Patents

Literature

128results about How to "Beautiful packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

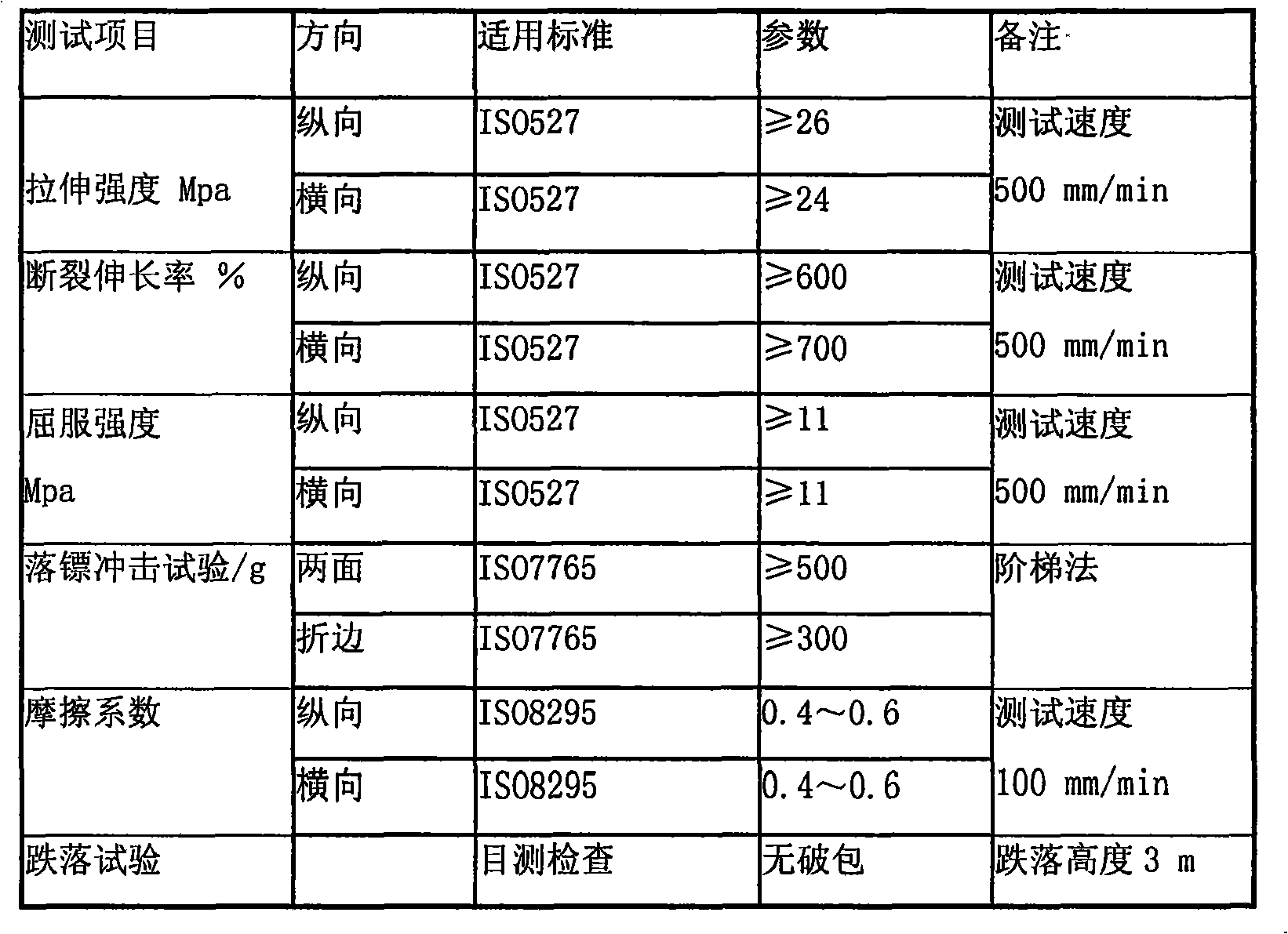

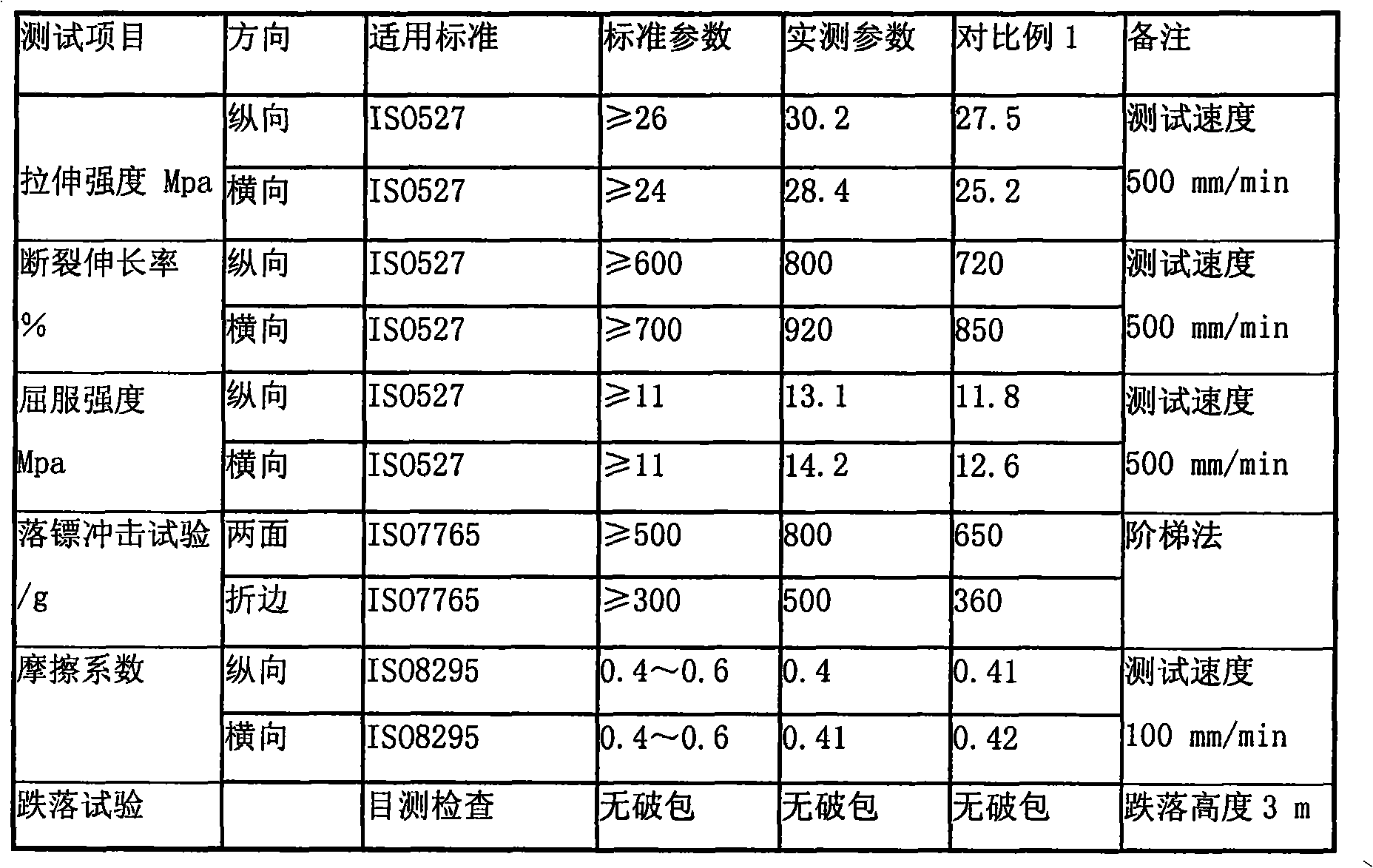

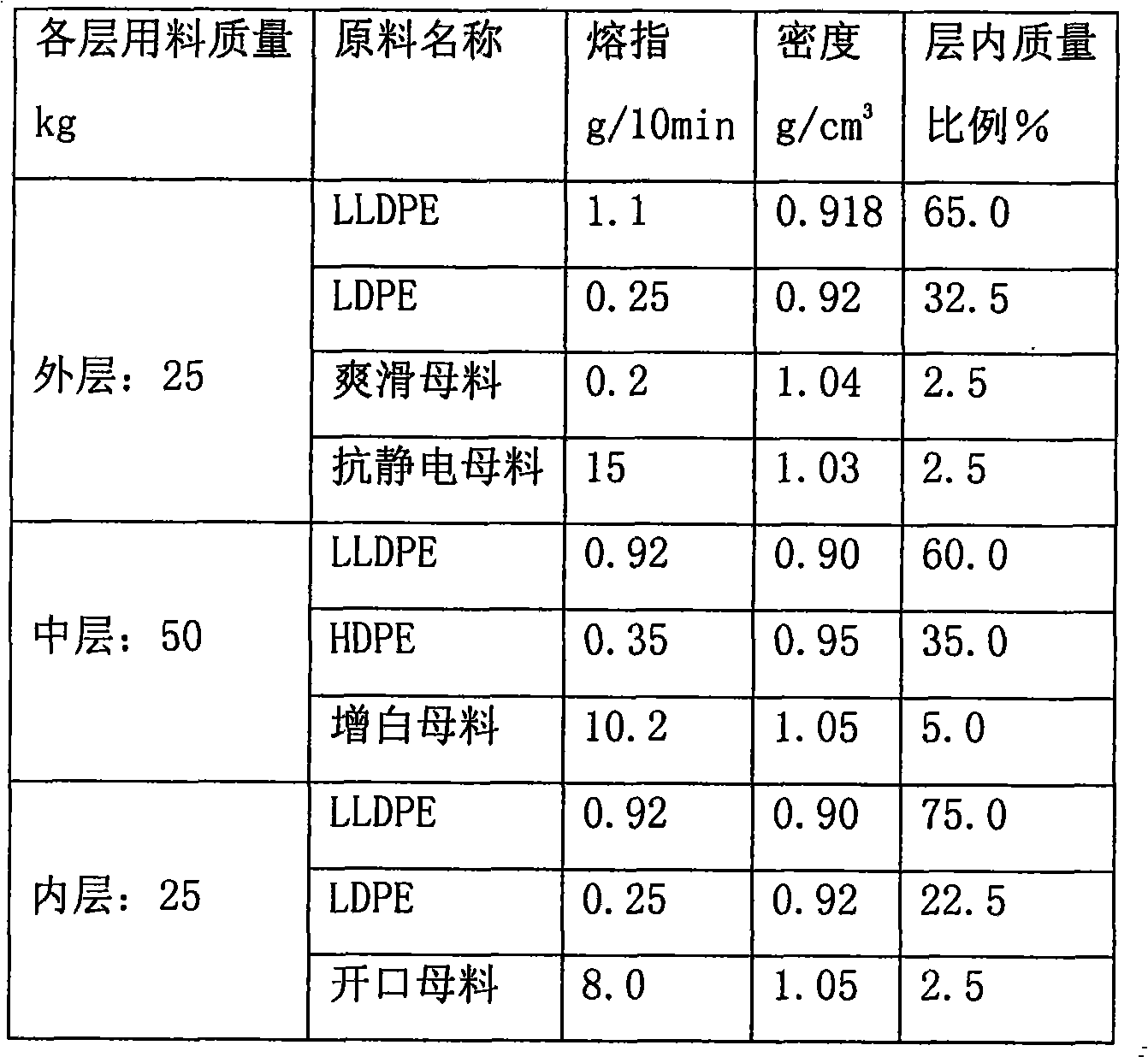

Polyethylene repackaging film material composition

ActiveCN101255249AHigh strengthImprove puncture resistanceLow-density polyethyleneLinear low-density polyethylene

A polyethylene heavy packaging film composite can be widely used for producing blisterpack, such as FFS package, large goods package, tray package and so on, which can effectively improve the all round performance of packaging film, and make the package of goods more beauty, firm, green and effective. The film composite comprises: linear low density polyethylene accounting for 60-80% of the sum of the material, low density polyethylene accounting for 5-25% of the sum of the material, metallocene linear low density polyethylene accounting for 10-30% of the sum of the material, additive accounting for 3-7% of the sum of the material. An automatic feed proportioning system feeds the material of three extruders to die head and the heavy packaging film combination is obtained after three-layer extruding and mixing. The additive is combination of one or several kinds of slippery agent, antistatic agent, antioxidant, opening agent, thermal stabilizer.

Owner:SINOPEC YANGZI PETROCHEM

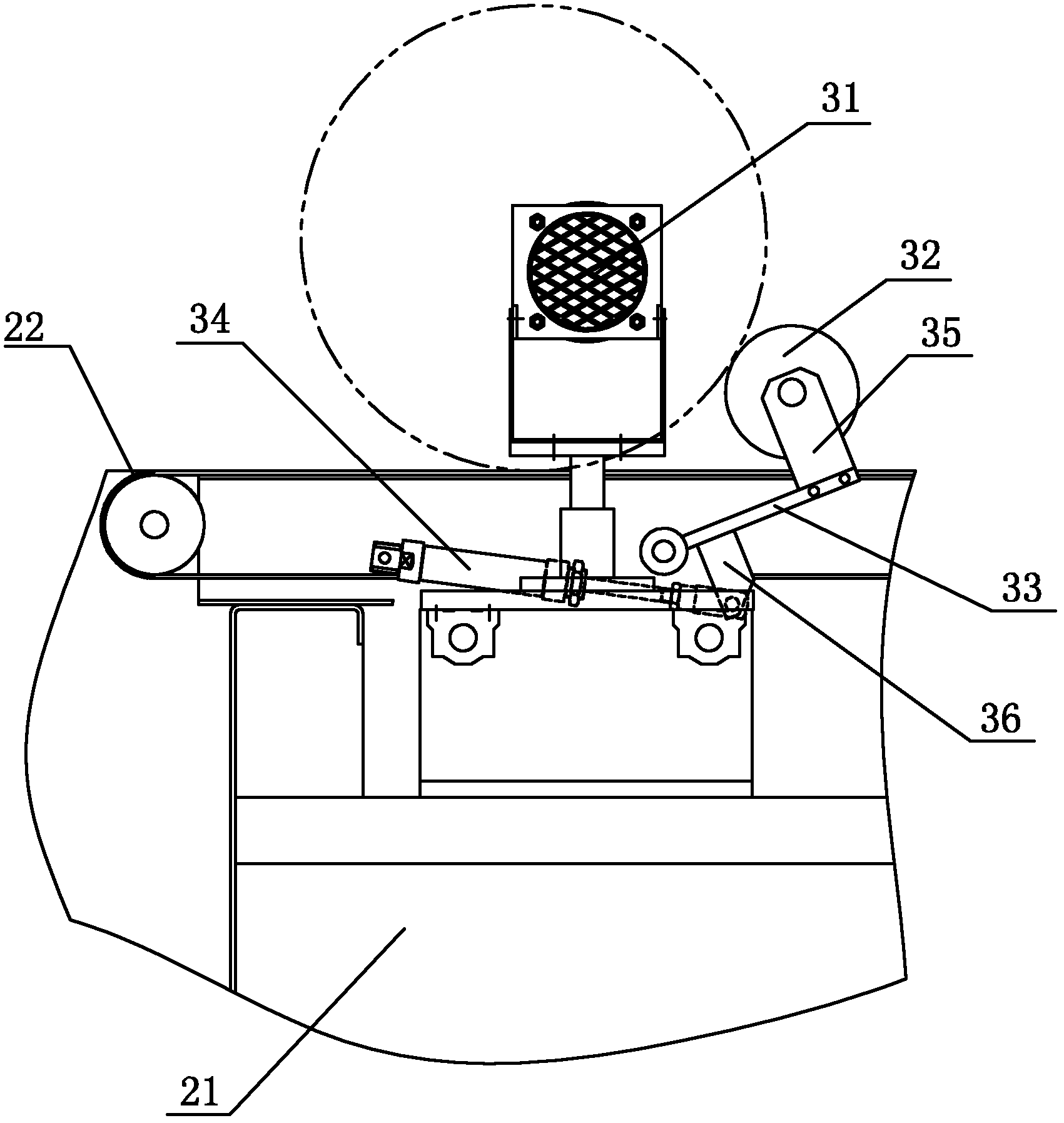

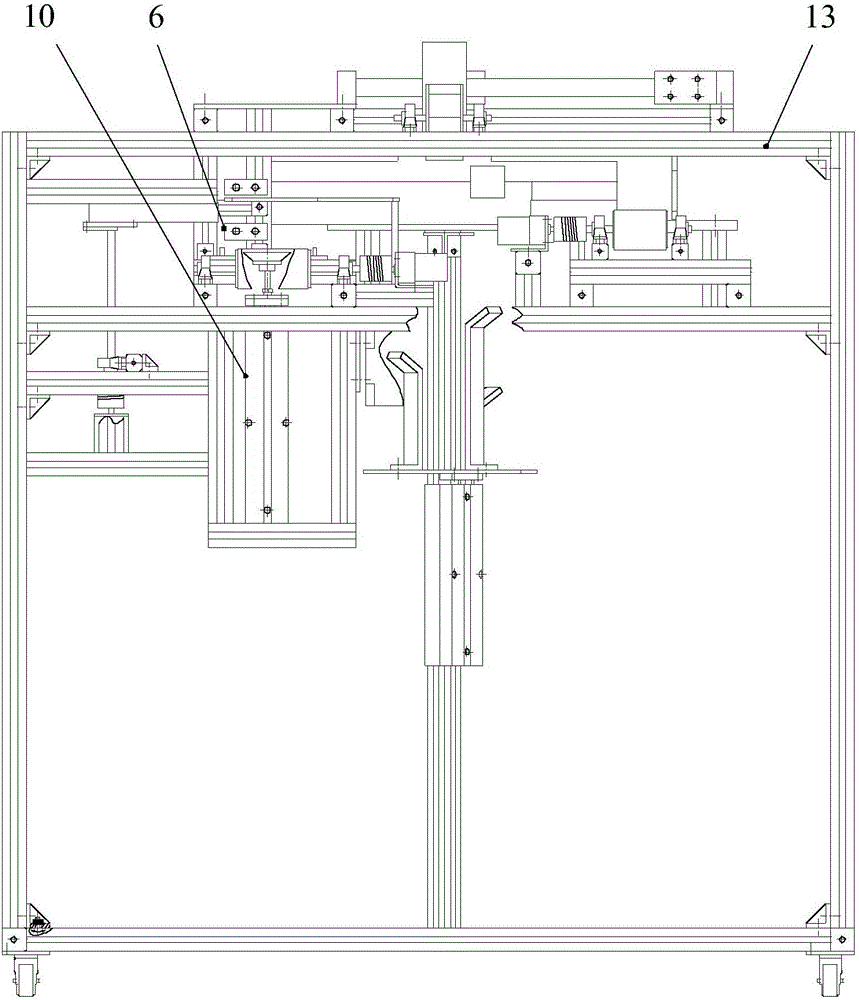

PE (polyethylene) film packaging machine for cloth roll

The invention discloses a PE (polyethylene film packaging machine for a cloth roll, comprising a rack, a cloth inlet conveying mechanism, a PE film automatic packaging mechanism, an end part cutting mechanism and a conveying belt. The PE film packaging machine is characterized in that a heat blower device and an end part pressing device are sequentially arranged at the rear side of the end part cutting mechanism, so that a PE film at the end part of the cloth roll processed by the end part cutting mechanism can be subjected to end part flattening treatment, smoothness of packaging of the end part of the cloth roll is effectively improved, and overall packaging of the cloth roll is more beautiful.

