Patents

Literature

75 results about "Bentonite suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

DrillingOwing to its rheological properties and thixotropy of aqueous suspensions, bentonite is used as a mud constituent for oil and water well drilling. Its functions are mainly to stabilise the borehole, seal the borehole walls, and remove drill cuttings.

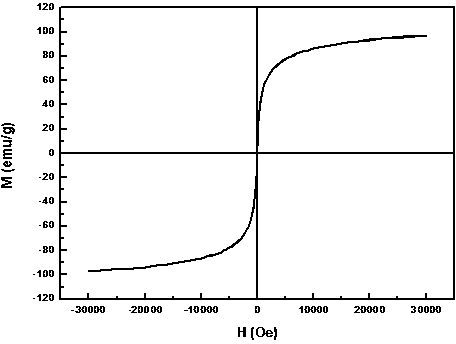

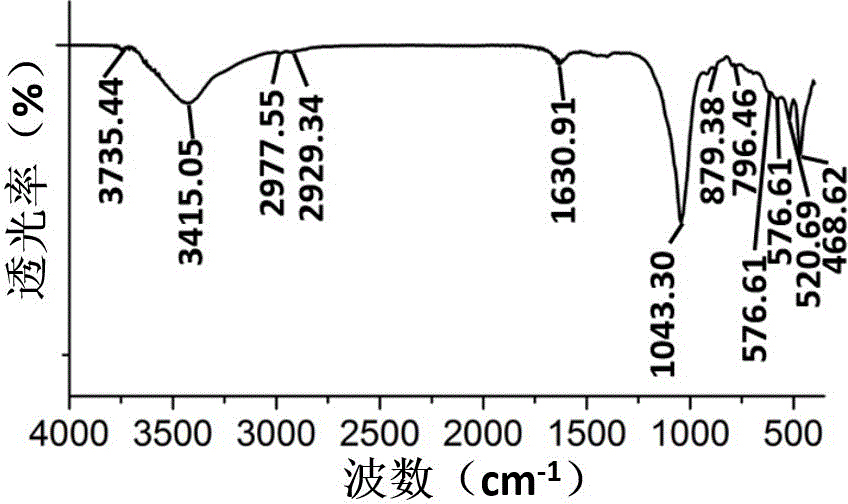

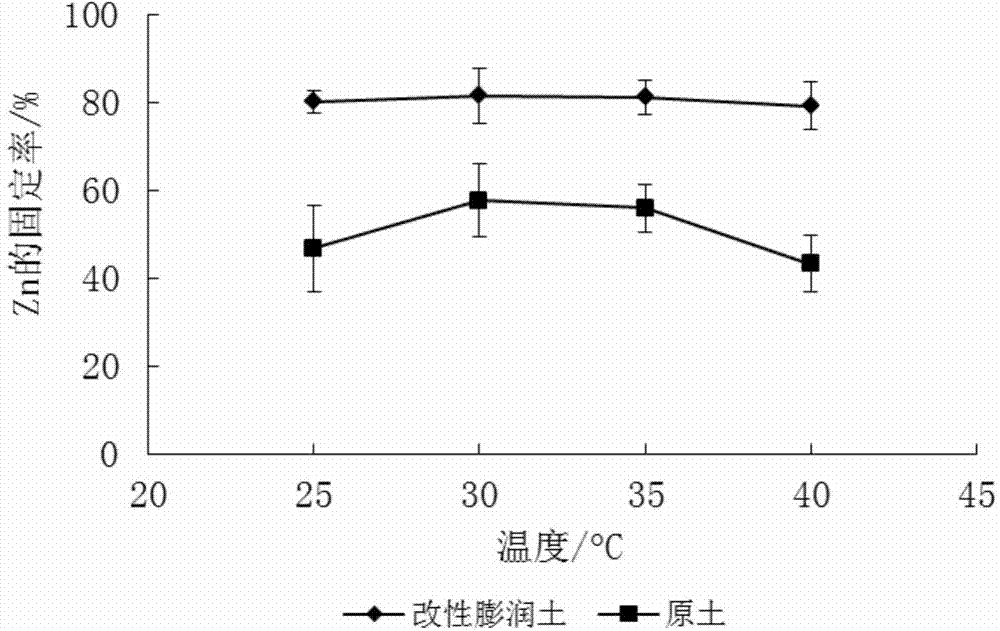

Preparation method of superparamagnetic bentonite-based water treating agent

ActiveCN104174354AGood adsorption and purification of industrial wastewaterFacilitate solid-liquid separationOther chemical processesWater/sewage treatment by sorptionSodium BentoniteBentonite suspension

The invention discloses a preparation method of a superparamagnetic bentonite-based water treating agent and belongs to the field of environmental protection and adsorbing-method water treatment. The preparation method comprises the following steps: (1) preparing modified bentonite suspension; (2) preparing a mixed aqueous solution of deionized water or distilled water of an inorganic or organic iron source containing Fe<2+> and Fe<3+>; (3) preparing an alkaline-substance aqueous solution; (4) carrying out synthesis in a reaction container; and (5) cleaning, drying and grinding. The preparation method disclosed by the invention has the advantages that the adsorptivity is good, the magnetic separation and recycling are easy, the preparation process is simple, materials are easily available, the reaction is mild and the effect of adsorbing coal slime and other impurities in coal-slime water is relatively good.

Owner:TAIYUAN UNIV OF TECH

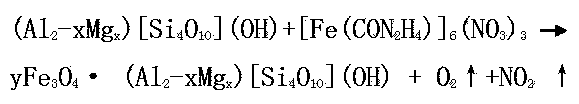

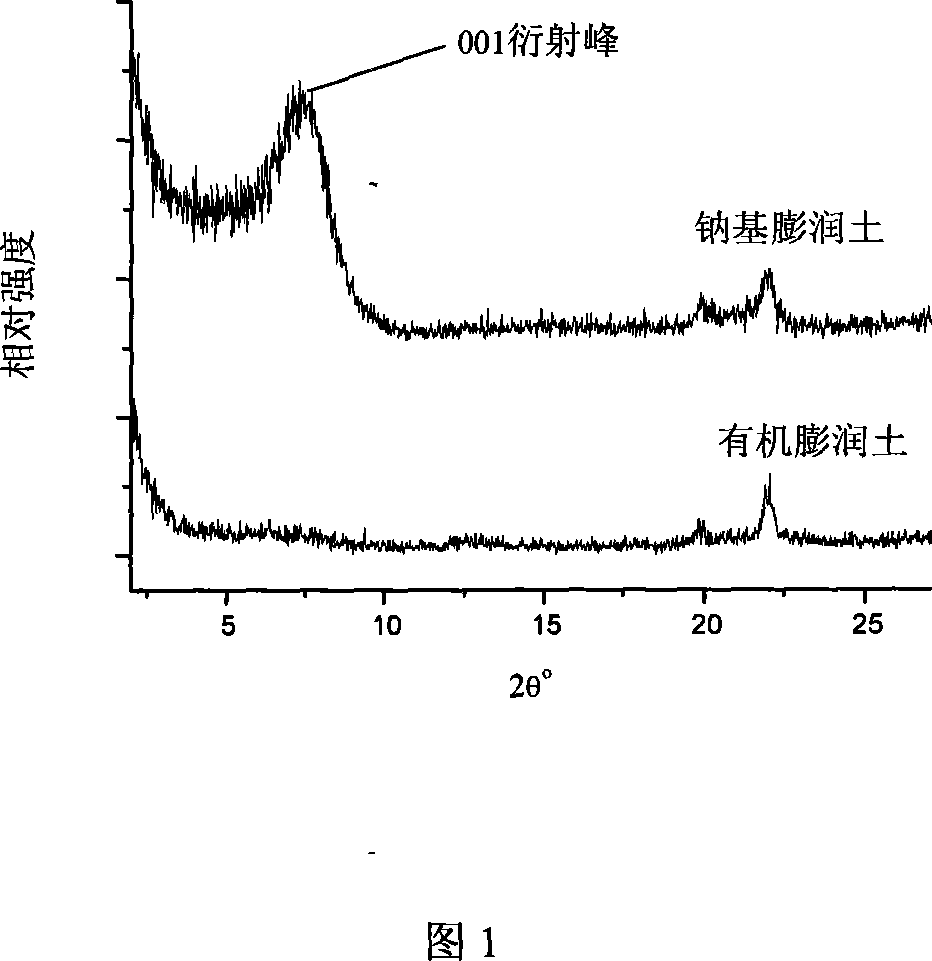

Method for preparing organophilic bentonite

InactiveCN101182393APigment treatment with non-polymer organic compoundsSodium BentoniteBentonite suspension

The invention relates to a preparation method of organic bentonite, which adopts natural sodium bentonite or artificial sodium bentonite, disperses with water, removes impurities through centrifugation, obtains sodium bentonite suspension as raw material, and adds anion with a concentration of 1 to 4 wt%. Surfactant, mixed evenly, its addition is 0.5~2mol per kilogram of Na-montmorillonite in the suspension; the addition of precipitant is 0.5~2mol, so that the anionic surfactant forms chemical adsorption and Physical adsorption becomes organic bentonite and produces hydrophobic precipitates. After separation, washing to remove ions, drying and crushing, organic bentonite is obtained. The XRD spectrum of the sample shows that the bentonite is in a completely exfoliated state and has better compatibility with organic substances.

Owner:NORTHEASTERN UNIV

Preparation and recovery methods for magnetic clay adsorption material

InactiveCN105126743AEasy to makeStrong paramagnetic propertiesOther chemical processesAlkali metal oxides/hydroxidesRecovery methodBentonite suspension

The invention provides preparation and recovery methods for a magnetic clay adsorption material. The preparation process comprises adding a strong base substance into an aqueous solution of a mixture of inorganic ferric / ferrous compounds under the circumstances of nitrogen protection and sufficient stirring, so as to prepare a magnetic nanoparticle; adding an ethanol solution of a surfactant into an aqueous solution of the prepared magnetic nanoparticle, and fully stirring and mixing for reaction; fully mixing a bentonite suspension fully swelled by water with the surface-functionalized magnetic nanoparticle for reaction; and performing sufficient magnetic separation on the reaction product and washing off superfluous metal and nonmetal ions, so as to obtain the magnetic clay material. The magnetic clay material adsorbing dye pollutants can be reestablished and reused through gamma radiation of a 60 Co radioactive source. The provided preparation method is simple, and the prepared magnetic clay absorption material is convenient to use, high in adsorption efficiency, and repeatedly reusable.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method and application of composite bentonite for wastewater treatment

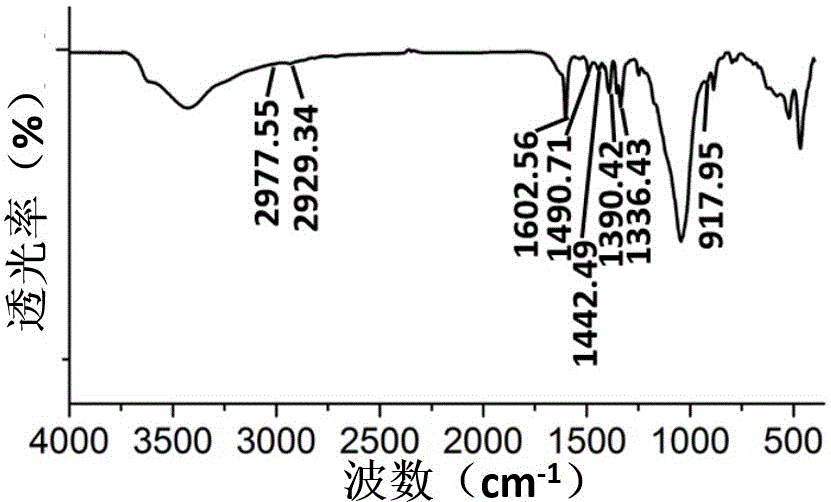

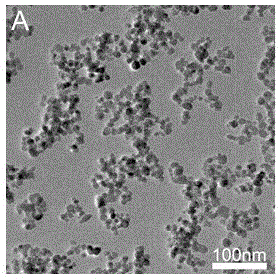

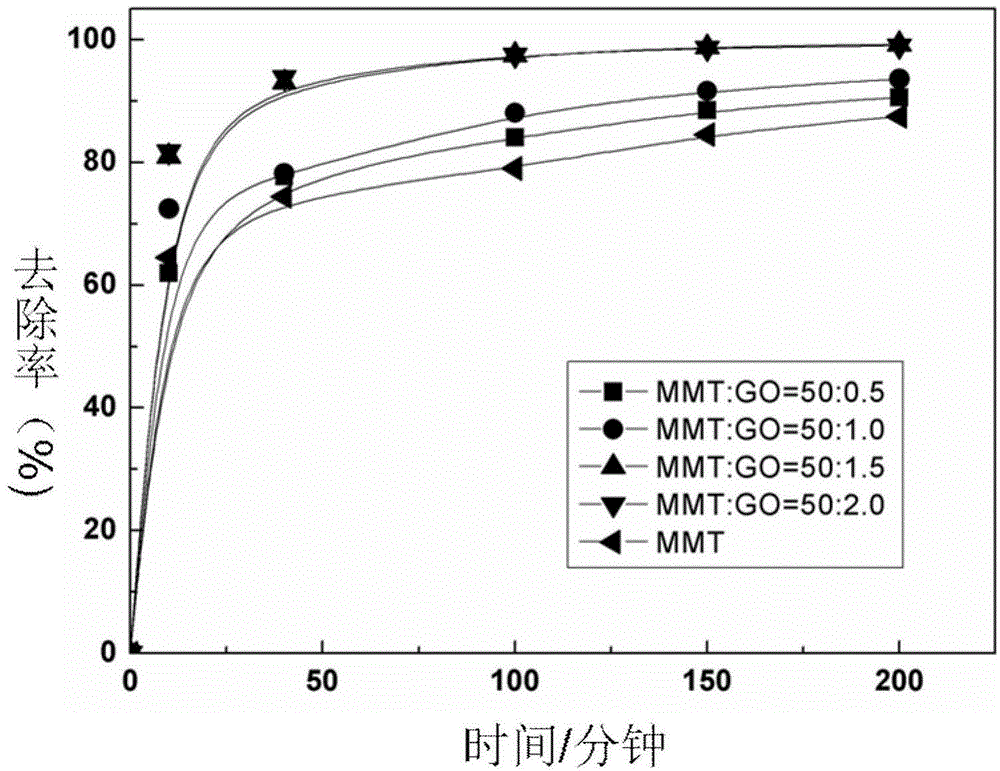

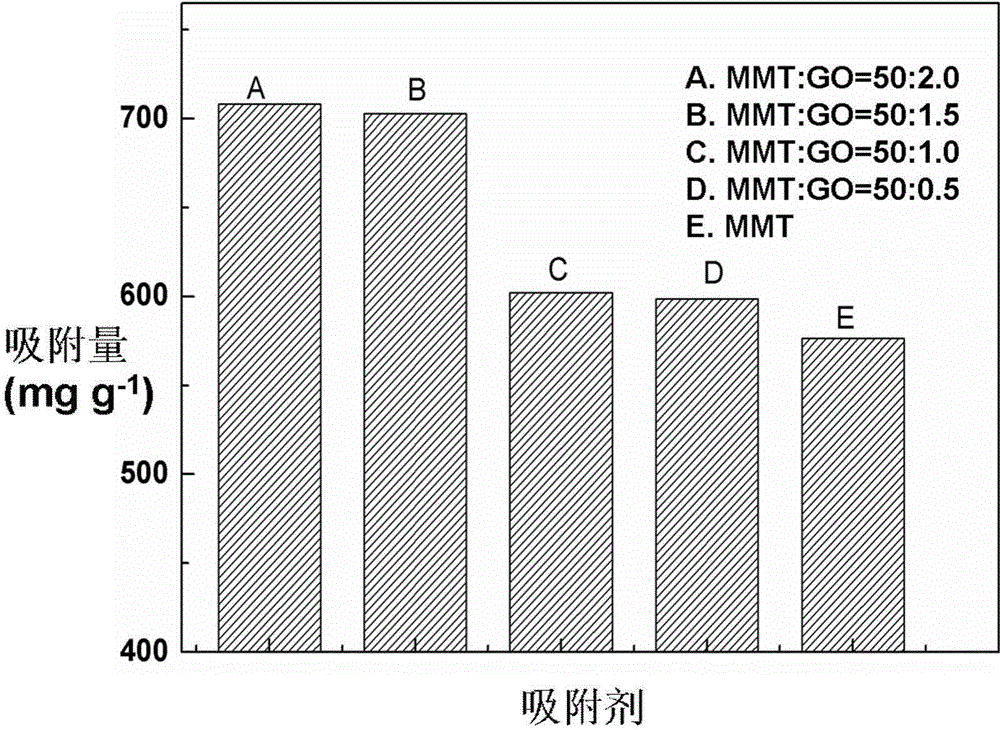

InactiveCN104437359AImprove adsorption capacityEfficient removalOther chemical processesWater contaminantsOrganic dyeSorbent

The invention relates to a wastewater treatment adsorbent, and particularly relates to a preparation method and application of composite bentonite for wastewater treatment. The composite bentonite is prepared from the following raw materials in parts by weight: 50 parts of bentonite and 0.5-2 parts of graphite oxide; the preparation method comprises the following steps: dispersing the bentonite in water by using ultrasonic waves to obtain a uniform bentonite suspension; dispersing the graphite oxide in water, and stripping by using ultrasonic waves to obtain a uniform graphite oxide solution; and mixing the bentonite suspension with the graphite oxide solution, centrifugally dehydrating and washing, and drying to obtain the composite bentonite for wastewater treatment. The composite bentonite for wastewater treatment, disclosed by the invention, is simple in synthesis method, low in production cost, simple to operate when used for removing organic dyes from water, friendly to environment, obviously better than existing natural bentonite in organic dye adsorption and good in industrial application prospect.

