Method for preparing nano-cellulose antibacterial composite material through on-line culture

A technology of nanocellulose and composite materials, which is applied in the field of on-line culture and preparation of nanocellulose antibacterial composite materials, can solve the problems of poor drug loading and sustained release, inability to absorb in time, secondary trauma, etc., to save fermentation time, The effect of shortening the production cycle and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Bacteria culture

[0042] Insert Acetobacter xylinum into 300mL liquid medium (per 1L of water, 20g of mannitol, 3g of peptone, 5g of yeast extract, pH 3.0, sterilized at 121°C for 20min; or 200g of glucose, 5g of yeast extract, Tryptone 5g, citric acid 1.15g, Na 2 HPO 4 2.7g, 1L of water, pH 7.5, sterilized at 121°C for 20min) for expansion, cultured on a shaking table at 20°C, 100r / min or standing for 12h before use;

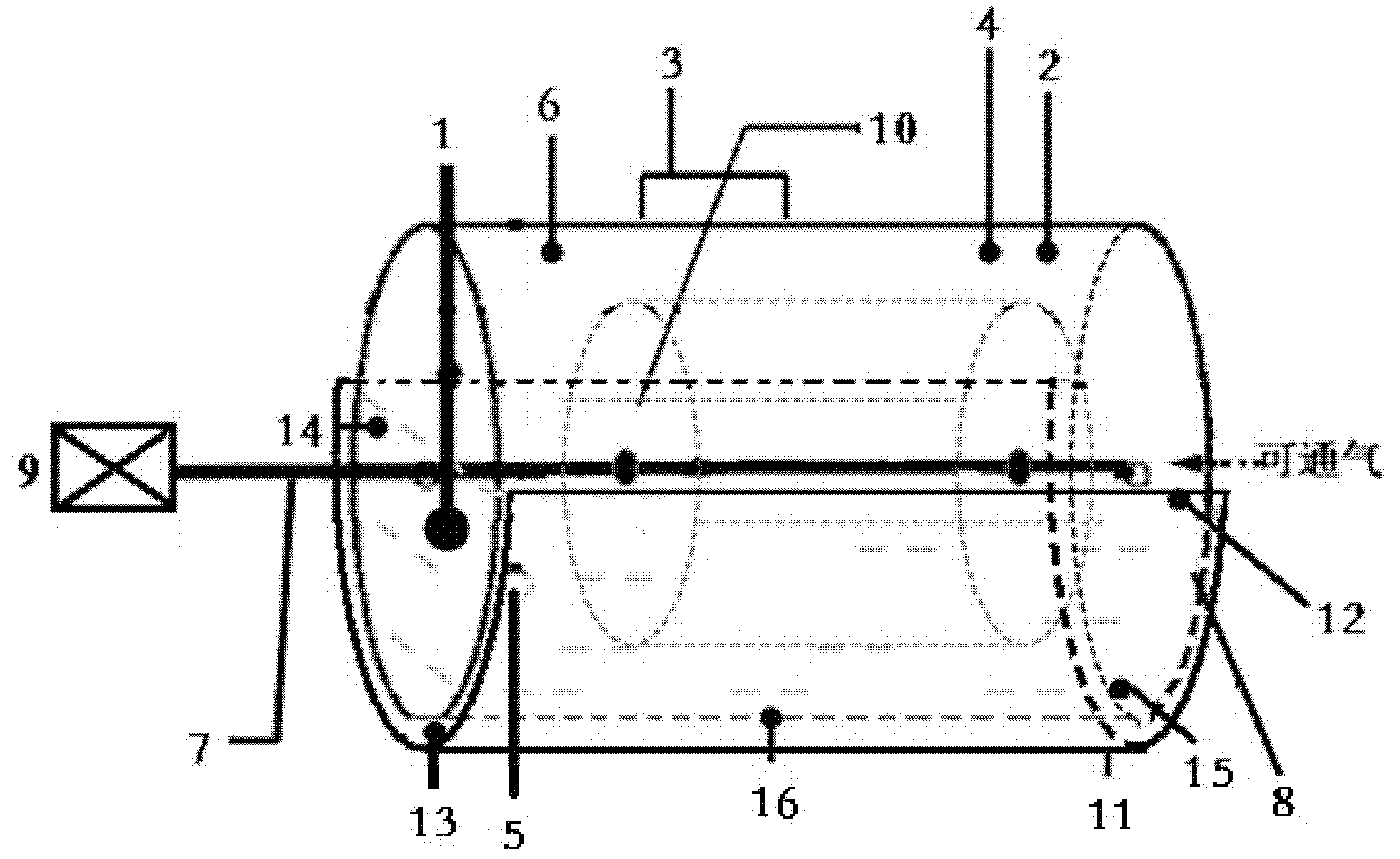

[0043] (2) Fermentation preparation of bacterial cellulose composite antibacterial film

