Solution film formation method and device of organic material

A technology of solution film formation and organic materials, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of less than 10% material usage, uneven coating process, and inability to form patterns, etc. To achieve the effect of accelerating thermal movement, improving film quality and reducing the difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

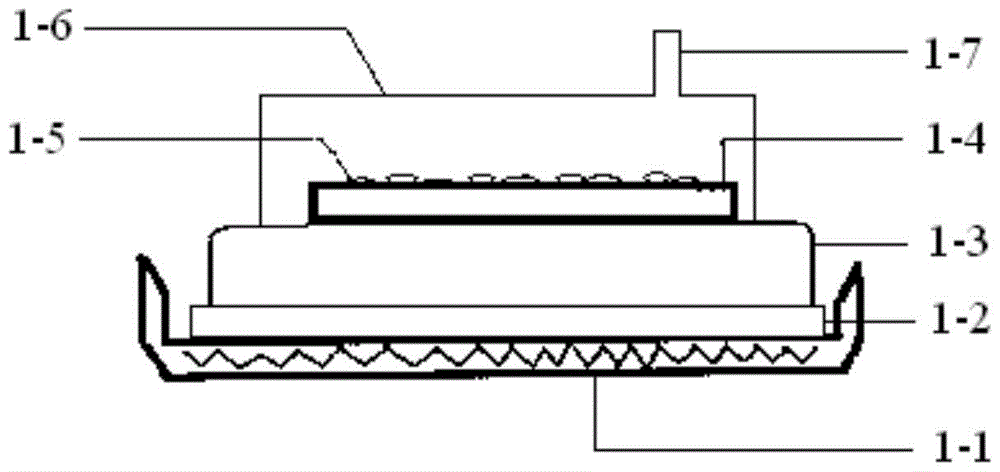

[0034] A solution film-forming device for organic materials, the schematic diagram of which is shown in figure 1 shown. 1-1 in the figure is a variable frequency vibration generator, which can provide high-frequency reciprocating translational motion required by the film forming process. Its power can be adjusted, and the frequency range of high-frequency vibration is controlled between 10Hz and 100MHz. The amplitude is controlled between 1 micron and 1000 microns, and the time is controlled between 1 and 60 minutes.

[0035] 1-2 in the figure is a damping layer, which connects the electric heating plate 1-3 and the frequency conversion vibration generator 1-1, and transmits the motion of the frequency conversion vibrator to the electric heating plate. The use of damping materials can limit the range of motion, reduce risks and improve product yield.

[0036] 1-3 is an electric heating plate among the figure. The lower part is 1-2 damping layer, and there are clamping posit...

Embodiment 2

[0042] A solution film-forming method of an organic material in this embodiment, the specific steps are as follows:

[0043] (1) Pre-film formation: Dissolve the dendrimer sample (bis[4-(9,9-diphenyl)-9,10-dihydroacridine)phenyl]sulfone) in a volume ratio of 40:40 : 15:5 chloroform: toluene: anisole: in the mixed solvent of tetrahydronaphthalene, obtain film-forming solution; Substrate adopts ITO glass substrate, glass substrate is added detergent ultrasonic treatment with isopropanol, acetone, deionized water 10min, then rinse with deionized water; use a 3 micron coating rod to coat the film-forming solution on the substrate to obtain a liquid film;

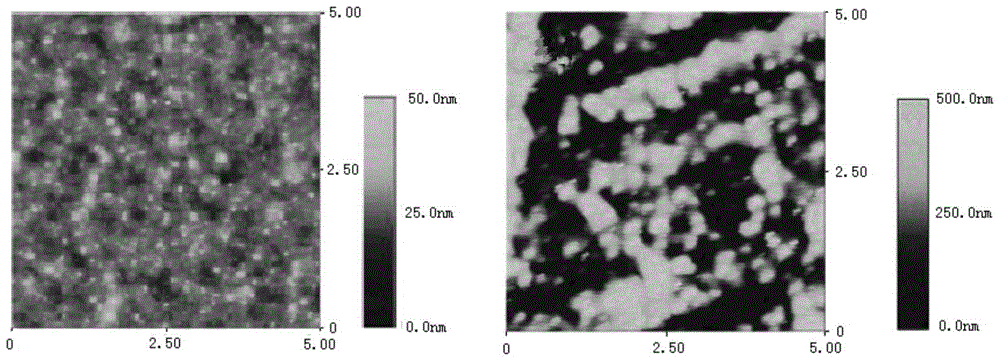

[0044] (2) Dynamic drying: the substrate with liquid film in step (1) is transferred to the equipment shown in embodiment 1, the frequency conversion vibration generator is turned on, the frequency used is 1000Hz, the power selected is 100W, and the amplitude is controlled At 1-5 microns, the processing time is 30 minutes; whil...

Embodiment 3

[0047] A solution film-forming method of an organic material in this embodiment, the specific steps are as follows:

[0048] (1) Pre-film formation: Dissolve the dendrimer sample bis[4-(9,9-diphenyl)-9,10-dihydroacridine)phenyl]sulfone in a volume ratio of 30:50:13 : 7 chloroform: toluene: anisole: in the mixed solvent of tetrahydronaphthalene, obtain film-forming solution; Substrate adopts ITO glass substrate, glass substrate is added ultrasonic treatment 10min with Virahol, acetone, deionized water, Then rinse it with deionized water; the solution deposition is applied by spraying-film-drawing method, after spraying with a micro-sprayer, and then smearing with a silk screen, the film-forming solution is coated on the substrate to obtain Liquid film;

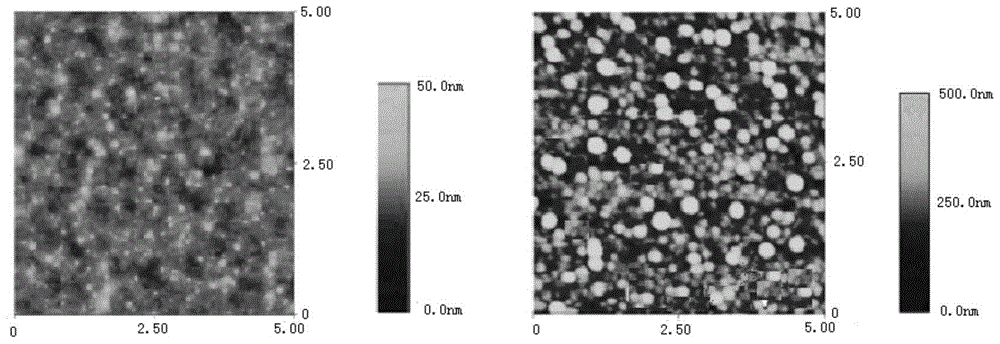

[0049] (2) Dynamic drying: the substrate with liquid film in step (1) is transferred to the equipment shown in embodiment 1, the frequency conversion vibration generator is turned on, the frequency used is 1000Hz, the power se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com