Patents

Literature

120results about How to "Expand the range of raw materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

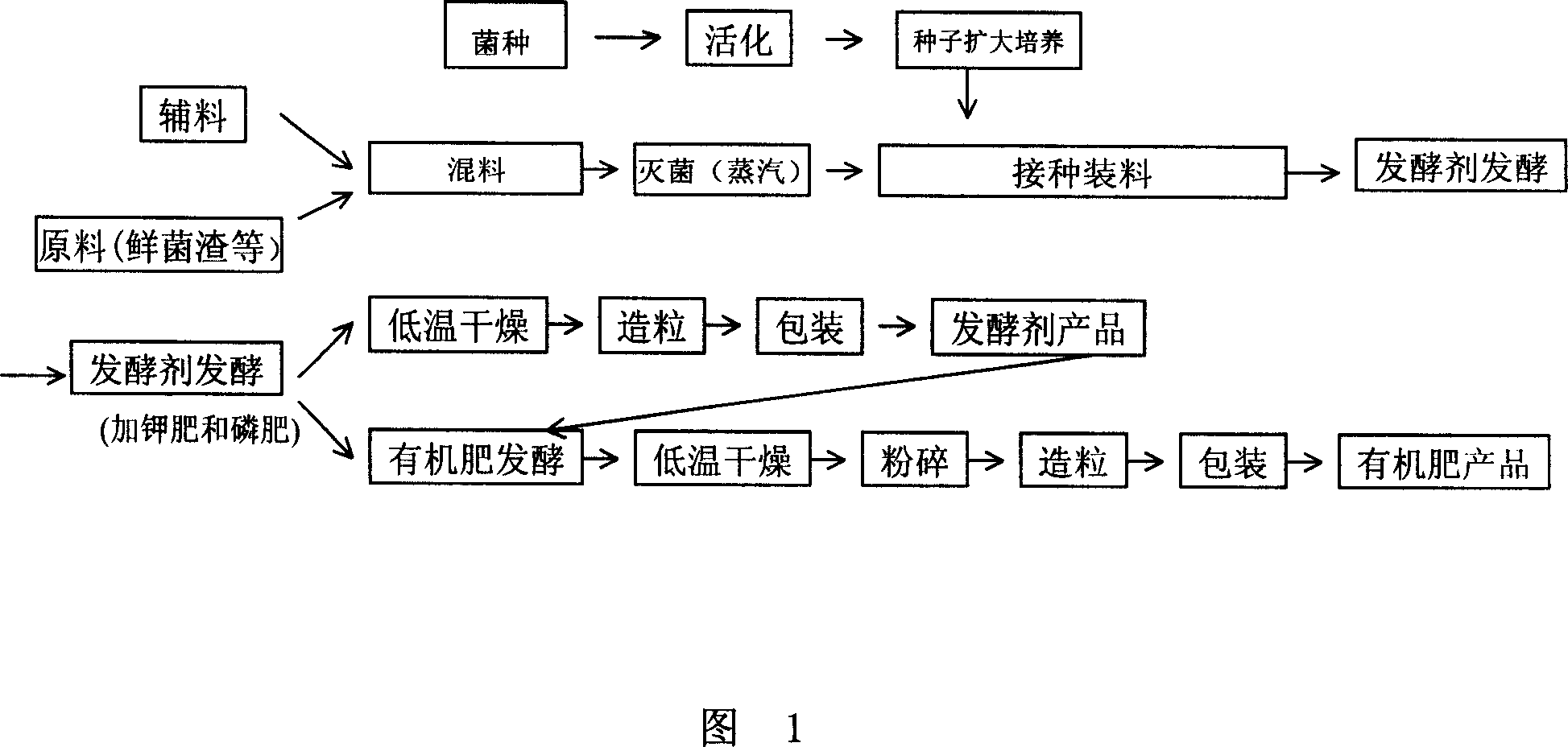

Fertilizer leaven and preparation method and application thereof

InactiveCN101041807ASimple processReduce manufacturing costFungiBacteriaBacillus licheniformisAzotobacter chroococcum

The invention discloses a method to prepare leaven of fertilizer and application, which is characterized by the following: allocating raw material with mass ratio at 10-80 wt industrial residue of ferment, 5-30 wt straw, 5-30 wt cake meal, 10-30 wt bran or rice bran, 1.5-2 wt aquacare, 0.5-1 wt NaCl and or amylaceum, and 1-30 wt brown ball Azotobacter (Azotobacter chroococcum), 1-30 wt bacillus megaterium (Bacillus megaterium), 1-30 wt bacillus licheniformis (Bacillus licheniformis), 1-30 wt plant lactobacillus (Lactobacillus plantarum) and 1-30 wt 1-5 strain of saccharomycopsis fibuligera (Saccharomycopsis fibuligera); producing the product.

Owner:北京世纪发展科技有限公司

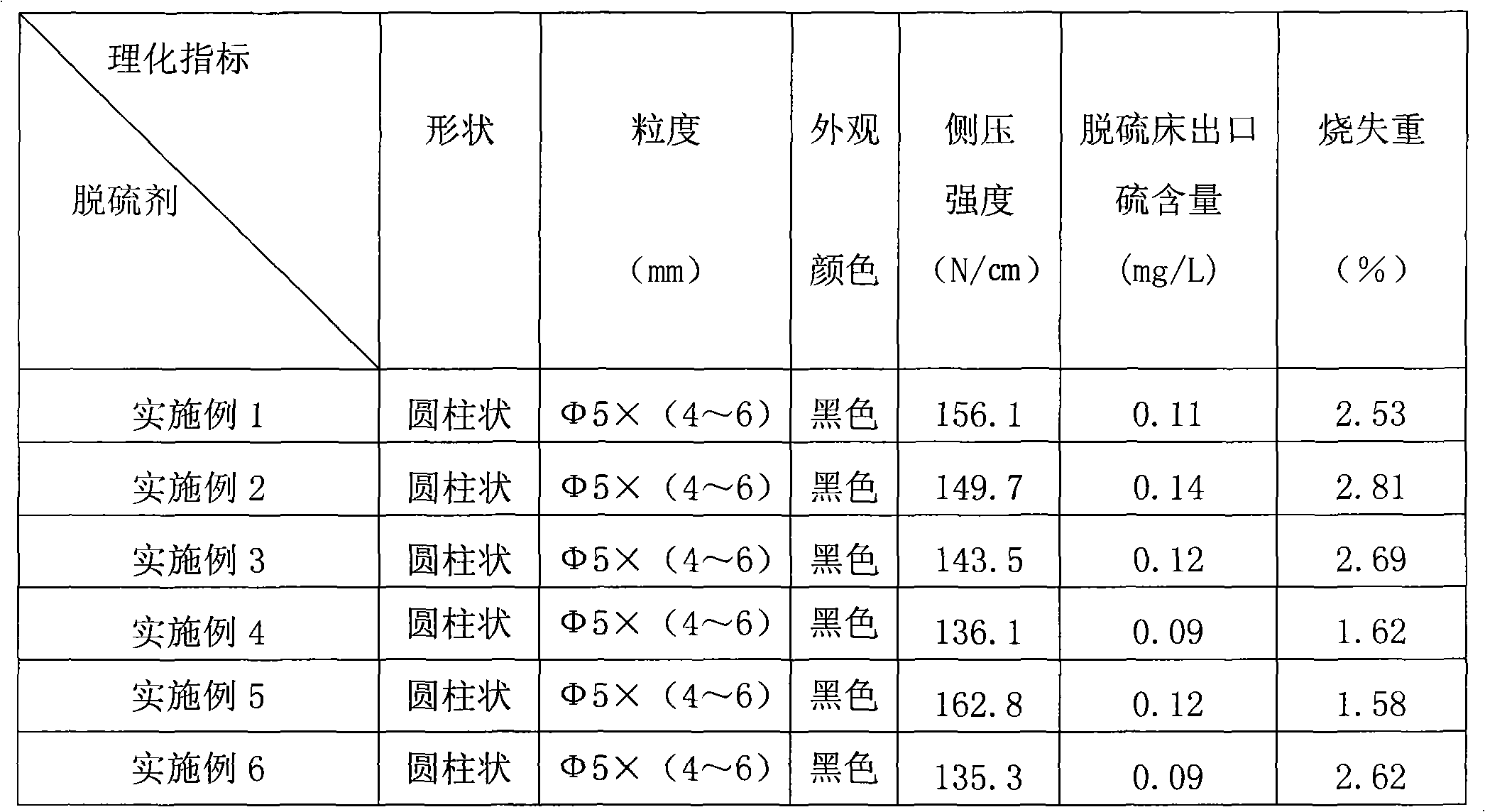

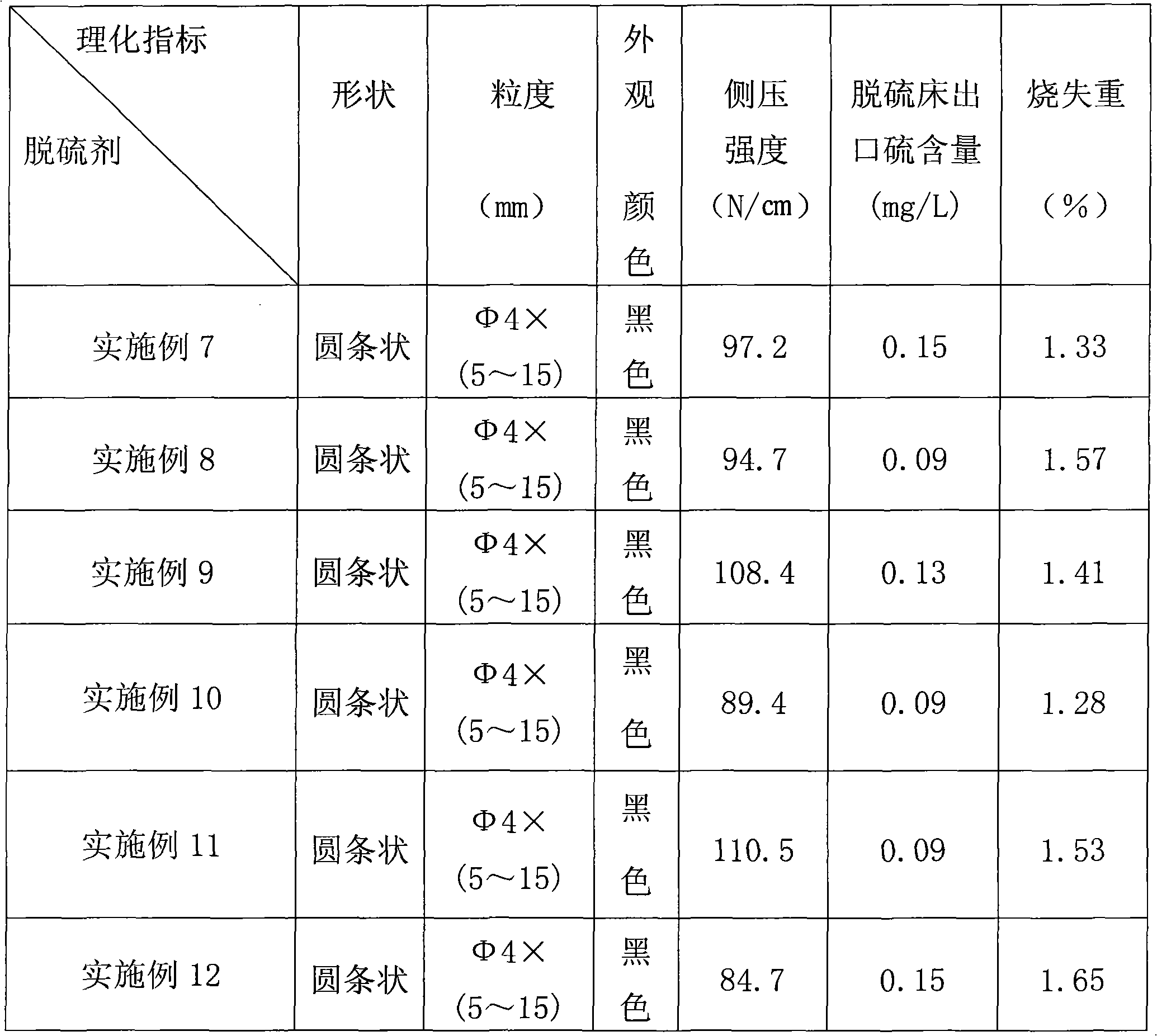

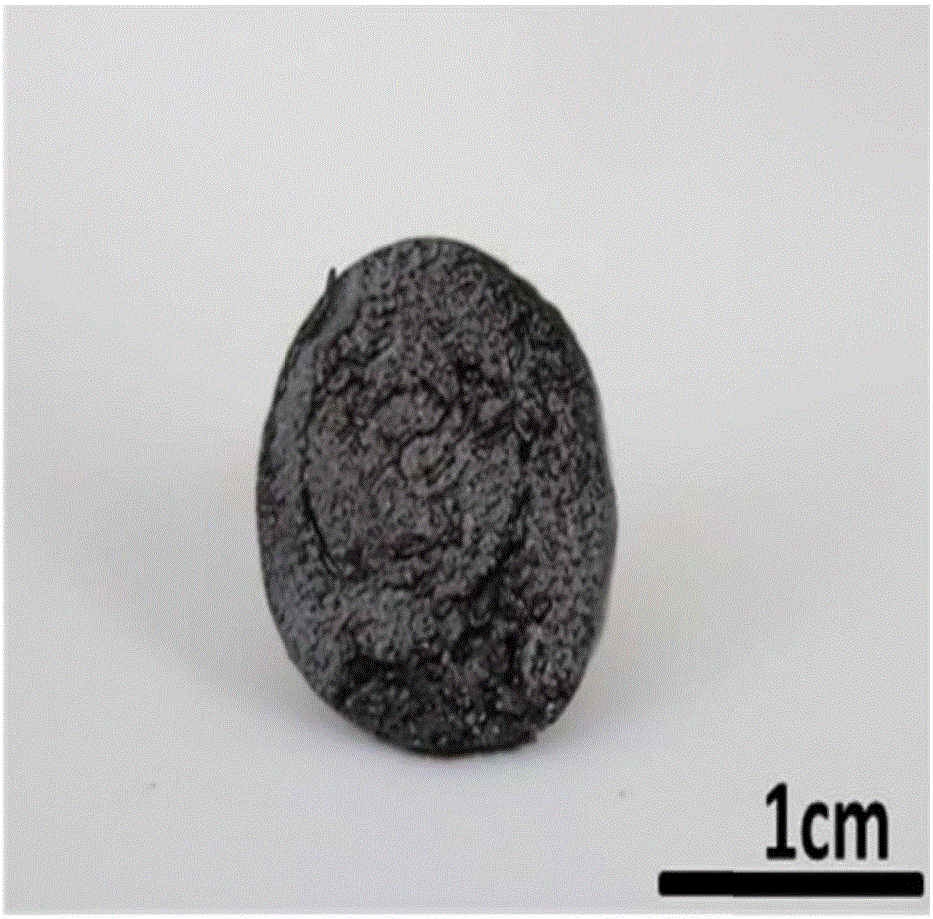

Desulfurizing agent for reforming stock oil and preparation method thereof

InactiveCN101643664AExpand the range of raw materialsLow raw material costRefining with metal oxidesAluminiumSulfide

The invention relates to a desulfurizing agent for reforming stock oil and a preparation method thereof, in particular to the desulfurizing agent used for desorbing sulfides in the reforming stock oilsuch as H2S and the like. The desulfurizing agent is characterized by consisting of 10%-40% of ZnO, 15%-22% of NiO, 10%-17% of Al2O3, 5%-22% of SiO2 and the balance inevitable impurities. The desulfurizing agent takes zinc and nickel as active components and bentonite (or diatomite, or white clay, or zeolite, or high-alumina cement and or common cement) as a carrier, and active components thereofare directly present in the form of oxides of zinc and nickel or oxides transformed by corresponding carbonate (basic carbonate) and nitrate. In the invention, the desulfurizing agent has enlarged raw material range, thus effectively reducing raw material cost, simplifying production process of the desulfurizing agent, lowering production cost, improving strength to more than twice, and prolonging service life of the desulfurizing agent.

