Patents

Literature

556 results about "High energy laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Tactical High-Energy Laser, or THEL, was a laser developed for military use, also known as the Nautilus laser system. The mobile version is the Mobile Tactical High-Energy Laser, or MTHEL.

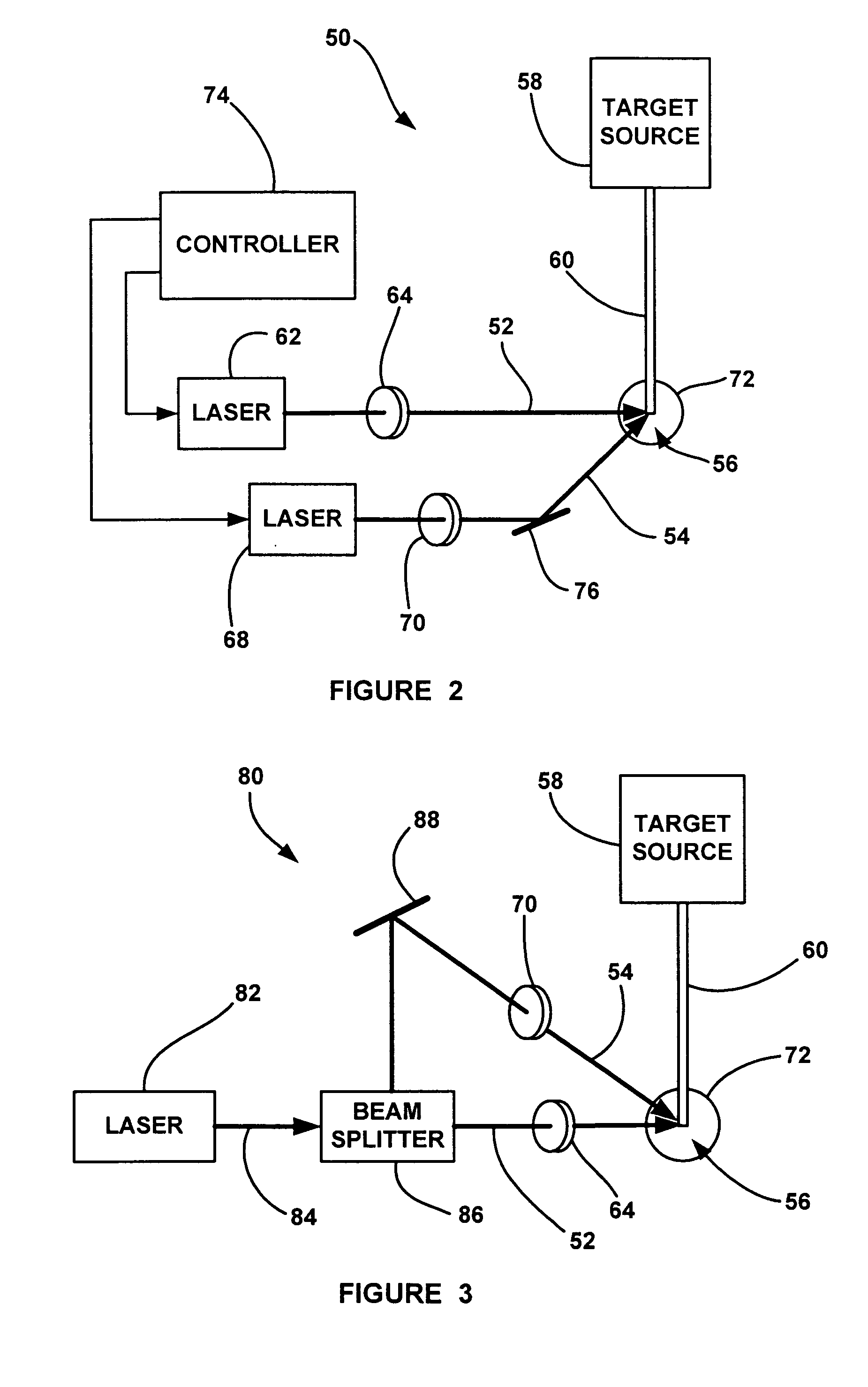

Laser-produced plasma EUV light source with pre-pulse enhancement

InactiveUS20040264512A1Laser using scattering effectsSemiconductor/solid-state device manufacturingBeam splitterHigh energy

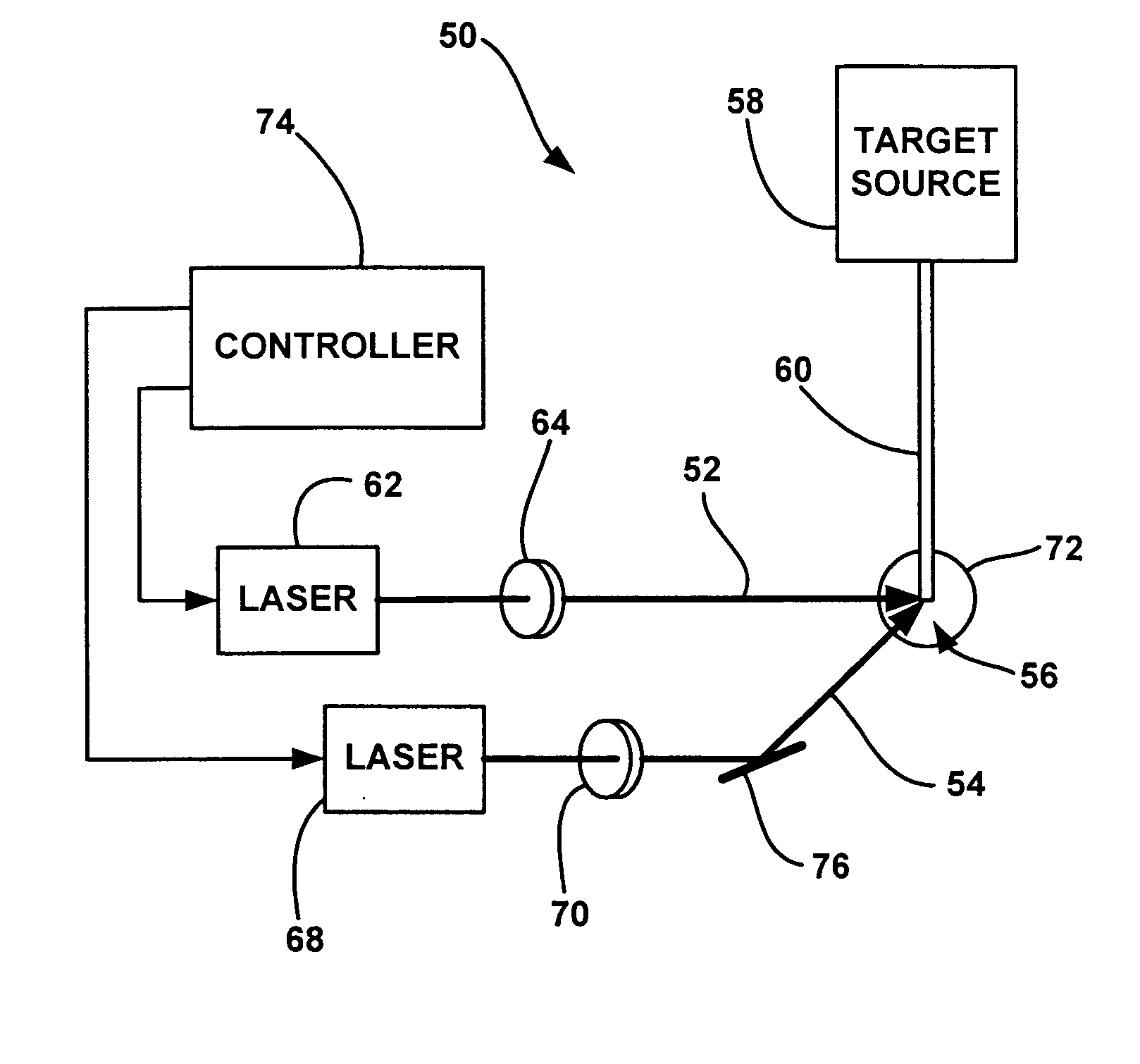

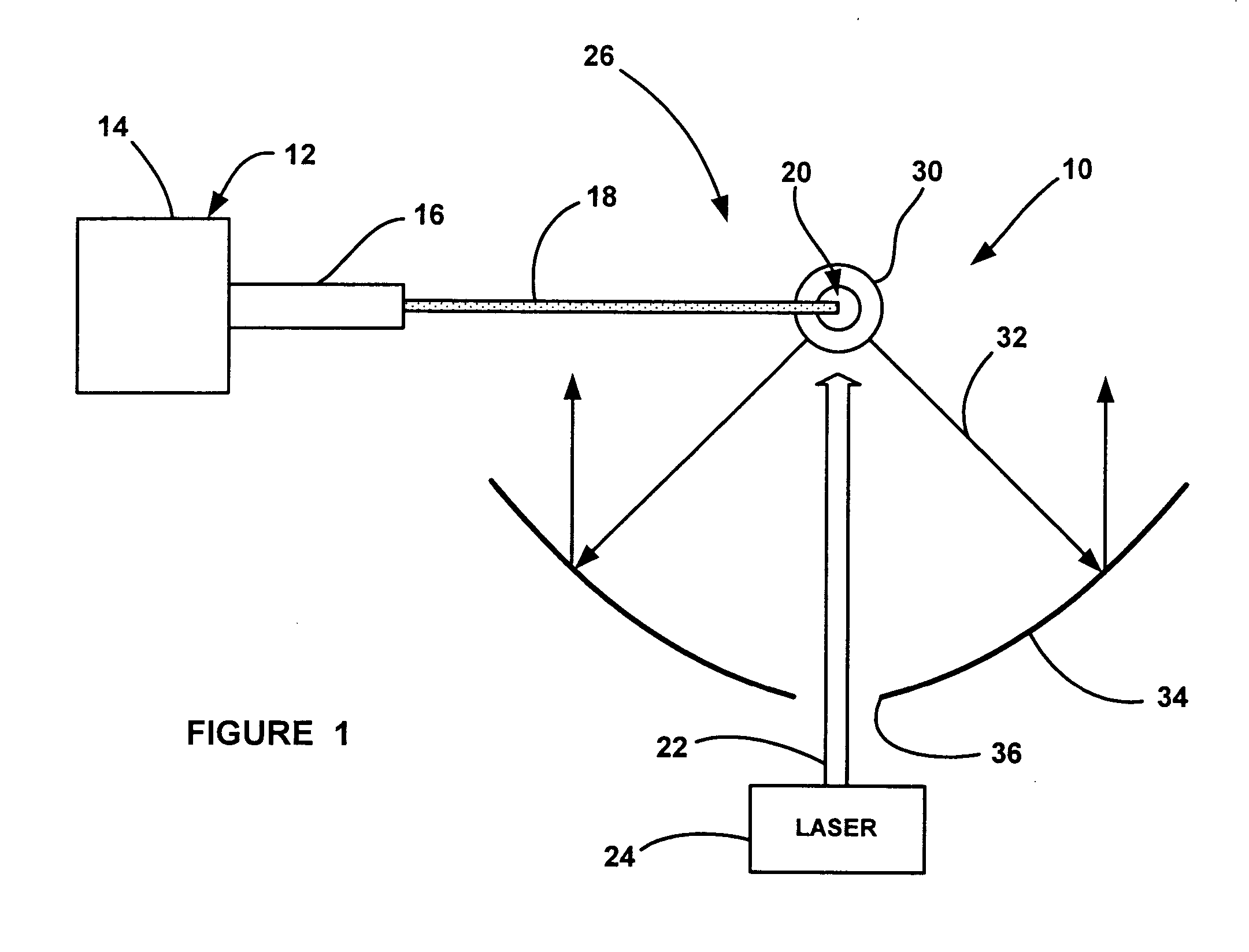

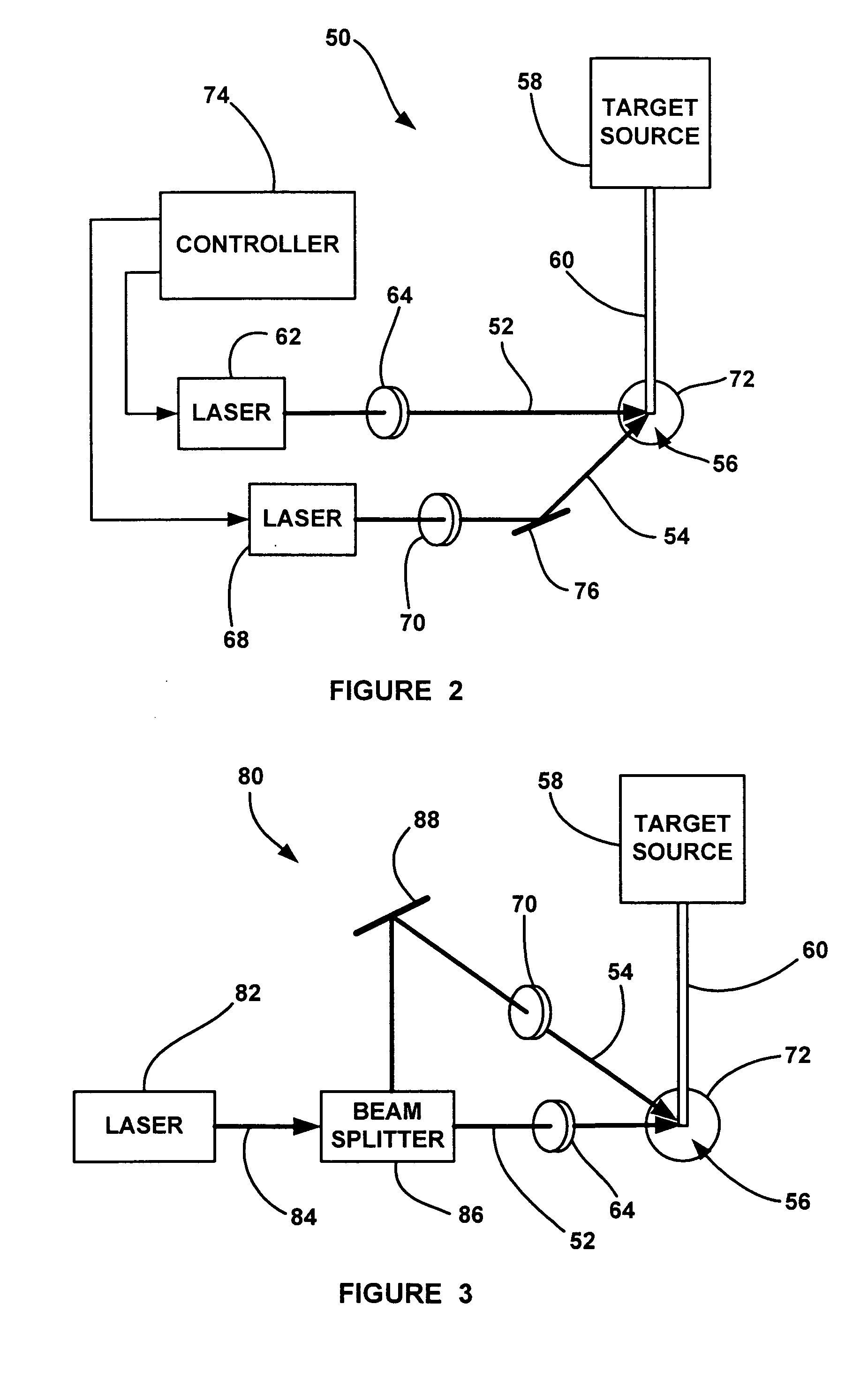

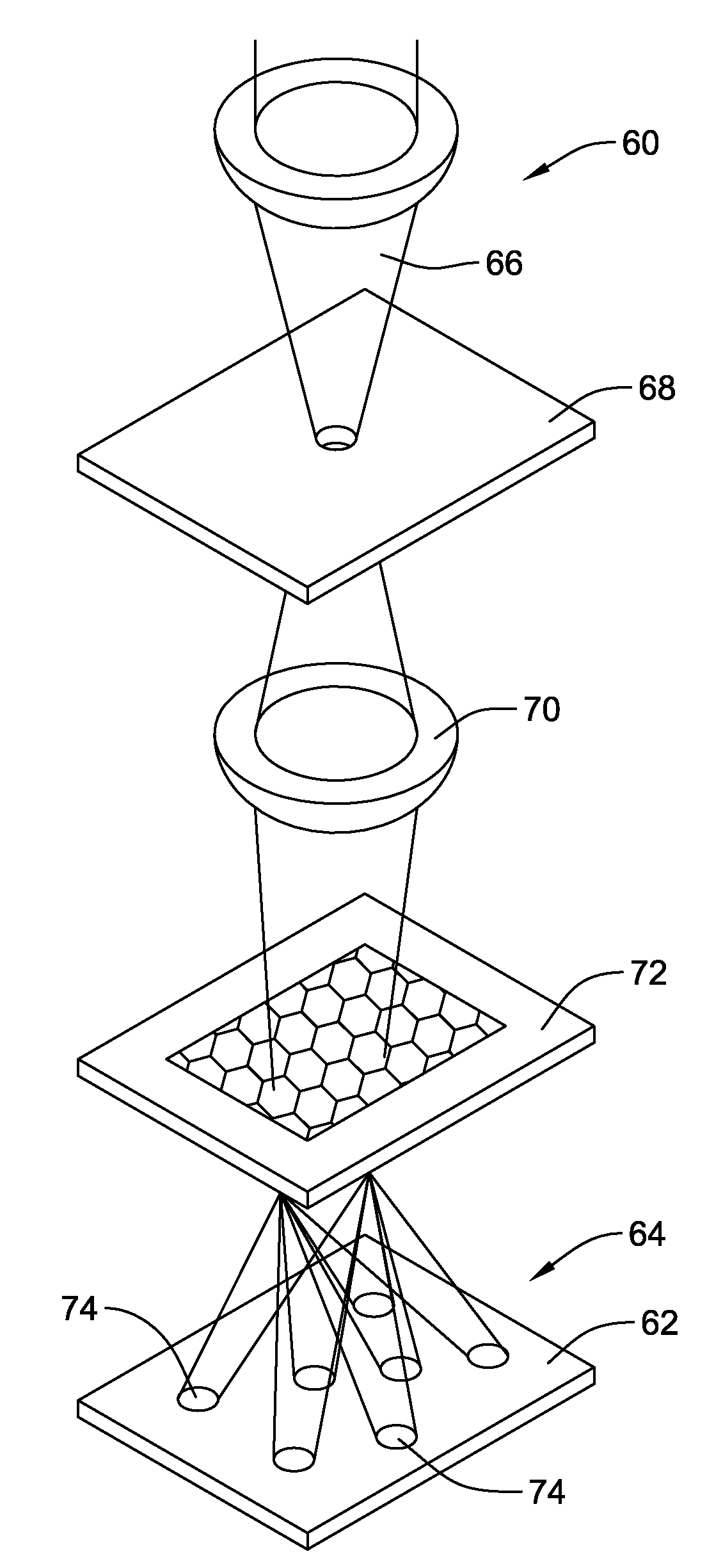

An EUV radiation source that employs a low energy laser pre-pulse and a high energy laser main pulse. The pre-pulse generates a weak plasma in the target area that improves laser absorption of the main laser pulse to improve EUV radiation emissions. High energy ion flux is reduced by collisions in the localized target vapor cloud generated by the pre-pulse. Also, the low energy pre-pulse arrives at the target area 20-200 ns before the main pulse for maximum output intensity. The timing between the pre-pulse and the main pulse can be reduced below 160 ns to provide a lower intensity of the EUV radiation. In one embodiment, the pre-pulse is split from the main pulse by a suitable beam splitter having the proper beam intensity ratio, and the main pulse is delayed to arrive at the target area after the pre-pulse.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

