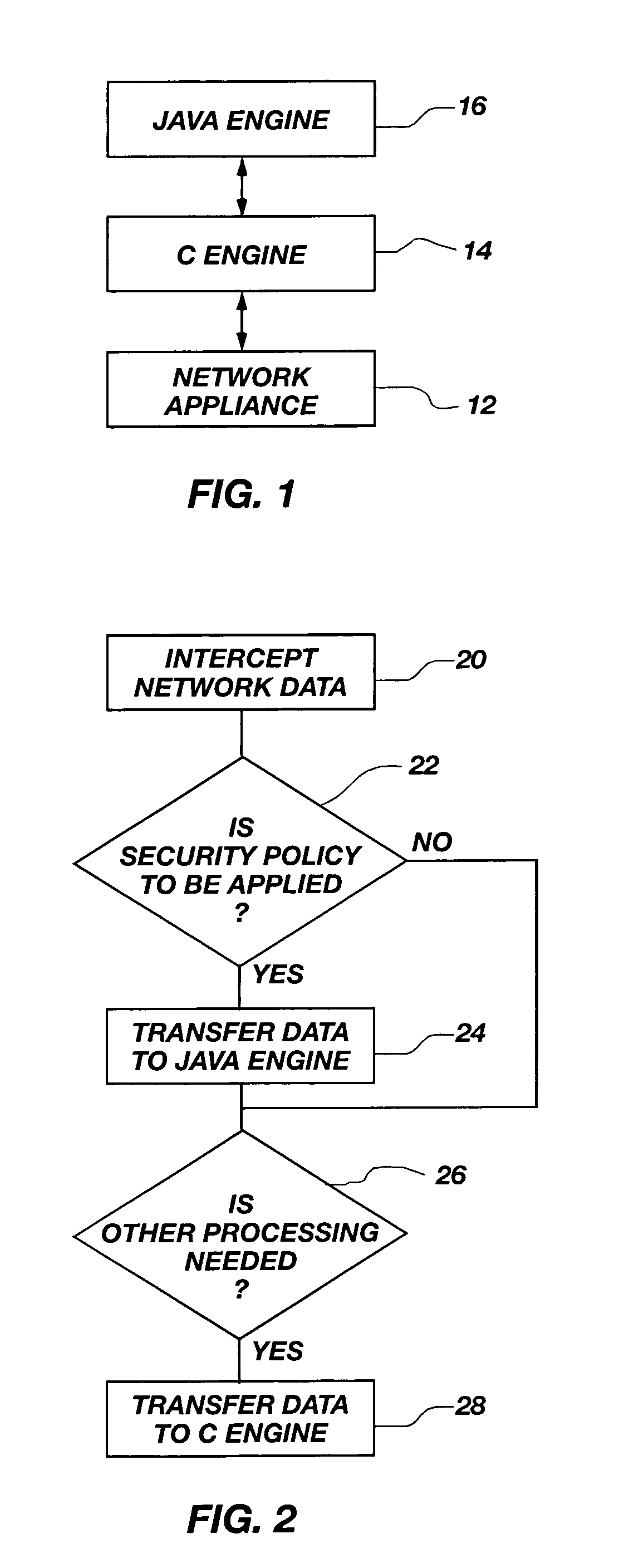

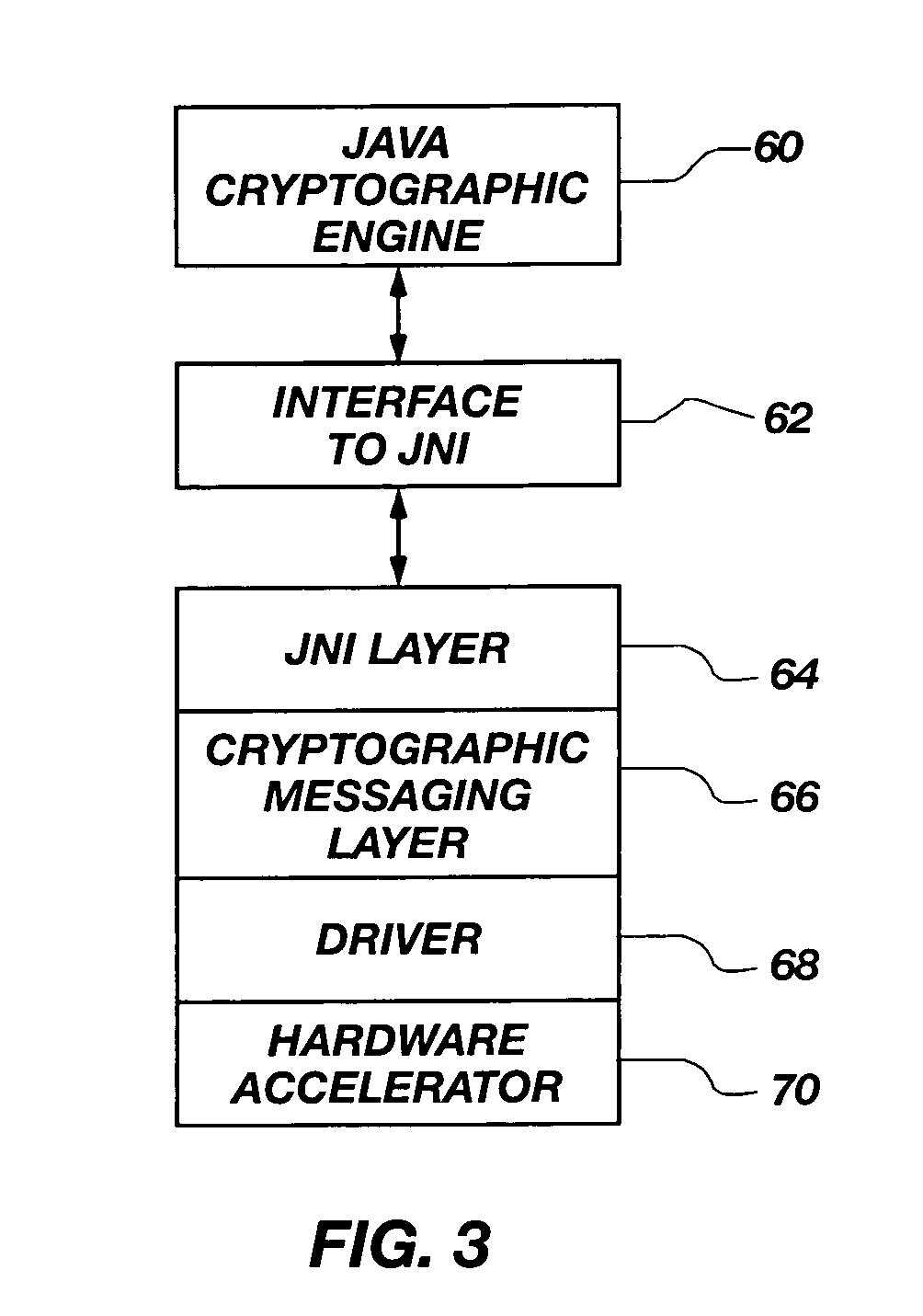

Hybrid Java-C network appliance

InactiveUS20050132210A1Quick updateReduce edgeUnauthorized memory use protectionHardware monitoringXML EncryptionIntegrated software

A network appliance that runs both C and Java integrated software to provide a flexible architecture for rapid prototyping of XML security functionality, including SSL acceleration, XML encryption, XML decryption, XML signature, and XML verification, while the network appliance continues to provide high-speed performance.

Owner:YUNIS MAMOON +2

Intermediate bone block and its use in bone block assemblies and assembled bone-tendon-bone grafts

The present invention is directed to bone block assemblies suitable for binding to a soft tissue to form an implantable graft, and to such implantable grafts. A particularly preferred graft is a bone-tendon-bone graft. In its simplest aspect, the present invention is directed to an intermediate bone block comprising a machined segment of cortical bone, cancellous bone or both.

Owner:RTI BIOLOGICS INC

Adjustable and fixed assembled bone-tendon-bone graft

ActiveUS8470038B2Add featureHigh tensile strengthBone implantLigamentsBone tendon boneBiomedical engineering

The present invention relates to a bone-tendon-bone graft and components. Embodiments of the present invention comprise an intermediate bone block that is used to adjustably secure soft tissue (e.g., tendon) in a patient. Embodiments of intermediate bone blocks of the present invention are used singly or in combination with one or more bone blocks to form a bone block assembly for securing soft tissue. The present invention further relates to an assembled bone-tendon-bone graft for implantation in humans comprising the intermediate bone block and a length of soft tissue. A bone-tendon-bone graft comprises a length of soft tissue extending from a first assembled bone block to a second bone block and then doubles back to said first assembled bone block. Depending upon the embodiment, the second bone block fixedly or slideably attaches to the length of soft tissue and facilitates it doubling back to the first assembled bone block.

Owner:RTI BIOLOGICS INC

Polishing disc for a tool for the fine machining of optically active surfaces particularly on spectacle lenses and method for its production

ActiveUS8246424B2Constant axial thicknessUniform wearFlexible-parts wheelsGrinding devicesMachined surfaceEngineering

A polishing disc for a tool for the fine machining of optically active surfaces, particularly on spectacle lenses as workpieces, comprises a main body which has a center axis and on which there is fixed an intermediate layer which is softer than the main body and on which a polishing agent carrier rests. The intermediate layer has, with respect to the center axis, a radial inner region of substantially constant axial thickness and an adjoining radial outer region. The latter is formed or is fixed to the main body in a particular way so as to prevent the edge of the polishing disc from being imprinted on the machined surface of the workpiece in the form of very fine, scratch-like microstructures. Also proposed is a simple method which can be used to produce such a polishing disc.