Owner:JINDUICHENG MOLYBDENUM CO LTD

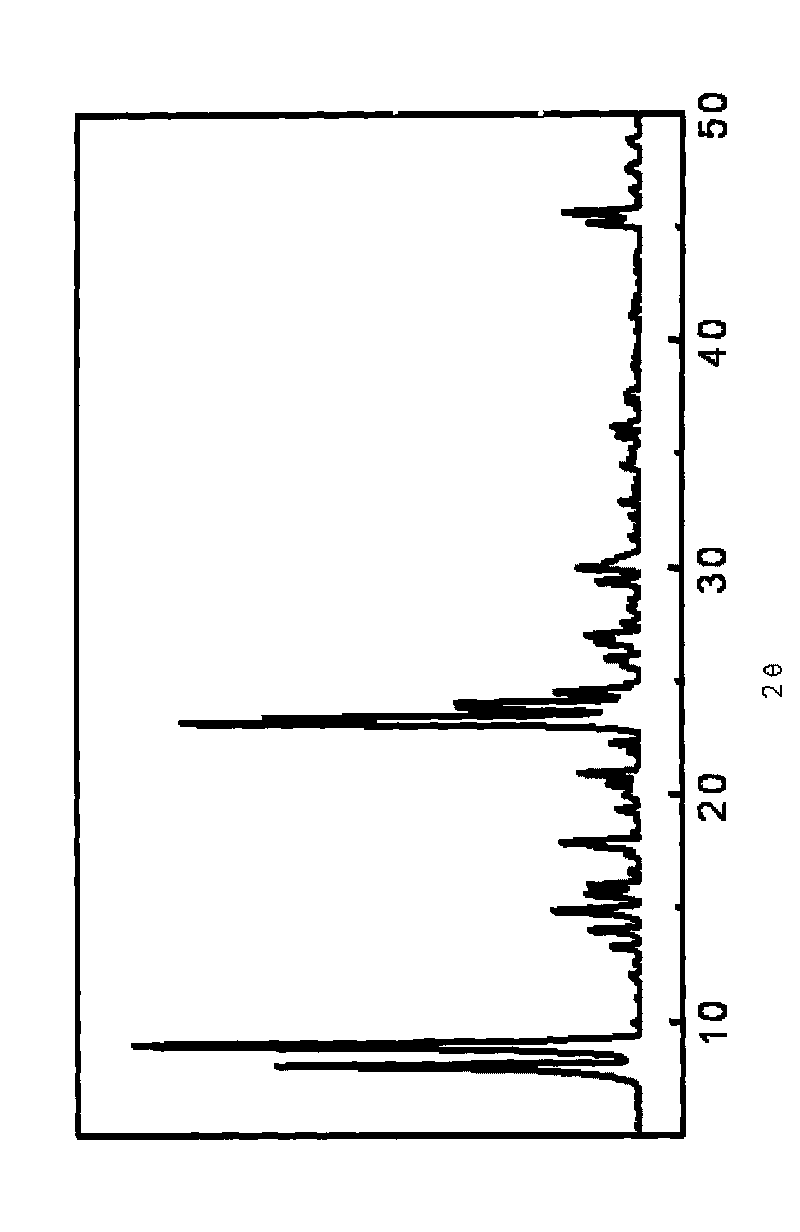

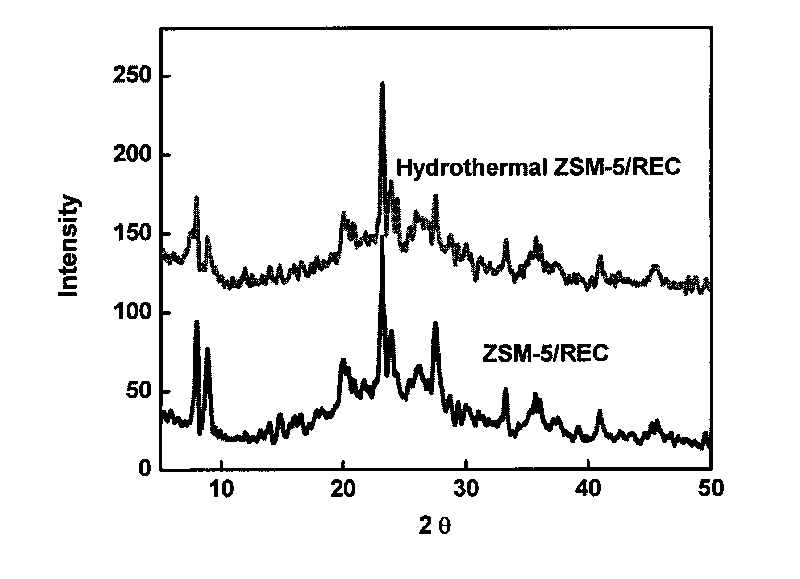

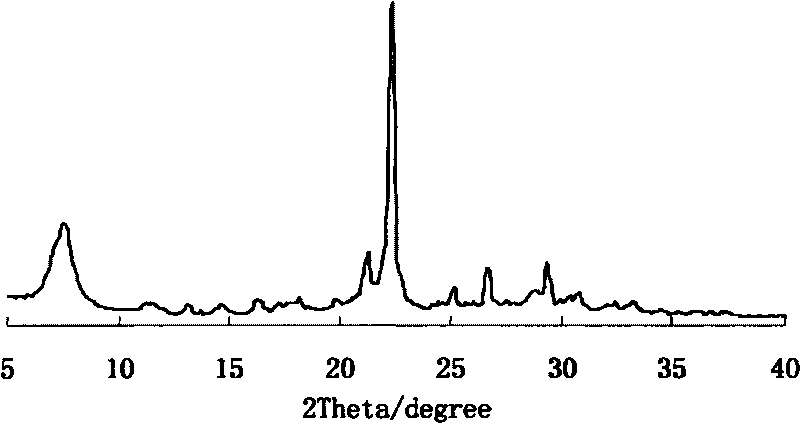

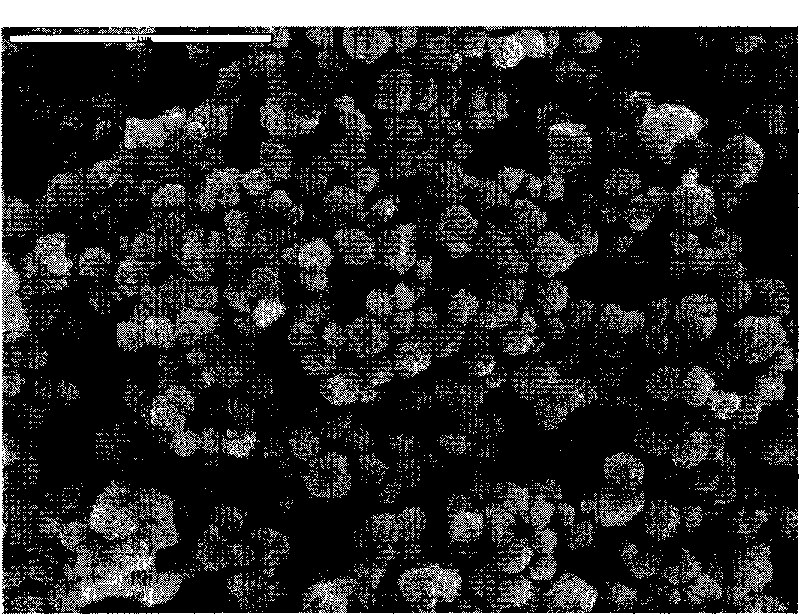

Method for preparing ZSM-5 molecular sieves

ActiveCN101723405AExpand the range of raw materialsReduce manufacturing costPentasil aluminosilicate zeoliteSiliconPhotochemistry

The invention provides a method for preparing ZSM-5 molecular sieves, which are prepared by using a natural rectorite mineral to provide an aluminum source and part of silicon source for synthesizing molecular sieves, and by adding a template agent to perform crystallization reaction under a hydrothermal condition. The implementation of the method of the invention expands the range of the raw materials for synthesizing the ZSM-5 molecular sieves, opens a new application field of natural rectorite and provides the ZSM-5 molecular sieves with high stability.

Owner:邵武绿闽环保科技有限公司

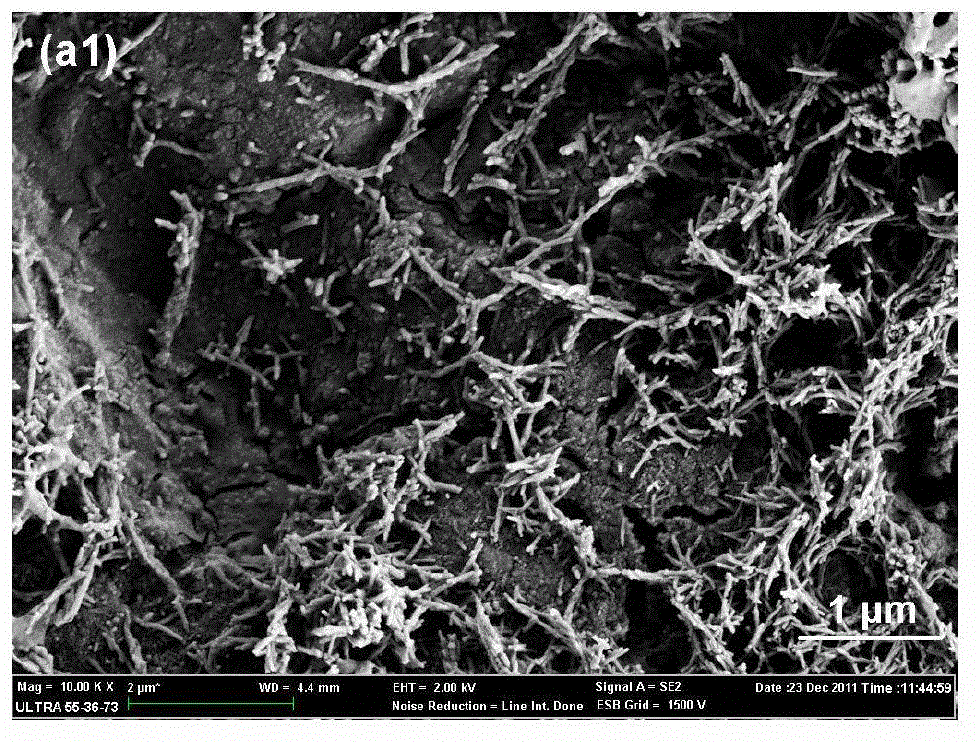

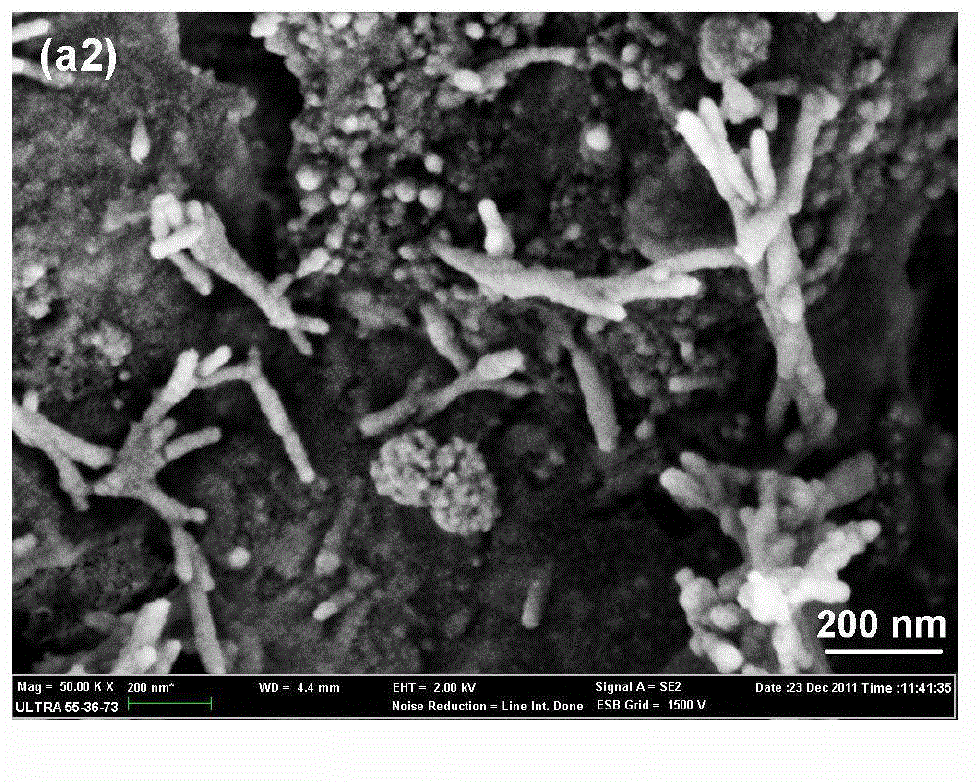

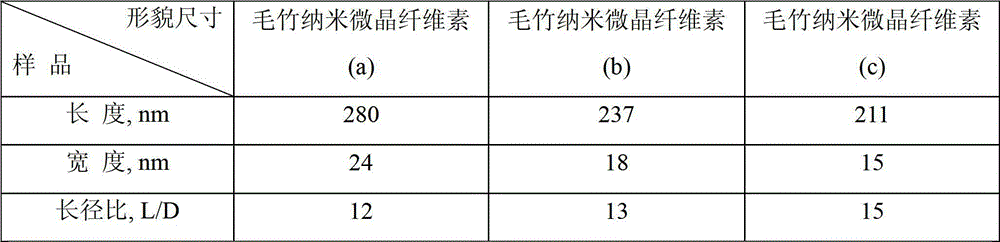

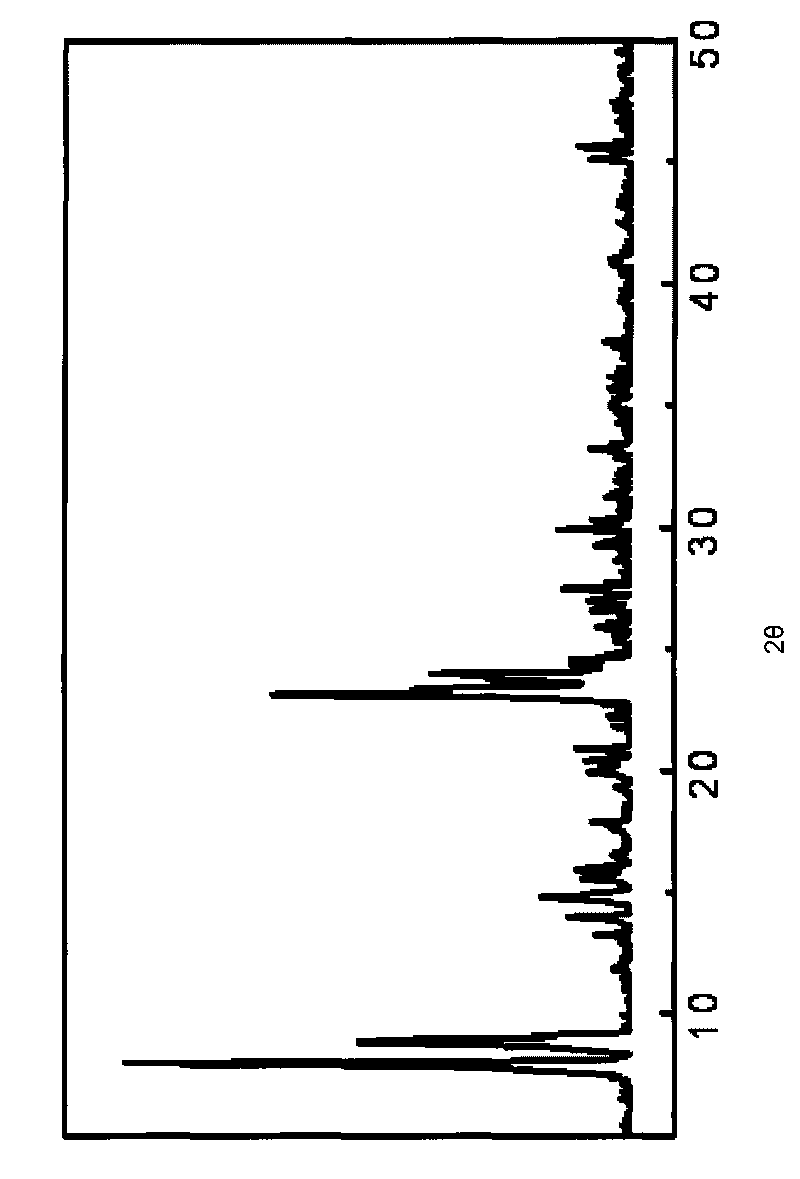

Method for chemically preparing nano microcrystalline cellulose by utilizing moso bamboo

InactiveCN102911274AAccelerate the breakthrough of raw material source limitationsAchieved bakedOrganic acidFiber

The invention discloses a method for chemically preparing nano microcrystalline cellulose by utilizing moso bamboo. The adopted method has key points that the moso bamboo is respectively subjected to alkali solution treatment and chlorine-containing solution treatment to purify cellulose, moso bamboo fibers are catalyzed and hydrolyzed by adopting an organic acid and a moso bamboo nano microcrystalline cellulose product is collected by virtue of an ultrafiltration membrane. The method disclosed by the invention is rapid and efficient and is especially applicable to preparation of nano microcrystalline cellulose by adopting the moso bamboo raw material. According to the method disclosed by the invention, a moso bamboo resource is introduced into a fiber raw material used for preparing the nano microcrystalline cellulose, the range of the raw material used for preparing the nano microcrystalline cellulose is expanded, rapid break-through of limitation of source of the raw material of the nano microcrystalline cellulose can be facilitated, and an innovative thinking is provided for high-valued utilization of the moso bamboo resource, so that economic income of peasant in bamboo regions in China can be reliably increased, and the method disclosed by the invention has practical significance.