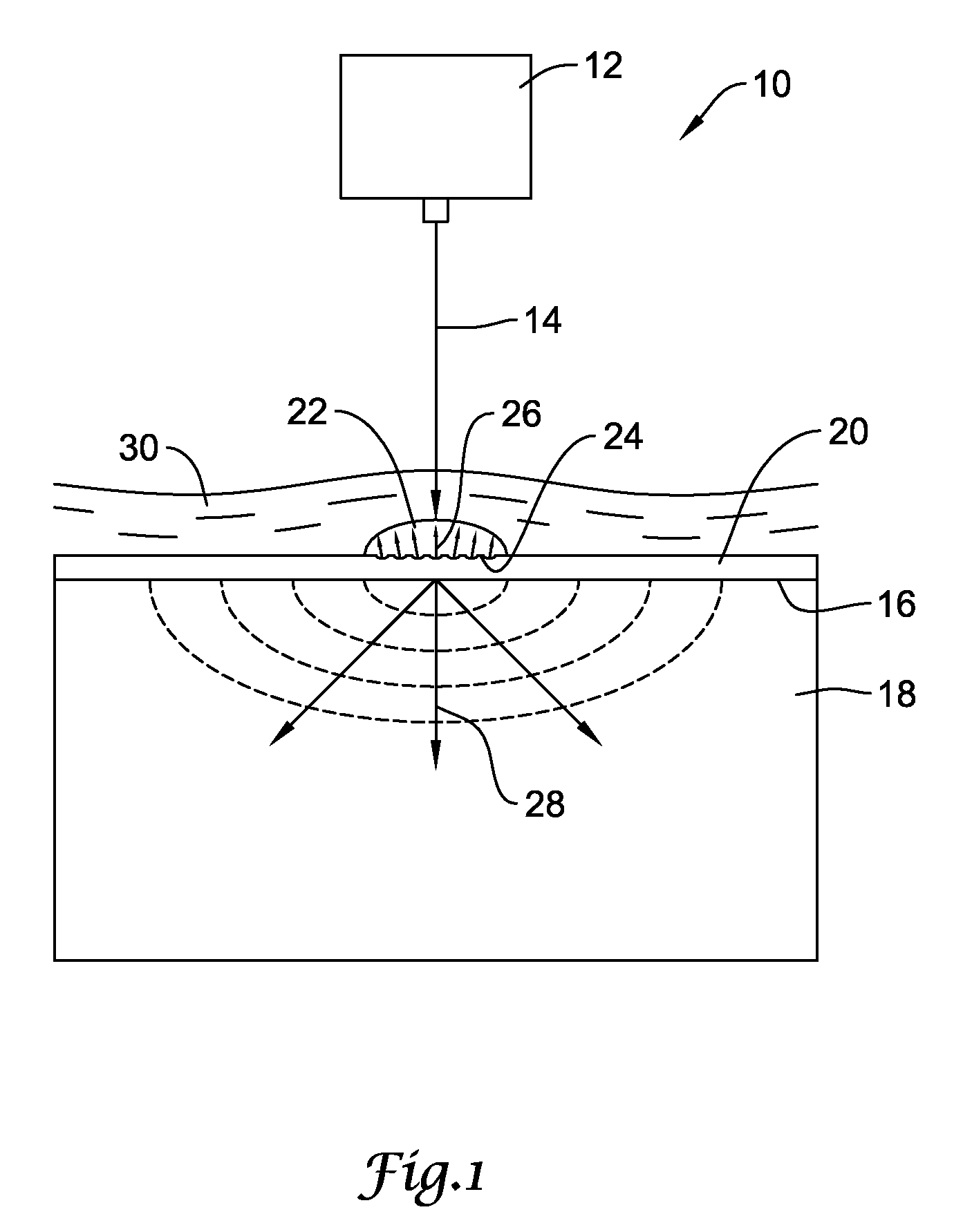

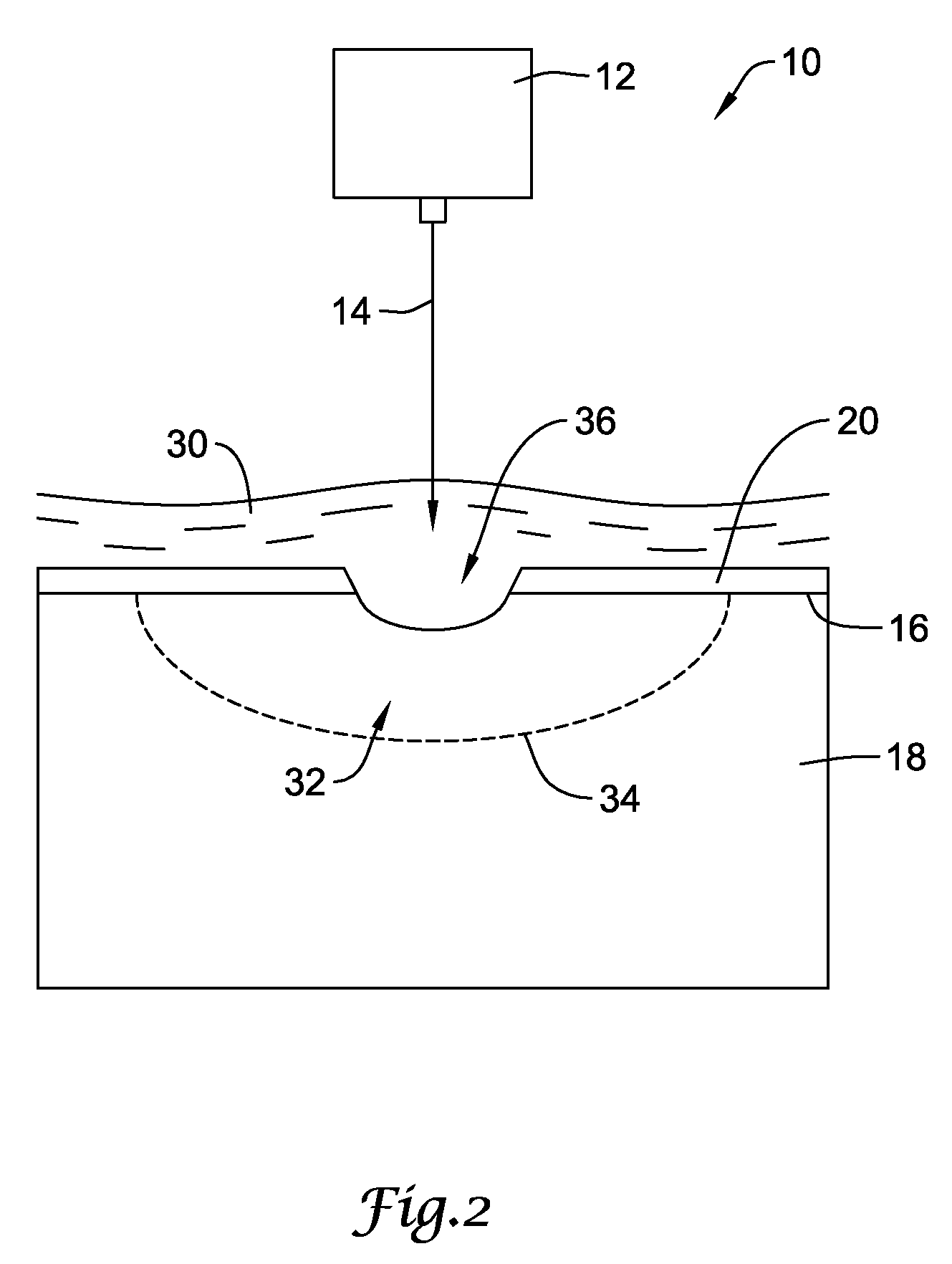

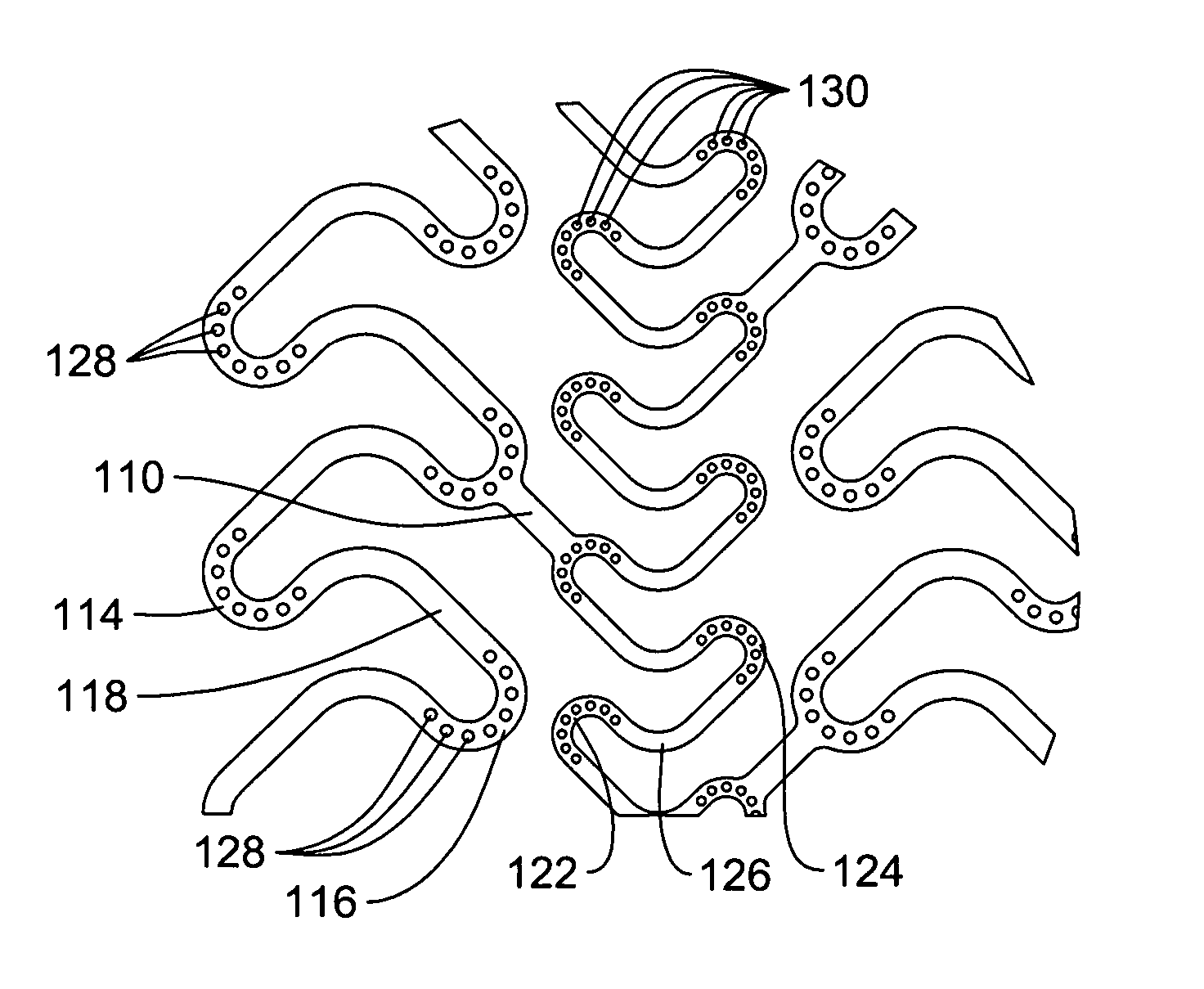

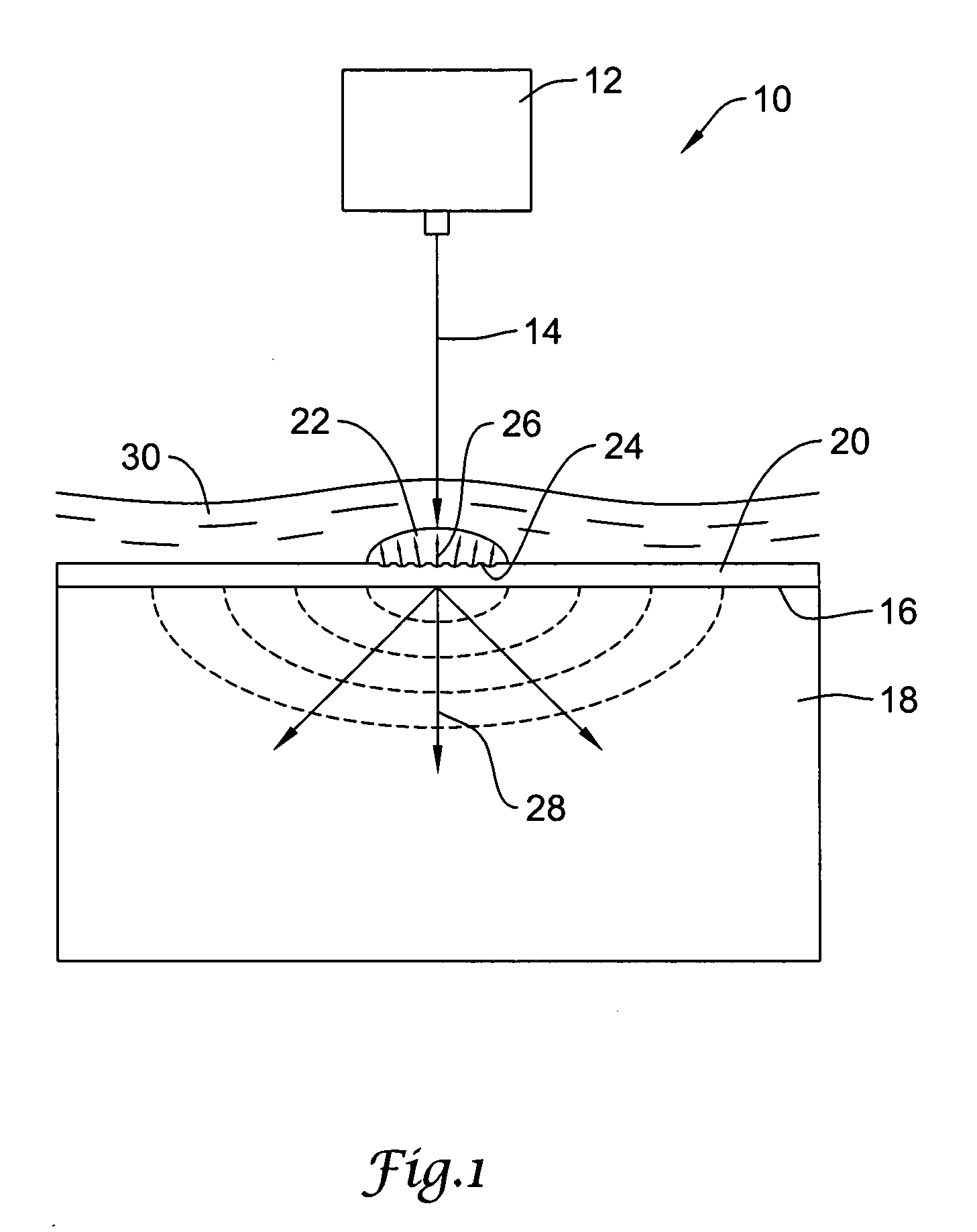

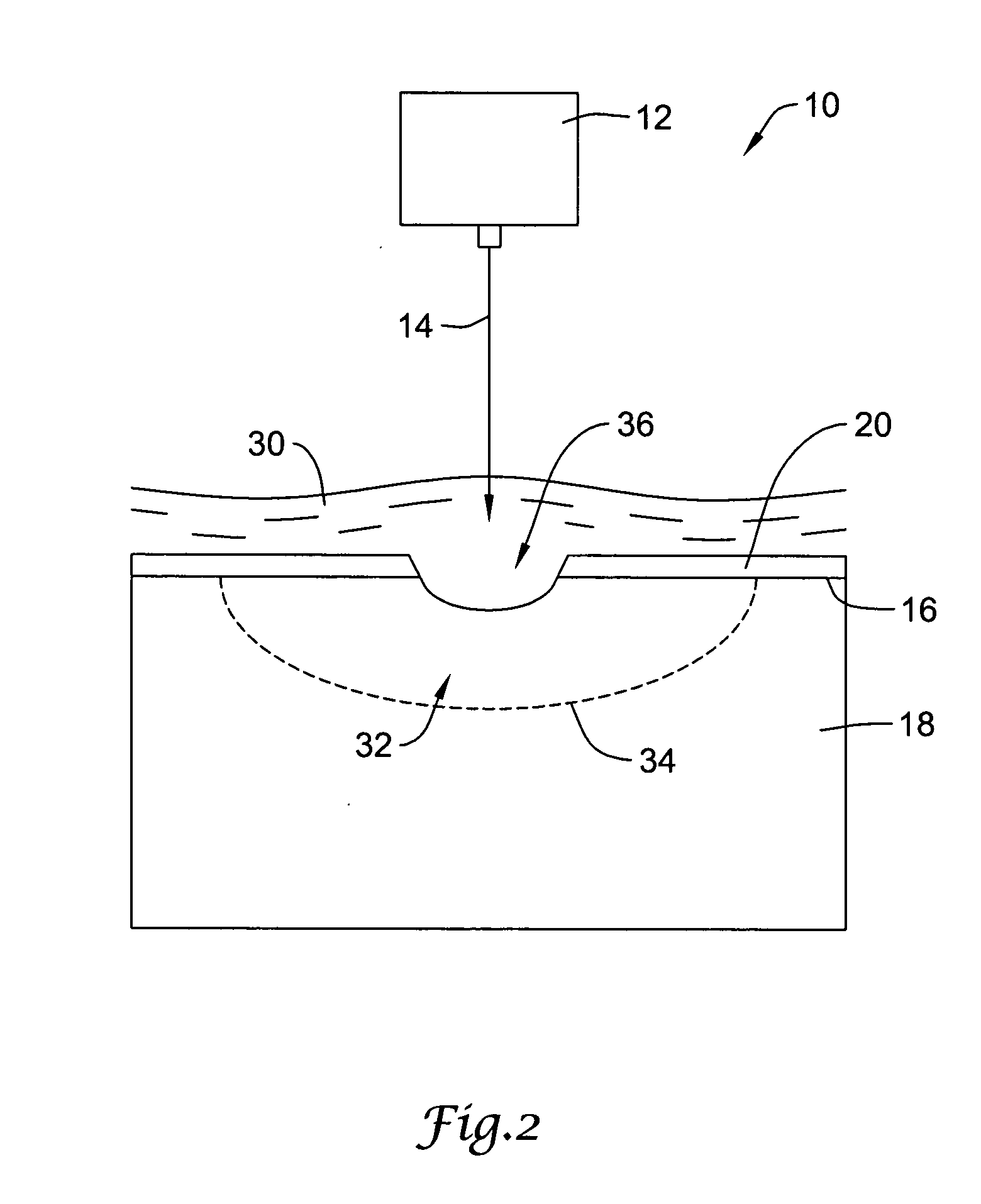

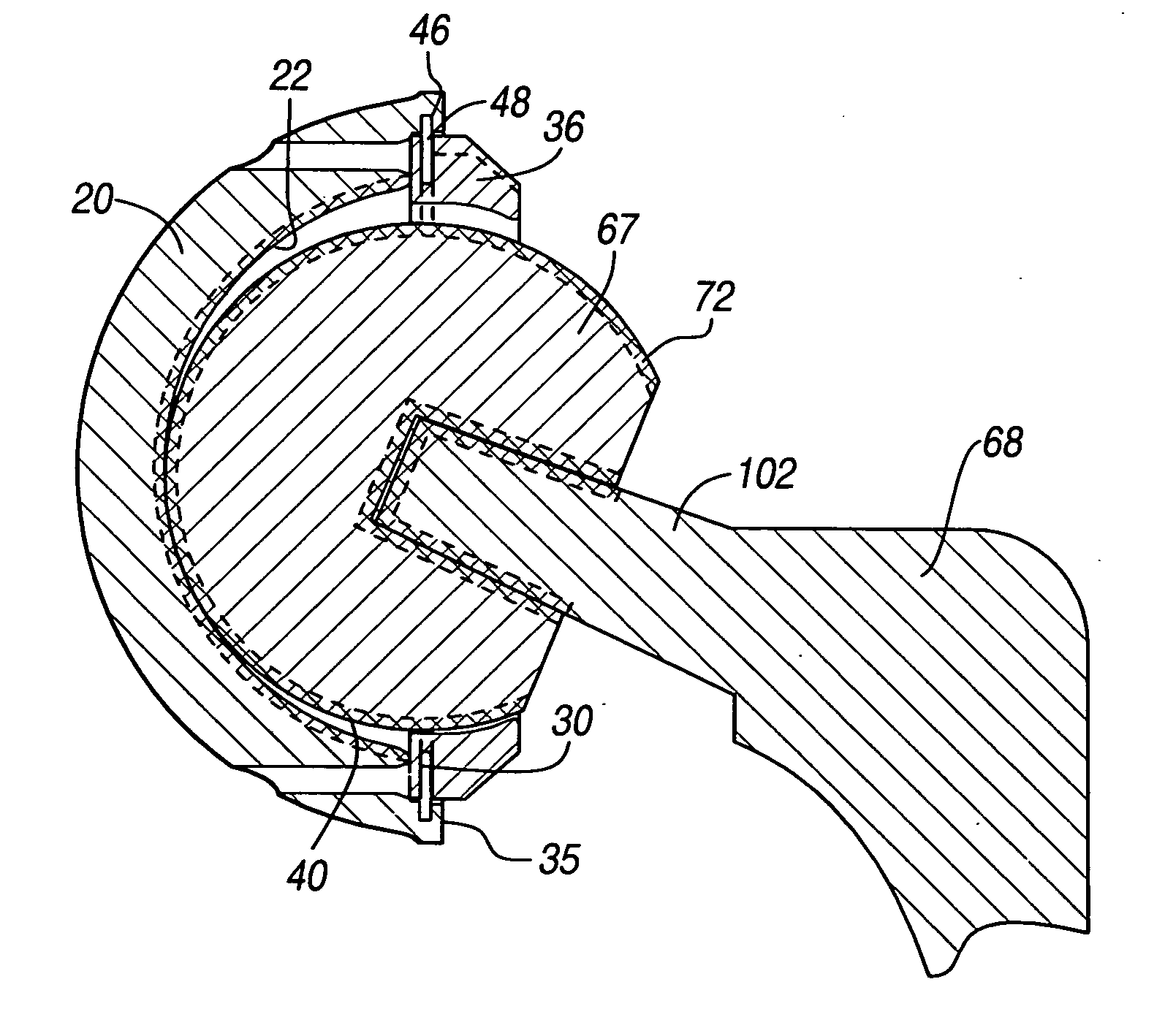

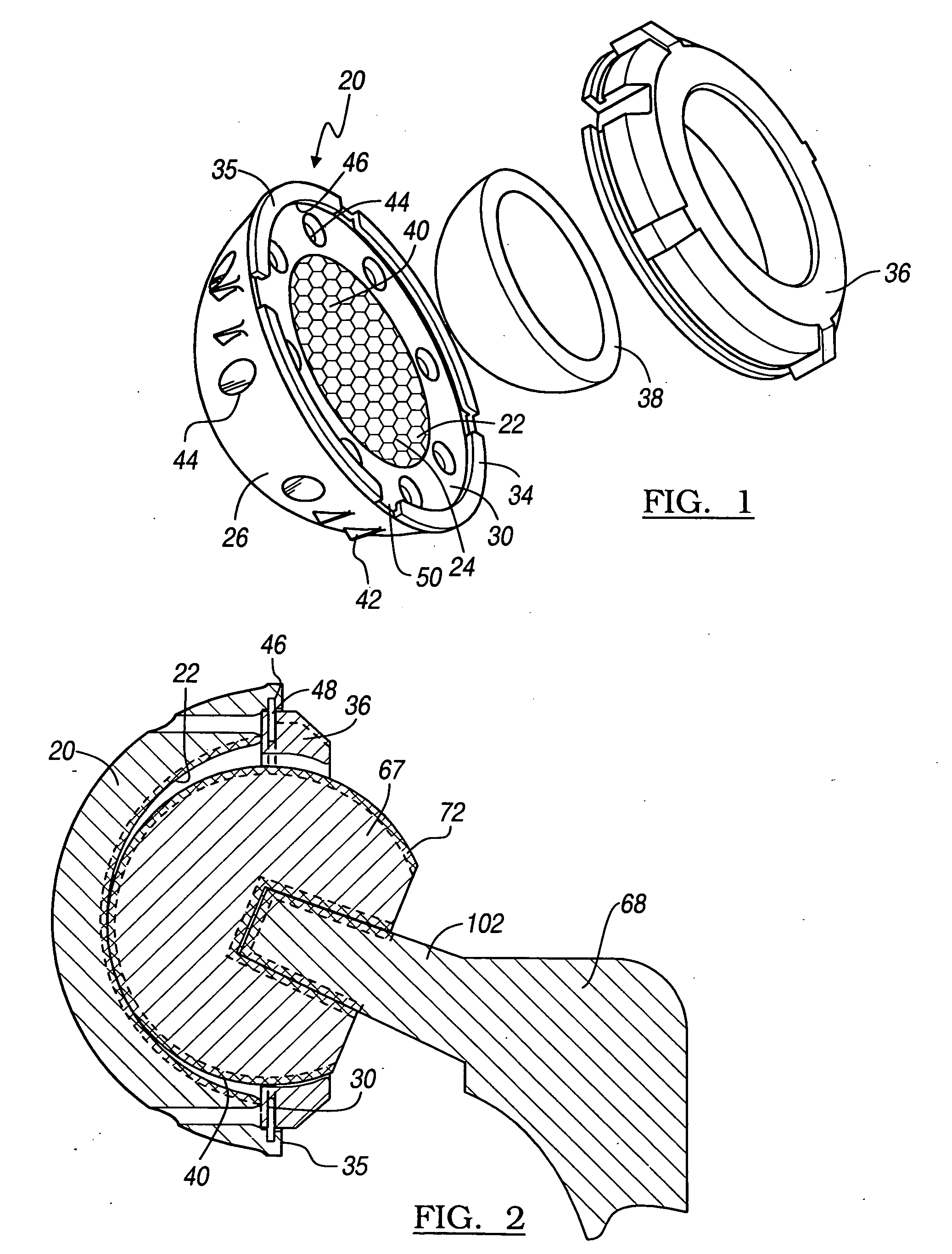

Laser shock peening of medical devices

InactiveUS20090043228A1Improve fatigue strengthIncrease flexibilityStentsCatheterShock waveTarget surface

A laser shock peening process for producing one or more compressive residual stress regions in a medical device is disclosed. A high-energy laser apparatus can be utilized to direct an intense laser beam through a confining medium and onto the target surface of a workpiece. An absorption overlay disposed on the target surface of the workpiece absorbs the laser beam, inducing a pressure shock wave that forms a compressive residual stress region deep within the workpiece. Medical devices such as stents, guidewires, catheters, and the like having one or more of these compressive residual stress regions are also disclosed.

Owner:BOSTON SCI SCIMED INC

Laser shock peening of medical devices

A laser shock peening process for producing one or more compressive residual stress regions in a medical device is disclosed. A high-energy laser apparatus can be utilized to direct an intense laser beam through a confining medium and onto the target surface of a workpiece. An absorption overlay disposed on the target surface of the workpiece absorbs the laser beam, inducing a pressure shock wave that forms a compressive residual stress region deep within the workpiece. Medical devices such as stents and guidewires having one or more of these compressive residual stress regions are also disclosed.

Owner:BOSTON SCI SCIMED INC

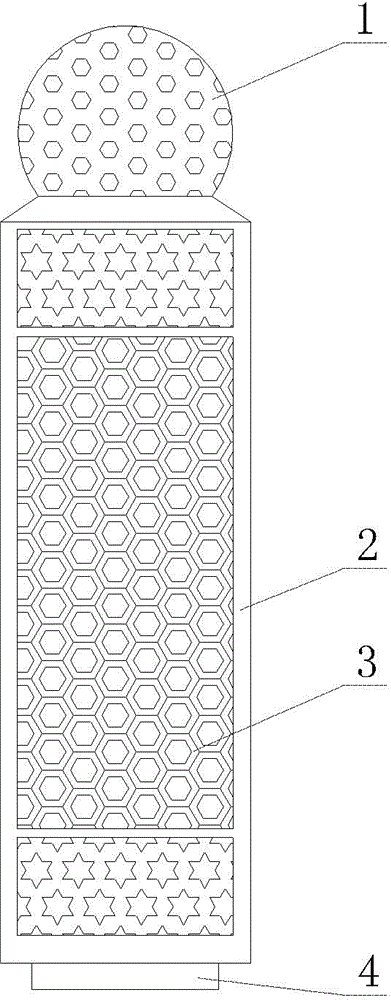

3D (three dimensional) printing manufacturing method of seal

InactiveCN103143706AOvercome the problem of single structure formImprove production efficiencyIncreasing energy efficiencyGraphicsManufacturing technology

The invention provides a 3D (three dimensional) printing manufacturing method of a seal, which can solve problems of single structural forms of traditional seals and complicated manufacture and high costs of metal seals. The 3D printing manufacturing method adopts an additive manufacturing technology for manufacturing the seal and includes that firstly, computer 3D modeling is performed on a whole structure of the seal; then, a computer 3D model is divided into a series of two dimensional graphics in the direction of a Z axis according an equal layer thickness, and a corresponding laser scanning path is generated according to the two dimensional graphics; material powder laid on the surface of a processing platform of an additive manufacturing device in advance is scanned by high-energy laser or electronic beams according to the laser scanning path and consolidated on the surface of the processing platform after the material powder is scanned to be melted; after a layer of pattern is melted on the surface of the processing form, a layer of material powder is laid on the surface of the processing platform, and the material powder is scanned by laser till the seal is integrally formed; and then, the seal melted on the processing platform and the processing platform are moved out from the additive manufacturing device, and the seal is separated from the surface of the processing platform.

Owner:WUXI ANDI LIJIE TRADE

Laser-produced plasma EUV light source with pre-pulse enhancement

InactiveUS6973164B2Improves laser absorption of laserLess likely to damageLaser using scattering effectsSemiconductor/solid-state device manufacturingBeam splitterVapor cloud

An EUV radiation source that employs a low energy laser pre-pulse and a high energy laser main pulse. The pre-pulse generates a weak plasma in the target area that improves laser absorption of the main laser pulse to improve EUV radiation emissions. High energy ion flux is reduced by collisions in the localized target vapor cloud generated by the pre-pulse. Also, the low energy pre-pulse arrives at the target area 20–200 ns before the main pulse for maximum output intensity. The timing between the pre-pulse and the main pulse can be reduced below 160 ns to provide a lower intensity of the EUV radiation. In one embodiment, the pre-pulse is split from the main pulse by a suitable beam splitter having the proper beam intensity ratio, and the main pulse is delayed to arrive at the target area after the pre-pulse.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Method and apparatus for surface hardening implants

A method for producing a prosthetic having metal articulating surfaces is disclosed. The method includes impinging at least a portion of the articulating surface with high energy laser electromagnetic radiation, to form a lasershot peened surface. A hardened portion of the surface is then post-processed to form a layer having a predetermined finish.

