Method for manufacturing and securing metal decorations for products

A technology of metal decoration and fixing method, applied in clothing, accessories, clothing and other directions, can solve the problems of inability to form, damage metal decoration parts, and reduce the elegance of products, and achieve the effect of reducing thickness, improving workability, and beautiful outer packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The terms and words used in this specification and the claims should not be construed as limited to the usual dictionary meanings, but the inventors can properly define the concepts of the terms in order to explain their invention in the best way, Meanings and concepts that should be construed as conforming to the technical thought of the present invention are considered.

[0041] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

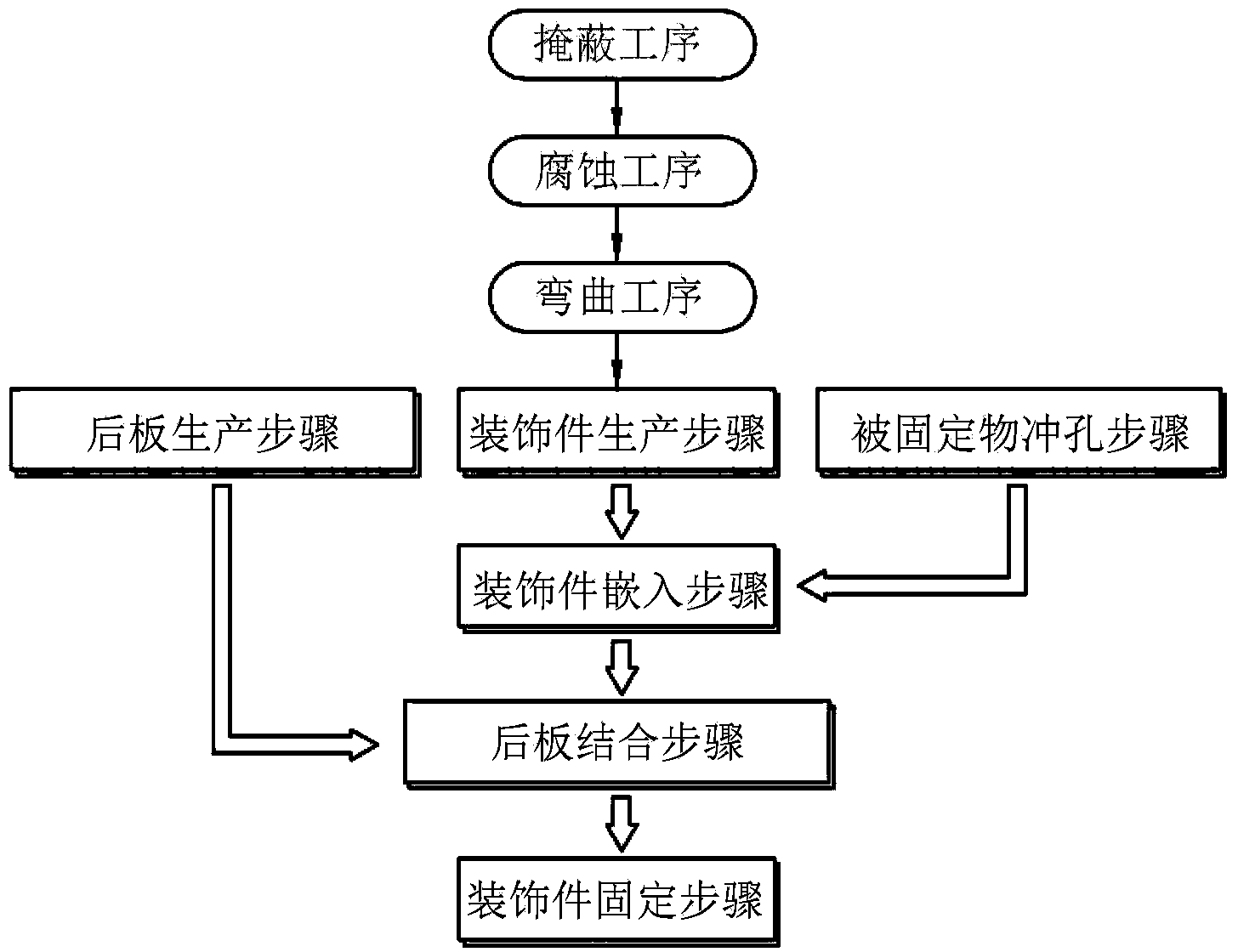

[0042] figure 1 It is an overall process diagram related to the manufacturing and fixing method of the metal decoration of the present invention.