Owner:YUYAO TEXTILE MACHINERY

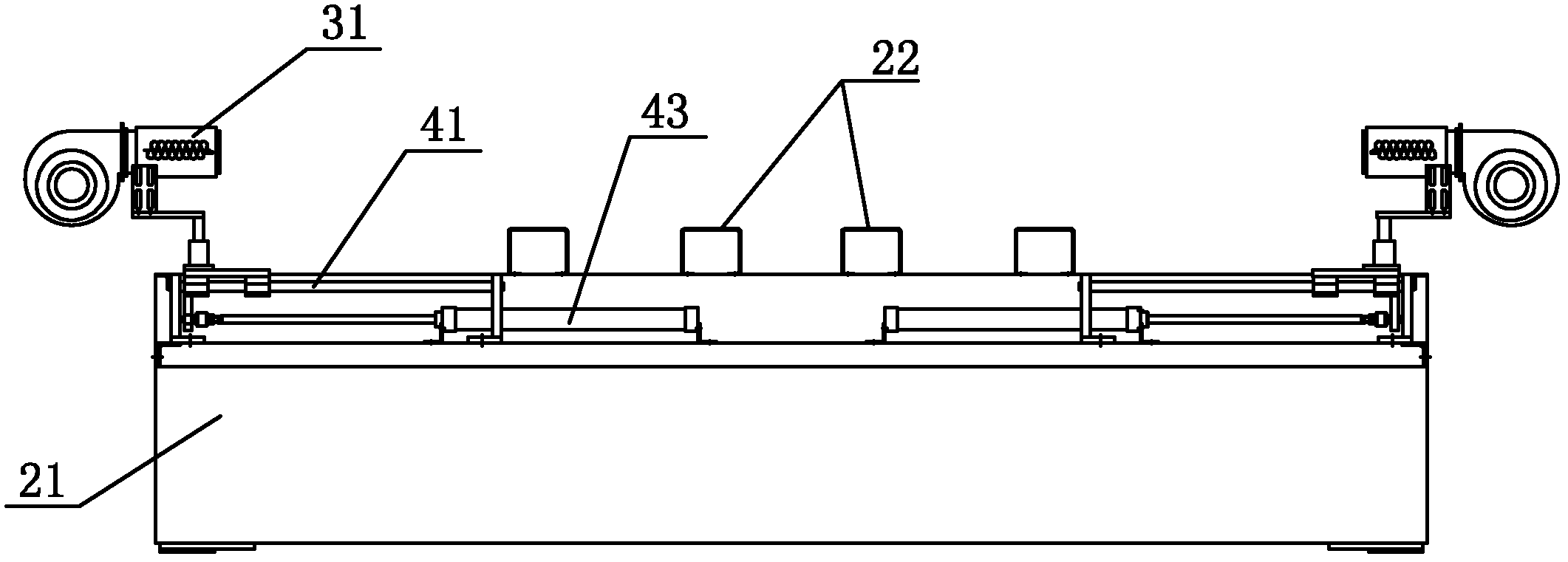

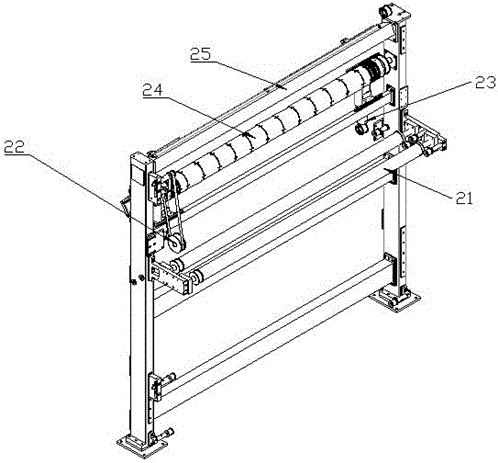

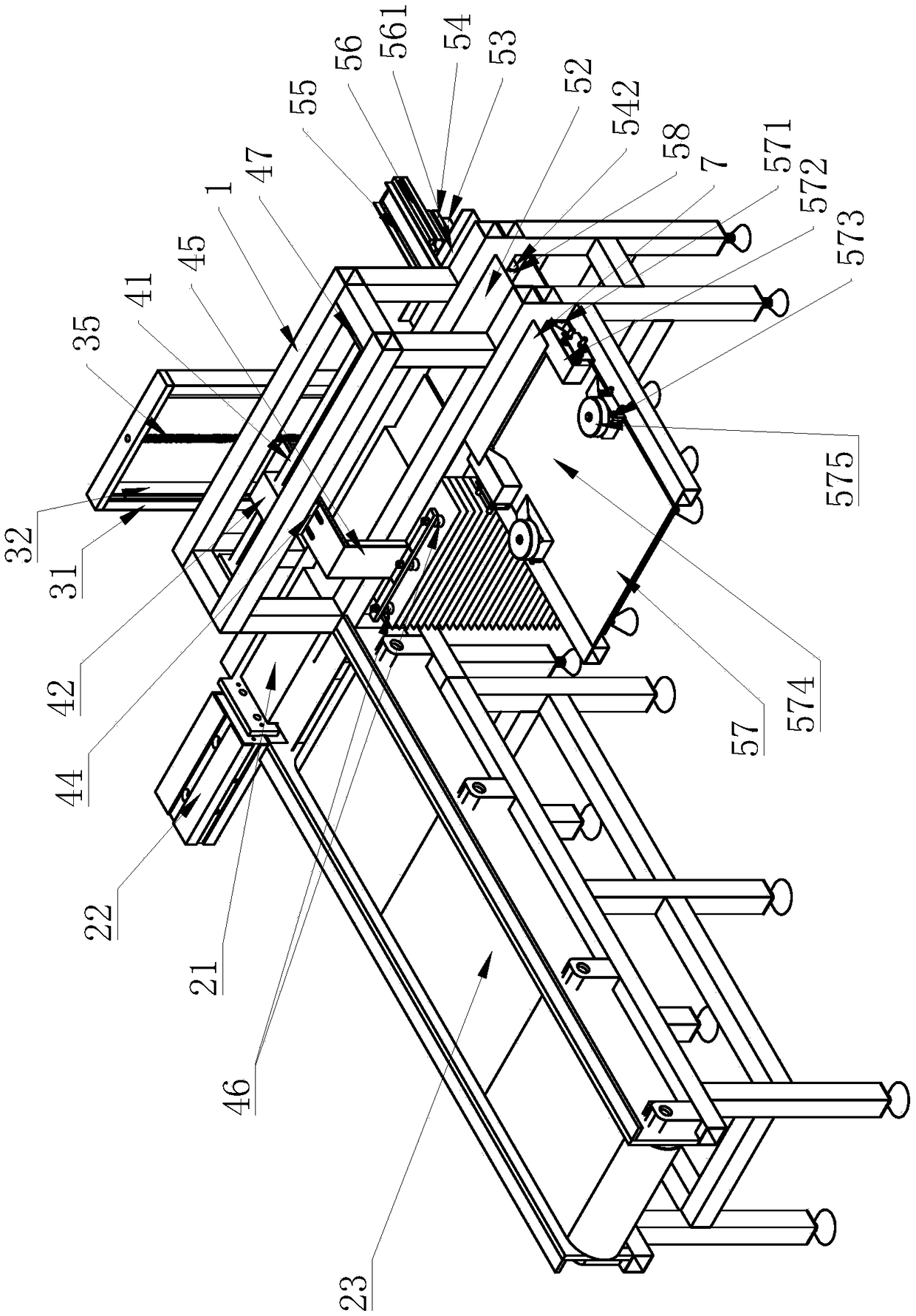

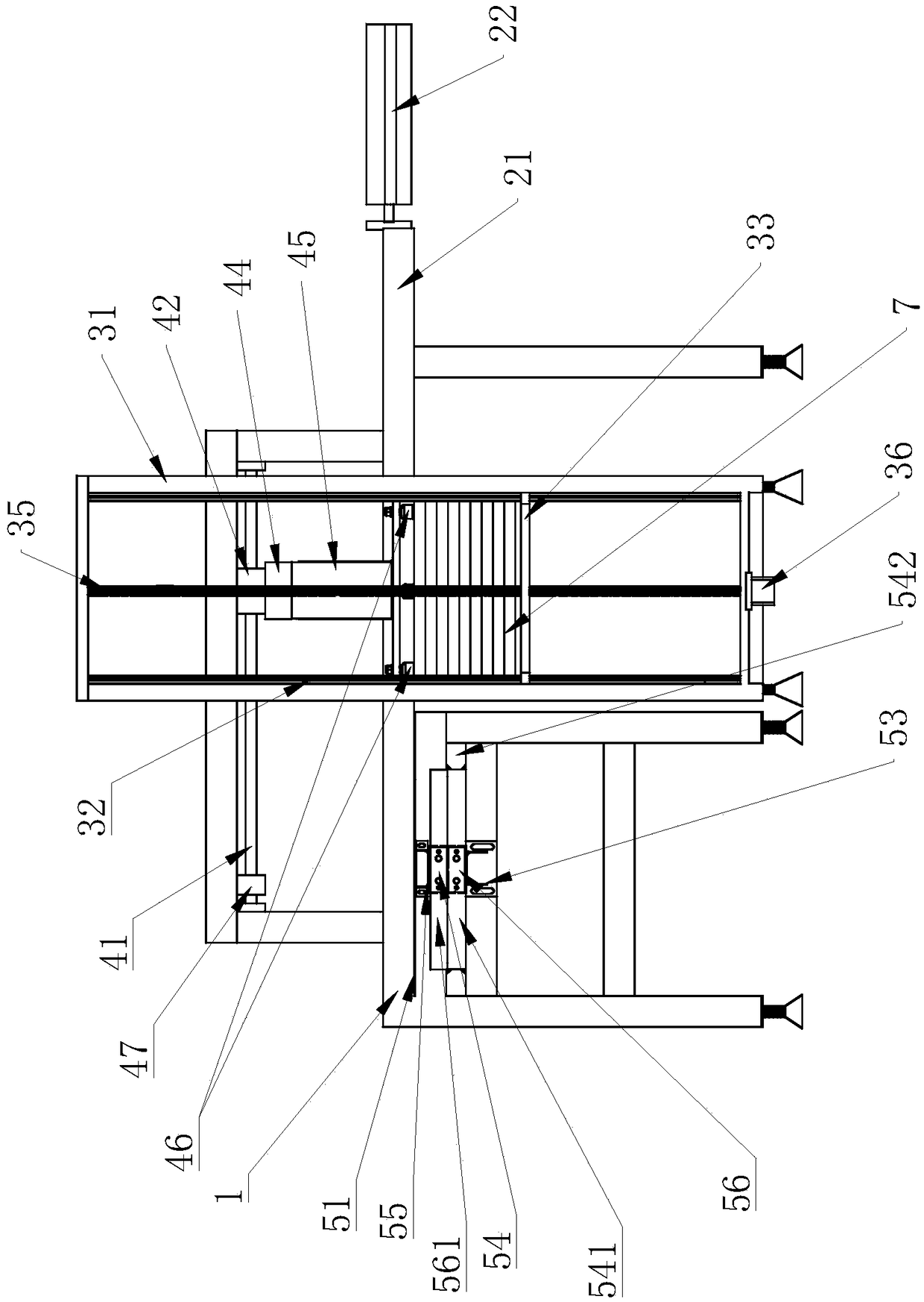

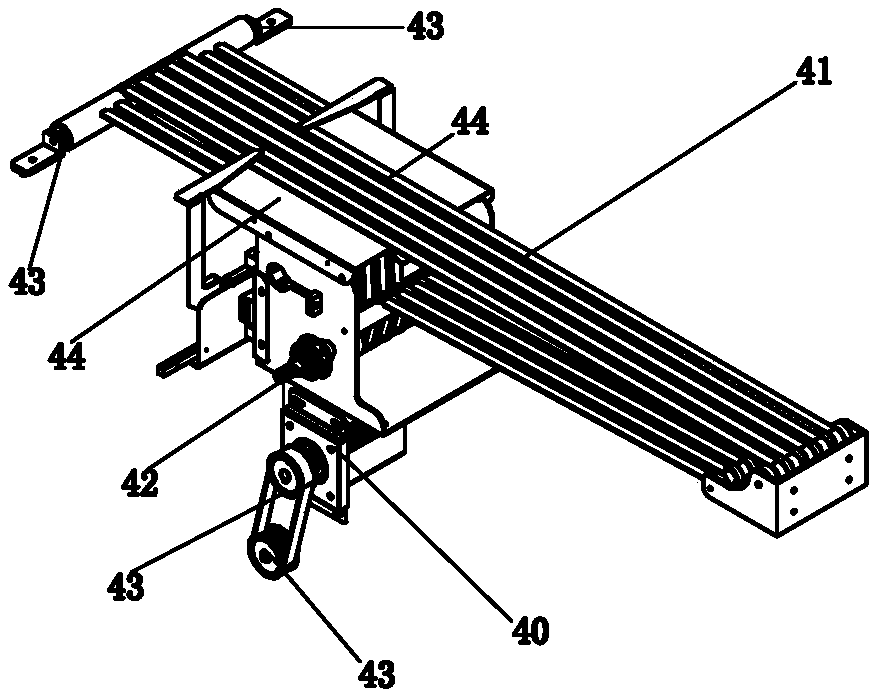

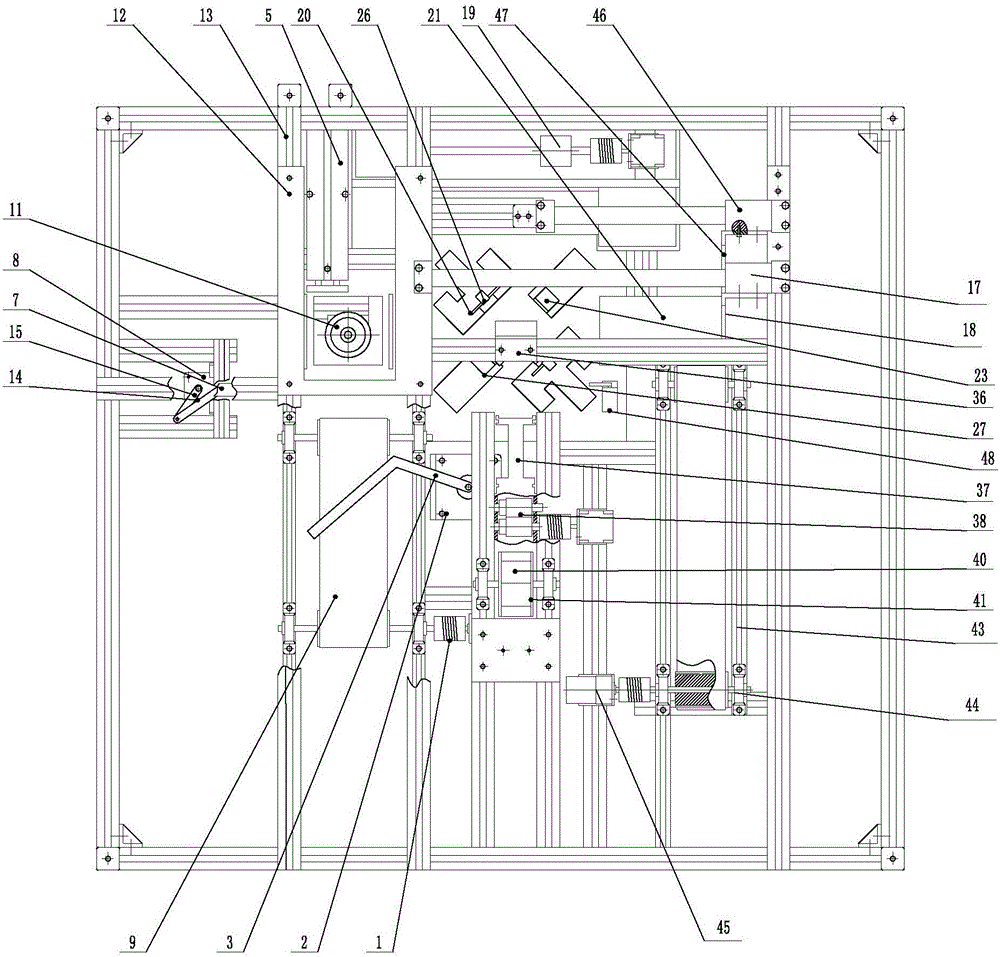

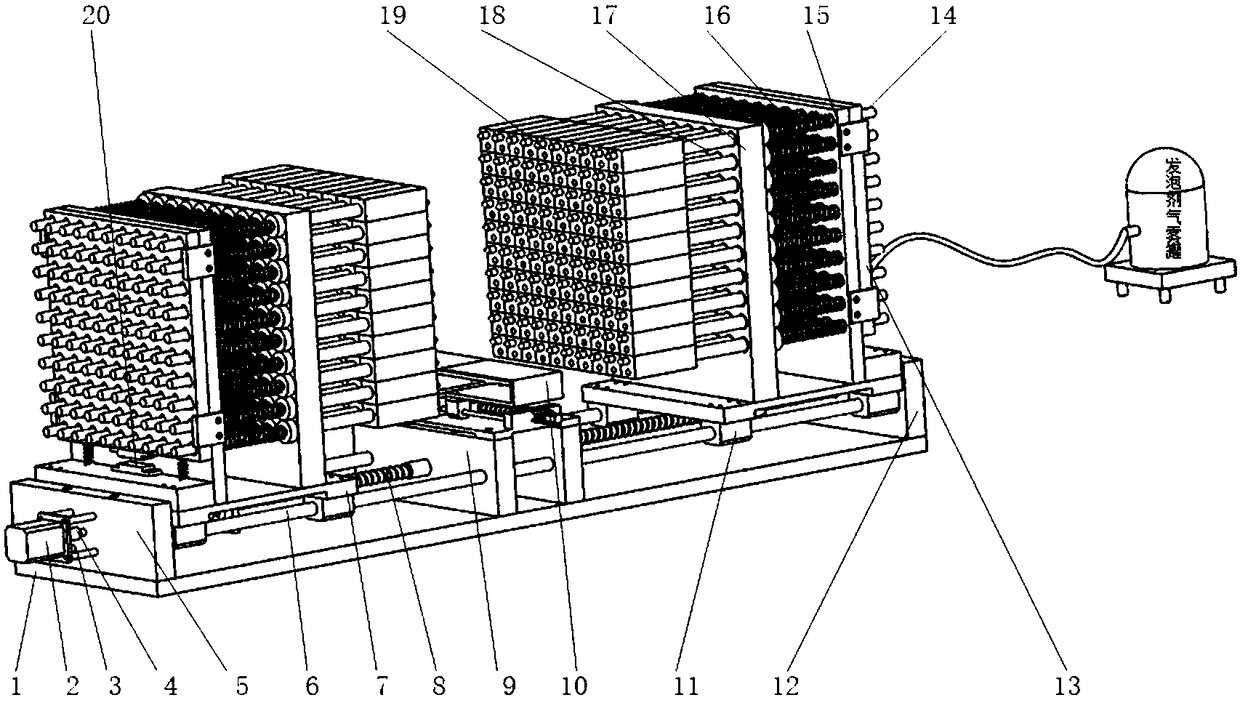

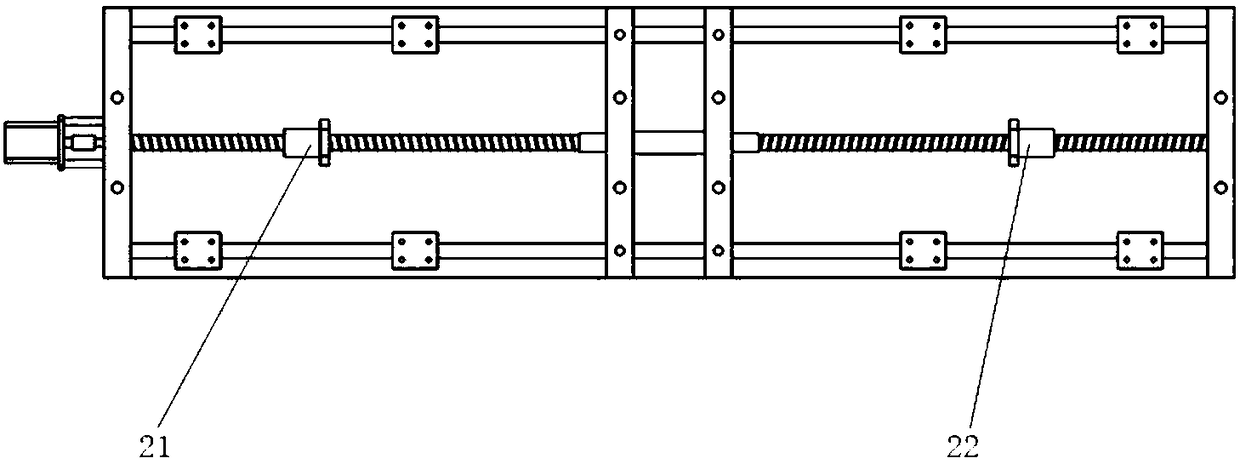

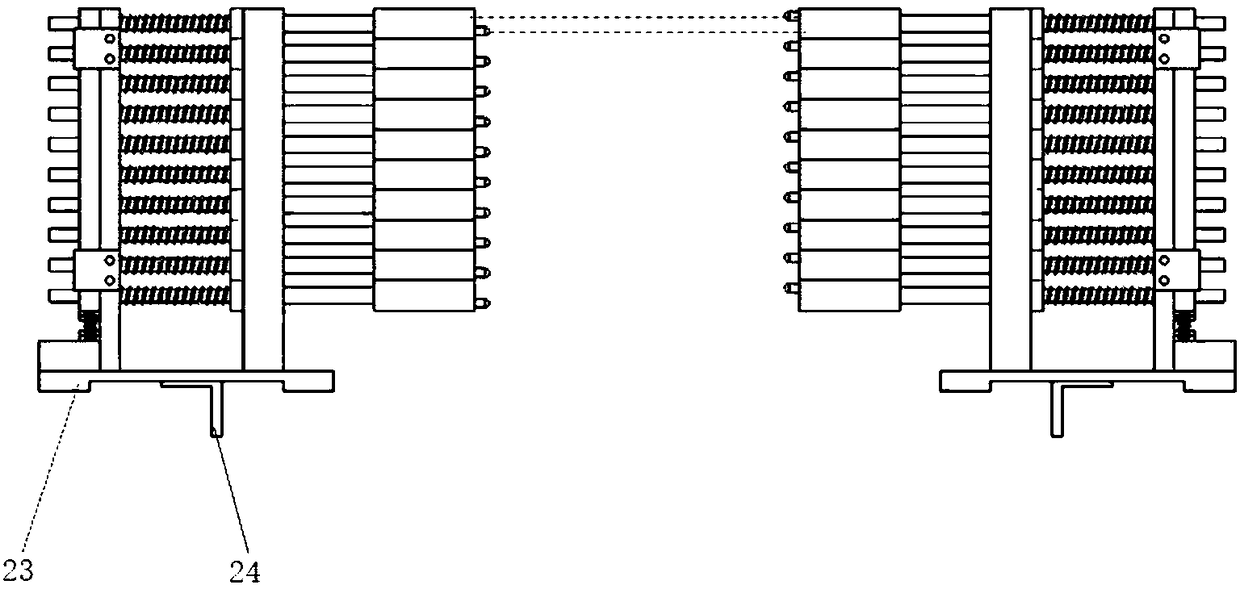

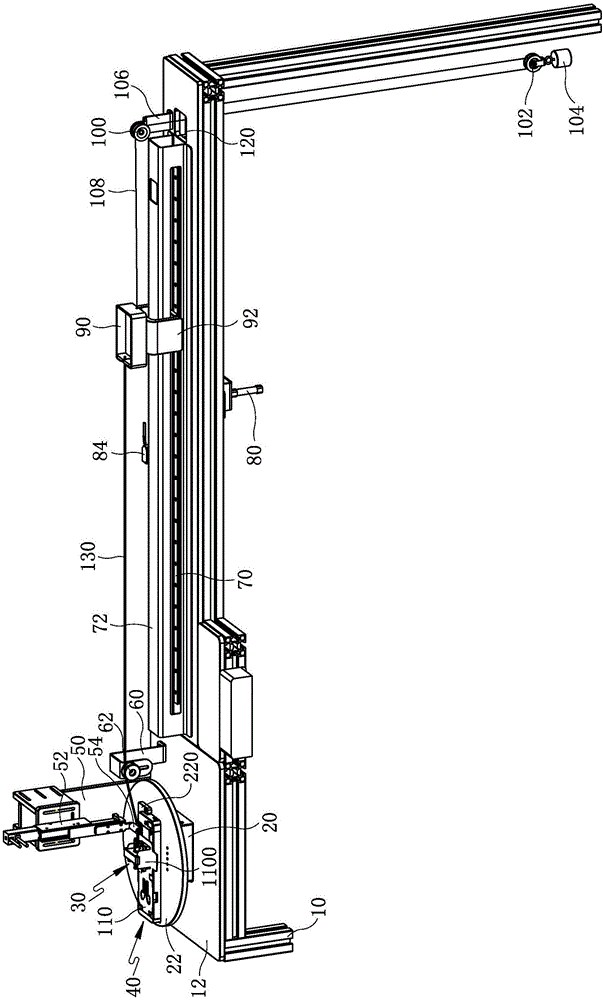

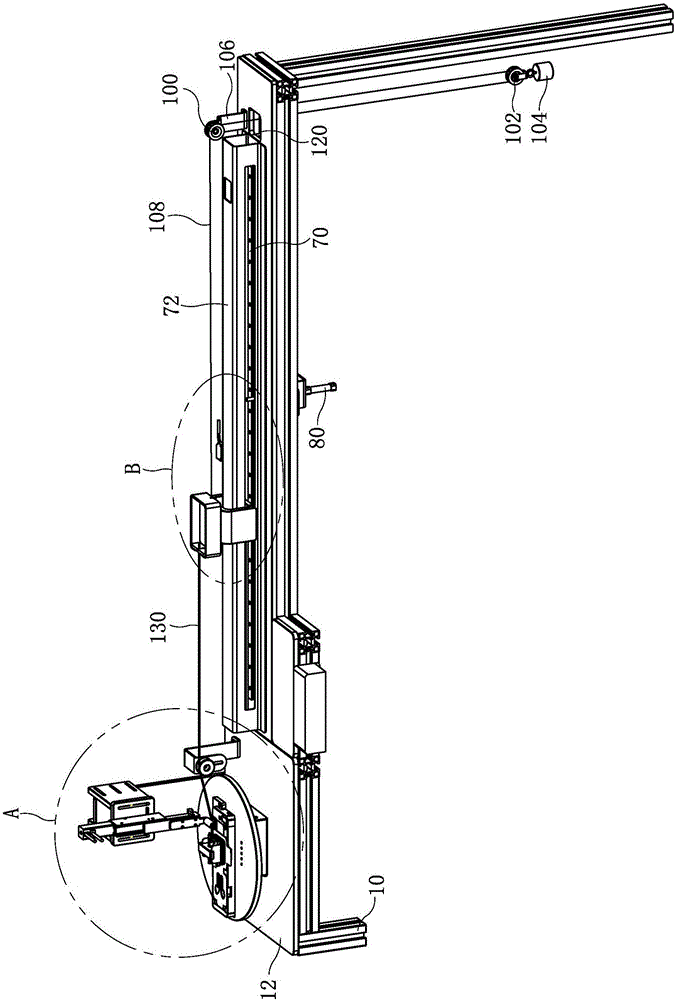

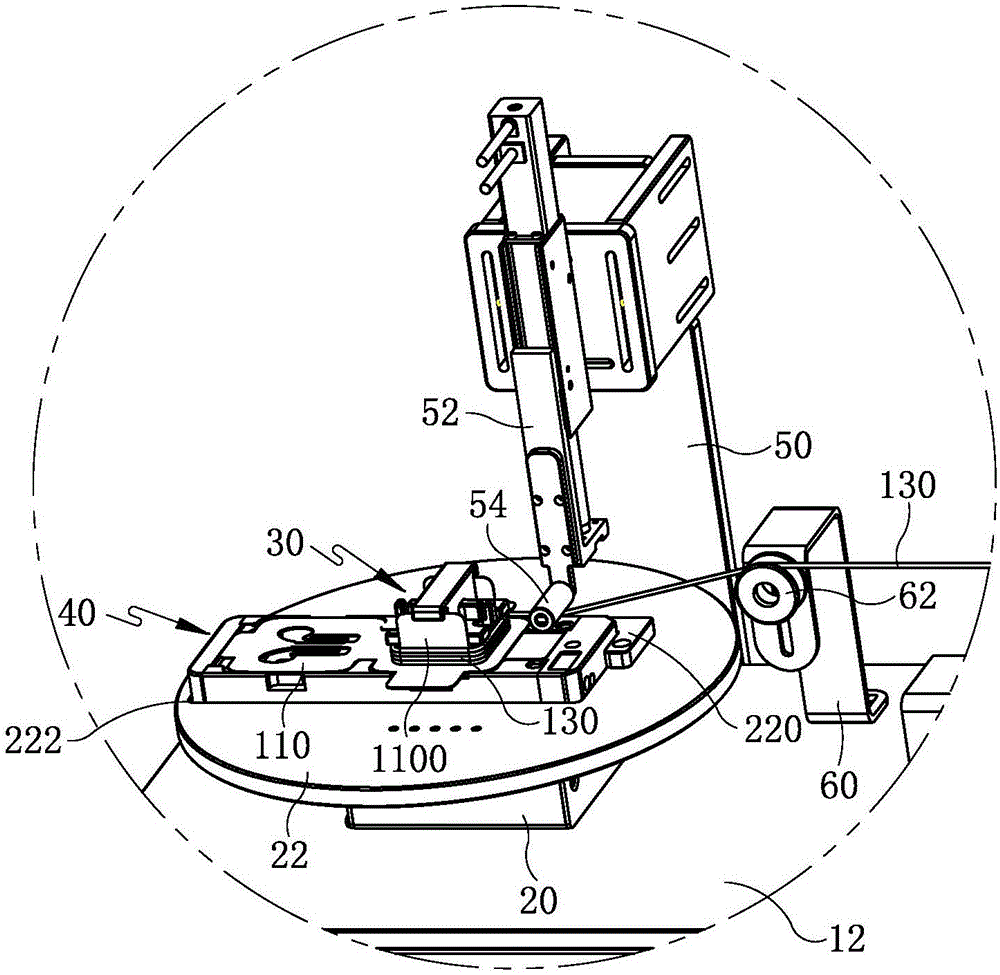

Full-automatic integrated air column bag packaging machine

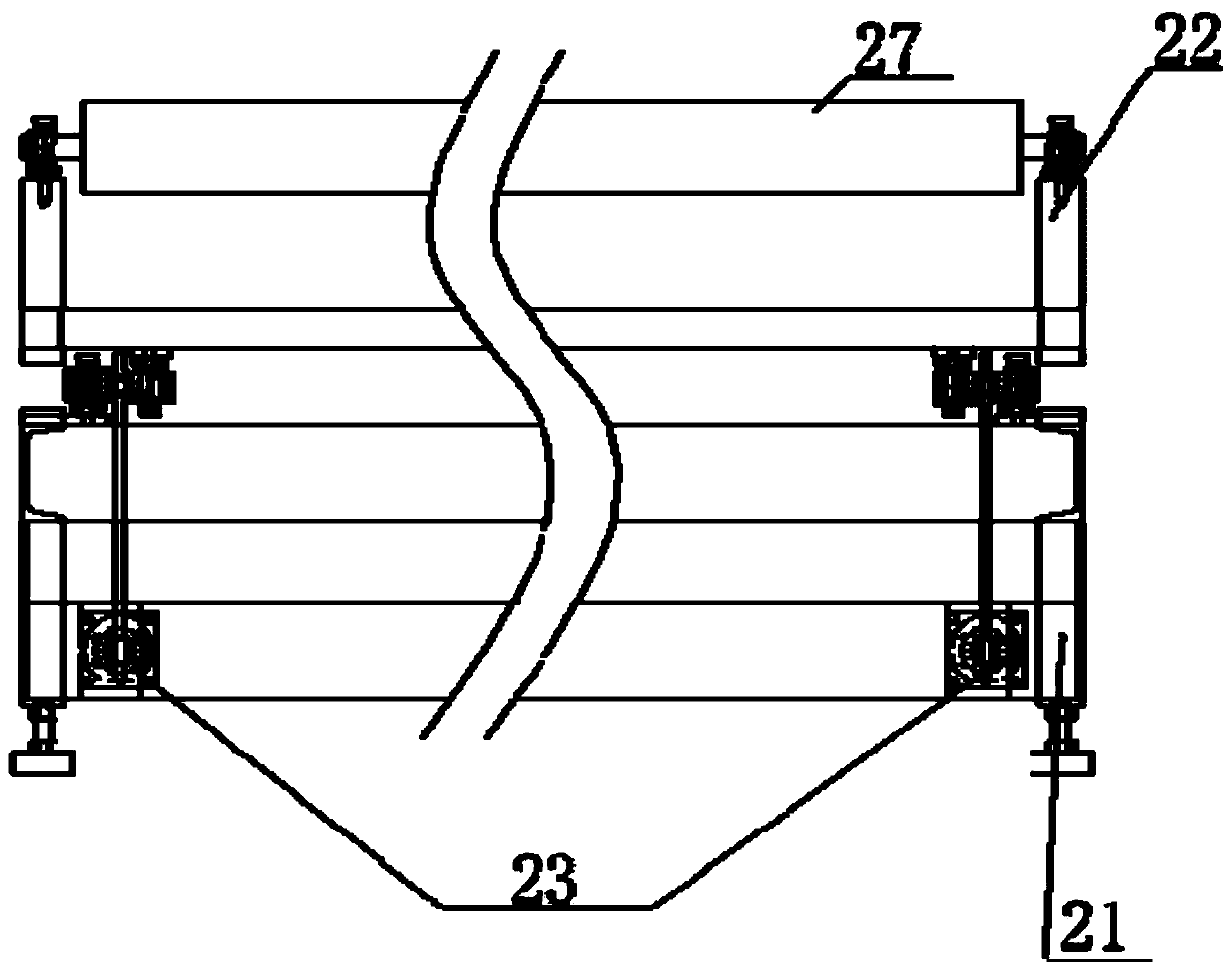

InactiveCN105691688ASimple structureReasonable designConveyor wrappingWrapper twisting/gatheringPulp and paper industrySystem safety

The invention discloses a full-automatic integrated air column bag packaging machine. The full-automatic integrated air column bag packaging machine comprises a rack, wherein a winding roller and a redirection roller are rotatably installed on the top of the rack, the winding roller is positioned on the front side of the redirection roller, the winding roller is parallel to the redirection roller, an air column bag clamp is installed on the lower part of the rack, the end of an air column bag bypasses the redirection roller and then is clamped by the air column bag clamp, a block pushing mechanism is installed on the front side of the rack, both the winding roller and the redirection roller are positioned above the block pushing mechanism, the block pushing mechanism is positioned above the air column bag clamp, a vertical pressing heat sealing device and a transverse pressing heat sealing cutting device are installed on the rear side of the rack, and the transverse pressing heat sealing cutting device is positioned between the redirection roller and the vertical pressing heat sealing device. The full-automatic integrated air column bag packaging machine has the advantages of reasonable structural design, rapidity and convenience in packaging, high packaging efficiency, stability and reliability in block pushing, attractive appearance and environmental friendliness of packaging materials, the problem of heavy workload caused by manual packaging is solved, an accurate positioning function is realized, and the system safety is increased.