Owner:SATISLOH AG

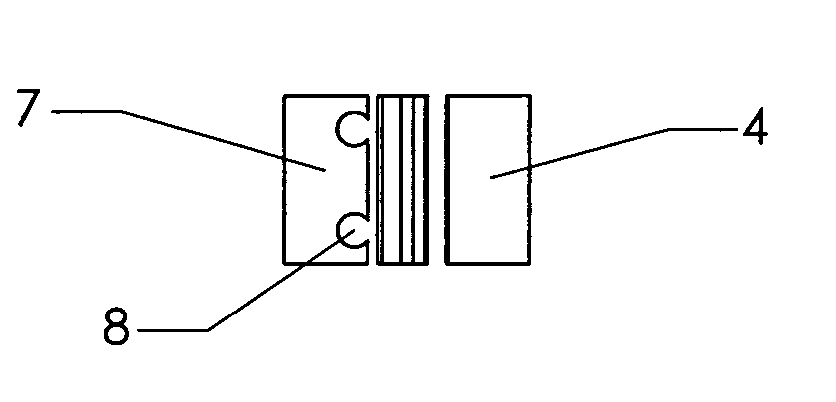

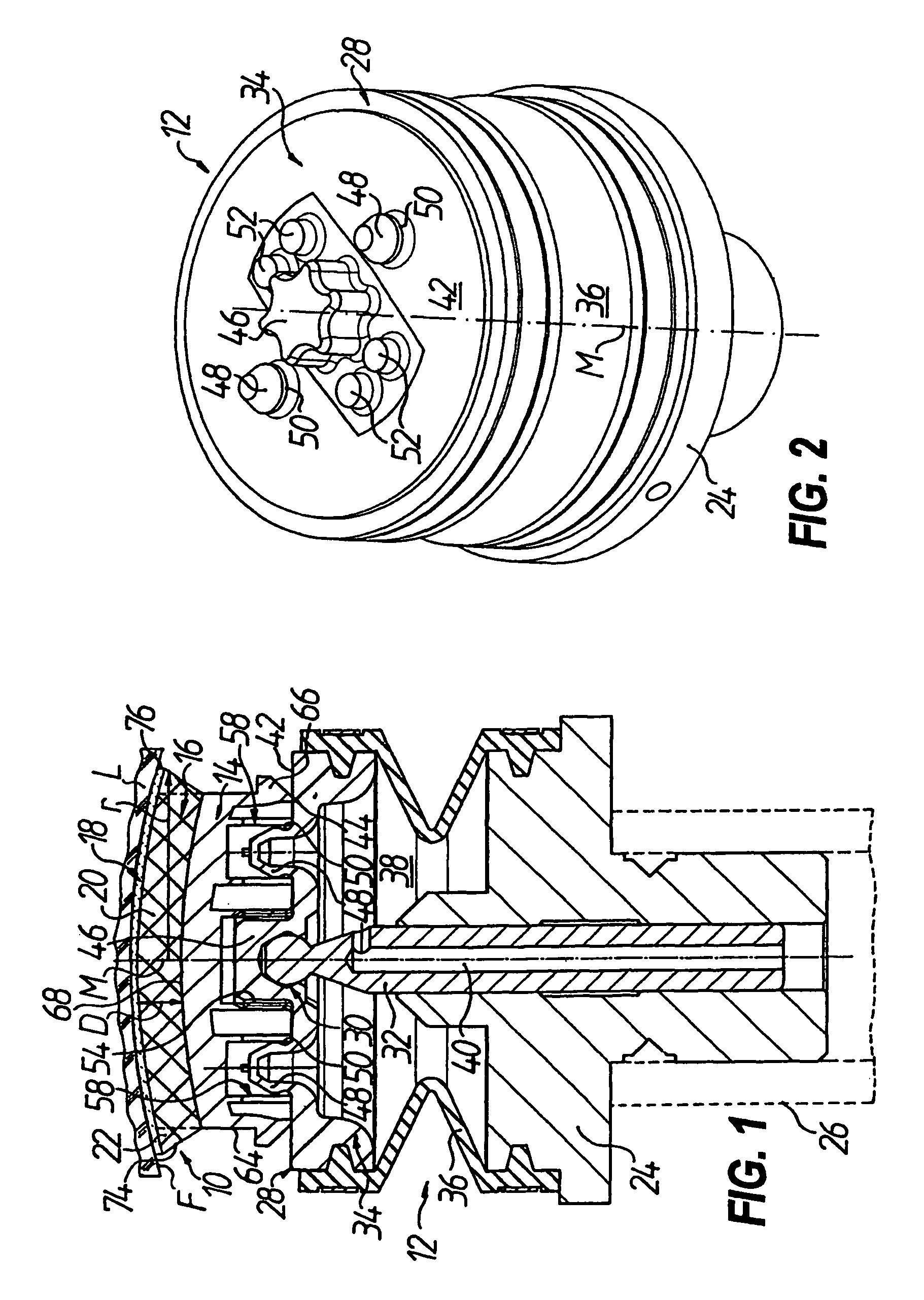

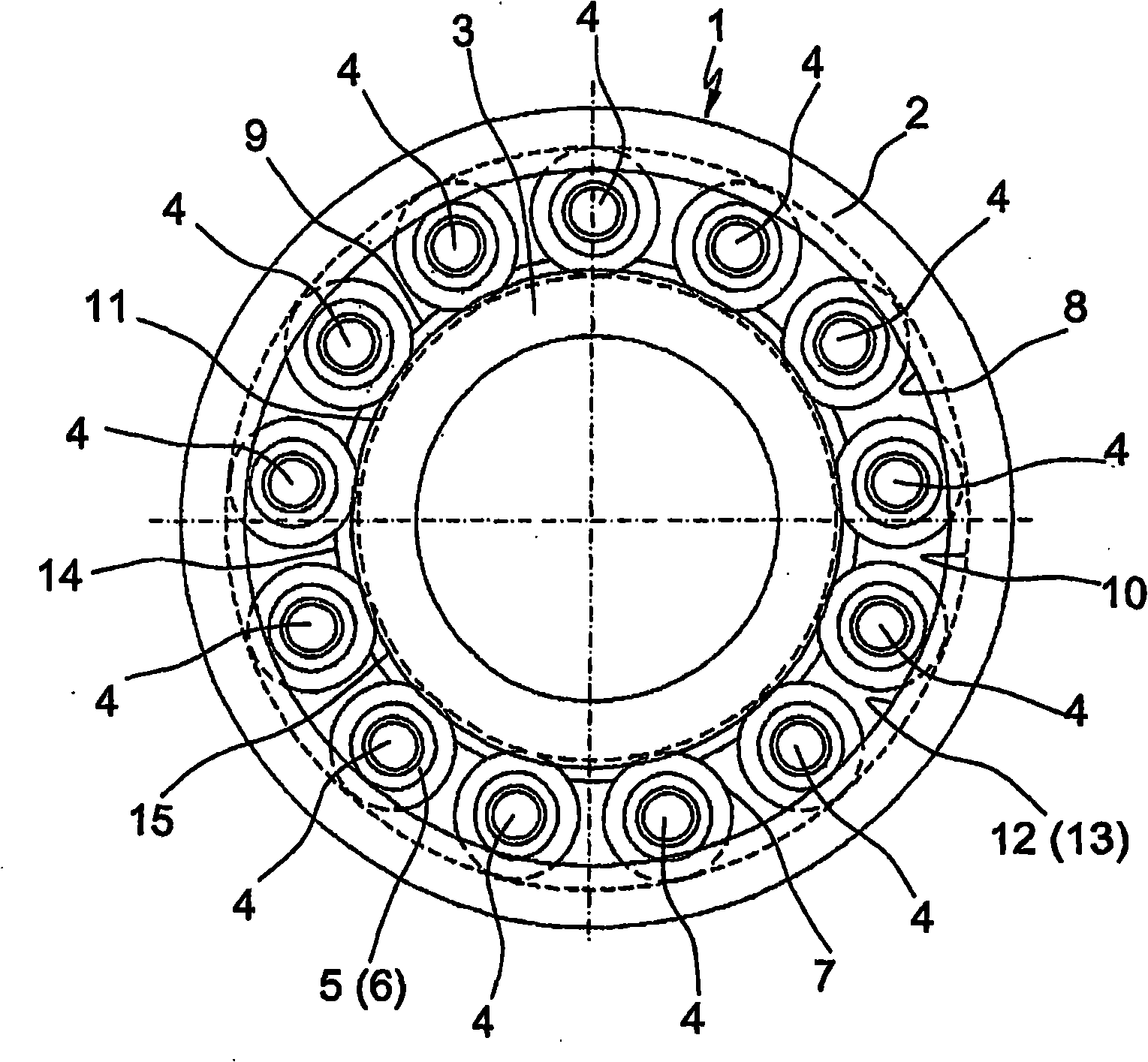

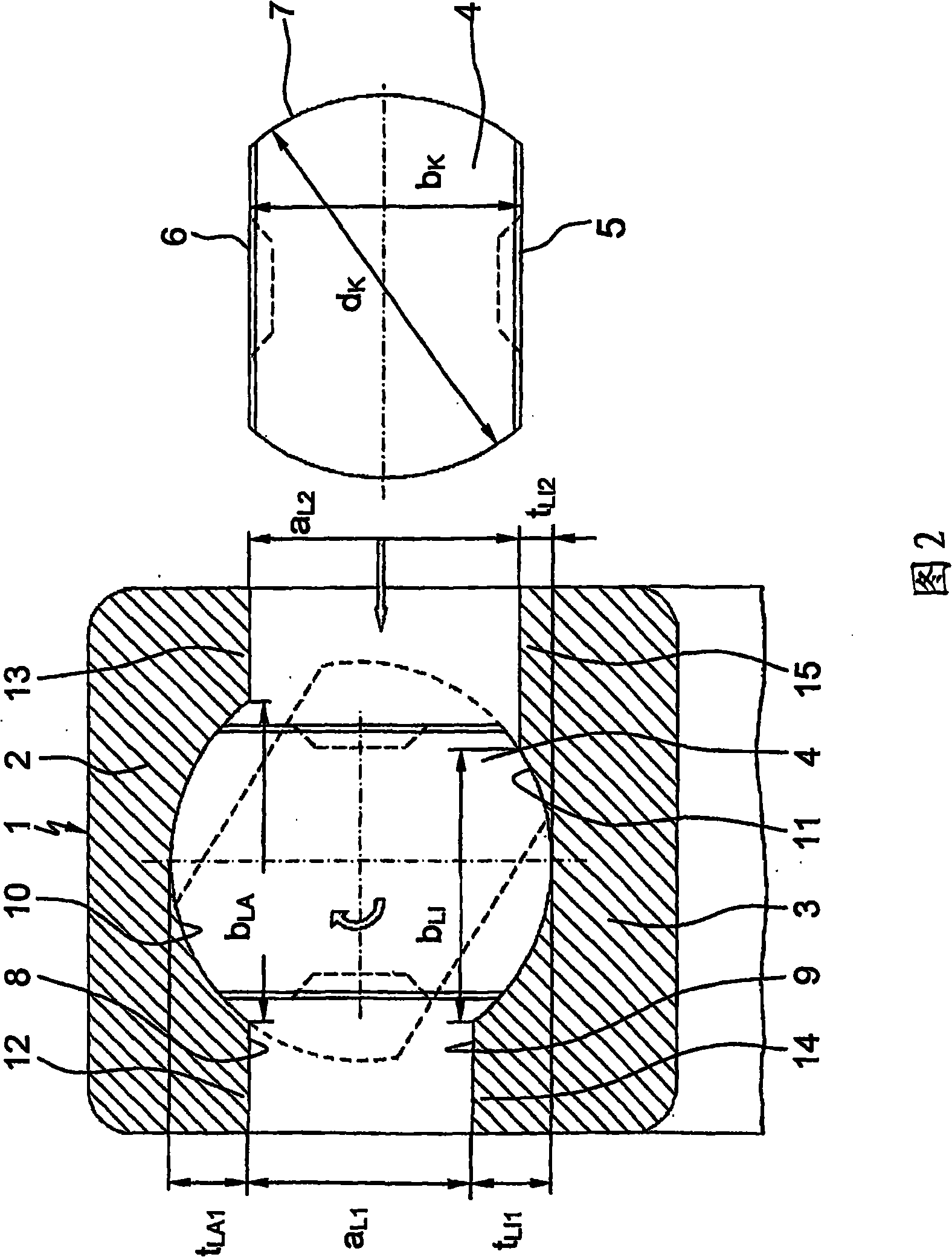

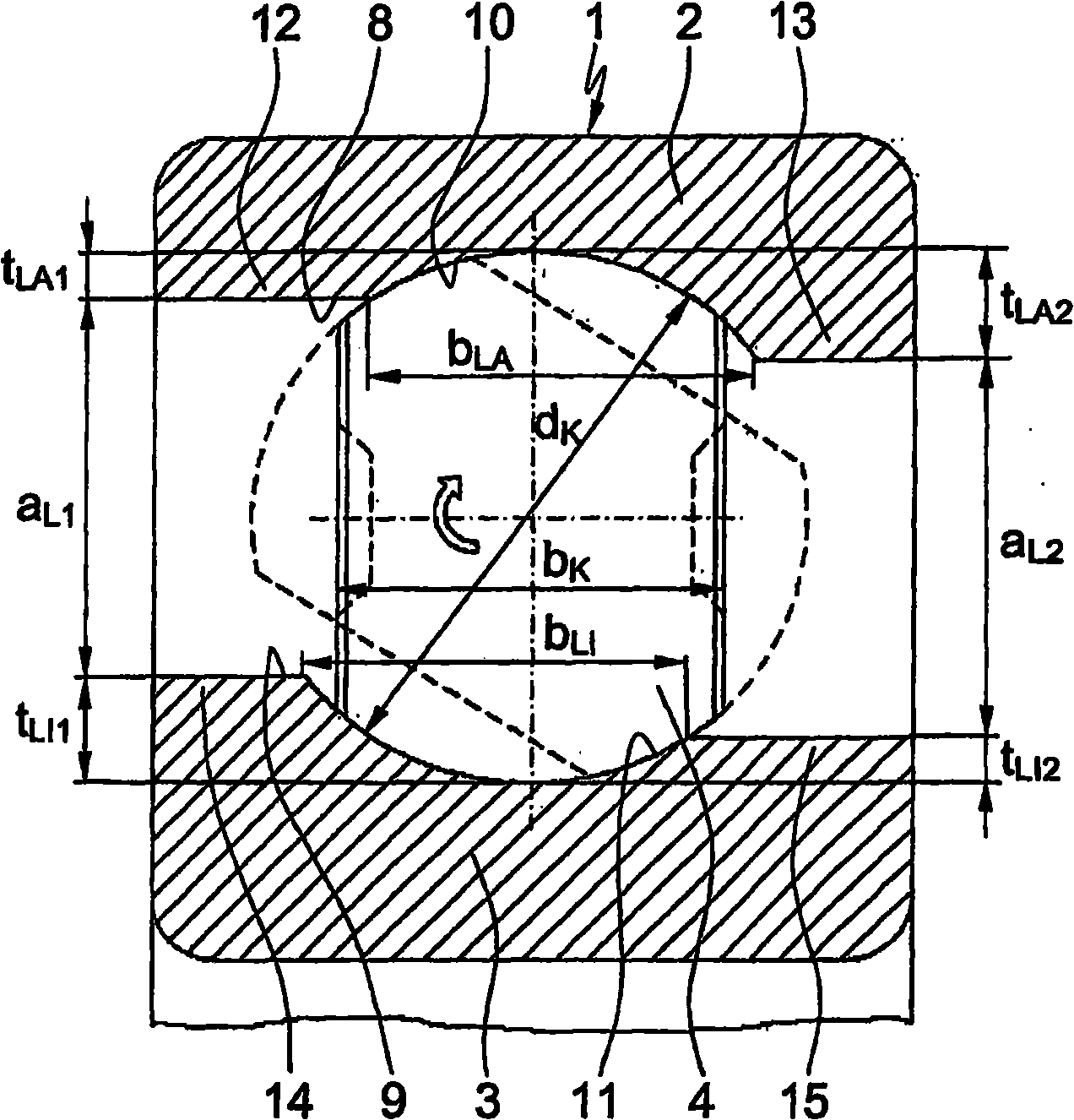

Radial rolling bearing, in particular single-row spherical-roller bearing

InactiveCN101346551AEasy to assembleLower the altitudeRoller bearingsShaftsRolling-element bearingEngineering

The invention relates to a radial rolling bearing, in particular single-row spherical-roller bearing, which is composed substantially of an outer bearing ring (2) and an inner bearing ring (3) and of a plurality of spherical rollers (4), which spherical rollers (4) are arranged between said bearing rings (2,3), which spherical rollers (4) have in each case two side faces (5,6) which are flattened symmetrically from a spherical basic shape and are arranged parallel to one another, and which spherical rollers (4) are retained with uniform spacing to one another in the peripheral direction by means of a bearing cage. Here, the spherical rollers (4) have a width (bk) between their side faces (5,6) of approximately 70% of the diameter (dk) of their spherical basic shape, and roll with their running faces (7) in two groove-shaped raceways (10,11) which are formed in the inner side (8) of the outer bearing ring (2) and in the outer side (9) of the inner bearing ring (3). According to the invention, at least one of the axial rims (12, 13, 14, 15) which delimit the groove-shaped raceways (10,11) in the bearing rings (2,3) is designed to be reduced in radial height such that the radial bearing (1) can, by means of the increased spacing (aL2) of said rim (12, 13, 14, 15) to the radially opposite rim (12, 13, 14, 15), be equipped with an increased number of spherical rollers (4) in an axial assembly process.

Owner:SCHAEFFLER KG

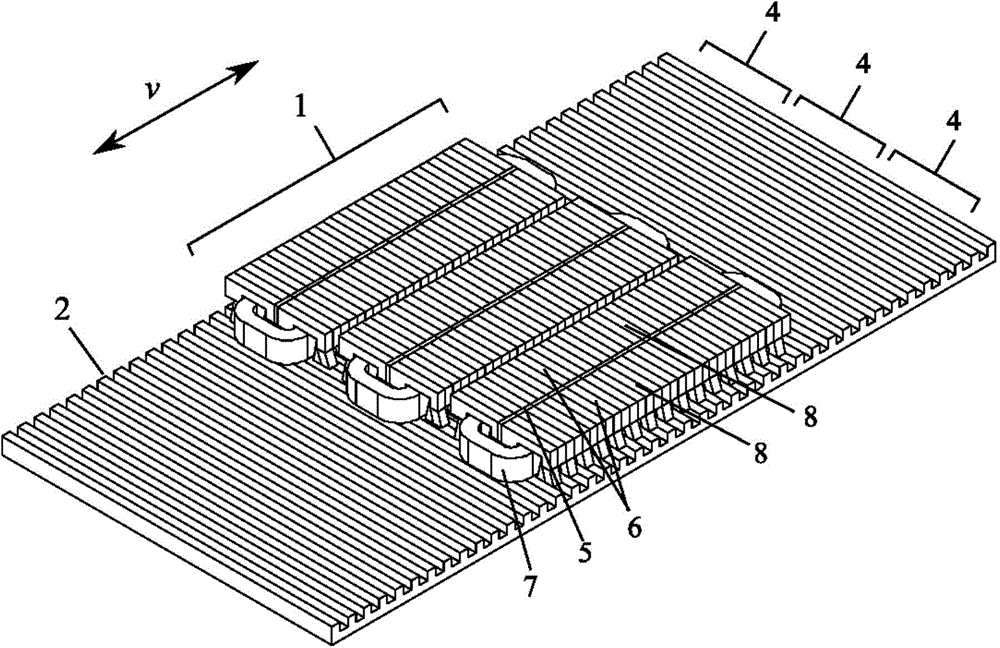

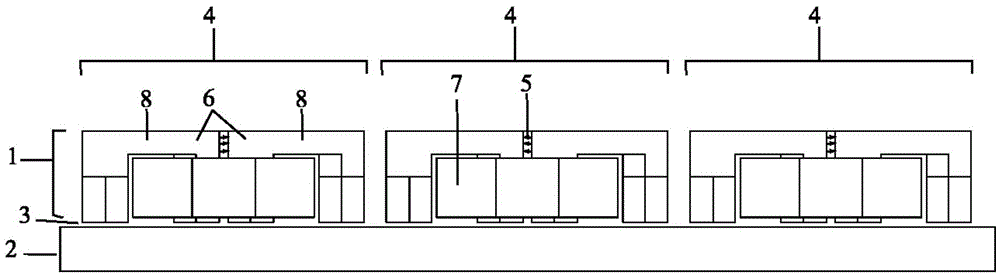

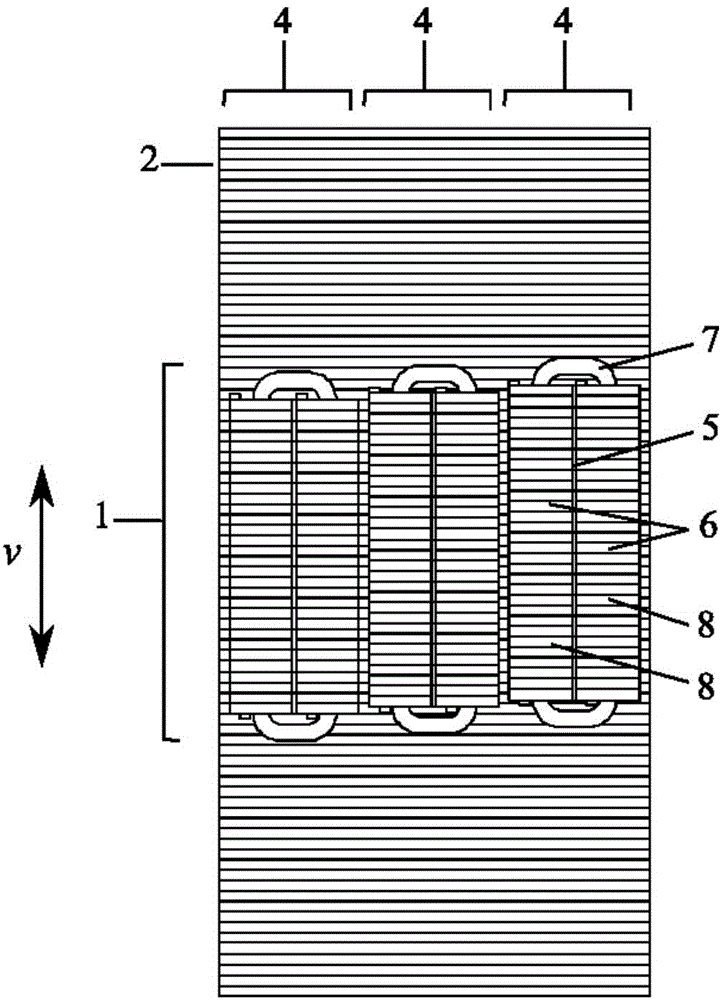

Flat-plate-type transverse magnetic flux switching permanent magnet linear motor

InactiveCN104167897AEasy to processIncrease production capacityPropulsion systemsElectrical steelElectric machine

The invention discloses a flat-plate-type transverse magnetic flux switching permanent magnet linear motor. The motor comprises a flat-plate-type motor primary and a flat-plate-type motor secondary, wherein the motor primary and the motor secondary are oppositely installed, an air gap face is arranged between the motor primary and the motor secondary, and permanent magnets and windings are installed on the motor primary and operate based on a magnetic flux switching principle. The motor is characterized in that the motor primary further comprises one or more primary units, each primary unit comprises a primary unit iron core, each primary unit iron core is composed of two primary unit iron core blocks perpendicular to the moving direction v, and the primary unit iron core blocks are formed by overlapping primary electrical steel sheets in the moving direction v; the motor secondary is formed by overlapping secondary electrical steel sheets in the moving direction v. The motor has the advantages that the structure and the production technology are simple, the primary and the secondary can be overlapped for reducing iron loss, the utilization rate of the permanent magnets and the windings is high, a permanent magnetic circuit is even in magnetic conductance and small in positioning force and eddy current, power thrust is only related to the length of the motor, and rapid designing in batches can be performed.