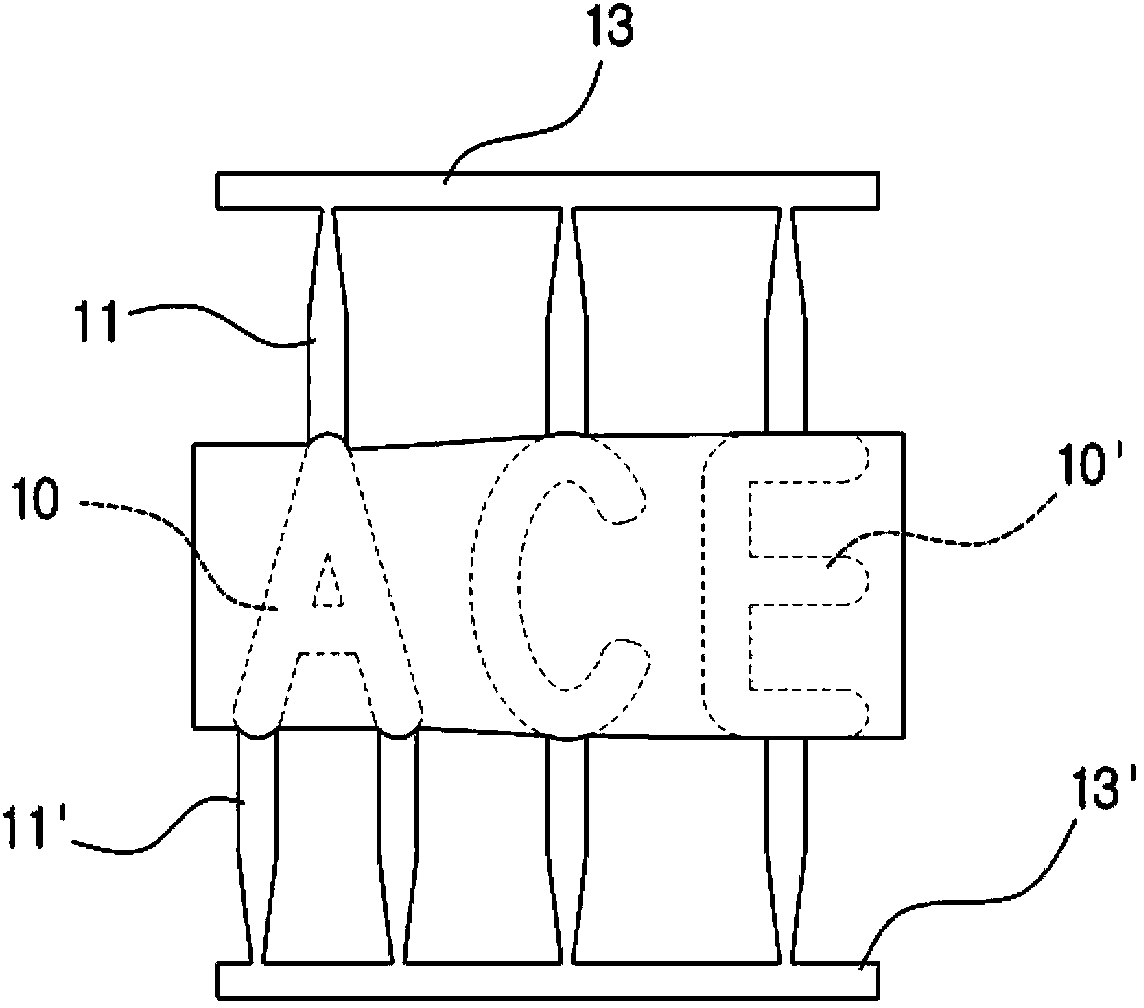

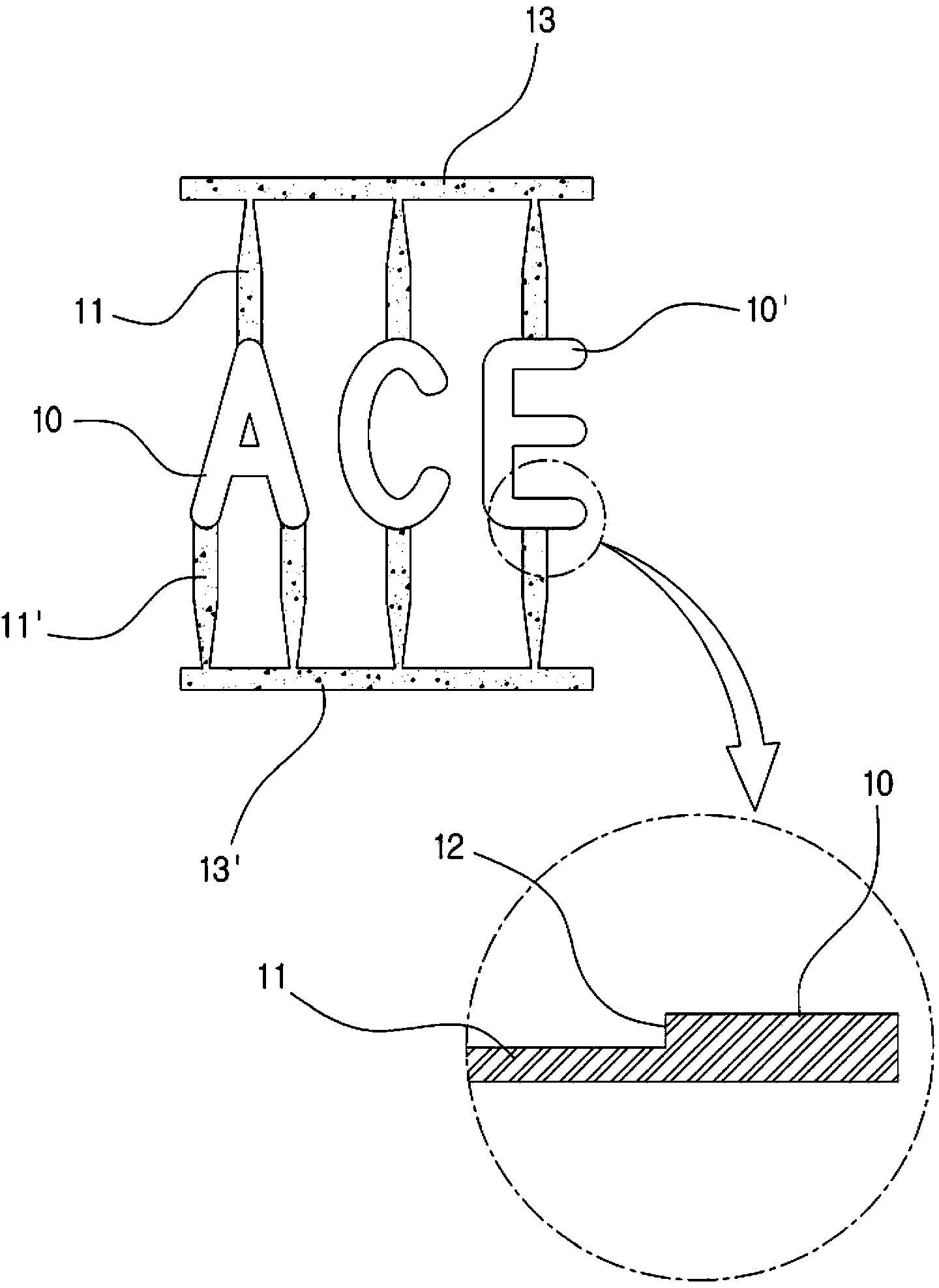

[0043]As shown in the figure, the manufacturing and fixing method of the metal decorative part of the present invention respectively includes the metal decorative parts 10, 10' manufactured through the decorative part production step and the rear plate 20 manufactured through the rear plate production step and fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com