Patents

Literature

463 results about "Bentonite powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gravel attapulgite flower ceramsite

ActiveCN102503372BHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePhysical chemistryMaterials science

The invention discloses gravel attapulgite flower ceramsite. The key point of the technical scheme is that the gravel attapulgite flower ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, kieselguhr tailing powder and rice husk powder.t. The gravel attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, baking, cooling, smashing, sieving and packaging. The gravel attapulgite flower ceramsite is an irregularly-shaped granule, and has a rough and porous surface, light weight, high strength and high water absorption. The gravel attapulgite flower ceramsite can be soaked in water without being cracked and release nutrition required by flowers continuously and slowly. The gravel attapulgite flower ceramsite is produced by utilizing the sludge and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the gravel attapulgite flower ceramsite is suitable for planting the flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Spherical attapulgite flower ceramsite

ActiveCN102503539AReduce manufacturing costHigh strengthCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses spherical attapulgite flower ceramsite. The key points of the technical scheme are that the spherical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The spherical attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The spherical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength and water absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the spherical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, the cylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Cylindrical attapulgite flower ceramsite

ActiveCN102503537AHigh strengthLower sintering temperatureCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses cylindrical attapulgite flower ceramsite. The key points of the technical scheme are that the cylindrical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The cylindrical attapulgite flower ceramsite is produced by the following stepsof mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The cylindrical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength andwater absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the cylindrical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, thecylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Gravel attapulgite flower ceramsite

ActiveCN102503372AHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePhysical chemistryMaterials science

The invention discloses gravel attapulgite flower ceramsite. The key point of the technical scheme is that the gravel attapulgite flower ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, kieselguhr tailing powder and rice husk powder.t. The gravel attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, baking, cooling, smashing, sieving and packaging. The gravel attapulgite flower ceramsite is an irregularly-shaped granule, and has a rough and porous surface, light weight, high strength and high water absorption. The gravel attapulgite flower ceramsite can be soaked in water without being cracked and release nutrition required by flowers continuously and slowly. The gravel attapulgite flower ceramsite is produced by utilizing the sludge and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the gravel attapulgite flower ceramsite is suitable for planting the flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Baking-free gravel attapulgite building garbage ceramsite

InactiveCN102503281AUniform particle sizeImprove yieldSolid waste managementExpanded clay aggregateWaste material

The invention discloses baking-free gravel attapulgite building garbage ceramsite. The key point of the technical scheme is that the baking-free gravel attapulgite building garbage ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, building garbage powder, red bentonite powder, kieselguhr tailing powder and cement. The baking-free gravel attapulgite building garbage ceramsite is produced by the following steps of mixing the ingredients, granulating, maintaining, sieving and packaging.. The baking-free gravel attapulgite building garbage ceramsite is an irregularly-shaped granule and has a rough and hard surface light weight, high strength, high durability and a good heat-preserving and sound-insulating effect; and a large amount of fine pores are formed in the granule. The baking-free gravel attapulgite building garbage ceramsite is produced by utilizing the building garbage and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the baking-free gravel attapulgite building garbage ceramsite is suitable for producing concrete heat-preserving building blocks and heat-preserving and sound-insulating materials.

Owner:许庆华

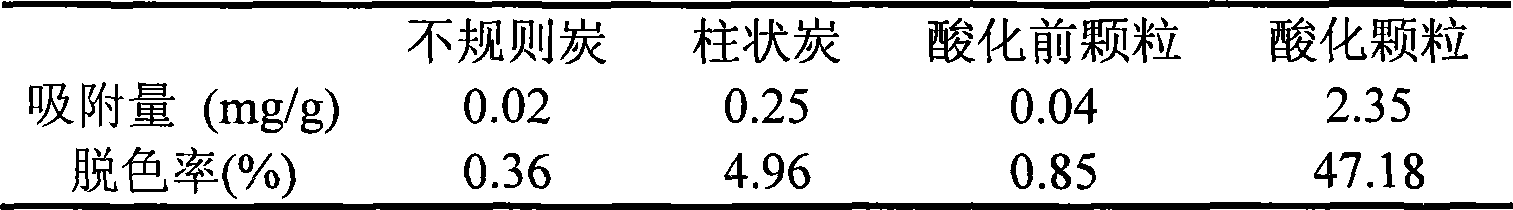

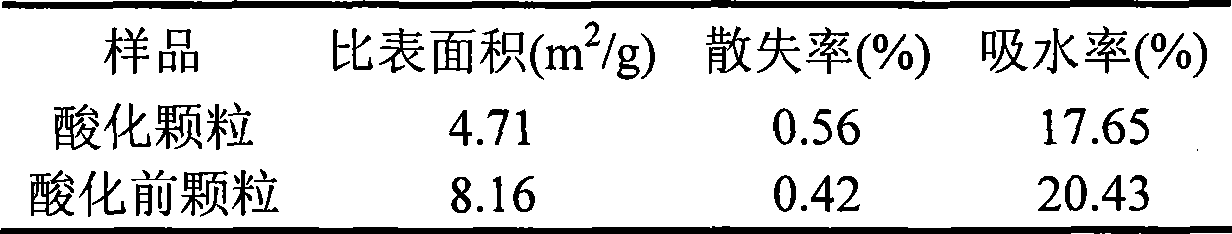

Preparation method of acidification sludge bentonite granules

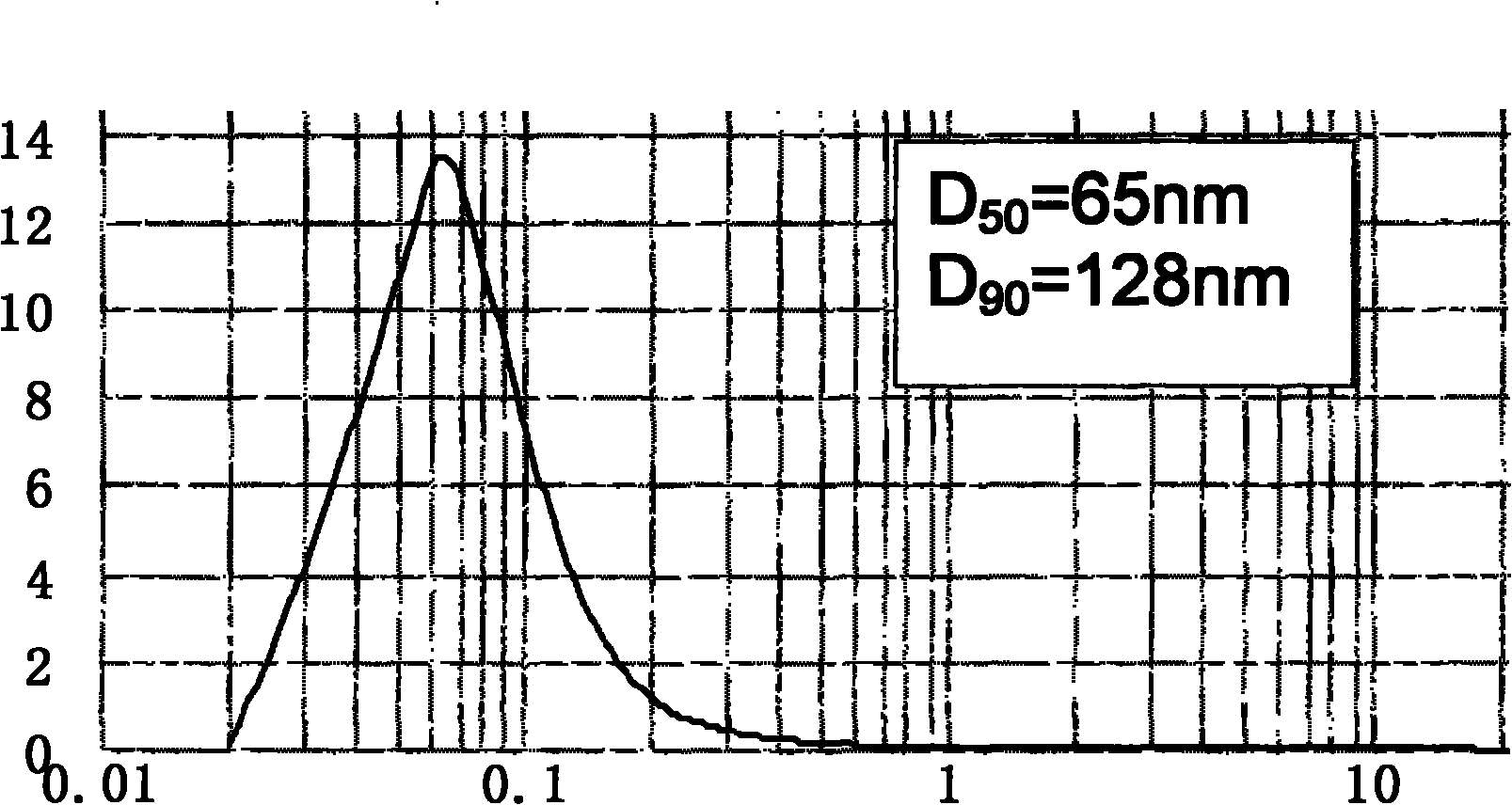

InactiveCN101362073AReasonable designSimple processOther chemical processesGranulation by material expressionSodium BentoniteSludge