Owner:XIAN UNIV OF SCI & TECH

Heat-resistance type transfer aluminum plated paper and its producing process

InactiveCN101050605AImprove adhesionGood flexibilityNon-fibrous pulp additionPhysical paper treatmentAdhesiveHeat resistance

The present invention relates to a temperature-resistant type transfer aluminized paper and its production process. Said process successively includes the following steps: coating release layer on the film; coating anchoring layer on release layer; vacuum aluminizing on the anchoring layer; coating adhesive on the aluminized layer; then making them be combined with paper; stripping film from release layer so as to obtain the invented temperature-resistant type transfer aluminized paper.

Owner:SHAOGUAN DONGYANGGUANG PACKAGE PRINTING CO LTD

Forming and sealing method for food packaging

ActiveCN104443571AImprove sealing efficiencyImprove continuityWrapper twisting/gatheringEngineeringFood packaging

The invention discloses a form-seal method for food packaging. The method sequentially includes the steps of a bag forming process, a vertical sealing process and a transversal sealing process, wherein the bag forming process includes folding an entire roll of packaging film into square film bags through a bag forming unit, the transversal sealing process includes performing corner inserting and heat-sealing to the front ends of the square fill bags filled with food after being vertically sealed, by a knife-sealing corner-inserting unit, cutting the rear ends of the square film bags in advance, then performing corner inserting and heat-sealing to obtain the finished products. During the transversal sealing process, the vertically sealed square film bags can be successively subjected to end corner inserting and sealing by adopting the knife-sealing corner-inserting unit, and thereby the efficiency of forming and sealing of a whole package is improved and the sealing effect is better.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

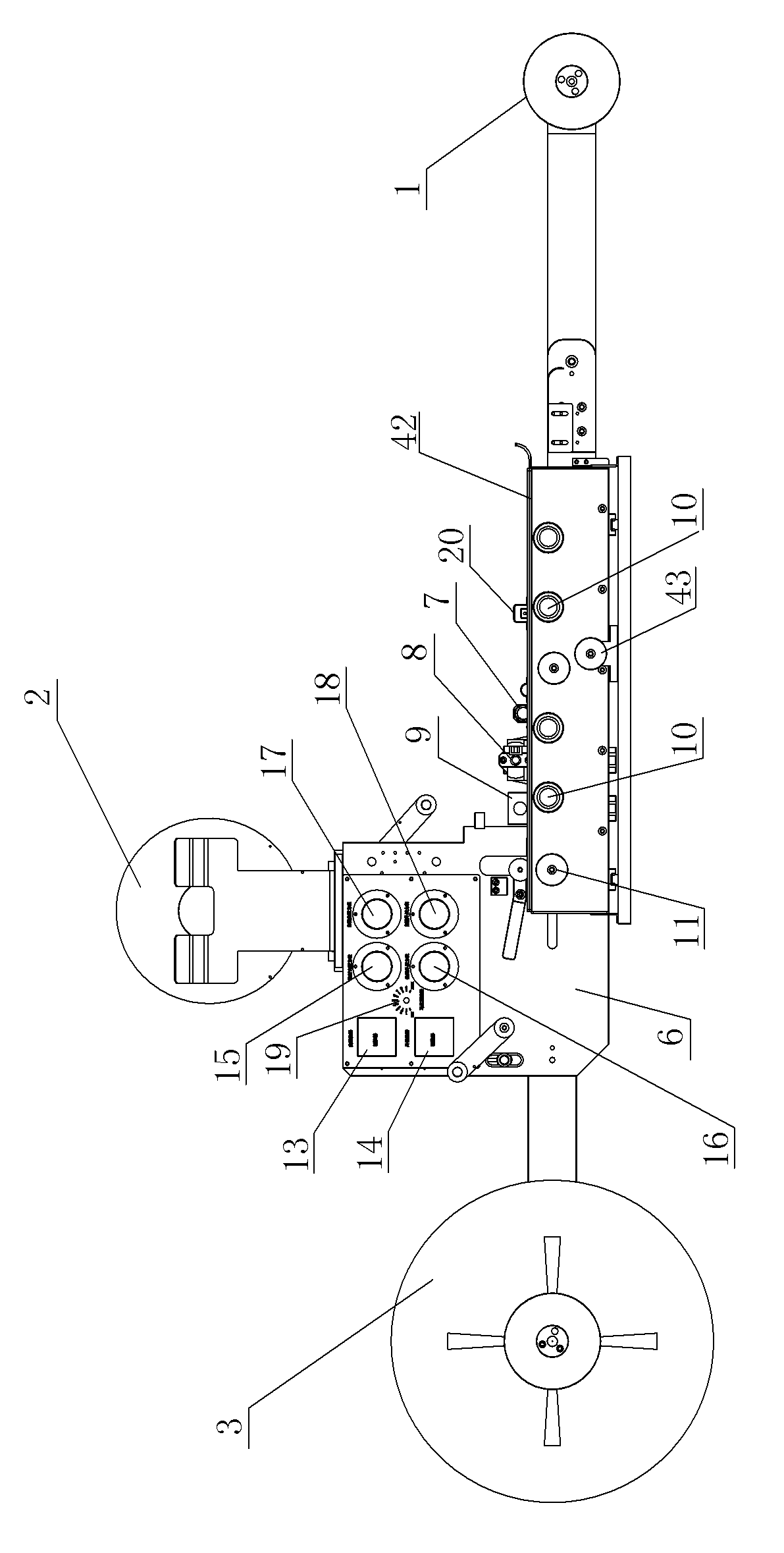

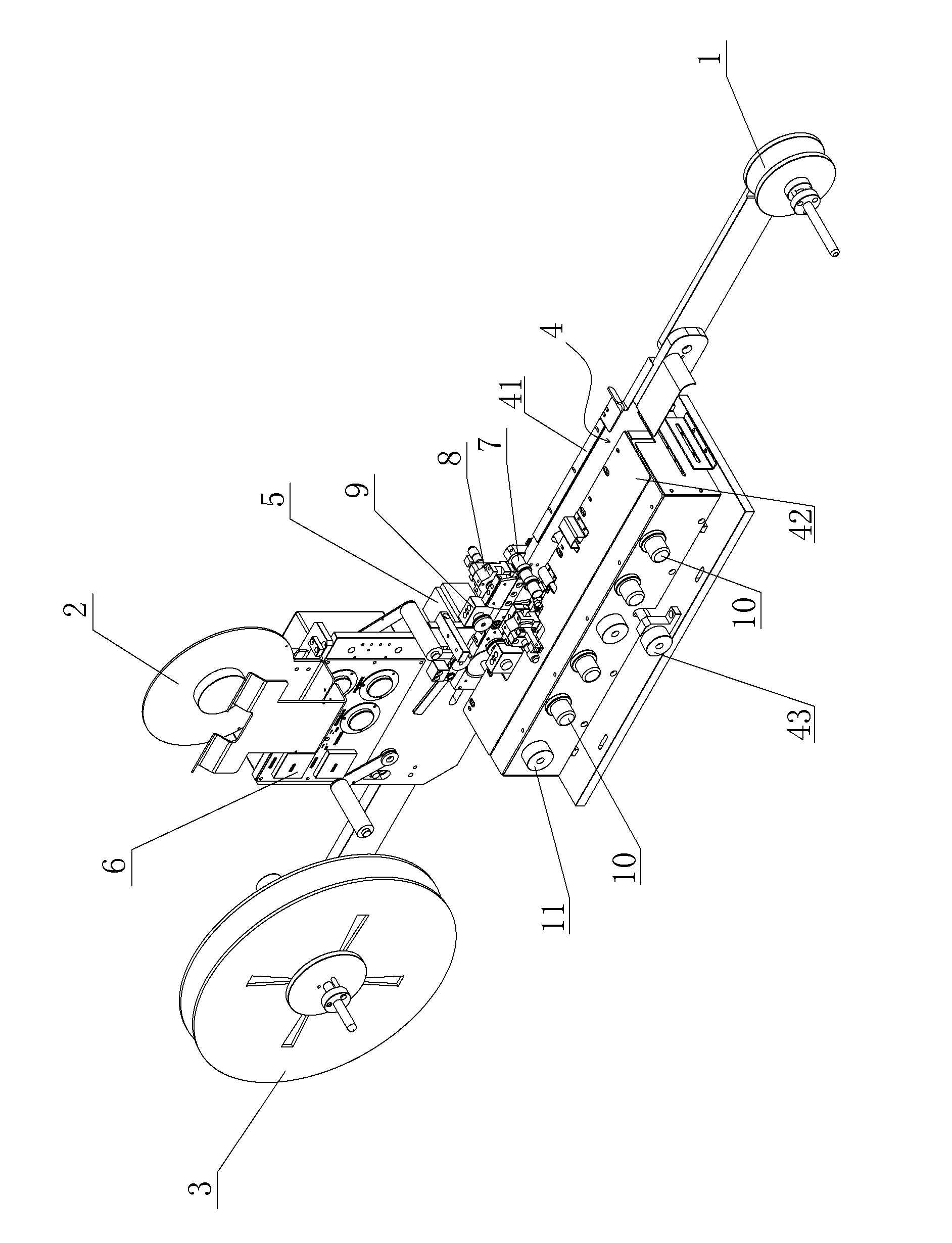

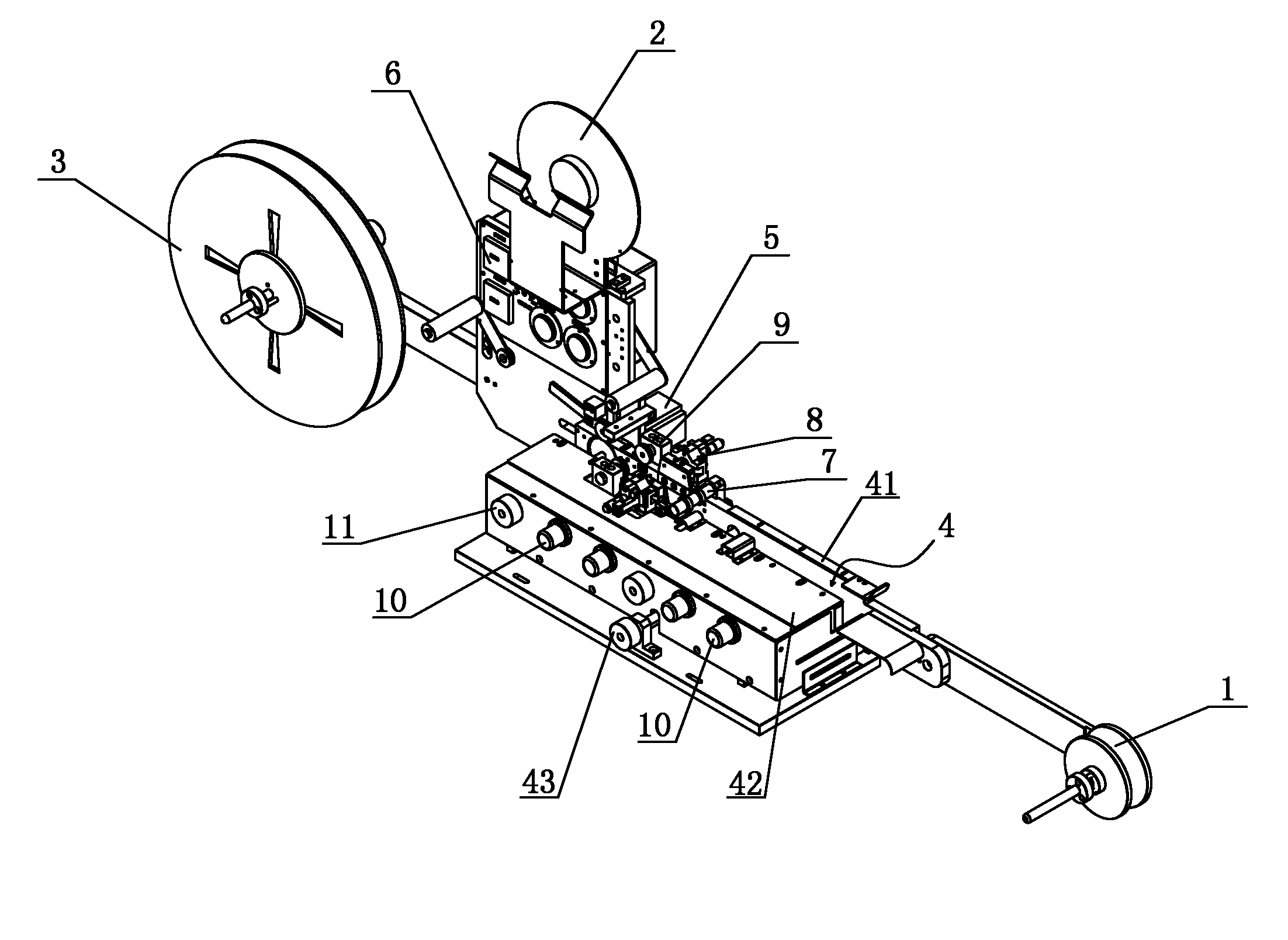

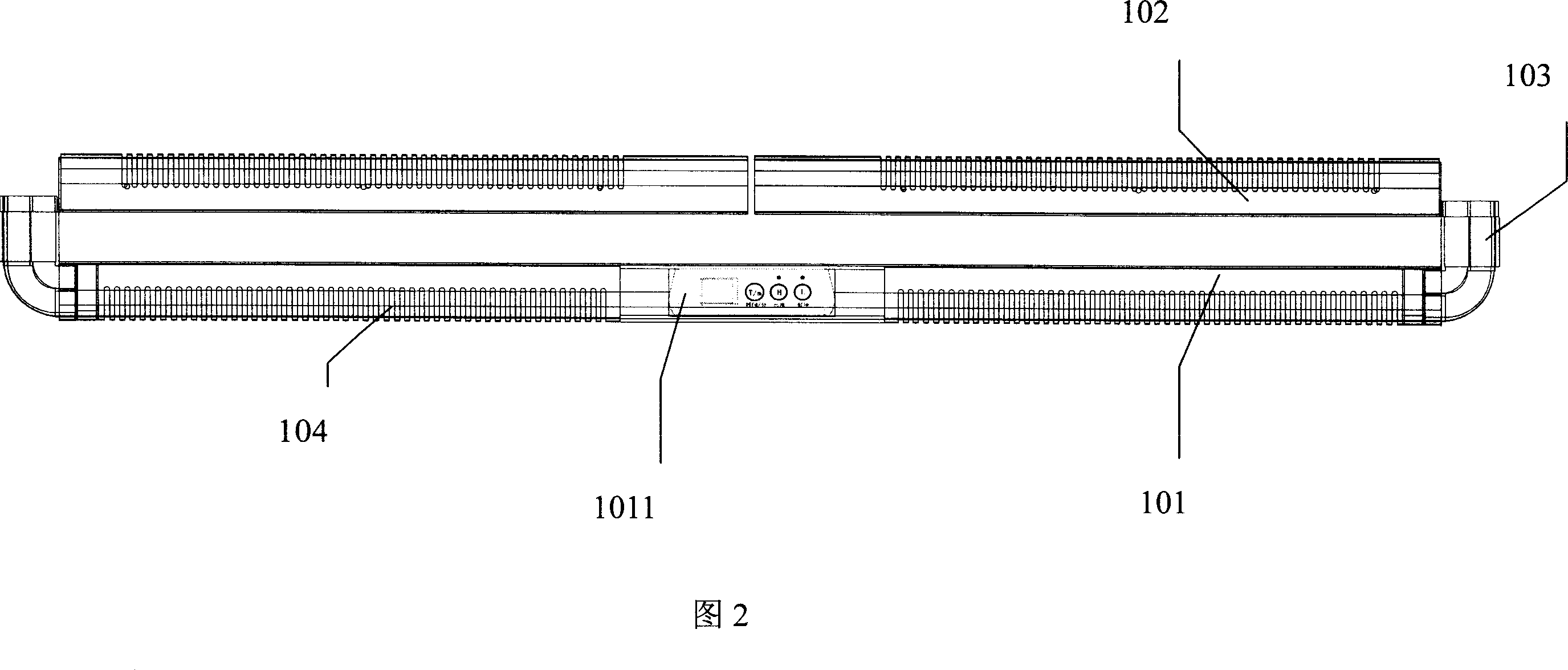

Carrier tape packaging machine with self-adhesion and/or heat sealing functions

InactiveCN102126569AAdjustable packing widthImprove airtightnessWrapper twisting/gatheringEngineeringDrive motor

The invention disclose a carrier tape packaging machine with self-adhesion and / or heat sealing functions, comprising a carrier tape feed tray, an upper tape feed tray, a material receiving tray, a conveying track, a driving motor, a guiding device and a control instrumental board, wherein, the carrier tape feed tray and the material receiving tray are respectively arranged at the two sides of the conveying track; the control instrumental board is arranged at one side of the conveying track and is provided with the upper tape feed tray; a heat-seal device and a cold-seal device are arranged at the back of the guiding device on the conveying track; the heat-seal device and the cold-seal device are respectively connected with a heat-seal reducing valve and a cold-seal reducing valve; and the heat-seal reducing valve and the cold-seal reducing valve are respectively connected the control instrumental board. The carrier tape packaging machine provided by the invention has the advantages of high automation, high efficiency and self-adhesion and / or heat sealing functions.

Owner:DONGGUAN LONGSHUN AUTOMATION TECH

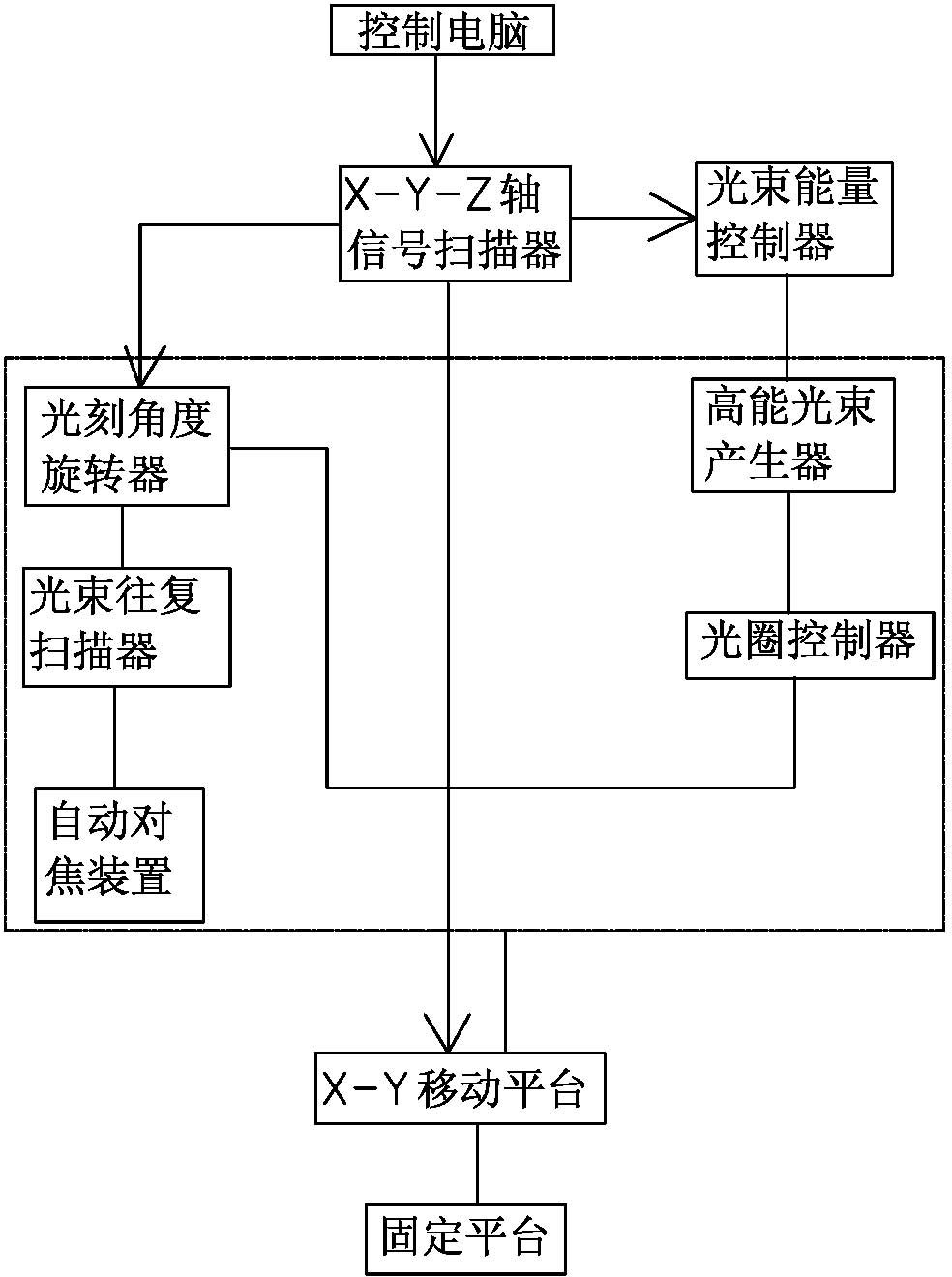

Microstructural stereoscopic anaglyph image-text platemaking method and device

ActiveCN102183878ALow costEye-catching visual impact effectPhotomechanical exposure apparatusMicrolithography exposure apparatusHigh energyLight beam

The invention relates to a microstructural stereoscopic anaglyph image-text platemaking method and device. The microstructural stereoscopic anaglyph image-text platemaking device comprises a control computer, an X-Y-Z axis signal scanner, an X-Y mobile platform, a light beam energy controller, a high energy light beam generator, an aperture controller, a photoetching angle rotator, a light beam reciprocating scanner, an automatic focusing device and a fixed platform for installing of light-resistance glass; and the X-Y-Z axis signal scanner is core equipment of the microstructural stereoscopic anaglyph image-text platemaking device. In the invention, stereoscopic anaglyph image-texts manufactured by single-beam high energy laser or electronic beams can be copied to plastic films, paper and plastic products through various conventional technologies, such as mold pressing, ultraviolet curing and molding, extrusion molding, electronic beam curing and molding, and the like, and therefore low-cost production in large scale can be realized.

Owner:中丰田光电科技(珠海)有限公司

Paper money plastic packaging machine and plastic packaging method

InactiveCN104691815ACompact structureReduce volumePaper article packagingWrappingThermoplasticPlastic packaging

The invention discloses a paper money plastic packaging machine and a plastic packaging method. A plastic sealing film input mechanism and a paper tape film input mechanism of the plastic sealing machine input a plastic sealing film and a paper tape film to a film feeding mechanism respectively; a thermal transfer machine prints paper money sign sealing information on the paper tape film; a mould pulling mechanism pulls the plastic sealing film and the paper tape film to an assigned position on the other side of a working platform; a film cutting mechanism is used for cutting the plastic sealing film and the paper tape film; a locating mechanism comprises a bearing and receiving plate and an edgefold device; the edgefold device is arranged at the periphery of the bearing and receiving board; the plastic sealing film and the paper tape film drop on the bearing and receiving plate after the plastic sealing film and the paper tape film are cut; to-be-plastic-sealed money is placed on the paper tape sealing film; the bearing and receiving plate conducts up-and-down motion under the action of a lower pressing plate and a spring; the edgefold device folds the plastic sealing film and the paper tape film; a thermoplastic mechanism is used for conducting thermoplastic on the plastic sealing film or the paper tape film. The plastic sealing machine is driven electrically, can fulfill pre-wrapping and plastic sealing film packaging at single working station, and has the advantages that the plastic sealing machine is simple in structure, small in size and low in noise, and saves materials.