Owner:SOUTHEAST UNIV

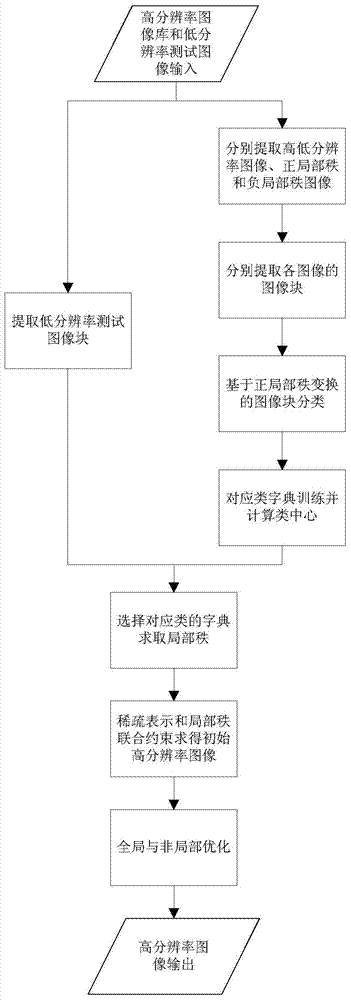

Local rank priori based single-image super-resolution reconstruction method

ActiveCN104123707APromote reconstructionReduce blemishesImage enhancementReconstruction methodMethod of undetermined coefficients

The invention provides a local rank priori based single-image super-resolution reconstruction method. The method is characterized by comprising the following steps: performing the learning method to obtain local priori information of a high-resolution image; limiting a local rank of the high-resolution image to be reconstructed through minimum energy functions according to the priori information; converting the minimum energy functions into a reconstruction model under the limitation of the local rank. According to the method, a local and non-local combined optimization model is proposed according to the non-local characteristics of the image; a local-rank-base optimized weight calculation method is also proposed for obtaining higher non-local weight. With the adoption of the method, the high-resolution image with more details can be reconstructed well by utilizing the reconstruction model; in addition, the flaws of a reconstructed image can be reduced, and the side edge of the image can be sharpened.

Owner:上海厉鲨科技有限公司

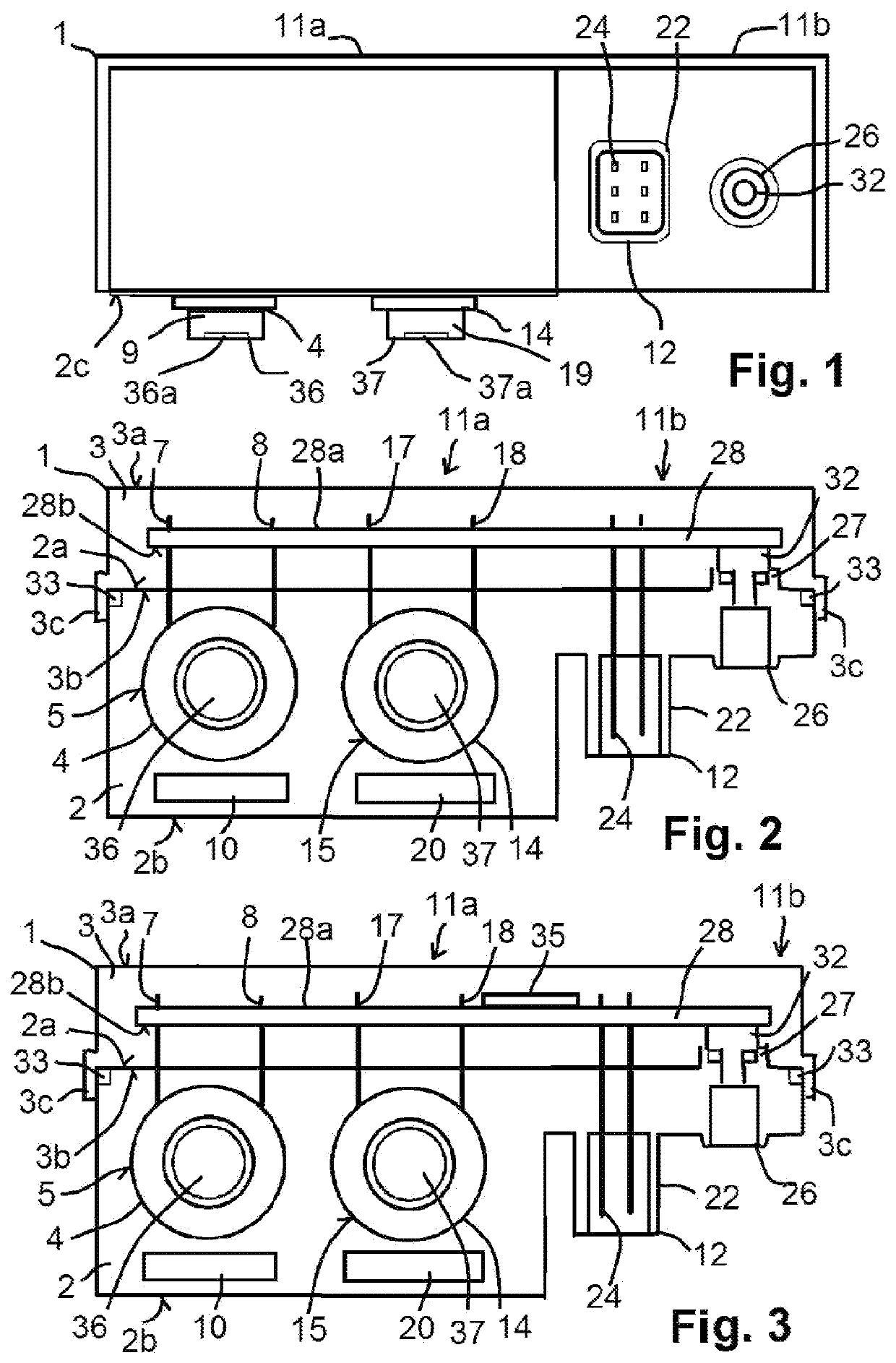

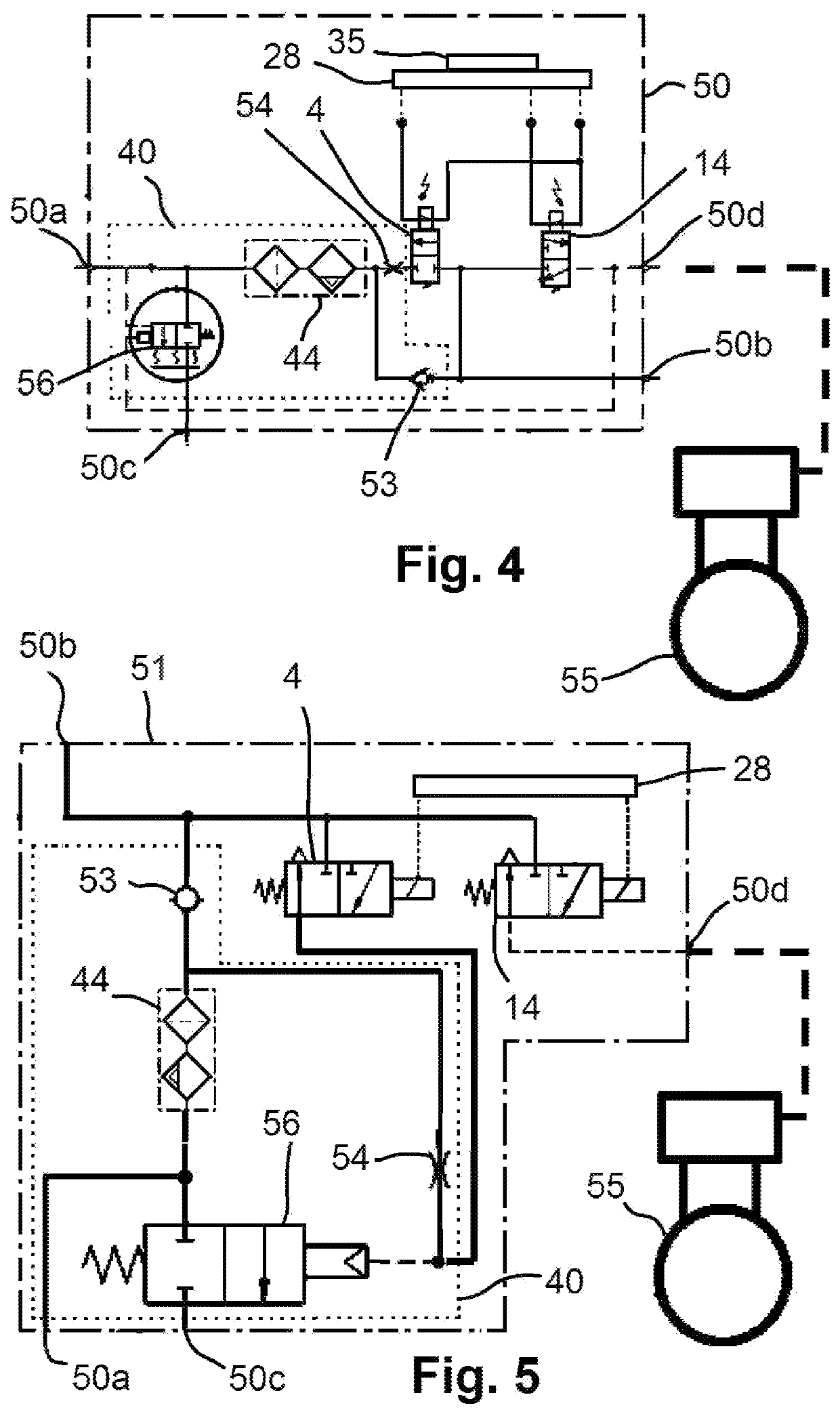

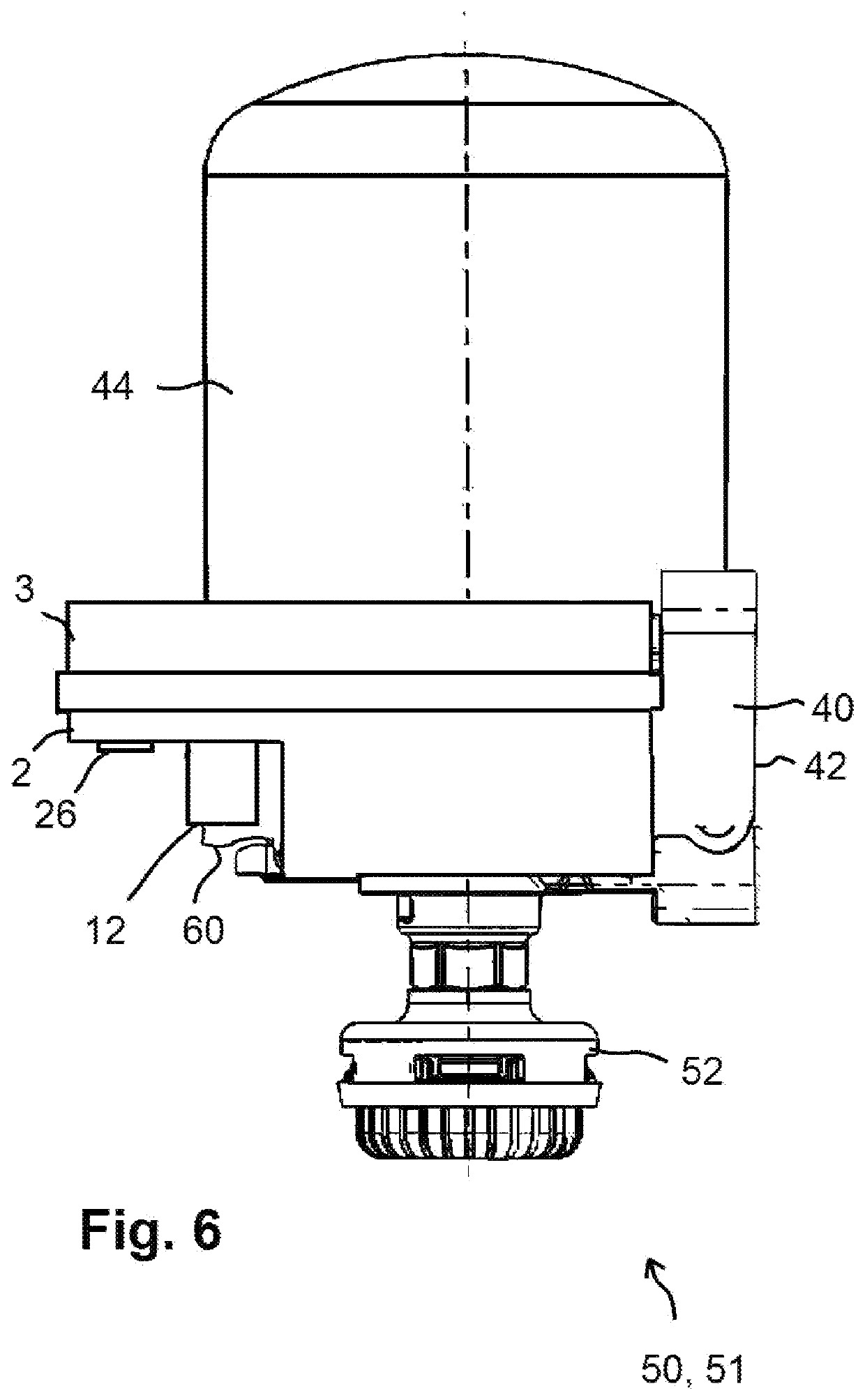

Control module of an air treatment system of a utility vehicle

PendingUS20210323529A1Undesired leakageReliable preventionServomotor componentsServometer circuitsPlastic materialsAir treatment

A control module for an air treatment system of a utility vehicle comprises the following: a first and second pneumatic magnetic valve having a first or second coil, connecting pins, and armatures accommodated in the coils, a circuit carrier, and a module housing that is cast from a plastic material, into which housing the coils are cast. The connecting pins project from a first side of the module housing and are electrically connected to the circuit carrier. A plug-in connection for receiving a connection plug is formed in the module housing, wherein the plug-in connection has plug-in pins, which extend through the module housing and are electrically connected to the circuit carrier. The module housing has a mounting surface having pneumatic connections for installation on an air dryer housing of an air dryer.