The invention relates to a preparation method of acidified sludge bentonite particles, pertaining to the technical field of environmental protection. Sludge and nano-bentonite powder are mixed together according to a certain ration, porous sludge bentonite particles are prepared by roasting under high temperature and the activity of the porous sludge bentonite particles is further modified by sulphuric acid to prepare the acidified sludge bentonite particles. The acidified sludge bentonite particles is yellow solid particles, with organic substance content reaching 165.788mg / g, specified surface area being 4.71m<2> / g, lost ratio being 0.56 percent and water absorptivity being 17.65 percent. The preparation method has the advantages of simple technology, economic efficiency, low cost, and the like, and the prepared acidified sludge bentonite particles have stable quality, uniform appearance and good absorptivity, thereby not only realizing the utilization of sludge as resource and the reduction of the pollution caused by the sludge, but also having wide application value in the aspect of decoloring processing of waste water produced in printing and dyeing, and realizing the purpose of treating waste by utilizing waste.

Owner:SHANDONG UNIV

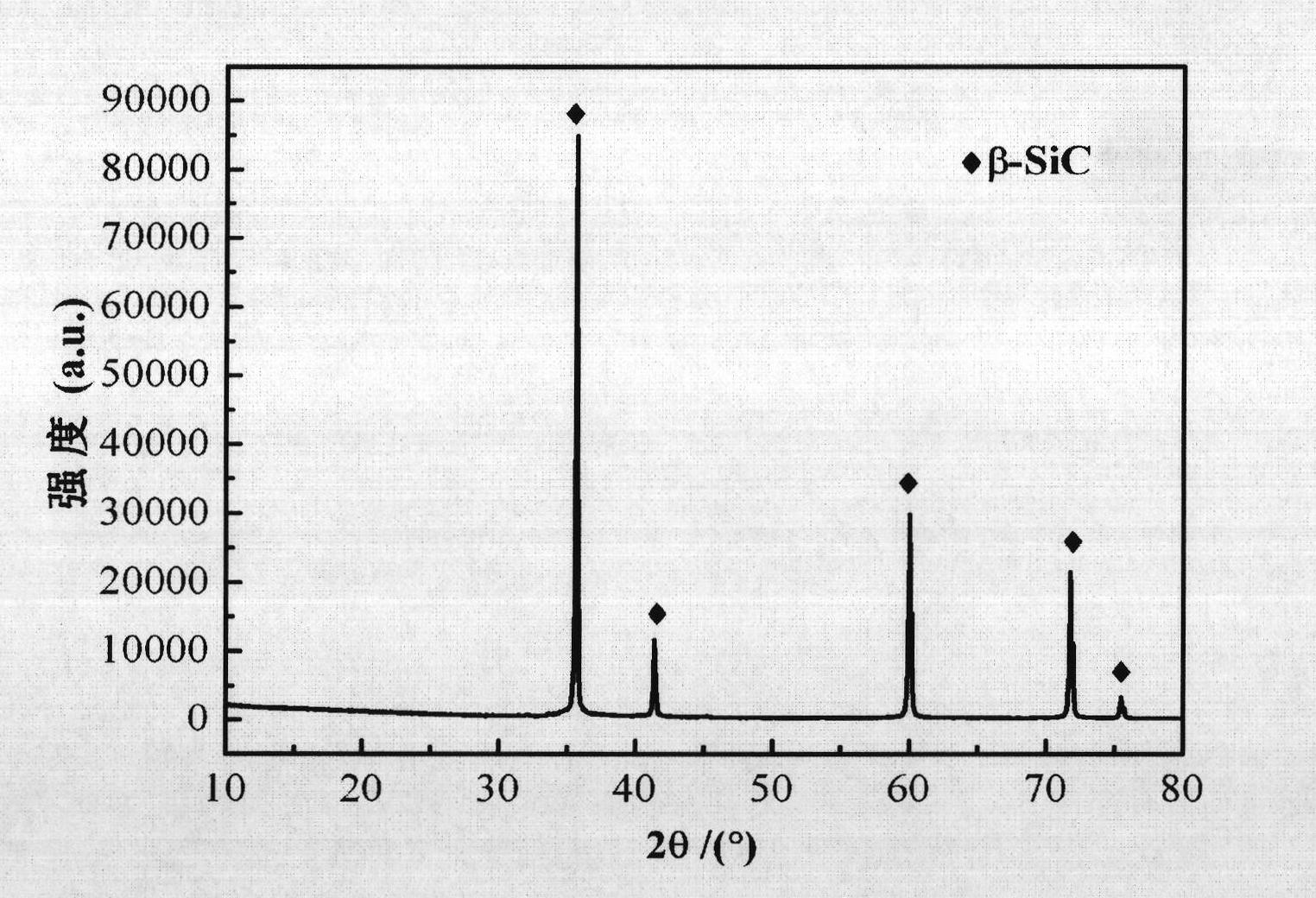

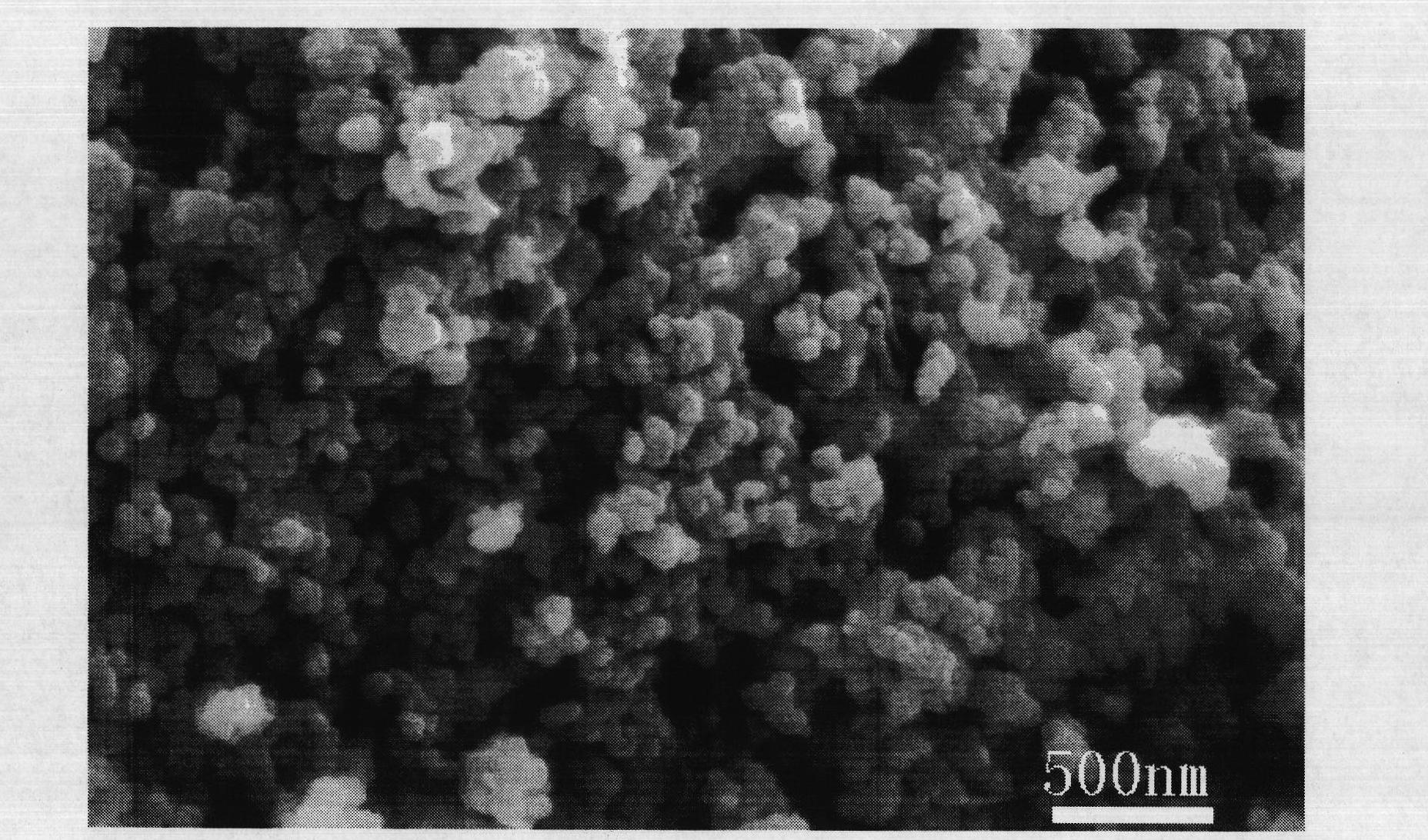

Nanometer silicon carbide-series infrared radiation coating and preparation method thereof

The invention belongs to the field of far infrared energy-saving coating used for a high-temperature industrial furnace, which particularly relates to a nanometer silicon carbide-series infrared radiation coating and a preparation method thereof. The coating is composed of a powder radiation material, a binding material, a slurry accessory ingredient and water, wherein the mass ratio of the waterto the powder radiation material is (0.5-2):1; the binding material is 10-30% of the total mass of powder radiation material; the slurry accessory ingredient is 0.1-3% of the total mass of powder radiation material; and the powder radiation material is composed of nanometer silicon carbide powder, zirconia powder, chromium hemitrioxide powder, ferric oxide powder, nickel oxide powder, bentonite powder and siliceous dust powder. The infrared energy-saving radiation coating disclosed by the invention has the advantages of high radiation coefficient and excellent thermal shock resistance. After high-temperature sintering, a sintering layer is formed on a refractory brick or cellucotton, the sintering layer can be firmly adhered on the surface of the lining of a kiln to perform the energy-saving effect on increasing radiant heat utilization and reducing heat loss.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Production method of casting alcohol based paints using resin bonded sand

InactiveCN101288898AEasy to useImprove stabilityFoundry mouldsFoundry coresPolyvinyl butyralSodium Bentonite

The invention provides a production method for casting alcohol-based coating with a resin sand, comprising the compositions as follows: high bauxite powders, graphite powders, dextrin powders, bentonite powders, polyvinyl butyral, ferric oxide powders, colophony and 665 phenolic resin; the proportion of the composition is as follows: 60% of high bauxite powders, 20% of graphite powders, 5%-7% of dextrin powders, 5%-7% of bentonite powders, 0.5%-1% of polyvinyl butyral, 2%-3% of ferric oxide, 2%-3% of colophony and 2%-3% of 665 phenolic resin. The method of the invention solves the problems of the current clay sand dry-typed casting coating such as high cost, coarse surface after coating and easy cracking and is suitable for the application in the casting production.

Owner:QINGDAO HAILONG MACHINERY GRP

Attapulgite paper pulp floral clay and production method thereof

The invention discloses attapulgite paper pulp floral clay and a production method thereof. The attapulgite paper pulp floral clay is characterized by being prepared from high-viscosity attapulgite clay powder, bentonite powder, paper pulp sludge, aluminum sulfate, polyacrylamide, potassium permanganate, urea, potassium dihydrogen phosphate, sodium carboxymethyl cellulose and deionized water. The production method comprises the following steps of: dissolving the urea and the potassium dihydrogen phosphate in the paper pulp sludge, then adding the high-viscosity attapulgite clay powder and the bentonite powder in the paper pulp sludge, and stirring to form a mixture of the attapulgite paper pulp floral clay; adding a sodium carboxymethyl cellulose solution into the mixture and stirring to form a semi-finished product of the attapulgite paper pulp floral clay; adding the semi-finished product into a die, and pressing into a finished product of the attapulgite paper pulp floral clay by using a press machine. The attapulgite paper pulp floral clay contains nutrient ingredients required by fresh flowers, is beneficial to the normal growth of branches and leaves and prolonging the florescence, has low waste utilization cost, and is suitable for retaining freshness of fresh flowers in florists, hotels, office buildings and families.