Owner:GUANGDONG DESOUL INTELLIGENT TECH CO LTD

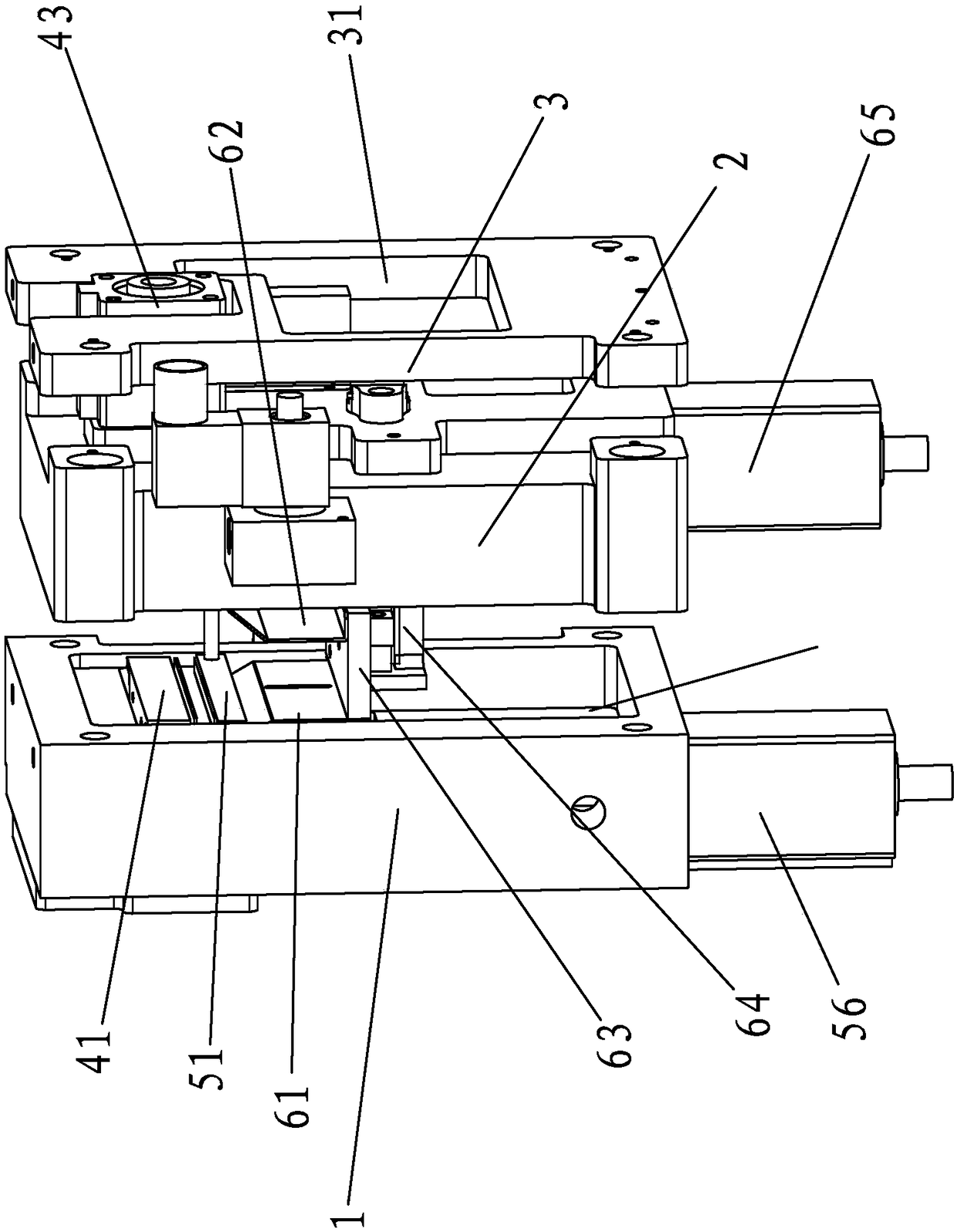

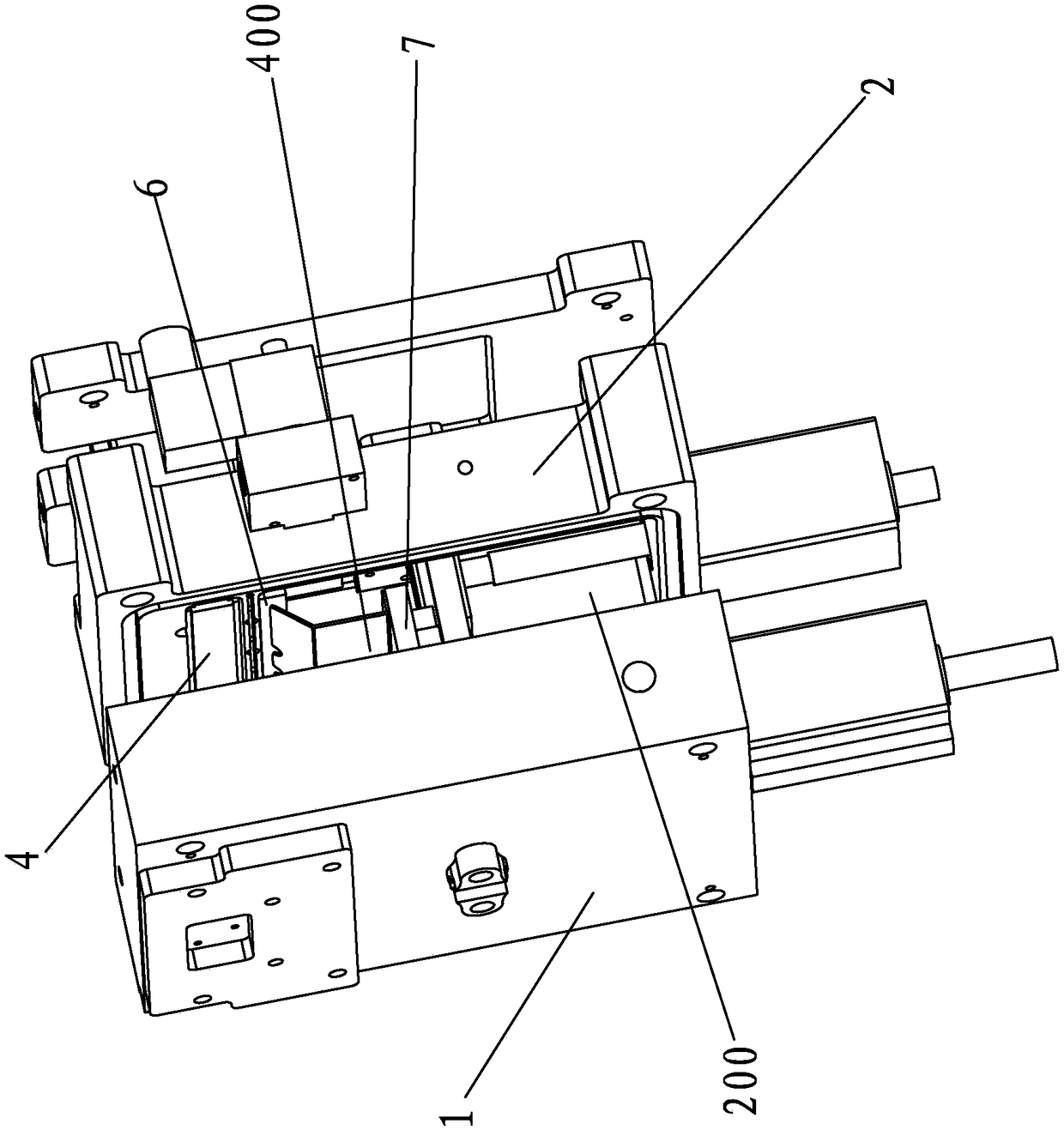

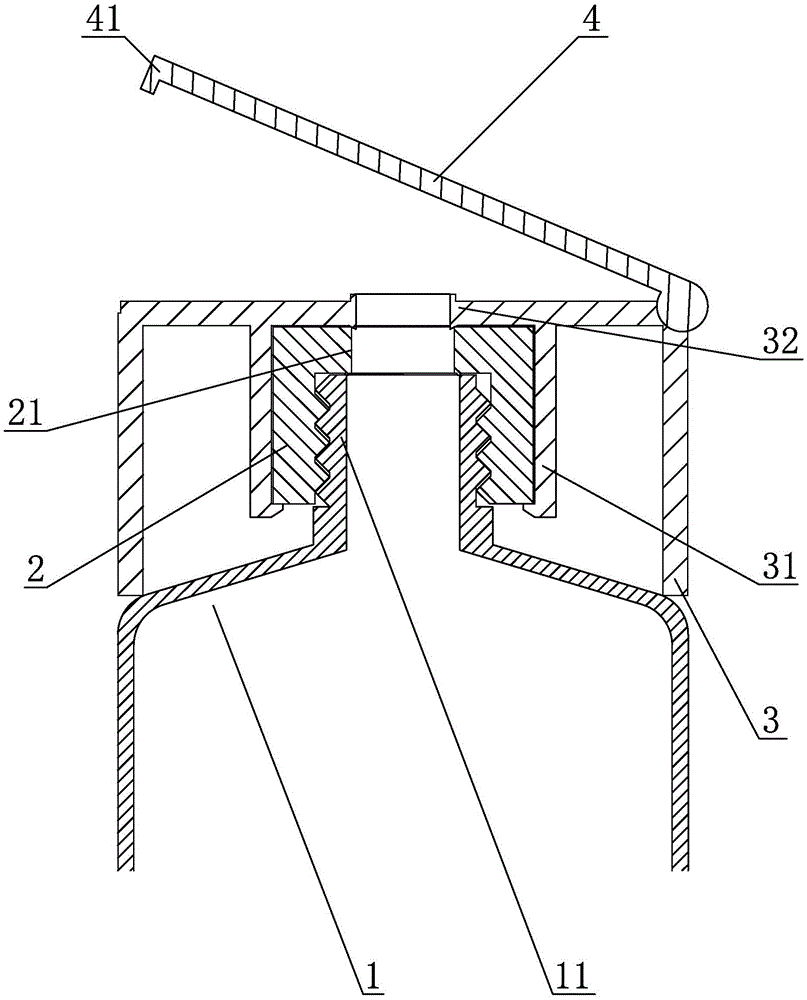

Banknote pre-enveloping and plastic-packaging mechanism and control method thereof

InactiveCN104670552ACompact structureReduce volumePaper article packagingWrappingPlastic packagingPaper tape

The invention discloses a banknote pre-enveloping and plastic-packaging mechanism and a control method thereof. The mechanism comprises a thermoplastic mechanism and a positioning mechanism, wherein the positioning mechanism comprises a pressing plate, a spring, a bearing plate and an edge folding device; the edge folding device is arranged on the periphery of the bearing plate; a piece of plastic-packaging film and a piece of paper tape film in preset length are arranged on the bearing plate, and the paper tape film is arranged on the plastic-packaging film; bundled banknotes are arranged on the paper tape film; the bundled banknotes and the bearing plate are pressed to a specified position by the pressing plate; the film is then cut off by a film cutting mechanism; the edge folding device is used for folding the plastic-packaging film and the paper tape film; the main body of the thermoplastic mechanism is arranged above the bearing plate; thermo-sealing pressing plates of the thermoplastic mechanism are arranged on the upper side and both sides of the bearing plate; when the paper tape film is folded, the thermo-sealing pressing plate in the corresponding direction carries out plastic sealing on the paper tape film; when the plastic-packaging film is folded, the thermo-sealing pressing plate in the corresponding direction carries out plastic sealing on the plastic-packaging film. The banknote pre-enveloping and plastic-packing mechanism and the control method thereof realize the effect that paper tape pre-enveloping and plastic packaging of the plastic-packaging film are carried out in one station; the structure is small, and the maintenance is convenient.

Owner:GUANGDONG DESOUL INTELLIGENT TECH CO LTD

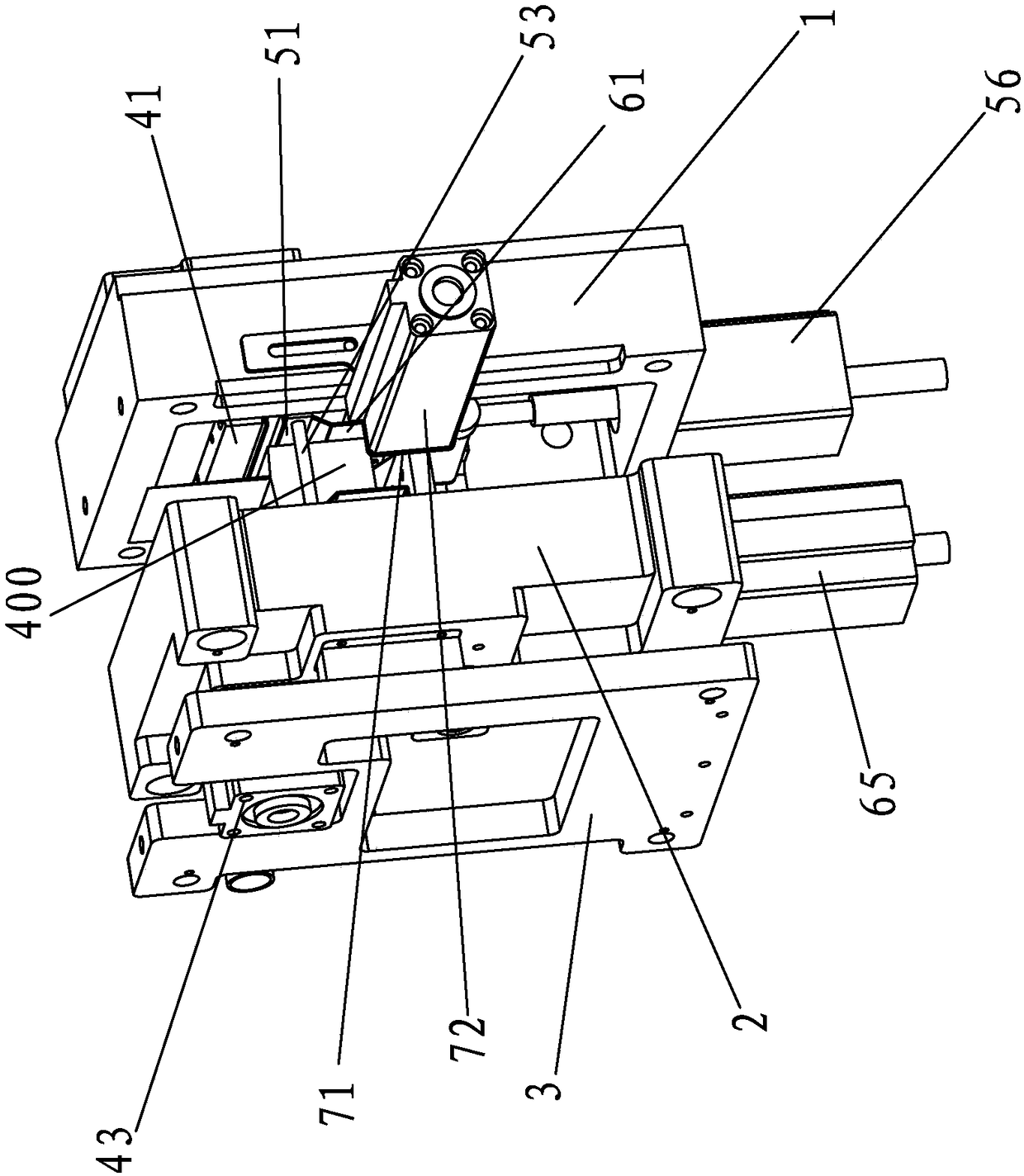

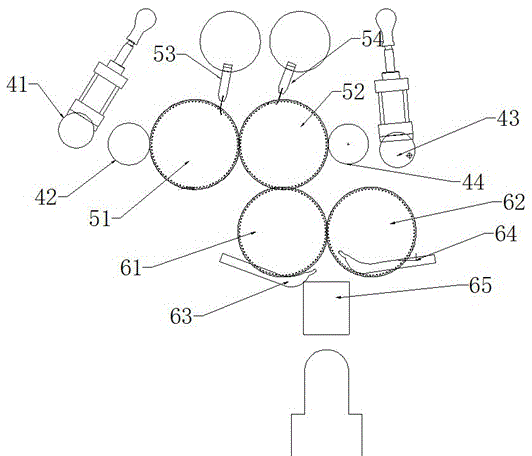

Packaging mechanism for tea packaging machine

PendingCN108327974AReduce air volumeSave production spacePackaging under vacuum/special atmosphereBlack teaEngineering

The invention discloses a packaging mechanism for a tea packaging machine. The packaging mechanism for the tea packaging machine comprises a fixed mold base, a movable mold base subjected to mold closing opposite to the fixed mold base, an upper hot sealing mechanism performing hot pressing sealing on tea packaging bags, an upper shaping mechanism providing lower pressure for the tea packaging bags, and a lower shaping mechanism providing upper pressure for the tea packaging bags; the fixed mold base and the movable mold base are each concavely provided with a vacuum cavity with a vacuum gas hole; the upper hot sealing mechanism comprises a fixed heating strip and a movable clamping strip; the upper shaping mechanism comprises a first shaping block and a second shaping block which can movedownwards synchronously; the lower shaping mechanism is provided with a left side plate, a right side plate and a shaping cavity; the lower shaping mechanism is located below the upper shaping mechanism and is between the fixed mold base and the movable mold base; and the fixed mold base is fixedly provided with a push-out mechanism for pushing the tea packaging bags out. Compared with the priorart, the packaging mechanism for the tea packaging machine can be used for packaging green tea and black tea, diverse in packaging function and achieves dual purposes, and the producing cost and the spaced occupied by the machine are greatly saved for tea merchants.

Owner:安溪县钱盛自动化设备有限公司

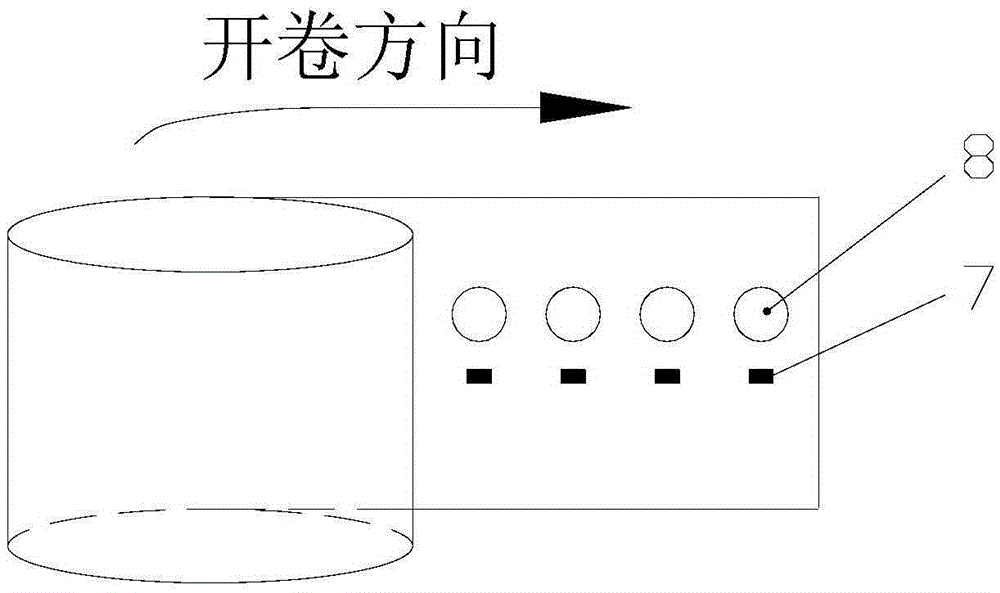

Stretching and winding film for automatic steel reel winding and packaging and manufacturing method thereof

InactiveCN105774166AAvoid breakingPrevent rustFlexible coversWrappersLinear low-density polyethyleneEngineering

The invention discloses a stretching and winding film for automatic steel reel winding and packaging.The stretching and winding film is prepared from, by weight, 30-60% of linear low density polyethylene LLDPE, 20-50% of metallocene linear low density polyethylene MLLDPE and 2-20% of ethylene and alpha-olefin copolymer toughened resin.A manufacturing method of the stretching and winding film for automatic steel reel winding and packaging comprises the following steps of material selection and production.According to the stretching and winding film for automatic steel reel winding and packaging and the manufacturing method of the stretching and winding film, the film is high in strength and toughness and good in adhesiveness, the problem that a steel reel is damaged due to the low strength of a stretching and winding film, the problem that a steel reel incision is cracked due to the low toughness of the stretching and winding film and the problem that the steel reel sealing performance is poor due to the low adhesiveness of the stretching and winding film are solved, and the increasingly-stringent requirements of automatic steel reel winding and packaging are met.

Owner:MAANSHAN STEEL PACKAGING MATERIALS TECH CO LTD

Nutrient medium for flowers

InactiveCN1810738ABeautiful shapeImprove fertilizer efficiencyOrganic fertilisersFertilizer mixturesBiotechnologyGrowth plant

The present invention discloses one kind of nutrient medium for flowers, and belongs to the field of the flower fertilizer technology. The nutrient medium for flowers consists of plant stalk decayed fertilizer, plant growth inhibitor, plant growth controlling agent, liquid water curing agent, medium and trace elements, microbial liquid, and nutritious elements mixed together in certain proportion, and is brown paste. It can control the growth speed and direction one plant and dinate flower height and crown degree, and has the advantages one saving water, convenient management and no pollution.

Owner:江苏心实肥业集团有限公司

Carton packaging machine

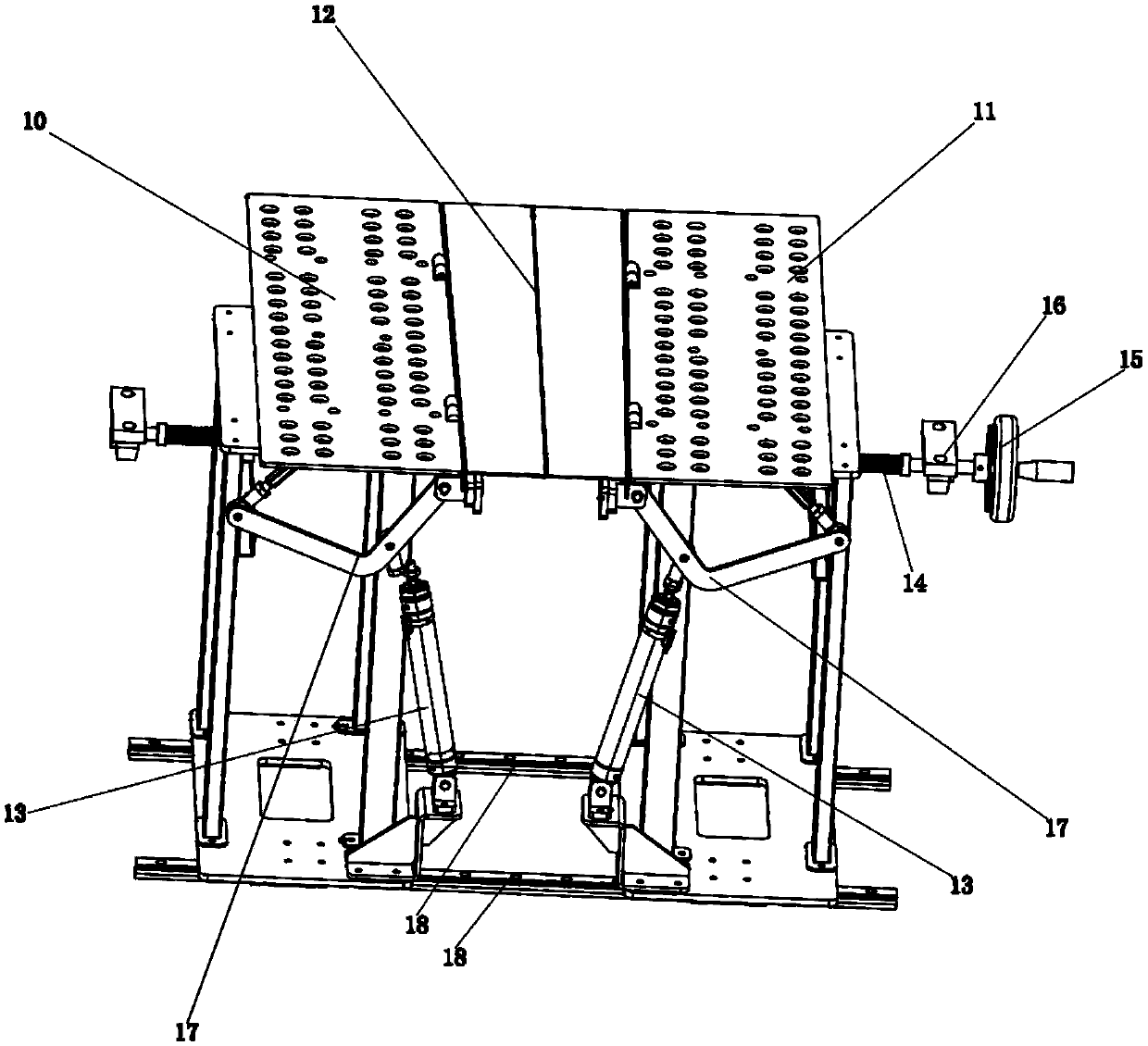

PendingCN106742211ATied tightlyEasy to transportPaper article packagingBundling machine detailsCartonEngineering

The invention relates to the technical field of packaging equipment, in particular to a carton packaging machine. The carton packaging machine comprises a machine body. A first operating platform and a second operating platform are fixedly installed on the machine body, and a certain distance is reserved between the first operating platform and the second operating platform. Protection covers are arranged at the two sides of the second operating platform. The top ends of the protection covers are connected through a horizontal baffle. A driving device is installed at the rear end of the second operating platform. A pressing plate is installed above the top of the second operating platform. The driving device is controlled by a foot switch connected with the driving device. The pressing plate is driven by a pair of air cylinders installed at the bottom of the horizontal baffle. A conveying belt and a sliding chute connected with the conveying belt are arranged at the right side of the first operating platform. A positioning block is arranged at the side, close to the driving device, of the surface of the second operating platform. The carton packaging machine is easy and convenient to operate, and the effect that packaged cartons are tightly bundled without being loosened can be guaranteed; and the packaged cartons are moved and transported through the conveying belt and then are discharged through the sliding chute, the labor intensity can be effectively relieved, and working efficiency is improved.

Owner:山东叶华纸制品包装有限公司

Equipment, method and system for automatically folding clothes, making bags, bagging and sealing

PendingCN109941537AImprove efficiencyReduce labor costsWrapper twisting/gatheringIndividual articlesEngineeringClothes hanger

The invention provides equipment for automatically folding clothes, making bags, bagging and sealing. The equipment is characterized by comprising a machine frame, and the frame is provided with a plurality of folding devices, a shovel plate device, a clothes blocking device, a multi-section conveying device, a clothes plate device, a top clothes hanger device, a bag pulling device, a bag openingdevice, a sealing and cutting device, a material rolling film feeding device, a bag pressing device and a control device. The invention provides equipment, a method and a system for automatically folding clothes, making bags, bagging and sealing, so that most clothes can be bagged and sealed automatically through a machine, the efficiency can be improved, the labor cost can be reduced, packaging is attractive, and sale is facilitated.

Owner:深圳市领创自动化技术有限公司

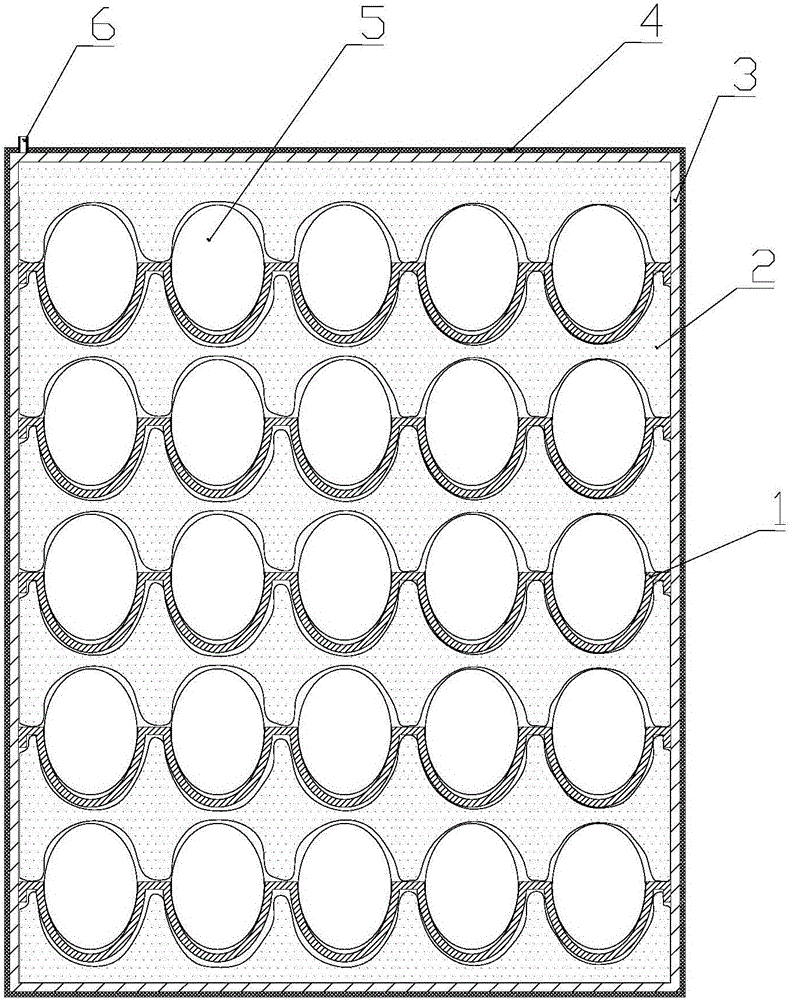

Packing method and packing device for poultry eggs

InactiveCN105775398AEnsure stabilityAvoid breakingPackaging eggsPackaging under vacuum/special atmosphereZoologyPacking method

The invention relates to a packing method for poultry eggs. The packing method comprises the following steps of the step s1, putting the poultry eggs into poultry egg trays; the step s2, stacking up the poultry egg trays in which the poultry eggs are put in the step s1 layer by layer, and paving inflated buffering air pockets between every two layers of the trays in which the put poultry eggs are put; and the step s3, loading the piled poultry egg trays in the step s2 into vacuum packaging bags, and performing air exhausting on the vacuum packaging bags. According to the packing method disclosed by the invention, the shock-absorb effect is good, the failure rate in the transporting process can be effectively reduced, and besides, the cost is low. The invention further provides a packing device for the poultry eggs.