Owner:CHINA WEST NORMAL UNIVERSITY

Preparation method of modified bentonite particle retention aid for papermaking

InactiveCN102011337AGood removal effectHigh content of active ingredientsRetention agents additionBentonite suspensionPapermaking

The invention relates to a preparation method of a modified bentonite particle retention aid for papermaking, comprising the following steps of: mechanically pulverizing mined natural bentonite into particles below 200 meshes, then dispersing the pulverized bentonite in water, and washing and sieving to remove impurities; adding an acid solution into bentonite suspension for reacting and then separating to remove the precipitated impurities; extruding and dehydrating the separated bentonite suspension, repeatedly washing and extruding until the pH value is 3-6.5; and finally, diluting and dispersing bentonite subjected to acidization with water, adding sodium salt for reacting and then diluting the bentonite suspension until the mass concentration is 0.01-5% to obtain the modified bentonite particle retention aid. In the invention, the adopted two-step modification method can be used for favorably removing the impurities in the bentonite so as to improve the content of the active ingredients in the bentonite, and in addition, the extrusion and dehydration treatment can be carried out before drying so as to improve drying efficiency and reduce production cost. The method benefits the improvement of the quality of the bentonite particle retention aid and use effect of the same in papermaking.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method for modified bentonite

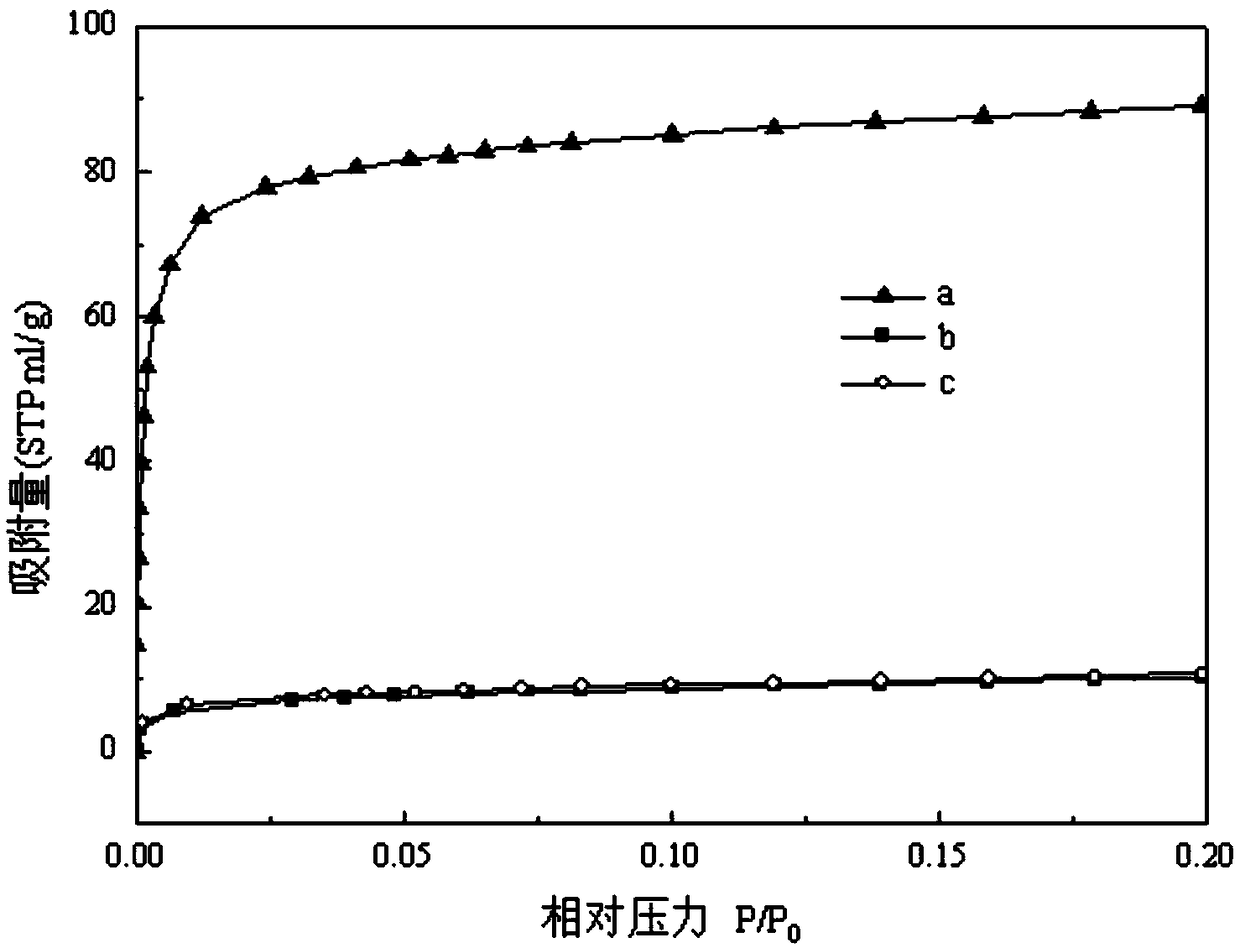

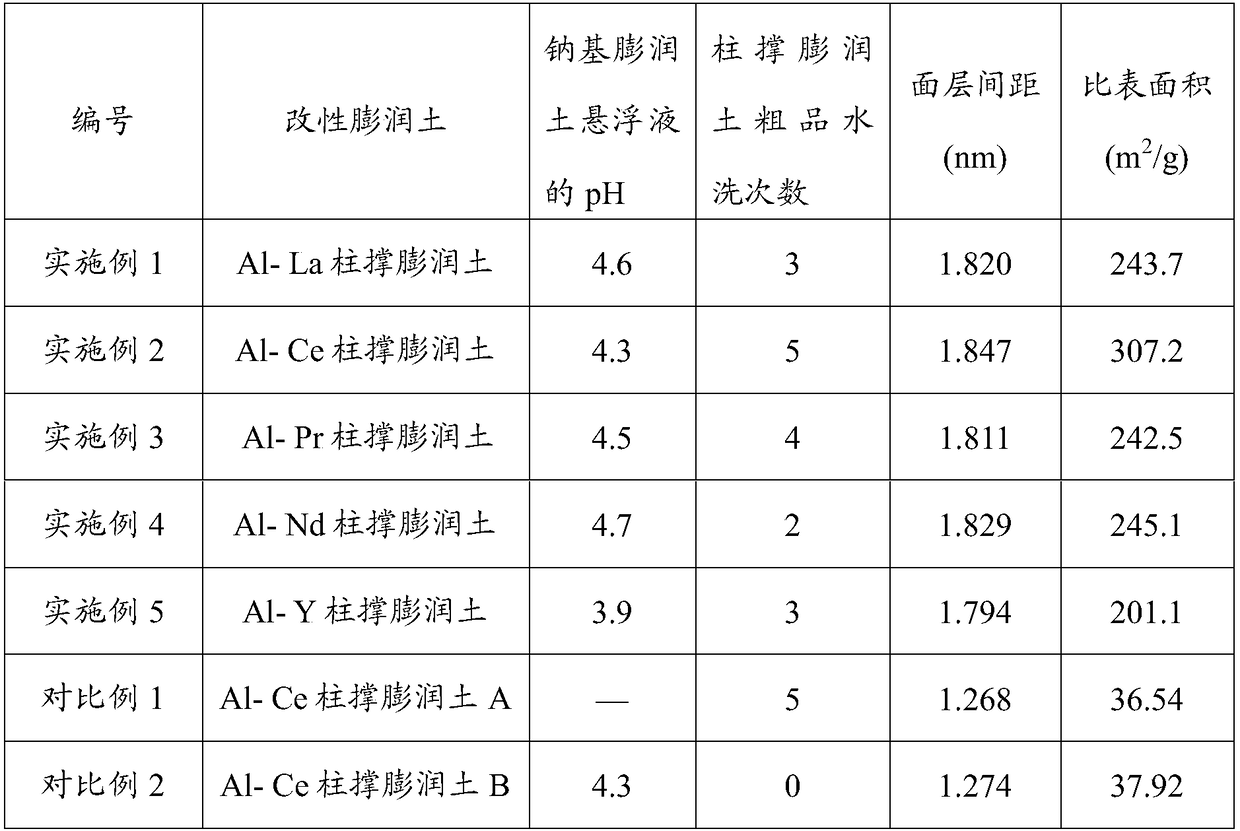

InactiveCN109279616AIncrease the areaSimple manufacturing processNanotechnologySilicon compoundsSodium BentoniteSurface layer

The invention discloses a preparation method for modified bentonite, comprising: (1) mixing a calcium bentonite slurry with a sodium salt modifier to obtain a first mixed liquid, and treating the first mixed liquid to obtain sodium bentonite, and using the sodium bentonite to prepare a sodium bentonite suspension having a pH value of 3.0 to 6.0; (2) mixing a soluble aluminum salt solution with a soluble rare earth salt solution to obtain a second mixed solution, and dropwise adding an alkaline solution to the second mixed solution to obtain a pillaring agent; and (3) mixing the pillaring agentwith the sodium bentonite suspension to obtain a modified bentonite crude product, and then conducting multiple times of water washing, drying and calcination to obtain the modified bentonite. The method of the present invention is advantageous for achieving industrial production, and is capable of obtaining modified bentonite having significantly increased surface layer spacing and specific surface area.

Owner:BAOTOU RES INST OF RARE EARTHS

Thin layer multi coloured sand wall shaped paint

The present invention discloses a thin-layer multicolour sand textured architectural coating. Its formula composition includes the following components: (by wt%) 20-60% of various colour stone powders, 2-6% of polyvinyl alcohol hydrosol, 5-20% of hydroxyethyl cellulose hydrosol, 15-65% of film-forming resin emulsion, 0-10% of colour coating film, 0.5-1.5% of film-forming adjuvant, 0.5-10% of covering filling material, 2-5% of bentonite suspension, 0-5% of water-base various colour pastes and the rest is water.

