Vinegar workshop round pool fermenting grain turning-over machine set

A grain turning machine and grain turning technology, which are applied in the field of grain turning machines, can solve the problems of inability to turn grains with vinegar, poor turning effect in a circular fermentation tank, difficulty in a bar-shaped fermentation pool, etc. Improve installation efficiency and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

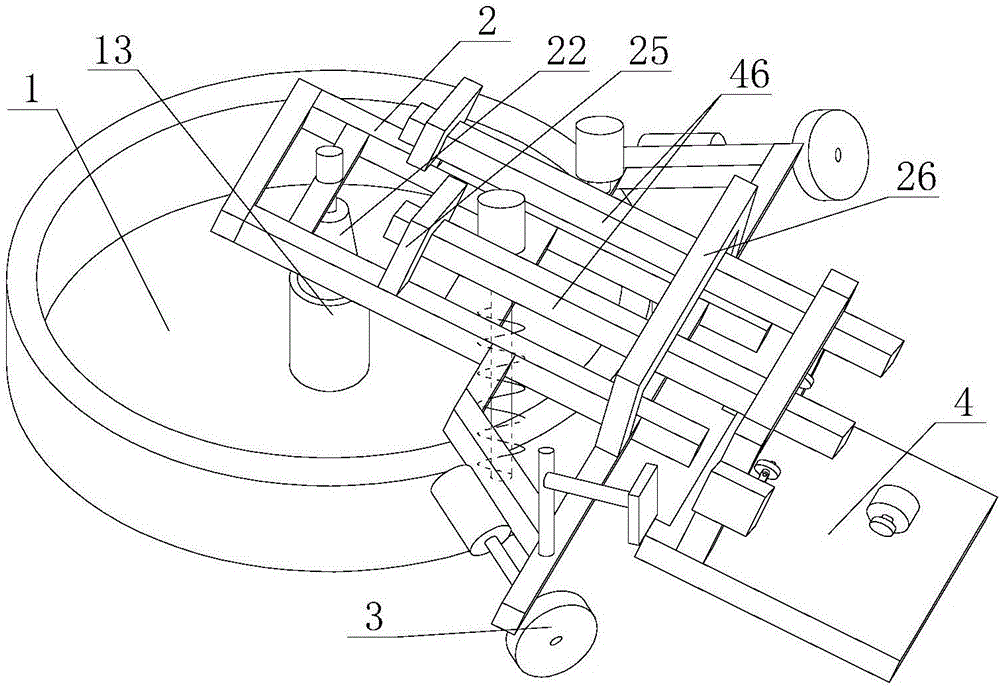

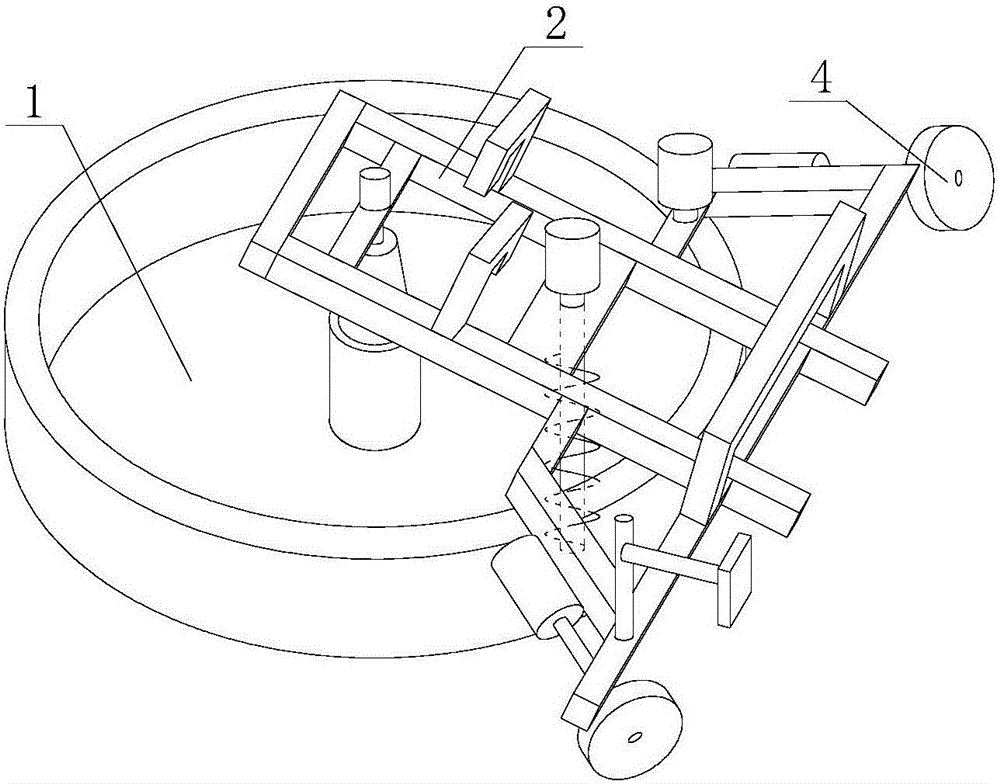

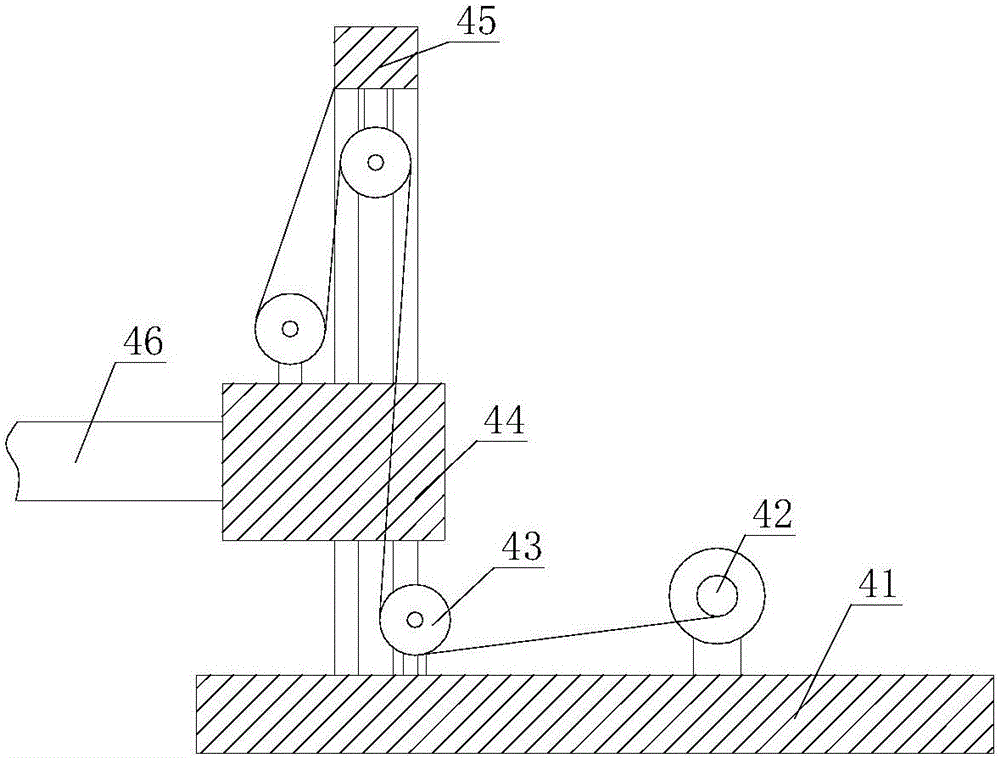

[0055] A kind of 2 groups of round fermented grains turning machines, which include a circular fermentation tank 1, a fermenting grains turning machine 2 and a frame lifting device 4; Rotating in a circular shape, the rotating grain turning machine 2 can act on the vinegar grains in the circular fermentation tank 1 and fully and effectively turn the vinegar grains; the frame body lifting device 4 is connected with the grain turning machine 2 , The frame body lifting device 4 can lift or lower the unstrained grains turning machine 2, so as to facilitate the installation of the unstrained grains turning machine 2 on the circular fermentation tank 1. The circular fermentation tank 1 includes a circular tank edge 11, forming a cylindrical chamber in the circular tank edge 11, and the cylindrical chamber is the vinegar unstrained spirits pool 12, and the raw materials are in the vinegar unstrained grains pool 12 Carry out vinegar grains, ferment, and finally produce vinegar. The c...

Embodiment 2

[0057] On the basis of Embodiment 1, the positioning mechanism 22 includes a positioning drive device 221, one end of which is fixedly connected to the frame 21, wherein the positioning drive device 221 can be fixedly connected to the frame 21, so that the positioning drive The device 221 cannot rotate on the frame 21 ; The end of the output shaft 222 of the positioning drive device 221 is connected with a positioning sleeve 223 whose shape and size match the shape and size of the positioning column. When the fermenter 2 is installed and connected to the circular fermentation tank 1, the positioning sleeve 223 of the fermenter 2 can be set on the positioning column 13 at the center of the circular fermentation tank 1, and the whole fermenter 2 can be Rotate around the axis of the positioning post 13 . As preferably, the positioning column and the positioning sleeve 223 are all arranged in a conical structure with a small upper part and a large lower part, and the positioning ...

Embodiment 3

[0059] On the basis of Embodiment 1 or Embodiment 2, the grains turning mechanism 23 includes a grains turning drive device 231, which is fixedly connected to the frame 21; one end of the grains turning drive device 231 is provided with a rotating A shaft 232, the end of the rotating shaft 232 is connected with a helical stirring paddle 233, so the screw paddle 233 can be driven to rotate by the turning device 231.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com