Owner:张满仓

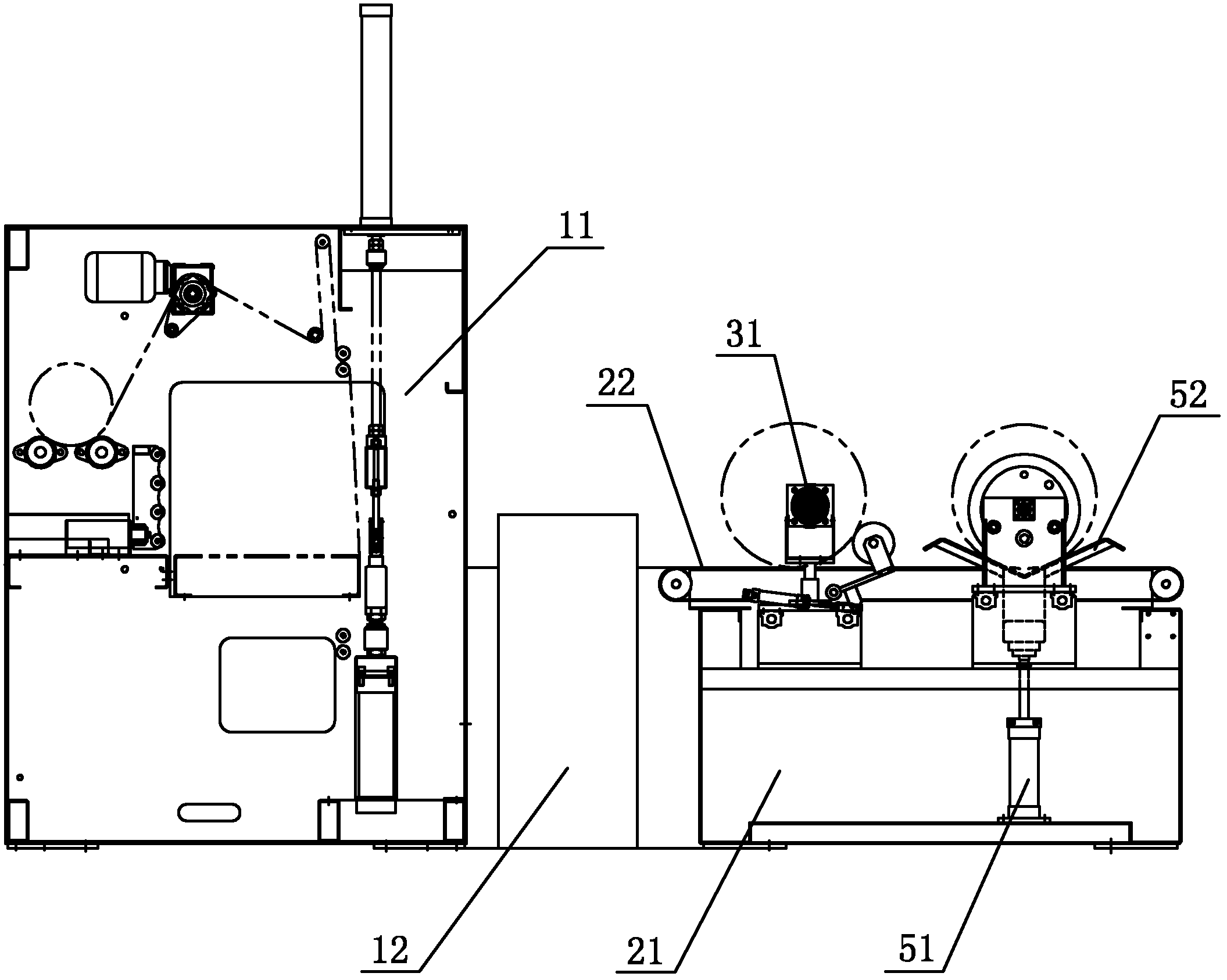

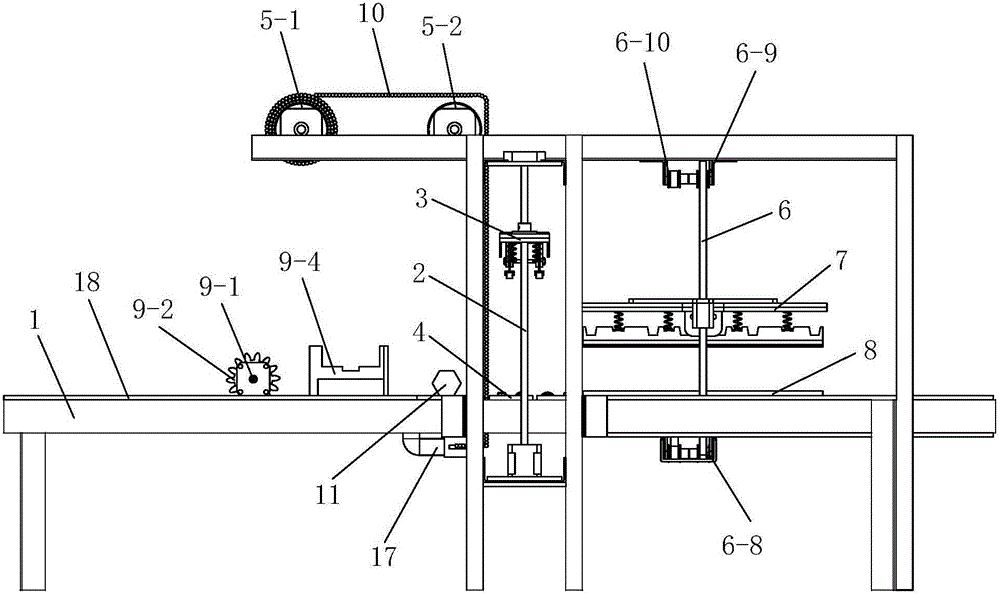

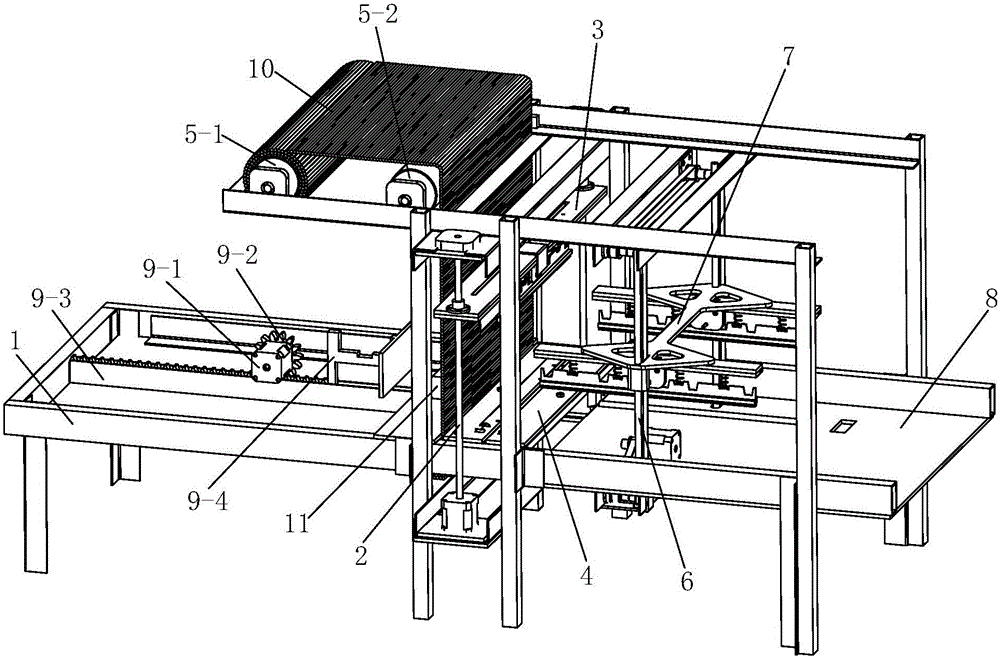

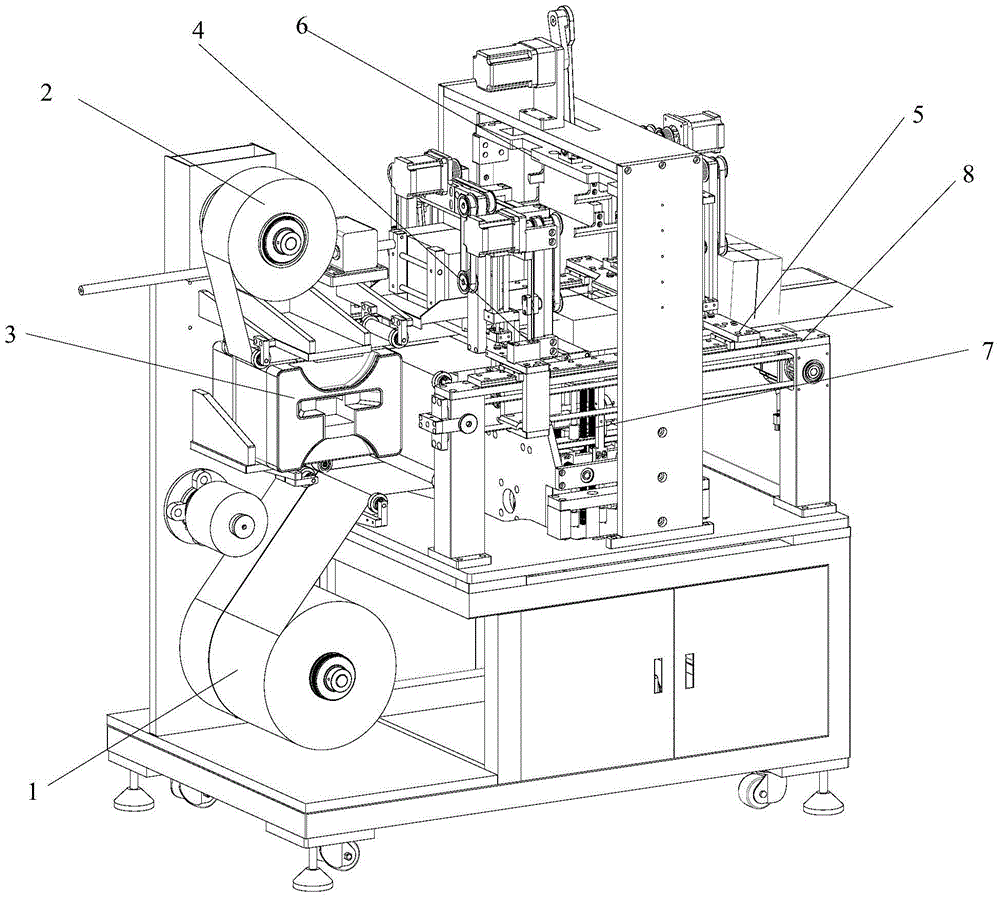

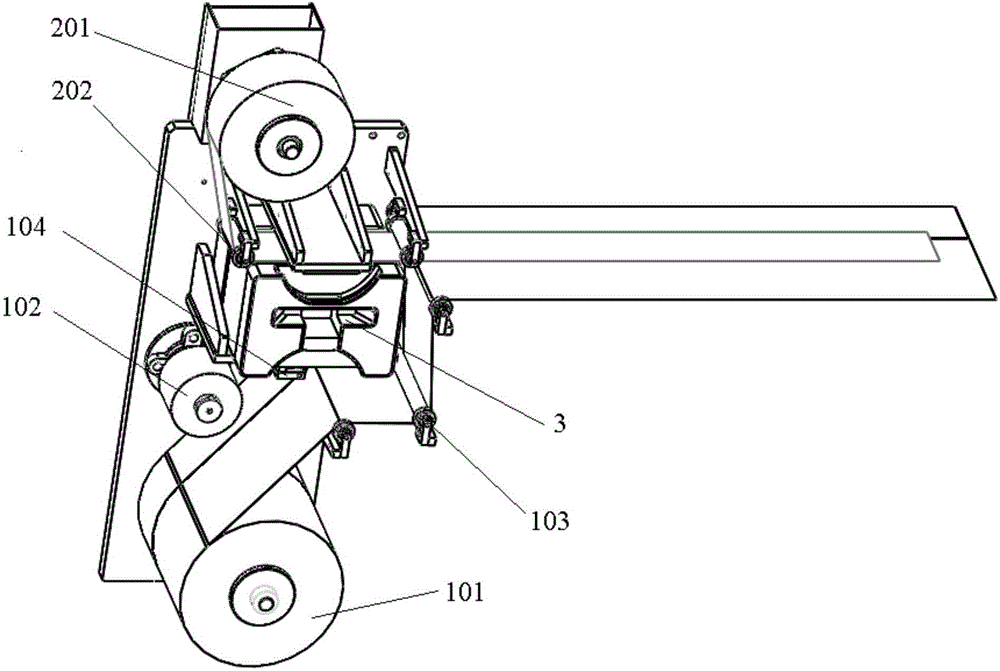

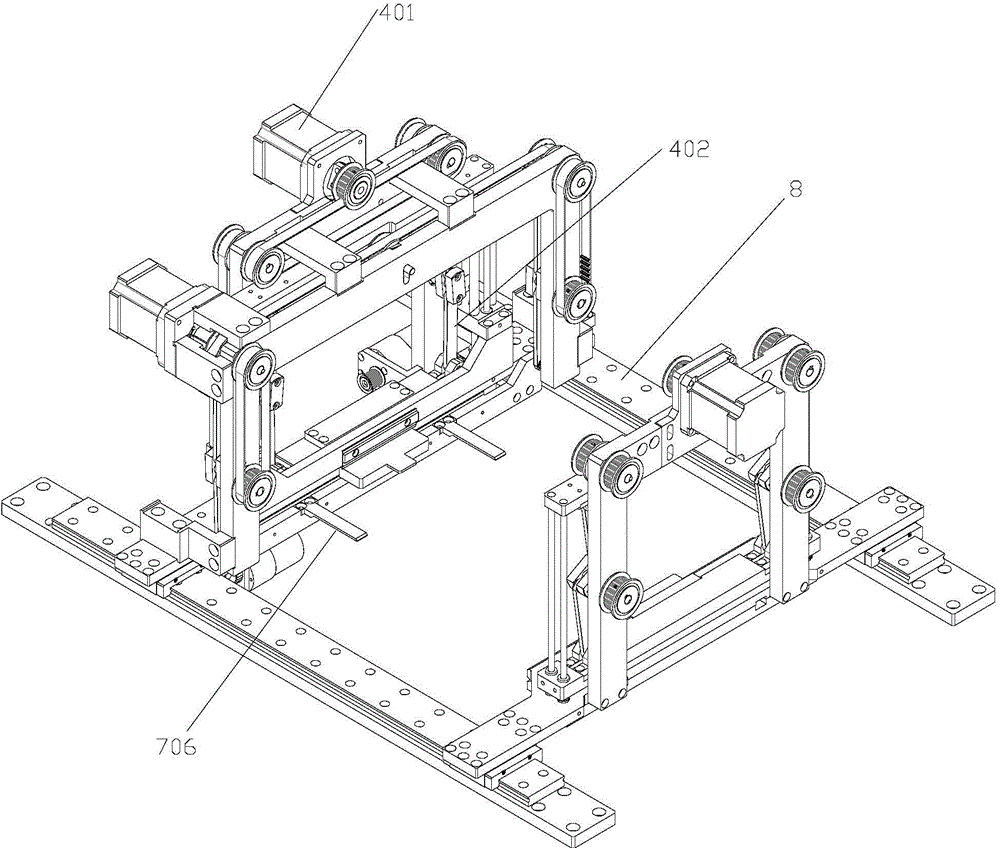

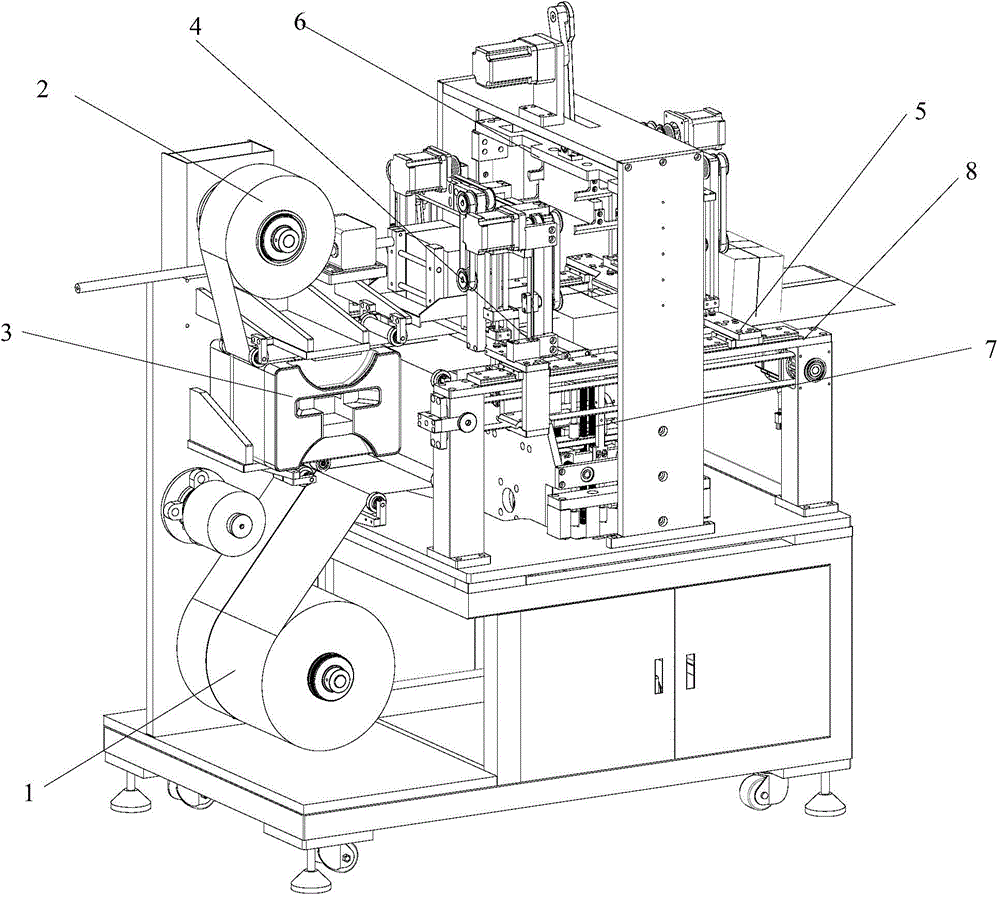

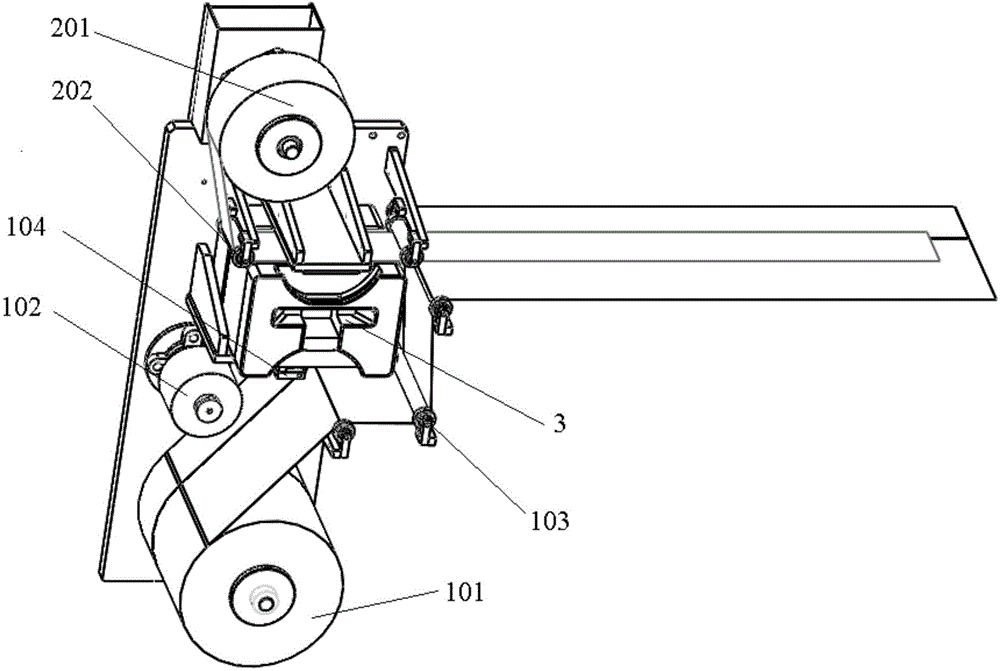

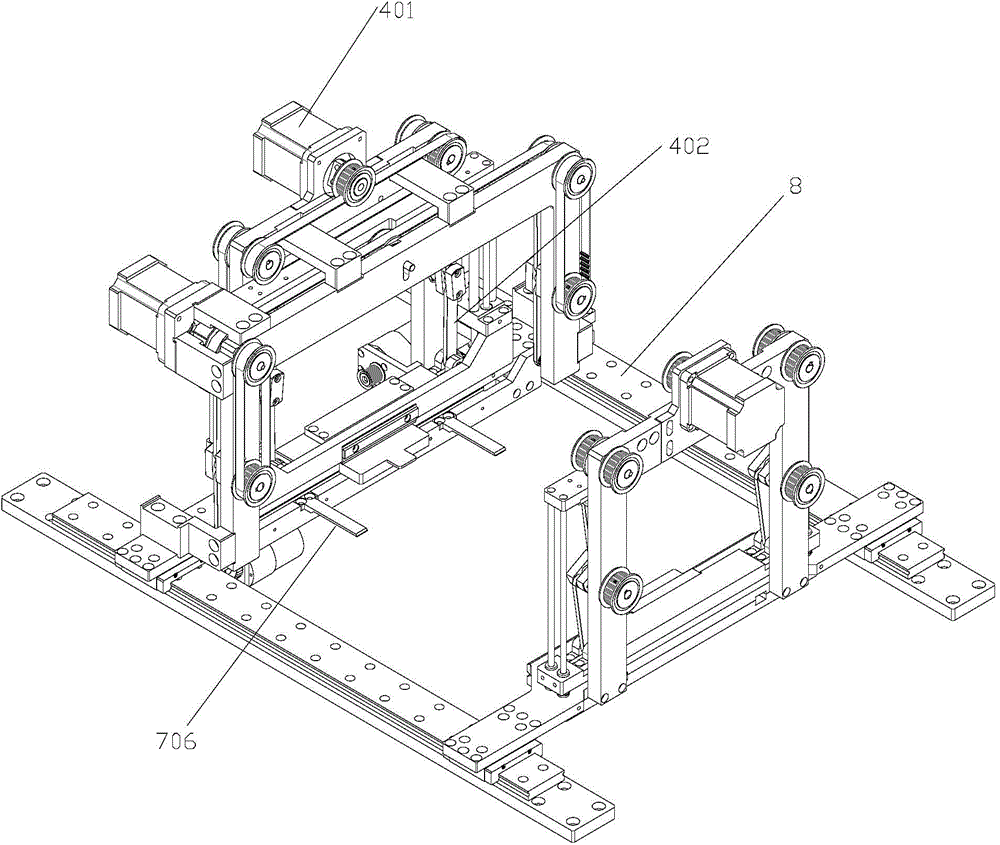

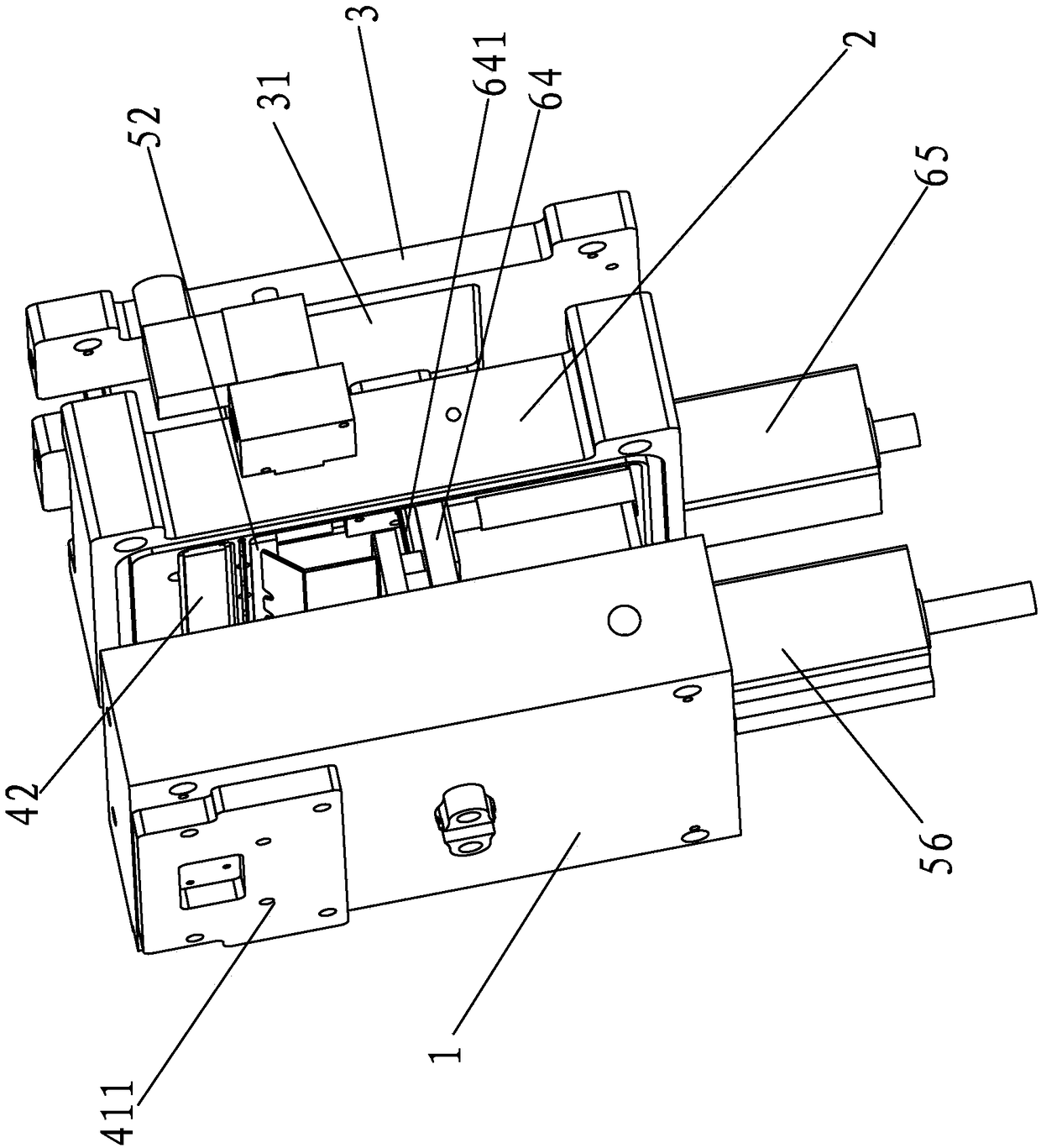

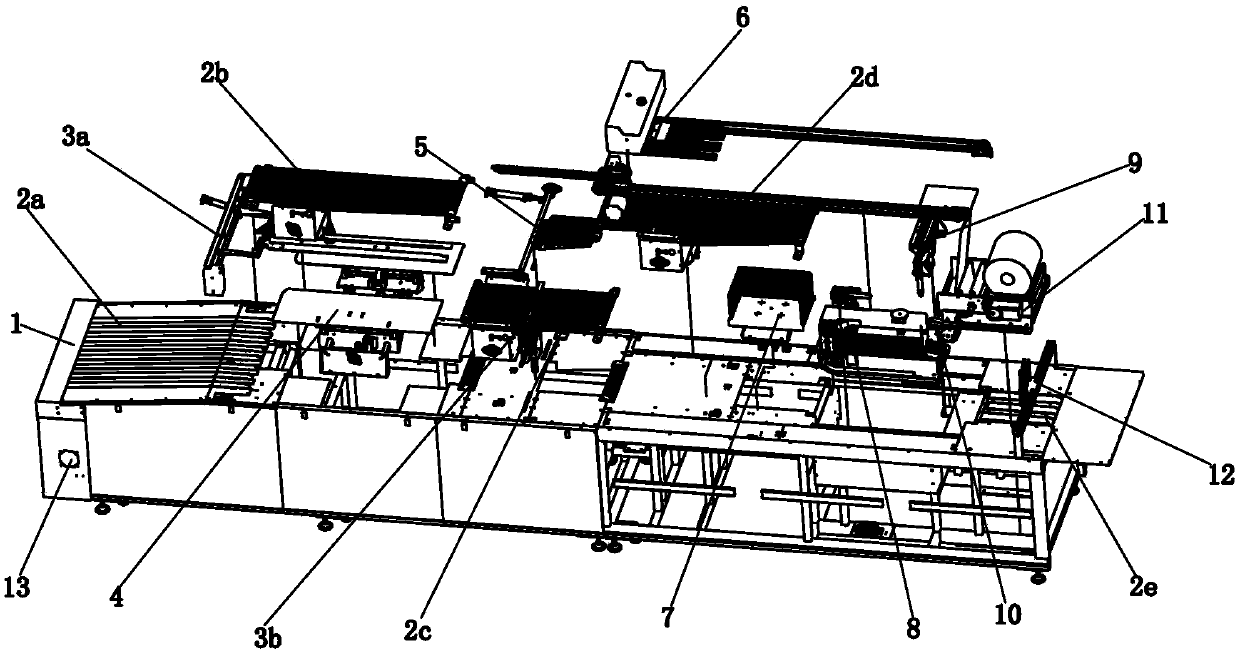

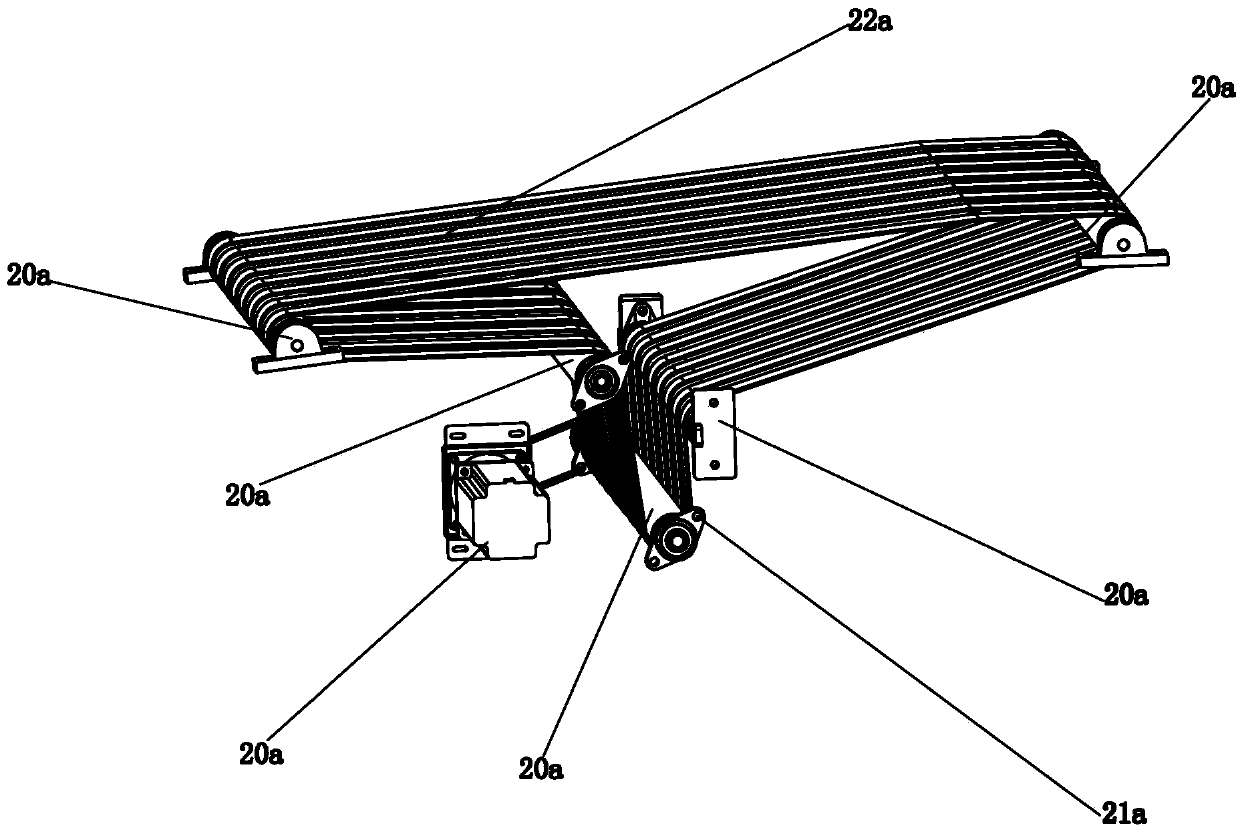

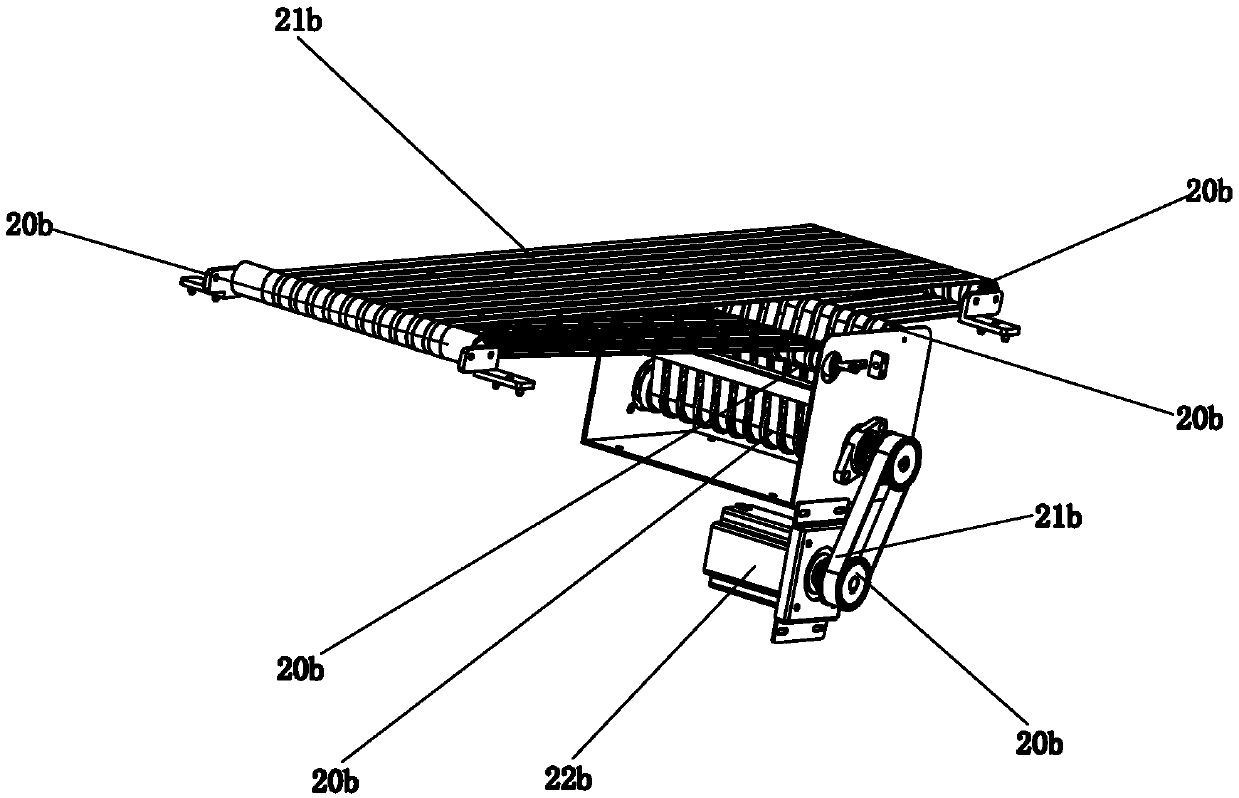

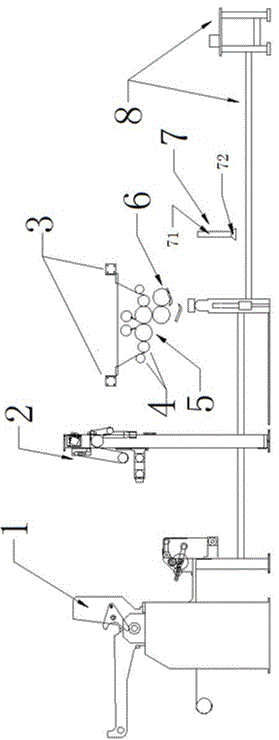

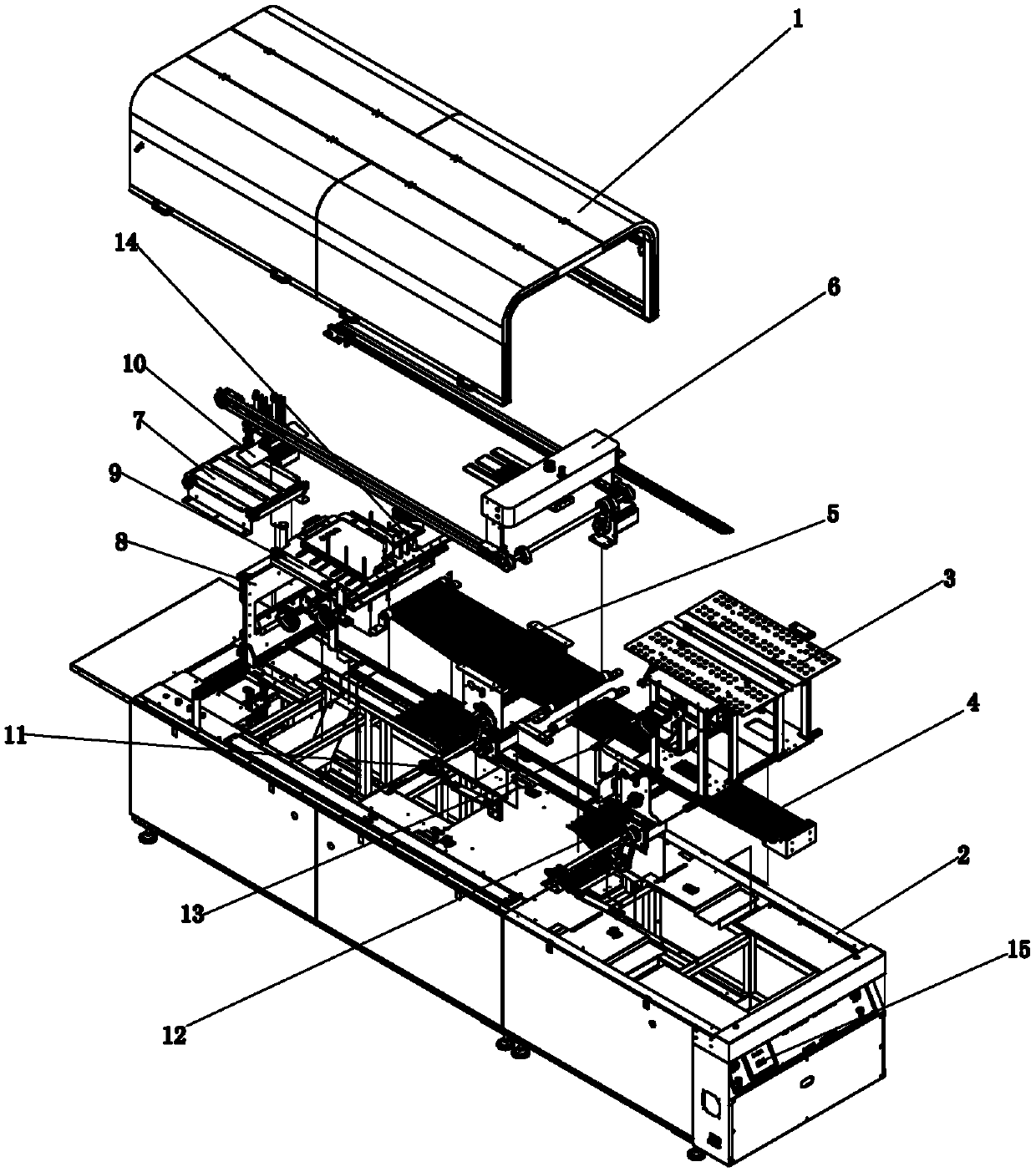

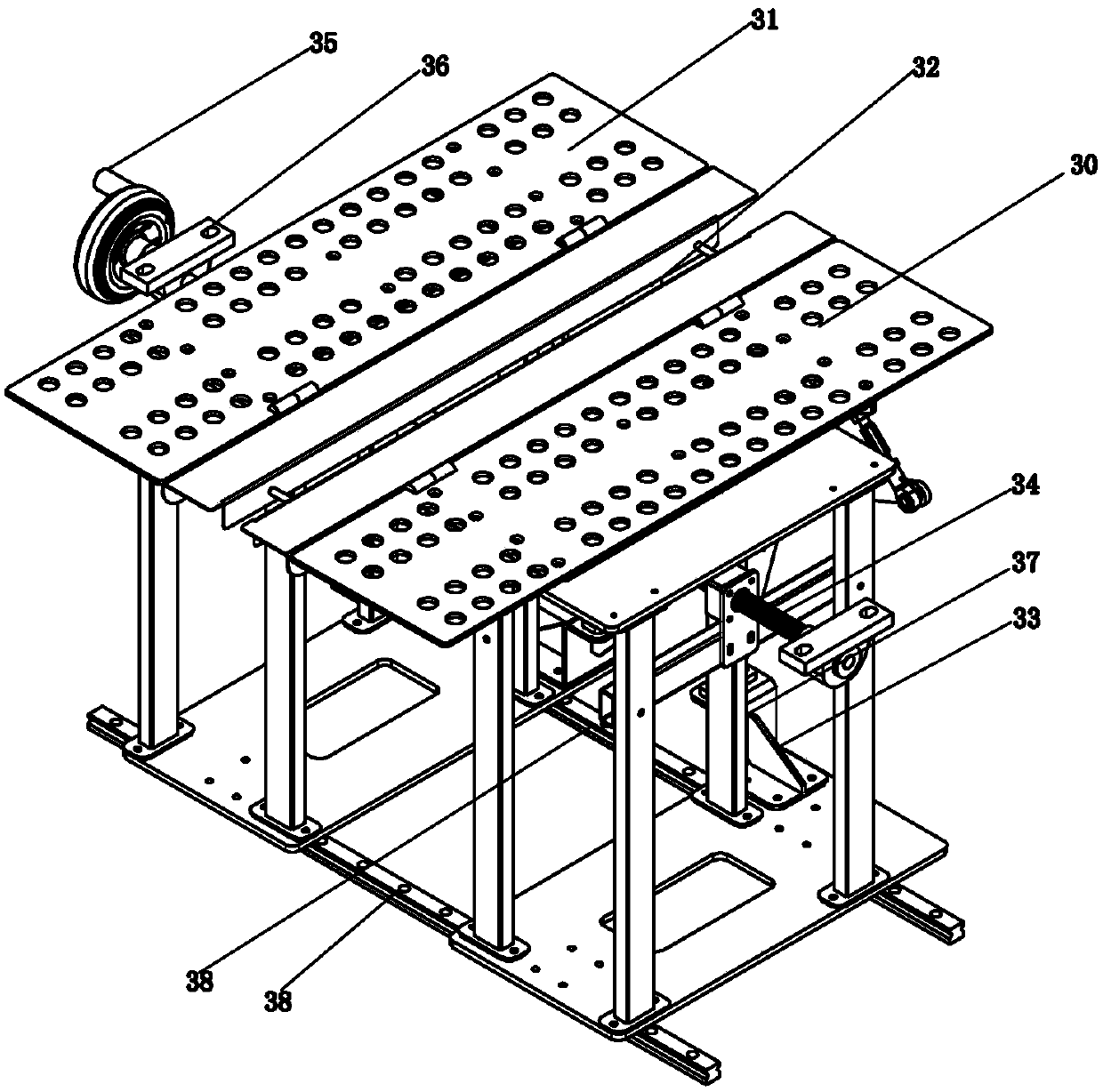

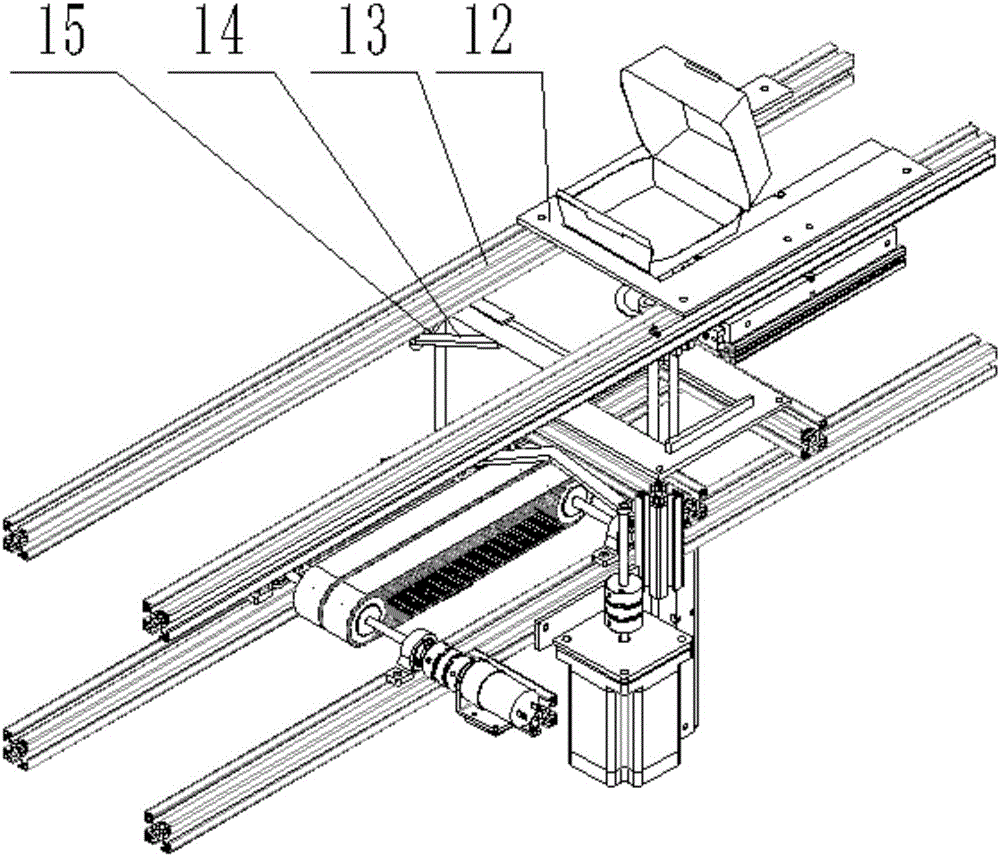

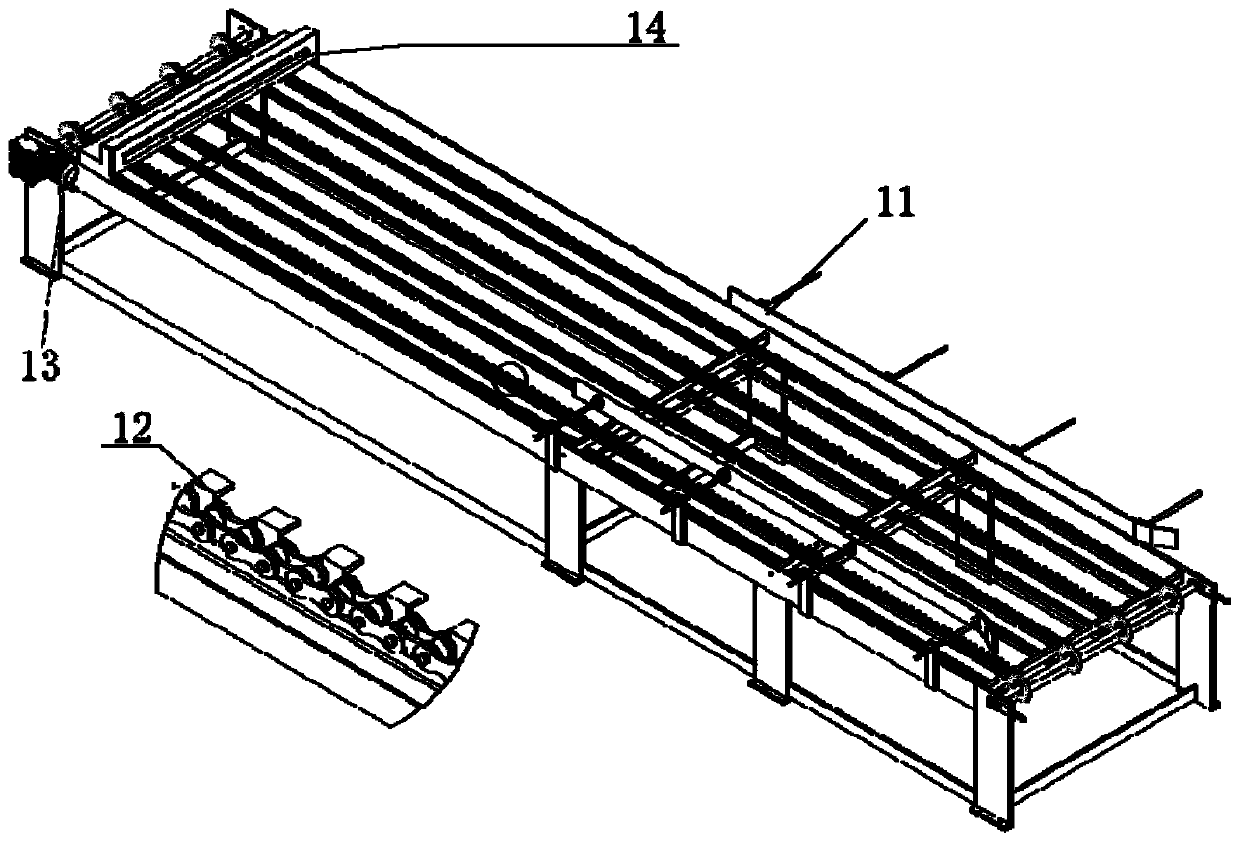

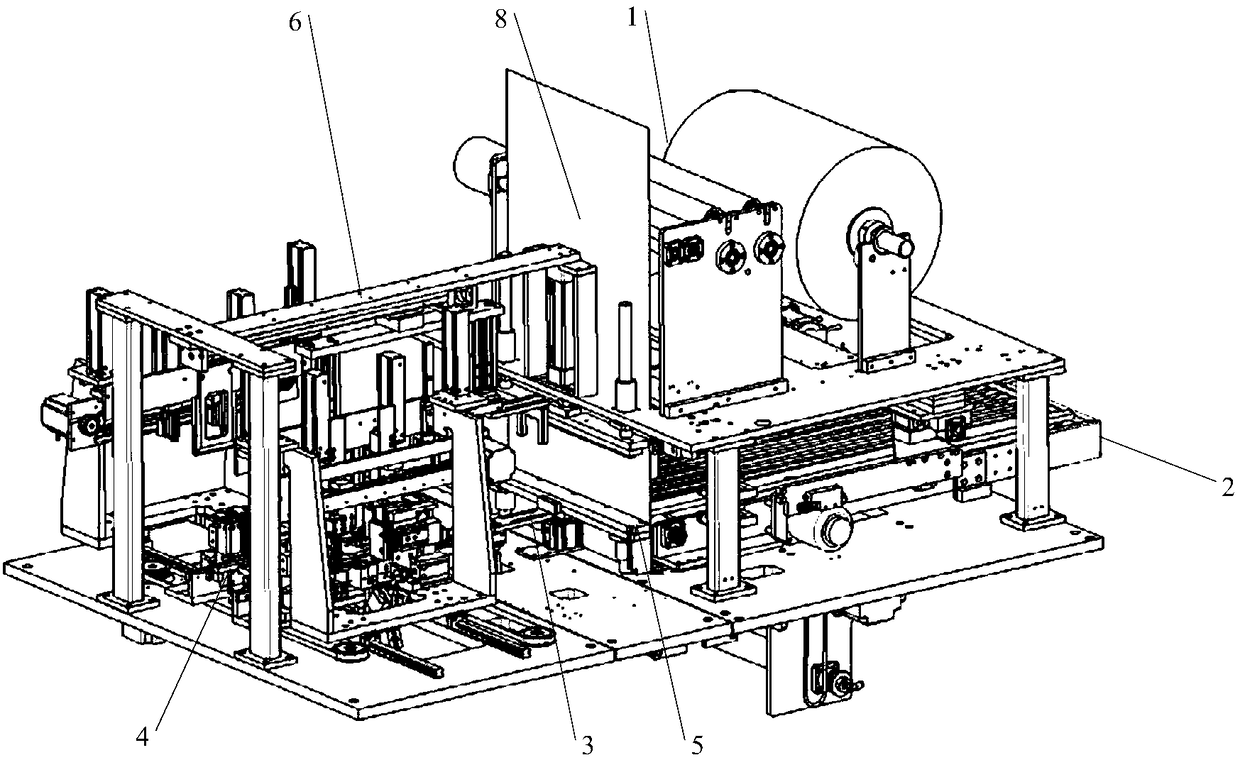

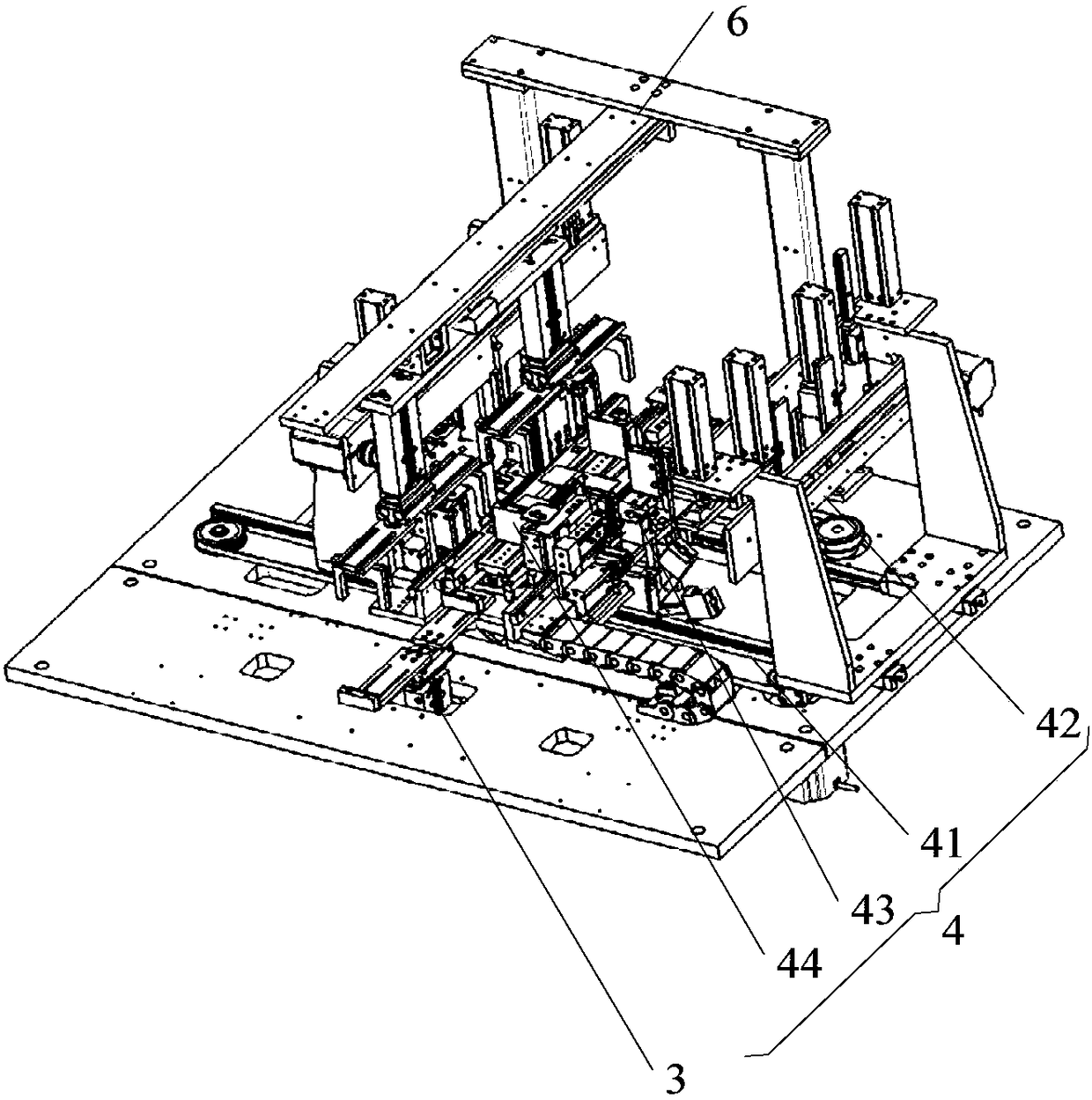

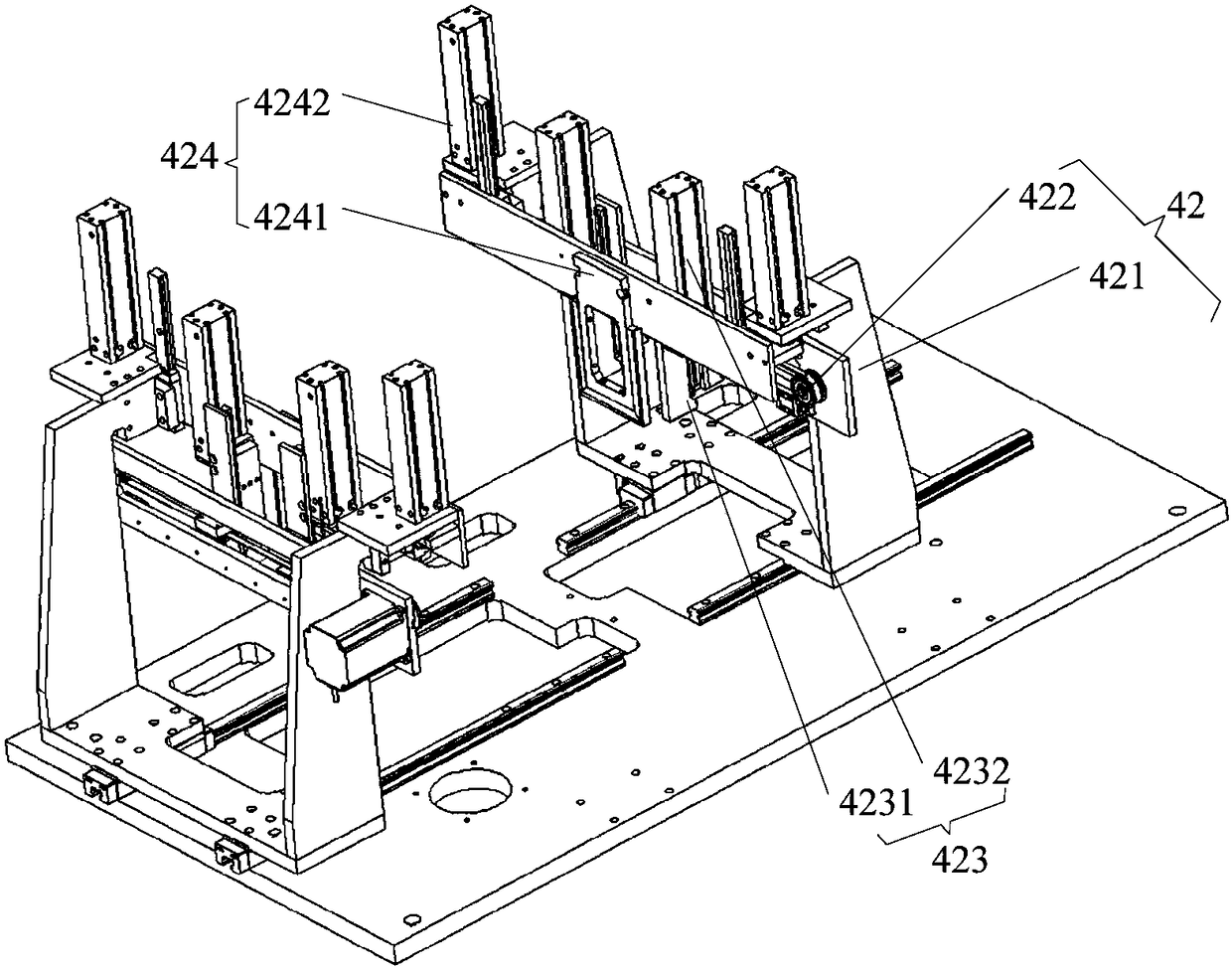

Automatic folding machine for extracted paper

ActiveCN105329699AIncrease productivityReduce labor costsFolding thin materialsRolling paperPulp and paper industry

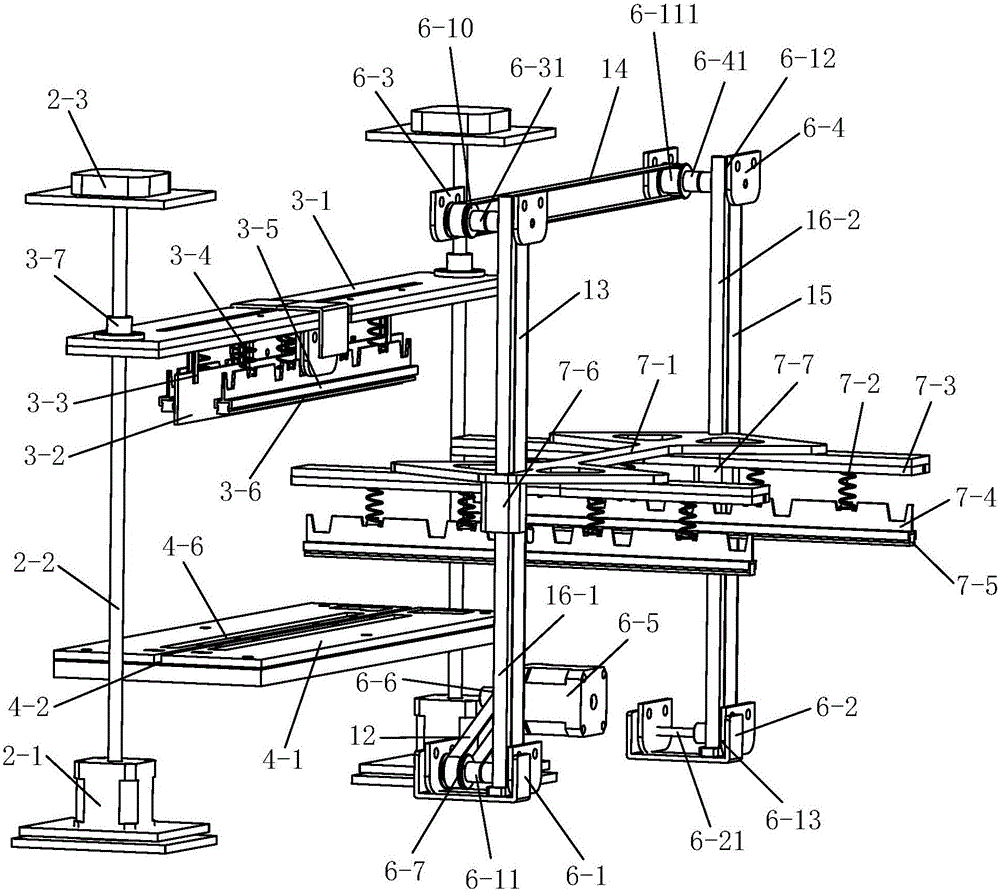

The invention relates to an automatic folding machine for extracted paper and boxes of paper. The automatic folding machine comprises a raw paper supply device (1) used for storing and supplying roll paper, a raw paper trimming device (2), line pressing wheels (3) used for pressing the paper to generate press lines, traction devices (4), a paper cutting device (5), a folding device (6), a prepressing device (7) and a discharged paper conveying device (8), wherein the raw paper supply device (1) is connected with the line pressing wheels (3) installed above the traction devices (4); the traction devices (4) are installed on the two sides of the paper cutting device (5); the folding device (6) is installed below the paper cutting device (5). The automatic folding machine for extracted paper is high in production efficiency, can achieve automatic packaging of extracted paper, reduces labor cost, and is low in energy consumption.

Owner:欧克科技股份有限公司

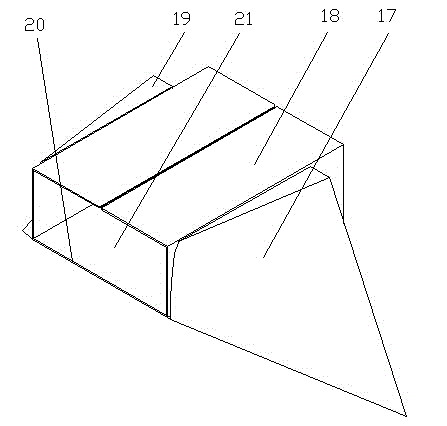

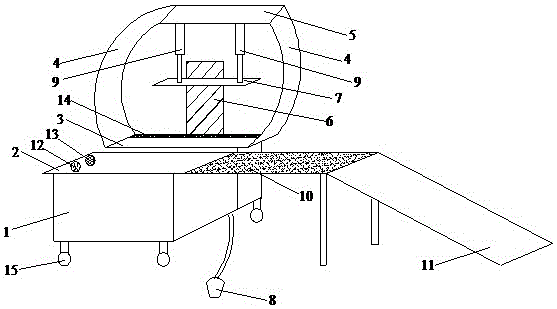

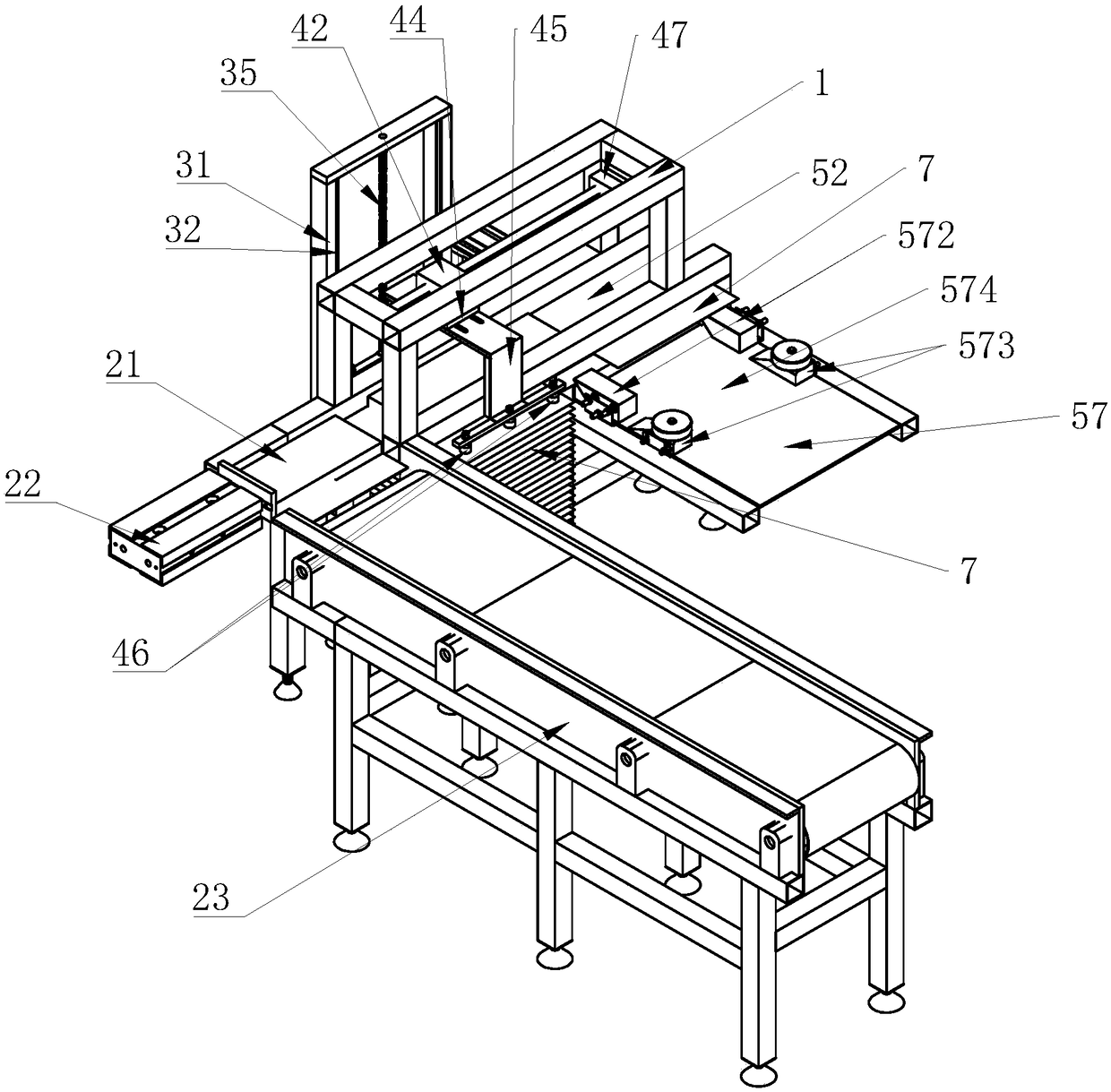

Dark green tea packaging method

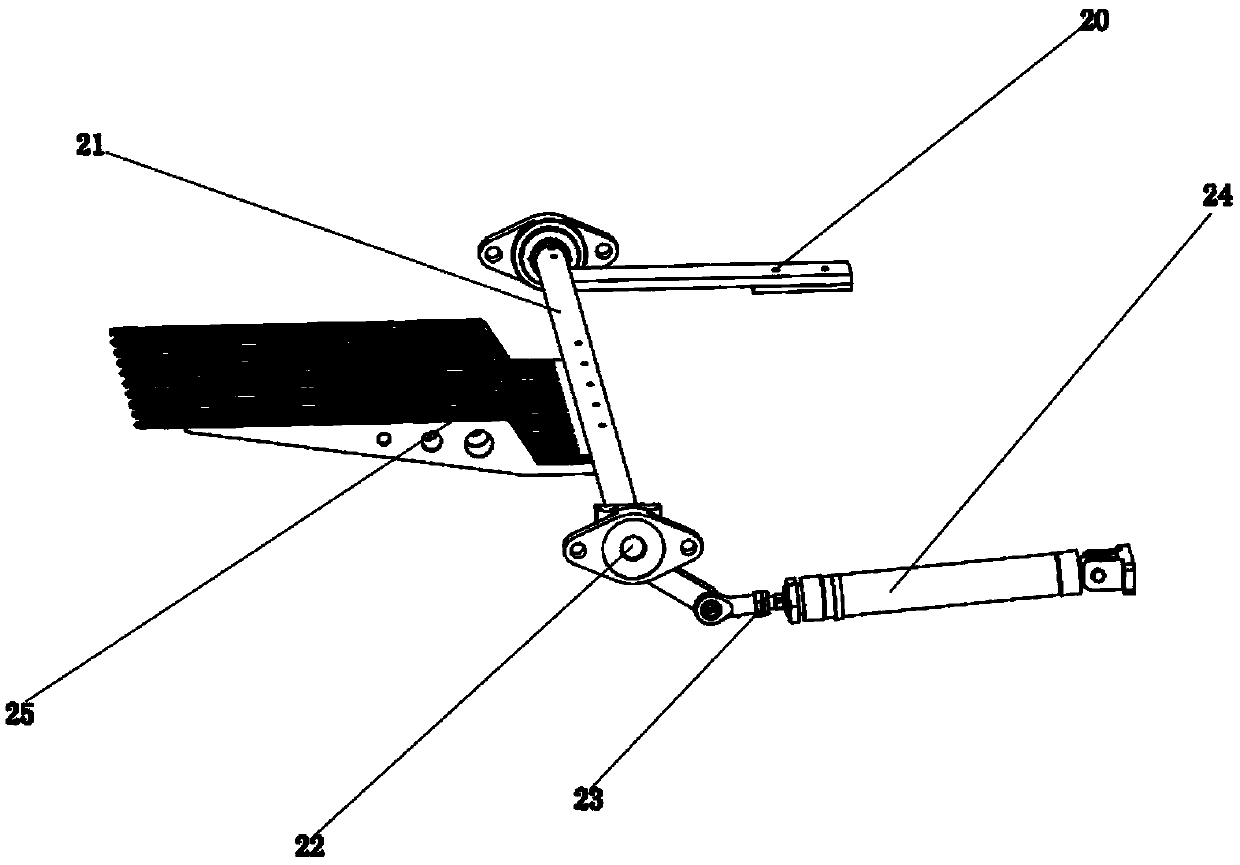

ActiveCN108974419APacked tightlyBeautiful packagingWrapping material feeding apparatusWrappingPulp and paper industryGreen tea

