Method for preparing geopolymeric material from bentonite

A technology of geopolymerization and bentonite, applied in cement production, etc., can solve the problems of raw material limitation, high environmental risk, large difference in composition and structure of silicon-aluminum solid waste, etc., and achieve the effect of improving strength performance and expanding the range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through specific experimental examples. The equipment used in the embodiment of the present invention is conventional equipment, and the raw materials used are conventional raw materials.

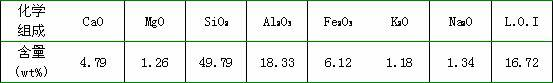

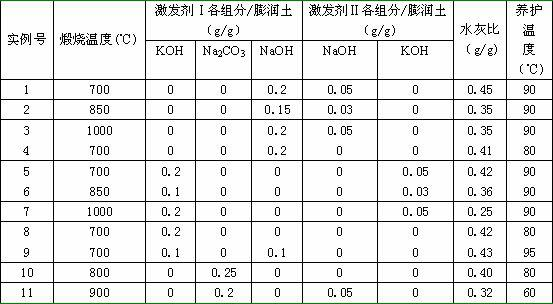

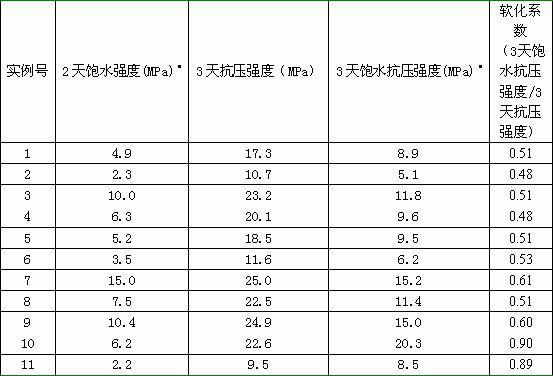

[0014] The chemical composition analysis results of the bentonite used in the examples of the present invention are shown in Table 1. Polycrystalline X-ray diffraction analysis of the bentonite showed that its phases were mainly α-quartz, montmorillonite and calcite, and also contained a small amount of limonite and chlorite. Add appropriate amount of water to prepare the activator I into a solution. The activator I includes NaOH, KOH and anhydrous sodium carbonate NaCO 3 Three kinds. The activator I liquid slurry is uniformly mixed with the above-mentioned bentonite powder which has been ball-milled to a particle size of 200 mesh with a sieve residue of 7% of the total mass, and then calcined at 700-1000°C for 2-4 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com