Owner:巢启

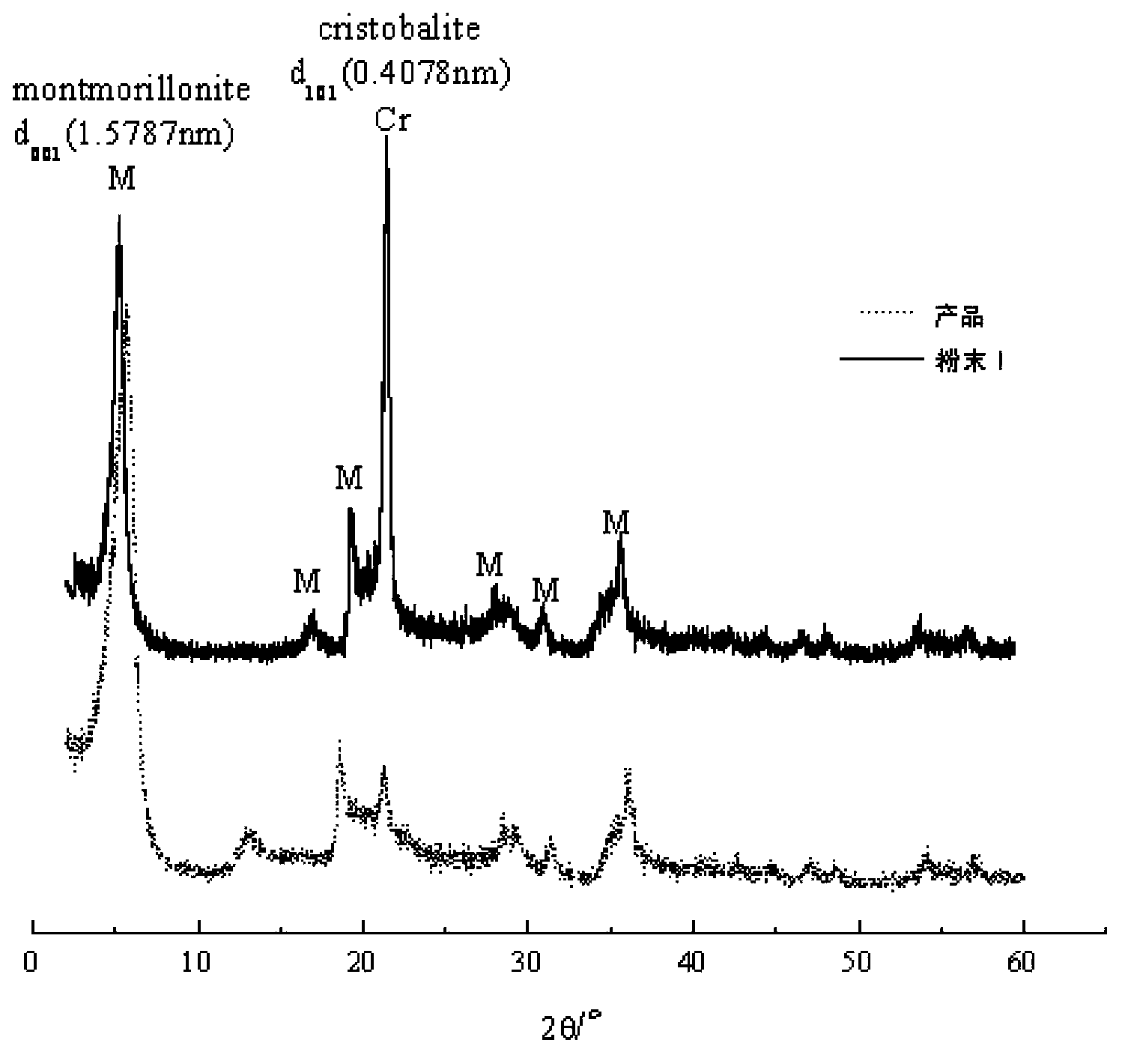

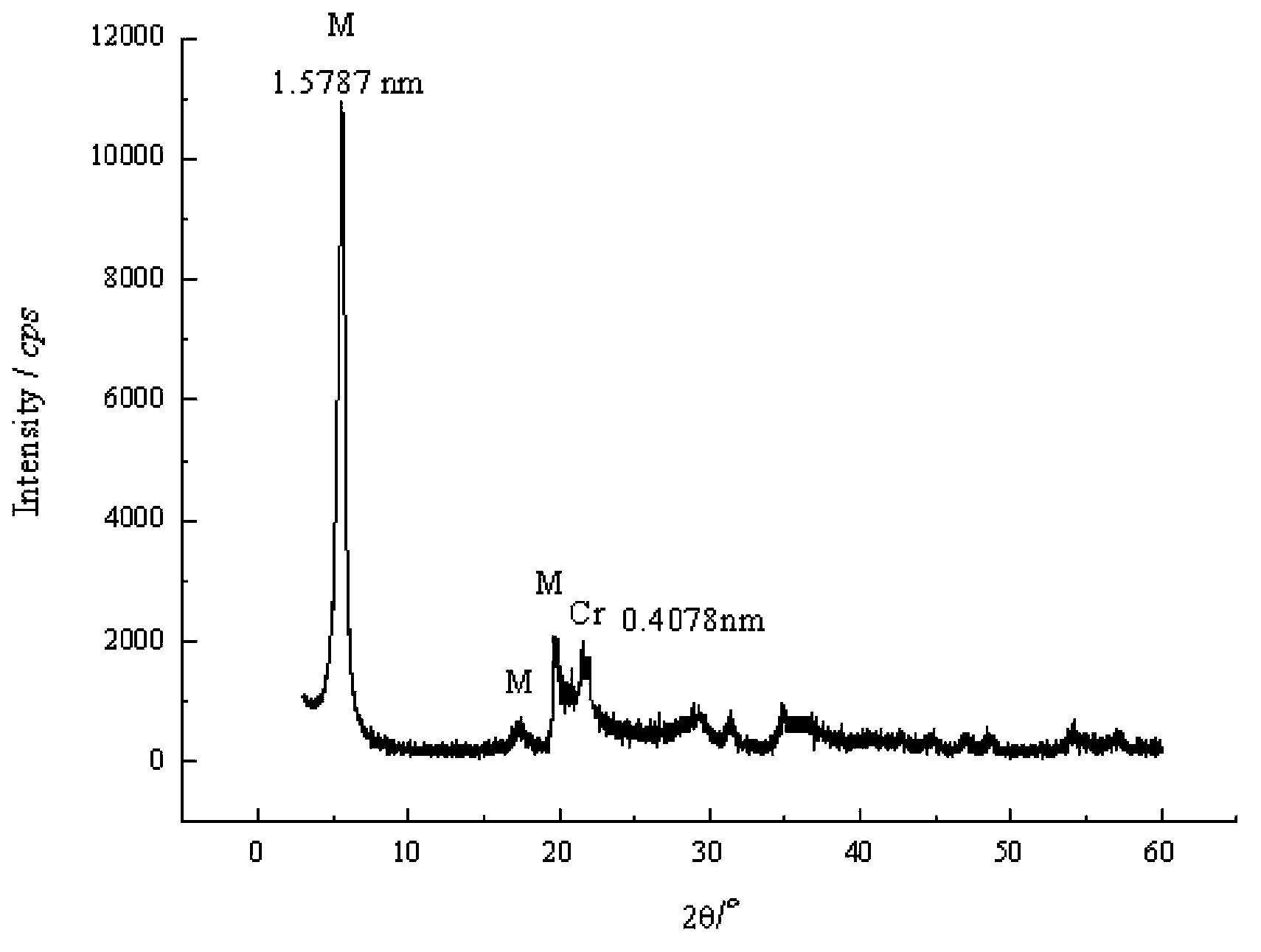

Method of separating and purifying montmorillonite from calcium bentonite

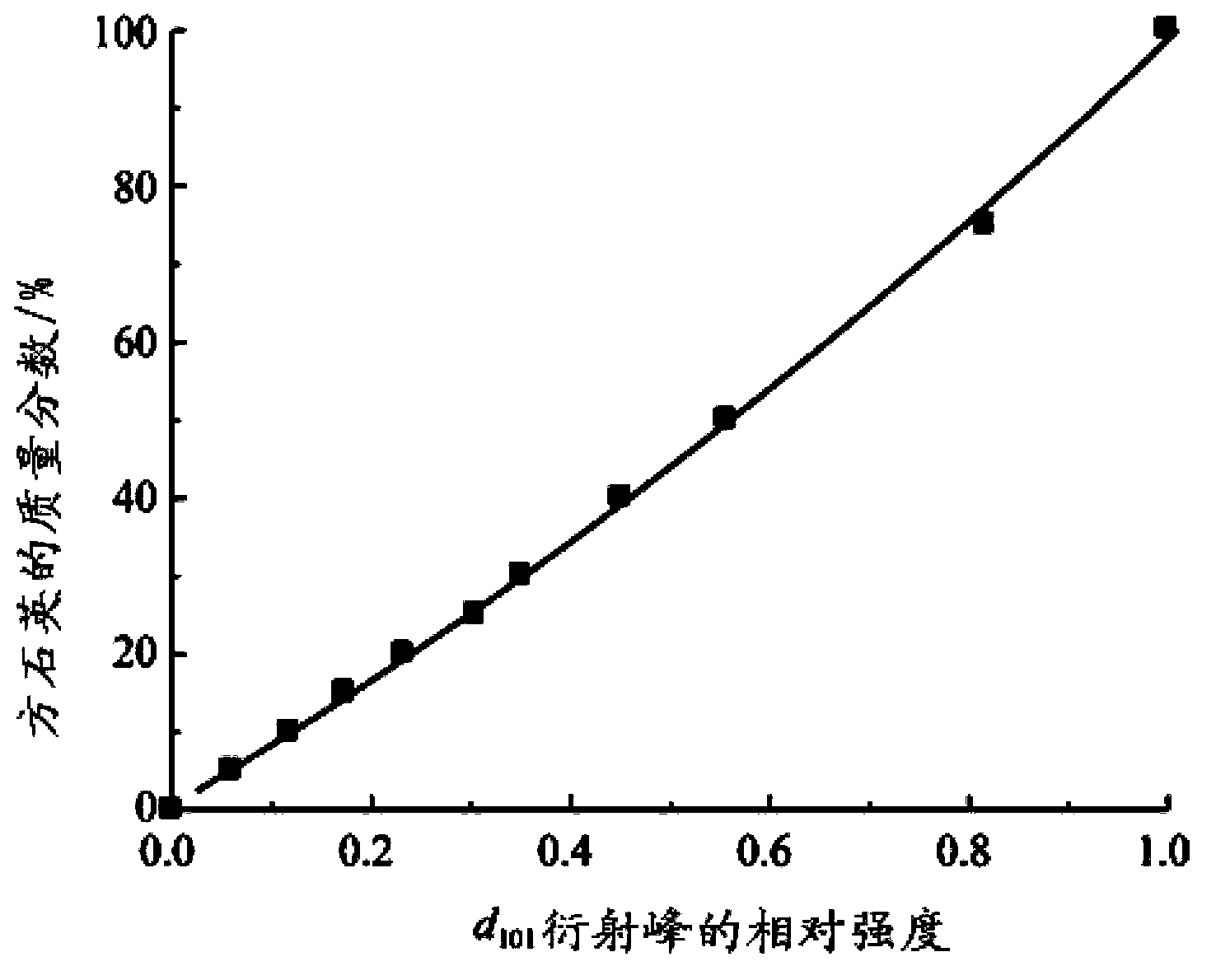

ActiveCN103848430AChemical structure unchangedMild chemical propertiesSilicon compoundsChemical structureSodium Bentonite

The invention discloses a method of separating and purifying montmorillonite from calcium bentonite. The method includes: adding dispersants such as sodium carbonate into a bentonite suspension, adjusting the pH value of the suspension, separating to obtain primarily-purified montmorillonite, adjusting the pH value of a suspension of the primarily-purified montmorillonite to a certain value, performing ultrasonic wave processing, and separating to obtain the high-purity montmorillonite. The chemical structure of the montmorillonite is unchanged. A superfine cristobalite impurity concomitant with the montmorillonite in the calcium bentonite is effectively removed. By ultrafine particle dispersion, the superfine cristobalite particles and the montmorillonite are depolymerized, thus enhancing dispersion and suspension capability of the superfine cristobalite particles and the montmorillonite. The cristobalite is removed by utilization of fractional centrifugation so as to obtain the high-purity montmorillonite, thus solving the technical problem that the cristobalite is hard to remove in the montmorillonite purification. The method has characteristics of simple process, mild conditions, cheap and easily available raw materials, low equipment requirements, high added value of products, and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

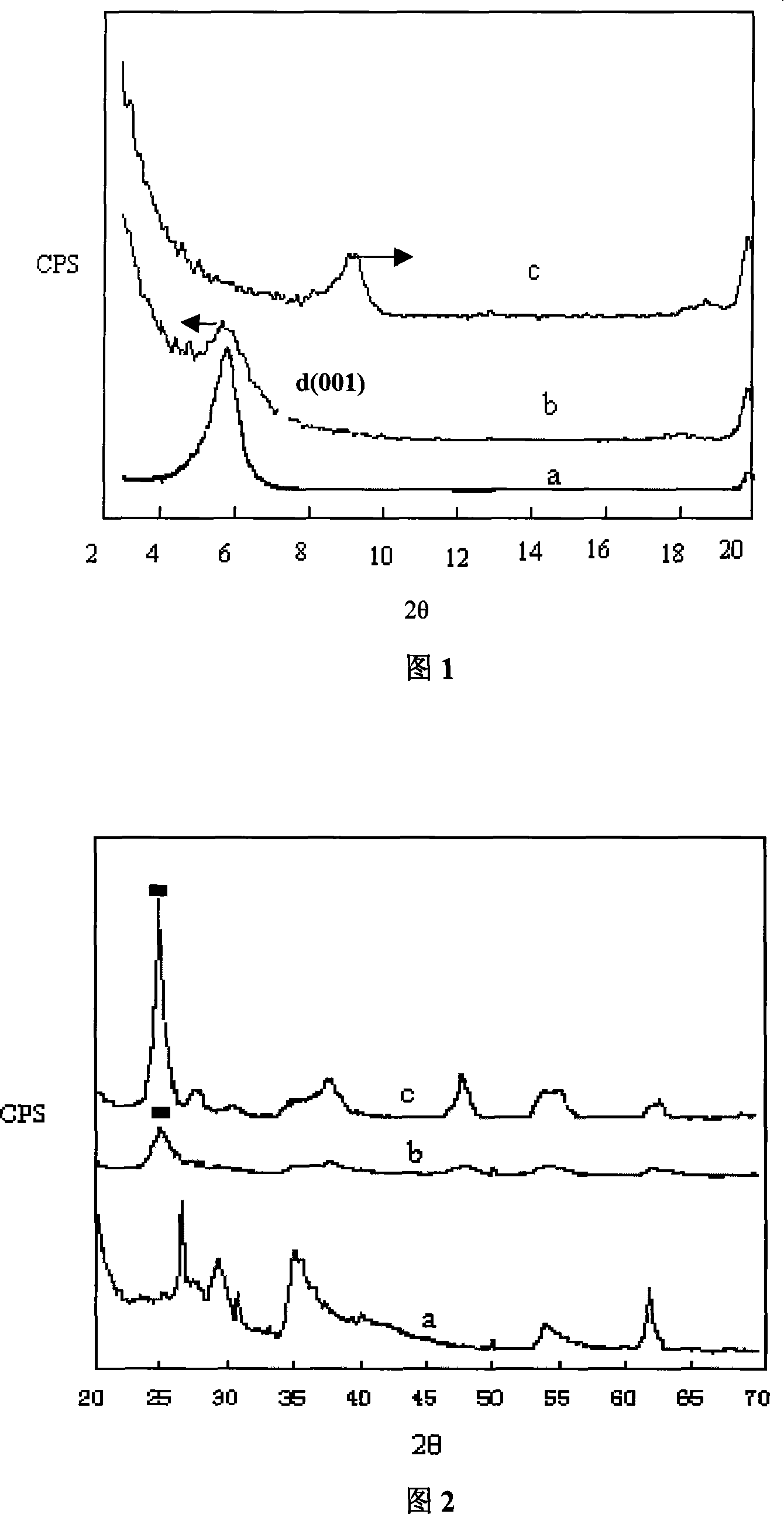

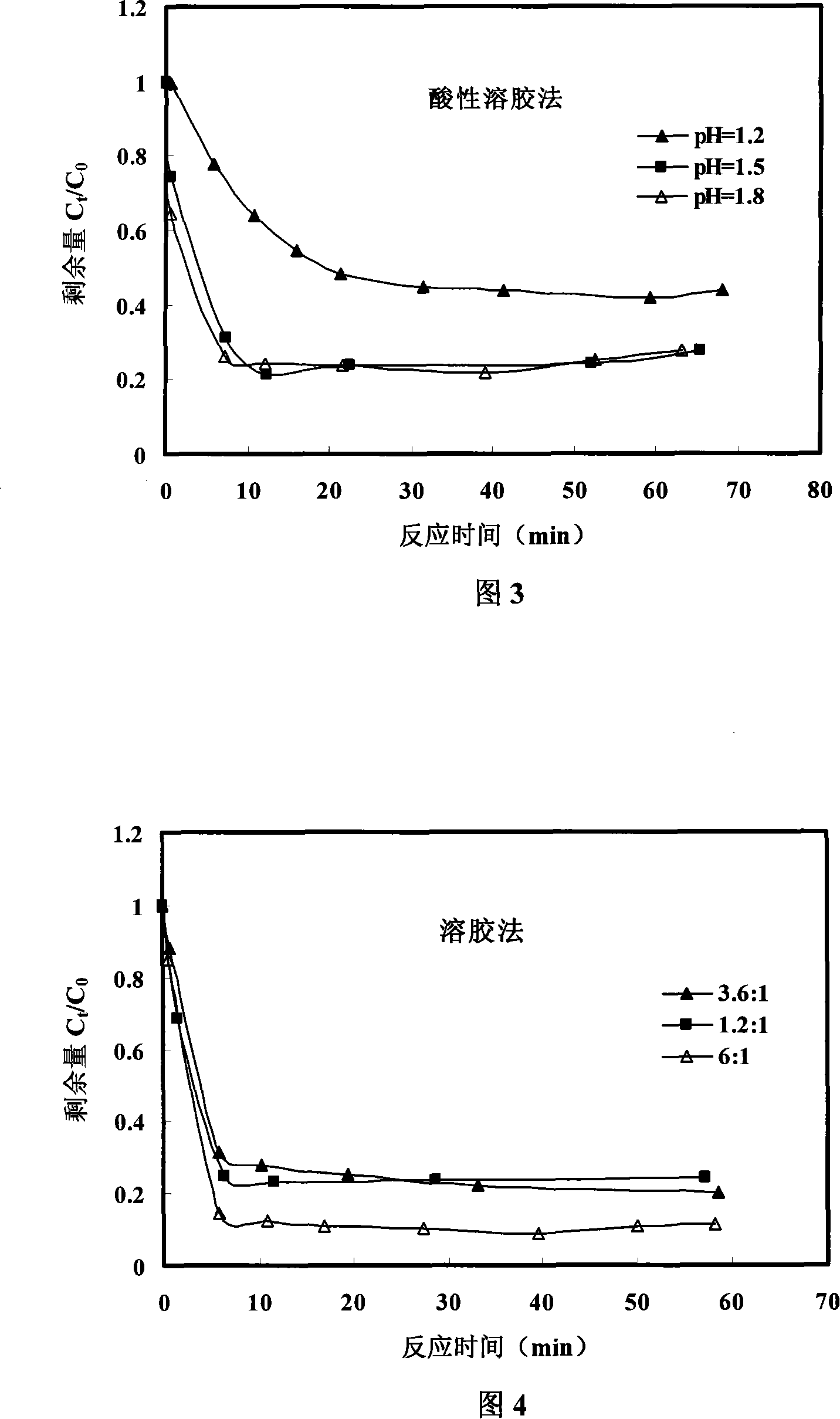

TiO2 column-supporting alta-mud adsorption-photocatalysis integrated process for preparation of catalysts

InactiveCN101138715AEliminate effects of catalytic efficiencyEliminate the effects ofPhysical/chemical process catalystsDispersed particle separationSodium BentoniteBentonite suspension

The present invention discloses a preparation method for absorption of an integrated photo-catalyst by TiO2 pillared bentonite. The method comprises the following steps: (1) tetrabutyl titanate is added into absolute ethanol; the molar ratio of the absolute ethanol and the tetrabutyl titanate is 1.2-6:1; the absolute ethanol and the tetrabutyl titanate are mixed form a light yellow gel A, which is aged in the air for use; (2) the bentonite is used; a cation exchange amount of the bentonite is 0.5-0.9 of the molar amount of tetrabutyl titanate; after the bentonite is fully soaked with water, a bentonite suspension B is formed; (3) the suspension B is added into the sol A, and the suspension B and the sol A are fully agitated; then the solid-liquid separation and the water-washing are conducted; the compound is dried, grinded, calcined and cooled down. The present invention is simple in the operation. Materials for the present invention can be easily got at a low price, so the manufacture cost of the present invention is low. Compared with an acid sol method, as no acid or alkali has to be added in the preparation course of the present invention, the operation is simplified and affection of inorganic ions on the catalysis performance of the catalyst.