Owner:BIOMET MFG CORP

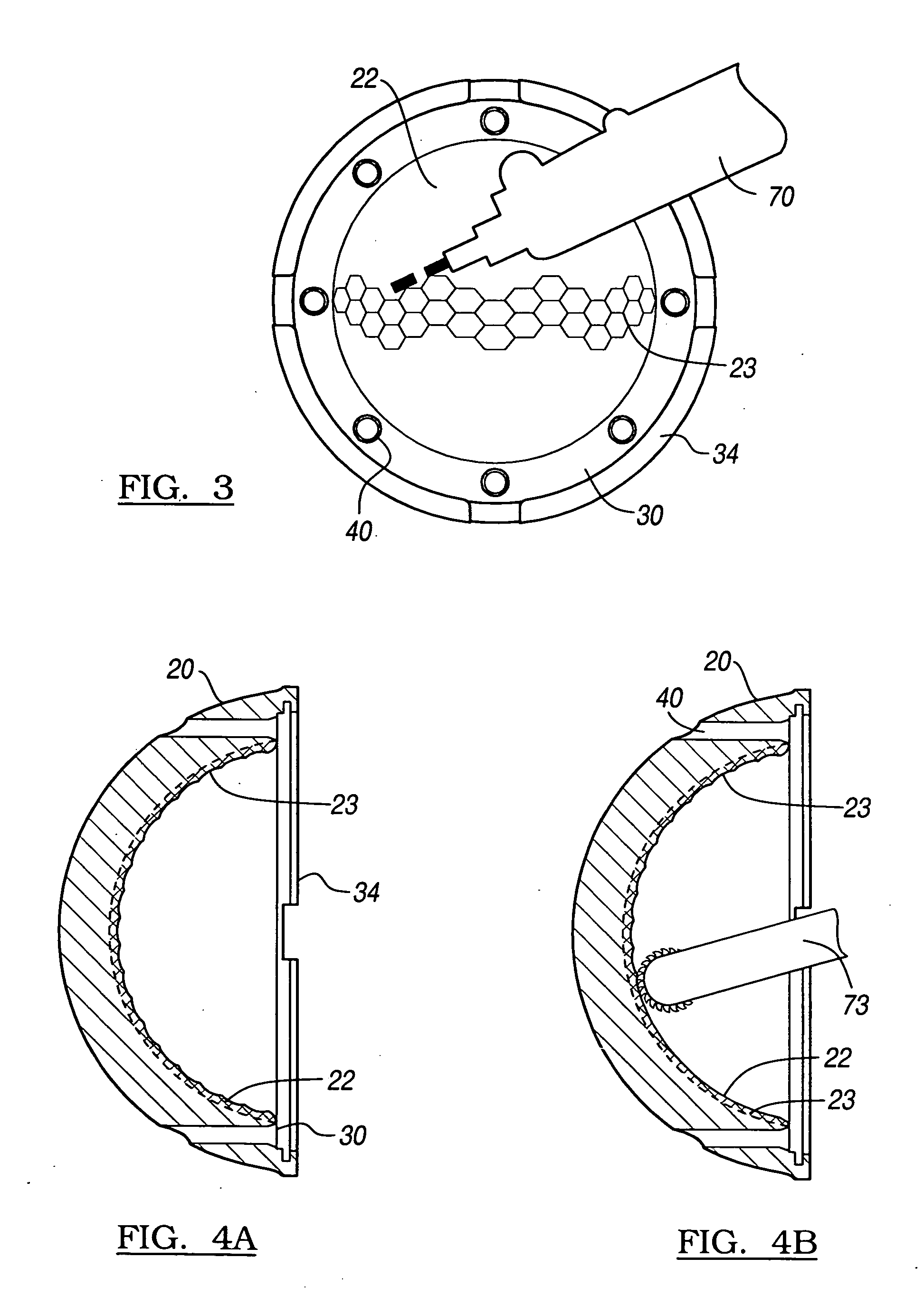

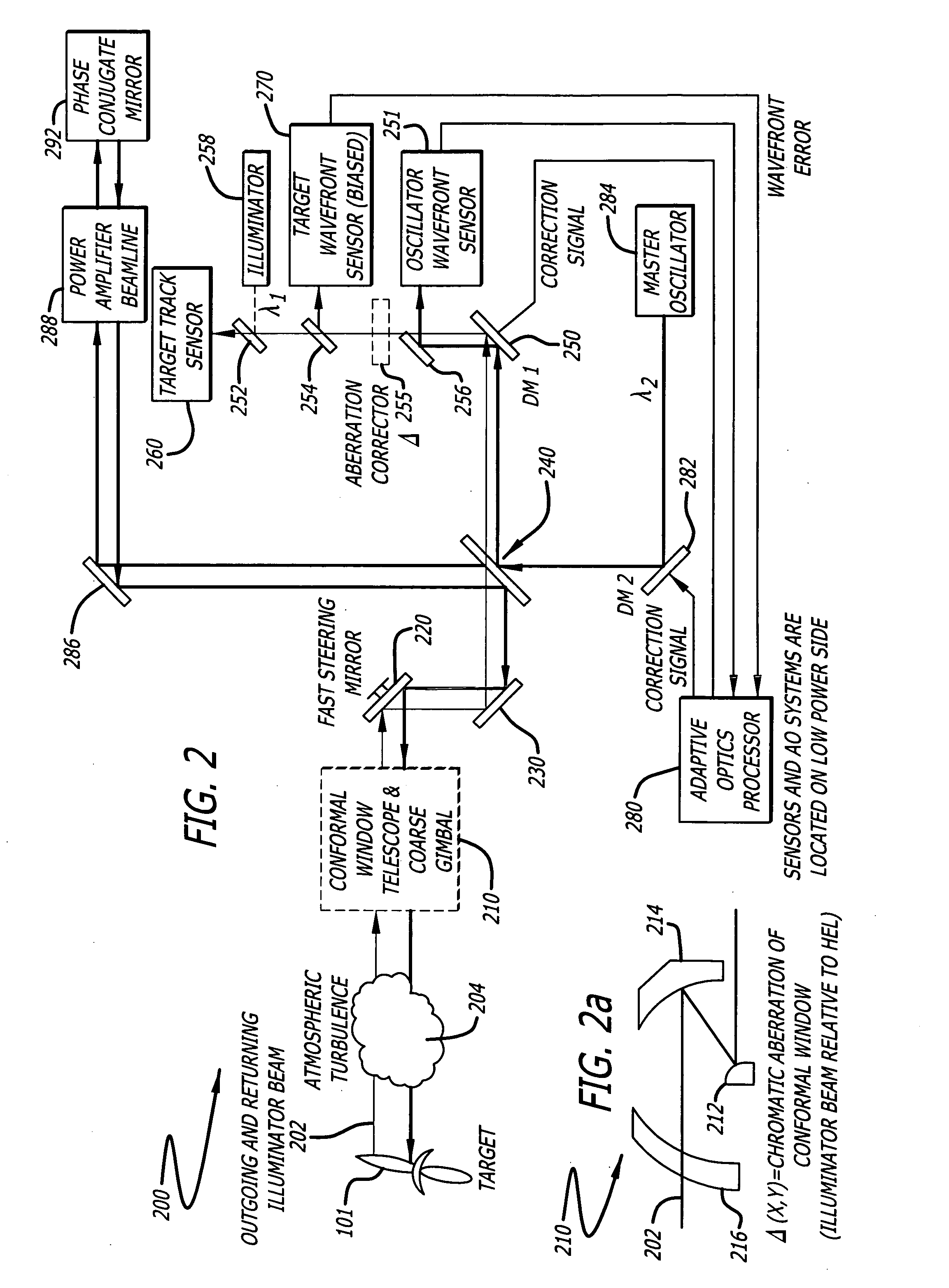

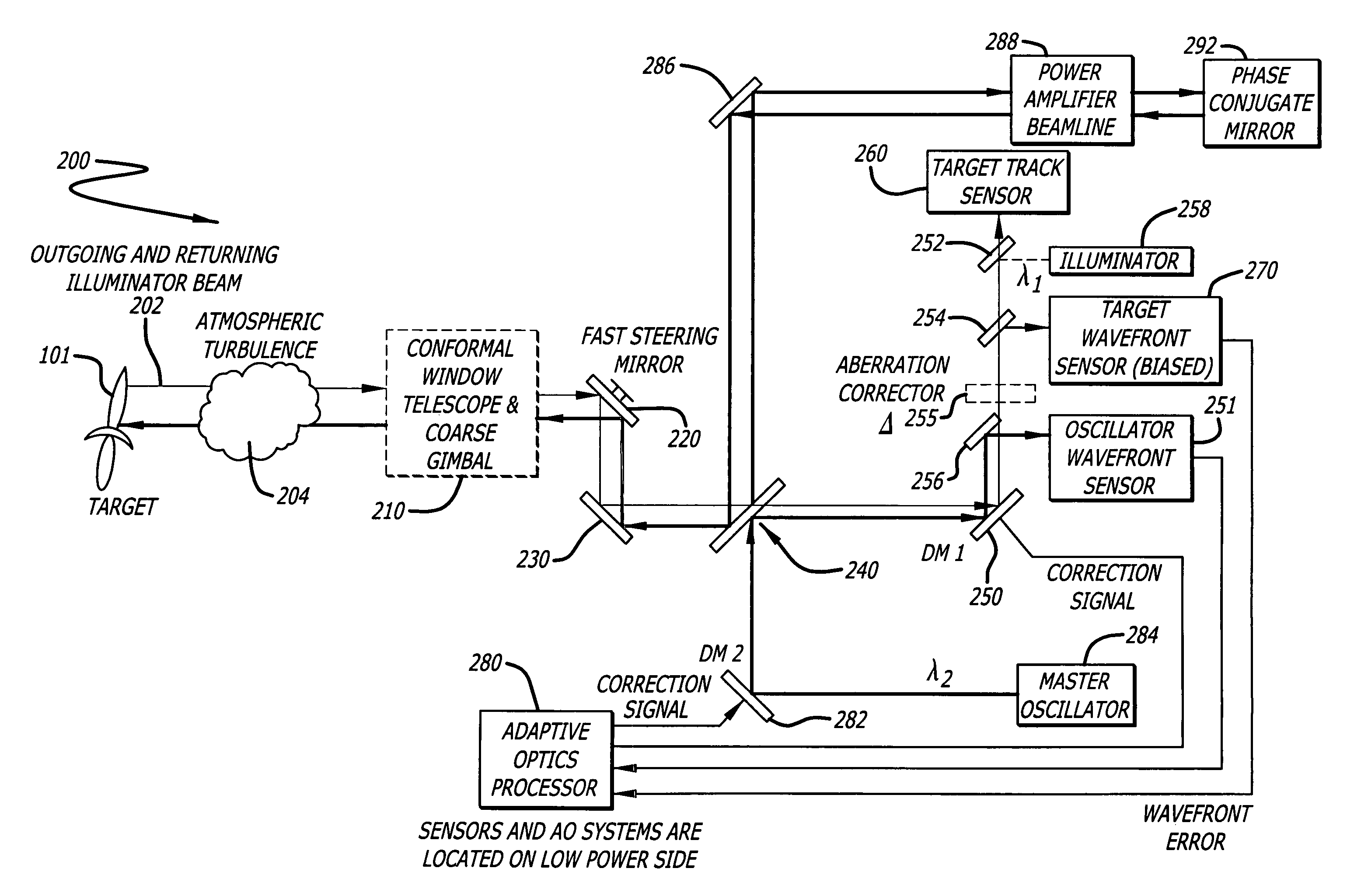

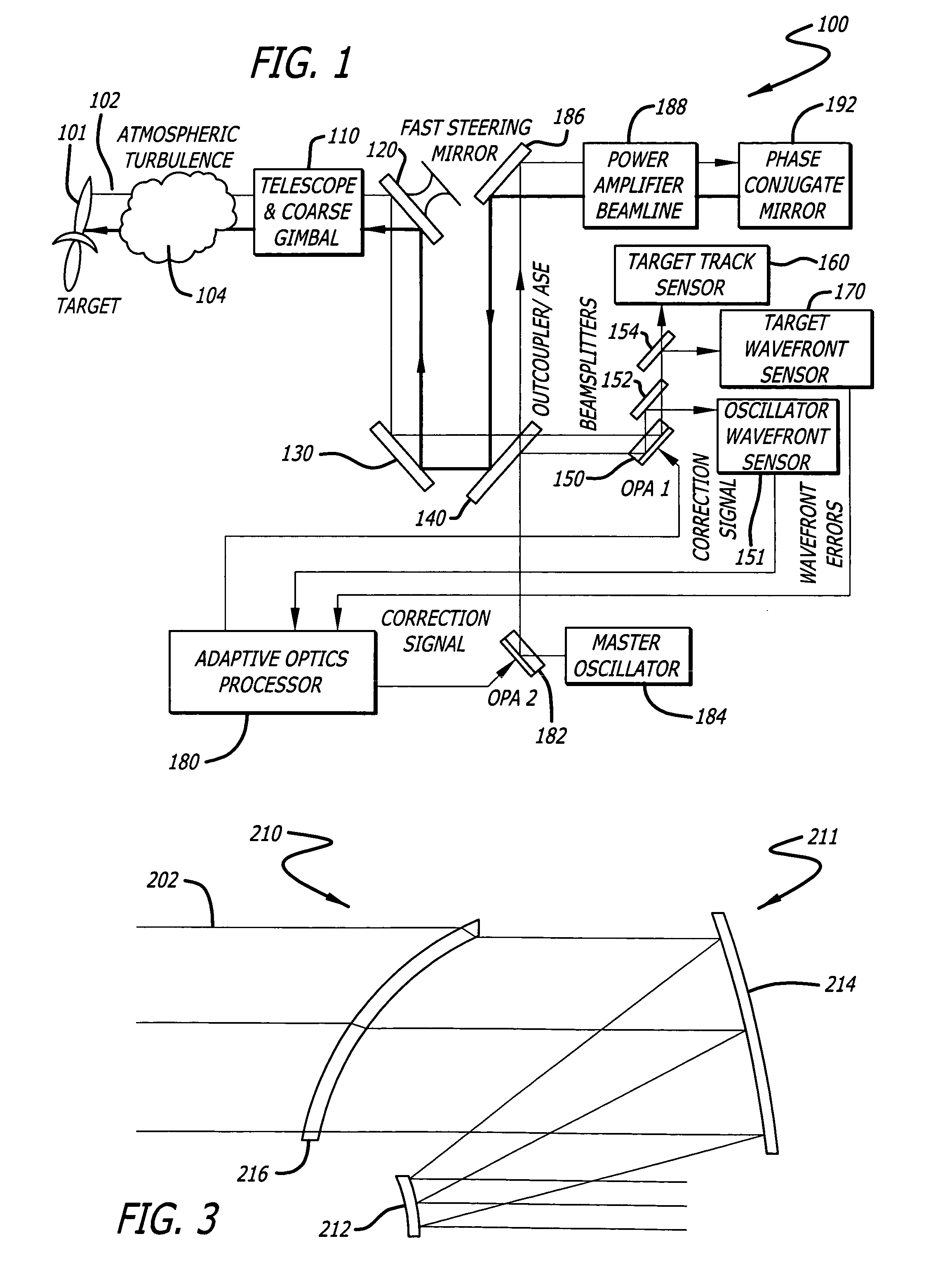

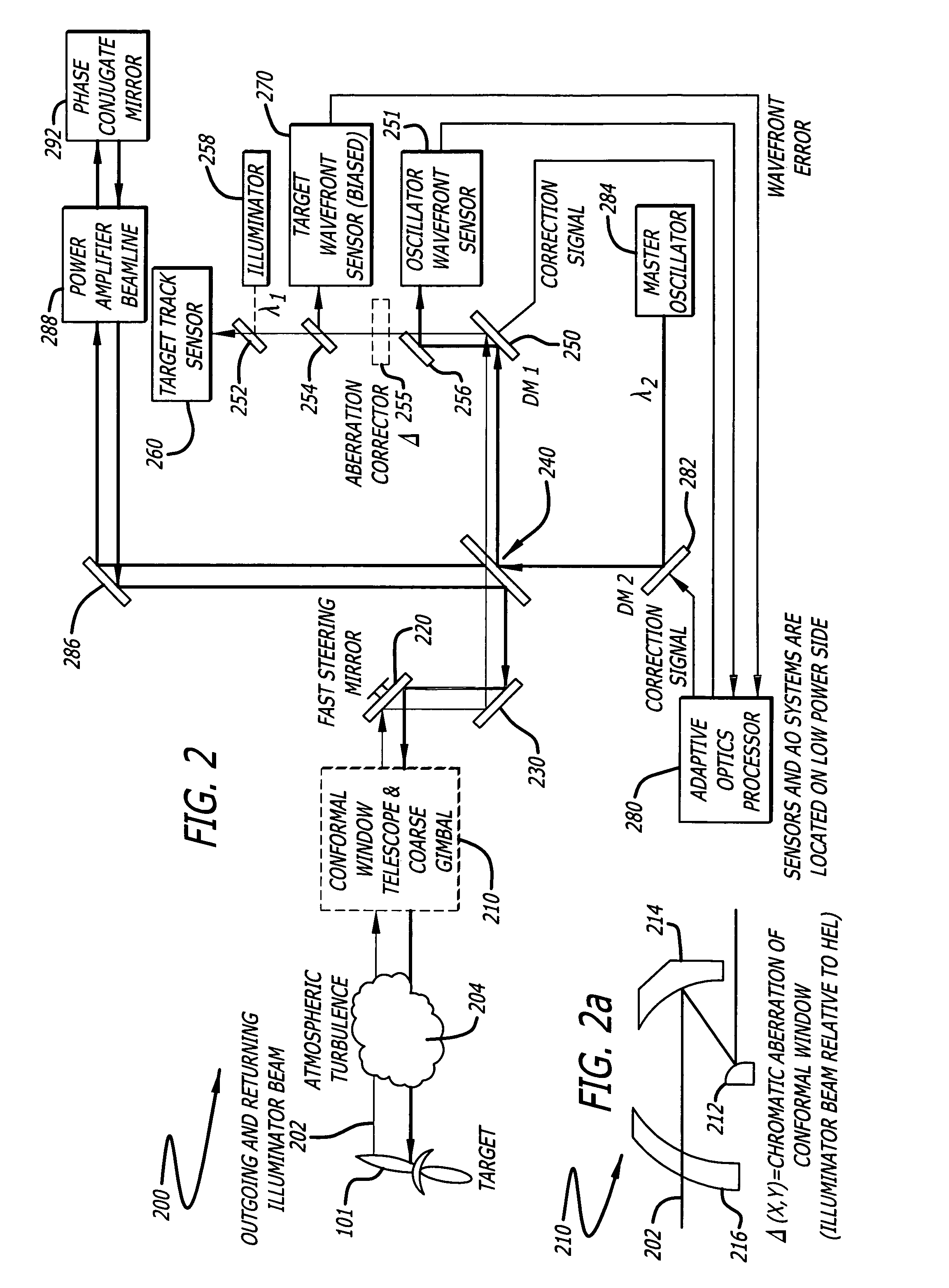

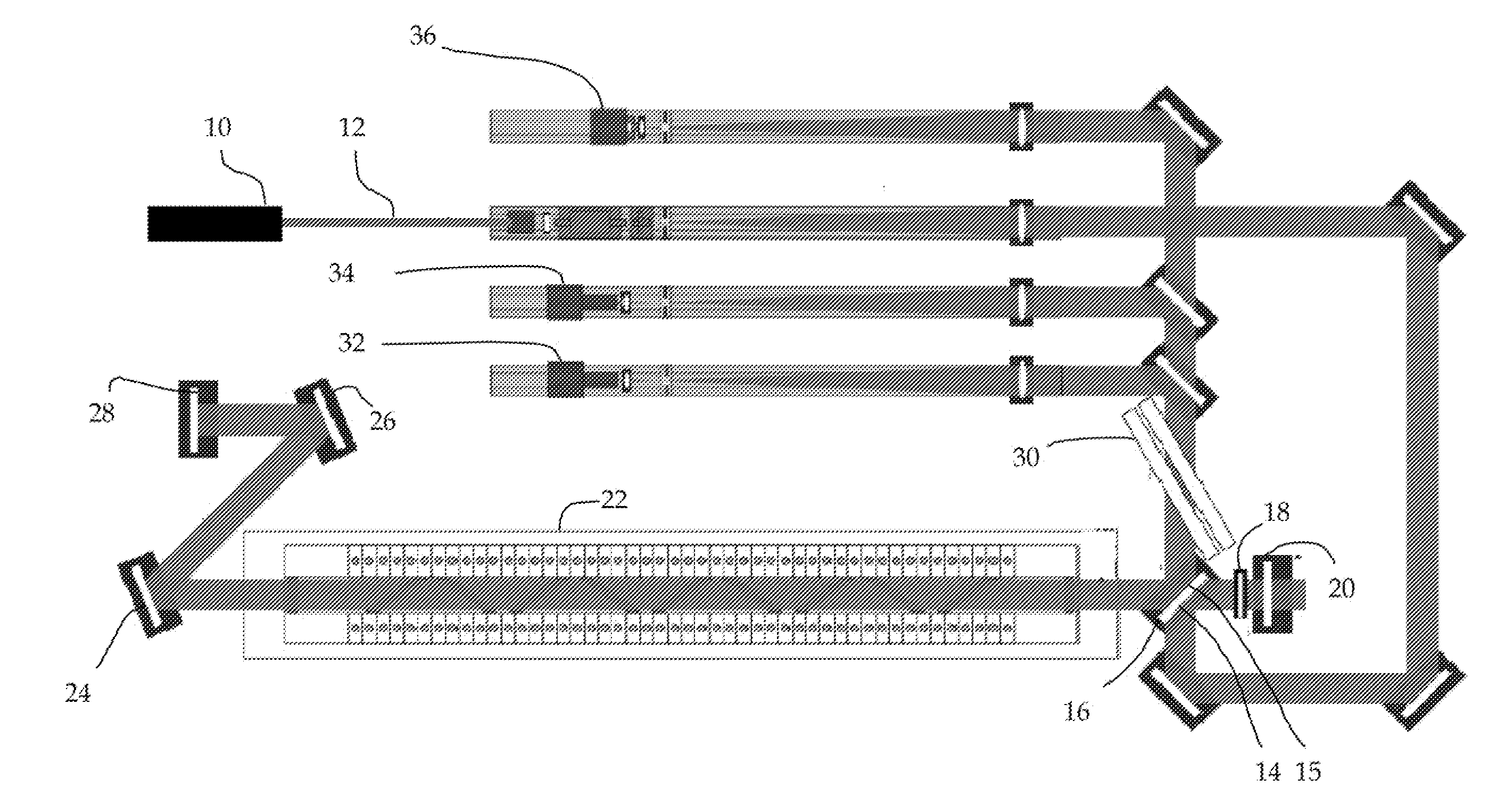

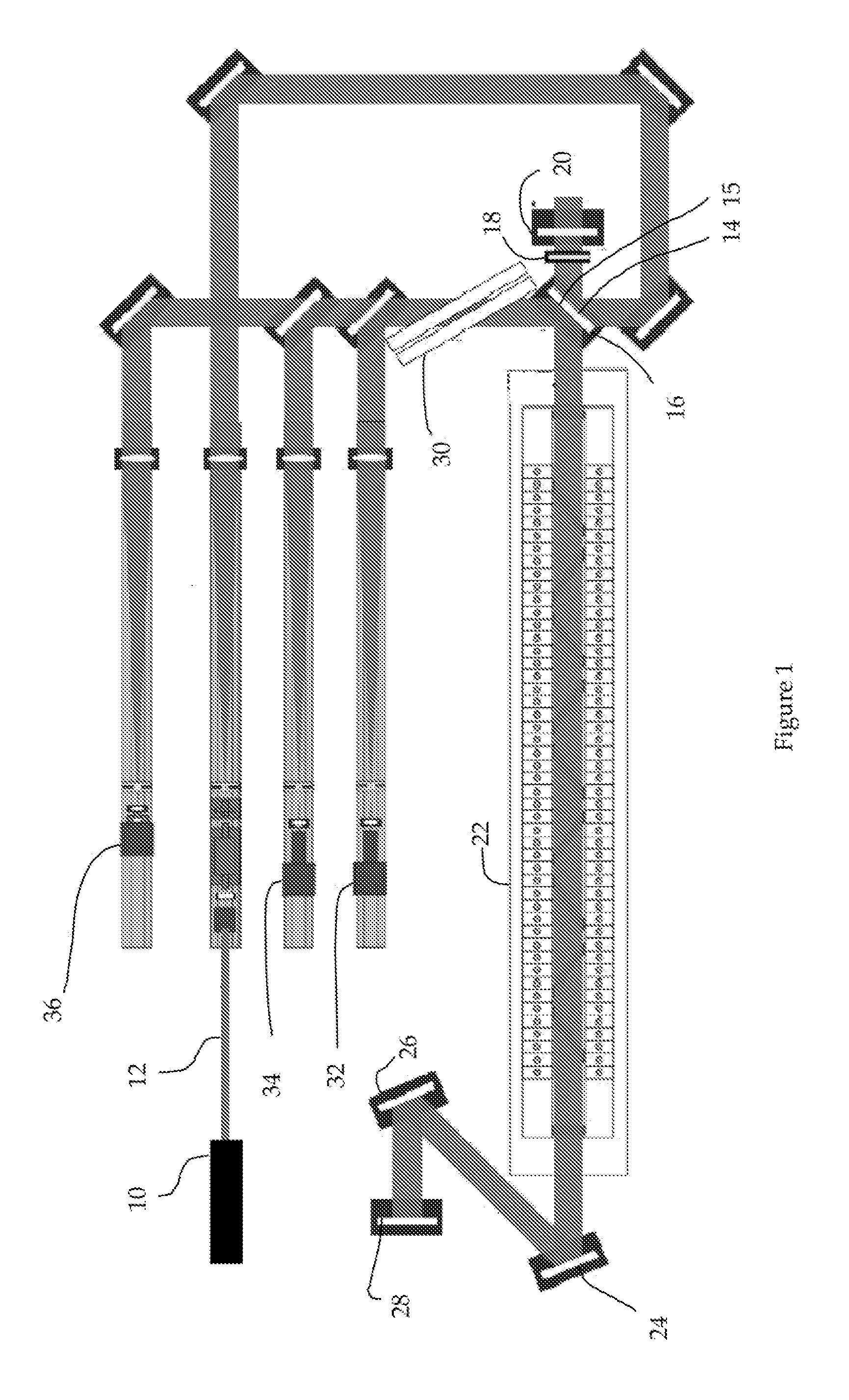

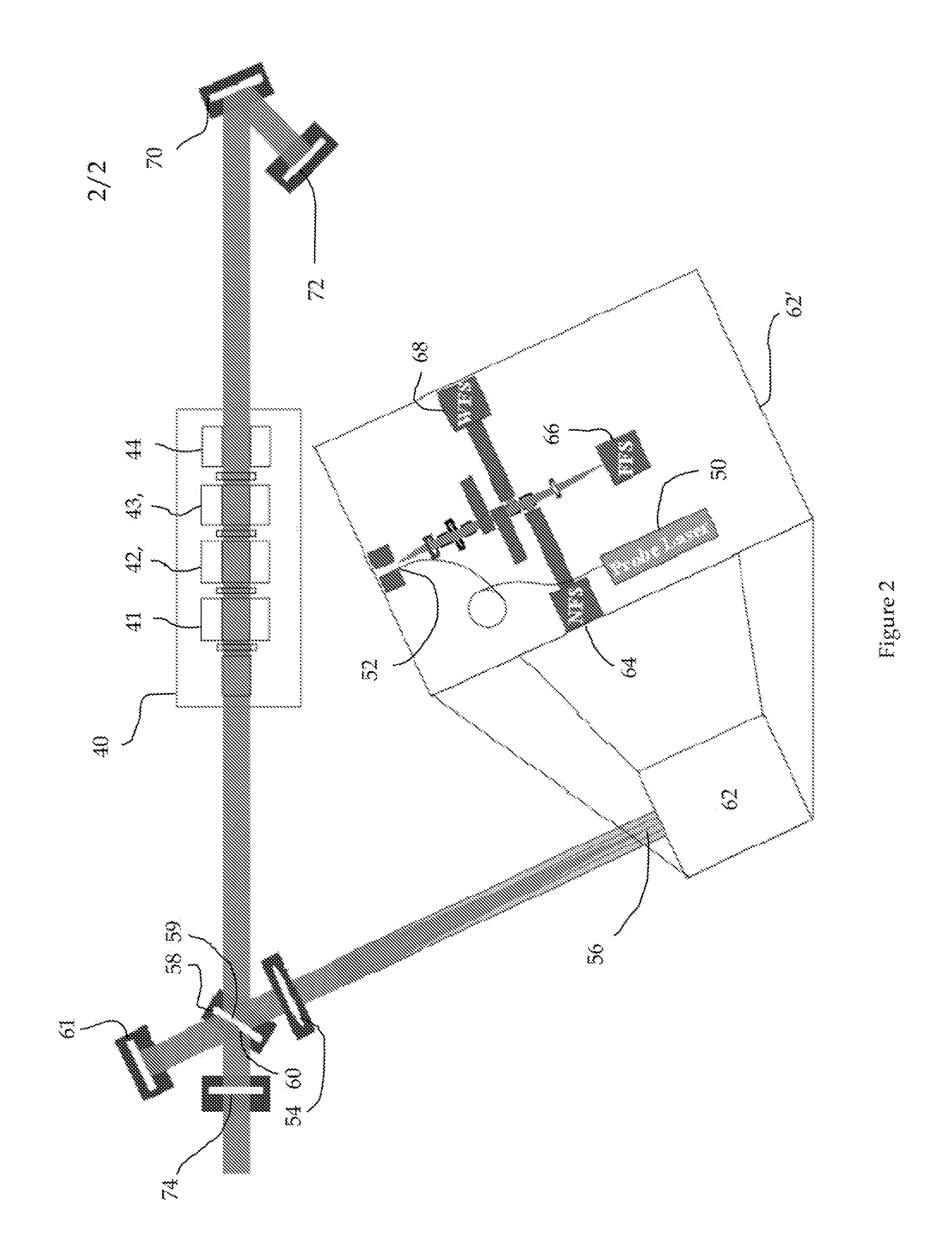

Beam director and control system for a high energy laser within a conformal window

ActiveUS20080042042A1Photometry using reference valueMaterial analysis by optical meansCorrection algorithmWavefront sensor

A beam control system and method. The system includes an illuminator for providing a first beam of electromagnetic energy at a first wavelength; a source for providing a second beam of electromagnetic energy at a second wavelength; and an arrangement for compensating wavefront errors in the second beam using a bias representative of a comparison between the first wavelength and the second wavelength. In the illustrative embodiment, the arrangement includes a processor which corrects wavefront errors using a bias representative of a difference between said first wavelength and said second wavelength. In the disclosed application, a target wavefront sensor is included and the laser is a high-energy laser beam. The wavefront errors include a chromatic aberration and the errors are compensated using a deformable mirror and a correction algorithm executed by an adaptive optics processor. In one alternative embodiment, the errors are compensated using an optical aberration corrector. The aberration corrector may be a holographic optical element or other suitable device. In another alternative embodiment, the errors are corrected with the above embodiment in combination with the use of “woofer” and “tweeter” correcting elements with the woofer being a long stroke low frequency element and the tweeter being a short stroke high frequency element.

Owner:RAYTHEON CO

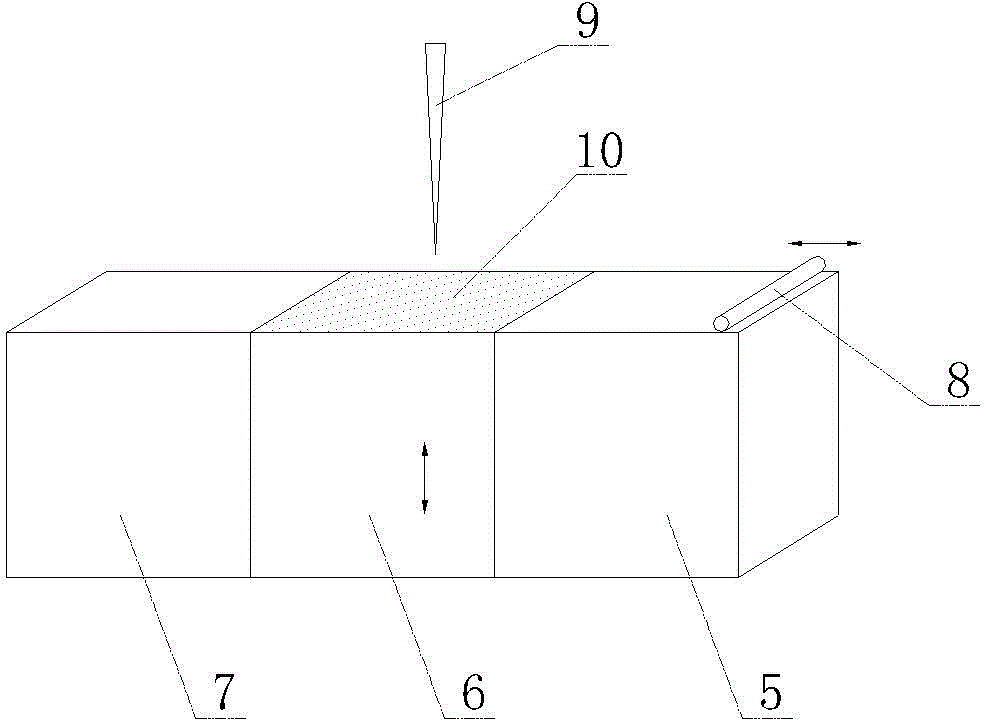

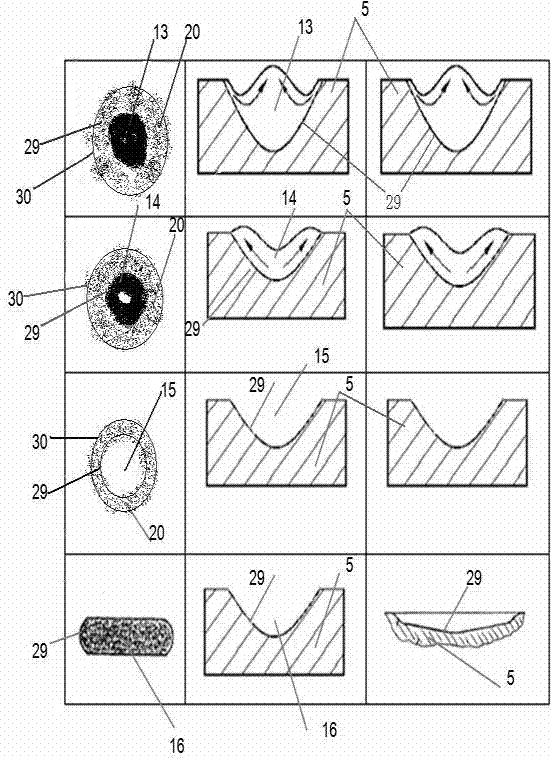

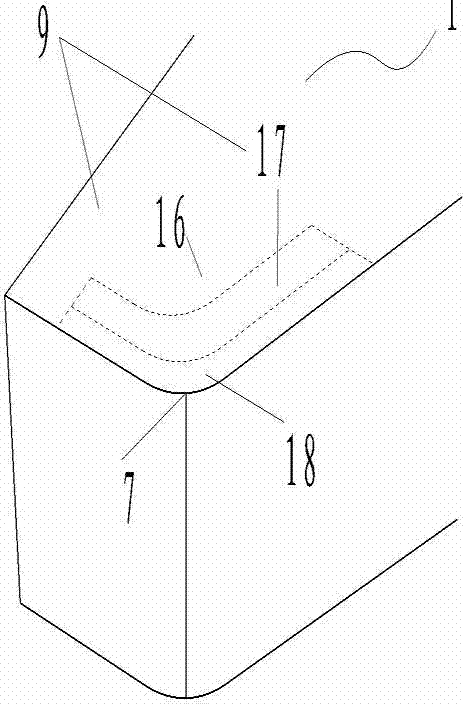

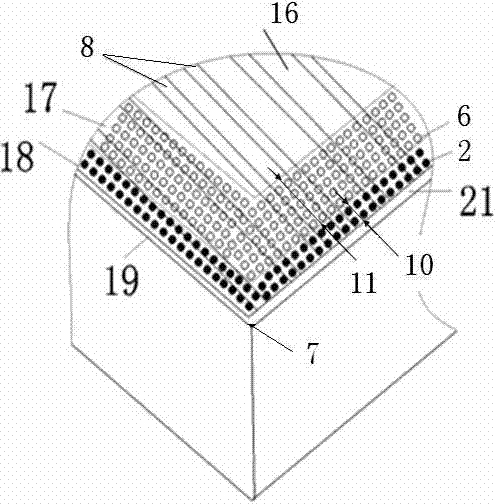

Compound model processing method and device for cutter

ActiveCN102962656AReduce wearImprove performanceMeasurement/indication equipmentsLaser beam welding apparatusNumerical controlHigh energy

The invention provides a compound model processing method and device for a cutter, relating to the active processing of microtexture compound morphologies on the main friction and abrasion surfaces of the cutter, and belonging to the field of machinery manufacture. Three microstructural models, namely micro concave cavities, fused bulges and micro grooves respectively, are processed at the main friction and abrasion parts of the cutter through high energy laser beams or high energy electron beams. With the adoption of the compound model processing method and device for the cutter, the continuous service life of the cutter is prolonged, the cutting quality of the cutter is improved, the surface quality and the cutting and cooling performances after the processing of a workpiece are improved, and the machining cost of metal cutting is lowered. The invention also discloses the processing device for applying the compound mould processing method; and the device is integrated with a high energy technique and a numerical control technique, so that predetermined compound microstructural morphologies and distributions thereof can be processed on the main cutting working face of the cutter efficiently and stably. Processing objects for the method and the device thereof provided by the invention are various cutters during the cutting processing.