Owner:ZHEJIANG SCI-TECH UNIV

ZSM-5/rectorite composite catalytic material and preparation method thereof

ActiveCN101722024AExpand the range of raw materialsGranular regulationMolecular sieve catalystsIn situ crystallizationSynthesis methods

The invention provides a ZSM-5 / rectorite composite catalytic material and a preparation method thereof. The composite material is a crystal product formed by in-situ crystallization and by using a natural rectorite mineral to provide an aluminum source and part of silicon source for synthesizing molecular sieves and using the natural rectorite mineral as a matrix for growing the molecular sieves. In the composite material, the content of the ZSM-5 molecular sieves is no less than 10 mass percent, and the silicon to aluminum ratio of the ZSM-5 molecular sieves is 20 to 60. The ZSM-5 / rectorite composite catalytic material provided by the invention has excellent hydrothermal stability. The material expands the range of the raw materials used for preparing molecular sieve materials by an in-situ synthesis method as well as the application range of the natural rectorite mineral.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

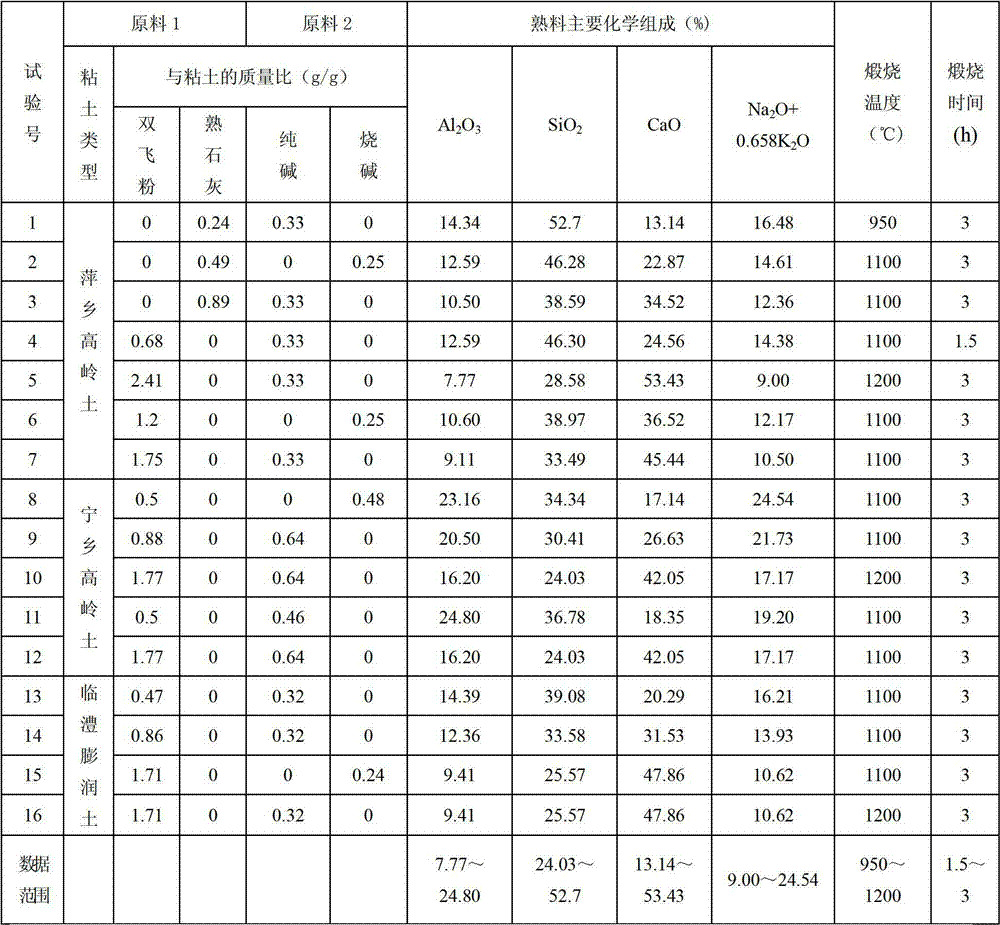

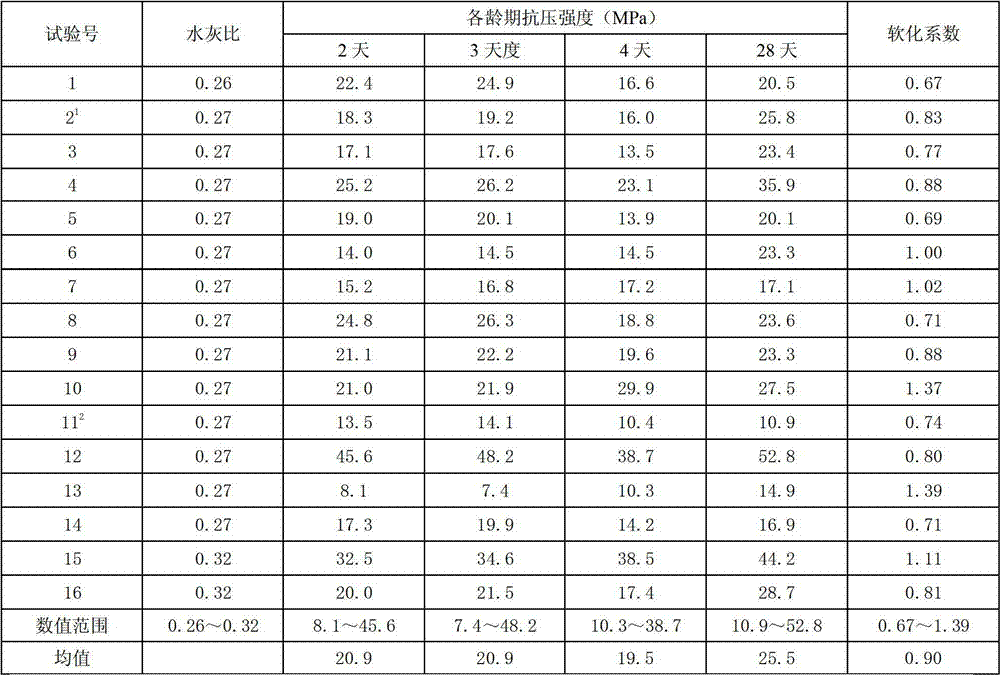

Preparation of single-component alkali-activated cement and application method thereof

ActiveCN102730996AExpand the range of raw materialsEasy to GrindClinker productionAlkali activatedMixed materials

The invention belongs to the novel cement material field and specifically relates to the preparation of a single-component alkali-activated cement and an application method thereof, wherein a raw material 1 including SiO2, Al2O3, and CaO are mixed with the raw material 2 including Na2O in a certain ratio; the ratio should be decided so that the percentage of the weight of each component of the calcined product, which is obtained by calcining the mixed materials at a temperature greater than or equal to 1100 DEG C, in the total weight is as follows: Al2O3: 8-25%; SiO2: 24-55%; CaO: 10-55%; and Na2O +0.658K2O: 6-25%; after being calcined at a temperature ranging from 950-1200 DEG C for 1.5-3 h, the mixed materials are then ground to obtain cement powder; the cement powder is mixed with water into paste; next, the paste is cured at 50-80 DEG C for 2-3 days so that neat cement paste briquettes excellent in strength can be obtained; and the strength can be continuously increased if curing is continuously performed under normal temperature. The preparation of the single-component alkali-activated cement has the following advantages that: the raw material range of the alkali-activated cement is greatly expanded; the storage, transportation and utilization of the cement are more convenient; and the improvement of the cementitious activity of the cement and the reduction of the cost are expected to be realized.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method for completely biodegraded high amylose starches base thin film

The invention relates to a preparation method of a fully biodegraded high-amylose based film. The invention resolves the problem that the present plastic film cannot be fully biodegraded. The preparation method of the fully biodegraded high-amylose based film includes following steps: (1) Gelatinization; (2) Blending; (3) Plasticization and Crosslinking; (4) Degasification and Drying, and the fully biodegraded high-amylose based film can be obtained by the preparation method. The products produced by the invention are characterized in safety, nontoxicity, full biodegradation, etc., thus having good use performance and degradation performance.

Owner:HARBIN INST OF TECH

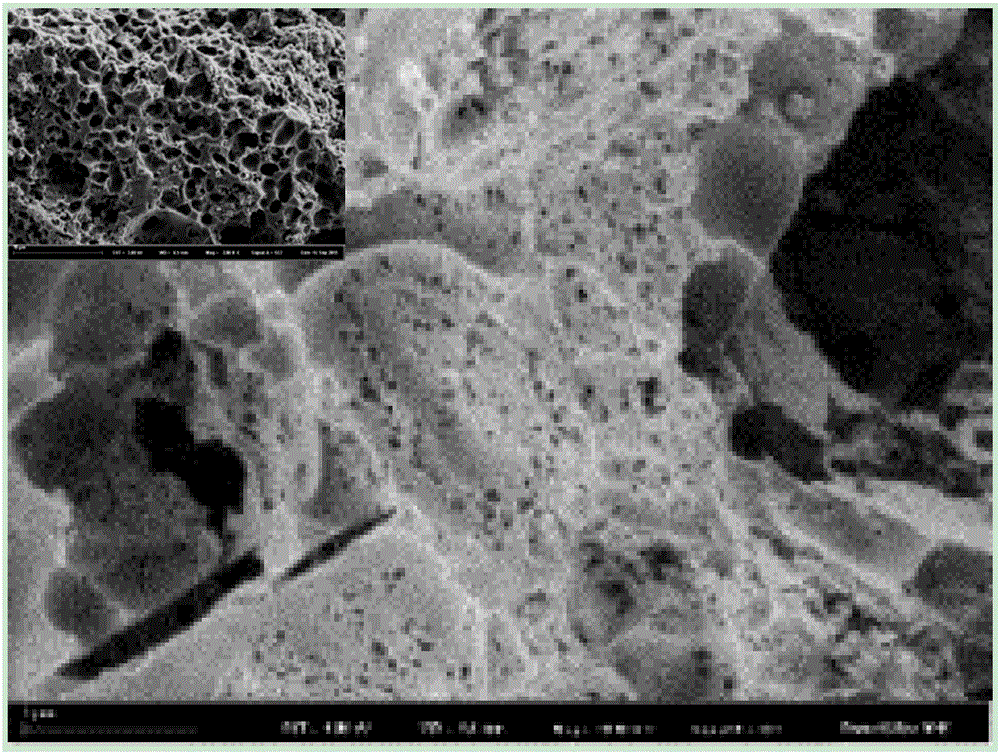

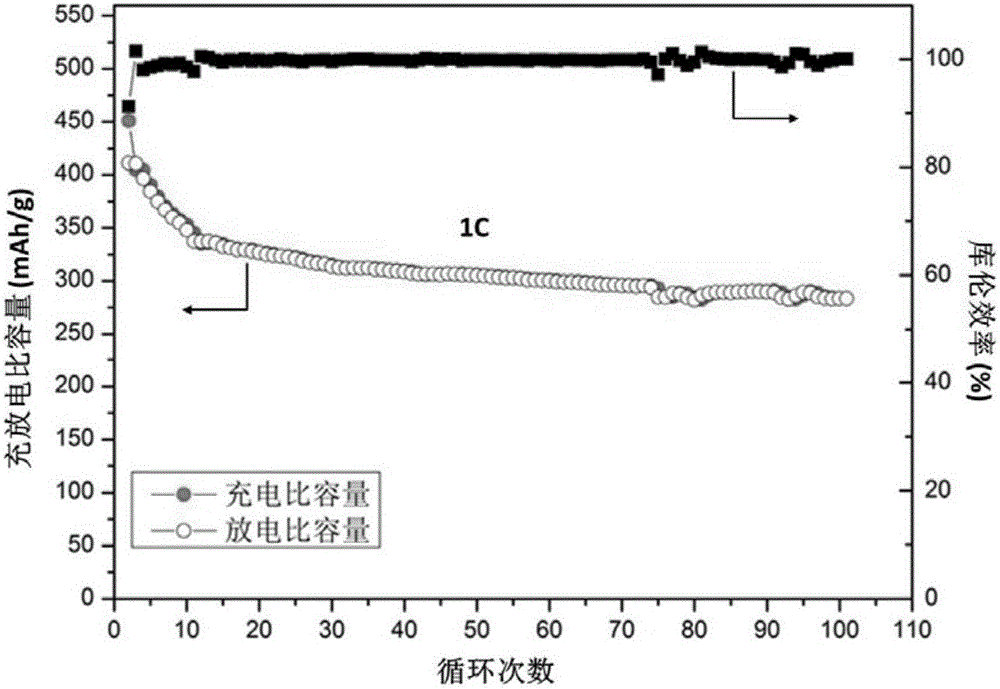

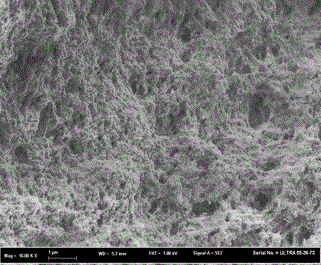

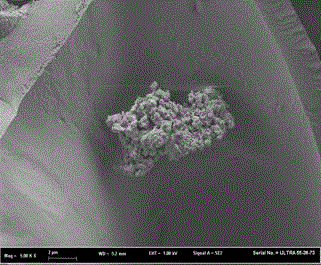

Method for preparing Li-S battery anode materials by taking algae as carbon source

The invention discloses a method for preparing Li-S battery anode materials by taking algae as a carbon source. The key point of the method is that the algae is dissolved by alkaline solution, a porous carbon structure rich in nitrogen is formed after high-temperature carbonization treatment, the porous carbon structure and subliming elemental sulfur are subjected to ball milling mixing, and a C / S compound material is obtained through high-temperature recrystallization and is used for the Li-S battery anode material. The material has stable electrochemical performance. The method has the advantages of environment protection, convenience and quickness in material obtaining, and low cost and is especially suitable for preparing the Li-S battery anode material.