Owner:WABCO GMBH

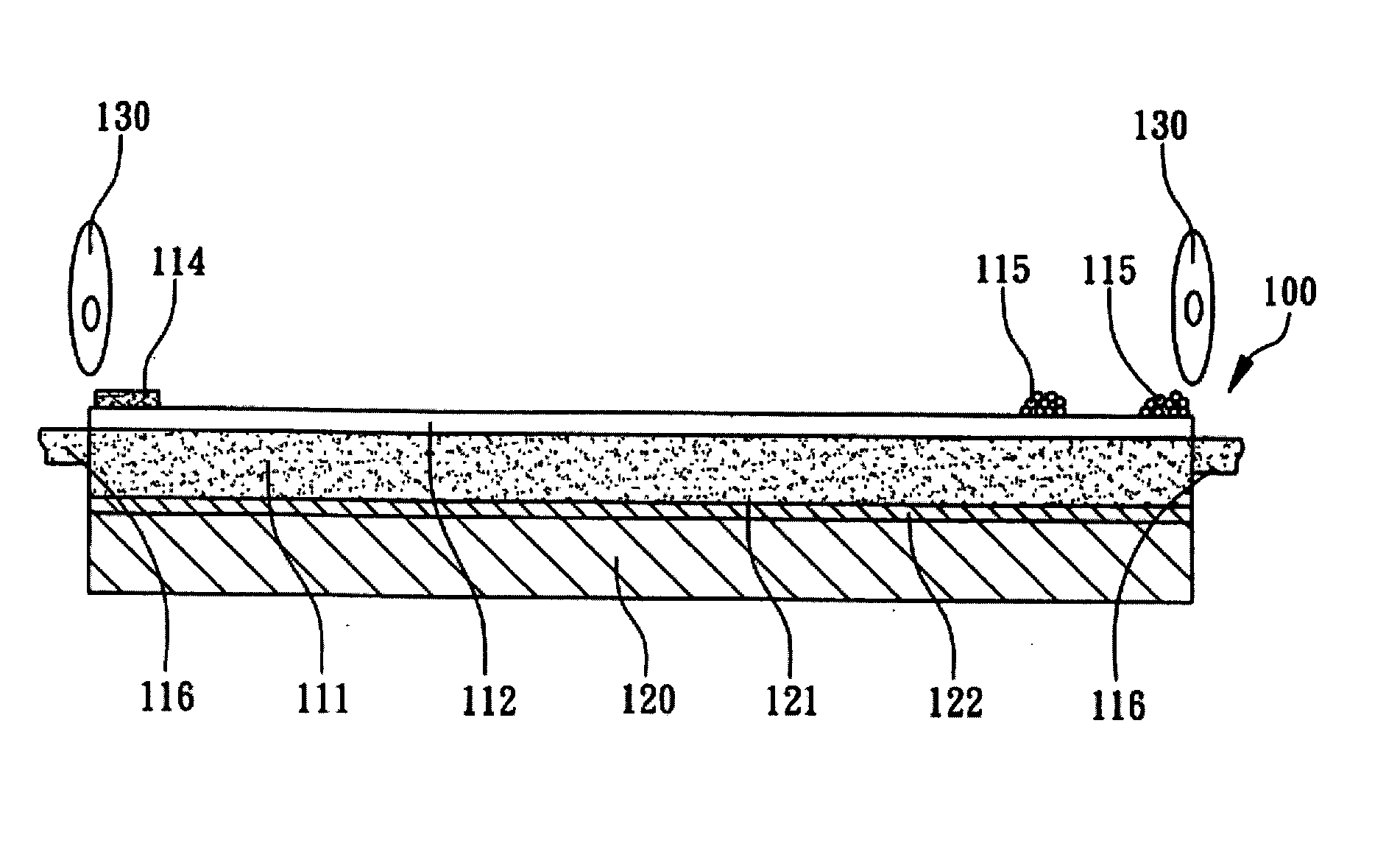

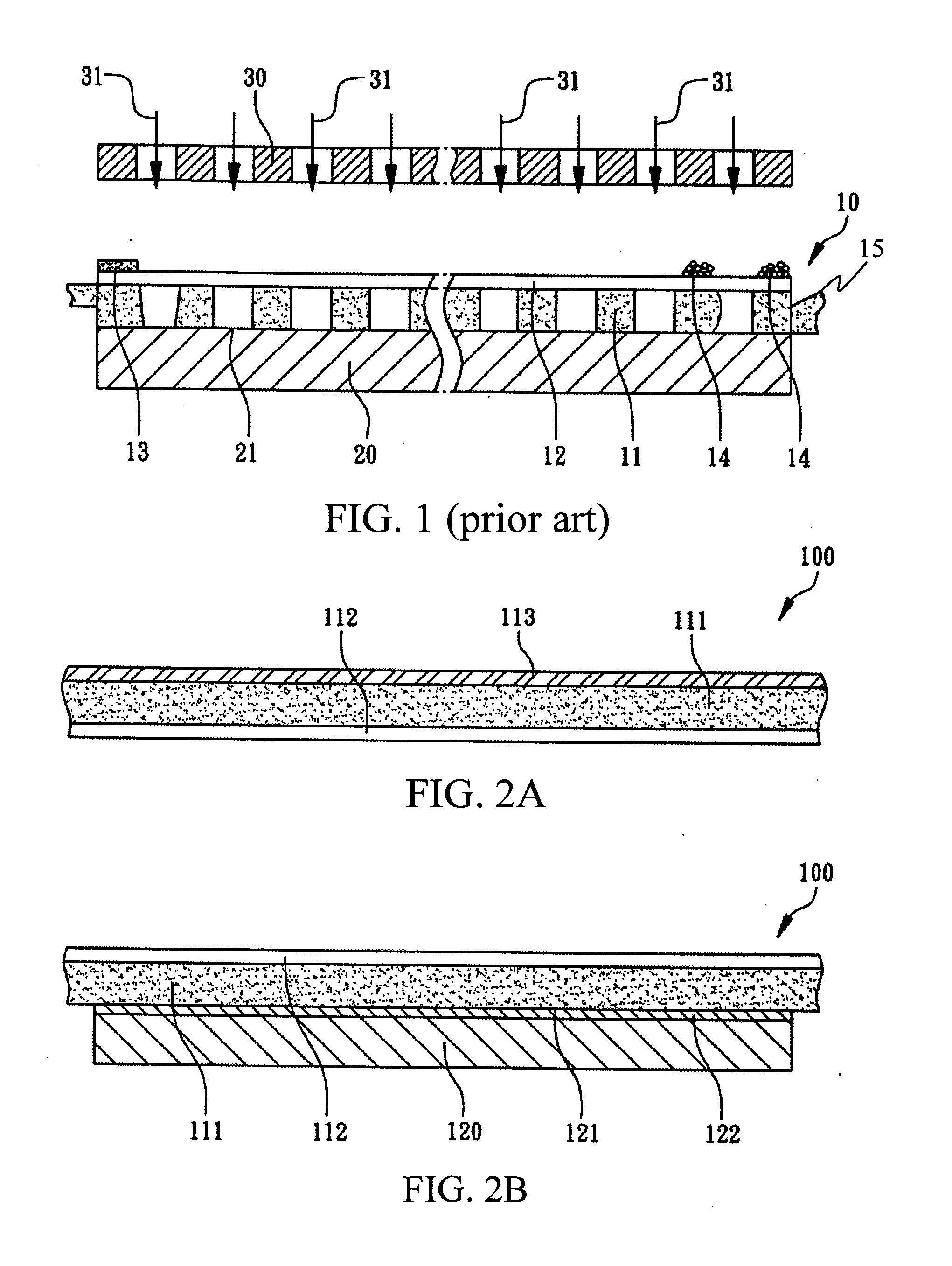

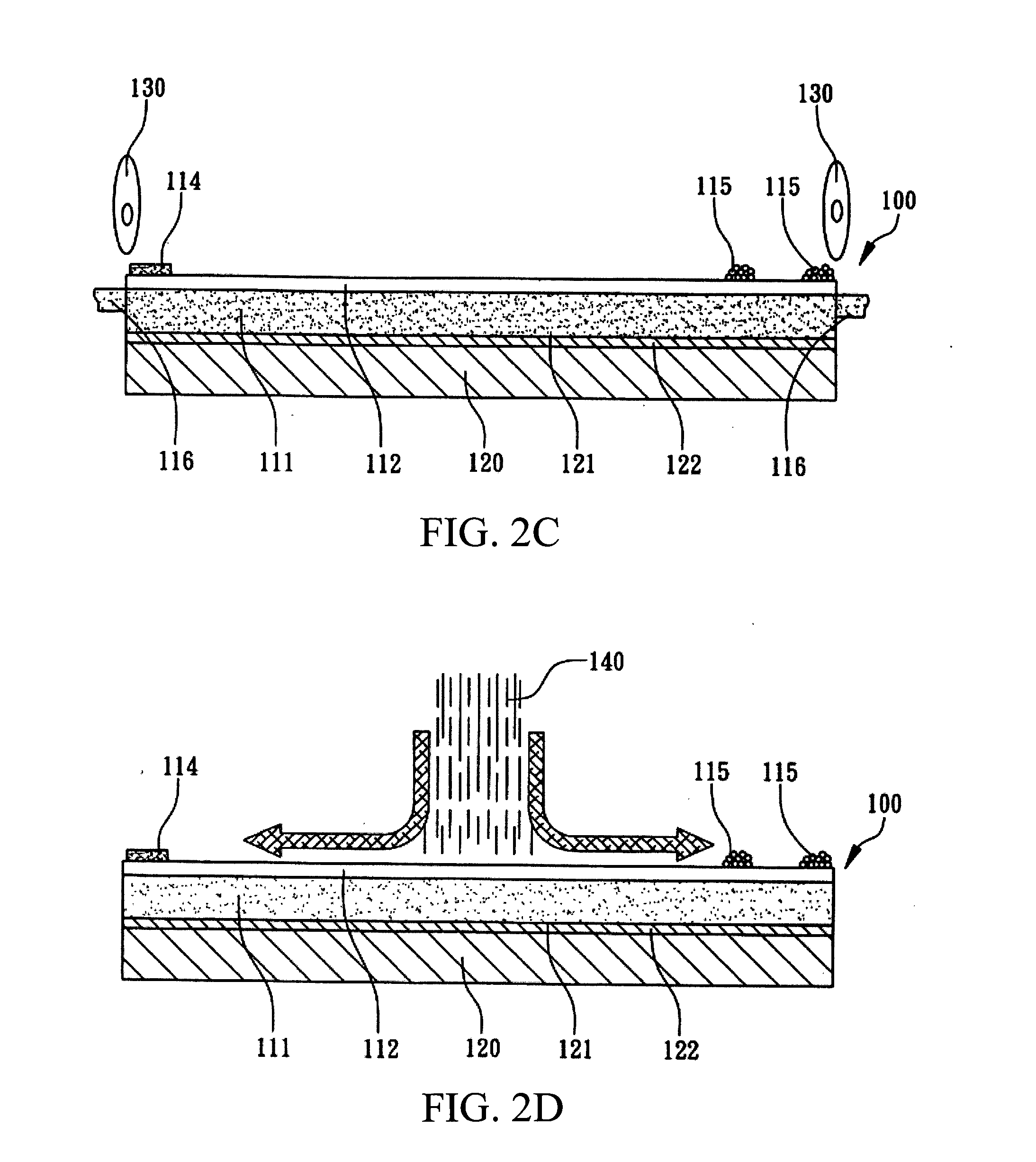

Method for utilizing dry film

InactiveUS20060188826A1Accurate exposureGood yieldPhotomechanical apparatusOriginals for photomechanical treatmentCompound (substance)Engineering

A method for utilizing a dry film is provided. A dry film is pressed onto a substrate, such as a wafer. The dry film includes a photoresist layer tightly attached to the substrate and an exposed carrier film with light transmission. Before exposure and development, the carrier film of the dry film is cleaned in a darkroom, wherein the cleaning method may include a step of chemical spraying and a step of rinsing through DI water. Accordingly, the contaminant on the carrier film can be removed. In addition, the dry film burrs can be also removed. Thus, an excellent production yield for sequent exposure and development can be achieved.

Owner:ADVANCED SEMICON ENG INC

Epitaxial wafer for heterojunction type field effect transistor

ActiveUS9111839B2Reduce dislocation densityReduce edgeSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionField-effect transistor

An epitaxial wafer for a heterojunction type FET includes an AlN primary layer, a stepwisely composition-graded buffer layer structure, a superlattice buffer layer structure, a GaN channel layer, and a nitride semiconductor electron supply layer, which are sequentially provided on a Si substrate, the stepwisely composition-graded buffer layer structure including a plurality of AlGaN buffer layers provided on each other such that an Al composition ratio is sequentially reduced, an uppermost layer thereof having a composition of AlxGa1−xN (0<x), a plurality of sets of an AlyGa1−yN (y≦1) superlattice constituting layer and an AlzGa1−zN (0<z<y) superlattice constituting layer being provided on each other alternately starting from one of the AlyGa1−yN superlattice constituting layer and the AlzGa1−zN superlattice constituting layer in the superlattice buffer layer structure, the AlxGa1−xN buffer layer and the AlzGa1−zN superlattice constituting layer satisfying x−0.05≦z≦x+0.05.

Owner:MURATA MFG CO LTD

Hybrid Java-C network appliance

InactiveUS7516333B2Quick updateReduce edgeUnauthorized memory use protectionHardware monitoringIntegrated softwareXML Encryption

A network appliance that runs both C and Java integrated software to provide a flexible architecture for rapid prototyping of XML security functionality, including SSL acceleration, XML encryption, XML decryption, XML signature, and XML verification, while the network appliance continues to provide high-speed performance.