Owner:ZHEJIANG UNIV

Preparation method of peel-off type bentonite supported silver phosphate catalyst

ActiveCN103691462AIncrease contactEnhanced mass transferPhysical/chemical process catalystsSodium BentoniteBentonite suspension

The invention discloses a preparation method of a peel-off type bentonite supported silver phosphate catalyst. The preparation method comprises the steps of adding dry bentonite powder to a cation surface active agent solution, stirring and standing to form a cation modified bentonite suspension; dissolving ammonium carbamate in methyl alcohol and adding silver oxide, stirring and gradually dissolving the silver oxide to form an organic complex of silver; adding the organic complex of silver into the cation modified bentonite suspension, stirring, performing precipitating separation and drying; putting the dried product in a microwave oven, and carrying out microwave irradiation; and adding the product irradiated by microwave to a phosphoric acid solution, stirring, performing precipitating separation and drying to obtain a peel-off type bentonite supported silver phosphate catalyst. As the bentonite is in a peel-off state, a large bentonite inner surface area becomes an external surface area; the silver phosphate supported on the surface is easily illuminated in a photo-catalytic process and easily contacted with organic matters to be processed, so that mass transfer is facilitated.

Owner:无锡智慧兴宜信息技术有限公司

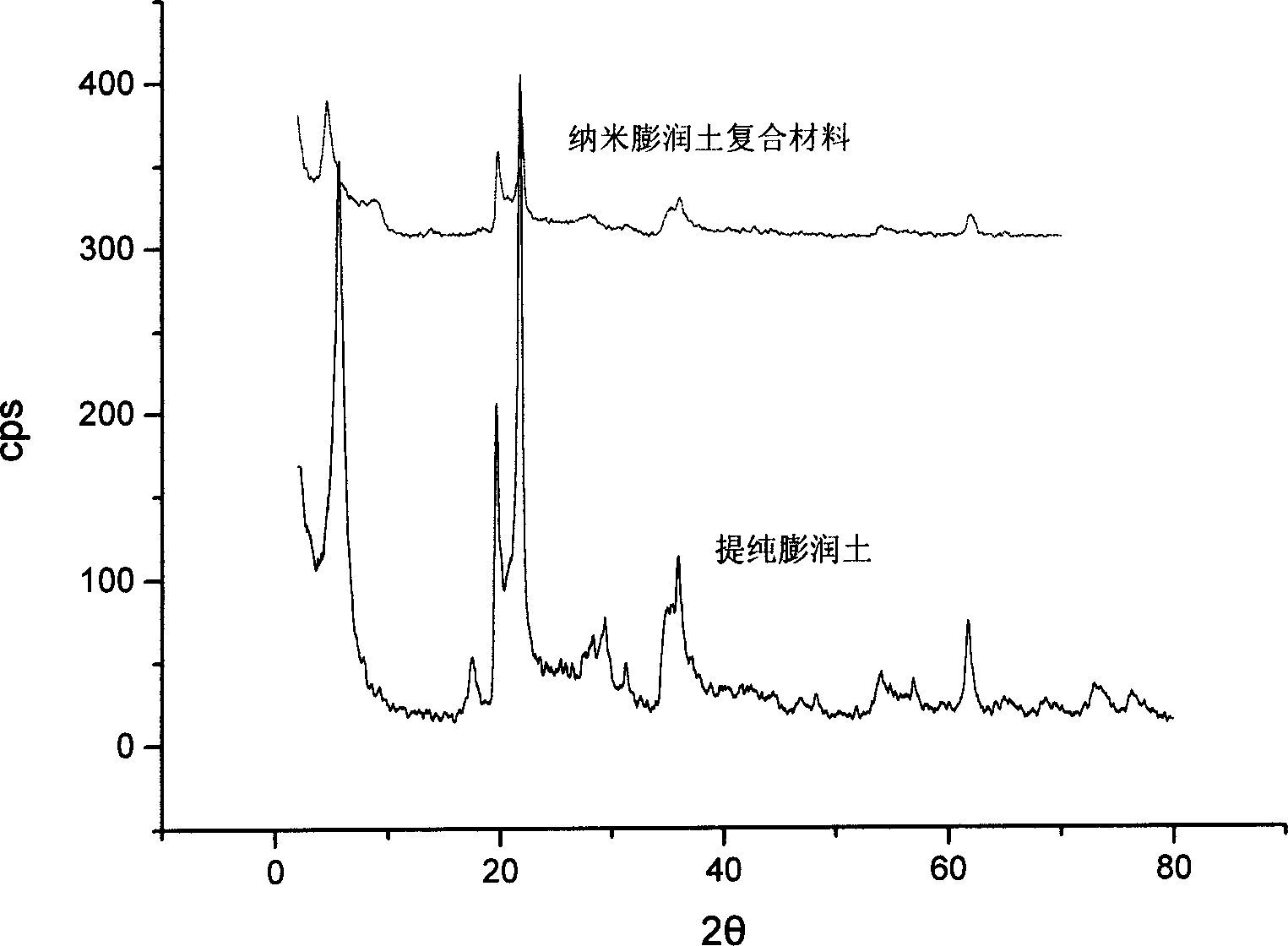

Process for preparing nano titanium dioxide bentonite composite material

InactiveCN1683073ASignificant adsorptionSignificant catalytic effectOther chemical processesCatalyst activation/preparationSodium BentoniteBentonite suspension

The preparation process of nano composite titania / bentonite material includes the following steps: 1) adding water into sodium base or calcium base bentonite for expanding and shearing at high speed to obtain bentonite suspension; 2) adding TiCl2 into anhydrous alcohol via stirring and ageing to prepare transparent solution A; 3) dropping solution A into the mixed solution of glycerin and water in certain volume ratio via stirring and ageing to prepare transparent solution B; and 4) dropping bentonite suspension in certain amount into solution B while stirring, reacting inside one high pressure reactor with PTFE lining at 80-200 deg.c for 1-15 hr, washing the discharged product until no Cl ion and drying. The process is simple, practical and suitable for industrial production, and the product is a excellent photocatalyst.

Owner:SHANXI UNIV

Process for converting calcium bentonite to sodium bentonite

InactiveUS20170260098A1Easy to controlLarge particle sizeClay processing apparatusDrilling compositionSodium BentoniteBentonite suspension

Method of converting calcium bentonite to sodium bentonite that is suitable for use as drilling mud or a cement additive. After the addition of a calcium bentonite sample to a prepared soda ash solution at predetermined soda ash / bentonite weight ratios, the bentonite suspension is continuously heated and stirred for up to 24 h. The heating and stirring are crucial towards enhancing the sodium activation of the bentonite, as well as other rheological properties of the bentonite.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Organic bentonite for white oil-based drilling fluid and preparation method thereof

InactiveCN104031623AHigh viscosityImprove hydrophobicity and lipophilicityDrilling compositionSodium BentoniteBentonite suspension

The invention relates to organic bentonite for white oil-based drilling fluid of the petroleum industry, the natural gas industry and the like, and a preparation method of the organic bentonite. The hydrophobicity, the lipophilicity and the high-temperature resistance of the organic bentonite are improved, and the organic bentonite is good in compatibility, high in system viscosity and moderate in dynamic shearing force. According to the technical scheme, the organic bentonite comprises the following raw materials in percentage by mass: 60-80 parts of sodium bentonite as the bentonite, 10-30 parts of m-alkyl trimethyl ammonium halide as quaternary ammonium salt, 2-10 parts of sodium lauryl sulfate, sodium dodecyl sulfate or sodium dodecyl benzene sulfonate as an anionic surfactant. The preparation method comprises the following steps: screening the bentonite, adding water to prepare bentonite suspension, adding a quaternary ammonium salt solution into the bentonite suspension for once modification, further adding an anionic surfactant solution into the suspension for secondary modification, and finally aging, drying, crushing and screening so as to prepare the organic bentonite. The product is simple in production process and convenient to operate, and is used as drilling fluid as the hydrophobicity, the lipophilicity and the high-temperature resistance are all improved.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of high-dispersion organic bentonite

InactiveCN106179232AGood dispersionImprove surface activityOther chemical processesWater/sewage treatment by sorptionSodium BentoniteBentonite suspension

The invention relates to a preparation method of high-dispersion organic bentonite, and belongs to the field of chemical industry. The method comprises the steps that octadecyl trimethyl ammonium chloride and tetramethyl ammonium bromide serve as organic modifiers to conduct organic modification on sodium-based bentonite powder, treatment is conducted, and organic bentonite suspension is obtained; tea seed cake is subjected to fermentation, by means of tea saponin, inoculation of bacillus subtilis and inoculation of pseudomonas aeruginosa are conducted, culture is conducted, and biosurfactant is obtained; the biosurfactant and the organic bentonite suspension are mixed, and the dispersing performance of sodium-based bentonite is improved. According to the preparation method of the high-dispersion organic bentonite, the biosurfactant and the organic bentonite suspension are mixed, the surface activity of organic bentonite particles is improved, the dispersing performance of the organic bentonite can be improved, the specific surface area can reach 50 m<2> / g to 100 m<2> / g, the preparation steps are simple, and the required cost is low.

Owner:仇颖莹

Method of producing sodium bentonite

InactiveUS20170152184A1Increasing water controlLarge particle sizeClay processing apparatusDrilling compositionSodium BentoniteBentonite suspension

Method of converting calcium bentonite to sodium bentonite that is suitable for use as drilling mud or a cement additive. After the addition of a calcium bentonite sample to a prepared soda ash solution at predetermined soda ash / bentonite weight ratios, the bentonite suspension is continuously heated and stirred for up to 24 h. The heating and stirring are crucial towards enhancing the sodium activation of the bentonite, as well as other rheological properties of the bentonite.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

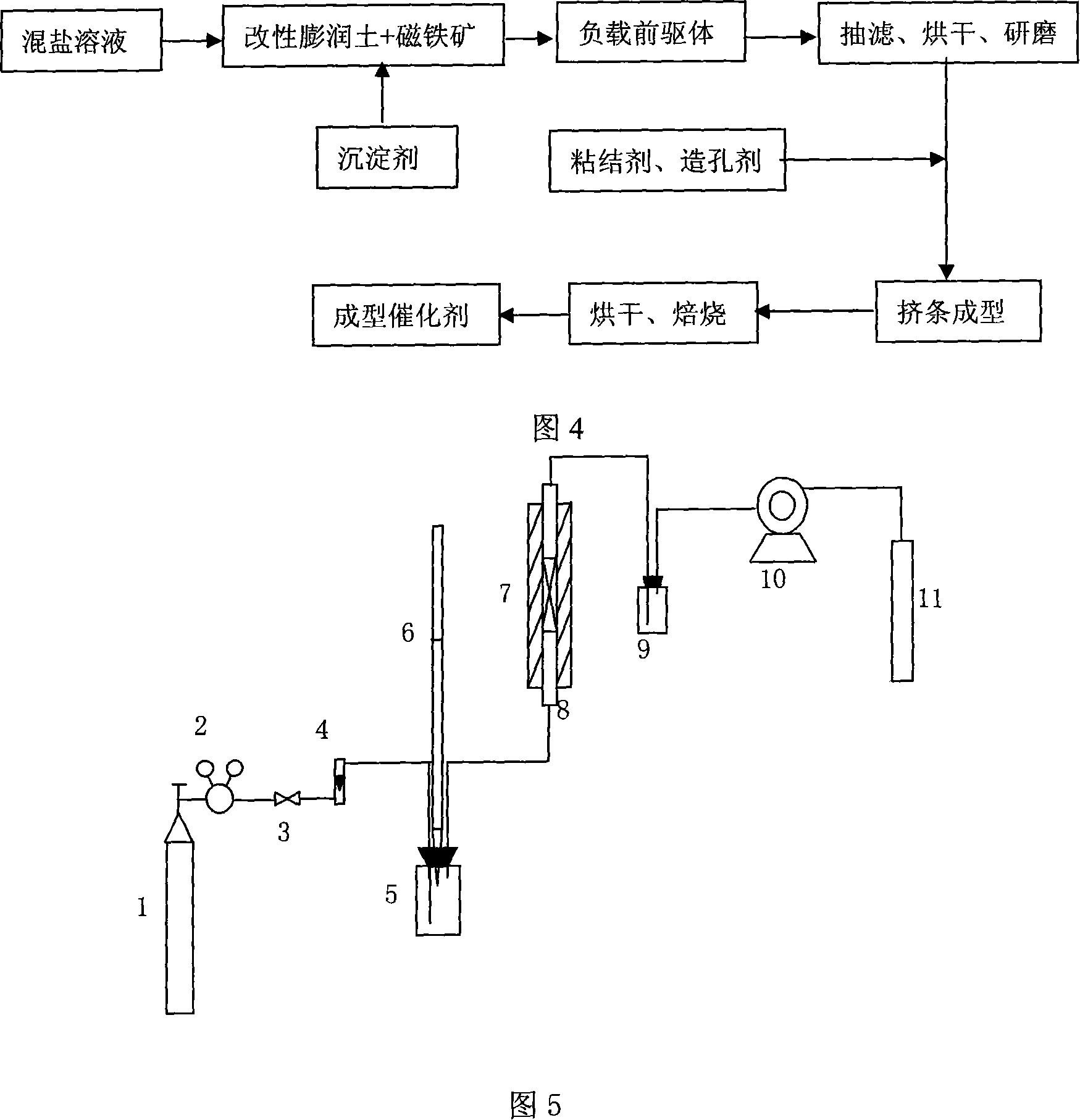

Composite cross-linking pole support bentonite intercalation desulfurizer and preparation method thereof

InactiveCN101148605AEfficient removalHigh desulfurization precisionOther chemical processesHydrocarbon oils refiningCross-linkWater baths

The present invention provides one kind of composite cross-linked organic pillared interlayer bentonite desulfurizer and its preparation process. The preparation process includes the following steps: compounding sodium bentonite slurry, adding ZnCl2 solution, ion exchanging for 12 hr and regulating pH to 6.0; dropping the mixed slurry into Keggin solution to prepare organic pillared bentonite; dropping organic intercalating agent in the amount of 0.6 CEC sodium bentonite into the composite cross-linked pillared bentonite suspension at 75 deg.c, stirring for 2 hr, centrifugally cleaning, drying at room temperature, grinding to 200 mesh to obtain organic-inorganic composite cross-linked pillared interlayer bentonite; heating the mixed solution of Zn(NO3)2, Cu(NO3)2 and Mn(NO3)2 in a water bath, adding the modified bentonite and magnetite and dropping Na2CO3 precipitant; cooling to room temperature, vacuum suction filtering, stoving and grinding to obtain the desulfurizer.