Owner:HANGZHOU DIANZI UNIV

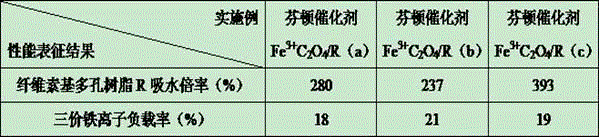

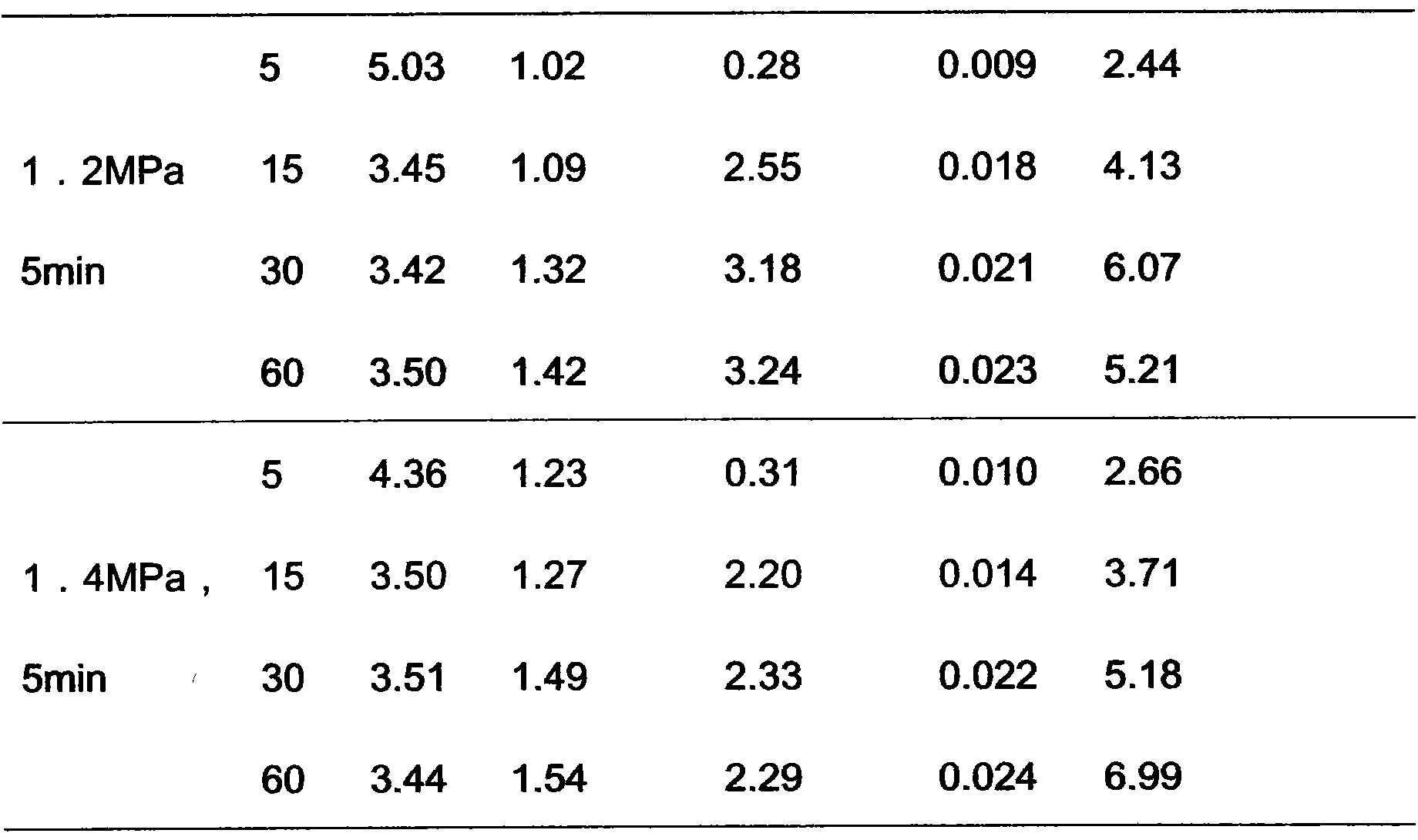

Preparation method for bamboo pulp cellulose-based integrated Fenton catalyst Fe<3+>C2O4/R

InactiveCN104646062AExpand the range of raw materialsIncrease economic incomeWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsOXALIC ACID DIHYDRATEPollutant

The invention discloses a preparation method for a bamboo pulp cellulose-based integrated Fenton catalyst Fe<3+>C2O4 / R. The preparation method is characterized in that tri-valent iron and oxalic acid are subjected to coordination to form a complex Fe<3+>C2O4, and the complex Fe<3+>C2O4 is loaded on bamboo pulp cellulose-based porous resin R synthesized by bamboo pulp to form the integrated Fenton catalyst Fe<3+>C2O4 / R; under visible light, hydrogen peroxide can be catalyzed in an acceleration manner to degrade dye type organic pollutants in printing and dyeing wastewater. A product prepared by the method is high in efficiency, environment-friendly and low in cost; the problems of secondary pollution, high oxidization cost, low degrading efficiency and the like which are caused by a fact that the Fenton reagent cannot be repeatedly used in the conventional dye type organic pollutant Fenton oxidization degrading are solved, and the creation concept of using bamboo resources in China in a high value is provided, and thus the preparation method has obvious environmental and social significance.

Owner:ZHEJIANG SCI-TECH UNIV

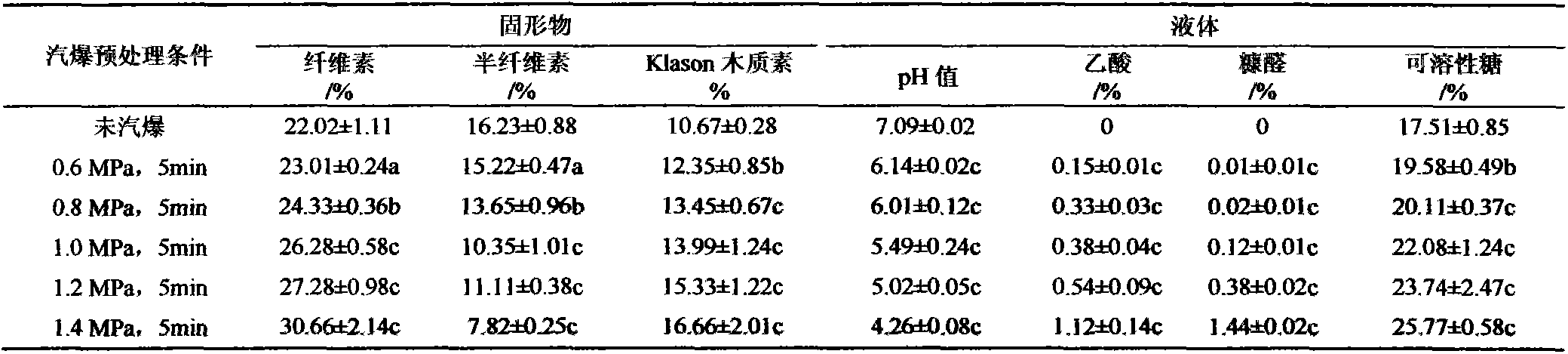

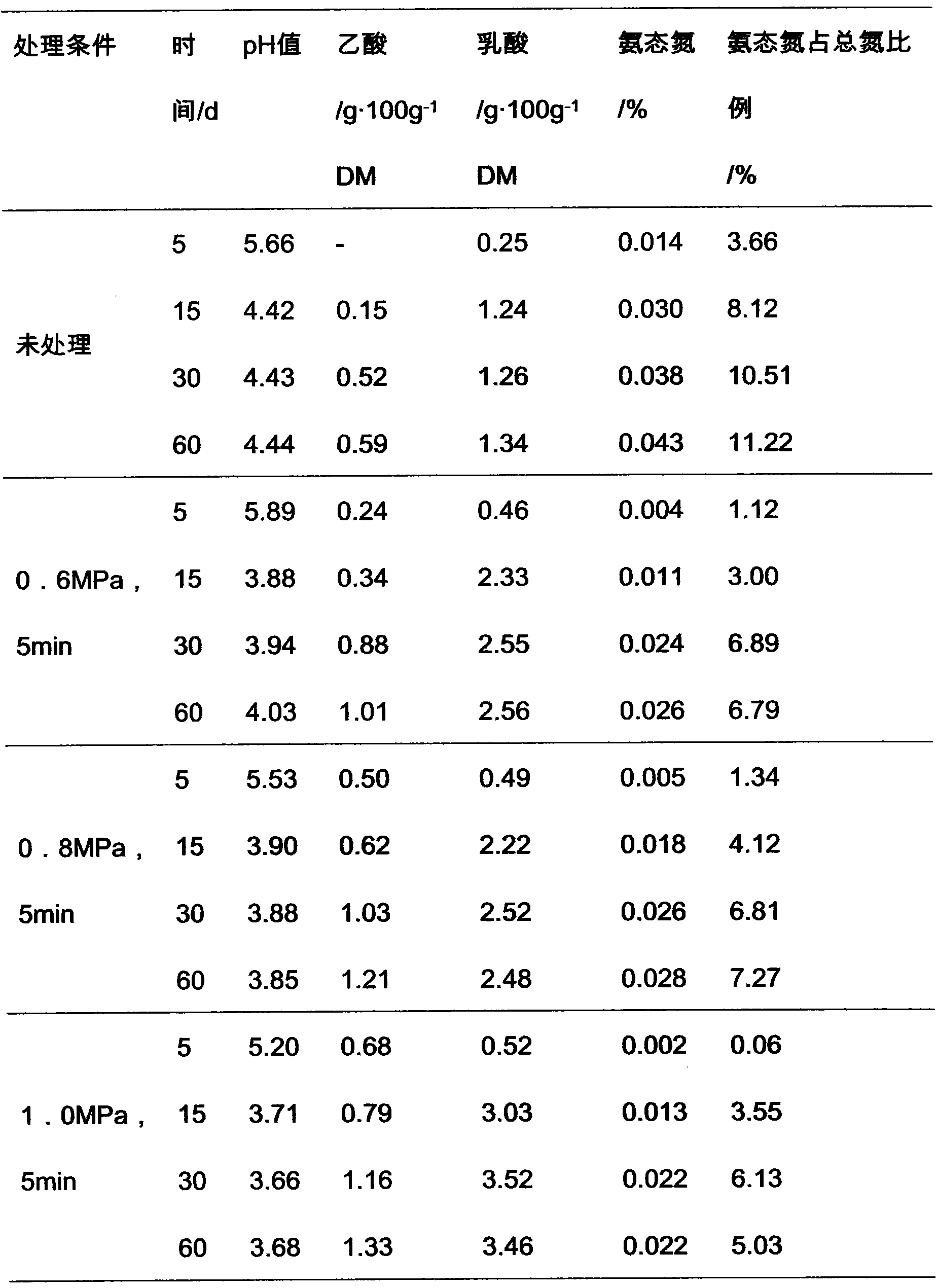

Method for producing silage by using dry yellow cornstalks

ActiveCN103461669AIncrease the window periodExpand the range of raw materialsFood processingAnimal feeding stuffWindow periodFermentation

The invention discloses a method for producing silage by using dry yellow cornstalks. The method for producing the silage by using the dry yellow cornstalks comprises the steps that preprocessing is carried out on the dry yellow cornstalks through low-strength steam explosion, hemicellulose of the dry yellow cornstalks is partly degraded into monosaccharide and oligosaccharide, the shielding effect of lignin and the hemicellulose on cellulose is partly removed, the water content of the cornstalks after steam explosion is adjusted, and fermentation storage is carried out under the anaerobic condition. When the method for producing the silage by using the dry yellow cornstalks is adopted, the existing situation that ensiling operation cannot be carried out on the dry yellow cornstalks, and a certain amount of inoculant or enzymic preparations need to be added to the dry yellow cornstalks is changed, anaerobic fermentation can be carried out on the dry yellow cornstalks to produce the high-quality silage, the range of the raw material sources of the silage is expanded, the processing window period of ensiling operation is prolonged, and commercial production of the silage becomes possible.

Owner:MENOBLE

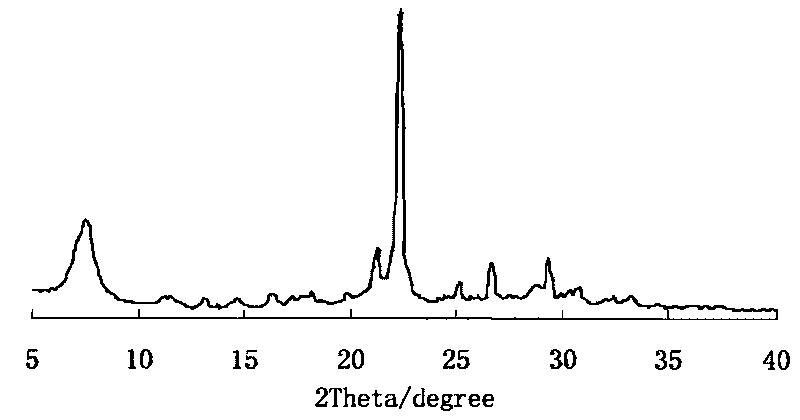

Method for synthesizing granular beta molecular sieve with montmorillonoid

InactiveCN101723398AExpand the range of raw materialsLow costCrystalline aluminosilicate zeolitesMolecular sieveCore shell

The invention relates to a method for synthesizing a granular beta molecular sieve with montmorillonoid, comprising the following steps: acidification treatment and high-temperature roasting are carried out to the montmorillonoid, and the montmorillonoid which is acidified is soaked and heated by template agents, and then the montmorillonoid which is activated is used as raw material to provide total or partial aluminum source, and then the granular beta molecular sieve is prepared by adding template agents and carrying out hydrothermal crystallization; in the invention, the prepared beta molecular sieve grows on the surface of the montmorillonoid closely, so as to form a similar core-shell structure, and the catalytic reaction efficiency is improved by shortening the diffused route of reactants and product molecules in a molecular sieve crystal. The method not only expands the raw material range for synthesizing the beta molecular sieve, but also further reduces the preparation cost of the beta molecular sieve with a crystal seed method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing needle coke raw material by using medium and low temperature coal tar

ActiveCN102786984AGuaranteed catalytic effectLow costTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonPtru catalyst

The invention relates to a process for preparing a needle coke raw material by using medium and low temperature coal tar, which comprises the following steps: 1) distilling the medium and low temperature coal tar, separating to obtain heavy distillate with the temperature more than 350DEG C; 2) sending the heavy distillate of the medium and low temperature coal tar to a reactor, under the existence of a catalyst, introducing hydrogen into the reactor, performing hydropyrolysis on the heavy distillate, wherein the catalyst is a Fe catalyst and the mass of the catalyst accounts for 0.01-3% of mass of the heavy distillate; the pressure during the hydropyrolysis is 7-12 MPa and the temperature is 350-550 DEG C; 3) sending the products after hydropyrolysis in the step 2) to a separator, and separating to obtain lower oil and higher oil; and 4) performing physical separation on the higher oil, and removing the catalyst. According to the hydropyrolysis treatment of the medium and low temperature coal tar, the content of condensed polycyclic aromatic hydrocarbons can be greatly increased and the raw material suitable for preparing needle coke can be obtained.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

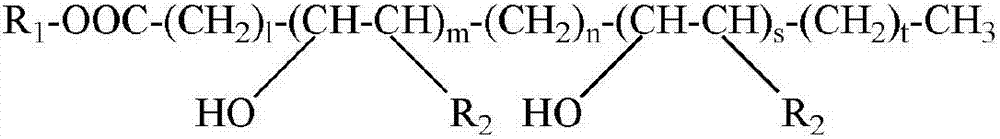

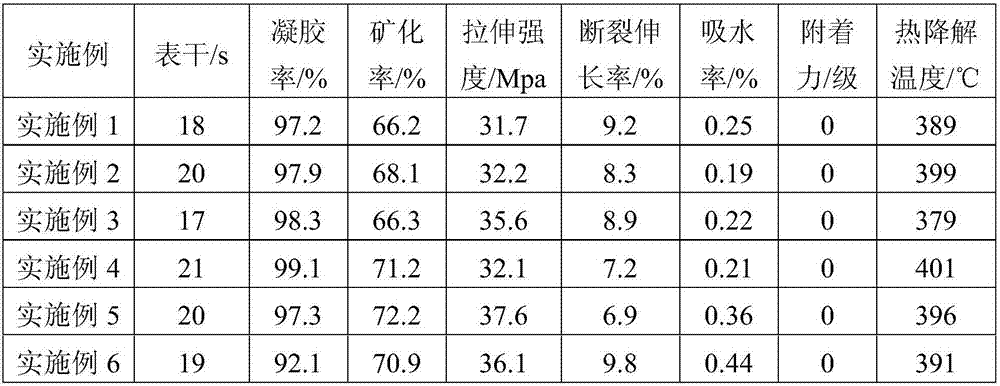

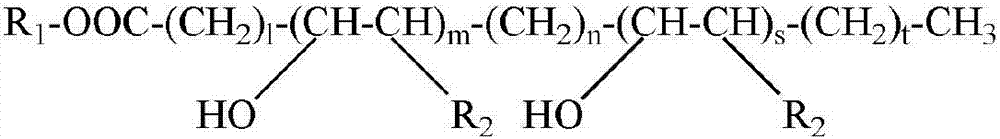

Tung-oil-based biodegradable UV curing adhesive, and preparation method and application thereof

ActiveCN107189750APromote degradationRelieve pressurePolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention belongs to the technical field of UV curing high polymer materials, and discloses a tung-oil-based biodegradable UV curing adhesive, and a preparation method and application thereof. The preparation method provided by the invention comprises the following steps of (1) heating tung oil to 60 to 80 DEG C; then, adding an alkaline solution of ethylene glycol; under the stirring condition, performing backflow reaction for 50 to 80 min to obtain ethanol eleostearate; (2) adding a mixture of diisocyanate and a catalyst into preheated plant oil-based polyhydric alcohol; performing heat insulation reaction for 2 to 4h to obtain an intermediate product; lowering the temperature; adding the ethanol eleostearate in the step (1); performing reaction for 2 to 3h to obtain a prepolymer; (3) mixing the prepolymer in the step (2), an active diluent and an auxiliary agent; or adding a cationic photoinitiator and a free radical photoinitiator; performing uniform stirring to obtain the UV curing adhesive. Under the UV illumination, the UV curing adhesive can be fast cured into a film under the initiation effects of an aerobic nonluminous initiator or the cationic photoinitiator and the free radical photoinitiator.