Owner:YUNIS MAMOON +2

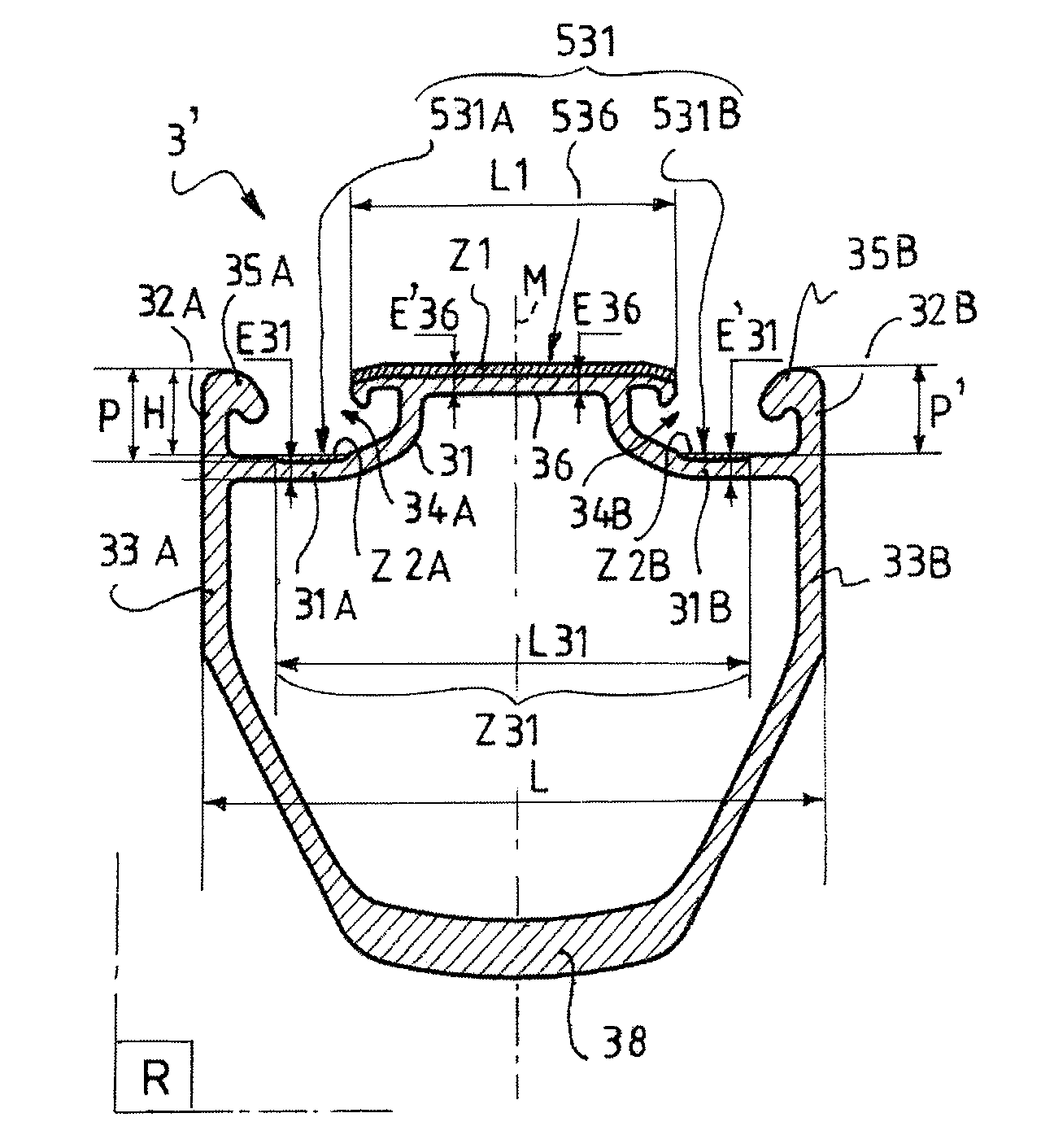

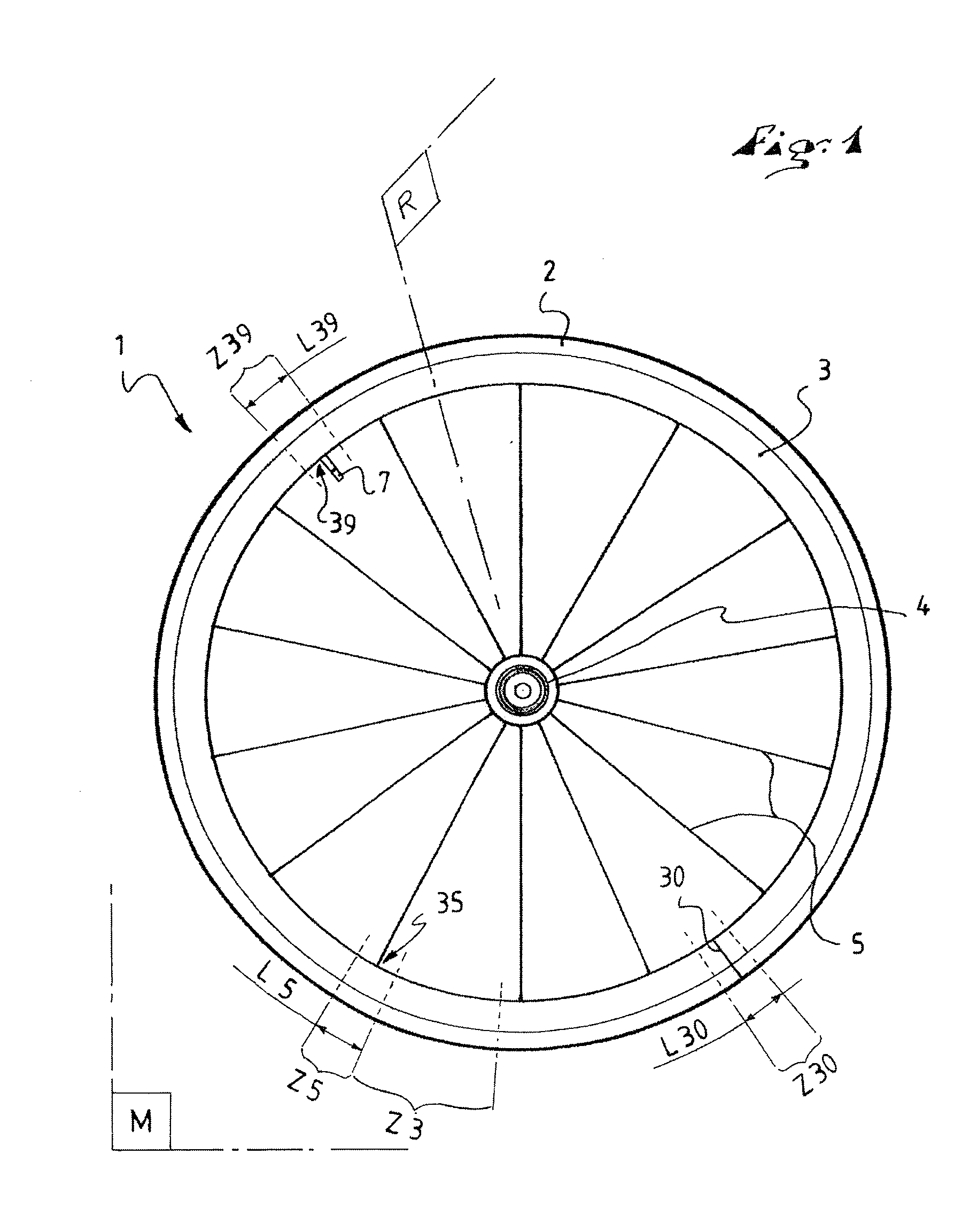

Cycle wheel rim and manufacturing method therefor

A cycle wheel rim adapted to receive an open tire. The rim has a U-shaped radial cross section, with two sidewalls located on opposite sides of a median plane of the rim, and a lower bridge connecting the sidewalls. An upper bridge connects the sidewalls to form a closed contour. The upper bridge includes a median zone extending on opposite sides of the median plane. In the median zone and on a circumferential portion of the rim greater than or equal to 50% of its circumference, a reduced thickness of the upper bridge is less than 0.75 mm, or in an alternative embodiment, less than 0.65 mm.

Owner:MAVIC SA

Preparation method of super-hydrophobic coating

ActiveCN110434034AIncreased complexityAdding complexity, increasing the hydrophobicity of the superhydrophobic coatingPretreated surfacesSpecial surfacesMicro nanoSilanes

The invention relates to a preparation method of a super-hydrophobic coating. According to the etching method, three different steeping liquors are correspondingly used for steeping for some time, inthis way, the etching rate is increased by using the different steeping liquors for steeping, the etching rate is increased by adopting the specific steeping liquor proportion, the side etching amountand bulges are reduced by increasing the etching rate, the micro-nano shape formed on the surface of a copper sheet is more complicated, and the hydrophobicity, the friction resistance and the fracture resistance of the super-hydrophobic coating are improved. Fluoroalkyl silane and silane with the boiling points being similar are selected to be better deposited on the surface of matrix copper etched well, so that the coating has the very low surface energy, the quality of the coating is relatively stable, the good hydrophobic effect is reached, the corrosion resistance and cleanness of the copper are better, and the service life is longer.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

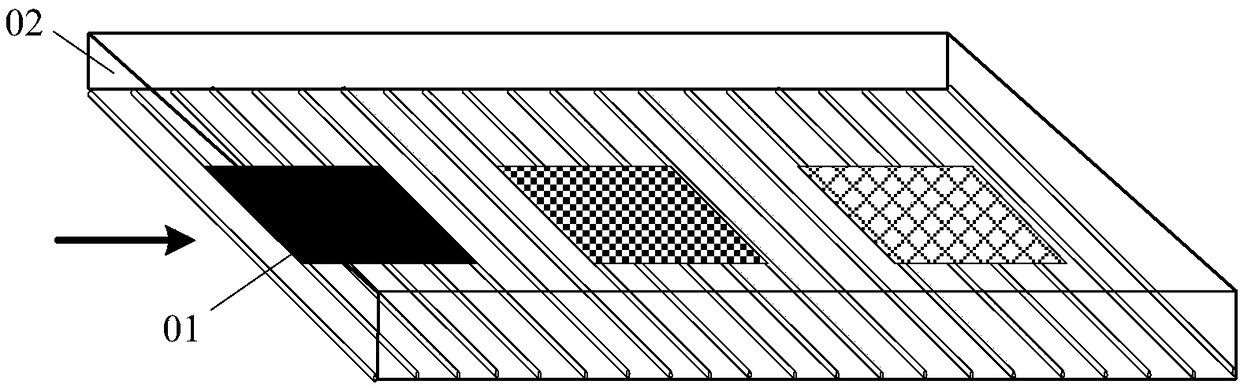

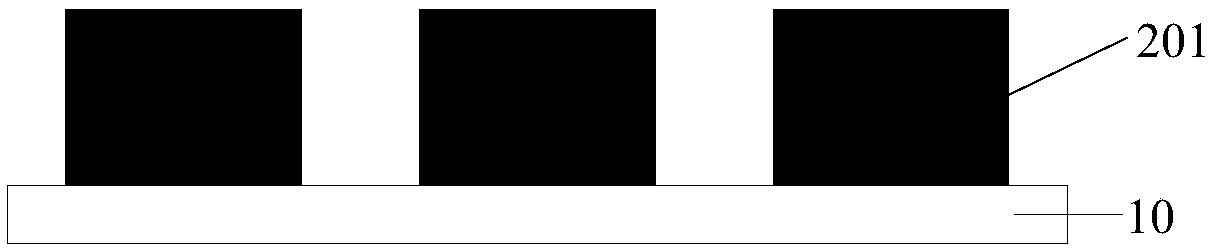

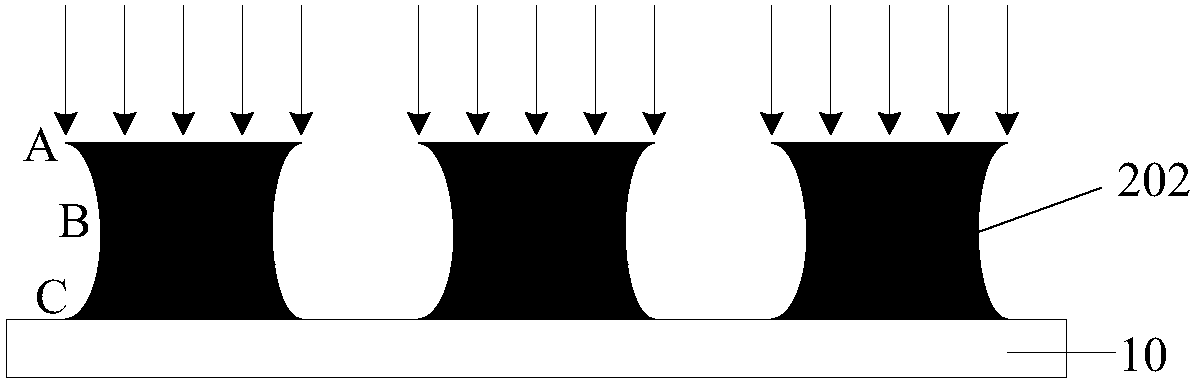

Developing device and developing method thereof, and photoetching equipment

InactiveCN108255024AReduce edgeGood uniformity of CD valuePhotosensitive material processingPhotolithographyEngineering

The embodiments of the invention provide a developing device and a developing method thereof, and photoetching equipment, and relate to the technical field of photolithography, aiming at solving the problem that the uniformity of CD values in a horizontal direction of patterns obtained by means of development of the existing developing device is poorer. The developing device comprises at least onedeveloping chamber, a plurality of spray devices and a transmission device, wherein the plurality of spray devices are distributed in the at least one developing chamber, and are used for spraying developing liquid onto substrates to be developed; the plurality of spray devices respectively spray developing liquid with different concentrations; the transmission device is used for conveying the substrates to be developed so as to enable the substrates to be developed to pass through the position under the plurality of spray devices one by one. The developing device and the developing method thereof are applied in a development process.

Owner:BOE TECH GRP CO LTD +1

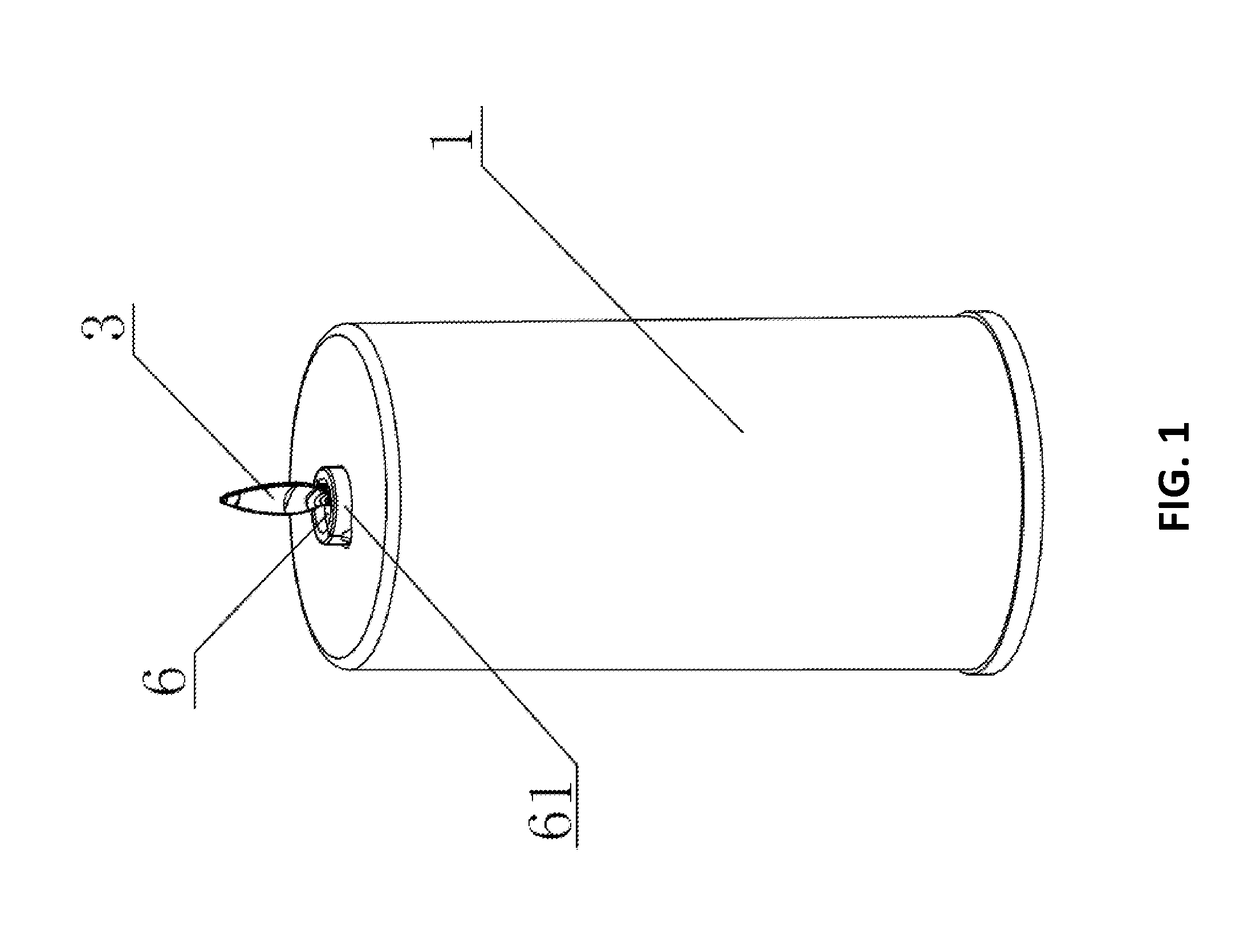

Electronic candle

InactiveUS20190014641A1Improve accuracyIncrease spaceElectrical apparatusElectric circuit arrangementsCandlePulp and paper industry

An electronic candle may include a main candle body, a signal processing module, a candle flame piece, a lighting unit to light up the candle flame piece and an air flow detecting unit, wherein the candle flame piece extends from a through hole from an inner portion of the main candle body to an outer portion thereof, and edges of the candle flame piece axially shrinks towards a center portion of the candle flame piece; the lighting unit is disposed below the candle flame piece to light up the candle flame piece; the air flow detecting unit is disposed at an inner portion of the electronic candle, and the air flow detecting unit and the lighting unit are both connected to the signal processing module.

