Microstructural stereoscopic anaglyph image-text platemaking method and device

A technology of three-dimensional relief and microstructure, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., to achieve the effect of beautiful packaging and advanced anti-counterfeiting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

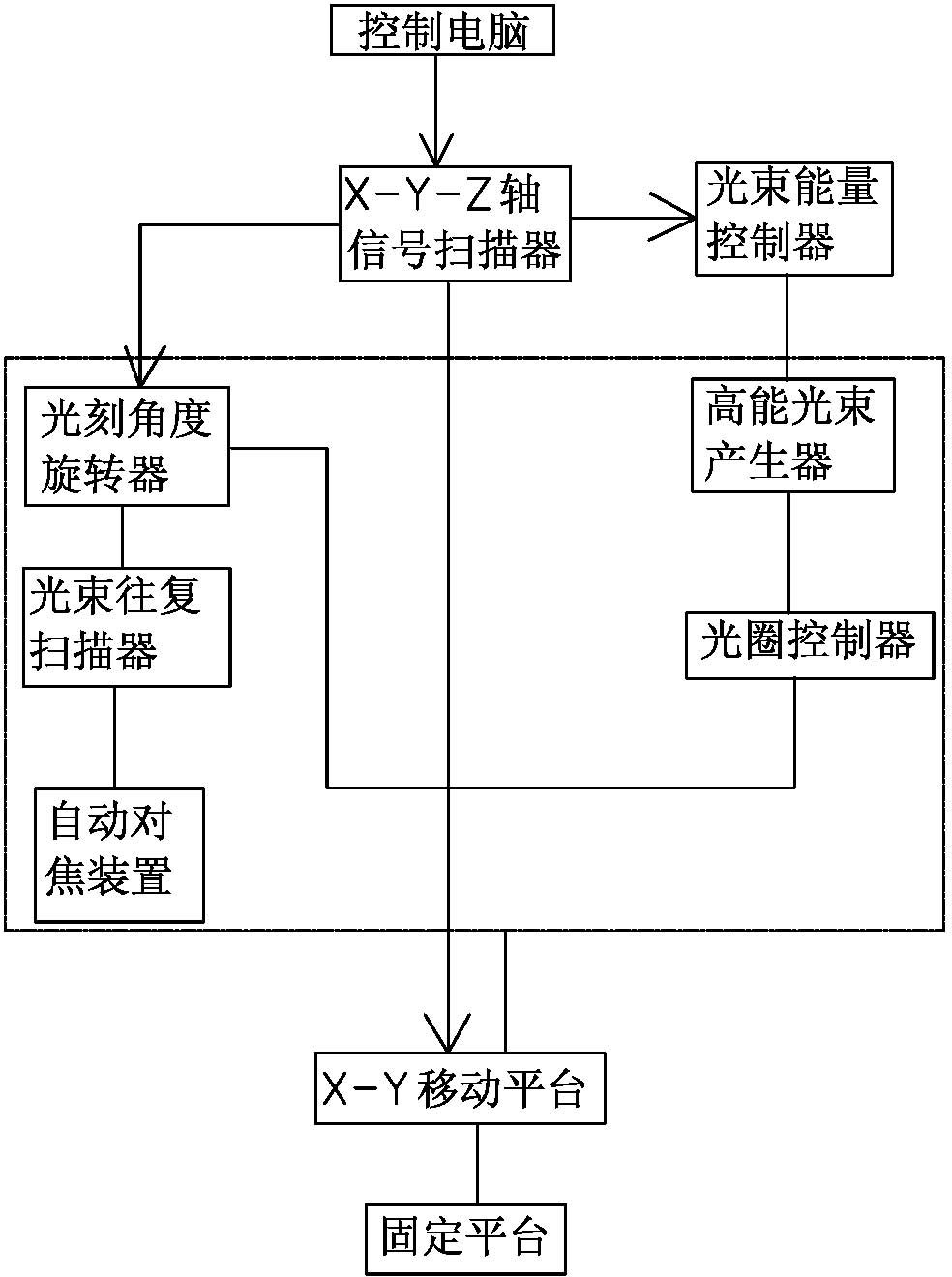

[0020] Such as figure 1 As shown, the microstructure three-dimensional relief graphic plate-making device of this embodiment includes a control computer, an X-Y-Z axis signal scanner, an X-Y moving platform, a beam energy controller, a high-energy beam generator, an aperture controller, a lithography angle rotator, and a beam Reciprocating scanner, auto focus unit and fixed platform for setting photoresist glass.

[0021] The control computer is connected to the X-Y-Z axis signal scanner, the X-Y-Z axis signal scanner is respectively connected to the lithography angle rotator, the beam energy controller and the X-Y mobile platform, the beam energy controller is connected to the high-energy beam generator signal, and the high-energy beam is generated The output end of the device is set up in order from near to far: aperture controller, lithography angle rotator, beam reciprocating scanner and auto-focus device, high-energy beam generator, aperture controller, lithography angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com