Owner:南通金茂防爆电气有限公司

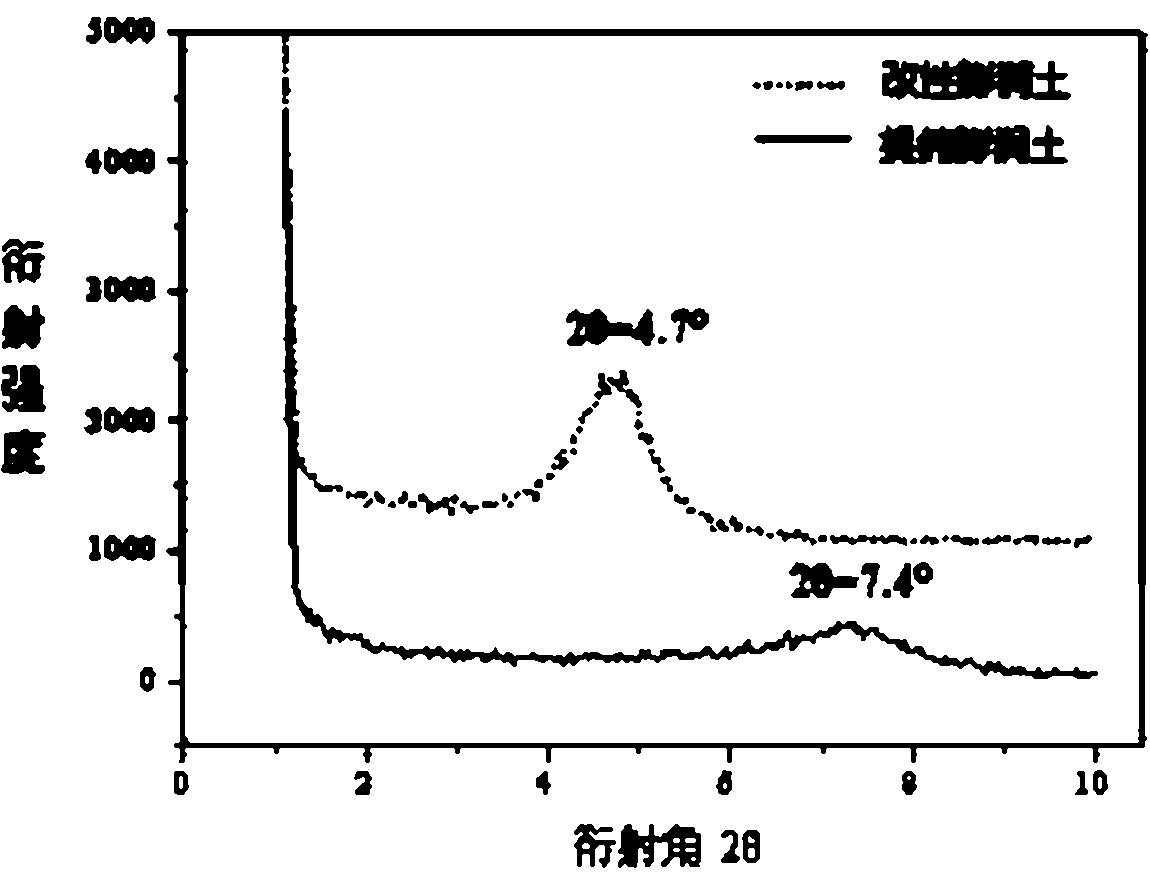

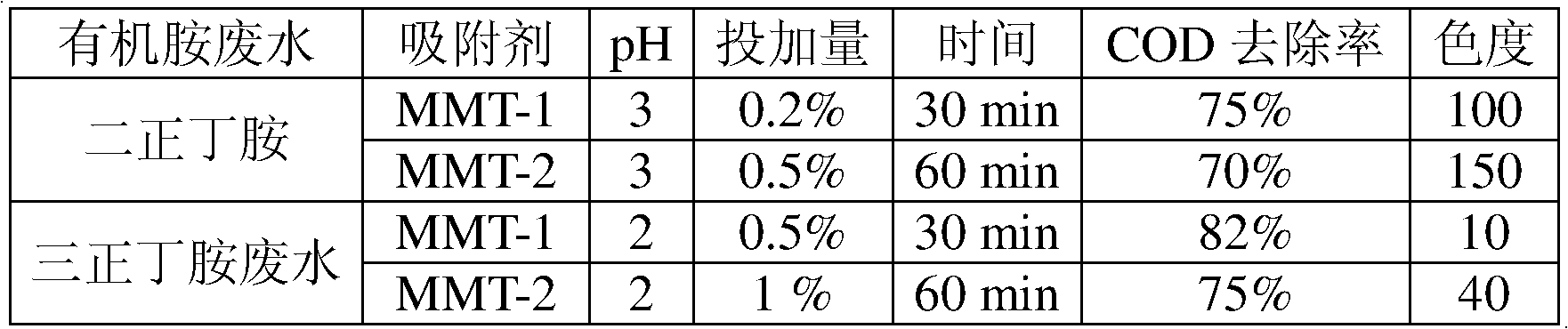

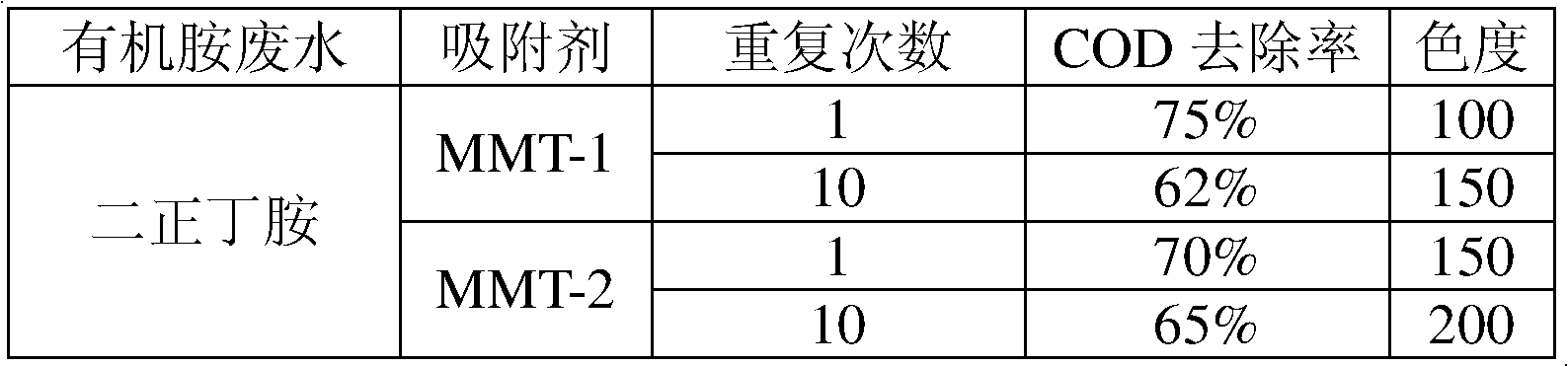

Organic wastewater modified bentonite adsorbent and preparation method thereof

InactiveCN102151544ADecolorization reachedIncrease the interlayer spacingOther chemical processesWater contaminantsSorbentWastewater

The invention discloses an organic wastewater modified bentonite absorbent and a preparation method of the absorbent. The preparation method comprises the following steps: taking organic amine type of pollutants in organic wastewater as modifying agents, taking purified bentonite powder as raw materials, adding the purified bentonite powder into the organic amine type of wastewater to agitate for 10-120 minutes at the normal temperature, and then filtering to obtain an organic wastewater modified bentonite filter cake; drying and grinding the organic wastewater modified bentonite filter cake under the condition of 90-105 DEG C to obtain organic wastewater modified bentonite, then placing the organic wastewater modified bentonite into a muffle furnace for roasting, and cooling to the normal temperature to obtain the organic wastewater modified bentonite adsorbent. The organic wastewater modified bentonite adsorbent and the preparation method have the advantages that firstly, the pollutants in the wastewater are taken as the modifying agents to realize the effect of treating the wastes with the wastes; secondly, the modification time is short; thirdly, the pollutant removal efficiency is high, and the decoloring effect is remarkable; fourthly, the solid-liquid separation is quick; and fifthly, the processing cost is low.

Owner:HUNAN CHEM RES INST

Attapulgite river bottom silt ceramsite sand

ActiveCN102515697AHigh strengthReduce energy consumptionFluid removalCeramic materials productionSoil scienceExpanded clay aggregate

The invention discloses attapulgite river bottom silt ceramsite sand. The technical scheme is mainly characterized in that the attapulgite river bottom silt ceramsite sand is composed of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, river bottom silt, red bentonite powder, fly ash, and bauxite tailings. The attapulgite river bottom silt ceramsite sand is prepared by carrying out steps of mixing, granulating, baking, cooling, sieving and packaging on the ingredients of the attapulgite river bottom silt ceramsite. The attapulgite river bottom silt ceramsite is spherical and has the advantages of high strength, low crushing rate, stable quality, porous inner part, corrosion resistance, and good frost resistance and earthquake resistance. The attapulgite river bottom silt ceramsite sand can be produced by comprehensively utilizing the river bottom silt and the tailings, so that the attapulgite river bottom silt ceramsite is good for improving the resource utilization rate, changing wastes to valuable things, reducing the occupied land area, and protecting and purifying the environment; and the attapulgite river bottom silt ceramsite sand is applicable to producing oil field fracturing propping agents and heat-preservation and sound-proof materials.

Owner:南通久通建筑机械有限公司

Polymer and bentonite drilling mud

InactiveCN102757199AHighlight substantive featuresSignificant progressDrilling compositionCarboxymethyl cellulosePolymer science

The invention relates to polymer and bentonite drilling mud which is formed by mixing bentonite powder and a polymer, wherein the polymer is a mixture of carboxymethyl cellulose and polyacrylamide; the mass ratio of the bentonite powder to the polymer is 100: (1-3); and the mass ratio of carboxymethyl cellulose to polyacrylamide is (15-30): 1. The polymer and bentonite drilling mud is formed by mixing sodium-based bentonite, a viscosity-enhancing polymer and a leakage-reducing polymer additive; drillings and sandstone in a drilling fluid can be effectively suspended and carried; thin and compact mud films can be formed under drilling pressure; moisture in the drilling fluid is prevented from penetrating into gaps on a well wall and running off into the stratum; the drillings are effectively suspended while at rest; and meanwhile, the pressure of a drill bit is favorably reduced and the service life of a drill tool is prolonged.