Owner:SOUTH CHINA AGRI UNIV

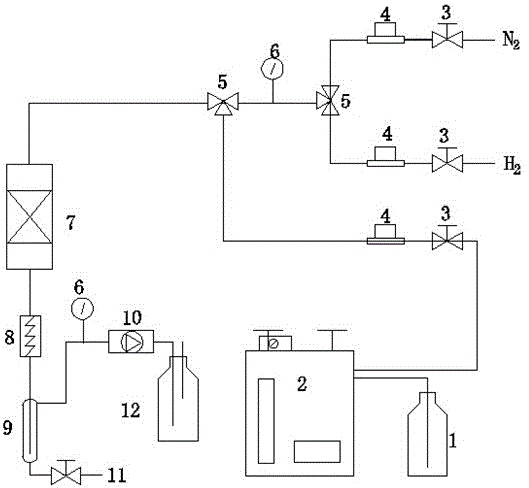

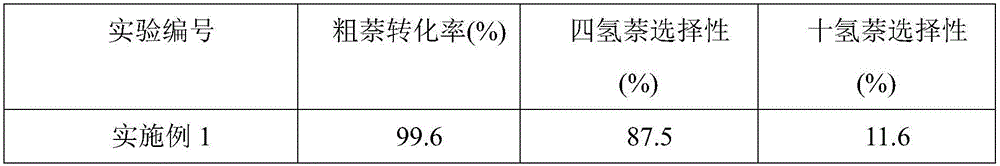

Catalyst used for reaction for preparing tetrahydronaphthalene through naphthalene hydrogenation and preparation method and application of catalyst

ActiveCN106563476AHigh activityImprove stabilityMolecular sieve catalystsHydrocarbon by hydrogenationActive componentCatalyst support

The invention discloses a catalyst used for a reaction for preparing tetrahydronaphthalene through naphthalene hydrogenation and a preparation method and application of the catalyst. The catalyst comprises a catalyst carrier, active components and auxiliaries, and the active components and the auxiliaries are loaded on the catalyst carrier. The catalyst is good in activity and stability, is not high in requirement for raw materials, and is applicable to the reaction for preparing the tetrahydronaphthalene through naphthalene hydrogenation, wherein the naphthalene content is larger than or equal to 94%, the naphthalene conversion rate can be higher than 95%, and the selectivity of the tetrahydronaphthalene is higher than 85%. A preparation process of the catalyst is simple, scientific and convenient to operate, equipment is simple, and the investment cost is low.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Sludge microcrystalline glass and its preparation method

The invention relates to a sludge microcrystalline glass and method for production, wherein the microcrystalline glass comprises (by weight portions) calcinations sludge 45-80 parts, lime stone 12-30 parts, dolomite 8-25 parts, gypsum 0-10 parts, and antimony trioxide 0-1 part, the sum of weight parts for each raw material is 100, the calcinations sludge is prepared through drying wet sludge from waste water treatment plant, calcining 1-3 hours at 800-1100 deg C in kilns, finally cooling down and crushsing.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Lithium-ion battery separator prepared by polyethylene mixture and preparation method of lithium-ion battery separator

ActiveCN103887465AExpand the range of raw materialsHigh porositySecondary cellsCell component detailsFilm materialLithium electrode

The invention discloses a lithium-ion battery separator prepared by a polyethylene mixture and a preparation method of the lithium-ion battery separator. The invention relates to a polyolefin microporous film material for the lithium-ion battery separator and a preparation method of the polyolefin microporous film material. The method comprises the following steps: fully swelling ultrahigh molecular weight polyethylene (UHMWPE) and a certain types of diluents to form UHMWPE jell; performing melt blending on a certain amount of UHMWPE jell and high-density polyethylene (HDPE) on a double-screw extruder, performing extrusion casting on a blending resin on casting equipment, and preparing a casting base film with a perfect oriented lamellar crystal structure; and performing heat treatment on the casting base film to perform cold drawing and hot drawing, and performing heat setting to prepare the polyethylene microporous film. The limitation on the range of raw material resin melt flow rate (molecular weight) range in the process of preparing the polyethylene microporous film in a conventional uniaxial stretching process is broken, the casting base film with the perfect oriented lamellar crystal structure is prepared by using polyethylene resin with wide melt flow rate range, and the polyethylene resin raw material range suitable for preparing the polyethylene microporous film in the uniaxial stretching method is widened.

Owner:CHANGZHOU UNIV

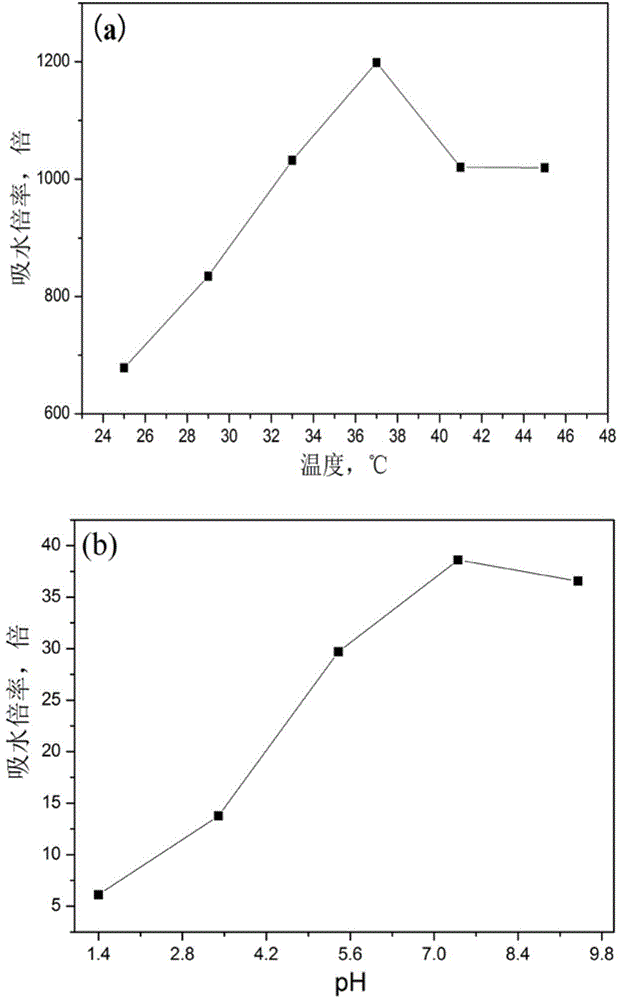

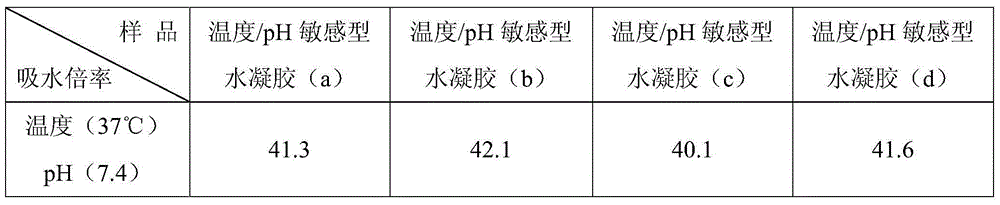

Method for preparing temperature/pH sensitive hydrogel by using bamboo dissolving pulp

The invention discloses a method for preparing a temperature / pH sensitive hydrogel by using bamboo dissolving pulp. The key point of the method is that the method comprises the steps of: carrying out crushing and sieving for pre-treatment of the bamboo dissolving pulp; dissolving the obtained bamboo dissolving pulp powder by using a mixed aqueous solution of sodium hydroxide and urea to obtain a cellulose solution of the bamboo dissolving pulp; and carrying out copolymerization with acrylic acid, acrylamide and N-isopropylacrylamide to obtain the temperature / pH sensitive hydrogel. The method is fast and efficient, and is particularly suitable for a technical process for preparing the temperature / pH sensitive hydrogel by using bamboo cellulose. A bamboo resource is introduced into raw materials for preparing the temperature / pH sensitive hydrogel, so that the supply range of the raw materials of the hydrogel is expanded, and the limitation on the raw material source of the temperature / pH sensitive hydrogel is quickly broken through preferably. Meanwhile, the invention provides an innovative concept for high value utilization of the bamboo source, so that the economic income of farmers in bamboo regions of China can be practically improved, and the method has important practical significance and application value.

