Liquor fermentation device

A fermentation device and liquor technology, applied in the preparation of alcoholic beverages, etc., can solve problems such as lack of microorganisms and materials, large influence of fermentation temperature, insufficient top temperature, etc., to achieve the effects of ensuring fermentation quality, stable fermentation process, and breaking through structural limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

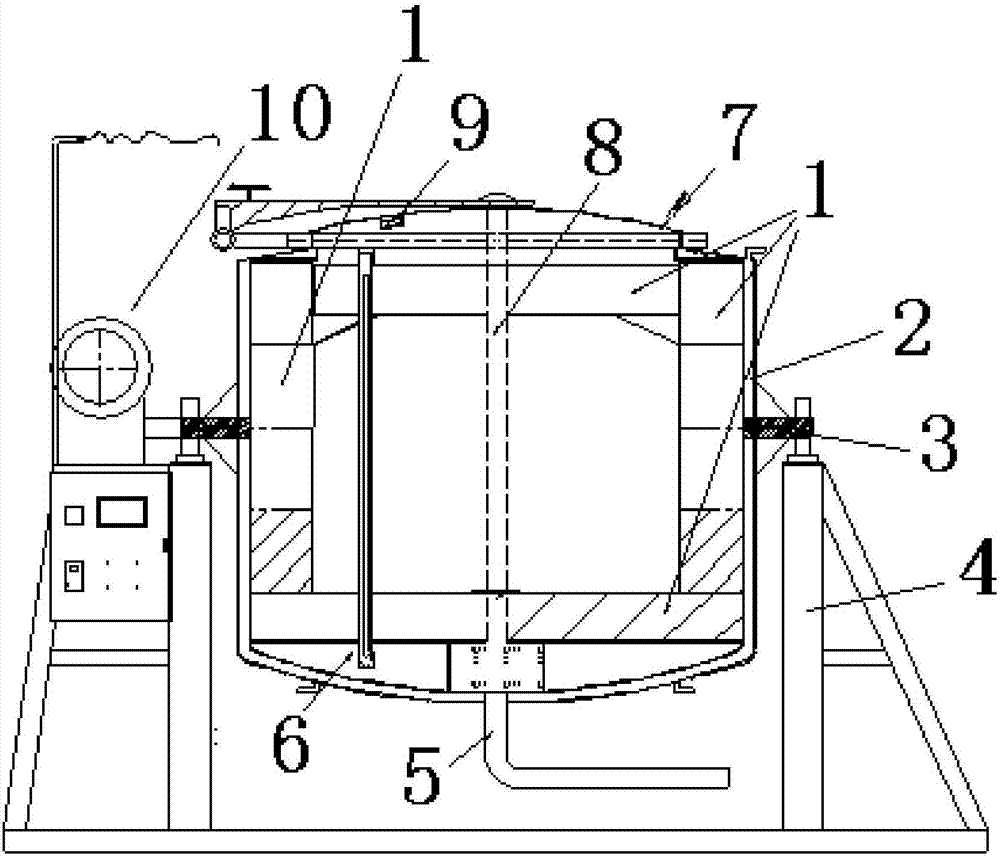

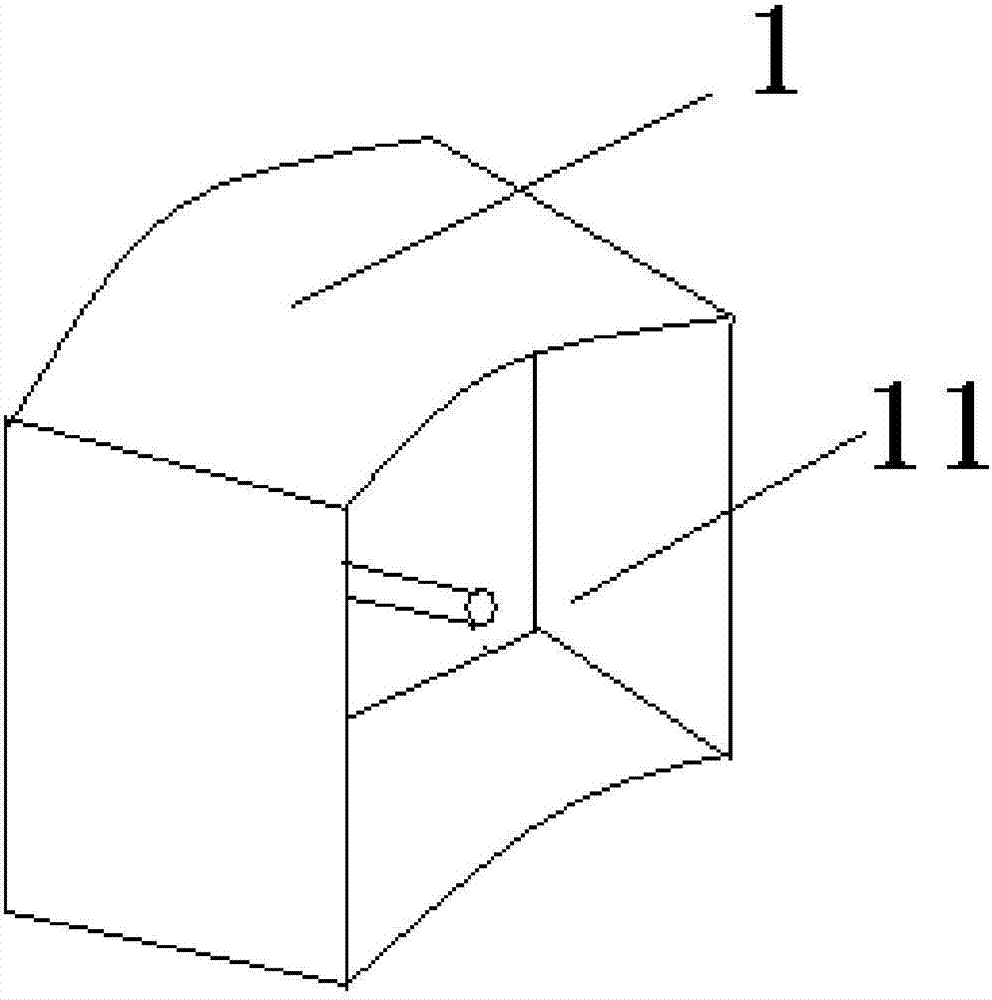

[0020] Such as figure 1 , figure 2 The shown liquor fermentation device includes a fermentation tank body 2 and at least one pit mud module 1, which is detachably and uniformly arranged on the inner wall of the fermentation tank body 2, and pit mud module 1 is provided with pit mud.

[0021] For the existing mud pit fermentation device, the microbial system and materials in the pit mud at the bottom and the pit mud near the bottom of the four walls are relatively rich, while the microorganisms and materials in the middle and upper pit mud are relatively deficient, which leads to poor fermented grains at the bottom. There is a big difference in the effect of the distilled grains and fermented grains in the middle and upper layers and the corresponding parts of the pit mud, and the quality of the base wine produced is obviously better than that in the middle and upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com