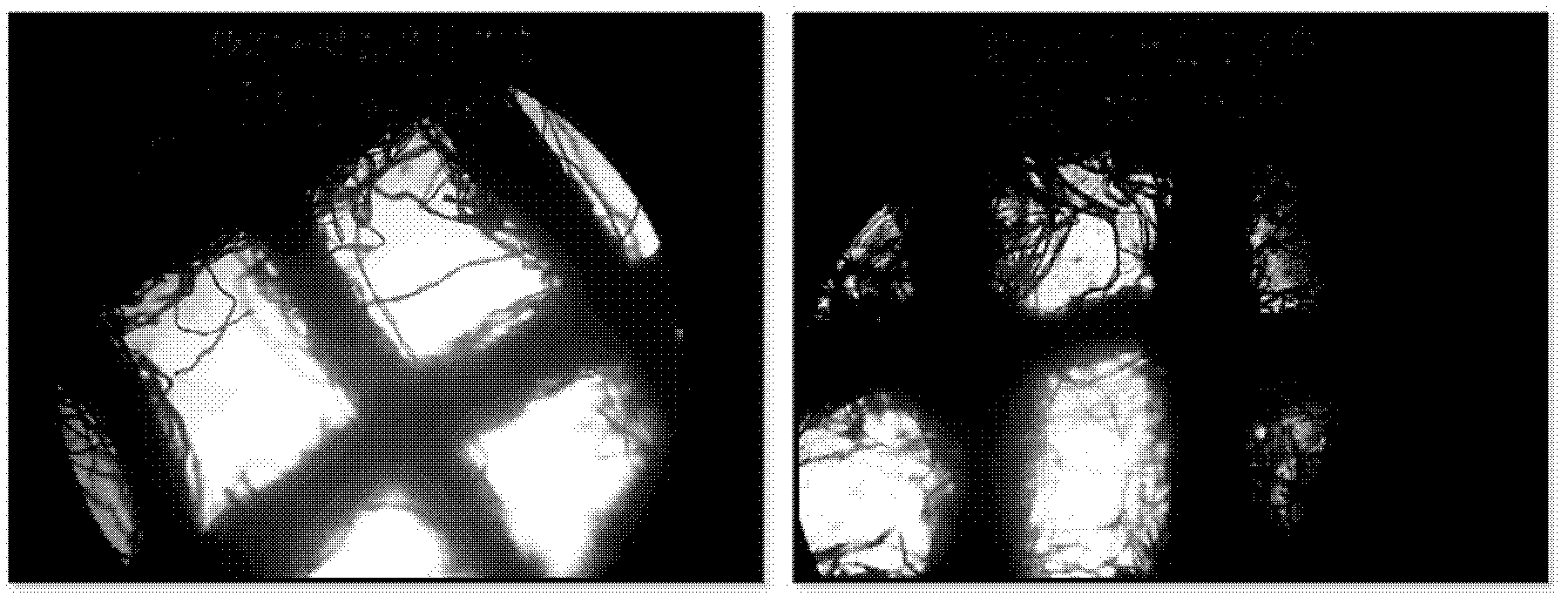

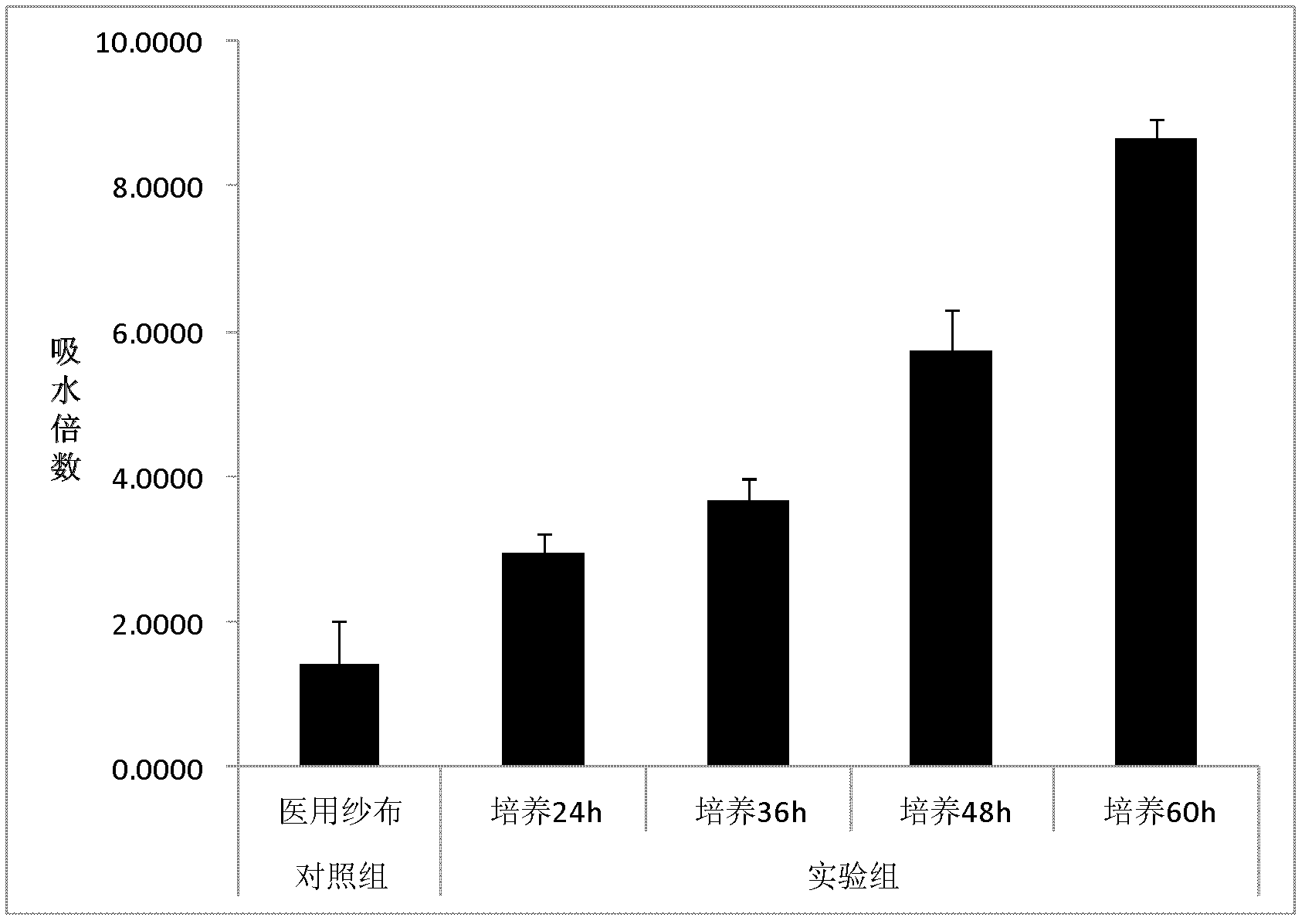

[0044] The liquid culture medium containing the production strain prepared in step (1) is transferred to a bioreactor equipped with a fixed gauze or silk skeleton material drum, and then the drum rotates at a speed of 7, 15, 30 and 60rpm for disturbance cultivation After 1 day of dynamic culture at 30°C, add different concentrations of chitosan solutions to the culture medium regularly, and then culture for 2-7 days to obtain bacterial cellulose / gauze / chitos...

Embodiment 2

[0055] (1) Bacteria culture

[0056] Put kombucha (kombucha) into 300mL liquid seed culture medium (per 1L of water, green tea 5g, glucose 10, peptone 3g, yeast extract 5g, pH3 .0, pasteurized for 30min; per 1L of water, 100g of glucose, 3g of peptone, 5g of yeast extract, pH 7.5, sterilized at 121°C for 20min) to expand culture, cultured on a shaking table at 25°C, 150r / min or After 24 hours of static culture, it is ready for use;

[0057] (2) Fermentation preparation of bacterial cellulose antibacterial composite film

[0058] Transfer the liquid culture medium containing the production strain prepared in step (1) to a bioreactor equipped with a drum fixed with a polyester, nylon or polypropylene skeleton material, then rotate