Owner:ZHEJIANG SCI-TECH UNIV

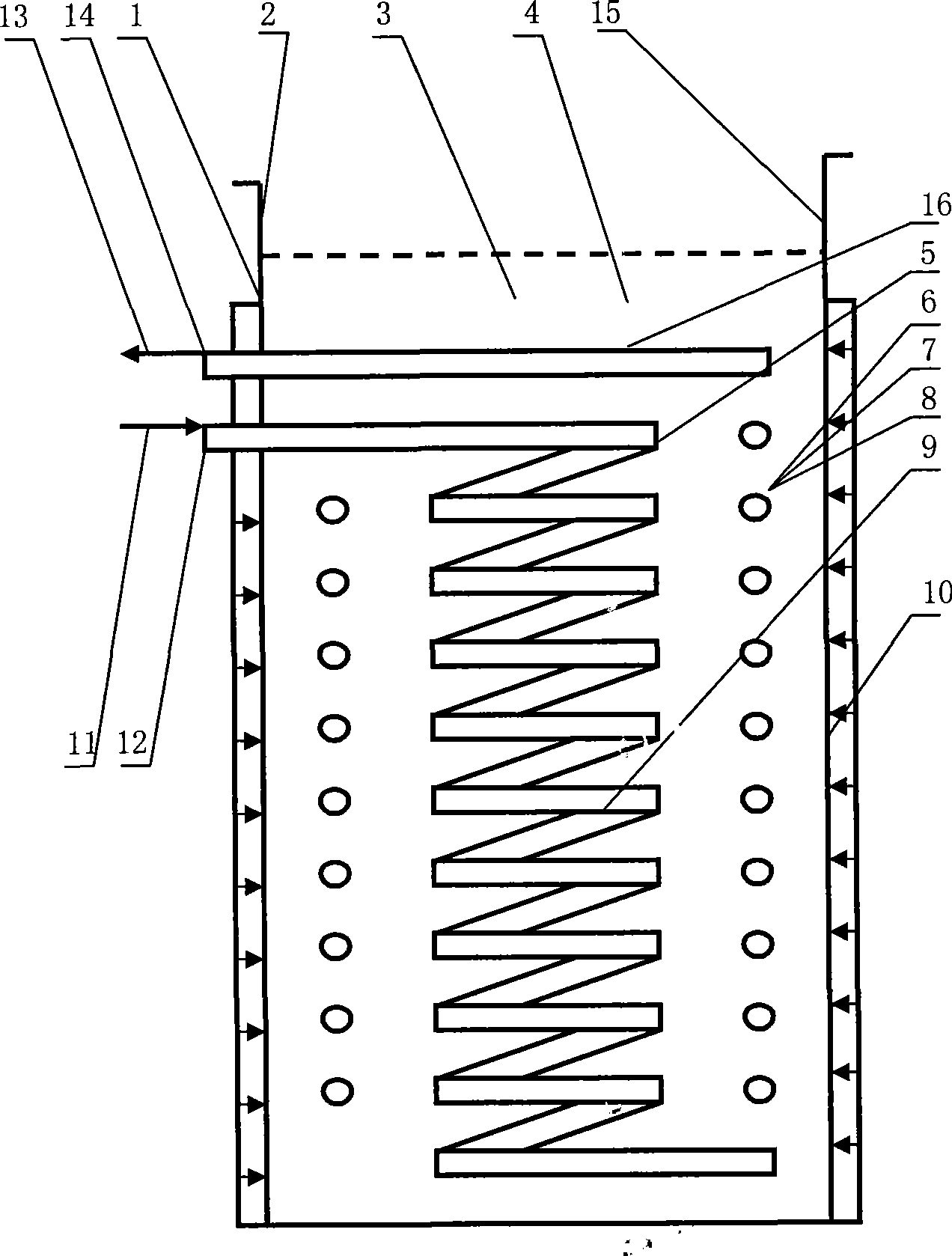

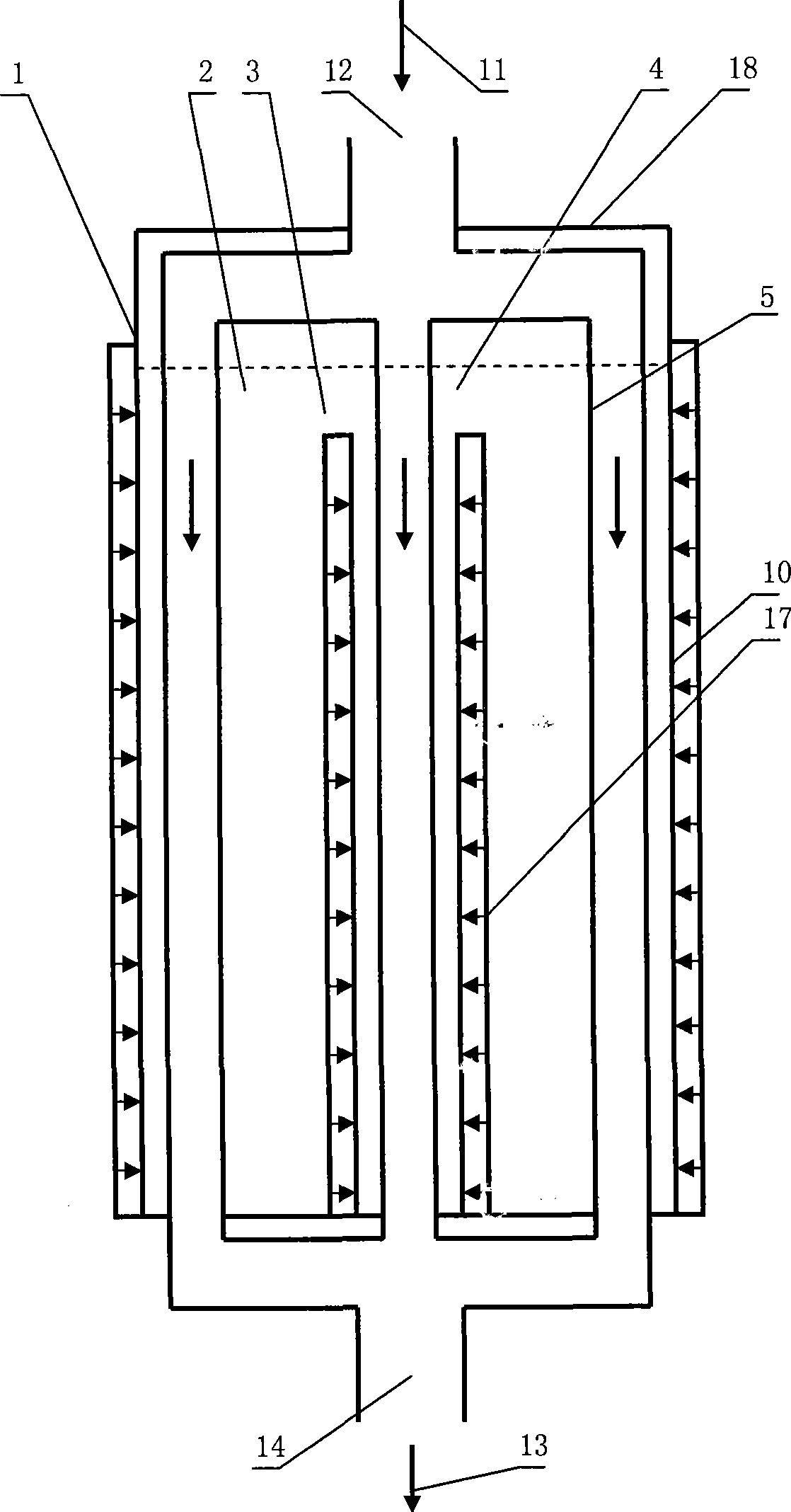

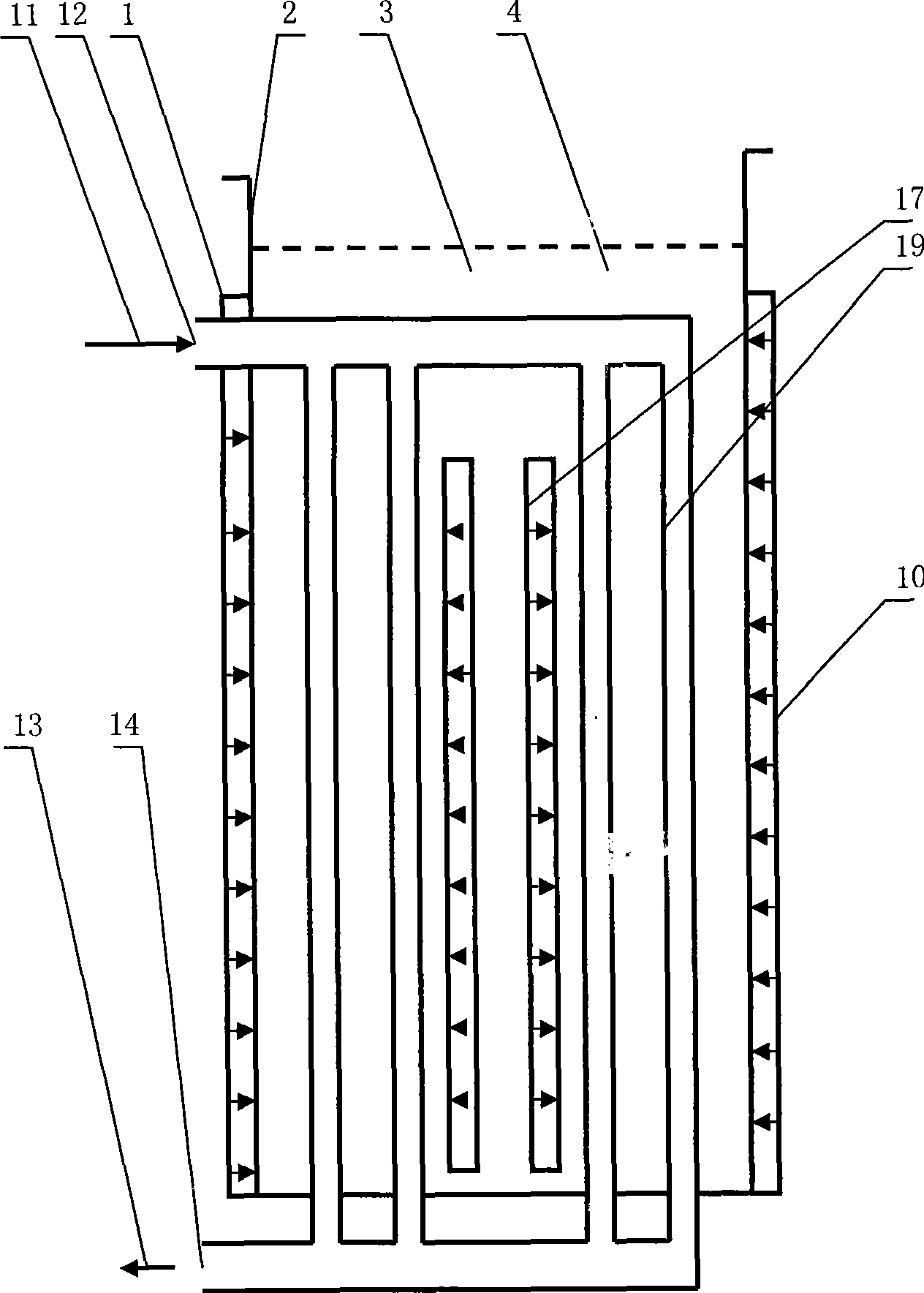

Tubular purification method and tubular purification tank

InactiveCN101476038ASmall volumeReduce in quantityProcess efficiency improvementLiquid mediumPurification methods

The invention provides a pipe type purifying method, the set purifying process of the solution to be purified is completed in a nonconservative pipe type purifying groove.The solution to be purified is a solution containing at least one granular solute; the pipe type purifying groove comprises a cavity full of liquid medium, at least one ultrasound wave source apparatus immersed in the liquid medium and at least one coiled apparatus full of the solution to be purified; the purifying process is that in the nonconservative flow process, the solution to be purified is irradiated in a insulation state by effective ultrasonic wave.

Owner:佛山市兴民科技有限公司

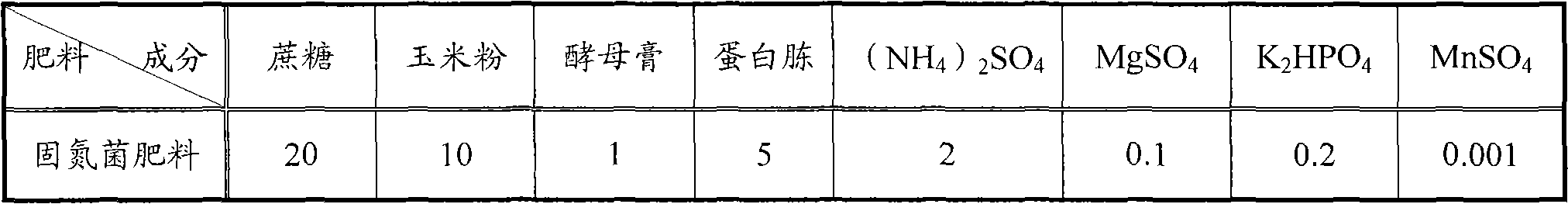

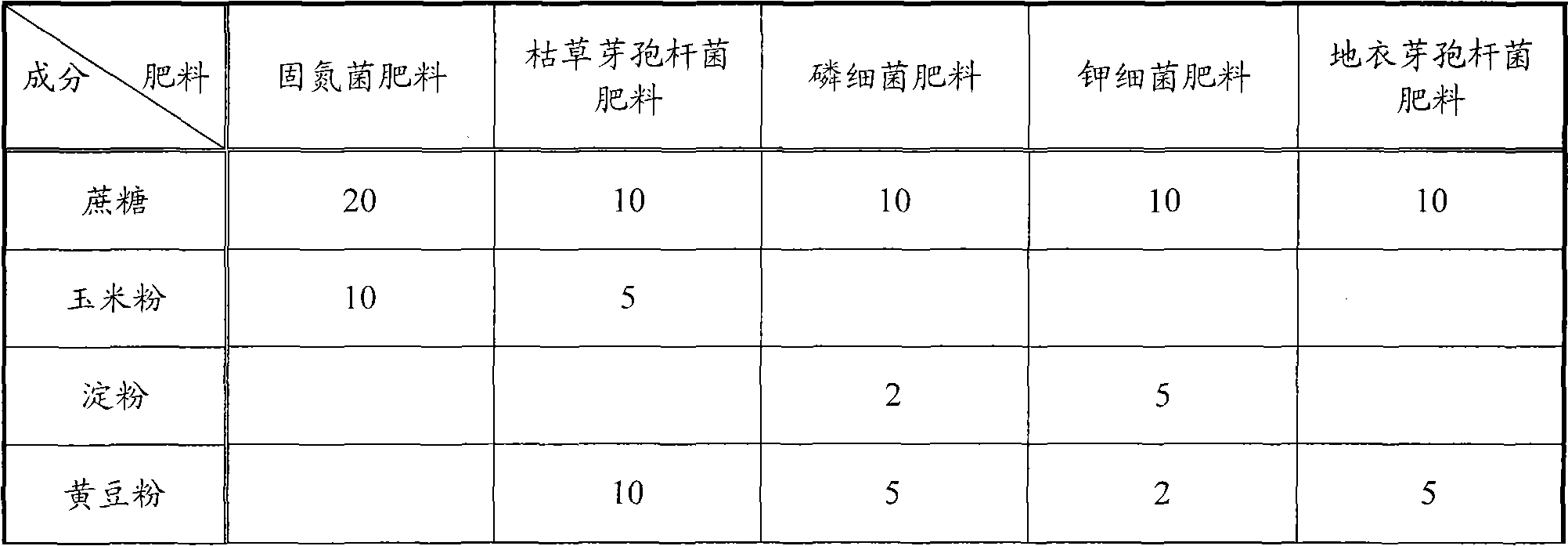

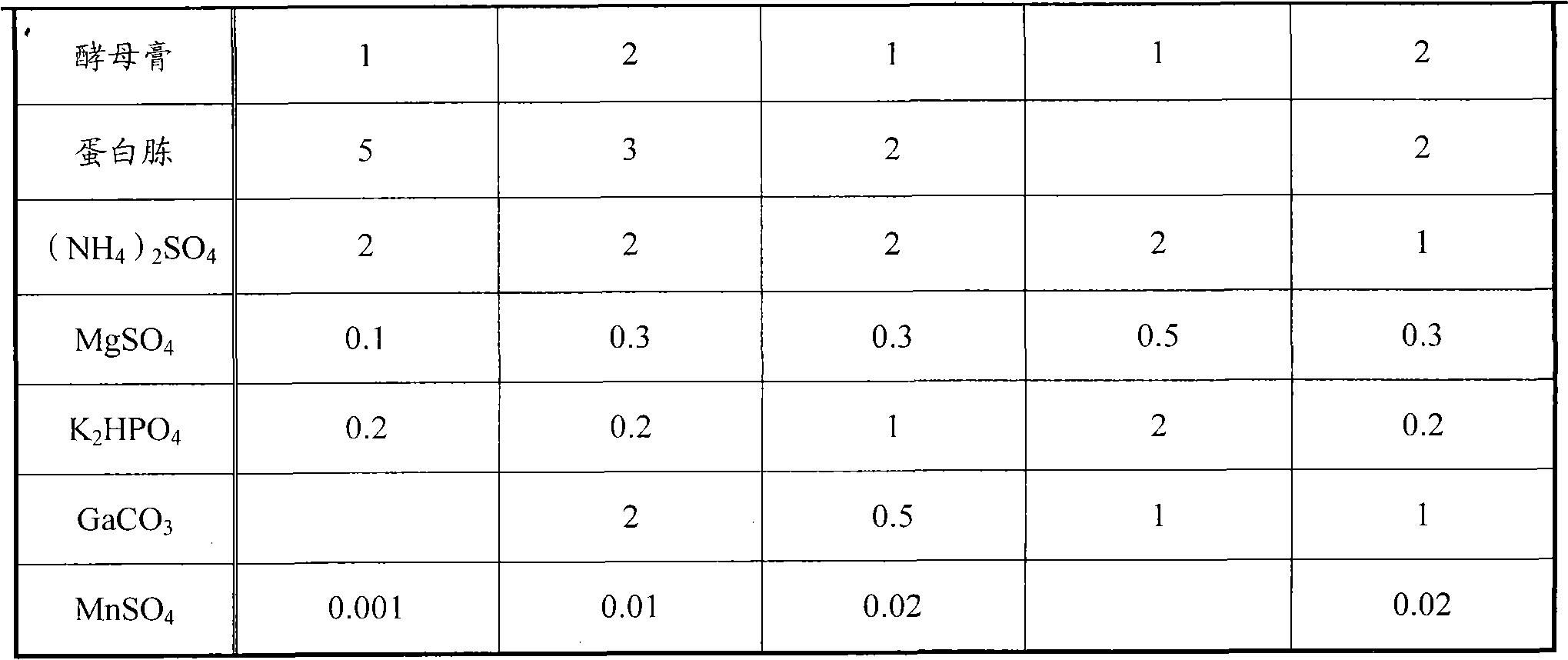

Preparation method of microbial fertilizer

InactiveCN101774856ALow bacteria contentExpand the range of raw materialsFertilizer mixturesMicroorganismBiofertilizer

The invention provides a preparation method of microbial fertilizer. The method comprises the following steps: (a) regulating pH value of biomass power plant ash; (b) fermenting microbial strains; and (c) mixing the fermented microbial strain liquid and the pH value regulated biomass power plant ash in proportion. The preparation method of microbial fertilizer in the invention adopts biomass power plant ash as fundamental carrier to prepare microbial fertilizer, thus efficiently utilizing the ash discharged by biomass power plant; doped bacteria content in biomass power plant ash is low under the prerequisite that ash discharging process is controlled, thus sterilization process is omitted and resource is centralized. The invention efficiently broadens raw material range for microbial fertilizer and reduces cost of microbial fertilizer. The method enhances utilization value of power plant ash and alleviates pollution to the environment caused by biomass power plant ash.

Owner:凯迪阳光生物能源投资有限公司

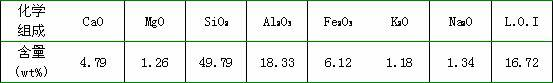

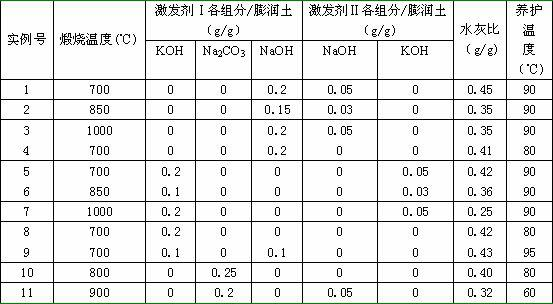

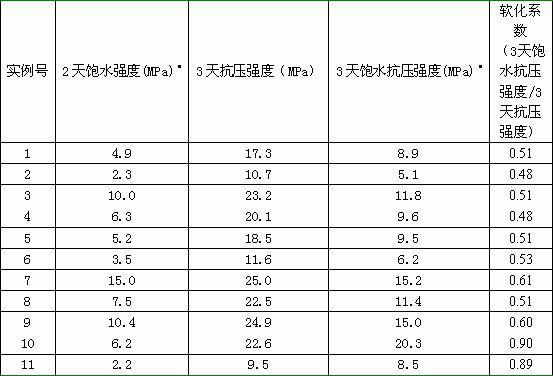

Method for preparing geopolymeric material from bentonite

InactiveCN102491658AImprove strength propertiesExpand the range of raw materialsCement productionSolid phasesAqueous solution

The invention discloses a method for preparing a geopolymeric material from bentonite. The method comprises the following steps of: uniformly mixing the bentonite with an excitant I, wherein the granularity of a solid phase in a mixture is less than or equal to 10 percent of the mass ratio of 200-mesh screen residues, and the mass ratio of the excitant I to the bentonite is 0.1-0.25; (2) calcining the mixture obtained in the step (1) at the high preserved temperature of 700-1,000 DEG C for 2-4 hours, and regrinding a calcining product to obtain chamotte powder, wherein granularity of the chamotte powder is less than or equal to 10 percent of the mass ratio of 200-mesh screen residues; and (3) doping an aqueous solution of an excitant II into the chamotte powder obtained in the step (2), mixing uniformly, compacting by vibrating, and preserving in a wet state at the temperature of 60-95 DEG C to obtain the geopolymeric material, wherein a water cement ratio, i.e., the mass ratio of theaqueous solution of the excitant II to the chamotte powder is 0.2-0.4; and the mass ratio of a solid phase in the excitant II and the non-calcined bentonite is 0-0.05. The method plays a remarkable role in expanding raw material sources, reducing cost, enhancing use convenience, and the like.