Owner:JIANGSU UNIV

Beam director and control system for a high energy laser within a conformal window

ActiveUS7626152B2Photometry using reference valueMaterial analysis by optical meansCorrection algorithmWavefront sensor

Owner:RAYTHEON CO

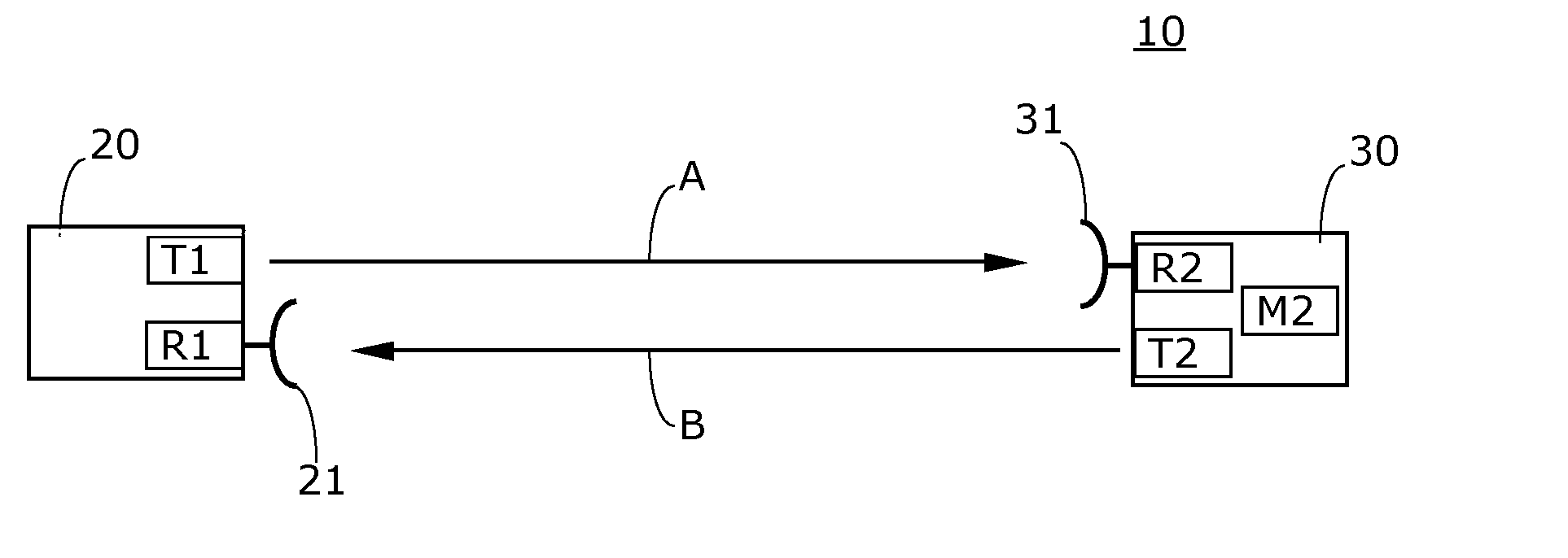

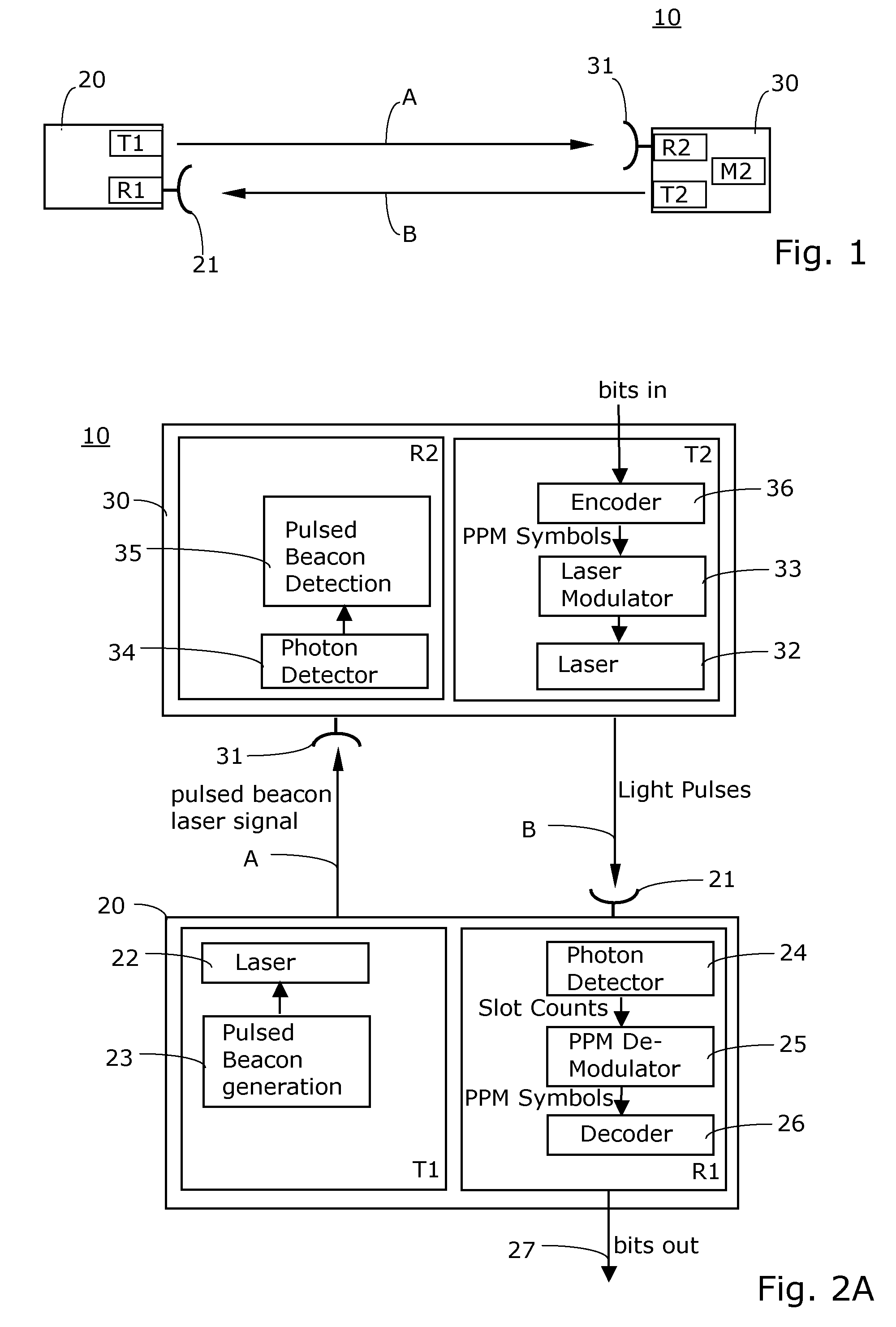

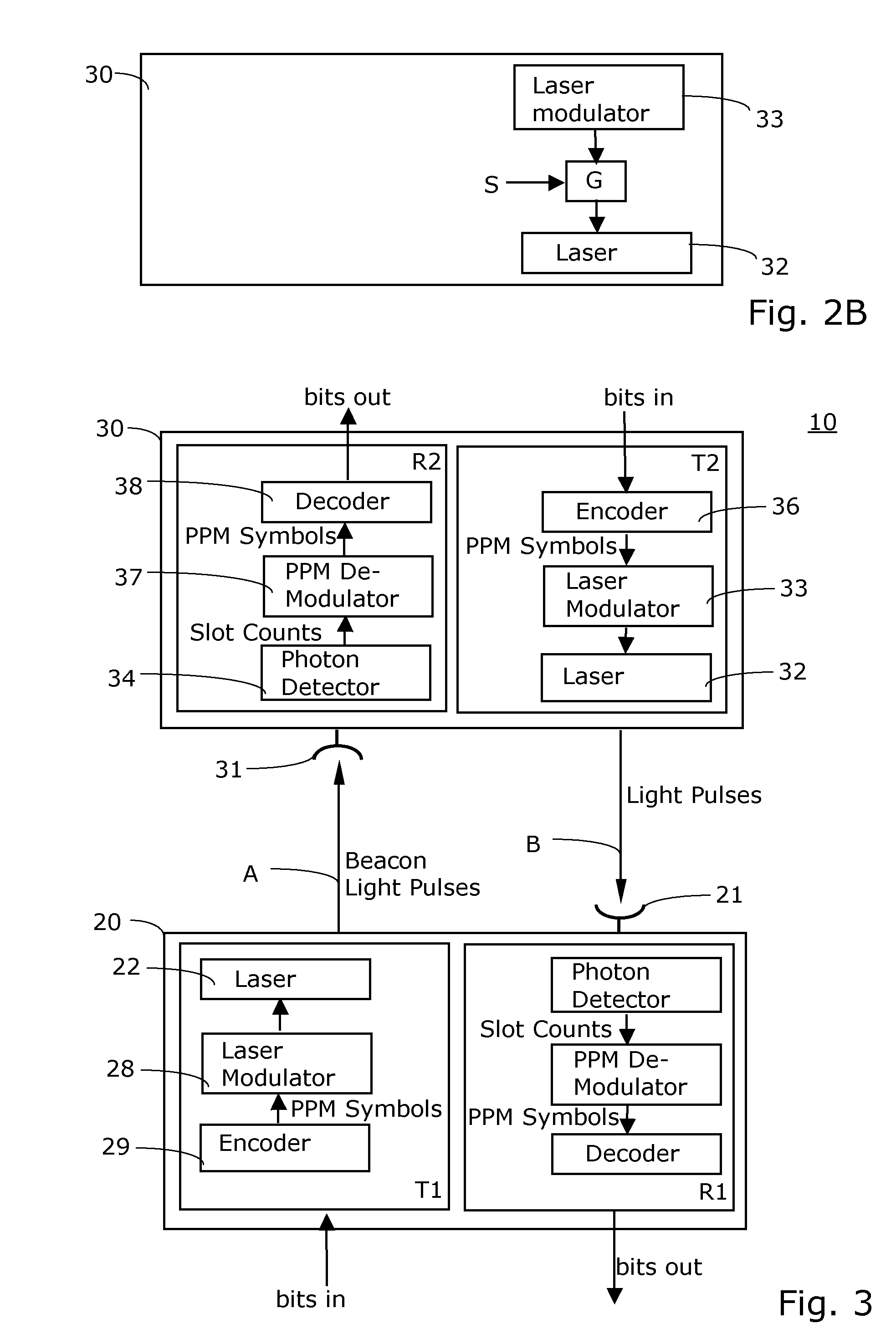

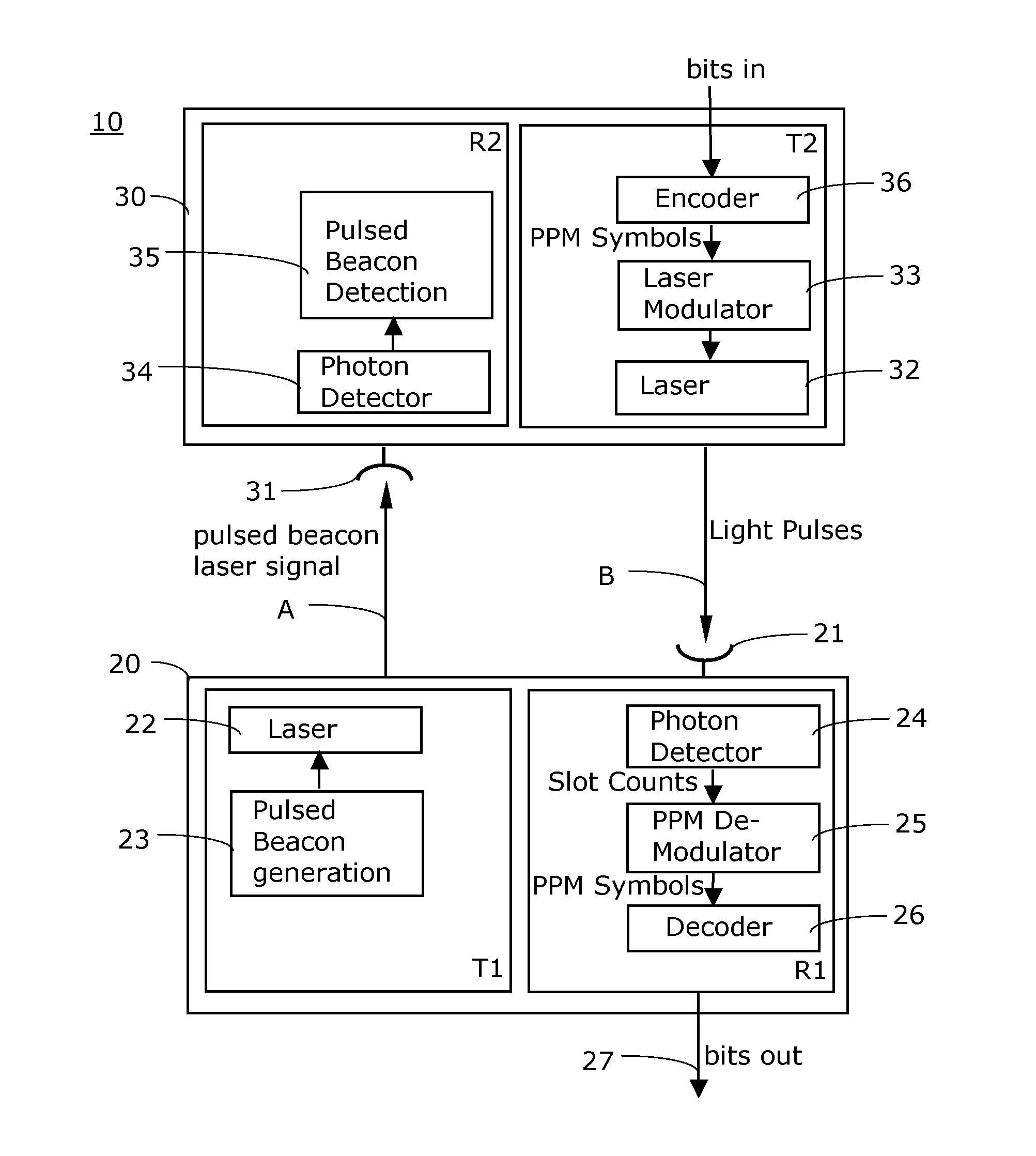

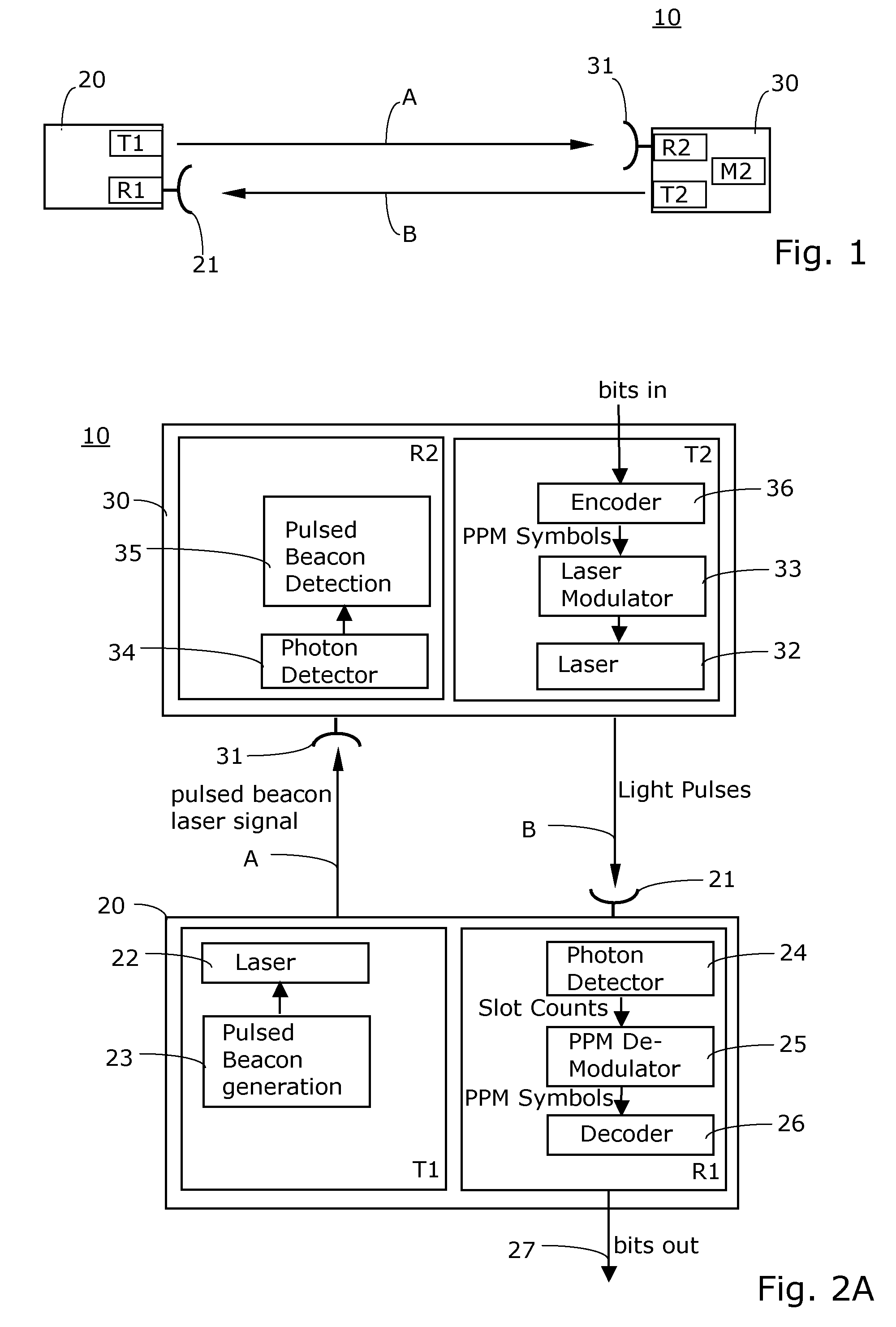

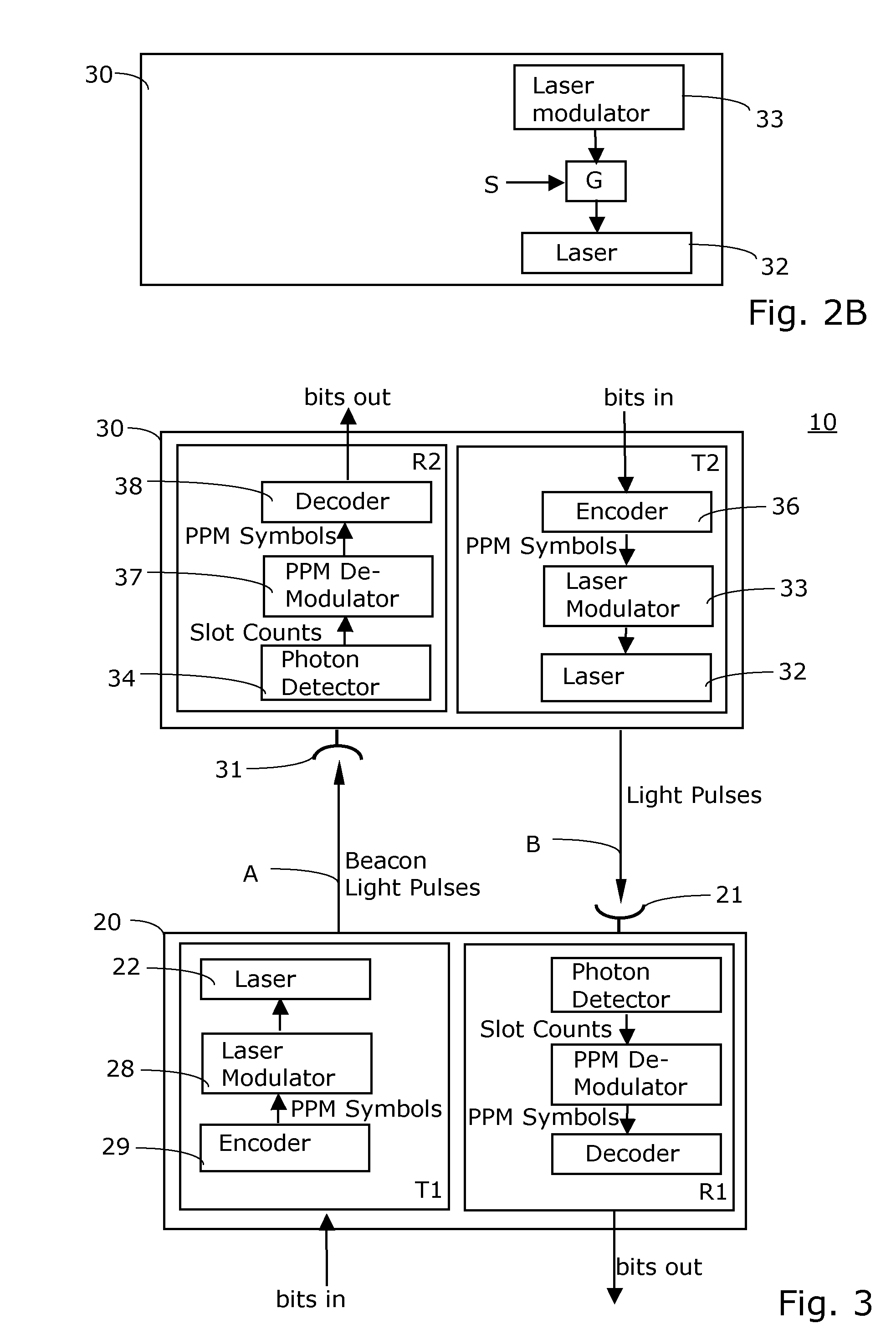

Bi-directional optical communications system and corresponding method

ActiveUS20080131134A1Signal to noise ratio is smallRobust communicationPulse automatic controlSatellite communication transmissionCommunications systemHigh power lasers

Bi-directional laser communications system comprising a first transceiver and a second transceiver for establishing two optical channels there between. The first transceiver comprises a first transmitter with a pulsed high-power laser source for transmitting a pulsed beacon laser signal into a first of said optical channels. The second transceiver comprises a receiver with an optical antenna for receiving said pulsed beacon laser signal, said second transceiver and / or a receiving optic of said second transceiver being adjustable so that it can be adjusted with respect to said pulsed beacon laser signal. The second transceiver further comprises a second transmitter with a laser for transmitting a high energy laser signal into a second of said optical channels, and means for a separation of said first optical channel and said second optical channel. These means prevent the high energy laser signals from being transmitted into said second optical channel whenever said pulsed beacon laser signal is expected to arrive through said first optical channel.