Owner:FENG JUNJIE +1

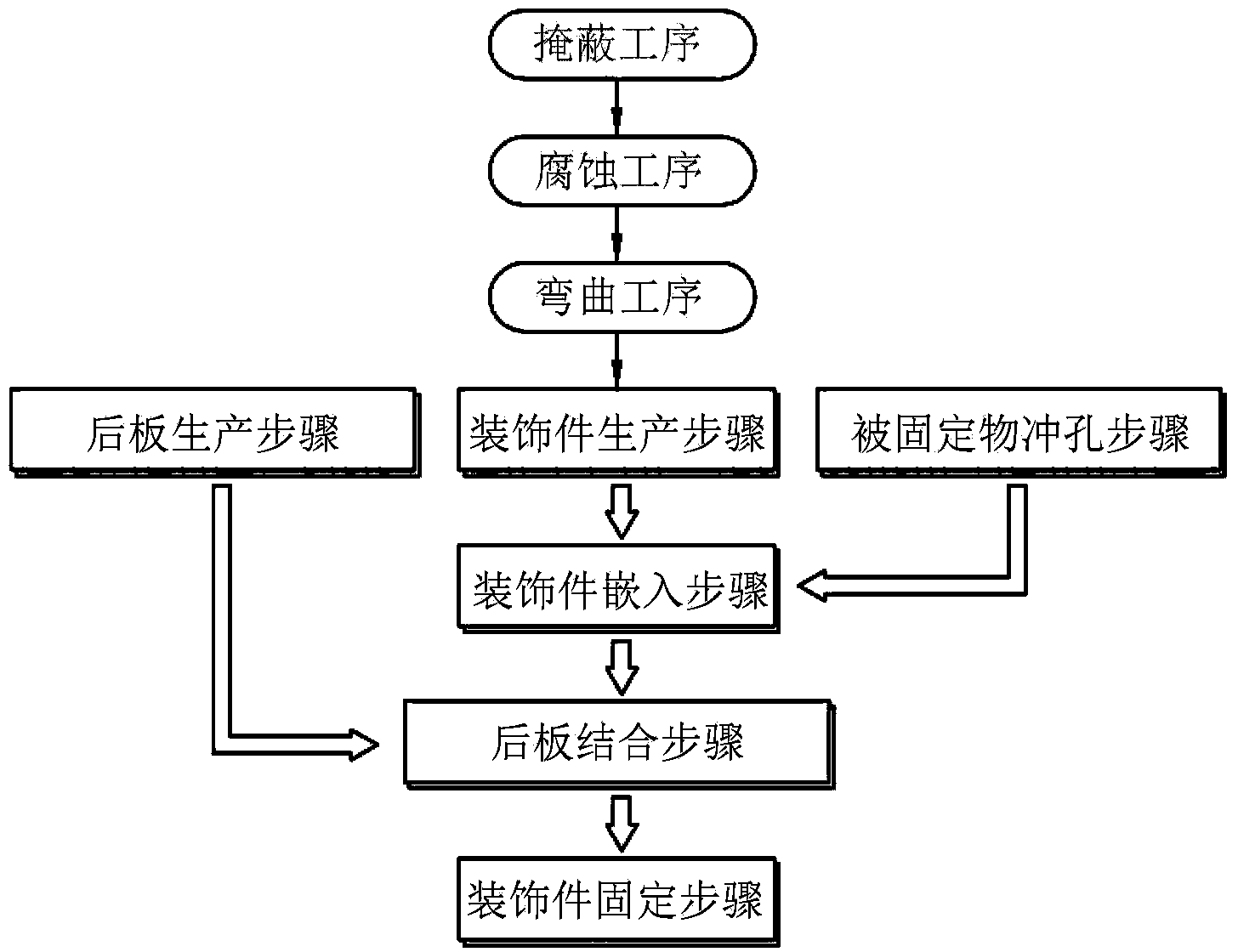

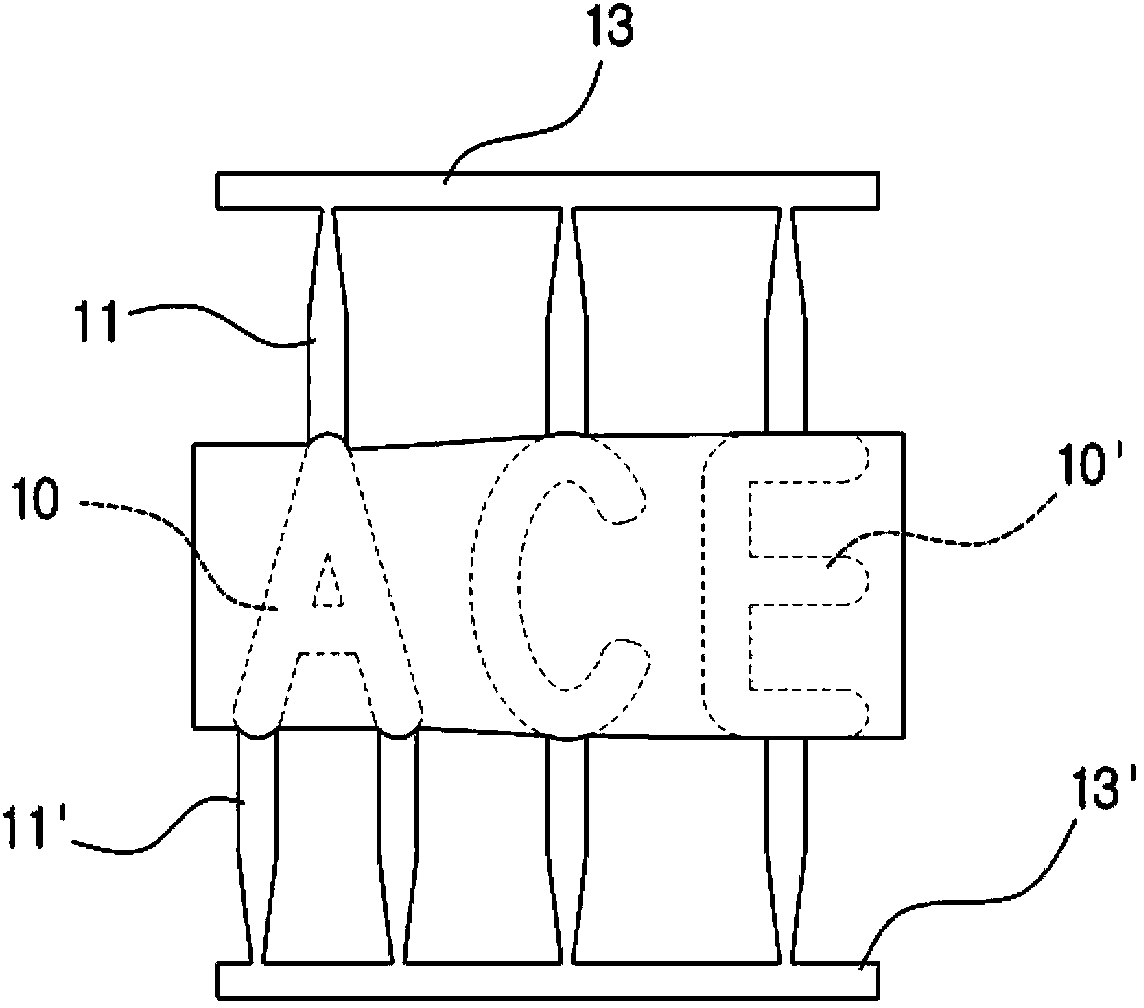

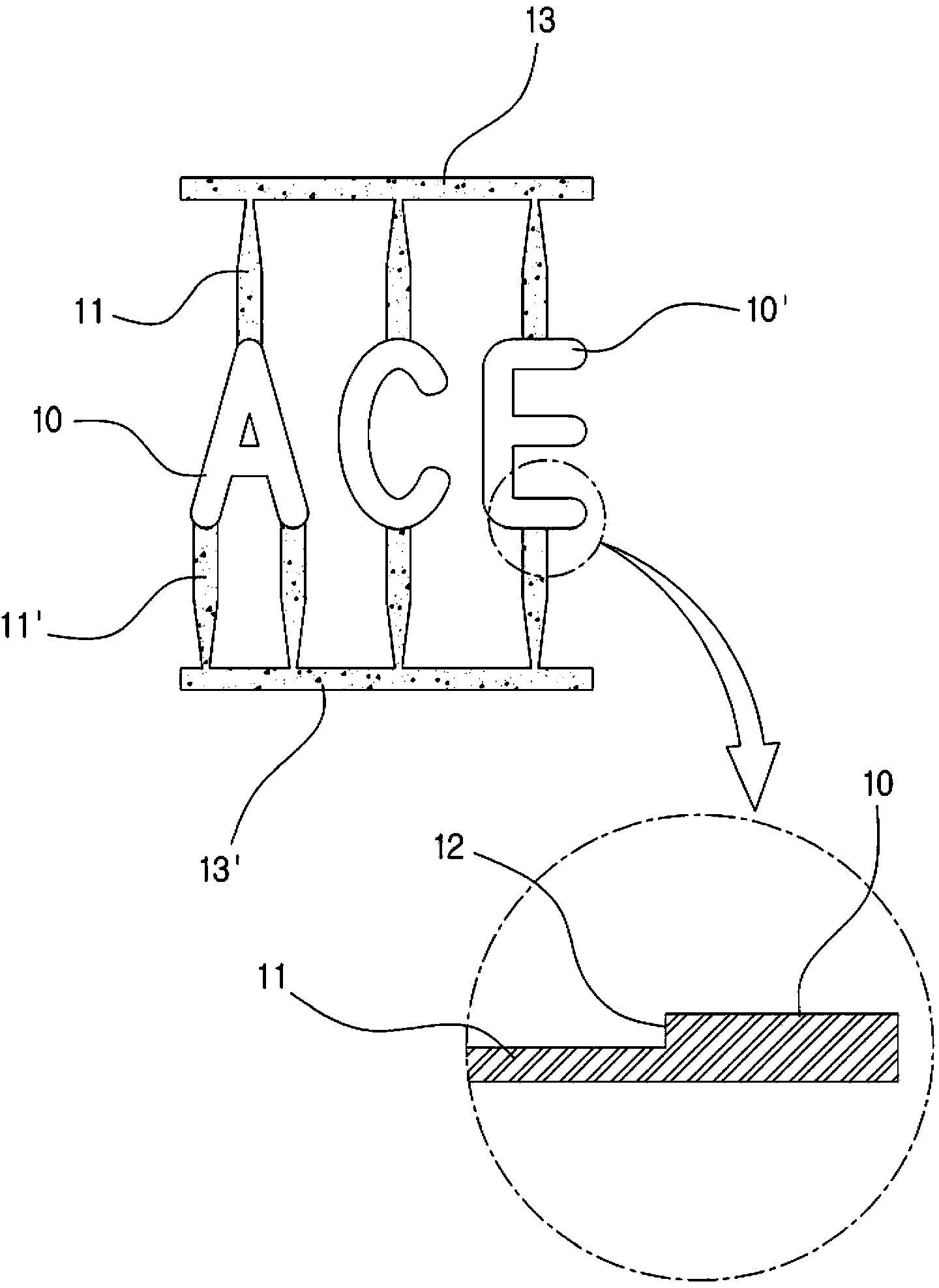

Method for manufacturing and securing metal decorations for products

InactiveCN104337065AIncreasing the thicknessReduce thicknessGarmentsOther accessoriesEngineeringMetal

The present invention relates to metal decorations for displaying a logo or a trademark of goods or a company in the form of characters or figures on the surface of various products. More particularly, in order to have securing legs and connecting rods with a thinner thickness than the thickness of the metal decorations, the metal decorations and the securing legs are formed by corrosion; a product and a rear plate are each punched at positions corresponding to the securing legs; and after severing the connecting rods of the securing legs, each of the metal decorations is secured to the product and rear plate. Accordingly, even if the securing legs are bent, due to the securing legs being formed with a different thickness from the metal decorations, the borders of the metal decorations are unaffected, thus, it is possible to manufacture the metal decorations with distinct borders, and it is possible to improve workability as well as reducing damage to the product by reducing the thickness of the securing legs. In addition, the metal decorations or the securing legs are prevented from protruding from the surface of the product or the rear plate, due to grooves being formed, in the rear plate for securing the metal decorations, with a depth corresponding to the thickness of the metal decorations or the thickness of the securing legs, thereby achieving effects of producing a more luxurious product and providing an elegant exterior.