Owner:HARBIN ENG UNIV

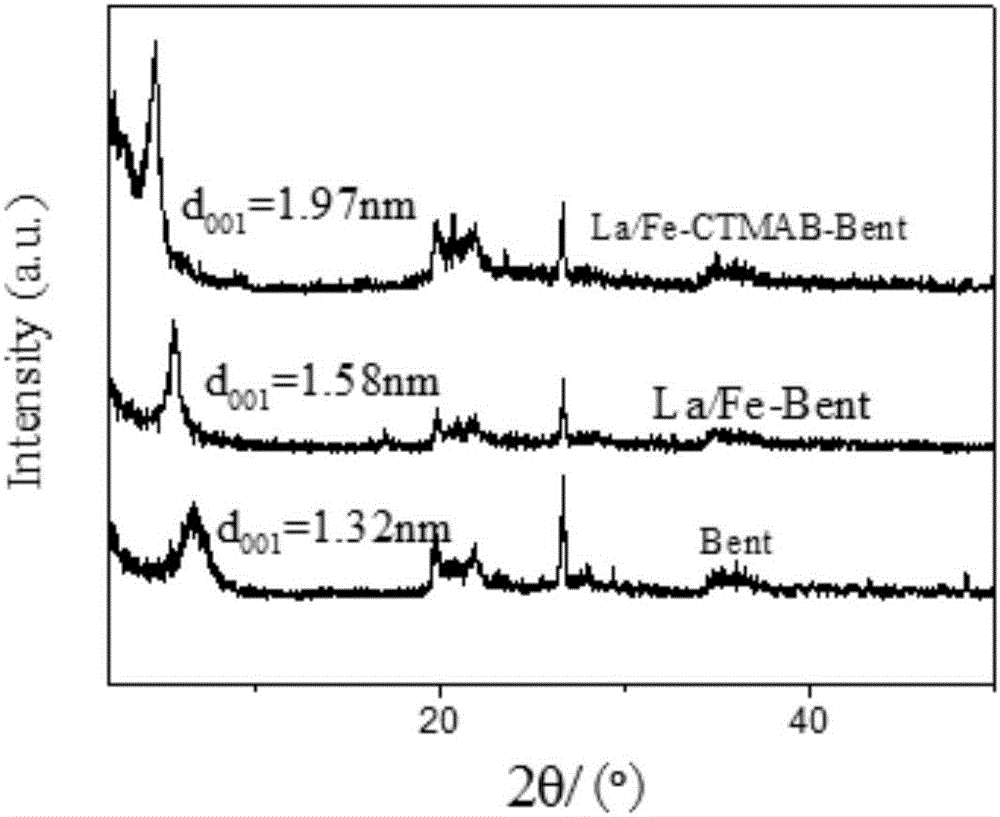

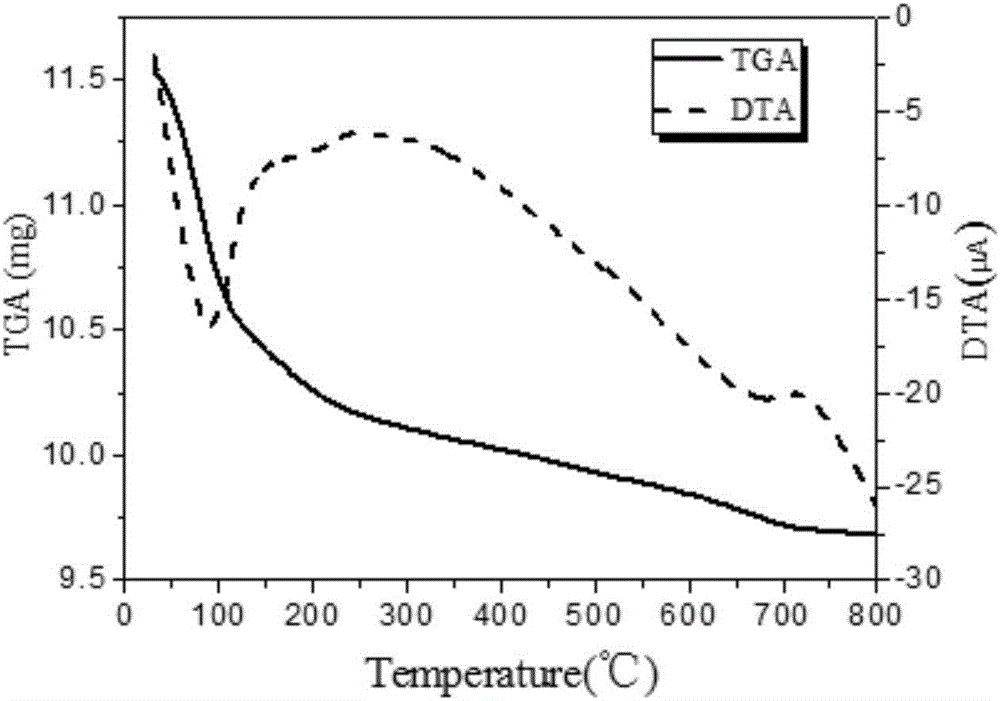

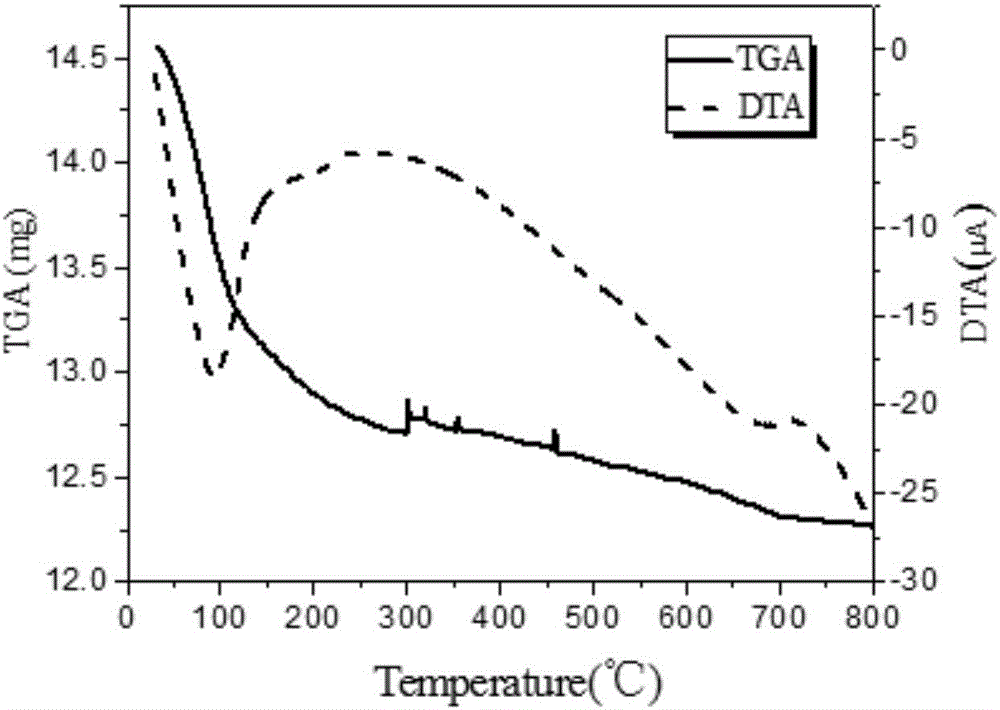

Preparation method of La-Fe/CTMAB (cetyltrimethylammonium bromide) composite modified bentonite adsorbing material

ActiveCN106378119AImprove stabilityHydrophobicOther chemical processesWater contaminantsWater bathsFiltration

The invention discloses a preparation method of a La-Fe / CTMAB (cetyltrimethylammonium bromide) composite modified bentonite adsorbing material. The preparation method comprises the following steps: preparing a polycarbonyl iron solution and a La(NO3)3 solution, adding the polycarbonyl iron solution and La(NO3)3 solution into a bentonite raw soil suspension to obtain a La-Fe inorganic modified bentonite suspension, carrying out vacuum filtration, washing, drying and grinding to obtain La-Fe inorganic modified bentonite, adding the La-Fe inorganic modified bentonite into a CTMAB solution, treating in a thermostatic water bath, stirring and aging to obtain a La-Fe / CTMAB inorganic-organic composite modified bentonite suspension, and carrying out vacuum filtration, washing, drying and grinding to obtain the La-Fe / CTMAB composite modified bentonite adsorbing material. The method solves the problem of poor adsorbability of bentonite raw soil for organic pollutants in the prior art.

Owner:XIAN UNIV OF TECH

Bentonite, biological polysaccharide plural gel immobilized cell carrier and preparation method thereof

InactiveCN101157914ALow curing temperatureHigh mechanical strengthOn/in organic carrierOn/in inorganic carrierCarrageenanSodium Bentonite

The invention relates to an immobilized cell carrier of bentonite and biological polysaccharide compound gel, which comprises the materials according to the following volume proportion: 40 to 60 proportions of bentonite suspension solution, 40 to 60 proportions of compound polysaccharide solution, 120 to 180 proportions of potassium chloride solution; concentration of the bentonite suspension solution is 0.02 to 0.04 g / ml; concentration of the compound polysaccharide solution is 0.024 to 0.048 g / ml which is a mixed solution of carrageenan and guar gum, wherein, weight ratio of the carrageenan and the guar gum is between 5 : 0.8 and 5:1.2; concentration of the potassium chloride solution is 1.5 to 2.5 percent. The invention adopts bentonite, biological polysaccharide compound as materials to prepare polymer sphere, which has the advantages of high mechanical strength, wide scope of pH value application, good heat stability, poisonless and good biocompatibility, and can be used for various fields such as foodstuff, biomedicine, bioengineering, etc., as an immobilized cell carrier.

Owner:NORTHWEST NORMAL UNIVERSITY

Retention aid for paper making and preparation method thereof

InactiveCN106283861AWill not cause churnNo cloggingRetention agents additionWater filterBentonite suspension

The invention discloses a retention aid for paper making and a preparation method thereof. The retention aid for paper making is prepared from the following raw materials in parts by weight: water, cationic polyacrylamide, natural bentonite, aluminum oxide, poly magnesium chloride, chitosan, hydrochloric acid and catalysts. The preparation method of the retention aid for paper making comprises the following concrete steps that materials are taken; the natural bentonite is crushed, washed and sieved to remove impurities; then, the hydrochloric acid is added to take a reaction to obtain bentonite suspension; the cationic polyacrylamide and the water are added into a reaction tank; the catalysts are added; heating is performed; heat insulation reaction is performed; then, the aluminum oxide, the chitosan, the poly magnesium chloride and the bentonite suspension are sequentially added for reaction; then drying is performed to obtain a finished product. The preparation method provided by the invention has the advantages that the preparation method is simple; the production cost is low; the method is suitable for mass production; the water, the cationic polyacrylamide, the natural bentonite and the aluminum oxide achieve mutual synergistic effects; a large number of micro pores with small particle diameters exist in the natural bentonite, so that the fiber and fine material loss cannot be caused, the water filtering passage blockage cannot be caused, and the net part water filtering is smooth.