Owner:OERLIKON SPACE

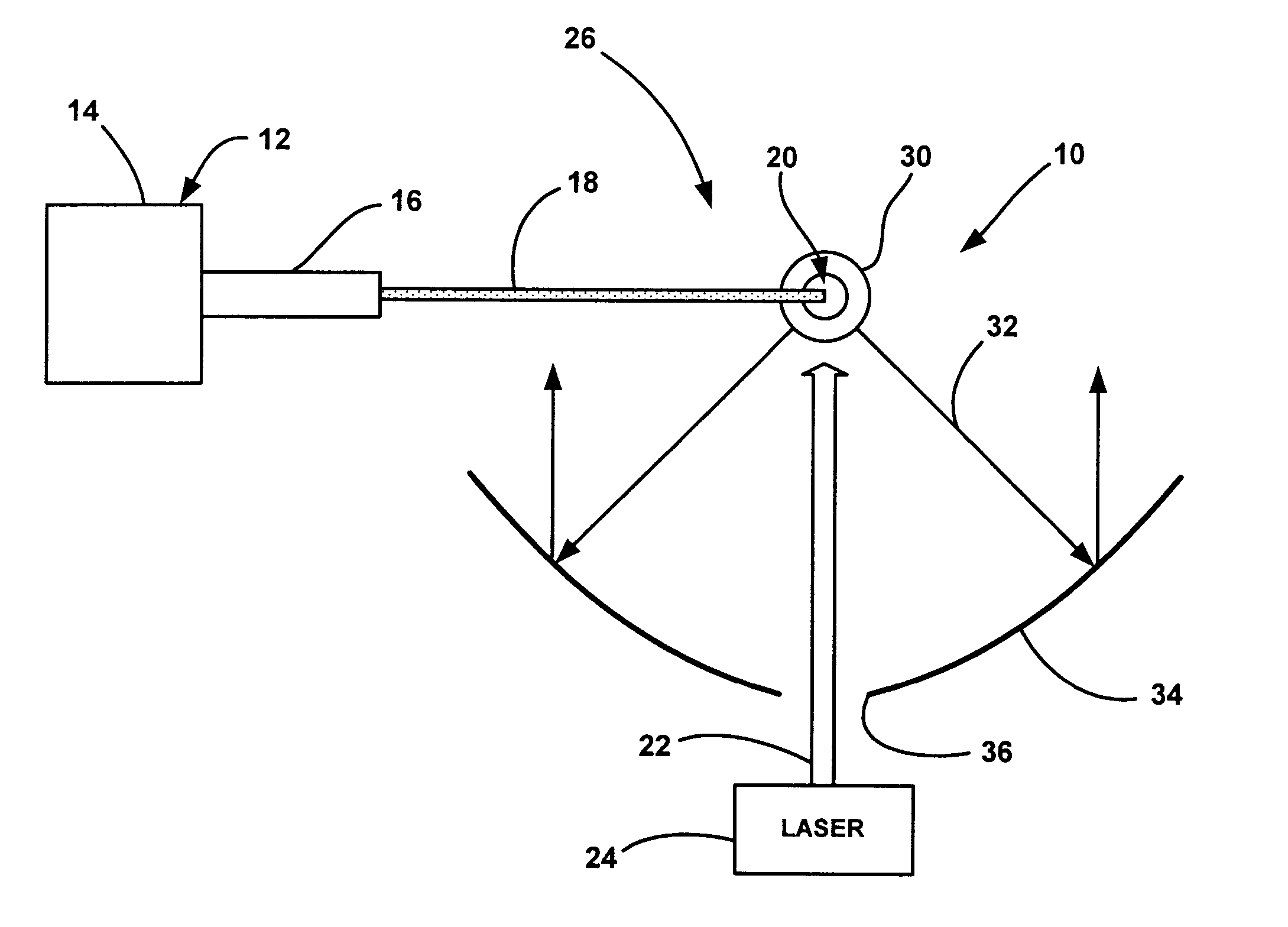

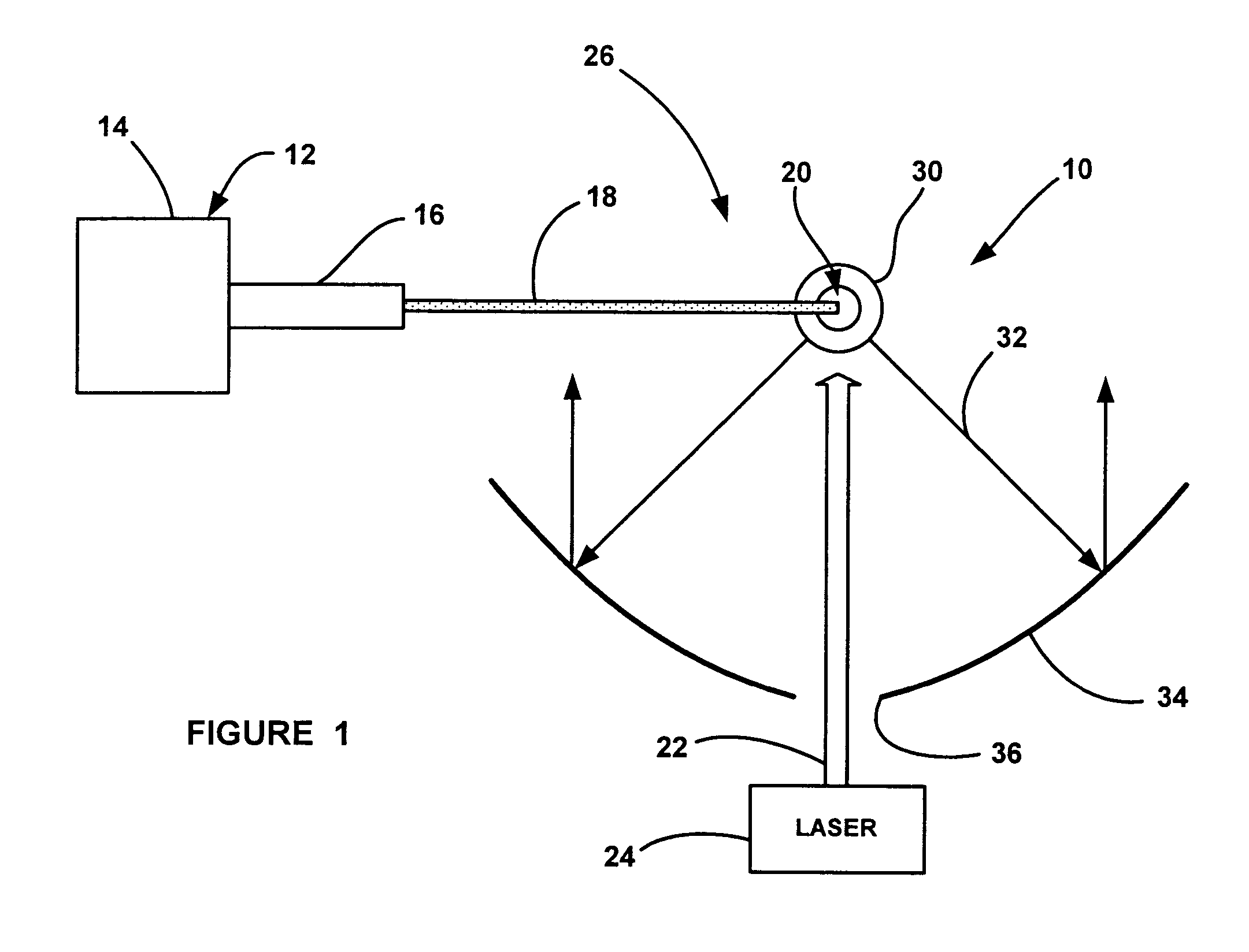

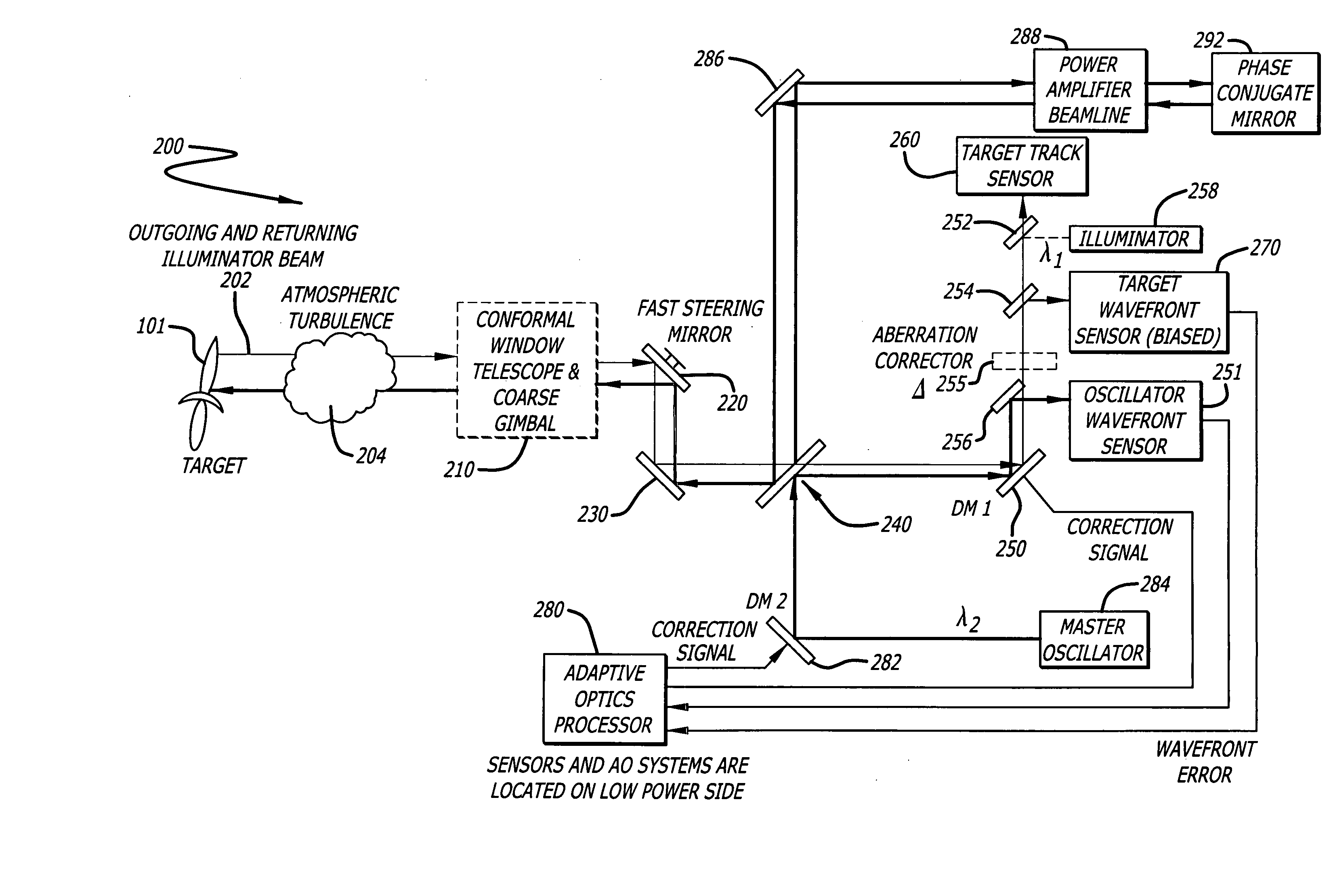

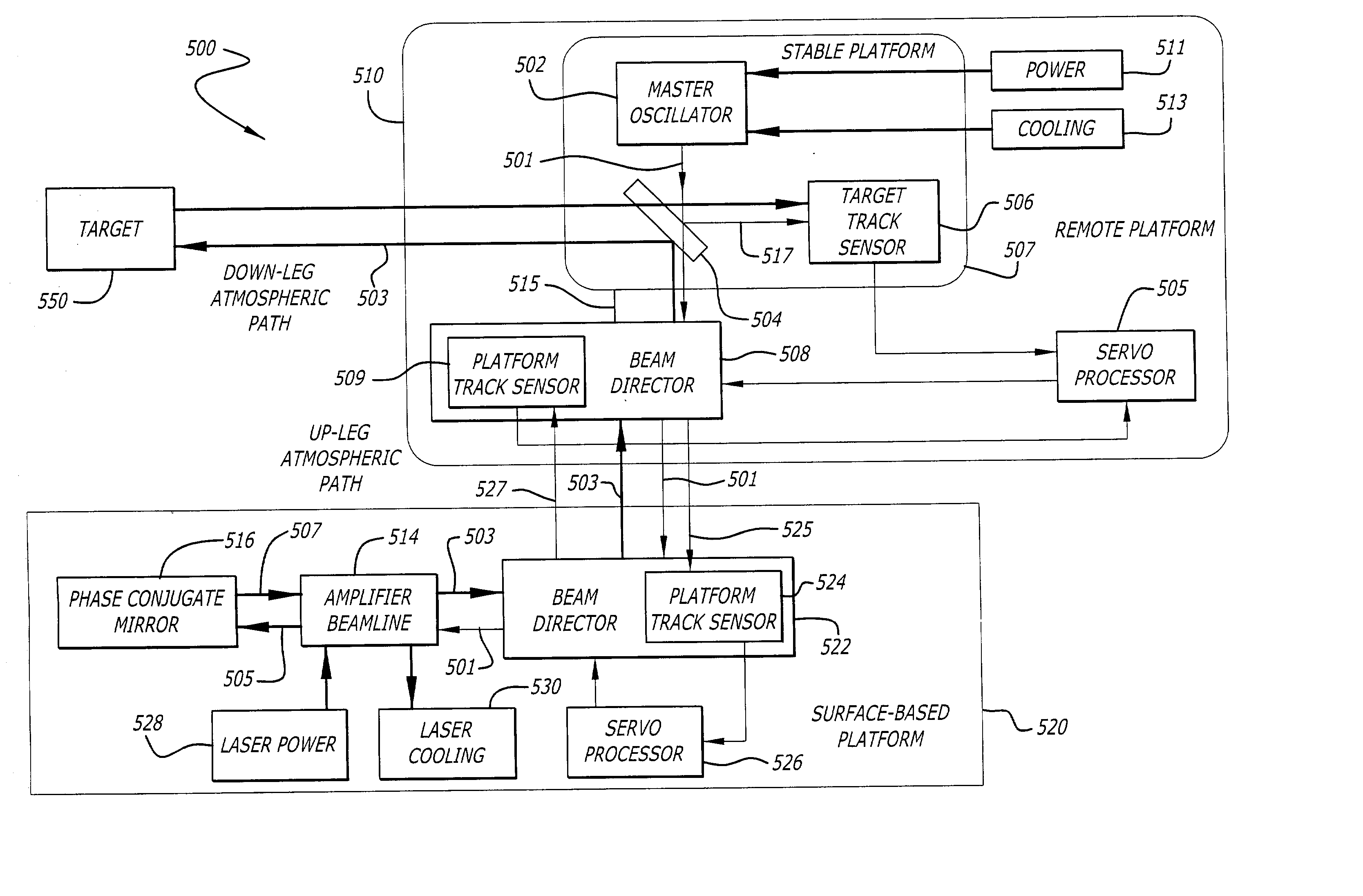

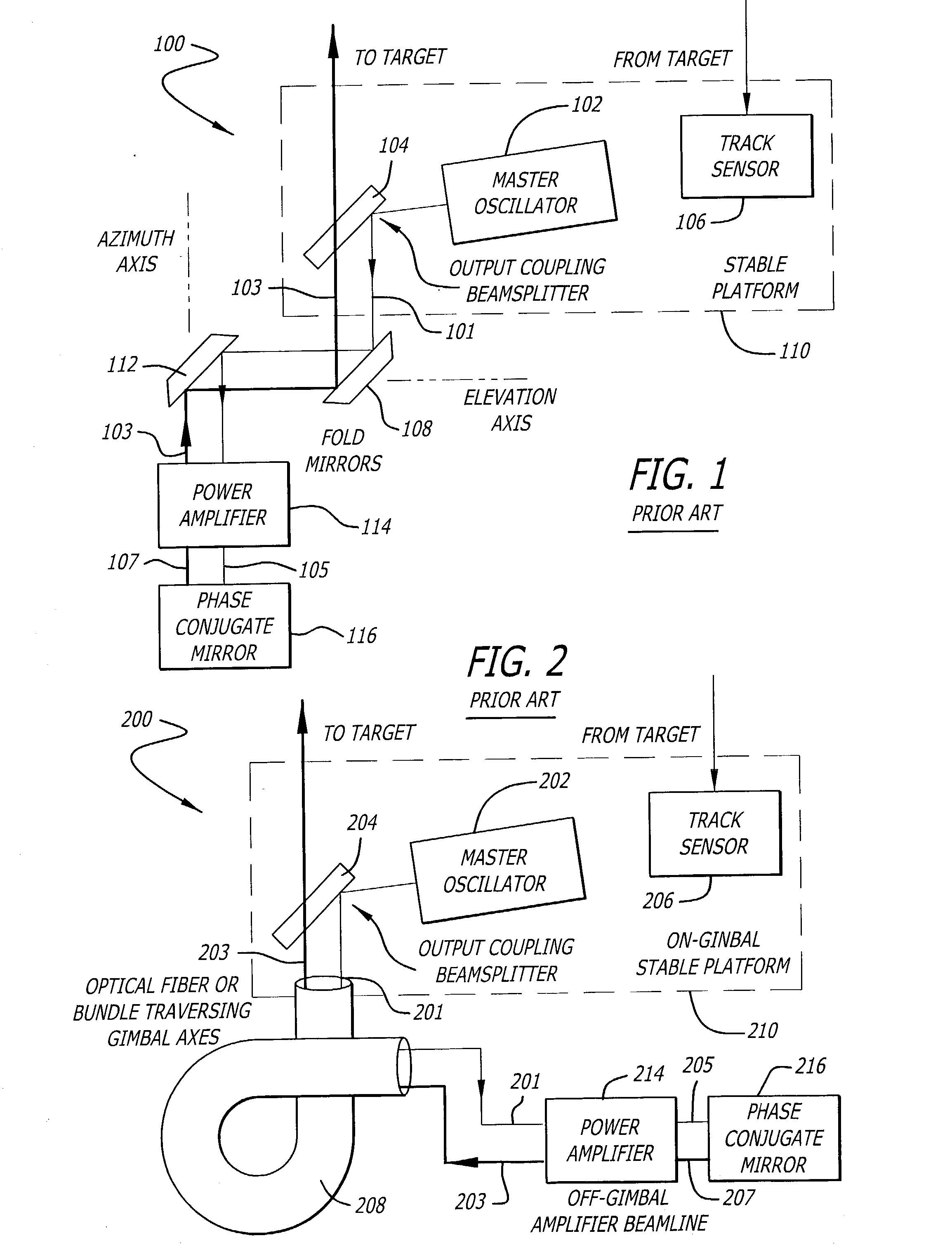

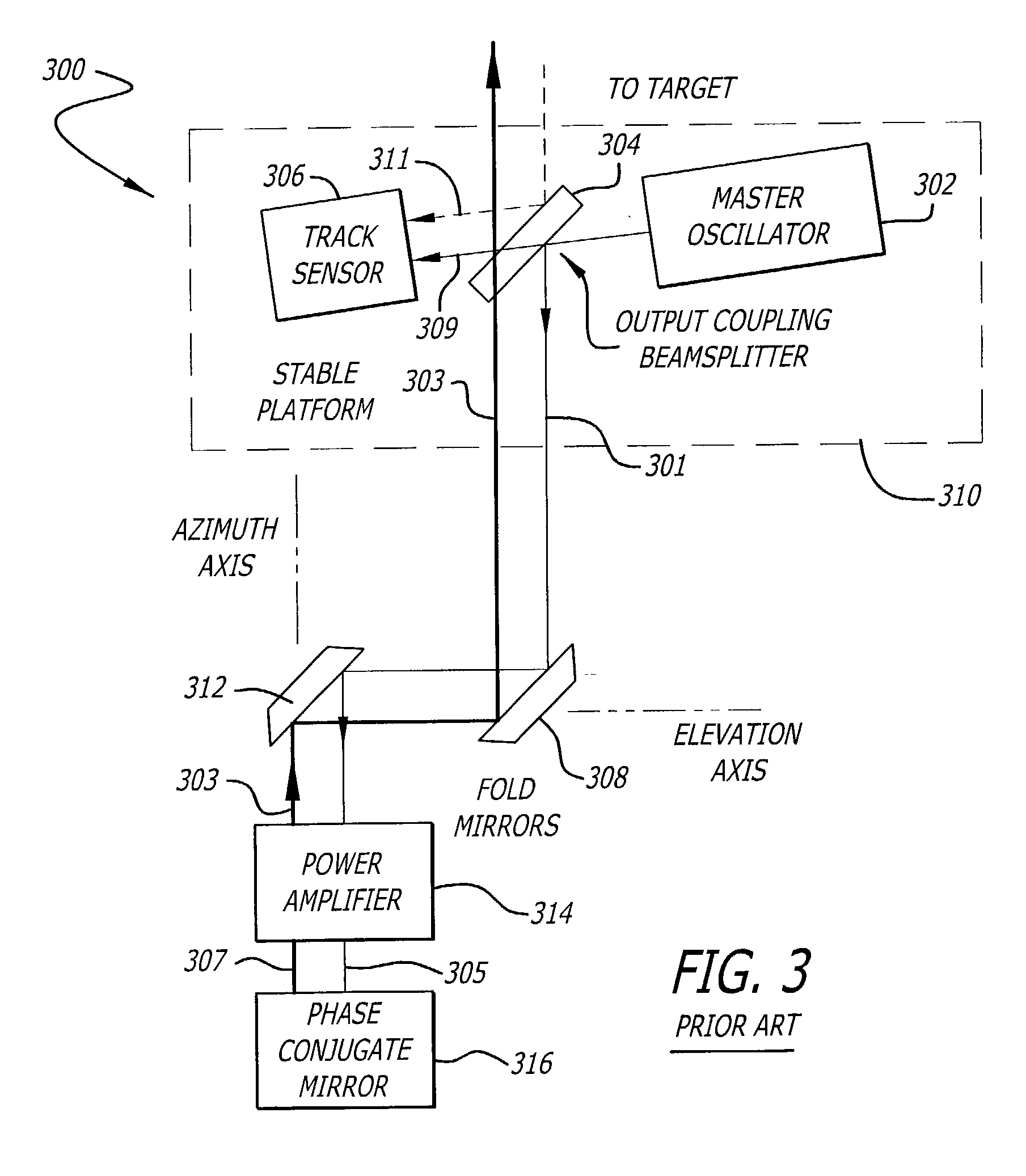

Phase conjugate relay mirror apparatus for high energy laser system and method

A system for directing electromagnetic energy. The inventive system includes a first subsystem mounted on a first platform for transmitting a beam of the electromagnetic energy through a medium and a second subsystem mounted on a second platform for redirecting the beam. In accordance with the invention, the second platform is mobile relative to the first platform. In the illustrative embodiment, the beam is a high-energy laser beam. The first subsystem includes a phase conjugate mirror in optical alignment with a laser amplifier. The first subsystem further includes a beam director in optical alignment with the amplifier and a platform track sensor coupled thereto. In the illustrative embodiment, the second subsystem includes a co-aligned master oscillator, outcoupler, and target track sensor which are fixedly mounted to a stabilized platform, a beam director, and a platform track sensor. In the best mode, the stable platform is mounted for independent articulation relative to the beam director. A first alternative embodiment of the second subsystem includes first and second beam directors. The first beam director is adapted to receive the transmitted beam and the second beam director is adapted to redirect the received beam. In accordance with a second alternative embodiment, an optical fiber is provided for coupling the beam between the first platform and the second platform.

Owner:RAYTHEON CO

Bi-directional optical communications system and corresponding method

ActiveUS7991294B2Signal to noise ratio is smallRobust communicationPulse automatic controlSatellite communication transmissionTransceiverCommunications system

Bi-directional laser communications system comprising a first transceiver and a second transceiver for establishing two optical channels there between. The first transceiver comprises a first transmitter with a pulsed high-power laser source for transmitting a pulsed beacon laser signal into a first of said optical channels. The second transceiver comprises a receiver with an optical antenna for receiving said pulsed beacon laser signal, said second transceiver and / or a receiving optic of said second transceiver being adjustable so that it can be adjusted with respect to said pulsed beacon laser signal. The second transceiver further comprises a second transmitter with a laser for transmitting a high energy laser signal into a second of said optical channels, and means for a separation of said first optical channel and said second optical channel. These means prevent the high energy laser signals from being transmitted into said second optical channel whenever said pulsed beacon laser signal is expected to arrive through said first optical channel.

Owner:OERLIKON SPACE

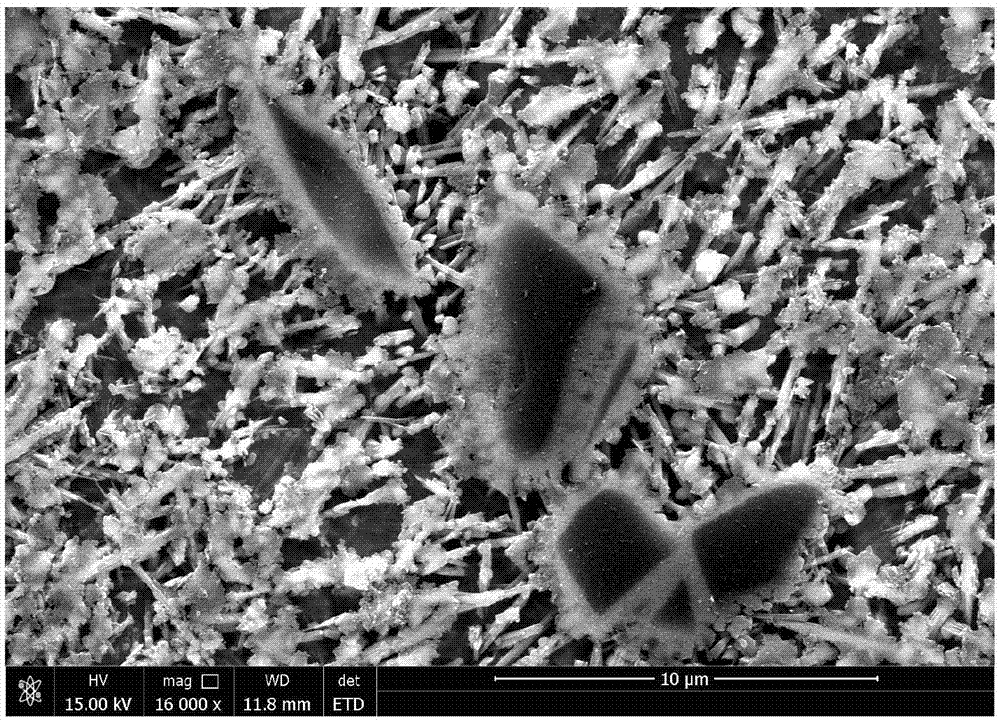

Nano ceramic particle reinforced nickel-based superalloy composite material and laser 3D printing forming method thereof

InactiveCN104745887AGood high temperature corrosion resistanceImprove wear resistanceAlloy compositeHigh energy laser

The invention discloses a nano ceramic particle reinforced nickel-based superalloy composite material and a laser 3D printing forming method thereof. A nickel-based superalloy with the particle size of 15-45mu m is taken as a matrix, CrC with the particle size of 40-100nm is taken as a reinforced phase, and the addition amount of CrC is 2.0-8.0% by weight of the composite material matrix; a nano CrC particle hybrid reinforced nickel-based superalloy composite material part has the advantages of good high-temperature anti-corrosion property, abrasion resistance, high temperature creep and the like and can meet special performance requirements of an aero-engine hot end component at high temperature; a high-energy laser forming method is applicable to preparation of a difficult-to-process material and forming of a complex part; and a forming die is not needed, so that a manufacturing cycle is shortened, and the cost is reduced.

Owner:JIANGSU SILAIMU INTELLIGENT TECH CO LTD

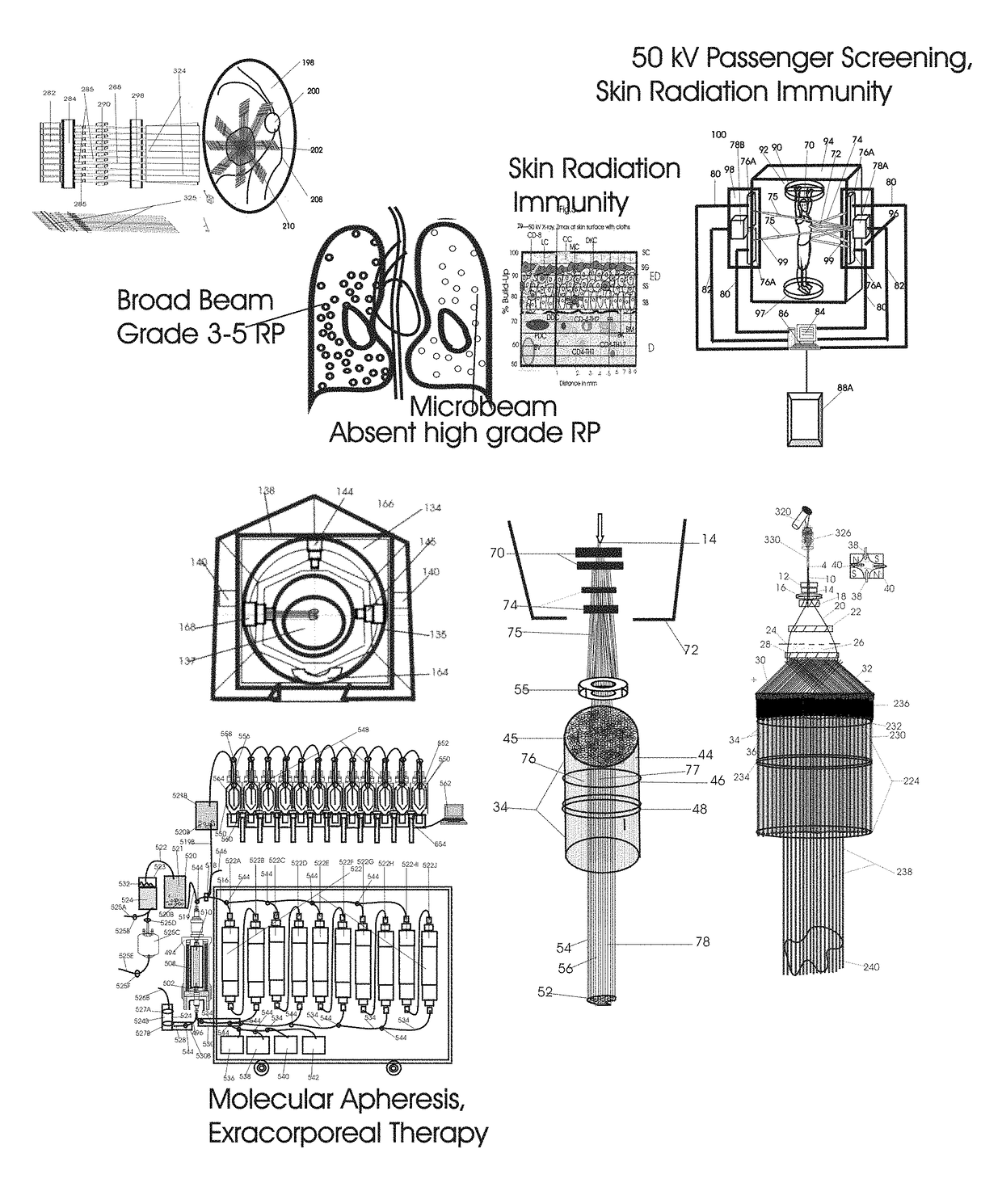

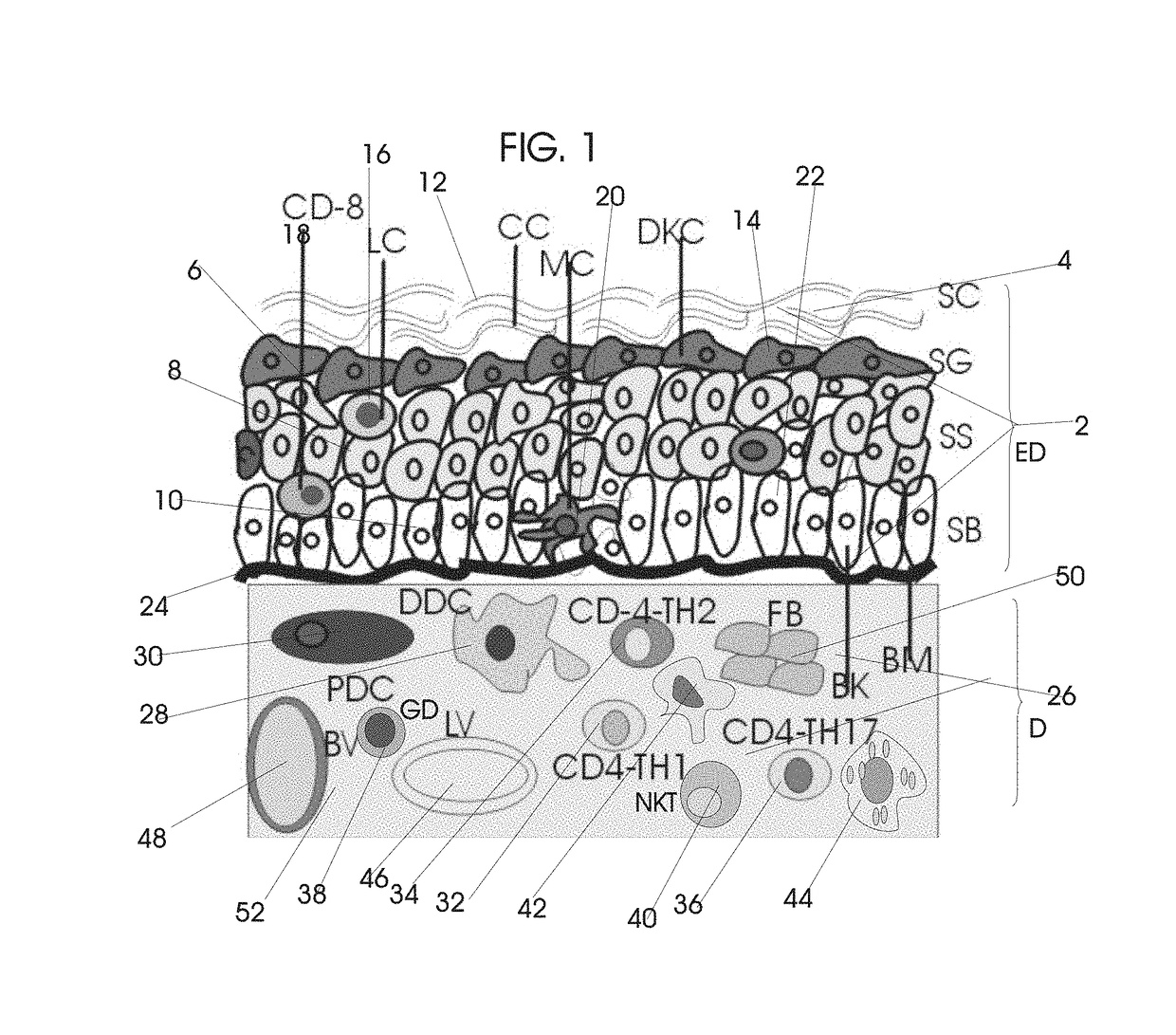

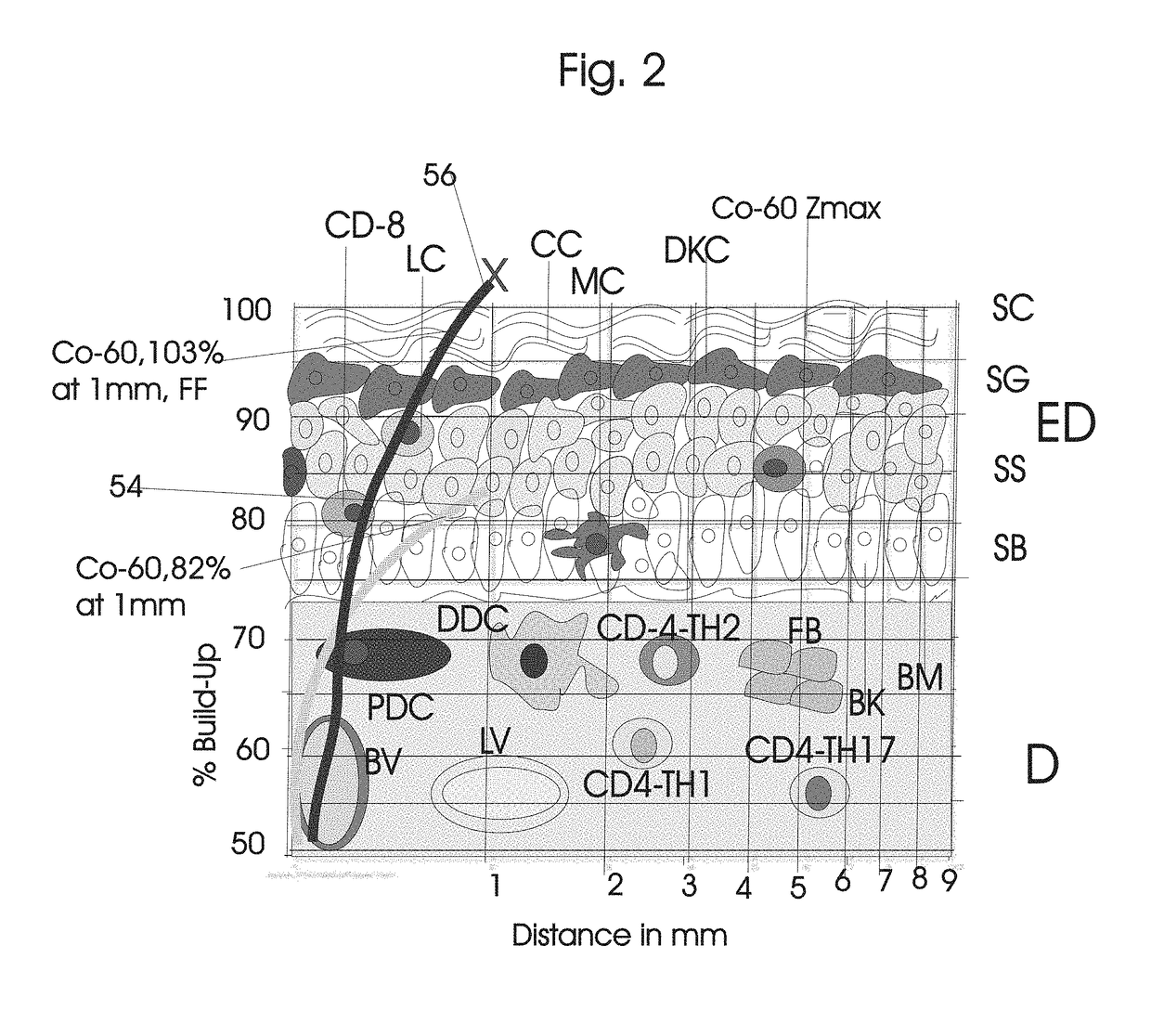

Normal Tissue Toxicity Reducing Microbeam-Broadbeam Radiotherapy, Skin's Radio-Response Immunotherapy and Mutated Molecular Apheresis Combined Cancer Treatments

InactiveUS20180154183A1Improve treatment outcomesIncreased toxicityOther blood circulation devicesHaemofiltrationAbnormal tissue growthGamma ray

Normal tissue complications limit curative broadbeam radiotherapy to tumors including lung cancer. Radiation retinitis causing blindness limits quality of life and long term survival for patients with ocular melanoma. This invention pertains to alternative, normal tissue sparing 100 to 1,000 Gy microbeam radiations with least normal tissue complications and concomitant radio-immunotherapy by innate immune response of epidermis and dermis to low dose radiation with 50 kV X-rays. Total body skin radiation with former airport passenger screening machines with 50 kV X-ray is disclosed. Microbeams are generated without contaminating scatter and neutron radiations from collinear gamma ray and electron beam produced by inverse Compton interaction with high energy laser and electron beam and from proton and carbon ion beams in tissue equivalent cylindrical collimators. Extracorporeal immunotherapy and chemotherapy and apheresis of mutated subcellular particles released into circulation in response to cancer-therapies are by clinical continuous flow ultracentrifugation combined chromatography.