The invention provides a dark green tea packaging method which comprises a dark green tea automatic packaging machine. The dark green tea automatic packaging machine comprises a machine frame, a feeding assembly, a paper lifting assembly, a paper adsorption assembly and a packaging assembly, wherein the feeding assembly, the paper lifting assembly, the paper adsorption assembly and the packaging assembly are installed on the machine frame. The packaging assembly comprises a paper inserting slot arranged on the machine frame, and the machine frame is provided with a packaging groove below the paper inserting slot. A first air cylinder is fixed to one side of the machine frame through a first support, a push plate is fixed to a piston rod of the first air cylinder, first forming blocks are fixed to the two ends of the push plate, a second air cylinder is fixed to the machine frame and located above the first air cylinder, and a scraper blade is fixed to a piston rod of the second air cylinder. An extension plate is fixed to the other side of the machine frame in the horizontal direction, and two second forming blocks, two first guide inclined blocks and two second guide inclined blocks are sequentially fixed to the upper surface of the extension plate in the mode of extending outwards from the machine frame. The dark green tea packaging method has the advantages of being high inautomation degree, high in packaging efficiency and the like.

Owner:HUBEI UNIV OF SCI & TECH

Equipment, method and system for automatically packaging clothes

PendingCN109896097AImprove efficiencyReduce labor costsWrapper twisting/gatheringIndividual articlesBiomedical engineeringShovel

The invention provides equipment for automatically packaging clothes. The equipment for automatically packaging the clothes comprises a machine cover and a machine frame, wherein a plurality of folding devices, a plurality of sections of conveying devices, a clothes shovel device, a bag sealing device, a bag placing device, a bag pressing device, a clothes blocking device, a bag supporting deviceand a control operation device are arranged on the machine frame. According to the equipment, a method and a system for automatically packaging the clothes, most clothes can be automatically packagedby machines, the efficiency can be improved, the labor cost can be reduced, the packaging is attractive, and the selling is convenient.

Owner:深圳市领创自动化技术有限公司

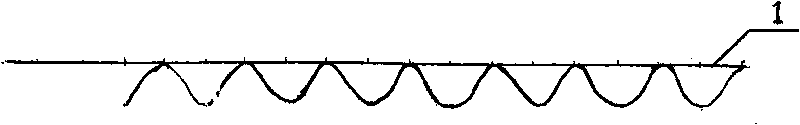

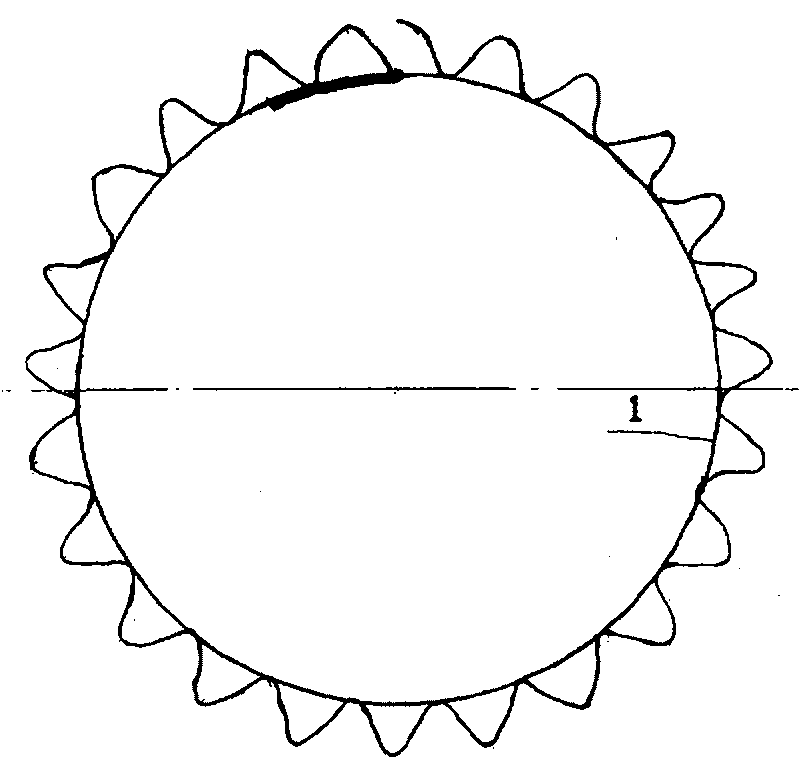

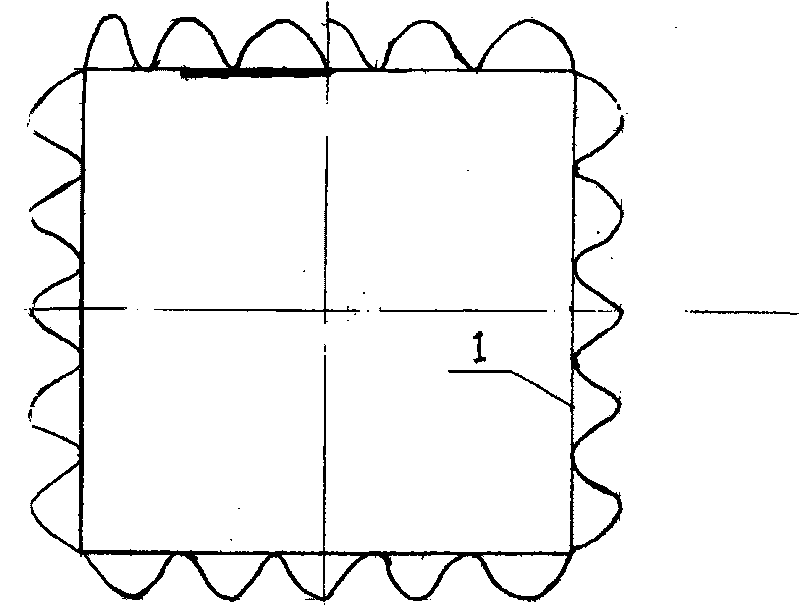

Corrugated board full paper barrel