Owner:HUNAN UNIV OF SCI & TECH

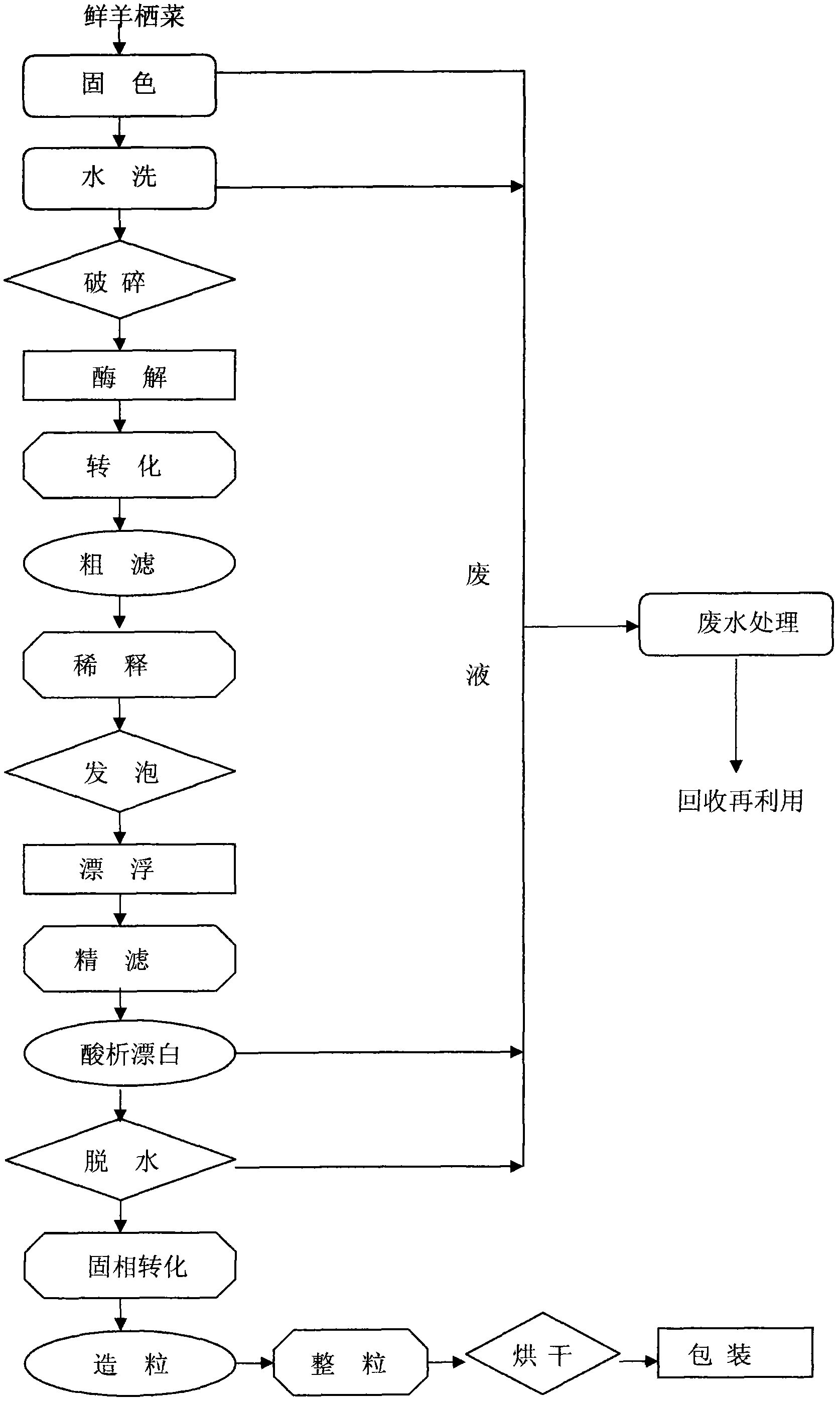

Method for extracting algin from fresh Sargassum fusiforme

ActiveCN102718884AExpand the range of raw materialsImprove high calcium contentSolid phasesSARGASSUM FUSIFORME

The invention relates to a method for extracting algin from fresh Sargassum fusiforme. The method comprises the following steps of dye fixation, water washing, fragmentation, enzymatic hydrolysis, transformation, coarse filtration, dilution, foaming and floating, fine filtration, acidification bleaching, dehydration, solid phase transformation, granulation, finishing and drying. The method provided by the invention has the advantages that 1, an enzymatic hydrolysis technology is adopted and thus the problem that algin is difficultly extracted from Sargassum fusiforme is solved; and fresh Sargassum fusiforme is used as a raw material for production of low-viscosity and ultralow-viscosity algin and thus a raw material source range of algin processing is widened; 2, an acidification technology replaces the traditional calcification technology and thus the problems of high calcium content, poor water-solubility and high insoluble substance content of the traditional algin are improved; and 3, a NaClO solution is dropwisely added into an extraction system during acidification to realize bleaching and thus the traditional bleaching technology characterized in that chlorine is fed into an algin solution subjected to fine filtration to realize bleaching is modified so that bleaching effects are better and technical processes are safer.

Owner:青岛聚大洋藻业集团有限公司

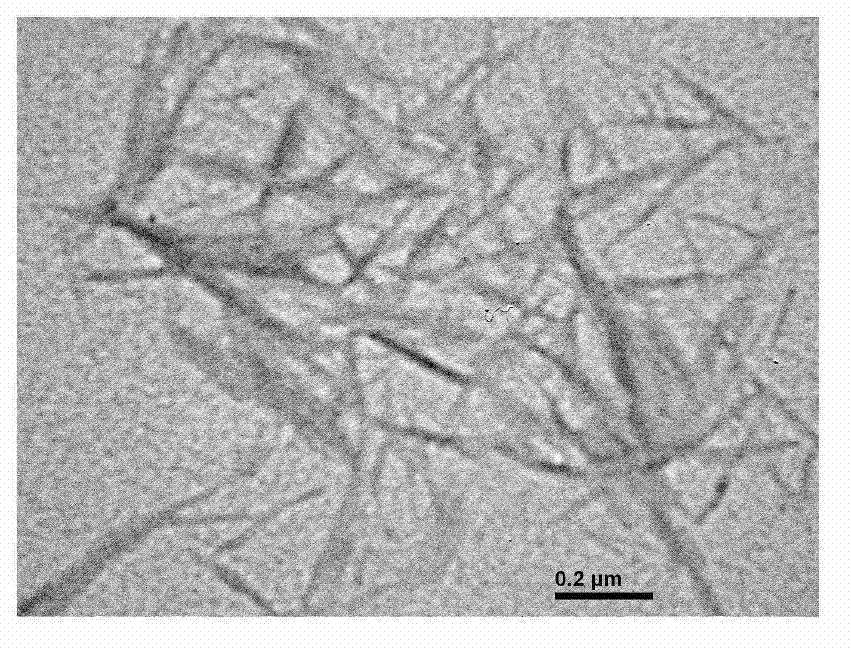

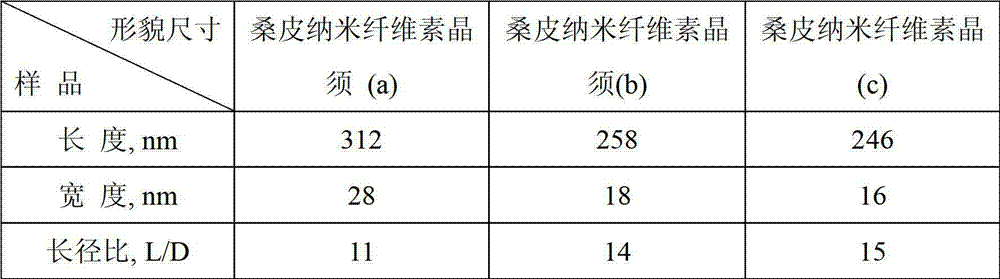

Method for preparing nanocellulose whisker by utilizing abandoned mulberry bark

InactiveCN103031770AIncrease economic incomeExpand the range of raw materialsPulp bleachingPulping with inorganic basesFiberUltrafiltration

The invention discloses a method for preparing a nanocellulose whisker by utilizing abandoned mulberry bark. The method comprises the following essential steps: carrying out a treatment on the mulberry bark by utilizing an alkali solution containing chlorine so as to purify cellulose; carrying out a catalytic hydrolysis on mulberry bark fibers by utilizing mineral acid; and collecting the nanocellulose whisker of the mulberry bark by utilizing an ultrafiltration membrane. The method is quick and efficient, and is especially suitable for preparation of the nanocellulose whisker taking the mulberry bark as a raw material. According to the invention, the abandoned mulberry bark source is added to the raw material for preparing the nanocellulose whisker, so that the range of the raw material for preparing the nanocellulose whisker is enlarged. Therefore, the limit on the raw material source of the nanocellulose whisker is broken through more quickly. In addition, the innovative idea for utilizing the abandoned mulberry bark source with a high value is put forward. As a result, the economic income of mulberry practitioners in China is improved feasibly. Consequently, the method provided by the invention has an important practical significance.

Owner:ZHEJIANG SCI-TECH UNIV +1

Method using high magnesium phosphorus gangue smelting reduction to prepare metal magnesium

InactiveCN102534253AExpand the range of raw materialsSave the cost of mining and crushingFerrosiliconDolomite

The invention discloses a method using high magnesium phosphorus gangue smelting reduction to prepare metal magnesium, which comprises the following steps of (1) calcining high magnesium phosphorus gangue into high magnesium phosphorus gangue calcined dolomite at the temperature of 900 DEG C to 1200 DEG C; (2) burdening the high magnesium phosphorus gangue calcined dolomite, ferrosilicon alloy, alumina and silica according to certain mass percent, and mixing evenly to obtain mixed materials; and (3) adding the mixed materials in a reduction reactor to perform smelting reduction reaction at the certain temperature and pressure, and collecting condensed magnesium vapor generated in reaction to achieve metal magnesium. The method has the advantages of being low in cost of raw materials, easy to operate reaction and high in metal magnesium recycling rate, turning waste into wealth, well recycling magnesium resource in the high magnesium phosphorus gangue and having obvious economic and environmental benefits.

Owner:WENGFU (GRP) CO LTD

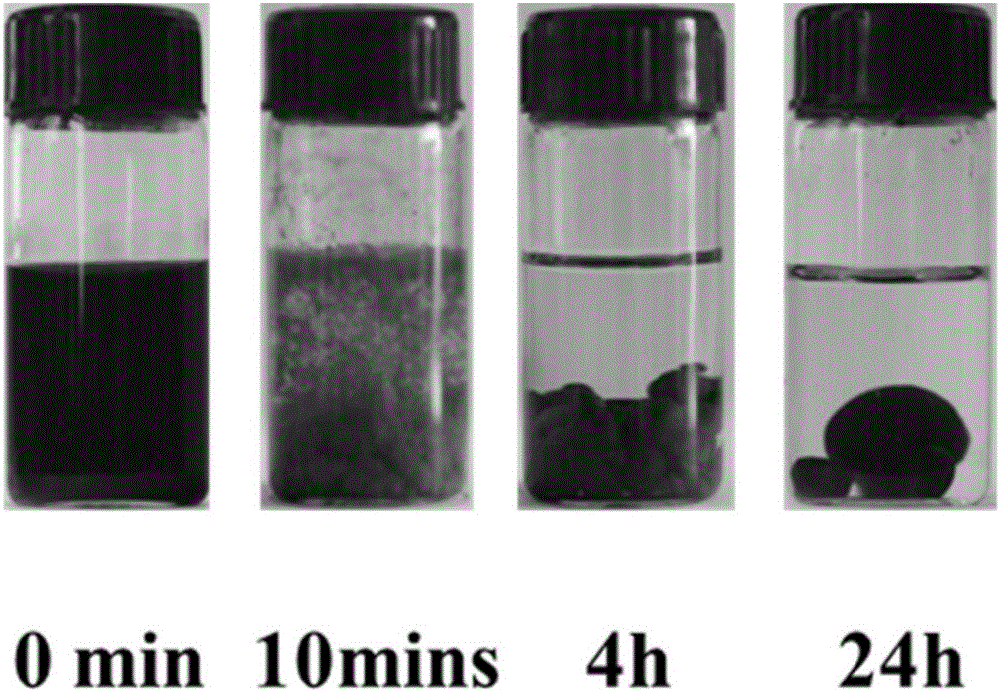

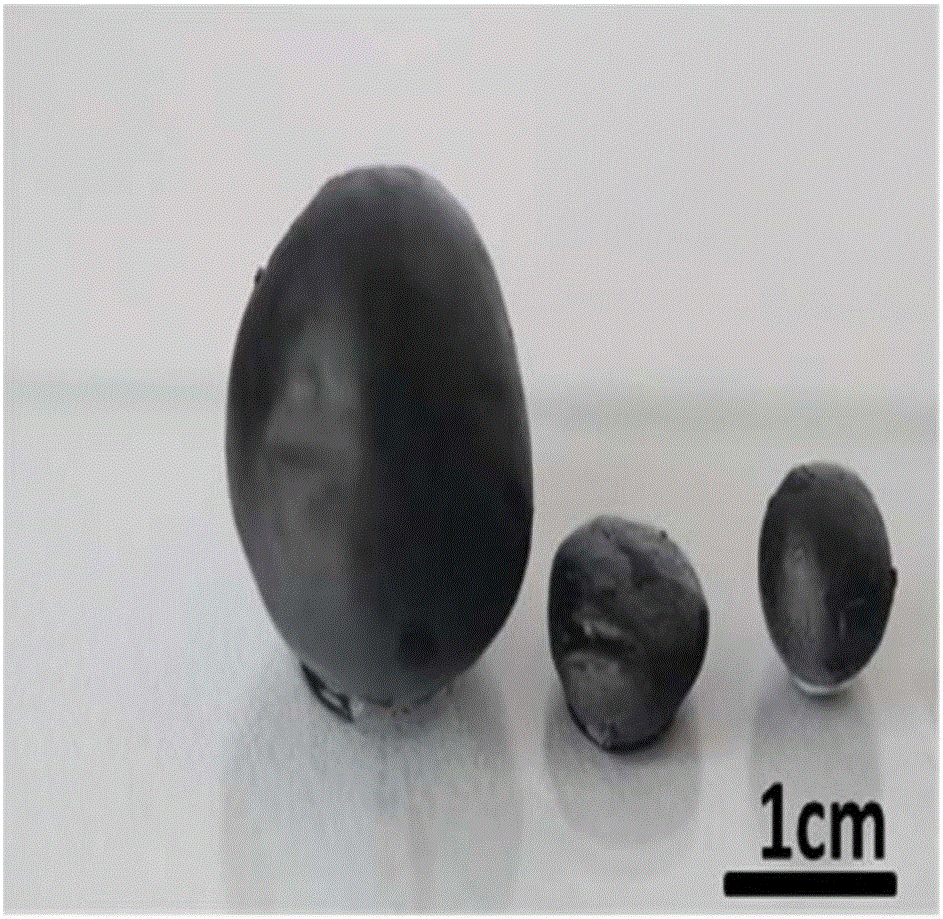

3D printing material and 3D printing product based on oxidized graphene and preparation methods of 3D printing material and 3D printing product

ActiveCN106315575AReduce printing costsExpand the range of raw materialsAdditive manufacturing apparatusGrapheneElectrostatic attractionAniline

The invention discloses a 3D printing material and a 3D printing product based on oxidized graphene and preparation methods of the 3D printing material and the 3D printing product. Main ingredients of the 3D printing material based on the oxidized graphene are the oxidized graphene, aniline and water. By the characteristic that electrostatic attraction, hydrogen bonds and Pi-Pi interact between the oxidized graphene and the aniline, the oxidized graphene and the aniline are combined with each other together to prepare the 3D printing material, the range of raw materials of the 3D printing material is expanded, moreover, the prepared 3D printing material is suitable in viscosity and can be formed at normal temperature without being heated, therefore, the 3D printing material can meet requirements of 3D printing, a corresponding 3D printing process and structures of devices can be simplified to reduce costs for 3D printing, and then the 3D printing material is suitable for large-scale production of 3D printing products.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

Preparation method of completely biodegraded thin film

InactiveCN104479154AExpand the range of raw materialsExcellent performance and degradation performanceChemistryAldehyde

The invention discloses a preparation method of a completely biodegraded thin film. The preparation method comprises the following steps: (1) mixing high amylosestarch with water to obtain starch milk with mass concentration of 13-17%, adjusting the pH value of the starch milk to 8.5-9.5 by 0.3-0.5mol / L sodium hydroxide, heating the starch milk to 90-110DEG C and gelatinizing for 20-40min at a stirring speed of 300-400r / min; (2) blending a polyvinyl alcohol water solution with mass concentration of 7-9% with the starch milk at a stirring speed of 100-140DEG C, wherein the mass ratio of the polyvinyl alcohol to the high amylose starch is 4: 6. The amylose starch content of the used high amylose maize starch is 80-82%; a glyoxal water solution is dripped to ensure that glyoxal is fully reacted to completely join the crosslinking; membrane liquid vacuum degassing is carried out to remove the bubbles caused in the stirring process.

