Bio-enzyme auxiliary pulping method

A biological enzyme and pulp technology, which is applied in pulp beating/refining method, cellulose treatment using microorganisms/enzyme, textiles and papermaking, etc., can solve the problems of difficulty in improving the beating degree of softwood pulp and insignificant improvement effect, etc. Achieve the effect of increasing fiber surface area and intermolecular molecular bonding force and promoting the degree of fibrosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

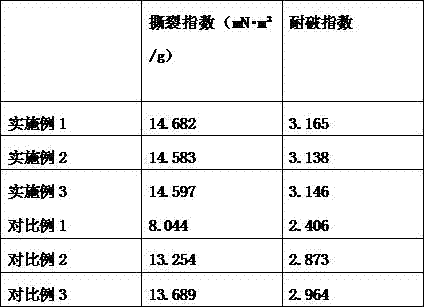

Examples

Embodiment 1

[0018] A kind of biological enzyme assisted beating method, the used raw material of described beating method is 100% natural color coniferous wood pulp board, comprises the following steps:

[0019] (1) Thaw the natural softwood pulp board with a mass fraction of 100% with a hydraulic pulper for a certain period of time, and then stir at a constant speed;

[0020] (2) Add a certain amount of enzyme and nano-bentonite suspension to the decomposed slurry, treat it at a certain temperature for a period of time, and then inactivate the slurry;

[0021] (3) Beat the treated slurry through a PFI refiner.

[0022] Further, in the step (1), the time for the hydropulper to disperse is 40 minutes.

[0023] Further, in the step (1), the stirring is carried out at a fixed speed, the rotating speed is 350r / min, and the stirring time is 20-25min.

[0024] Further, a certain amount of enzyme in the step (2) is cellulase, and the added amount is 0.18 IU / g slurry.

[0025] Further, the pre...

Embodiment 2

[0028] A method for biological enzyme-assisted beating, wherein the raw material used in the beating method is 100% natural color coniferous wood pulp board, which is characterized in that, comprising the following steps:

[0029] (1) Thaw the natural softwood pulp board with a mass fraction of 100% with a hydraulic pulper for a certain period of time, and then stir at a constant speed;

[0030] (2) Add a certain amount of enzyme and nano-bentonite suspension to the decomposed slurry, treat it at a certain temperature for a period of time, and then inactivate the slurry;

[0031] (3) Beat the treated slurry through a PFI refiner.

[0032] Further, the time for the hydropulper to disperse in the step (1) is 45 minutes.

[0033] Further, in the step (1), the stirring is carried out at a fixed speed, the rotating speed is 380 r / min, and the stirring time is 25 min.

[0034] Further, a certain amount of enzyme in the step (2) is cellulase, and the added amount is 0.18-0.22 IU / g ...

Embodiment 3

[0038] A method for biological enzyme-assisted beating, wherein the raw material used in the beating method is 100% natural color coniferous wood pulp board, which is characterized in that, comprising the following steps:

[0039] (1) Thaw the natural softwood pulp board with a mass fraction of 100% with a hydraulic pulper for a certain period of time, and then stir at a constant speed;

[0040] (2) Add a certain amount of enzyme and nano-bentonite suspension to the decomposed slurry, treat it at a certain temperature for a period of time, and then inactivate the slurry;

[0041] (3) Beat the treated slurry through a PFI refiner.

[0042] Further, in the step (1), the time for the hydropulper to disperse is 42 minutes.

[0043] Further, in the step (1), stirring is carried out at a fixed speed, the rotating speed is 360r / min, and the stirring time is 20-25min.

[0044] Further, a certain amount of enzyme in the step (2) is cellulase, and the added amount is 0.20 IU / g slurry....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com