The invention provides a corrugated board full paper barrel, which is mainly characterized in that a corrugated board barrel body is made into a section of flat board through removing one to two flutes from one end of a single-side corrugated board in the vertical direction of the flutes, the other end and the flat board are intersected and glued for forming a corrugated board barrel body. Surface paper is glued on the outer side of the flutes of the corrugated board barrel body, or one layer or more than one layer of single-side corrugated board barrel is glued on the outer side of the flutes of the corrugated board barrel body to be made into the corrugated board barrel bodies in various specifications. The invention solves the problem that joints parts are overlapped, and the mechanized production can not be realized in the prior art. Compared with the prior art, the invention has the advantages of both the original full paper board barrel and the corrugated paper box, and also has the advantages of high intensity, high toughness, strong integral structure, high compression strength, labor and time saving during package, beautiful appearance, convenient beautification, decoration and the pattern color printing on the outer surface of the barrel, difficult package loosening and damage in the transportation process, good use performance and the like. In addition, the mechanized production can be realized conveniently, and the cost can be greatly reduced.

Owner:枣阳天立包装实业有限公司

Process for making environment-friendly fragrant scroll pencil

InactiveCN102463780ABeautiful packagingIncrease the fragranceNon-propelling pencilsFlavorPulp and paper industry

The invention discloses a process for making an environment-friendly fragrant scroll pencil, which relates to the field of stationery. The process comprises the following steps of: 1, cutting kraft paper and preparing for a pencil lead; 2, putting about 10 percent of fragrances into glue for blending; 3, uniformly smearing the blended glue on the pencil lead and newspapers, and putting into a rolling machine for rolling and molding; 4, drying, flattening and surfacing a molded pencil; and 5, printing a pattern on the surface of the pencil. A single finished pencil can be put into a special pencil-shaped transparent environment-friendly PP (Propene Polymer) tube, so that an overall package of the pencil is attractive, and the fragrance of the pencil can be kept for a long time; and the environmentally-friendly fragrant scroll pencil can be used for replacing the conventional wooden pencil, is easy to make and cut, is low in cost, is free from lead breakage, is environment-friendly, contributes to energy saving, can be used repeatedly, has a novel package, and is fragrant, safe and nontoxic.