Owner:TIANJIN KAIXUAN PLASTIC PROD

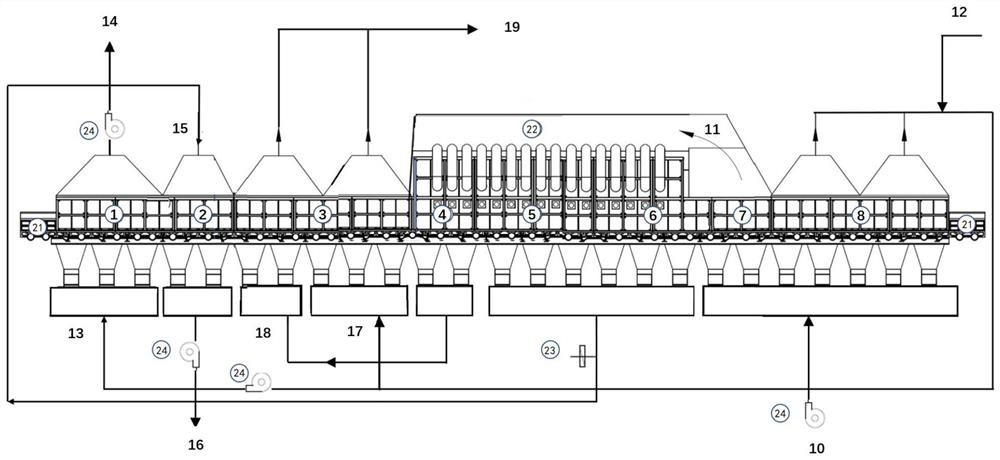

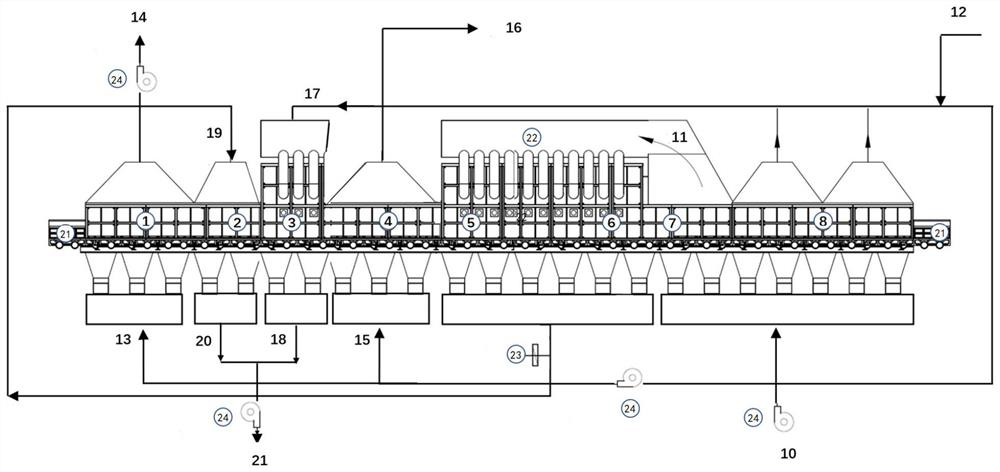

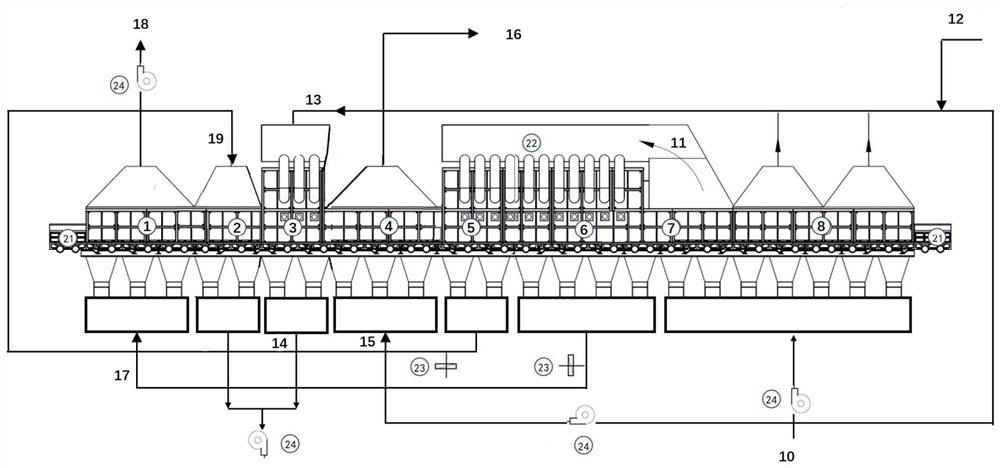

Kiln system and method for firing ceramsite containing calorific value raw materials and producing waste heat as byproduc

ActiveCN112880394AExpand the range of raw materialsEfficient use ofCharge composition/stateCharge treatment typeHot blastPyrolysis

The invention provides a kiln system and a method for firing ceramsite containing calorific value raw materials and producing waste heat as a byproduct, and belongs to the field of ceramic product firing and kilns. The kiln system comprises a drying section, a preheating section, a sintering section, a soaking section and a cooling section, and further comprises a decarburization section arranged between the drying section and the preheating section; the decarburization section comprises an ignition area, a hot air combustion / pyrolysis area and a waste heat recovery pipeline, a heat source is introduced into an ignition area, so that the temperature of the ceramsite containing the calorific value raw materials in the area is 400-900 DEG C, and the hot air combustion / pyrolysis area is used for combustion or pyrolysis of carbon-containing materials and organic components in the calorific value raw materials in the ceramsite; and a waste heat recovery pipeline is used for discharging the decarburized flue gas and recovering heat released after combustion / pyrolysis of the ceramsite raw material containing heat value in the flue gas. According to the method, the raw material range of the ceramsite is expanded, ceramsite black cores and quality reduction caused by high-mixing-amount and high-calorific-value solid waste are avoided, meanwhile, decarburization heat is recycled and utilized, and the method is low in comprehensive energy consumption, balanced in temperature control and environmentally friendly.

Owner:SHANDONG ECON ENERGY SAVING TECH +1

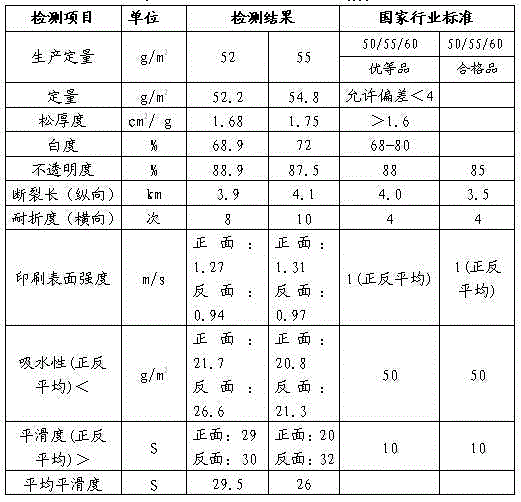

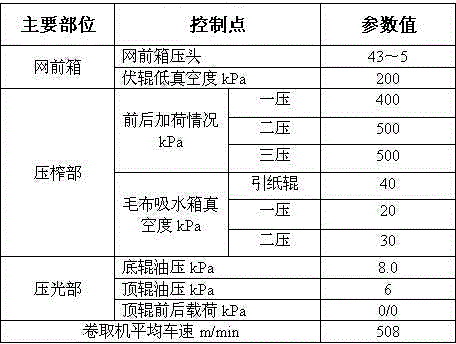

Lightweight paper made from high-proportion bamboo pulp and making method of lightweight paper

ActiveCN104947498AExpand the range of raw materialsLow costNon-fibrous pulp additionPaper/cardboardPulp (paper)Papermaking

The invention discloses a lightweight paper made from a high-proportion bamboo pulp and a making method of the lightweight paper and relates to the papermaking field. The lightweight paper is prepared from a mixed pulp of a chemical bamboo pulp, a mechanical pulp and a long-fiber CTMP pulp in the weight ratio of (50-55): (45-40): (5-10), and the following accessories in percentage by weight: 1.2% of starch, 10% of talcum powder, 0.6%-0.8% of dispersed rosin size, 6%-7% of aluminum sulfate, and 0.2kg / t of polyacrylamide PL1510; in the papermaking process: the indices, such as beating degree and ISO whiteness, of the chemical bamboo pulp and the mechanical pulp before blending are controlled; the following quality indices of the pulp applied to a screen are controlled: pH value of 5.8-6.2, concentration of 0.7-0.9% and beating degree of 47-55degree S. According to the lightweight paper, the high-proportion bamboo pulp is adopted, the raw material range of the lightweight paper is expanded, the product cost is low, the product is pure environmentally friendly and green, and the pollution load is low.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

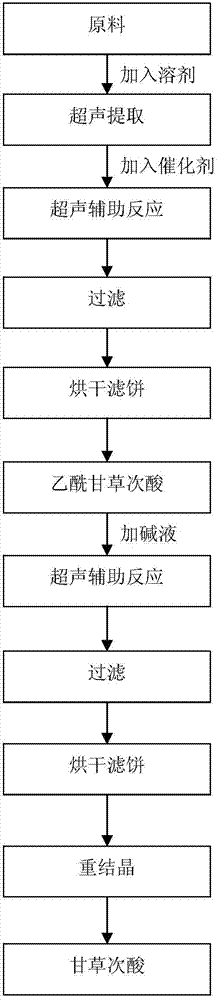

Glycyrrhetinic acid preparation method

The invention discloses a glycyrrhetinic acid preparation method which comprises the following steps: (1) filter liquor is obtained by ultrasonic extraction of licorice extract, the licorice extract comprises 9%-70% by mass of glycyrrhizic acid; (2) under ultrasonic conditions, a catalyst is added to the filter liquor for the acetylation to obtain acetyl glycyrrhetinic acid; the catalyst is any one of sulfuric acid, hydrochloric acid and phosphoric acid; and (3) in the presence of ultrasonic and alkaline conditions, the glycyrrhetinic acid is obtained by deacetylation of the acetyl glycyrrhetinic acid. According to the method, by ultrasonic extraction and ultrasonic reaction technology, the reaction time is significantly shortened, the solvent consumption is reduced, environmental pollution is little, side reaction is less, the conversion rate is obviously improved, the liquorice extract is used as a raw material, the raw material range is expanded, the problems of high raw material cost, long reaction time, serious environmental pollution and the like are solved, production cost is low, product purity is high, and the method is suitable for mass production.

Owner:普凡生生物科技(北京)股份有限公司

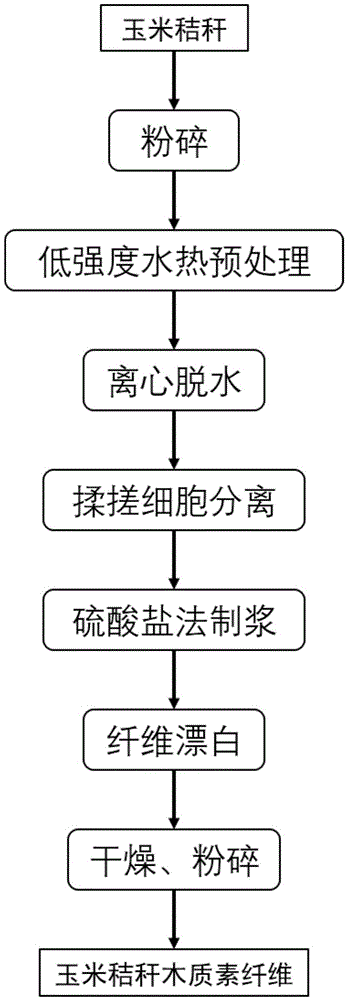

Method for preparing lignin fibers for roads from corn straws

InactiveCN105542192AExpand the range of raw materialsIncrease profitSolid waste managementFiberSulfate

The invention discloses a method for preparing lignin fibers for roads from corn straws, which comprises the following basic steps: carrying out low-intensity hydrothermal pretreatment on corn straws to partially dissociate the connection among cells, separating fibrocytes and impure cells by using a straw kneader, pulping the separated fiber material by a sulfate process to remove lignin and hemicellulose, decolorizing the fibers by using an acidic sodium chlorite solution, drying and pulverizing to obtain the flocculent lignin fibers. By using the agricultural waste corn straws instead of the needle-leaf wood to produce the lignin fibers, the method widens the production raw material range and reduces the environmental pollution sources.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

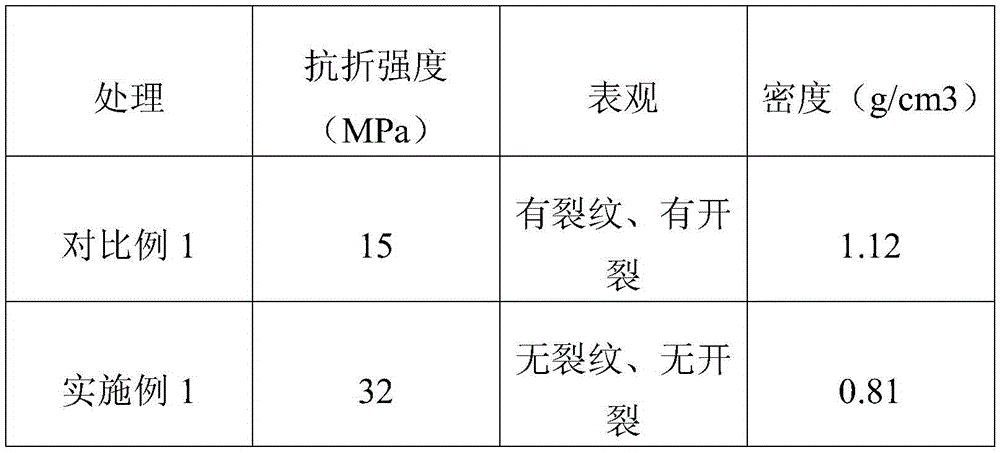

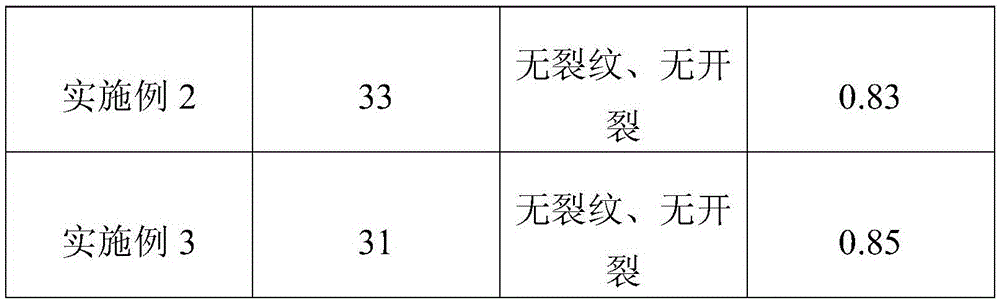

Cement particle board and preparation method thereof

InactiveCN105541265AReduce manufacturing costShorten the production cycleSolid waste managementWood shavingsPortland cement

The invention belongs to the technical field of building materials, and in particular relates to a cement particle board and a preparation method thereof. The cement particle board is characterized by comprising the following components in parts by weight: 10-40 parts of wood shavings, 15-50 parts of high-calcium coal ash, 30-55 parts of sulfate aluminum cement, 2-5 parts of sodium silicate and 0.2-2.2 parts of calcium chloride. The cement particle board provided by the invention is light in weight, high in strength and low in manufacturing cost; as sulfate aluminum cement is adopted to replace ordinary Portland cement of the prior art, the cement particle board provided by the invention is short in production period, and the production efficiency is greatly improved.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com