Owner:SAHADEVAN VELAYUDHAN

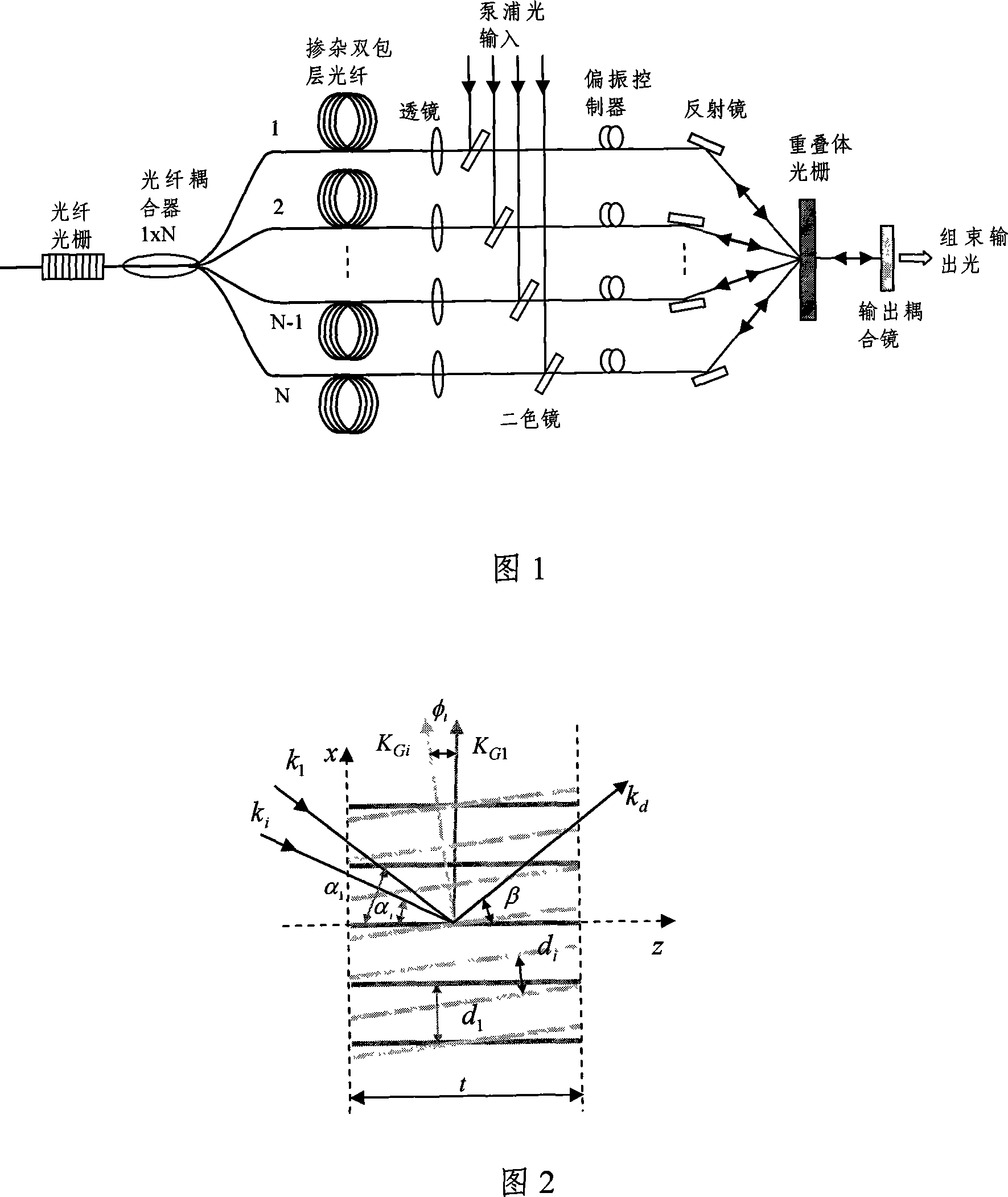

Multi-path optical fiber laser coherent beam combination device and coherent beam combination method

InactiveCN101159365ARealize bundleAchieve phase interlockCladded optical fibreOptical resonator shape and constructionGratingLight beam

The invention discloses a multi-channel optical-fiber laser coherence beam combination device and a coherence beam combination method based on overlapped body grating. The device comprises an optical-fiber coupler, a doping double-clad optical-fiber, a lens, a dichroiscope, a reflector, a polarization controller, a reflector, an overlapped body grating and an output coupling mirror connected in sequence at one side of the optical-fiber grating. The method is able to realize the multi-channel optical-fiber laser coherence beam combination without complex phase detection and control to each beam. The phases of each beam realize interlocking by sharing a resonator composed of the output coupling mirror and the optical-fiber grating. Each beam realizes the coherent superposition in the near-field and far-field to significantly enhance the output power and the brightness of the optical-fiber laser through the overlapped body of grating. The invention features the simple structure and complex structure without increasing as the increase of the beam combination laser, and is able to be widely applied in the field needing the large power optical-fiber laser as the light source, thereby capable of gaining the large power, high beam quality as well as compact high-energy laser system.

Owner:AIR FORCE UNIV PLA

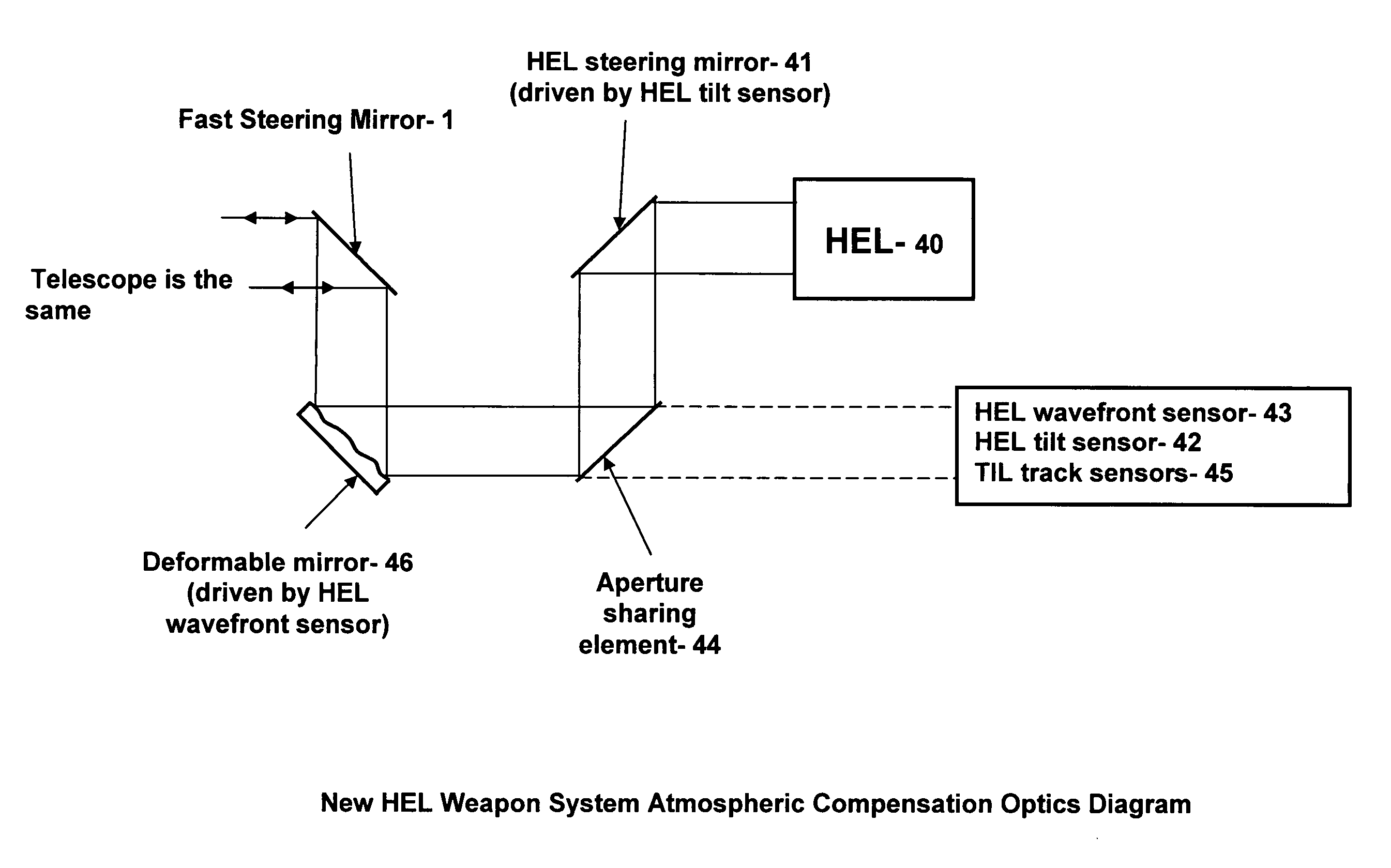

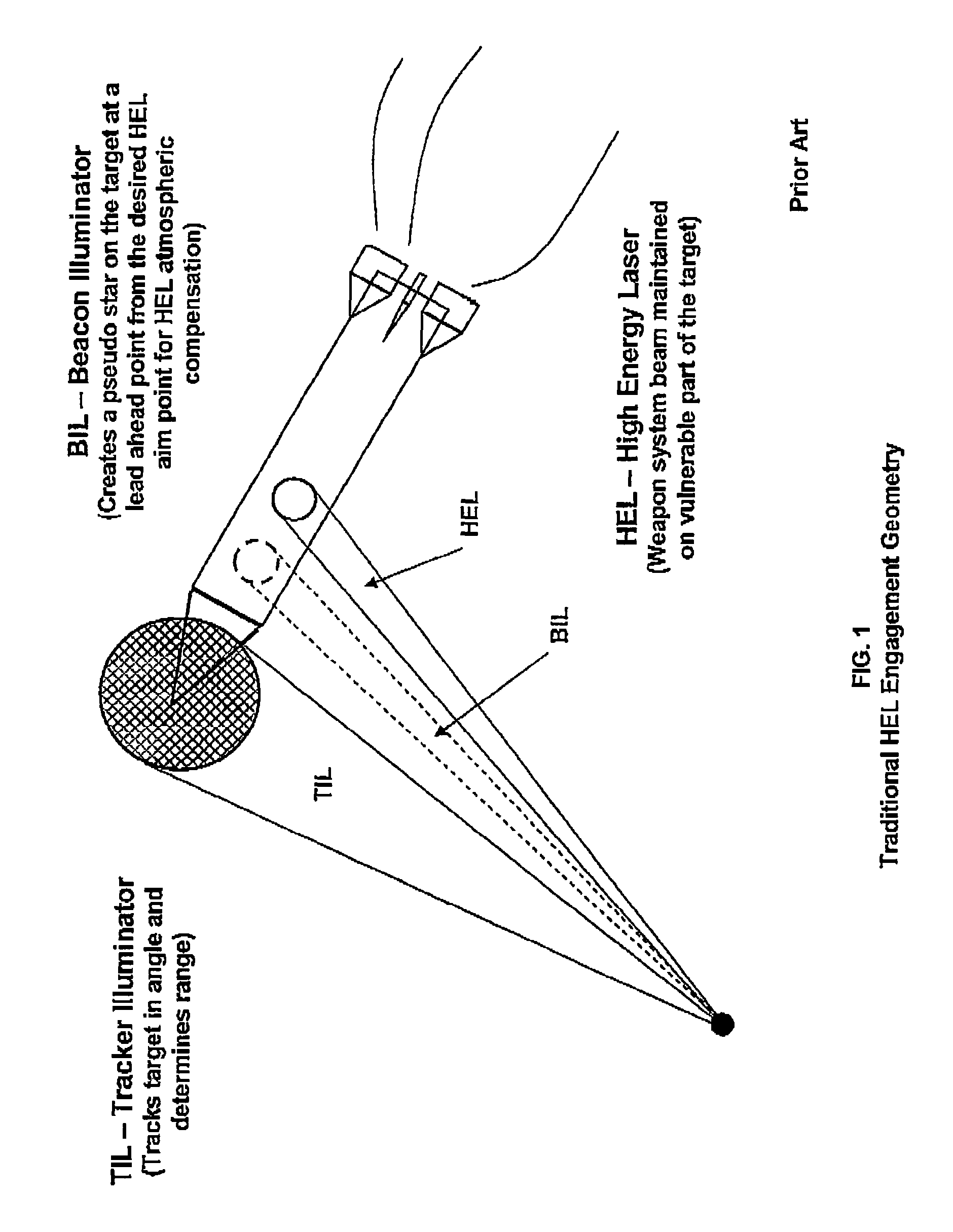

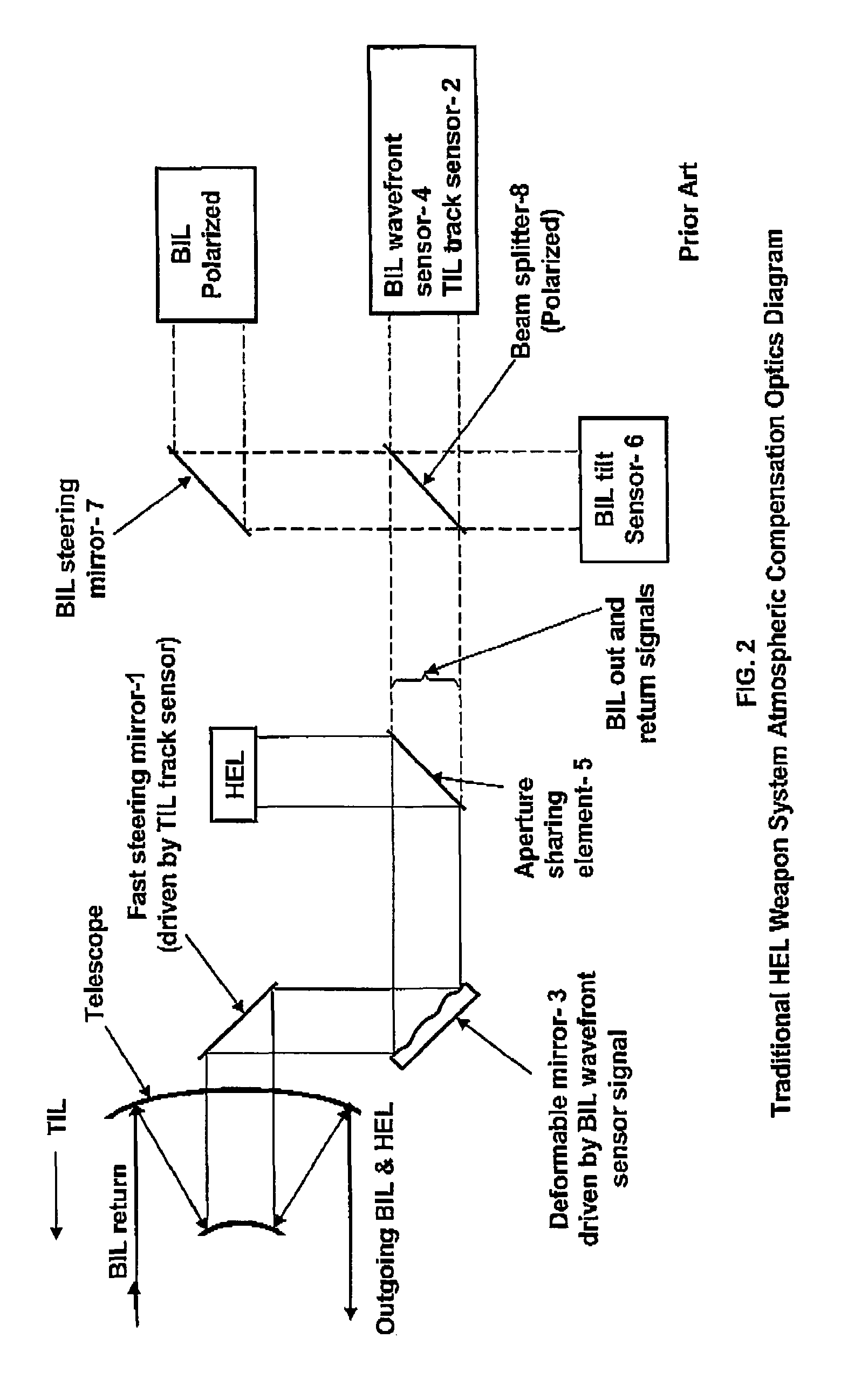

High-energy laser atmospheric compensation and aimpoint maintenance

A high-energy laser weapon system in which the high-energy laser beam itself is used to correct for atmospheric fluctuations thereby replacing a separate beacon illuminator system. The high-energy laser is turned off (negative pulse) periodically for a very short period giving a wavefront sensor an opportunity to measure the return of the high-energy laser beam from the target. A wavefront sensor drives a deformable mirror based on this return signal avoiding wavelength anisoplanatism. In addition, the high-energy laser weapon can be snapped ahead of the path of the target during the negative pulse to avoid tilt anisoplanitism.

Owner:THE GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE UNITED STATES AIR FORCE

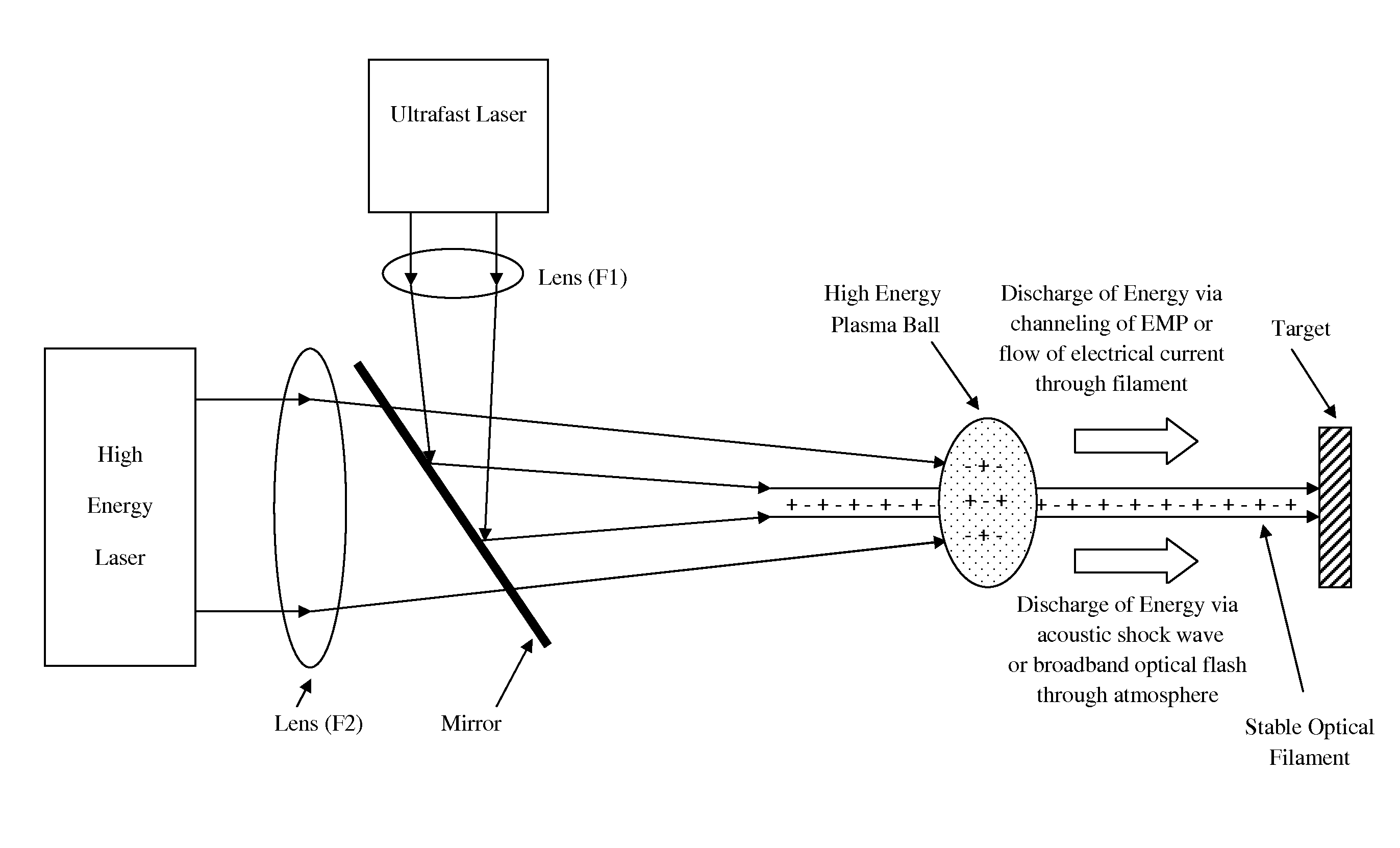

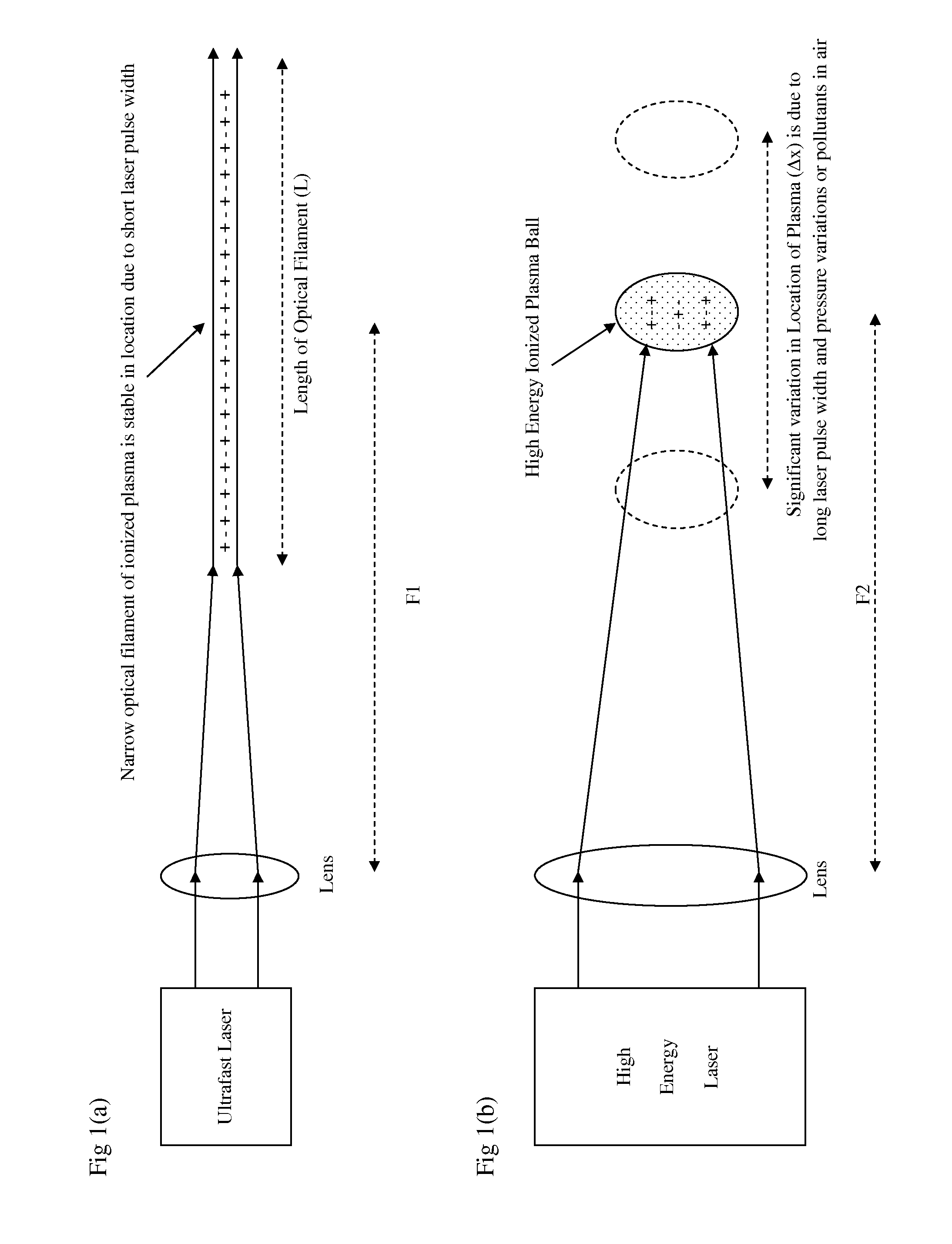

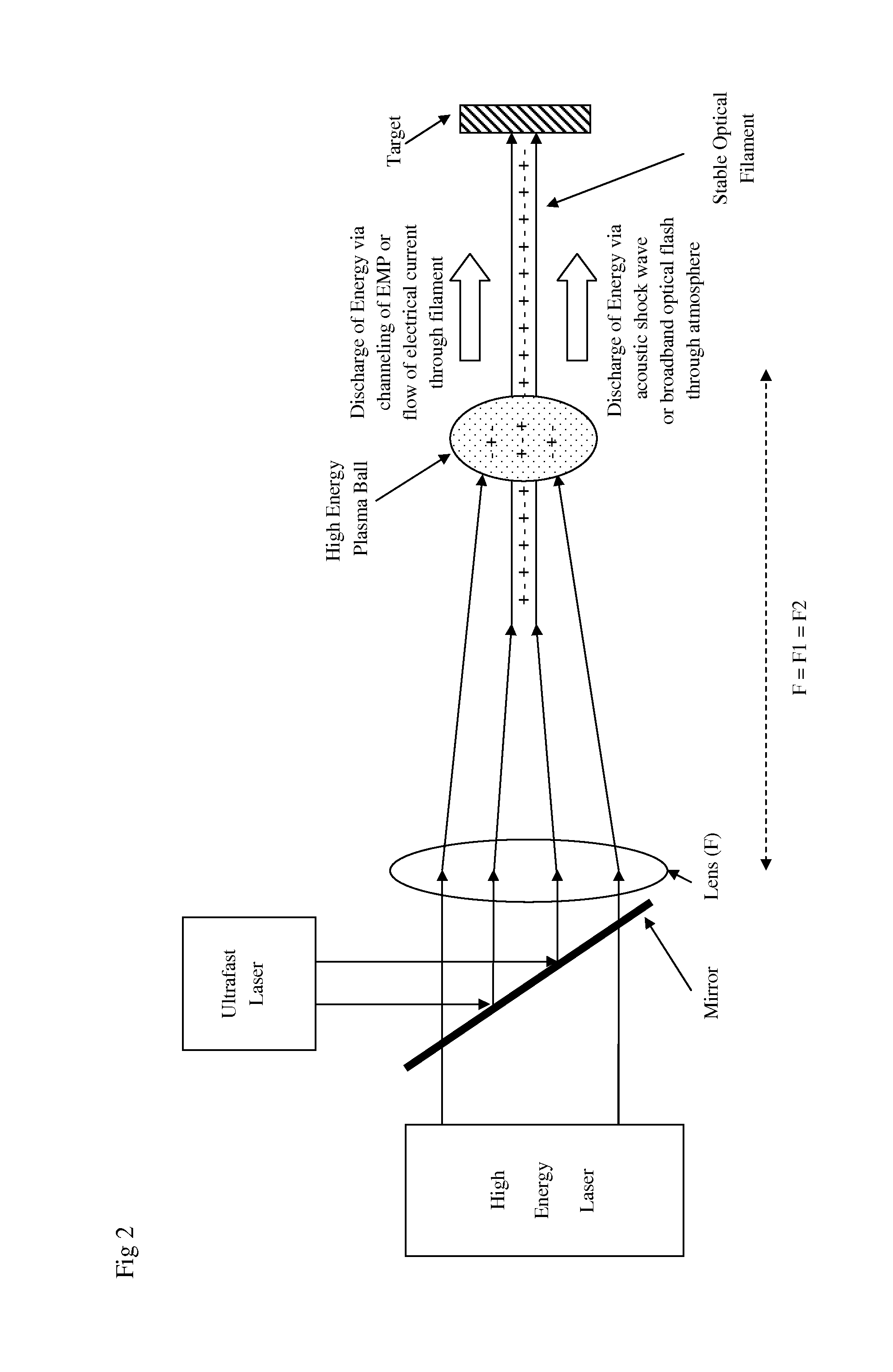

Laser Guided and Laser Powered Energy Discharge Device

InactiveUS20160097616A1Readily and efficiently conductedGuaranteed normal transmissionStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsHigh energyElectrical connection

The present invention relates to a laser guided and powered directed energy weapon that combines two different lasers to accurately and efficiently deliver a high energy electromagnetic pulse (EMP) to a target at long range. The method uses a high energy laser pulse with relatively long pulse duration focused in air to create a plasma ball which emits an intense EMP. Typically the long pulse duration of high energy lasers would severely limit focal accuracy and effective range because of air pressure variations and pollutants in the atmosphere. However the present invention uses a second ultrafast laser to create a long thin optical plasma filament between the variable location of the plasma ball and the target to act as a stable electrical connection or conducting wire. Consequently EMP can be efficiently channeled to the target via the optical filament, thereby dramatically increasing potential accuracy, range and energy delivery efficiency.

