Fully automatic intelligent fermenting grain turning machine

A fermented glutinous rice machine and fully automatic technology, which is applied in the field of fermented glutinous rice machine, can solve the problems of inability to guarantee the stable fermentation of vinegar fermented glutinous rice material, low fermenting efficiency, uncontrollable stroke, depth, and frequency of fermented glutinous rice, so as to ensure stable fermentation. , Improve the efficiency of turning grains, and eliminate the effect of turning the dead ends of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated below in conjunction with the accompanying drawings and specific examples, and these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

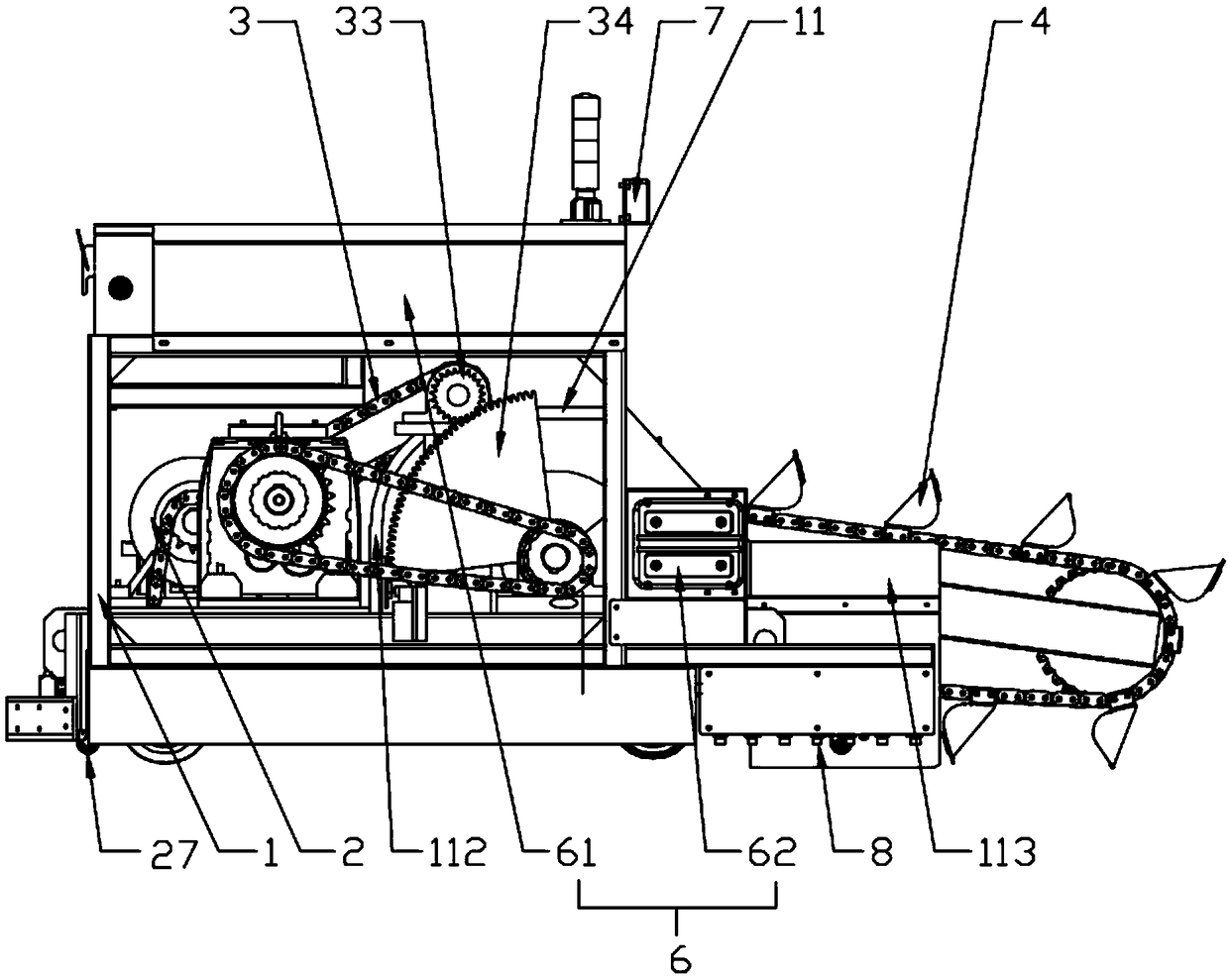

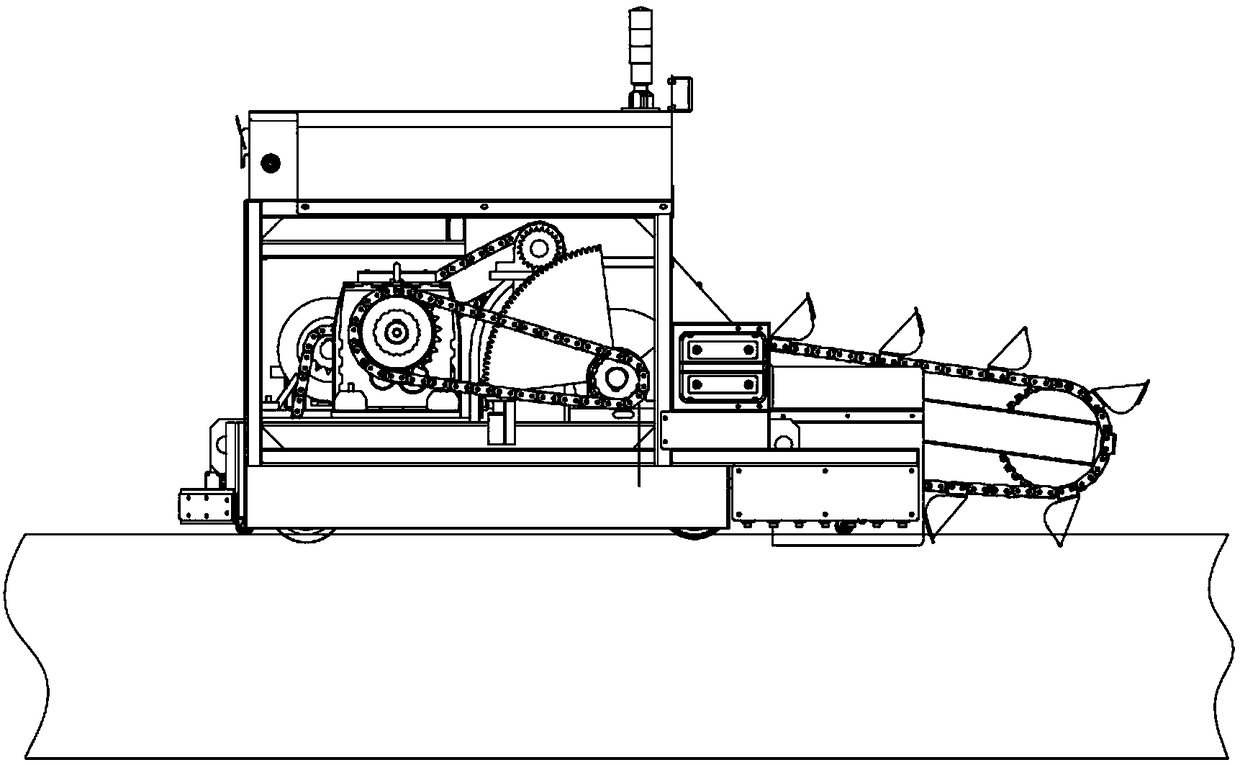

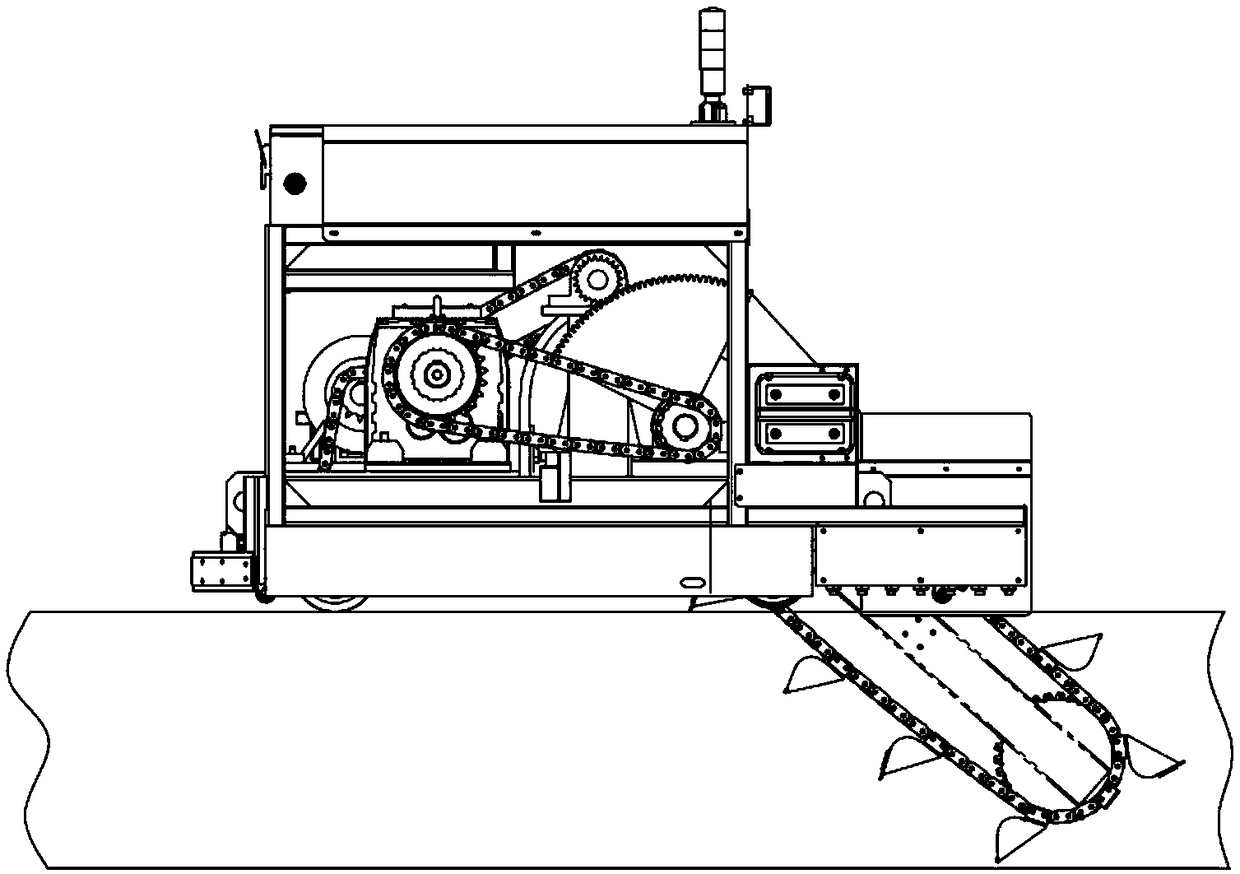

[0027] A fully automatic intelligent unstrained spirits turning machine, as attached Figure 1-4 As shown, it includes a frame 1, a traveling mechanism 2 installed at the bottom of the frame 1, a positioning sensor 8, a swing mechanism 3 installed on the frame 1, a turning mechanism 4, a control mechanism 5, a power supply assembly 6, and an ultrasonic sensor 7 .

[0028] The walking mechanism 2, the swinging mechanism 3, the turning mechanism 4, the ultrasonic sensor 7, and the positioning sensor 8 are respectively associated with the signals of the control mechanism 5; The front of the swing mechanism 3 is fixed with it to form a fixed point, and the swing mechanism 3 turns over to drive the grain turning mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com