Owner:捷高科技(苏州)有限公司

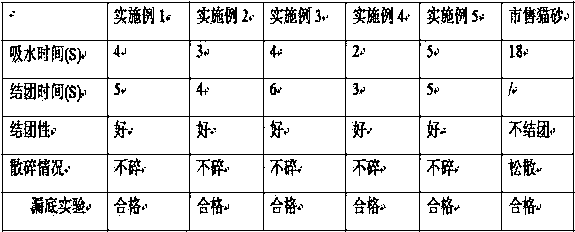

Attapulgite solid water mud for inserting flowers and production method thereof

The invention discloses attapulgite solid water mud for inserting flowers and a production method thereof. The technical scheme of the invention is characterized in that the attapulgite solid water mud for inserting flowers is prepared from high-viscosity attapulgite clayey silt, bentonite powder, granular high water-absorption resin, urea, monopotassium phosphate and deionized water. The production method comprises the following steps of: firstly, adding the urea and the monopotassium phosphate into the deionized water for stirring; adding the high-viscosity attapulgite clayey silt and the bentonite powder into a stirrer for stirring to form a semi-finished product; adding the semi-finished product into a transparent vessel; and then adding solid water on the semi-finished product to form a finished product of the attapulgite solid water mud for inserting flowers. The attapulgite solid water mud for inserting flowers has distinct gradations, is provided with glittering and translucent solid water on the upper part and attapulgite mud for inserting flowers, having with high viscosity and strong water-retaining property at the lower part, contains nutrition constituents needed by the growth of fresh flowers, ensures that the fresh flowers inserted in the attapulgite solid water mud for inserting flowers are upright and beautiful and have high enjoyment effect, and is suitable for keeping flowers in flower shops, hotels, office buildings and houses fresh.