Owner:WEIGOLD DR ADAM MARK

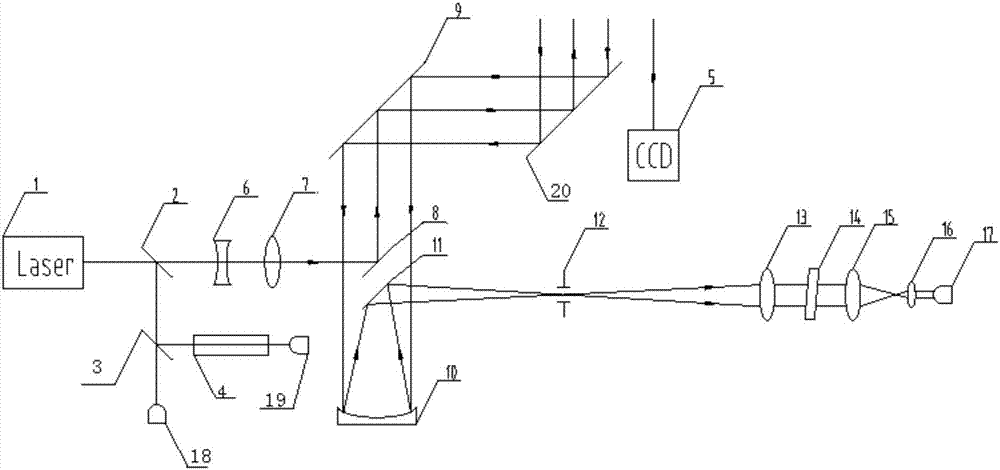

High sensitivity gas pollution detection laser radar system

PendingCN106970392AReduce difficultyHigh detection sensitivityMaterial analysis by optical meansElectromagnetic wave reradiationRadar systemsLine width

The invention discloses a high sensitivity gas pollution detection laser radar system comprising an intermediate infrared tunable narrow linewidth high energy laser device, a wavelength and power monitoring module, an optical transmit-receive module, an aiming module and a data processing module that are integrated; the intermediate infrared tunable narrow linewidth high energy laser device is used for emitting intermediate infrared laser, one part of the intermediate infrared laser is subjected to wavelength monitoring and power monitoring via the wavelength and power monitoring module, the other part is emitted out to a detection object via the optical transmit-receive module, the detection object is aimed at via the aiming module, echo signals in the detection object are reflected back via the intermediate infrared laser are received via the optical transmit-receive module, then the echo signals are transmitted to the data processing module and are subjected to processing and analyzing operation, and a polluted gas concentration value is obtained. The high sensitivity gas pollution detection laser radar system can be used for conducting real time monitoring and data analyzing operation on main atmosphere pollutant concentration indexes.

Owner:NANJING INST OF ADVANCED LASER TECH

Material increasing manufacturing method of pure tungsten metal

ActiveCN104889392AHigh densityImprove performanceAdditive manufacturing apparatusSlice thicknessShielding gas

The invention relates to a material increasing manufacturing method of pure tungsten metal. The manufacturing method comprises steps of taking ball-shaped pure tungsten powder particles; screening out and mixing tungsten powder small particles and tungsten powder big particles to obtain mixed powder bodies; installing a metal substrate on an optical fiber laser work bench; filling a powder body stock bin with the mixed powder bodies and sealing a shaping cavity body; using a vacuum pump to pump the interior of the shaping cavity body to be in vacuum degree of -90Kpa; inputting protection gas into the shaping cavity body; repeating vacuumization and protection gas inputting so as to allow the oxygen content in the shaping cavity body to be reduced to less than 300ppm; scanning the sacrificing area of the metal substrate with laser until the oxygen content is reduced to less than 50ppm; sending the mixed powder bodies in the powder body stock bin to the metal substrate by a powder laying machine; using a powder laying scraper to lay the powder bodies so as to obtain a mixed powder body thin layer; fusing the mixed powder bodies in a shaping slicing area via high-energy laser beams; refusing the mixed powder bodies after each layer is shaped; after the refusing is finished, reducing the work bench by one slice thickness; and repeating the laser shaping and refusing until the whole part is finally shaped.

Owner:TSINGHUA UNIV

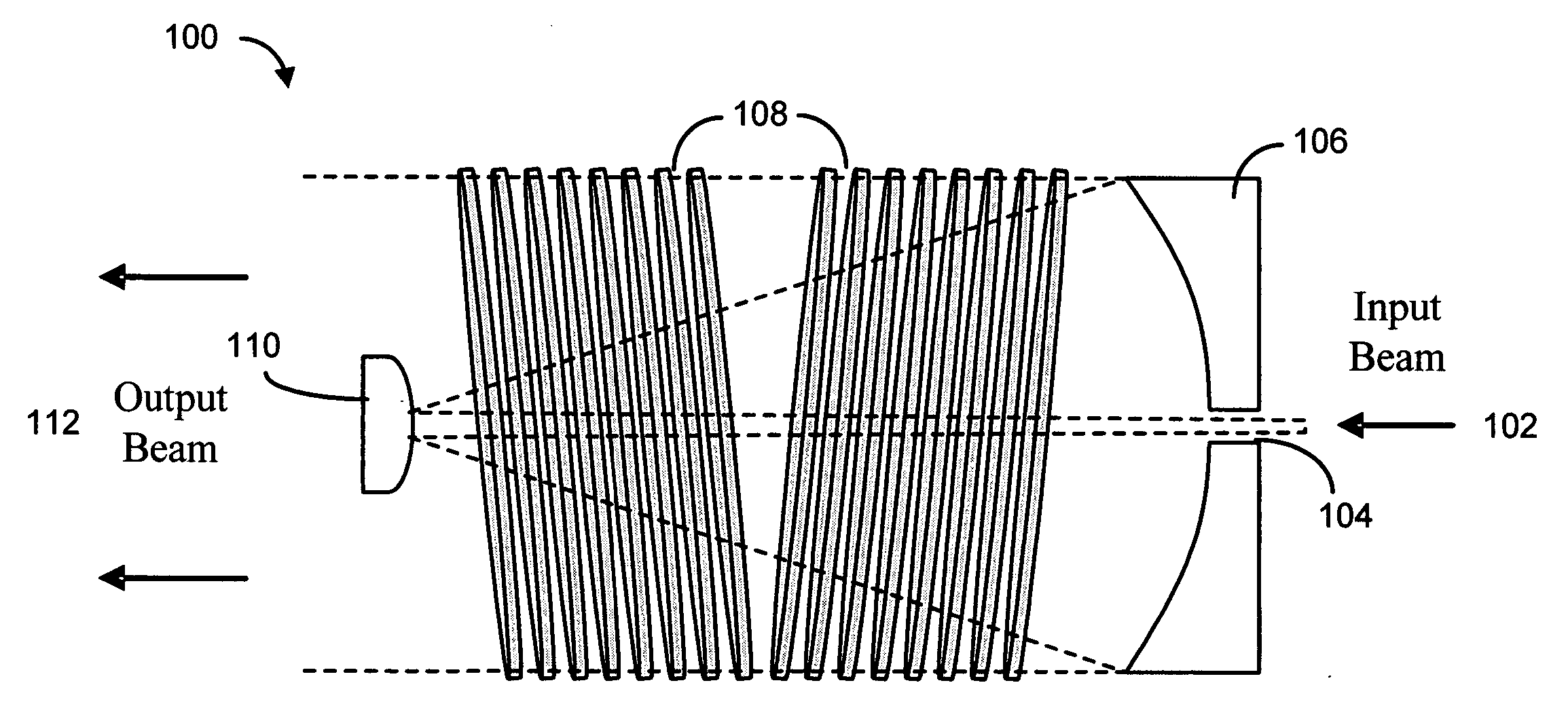

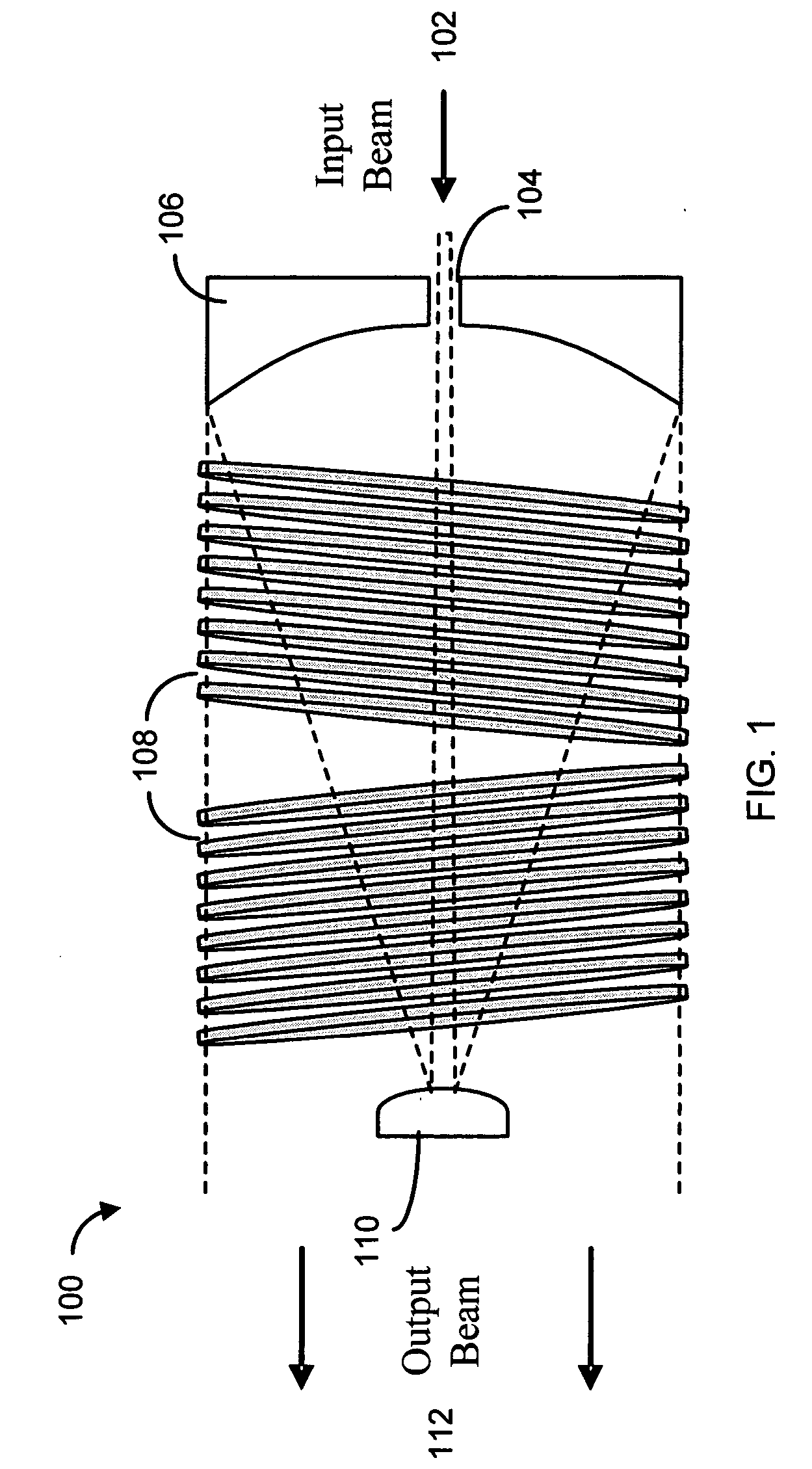

Amplifying of high energy laser pulses

InactiveUS20050213630A1Remove heatImprove efficiencyLaser detailsDiagnosticsAudio power amplifierLight beam

The present invention provides a method of amplifying a beam of laser pulses by producing an amplified collimated beam of pulses using an amplifier, spatially spreading the amplified collimated beam of pulses into an expanded beam of pulses, introducing the expanded beam of pulses into the amplifier a second time to produce a twice amplified beam of pulses, recollimating the twice amplified beam of pulses to produce a twice amplified collimated beam of pulses such that the twice amplified collimated beam of pulses is of essentially the same cross-section as the amplifier, and introducing the twice amplified collimated beam of pulses into the amplifier a third time to produce a thrice amplified collimated beam of pulses such that the re-collimated beam sweeps essentially the entire volume of the amplifier.

Owner:RAYDIANCE

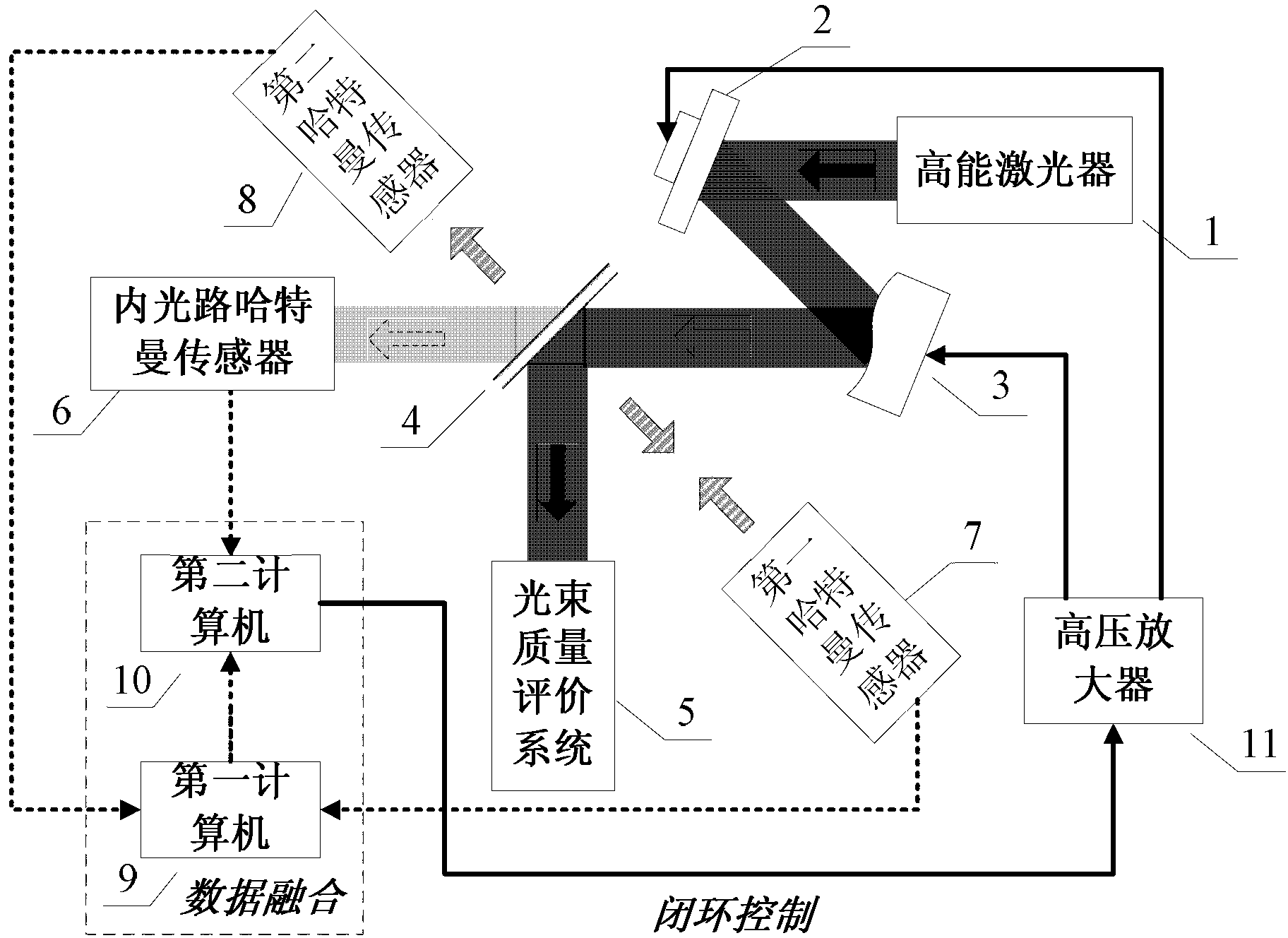

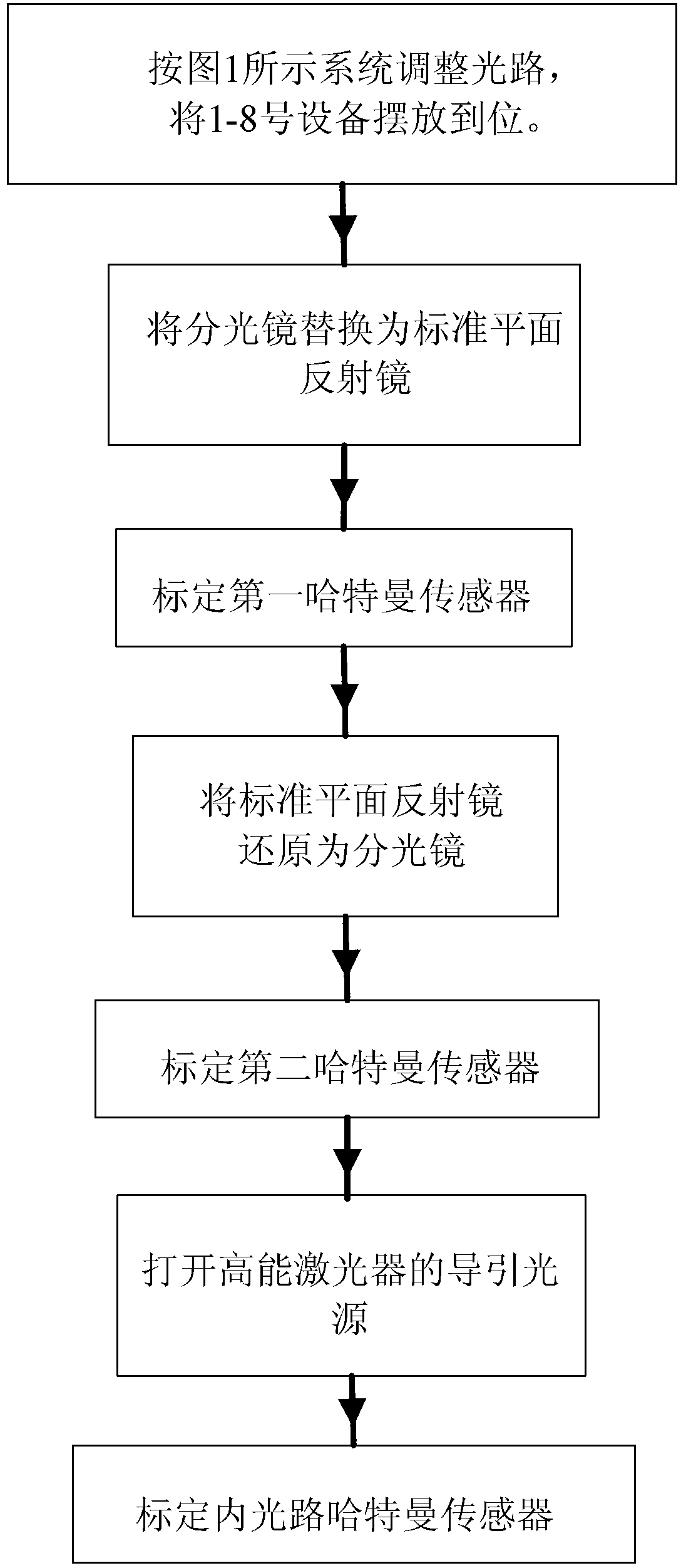

Full light path aberration correction system and full light path aberration correction method based on double Hartmann sensors

ActiveCN102980743ASolve the problem of construction process limitationHigh measurement accuracyTesting optical propertiesOptical elementsAudio power amplifierMultiple sensor

Provided are a full light path aberration correction system and a full light path aberration correction method based on double Hartmann sensors. The correction system comprises an efficient laser, a wavefront corrector, a spectroscope, a optical quality evaluation system, an inner light path Hartmann sensor, a first Hartmann sensor, a second Hartmann sensor, a data combining assembly and a high voltage amplifier. The correction method based on the correction system uses two Hartmann sensors to simultaneously measure reflection and transmission aberration of the spectroscope and uses a data combining method not relying on response arrays to transmit aberration of the spectroscope to the inner light path Hartmann sensor to control the wavefront corrector to correct the full light path aberration. The full light path aberration correction system and the full light path aberration correction method based on double Hartmann sensors has the advantages of being simple in principle, convenient to achieve, capable of resolving the problem of limit of component structure process in the prior art, capable of improving data combing rate between multiple sensors and capable of effectively promoting outlet light beam quality of the efficient laser system.

Owner:NAT UNIV OF DEFENSE TECH

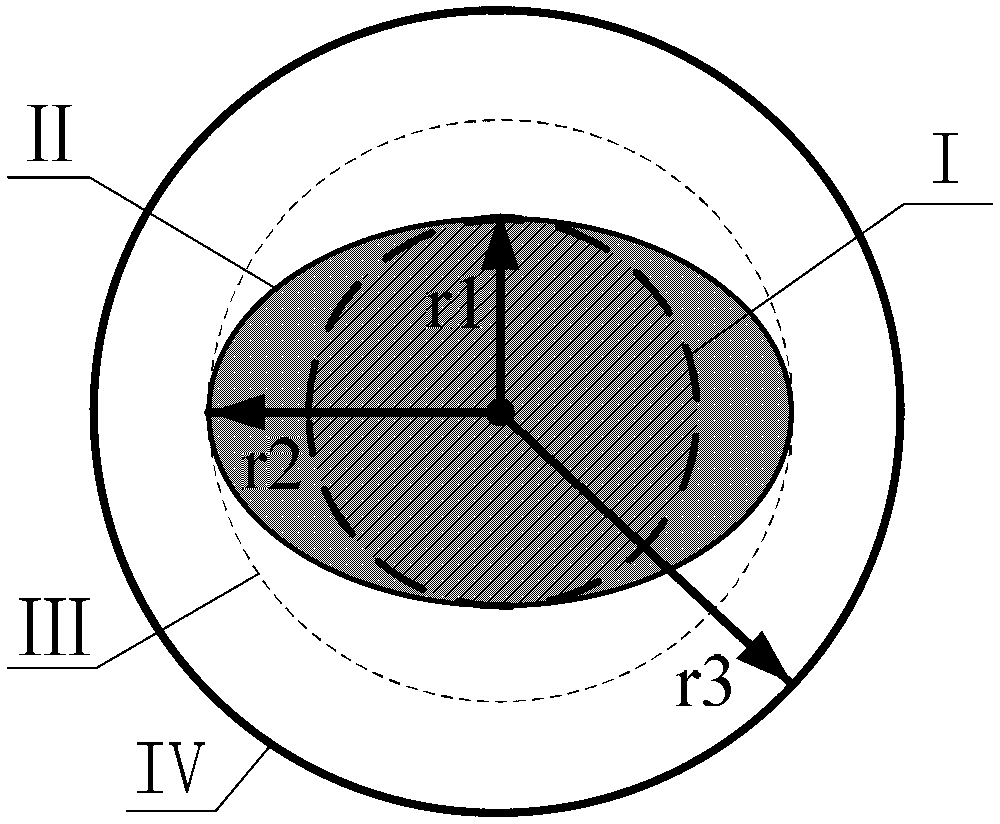

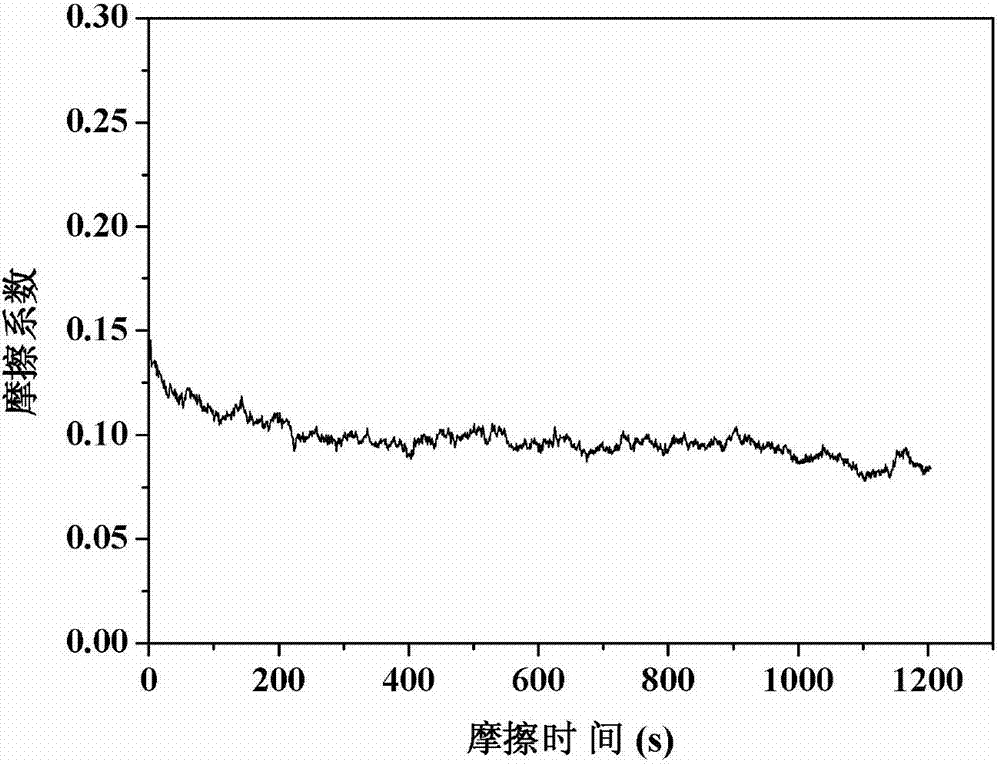

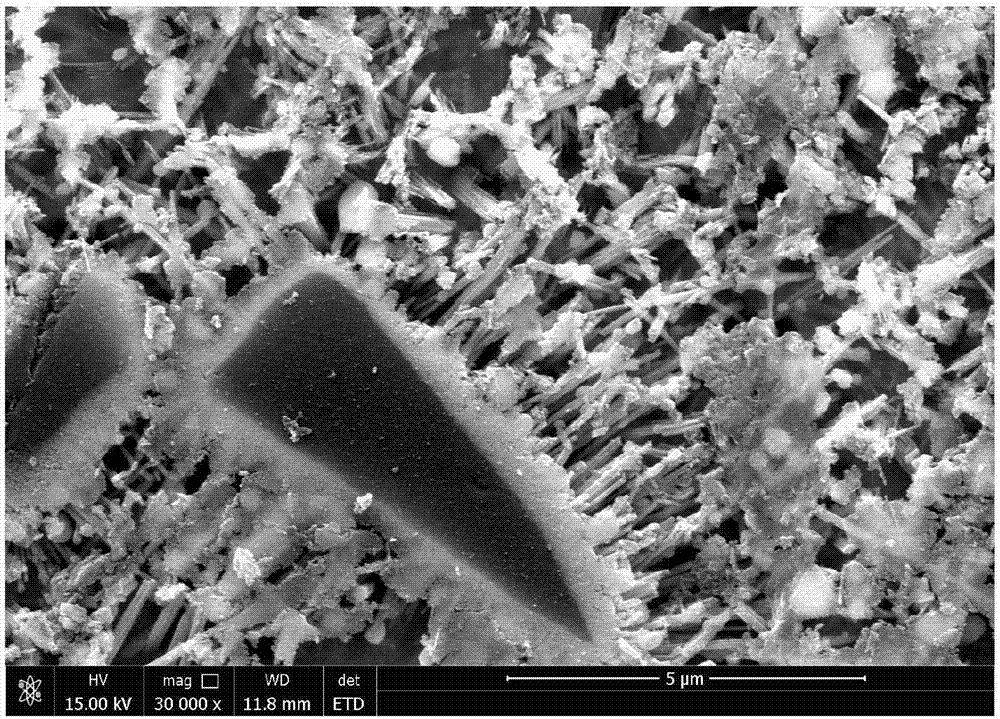

Medical high abrasion resistance titanium alloy composite and gradient in-situ nano multiphase abrasion reduction medical titanium alloy 3D printing method

ActiveCN107130138AFast formingHigh diffusion activityAdditive manufacturing apparatusIncreasing energy efficiencyHigh energyBoron carbide

The invention discloses a medical high abrasion resistance titanium alloy composite and a gradient in-situ nano multiphase abrasion reduction medical titanium alloy 3D printing method. The physical characteristics of boron carbide ceramic and a titanium alloy are combined, a laser selective melting forming process is adopted, and under the effect of high energy lasers, active elements of carbon and boron can be conveniently diffused outwards in a radial gradient mode along boron carbide ceramic particles, and nano ceramic reinforced phases such as Ti-B, TiB2 and TiC can be easily synthesized through the carbon, the boron and the medical titanium alloy. On one hand, forming of a gradient ceramic particle / titanium alloy interface is promoted, and wettability of the gradient ceramic particle / titanium alloy interface is remarkably enhanced; and on the other hand, based on good physical properties and the uniform dispersion strengthening effect of the in-situ synthesis multiphase nano ceramic particles, the friction and abrasion characteristics of the medical titanium alloy can be effectively improved, manufacturing of the high performance medical titanium alloy is achieved, and the medical high abrasion resistance titanium alloy has good clinical application prospects and economic value.