Owner:许军

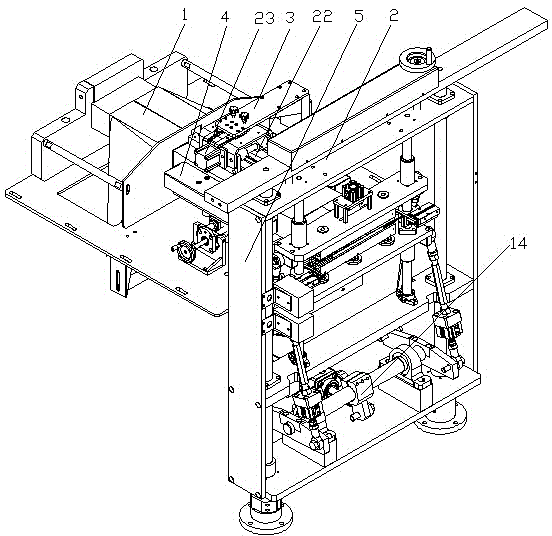

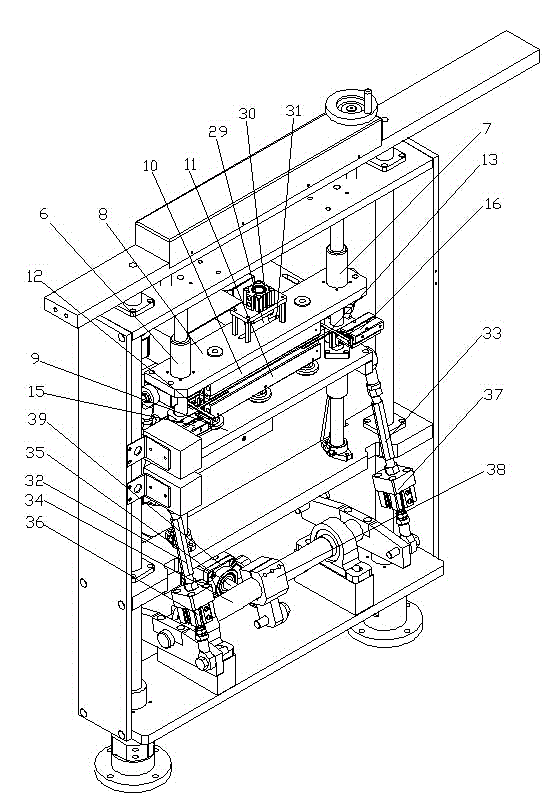

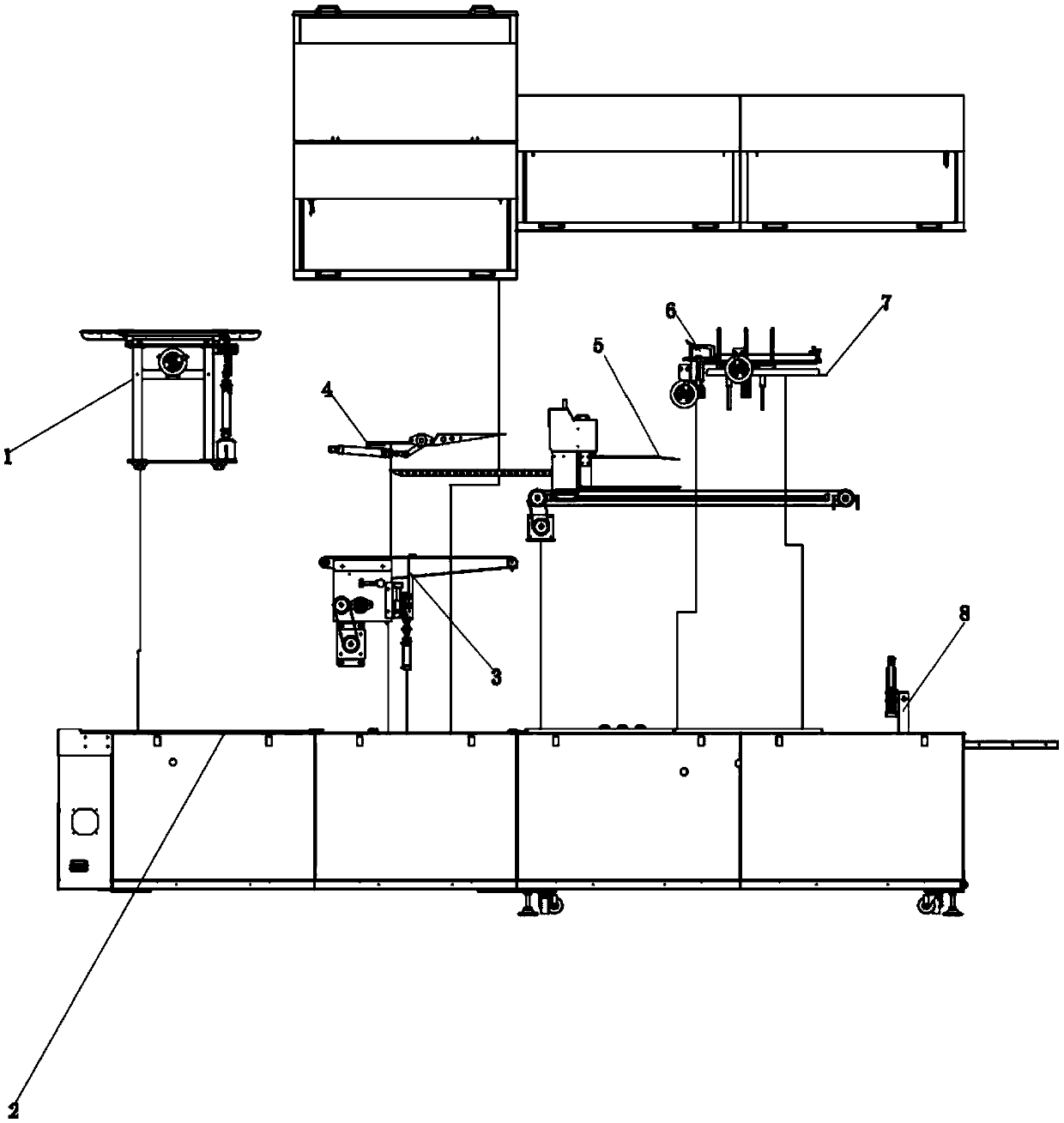

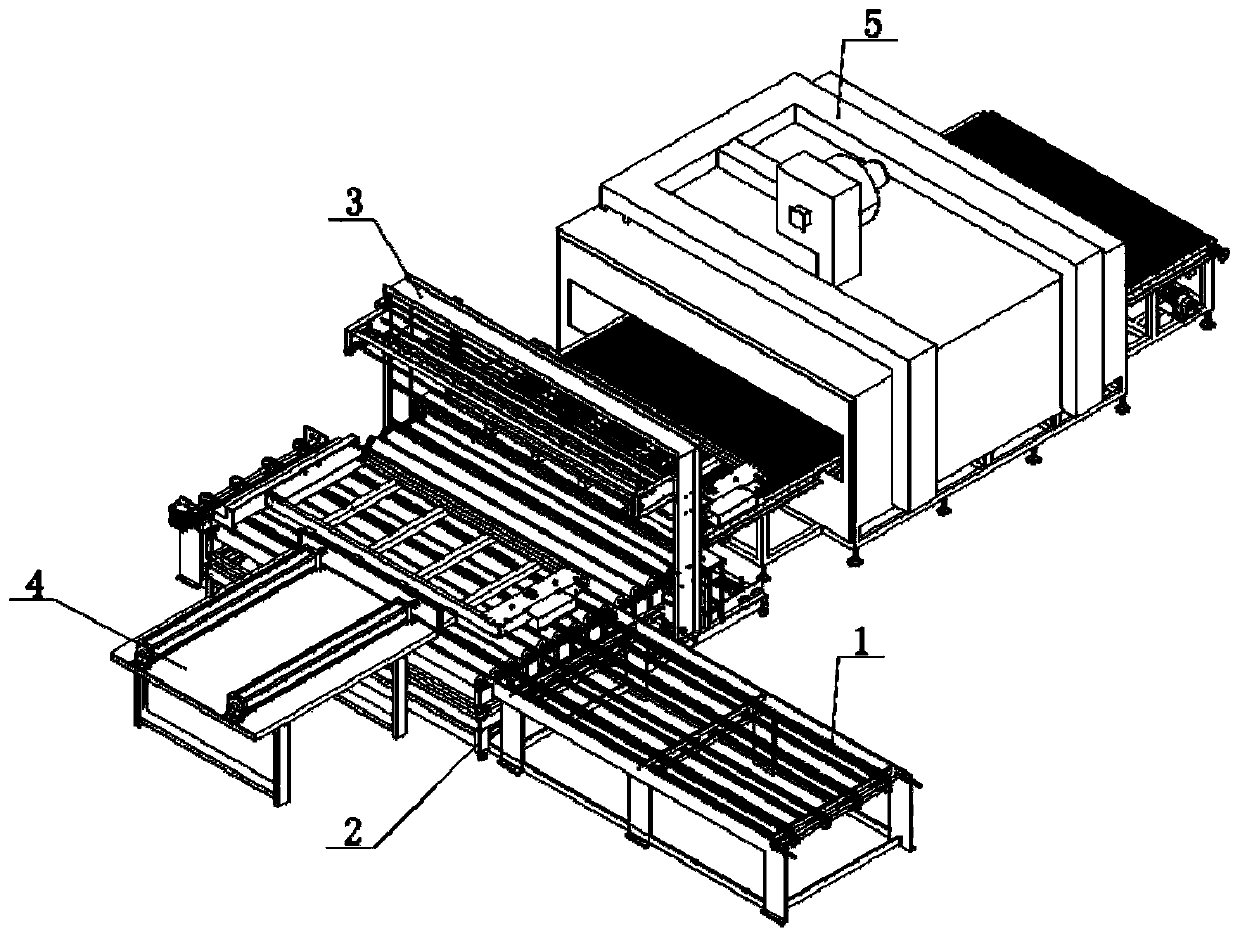

Full-automatic hamburger packaging machine

ActiveCN105857703AFully automatedBeautiful packagingWrapper folding/bending apparatusPackaging bakeryMeat burgerPackaging machine

The invention provides a full-automatic hamburger packaging machine. The hamburger packaging machine comprises a rack and a hamburger boxing device, wherein the hamburger boxing device comprises a box taking mechanism, a hamburger push mechanism, a covering and discharging mechanism and a placement platform; the placement platform is used for placing a hamburger box; the box taking mechanism comprises a box taking air cylinder and a box taking suction cup; the box taking suction cup is arranged at the upper end of a telescopic rod of the box taking air cylinder; the box taking suction cup is located below the placement platform; a push air cylinder and a boxing push plate are arranged on the rack; the boxing push plate is used for pushing the hamburger wrapped with paper to slide along a channel; the boxing push plate is arranged at the action end of the push air cylinder; the boxing push plate is located in the channel; an outlet of the channel is formed in a boxing station; the boxing station is located at the lower part of the placement platform; the covering and discharging mechanism comprises a covering air cylinder, a discharge air cylinder and an output synchronous belt; the covering air cylinder is located at the upper part of the discharge air cylinder; the covering air cylinder and the discharge air cylinder are located at the rear side of the boxing station; the output synchronous belt is located in the front part of the boxing station. The full-automatic hamburger packaging machine can operate automatically; time and labor are saved; and the work efficiency is relatively high.

Owner:ZHEJIANG UNIV OF TECH

Automatic packaging equipment, method and system

ActiveCN109896096AImprove efficiencyReduce labor costsWrapper twisting/gatheringIndividual articlesEngineeringComputer engineering

The invention provides automatic packaging equipment. The automatic packaging equipment comprises a machine frame, a folding device, a conveying device, a clothes pressing device, a clothes scraping device, a bag expanding device, a bag placing device, a bag pressing device, a sealing device and a running control device are arranged on the machine frame. According to the provided automatic packaging equipment, method and system, automatic packaging work of most of clothes can be completed through the machine, moreover, the efficiency can be improved, the labor cost can be reduced, the packaging is attractive, the sales can be facilitated and the like.

Owner:深圳市领创自动化技术有限公司

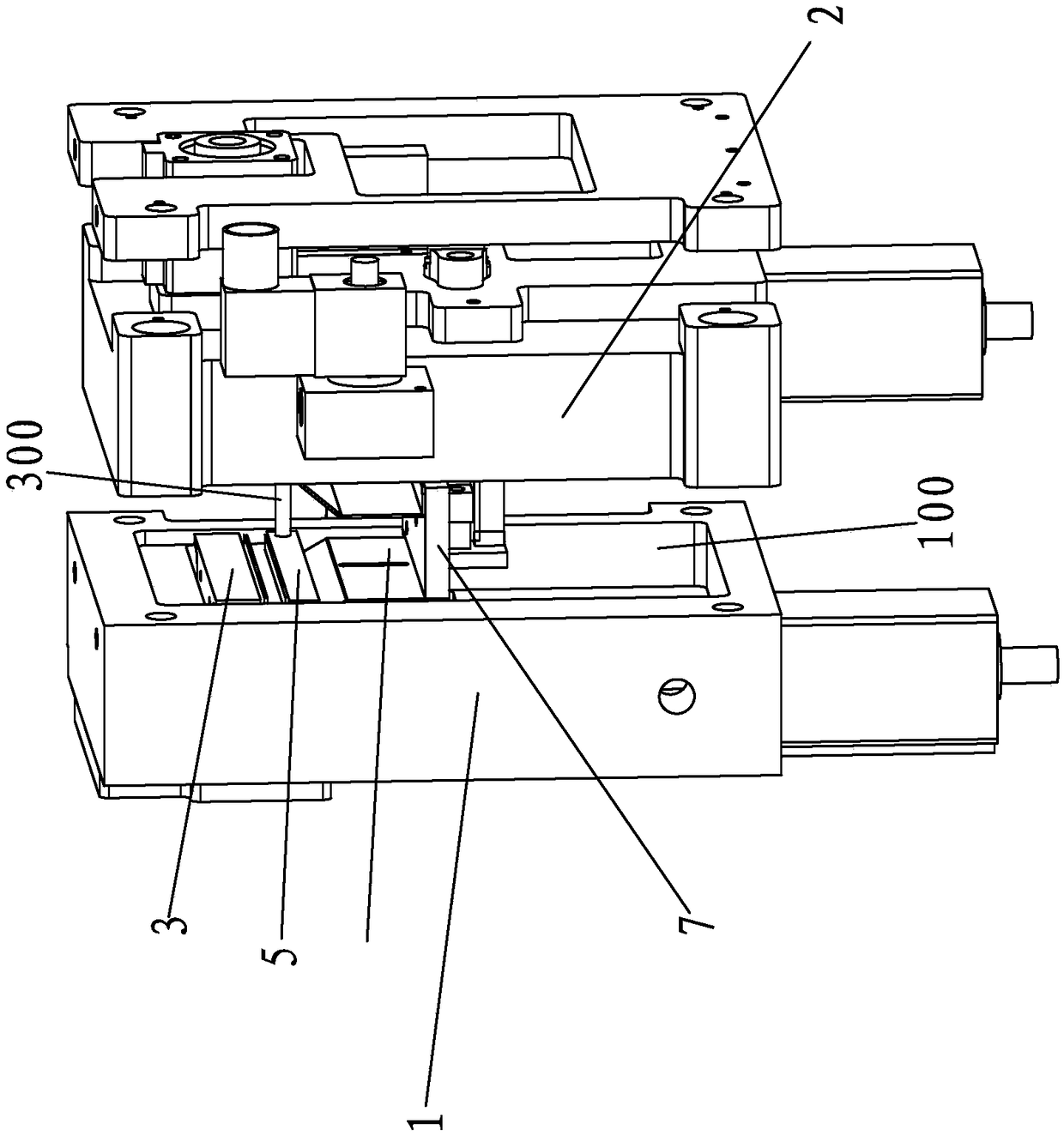

Tea leaf packing process

ActiveCN108382672APreservation effectImprove freshnessPackaging by pressurising/gasifyingPacking procedureEngineering

The invention discloses a tea leaf packing process. The tea leaf packing process includes a pre-treatment procedure and a packing procedure. The packing procedure is implemented through the followingsteps that (1) packing bags fall; (2) die closing is performed, and the tea leaf packing bags on a shaping cavity are completely contained in an airtight cavity; (3) primary vacuumizing is performed on the airtight cavity of the step (2); (4) sealing is performed, specifically, hot-pressing sealing is performed on the primarily vacuumized packing bags in the airtight cavity; (5) secondary vacuumizing on the airtight cavity is started; (6) primary vacuum breaking is performed on the airtight cavity; (7) upper shaping treatment is performed in the airtight cavity; (8) lower shaping treatment isperformed in the airtight cavity; (9) tertiary vacuumizing is performed on the airtight cavity; (10) secondary vacuum breaking is performed on the airtight cavity; and (11) die opening is performed, shaped packing bags on the shaping cavity are taken out, and then tea leaf packing is finished. Compared with the prior art, by means of the tea leaf packing process, the fresh-keeping effect of tea leaves in the bags is good, no tea leaf piece residue exists, six-side shaping is achieved, and therefore the advantages of good packing and shaping effects, attractive packing and many procedures are achieved.

Owner:安溪县钱盛自动化设备有限公司

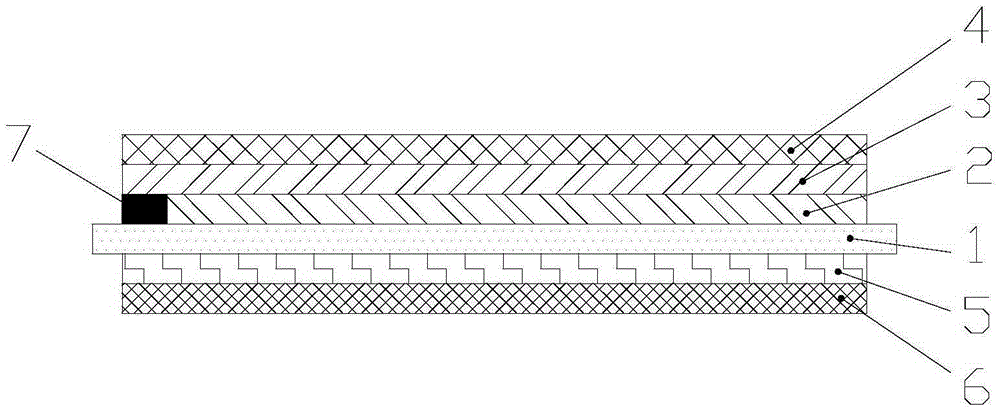

High-performance compound substrate membrane containing positioning lasing and printing pattern and making method of compound substrate membrane

InactiveCN105383200AWon't change colorGood followabilityLamination ancillary operationsSynthetic resin layered productsInformation layerAdhesive

The invention relates to a high-performance compound substrate membrane containing a positioning lasing and printing pattern. The high-performance compound substrate membrane comprises a positioning printing layer 4, a medium layer 3, an information layer 2, a positioning base material 1, a compound adhesive 5 and a substrate membrane body 6 which are sequentially compounded from top to bottom. A making method of the high-performance compound substrate membrane comprises the steps that the surface of the positioning base material 1 is evenly coated with the information layer 2; a lasing information pattern containing a positioning tag is made through processing and making of the information layer 2 and a lasing plate, and the lasing information pattern is plated with an aluminum or SiO2 or ZnS medium layer, so that the pattern is more brilliant; finally, the positioning printing layer 4 is made on the surface of the medium layer, the other face of the positioning base material 1 is compounded with the substrate membrane body 6 through the compound adhesive 5, the made compound substrate membrane is put in a drying room with the temperature ranging from 40 DEG C to 50 DEG C to be baked for 24 h, and the high-performance compound substrate membrane is obtained after the performance is stable. Compared with the prior art, higher anti-counterfeiting value is achieved, an article can have uniqueness and good following performance, and the non-follow-up problem produced by a conventional coating membrane can be solved.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

Flexible filling packaging device and method for automatically fitting shape of article

ActiveCN108569448AHigh degree of automationSave on packaging materialsPackagingFoaming agentEngineering

The invention discloses a flexible filling packaging device and a method for automatically fitting a shape of an article. A mechanical structural system of the device mainly comprises a base driving part, a mould part, an article supporting part and a foaming agent aerosol can; the driving part completes the opening and closing movement of the mould part; the mould part comprises a certain numberof flexible rod pieces; the flexible rod pieces are attached to each other; the flexible rod pieces at different positions touch different positions of the article to form a mold cavity similar to theshape of the article; the article to be packaged is placed on a supporting table before the mould part is closed; after the mould part is closed, the supporting table is removed, and the article doesnot fall down; after the mould part is closed, a foaming agent is ejected from certain rod piece units in the mould part through a pipe from the foaming agent aerosol can; the mold cavity formed after the mould part is closed is relatively airtight; and the foaming agent does not overflow. The method provided by the invention saves packaging materials to a great extent, and the surface of the package is accompanied by 'salient points', so that the anti-shock effect is enhanced, and the packaging is attractive in appearance.

Owner:BEIJING UNIV OF TECH

Packaged container cover directive structure

ActiveCN105480544AEasy to observeBeautiful packagingFlexible containersPliable tubular containersMechanical engineeringExtrusion

The invention provides a packaged container cover directive structure which comprises a container and a cover body, wherein a first extrusion hole is formed in the top of the container; an outer thread is formed on the first extrusion hole; the cover body comprises a connecting piece, a sleeving cover and a movable overturning plate; inner thread is formed on the connecting piece; a second extrusion hole is formed at the top of the connecting piece; a buckling device is arranged in the sleeving cover; a third extrusion hole is formed at the top of the sleeving cover; the sleeving cover is buckled with the connecting piece by the buckling device; the first extrusion hole, the second extrusion hole and the third extrusion hole are all located on a same straight line; one end of the movable overturning plate is hinged with the sleeving cover, and the other end of the movable overturning plate has a cover lifting position. The packaging container cover directive structure can align the cover lifting position to a certain specific direction of the container, so that the product is attractive in package, and users can conveniently obverse marks or contents in a specific direction of the container in use. The packaged container cover directive structure is used for packaging containers of semifluid.

Owner:冼志忠

Counterweight-frame heat-shrinkable film packaging machine

PendingCN110065682AIncrease productivityReduce labor intensityWrappers shrinkageThin membraneElectrical control

The invention discloses a counterweight-frame heat-shrinkable film packaging machine. The machine mainly comprises a longitudinal chain conveyor, a transverse unpowered roller conveyor, a film supplying and wrapping mechanism, a pushing device, a heat drying machine and electrical control part, and a counterweight frame, wherein the longitudinal chain conveyor is arranged behind the pushing device, the transverse unpowered roller conveyor is arranged in a cavity inside the longitudinal chain conveyor, the film supplying and wrapping mechanism is arranged behind the transverse unpowered rollerconveyer, and the heat drying machine and electrical control part is connected behind the film supplying and wrapping mechanism. According to the counterweight-frame heat-shrinkable film packaging machine, a heat shrinkable film is used as a packaging carrier, and a mechanical packaging method is adopted to replace a traditional wooden box packaging or manual winding film packaging; the packagingproduction efficiency is improved, the labor intensity is reduced, the product package is attractive, and the resource loss is reduced.

Owner:HANGZHOU HOPMANN ELEVATOR

Full-automatic underseal plastic-envelop machine

The invention discloses a full-automatic underseal plastic-envelop machine. The full-automatic underseal plastic-envelop machine comprises a film conveying device, a box conveying device, a packagingbox transfer device, a plastic package film cutting device, a plastic package end cutting device and a transferring device, wherein the box conveying device is used for conveying a packaging box to the film conveying device to be coated with a film, and then conveying the packaging box to the packaging box transfer device; the plastic package film cutting device is arranged between the box conveying device and the packaging box transfer device, and is used for cutting the plastic package film and sewing the cut plastic package film in the film conveying device and the packaging box; the transferring device is arranged above the packaging box transfer device and the plastic package end cutting device, and is used for moving the packaging box from the packaging box transfer device to plasticpackage end cutting device and from the plastic package end cutting device to a next station; and the plastic package end cutting device is used for cutting the plastic package film of the end part of the packaging box. According to the full-automatic underseal plastic-envelop machine, a packaging box plastic package tangent line can be automatically controlled to be in the bottom edge position of the packaging box, product packaging is more beautiful, the visual effect is good, and the product image is remarkably improved.

Owner:深圳市利和兴股份有限公司

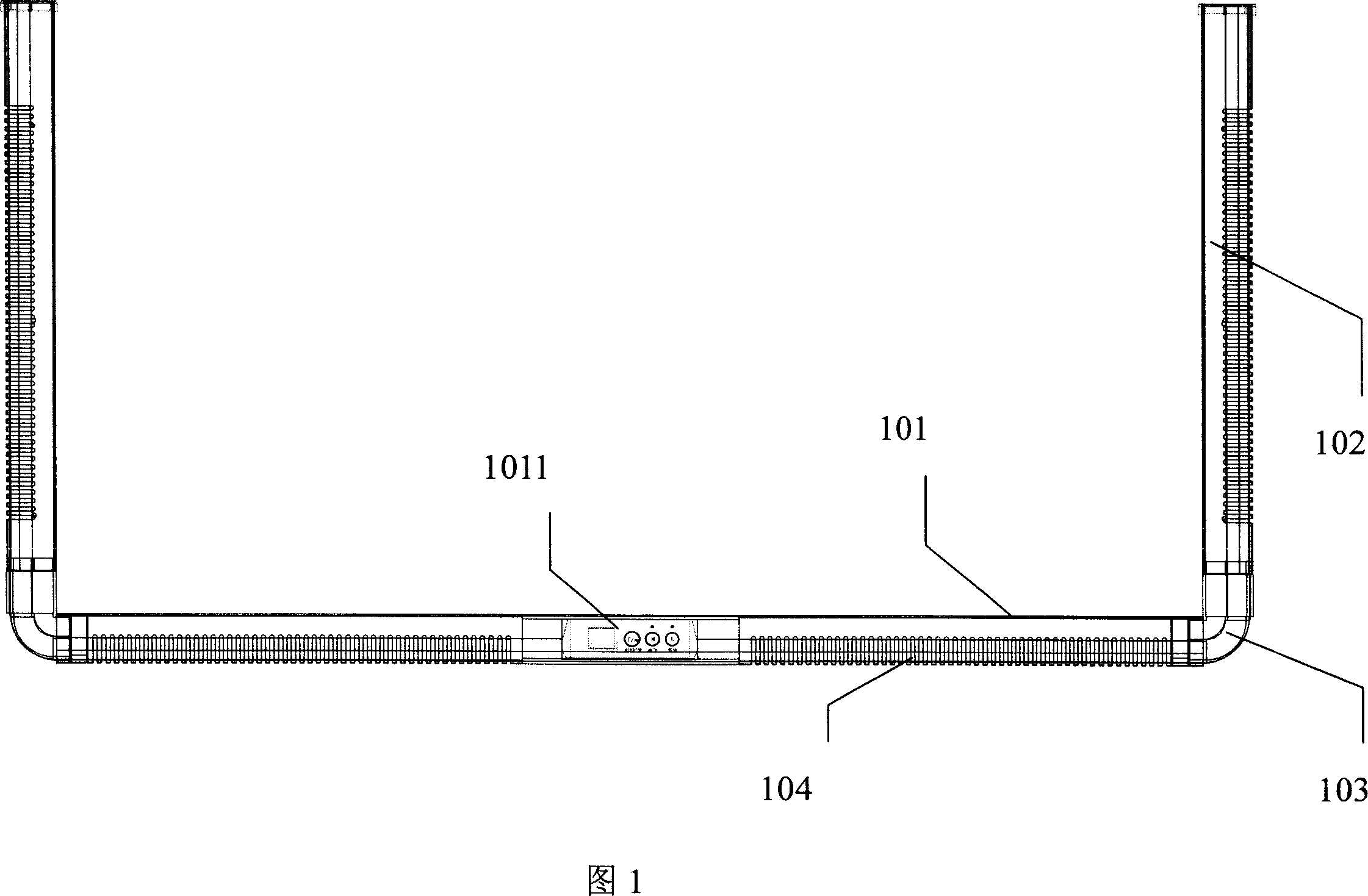

Wire winding device

The invention discloses a wire winding device, and relates to the technical field of electronic product packaging equipment. The wire winding device comprises a rotating disc, a product placement box sliding in the radial direction of the rotating disc, a wire guiding wheel located between the rotating disc and the product placement box and a wire height adjusting wheel located between the wire guiding wheel and a wire winding supporting block and moving vertically; the rotating direction of the rotating disc is the horizontal direction; a packaging box placement groove is formed in the rotating disc; the wire winding supporting block is arranged in the position, corresponding to the rotating center of the rotating disc, in the packaging box placement groove; a positioning part used for fixing a wire winding part of a product packaging box is arranged on the wire winding supporting block; and wire clamping grooves are formed in the product placement box. According to the wire winding device, wire winding can be carried out automatically, the wire winding efficiency is high, the wound wires are orderly and closely arranged, the consistency of product packaging is high, and the attractiveness is high; and meanwhile, the structure is simple, the operation is convenient, and the cost is low.

Owner:GOERTEK INC

Foldable smoke-guiding machine

InactiveCN1979012ASmall form factorReduce weightDomestic stoves or rangesLighting and heating apparatusIntegratorEngineering

The invention relates to a folding smoke guiding machine that includes main pipe and side pipe. The feature is that the main pipe connects to the side pipe by matched bight bend, which is fixed at two ends of the main pipe. Another end of the bight bend is connected to side pipe to form an integrator with main pipe. The invention has the advantages of convenient to uninstall, easy to clean, small volume, light weight and convenient to package and store.

Owner:PHICO PRECISION ELECTRONICS IND SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com