Owner:南通金茂防爆电气有限公司

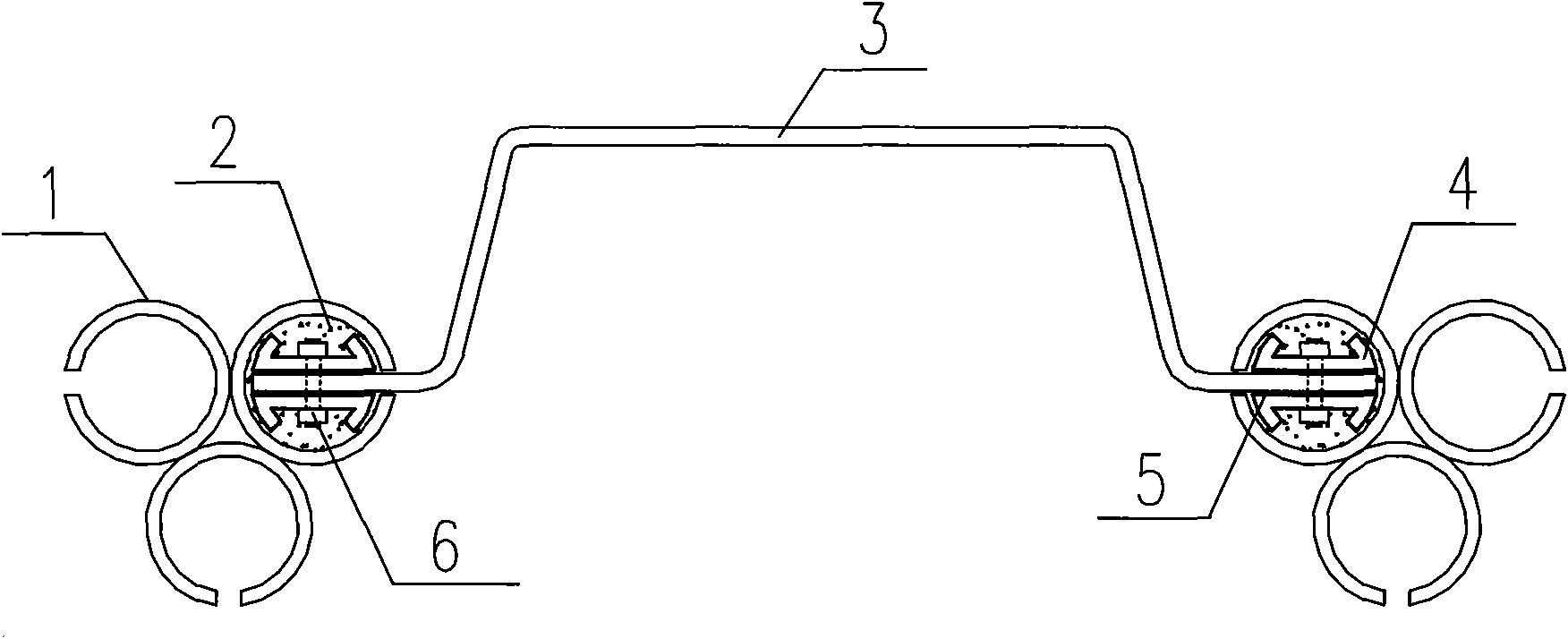

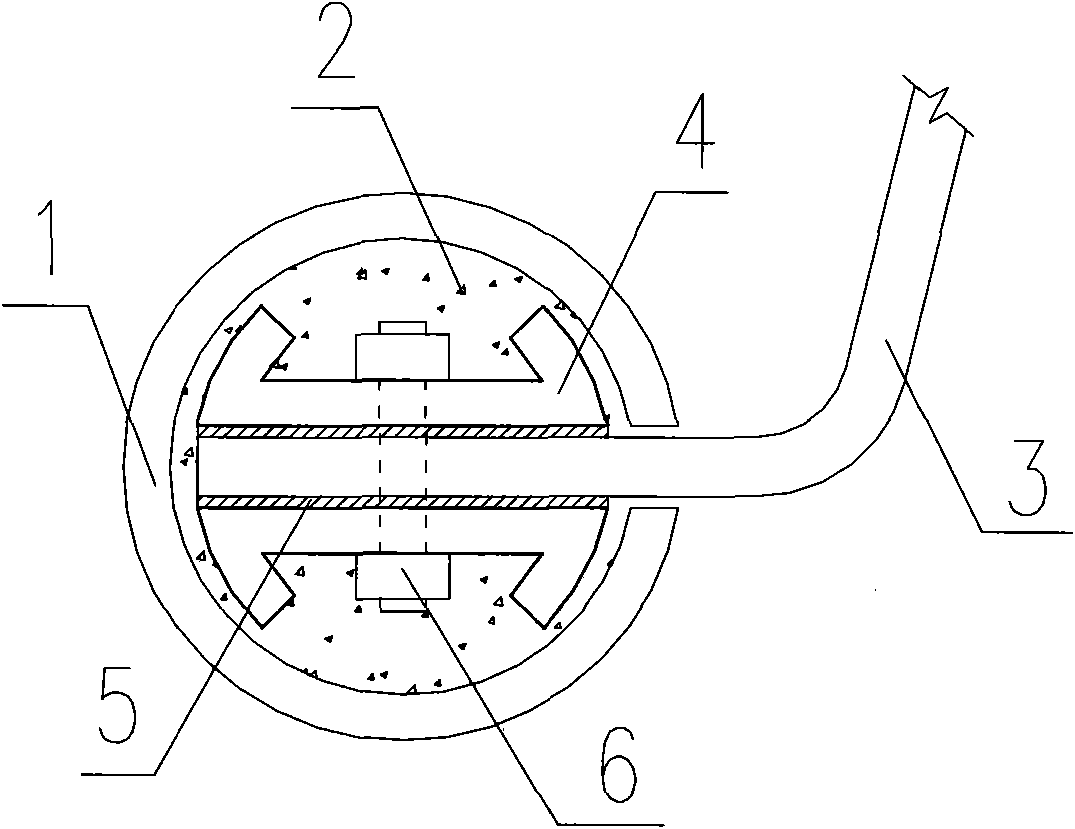

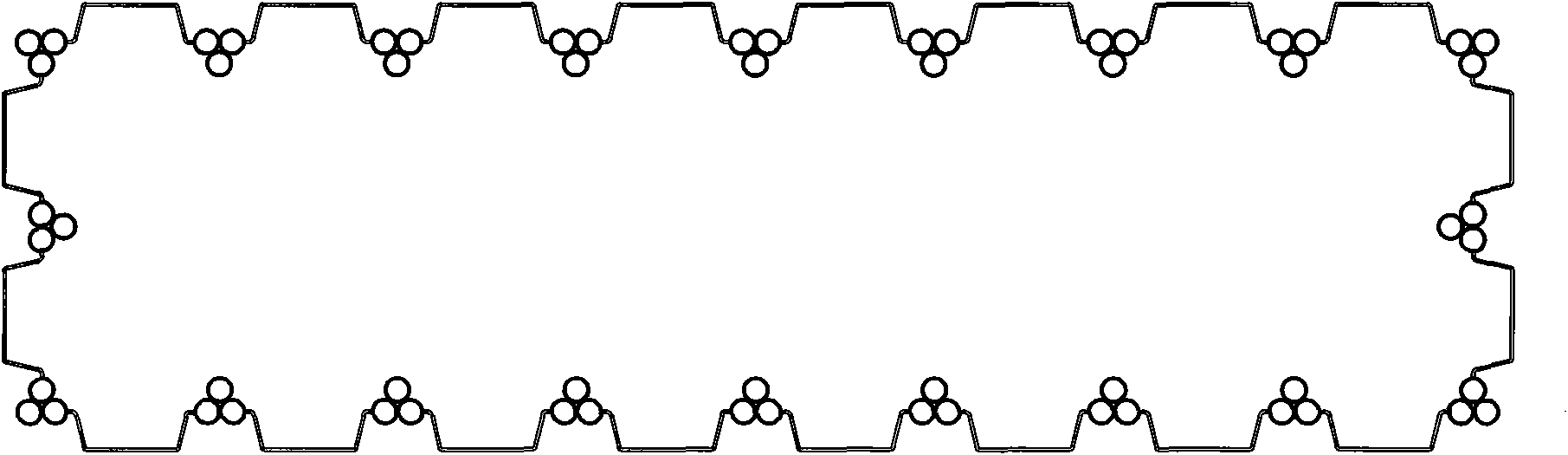

Waterproof sheet pile cofferdam and construction method thereof

InactiveCN101597904AReduce the impactImprove carrying capacityFoundation engineeringSheet steelRed mud

A waterproof sheet pile cofferdam is provided with a plurality of cluster steel pipe piles; two adjacent cluster steel pipe piles are connected by steel plate baffles, each cluster steel pipe pile is formed by welding at least two steel pipes as the long pile of the cofferdam, each steel pipe is provided with a gap running through the steel pipe, limited blocks are arranged between the insertion edges of the steel plate baffles and the gaps, the steel pipes of the cluster steel pipe piles are internally provided with waterproof fillers prepared by the mixture of 40-50% of bentonite, 20-25% offly ash, 25-35% of red mud.

Owner:NANTONG HUAGONG MACHINERY +1

Organic modified granular bentonite/attapulgite absorbent and preparation method thereof

InactiveCN104069803ASimple processLarge particle sizeOther chemical processesWater/sewage treatment by sorptionCation-exchange capacityActive agent

The invention relates to an organic modified granular bentonite / attapulgite absorbent and a preparation method thereof. The preparation method adopts the technical scheme that bentonite powder and attapulgite powder are taken as main raw materials and mixed at the mass ratio of 1:(0.1-0.5); the mixture of the bentonite powder and the attapulgite powder is uniformly mixed with water at the mass ratio of 1:(1.2-2),dried for 16-32h at 90-110 DEG C, crushed into granular bentonite / attapulgite with the grain size of 0.2-2 mm and then calcined for 2-2.5 h at 550-850 DEG C; finally, the calcined granular bentonite / attapulgite is modified with a surface active agent, which is 50-400 percent CEC (Cation Exchange Capacity) of the calcined granular bentonite / attapulgite, under a stirring condition to obtain the organic modified granular bentonite / attapulgite absorbent. The preparation method is simple in process and causes no secondary pollution; the prepared organic modified granular bentonite / attapulgite absorbent has the characteristics of large grain size, excellent adsorption property and high strength and is applicable to treatment of wastewater containing chlorophenol.

Owner:WUHAN UNIV OF SCI & TECH

High-strength permeable concrete and method for preparing same

The invention discloses high-strength permeable concrete and a method for preparing the same. The high-strength permeable concrete comprises, by weight, 30-40 parts of coarse aggregate, 20-30 parts ofsulphoaluminate cement, 5-10 parts of converter steel slag, 2-4 parts of calcined meta-bentonite powder, 4-8 parts of fly ash, 1-3 parts of silicon powder, 3-8 parts of iron tailings sand, 4-8 partsof ceramsite, 2-5 parts of coal gangue powder, 2-8 parts of reinforcing fibers, 2-5 parts of sodium silicate, 2-4 parts of bauxite, 0.5-1.5 parts of adhesion agents, 0.3-0.8 part of water reducing agents, 1-3 parts of gel and 0.1-0.5 part of dispersing agents. The high-strength permeable concrete and the method have the advantages that the high-strength permeable concrete is excellent in permeability performance, strength and frost resistance, and the method is simple, is easy to implement and has a good application prospect.

Owner:合肥慧林建材有限公司

Unburned spheroidal attapulgite building rubbish ceramic grain

ActiveCN102515814AImprove resource utilizationReduce land occupationSolid waste managementCeramicwareExpanded clay aggregateBentonite powder

The invention discloses an unburned spheroidal attapulgite building rubbish ceramic grain. According to the technical scheme, the unburned spheroidal attapulgite building rubbish ceramic grain is composed of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, building rubbish powder, red bentonite powder, kieselguhr tailing powder and cement. The raw materials of the unburnedspheroidal attapulgite building rubbish ceramic grain are mixed, pelletized, maintained and screened, and then are packed as the unburned spheroidal attapulgite building rubbish ceramic grain. The unburned spheroidal attapulgite building rubbish ceramic grain is spheroidal in shape, has a rough and hard surface, is provided with fine pores inside and is the building ceramic grain with light weight, high strength, excellent chemical stability, durability and excellent heat-insulating and sound-insulating effect. The building rubbish and tailings are comprehensively utilized to produce the unburned spheroidal attapulgite building rubbish ceramic grain, so that the use ratio of resources is increased, the waste is turned into the wealth, and the environmental protection is achieved. The unburned spheroidal attapulgite building rubbish ceramic grain is suitable for the production of ceramic grain concretes and heat-insulating and sound-insulating materials.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