Owner:TIANJIN YOUWEI PRINTING PACKAGING

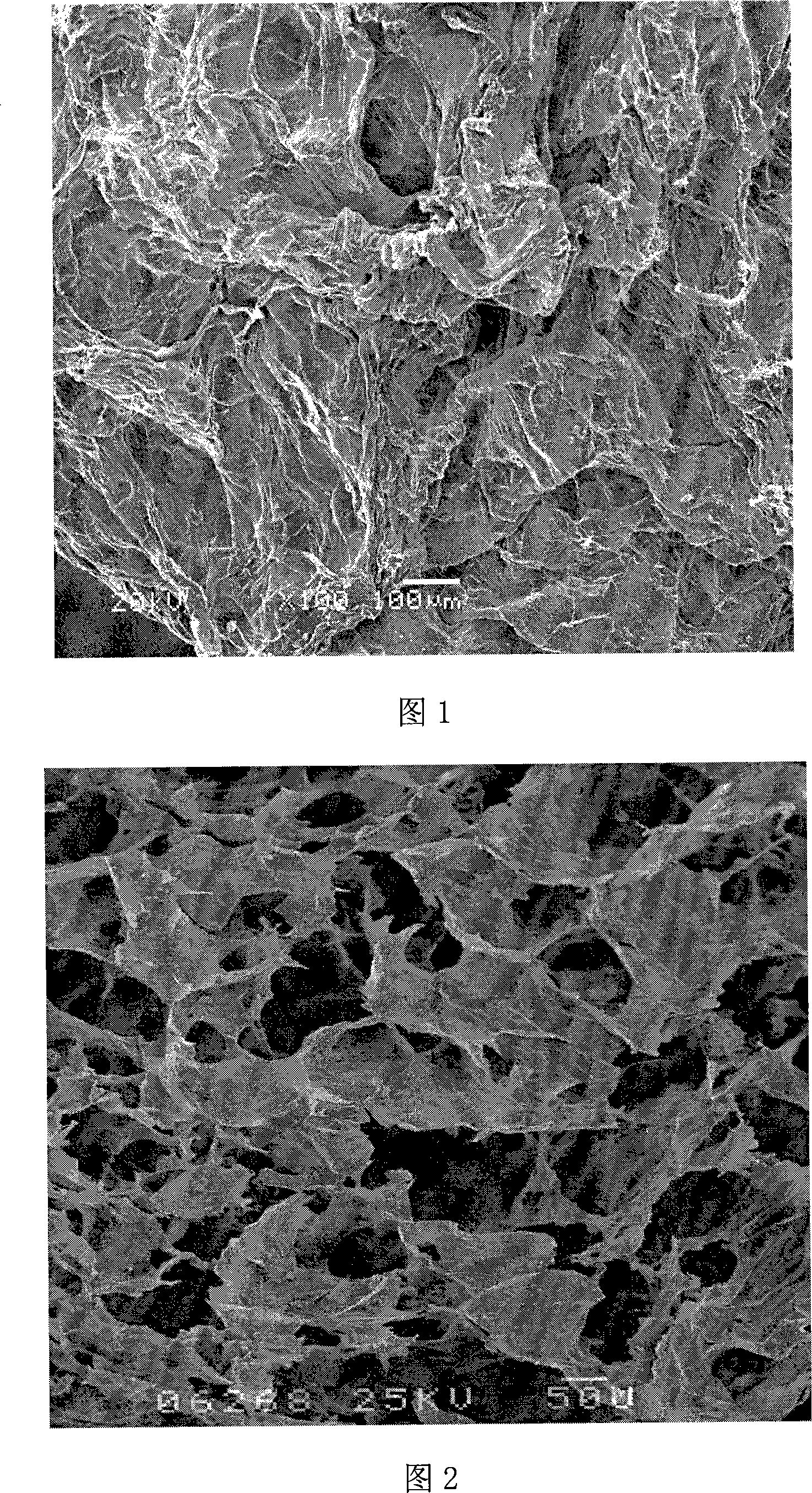

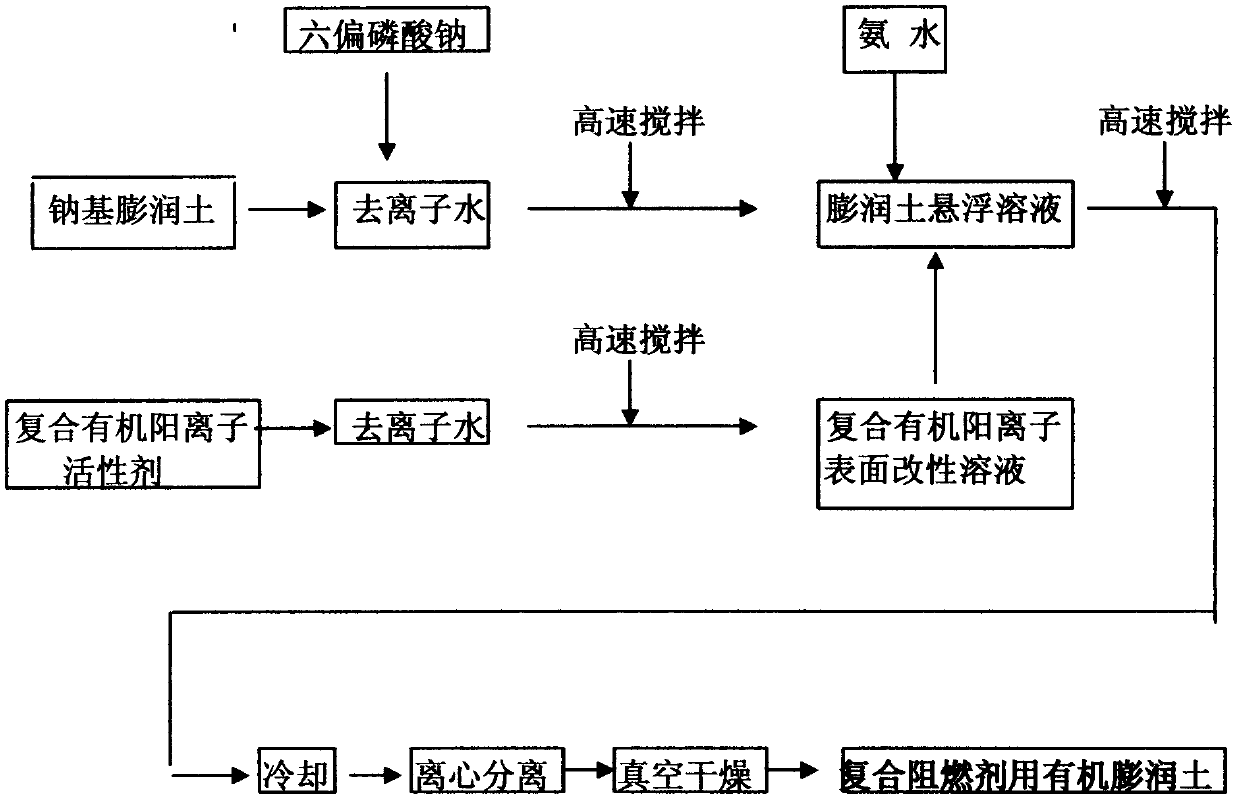

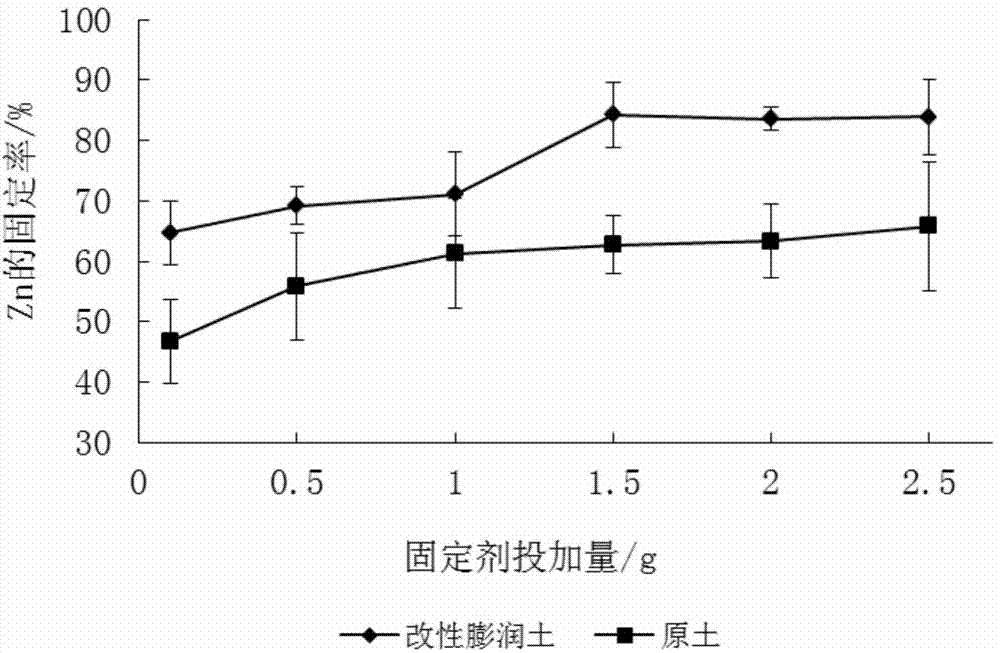

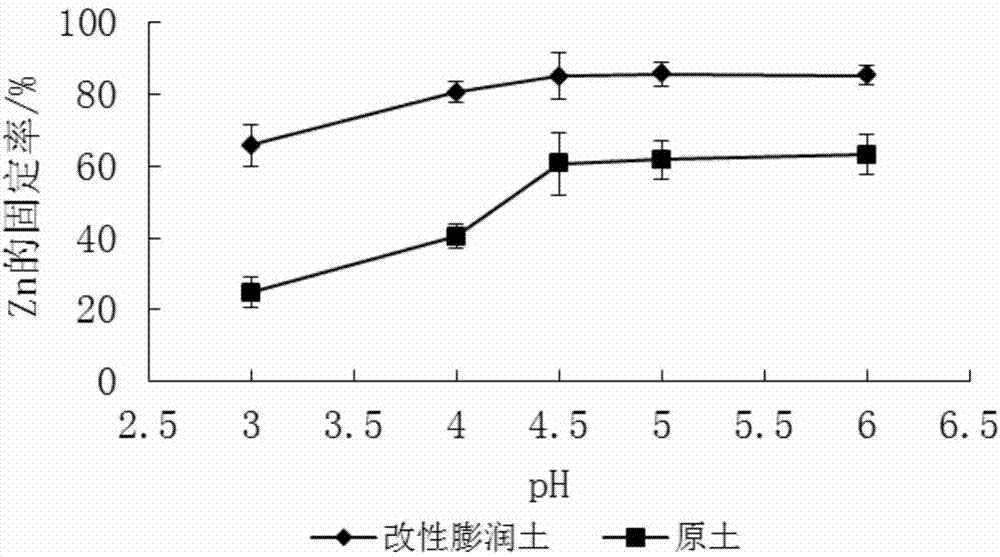

Organic bentonite for composite flame retardants and preparation process thereof

InactiveCN102604441AImprove flame retardant performanceImprove lipophilicityPigment treatment with non-polymer organic compoundsCompound organicSodium Bentonite

The invention provides a preparation process for an organic bentonite for composite flame retardants, which adopts sodium bentonite as a raw material to be mixed with composite organic cation surfactant. The preparation process is characterized in that: 3 to 4 parts of sodium hexametaphosphate is added into 300 to 500 parts of deionized water, 30 to 50 parts of sodium bentonite is then added, and after high-speed agitation, bentonite suspension solution is produced; 12 to 20 parts of composite organic cation surfactant is added into 120 to 200 parts of solvent, and after high-speed agitation, composite organic cation surface modifier solution is produced; under the state of high-speed agitation, the composite organic cation surface modifier solution is added into the bentonite suspension solution, ammonia is used for regulating the pH of the mixed solution to be 8 to 9, agitation is carried out under thermostatic waterbath of 75 DEG C to 85 DEG C for 2 hours, centrifugal separation is carried out after the temperature is cooled to the room temperature, and after vacuum drying under 80 DEG C to 90 DEG C and grinding, the organic bentonite for the composite flame retardants is prepared. The organic bentonite obtained by the method has good lipophilicity and a good flame-retardant effect, and can be applied in the modification of paint, ink and plastic, and while the dosage of other flame retardants is reduced and the cost is saved, the flame-retardant property and mechanical property of polymer can be enhanced as well.

Owner:SHANDONG UNIV OF TECH +1

Method for producing modified bentonite by using urea-chitosan

ActiveCN104492387AGood removal effectLow requirements for production conditionsOther chemical processesWater bathsSorbent

The invention discloses a method for producing modified bentonite by using urea-chitosan, which includes the following steps: on a weight basis, adding 1-5 parts of urea into 40-60 parts of bentonite, mixing and grinding, adding 400-700 parts of water to obtain a bentonite suspension; on a weight basis, dissolving 3-7 parts of chitosan into an acetic acid solution with a mass fraction of 1.0-3.0% to obtain a chitosan acetic acid solution with a chitosan mass fraction of 1.0-2.0%; dropwise adding the chitosan acetic acid solution into the bentonite suspension in a water bath, water-bathing for 2-3h, cooling and filtering, washing a filter cake with water, drying, grinding and sieving the filter cake to obtain the modified bentonite. The inventive method has the advantages of simple process and low production condition requirements; and the resulting adsorbent has obvious removal effect in acidic condition, the production process is convenient and feasible, and has good application prospects.

Owner:GUANGXI UNIV

Shearing-potentiation organic soil for drilling and preparation method thereof

InactiveCN103992776AImprove cutting effectHigh ratio of dynamic plasticDrilling compositionBentonite suspensionActive agent

The invention relates to a shearing-potentiation organic soil for drilling, belonging to the technical field of organobentonite modification in petrochemical industry. The preparation method comprises the following steps: preparing required amounts of bentonite, sodium carbonate, sodium hydroxide or potassium hydroxide into a bentonite suspension; preparing a bis-quaternary ammonium salt cationic surfactant, an auxiliary dispersant, a nonionic surfactant, white oil and water into a composite modifier emulsion; stirring with tetrabutylammonium bromide and other secondary modifiers at 60-80 DEG C for 60-120 minutes, drying, and pulverizing to obtain the shearing-potentiation organic soil for drilling. The shearing-potentiation organic soil for drilling has the advantages of favorable shearing-potentiation effect and high ratio of dynamic shear force, is more suitable to be used in an all-oil-base low-solid drilling fluid system, has favorable suspension and cutting carrying effects.

Owner:克拉玛依市金鑫科技有限公司

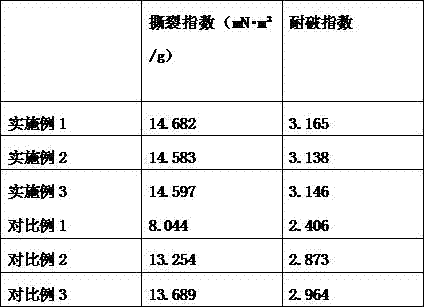

Bio-enzyme auxiliary pulping method

InactiveCN107254794AImprove water absorptionImprove conveniencePulp beating/refining methodsCellulose treatment using microorganisms/enzymesFiberPort fuel injection

The invention discloses a bio-enzyme auxiliary pulping method and relates to the technical field of paper making. In the bio-enzyme auxiliary pulping method, a 100% original-color needle wood-pulp board is taken as a raw material, and the bio-enzyme auxiliary pulping method comprises the following steps: (1) performing defibering on the 100% original-color needle wood-pulp board for a certain time by using a hydrapulper, and stirring at a fixed rotation speed; (2) putting certain amounts of an enzyme and a nano bentonite suspension into the defibered pulp, treating for a certain time at certain temperature, and performing deactivation treatment on the pulp material; and (3) pulping the treated pulp material by using a PFI (Port Fuel Injection) pulper. As the pulp material is treated by using the enzyme and the nano bentonite suspension, the surface of a fiber can be activated and loosened, the water absorption swelling and fine fibration of the fiber can be improved, the fiber is cut off and devillicated under further mechanical action, the fiber surface area and the intermolecular binding force are increased, and after paper is made of the fiber, the energy consumption of pulping is reduced while the physical properties are improved.