the drum to carry out disturbance cultivation at a speed of 15 rpm, at 30 ° C After 1 day of dynamic culture, regularly add different concentrations of chitosan solutions to the culture medium, and then harvest the film-forming product after 2-7 days...

Embodiment 3

[0064] (1) Bacteria culture

[0065] Insert Gluconacetobacter xylinus into 300mL liquid medium (per 1L of water, maltose 100g, peptone 3g, yeast extract 5g, pH 4.5, sterilized at 121°C for 20min; or fructose 160g, yeast extract 5g, tryptone 5g, citric acid 1.15g, Na 2 HPO 4 2.7g, 1L of water, pH 6.0, sterilized at 121°C for 20min) for expansion, cultured on a shaking table at 30°C, 250r / min or standing for 48h before use;

[0066] (2) Fermentation preparation of bacterial cellulose antibacterial composite film

[0067] Transfer the liquid culture medium containing the production strain prepared in step (1) to a bioreactor equipped with a titanium metal mesh drum, then rotate the drum at a speed of 15 rpm for disturbed culture, and after dynamic culture at 30°C for 1 day, periodically Add different concentrations of sodium alginate solutions to the culture medium, and then cultivate for 7 days to obtain the bacterial cellulose antibacterial composite film;

[0068] Or get t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com