Bentonite clay particles and preparation method thereof

InactiveCN105727884ALarge specific surface areaImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesActivated carbonCarbonate

The invention discloses bentonite clay particles and a preparation method thereof.The bentonite clay particles are prepared from bentonite powder, activated carbon, carbonate and silicate, wherein the activated carbon accounts for 8-20% of the bentonite powder by mass, the carbonate accounts for 0.02-0.05% of the bentonite powder by mass, and the silicate accounts for 0.02-0.05% of the bentonite powder.The bentonite clay particles include activated carbon; due to addition of the activated carbon, multiple holes can appear in the bentonite clay particles, the specific surface area of the particles is increased, and the good adsorption capacity is achieved.

Owner:张兴华

Preparation and application methods of special fertilizer for continuous-cropping isatis indigotica

InactiveCN102040416AGuaranteed nutritionImprove the rhizosphere environmentBio-organic fraction processingOrganic fertiliser preparationDiseaseContinuous cropping

The invention relates to preparation and application methods of a special fertilizer for continuous-cropping isatis indigotica, belonging to preparation and application of fertilizers. The preparation method comprises the following steps of: mixing dairy manure, chicken manure, corn stalk powder, corn flour and organic material decomposing inoculants, adding water and stirring, preserving moisture and fermenting; drying and smashing a fermented mixture material, adding humic acid powder and bentonite powder, and continuously drying to obtain a main material; uniformly mixing corn stalk segments, the corn stalk powder, sorghum stalk powder, calcium superphosphate and potassium sulphate to prepare an auxiliary material; and uniformly mixing the main material with the auxiliary material by the weight ratio of 1:(1-4) to prepare the special fertilizer for the continuous-cropping isatis indigotica. The application method is characterized in that 1500-2600kg of the special fertilizer for the continuous-cropping isatis indigotica is applied per 667m<2> and ploughed under the deep soil of 15 centimeters to 30 centimeters. In the invention, the nutrients required for the growth of the isatis indigotica are ensured, and meanwhile, organic matters, beneficial bacteria and the like are added for improving the rhizosphere environment according to the growth characteristics of the isatis indigotica, therefore, an auto-toxic substance is degraded, the occurrence of diseases is reduced, and the effect of continuous high and stable yield of the isatis indigotica is achieved.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Magnesium olivine modified powder coating and preparation method thereof

ActiveCN102653640AImprove permeabilityIncreased apparent quality levelPowdery paintsQuality levelMethylcellulose Powder

The invention relates to a magnesium olivine modified powder coating and a preparation method thereof. The magnesium olivine modified powder coating is prepared from the following raw materials in parts by weight: 2-16 parts of magnesium olivine powder, 10-32 parts of mullite powder, 10-26 parts of zircon powder, 15-30 parts of quartz powder, 3-5 parts of lithium-base bentonite powder, 1.5-3.5 parts of dextrin powder, 1-3 parts of white latex powder and 2-4 parts of carboxy methylcellulose powder; and the preparation method comprises the following steps of: evenly mixing the raw materials in proportion, and grinding for 2-3 hours, thus obtaining the magnesium olivine modified powder coating. As magnesium olivine is modified, the magnesium olivine modified powder coating is neutral at high temperature, thus being applicable to producing alkaline high-alloy steel, acidic low-alloy steel and iron castings; furthermore, the magnesium olivine modified powder coating can well prevent molten steel and molten iron from permeating since the solid phase self-sintering property of the magnesium olivine is well maintained; and when the castings are cleaned, the coating can be stripped off in pieces or blocks, so that the surface quality level of the castings can be improved.