Owner:洋紫荆牙科器材(深圳)有限公司

High reflection film of silicon carbide reflection mirror within visible light wave range, and its production method

InactiveCN101315435AReduce weightLower launch costsMirrorsVacuum evaporation coatingHigh energyHigh energy laser

The invention relates to a high reflective film for a silicon carbide reflecting mirror in the visible light wave band and the preparation method thereof. At present, the reflection factor of the surface of a reflecting mirror in a specific wavelength range is a key index in order to meet the design requirements of equipment such as large space telescopes, large terrestrial telescopes, early-warning satellites, explorer satellites, reconnaissance satellites, meteorological satellites, high energy lasers and laser radars. A reflecting mirror body in a complex shape is prepared by adopting the reactive sintering method, basic mechanical treatment and surface treatment are performed to the reflecting mirror, and then the following steps are adopted: firstly, the surface of the reflecting mirror is cleaned; secondly, filming treatment is performed with a magnetic control sputtering apparatus; and thirdly, the reflecting film layer is fine-finished. The invention is applied to the preparation method for the reflecting film of the silicon carbide reflecting mirror in the visible light wave band with the reflection factor larger than 97 percent.

Owner:HARBIN INST OF TECH

Dichroic beamsplitter for high energy laser diagnostics

Wavefront control techniques are provided for the alignment and performance optimization of optical devices. A Shack-Hartmann wavefront sensor can be used to measure the wavefront distortion and a control system generates feedback error signal to optics inside the device to correct the wavefront. The system can be calibrated with a low-average-power probe laser. An optical element is provided to couple the optical device to a diagnostic / control package in a way that optimizes both the output power of the optical device and the coupling of the probe light into the diagnostics.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

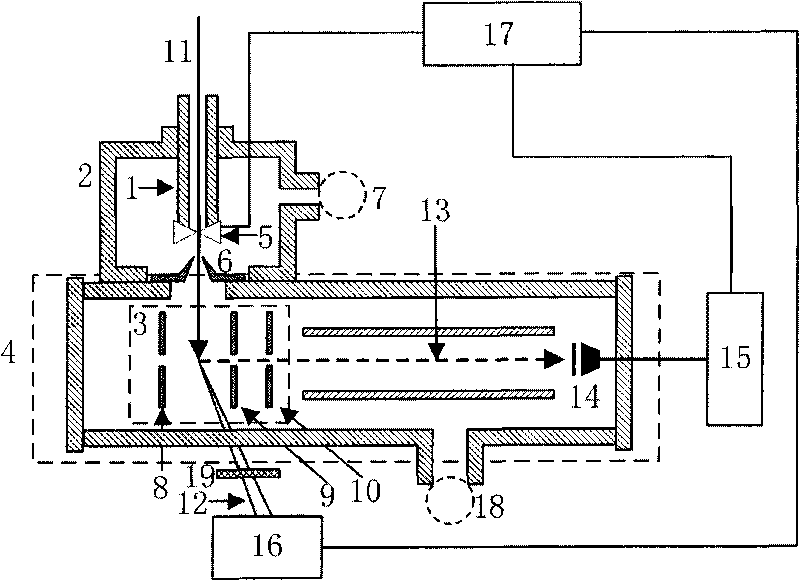

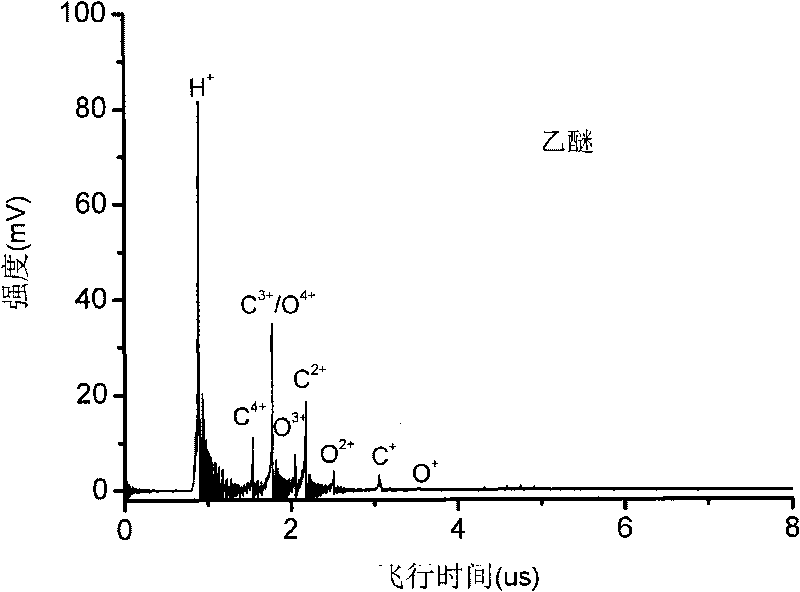

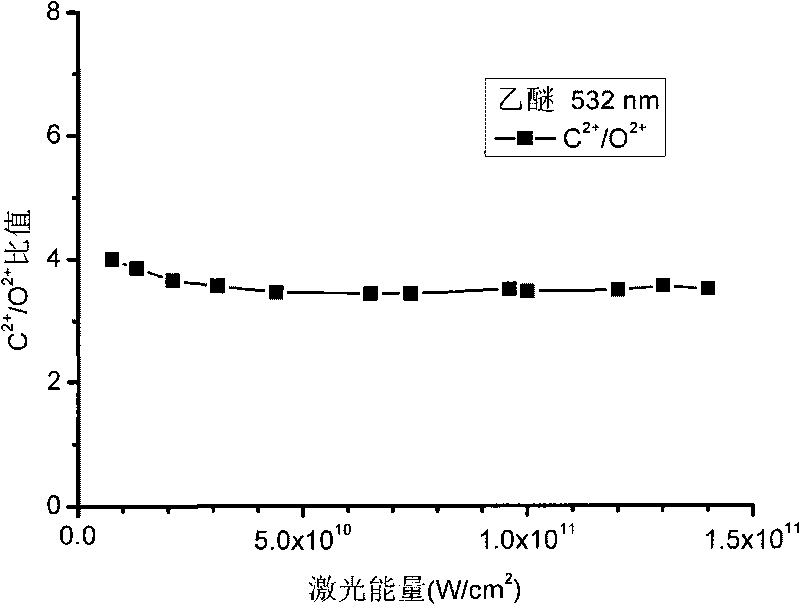

Time-of-flight mass spectrometer for measuring ratio of nano-particle component elements in real time

InactiveCN101750265AImprove hit efficiencyMaterial analysis by electric/magnetic meansBeam sourceSpectrograph

The invention relates to a time-of-flight mass spectrograph, in particular to a time-of-flight mass spectrometer for measuring ratio of nano-particle component elements in real time, comprising a pulse sampling device, a beam source chamber and a time-of-flight mass spectrum mass analyzer provided with an ionization chamber. The time-of-flight mass spectrometer is characterized in that the ionization chamber is positioned in the time-of-flight mass spectrum mass analyzer, the front end of the pulse sampling device is connected with a pulse valve, the pulse sampling device is inserted into the beam source chamber, the beam source chamber is positioned directly above the laser ionization chamber, the outlet of the beam source chamber is connected with the laser ionization chamber through a nozzle, a nanosecond long wavelength high-energy laser is installed at the outer side of the time-of-flight mass spectrum mass analyzer, the high-energy laser beams emitted by the laser pass through the ionization chamber vertically so as to ionize nano-particles completely into univalent and high valence ions, the ratio of the high valence ions can accurately reflect the ratio of nano-particle component elements, and the ions produced by ionization can be recorded by the time-of-flight mass spectrograph. The invention can measure the ratio of nano-particle component elements rapidly, and the measurement is not influenced by ionization laser energy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Solution-curing quick-molding manufacturing method

InactiveCN104228067AVarious production methodsExpand the range of raw materialsDevice formPhysical layer

The invention discloses a solution-curing quick-molding manufacturing method which comprises the following steps: preparing a raw solution material; carrying out program cutting and layering on a to-be-formed product by virtue of a computer; controlling the start and stop of a pump, the flow rate of the pump and the motion track of a printing sprayer by virtue of the computer, so that chemical or physical change occurs during the contact of the raw solution material and coagulating bath and the raw solution material is cured and formed; controlling a liftable work platform to descend to the height which is the same as the thickness of a virtual layer after printing of a physical layer is completed; repeating the previous step until all the physical layers corresponding to the virtual layers are printed. According to the method, the raw solution material is uses as a raw material for rapid material increasing manufacturing; the raw material scope of rapid material increasing manufacturing is widened; the production method of rapid material increasing manufacturing techniques is enriched; meanwhile, during the producing and manufacturing process of the solution-curing quick-molding manufacturing method, no heating device such as a high energy laser is needed; the production process is low in energy consumption and easy to control; the device is relatively simple; the method can be easily used in large-scale application.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

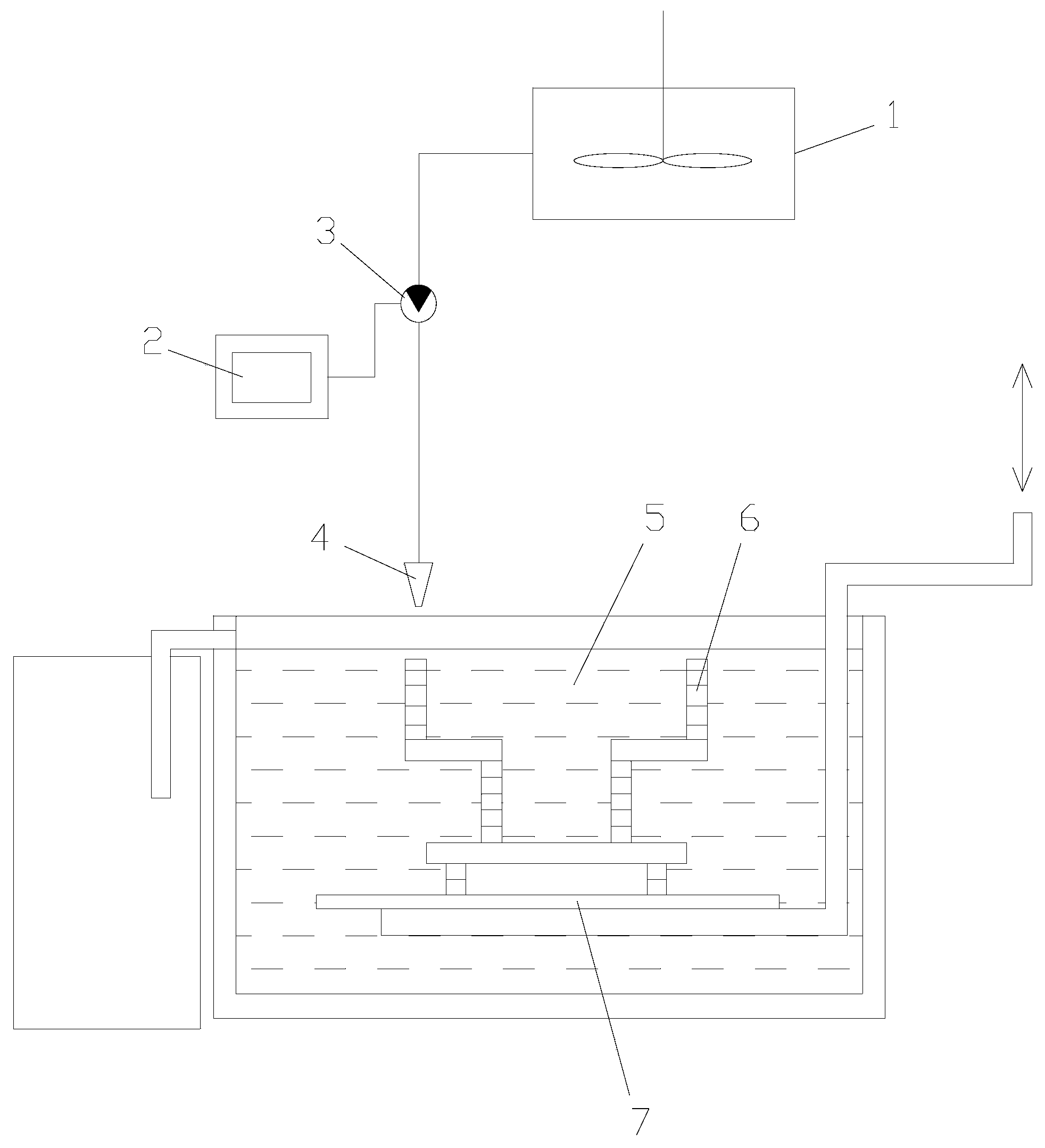

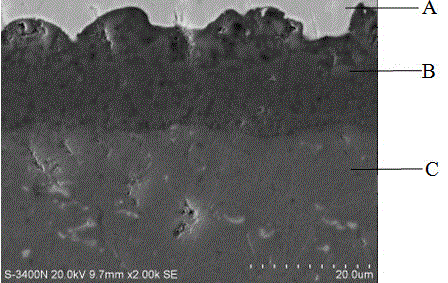

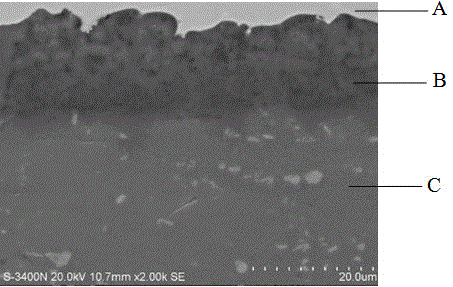

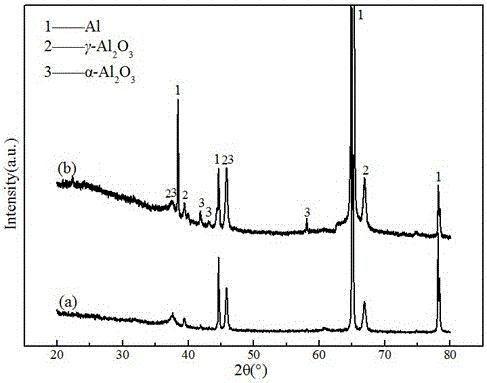

Method for improving compactness of aluminum alloy micro-arc oxide coating

InactiveCN106637337AImprove densification performanceHigh hardnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for improving compactness of aluminum alloy micro-arc oxide coating, and belongs to the technical field of aluminum alloy surface modification. The method comprises the following steps of: grinding an aluminum alloy sample to be smooth, ultrasonically cleaning the aluminum alloy sample, putting the ultrasonically-cleaned aluminum alloy sample into electrolyte to perform micro-arc oxidization treatment, thereby preparing an aluminum-alloy micro-arc oxidation coating; and finally, performing laser scanning processing on the aluminum-alloy micro-arc oxidation coating by high-energy laser beams generated by laser unit equipment. The method disclosed by the invention can improve the structure of the aluminum-alloy micro-arc oxidation coating, so that a metastable phase in the coating is converted into a stable phase. The method effectively improves the problems that compaction of the coating is relatively poor as a result of porous characteristics, and the energy consumption for obtaining the micro-arc oxidation coating with good compactness is high, so that corrosion and wear resistance of the micro-arc oxidization coating is greatly improved; and moreover, the method is simple in process, is good in repeatability, and can be used for industrial large-area preparation.

Owner:GUANGXI UNIV +2

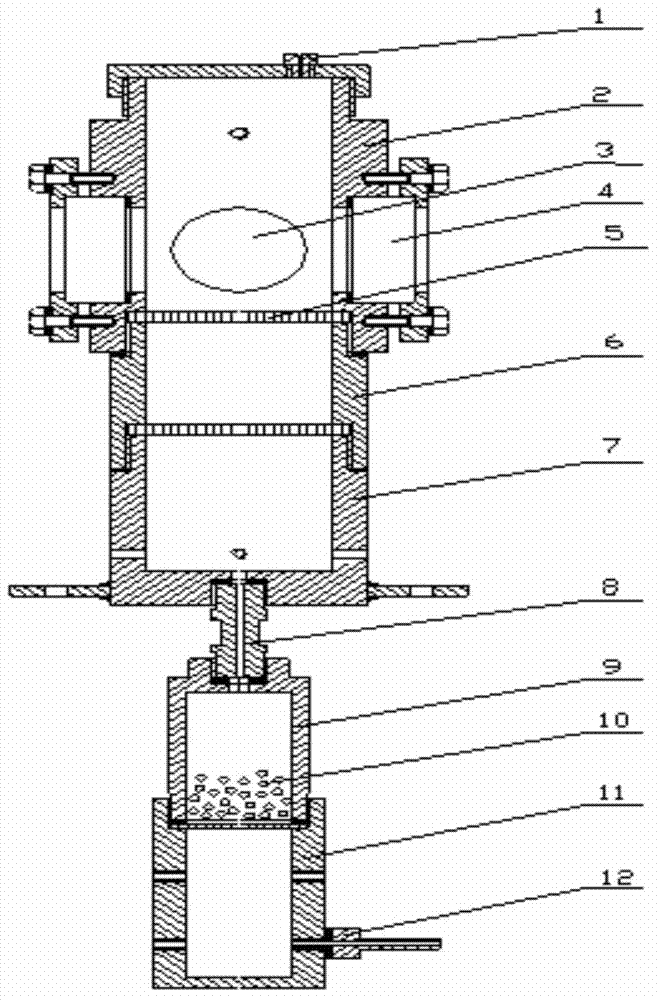

Particle airflow suspension laser ignition experiment device

InactiveCN104330519ATo achieve the purpose of the ignition processChemical analysis using combustionCombustorShoot

The invention discloses a particle airflow suspension laser ignition experiment device belonging to the technical field of solid rocket engines. The particle airflow suspension laser ignition experiment device enables particles to suspend in space in a combustor by means of tiny airflow, and the particles are not in contact with a metal wall plate, and are continuously heated and ignited by using a high-energy laser igniter. A gas environment is adjustable, single gas can be fed or different kinds of gases are simultaneously fed so that the purpose of testing particle ignition processes under different gas environments is achieved. Four transparent windows are arranged on the combustor, wherein two windows are observation windows and two windows are germanium glass windows; a working process is observed and tested by means of the two observation windows, laser generated by the laser igniter shoots into the combustor by means of the two germanium glass windows, the power of the laser igniter is regulated, and the particles suspending in the combustor are heated and ignited; a detailed process of particle ignition combustion are shot by means of the observation windows by using a high-speed photography system. The experiment device can be used for researching ignition and combustion characteristics of metal particles and nonmetal particles.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

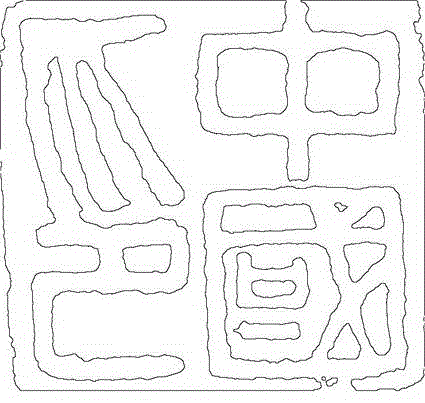

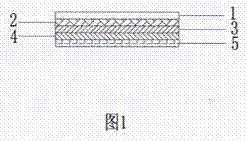

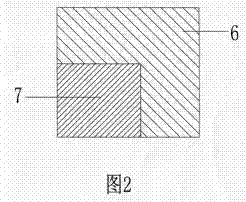

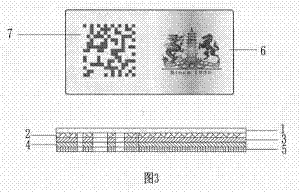

Composite multifunctional anti-counterfeiting mark manufactured by utilizing laser etching

InactiveCN102214412AEasily judge authenticityEasy to useStampsUser identity/authority verificationLaser etchingVisual observation

The invention provides a composite multifunctional anti-counterfeiting mark manufactured by utilizing laser etching. With respect to adopted technical means, the composite multifunctional anti-counterfeiting mark manufactured by utilizing laser etching is composed of a thin film layer, a stripping layer, a mould pressing layer, an aluminized layer and a glue layer; an optical variable image is provided with a reserved position which is added with a background pattern with the anti-counterfeiting function; the substances of the mould pressing layer and the aluminized layer in the background pattern are selectively gasified by high-energy laser to obtain an image, characters or marks which are formed by a blank position and the background pattern; consumers can easily judge the authenticity of the product by the direct visual observation by virtue of the high anti-counterfeiting performance of the optical variable image on the mark and the uniqueness of a two-dimension code and the optical variable image which are located and processed; and the invention can also provide a platform to form an interaction between the consumer and a product manufacturer by utilizing a terminal device, so that the anti-counterfeiting mark provided by the invention achieves the purposes of market popularization, market information collecting and product tracking while the information of the product is assured.

Owner:YUNNAN HOLOBEAM SECURITY TECH

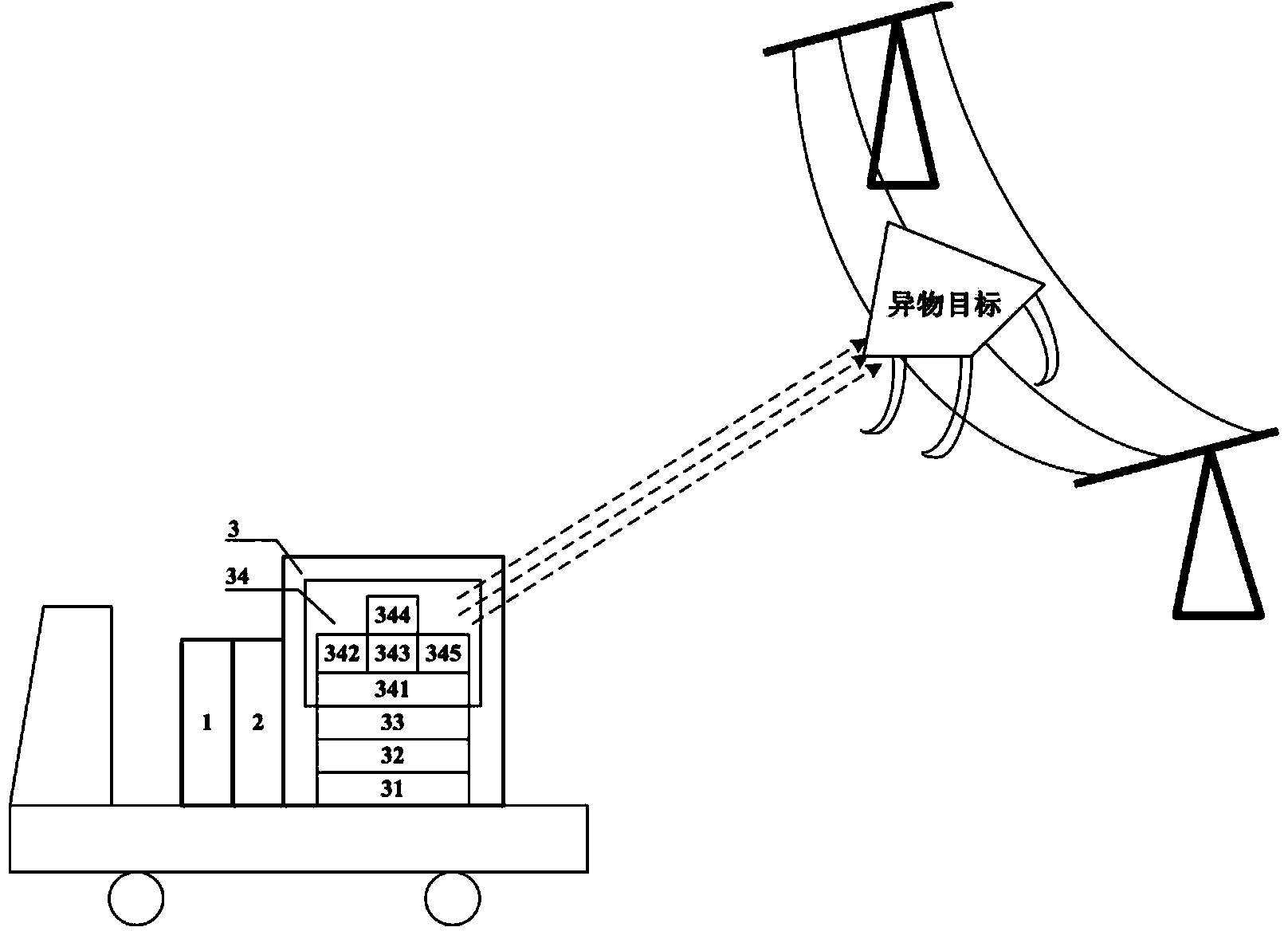

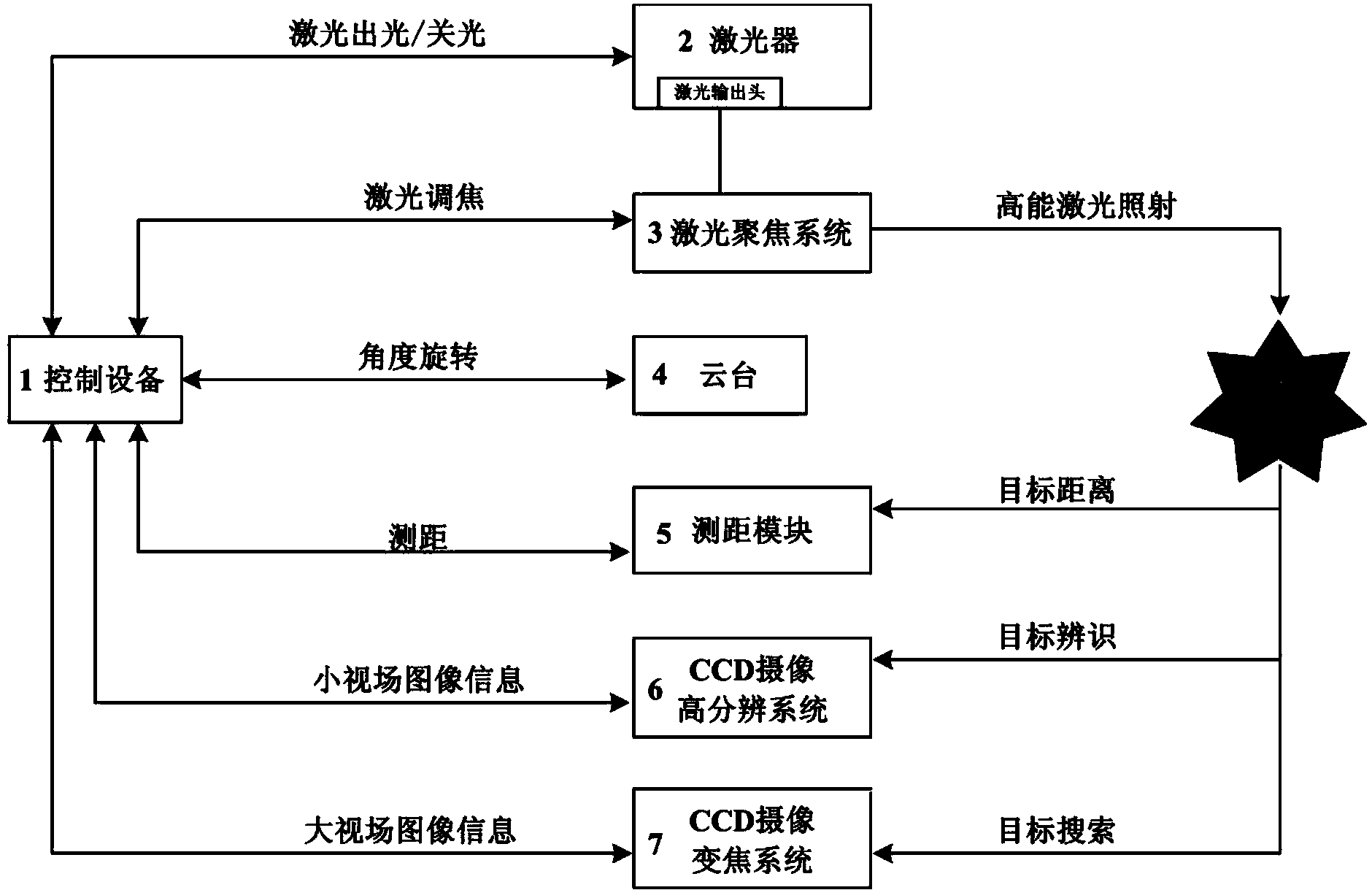

Method and device for removing high voltage transmission line foreign matter by means of laser electrification

InactiveCN104377590ALive clear implementationWork without power outageApparatus for overhead lines/cablesForeign matterLaser light

The invention discloses a method and device for removing high voltage transmission line foreign matter by means of laser electrification. The method and device are used for removing kites, plastic films, balloons, banner advertisements and other foreign matter which threatening high voltage transmission line operation safety. According to the method and device, laser light is used as working media, a pan-tilt is used as a rotating device, foreign matter object searching, recognition and collimation are achieved through image information, laser automatic focusing is achieved through distance information, and electrification removing of foreign matter is achieved by radiating focused high energy laser on the foreign matter object. Remote, non-contact and electrification removing of the foreign matter is achieved, the foreign matter removing speed is high, all the work is completed on the ground, and a worker does not need to carry out hazardous operation such as climbing a telegraph pole and being online and gets away from a high voltage electric field. The device has the image information collection and processing function, can check the foreign matter removing effect in real time, and has the good visualization experience, and laser light can avoid a high voltage transmission line when emitted and will not damage the cable.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com