Owner:SUNS +3

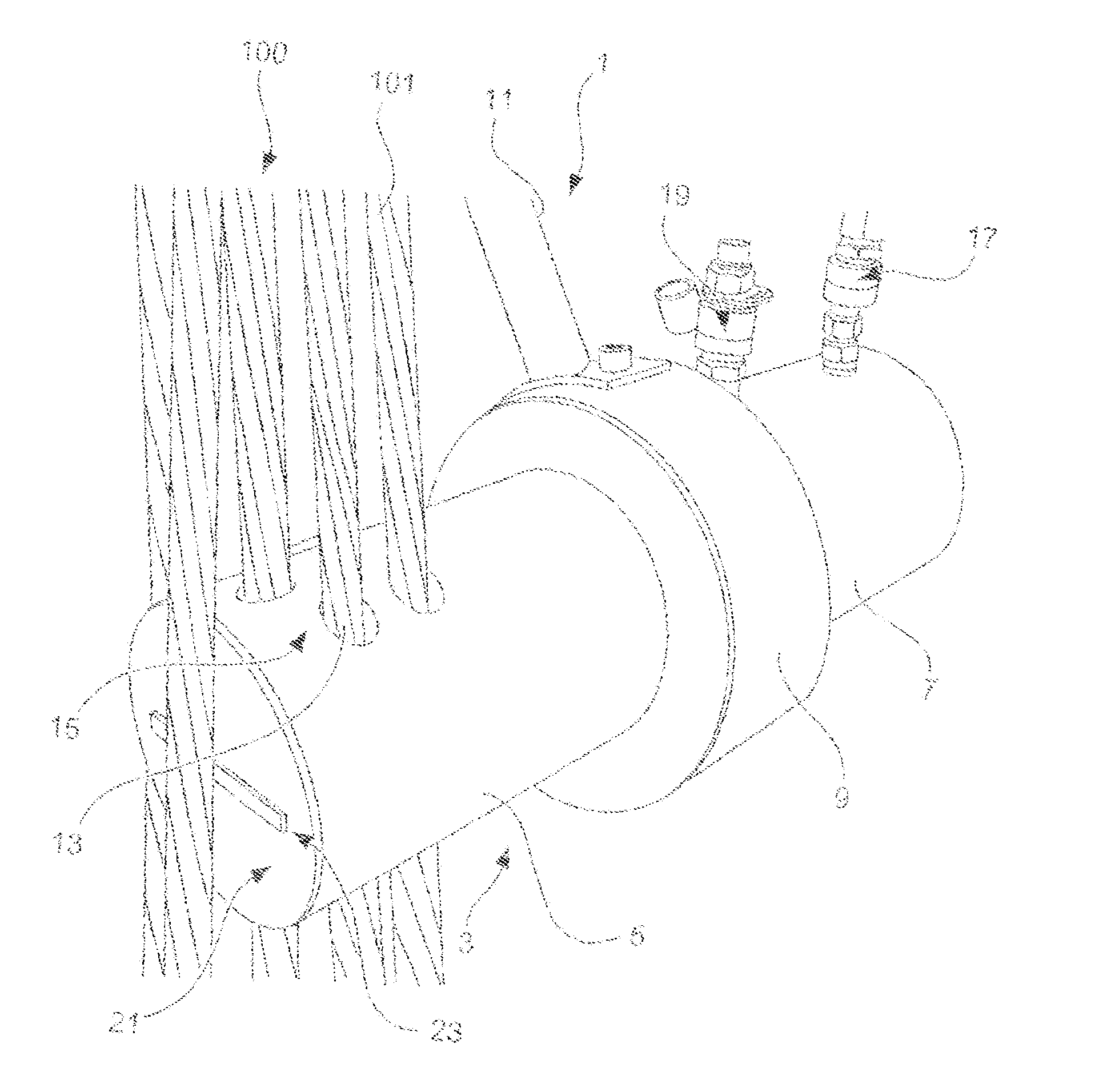

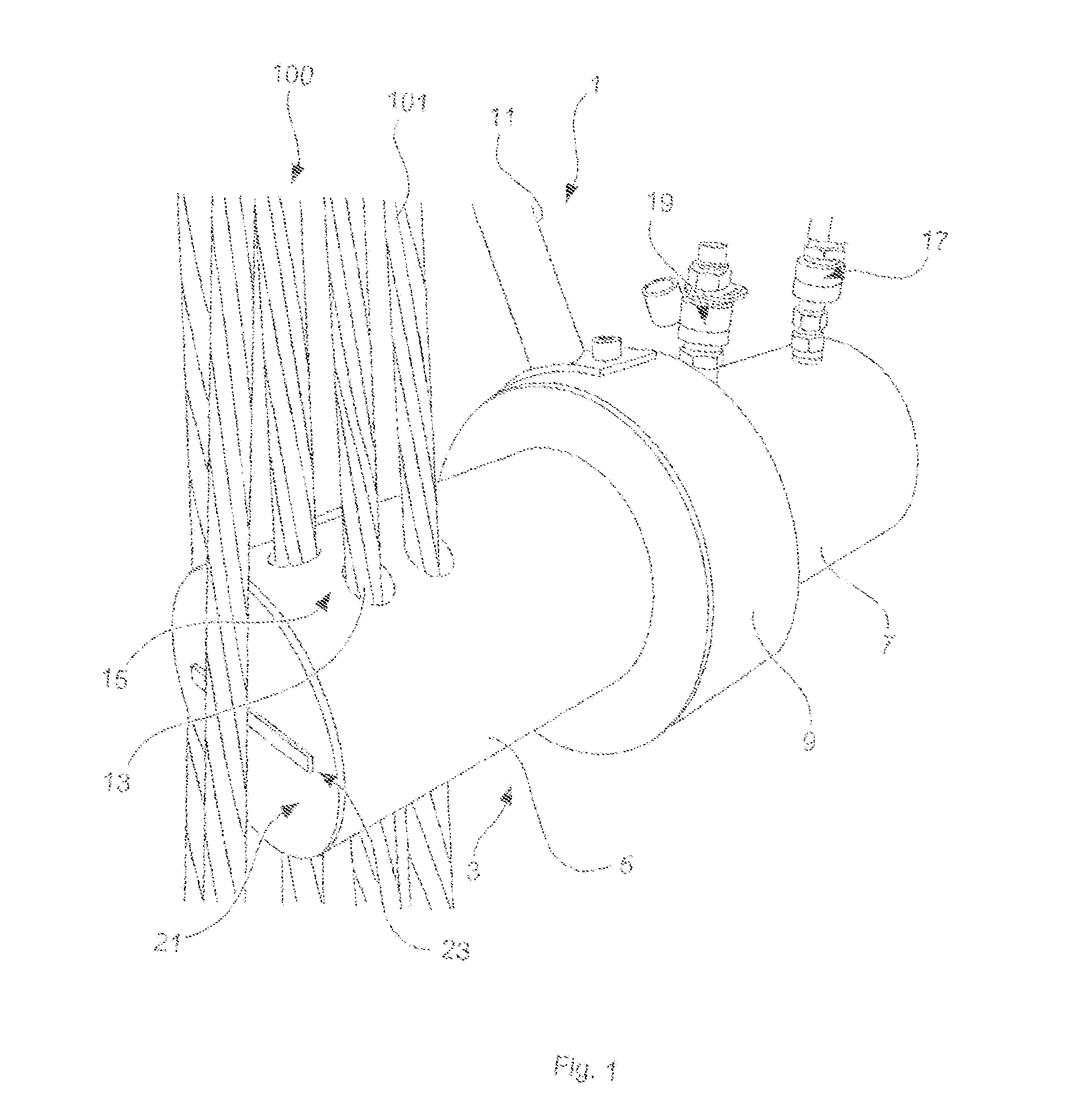

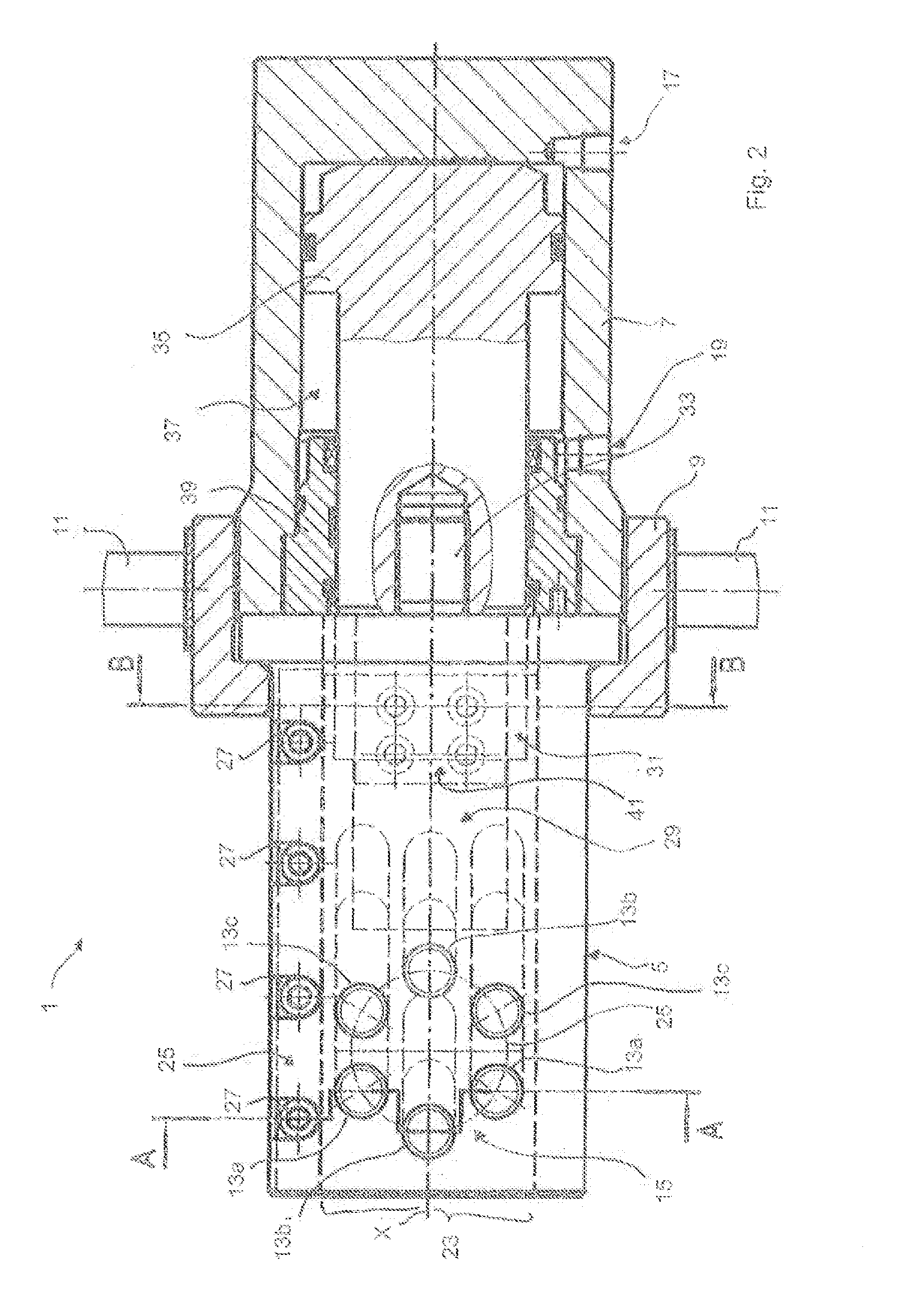

Pre-stressing tendon separation device

ActiveUS20150283629A1Improve compromiseReduce edgePortable handheld shearing machinesMetal working apparatusPre stressingEngineering

One or more embodiments concerns a stranded tensioning wire severing apparatus for stranded tensioning wires of steel, in particular stranded tensioning wires of prestressed concrete structures such as for example pylons of wind power installations, which is adapted to sever a bundle comprising a plurality of stranded tensioning wires in one working operation.One embodiment proposes that the apparatus has a housing, a cutting body arranged within the housing, and a plurality of passage openings corresponding to the plurality of stranded tensioning wires, which extend through the housing, wherein the passage openings are each penetrated by a slot adapted to receive the cutting body, and the cutting body has one or more cutting edges and is drivable in the housing movably in a cutting direction relative to the passage openings in such a way that the cutting edge or edges completely transit through the passage openings.