Owner:湖北镁兴科技股份有限公司

Acid modified bentonite adsorbent and preparation method thereof

InactiveCN103894145ALarge specific surface areaImprove adsorption capacityOther chemical processesSodium BentoniteSorbent

The invention provides an acid modified bentonite adsorbent and a preparation method thereof. According to the acid modified bentonite adsorbent provided by the invention, the total pore volume is 0.20-0.40cm<3> / g, and the specific surface area is 90.0-160.0m<2> / g. The preparation method of the acid modified bentonite adsorbent comprises the following steps of mixing a bentonite powder as a raw material and an aqueous solution of acid; carrying out hydrothermal reaction treatment on the mixed slurry, and performing suction filtering on the bentonite slurry after the hydrothermal reaction treatment; and drying and crushing a modified bentonite filter cake after suction filtration to obtain the bentonite adsorbent. With the adoption of the acid modified bentonite adsorbent, the modified bentonite has higher specific surface area and has good performance in the aspect of adsorption.

Owner:PETROCHINA CO LTD +1

Fire-resistant flame-retardant composite thermal insulation mortar and preparation method thereof

The invention discloses fire-resistant flame-retardant composite thermal insulation mortar which is characterized by comprising the following raw materials in parts by weight: 300 to 350 parts of cement, 40 to 45 parts of clay powder, 23 to 26 parts of quartz powder, 12 to 15 parts of hydroxy propyl methyl cellulose ether, 40 to 45 parts of polypropylene short fiber, 30 to 35 parts of building crushed brick powder, 8 to 10 parts of antimony trioxide, 5 to 6 parts of sodium metasilicate, 4 to 5 parts of bentonite powder, 40 to 45 parts of oxidized starch, 24 to 28 parts of calcium propionate, 10 to 12 parts of borax, 30 to 35 parts of expanded pearlite powder, 5 to 10 parts of silica sol, 4 to 6 parts of modified nano-carbon powder, and 600 to 650 parts of water. The fire-resistant flame-retardant composite thermal insulation mortar mainly has the advantages that the workability, water-retaining property and heat insulating efficiency can be improved; common problems such as flaking, cracking and the like are solved; the anti-freezing, water-reducing, impermeable, durable, anti-crack, heat-insulating and heat-proof functions are realized after hardening.

Owner:BENGBU TIANWANG FISHING NEED SUPPLIES

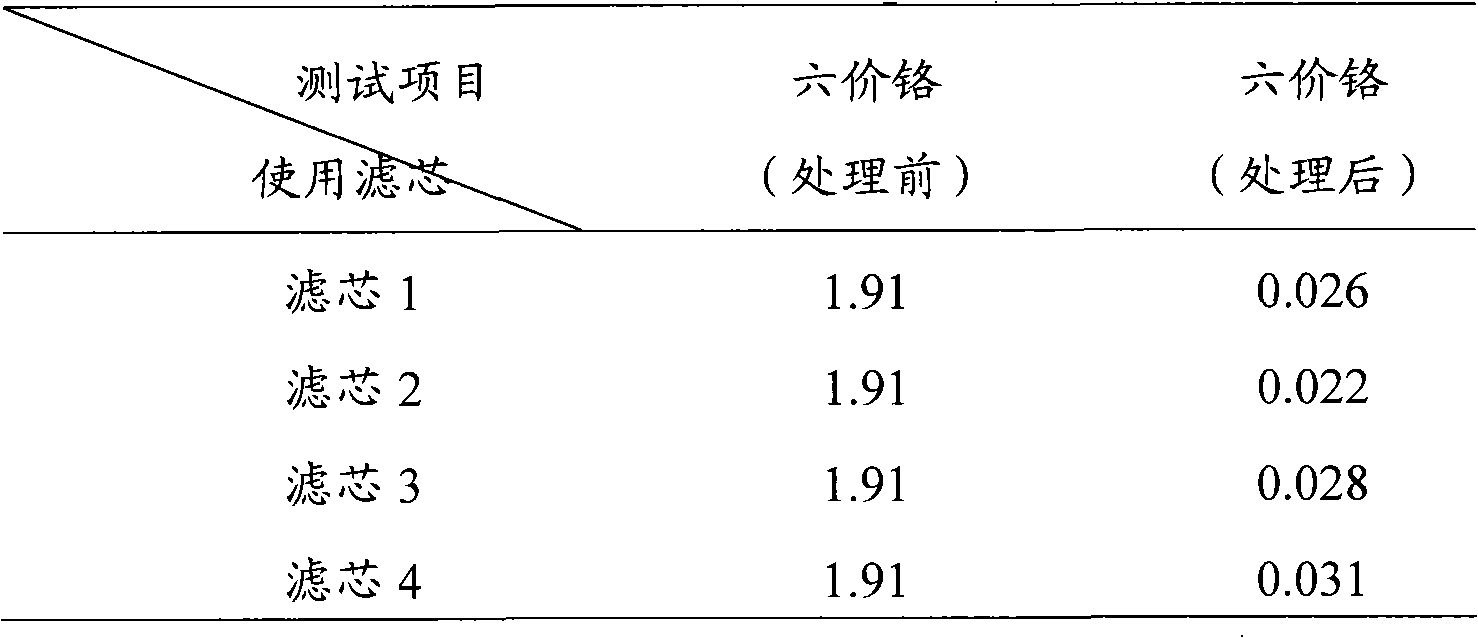

Filter medium for removing hexavalent chromium from drinking water and preparation method thereof

InactiveCN101844004AEasy to useEfficient removalOther chemical processesFiltration separationActivated carbonFoaming agent

The invention discloses a method for preparing a filter medium for removing hexavalent chromium from water, which comprises the following steps of: a) mixing raw materials, namely ultra-high molecular weight polyethylene powder, powdered activated carbon, magnesium hydroxide powder, bentonite powder and a foaming agent in a weight ratio of 200-300:50-200:50-200:50-120; and b) pressing the mixture obtained by the step a) in a mold, sintering and cooling. Compared with the prior art, the filter medium has the advantages that: the prepared filter medium can efficiently and quickly remove the hexavalent chromium from drinking water; in addition, the filter medium is simple and convenient to use and is suitable for treating drinking water at a home terminal; and detection results show that the filter medium prepared by the method has the removal rate of 95 to 99 percent for the hexavalent chromium in the drinking water.