Owner:ANHUI BILUN DOMESTIC PAPER CO LTD

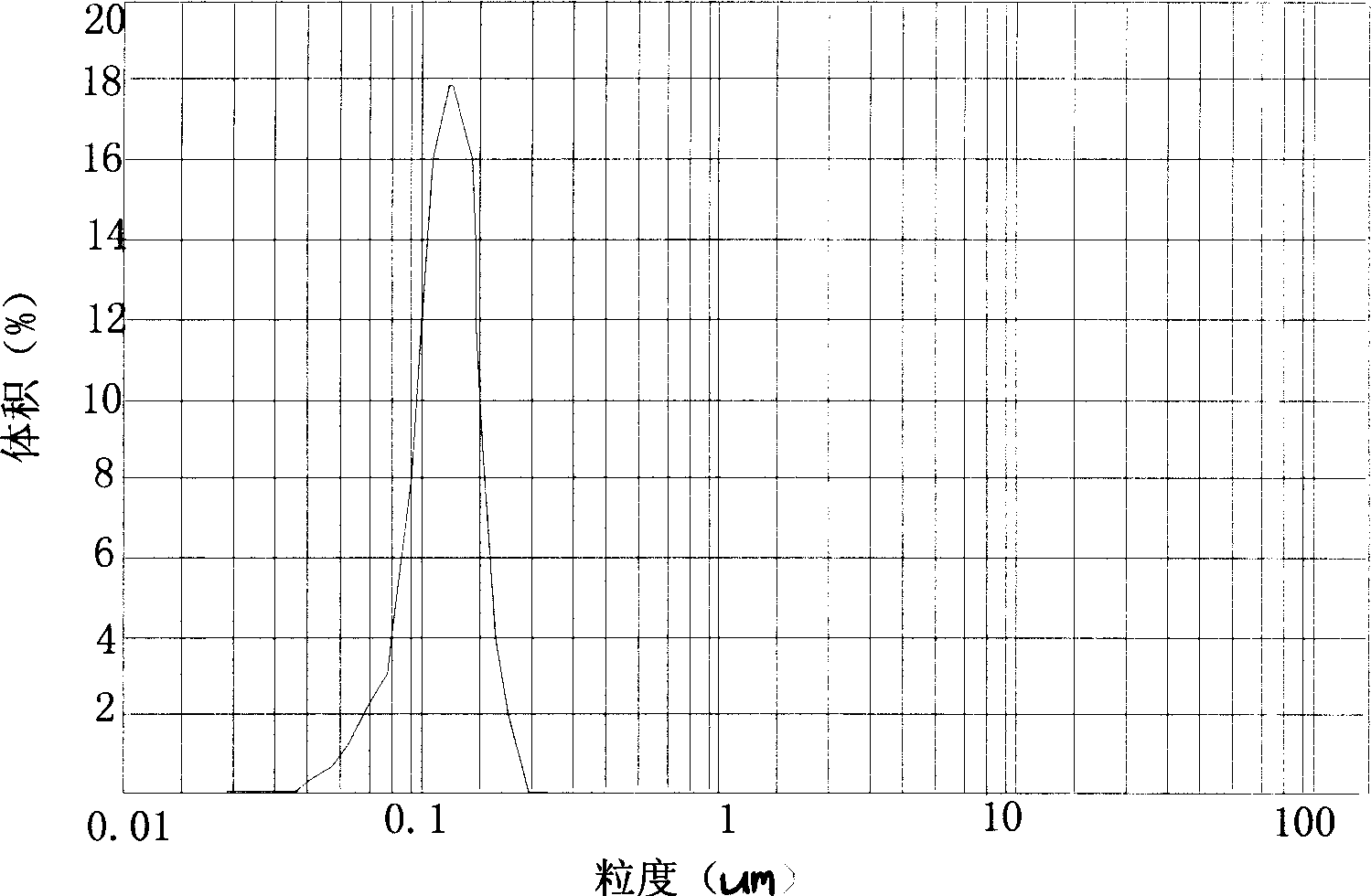

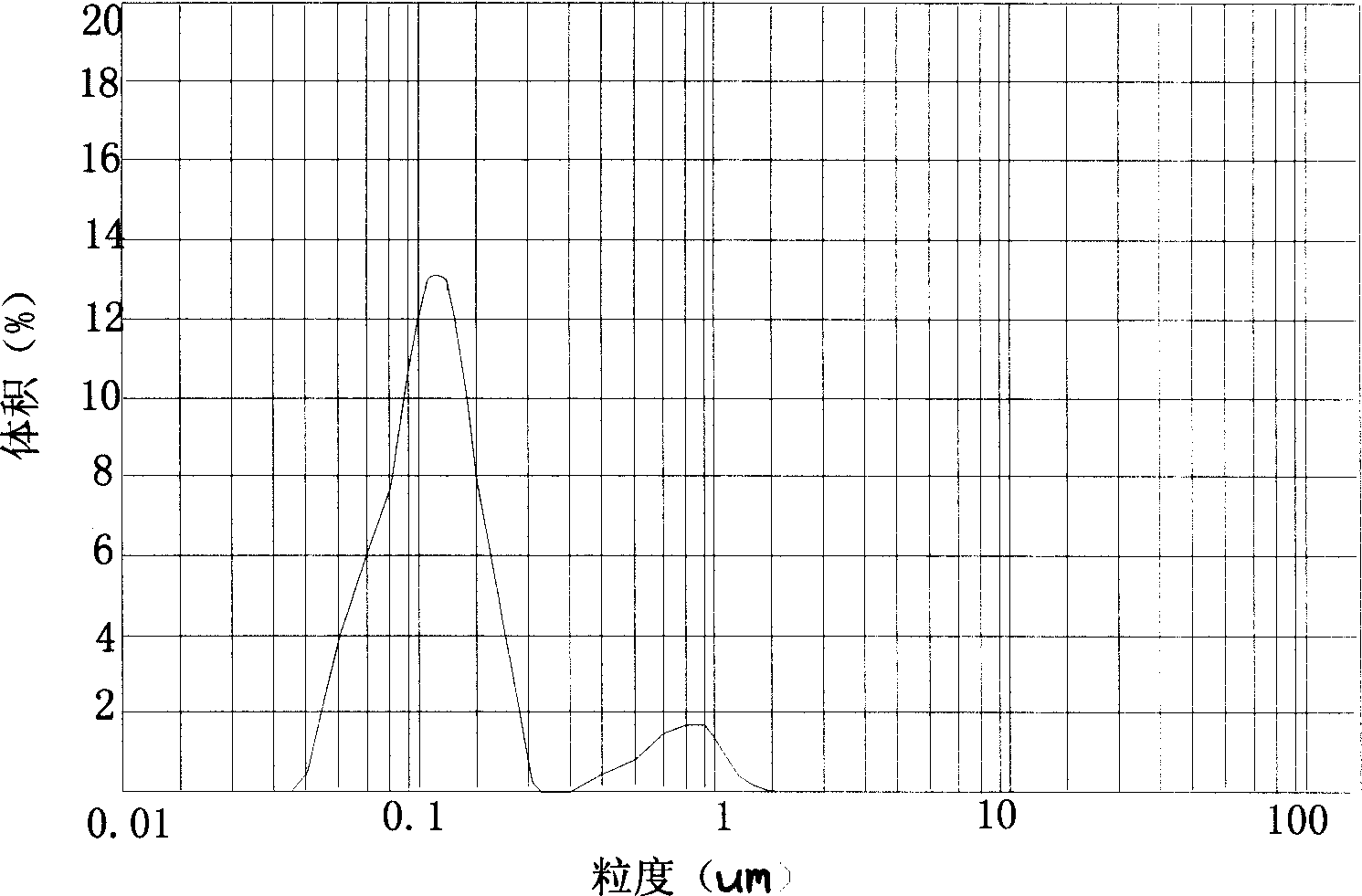

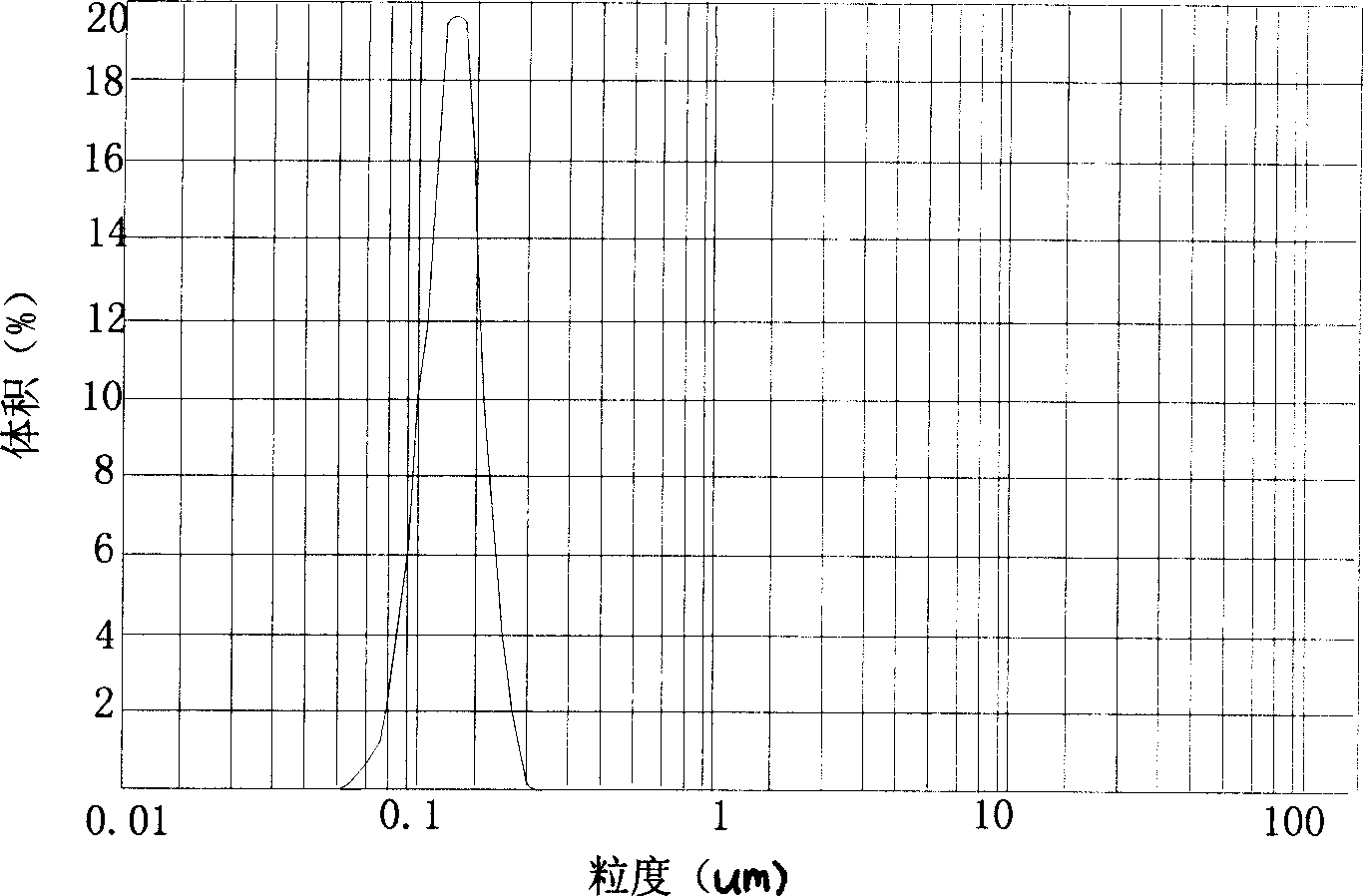

Method for preparing superfine natrium bentonite grout

InactiveCN1843910AChange granularityImprove anti-settling effectSilicon compoundsSodium BentoniteBentonite suspension

Disclosed is a method for preparing superfine natrium bentonite grout, which mainly comprises the following steps: (1) charging 1-50 parts by alta-mud weight of water into sodium bentonite or calcium bentonite containing montmorillonite higher than 92%, fully stirring and moistening, obtaining suspending liquid, (2) charging 0-0.1 part of sodium agent into the suspending liquid, stirring 10-60 minutes, (3) ball grinding the suspending liquid.

Owner:浙江安吉县宇宏粘土有限公司 +1

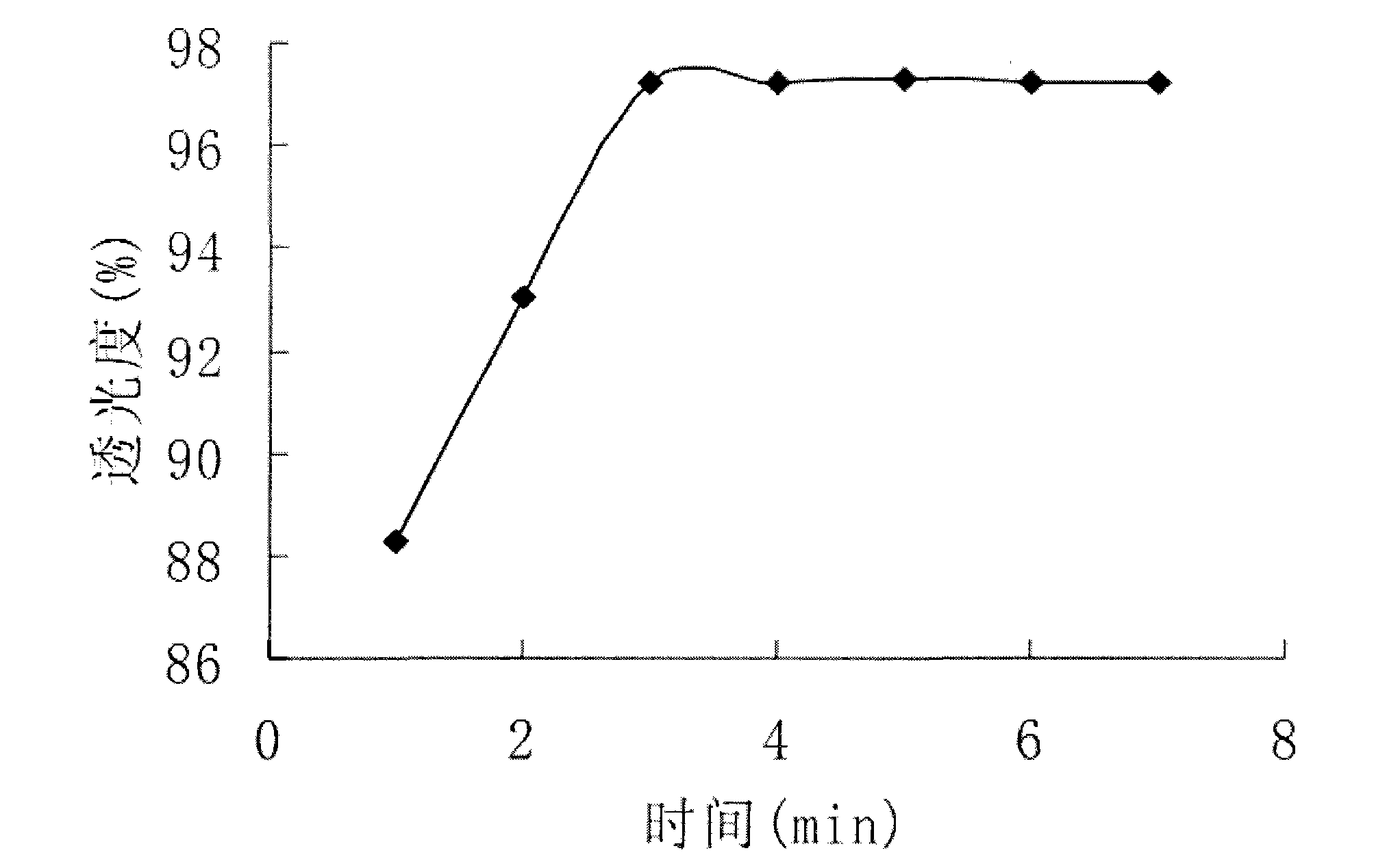

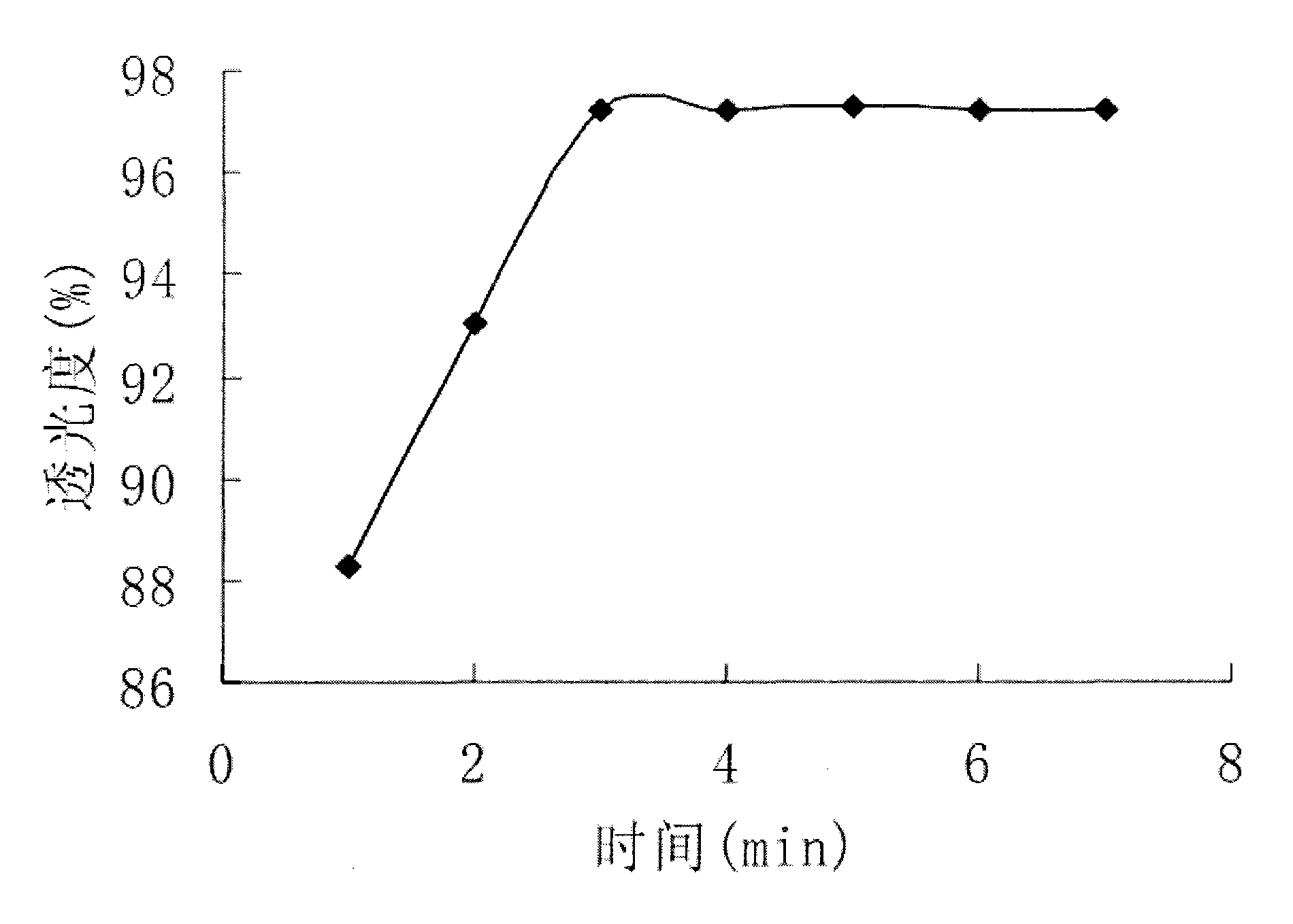

Method for testing influence of flocculation time on flocculation performance of cationic flocculant

InactiveCN102466628ASimple test stepsShort test timeTransmissivity measurementsFlocculationBentonite suspension

The invention discloses a method for testing the influence of flocculation time on the flocculation performance of a cationic flocculant. The method for testing the influence of the flocculation time on the flocculation performance of the cationic flocculant comprises the following steps of: preparing the cationic flocculant; preparing sodium-based bentonite suspensions with different pH values as simulation water samples; taking the simulation water samples with different pH values, respectively placing the simulation water samples in a reaction vessel and adding the flocculant with same amount as that of each simulation water sample; and respectively measuring transmittances of liquids in the reaction vessel, and further analyzing the influence of the pH value on the flocculation performance, and the like. According to the invention, by changing different flocculation time, the flocculation performance of the cationic flocculant can be measured respectively, and the influence of the flocculation time on the flocculation performance of the cationic flocculant is further analyzed; and the method disclosed by the invention has the advantages of simple test steps and short test time and provides references for application of the cationic flocculant to wastewater treatment.