Owner:WOBBEN PROPERTIES GMBH

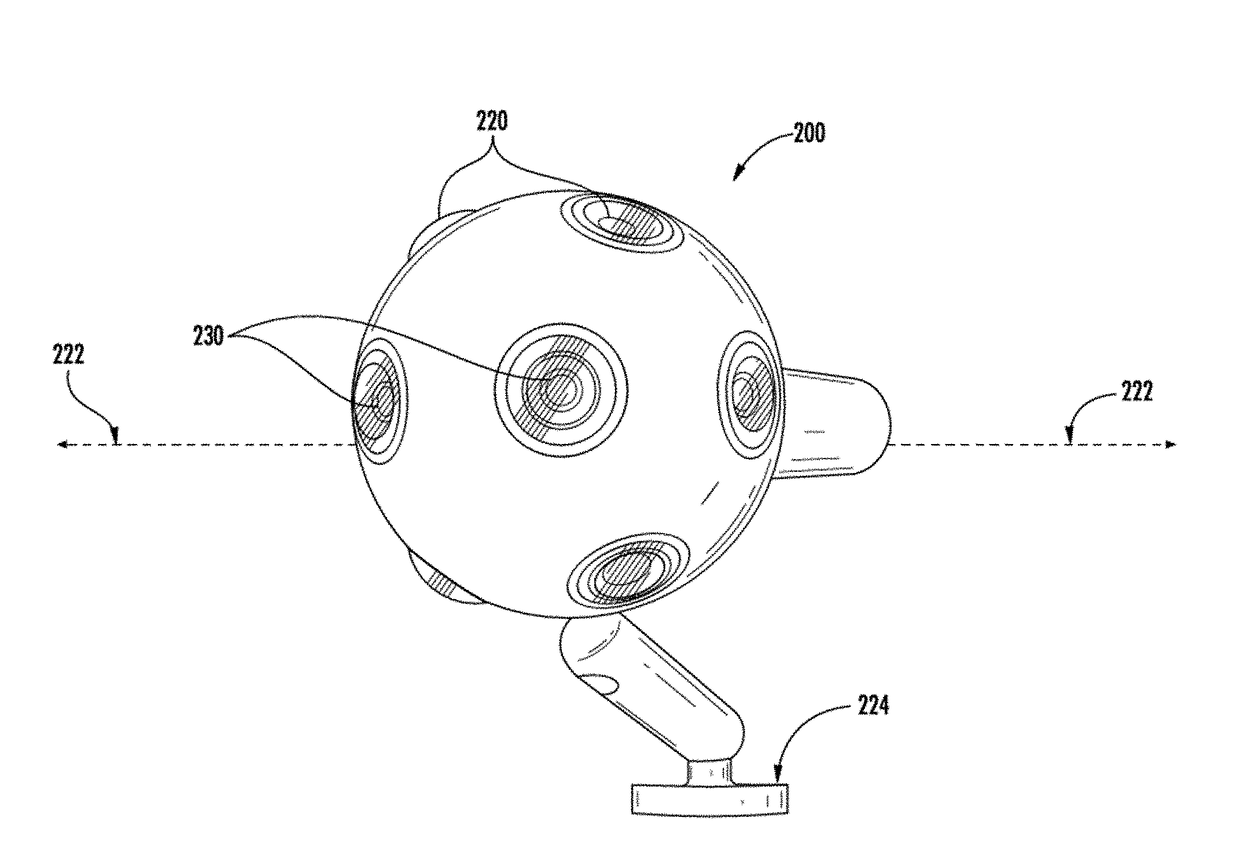

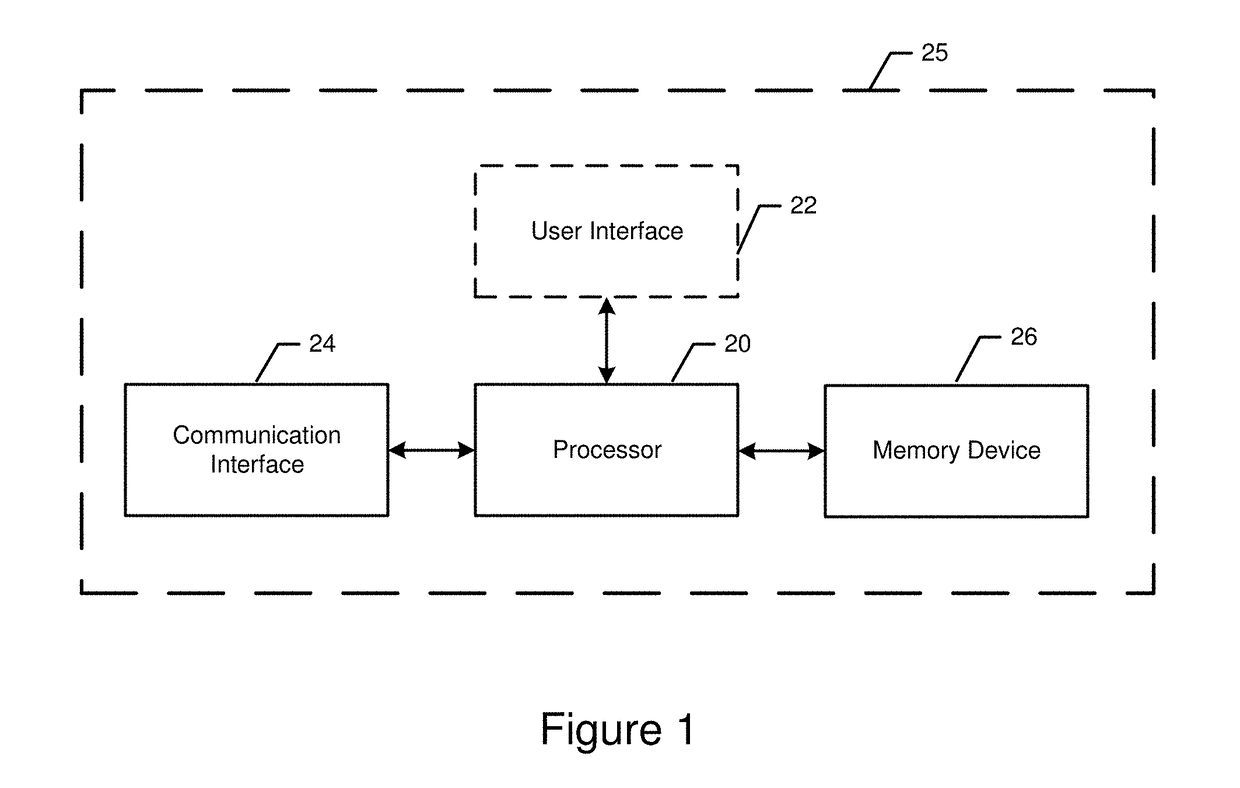

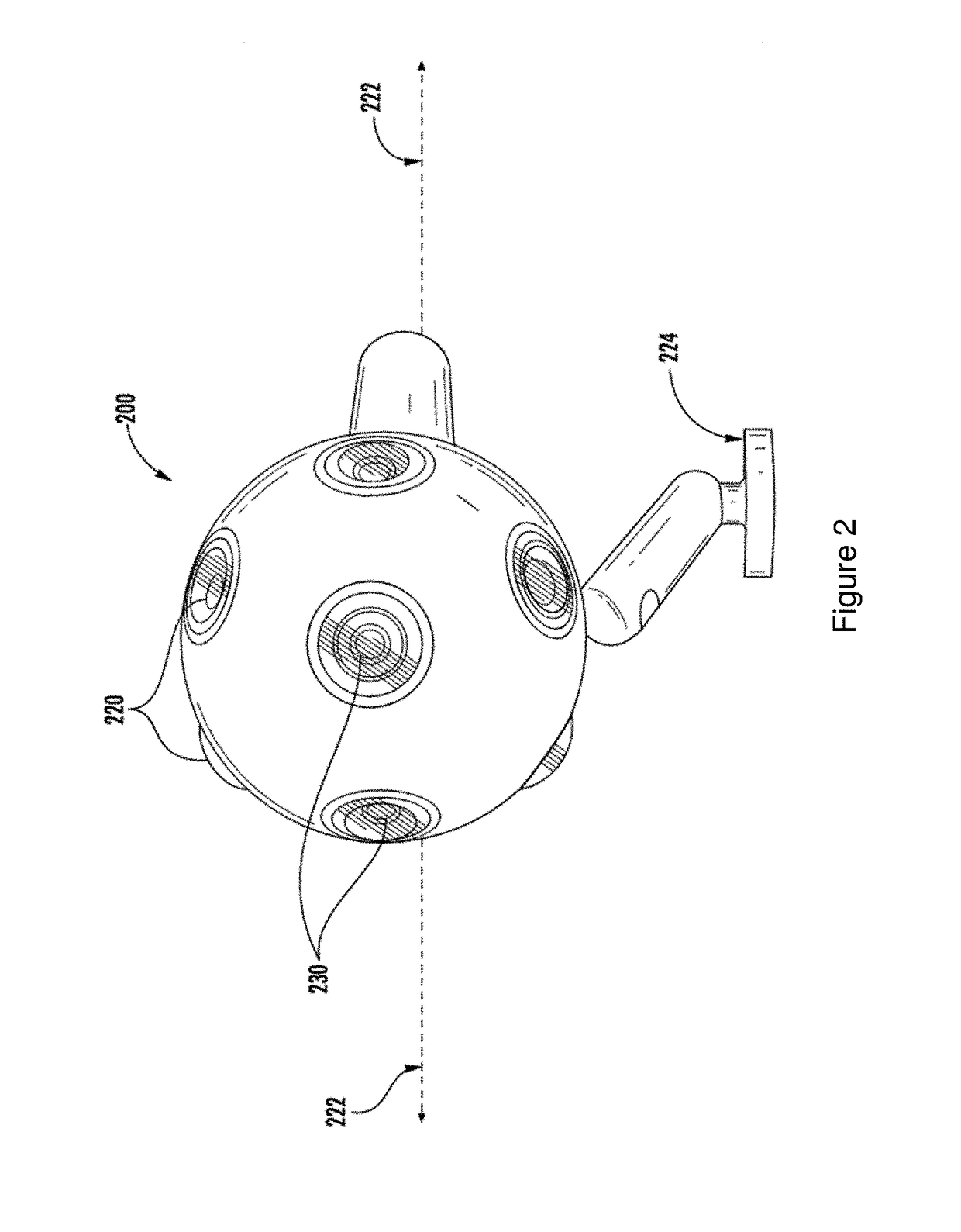

Method, apparatus and computer program product for generating composite images with three-dimensional effects and reducing pole contraction lines

InactiveUS20180241982A1Increase generationSmooth transitTelevision system detailsGeometric image transformationPattern recognitionComputer graphics (images)

A method, apparatus and computer program product are provided for improved generation of composite images for display in three-dimensional environments. Images may be adjoined to form three-dimensional composite images, but the composite images may be subject to contraction lines. The adjoining images or composite image may be processed with circular matching and mixed blending to reduce the contraction lines near the seams of the images and to improve image quality. The circular matching includes adjusting pixel colors and / or intensity values so that pixels corresponding by circular symmetry match in color and / or intensity. The composite image may be smoothed by mixed blending to eliminate or reduce abrupt edges in the area of the circular matching. The resulting composite image provides improved image quality and realistic three-dimensional effects.

Owner:NOKIA TECHNOLOGLES OY

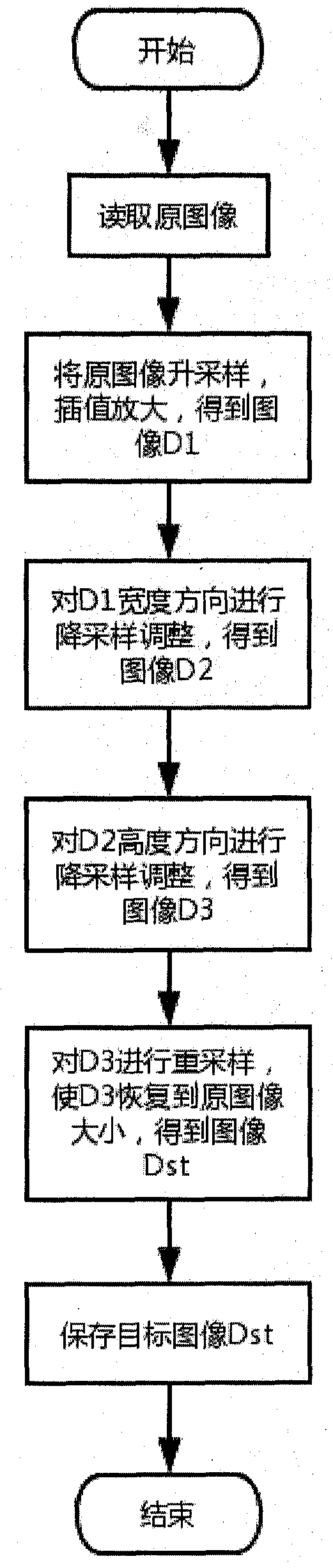

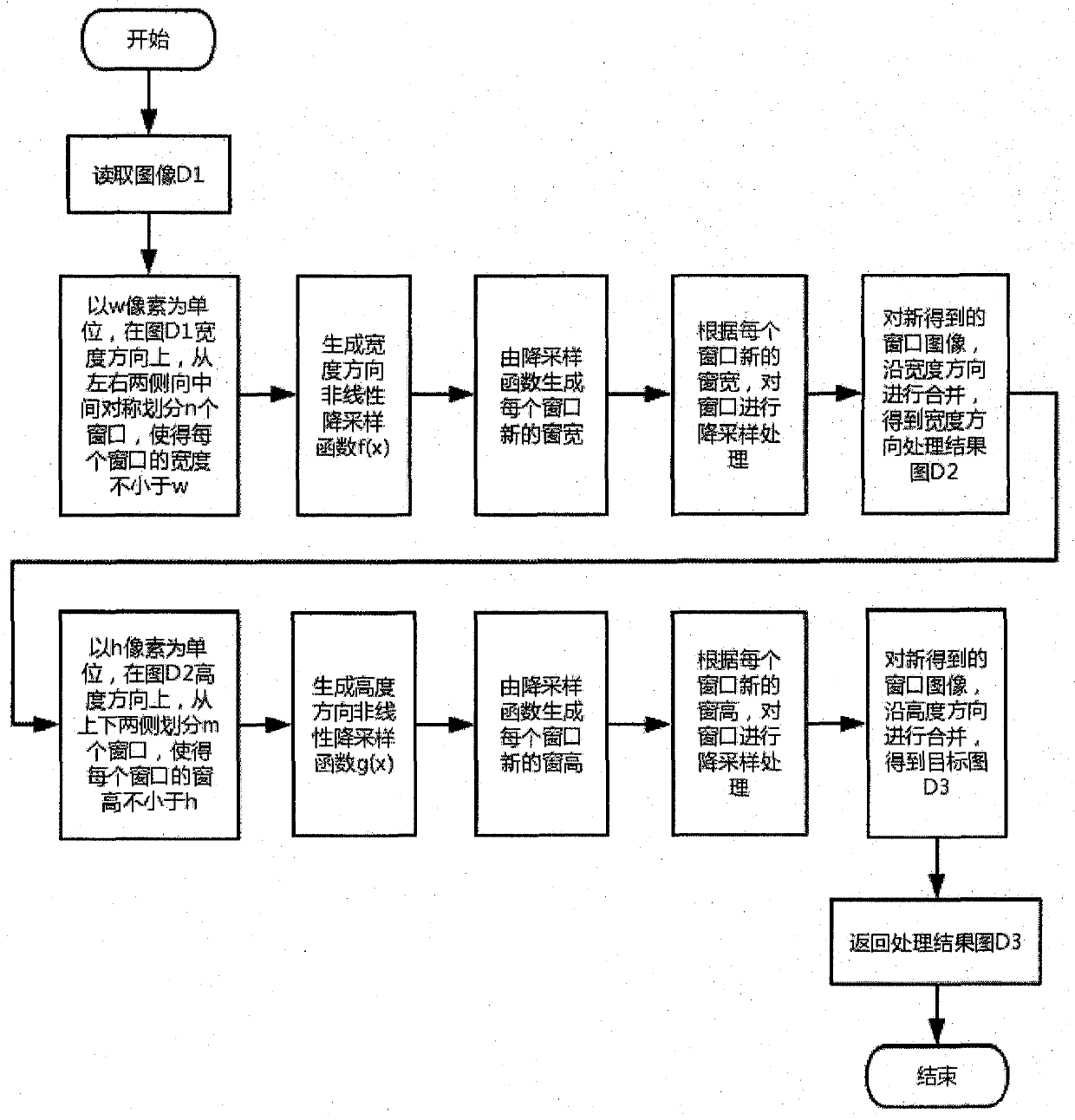

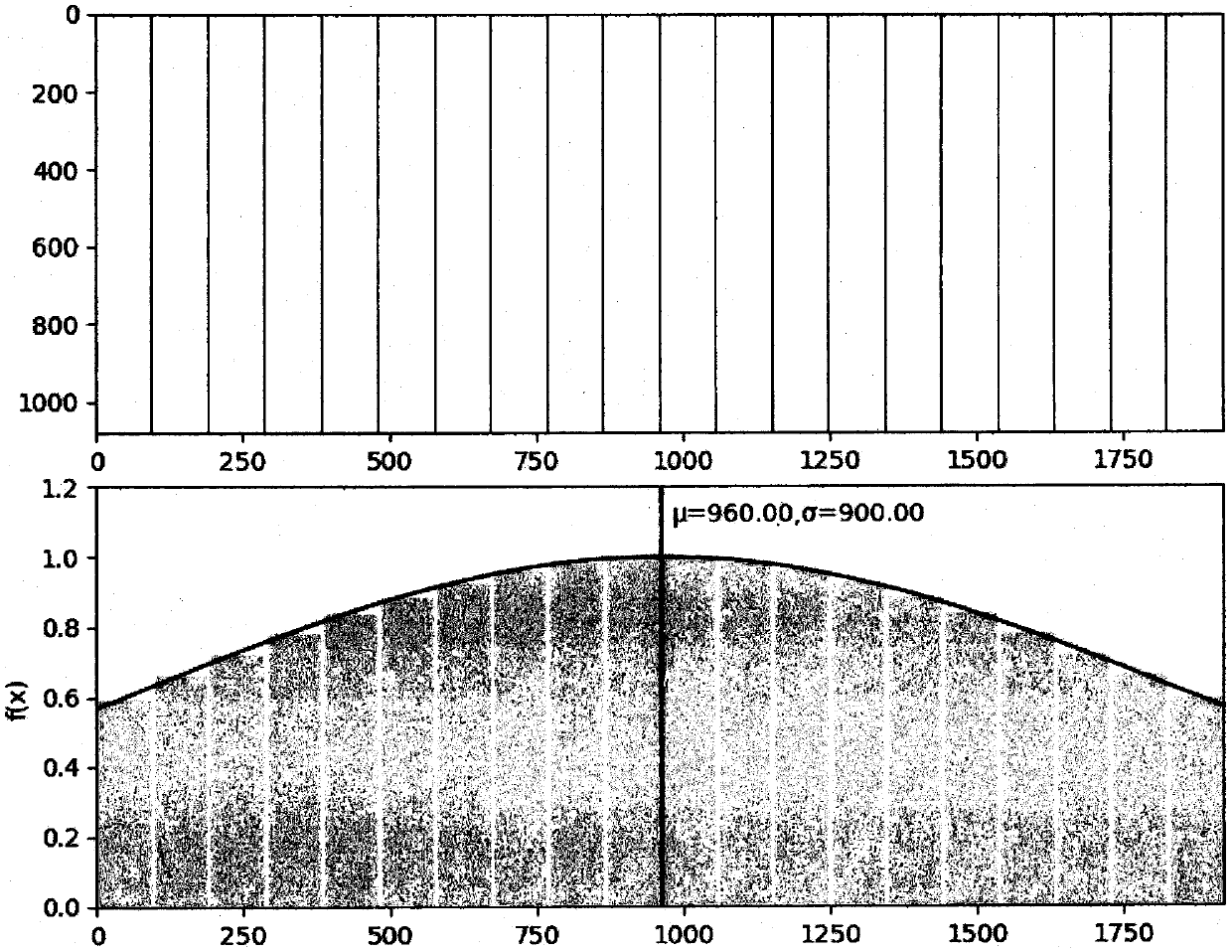

An image center enhancement processing method for simulating human eyes

PendingCN109785230AReduce edgeImage enhancementGeometric image transformationComputer scienceVisual perception

The invention provides an image center enhancement processing method for simulating human eyes, which highlights an image center area and has stronger visual impact. According to the method, a non-linear function is used for modulating a resampling rate, resampling processing is carried out on an image, more pixels are distributed to a central area of the image, so that the middle area of the image is highlighted, edge details are weakened, a non-linear optic nerve distribution mechanism of human eyes is simulated, and a picture presents a feeling closer to the human eyes.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com