Owner:QIDI ELECTRIC GROUP

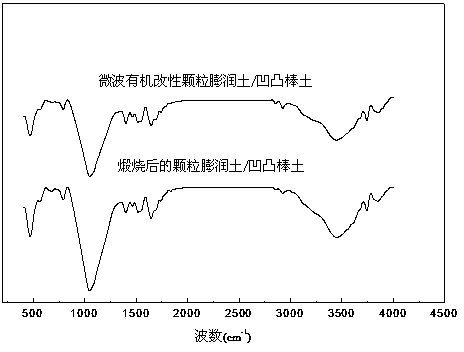

Microwave organic modified particle bentonite/attapulgite adsorbent and preparation method thereof

InactiveCN104069822AHigh strengthImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesSorbentPhysical chemistry

The invention relates to a microwave organic modified particle bentonite / attapulgite adsorbent and a preparation method thereof. The technical scheme is as follows: bentonite powder and attapulgite powder are used as main raw materials and mixed at the mass ratio of 1: (0.3-0.5); the bentonite powder and the attapulgite powder, and water are uniformly mixed at the mass ratio of 1: (1.2-2), dried at the temperature of 100-110 DEG C, smashed until the particle diameters are within 0.2-0.9 mm and calcined for 2-2.5 h at the temperature of 720-780 DEG C; under the microwave condition, the mixture is modified by the hexadecyl trimethyl ammonium bromide equivalent to 25-200% of calcined particle bentonite / attapulgite to obtain the microwave organic modified particle bentonite / attapulgite adsorbent. According to the invention, the microwave organic modified particle bentonite / attapulgite adsorbent is simple in technology, short in modified time, environment-friendly and low in energy consumption; prepared microwave organic modified particle bentonite / attapulgite adsorbent is great in particle diameter, good in adsorptive performance and suitable for the treatment of wastewater containing heavy metal irons and chlorophenol.

Owner:WUHAN UNIV OF SCI & TECH

Treatment method of organic wastewater through synthesis-free heterogeneous Fenton treatment

InactiveCN102765800AFew synthetic stepsShort purification timeWater/sewage treatment by oxidationCation-exchange capacitySodium Bentonite

The invention provides a treatment method of organic wastewater through synthesis-free heterogeneous Fenton treatment. The treatment method comprises the following steps of directly adding ferrous ion salt, H2O2 and bentonite powder in waste water, enabling solid-liquid mass ratio of bentonite and the waste water to be 1:1000-10000, enabling ferrous ionic charge mole number to be 50-100% of added bentonite cation exchange capacity, enabling molar ratio of Fe2+ and the H2O2 to be 500-1000:1, adjusting the pH value to be 5-6, stirring and reacting for 5-10min, conducting solid-liquid separation, and enabling the waste water to be discharged after reaching the standard. A series of complex synthesis steps of an original bentonite loaded ferric oxide catalytic agent before application are removed. Purification treatment time of the organic wastewater is shortened, and efficiency is improved. Cation exchange characteristics of the bentonite is used, iron ion is exchanged to a bentonite layer while the iron ion expresses catalytic action, loss of the iron ion is avoided, pollution of the iron ion in water is avoided, and possibility of reutilization is improved.

Owner:CHANGZHOU UNIV

Environment-friendly building material formed by shell powder and preparation method

The invention discloses an environment-friendly building material formed by shell powder and a preparation method. The building material comprises the following components by weight: 20 to 50 parts of the shell powder, 20 to 50 parts of diatomite, 10 to 20 parts of kaolin, 1 to 5 parts of nanoscale titanium dioxide, 5 to 20 parts of quartz powder, 5 to 10 parts of talcum powder, 1 to 5 parts of cellulose, 10 to 15 parts of sepiolite powder, 10 to 20 parts of bentonite powder, 10 to 15 parts of vermiculite fine powder, 5 to 10 parts of calcined gypsum powder, 1 to 5 parts of negative ion powder, 10 to 20 parts of a photocatalyst, 10 to 20 parts of ground calcium carbonate powder and 10 to 30 parts of white carbon black. The building material provided by the invention does not use any harmful matter, is insusceptible to emitting harmful gases like formaldehyde, benzene, ammonia gas and total volatile organic compounds (TVOC), has functions of adsorbing and decomposing the harmful gases and a certain breathing humidity-adjusting function, and can effectively kill a variety of bacteria.

Owner:韩泽龙

Preparation method of nitrogen- and phosphorus-doped graphene sheet

The invention discloses a preparation method of a nitrogen- and phosphorus-doped graphene sheet. The preparation method particularly includes following steps: adding bentonite to a proper amount of a tetramethyl ammonium bromide solution, stirring the mixture, aging the mixture, adding 4-dimethylamino pyridine and n-butyl phosphate, stirring the mixture in a constant-temperature water bath at 60-70 DEG C for 6-8 h, separating a precipitation from liquid, washing the precipitation with deionized water for 2-3 times, drying and grinding the precipitation, sieving the precipitation through a sieve being 20-40 in meshes to obtain modified bentonite powder, heating the modified bentonite powder in a vacuum tubular furnace to 400-600 DEG C under a vacuum condition for calcining the powder for 2-4 h, adding the calcined powder in a hydrofluoric acid solution, separating the precipitation and finally heating the precipitation to 2000-2500 DEG C under the vacuum condition to perform heat treatment for 3-6 h, and cooling a product to obtain the nitrogen- and phosphorus-doped graphene sheet. The preparation method is simple in raw materials and is mild in conditions.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

Bentonite cat litter and preparation method thereof

InactiveCN107897009APermanent charged functionGood dispersionAnimal housingFood colouringAbsorption effect

The invention belongs to the field of pet supplies, and particularly relates to bentonite cat litter and a preparation method thereof. The bentonite cat litter is prepared from, by weight, 70-80 partsof bentonite powder, 35-45 parts of tourmaline powder, 35-45 parts of nanometer TiO2 powder, 30-45 parts of hydroxyapatite powder, 20-25 parts of bamboo charcoal powder, 10-15 parts of cinnamomum camphora leaves, 10-15 parts of flos buddlejae, 15-20 parts of rhizoma osmundae, 10-15 parts of downy ground cherry fruits or herbs, 8-12 parts of celastrus angulatus, 15-18 parts of herba polygoni avicularis, 20-25 parts of water and 2-3 parts of food colouring. The bentonite cat litter is high in water absorption effect, good in deodorization and sterilization effects, natural, free of pollution, capable of serving the organic fertilizer to be buried and high in utilization rate.

Owner:陈燕蓉

Preparation method of peel-off type bentonite supported silver phosphate catalyst

ActiveCN103691462AIncrease contactEnhanced mass transferPhysical/chemical process catalystsSodium BentoniteBentonite suspension

The invention discloses a preparation method of a peel-off type bentonite supported silver phosphate catalyst. The preparation method comprises the steps of adding dry bentonite powder to a cation surface active agent solution, stirring and standing to form a cation modified bentonite suspension; dissolving ammonium carbamate in methyl alcohol and adding silver oxide, stirring and gradually dissolving the silver oxide to form an organic complex of silver; adding the organic complex of silver into the cation modified bentonite suspension, stirring, performing precipitating separation and drying; putting the dried product in a microwave oven, and carrying out microwave irradiation; and adding the product irradiated by microwave to a phosphoric acid solution, stirring, performing precipitating separation and drying to obtain a peel-off type bentonite supported silver phosphate catalyst. As the bentonite is in a peel-off state, a large bentonite inner surface area becomes an external surface area; the silver phosphate supported on the surface is easily illuminated in a photo-catalytic process and easily contacted with organic matters to be processed, so that mass transfer is facilitated.

Owner:无锡智慧兴宜信息技术有限公司

Antioxidant coating for surface of aluminum oxide-silicon carbidee-carbon brick

The invention relates to an antioxidant coating for the surface of an aluminum oxide-silicon carbidee-carbon (ASC) brick. The antioxidant coating is aqueous paste substance formed by mixing a component A and a component B by a weight part proportion of 100:101.5-102.5, wherein the component A is powder formed by mixing 50-70 parts by weight of glaze powder, 2-5 parts by weight of alpha-AL2O3 micro-powder, 1-7 parts by weight of bentonite powder, 1-3 parts by weight of SiO2 micro-powder and 26-35 parts by weight of silicon carbide powder; the component B viscous fluid formed by dissolving 1.5-2.5 parts by weight of carboxymethyl cellulose into 100 parts by weight of water, and the glaze powder in the component A is fine powder prepared by drying and grinding an material formed by mixing, melting and quenching 40-60 parts by weight of borax, 12-18 parts by weight of quartz, 8-15 parts by weight of sodium carbonate, 12-15 parts by weight of calcite and 8-12 parts by weight of albite. After coated with the antioxidant coating, ASC bricks of the lining of a torpedo type mixed iron car has the service life prolonged at least for 50 heating numbers, which saves the refractory material.

Owner:常州市武进第一耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com