Owner:李波

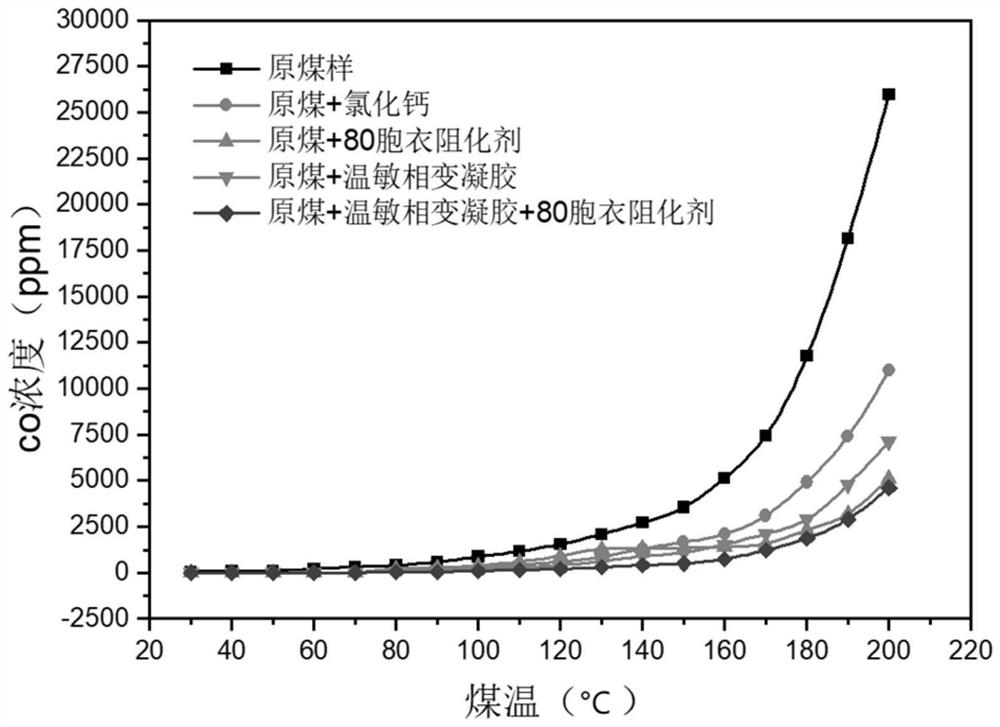

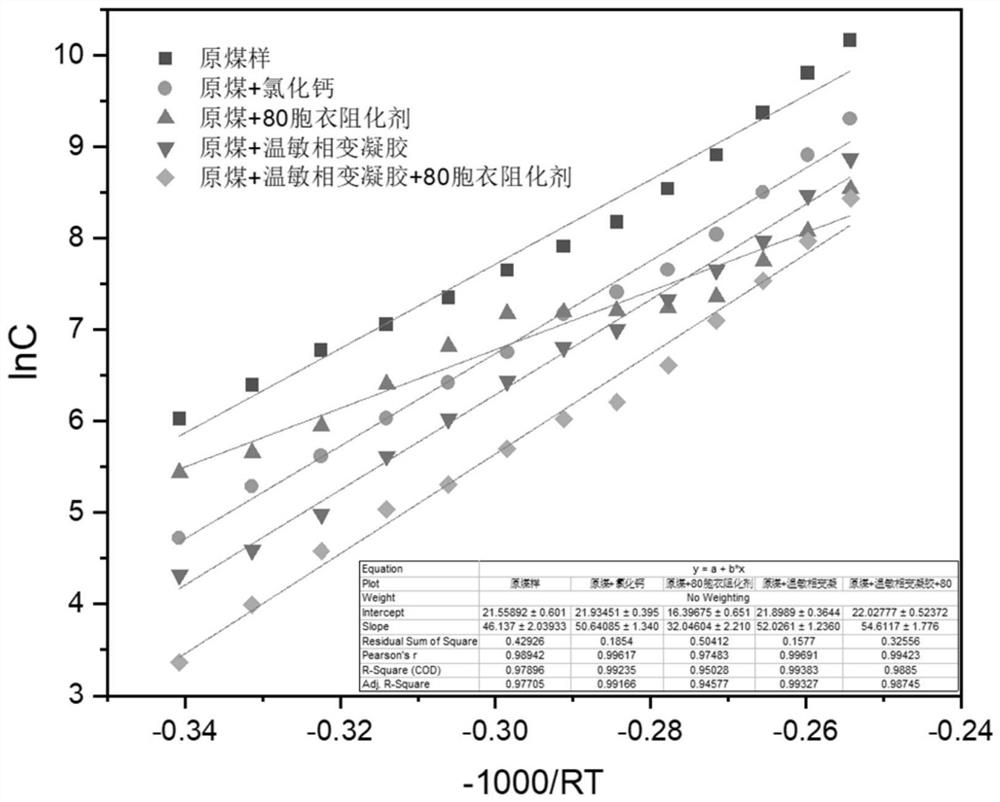

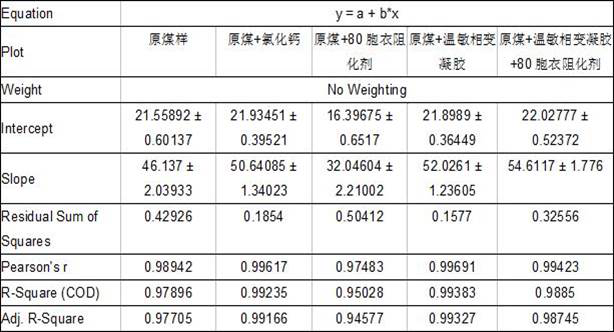

Temperature-sensitive phase-change gel material for inhibiting spontaneous combustion of coal as well as preparation method and application of temperature-sensitive phase-change gel material

ActiveCN113174270AWill not polluteSimple preparation processHeat-exchange elementsFire extinguisherCelluloseBentonite suspension

The invention discloses a temperature-sensitive phase-change gel material for inhibiting spontaneous combustion of coal as well as a preparation method and an application of the temperature-sensitive phase-change gel material. The temperature-sensitive phase-change gel material comprises the following components: a water-absorbing monomer polyethylene glycol, methyl cellulose, sodium carboxymethyl cellulose, magnesium hydroxide, a bentonite suspension, a kaolin suspension and the balance of water at 40-50 DEG C, and the temperature-sensitive phase-change gel material is prepared by blending and weak crosslinking. For an inclined coal seam, after the temperature-sensitive phase-change gel material and a temperature-sensitive coating inhibitor are uniformly mixed, a mixture has relatively strong fluidity in an initial low-temperature state, coating small balls can be transported to a goaf and a coal seam prone to spontaneous combustion through a pipeline, and the effect of bonding the coating small balls to the inclined coal seam is achieved; if the temperature of the coal seam is raised to 60-70 DEG C through spontaneous combustion, the temperature-sensitive coating releases the inhibition solution, the temperature-sensitive colloid makes contact with the inhibition solution, salting-out occurs, phase change occurs at about 78 DEG C, the temperature-sensitive colloid permeates into coal seam cracks and is dehydrated to generate a quasi-solid with a film, and 70 DEG C wax combustion of the temperature-sensitive coating inhibitor is effectively inhibited. The long-term low-temperature oxidation inhibition and high-temperature flame-retardant effects on the coal are realized.

Owner:CHINA UNIV OF MINING & TECH

Preparation method for silicon carbide nanosheet

A disclosed preparation method for a silicon carbide nanosheet comprises the following steps: dropwise adding a hexadecyl trimethyl ammonium bromide solution into a bentonite suspension in water bath, after dropwise adding is finished, dropwise adding acetone, after dropwise adding is finished, continuing to stir under same conditions, and finally performing centrifugal separation, washing, baking and grinding; putting the powder into a tubular furnace, carbonizing under protection of N2, putting the carbonized solid into a bottle, adding a hydrochloric acid solution, stirring, performing solid-liquid separation, washing and baking; putting the obtained particle in a tubular furnace, under protection of argon, heating according to a program for calcining, and cooling to room temperature, immersing the calcined product in a mixed acid of hydrofluoric acid and hydrochloric acid, washing off unreacted silicon dioxide, washing by deionized water and drying, so as to obtain the silicon carbide nanosheet. The method employs silicon in bentonite as a raw material and fully utilizes the lamellar structure of bentonite, and the method is cheap in raw material source, controllable in process, and easy for industrialized production.

Owner:CHANGZHOU UNIV

Process for preparing adsorbent simultaneously removing hydrogen chloride and mercury steam

InactiveCN1820841AImprove thermal stabilityPlay a synergistic roleOther chemical processesAluminium chlorideBentonite suspension

The present invention discloses preparation process of adsorbent for removing HCl and Hg steam simultaneously. The preparation process includes the following steps: 1. mixing bentonite suspension and ammonium cetyl trimethyl bromide at 50-100 deg.c for 10-24 hr, adding dodecylamine and polyhexenol and mixing for other 10-24 hr, adding ethyl silicate until creating precipitate, drying the precipitate at 80-100 deg.c for 12 and heating at 200-500 deg.c for 6 hr to obtain powder; and 2. compounding mixture solution of magnesium chloride, titanium tetrachloride and aluminum chloride, soaking the powder inside the mixture solution for 24 hr, dropping excessive dilute ammonia water to react, drying the product, and annealing at 300-600 deg.c to obtain the adsorbent. The adsorbent can remove HCl and Hg steam simultaneously, and has high removing effect, low cost and high heat stability.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Preparation method of lining material for furnace for producing white carbon black

The invention provides a preparation method of a lining material for a furnace for producing white carbon black and relates to the field of new materials. The preparation method comprises the steps of dissolving hydrochloric acid in deionized water to obtain an acid liquid; dissolving vanadium (III) acetylacetonate in deionized water to obtain vanadium (III) acetylacetonate solution; mixing basic zirconium carbonate with deionized water to obtain basic zirconium carbonate mixed liquid; adding deionized water to bentonite to obtain bentonite suspension; adding the basic zirconium carbonate mixed liquid into the bentonite suspension, stirring for 2 h, adding the acid liquid during stirring, and regulating pH to 4.8; adding the vanadium (III) acetylacetonate solution, stirring for 1.5 h, and standing and aging for 10 h to obtain a slurry; filtering, washing filter cakes with deionized water until there is no Cl-, and drying; grinding to obtain the lining material for a furnace. The lining material of the invention is suitable for the furnace for producing white carbon black and may act as a lining material for a furnace to avoid the direct contact between production materials for white carbon black and a furnace body, improve product purity, and prolong the life of the furnace.

Owner:ANHUI LONGQUAN SILICON MATERIAL

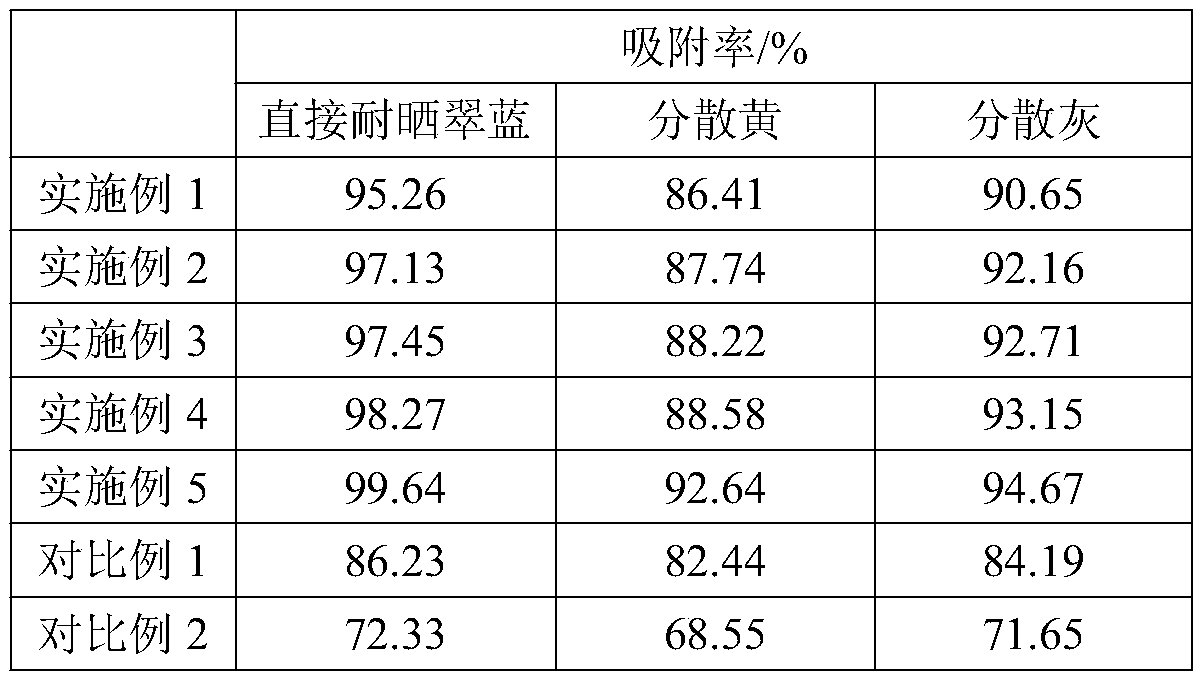

Preparation method of iron-magnesium compound coated bentonite composite powder adsorbent, and application of adsorbent in treatment of dye wastewater

ActiveCN109174065ALarge specific surface areaStrong adsorption and decolorization abilityOther chemical processesWater contaminantsChemical industrySorbent

The invention provides a preparation method of an iron-magnesium compound coated bentonite composite powder adsorbent, and an application of the adsorbent in the treatment of dye wastewater, and belongs to the technical fields of chemical industry and environmental protection. The preparation method of the iron-magnesium compound coated bentonite composite powder adsorbent comprises the followingsteps: dissolving ferrous sulfate and magnesium sulfate in deionized water to obtain a salt solution for later use; fully expanding bentonite with deionized water, adding cetyltrimethylammonium bromide, and performing uniform mixing to obtain a bentonite suspension; and adding the bentonite suspension into a three-necked flask, adding the salt solution under a stirring condition, dropwise adding asodium hydroxide solution, carrying out a reaction for 4 h, stopping stirring, titrating the obtained solution with hydrochloric acid until the solution is neutral, performing suction filtration, drying the obtained solid, and then calcining the dried solid in a muffle furnace to obtain the iron-magnesium compound coated bentonite composite powder adsorbent. The iron-magnesium compound coated bentonite composite powder adsorbent prepared in the invention has good adsorbing and decolorizing effects on the dye wastewater.

Owner:管敏富

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com